AlTiN-AlCrN super hard nano multilayer composite coating hob and preparation method thereof

A composite coating and nano-multi-layer technology, which is applied in coatings, gear tooth manufacturing devices, chemical instruments and methods, etc., can solve the problems of reduced deformation resistance and reduced hardness, so as to reduce stress, increase density, and achieve good The effect of binding force and wear and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

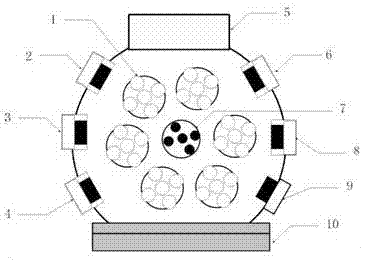

Method used

Image

Examples

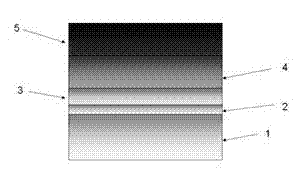

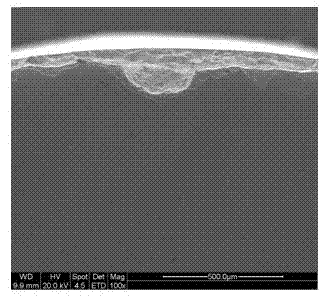

Embodiment 1

[0043] Example 1: At 250°C and in an argon environment, after glow cleaning the high-speed steel and hard alloy hobbing cutters, a 20-nanometer-thick transition metal Cr bonding layer was deposited at 0.01Pa and -900V; at 0.1 A 100nm thick CrN layer was deposited under Pa, -100V conditions; a nano-AlTiN / CrN support layer was deposited under the conditions of 0.5 pressure and -50V bias; the thickness of the single-layer AlTiN nano-layer was 3 nm, and the thickness of the single-layer CrN layer was 2 nm. The thickness of the AlTiN / CrN multilayer film is 500 nm. Finally, the AlTiN / AlCrN multilayer coating is deposited under the condition of 0.5Pa pressure and -50V bias; in the AlTiN / AlCrN multilayer film, the thickness of the single-layer AlTiN nanometer layer is 3 nanometers, and the thickness of the single-layer AlCrN layer is 2 nanometers. The thickness of the AlTiN / AlCrN multilayer film is 1 micron. The total thickness of the coating is controlled at 1.62 microns, and after ...

Embodiment 2

[0044] Example 2: At 350°C and in an argon environment, after glow cleaning the high-speed steel and hard alloy hobbing cutters, a 40-nanometer-thick transition metal Cr bonding layer was deposited at 0.05Pa and -950V; at 0.5 A 150nm thick CrN layer was deposited under Pa, -150V conditions; an AlTiN / CrN support layer was deposited under 1Pa pressure, -70V bias conditions; the thickness of the single-layer AlTiN nano-layer was 4 nm, and the thickness of the single-layer CrN layer was 3 nm. The thickness of the AlTiN / CrN multilayer film is 1.4 microns. Finally, the AlTiN / AlCrN multilayer coating is deposited under the condition of 1Pa pressure and -80V bias; in the AlTiN / AlCrN multilayer film, the thickness of a single layer of AlTiN nanometer layer is 4 nanometers, and the thickness of a single layer of AlCrN layer is 4 nanometers. The thickness of the AlTiN / AlCrN multilayer film is 3.2 microns. The total thickness of the coating is controlled at 4.79 microns, and after the pr...

Embodiment 3

[0045] Example 3: At 400°C and in an argon environment, after glow cleaning the high-speed steel and hard alloy hobbing cutters, deposit a 50-nanometer-thick transition metal Cr bonding layer at 0.08Pa and -1000V; at 1.5 A 200nm thick CrN layer was deposited under Pa, -200V conditions; an AlTiN / CrN support layer was deposited under 2.5Pa pressure, -100V bias conditions; the thickness of the single-layer AlTiN nano-layer was 4 nm, and the thickness of the single-layer CrN layer was 4 nm. The thickness of the AlTiN / CrN multilayer film is 3.2 microns. Finally, the AlTiN / AlCrN multilayer coating is deposited under the condition of 3Pa pressure and -150V bias; in the AlTiN / AlCrN multilayer film, the thickness of the single-layer AlTiN nano-layer is 4 nanometers, and the thickness of the single-layer AlCrN layer is 4 nanometers. The thickness of the AlTiN / AlCrN multilayer film is 4.8 microns. The total thickness of the coating is controlled at 8.25 microns, and after the preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com