Patents

Literature

59 results about "Veneer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In dentistry, a veneer is a layer of material placed over a tooth, veneers improve the aesthetics of a smile and/or protect the tooth's surface from damage. There are two main types of material used to fabricate a veneer: composite and dental porcelain. A composite veneer may be directly placed (built-up in the mouth), or indirectly fabricated by a dental technician in a dental lab, and later bonded to the tooth, typically using a resin cement. Usually used for treatment of adolescent patients who will require a more permanent design once they are fully grown. The lifespan of a composite veneer is approximately 4 years. In contrast, a porcelain veneer may only be indirectly fabricated. A full veneer crown is described as "a restoration that covers all the coronal tooth surfaces (Mesial, Distal, Facial, Lingual and Occlusal)". Laminate veneer, on the other hand, is a thin layer that covers only the surface of the tooth and generally used for aesthetic purposes. These typically have better performance and aesthetics and are less plaque retentive.

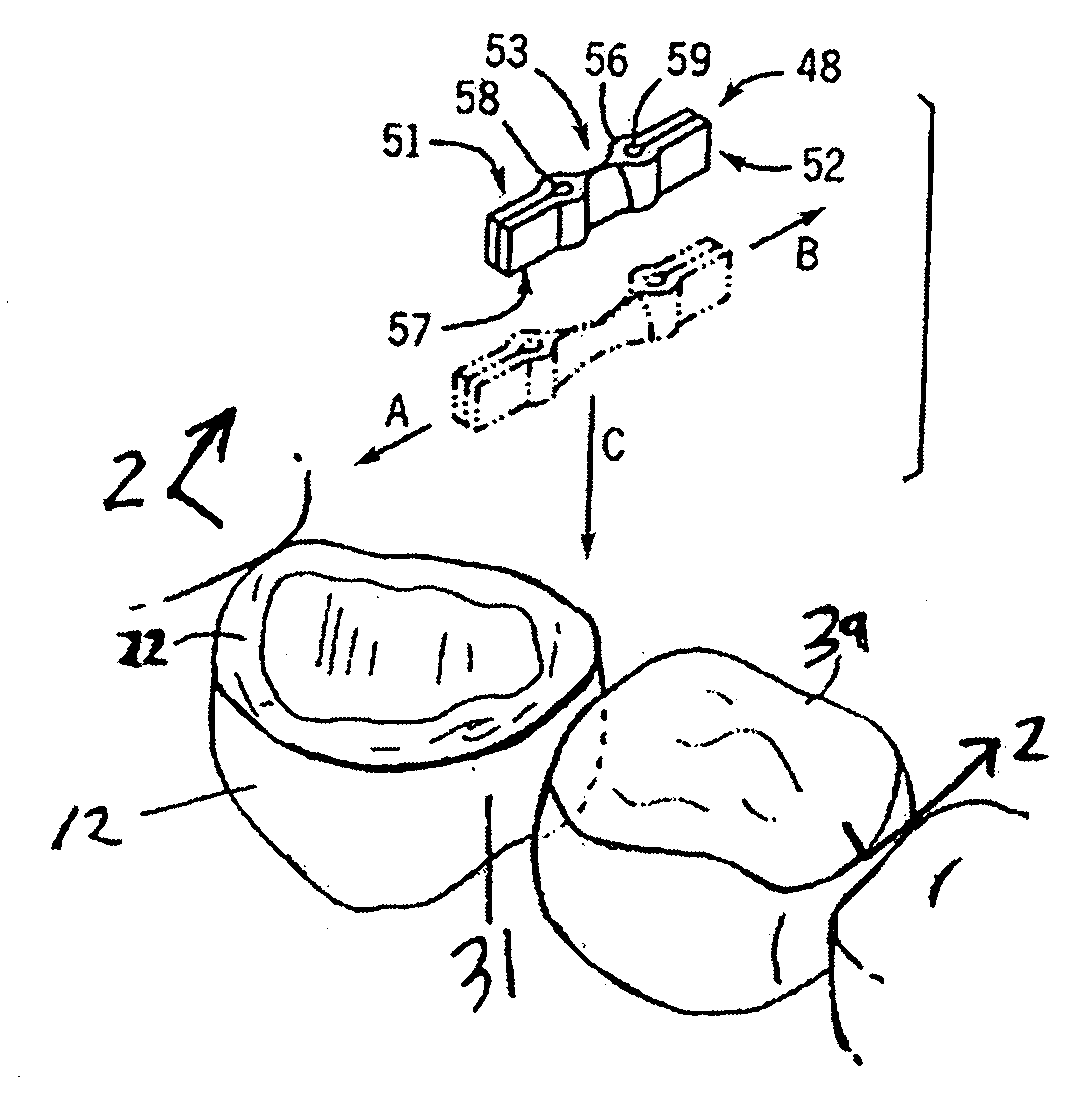

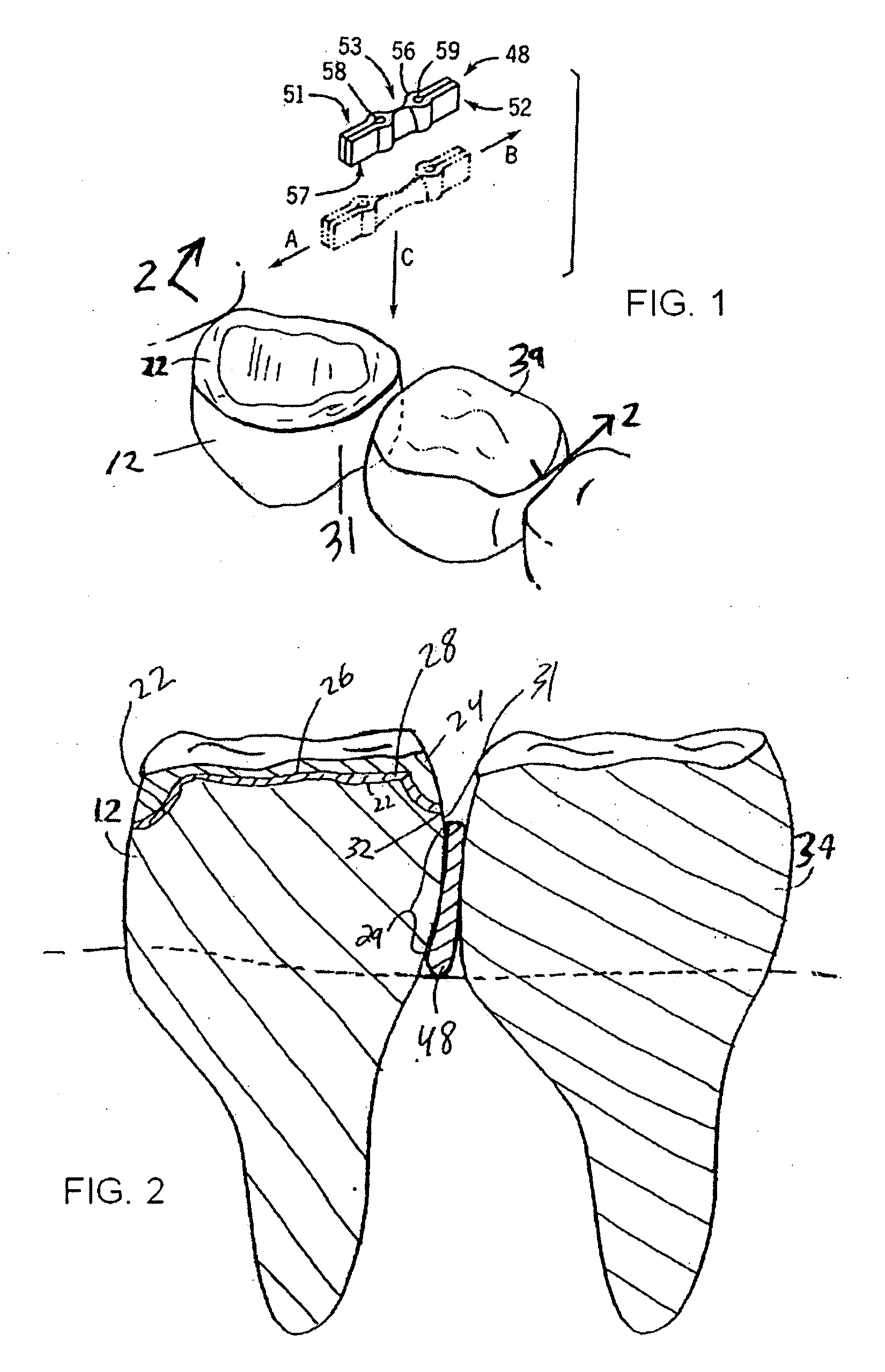

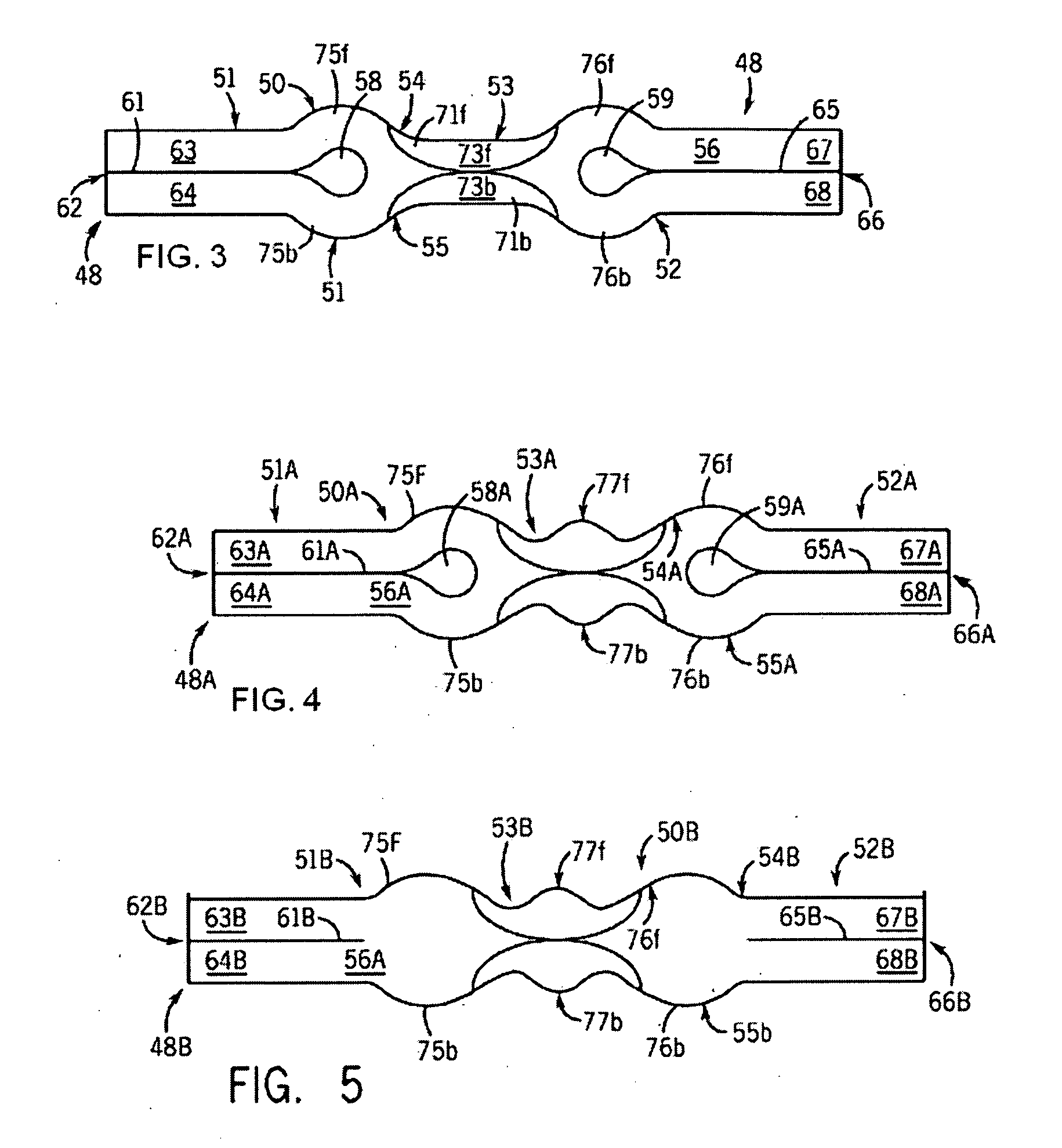

Methods and Devices for Fixed Dental Restoration

This invention relates to methods and devices for restoring teeth using fixed restorations. In particular, the invention provides a system, kit, and devices for the management of interproximal areas for traditional cementation and / or bonding of dental crowns, onlays, inlays, veneers and bridges. In the method, a barrier is positioned in contact with the tooth being restored and an adjacent tooth to cover a section of the tooth being restored and to create separation of the tooth being restored and the adjacent tooth. Cement is applied to the first mating surface of the fixed restoration and / or to the second mating surface of the tooth, and the first mating surface of the fixed restoration and the second mating surface of the tooth are positioned adjacent each other to seat the fixed restoration on the tooth. The barrier covers a section of the tooth being restored to prevent cement from bonding to the section of the tooth. This eliminates the need to remove hardened cement from this section of the tooth.

Owner:CLARK DAVID J

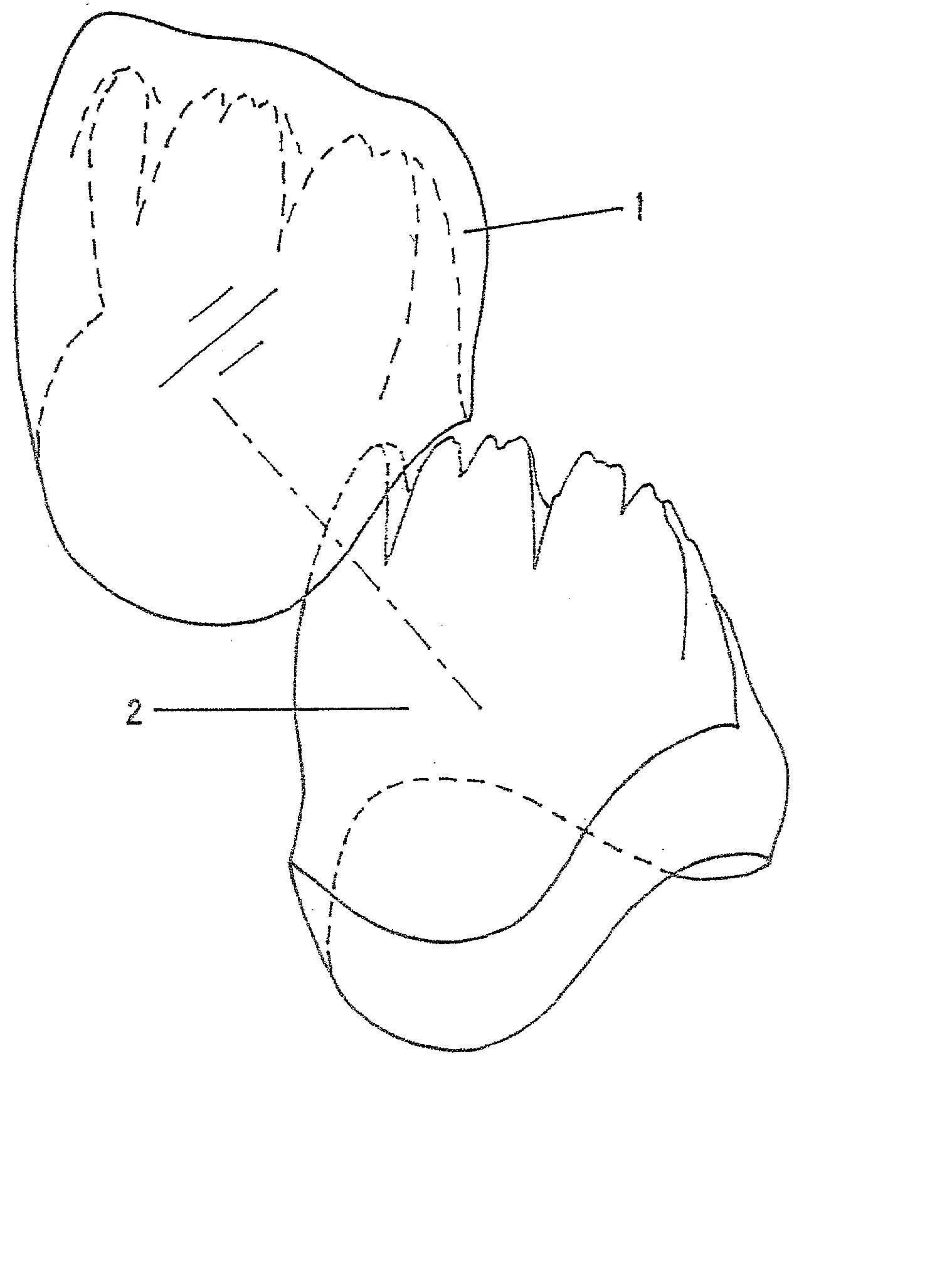

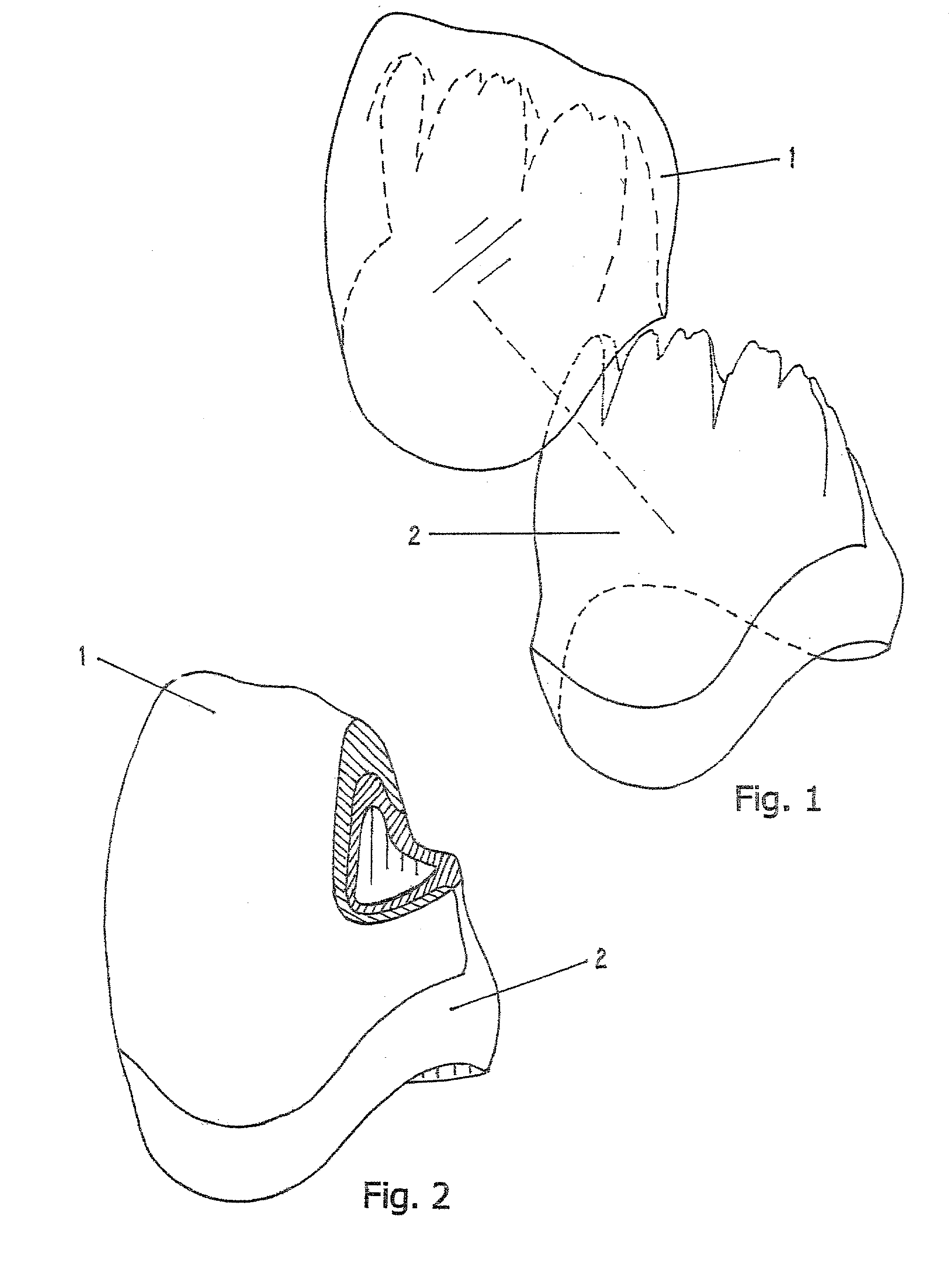

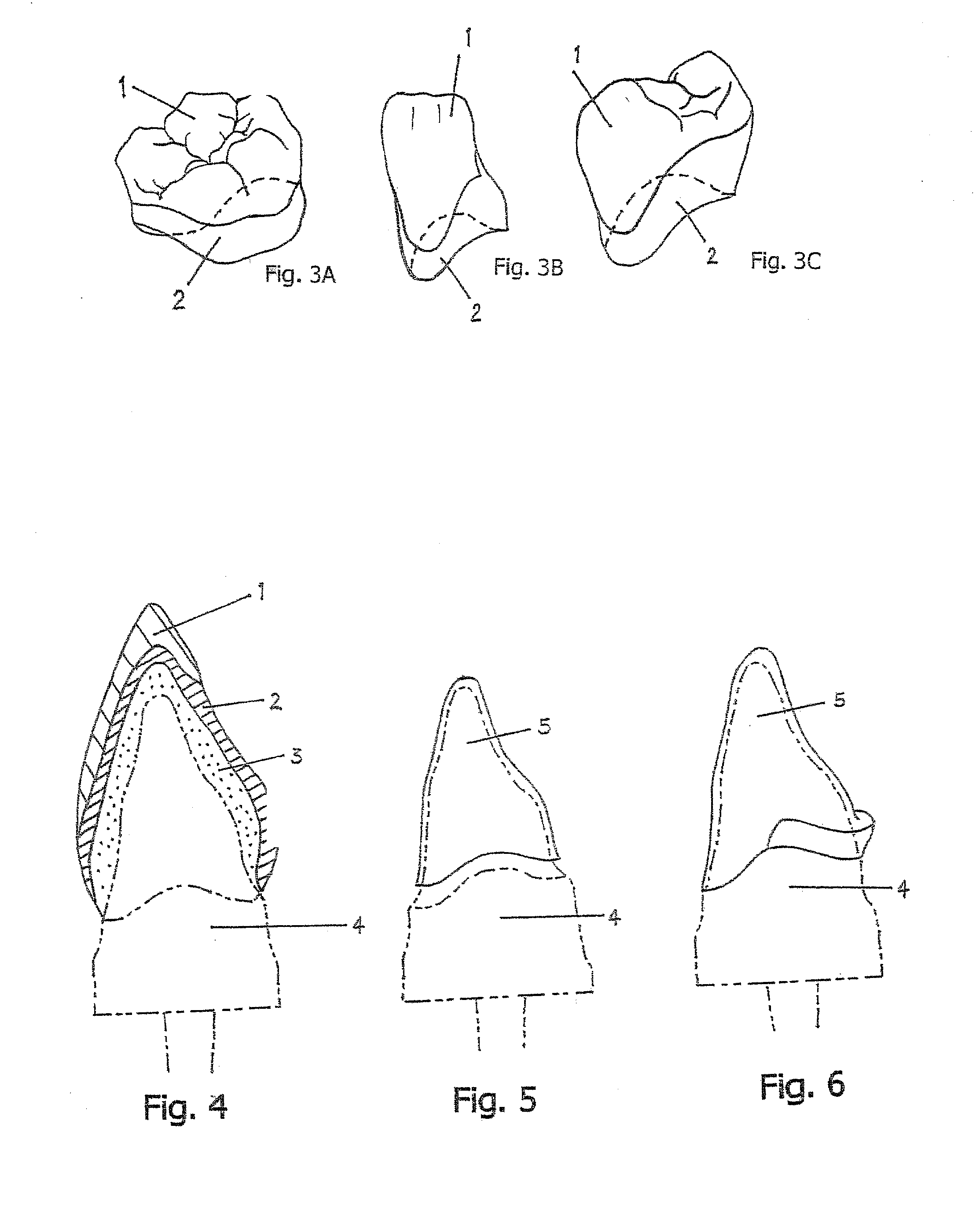

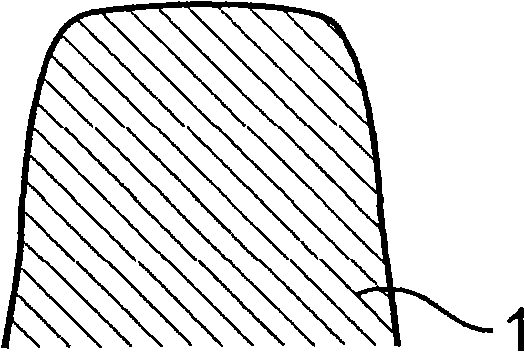

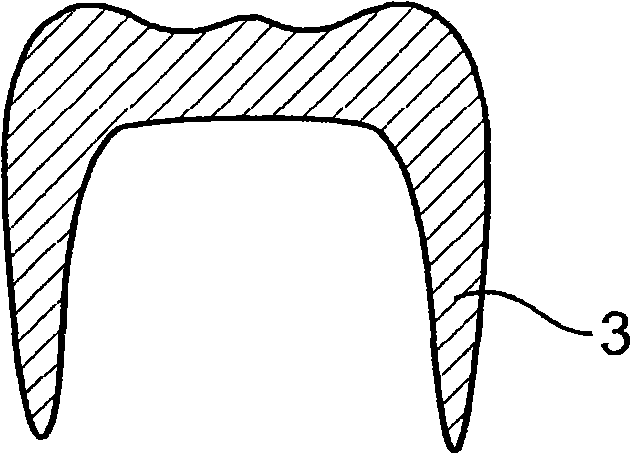

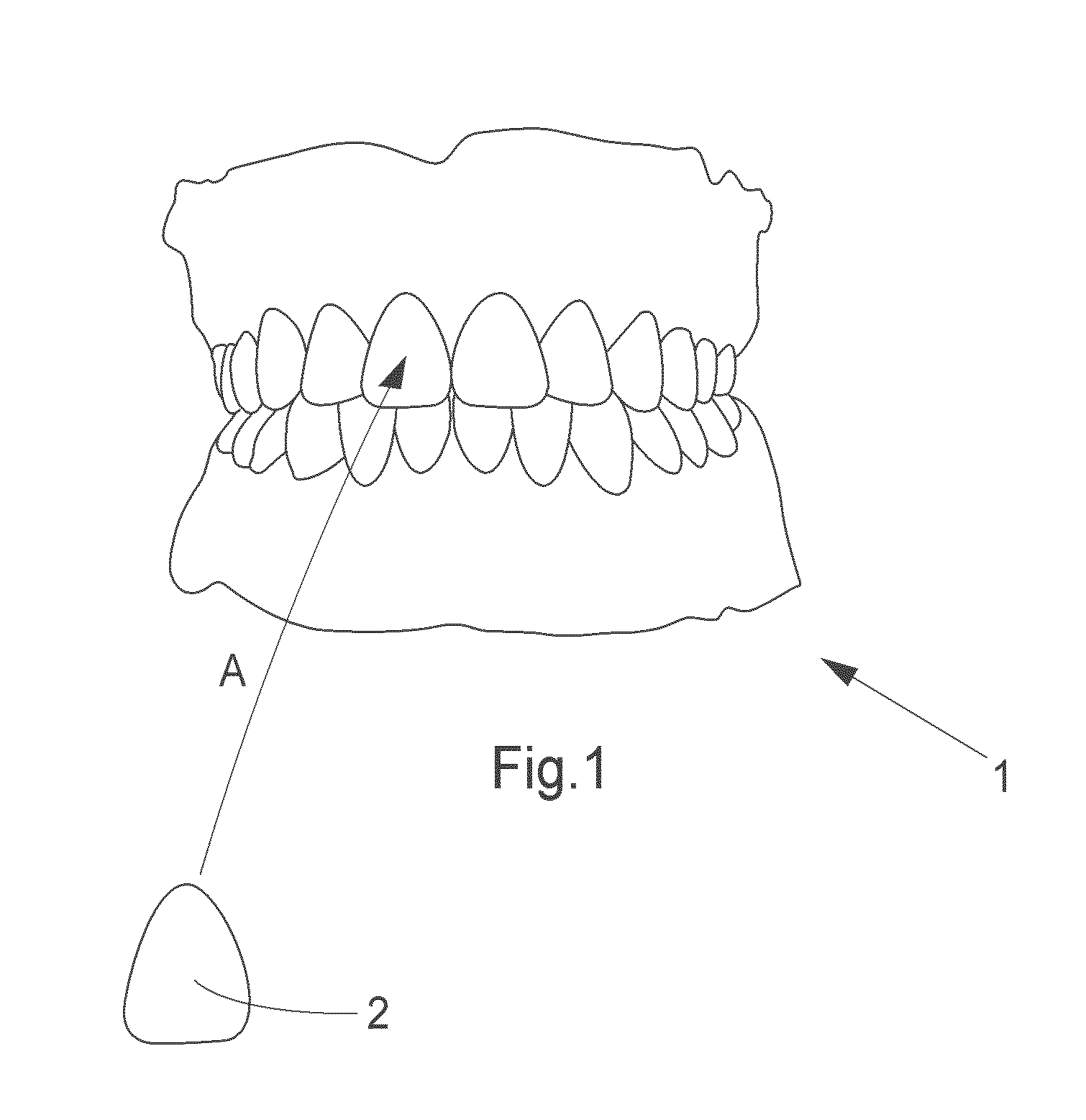

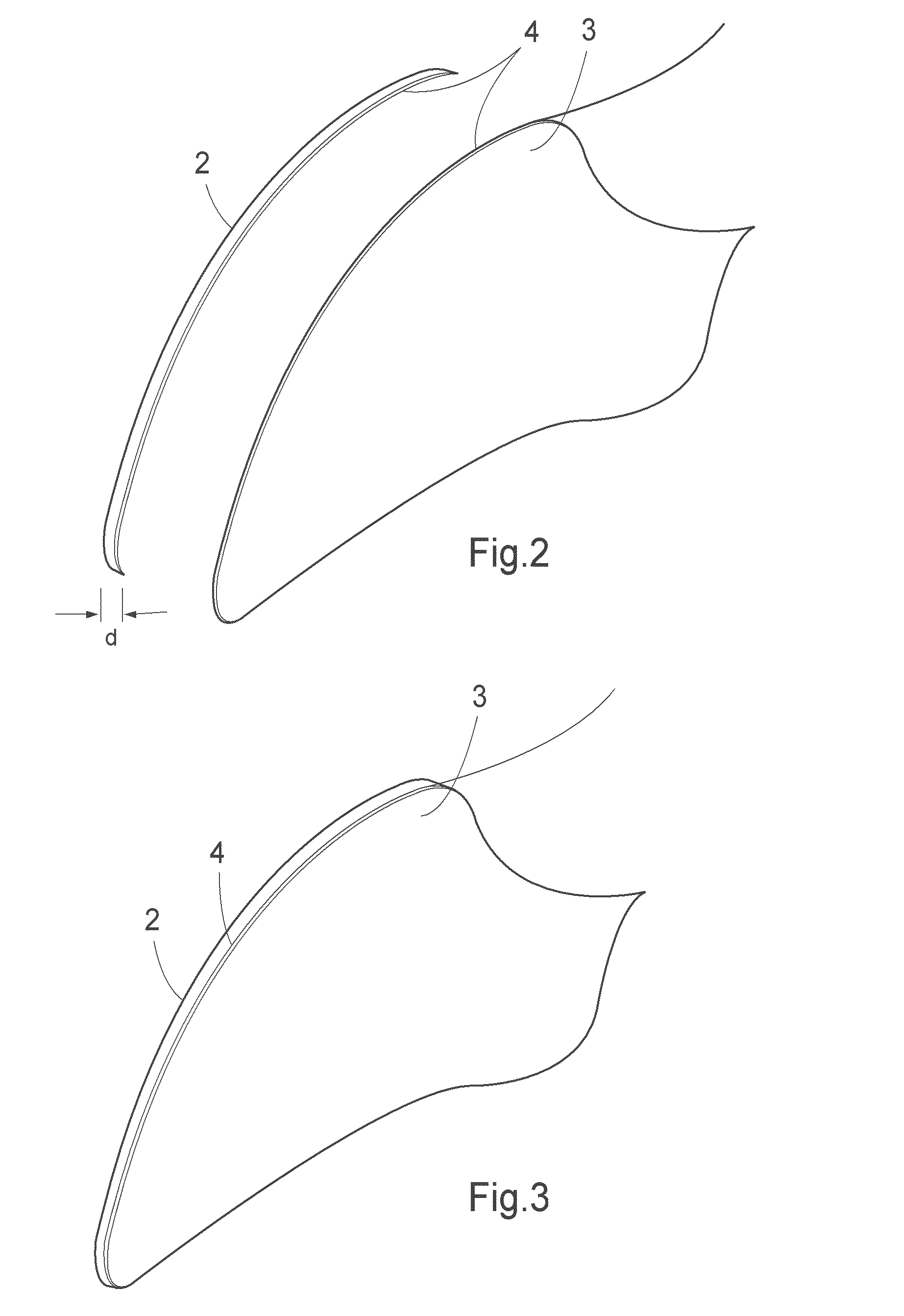

Back casting prefabricated incisal veneers

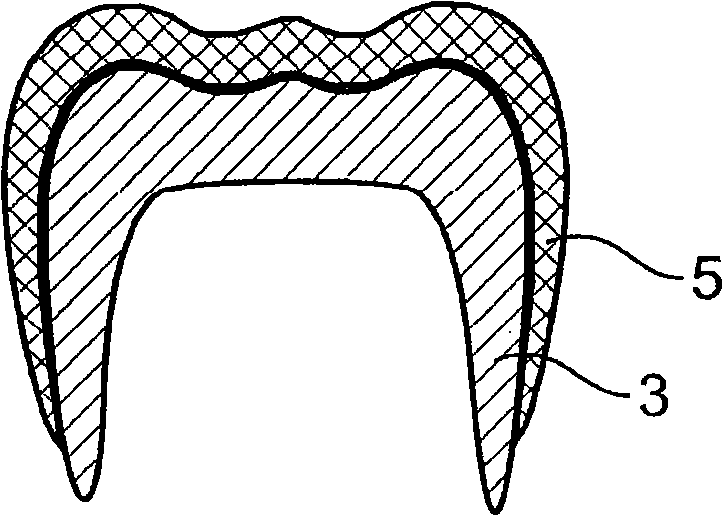

An improved lost wax method for fabricating dental devices, a prefabricated incisal veneer (1) is selected from among a group of said veneers having predetermined shapes, shades, and sizes. Wax is applied (2 and 3) to the incisal veneer to create a wax buildup onto a model (4) or prefabricated coping (5). Subsequently, a sprue is attached to the applied wax (2 and 3) and the wax buildup is removed from the model (4) for investing and burnout to create a lost wax mold. For a crown with a substructure, the incisal veneer (1) and the coping (5) are both cast in place with press ceramic, press thermoplastic material, or by injecting a curable resin, composite, or epoxy material into the lost wax mold.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

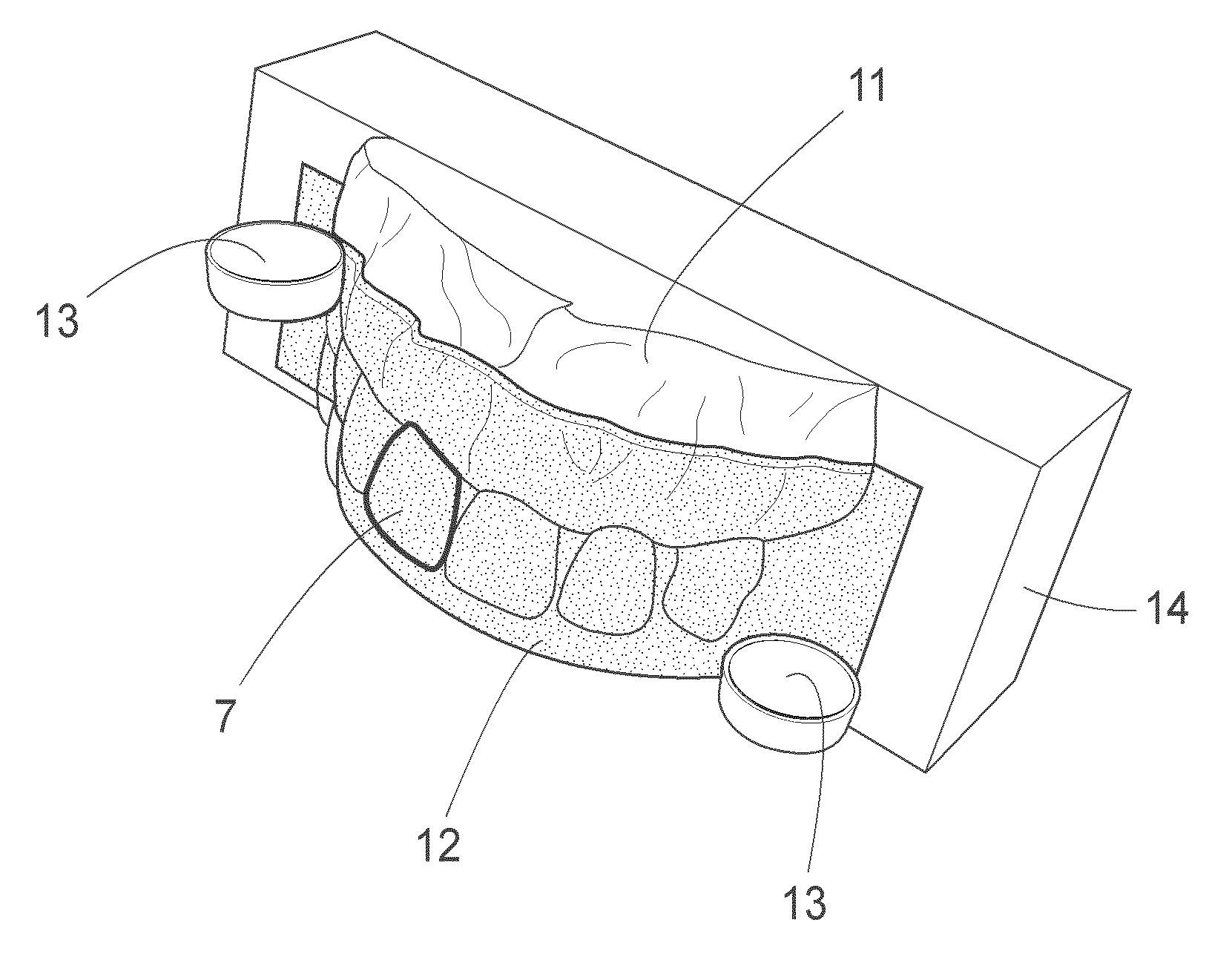

Method and system for producing a dental prosthesis

ActiveCN101360463AEasy to useImprove aestheticsTooth crownsArtificial teethDenturesUniform - quality

The invention relates to a method (100, 200, 300) for producing a dental prosthesis (17) with a framework (3) and a veneer (15), in particular for producing a crown, a bridge, an inlay or an onlay. The invention further relates to a system (40, 50) for producing a dental prosthesis (17) with a framework (3) and a veneer (15) and to a corresponding computer program. To allow the dental prosthesis (17) to be produced in a short time and in uniform quality, irrespective of the skill of the operator, the following steps are provided: definition (110, 210, 310) of three-dimensional geometrical data of the veneer (15), provision (101) or preparation (218, 318) of the framework (3), production (120, 220, 320) of a model (5, 5a, 5b, 5c, 5d) of the veneer (15) on the basis of the three-dimensional geometrical data of the veneer (15), on the framework (3) or separately, formation (124, 224, 324) of a female impression (11) of the veneer (15) by inclusion (126, 226, 326) of the model (5, 5a, 5b, 5c, 5d) between the framework (3) and a shaping material (9), and then removal (128, 228, 328) of the model (5, 5a, 5b, 5c, 5d), and filling (130, 230, 330) of the female impression (11) with veneer material for producing the veneered dental prosthesis (17).

Owner:BEGO BREMER GOLDSCHLAGEREI WILH HERBST

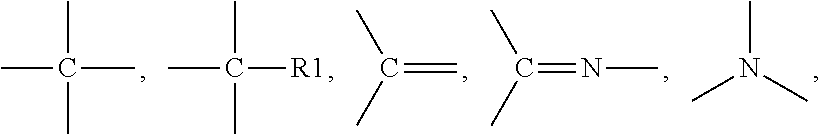

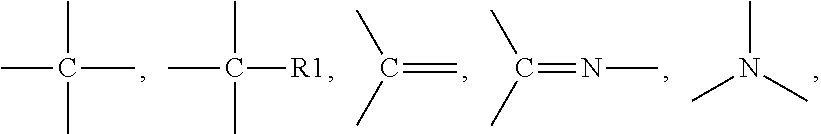

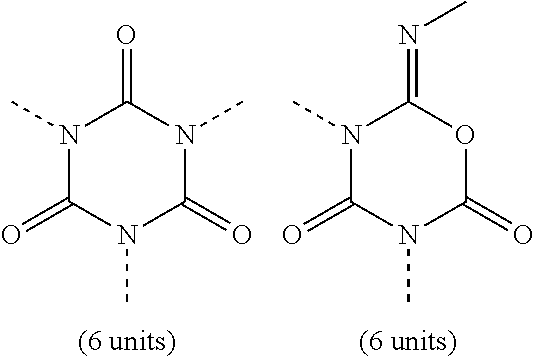

Hardenable dental composition containing a mixture of agglomerated and aggregated nano-particles, kit of parts and use thereof

The invention relates to a dental composition comprising—filler (F1) comprising aggregated nano-sized particles in an amount of from about 30 to about 70 wt. %, —filler (F2) comprising agglomerated nano-sized particles in an amount from about 1 to about 20 wt. %, —hardenable component (A1) being an urethane(meth)acrylate with a functionality of at least 2 and having a molecular weight from about 400 to about 3,000 g / mol, —hardenable component (A2) being a radically polymerizable (meth)acrylate with a functionality of at least 2 being different from component (A1), —redox curing initiator system, the dental composition not comprising non-agglomerated nano-sized filler in an amount above about 10 wt. %, wt. % with respect to the weight of the whole composition. The dental composition is in particular useful as or for production of permanent crown and bridges, inlays, onlays and veneers.

Owner:3M INNOVATIVE PROPERTIES CO

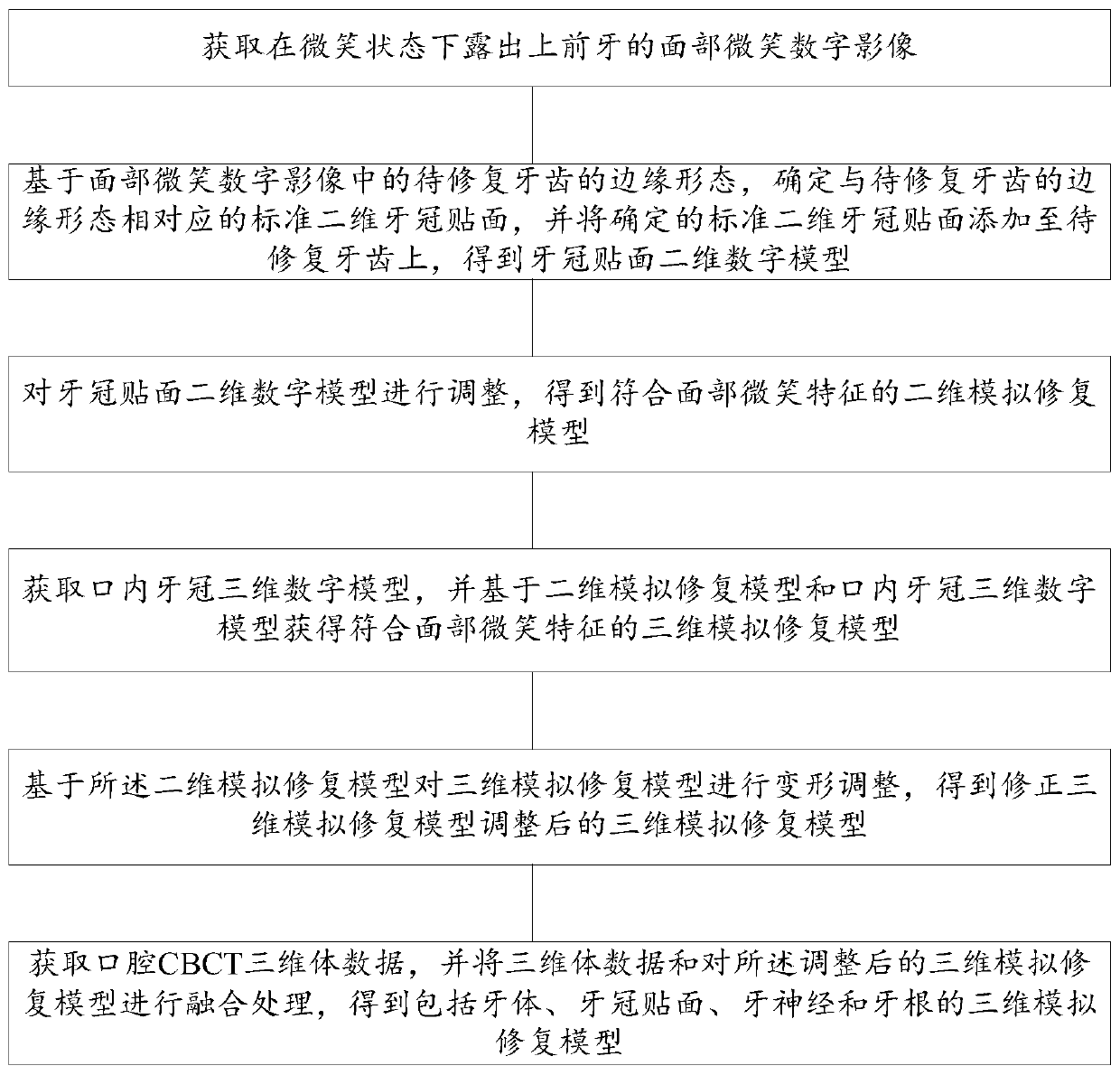

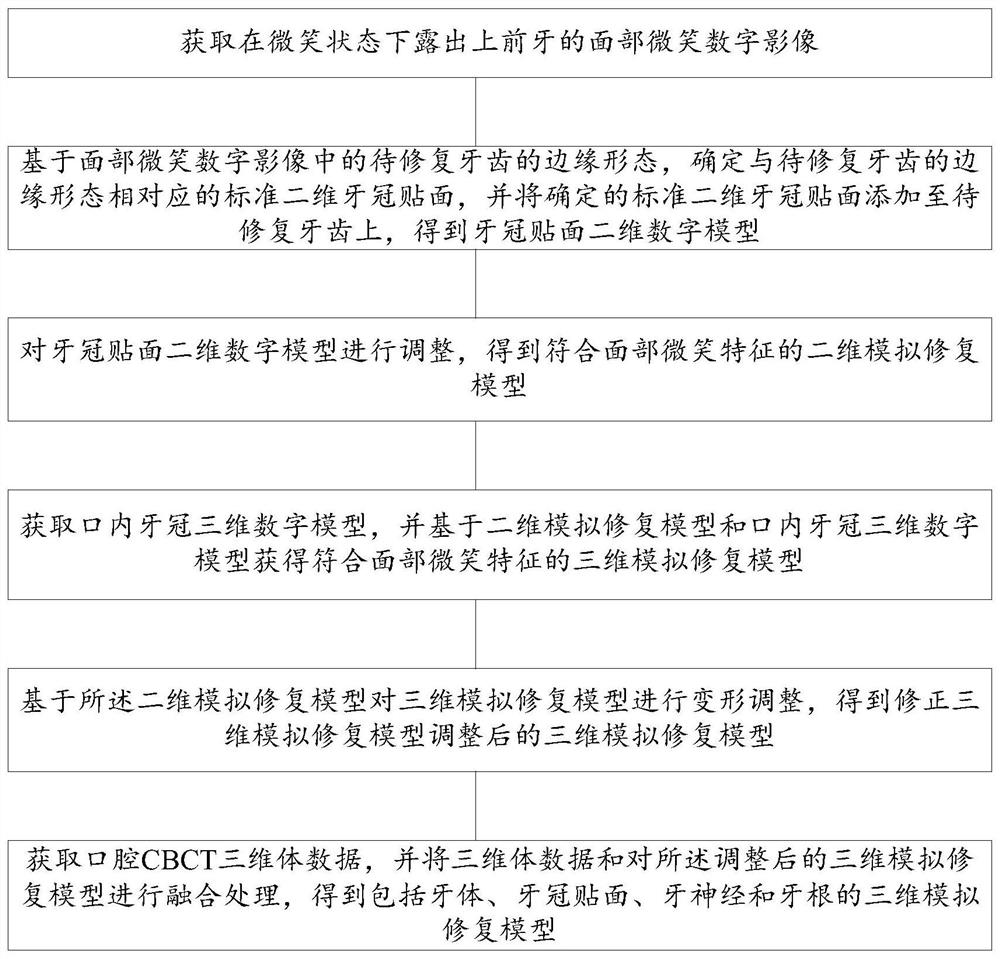

Dental restoration model manufacturing method and system based on multi-source image

ActiveCN111415419AEffective Guidance BasisImage enhancementImage analysisThree dimensional simulationDICOM

The invention provides a dental restoration model manufacturing method based on a multi-source image, and the method comprises: determining a standard two-dimensional dental crown veneer correspondingto the edge form of a to-be-restored tooth based on the obtained edge form of the to-be-restored tooth of a face smile digital image, and obtaining a dental crown veneer two-dimensional digital model; then, adjusting the dental crown veneering two-dimensional digital model to obtain a two-dimensional simulation repair model conforming to facial smile characteristics; then, based on the two-dimensional simulation repair model and the intraoral dental crown three-dimensional digital model, obtaining a three-dimensional simulation repair model conforming to facial smile characteristics; and finally, based on a Dicom three-dimensional body model shot by oral cavity CBCT, registering and fusing with a three-dimensional simulation repair model to obtain a model, which can be used for clinical analysis such as dental crown repair measurement, tooth root change diagnosis and the like. The method can provide an effective guidance basis for dental restoration and tooth change prediction.

Owner:西安知北信息技术有限公司

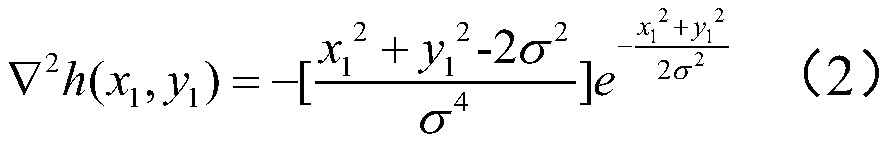

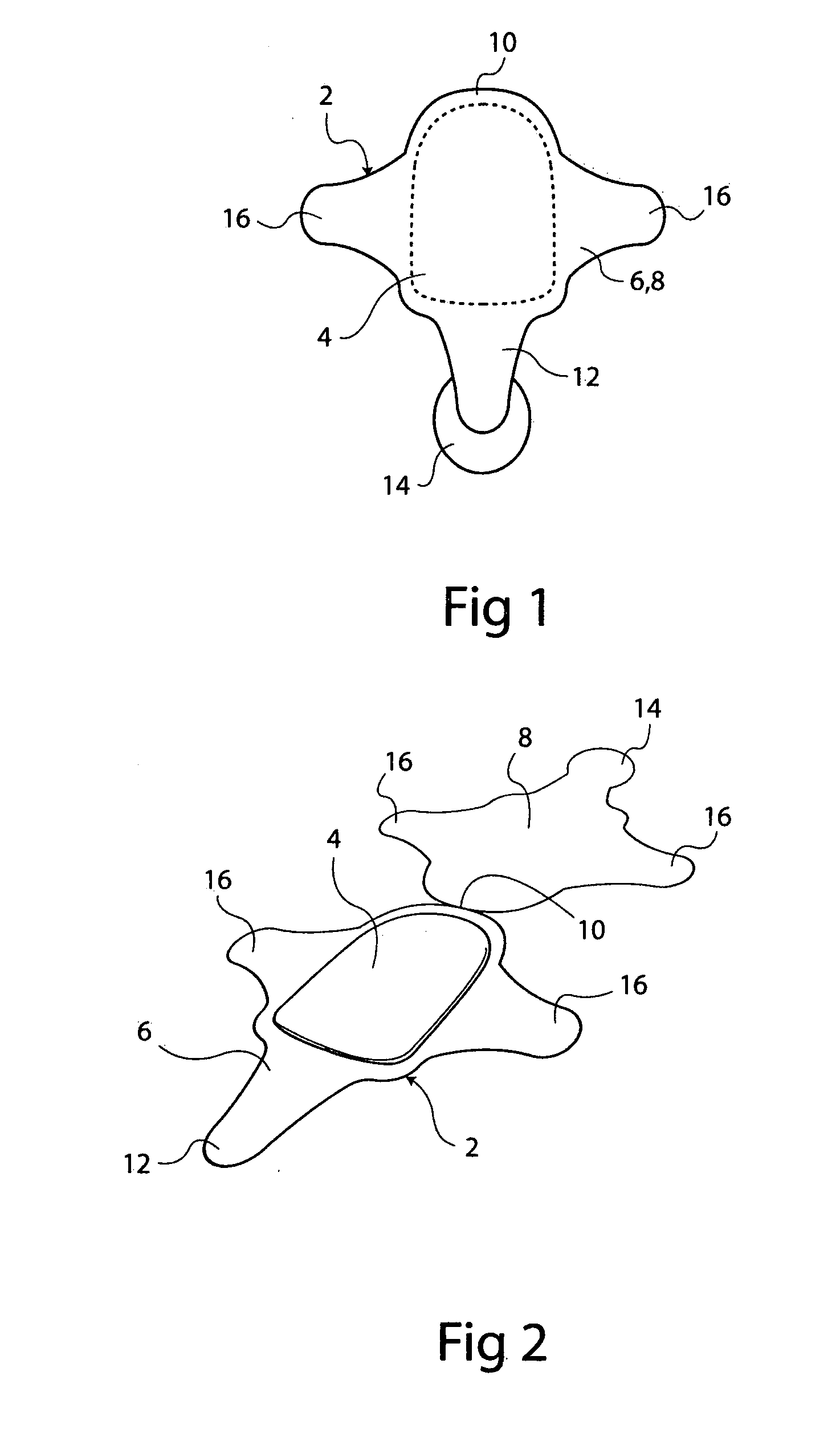

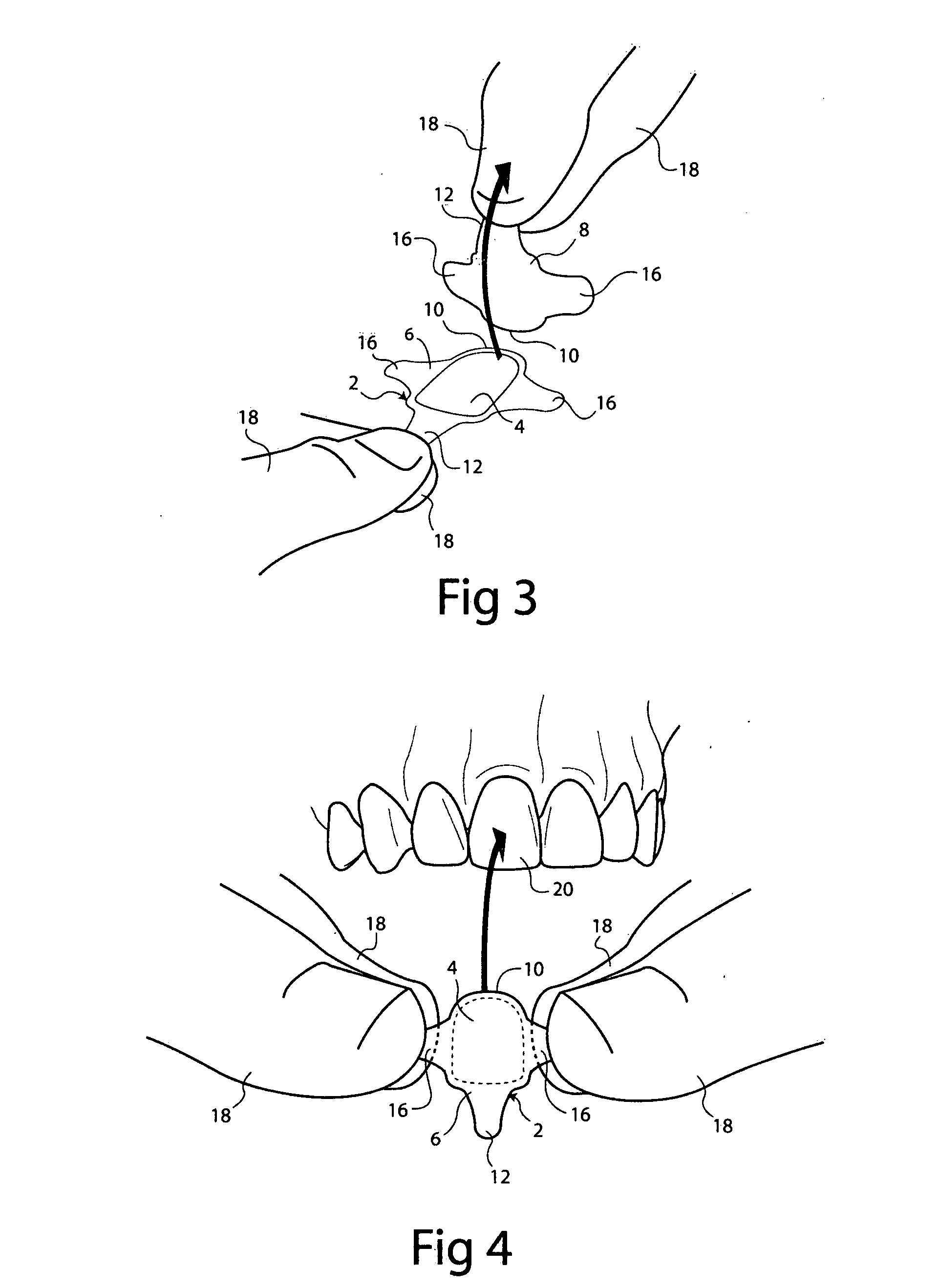

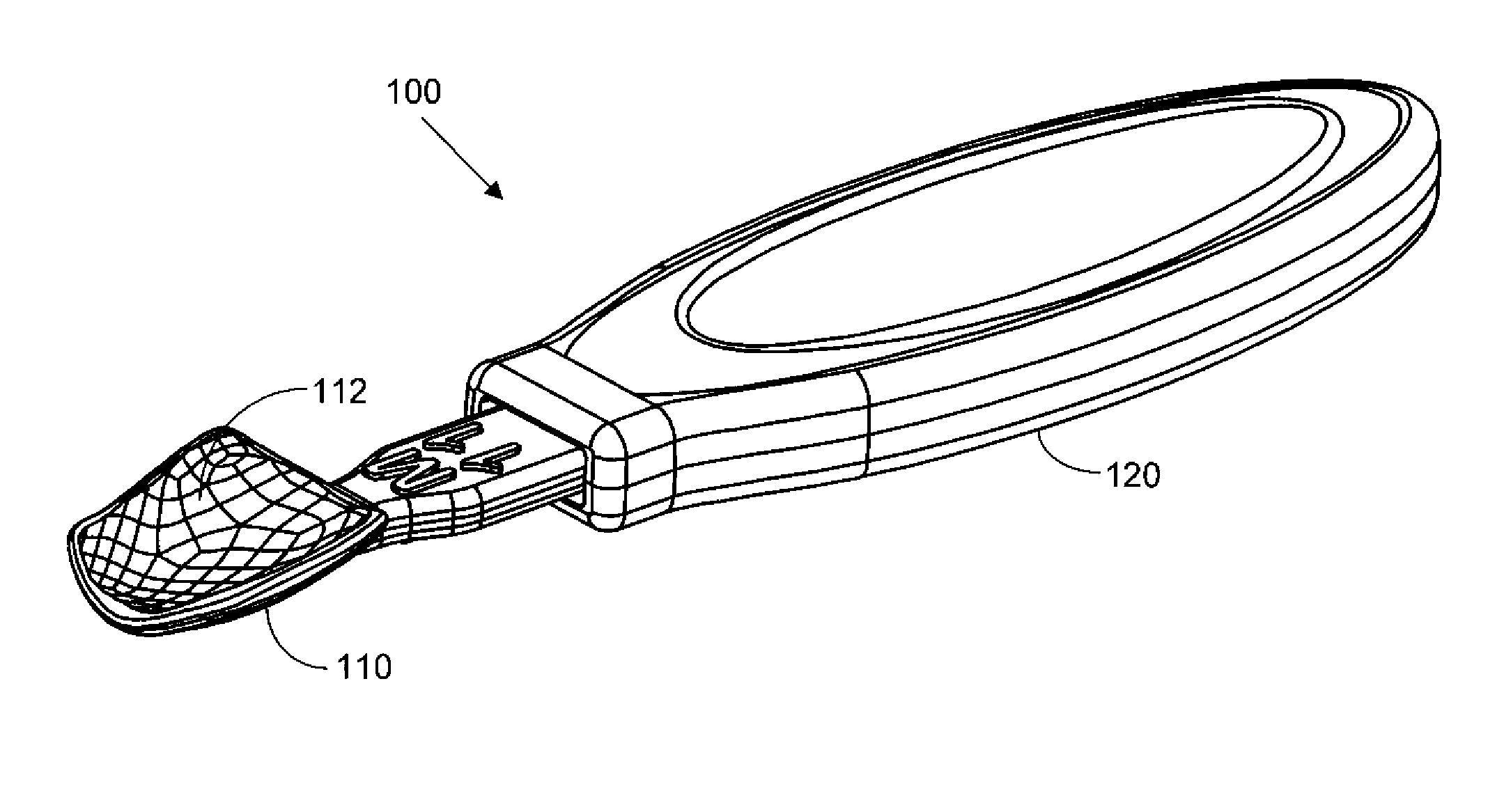

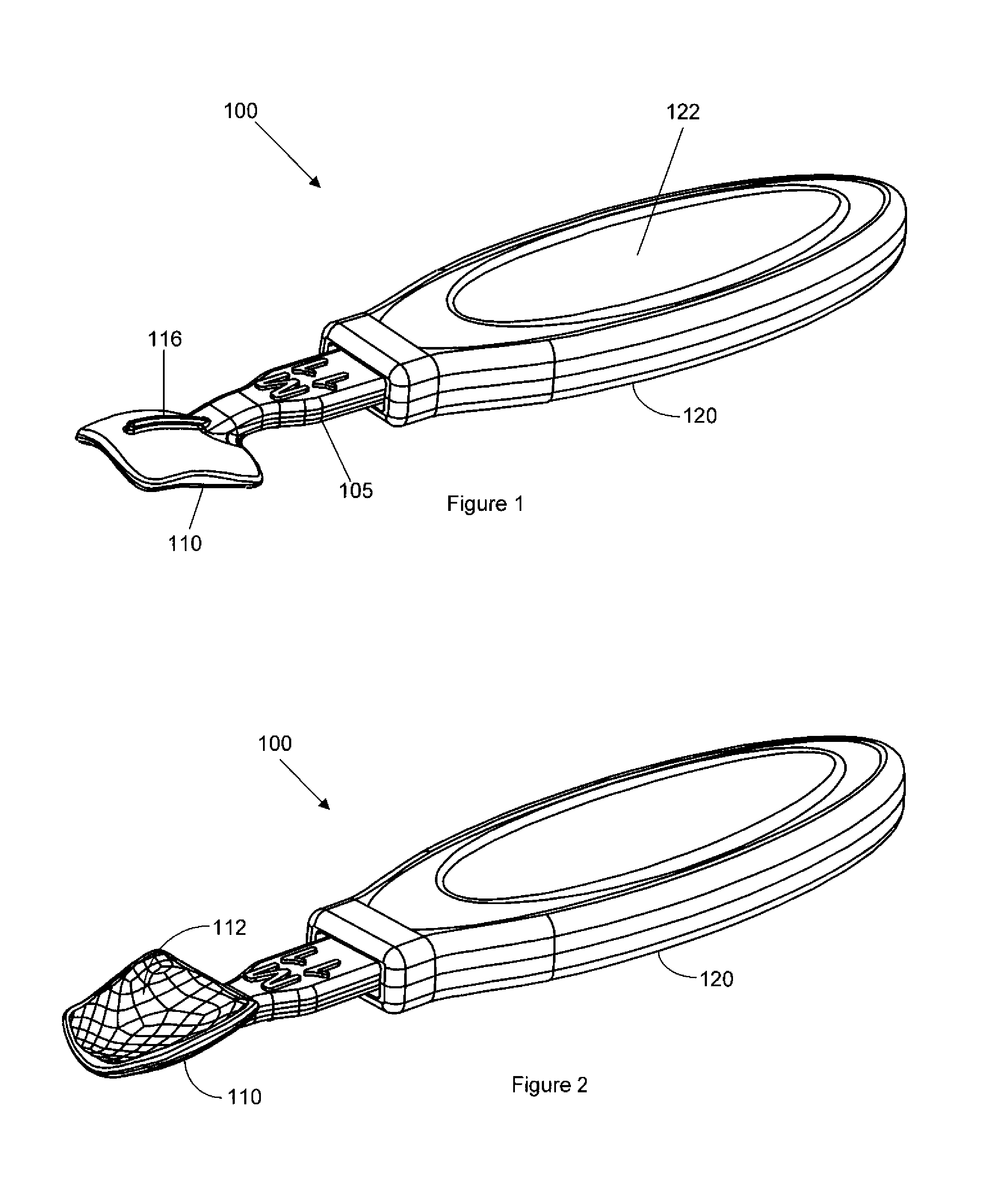

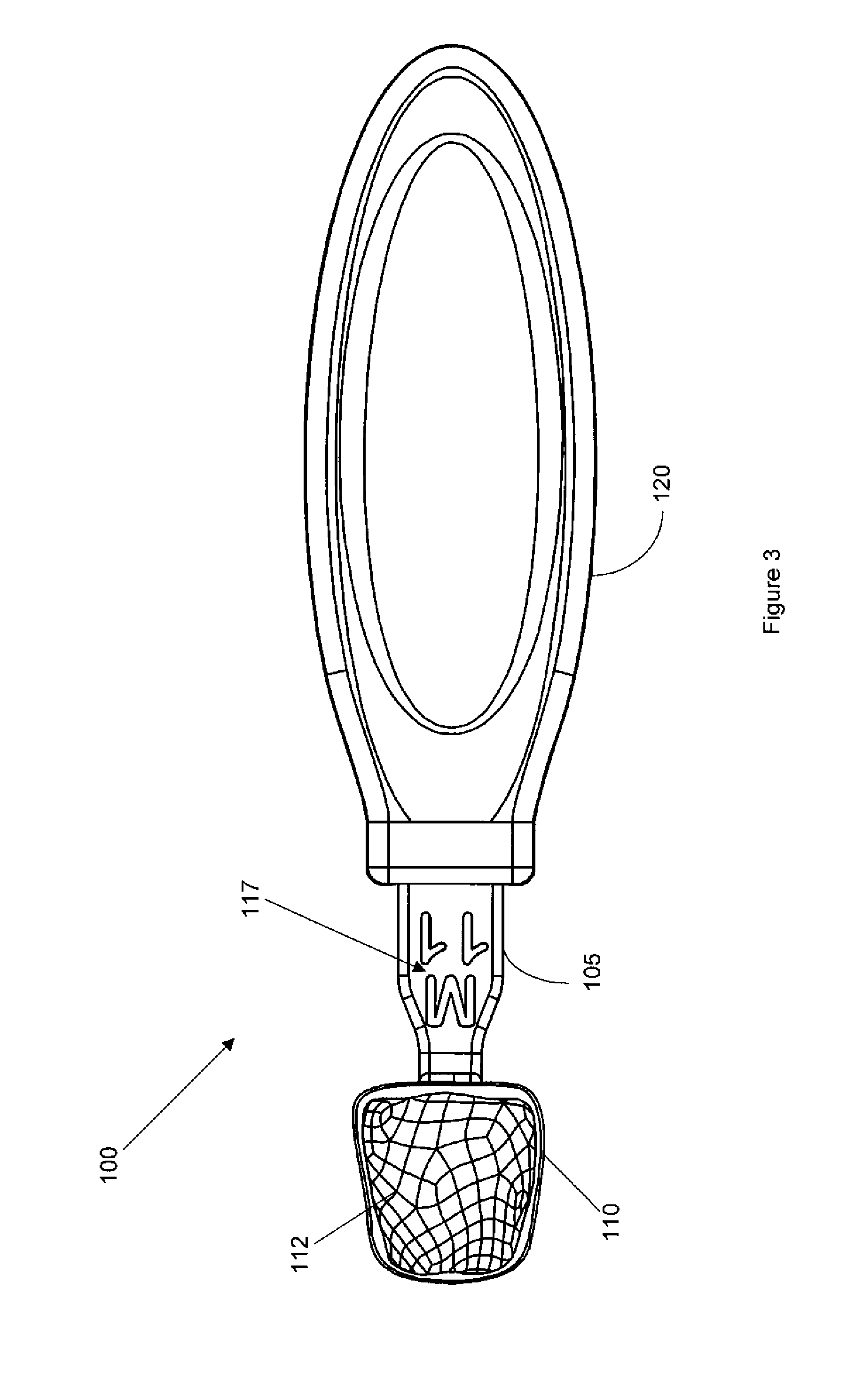

Direct press on veneer

ActiveUS20080131845A1Increased durabilityGood lookingTooth pluggers/hammersFilling facetsRestorative materialEngineering

A direct resin veneer (2) for creating a veneer on a tooth surface comprising a thin planar expanse of an uncured restorative material, or direct resin veneer (4). The veneer (4) has a generally tooth configuration that is generously sized to permit adequate coverage for any tooth. Adhered to at least one side of the restorative material is a flexible pliant non-sticky planar sheath (6). The sheath (6) material has a curved gingival arch contour (10) for gum line alignment and various tab-like protrusions that permit placement upon a tooth. An inferior peeling tab (12) allows for sheath to be separated from the resin veneer (4) subsequent to tooth surface placement. And the lateral grasping tabs (16) permit delivery to a tooth's surface.

Owner:VISCOMI BRIAN D

Dental product comprising at least one veneer

InactiveUS20120183921A1Improve aestheticsGood lookingFilling facetsDental toolsDental ProductTooth veneers

Certain embodiments relate to an individualized dental product ready for application. The dental product can include at least one tooth veneer which is of a ceramic material, is plate-like and has a plate thickness of at least about 0.08 mm. In some embodiments, the thickness is less than 0.2 mm, less than 0.14 mm or less than 0.1 mm. Certain embodiments also relate to a method of improving the aesthetics of a tooth. The method can include placing a dental product onto a tooth surface.

Owner:NOBEL BIOCARE SERVICES AG

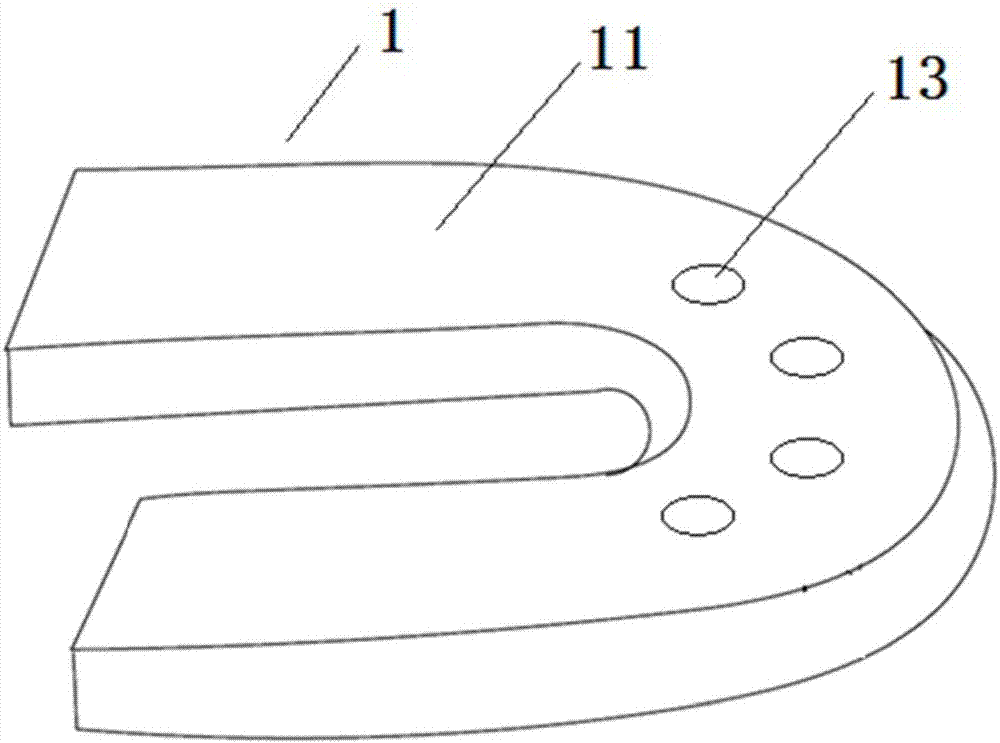

Device and method for molding resin veneer

ActiveCN107126272AWork lessShape adjustableTeeth fillingTeeth cappingEngineeringAtmospheric pressure

The invention discloses a molding device for a resin veneer for dental cosmetics, and a method for preparing the resin veneer by using the molding device. The molding device for the resin veneer comprises an outer-layer thermoplastic membrane guide plate, an inner-layer transparent silicon rubber female mold and a high-filler fluid resin injection hole. When the molding device is operated inside a mouth of a patient, an improved molding injection technique is implemented according to an atmospheric pressure principle, so that bubbles can be reduced to the maximum extent, and in addition, the resin veneer can be relatively efficiently molded.

Owner:西安知北信息技术有限公司

Method for producing a denture

ActiveCN104224336AIncrease flexibilityAchieve aestheticsImpression capsTooth crownsDenturesProsthesis

The invention relates to a method for producing a denture. In one embodiment, a prosthetic baseplate (4) and multiple tooth stump prostheses (6) are produced by applying a CAD model and pre-fabricated veneers (8) are affixed on the tooth stump prostheses (6), whereby the thickness values of the veneers (8) are taken into consideration during generation of the CAD model of the tooth stump prostheses (6). The invention also relates to a denture, in particular fabricated through a method of this type, in which multiple tooth stump prostheses (6) are affixed in a prosthetic baseplate (4) or are structured to be the same part as the prosthetic baseplate (4) and a veneer (8) is affixed in coronal position on at least one tooth stump prosthesis (6), preferably a veneer (8) is affixed in coronal position on each tooth stump prosthesis (8).

Owner:HERAEUS KULZER

Method and apparatus for preparing contoured glazed composite dental veneers

Disclosed is a template for forming a veneer on a tooth using a composite resin material that is curable by radiation. The template includes a tooth-contacting portion having a smooth concave surface for contacting the composite, the smooth concave surface having a shape that is complementary to a desired natural tooth shape. The tooth-contacting portion is formed of a material capable of transmitting the radiation such that the composite is curable through the tooth-contacting portion to form a veneer having a surface shape that conforms to the desired natural tooth shape. Also disclosed is a kit including a plurality of such templates and a method of using the templates to form a veneer.

Owner:DENTAL ART INNOVATIONS

A digital dental aesthetic restoration method

The invention provides a digital oral aesthetic repair method, and particularly relates to a method for designing dental crown veneers for patients. The digital oral aesthetic repair method includes following steps: acquiring face smile digital images and an intraoral tooth crown three-dimensional digital model of a patient; utilizing the face smile digital images to acquire a two-dimensional digital aesthetic design list; mutually overlapping the two-dimensional digital aesthetic design list and the intraoral tooth crown three-dimensional digital model through three-dimensional point cloud digital splicing technology; adding a standard three-dimensional tooth crown veneer digital model into a corresponding position in the intraoral tooth crown three-dimensional digital model; performing deformation adjusting on the standard three-dimensional tooth crown veneer digital model according to the two-dimensional digital aesthetic design list to acquire a three-dimensional digital model of a tooth crown veneer designed for the patient. The three-dimensional digital model is mainly applied in oral implanting, orthodontics and aesthetic repair, can simulate repair effect of the patients before operation and guide work of doctors and technicians during operation and is a quite effective tool for communication between doctors and patients, between doctors and between doctors and technicians.

Owner:西安知北信息技术有限公司

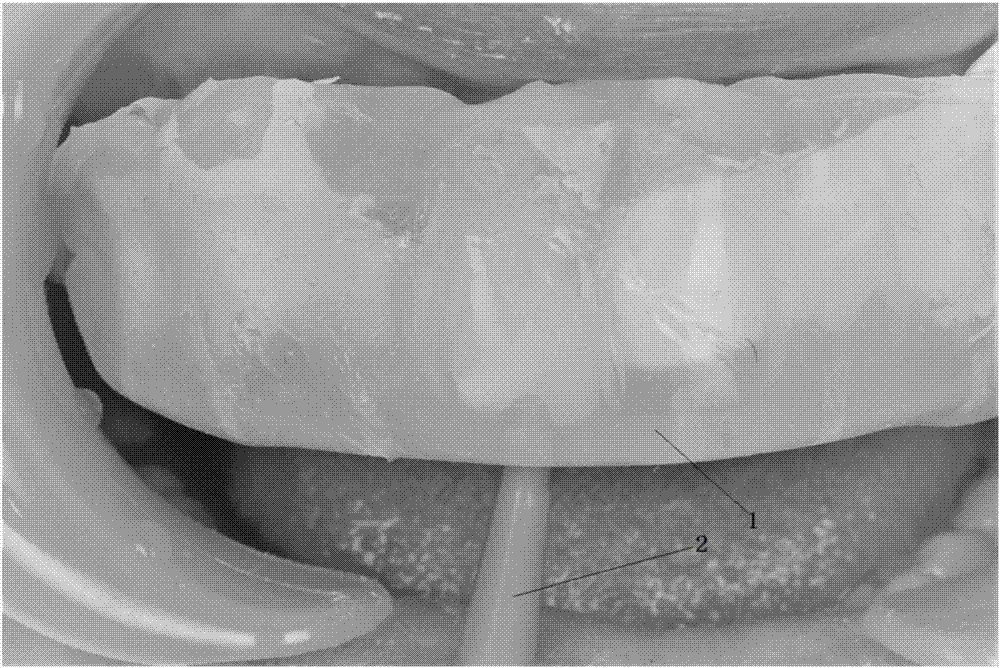

Noninvasive whitening adhesion technology based on bridge veneers

ActiveCN111658186AImprove fitImprove experienceTeeth fillingDental impression compositionsMouth openingBiomedical engineering

The invention discloses a noninvasive whitening adhesion technology based on bridge veneers. A traditional impression technology is adopted, a fitting degree between repaired teeth is improved, high-hardness crystal ceramics are used as tooth defect repair matrices, and the two operation processes of bridge veneer adhesion and defect tooth shaping are combined into one, so that the mouth-open operation time of a patient is greatly shortened, and the working efficiency of a dentist, and an experience degree and a comfort feeling of the patient are improved.

Owner:山西米兔斯美容管理有限公司

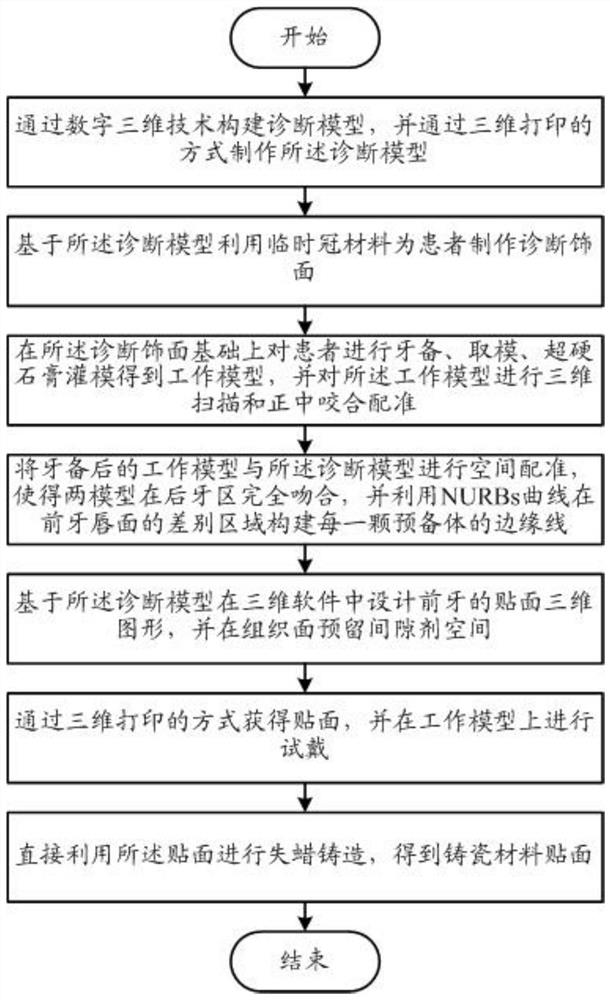

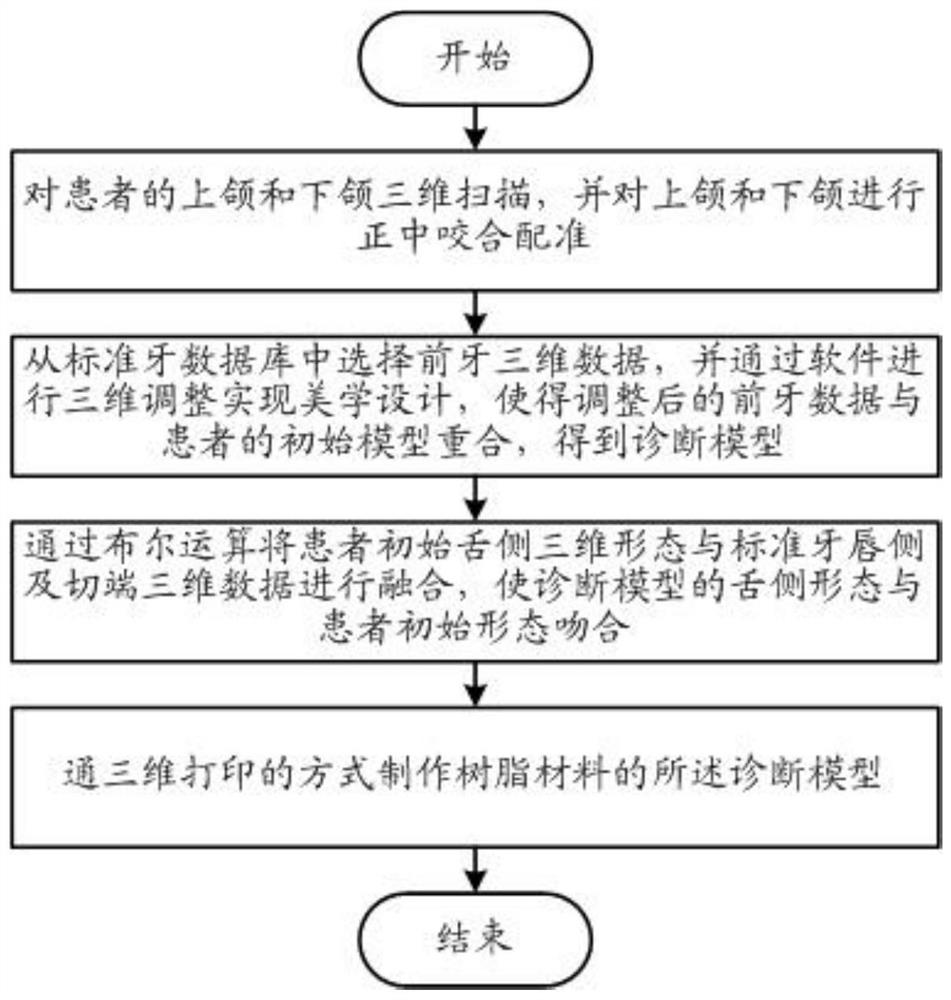

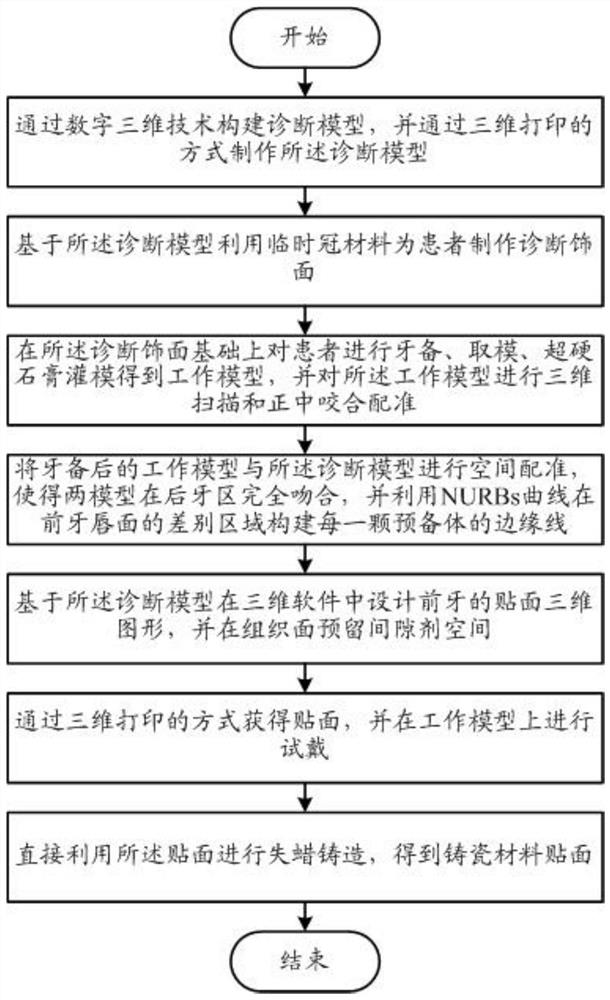

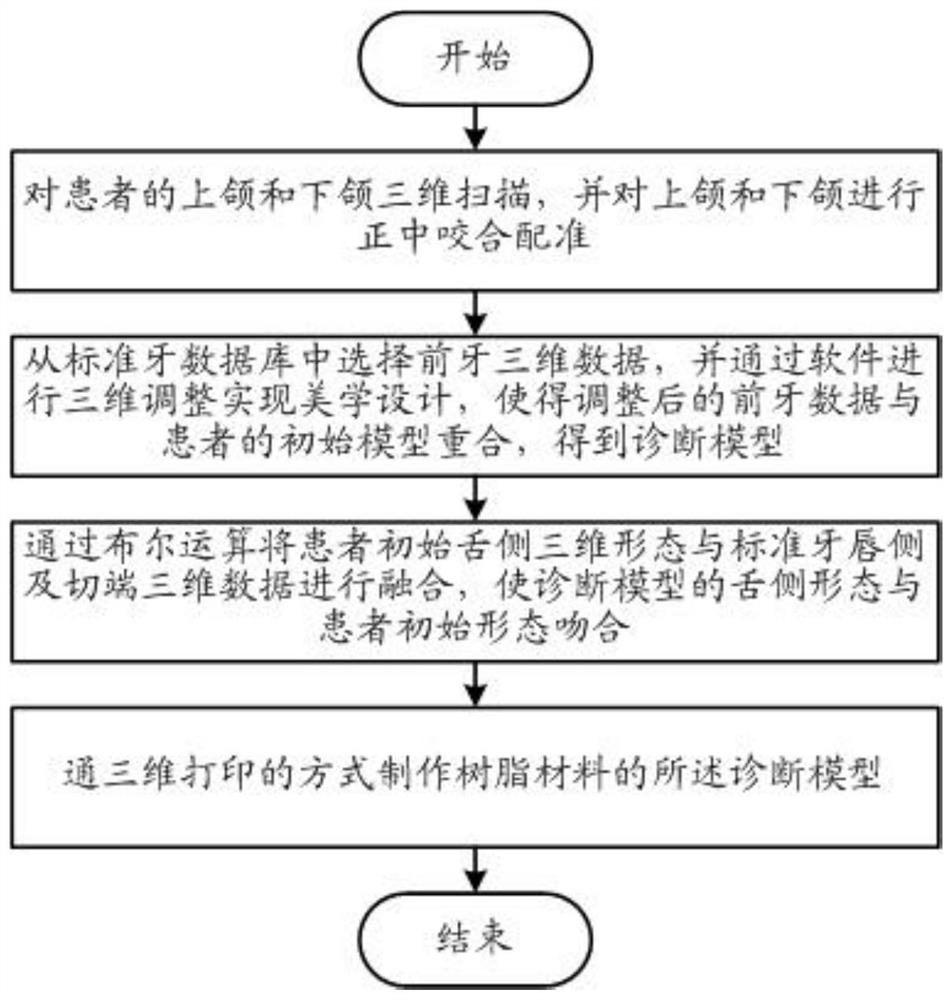

A kind of manufacturing method of cast porcelain dental veneer

ActiveCN111973293BEnsure tightnessUnified functionTeeth fillingTeeth cappingEngineeringBite registration

The invention relates to a manufacturing method of cast porcelain dental veneer, comprising the following steps: constructing a diagnostic model by digital three-dimensional technology, and making the diagnostic model by means of three-dimensional printing; making a diagnostic model for a patient based on the diagnostic model using a temporary crown material Veneering; on the basis of the diagnostic veneer, perform tooth preparation, impression taking, and superhard plaster filling of the patient to obtain a working model, and perform three-dimensional scanning and centric occlusal registration on the working model; the work after tooth preparation The spatial registration of the model and the diagnostic model is carried out so that the two models are completely consistent in the posterior region, and the edge line of each preparation is constructed in the difference area of the anterior labial surface by using the NURBs curve; The veneer is directly used for lost-wax casting to obtain a veneer made of cast porcelain material. The cast porcelain tooth veneer made by the invention achieves the unity of appearance and function after restoration.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Cast porcelain tooth veneer production method

ActiveCN111973293ANormal reachNormal lateral movementTeeth fillingTeeth cappingDental veneersCentric occlusion

The invention relates to a cast porcelain tooth veneer production method which comprises the following steps of: constructing a diagnosis model by a digital three-dimensional technology, and producingthe diagnosis model in a three-dimensional printing manner; based on the diagnosis model, producing a diagnosis finish for a patient by utilizing a temporary crown material; carrying out tooth preparation, impression taking and die stone cast pouring on the patient to obtain a working model on the basis of the diagnosis finish, and carrying out three-dimensional scanning and centric occlusion registration on the working model; carrying out space registration on the working model after tooth preparation and the diagnosis model so as to enable two models to be completely fit in a back tooth region, and constructing an edge line of each preparation body in a differential region of a front tooth lip surface by utilizing an NURBs curve; obtaining a veneer in a three-dimensional printing manner; and carrying out dewaxing casting directly by utilizing the veneer so as to obtain a cast porcelain material veneer. The cast porcelain tooth veneer produced by the invention achieves unification ofaesthetics and functionality after repair.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

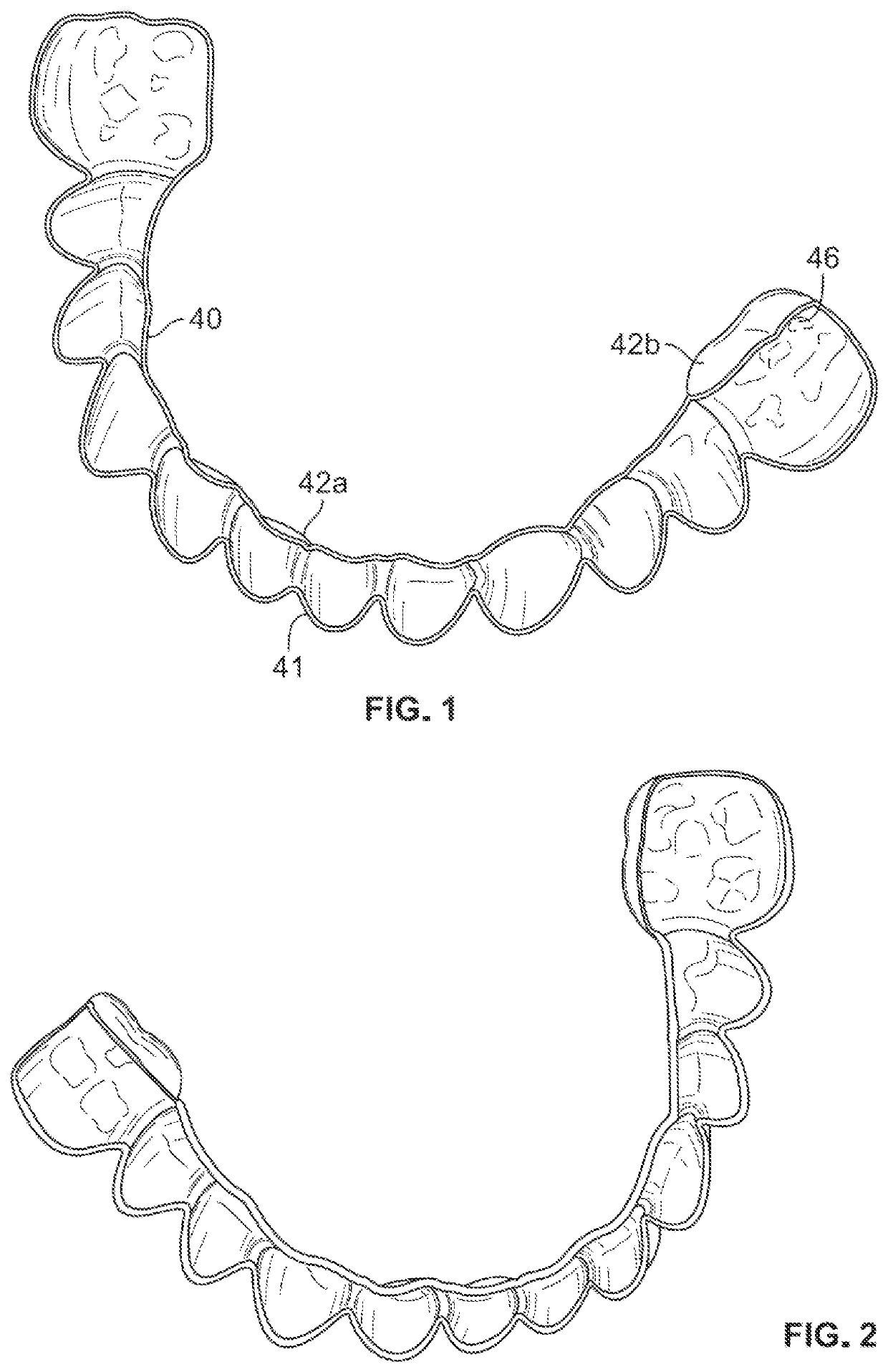

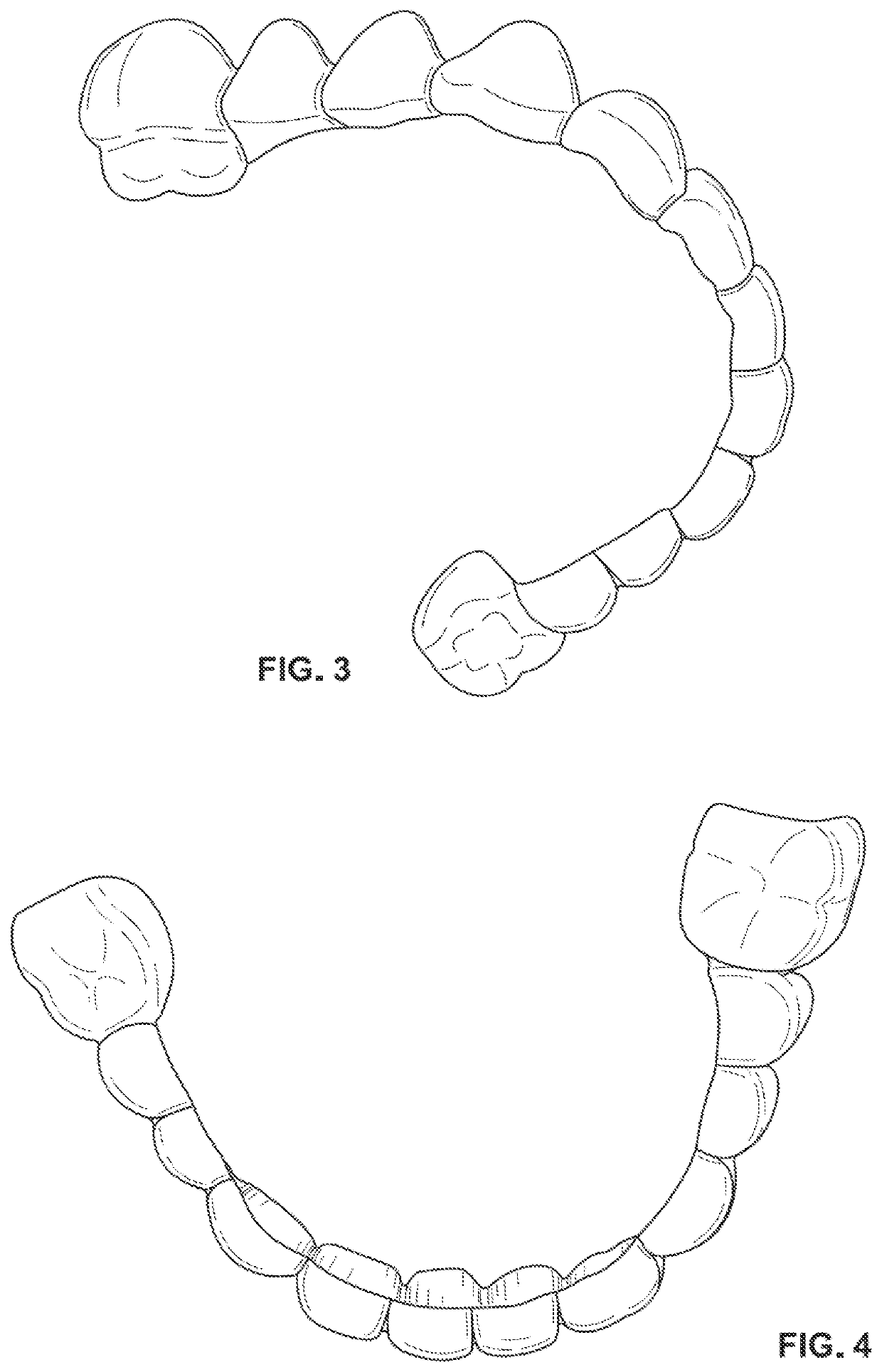

Customized dental veneers

Described is a customized removable cosmetic or aesthetic dental veneer that secures onto a row of teeth of a patient. The dental veneer may include a pair of rear portions that secure it onto the row of teeth, each rear portion positioned at a distal end of the veneer and having: buccal, occlusal and lingual sides for one or more rear tooth, and a front portion between the pair of rear portions that covers the buccal and occlusal surfaces of the teeth between the pair of rear portions but is free of a side that covers a majority of the lingual surface of any tooth of the row of teeth between the pair of rear portions. A slot and apertures may also be provided for occlusal portions of the rear teeth. Also described is a veneer without such rear portions, which may be used with an adhesive.

Owner:SHINY SMILE VENEERS LLC

Systems and Methods of Simulating Colors, Opacities and Other Optical Variables in Dental Restoration

InactiveUS20210251733A1Overcome deficienciesIncrease reflectionTeeth fillingTeeth cappingDental SpecialtyBiomedical engineering

There are challenges in the prior art of matching new dental work with the color, chroma, translucency and other optical characteristics of existing teeth. The disclosed embodiments overcome shortfalls in the prior art by using an artful combination of stump replicas in convex and / or magnetic attachment to crown or veneer replicas. The disclosed layering and attachment techniques using separate stump and veneer replicas avoid the use of subjective and speculative evaluations by dental professionals in matching proposed dental work to existing dental conditions.

Owner:AESTHETIC PRESS LLC

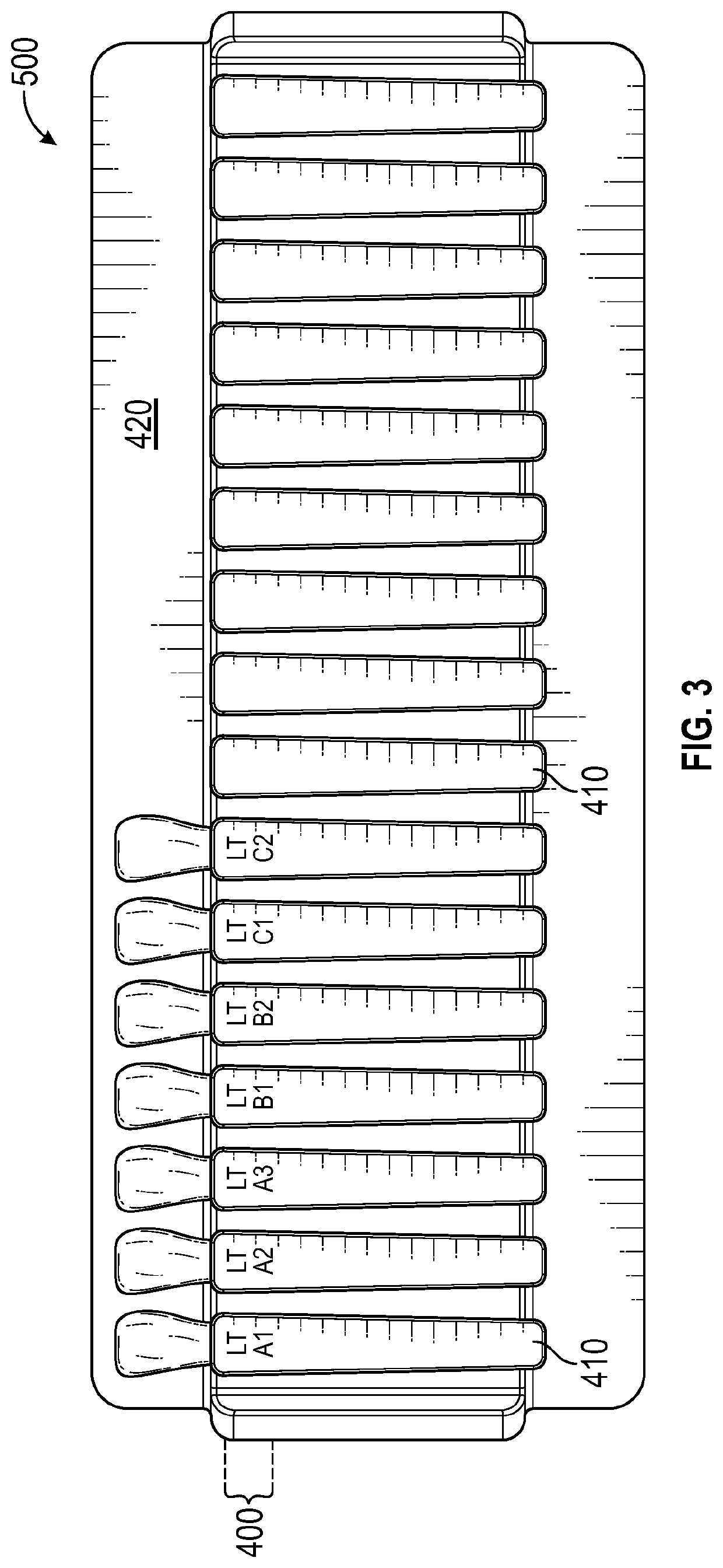

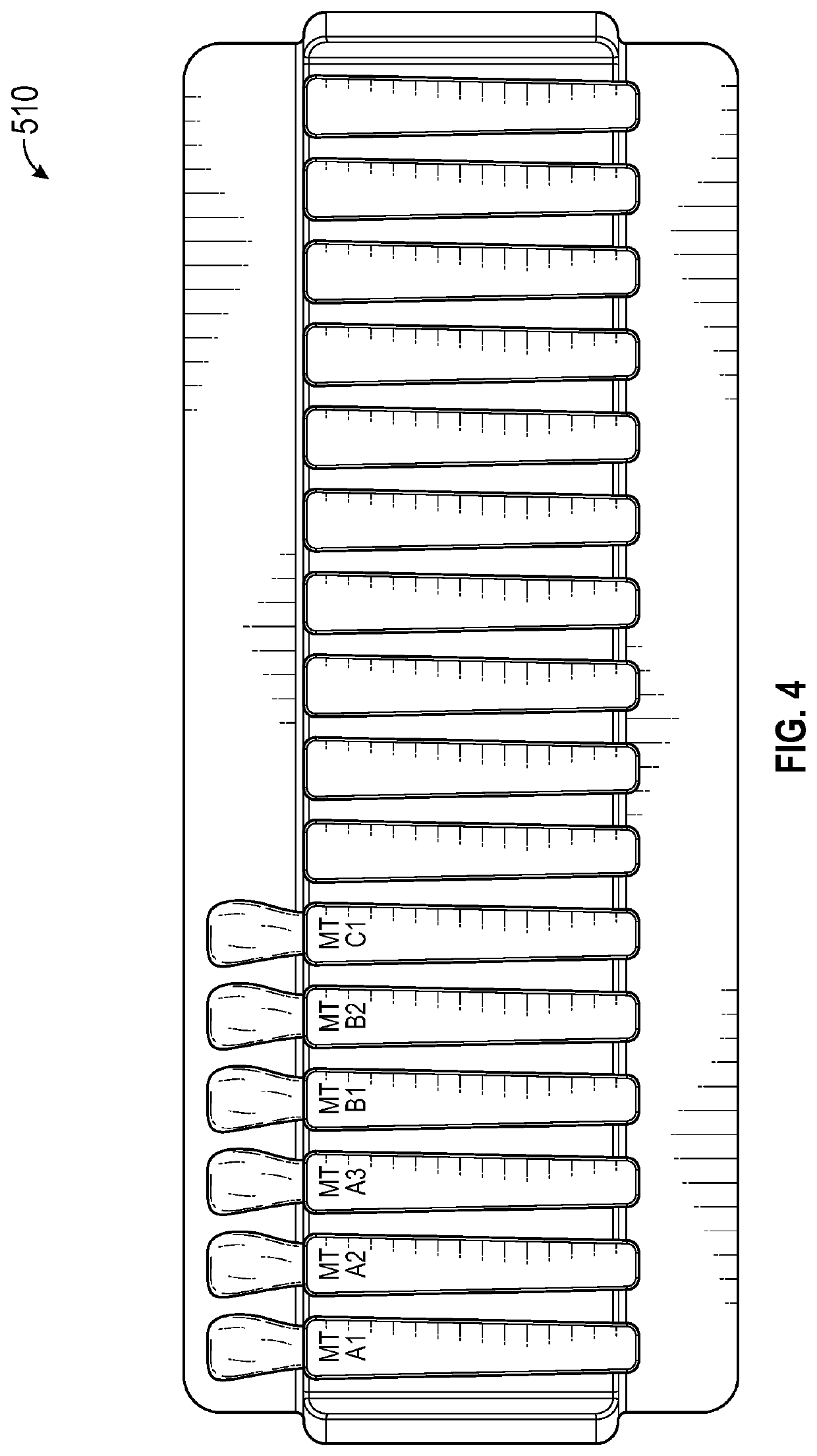

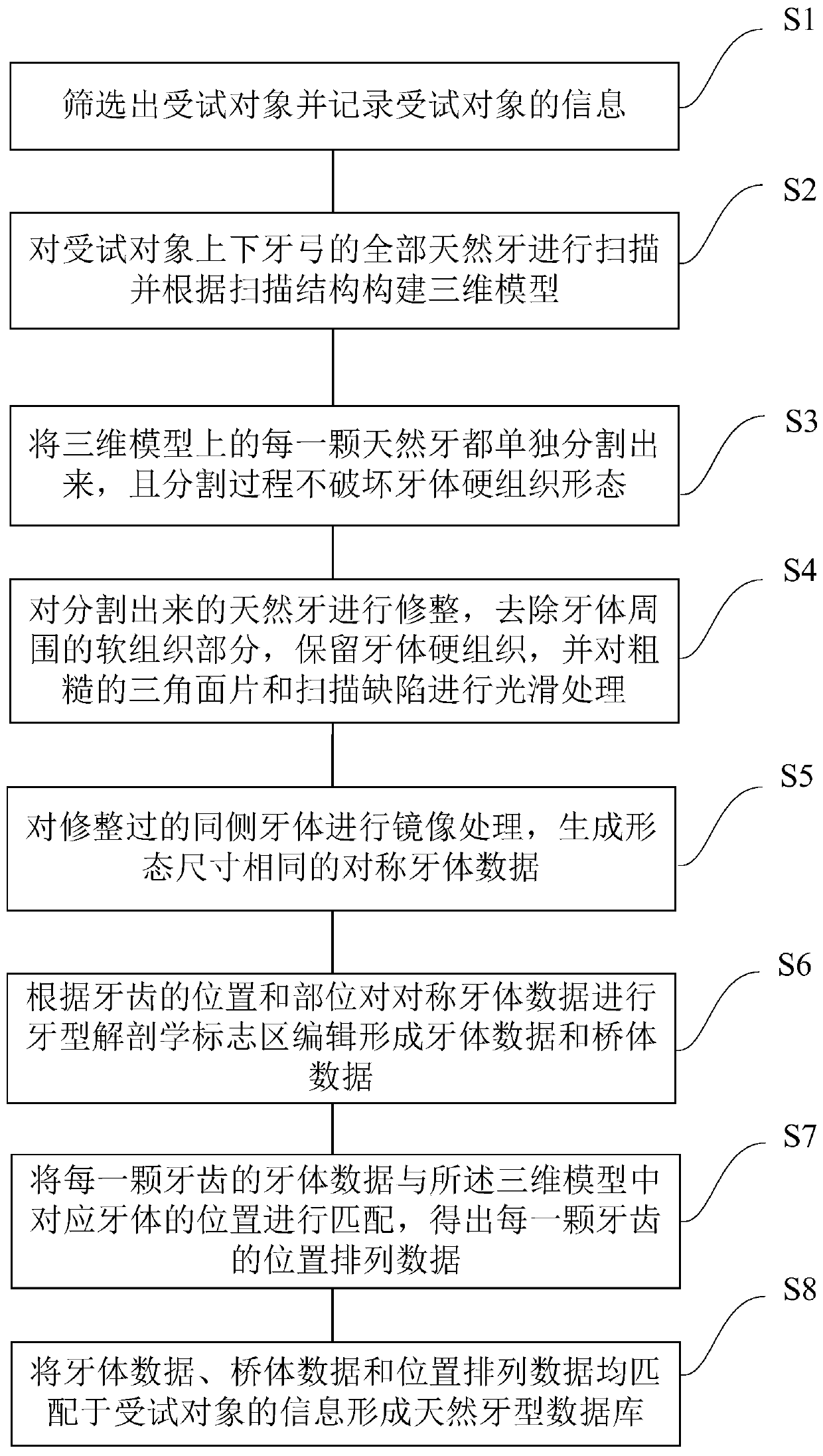

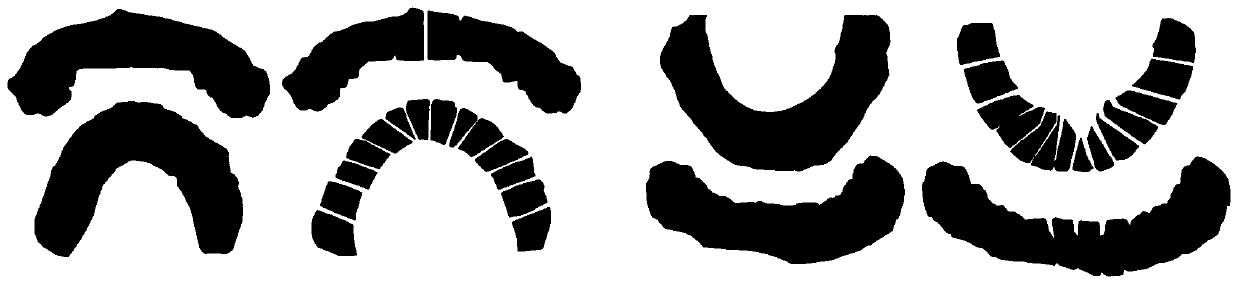

A method and system for constructing a natural tooth type database

ActiveCN110334444BImprove processing efficiencyImprove aestheticsImage enhancementImage analysisNatural toothAnatomical landmark

The invention discloses a method for constructing a natural tooth type database, comprising the following steps: 1. Recording object information; 2. Obtaining a digital model; 3. Segmenting dentition data; 4. Modifying tooth shape; 5. Mirror image processing; 6. . Tooth type anatomical landmark area editing; 7. Dental data positioning editing; 8. Natural tooth type database import. The invention also discloses a system for constructing a natural tooth type database. The present invention is a method and system for constructing a natural tooth type database. The construction of the natural tooth type database is completed through the above-mentioned technology, which solves the problems of tooth type mismatch, single shape, lack of natural shape texture, and poor aesthetics in the current digital design of dental restoration; Moreover, the natural tooth database constructed by this method can be used in any digital restorative design, such as crowns, bridges, veneers, inlays, removable partial dentures, and complete dentures; Matching profile data.

Owner:SICHUAN UNIV

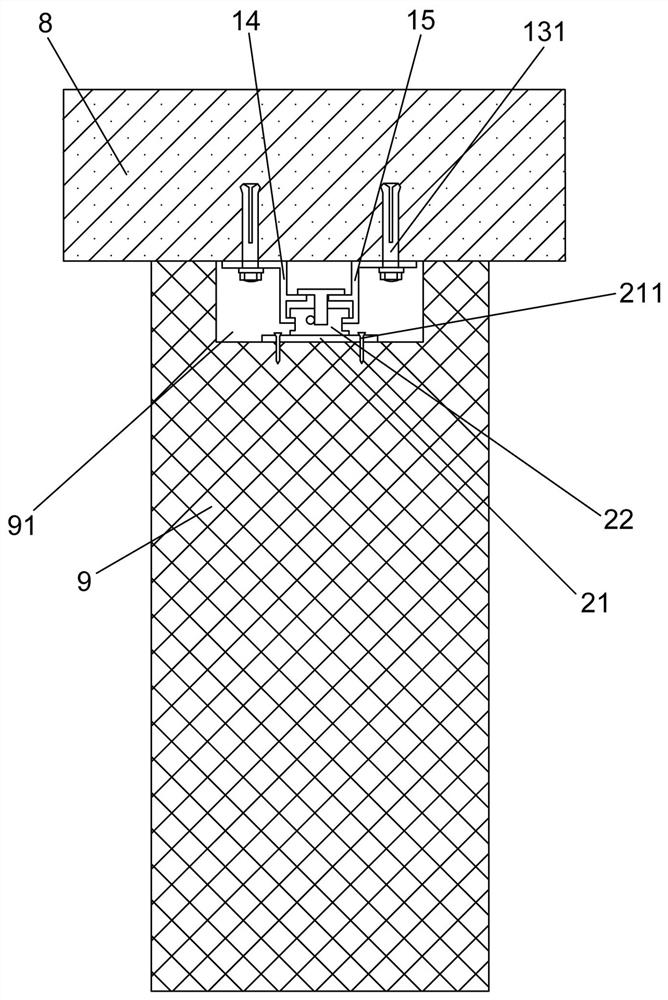

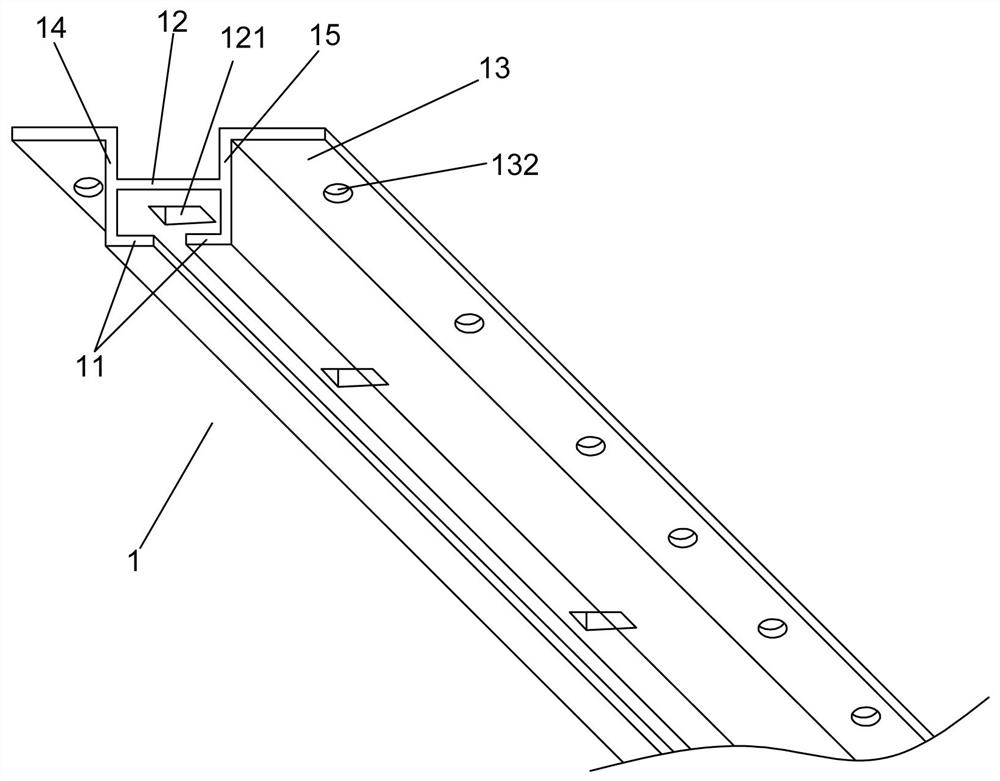

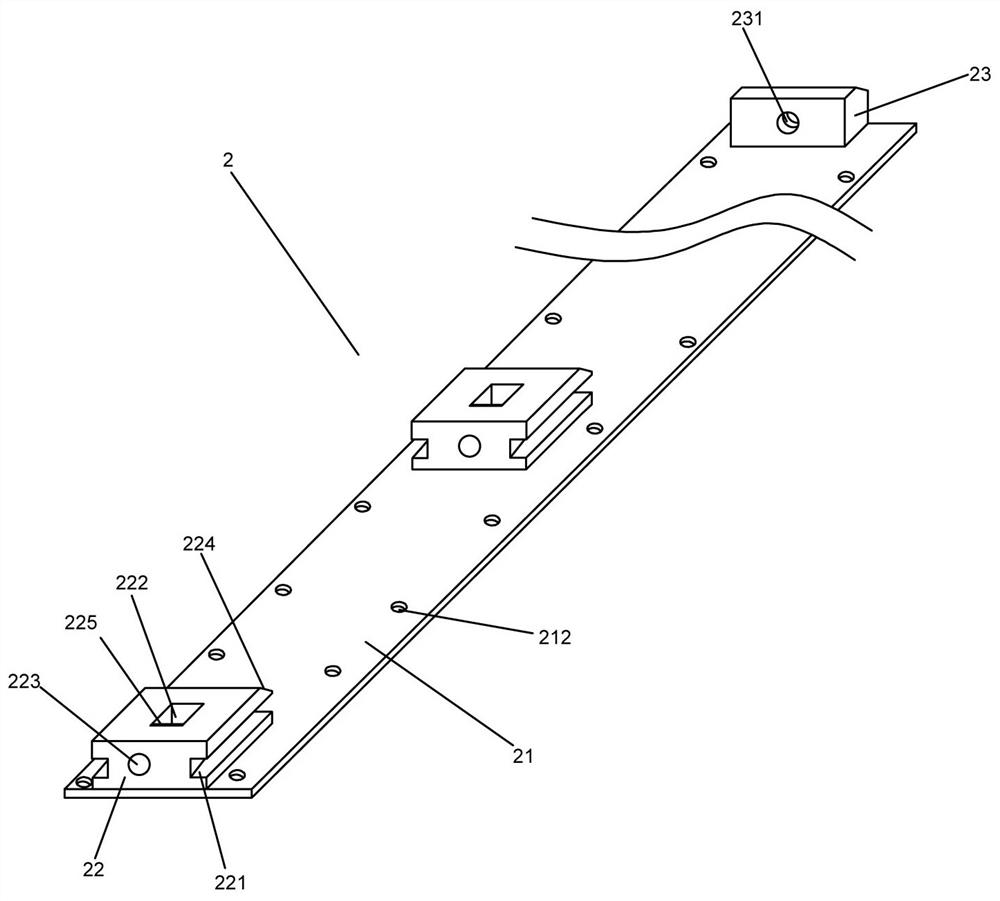

Connecting assembly with good stability

PendingCN112962905AImprove stabilitySimple structureCovering/liningsStructural engineeringMechanical engineering

The invention provides a connecting assembly with good stability, and relates to the technical field of decoration design. The connecting assembly comprises a first connecting piece and a second connecting piece, wherein the second connecting piece comprises a bottom plate and a clamping plate; the side face of the clamping plate is provided with a sliding groove; the first connecting piece is provided with a protruding block; the width of the sliding groove is larger than the thickness of the protruding block; the first connecting piece is provided with an adjusting plate; an adjusting hole is formed in the adjusting plate; a first groove and a second groove are formed in the clamping plate; the second groove communicates with the first groove; a functional plate extending in the direction of the first groove is arranged in the adjusting hole; a functional rod connected with the functional plate is arranged in the second groove; first clamping teeth are arranged on the side edge of the functional plate; and second clamping teeth meshed with the first clamping teeth are arranged on the outer side of the functional rod. According to the invention, the structure is simple, the assembly type installation efficiency is high, the position of a veneer can be adjusted after the veneer is installed, no gap exists between the veneer and a wall body, the stability is good, and the safety is high.

Owner:ZHEJIANG YASHA DECORATION

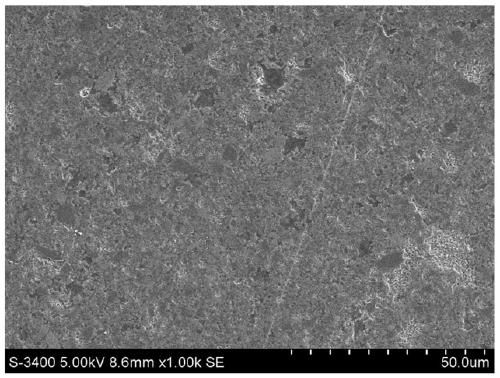

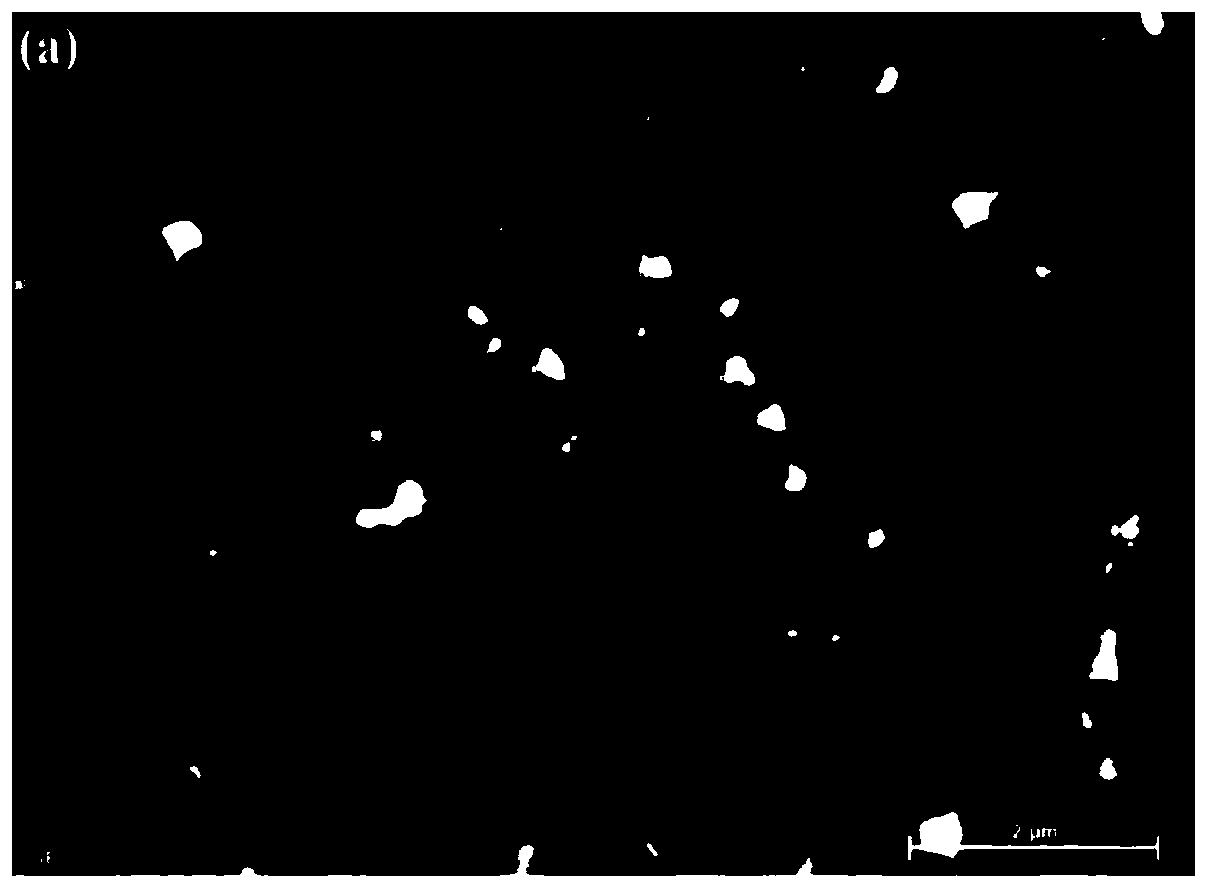

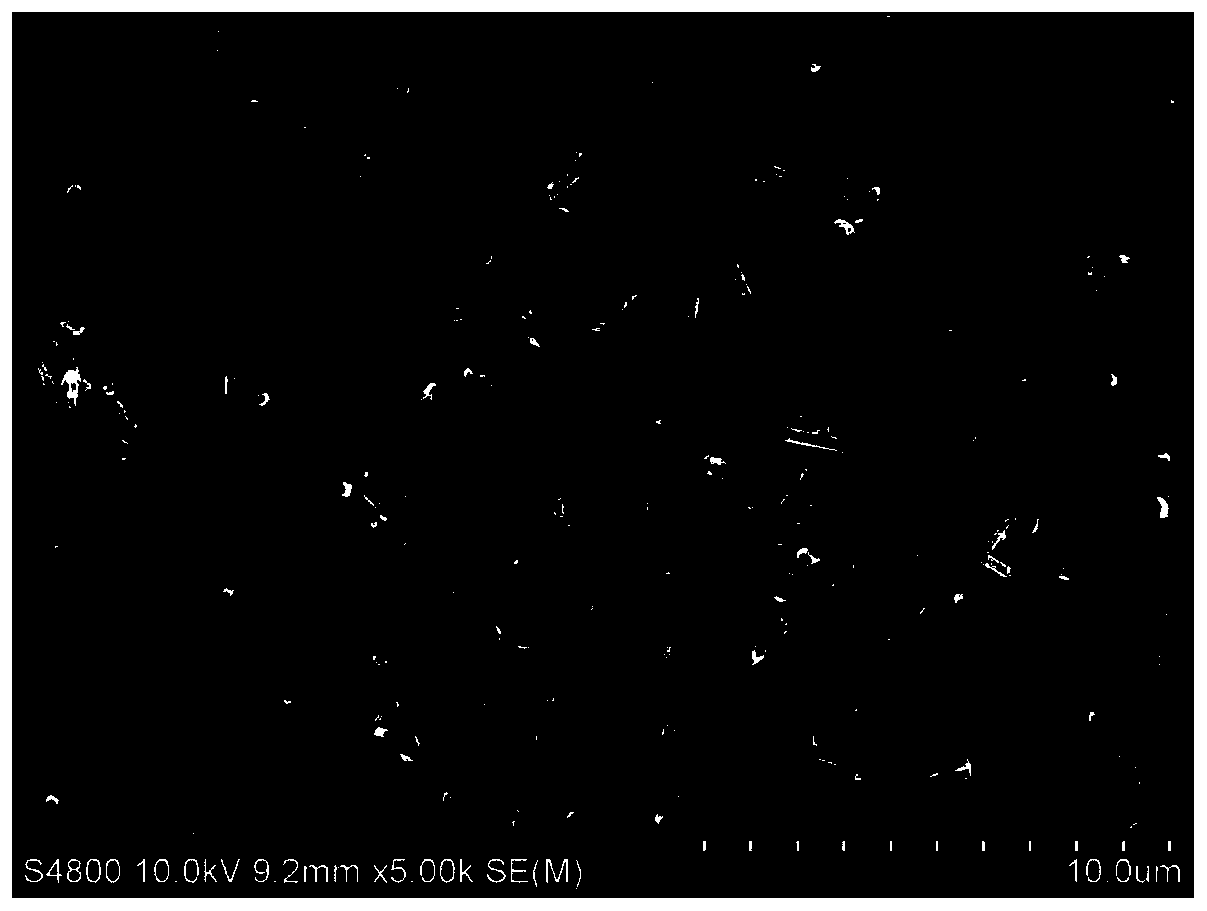

A kind of composite ceramic material and its manufacturing method and application

ActiveCN106830928BHigh strengthImprove machinabilityImpression capsDentistry preparationsCompression moldingComposite ceramic

The invention relates to a composite ceramic material, and a preparation method and application thereof. Specifically, the invention relates to a method for preparing the composite ceramic material. The method comprises the following steps of compression molding, high-temperature sintering, surface treatment, osmotic treatment and resin recombination. The invention also relates to the composite ceramic material prepared by the method and the application of the composite ceramic material in preparing a repairing material for tooth bodies or other hard tissues. The method disclosed by the invention has the advantages that the technology is simple, the operation is easy, and the like; the composite ceramic material prepared by the method has the advantages that the strength is high, the machinability is good, the elastic modulus and the hardness are similar to the tooth bodies, and the like, and is particularly suitable for being used as a repairing material of the tooth bodies, for example, the composite ceramic material can be used for preparing a dental crown, a veneer, an inlay and an onlay and can also be used for repairing other hard tissues.

Owner:哈工宁伯医疗科技泰州有限公司

Method and system for making dental restoration model based on multi-source images

ActiveCN111415419BEffective Guidance BasisImage enhancementImage analysisThree dimensional simulationDICOM

Owner:西安知北信息技术有限公司

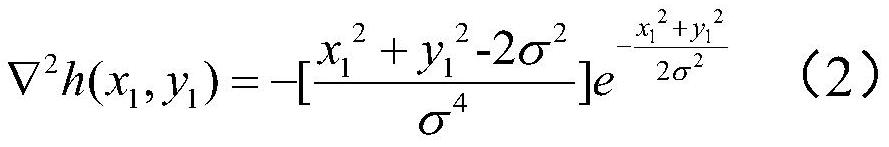

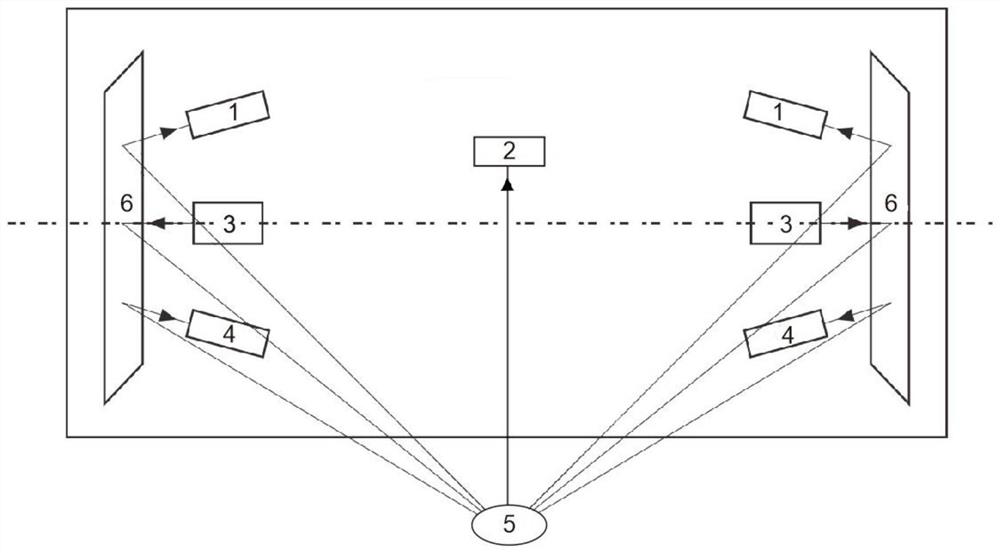

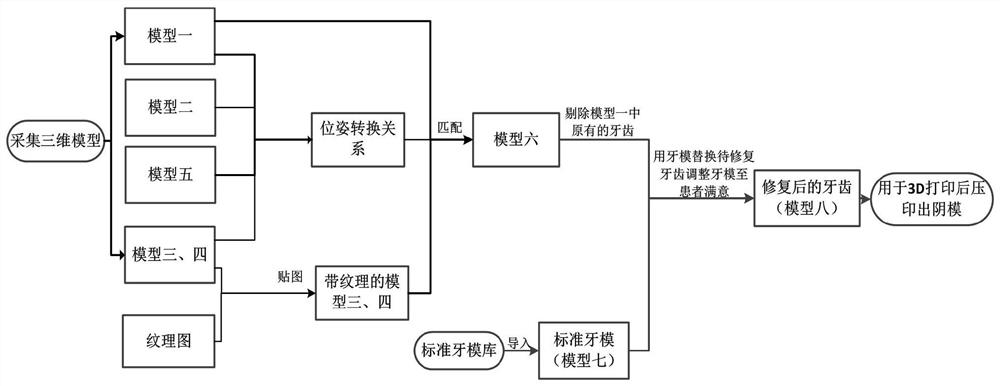

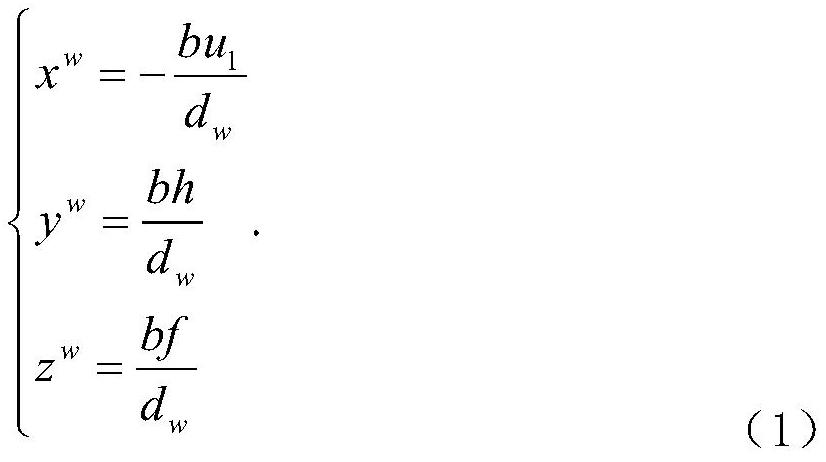

A dental restoration design method and device based on a three-dimensional scanning device

ActiveCN108062792BSpeed up the beauty design processImprove communication efficiencyImage enhancementImage analysisDental castEntire tooth

The invention discloses a dental restoration design method and device based on a three-dimensional scanning device. The three-dimensional scanning device quickly acquires a three-dimensional human face model and a patient's high-precision digital three-dimensional model of teeth. Through the matching relationship between the two models, it is registered into the mouth of the face model. At the same time, attach texture to the digital 3D model of teeth in various ways, and then take a single or multiple standard dental models to replace the single or multiple teeth to be repaired. Restoration design is carried out by adjusting standard dental model parameters, and at the same time display the three-dimensional model of the tooth after restoration to realize dental restoration design. The design parameters can be directly used to process and manufacture diagnostic veneers in dental aesthetic restoration, which saves the link of diagnostic wax-up in dental aesthetic restoration and speeds up the entire dental cosmetic design process. The digital smile design based on 3D can overcome many defects of 2D DSD and perfect the DSD design.

Owner:SUZHOU DEKA TESTING TECH CO LTD

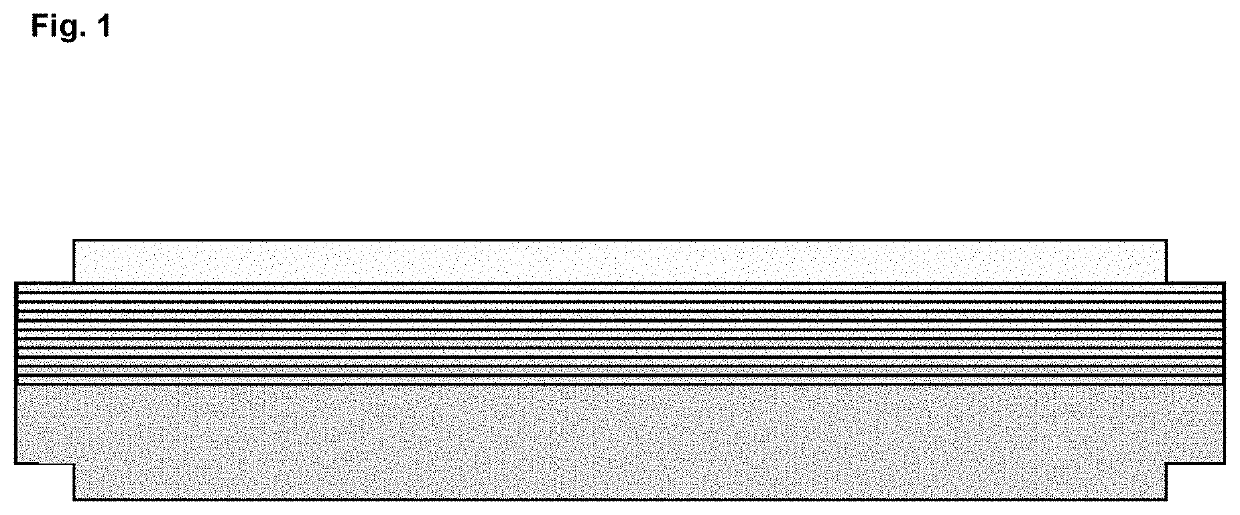

Multi-layered Zirconia Dental Blank With Reverse Layers, Process for its Preparation and Uses Thereof

ActiveUS20220104925A1Reduced strengthIncrease contentImpression capsArtificial teethBiomedical engineeringImplant

The present invention relates to a novel multi-layered zirconia dental blank comprising at least two reverse layers. Further, the invention relates to a process for the preparation of such a multi-layered zirconia dental blank. The invention also relates to the use of such a multi-layered zirconia dental blank for the production of a dental article. Preferred dental articles are artificial teeth, inlays, onlays, bridges, crowns, veneers, facings, crown frameworks, bridged frameworks, implants, abutments, copings or orthodontic appliances. Moreover, the invention relates to a process for producing a dental article out of such a multi-layered zirconia dental blank.

Owner:PRITIDENTA

Method and apparatus for preparing contoured glazed composite dental veneers

Owner:DENTAL ART INNOVATIONS

A kind of silicon nitride-resin dual continuous phase composite ceramic material and its manufacturing method and application

ActiveCN107056319BHigh strengthImprove machinabilityCeramicwareComposite ceramicRestorative material

The invention relates to a silicon nitride-resin dual-continuous phase composite ceramic material and a manufacturing method and application thereof. Specifically, the present invention relates to a method for manufacturing a silicon nitride-resin bicontinuous phase composite ceramic material, the method including molding, high-temperature sintering, surface treatment, infiltration treatment and resin compounding steps. The present invention also relates to the silicon nitride-resin bicontinuous phase composite ceramic material prepared by the method and the application of the composite ceramic material in manufacturing tooth or other hard tissue restoration materials. The method of the present invention has the advantages of simple process and easy operation, etc. The composite ceramic material prepared by the method has the advantages of high strength, good processability, elastic modulus and hardness similar to tooth body, etc., and is especially suitable for tooth restoration Materials, e.g. for the manufacture of crowns, veneers, inlays, onlays, but also for the restoration of other hard tissues.

Owner:哈工宁伯医疗科技泰州有限公司

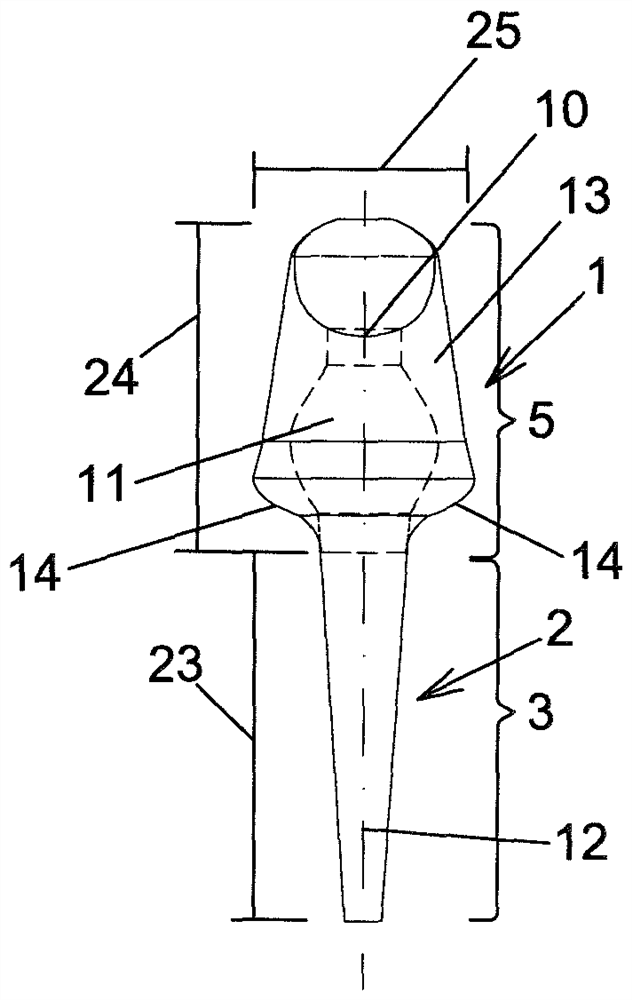

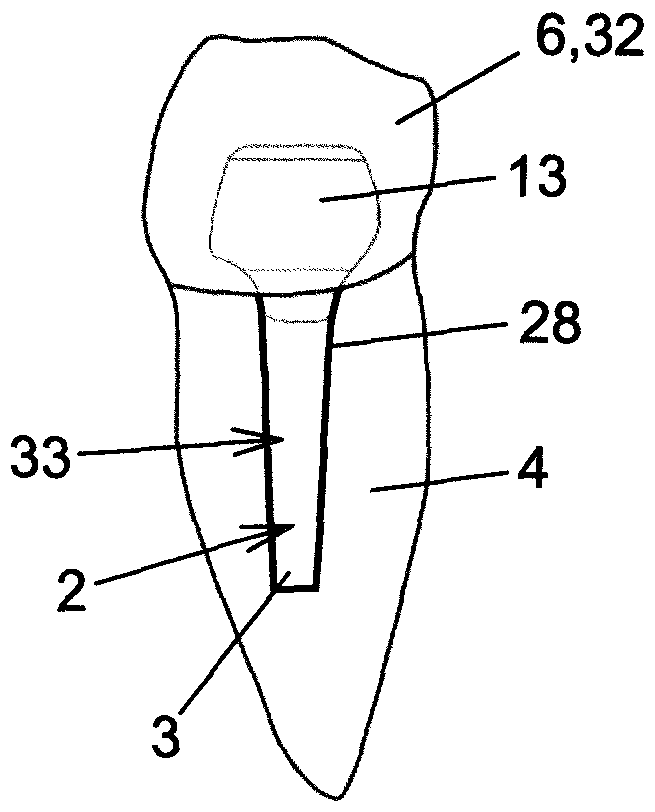

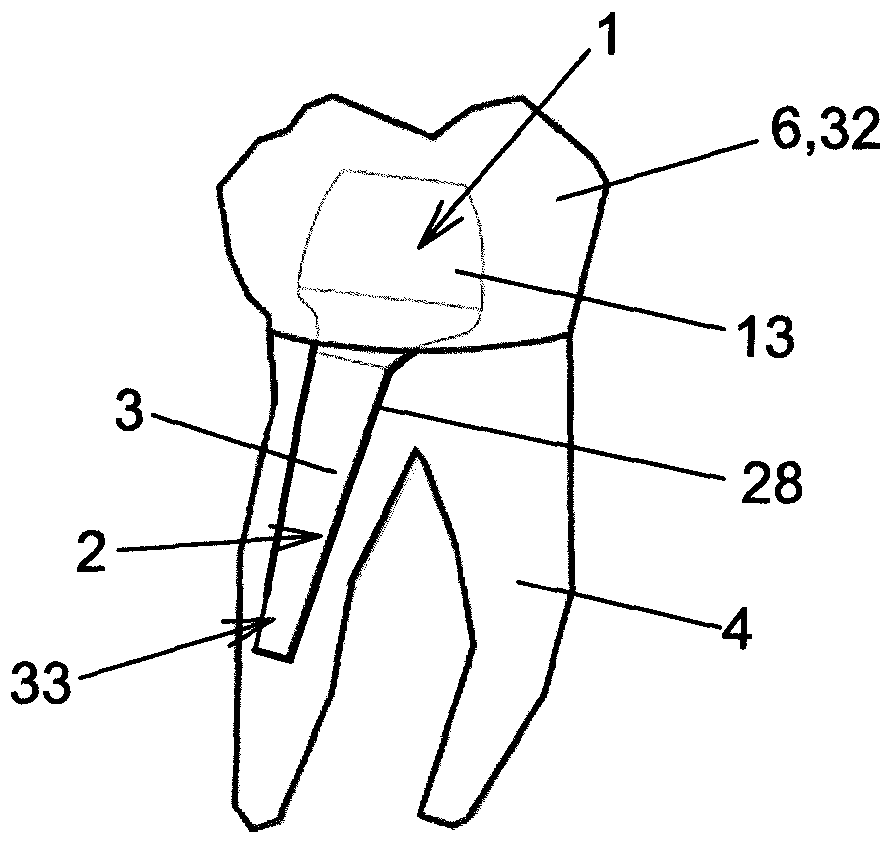

endodontic pin

Endodontic pin (1) with a base pin (2), wherein the base pin (2) has a root area (3) for fixing the base pin (2) in a natural tooth root (4) and a The crown veneer (6) is fixed at the endodontic pin (1) and / or in the coronal region (5) arranged in the natural tooth crown (32), and the base pin (2) consists of a composite material (7) which has At least one organic binder (8), wherein the composite material (7) has glass particles (9) as filler.

Owner:雪绒花牙科产品有限责任公司

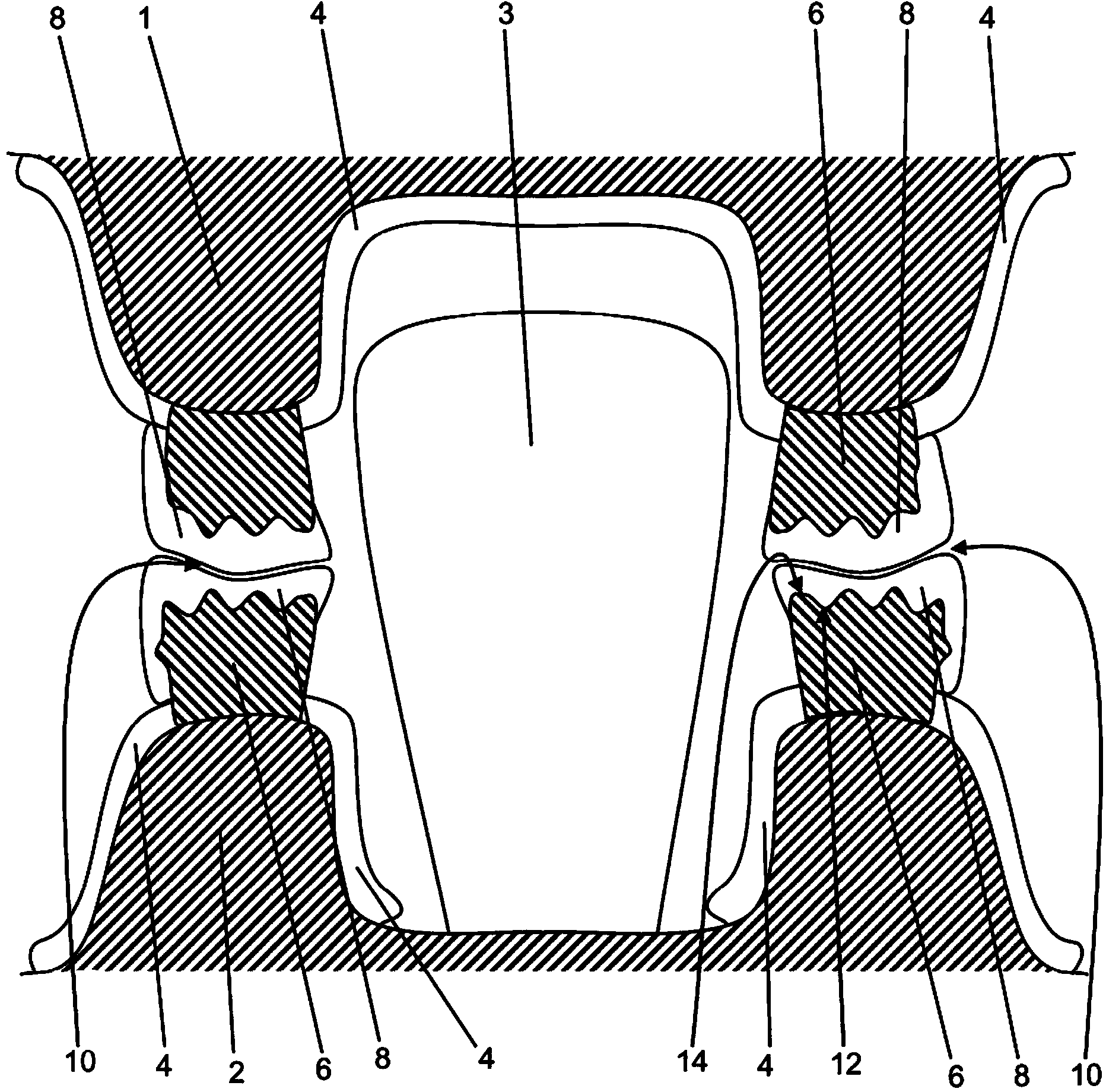

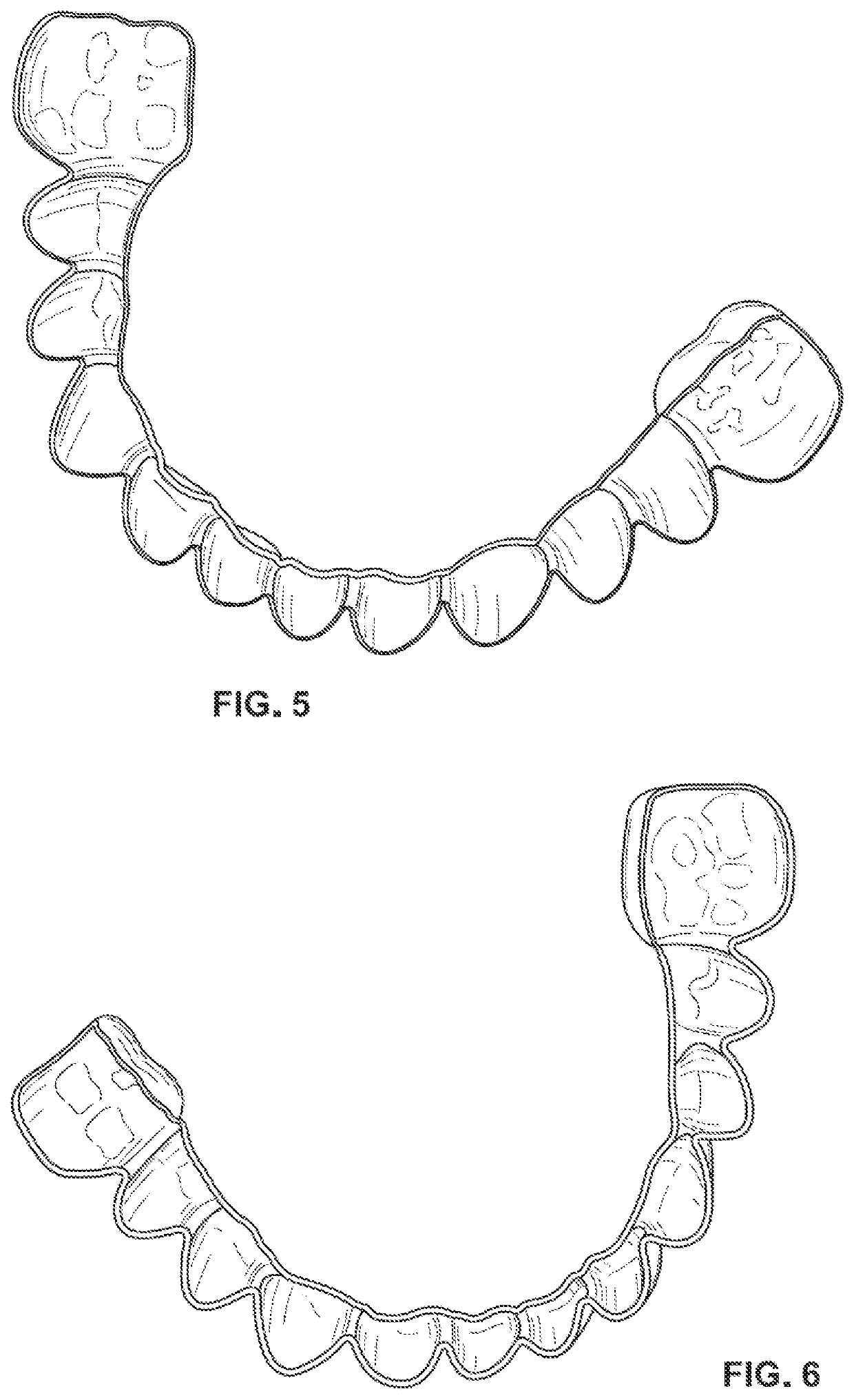

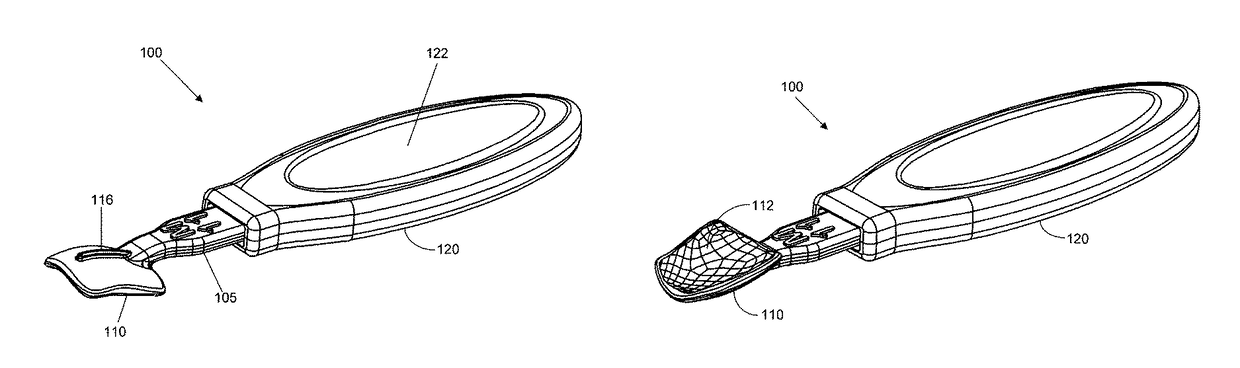

Matrices for dental restoration

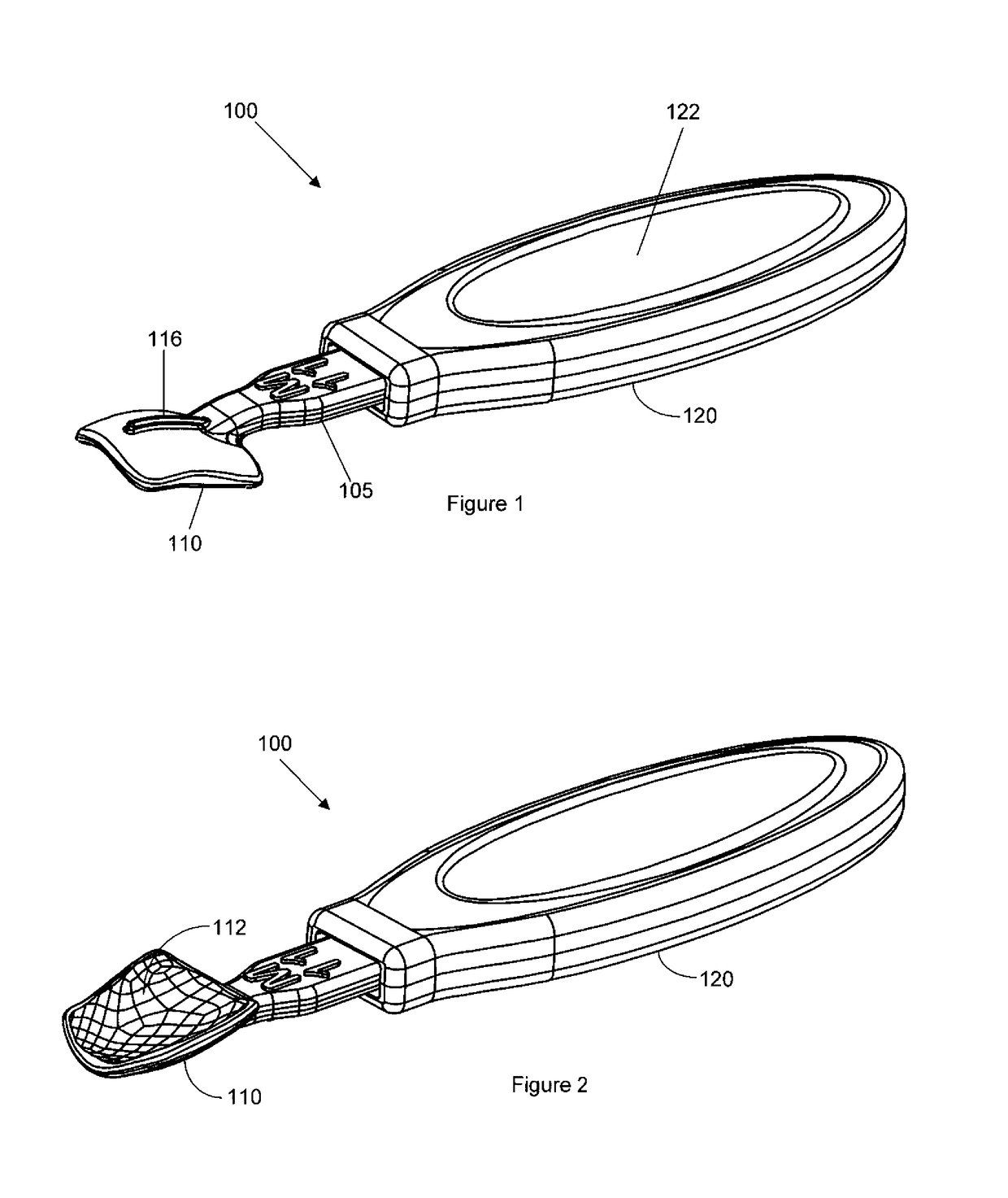

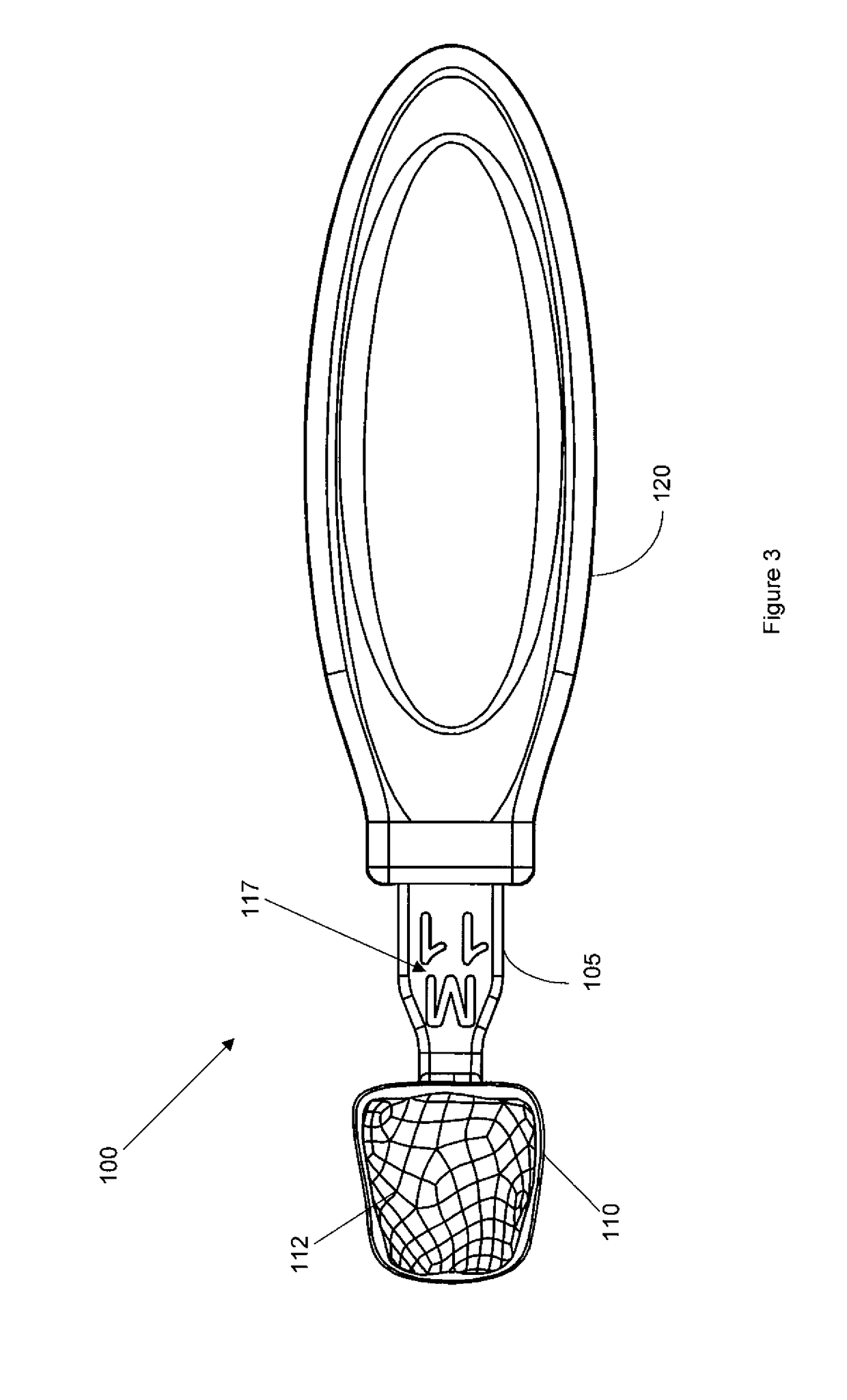

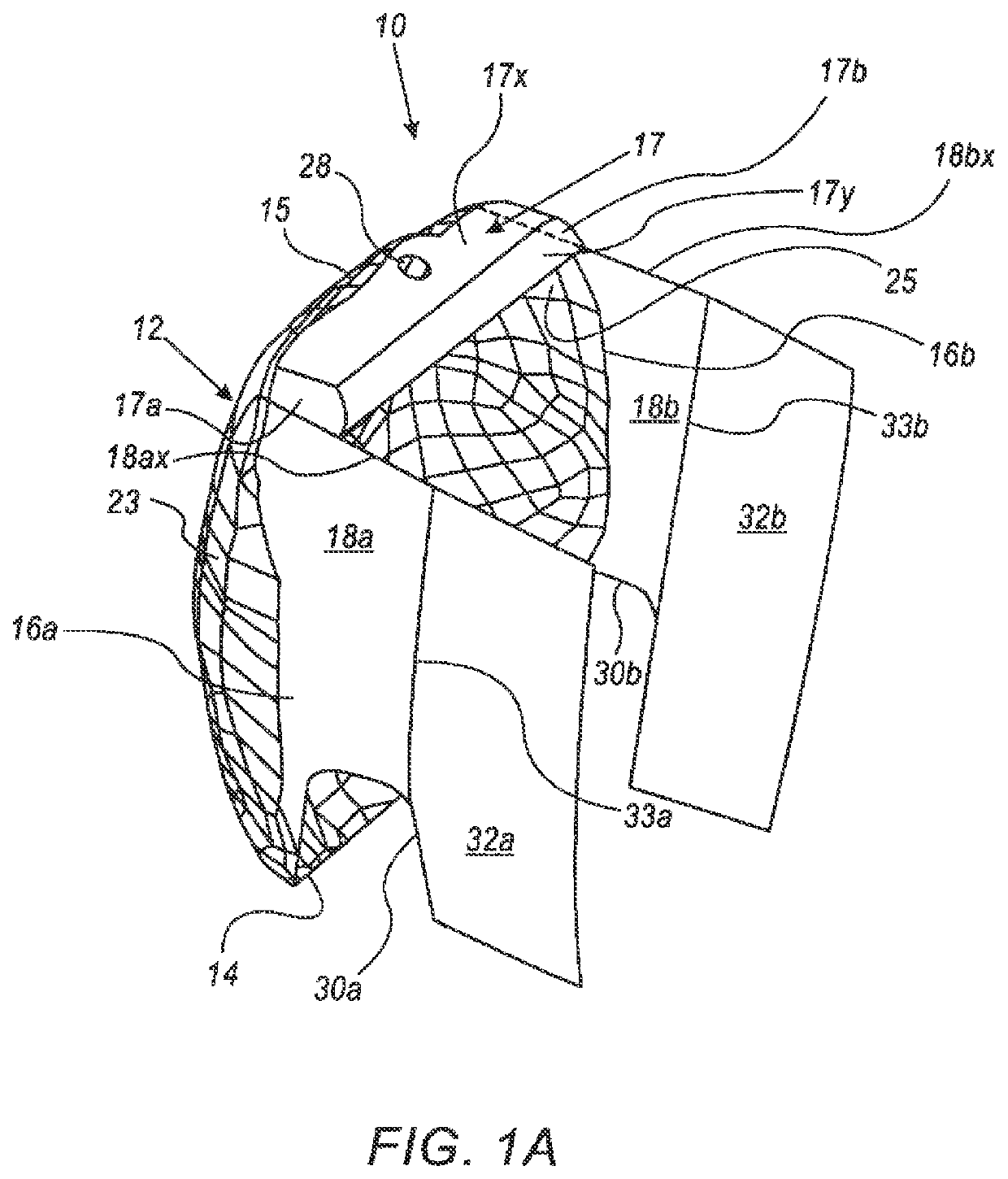

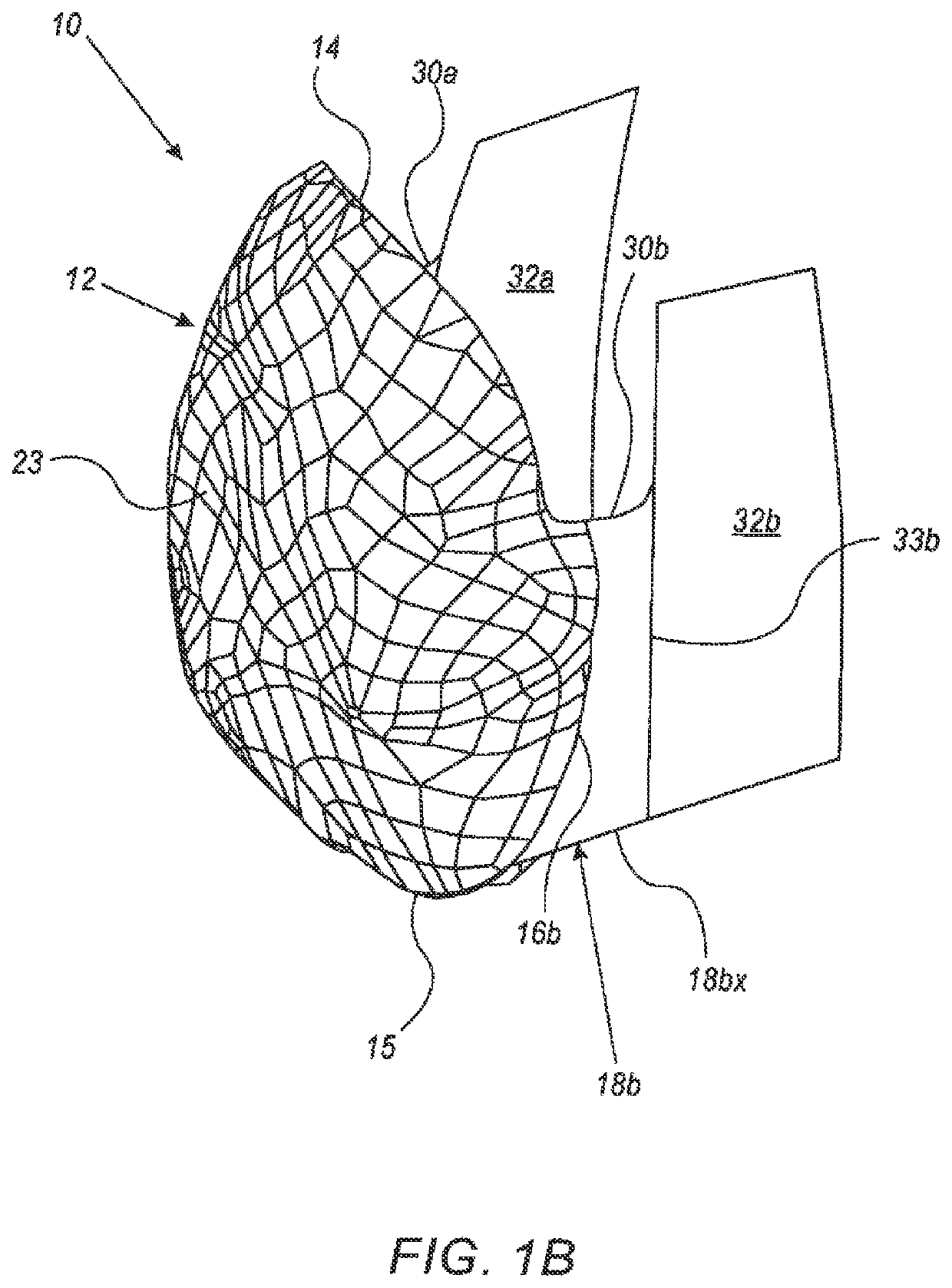

PendingUS20220249199A1Precise processingExtremely hygienic and sanitaryArtificial teethDental aidsUltraviolet lightsBiomedical engineering

A dental matrix includes an outwardly extending column, which is engaged by an instrument, allowing the dentist to move the instrument and maneuver the matrix into position on the operative tooth to create a cavity for the veneer. The cavity is filled with curable material, which is cured by light, such as ultraviolet light, and once curing is complete, the matrix is removed from the tooth, which now has the veneer formed thereon.

Owner:IVENEER LTD

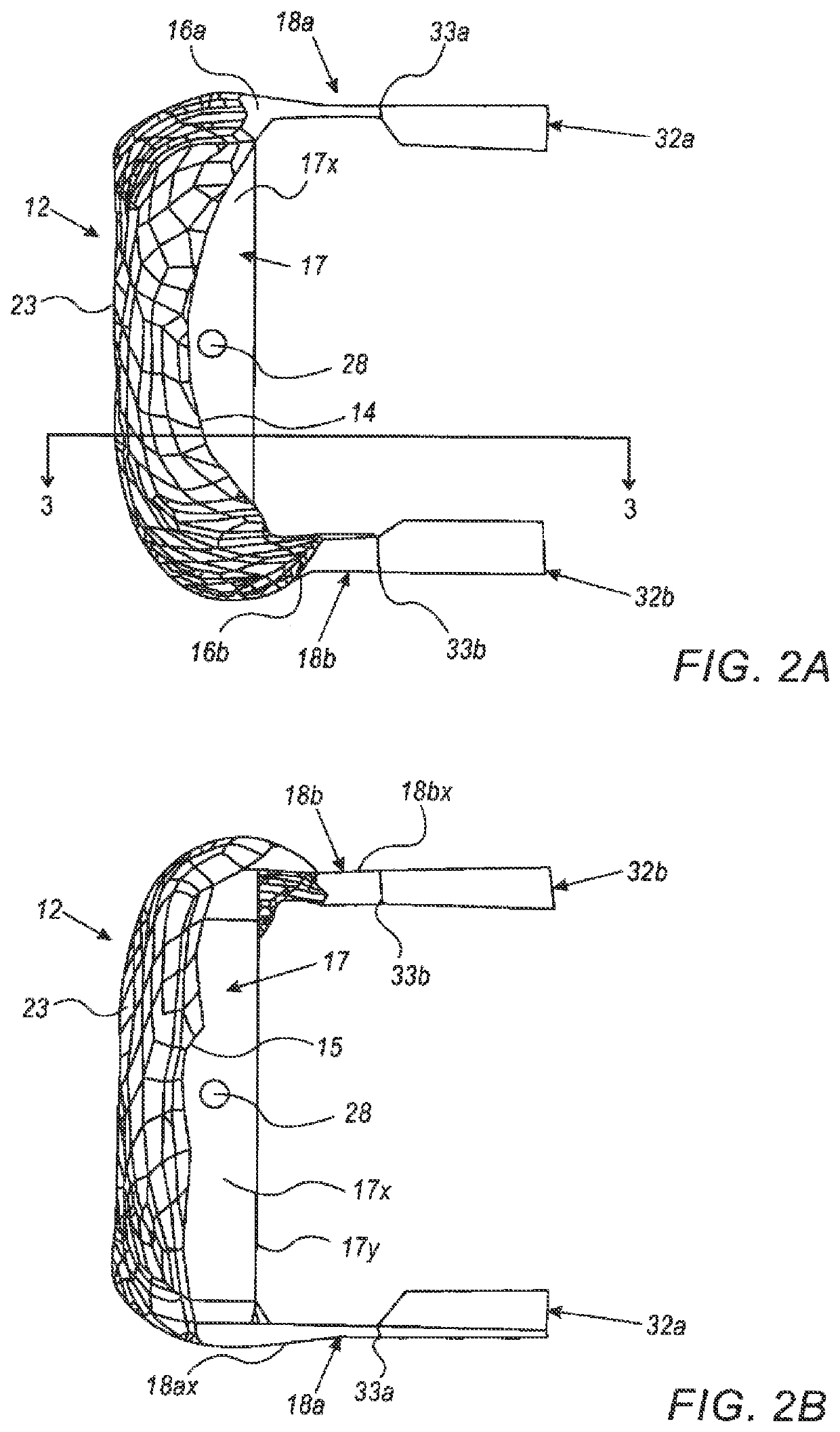

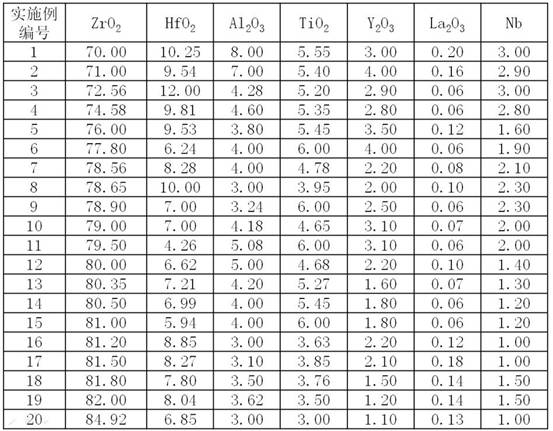

Ceramic dental veneer and preparation method thereof

ActiveCN107397683BNo precipitationHigh strengthImpression capsMedical preparationsHazardous substanceVeneer

The invention discloses ceramic veneer for a tooth. The ceramic veneer is prepared from components in percentage by mass as follows: 70%-85% of ZrO2, 4%-12% of HfO2, 3%-8% of Al2O3, 3%-6% of TiO2, 1%-4% of Y2O3, 0.05%-0.2% of La2O3 and 1%-3% of Nb through mixing and firing, wherein the average particle size of the raw materials ranges from 0.05 mu m to 0.3 mu m. The ceramic veneer for the tooth is made from safe and non-toxic raw materials, can be soaked in saliva for a long time without separating out harmful substances and cannot deform or become crisp even if used for a long period of time.

Owner:深圳市一诺牙科技术有限公司

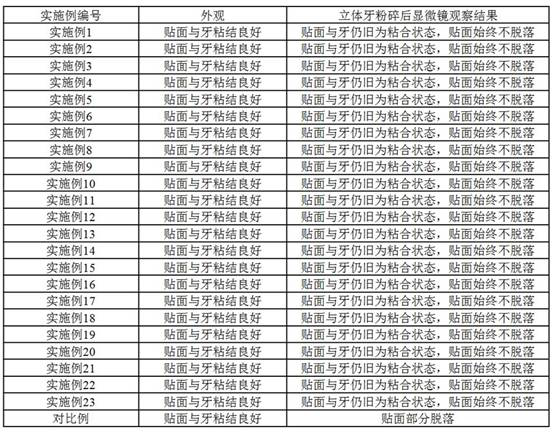

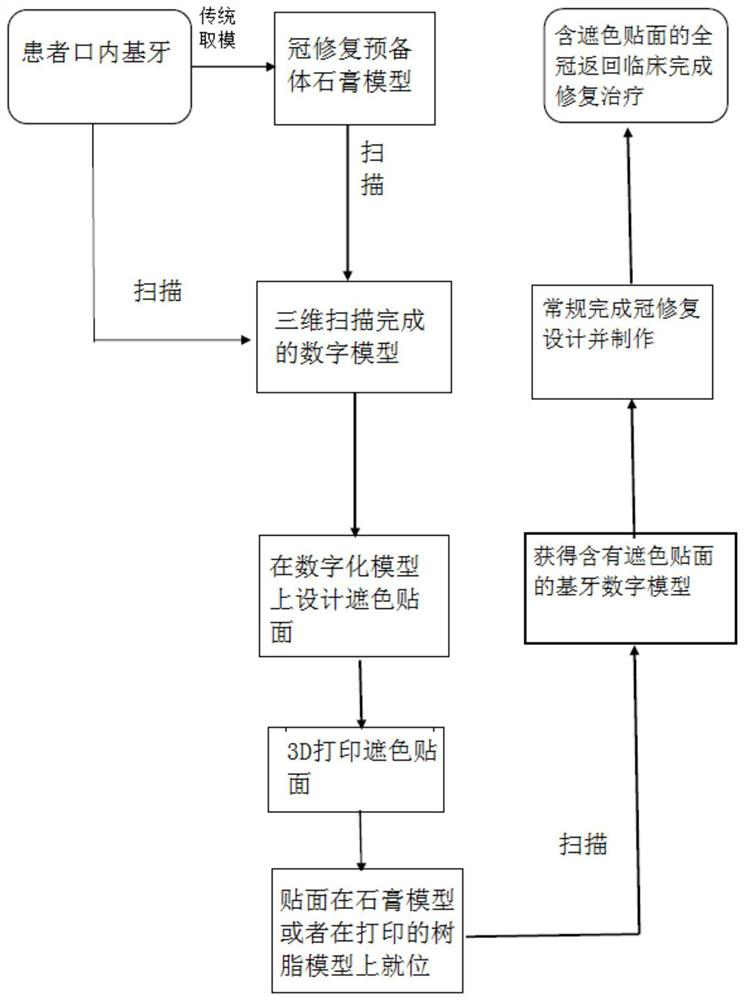

A method for making a color-shielding veneer in an oral crown

ActiveCN113520631BExpand the scope of clinical aesthetic treatmentShadeTeeth fillingTeeth cappingOptical scannersDiscolored tooth

The invention discloses a method for making a color-shielding veneer in an oral crown. Based on a digital optical scanner and denture design software, a color-shielding veneer is produced by using 3D printing technology. The color-shielding veneer uses low-transmittance ceramic materials. Through the design of the veneer range on the digital abutment model, crystallization after the 3D printing technology is completed, it will be placed on the abutment preparation to cover the discolored tooth, and facilitate the restoration of the high-transparency all-ceramic material crown. The veneer made by this method expands the scope of clinical application of high-permeability ceramic materials such as glass ceramics, enhances the strength of the restoration, and improves the patient's experience and satisfaction in seeing a doctor.

Owner:合肥市口腔医院

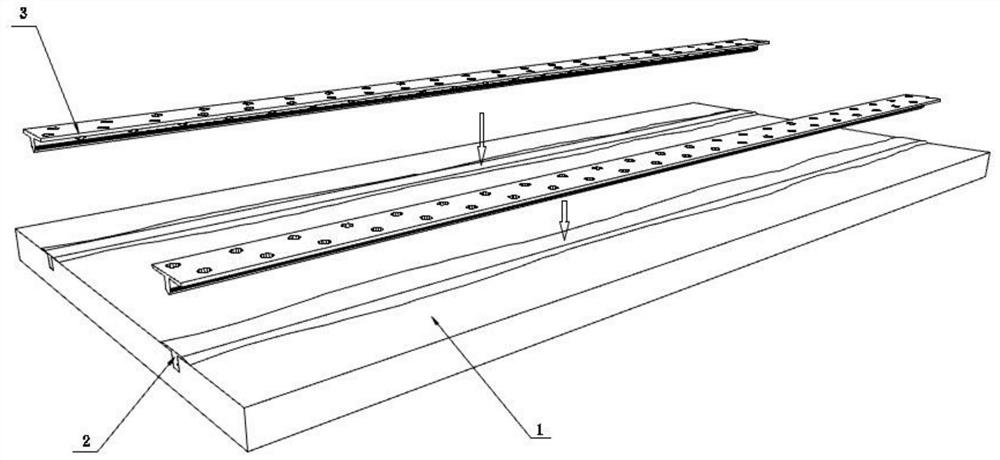

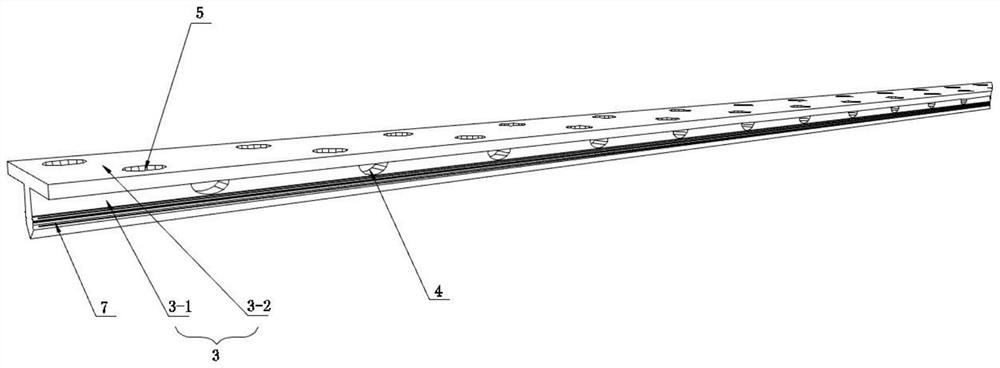

Positioning piece for controlling installation deformation of marble veneer and installation method

PendingCN112031317AReduce warpage and other problemsWill not deformCovering/liningsAdhesive cementStructural engineering

The invention discloses a positioning piece for controlling installation deformation of a marble veneer. The positioning piece comprises the marble veneer, wherein a plurality of grooves are formed inthe back surface of the marble veneer; T-shaped positioning pieces are installed in the grooves through adhesives; each T-shaped positioning piece comprises a vertical plate and a horizontal plate which are distributed in a right-angle mode; a first through hole and a second through hole are formed in each vertical plate and the corresponding horizontal plate respectively; the vertical plates areinserted into the grooves and are fixedly connected through the adhesives; and the adhesives sequentially overflow from the first through holes to the second through holes under the extrusion of thevertical plates, and are flattened and cured to form rubber nail caps. An installation method of the positioning piece for controlling the installation deformation of the marble veneer comprises the following steps that the positions and the sizes of the grooves in the back surface of the veneer are determined, and the adhesives are added into the grooves; the vertical plates of the T-shaped positioning pieces are pressed into the grooves, and the adhesives in the grooves overflow from the second through holes under the extrusion of the T-shaped positioning pieces; the overflowing adhesives are flattened and cured to form the rubber nail caps; and the stable and deformation-resistant marble veneer is formed.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

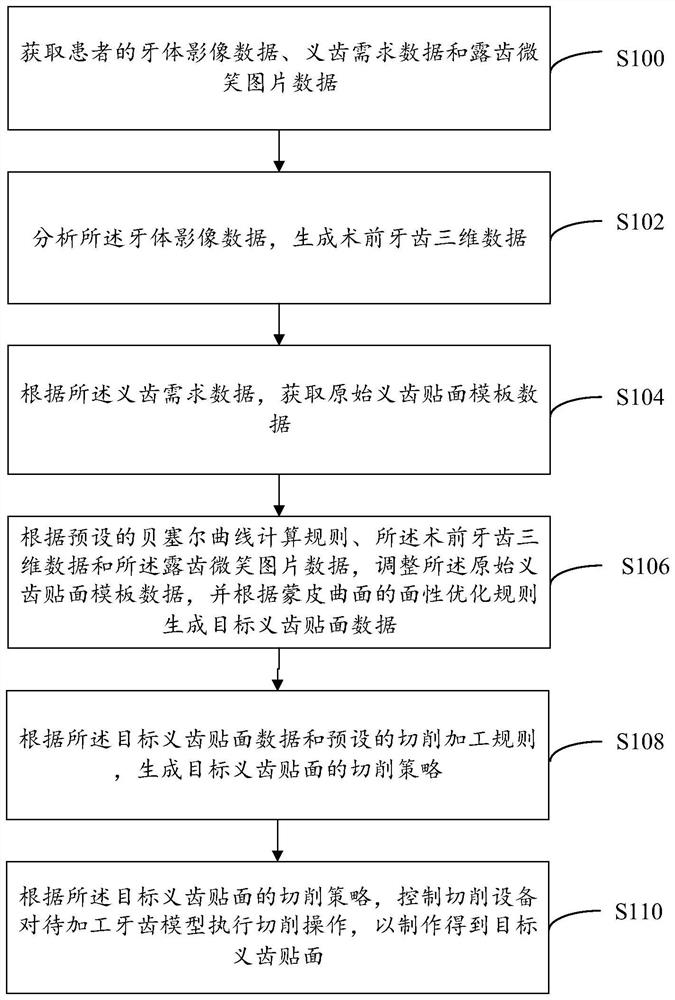

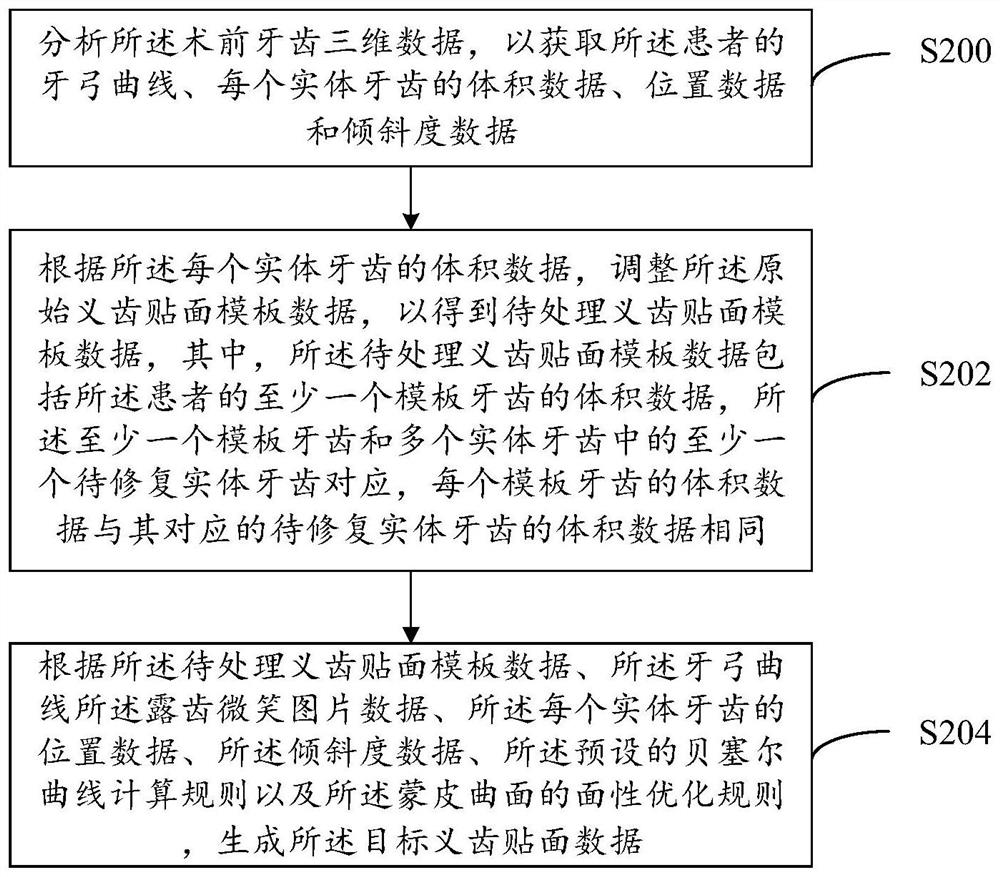

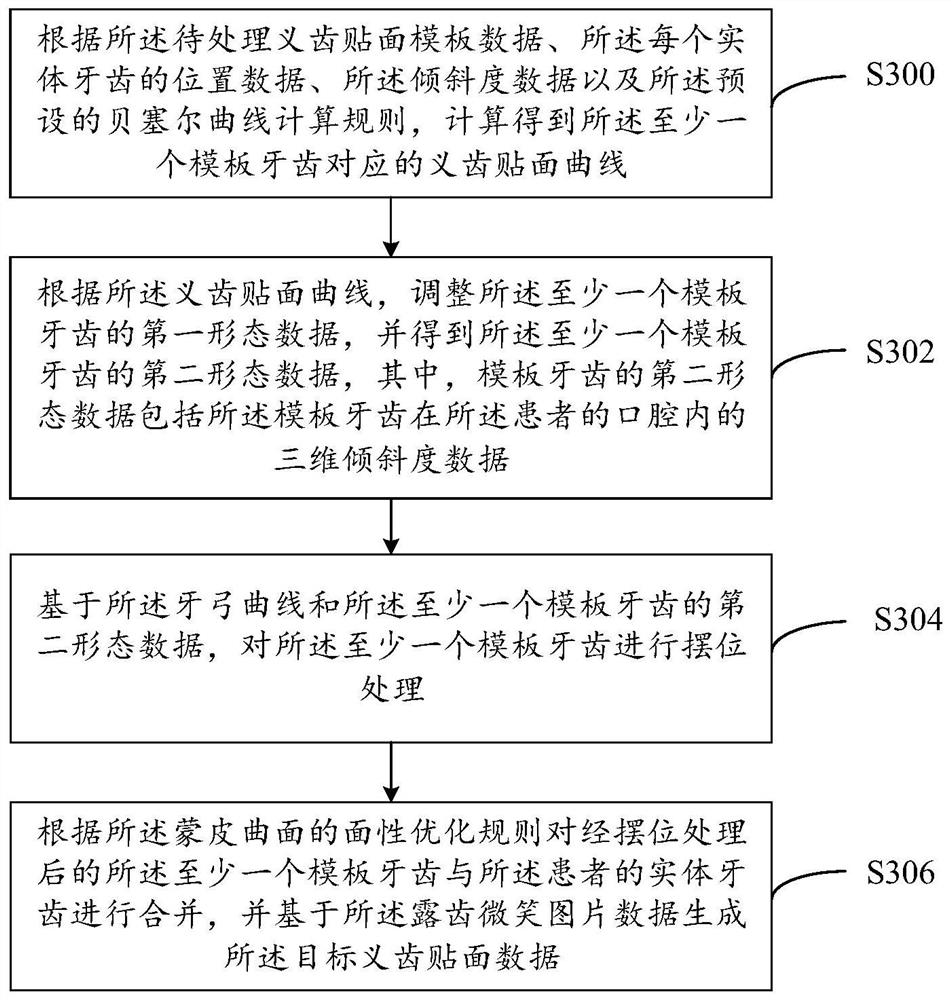

False tooth veneering manufacturing method and system, computer equipment and readable storage medium

PendingCN114145869AImprove efficiencyHigh precisionGeometric CADImage enhancementDenture DesignData profiling

The invention provides a false tooth veneering manufacturing method. The false tooth veneering manufacturing method comprises the following steps: acquiring tooth image data, false tooth demand data and tooth-exposed smile picture data of a patient; analyzing the tooth image data to generate preoperative tooth three-dimensional data; obtaining original denture veneering template data according to the denture demand data; according to a Bezier curve calculation rule, the preoperative tooth three-dimensional data and the tooth exposure smile picture data, adjusting original denture veneering template data, and generating target denture veneering data; generating a cutting strategy of the target denture veneer according to the target denture veneer data and a preset cutting processing rule; and according to the cutting strategy of the target denture veneer, controlling cutting equipment to perform cutting operation on the to-be-processed tooth model so as to obtain the target denture veneer. The method directly depends on computer software to calculate and obtain the target denture veneering data, the automation degree is high, the denture design efficiency and precision are improved, and then the follow-up denture veneering manufacturing efficiency and precision are improved.

Owner:SHENZHEN UP3D TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com