Intelligent optimization control system of blast furnace hot-blast stove

A technology of intelligent optimization and control system, applied in general control system, control/regulation system, blast furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

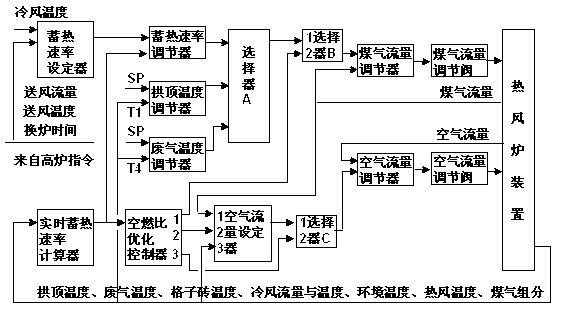

[0032] As shown in the attached figure, the heat storage rate setter receives the cold air temperature signal and the load signal from the blast furnace station, including information such as hot air temperature, hot air flow rate, and furnace replacement time, and calculates the real-time heat storage rate setting value of the hot blast stove, and its output Connected to the setpoint terminal of the heat storage rate regulator; the real-time heat storage rate calculator accepts vault temperature, checker brick temperature, exhaust gas temperature and ambient temperature, cold air flow, cold air temperature and hot air temperature, and gas composition measurements from the hot blast furnace signal to calculate the real-time heat storage rate of the hot blast stove, and its output is connected to the measured value end of the heat storage rate regulator. The physical meaning of the output of the heat storage rate regulator is the set value of the gas flow. The value range is 80~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com