Connecting assembly with good stability

A technology for connecting components and stability, applied in the field of decoration design, can solve problems such as safety, hidden dangers, falling off, etc., and achieve the effect of fast installation efficiency, high safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

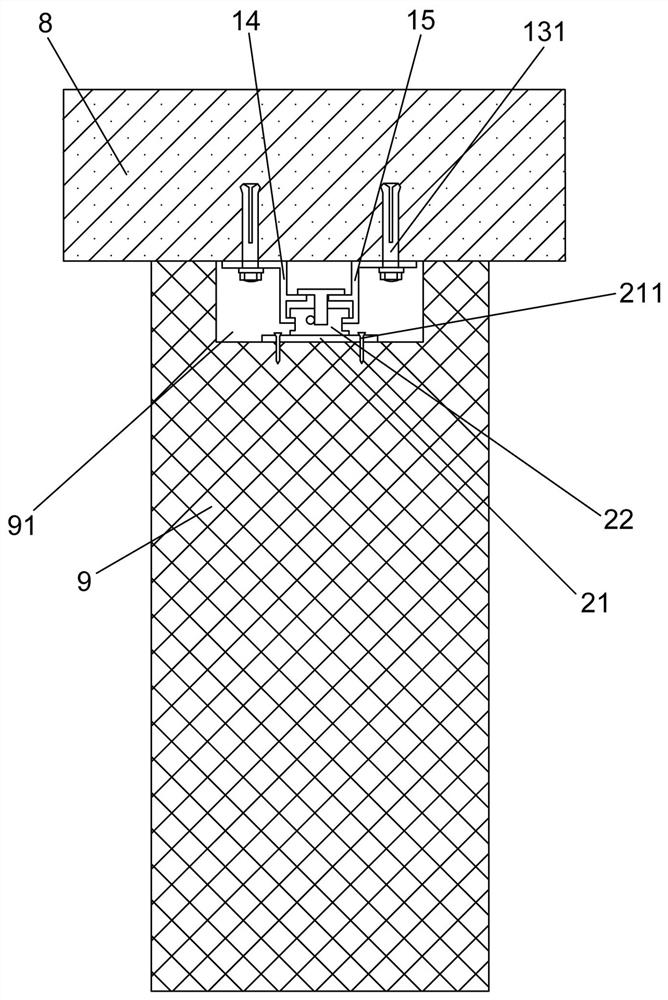

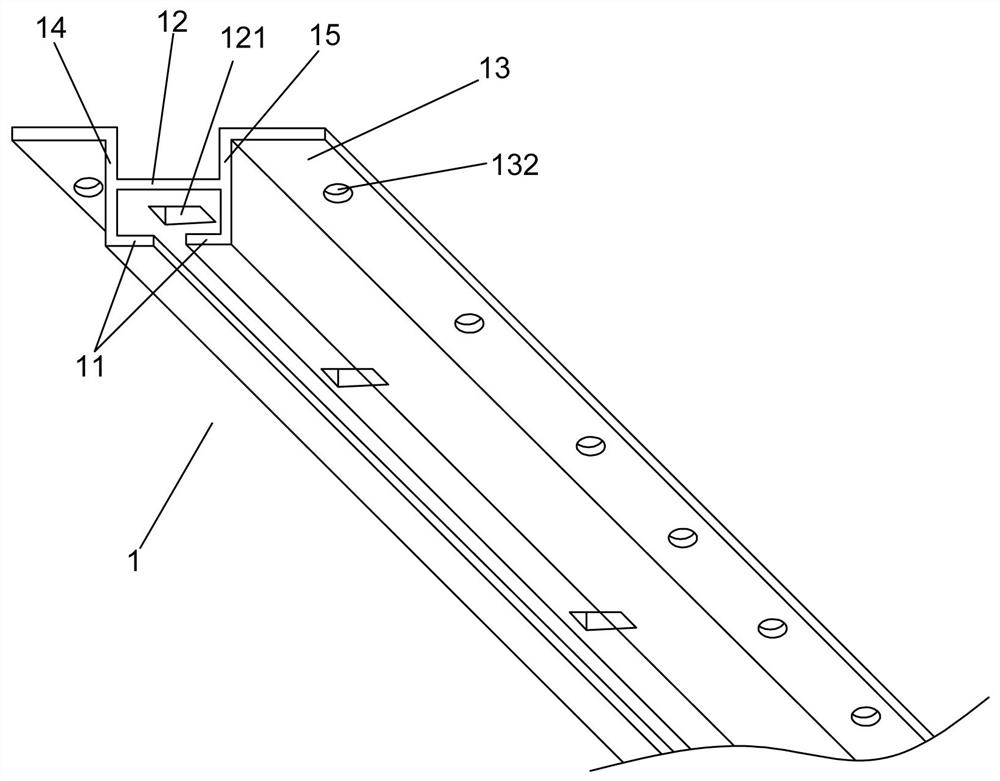

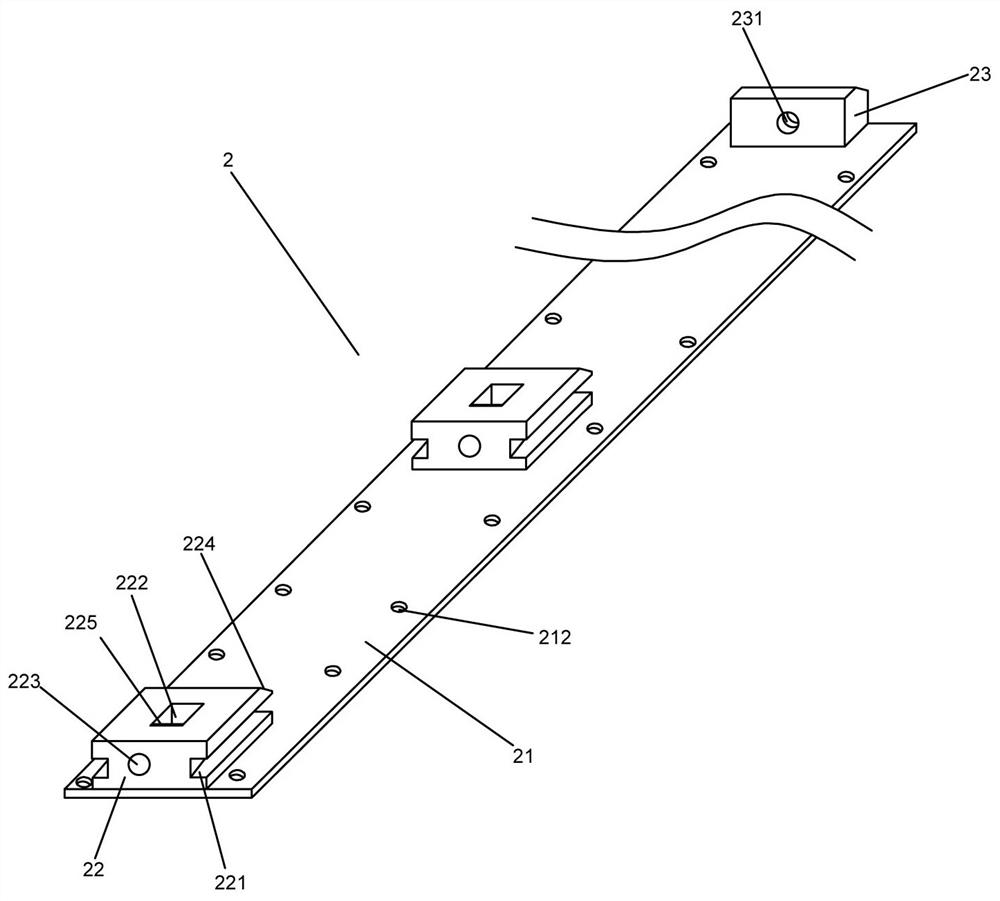

[0033] Example 1: Such as Figure 1 to 6 As shown, only one of the embodiments of the present invention, a good stability connection assembly, including a first connecting member 1 disposed on the fixing plate 8 and one end provided in the forming panel 9 close to the fixing plate 8 The second connector 2 in the groove 91, the second connecting member 2 includes a bottom plate 21 and a card plate 22 disposed to the first connecting member 1 direction, the cardboard 22. The side surface is provided with a slot 221, and the first connector 1 is provided with a raised block 11 extending into the chute 221 adjacent to one end of the bottom plate 21, the width of the chute 221, which is greater than the convex block. The thickness of 11, the first connector 1 is provided with an adjustment plate 12, and the adjustment hole 121 is provided on the adjustment hole 12, and the card plate 22 is provided with a vertically extended square first groove 222 and with The first groove 222 is horiz...

Embodiment 2

[0045] Example 2, still Figure 1 to 6 As shown, only one of the embodiments of the present invention, on the basis of the first embodiment, a stable connection assembly of the present invention, and the first vertical plate 14 and the first, respectively, respectively. The two vertical plate 15, in practice, the adjustment board 12 is disposed between the first vertical plate 14 and the second vertical plate 15 and functions to connect the first vertical plate 14 and the second vertical plate 15, the cardboard 22 is at least A portion of the C-shaped space enclosed in the first vertical plate 14, the adjustment plate 12, and the second vertical plate 15, and slides in the extended direction of the first connector 1 in this space.

[0046] Moreover, the first vertical plate 14 and the second vertical plate 15 are provided with a pad 13 away from one end of the second connecting member 2. The pad 13 is provided with a first bolt 131 for connecting to the fixing plate 8 and a first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com