Patents

Literature

1340results about How to "Small expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

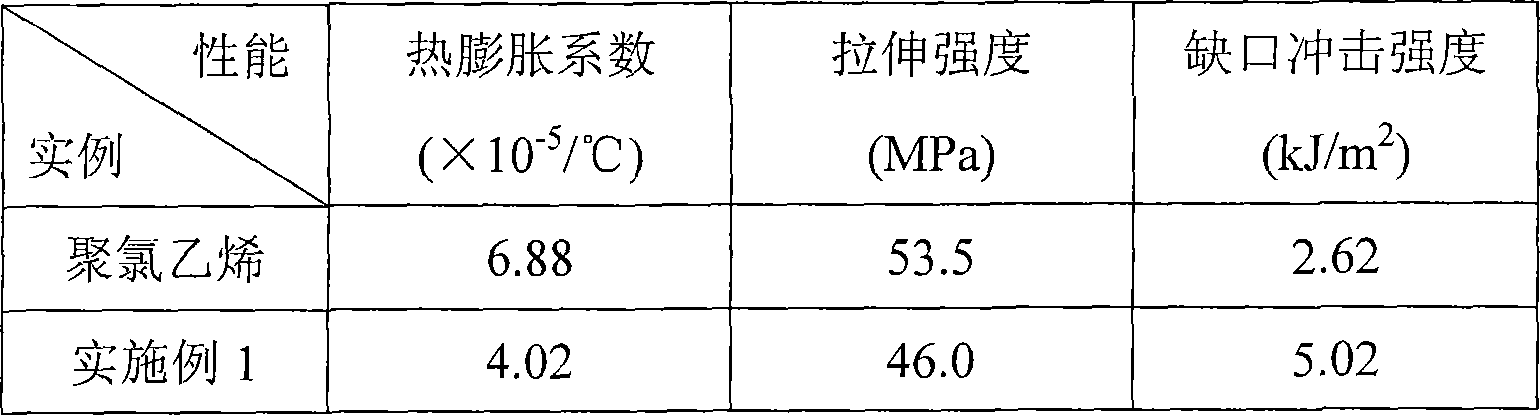

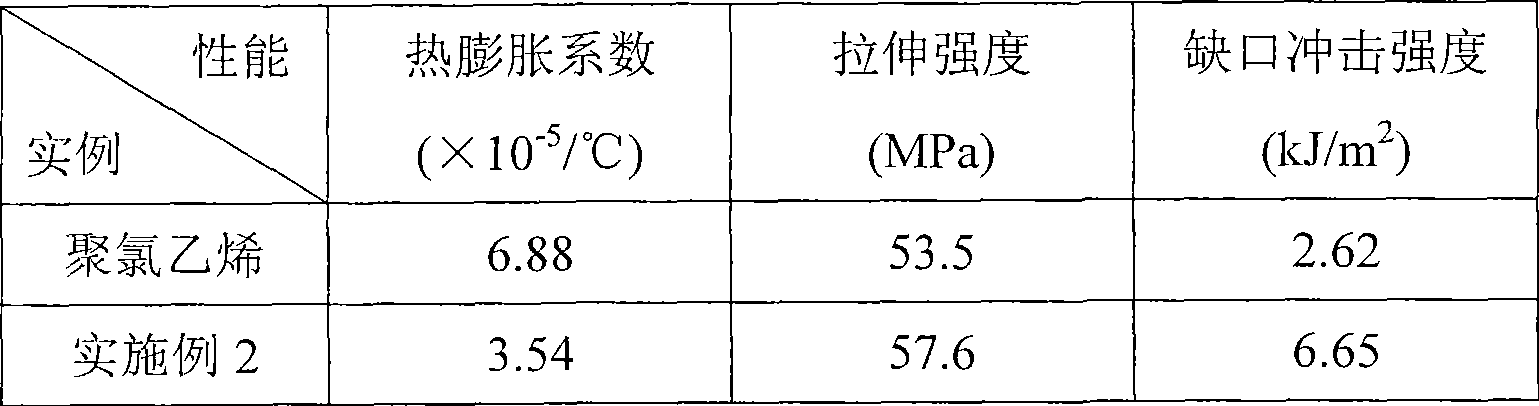

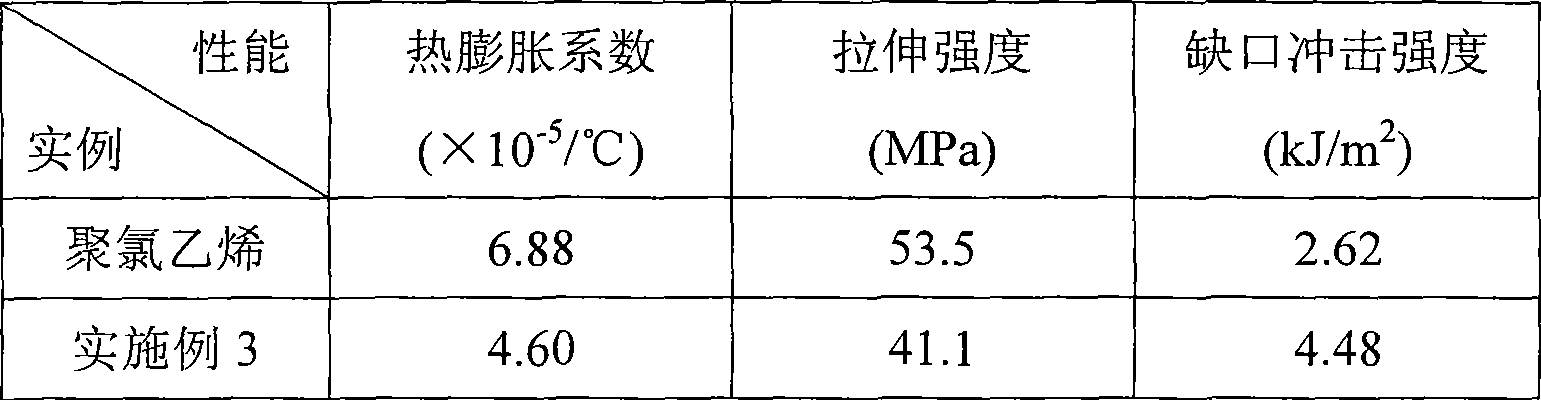

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

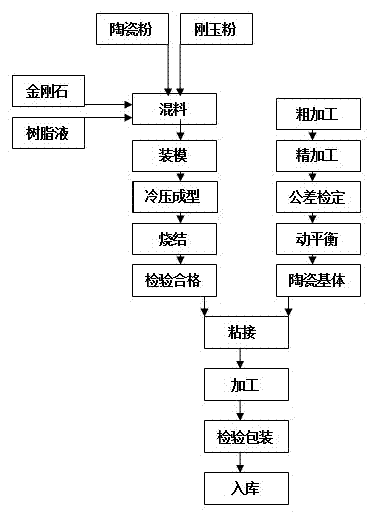

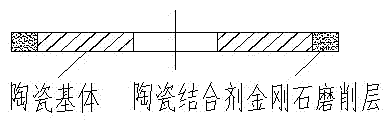

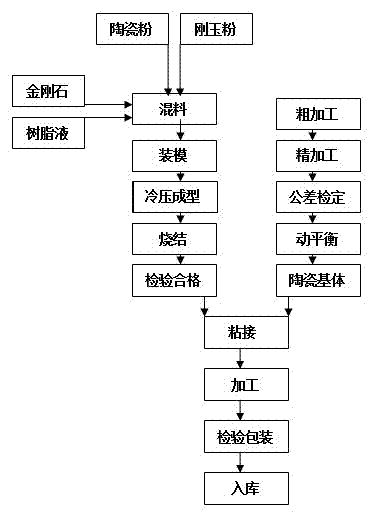

Special ceramic bond diamond grinding wheel for grinding diamond

InactiveCN102229122AHigh strengthSmall expansion coefficientAbrasion apparatusGrinding devicesDiamond grindingCeramic

The invention belongs to the field of diamond grinding wheels, and particularly relates to a ceramic bond and a method for manufacturing a ceramic bond diamond grinding wheel for grinding a diamond by adopting the ceramic bond. The ceramic bond is prepared from the following raw materials in percentage by weight: silicon dioxide, borax, lithium hydroxide, zinc oxide, calcium oxide and aluminum oxide; and the ceramic bond is obtained through the steps of: mixing the raw materials, then smelting at the high temperature of 1300+ / -5 DEG C, cooling, then performing ball milling to prepare ceramic powder, and sieving through a standard sieve of 180 meshes. The ceramic bond provided by the invention has high intensity and a low coefficient of expansion, so that the ceramic bond can be perfectly matched with the adopted ceramic grinding wheel basal body. The diamond grinding wheel manufactured by adopting the ceramic bond has good heat conductivity and heat resistance; and compared with the traditional resin bond diamond grinding wheel, the ceramic bond diamond grinding wheel not only ensures that the diamond is excellently sintered at the temperature of not being carbonized, but also ensures that grinding grains are always at an excellent holding state without falling off when grinding is carried out. The special ceramic bond diamond grinding wheel has the grinding efficiency and service life far higher / longer than that of the traditional grinding wheel, and has a comprehensive benefit which is increased by over 50%.

Owner:SUZHOU SAILI PRECISION TOOLS

High-strength invar alloy and its alloy wire rod production method

ActiveCN1743490AReasonable designHigh strengthFurnace typesMetal rolling arrangementsInvar alloyWire rod

A high intensity invariable steel and a production method for it's wire rod characterizes in taking Fe-36Ni alloy as the base added with W, V and C in the following weight percentage: C 0.15 to 0.40, Si is not greater than 0.60, Mn is not greater than 0.8, p is not greater than 0.025, S is not greater than 0.02, Ni: 34.0 to 42.0, co is not greater than 3.5, Cr is not greater than 0.5, Cu is not greater than 0.2, W: 1.5 to 5.0, v 0.3 to 1.2, Mo is not greater than 0.5, the rest is Fe and unavoidable impurities, W.V is greater than 1.5, c=0.9-1.3(0.033w+0.2V). The production method includes: 1, processing the steel ingot into rods then to wire rods (phi=10 to 15mm) 2, applying special twice cold processing deformation and hot process, the twice cold-draw deformations are 20-70%, 55 to 95% then they are hot processed under 450-750 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD +1

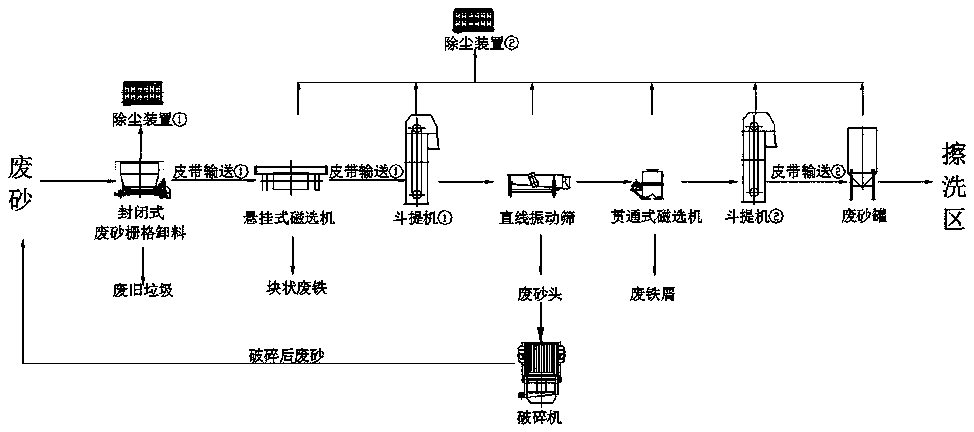

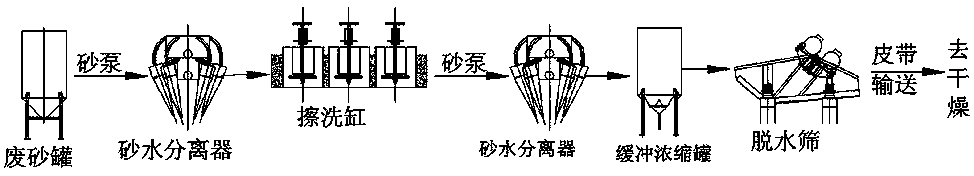

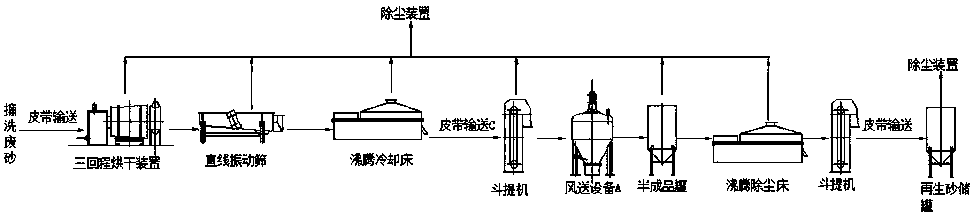

Foundry waste sand regeneration and reuse method and device

ActiveCN103406490ALow impurity contentReduce workloadMould handling/dressing devicesMagnetic separatorIon

A foundry waste sand regeneration and reuse method comprises the following steps: pretreatment of waste sand: the original waste sand is removed with waste garbage through a closed grid unloader, removed with waste iron through a suspension type magnetic separator, removed with large-particle waste sand through a linear vibrating screen, and removed with waste scrap ions through a cut-through magnetic separator, and then enters a waste sand storage tank for storage; cleaning of waste sand: the pretreated waste sand is conveyed to a cleaning area through a sand pump, is introduced to the sand-water separator to remove part of water, then enters a scrubbing-cleaning combined tank for scrubbing and cleaning, enters a buffering concentration tank for sedimentation and concentration, and finally enters a dewatering screen to get rid of part of the water; drying: after the above processing, the waste sand is subjected to low-temperature drying or high-temperature roasting to obtain reclaimed sand, then the reclaimed sand is put into a regeneration sand tank for storage; lamination of regenerated sand: the measured regenerated sand is heated to a certain temperature through a heater, and is put into a precoated sand blender together with adhesive to mix evenly, then the mixture is cooled to room temperature to obtain the precoated sand, and the precoated sand is put into a bucket for storing finished sand.

Owner:广西兰科资源再生利用有限公司

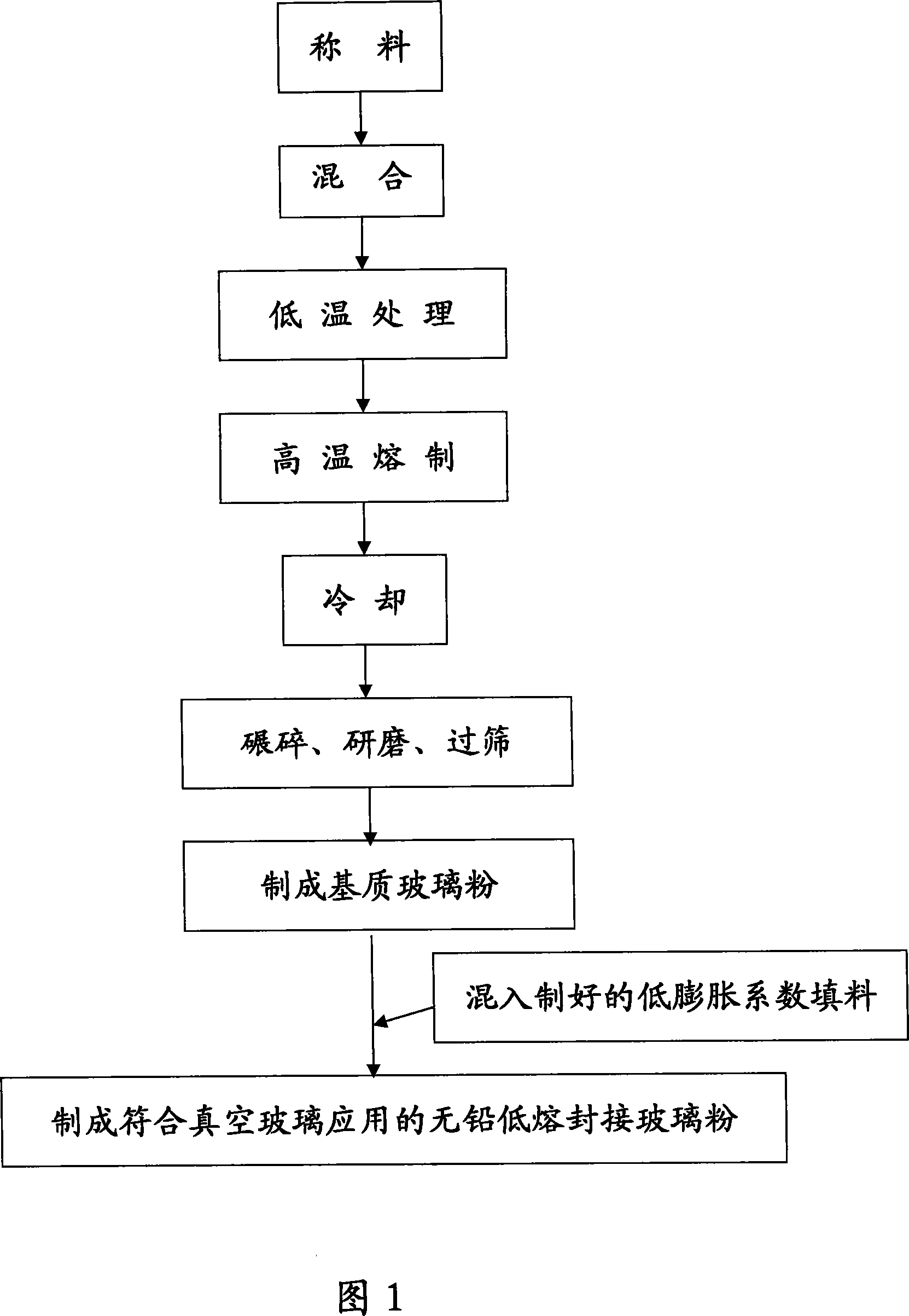

No-lead RE doped sealing glass powder with low smelting point and its production process

The present invention discloses one kind of no-lead RE doped sealing glass powder with low smelting point for vacuum glass sealing and its preparation process. The no-lead sealing glass powder has P2O5, SnO and ZnO as basic glass oxides and mixed RE oxide of La, Yt and Nd added, with the weight ratio between the basic glass oxides and the mixed RE oxide being (30.0-381.5) to (0.12-19.0). The no-lead sealing glass powder of the present invention with doping mixed RE oxide has lowered glass smelting and sealing temperature, raised chemical stability and lowered thermal expansion coefficient of glass as well as lowered environmental pollution. It is used in sealing electronic device and element and vacuum glass.

Owner:CHINA BUILDING MATERIALS ACAD

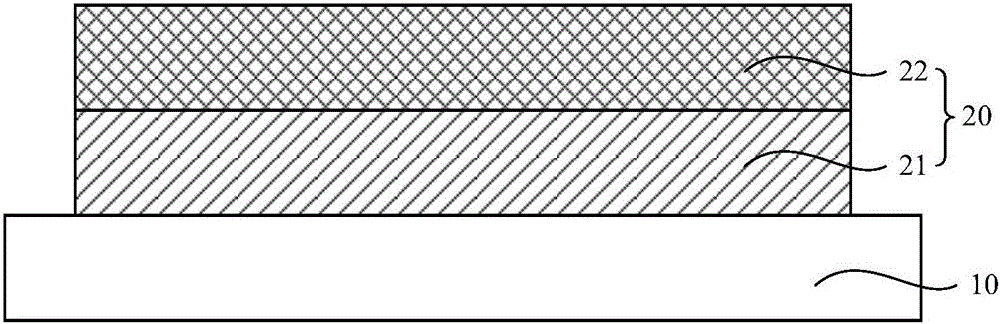

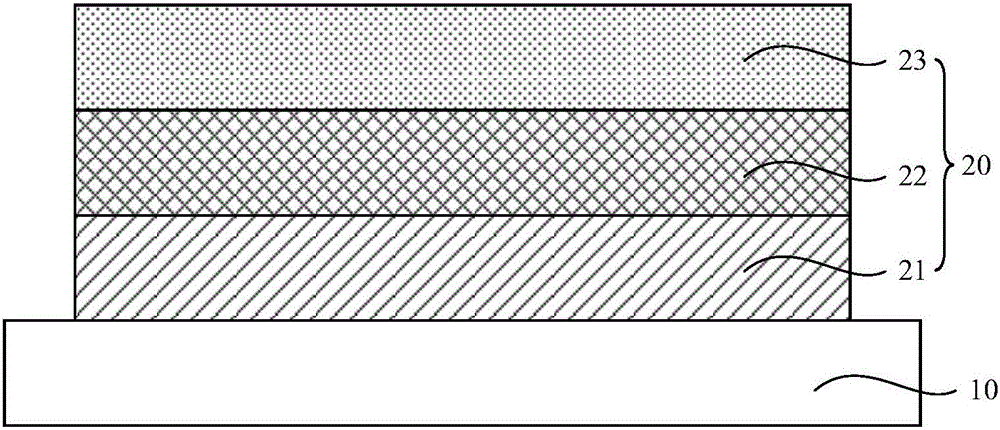

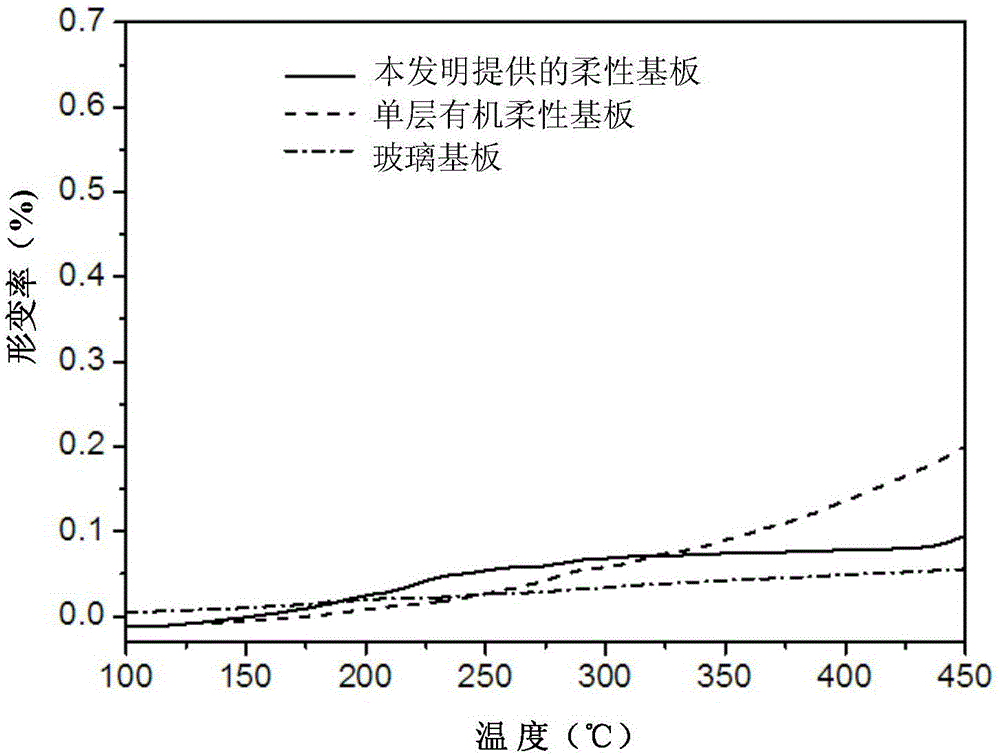

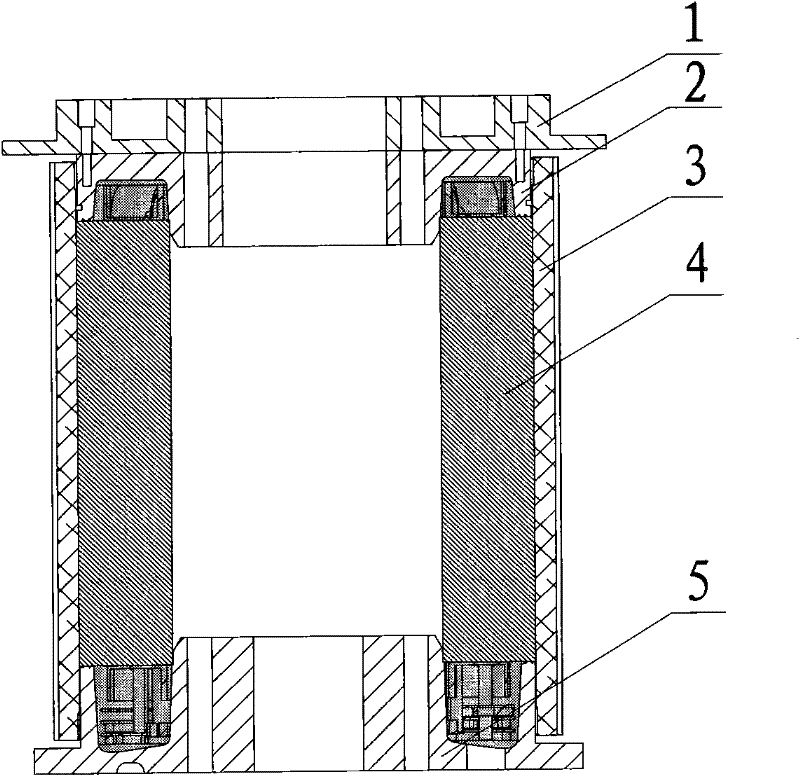

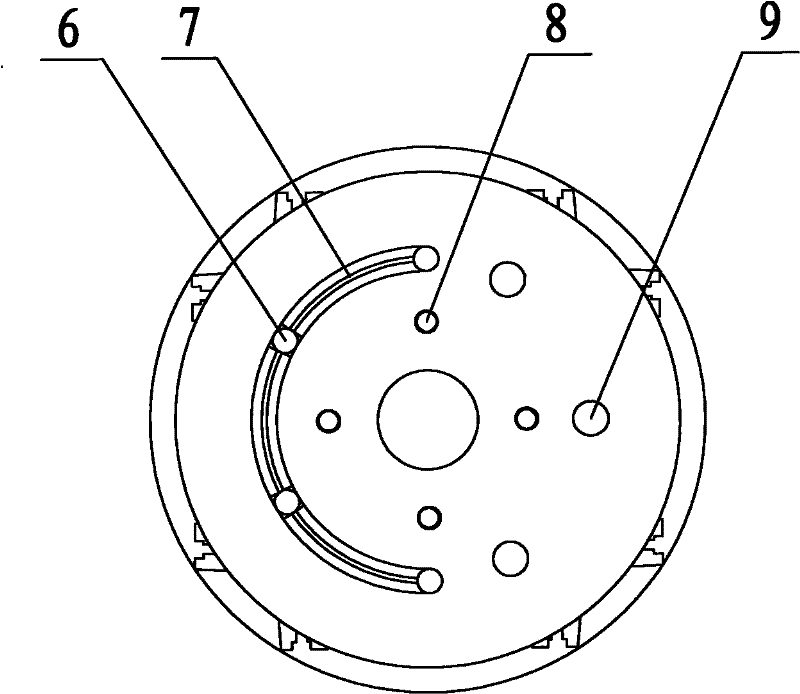

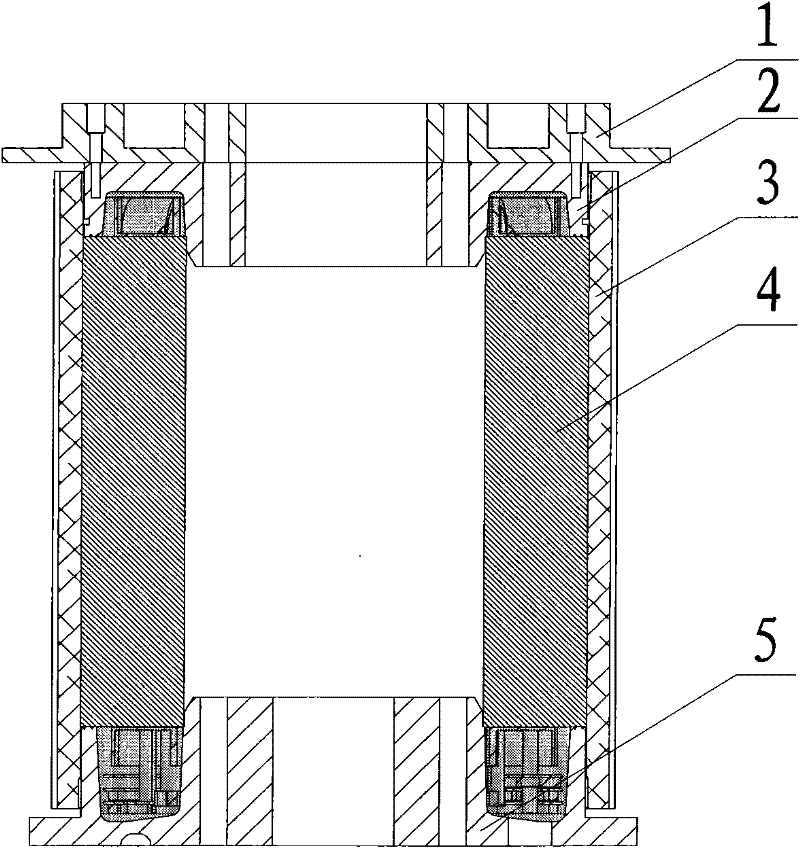

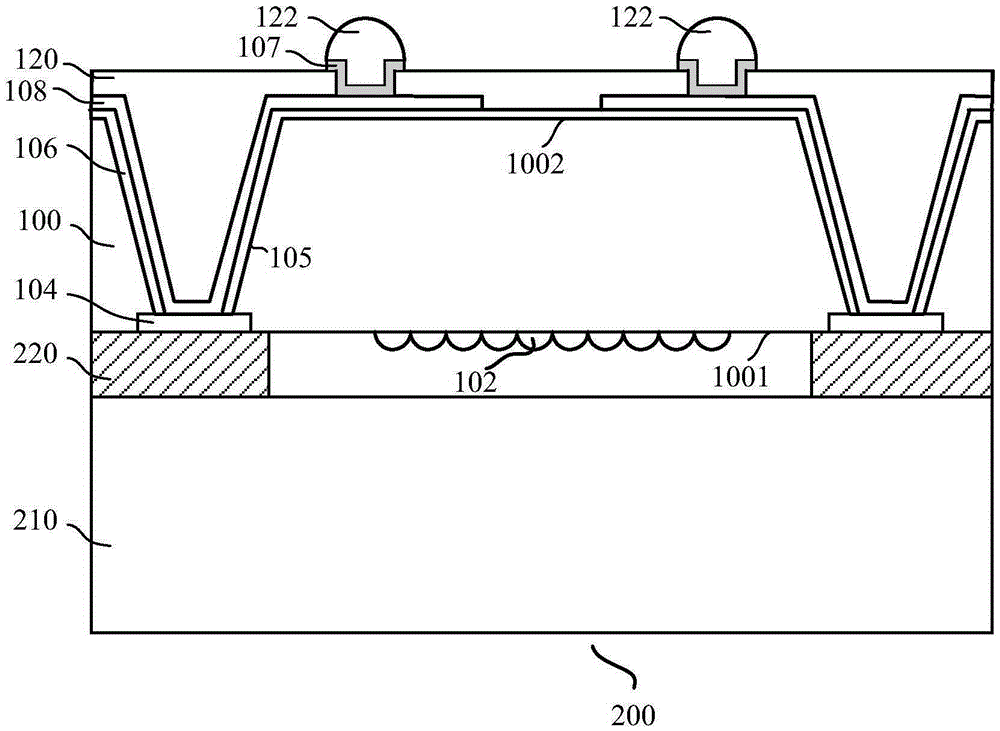

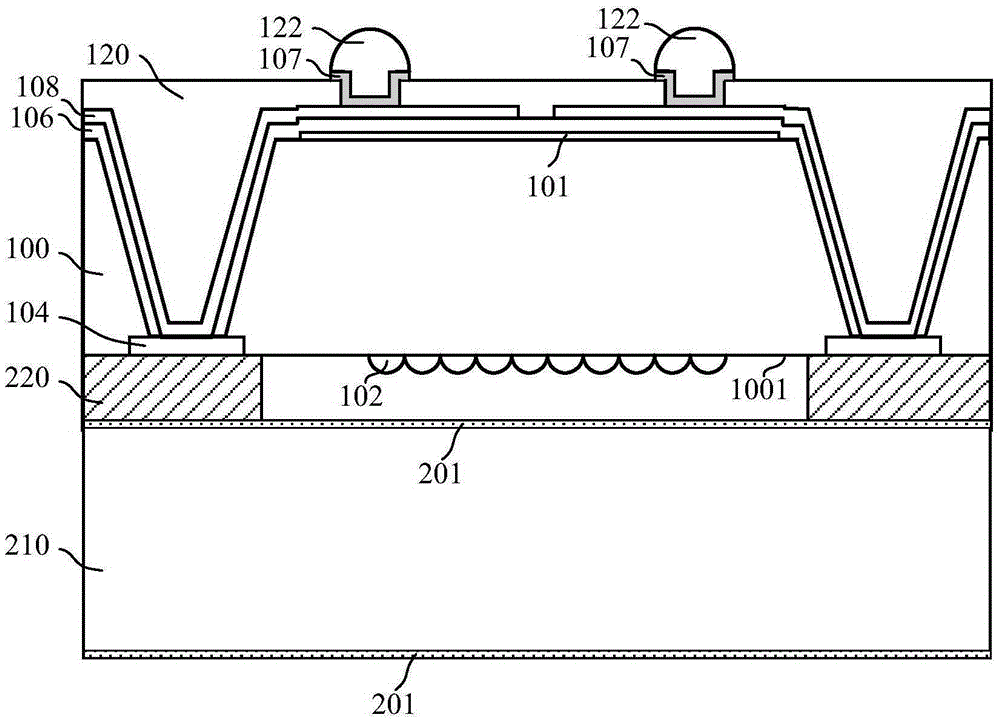

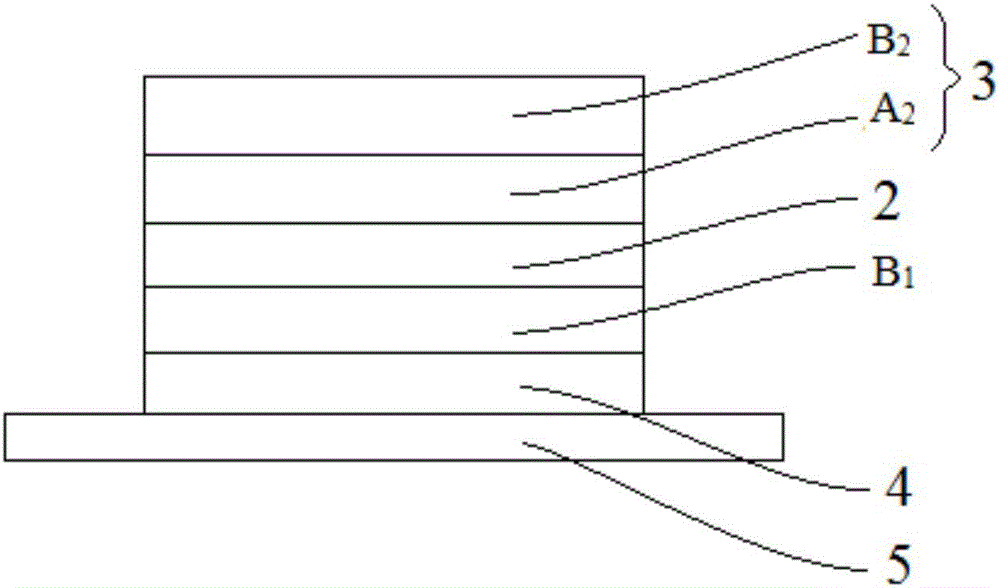

Flexible substrate, preparation method of flexible substrate and flexible display device

PendingCN106206945ASmall expansion coefficientExpansion coefficient matchingMaterial nanotechnologyFinal product manufactureComposite structureOrganic inorganic

The invention relates to the technical field of display and discloses a flexible substrate, a preparation method of the flexible substrate and a flexible display device to solve the technical problems that as a rigid auxiliary substrate is prone to warping, the process precision is low when a display device is prepared. The flexible substrate comprises a first organic layer and an inorganic buffer layer which are sequentially stacked. An organic-inorganic composite structure is formed by the first organic layer and the inorganic buffer layer. The expansion coefficient of the inorganic buffer layer is smaller than the expansion coefficient of the first organic layer. Under the interaction of the first organic layer and the inorganic buffer layer which form the organic-inorganic composite structure, the expansion coefficient of the flexible substrate is reduced; the expansion coefficient of the flexible substrate is matched with the expansion coefficient of the rigid auxiliary substrate better, the risk that the rigid auxiliary substrate warps is reduced, and the process precision is increased when the display device is prepared. The flexible substrate is applied to the flexible display device.

Owner:BOE TECH GRP CO LTD

Motor stator core potting process

InactiveCN102280975AImprove potting efficiencyEasy to remove the moldManufacturing stator/rotor bodiesEpoxyEngineering

The invention provides a filling and sealing process of a motor stator core. The filling and sealing process comprises the following steps of: (1) preparing a filling and sealing material; (2) arranging an upper die filling and sealing die and a lower die filling and sealing die on a motor stator and positioning; (3) injecting the prepared filling and sealing material from an upper die plate; and (4) curing at 75-85 DEG C for 20-40 percent. The filling and sealing material is prepared from the following raw materials, such as epoxy resin, a diluting agent, a curing agent, a flexibilizer, silicon micropowder, and the like according to certain proportions. Compared with the prior art, the invention has the advantages that the filling and sealing time is greatly shortened, the operation is convenient, the filing and sealing efficiency of a motor is effectively improved, and energy consumption is saved; the stator has high surface finish quality and good insulation and waterproofing property; meanwhile, the mechanical property of the motor is improved, and the running stability of the motor is better ensured.

Owner:NANJING GAOQI ELECTRIC

Moon-white Song-dynasty official and brother kiln glaze material, moon-white Song-dynasty official and brother kiln porcelain and preparation method of porcelain

The invention relates to moon-white Song-dynasty official and brother kiln porcelain, a moon-white Song-dynasty official and brother kiln glaze material and a preparation method of the porcelain. The moon-white Song-dynasty official and brother kiln porcelain comprises a porcelain body and a glaze layer, wherein a preform body for preparing the porcelain body consists of the following materials by weight percent: 30% of stone-layer porcelain clay, 40% of Mudaikou purple gold clay and 30% of Yuandi porcelain clay; the glaze material for preparing the glaze layer consists of the following materials by weight percent: 20%-35% of Baoxi Wutou glaze clay, 7%-10% of quartz powder, 2%-5% of Mudaikou purple gold clay, 18%-23% of limestone, 15%-20% of potassium feldspar, 17%-10% of kaolin and 8%-10% of talcum powder. The preparation method comprises the following steps: forming paste, drying the porcelain body, performing biscuit firing, applying internal and external glaze and performing glaze firing on the basis of the raw materials. The moon-white Song-dynasty official and brother kiln porcelain is pure and mild in glaze color, good in thermal stability and high in overall quality.

Owner:龙泉市建春青瓷厂

Lead- and zinc-free transparent fritted glaze

A fritted glaze without Pb and Zn for ceramics contains SiO2, Al2O3, CaO, MgO, K2O, Na2O, SrO, Li2O, B2O3, Fe2O3, Bi2O3 and Y2O3 proportionally. Its advantages are high adhesion, smooth and bright surface, and gay color.

Owner:JIANGSU BAIFU TECH CO LTD

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

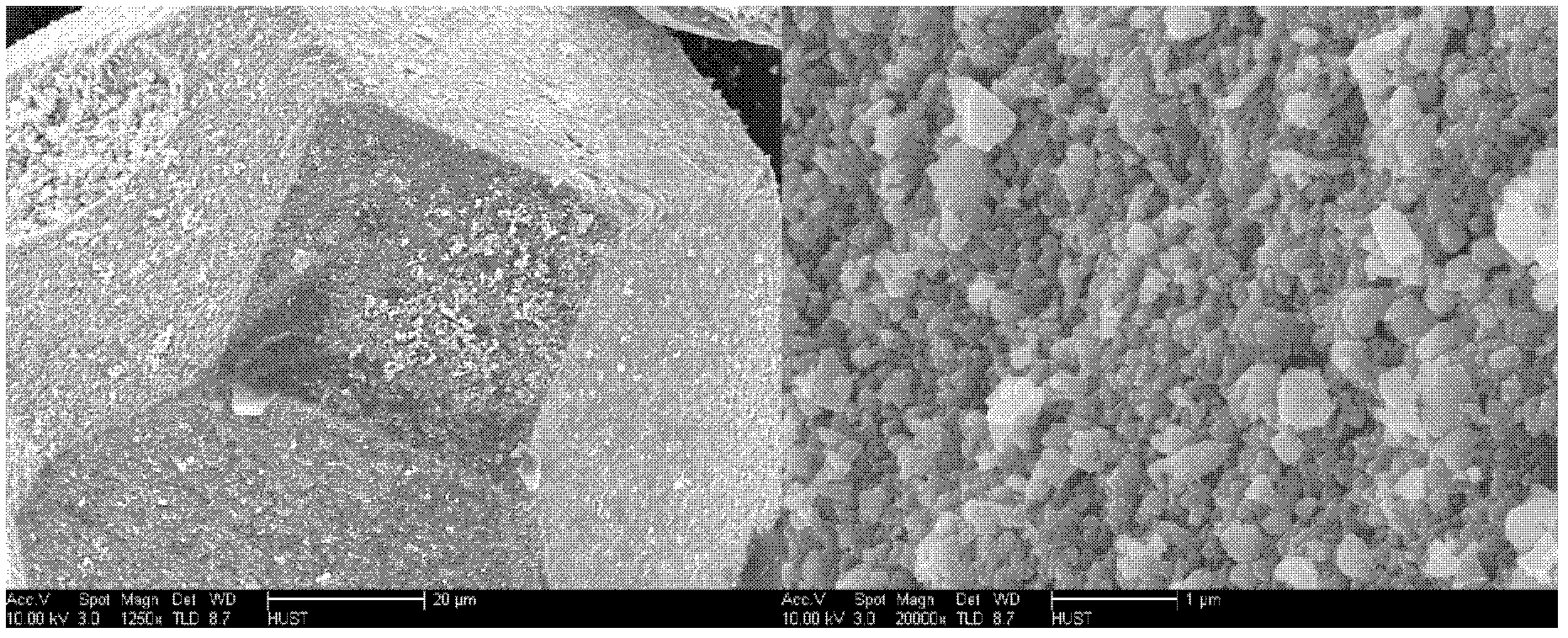

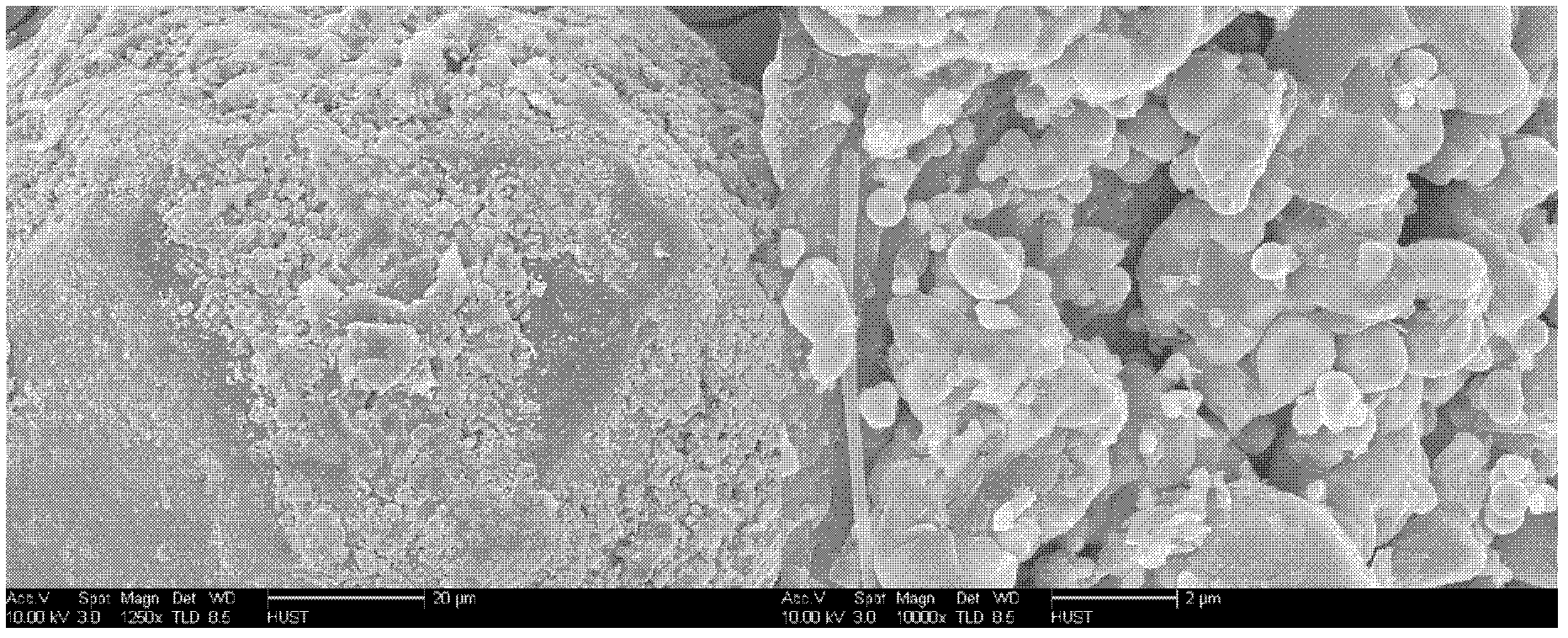

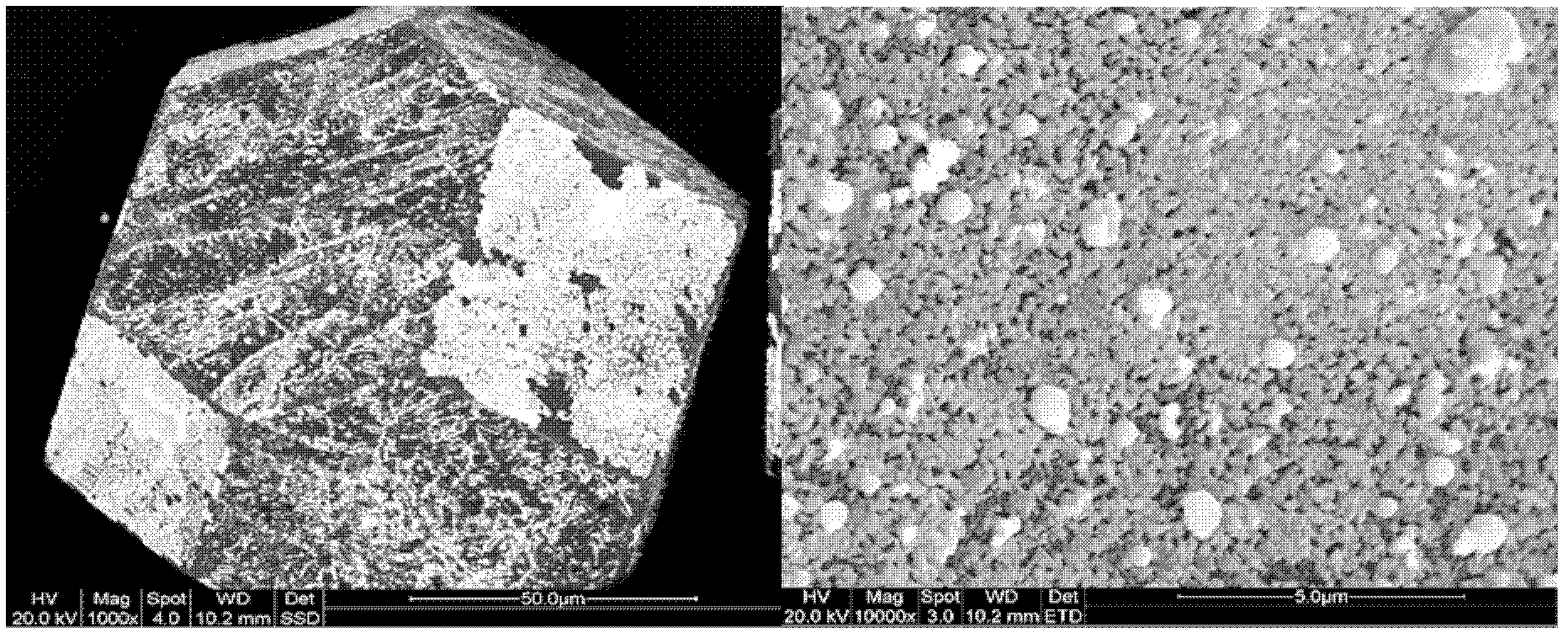

Method for preparing diamond-copper composite material by virtue of metallization of high-temperature blending surface

InactiveCN102383014AImprove wettabilityControllable coefficient of thermal expansionRoom temperatureCarbide

The invention belongs to a preparation technique of a copper-based composite material, and discloses a method for preparing a diamond-copper composite material by virtue of metallization of a surface. The method comprises the following steps of: mixing diamond micropowder with copper powder and powder formed by strong carbide elements, wherein the particle size of diamond is 80-300mu m, the content of the strong carbide elements is 1-10wt%, and the mass fraction of the copper powder is 20%-85%; blending the obtained mixed powder for 10-90 minutes at the temperature of 1050-1150 DEG C, and then cooling along with a furnace; sieving to select the powder with the particle size of 80-300 mu m; mixing the mixed powder with the copper powder again, wherein the mass fraction of the copper powderis 40%-95%; quickly heating the mixed powder material to 850-950 DEG C for sintering at the sintering pressure of 30-50MPa; and then, cooling the obtained product to a room temperature along with thefurnace to obtain the diamond-copper composite material. The method for preparing the diamond-copper composite material has the advantages that the operability of the metallization of the surface of the diamond is strong; the process is simple; the wetting property of a matrix and an enhancer in the prepared diamond-copper composite material is improved greatly; and as an electronic encapsulatingmaterial, the composite material has better comprehensive property, wherein the thermal conductivity is up to 672 W / m.K, the thermal expansion is lower than 7.6 mu m / m. DEG C, and the compactness reaches above 96%.

Owner:HUAZHONG UNIV OF SCI & TECH

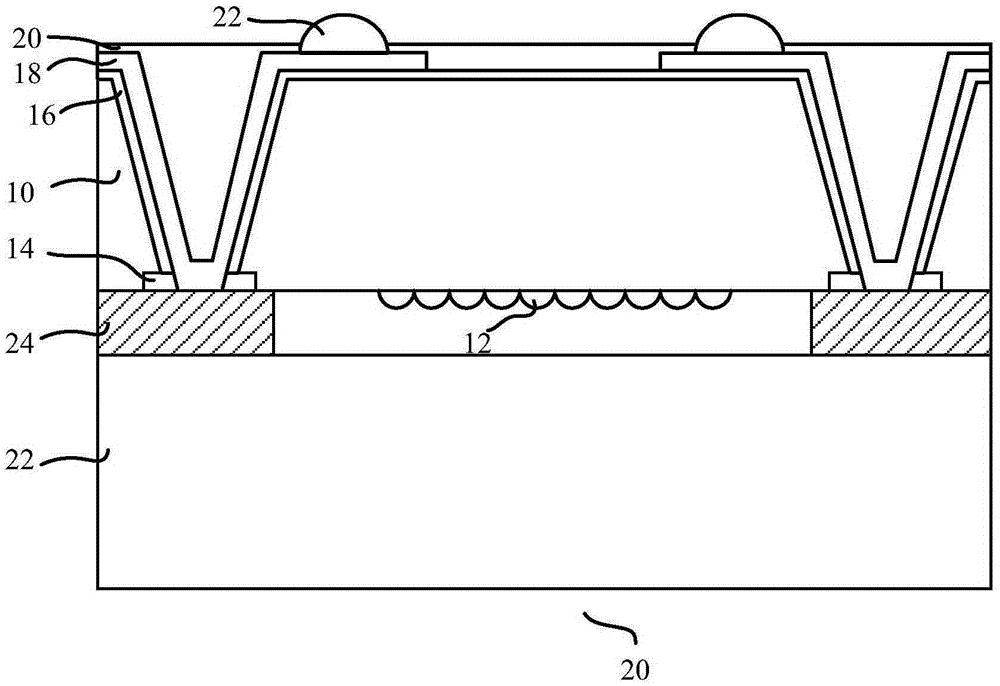

Image sensing chip packaging structure and packaging method

The invention provides an image sensing chip packaging structure. The packaging structure comprises an image sensing chip which has a first surface and a second surface, which are opposite, wherein the first surface is provided with an image sensing area and a welding pad arranged around the image sensing area; a through hole running from the second surface to the welding pad; an electrical wiring layer arranged along the inner wall of the through hole and extending to the second surface, wherein the electrical wiring layer is electrically connected with the welding pad; a solder resist layer filling the through hole and covering the electrical wiring layer, wherein an opening is formed in the solder resist layer, and the bottom portion of the opening exposing the electrical wiring layer; a guide welding pad covering the inner wall of the opening and the bottom portion of the opening and extending to the solder resist layer, wherein the guide welding pad is electrically connected with the electrical wiring layer; and welding bumps arranged on the guide welding pad, wherein the welding bumps are electrically connected with the guide welding pad. The structure reduces the defects of the image sensing chip electrical wiring layer.

Owner:CHINA WAFER LEVEL CSP

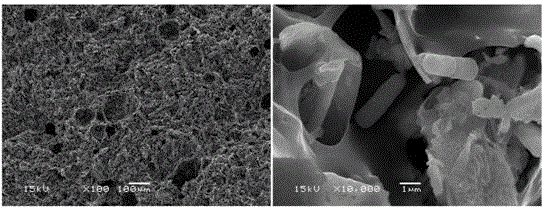

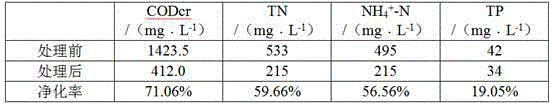

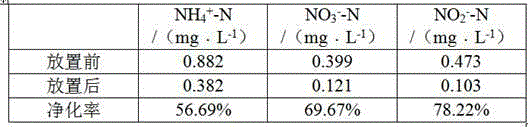

Bacteria immobilization particles for water purification and preparation method of bacteria immobilization particles

ActiveCN104894099AImprove adsorption capacityReduce harmOn/in organic carrierOn/in inorganic carrierActivated carbonEnvironmental chemistry

The invention discloses bacteria immobilization particles for water purification and a preparation method of the bacteria immobilization particles, and belongs to the technical field of water treatment. The preparation method comprises the following steps: preparing a bacteria concentrate through flocculation by utilizing activated carbon, diatomite and a chitosan acetic acid solution; adding diatomite, bentonite, silicon dioxide and a polyvinyl alcohol-sodium alginate mixed solution into the concentrate for stirring; carrying out granulation with a granulator to prepare the bacteria immobilization particles. The prepared bacteria immobilization particles are high in biological activity, high in bacteria content (5*10<9>-1*10<10> CFU / g), short in starting time, and high in reaction speed, has a honeycomb structure (100-300 m<2> / g in specific surface area) suitable for bacteria apposition growth and mass transfer, and can be used for immobilizing bacteria for long, prohibiting the invasion of external hazardous materials, and permanently and efficiently treating sewage in different environments and of different water quality types; meanwhile, industrialized production is available for a whole bacteria immobilization particle preparation process, and the prepared bacteria immobilization particles are high in mechanical property, long in service life, and convenient to store and convey.

Owner:CENT LAB FUJIAN ACADEMY OF AGRI SCI +1

Thin wall cordierite carrier for ceramic honeycomb catalyst and method for preparing the same

InactiveCN1827217AEasy alignmentSmall expansion coefficientCatalyst carriersCeramicwarePorosityCordierite

The invention relates to the improvement on the ceramic beehive catalyst carrier, especially providing a ceramic beehive catalyst carrier with high mechanical strength and lower expansion parameter and preparing method. The invention is characterized in that: said beehive catalyst carrier is the alumina micro powder in 12-15%WT whose average particle diameter is less than 2 micron; the sheet kaolin and / or clay micro powder in 43-47% whose average particle diameter is less than 2 micron, the sheet steatite micro powder in 33-37% whose average particle diameter is 5-15 micron, and the fuse quartz in 6-12% whose average particle diameter is less than 2 micron to be mixed, molded and baked to attain the cordierite whose total amount is 92-96%, wherein, the Al203, MgO and SiO2 are each in 36-37%, 13.0-14.0% and 50-52%. The invention adds surface active agent in the mixture when in preparation. The prepared beehive cordierite total amount with 600 hole / square inch can reach 92-96%, the expansion parameter can reach 0.8X10-6 / Deg. C (800Deg. C to room temperature), and the factor of porosity can reach 39-40%. The invention can reduce the ignition temperature 25-40Deg. C, and reduce the tail gas discharge of nitrogen oxygen compound and carbon monoxide of vehicle 5-10% to meet the demand of Europe III standard.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY +1

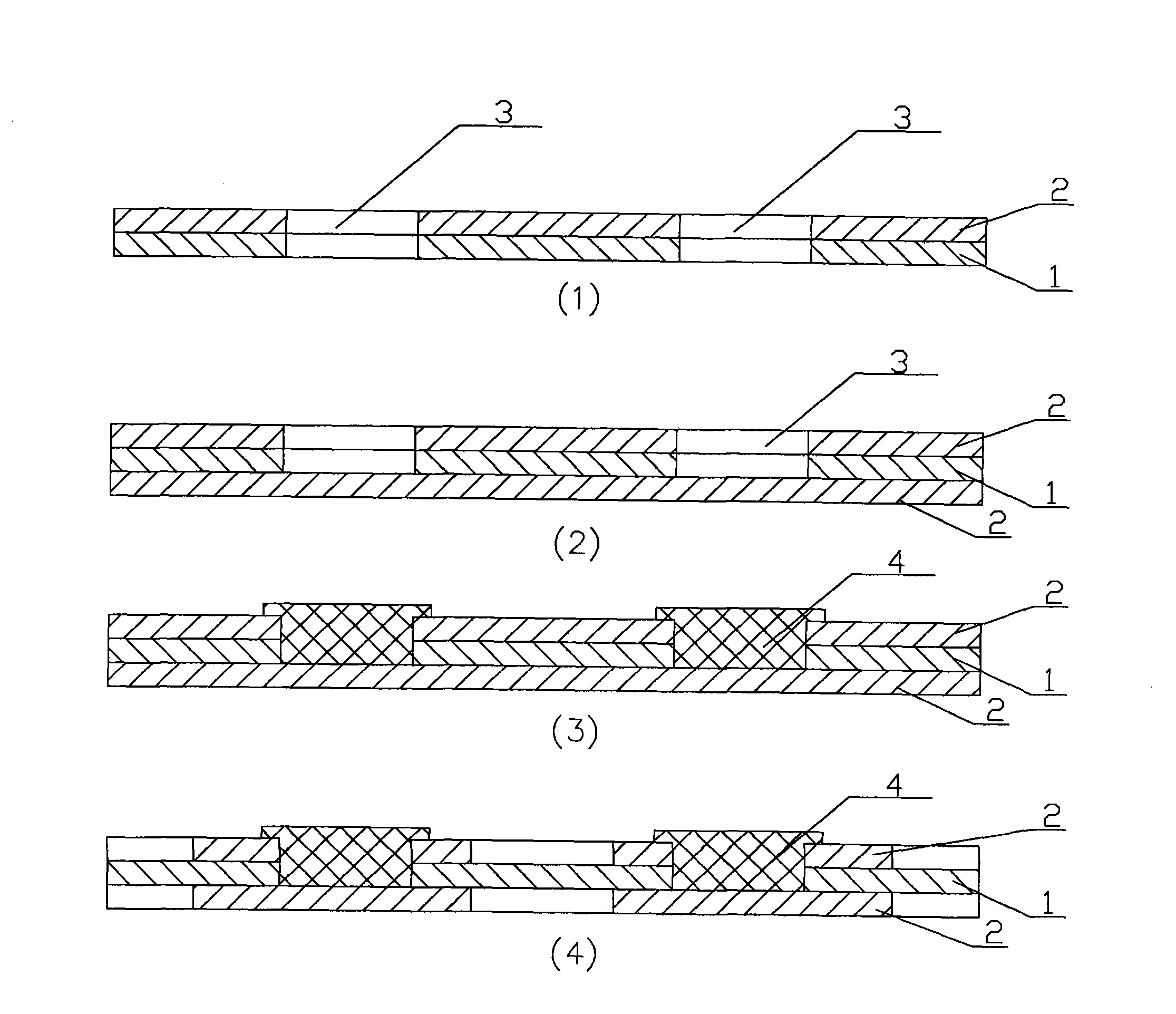

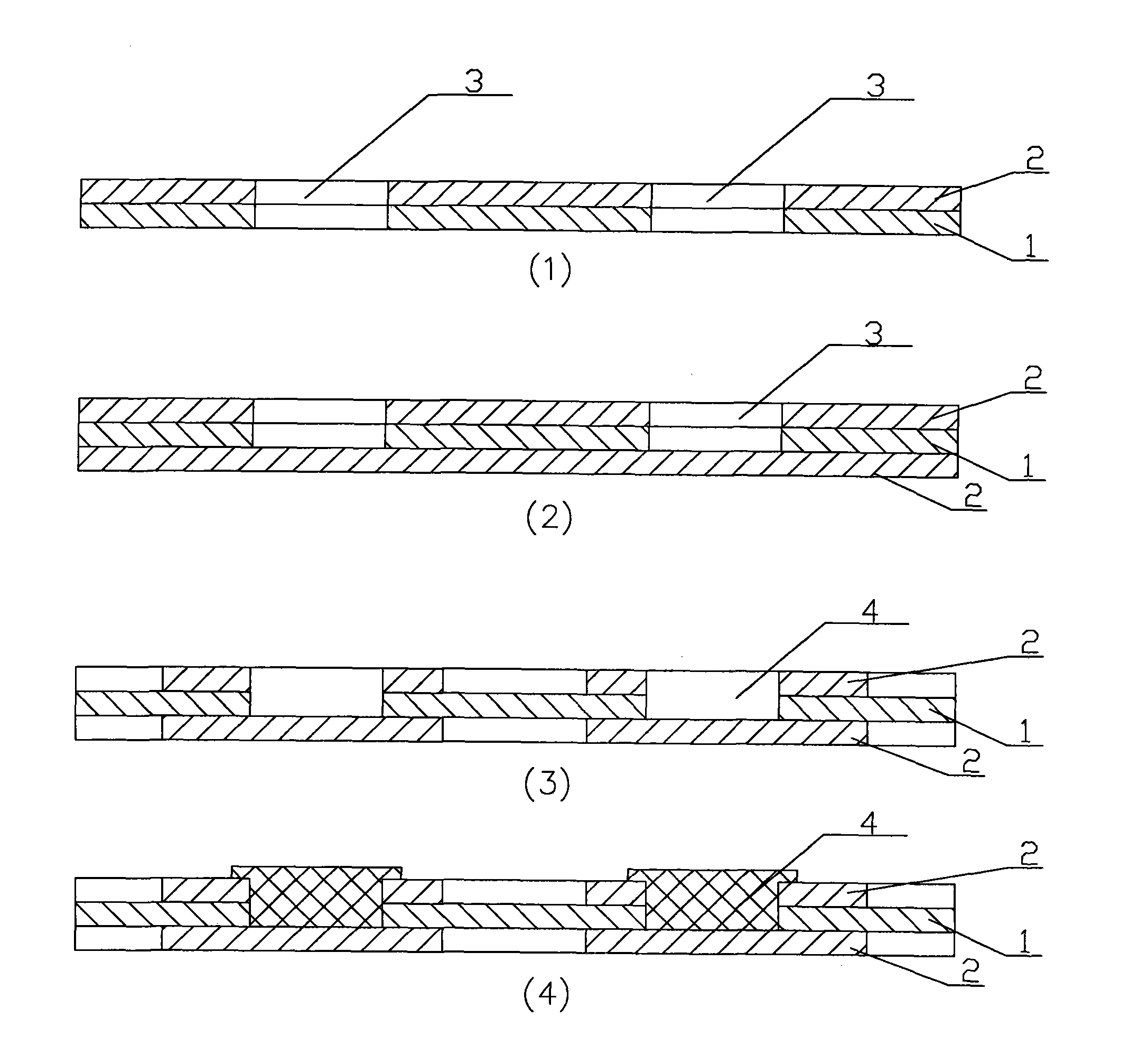

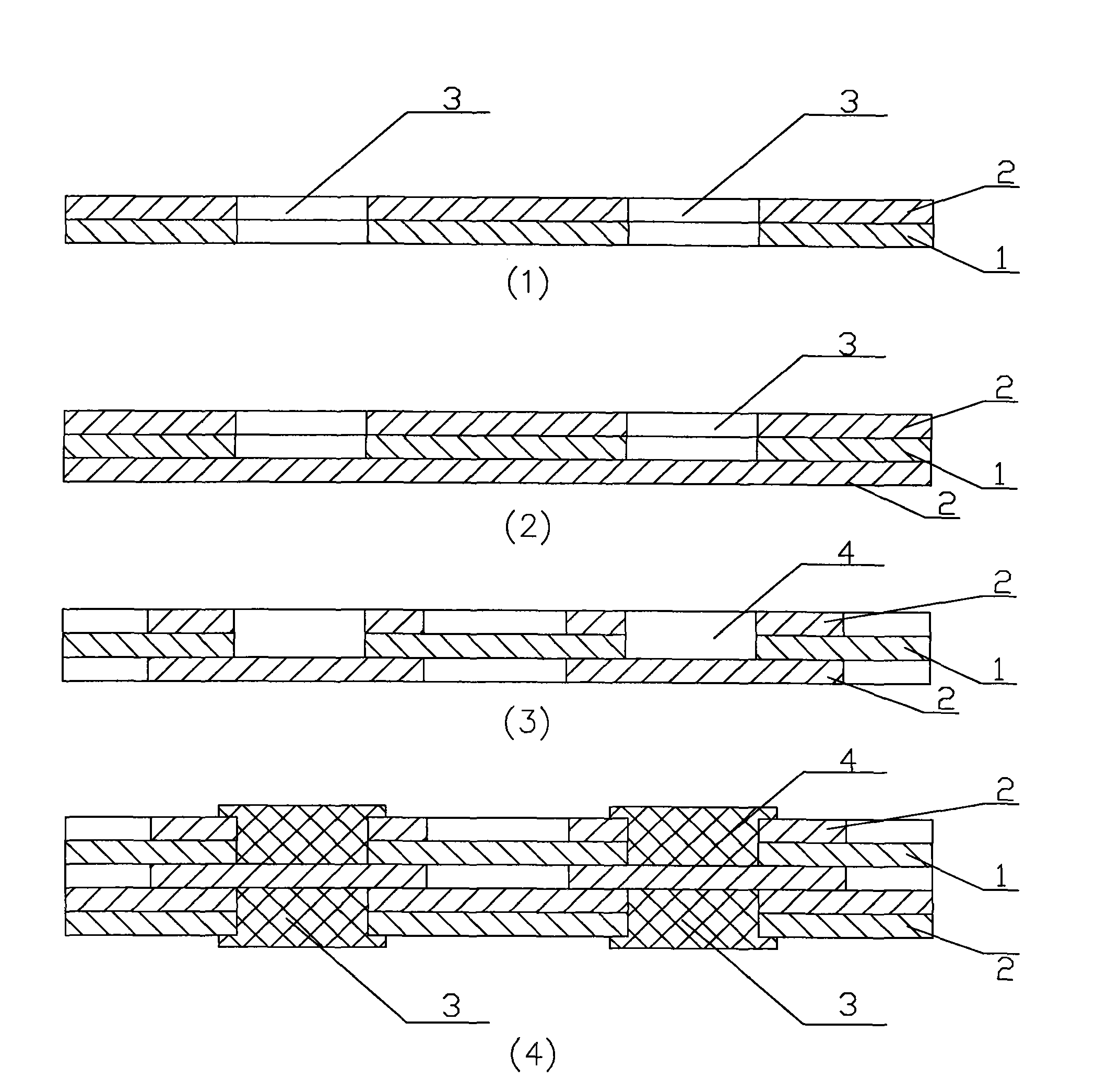

Conductive adhesive for circuit board, single/double-sided multi-layer printed circuit board, and production method

InactiveCN102559092AVarious curing methodsSmall expansion coefficientNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElectricityAdhesive

The invention discloses a conductive adhesive for conducting the plug hole of a circuit board, comprising the following components in ratio by weight: 5-29% of (A) high-temperature-resistant resin, at least 70-5% of (B) tin or tin alloy conductive particles, and the balance of (C) other metallic or non-metallic conductive particles. The invention further discloses a double-sided multi-layer printed circuit board produced by the conductive adhesive and a method for producing the circuit board, wherein the method comprises the following steps of: pre-pressing the copper foil of one side on any one side of an insulating base material at a low temperature to form a single-sided copper-coated base material; machining a conducting hole, compounding the copper foil of the other side on the other side of the insulating base material to form the conducting hole; printing the conductive adhesive containing 5-29% by volume of high-temperature-resistant resin, 70-5% of tin or tin alloy particles, and conductive particles in a groove and then curing, so as to electrically connect the copper foils of the both sides; and machining circuits on the both sides of the double-sided circuit board. The conductive adhesive for conducting the plug hole of a circuit board disclosed by the invention has the advantages of being less in cost, good in adsorbability, wide in application range, good in quality guarantee coefficient, and convenient in operation.

Owner:吴祖

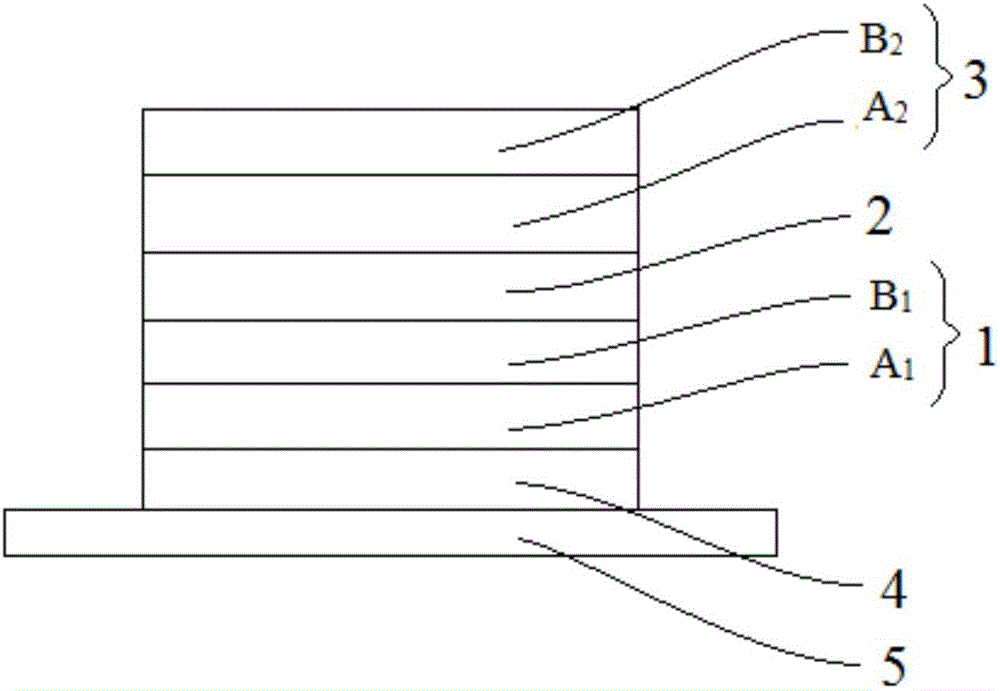

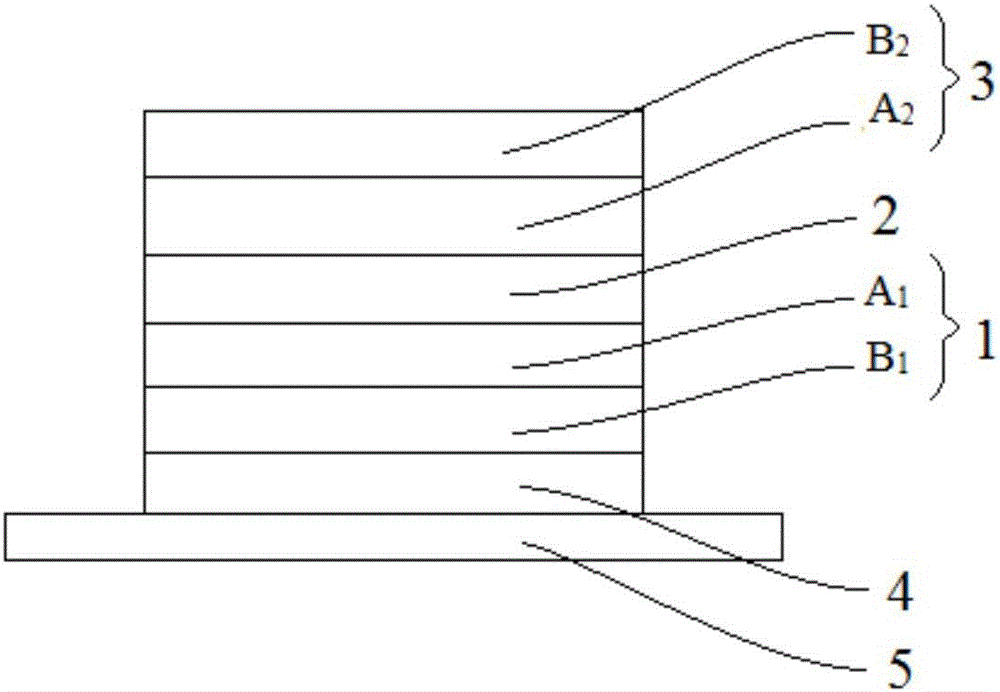

Thin film packaging method and structure

InactiveCN106299153ASmall expansion coefficientHigh expansion coefficientSolid-state devicesSemiconductor/solid-state device manufacturingPhysical vapor depositionInorganic materials

The application relates to the technical field of display, and particularly relates to a thin film packaging method and structure. The thin film packaging method disclosed by the application at least comprises the following steps of: sequentially preparing a first inorganic material layer, an organic material layer and a second inorganic material layer on the surface of a device to be packaged, and when the first inorganic material layer and / or the second inorganic material layer is prepared, firstly, preparing an inorganic layer A by adopting a physical vapor deposition method or a chemical vapor deposition method, and then preparing an inorganic layer B on the surface of the inorganic layer A by adopting an atomic layer deposition method; or, preparing the inorganic layer B by adopting the atomic layer deposition method, and then preparing the inorganic layer A on the surface of the inorganic layer B by adopting the physical vapor deposition method or the chemical vapor deposition method. According to the thin film packaging method and structure disclosed by the application, a composite inorganic layer prepared by utilizing the physical vapor deposition method or the chemical vapor deposition method and the atomic layer deposition method is gradually varied in density, so that a deviation of coefficients of thermal expansion of the prepared inorganic layer and organic material layer is reduced, and bending resistance of a display screen is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

Processing method of anti-fatigue aluminum alloy foaming die cast

The invention discloses a processing method of an anti-fatigue aluminum alloy foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and thermal treatment. According to the invention, an appropriate amount of rare earth elements La, Ce and Y are added to the aluminum alloy, so that the hydrogen content in the alloy and the alloy yielding anisotropy can be reduced, the alloy plasticity and the anti-fatigue property of the alloy are obviously increased, and at the same time the wear resistance, thermal resistance and high-temperature strength of the alloy can also be improved. The processed aluminum alloy refrigerator foaming die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州晨润工贸有限公司

Artificial granite, marble mechanical fitting and its preparing method

ActiveCN1709817AReduce stepsShorten the timeAuxillary shaping apparatusMeasuring instrumentGranularity

The invention discloses one kind of man-made granite, the marble's mechanical fitting and its preparation method, which belonged to the mechanical fitting processing domain. The man-made granite, the marble's mechanical fitting, which is made from the sizing material with percent by weight is 80% - 93% aggregate and 20% - 7%, after the ingredient, the pattern making, dense and so on the craft. Among them, the aggregate is the granularity- 0.01-25mm natural granite pellet or the marble pellet. Compares with the existing technology, this invention man-made granite, the marble mechanical fitting has stronger vibration hinder and lower cost, which widely applies to the engine bed equipment, the check-out facility, measure instrument fitting.

Owner:周卫

Porous ceramic carrier for high-temperature and high-pressure inorganic filtering membrane and preparation method for porous ceramic carrier

The invention discloses a porous ceramic carrier for a high-temperature and high-pressure inorganic filtering membrane and a preparation method for the porous ceramic carrier. The porous silicon carbide ceramic carrier is prepared by silicon carbide, a binding agent and a pore-forming agent, wherein the mass ratio of the silicon carbide to the binding agent is 80-90:10-20, and the utilization quantity of the pore-forming agent is 35-45% of the sum of the volumes of the silicon carbide, the binding agent and the pore-forming agent. The preparation method includes adding the binding agent and the pore-forming agent in silicon carbide powder; performing ball milling, drying and vacuum heat casting forming; and performing pressureless sintering for a formed blank. Sintering temperature rangesfrom 1250 DEG C to 1350 DEG C, and heat insulation time ranges from 2 hours to 4 hours. As raw materials form main materials by means of fine size grading, the binding agent and the pore-forming agent are added by a special process, technologies such as unique vacuum heat casting forming and the like are adopted, and mechanical strength and porosity of the porous carrier can be improved effectively. The prepared silicon carbide porous ceramic carrier has excellent performances of fine thermal shock resistance, low coefficient of thermal expansion, fine mechanical and chemical stability at high temperature and under high pressure, and the like.

Owner:TSINGHUA UNIV

LCD sheet glass

The invention discloses a base plate glass with rare-earth element to dope liquid crystal display device (TFT-LCD), which is characterized by the following: comprising glass basic oxide, lanthanum oxide, cerium oxide, neodymium oxide and or yttrium oxide; setting the mass ratio at (60. 5-195):(0. 003-28) of the glass basic oxide and all rare-earth oxide; adding at least three rare-earth oxide; improving the fusion of the glass; accelerating clarification and equalization in the course of formation; preventing glass crystallizer; decreasing the liquid phase temperature; delaying devitrification speed of the glass; fitting for productive technology of float glass; improving chemical stability of the glass; decreasing the expansion coefficient; fitting for large scale float glass procession.

Owner:CHINA BUILDING MATERIALS ACAD

Green body of environment-friendly ceramic tile, environment-friendly ceramic tile and preparation method of ceramic tile

The invention relates to the field of building materials and particularly relates to a green body of an environment-friendly ceramic tile, the environment-friendly ceramic tile and a preparation method of the ceramic tile. The green body of the environment-friendly ceramic tile comprises the following components in parts by mass: 20-25 parts of dolomite clay, 35-56 parts of ceramic wastes, 10-15 parts of limestone, 5-10 parts of aluminum ores and 8-15 parts of soft clay. The strength of the green body of the polished waste ceramic tile is larger than 0.25MPa, and the drying strength of the green body is larger than 1.8MPa; the whiteness of a finished product of the ceramic tile is high and higher than that of the like product; and environment pollution is greatly reduced, and the ceramic wastes are changed into things of value.

Owner:SICHUAN JIANHUI CERAMIC CO LTD

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261AHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

The invention relates to a preparation method of high-conductivity aluminum alloy and belongs to the field of nonferrous metal materials. The preparation method comprises the following steps of: preparing an aluminum ingot comprising the following alloy elements in percentage by weight: 4.5 to 13.5 percent of Si (silicon), 0.1 to 1.5 percent of Mg (magnesium) and not more than 0.1 percent of impurity elements, smelting the aluminum ingot in a furnace, adding 0.1 to 0.3 percent of zirconium which serves as additive for the alloying treatment, uniformly mixing, then adding 0.1 to 1.35 percent of rare-earth element for degeneration, purifying, degassing and deslagging, and covering the surface of aluminum liquid with a solid covering agent; casting to prepare the aluminum alloy conductor material; and carrying out the first-stage aging treatment and the second-stage aging treatment on the aluminum alloy conductor material, discharging and cooling with air. The manufactured aluminum-silicon alloy can meet the requirements on the aluminum alloy material conductivity and the mechanical property; and moreover, the preparation process is simple, the cost is low, and the mass production is easy to realize.

Owner:JIANGSU UNIV

Artificial float stone and its manufacturing method

The invention relates an approach to produce artificial pumice. It is burned by nether materials: inorganic material, sodium hydroxide, borax, Paris white, carbon dust and isinglass. Thereinto, inorganic material is selected from minerals or clay. It follows nether steps: mixing above materials in terms of given ratio, cracking blending to 60-200 items and loading into a module to bake.

Owner:郭勇

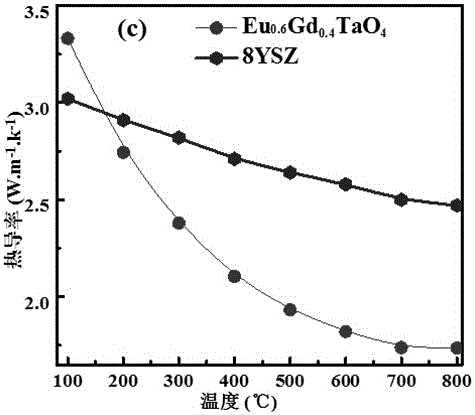

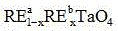

Preparation method of double-rare-earth-ion tantalite high-temperature ceramic

The invention relates to a preparation method of double-rare-earth-ion tantalite high-temperature ceramic and belongs to the technical field of high-temperature ceramic preparation. The molecular formula of the double-rare-earth-ion tantalite high-temperature ceramic is shown in the description (REa / REb = Y, La, Nd, Sm, Eu, Gd, Dy, Er and Yb, and REa and REb are not the same type of rare earth elements). The used raw materials are rare earth oxide and tantalum oxide andare weighed in proportion, the weighed raw materials and absolute ethyl alcohol are put in a ball milling tank for mixing and sealing, then the mixture is put on a planetary ball mill for ball milling, the mixture can be evenly mixed, and primary sintering is performed after the mixed powder is dried and screened; the cooled and taken-out sample is grinded, ball-milled, dried and screened and then is put in a mold for compaction, and then secondary sintering is performed. The preparation method is high in purity, low in impurity content, low in product device cost and suitable for batch production, and the product is expected to be a novel ceramic material resistant tohigh temperature, oxidation and abrasion.

Owner:KUNMING UNIV OF SCI & TECH

Medium-temperature hard fine porcelain with high whiteness, high transparency and high strength and preparation method of medium-temperature hard fine porcelain

InactiveCN105693202AGood visible light transmittanceSmall expansion coefficientClaywaresSlurryFineness

The invention relates to medium-temperature hard fine porcelain with high whiteness, high transparency and high strength and a preparation method of the medium-temperature hard fine porcelain. The medium-temperature hard fine porcelain with high whiteness, high transparency and high strength is prepared from the following chemical components in parts by weight: 66 to72 parts of SiO2, 23 to 28 parts of Al2O3, 0.5 to 4 parts of CaO, 0.3 to 3 parts of MgO, 1 to 5 parts of K2O, 0.5 to 2.5 parts of Na2O and 0.2 to 1 part of B2O3. The preparation method of the medium-temperature hard fine porcelain with high whiteness, high transparency and high strength comprises the following steps of firstly, burdening; secondly, performing ball milling; thirdly, detecting the fineness of slurry; fourthly, sieving and removing iron; fifthly, ageing; sixthly, performing slip casting; seventhly, primary drying; eighthly, fettling; ninthly, glazing; tenthly, performing secondary drying; eleventhly, firing.

Owner:南京豪祺新材料有限公司

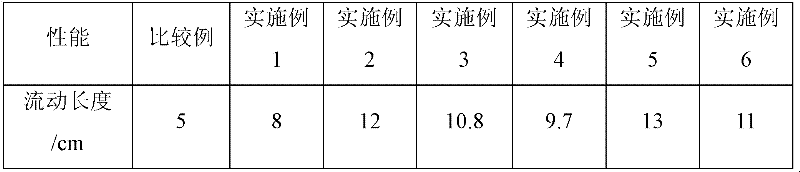

Filler compound and copper clad laminate made of same

InactiveCN102212250AImprove liquidityEasy to operateSynthetic resin layered productsMetal layered productsHeat resistanceCopper foil

The invention relates to a filler compound and a copper clad laminate made of the same. The filler compound comprises two or more than two fillers with different particle diameters, a surface treatment agent and a solvent. The content of the fillers is 50-95% of the total weight of the filler compound and the content of the surface treatment agent is 0.1-5% of the total weight of the filer compound. The copper clad laminate made of the filler compound includes a plurality of superimposed pre-dipping bodes and a copper foil covered at one side or two sides of the plurality of superimposed pre-dipping bodes. Each pre-dipping body comprises a base material and a filler compound which is attached on the base material by impregnating and drying. In the invention, two or more than two fillers with different particle diameters are compounded to improve the liquidity of the filler compound, therefore, not only are the problems of dispersion and high viscosity of high filler content solved, but also the operation is easy and the application range is wide, furthermore, the expansion coefficient and the water absorption of the copper clad laminate made of the filler compound are reduced, and the heat resistance of the copper clad laminate is improved.

Owner:GUANGDONG SHENGYI SCI TECH

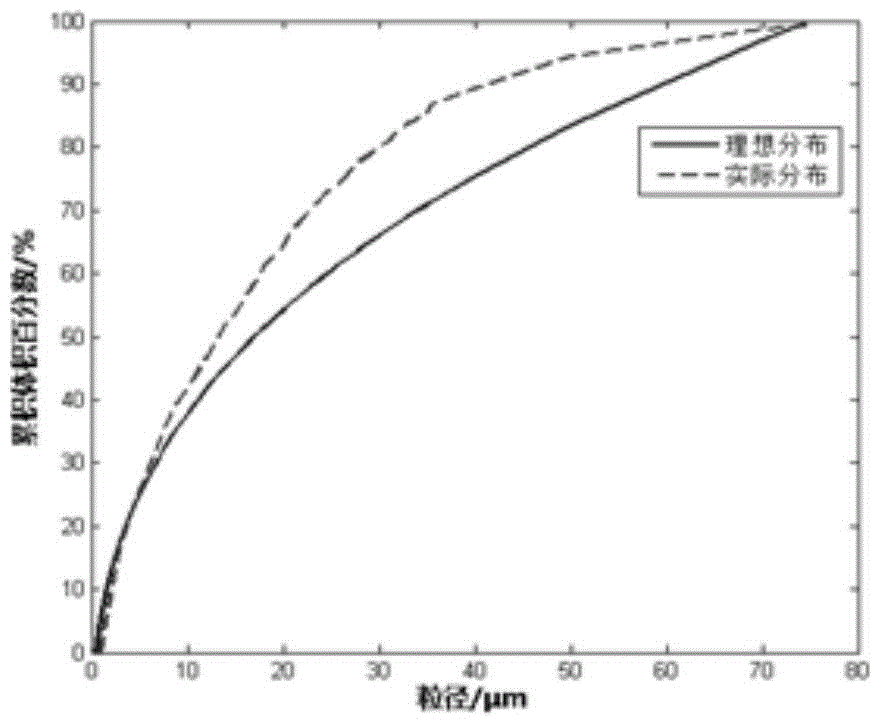

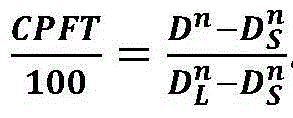

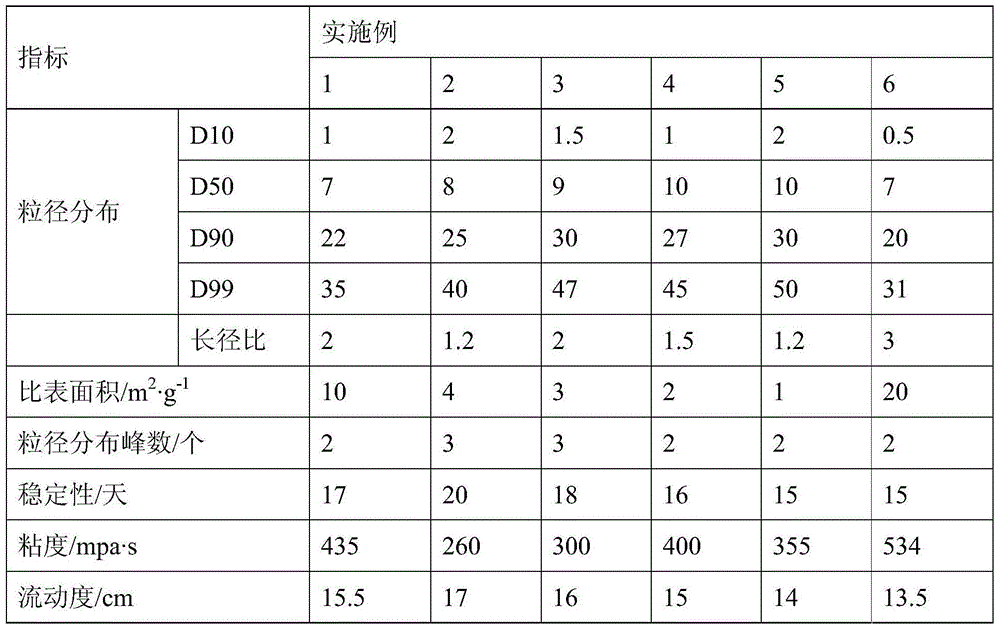

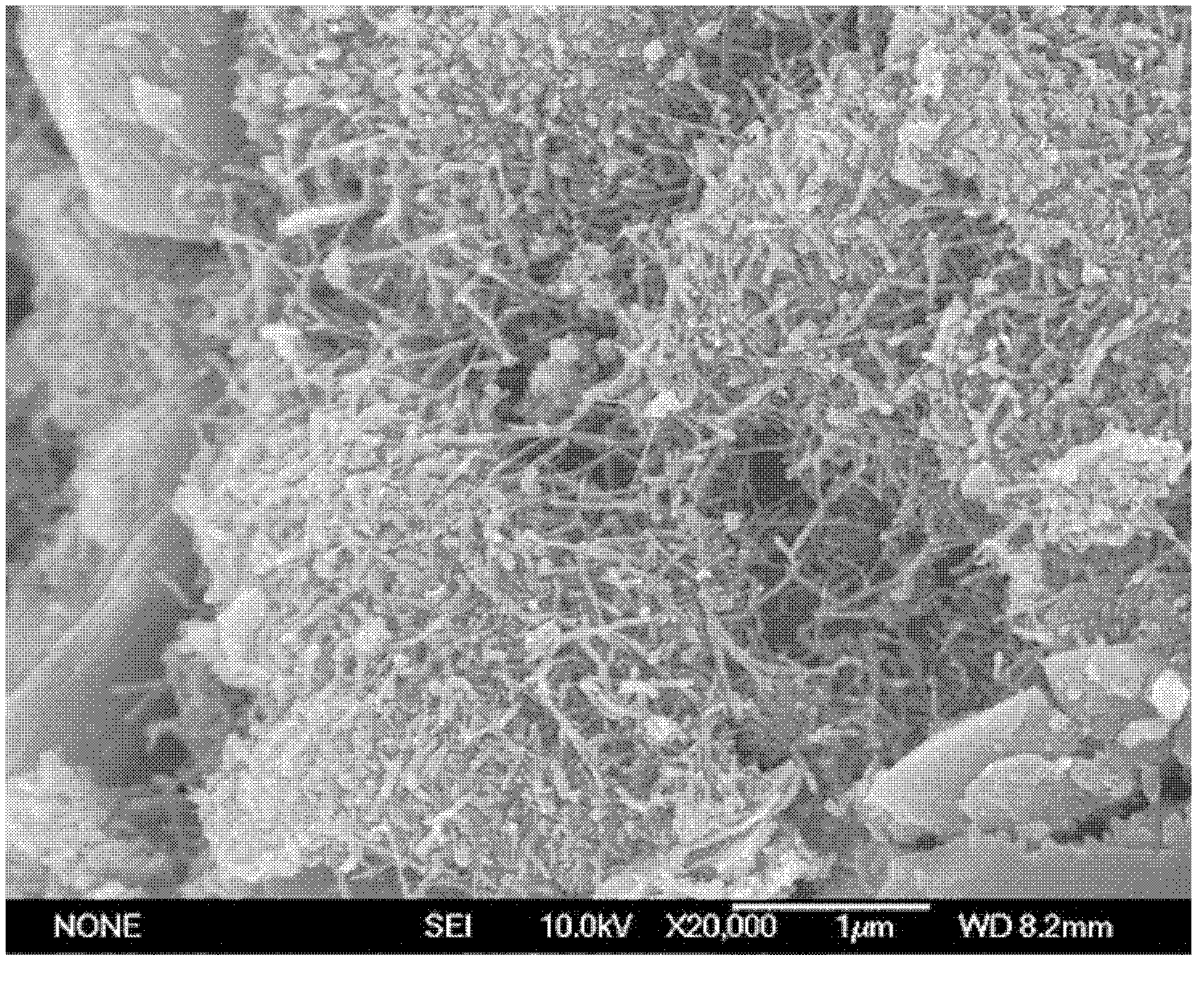

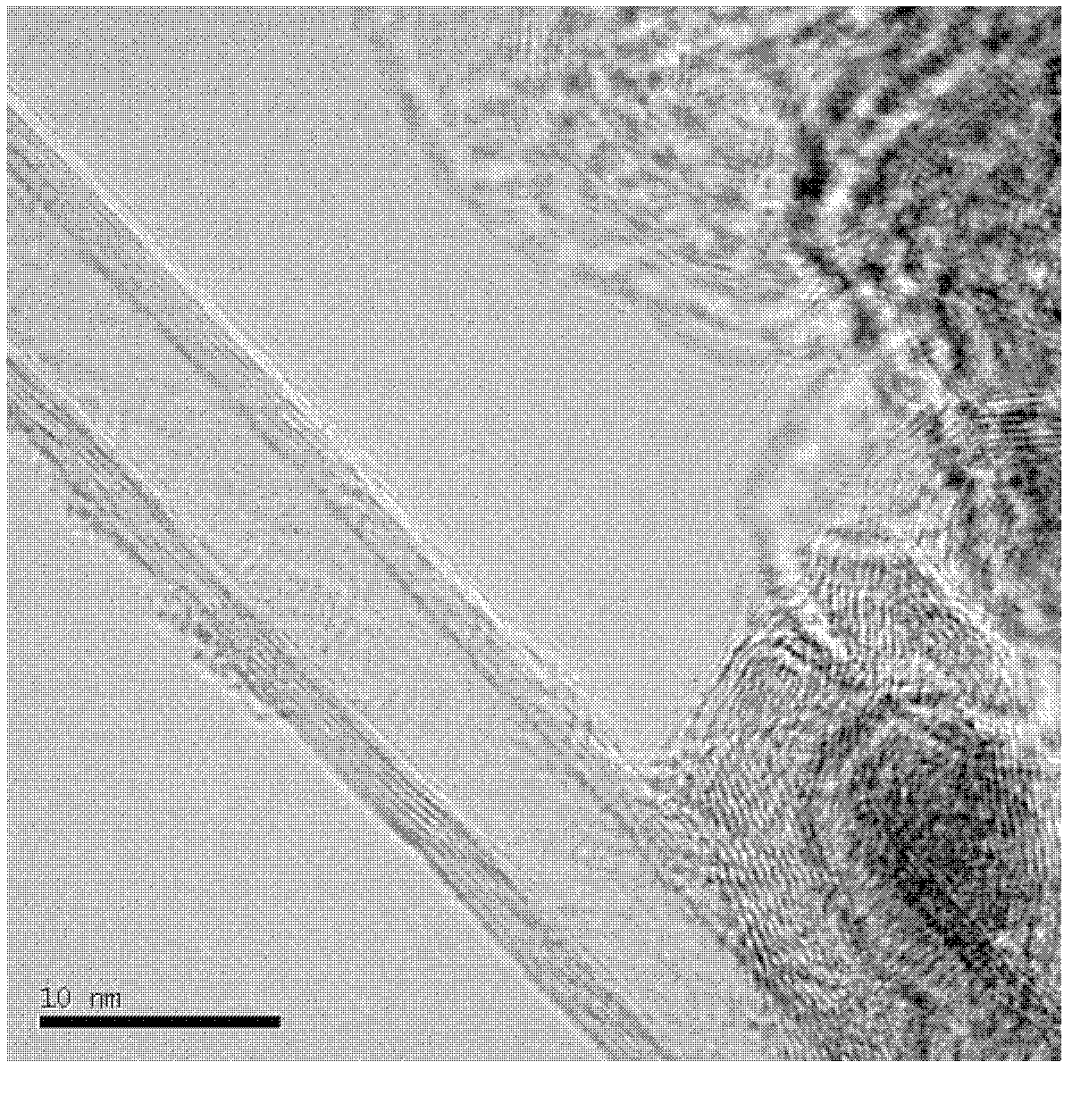

Filler composition and application thereof

ActiveCN104558689AImprove liquidityImprove stabilitySynthetic resin layered productsMetal layered productsThermal dilatationPolymer science

The invention relates to a filler composition and application thereof. The filler composition comprises an angular siliceous micro powder filler, and can be used for preparing a copper clad laminate substrate and bonding sheet resin composition. The filler composition is formed by an angular silicon dioxide with the specific particle size distribution or the mixture of at least two angular silicon dioxides with different particle sizes and the specific particle size distribution, the flowability of the composition and the sedimentary stability in a solution or resin system can be improved, the coefficient of thermal expansion is reduced remarkably, the bonding interface between resin and an inorganic filler, the interlayer adhesiveness between laminates and the adhesive force between a resin layer and a copper foil are improved, and the production cost is reduced greatly.

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

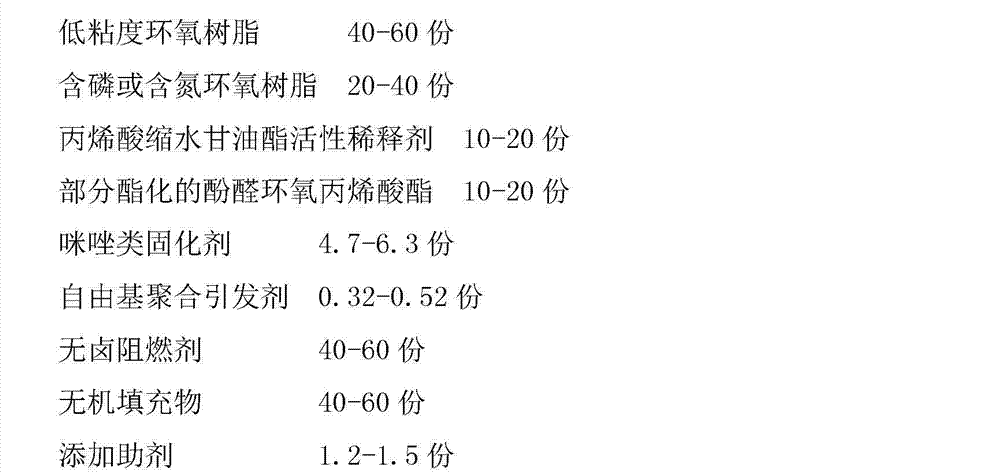

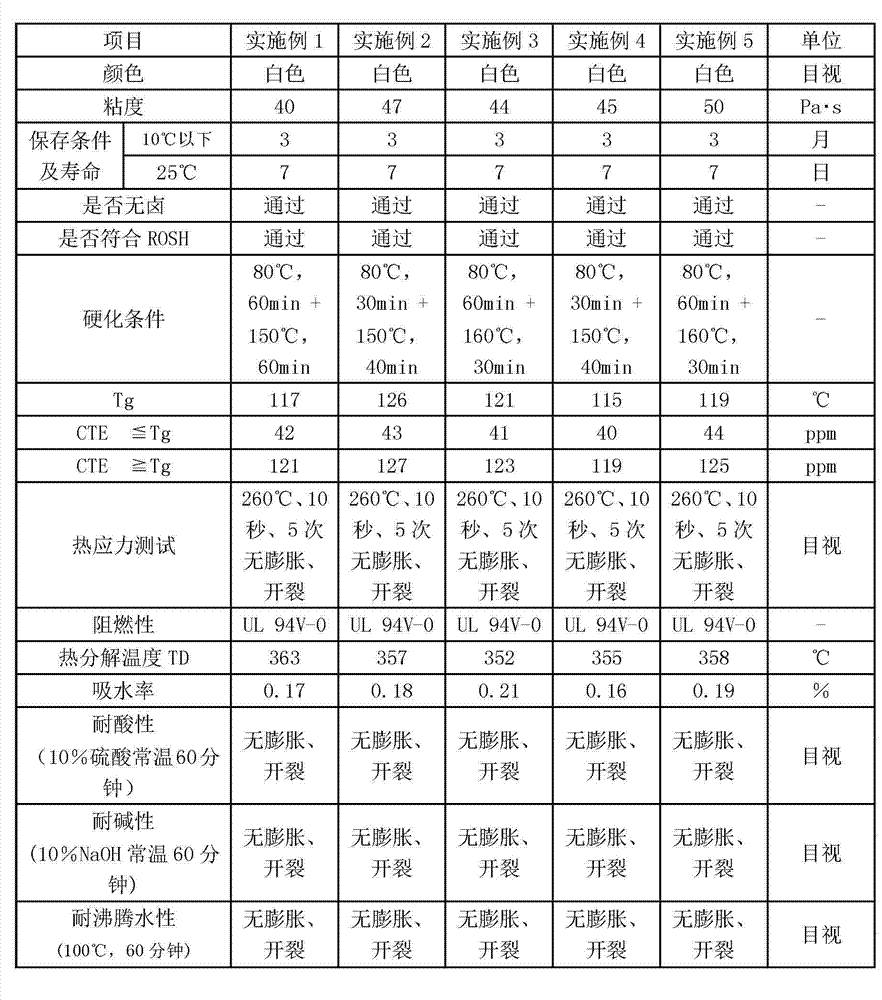

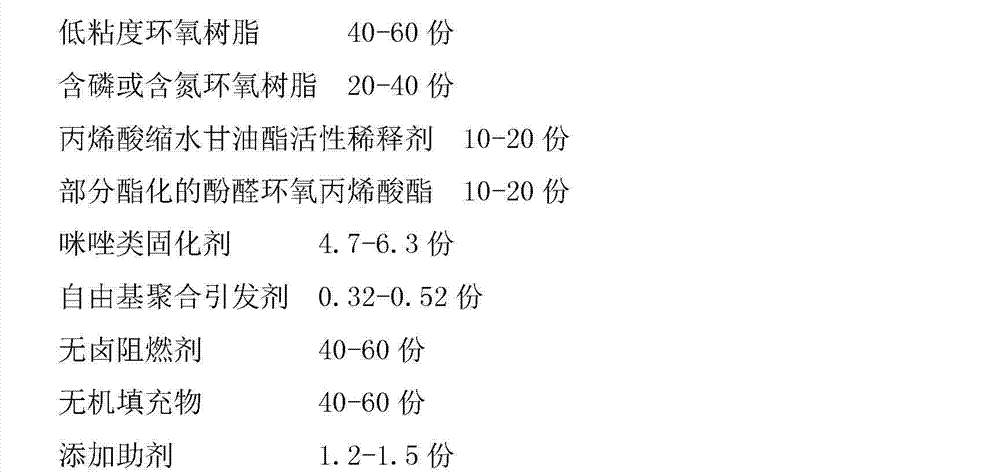

Halogen-free flame-retardant solvent-free double-curing ink composition and preparation method thereof

ActiveCN102732096ASmall coefficient of thermal expansionGuaranteed thermal stabilityInksSolvent freeThermal deformation

The invention relates to electronic materials and preparation, and aims to provide a halogen-free flame-retardant solvent-free double-curing ink composition and a preparation method thereof. The composition comprises the following components: low-viscosity epoxy resin, epoxy resin containing phosphorus or nitrogen, glycidyl acrylate reactive diluent, partially-esterified phenolic epoxy acrylate, imidazole curing agent, free radical polymerizing initiator, halogen-free flame retardant, inorganic filler and additives. The preparation method comprises the following steps of: mixing, dispersing and grinding the raw materials until the viscosity reaches 40 to 50 Pa.s per 25 DEG C, dispersing and uniformly agitating the raw materials after the grinding is stopped, and finally filtering, filling and packaging the raw materials. The halogen-free flame-retardant solvent-free double-curing ink composition has the advantages that the possibility of fire hazards caused by ink introduction when a hole is blocked can be reduced by virtue of halogen-free and flame-retardant performance; with adoption of a double-curing technology with free radical polymerizing and epoxide ring-opening addition polymerization, the halogen-free flame-retardant solvent-free double-curing ink composition has a high curing degree, a high temperature in thermal deformation, a low expansion coefficient, low water absorption and high heat resistance; the viscosity of the ink is easy to adjust, and thus the requirements on the use of the ink in different seasons can be ensured; and the curing material is moderate in rigidity and has the characteristic of grindability.

Owner:ELEK & ELTEK ELECTRONICS KUNSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com