Patents

Literature

47 results about "Dental laboratory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dental laboratories manufacture or customize a variety of products to assist in the provision of oral health care by a licensed dentist. These products include crowns, bridges, dentures and other dental products. Dental lab technicians follow a prescription from a licensed dentist when manufacturing these items, which include prosthetic devices (such as denture teeth and implants) and therapeutic devices (such as orthodontic devices). The FDA regulates these products as medical devices and they are therefore subject to FDA’s good manufacturing practice ("GMP") and quality system ("QS") requirements. In most cases, however, they are exempt from manufacturer registration requirements. Some of the most common restorations manufactured include crowns, bridges, dentures, and dental implants. Dental implants is one of the most advanced dental technologies in the field of dentistry.

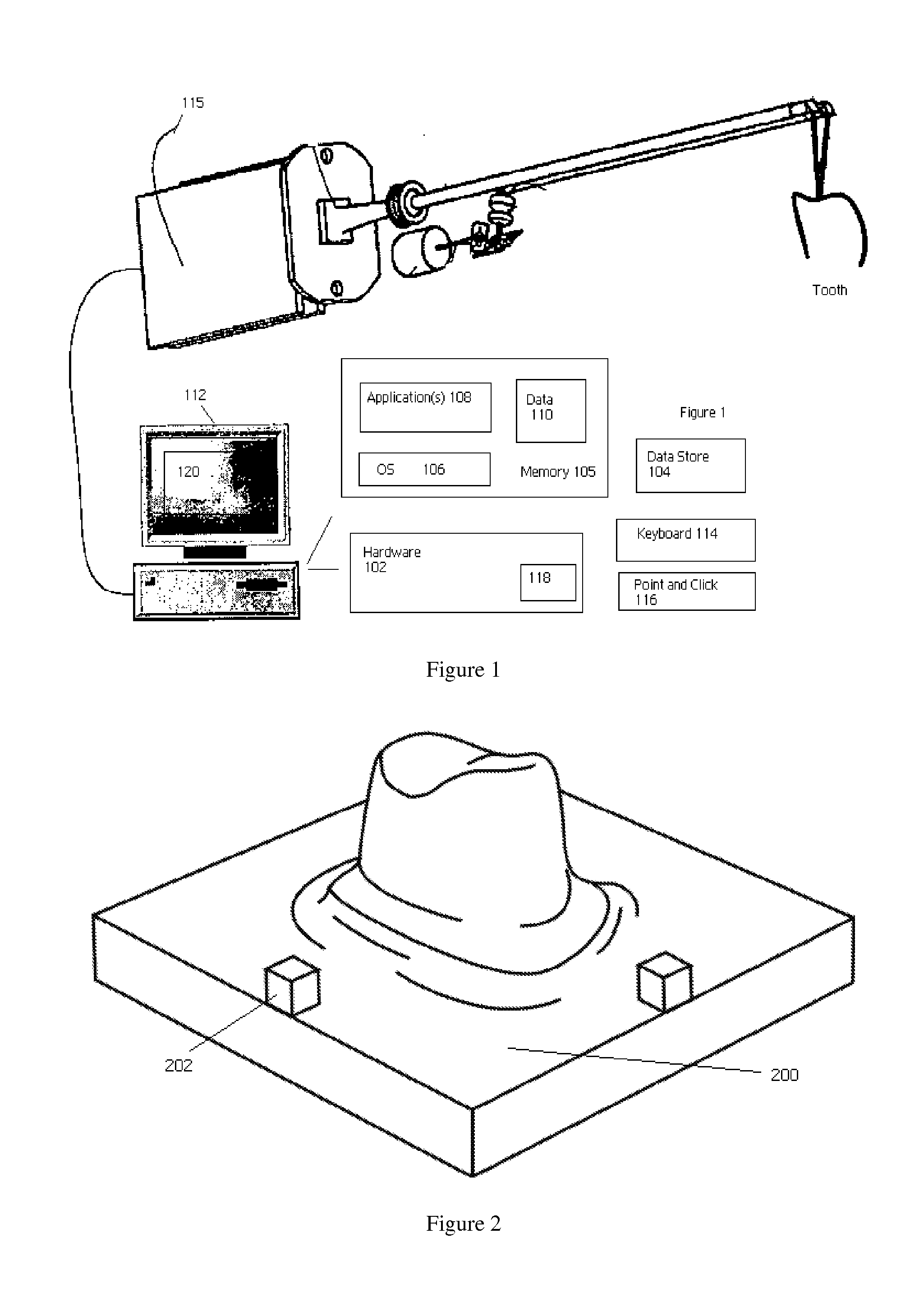

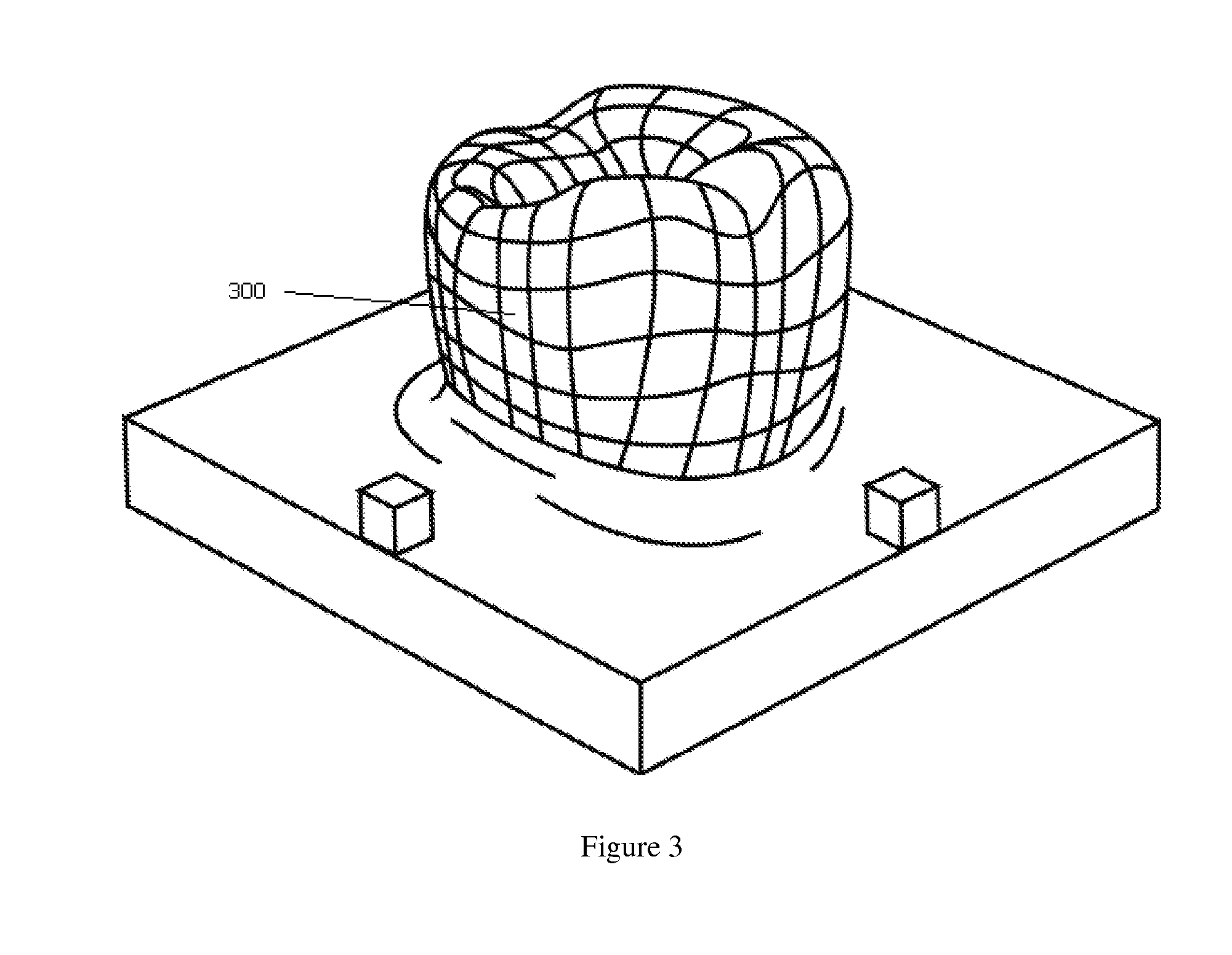

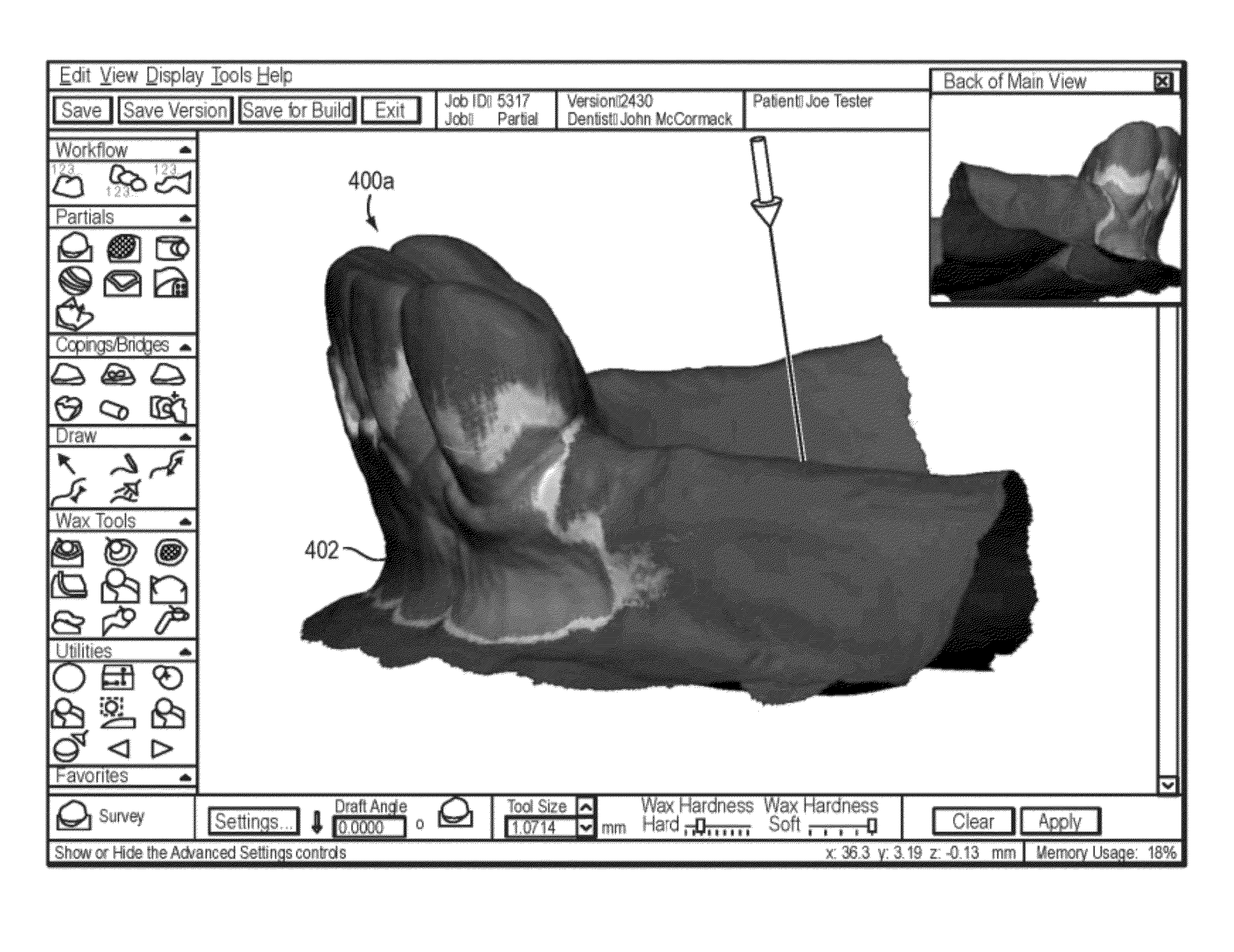

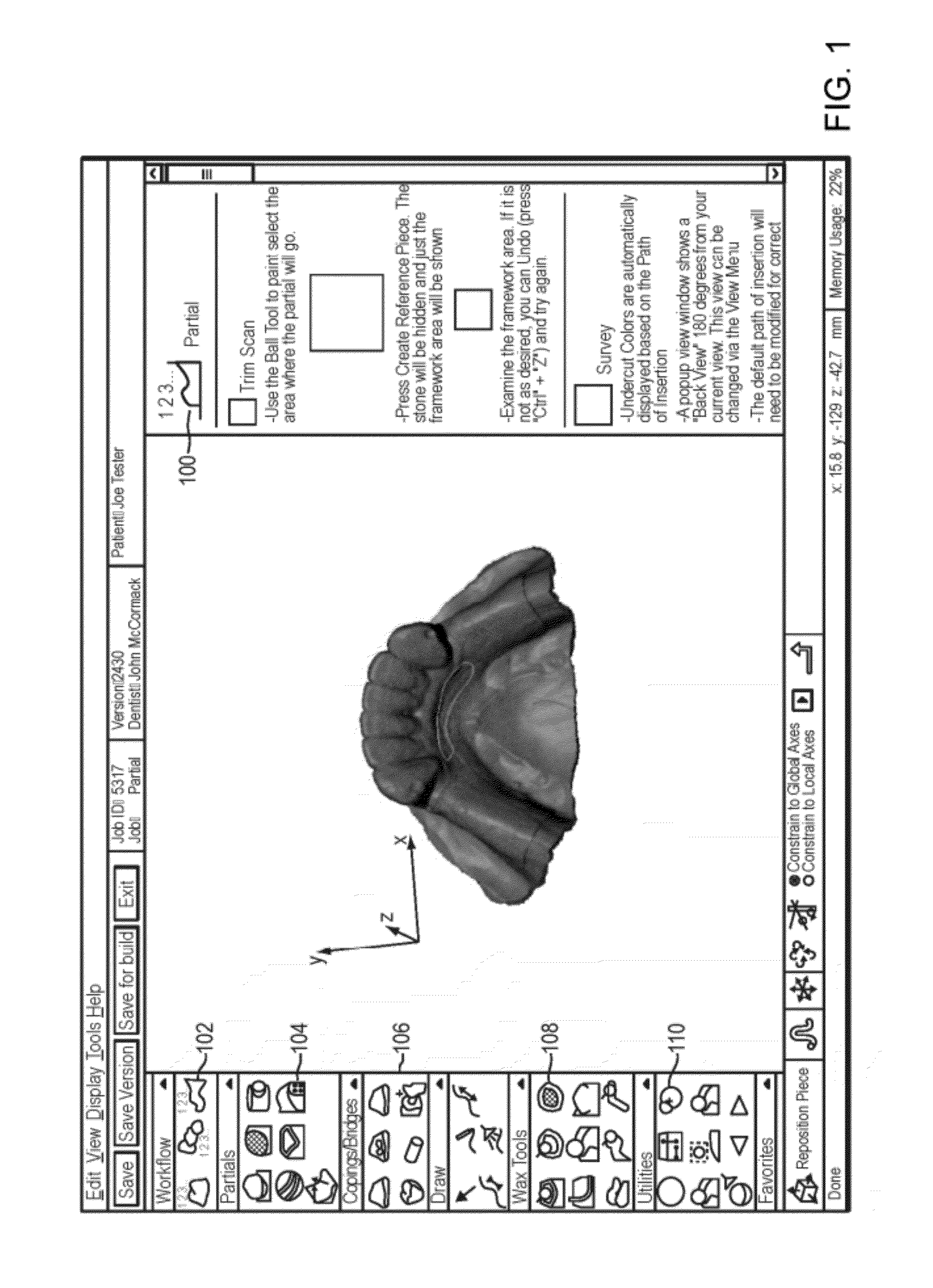

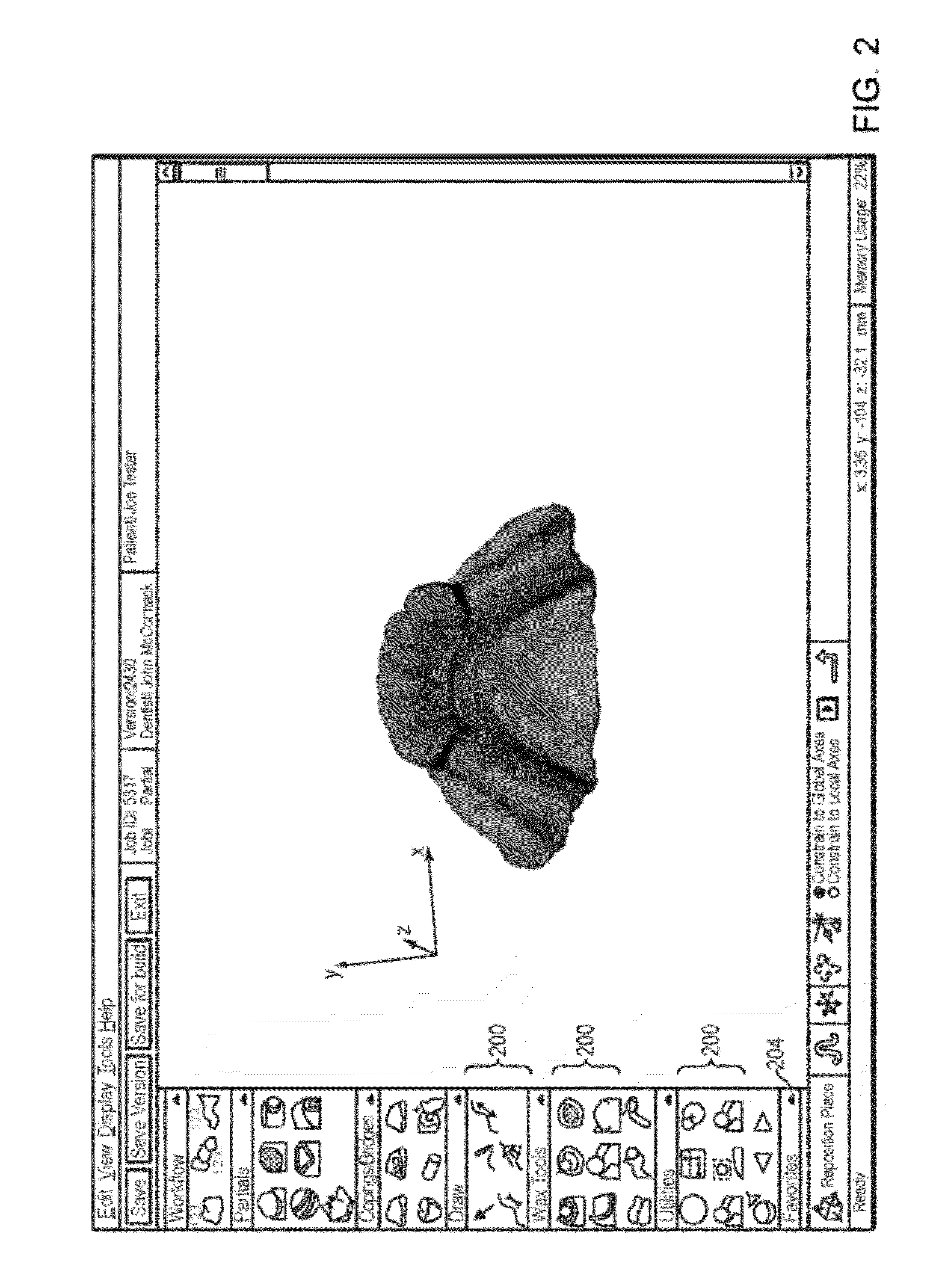

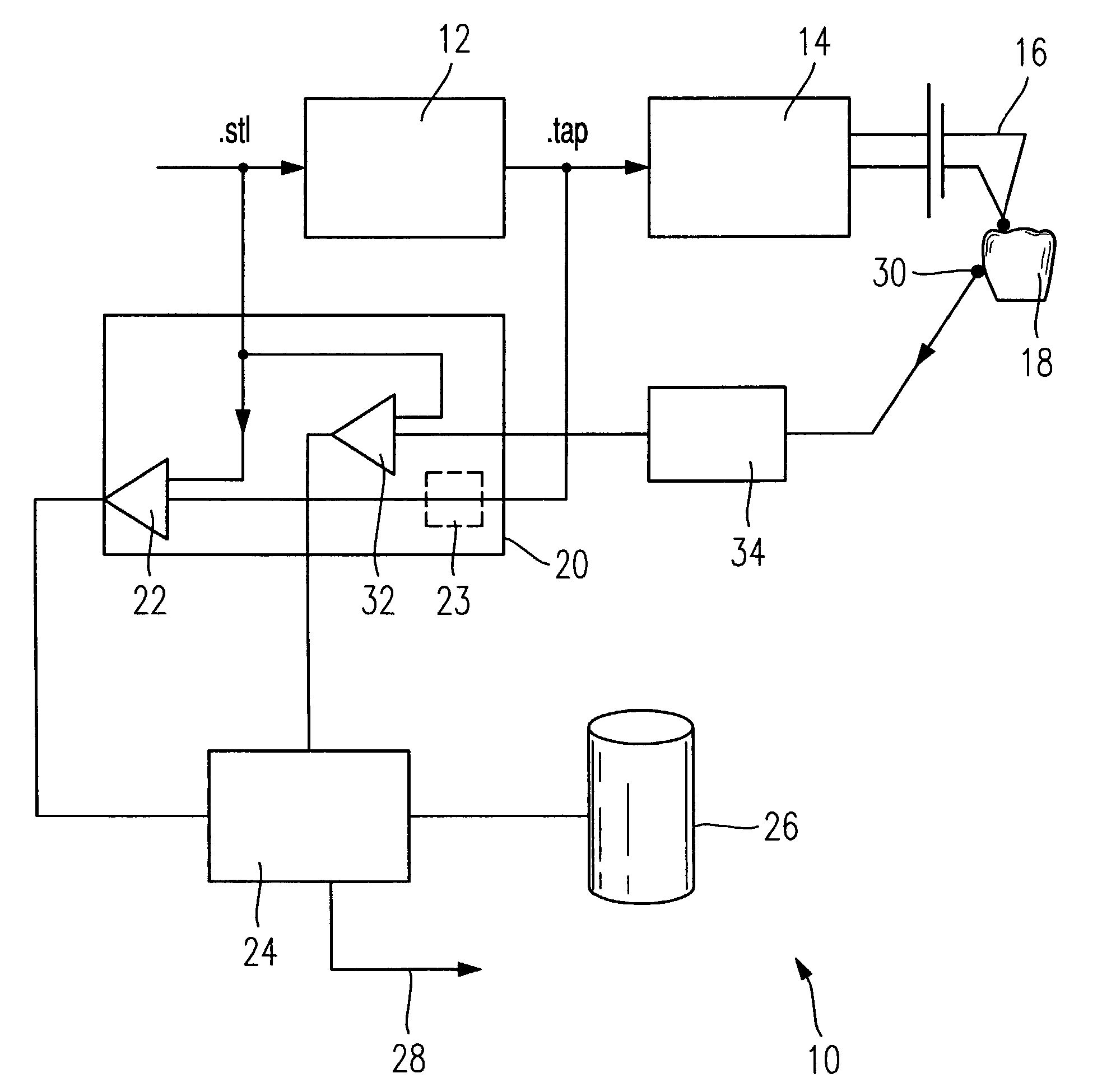

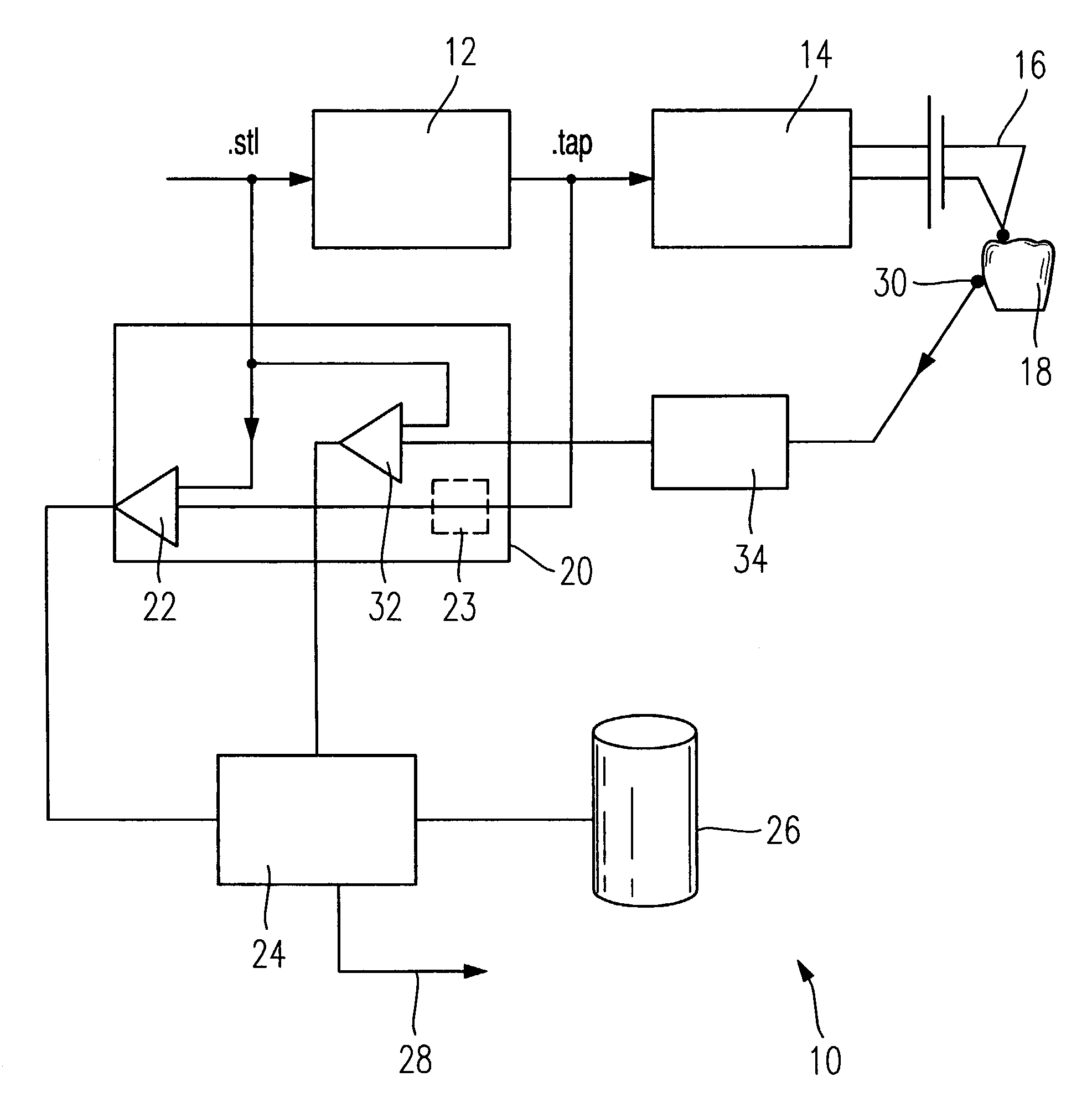

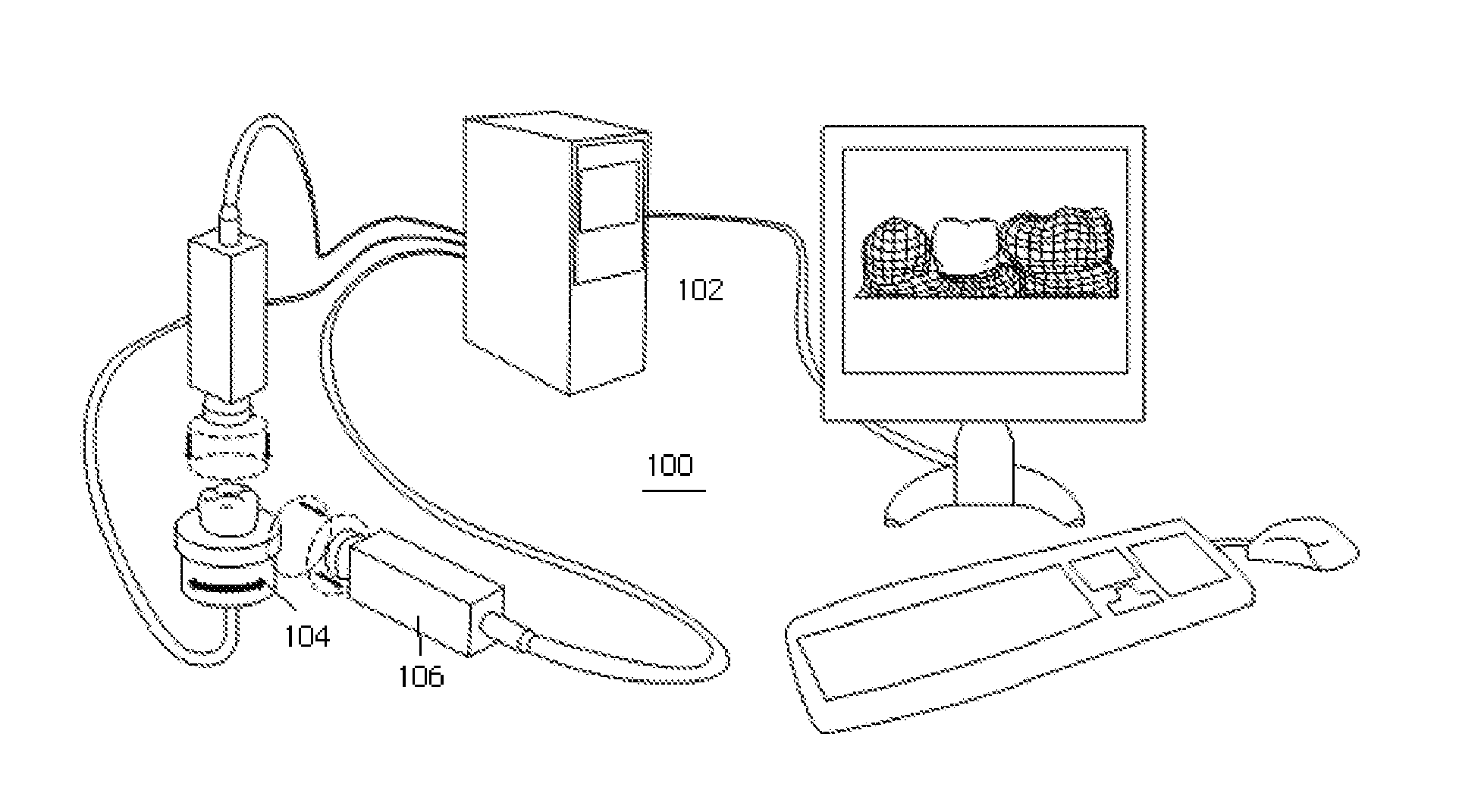

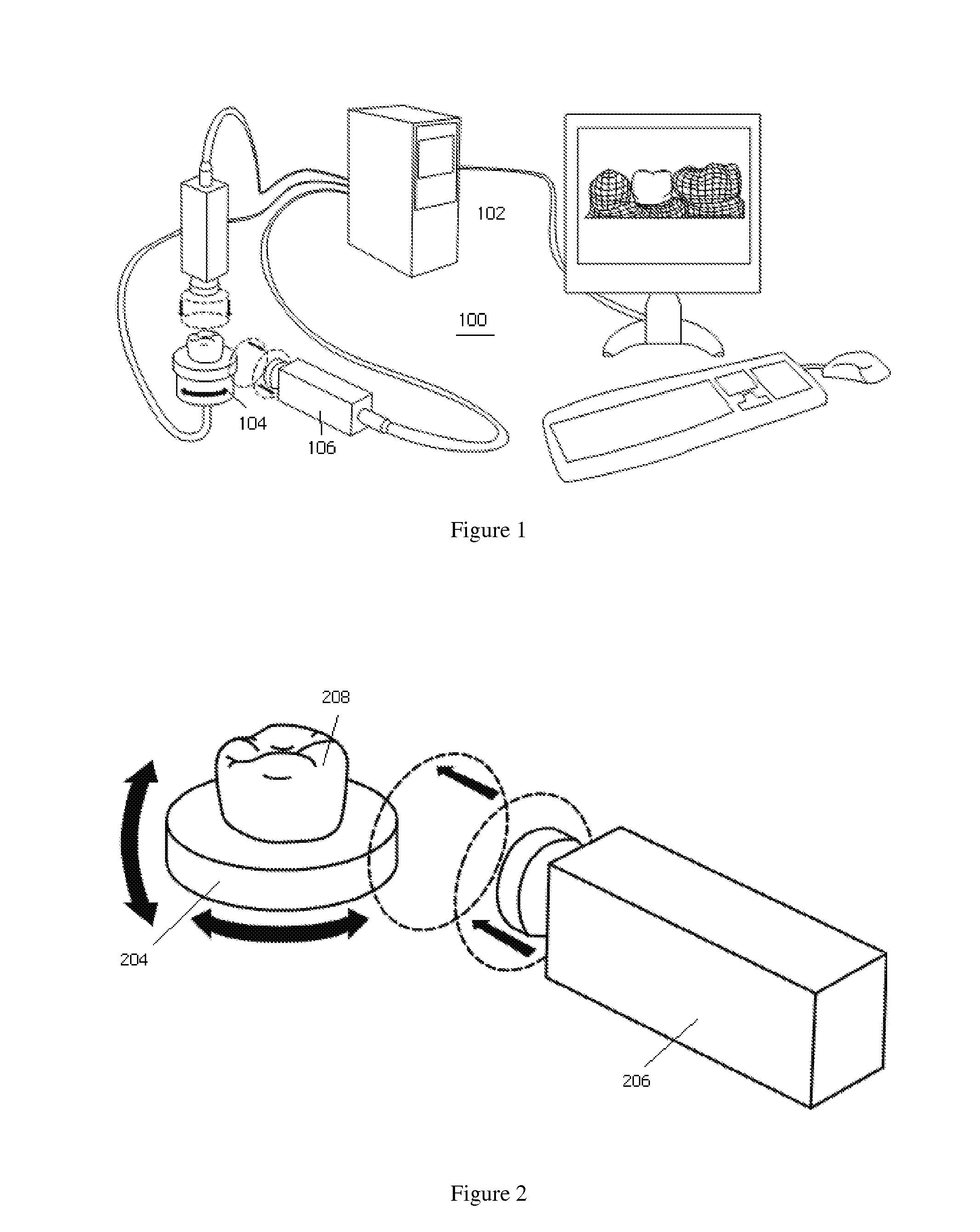

Haptically enabled dental modeling system

InactiveUS20090248184A1Minimal distortionGood choiceInput/output for user-computer interactionAdditive manufacturing apparatusDigital dentistryEngineering

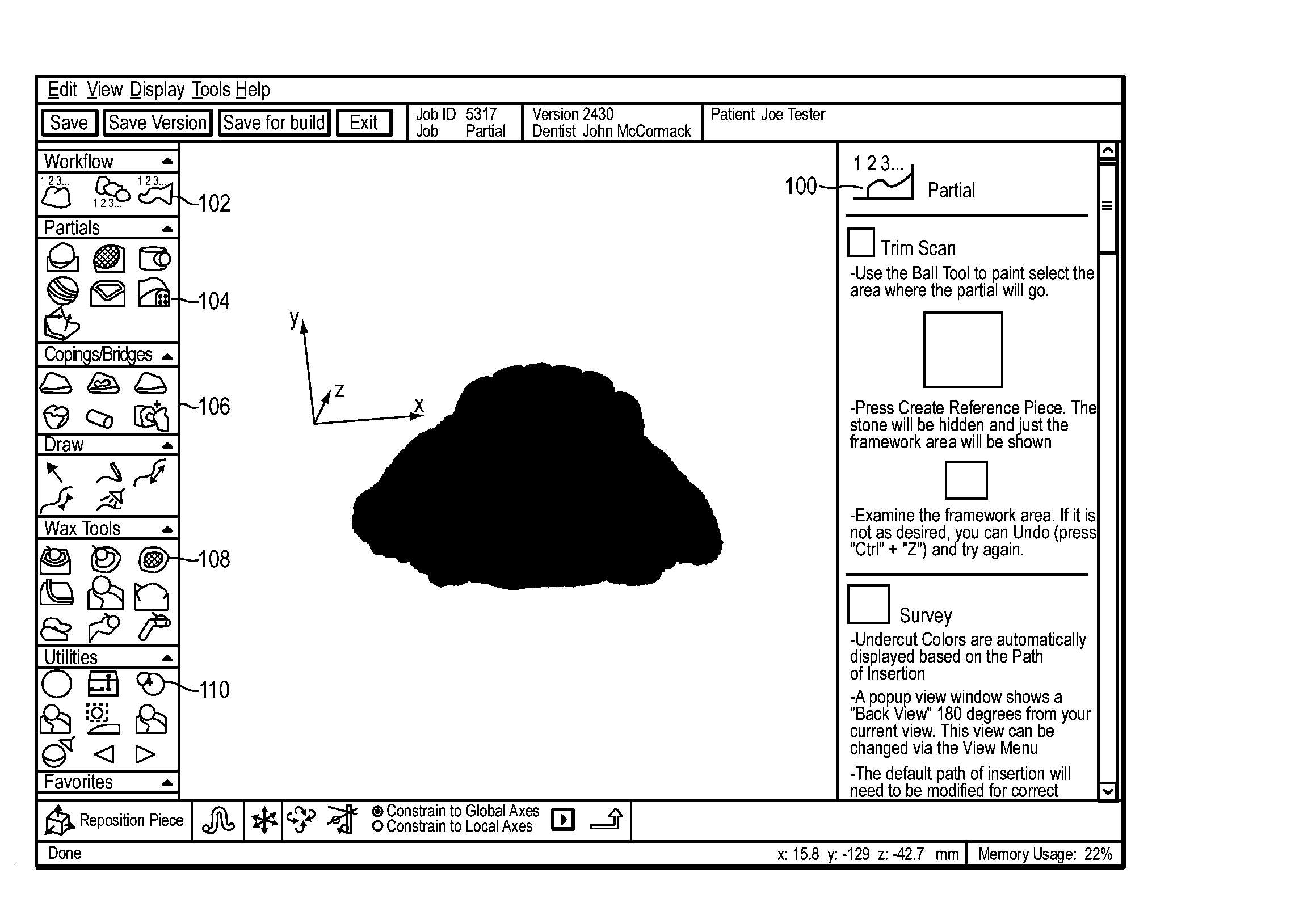

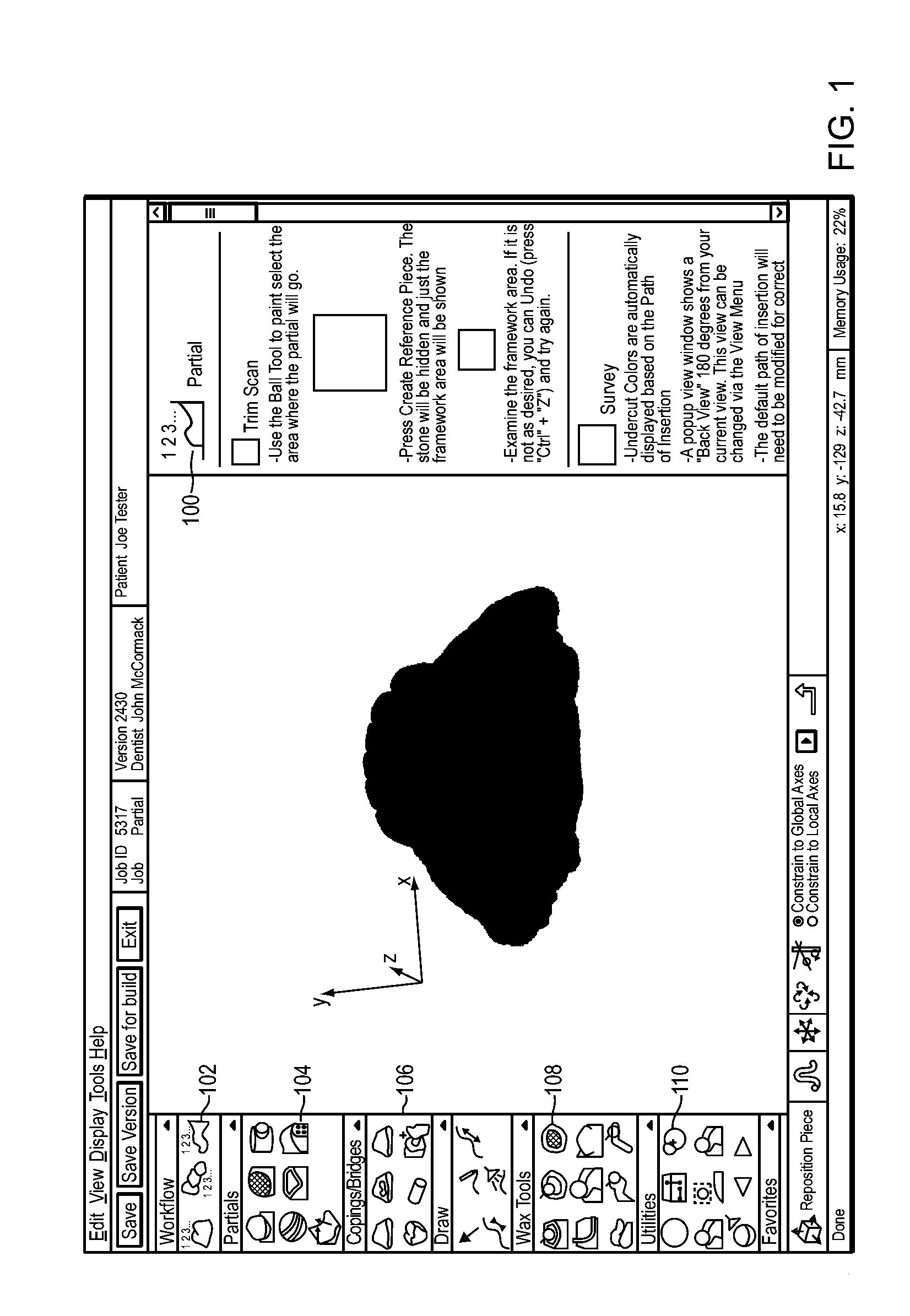

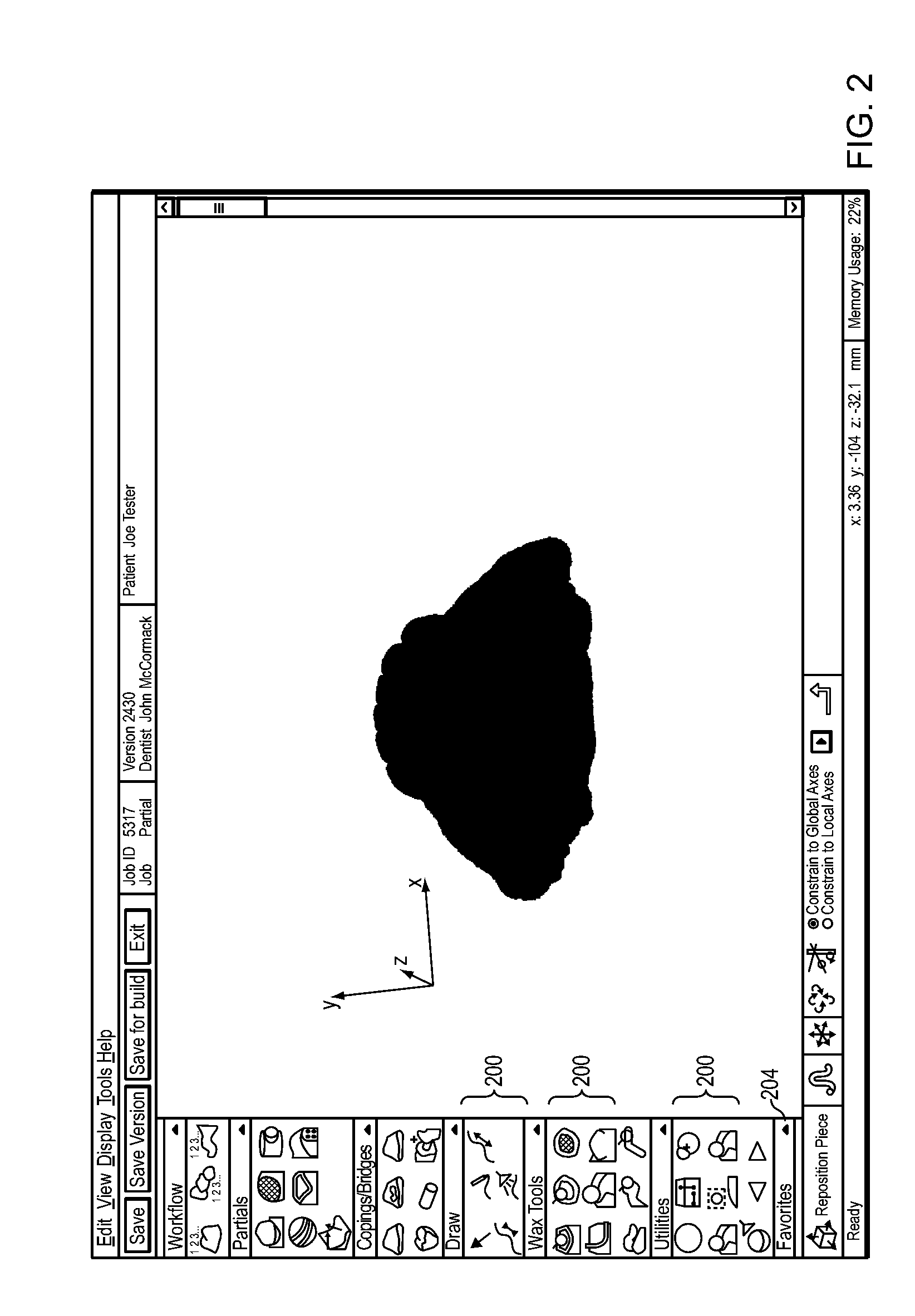

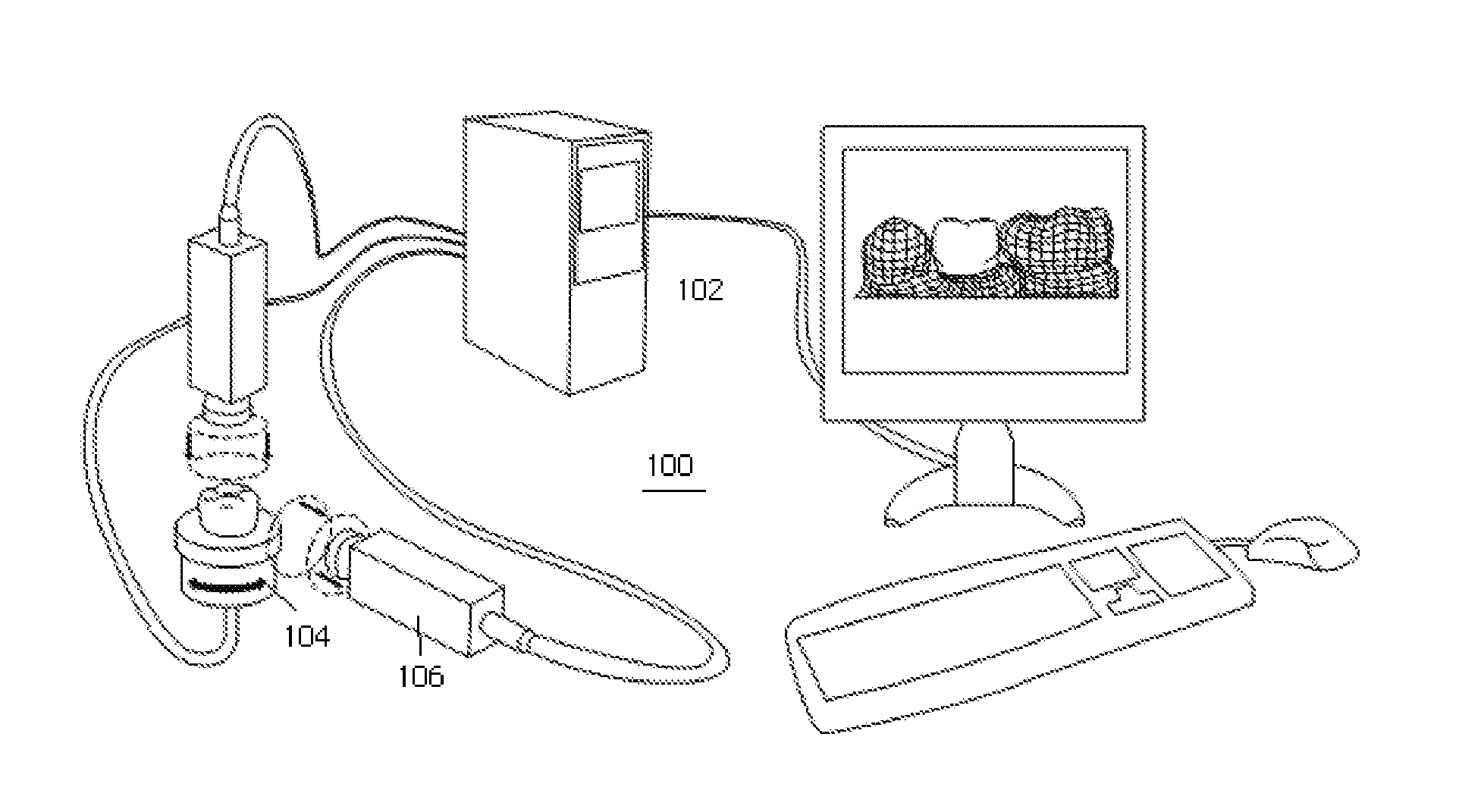

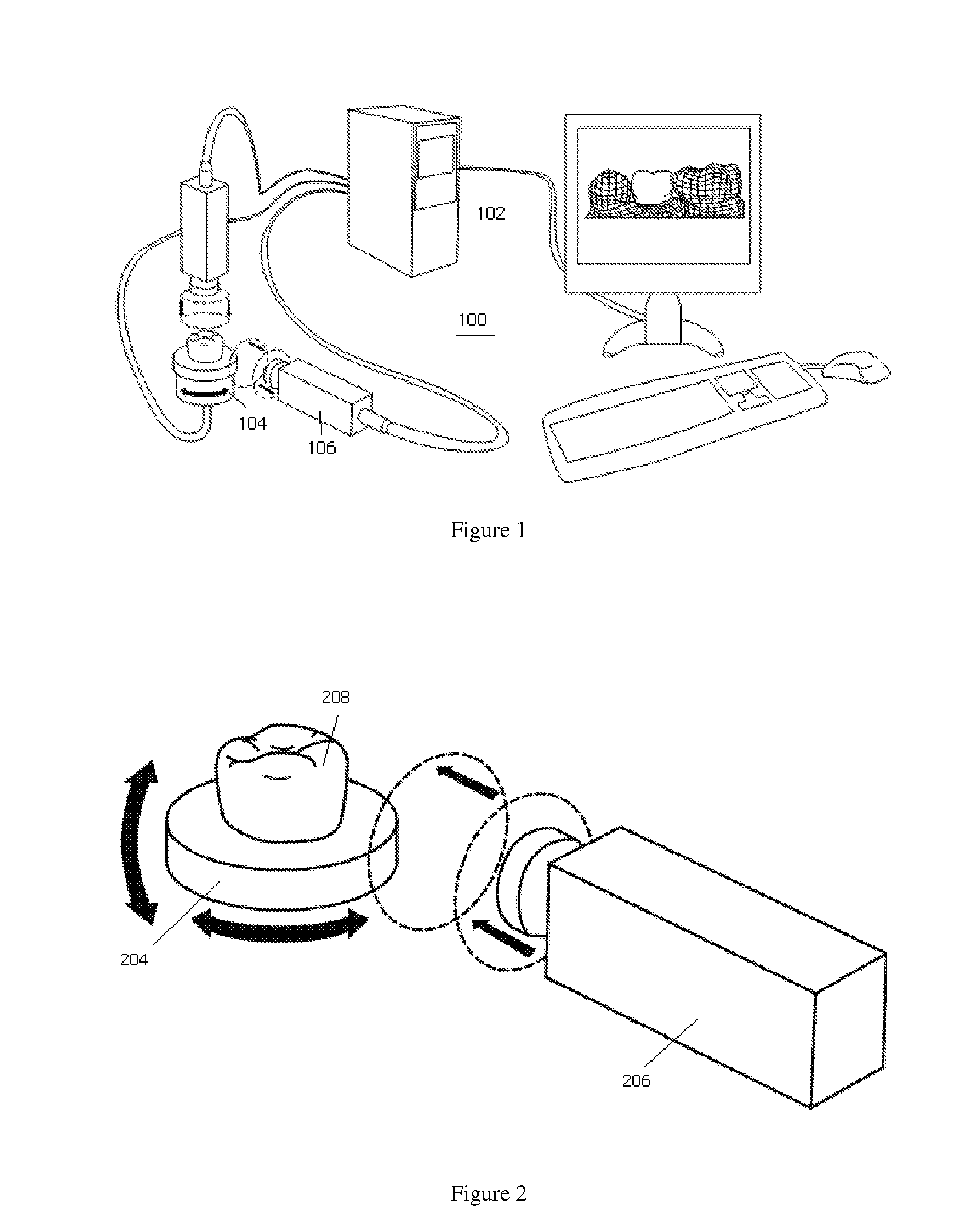

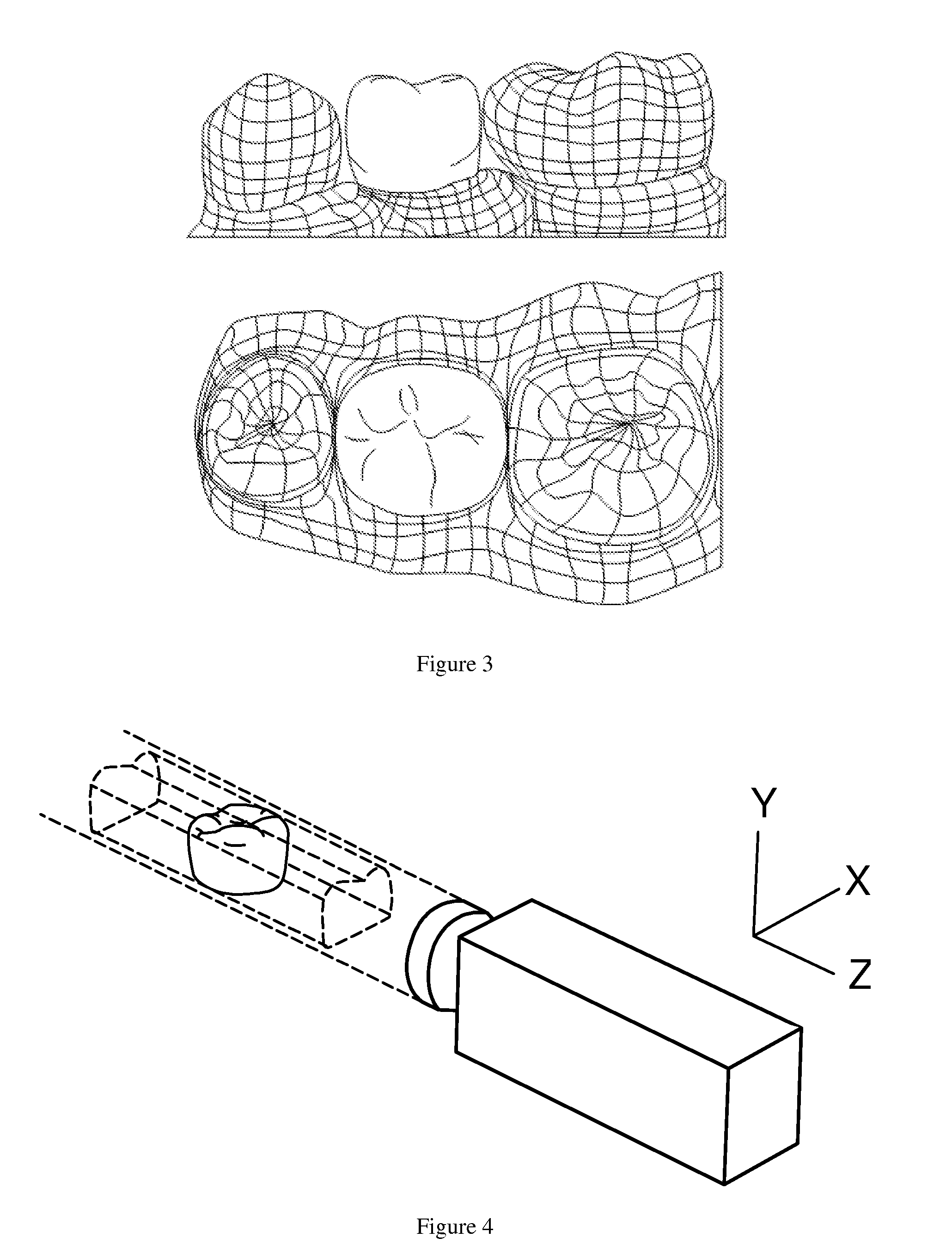

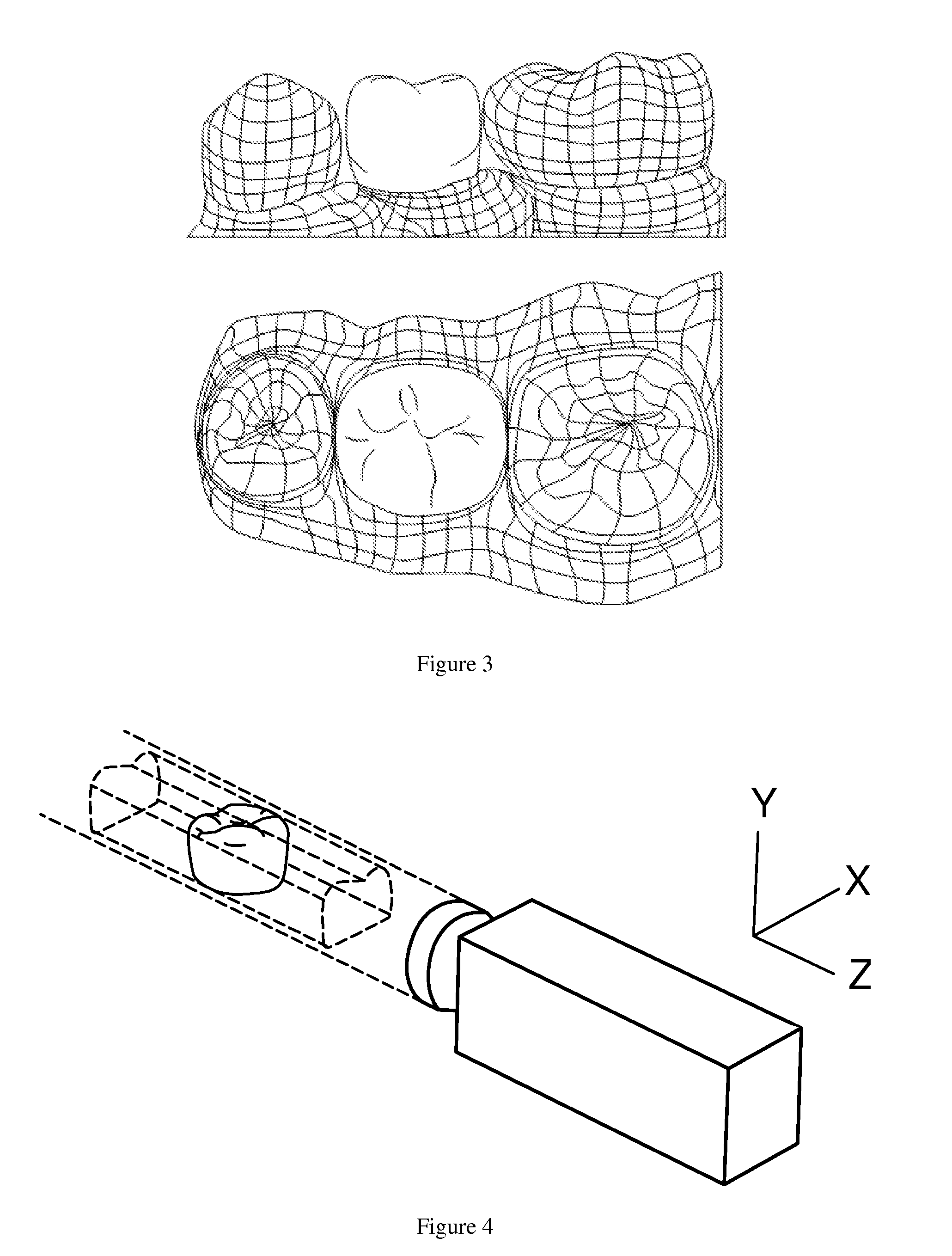

The invention provides a digital dentistry system that utilizes a haptic interface and features a computer-based design application configured to allow the intuitive construction of irregular, amorphous three-dimensional structures typically seen in dental restorations, utilizing, where appropriate, the design skills of a user. In certain embodiments, the system provides a comprehensive digital solution for dental labs in the business of creating dental restorations such as partial frameworks, crowns, copings, bridge frameworks, implants and the like, with a sense of touch provided by a haptic interface device.

Owner:SENSABLE TECH

Augmented reality system for a dental laboratory

InactiveUS20070211081A1Correcting occlusionMedical simulationImpression capsDental OfficesDental laboratory

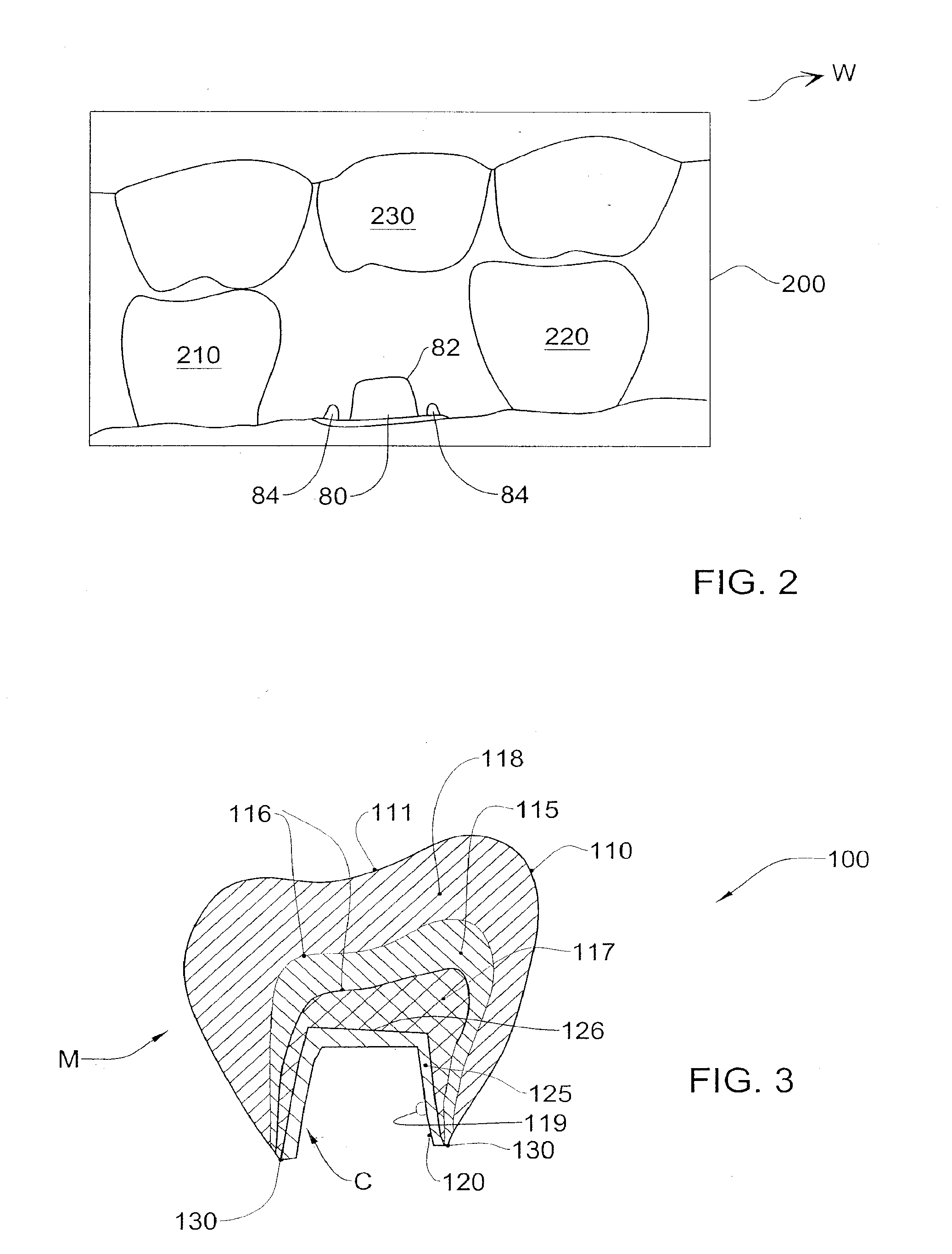

An augmented reality system for integrating video imagery of an actual dental restoration into a computer-implemented display of a model (that represents a preparation, mesial / distal neighbors, and opposing occlusion) that has been generated from a 3D scan of a patient. The 3D scan data may be generated at a dental office remote from a location at which the augmented reality system is implemented. In one embodiment, the 3D scan data is provided to the augmented reality system as a digital impression.

Owner:D4D TECH LP

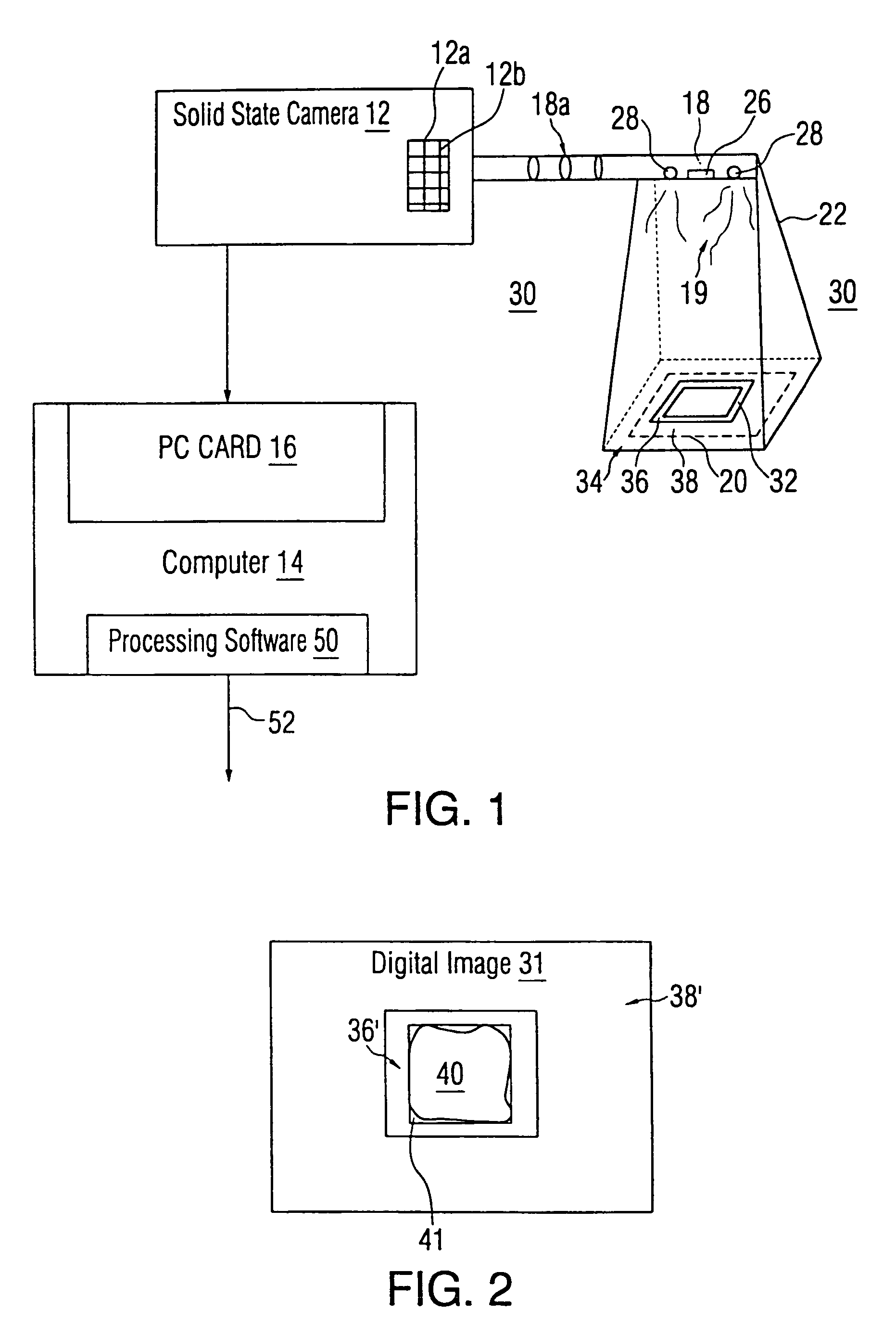

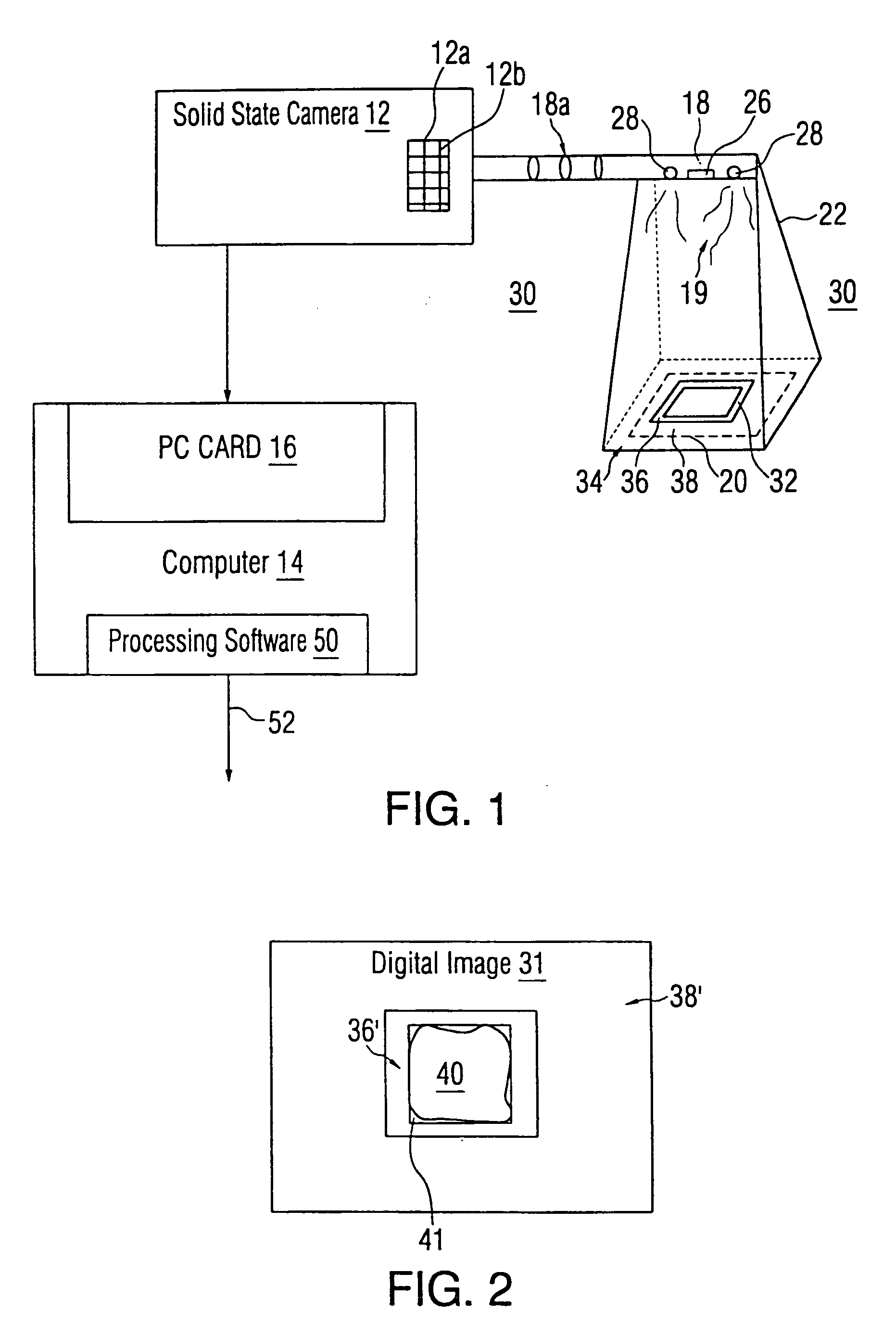

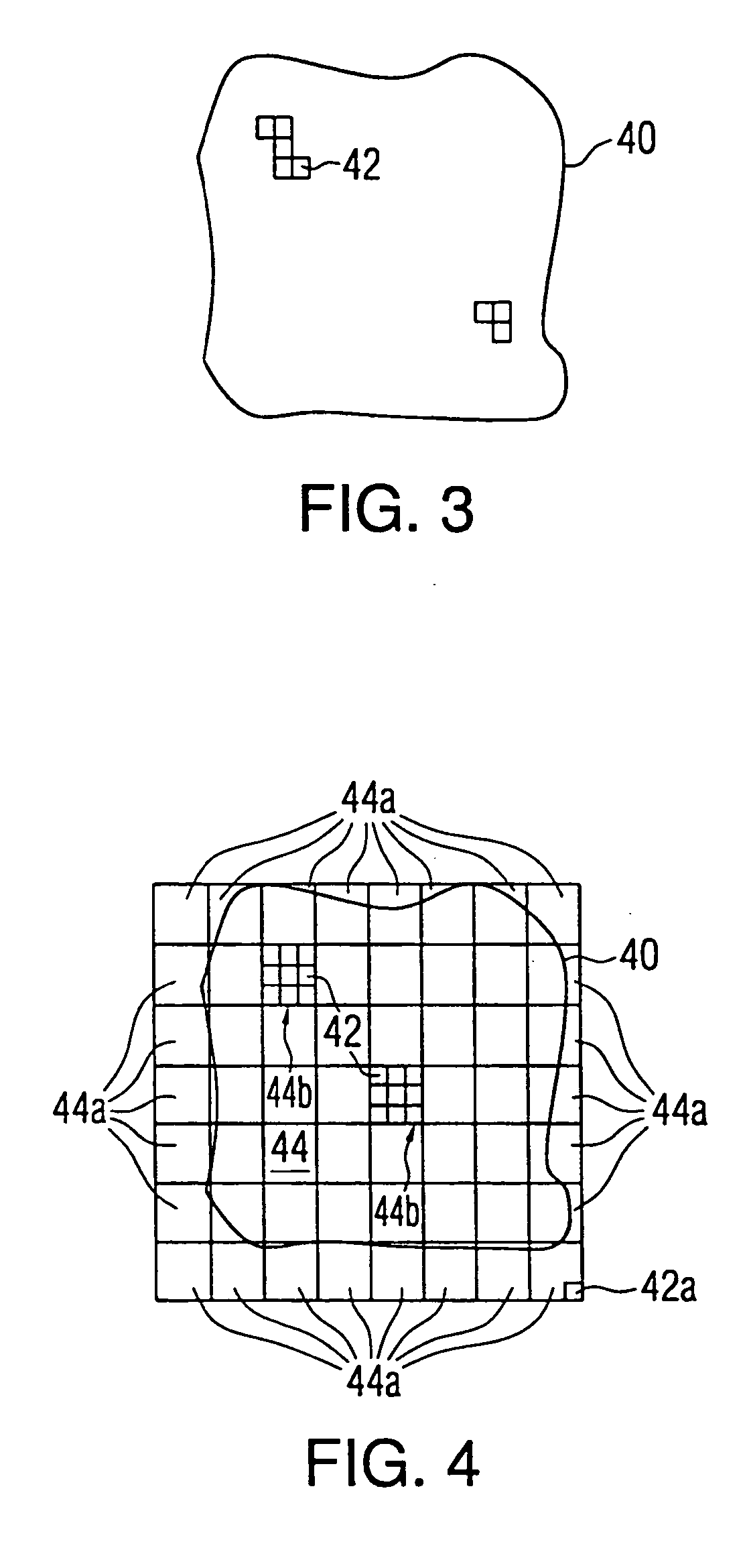

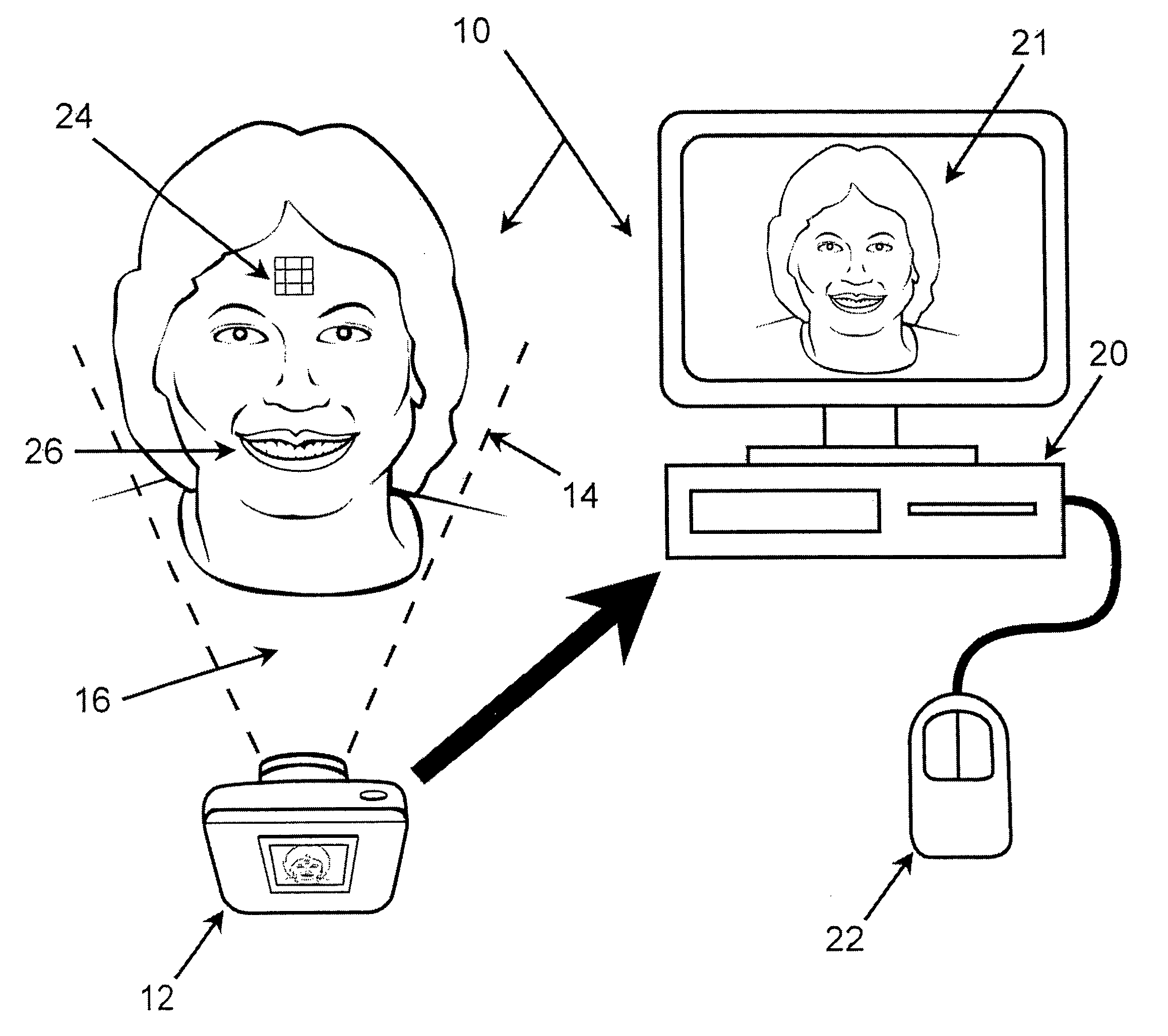

Method, apparatus and system for automated tooth shade analysis and matching

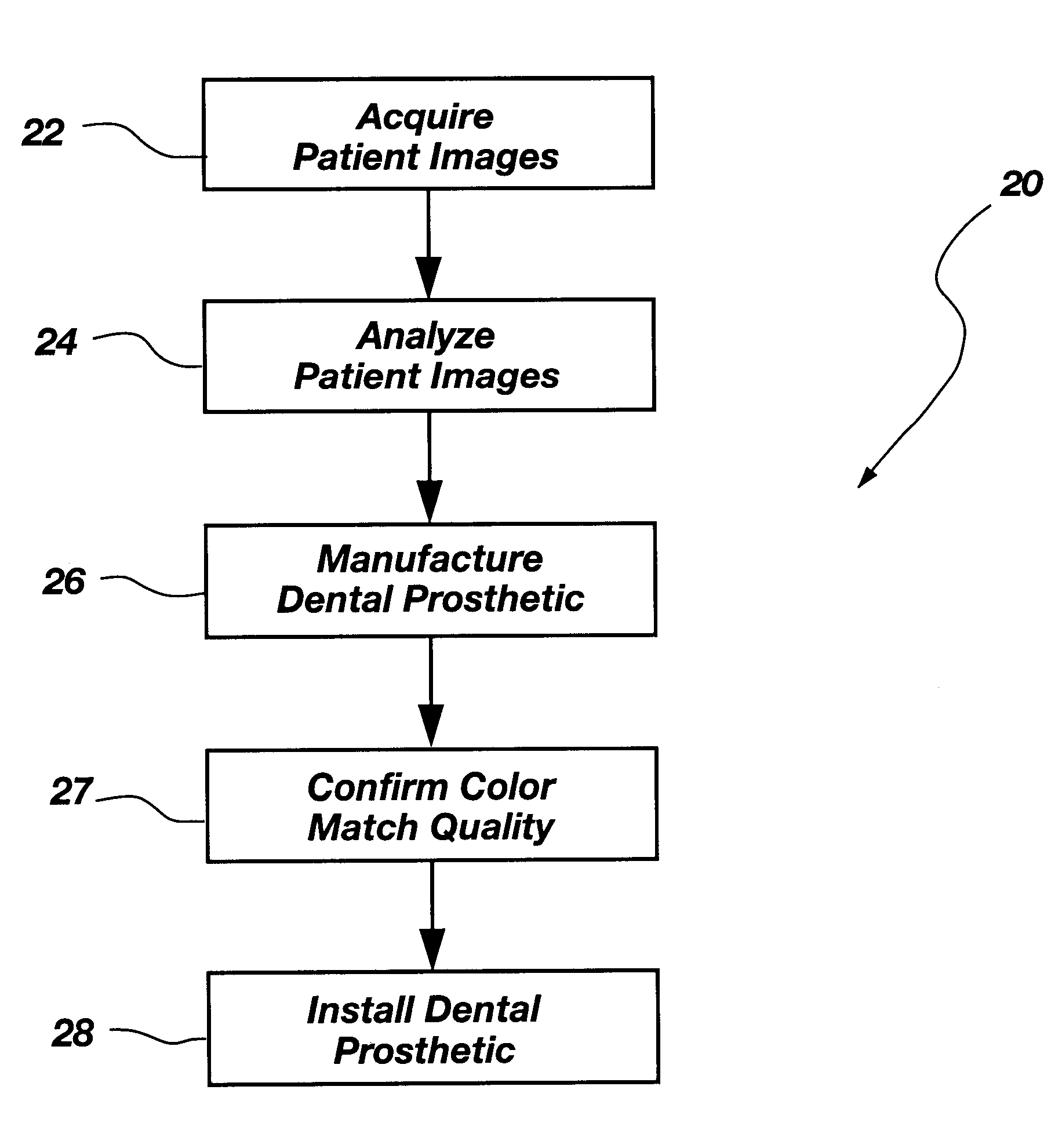

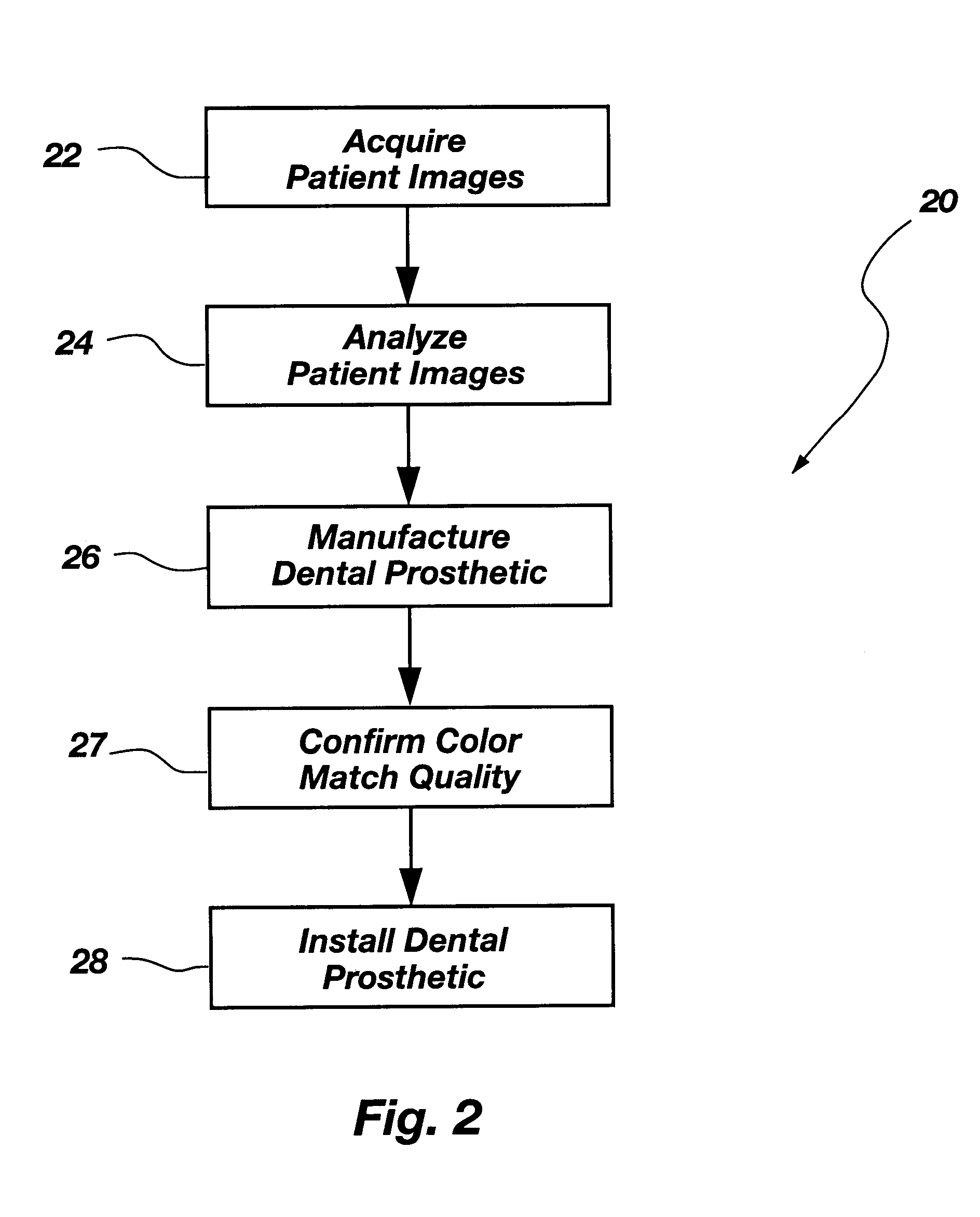

Methods, apparatuses and systems for tooth shade analysis and matching are disclosed. A method embodiment according to the invention includes acquiring at least one image, the image including one or more teeth of a patient and normalization references, normalizing the at least one image in accordance with the normalization references, determining the color of the teeth as composed of colors from one or more selected shade standards, communicating the standardized color information to a dental laboratory, manufacturing a dental prosthesis based on the standardized color information and installing the dental prosthetic. Normalization is performed to correct patient images for variations in lighting conditions and image source. Normalization references include a black reference, a white reference and at least one color reference. The normalized image is standardized by matching the pixels of the normalized image to selected shade standards. Selected shade standards may include incisal tooth shade standards. The standardized color image and / or analysis may be communicated to a dental laboratory according to aspects of the invention. The dental prosthesis can then be manufactured by a lab technician by referring to the standardized image. Color models according to the invention may include RGB, HSI and other models for representing color images. The methods, apparatuses and systems for tooth shade analysis and matching are also applicable to direct restorations of natural teeth, such as repair of chipped or broken teeth.

Owner:DENTECH

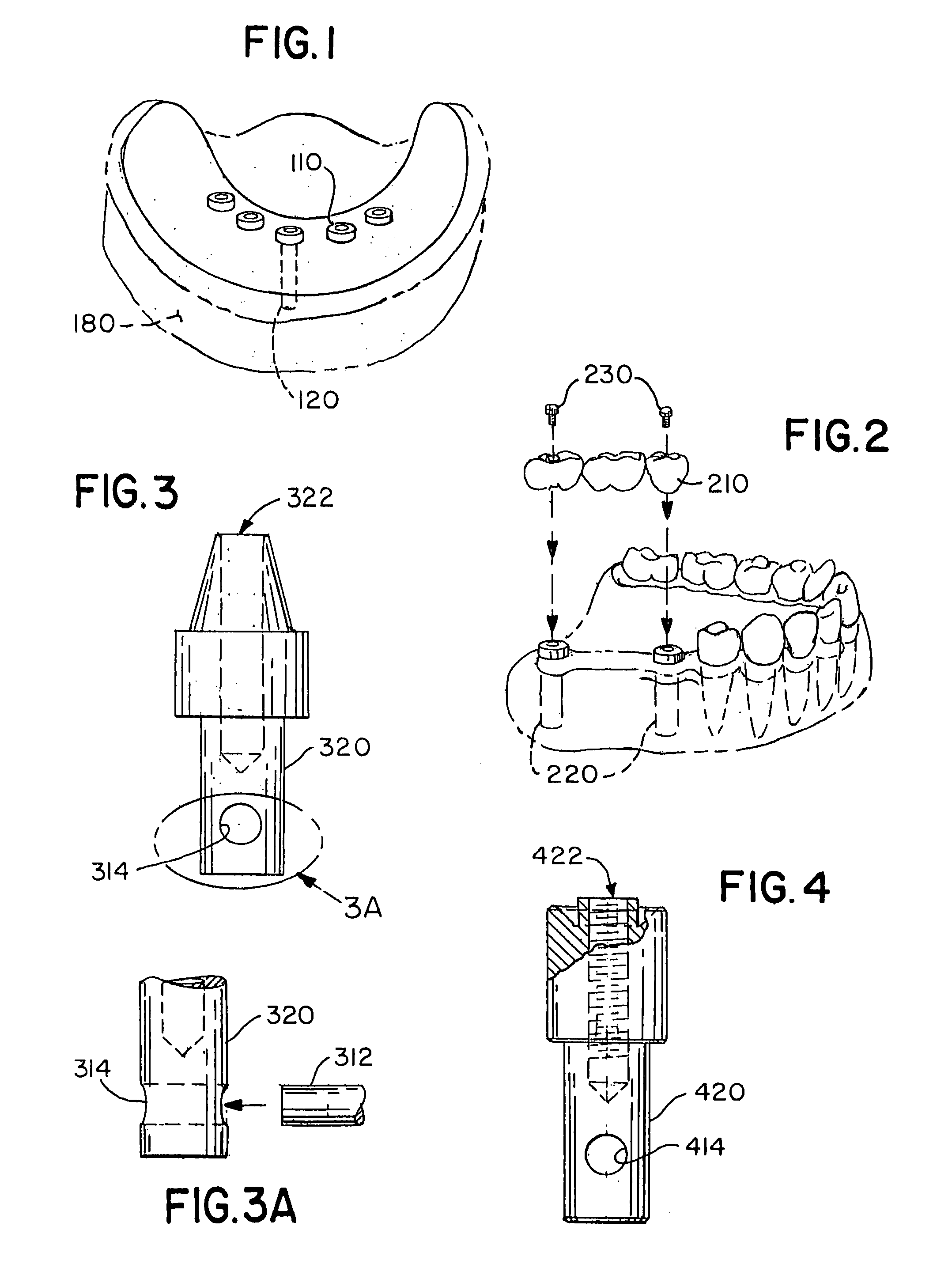

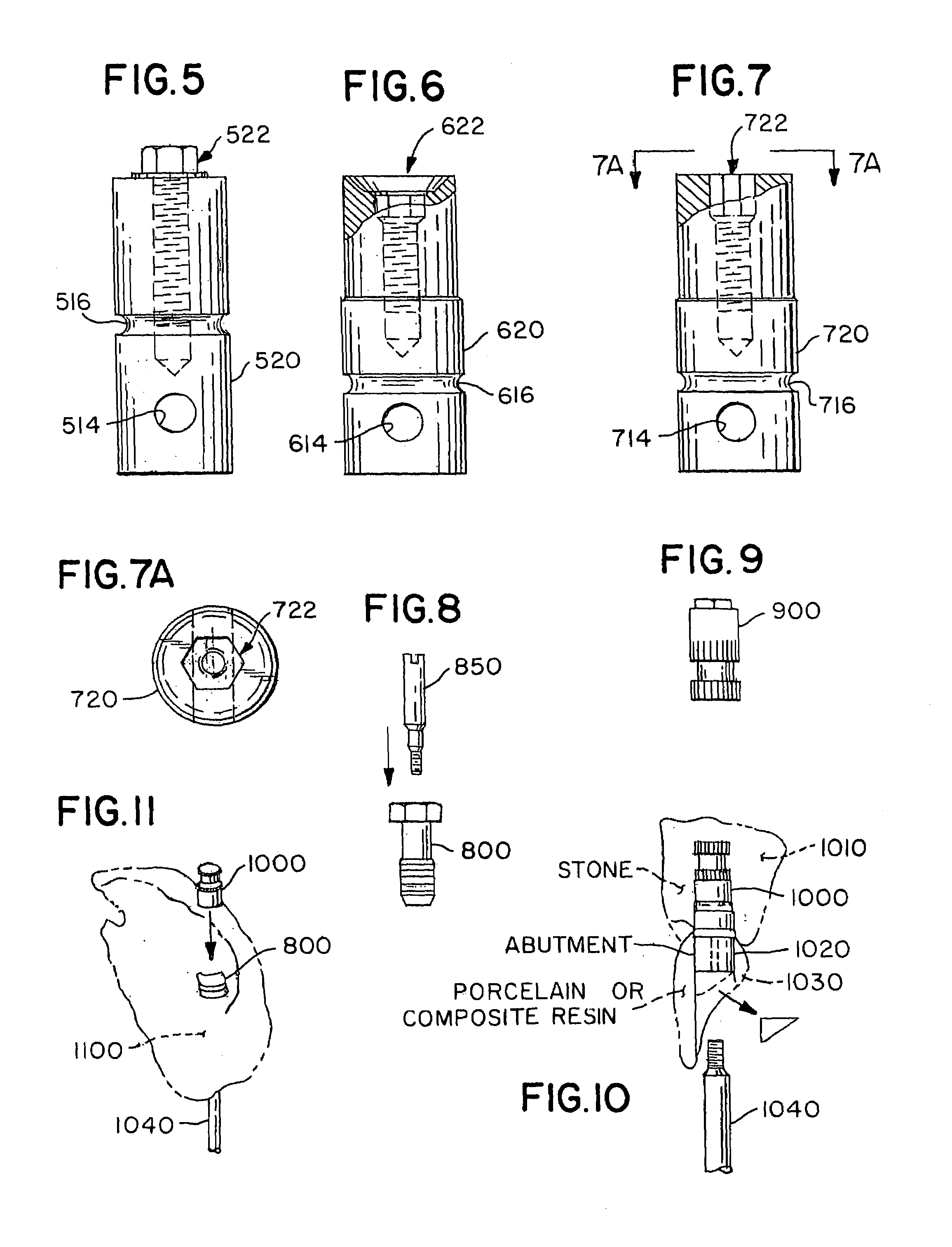

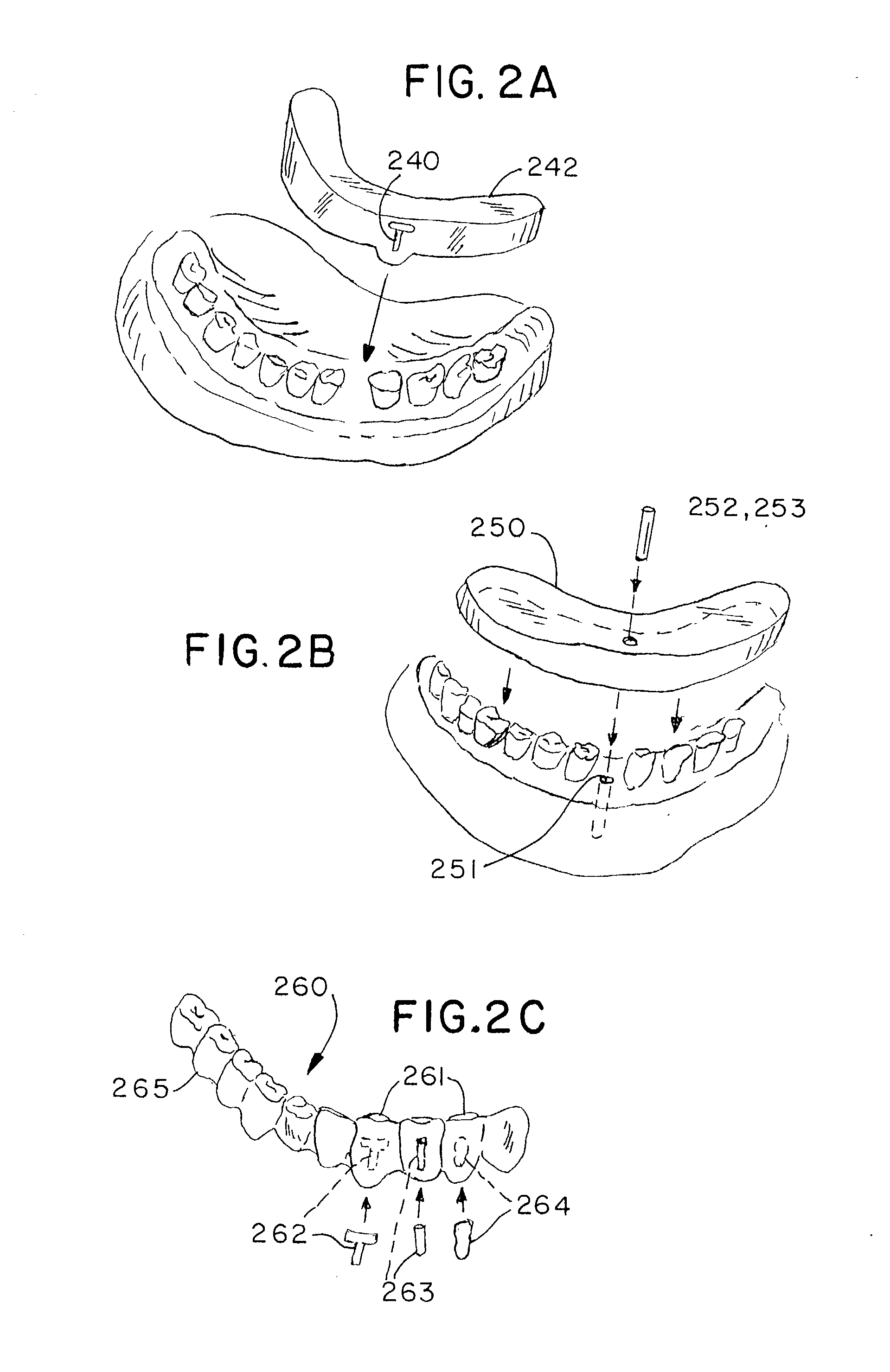

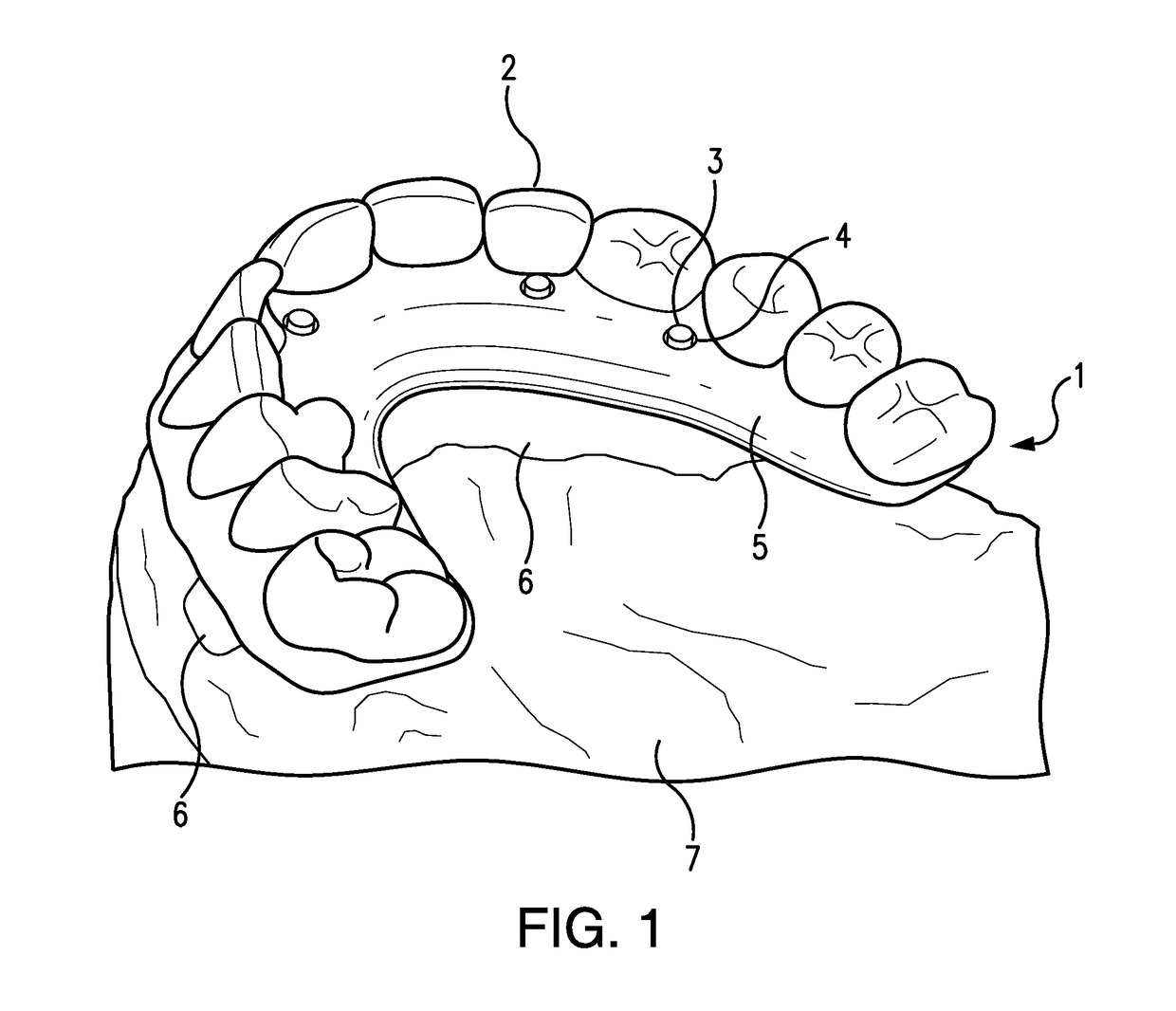

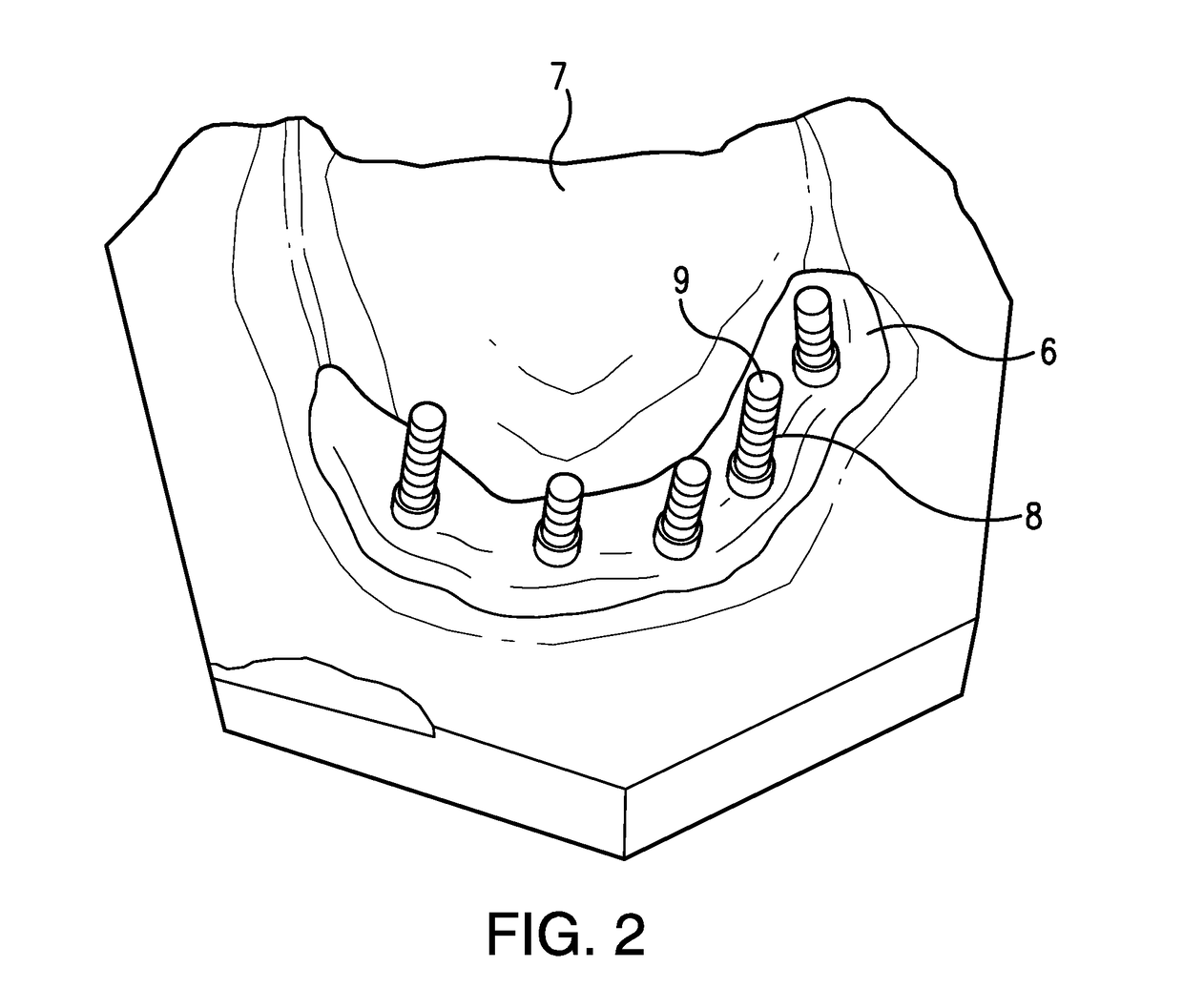

Stable dental analog

An implant analog includes an abutment that can be mounted in the dental lab replica of the relevant section of a patient's mouth more securely than heretofore possible. Because of the implant analog, a crown will attach more accurately to the implant in the patient's mouth. The analogs have a pin or other protrusion that projects from the base of the analog. The analog has substantially the same height and dimensions as a conventional implant and abutment.

Owner:CLM ANALOGS LLC

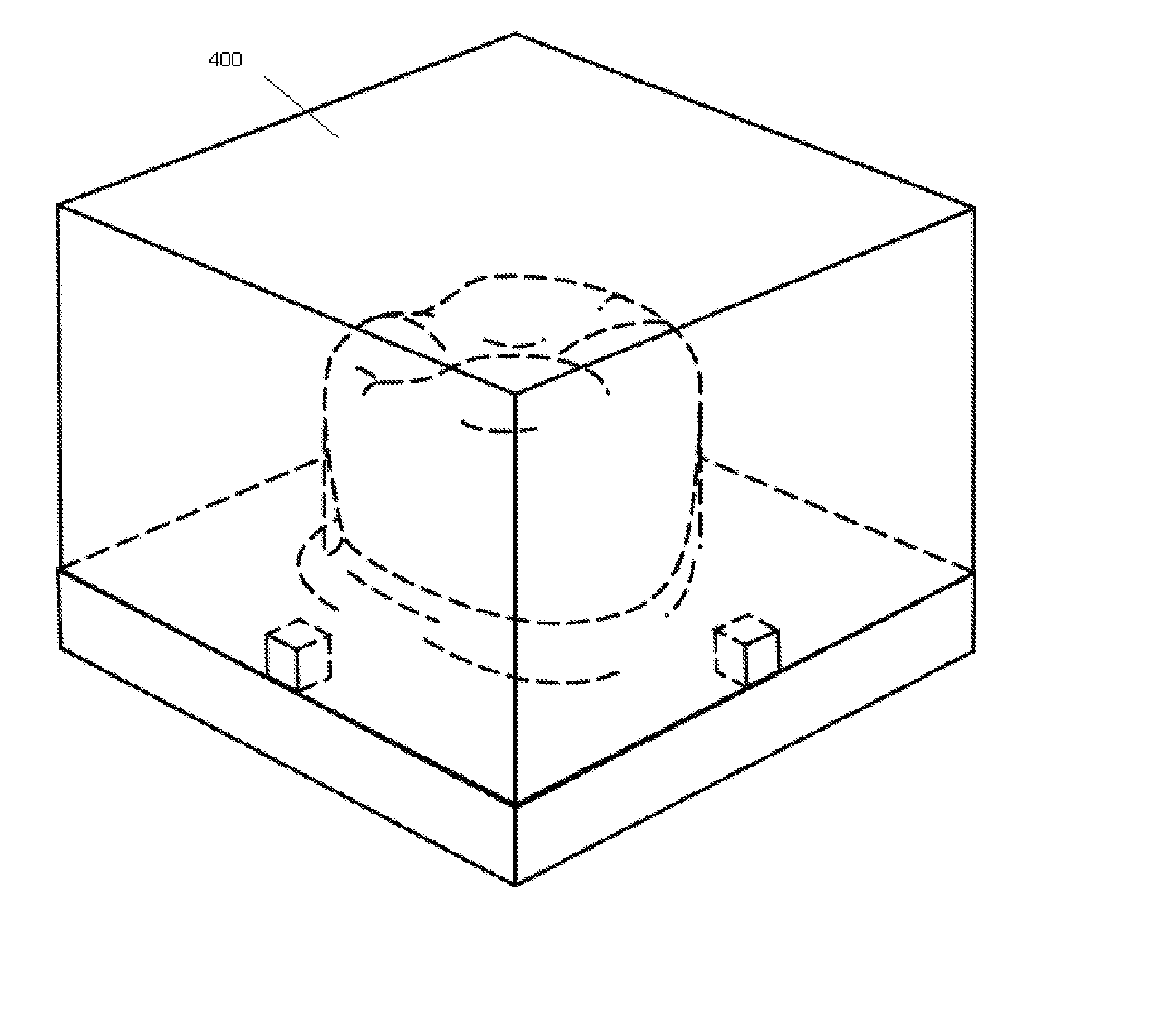

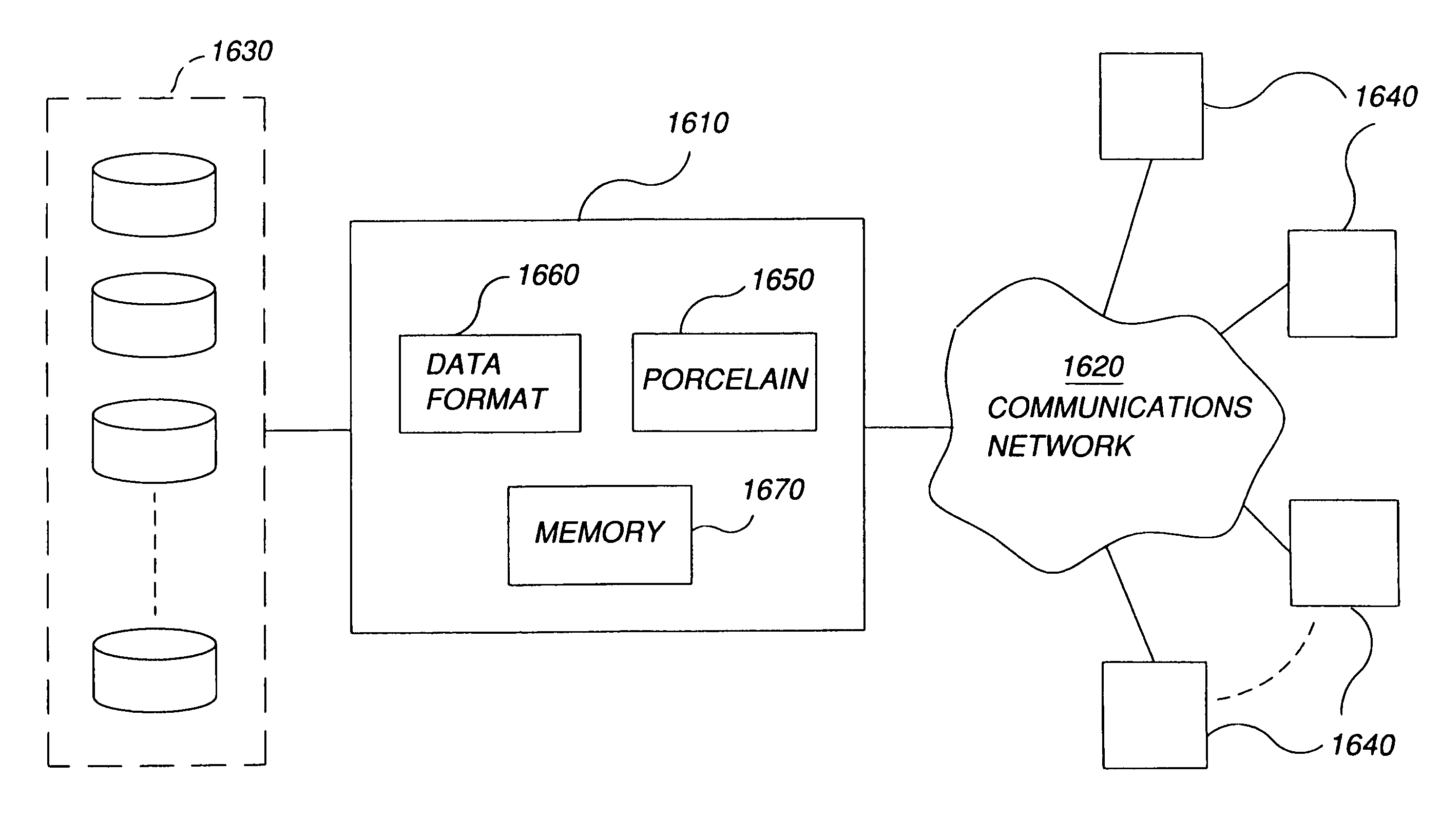

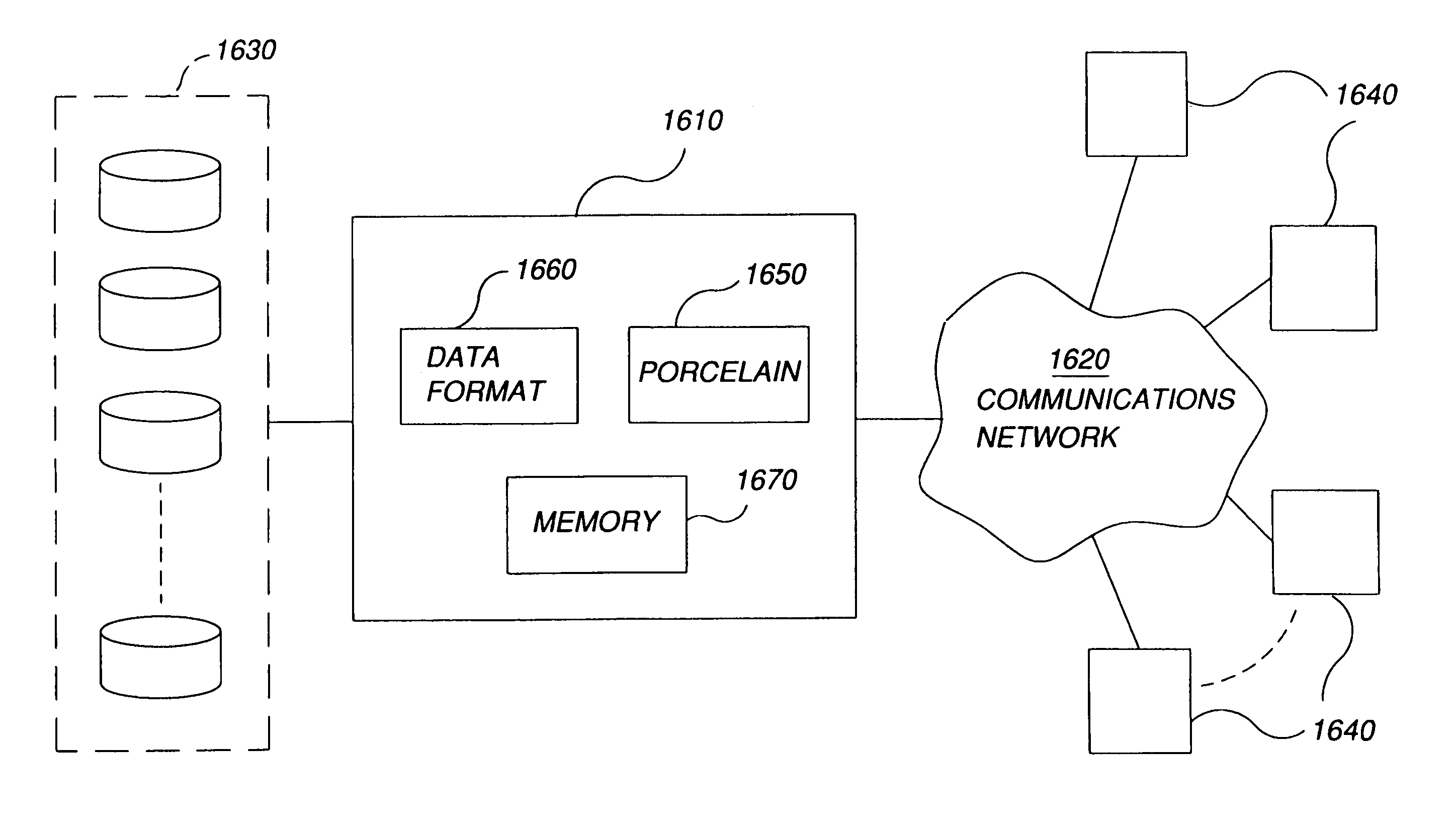

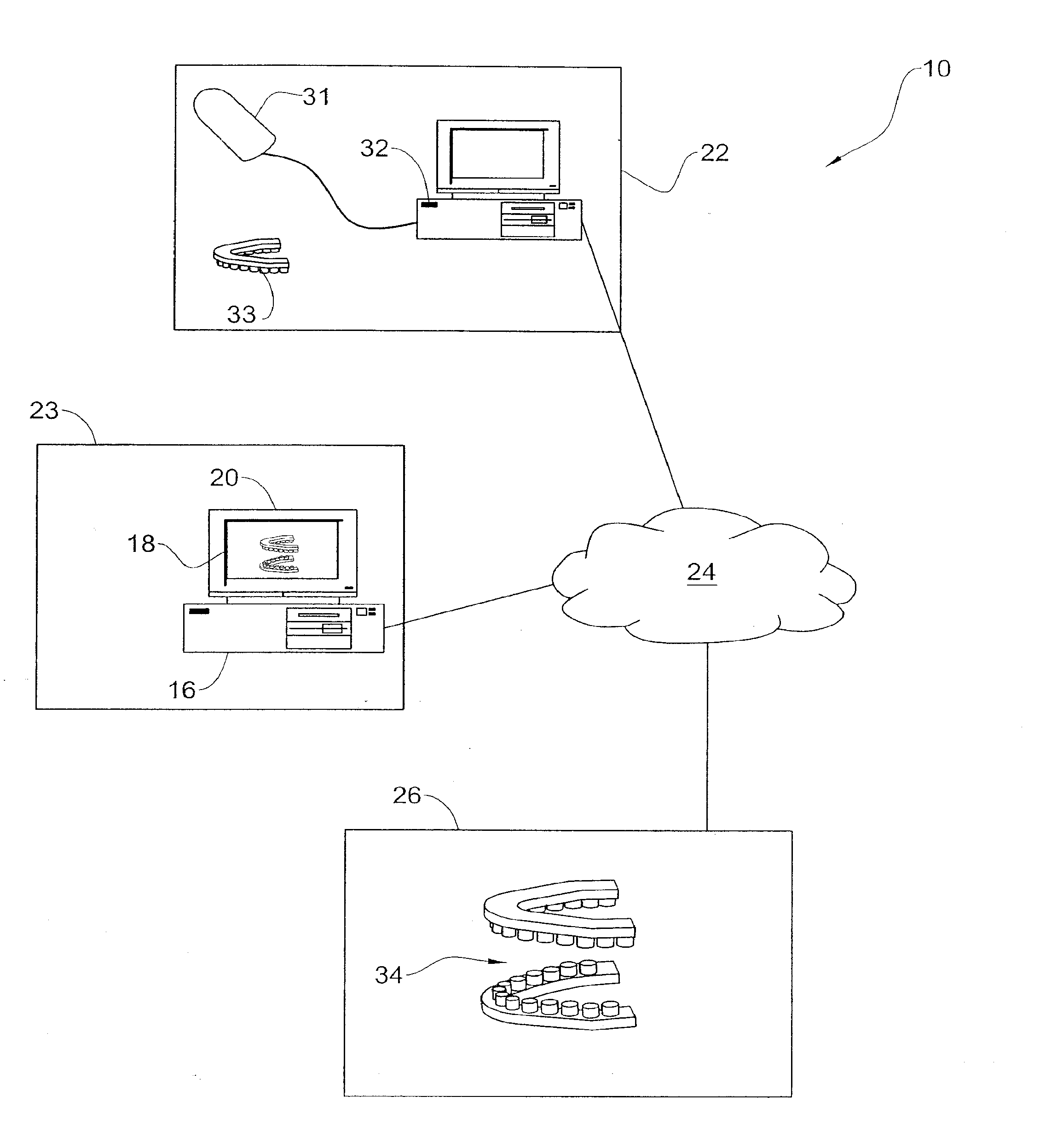

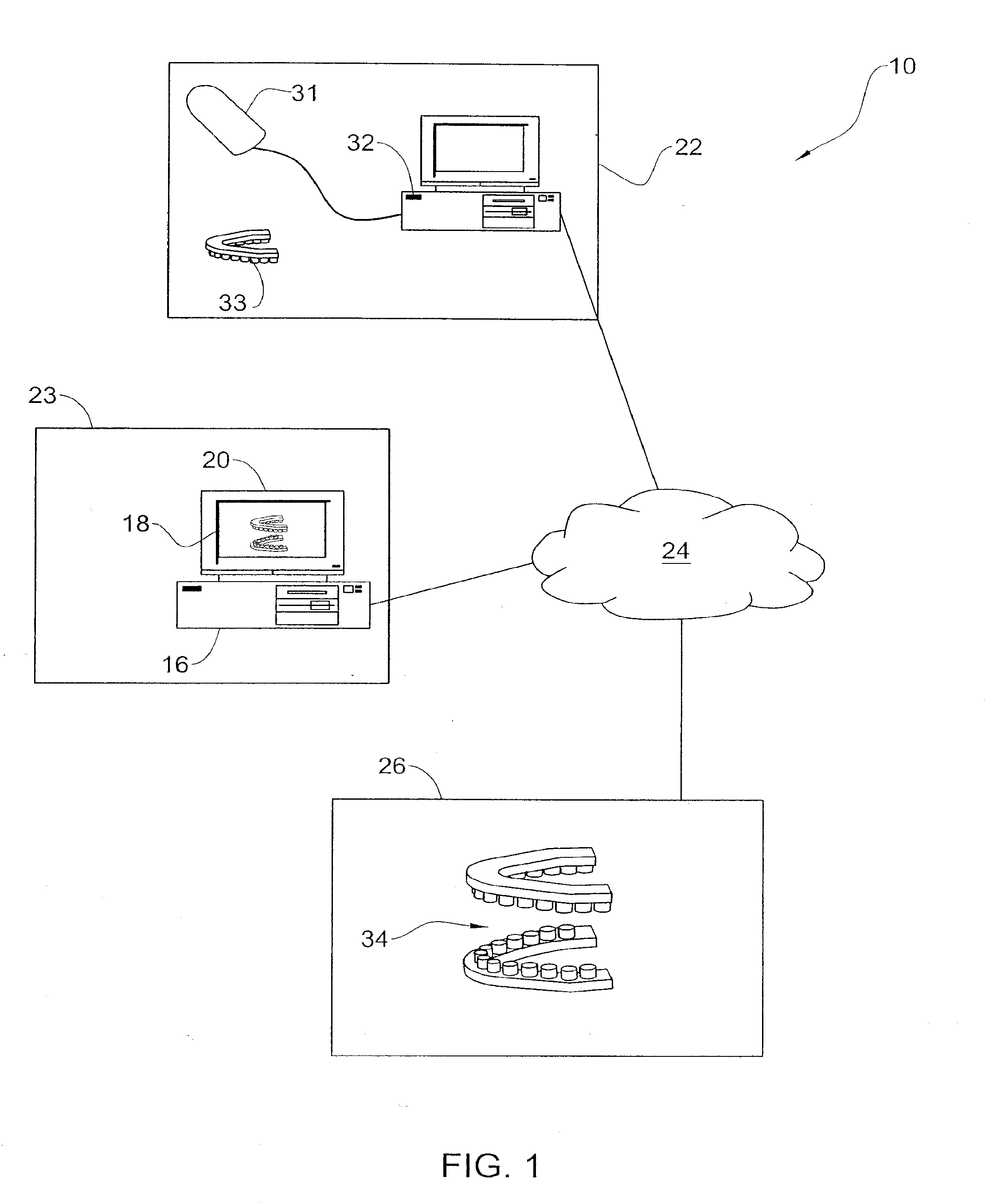

Digital impression for remote manufacturing of dental impressions

A “digital impression” is provided in lieu of a physical “dental” impression. A 3D digitizer is used to capture the digital impression, e.g., by scanning in a patient's oral cavity. A digital impression “data set” is formed using a computer-implemented method. The method begins by generating a three dimensional (3D) restoration model. Then, a bounding volume of the restoration model is computed. The bounding volume is defined as at least a minimum 3D volume that contains the 3D model. Thereafter, a lower solid 3D model, and an upper solid 3D model are created; these lower and upper models have a predetermined relationship with one another. In particular, when superimposed upon one another within the bounding volume, the lower and upper 3D models define a cavity into which the restoration model is adapted to fit. The restoration model, the lower solid 3D model and the upper solid 3D model are then aggregated into the data set to form the digital impression. Typically, the digital impression is generated at a first location, i.e., a dental office, and then transmitted to a second location, a dental laboratory, remote from the first location. Such transmission is conveniently done over a network, such as a TCP / IP network (e.g., the Internet). A dental item is then manufactured at the second location. Thus, for example, the lower solid 3D model may be used to build a coping, or the restoration model itself used to build a restoration. In the latter case, information in the data set may be used to check a fit of the restoration.

Owner:D4D TECH LP

Haptically enabled dental modeling system

InactiveUS8359114B2Minimal distortionGood choiceInput/output for user-computer interactionAdditive manufacturing apparatusTouch PerceptionSkill sets

The invention provides a digital dentistry system that utilizes a haptic interface and features a computer-based design application configured to allow the intuitive construction of irregular, amorphous three-dimensional structures typically seen in dental restorations, utilizing, where appropriate, the design skills of a user. In certain embodiments, the system provides a comprehensive digital solution for dental labs in the business of creating dental restorations such as partial frameworks, crowns, copings, bridge frameworks, implants and the like, with a sense of touch provided by a haptic interface device.

Owner:SENSABLE TECH

Interactive dental restorative network

InactiveUS7581953B2Save effortShorten the timeOptical radiation measurementTeeth fillingDental laboratoryDental surgeon

The invention relates to a computer readable medium that includes one or more programs for carrying out a method for restoration of a patient's tooth. The method includes the steps of generating an electronic image of a patient's tooth; providing a preliminary treatment plan for addressing the dental needs of the patient; and forwarding the electronic image and preliminary treatment plan to a dental laboratory so that technician can evaluate the image and treatment plan and in a manner such that the technician and dentist can review and discuss the preliminary treatment plan.

Owner:LEHMANN MARYANN

Three-dimensional fabricating material systems and methods for producing layered dental products

ActiveUS20170360534A1Highly shapeHigh wear resistanceAdditive manufacturing apparatusImpression capsFull denturesDental Product

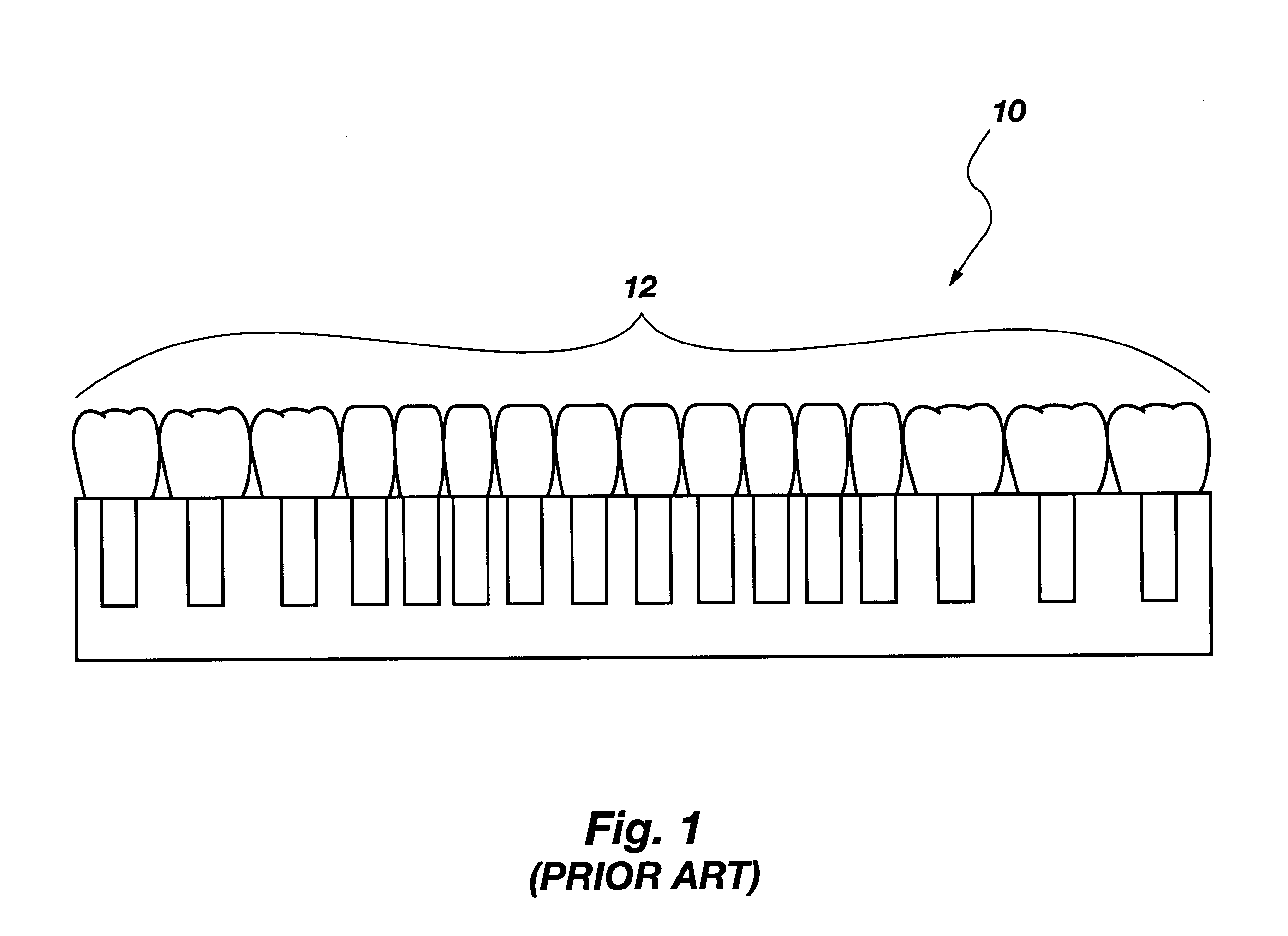

This invention designs and builds multiple layers (two layers or more) of various dental devices, specifically denture base or denture, where printed multiple layered denture base with teeth cavities to receive artificial denture tooth materials to form final dental devices, such as partial and full dentures. It can also print denture teeth. This invention also designs and prints multiple layers (two layers or more) of denture base with artificial denture teeth to form final dental devices, such as partial and full dentures. A method for manufacturing a layered denture is provided. The invention provides a multiple layered denture base materials for printing a denture base. The invention also provides a multiple layered denture tooth materials for printing artificial denture teeth. Highly shape adjustable or shape memory polymer layer(s) may be used in these multiple layered denture base forms. Different layer of material has different mechanical and physical properties to meet different need, which provide added benefits to the patients, dental professional and dental laboratory.

Owner:DENTSPLY SIRONA INC

Dental implant management system and method

InactiveUS20150019252A1Good for dental healthFacilitate communicationDental implantsMechanical/radiation/invasive therapiesExecution planDental laboratory

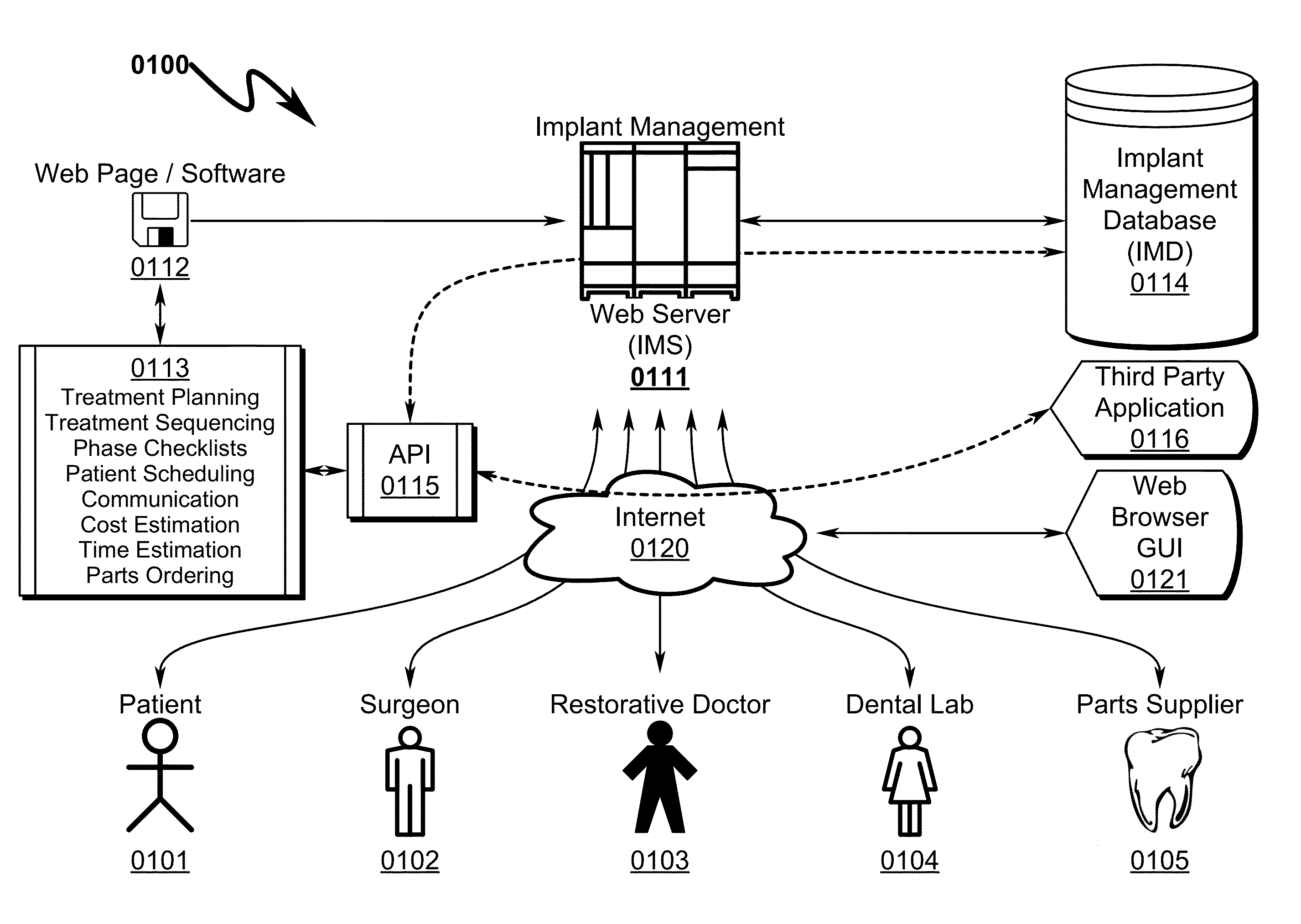

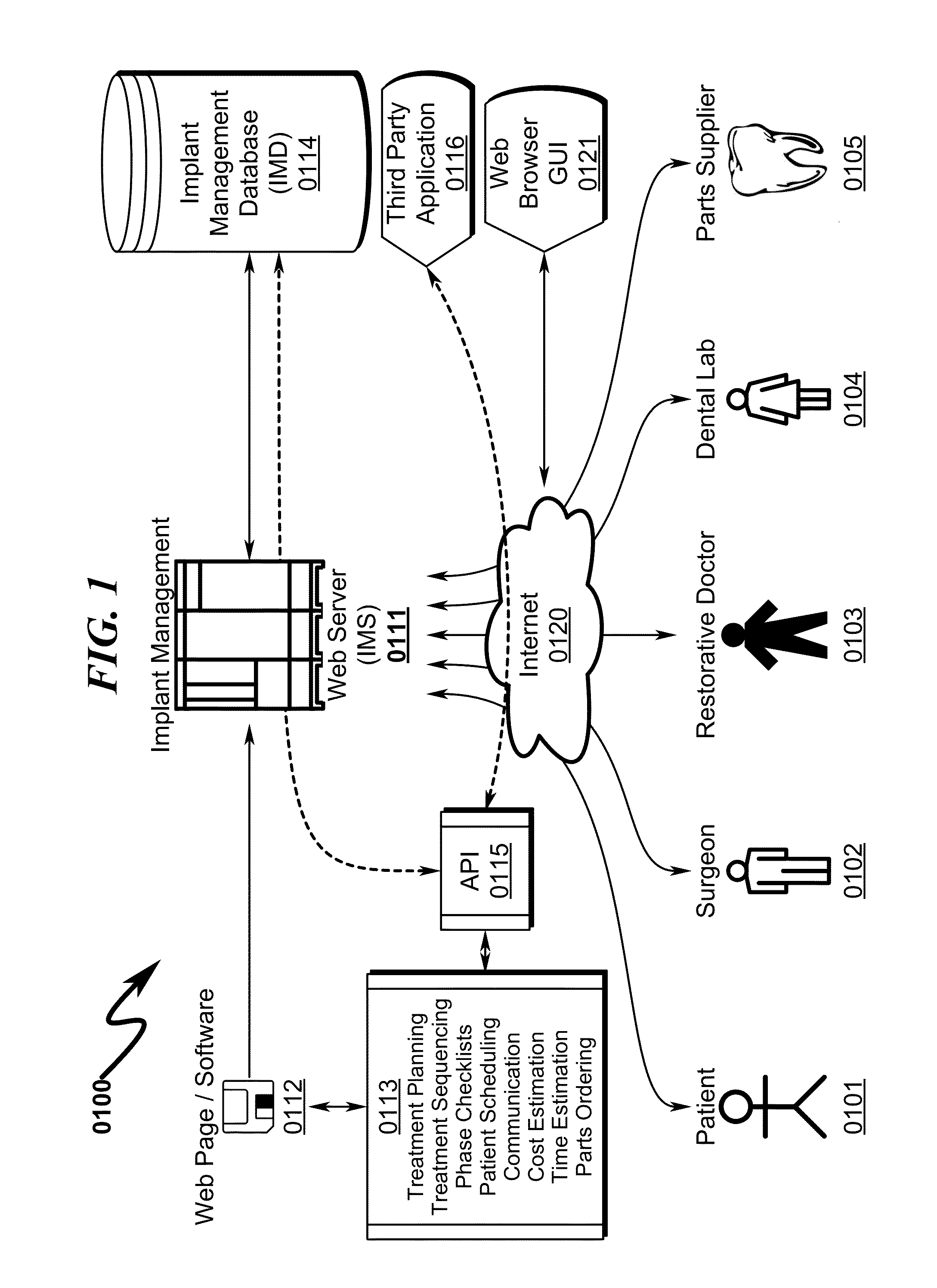

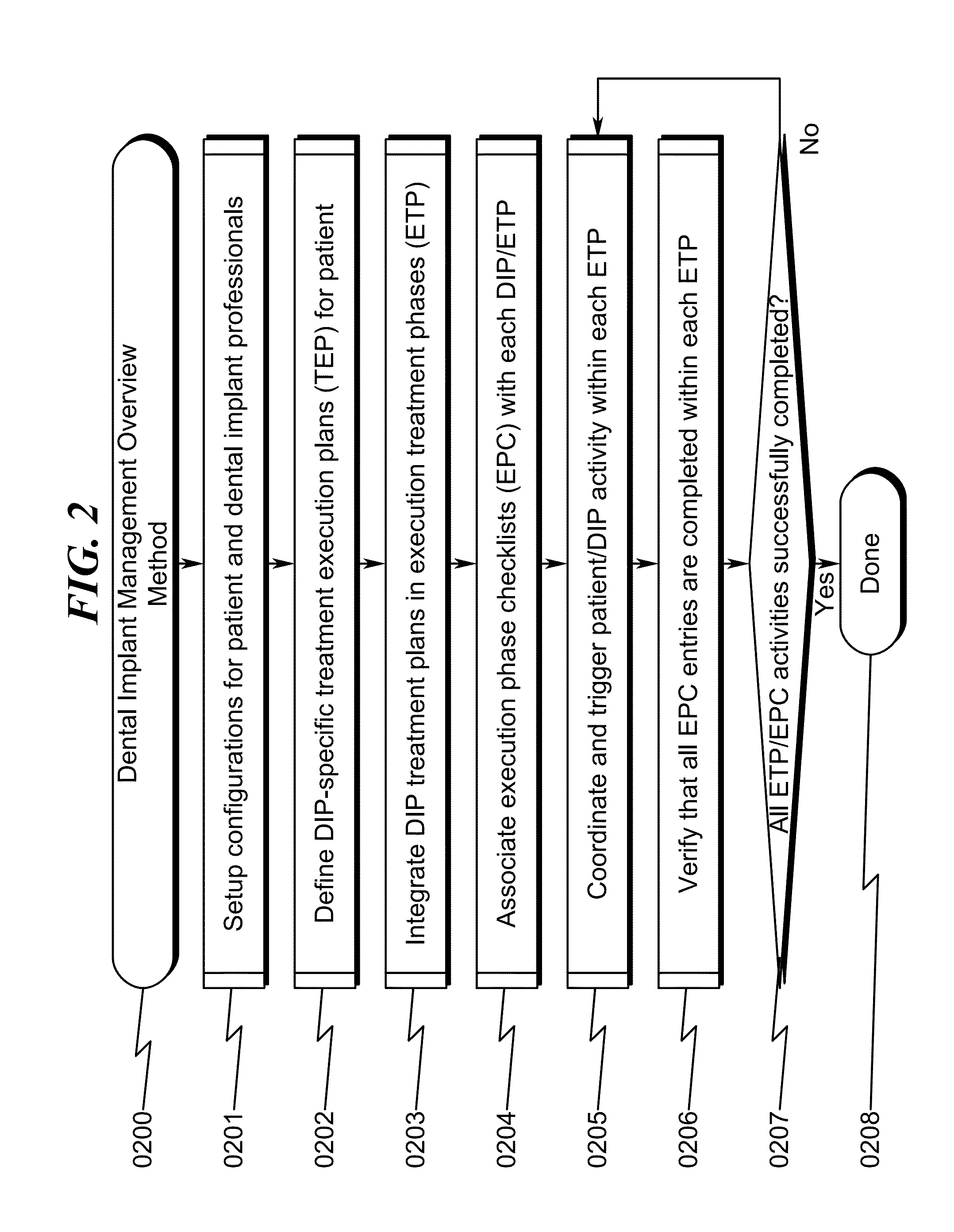

A dental implant management system / method that improves communication and coordination between parties associated with dental implant procedures is disclosed. The system / method operates to permit each dental implant professional (DIP) (typically a surgeon, restorative doctor, and dental laboratory) to iteratively generate a patient treatment execution plan (TEP) for the dental implant procedure that is generally structured within execution treatment phases (ETP) and automatically coordinated among each DIP. The ETP typically defines FOUNDATION, IMPLANT PLACEMENT, RESTORATIVE, and MAINTENANCE phases that may each incorporate custom execution phase checklists (EPC) that permit each DIP to ensure that critical elements of their TEP are properly executed. Coordination of the various DIP-generated TEPs is integrated with treatment planning / sequencing, patient scheduling, DIP fee estimation, and dental parts procurement to ensure maximum revenue to each DIP while simultaneously improving the probability of a successful dental implant procedure for the patient.

Owner:CENTGISTIX

Methods for making provisional and long-term dental crowns and bridges

The invention provides methods of making provisional and long-term dental restorations, particularly dental veneers, crowns and bridges. In one embodiment, the restoration can be fabricated indirectly by a dental laboratory. In another version, a dental practitioner can make the restoration chairside for a patient in a dental office. A polymerizable dental composite material, which is dimensionally shape-stable in its uncured state, is used to make the restoration. A substructure such as a metal coping can be used to support the polymerizable material. The material includes a polymerizable acrylic compound, polymerization initiator system capable of being activated by light or heat, and preferably a filler material. The resulting dental restoration has good aesthetics, mechanical strength, and margins and contacts.

Owner:SUN BENJAMIN JIEMIN +2

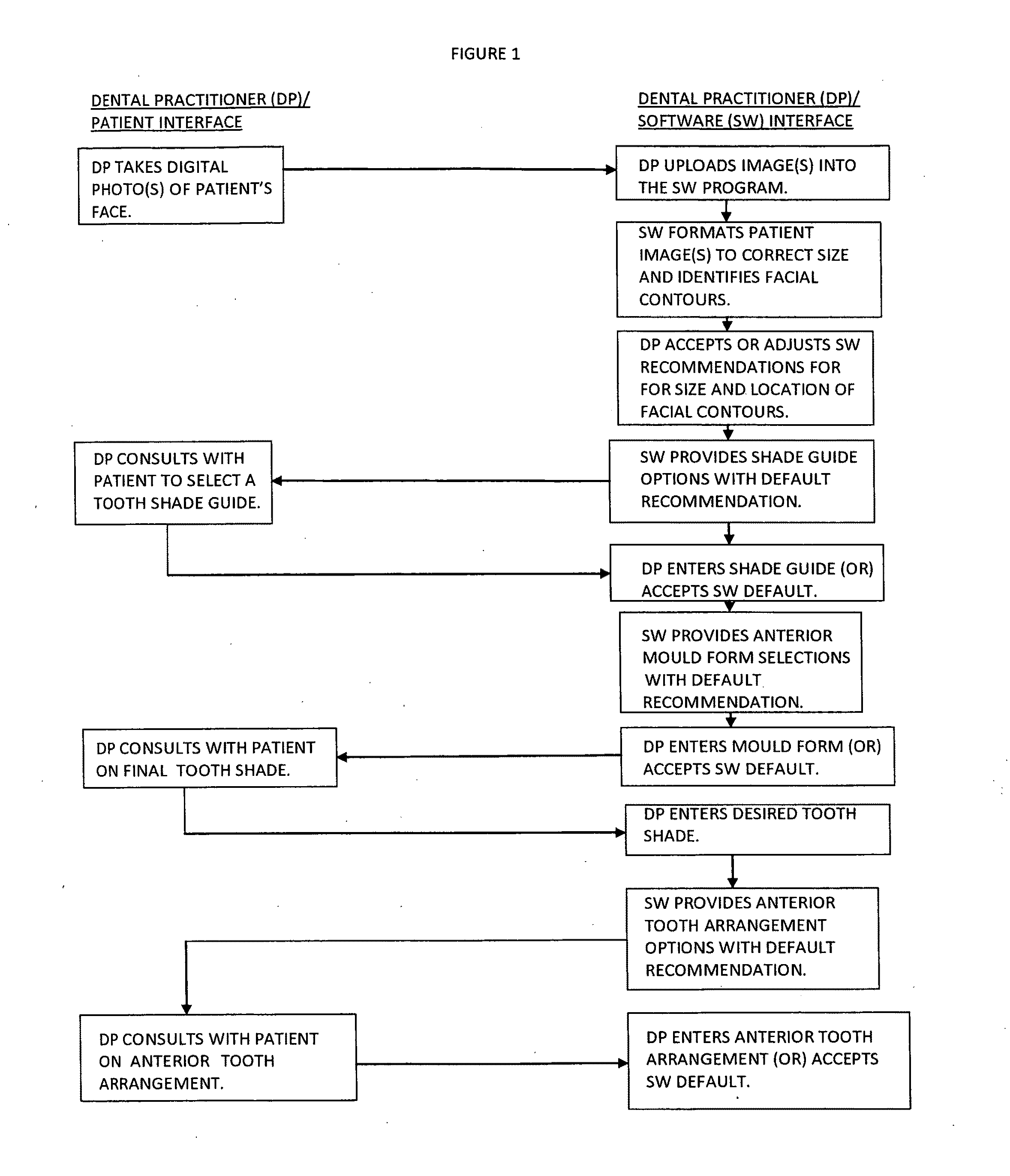

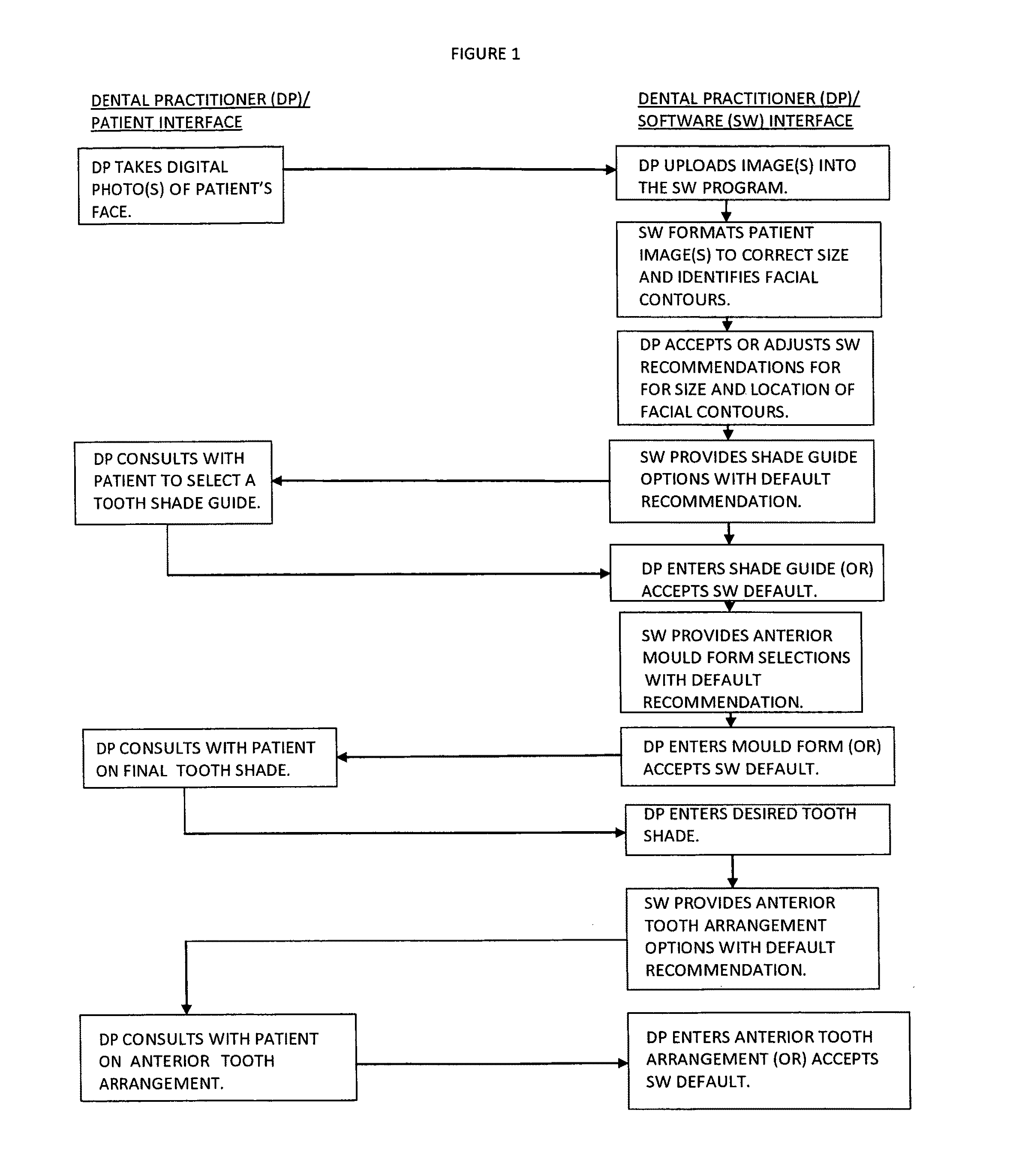

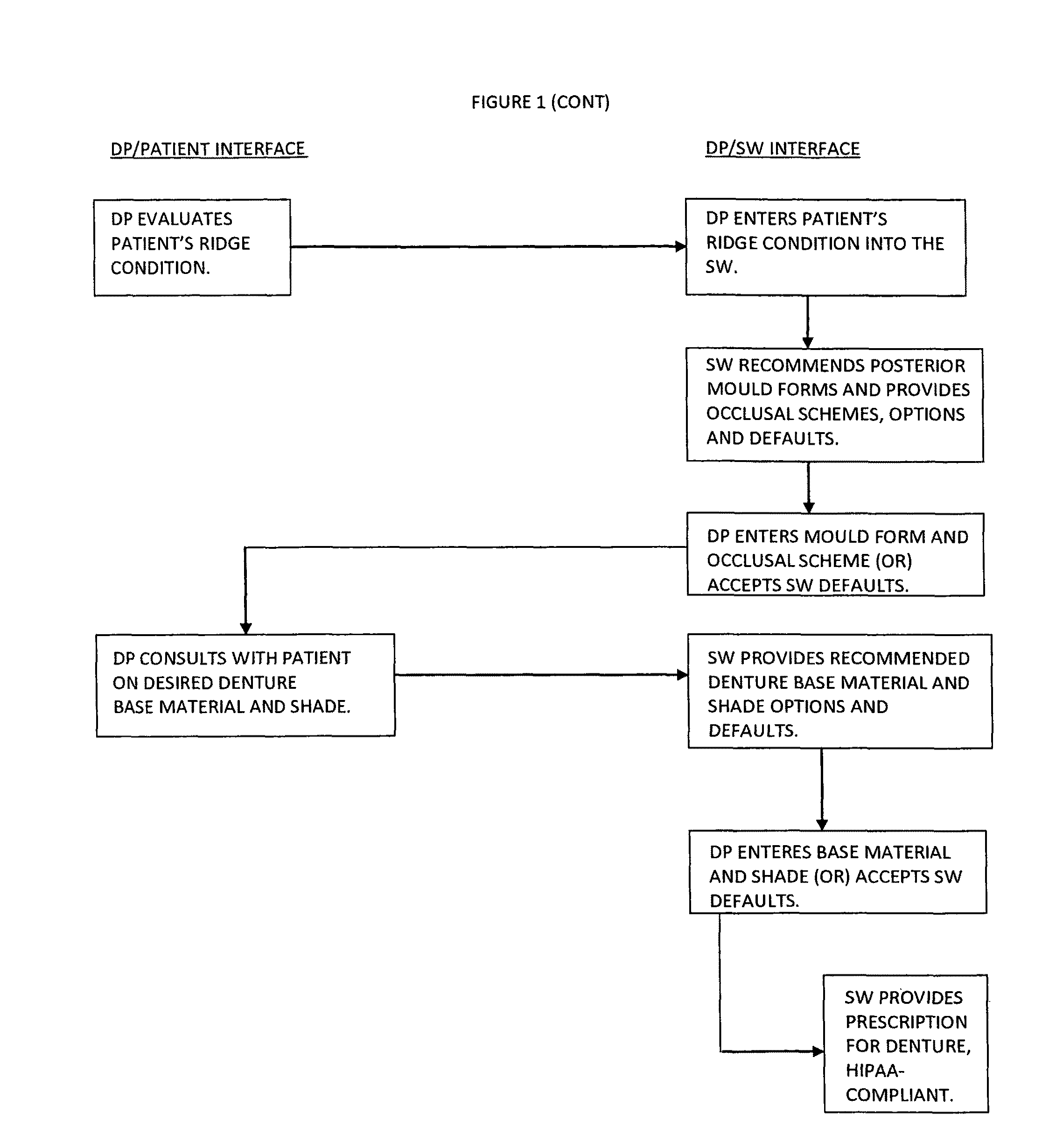

Methods for designing a customized dental prosthesis using digital images of a patient

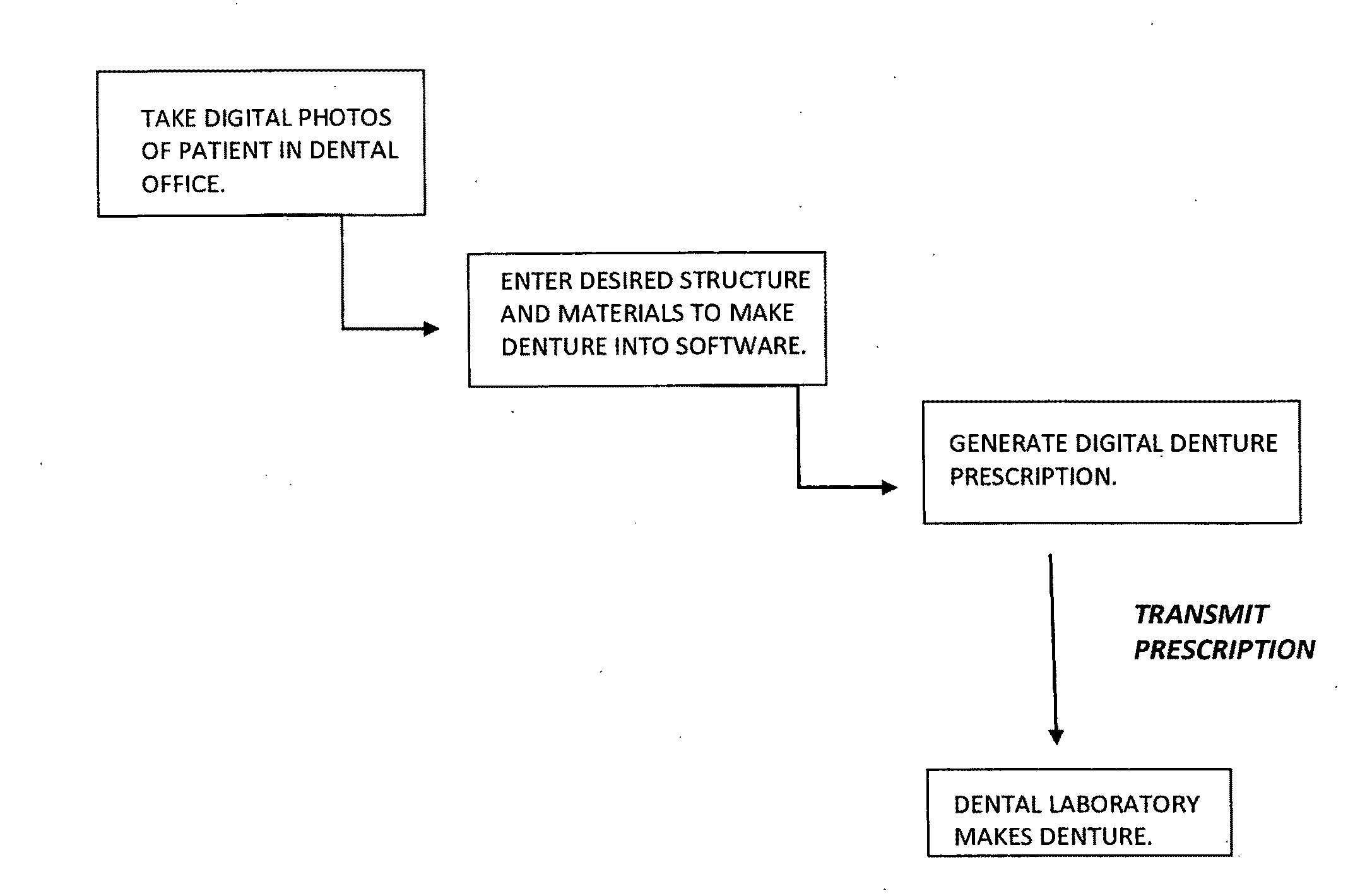

Methods and systems for producing customized dental restoration and prosthesis, particularly denture prescriptions using a computer software program are provided. In this system, digital photographs of the patient to be fitted with the denture are taken, and the photographs are transferred to the software program. Based on these photographs, the program makes certain calculations. The program then prompts the dental professional to select the desired materials and structure for the denture. Based on this input, the program automatically produces a prescription for the denture. The digital prescription is sent to a dental laboratory for making the denture.

Owner:DENTSPLY SIRONA INC

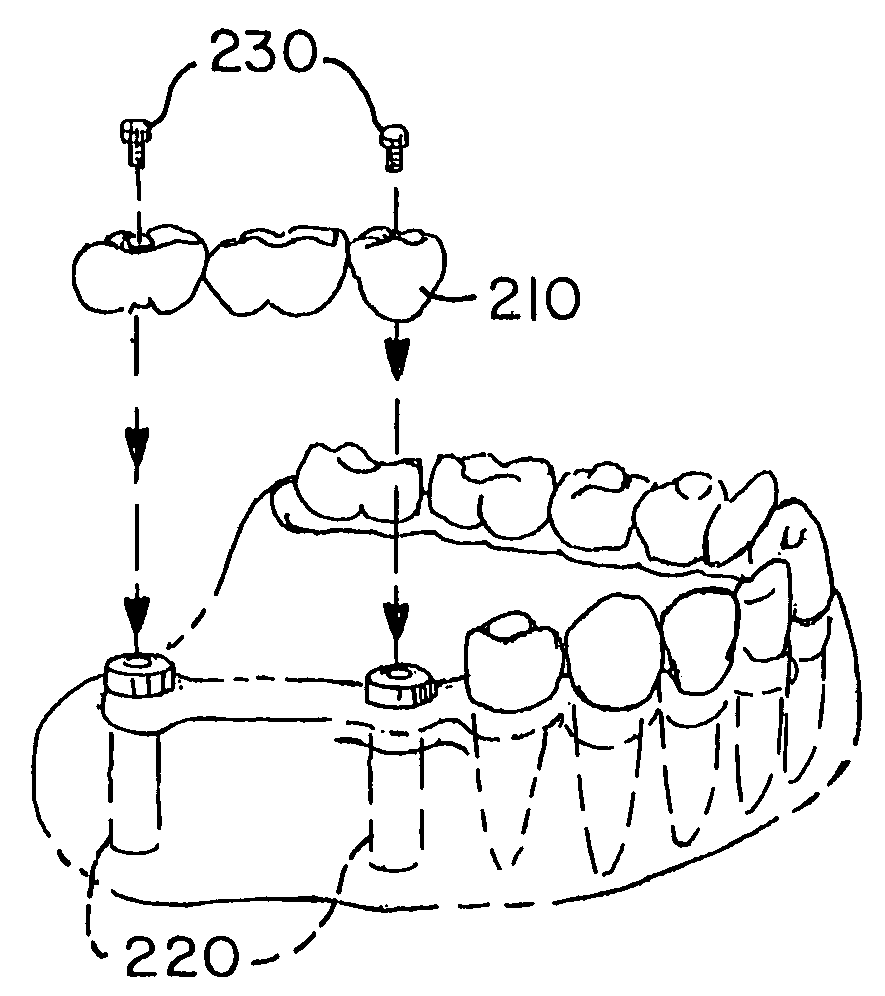

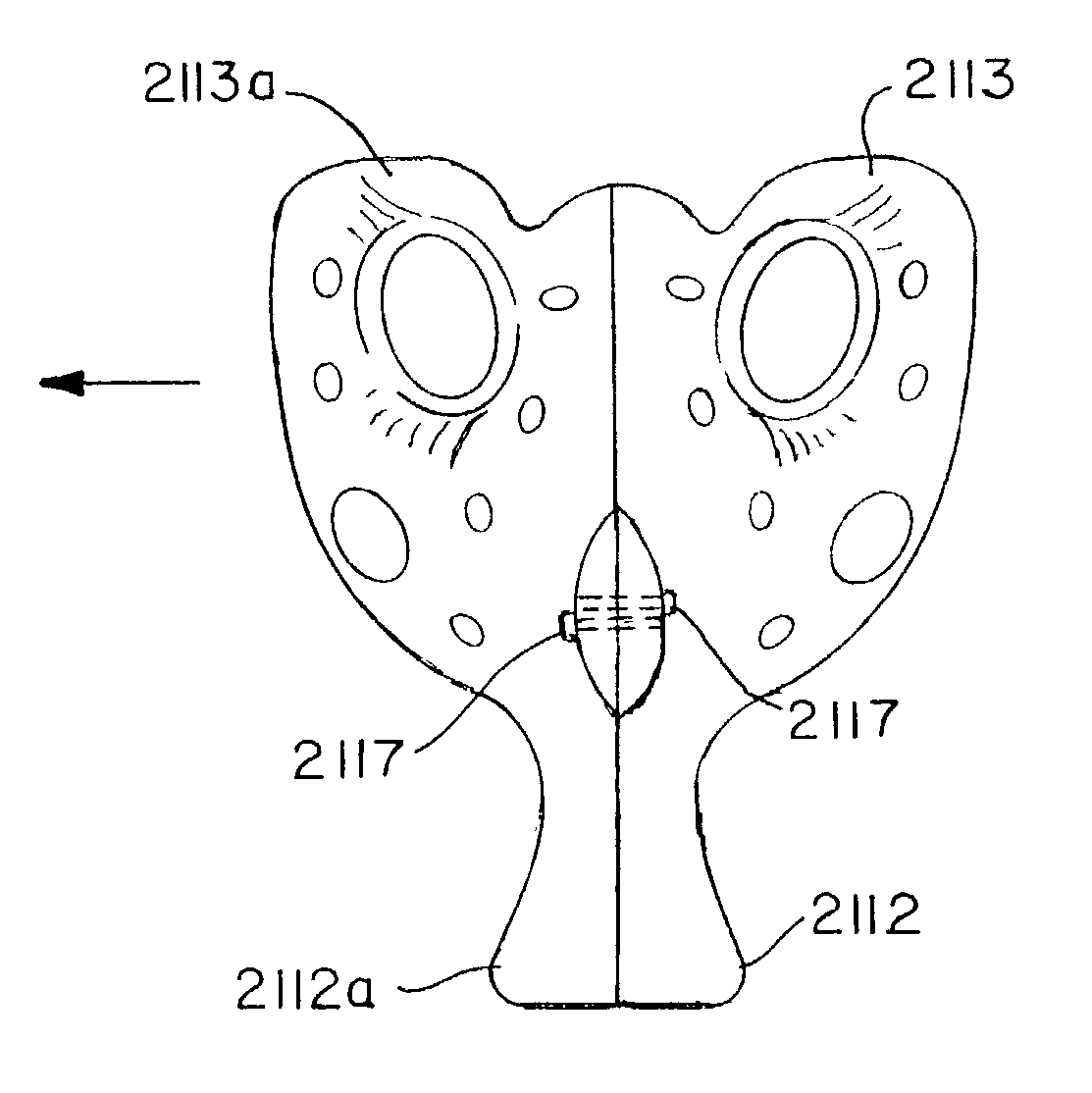

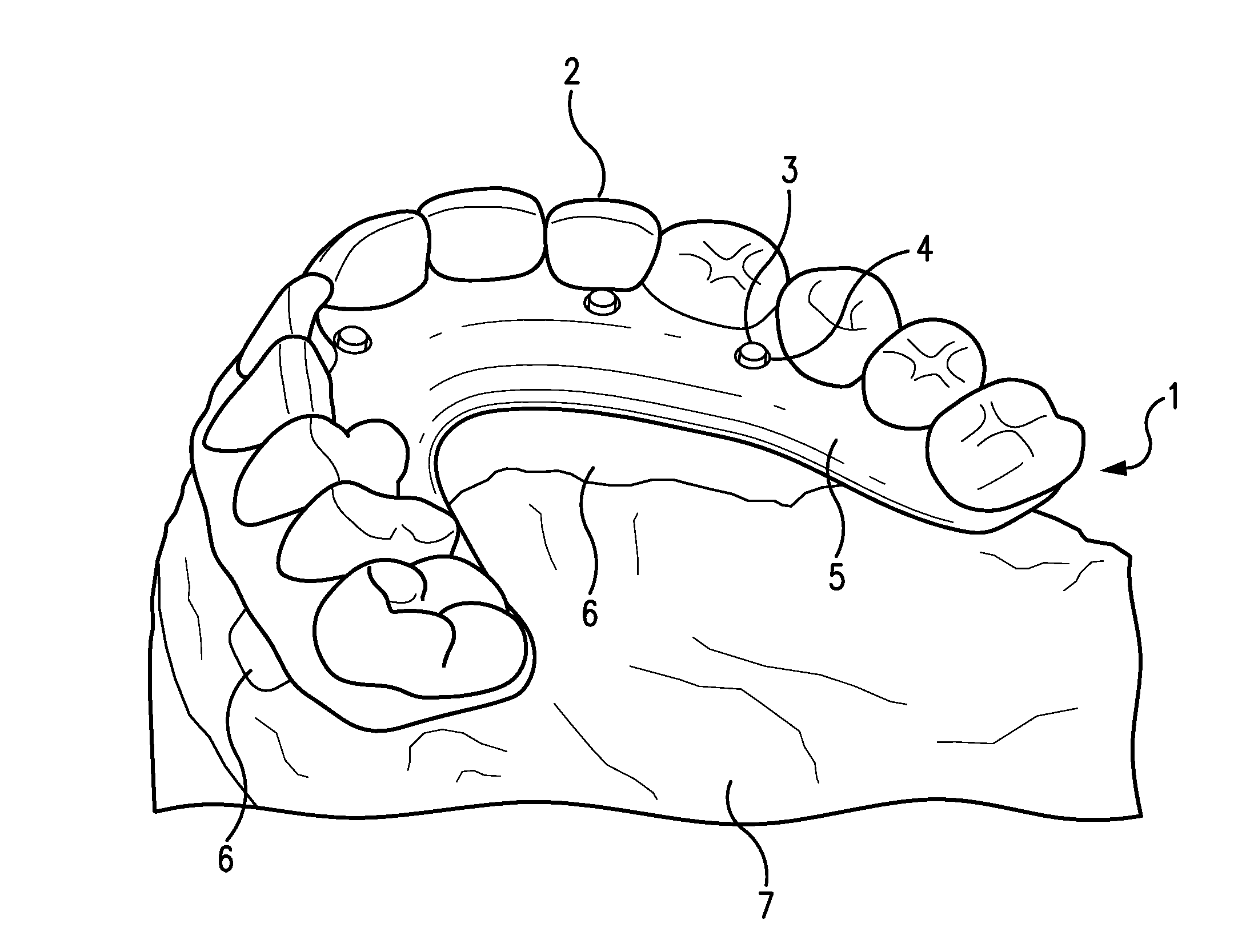

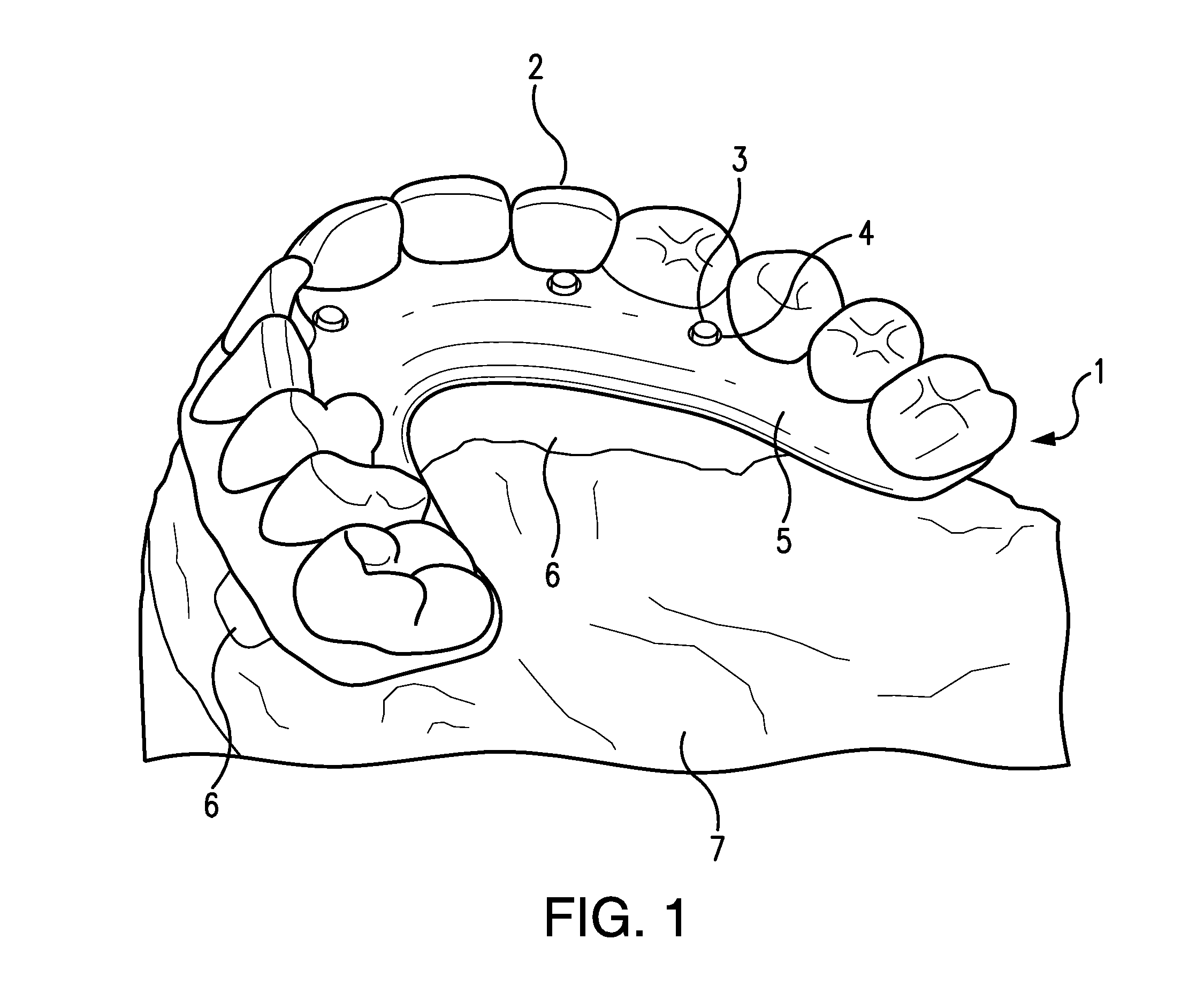

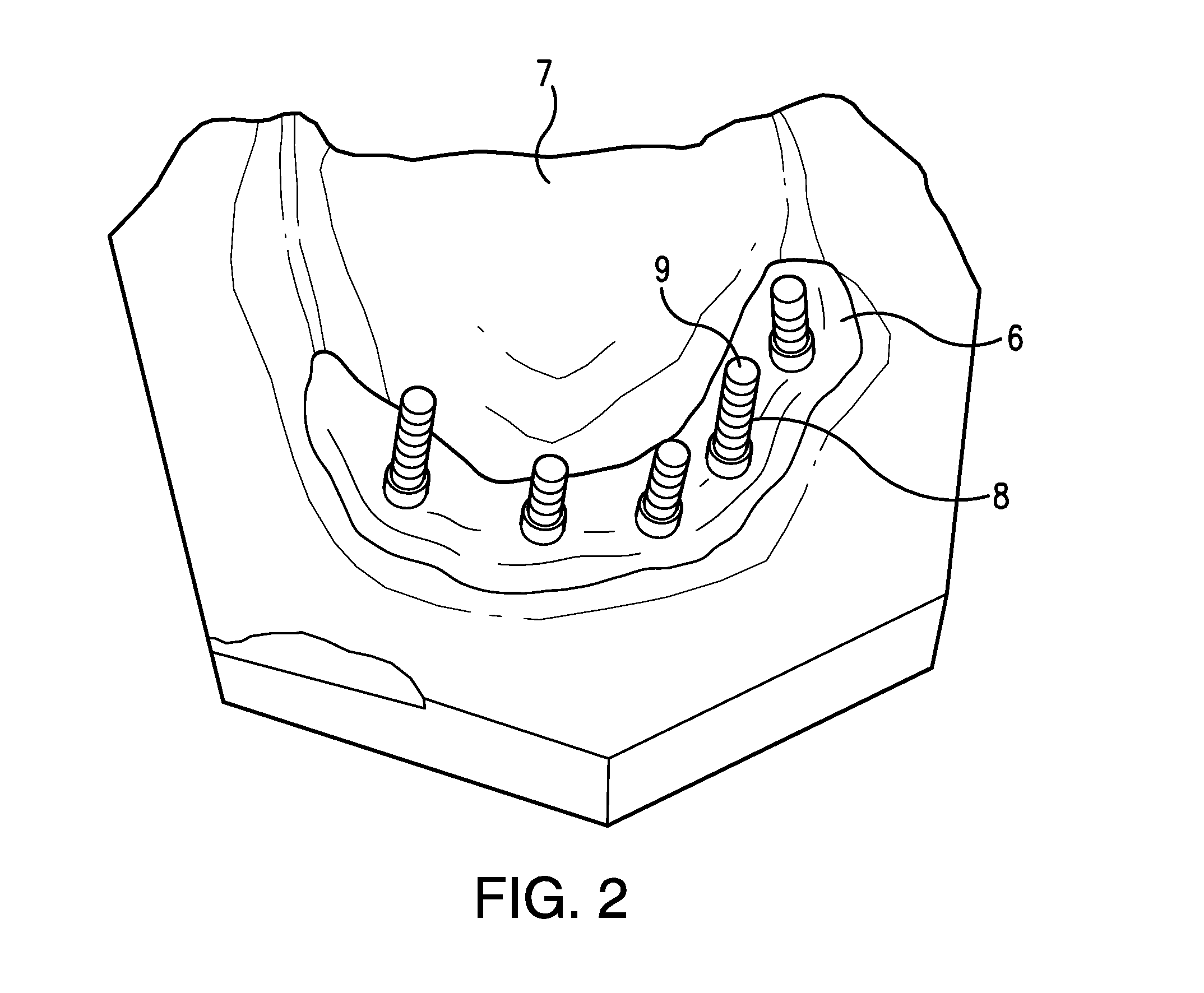

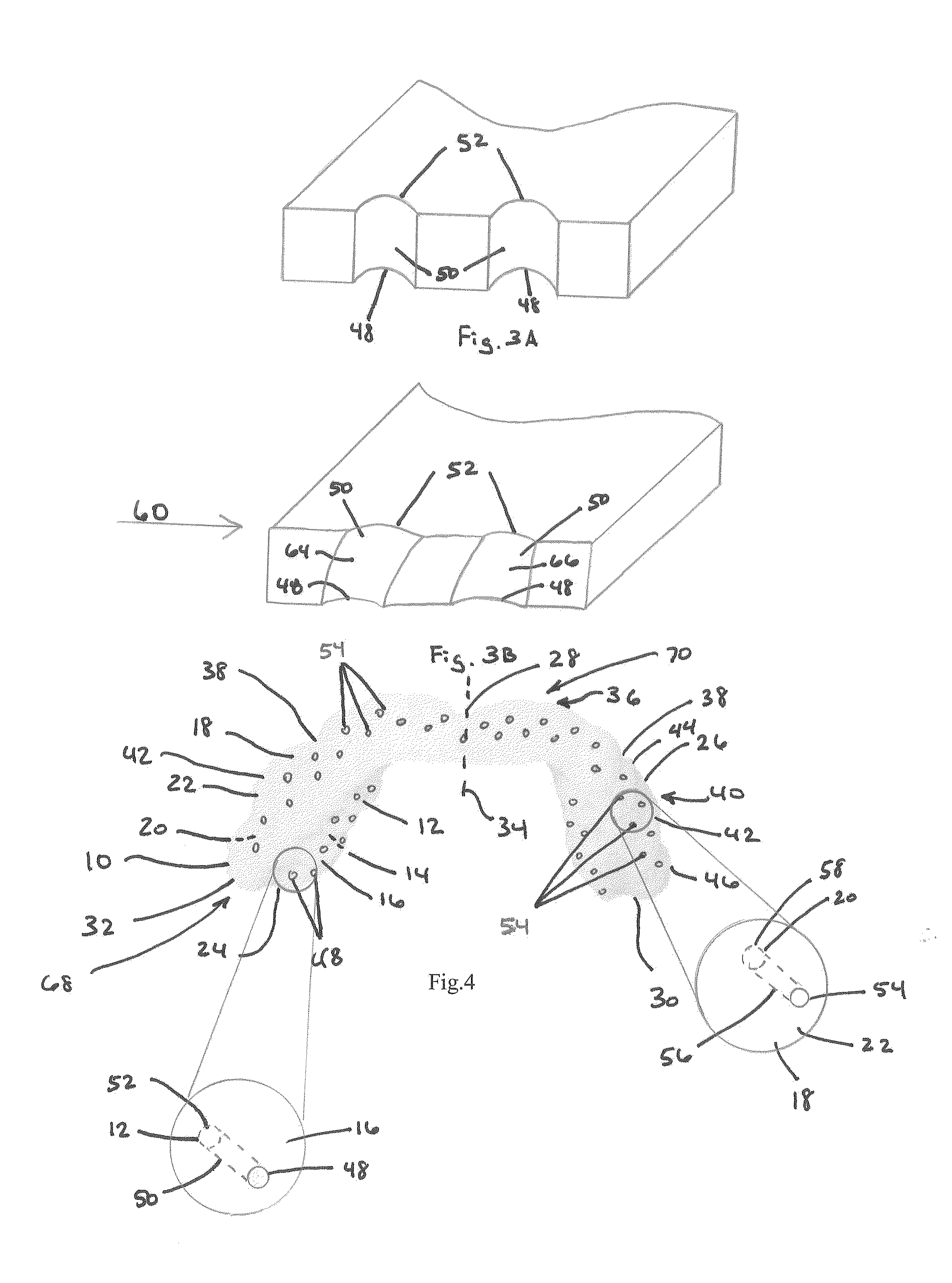

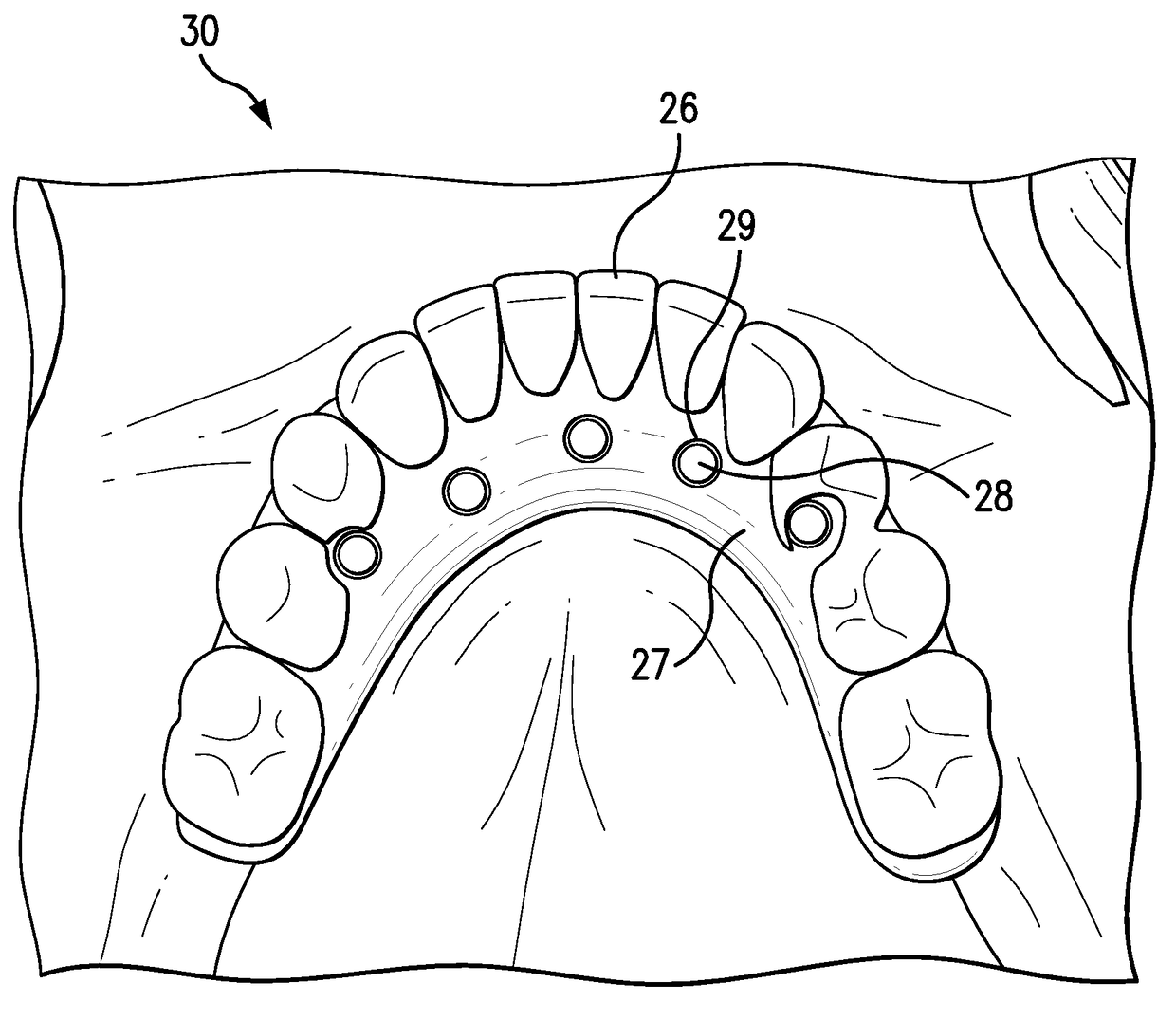

Stable dental analog systems

A stable dental prosthesis system includes transparent guides with radio opaque markers therein to accurately position an implant in a jaw. To make the prosthesis for the implant, an implant analog is used with an abutment that can be mounted in the dental lab replica of the relevant section of a patient's mouth securely. The analogs have a pin or other protrusion that projects from the base of the analog. The system also includes a perforated tray for accommodating protruding implant impression copings therethrough when the impression mold is made of the dental patient's mouth. A generally flat articulation wafer connects one impression of one jaw to an opposing wax impression of an opposite jaw, so that upper and lower prosthesis are in positional register. A flexible frame may also be provided for temporary teeth before osseointegration of the implant with the jaw bone.

Owner:MAROTTA LEONARD

Interactive dental restorative network

InactiveUS20050003329A1Save effortShorten the timeOptical radiation measurementTeeth fillingInitial treatmentDental laboratory

The invention relates to a computer readable medium that includes one or more programs for carrying out a method for restoration of a patient's tooth. The method includes the steps of generating an electronic image of a patient's tooth; providing a preliminary treatment plan for addressing the dental needs of the patient; and forwarding the electronic image and preliminary treatment plan to a dental laboratory so that technician can evaluate the image and treatment plan and in a manner such that the technician and dentist can review and discuss the preliminary treatment plan.

Owner:LEHMANN MARYANN

Apparatuses and methods for making a final hybrid prosthesis to be attached to dental implants

ActiveUS20140272797A1Short timeLess dental laboratory timeDental implantsImpression capsProsthesisDental laboratory

The present invention includes apparatuses and methods for making a final hybrid prosthesis to be attached to one or more dental implants. One preferred method includes the step of making a temporary hybrid prosthesis and at about the same time also making a duplicate temporary hybrid prosthesis. The duplicate temporary hybrid prosthesis permits the final hybrid prosthesis to be made with fewer visits to a restorative dentist and with less dental laboratory time than is currently needed when making a final hybrid prosthesis.

Owner:PRESTIPINO ANTHONY

Method and apparatus for producing a dental product

InactiveUS6968247B2High rate of acceptanceHigh rateNuclear monitoringDigital computer detailsControl dataDental Product

A stock removal workshop for the production of a dental restoration product includes a stock removal machine operable to remove stock material from a blank such that there remains a dental product having the desired geometry requisitioned by a dental practice or a dental laboratory. A stock removal plotter controls the stock removal machine operation and converts requisition data received from the dental practice or the dental laboratory which characterizes a virtual model of the requisitioned dental product into control data for controlling the stock removal machine operation. A geometry following assembly characterizes the geometry of the produced dental product via a geometry following operation and a comparison device compares the geometry characterizing data relating to the produced dental product with the requisition data to determine deviations therebetween.

Owner:IVOCLAR VIVADENT AG

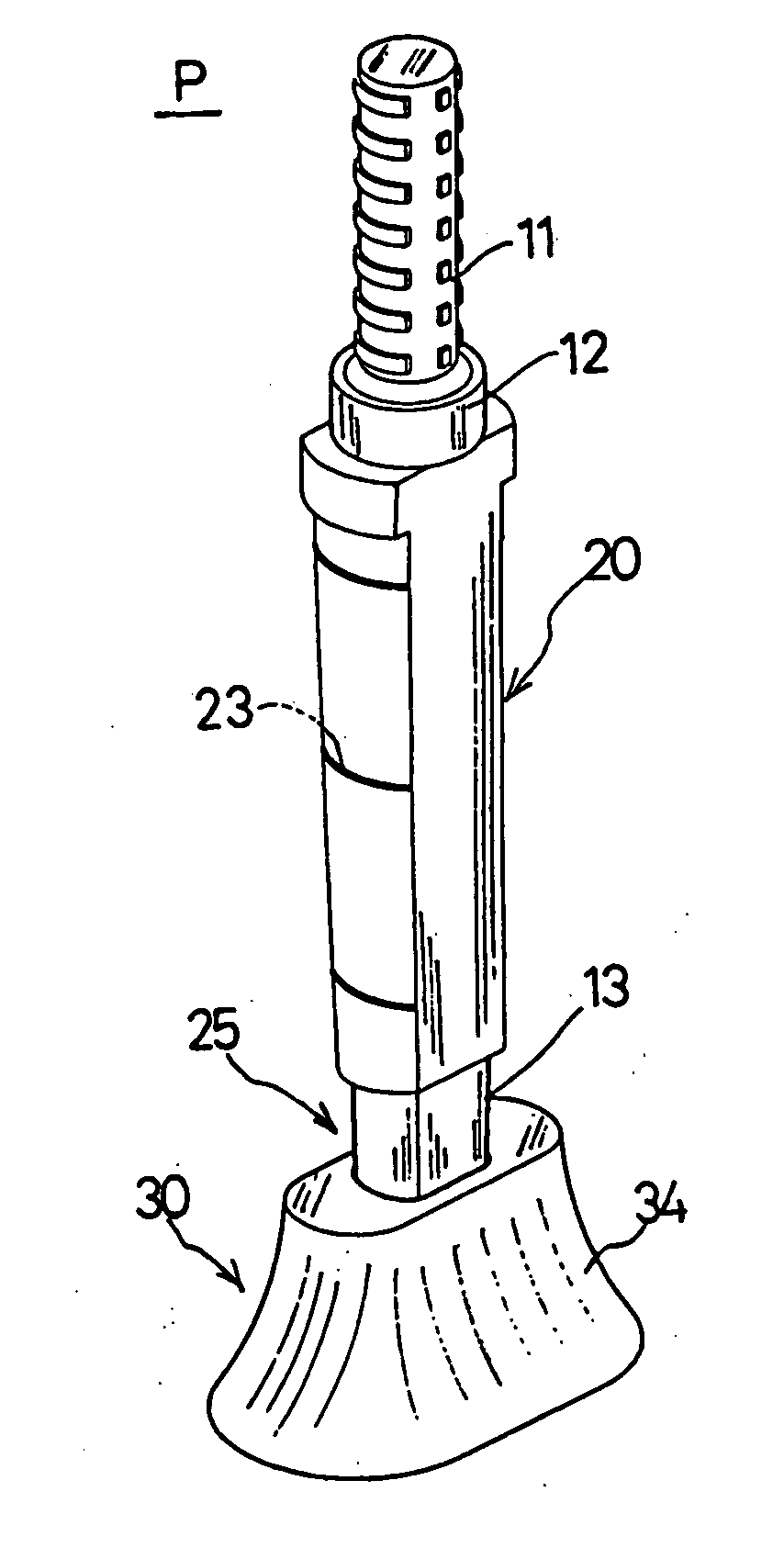

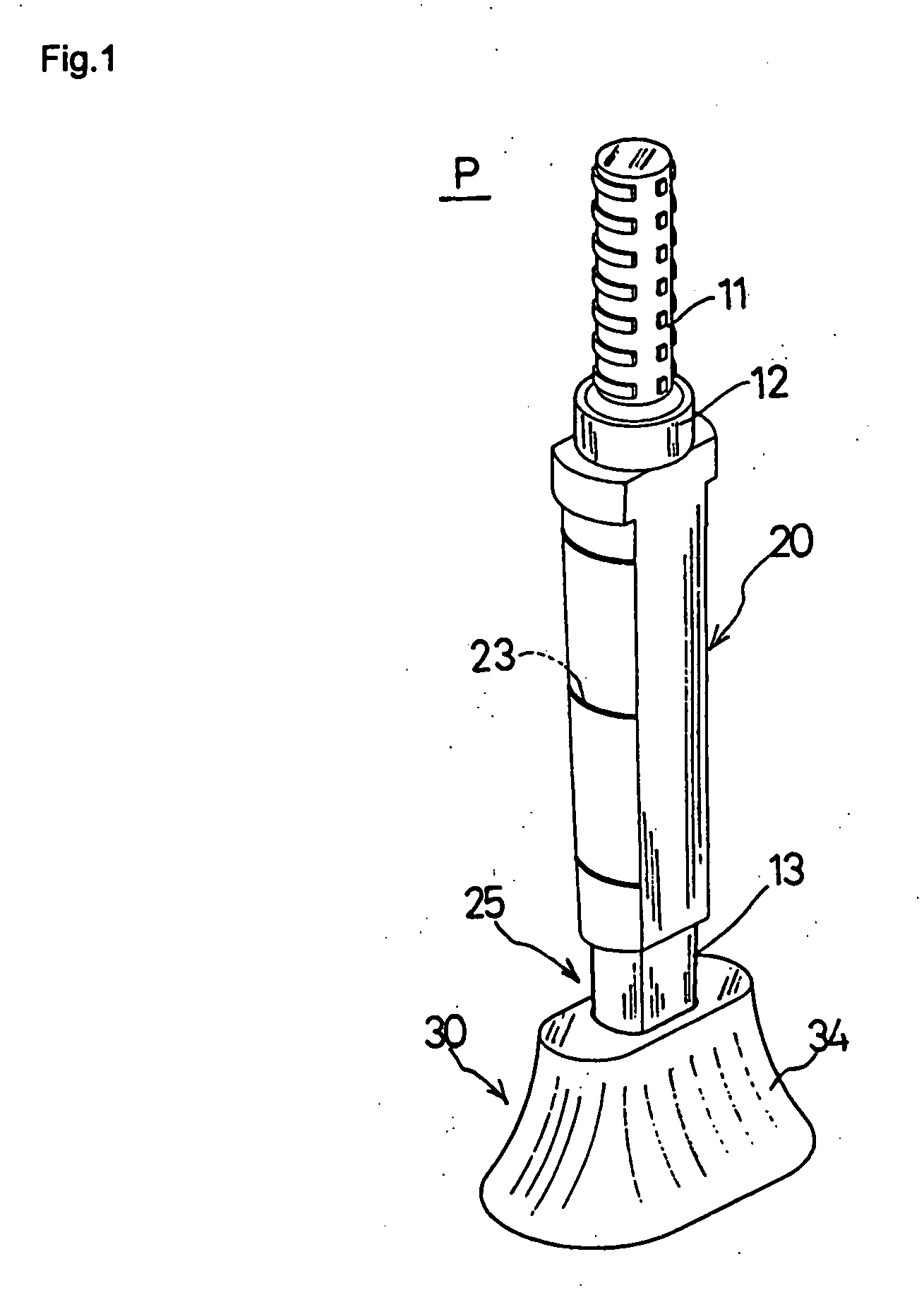

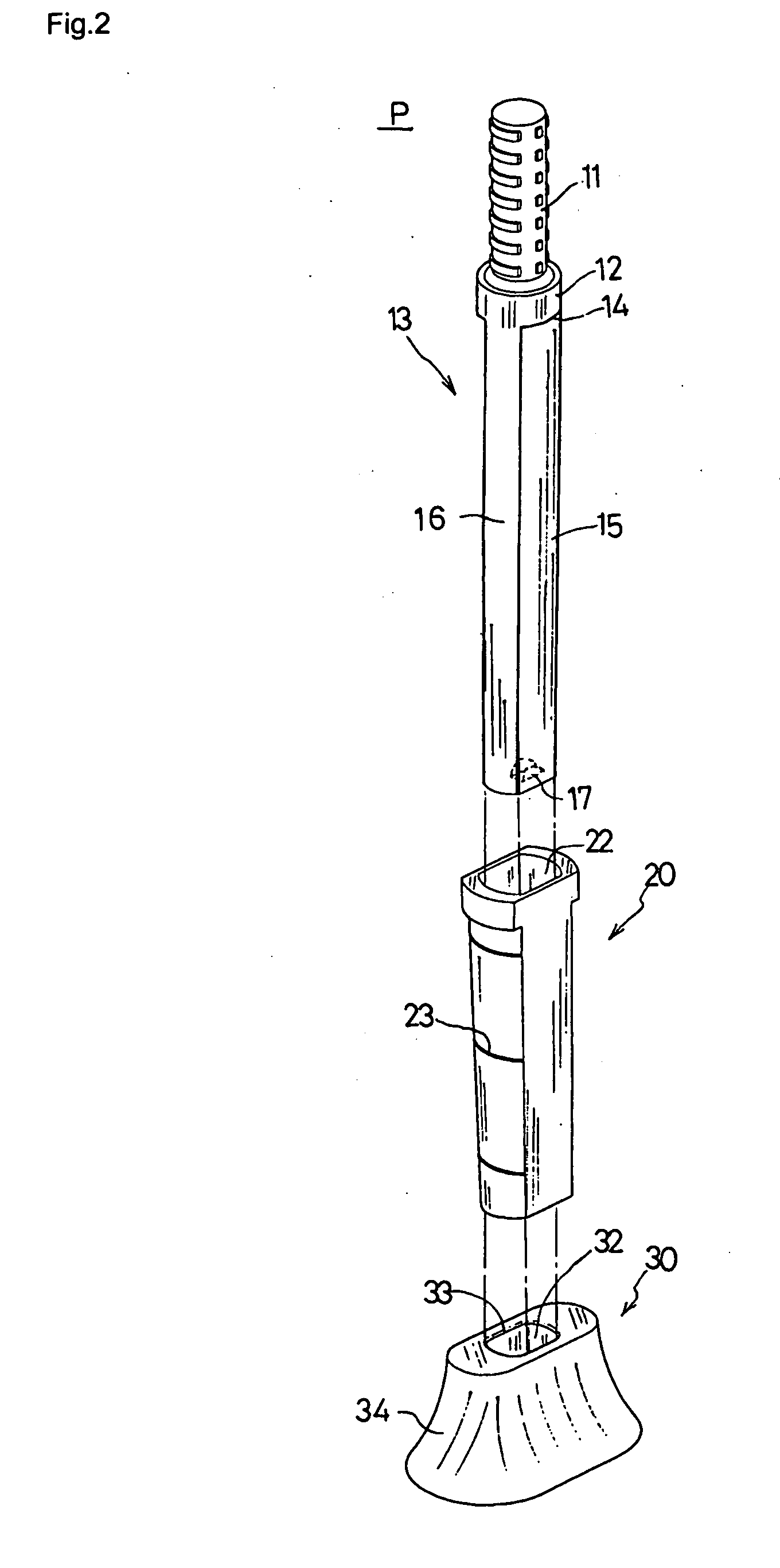

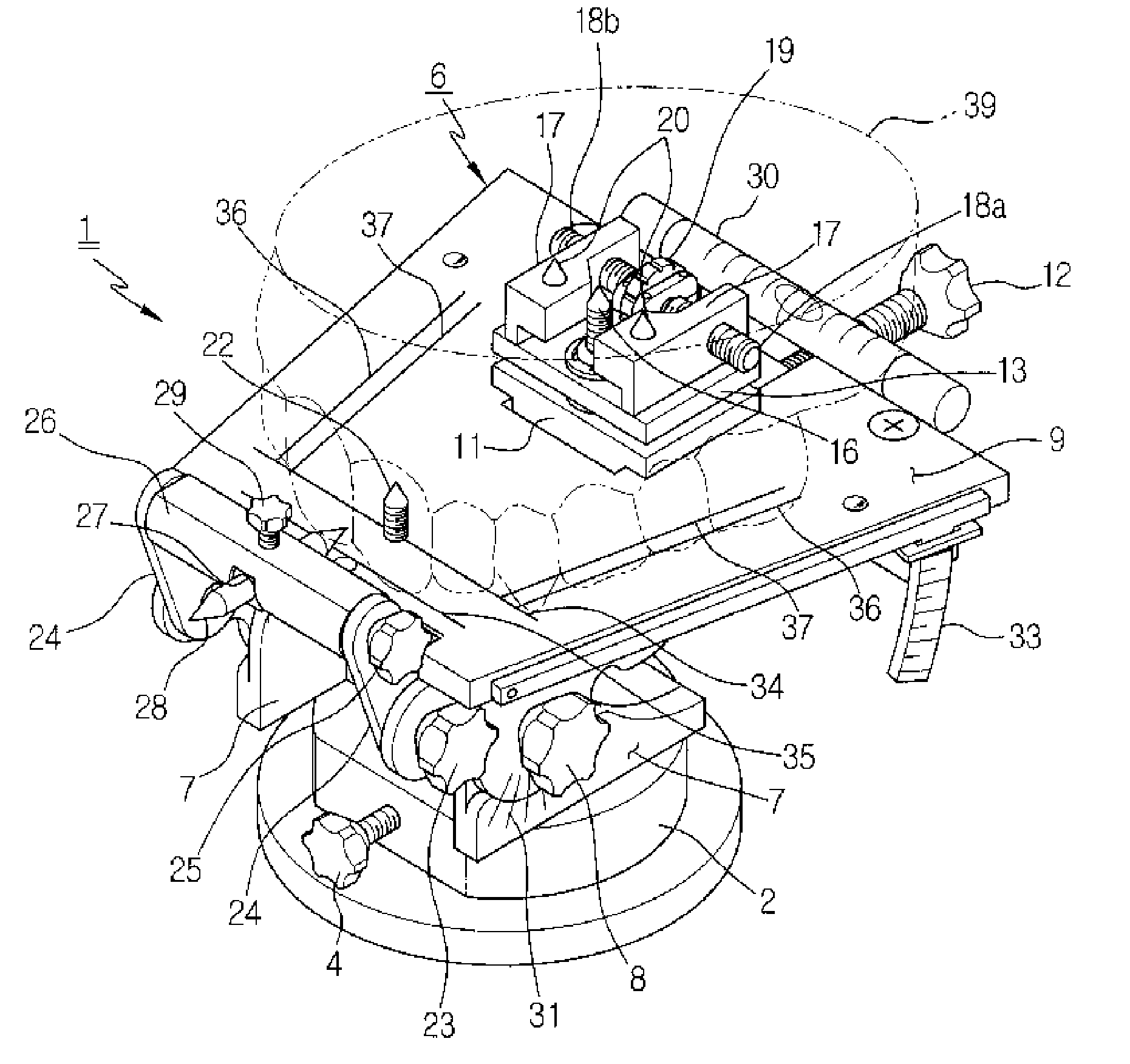

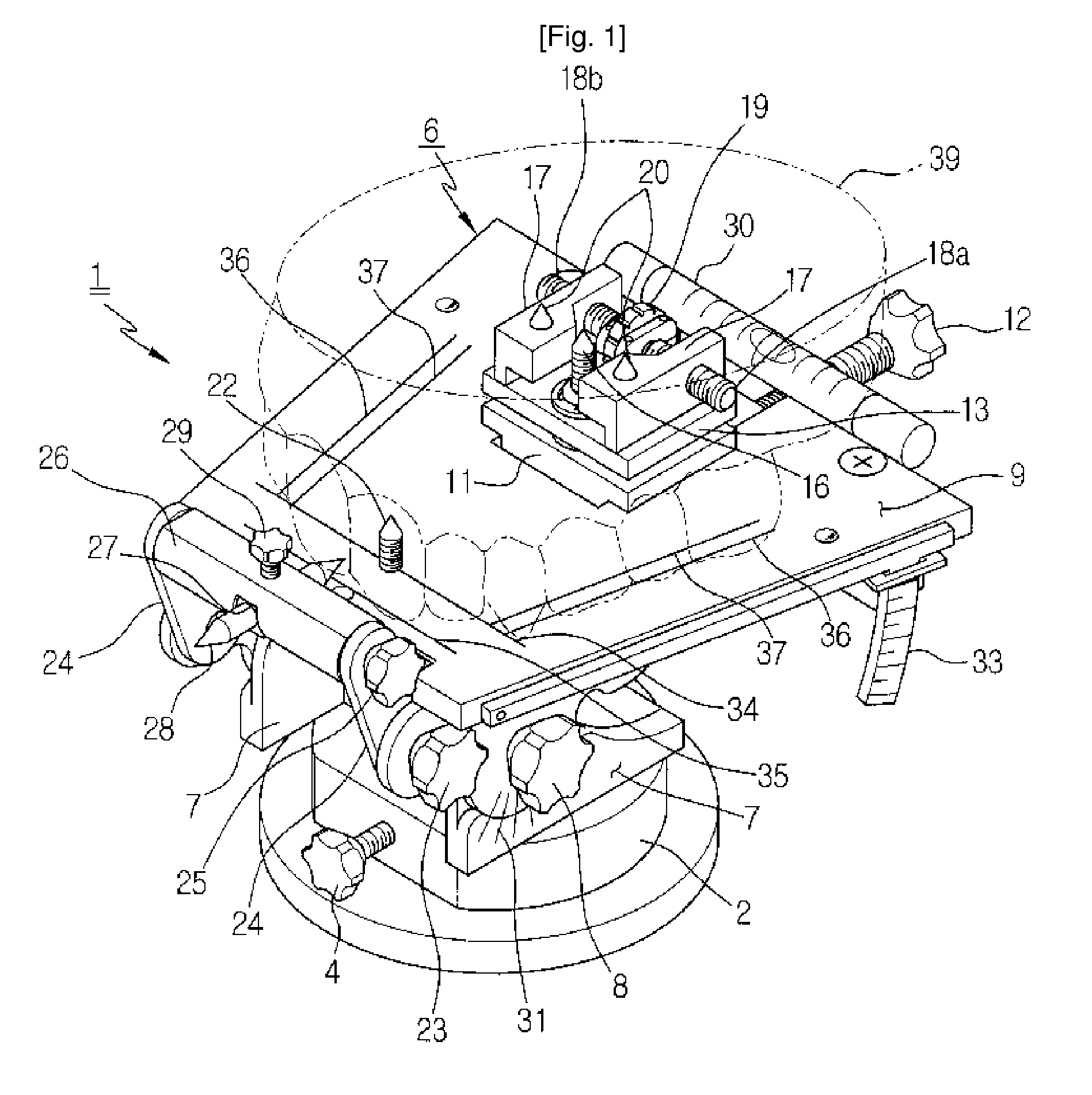

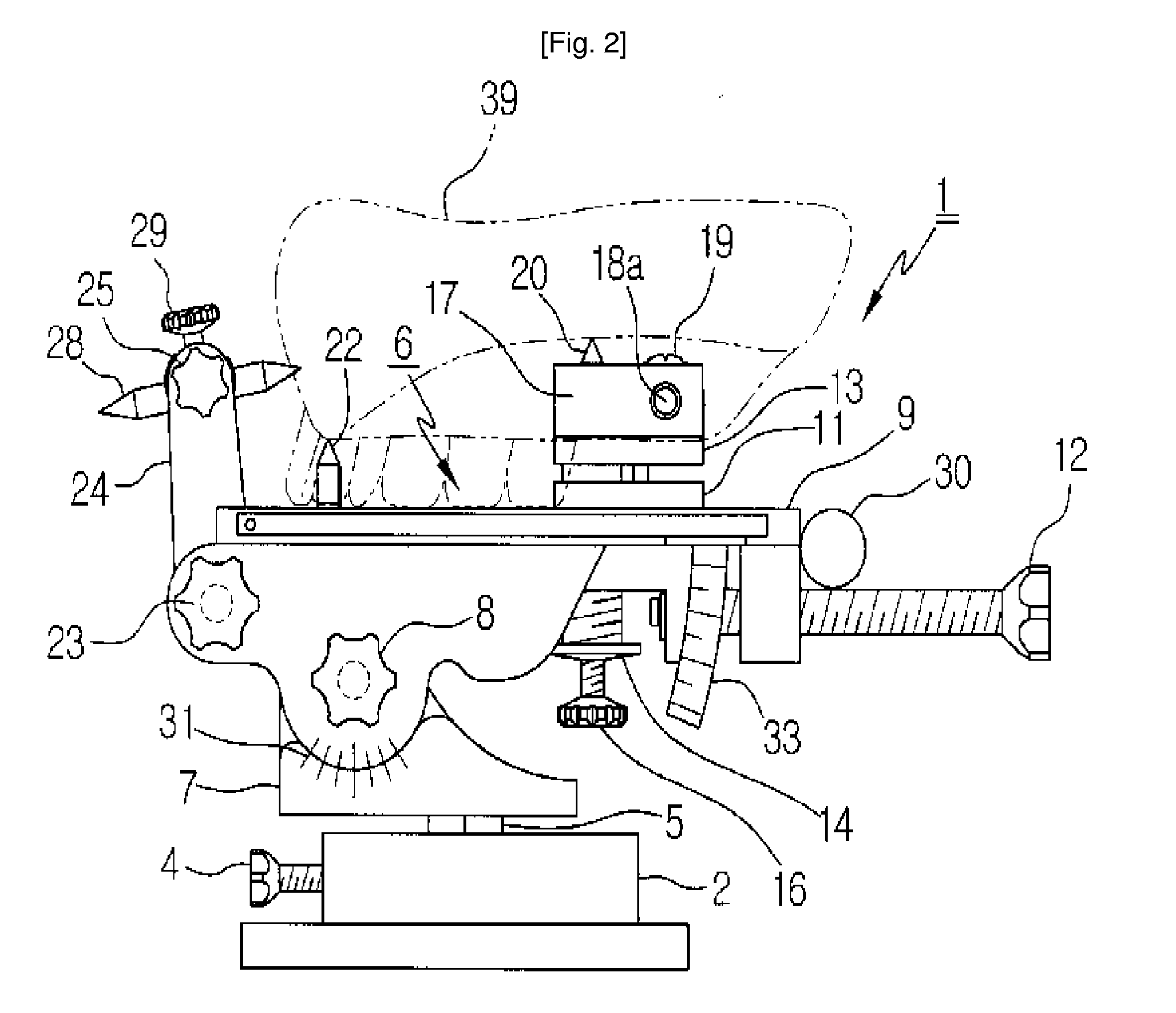

Pin for fixing dental model

InactiveUS20050233278A1Increase workflowIncrease productivityImpression capsDental ArticulatorsAdhesive

Provided is a dowel pin for fixing a dental model with a cap to be used to connect a dental model die with the dental model during the formation of a model of patient's teeth in a dental hospital or a dental laboratory. The dowel pin for fixing a dental model includes a top fixing portion having a knurling formed along an outer circumference such that it is inserted into the bottom of the dental model to a predetermined depth and firmly fixed by an adhesive, and a body formed at a lower portion of the top fixing portion by a predetermined length so that it is inserted or fitted into a pin hole of an articulator or a die on which the dental model is seated, the body having a stopper at its top portion, the stopper having a sectional area larger than that of the top fixing portion and contacting the bottom of the dental model, wherein a body cap having a plurality of separation barriers formed on an outer surface is fitted into the lower portion of the body having the stopper formed thereat, so that the body cap is firmly attached to a hardened dental model die after being embedded therein, and an end cap spaced a predetermined distance apart from the body cap is fitted to a distal end of the body in such a way as to expose a portion of the body.

Owner:KIM YUNSOON

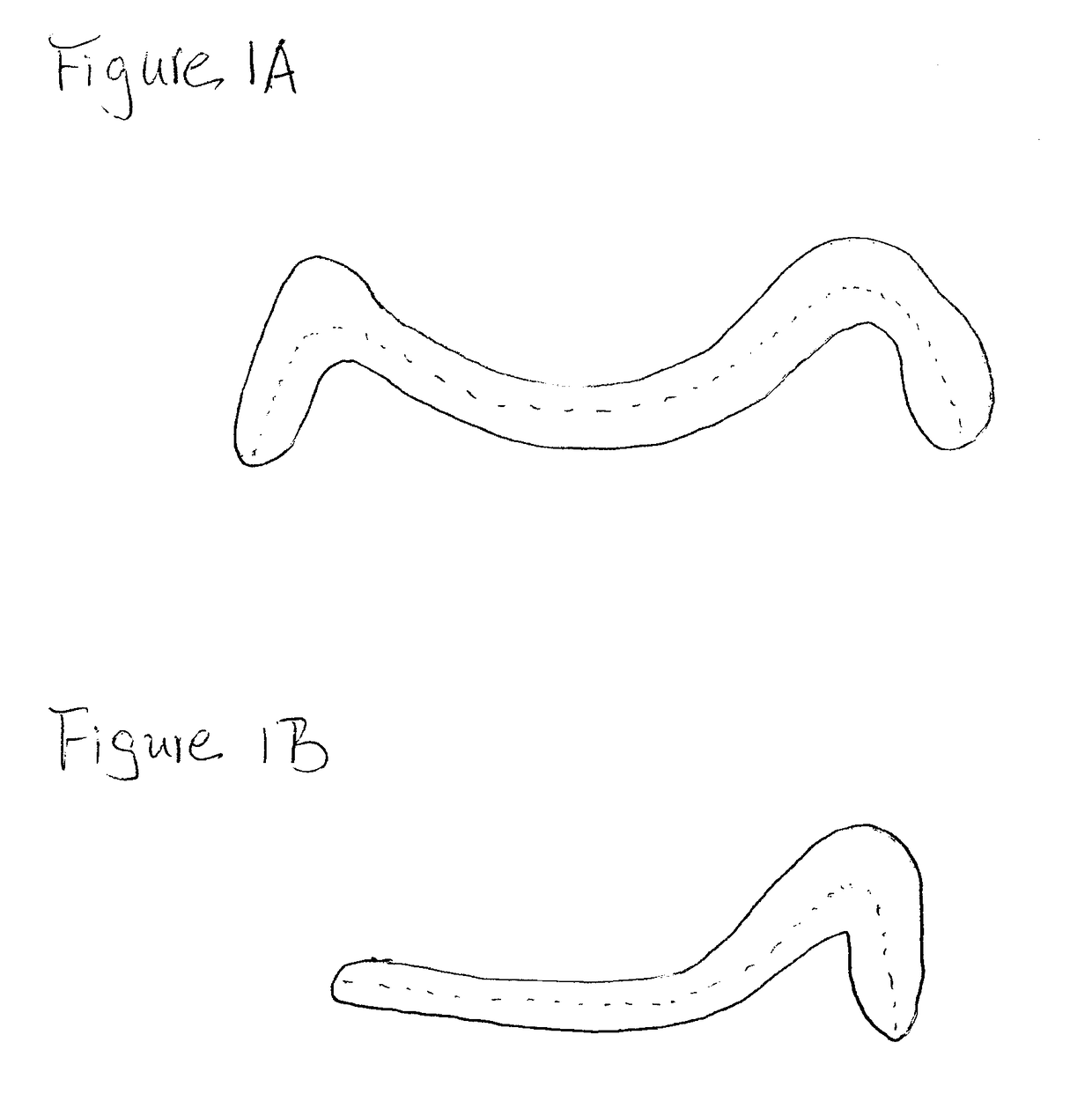

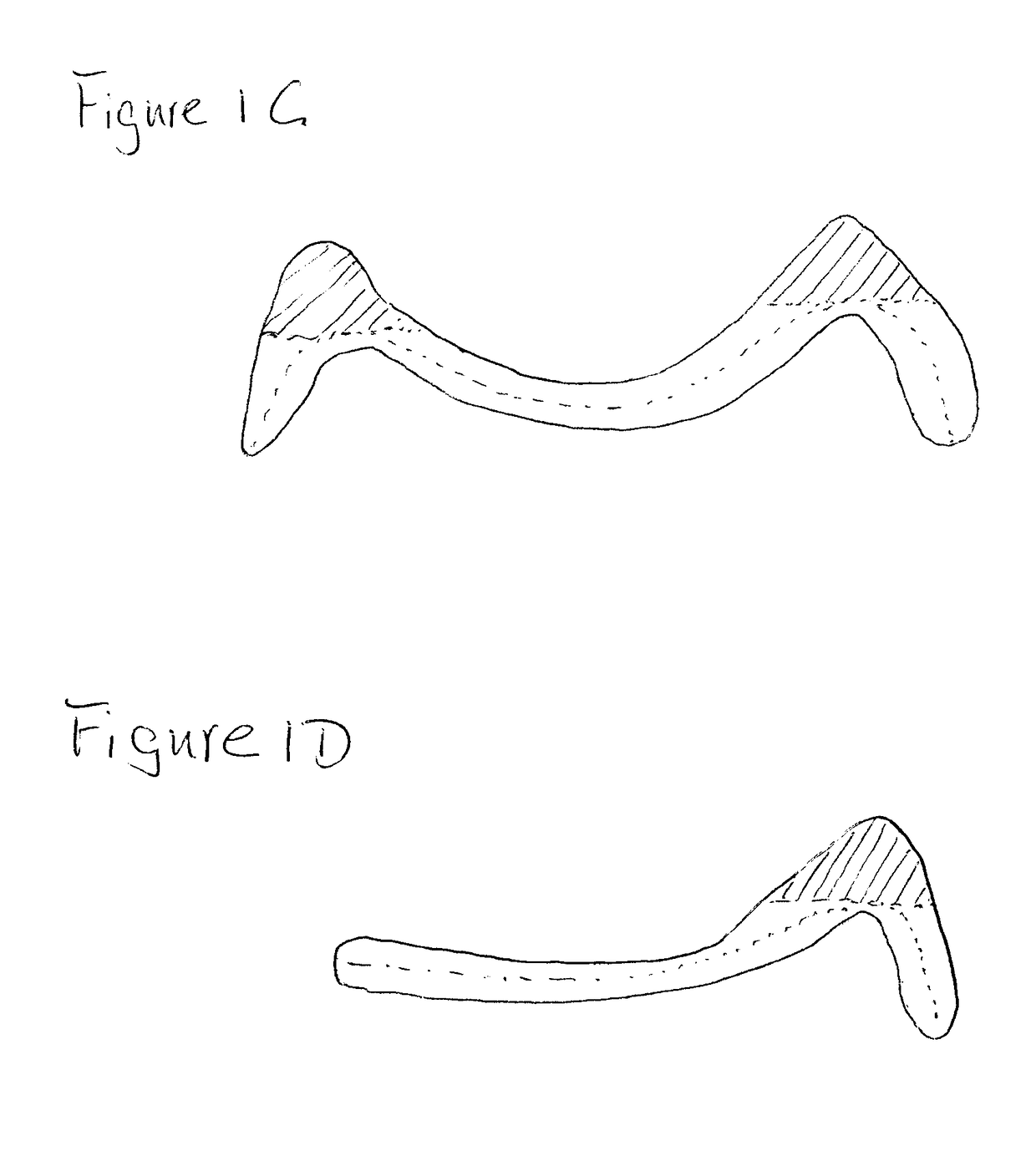

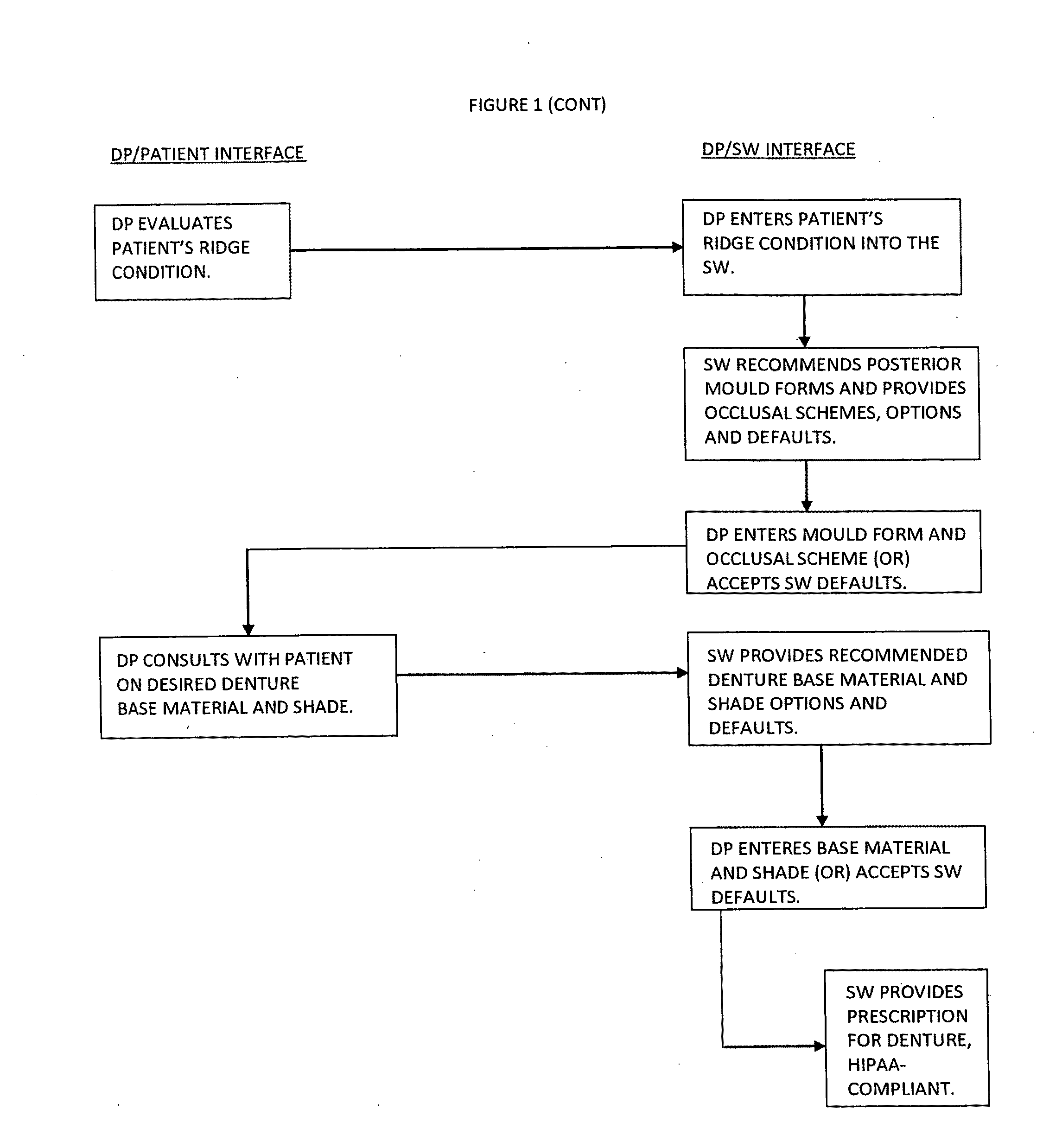

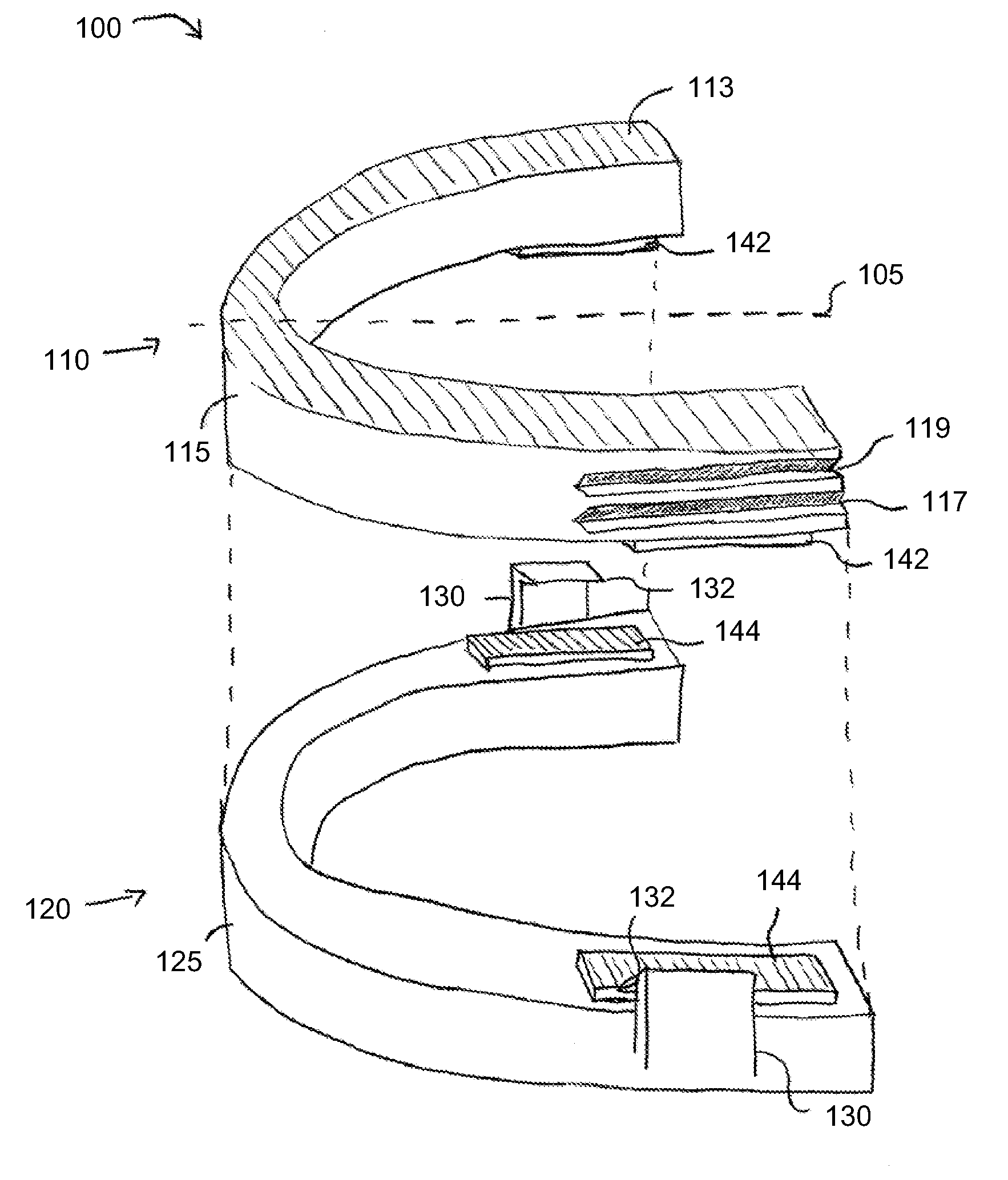

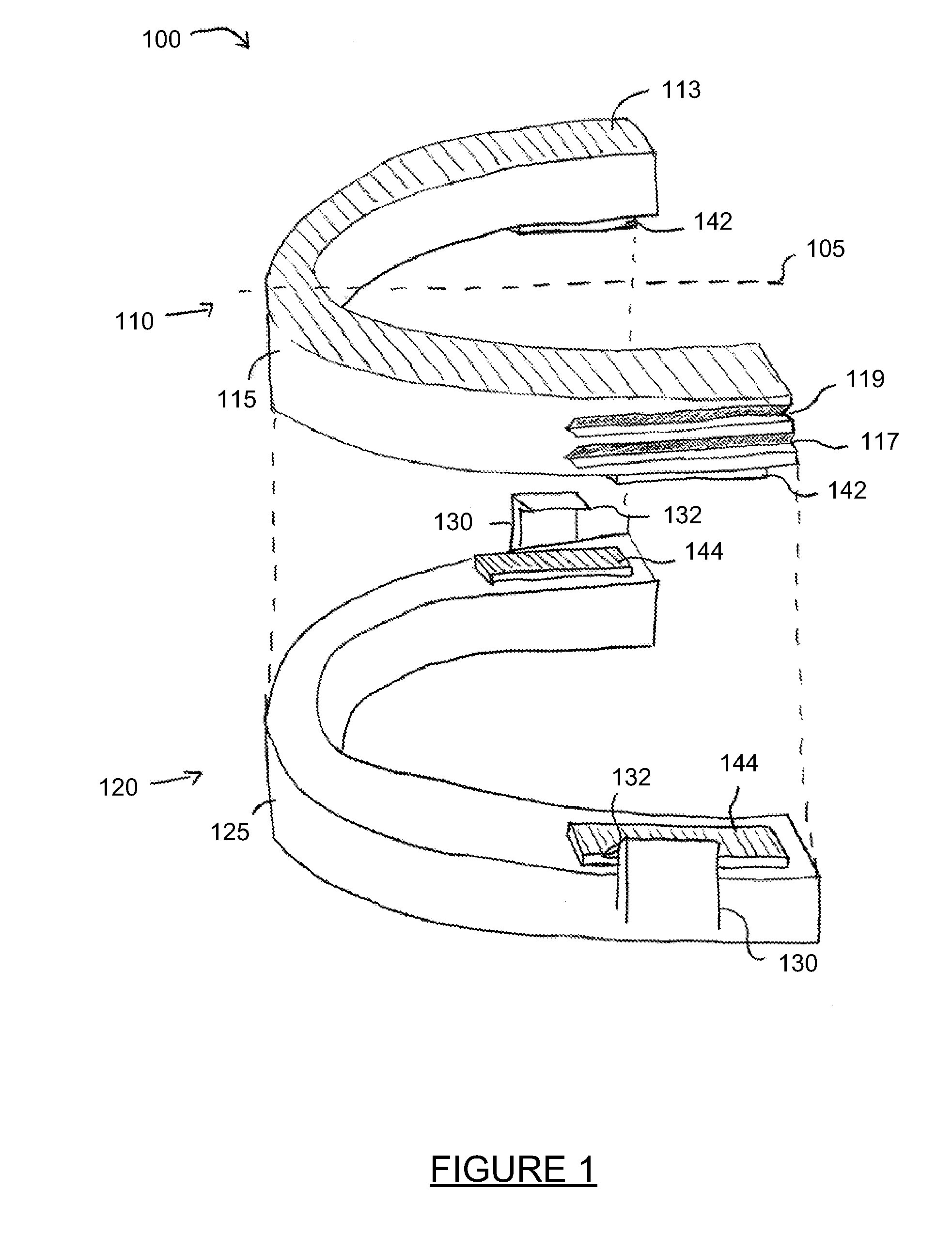

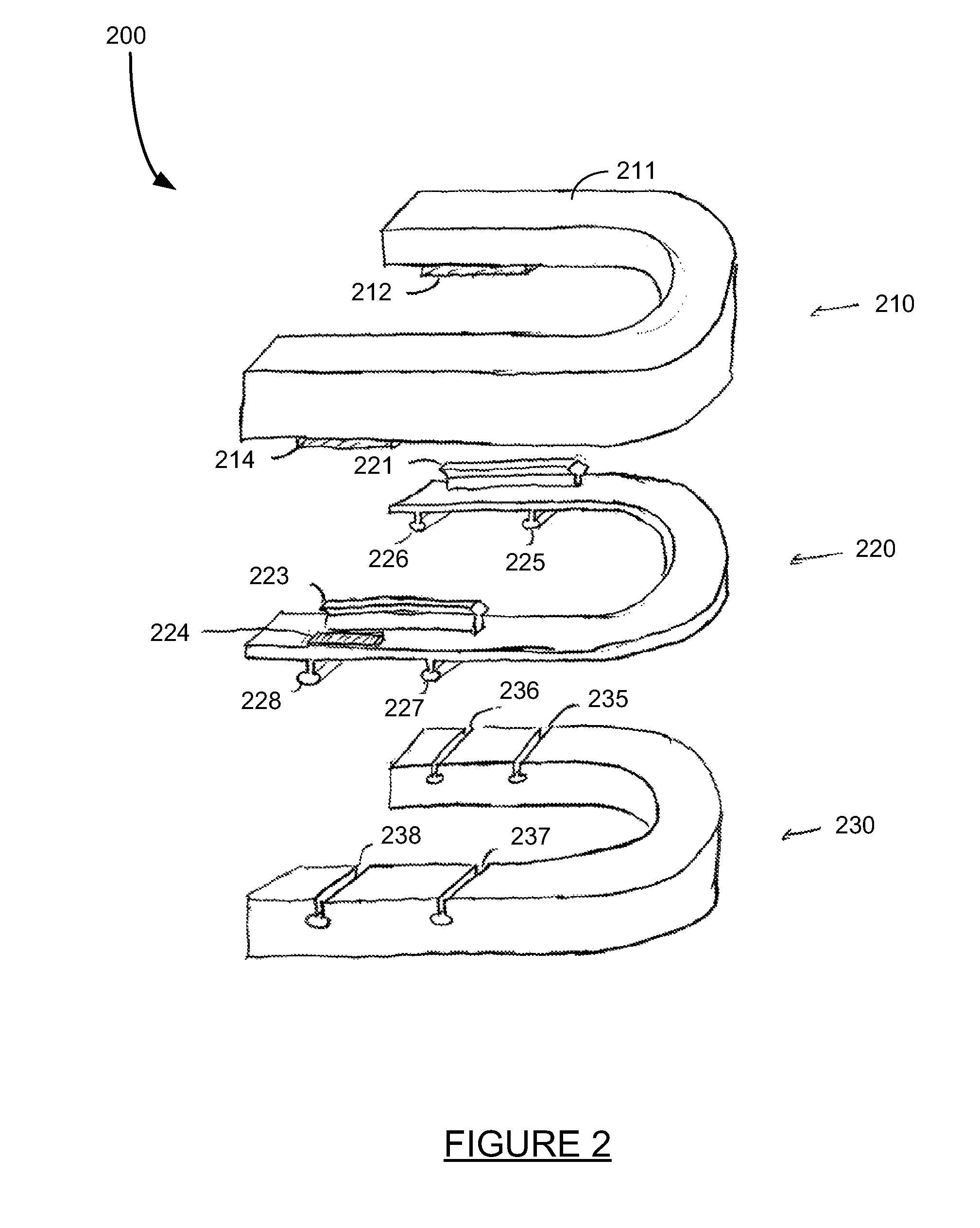

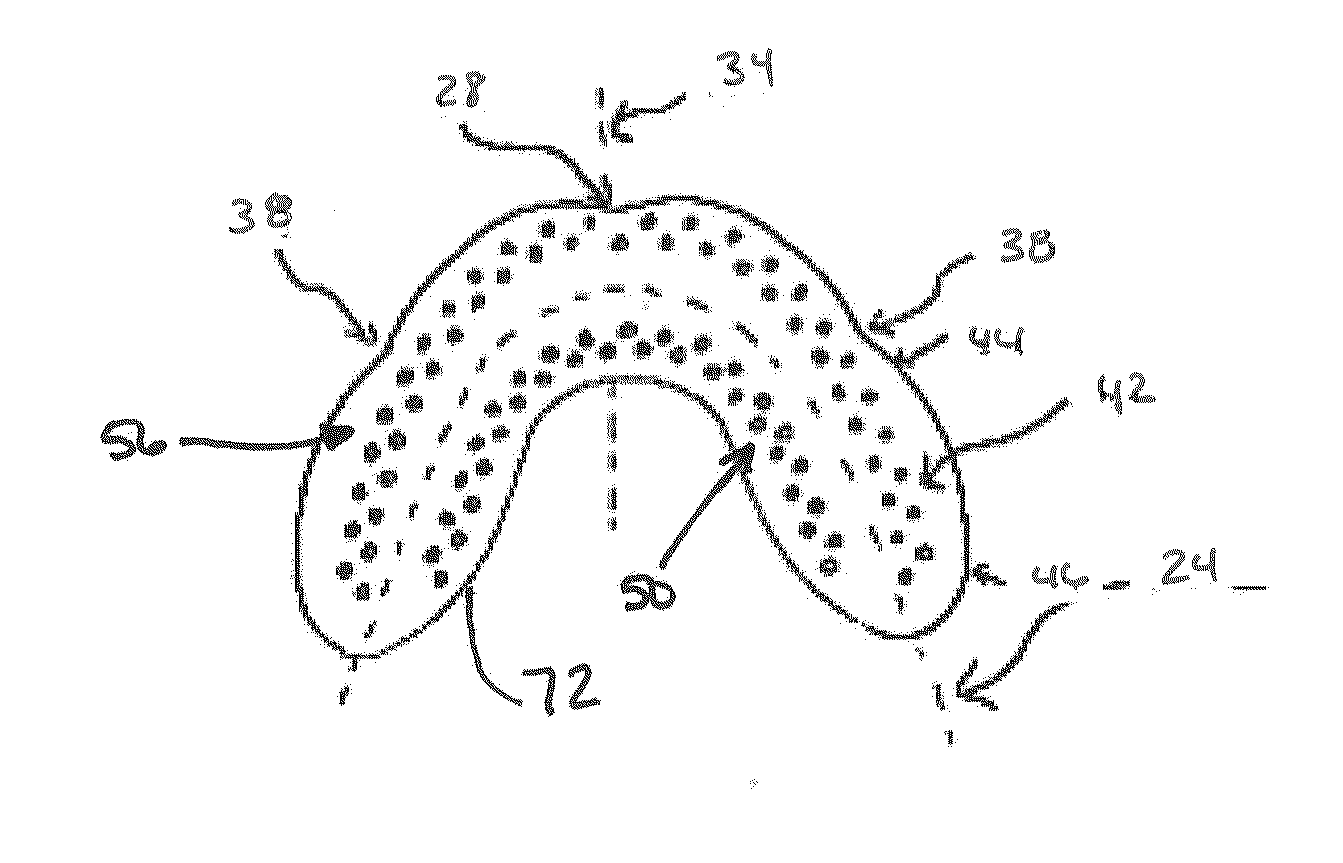

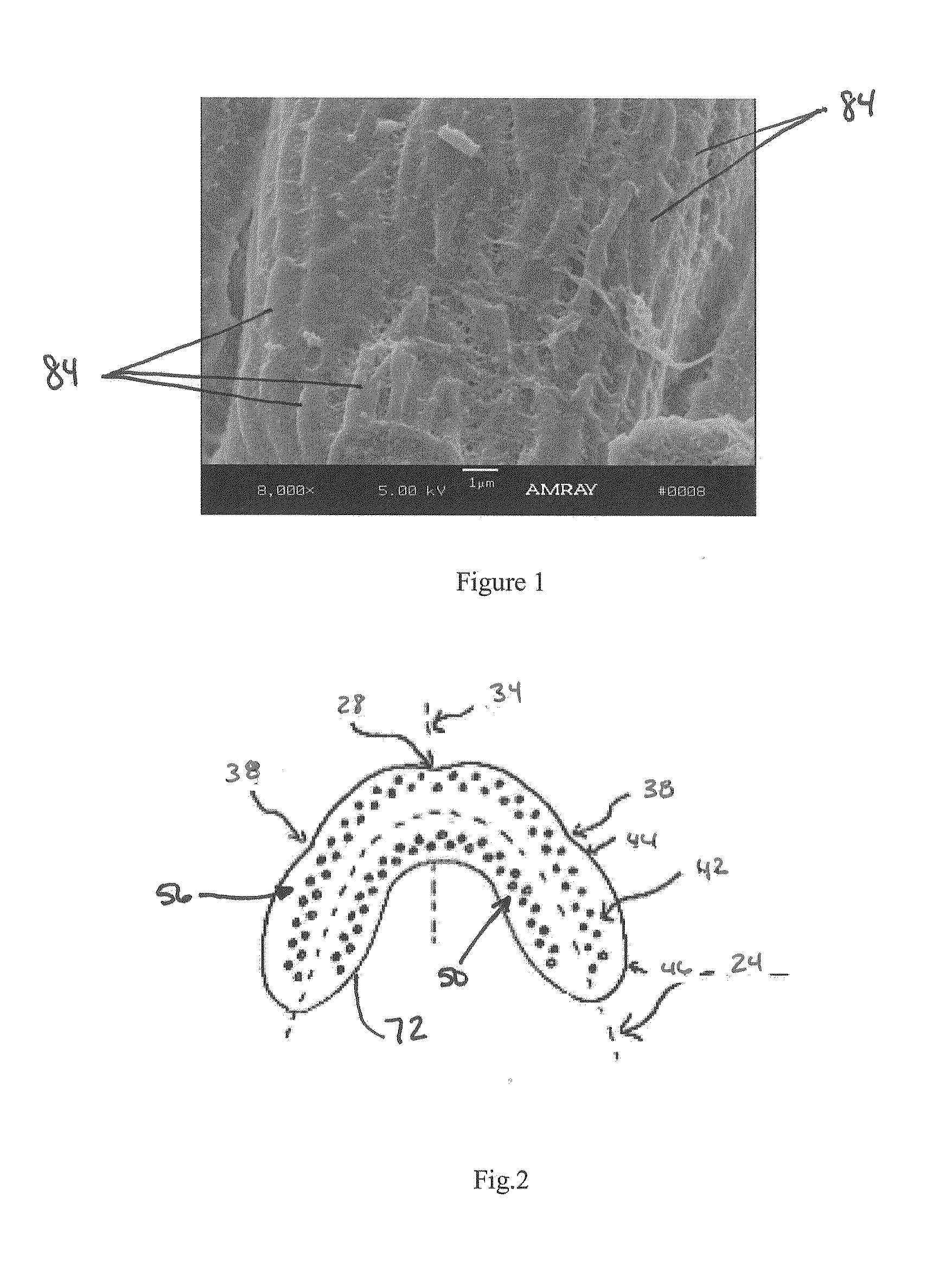

Self-titratable mandibular repositioning device

The present technology provides a mandibular repositioning device (MRD) which may be self titratable. The MRD may be repositioned relative to the maxilla, e.g., the mandible may be brought, via the device, to a position forward of a neutral resting and / or bite position. The MRD allows for adjusting the maintained forward position by simply biting-down to preserve the desired degree of mandibular advancement. The present technology also allows for movement of the mandible in a lateral direction. The lateral movement is allowed for any forward longitudinal positioning of the mandible. The MRD may use a plurality of components that are coupled together and allow for lateral and longitudinal motion between each other. The present technology may be used in MRDs which may be self-fitted, typically by immersing the device in hot water and then biting into the device, making an impression of the teeth in the softened thermoplastic polymer. It may also be applied to MRDs that do not require any fitting to the teeth and to devices that are custom-fabricated by dental labs.

Owner:SLEEP SCI PARTNERS

Long lasting dental restorations and methods for preparation thereof

The invention is directed to methods for the preparation of a long-lasting dental restoration, a kit for the preparation of a long-lasting dental restoration comprising one or more containers containing: a first polymerizable compound; a second polymerizable compound; a curing agent for a first polymerization process; a curing agent for a second polymerization process; an inorganic filler; and a pigment; and optionally containing instructions for use thereof. The invention is further directed to a long-lasting dental restoration comprising: a polymeric matrix comprising at least two polymeric systems; an inorganic filler; and a pigment, wherein said long lasting dental restoration is formed by at least two curing processes of said polymeric systems, and to methods for the preparation of a dental restoration, wherein said dental restoration is either fully or partially structured chair-side or it is fully structured in a dental laboratory.

Owner:CORONA DENT

Methods for designing a customized dental prosthesis using digital images of a patient

Methods and systems for producing customized dental restoration and prosthesis, particularly denture prescriptions using a computer software program are provided. In this system, digital photographs of the patient to be fitted with the denture are taken, and the photographs are transferred to the software program. Based on these photographs, the program makes certain calculations. The program then prompts the dental professional to select the desired materials and structure for the denture. Based on this input, the program automatically produces a prescription for the denture. The digital prescription is sent to a dental laboratory for making the denture.

Owner:DENTSPLY SIRONA INC

Augmented reality system for a dental laboratory

Owner:D4D TECH LP

Device for attaching dental model to articulator

InactiveUS20100009318A1Easy to manufactureDental articulatorsEducational modelsBuilding constructionBiological body

The present invention relates to a device for attaching a dental model to a variety of articulators for reproducing oral motions as a sagittal plane of a patient's organism and the left and right side points having the same height relative to the sagittal plane are found to mount the dental model at the articulators in a range for reproducing fatigue oral motions thereon, thereby helping the fabrication of the dental prosthesis inclusive of clinical treatment planning according to the extrusion and intrusion causes, the reasonable articulation re-construction in a dental laboratory process, and artificial teeth arrangements.

Owner:KIM BYUNG GEUN

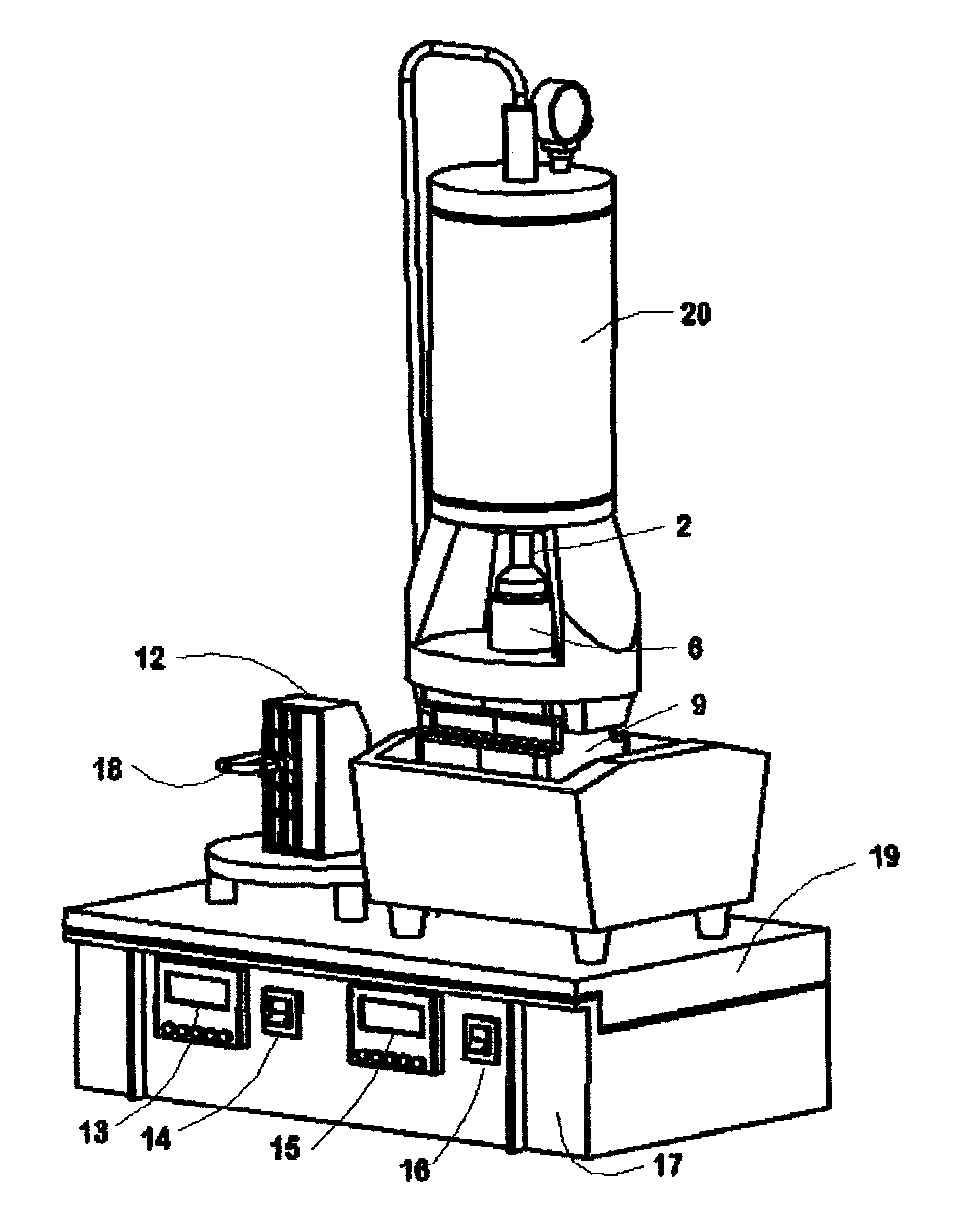

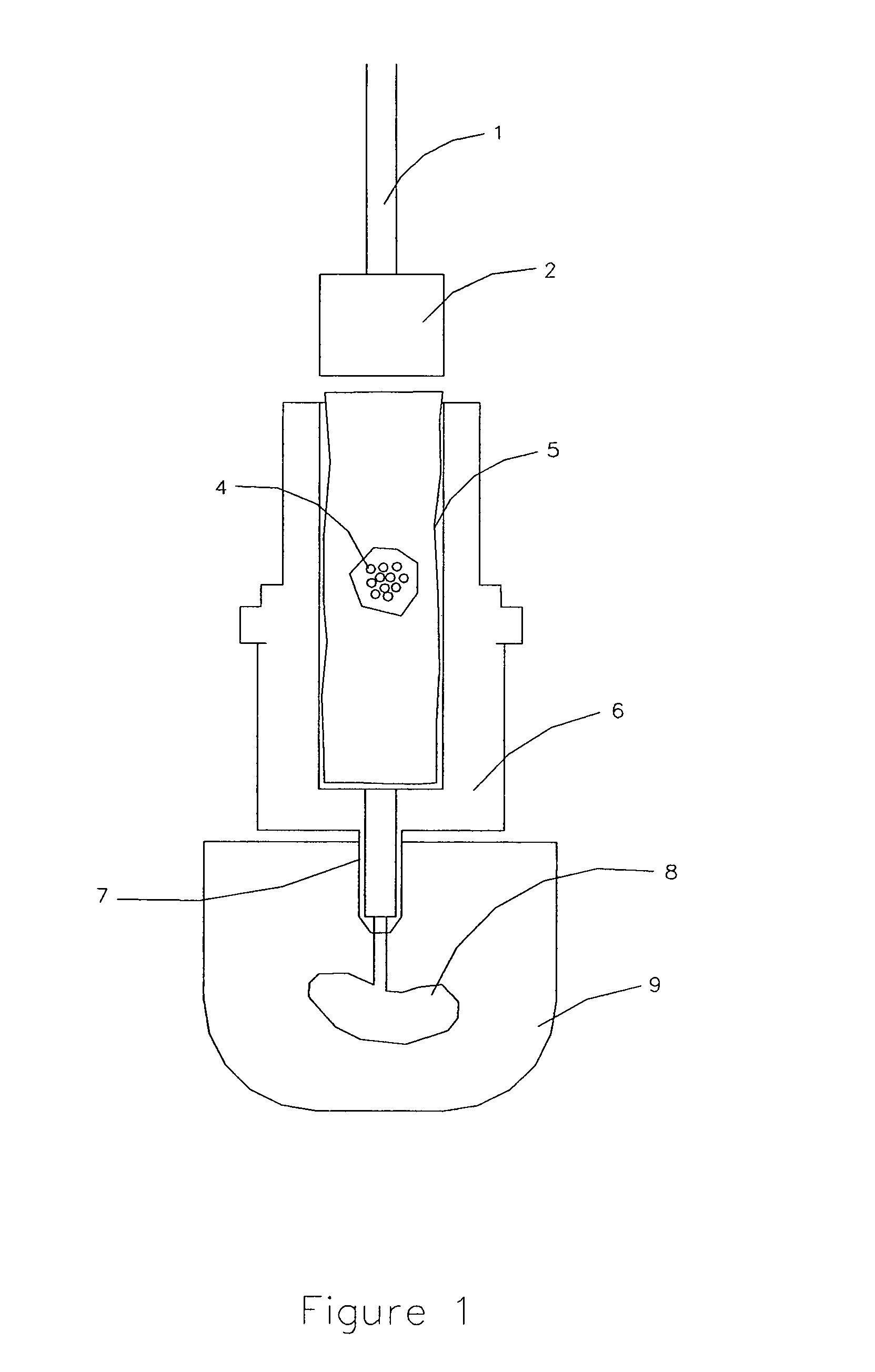

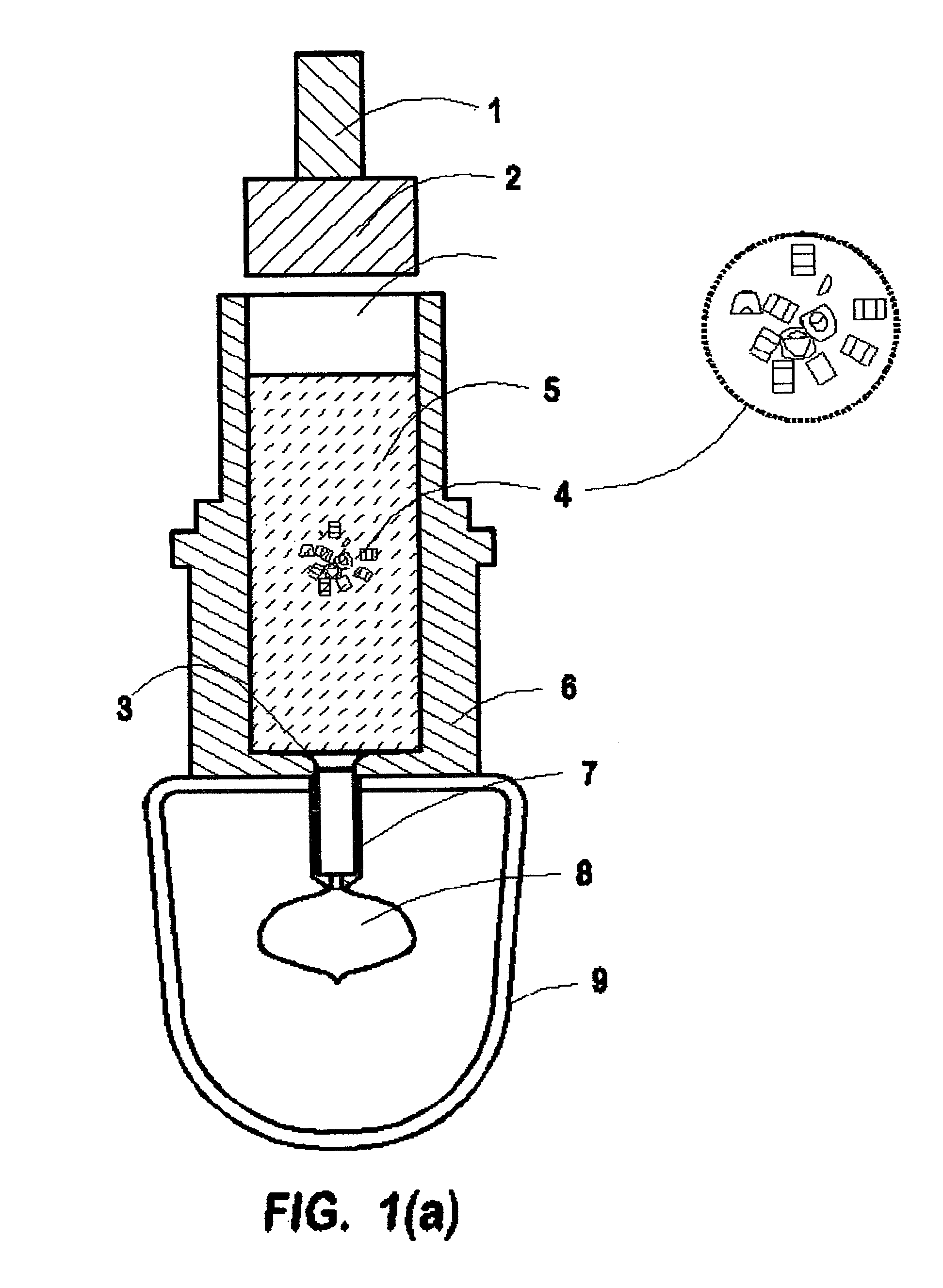

Apparatus for producing dental prostheses

Disclosed are an apparatus, materials, devices and methods for the use of a variety of thermoplastic resins in fabricating dental prostheses without the use of expensive hot-press equipment unavailable to most dental laboratories. The prostheses made by the process and materials disclosed herein provide more attractive and longer lasting prostheses with significant savings in both costs and materials. Among the aims of the technology disclosed is to save time and money for the dental industry (dentists, dental labs) and the dental consumer / patient.

Owner:CDM DENTAL LLC

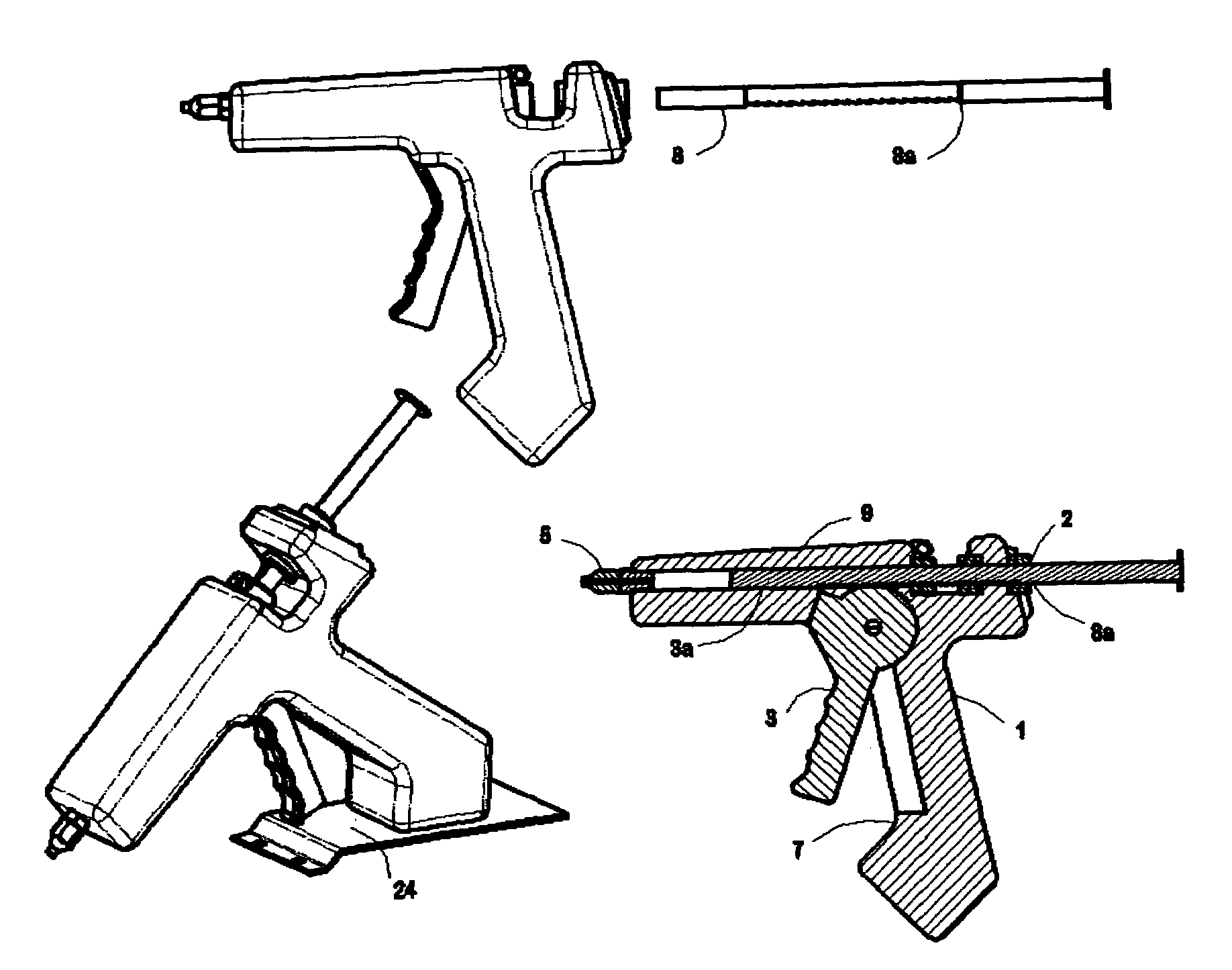

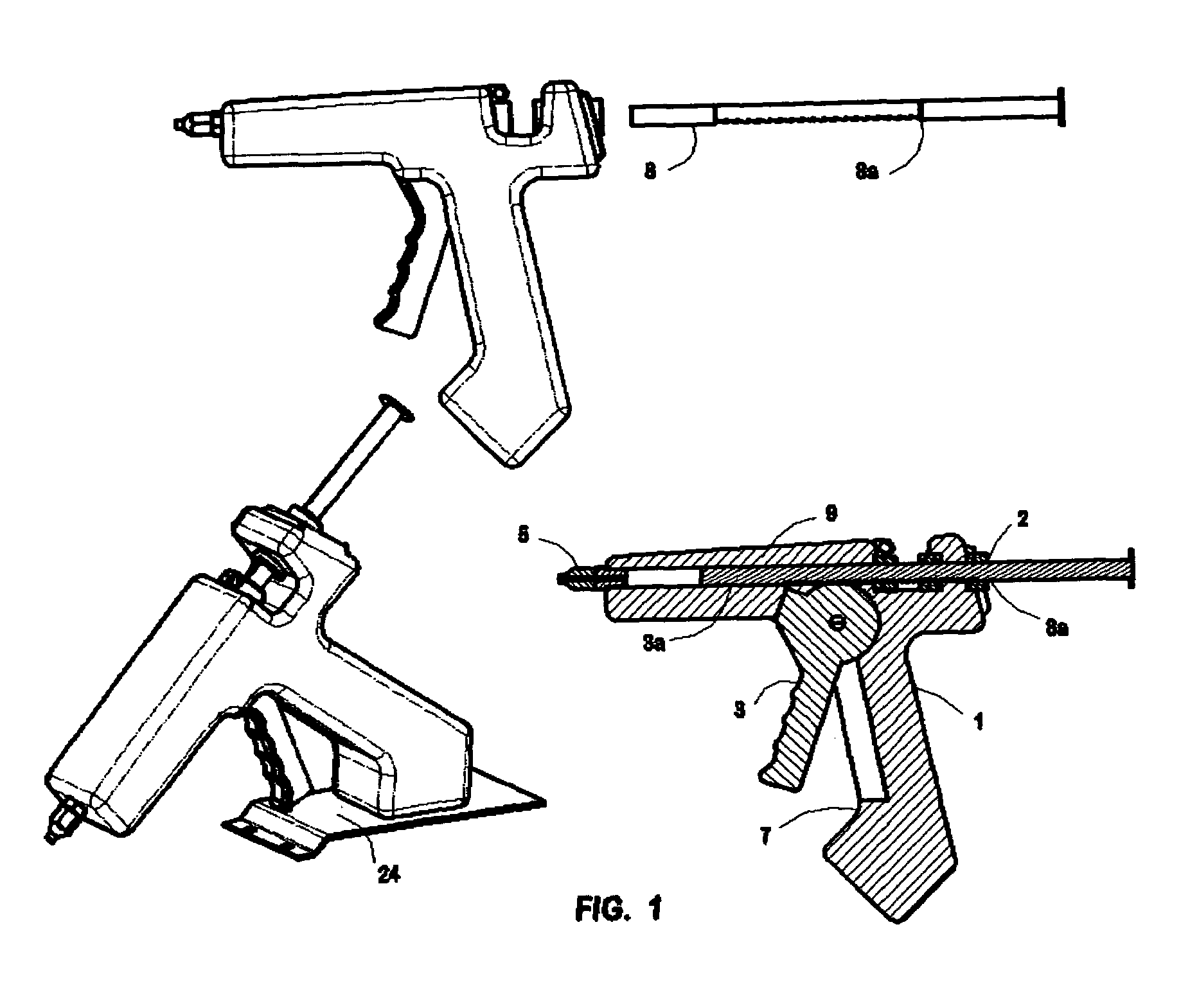

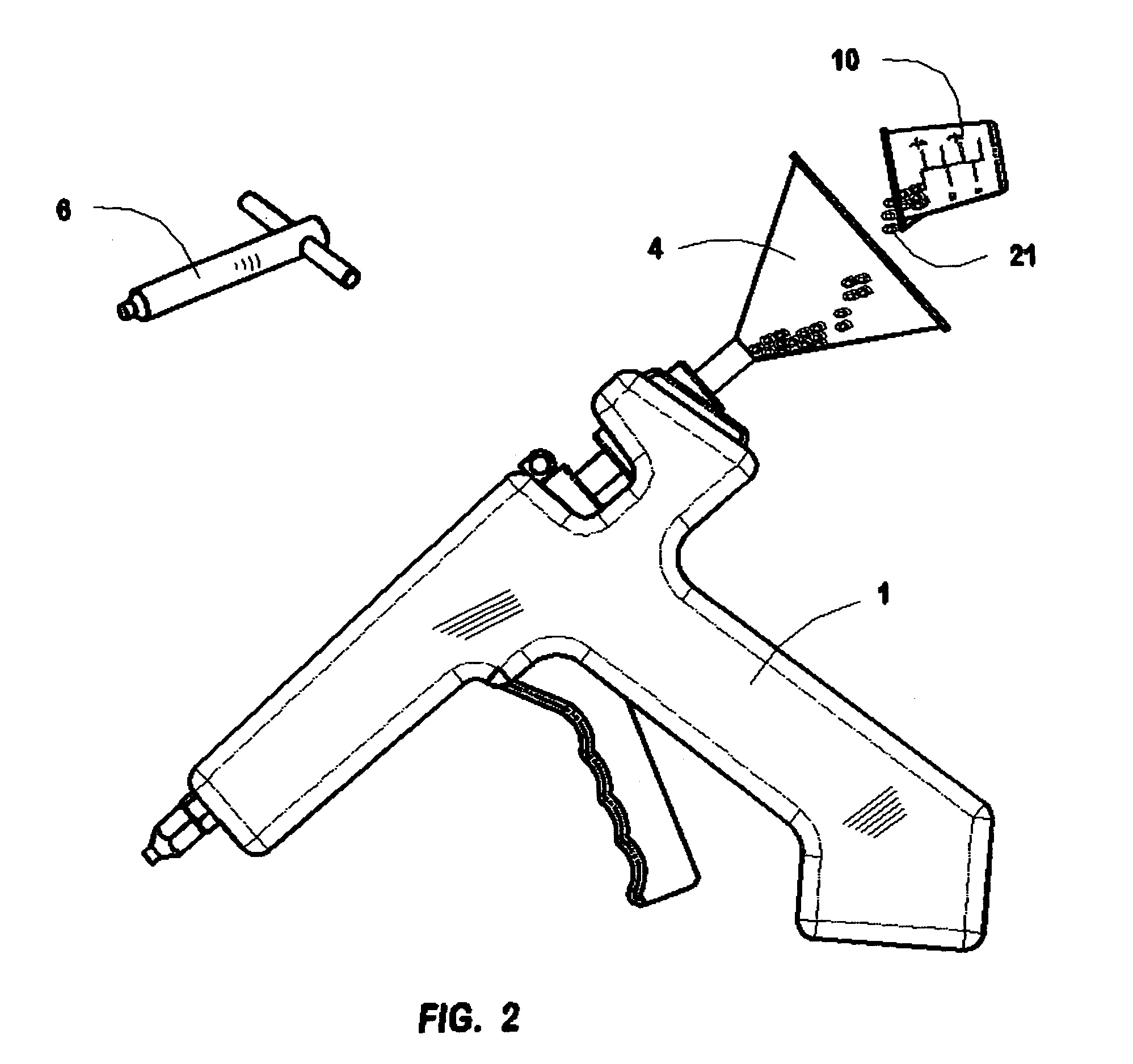

Apparatus, method, and kit for fabricating dental clasps

The invention disclosed herein relates to an efficient and inexpensive way to form dental clasps and fixed single unit temporary prostheses from molten thermoplastic resin. The apparatus and method allow a dental laboratory to make non-metallic clasps using an inexpensive handheld thermoplastic injection unit / gun that injects molten resin into a model of the clasp made from wax. A silicone putty matrix allows the resin to flow into a vacated wax model of the clasp. The time and money needed for this is much less than is needed to create such clasps using hot press equipment.

Owner:CDM DENTAL LLC

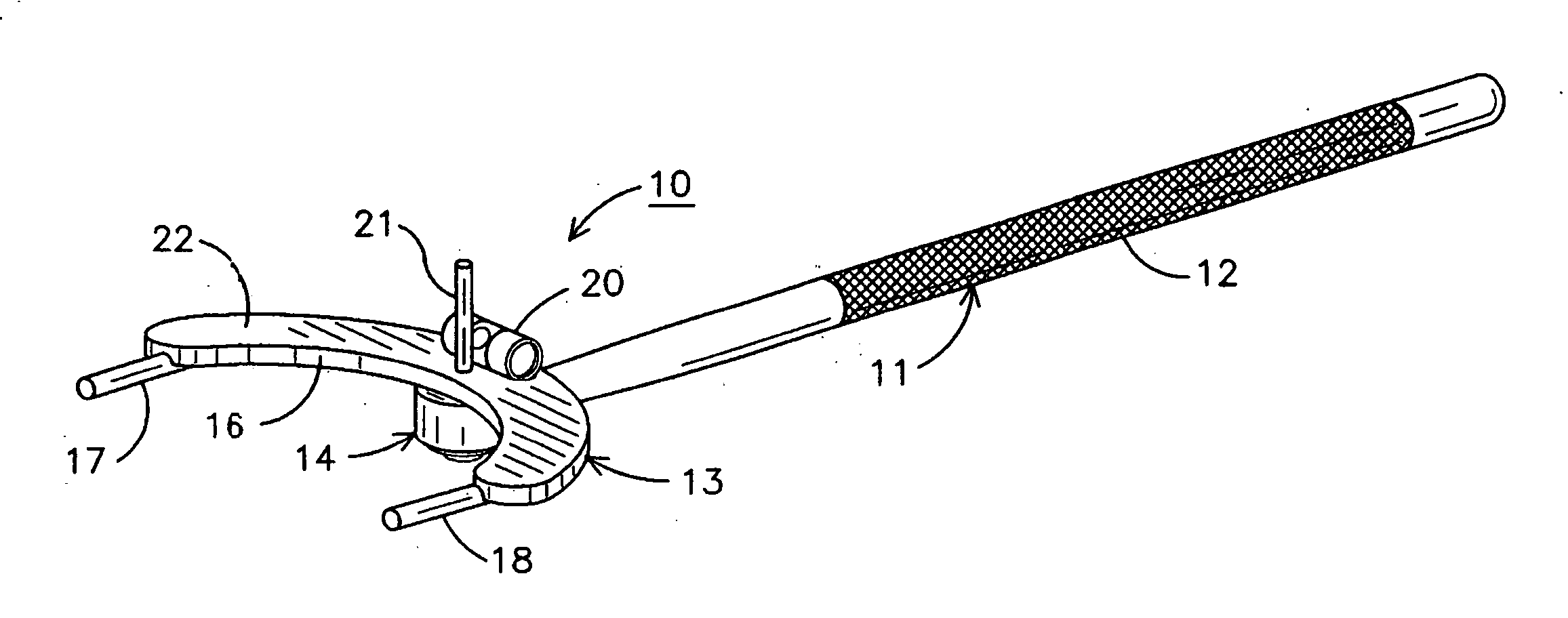

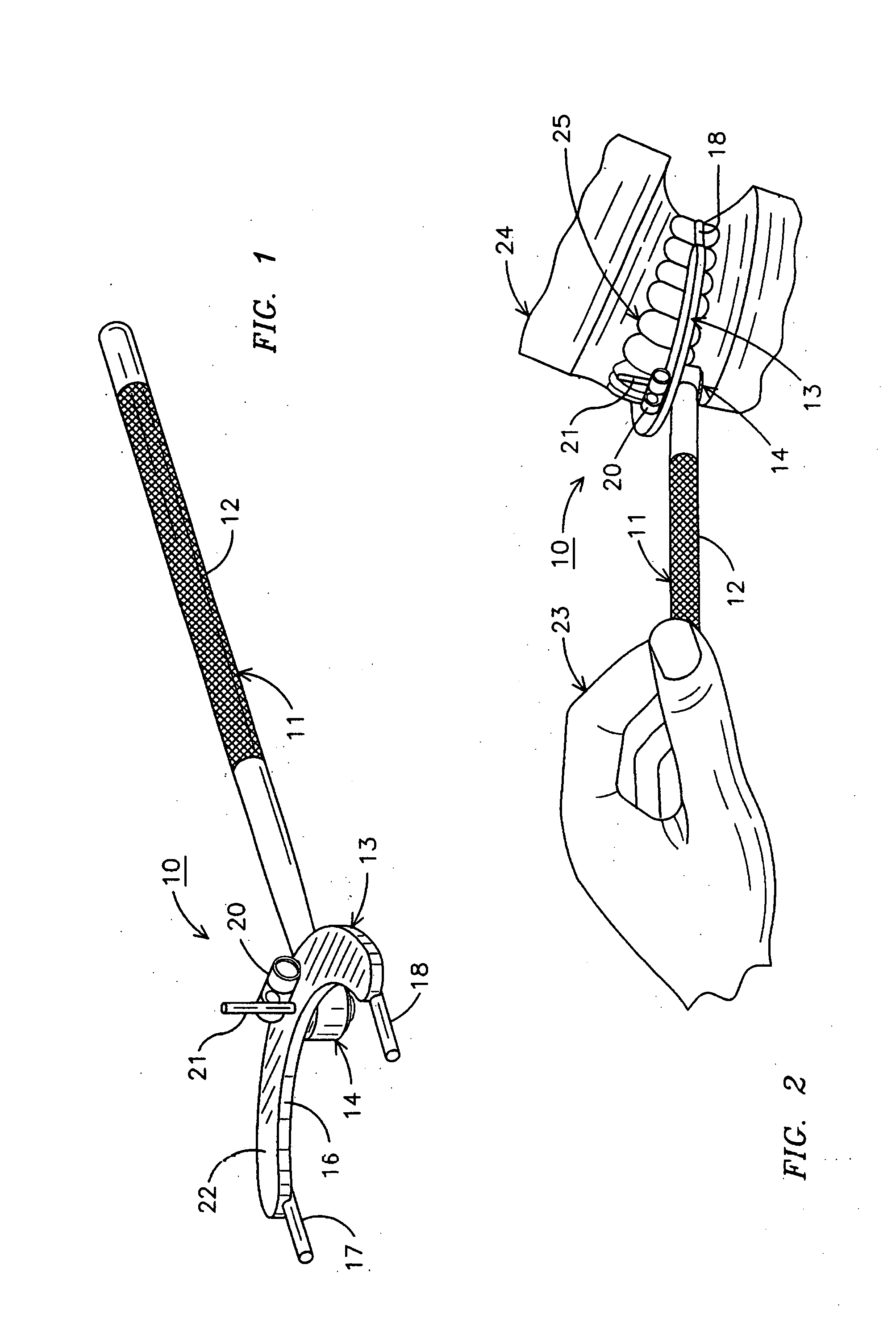

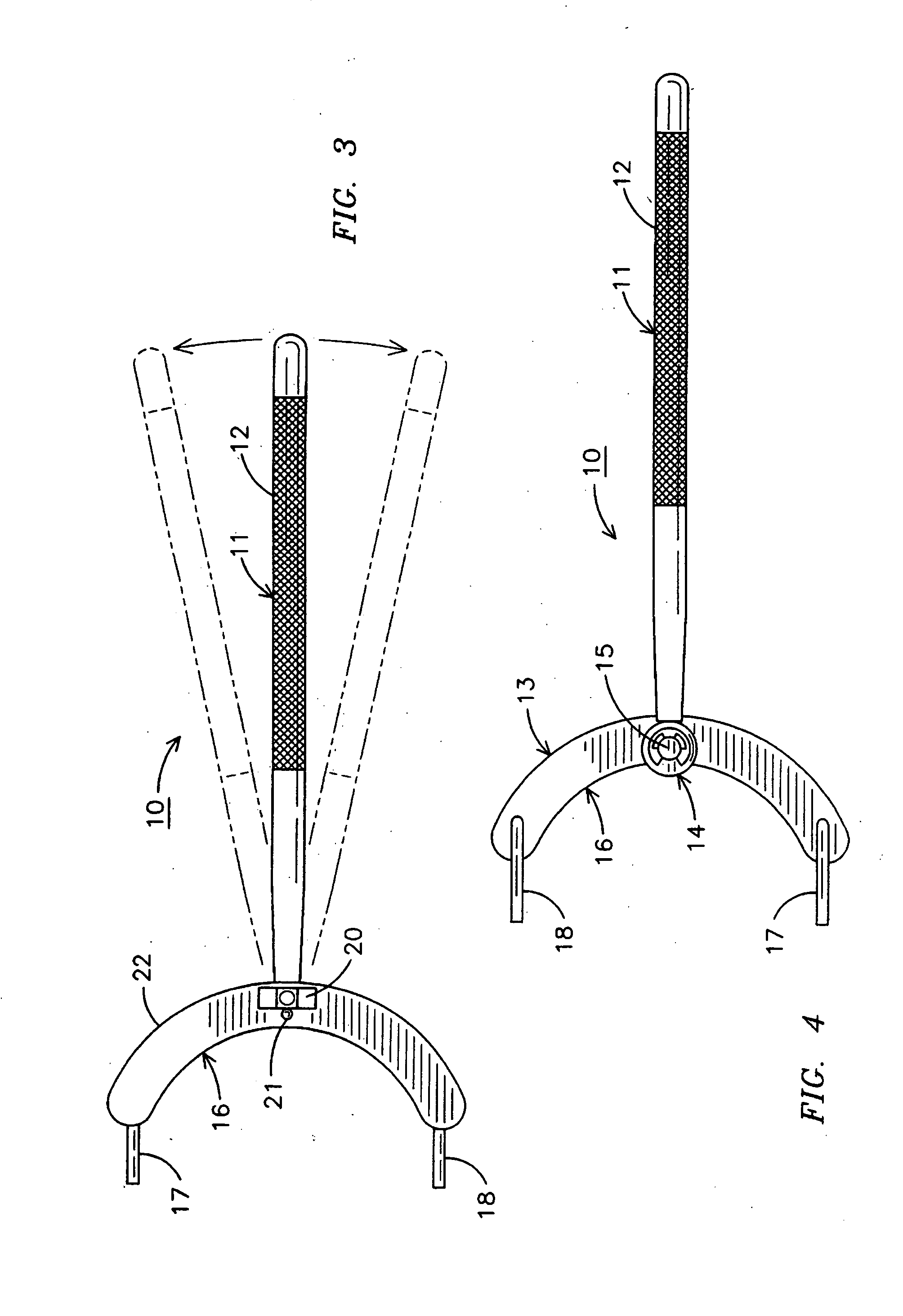

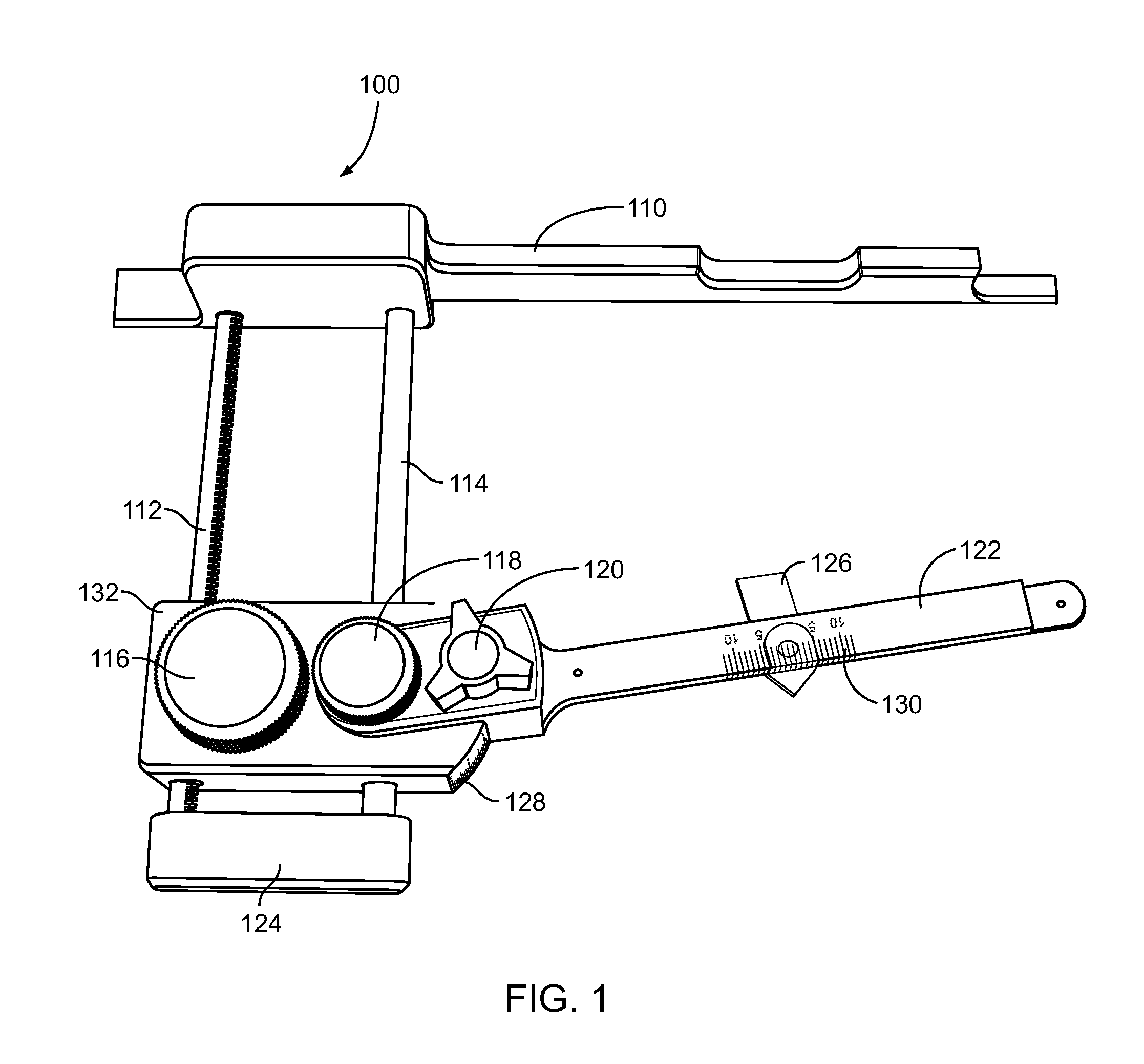

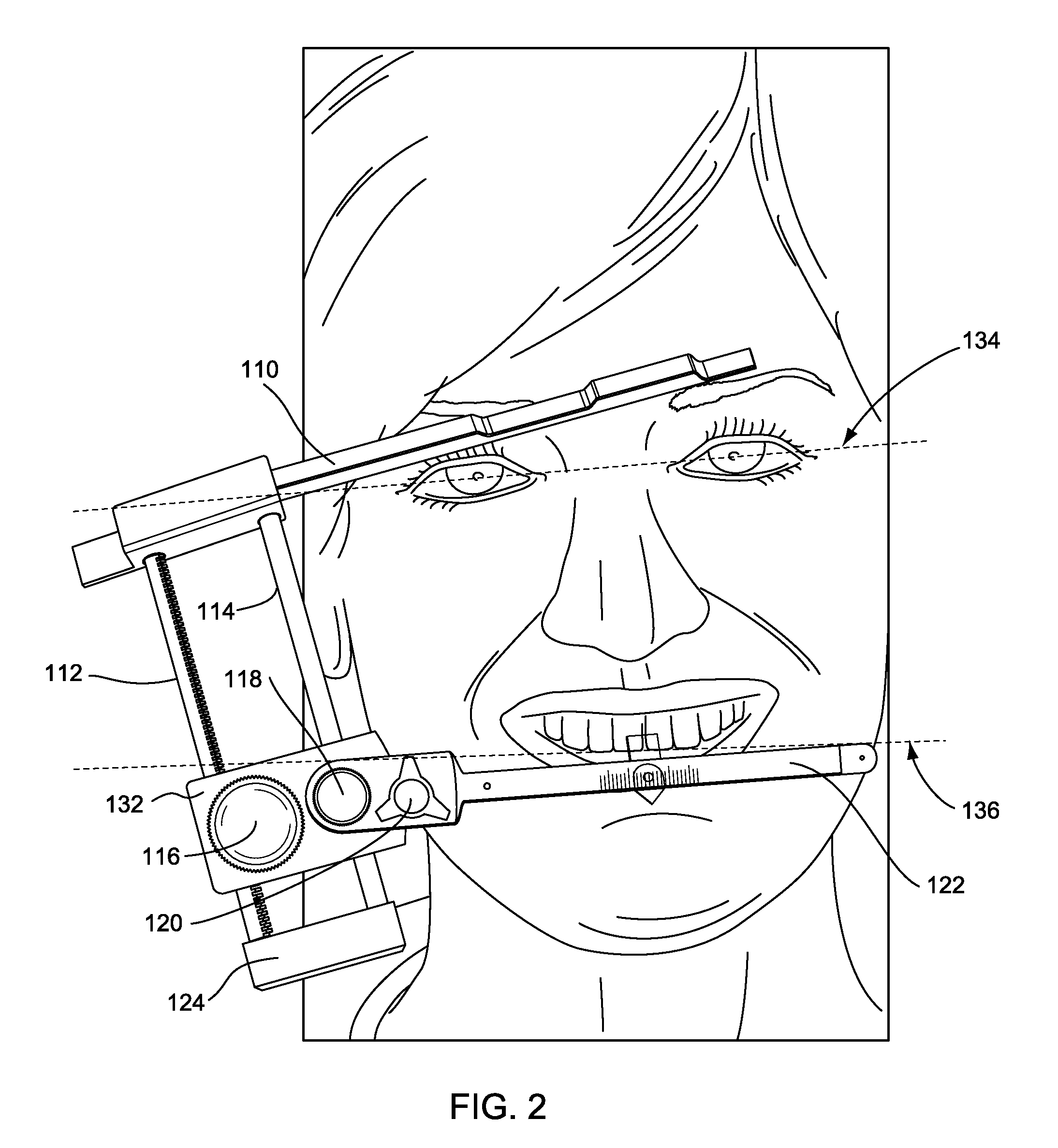

Dental alignment instrument

InactiveUS20060188839A1Accurate collectionEasy to determineDental articulatorsEducational modelsDental instrumentsHand held

Owner:ADAMS SUZANNE

Custom-Formable Night Grinding Appliance and Method of Use

ActiveUS20140338675A1Low softening pointEasy to breatheSnoring preventionNon-surgical orthopedic devicesHealth professionalsBiomechanics

Disclosed is a dental appliance composed of a thermo-plastic polymer with low compressibility, high toughness, and high tensile strength, with a low softening point. The appliance has perforations that enable it to be easily custom-fitted by the user or a health professional. The appliance begins as a generally U-shaped, unformed dental tray that is significantly thinner than existing dental appliances. Once fitted, the dental appliance provides superior protection against damage to the enamel of the teeth and abrasion of the teeth due to bruxism or other mechanism leading to biomechanical wear of dental surfaces. The perforations facilitate the custom-fitting process by allowing the user to suck air through the perforations, thus applying a negative pressure between the material and the teeth while the material is still soft and pliable. This enables a user or health professional to within minutes create a final product that rivals the quality and fit of an appliance made by dental laboratories using dentist made impressions.

Owner:AKERVALL TECH

Apparatuses and methods for making a final hybrid prosthesis to be attached to dental implants

The present invention includes apparatuses and methods for making a final hybrid prosthesis to be attached to one or more dental implants. One preferred method includes the step of making a temporary hybrid prosthesis and at about the same time also making a duplicate temporary hybrid prosthesis. The duplicate temporary hybrid prosthesis permits the final hybrid prosthesis to be made with fewer visits to a restorative dentist and with less dental laboratory time than is currently needed when making a final hybrid prosthesis.

Owner:PRESTIPINO ANTHONY

Method and system for designing and producing dental prostheses and appliances

A virtual model of an intraoral cavity is provided, wherein this process is initialized by a dental clinic, and the design and manufacture of a suitable dental prosthesis for the intraoral cavity is shared between a dental lab and a service center.

Owner:ALIGN TECH

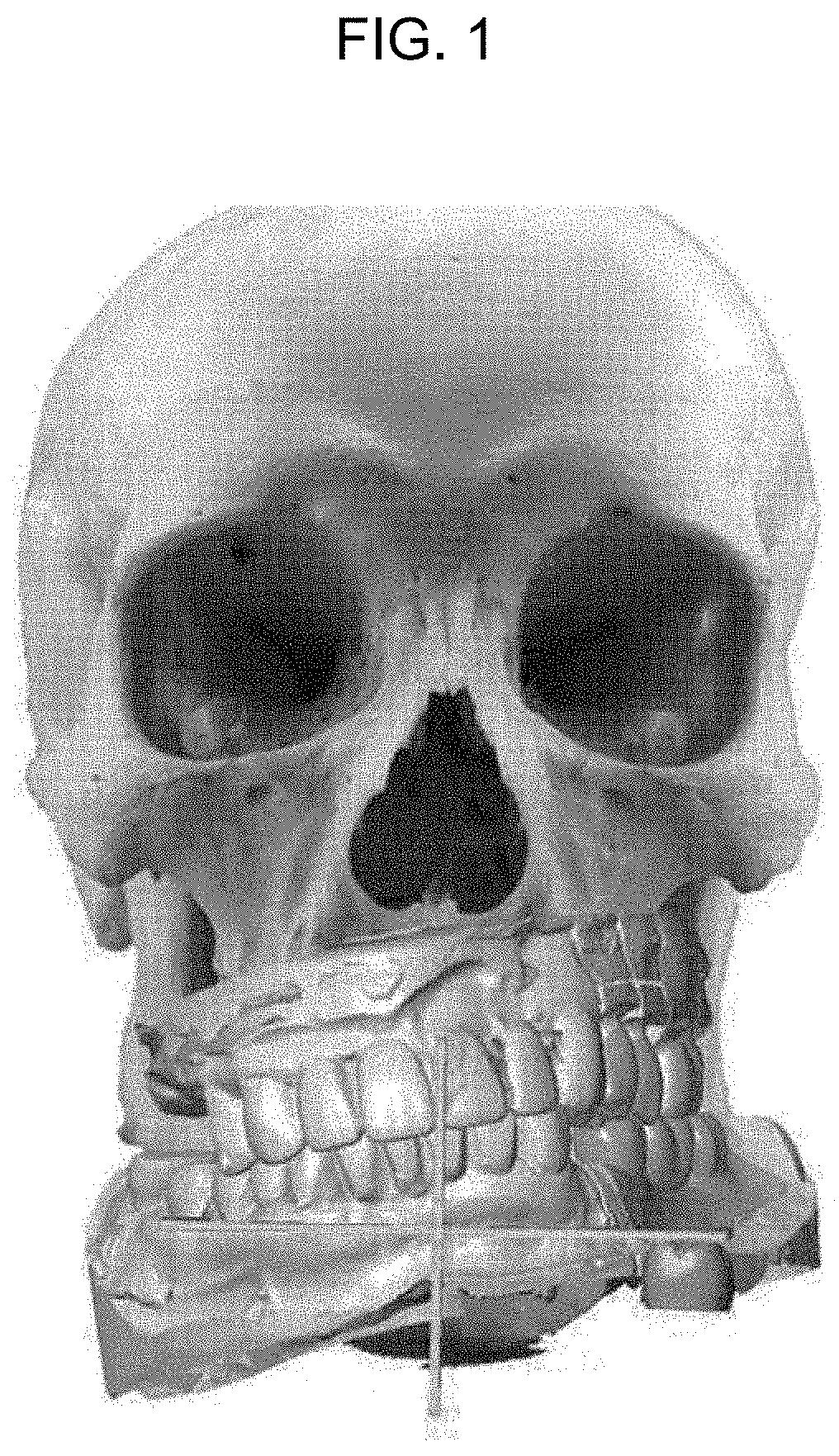

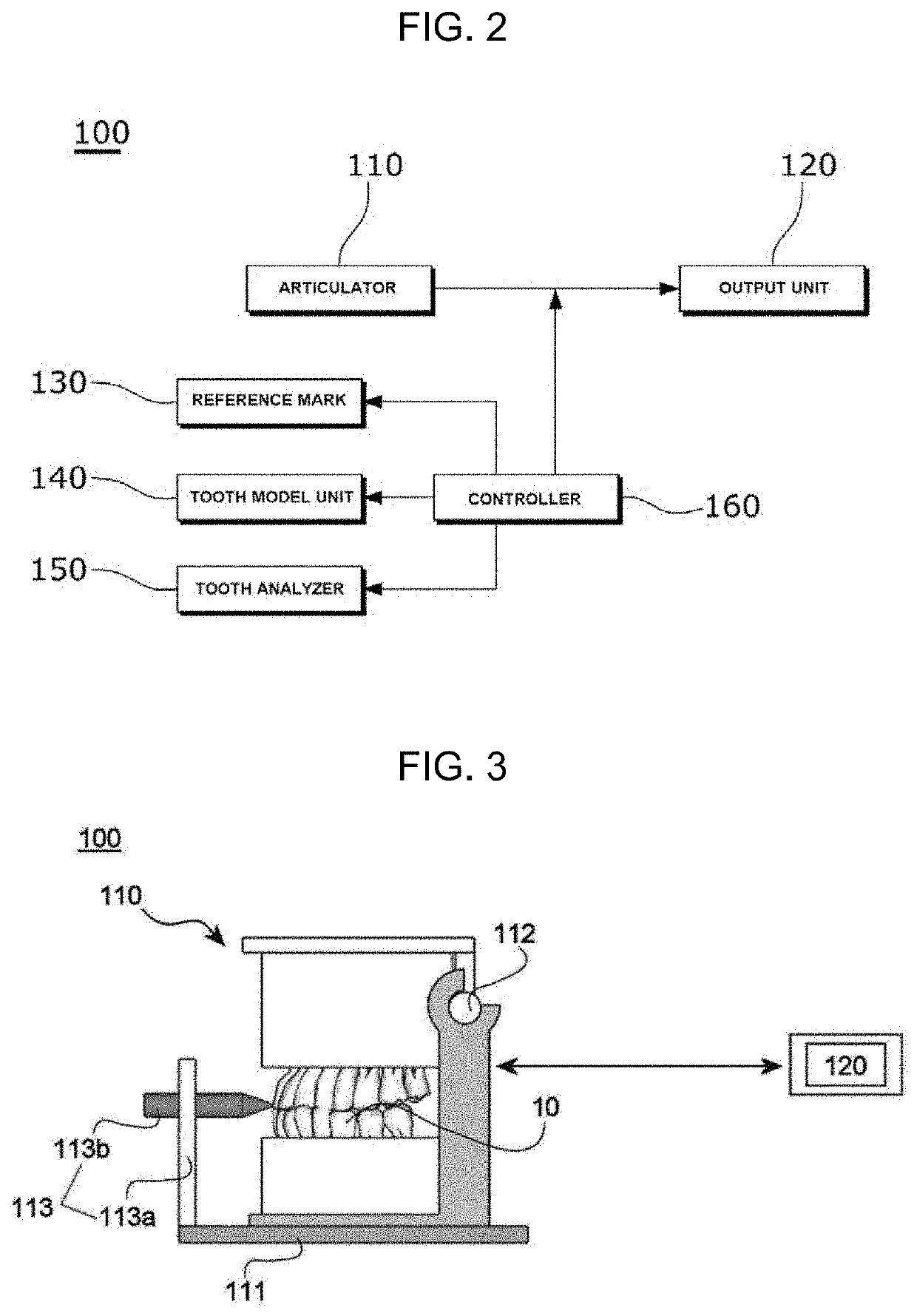

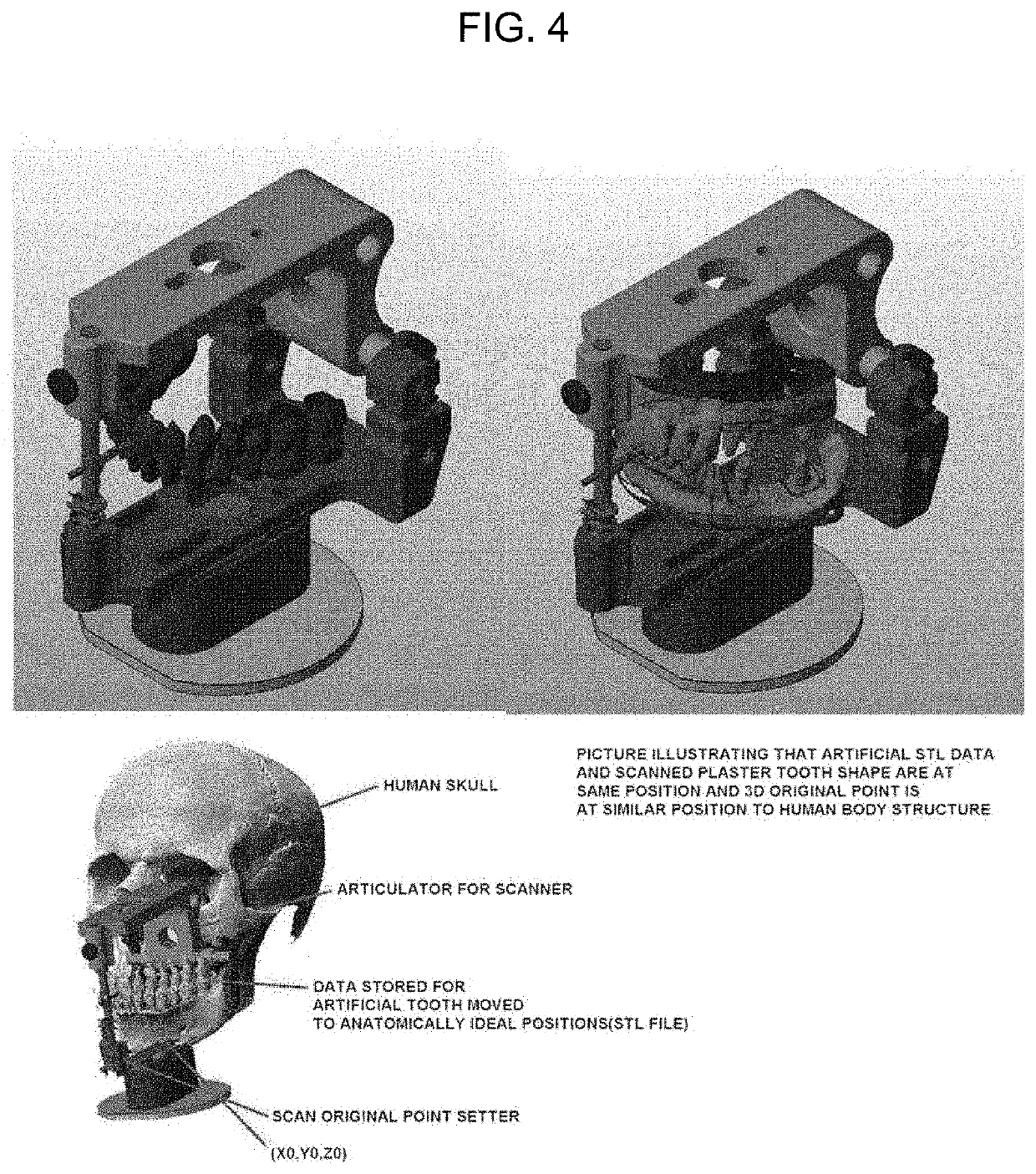

Digital three-dimensional tooth model system

PendingUS20210353394A1Improve accuracySmooth masticationImpression capsDental articulatorsDental laboratoryDental cast

The present invention relates to a digital three-dimensional tooth model system. The digital three-dimensional tooth model system includes: an articulator mounted in a scan region of a tooth model scanner that creates virtual 3D tooth model data by scanning a tooth model and having a tooth model to be scanned installed thereon; an output unit connected to the articulator and matching and outputting position data of a tooth model scanned by the tooth model scanner and data storing anatomically ideal positions on an image; a reference mark composed of lines that can be vertically and horizontally analyzed; a tooth model unit composed of an upper jawbone tooth model and a lower jawbone tooth model designed by a digital tooth design program, and having modules each composed of the reference mark and the upper jawbone tooth model and the lower jawbone tooth model, respectively; and a tooth analyzer disposed between the upper jawbone tooth model and the lower jawbone tooth model. Accordingly, it is possible to increase accuracy by accurately positioning a tooth model in a peculiar scan region, using a tooth model scanner required to fabricate a digital three-dimensional tooth model at a dental clinic or a dental laboratory, and to enable smooth mastication and good pronunciation by enabling tooth models to be quickly and accurately engaged at ideal positions through modularization of a digital three-dimensional model and a reference line that enables positioning at anatomically ideal positions.

Owner:LEE WOO HYOUNG

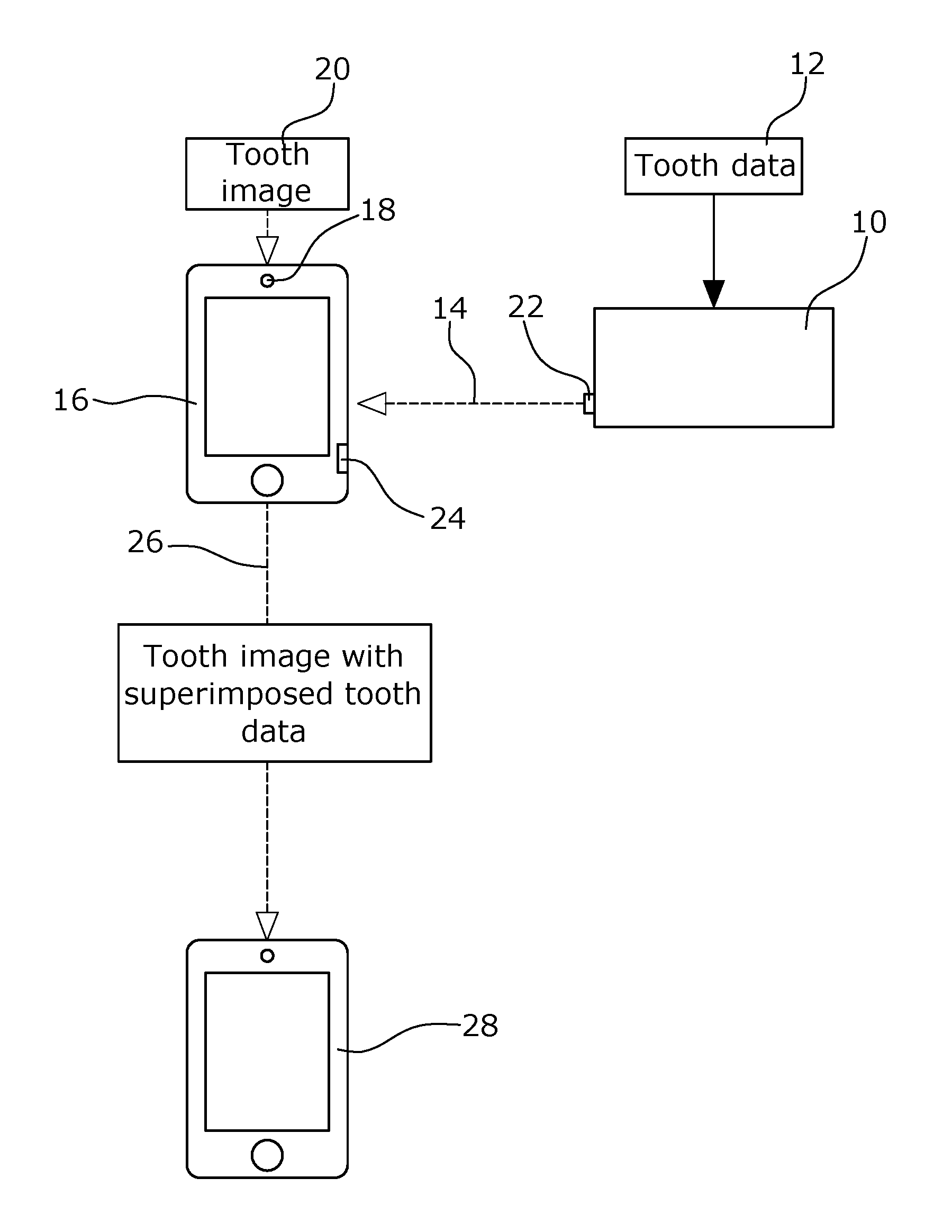

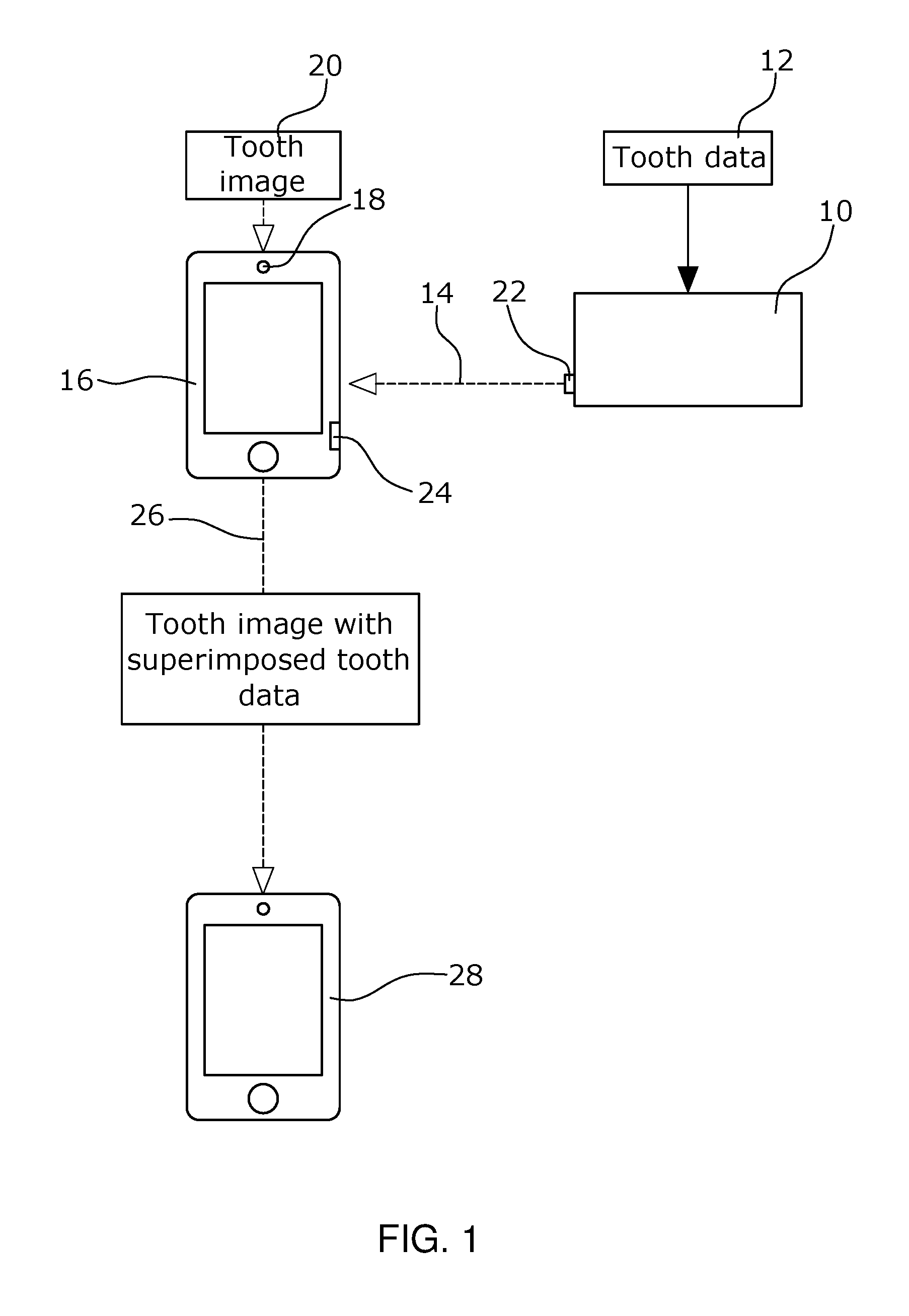

Support system for the manufacture of dental restorations

ActiveUS20160278890A1Easy to carryAllocation can be extremely simple and reliableImage enhancementTelevision system detailsSupporting systemMeasurement device

A support system for the manufacture of dental restorations comprises a measurement device for determining the tooth data, particularly the tooth color and color coordinates, and a data processing device including a camera for capturing a tooth image. The data processing device comprises a reception module and the measurement device comprises a transmission module, for direct transmission of measured tooth data from the measurement device to the data processing device. The support system further comprises an allocation module integrated into the data processing device for allocating the received tooth data to the tooth image, and a transmission module integrated into the data processing device for transmission of the tooth image inclusive of allocated tooth data to a data processing device of a dental laboratory.

Owner:VITA ZAHNFABRIK H RAUTER GMBH & CO KG

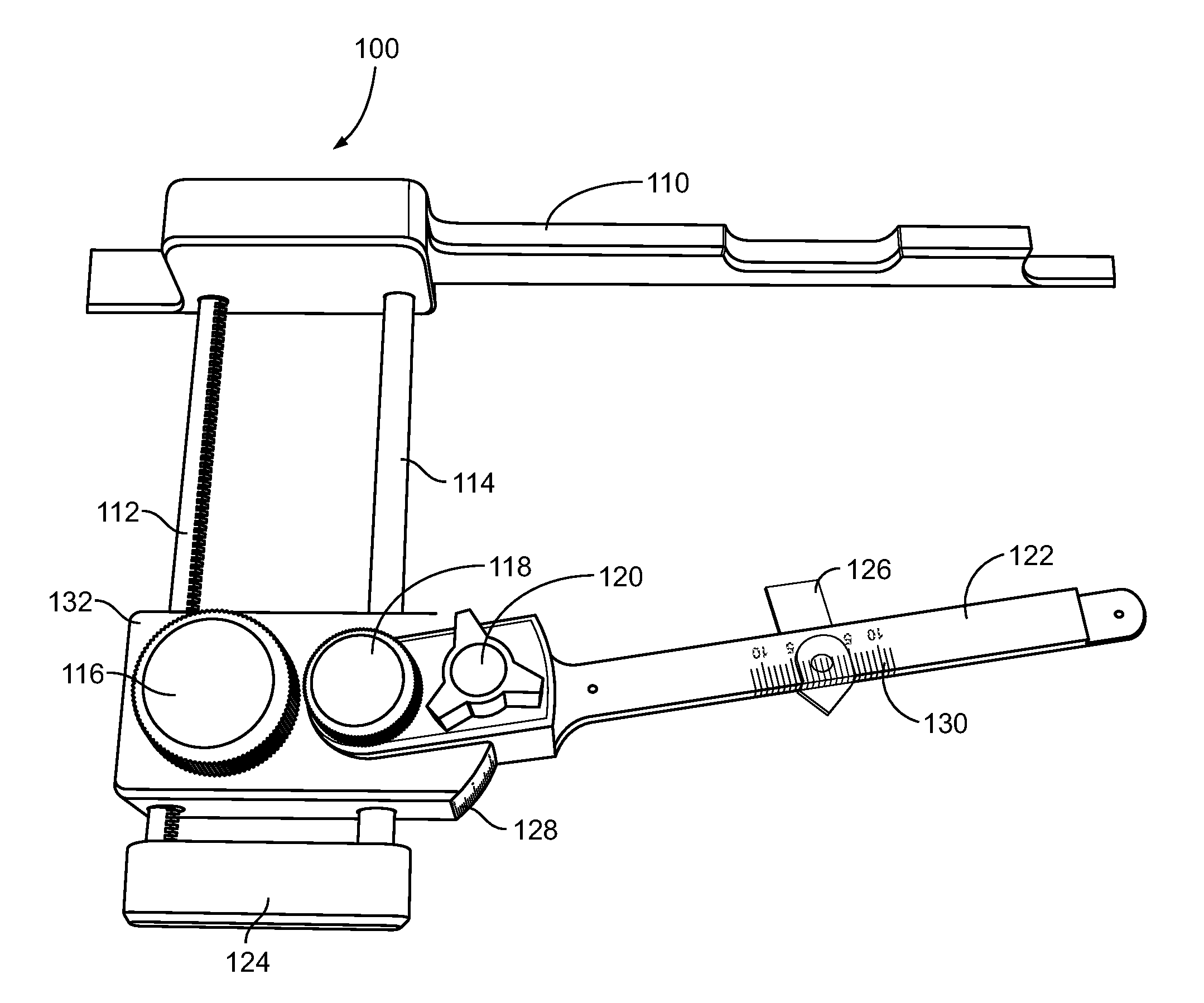

Dental measuring device

Dental devices are disclosed which allows a dental laboratory to accurately create upper front teeth and dentures to the dentist's specific instructions. The interpupillary line and the incisal lines are used to fabricate teeth which are more symmetrical and therefore are more esthetically pleasing than prior devices and procedures. The angle and the distance between the interpupillary line and the incisal line are measured and recorded with a smile guide device.

Owner:BASTA THOMAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com