Patents

Literature

506 results about "Degree of precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

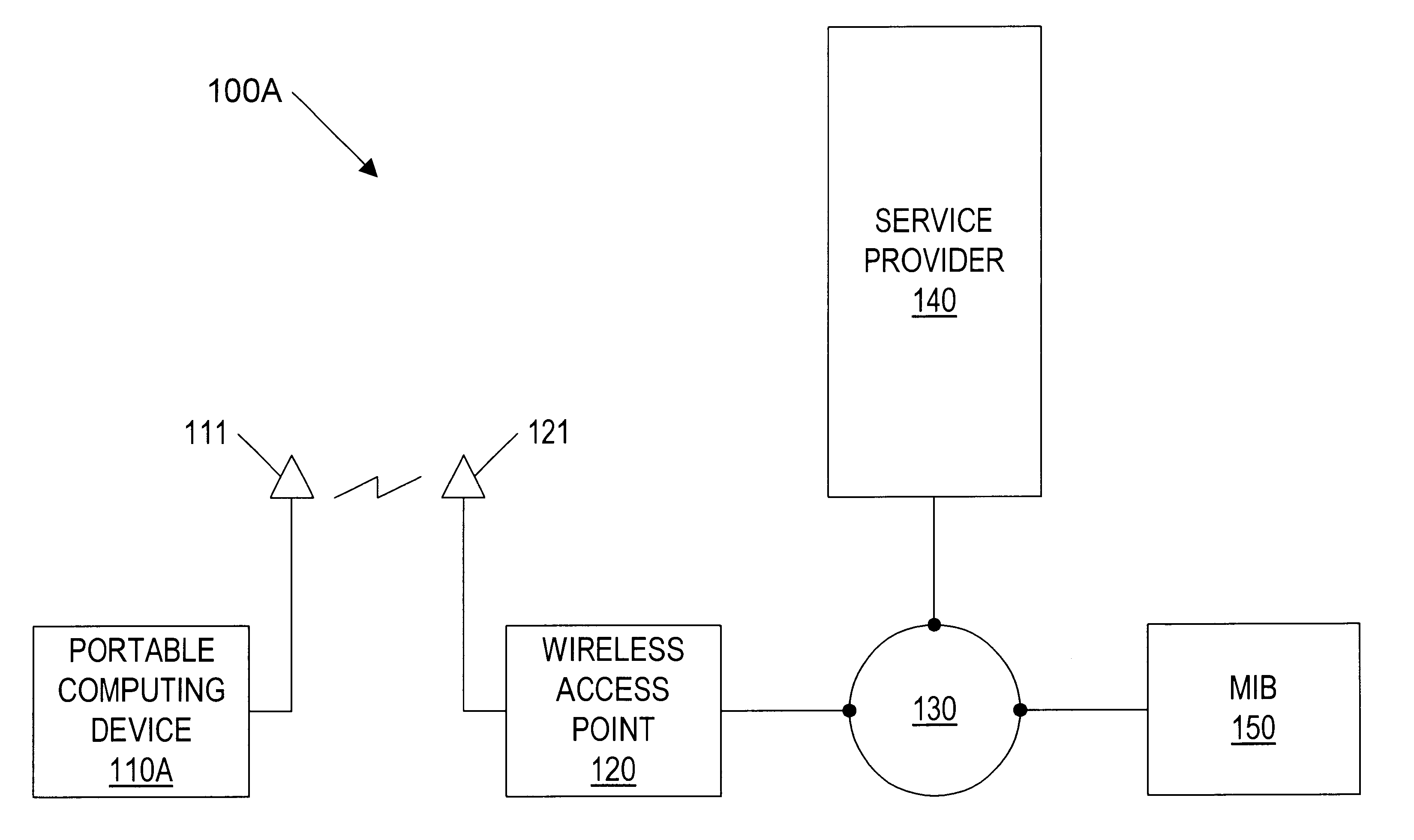

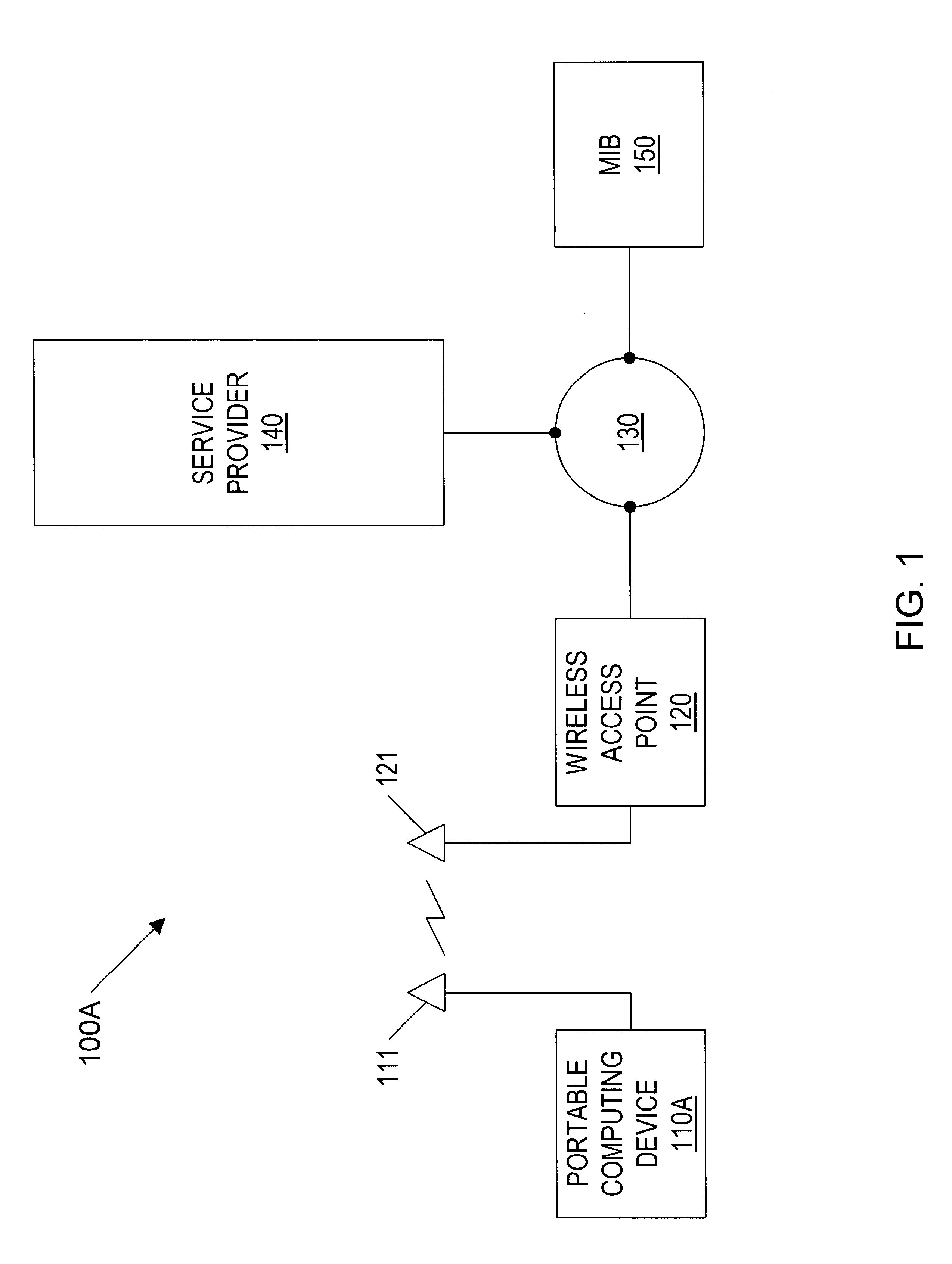

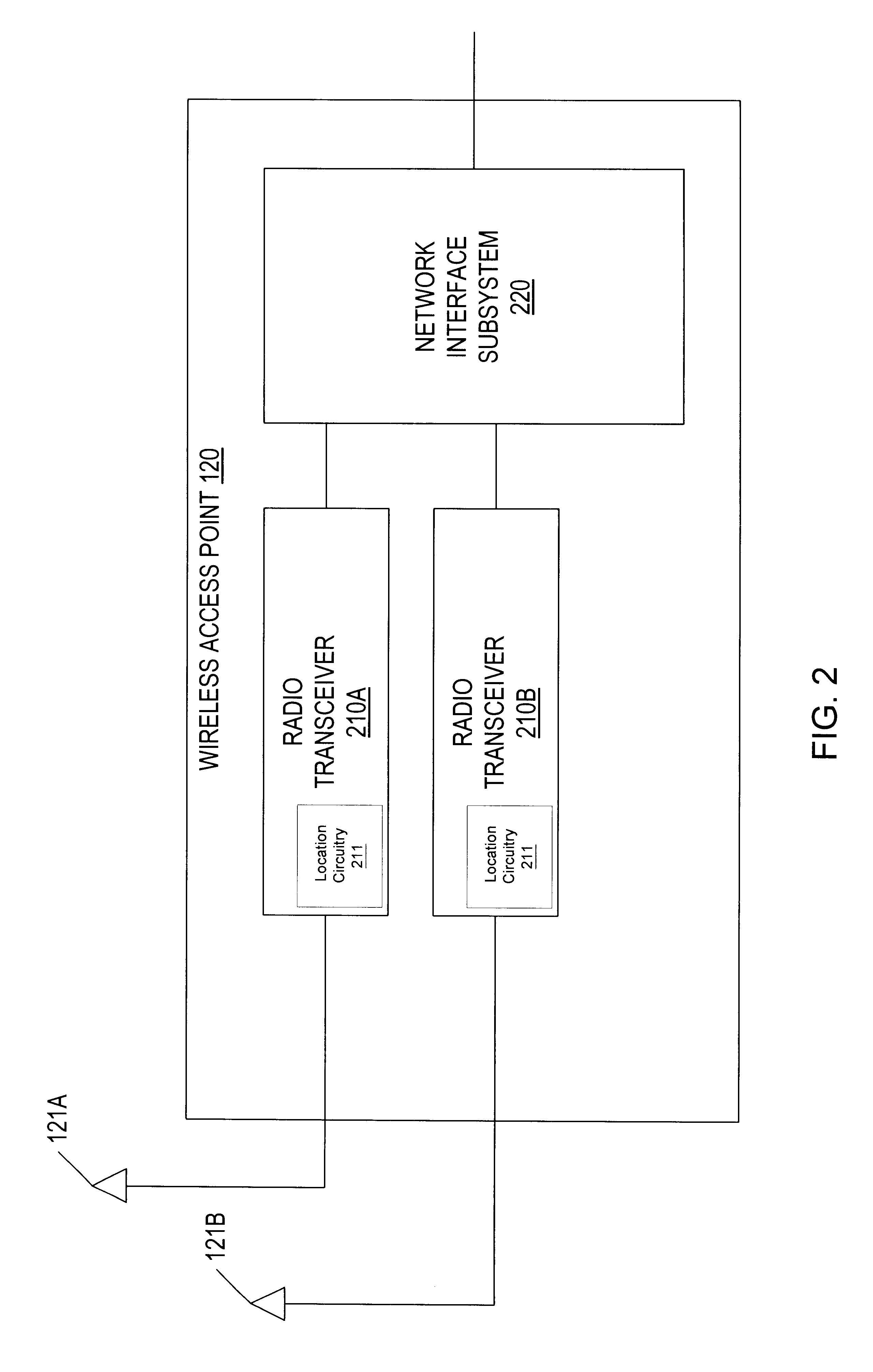

Geographic-based communication service system with more precise determination of a user's known geographic location

InactiveUS6414635B1Direction finders using radio wavesNetwork topologiesGeographic regionsGeolocation

A geographic based communications service system that includes a network and a plurality of access points connected to the network and arranged at known locations in a geographic region. One or more service providers or information providers may be connected to the network to provide services or information on the network. Content provided by the service providers may be based on the known geographic location of the user of a portable computing device (PCD). The known geographic location may be determined with a high degree of precision, using one or more access points and one of several different techniques. In one embodiment, the geographic location of the PCD may be determined within a radius of ten feet. Access points may be configured to determine the bearing of a signal received from a PCD, as well as the strength of the signal transmitted by the PCD. Access points may also be configured to send and receive signals with time stamps. These time stamps may be used to calculate signal travel time, thereby allowing a determination of the distance between an access point and a PCD. Each access point may include location circuitry. The location circuitry may include both analog and digital circuitry configured to perform the various methods used to determine the precise geographic location.

Owner:META PLATFORMS INC

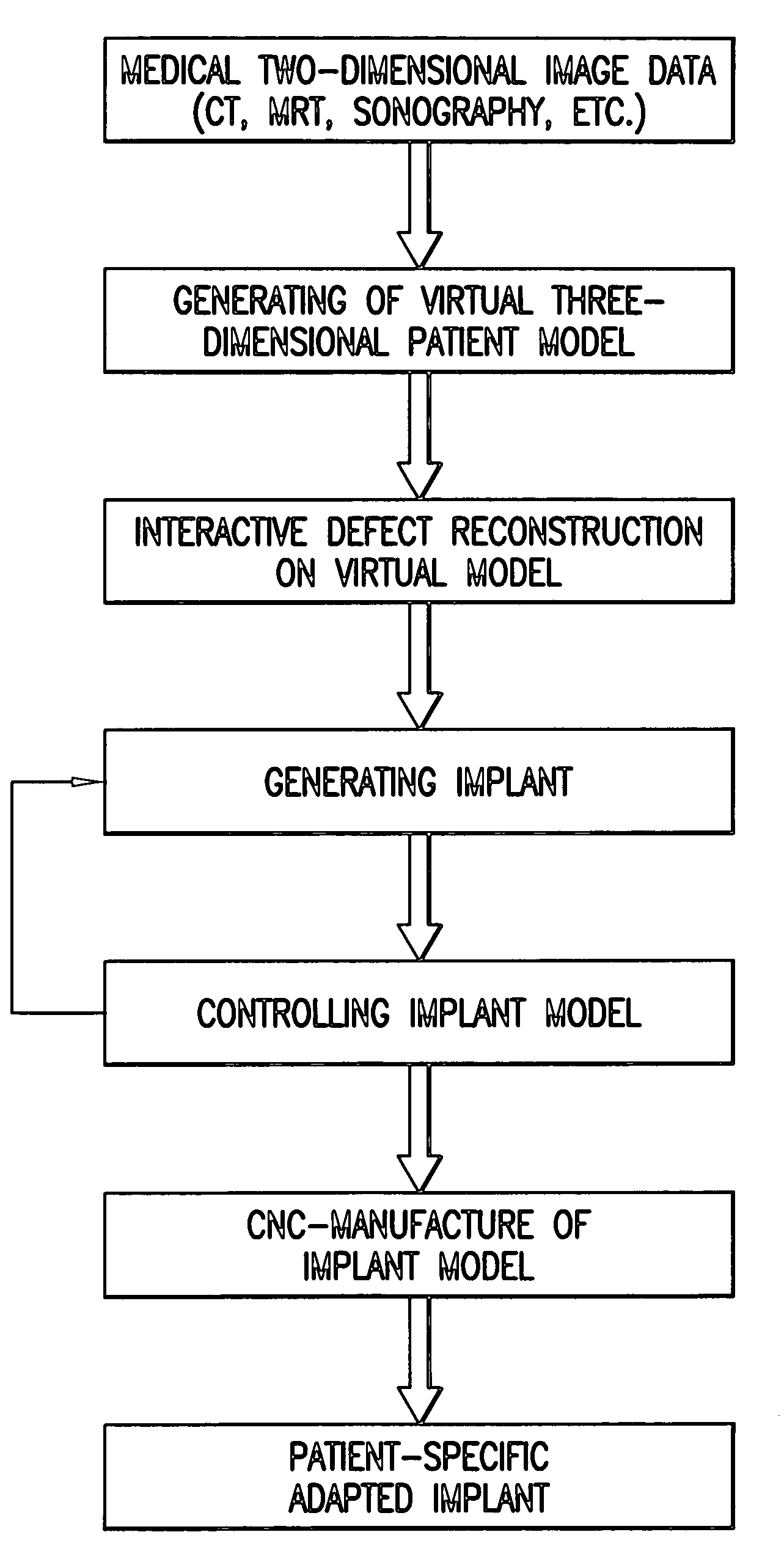

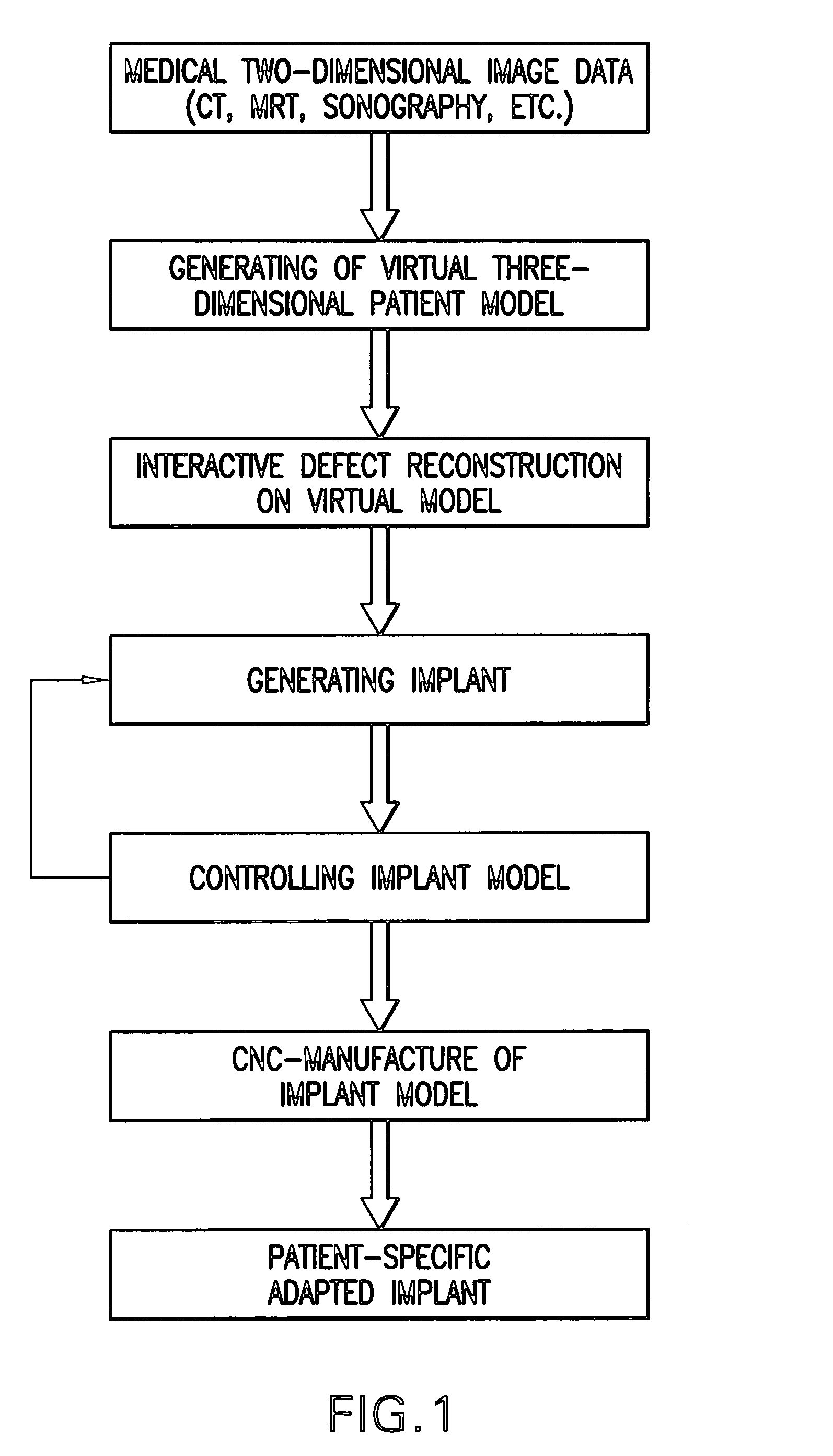

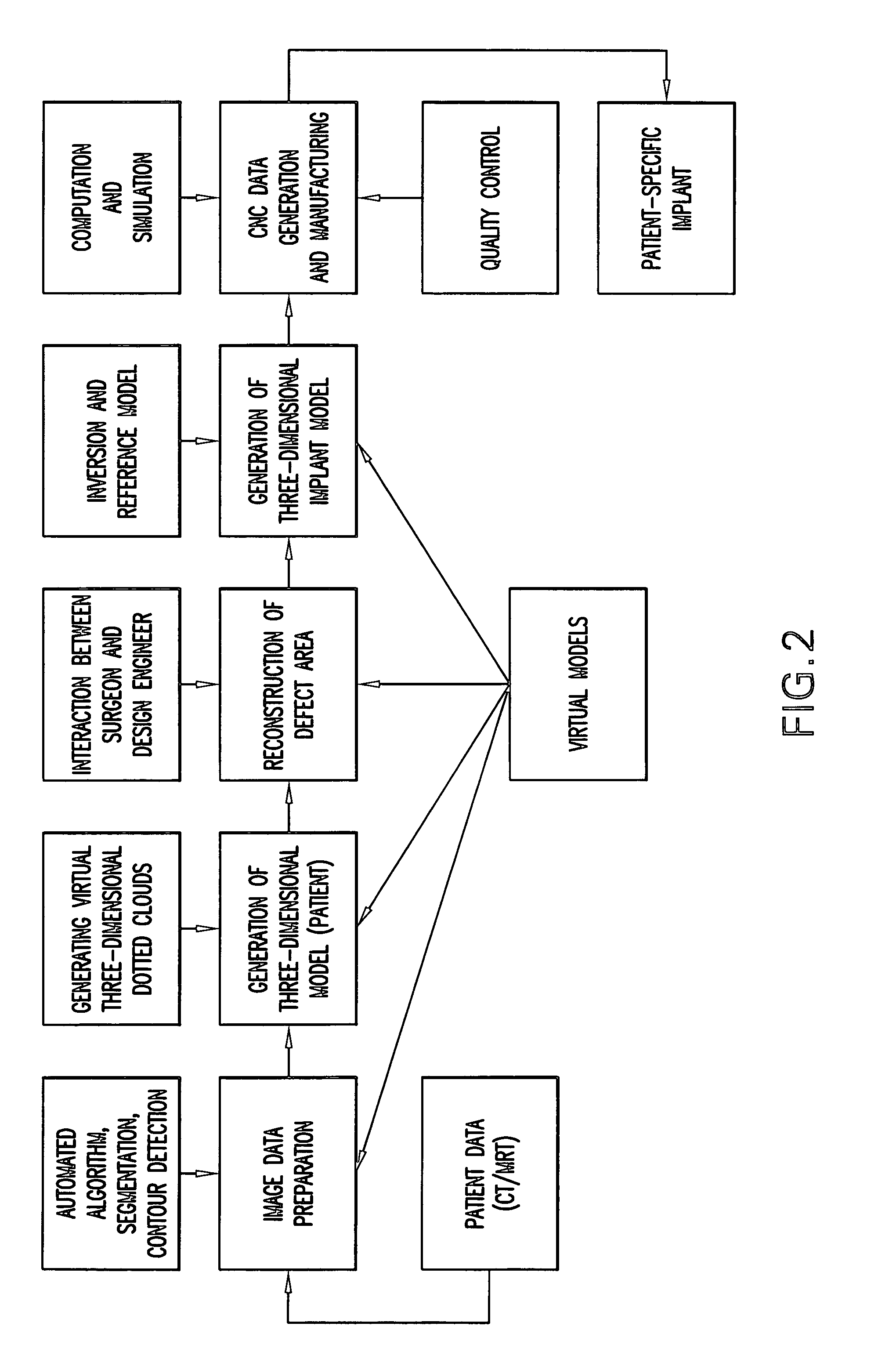

Method for generating patient-specific implants

InactiveUS6932842B1Exact fitShorten the timeProgramme controlComputer controlReference modelPatient model

An implant is generated which is functionally and aesthetically adapted to the patient with a greater degree of precision, irrespective of the size, form and complexity of the defect, whereby the implant can be produced and operatively inserted into the patient over a short time period and in a simple manner. A virtual three-dimensional model of the patient which is formed from existing recorded (two-dimensional) image data of the patient is compared with real medical reference data. The comparison which is, for example, carried out using a data bank with test person data enables a reference model object which is most suited to the patient or closest to the patient model to be selected or formed and a virtual implant model is generated accordingly. Computer numeric control data is directly generated from the implant model which is generated virtually in the computer for program-assisted production of the implant.

Owner:3DI

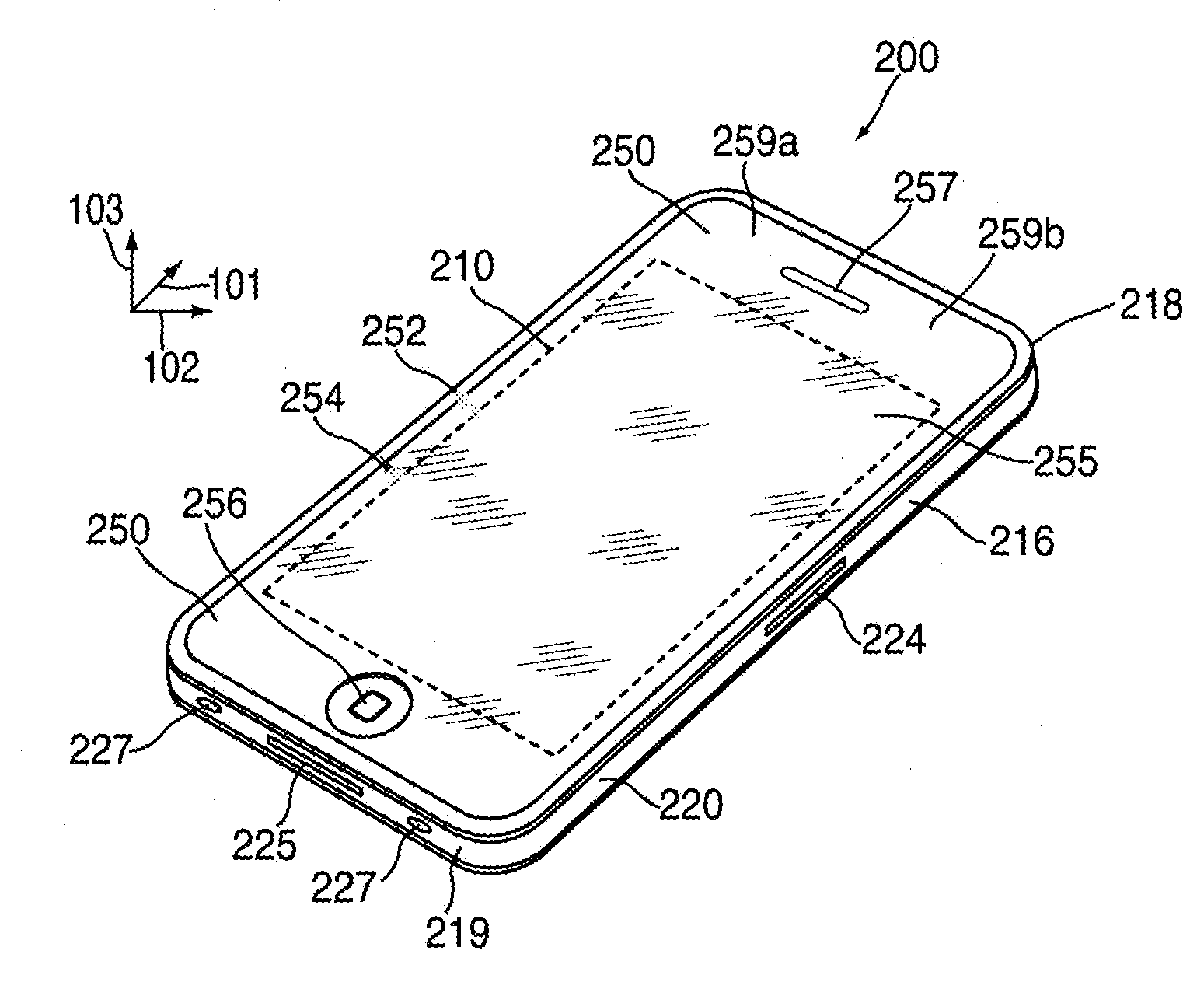

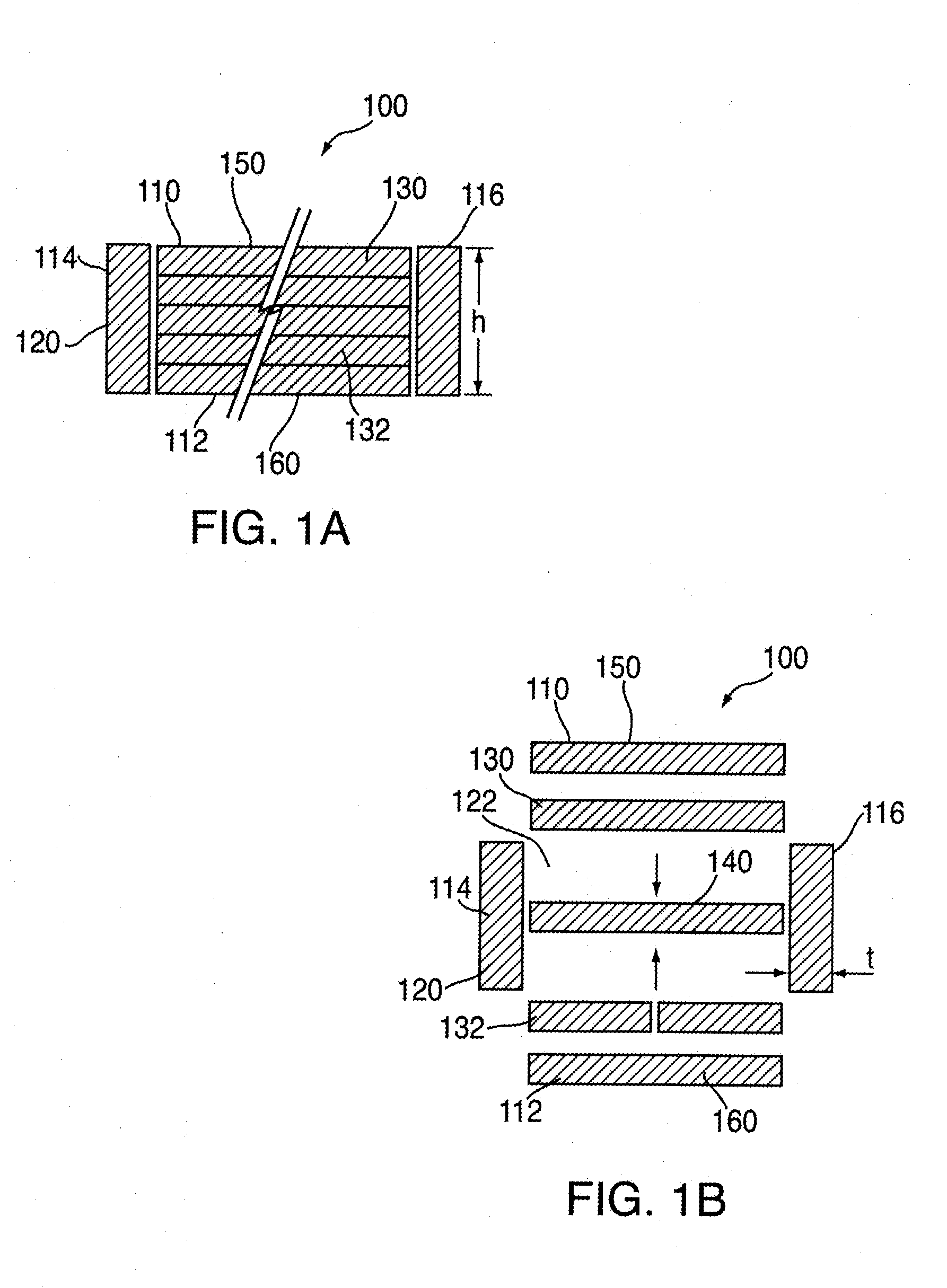

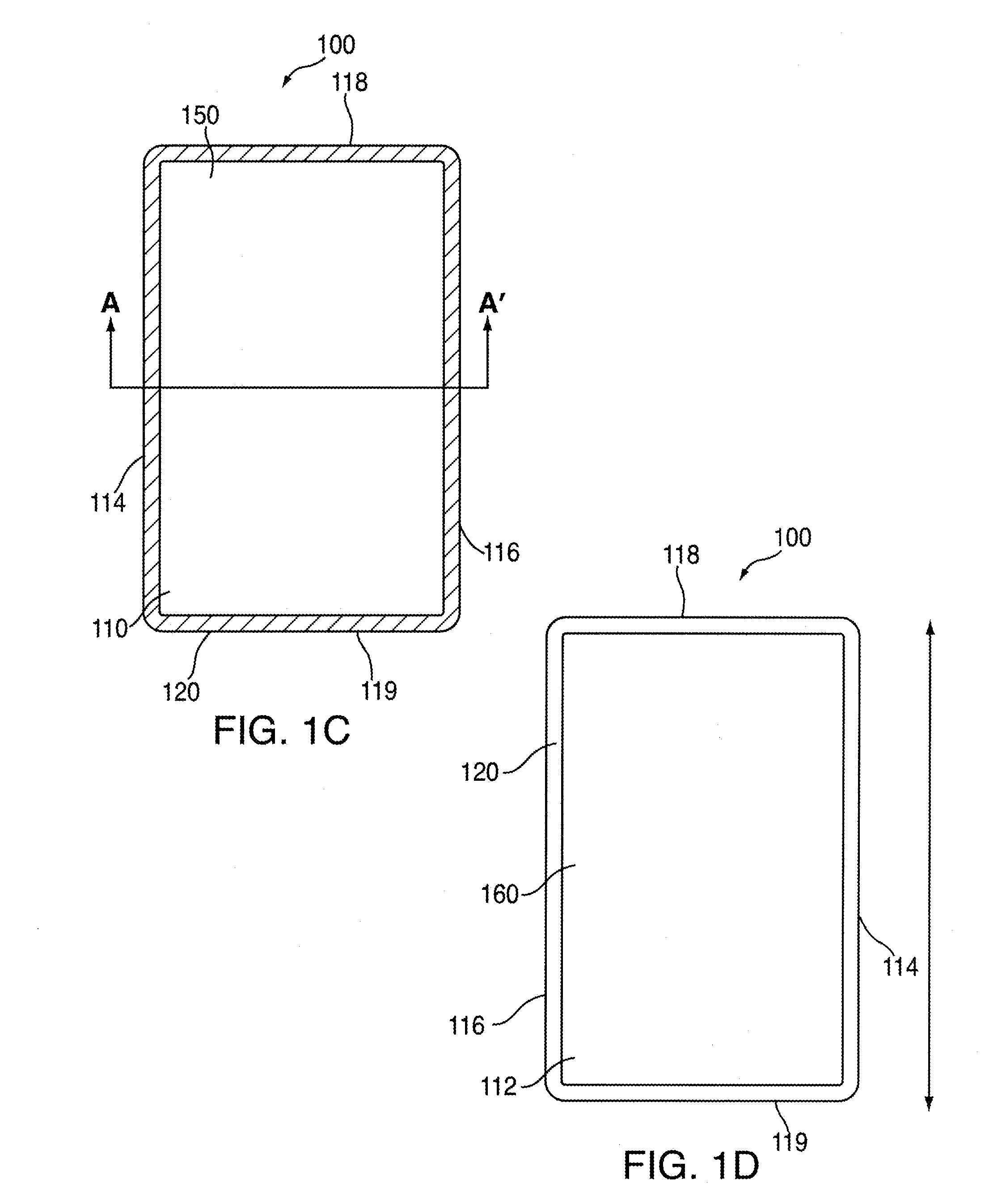

Offset Control for Assemblying an Electronic Device Housing

ActiveUS20110186345A1Wave amplification devicesDigital data processing detailsEngineeringElectrical and Electronics engineering

Housings for electronic devices are disclosed. According to one aspect, adjoining surfaces of electronic device housings can be mounted or arranged such that adjoining surfaces are flush to a high degree of precision. The electronic devices can be portable and in some cases handheld.

Owner:APPLE INC

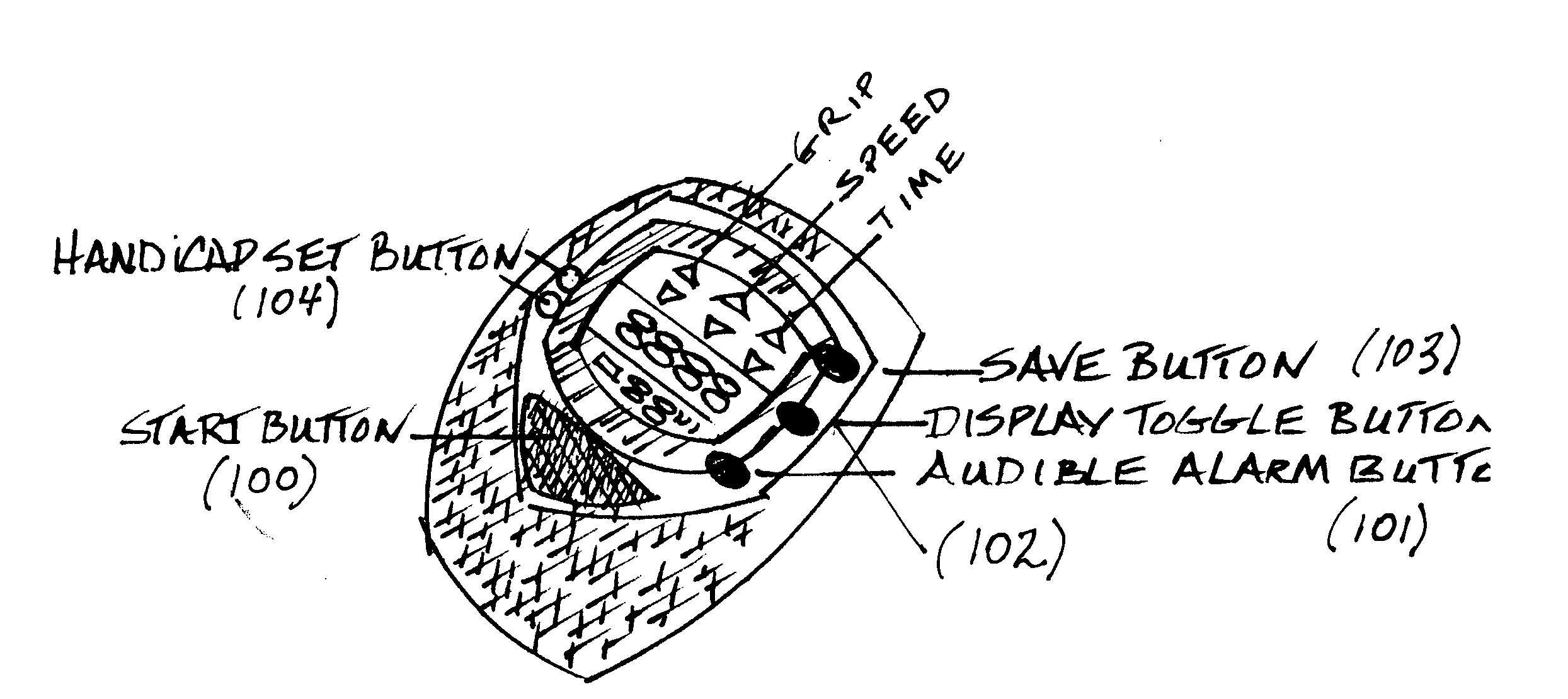

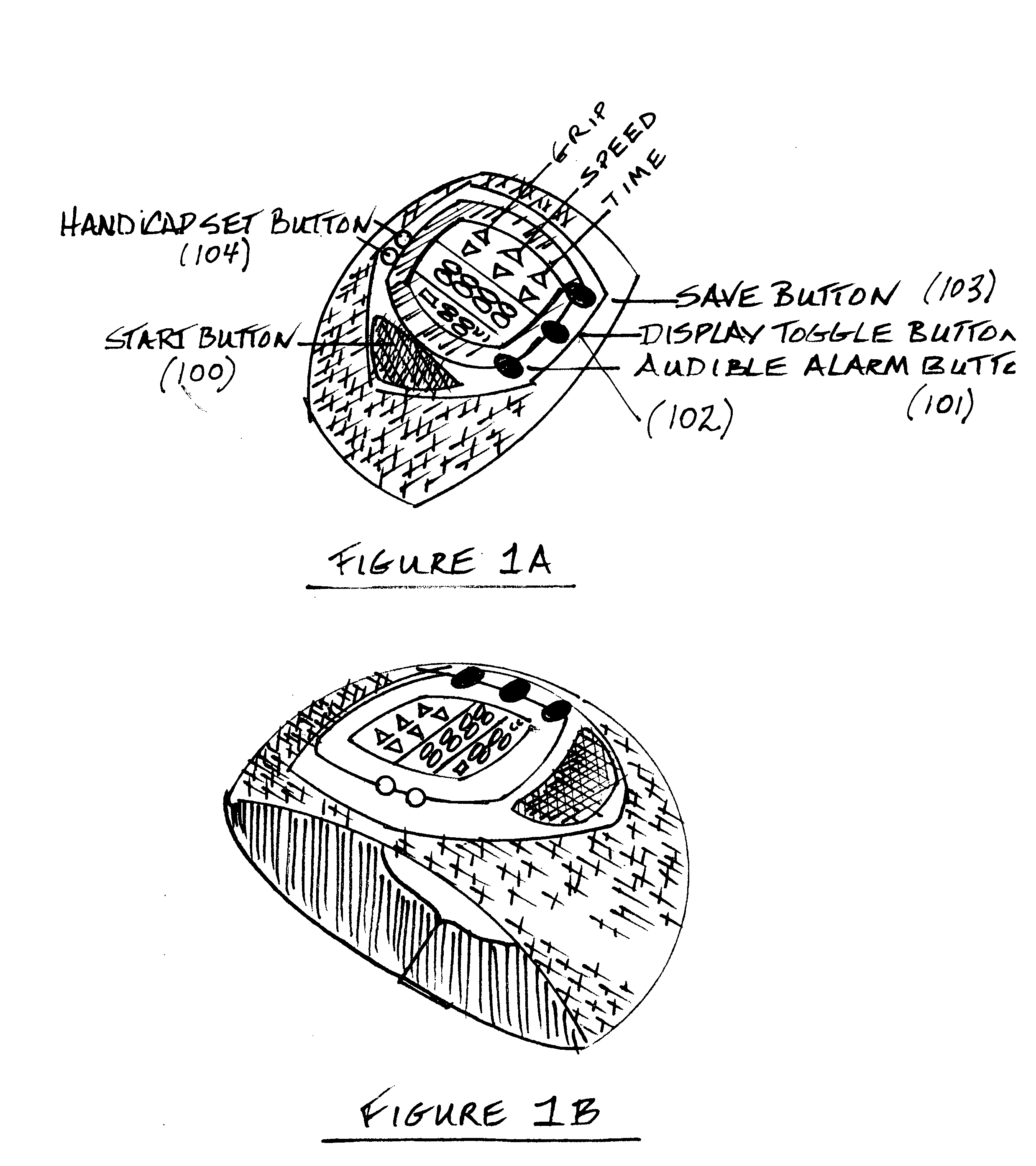

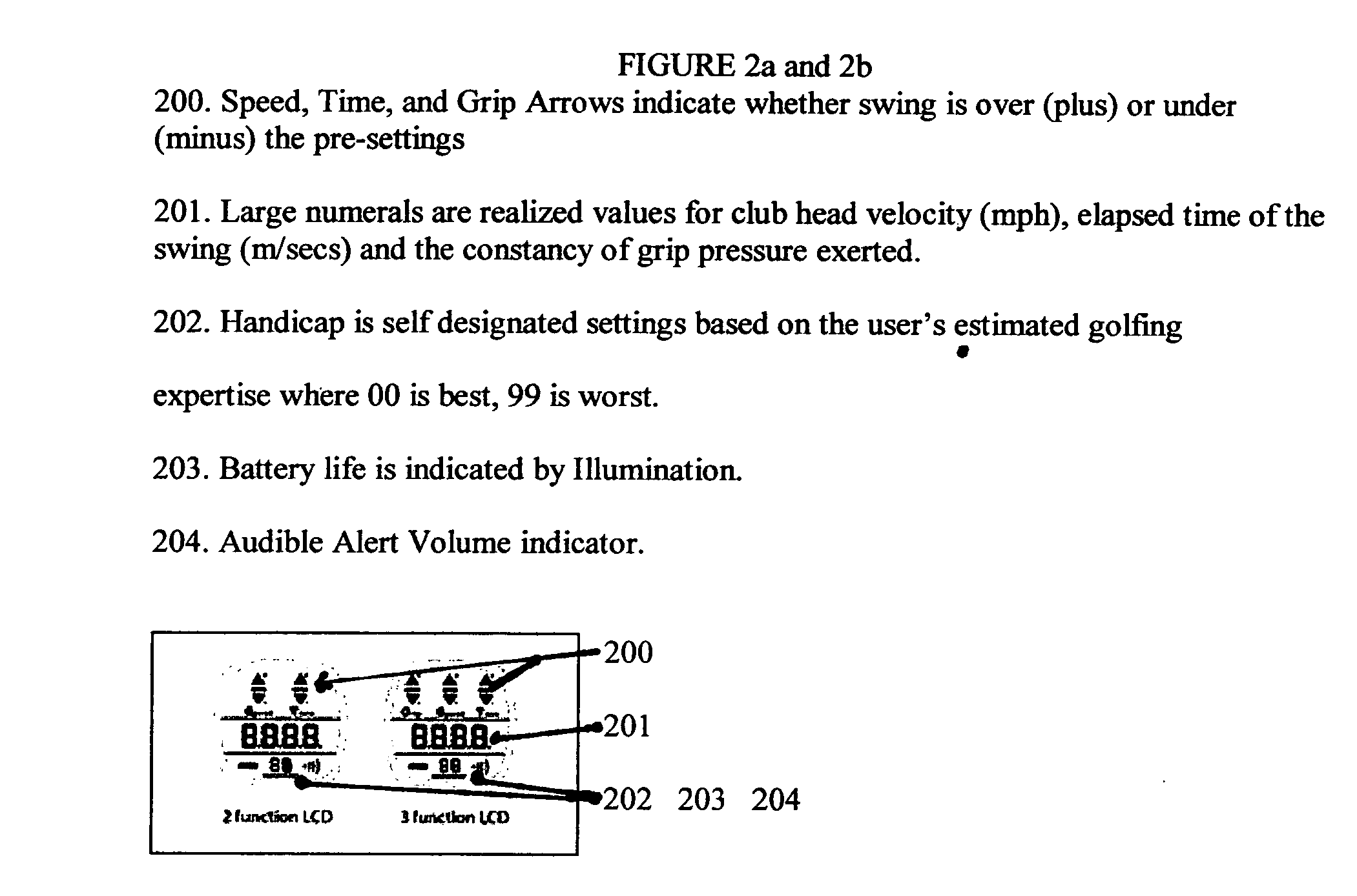

ShotwatchTM

ActiveUS20060199659A1Promote resultsEnhance muscle memoryBall sportsGolfing accessoriesMonitoring systemEngineering

A swing monitoring system in the form of a wrist mounted unit which includes multi-function instrumentation with extremely high degrees of precision that monitors a plurality of critical components of the swing of a golf club, tennis racquet, baseball bat hockey stick or the like. In particular, motion sensors that discriminate finite changes in the timing and speed of the swing are disposed in a housing mounted on a wrist bank analogous to a common wrist watch or timepiece. In addition, sensors are disposed in the wrist strap for detecting changes in grip pressure during the act of swinging any of the above mentioned equipment. The detected parameters are displayed on a LCD which is part of the instrumentation. Desired parameters can be saved in memory and the components of subsequent swing are compared to those saved, and if they are different, an audible alarm or signal is activated. The exactness of the subsequent trail swings relative to those saved in memory is a function of the handicap or other self designated indicator of skill level of the user.

Owner:CALDWELL THEODORE WEISSENBURGER

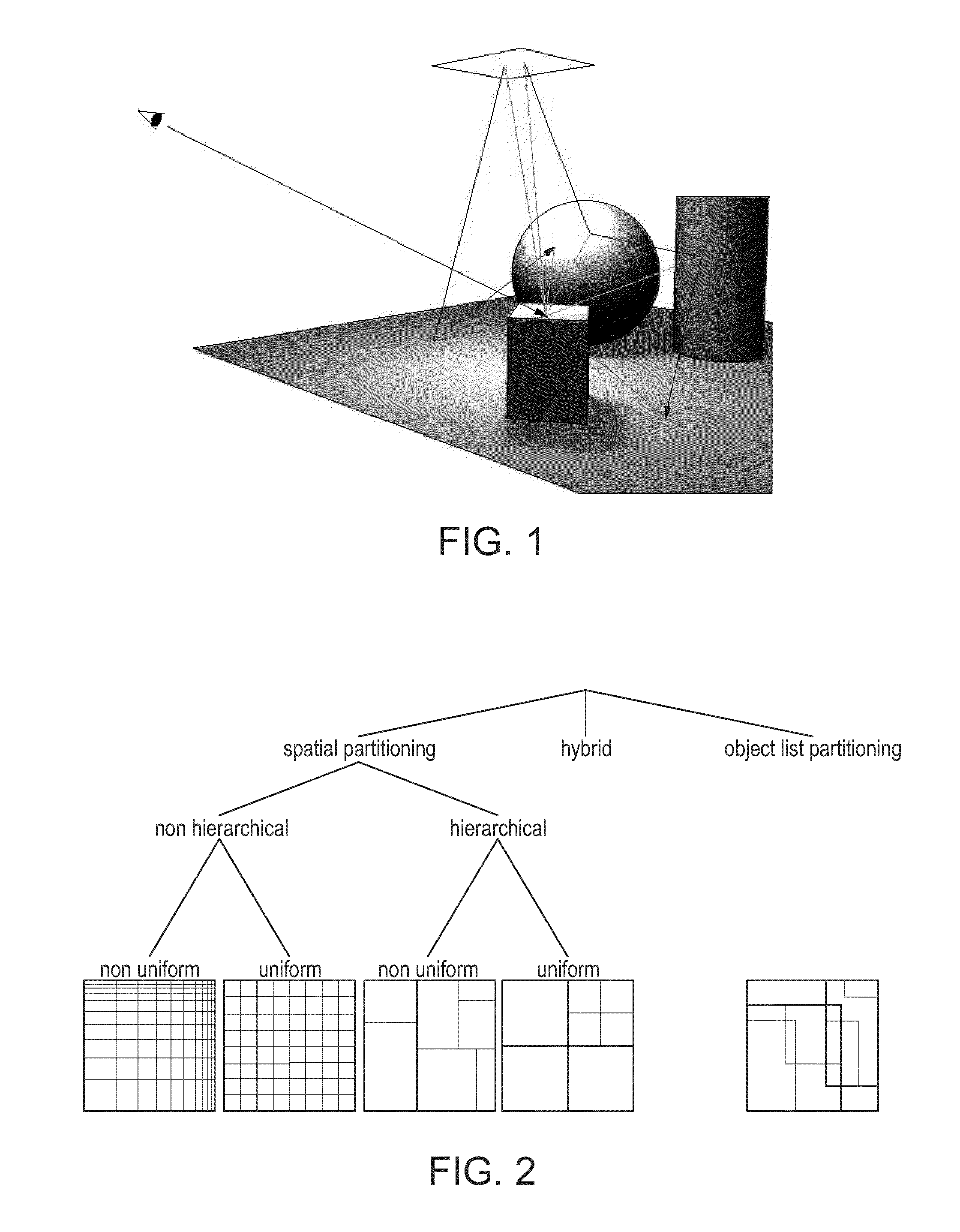

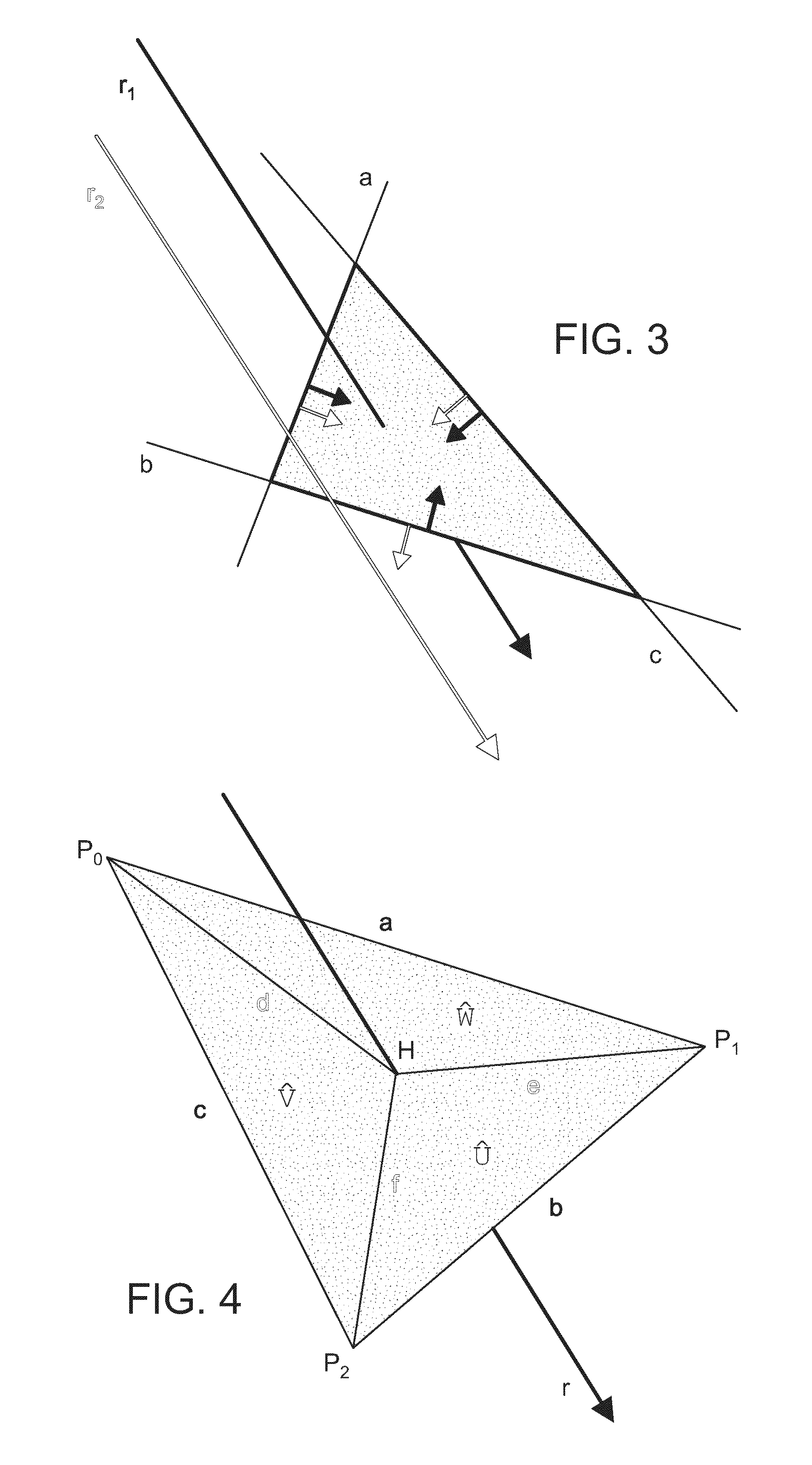

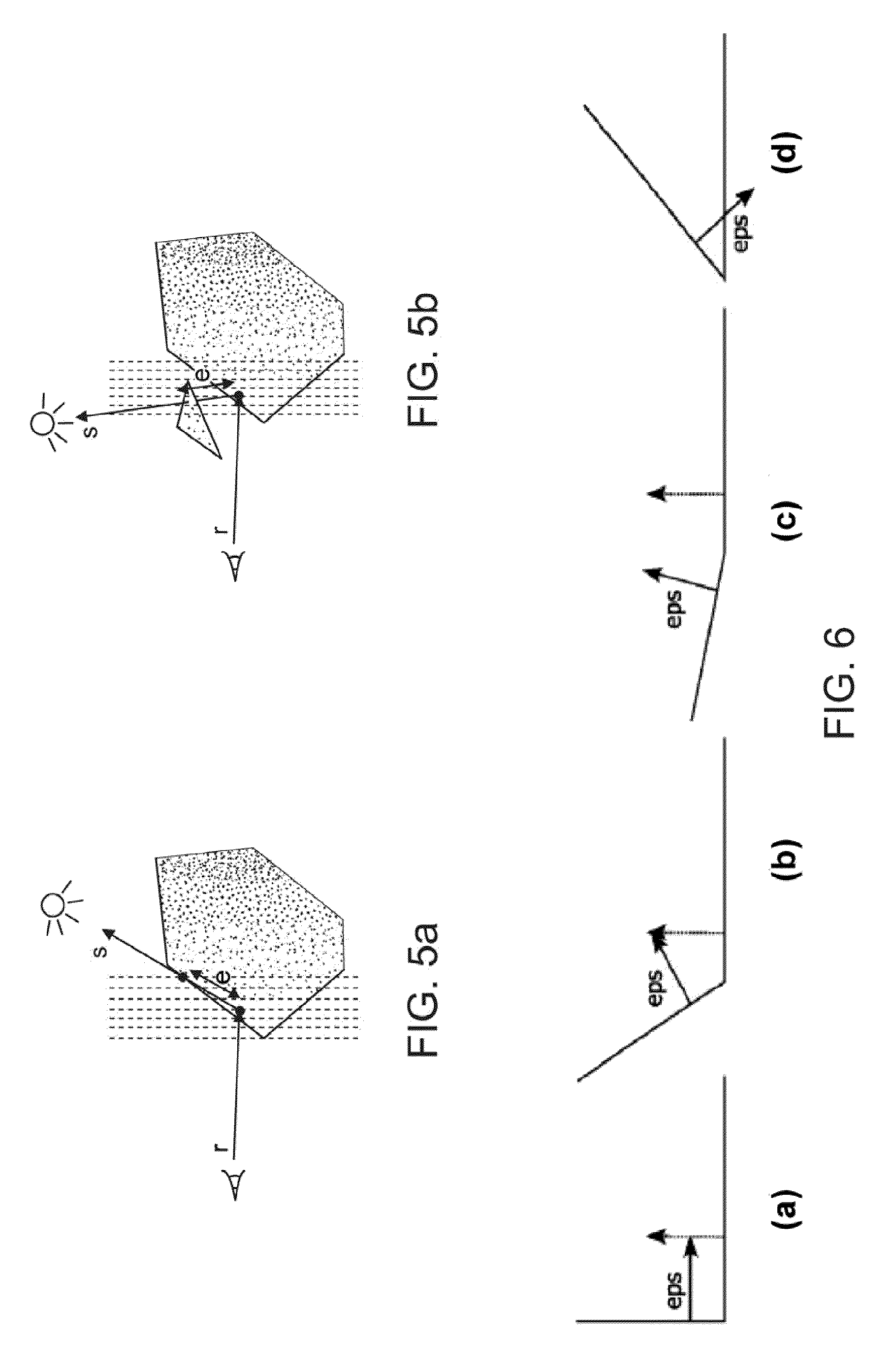

Quasi-monte carlo light transport simulation by efficient ray tracing

Methods, systems, devices and computer program code (software) products operable within a computer graphics system or other computer system enable quasi-Monte Carlo (QMC) light transport simulation by ray tracing: and include constructing a bounding interval hierarchy (BIH), within a computer, using quantized planes to reduce memory requirements while maintaining a selected degree of precision.

Owner:MENTAL IMAGES

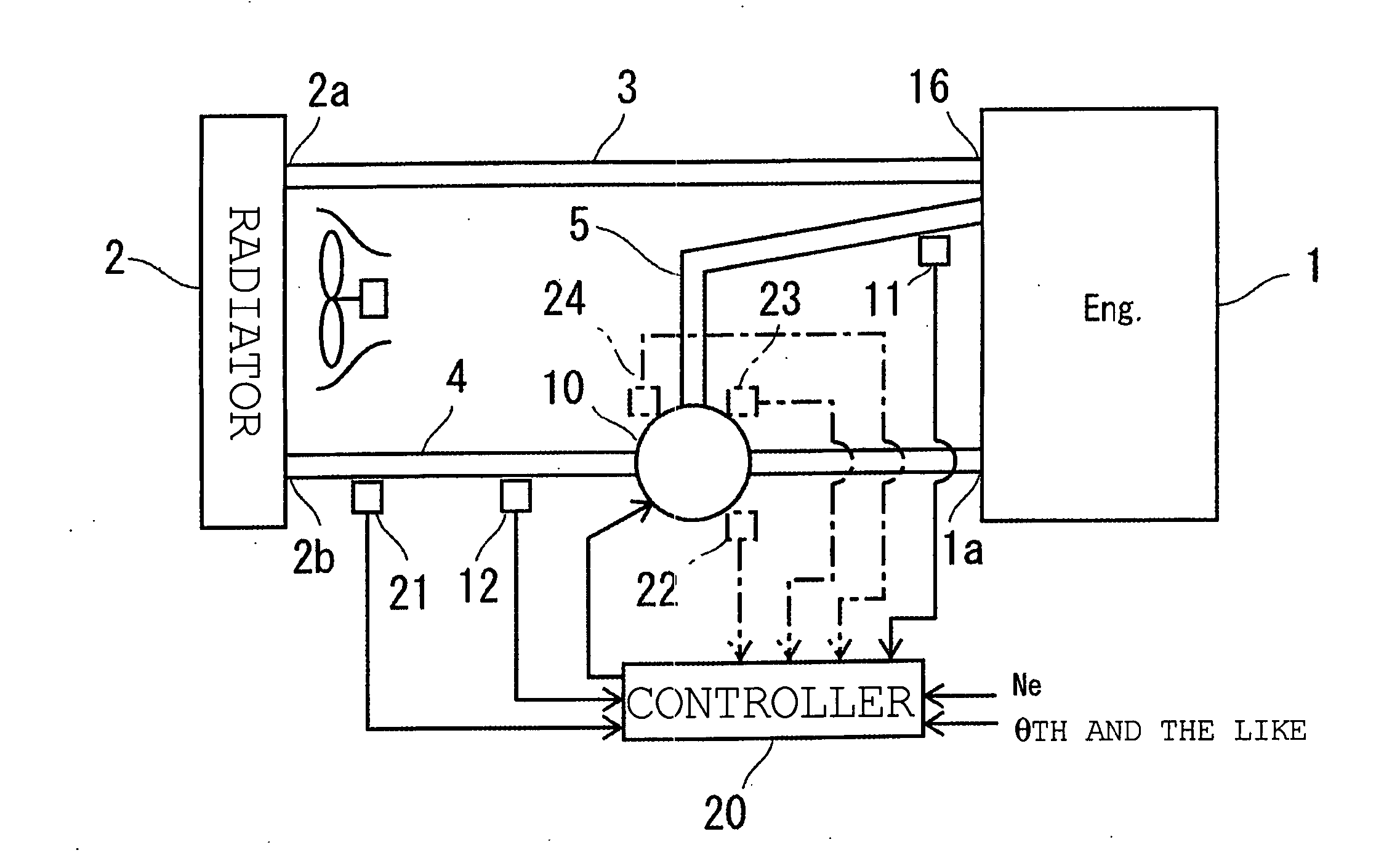

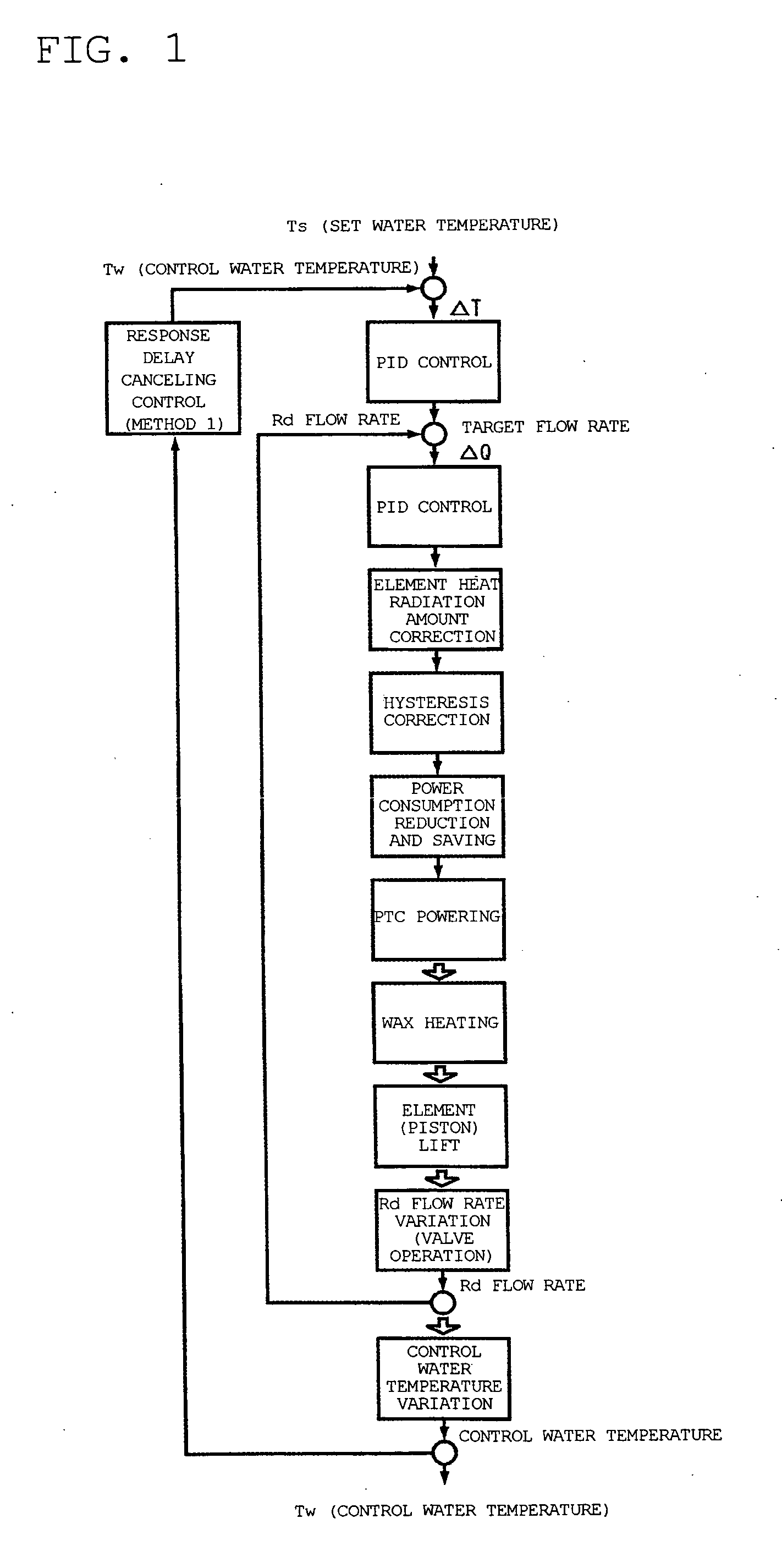

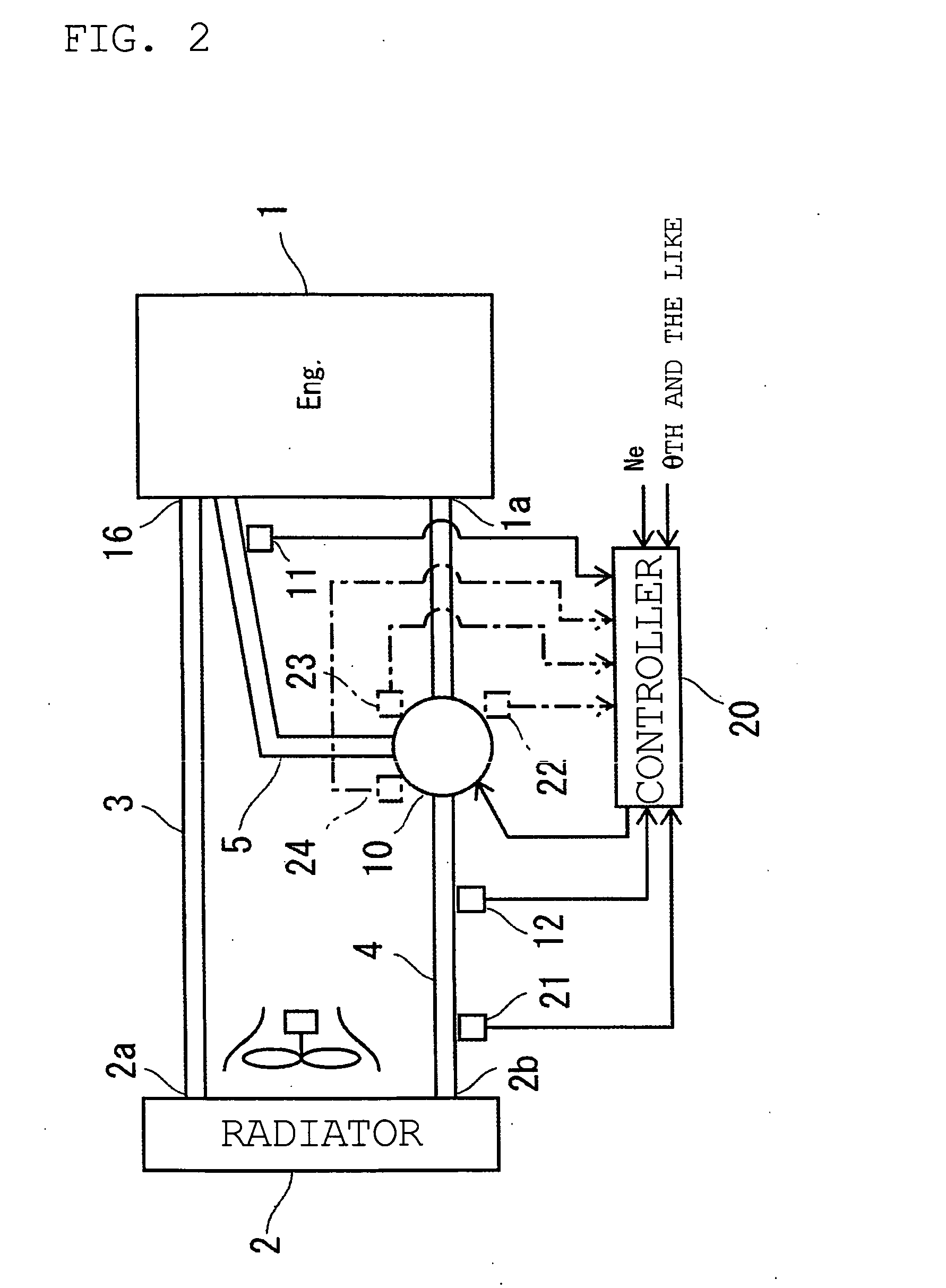

Method of controlling electronic controlled thermostat

ActiveUS20050006487A1Reliable improvement in fuel consumptionPoor temperature controlTemperature control without auxillary powerElectrical controlResponse delayEngineering

An electronically controlled thermostat control method is obtained which makes it possible to eliminate the response delay from the time that the required cooling water temperature is set to the time that the actual cooling water temperature reaches the set water temperature by controlling the flow rate, and to realize high cooling water temperature tracking characteristics with a high degree of precision at a low cost. The method of the present invention is characterized in that in an electronically controlled thermostat which is used to control the cooling water temperature of an engine, and which comprises an actuator that can arbitrarily vary the degree of valve opening without depending only on the actual cooling water temperature, the actuator is controlled by the control controller, which has means for calculating the elapsed time from the powering of the actuator to the variation of the water temperature for predicting the water temperature after the elapsed time when the cooling water temperature is controlled to an arbitrarily set water temperature, and the actuator is controlled in advance in accordance with the above-described predicted water temperature.

Owner:NIPPON THERMOSTAT CO LTD

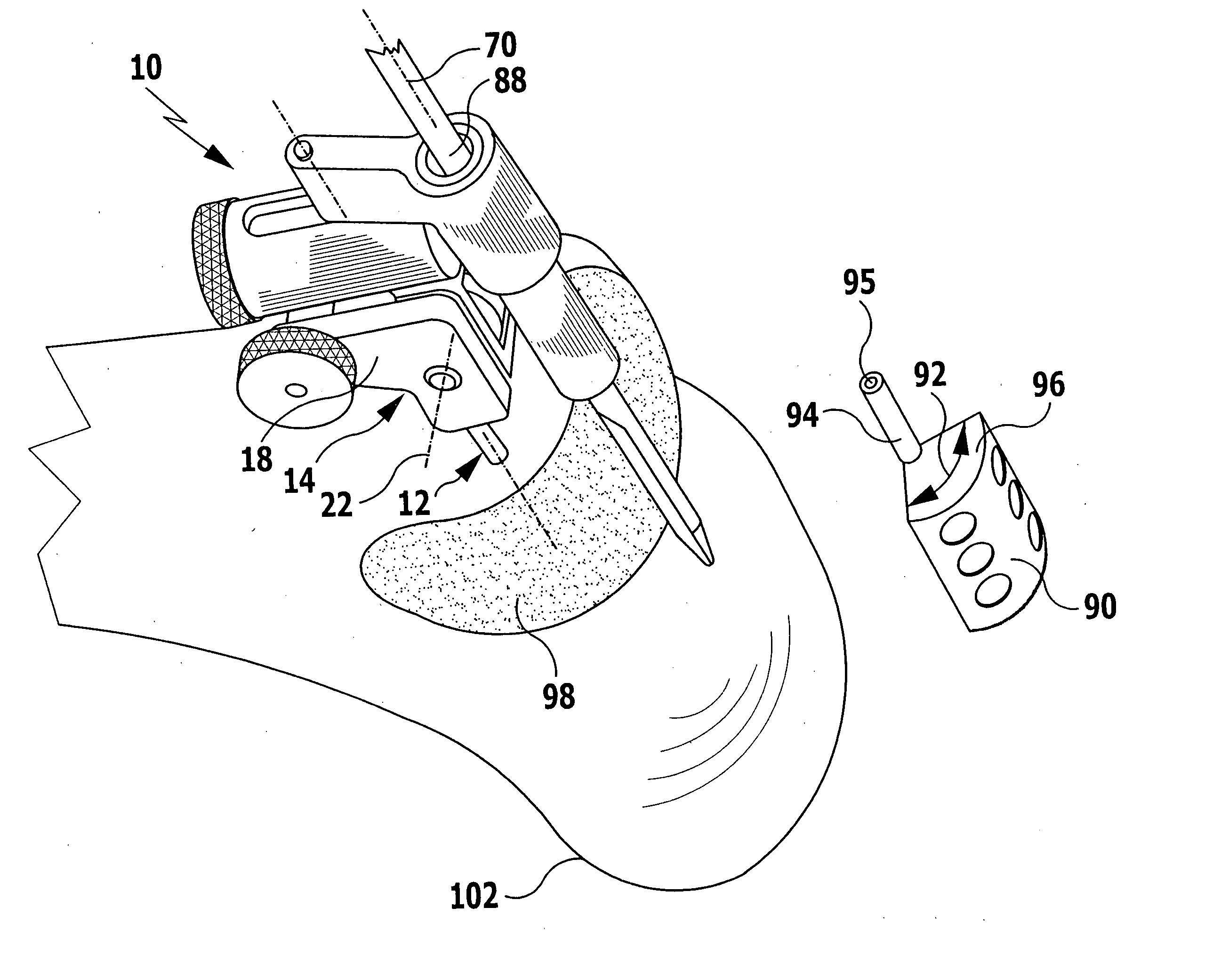

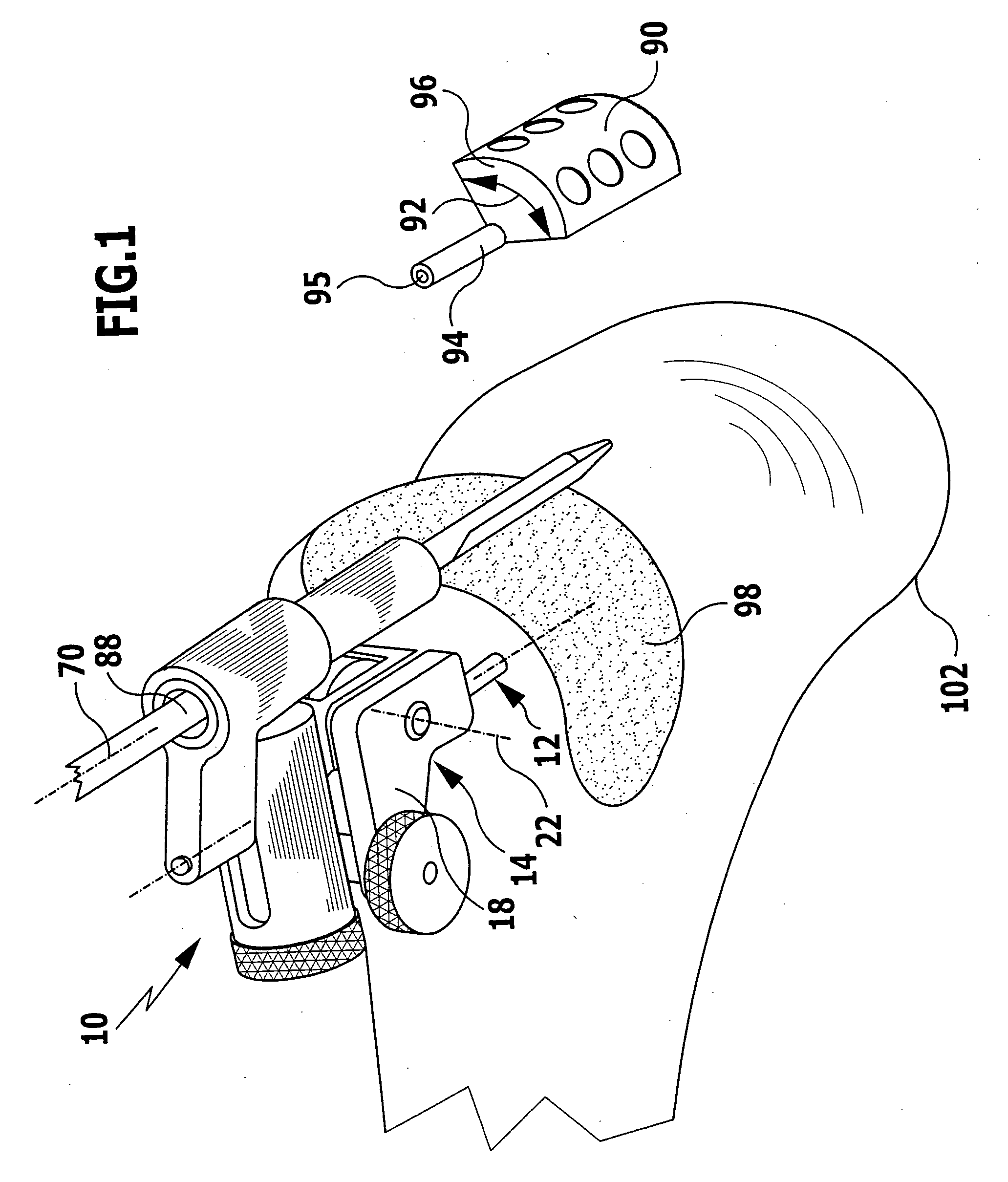

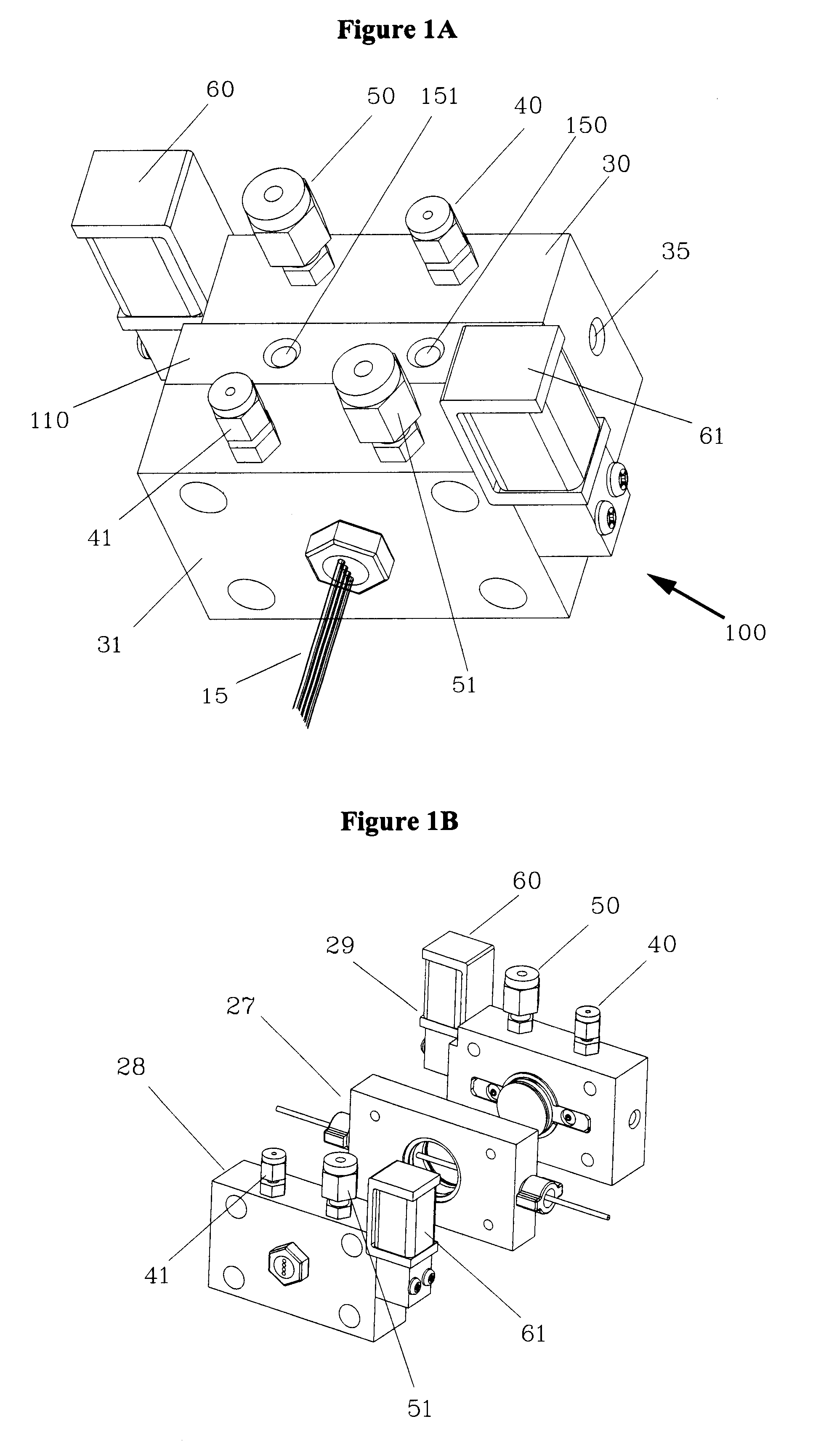

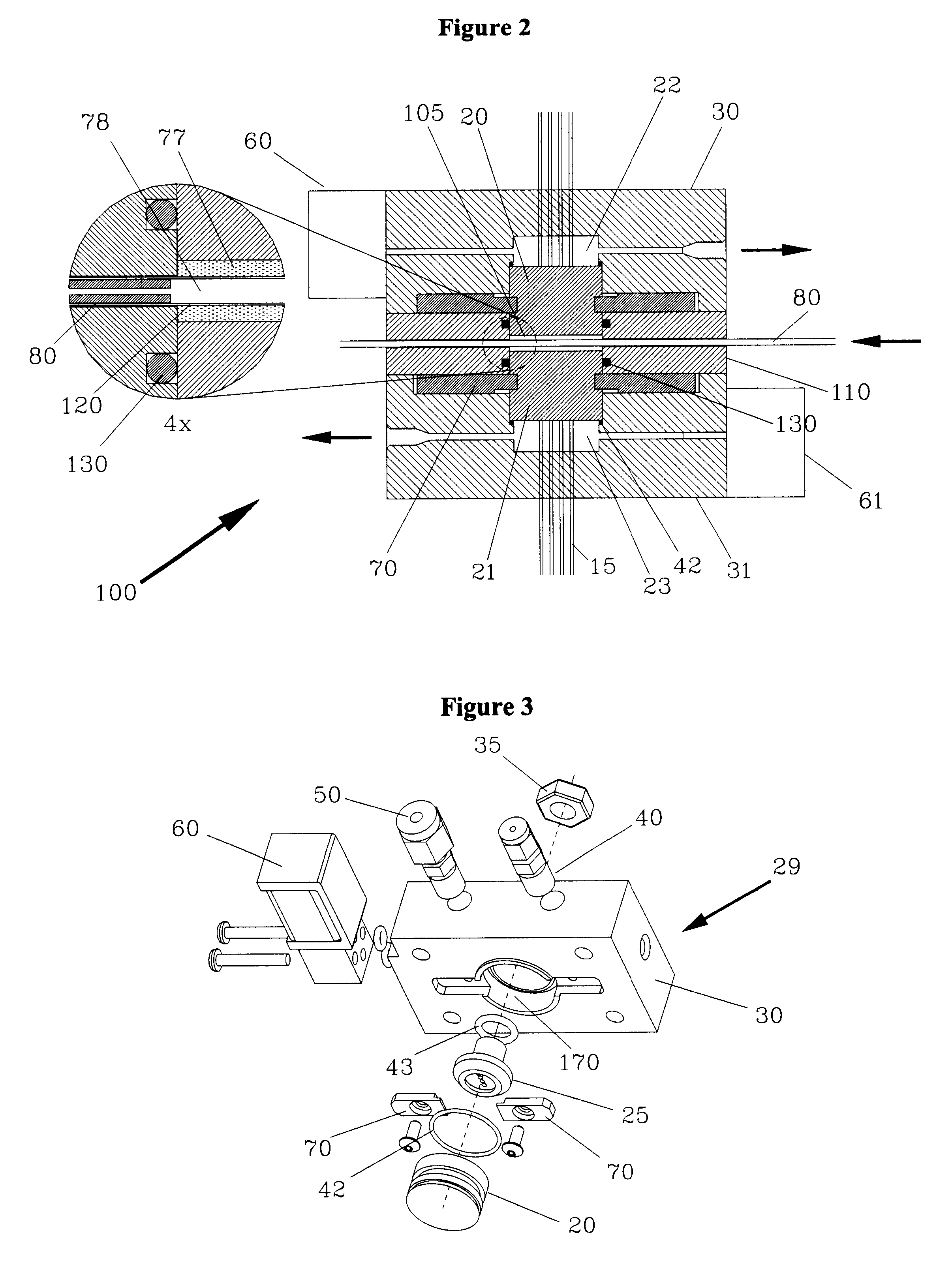

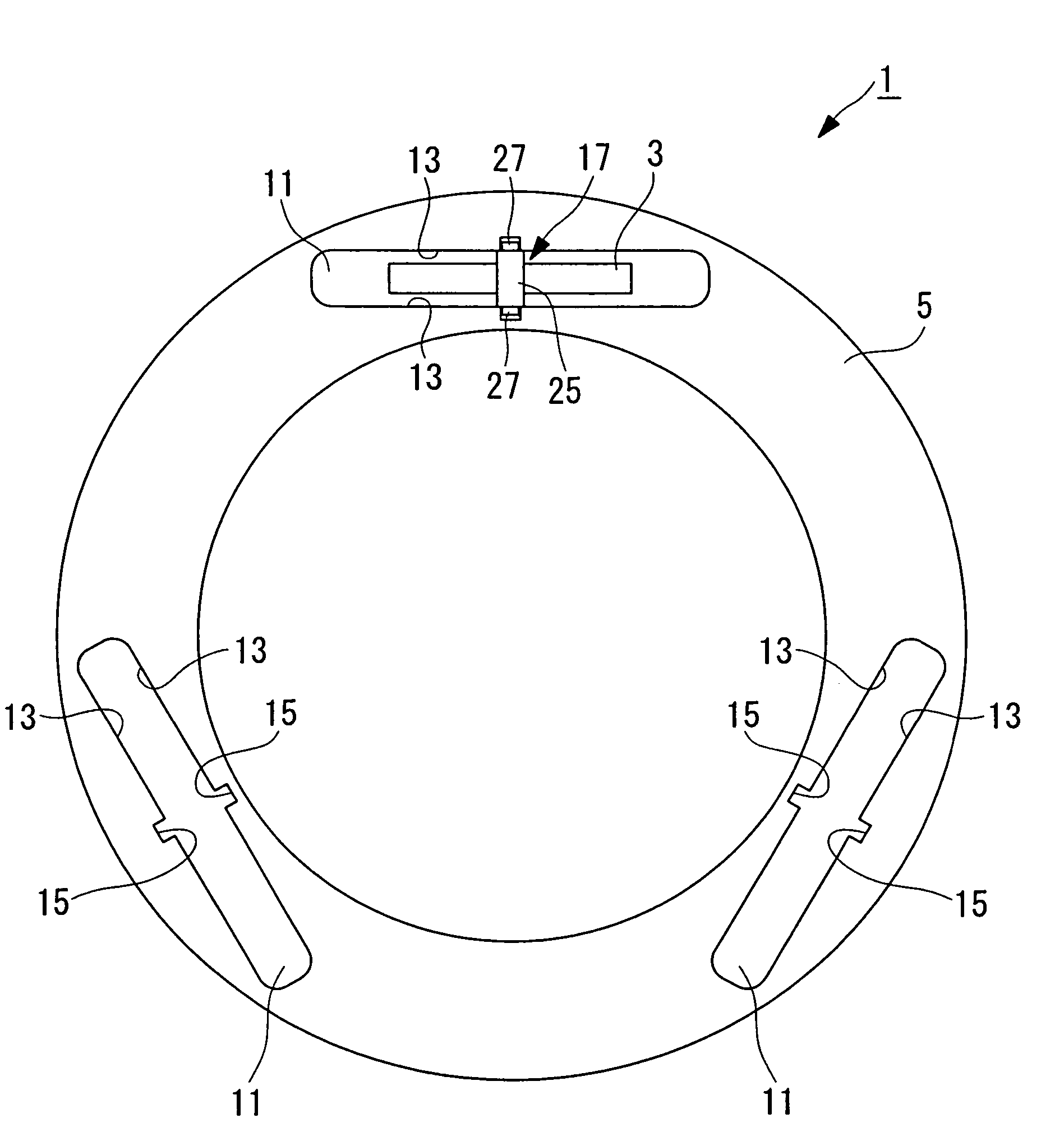

Surgical positioning and holding device

InactiveUS20060052791A1Securely holdJoint implantsNon-surgical orthopedic devicesEngineeringSurgical department

In order to improve a surgical positioning and holding device for positioning and holding a guide for a surgical machining tool, with at least one fastening element for fixation to a bone to be machined and with a platform held on the at least one fastening element so as to hold the guide, so that anchoring surfaces may be prepared in a simple manner and with a high degree of precision on a bone to be machined, it is proposed that the guide be mounted for rotation about a first axis of rotation and be designed such that at least one surface concentric with the first axis of rotation may be prepared with the machining tool guided in or held on the guide.

Owner:AESCULAP AG

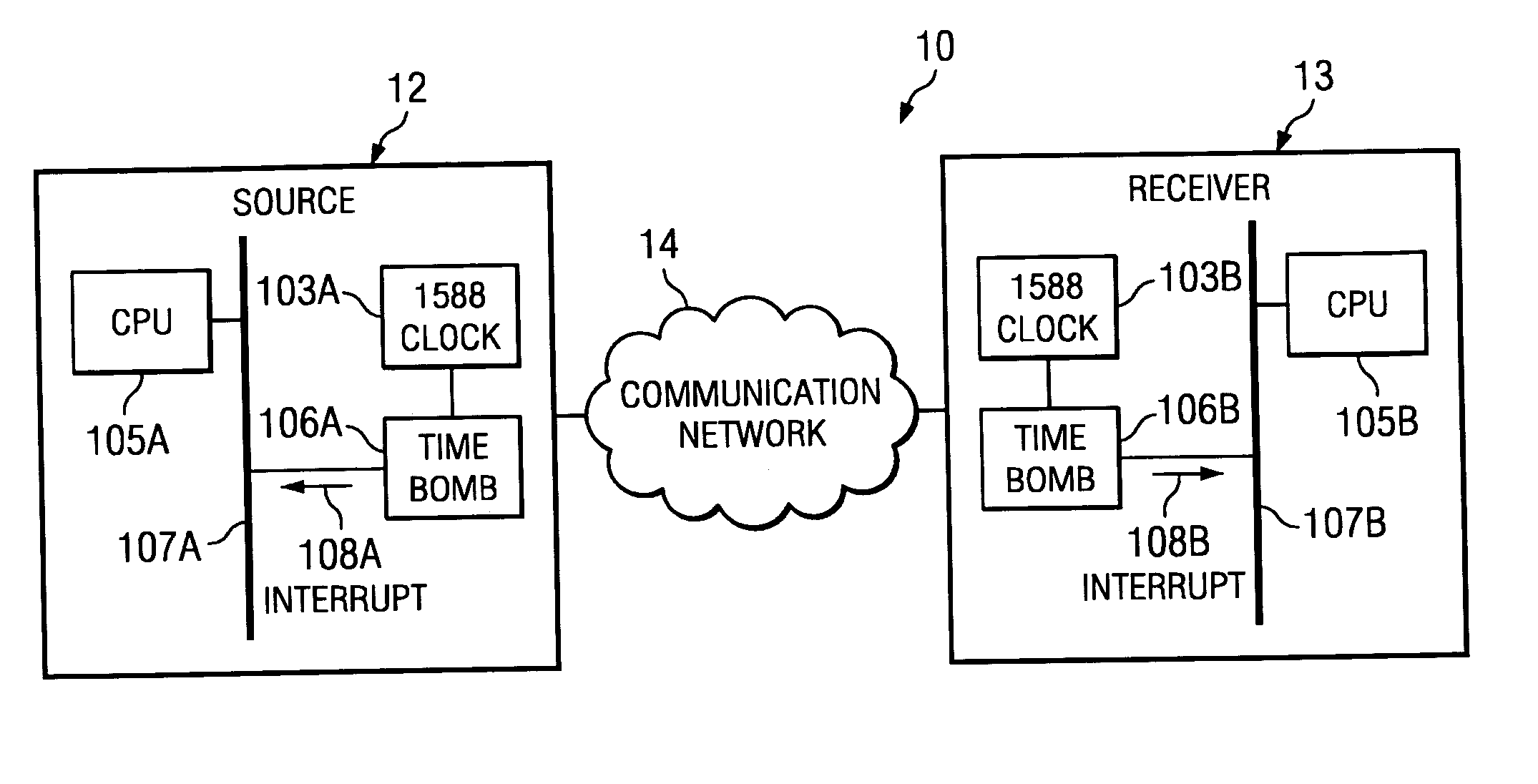

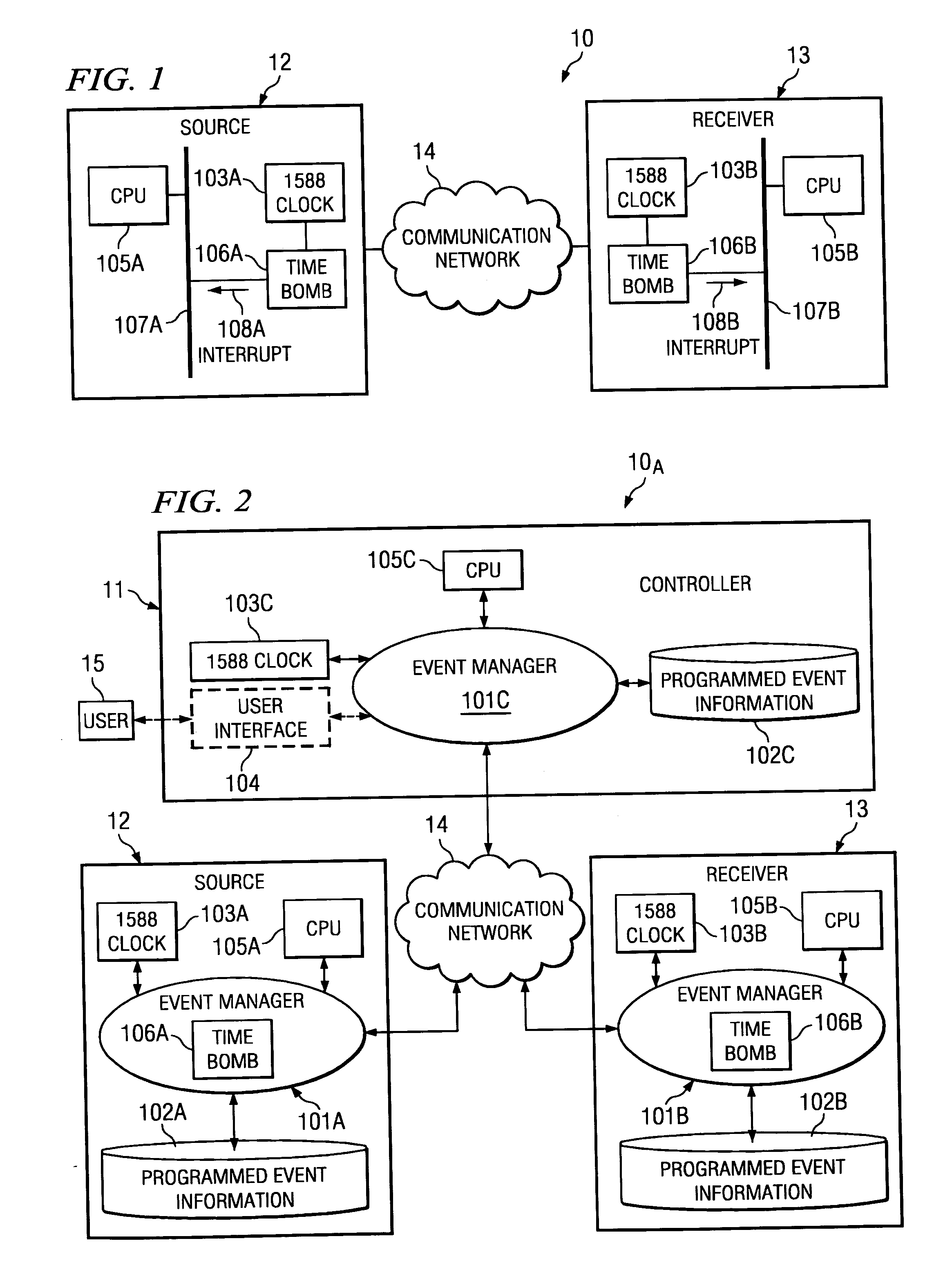

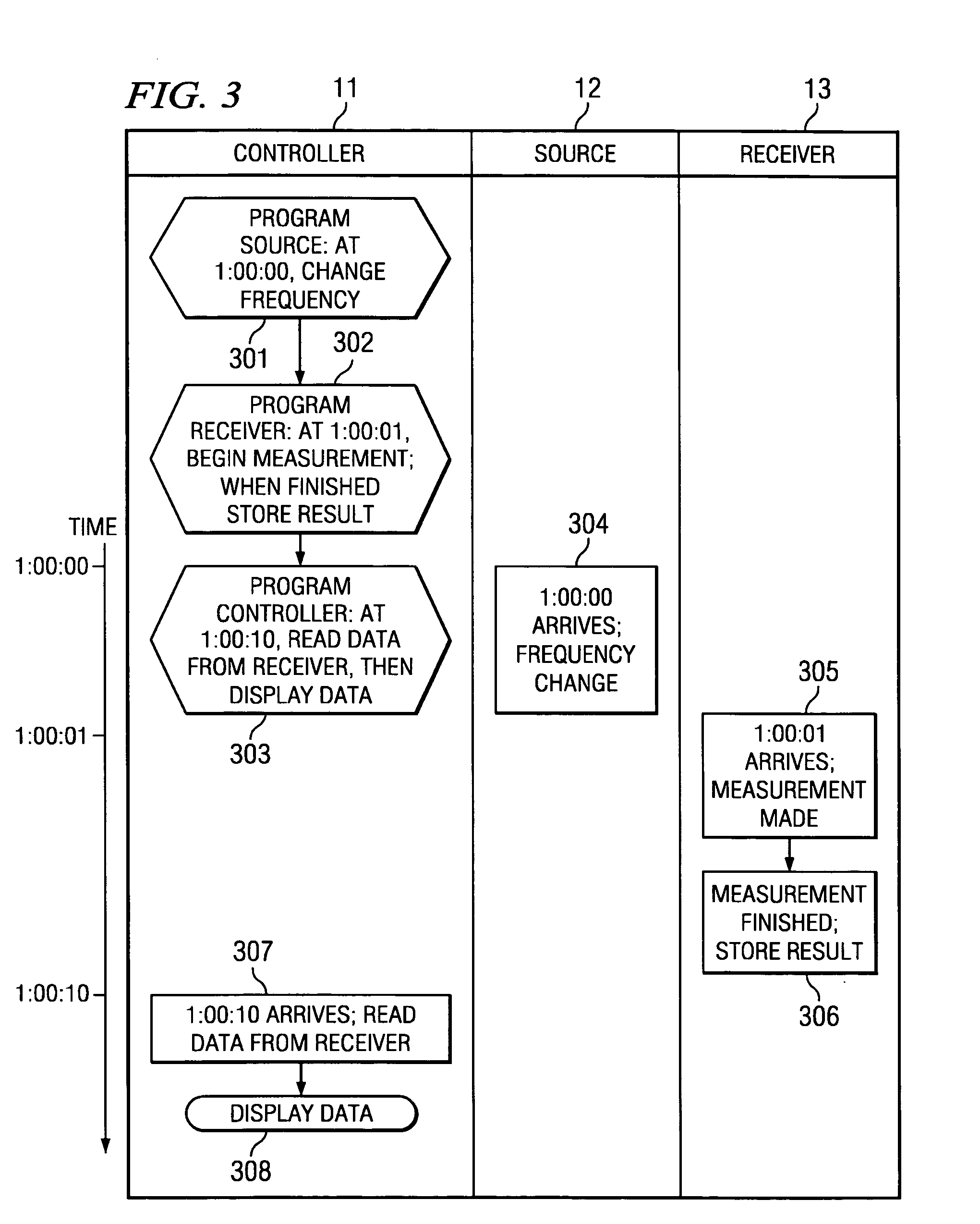

System and method for coordinating the actions of a plurality of devices via scheduling the actions based on synchronized local clocks

A system and method are provided which coordinate the actions of a plurality of devices via scheduling occurrence of the actions based on synchronized local clocks of the devices. Thus, a plurality of devices are communicatively coupled via a communication network, and the devices have their local clocks synchronized to a high degree of precision, using IEEE 1588, NTP, or some other technique for synchronizing their local clocks. “Time bombs” can be scheduled on the devices to coordinate the occurrence of actions between the devices in accordance with the detonation times set for the respective time bombs. In certain embodiments, not only the detonation time, but also the respective action to be triggered upon detonation is programmable for each device. The time bombs implemented on the various devices can be used to coordinate the operations of the various devices with a high degree of temporal precision.

Owner:KEYSIGHT TECH

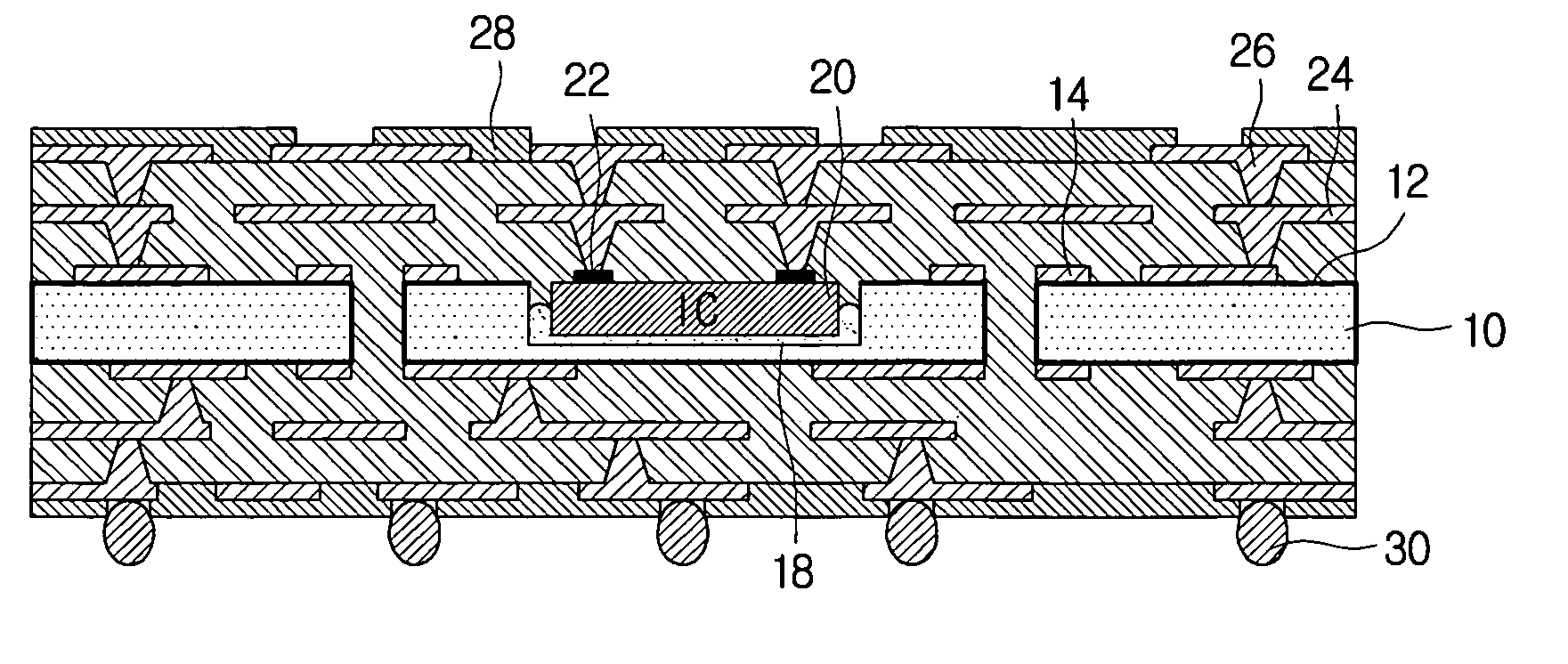

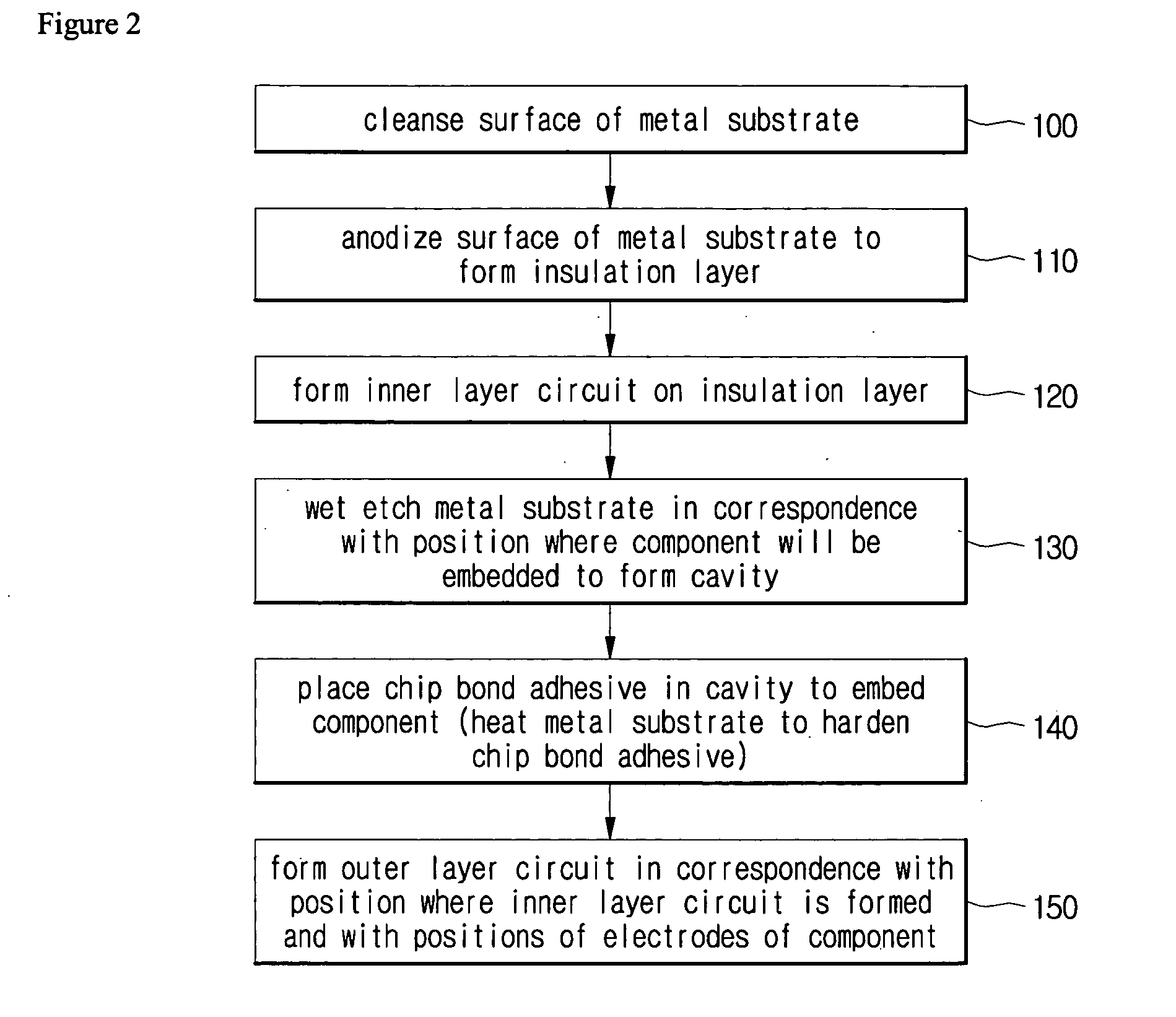

Printed circuit board and manufacturing method thereof

InactiveUS20070074900A1Increase stiffnessImprove heat-releasing propertyPrinted circuit assemblingPrinted electric component incorporationManufacturing cost reductionEtching

A printed circuit board and manufacturing method thereof are disclosed. By use of a method of manufacturing a printed circuit board, which uses a metal substrate as a core member and has an electronic component embedded in the metal substrate, mainly comprising: (a) anodizing at least one surface of the metal substrate to form at least one insulation layer, (b) forming an inner layer circuit on the at least one insulation layer, (d) placing chip bond adhesive in correspondence with a position where the electronic component is to be embedded and mounting the electronic component, and (e) forming an outer layer circuit in correspondence with a position where the inner layer circuit is formed and with positions of the electrodes of the electronic component, and which may further comprise an operation (c) of etching the metal substrate to form a cavity in correspondence with a position where the electronic component is to be embedded between the operations (b) and (d), a metal substrate, such as that of aluminum, etc., is rendered electrically insulating by applying an anodizing process and is used as a core member in a printed circuit board, so that bending stiffness and heat-releasing property are improved; wet etching can be applied, so that manufacturing costs are reduced; and a chip bond adhesive, die attach film, or nonconductive paste, etc., that is high in thixotropy is used in embedding the electronic component, so that the degree of precision may be increased for the position and height of the electronic component when embedding the electronic component.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

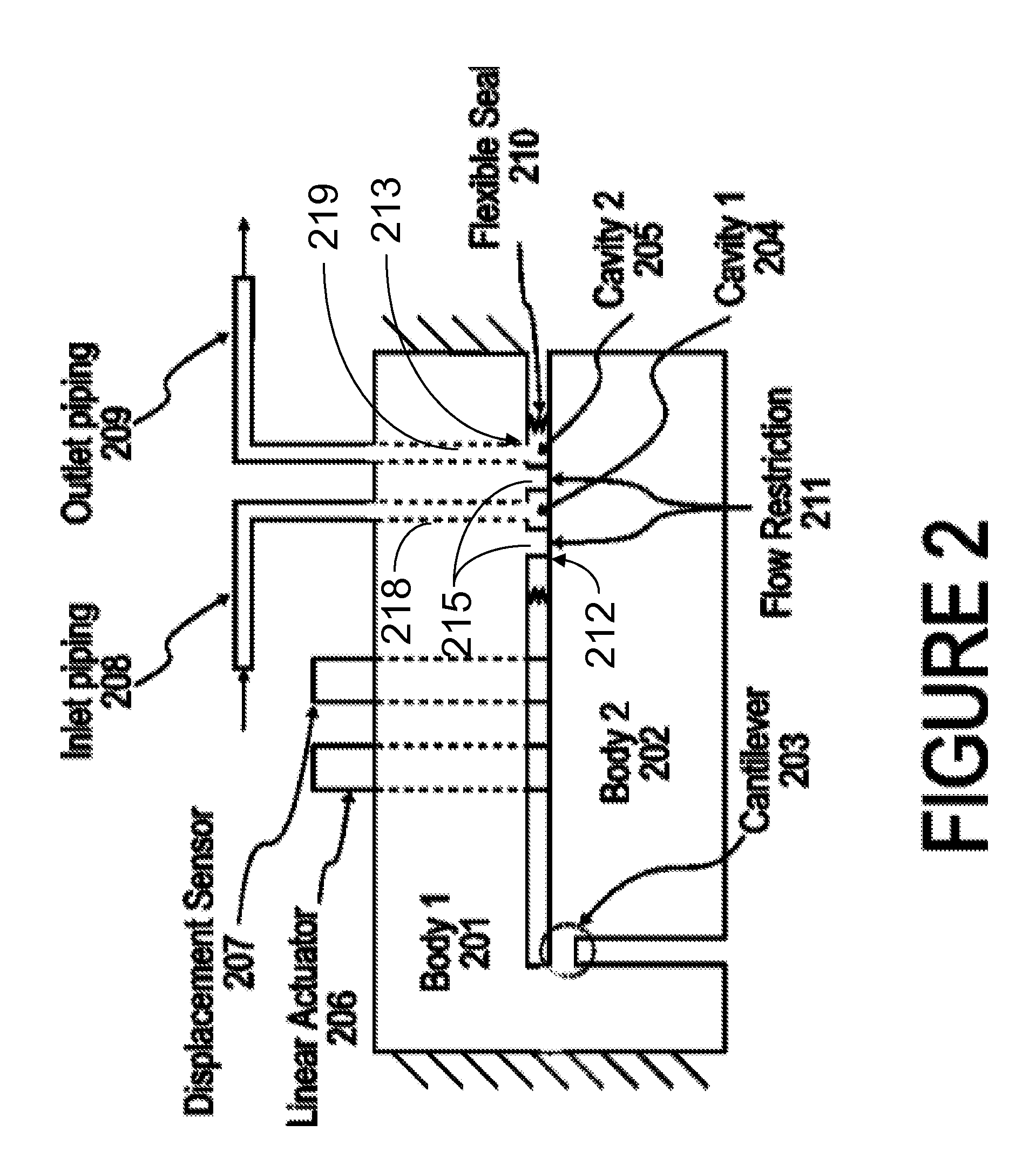

Programmable tracking pressure regulator for control of higher pressures in microfluidic circuits

InactiveUS6662818B2Low costImprove precision controlValve arrangementsControlling ratio of multiple fluid flowsCapillary networkEngineering

Regulator for precision control of pressure based on a means of measuring pressure differentials. More specifically, the present invention provides a pressure control that tracks a relatively high background pressure, and applies a positive or negative offset to create the small pressure differentials that can be utilized to transport fluids within a capillary network. The present invention is also directed to a method of controlling microfluidic elements (such as donut cavities) with a high degree of precision. In high performance liquid chromatography applications, this is accomplished using tracking pressure regulators to measure and respond to the difference between the liquid pump pressure and the regulated pneumatic pressure.

Owner:PERSPECTIVE BIOSYST

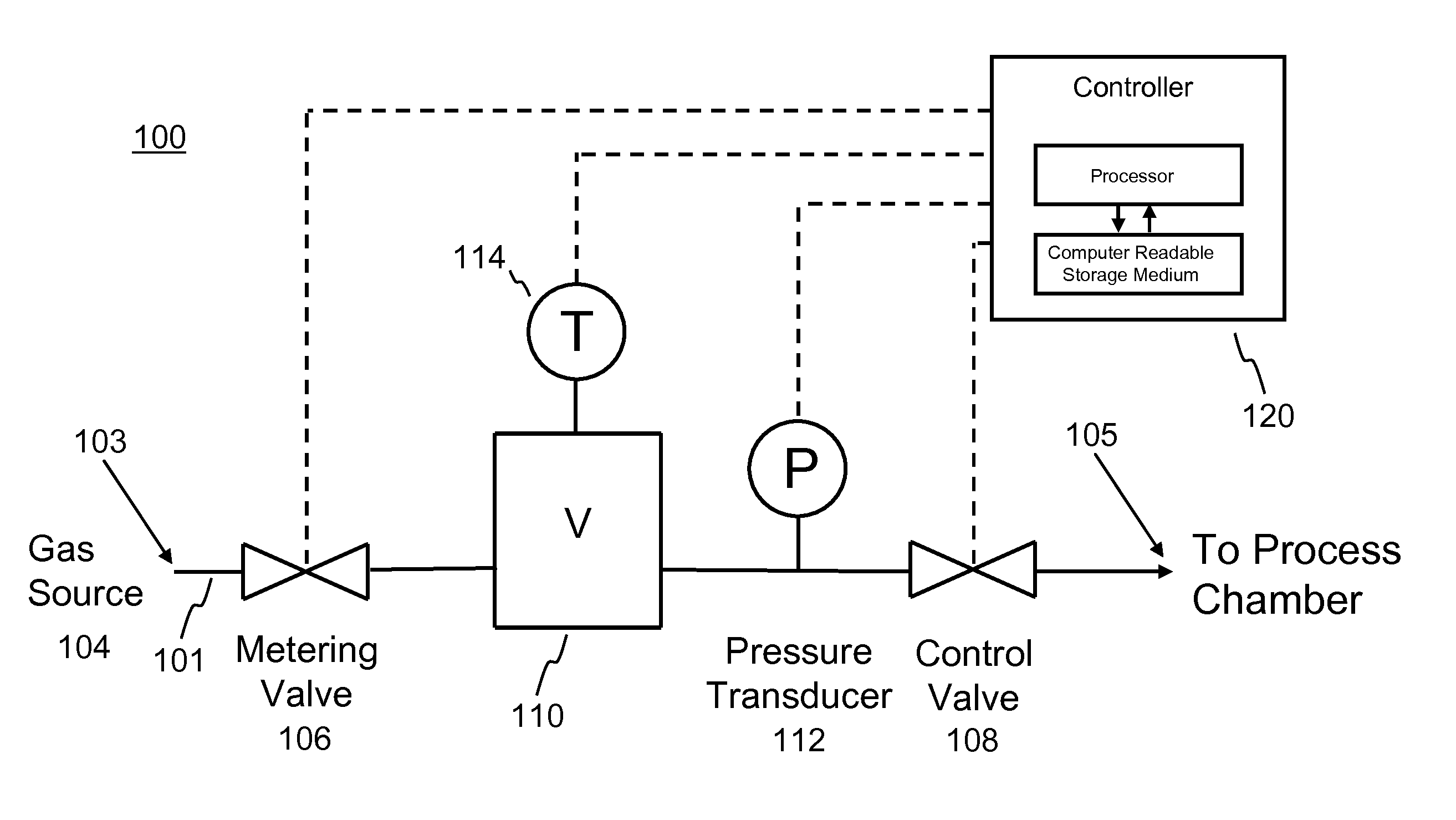

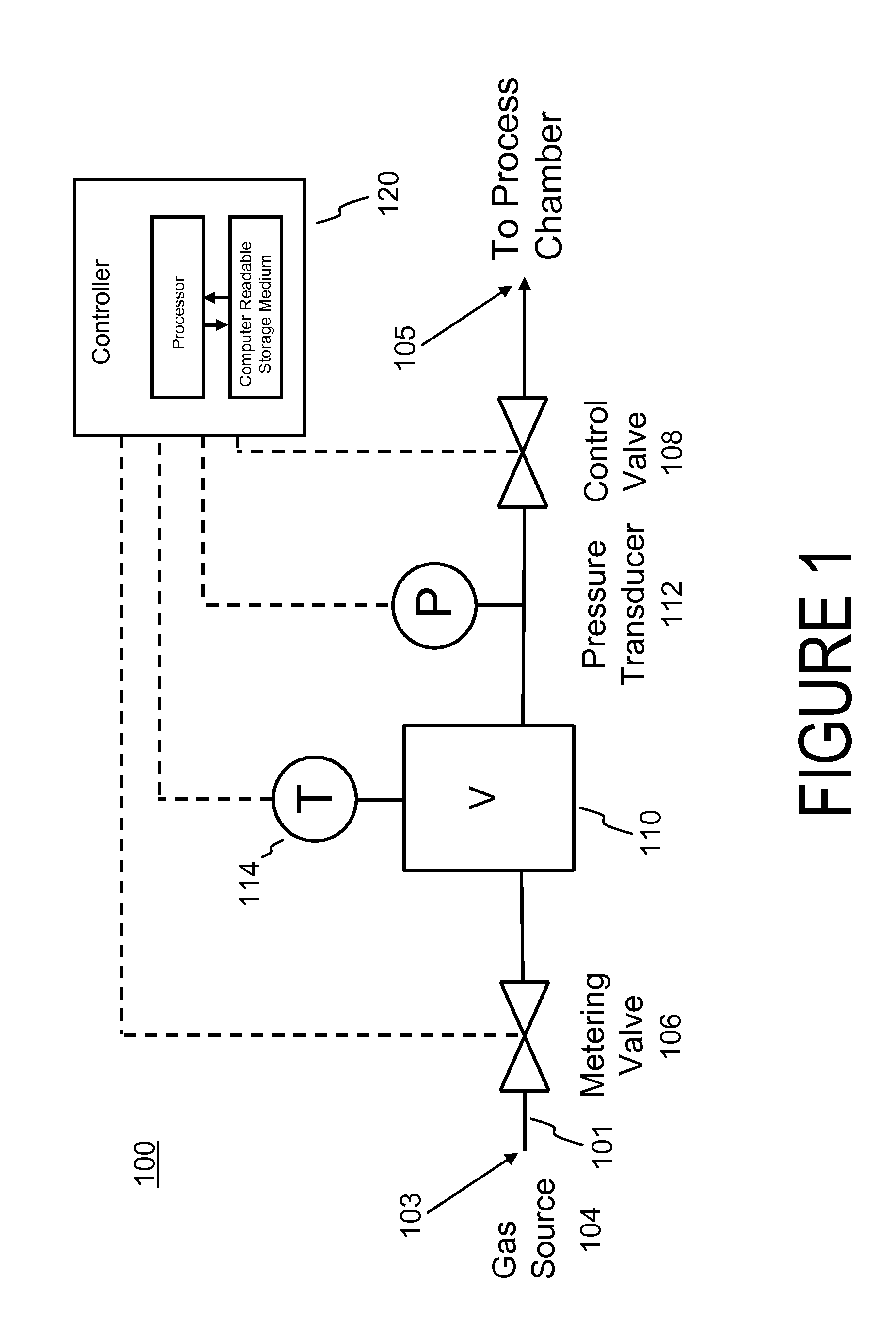

Method and apparatus for gas flow control

InactiveUS20110108126A1High precisionDiaphragm valvesOperating means/releasing devices for valvesEngineeringStreamflow

A method and apparatus for self-calibrating control of gas flow. The gas flow rate is initially set by controlling, to a high degree of precision, the amount of opening of a flow restriction, where the design of the apparatus containing the flow restriction lends itself to achieving high precision. The gas flow rate is then measured by a pressure rate-of-drop upstream of the flow restriction, and the amount of flow restriction opening is adjusted, if need be, to obtain exactly the desired flow.

Owner:PIVOTAL SYST CORP

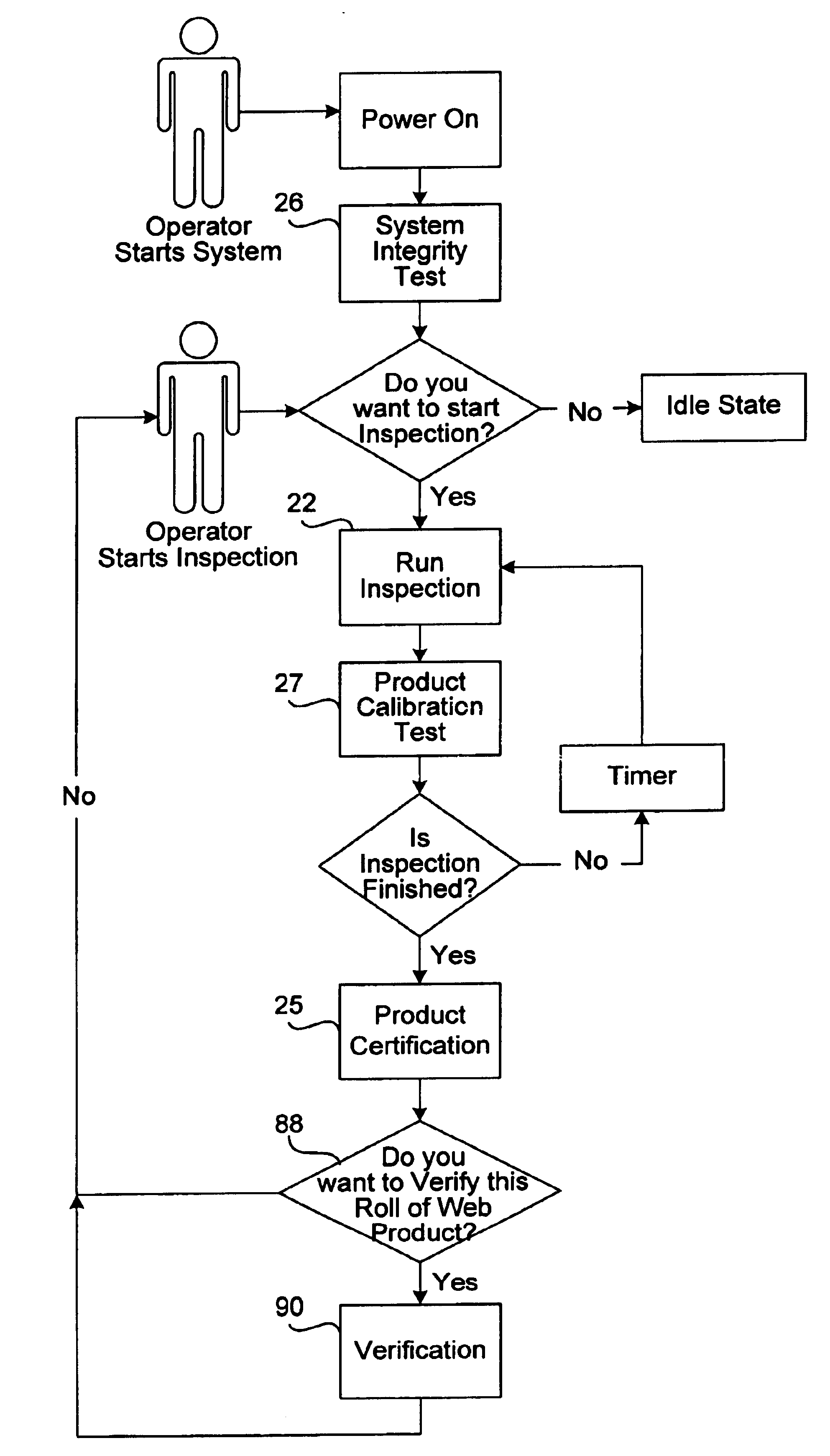

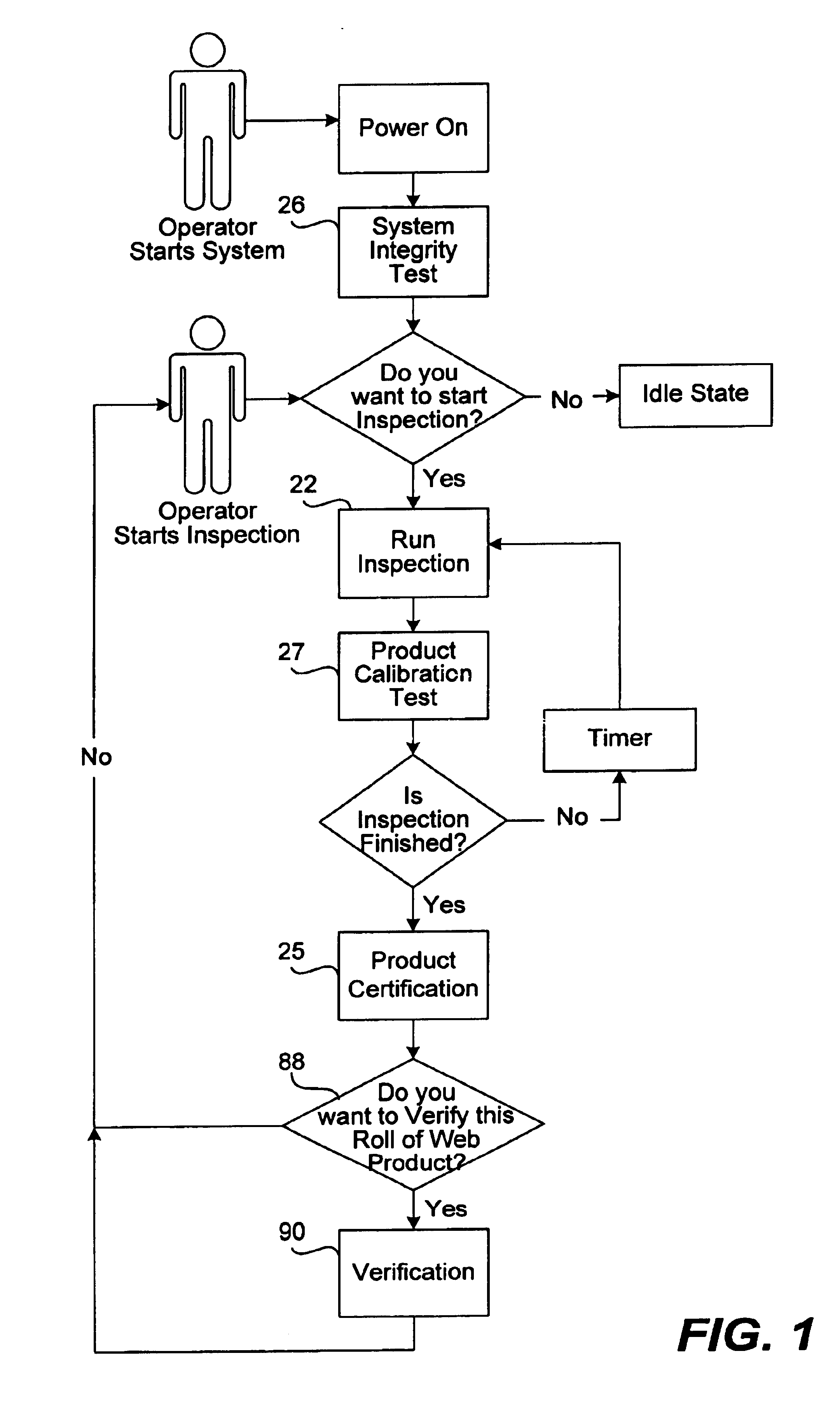

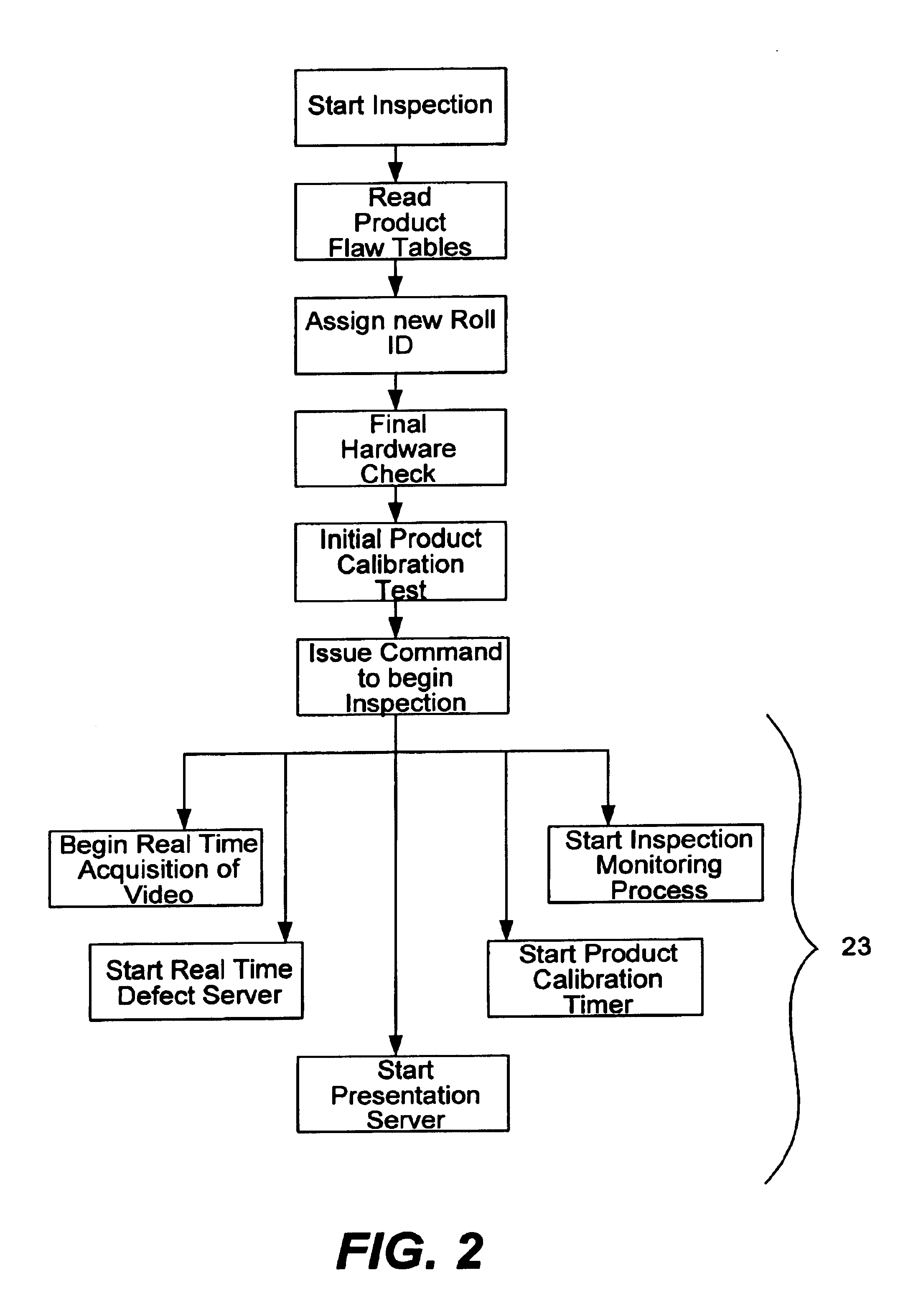

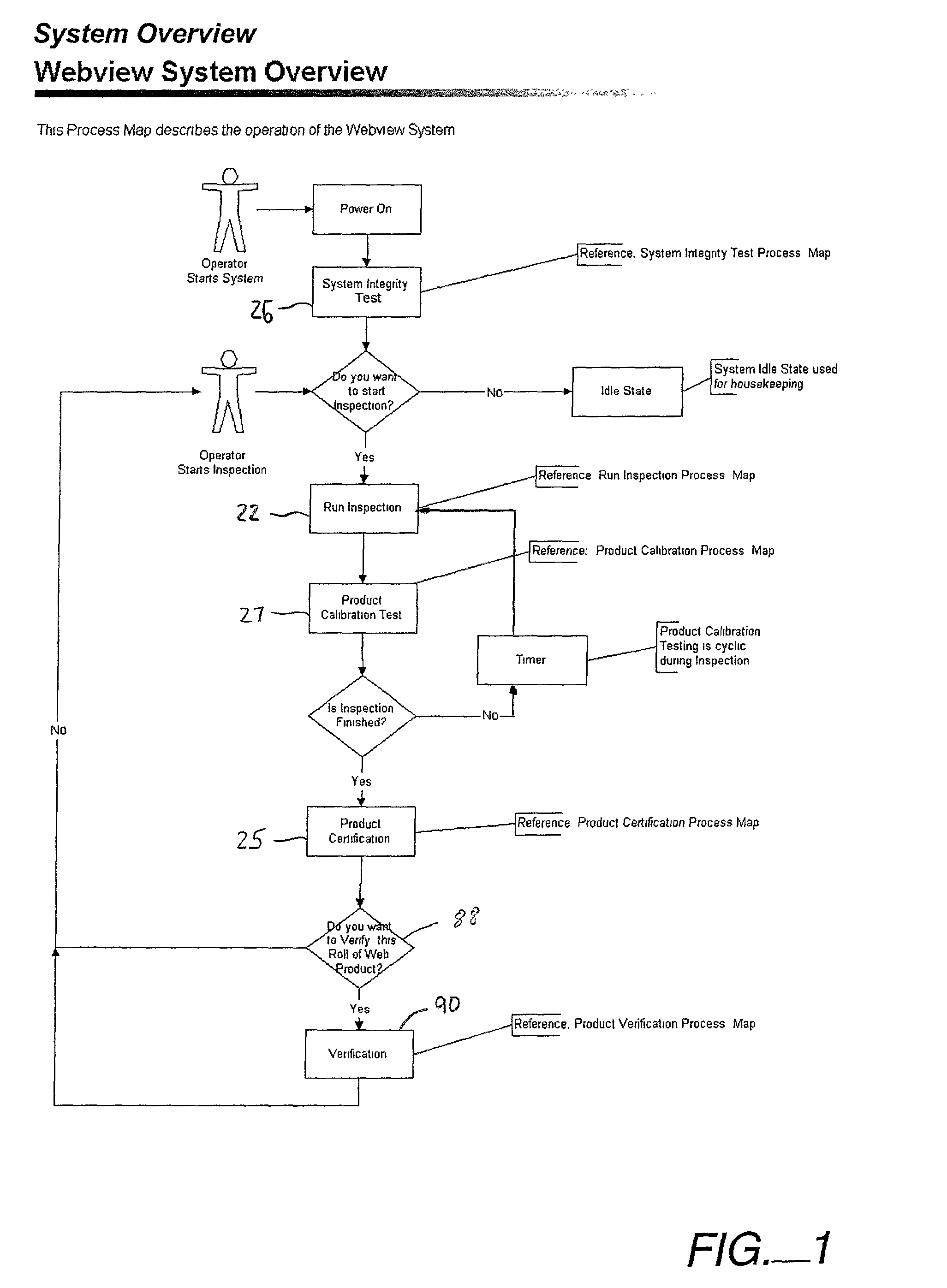

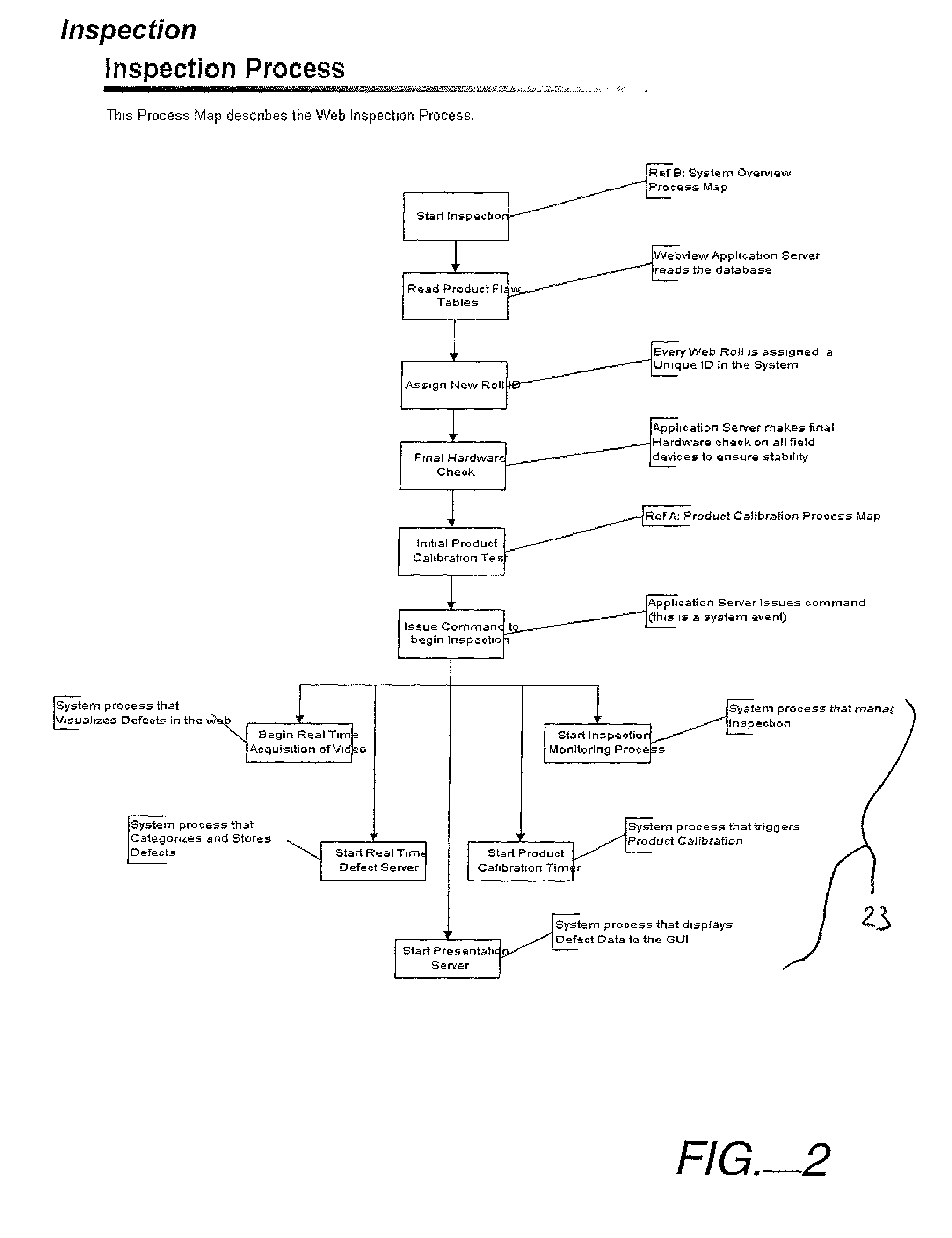

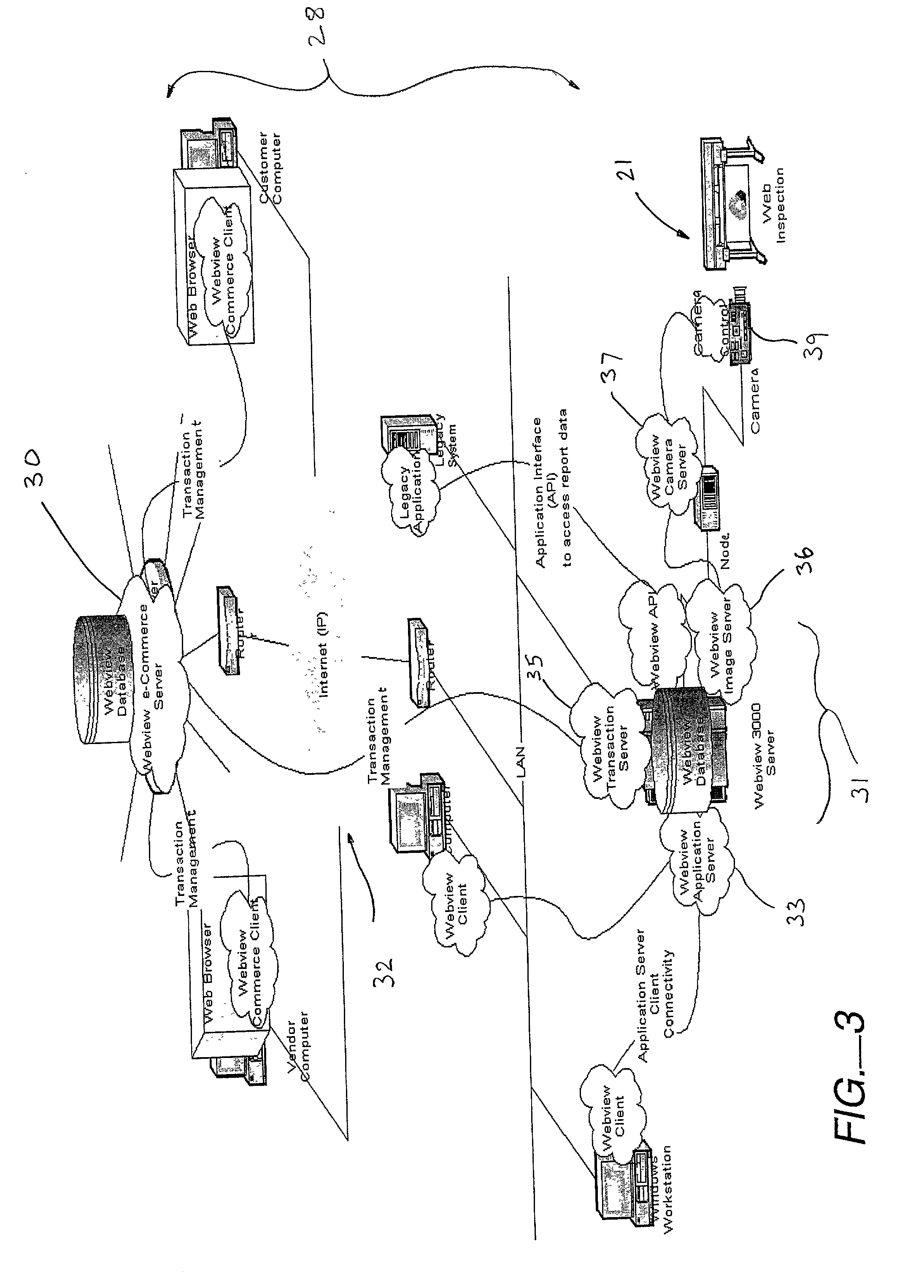

Certification and verification management system and method for a web inspection apparatus

InactiveUS6934028B2Simple sharing and exportInvestigating moving sheetsCharacter and pattern recognitionMachine visionAuthentication system

A certification system and method for inspecting of a roll of web material through a web inspection system which includes the inspection of the roll of web material to determine the number, type and location of one or more detectable flaws along the web material. This data “object” representation of the roll map is recorded, and then compared to predetermined product set-up parameters and machine vision hardware integrity data to determine the accuracy of the web inspection. The generated “certification” assures with a substantial degree of precision that the machine vision hardware is calibrated and operating correctly, and that the correct system setup parameters for the particular web product being inspected are being applied.

Owner:WEBVIEW

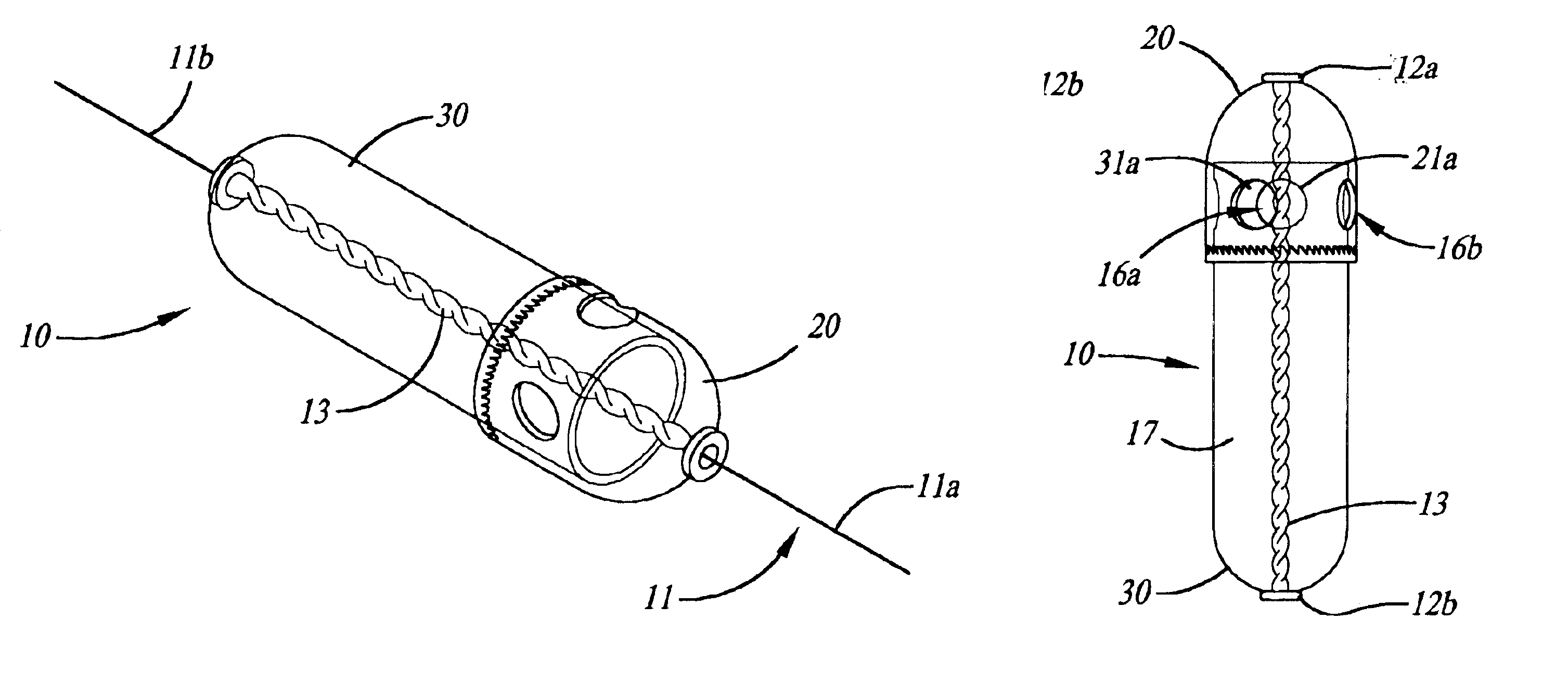

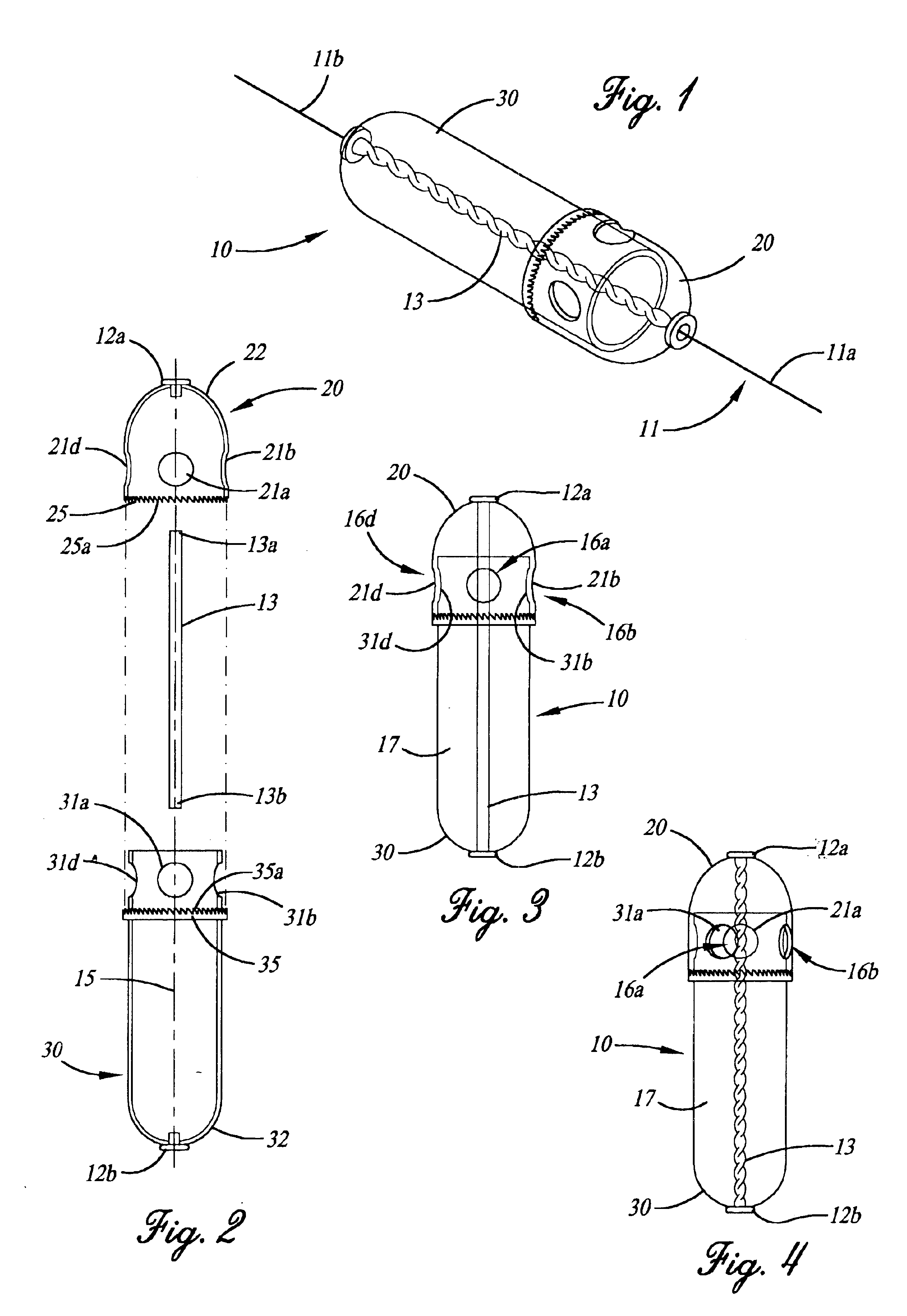

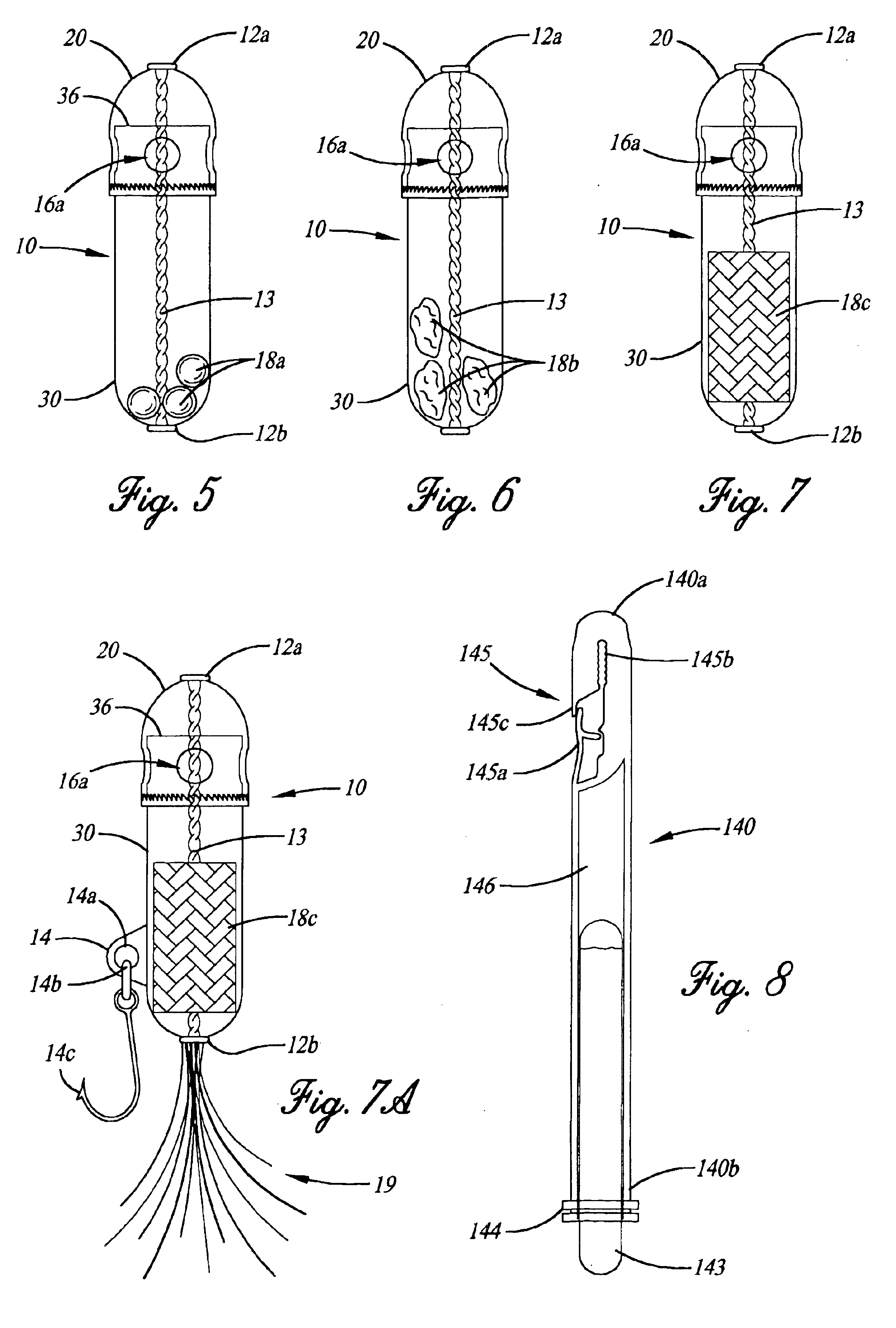

Adjustable buoyancy floating fish lure

A floating fishing lure having the capability to adjust the buoyancy of the fish lure with a high degree of precision, such that the fish lure has fore and aft chamber sections connected and held together by an attaching means. Disposed on each fore and aft chamber sections are a plurality of buoyancy windows, one set of which will coincidentally overlie the other set of buoyancy windows as the fore chamber section is rotationally moved in regard to the aft chamber section. By changing the rotational placement of the two sections, valve aperture openings are produced that regulate the air to water ratio within the fish lure, thereby controlling its buoyancy. Additional fish attractors, hooks and illuminators can be added to the fishing lure.

Owner:CRAMSEY JOHN F

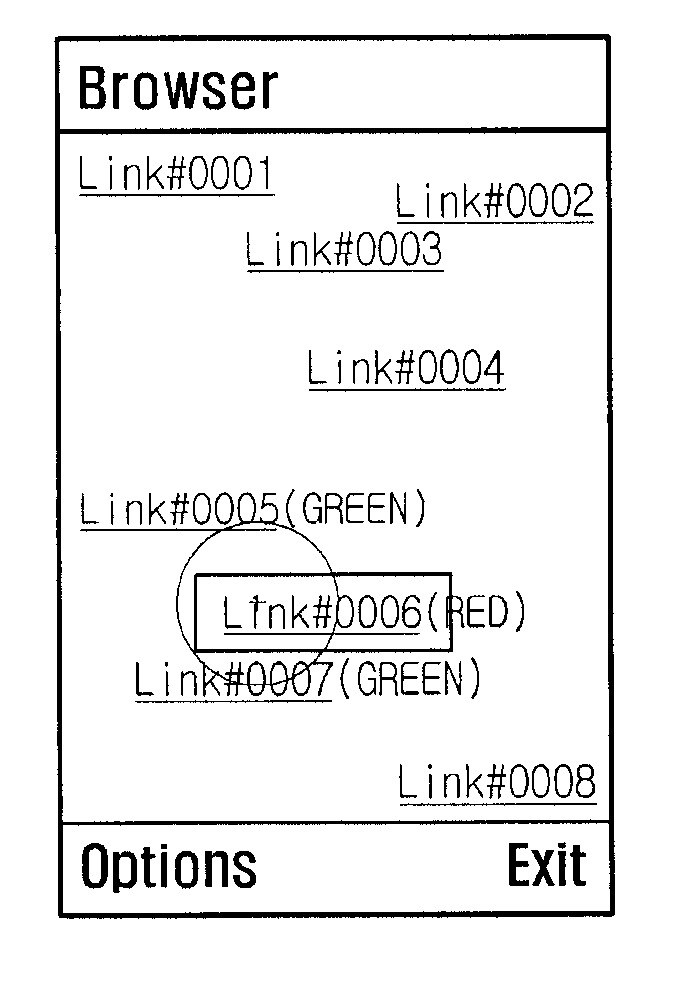

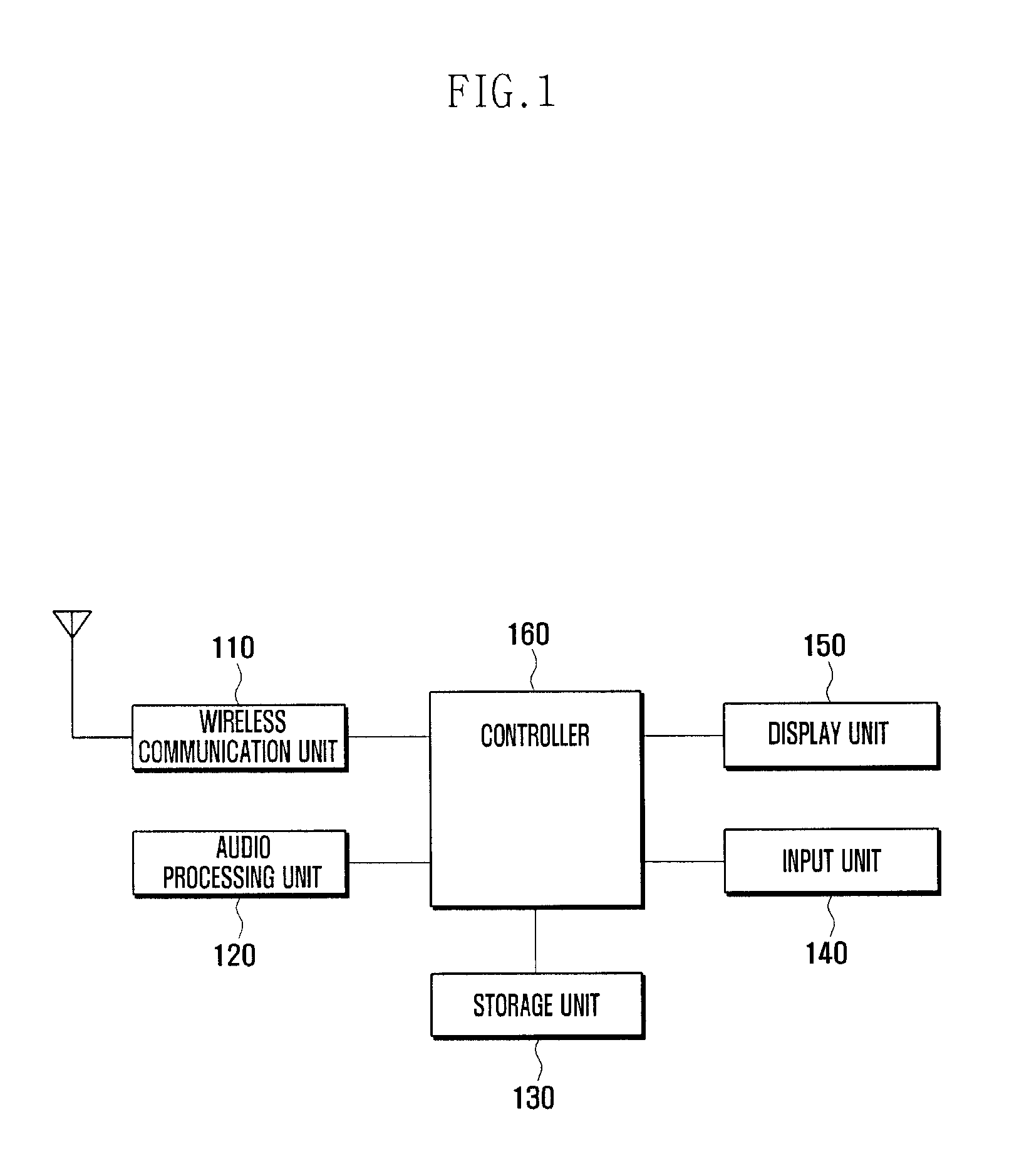

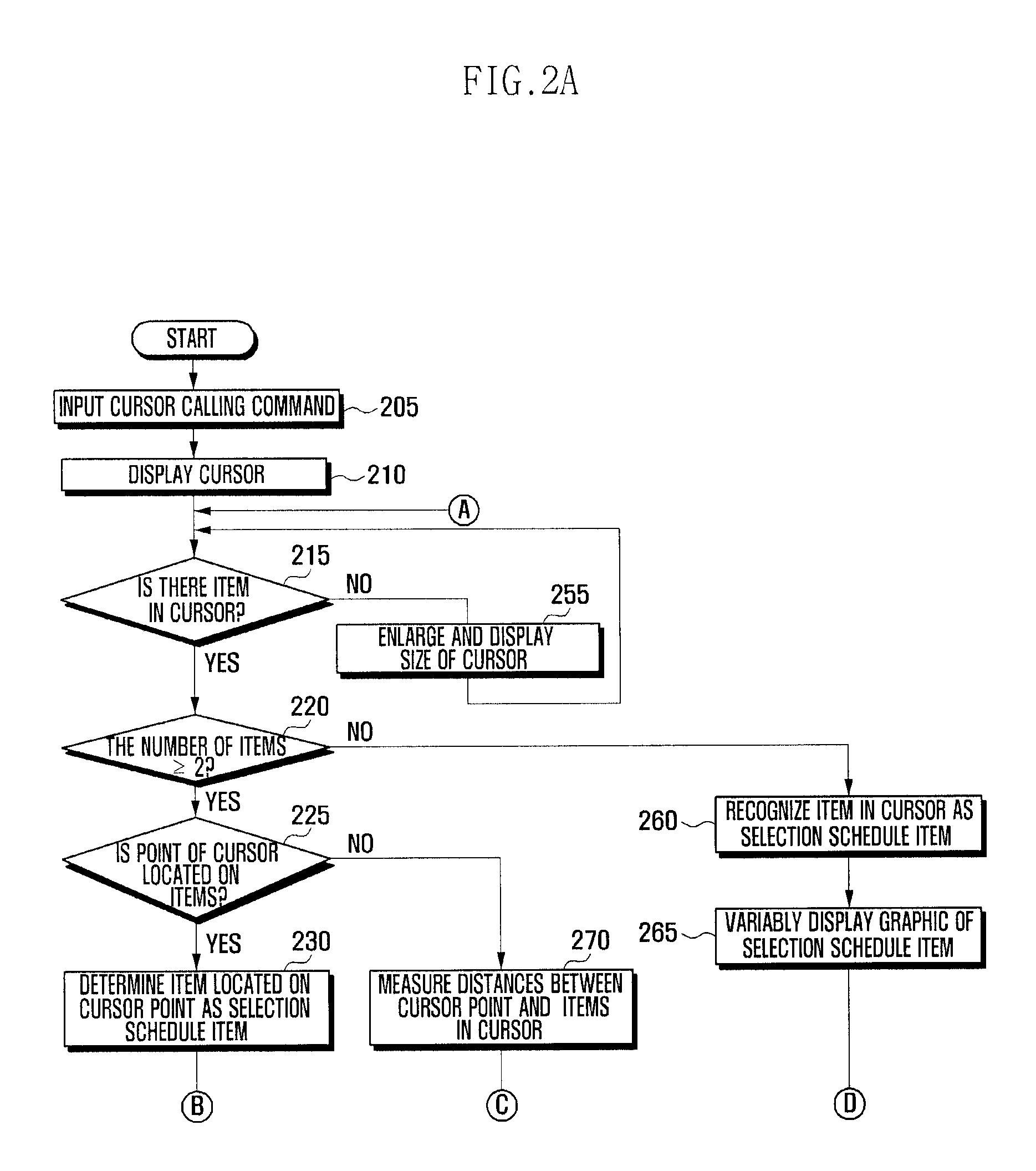

Method and apparatus of selecting an item

InactiveUS20100262933A1Input/output for user-computer interactionTransmissionDatabaseDegree of precision

A method and an apparatus of selecting an item rapidly and with a high degree of precision in devices including but not limited to portable terminals. The method of selecting an item includes: displaying a cursor having an area where an item can be selected; checking an item located in the area; and recognizing the item in the area as a selection schedule item. A user may quickly select a desired item to execute a properly corresponding function.

Owner:SAMSUNG ELECTRONICS CO LTD

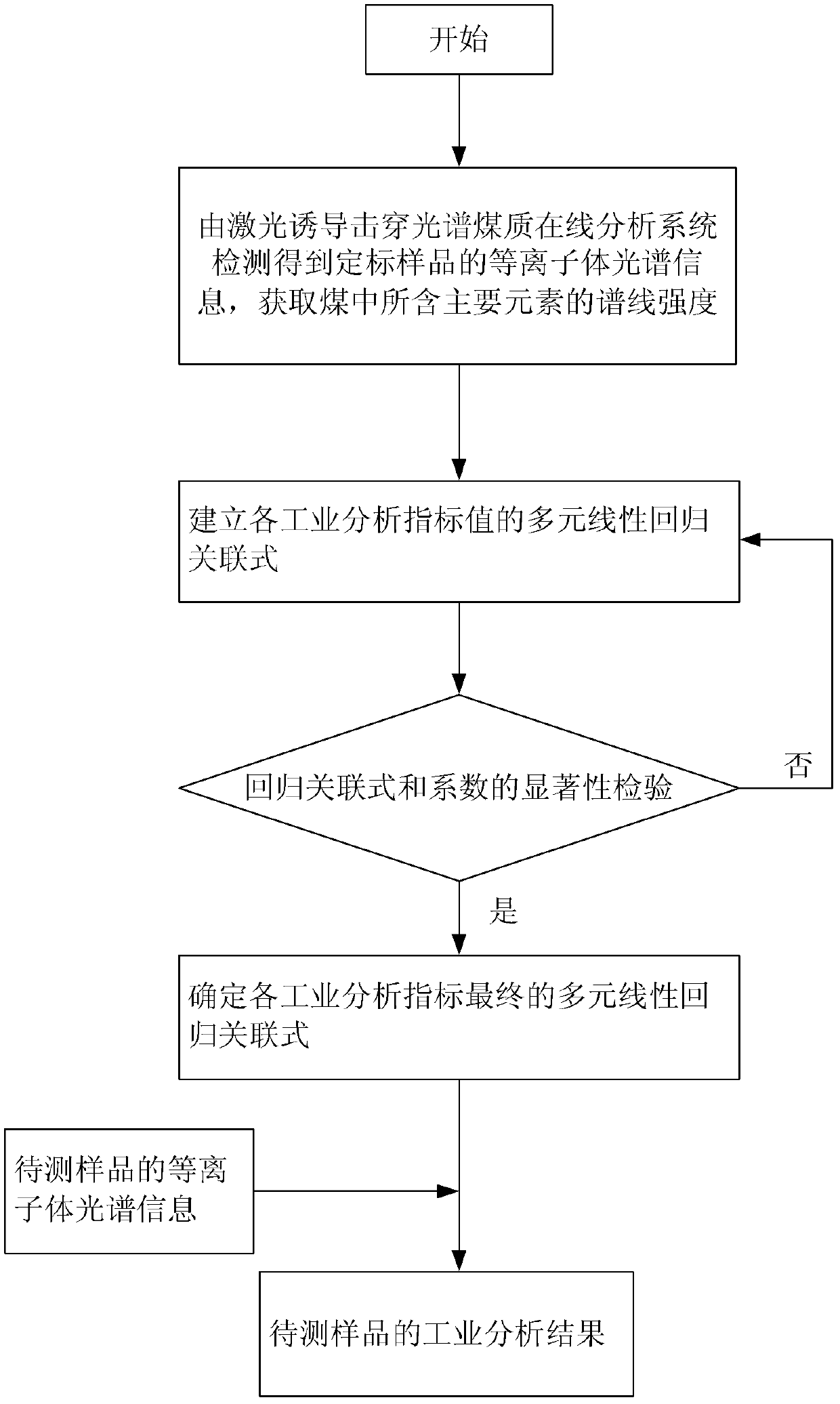

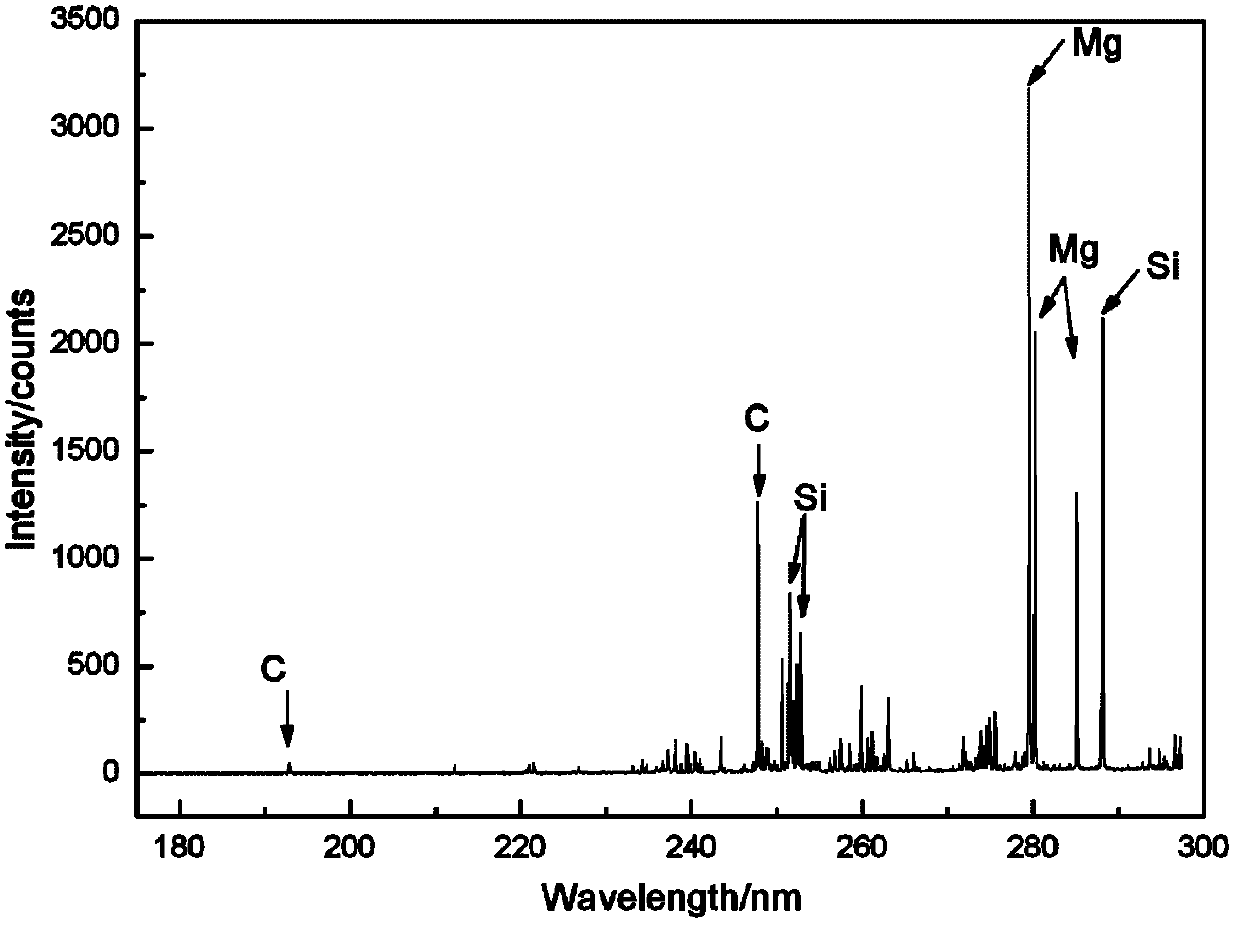

Proximate analyzing method for coal quality base on multivariate linear regression

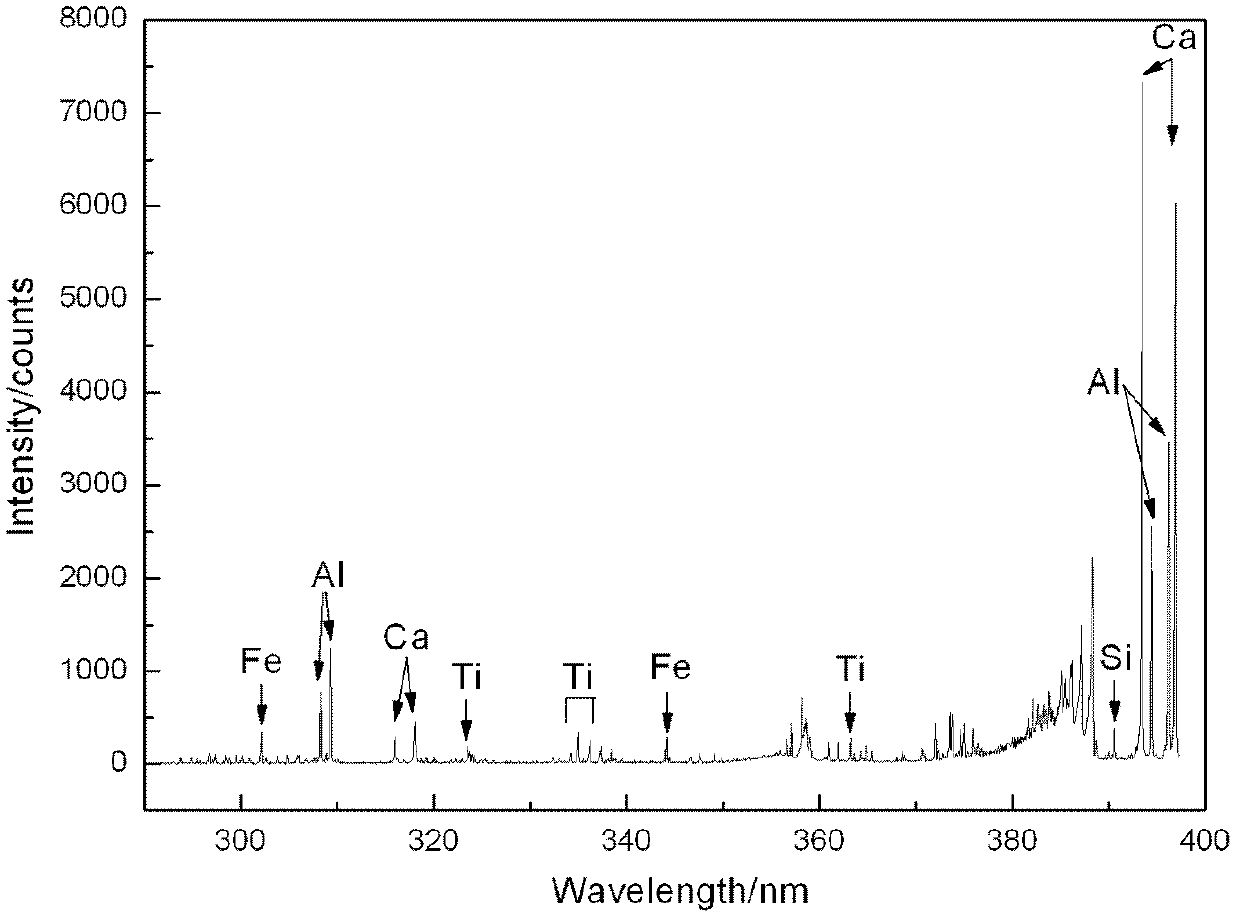

ActiveCN102313722AImprove resource utilizationImprove energy efficiencyAnalysis by material excitationProximateLaser-induced breakdown spectroscopy

The invention discloses a proximate analyzing method for coal quality base on multivariate linear regression, The invention is characterized in that a set of samples with known proximate analysis index values is used, plasma spectrum data is obtained by detection of a coal quality on-line analysis system of LIBS (Laser-Induced Breakdown Spectroscopy), the proximate analysis of fire coal samples to be measured by a multivariate linear regression correlation of each proximate analysis index value are respectively established, the characteristic spectral line strength which has substantial contribution to proximate analysis index values is respectively introduced through the established multivariate linear regression correlation to obtain the proximate analysis results. According to the invention, the spectral line information of correlative elements which has substantial contribution to each proximate analysis index is comprehensively utilized, the process for analyzing the index by fire coal proximate analyzed by the LIBS can be simplified, and the speed and the accuracy of the quantitative analysis can be raised.

Owner:SOUTH CHINA UNIV OF TECH +1

Method of fabrication of micro- and nanofilters

InactiveUS20100181288A1Reduce dimensionReduce pore of pore diameterMembranesSemi-permeable membranesPorosityVolumetric Mass Density

Micro- and nanofilters have a wide range of applications in many fields, including medical diagnostics, drug delivery, medical implants, and hemodialysis. Some issues that limit commercial application of current nanofilters in medicine are low pore density, non-uniform pore size, and the use of materials that are not biocompatible. A method is described to fabricate high porosity polymer and diamond micro- and nanofilters producing smooth, uniform and straight pores of high aspect ratio. Pore size, density, and shape can be predetermined with a high degree of precision by masks and controlled etch. The method combines energetic neutral atom beam lithography and a mask. This technology allows etching polymeric materials in a clean, well-controlled, and charge-free environment, making it very suitable for fabricating nanofilters and other components for biomedical applications.

Owner:CREATV MICROTECH +1

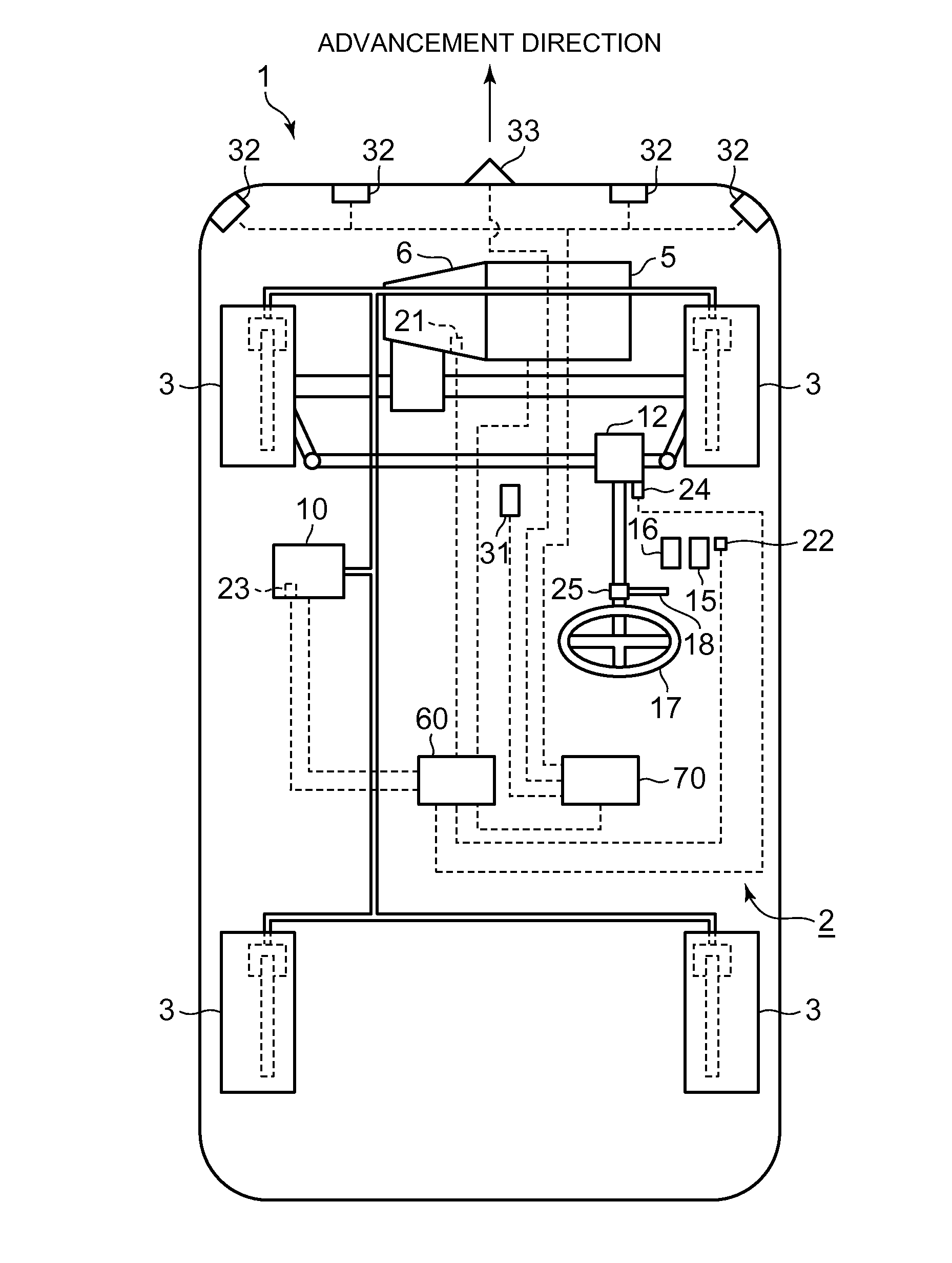

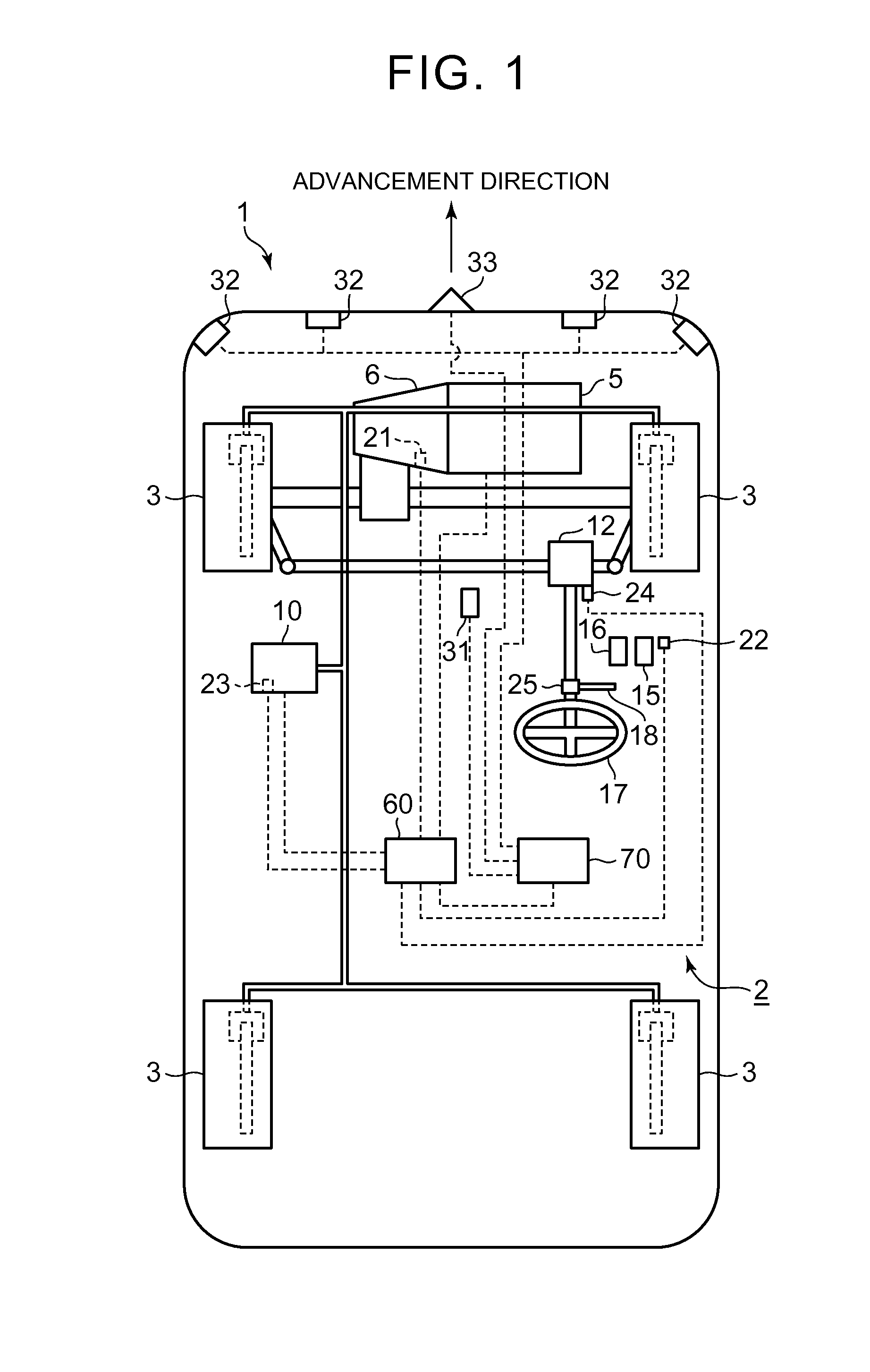

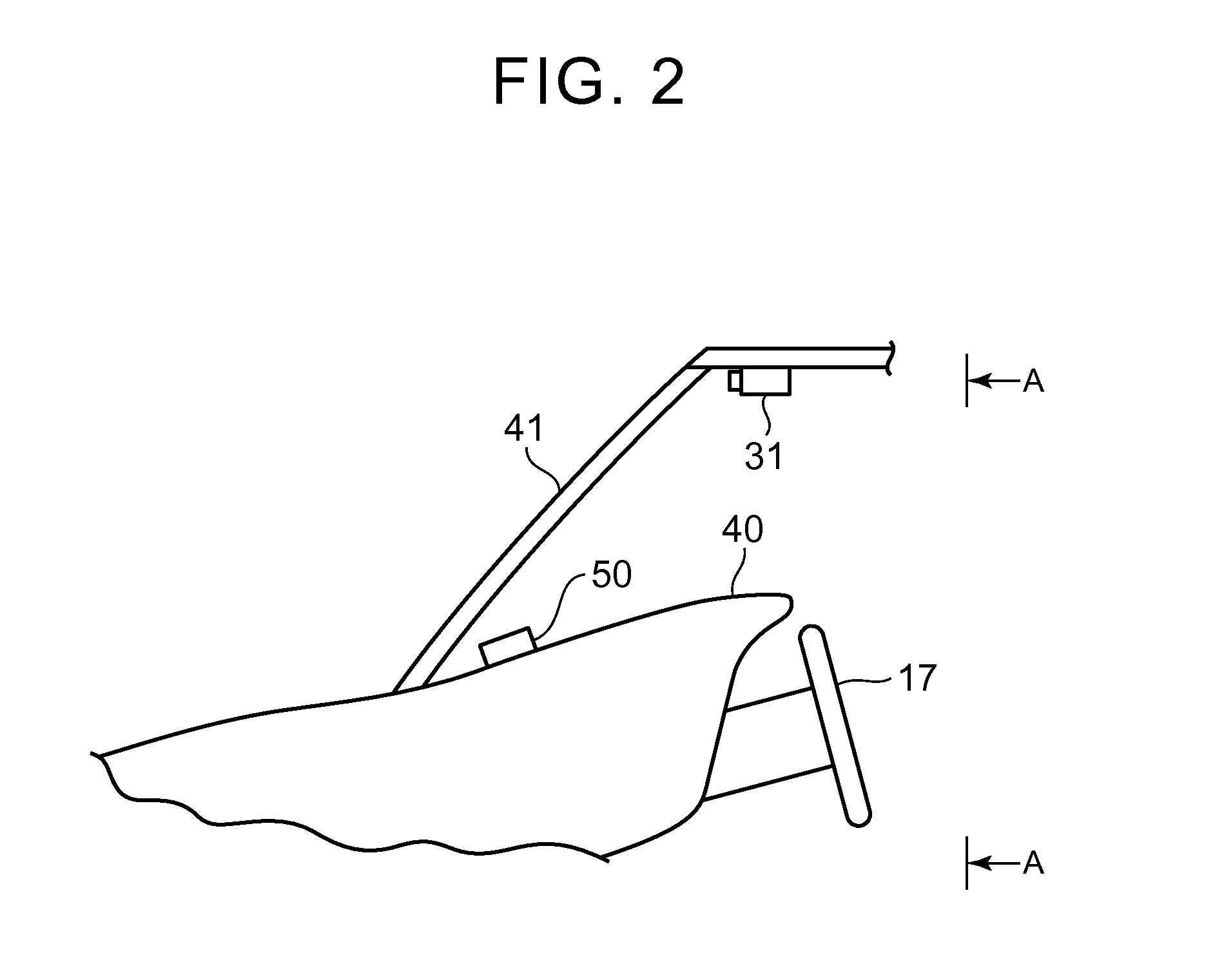

Driving assistance apparatus

ActiveUS20150046038A1High precisionSteering initiationsDigital data processing detailsDriver/operatorSteering control

To provide a driving assistance apparatus that can detect an intersection at which driving assistance is required with a high degree of precision so that the driving assistance can be provided more appropriately, a driving assistance apparatus 2 includes: a vehicle speed acquisition unit 64 that obtains information indicating a vehicle speed of a vehicle 1; an assistance condition determination unit 98 that determines whether or not an assistance activation condition, which is a condition for providing a driver of the vehicle 1 with driving assistance, is satisfied on the basis of whether or not a vehicle speed V obtained by the vehicle speed acquisition unit 64 is equal to or lower than a reference vehicle speed V1, and on the basis of information relating to an intersection or a preceding vehicle in front of the vehicle 1; and an assistance execution unit 100 that executes, as the driving assistance, assistance including at least one of warning issuance to the driver, braking control, and steering control when the assistance condition determination unit 98 determines that the assistance activation condition is satisfied.

Owner:TOYOTA JIDOSHA KK

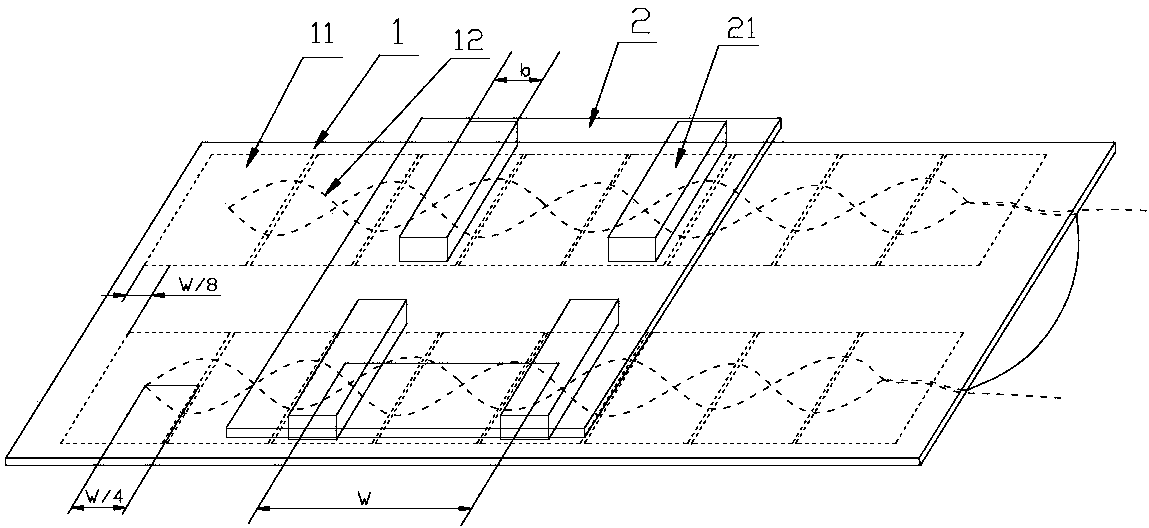

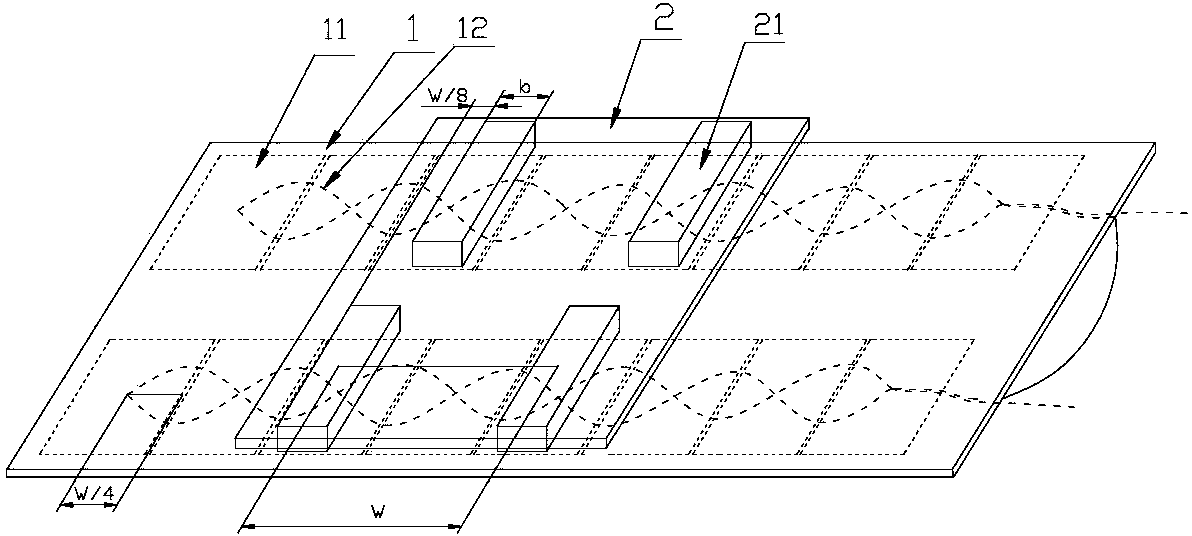

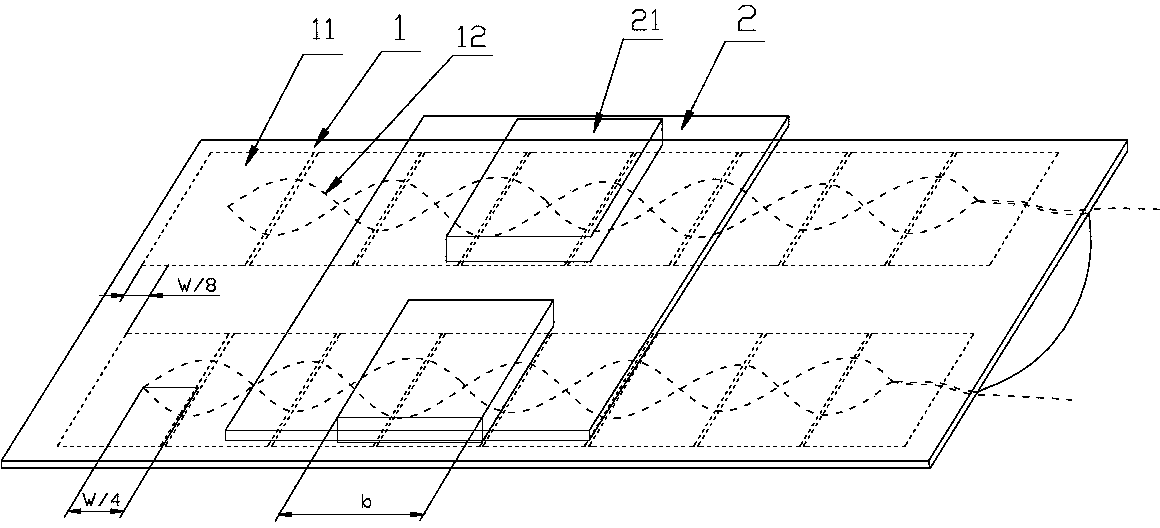

Time grating linear displacement sensor

InactiveCN103644834AImprove resolutionSimple structureUsing electrical meansGratingExcitation signal

The invention discloses a time grating linear displacement sensor. The time grating linear displacement sensor comprises a fixed ruler and a movable ruler, wherein the fixed ruler is composed of a fixed ruler base body and two same and parallel sensor units arranged on the upper portion and the lower portion of the fixed ruler base body, wherein each sensor unit comprises exciting coil and induction coils. The exciting coils are formed by sequentially arranging a plurality of forward-wound plane rectangular spiral exciting coils and a plurality of reverse-wound plane rectangular spiral exciting coils along a measurement direction in a staggered mode, and the exciting coils can generate a magnetic field which changes according to sine rules. The induction coils are formed by sequentially arranging a plurality of forward-wound induction coils and a plurality of reverse-wound induction coils along the measurement direction in a staggered mode. The movable ruler and the fixed ruler generate relative movement along the measurement direction, the induction coils which are connected in series in the sensor units together output induction signals of constant amplitudes, phase demodulation processing and high frequency clock pulse interpolation are performed on the induction signals and excitation signals, and linear displacement is obtained after conversion. The time grating linear displacement sensor can double the resolving power of the time grating linear displacement sensor under the condition that the degree of precision of scale marks is not increased.

Owner:CHONGQING UNIV OF TECH

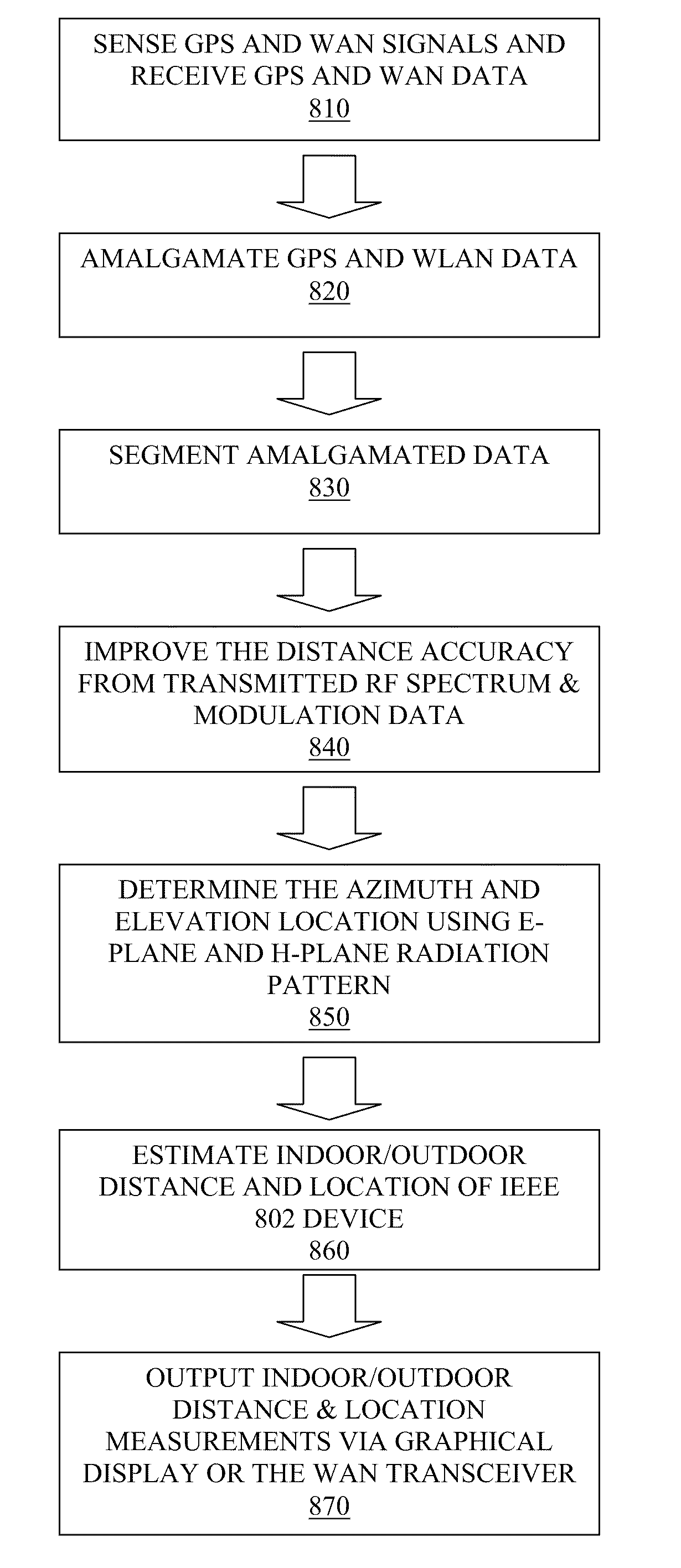

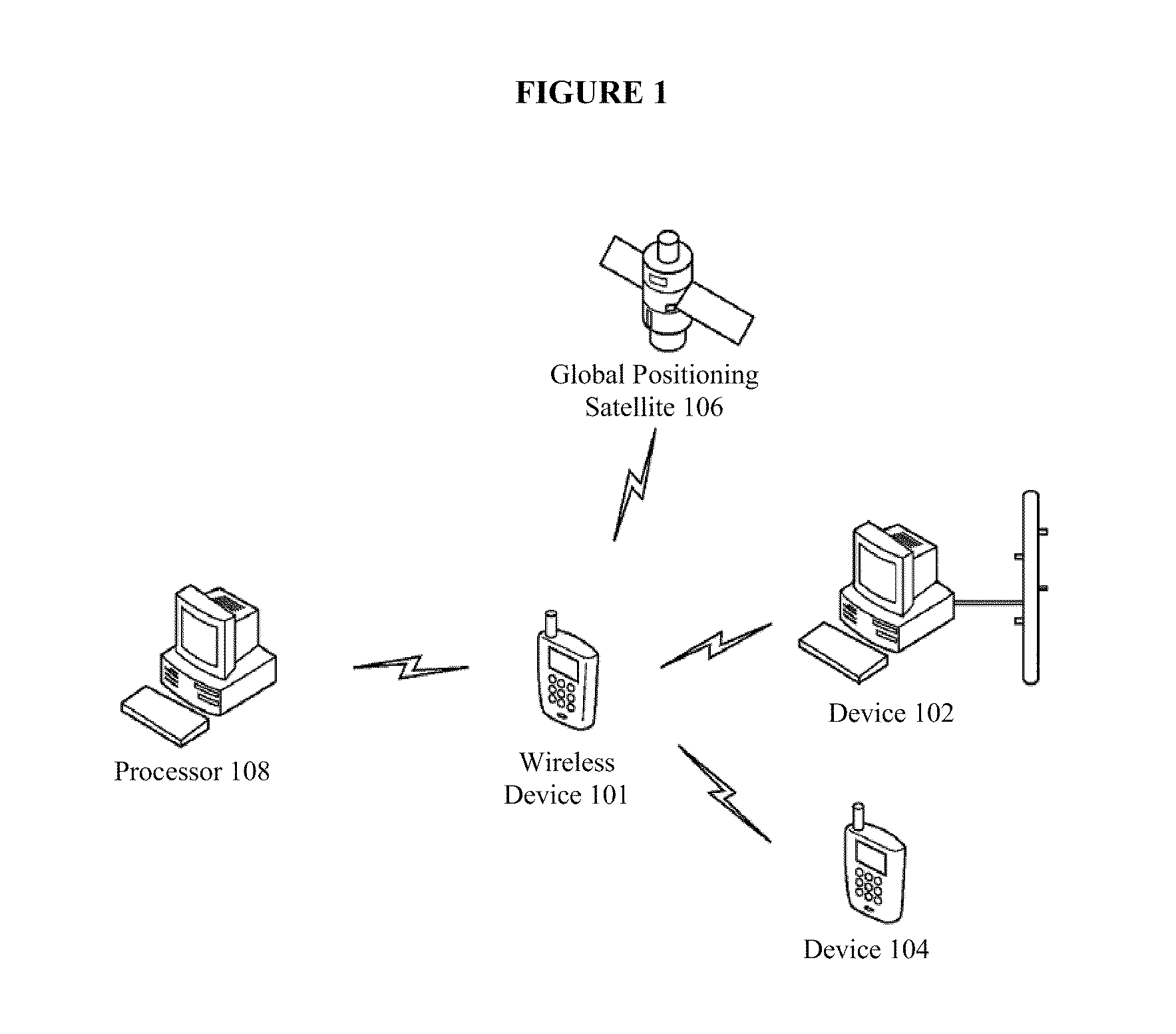

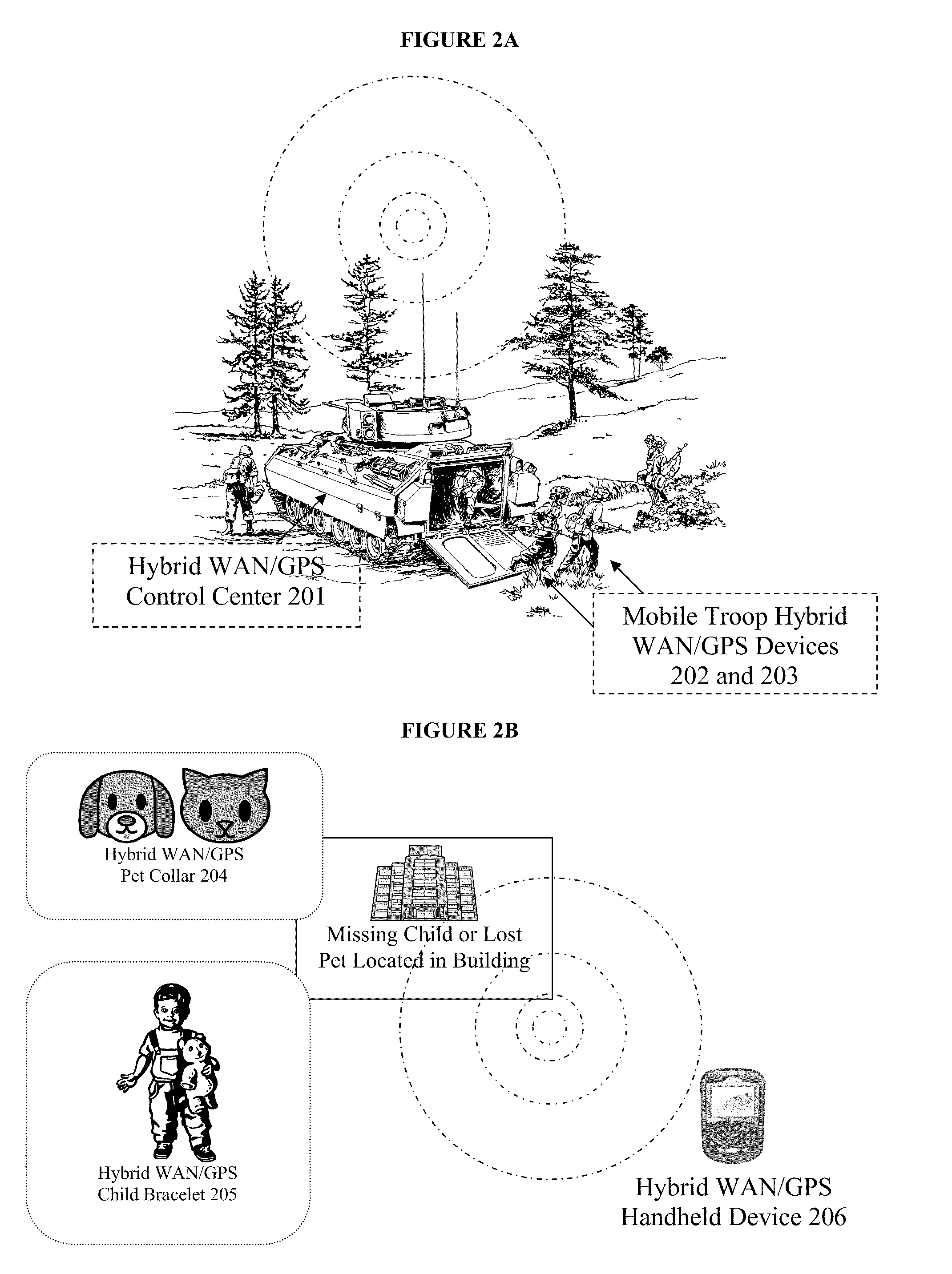

Hybrid wireless area network (WAN) and global positioning system (GPS) circuit board and method for seamless indoor and outdoor tracking

InactiveUS20110187591A1Reduce computational overheadImprove distance accuracyPosition fixationSatellite radio beaconingArea networkLocation tracking

Systems and methods for distance and location tracking a wireless device are disclosed. More specifically, according to one aspect of the present disclosure, a Wireless Area Network-Location Based Services (WAN-LBS) algorithm that utilizes a hybrid Wireless Area Network (WAN) and Global Positioning System (GPS) circuit board and method for seamless indoor and outdoor tracking is disclosed. The WAN-LBS algorithm, in conjunction with the hybrid WAN / GPS circuit board, optimizes the degrees of precision and accuracy for distance measurements in locating a fixed or mobile IEEE 802® device. In one embodiment, the hybrid WAN / GPS circuit board according to the present disclosure integrates the data of a GPS receiver and several IEEE 802 standards based receivers. In another embodiment, the WAN-LBS algorithm according to the present disclosure utilizes received data, acquired by the hybrid circuit board, to calculate distances to the tracking devices, seamlessly in both indoor and outdoor environments.

Owner:WALKER SR JONATHAN B

Method for preparing veneer ceramic-free full anatomic form zirconia dental crown

ActiveCN102302381AHigh strengthHigh transparencyTooth crownsTeeth cappingComputer assistanceTooth Preparations

The invention relates to a method for preparing a veneer ceramic-free full anatomic form zirconia dental crown. The method comprises the steps of: adopting a CAD (Computer-aided Design) / CAM (Computer-aided Manufacturing) system, and clinically fabricating an impression and a plaster model after tooth preparation; scanning by using a three-dimensional model scanner, establishing a digital model ona computer, and designing a dummy form through computer assistance; cutting a dummy form through a numerically-controlled lathe, trying wearing on the model, and adjusting the form; burnishing; painting; and glazing, and finally completing the fabrication of the dummy. The veneer ceramic-free full anatomic form zirconia dental crown provided by the invention has high strength and good light transmission, the treatment of applying ceramics is not required, and no hazard of ceramic fracture exists; the degree of precision is high due to computer control during the overall process; and the grinding amount for tooth preparation is small, and an ideal effect can be achieved with 1mm space.

Owner:SHENZHEN UPCERA DENTAL TECH

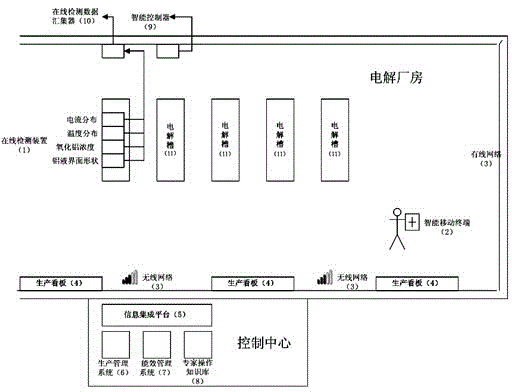

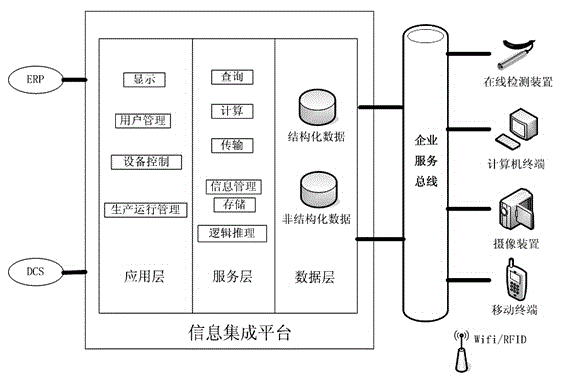

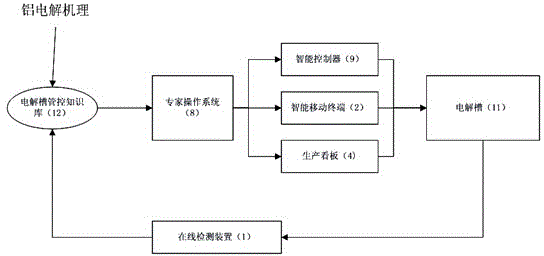

Aluminum electrolytic MES system based on accurate perception and intelligent decision

ActiveCN105467946ARealize precise perceptionReal-time detection of real-time production dataEnergy industryTotal factory controlManagement efficiencyInformation integration

The present invention discloses an aluminum electrolytic MES system based on an accurate perception and an intelligent decision. The system comprises an electrolytic tank online detection device (1) for detecting aluminum electrolytic real-time production data, an online detection data collection device (10) for collecting real-time production data, an intelligent mobile terminal (2) for obtaining the position information of an operator, a plant wireless or wired network (3), a production billboard (4) for information display, an information integration platform (5), a production management system (6) based on production process real-time data, an aluminum electrolytic process energy management system (7), an expert operation system (8) based on electrolytic tank (11) real-time production data, and an intelligent controller (9) for production control. According to the system, the degree of precision and the automation level of the aluminum electrolytic production management and control can be improved, the management efficiency is improved, and the influence on aluminum electrolytic production brought by personnel technology and management level differences can be reduced.

Owner:GUIYANG AL-MG DESIGN & RES INST

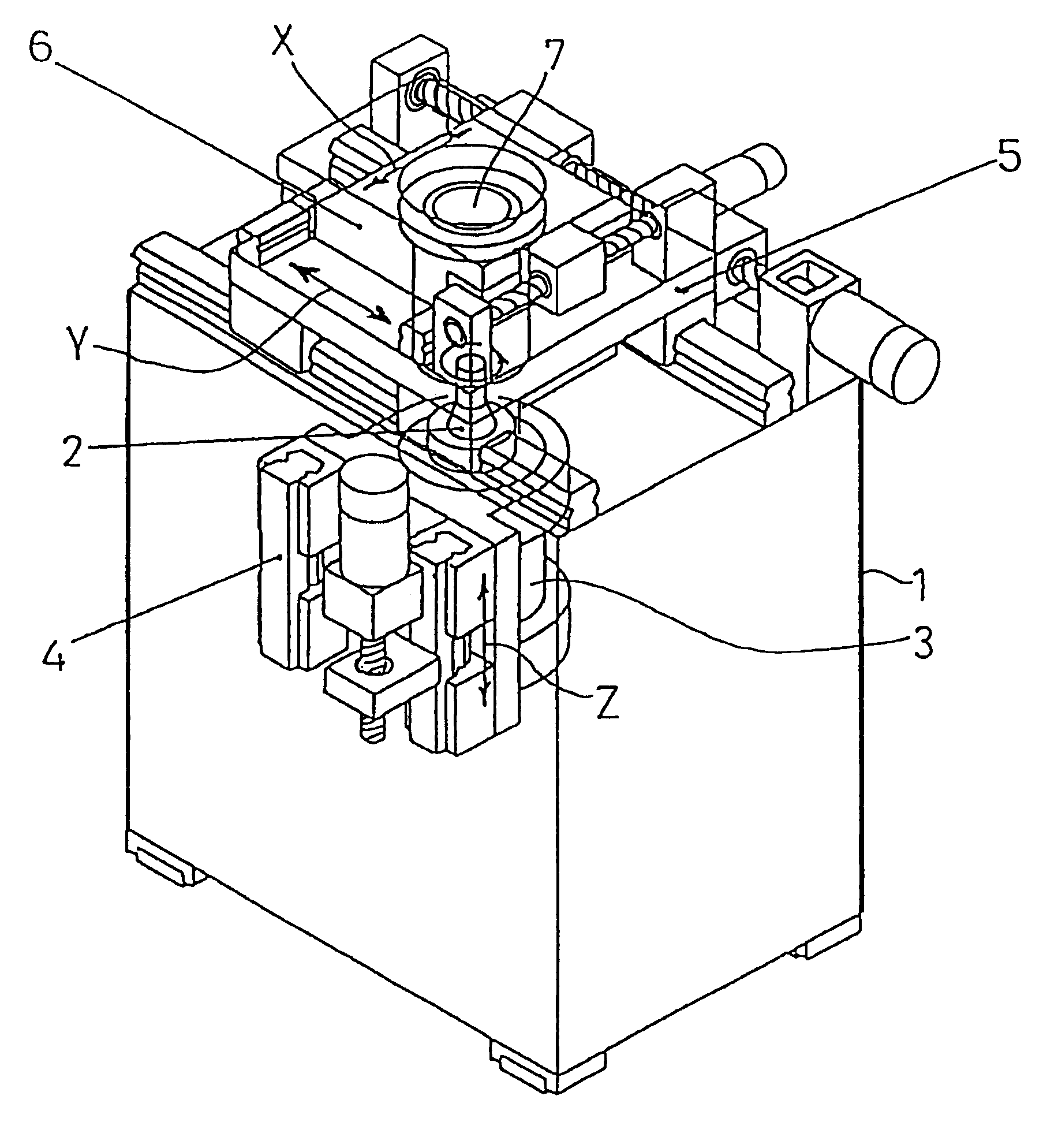

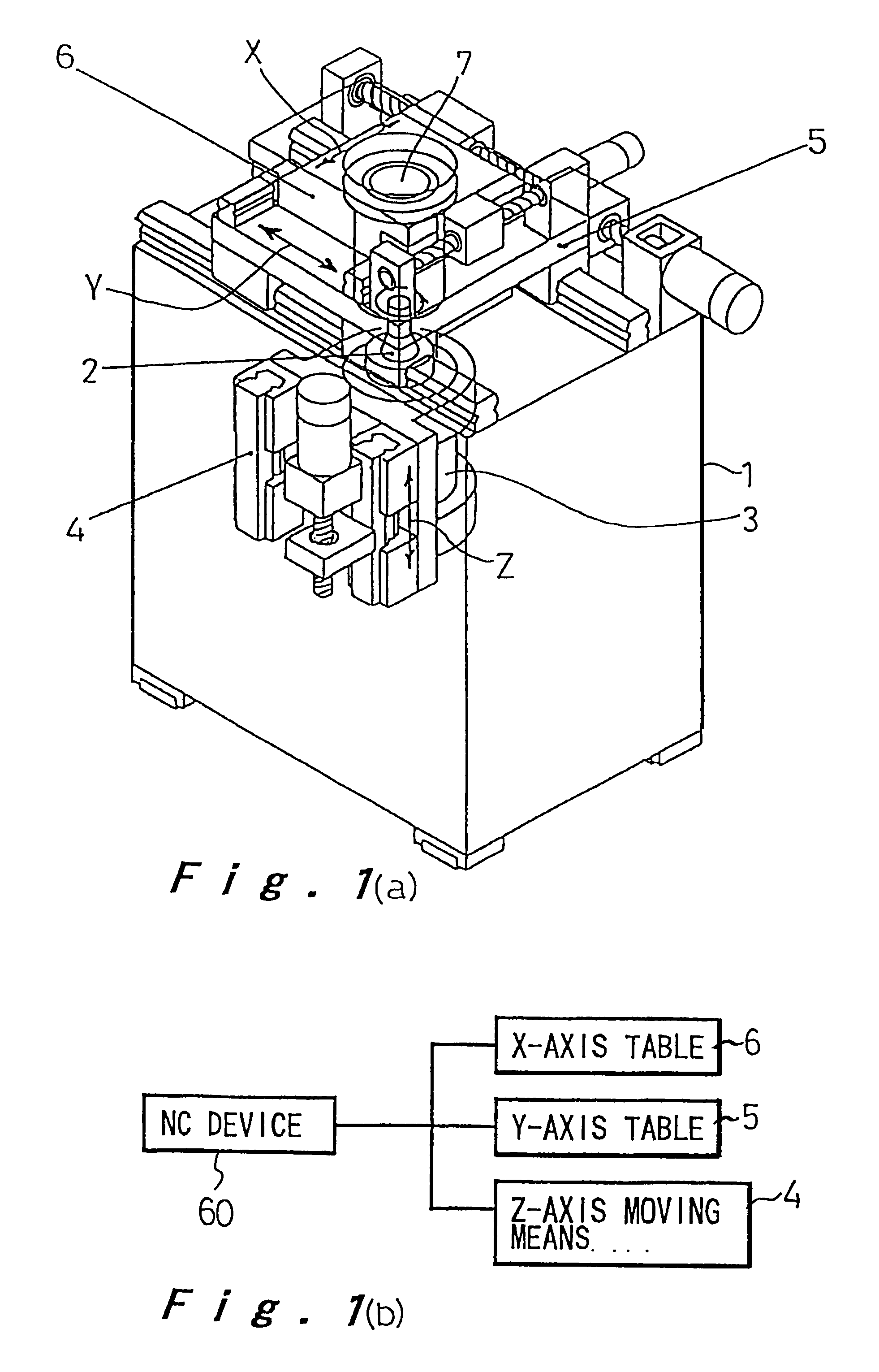

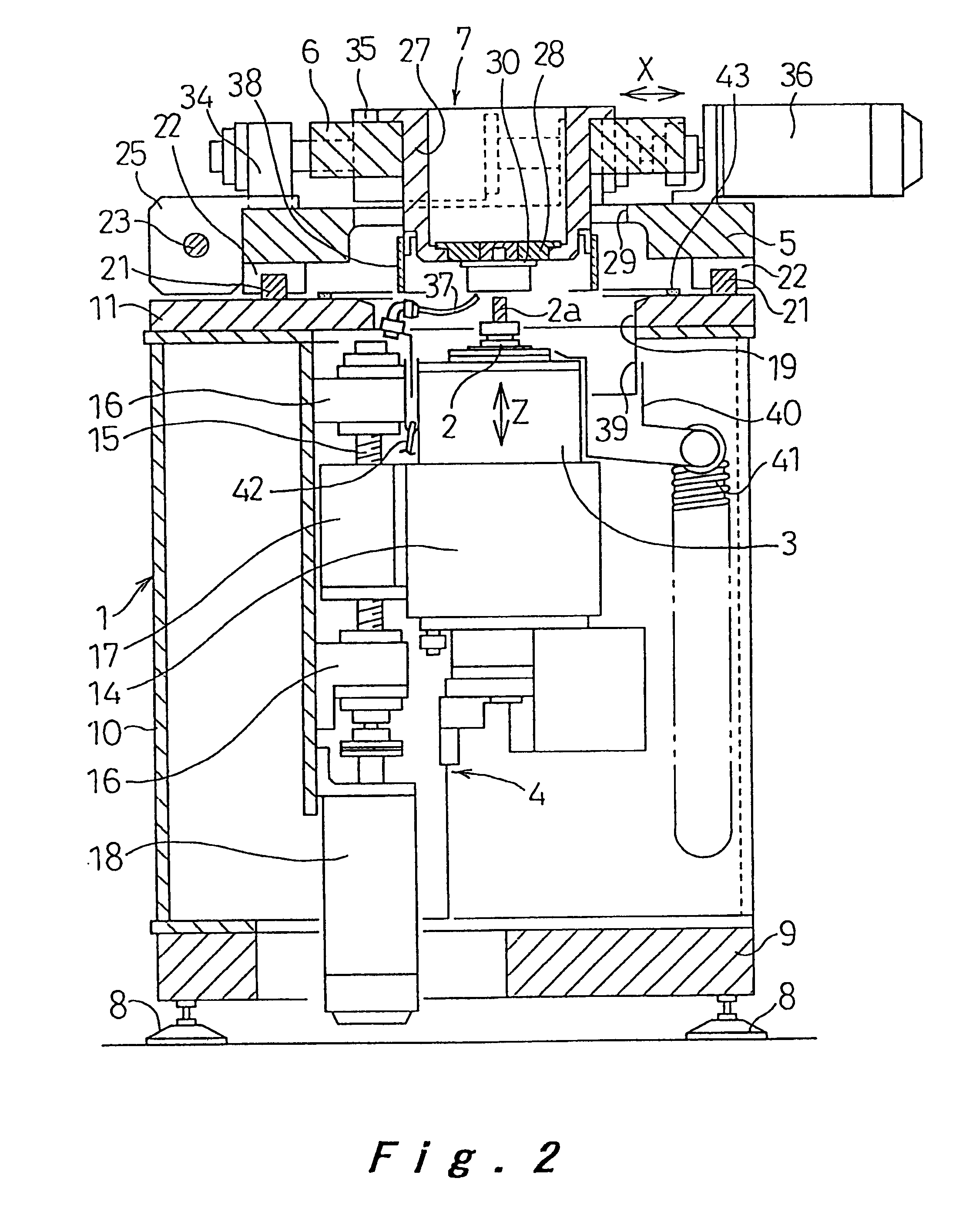

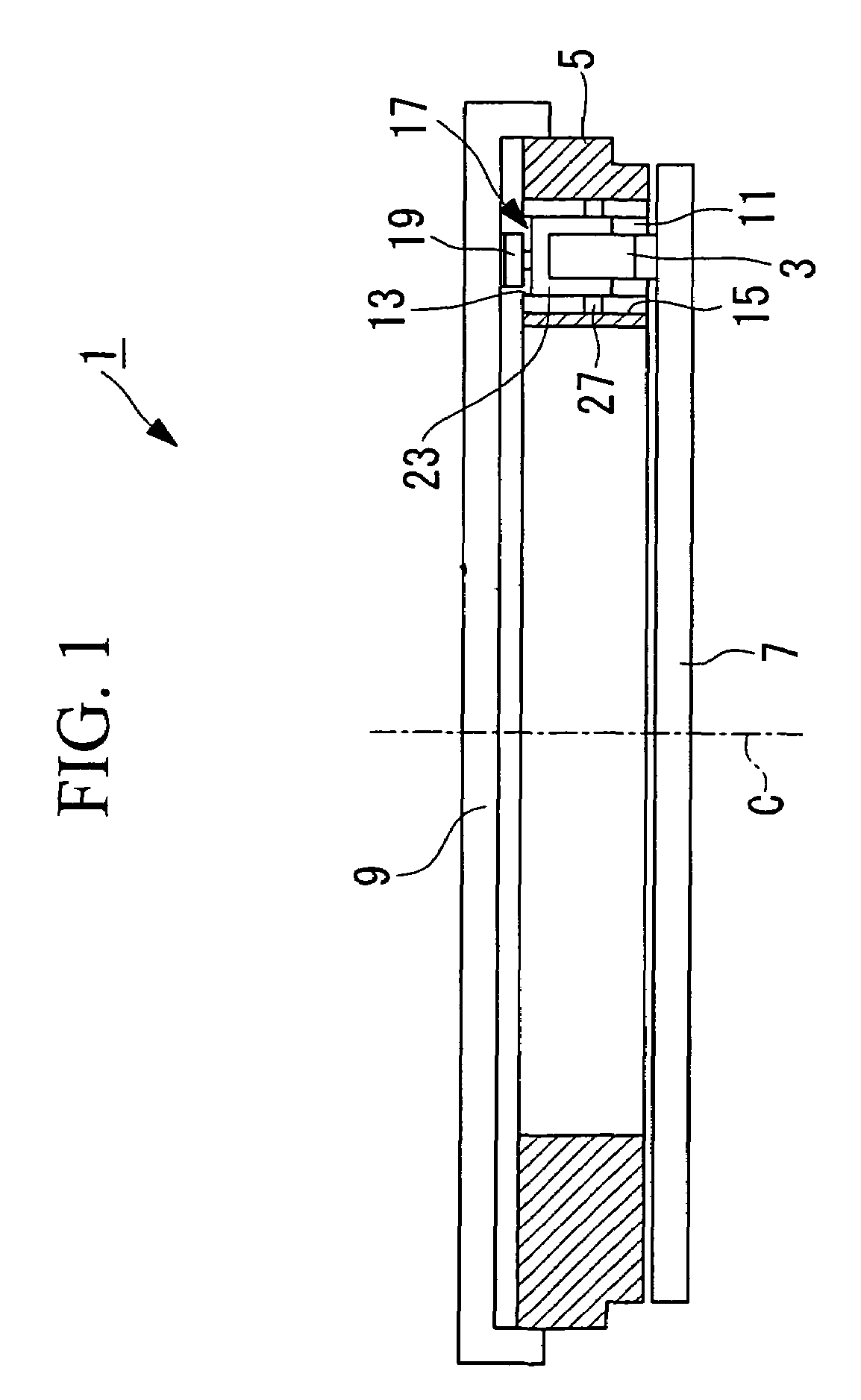

Machine tool

InactiveUS6220799B1Compact structureInhibit bad effectsPlaning/slotting machinesMilling machinesEngineeringMachine tool

A machine tool of small scale, light weight, and low cost, yet accomplishing a high degree of precision in machining. A spindle (2) is encased in a body frame (1) and disposed preferably in such a manner that the spindle (2) is movable along an axial center thereof or Z-axis direction by means of a Z-axis moving means (4). Either Y-axis table (5) or an X-axis table (6), at least being capable of moving along X-axis or Y-axis direction, or both is provided at one end of the spindle (2) on one side of the body frame (1) and arranged to be vertical with respect to the axial center of the spindle (2).

Owner:PANASONIC CORP

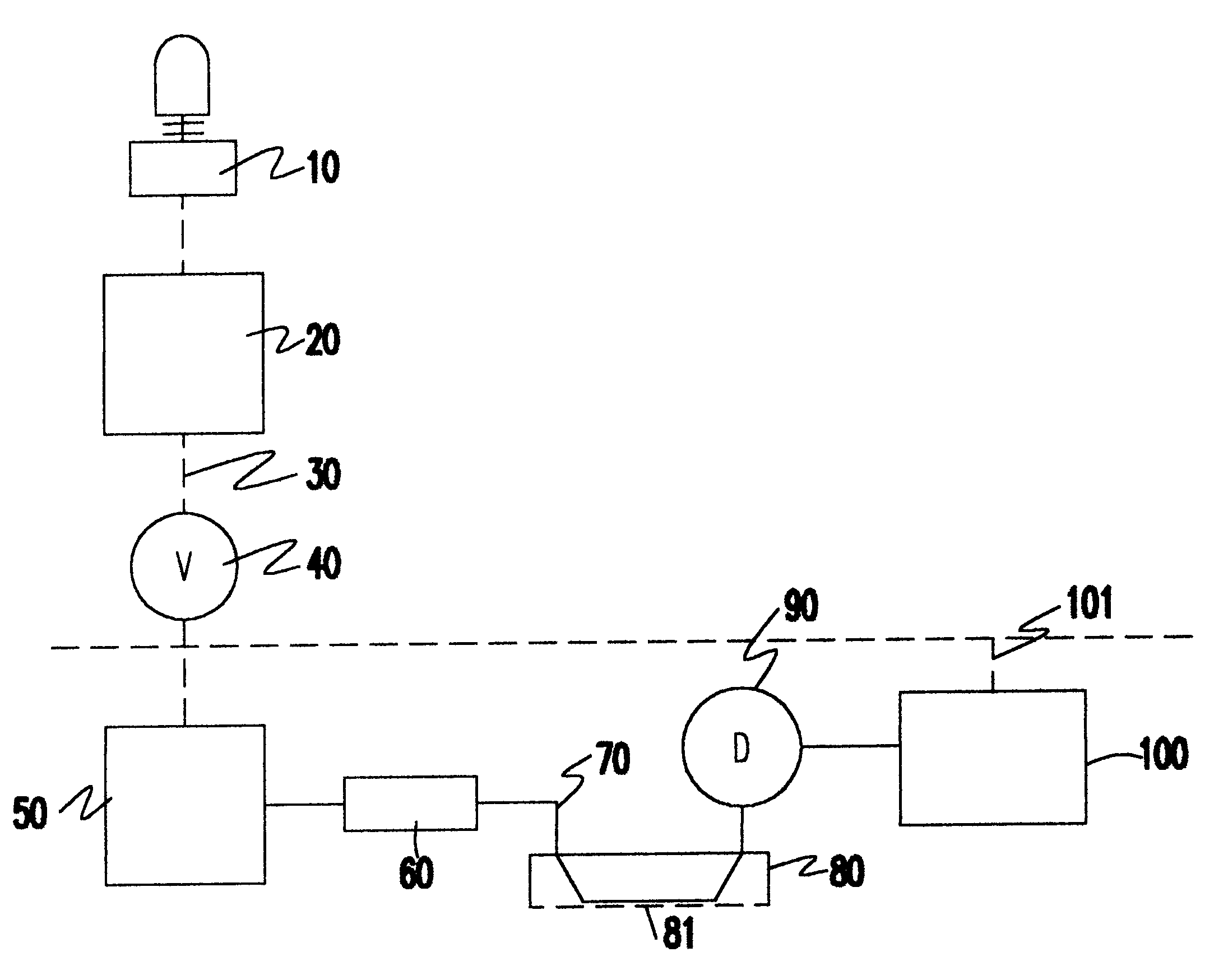

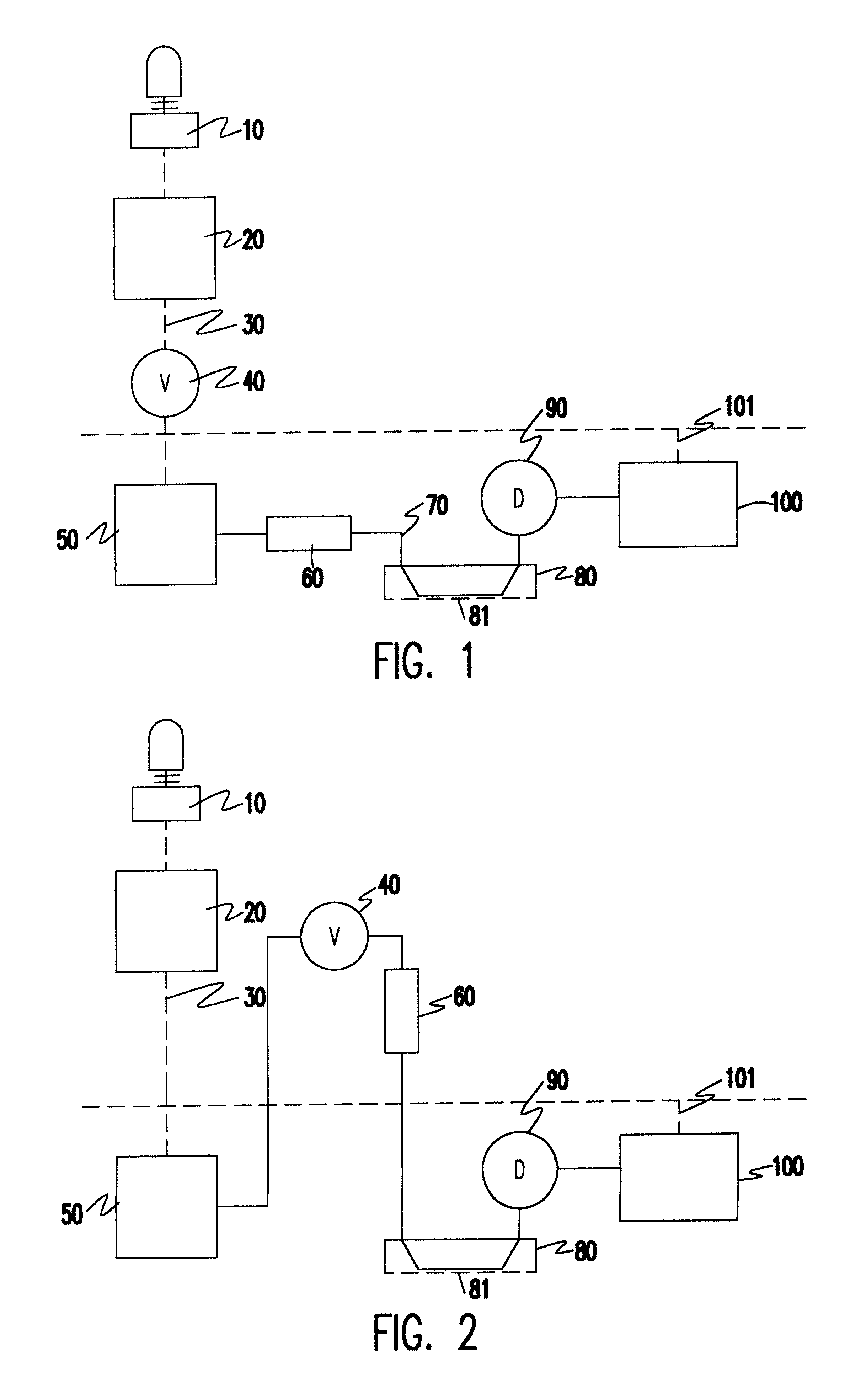

Certification and verification management system and method for a web inspection apparatus

InactiveUS20010030749A1Simple sharing and exportInvestigating moving sheetsCharacter and pattern recognitionMachine visionVisual perception

A certification system and method for inspecting of a roll of web material through a web inspection system which includes the inspection of the roll of web material to determine the number, type and location of one or more detectable flaws along the web material. This data "object" representation of the roll map is recorded, and then compared to predetermined product set-up parameters and machine vision hardware integrity data to determine the accuracy of the web inspection. The generated "certification" assures with a substantial degree of precision that the machine vision hardware is calibrated and operating correctly, and that the correct system setup parameters for the particular web product being inspected are being applied.

Owner:WEBVIEW

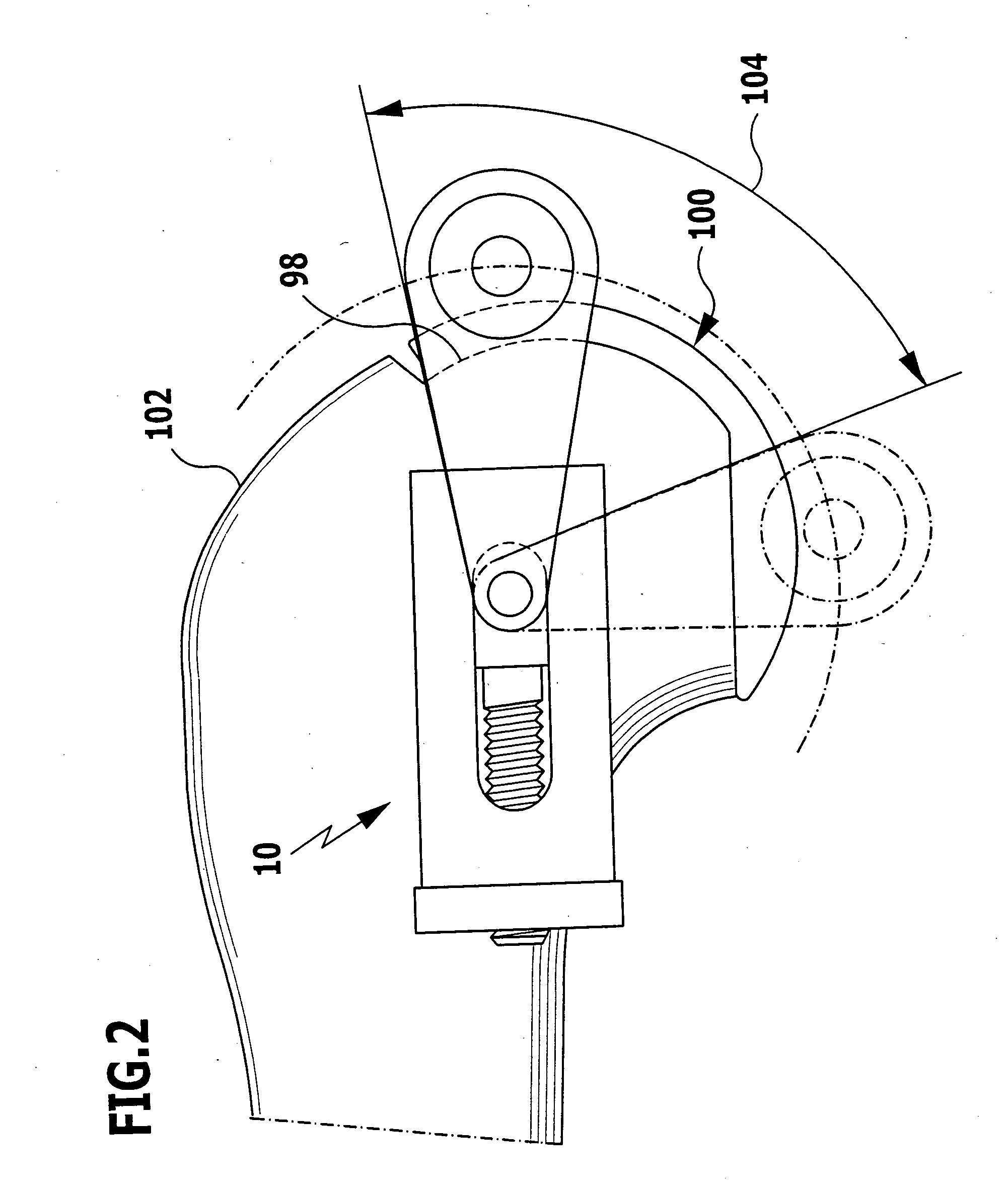

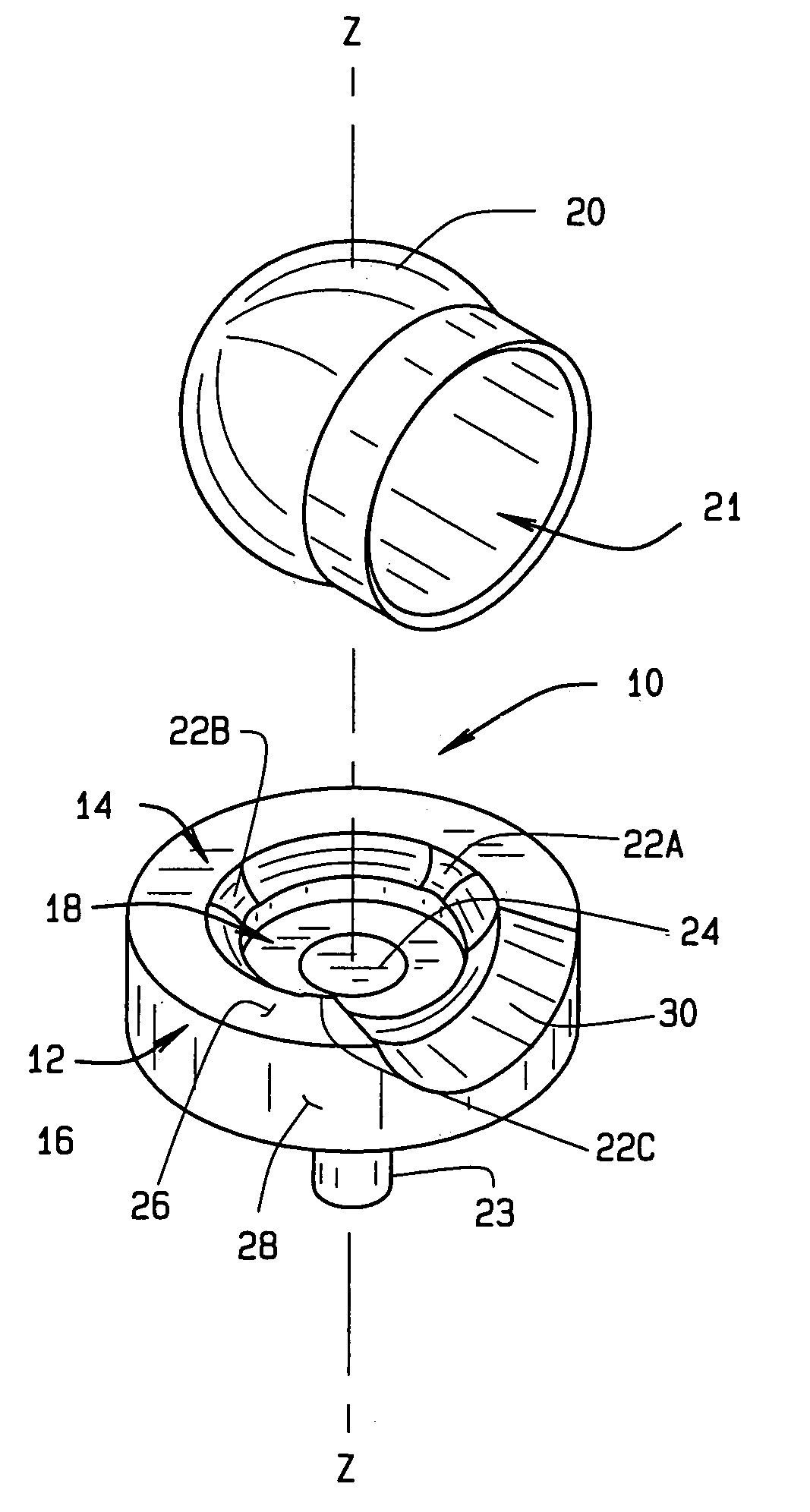

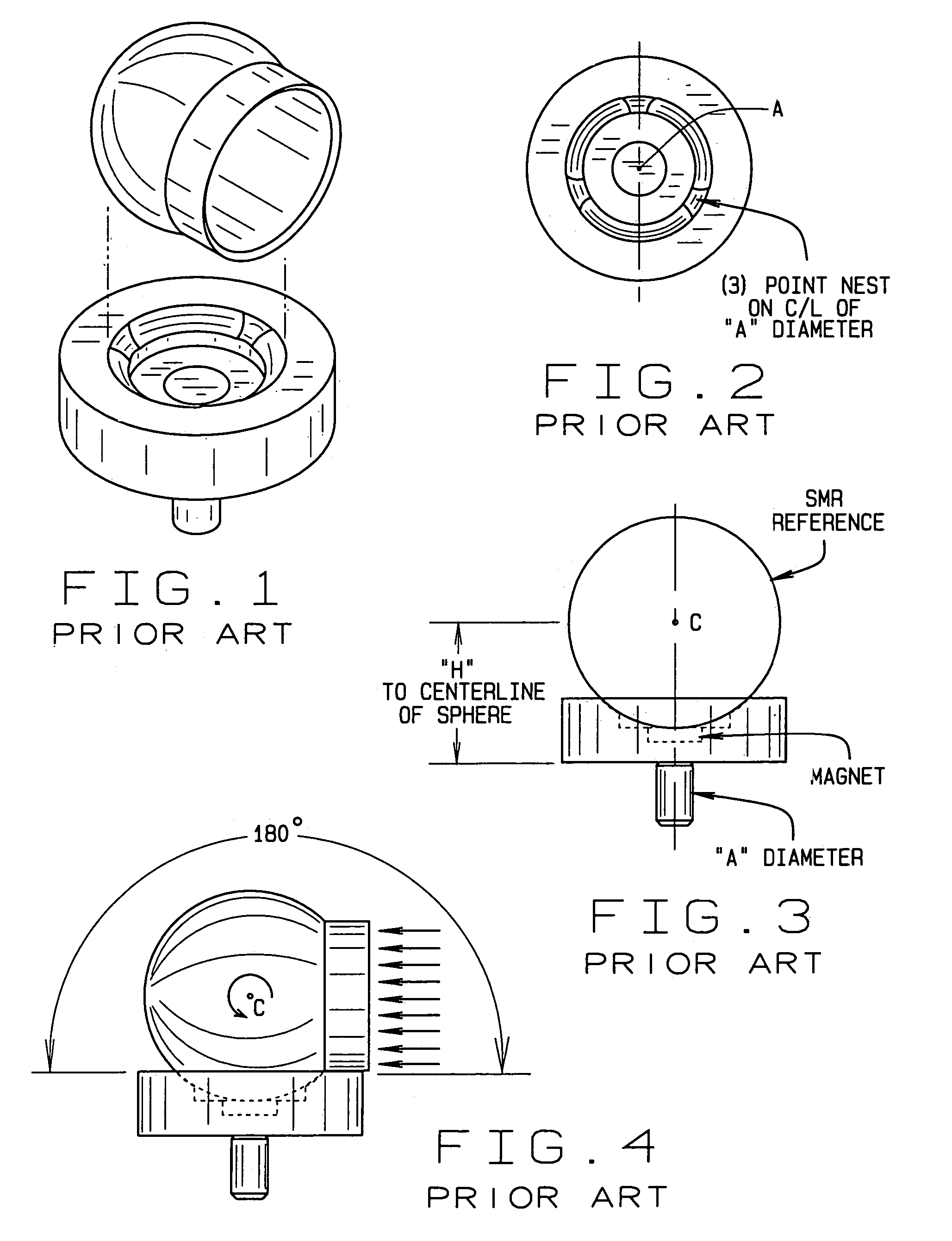

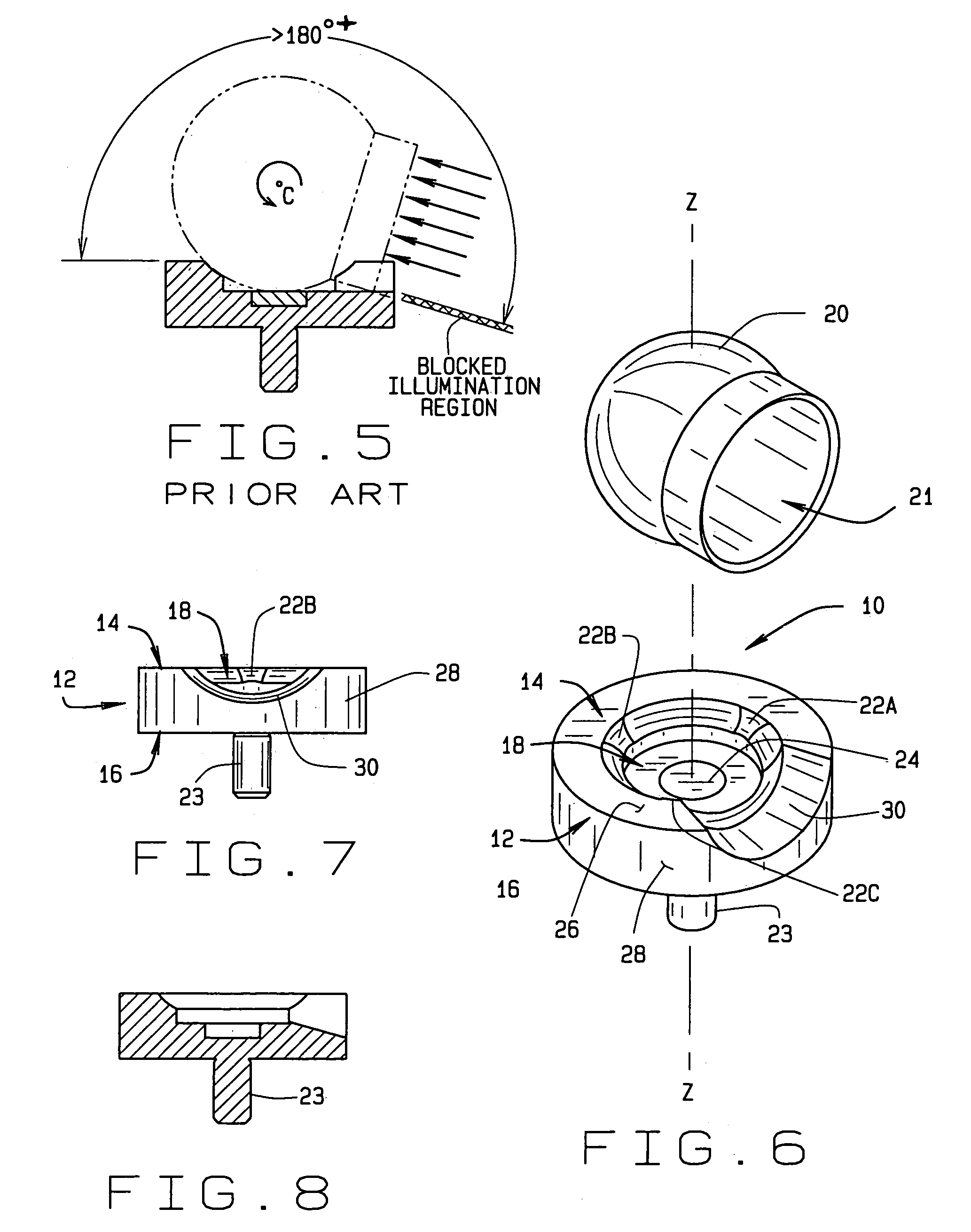

Spherical retro-reflector mount negative

A sphere mount for a ball mounted retro-reflector having a perimeter recess and a base shank. The sphere mount is configured to receive a ball mounted retro-reflector in a centrally disposed conical nest, such as a three-point conical nest, and to position it with a high degree of precision over the central axis of the base shank to within ±0.0005 of an inch. The perimeter recess is in the form of a single oblique scallop, orientated from the upper surface to the lower surface, and permits a maximum negative acceptance angle for incident light to a mounted spherical retro-reflector with no occlusion by the sphere mount perimeter.

Owner:HUBBS MACHINE & MFG

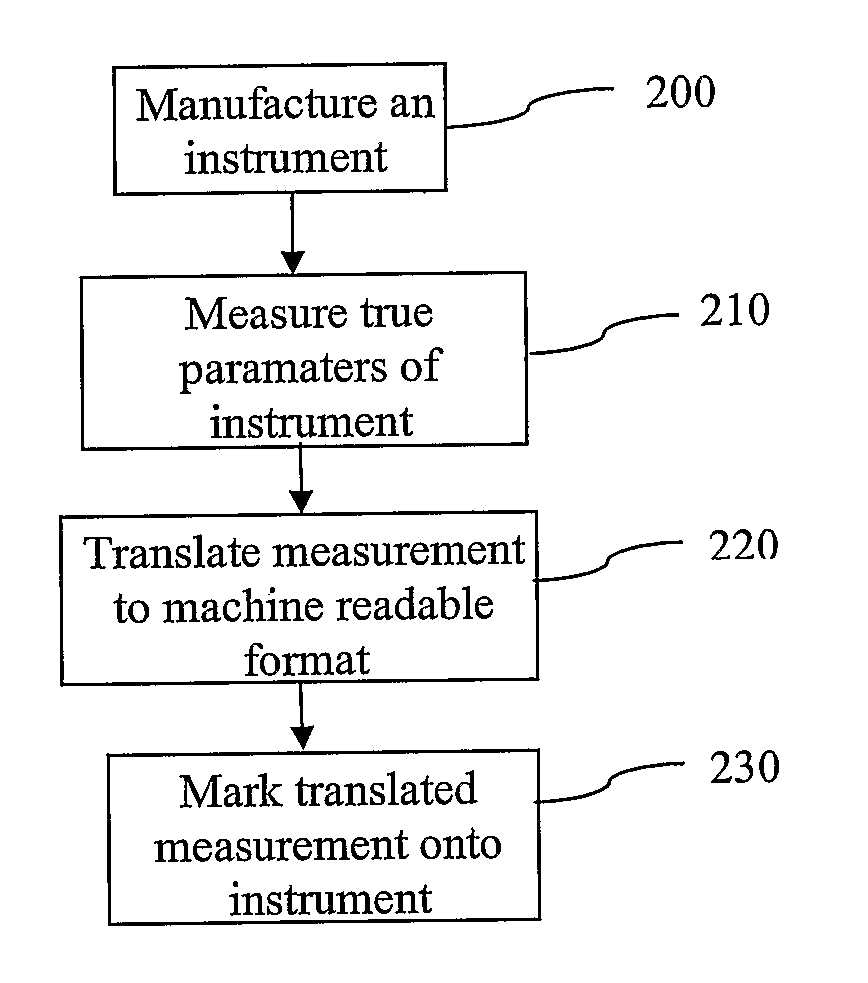

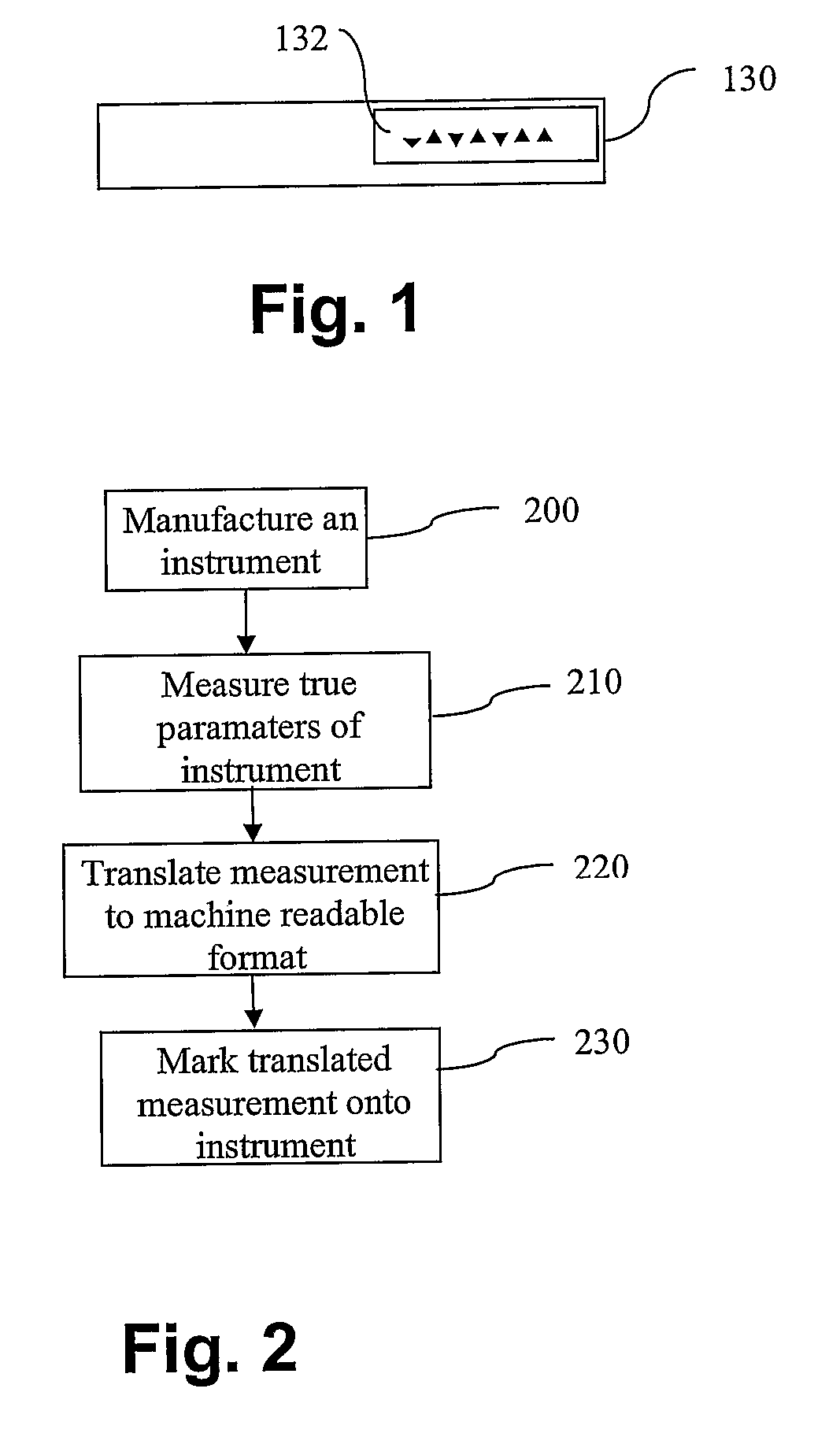

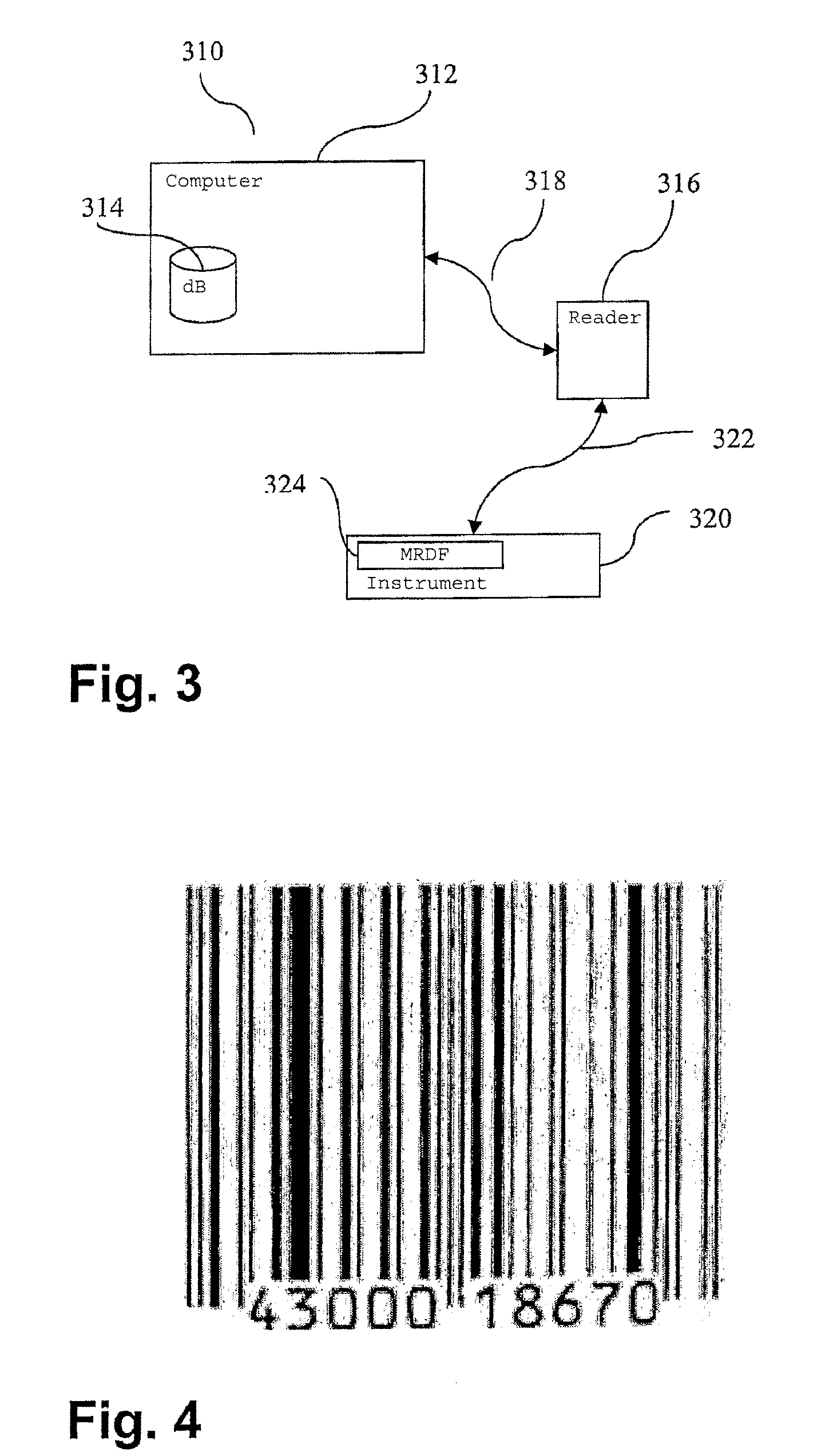

Method for permanent calibration based on actual measurement

ActiveUS7634374B2Character and pattern recognitionDiagnostic recording/measuringComputer-assisted surgeryBiomedical engineering

There is described a method of manufacturing a device to be used with a computer-aided surgery system, a method of calibrating the device, and the device itself. After fabrication, the device is measured to obtain true parameters thereof. The true parameters are stored on a storage medium associated with the device and include measurement data of high precision relating to dimensions of the device as well as to relative positioning of a tracker on the device with respect to the device. The true parameters are entered into the system and when the tracker is located in the 3D environment, the device can then be located in the 3D environment with a high degree of precision using the true parameters.

Owner:ORTHOSOFT ULC

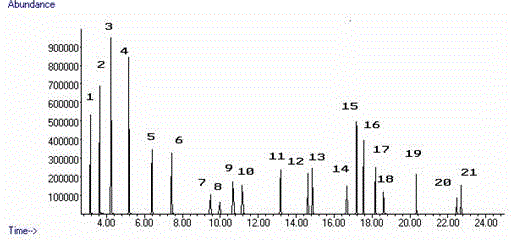

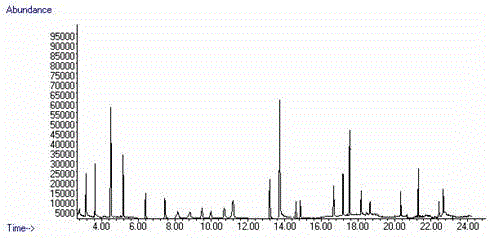

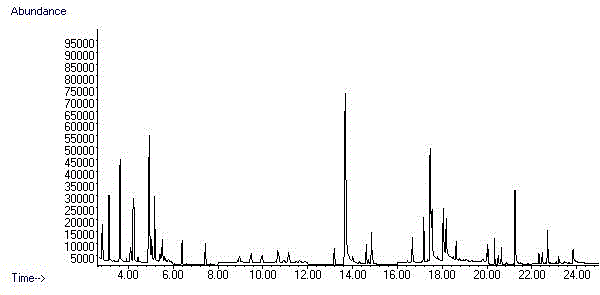

Detection method for residual quantity of multiple preservatives in cosmetics

InactiveCN103063764AAchieving Simultaneous DetectionGood linear relationshipComponent separationGas phaseMass spectrography

The invention relates to the field of analytical chemistry and food safety, in particular to a detection method for residual quantity of multiple preservatives in cosmetics. According to a gas chromatography-mass-spectrography detection method which can detect the residual quantity of multiple preservatives in cosmetics simultaneously, sample extraction and purification are respectively processed according to differences of sample shapes and properties, and then a gas chromatography-mass spectrometer is adopted to carry out qualitative determination and quantitative assay. The detection method achieves simultaneous detection of 21 preservatives, and has the advantages of being simple and convenient, fast, sensitive, and the like. The detection minimum, the recovery rate and the degree of precision of the method all meet relevant demands for preservative detection in the cosmetics at home and abroad, so the method is suitable for detection and monitoring of the preservatives in the cosmetics.

Owner:林维宣

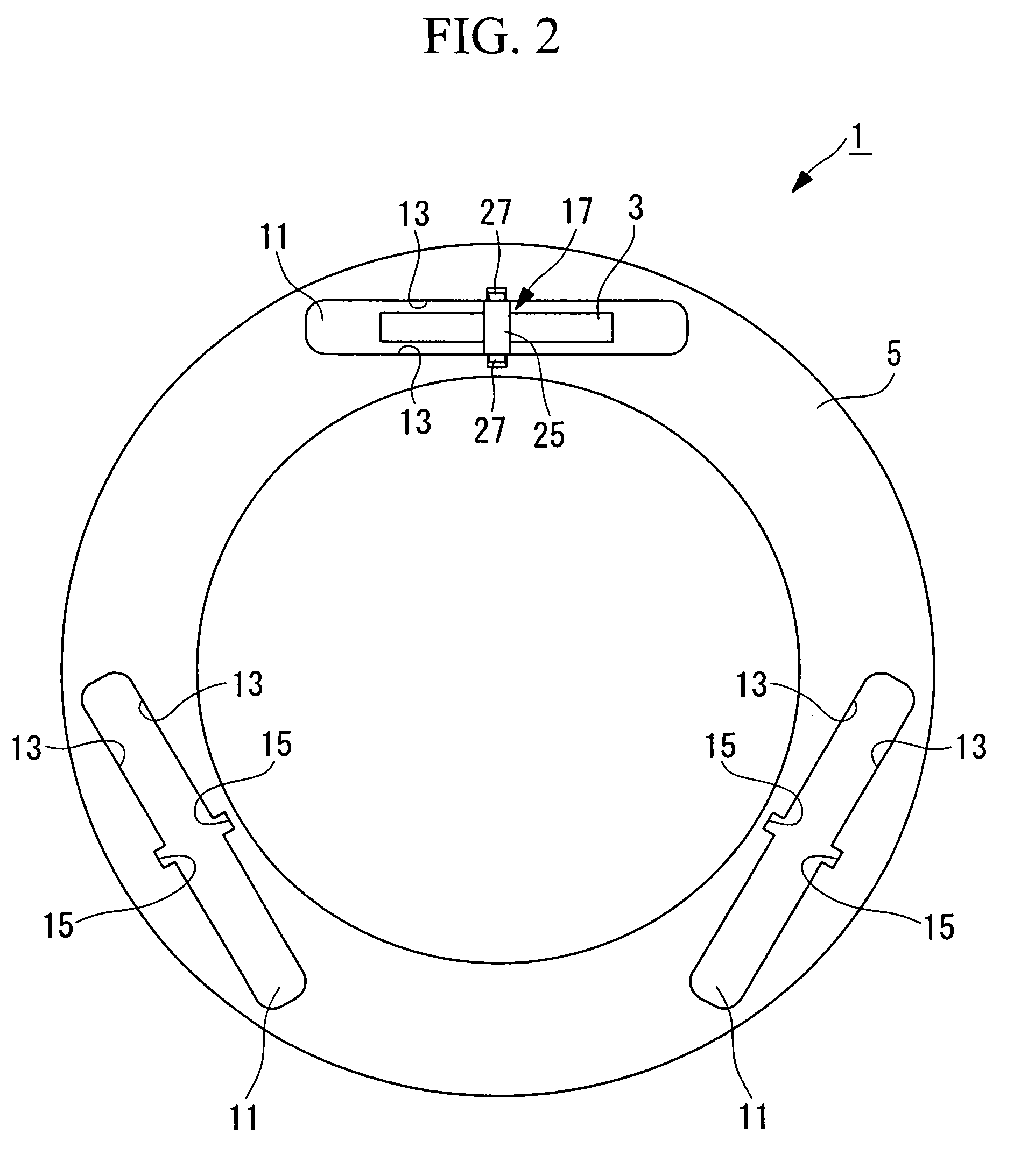

Ultrasonic driving apparatus

InactiveUS7432633B2High positioning accuracyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesEngineeringMechanical engineering

The invention provides an ultrasonic driving apparatus in which an oscillator contained therein is pressed against a driven member and can be positioned with a high degree of precision. The invention includes an oscillator for generating vibrations when supplied with electrical power; a holding member fixed to the oscillator; an urging member for urging the oscillator in a predetermined direction; and a support member for supporting the holding member so as to be capable of moving in the predetermined direction, wherein positioning portions for setting, with a certain degree of precision, the position of the oscillator which is projected onto a plane substantially orthogonal to the predetermined direction are provided in the holding member and the support member.

Owner:OLYMPUS CORP

Robot motion path planning method

The invention provides a robot motion path planning method. The robot comprises a host, a mechanical arm, a microcontroller and a camera, wherein the host is connected with the microcontroller, and the microcontroller is connected with a steering gear on the mechanical arm and is used for controlling the motion of the mechanical arm; the host is connected with the camera. A RGBD (Red Green Blue Depth) camera of the robot can shoot information in the captured range to realize the follow-up of the human body and the human arm; the degree of freedom and the degree of precision of the mechanical arm of the robot in the motion planning process can be improved, and are fused on time, space and data to improve the system adaptability and environmental space recognition ability, so that the robot moves in accordance with a correct planning trajectory, and thus the path planning of the mechanical arm of the robot can be realized at high degree of freedom, the work efficiency is high, and the computation amount is small.

Owner:湖南晖龙集团股份有限公司

Process and measuring system for detection of substances emitted or perspired through the skin

InactiveUS6183418B1Minimize impactInexpensive productionTesting beveragesPreparing sample for investigationDiffusionQuantitative determination

The process for detection and for quantitative determination of substances emitted or perspired through the skin is derived from flow diffusion analysis. The measuring system conceived for this purpose uses a diffusion half cell through which an acceptor medium flows and which is closed by a membrane. For the duration of the measurement, the membrane is brought into contact with the skin or a closed gas volume formed over the skin. With the process and the related measuring system, the blood alcohol level can be determined with a good degree of precision indirectly via the quantity of (gaseous) ethanol emitted through the skin.

Owner:MOLLER MEDICAL +2

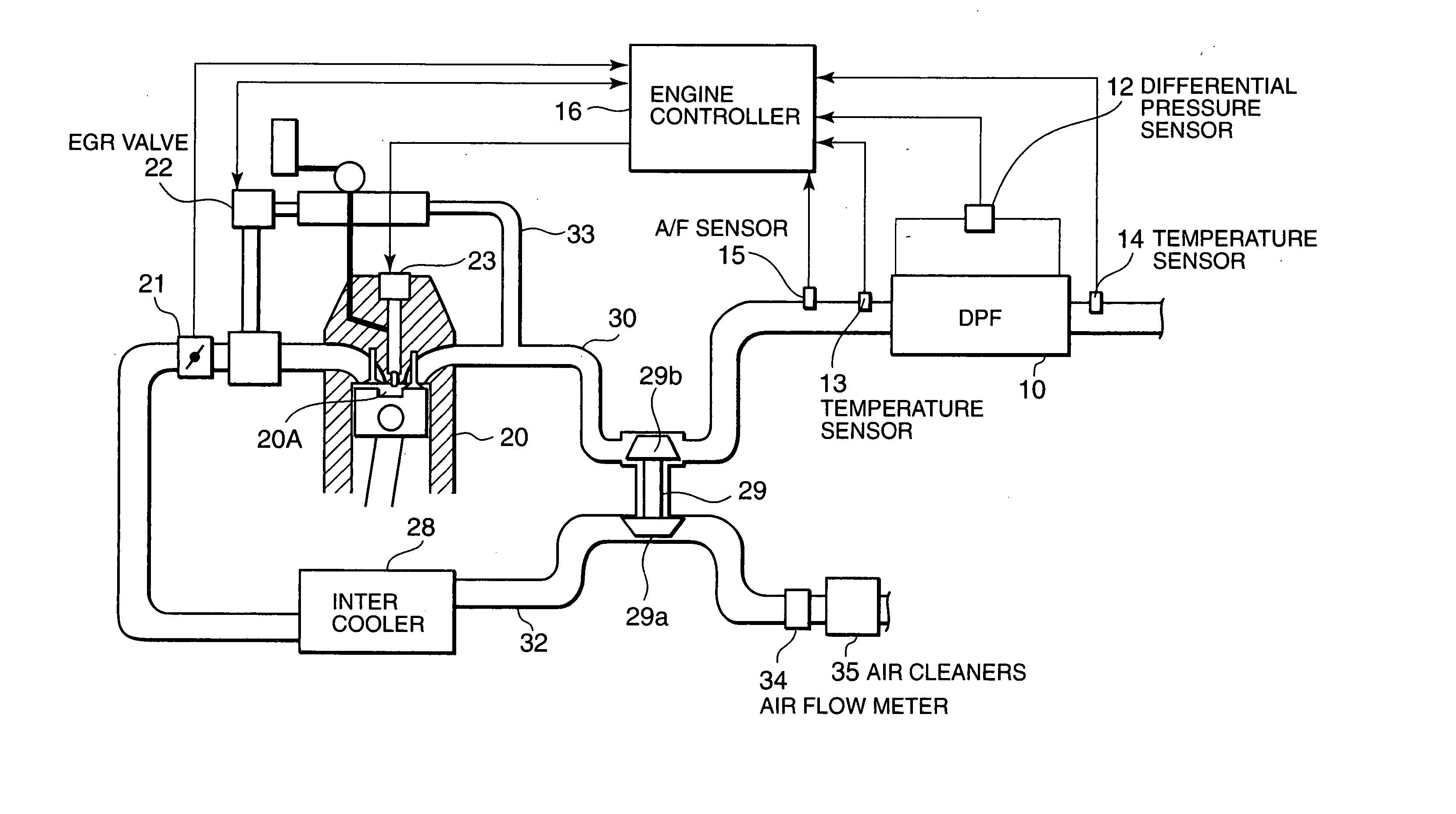

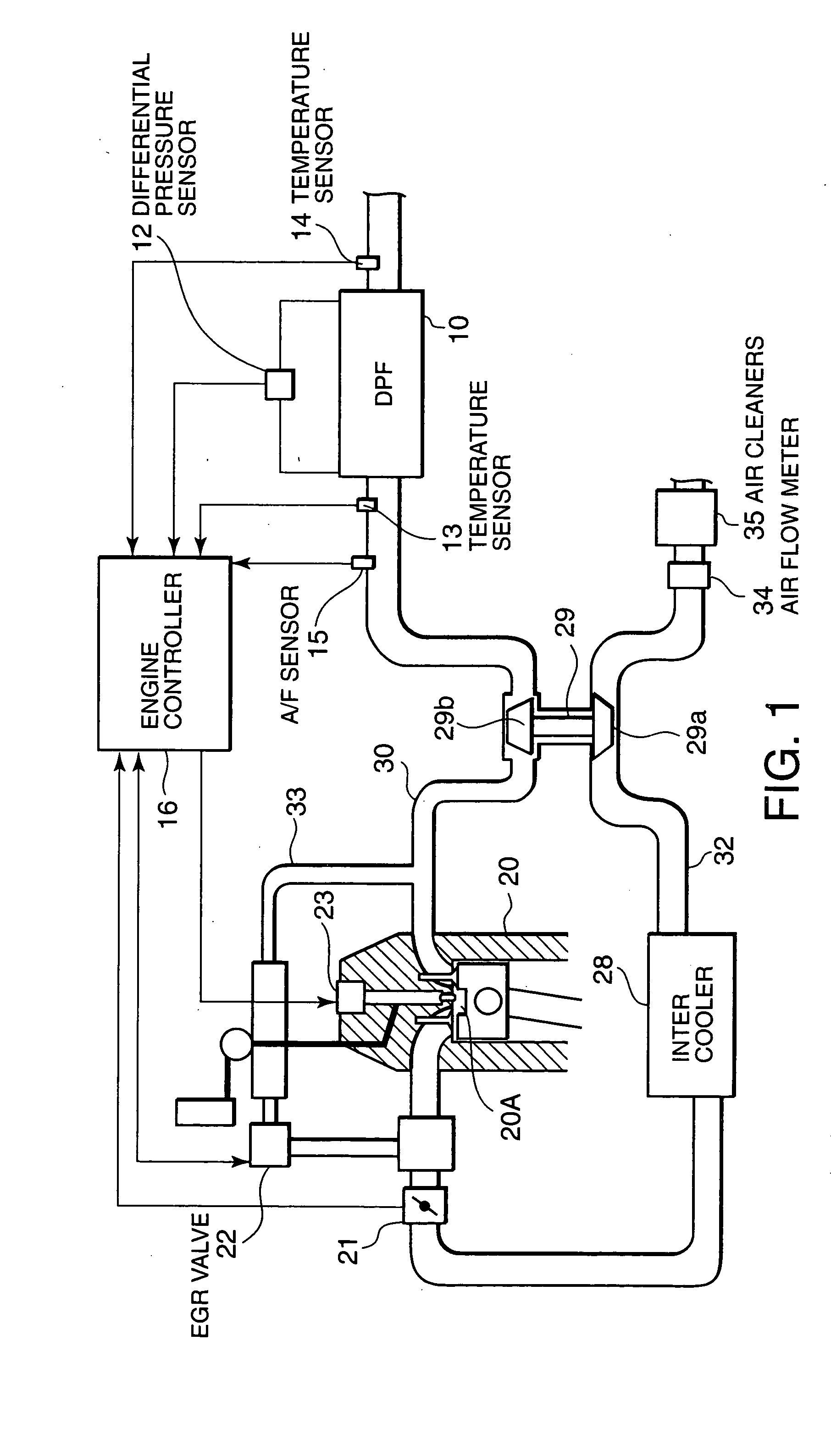

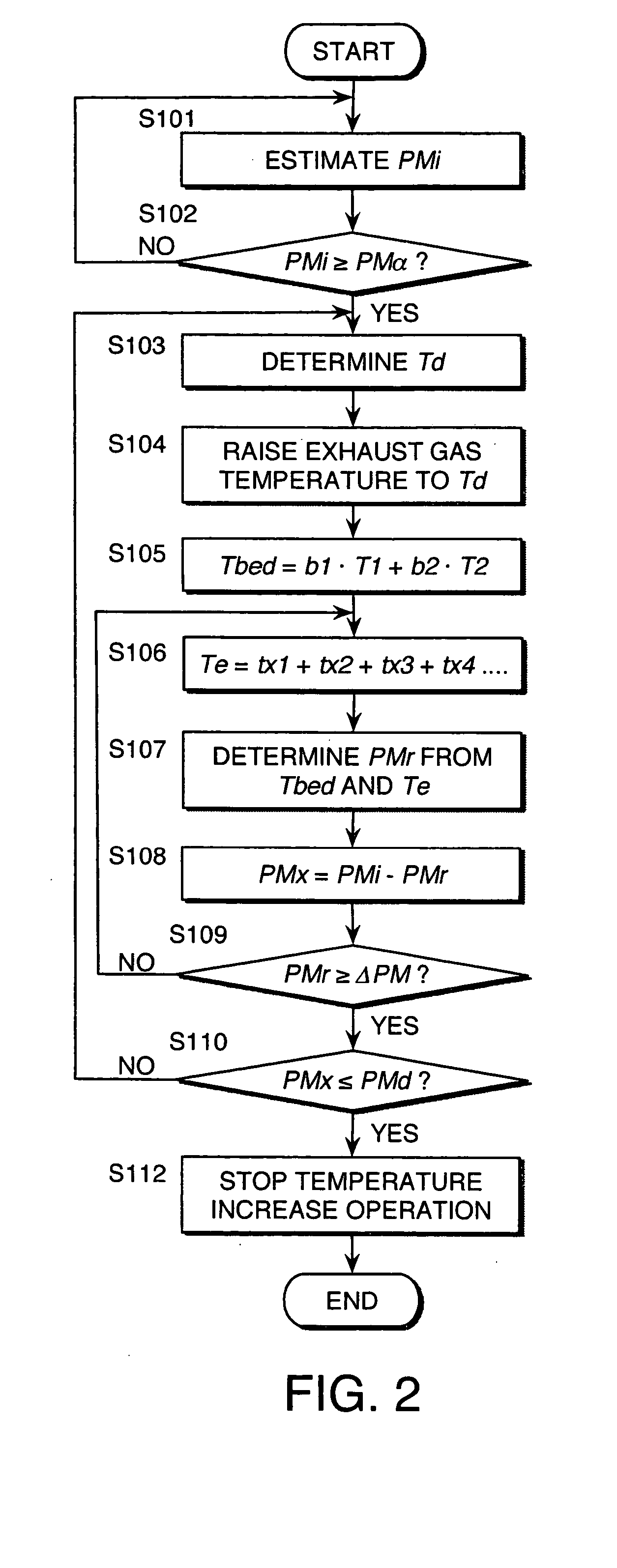

Regeneration control of diesel particulate filter

InactiveUS20050056009A1Does not consume energyHigh precisionElectrical controlInternal combustion piston enginesDiesel particulate filterFuel injection

To regenerate a diesel particulate filter (10) which traps particulate matter contained in the exhaust gas of a diesel engine (20), a controller (16) raises the temperature of the exhaust gas through fuel injection control of a fuel injector (23), and thus burns the particulate matter trapped in the filter (10). The controller (16) cumulatively calculates the time during which the temperature of the filter (10) exceeds a target temperature as an effective regeneration time. By estimating the amount of particulate matter remaining in the filter (10) on the basis of the effective regeneration time, the controller (16) estimates the amount of remaining particulate matter with a high degree of precision and without consuming energy, whereupon regeneration of the filter (10) through fuel injection control ends.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com