Patents

Literature

1685 results about "Blast furnace gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blast furnace gas (BFG) is a by-product of blast furnaces that is generated when the iron ore is reduced with coke to metallic iron. It has a very low heating value, about 93 BTU/cubic foot (3.5 MJ/m³), because it consists of about 60 percent nitrogen and 18-20% carbon dioxide, which are not flammable. The rest is mostly carbon monoxide, which has a fairly low heating value already and some (2-4%) hydrogen. It is commonly used as a fuel within the steel works, but it can be used in boilers and power plants equipped to burn it. It may be combined with natural gas or coke oven gas before combustion or a flame support with richer gas or oil is provided to sustain combustion. Particulate matter is removed so that it can be burned more cleanly. Blast furnace gas is sometimes flared without generating heat or electricity.

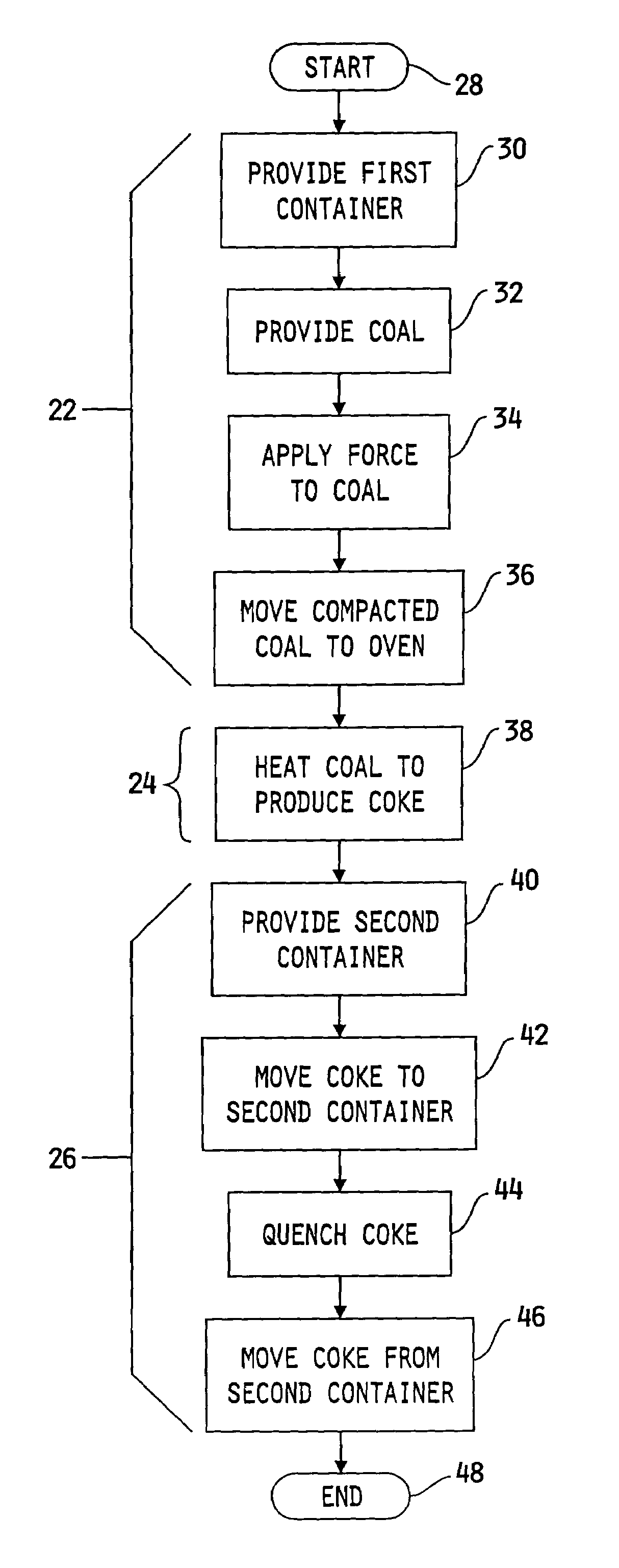

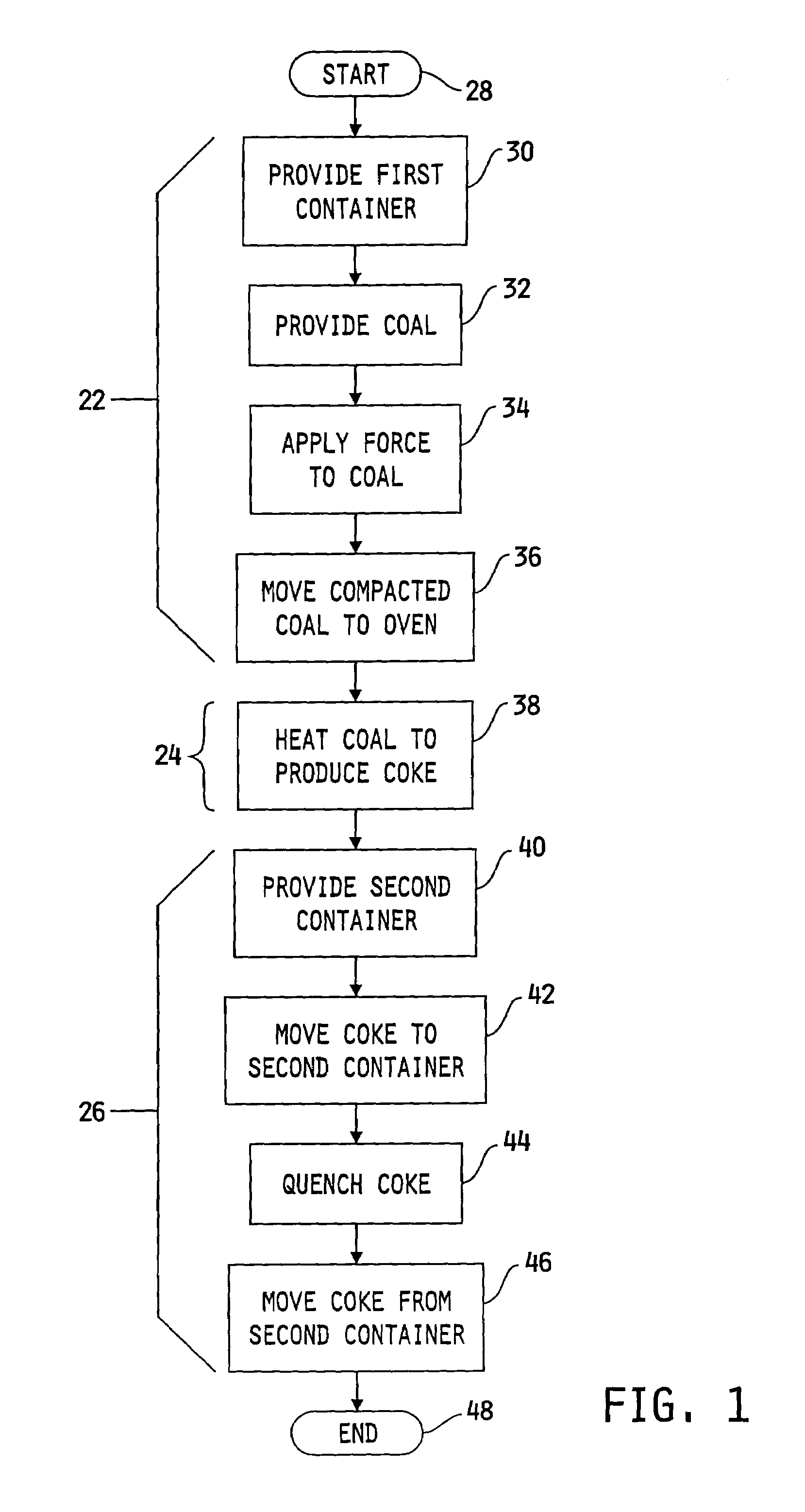

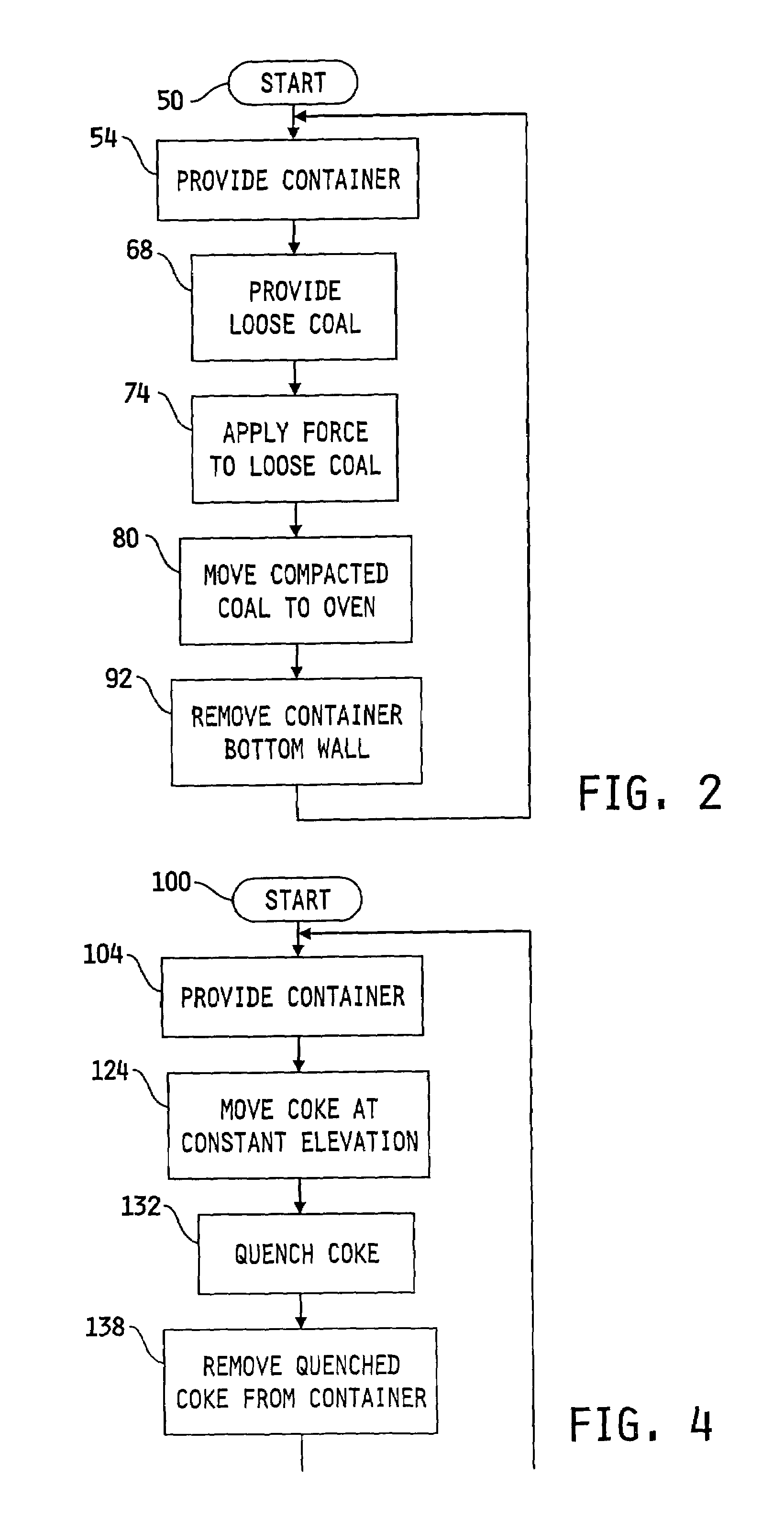

Method for producing blast furnace coke through coal compaction in a non-recovery or heat recovery type oven

A method for producing non-recovery / heat recovery coke may include the steps of providing a container, disposing a volume of loose coal into the container such that a vertical dimension of the volume of loose coal in the container is smaller than a horizontal dimension of the volume of loose coal, applying a force to the coal in the container to produce a volume of compacted coal having a substantially uniform density which is larger than that of the loose coal, disposing the compacted coal into a non-recovery / heat recovery type oven, and heating the compacted coal to produce coke. The method may also include the steps of providing a container, and moving the non-recovery / heat recovery coke mass from the oven at a substantially constant elevation to the container, quenching the coke mass in the container to produce a quenched coke mass, and removing the quenched coke mass from the container.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Iron coke for blast furnace and preparing method thereof

InactiveCN103468289AEnsure Strength IndexBest heating speedCoke ovensBlast furnace detailsCoke ovenUltimate tensile strength

The invention relates to iron coke for a blast furnace and a preparing method thereof. The iron coke comprises 5wt%-20wt% of iron ore powder and 80wt%-95wt% of mixed coal; the mixed coal is formed by mixing 25wt%-29wt% of one third of coking coal, 40wt%-44wt% of coking coal, 7wt%-11wt% of lean coal, 6wt%-10wt% of gas-fat coal and 12wt%-16wt% of fat coal; the iron ore powder and the mixed coal are mixed uniformly with water and tamped before entering the blast furnace, and are placed into the blast furnace when the temperature is 800 DEG C, the temperature is increased at the speed of 2 DEG C per minute to 3 DEG C per minute, the iron ore powder and the mixed coal are discharged from the blast furnace when the temperature is 950-1050 DEG C, and the iron coke is obtained by adopting a wet way of quenching the coke. According to the iron coke and the preparing method, the performance, the ratio, the particle size and the composition and the like of the iron ore powder and the mixed coal are optimized, and the strength and the reactivity of the iron coke can meet the requirement of the blast furnace process under the circumstance of not adding binding agents.

Owner:WUHAN UNIV OF SCI & TECH

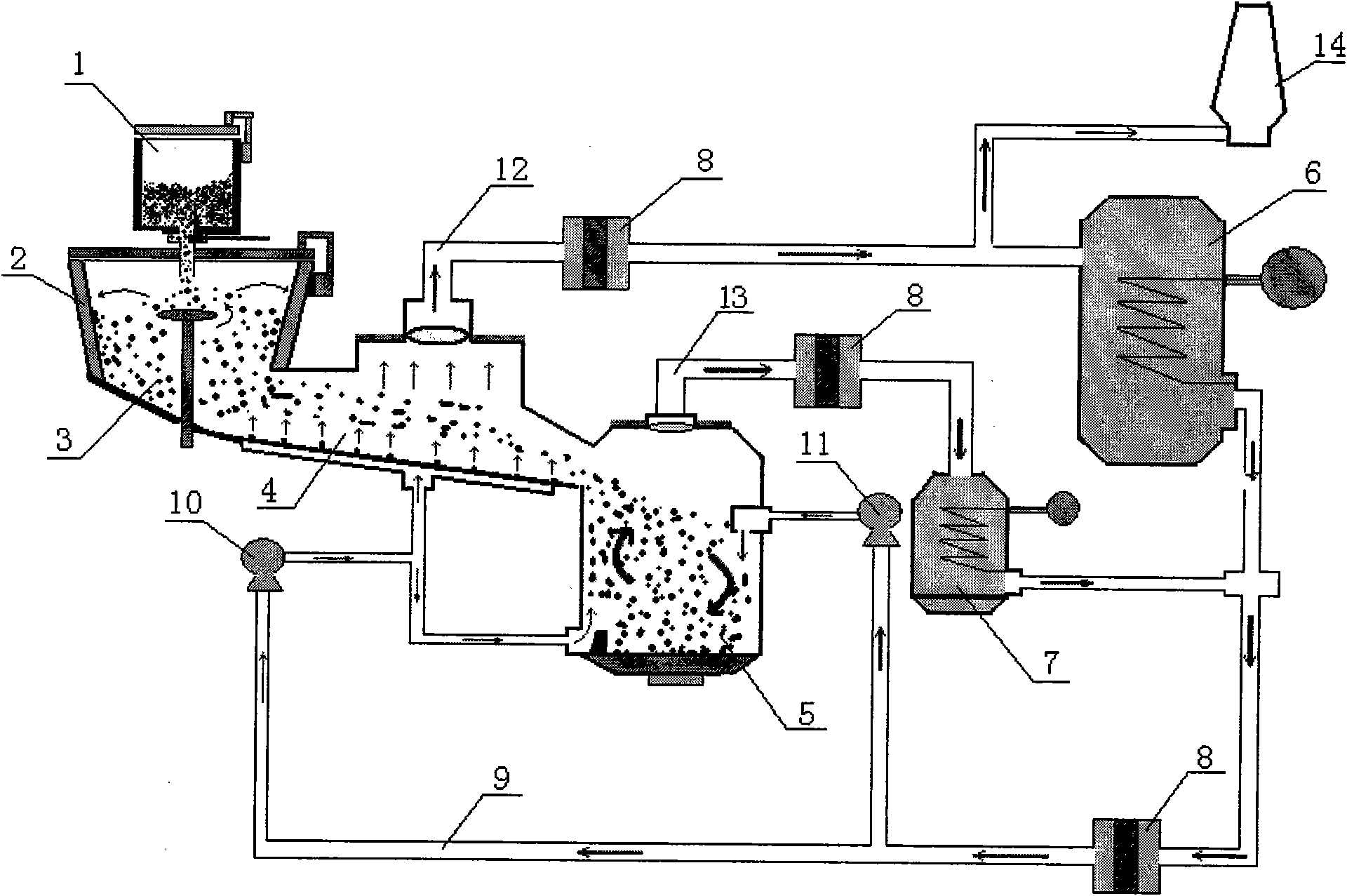

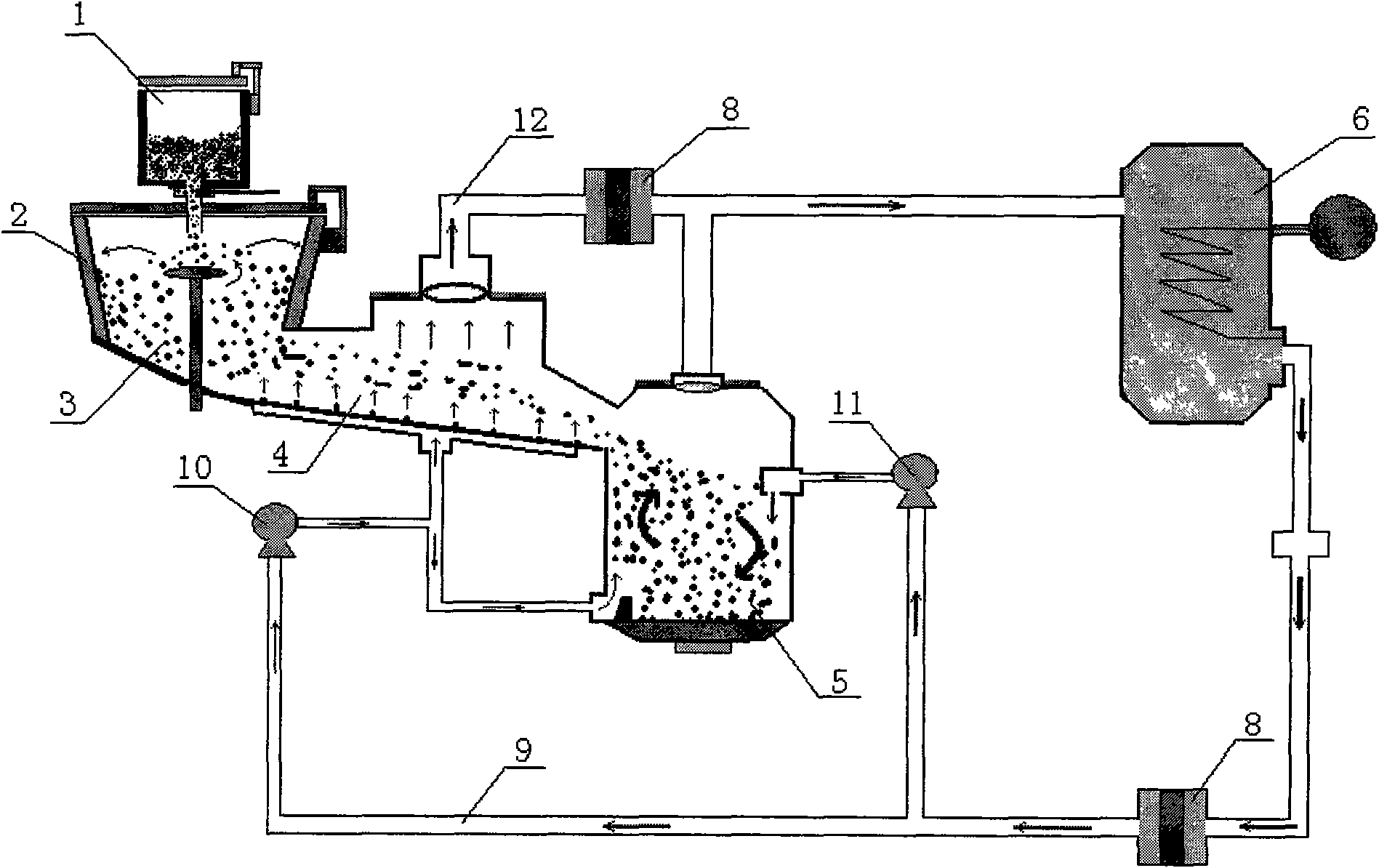

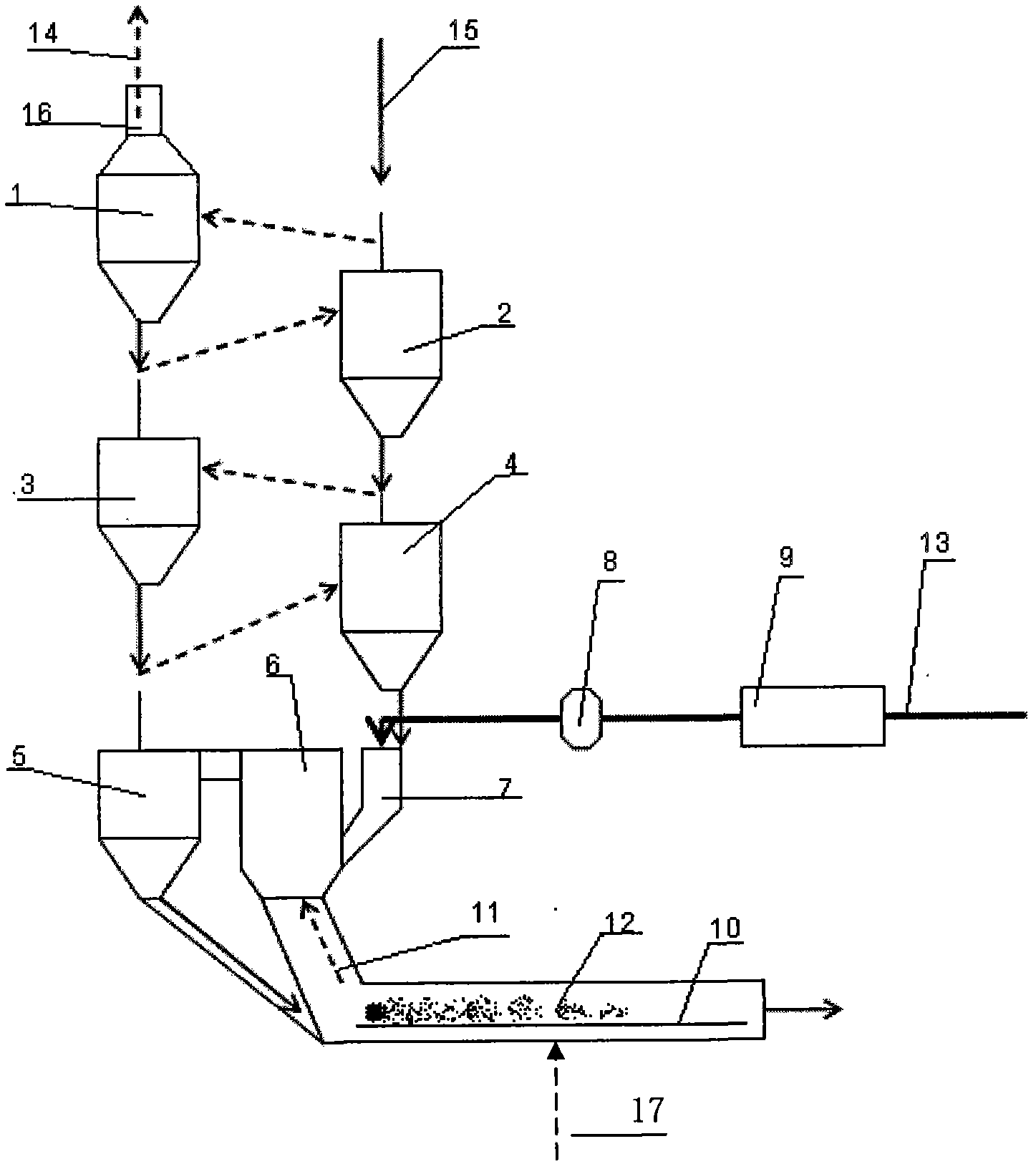

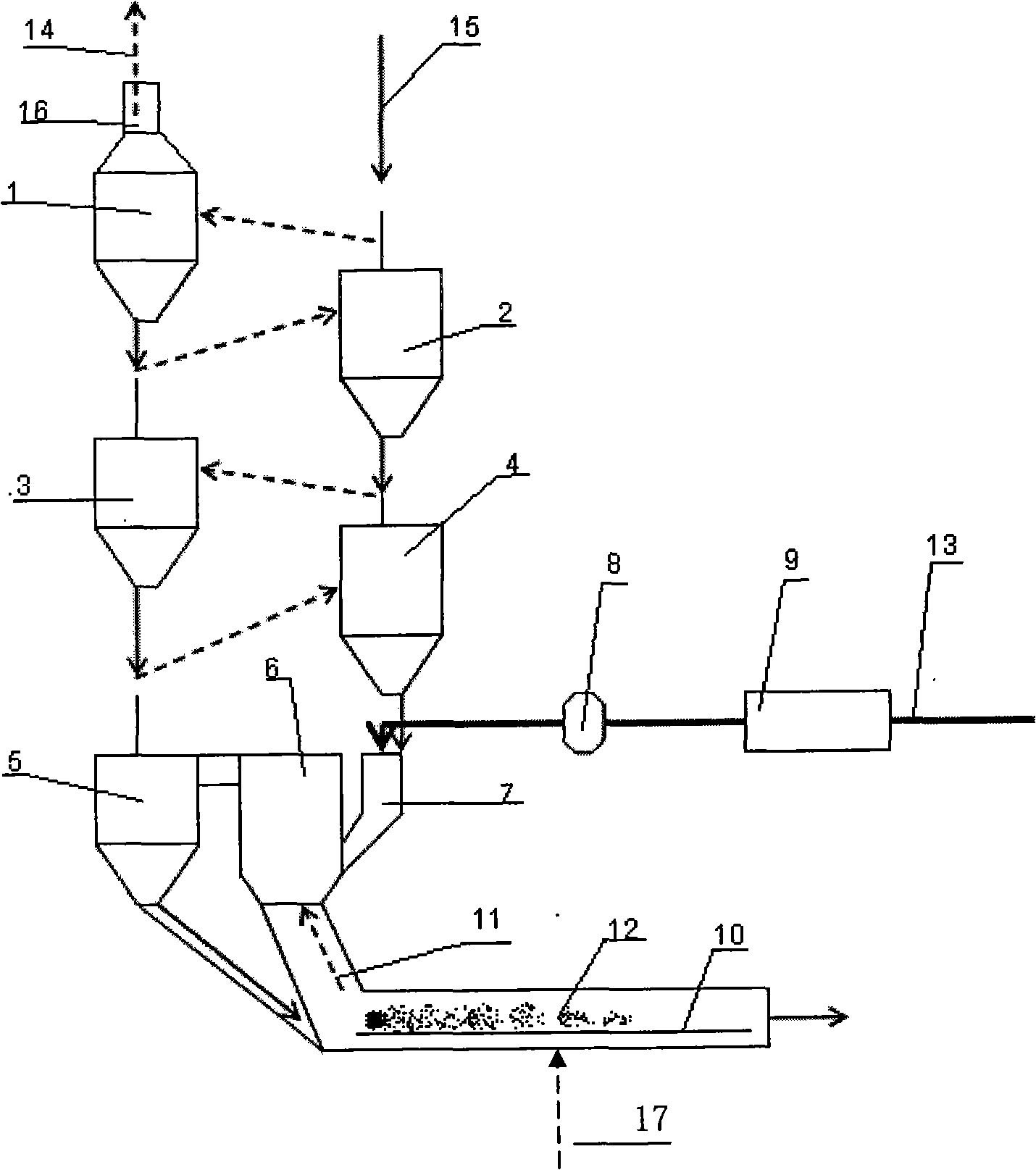

Molten blast furnace slag sensible heat recovery method and device

InactiveCN101660014ASave energyRecycling and recovery technologiesProcess efficiency improvementRecovery methodThermal energy

The invention relates to the field of energy recovery utilization and in particular to a molten blast furnace slag sensible heat recovery method and a device; the method is characterized in that: themolten blast furnace slag carries out a first heat recovery in a granulator, and then a second heat recovery is carried out by a vibrated bed, and then a third heat recovery is carried out in a fluidized bed, and the reclaimed heat energy is reutilized or converted in a hot air or power generating way; the realization steps are that: 1) the molten blast furnace slag is arranged in the granulator for granulation; 2) the blast furnace slag granules carry out heat exchange in the vibrated bed; 3) the blast furnace slag granules carry out heat exchange in the fluidized bed; 4) after heat exchangeis carried out, the heat is used for power generation from air or is directly utilized in a hot wind way. The method has the beneficial effects that: the sensible heat of the molten blast furnace slagis utilized respectively in a way of waste heat stream power generation and in a way of blast furnace hot wind, compared with the existing water quenching method, 1.0-1.2t of fresh water can be savedwhen processing 1t of molten slag, and sulfides H2S and SO2 are not produced, and energy equivalent to 47kg of standard coal is saved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

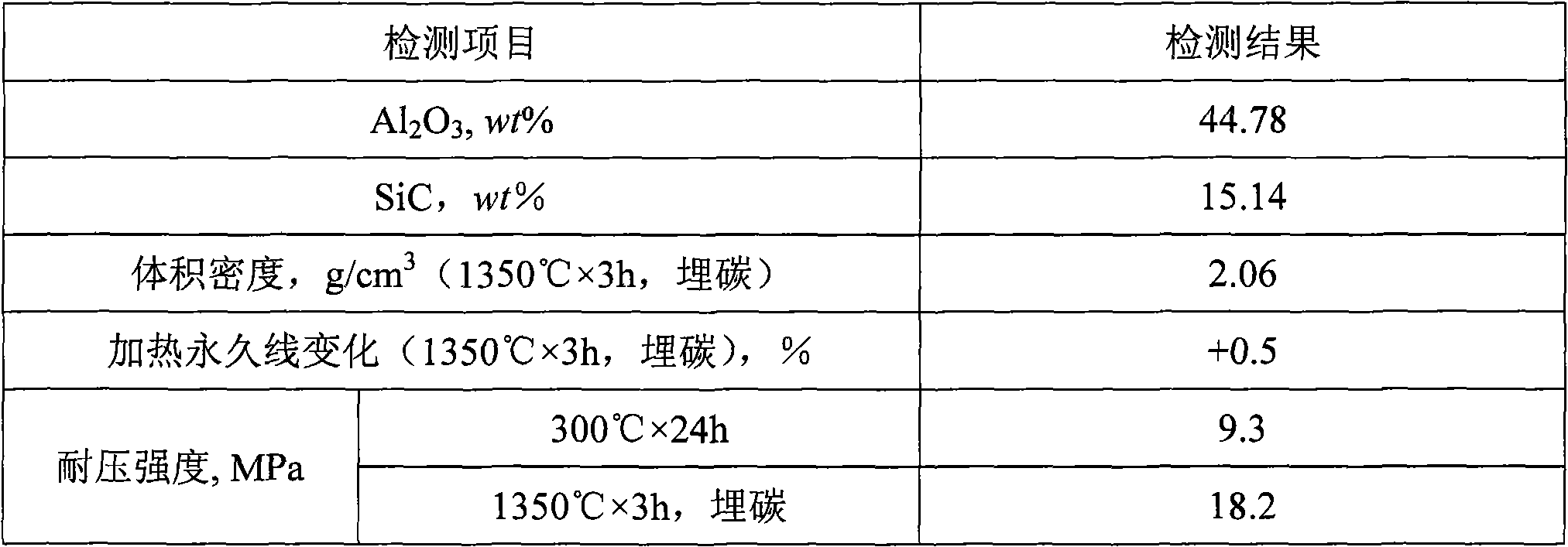

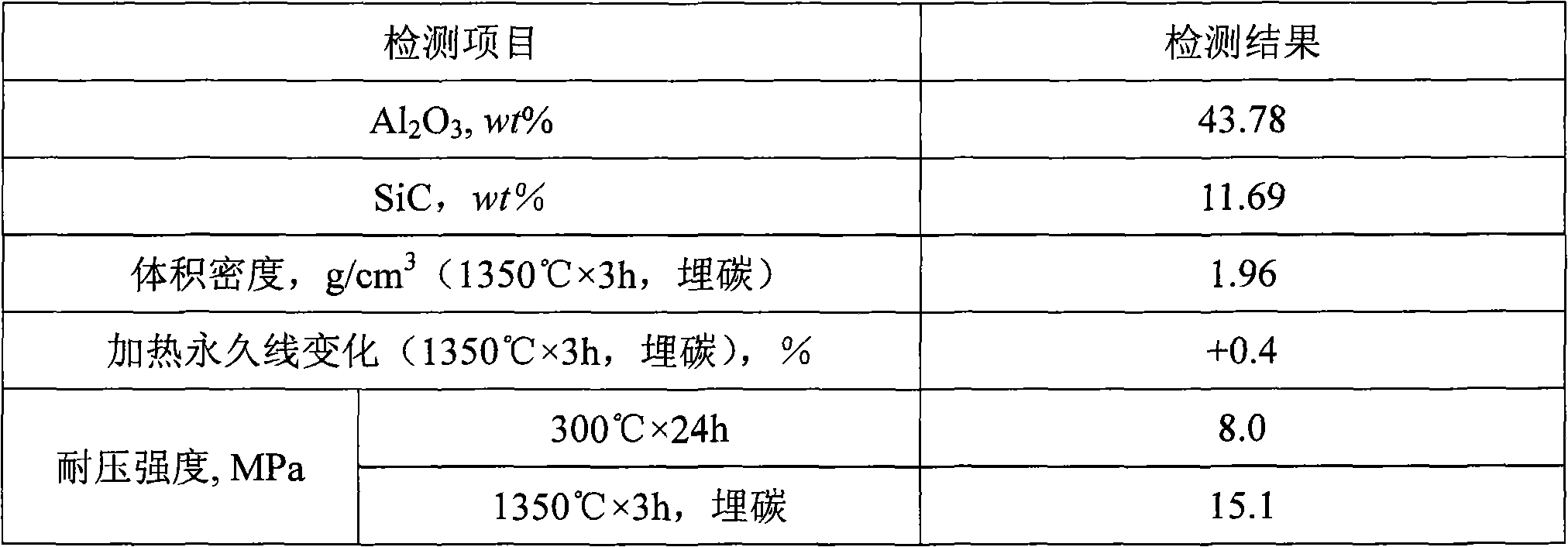

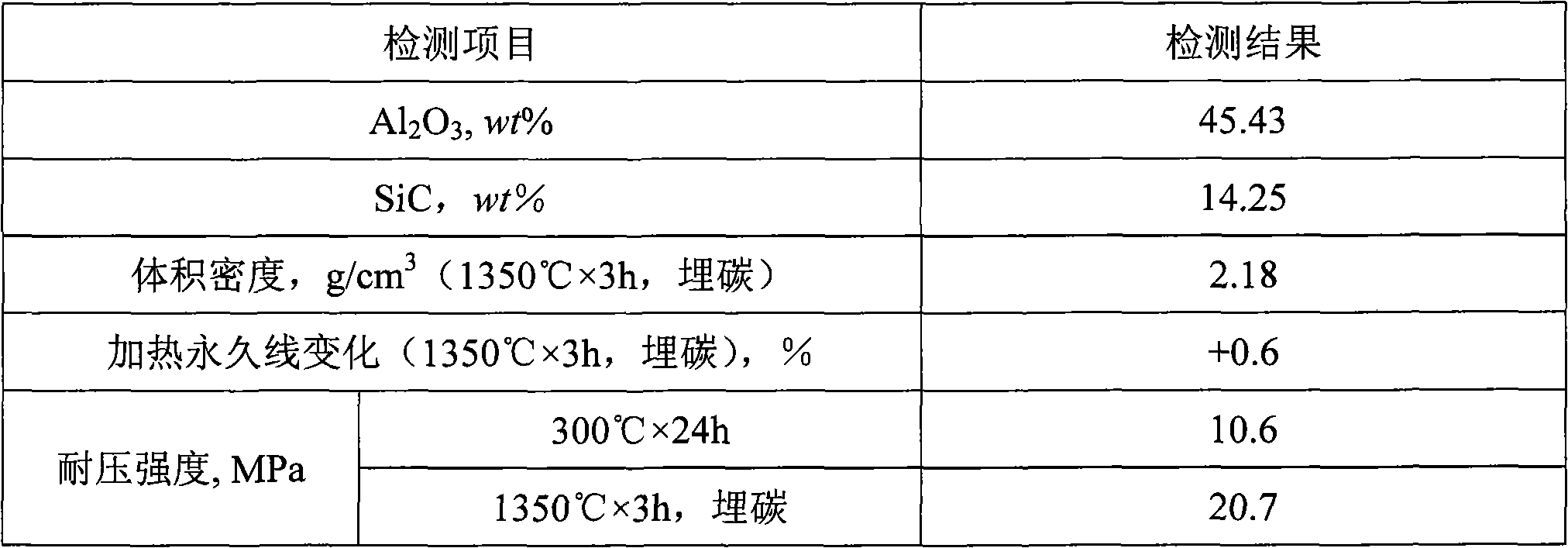

Method for producing waterless taphole mix for blast furnace from high-alumina waste refractory materials

The invention discloses a method for producing a waterless taphole mix for a blast furnace from high-alumina waste refractory materials. The produced low-cost waterless taphole mix can satisfy the operating requirements for plugging tapholes of large and medium blast furnaces. The method comprises the selection of raw materials for production, the processing of the raw materials for production, the proportioning of the raw materials for production, and the production process. The waterless taphole mix produced by the method has the characteristics of low cost, good plasticity and sintering property, high middle-and-high-temperature strength, favorable slag and iron erosion resistance and the like, and can completely satisfy the operating requirements of large and medium blast furnaces. Compared with the existing waterless taphole mix, the cost can be reduced by 40-60%; since a great amount of waste refractory materials are used, the emission of the solid waste can be decreased, and a great amount of high-quality refractory materials such as brown corundum, premium / extra grade alumina and the like can be saved; and meanwhile, the energy consumption and the emission of carbon dioxide gas during the smelting of brown corundum and premium / extra grade alumina can be decreased.

Owner:UNIV OF SCI & TECH LIAONING

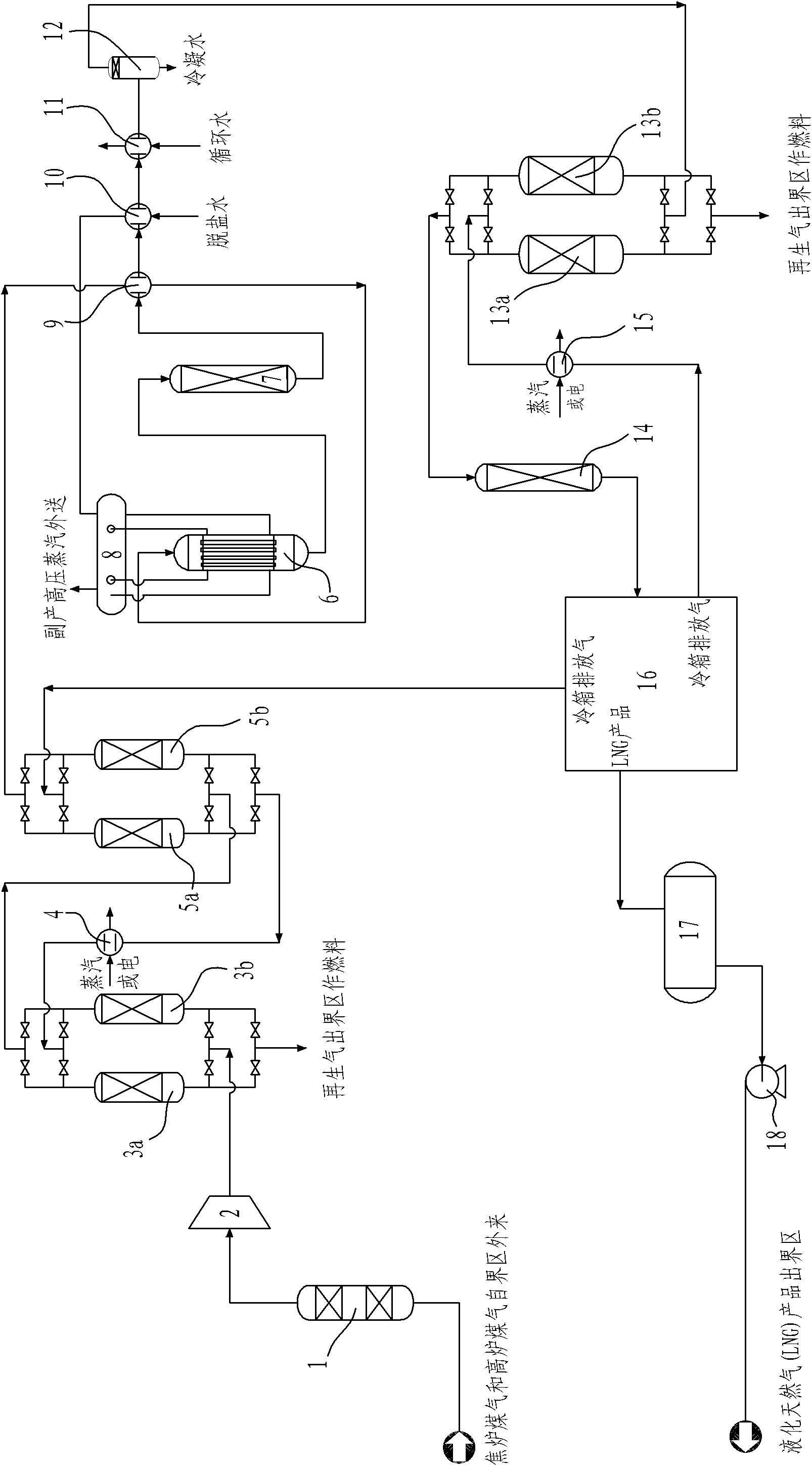

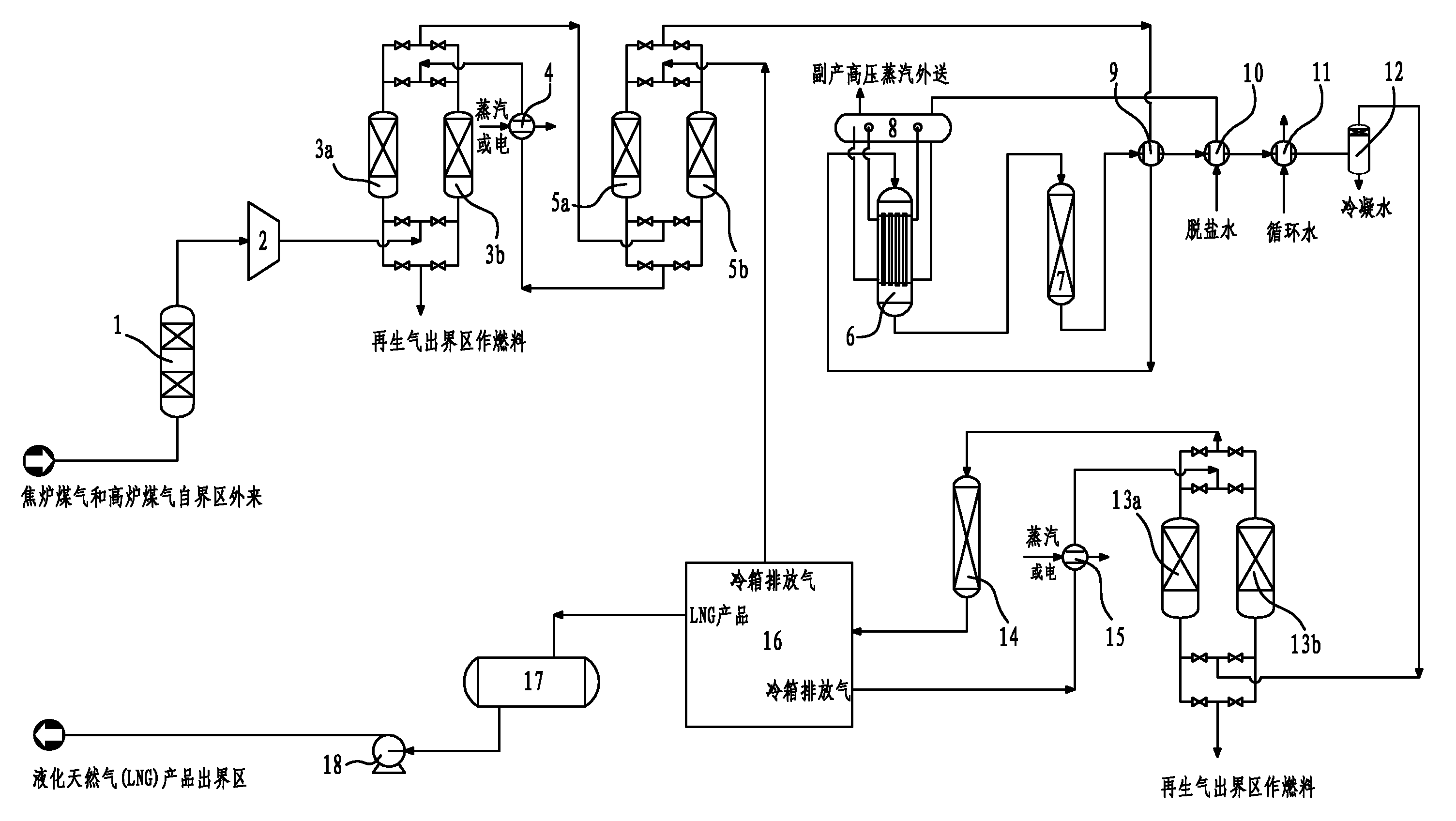

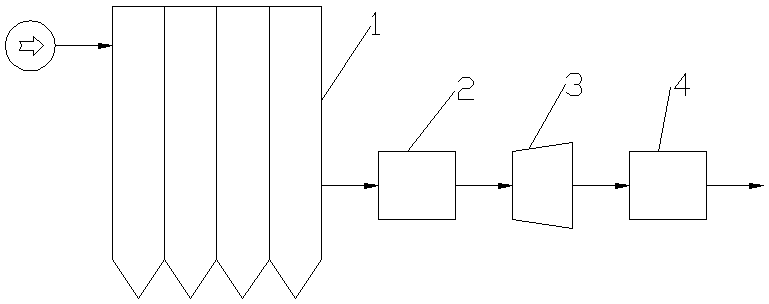

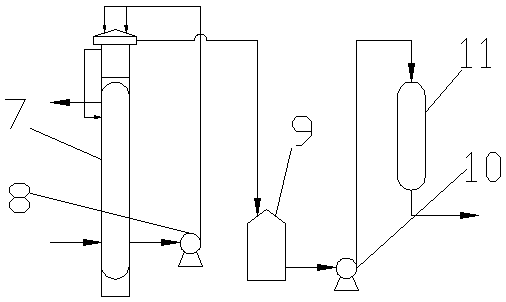

Method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas

InactiveCN102250658AEasy to operateSimple processGaseous fuelsGas purification with selectively adsorptive solidsMethanationImpurity

The invention discloses a method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas. In the technology, the coke oven gas and the blast furnace gas are taken as the raw materials, the raw materials are subjected to normal-temperature normal-pressure dry desulfurization, gas compression, gas adsorption purification, gas isothermal-adiabatic serial methanation, gas adsorption drying and demetalization, freezing liquefication separation and other technical processes, and high-quality liquefied natural gas with the purity of over 99 percent is produced. By the technology, harmful impurities such as sulfur, naphthalene, tar, benzene, mercury and the like in the gas can be efficiently and easily removed fully at low cost, and components with low value, such as H2, CO, CO2 and the like are completely converted into required CH4 component with high value, so the method has the characteristics of low requirement on quality of feed gas, high yield of liquefied natural gas product, high product purity, low production energy consumption, no environmental pollution, reliable flow, low investment, simple operation and good economic benefit.

Owner:SHANGHAI HANXING ENERGY TECH

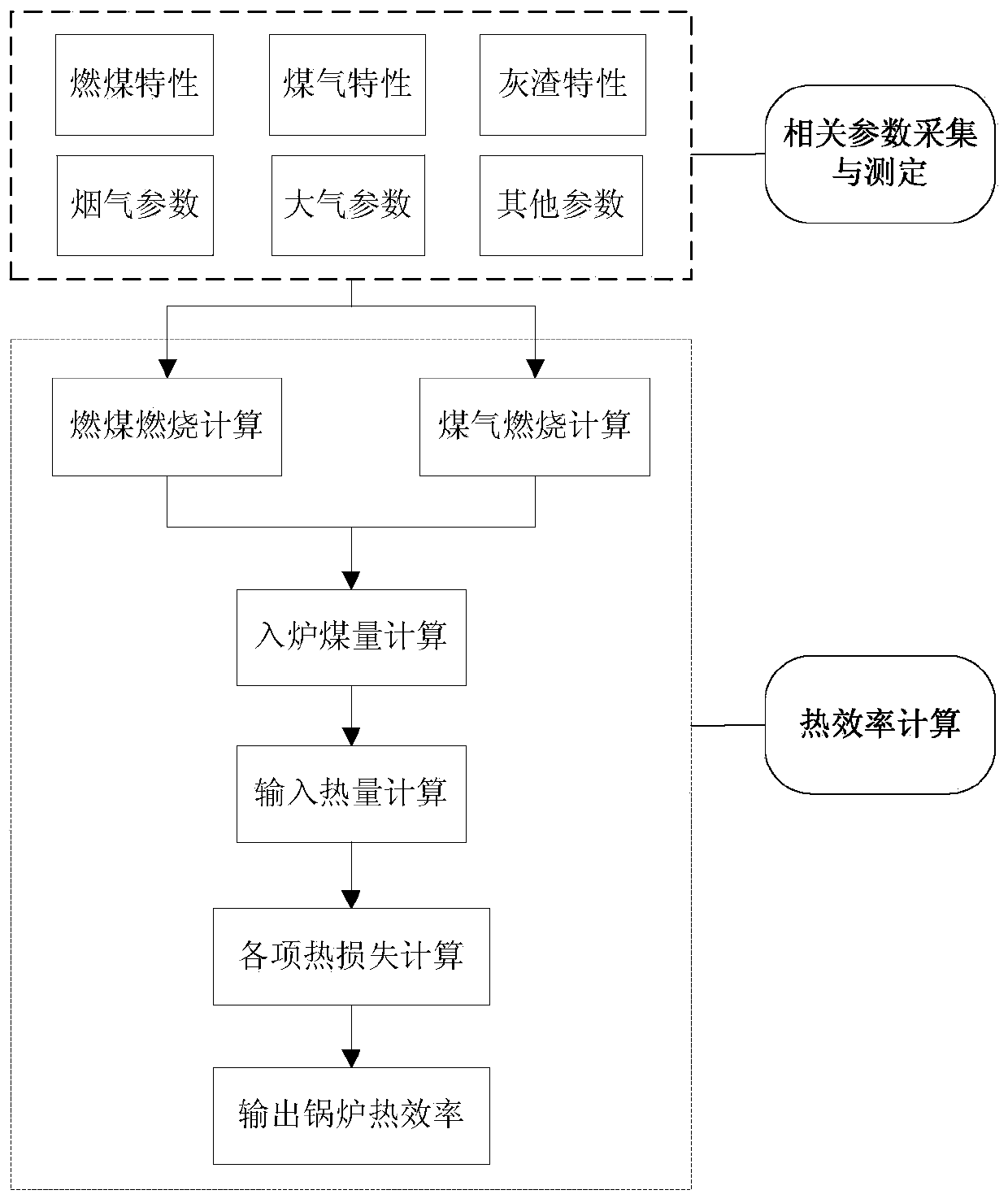

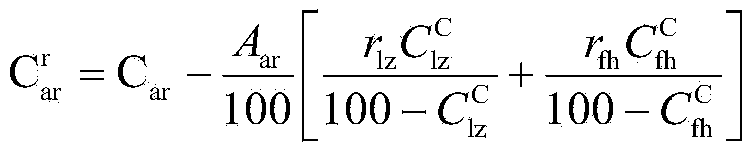

Method for calculating thermal efficiency of coal dust and blast furnace gas co-combustion boiler

ActiveCN104008297ACalculations went wellAvoid errorsCombustion using gaseous and pulverulent fuelSpecial data processing applicationsCombustionCoal dust

The invention discloses a method for calculating thermal efficiency of a coal dust and blast furnace gas co-combustion boiler. The method is designed against the problem that in configuration in the prior art, boilers of storage type coal pulverizing systems cannot accurately obtain the boiler inlet coal quantity under the corresponding working conditions when the thermal efficiency of the boilers is calculated. The method for calculating the thermal efficiency comprises the steps of collection and measurement of relevant parameters, fire coal combustion calculation, gas combustion calculation, boiler inlet quantity calculation, boiler inlet coal quantity calculation, input heat calculation, calculation of various heat losses and thermal efficiency calculation of the boiler. According to the method, the thermal efficiency calculation of the boiler is performed by accurately calculating the boiler inlet coal quantity, main adverse factors influencing the boiler thermal efficiency are found out by analyzing boiler thermal efficiency calculation results, guidance is provided for modification and optimized running of the boiler, and the goal of energy saving and consumption reduction is achieved.

Owner:HUATIAN ENG & TECH CORP MCC

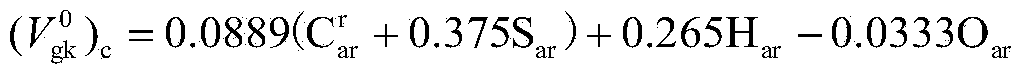

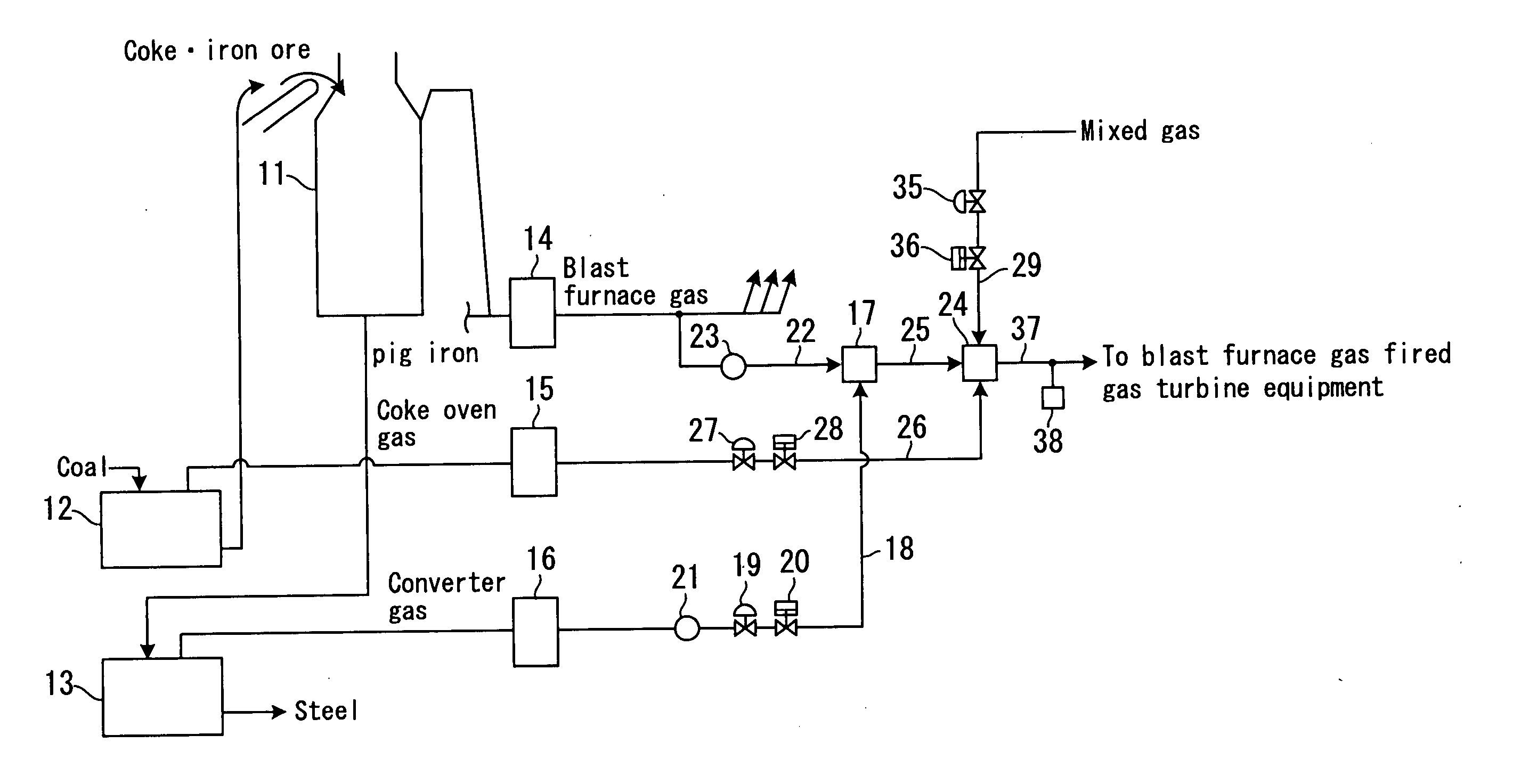

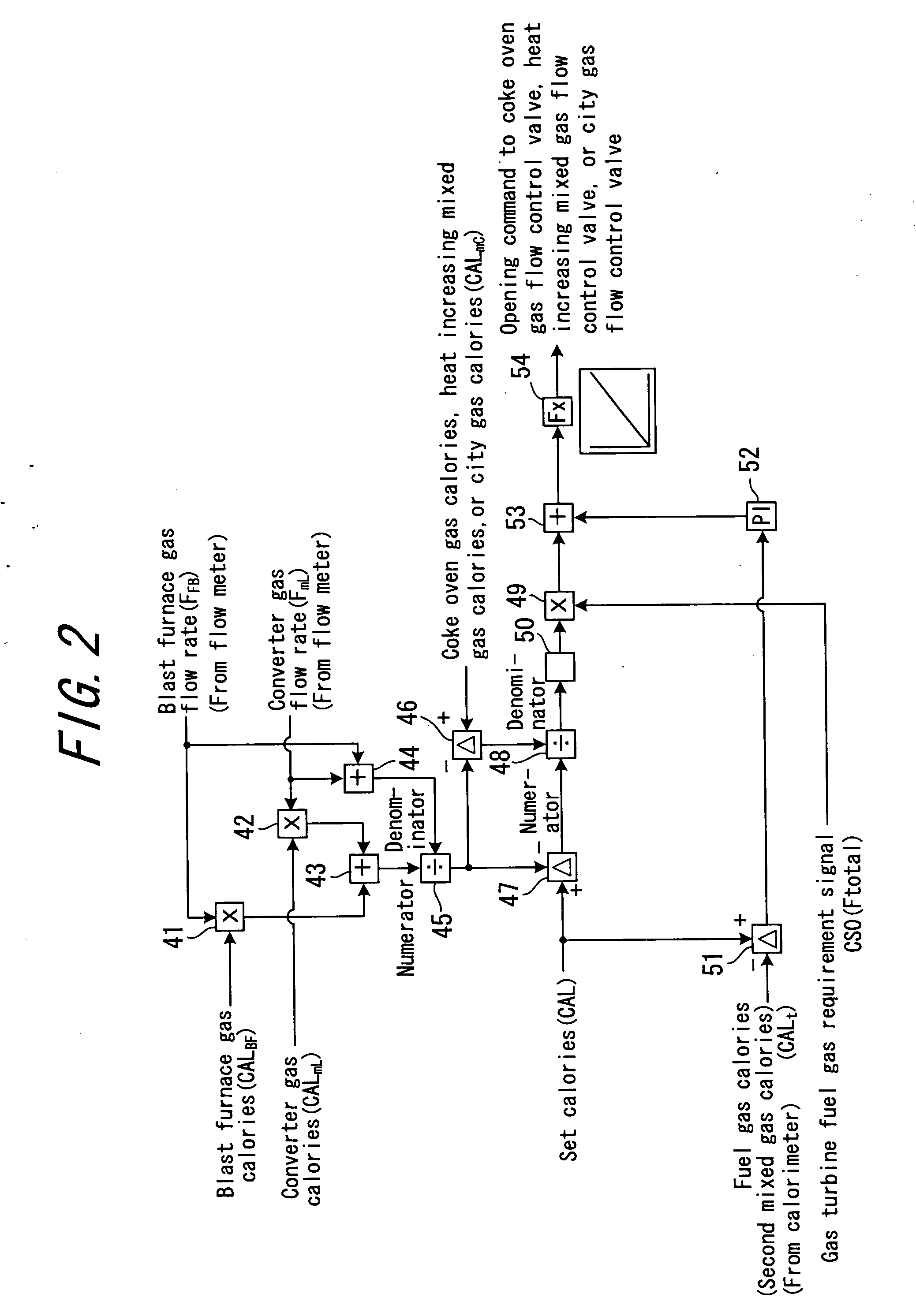

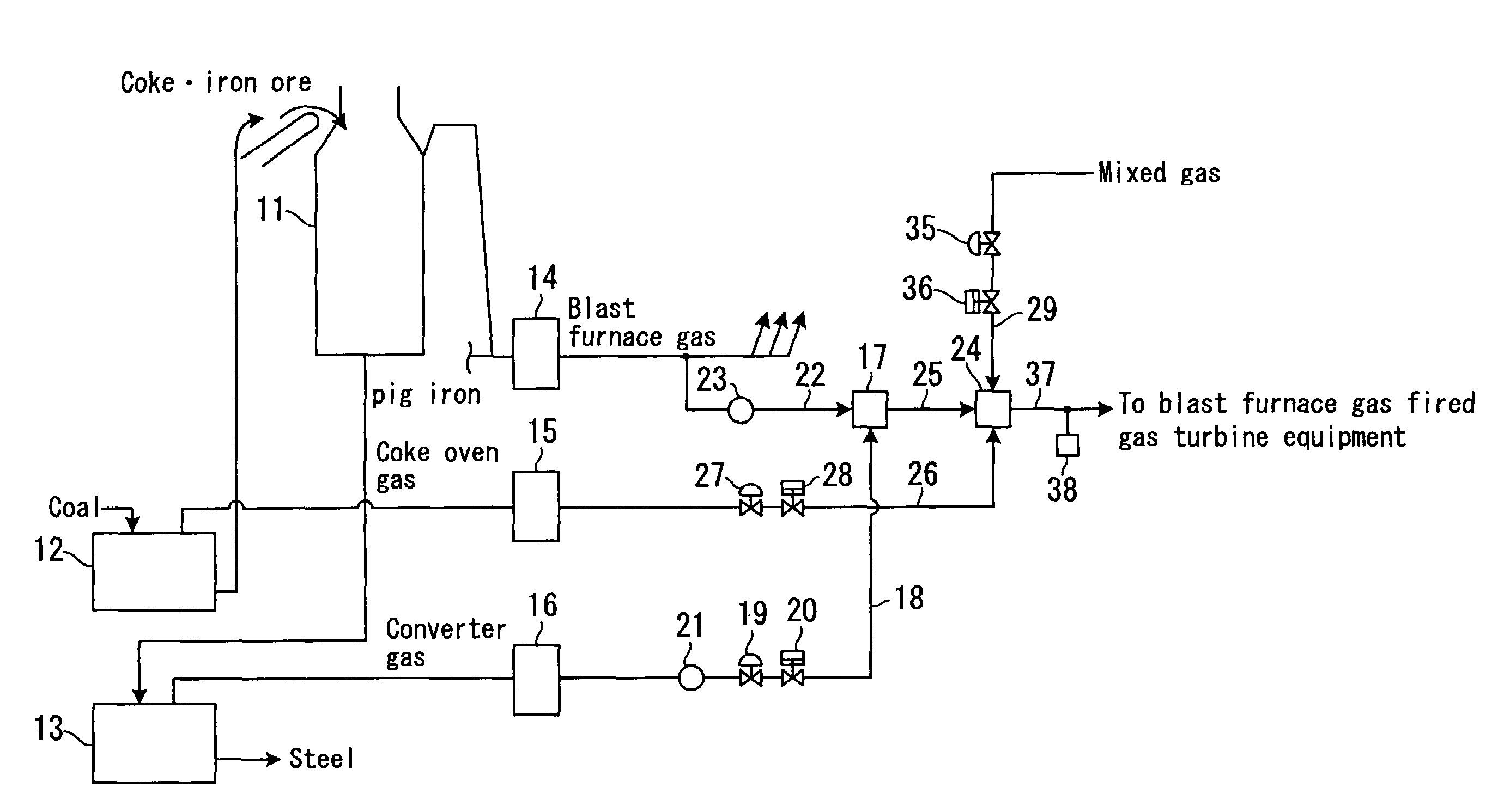

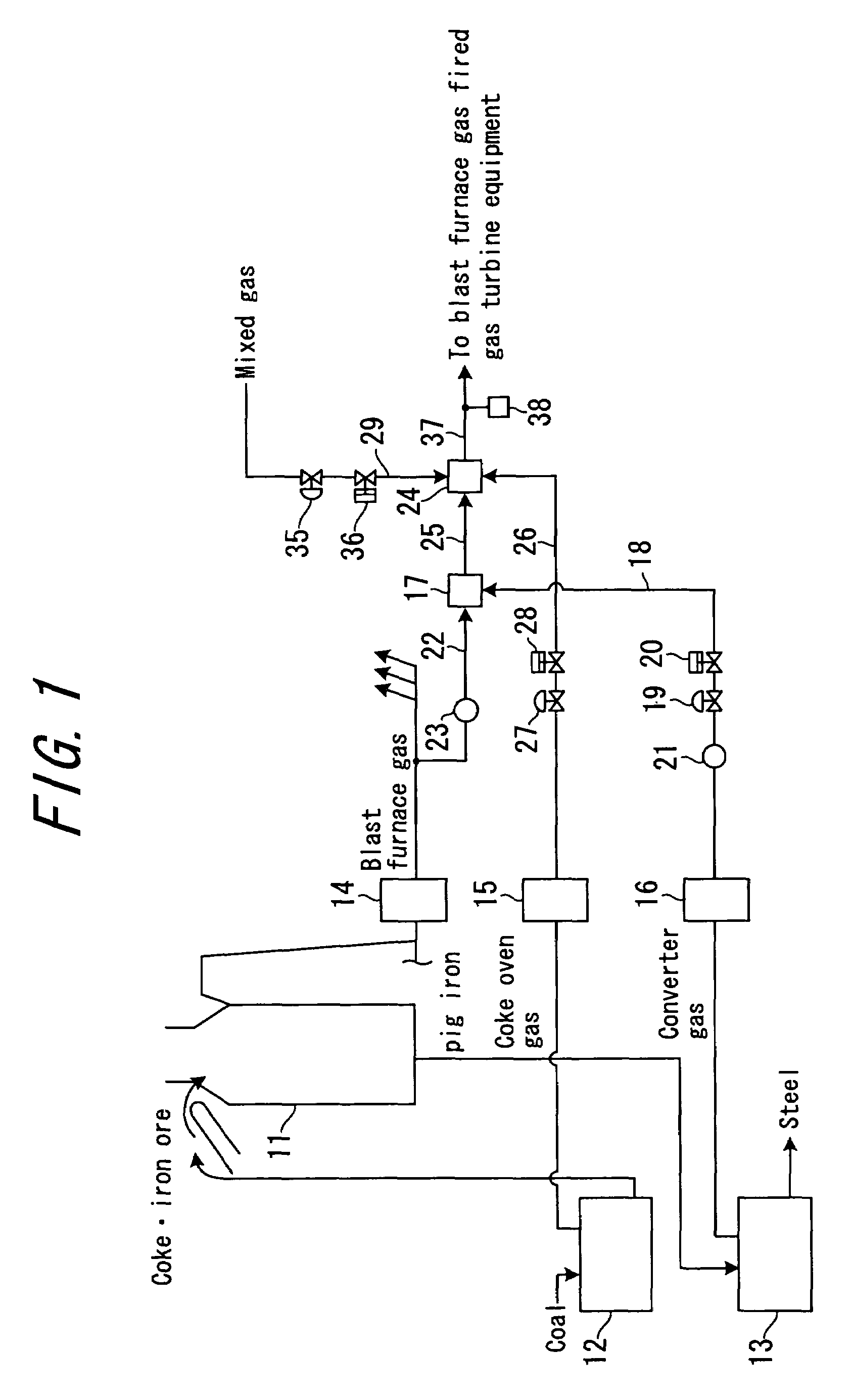

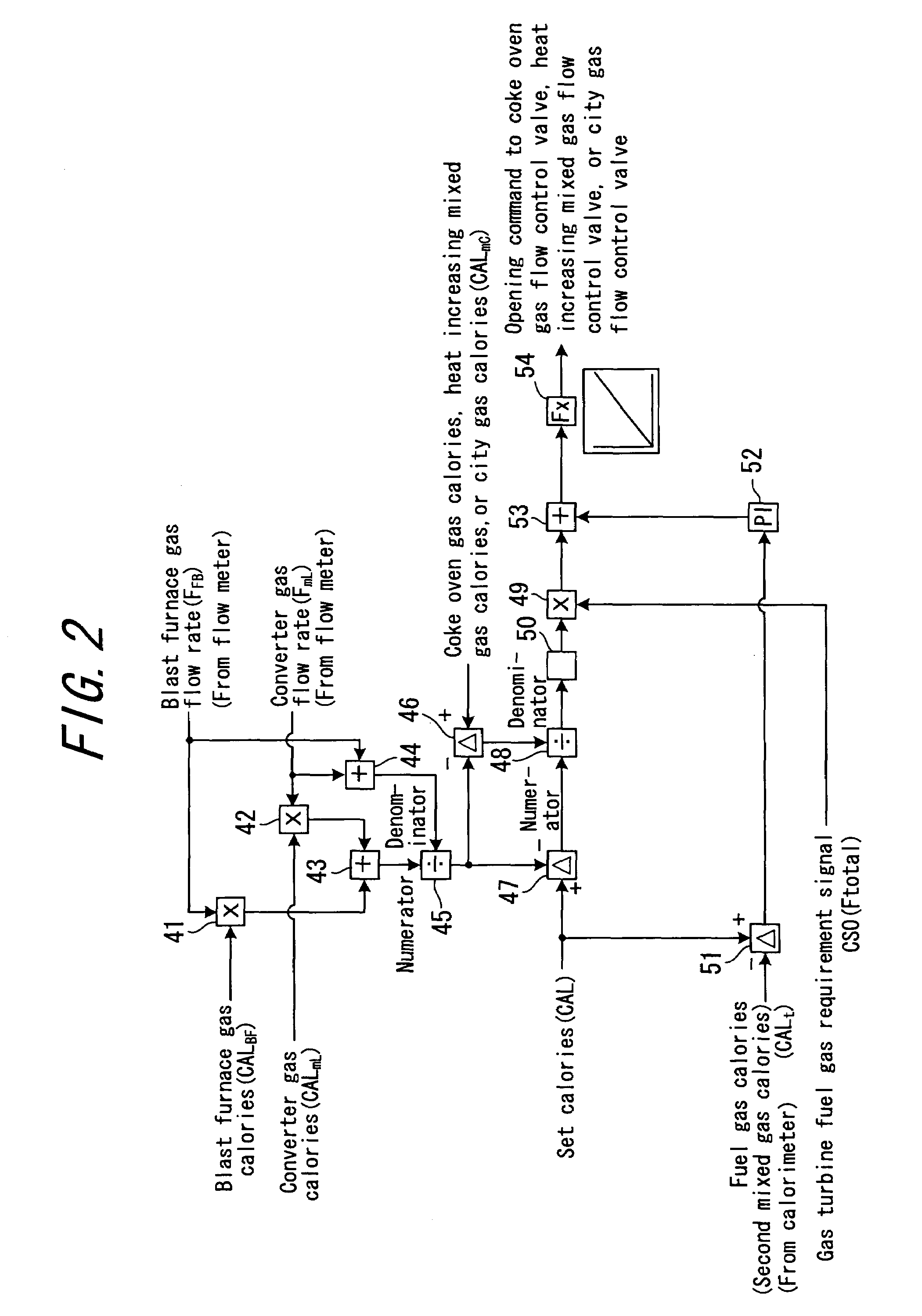

Fuel gas calorie control method and device

ActiveUS20060234171A1Excessive mixingEasy to controlBurnersGas modification by gas mixingMixed flowEngineering

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

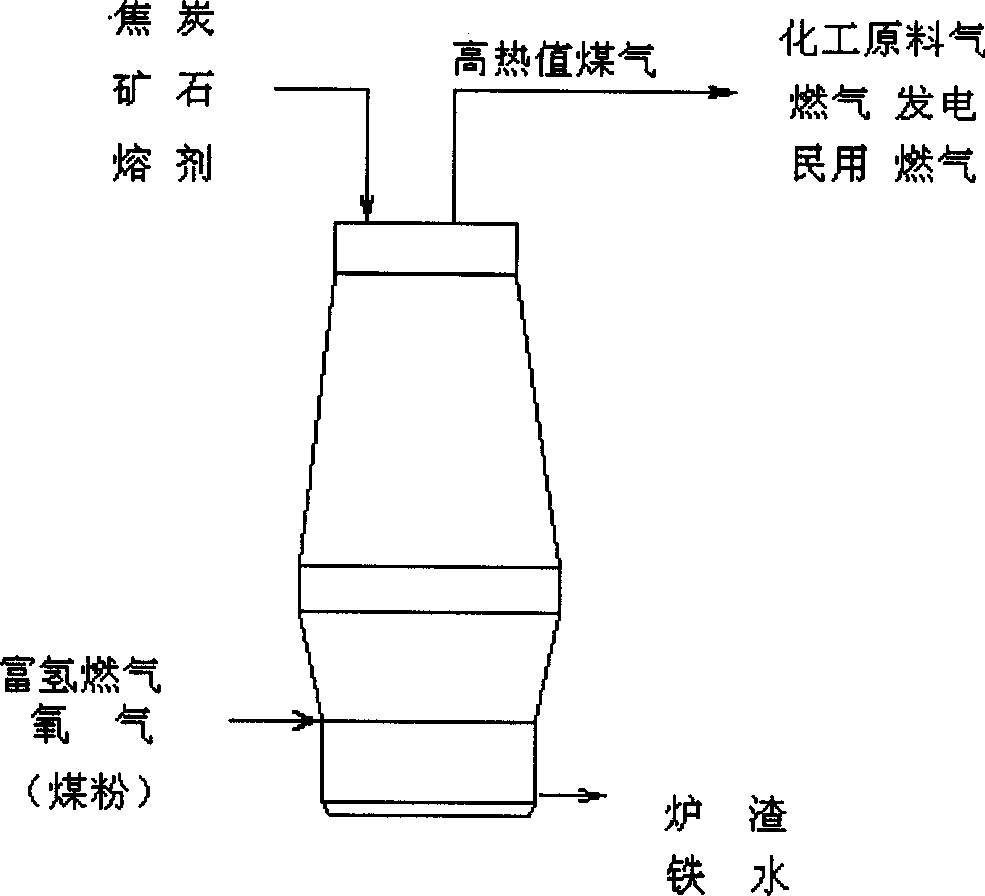

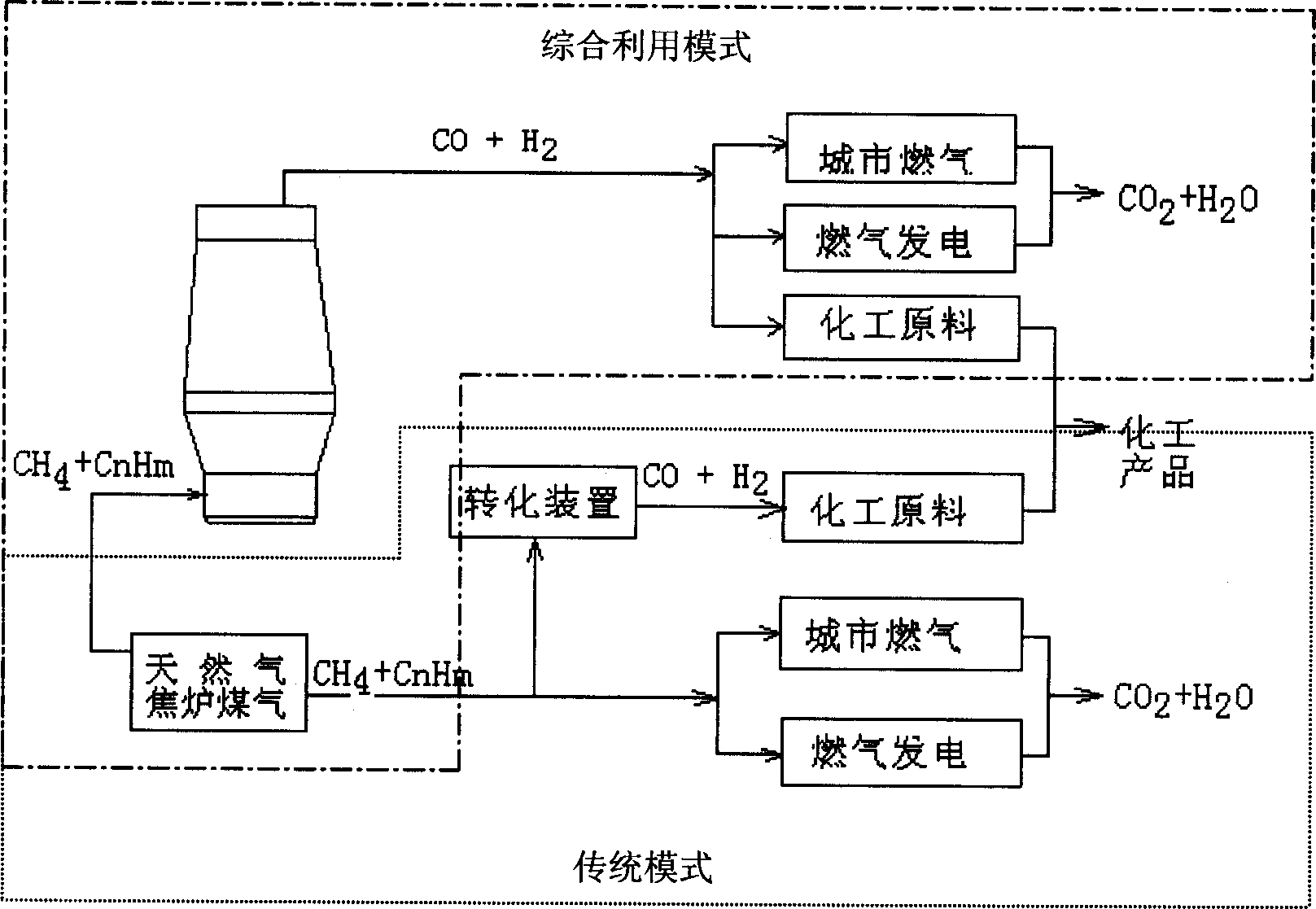

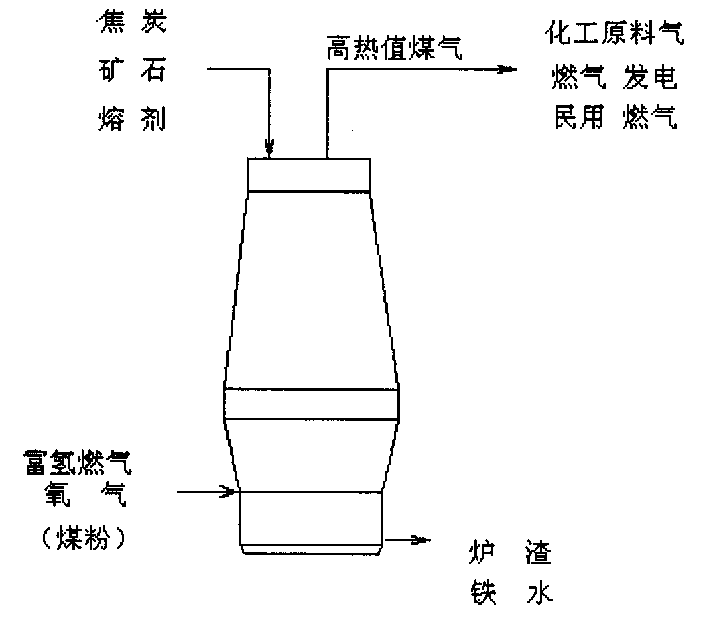

Blast furnace iron-making technique with hydrogen-rich fuel gas, pure oxygen and thus high efficiency and low CO2 exhaust

InactiveCN1487097AReduce focal ratioSolving the Contradiction of Insufficient Heat in the Upper Part of the Blast Furnace due to Less Blast Furnace GasBlast furnace detailsHydrogenCoke oven

The blast furnace iron-making technique includes blowing hydrogen-rich fuel gas in the blast hole of blast furnace of amount 500-1000 cu m / ton iron; normal temperature pure oxygen blasting while eliminating traditional hot blast furnace; gas in bosh containing H2 in 30-60 % except CO; gas in hearth top connecting CO+H2 in 85-95 %; and controlling the theoretic combustion temperature in 1800-2200 deg.c. The blast furnace iron-making technique can lower the blast furnace in 1800-2200 deg.c. The blast furnace iron-making technique can lower the blast furnace coke ratio to below 250 Kg / ton iron, lower CO2 exhaust by 400-600 Kg / ton iron and produce high heat value gas capable of being used as secondary energy source.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for recycling iron from waste red mud in alumina production

InactiveCN103074456AHigh recovery rateGood quality pig ironBlast furnace detailsProcess efficiency improvementRed mudSlag

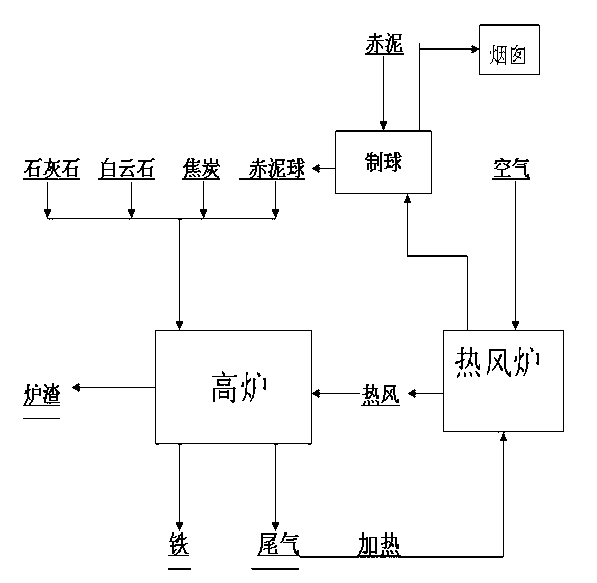

The invention relates to a method for recycling iron from waste red mud in alumina production. The method is characterized in that waste red mud in alumina production is dried, the moisture content after drying ranges from 1% to 10%, the particle size of the smashed red mud is less than or equal to 0.15mm, and the red mud is manufactured into pellets of 15mm to 50mm under the pressure ranging from 10kN to 70kN. Heat produced by blast furnace gas burning is used to dry the red mud pellets to be with a moisture content less than or equal to 1%, then the dried red mud pallets, coke, limestone and dolomite are mixed according to the proportion and added into a blast furnace to be smelted directly, finally the mixture is separated through iron slag to obtain metallic iron and slag, iron can directly serve as a steel-making material, and the slag can be recycled for subsequent comprehensive utilization. According to the method, industrial waste serves as a main material, environmental pollution is reduced, and the waste can be recycled; and the method has the advantages that the quality of the recycled iron is good, the iron recovery rate is high and can achieve more than 98%, the technological process is simple, the production is easily achieved, and tailings after iron removal are easily processed.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

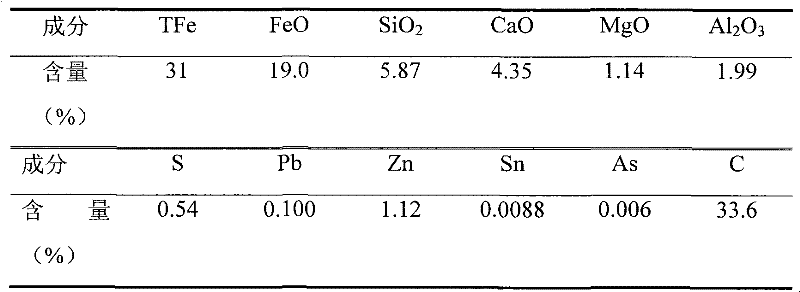

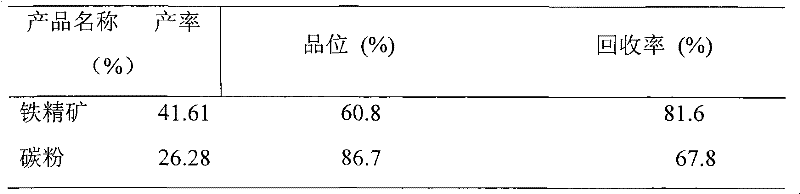

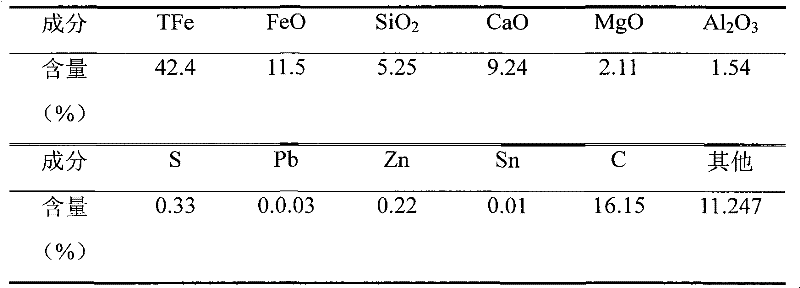

Technology for recovering iron ore concentrate and coke powder from blast furnace gas dust or gas sludge

InactiveCN102392125AHigh recovery rateThe process is simple and continuousFlotationProcess efficiency improvementSludgeMagnetization

The invention relates to a technology for recovering iron ore concentrate and coke powder from blast furnace gas dust or gas sludge, characterized by using coke carried by the gas dust (sludge) as a reducing agent, carrying out magnetization roasting on the gas dust (sludge), converting the weak magnetic iron ore in the gas dust (sludge) into strongly magnetic mineral, then recovering through magnetic separation, and recovering excess carbon powder through flotation. The technology comprises the following main steps: 1) sending the dried gas dust (sludge) in a furnace, and carrying out reduction magnetization roasting; 2) carrying out wet grinding and weak magnetic separation on the roasted gas dust (sludge) to obtain the iron ore concentrate; and 3) carrying out flotation on the magnetically selected tailings to obtain the coke powder. The technology has the advantages of simple and continuous process, low energy consumption, and high recovery rate of iron and carbon, and realizes the comprehensive utilization of the gas dust (sludge).

Owner:INNER MONGOLIA UNIV OF SCI & TECH

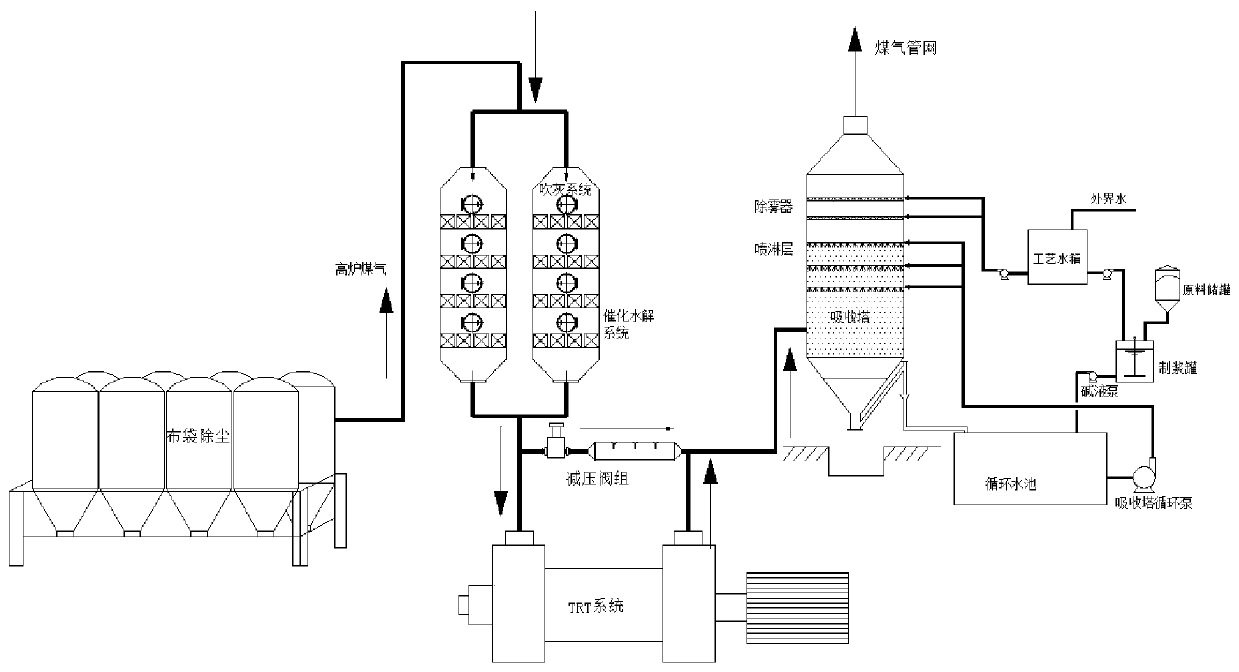

Fine desulfurization process for blast furnace gas

InactiveCN110643395ALow running costLittle resistance lossEnergy inputGas purification by catalytic conversionThermodynamicsDust control

The invention provides a fine desulfurization process for blast furnace gas, and belongs to the technical field of gas desulfurization. The process specifically comprises the following steps that blast furnace gas enters an organic sulfur hydrolysis system after being subjected to bag dust removal; and the hydrolyzed gas enters a top pressure recovery turbine power generation device and then enters a wet alkali washing desulfurization system. The organic sulfur hydrolysis system comprises a hydrolysis reactor and an acoustic wave soot blowing system, and the wet alkali washing desulfurizationsystem comprises an absorption tower, a circulating water tank, a circulating water pump, an alkali liquor storage tank, an alkali liquor pump, a process water tank and a process water pump. The process can effectively reduce resistance loss caused by the hydrolysis system and save large operation cost for enterprises.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

Device and method for top gas enrichment utilization of blast furnace

InactiveCN102220443AReduce cloggingAvoid damageBlast furnace detailsIncreasing energy efficiencyReduction rateEngineering

The invention relates to a device and method for top gas enrichment utilization of a blast furnace, in particular to a device and method for using top gas in a blast furnace production process, belonging to the field of smelting pig iron with the blast furnace. The device is characterized in that: a tee joint is arranged on a pipeline between a gas purifying and de-dusting system and an excess pressure power generation device; a gas pressurization device, a gasification furnace and a gas back-eject hole which is formed on the blast furnace are connected through the pipeline and a valve to form one way of the tee joint; the gasification furnace is provided with an oxygen supply pipeline and a coal blending device; the enriched gas, after being pressurized, enters the gasification furnace and is subjected to gasification reaction with oxygen and powder coal in the pressurized gasification furnace; a reaction product is ejected into the blast furnace for smelting iron through the back-eject hole which is formed on the blast furnace; the excess pressure power generation device is respectively connected with a hot blast heater, a power plant boiler pipeline and a valve through a gas distributor to form another way of the tee joint; and the generated hot air is fed into the blast furnace through a nozzle. The device has the advantages of novel conception, simple process flow, easiness in implementation, safety and reliability in operation and capabilities of increasing the calorific value of gas, ejecting back to smelt iron, increasing the indirect reduction rate, reducing the coal ratio, reducing blast furnace slag and CO2 emission, regulating and controlling the width of a cohesive zone of the blast furnace, ensuring long-term smooth running of the blast furnace, avoiding diffusion of the top gas, saving energy and contributing to environment friendliness.

Owner:MAANSHAN IRON & STEEL CO LTD

Iron-containing zinc powder recycling process

InactiveCN104073649AComplete restorationImprove thermal efficiencyProcess efficiency improvementShaft furnaceSteelmakingHigh energy

The invention discloses a recycling process of iron-containing zinc powder generated in an iron and steel process. The process comprises the following steps: mixing dried iron-containing zinc powder with a binder, and pelletizing by a pelletizer to obtain green balls; feeding the green balls into a shaft furnace and heating to 1100-1300 DEG C; reducing iron in the shaft furnace to sponge iron; converting reduced zinc at high temperature into zinc steam which is discharged out of the shaft furnace with coal gas and enters into a two-stage dedustor; and feeding dedusting mud obtained from the dedustor into a settling pond, and filtering, settling, thickening and drying to obtain zinc powder. The iron-containing zinc powder mainly comprises blast furnace gas ash, gas mud, dedusting ash, converter steelmaking dust and continuous casting steel rolling scrap iron generated in the iron and steel production. By adopting a treatment mode of the shaft furnace, the problem such as large rotary kiln equipment, low utilization ratio of in-kiln volume and high energy consumption is solved. Coal base is directly reduced at a high speed, and meanwhile, zinc in dust is further recovered.

Owner:WISDRI ENG & RES INC LTD

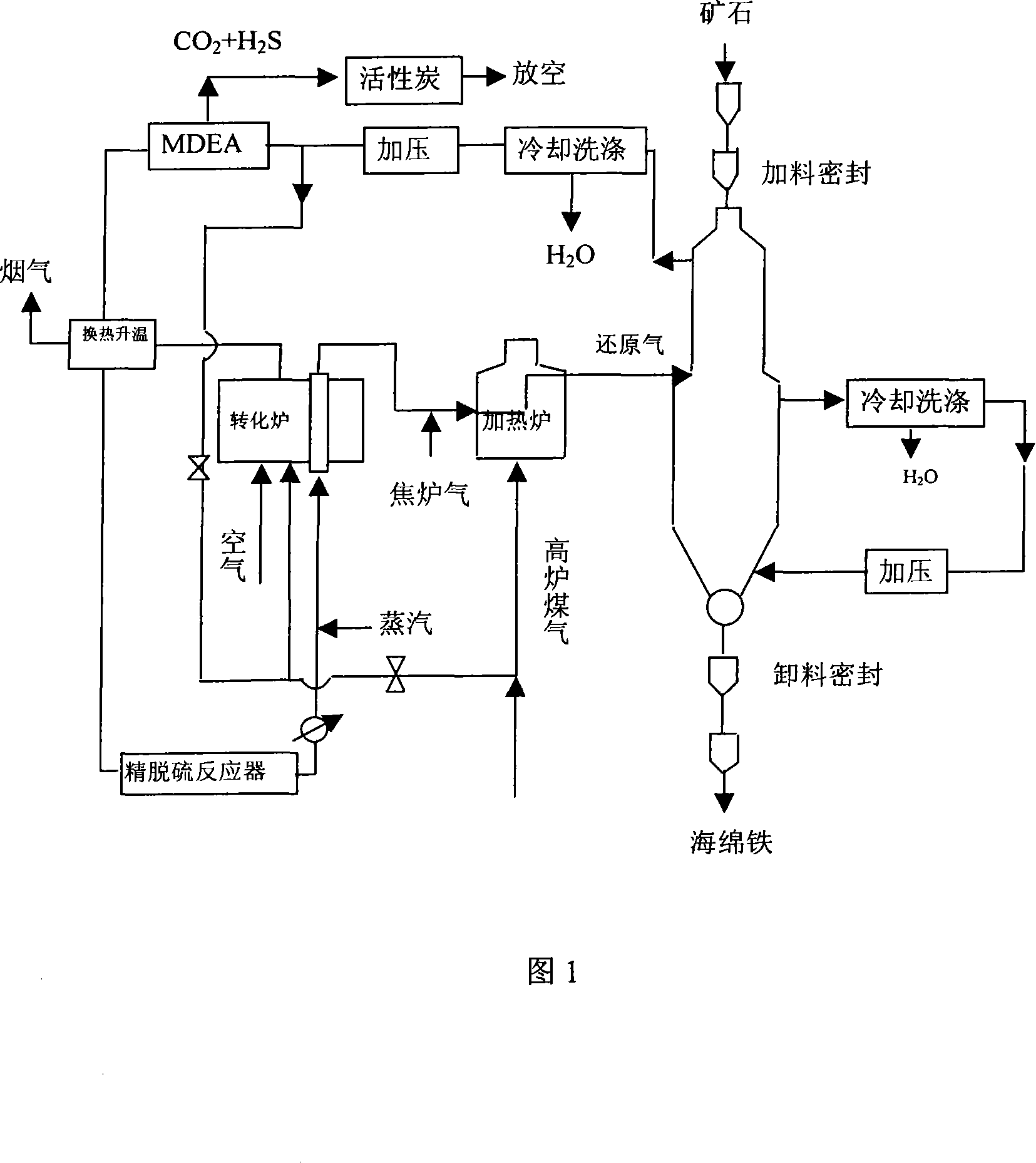

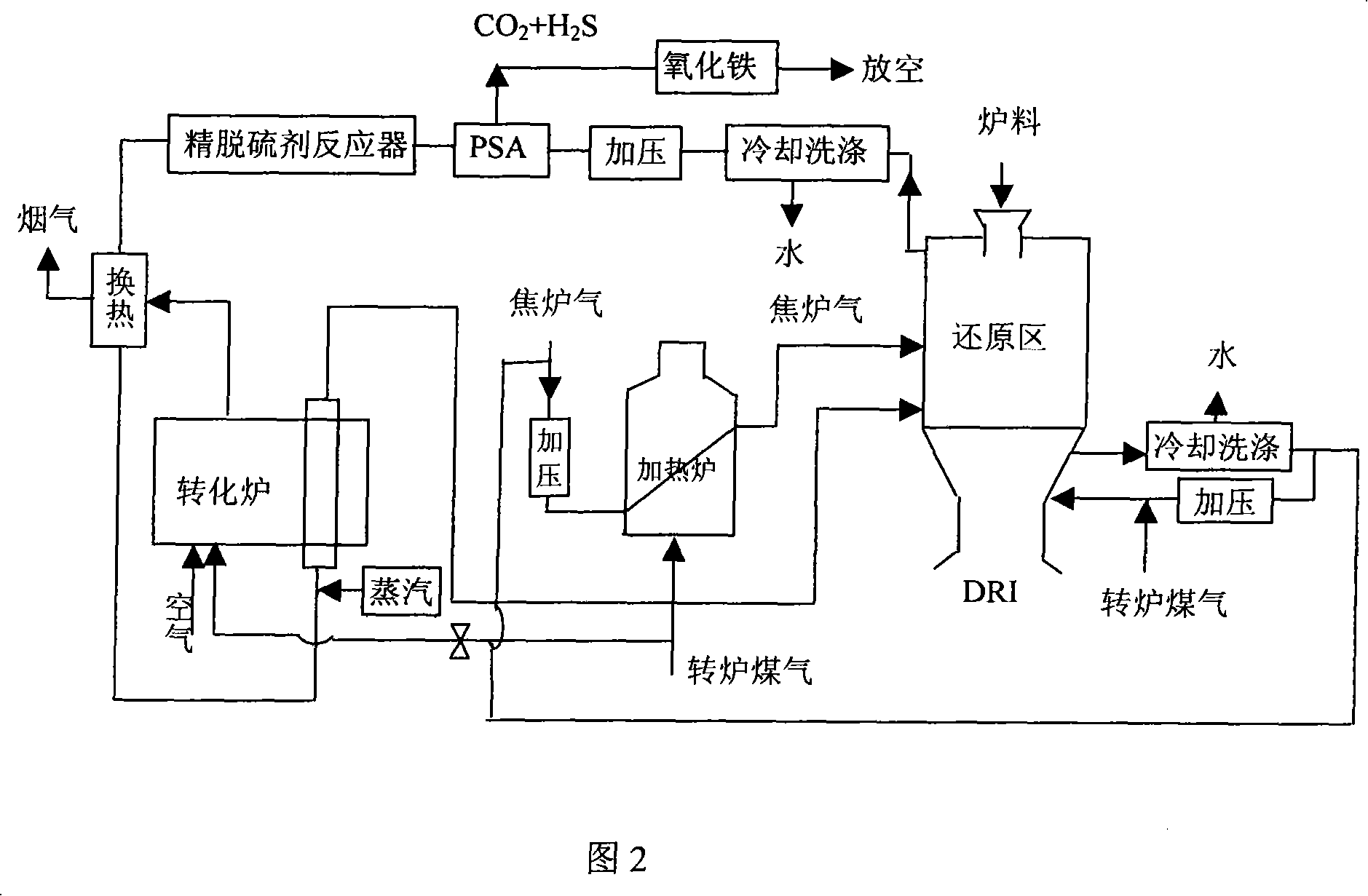

Method and device for producing sponge iron by using reducing gas prepared from coke oven gas

An invention relates to production of sponge iron by using coke oven gas directly, carried out by: mixing purified blast furnace gas with converter gas and blast-furnace gas and one or two kinds of reduced off-gas as well, feeding into upper reduction zone of reactor of vertical shifting bed to reduce ores containing iron oxide, discharging after cooling down in cooling zone of a reduction furnace. End gas is treated by cooling, removing dust, dewatering and pressuring, separating acid gases and inert gases, and then de-sulfurizing, heating in a heat exchanging section to be fed into methane inverting section, feeding the inverted gas to the upper reduction zone said above. An apparatus concerned with the said process is involved. End gas can be used effectively to produce sponge iron at low cost and eliminate sulfur pollution. Methane inverting catalyst can be used durably.

Owner:张文慧 +1

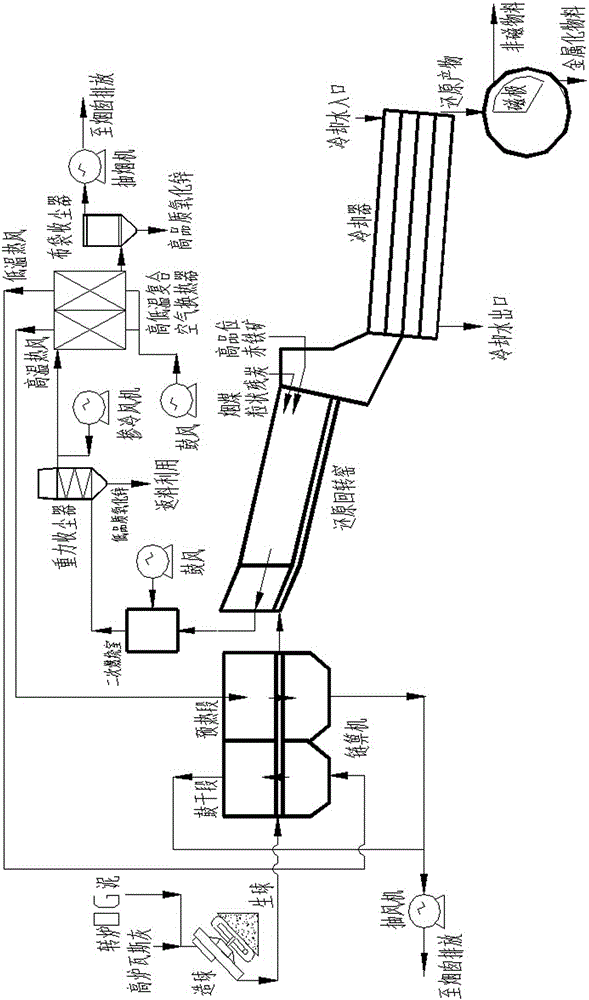

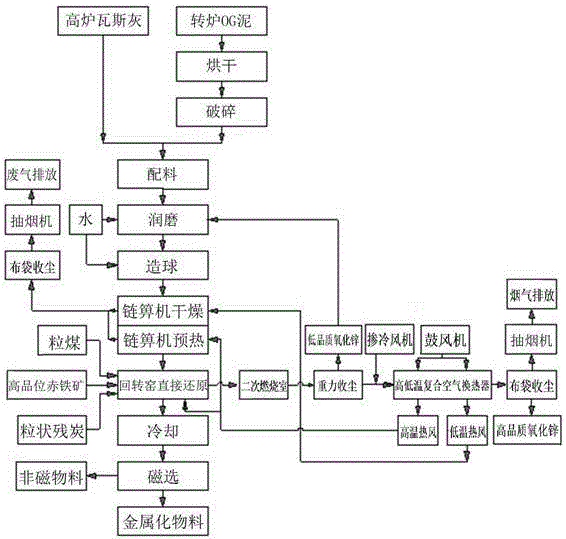

Method for treating high-zinc iron-containing slime through utilizing rotary kiln

ActiveCN106367600AEfficient use ofReduce loadRotary drum furnacesProcess efficiency improvementLarge particleMagnetic separation

The invention relates to a method for treating high-zinc iron-containing slime through utilizing a rotary kiln. The method comprises the steps that blast furnace gas ash and converter OG mud are mixed and pelletized; wet pellets are dried and preheated, and a drying and preheating heat source is hot air generated by high-temperature flue gas of the rotary kiln after passing through a high-low temperature composite air heat exchanger; a pea coal spray gun, a carbon residue spray gun and an ore grain spray gun are arranged at a kiln head of the rotary kiln, and high-volatile matter coal, residual carbon and high-grade iron ore are sprayed into the kiln; the dried pellets are fed into the rotary kiln, and high-temperature metallized pellets are obtained after the dried pellets are subjected to direct reduction and high-temperature solidification in the rotary kiln; after being cooled to the normal temperature, materials like the metallized pellets and excess carbon residue are subjected to magnetic separation, and metallized pellets are obtained; and large-particle dust is removed from the high-temperature flue gas of the rotary kiln, the high-temperature flue gas enters the high-low temperature composite air heat exchanger to be cooled, the cooled flue gas enters a bag-type dust collector, and zinc oxide powder is recycled. According to the method, the high-zinc iron-containing slime generated by iron and steel enterprises is efficiently utilized, and environmental pollution caused by stacking of the high-zinc iron-containing slime is solved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

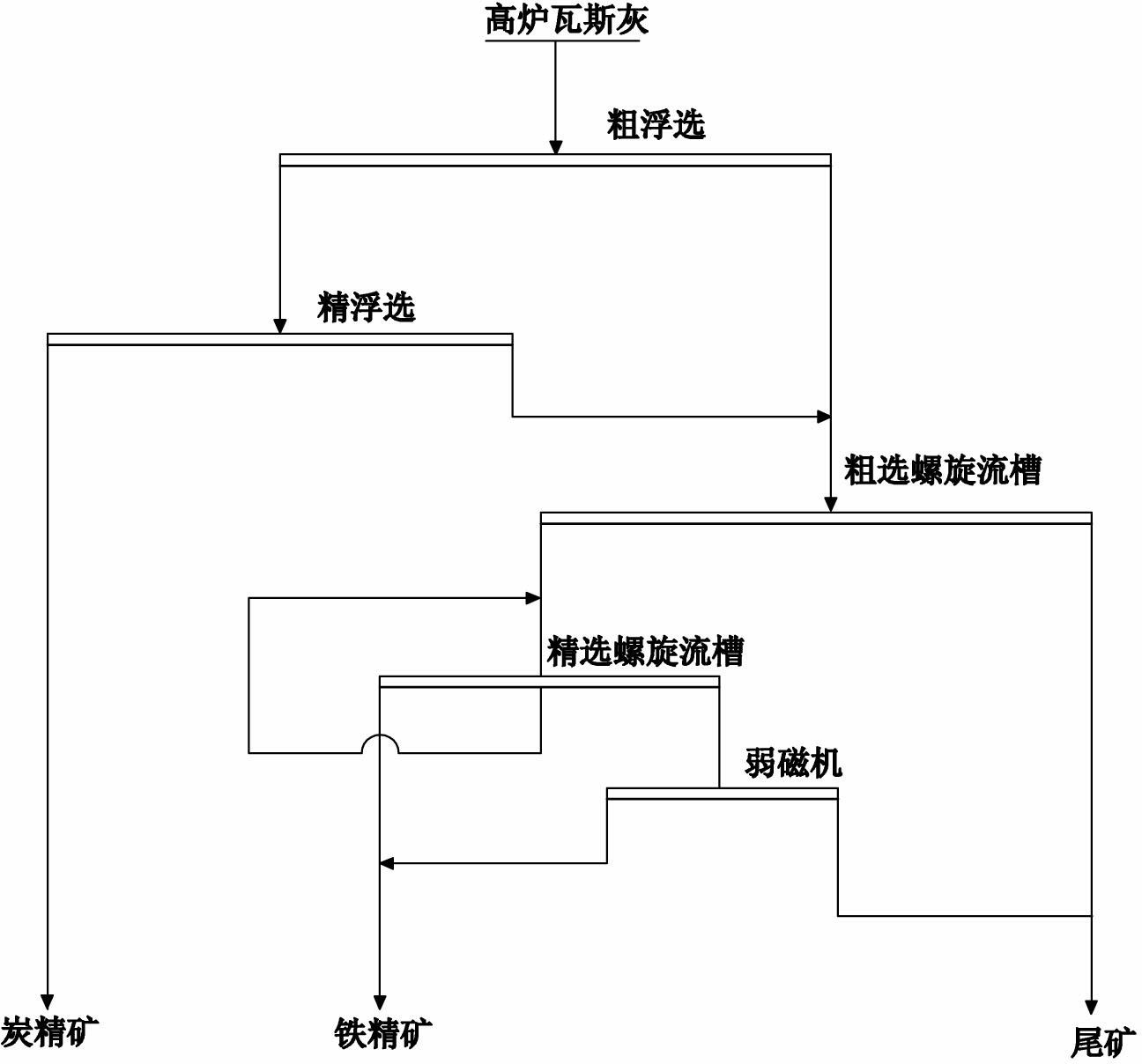

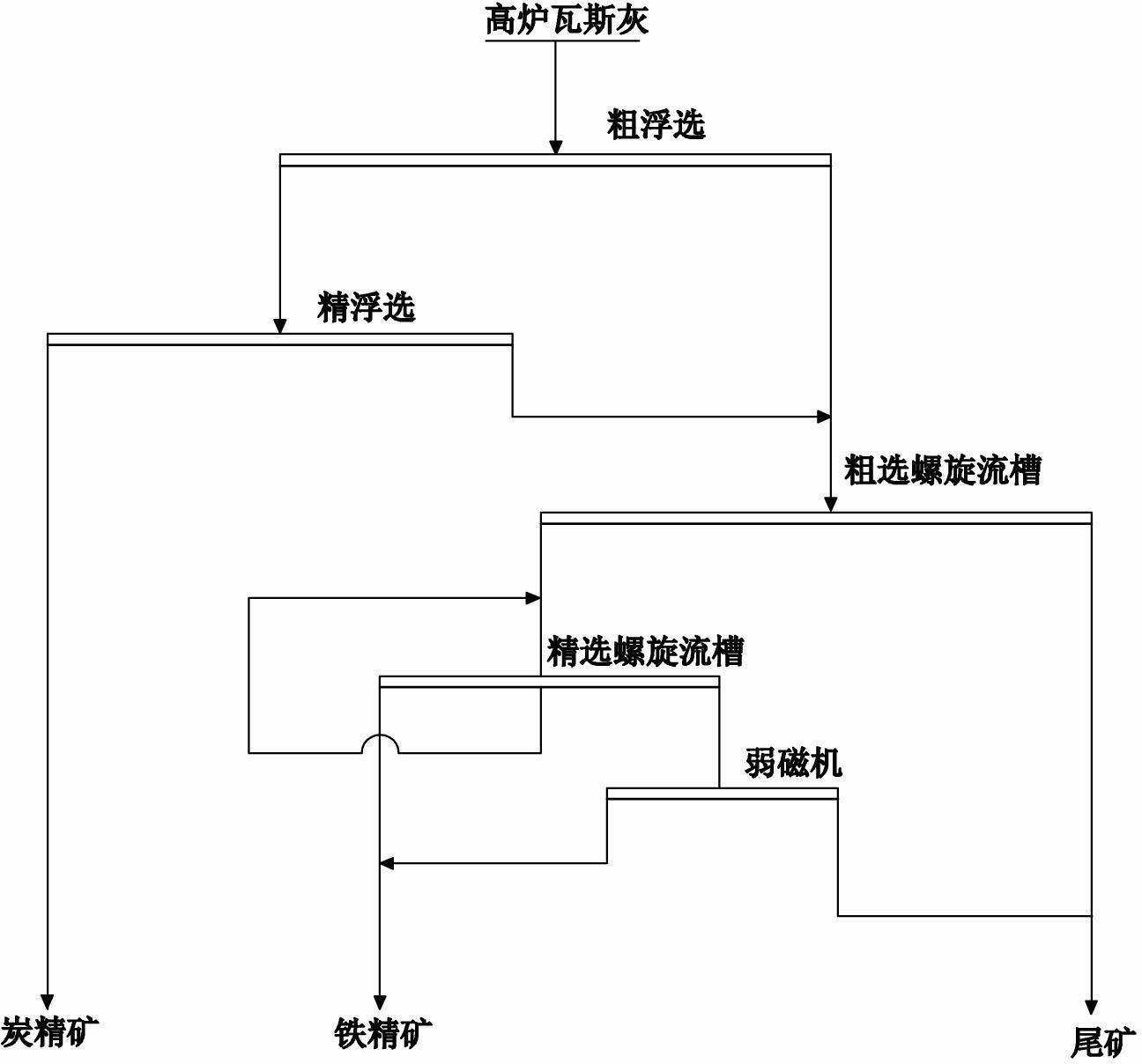

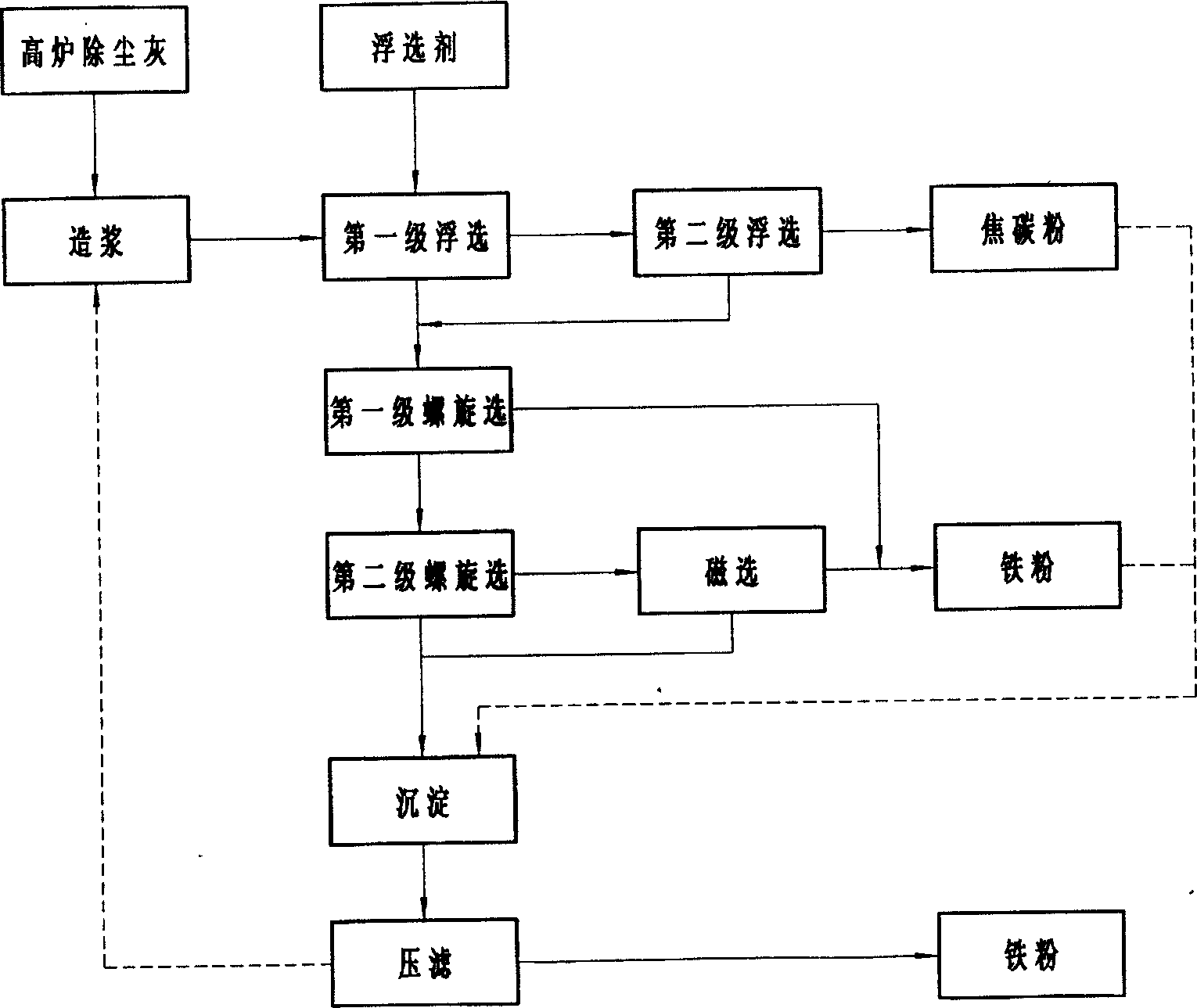

Process for recovering iron and carbon elements from blast furnace gas ash

ActiveCN102319617AGood enrichment and recovery effectHigh removal rateRecycling and recovery technologiesFlotationSlurryProcess configuration

The invention relates to the technical field of blast furnace ash resource reutilization, in particular to a process for recovering iron and carbon elements from blast furnace gas ash. A flotation method is adopted for recovering carbon, a re-separation and magnetic separation method is adopted for recovering iron, the total separation process is the combined technical process flow of flotation, re-separation and magnetic separation, the gas ash enters the coarse flotation after the slurry preparation and medicine adding, coarse flotation concentrates enter fine flotation, the fine flotation concentrates are final carbon concentrates, coarse flotation tailings and fine flotation tailings enter a re-separation coarse separation spiral chute to separate out re-separation tailings, the coarse spiral concentrates enter a fine separation spiral chute to obtain re-separation concentrates, ores in a fine separation spiral chute carries out self circulation, the tailings in the fine separation spiral chute enter a weak magnetic separation machine for carrying out magnetic separation, the weak magnetic concentrates and the re-separation concentrates are combined into final iron concentrates, and the weak magnetic tailings and the re-separation tailings are combined into final tailings. The process has the beneficial effects that the process is simple, the varieties of reagents are few,the process configuration is reasonable, the purification and impurity removal effects are obvious, the product quality is better, the recovery rate is high, and a new path is provided for the comprehensive utilization of the blast furnace gas ash.

Owner:ANSTEEL GRP MINING CO LTD

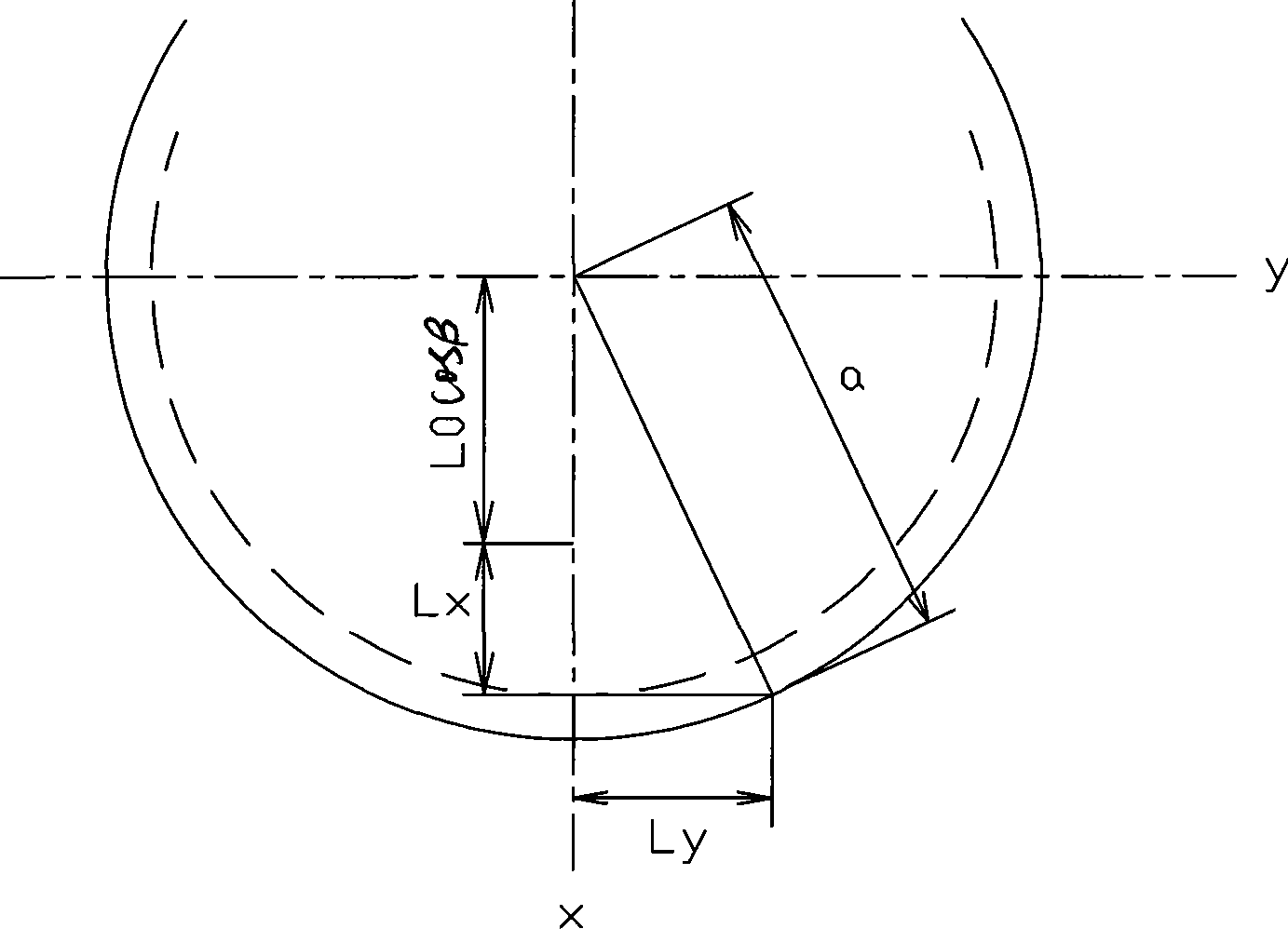

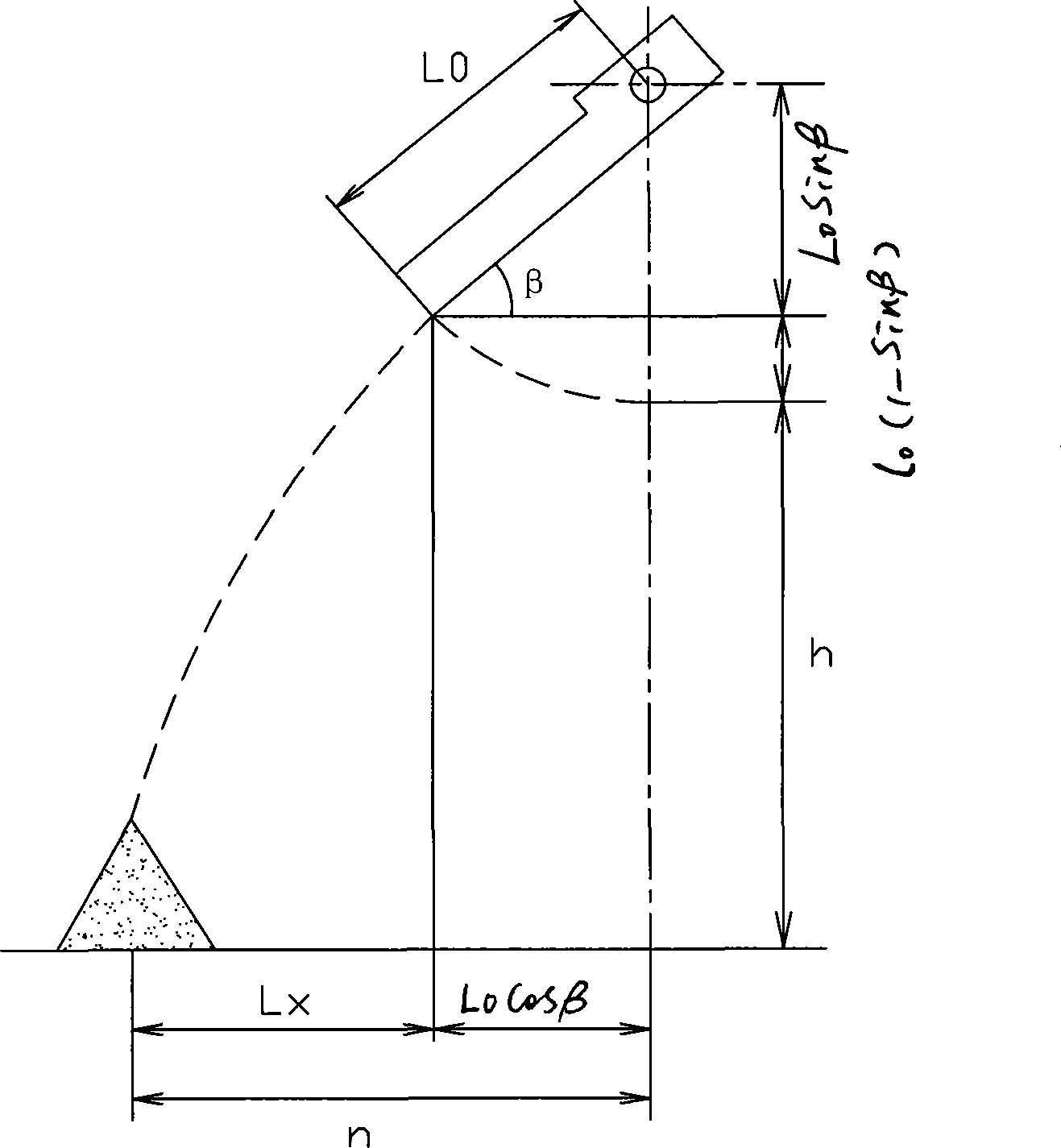

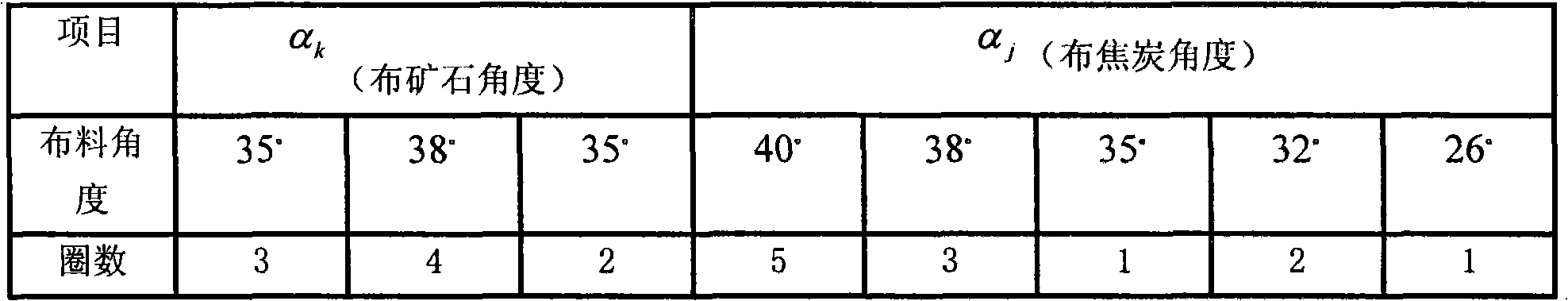

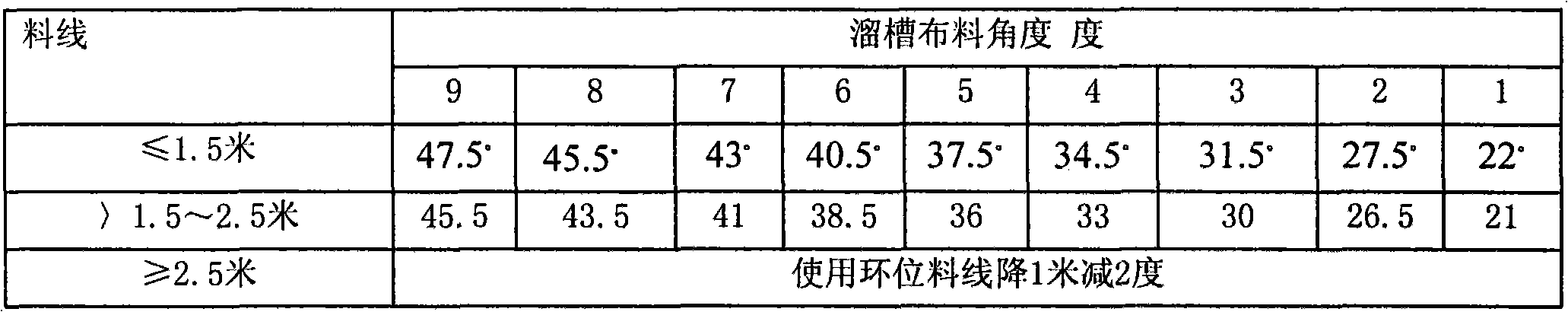

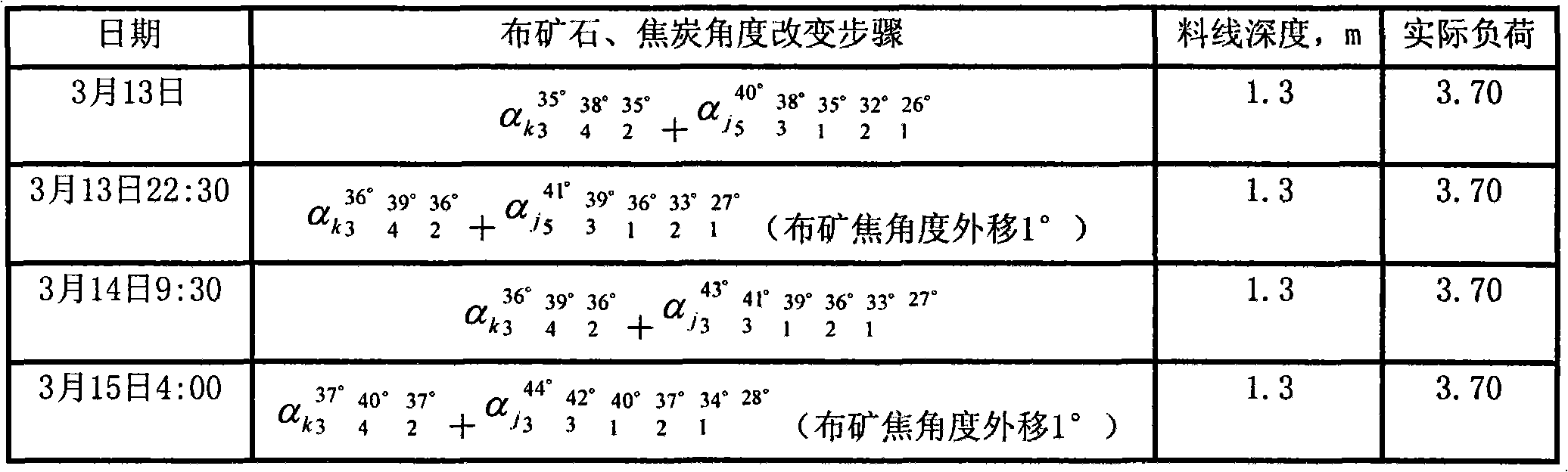

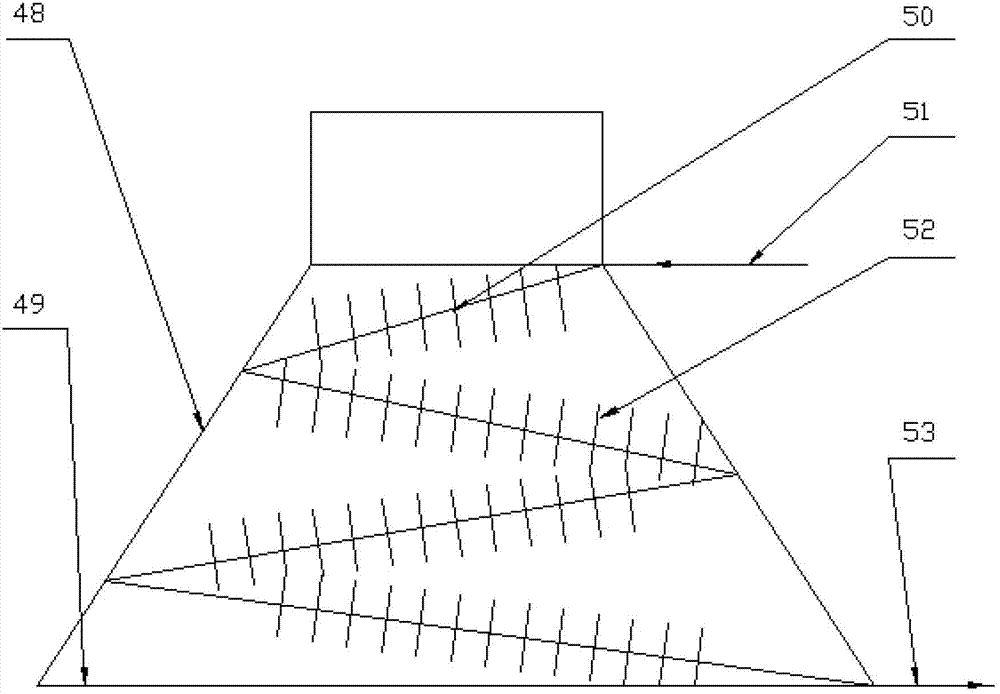

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Dust-separation zinc extraction method

InactiveCN101343693ATo achieve the purpose of turning waste into treasureImprove resource utilizationSolid waste managementProcess efficiency improvementResource utilizationWaste material

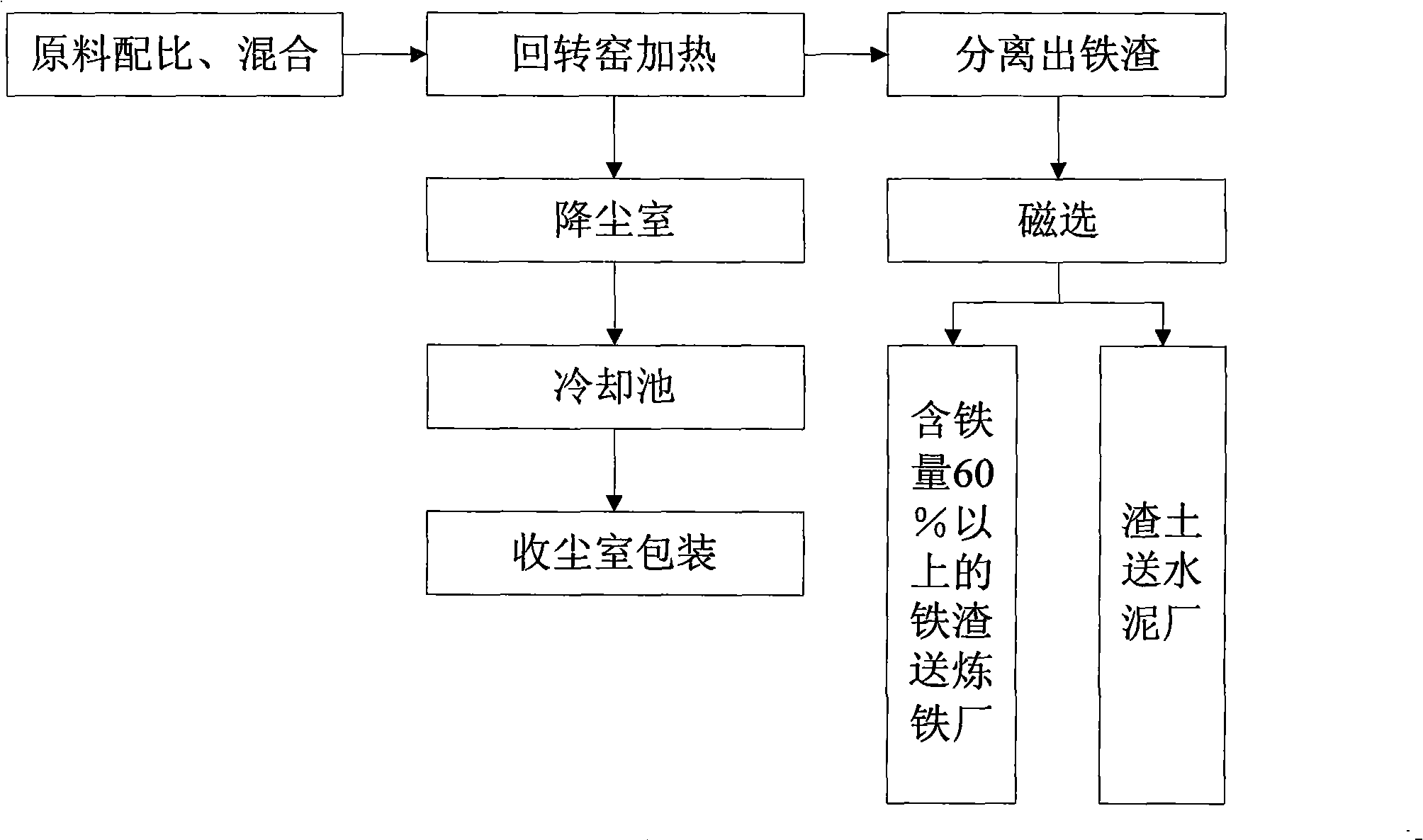

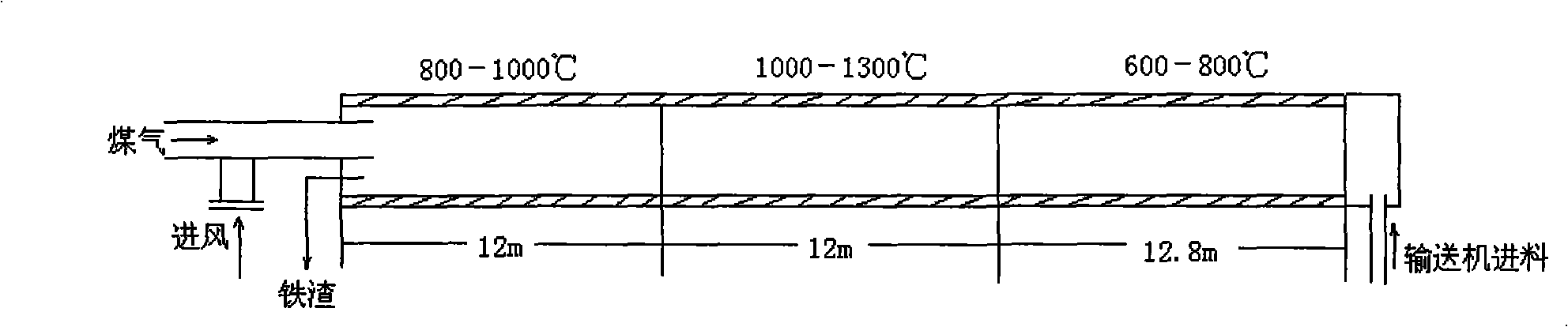

Disclosed is a dust removal and zinc extraction method. Raw materials are mixed and evenly stirred through a loader according to weight proportion, 30 percent to 40 percent of blast furnace dust removal ashes, 25 percent to 35 percent of power plant dust removal ashes, 25 percent to 35 percent of blast furnace gas slime, 5 percent to 10 percent of anthracite coal are evenly delivered to a rotary kiln to be heated for refining through a conveyor, then are delivered into a dedusting chamber to experience the atomization and separation, the raw materials are delivered into a cooling pond then and zinc oxide powder is forcedly sent into a dust collecting chamber by a suction blower, the dust is collected through a bag and is supplied to a zinc supply smeltery as the raw material. The iron residues separated in the heating and extracting process in the rotary kiln are magnetically separated through a magnet separator, the iron residues with the iron content of 60 percent are delivered to an iron smelting plant, and the residue soil is supplied to a cement plant as the raw material. The invention has the advantages that the iron residues and zinc powder are extracted and separated through adopting the processed waste material dust removal ashes in large-scale smelting enterprises, the purpose of changing wastes into valuables is realized, and the resource utilization rate is enhanced.

Owner:NANJING BANQIAO SLAG

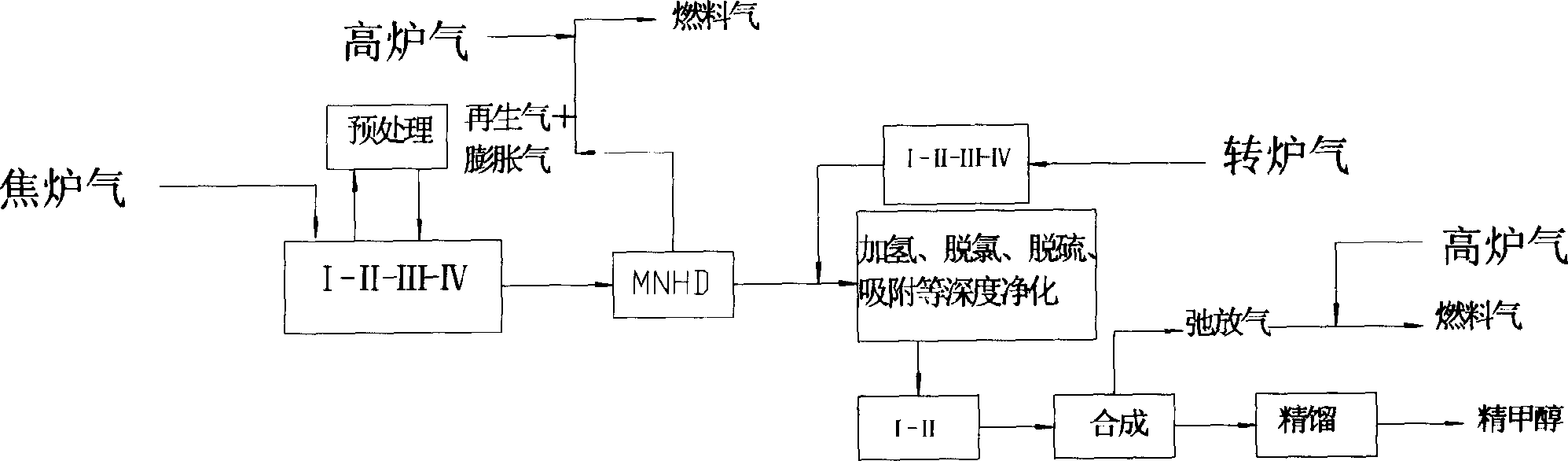

Process for preparing methanol by making steel enterprises coke oven gas and converter gas as raw material

InactiveCN1803746AMeet export requirementsHigh calorific valueOrganic compound preparationHydroxy compound preparationProcess engineeringCoke oven

The disclosed preparation method for methanol comprises: using treated and initial desulfurized coking gas from the iron and steel enterprise to mix directly with the converter gas or first extracting H2 or CO, or discharging gas for the methanol synthesis pond to recover H2 and then mix with the coking gas and converter gas to adjust into the composite gas fit to technical request with (H2-CO2) / (CO+CO2) ratio as 2.05~2.10. Wherein, recovering all produced tail gas to dope with blast furnace gas and prepare the fuel gas for enterprise. This invention realizes comprehensive utilization for the three gases.

Owner:昆山市迪昆精细化工公司 +1

Method for treating blast furnace dust

InactiveCN1699606ARaise the gradeImprove selection rateSolid waste disposalRecycling and recovery technologiesIron powderFiltration

The present invention discloses an ash removal method for blast furnaces. It belongs to metallurgical technology field. Its main characteristic is mixing blast furnaces ashes with water to make slurry. The slurry is separated to obtain coke powder of high grade through the first and second floatation separation. The slurry containing more iron from first and second floatation machine is pumped into the first and second spiral chute. After gravity selection, magnetic selection, the high grade iron powder is obtained. The waste water passes through pressure filtration to recycle fine iron powder. The filtrated water is reused to make slurry for blast furnaces ash removal. The present invention is used to treat dedusting ashes from blast furnaces. As compared with the existing technologies, the invention can considerably increase the yield of iron powder selection and the grade of the iron powder and coke powder, and also avoid making new environment pollution.

Owner:LIUZHOU QINGYU ENVIRONMENTAL PROTECTION IND DEV

Method for producing active pulverized lime by utilizing coal gas to calcine limestone through suspended state pre-heating decomposing furnace

The invention relates to a method for producing active pulverized lime by utilizing coal gas to calcine limestone through a suspended state pre-heating decomposing furnace, which belongs to the field of environment protection production of building materials. The method comprises the voltage stabilizing and conveying process of coal gas, the combustion heating process of the coal gas in a decomposing furnace for sufficiently combusting the coal gas in the suspended state pre-heating decomposing furnace to obtain the active quicklime powder as staflux in the lime calcining production, and the process for cooling the lime by a grate type cooler. Coke-oven coal gas, blast furnace coal gas, converter coal gas and mixed coal gas in the metallurgy production process are respectively adopted as fuel for replacing the coal powder in the traditional process for calcining and decomposing the lime powder. The method solves the problem of environment pollution caused by coal firing, improves the utilization rate of the excessive coal gas generated during steel making, reduces the outwards discharge of the coal gas, simultaneously improves the production efficiency and the heat efficiency of the lime calcination, and improves the activity of the lime.

Owner:SHANDONG IRON & STEEL CO LTD

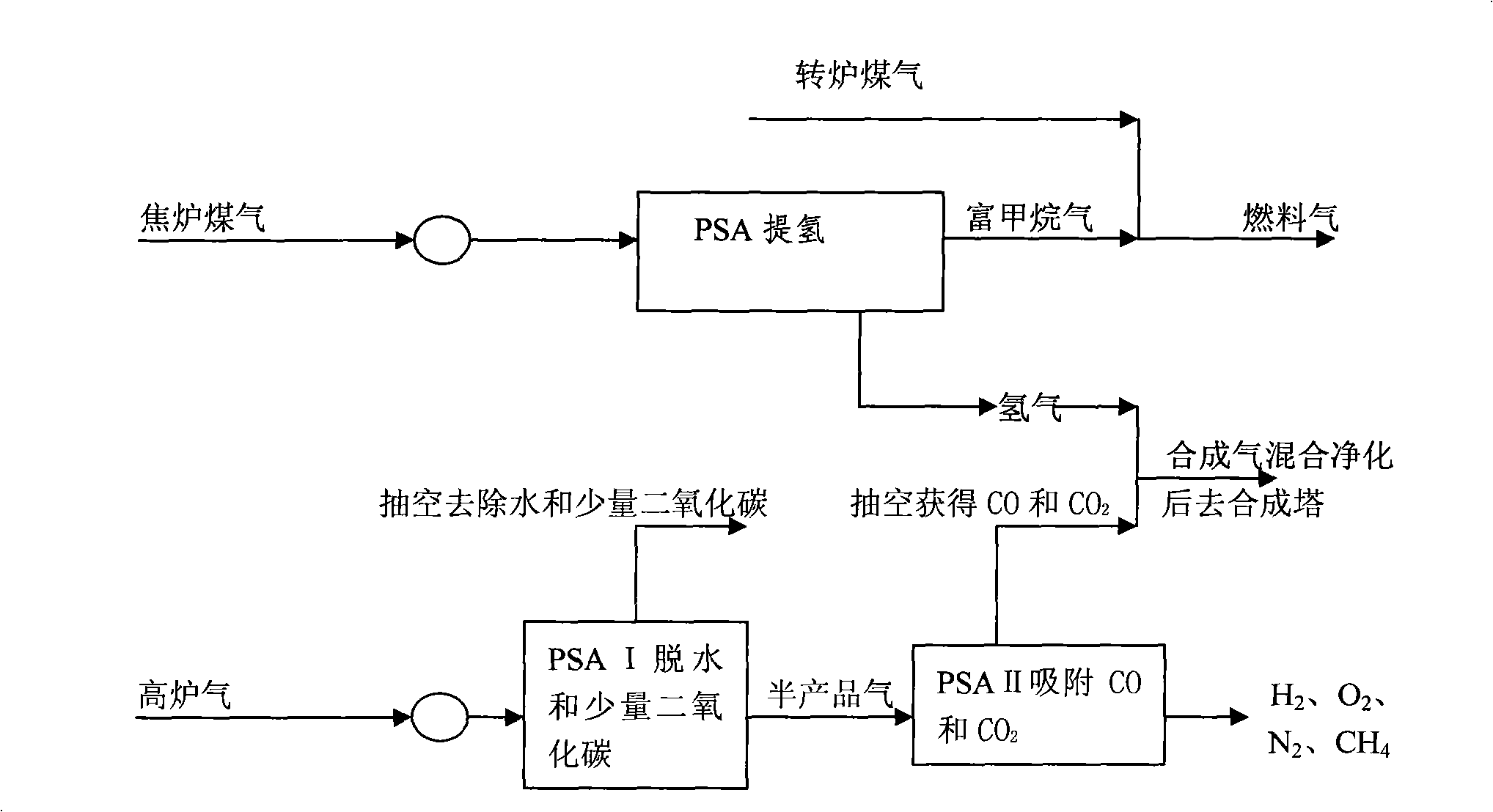

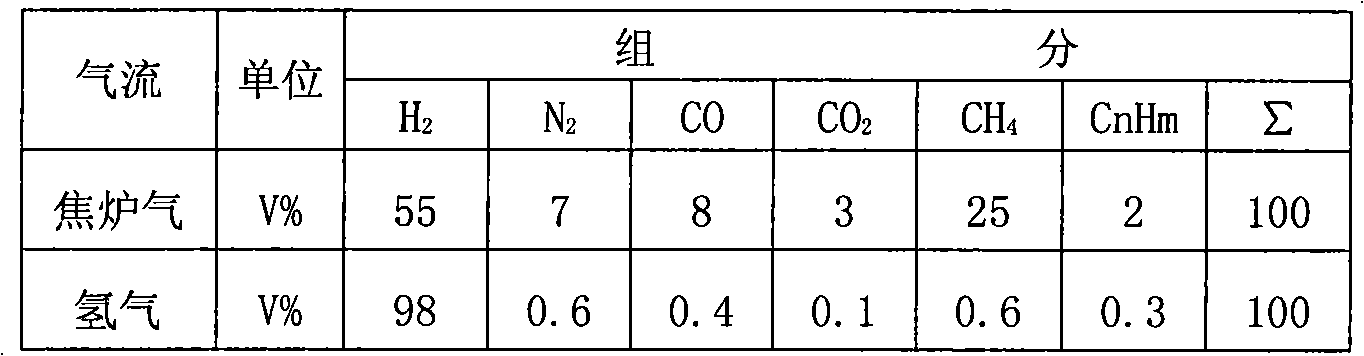

Method for preparing methanol synthesis gas with oven gas and blast furnace gas

InactiveCN101343580AEmission reductionReduce chemical reactionsGaseous fuelsChemical reactionSorbent

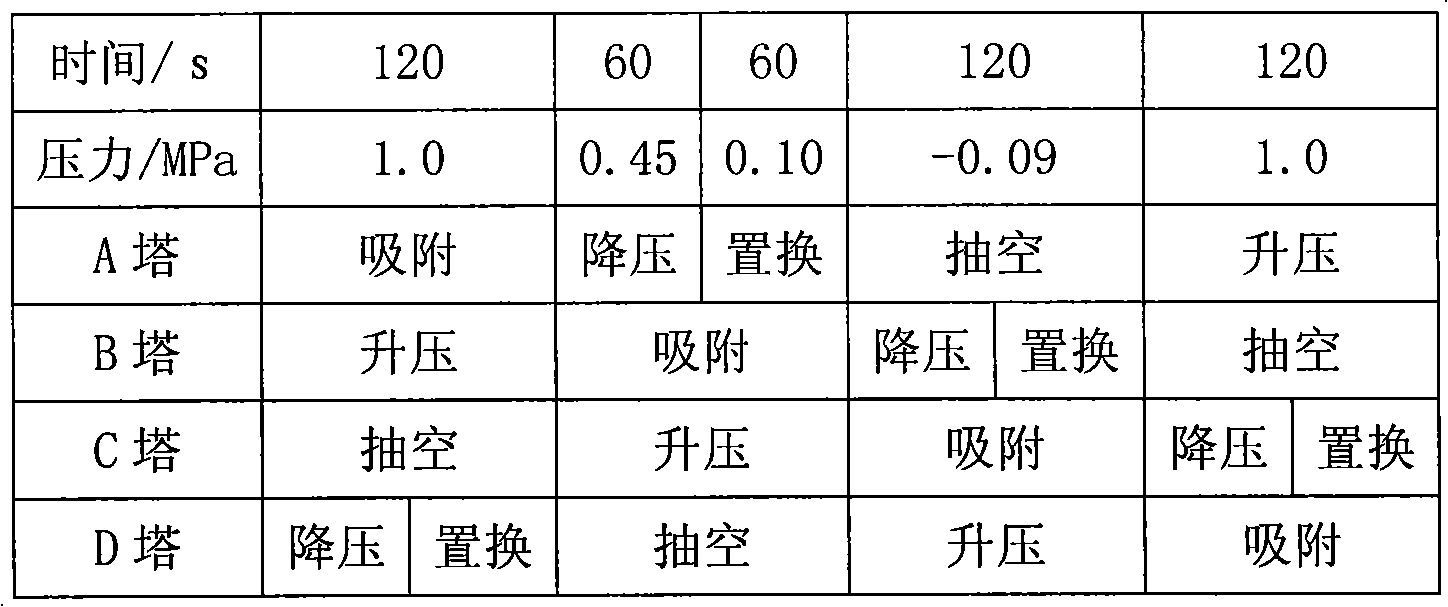

The invention discloses a preparation method for methanol synthetic gas through coke oven gas and blast furnace gas. The preparation method adopts coke oven gas as the raw material, and H2 is extracted through pressure swing adsorption; the blast furnace gas with high yield and relatively low calorific value is adopted as the raw material, an adsorbent which can adsorb CO and CO2 is utilized to simultaneously extract and reclaim the CO and the CO2 in the blast furnace gas, and then the H2, the CO and the CO2 are mixed and prepared into the methanol synthetic gas. The hydrogencarbon ratio f value of the methanol synthetic gas prepared according to the method is within the optimum range of 2.05 to 2.60, and the contents of nitrogen gas and other impure gases are suitable for the methanol production. The by-product gas generated during the steel production process is utilized to prepare the methanol synthetic gas, the useful components in the gas are utilized, the discharging of harmful substances into the environment is reduced, and not only the chemical reaction can not occur during the process, but also the carbon adding is not required, the technical process is short, the process is simple, and the cost is low, so the preparation method is one of the preferable methods for the preparation of methanol synthetic gas.

Owner:SICHUAN TIANYI SCI & TECH

Waste heat utilization-containing active carbon thermal desorption method and apparatus thereof

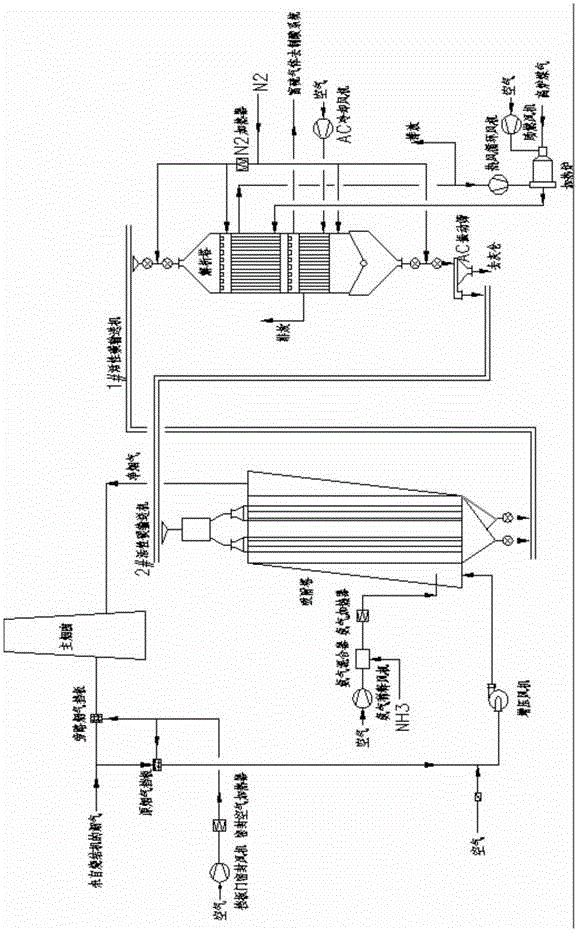

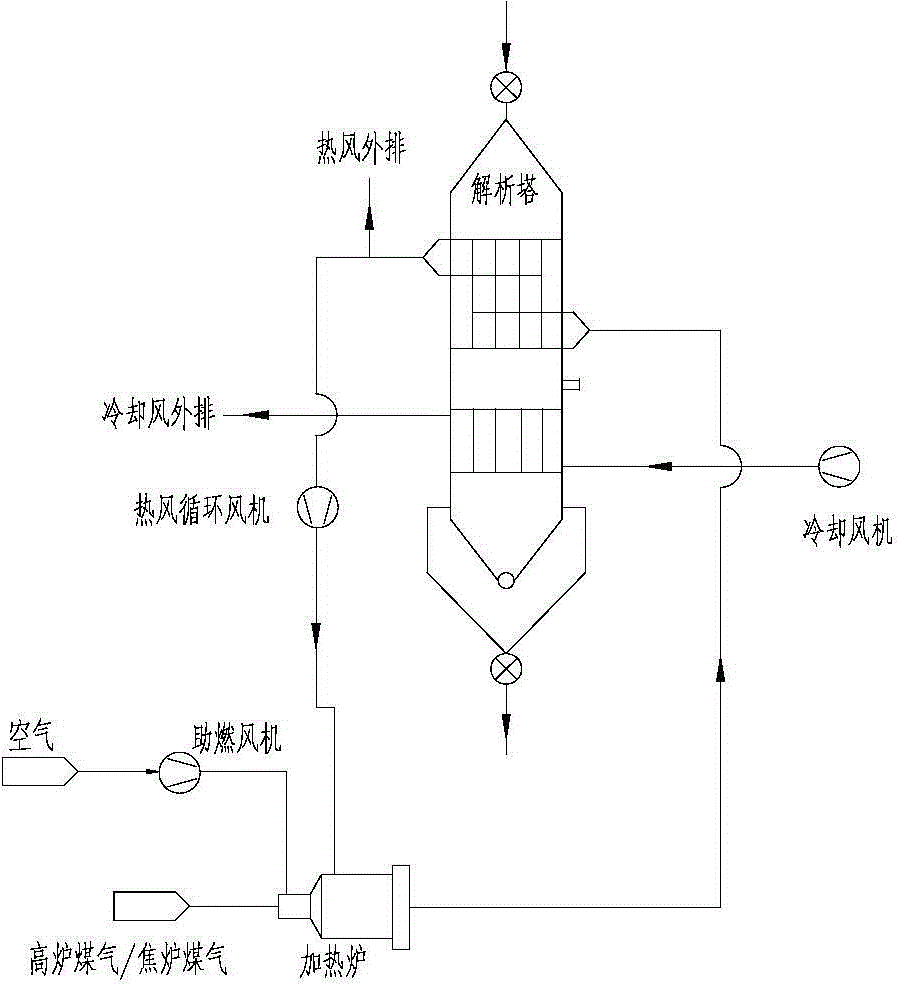

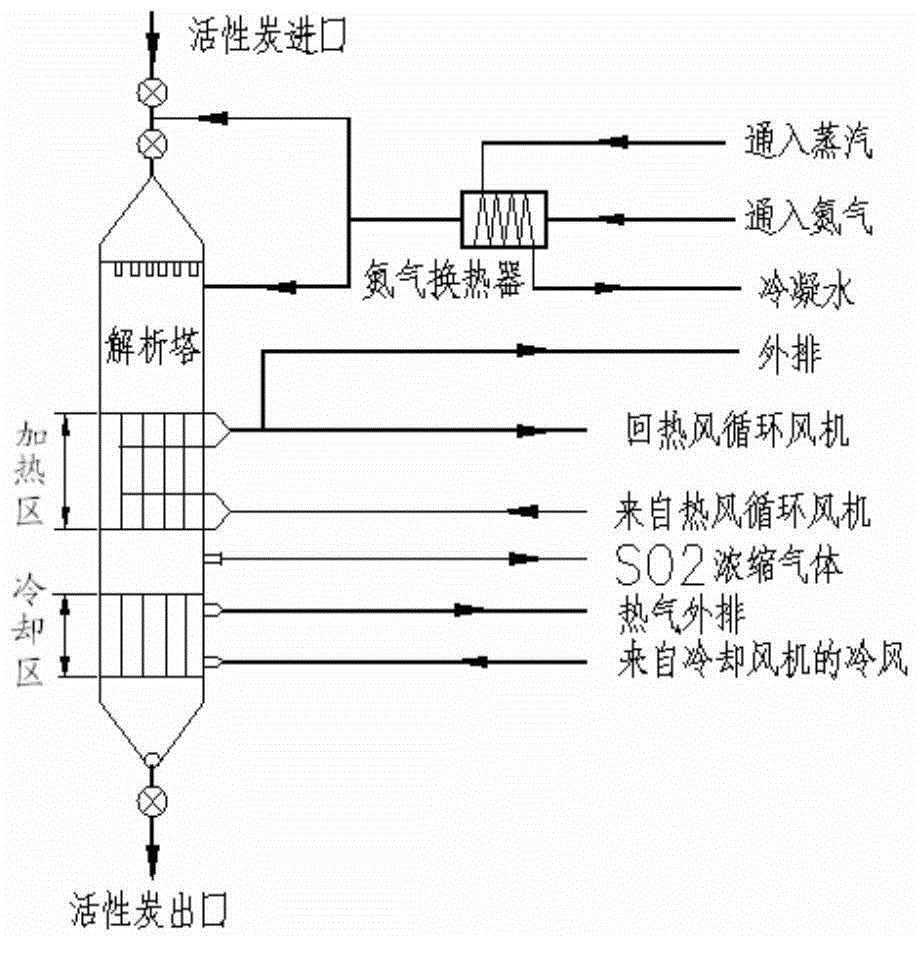

ActiveCN105618019ALow running costReduce consumptionOther chemical processesDispersed particle separationCombustion chamberThermal desorption

The invention provides a waste heat utilization-containing active carbon thermal desorption method. The method comprises the following steps: adsorbing sulfur oxides, nitrogen oxides and other pollutants in the active carbon adsorption tower of a desulphurization and denitration device by active carbon; allowing blast furnace gas or coking coal gas to flow through a heat exchanger in order to be preheated, conveying the preheated gas to the combustion chamber of a heating furnace, combusting the preheated gas, allowing high temperature hot wind (G0) discharged from the combustion chamber to flow through one temperature adjusting zone of the tail portion of the heating furnace to undergo temperature adjustment and become cooled hot wind (G1), conveying the hot wind (G1) to the heating zone of a desorption tower to desorb the active carbon, and discharging further cooled hot wind (G1') from the heating zone. Parts of the hot wind (G1') are used in preheating of the blast furnace gas or coking coal gas in the heat exchanger. Parts of the cooled wind (G2') discharged from the cooling zone of a desorption tower are used to carry out gas sealing of raw flue gas baffle plates, purified flue gas baffle plates and bypass baffle plates arranged in the whole desulphurization and denitration device. The invention also provides an active carbon desorption apparatus.

Owner:HUNAN ZHONGYE CHANGTIAN ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Multi-ring matrix burden distribution process for bell-less top of blast furnace

InactiveCN101845528AThe reduction is not obvious or even reverse regulationLower fuel ratioBlast furnace componentsBlast furnace detailsDistribution matrixThroat

The invention relates to a multi-ring matrix burden distribution process for a bell-less top of a blast furnace, belonging to the technical field of burden distribution of blast furnaces. A multi-ring burden distribution process is combined with a burden distribution matrix, and the burden distribution matrix is set according to 9-11 ring sites; generally, 4-6 ring sites are selected for distributing coke, and 3-5 ring sites are selected for distributing ore; the number of turns on each ring site for distributing coke is selected preferably to enable the coke to be laid horizontally; the number of turns on each ring site for distributing ore is selected to control the ore coke ratio on the furnace throat radius, thereby controlling radial distribution of coal gas flow; and the number of turns for distributing coke and distributing ore is generally controlled to be 10-14 turns. The invention can obtain furnace throat coal gas distribution in which coal gas at edges has certain passages and coal gas in the center develops, and the burden distribution is flexible and adjustable, thereby keeping stable and smooth operation of the blast furnace, realizing the purposes of opening the center and stabilizing the edges, improving the utilization ratio of coal gas, reducing the fuel ratio of the blast furnace, and further reducing the production cost.

Owner:SHOUGANG CORPORATION

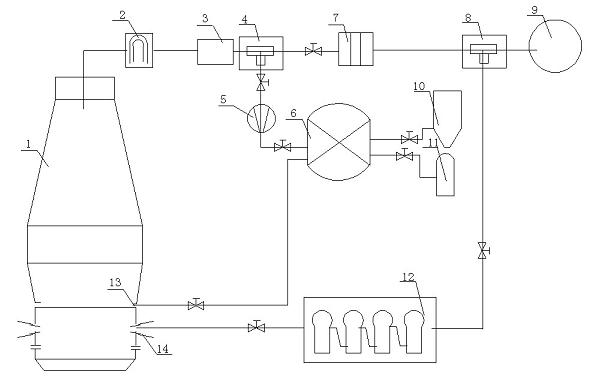

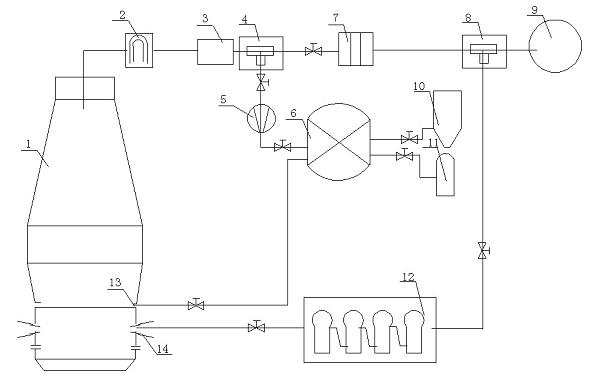

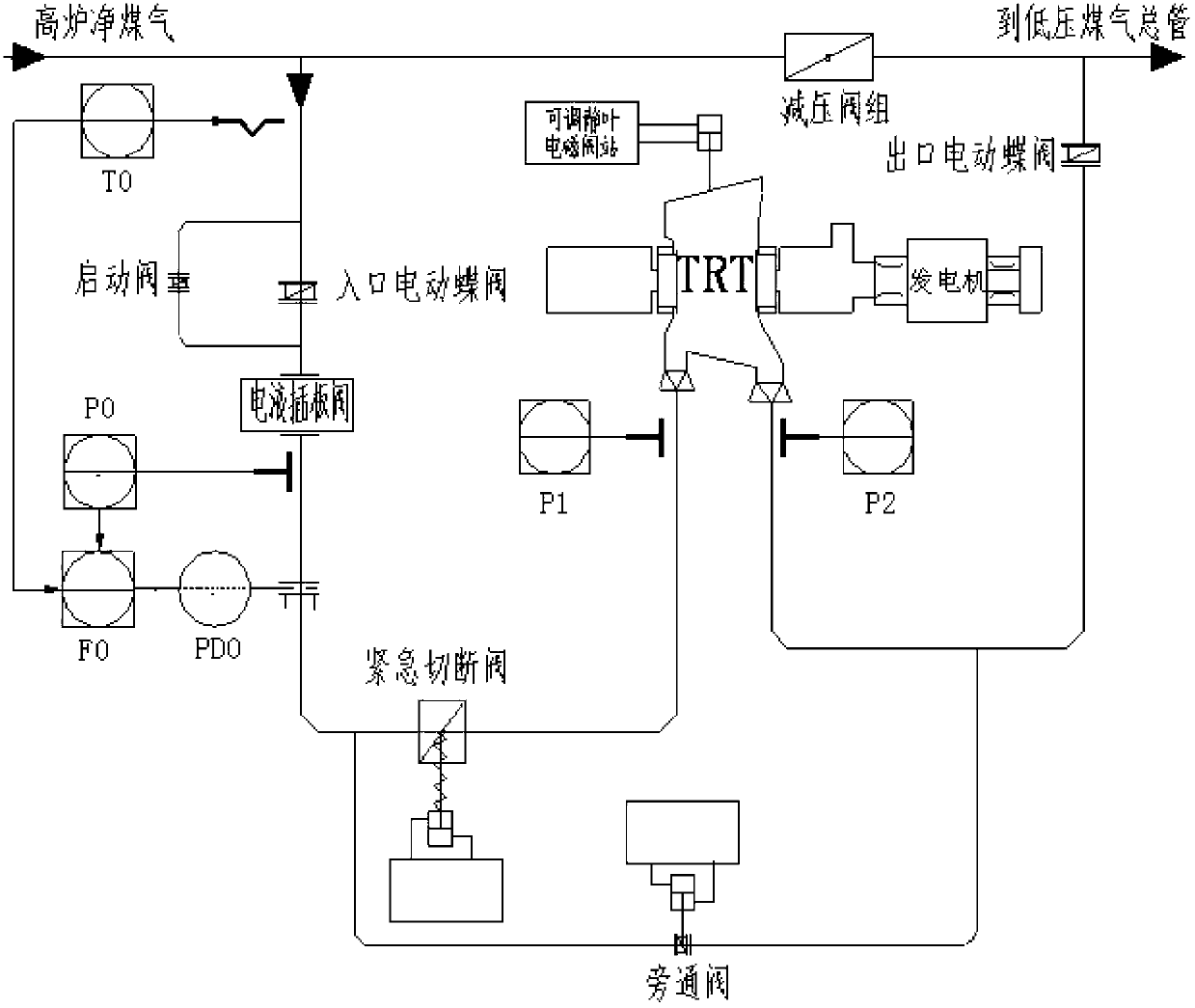

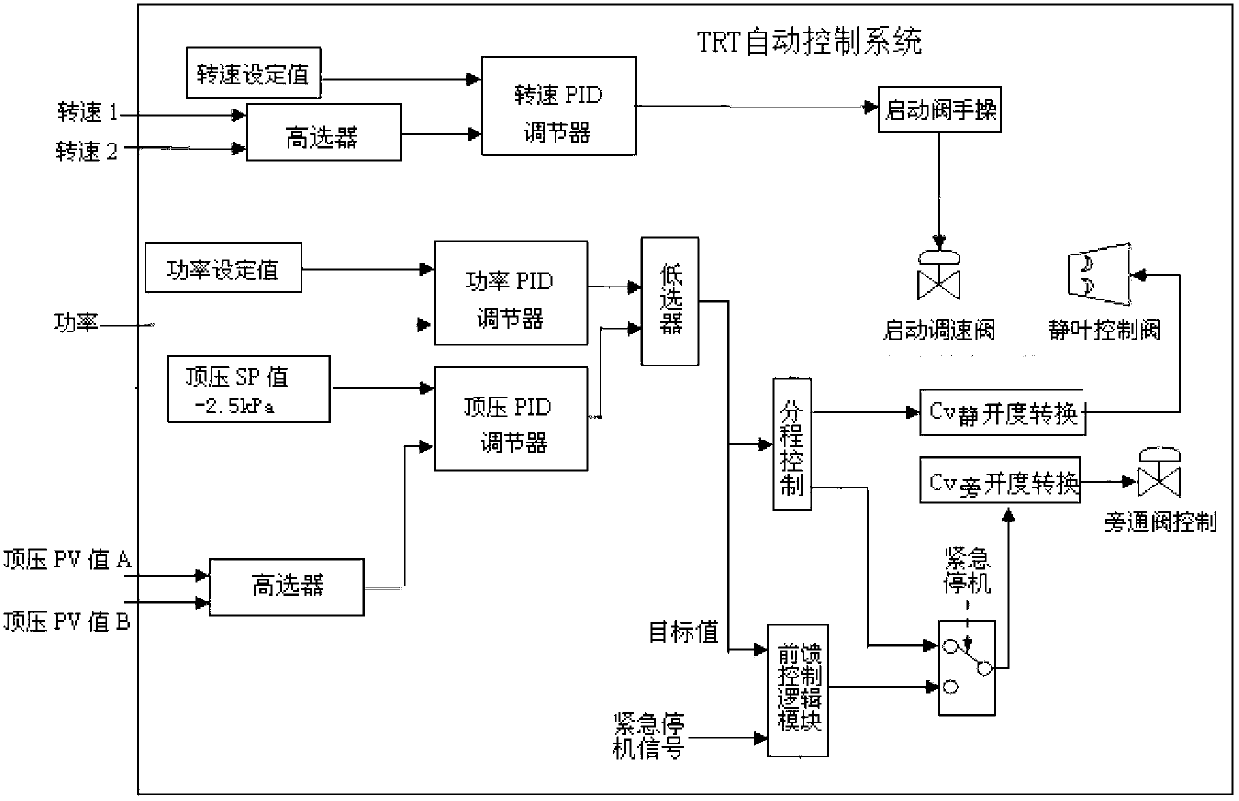

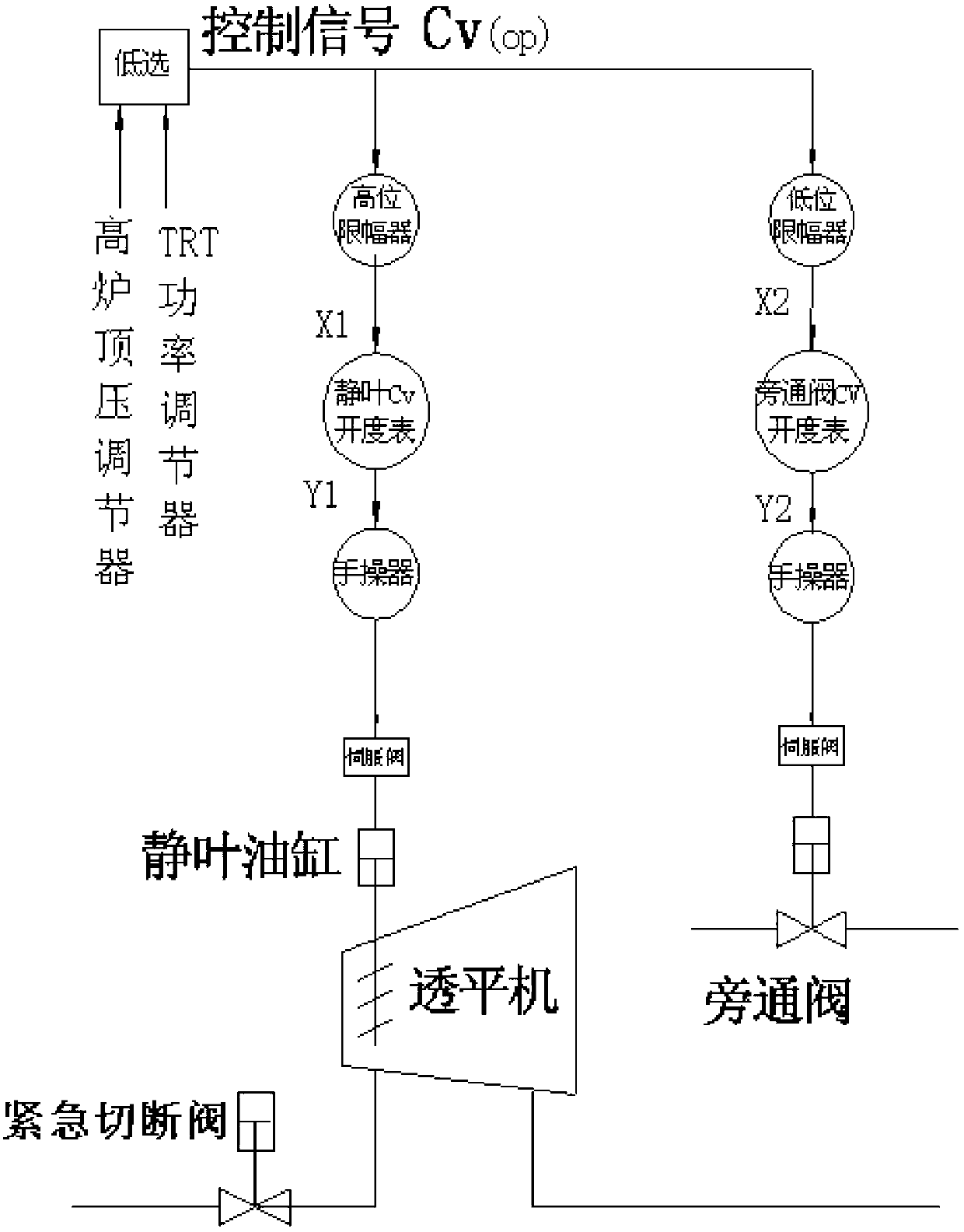

Automatic control method for top pressure of TRT (blast furnace top gas recovery turbine unit) system

InactiveCN102994672AA New Approach to SecurityA new way to be reliableBlast furnace detailsMachines/enginesAutomatic controlEngineering

The invention provides an automatic control method for the top pressure of a TRT (blast furnace top gas recovery turbine unit) system, which comprises the following steps of: converting the gas flow of the system into a Cv value, and creating a Cv-opening relation table of a stationary blade and a Cv-valve opening relation table of a bypass valve; controlling the TRT system by a speed PID regulator, a power PID regulator and a top pressure PID regulator respectively; controlling the top pressure in an operation stage of the TRT system, wherein the power PID regulator and the top pressure PID regulator of the system are connected to a split-ranging controller through a low selector; controlling the opening of the stationary blade and the opening of the bypass valve according to a split-ranging control principle; and after the system receives an emergency stop signal, closing an emergency cut-off valve, opening the bypass valve and controlling to slowly close the bypass valve, and regulating the pressure of the blast furnace by a pressure reducing valve group. The method provided by the invention solves the technical problems of low stability in regulating the top pressure of the blast furnace by the TRT, low generating efficiency, limited regulation ability, great fluctuation of pressure in the emergency stop process and the like caused by inaccurate performance data of the valve and insufficient circulation of TRT design.

Owner:武汉钢铁有限公司

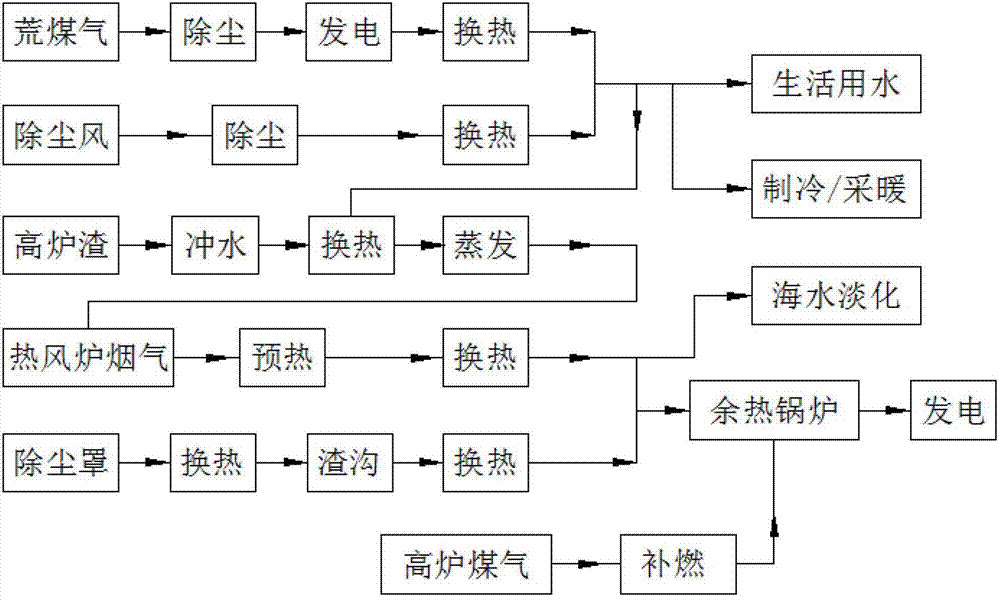

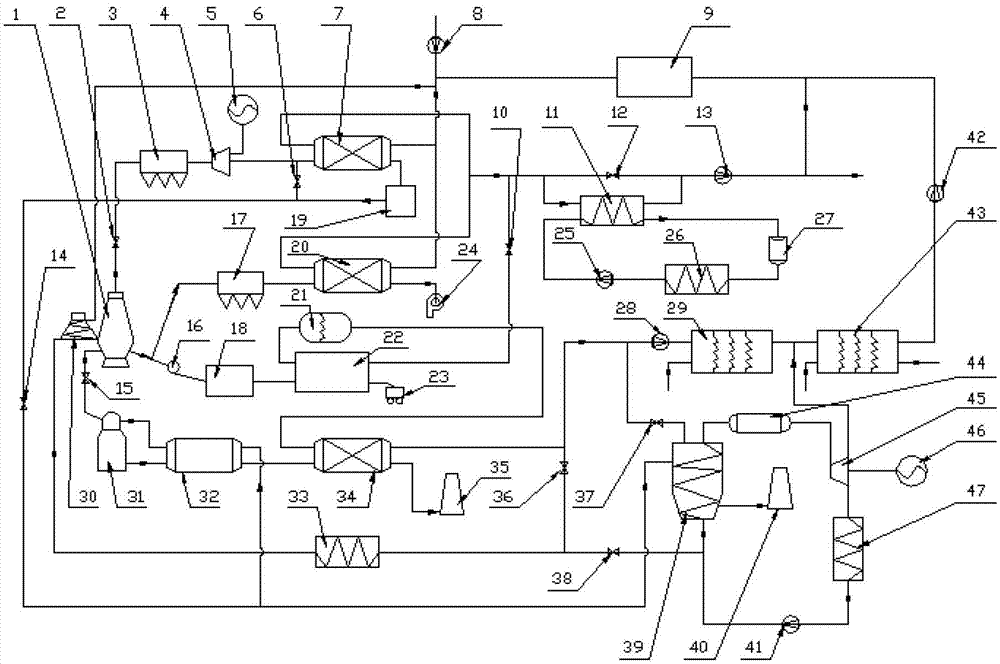

Steelmaking residual heat step recycling method

ActiveCN102851420ASolve effective useEnable fair useBlast furnace detailsIncreasing energy efficiencySteelmakingDitch

The invention discloses a steelmaking residual heat step recycling method. The invention belongs to the technical field of steel industry iron-making residual heat and residual energy utilization. The method is adopted under a condition for further utilizing iron-making low-grade residual heat, and comprises step recycling and high-efficiency utilizations of blast furnace gas residual heat, dust removal air residual heat, water slag residual heat, hot air furnace low-temperature flue gas waste heat, and dust cover and slag ditch residual heat. According to the technical scheme, blast furnace gas residual heat and dust removal air residual heat obtained after furnace top residual pressure power generation are connected in parallel, and are supplied for domestic water, cooling, or heating. Recycled water slag residual heat and flue gas residual heat obtained after hot air furnace gas heat exchanger are connected in parallel, and are used for supplying a heat source for low-temperature seawater desalination. Recycled dust cover residual heat and slag ditch surface radiation heat are connected in parallel, and are supplied for blast furnace gas supplementary firing residual heat boiler power generation. After powder generation, high-temperature seawater desalination is realized by a steam method. Cooling water and domestic water are treated and are adopted as inlet water replenishment. Through step recycling and graded utilization of the low-grade residual heat and residual energy, steel system comprehensive energy consumption can be reduced to a maximal extent, and energy resource reasonable utilization and comprehensive optimized utilization can be realized.

Owner:SHOUGANG CORPORATION

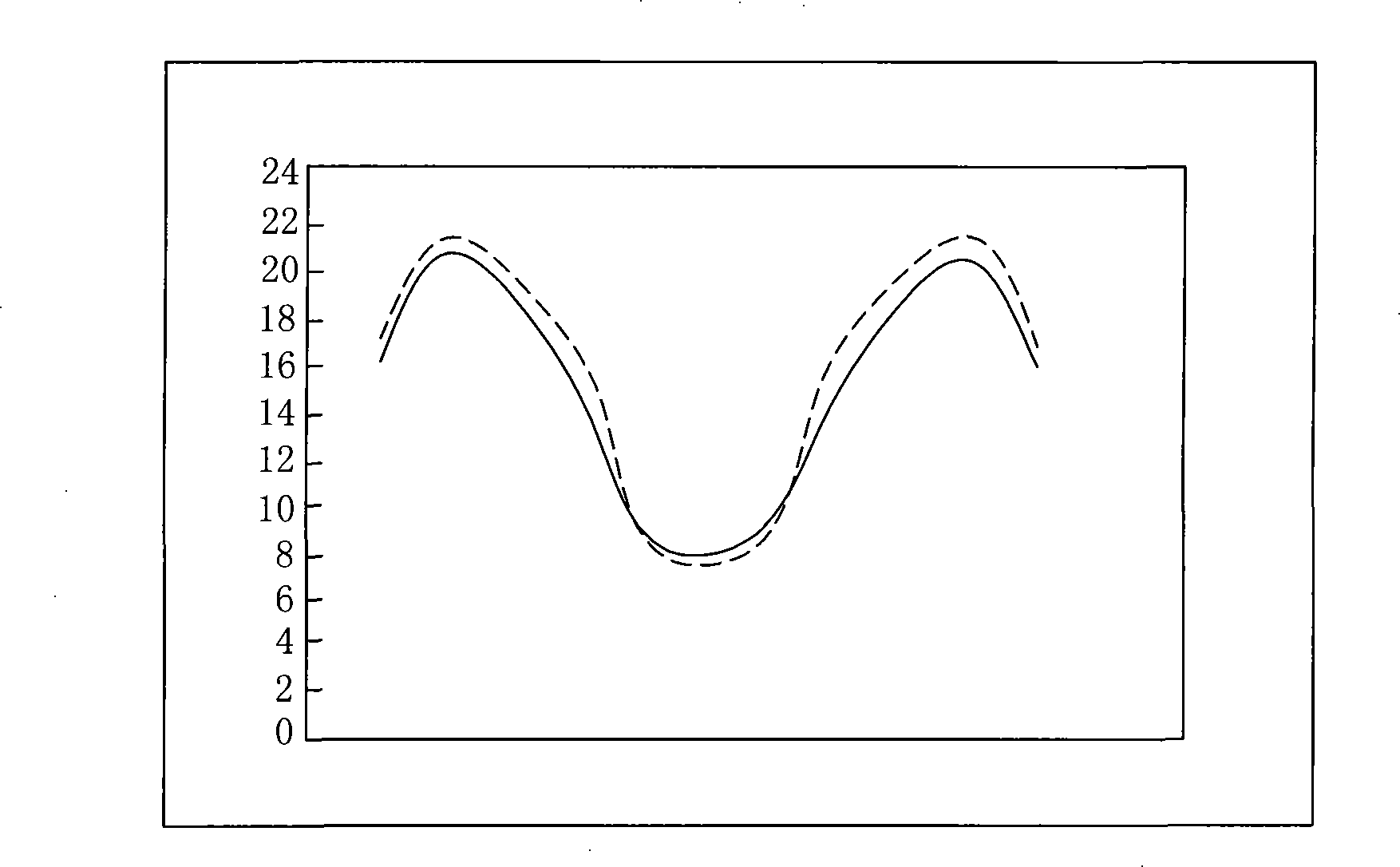

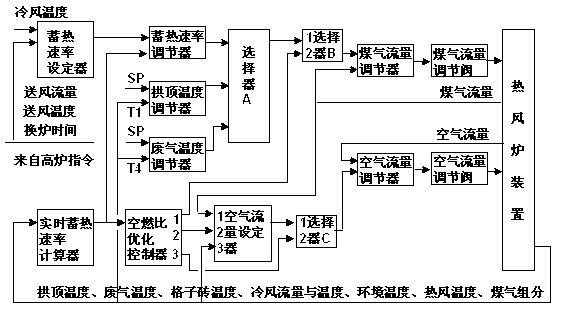

Intelligent optimization control system of blast furnace hot-blast stove

ActiveCN102912055AIncrease profitGuaranteed energy savingBlast furnace detailsHeating stovesHeat balanceTrial and error

The invention discloses an intelligent optimization control system of a blast furnace hot-blast stove, which relates to the technical field of blast furnace ironmaking optimization control and can reduce coal gas consumption, ensure equipment safety and prolong the service life on the premise of ensuring that the required hot-blast temperature and flow of a blast furnace are satisfied. The system is technically characterized in that the on-line calculation of a heat accumulation rate is realized based on heat balance, a reasonable heat accumulation rate setting curve is set according to the required total heat amount of blast and heating time of the blast furnace and the heat accumulation rate characteristic of a hot-blast stove, the amount of fuel in the heating stage is controlled in real time according to the heat accumulation rate, and the calculated amount of fuel is limited according to accepted upper limits of arch crown temperature and exhaust gas temperature processes. The system fully meets the demands of the blast furnace for hot blast, reduces lost heat carried away by waste gas and simultaneously ensures the equipment safety; and furthermore, the air-fuel ratio is optimized by taking the heat accumulation rate as the optimization target value and using a trial-and-error self-optimization algorithm, so that the fuel utilization is maximized, and the energy saving of the device is ensured at multiple levels.

Owner:北京和隆优化科技股份有限公司

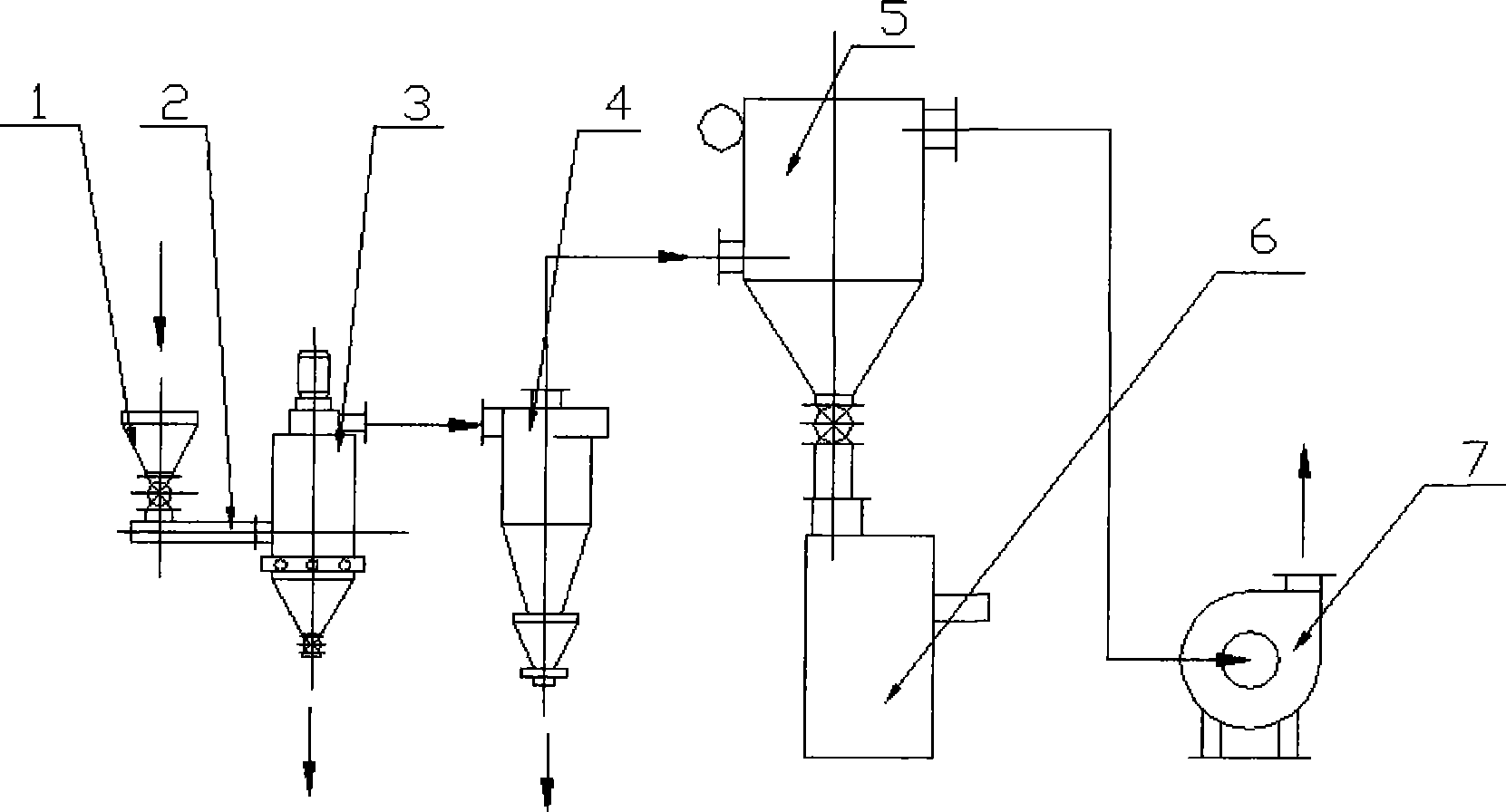

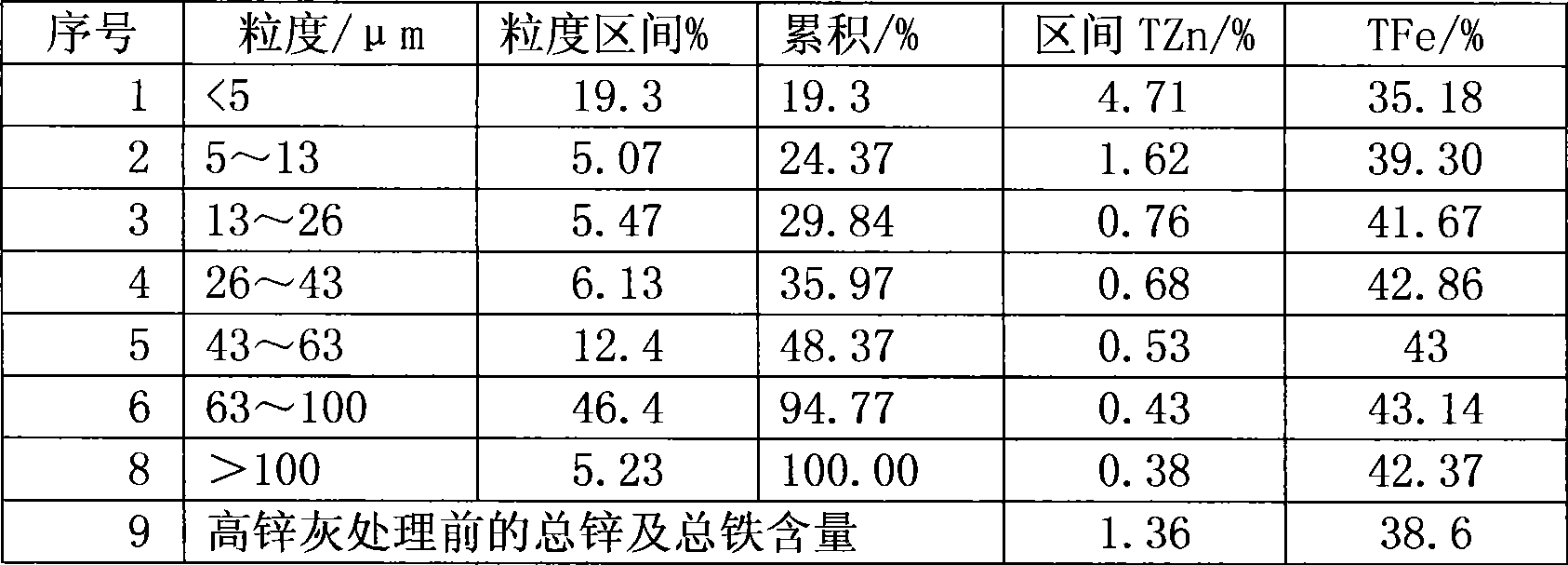

Method for separating zinc-containing substance of blast furnace dry method dust separation ash

ActiveCN101428278AImprove matchNovel and flexible methodCombination devicesGas current separationAir volumeAir classifier

The invention discloses a method for separating zinc contained material from blast furnace gas dry precipitator dust, and the pretreatment for the blast furnace gas dry precipitator dust achieves the purpose of reducing dezincing load at the terminal of the blast furnace gas dry precipitator dust. The key points are that the blast furnace gas dry precipitator dust is absorbed into the main machine of an air classifier through negative pressure with a vacuum degree of 0.4 to 0.6 kgf / cm<2> which is produced by a Roots blower. Self shunt can be realized in a gravity field, most of thick grains deposit on the bottom part of the classifier, the rotating speed of the classified wheel of the classifier main machine can be adjusted within a scope of 2000 rpm to 9000 rpm, the supply air volume is also adjusted, a secondary assorted cut is performed on the fine grained precipitator dust, and a high zinc contained precipitator dust accounting for 10 to 30 percent of the inlet amount can be cut out, and the high zinc contained precipitator dust can be packed by a packaging machine for other treatment after being collected. The invention can be used for recycling low zinc ash of which low zinc ash is no less than 75 percent and the total content of zinc is less than 1 percent, and is applicable to pretreatment for dezincification of the blast furnace gas dry precipitator dust, and zinc accumulation during the reusing process of high zinc contained precipitator dust is reduced.

Owner:SHOUGANG CORPORATION

Fuel gas calorie control method and device

ActiveUS7396228B2Calorie controlEasy to controlBurnersTurbine/propulsion fuel supply systemsMixed flowProduct gas

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

Desulfurization purification method for blast furnace gas

InactiveCN109609202ARelieve pressureLow running costGas contaminants removalGas dust removalThermal energyPurification methods

The invention discloses a desulfurization purification method for blast furnace gas. The method comprises the steps that S1, the blast furnace gas is dedusted through a dry-method cloth bag dedustingdevice and then enters an organic sulfur conversion device, and organic sulfur is converted into H2S; S2, H2S enters a blast furnace top gas recovery turbine unit for recycling pressure energy and hotenergy; S3, the cooled blast furnace gas enters a wet-method desulfurization device for removing hydrogen sulfide again and then enters all user units. According to the method, based on the temperature and pressure of the blast furnace gas, organic sulfur conversion is conducted, after the blast furnace gas passes through the blast furnace top gas recovery turbine unit (TRT), the temperature of the blast furnace gas is lowered, H2S removal is conducted, and sulfide in the blast furnace gas is removed. Recycling of pressure energy and hot energy of the blast furnace gas by the blast furnace top gas recovery turbine unit is not influenced.

Owner:武汉禾谷环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com