Patents

Literature

217 results about "Carbon dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dust is an artistic technique in which carbon dust is applied to a prepared surface via dry brushes. Highlights may be painted on or scratched out later in the process. Dust is prepared by rubbing carbon pencils against an abrasive surface, such as a metal file. The technique was popularized by Max Brödel (1870-1941) and became widely used among medical and scientific illustrators in the twentieth century.

Carbon nano tube strengthening toughening silicon carbide ceramic and preparation method thereof

The invention discloses a carbon nano tube strengthening toughening silicon carbide ceramic. The ceramic is prepared from raw materials comprising silicon carbide powder, boron carbide micro powder, carbon dust, carbon nano tube, agglomerant and dispersing agent of which the weight ratio is 100:0.5-3:1.5-8:0.5-3:3-6:0.2-3.0. Hot pressed sintering or sintering-free process is adopted for preparation. A carbon nano tube strengthening hot pressed sintering silicon carbide material has the high flexural strength of 593MPa, weibull modulus achieves 14.7, reliability is substantially improved compared with general silicon carbide, excellent mechanical property of a carbon nano tube functions in the silicon carbide, and the prepared silicon carbide ceramic has excellent strengthening toughening performance.

Owner:NINGBO VULCAN TECH CO LTD

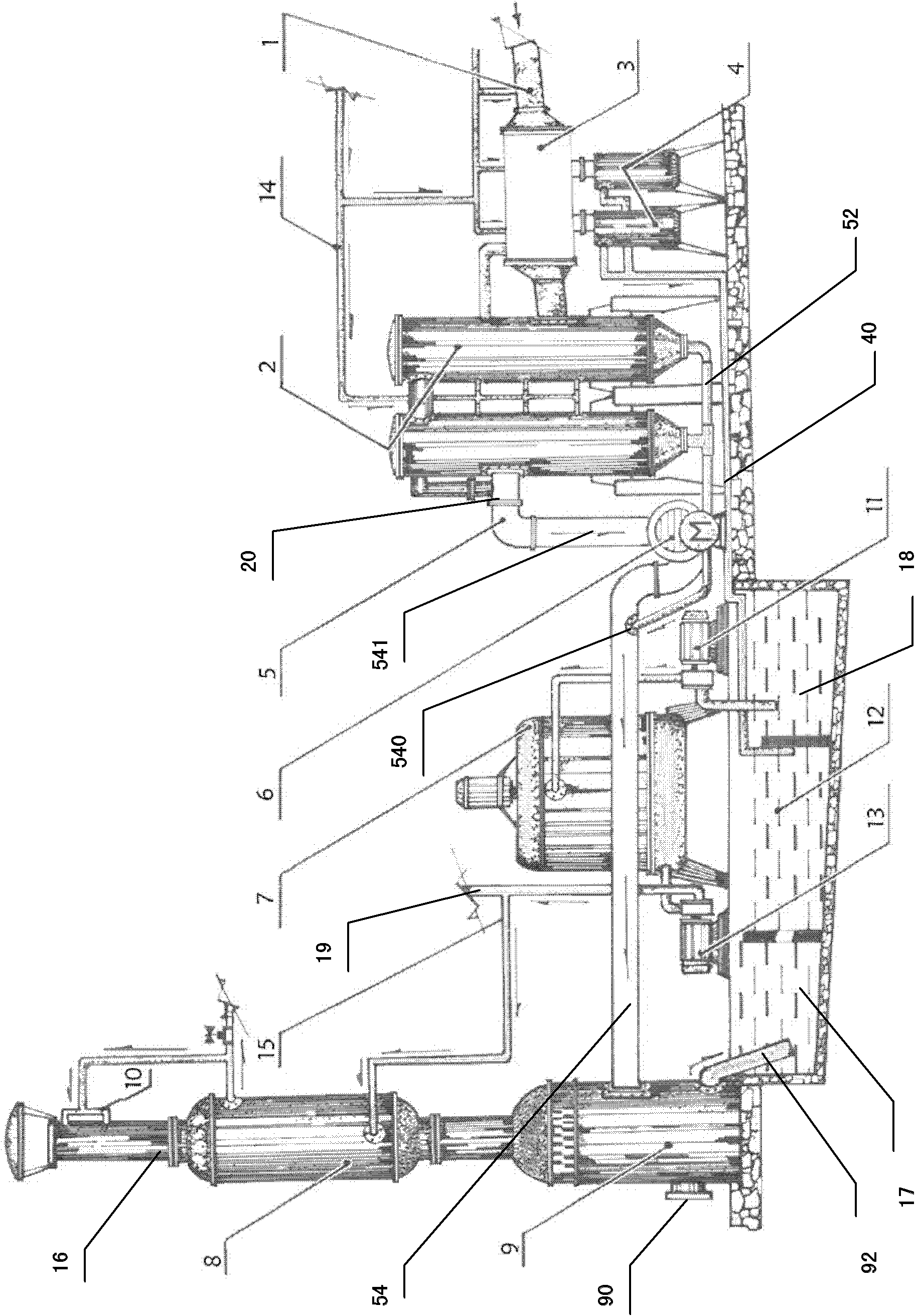

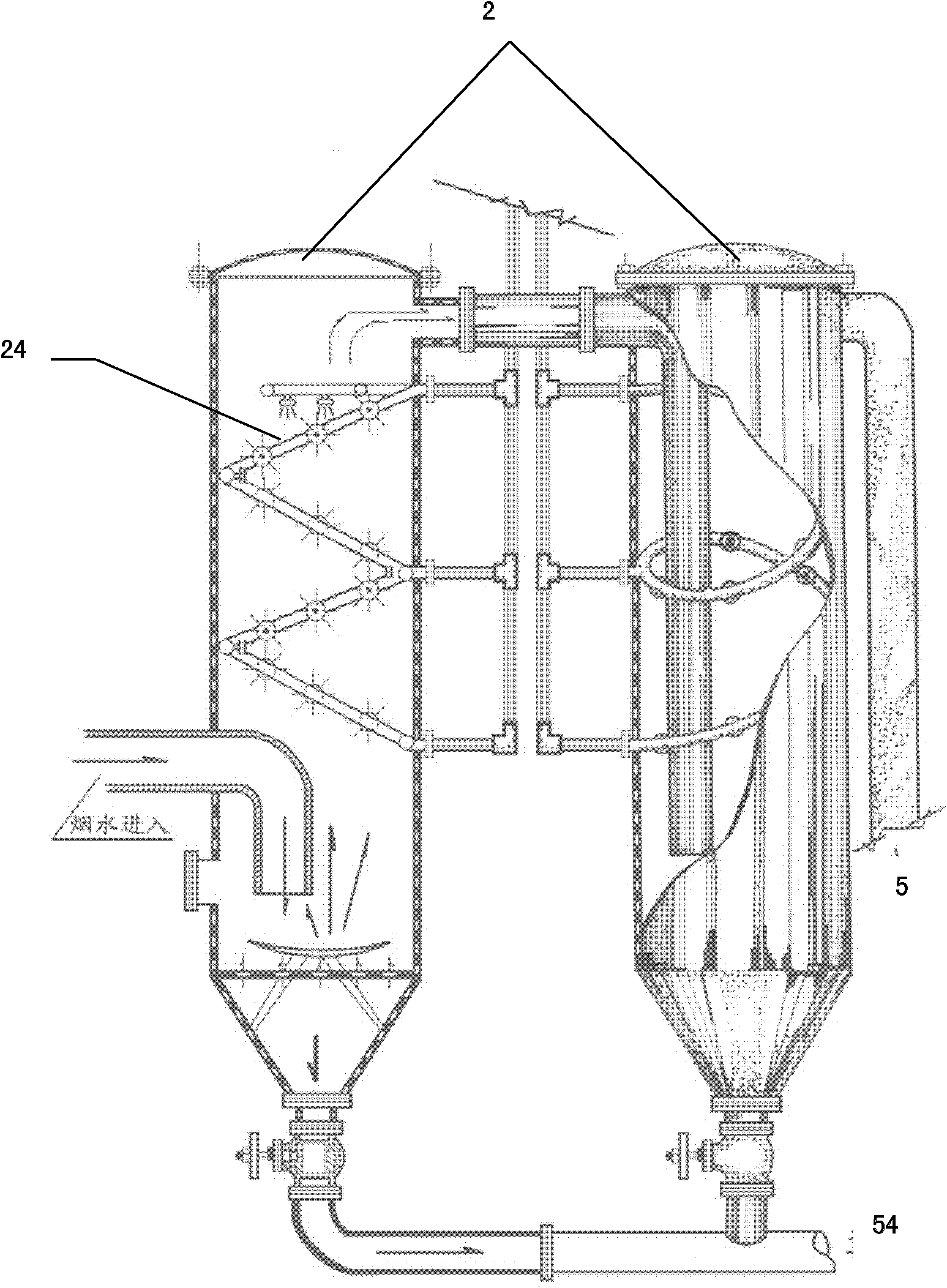

Tail gas treatment system for through which

InactiveCN101816874AEmission reductionChange fragile defectsCombination devicesLighting and heating apparatusAtmospheric airFiltration

The invention discloses a fuel cracking furnace containing a boiler, horizontal waste plastics and a waste tyre cracking furnace tail gas treatment system, wherein, fuel comprises solid fuel and gas fuel or liquid fuel. The tail gas treatment system comprises a carbon dust particle filtration system connected with the fuel cracking furnace, a gas-solid separation system connected with the carbon dust particle filtration system, a flue gas emission system connected with the gas-solid separation system, and a circulating water cooling system. Compared with the prior art, the tail gas treatment system is environmental-friendly and economical; the system has long service life and convenient and fast assembly and disassembly; and the system can reduce or eliminate carbon dust particles in tail gas, and the emission temperature is approximately identical with the atmospheric temperature.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

Low-carbon and low-silicon steel deoxidation process

The invention relates to a low-carbon and low-silicon steel deoxidation process, comprising the following process flow: converter taping: tapping when the content of oxygen at the end point of the converter is over 500ppm; adding carbon powder at the beginning of the tapping for rough deoxidation, measured by the carbon dust of 0.15-0.25kgper ton of steel; adding aluminum iron for deoxidation alloying when the tapping is carried out to be 1 / 2 or 2 / 3, measured by the aluminum iron of 1.5-2.5kg / t steel; opening a steel ladle to an argon flushing station; supplementing aluminum iron: measuring the oxygen content of the steel ladle by using an oxygen probe, supplementing aluminum iron according to the measured oxygen content and adjusting the content of the oxygen of the steel ladle to be less than 50ppm; and flushing argon at the beginning of tapping at the flow of 300-400NL / min and adjusting the flow of bottom blowing argon gas to be 50-80NL / min when the steel ladle is opened to the argon flushing station for softly blowing argon. By using the carbon powder to deoxidize instead of the aluminum iron, the invention not only saves the cost of alloy, but also improves the purity of molten steel.

Owner:TANGSHAN GUOFENG IRON & STEEL

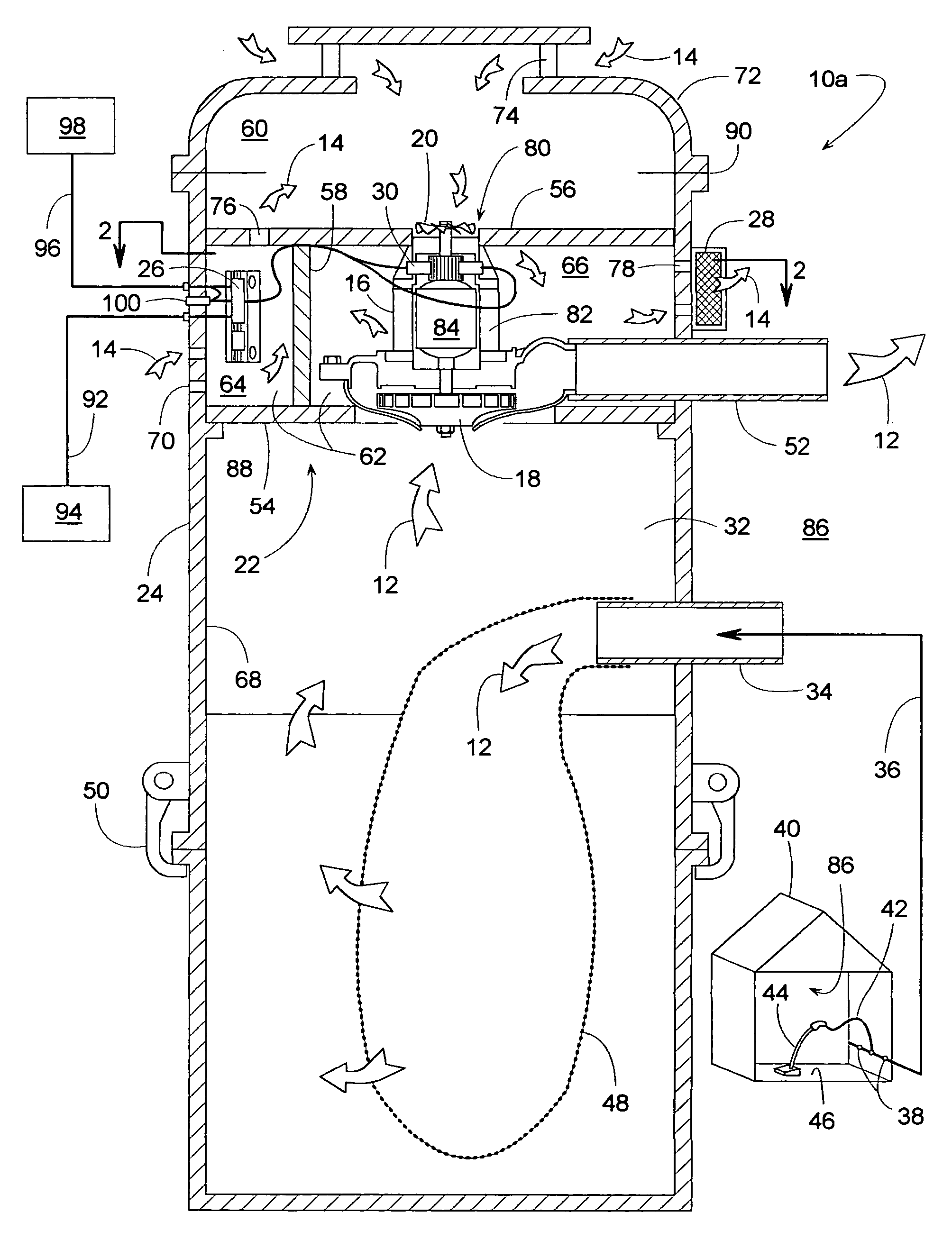

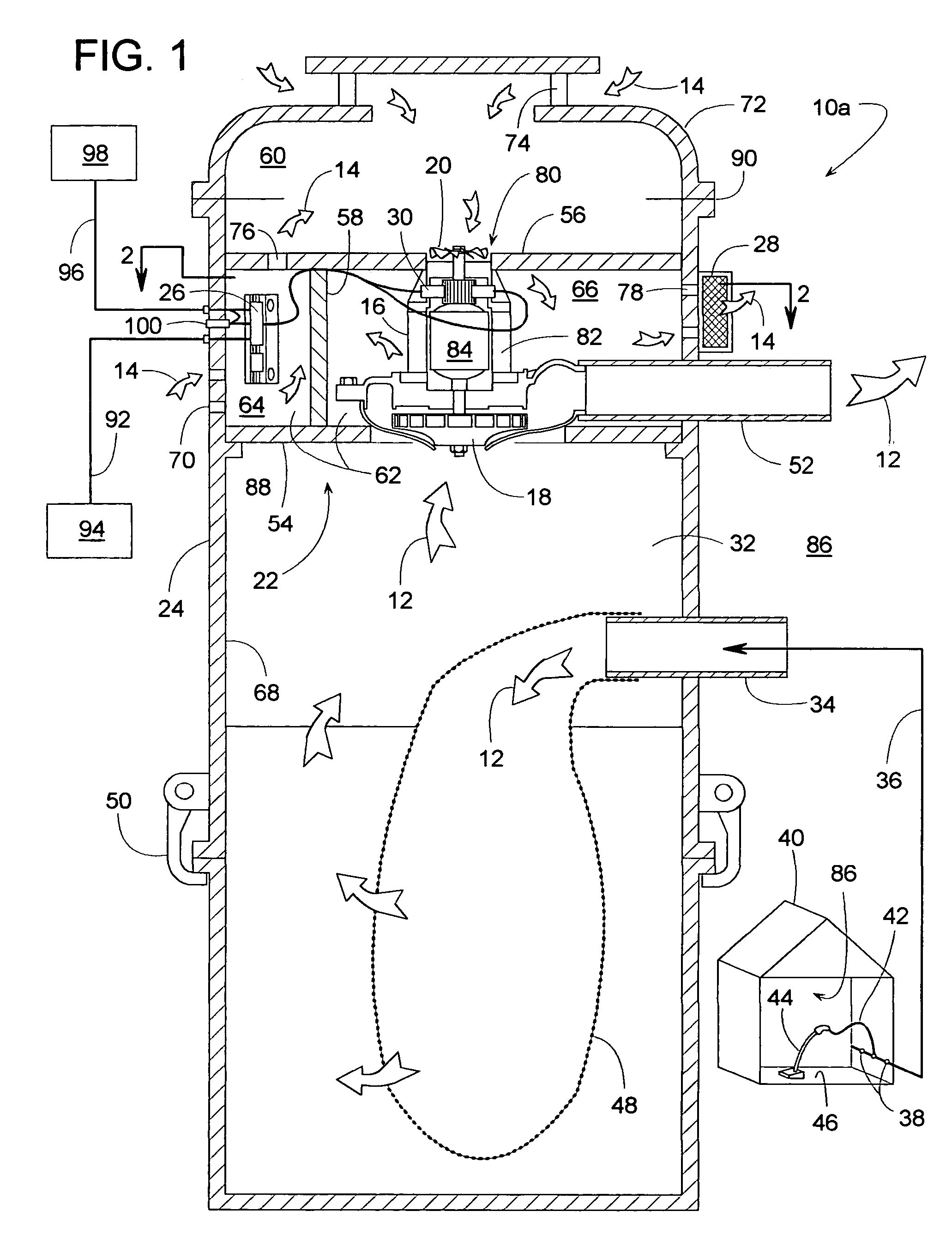

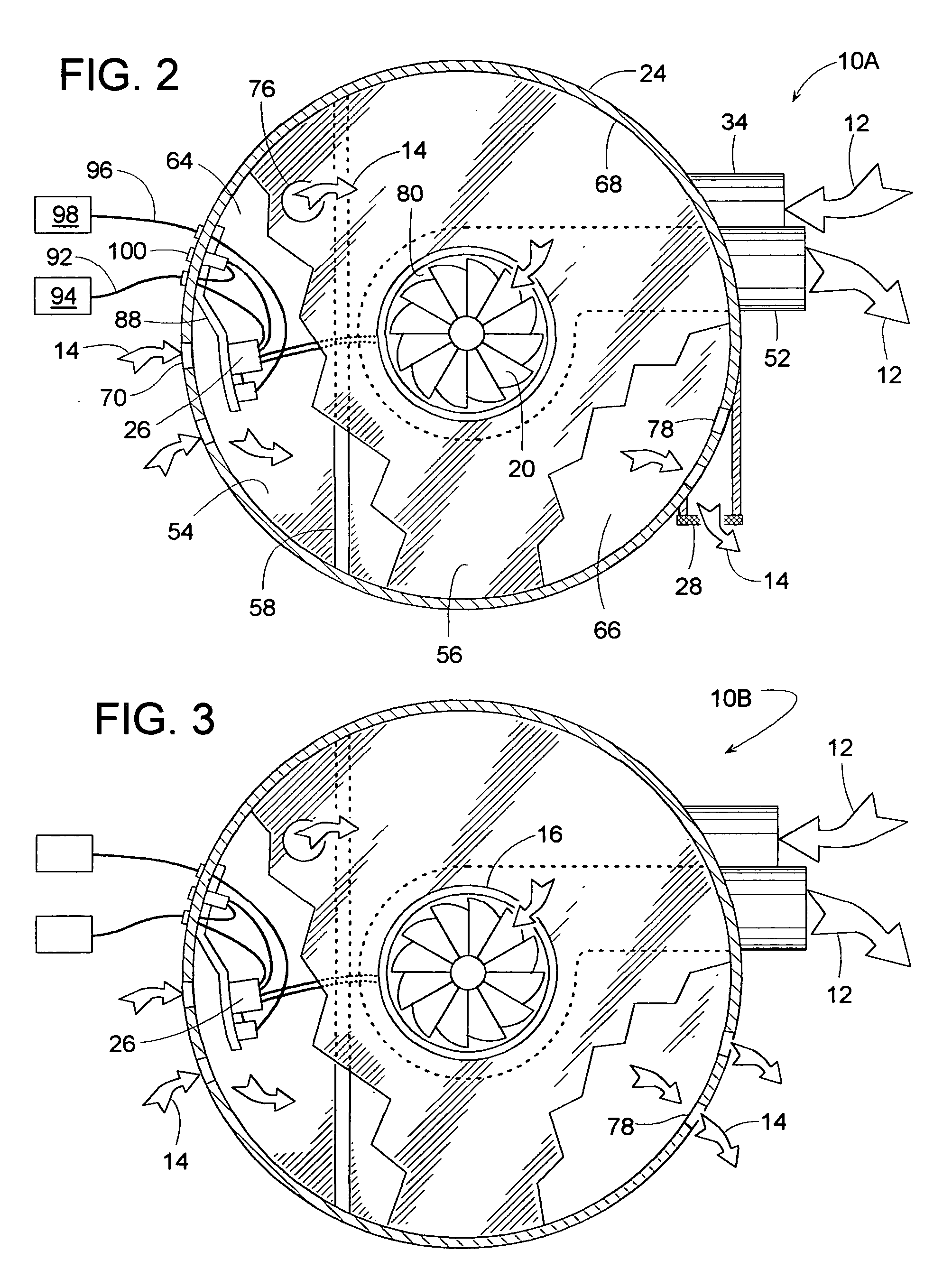

Central vacuum system with secondary airflow path

A central vacuum system includes a motor-cooling airflow path that provides sufficient cooling for the motor and its drive components even though the cooling air is partially restricted by a downstream filter that captures airborne carbon dust emitted from the motor's commutator brushes. A divider system creates multiple chambers within the vacuum system's canister, and in some embodiments, air passageways in the canister and in the divider system direct the cooling air through the chambers in a flow pattern that avoids contaminating the drive components with carbon dust.

Owner:BRUNEAU MARC

Artificial float stone and its manufacturing method

The invention relates an approach to produce artificial pumice. It is burned by nether materials: inorganic material, sodium hydroxide, borax, Paris white, carbon dust and isinglass. Thereinto, inorganic material is selected from minerals or clay. It follows nether steps: mixing above materials in terms of given ratio, cracking blending to 60-200 items and loading into a module to bake.

Owner:郭勇

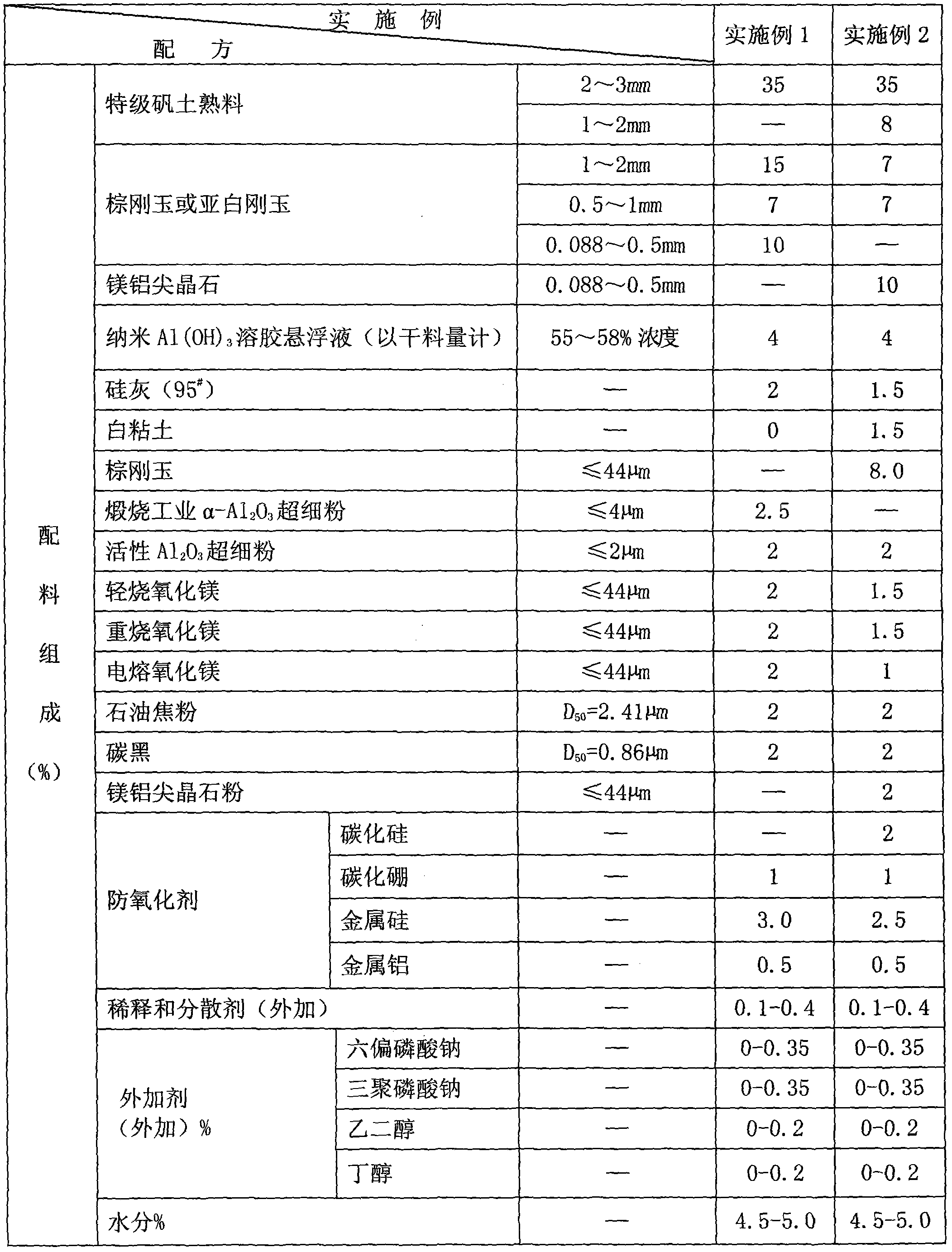

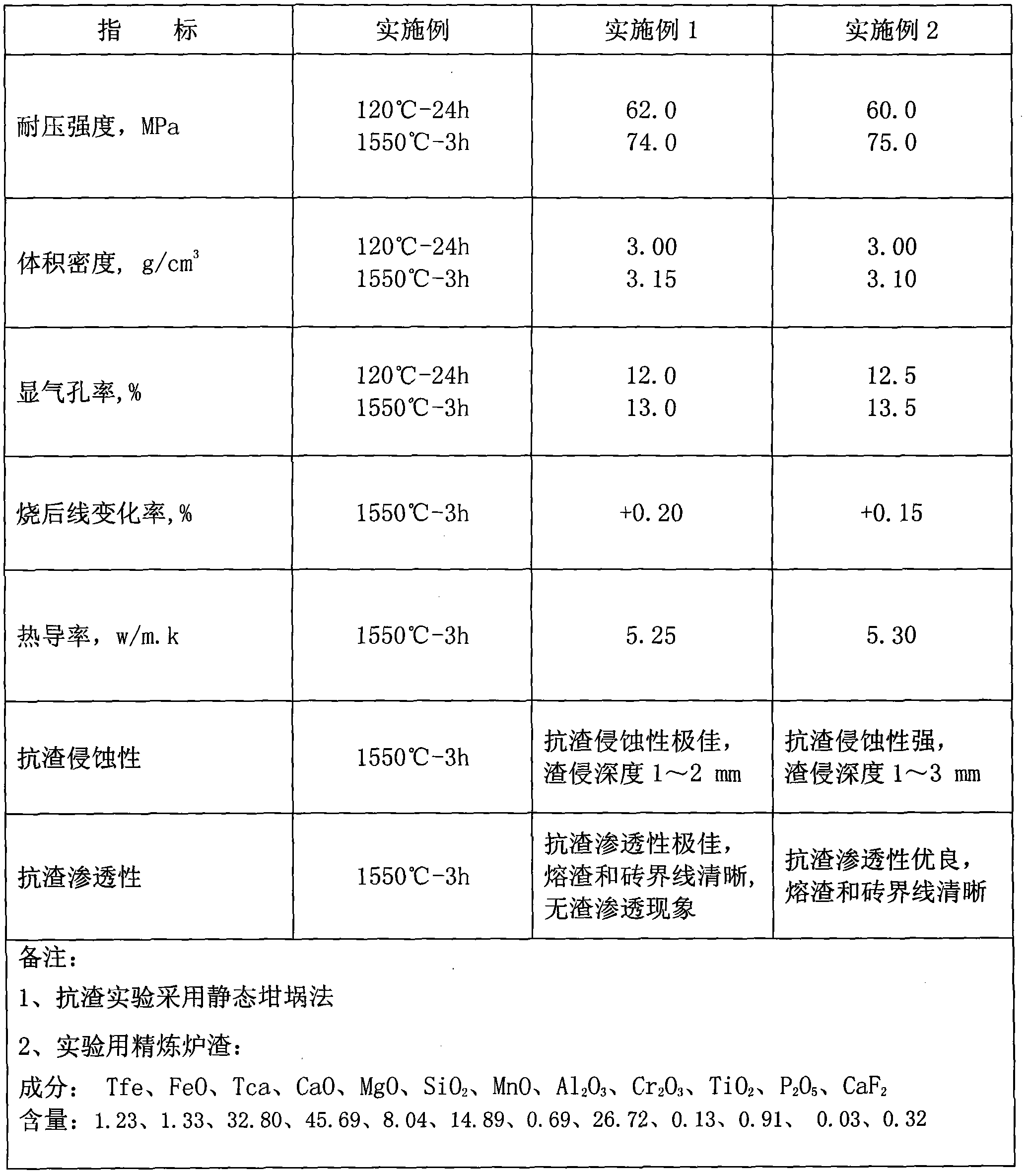

Bauxite-based nanometer composite oxide ceramic bond A1203-MgO-C unfired product and preparation method thereof

The invention relates to an A1203-MgO-C unfired product with carbon wrapped by nano Al2O3-MgO film and a preparation method thereof. The product uses natural high alumina bauxite (AlOOH) and sintered periclase (MgO) as initial raw material and employs method of sol-gel technology, which comprises following steps, putting superfine high alumina bauxite, carbon dust, water and additive into high speed impact mixer, carrying out coating process so as to let the materials have strong impact and mix with each other to form high density composite sol suspension liquid of carbon and aluminium hydroxide, therefore Al(OH)3 is mightily adsorbed on the surface of carbon, then realizing workmanship of coating powdered carbon by aluminium hydroxide. During the wet-milled process of mixture, the magnesium oxide powder and the mixture water in the matrix powder have hydration reaction to produce magnesium hydroxide sol, and the magnesium hydroxide sol and the aluminium hydroxide sol have situ synthesis reaction to produce nanostructured matrix of carbon-aluminium spinel to prepare A1203-MgO-C unfired product of the invention.

Owner:高树森

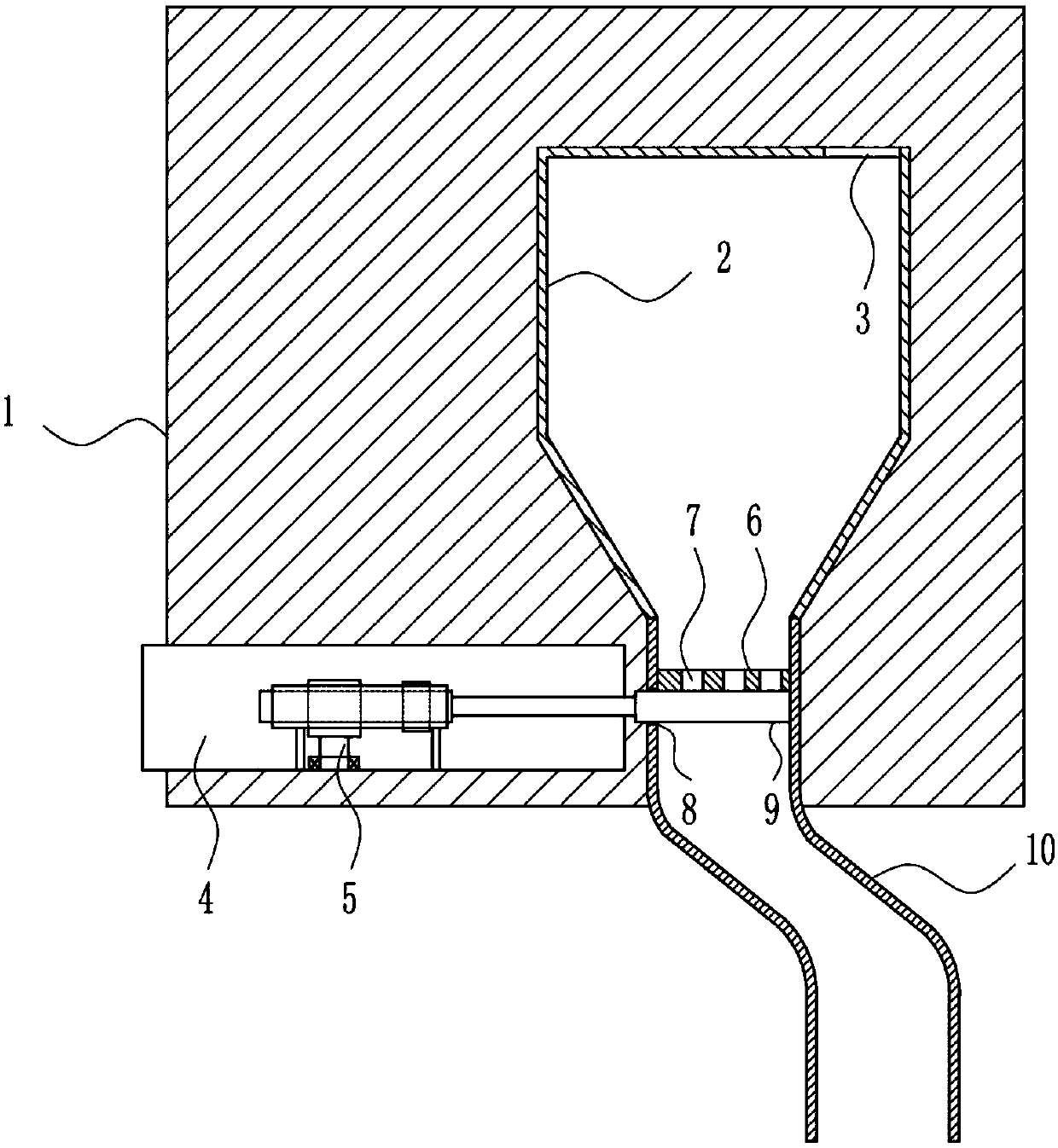

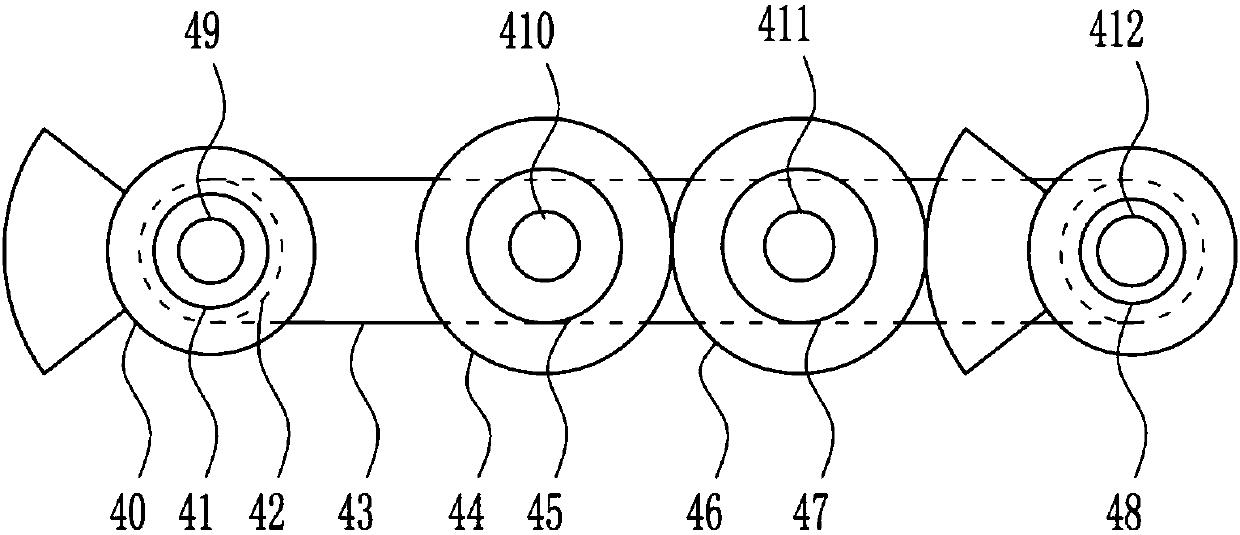

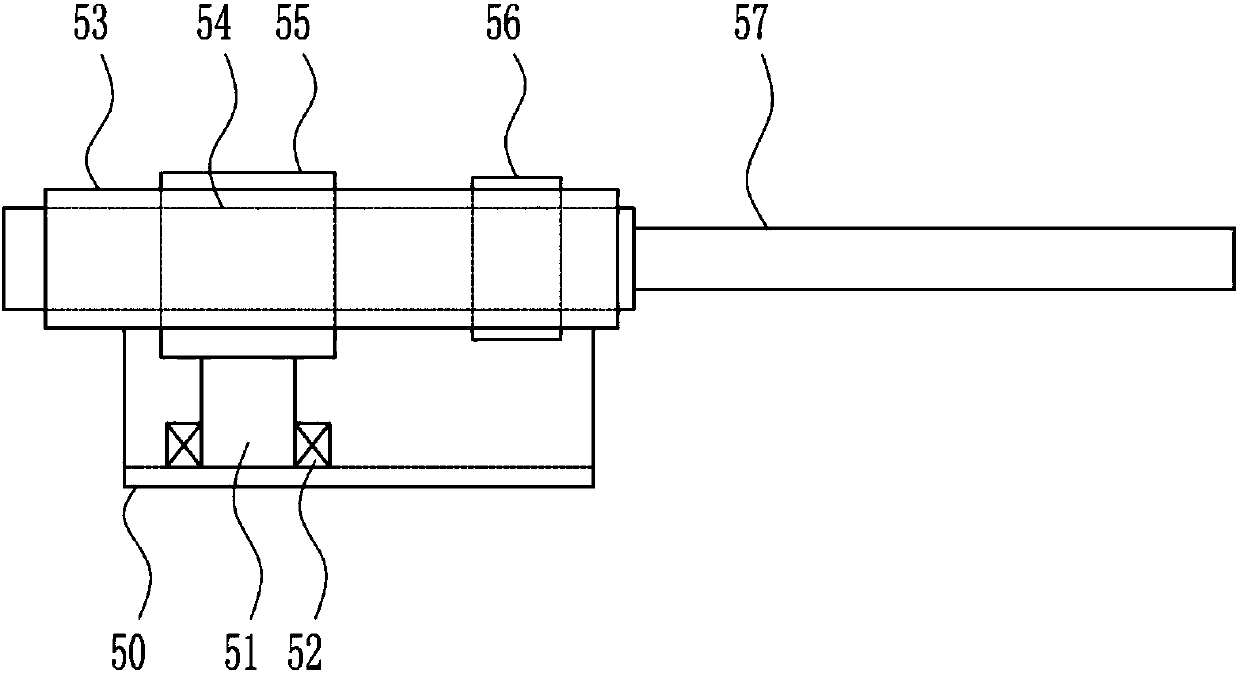

Intermittent feeding device for carbon dust

The invention relates to a feeding device, in particular to an intermittent feeding device for carbon dust. The technical problems are solved with the intermittent feeding device. The intermittent feeding device comprises an installation plate, a box body, a driving mechanism, a discharging mechanism, a baffle and others; the box body is arranged on the right side of the front wall of the installation plate, the driving mechanism and the discharging mechanism are arranged on the left side of the front wall of the installation plate, the driving mechanism is located behind the discharging mechanism, a first connecting plate is arranged on the right side of the discharging mechanism, a first through hole is formed in the right side of the top of the box body, a discharging pipe is arranged at the bottom of the box body, a third through hole is formed in the upper portion of the left wall of the discharging pipe, and the baffle is arranged between the left wall and the right wall of the upper portion of the discharging pipe. The intermittent feeding device can achieve intermittent quantified feeding, the carbon dust can be prevented from blocking a discharging port and adhering to thedischarging pipe, the first connecting plate can intermittently control the carbon dust to flow into the discharging pipe with the discharging mechanism, and the device is high in practicability.

Owner:珠海征图打印耗材有限公司

Colored activated carbon and method of preparation

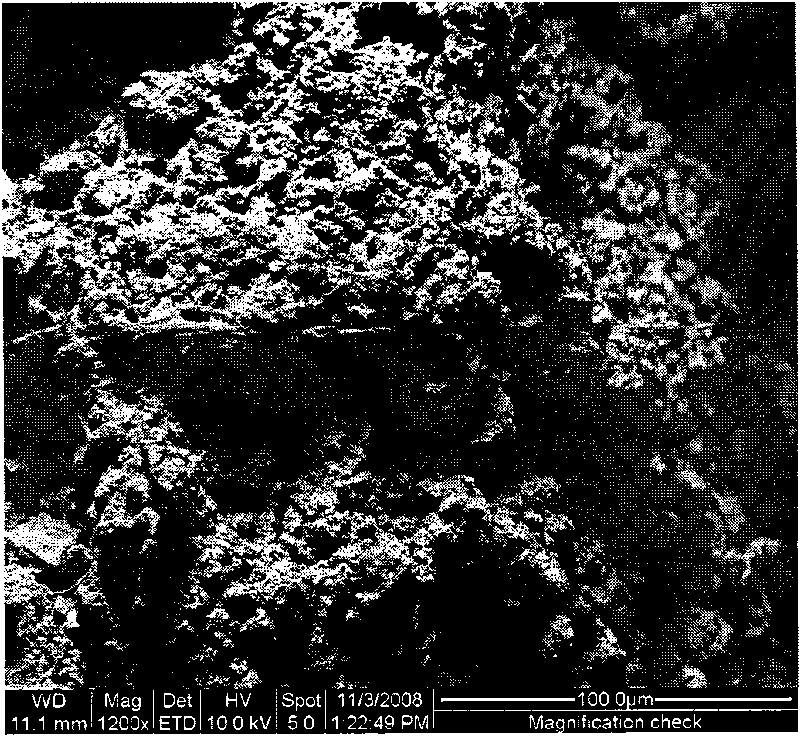

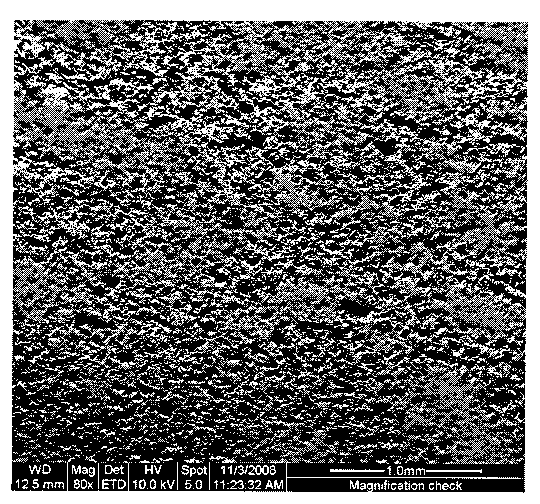

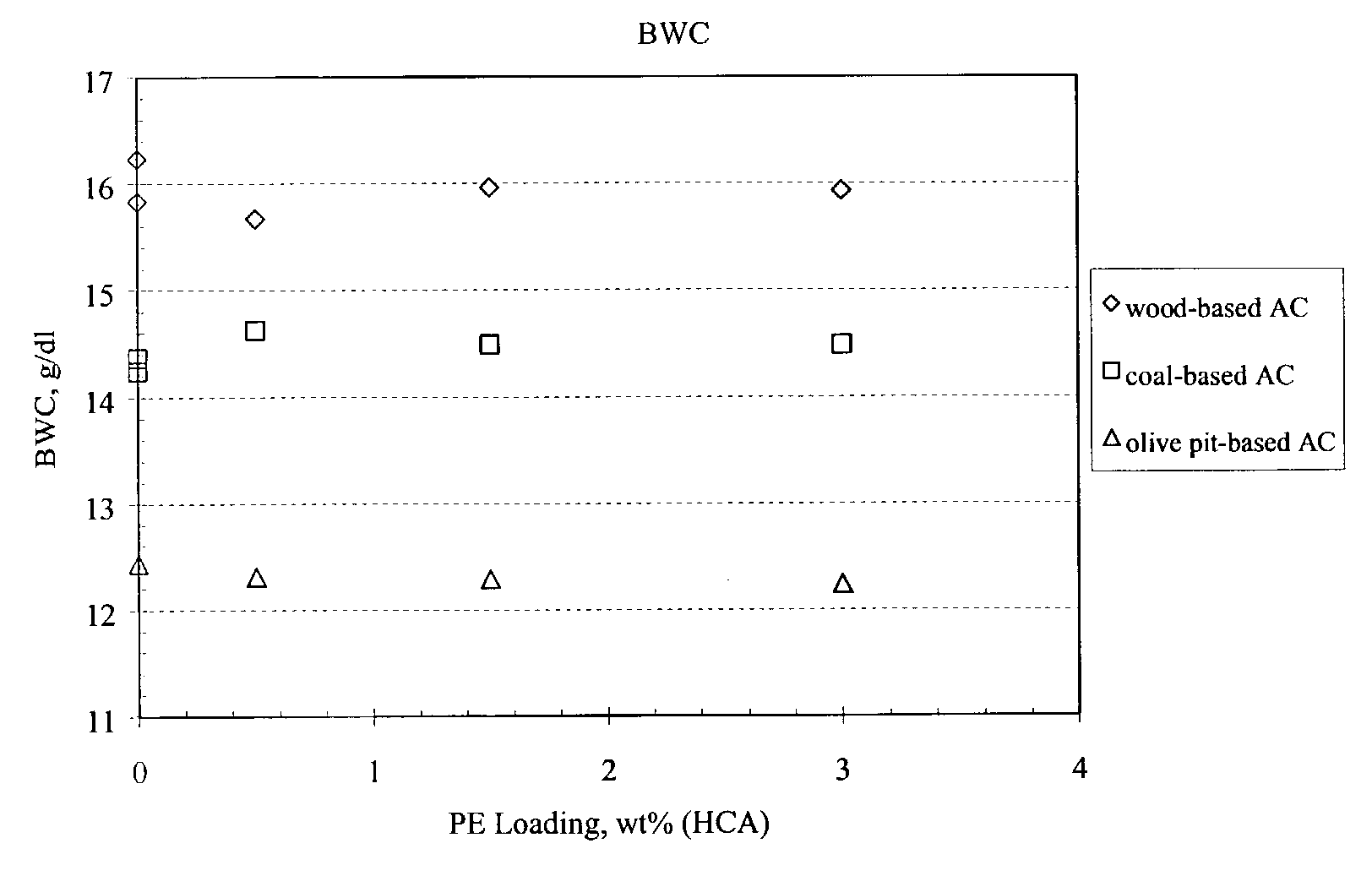

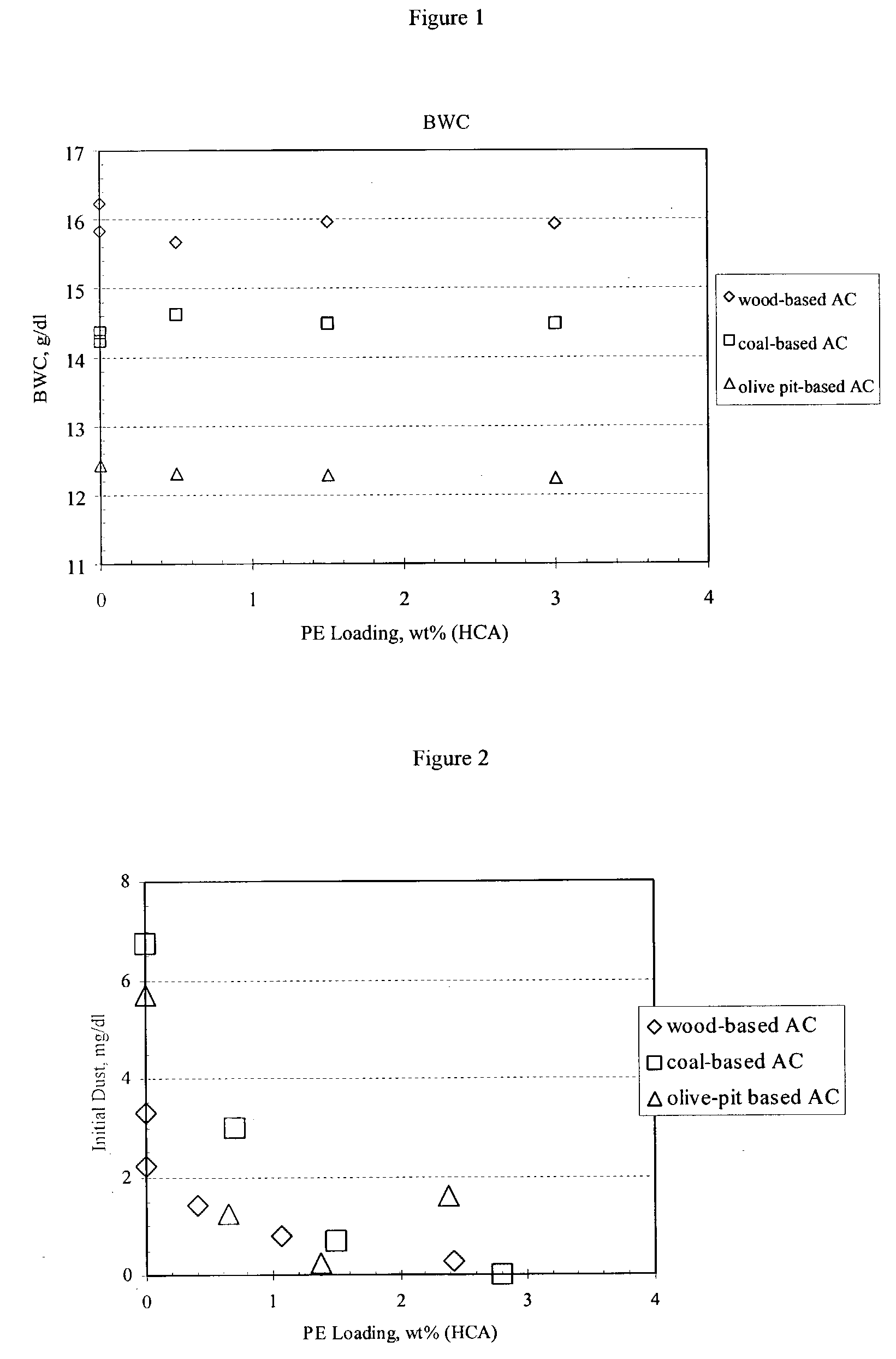

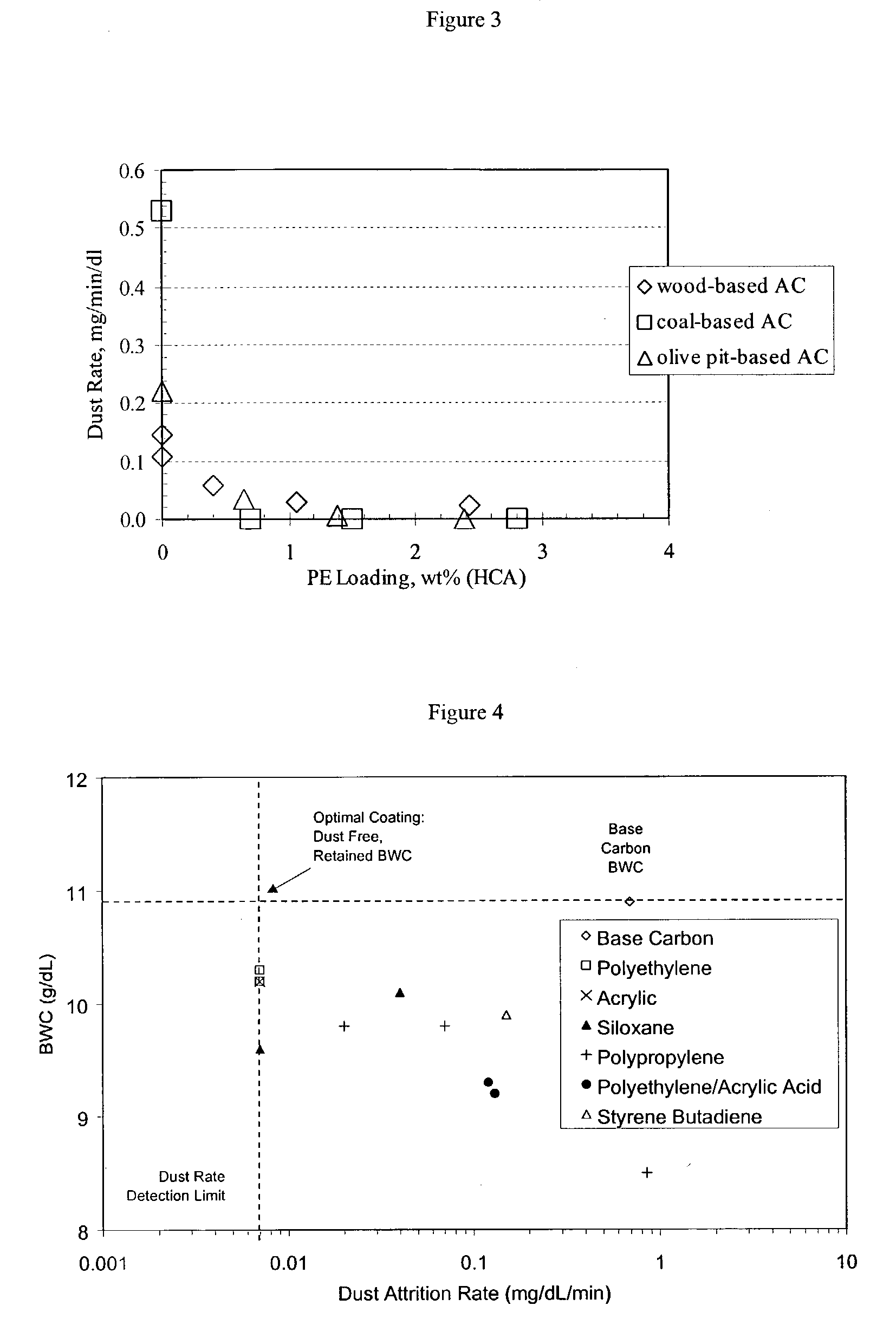

InactiveUS20050123763A1Compensation changesReduces, orCarbon compoundsSynthetic resin layered productsActivated carbonCarbon dust

Color-coated activated carbon and method of preparation are disclosed in the product of application of a thin, continuous coating of an insoluble colorant-containing polymer emulsion on the material, without causing a reduction in adsorption capacity of the untreated activated carbon. In addition, the resultant avoidance of carbon dust leads to improved performance for contaminant removal.

Owner:MEADWESTVACO CORP

Method for producing high intensity modified starch

The present invention provides a method for producing high intensity modified starch, including a neutralization reaction, casting stock and precipitating; a clarified starch solution is sucked into a reaction tank, aqueous vapor is injected into the reaction tank, then the clarified starch solution is heated until 65 DEG C, during which agitating the solution continually to play a function of conditioning and high-temperature enzyme extinguishing, the heating and agitating time is from 20 to 40 minutes; then wood carbon dust is added to discolor and desludge; a clear starch solution will be obtained after filtering by a compressor; the impurity in the starch is removed step by step by steps of concentrating, batching and high speed centrifugation, the technique is reasonable, the high intensity modified starch has high purity and adequate quality, and the product grade is improved.

Owner:界首市鸿顺生物科技有限公司

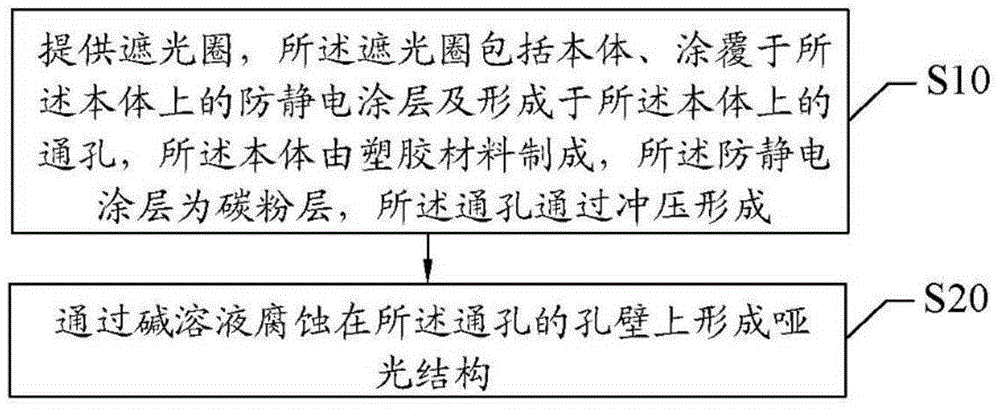

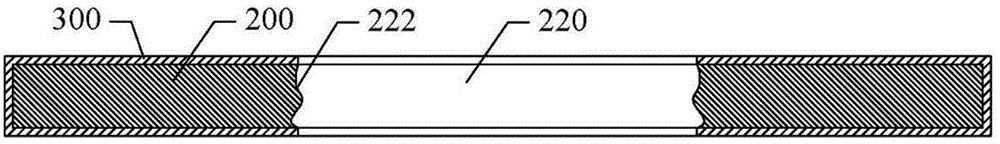

Shading ring processing method and shading ring

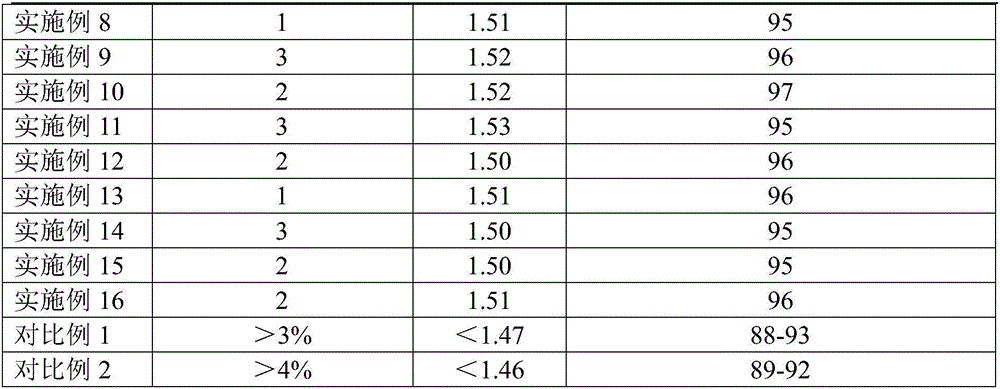

The invention discloses a shading ring processing method and a shading ring. The method comprises the following steps that the shading ring is provided, the shading ring comprises a body, an anti-static coating and a through hole, the anti-static coating coats the body, the through hole is formed in the body, the body is made of plastic materials, and the anti-static coating is a carbon dust layer; the wall of the through hole is corroded through aqueous alkali to form a matte structure. According to the shading ring processing method and the shading ring, the shading ring is processed inside an ultrasonic generator through aqueous alkali so that the matte structure can be formed on the wall of the through hole of the shading ring, the poor phenomena of dazzling, halo, ghosting and the like caused by reflection of the wall of the through hole are avoided, and therefore the photographing effect is ensured and the photographing product quality is improved.

Owner:东莞市山形光学有限公司

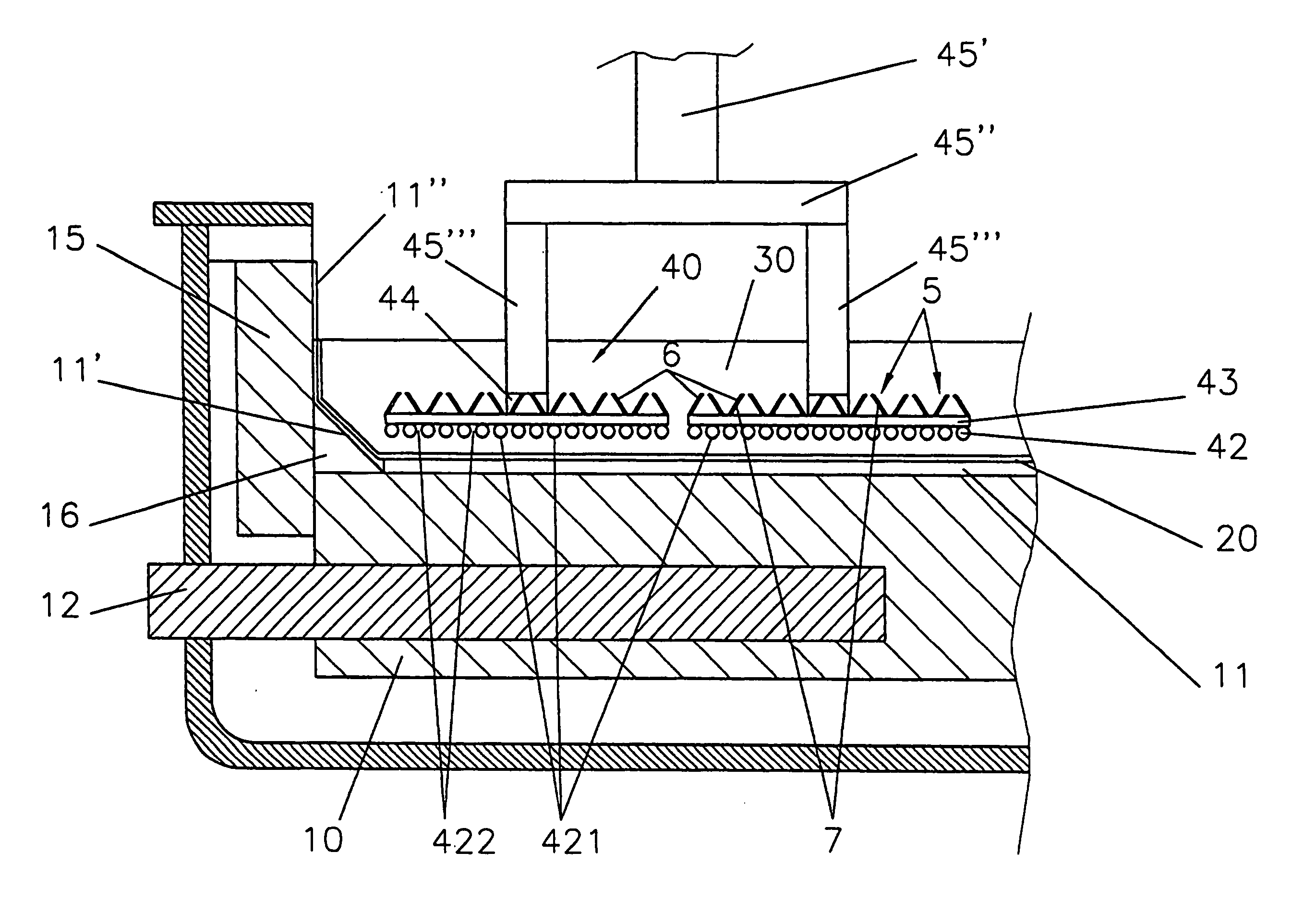

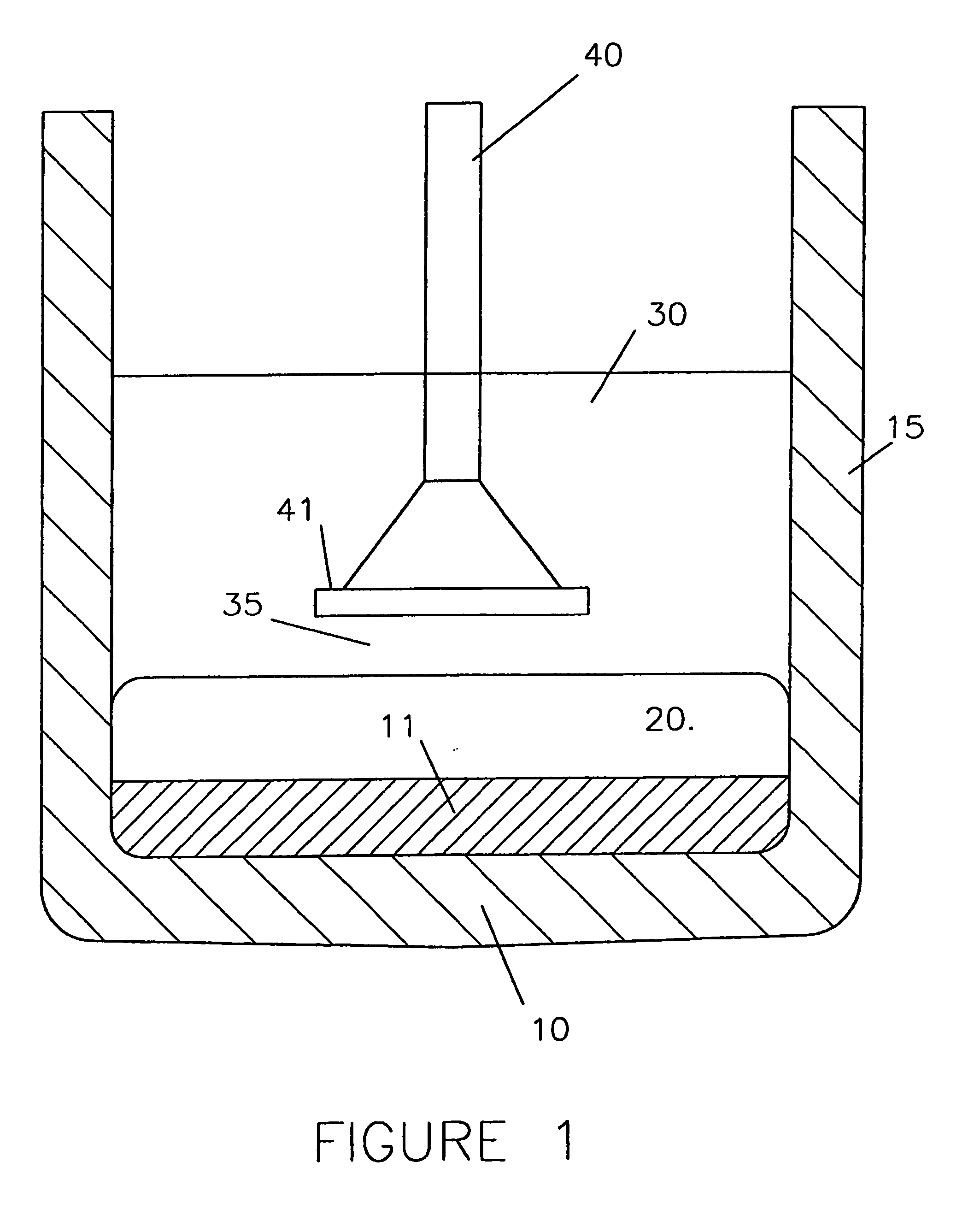

Prevention of dissolution of metal-based aluminium production anodes

InactiveUS20050269202A1Reduces cell 's current efficiencyImprove current efficiencyMachining electrodesIsotope separationAlloyDissolution

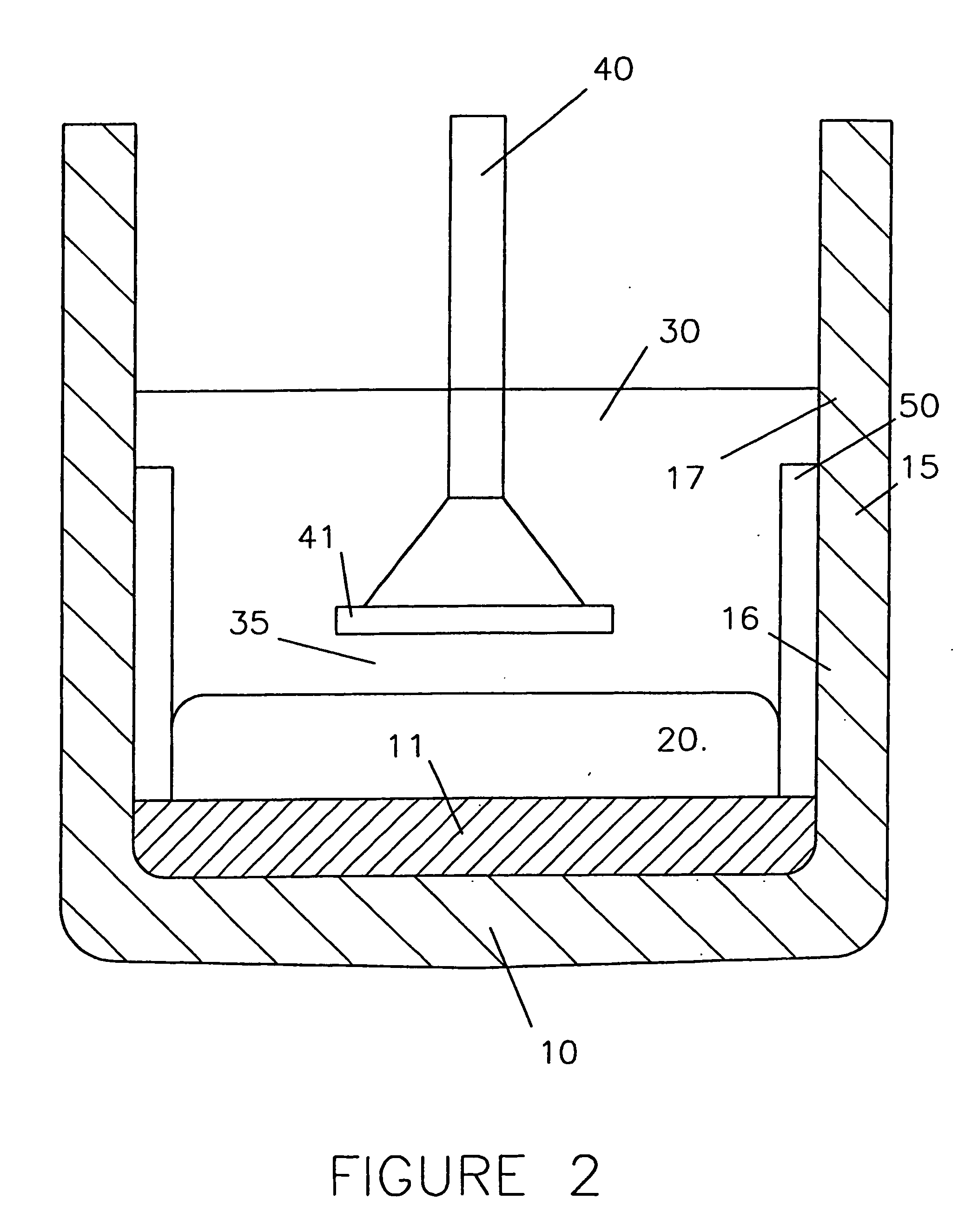

A method of inhibiting dissolution of a transition metal alloy anode (40) of an aluminium electrowinning cell comprises providing a barrier layer (11,20,50,50′) on a non-anodic structural cell material (15), such as carbon, and electrolysing alumina dissolved in a molten electrolyte (30). The non-anodic structural material is able to supply an oxidisable by-product to the electrolyte and / or is active for reducing electrolyte species exposed to the structural material into an oxidisable by-product, such as sodium metal or carbon dust. However, the barrier layer inhibits the presence in the molten electrolyte (30) of the oxidisable by-product that constitutes an agent for chemically reducing the anode's transition metal oxides and anodically evolved oxygen. This inhibits reduction of the anode's transition metal oxides by the oxidisable by-product and maintains the anodically evolved oxygen at a concentration such as to produce, at the alloy / oxide layer interface, stable and coherent transition metal oxides having a high level of oxidation. The barrier layer may comprise molten aluminium (20) and / or a layer of refractory hard material (11,50,50′).

Owner:DE NORA VITTORIO +1

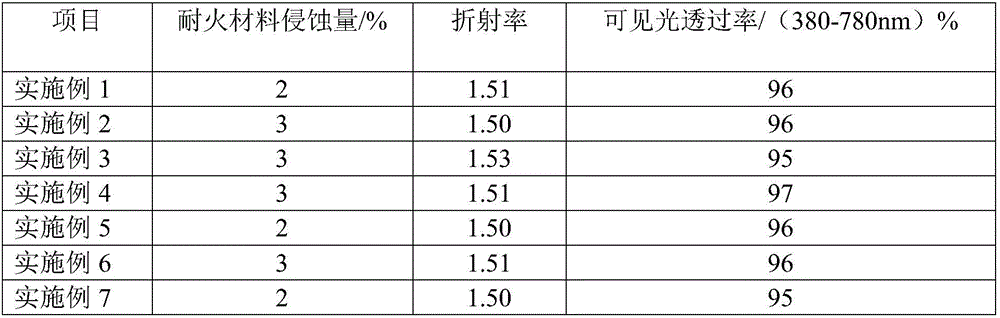

High borosilicate glass clarifying agent, and preparation method and application thereof

The present invention discloses a high borosilicate glass clarifying agent belonging to the technical field of glass clarifying agents. The glass clarifying agent is a compound clarifying agent comprising following raw materials in mass ratio: sodium sulfate to cerium oxide to lanthanum oxide to stannic oxide to carbon dust to halides in a mass ratio of (0.6-6.0):(0.01-2.0):(0.01-0.5):(0.01-0.8):(0.01-2.0):(0.5-6.0). The present invention also discloses a preparation method and application of the high borosilicate glass clarifying agent. The high borosilicate glass clarifying agent can realize continuous clarifying action in different temperature stages to ensure that glass liquid can continue to discharge bubbles in the different temperature stages so as to obtain products with a relatively excellent clarifying effect, the condition that the number per square meter of the bubbles greater than 0.02mm is not more than 1 is detected, the clarifying agent is poisonless, harmless, safe, environmentally friendly, and good in clarifying effect. Glass prepared by using the clarifying agent is low in bubble residue, and high in quality.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

Preparation method of high-porosity alumina porous ceramics

InactiveCN101734909AHigh strengthPlay a reinforcing roleCeramicwareCompression moldingRoom temperature

The invention discloses a preparation method of high-porosity alumina porous ceramics, which belongs to the technical field of ceramic preparation. The preparation method comprises the steps of: adding a sintering auxiliary agent and an intensifier in form of xerogel; and subjecting alumina skeletal materials, carbon dust, an ethocel composite pore-forming agent, a zirconium xerogel intensifier and a magnesium xerogel sintering auxiliary agent, which serve as raw materials, to ball-milling mixing, compression molding and heat-insulating sintering, and then cooling the mixture to a room temperature to obtain alumina porous ceramics. The preparation method has the key point that on the basis of pore forming of the pore-forming agent, zirconium xerogel serving as the intensifier and magnesium xerogel serving as the sintering auxiliary agent are added to improve the porosity and strength of the alumina porous ceramics. The preparation method has a simple process and is convenient to operate; and the prepared high-porosity alumina porous ceramics contain two air holes of different sizes and maintain high bending strength.

Owner:TIANJIN POLYTECHNIC UNIV

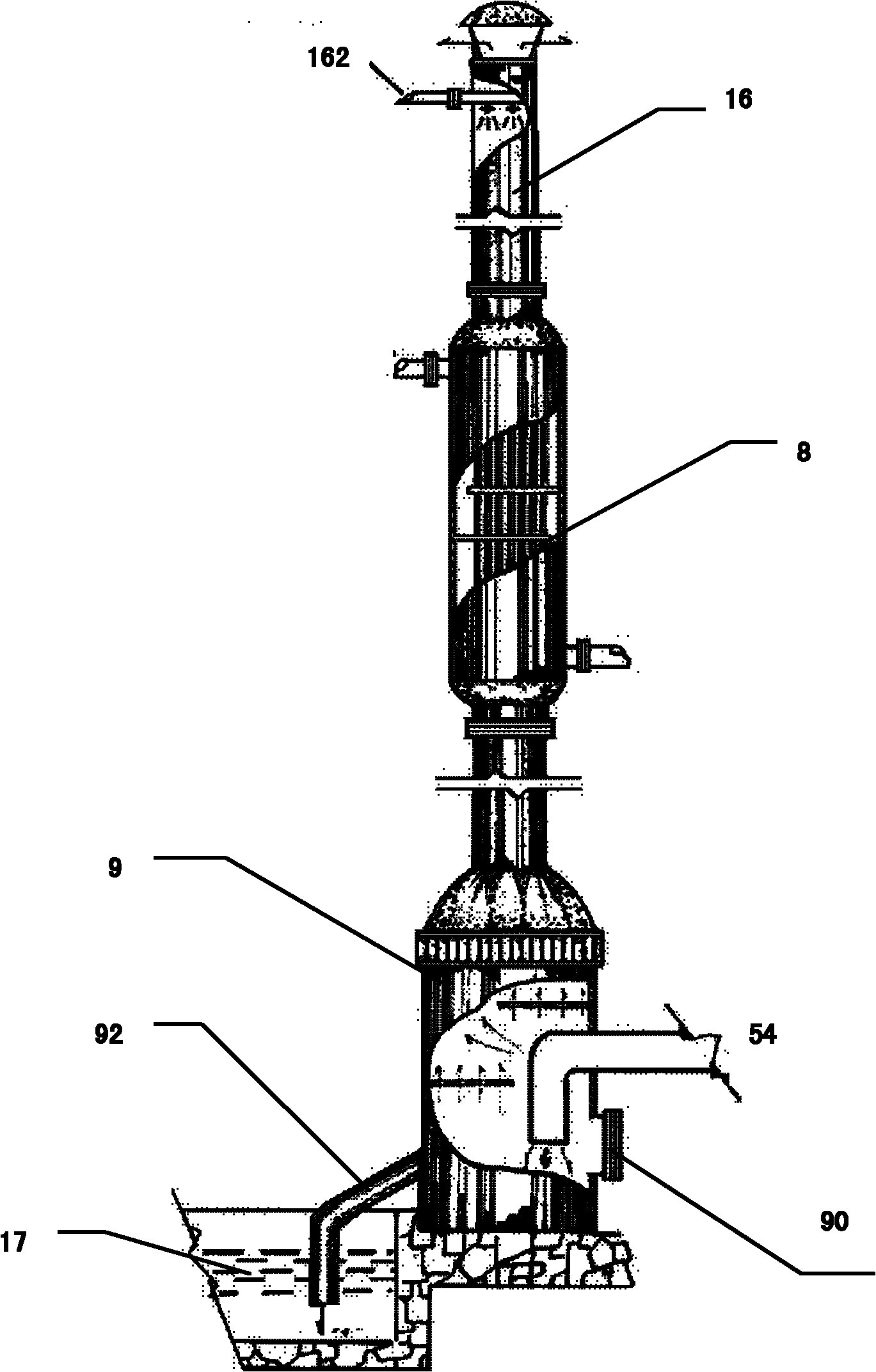

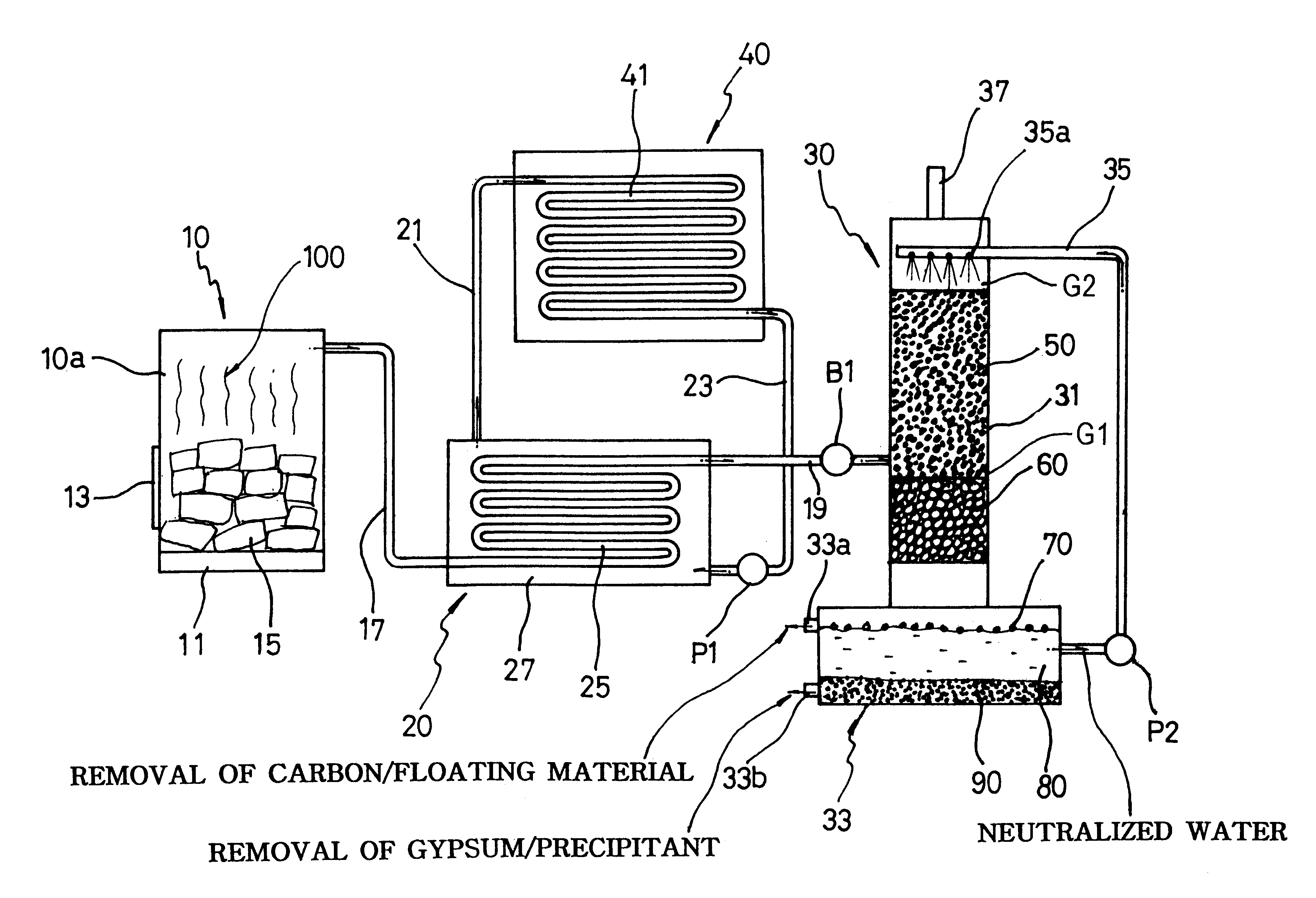

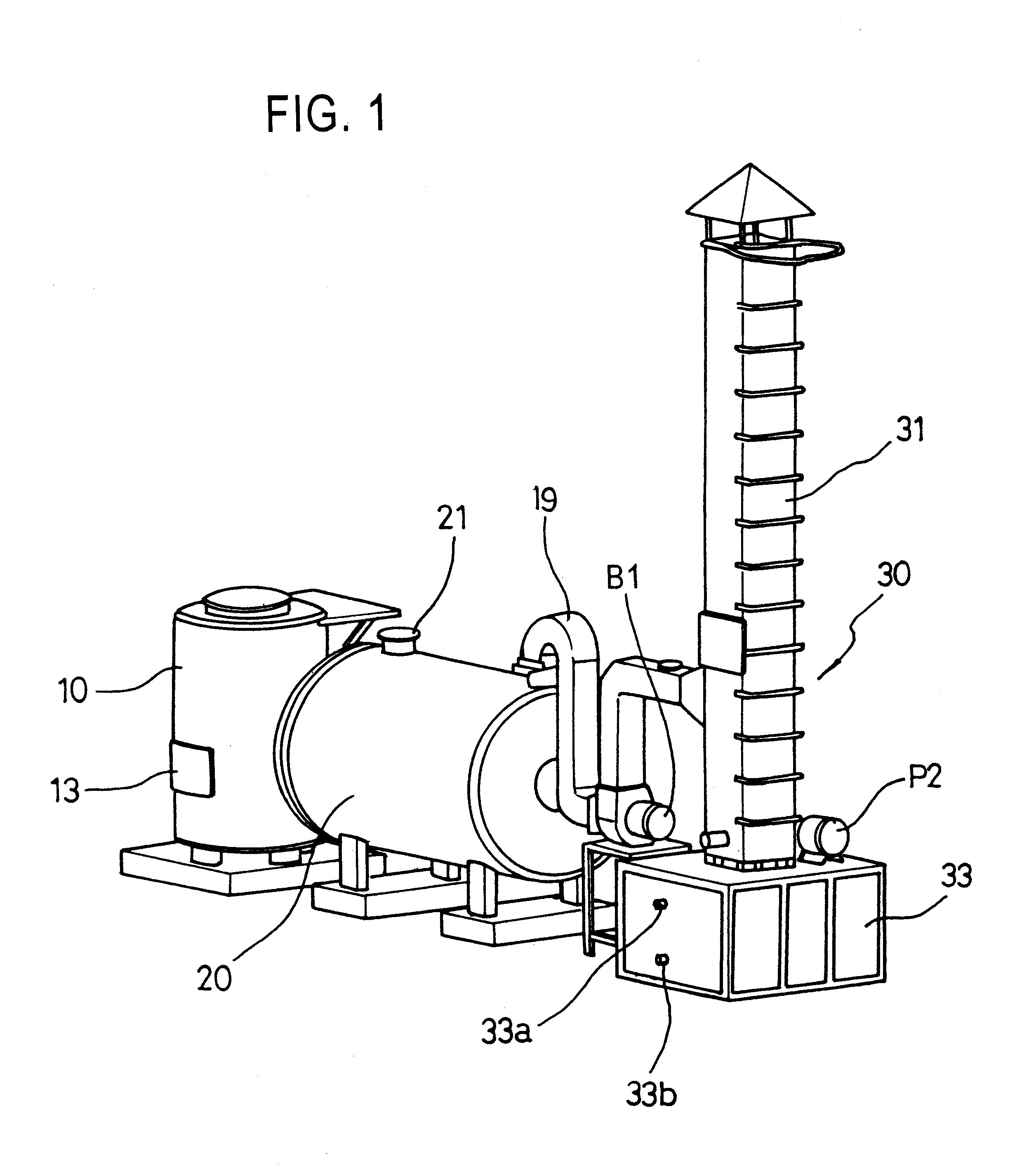

Small-scale boiler system using scrapped tires

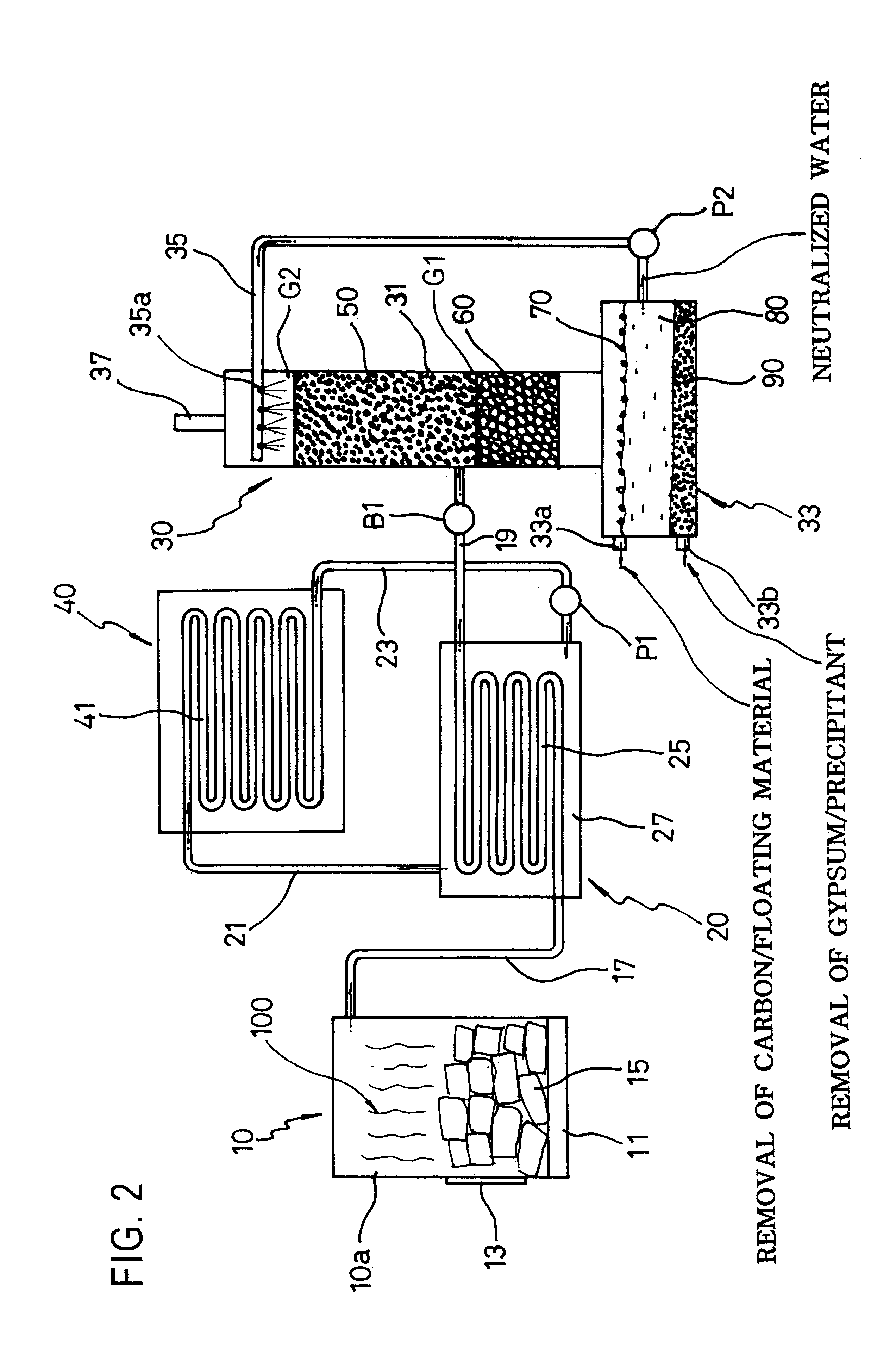

InactiveUS6294135B1Shorten the overall cyclePromote combustionCombination devicesRecuperative heat exchangersSprayerCarbon dust

A small-scale scrapped tire boiler system for heating a small-scale facility using heat generated by burning scrapped tires. The system includes a scrapped tire burner furnace, a heat exchanger for heating a cool heat transfer medium from the facility by the combustion gas from the furnace and supplying the heated medium to the facility, and an exhaust gas purifier for purifying sulfurous acid gas and carbon dust contained in exhaust gas. The purifier includes an exhaust gas tower having a vertical path to discharge the combustion gas, a water sprayer for spraying water from the upper side of the tower so that the sulfurous acid gas is made to melt to water and the carbon dust is made to adsorb to fall down, a neutralizer for precipitating sulfurous acid gas components into alkali salts in a sulfurous acid aqueous solution to thereby neutralize water, and a tank containing the solution and water. The precipitated alkali salts are removed from the bottom of the tank and the floating carbon dust is removed from the upper portion of the tank.

Owner:SEOUL NAT UNIV R&DB FOUND

Coated activated carbon for automotive emission control

InactiveUS7179382B2Reduction in adsorption velocityReduction in capacityCarbon compoundsPretreated surfacesActivated carbonPhysical chemistry

A method for avoidance of attrited carbon dust is disclosed to lead to improved canister performance in emission control. Product attrition by dusting of granular and shaped activated carbons is disclosed to be reduced significantly, or essentially eliminated, by the application of a thin, continuous polymer coating on the granular or shaped activated carbon, without a reduction in adsorption velocity or capacity of the activated carbon when used in automotive emission control canisters.

Owner:INGEVITY SOUTH CAROLINA

Dyestuff pollution magnetic adsorbing material and preparing method thereof

InactiveCN107321324AImprove stabilityEasy to degradeOther chemical processesWater contaminantsAcetic acidSorbent

The invention discloses a dyestuff pollution magnetic adsorbing material. The dyestuff pollution magnetic adsorbing material is prepared from, by weight, 0.5-1 part of beta-hydroxyalkylamide, 17-20 parts of ferrous chloride, 20-25 parts of iron chloride hexahydrate, 0.7-1 part of 8-hydroxyquinoline, 3-4 parts of allylpolyethyleneglycol, 40-50 parts of oxide complex carbon dust, 1-2 parts of sucrose acetate isobutyrate, 4-6 parts of diatomaceous earth, 0.5-1 part of sodium carboxymethylcellulose, and 2-3 parts of barium stearate. The dyestuff pollution magnetic adsorbing material is high in stability, and not prone to degradation, can be adapted to multiple dyestuff pollution effluent environments, after dyestuff in dyestuff pollution effluent is adsorbed, magnetic separation recycle is easy to achieve, secondary pollution cannot be caused, and the adsorbent itself cannot result in problems like heavy metal pollution to the environment neither.

Owner:霍邱金木鱼农业科技有限公司

Boron carbide composite material and preparation method thereof

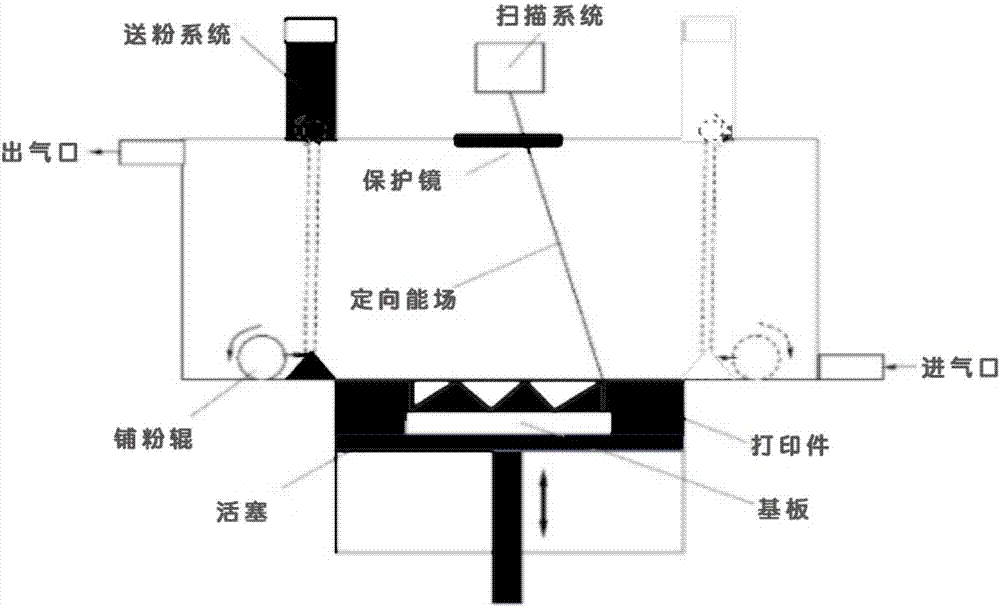

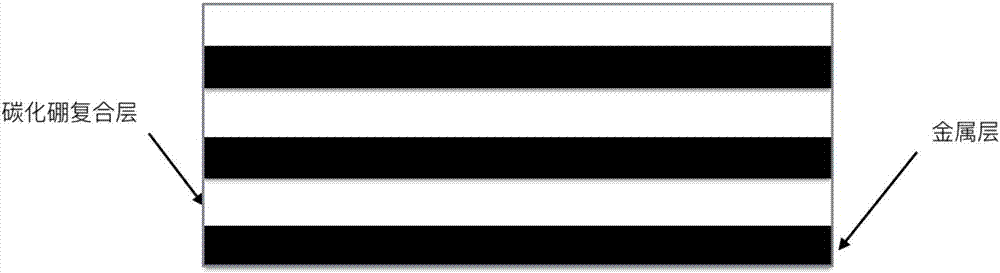

ActiveCN107141004ALow defect sensitivityImprove toughnessAdditive manufacturing apparatusShieldingNuclear reactorArgon atmosphere

The invention discloses a boron carbide composite material and a preparation method thereof. The boron carbide composite material is characterized by being prepared from the following components in percentage by mass: 30 to 60 percent of boron carbide powder, 5 to 25 percent of carbon dust, 10 to 25 percent of silicon powder and 15 to 45 percent of metal powder. The preparation method comprises the following steps: weighing the components according to corresponding proportions, taking out part of powder from the metal powder according to the demand for later use, and mixing remaining metal powder with other powder to obtain ceramic-metal mixed powder; respectively carrying out layer-by-layer sintering on the metal powder and the ceramic-metal mixed powder by adopting a directional energy field, and repeating the sintering process until material additive manufacturing is finished, wherein the atmosphere in the whole manufacturing process is a protective atmosphere such as vacuum atmosphere or argon atmosphere. The boron carbide composite material prepared by the preparation method disclosed by the invention is of a laminated structure, has the characteristics of high obdurability, good radiation resistance, low density, high reliability and the like, and can be widely used as a high-performance frictional material, an armored protection material, a storage material of a nuclear reactor spent fuel and the like.

Owner:HUAZHONG UNIV OF SCI & TECH +2

Bottom dusting electrical furnace steelmaking process

InactiveCN101787412ASmall particle sizeQuick responseProcess efficiency improvementElectric furnaceMelting tankSteelmaking

The invention relates to a bottom dusting electrical furnace steelmaking process. The technical scheme includes that the bottom of an electrical furnace 1 is provided with 1-6 bottom guns 3 based on electrical furnace steelmaking method with precharing system, current-carrying gas is adopted to blow powder into a metal pool by 1-6 bottom guns 3, and blowing amount of powder is 20-100wt% of addition when the powder is added into the furnace; wherein, the bottom guns 3 are arranged symmetrically or asymmetrically 0-0.7 time of furnace bottom radius away from the furnace bottom center; the bottom gun 3 is in contact or non-contact structure; the current-carrying gas is one of Ar, N2, natural gas, O2 and CO2; the powder is one or more than one of ground quick lime, limestone powder, ferric oxide powder, concentrate fines, carbon dust, dolomite powder, flousper powder, calcium carbide powder and alloy powder; powder granularity is 0.01-0.10mm; blowing technological parameters include that pressure is 0.3-1.2MPa, gas supply flow is 0.1-1.0Nm3 / t steel and powder gas ratio is 4-10. The invention has the characteristics that stirring effect is enhanced, metal material yield is improved and residue material utilization ratio is improved, duration of heating is shortened and steel quality is improved.

Owner:WUHAN UNIV OF SCI & TECH

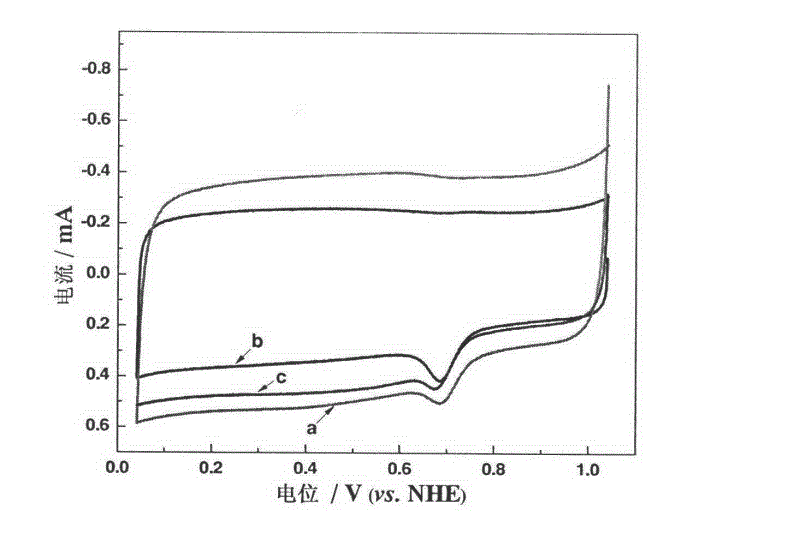

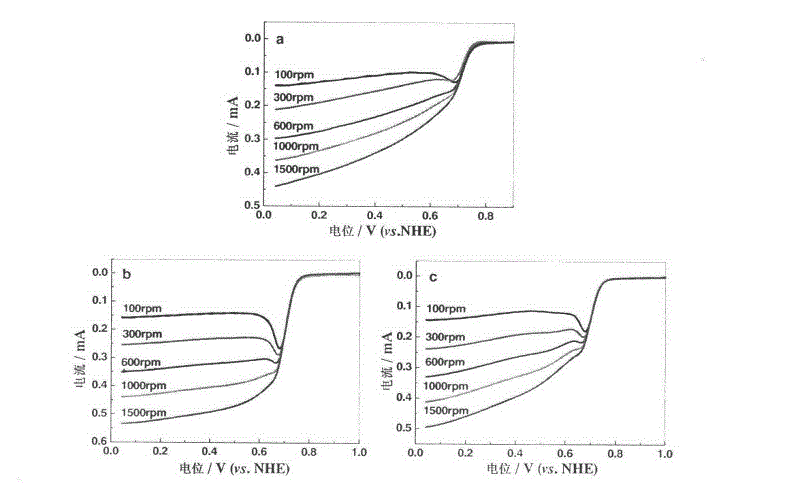

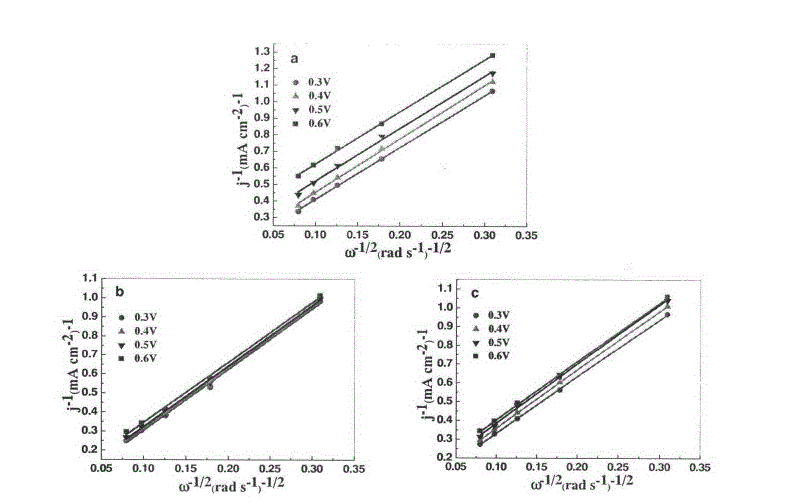

Preparation method for base metal oxygen reduction catalyst

InactiveCN102614915AImproving Oxygen Reduction Catalytic PerformanceLow costOrganic-compounds/hydrides/coordination-complexes catalystsCarbon dustOxygen

The invention discloses a preparation method for a base metal oxygen reduction catalyst. The preparation method includes following steps: weighing a defined amount of carbon dust treated by concentrated nitric acid; adding newly steamed pyrrole, oxidizing agent (ferric chloride) and doping agent (para-toluenesulfonic acid) in the carbon dust; decompressing and filtering mixed solution after uniformly stirring; then drying in a vacuum manner for a few of hours; weighing a defined amount of cobalt salt to be mixed with the mixed solution; decompressing and evaporating after uniformly stirring; and calcinating dried powder at a high temperature so as to obtain the base metal oxygen reduction catalyst with good electrochemical performances. The cheap and environment-friendly ferric chloride is used as the oxidizing agent, the base metal catalyst with the excellent oxygen reduction performance is prepared, the maximum peak potential of an oxygen reduction process catalyzed by the catalyst reaches 0.686V, and the maximum electron transfer number reaches 3.84.

Owner:EAST CHINA UNIV OF SCI & TECH +1

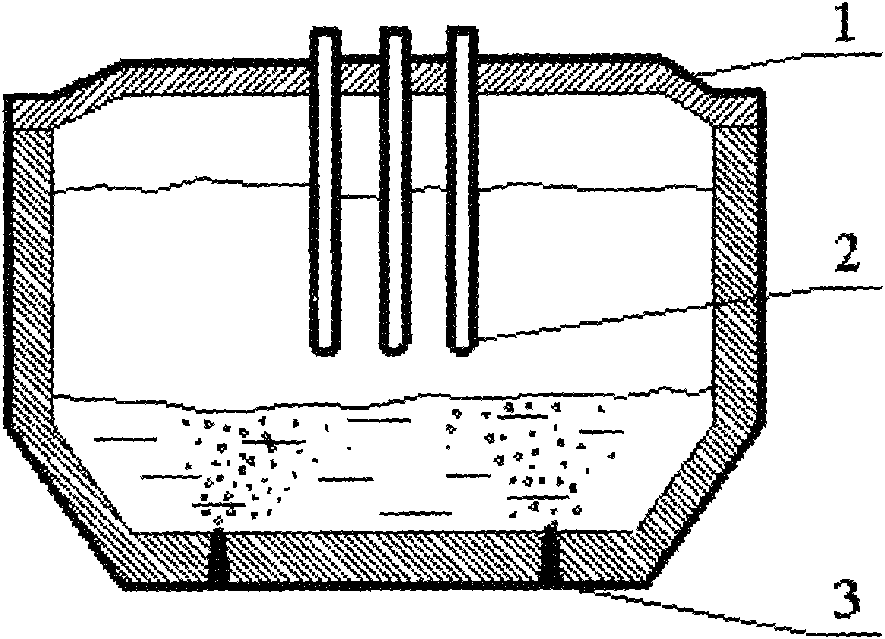

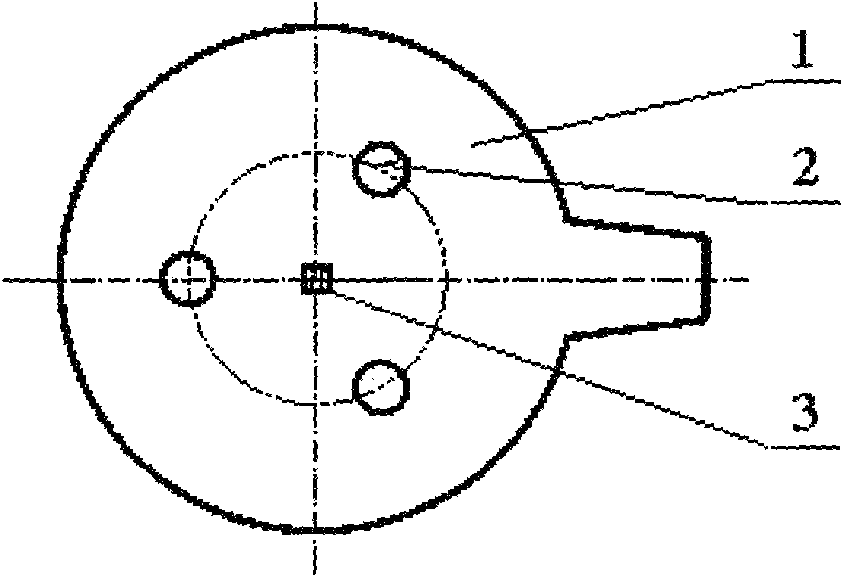

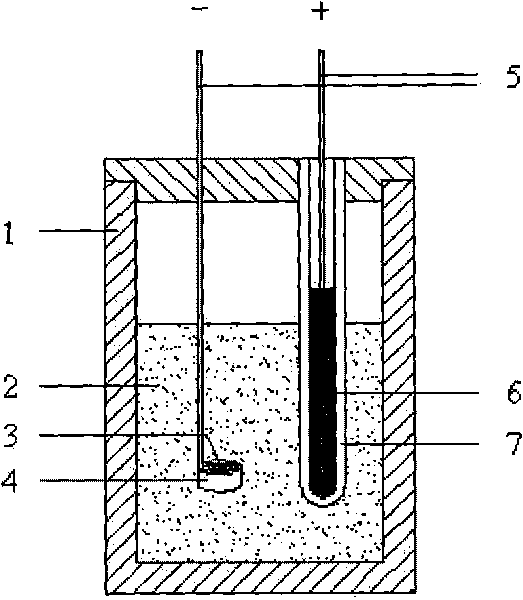

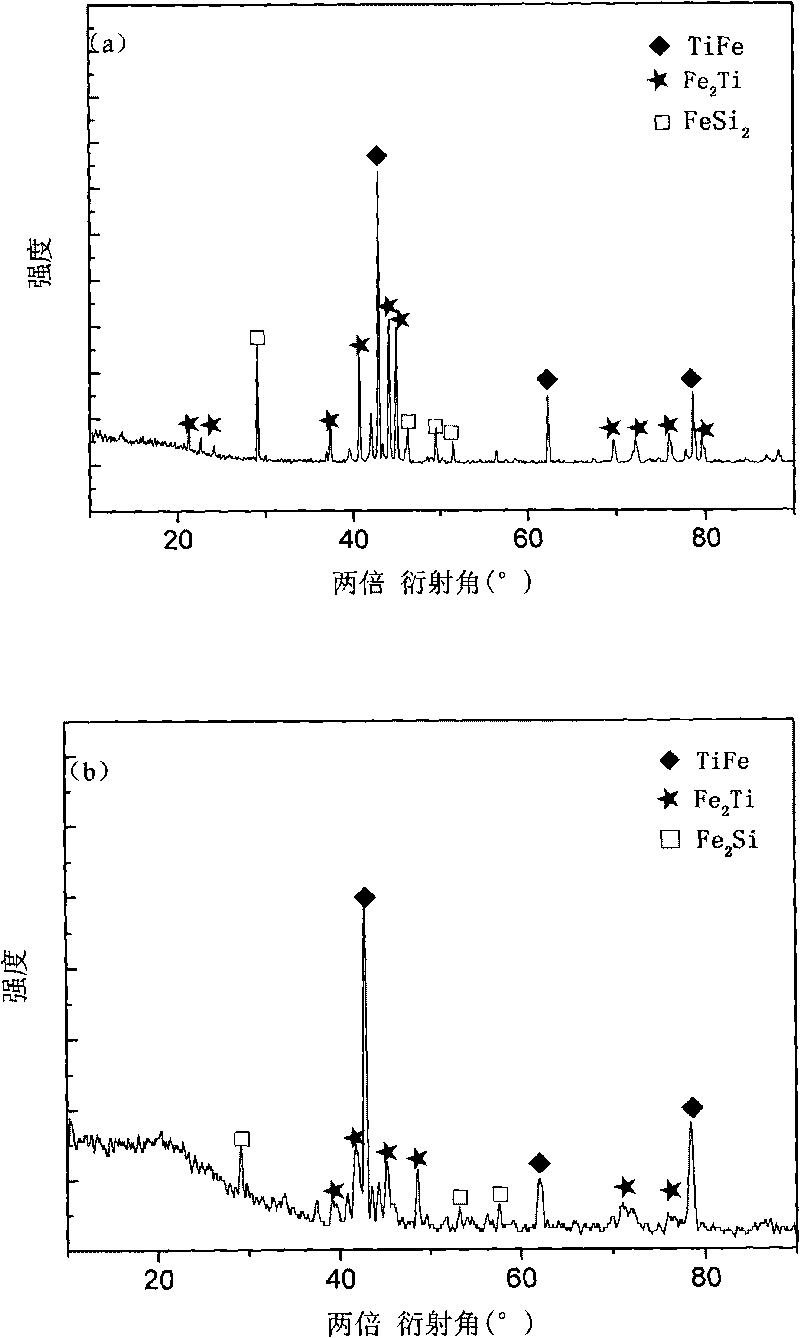

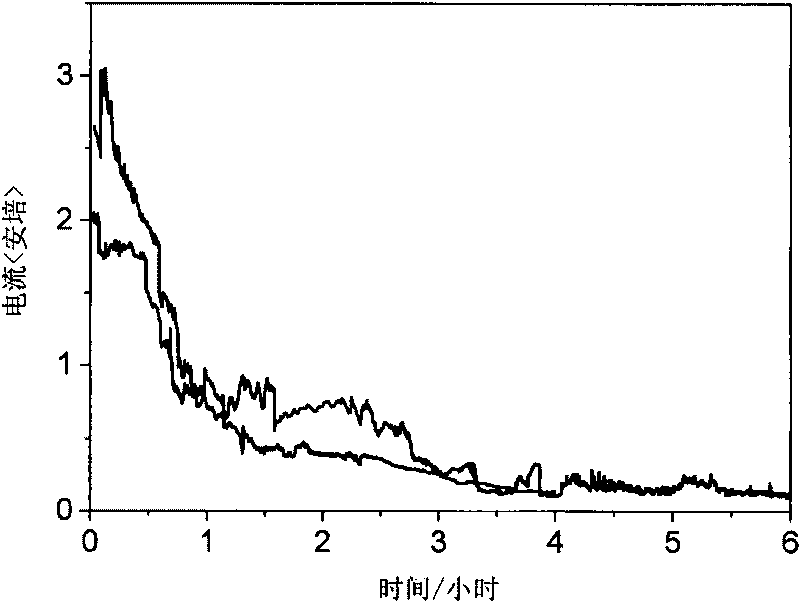

Method for directly preparing titanium alloy by titanium concentrate powder

The invention relates to a method for directly preparing titanium alloy by titanium concentrate powder, and belongs to the technical field of the preparation process for metal titanium alloys. The method mainly comprises the following steps: taking Gossampinus titanium concentrate powder as a raw material to obtain a fine material of titanium concentrate through ball milling and screening; then performing tabletting and sintering; winding round tablets on a molybdenum rod by using a fine molybdenum wire to prepare a cathode, or sintering the ore concentrate powder to form circular sheets, putting the circular sheets into a small stainless steel crucible directly, immersing the integral small stainless steel crucible into molten salt in an electrolytic cell, leading the small stainless steel crucible out by using the molybdenum wire as the cathode; taking copper solution of saturated carbon dust in a solid oxygen-permeable membrane tube as an anode; taking a corundum crucible as a reaction vessel, and taking CaCl2 as a molten salt electrolyte; taking high-purity argon as protective gas; performing electrolysis at a temperature of 1,100 DEG C under the constant voltage of between 3.5 and 4.0 V for 2 to 6 hours, taking the electrolyzed cathode out, and washing and drying the electrolyzed cathode to prepare the titanium alloy. The method has the characteristics of short flow, high efficiency, no pollution, low cost and the like.

Owner:SHANGHAI UNIV

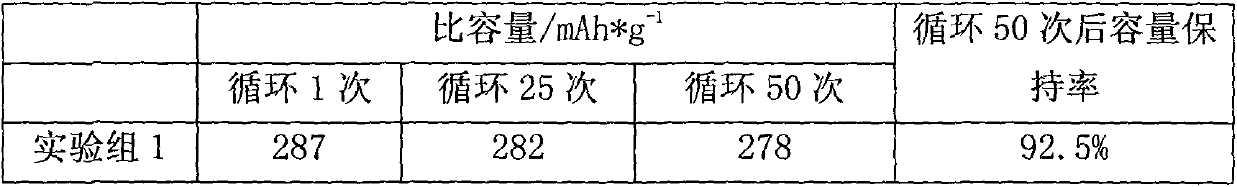

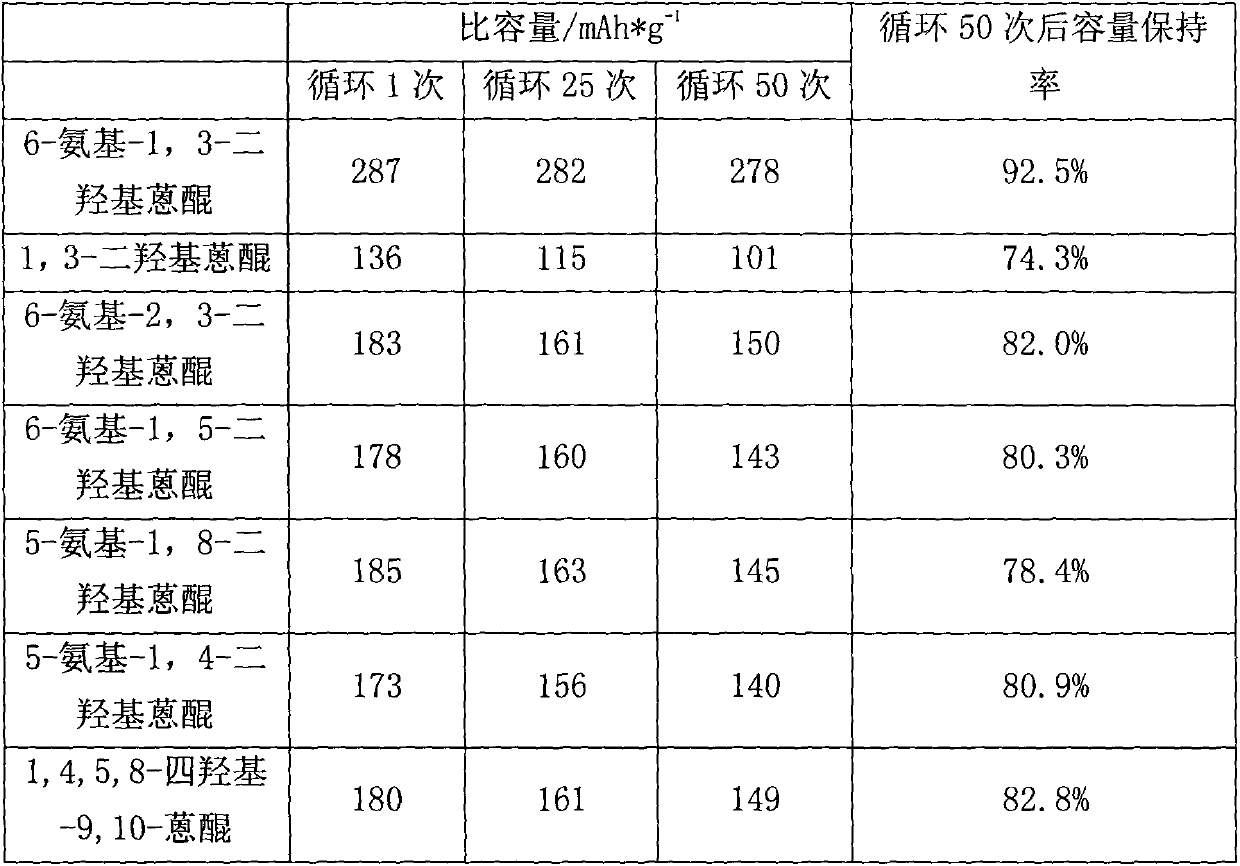

Anthraquinone lithium battery positive pole and preparation method thereof

The invention discloses an anthraquinone lithium battery positive pole and a preparation method thereof. The concrete preparation method comprises the following steps: (1) acetylene black powder is added to a grinding miller and ground for 0.5 hour to 2 hours, and the ground acetylene black powder is sieved by a 1000-mesh sieve; (2) anthraquinone derivatives, the sieved acetylene black powder, N, N-dimethyl formamide (DMF) are mixed, and blended by a mould wash mixer at a room temperature for one hour at the rotation speed of 600 r / min, so that treated carbon dust is obtained; (3) the treated carbon dust is mixed with polyvinylidene fluoride, so that positive pole slurry is obtained; and (4) the slurry is coated on an aluminum foil with a scraper and stoved dry, so that a positive pole sheet is obtained. The anthraquinone lithium battery positive pole is simple in preparation procedure and free from the phase of synthesis of polymers. A lithium battery prepared by means of the positive pole has the advantage of being large in specific capacity.

Owner:北京青晓宏拓医药科技发展有限公司

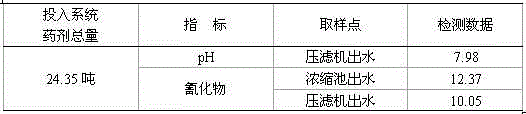

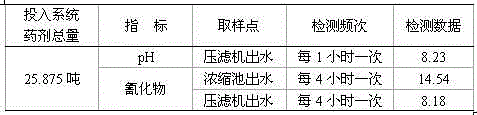

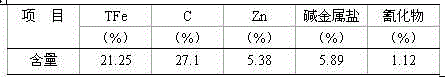

Comprehensive treatment method of dry reclaimed dust of blast furnace

The invention relates to a comprehensive treatment method of dry reclaimed dust of a blast furnace. The reclaimed dust mainly comprise the following ingredients: 15-25% of TFe, 14-30% of C, 4-6% of Zn, 5-7% of alkali metal salt, 0.5-1.9% of cyanide, 8-10% of SiO2, 2-3% of Al2O3, 15-21% of CaO and MnO, and small amounts of combined-state Pb and Cu or simple substances Pb and Cu. The technological process comprises the steps of unloading the dust, mixing, carrying out ball milling, performing flotation, reselecting and carrying out water treatment. After the method is applied to the dry reclaimed dusts of the blast furnace, environment-protection indexes reach the standard, and the contents of alkali metal, lead and zinc entering ore matching for sintering directly can be reduced greatly; the yield of fine powdered iron in dry reclaimed dusts is improved by 5-10%, the yield of the recycled carbon dusts is improved by 8-10% and the equipment failure rate is reduced remarkably.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Method for recovering and regenerating abandoned carbon dust of laser printer and laser duplicator

The invention discloses a method for recovering and regenerating abandoned carbon dust of a laser printer and a laser duplicator and aims to the method for recovering and regenerating the abandoned carbon dust of the laser printer and the laser duplicator, which is simple, is low in recovery cost and good in recovery effect. The method comprises the following steps of: recovering and gathering, namely recovering and gathering the abandoned carbon dust of the laser printer and / or the laser duplicator; drying, namely drying the recovered abandoned carbon dust; performing surface modification, namely performing surface modification on the recovered abandoned carbon dust by using a high-speed mixer; and screening, namely screening the semi-finished product carbon dust generated in the step of the surface modification so as to remove blocks generated by mixing. The method can be widely applied to the recovery field of the carbon dust of the laser printer and the laser duplicator.

Owner:ZHUHAI YIFAN DIGITAL TECH

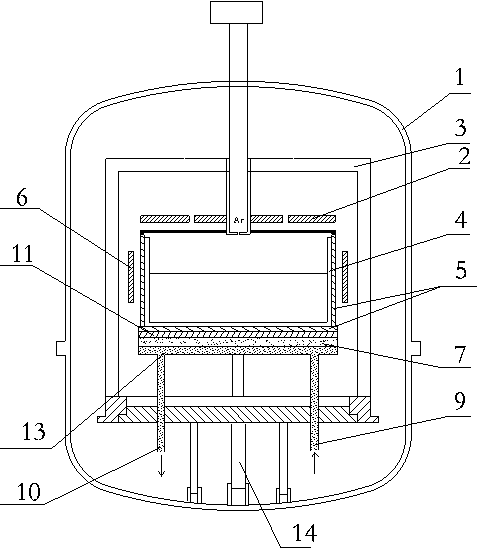

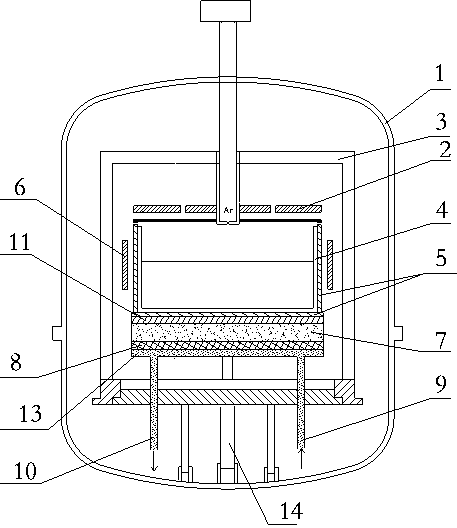

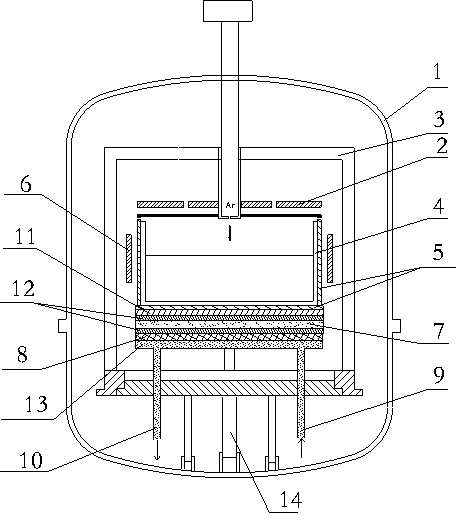

Water chilling ingot furnace and ingot casting process thereof

InactiveCN103451726AFacilitated releaseImprove yieldPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention discloses a water chilling ingot furnace and an ingot casting process thereof. A water cooling disc (13) is arranged at the lower end of a heat exchange table (11), located at the lower end of a bottom heater (7), internally provided with a flow cavity and provided with a water inlet (9) and a water outlet (10), wherein the water inlet (9) and the water outlet (10) are communicated through the flow cavity, and are respectively communicated with the outer end of a furnace body (1). The water chilling ingot furnace disclosed by the invention has the beneficial effects that the problem of influence on formation of columnar crystals due to transfer of heat of a crucible in a radial direction caused by lifting an insulating cage to dissipate heat from a side is solved by way of replacing the original mode of lifting the insulating cage to dissipate heat by water cooling; an insulating cage body in a lifting process is prevented from rubbing with the top of the insulating cage to generate carbon dust which is easy to enter the crucible to increase carbon impurity content of a silicon ingot so as to cause lattice deformation.

Owner:TIANWEI NEW ENERGY HLDG

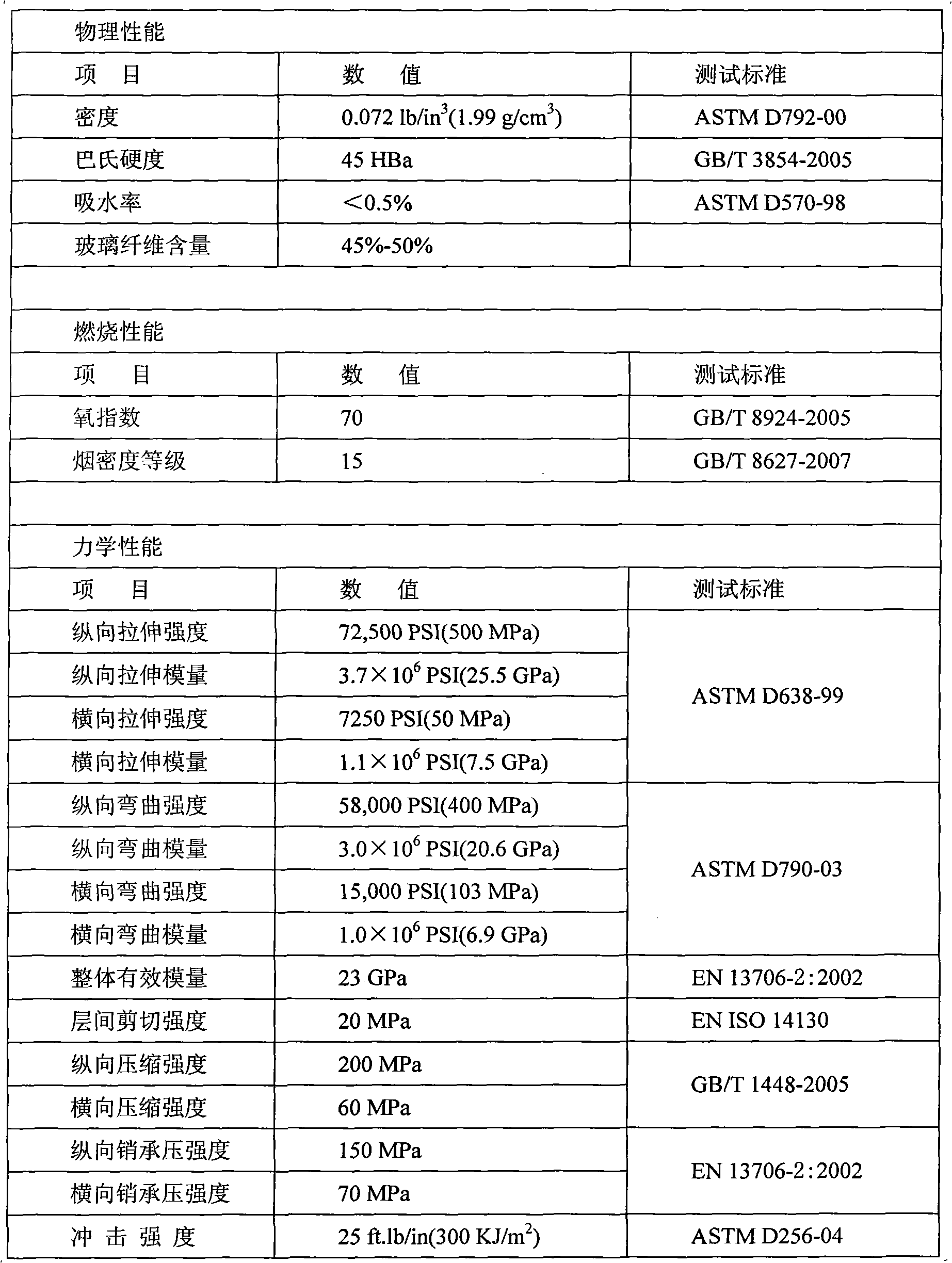

Preparation method of acrylic resin-based glass fiber reinforced plastic

The invention discloses a preparation method of acrylic resin-based glass fiber reinforced plastic, comprising the following steps of: pultruding 100 percent of acrylic resin, 150-200 percent of powdery aluminum hydroxide, 5-30 percent of carbon dust, 0.3-2.5 percent of benzoyl peroxide, 0.2-5 percent of polyethylene glycol and 0.5-6 percent of stearic acid or stearic acid salt by a pultrusion process; feeding the materials into a process tank; and continuously forming by using glass fiber yarn as a vector and a die for heating in three-section areas to obtain the acrylic resin-based glass fiber reinforced plastic. The acrylic resin-based glass fiber reinforced plastic has high combustion property and an oxygen index up to 70; in addition, after 150 parts of aluminum hydroxide and 5-30 parts of carbon dust are filled, the acrylic resin-based glass fiber reinforced plastic keeps high comprehensive mechanical properties, longitudinal stretching strength as high as 500MPa, longitudinal bending strength as high as 400MPa and elastic modulus up to 25.5GPa.

Owner:南京斯贝尔复合材料有限责任公司

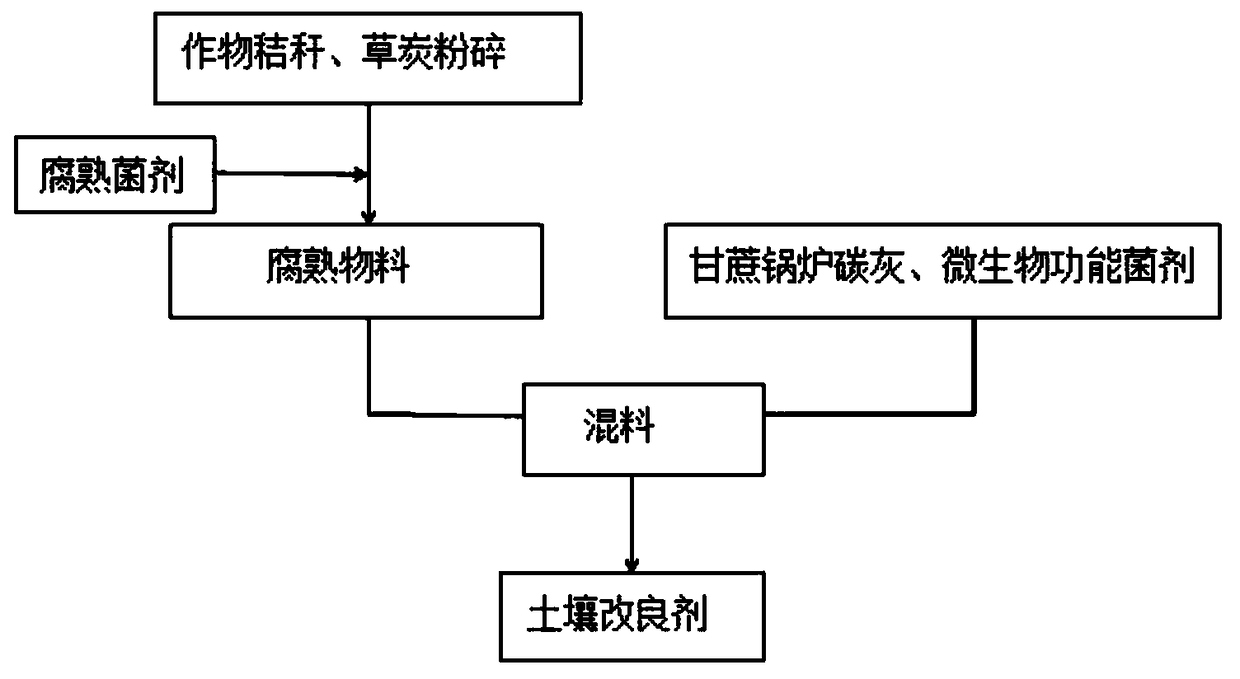

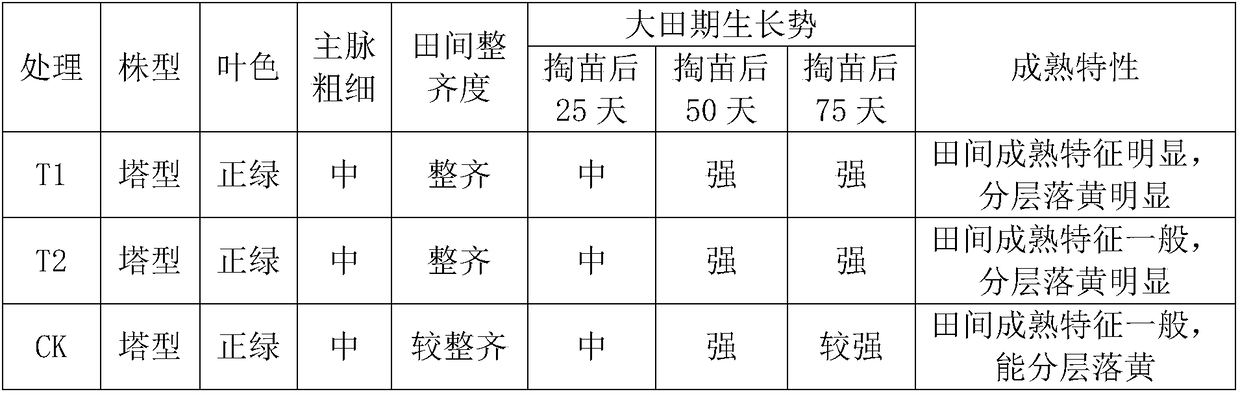

Soil improvement agent taking sugar refinery sugarcane boiler carbon dust as raw material as well as preparation method and application of soil improvement agent

InactiveCN109503290AImprove aggregate structureIncrease productionOrganic fertilisersFertilizer mixturesResource utilizationCarbon dust

The invention discloses a soil improvement agent taking sugar refinery sugarcane boiler carbon dust as a raw material. The soil improvement agent comprises 550 to 800 parts of sugarcane boiler carbondust, 200 to 450 parts of crop straw, 4 to 8 parts of a biological bacterial agent and 20 to 50 parts of turf. The preparation method comprises the following preparation steps: 1, after pulverizing the crop straw and the turf, adding rotten bacterial agents, perform fermentation at 65 DEG C for 20 days, turning the fermented materials once every 1 to 3 days, obtaining rotten materials after completely composing, and airing for future use; 2, adding the rotten materials into the sugarcane boiler carbon dust, adding the microbial bacterial agents with the beneficial function, stirring and mixing, and spraying, drying and granulating. The rich nutrients in the sugarcane boiler carbon dust are completely utilized and are compounded with the crop straw, the turf and the biological bacterial agent, the preparation process is simple and resource utilization of industrial waste is realized; in addition, the soil aggregate structure can be improved, the soil pH value can be adjusted, the soil fertilizer can be enhanced, the soil microecological environment can be harmonized, the quality of the corps can be improved, and the yield of the crops can be increased.

Owner:YUNNAN YUNYE FERTILIZER

Through-pore porous ceramic prepared by using pulverized fuel ash and preparation method of through-pore porous ceramic

InactiveCN108467258AIncrease dosageHigh porosityCeramic materials productionCeramicwarePotassiumPulverized fuel ash

The invention belongs to the field of ceramic materials and relates to a through-pore porous ceramic prepared by using pulverized fuel ash and a preparation method of the through-pore porous ceramic.The industrial solid waste pulverized fuel ash is taken as the raw material, a carbon dust is taken as a pore forming agent, a small quantity of kaolin and potassium feldspar is added as sintering aids, and the porous ceramic is obtained through ball-milling, mixing, dry pressing, and sintering at the high temperature. The mixing ratio of the solid waste of the method is up to 90%, wherein the mixing ratio of the pulverized fuel ash is up to 90% when the mixing ratio of the carbon dust is 5%, the proportion of the industrial solid waste pulverized fuel ash in the ingredients is greatly increased, and the purposes of treating the waste by the waste, comprehensively utilizing the resources and expanding the industry chain of circular economy are fulfilled. The total porosity of the porous ceramic is 38%-56%, the volume density is 1.1 g / cm<3> to 1.6 g / cm<3>, the water absorption is 24-50%, and the porous ceramic can be used for filtering high-temperature flue gas, sewage and the like, andthe application field of the industrial solid waste reutilization product is expanded.

Owner:BEIFANG UNIV OF NATITIES

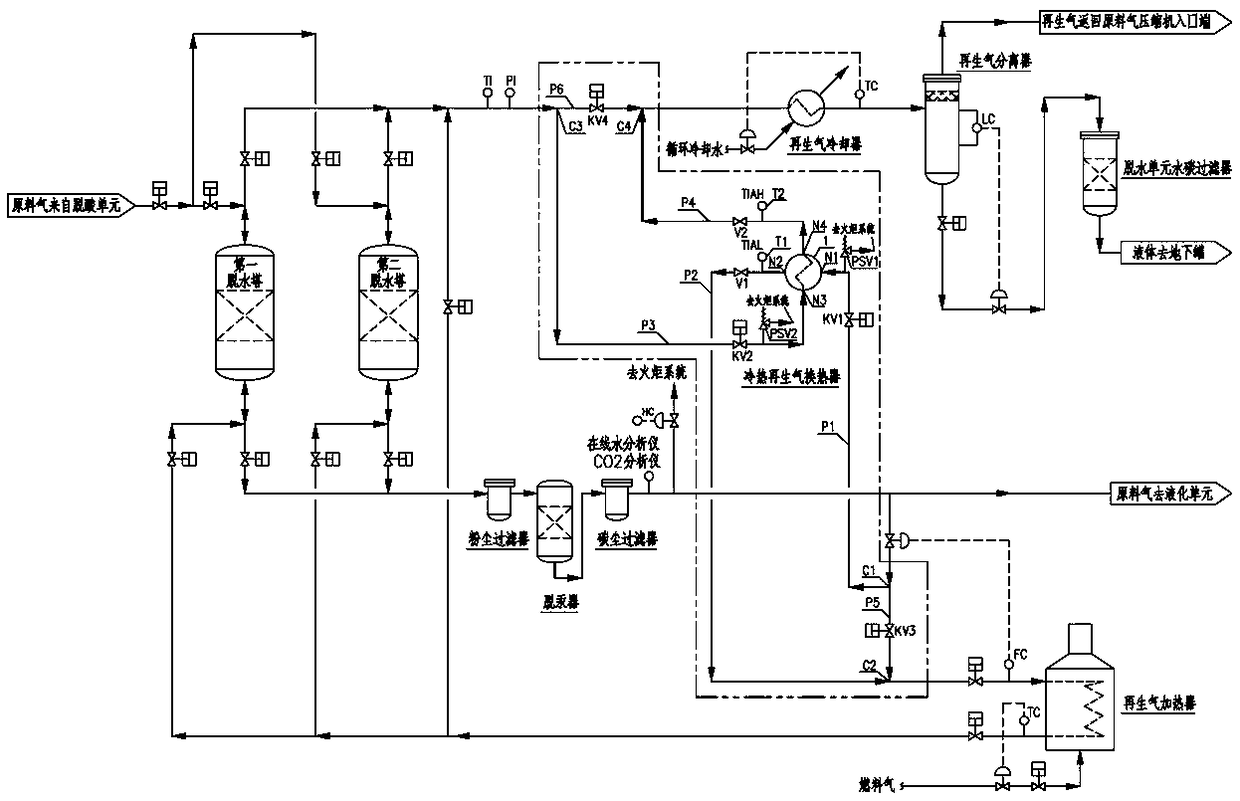

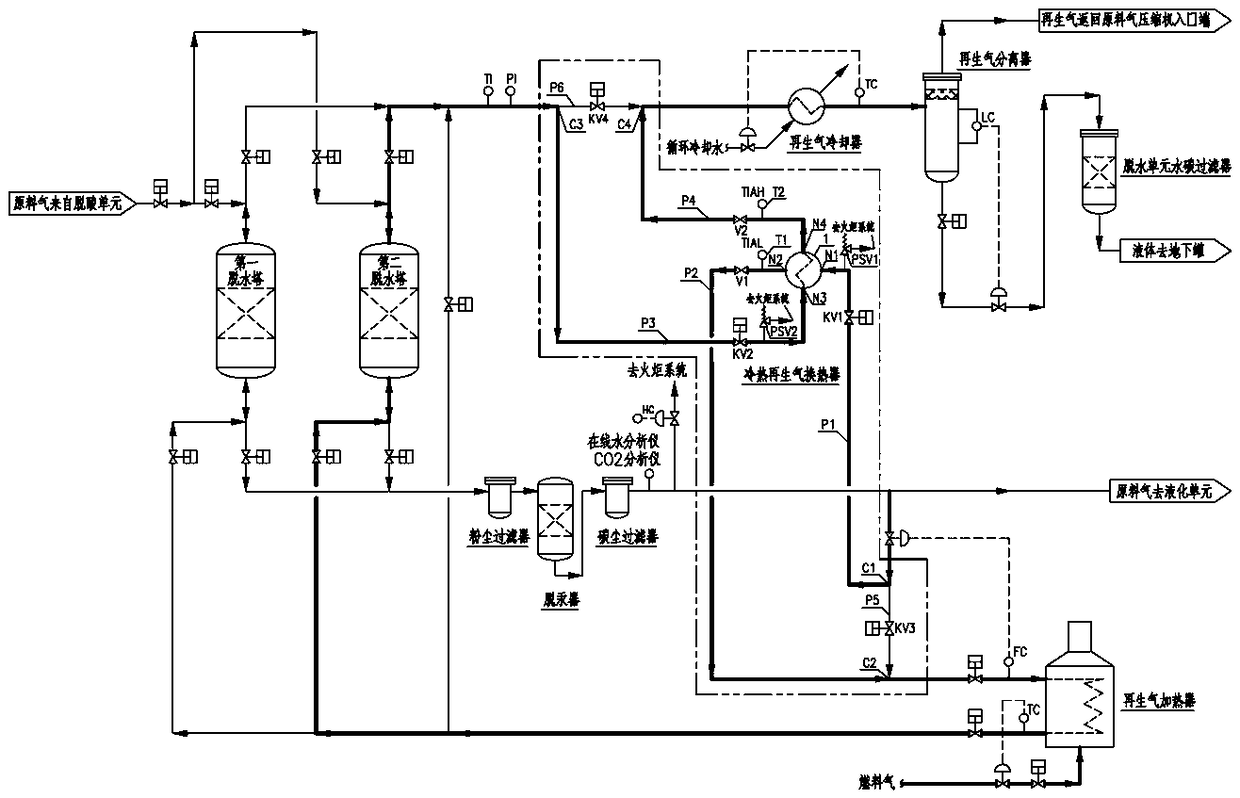

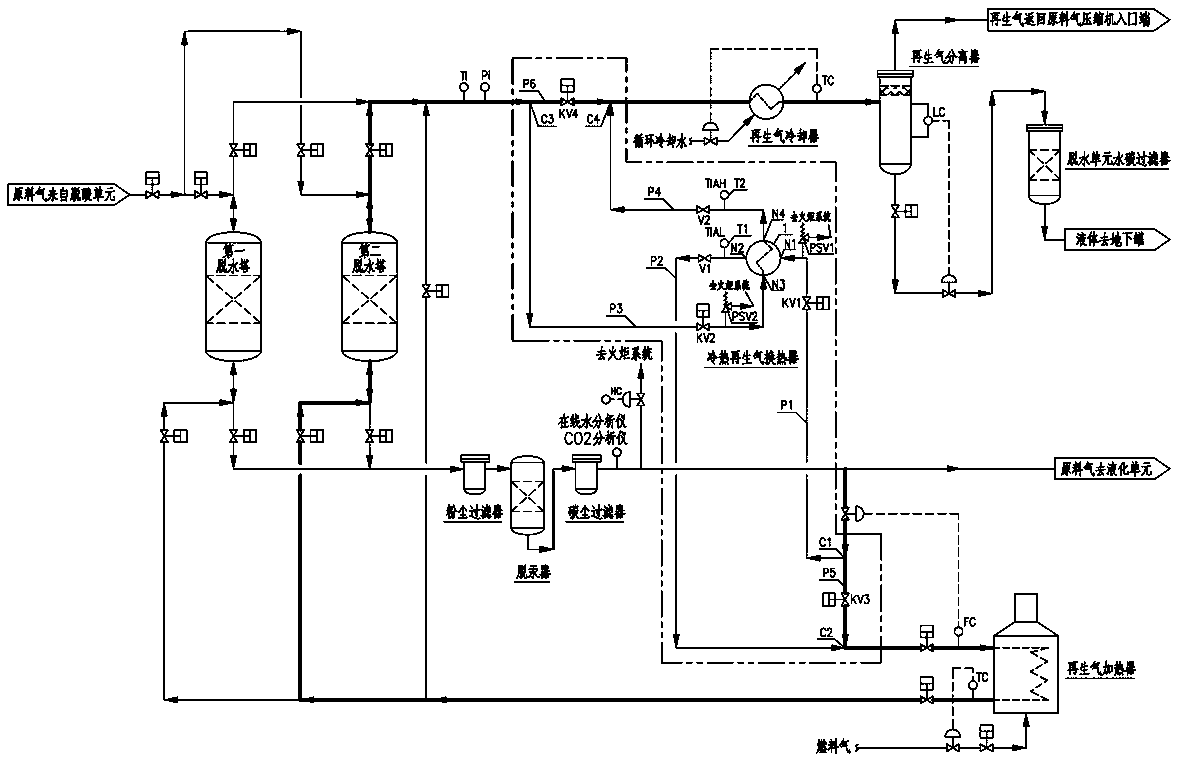

Natural gas dewatering system for using waste heat of molecular sieve regenerated gas

InactiveCN108822909ARealize waste heat recoveryReduce consumptionGas treatmentGaseous fuelsGas heaterGas cooler

The invention discloses a natural gas dewatering system for using waste heat of molecular sieve regenerated gas. The natural gas dewatering system comprises a first dewatering tower, a second dewatering tower, a dust filter, a mercury removal machine, a carbon dust filter, a regenerated gas heater, a regenerated gas cooler, a regenerated gas separator and a dewatering unit water carbon filter; a cold-hot regenerated gas heat exchange mechanism is additionally arranged and comprises a tube shell type cold-hot regenerated gas heat exchanger (1); hot regenerated gas and cold regenerated gas exchange heat in the cold-hot regenerated gas heat exchanger (1); the hot regenerated gas of a tube pass is cooled, and the cold regenerated gas of a shell pass is heated, so that the waste heat of the hotregenerated gas is recycled. A liquefaction plant with daily natural gas treatment capacity of one million standard m<3> / day is used as an example, the total heat regeneration annual operating time of two dewatering towers is 4,000 hours, and 1,800 MW waste heat can be recycled in one year and is equivalent to 268.28 tce (equivalent value) of standard coal. Through the natural gas dewatering system, the waste heat of the molecular sieve regenerated gas is recycled; the pollution to the environment is reduced; the natural gas dewatering system is energy-saving and environmentally friendly.

Owner:EAST CHINA ENG SCI & TECH

Plant fiber environmental protection decorative sheet

The invention discloses a plant fiber environmental protection decorative sheet. The decorative sheet is prepared from, by weight, 30-50 parts of carbon dust, 2-10 parts of resin, 5-20 parts of plant fiber, 1-4 parts of fire retardant, 1-5 parts of dispersing agent, 1-5 parts of zeolite powder, 2-6 parts of tea pole dregs, 5-15 parts of foaming control agent, 3-8 parts of CPE, 1-5 parts of yellow foaming agent, 1-5 parts of stearic acid, 2-7 parts of stabilizer, 30-50 parts of PVC, 20-50 parts of calcium powder, 10-20 parts of bamboo powder and 10-20 parts of bamboo ash. According to the plant fiber environmental protection decorative sheet, the preparing technique is very simple, the preparing process is environmentally protective and pollution free, and the prepared decorative sheet is capable of adsorbing and degrading hazardous substances such as sulfide, nitride, formaldehyde, benzene and phenol; meanwhile, the plant fiber environmental protection decorative sheet is low in production cost and good in economic benefits.

Owner:叶爱云

Rare earth alloy anode for electrodeposited zinc, and preparation method thereof

InactiveCN107012361AReduce investmentReduce burning lossPhotography auxillary processesProcess efficiency improvementRare-earth elementSlag

The invention relates to a rare earth alloy anode for electrodeposited zinc, and a preparation method thereof, which belong to the field of nonferrous metal application. The rare earth alloy anode for the electrodeposited zinc is prepared from the components in percentage by weight: 0.001 to 0.05 percent of rare earth, 0.2 to 0.5 percent of silver, and the balance lead. The preparation method comprises the steps of feeding a lead ingot into an industrial frequency furnace for melting, and fetching slags when the temperature reaches to 500 DEG C; when the melt temperature reaches to 600 DEG C, feeding a prefabricated lead-silver master alloy; adding a carbon dust covering agent in the industrial frequency furnace; when the melt temperature reaches to 650 DEG C, using a bell jar for adding a rare earth master alloy, and electromagnetically or mechanically stirring for 10min; carrying out closed over-entering and down-out constant-volume casting; and after casting a workblank, rolling and welding to obtain the rare earth alloy anode. According to the rare earth alloy anode for electrodeposited zinc, and the preparation method thereof provided by the invention, the rare earth with refined grains and an anode activation performance is selectively added on the basis of a Pb-Ag binary alloy, and the closed over-entering and down-out castig process is adopted, so that the rare earth investment is less, the burning loss is less, and the effective components in the rare earth in a finished product are ensured to meet the requirement.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com