Patents

Literature

17705results about How to "Reduce stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

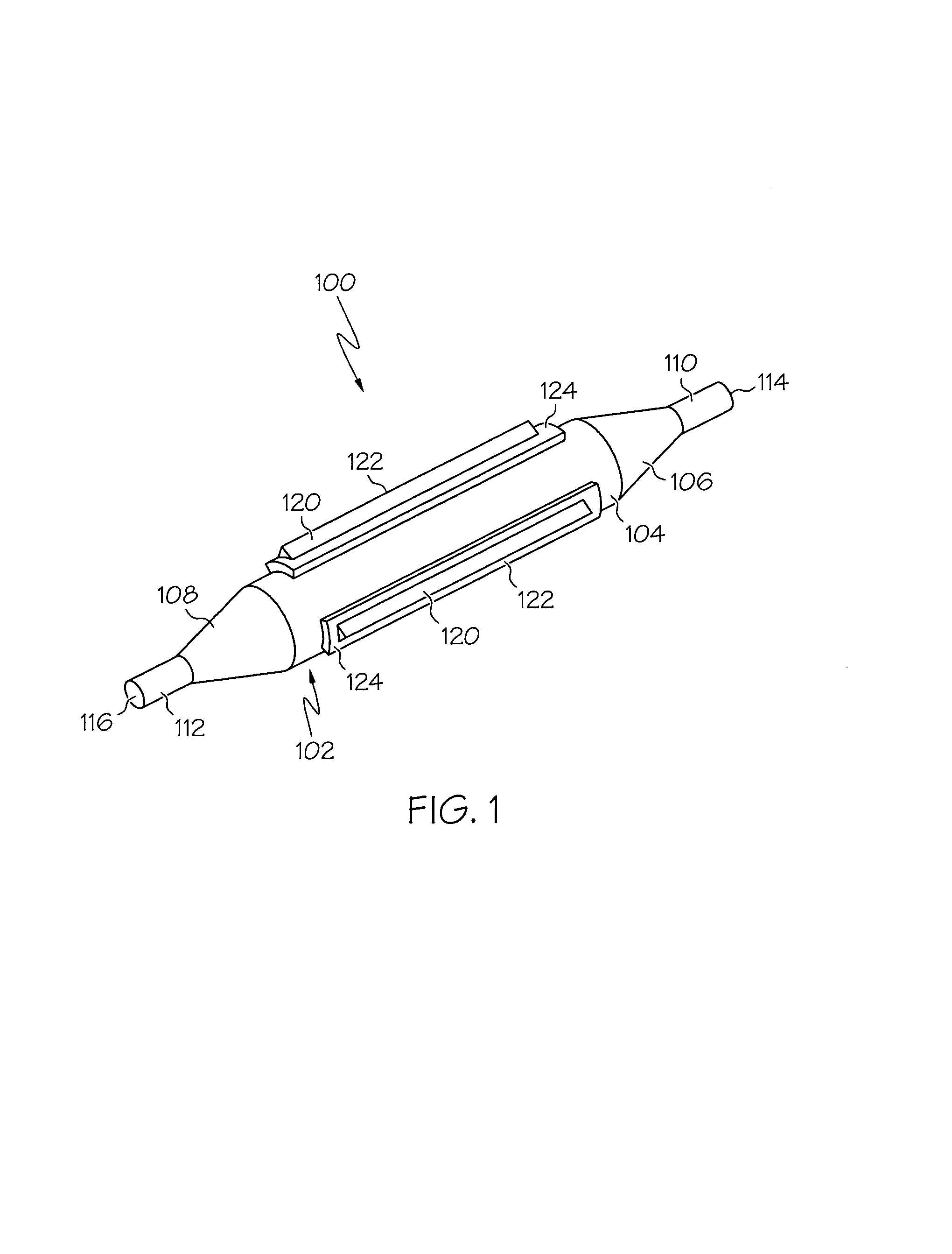

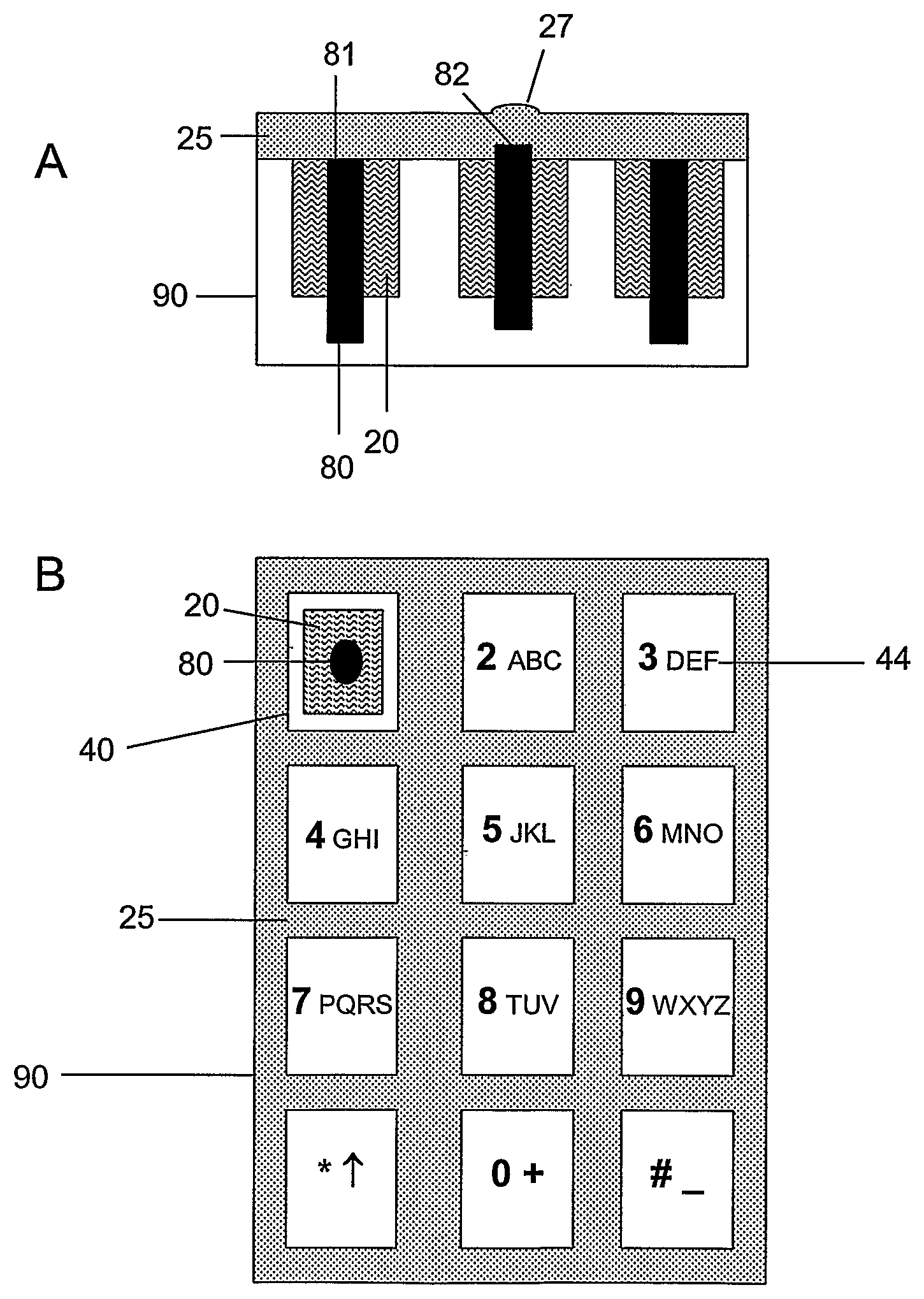

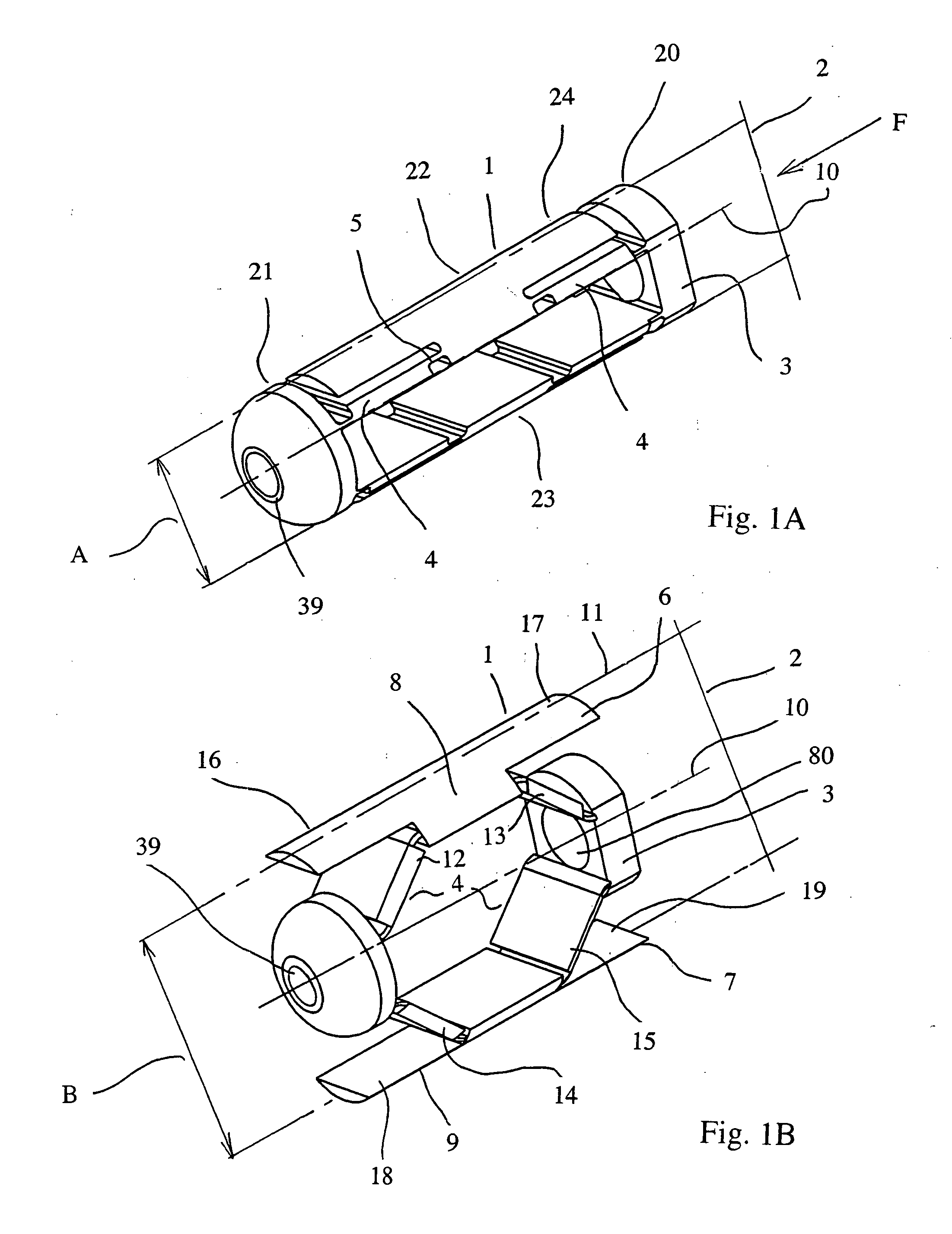

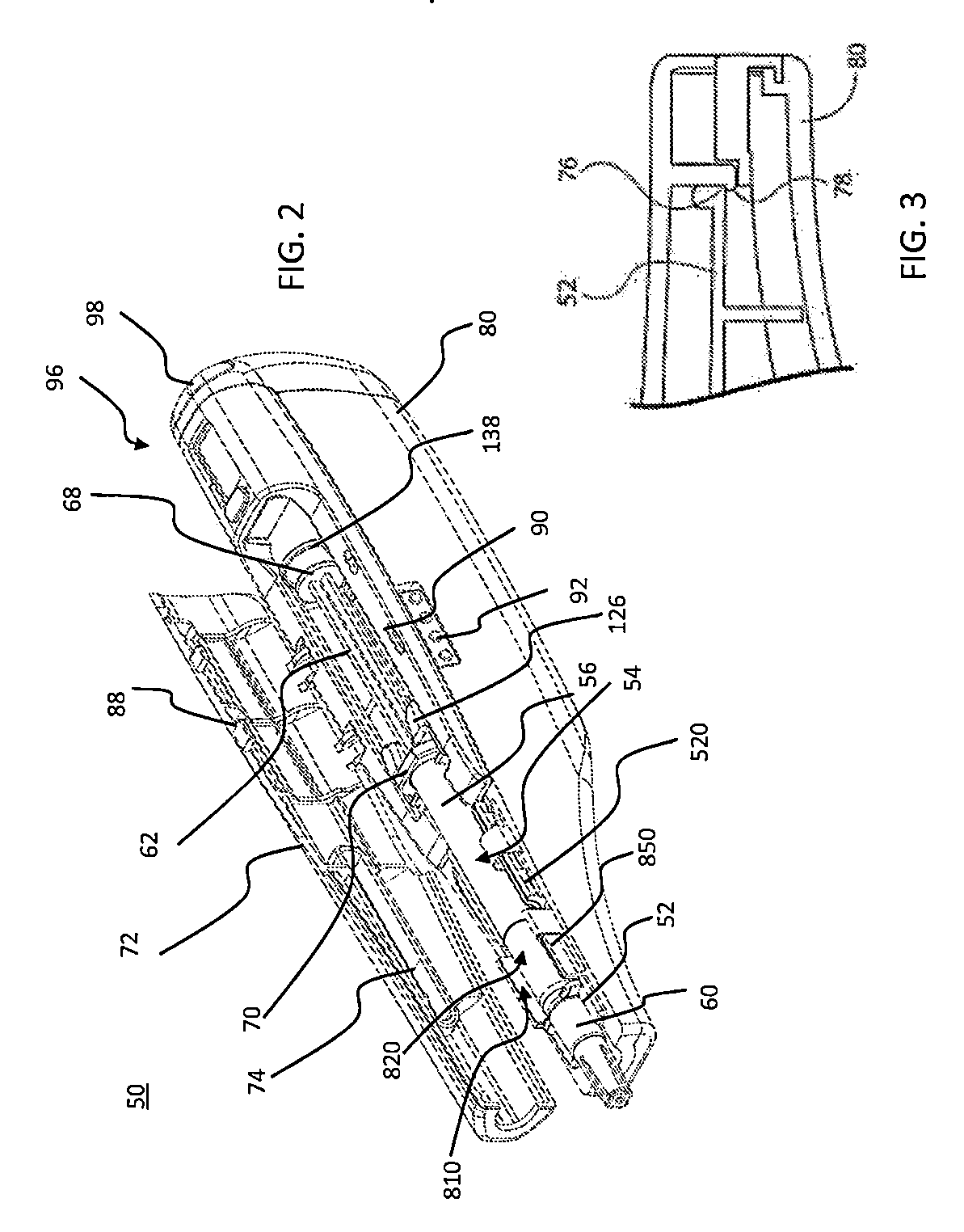

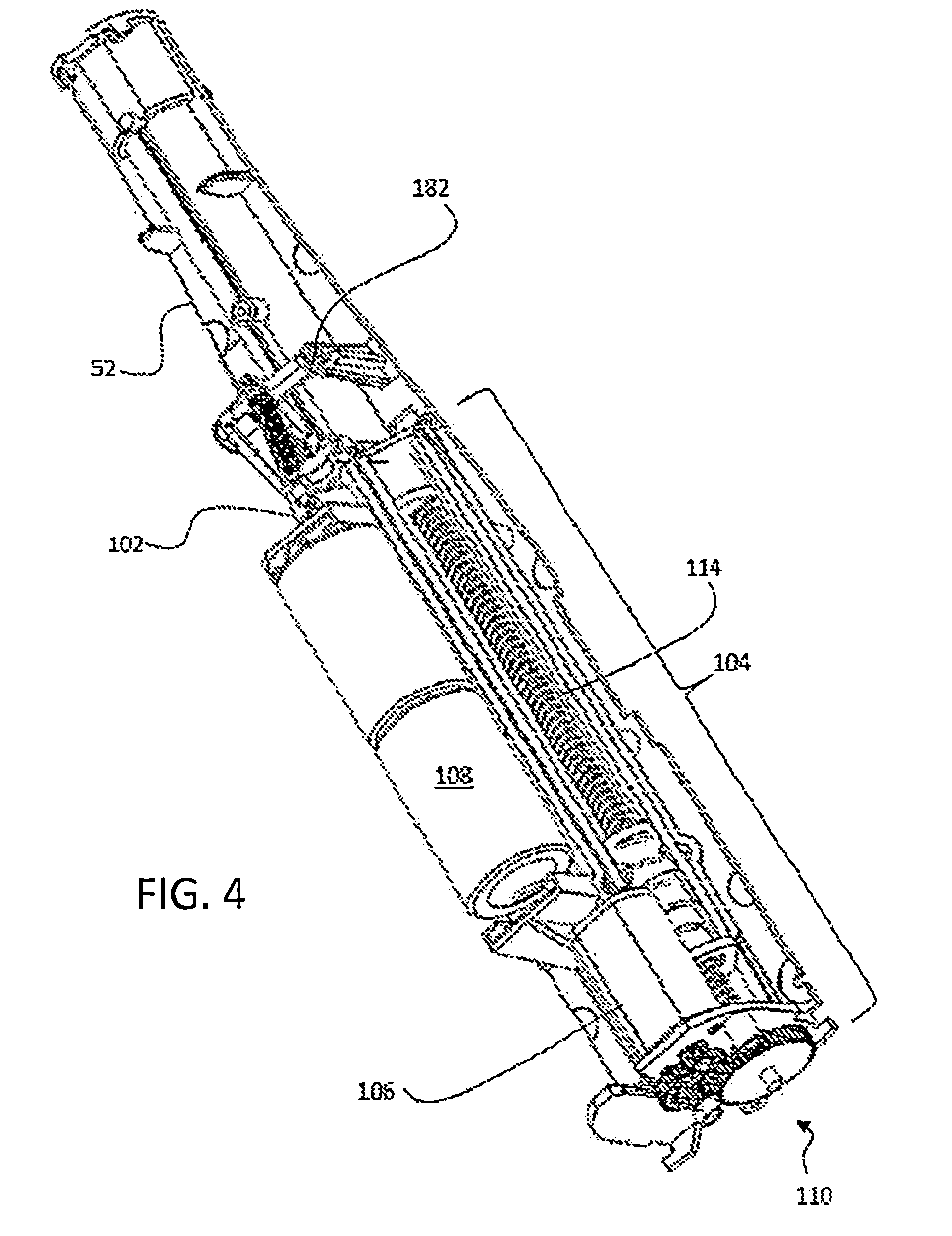

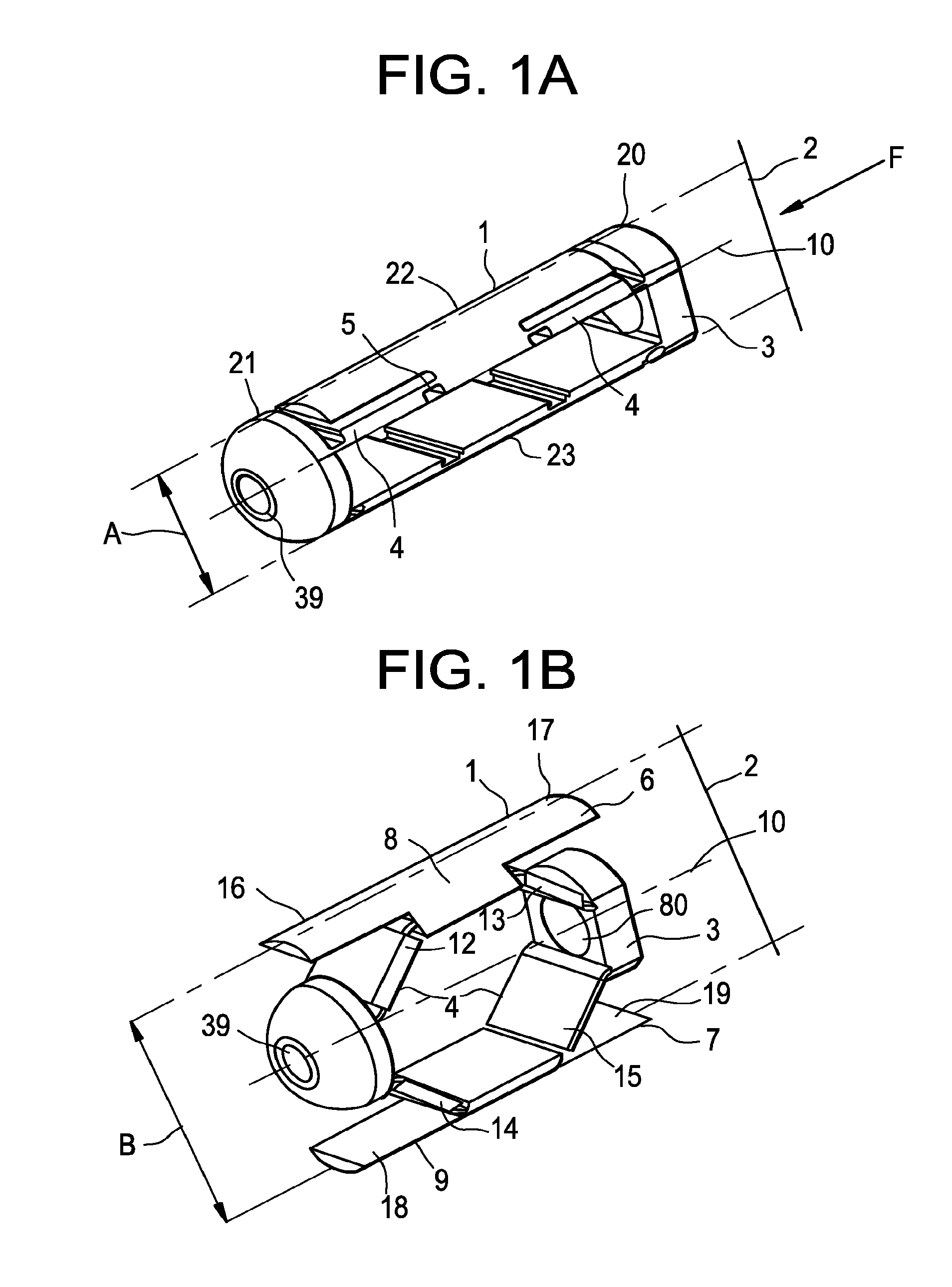

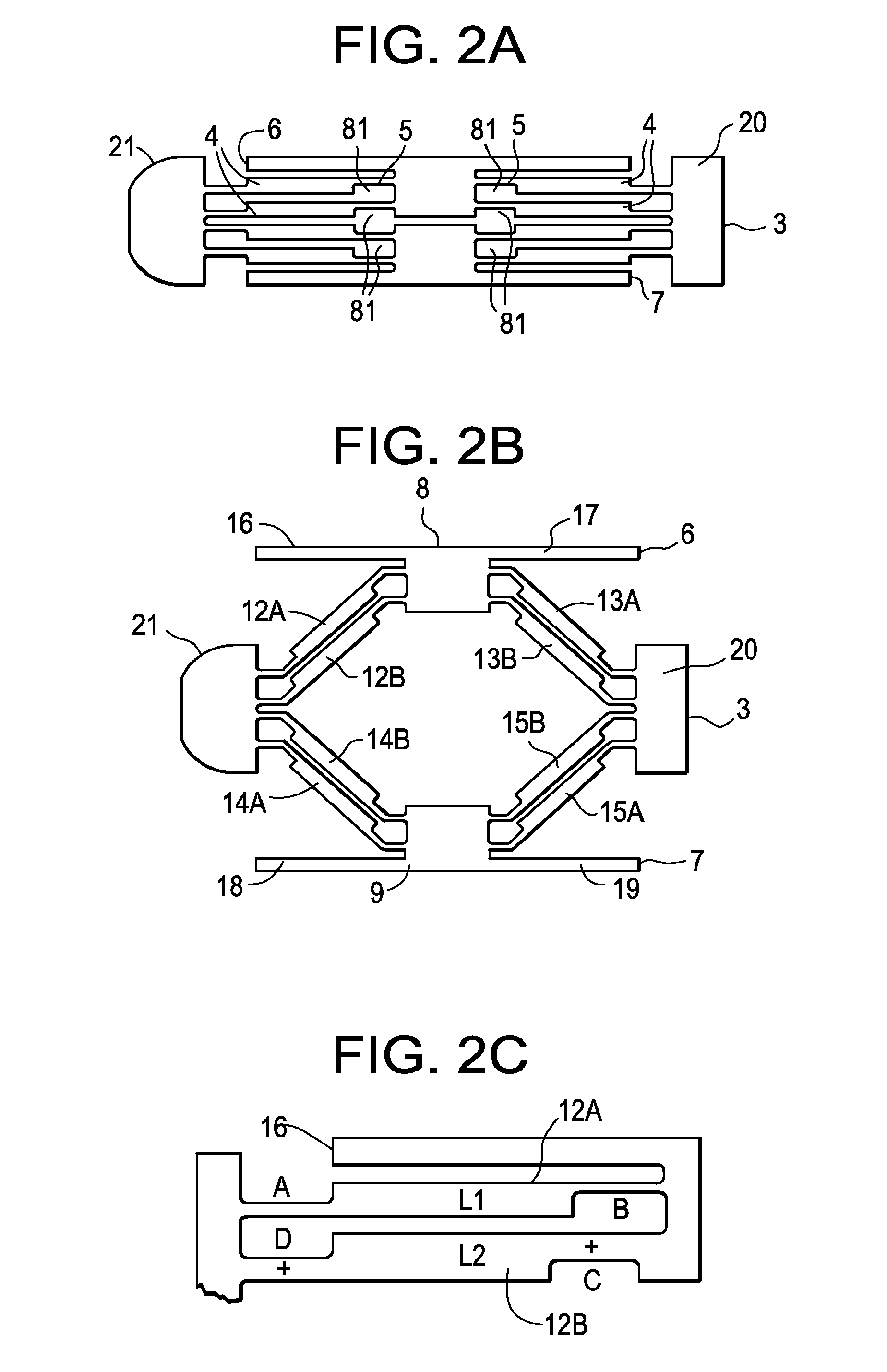

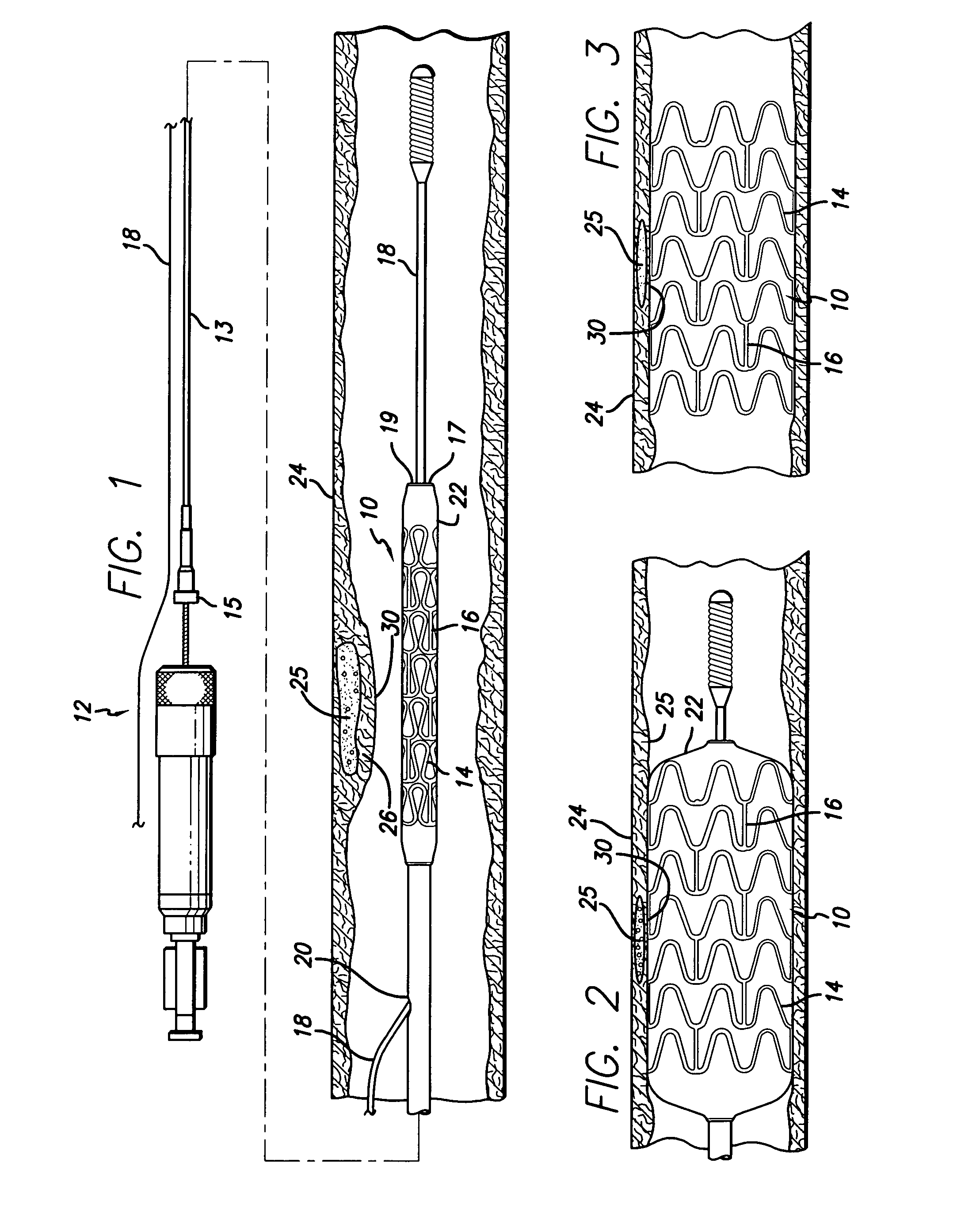

Medical device delivery sheath

InactiveUS20080188928A1Easy to collapseFacilitate resheathingStentsHeart valvesMedical deviceGuide tube

A support member for a catheter sheath is disclosed. The support member has a series of ribs with a distal member having integrated fingers for providing radial compliance. The support member provides sufficient axial stiffness to provide a desired pushability of a minimally invasive device for replacing a heart valve. Various alternative embodiments are also described.

Owner:BOSTON SCI SCIMED INC

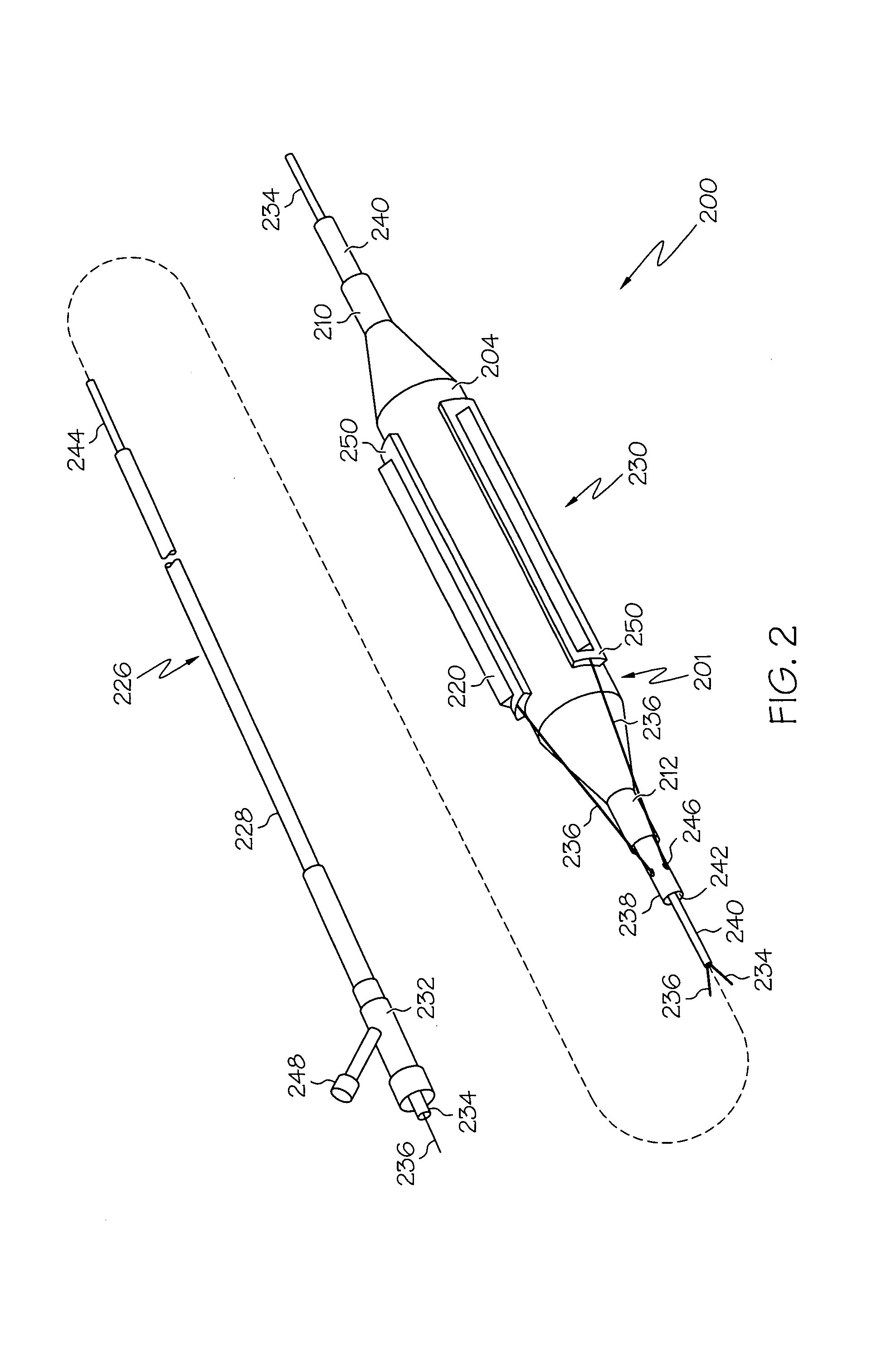

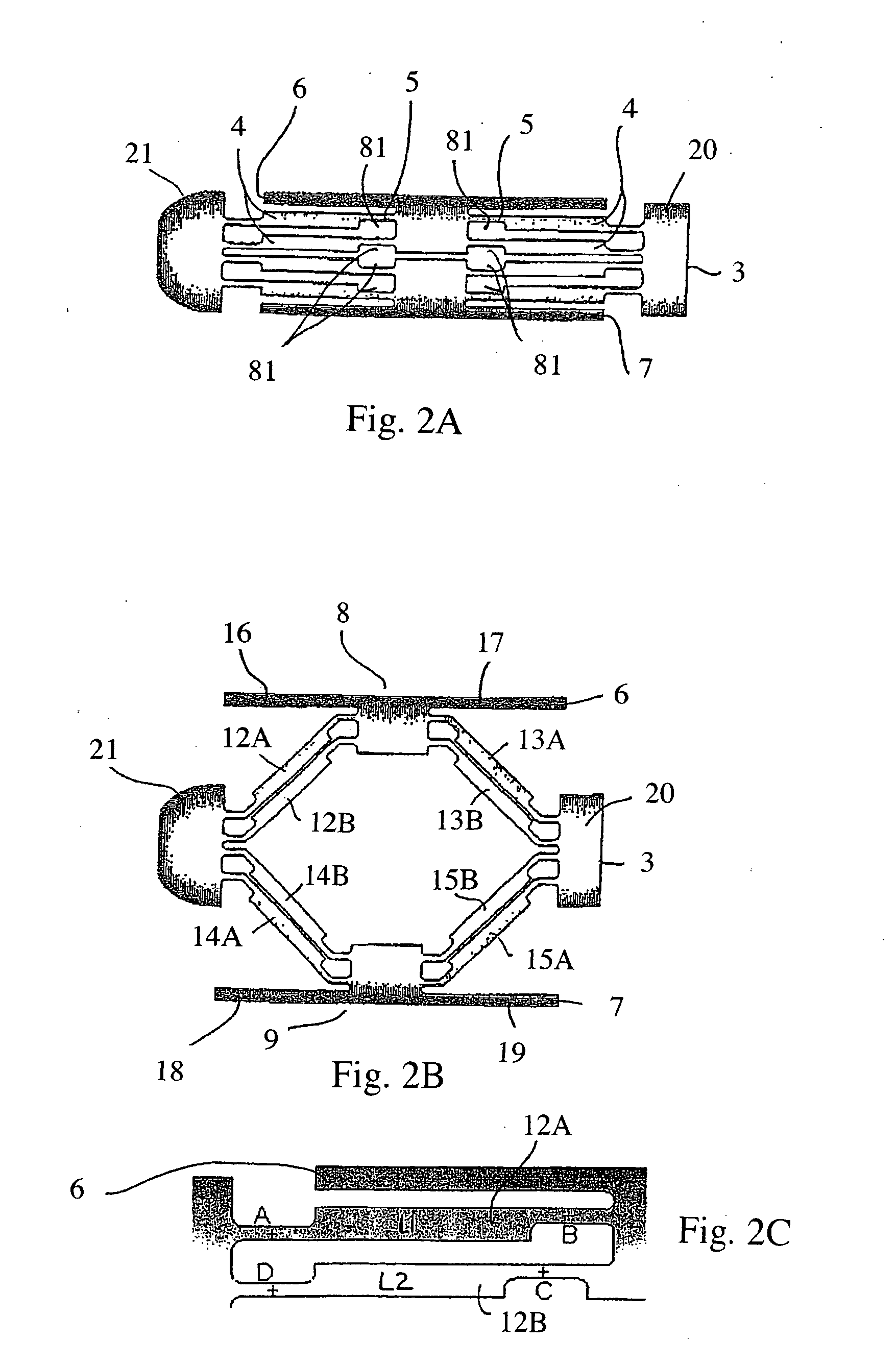

Catheter balloon with ultrasonic microscalpel blades

InactiveUS7153315B2Much sharper and cleaner incisionsCutting precision can be improvedCannulasSurgical instrument detailsBalloon catheterMedical treatment

The present invention provides a catheter balloon, and balloon catheter incorporating the catheter balloon, useful in medical dilation procedures. The catheter balloon includes at least one microscalpel operatively disposed on an outer surface thereof. The microscalpel may advantageously be operatively disposed relative to a power source so as to be controllably activatable. Also provided are methods of making the inventive balloon and / or catheter as well as methods of using the inventive catheter in a dilation / incising treatment.

Owner:BOSTON SCI SCIMED INC

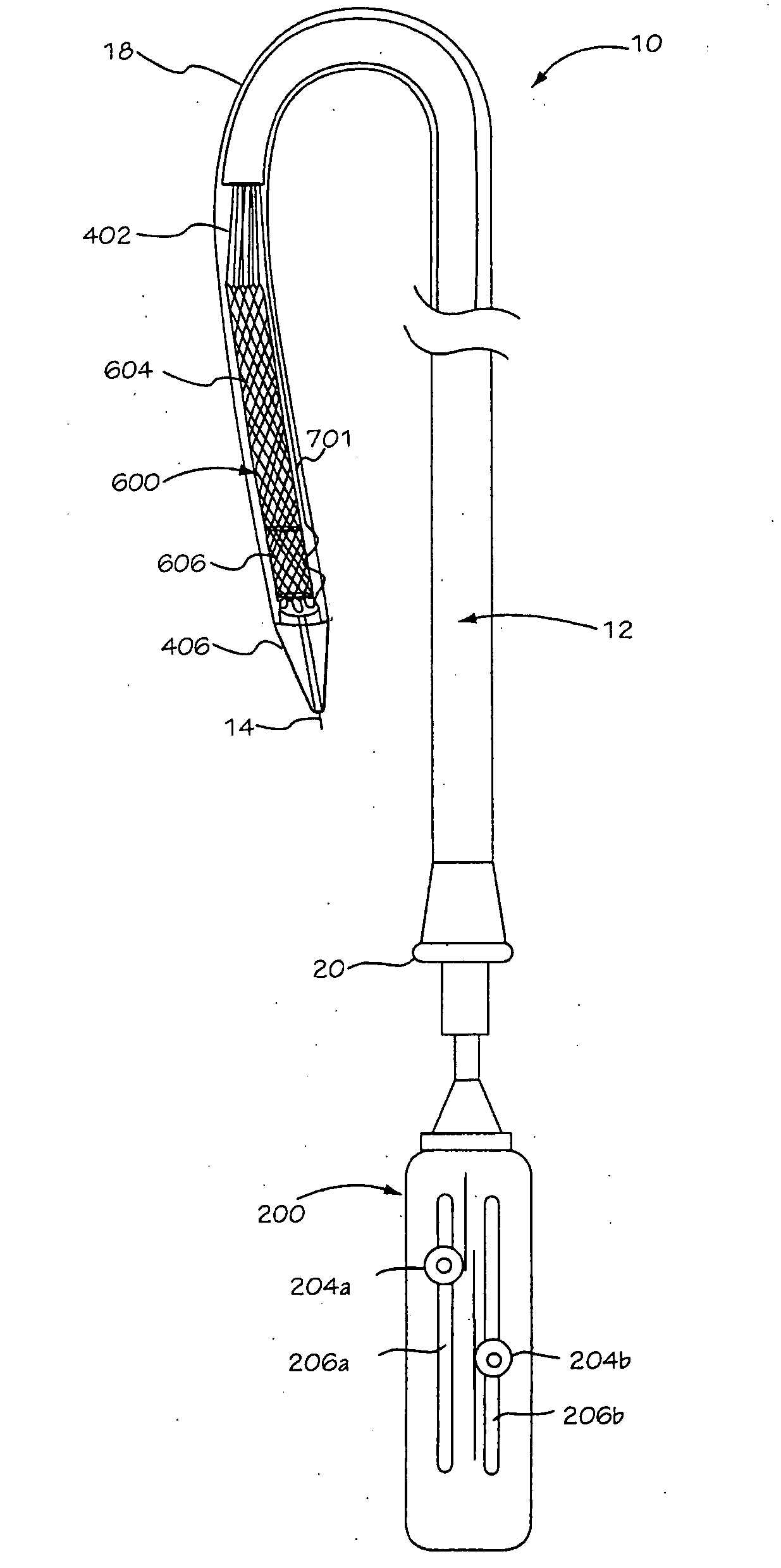

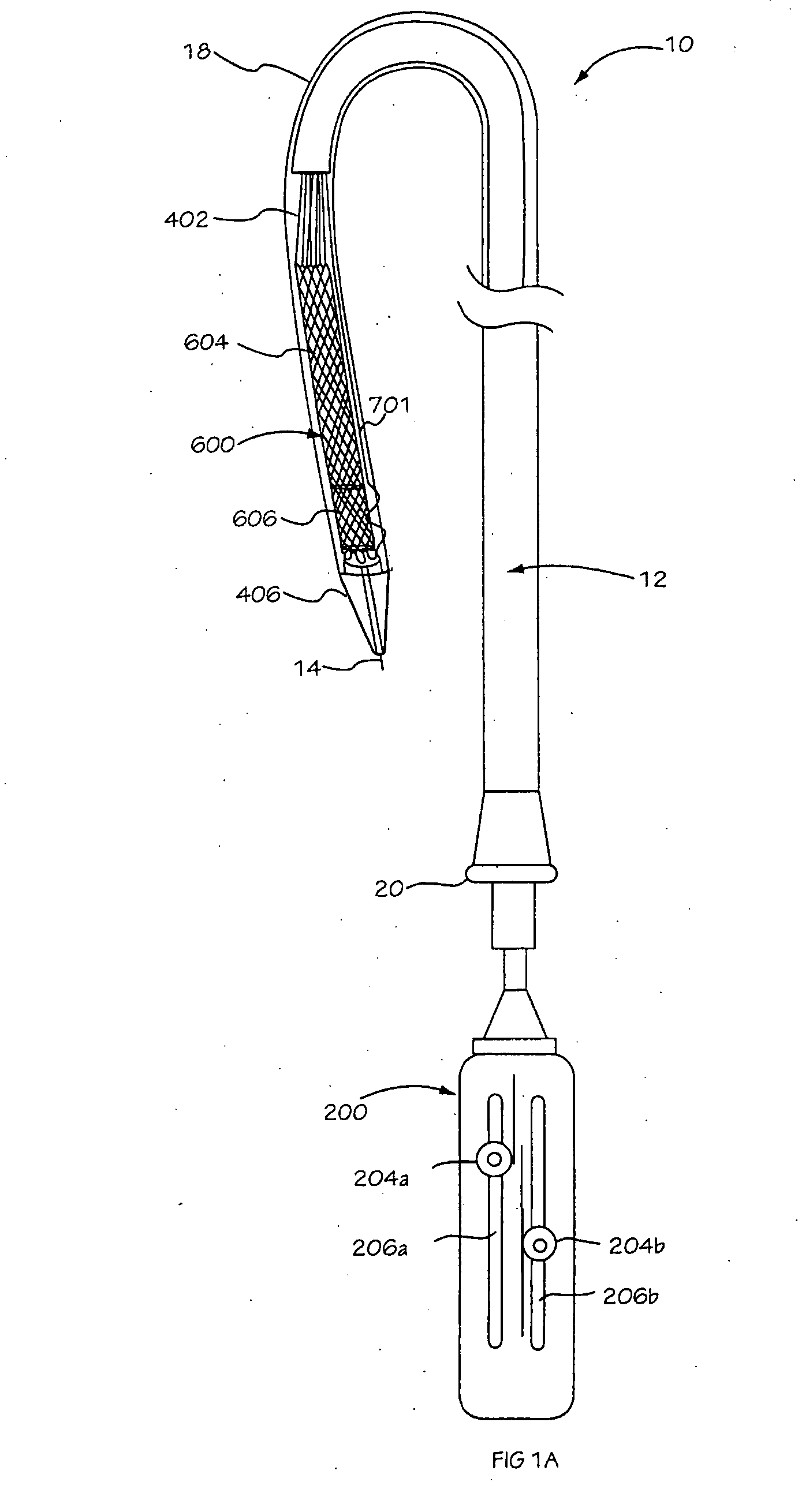

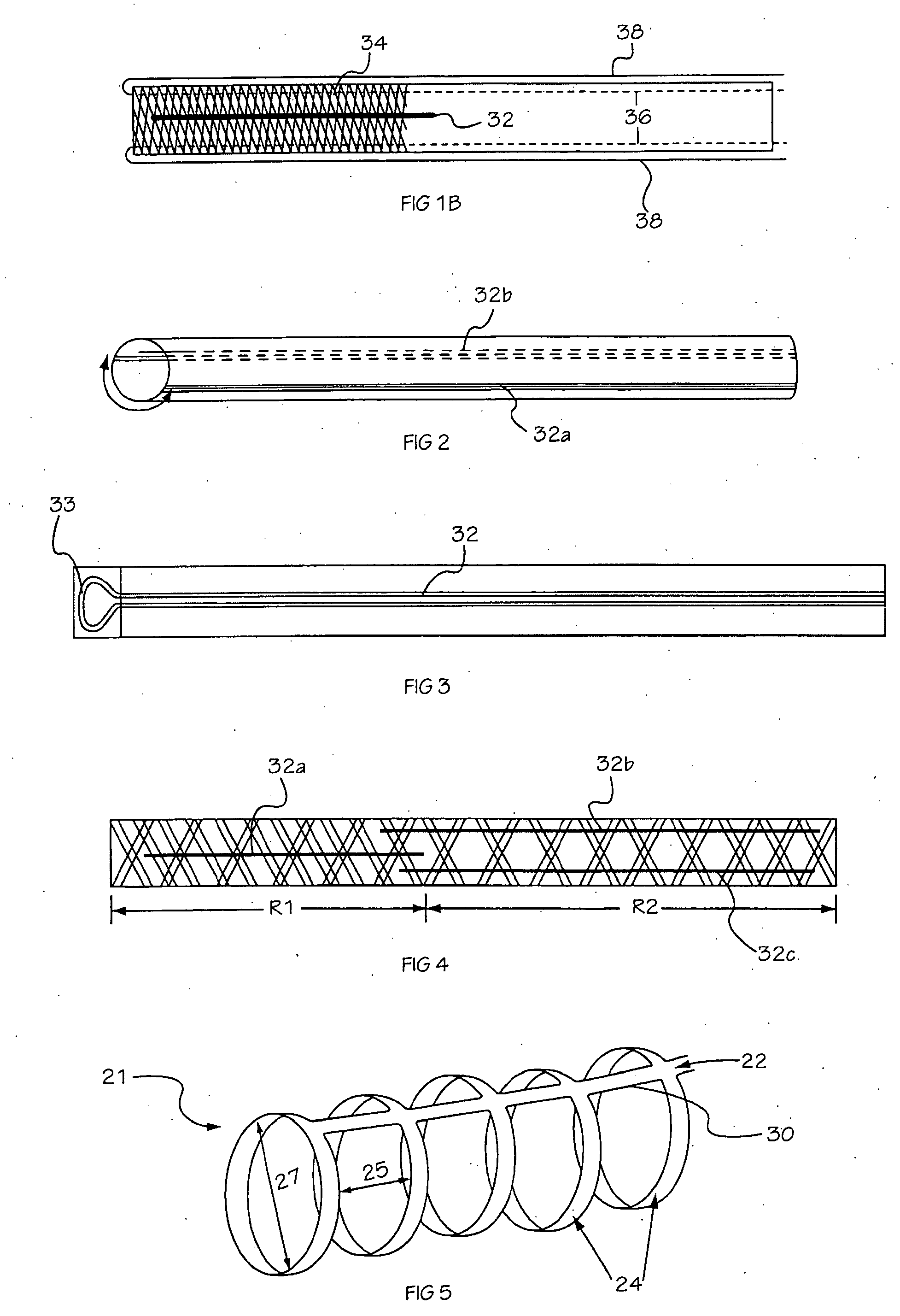

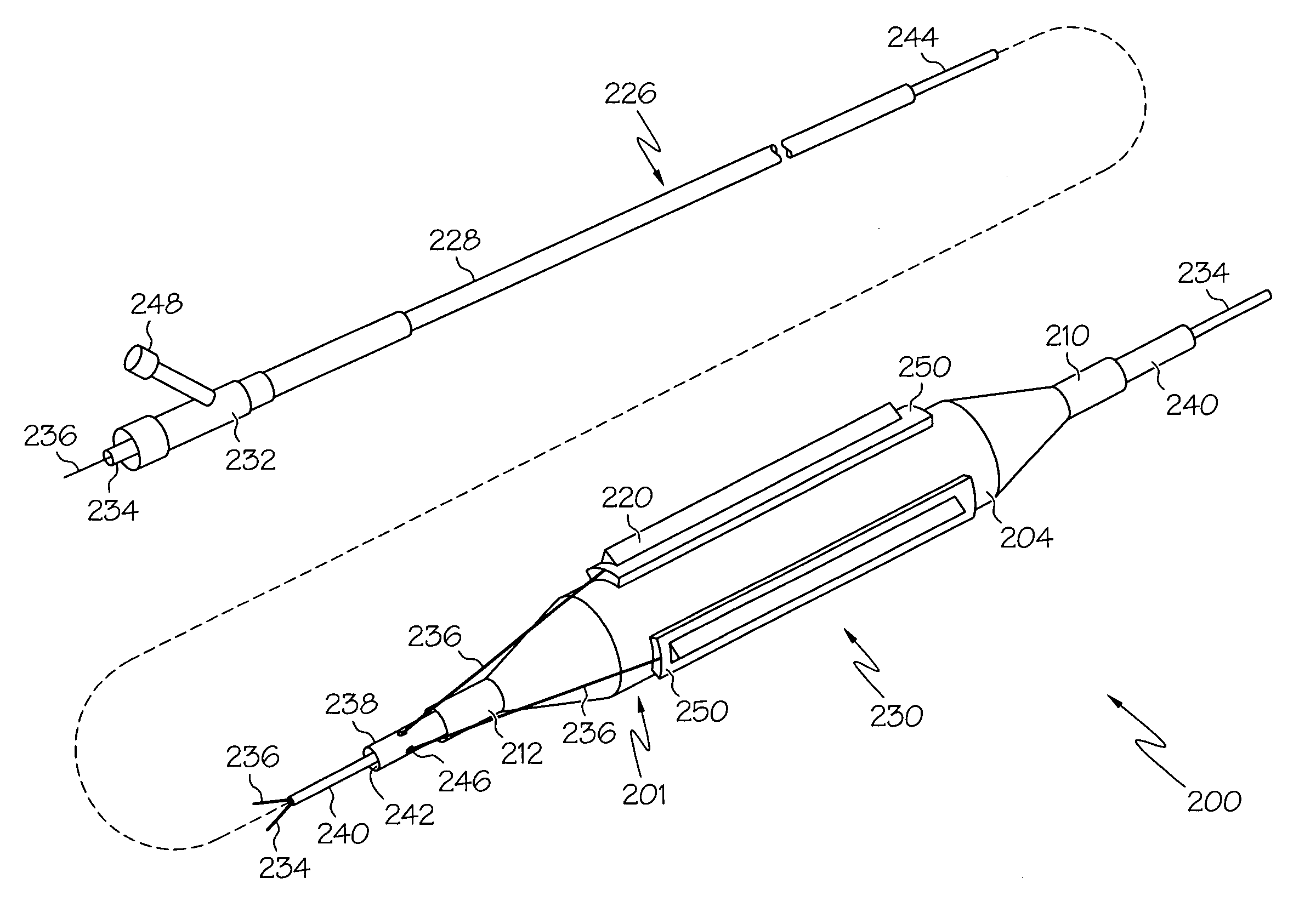

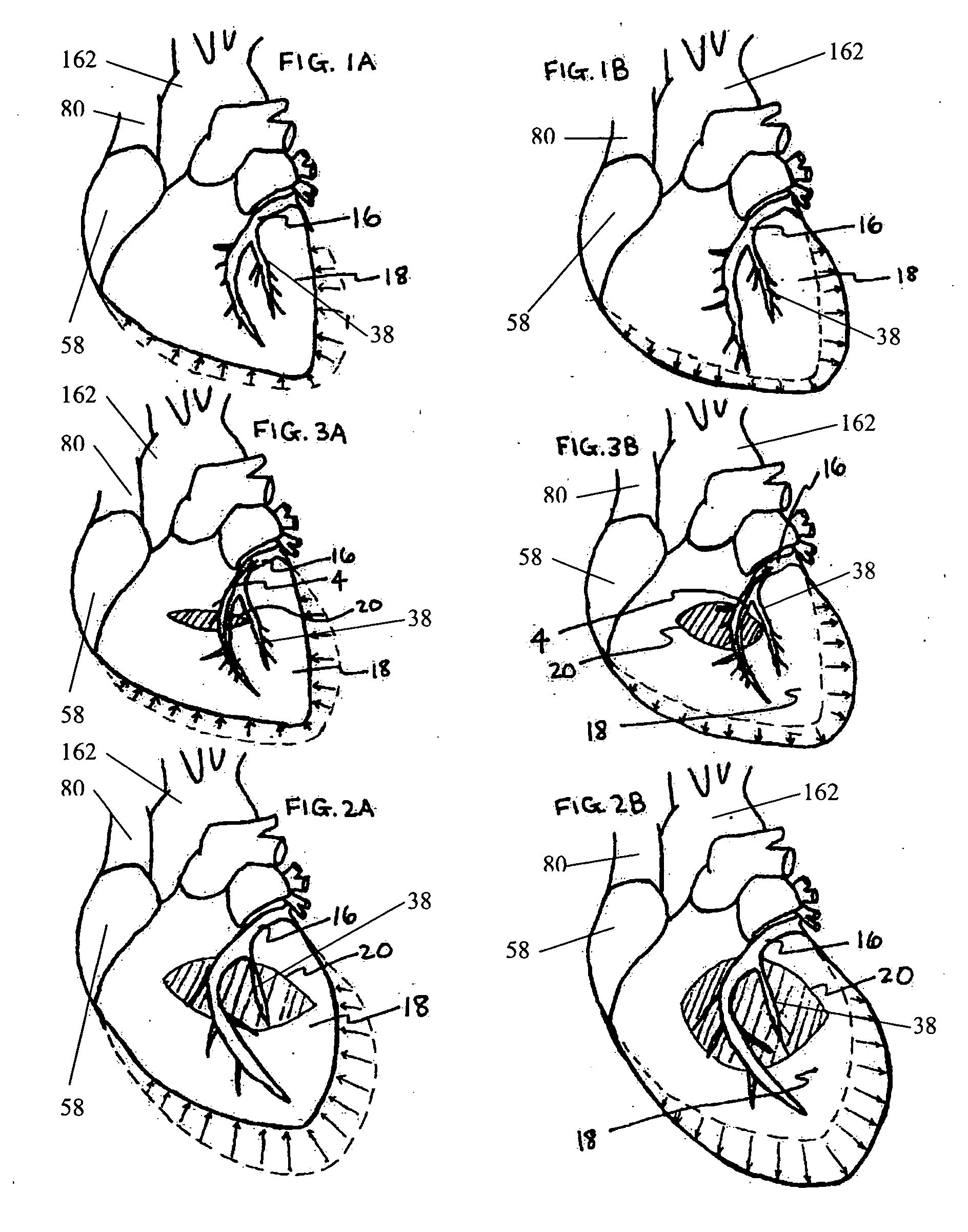

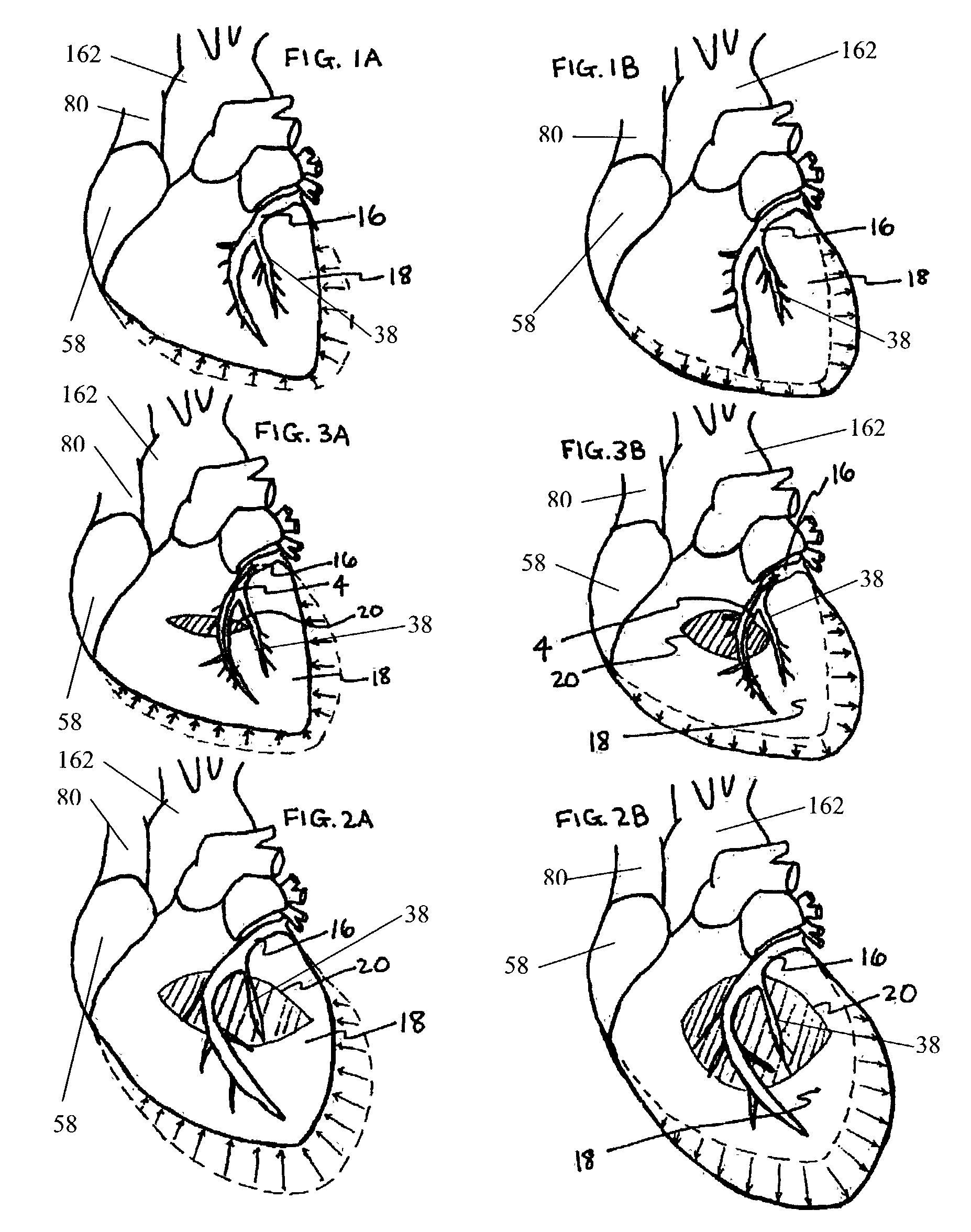

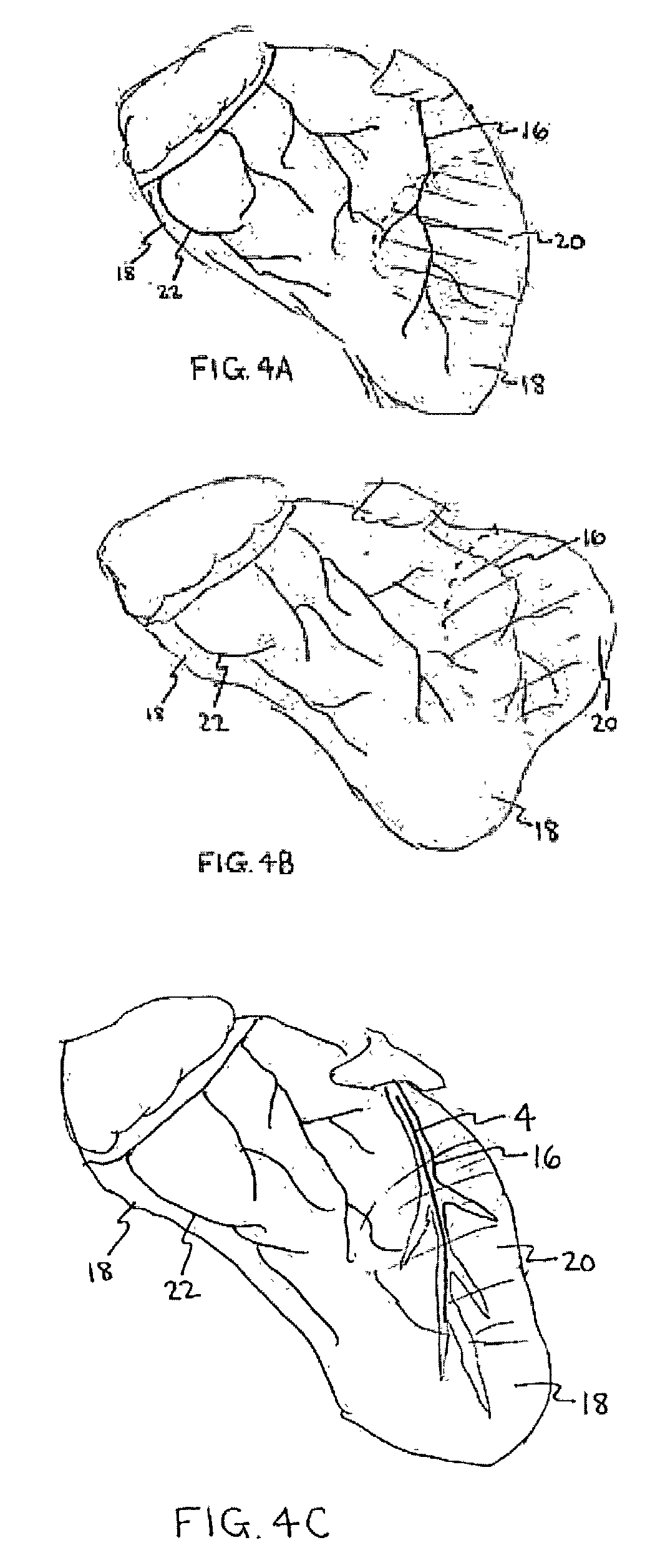

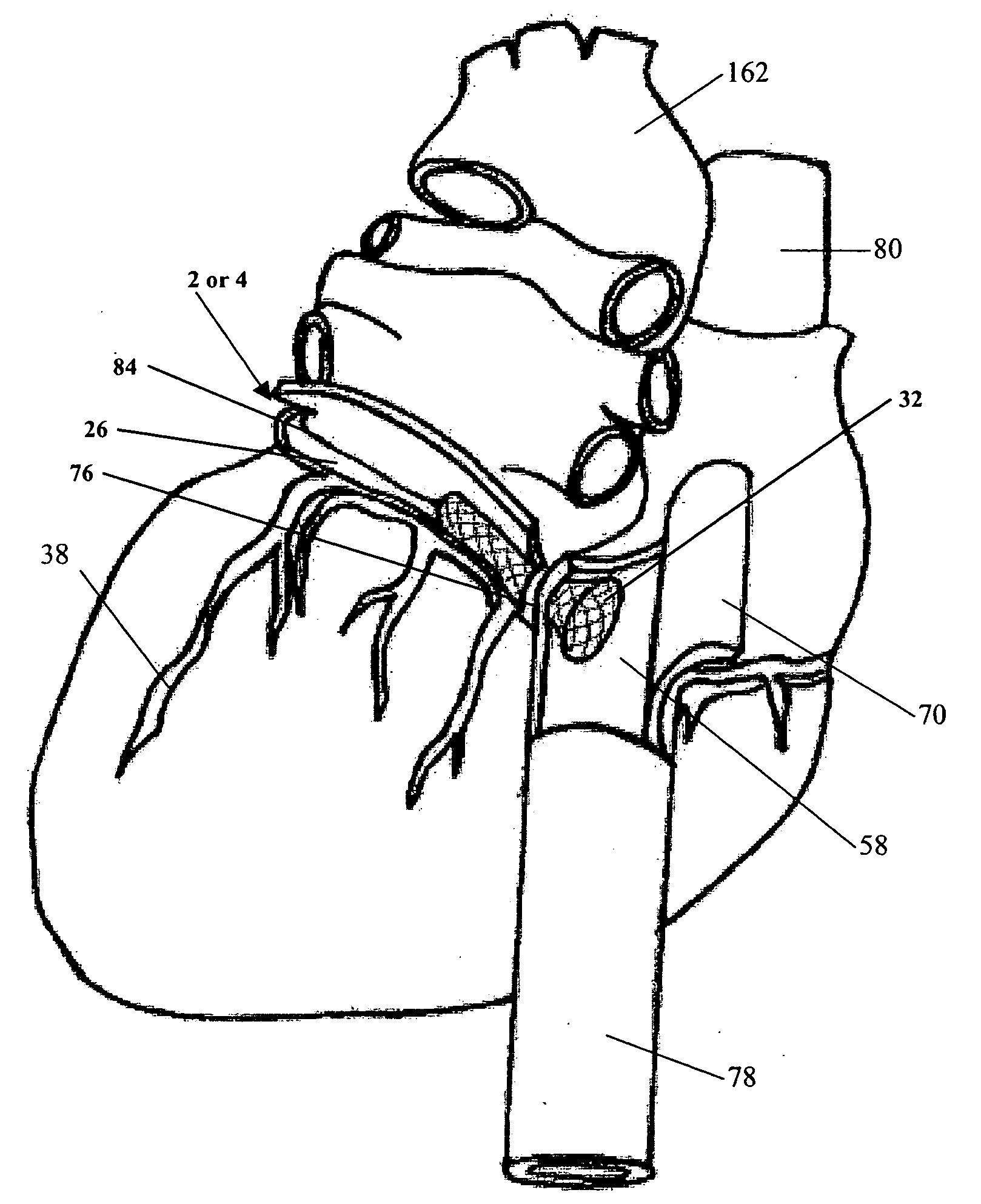

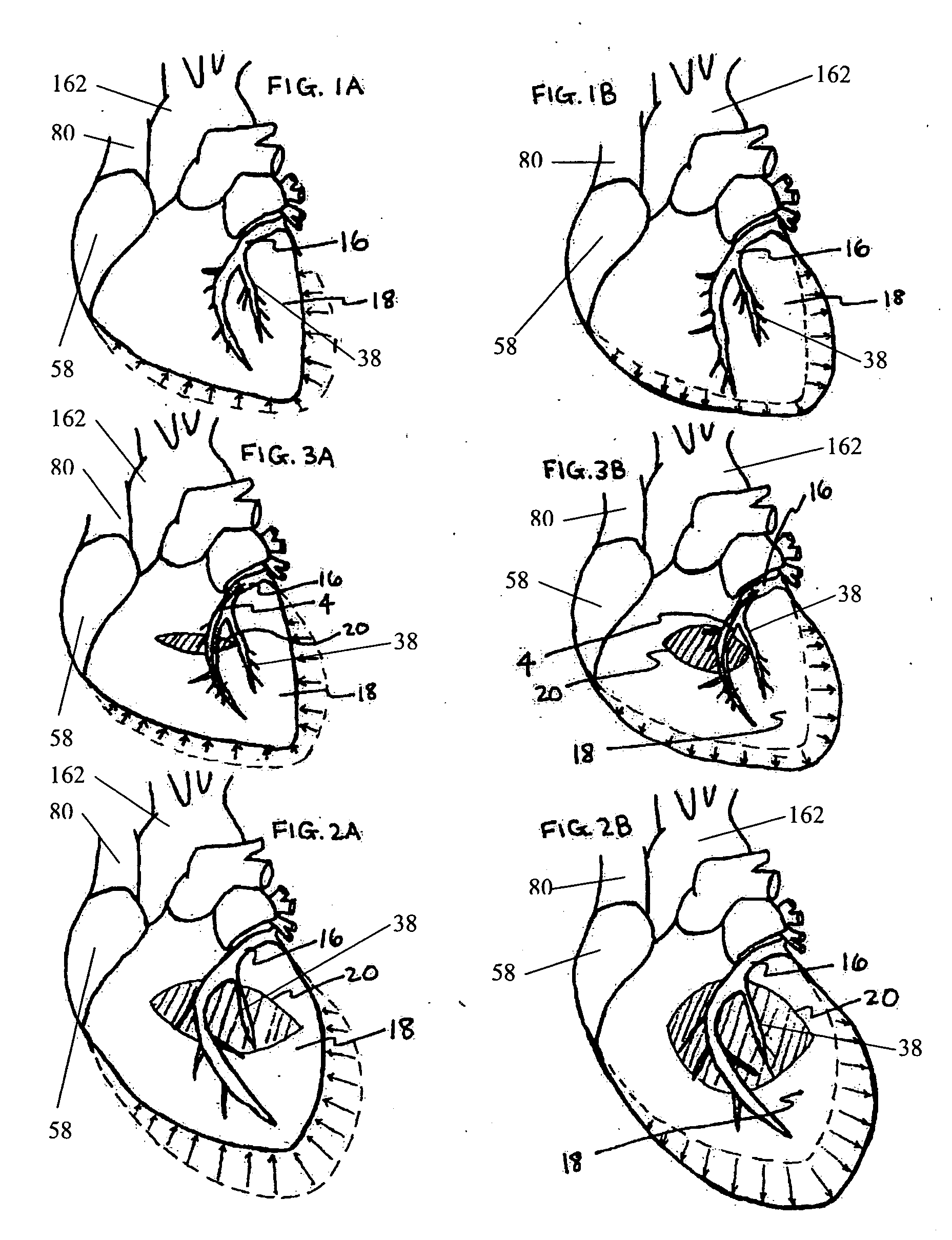

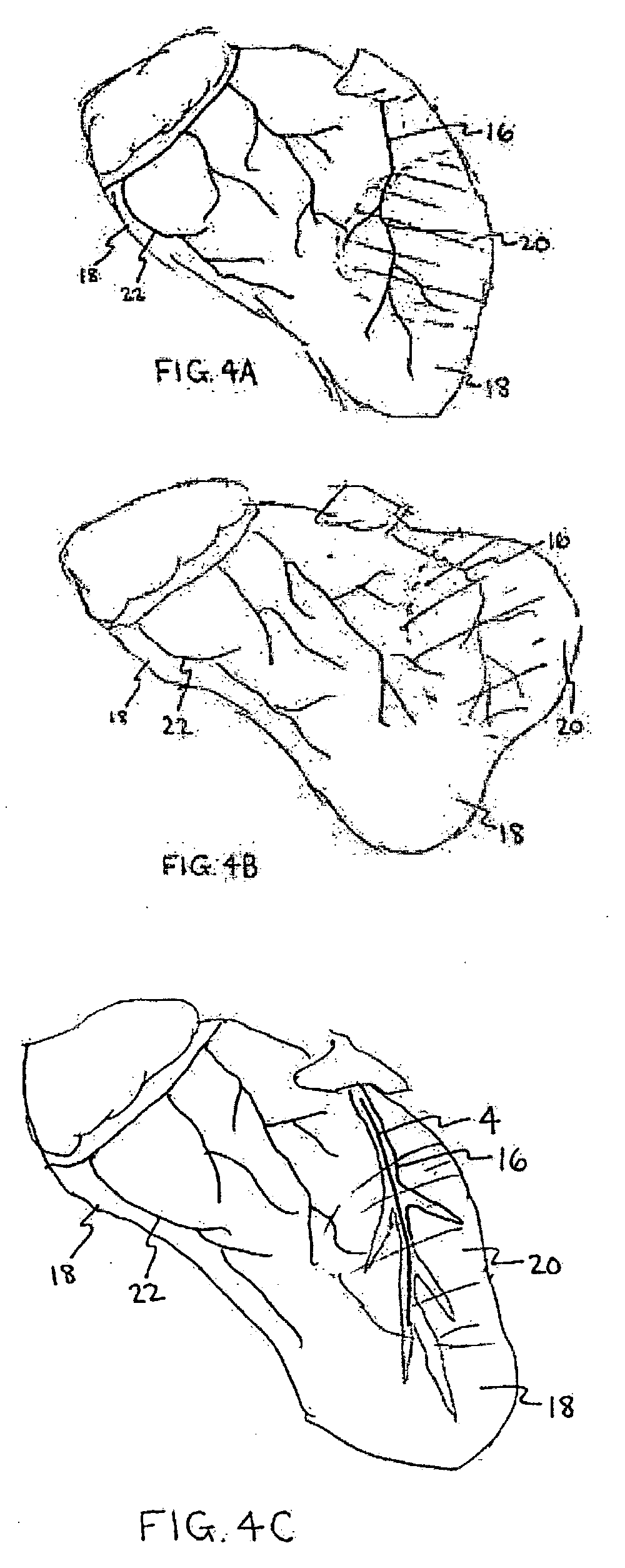

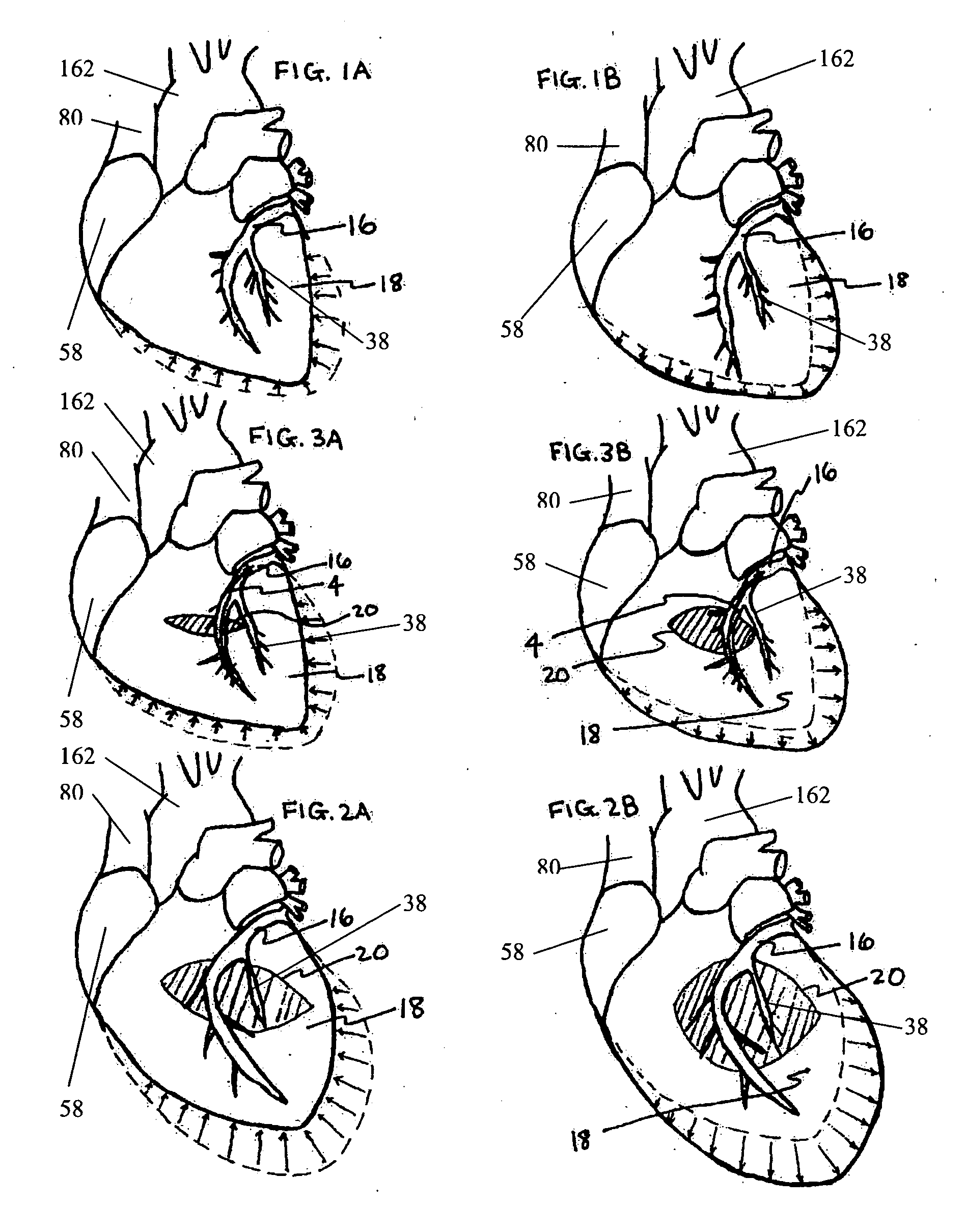

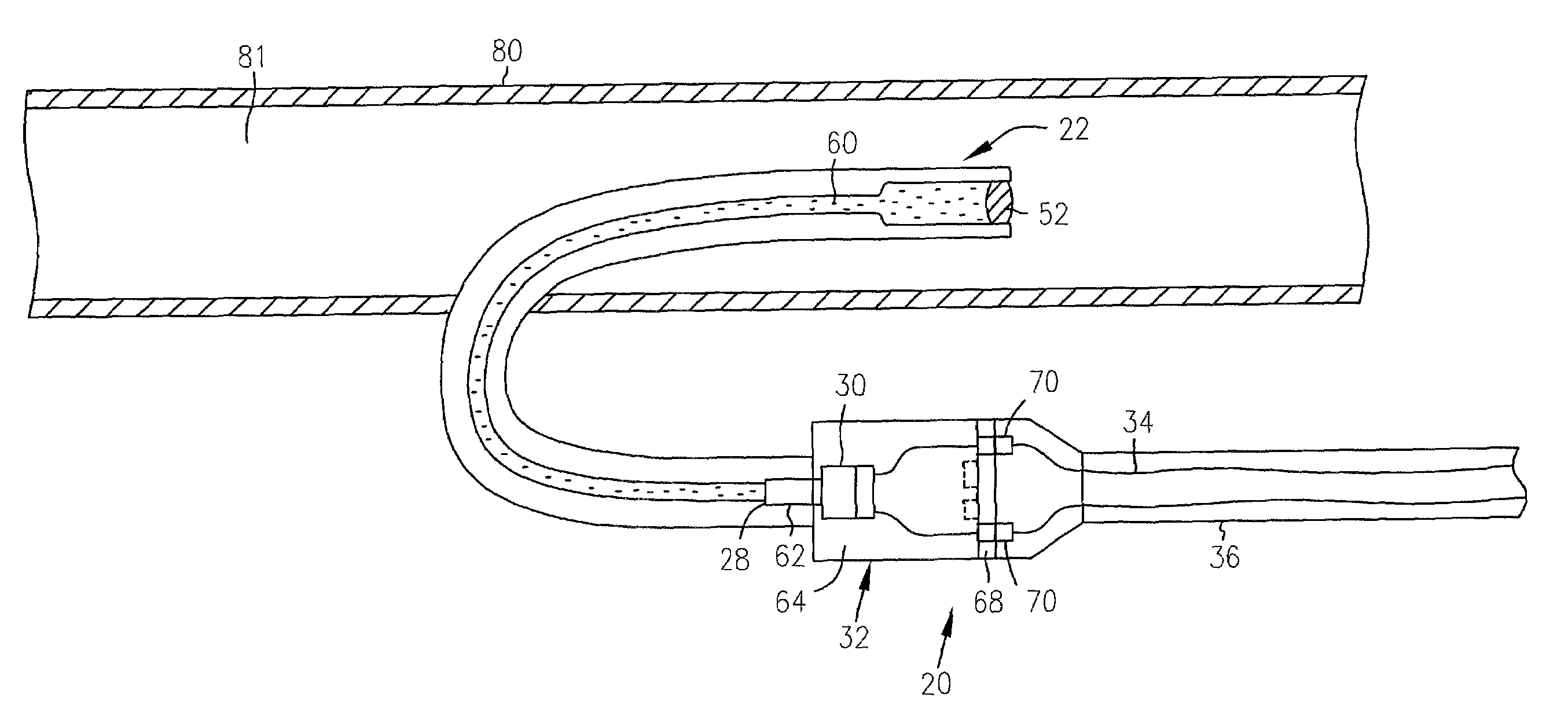

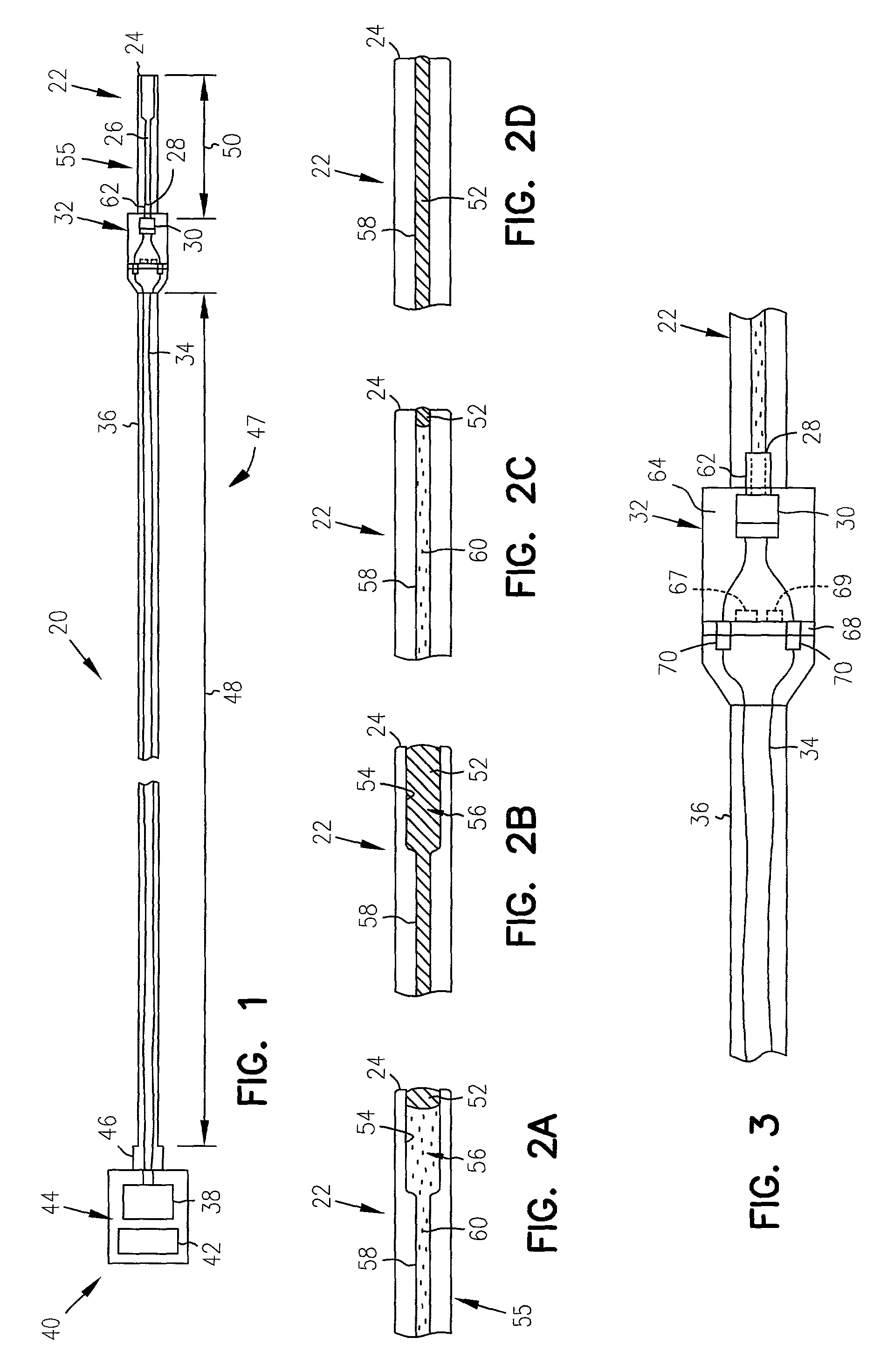

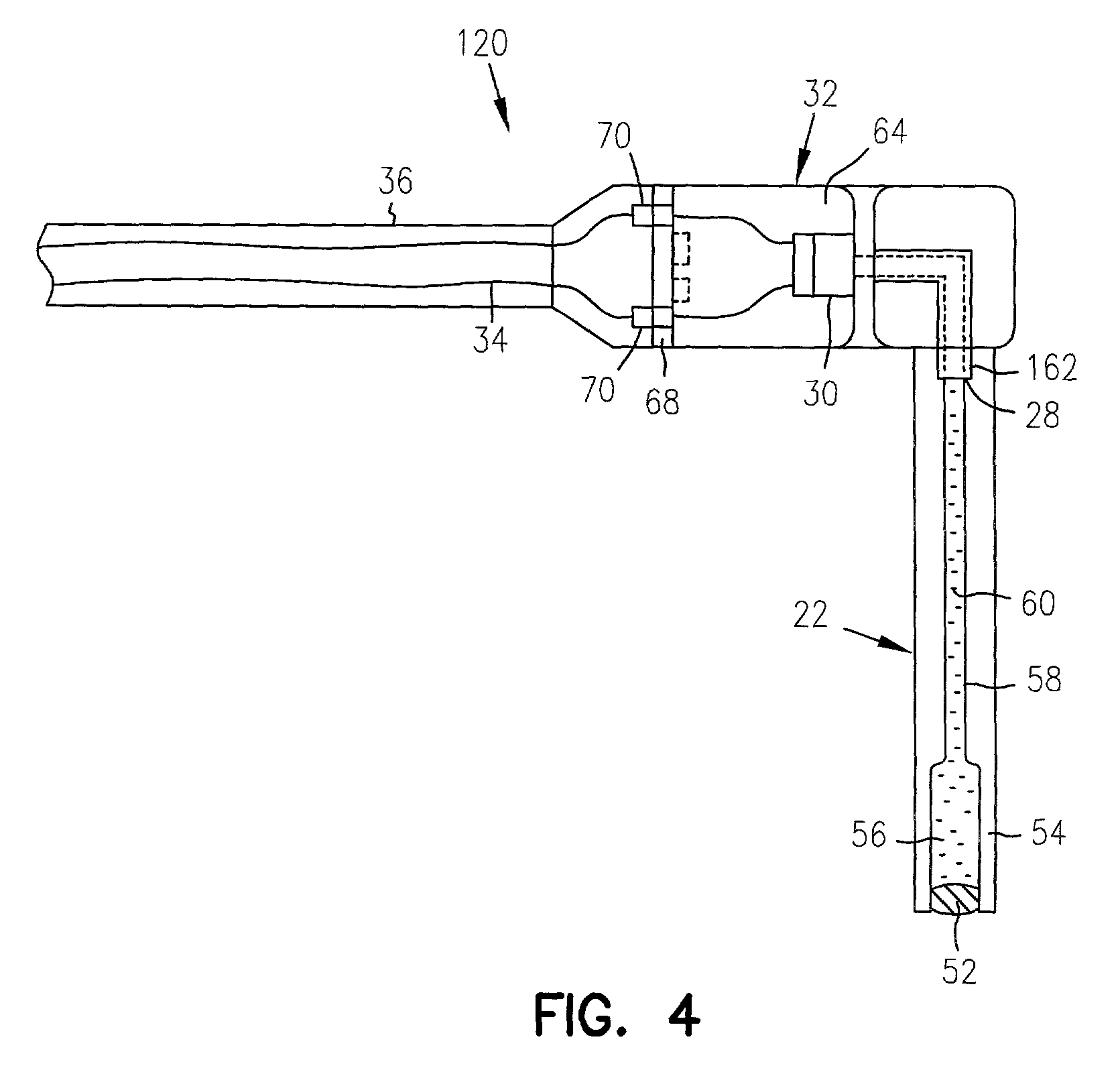

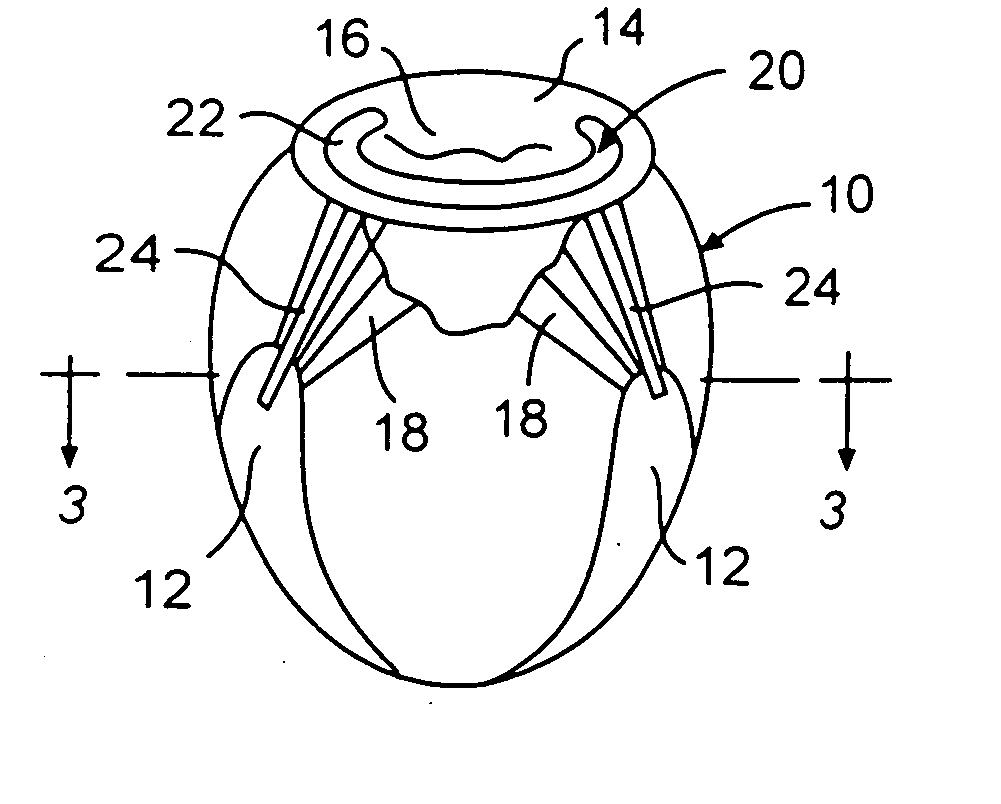

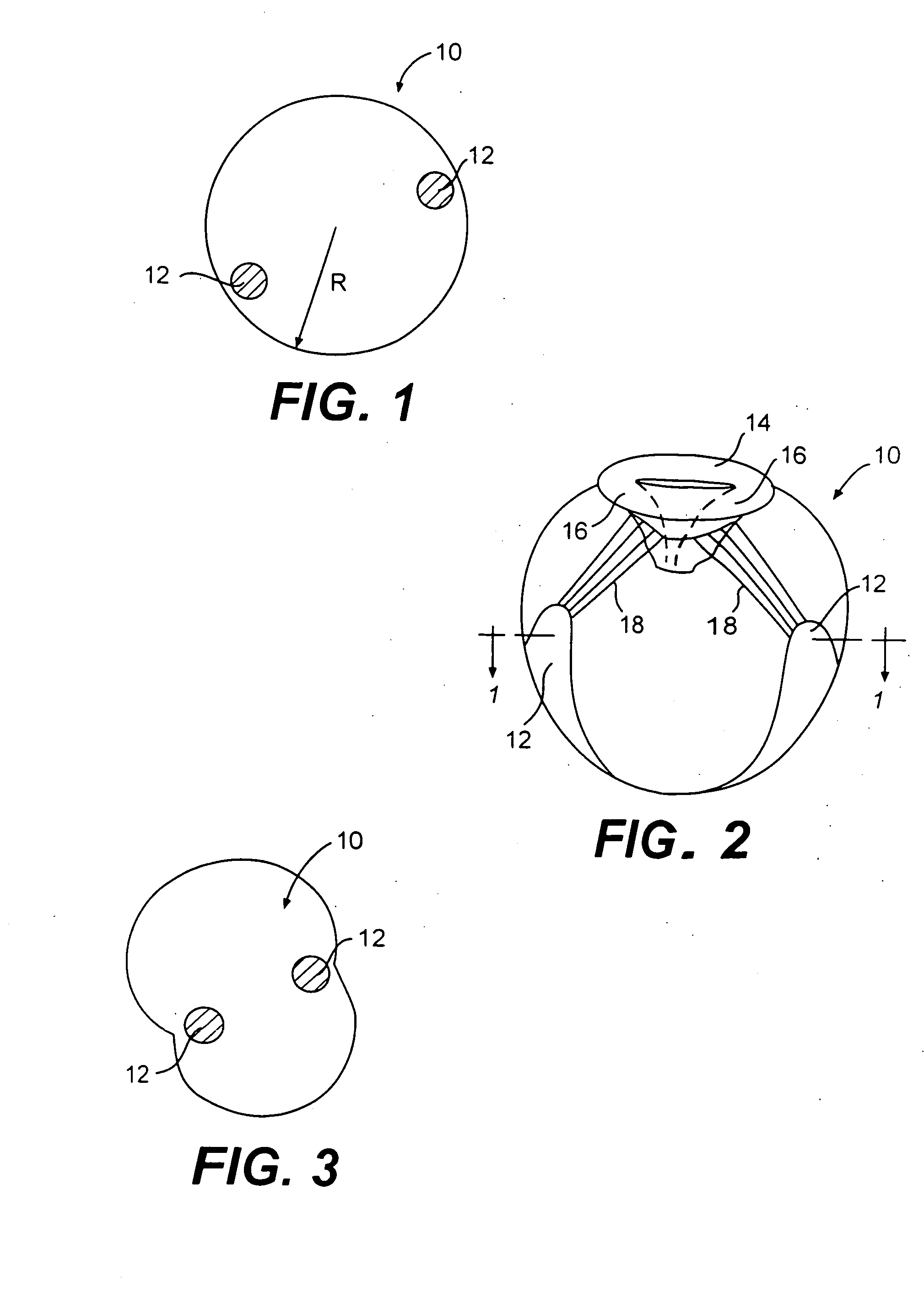

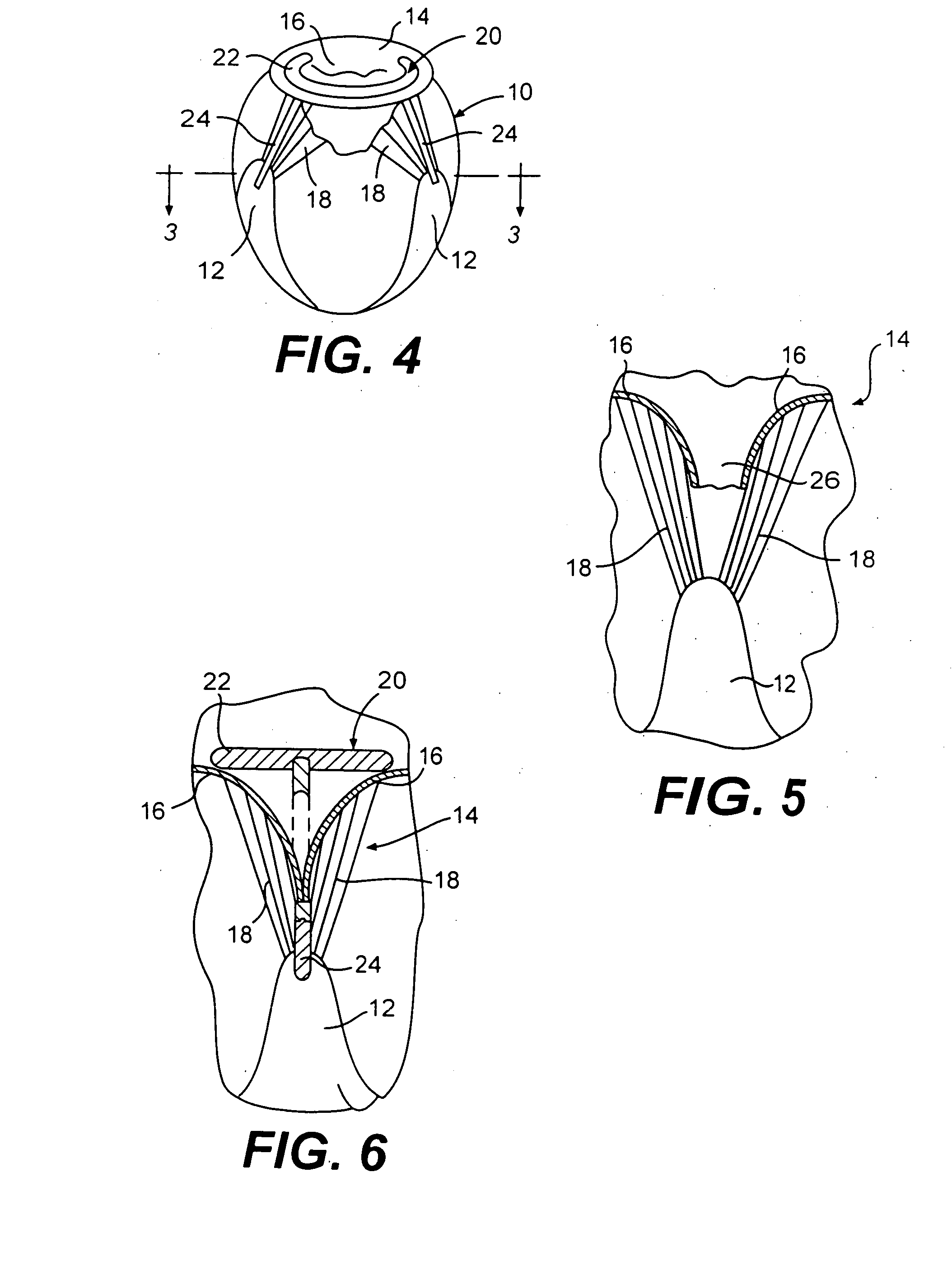

Systems for heart treatment

InactiveUS20050197694A1Reduce stressReduce/limit volumeSuture equipmentsElectrotherapyLeft ventricular sizeTherapeutic treatment

Described are devices and methods for treating degenerative, congestive heart disease and related valvular dysfunction. Percutaneous and minimally invasive surgical tensioning structures offer devices that mitigate changes in the ventricular structure (i.e., remodeling) and deterioration of global left ventricular performance related to tissue damage precipitating from ischemia, acute myocardial infarction (AMI) or other abnormalities. These tensioning structures can be implanted within various major coronary blood-carrying conduit structures (arteries, veins and branching vessels), into or through myocardium, or into engagement with other anatomic structures that impact cardiac output to provide tensile support to the heart muscle wall which resists diastolic filling pressure while simultaneously providing a compressive force to the muscle wall to limit, compensate or provide therapeutic treatment for congestive heart failure and / or to reverse the remodeling that produces an enlarged heart.

Owner:EXTENSIA MEDICAL

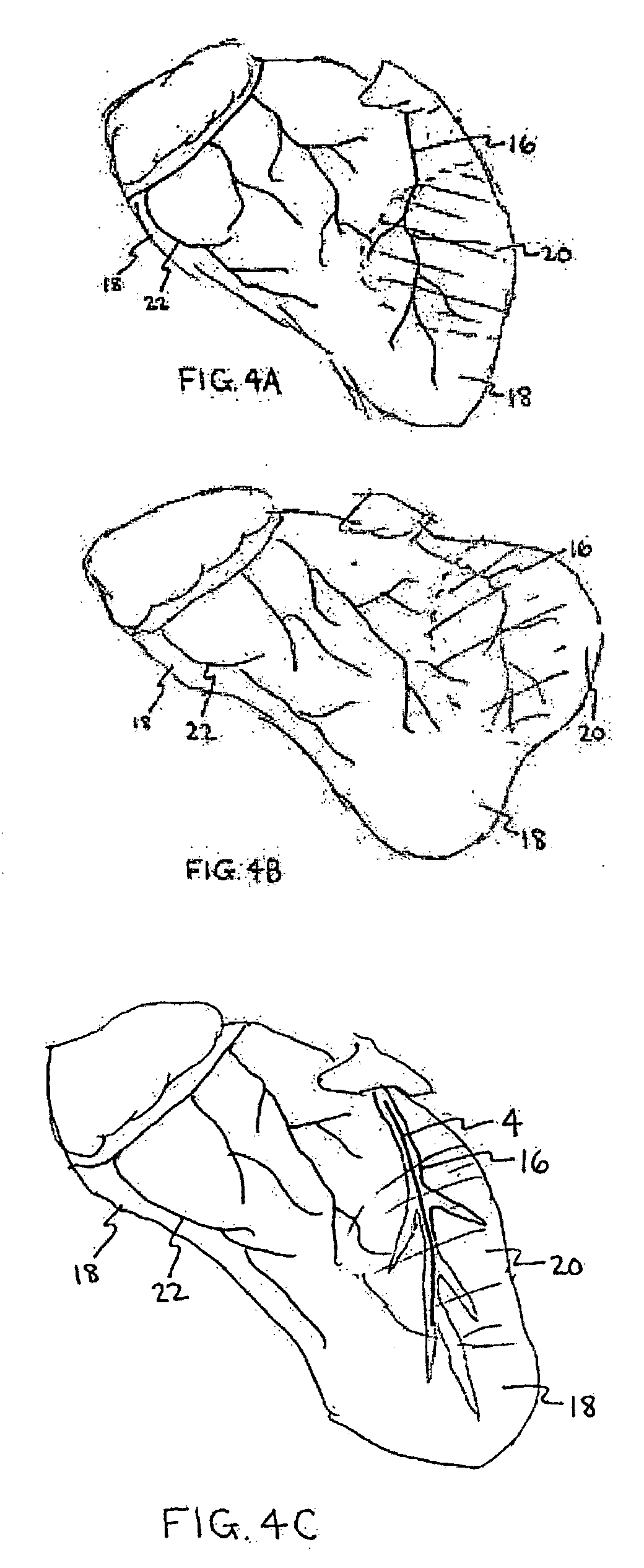

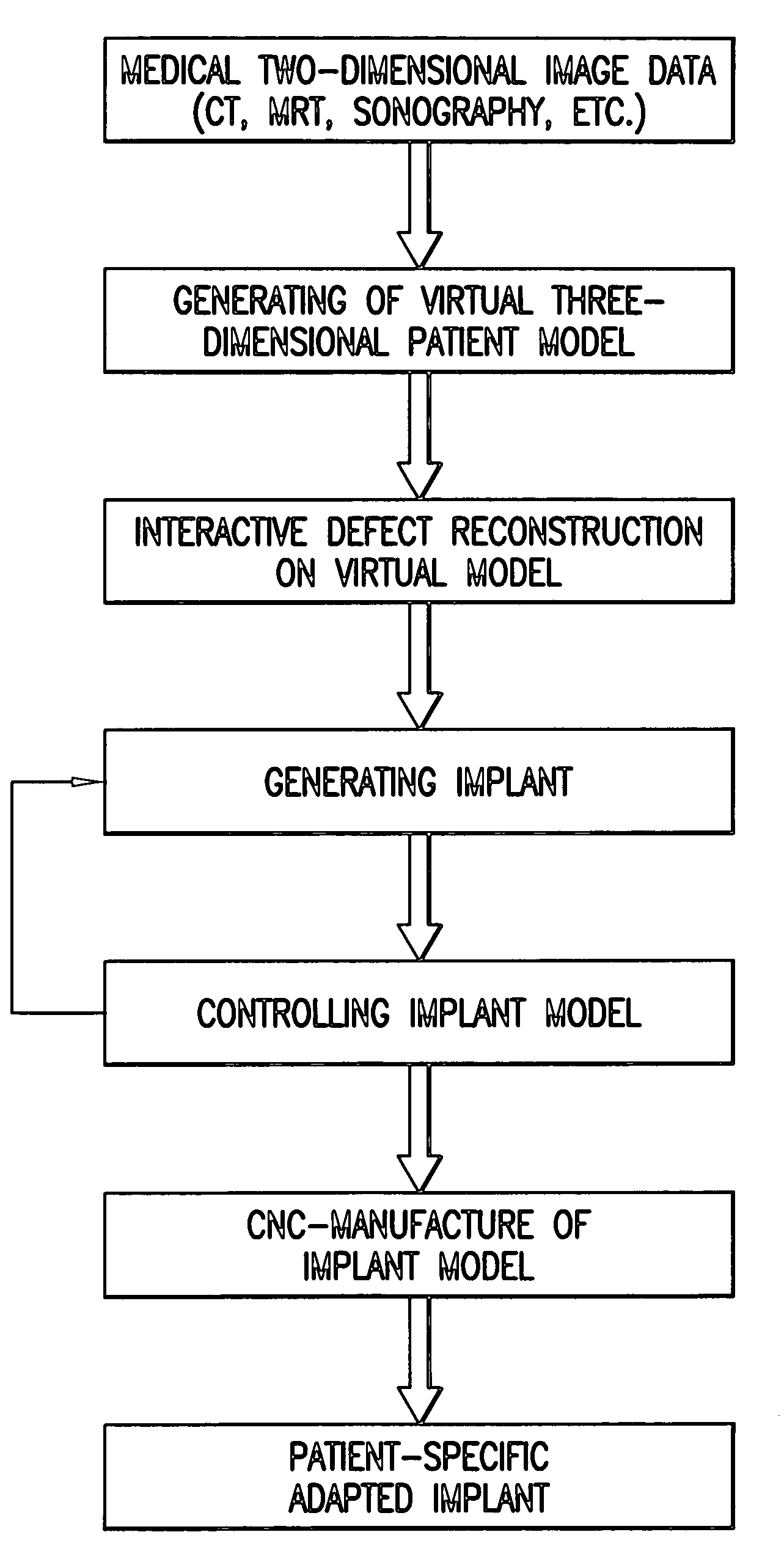

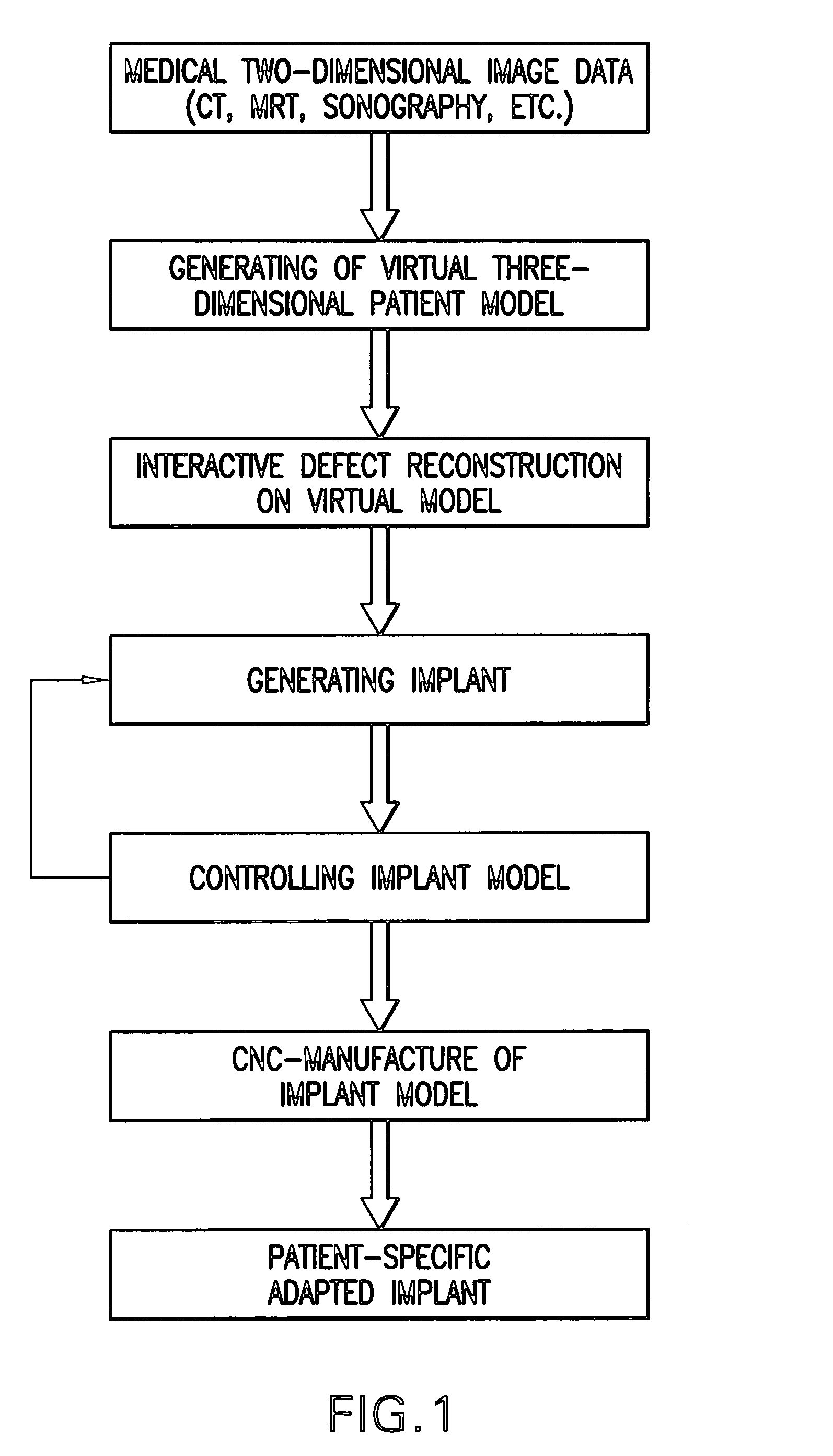

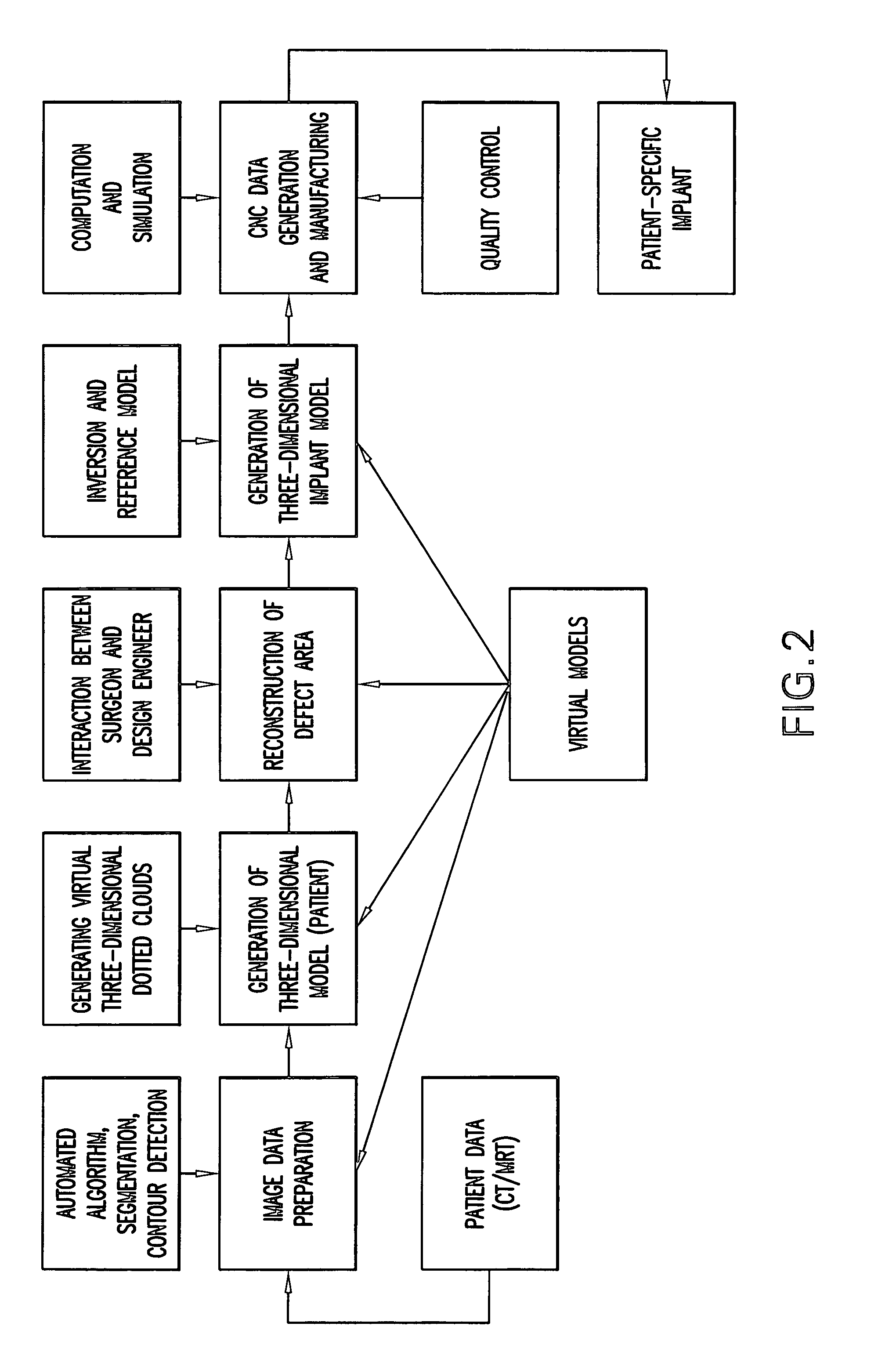

Method for generating patient-specific implants

InactiveUS6932842B1Exact fitShorten the timeProgramme controlComputer controlReference modelPatient model

An implant is generated which is functionally and aesthetically adapted to the patient with a greater degree of precision, irrespective of the size, form and complexity of the defect, whereby the implant can be produced and operatively inserted into the patient over a short time period and in a simple manner. A virtual three-dimensional model of the patient which is formed from existing recorded (two-dimensional) image data of the patient is compared with real medical reference data. The comparison which is, for example, carried out using a data bank with test person data enables a reference model object which is most suited to the patient or closest to the patient model to be selected or formed and a virtual implant model is generated accordingly. Computer numeric control data is directly generated from the implant model which is generated virtually in the computer for program-assisted production of the implant.

Owner:3DI

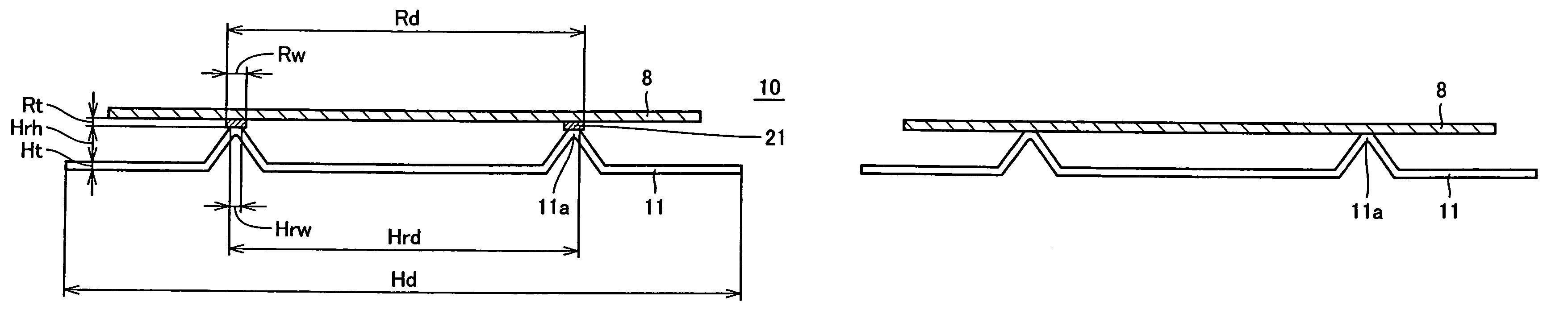

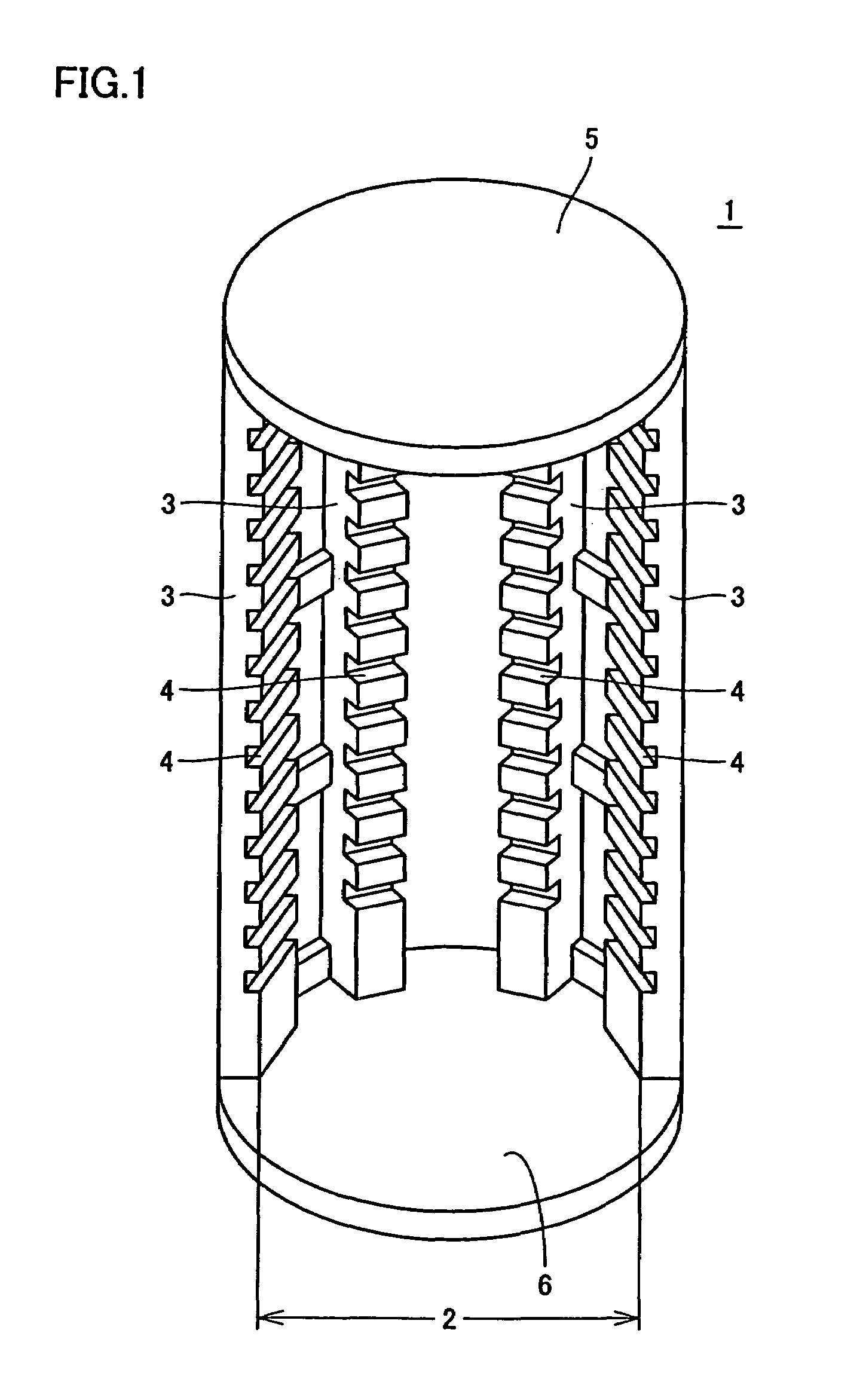

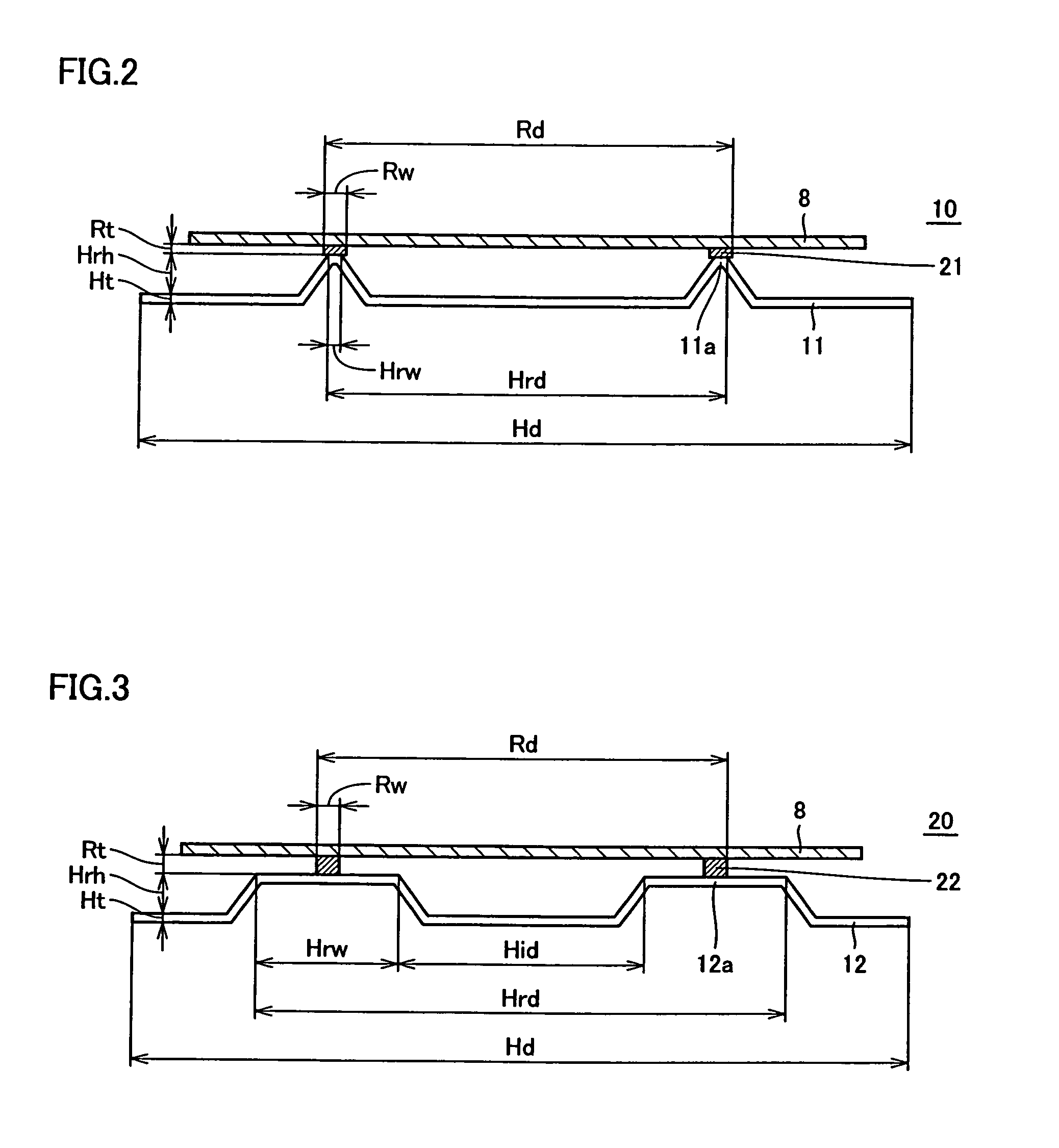

Heat treatment jig for semiconductor substrate

ActiveUS7329947B2Reduce stressSlips can be suppressed from occurringSemiconductor/solid-state device detailsCharge supportsSemiconductorSilicon

Owner:SUMITOMO MITSUBISHI SILICON CORP

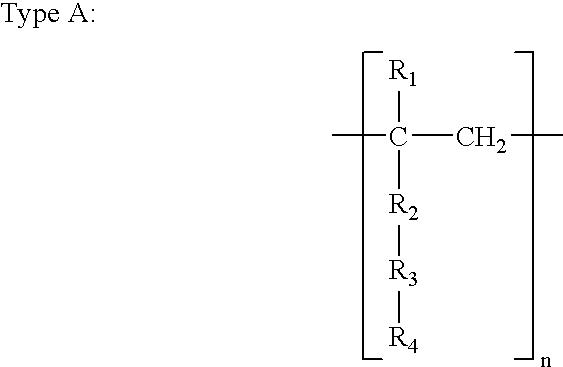

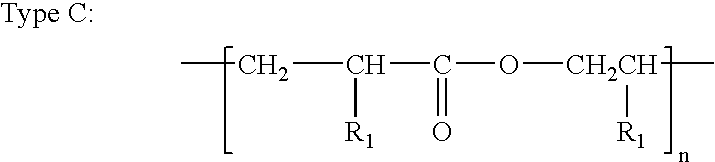

Polymer solution for nanoimprint lithography to reduce imprint temperature and pressure

InactiveUS20040110856A1Reduce pressureReduce the temperatureNanostructure manufactureDecorative surface effectsCross-linkVitrification

A method of forming features on substrates by imprinting is provided. The method comprises: (a) forming a polymer solution comprising at least one polymer dissolved in at least one polymerizable monomer; and (b) depositing the polymer solution on a substrate to form a liquid film thereon; and then either: (c) curing the liquid film by causing the monomer(s) to polymerize and optionally cross-linking the polymer(s) to thereby form a polymer film, the polymer film having a glass transition temperature (Tg); and imprinting the polymer film with a mold having a desired pattern to form a corresponding negative pattern in the polymer film, or (d) imprinting the liquid film with the mold and curing it to form the polymer film. The temperature of imprinting is as little as 10° C. above the Tg, or even less if the film is in the liquid state. The pressure of the imprinting can be within the range of 100 to 500 psi.

Owner:HEWLETT PACKARD DEV CO LP

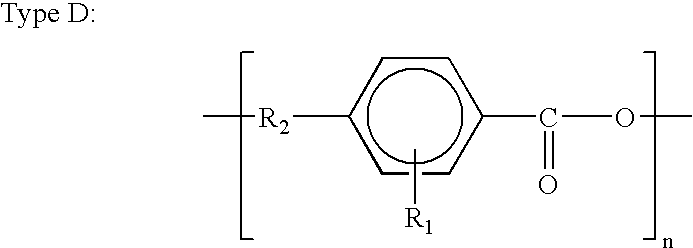

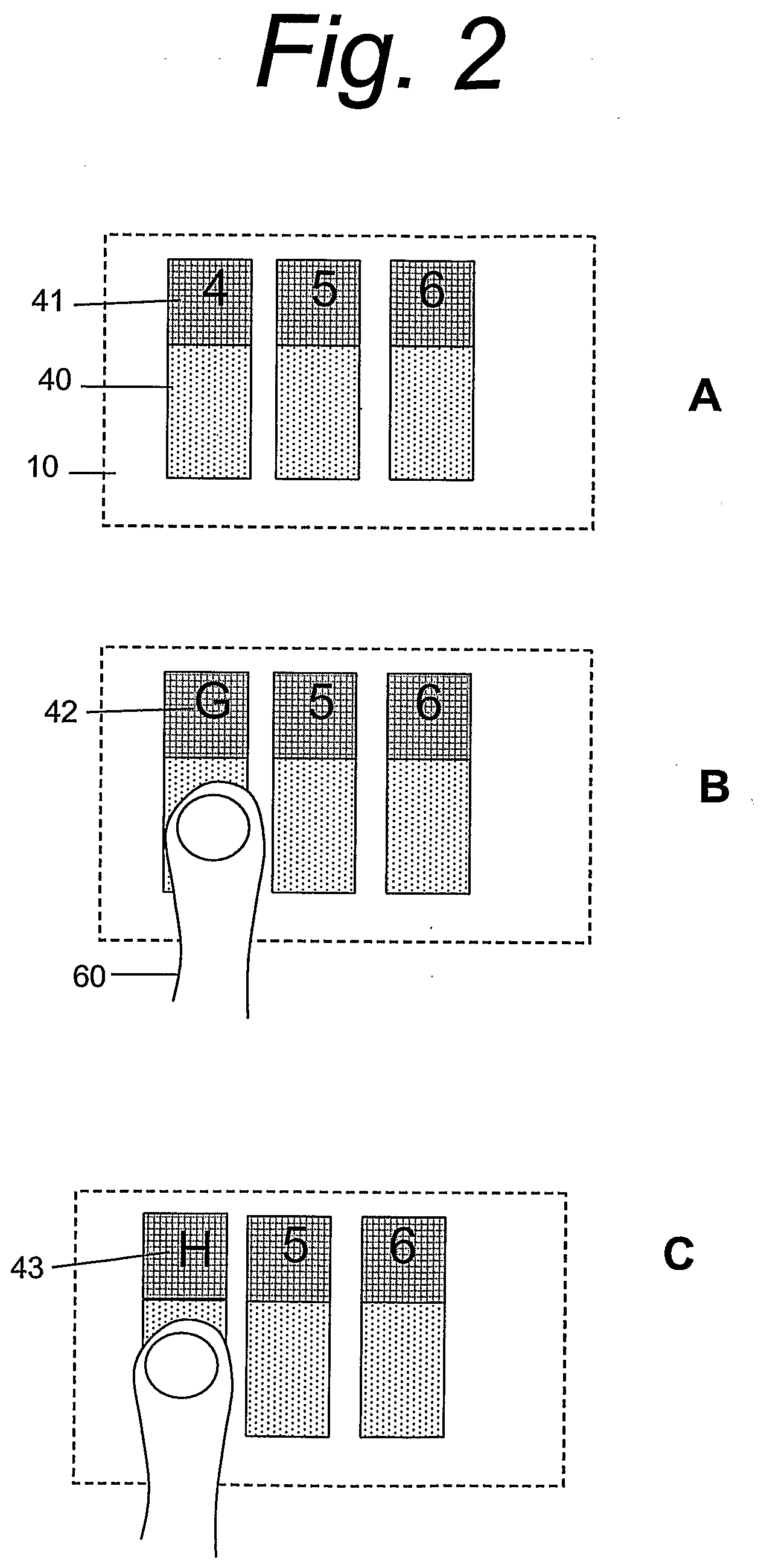

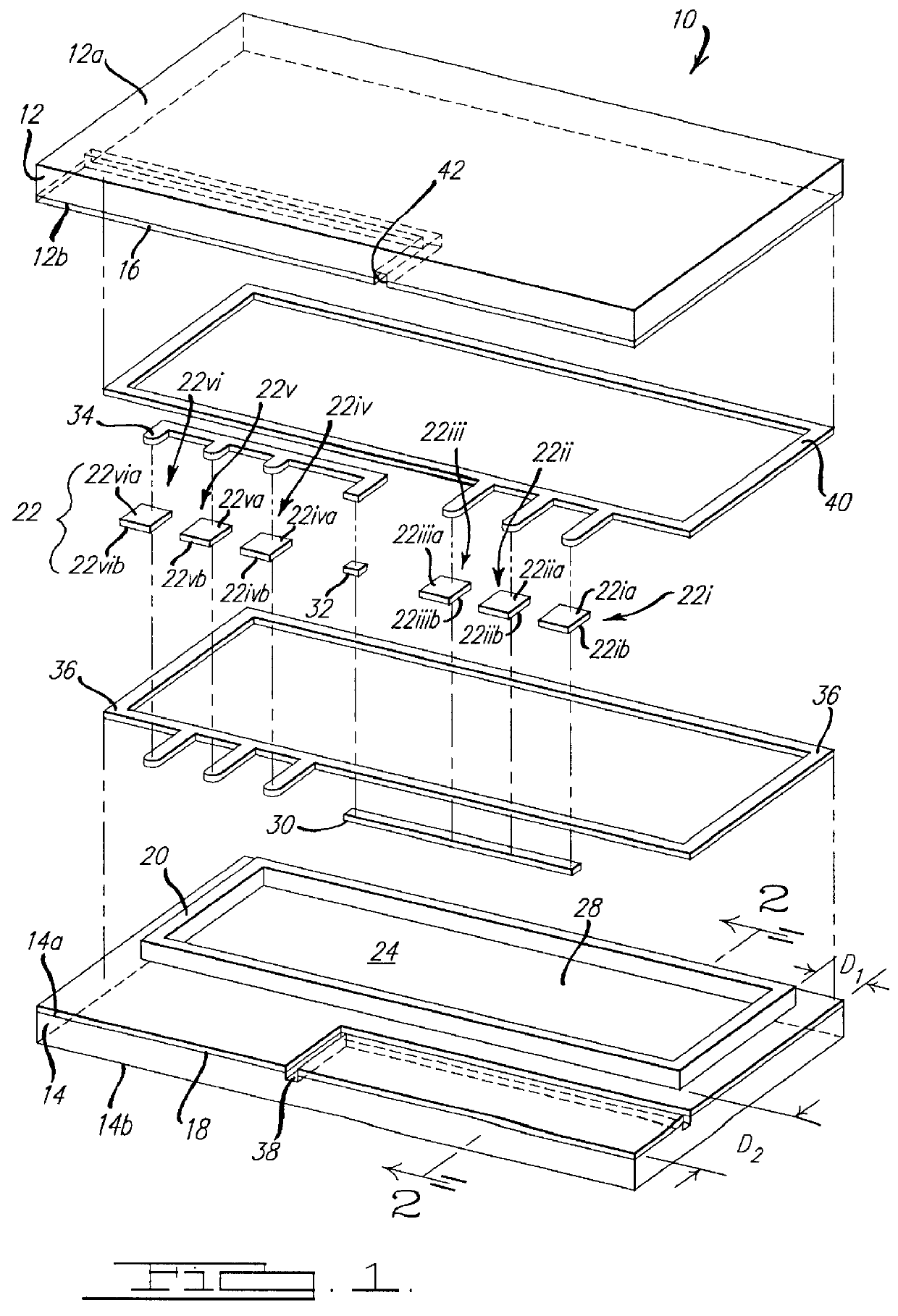

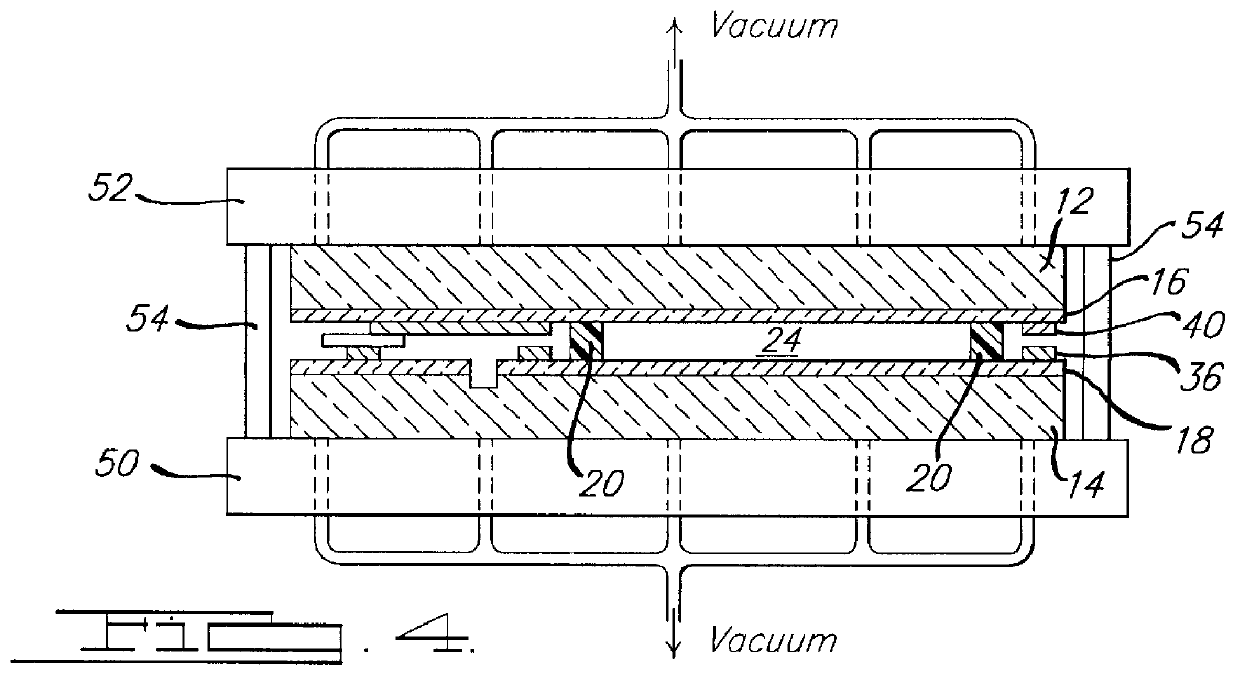

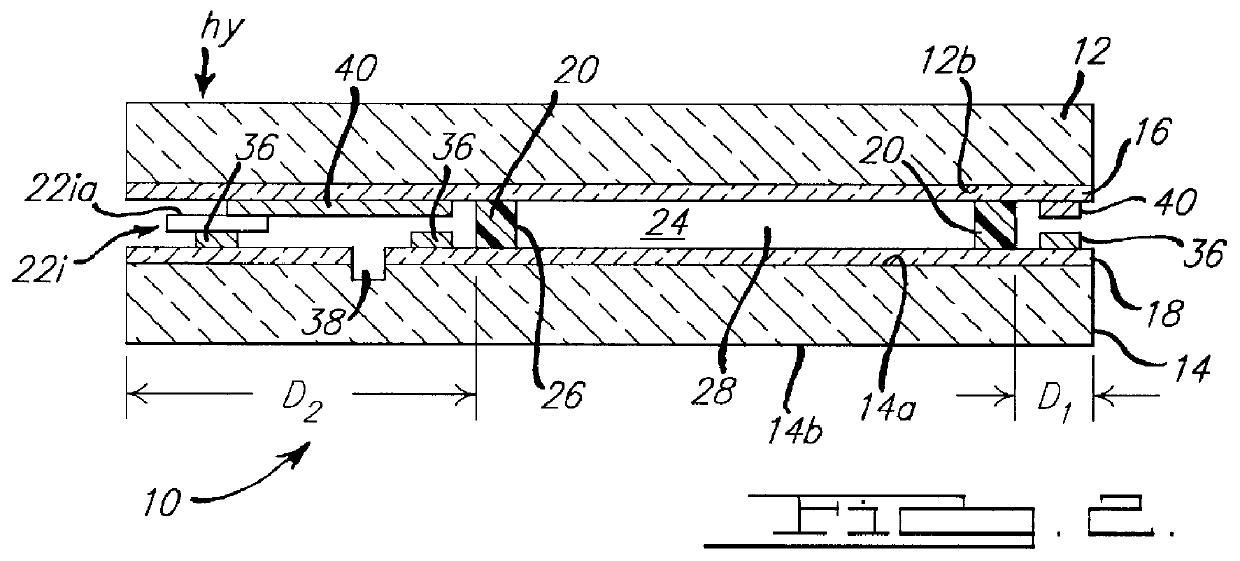

Input Device Having Multifunctional Keys

InactiveUS20080297475A1Reduce stressReduces unintended triggering of functionsInput/output for user-computer interactionCathode-ray tube indicatorsPhysical spaceComputer science

The invention relates to an input device having multifunctional keys, wherein the different functions are triggered by varying the pressure on the keys or by varying the depth to which the key is depressed or the distance it is moved (see FIG. 3). The input device requires substantially fewer keys than a standard qwerty keyboard to input data and requires less physical space. In certain instances the keyboard can be operated with one hand.

Owner:WOOLF TOD M +1

Methods and apparatuses for bone restoration

ActiveUS20060004455A1Reduce stressReduce injection pressureInternal osteosythesisBone implantRestoration methodBiomedical engineering

Methods and apparatuses for restoration of human or animal bone anatomy, which may include introduction, into a bone of an expansible implant capable of expansion in a single determined plane, positioning the expansible implant in the bone in order to correspond the single determined plane with a bone restoration plane and opening out the expansible implant in the bone restoration plane. A first support surface and a second support surface spread tissues within bone. The embodiments of the invention may also include injecting a filling material around the implant.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

Composite membrane and method for making the same

InactiveUS6878278B2Improve throughputEasy to adaptSemi-permeable membranesLoose filtering material filtersPolyamideReverse osmosis

A composite membrane and method for making the same, comprising a porous support and a polyamide surface. The subject membrane provides improved flux and / or rejection rates. The subject membrane is further capable of operating at lower operating pressures. The subject method includes reacting a polyfunctional amine with a polyfunctional acyl halide to form a polyamide. The method includes the step of contacting a complexing agent with the polyfunctional acyl halide prior substantial reaction between the polyfunctional acyl halide and a polyfunctional amine. The subject process is easily adapted to commercial scale manufacturing processes and is particularly suited for making nanofiltration and reverse osmosis composite membranes.

Owner:DOW GLOBAL TECH LLC

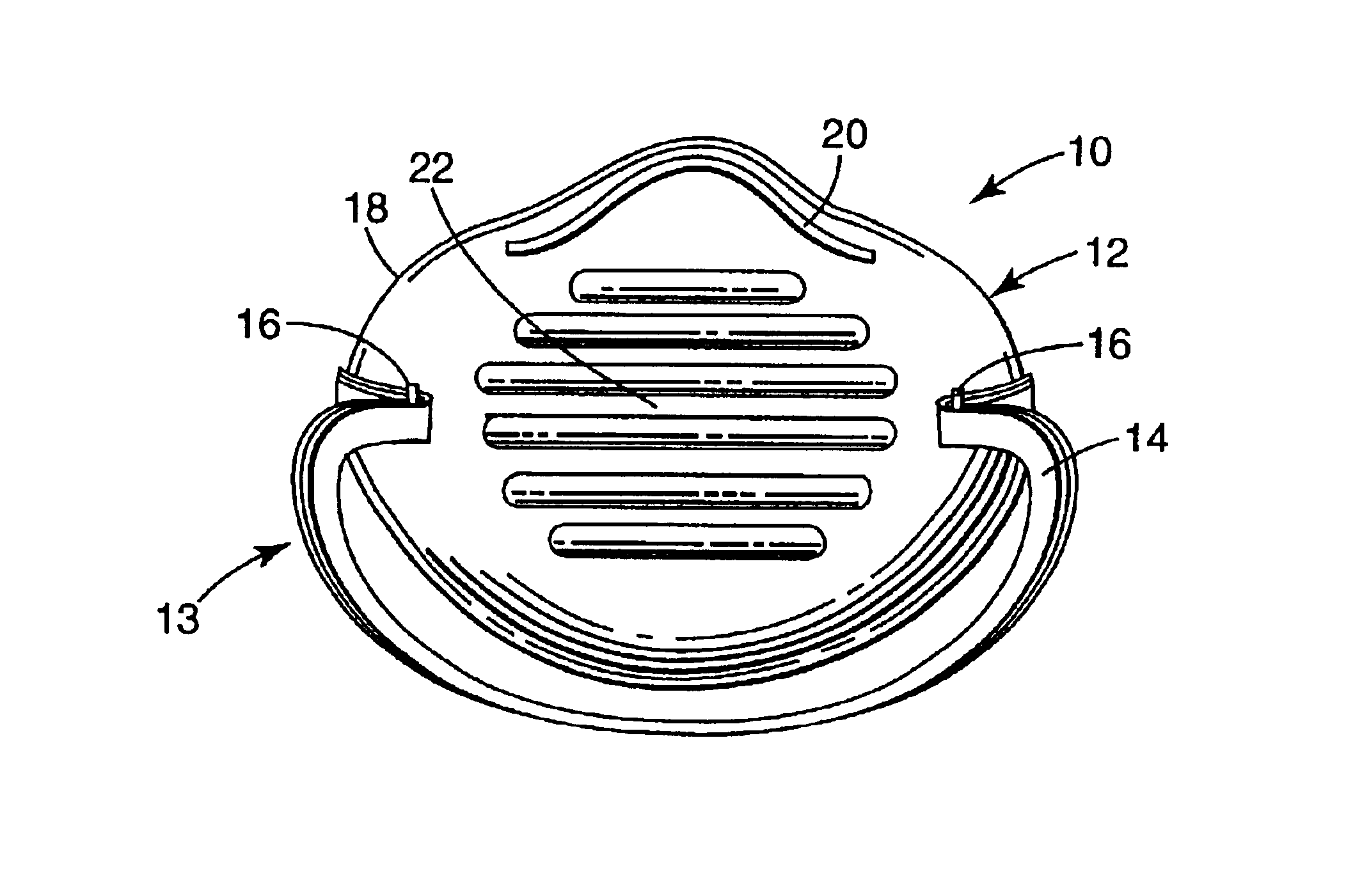

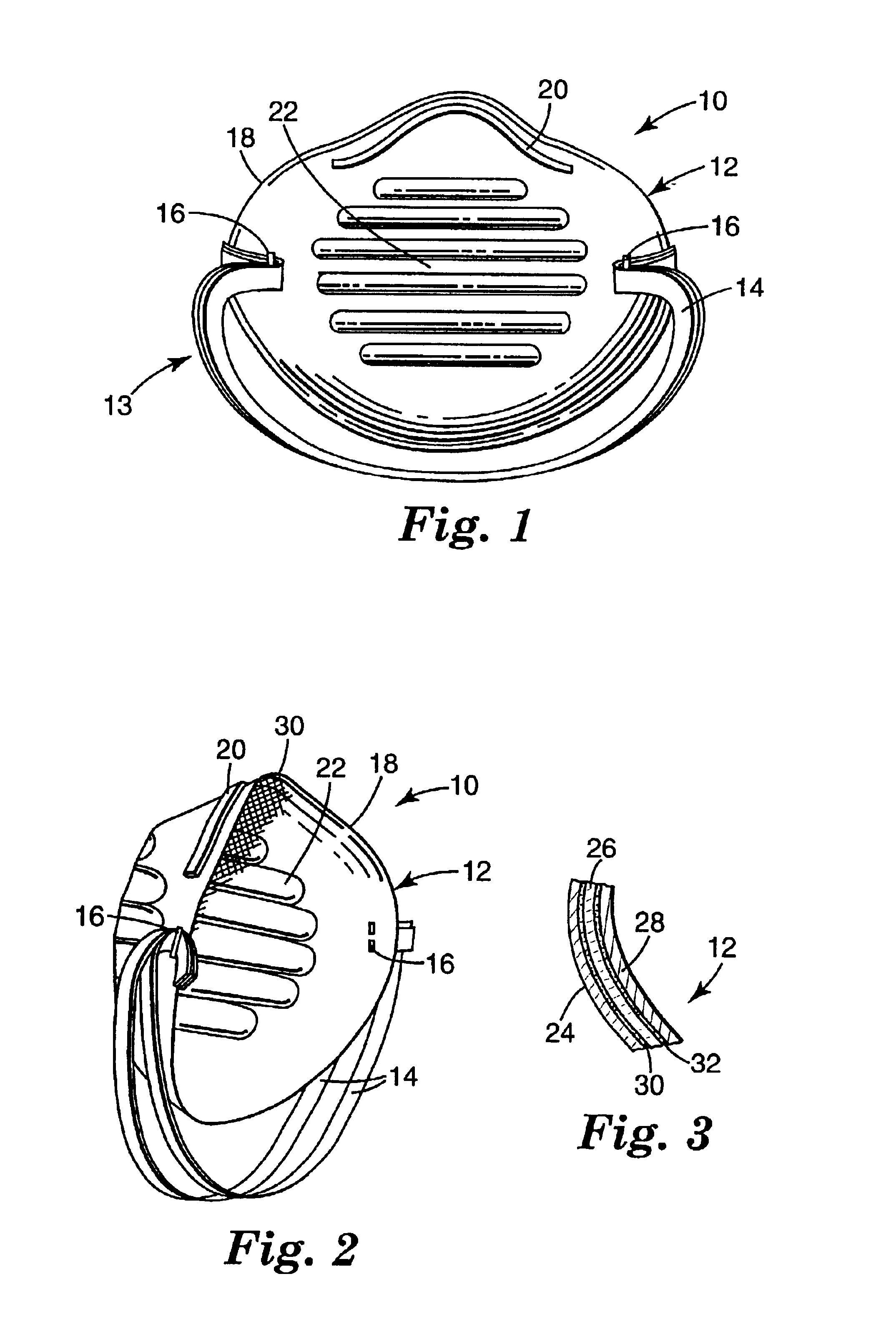

Crush resistant filtering face mask

InactiveUS6923182B2Reduce the possibilityImprove securityBreathing filtersBreathing masksFiltrationNose

A filtering face mask that includes a mask body that is adapted to fit over the nose and mouth of a person and a harness that is attached to the mask body. The mask body comprises i) a first shaping layer that has been molded; ii) a second shaping layer that has been molded; iii) a filtration layer that is disposed between the first and second shaping layers; iv) a first adhesive layer that adheres the first shaping layer to the filtration layer; and v) a second adhesive layer that adheres the second shaping layer to the filtration layer.

Owner:3M INNOVATIVE PROPERTIES CO

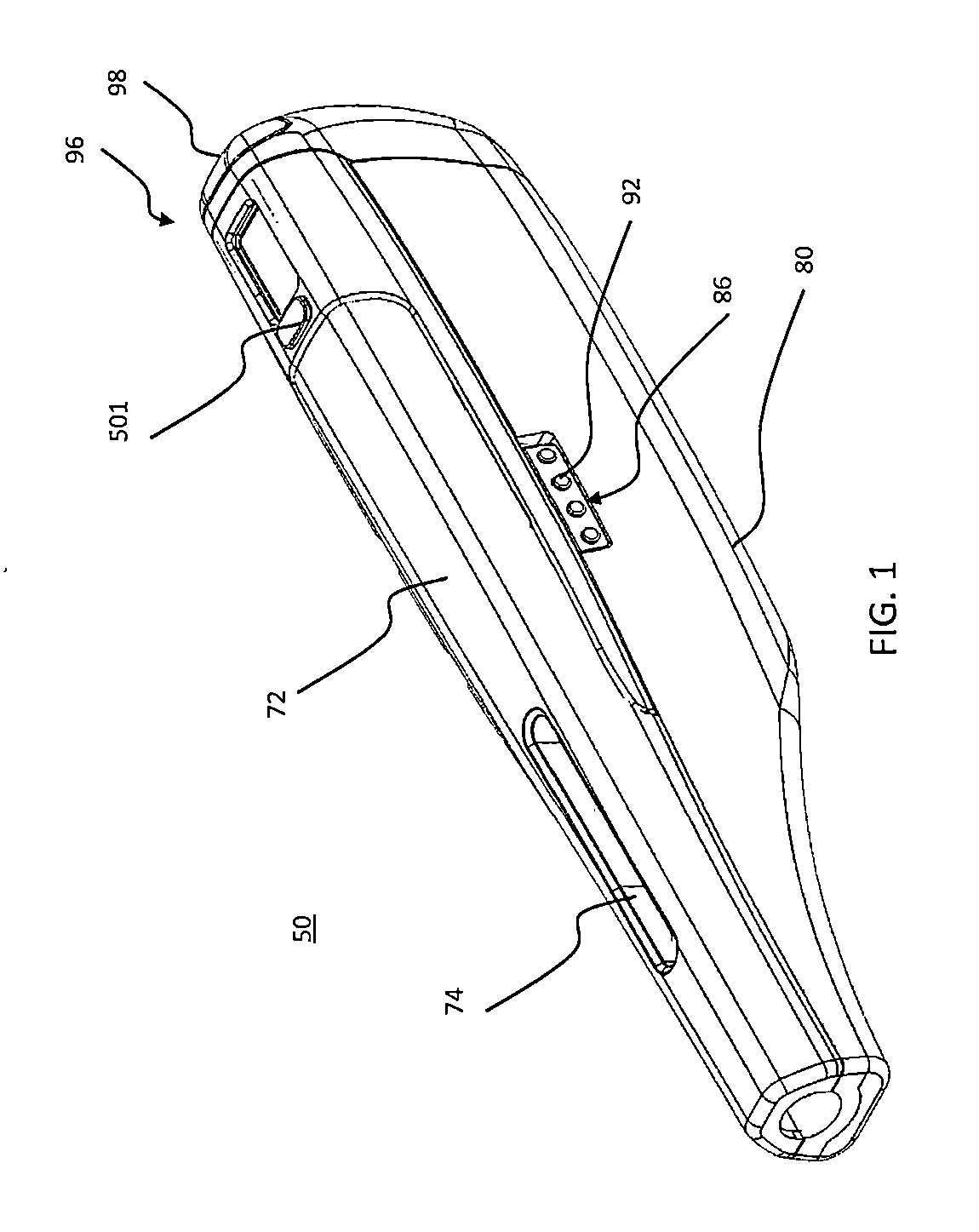

Sensor Systems for Drug Delivery Devices

ActiveUS20180236181A1Reduce care costsReducing its effectivenessAutomatic syringesDiagnosticsDrugEmbedded system

Systems for drug delivery devices include a temperature control system and an identification system. A temperature control system configured to sense and control temperature of a cartridge containing a drug includes a heater, one or more temperature sensors, and a control unit. An identification system configured to identify a cartridge containing a drug includes a control unit and a tag sensor that is electrically coupled to the control unit, wherein the tag sensor is activated upon detecting a presence of the cartridge. A drug delivery device includes both the temperature control system and the identification system such that the control unit of the device may process the information of the drug that is received from the tag sensor of the identification system, and based on at least a portion of the processed information, determine and control the temperature of the drug within a cartridge.

Owner:UN HOLDINGS LLC

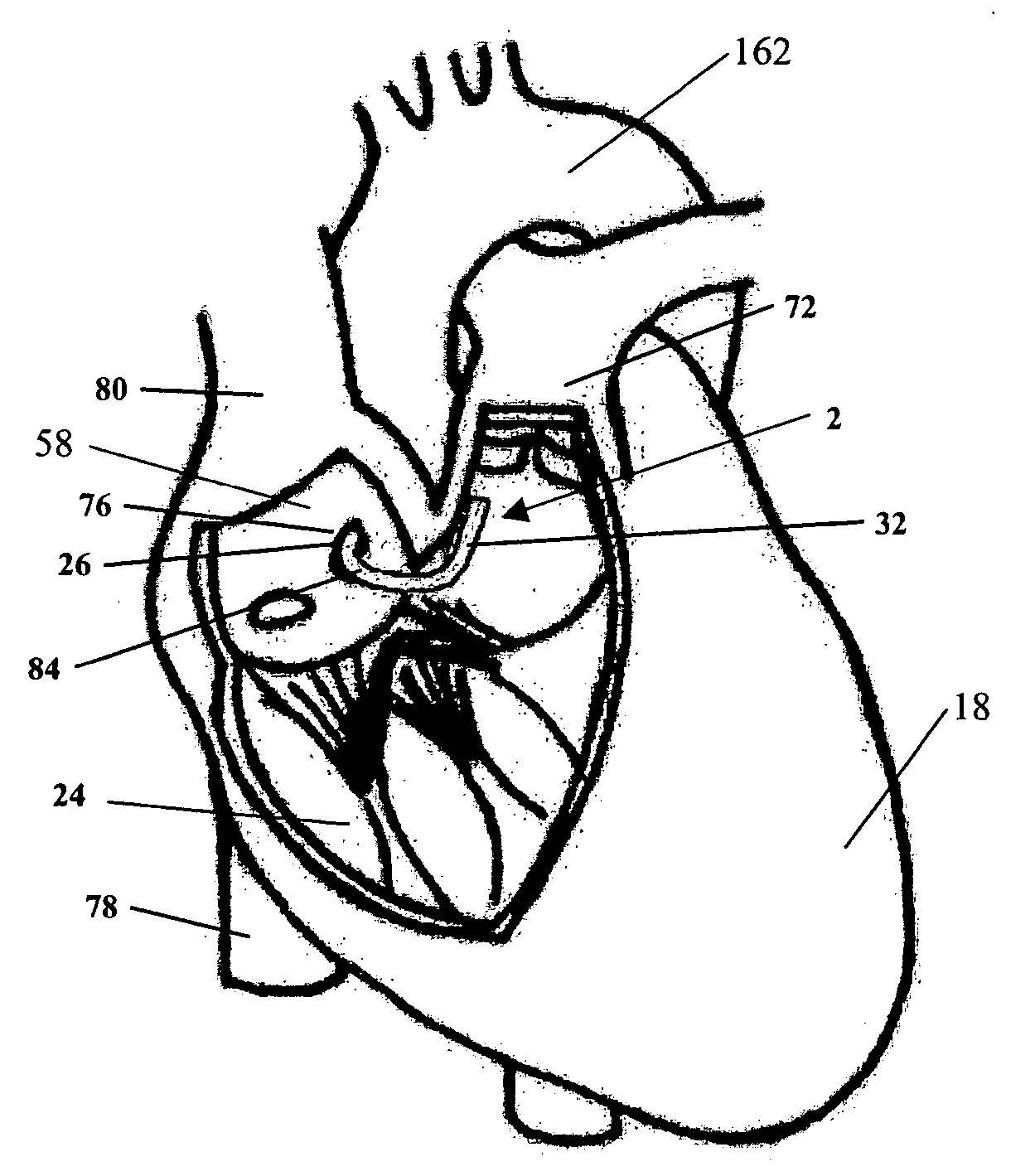

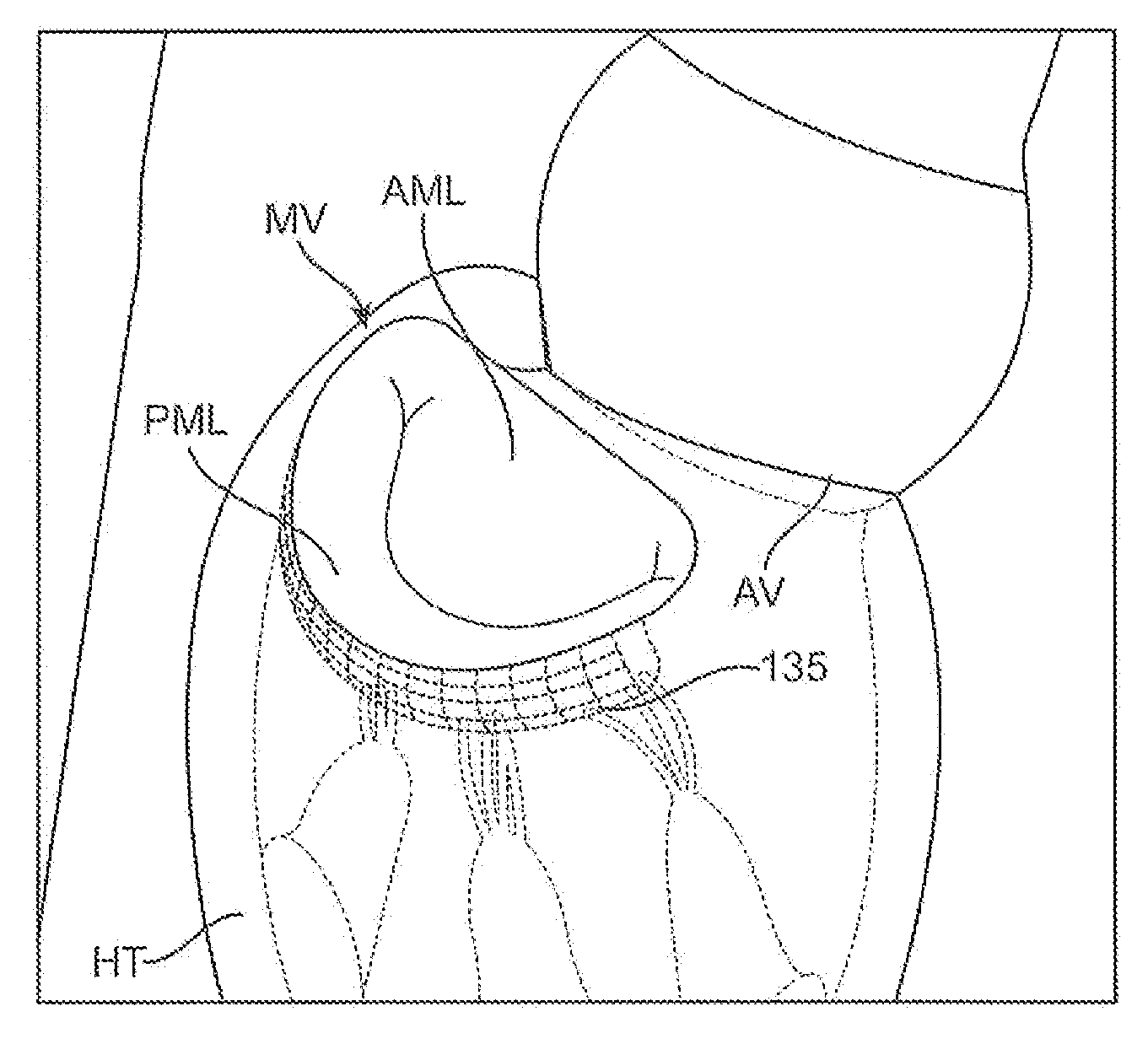

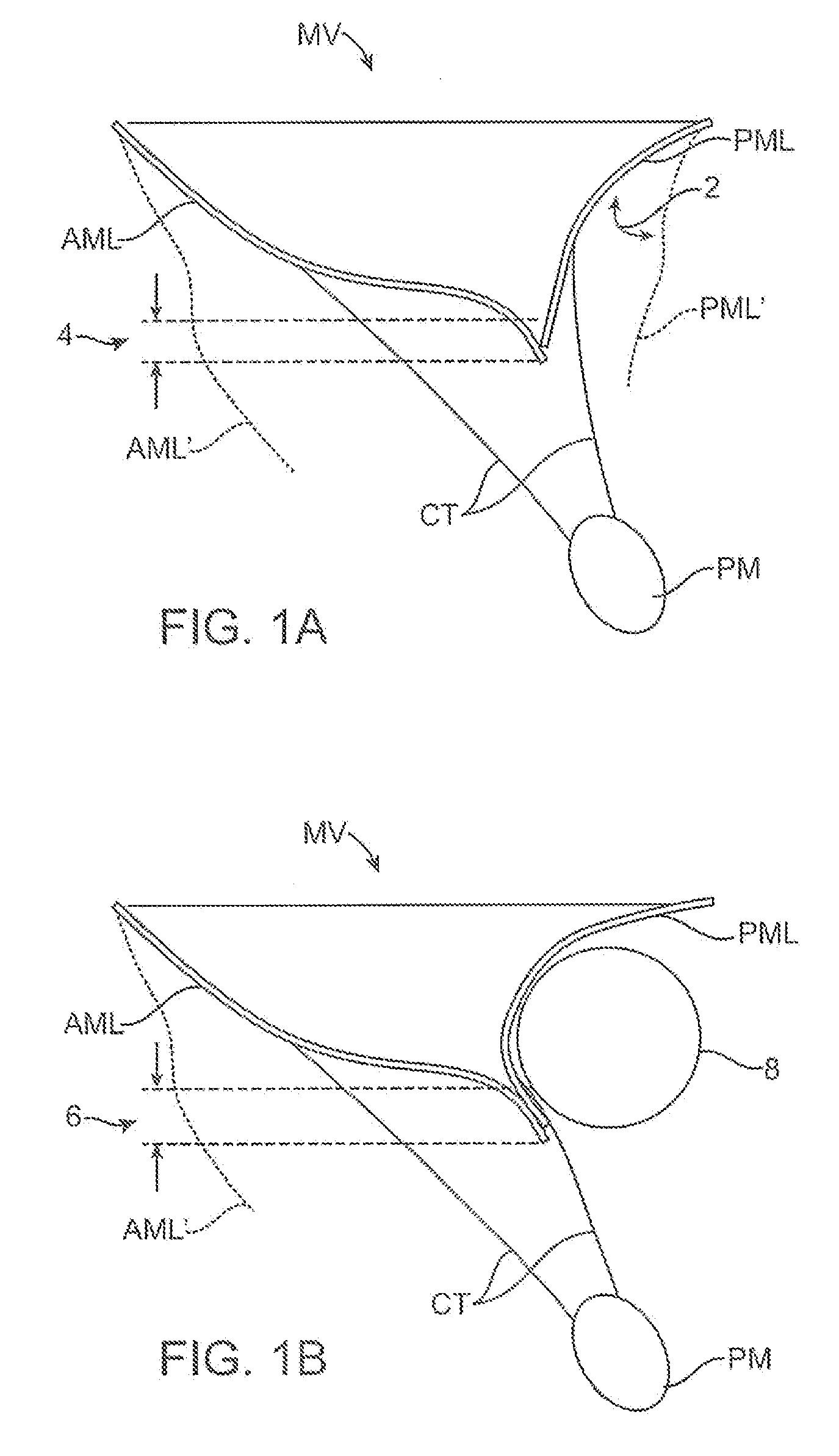

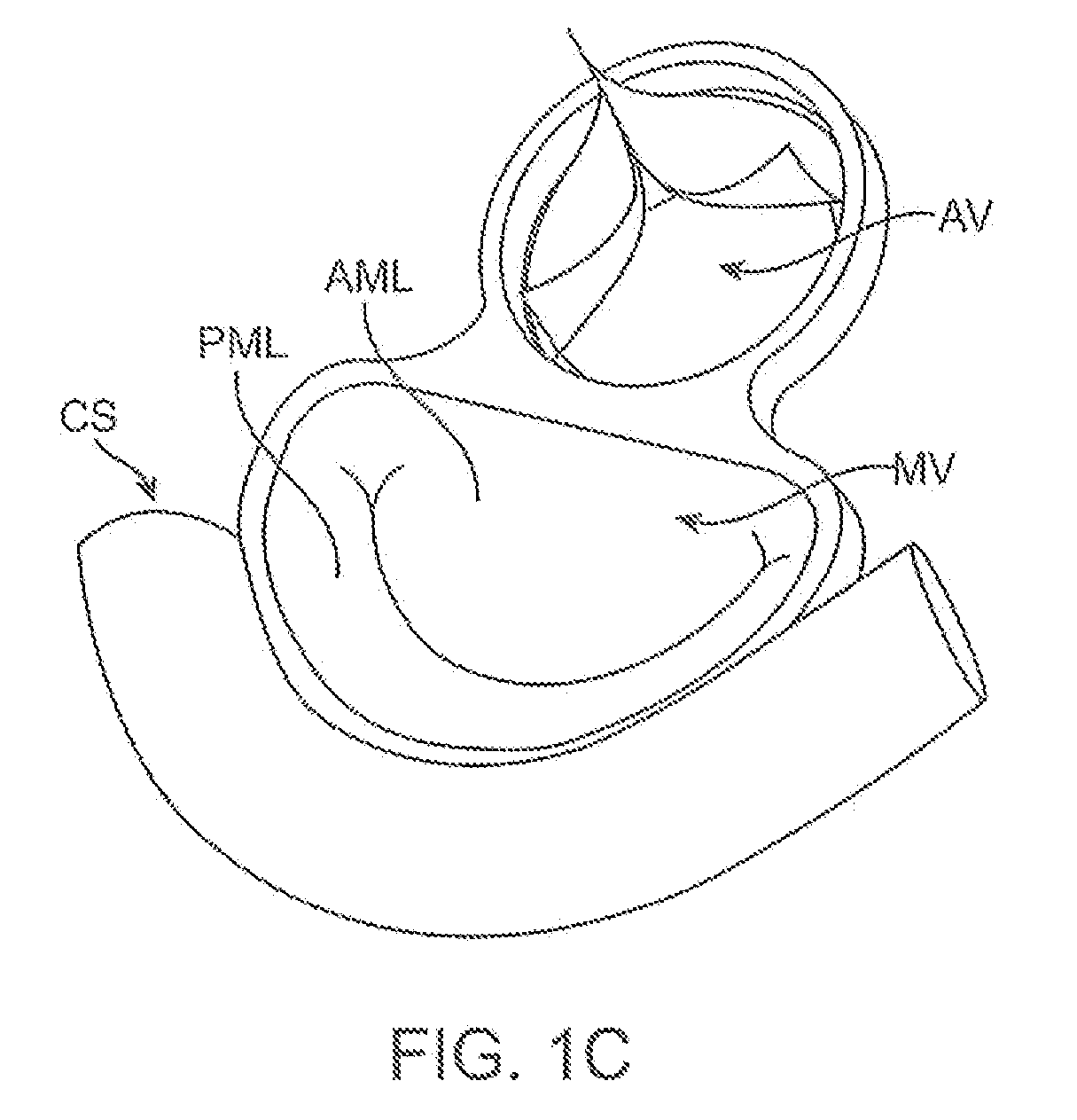

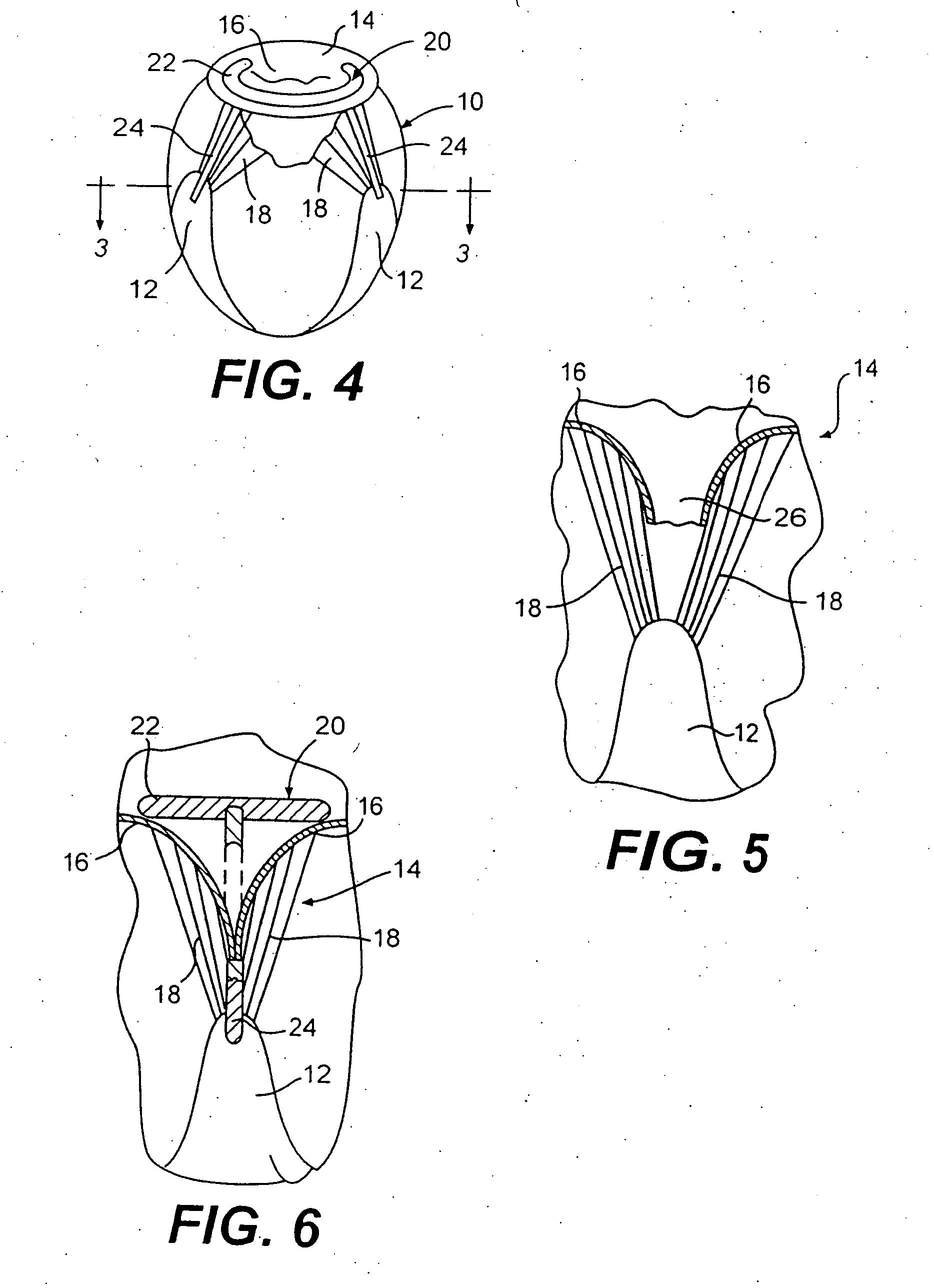

Methods and apparatus for mitral valve repair

InactiveUS20080039935A1Inhibiting and preventing prolapseSlide freelyAnnuloplasty ringsPosterior leafletSystole

Methods and apparatus for mitral valve repair are disclosed herein where the posterior mitral leaflet is supported or buttressed in a frozen or immobile position to facilitate the proper coaptation of the leaflets. An implantable apparatus may be advanced and positioned intravascularly beneath the posterior leaflet of the mitral valve. The apparatus may include one or more individual balloon members, each of which may be optionally configured with supporting integrated structures. A magnet chain catheter may be positioned within the coronary sinus and adjacent to the mitral valve to magnetically secure the apparatus in position beneath the posterior mitral leaflet. Alternatively, a split-ring device may be placed about the chordae tendineae supporting the mitral valve such that the ring slides along the chordae tendineae alternately against the mitral leaflet and towards the papillary muscles during systole and diastole.

Owner:BUCH WALLY +1

Systems for heart treatment

InactiveUS7144363B2Reduce stressReduce/limit volumeSuture equipmentsHeart valvesLeft ventricular sizeTherapeutic treatment

Owner:BAY INNOVATION GROUP

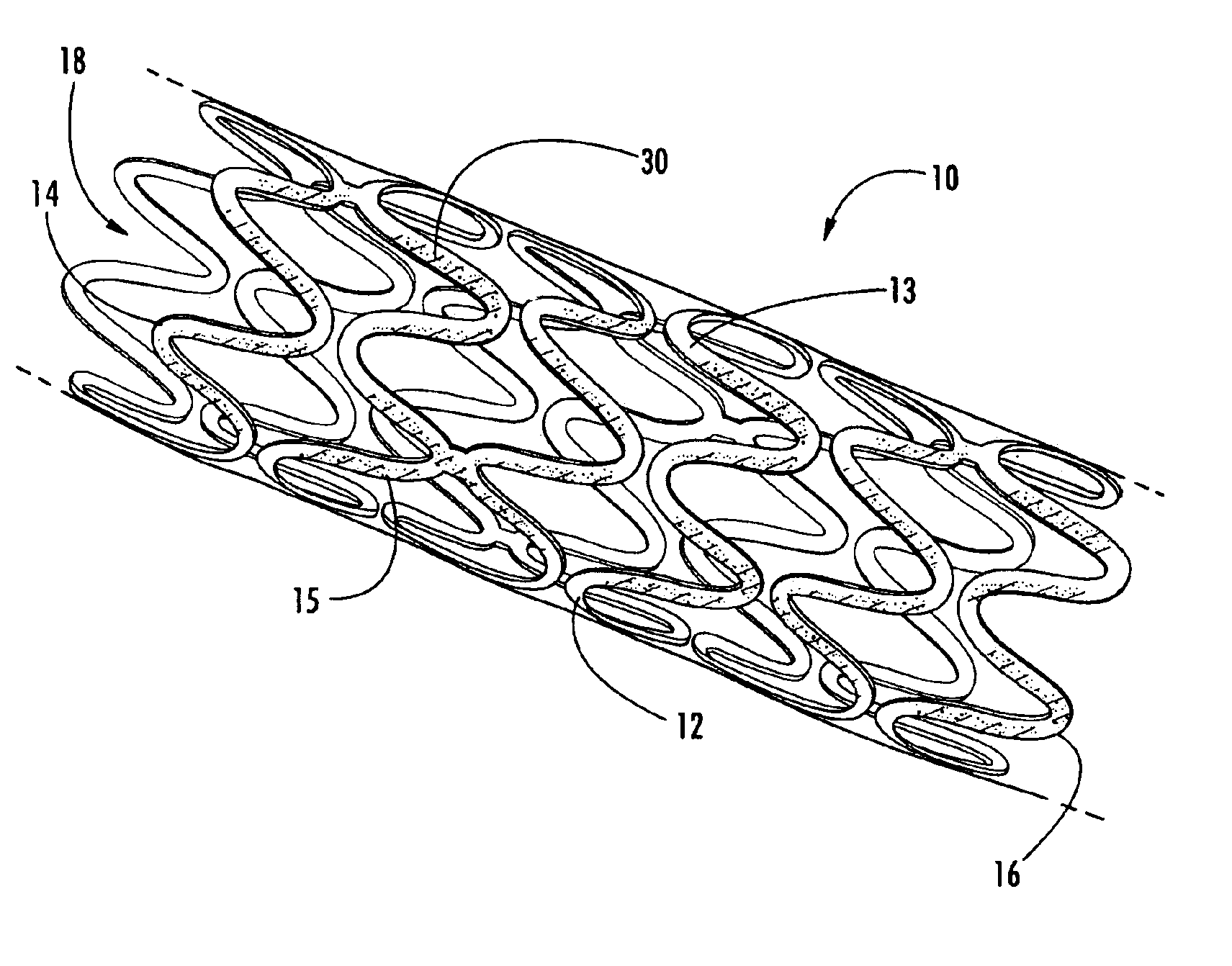

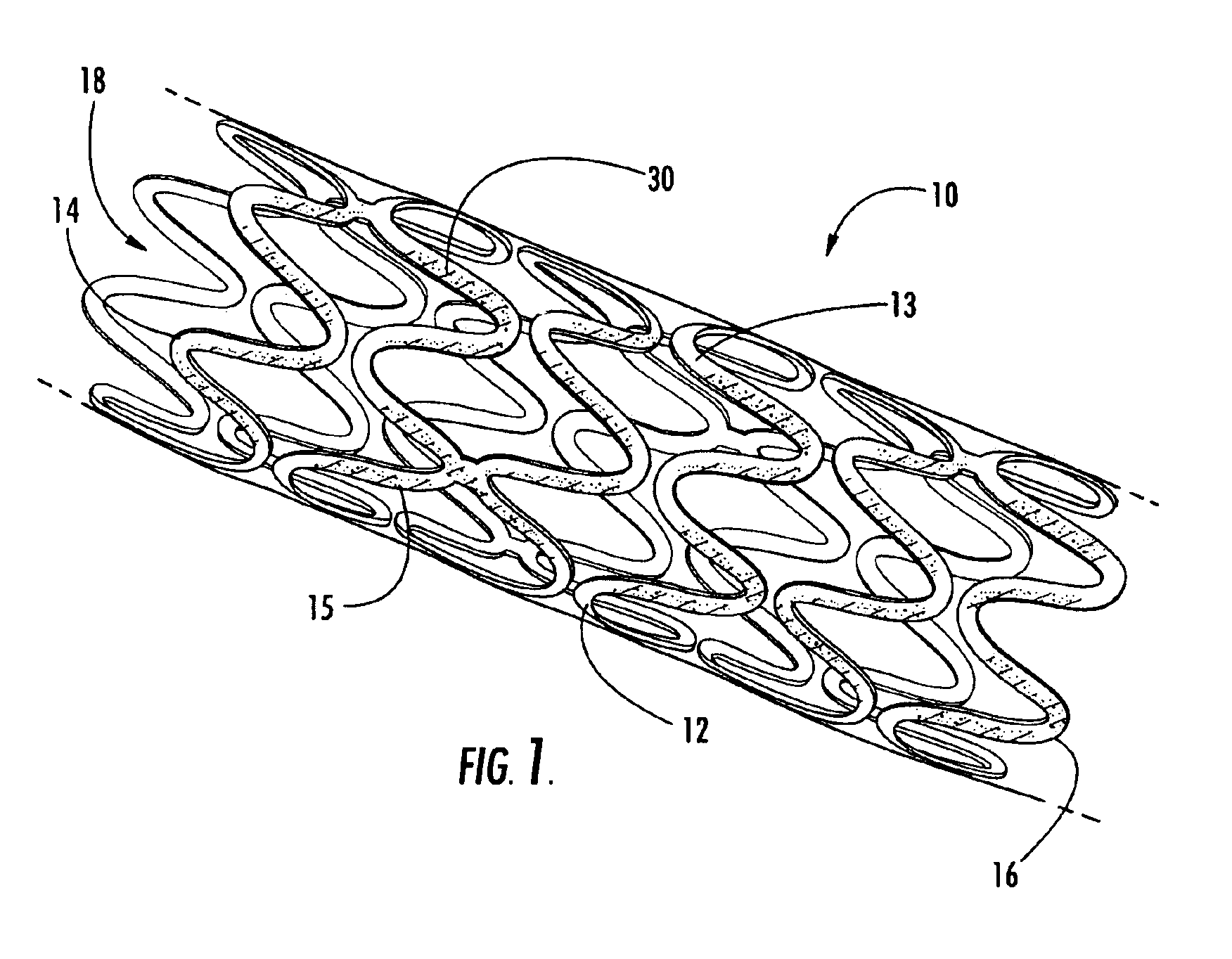

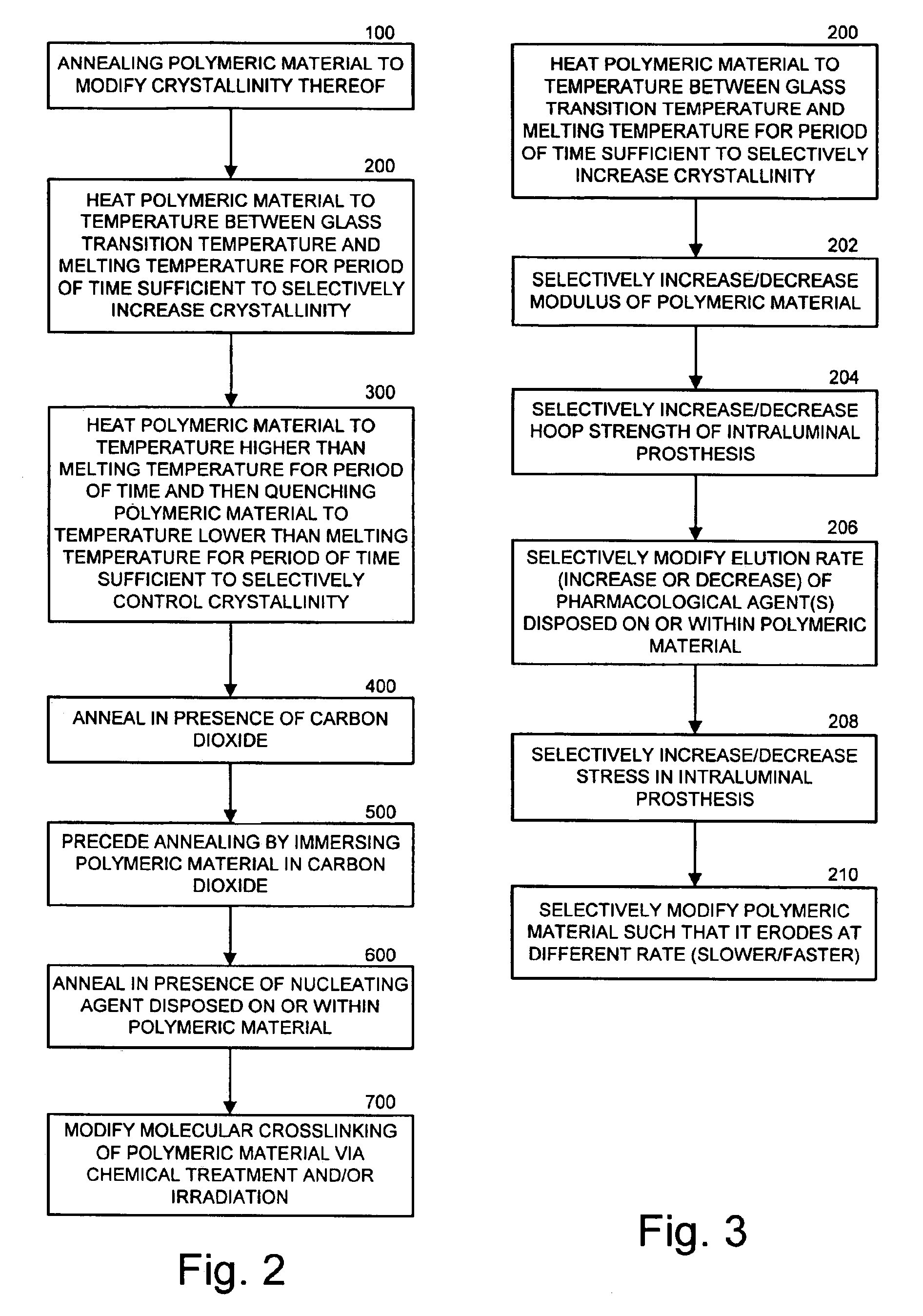

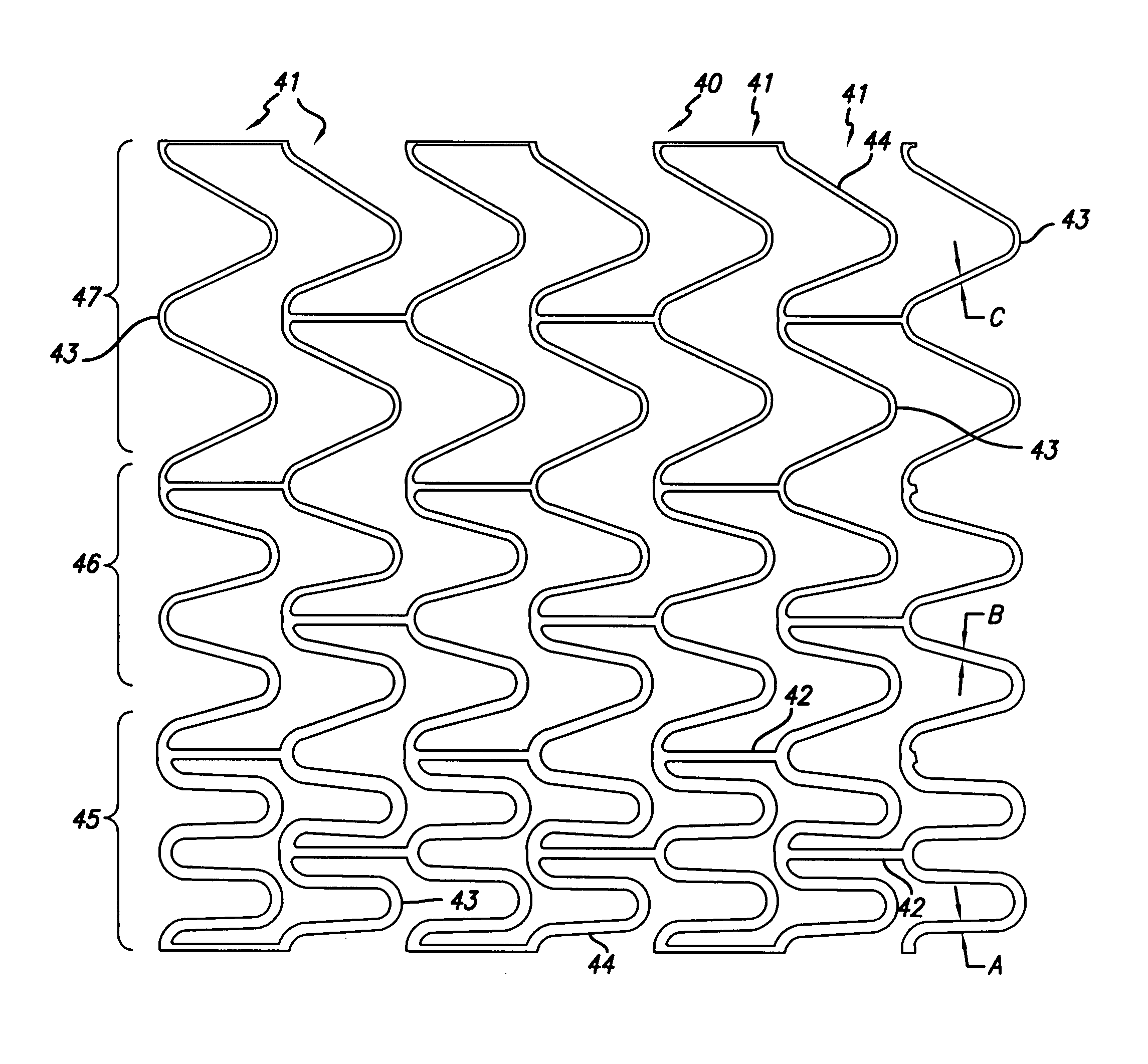

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

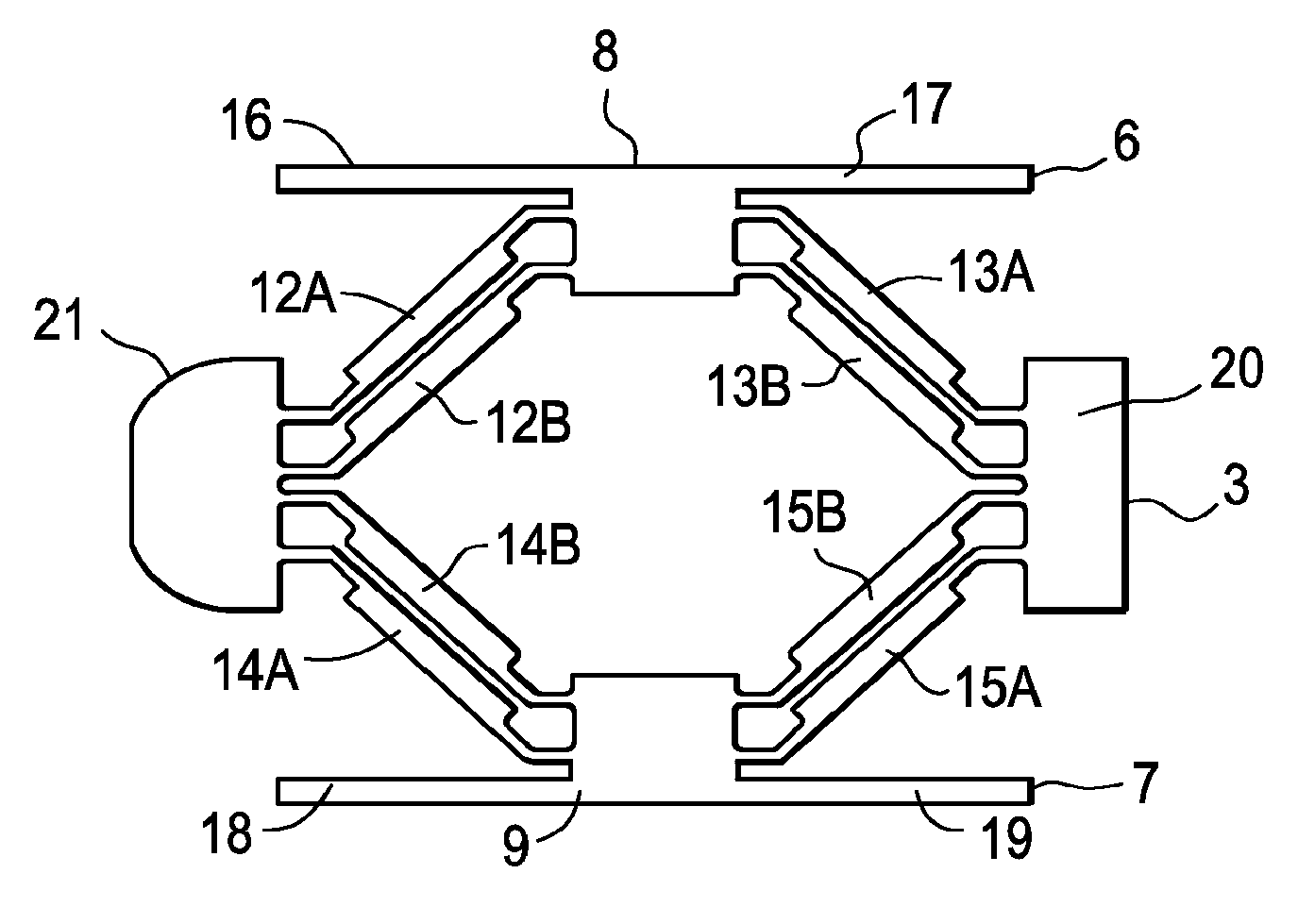

Methods and apparatuses for bone restoration

ActiveUS7846206B2Reduce stressReduce injection pressureInternal osteosythesisBone implantAnatomical structuresRestoration method

Methods and apparatuses for restoration of human or animal bone anatomy, which may include introduction, into a bone of an expansible implant capable of expansion in a single determined plane, positioning the expansible implant in the bone in order to correspond the single determined plane with a bone restoration plane and opening out the expansible implant in the bone restoration plane. A first support surface and a second support surface spread tissues within bone. The embodiments of the invention may also include injecting a filling material around the implant.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

Systems for heart treatment

InactiveUS20050197692A1Decreasing wall stressReinforce wallSuture equipmentsElectrotherapyLeft ventricular sizeTherapeutic treatment

Described are devices and methods for treating degenerative, congestive heart disease and related valvular dysfunction. Percutaneous and minimally invasive surgical tensioning structures offer devices that mitigate changes in the ventricular structure (i.e., remodeling) and deterioration of global left ventricular performance related to tissue damage precipitating from ischemia, acute myocardial infarction (AMI) or other abnormalities. These tensioning structures can be implanted within various major coronary blood-carrying conduit structures (arteries, veins and branching vessels), into or through myocardium, or into engagement with other anatomic structures that impact cardiac output to provide tensile support to the heart muscle wall which resists diastolic filling pressure while simultaneously providing a compressive force to the muscle wall to limit, compensate or provide therapeutic treatment for congestive heart failure and / or to reverse the remodeling that produces an enlarged heart.

Owner:EXTENSIA MEDICAL

Systems for heart treatment

InactiveUS20050197693A1Reduce wall stressReinforce wallSuture equipmentsElectrotherapyTherapeutic treatmentCongestive heart failure chf

Described are devices and methods for treating degenerative, congestive heart disease and related valvular dysfunction. Percutaneous and minimally invasive surgical tensioning structures offer devices that mitigate changes in the ventricular structure (i.e., remodeling) and deterioration of global left ventricular performance related to tissue damage precipitating from ischemia, acute myocardial infarction (AMI) or other abnormalities. These tensioning structures can be implanted within various major coronary blood-carrying conduit structures (arteries, veins and branching vessels), into or through myocardium, or into engagement with other anatomic structures that impact cardiac output to provide tensile support to the heart muscle wall which resists diastolic filling pressure while simultaneously providing a compressive force to the muscle wall to limit, compensate or provide therapeutic treatment for congestive heart failure and / or to reverse the remodeling that produces an enlarged heart.

Owner:EXTENSIA MEDICAL

Electro-optic window incorporating a discrete photovoltaic device and apparatus for making same

InactiveUS6045643ALimited amountSimple designStatic indicating devicesWelding/cutting auxillary devicesElectricityResistor

An electro-optic window is provided which is powered solely by at least one discrete photovoltaic cell within an electro-optic window. The electro-optic window has front and back spaced-apart glass elements sealably bonded together in a spaced-apart relationship and defining a chamber filled with an electro-optic material. The front glass element has a transparent conductive layer on the face of the front glass element confronting the rear glass element and the rear glass element has a transparent conductive layer on the face confronting the front glass element. The seal is generally disposed along the perimeter of three edges of both glass elements and some distance in from the remaining (fourth) edge. The photovoltaic assembly is electrically connected to the two transparent conductive layers and is placed on the outer perimeter along this fourth edge with the photon-absorbing side of all the photovoltaic cells within the photovoltaic assembly facing in one direction ("out" the window). When light impinges on the photovoltaic cell a current is created which darkens the electro-optic material in proportion to the amount of impinging light. By choosing the relative area of the photovoltaic assembly to produce the correct current for the electro-optically active window area, the darkening of the electro-optic portion can be directly and accurately controlled without the need for any circuit, wires or shorting resistors. In addition, an apparatus for making an electro-optic window having two members capable of securing and holding two glass elements in a spaced-apart and parallel relationship is provided. The glass elements may be secured by vacuum-applying members or simple clips. The glass elements may be held in a spaced-apart and parallel relationship by a hydraulic mechanism or by simple spacers placed between the securing members.

Owner:GENTEX CORP

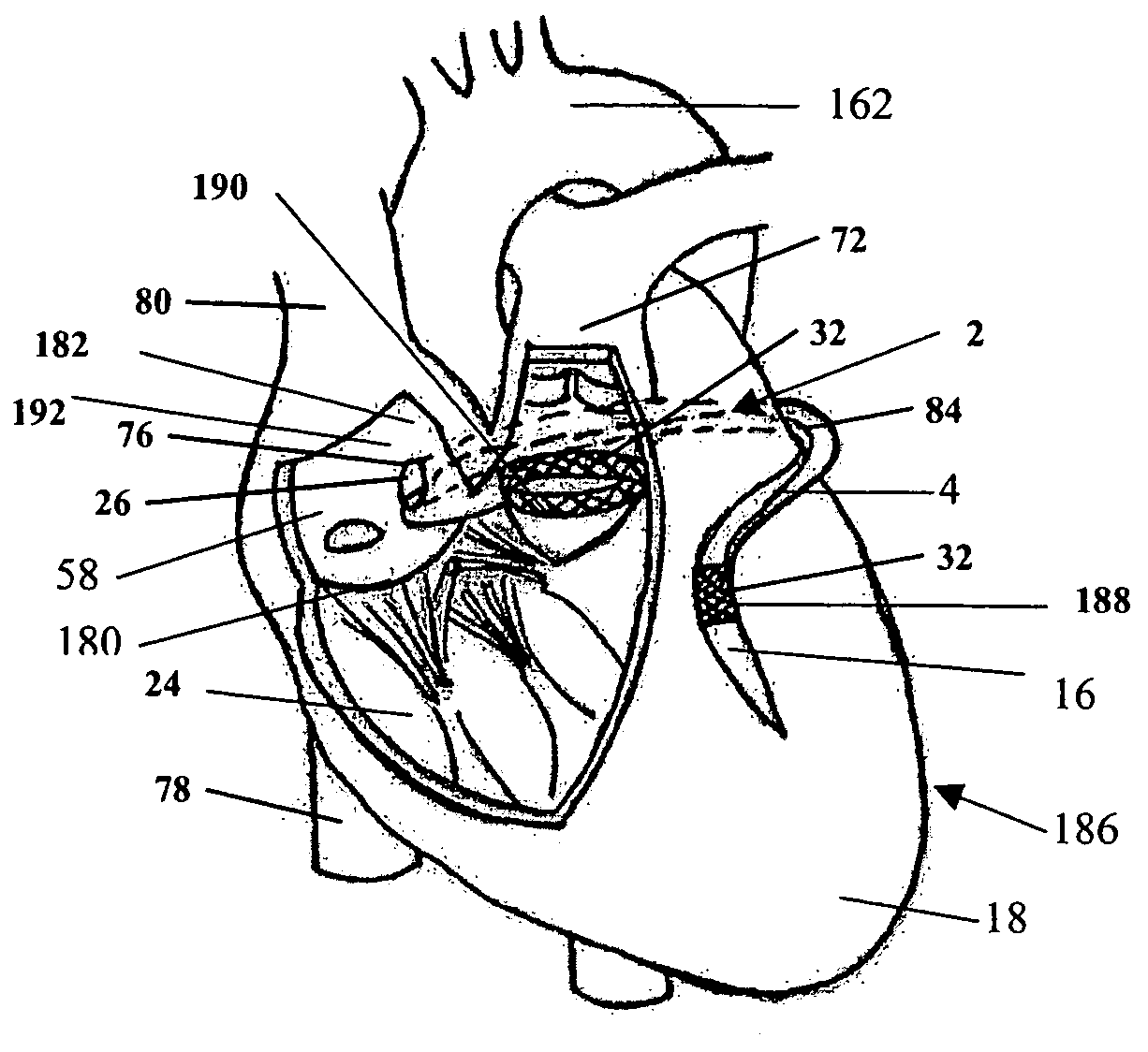

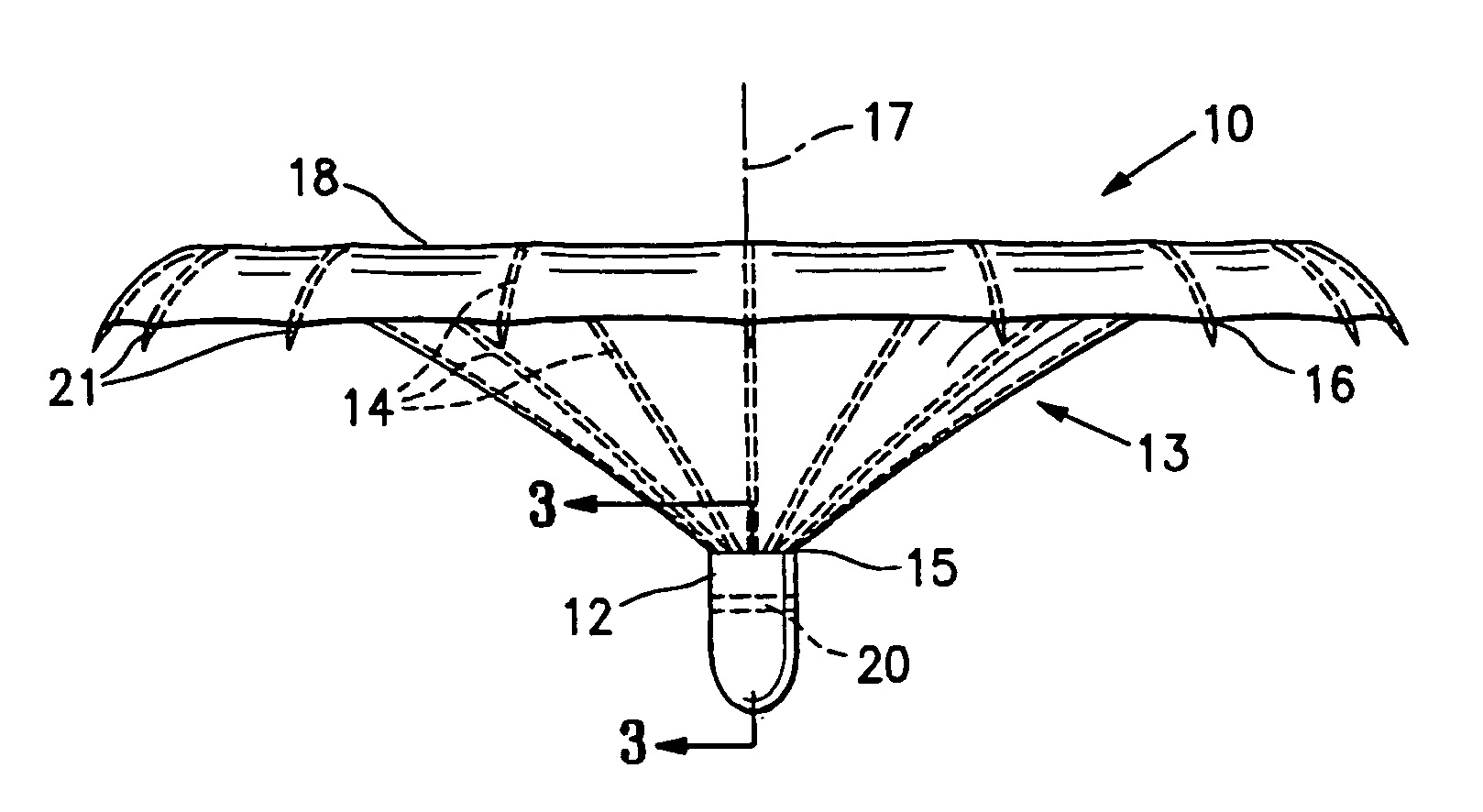

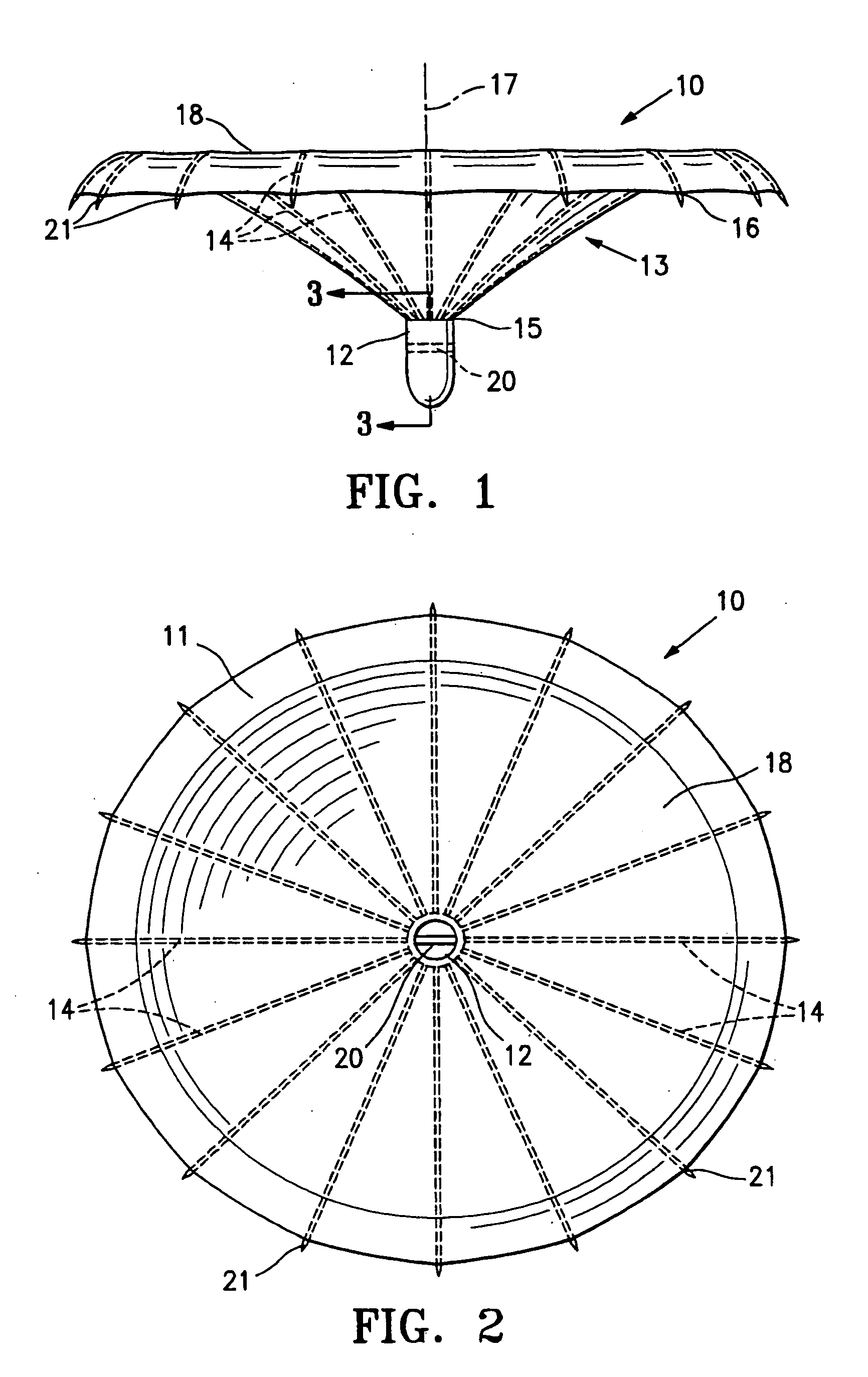

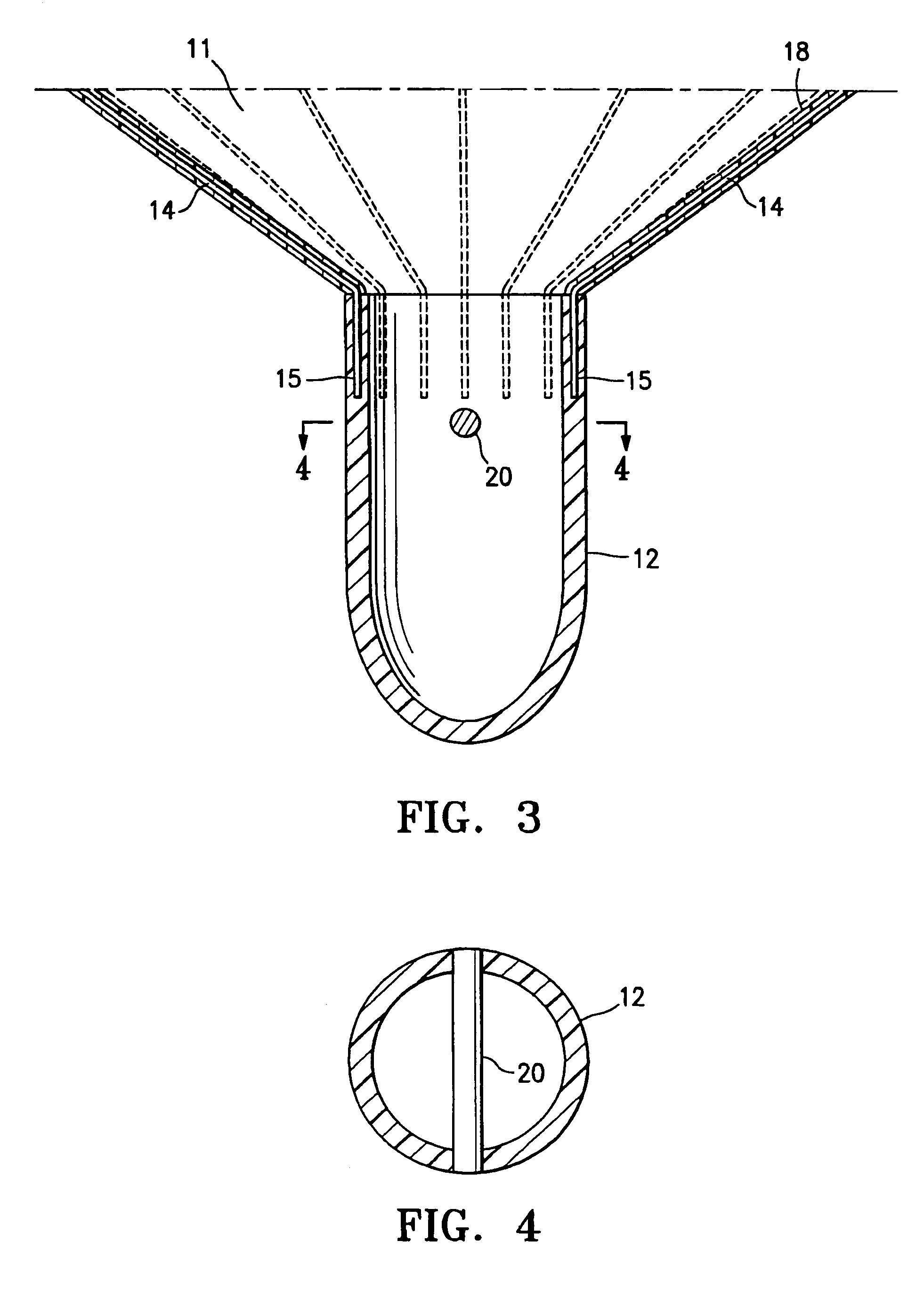

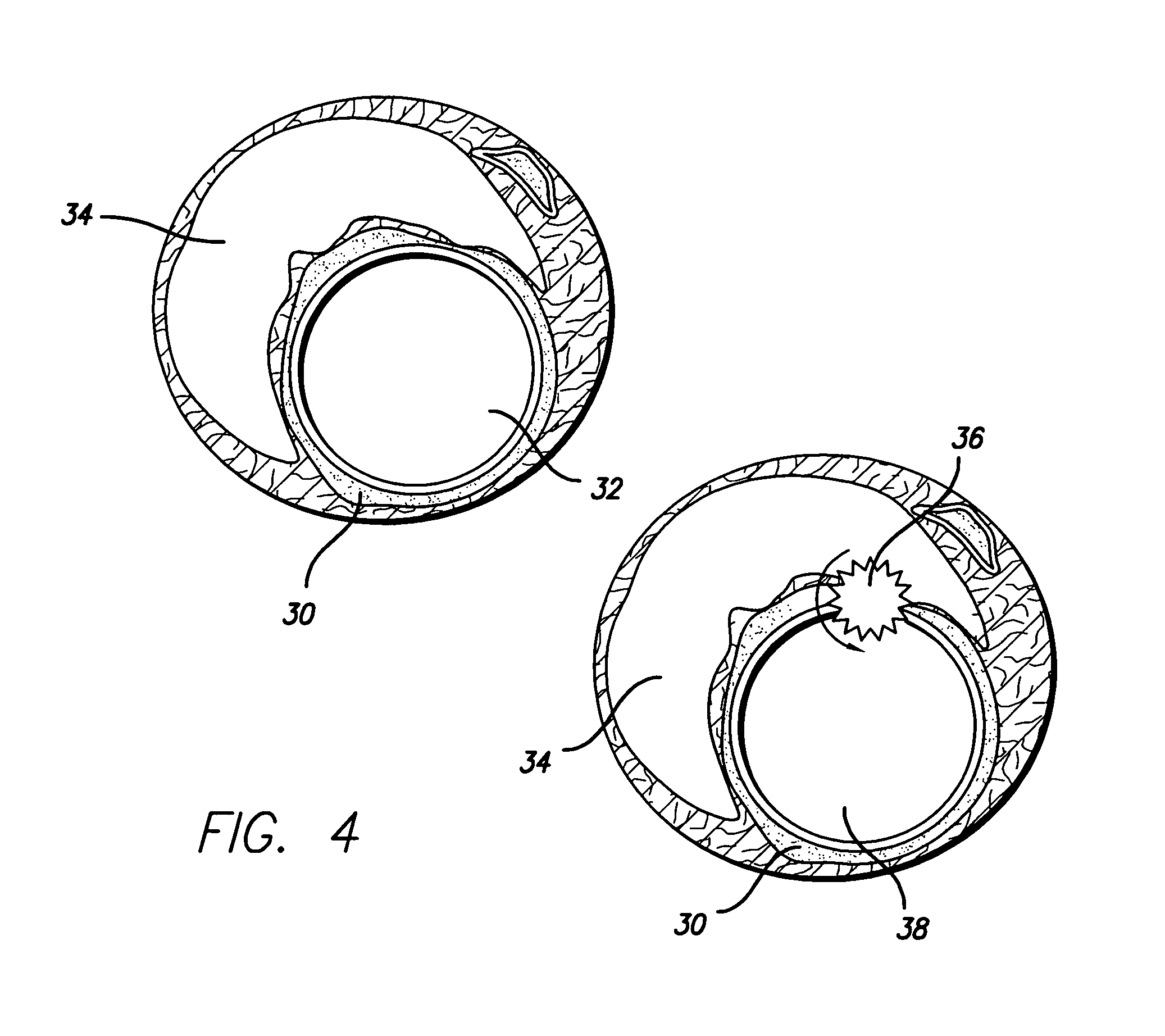

Ventricular partitioning device

InactiveUS20060030881A1Lower the volumeImprove ejection fractionOcculdersSurgical veterinaryHeart chamberNon traumatic

This invention is directed to a partitioning device for separating a patient's heart chamber into a productive portion and a non-productive portion. The device is particularly suitable for treating patients with congestive heart failure. The partitioning device has a frame-reinforced, expandable membrane which separates the productive and non-productive portions of the heart chamber. The proximal ends of the ribs of the frame have tissue penetrating elements about the periphery thereof which are configured to penetrate tissue lining the heart wall at an angle approximately perpendicular to a longitudinal axis of the partitioning device. The partitioning device has a hub with a non-traumatic distal end to engage the ventricular wall.

Owner:EDWARDS LIFESCIENCES CORP

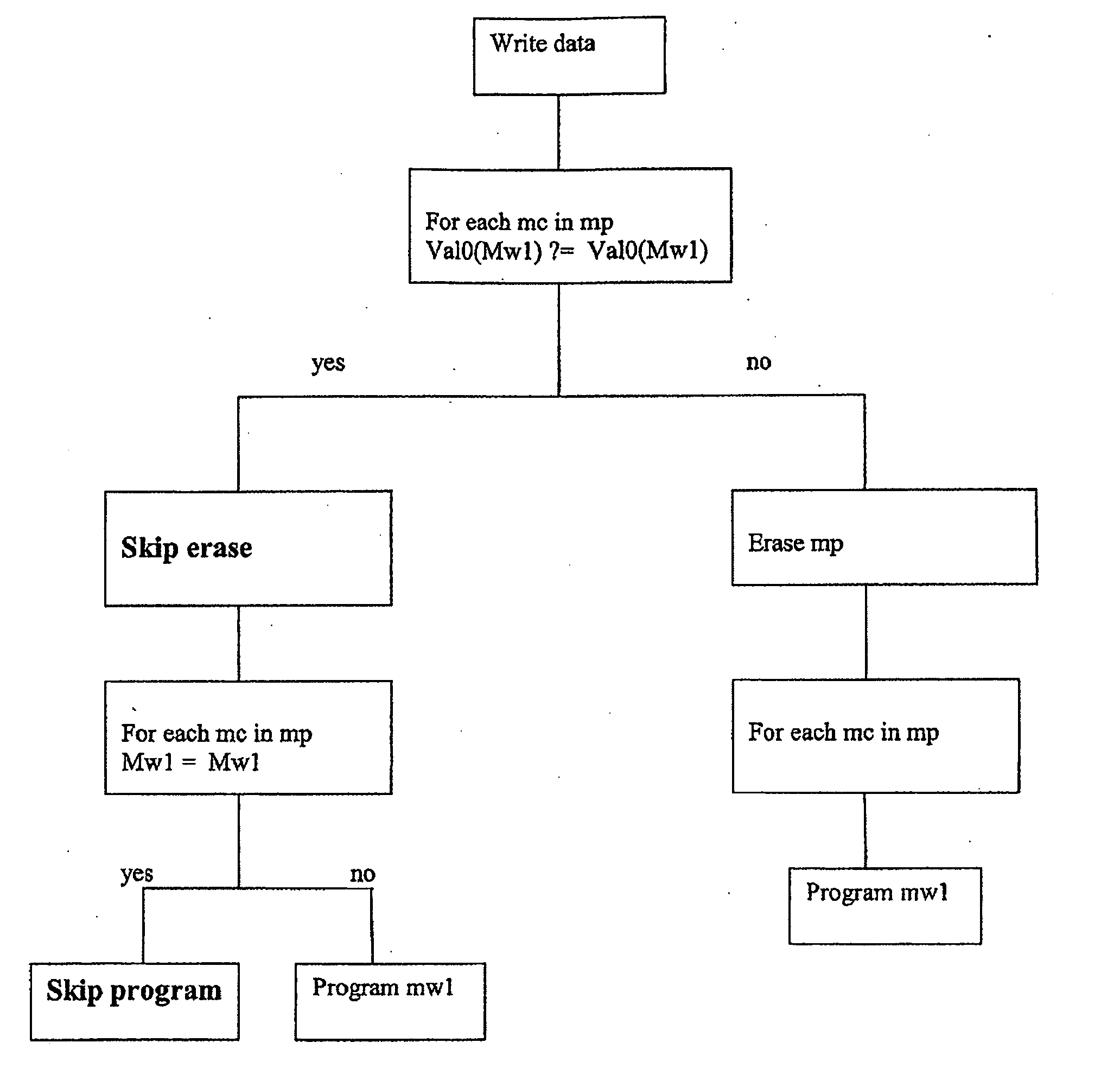

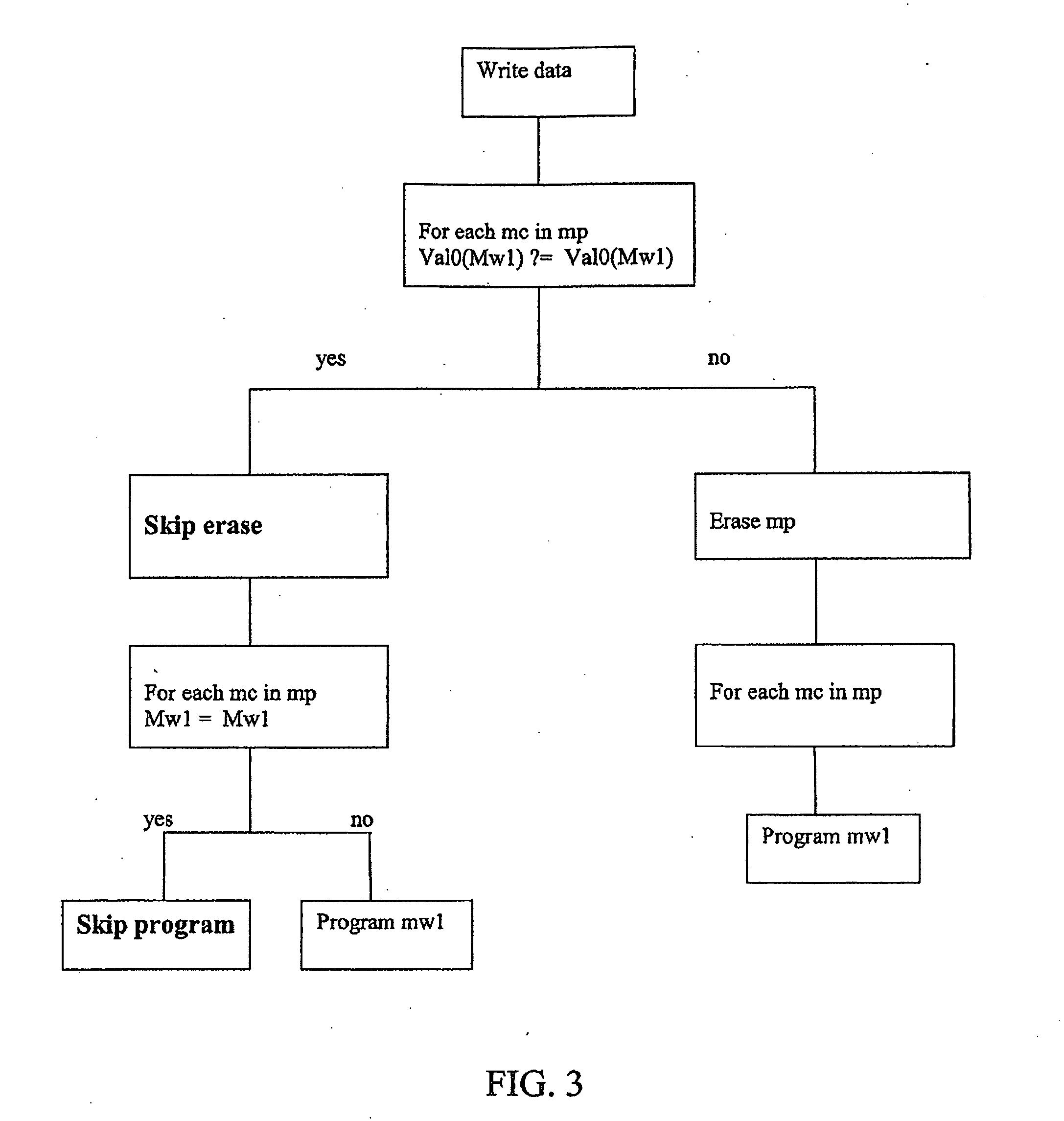

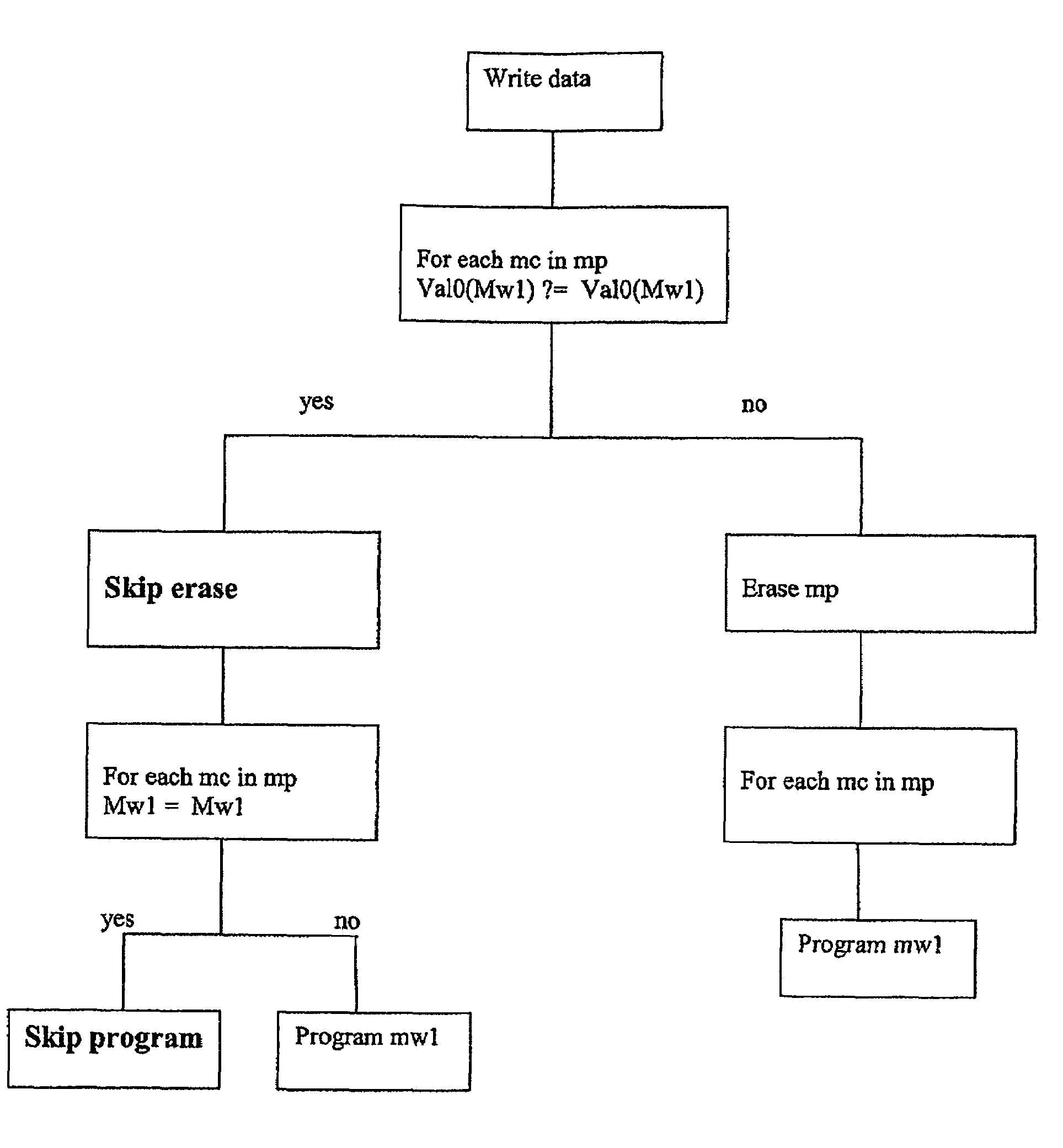

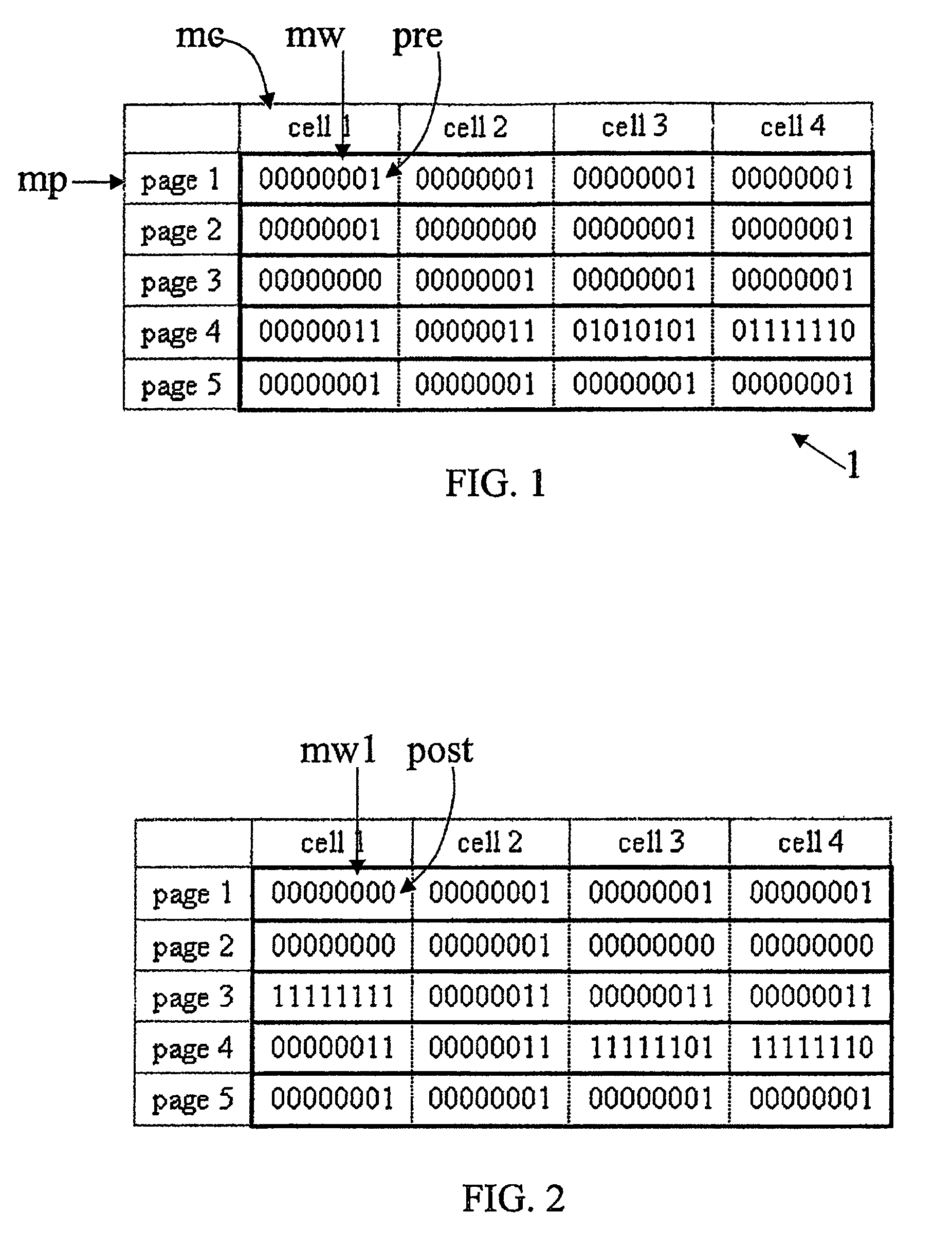

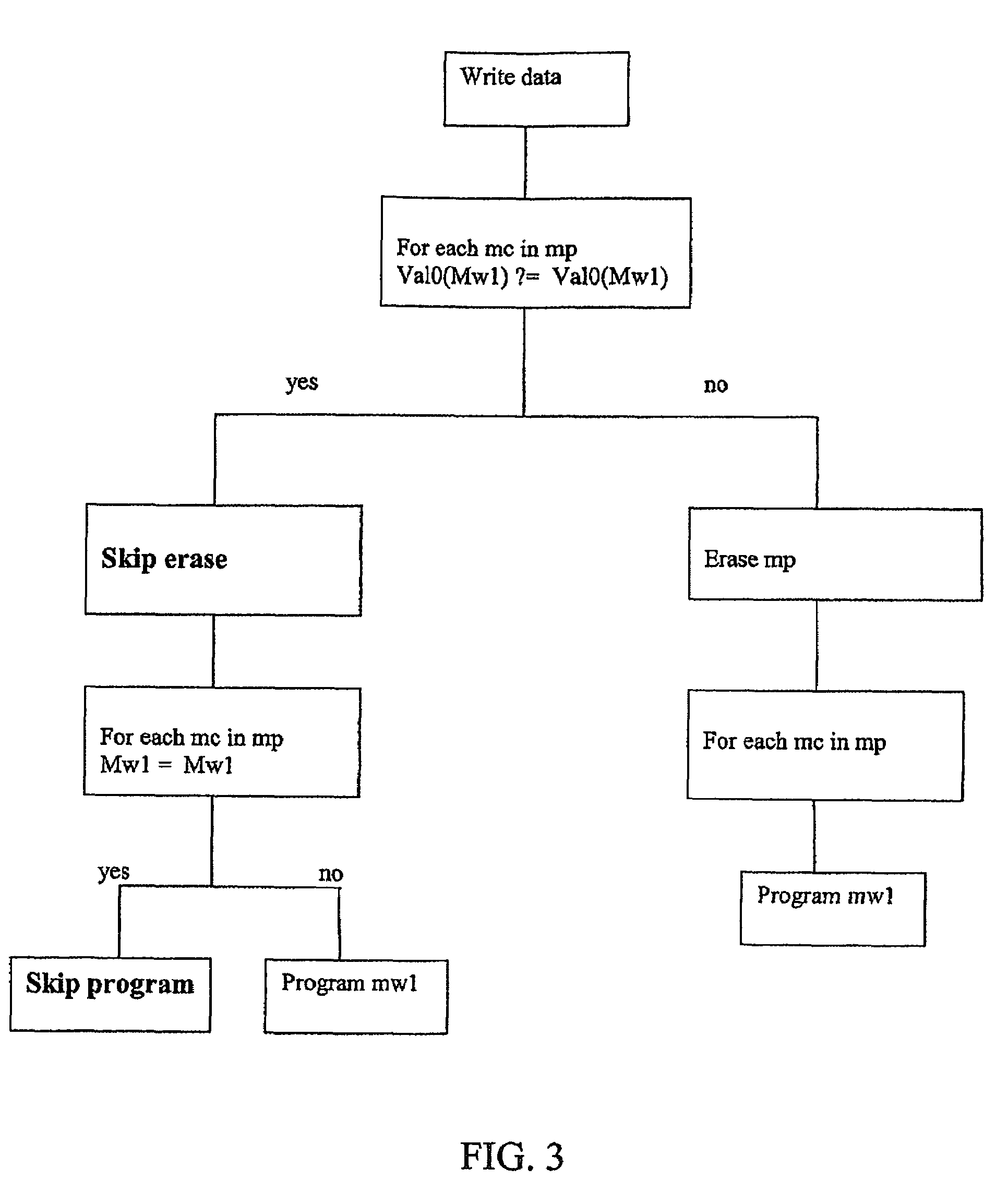

Method for writing data in a non volatile memory unit

ActiveUS20090046522A1Reduce in quantityExtended service lifeRead-only memoriesDigital storageComputer scienceNon-volatile memory

A method for writing data in a non volatile memory unit having memory pages includes a predetermined number of memory cells storing a memory word being a predetermined sequence of digital values. An erase operation erases the memory words in the memory page, setting the predetermined sequence of digital values to a sequence of complementary values. A program operation stores in the memory cell a word and sets a sequence of a word to be stored. For the memory cells of the memory page, the memory word is compared with the word to be stored. A positive check is returned if complementary values of the sequence correspond to complementary values of the predetermined sequence. If the check is negative, the erase operation is executed. The memory word is compared with the word to be stored and the program operation is executed if the word to be stored is different.

Owner:STMICROELECTRONICS INT NV

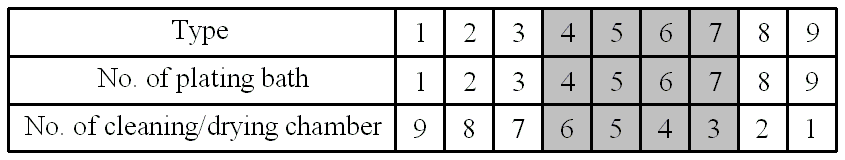

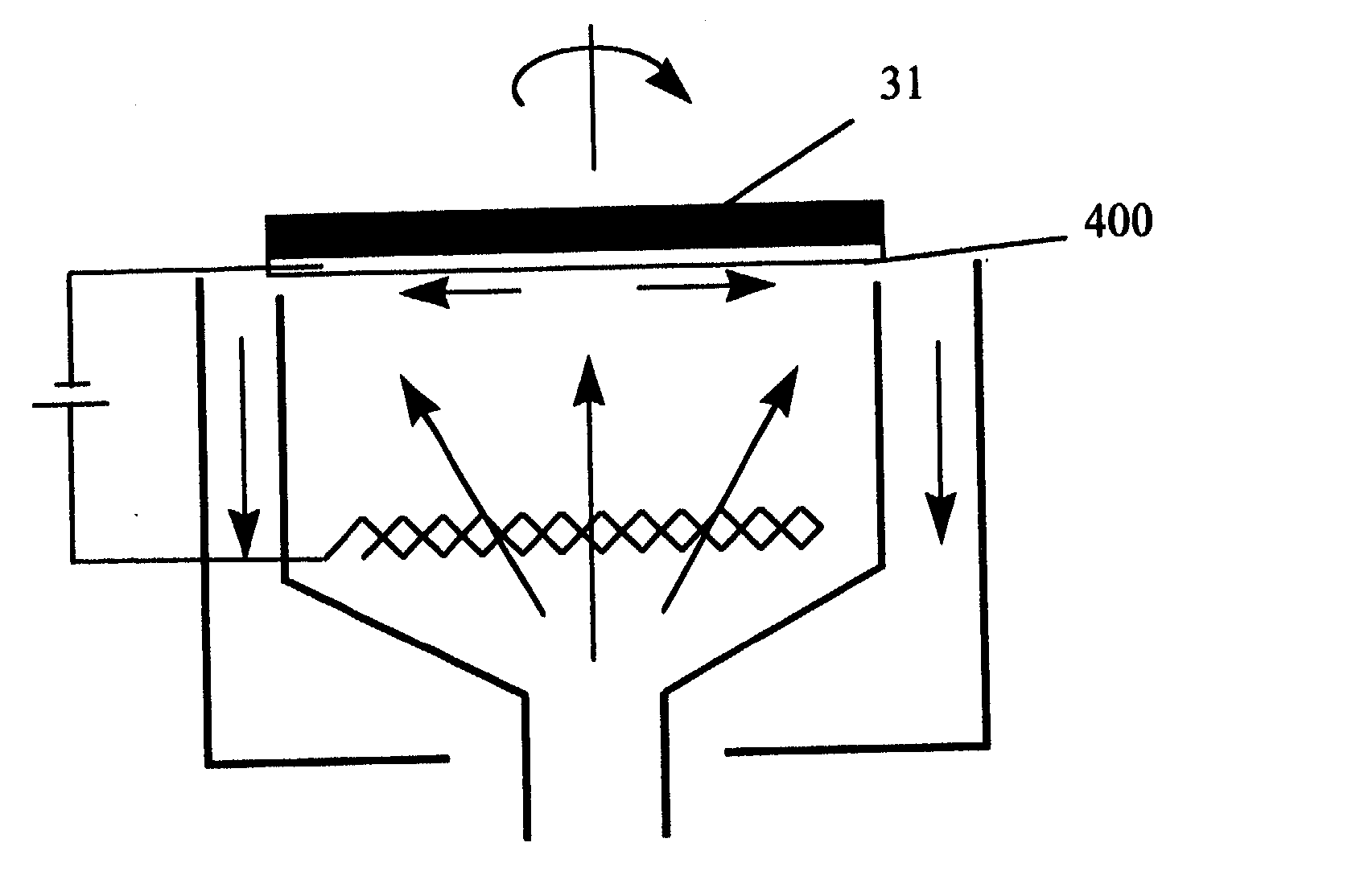

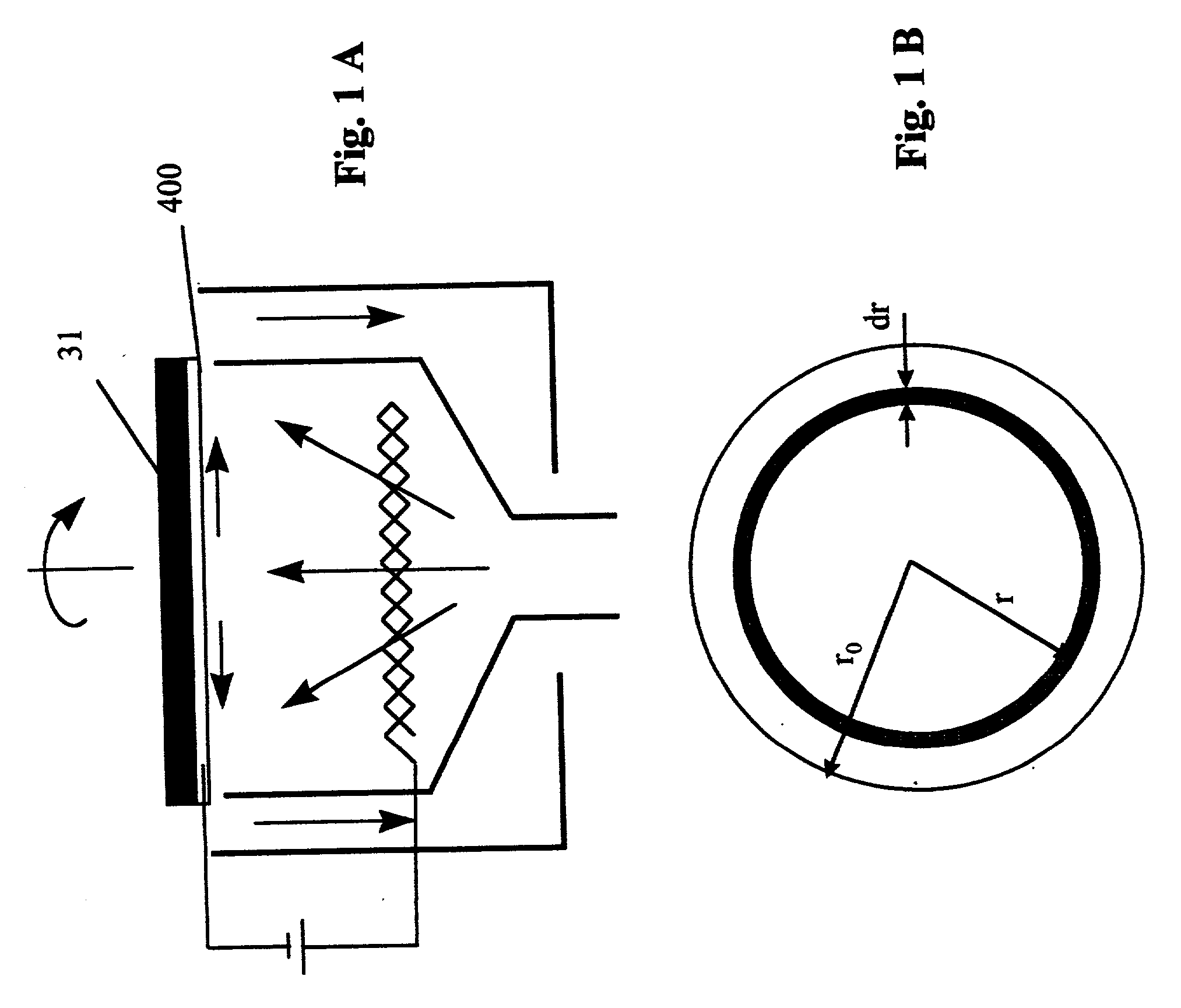

Plating apparatus and method

InactiveUS20020008036A1Strong Gap Filling CapabilityReduce stressCellsSemiconductor/solid-state device manufacturingElectrolyte leakageEngineering

An apparatus for plating a conductive film directly on a substrate with a barrier layer on top includes anode rod (1) placed in tube (109), and anode rings (2), and (3) placed between cylindrical walls (107) and (105), (103) and (101), respectively. Anodes (1), (2), and (3) are powered by power supplies (13), (12), and (11), respectively. Electrolyte (34) is pumped by pump (33) to pass through filter (32) and reach inlets of liquid mass flow controllers (LMFCs) (21), (22), and (23). Then LMFCs (21), (22) and (23) deliver electrolyte at a set flow rate to sub-plating baths containing anodes (3), (2) and (1), respectively. After flowing through the gap between wafer (31) and the top of the cylindrical walls (101), (103), (105), (107) and (109), electrolyte flows back to tank (36) through spaces between cylindrical walls (100) and (101), (103) and (105), and (107) and (109), respectively. A pressure leak valve (38) is placed between the outlet of pump (33) and electrolyte tank (36) to leak electrolyte back to tank (36) when LMFCs (21), (22), (23) are closed. A wafer (31) held by wafer chuck (29) is connected to power supplies (11), (12) and (13). A drive mechanism (30) is used to rotate wafer (31) around the z axis, and oscillate the wafer in the x, y, and z directions shown. Filter (32) filters particles larger than 0.1 or 0.2 mum in order to obtain a low particle added plating process.

Owner:ACM RES

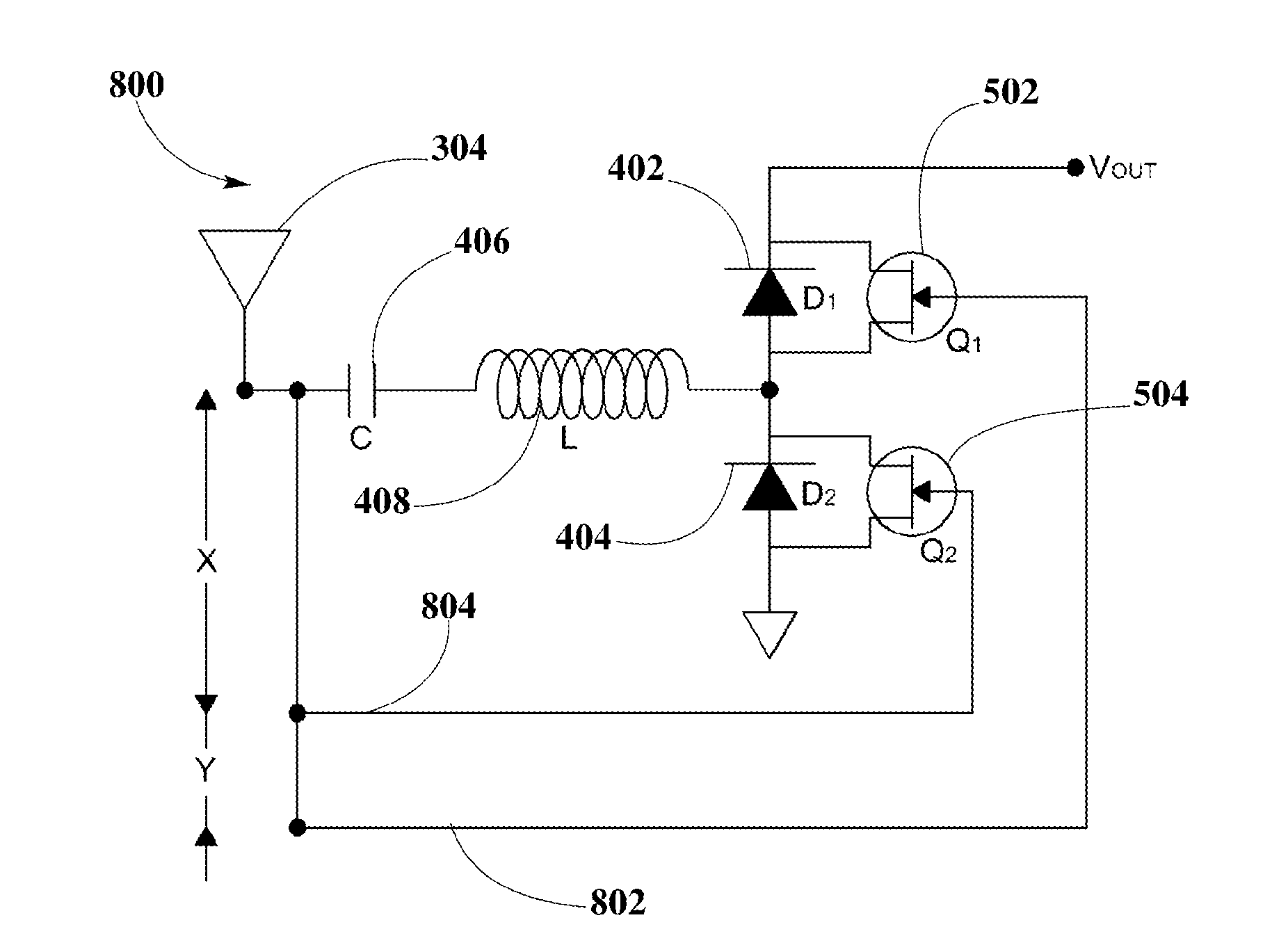

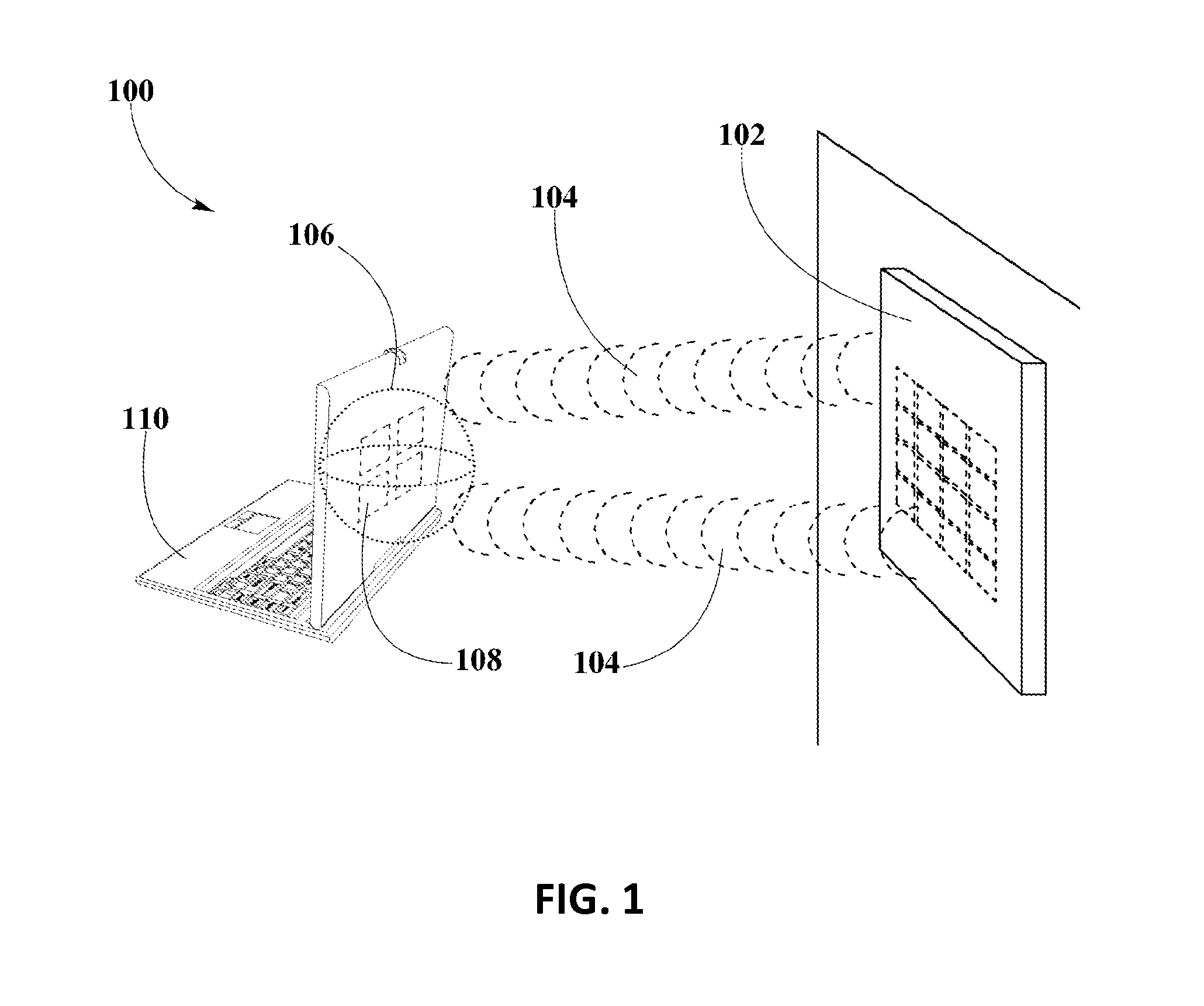

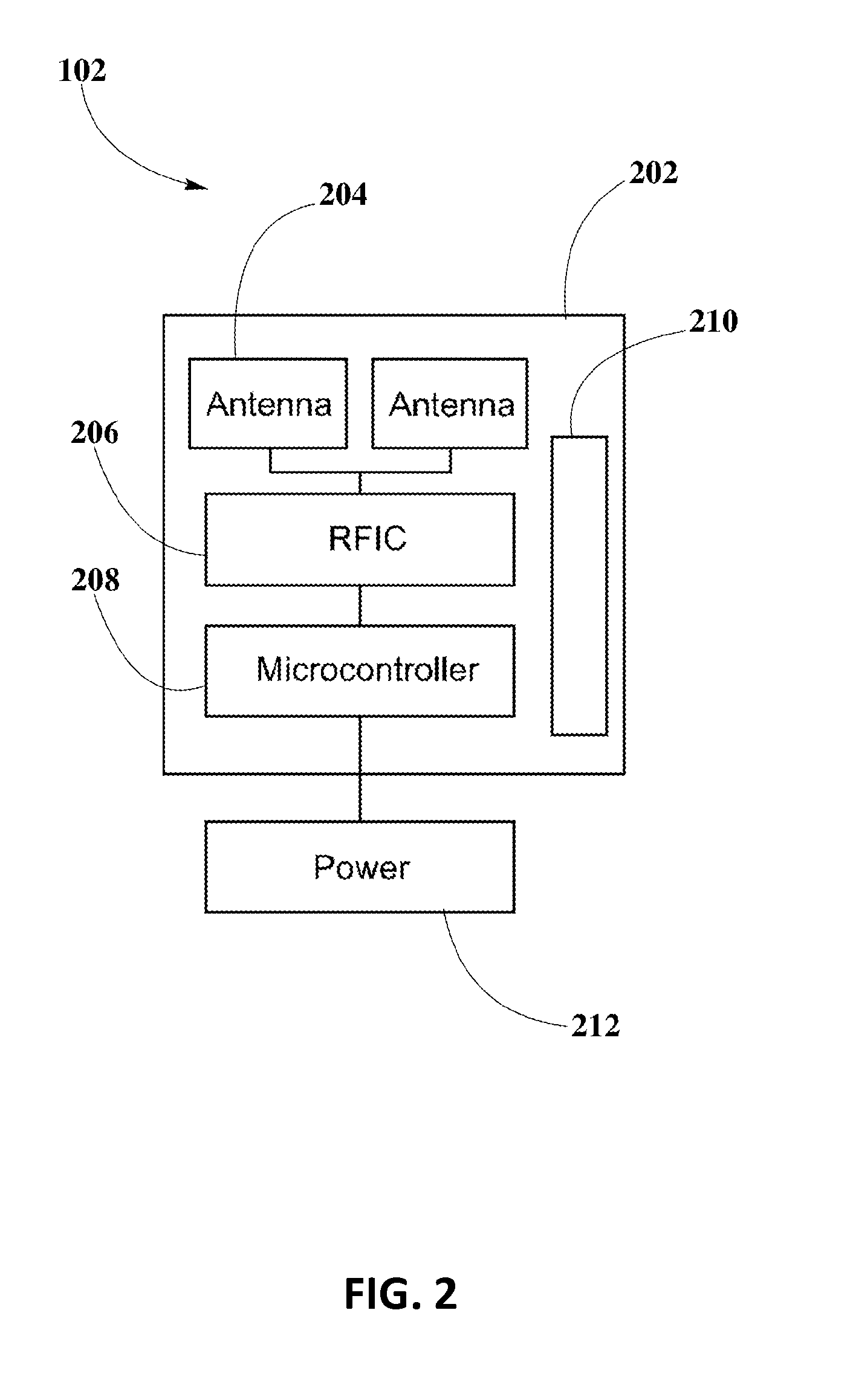

Synchronous Rectifier Design for Wireless Power Receiver

InactiveUS20150326143A1Lower forward voltage dropImprove efficiencyBatteries circuit arrangementsAc-dc conversion without reversalDelay-locked loopSwitching frequency

Synchronous rectifier circuit topologies for a wireless power receiver receiving a supply of power from a wireless transmitter are disclosed. The synchronous rectifier circuit topologies include a half-bridge diode-FET transistor rectifier for rectifying the wireless power into power including a DC waveform, using a control scheme that may be provided by a delay-locked loop clock, or phase shifters, or wavelength links to control conduction of FET transistors in the synchronous rectifier circuit topology, and maintaining a constant switching frequency to have the diodes, coupled to FET transistors, to allow current to flow through each one respectively at the appropriate timing, focusing on high conduction times. The synchronous rectifier circuit topologies may enable power transfer of high-frequency signals at enhanced efficiency due to significant reduction of forward voltage drop and lossless switching.

Owner:ENERGOUS CORPORATION

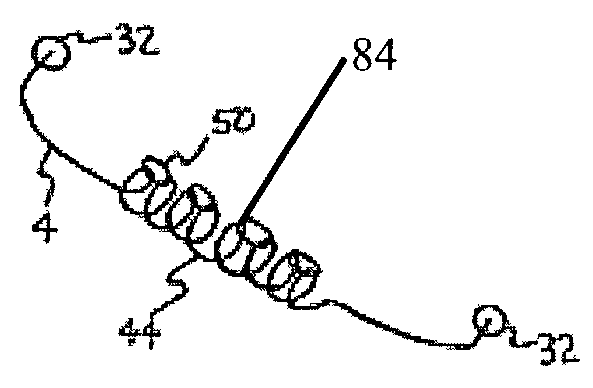

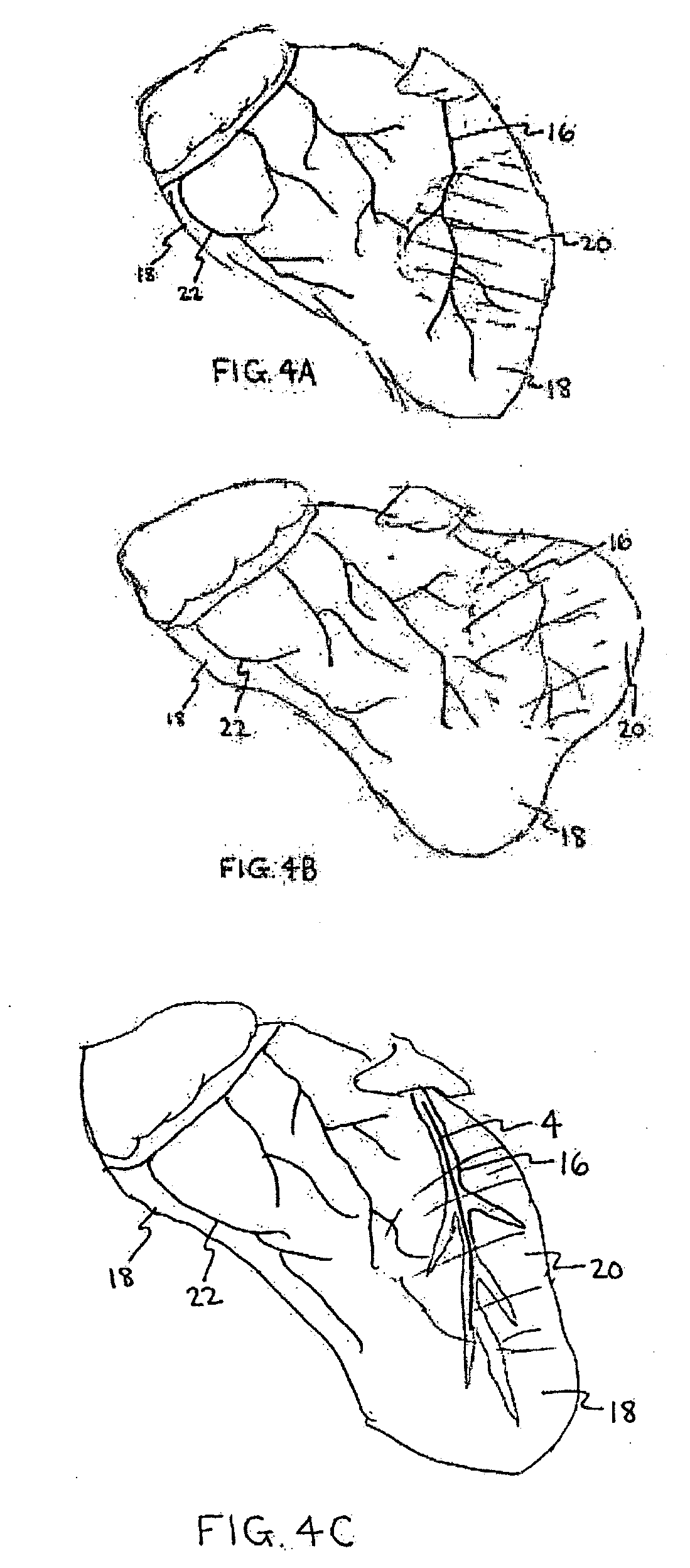

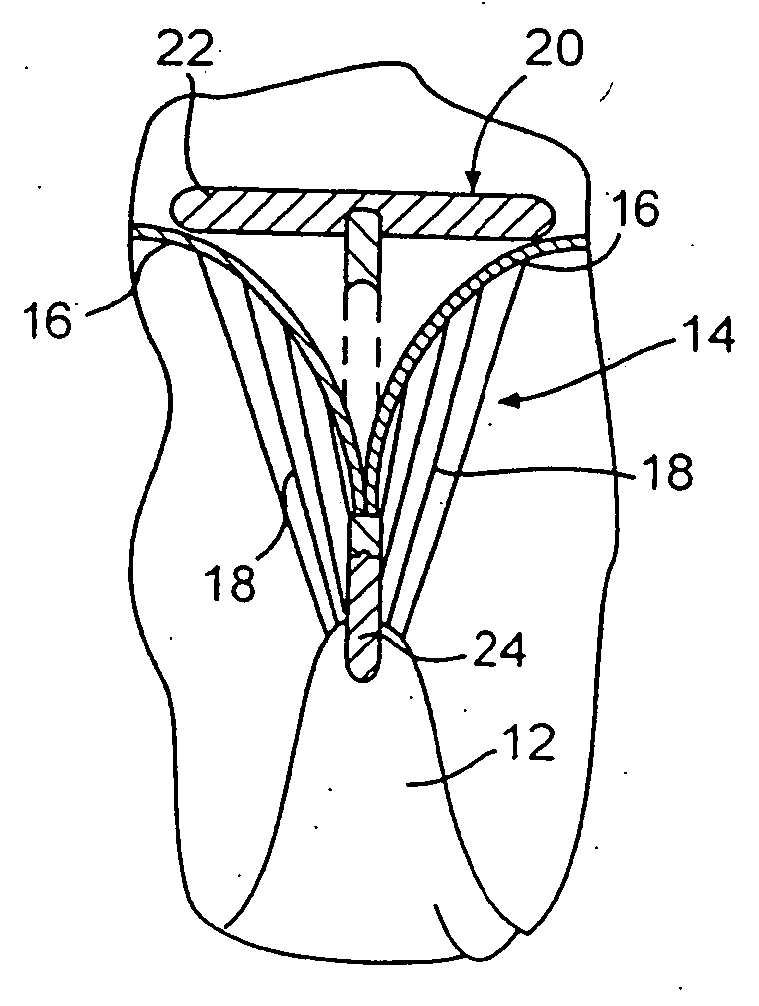

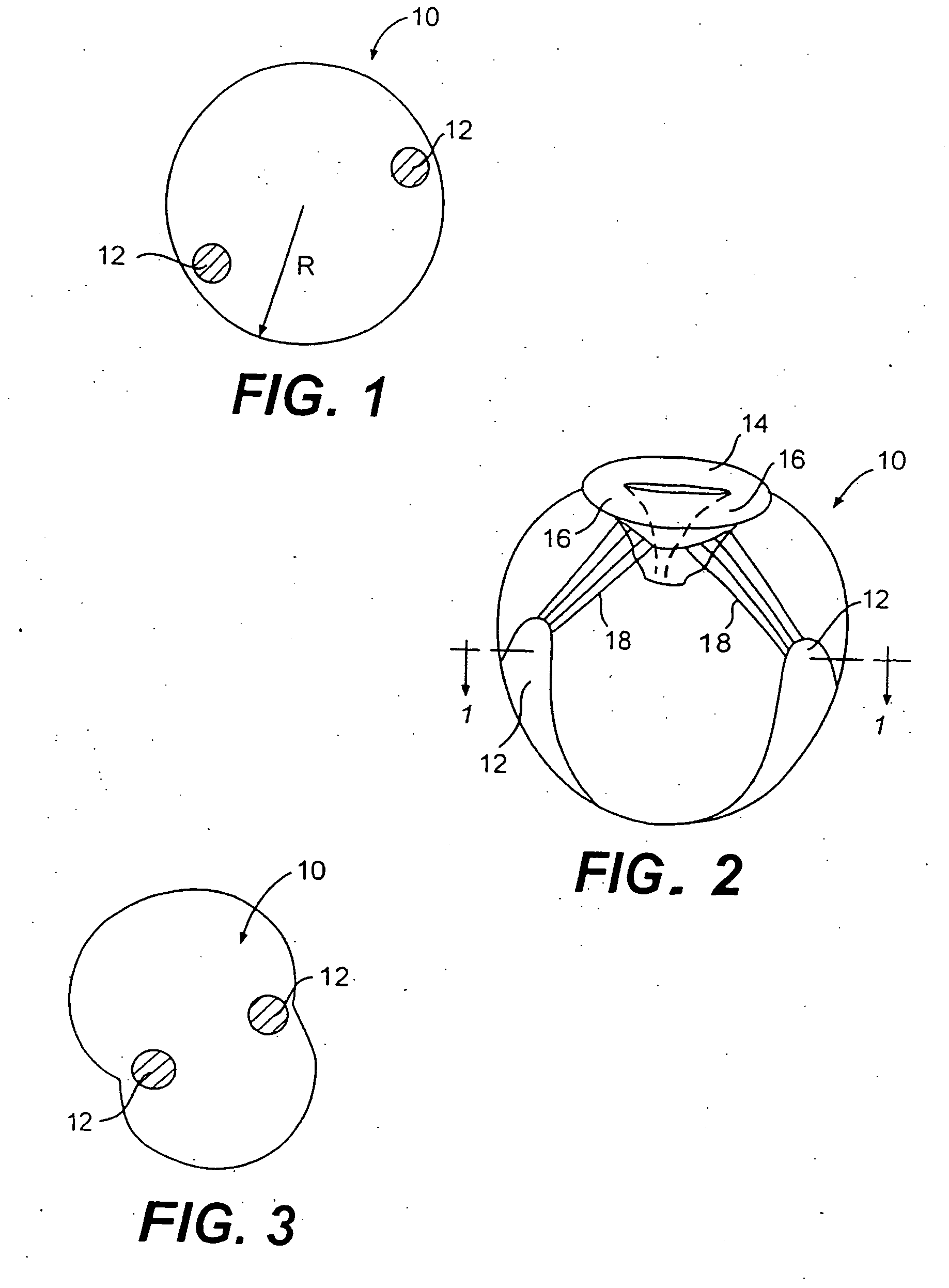

Valve to myocardium tension members device and method

InactiveUS20060195012A1Improved chamber geometryFunction increaseSuture equipmentsAnnuloplasty ringsCardiac muscleEngineering

A device for heart valve repair including at least one tension member having a first end and second end. A basal anchor is disposed at the first end of the tension member and a secondary anchor at the second end. The method includes the steps of anchoring the basal anchor proximate a heart valve and anchoring the secondary anchor at a location spaced from the valve such that the chamber geometry is altered to reduce heart wall tension and / or stress on the valve leaflets.

Owner:EDWARDS LIFESCIENCES LLC

Stent for treating vulnerable plaque

An intravascular stent is configured for asymmetrical differential deployment and to align with a fibrous cap to treat vulnerable plaque. The stent is configured so that reduced expansion forces are imparted during deployment to the fibrous cap, thereby reducing the likelihood of cap rupture. The stent includes cylindrical rings connected by links and a cover attached to a portion of the stent to differentially restrict stent expansion when the stent is expanded from a delivery diameter to an implanted diameter thereby creating asymmetrical circumferential deployment. The portion of the stent having the cover imparts lower expansion forces from the stent expansion onto the fibrous cap area than other portions of the stent not having the cover.

Owner:ABBOTT CARDIOVASCULAR

Pressure measurement device

InactiveUS7025727B2Sufficient dynamic responseLow pressureCatheterIntracranial pressure measurementMeasurement deviceTelemetry

A device measures pressures in animals and humans and includes a pressure transmission catheter (PTC) filled with a pressure transmitting medium and implantable in an area in having a physiological pressure. A transducer communicates with the pressure transmitting medium to provide a pressure signal representing variations in the physiologic pressure on electrical wires. A connecting catheter carries the electrical wires to signal processing and telemetry circuitry, which transmits a telemetry signal representing the pressure signal to a receiver external to the animal or human. A housing holds the signal processing and telemetry circuitry, but the transducer is remote from the housing. The device is particularly useful in measuring venous pressure, pulmonary pressure, bladder pressure, or intracranial pressure without significant head pressure artifact and with a sufficient dynamic response. One embodiment of the PTC includes a multi-durometer stem.

Owner:DATA SCI INT

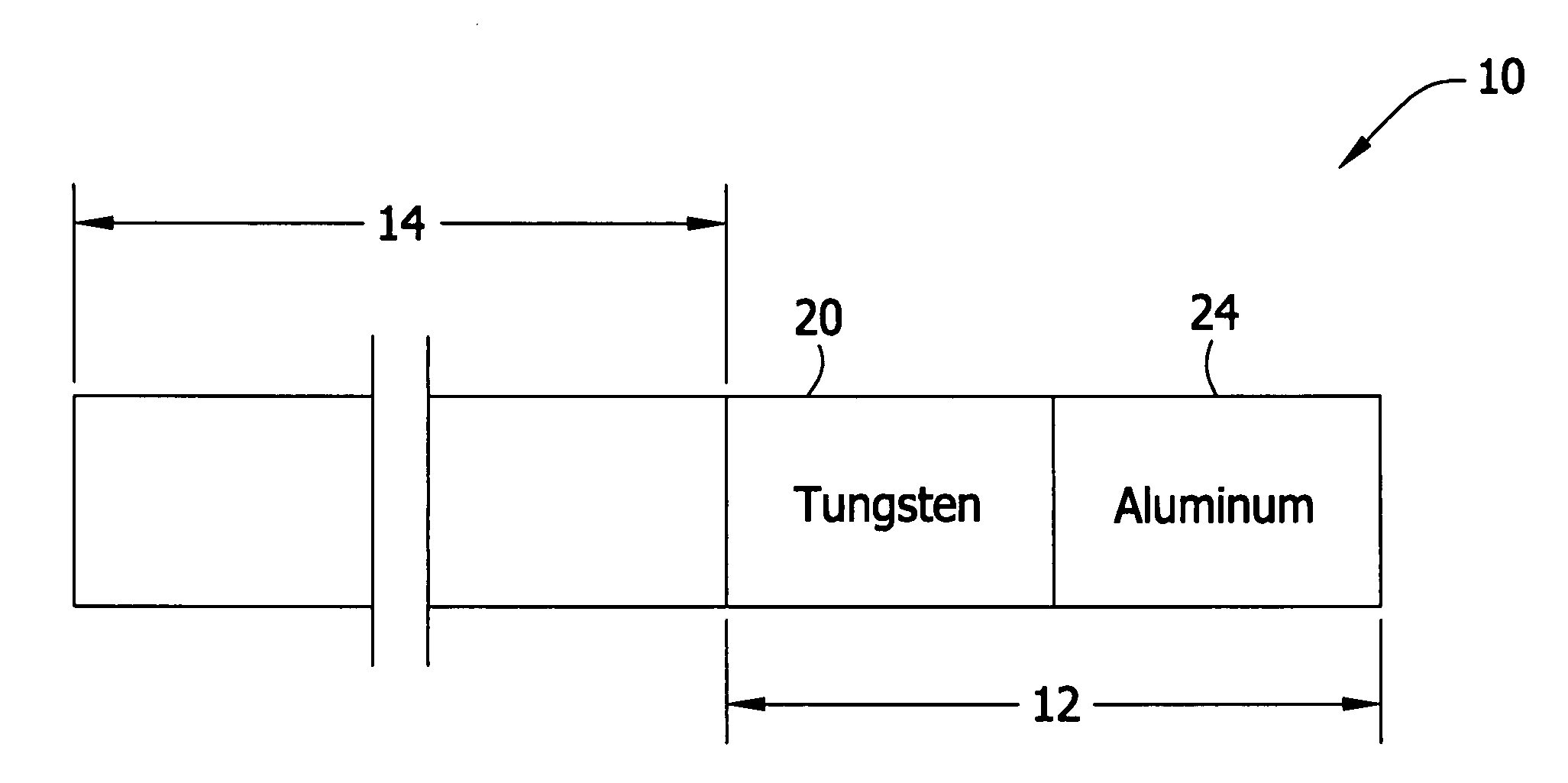

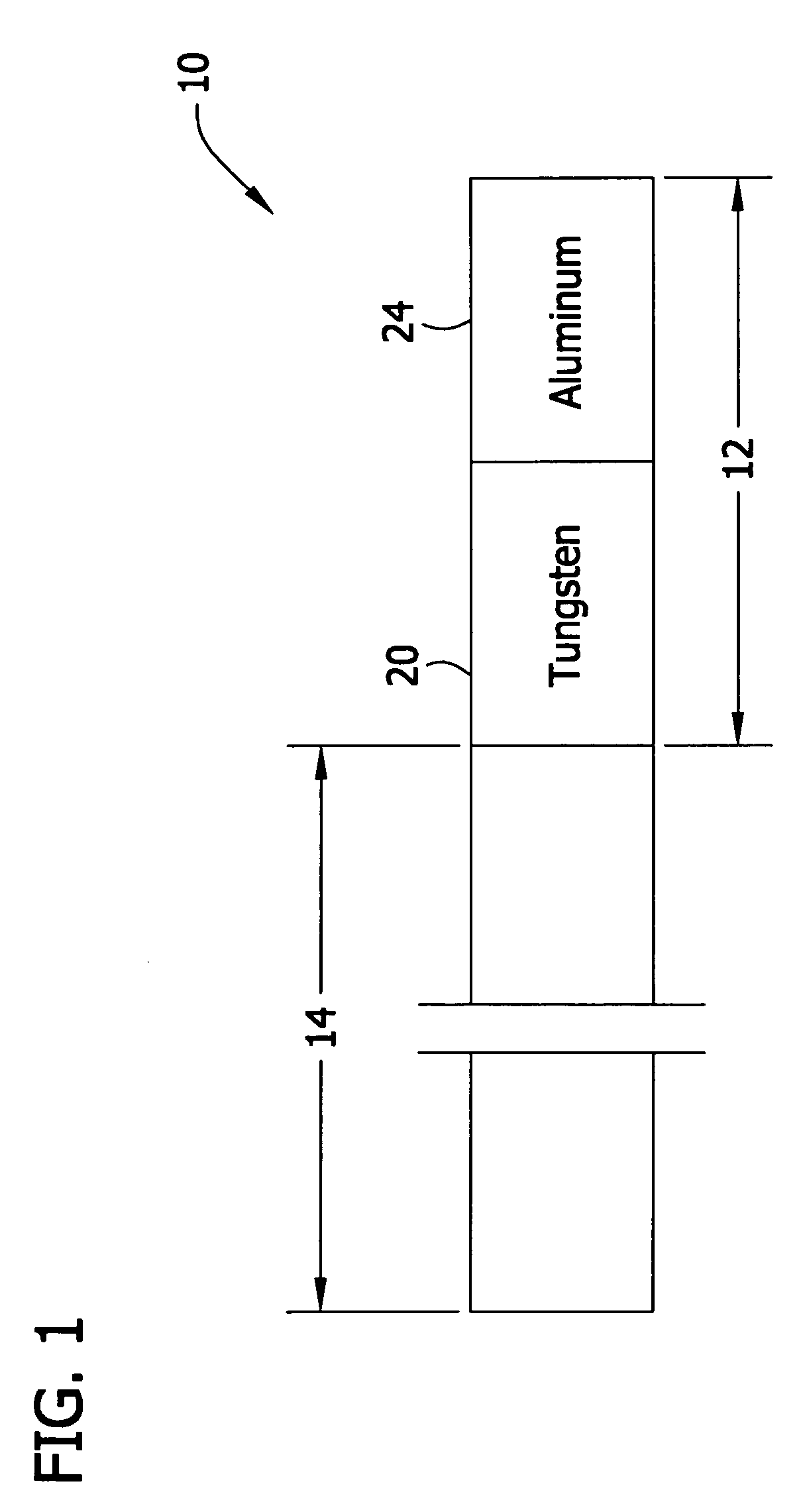

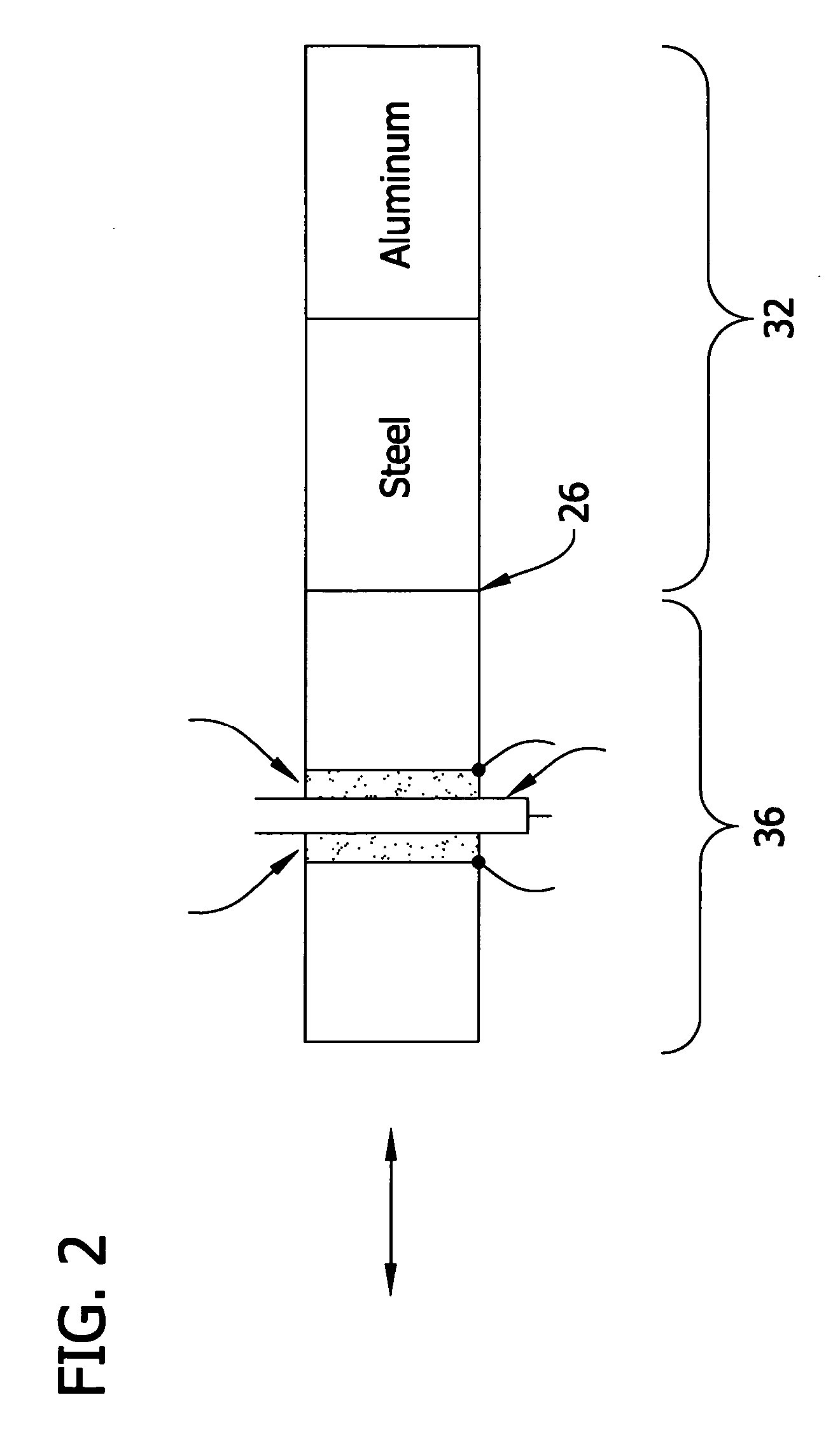

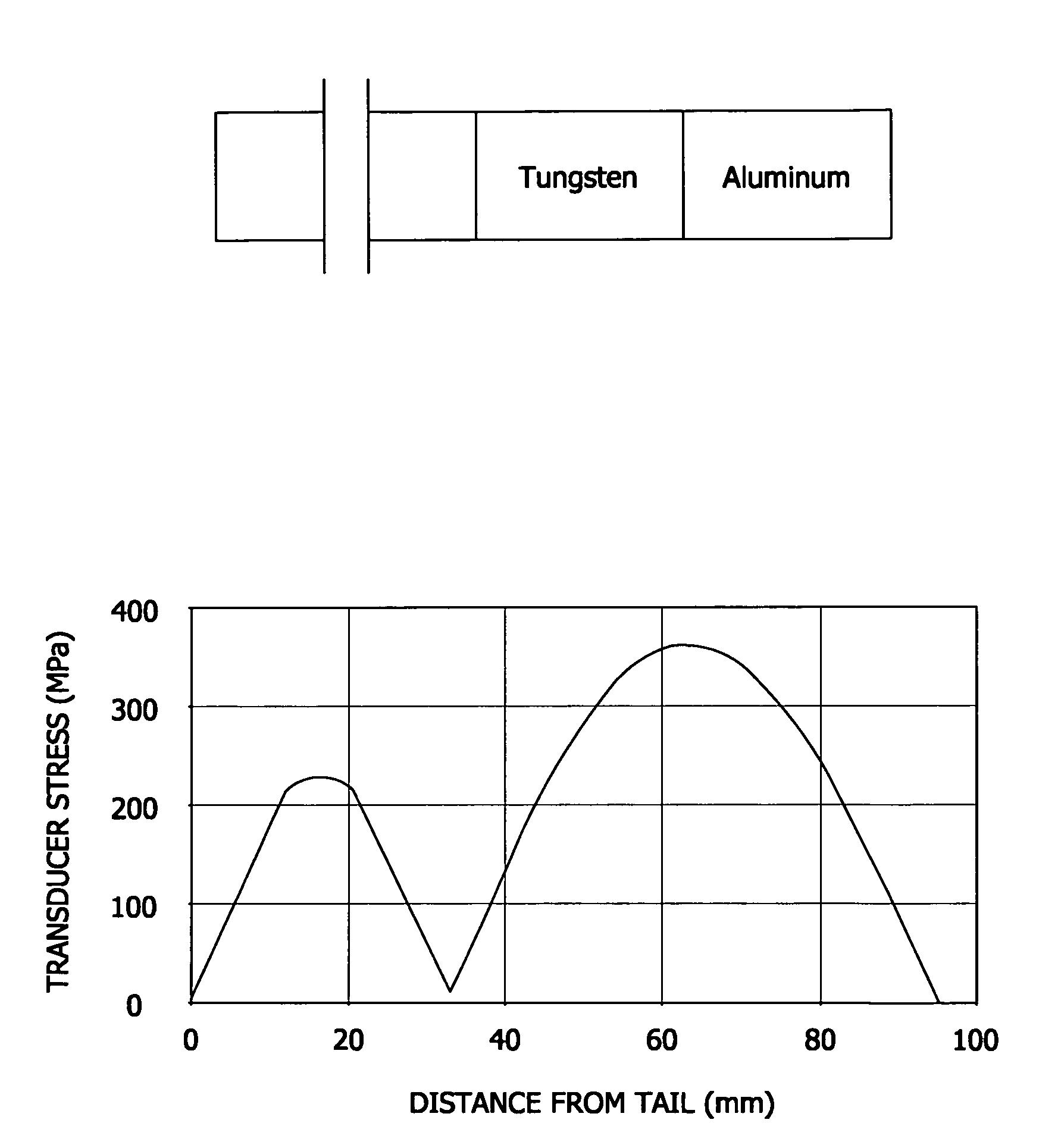

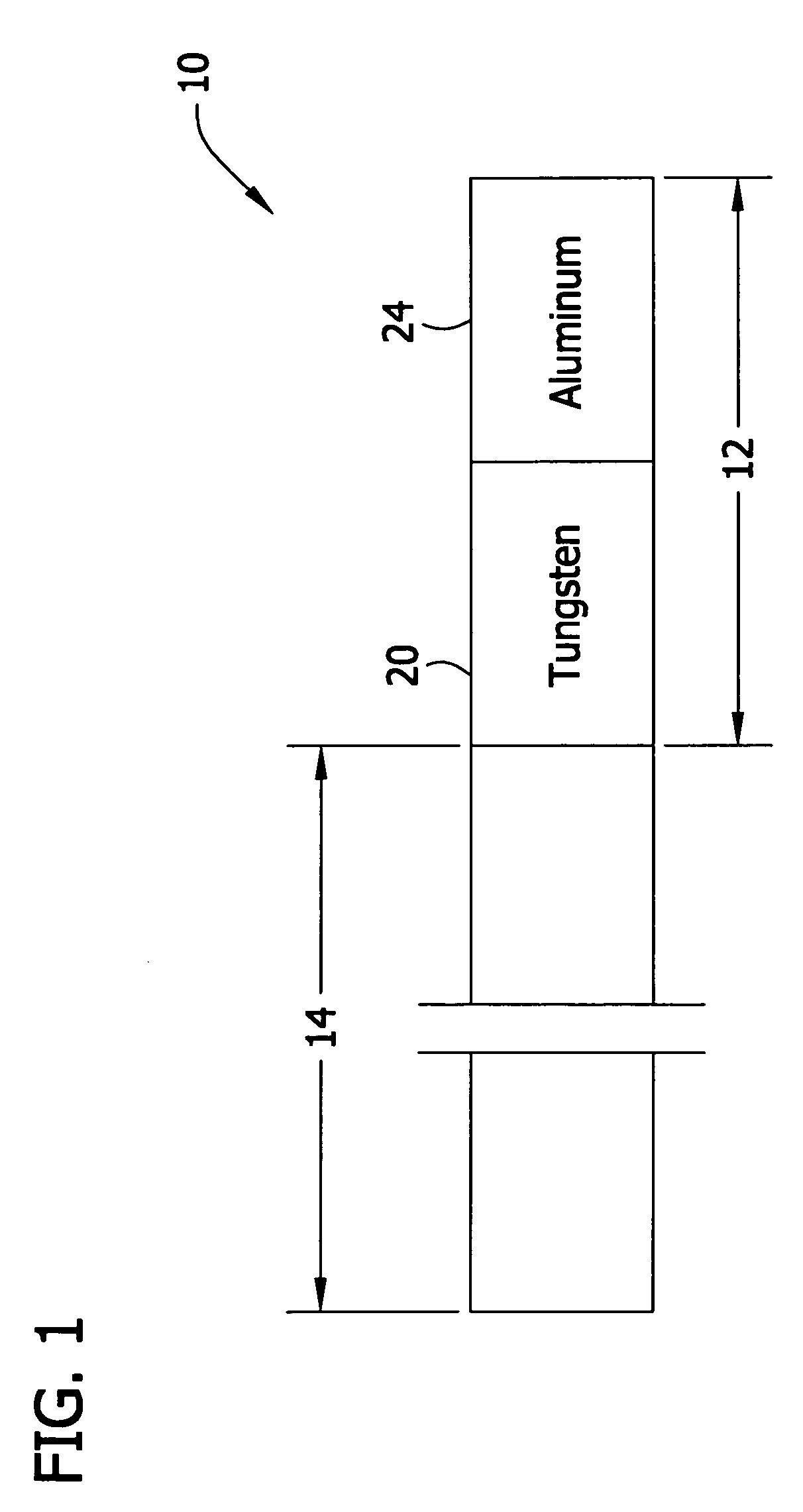

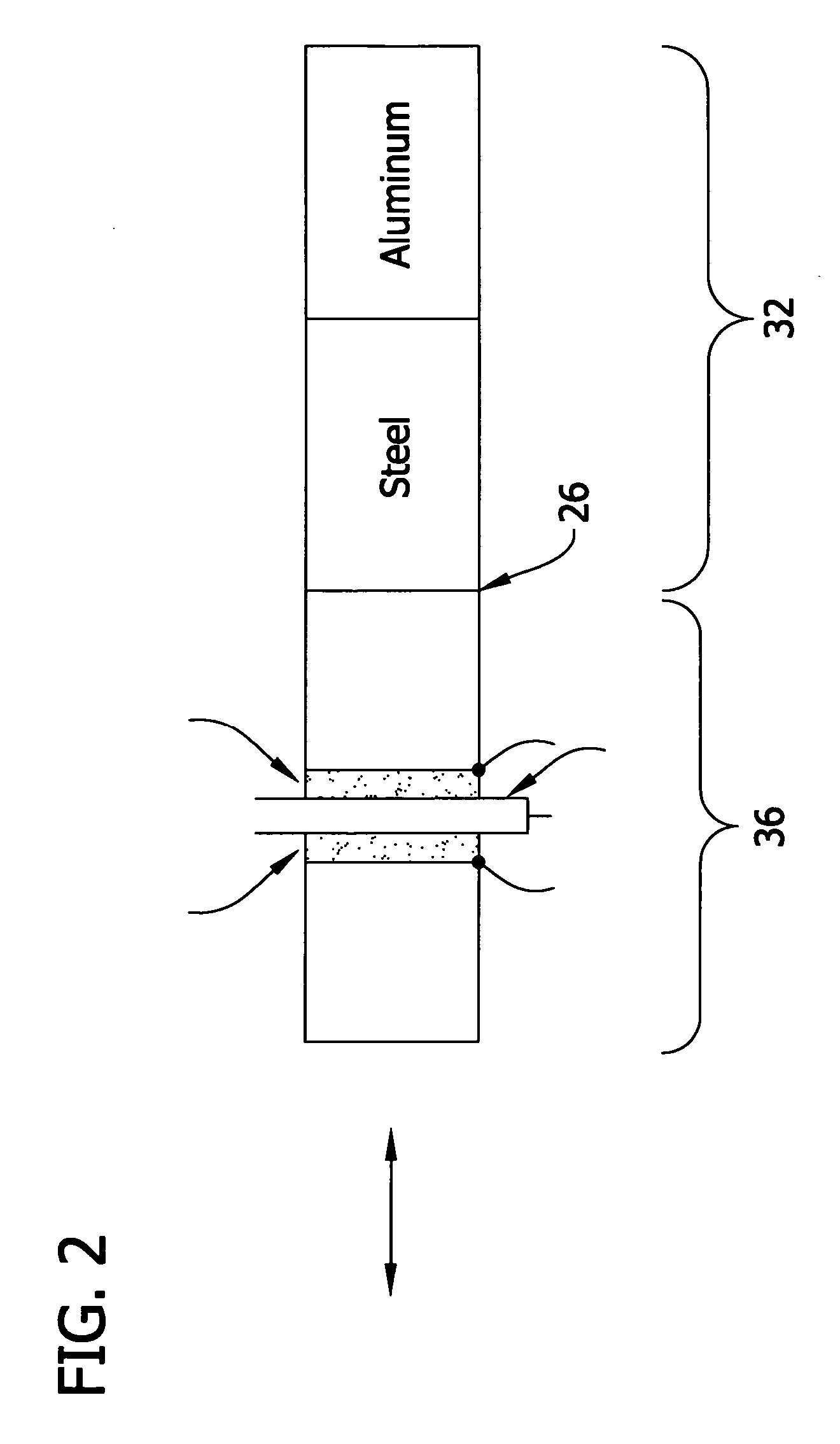

Amplifying ultrasonic waveguides

ActiveUS20070131034A1High magnificationReduce stressUltrasound therapyAnalysing solids using sonic/ultrasonic/infrasonic wavesWaveguideAcoustic impedance

Ultrasonic waveguides having improved velocity gain are disclosed for use in ultrasonic medical devices. Specifically, the ultrasonic waveguides comprises a first material having a higher acoustic impedance and a second material having a lower acoustic impedance.

Owner:PIEZOINNOVATIONS +1

Method for writing data in a non volatile memory unit

ActiveUS7639537B2Reduce in quantityExtended service lifeRead-only memoriesDigital storageComputer scienceNon-volatile memory

A method for writing data in a non volatile memory unit having memory pages includes a predetermined number of memory cells storing a memory word being a predetermined sequence of digital values. An erase operation erases the memory words in the memory page, setting the predetermined sequence of digital values to a sequence of complementary values. A program operation stores in the memory cell a word and sets a sequence of a word to be stored. For the memory cells of the memory page, the memory word is compared with the word to be stored. A positive check is returned if complementary values of the sequence correspond to complementary values of the predetermined sequence. If the check is negative, the erase operation is executed. The memory word is compared with the word to be stored and the program operation is executed if the word to be stored is different.

Owner:STMICROELECTRONICS INT NV

Amplifying ultrasonic waveguides

InactiveUS8033173B2High magnificationReduce riskUltrasound therapyAnalysing solids using sonic/ultrasonic/infrasonic wavesAcousticsWaveguide

Ultrasonic waveguides having improved velocity gain are disclosed for use in ultrasonic medical devices. Specifically, the ultrasonic waveguides comprises a first material having a higher acoustic impedance and a second material having a lower acoustic impedance.

Owner:PIEZOINNOVATIONS +1

Valve to myocardium tension members device and method

InactiveUS20060052868A1Decreasing wall stressImproving chamber performanceSuture equipmentsAnnuloplasty ringsCardiac muscleEngineering

A device for heart valve repair including at least one tension member having a first end and second end. A basal anchor is disposed at the first end of the tension member and a secondary anchor at the second end. The method includes the steps of anchoring the basal anchor proximate a heart valve and anchoring the secondary anchor at a location spaced from the valve such that the chamber geometry is altered to reduce heart wall tension and / or stress on the valve leaflets.

Owner:EDWARDS LIFESCIENCES LLC

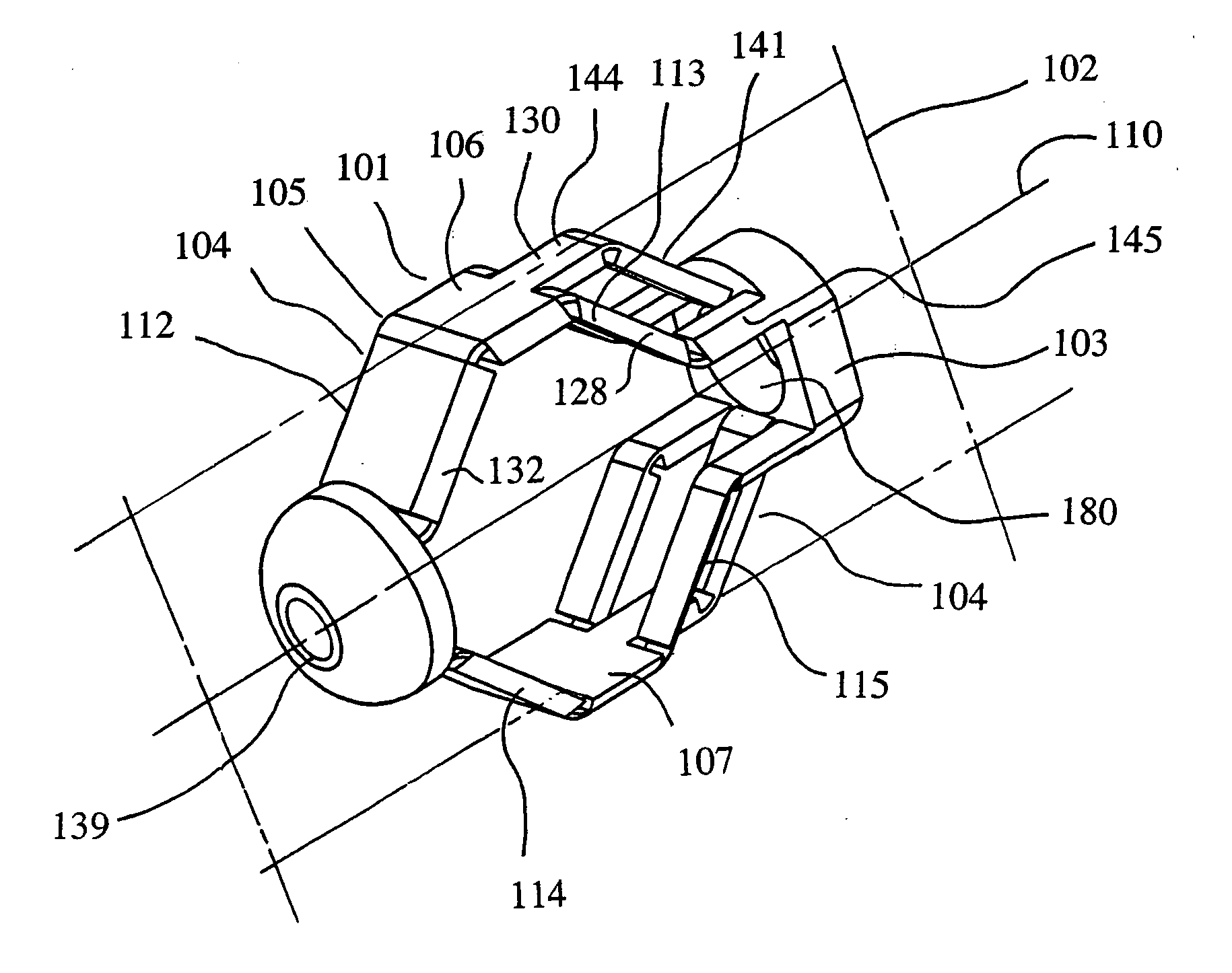

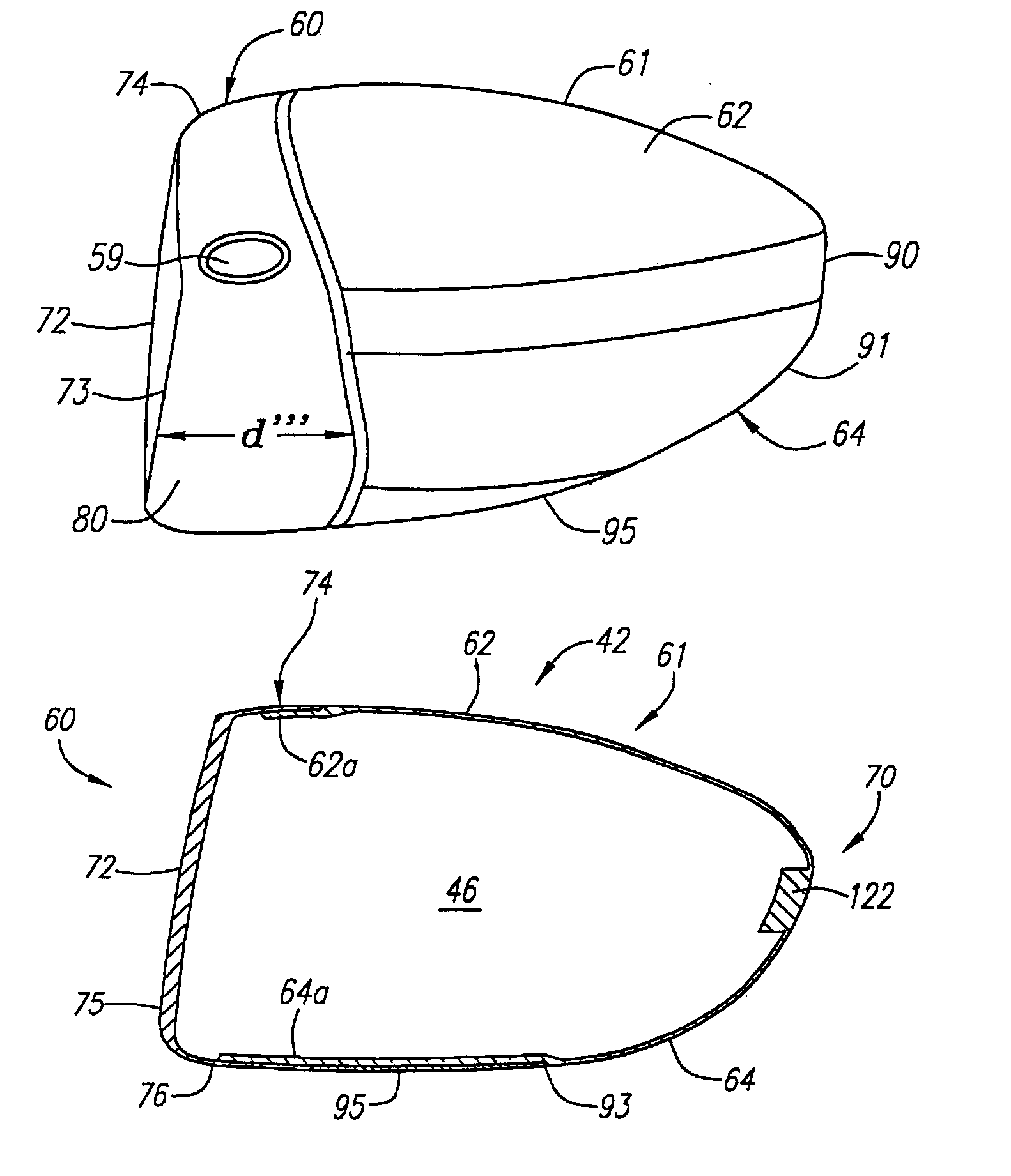

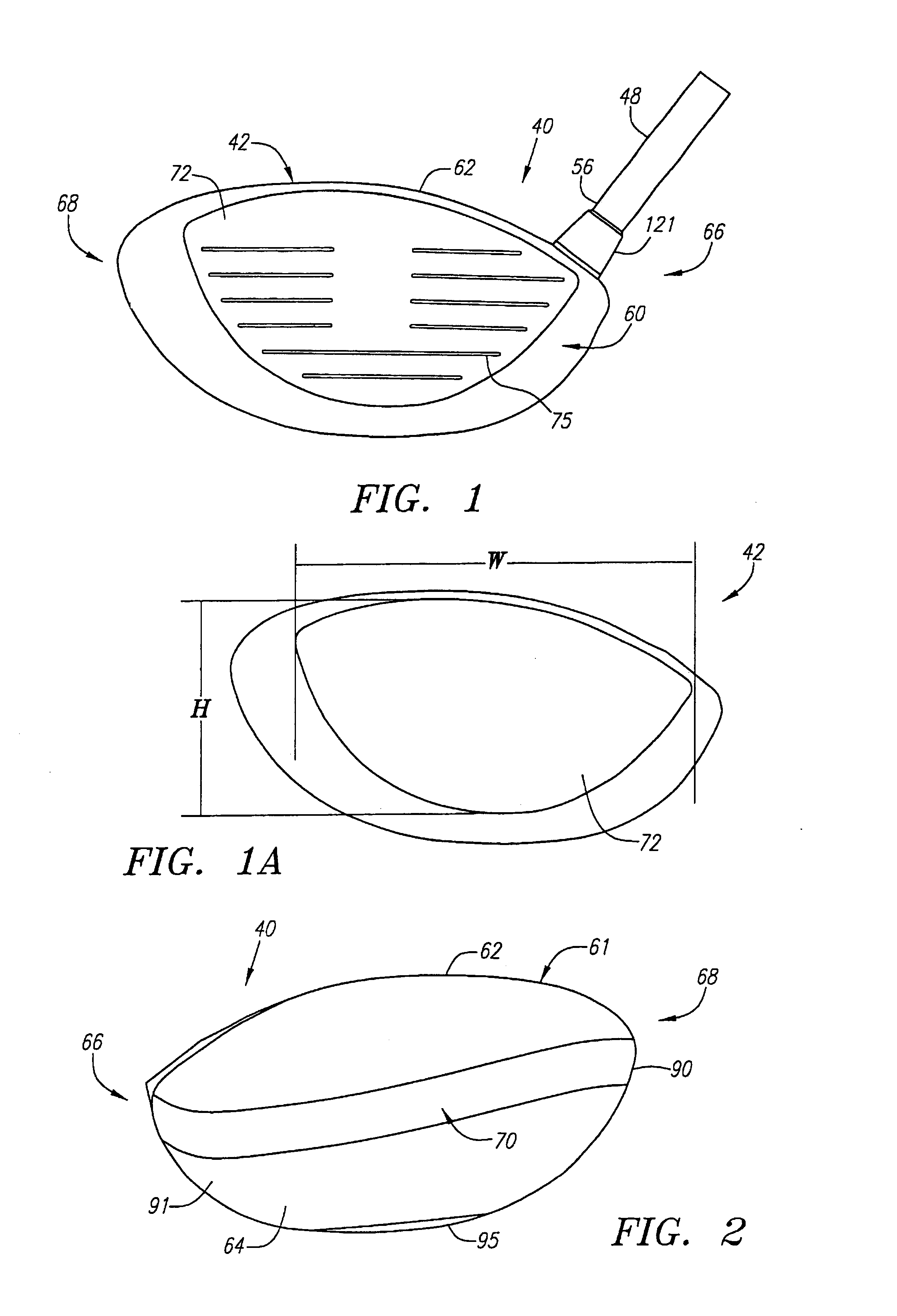

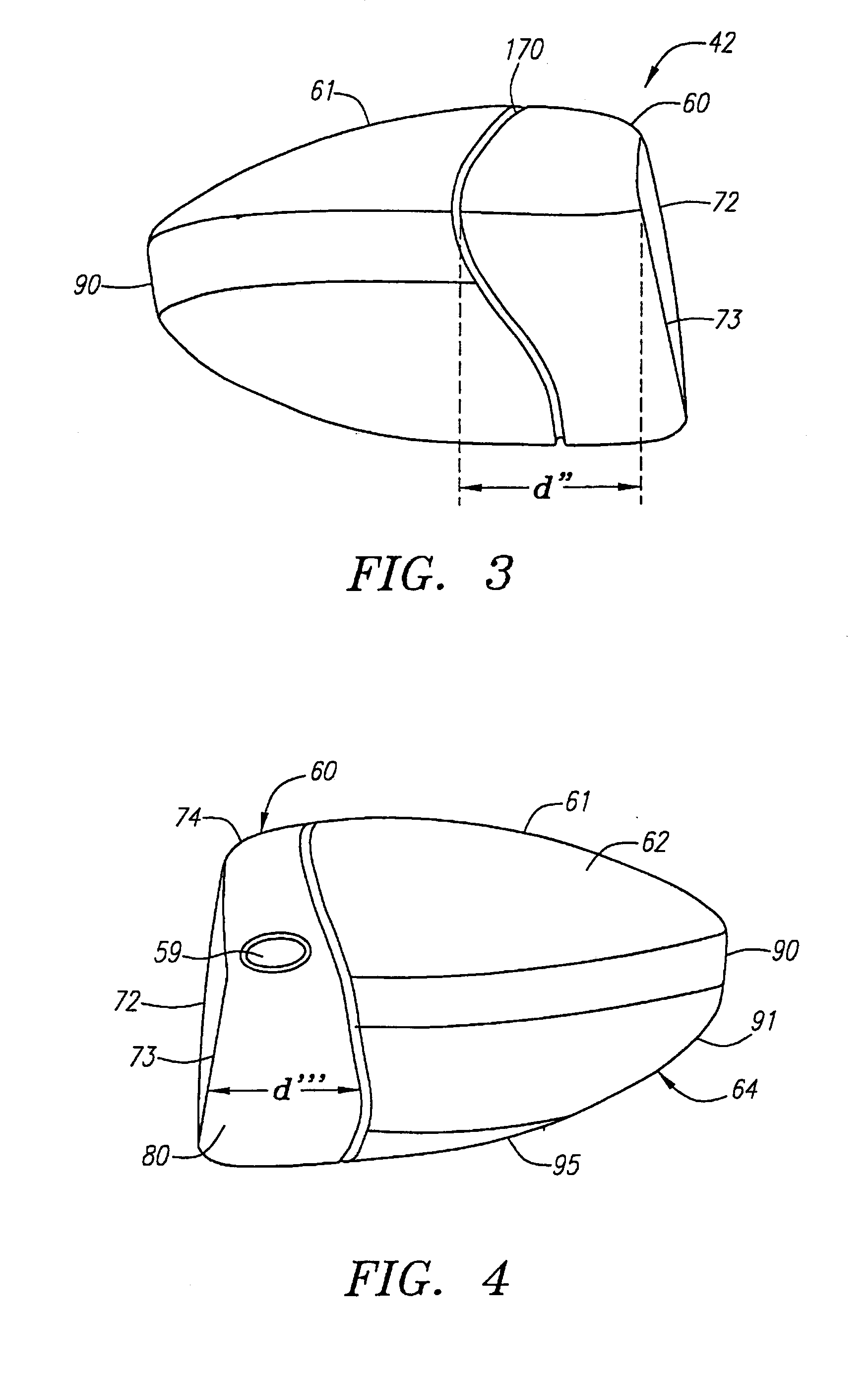

Bonded joint design for a golf club head

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is preferably composed of a non-metal material such as a composite material or a thermoplastic material. The face component (60) is bonded to the aft-body (61) with a leading edge (180) of an undercut portion (62a and 64a) of the aft-body positioned a distance of 0.100 inch to 0.500 inch from the interior surface (60a) of the face component (60) in order to reduce the stress on the bonded joint of between the face component (60) and the aft-body (61). The club head (42) has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com