Patents

Literature

463results about How to "Low softening point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850AStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force after sintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

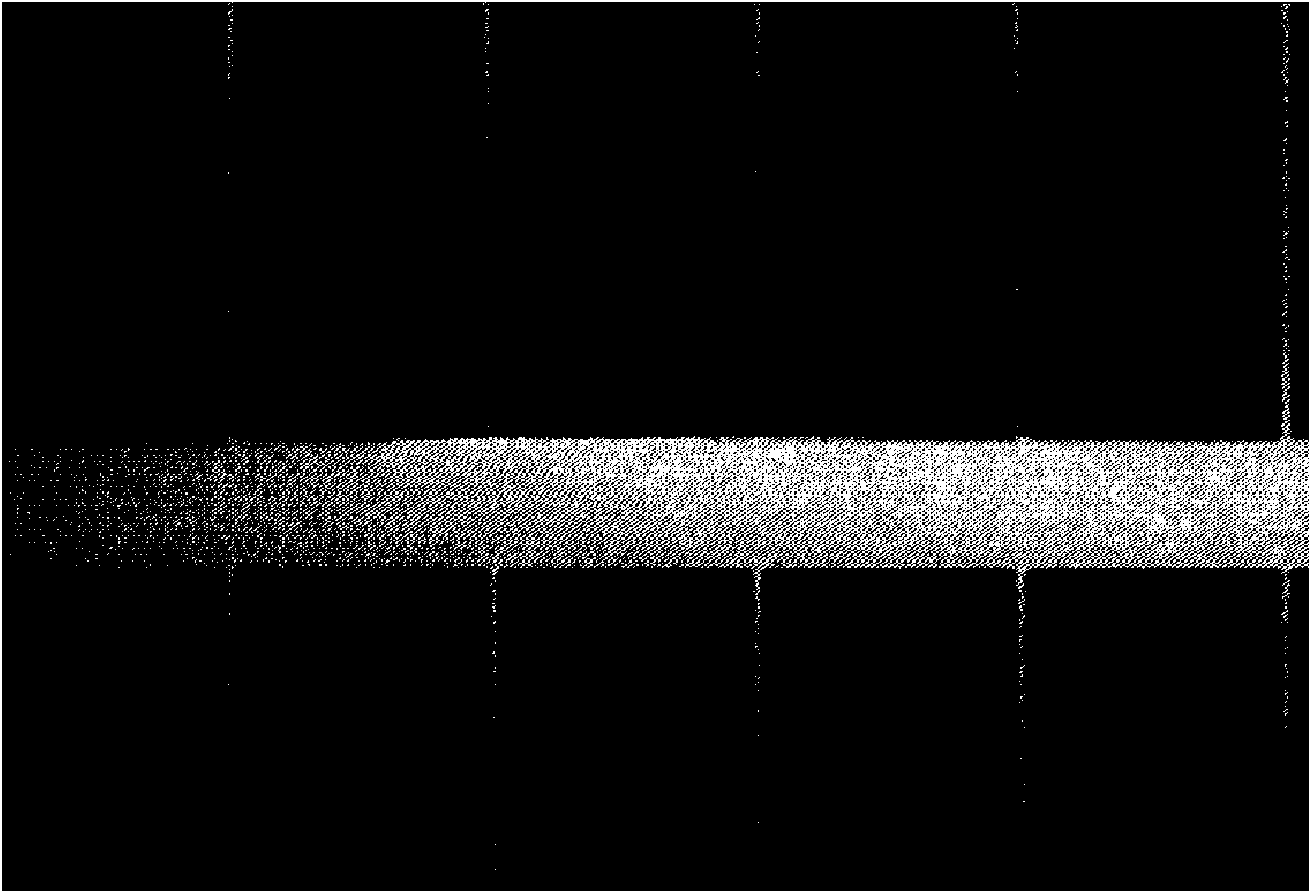

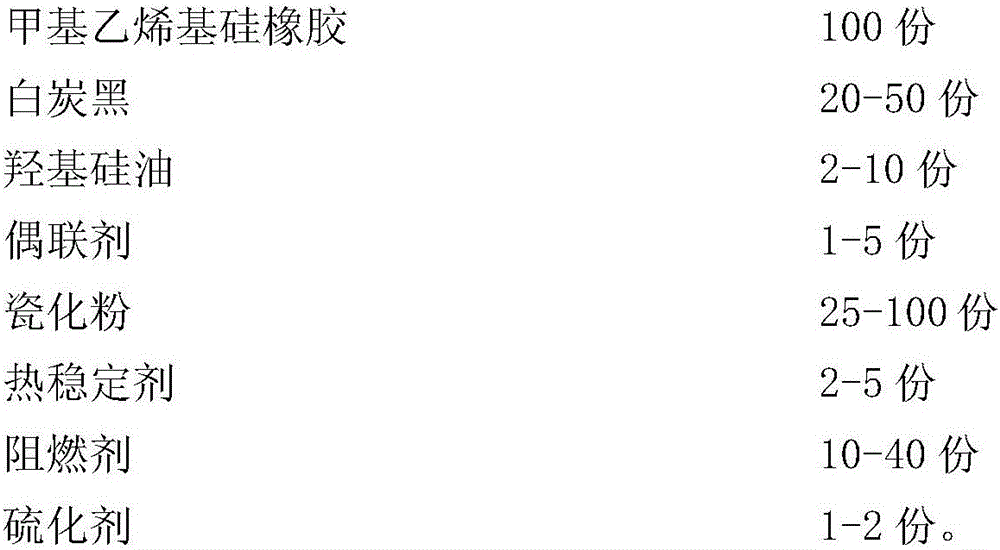

Preparation method of ceramizing fire-resistant silicon rubber

ActiveCN105694471AImprove flame retardant performanceWill not affect other performanceHalogenCombustion

The invention relates to a preparation method of ceramizing fire-resistant silicon rubber. The rubber comprises the following components in parts by weight: 100 parts of methyl vinyl silicon rubber, 20-50 parts of white carbon black, 2-10 parts of hydroxyl silicone oil, 1-5 parts of a coupling agent, 25-100 parts of ceramizing powder, 2-5 parts of a heat stabilizer, 10-40 parts of a fire retardant, and 1-2 parts of a vulcanizer. The preparation method includes the following steps: adding the methyl vinyl silicon rubber in a kneading machine; then adding the white carbon black and the hydroxyl silicone oil; mixing for 30 minutes at the temperature of 80 DEG C; then adding the coupling agent, the ceramizing powder, the heat stabilizer and the fire retardant; mixing for 1-1.5 hours; raising the temperature to be 100 DEG C and keeping high vacuum for 30 minutes; and after cooling to room temperature, adding the vulcanizer on an open mixing machine for mixing to obtain the ceramizing fire-resistant silicon rubber. The rubber has good mechanical property and electrical property at normal temperature, does not contain halogen, is smokeless and non-toxic during combustion, can be extinguished quickly and forms a ceramizing shell to guarantee integrity of the inside.

Owner:BEIJING UNIV OF CHEM TECH

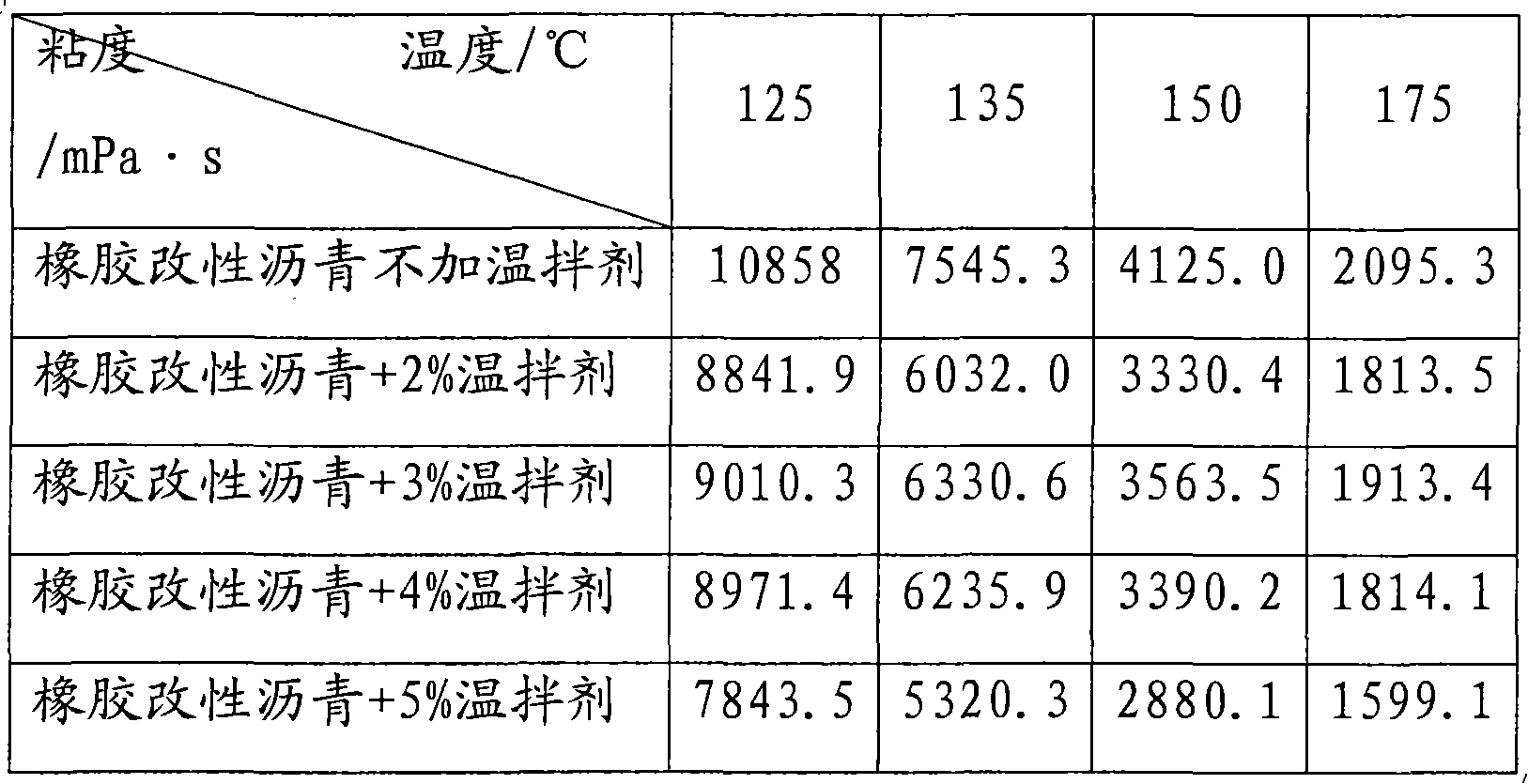

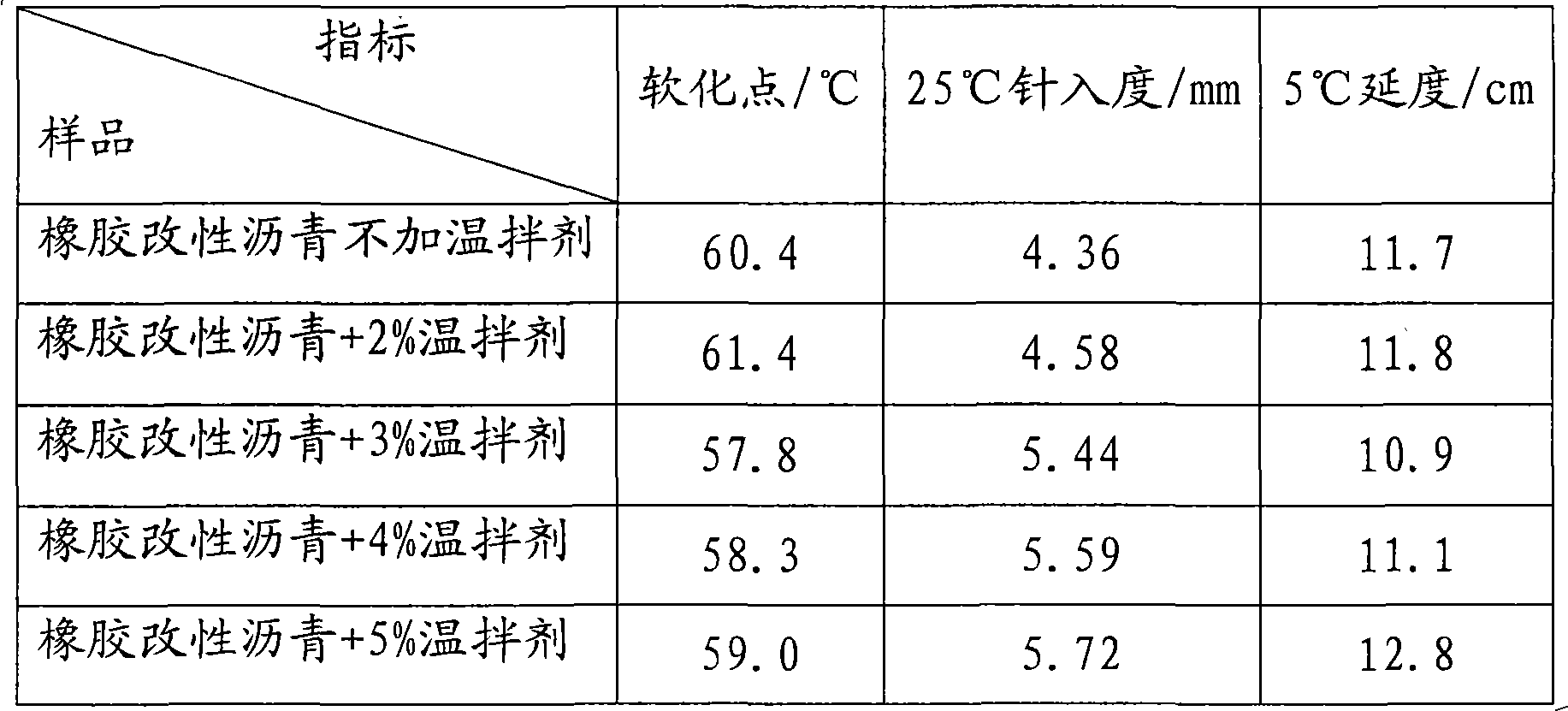

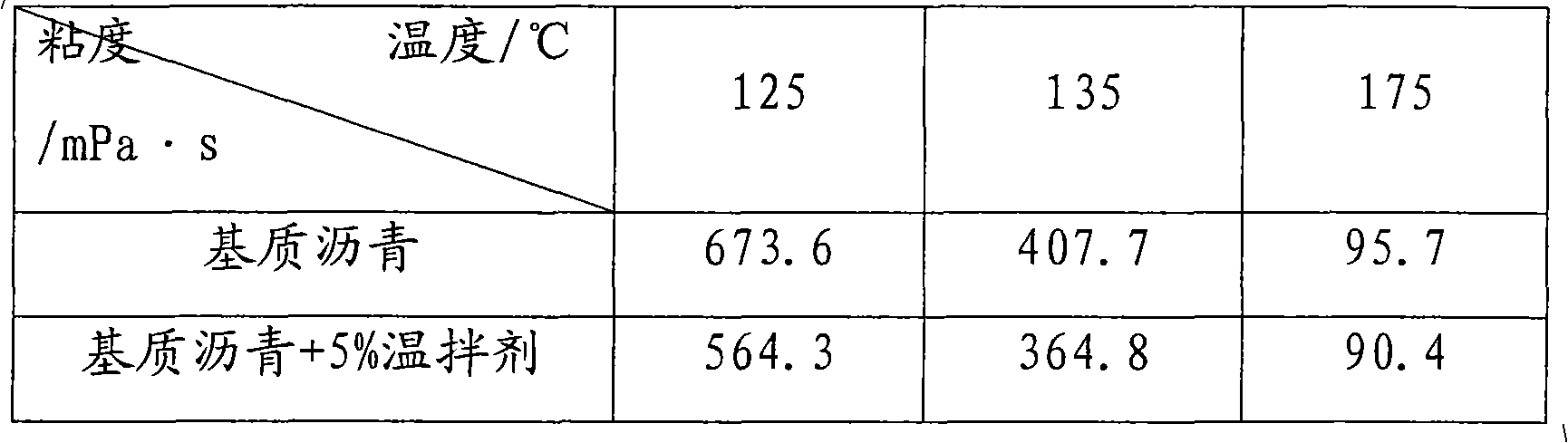

Rubber modified asphalt warm-mixing agent, preparation method and application

InactiveCN101831187ALow viscosityLow softening pointClimate change adaptationBuilding insulationsSurface-active agentsFatty alcohol

The invention discloses a rubber modified asphalt warm-mixing agent, a preparation method and application thereof. The warm-mixing agent comprises the following components in parts by weight: 100 parts of water, 5-30 parts of fatty alcohol sodium sulfate, 15-30 parts of palmitic acid, 5-30 parts of oleic acid, 1-20 parts of sodium dodecyl benzene sulfonate, 1-15 parts of cetyltrimethylammonium chloride and 10-30 parts of imidazoline-type cationic surface active agent ODD. The preparation method comprises the following steps of: adding the water in a container at the temperature of 65 DEG C, and then adding the following substances under the condition of stirring: the fatty alcohol sodium sulfate, the palmitic acid, the oleic acid, the sodium dodecyl benzene sulfonate, the cetyltrimethylammonium chloride and the imidazoline-type cationic surface active agent ODD, and stirring for 15 min to obtain the warm-mixing agent. The warm-mixing agent is directly applied to rubber asphalt or matrix asphalt to reduce the viscosity of the asphalt. The kinematic viscosity of the rubber powder asphalt added with the warm-mixing agent at the temperature of 150 DEG C can reach less than 3.0Pa.s of the kinematic viscosity at the temperature of 180 DEG C, and the production temperature can be reduced by about 30 DEG C, thereby not only preventing the rubber asphalt from being aged but also saving energy and reducing equipment loss.

Owner:BEIJING UNIV OF CHEM TECH

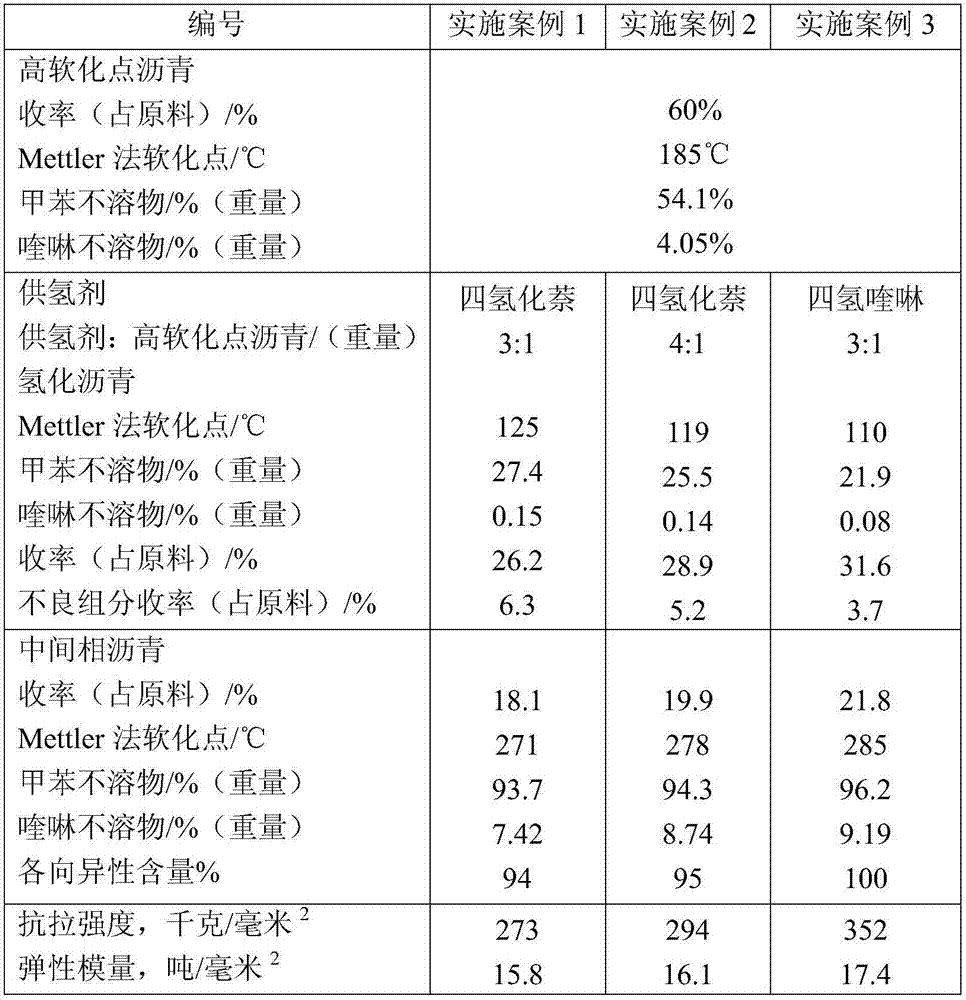

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

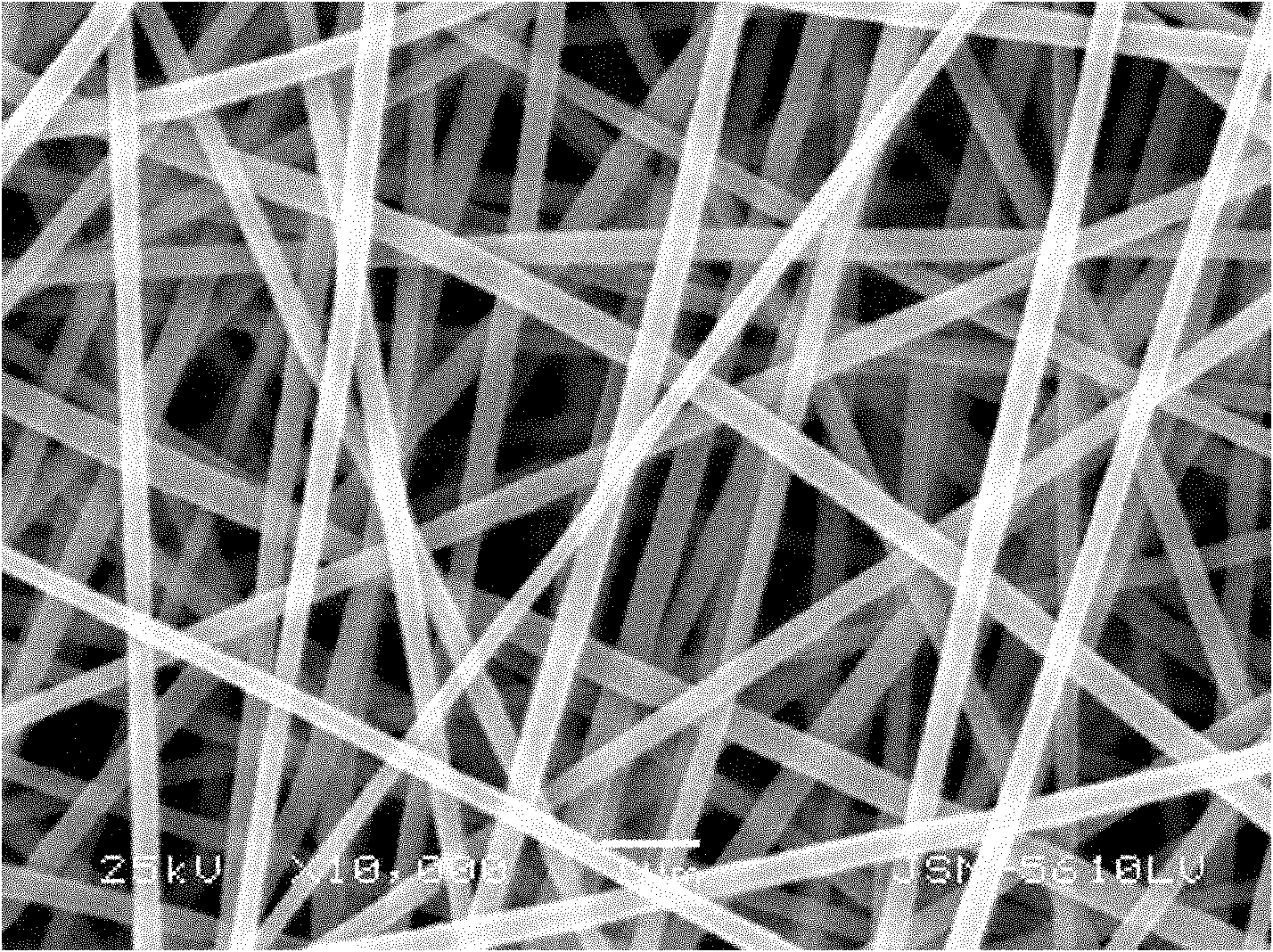

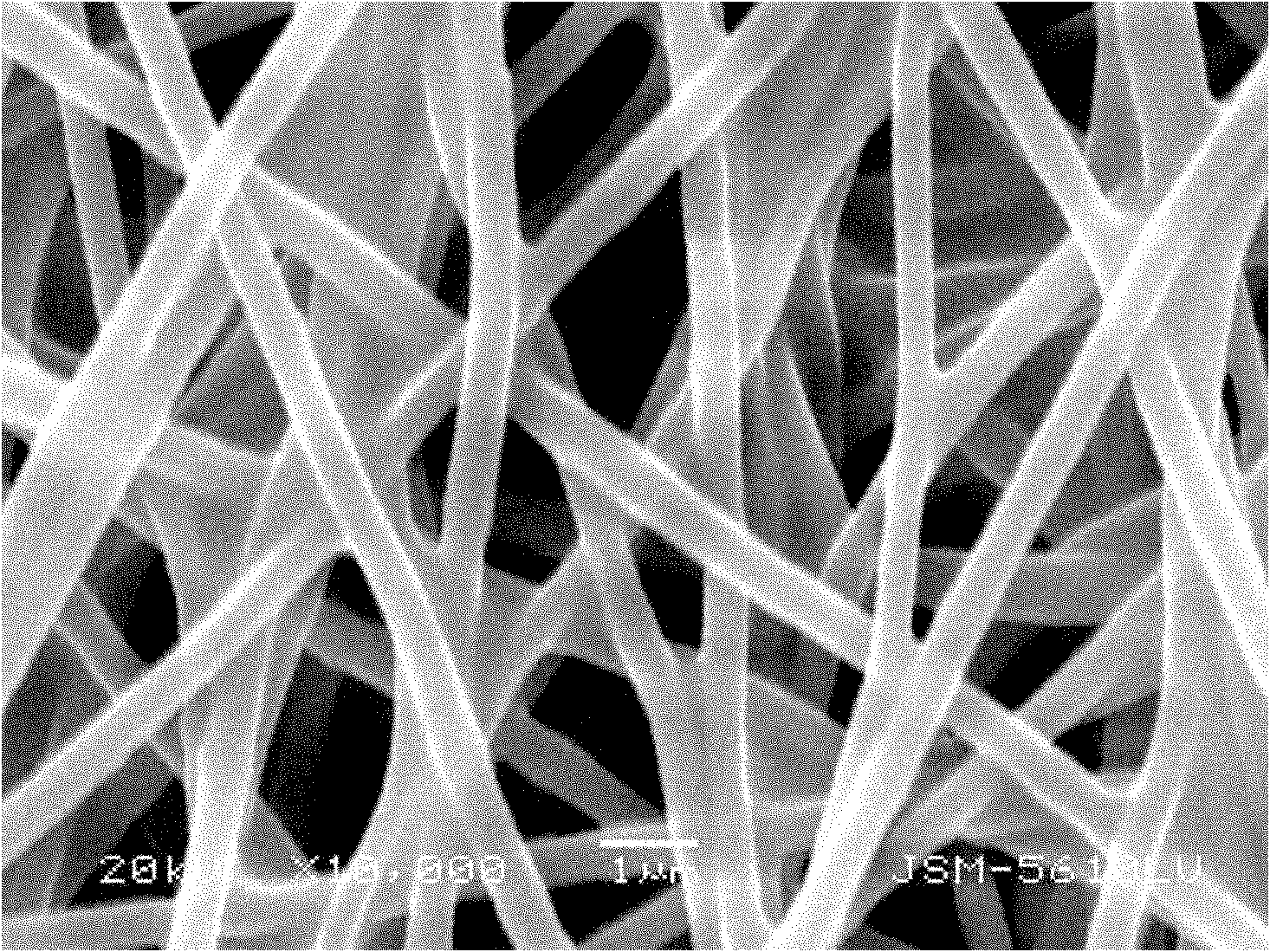

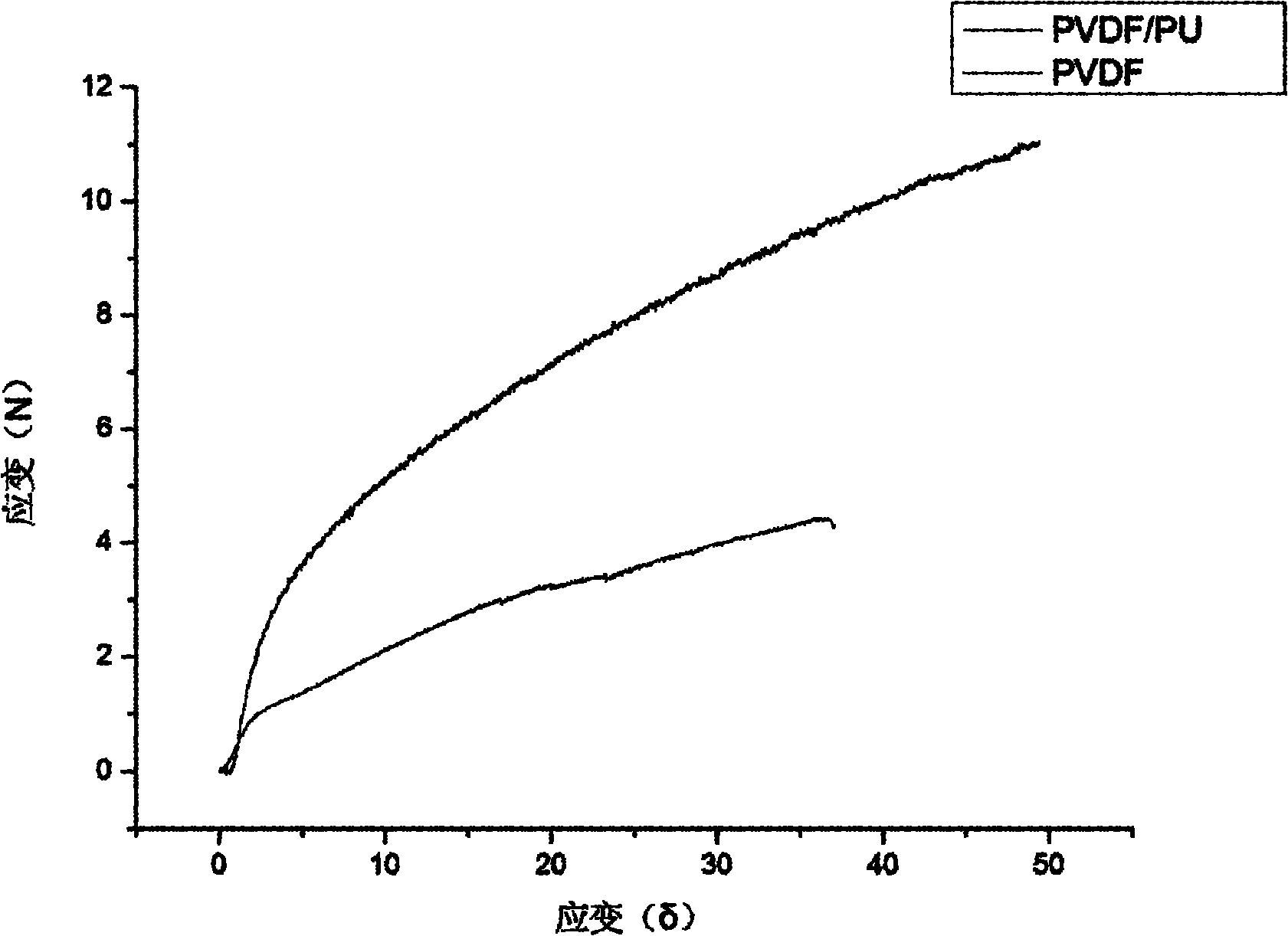

Reinforced nanofiber porous membrane and preparation method thereof

InactiveCN102140762AHigh porosityImprove wettabilityFibre typesCell component detailsFiberPolymer science

The invention relates to a reinforced nanofiber porous membrane and a preparation method thereof. The porous membrane is a two-component lithium ion battery diaphragm formed by compounding polymer resin with polyurethane, and has a semi-interpenetrating network structure, the porosity of 60 to 80 percent, and mechanical property which is 3 to 4 times higher than that of a polymer resin single-component porous membrane. The preparation method comprises the following steps of: preparing a polymer resin non-woven membrane by high-voltage electrostatic spinning, impregnating the non-woven membrane in solution of wet curing reaction polyurethane prepolymer with a high-reactivity isocyanate group, reacting -NCO in the polyurethane prepolymer with a -OH bond of water in air at room temperature to obtain the polyurethane through crosslinking and autopolymerization, so that nanofibers in the non-woven membrane are bonded to form a polymer resin and polyurethane two-component composite membrane, and the mechanical strength of the fiber membrane is greatly improved. The method is easy to operate, and the prepared non-woven membrane keeps the advantages of high porosity of a membrane prepared by an electrostatic spinning technology, and heat stability of the polymer resin, and has high ion permeability and affinity of electrolyte.

Owner:WUHAN UNIV OF TECH

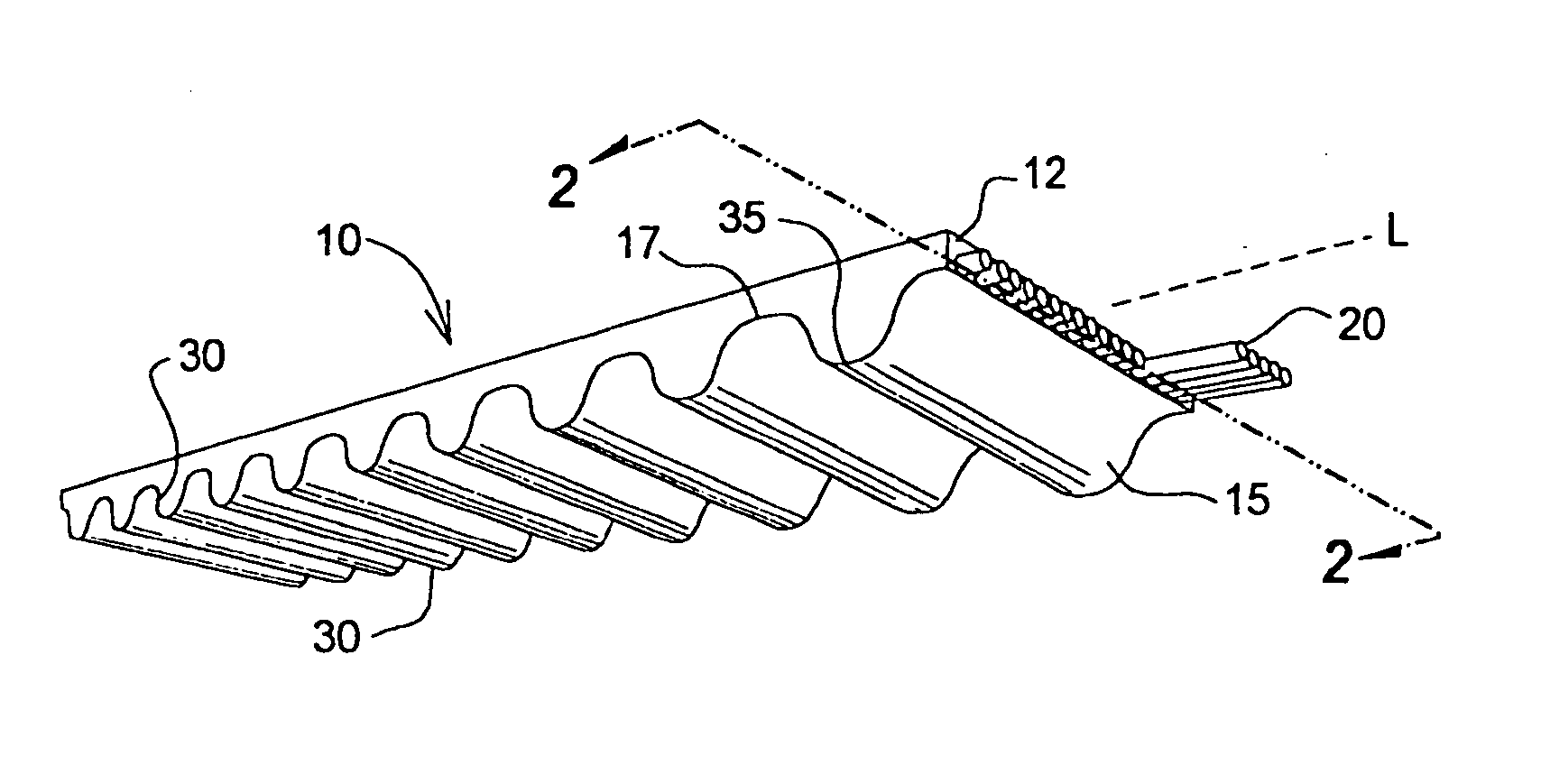

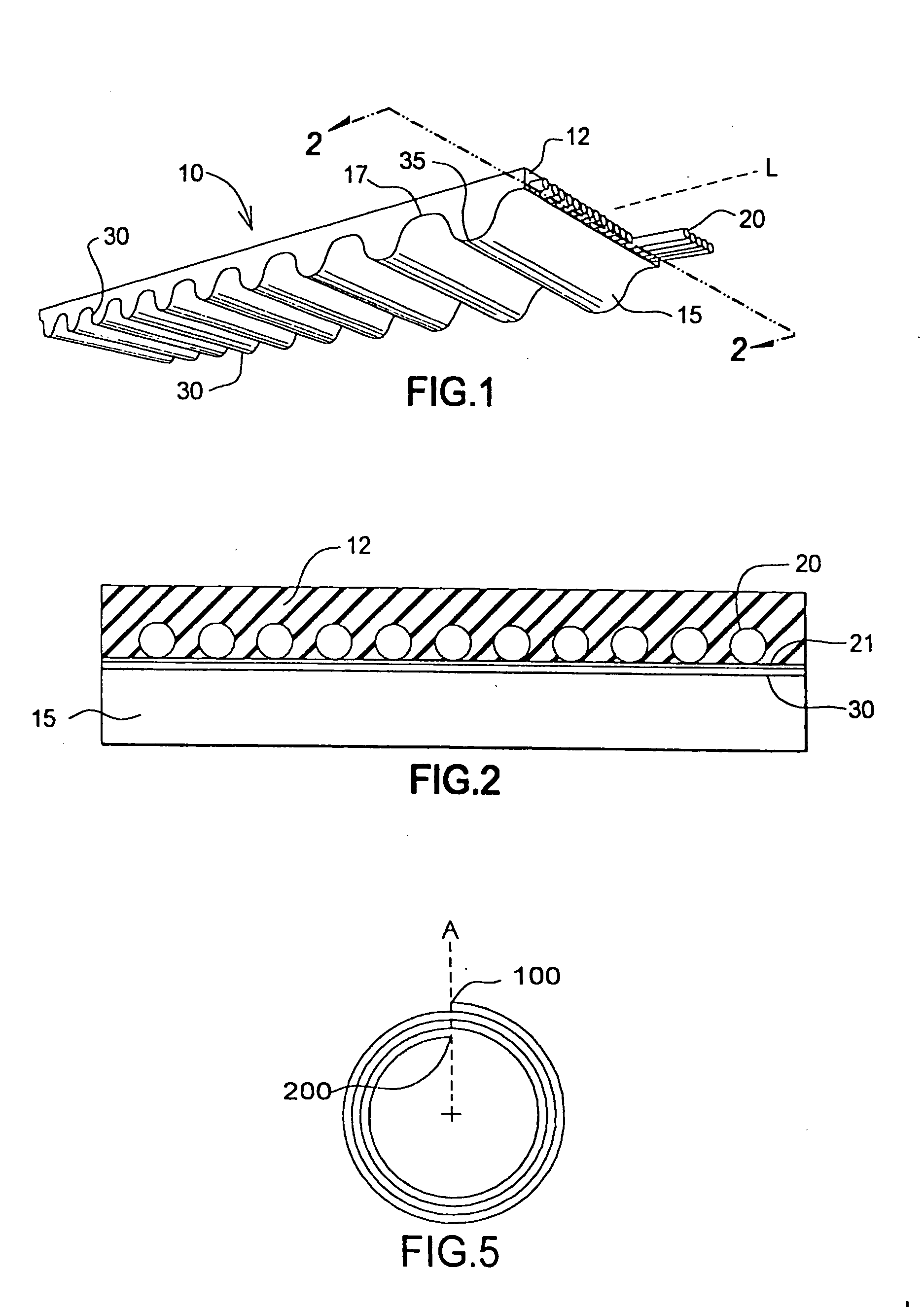

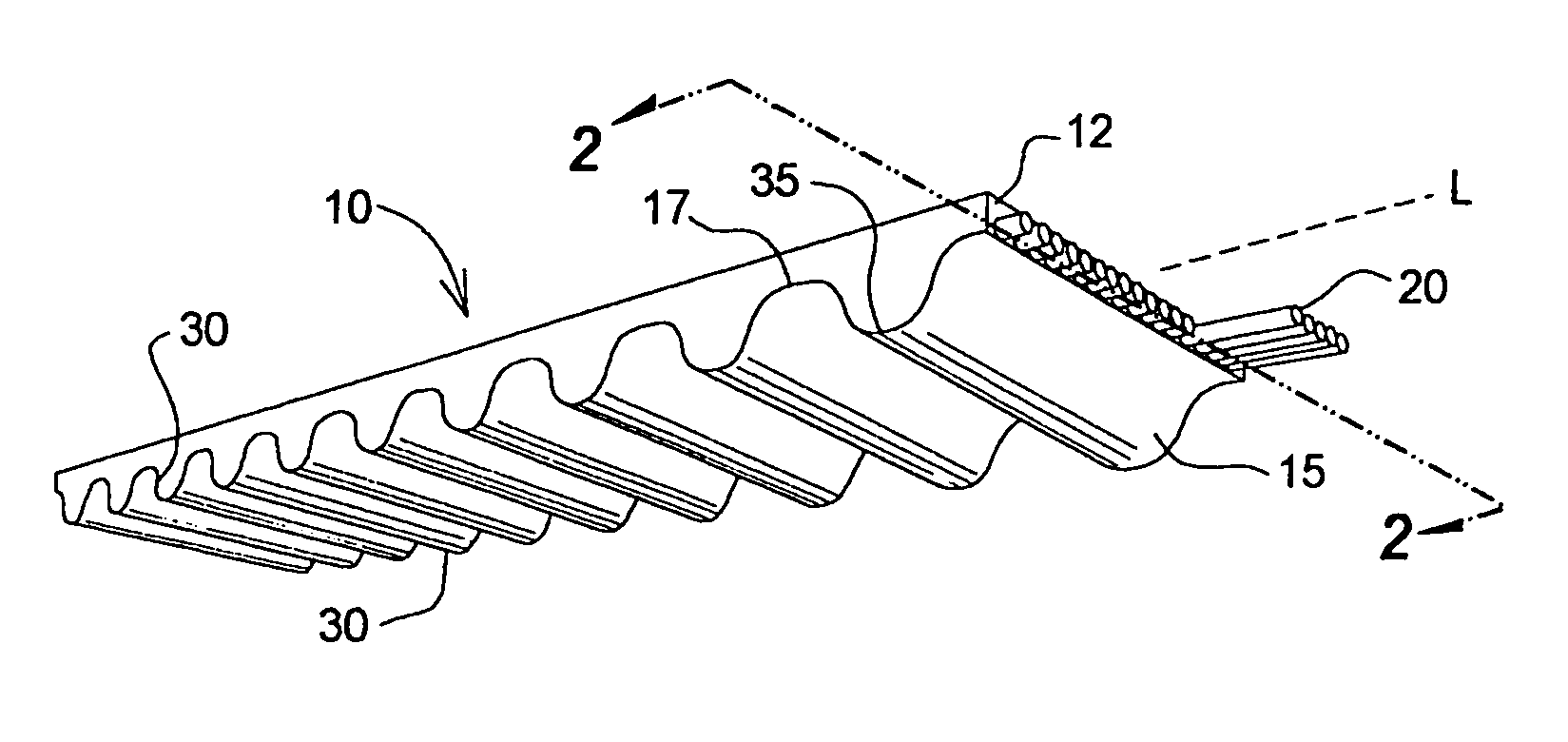

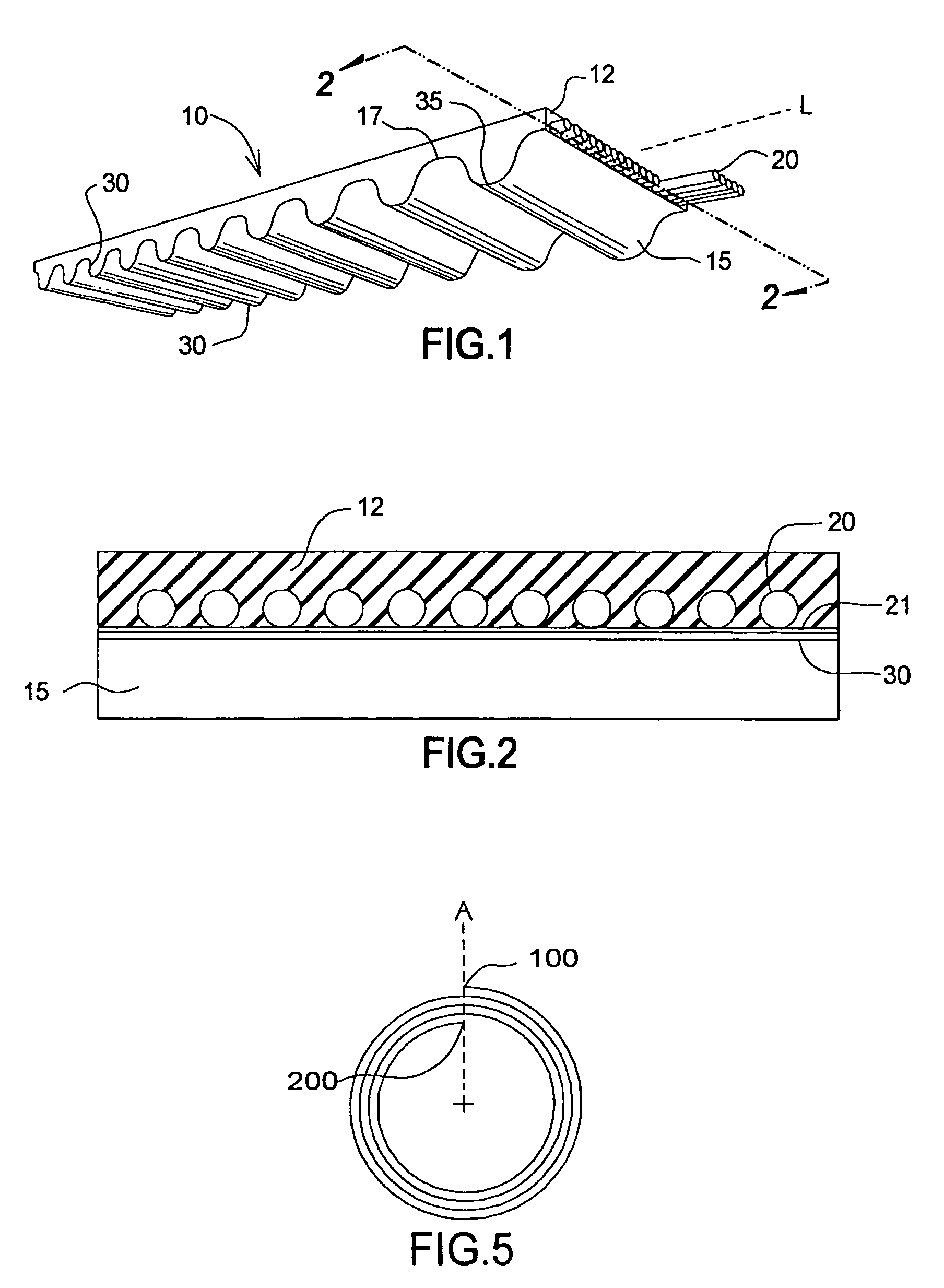

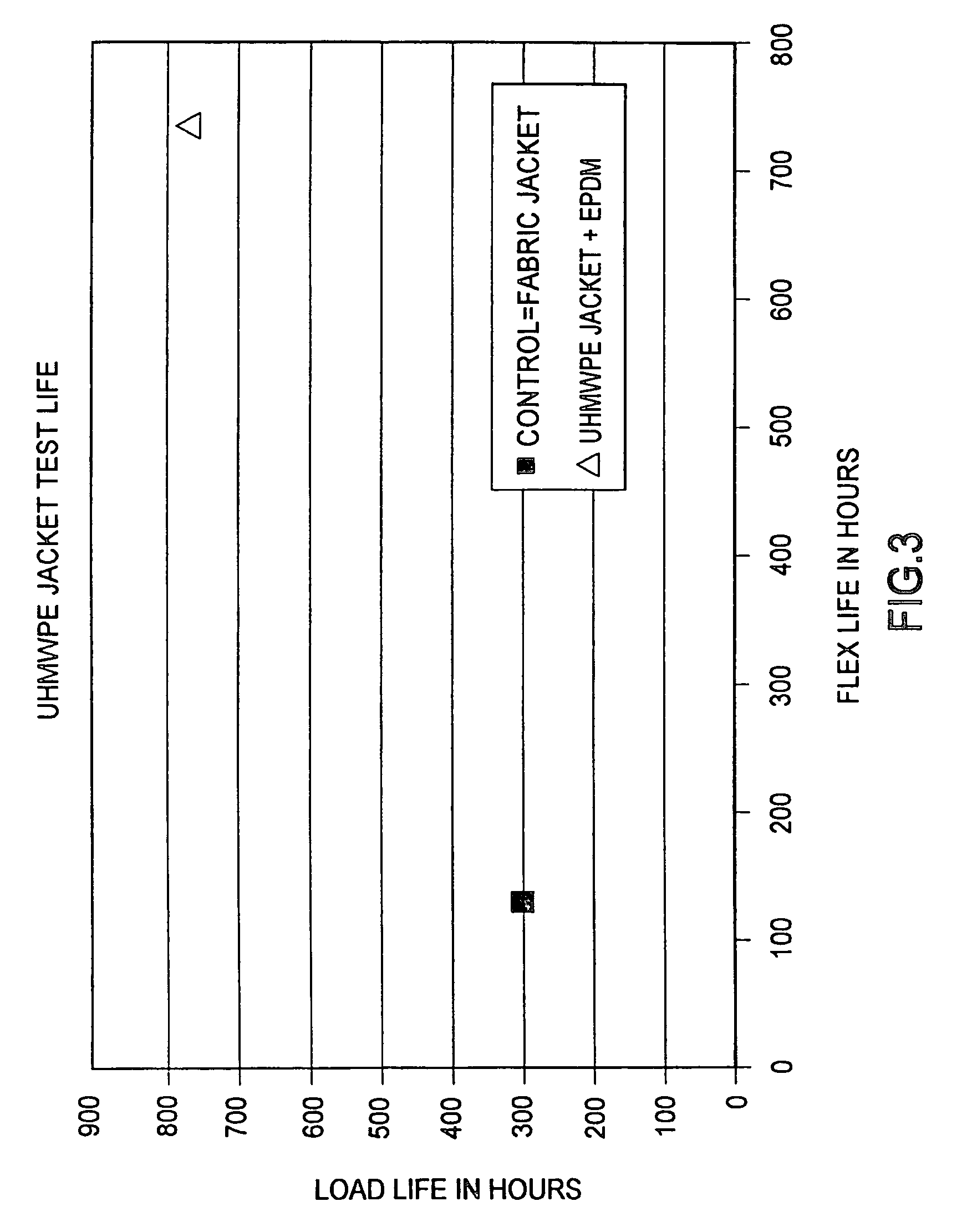

Thermoplastic jacket belt

A belt having a body, a tensile member and an outer surface. The body comprises an elastomer. An outer surface of the belt having a profile, foe example teeth. A layer of Ultra high molecular weight polyethylene thermoplastic (UHMWPE) is bonded to the profile surface. The layer bonded to the profile surface having a low softening point allowing it to conform to a mold shape prior to cure of the rubber body material. The layer having a molecular weight in the range of 3-7 million grams per mole. The layer causes the belt to exhibit superior abrasion resistance and flexibility while reducing the cost per belt as compared to fabric jacket belts. The UHMWPE jacket belt has significantly reduced dust and debris production during operation.

Owner:MARTIN DIETER +2

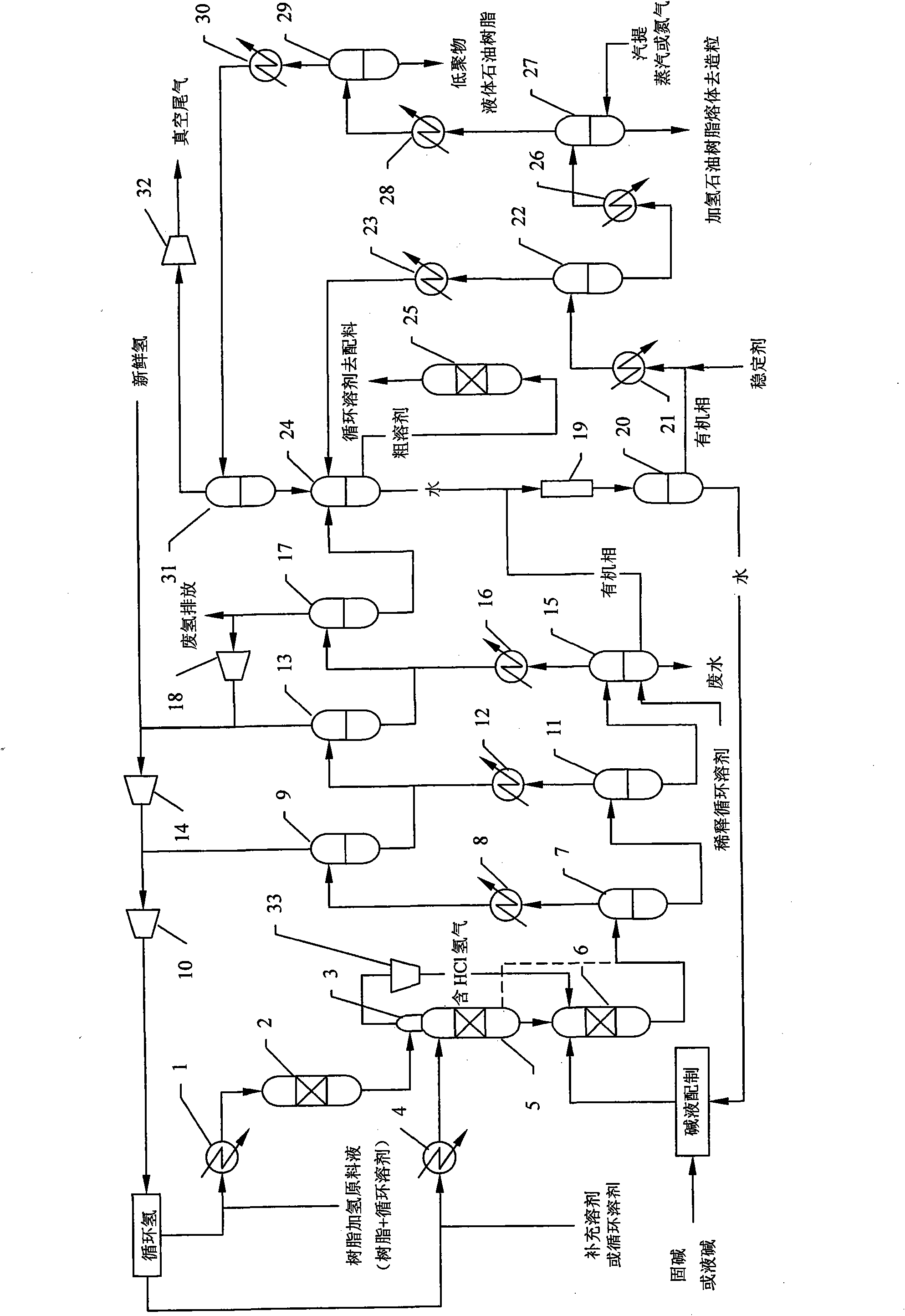

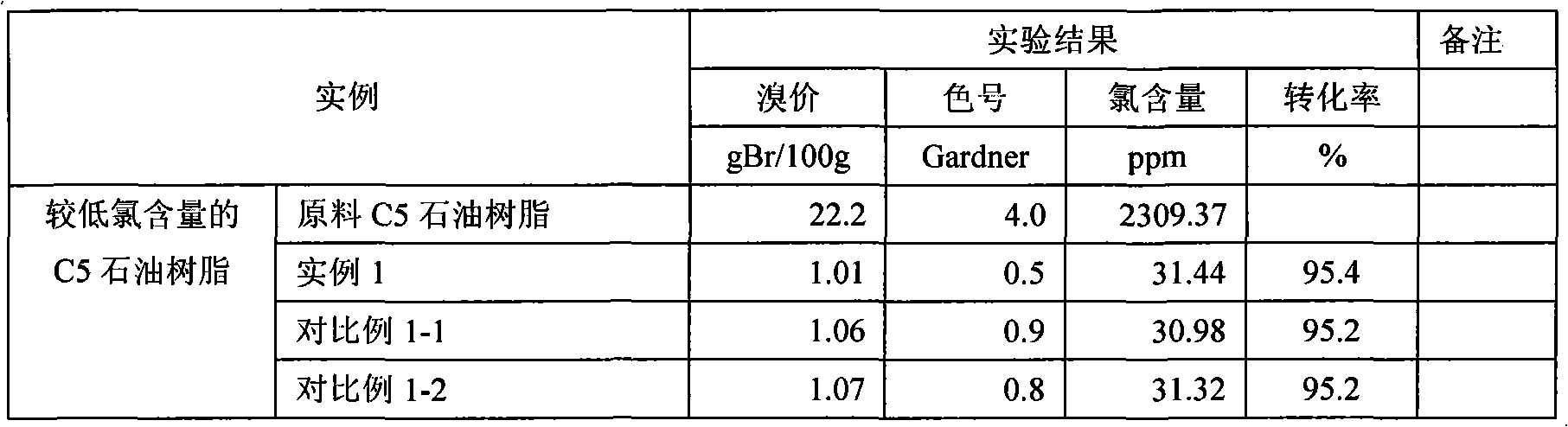

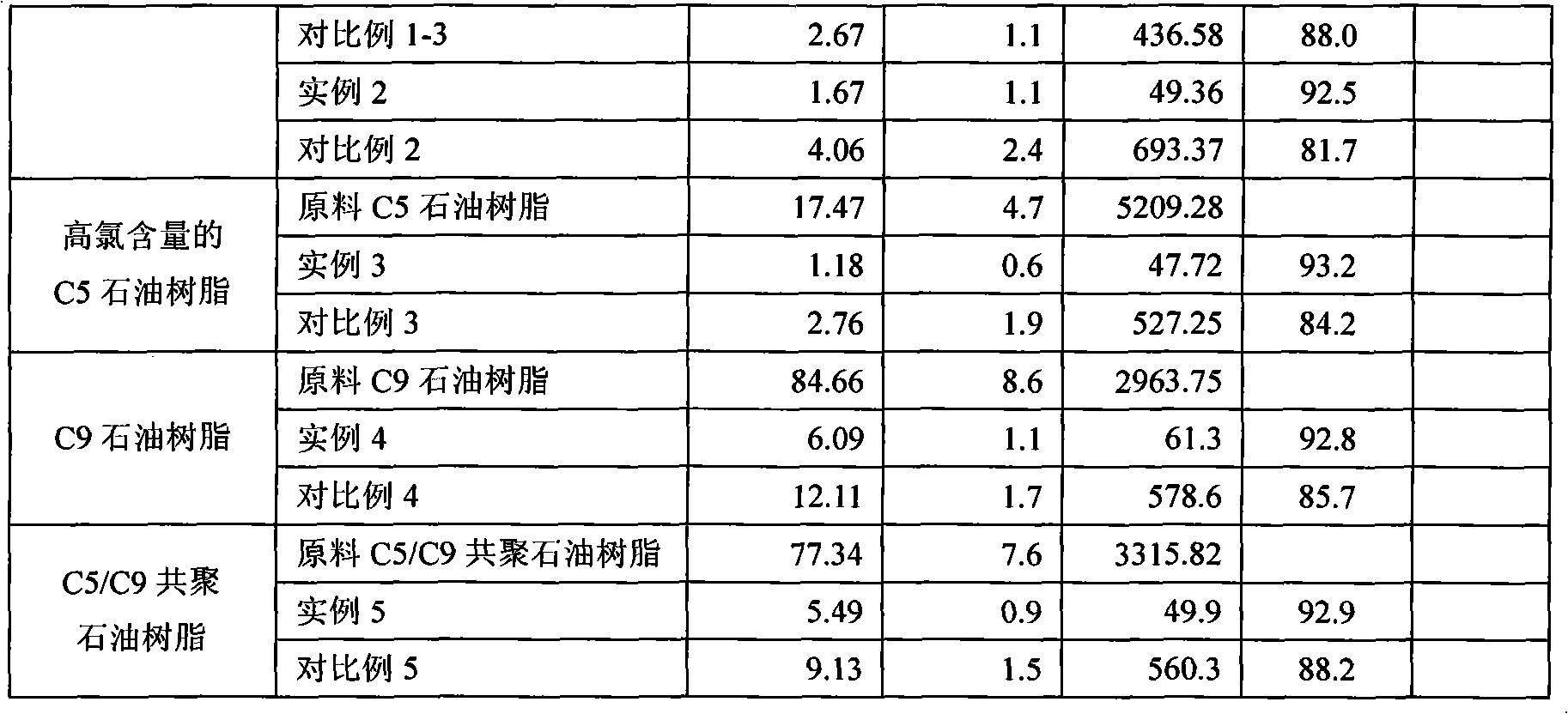

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

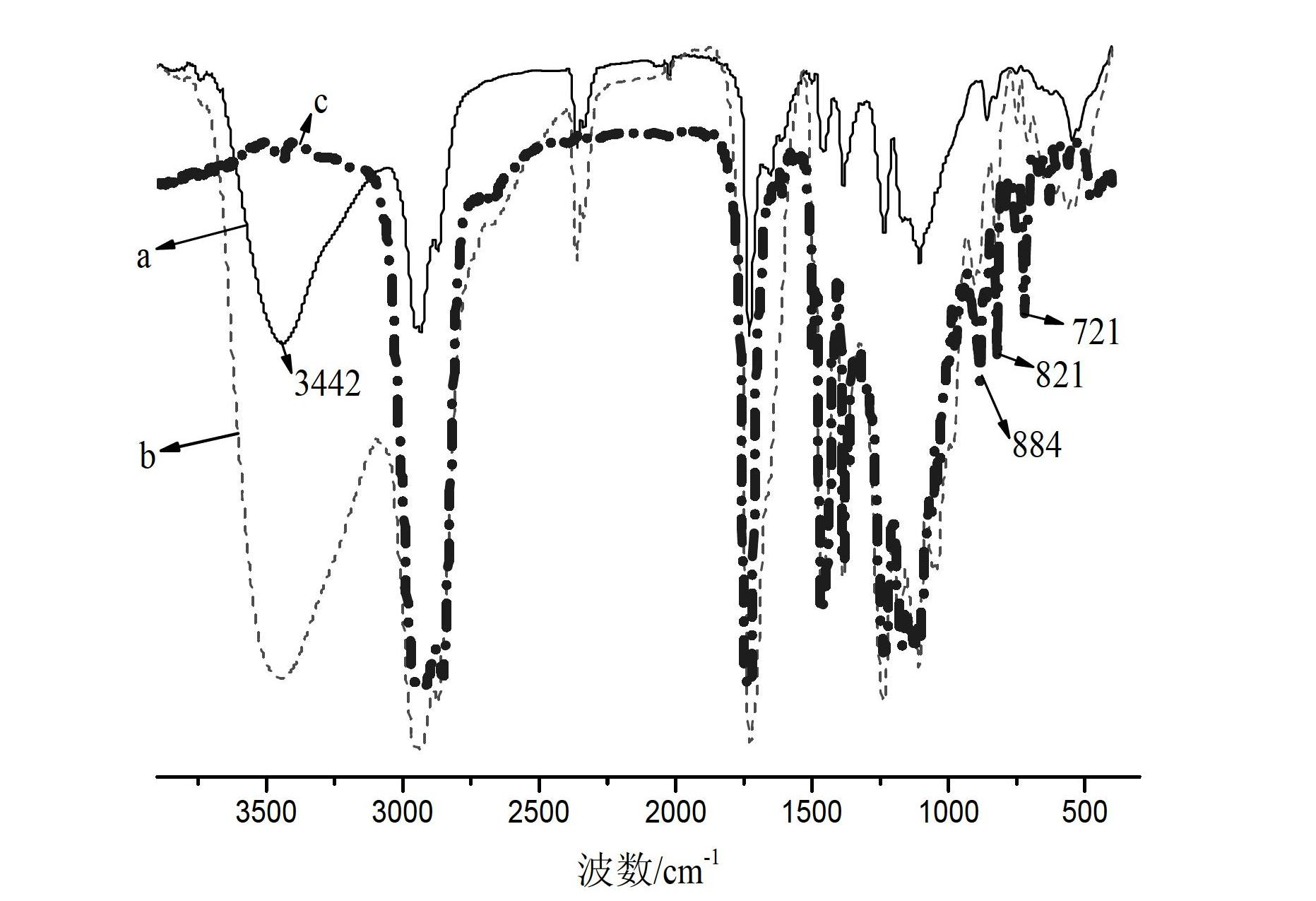

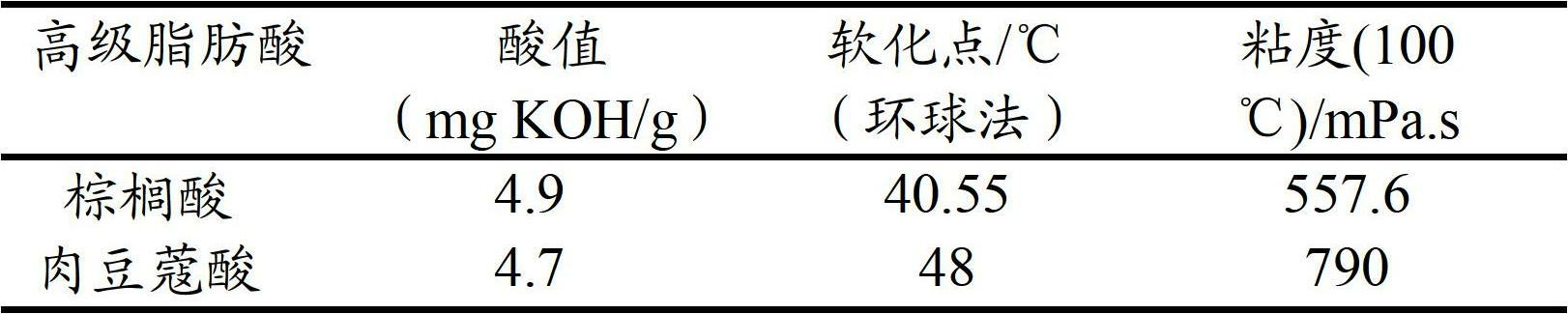

Low-temperature resistant rosin thickening resin, preparation method and usage thereof

ActiveCN102676062ALow softening pointLow viscosityNatural resin chemical modificationRosin adhesivesPolyolHot melt

The invention discloses a preparation method of low-temperature resistant rosin thickening resin, which comprises the following steps of: under the protection of inert gas, melting rosin, and reaction the melted rosin with polyalcohol for 4-24h at the temperature of 200-290 DEG C under the action of catalyst; discharging to obtain polyalcohol modified abietate; and then, under the protection of inert gas, reacting the obtained polyalcohol modified abietate with higher fatty acid at the temperature of 200-290 DEG C for 4-24h, and discharging to obtain the rosin thickening resin; or under the protection of inert gas, melting the rosin, and then adding catalyst, the polyalcohol and the higher fatty acid into the melted rosin, carrying out reaction for 4-24h at the temperature of 200-290 DEG C, and discharging to obtain the rosin thickening resin. The rosin thickening resin prepared by the method is low in softening point and viscosity and higher in cold resistance. Meanwhile, the invention also discloses the low-temperature resistant rosin thickening resin prepared by the method disclosed by the invention, and the usage of the low-temperature resistant rosin thickening resin in preparation of a hot melt pressure sensitive adhesive.

Owner:普洱科茂林化有限公司

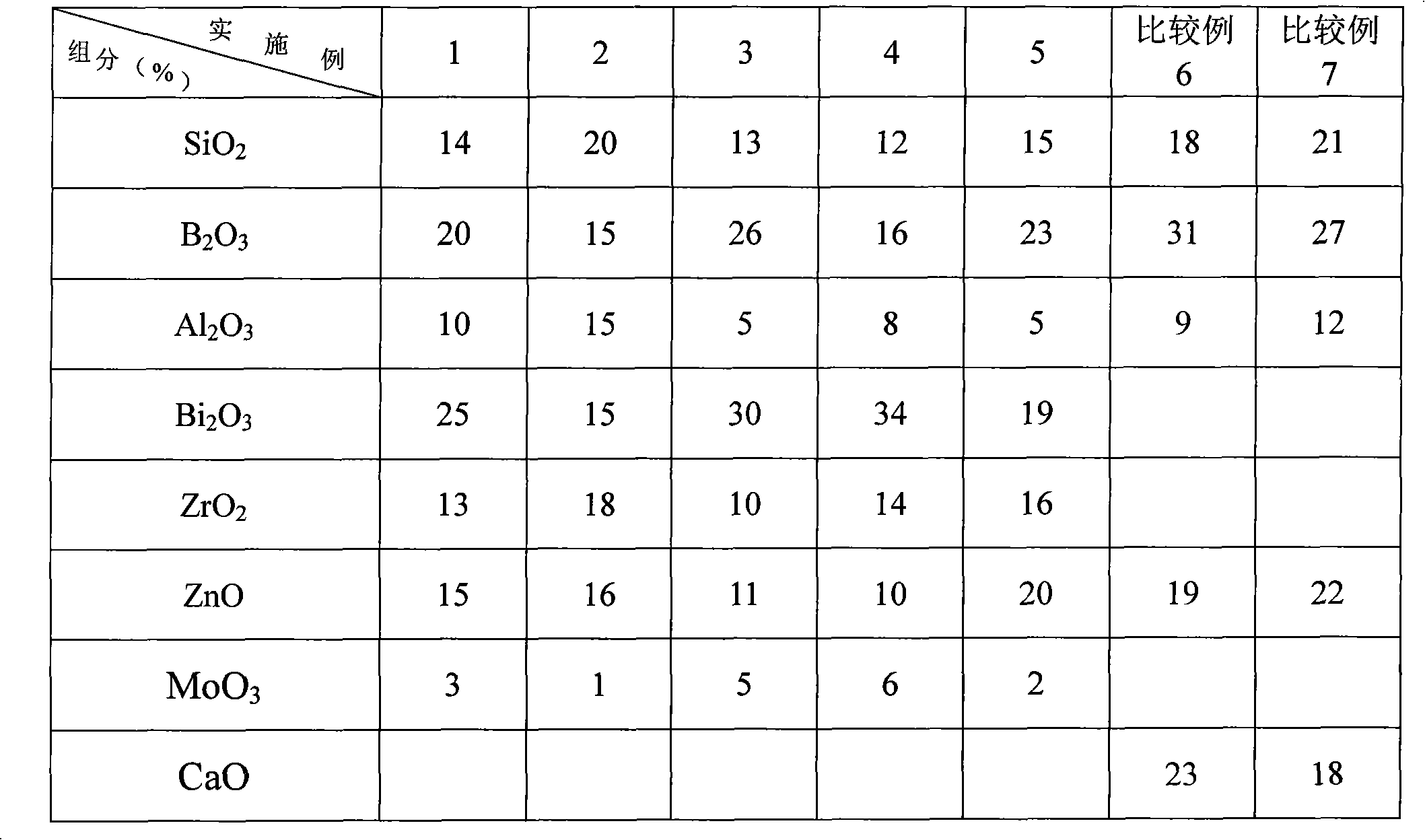

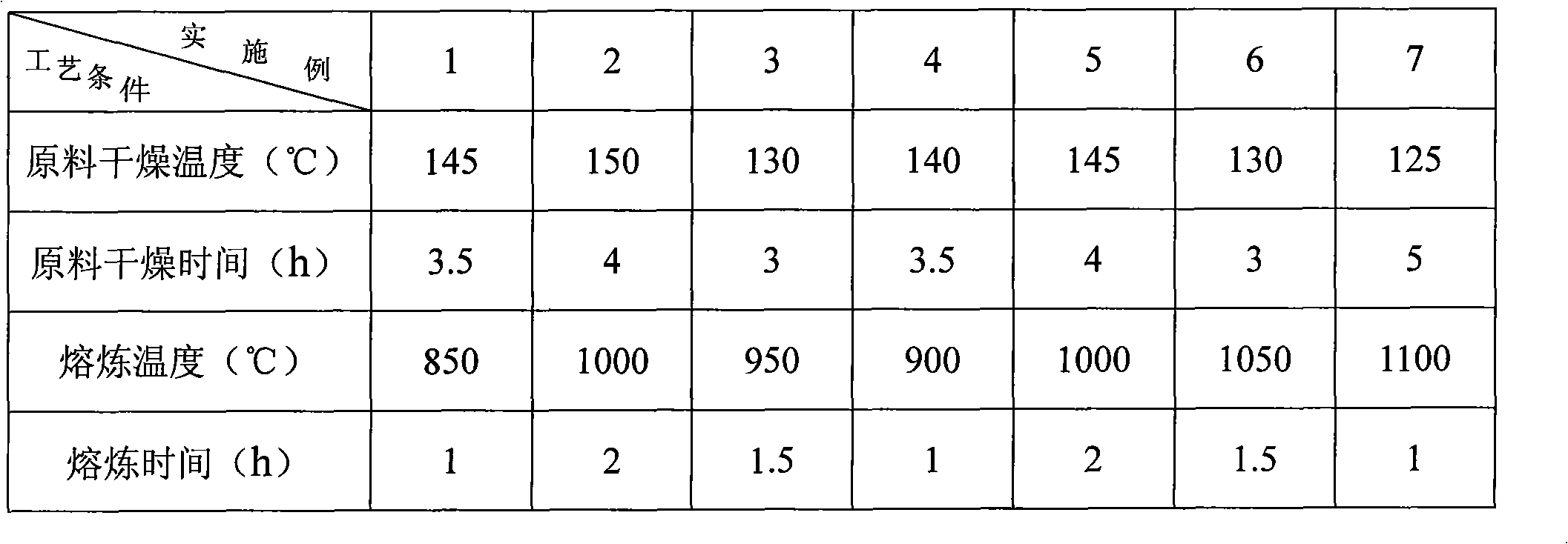

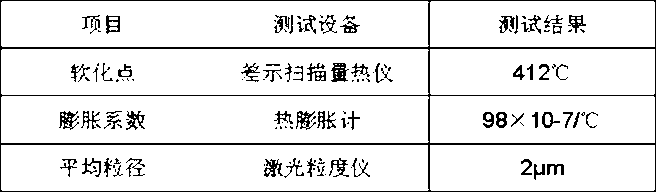

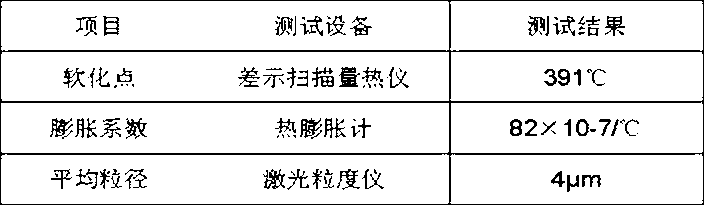

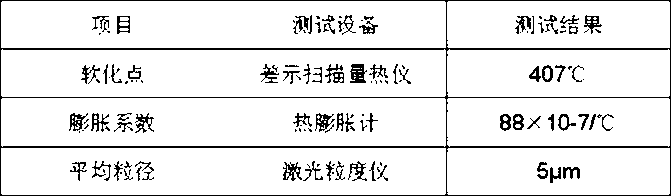

Inorganic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555388ASmall expansion coefficientLess bendingFinal product manufactureInorganic adhesivesAdhesiveSilicon solar cell

The invention provides inorganic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The inorganic adhesive comprises the following components by the weight part: 10% to 20% of SiO2, 15% to 30% of B2O3, 5% to 15% of Al2O3, 15% to 35% of Bi2O3, 10% to 18% of ZrO2, 10% to 25% of ZnO and 1% to 8% of MoO with the total amount being 100%. The preparation method comprises the following steps: putting the components forming the inorganic solvent into a mixer to mix the components uniformly; loading the mixed components into a porcelain crucible and placing the porcelain crucible into a baking oven to be dried at the temperature of 120 to 150 DEG C for 3 to 5 hours; then, placing the porcelain crucible into a high-temperature furnace to melt at the temperature of 800 to 1,100 DEG C for melting for 1 to 2 hours; carrying out water-quenching and oven-drying; milling the components with a planetary ball mill until the particle size is lower than 10 mum; and oven-drying the components to obtain the final product of the inorganic adhesive. The glass powder has lower softening temperature and high adhesion when the aluminum paste prepared from the inorganic solvent is used for sintering, so that the aluminum powder layer can be firmly adhered to silicon chips; the expansion coefficient is lower after sintering; the bending degree of cell chips is lower; and the breakage rate is reduced.

Owner:WUXI RUXING TECH DEV +1

A kind of electronic silver paste and its preparation process

ActiveCN102290118ALow melting pointLow softening pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteElectricity

The invention relates to electronic silver paste and a preparation process thereof, belonging to the technical field of production of such base materials as electronic ceramic components, thick film hybrid circuits, touch components and the like. The electronic silver paste is prepared by mixing and stirring 4-9% of glass powder, 63-80% of silver powder, 12-28% of organic carrier and 0.2-2% of additive, rolling, dispersing and grinding the mixture, then adding 1-2wt% of bismuth stearate, stirring the mixture uniformly and filtering the mixture with a screen. The electronic silver paste and the preparation process have the following beneficial effects: the glass powder system does not contain lead; the minimum grain size and shape of the silver powder are not strictly required; and the silver paste is especially suitable for the positive electrodes of the solar cells on the crystalline silicon solar cell silicon substrates produced in large batch and has excellent electrical property and mechanical property..

Owner:郴州雄风环保科技有限公司

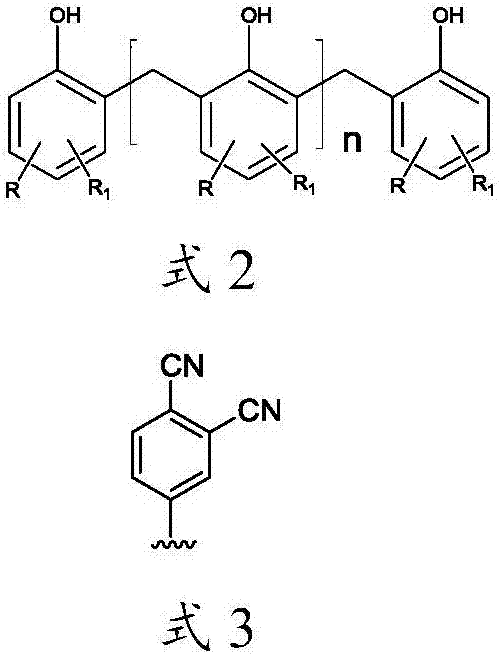

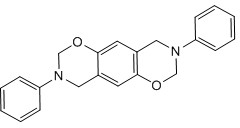

Nitrile resin monomer, nitrile resin polymer and preparation method of nitrile resin monomer and nitrile resin polymer

InactiveCN102976972ALow viscosityReduce liquidityCarboxylic acid nitrile preparationOrganic compound preparationPolymer scienceResin matrix

The invention discloses a nitrile resin monomer, a nitrile resin polymer and a preparation method of the nitrile resin monomer and the nitrile resin polymer, belonging to the technical field of organic polymer materials. The nitrile resin monomer is a tetraphthalonitrile resin monomer containing benzoxazine cycle, and the nitrile resin polymer is a product obtained by heating polymerization of the nitrile resin monomer. The nitrile resin monomer has a low viscosity, a good mobility and the processing performances of low-temperature curing and the like at a low temperature. The nitrile resin polymer has the good curing performances of self-flame resistance, adhesion, heat stability and the like. The resin monomer has the good processing performances of benzoxazine resins, and the resin polymer has the high-temperature resistance of nitrile resins, thus reducing the curing processing temperature and being capable of being used in a high-temperature temperature, namely, having the advantages of low temperature processing, medium temperature formation and high temperature use; and the resin monomer and the resin polymer can be used in the fields of coatings, adhesives, electronic packaging materials, aeronautics, astronautics, ships, resin matrix composites and the like. The preparation method is simple and easy to control, low in reaction temperature, energy-saving, and suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

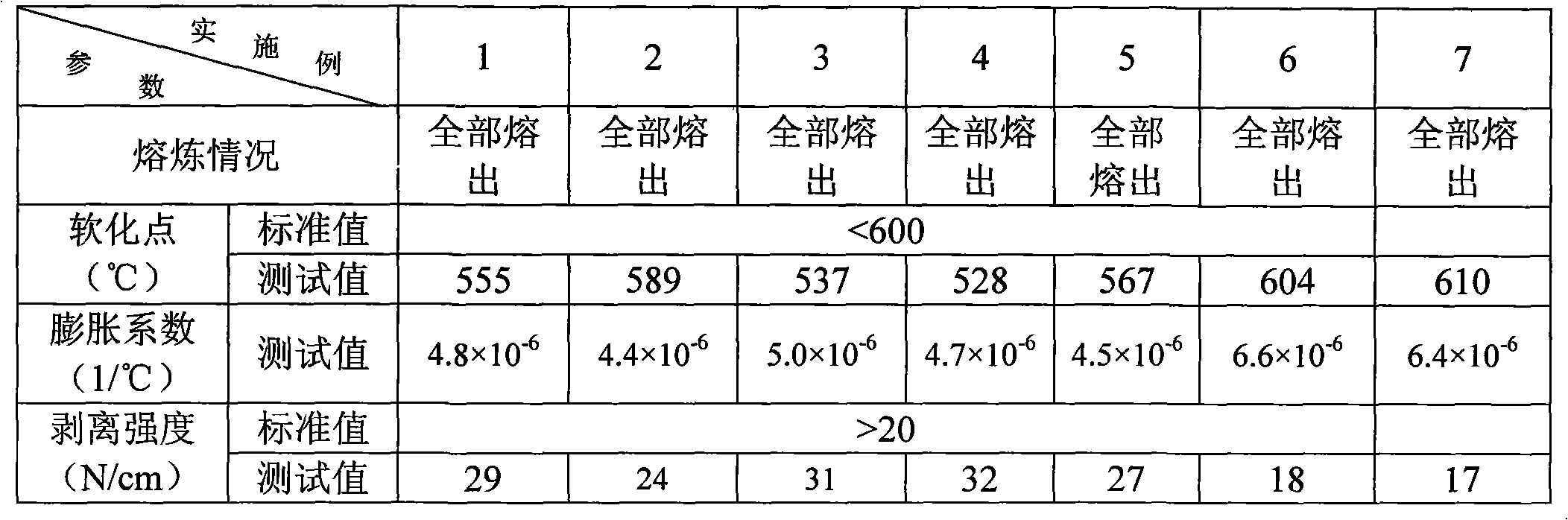

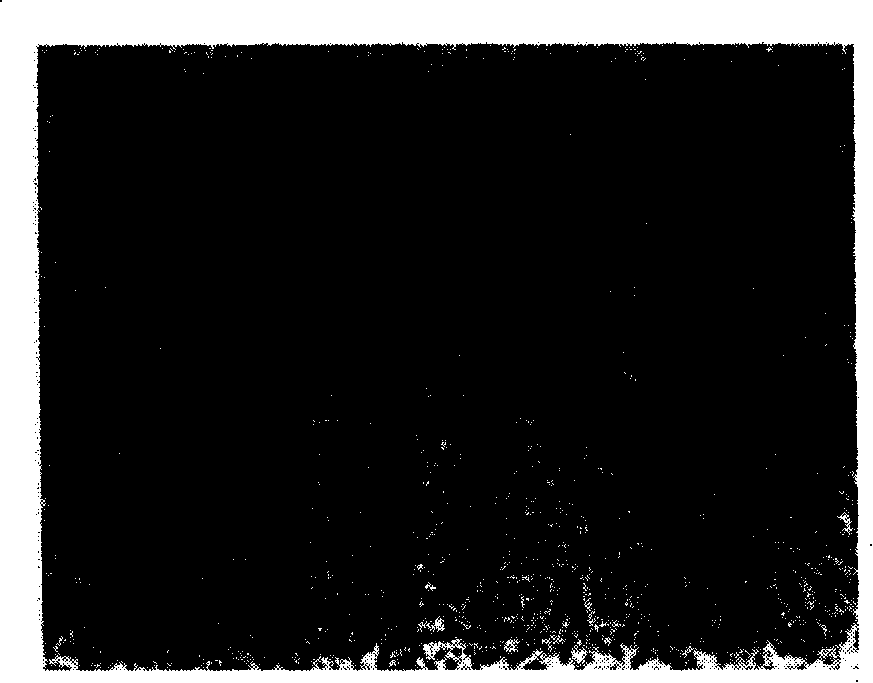

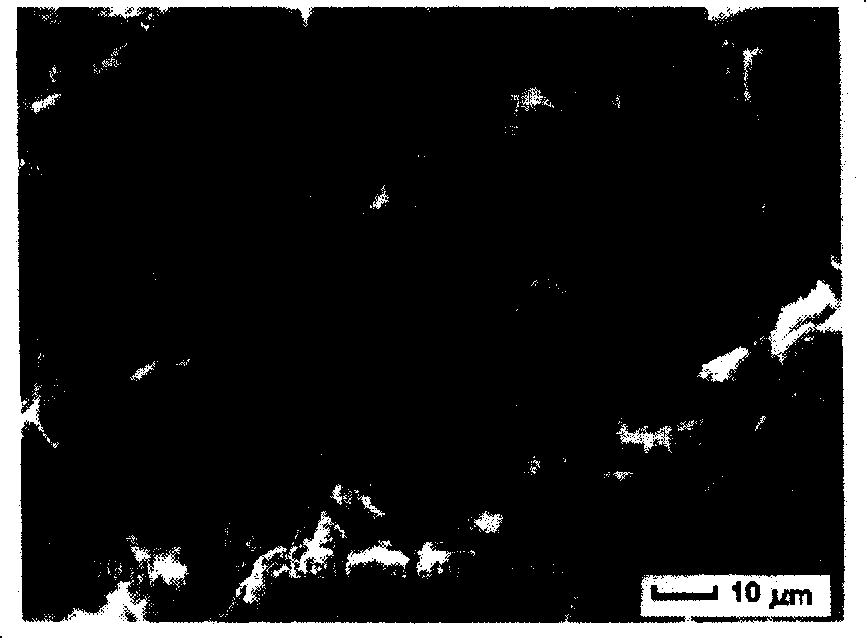

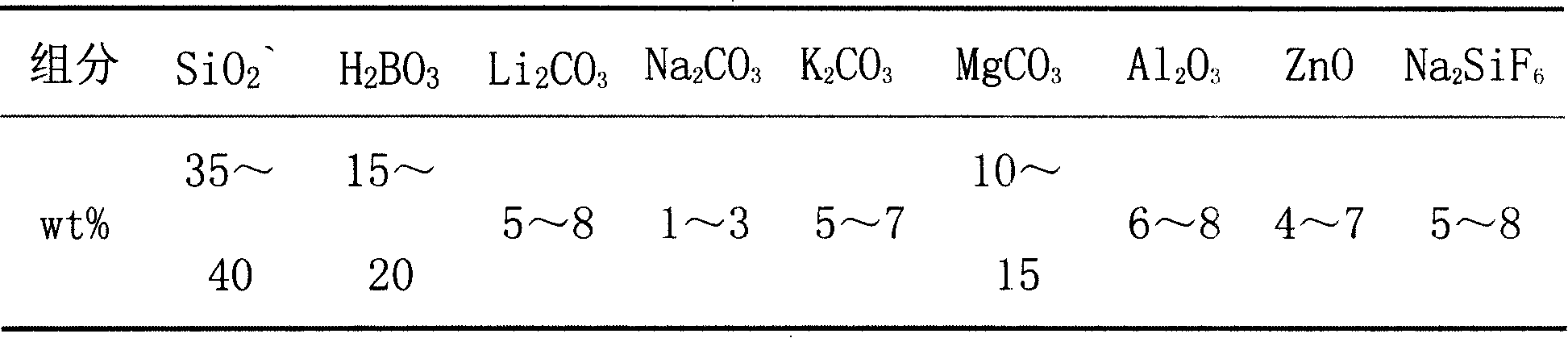

Glass-ceramics used as ultrahard material grinding wheel bond and preparation method thereof

The invention relates to a microcrystal glass and preparation method used as super-hard grinding wheel bond, which adopts the method that: quartz, boracic acid, alumina, zinc oxide, lithium carbonate, sodium carbonate, potassium carbonate and magnesium carbonate are used as basic glass materials and sodium fluorosilicate is used as nucleation agent, the materials are smelted to form the glass that is quenched and then smashed to glass powder; the glass powder is pressed, molded, and sintered, and crystallized under certain temperature so as to obtain the microcrystal glass; the main crystal phase of the microcrystal glass is fluorophlogopite, the microcrystal is a hexagonal flake structure, the size of the microcrystal is 1um-2um. The microcrystal glass can be used as super-hard grinding wheel bond in place of ceramic so as to improve the strength of super-hard grinding wheel greatly, thereby improving speed and service life of grinding wheel; the invention also has integrated with excellent performances of glass and porcelain enamel, such as wear-resistant, anti-corrosion, good anti-oxidation, excellent electrical property, adjustable expansion coefficient, and good thermal stability. The invention can widely be applied as structural materials, optical materials, and architecture materials.

Owner:HUNAN UNIV

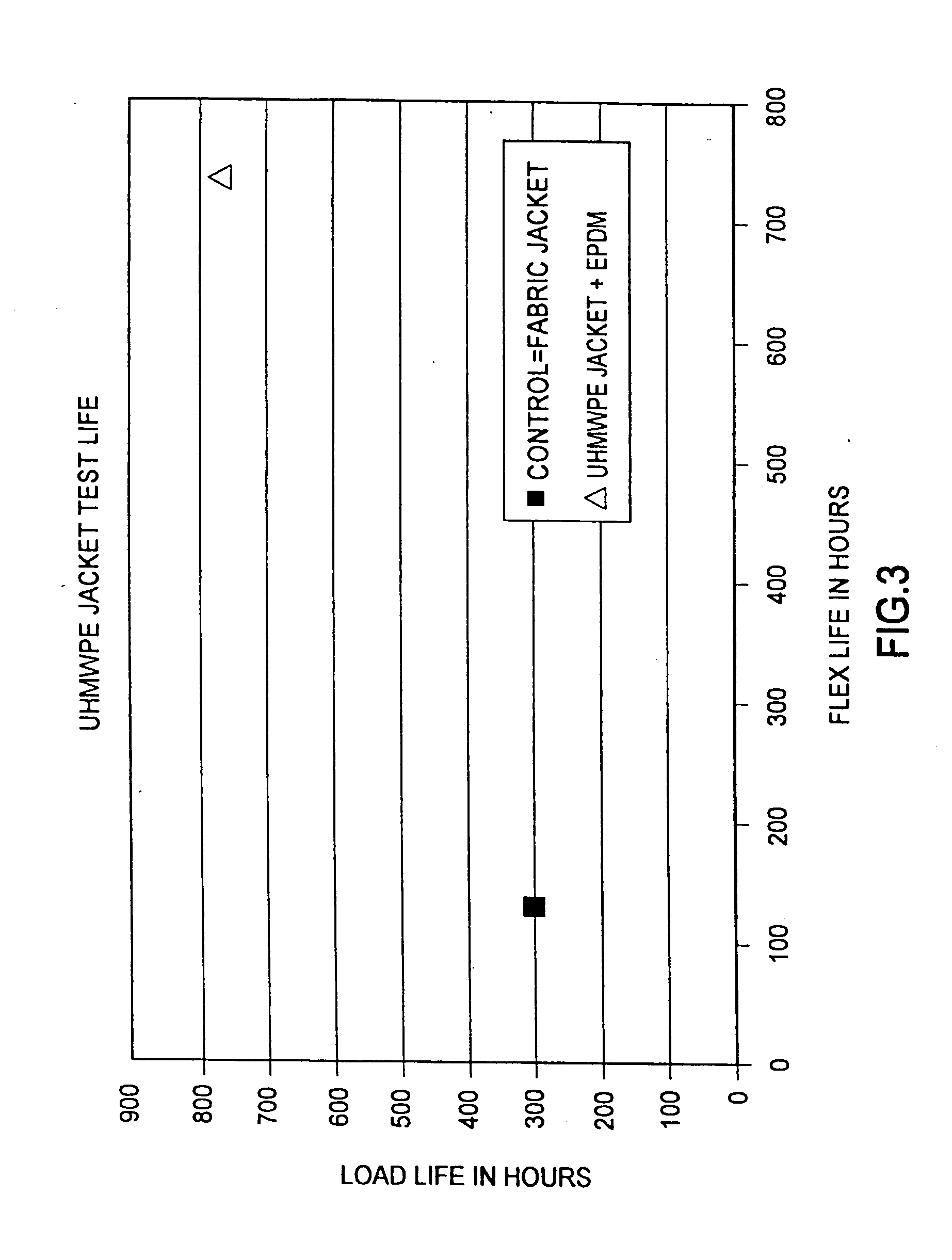

Thermoplastic jacket belt

InactiveUS7235028B2Increase resistanceLow softening pointV-beltsRopes and cables for vehicles/pulleyThermoplasticElastomer

A belt having a body, a tensile member and an outer surface. The body comprises an elastomer. An outer surface of the belt having a profile, foe example teeth. A layer of Ultra high molecular weight polyethylene thermoplastic (UHMWPE) is bonded to the profile surface. The layer bonded to the profile surface having a low softening point allowing it to conform to a mold shape prior to cure of the rubber body material. The layer having a molecular weight in the range of 3-7 million grams per mole. The layer causes the belt to exhibit superior abrasion resistance and flexibility while reducing the cost per belt as compared to fabric jacket belts. The UHMWPE jacket belt has significantly reduced dust and debris production during operation.

Owner:THE GATES CORP

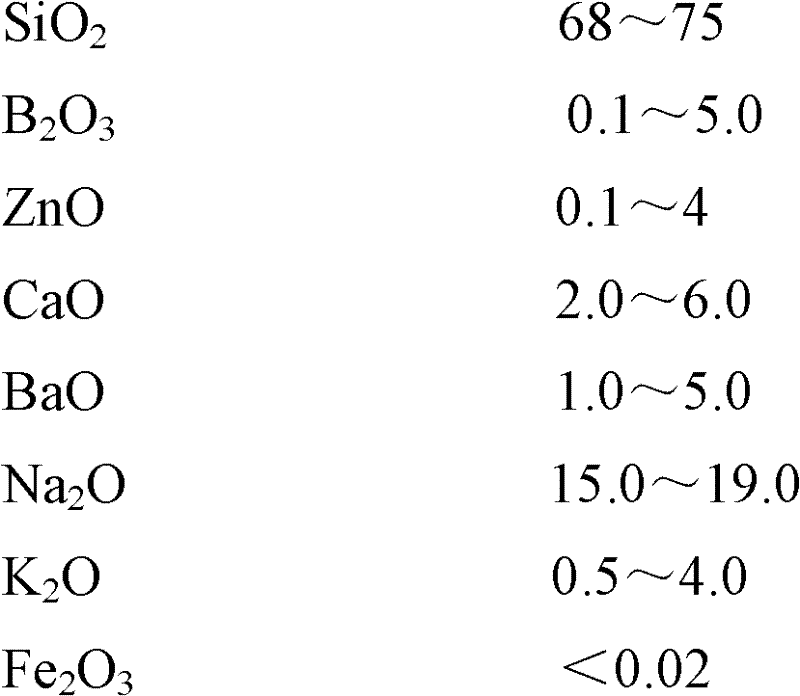

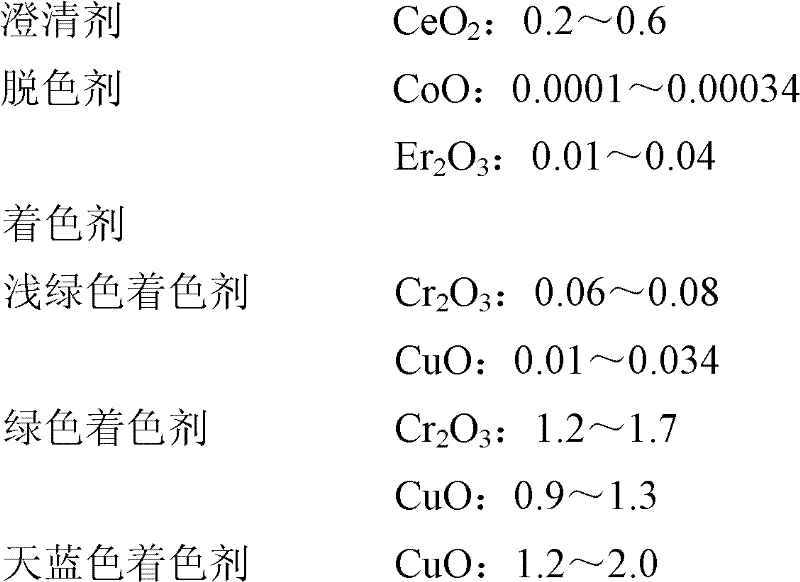

Leadless, cadmium-free and strontium-free glass and manufacture process thereof

The invention belongs to the technical field of an inorganic amorphous material, and particularly relates to a leadless, cadmium-free and strontium-free transparent colored glass component and a manufacture process thereof. The transparent colored glass component is characterized by only containing conventional oxides, such as SiO2, B2O3, ZnO, CaO, BaO, Na2O, K2O and the like without containing lead, cadmium or strontium which has great toxic effect. The invention has the advantages that: a decolorizing agent is added into the leadless, cadmium-free and strontium-free basic component to prepare a colorless transparent glass product; various coloring agents are added into the leadless, cadmium-free and strontium-free basic component to obtain the colored glass. Equipment or investment is not additionally increased, the glass product with good color, low softening point and long material property can be produced only by adopting existing raw material treatment, melting furnaces, hot melting furnaces, annealing furnaces, cold machining and other equipment, and the cost of the transparent colored glass is reduced by 2 to 4 times than that of conventional medium-lead and high-lead glass. The invention has wide application prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

Hot melting horseshoe gum resin

InactiveCN101649173AGood adhesionImprove sealingMineral oil hydrocarbon copolymer adhesivesOther chemical processesElastomerPlasticizer

The invention relates to hot melting horseshoe gum resin which is characterized by comprising the following components in percentage by weight: 30-50 percent of elastomer, 10-20 percent of asphalt, 25-40 percent of trackifing resin, 5-20 percent of plasticizer, 5-10 percent of filler and 0.2-0.5 percent of antioxidant. A product of the invention is used for corrosion protection of pipelines and has good bonding and sealing property, good low-temperature resistance, higher peel strength and stable performance.

Owner:江苏达胜热缩防护用品有限公司

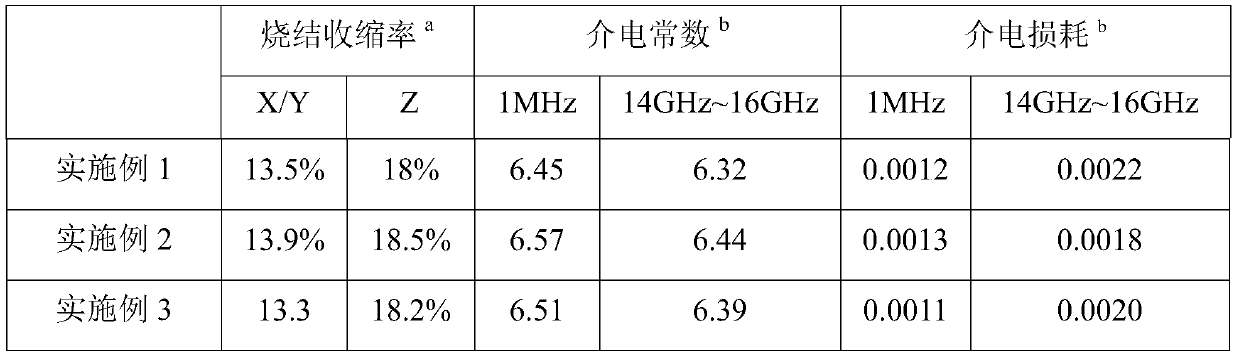

Low-dielectric LTCC green tape as well as preparation method and use thereof

The invention discloses a low-dielectric LTCC green tape as well as a preparation method and use thereof. The low-dielectric LTCC green tape is composed of a powder, a solvent, a dispersing agent, a binder and a plasticizer, wherein the powder is in a mass fraction of 40-60%, and prepared from 10-40wt% of a glass material, 1-10wt% of a low melting point oxide sintering aid and the balance of a ceramic material; the chemical composition of the ceramic material is Zn2-xSiO4-x, where x=0.05-0.3. In the present invention, the problem of low-temperature sintering ofZn2-xSiO4-x ceramic is solved byadding the crystallizable glass material and the sintering aid together, and the mechanical properties and the high-frequency electrical characteristics of the system can be improved.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Glass lubricant for hot extrusion of titanium alloy section bar

ActiveCN103602361AGood instant meltingSmall specific surface areaBase-materialsSurface roughnessTitanium alloy

The invention provides a glass lubricant combination for hot extrusion of a titanium alloy section bar at a temperature of 900 DEG C-1,200 DEG C. The lubricant is composed of glasses being powder-coated glass and glass-pad glass with novel glass formulas. The two types of glass are used in a roller coating stage and an extruding stage respectively. Compared with conventional products, the lubricant provided by the invention has better protective and lubricative performances. With the products provided by the invention, surface roughness of the titanium alloy section bar is low; defects are few; and coping rate can be significantly reduced.

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV +2

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

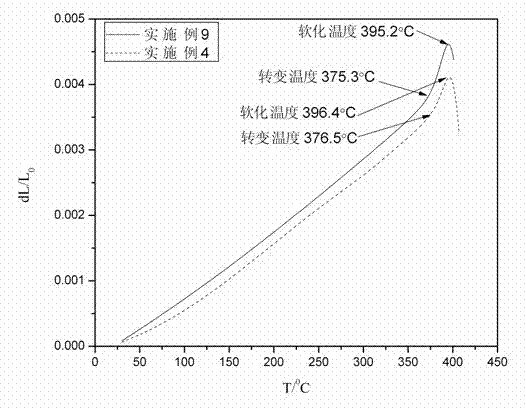

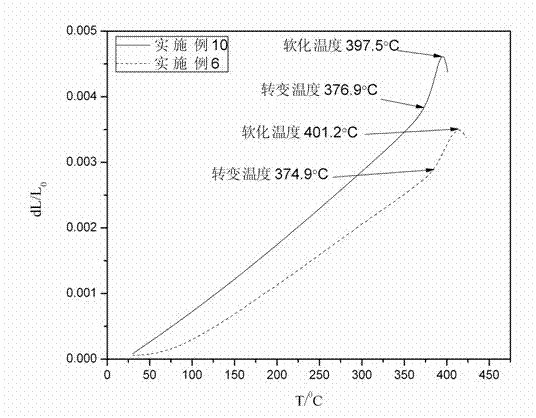

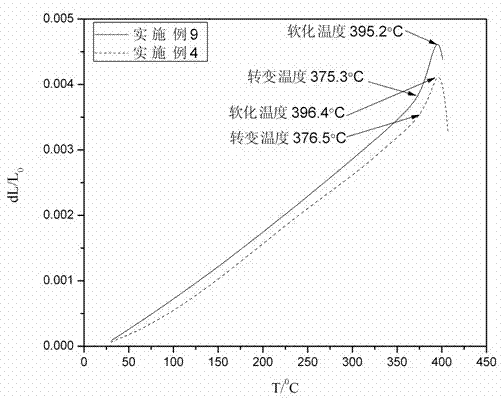

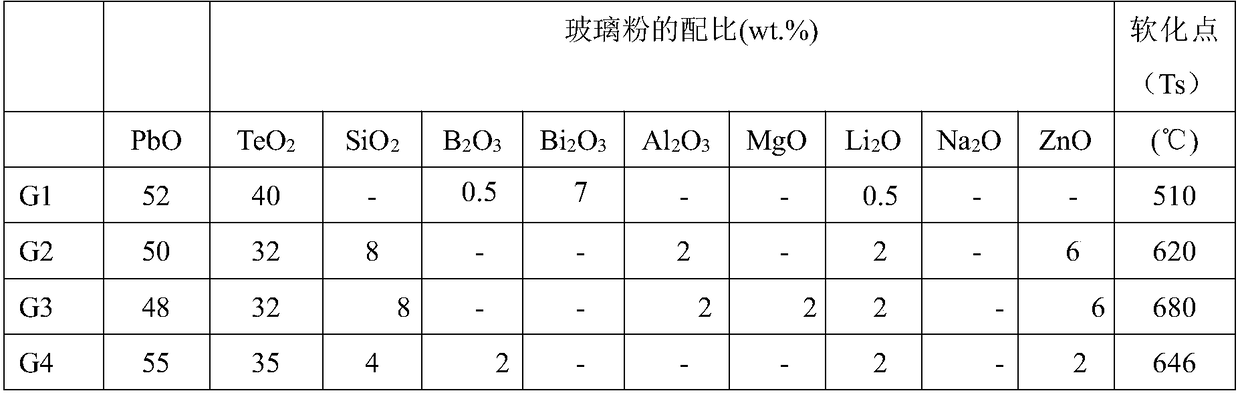

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

Method for preparing spinnable petroleum mesophase pitch

ActiveCN106929084AIncreased proportion of aromatic ringsHigh content of mesophaseWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberHydrogen

The invention discloses a method for preparing spinnable petroleum mesophase pitch. The preparation process comprises the following steps: carrying out heat treatment and reduced pressure distillation on petroleum medium temperature pitch nearly containing no toluene insoluble and quinoline insoluble, carrying out hydrotreatment in the presence of a hydrogen-donor solvent, and finally carrying out heat treatment to obtain the spinnable petroleum mesophase pitch. The prepared spinnable petroleum mesophase pitch has relatively low softening point, the content of mesophase is high, and the method is suitable for preparing high-performance carbon fibers.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

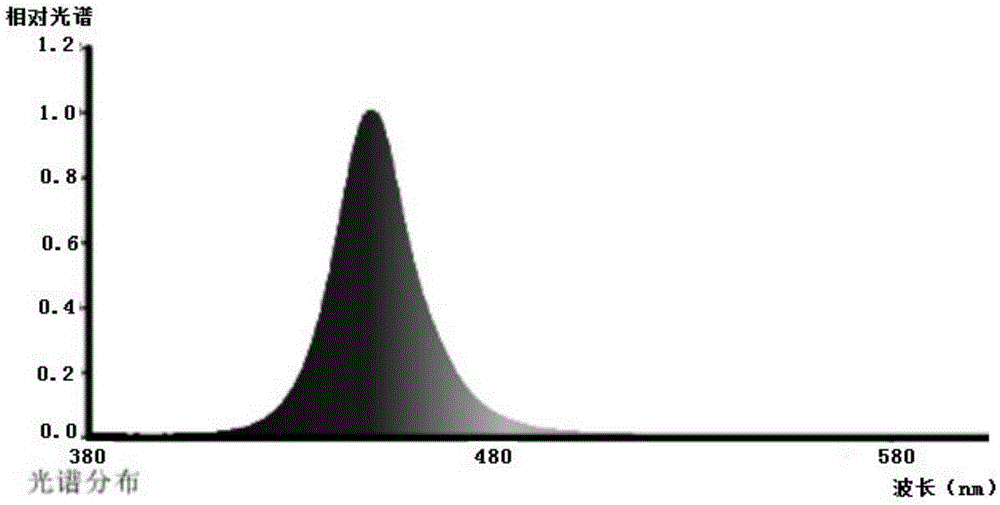

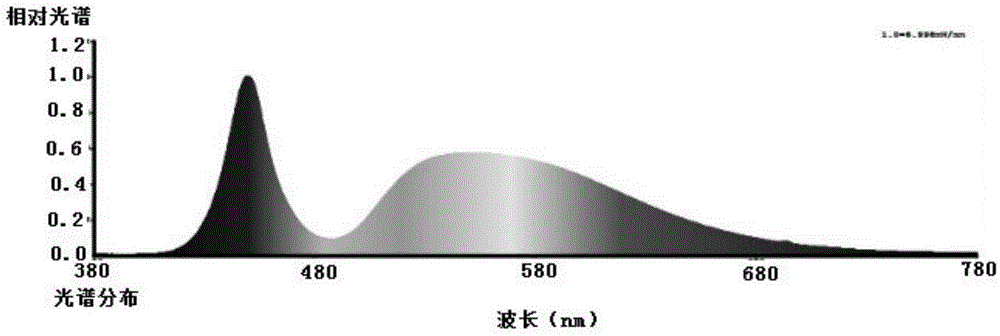

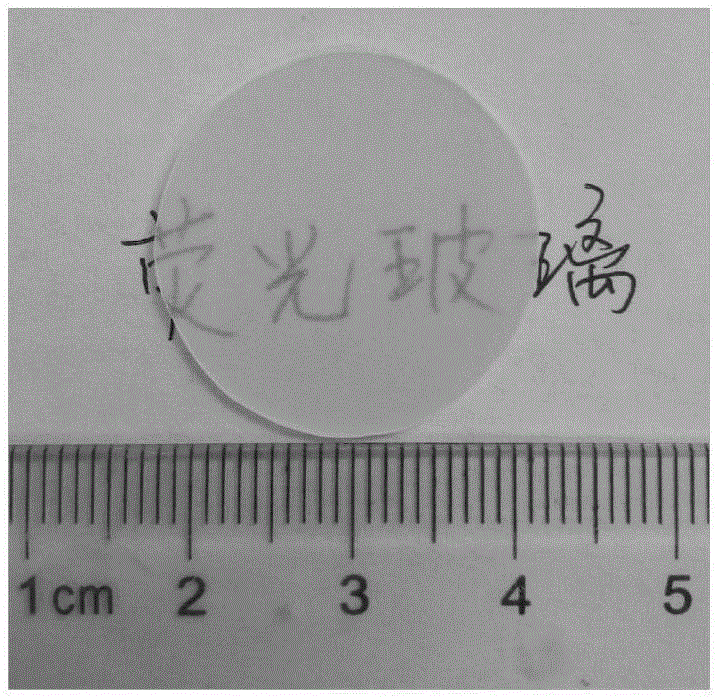

Ce:YAG fluorescent glass for white-light LED and preparation method of Ce:YAG fluorescent glass

The invention provides low-softening-point Ce:YAG fluorescent glass for white-light LED and a preparation method of the Ce:YAG fluorescent glass. According to the Ce:YAG fluorescent glass, Ce:YAG microcrystals are uniformly dispersed in an oxide glass matrix, and the addition amount of the Ce:YAG microcrystals is 1%-20% of the weight of the oxide glass matrix. The preparation method of the Ce:YAG fluorescent glass comprises the following steps: after uniformly mixing multiple oxide powder, and melting, so as to obtain a glass melt; rapidly pouring the glass melt into cold water, so as to obtain glass fragments; crushing and milling the glass fragments into uniform powder, and sieving; uniformly mixing sieved glass powder with Ce:YAG fluorescent microcrystals, heating, taking out the mixture, and forming, so as to obtain a green body; and annealing the green body, so as to obtain the low-softening-point Ce:YAG fluorescent glass for the white-light LED. The Ce:YAG fluorescent glass has the beneficial effects that formula components are few, the raw materials are cheap, the softening point is low, and the preparation process is simple; the Ce:YAG fluorescent glass is applicable to mass production; the obtained fluorescent glass material is high in transparency.

Owner:中科皓烨(东莞)材料科技有限责任公司

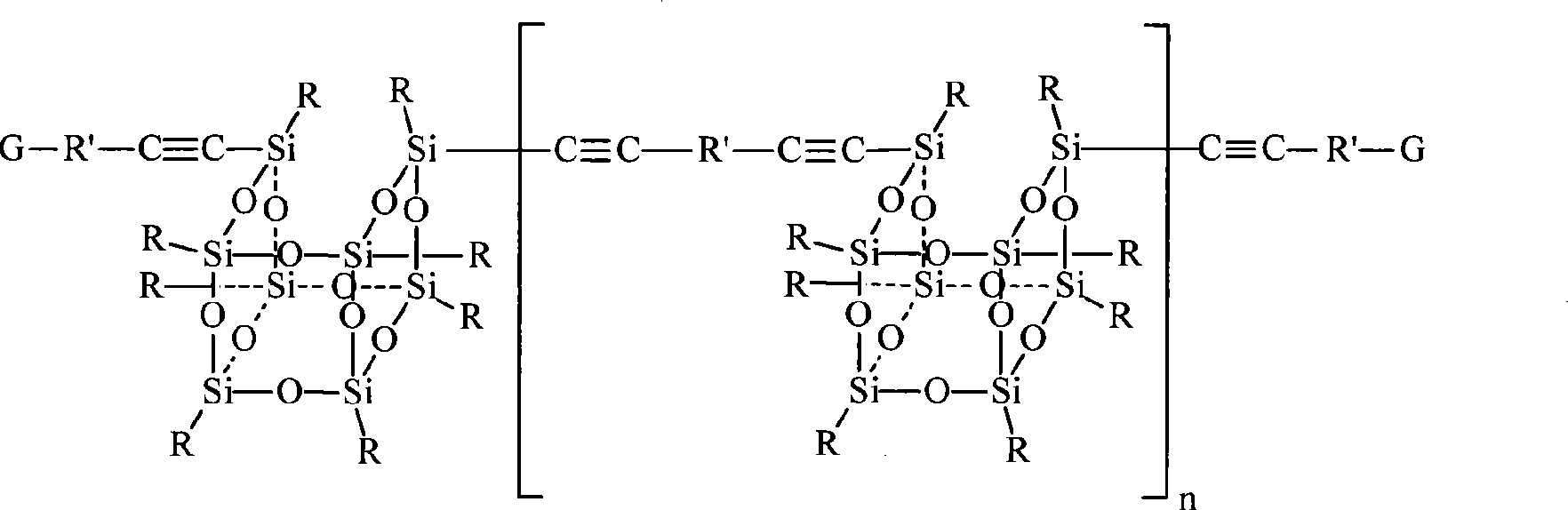

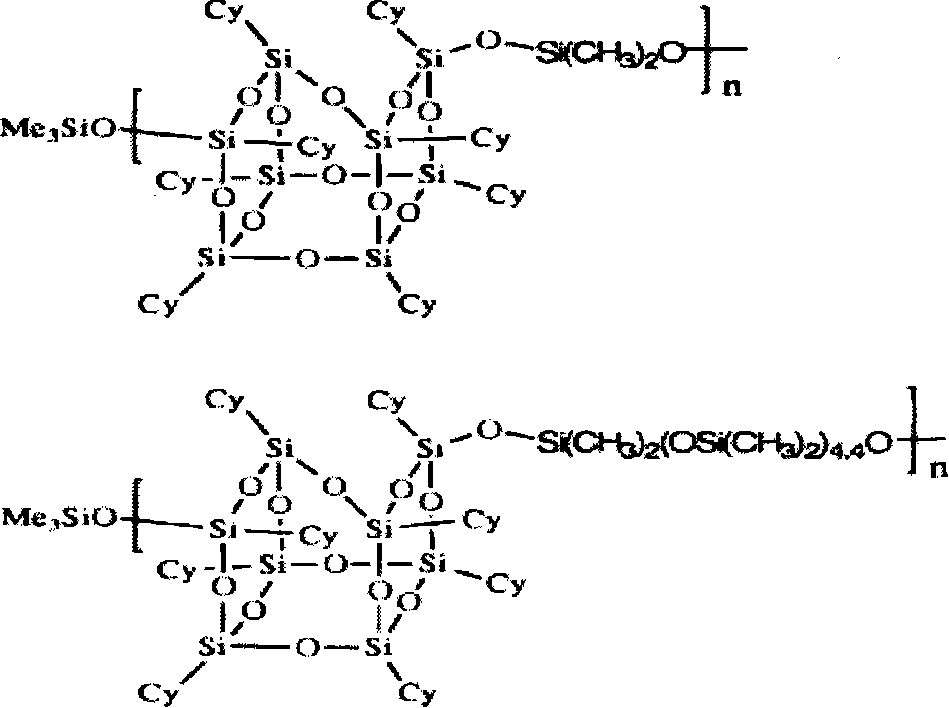

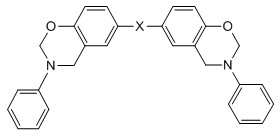

Clathrate sesquialter siloxane aryne resin containing octamethyl pyrophosphoramide and method for preparing the same

The present invention discloses an 8-methyl cage-shaped silsesquioxane resin with a structure as shown in the figure. The resin has the following characteristics: 1) the structure of the synthesized resin can be controlled; 2) the resin is solid at the room temperature; the softening point is low; the resin can be dissolved in a plurality of common solvents; and the application is convenient; 3) the resin can do the solidification reaction with the influence of heat, irradiation, or even light to form a highly cross-linked polymer; and no small molecules are released in the solidification process; 4) the solidified resin has good mechanical properties, excellent chemical resistance and high heat resistance or heat-resistant oxidation, that is, the high temperature of thermal decomposition and the residual rate of thermal decomposition; 5) the resin has good dielectric properties and thermal insulation properties after solidification; 6) the resin can do the ceramic reaction; 7) the resin and the fiber have good bonding performances. The mechanical properties of composite material are good.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalytic reaction type SBS modified asphalt regenerant and preparation method thereof

InactiveCN103819912AAroma reductionColloid structure recoveryBuilding insulationsPolymer sciencePtru catalyst

The invention relates to a catalytic reaction type SBS modified asphalt regenerant and a preparation method thereof. The catalytic reaction type SBS modified asphalt regenerant is prepared from raw materials by mass: 15%-35% of SBS modified asphalt, 55%-80% of catalytic cracking oil slurry, 1%-5% of a penetrating agent, 3%-8% of a SBS molecular structure restorative agent and 0.01%-0.05% of a catalyst. The regenerant provided by the invention can not only reduce chemical compositions and colloid structure of aged asphalt but also make aged and degraded SBS molecular chain structure restore well under the effect of the molecular structure restorative agent and the catalyst, thereby significantly increasing the performance of the regenerated SBS modified asphalt. The regenerant can relatively well improve the performance of the aged SBS modified asphalt.

Owner:WUHAN UNIV OF TECH

Method for preparing mesophase pitch through catalytic cracking oil slurry hydrogenation reduction and co-carbonization

ActiveCN105238431ALow mesophase contentHigh content of mesophaseWorking-up pitch/asphalt/bitumen by chemical meansCarbonizationSlurry

The invention provides a preparation method of petroleum base mesophase pitch with even high mesophase content. The FCC oil slurry of naphthenic crude oil or intermediate base crude oil serves as the raw material, under the action of a catalyst, haloalkane is mixed with the raw material, the temperature is increased to range from 280 DEG C to 350 DEG C, the pressure ranges from 0 MPa to 2 MPa, reaction is conducted for 5-20 h, and modified oil is obtained. Distillate oil, obtained at the temperature higher than 400 DEG C, of the modified oil is taken, the distillate oil is mixed with a co-carbonization agent, the temperature ranges from 360 DEG C to 480 DEG C, the reaction pressure ranges from 4 MPa to 10 MPa, reaction is conducted for 2-10 h, and the high-quality mesophase pitch is obtained. According to the preparation method of the petroleum base mesophase pitch with the even high mesophase content, preparation technology is simple and easy to operate, the anisotropic structure of the prepared mesophase pitch is uniform, the mesophase content is high and larger than 96 percent, the softening point is low, the temperature ranges from 240 DEG C to 260 DGE C, and the spinnability is good.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

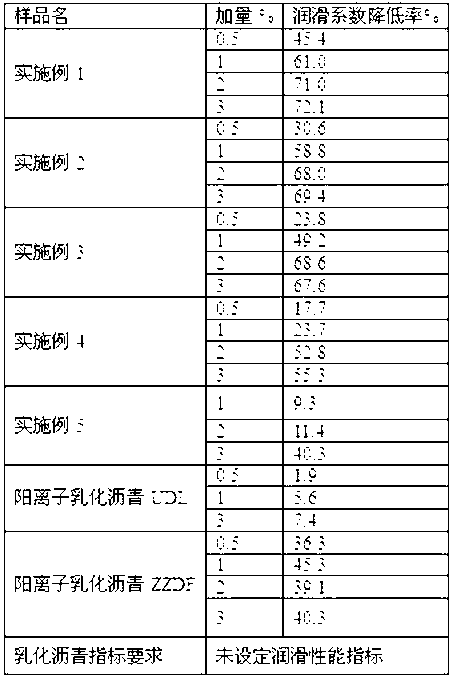

Low softening point emulsified asphalt for drilling fluid, and preparation method thereof

InactiveCN103265816AAchieve recyclingReduce consumptionDrilling compositionBuilding insulationsSlurrySolvent

The invention discloses a low softening point emulsified asphalt for a drilling fluid, and a preparation method thereof. The emulsified asphalt comprises, by weight, 25-50 parts of an oil slurry, 10-35 parts of a solvent oil, 1-4 parts of a non-ionic surfactant, 1-4 parts of a cation surfactant, 0-4 parts of a C2-C4 alcohol, and 30-40 parts of water. The preparation method comprises: adding a solvent oil and a non-ionic surfactant to an oil slurry, carrying out heating and uniform stirring to obtain an oil slurry mixing liquid, carrying out mixing heating stirring on water, a C2-C4 alcohol and a cation surfactant until the cation surfactant is dissolved, adding the oil slurry mixing liquid, and stirring at a temperature of 45-90 DEG C to obtain the low softening point emulsified asphalt. The emulsified asphalt has the following characteristics that: the emulsified asphalt is easily dispersed in water, and has characteristics of low softening point, good anti-sloughing effect and good lubricating performance; with the emulsified asphalt, the broken stratum can be well cemented at a low temperature, hole wall cracks can be plugged, and hole wall stability can be increased; and the emulsified asphalt can be widely used in geological drilling, petroleum and natural gas well drilling, geoheat drilling and the like, oil slurry recycling is achieved, and process cost is reduced.

Owner:BEIJING INST OF EXPLORATION ENG

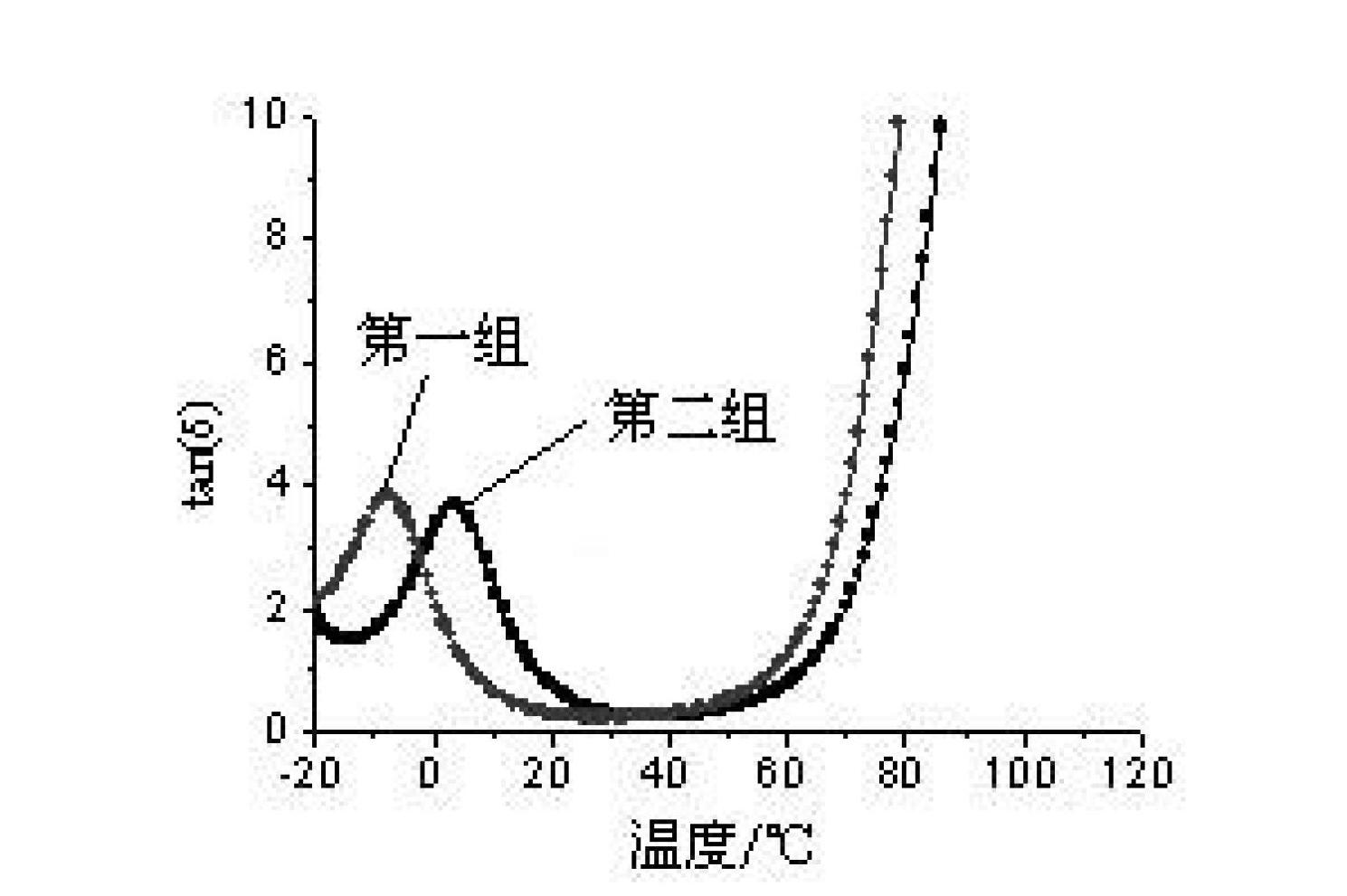

Low-melting-point resin material for three-dimensional printer and manufacturing method of low-melting-point resin material

ActiveCN104693637AProne to cloggingLarge specific surface areaAdditive manufacturing apparatusAcrylic resinFumed silica

The invention provides a low-melting-point resin material for a three-dimensional printer. The material comprises the following components in percentage by weight: 30-60% of styrene-acrylic resin, 10-50% of first polyester resin, 0-10% of second polyester resin, 1-15% of additives, 0.5-6% of wax, and 0.1-2% of fumed silica, wherein the glass transition temperature Tg of the styrene-acrylic resin is 55-65 DEG C and the softening point temperature T1 / 2 is 120-130 DEG C; the glass transition temperature Tg of the first polyester resin is 43-48 DEG C and the softening point temperature T1 / 2 is 80-85 DEG C; the glass transition temperature Tg of the second polyester resin is 45-65 DEG C and the softening point temperature T1 / 2 is 80-110 DEG C. By adopting the scheme, the glass transition temperature Tg of the low-melting-point resin material for the three-dimensional printer is 48-65 DEG C and the softening point temperature T1 / 2 is 85-110 DEG C. Therefore, the melting temperature of an FDM three-dimensional printer material is remarkably reduced, and the scald risk of an operator is correspondingly reduced while the energy consumption is reduced.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Lead-free glass powder for silver paste on back of crystalline silicon solar cell and preparation method thereof

The invention relates to a lead-free glass powder for silver paste on the back of a crystalline silicon solar cell and a preparation method thereof. The lead-free glass powder comprises the following raw materials in parts by weight: 40-70 parts of Bi2O3, 5-15 parts of B2O3, 0.5-5 parts of ZrO2, 10-20 parts of SiO2, 5-20 parts of ZnO, 1-5 parts of TiO2, 5-20 parts of Al2O3 and 1 part of P2O5. The preparation method comprises the following steps of: placing the raw materials in a mixer, and uniformly mixing to form a mixture; preheating a quartz crucible to 600-800 DEG C, placing the mixture in the quartz crucible and carrying out heat preservation for 20 minutes; then smelting for 20 minutes to 40 minutes at 900-1200 DEG C; pouring molten glass into deionized water for quenching, carrying out wet-process ball milling on the quenched glass to 2-5mu m, and drying to obtain the lead-free glass powder. The lead-free glass powder has the advantages that the technological process is simple, time consumption for smelting is short and cost is low; when in use, the lead-free glass powder has good wettability with silver powder and a silicon substrate; and after the lead-free glass powder is sintered, the adhesive force between the lead-free glass powder and the silicon substrate is above 5N.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

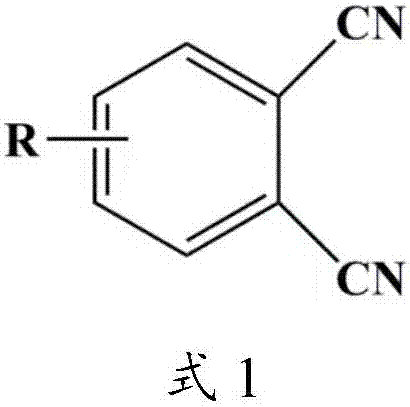

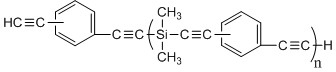

Oligomer containing fluorine and phthalonitrile, condensate and preparation method thereof

ActiveCN107266336ALow softening pointImprove solubilityCarboxylic acid nitrile preparationOrganic compound preparationSide chainPhthalonitrile

The invention discloses an oligomer containing fluorine and phthalonitrile, a condensate and a preparation method thereof. The method comprises the following steps: firstly, adopting fluorine-containing phenol and formalin for preparing a fluorine-containing linear phenolic resin; and by utilizing 4-nitro phthalonitrile to react with a phenolic hydroxyl group of the fluorine-containing linear phenolic resin, introducing a phthalonitrile group into the side chain thereof, thereby acquiring the oligomer containing fluorine and phthalonitrile. The oligomer can self-catalytically cure under the condition of no catalyst. The introduction of the fluorine-containing group can effectively reduce the dielectric constant and dielectric loss of the condensate. Compared with a fluoride-free phthalonitrile-containing phenolic oligomer, the oligomer disclosed by the invention has the advantages of lower softening point and better acetone solubleness; the dielectric property of the condensate formed by the oligomer is improved; the thermal performance and the mechanical property are basically kept; the oligomer can be used as a high temperature resisting wave-transmitting material which can be applied to the fields of aerospace or copper-clad plate, electronic packaging, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

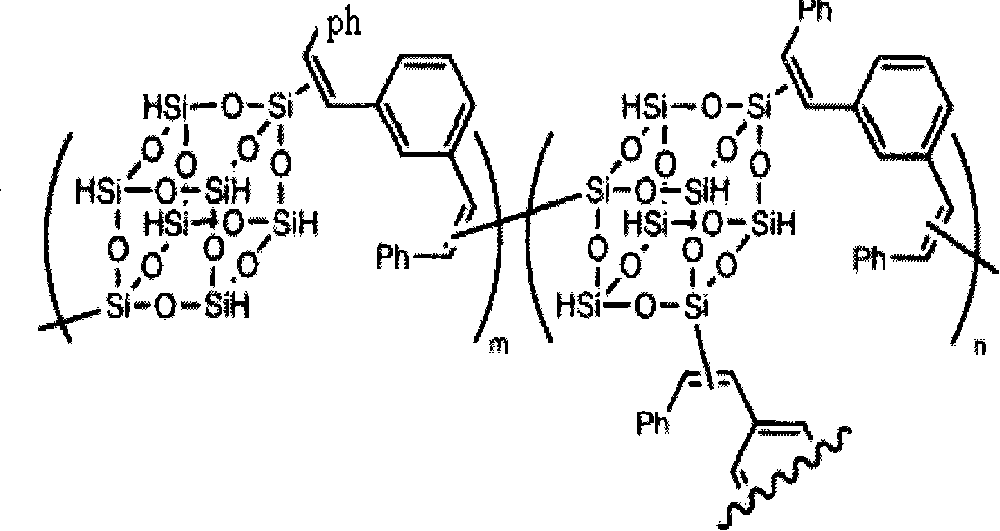

Bisphenol benzoxazine modified silicon-contained aryne resin and preparation method thereof

The invention discloses bisphenol benzoxazine modified silicon-contained aryne resin and a preparation method thereof. The preparation method comprises the following step: 50 to 95 percent (by mass) of silicon-contained aryne resin and 5 to 50 percent (by mass) of bisphenol benzoxazine resin are put into a reactor and stirred for 10 to 60 minutes at 100 to 120 DEG C to prepare the bisphenol benzoxazine modified silicon-contained aryne resin. The resin can synchronously form cured resin with a simultaneous interpenetrating network (SIN) structure through thermal polymerization. The bisphenol benzoxazine modified silicon-contained aryne resin prepared by the preparation method is high-performance resin with excellent high-temperature resistance and mechanical property and favorable adhesive property with fiber, and can be widely applied to the fields of spaceflight, aviation, electronics and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com