Patents

Literature

315 results about "Dental cast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

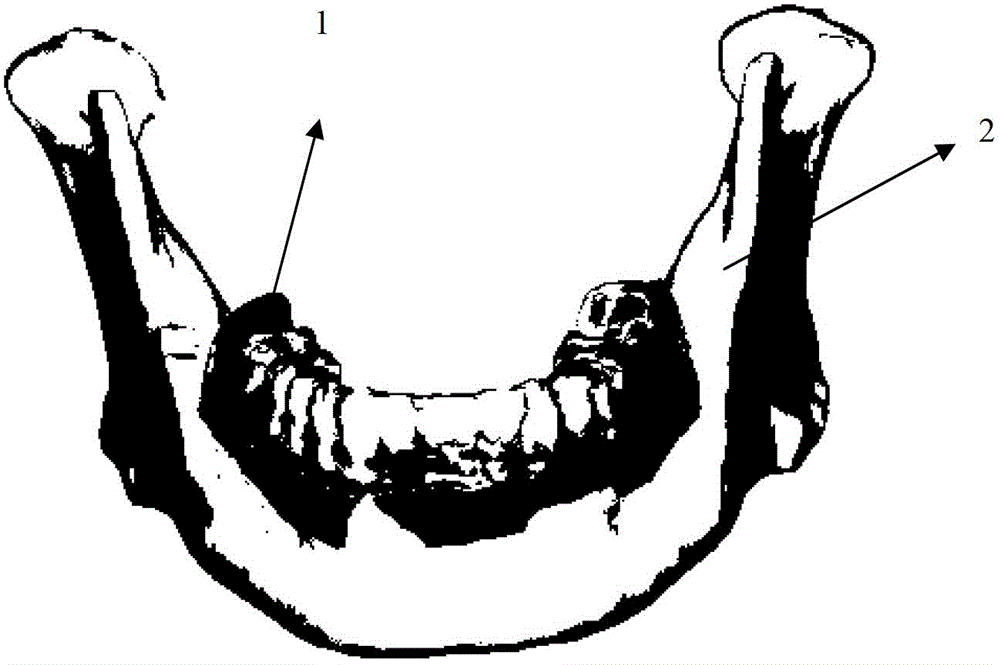

The dental cast (dental mould or dental model) is the positive reproduction of a patient's teeth and surrounding tissues obtained from a dental impression (which is a negative imprint of teeth and soft tissues). dental impression : the dental cast obtained from the impression :

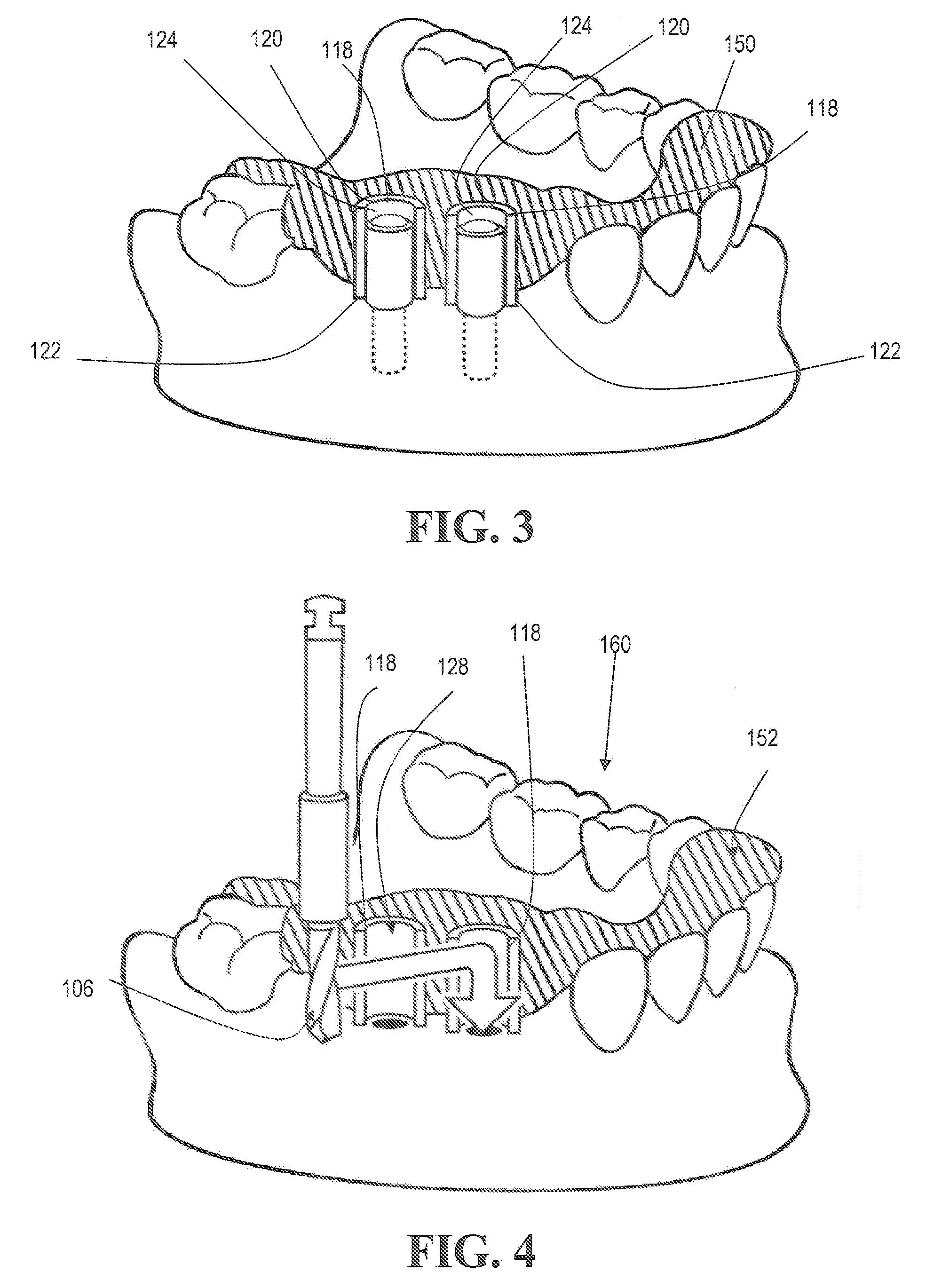

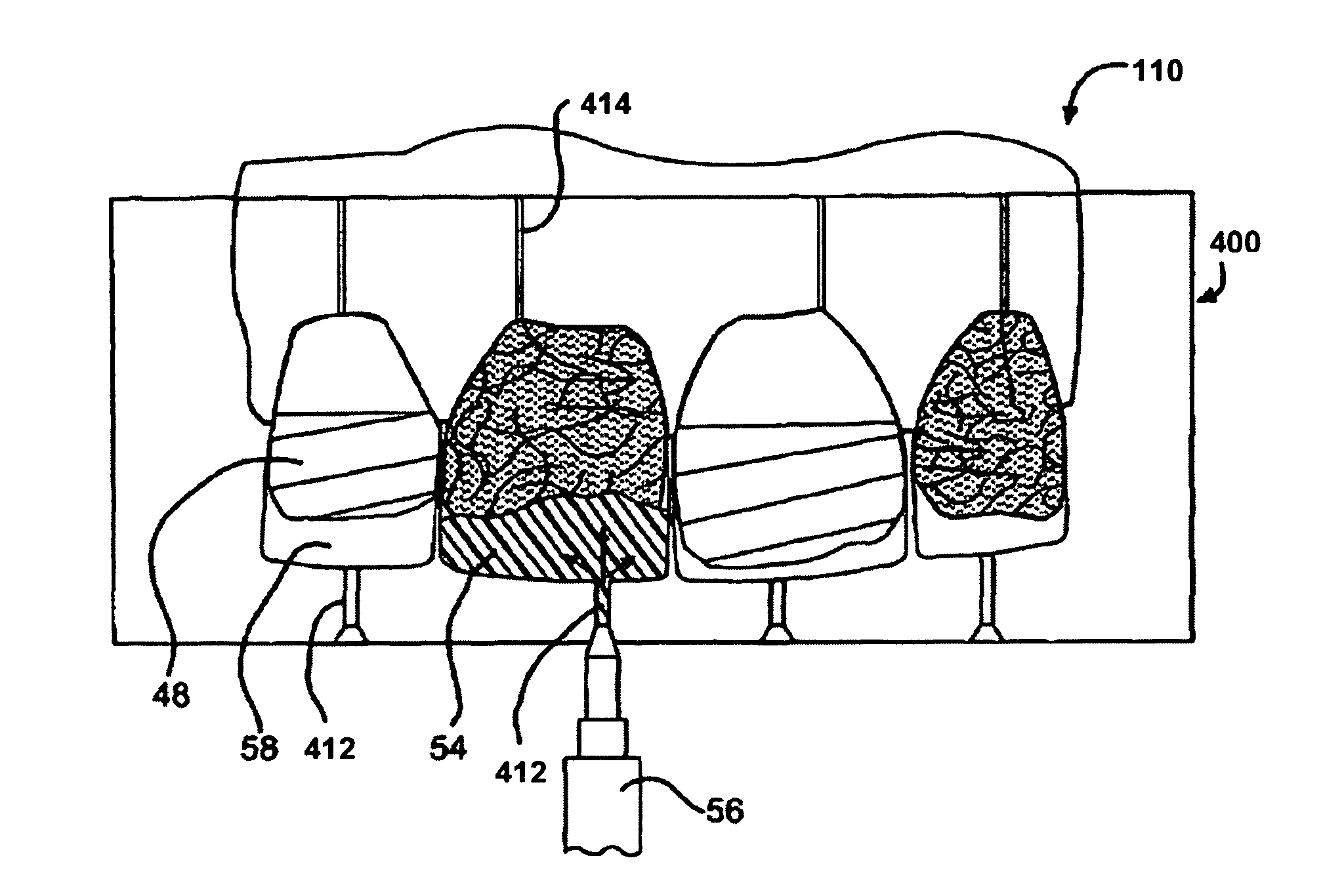

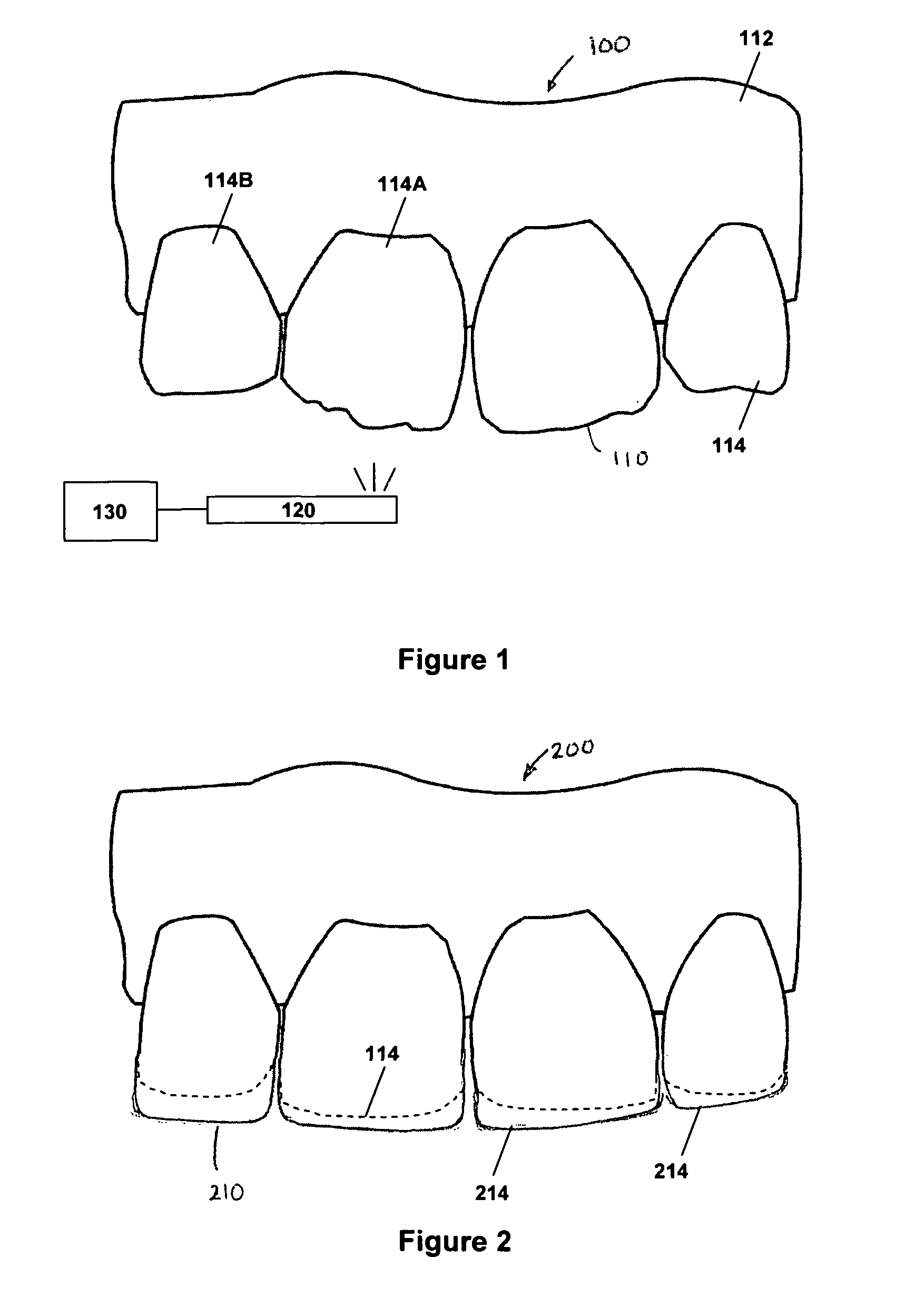

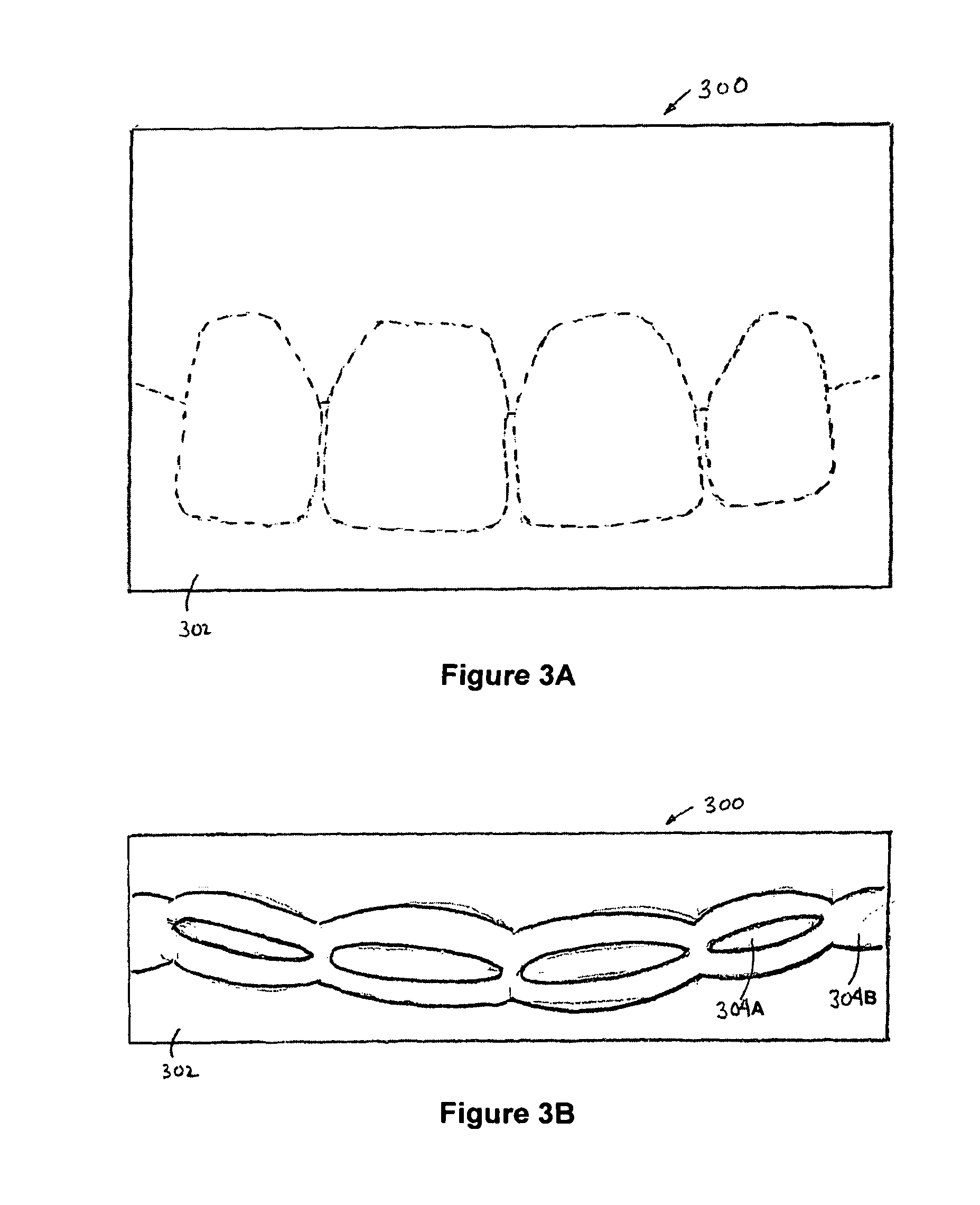

Method for dental restoration and related kit

ActiveUS20110212420A1Resist slippagePrecise alignmentTeeth fillingDental articulatorsEngineeringOral cavity

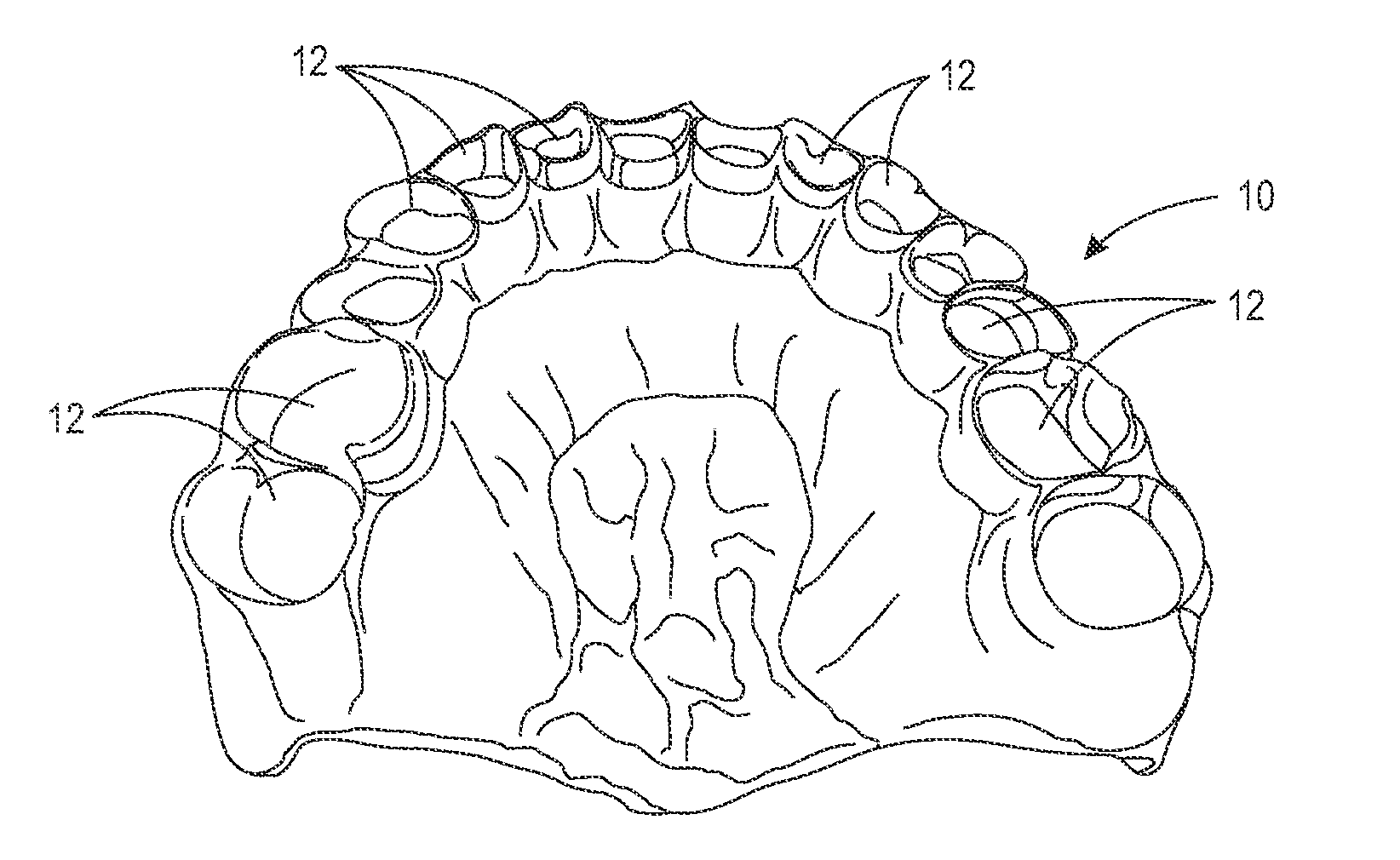

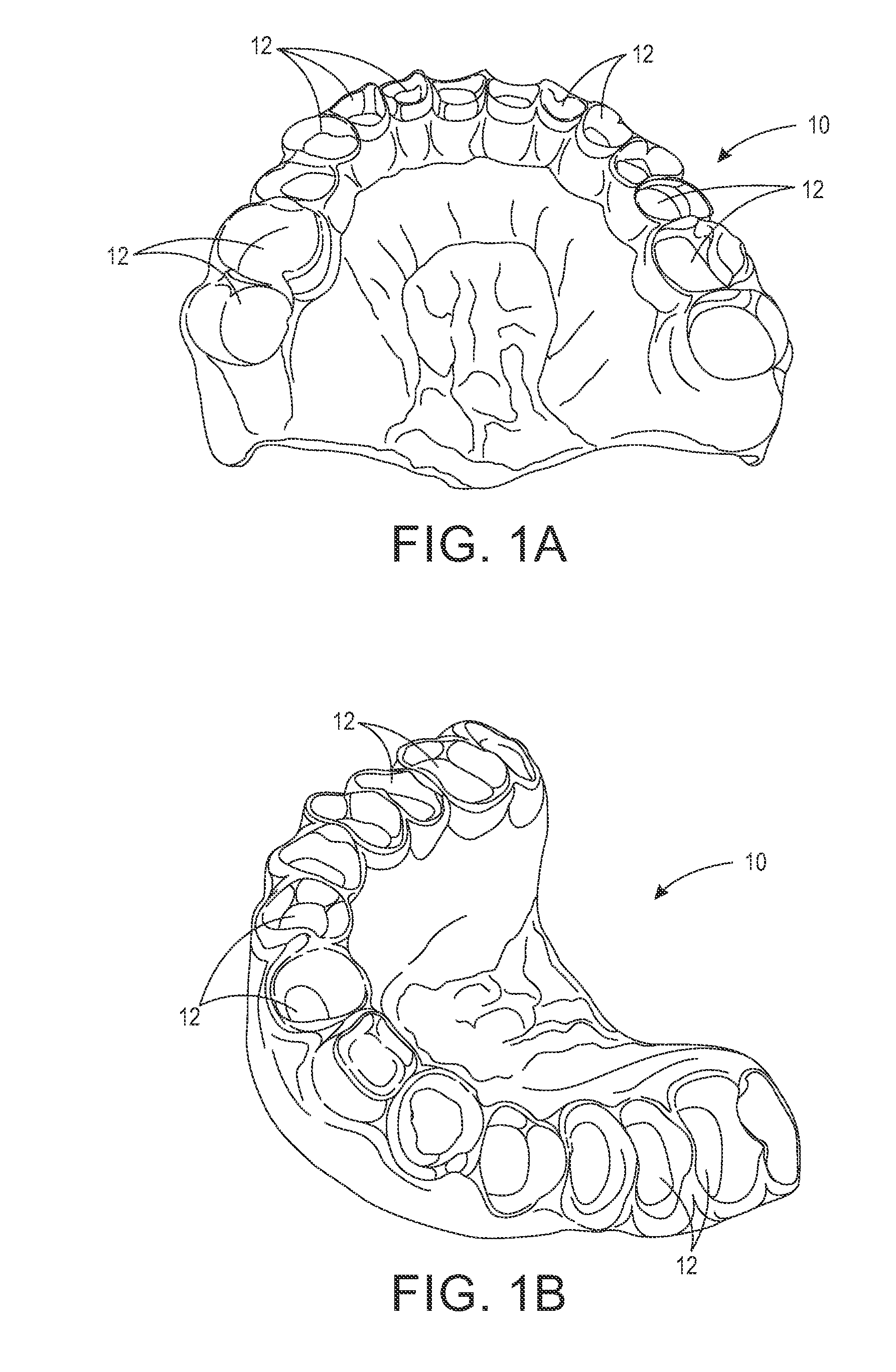

The disclosure generally relates to a method for forming a dental mold. The method generally includes: (a) scanning an existing dental structure to generate a three-dimensional first digital model of the existing dental structure, (b) modifying the first digital model of the existing dental structure to generate a three-dimensional second digital model of a planned dental structure; (c) generating a three-dimensional third digital model corresponding to a negative of the second digital model; (d) digitally sectioning the third digital model into at least one buccal model portion and at least one lingual model portion of the third digital model; and (e) creating a dental mold comprising at least one buccal mold portion and at least one lingual mold portion based on the sectioned third digital model. The disclosure also relates to (a) methods of assembling the dental mold over a tooth and a gum of a patient having an existing dental structure in need of dental restoration, (b) methods of performing a dental restoration on the existing dental structure of the patient using the dental mold, and (c) kits including components for forming the dental mold and / or for performing the dental restoration using the dental mold.

Owner:VUILLEMOT WILLIAM C

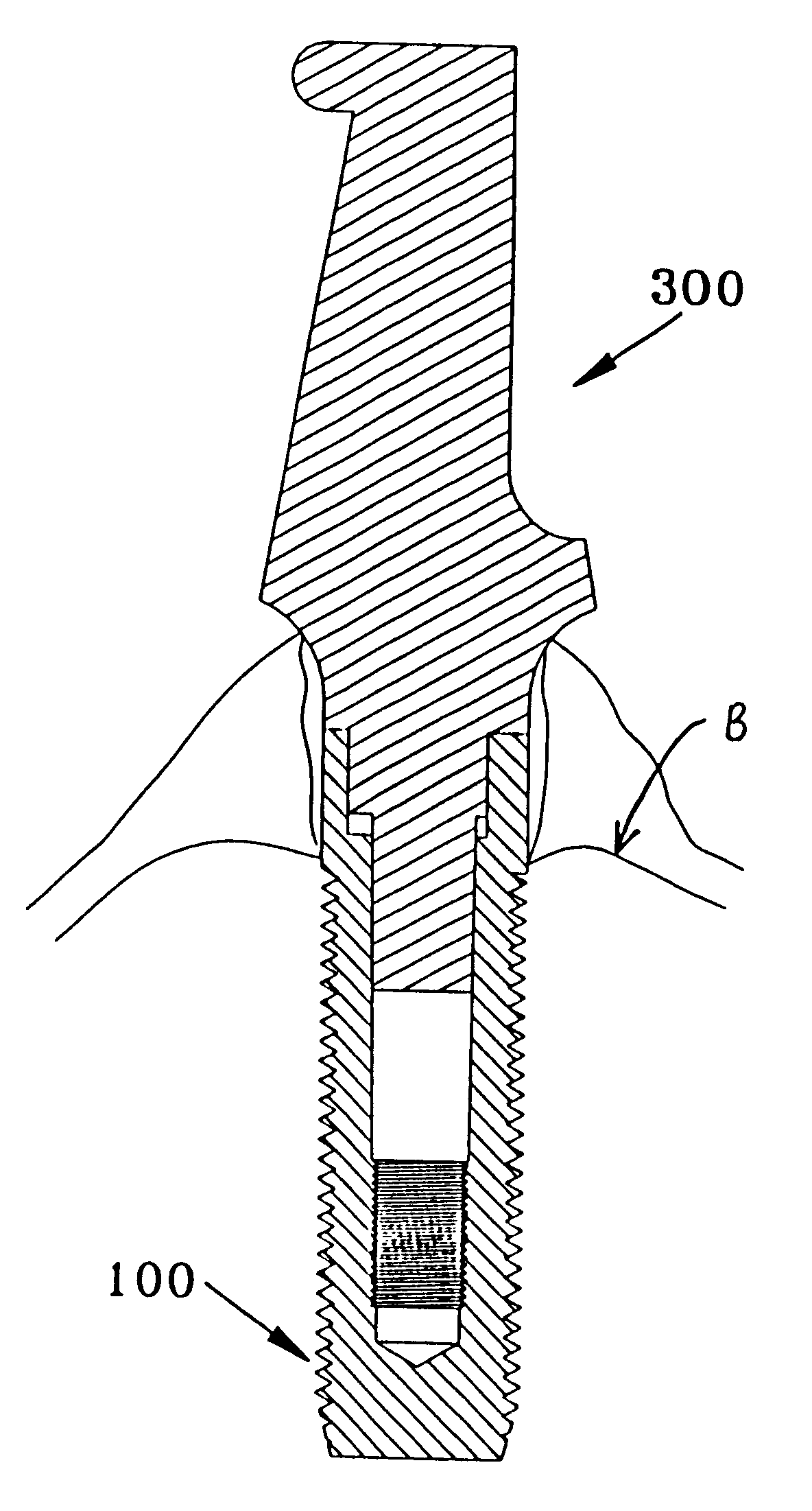

Dental implant system and method for effecting a dental restoration using the same

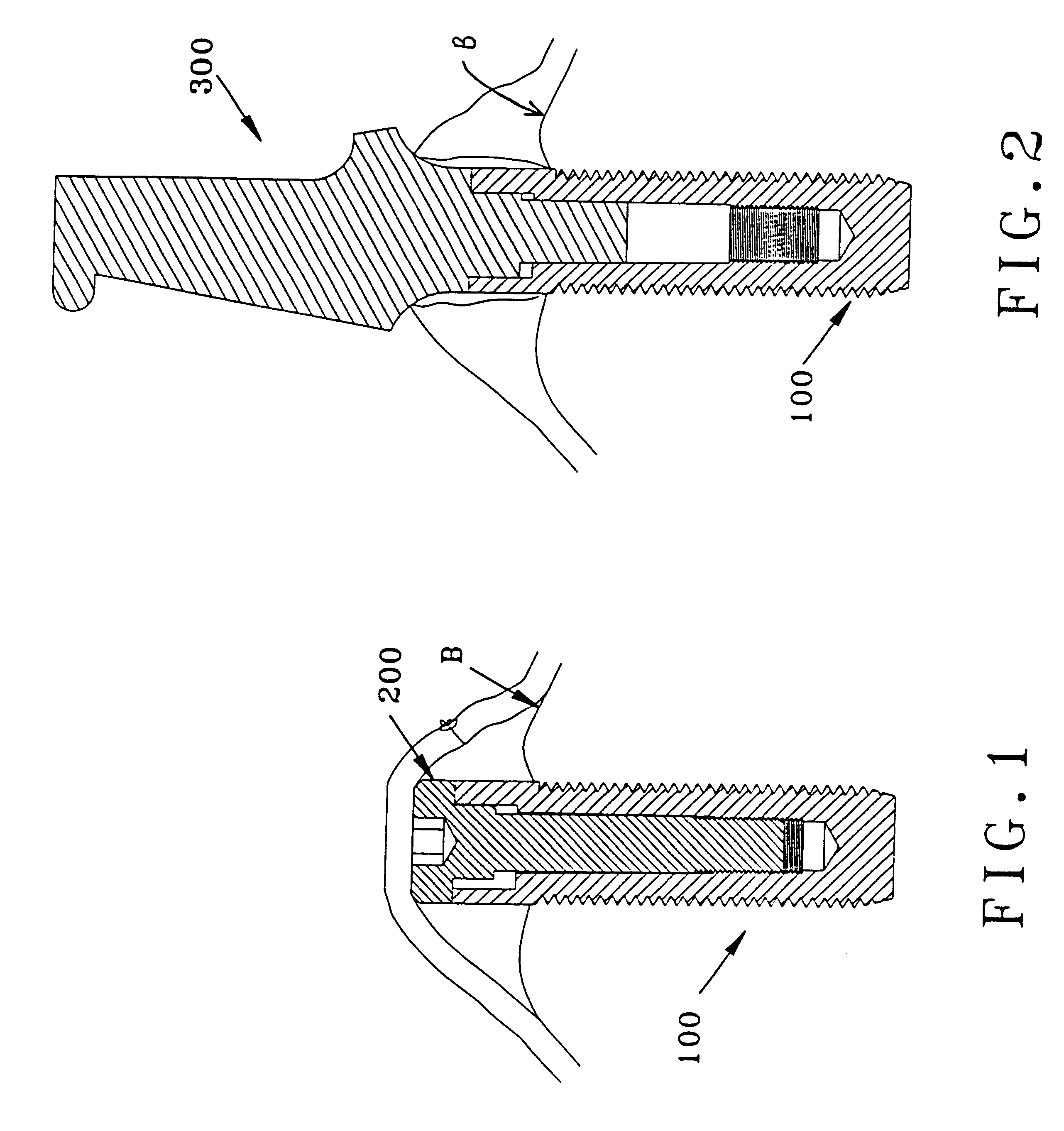

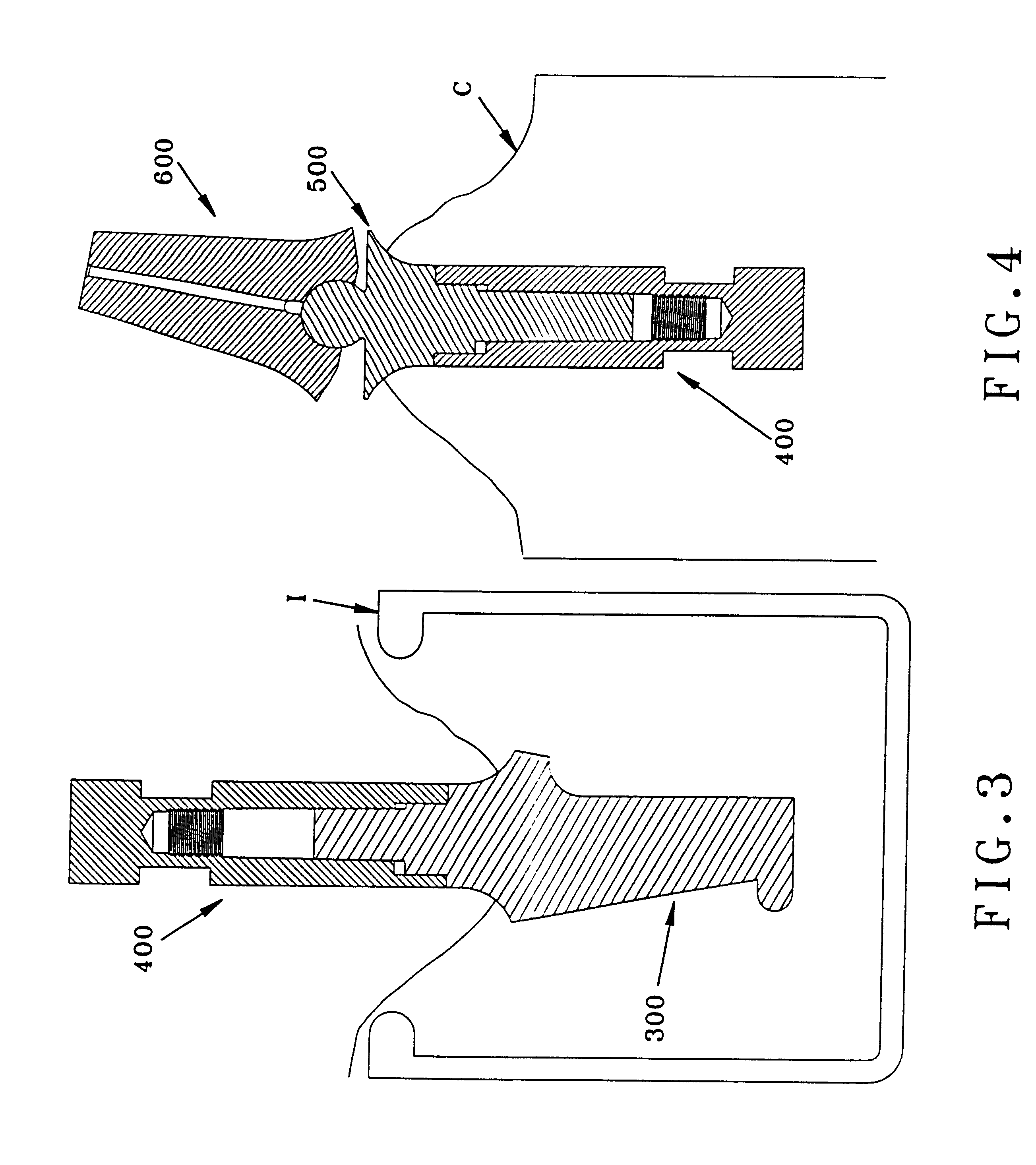

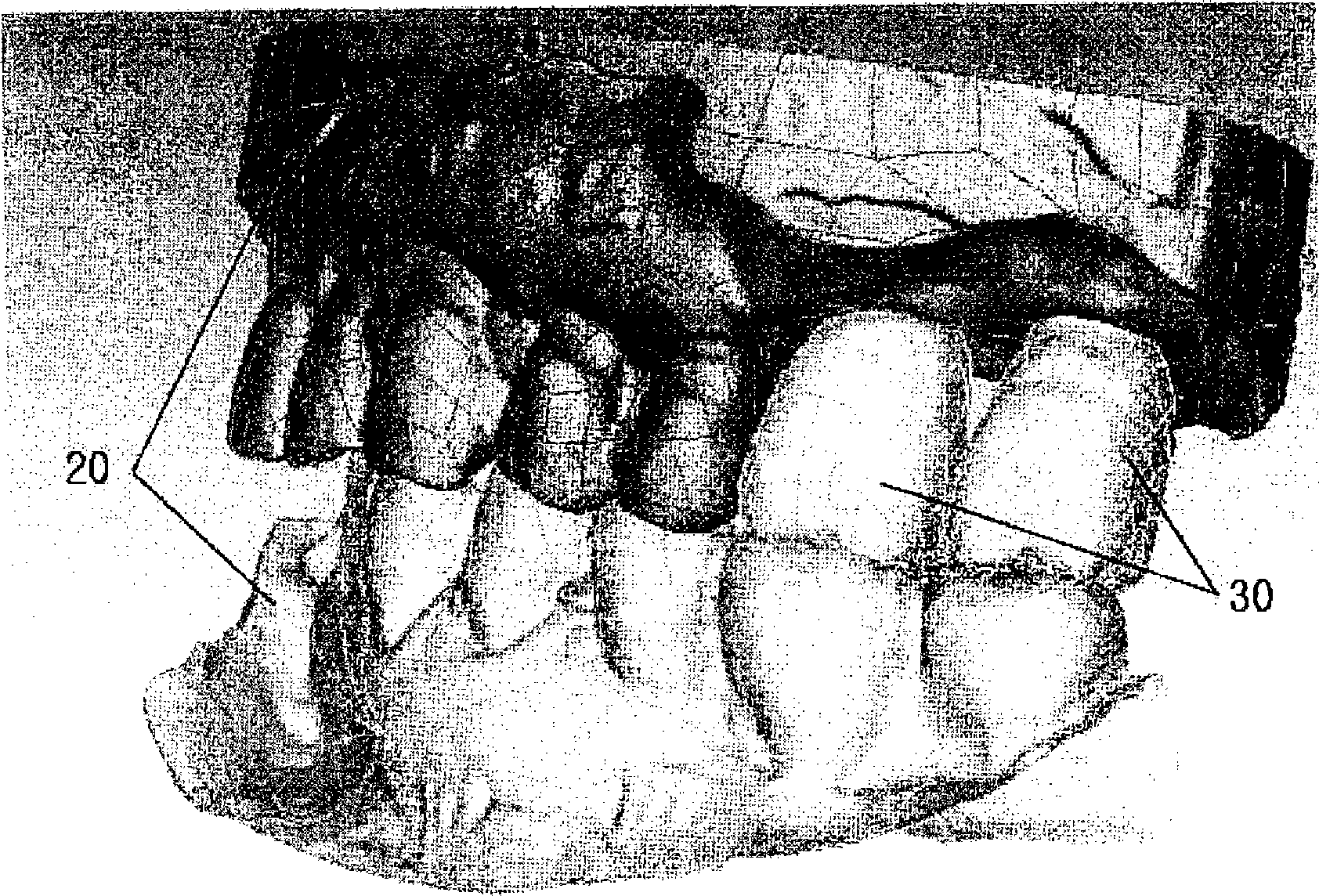

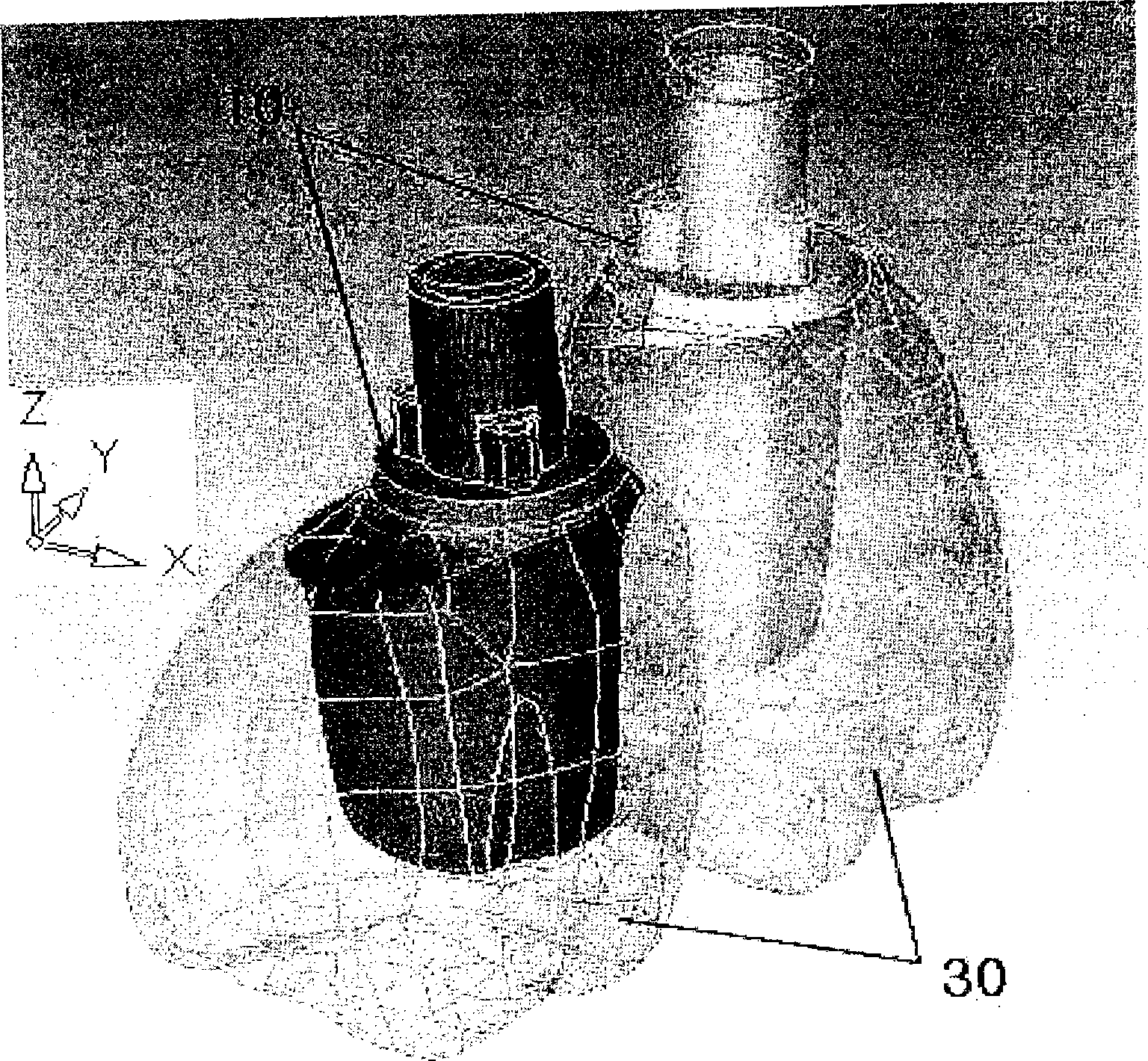

A dental implant system and method for effecting a dental restoration using the same. The dental implant system having an implant fixture adapted to be deployed in a bone; an impression coping adapted to be selectively deployed on the implant fixture and in a dental impression; a laboratory analog adapted to be selectively deployed on the impression coping and in a dental cast; a spherical abutment adapted to be selectively deployed on the laboratory analog; and a multiaxis abutment adapted to be adjustably deployed on the spherical abutment; wherein the spherical abutment and the multiaxis abutment are used to generate a cast permanent abutment which may be received by the laboratory analog and the implant fixture.

Owner:LUSTIG L PAUL +2

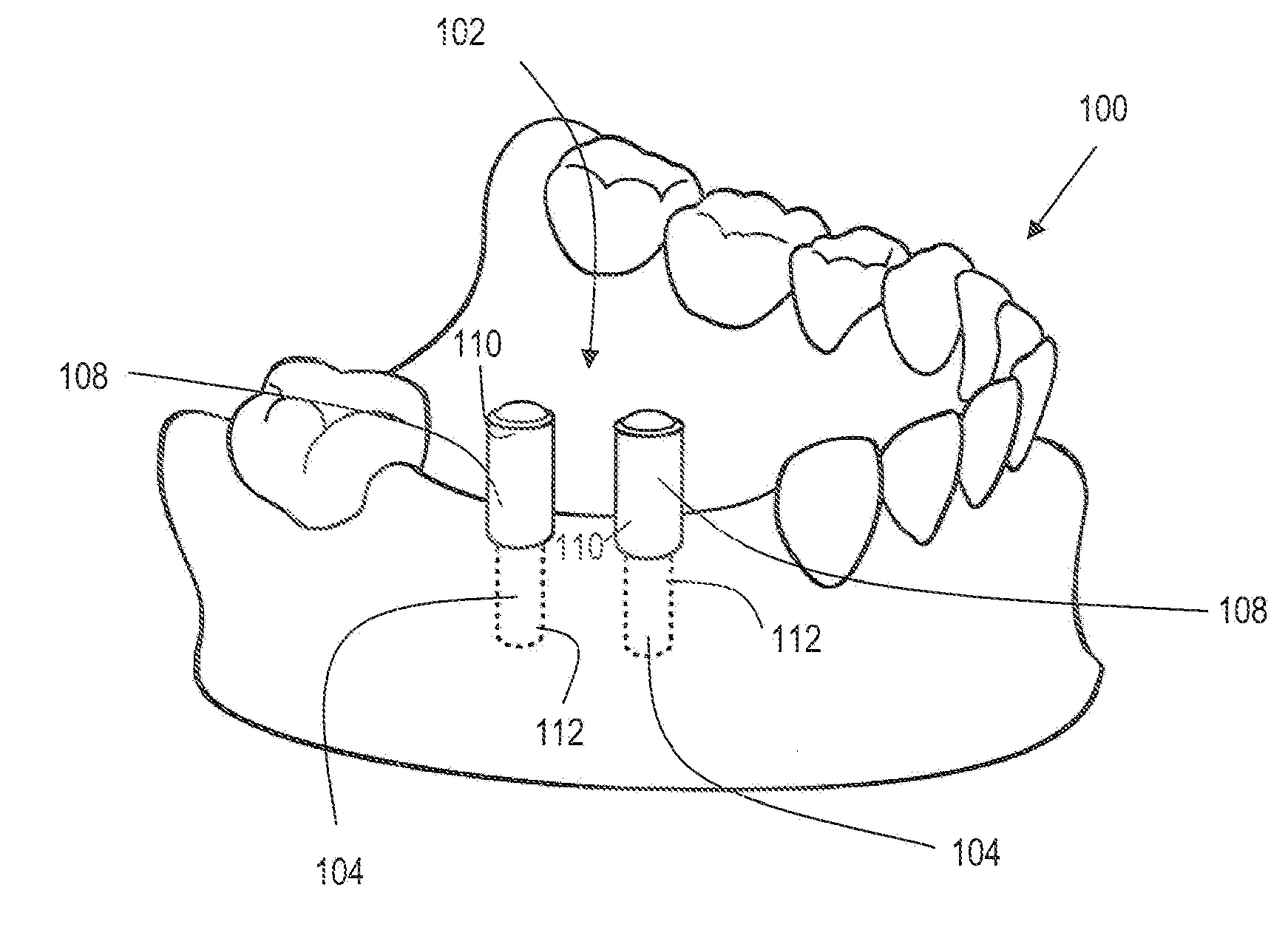

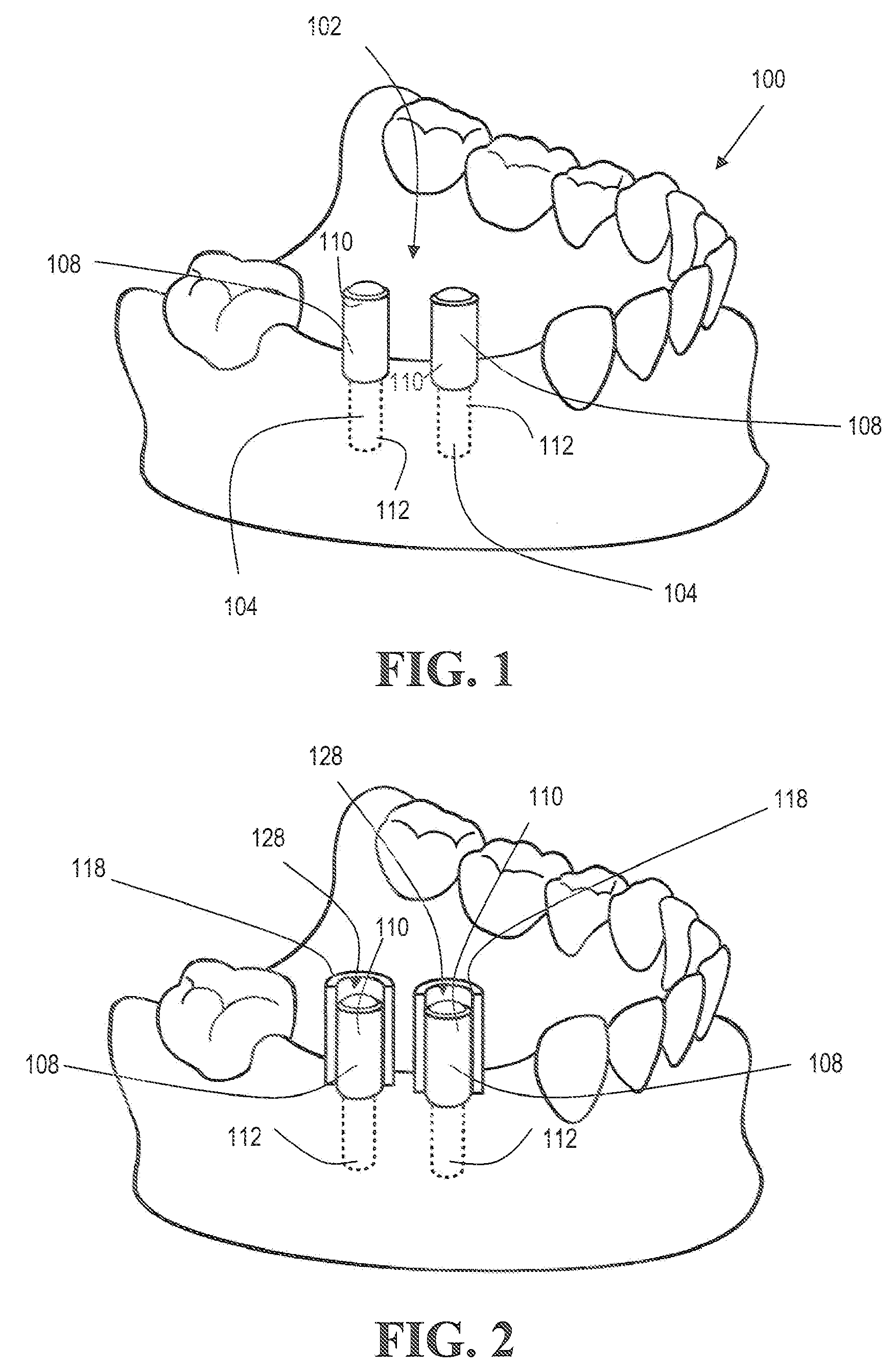

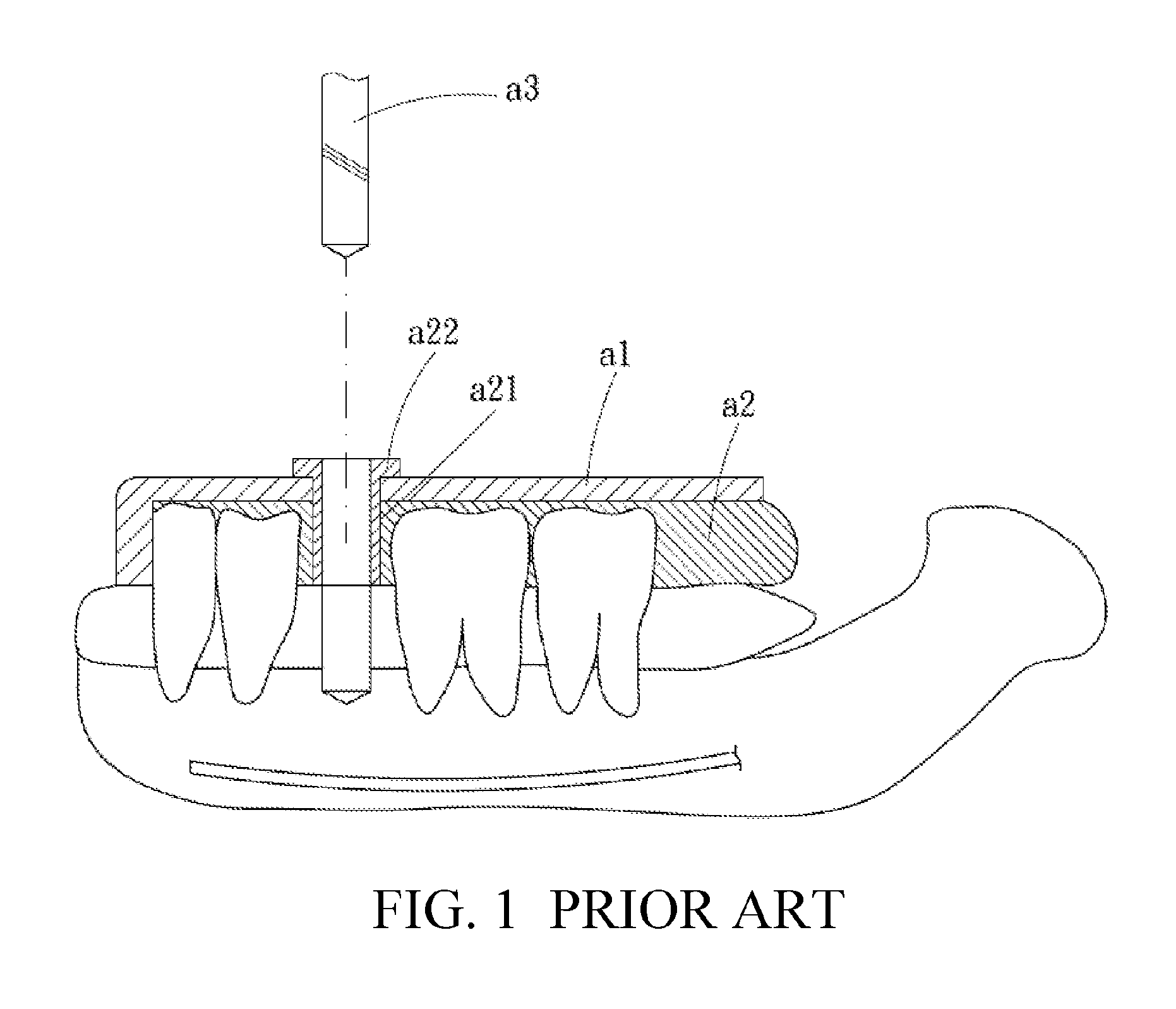

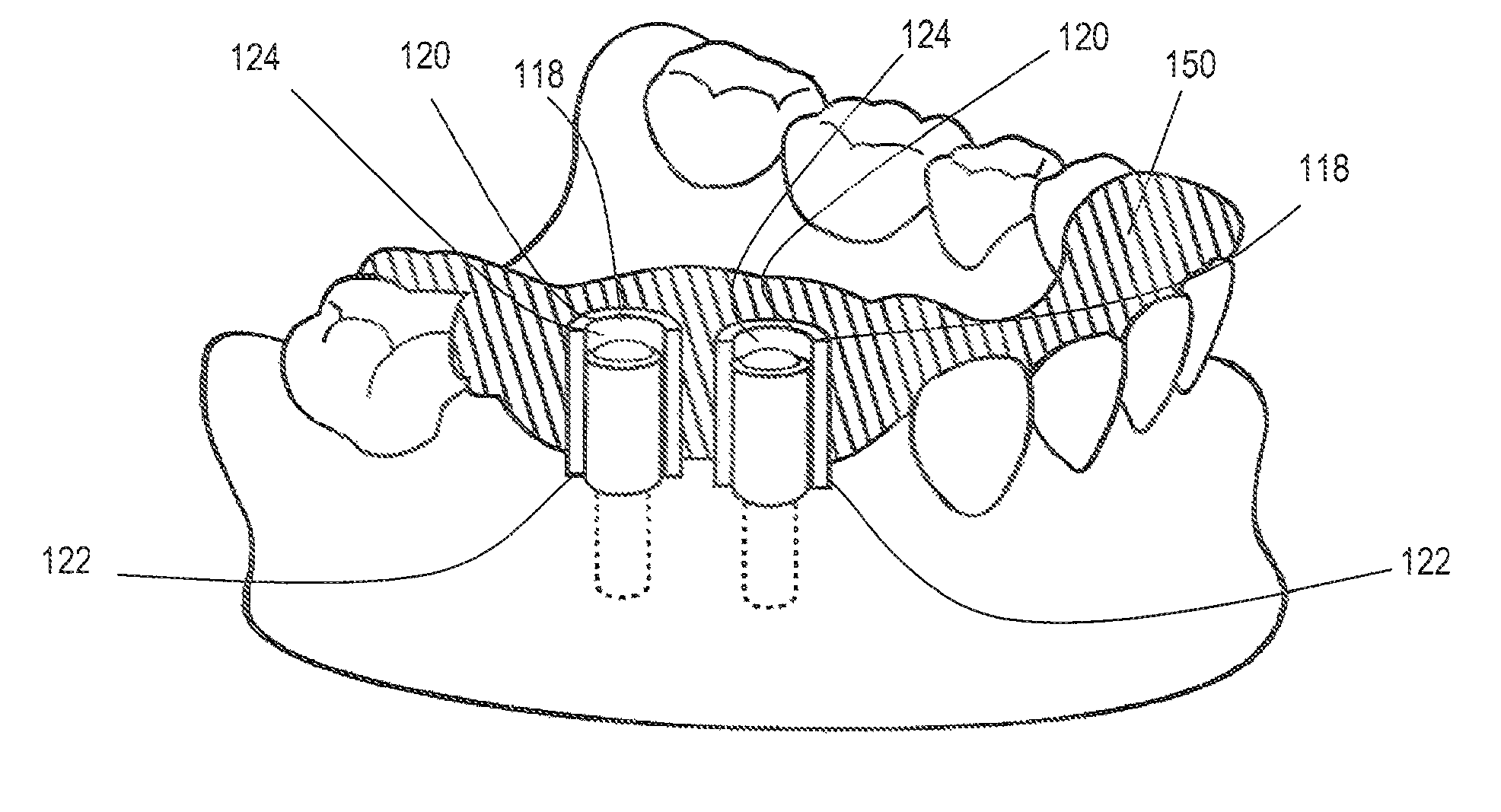

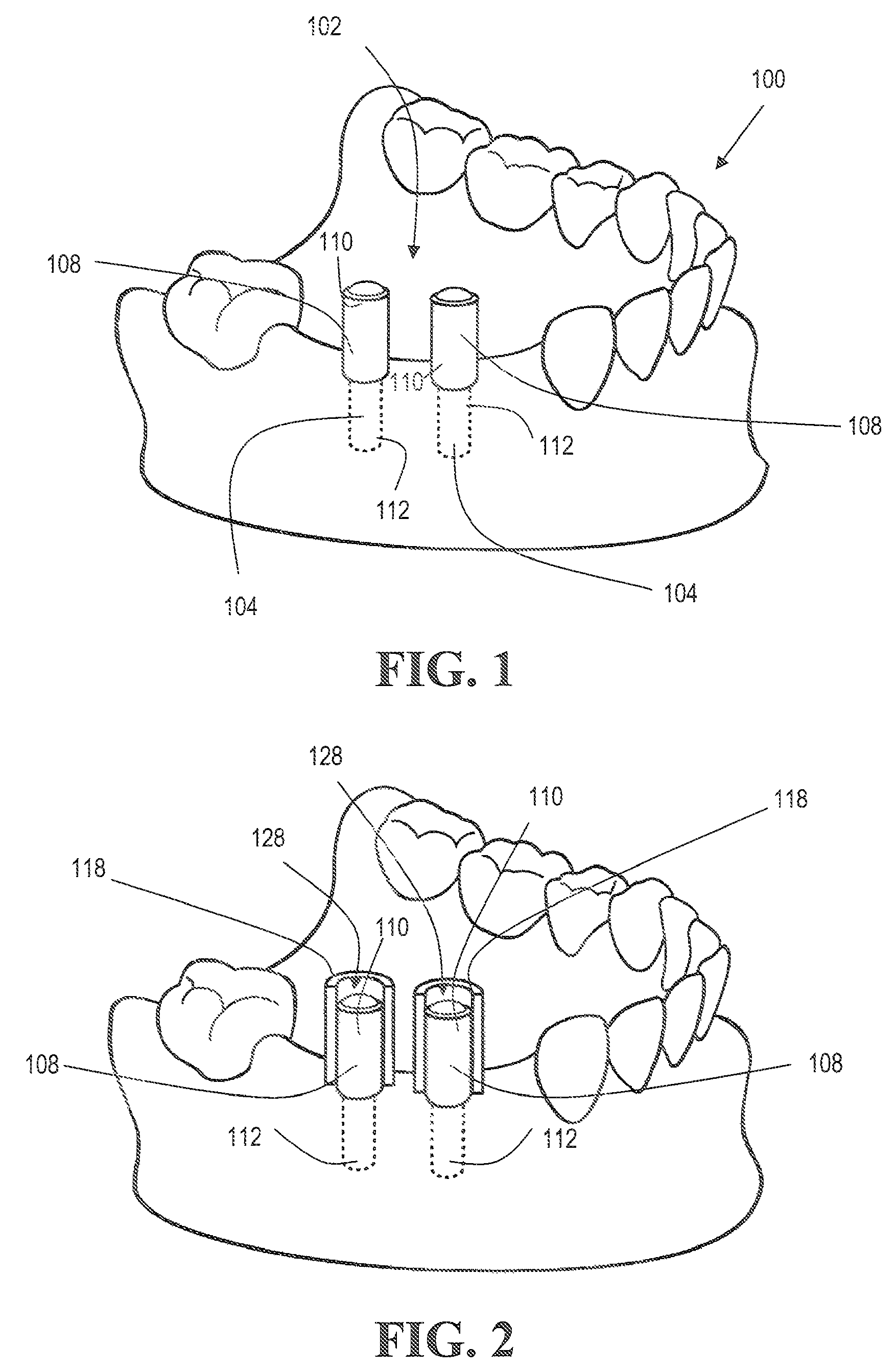

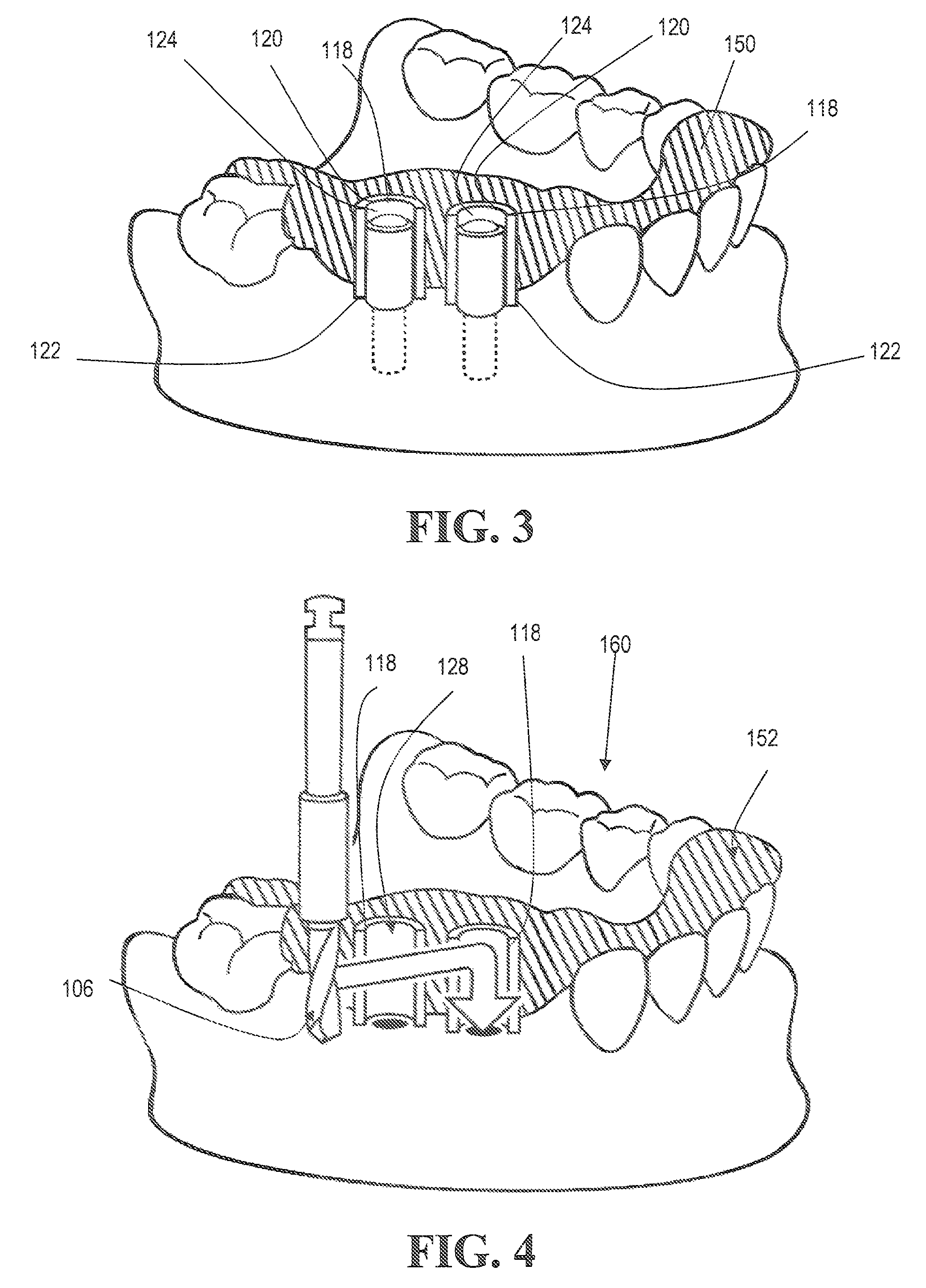

Method for making and using a template for locating a dental implant and components relating thereto

InactiveUS20080064005A1Accurate locationReduce the amount requiredDental implantsDental toolsCatheterMaxilla/Maxillary

A method for making a template for a dental implant osteotomy in an edentulous space of a patient's mandible or maxilla, and components relating thereto The method includes the steps of forming a dental cast of the patient's mandible or maxilla, drilling a hole into the dental cast wherein the location and orientation of the hole correspond to a desired location and orientation of the dental implant osteotomy, inserting a guide post into the hole, magnetically attaching a sleeve having a longitudinal gap to the guide post, applying a molding material to a portion of the dental cast and to a portion of an outer surface of the sleeve, allowing the molding material to cure, and removing the cured template including the sleeve embedded therein from the dental cast, whereby using the template in the patient's mouth provides a guide means for drilling the osteotomy.

Owner:MEITNER SEAN W

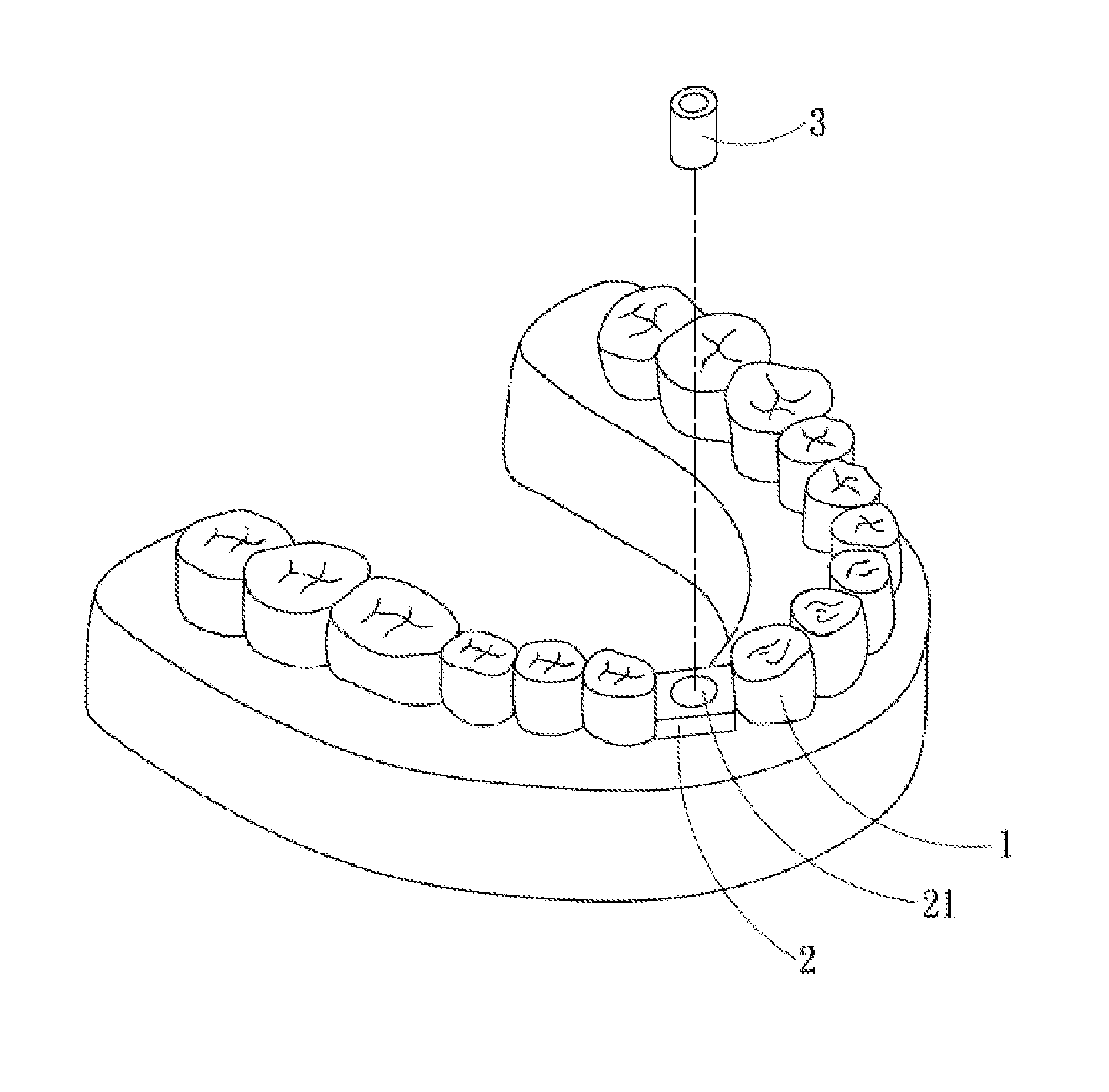

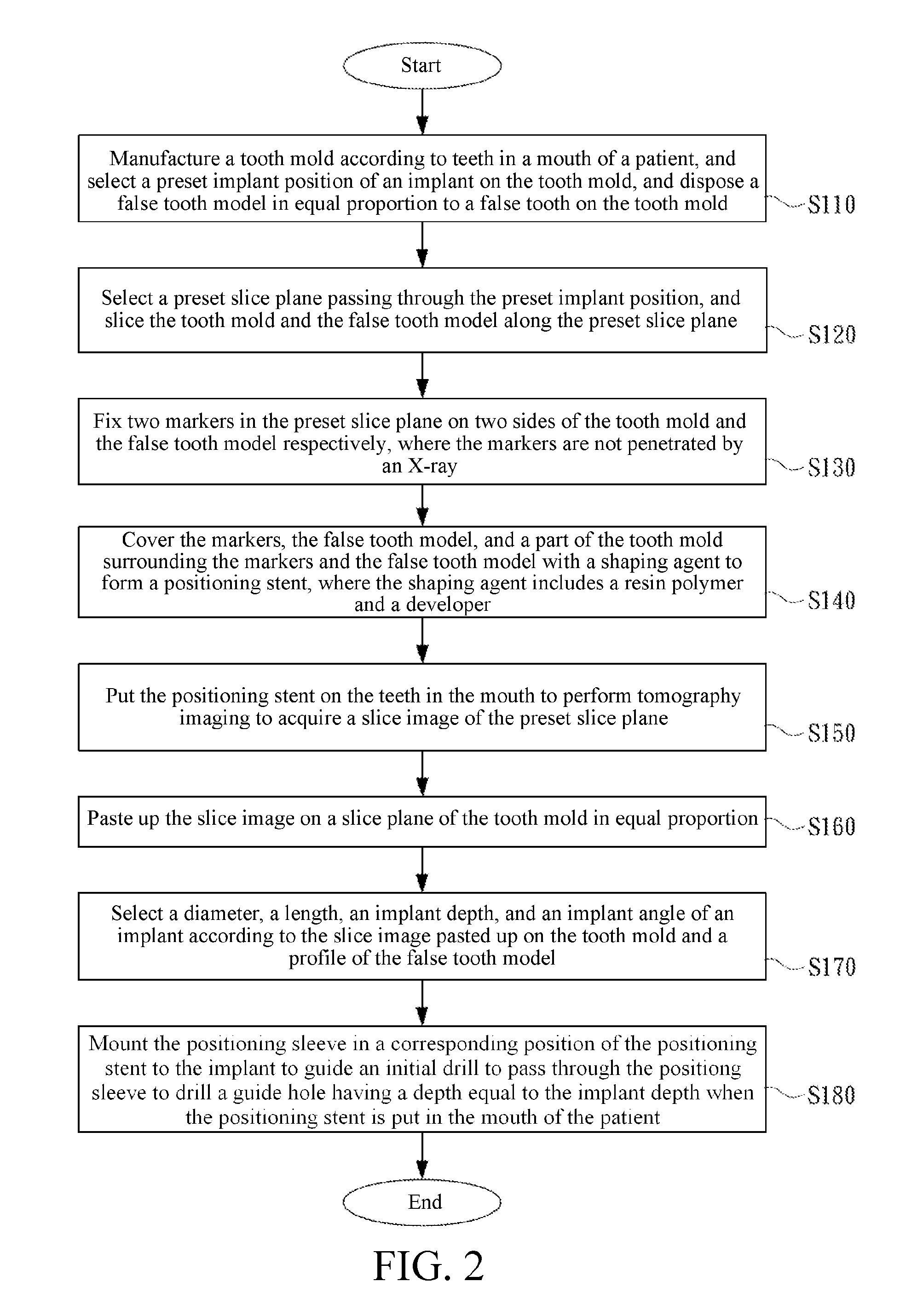

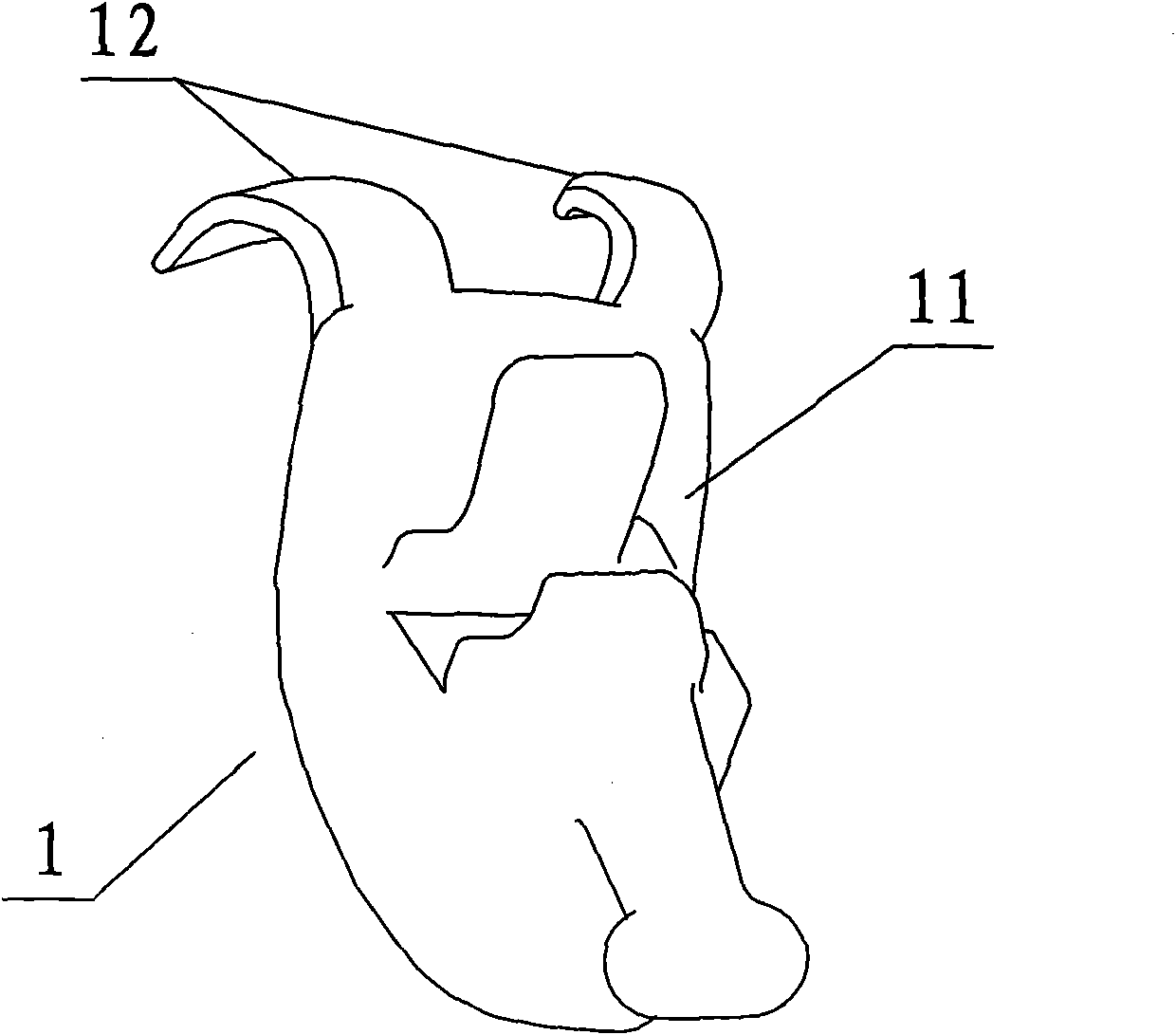

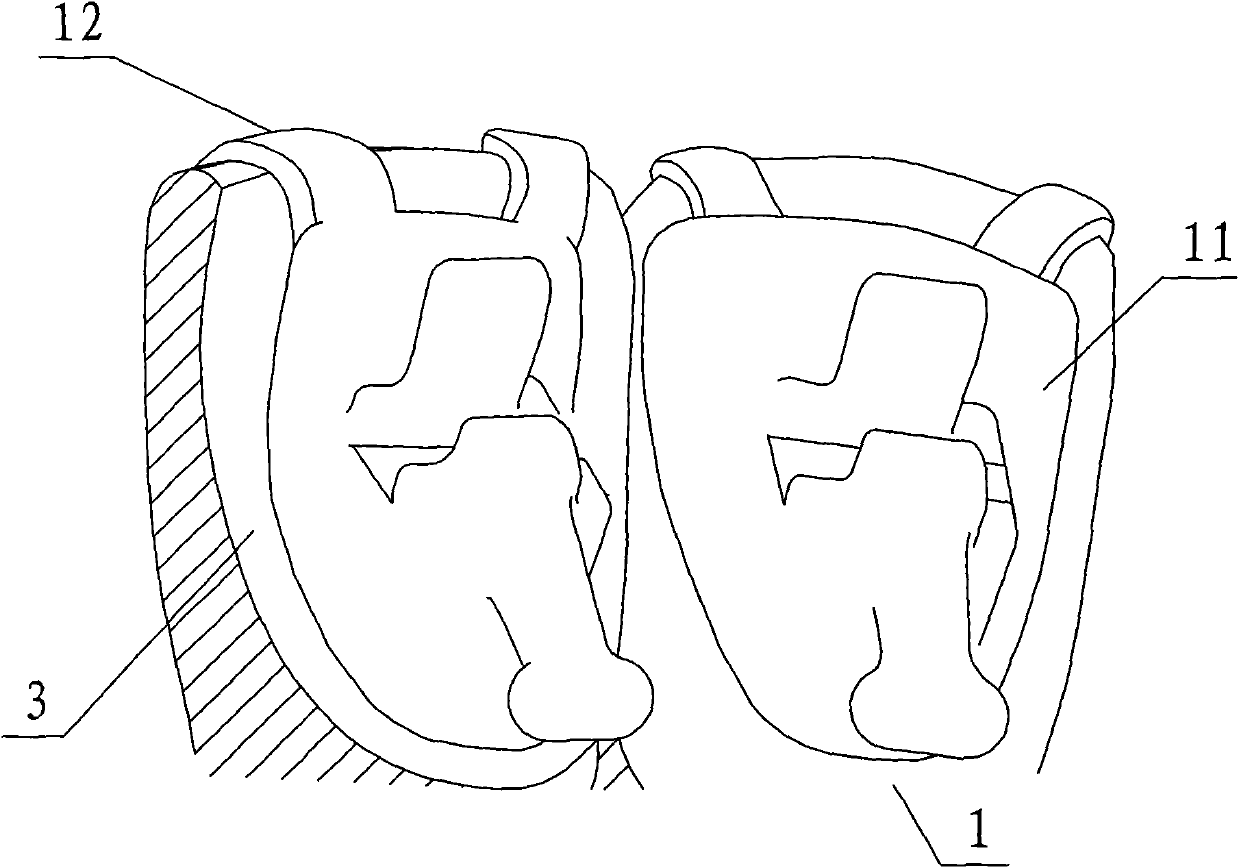

Dental positioning stent, and manufacturing method, using method and components for the same

InactiveUS20120135373A1Evaluate tooth implant surgery accuratelyAccurate assessmentDental implantsDental articulatorsInsertion stentDentures

A dental positioning stent for drilling an implant hole and a manufacturing method, a using method and components for the same are provided. The manufacturing method includes: slicing a tooth mold and a false tooth model along a preset slice plane; fixing two markers in the preset slice plane on two sides of the false tooth model respectively; covering the markers and the false tooth model with a shaping agent to form a positioning stent; putting the positioning stent on the teeth in a mouth to perform tomography imaging to acquire a slice image of the preset slice plane; mounting a positioning aid having a positioning hole in the positioning stent according to the slice image pasted up on the tooth mold to guide an initial drill. A dental positioning stent for tomography imaging, and a manufacturing method, a using method, and components thereof are provided.

Owner:CHENG PO KUN +3

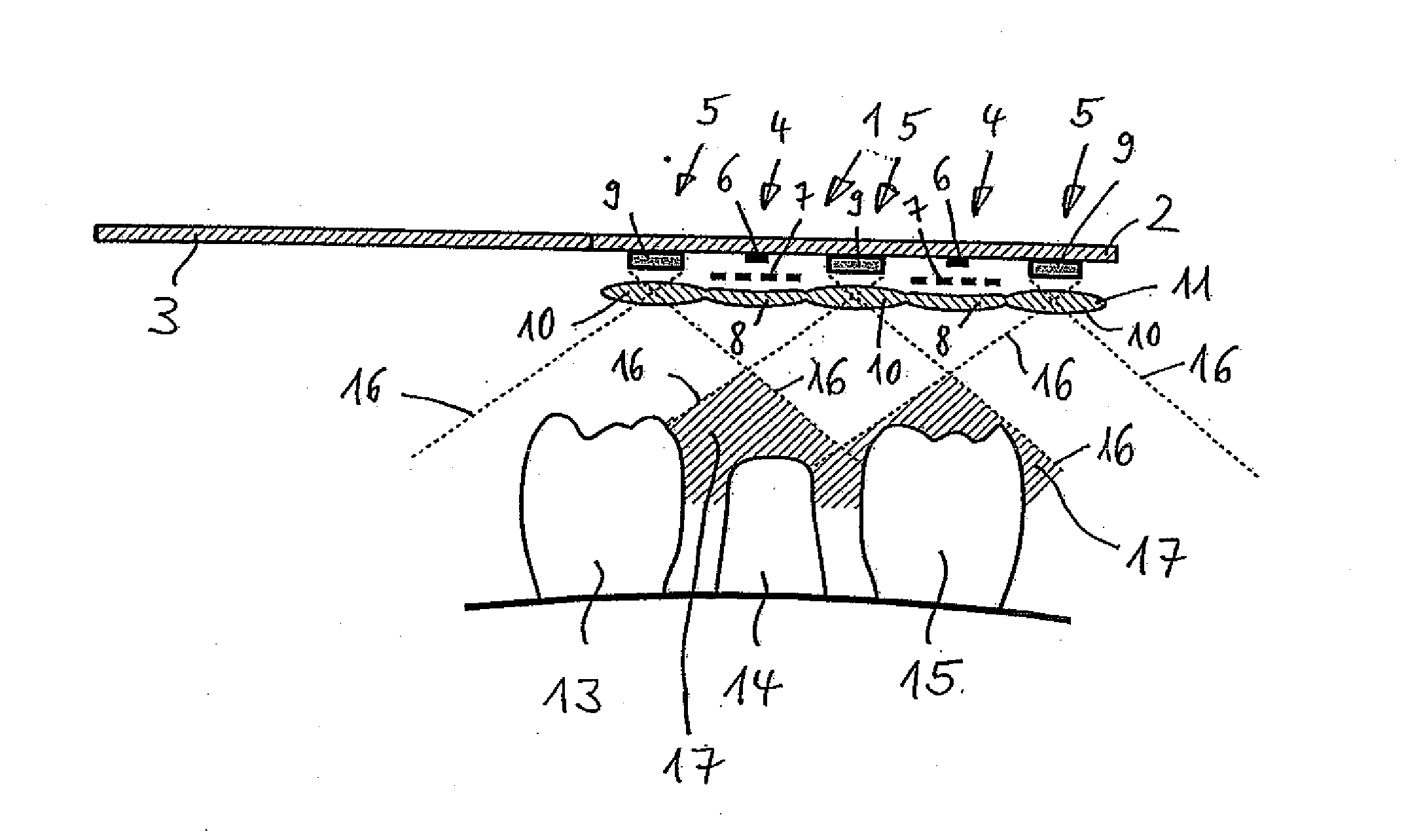

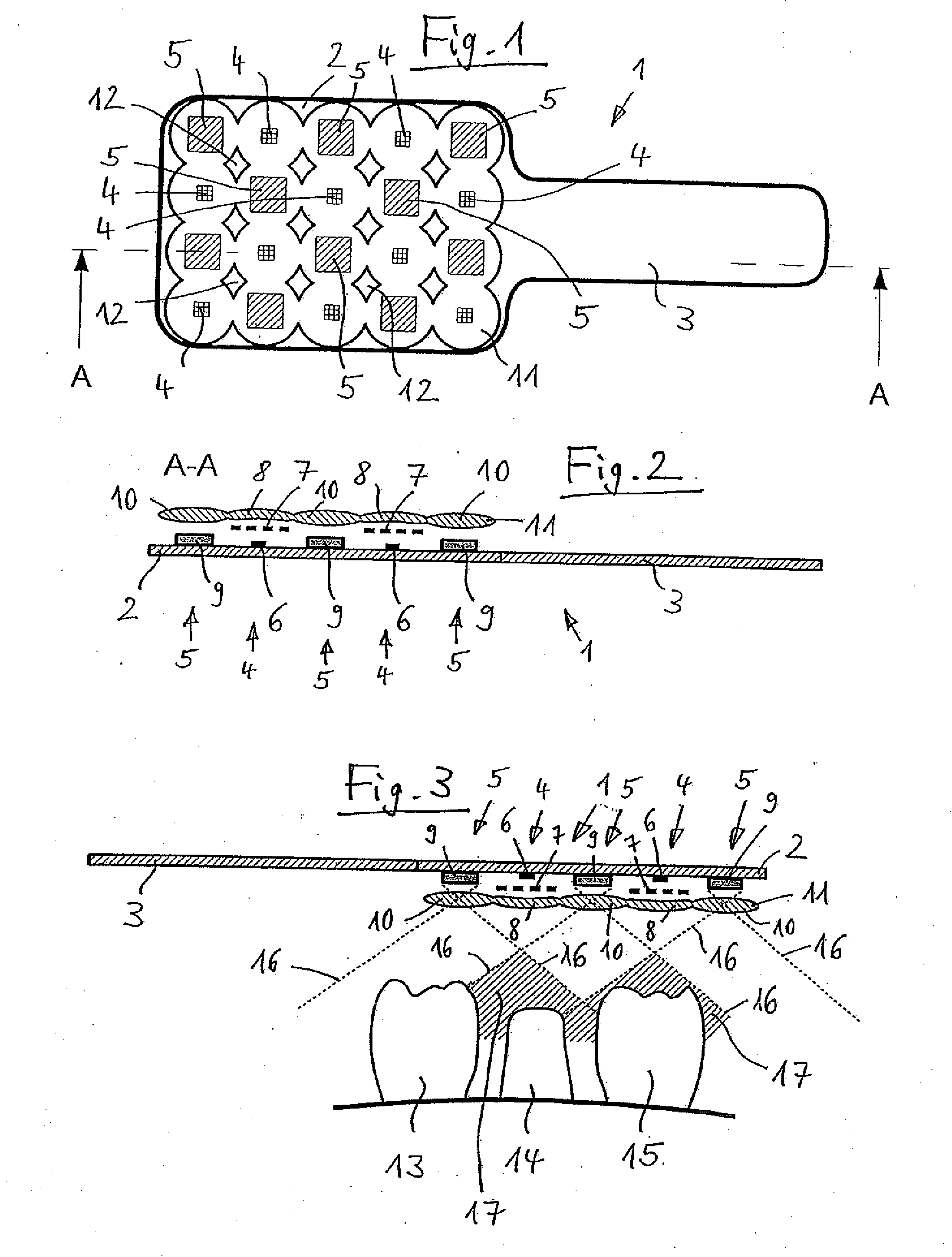

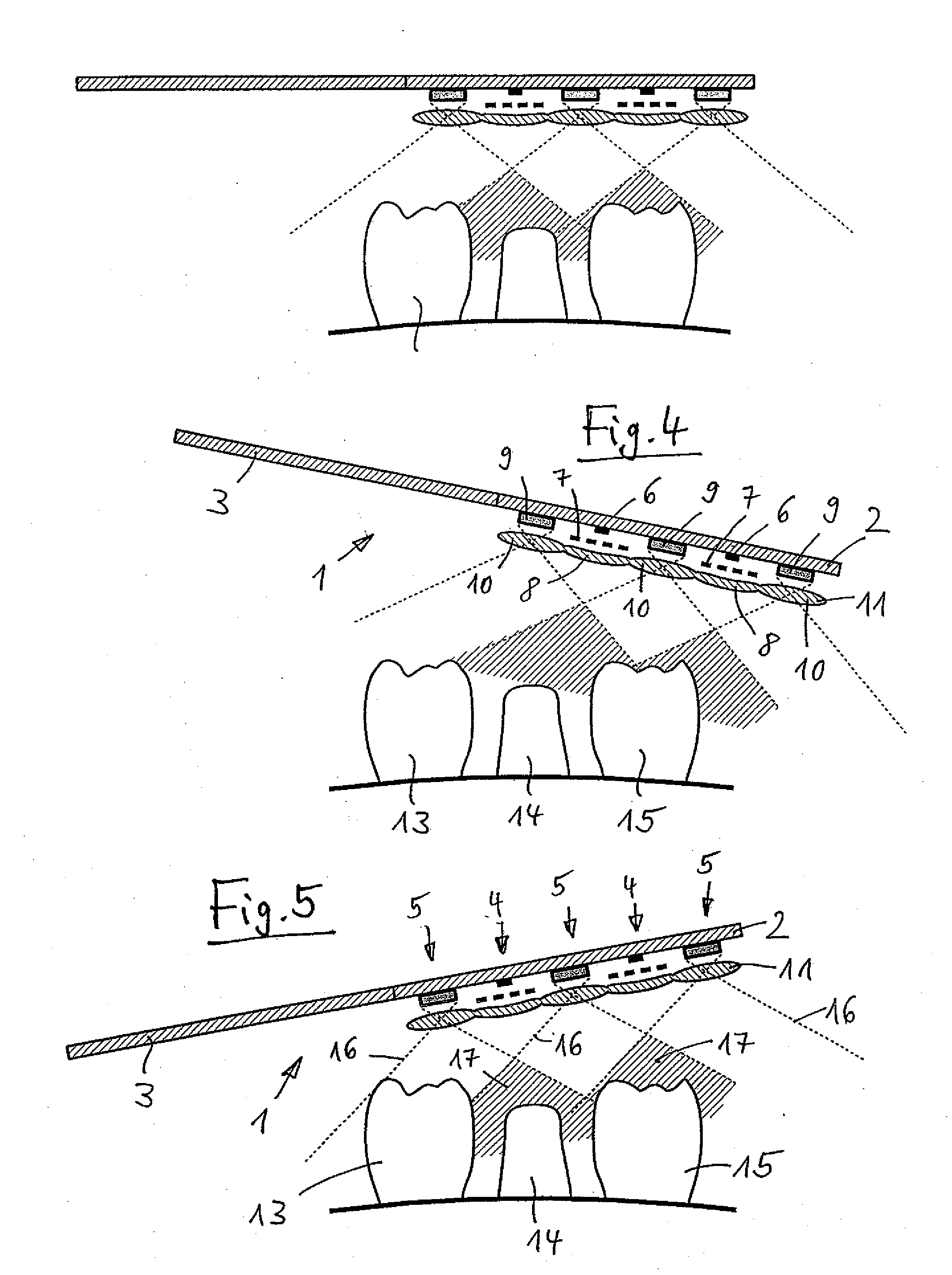

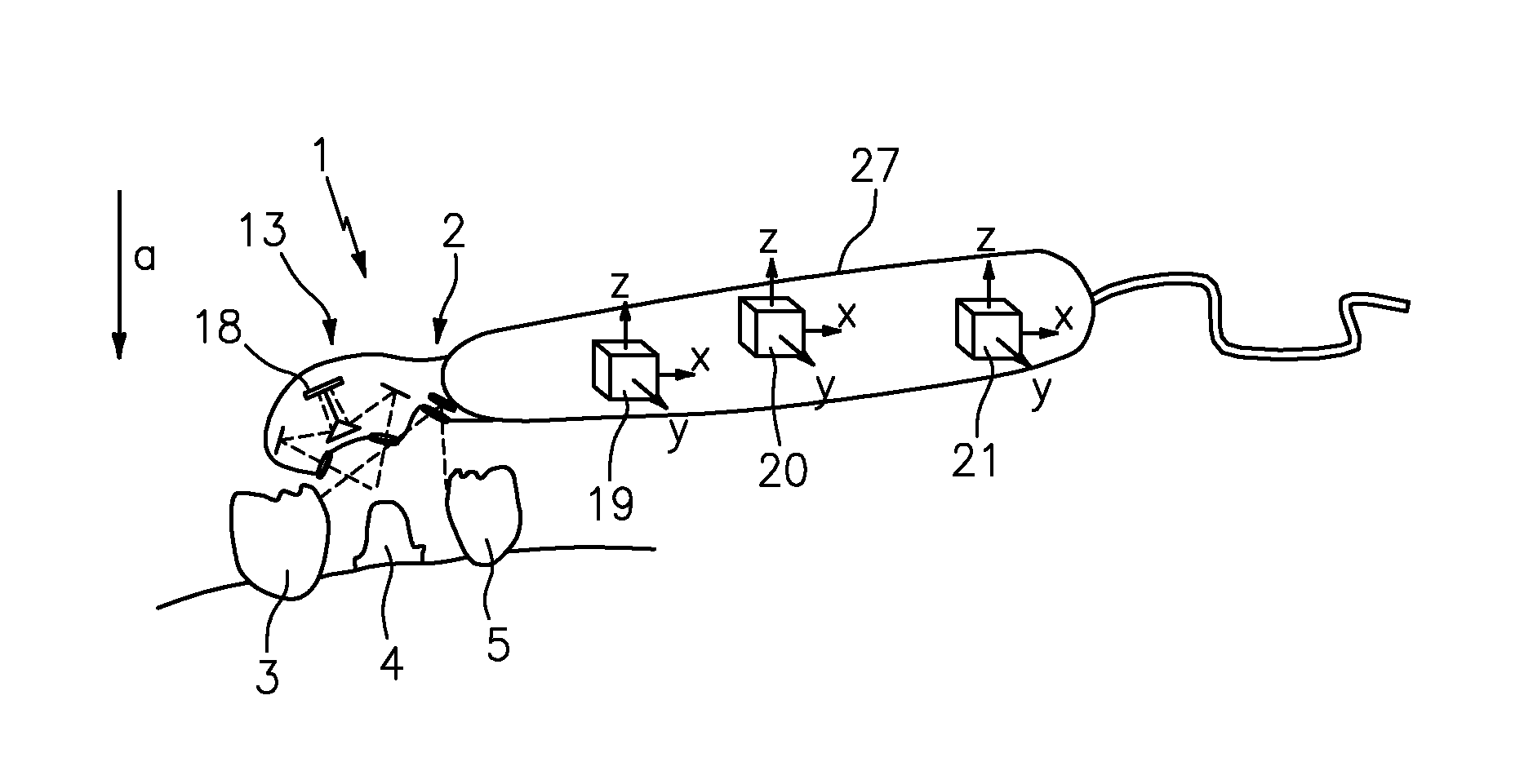

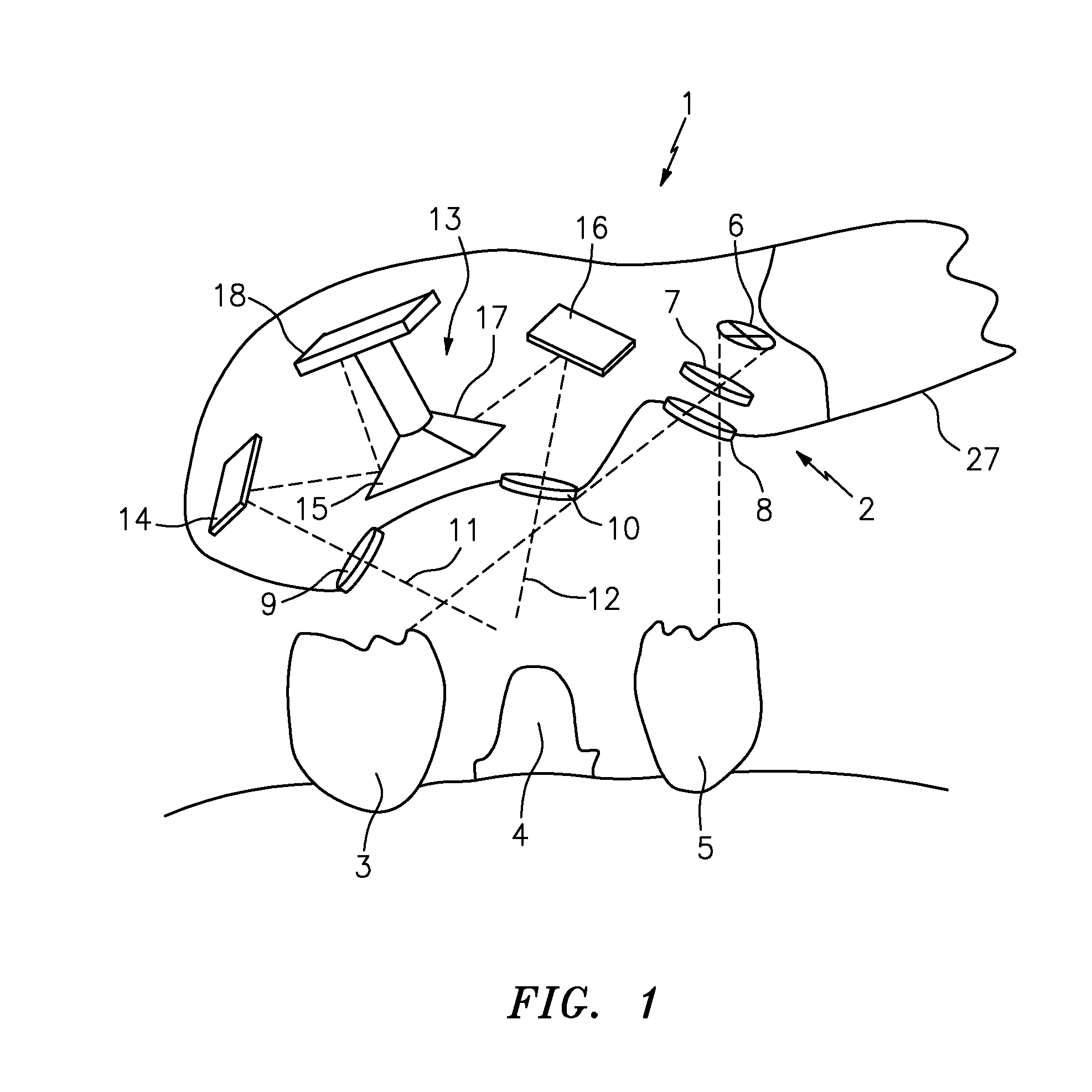

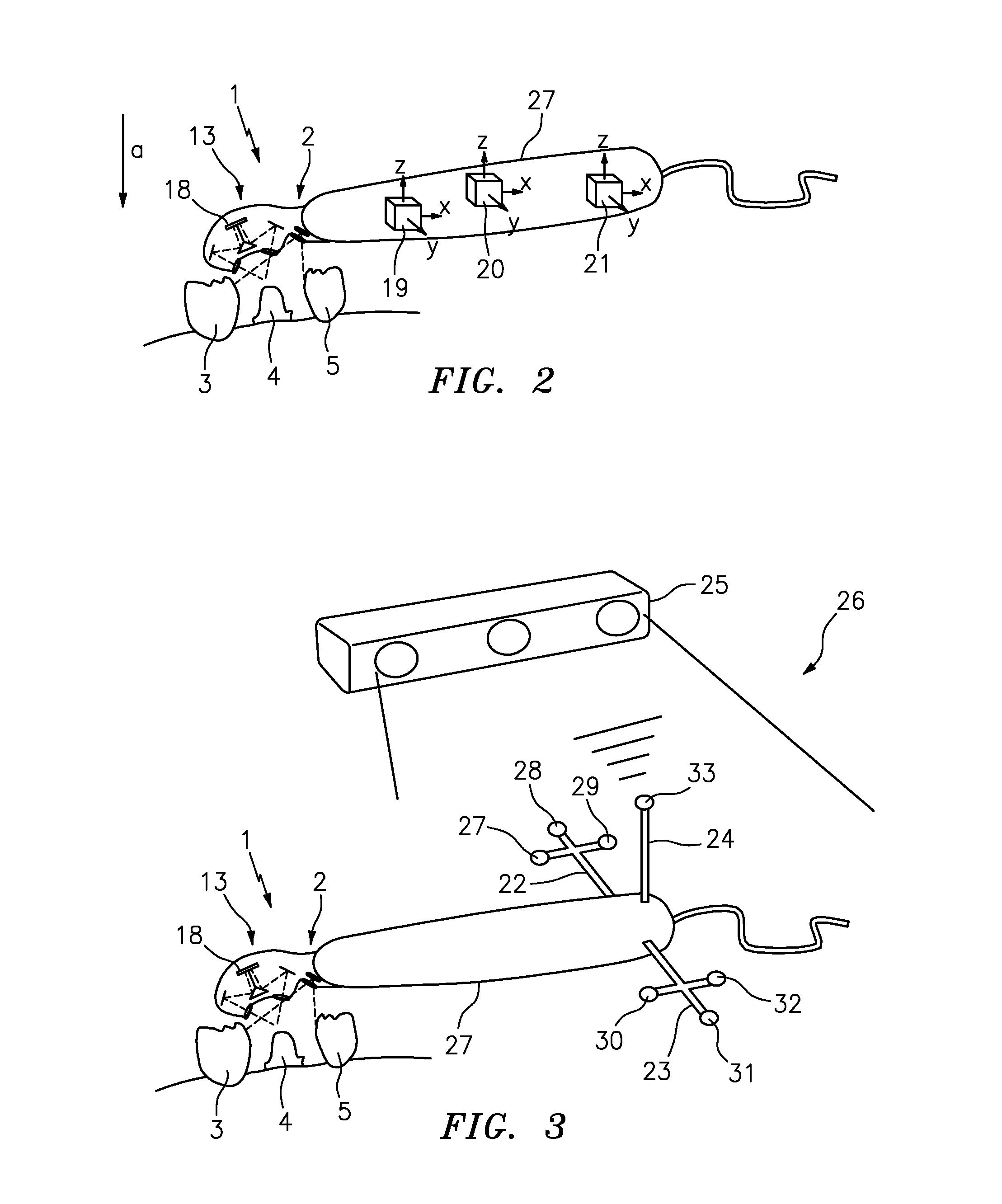

Device for Determining the 3D Coordinates of an Object, In Particular of a Tooth

ActiveUS20100239136A1Increase the number ofImpression capsPicture taking arrangementsDental castComputer science

A scanner is used for scanning an object, in particular one or more teeth (13, 14, 15) or a dental cast. An improved scanner comprises a carrier (2) on which a plurality of projectors (4) for projecting a pattern onto the object and a plurality of cameras (5) for recording the object are provided one beside the other in an array.

Owner:CARL ZEISS OPTOTECHN GMBH

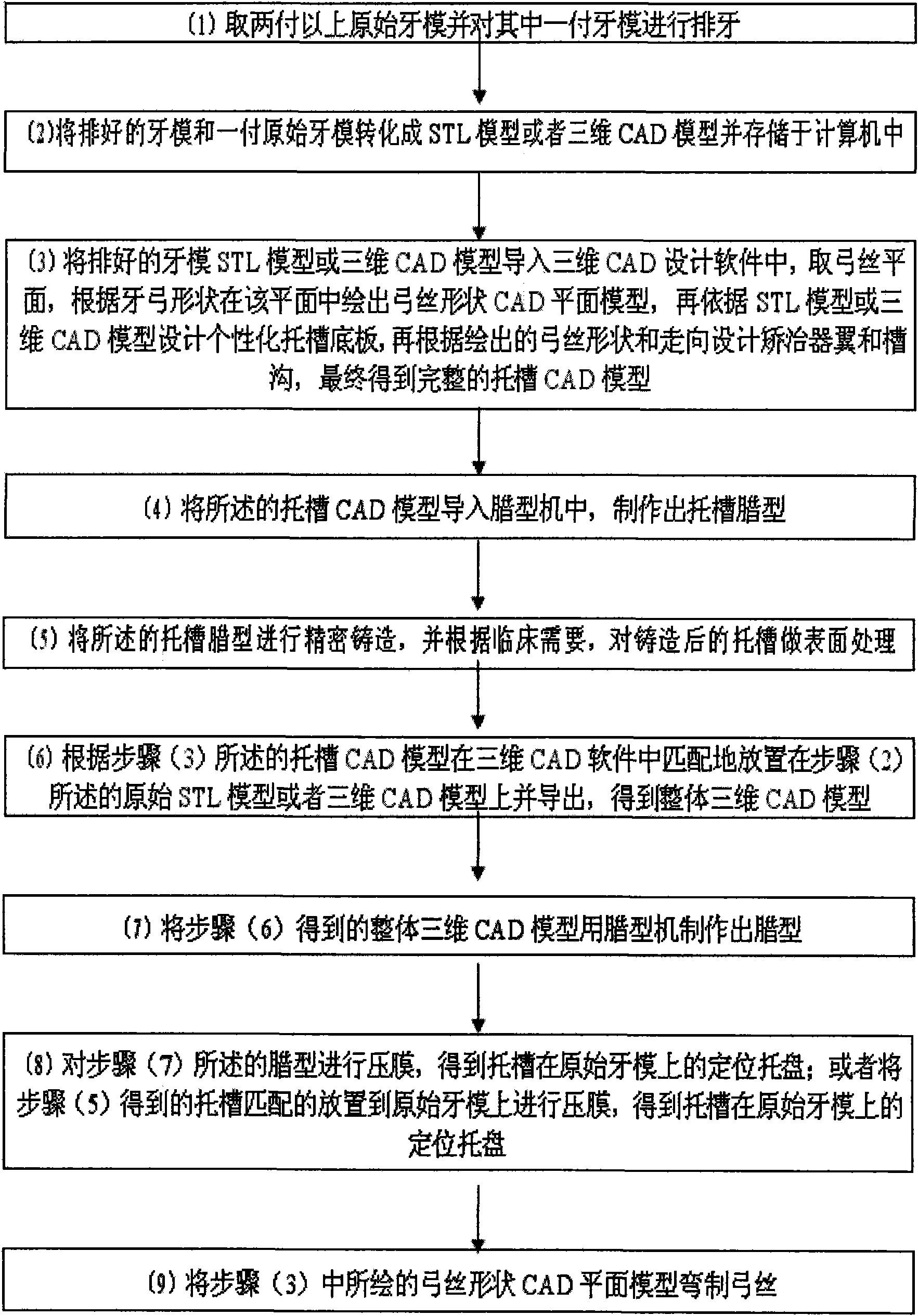

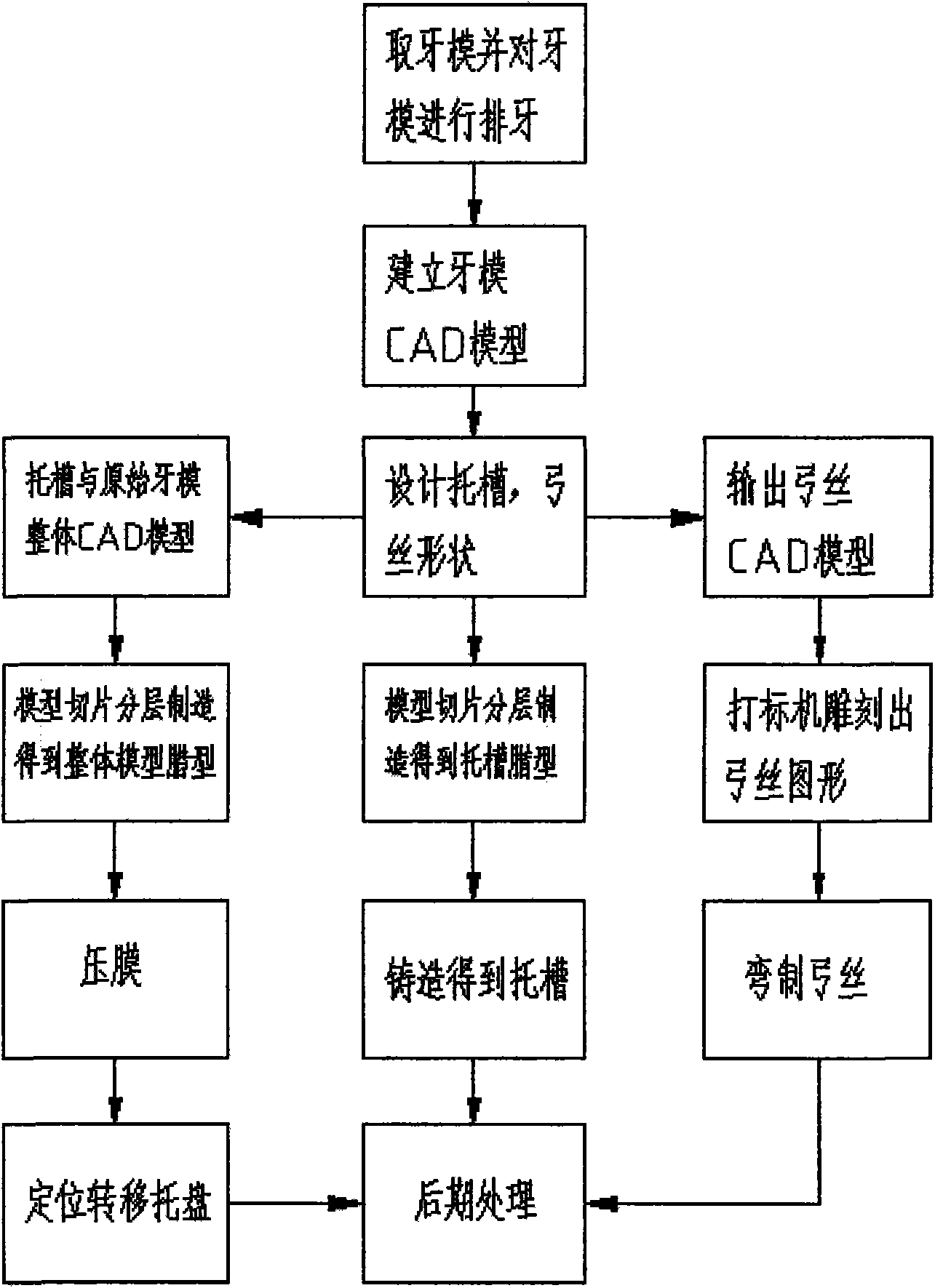

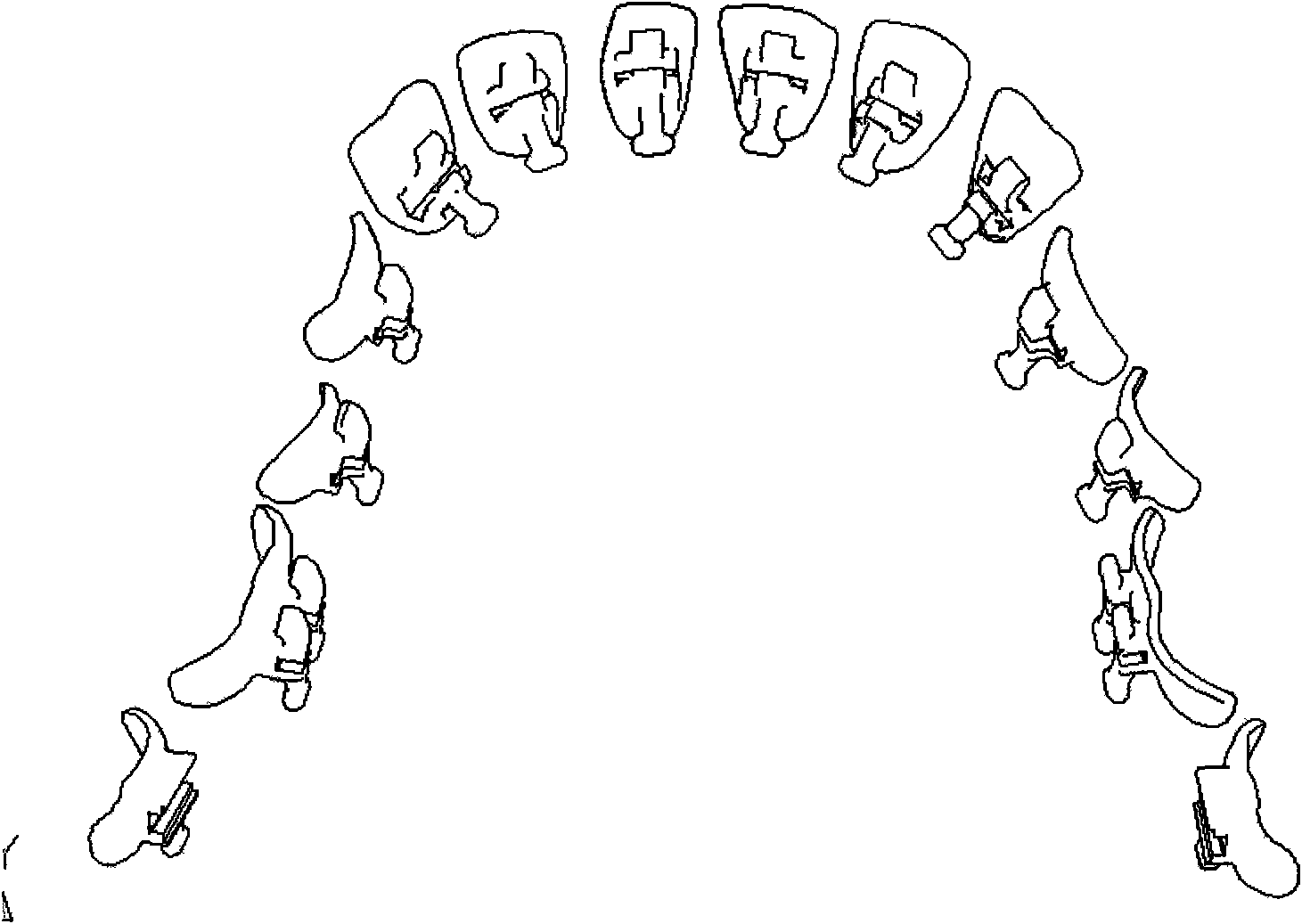

Manufacture method of individual orthodontic appliance for tongue

The invention discloses a manufacture method of an individual orthodontic appliance for a tongue, comprising the following steps: taking dental casts; manually arranging teeth for the dental casts; establishing a three-dimensional CAD model; plotting a plane of an arch wire and the arch wire; designing a single bracket CAD structural model; guiding the model into a quick wax model machine to obtain a wax model of the orthodontic appliance; casting the wax model to obtain a bracket after necessary surface treatment; putting the single bracket CAD structural model on the CAD models of original dental casts in a matching mode to obtain an integral CAD model; guiding the quick wax model machine to make the wax model; pressing a film of the wax model machine to obtain a positioning transfer tray and curving the arch wire according to a picture. The method can be used for realizing individual production according to individual requirements, and the prepared orthodontic appliance has the advantages of good matching with tooth shapes, high precision and permanence without deformation, is suitable for patients to wear for long and has small thickness, good supporting stability and convenient clinical operation. The method is widely applied to the production process of the orthodontic appliance.

Owner:GUANGZHOU RITON BIOMATERIAL

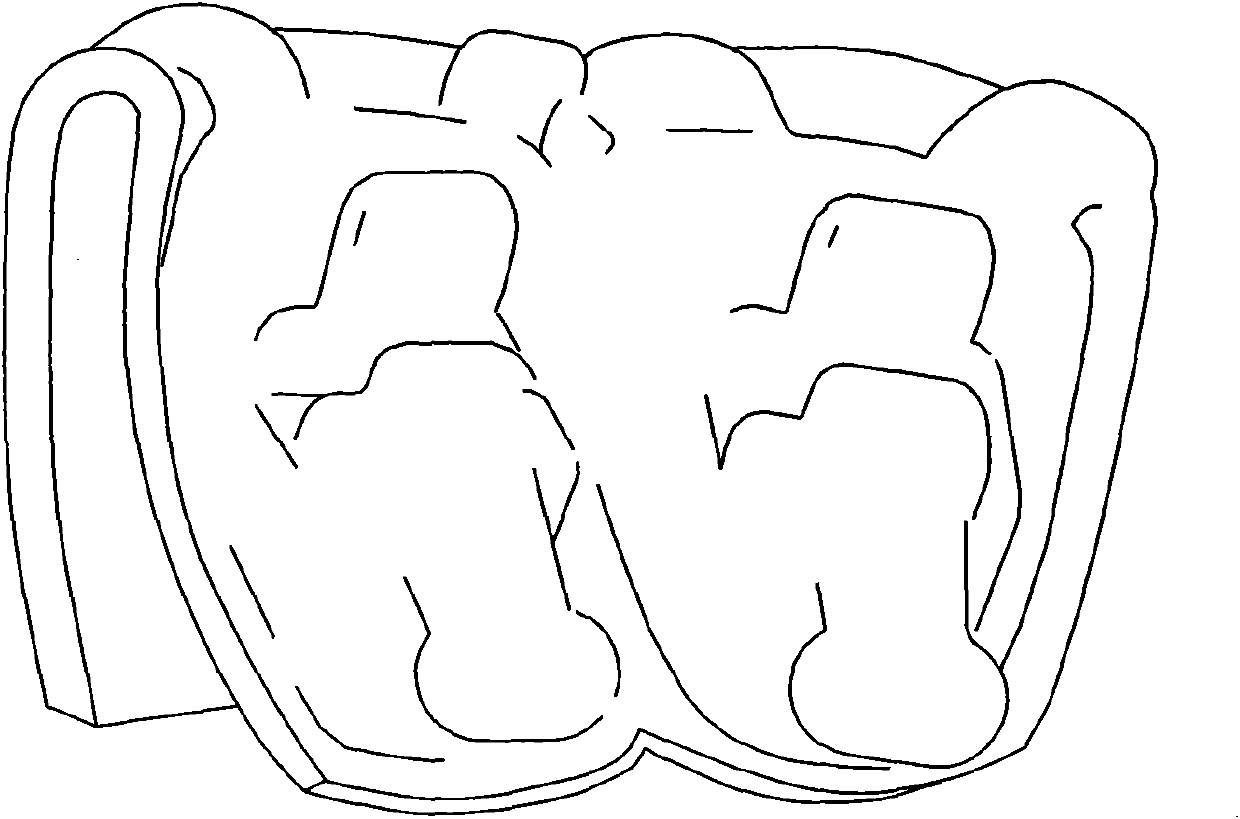

Molded denture and method and apparatus of making same

InactiveUS20160100917A1Reduce the possibilityMinimal number of stepAdditive manufacturing apparatusMechanical/radiation/invasive therapiesDenturesDental cast

A method for making a denture comprising creating three-dimensional models of top denture base, bottom denture base, and denture tooth molds; fabricating the molds by an additive manufacturing process; joining the bottom denture base mold to the top denture base mold to form a denture base mold cavity; injecting fluid synthetic denture base material into the mold cavity and curing the material to form the denture base; removing the bottom denture base mold from the top denture base mold, while leaving the denture base in the top denture base mold; joining the denture tooth mold to the top denture base mold to form a mold cavity defining the shape of denture teeth; and injecting fluid synthetic denture tooth material into the denture teeth mold cavity and curing the material to form the denture teeth joined to the denture base. An apparatus for making the denture is also disclosed.

Owner:GLOBAL DENTAL SCI

Method for making and using a template for locating a dental implant and components relating thereto

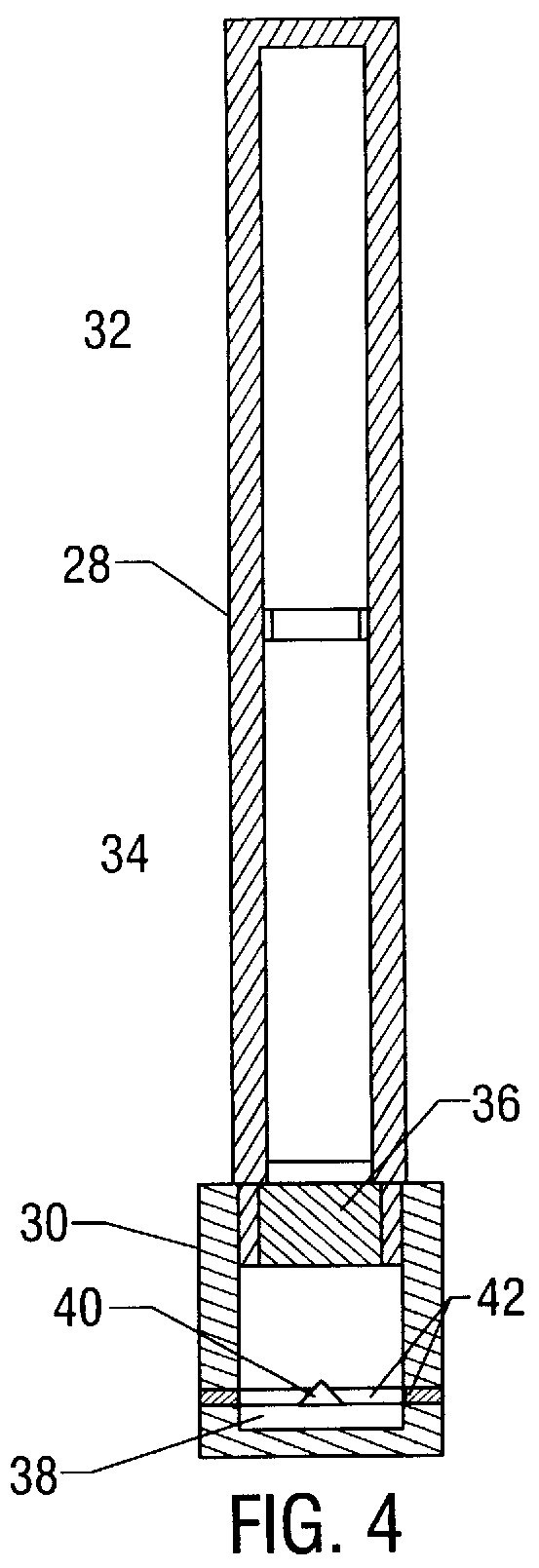

InactiveUS7845943B2Accurate locationReduce the amount requiredDental toolsBoring toolsMaxilla/MaxillaryDental cast

An apparatus used in forming a template for locating a dental implant osteotomy in a patient's mandible or maxilla. The apparatus includes a guide post and a sleeve having a longitudinal gap. A dental cast of a patient's mandible or maxilla is formed and a hole is drilled in the dental cast wherein the location and orientation of the hole corresponds to a desired location and orientation of the dental implant osteotomy. The guide post is inserted into the hole and the sleeve is magnetically attached. A molding material is applied to a portion of the dental cast and to a portion of an outer surface of the sleeve to form the template. The template, including the sleeve embedded therein, is removed from the dental cast and is used in the patient's mouth to provide a guide means for drilling the osteotomy.

Owner:MEITNER SEAN W

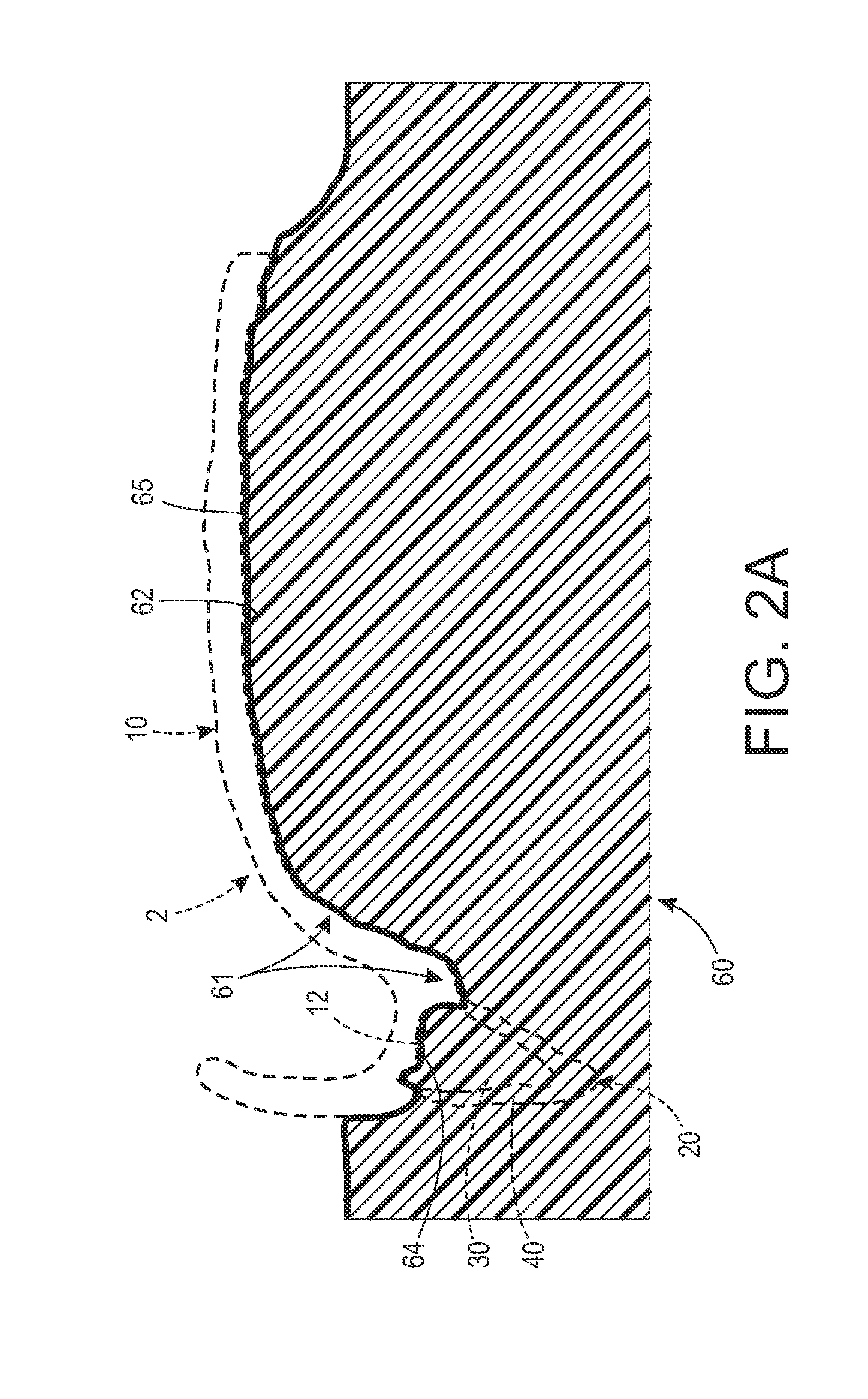

Method for dental restoration and related kit

The disclosure generally relates to a method for forming a dental mold. The method generally includes: (a) scanning an existing dental structure to generate a three-dimensional first digital model of the existing dental structure, (b) modifying the first digital model of the existing dental structure to generate a three-dimensional second digital model of a planned dental structure; (c) generating a three-dimensional third digital model corresponding to a negative of the second digital model; (d) digitally sectioning the third digital model into at least one buccal model portion and at least one lingual model portion of the third digital model; and (e) creating a dental mold comprising at least one buccal mold portion and at least one lingual mold portion based on the sectioned third digital model. The disclosure also relates to (a) methods of assembling the dental mold over a tooth and a gum of a patient having an existing dental structure in need of dental restoration, (b) methods of performing a dental restoration on the existing dental structure of the patient using the dental mold, and (c) kits including components for forming the dental mold and / or for performing the dental restoration using the dental mold.

Owner:VUILLEMOT WILLIAM C

Method for manufacturing the one body abutment of an implant

The invention discloses a method for manufacturing the one body abutment of an implant. Particularly, the method of manufacturing an abutment of an artificial tooth, includes an implant fixture installed in a jaw bone and a crown defining a contour thereof. The abutment is fixed to the implant fixture to connect the implant fixture to the crown. A three-dimensional image of an oral cavity of a patient is generated on a computer by 3D scanning of a dental plate of plaster. A virtual tooth is designed using the image of the oral cavity, in consideration of a row of teeth in a region from which a tooth is missing, the height of adjacent teeth and alignment with an upper or lower tooth. The shape of the abutment is designed according to the shape of the designed virtual tooth. Data on the designed abutment are transmitted to a precision machine. The designed abutment is cut using the precision machine to have a one body structure.

Owner:金正韩

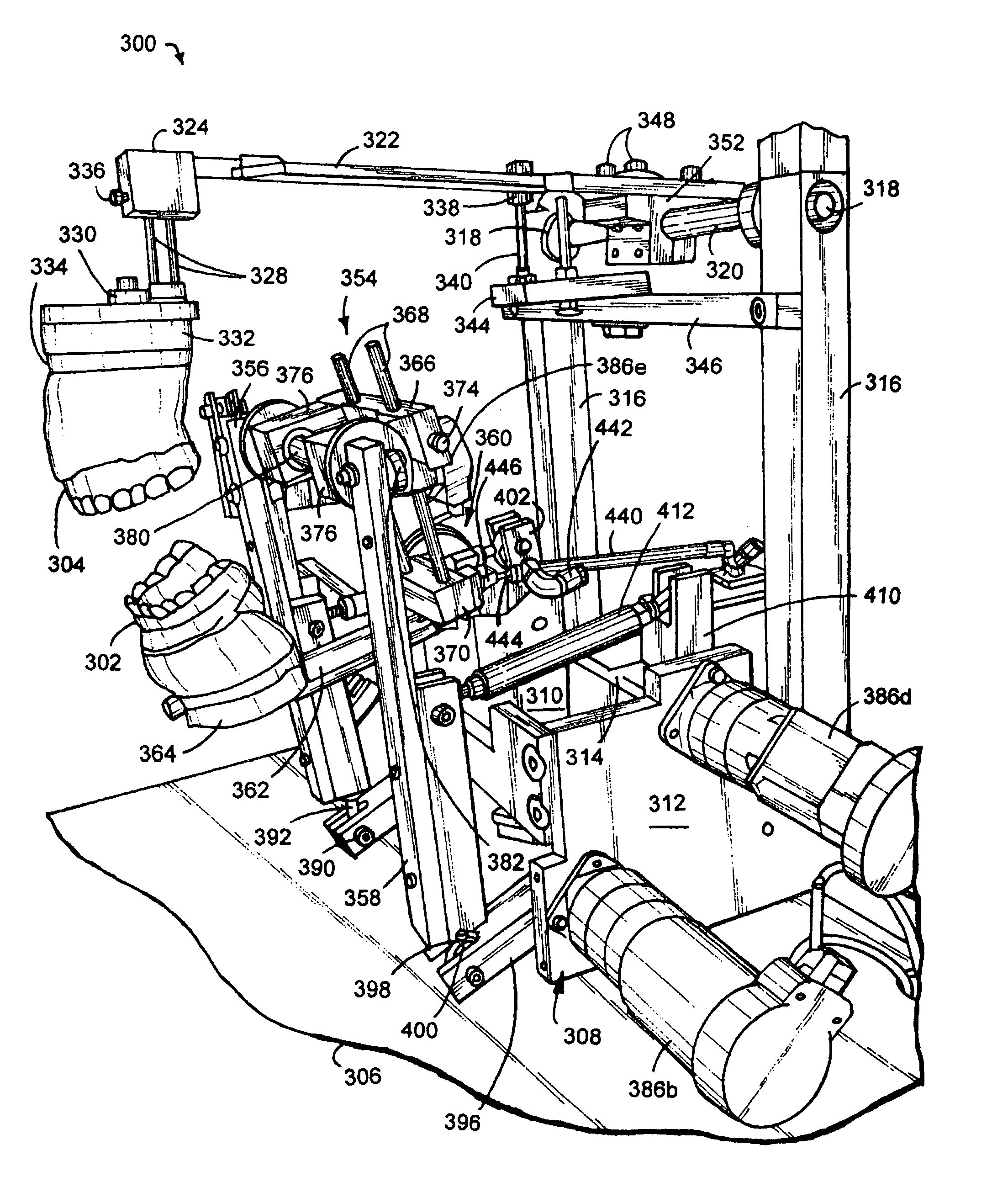

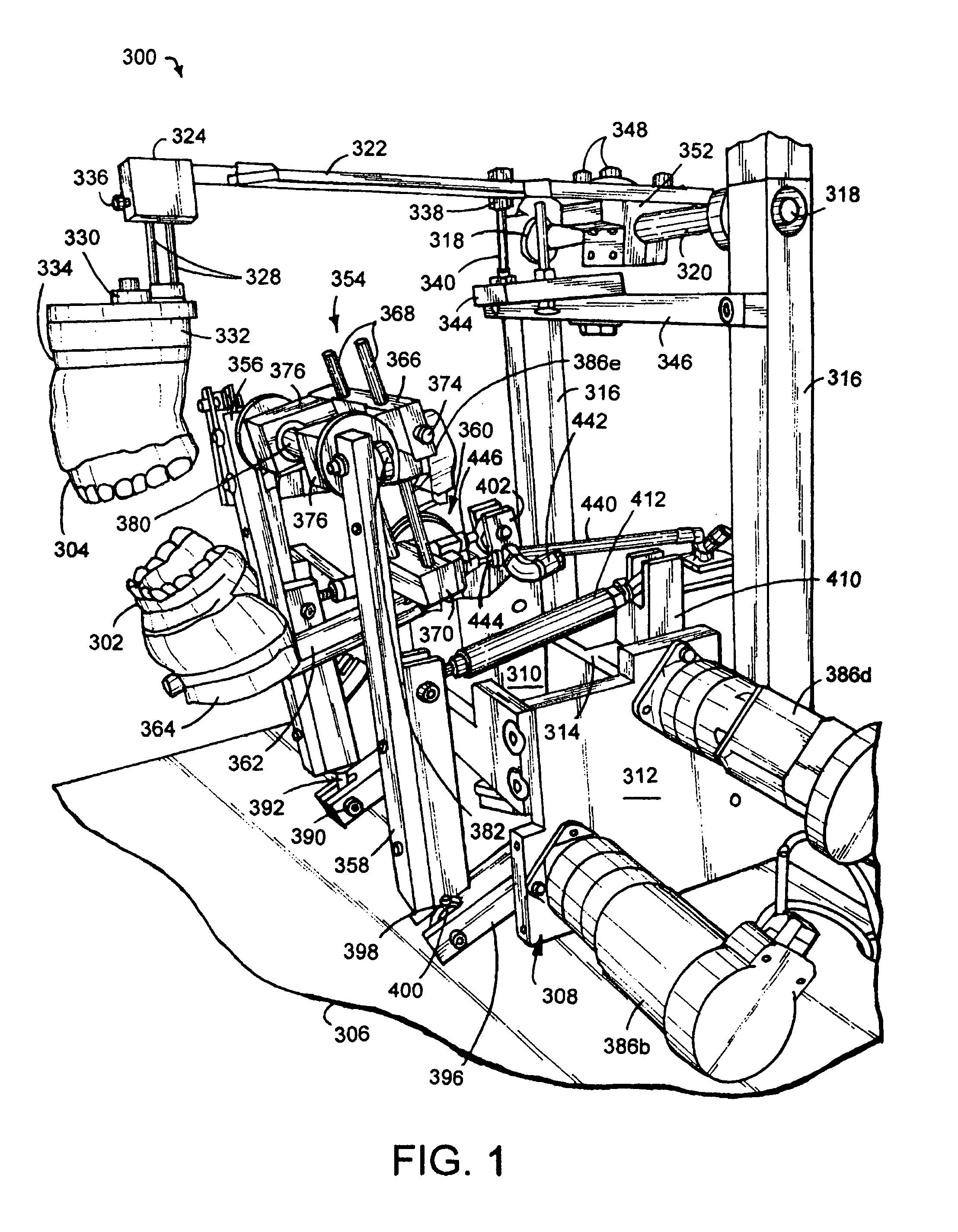

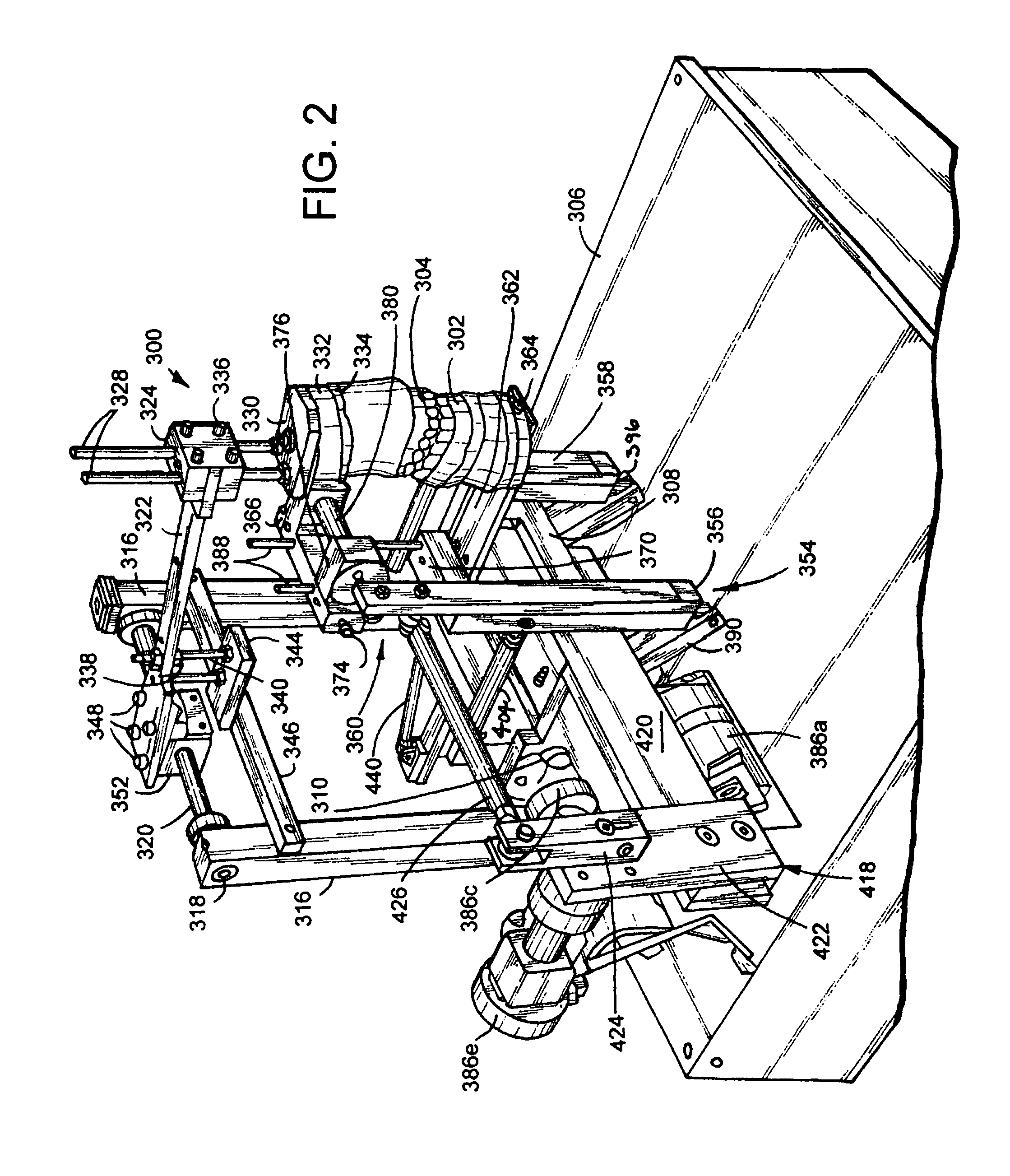

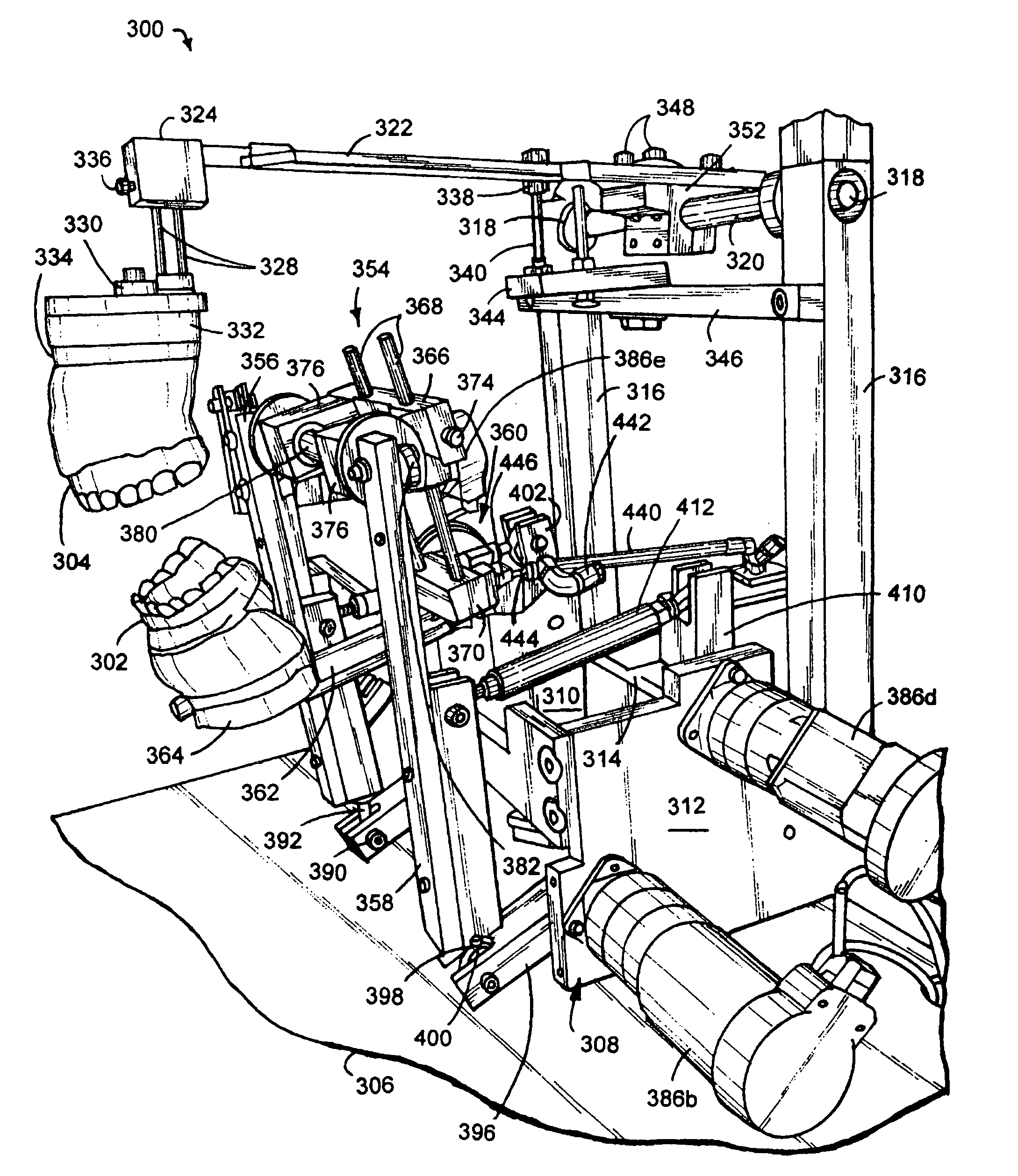

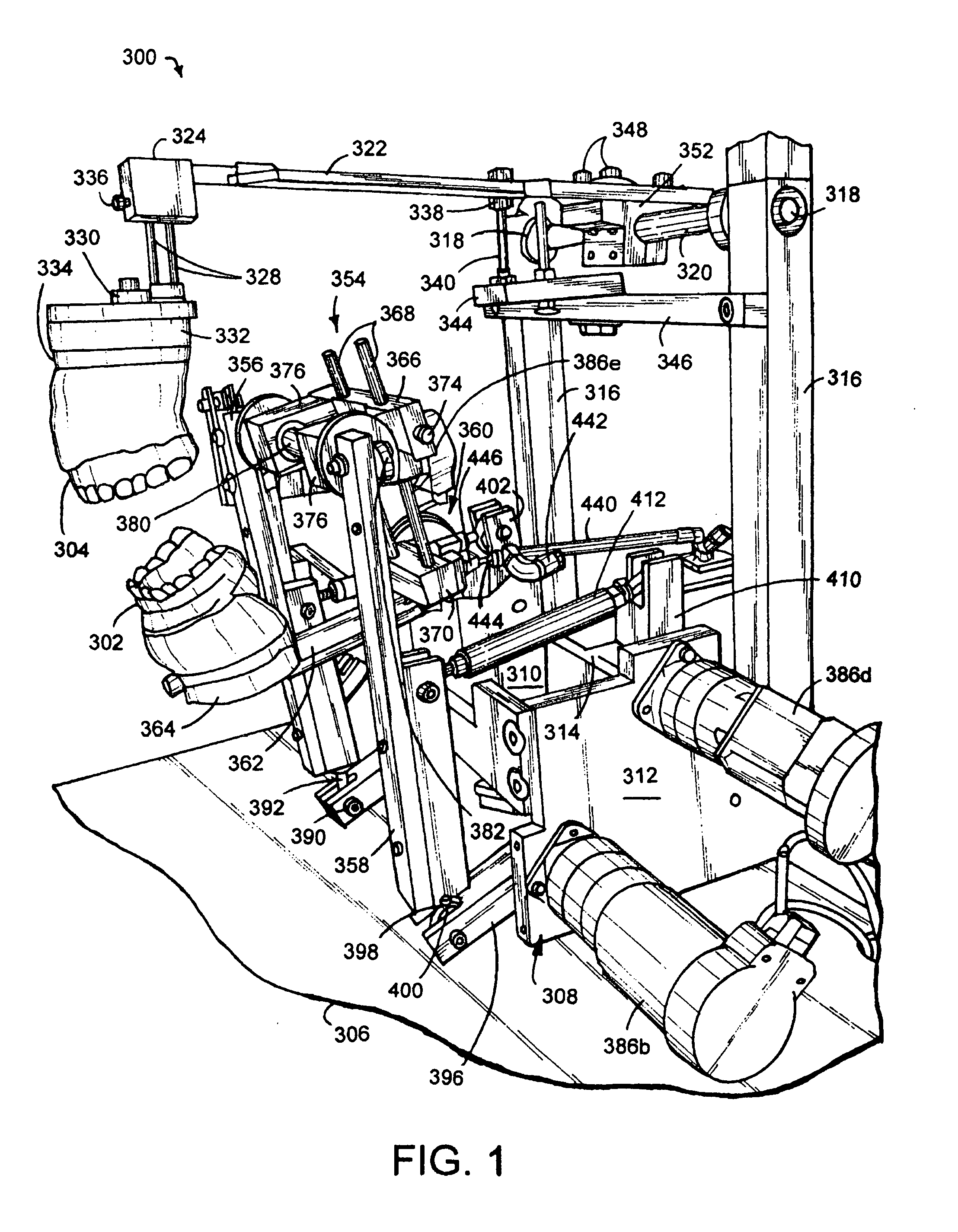

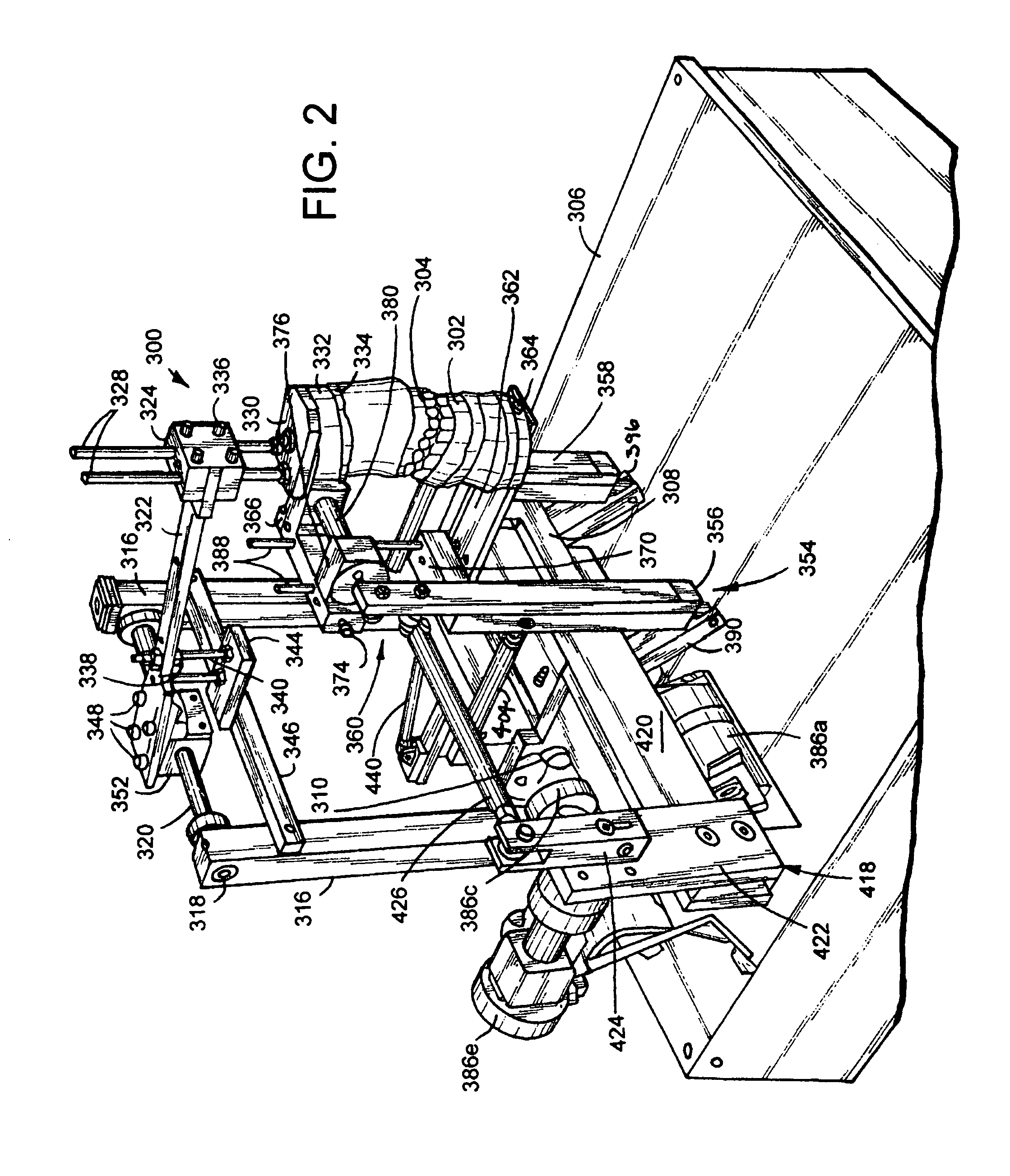

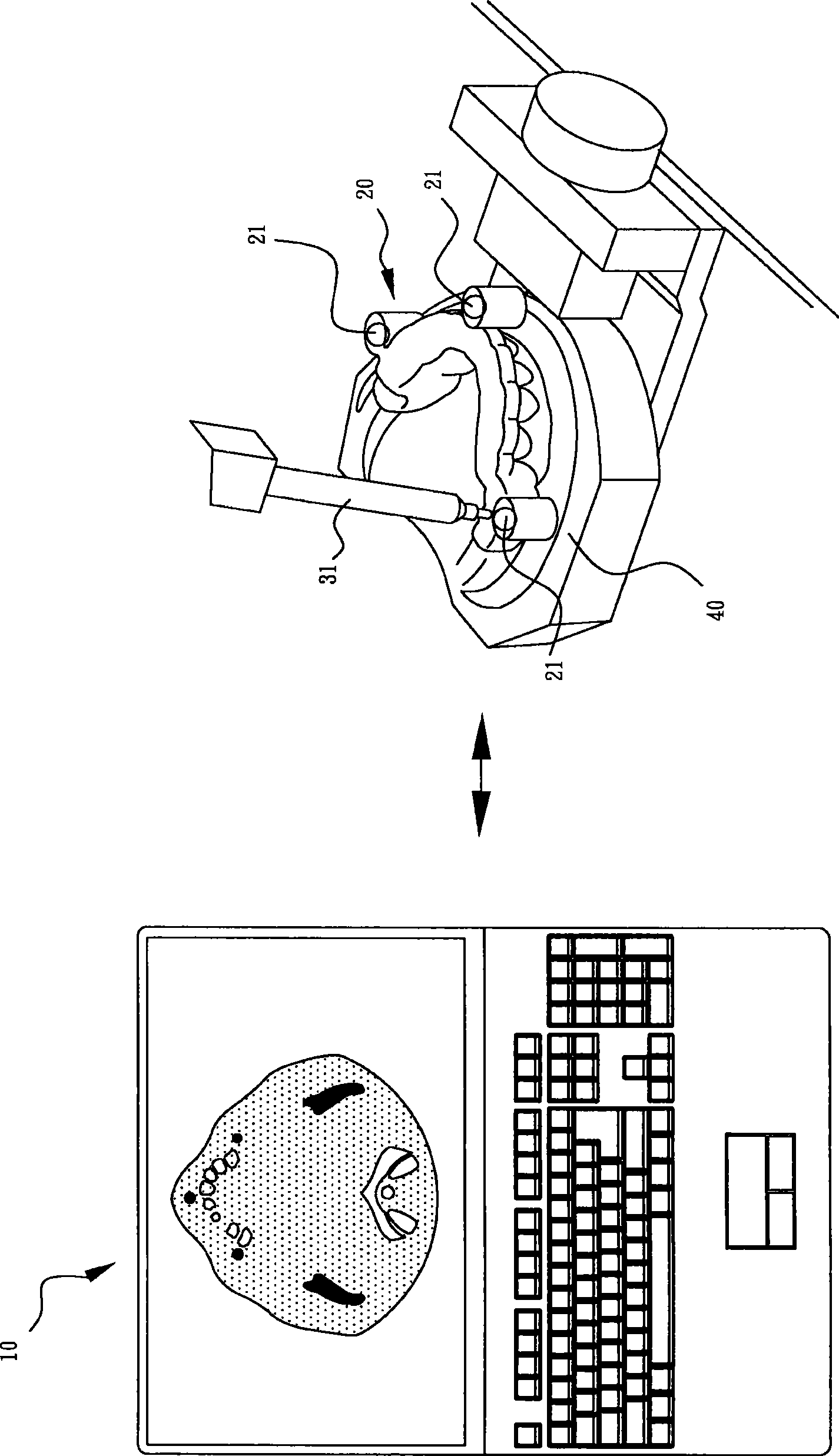

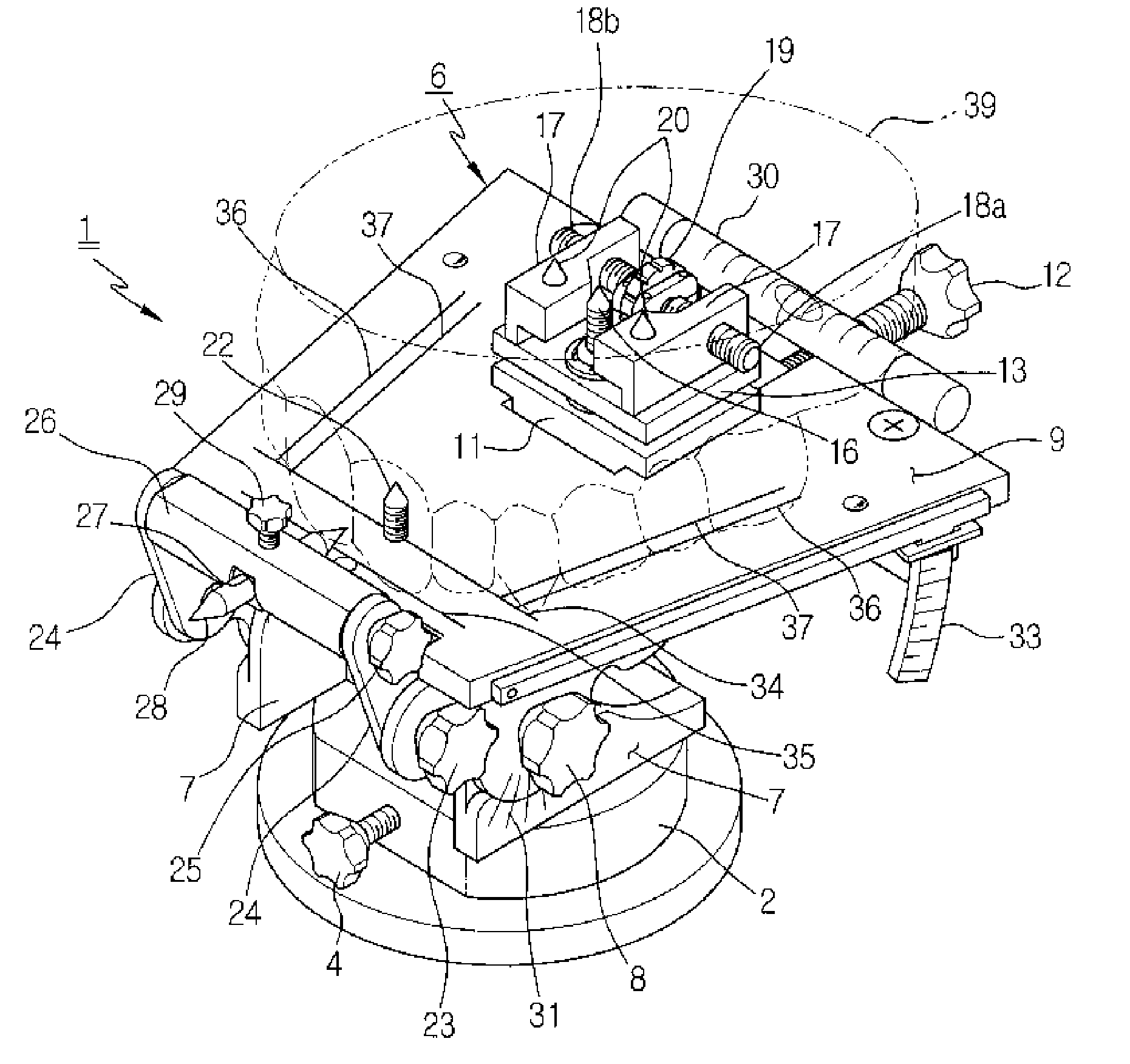

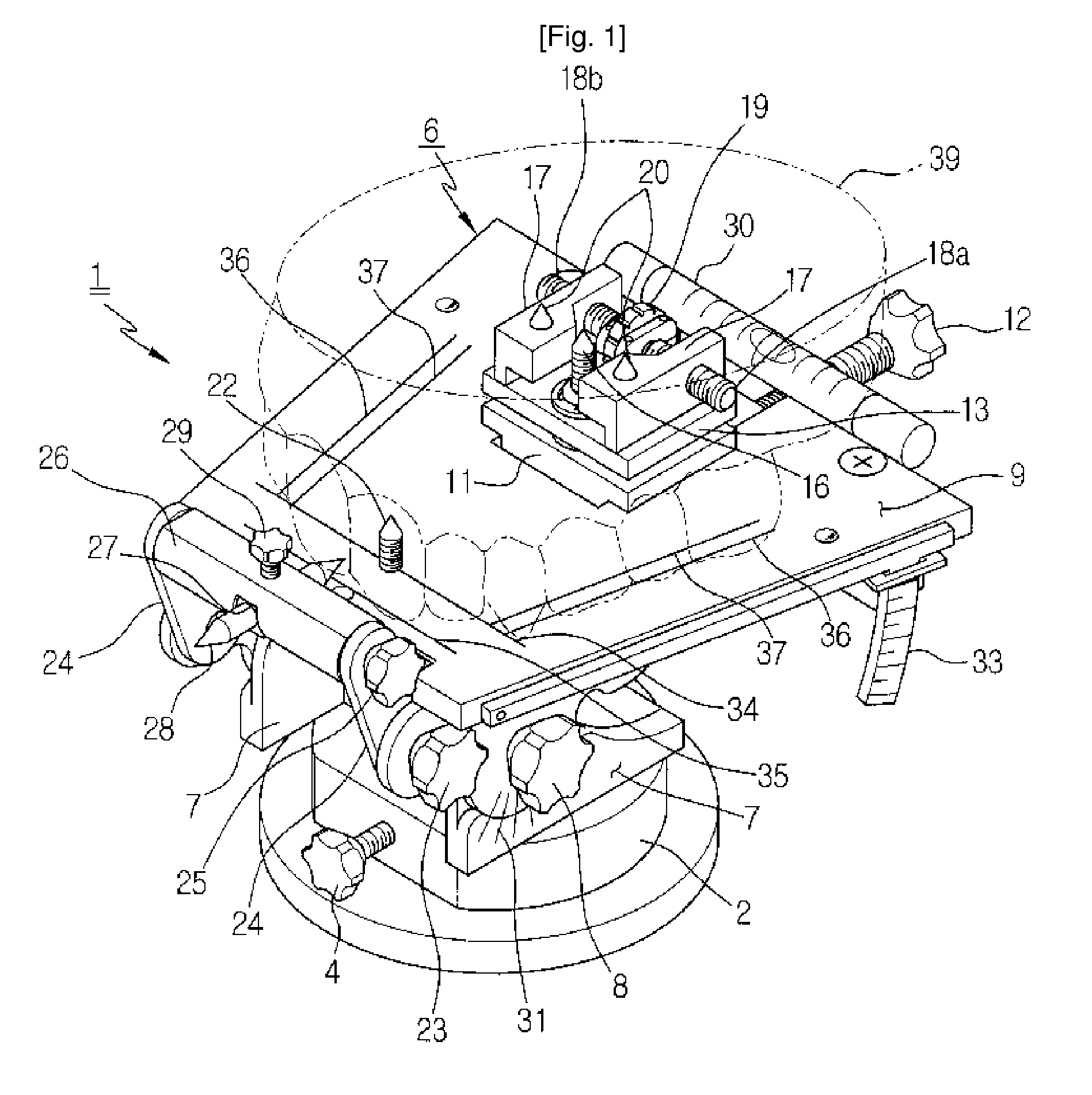

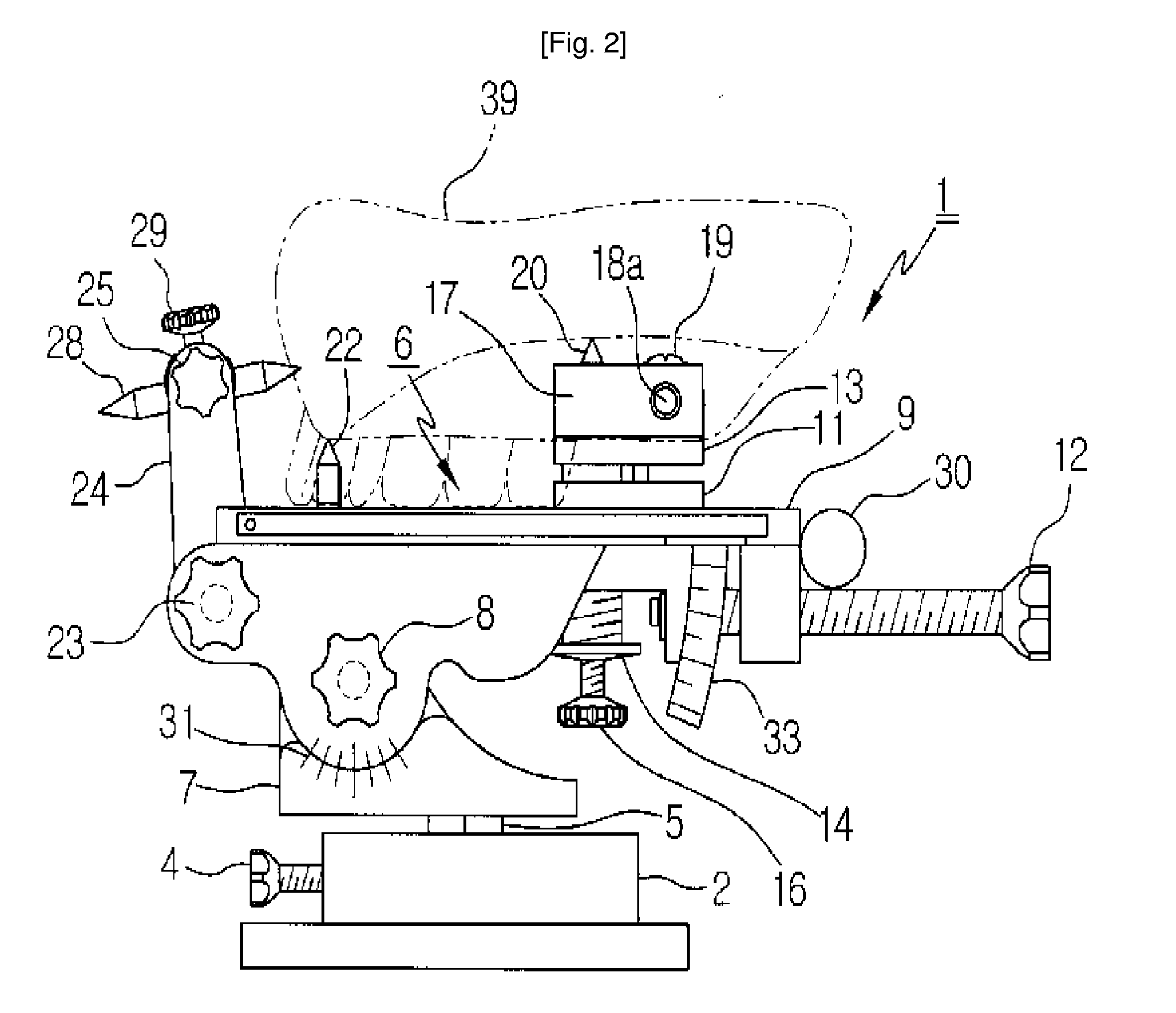

Apparatus and method for replicating mandibular movement

An apparatus to replicate and analyze movement of a mandible relative to a maxilla with dental casts thereof includes a base frame, an arm connected to the base frame and a suspension assembly positionable by a plurality of electro-mechanical actuators. The arm connects to the base frame and supports the dental cast of the maxilla in a fixed position relative to the base frame. The suspension assembly, having opposing first and second sides, supports the dental cast of the mandible in working relation to the dental cast of the maxilla. The plurality of actuators each selectively impart movement to the sides of the suspension assembly such that the movement of the mandible obtained during a recording process can be replicated on the apparatus in real time.

Owner:GNATH TECH DENTAL SYST

Manufacturing method of positioning tray and bracket with positioning hook used for manufacturing positioning tray

The invention discloses a manufacturing method of a positioning tray and a bracket with a positioning hook, which is used for manufacturing the positioning tray. The manufacturing method of the positioning tray comprises the following steps: obtaining an original dental impression and an ideal dental impression; converting the ideal dental impression to a three-dimensional digital model, drawing each bracket main body; drawing the positioning hook on each bracket main body; using a wax pattern machine to prepare the wax pattern of each bracket with the positioning hook; using the wax pattern as the mould core to cast the blank of the bracket with the positioning hook and perform surface treatment; assembling the treated bracket with the positioning hook on the original dental impression, pressing a film to obtain the positioning tray; and finally removing the positioning hook to obtain the bracket matched with the positioning tray. The bracket with the positioning hook is prepared for applying the method. The method of the invention is not required to prepare the integral mould of the bracket and the dental impression, thus greatly reducing the production cost; and the finished appliance can be prepared after the positioning hook is cut off without casting the bracket separately, thus saving the cost and shortening the production period.

Owner:GUANGZHOU RITON BIOMATERIAL

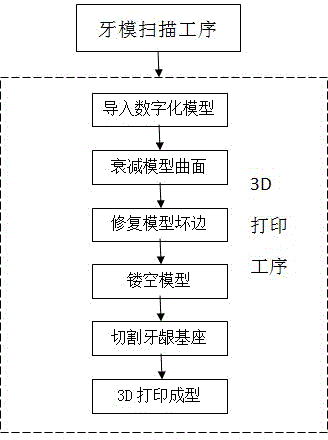

3D printed dental cast processing technology

The invention discloses a 3D printed dental cast processing technology which sequentially comprises a dental cast scanning step and a 3D printing step, wherein the 3D printing step sequentially comprises the following steps: 1) importing a digital model; 2) attenuating a hook face of the model; 3) repairing bad edges of the model; 4) hollowing the model; 5) cutting a gingiva substrate; and 6) 3D printing moulding. The 3D printed dental cast processing technology disclosed by the invention is used for changing the characteristic that photosensitive resin dental models obtained by virtue of a 3D printing moulding machine are solid models, saving a lot of photosensitive resin raw materials, reducing the printing and processing areas, shortening the printing moulding time, improving the processing efficiency and lowering the production cost and the transport cost.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

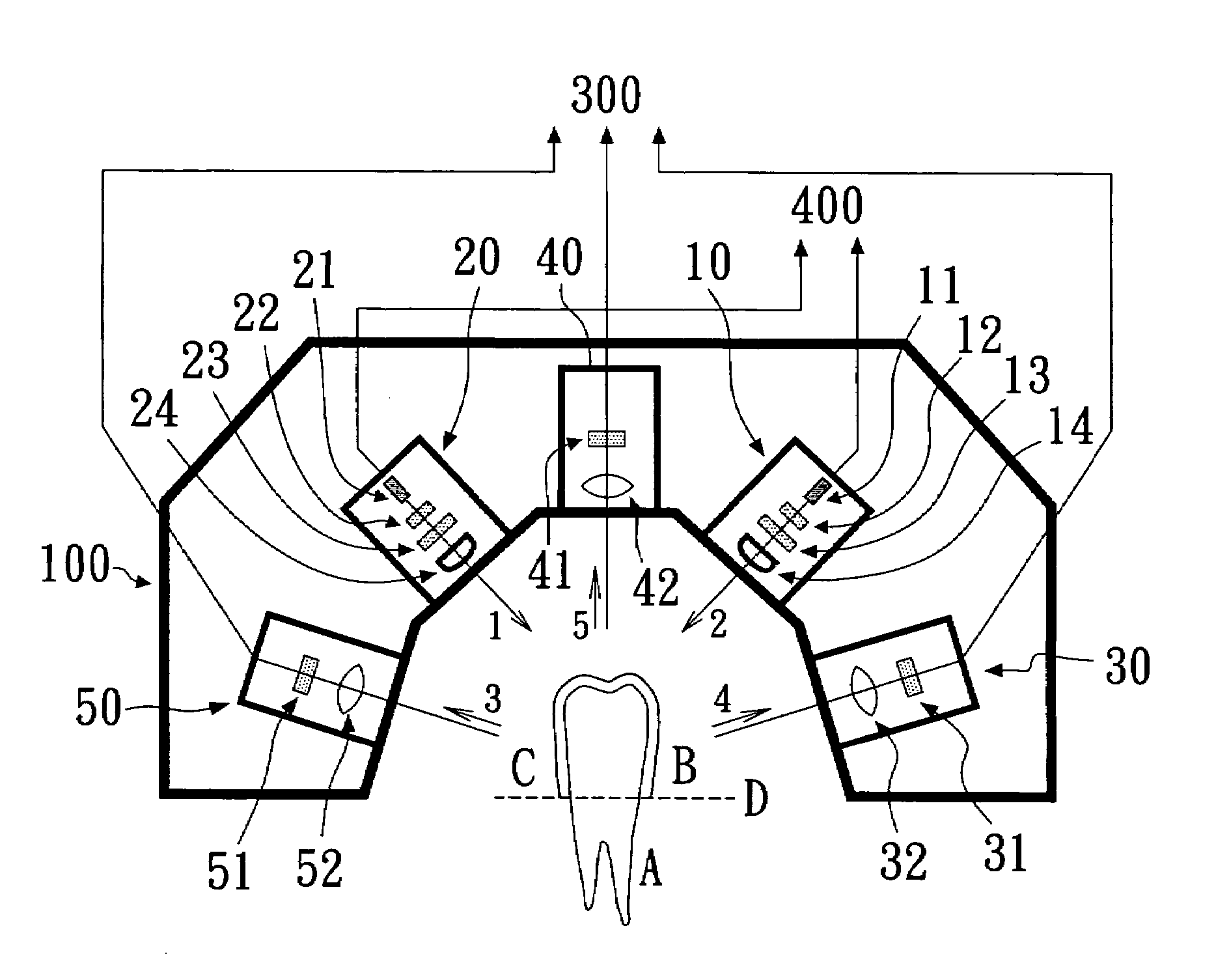

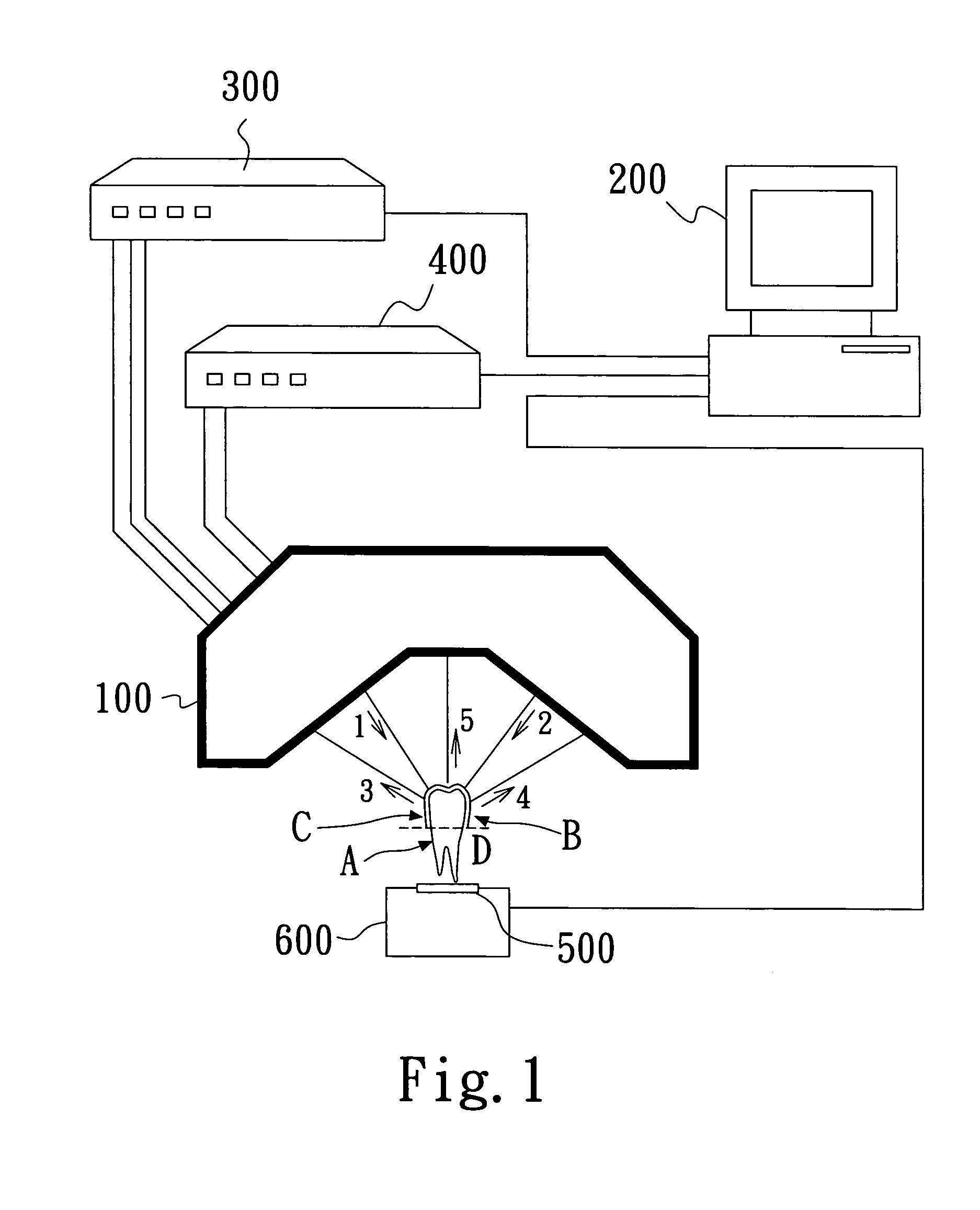

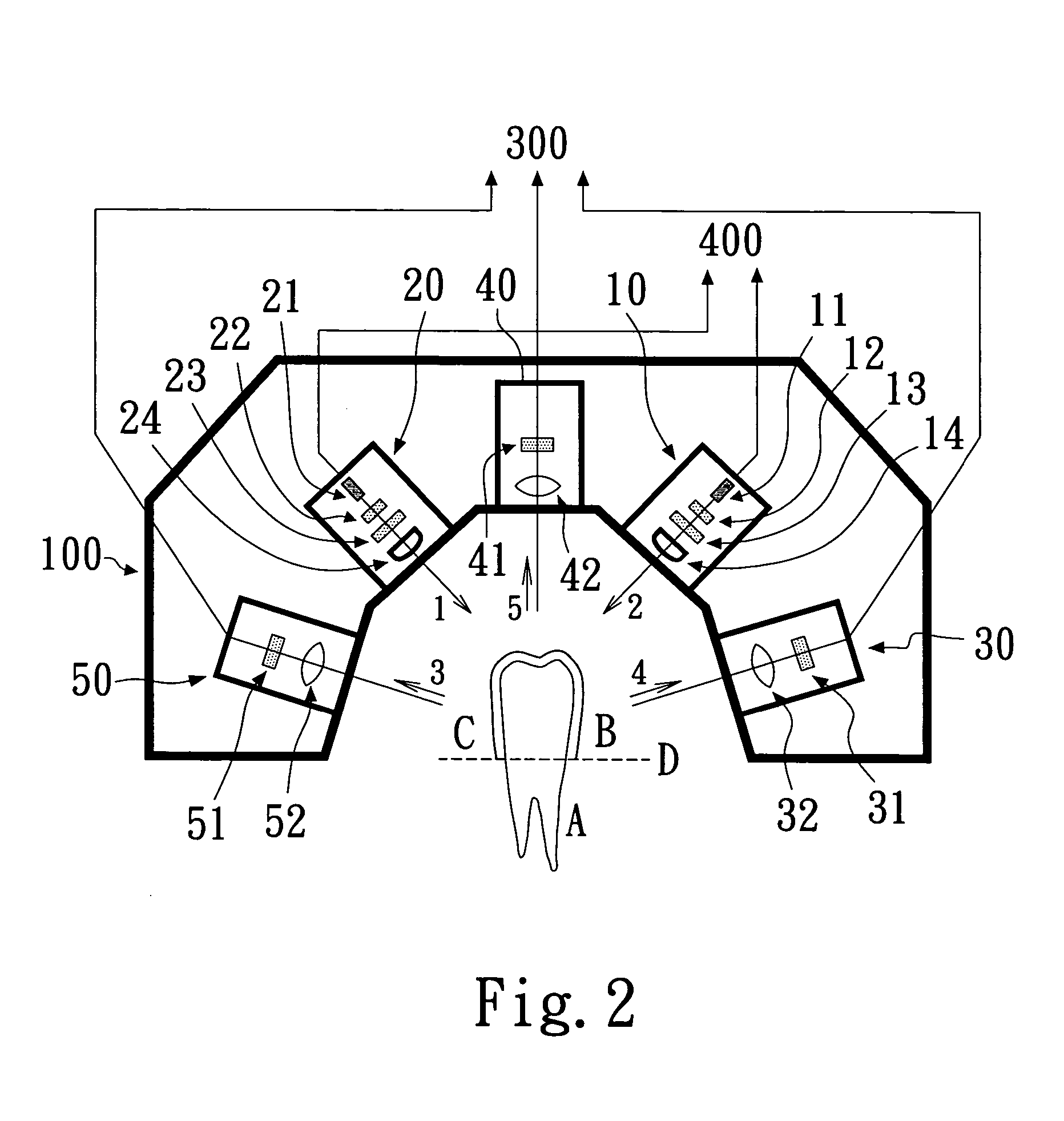

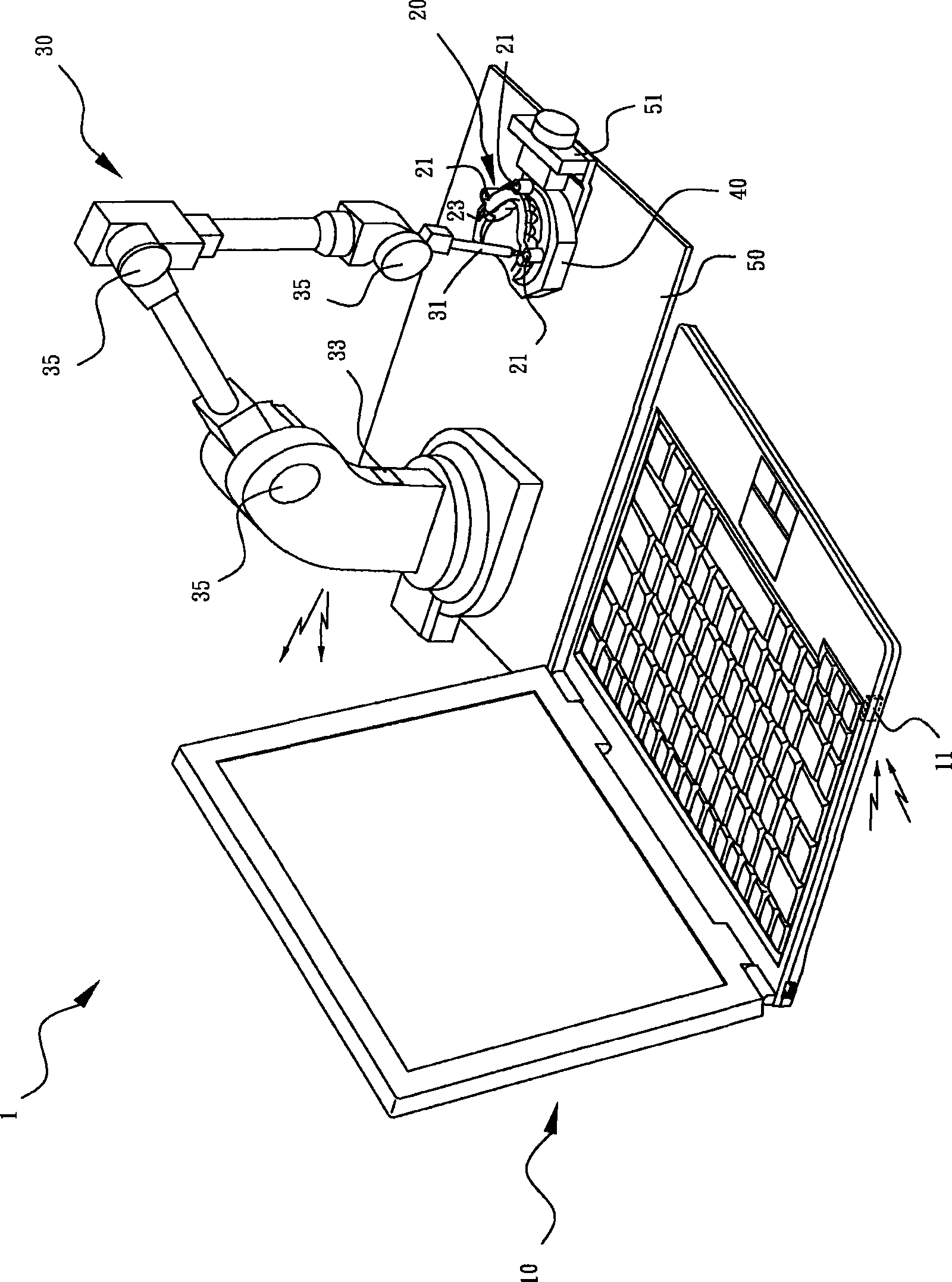

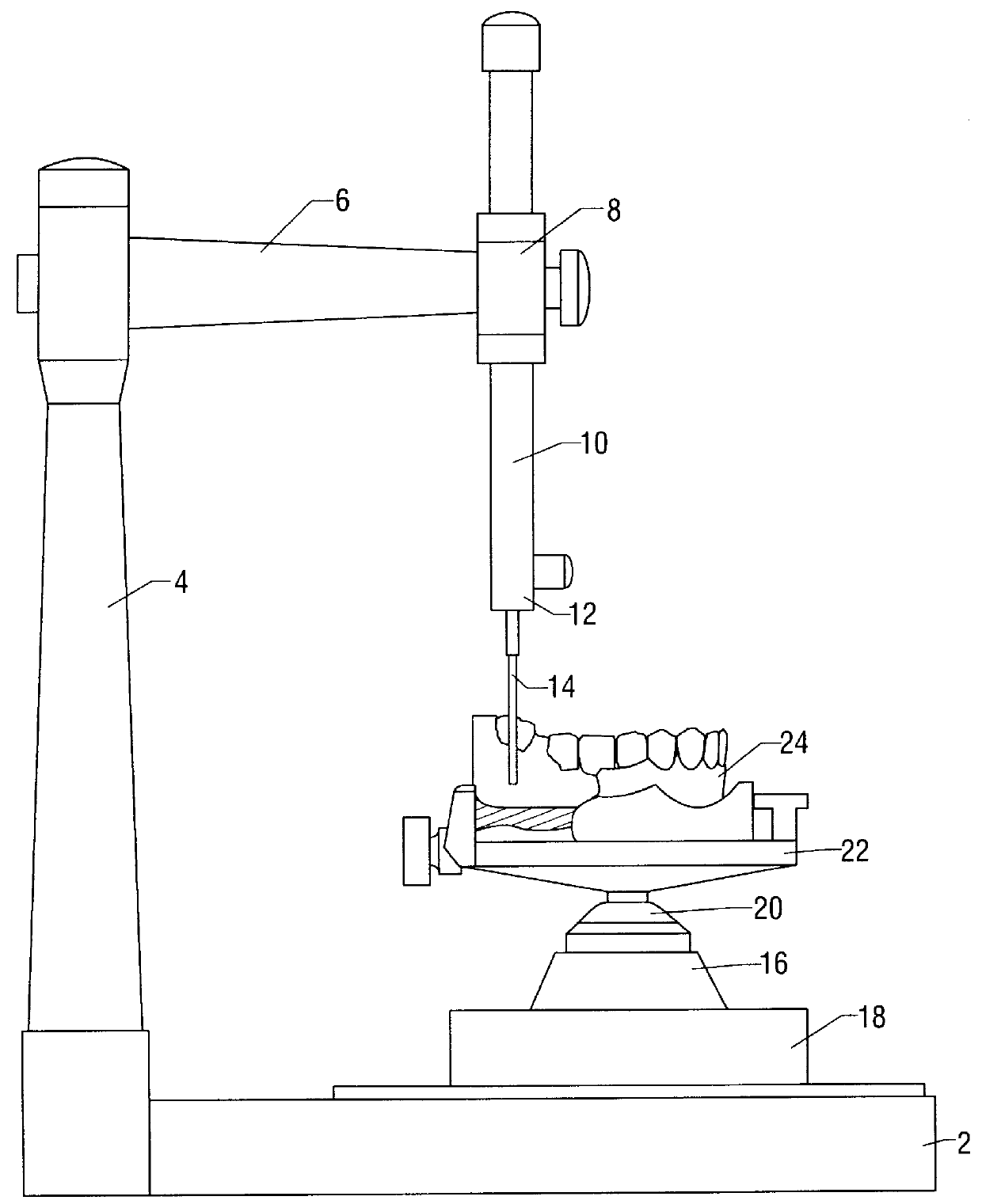

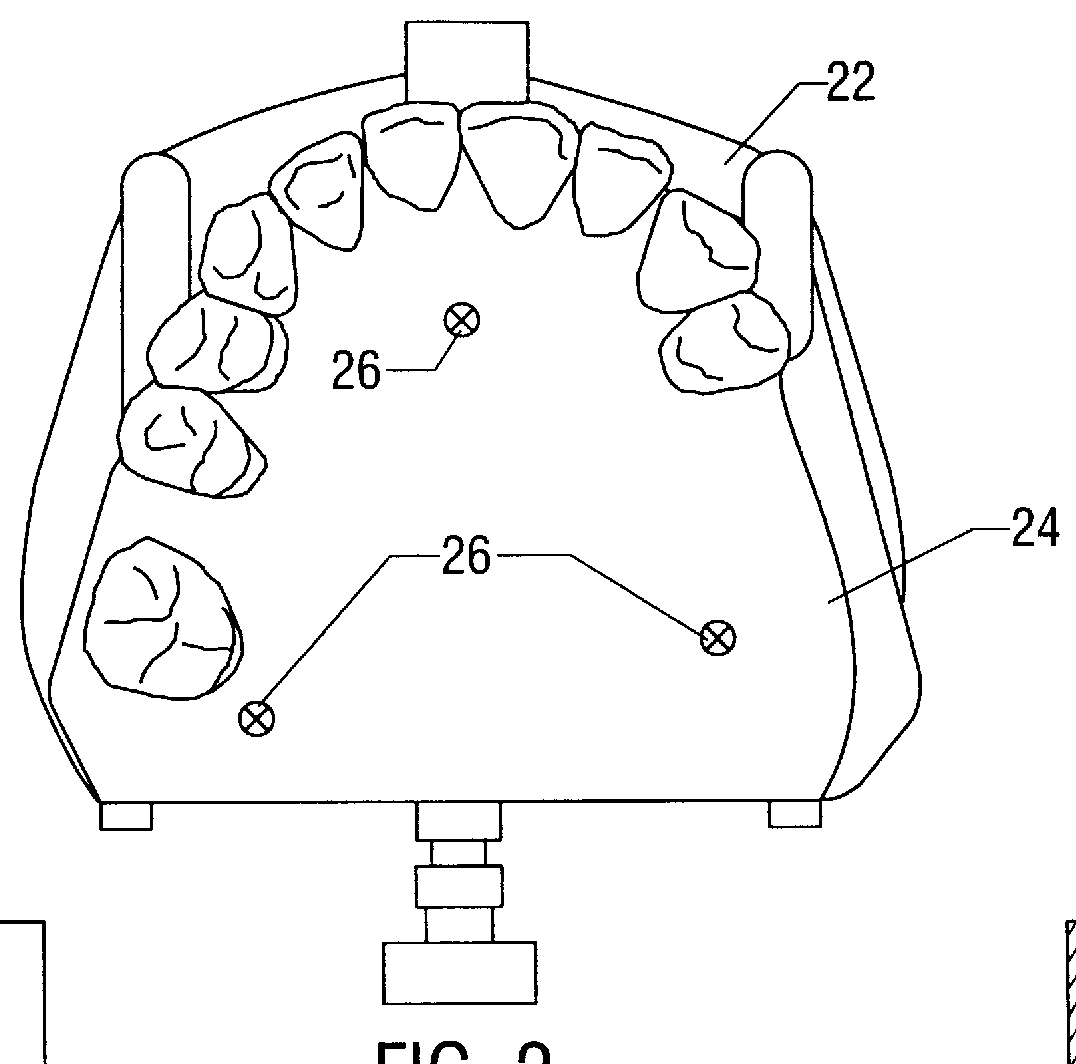

Apparatus and method for rapid and precise scanning of three-dimensional occlusal profile of dental cast

InactiveUS7259871B2Rapid and precise profile measurementImpression capsMechanical/radiation/invasive therapiesTriangulationDental cast

This invention relates to an apparatus and a method for rapid and precise scanning of the three-dimensional (3-D) profile of a dental cast. Disclosed is a measurement apparatus comprising two symmetrically arranged optical projection units and plural image capturing units each including optical components and optical lenses. The geometrical relationship between the optical projection units and the plaster dental cast are such arranged to ensure precise projection of laser beams and comprehensive measurement. The plural image capturing units serve to capture the reflected, structured light patterns, based on which patterns a 3-D occlusal profile is rapidly and precisely calculated through the triangulation principle, thereby allowing efficient and precise measurement of the 3-D occlusal profile of the plaster dental cast.

Owner:NAT TAIPEI UNIV OF TECH

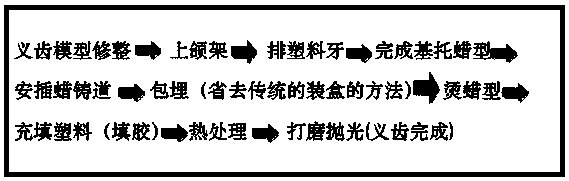

Manufacturing method of removable dentures

ActiveCN107854187AAvoid Coitus HeighteningAvoid Shrinkage Bubble PhenomenonArtificial teethWater bathsDental cast

The invention relates to a manufacturing method of removable dentures. Currently, the removable-denture manufacturing methods in all countries in the world are a thermos-coagulation packing method, need steps such as casing, filling, squeezer pressurizing and water bath polymerization (dental cast cooking pot), are complex in process, time-consuming and labor consuming, are non-uniform in moldingcase pressurizing and are difficult in precise mastering and control of heating speed and heating maintaining time during heat processing. The method has the advantages that the manufacturing flow oftraditional removable dentures is improved, joint height increasing and contraction bubbles of the removable dentures manufactured by the traditional manufacturing process are avoided, and the base-material filling of the partial removable dentures and attachment dentures can be performed; the models of the attachment dentures does not need to be pressurized on a squeezer, and the subfissure or deformation of the fixing-part porcelain teeth of the attachment dentures is avoided.

Owner:程昕

Apparatus and method for replicating mandibular movement

An apparatus to replicate and analyze movement of a mandible relative to a maxilla with dental casts thereof includes a base frame, an arm connected to the base frame and a suspension assembly positionable by a plurality of electro-mechanical actuators. The arm connects to the base frame and supports the dental cast of the maxilla in a fixed position relative to the base frame. The suspension assembly, having opposing first and second sides, supports the dental cast of the mandible in working relation to the dental cast of the maxilla. The plurality of actuators each selectively impart movement to the sides of the suspension assembly such that the movement of the mandible obtained during a recording process can be replicated on the apparatus in real time.

Owner:GNATH TECH DENTAL SYST

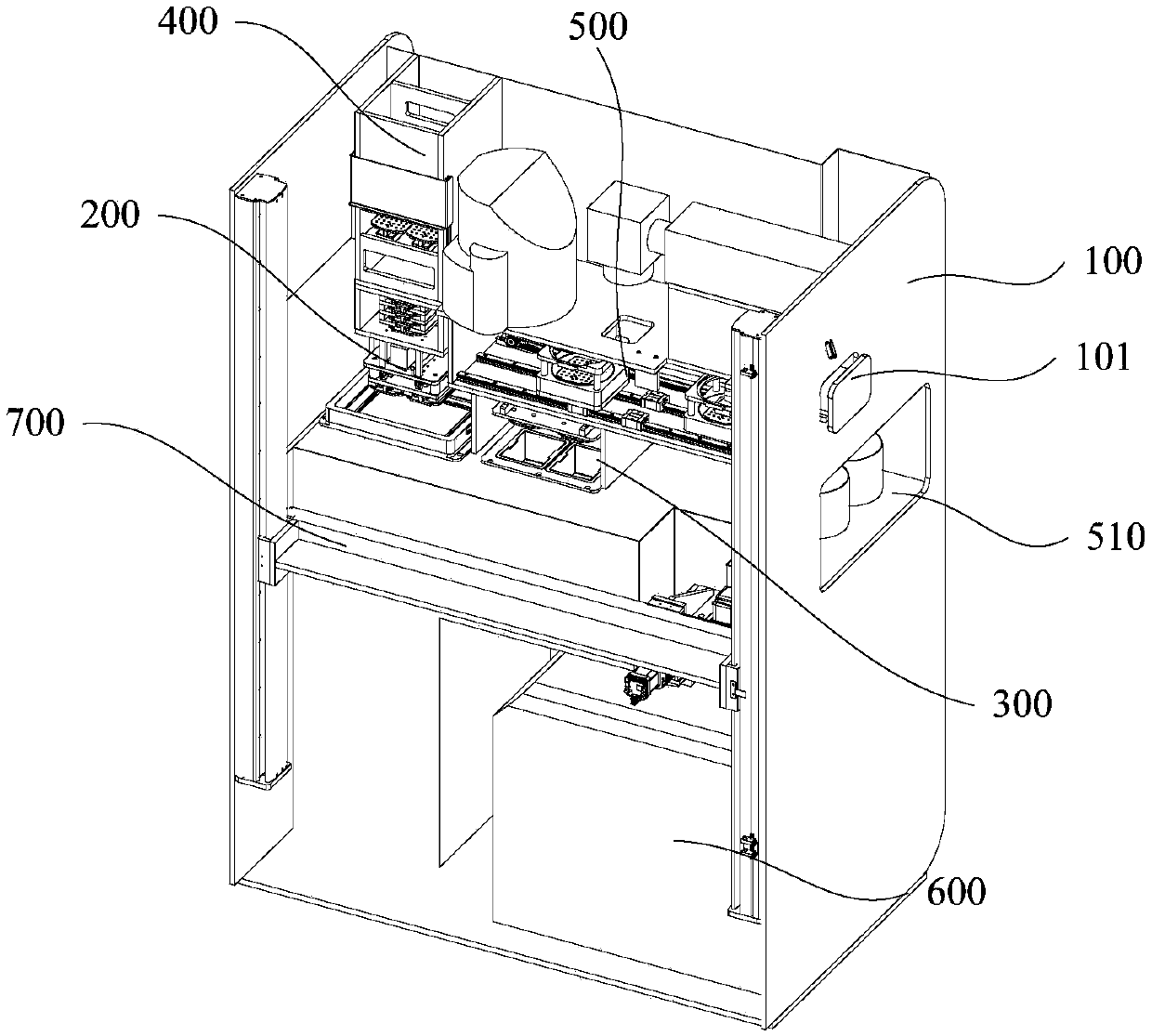

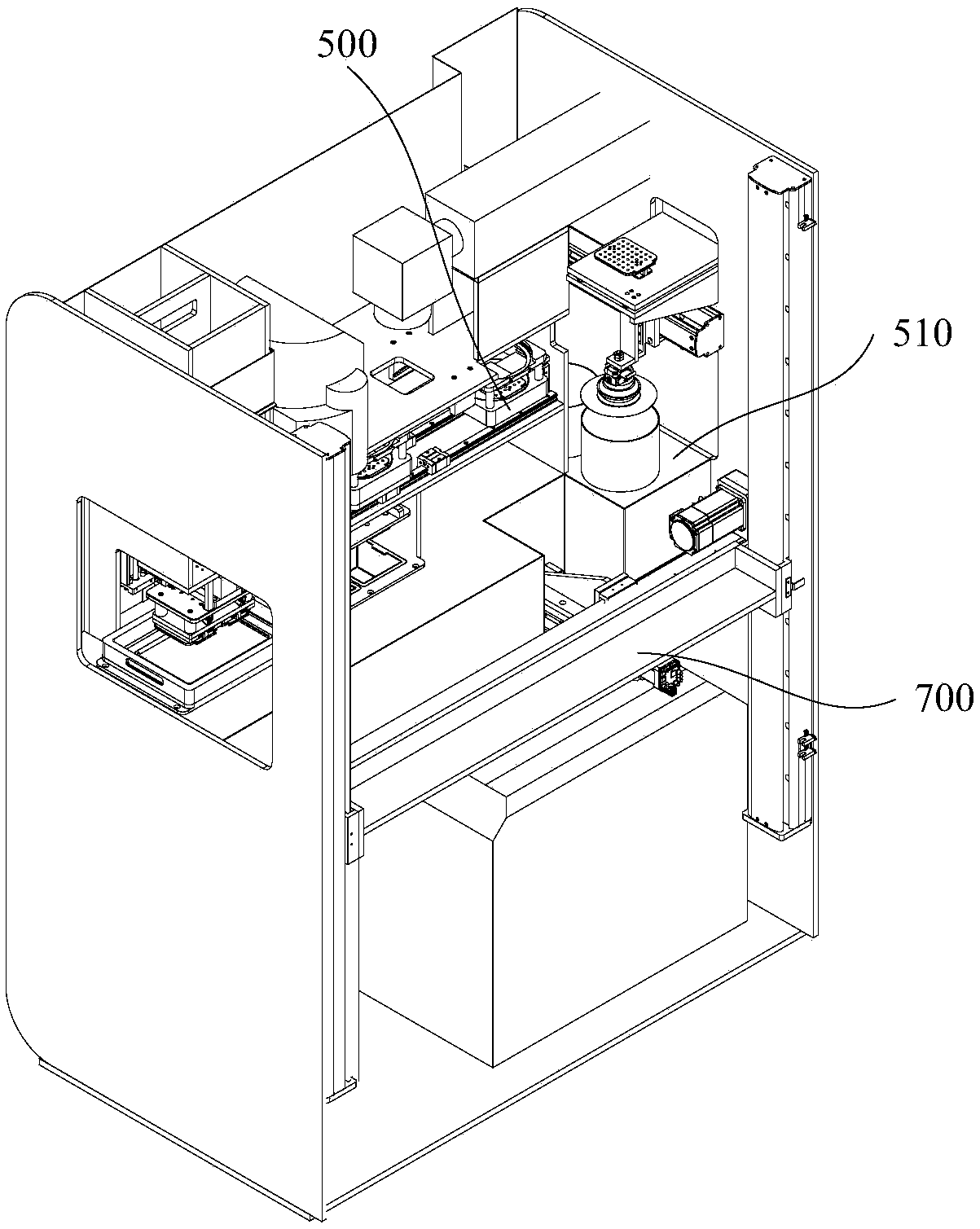

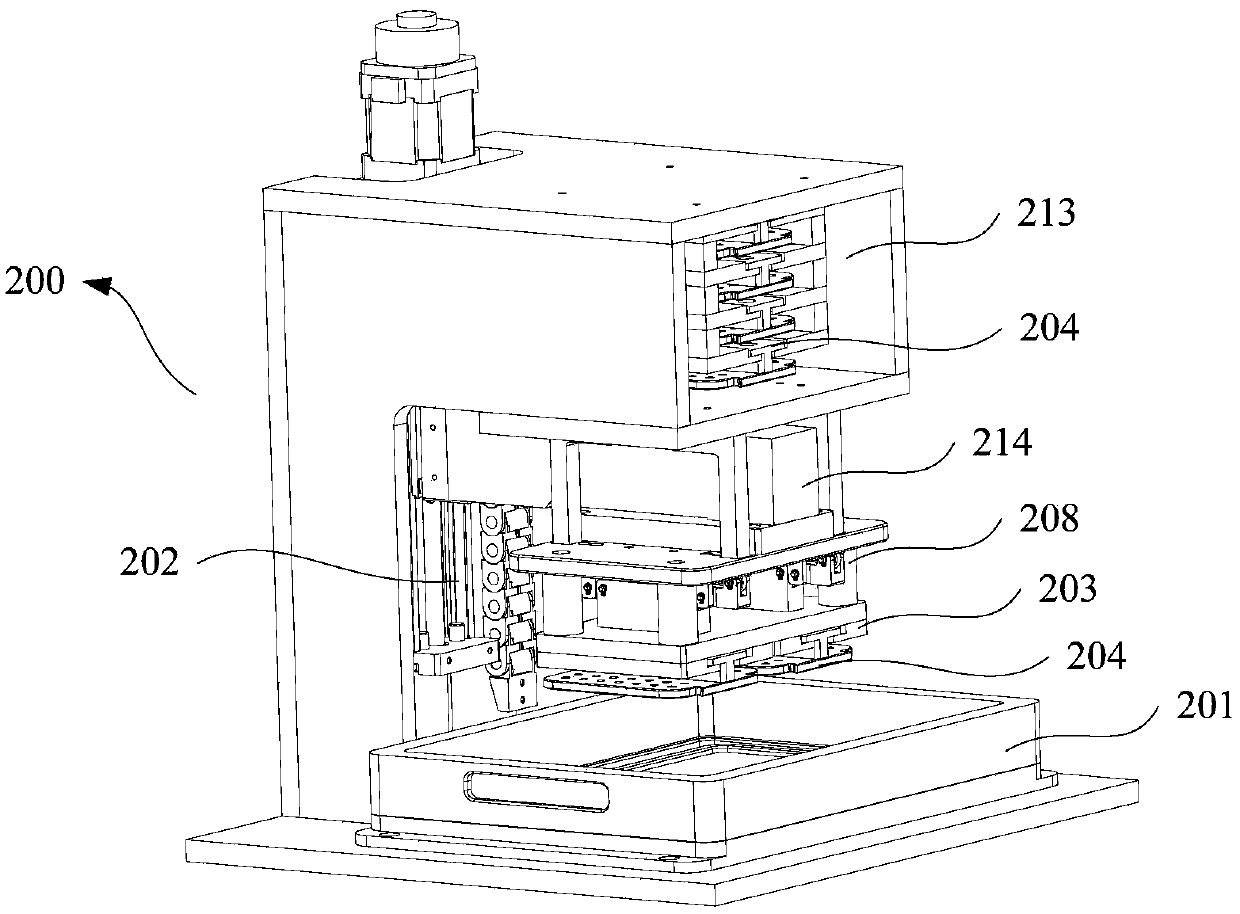

Integrated invisible tooth correcting device production equipment

The invention relates to the technical field of tooth correcting device production, in particular to integrated invisible tooth correcting device production equipment. The integrated invisible tooth correcting device production equipment comprises an equipment cabinet, a dental cast printing mechanism, an after-treatment mechanism, a film pressing mechanism, a cutting mechanism and a carrying mechanism, the dental cast printing mechanism, the after-treatment mechanism, the film pressing mechanism and the cutting mechanism are integrated in the equipment cabinet, and the carrying mechanism is matched with the dental cast printing mechanism, the after-treatment mechanism, the film pressing mechanism and the cutting mechanism separately; the dental cast printing mechanism is used for printingdental cast; the after-treatment mechanism is used for conducting after-treatment on the dental cast, wherein the after-treatment step involves one or more of cleaning, air drying and curing; the film pressing mechanism is used for conducting film pressing on the dental cast to form a dental socket middle product; the cutting mechanism is used for cutting the dental socket middle product to forma dental socket finished product; the carrying mechanism is used for driving the tooth cast, the tooth socket middle product or the dental socket finished product among all mechanisms for turnover processing or discharging. All production and preparing technologies of the tooth socket are integrated to one set of equipment, the equipment can be directly arranged in a clinic, instant diagnosis andtreatment are achieved, and the diagnosis and treatment time of a patient is greatly shortened.

Owner:GUANGZHOU HEIGE ZHIZAO INFORMATION TECH CO LTD

Method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding

The invention relates to the field of dental prosthesis, in particular to a method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding. The method comprises the following steps: a three-dimensional scanner is adopted to scan a dental cast, a three-dimensional stereoscopic image is formed, an ultra-thin veneer with the thickness of less than 0.5 mm is designed on the virtual image, after the ultra-thin veneer is designed, data is output to a 3D (three-dimensional) resin wax forming machine, the ultra-thin veneer is formed in the manners of resin-spraying, irradiation curing and printing, and then the formed resin wax pattern is subjected to embedded casting, grinding adjustment, try-in and glazing. Compared with the prior art, the method adopts a computer to design, and the conventional hand-made wax pattern is replaced by the resin wax pattern processed by the digital resin wax spraying, irradiation curing and printing processing, so that fabrication of porcelain laminate veneer with the thickness of less than 0.5 mm is realized. An aesthetic seeking patient with discolored teeth does not need tooth grinding and can receive tooth-whitening treatment without hurting teeth.

Owner:深圳市金悠然科技有限公司

Oral beauty repair method used on 3D cast metal bottom crown

InactiveCN106420083ARapid productionInhibit sheddingArtificial teethDesign optimisation/simulation3d shapesDental cast

The invention relates to an oral beauty repair method used on a 3D cast metal bottom crown. The method includes the steps that S1, an impression silicone rubber material or gypsum model provided by a doctor is scanned, or the intra-oral portion of a patient is directly scanned to obtain scanning data; S2, the scanning data is received remotely by a computer and analyzed through dental CAD software, designing is conducted according to oral clinical actual conditions of the patient, and a virtual crown 3D shape is formed on the computer; S3, the formed virtual crown data is transmitted to a special dental metal laser fusing forming device and printed directly in a 3D mode, and a denture metal bottom crown green body is formed; S4, the top of the base bottom crown of a denture dental model is polished, so that the thickness of the occlusion portion is larger than that of a finger-shaped structure at the cut end in the middle of the crown top; S5, a protective coating is sintered on the portion, except the occlusion portion, of the bottom crown of the dental mode; S6, the sintered dental model is dyed and glazed. 3D printing is conducted on a denture crude body through the special dental metal laser fusing forming device, and the size and the shape of dentures can be adjusted at any time.

Owner:广州锦冠桥实业有限公司

Individuation orthodontic method based on shape memory polymer arch wire

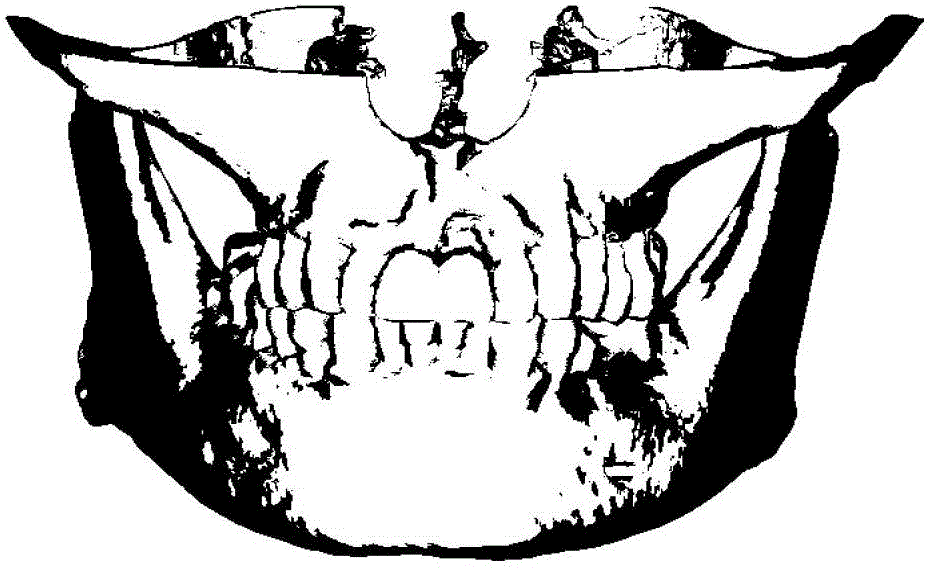

ActiveCN103054651ASustained and stable orthodontic correction forceShorten treatment timeOthrodonticsAfter treatmentComputed tomography

An individuation orthodontic method based on a shape memory polymer (SMP) arch wire includes: reconstructing a three-dimensional oral cavity model comprising skeletons and teeth according to computed tomography (CT) data of a patient, overlapping the three-dimensional oral cavity model with data of a patient tooth model after being scanned and reconstructed, and drawing up an orthodontic treatment scheme and obtaining a final dentition arrangement after treatment according to a tooth arrangement and a skeleton condition of the patient; then selecting brackets and determining bracket locations of all tooth on this basis; designing an orthodontic arch wire according to the bracket locations, wherein the shape of the orthodontic arch wire is matched with a dentition and bracket locations after orthodontic treatment and is the shape needed to be recovered in the memory of the SPM arch wire; and enabling the arch wire to soften after placing the arch wire in a set temperature environment during the clinical operating process, and therefore the arch wire can be conveniently fixed in the bracket on a central tooth of a patient oral cavity. The individuation orthodontic method based on the SMP arch wire can effectively achieve individuation orthodontic and eliminate potential safety hidden dangers.

Owner:盛源(河北)医疗产业有限公司

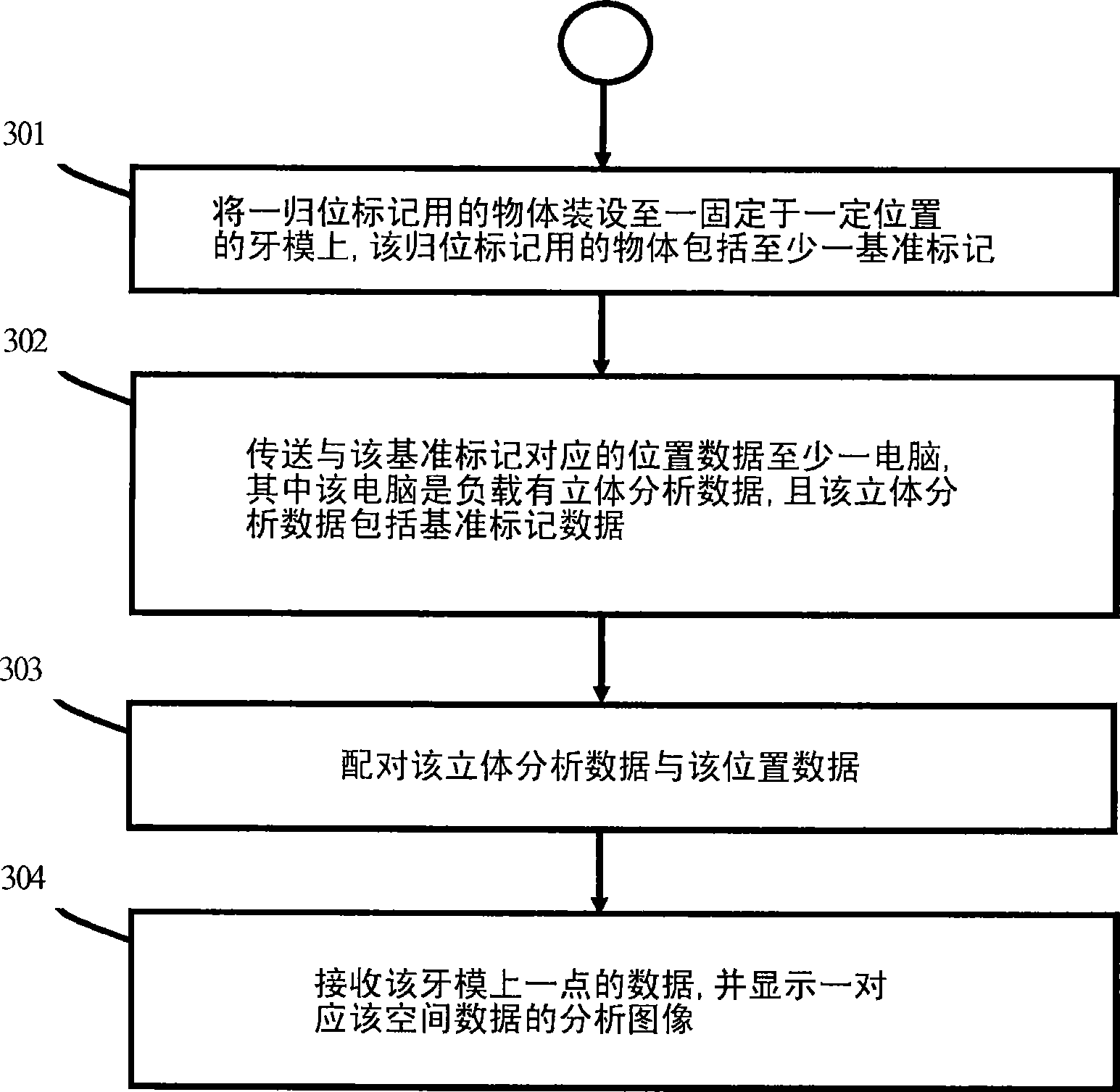

System for accelerating dentistry diagnoses and planning operation, and method thereof

ActiveCN101467890APreserve visual effectsPreserve haptic effectsRadiation diagnostics for dentistryDental prostheticsDental castDissection

The invention relates to a system for accelerating dental diagnosis and operation planning and a method thereof. The system comprises a computer for reading stereoscopic dissection information and presenting dissection images according to the stereoscopic dissection information, wherein, the information comprises reference mark information; an object for homing marks comprising at least a reference mark of which the position accords with the reference mark information; an addressing device for detecting one point on a dental cast and transmitting the space information corresponding to the point to the computer to establish the present of the dissection images. The system effectively integrates the good qualities of digital stereoscopic images and advantages of the dental cast, thus, users can utilize the high integration environment provided by the system of the invention to make the operation planning faster and more accurate.

Owner:杨炳德 +2

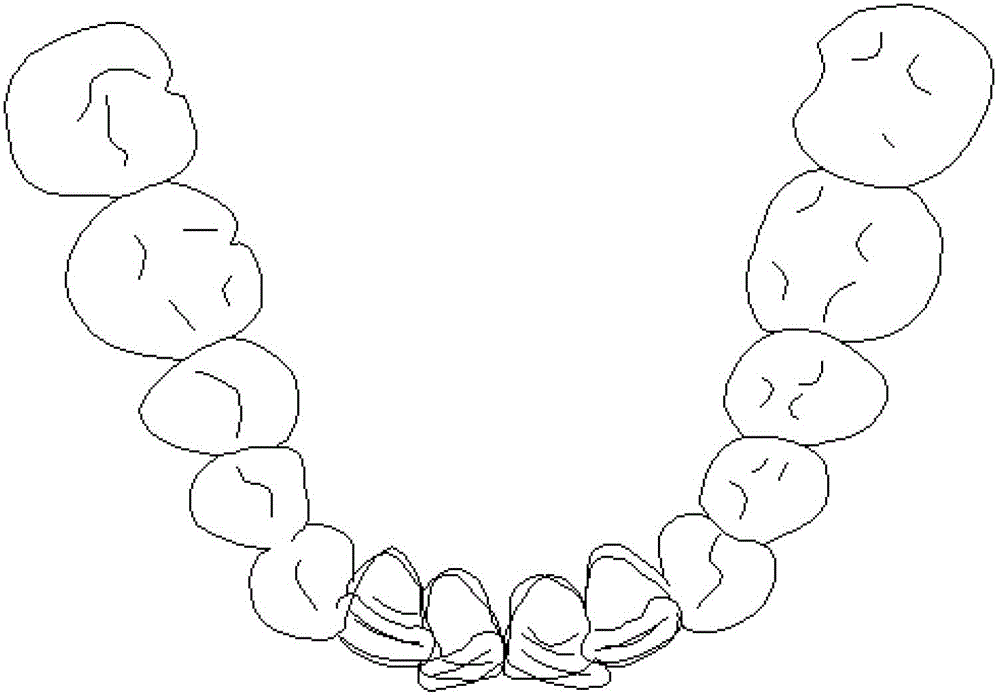

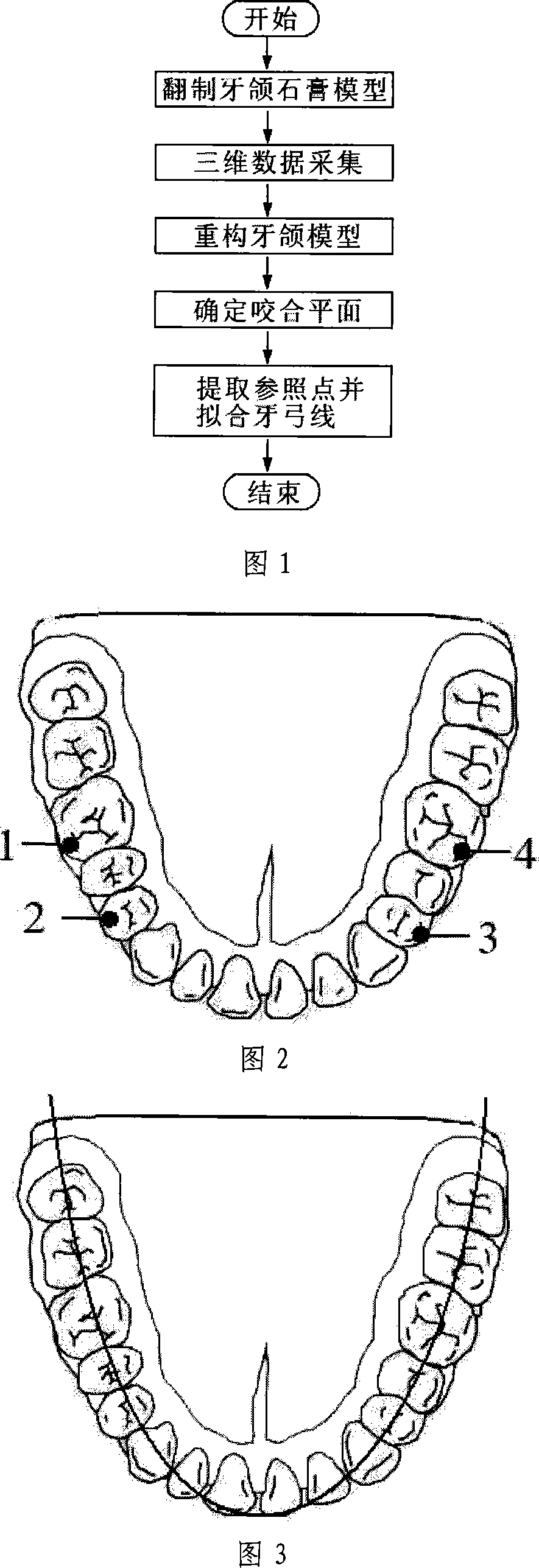

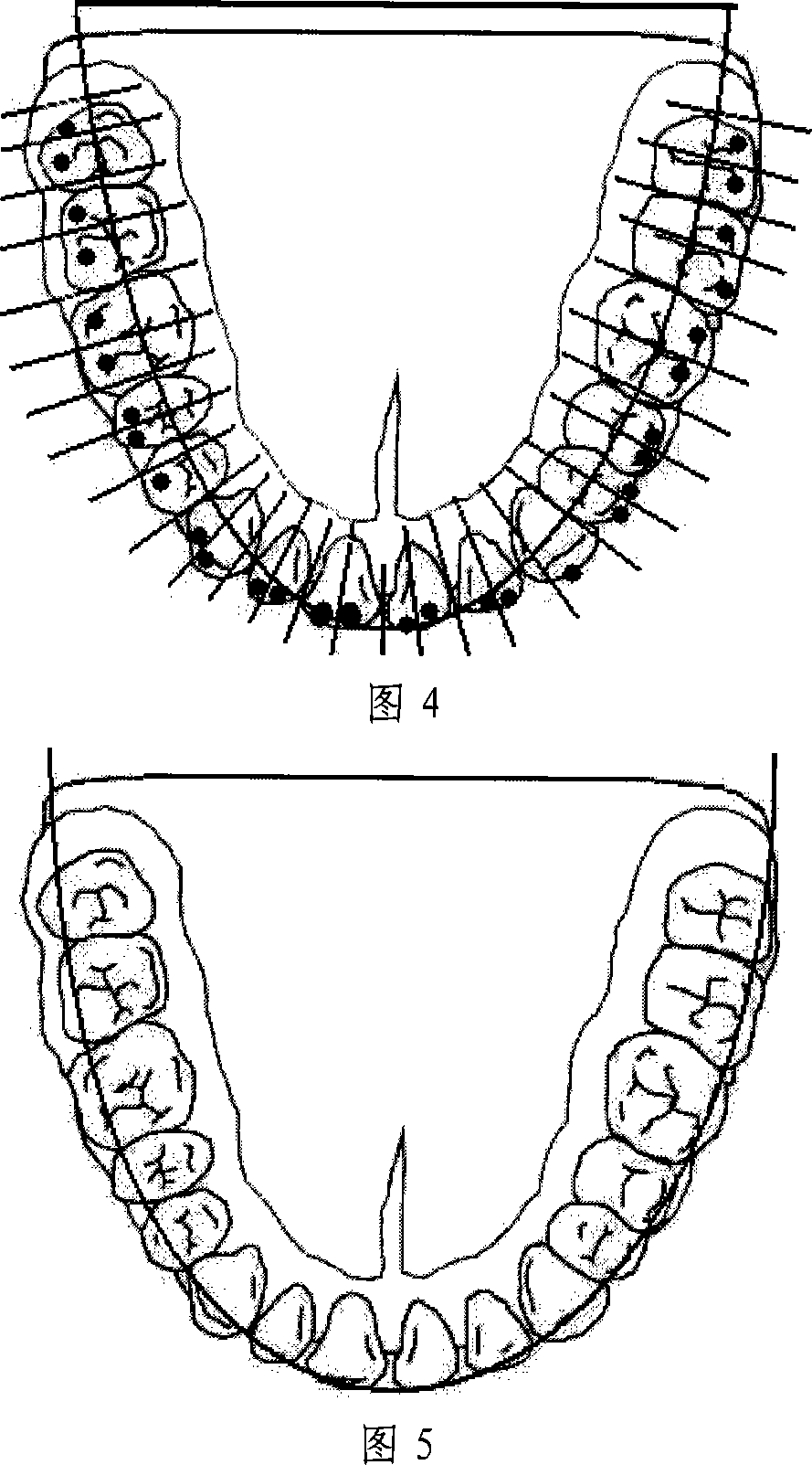

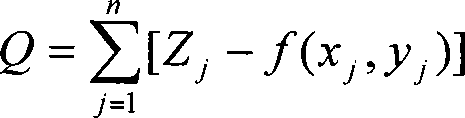

Method for fast and accurately detecting dental arch line on three-dimension grid dental cast

InactiveCN101103940AQuick extractionAutomatic extractionDentistrySpecial data processing applicationsComputer Aided DesignOcclusal plane

Disclosed is a quick and accurate detecting dental arch on a three-dimensional mesh dental model, belonging to the field of computer aided f. The method includes five steps, simple human-computer interactive confirmation of an occlusal plane, sifting initial reference point, fitting an initial dental arch, extracting the final reference point and fitting the final dental arch. The method of the invention only needs simple human-computer interactive operation which helps achieve high degree of automation and avoid the general complex computation; linear computation which is mainly used in the invention can detect dental arch on the three-dimensional dental model quickly, steadily and precisely, valued in application in the field of computer aided orthodontic aesthetics.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

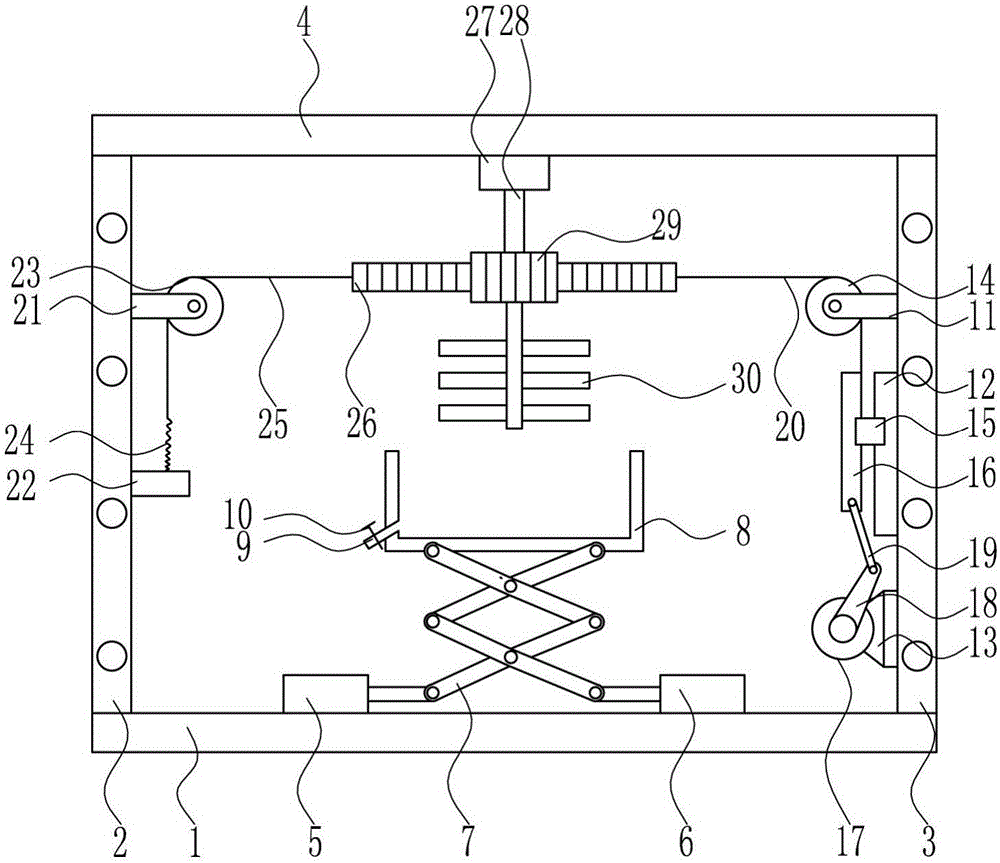

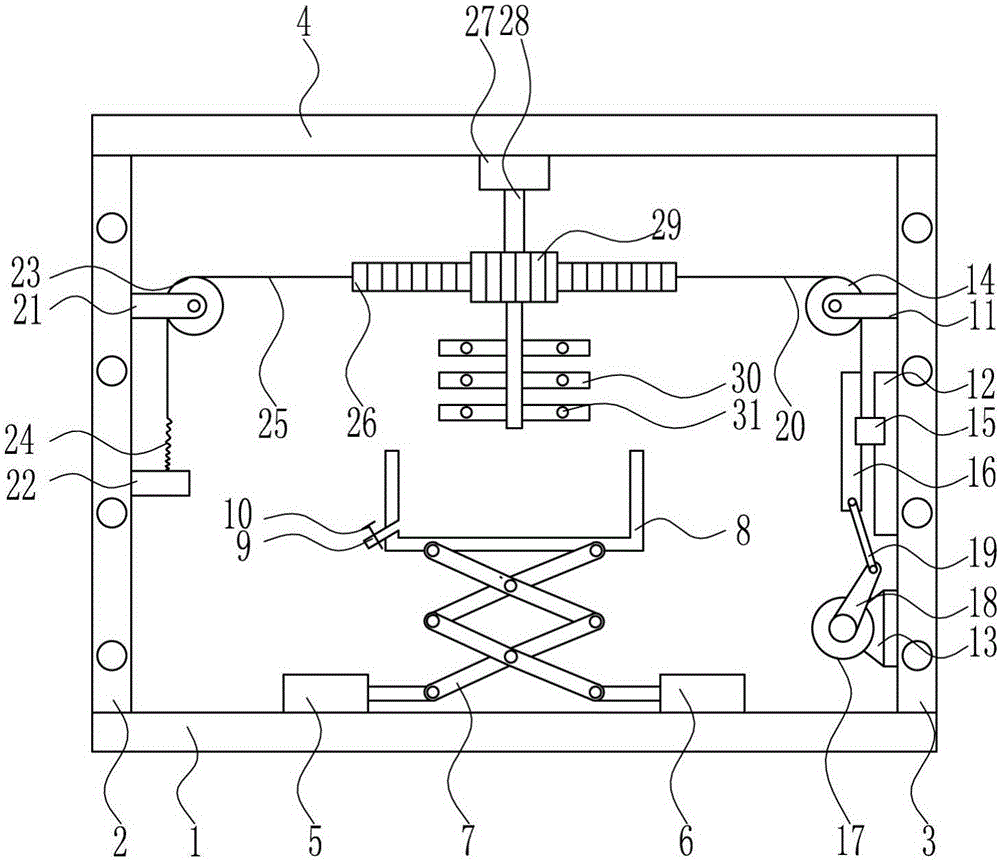

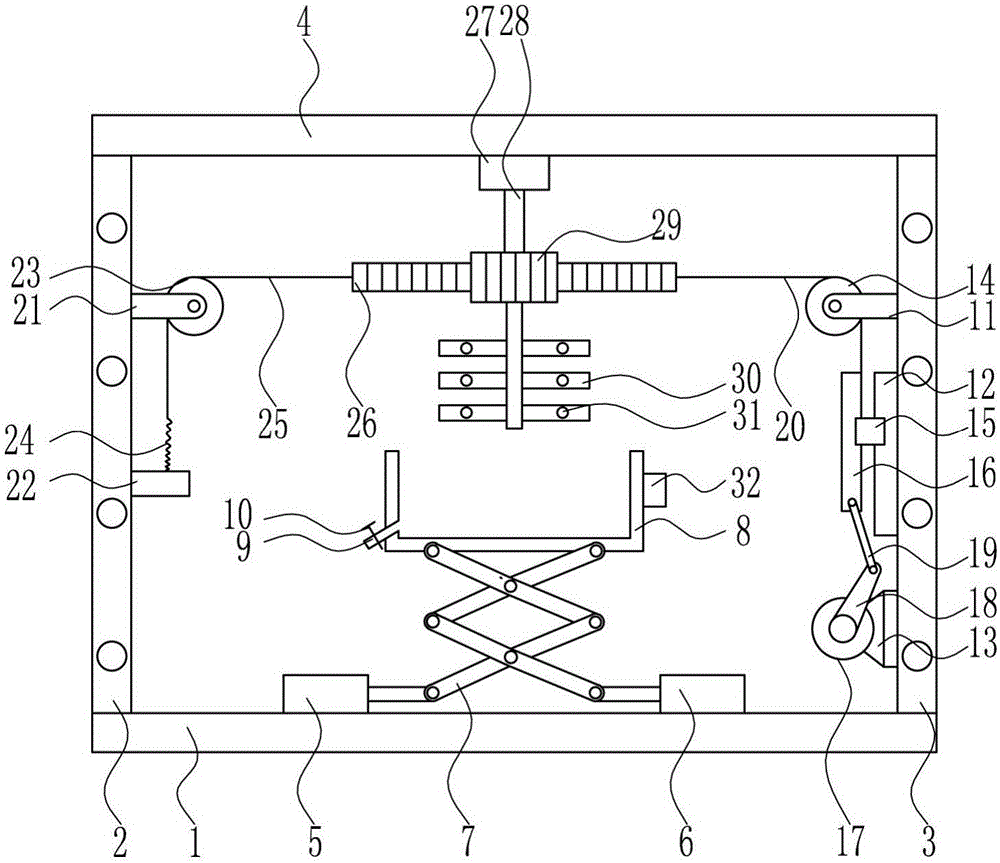

Dental cast raw material quick stirring device for medical stomatological department

InactiveCN106345344AStir wellImprove work efficiencyRotary stirring mixersTransportation and packagingDental castElectric control

The invention relates to a dental cast raw material stirring device, in particular to a dental cast raw material quick stirring device for medical stomatological department. The technical problem solved by the invention is to provide the dental cast raw material quick stirring device for the medical stomatological department, which has a good stirring effect and high work efficiency and is simple to operate. In order to solve the technical problem, the invention provides the dental cast raw material quick stirring device for the medical stomatological department. The dental cast raw material quick stirring device for the medical stomatological department comprises a bottom plate, a left frame, a right frame, a top plate, a first air cylinder, a second air cylinder, a telescopic frame, a stirring frame, a discharging hopper, an electric control valve, a first supporting rod, a sliding rail, a mounting base and the like, wherein the left frame, the first air cylinder, the second air cylinder and the right frame are arranged at the top of the bottom plate sequentially from left to right; the top plate is arranged at the top ends of the left frame and the right frame. The dental cast raw material quick stirring device for the medical stomatological department has good stirring effect and high work efficiency, is simple to operate, can quickly stir dental cast raw materials and improves the work benefit of enterprises; furthermore, the device is reasonably provided with a reinforcing rib.

Owner:李汉文

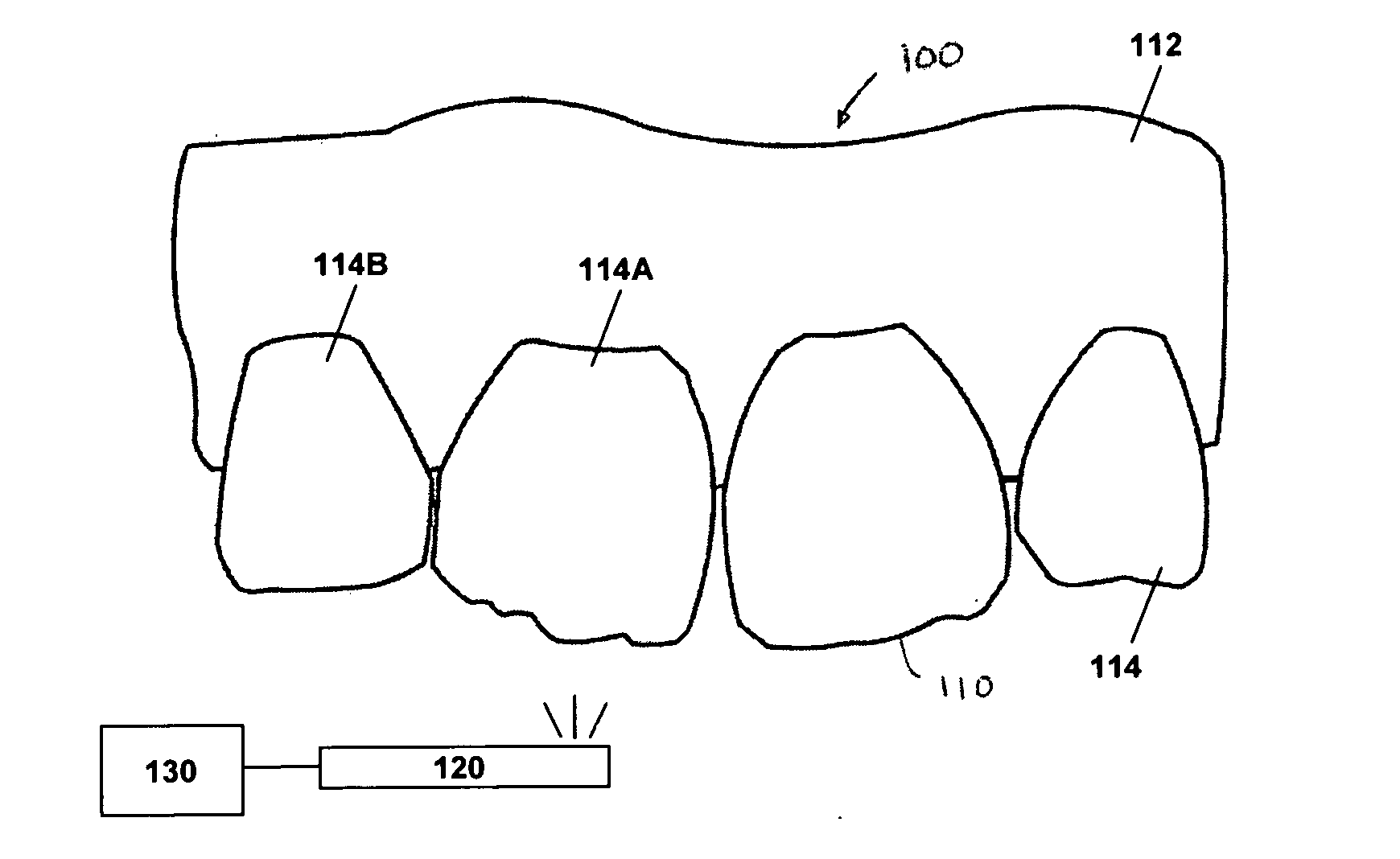

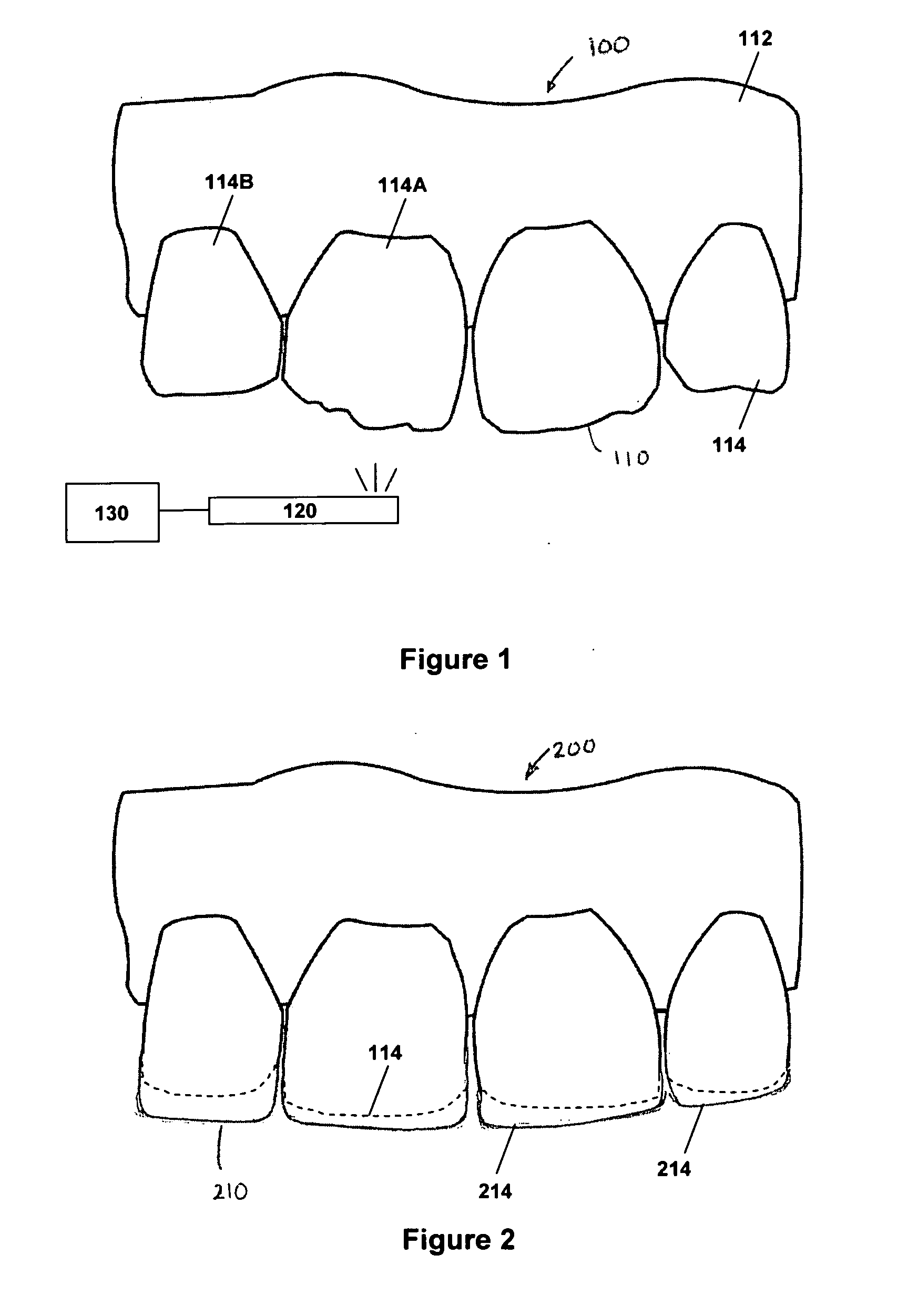

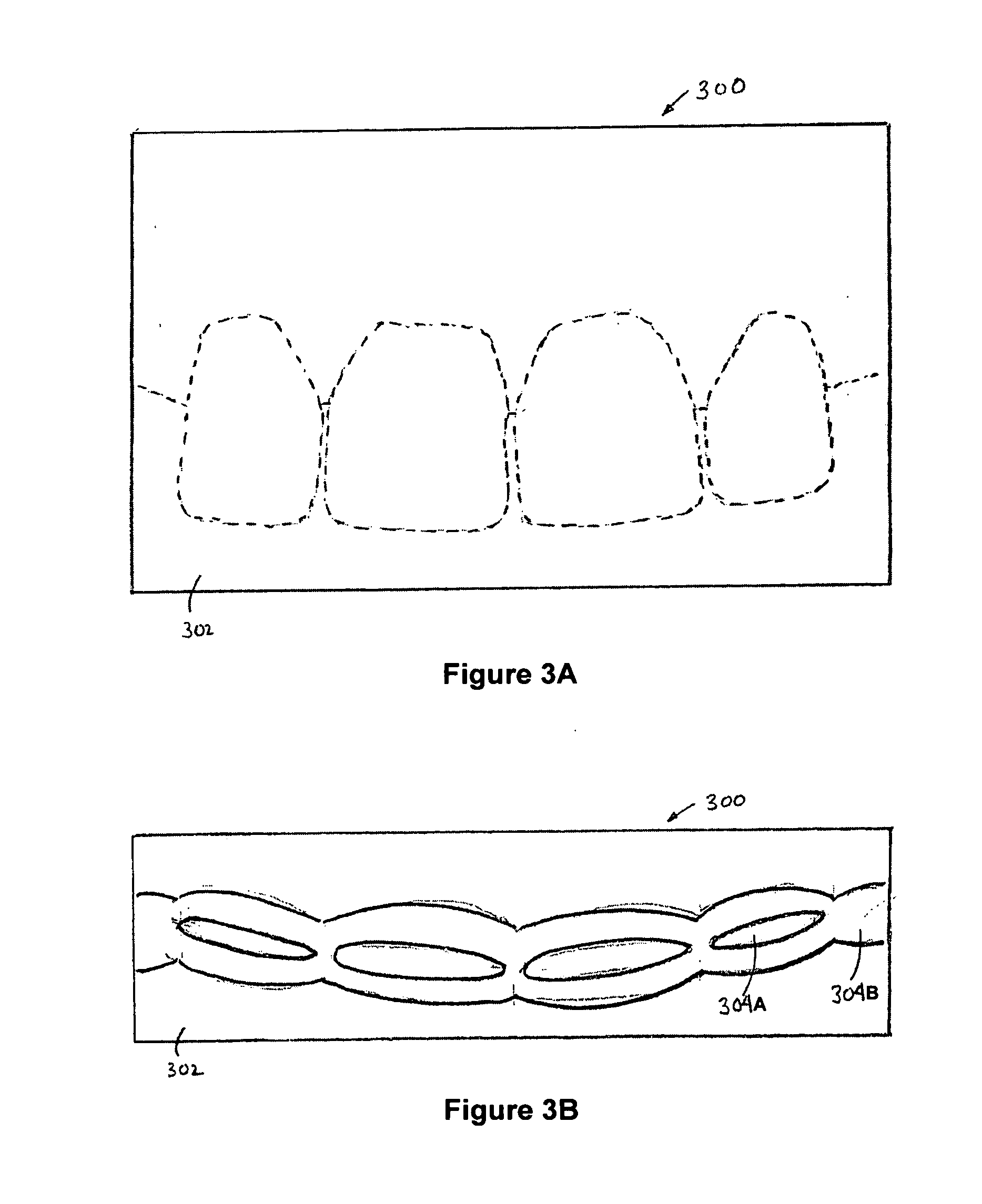

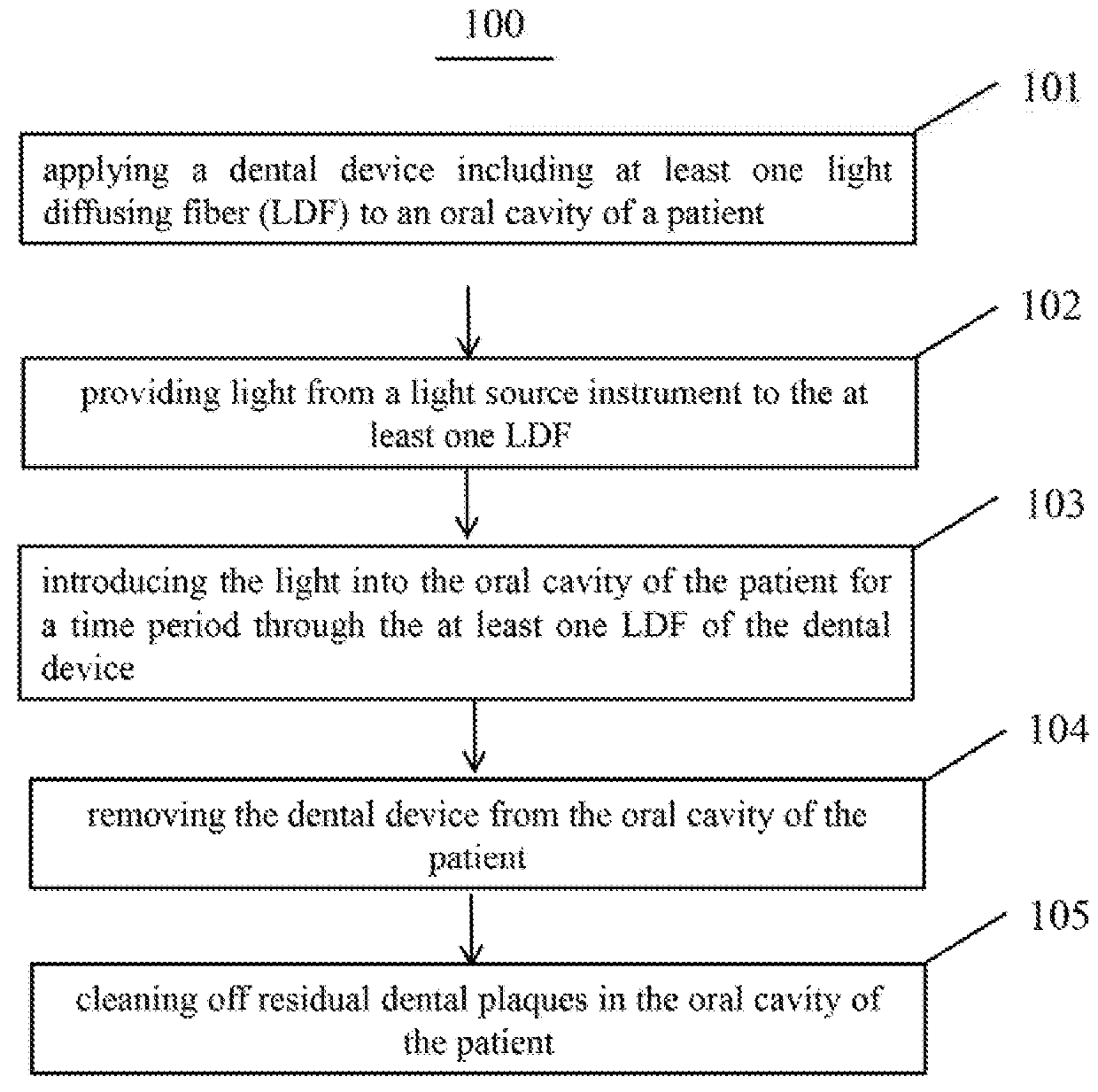

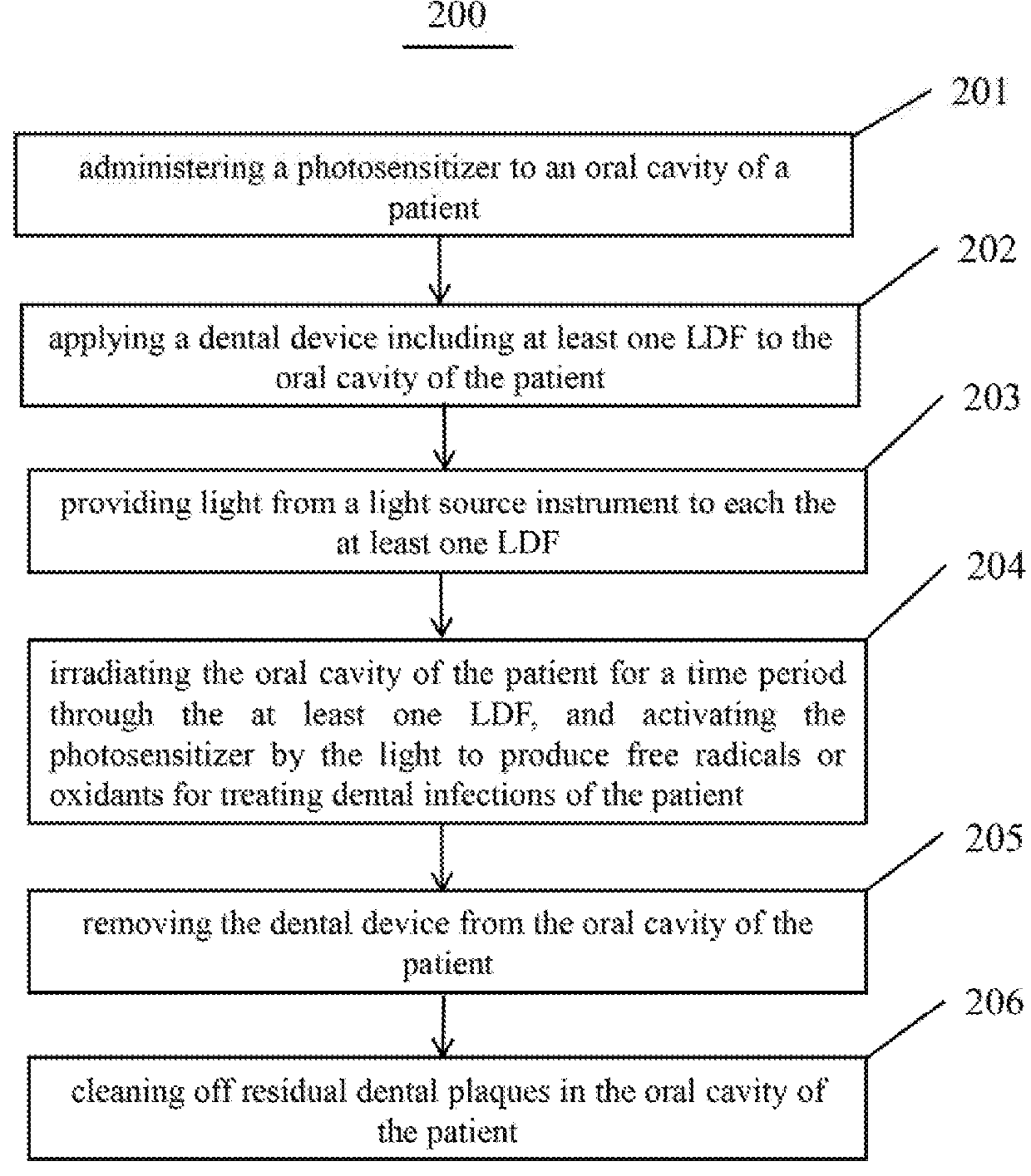

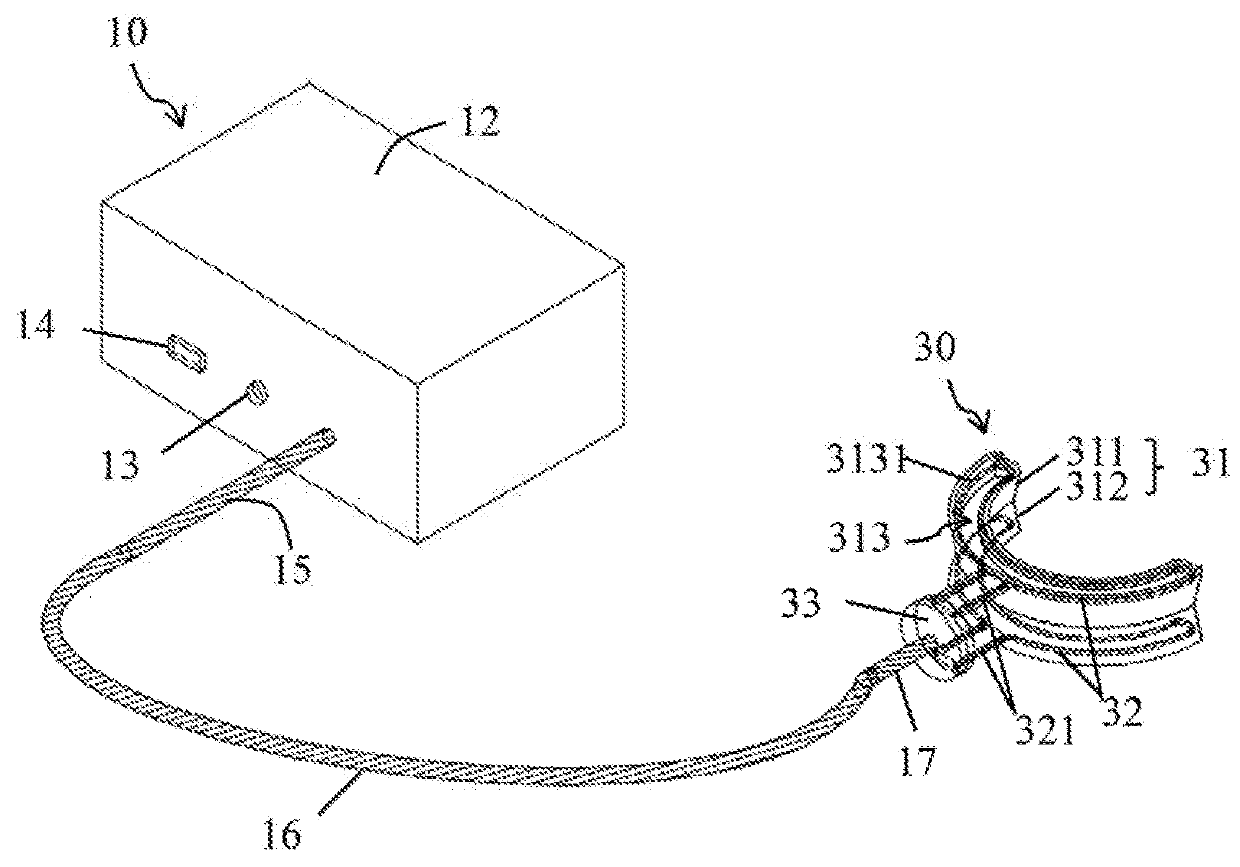

Dental device and photodynamic therapeutic system using same

A dental device for treating dental infection includes a dental cast comprising at least one groove to receive teeth and / or gums of a dental arch of the patient; and at least one light diffusing fiber arranged on the dental cast around the at least one groove. The dental device is used in a photodynamic therapeutic system, in which a light source instrument emits light onto a photosensitizer applied in mouth of the patient. The dental device is optically coupled to the light source instrument. The light for treating dental infection of the patient is transmitted by the at least one light diffusing fiber of the dental device and activates the photosensitizer to produce free radicals or oxidants to destroy the bacteria and microbes causing dental disease.

Owner:NAT CHENG KUNG UNIV

Planar light beam orientation device

The present invention provides a planar light beam orientation device comprising a light source, a beam disperser, and a housing coupled to the light source and holding the beam disperser. The housing is configured to have a beam aperture configured to project a planar beam of light therefrom. The planar light beam orientation device of the present invention is capable of projecting a 360 DEG planar beam of light. The device is particularly useful in the orienting and reorienting of dental casts in a dental surveyor.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method for making dental model mold through 3D printing

InactiveCN106073918AAvoid discomfortDesignableDental articulatorsEducational modelsOral medicineDental cast

The invention discloses a method for making a dental model mold through 3D printing. The method comprises the steps that a three-dimensional tooth model is established through 3D calculation according to Dicom-format CT scanning fault data of patient's teeth, and then a three-dimensional model of the dental model mold is obtained through processing and output to a 3D printer in an appropriate format to obtain the dental model mold of a patient. The gypsum model of the patient's teeth and whole or single / multiple resin or ceramic false teeth and the like clinically used in oral medicine can be obtained by filling gypsum, tooth making resin, ceramic powder and other materials in the obtained mold. A traditional impression taking method is replaced by utilizing the dental model mold made through 3D printing, the discomfort of the patient is greatly decreased, and various failure phenomena in the traditional impression taking operation are decreased. In addition, the dependence on the operator's proficiency of the making quality of traditional dental products is effectively decreased while the designability of the dental model, false teeth and other dental products is enhanced through computer aided design, the clinic practicability is good, the cost is low, and the method is easy to popularize.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Device for attaching dental model to articulator

InactiveUS20100009318A1Easy to manufactureDental articulatorsEducational modelsBuilding constructionBiological body

The present invention relates to a device for attaching a dental model to a variety of articulators for reproducing oral motions as a sagittal plane of a patient's organism and the left and right side points having the same height relative to the sagittal plane are found to mount the dental model at the articulators in a range for reproducing fatigue oral motions thereon, thereby helping the fabrication of the dental prosthesis inclusive of clinical treatment planning according to the extrusion and intrusion causes, the reasonable articulation re-construction in a dental laboratory process, and artificial teeth arrangements.

Owner:KIM BYUNG GEUN

Device for determining the 3D coordinates of an object, in particular of a tooth

Owner:CARL ZEISS OPTOTECHN GMBH

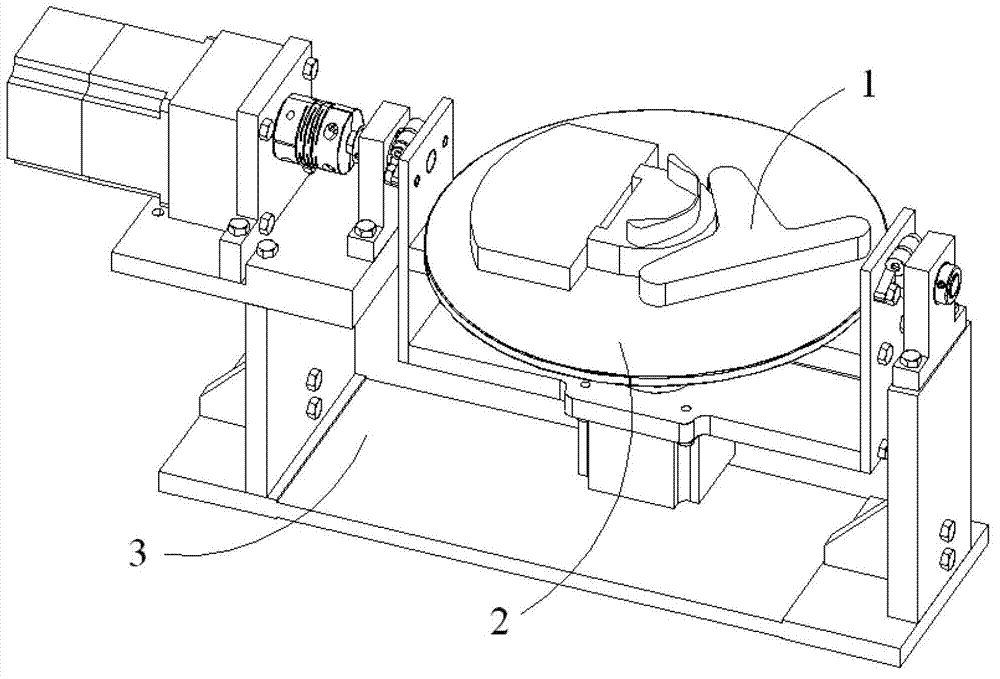

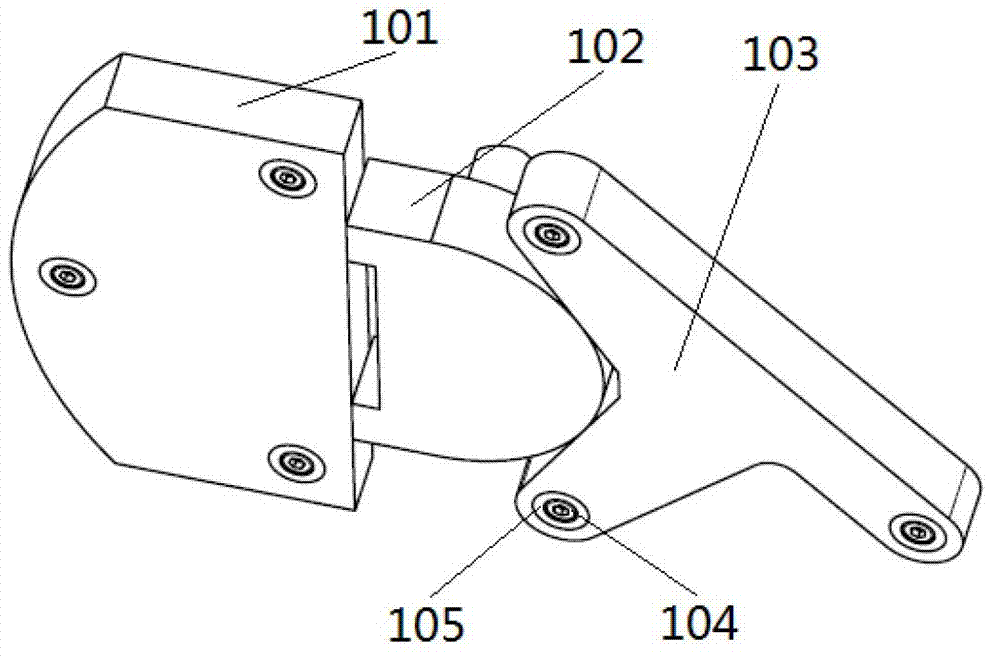

Gesture regulating device for three-dimensional measurement of dental cast

ActiveCN102853782AStable structureReduce mistakesUsing optical meansCouplingThree dimensional measurement

The invention discloses a gesture regulating device for a three-dimensional measurement of a dental cast. The gesture regulating device comprises a clamp part, a platform part and a bracket part; the clamp part is arranged on the upper surface of the platform part; the bracket part is of a U-shaped frame supporting structure; the platform part is arranged on the upper surface of the bracket part; the clamp part comprises a calibrating clamp, an adapting clamp and multiple magnets; the calibrating clamp is used for clamping a planar side of a dental cast; the adapting clamp has a curve profile which is used for clamping a curve side of the dental cast; the magnets are arranged in a cavity body at the bottoms of the calibrating clamp and the adapting clamp, and surfaces of the magnets which are exposed outside the cavity body are horizontal with the bottom surfaces of the calibrating clamp and the adapting clamp; the platform part comprises a turning motor, a turning motor base, a pair of couplings, a left turning shaft, a left turning side plate, a carrying platform, a right turning side plate, a pair of turning shaft bases, a right turning shaft, a pair of turning fixing rings, and a pair of turning bearings. According to the gesture regulating device, a gesture of the dental cast is automatically regulated, thereby achieving three-dimensional measurement in multiple angles.

Owner:HUAZHONG UNIV OF SCI & TECH

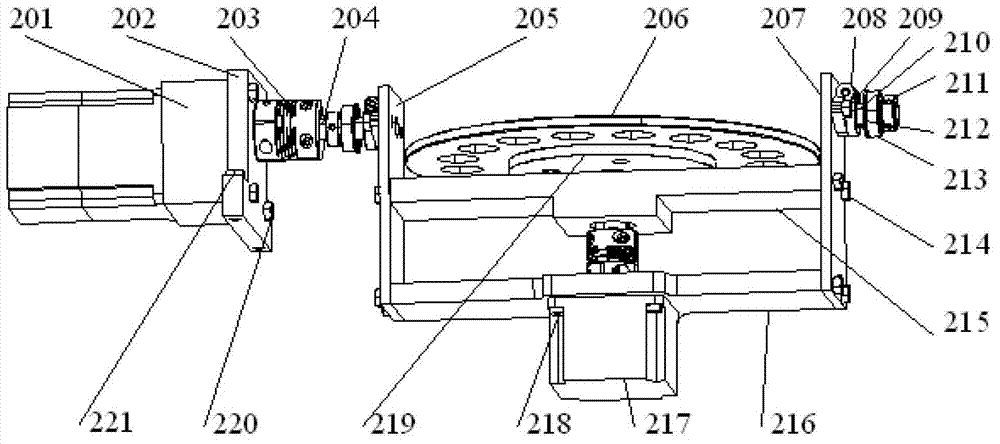

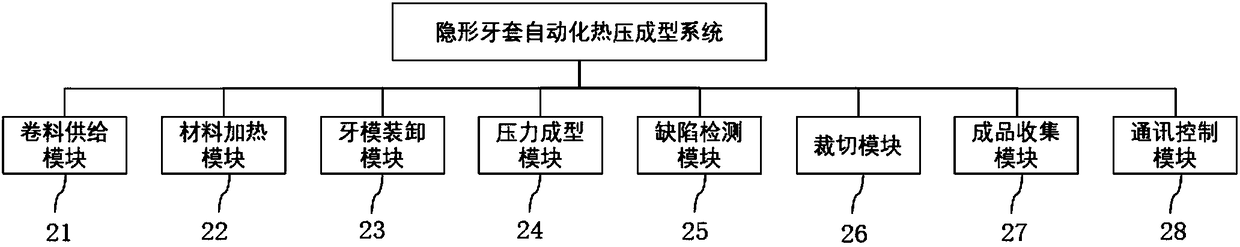

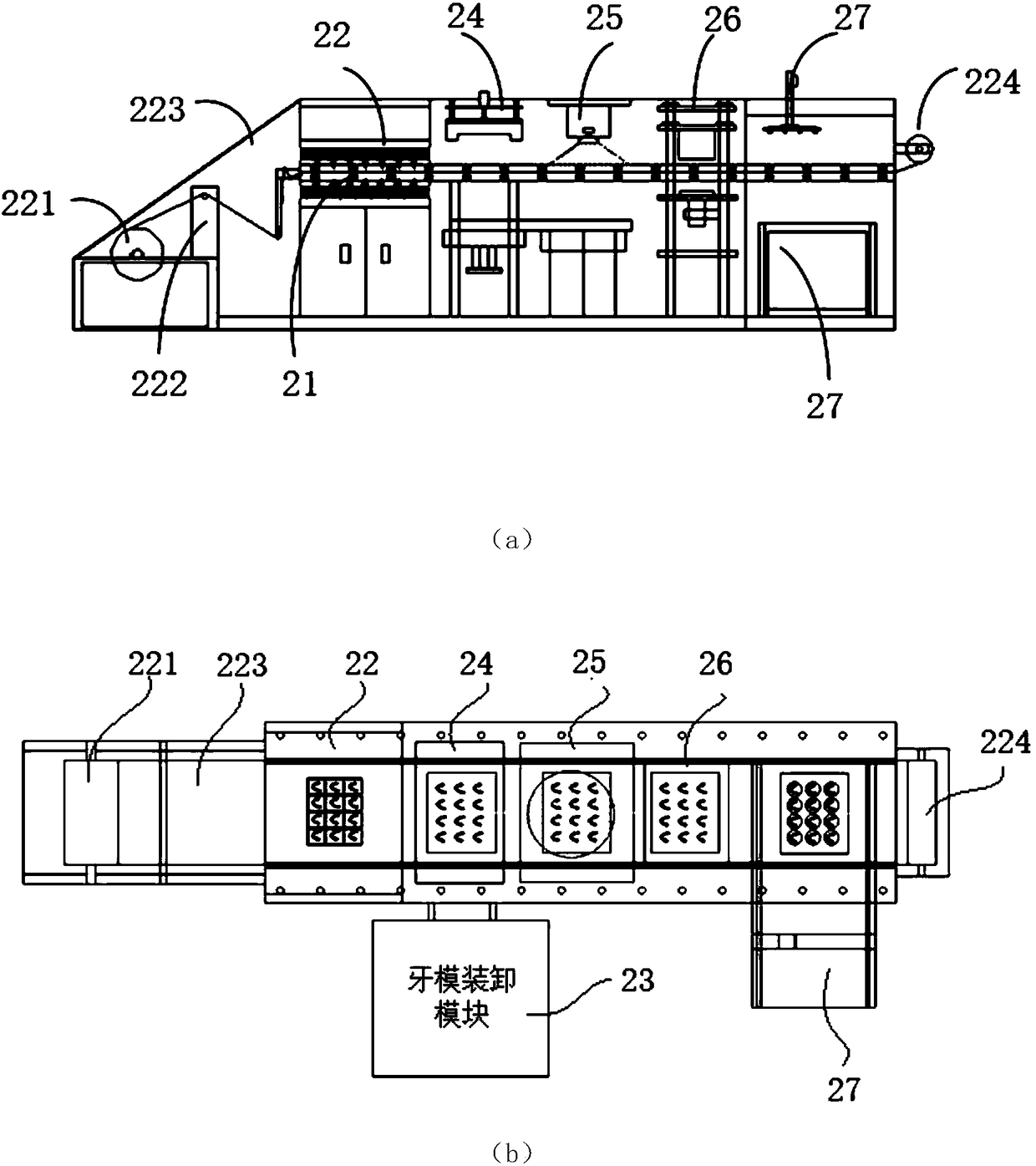

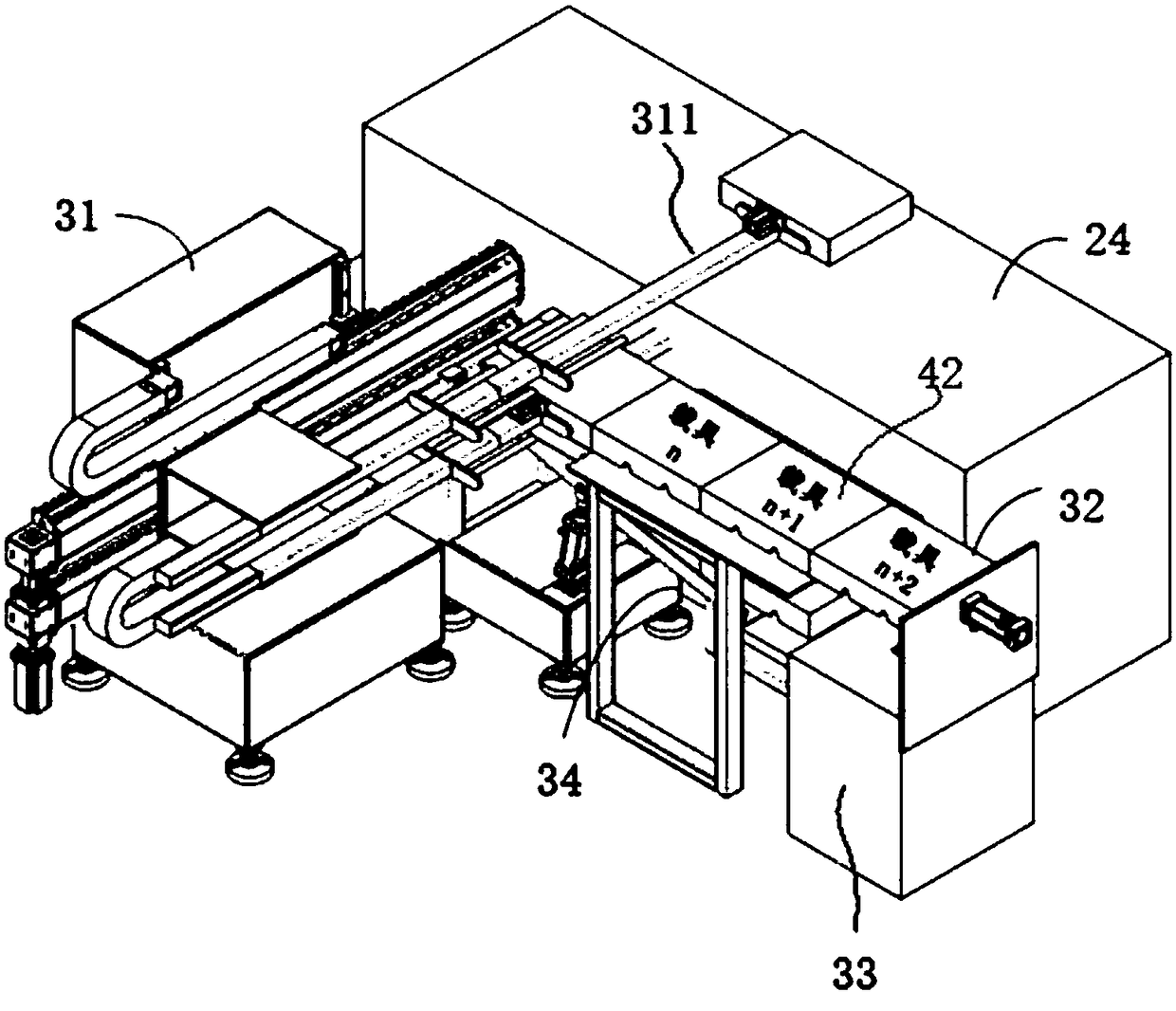

Hot press molding system and method of shell dental instrument scale production

InactiveCN109421200AHigh degree of automationReduce labor costsDomestic articlesDental instrumentsDental cast

The invention provides a hot press molding system and method of shell dental instrument scale production. The hot press molding system includes a coil material supply module, a material heating module, a dental cast loading and unloading module, a pressure molding module and a cutting module, wherein the coil material supply module is used for continuously feeding and receiving raw materials in the form of coil materials; the material heating module is used for heating raw material diaphragms from the upper and lower sides or one side; the dental cast loading and unloading module is used for automatically feeding more than one lower molds loaded with personalized dental models into the pressure molding module, the lower molds are transferred out of the forming station after completing hotpressing, molding, cooling and demoulding, and the subsequent lower molds are continuously and automatically fed and recycled; the pressure molding module is used for pressing and molding the heated and softened diaphragms through more than one upper and lower molds, and one-time molding of multiple products is supported by pressing and molding; and the cutting module is used for cutting a hot press molded appliance to remove peripheral materials. According to the hot press molding system and method of shell dental instrument scale production, the degree of automation is high, and labor costsare lowered; and in addition, through once molding of the multiple molds, the working efficiency is greatly improved.

Owner:WUXI EA MEDICAL INSTR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com