Comprehensive treatment method of dry reclaimed dust of blast furnace

A technology of dry dust removal and comprehensive treatment, which is applied in the fields of comprehensive utilization of resources and environmental protection. It can solve problems such as increased pH value, influence of mineral processing system, high salinity and cyanide ion, and achieves the effect of reducing equipment failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Comprehensive treatment method of blast furnace gas dry bag dust removal

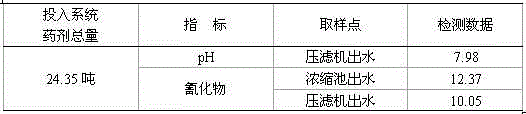

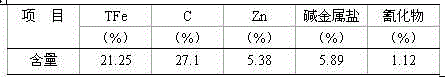

[0016] The main components of 3# blast furnace dust are shown in Table 1.

[0017] Table 1 Content of main components of 3# blast furnace dust

[0018]

[0019] The processing steps are:

[0020] (1) Ash discharge: put 20t of 3# blast furnace dry ash into the material tank and immediately soak it with circulating water.

[0021] (2) Mixing: Use a 5t grab crane to grab 5 buckets and put them into a mixing bucket with a diameter of 2.5m, add water 2.2 m deep into the mixing bucket, and configure the slurry concentration to be 26.2%, and stir in the mixing bucket for 15 minutes for backup use.

[0022] (3) Ball milling: the stirred pulp enters the ball mill for grinding, so that the large agglomerates and coarse particles are ground and dispersed, which is convenient for the beneficiation resolution of the subsequent flotation and gravity separation processes.

[0023] (4) Flota...

Embodiment 2

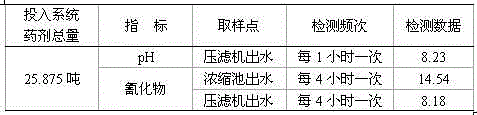

[0031] Embodiment 2: Comprehensive treatment method of blast furnace gas dry bag dust removal

[0032] The main components of 4# blast furnace dust are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com