Low-temperature resistant rosin thickening resin, preparation method and usage thereof

A tackifying resin and low-temperature-resistant technology, which is applied in rosin adhesives and chemical modification of natural resins, etc., can solve problems such as difficult to quickly wet the adhered surface, bonding failure, and increase the difficulty and cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

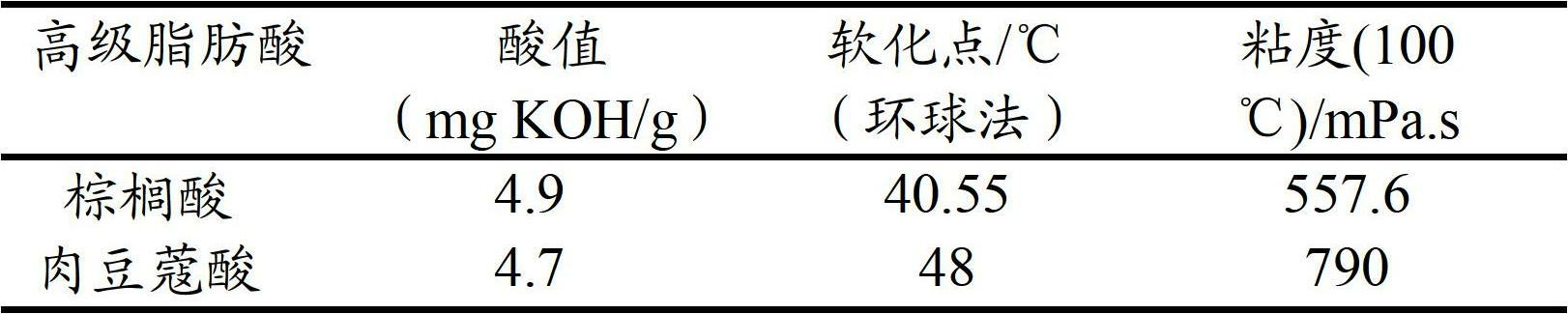

[0019] A kind of rosin tackifying resin, adopts following method to prepare:

[0020] Weigh 300g of rosin, crush it and put it into a four-necked flask, add 0.45g of catalyst 4,4'-thiobis(6-tert-butyl-3-methylphenol) at the same time, fill it with nitrogen and raise the temperature, when it reaches 220°C Start to add 50g of glycerin dropwise, keep warm at 260°C for 6h, and discharge to obtain rosin glyceride; weigh 40g of palmitic acid and 200g of rosin glyceride obtained above, and feed them into a four-necked flask at one time, fill with nitrogen to raise the temperature, and keep at 250°C for 7h After the material is discharged, palmitic acid rosin glyceride is obtained.

[0021] Or prepared by the following method: Weigh 300g of rosin, crush it and put it into a four-necked flask, add 60g of palmitic acid, catalyst 4,4'-thiobis(6-tert-butyl-3-methylphenol ) 0.45g, filled with nitrogen to raise the temperature, 50g of glycerin was added dropwise when it reached 220°C, and ...

Embodiment 2

[0024] A kind of rosin tackifying resin, adopts following method to prepare:

[0025] Weigh 300g of rosin, crush it and put it into a four-necked flask, add 0.45g of catalyst 4,4'-thiobis(6-tert-butyl-3-methylphenol) at the same time, fill it with nitrogen and raise the temperature, when it reaches 220°C Start to add 50g of glycerol dropwise, keep warm at 260°C for 6h, and then discharge to obtain rosin glyceride; weigh 35.62g of myristic acid and 200g of rosin glyceride obtained above, and feed them into a four-necked flask at one time, fill with nitrogen to raise the temperature, 250°C After 7 hours of heat preservation, the material was discharged to obtain rosin myristate glyceride.

[0026] Or prepared by the following method: Weigh 300g of rosin, crush it and put it into a four-necked flask, add 53.43g of myristic acid, catalyst 4,4'-thiobis(6-tert-butyl-3-methyl Base phenol) 0.45g, inflated with nitrogen to raise the temperature, when it reached 220°C, 50g of glycerin ...

Embodiment 3

[0029] A kind of rosin tackifying resin, adopts following method to prepare:

[0030] Weigh 300g of rosin, crush it and put it into a four-necked flask, add 0.45g of catalyst 4,4'-thiobis(6-tert-butyl-3-methylphenol) at the same time, fill it with nitrogen and raise the temperature, when it reaches 220°C Start to add 50g of glycerin dropwise, keep warm at 260°C for 6h, and discharge to obtain rosin glyceride; weigh 31.2g of lauric acid and 200g of rosin glyceride obtained above, and feed them into a four-neck flask at one time, fill with nitrogen to raise the temperature, and keep at 250°C for 7h After the material is discharged, rosin laurate glyceride is obtained.

[0031] Or prepared by the following method: Weigh 300g of rosin, crush it and put it into a four-necked flask, add 46.8g of lauric acid, catalyst 4,4'-thiobis(6-tert-butyl-3-methyl Phenol) 0.45g, inflated with nitrogen to raise the temperature, when it reached 220°C, 50g of glycerin was added dropwise, kept at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com