Lead-free glass powder for silver paste on back of crystalline silicon solar cell and preparation method thereof

A lead-free glass powder and solar cell technology, which is applied in the field of solar cells, can solve problems such as unstable solderability, poor adhesion between paste and silicon substrate, mismatch between expansion coefficient and silicon chip, and achieve The effect of lowering the softening point, improving the stability of the network structure, and reducing the expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of lead-free glass powder for silver paste on the back of crystalline silicon solar cell includes the following steps in sequence: (1) Prepare raw materials according to the following components and weight contents, Bi 2 O 3 : 40 servings, B 2 O 3 : 5 parts, ZrO 2 : 0.5 part, SiO 2 : 10 parts, ZnO: 5 parts, TiO 2 : 1 part, Al 2 O 3 : 5 servings, P 2 O 5 : 1 part (2) Put the above components into the mixer, and mix them evenly to form a mixture; (3) Preheat the quartz crucible to 600°C, put the above mixture into the quartz crucible, and keep the temperature at 600°C for a period of time 20min; then place the quartz crucible in a muffle furnace and smelt at 900°C for 20min; (4) pour the smelted glass into deionized water for quenching; (5) wet the quenched glass to 2μm, After drying, lead-free glass powder is obtained.

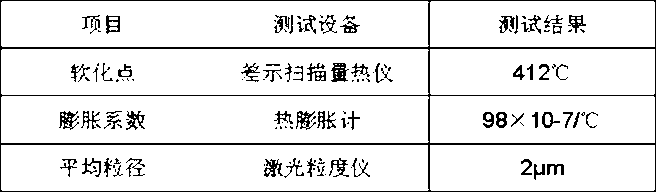

[0021] Take a small amount of prepared glass powder samples and test the softening point, expansion coefficient and par...

Embodiment 2

[0025] The preparation method of lead-free glass powder for silver paste on the back of crystalline silicon solar cell includes the following steps in sequence: (1) Prepare raw materials according to the following components and weight contents, Bi 2 O 3 : 55 servings, B 2 O 3 : 10 parts, ZrO 2 : 2 parts, SiO 2 : 15 parts, ZnO: 12 parts, TiO 2 : 3 parts, Al 2 O 3 : 13 servings, P 2 O 5 : 1 part; (2) Put the above components into the mixer, and mix them uniformly to form a mixture; (3) Preheat the quartz crucible to 700 ° C, put the above mixture into the quartz crucible, and keep the temperature at 700 ° C. time 20min; then put the quartz crucible in a muffle furnace and smelt at 1150℃ for 30min; (4) pour the smelted glass into deionized water for quenching; (5) wet the quenched glass to 4μm , lead-free glass powder is obtained after drying.

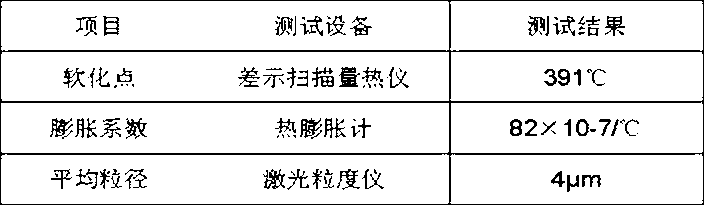

[0026] Take a small amount of prepared glass powder samples and test the softening point, expansion coefficient and particle ...

Embodiment 3

[0030] The preparation method of lead-free glass powder for silver paste on the back of crystalline silicon solar cell includes the following steps in sequence: (1) Prepare raw materials according to the following components and weight contents, Bi 2 O 3 : 70 servings, B 2 O 3 : 15 parts, ZrO 2 : 5 parts, SiO 2 : 20 parts, ZnO: 20 parts, TiO 2 : 5 parts, Al 2 O 3 : 20 servings, P 2 O 5 : 1 part; (2) Put the above components into the mixer, and mix them evenly to form a mixture; (3) Preheat the quartz crucible to 800 ° C, put the above mixture into the quartz crucible, and keep the temperature at 800 ° C. time 20min; then put the quartz crucible in a muffle furnace and smelt at 1200℃ for 40min; (4) pour the smelted glass into deionized water for quenching; (5) wet ball mill the quenched glass to 5μm , lead-free glass powder is obtained after drying.

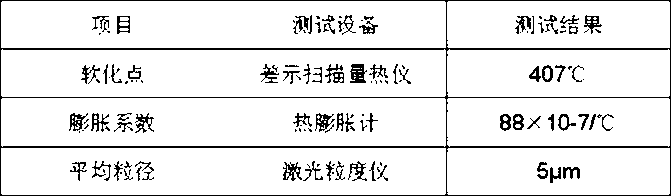

[0031] Take a small amount of prepared glass powder samples and test the softening point, expansion coefficient and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com