Patents

Literature

811results about "Heating stoves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

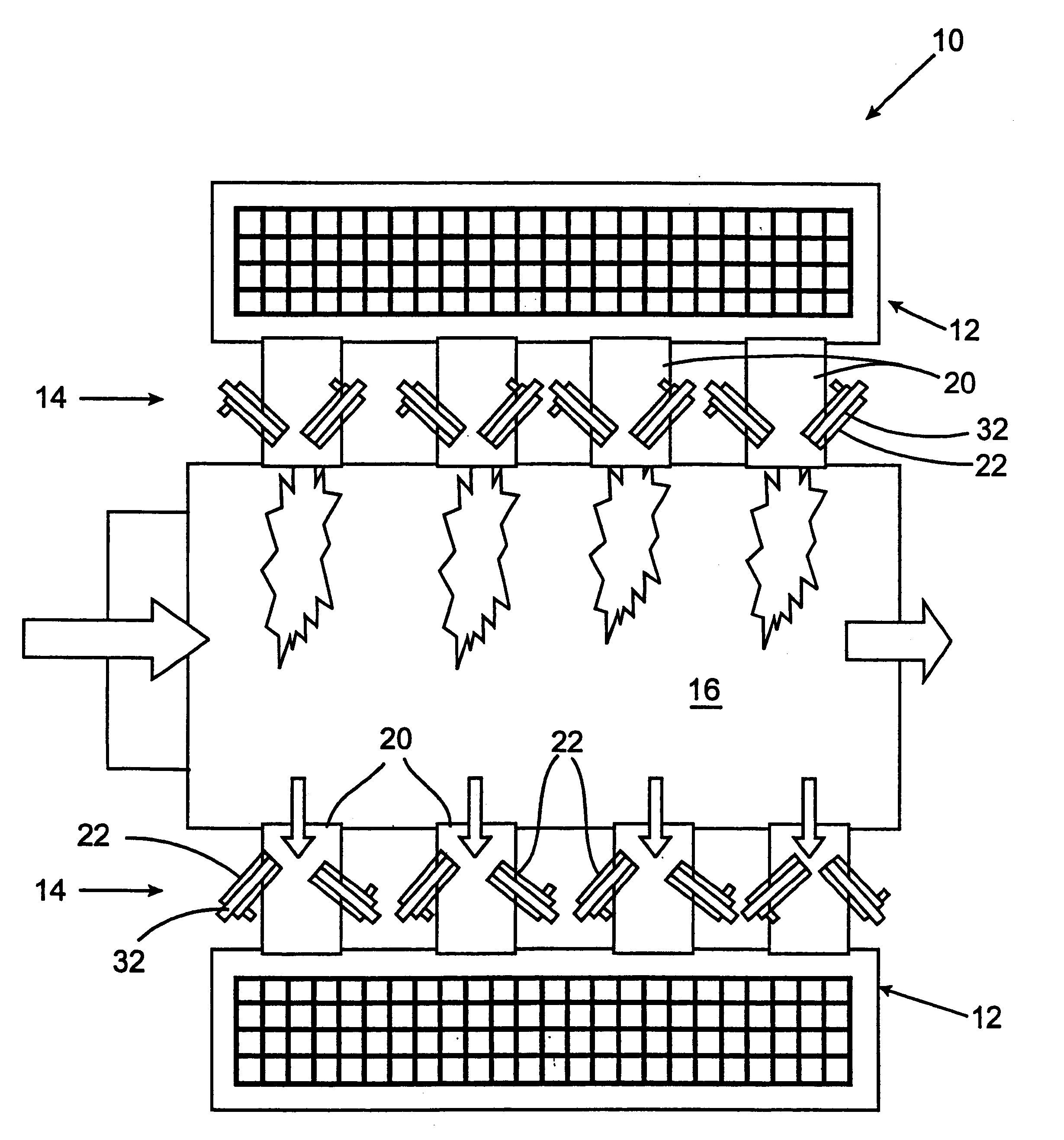

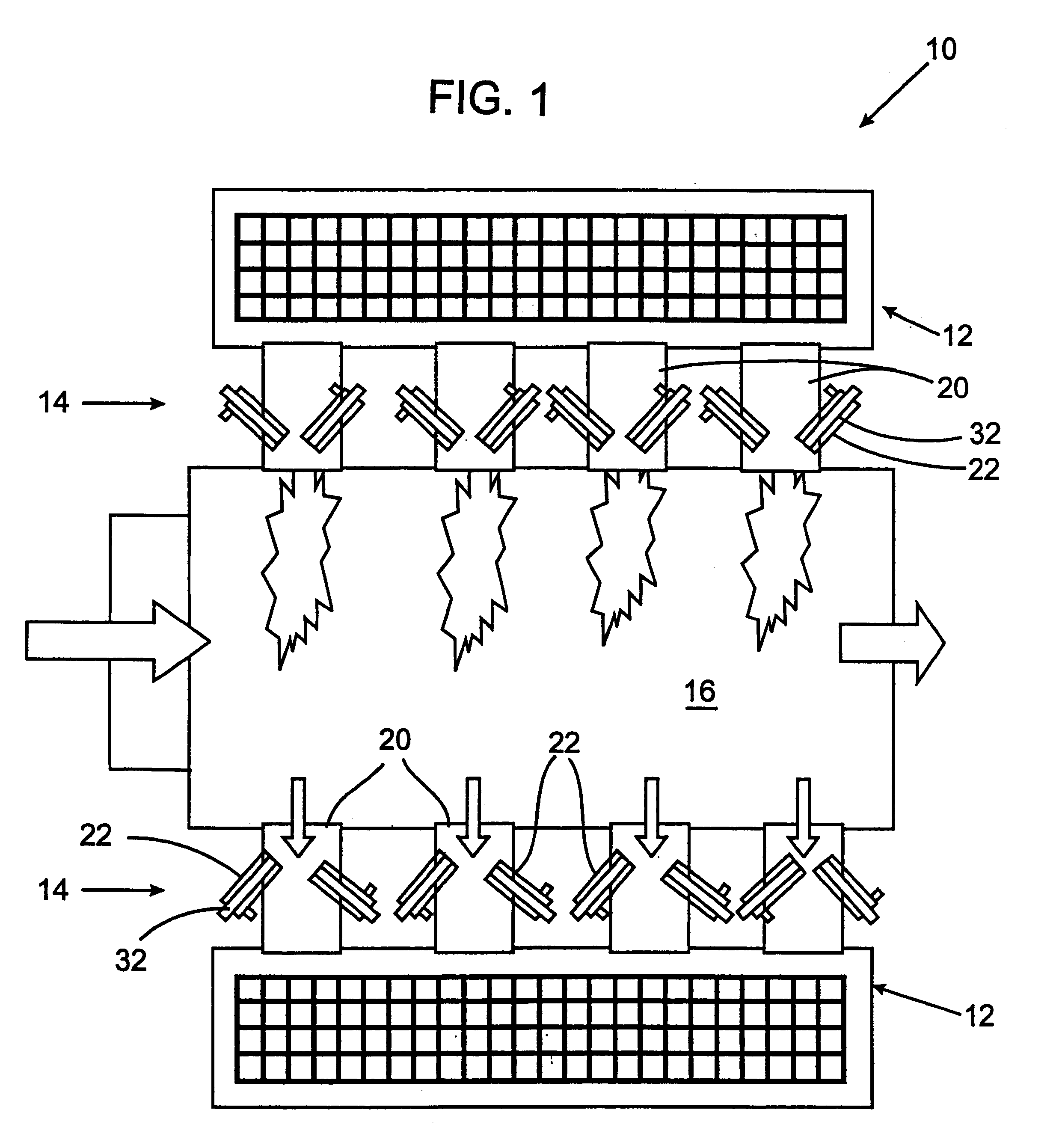

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

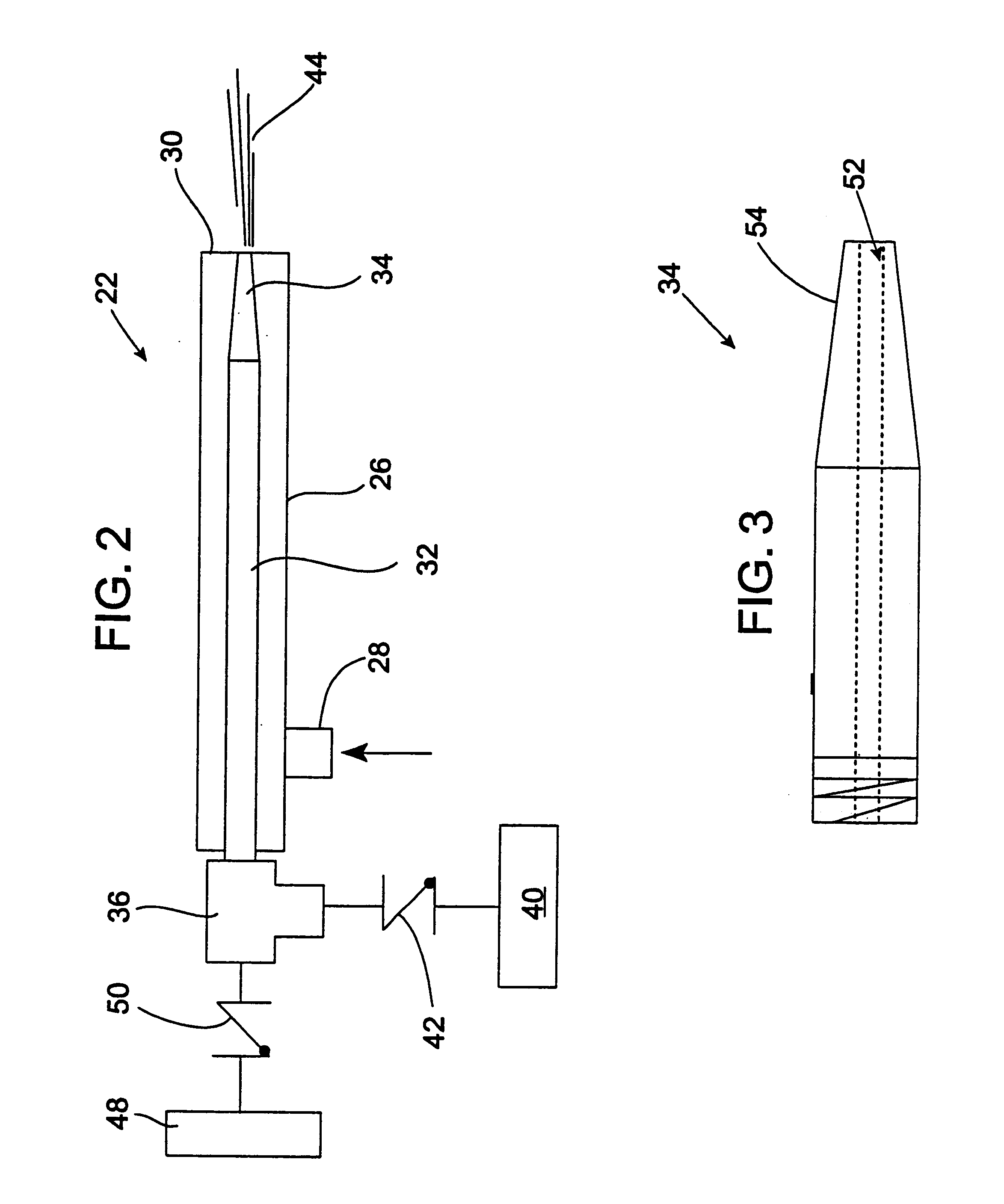

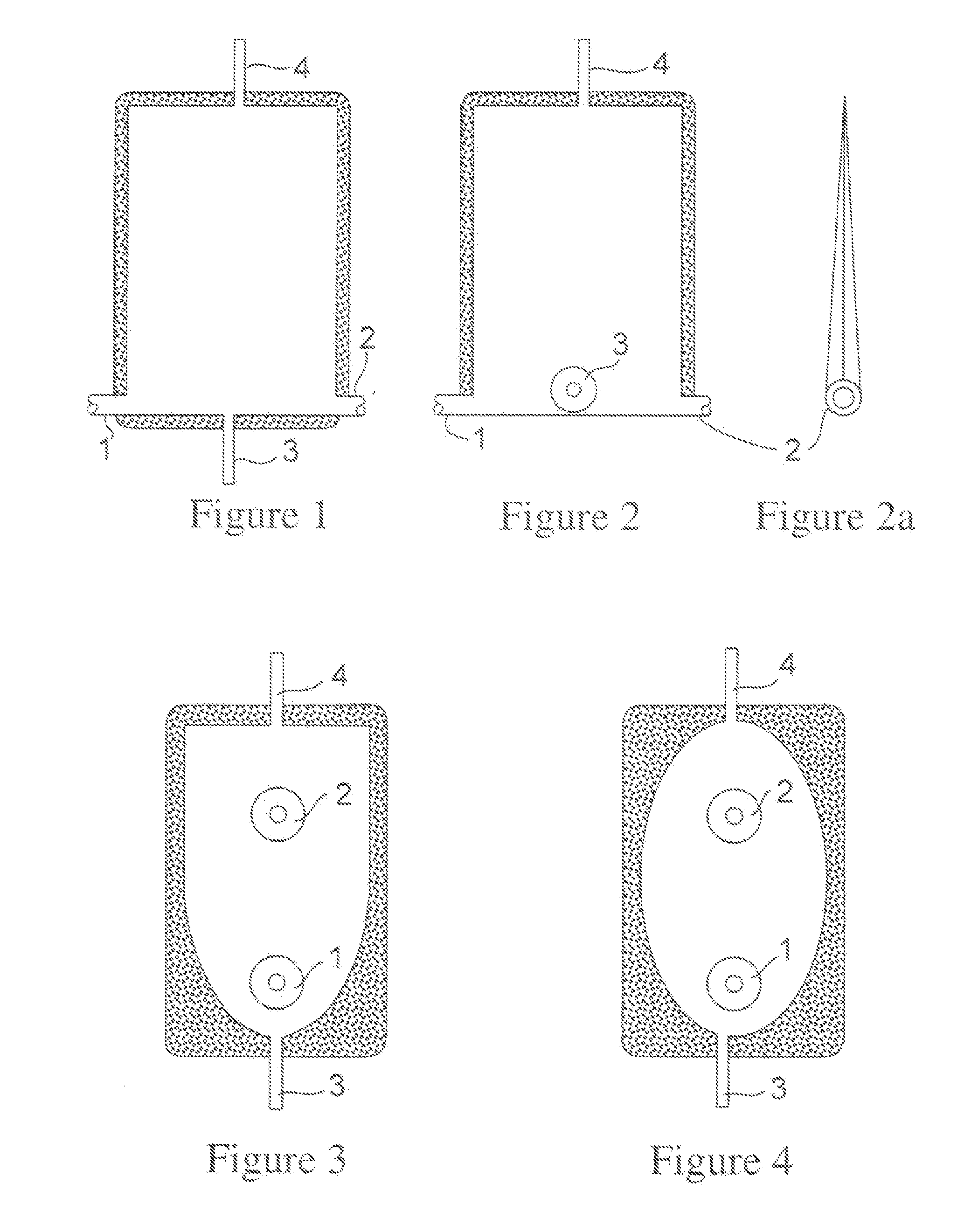

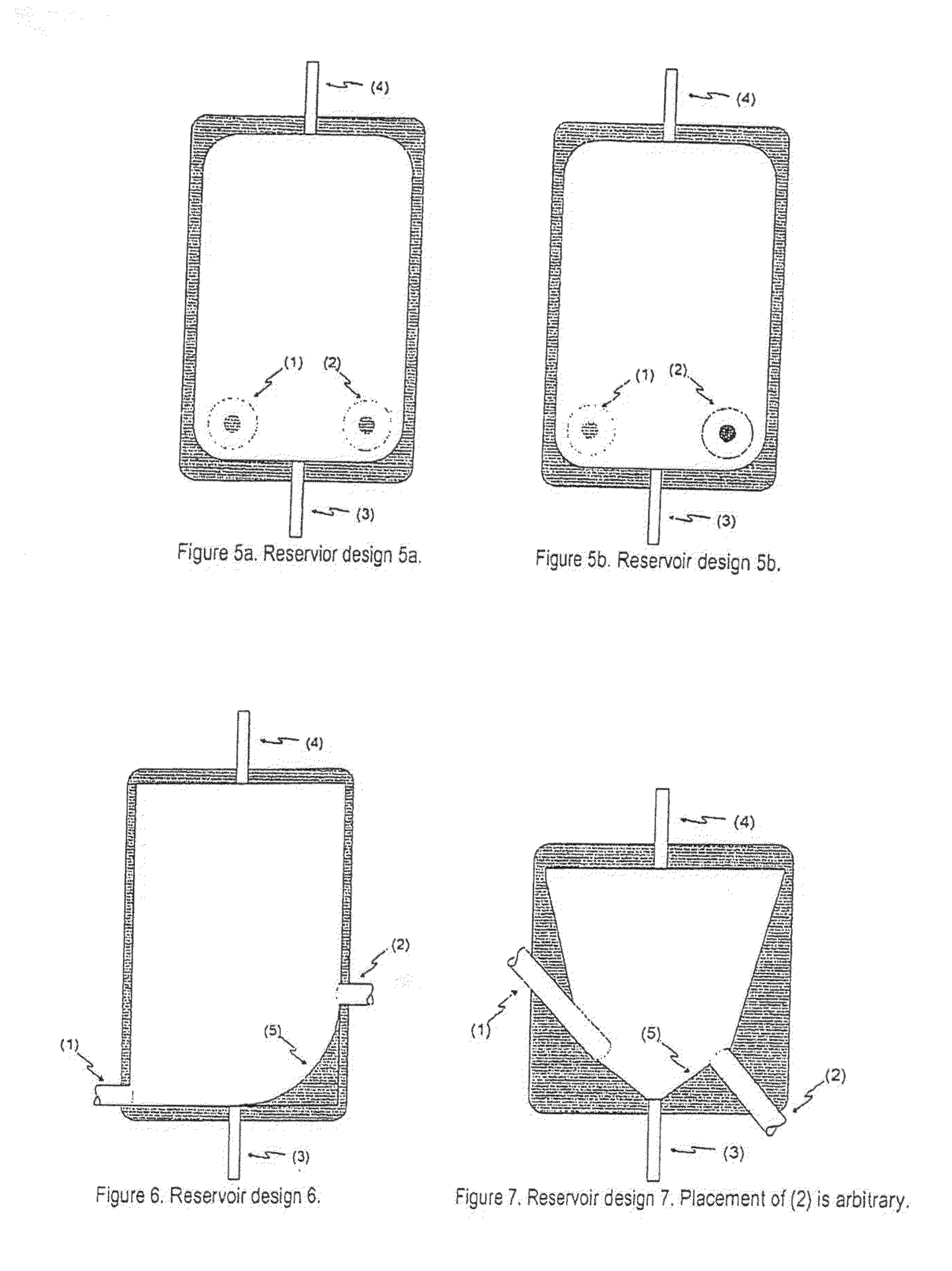

Reservoir For Liquid Dispensing System With Enhanced Mixing

InactiveUS20110120565A1Minimize any fluid dead zonesSuitable for installationBlast furnace detailsManufacturing convertersSystems designEngineering

Reservoir for a dispense system designed to maintain a suspending fluid flow within the reservoir. The fluid dispense system is particularly well suited to be manufactured in a single-use format comprising a fluid reservoir and fill tube assembly, particularly comprising a reservoir, tubing, fittings and connectors, and a needle. The system ensures uniformity within the liquid by moving the fluid through the product reservoir such as with a continuous or pulsating flow, and is designed to maintain the fluid in motion in order to maintain a homogenous solution. The reservoir is designed to minimize any fluid dead zones.

Owner:MILLIPORE CORP

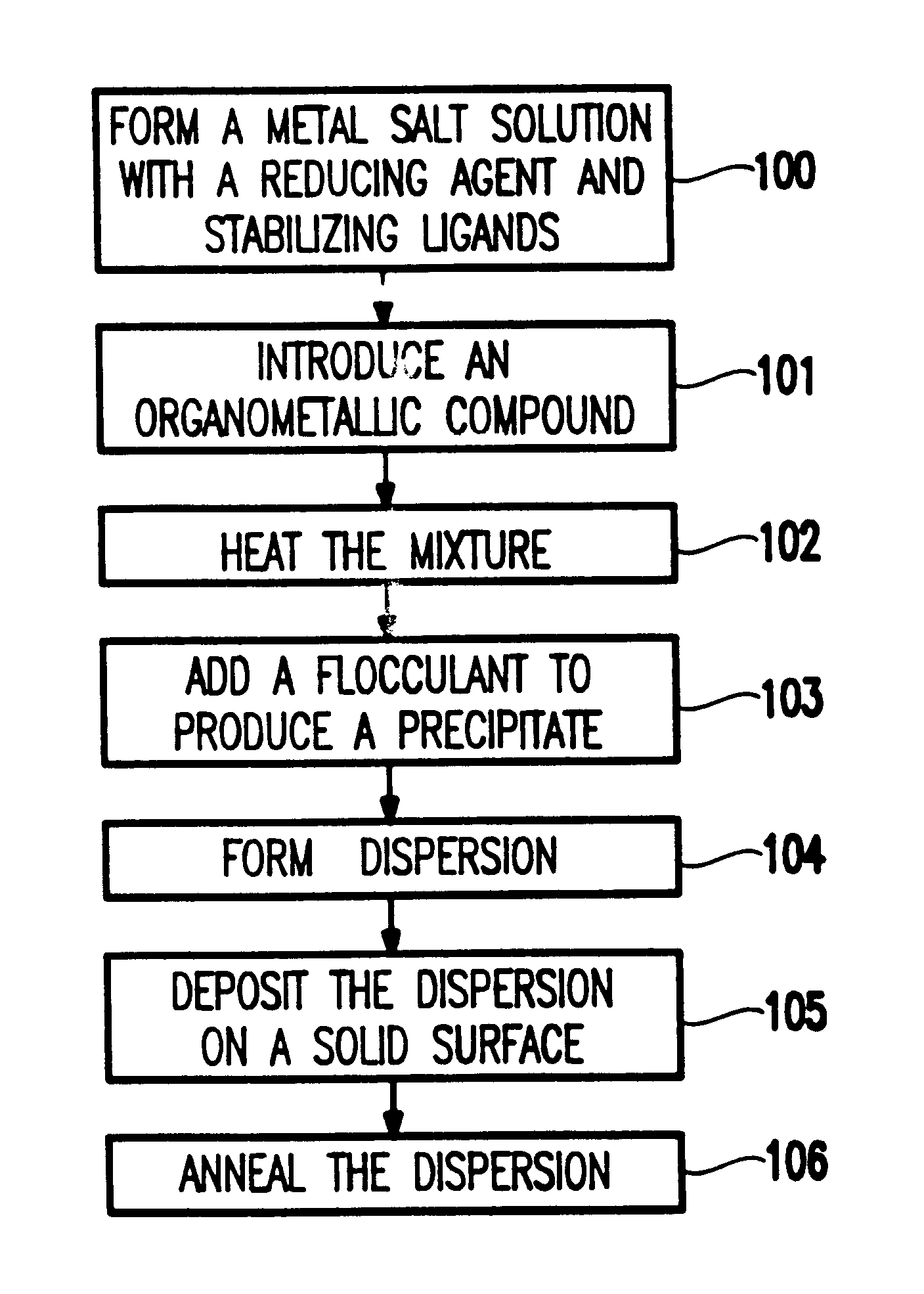

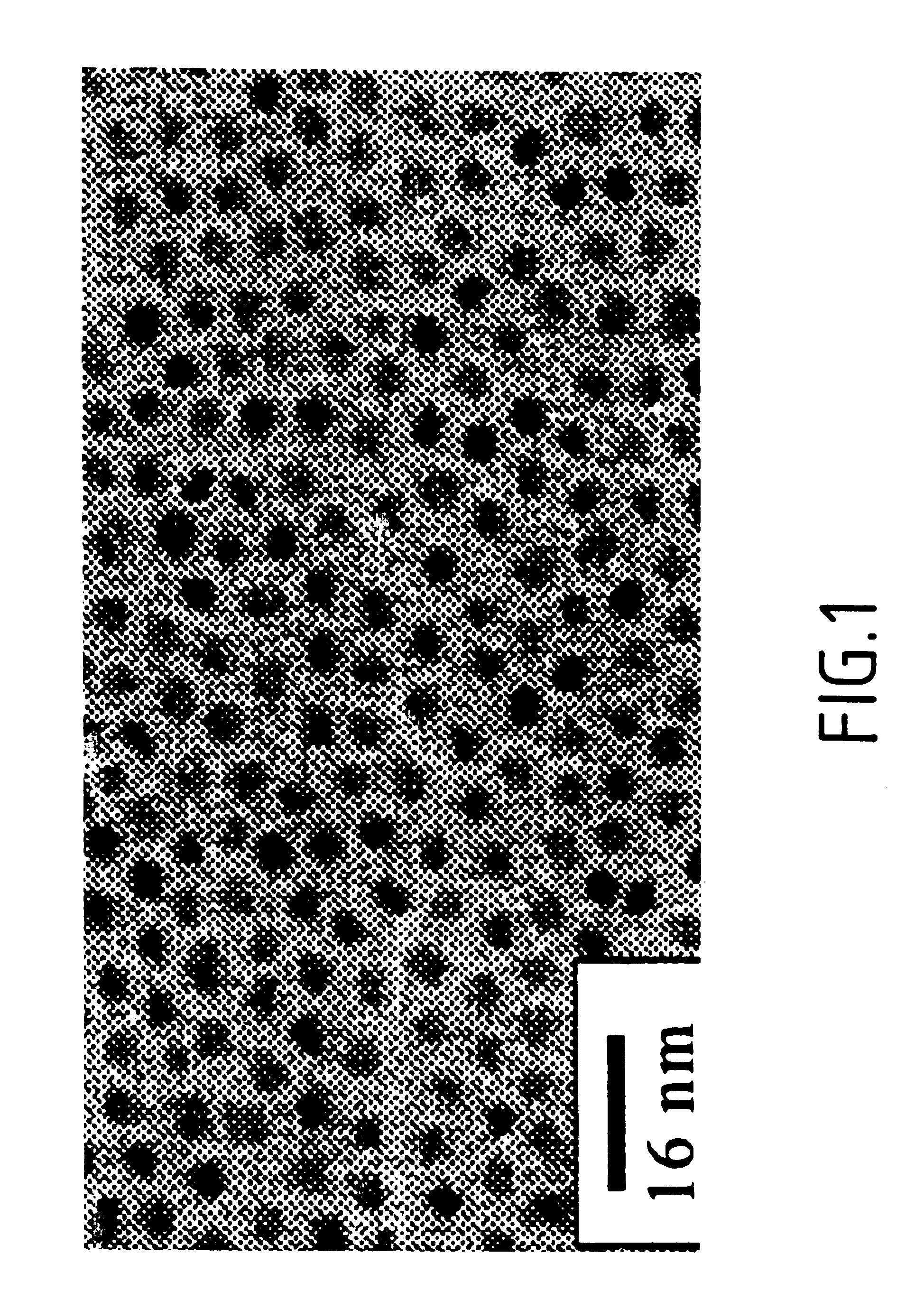

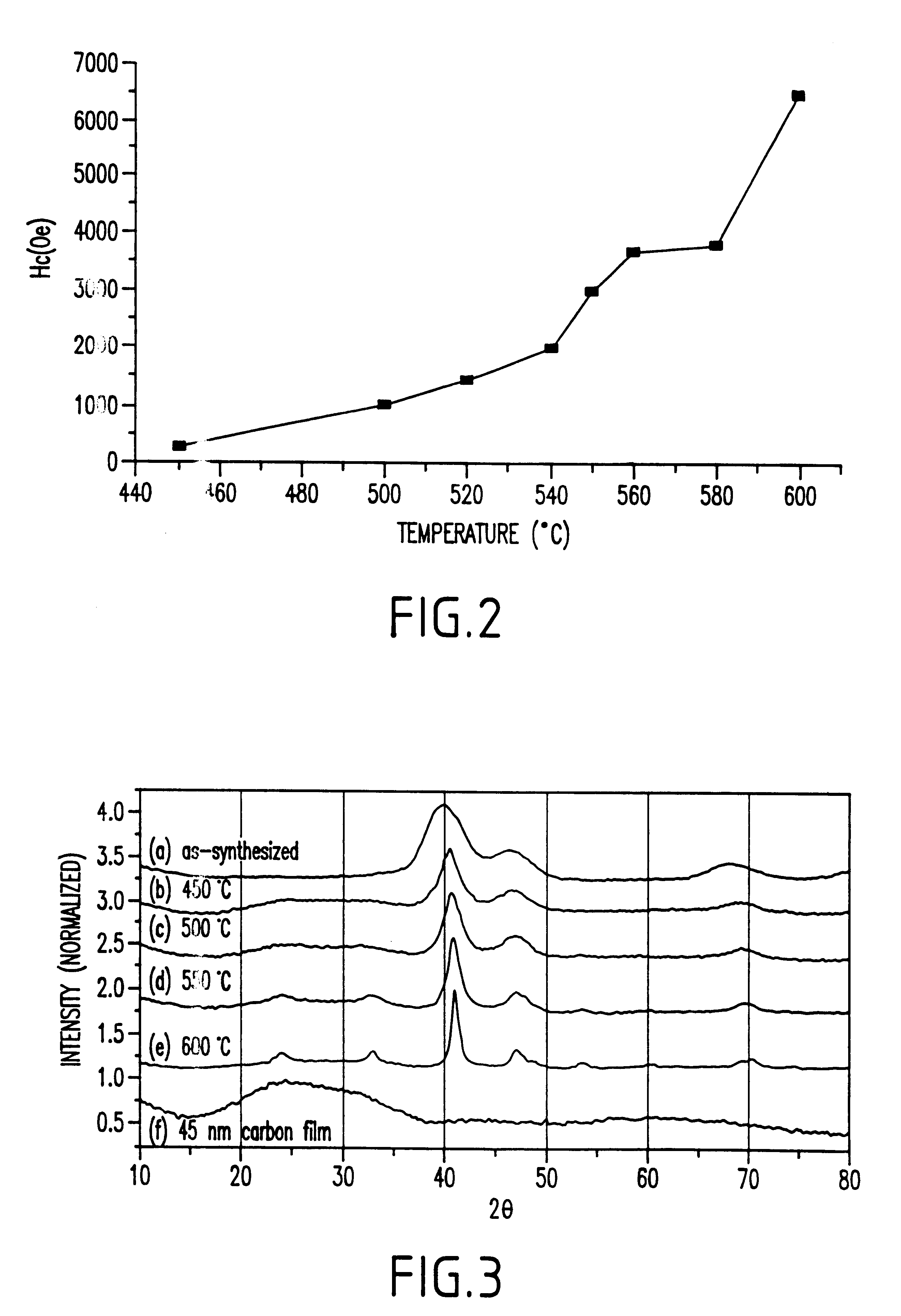

Chemical synthesis of monodisperse and magnetic alloy nanocrystal containing thin films

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

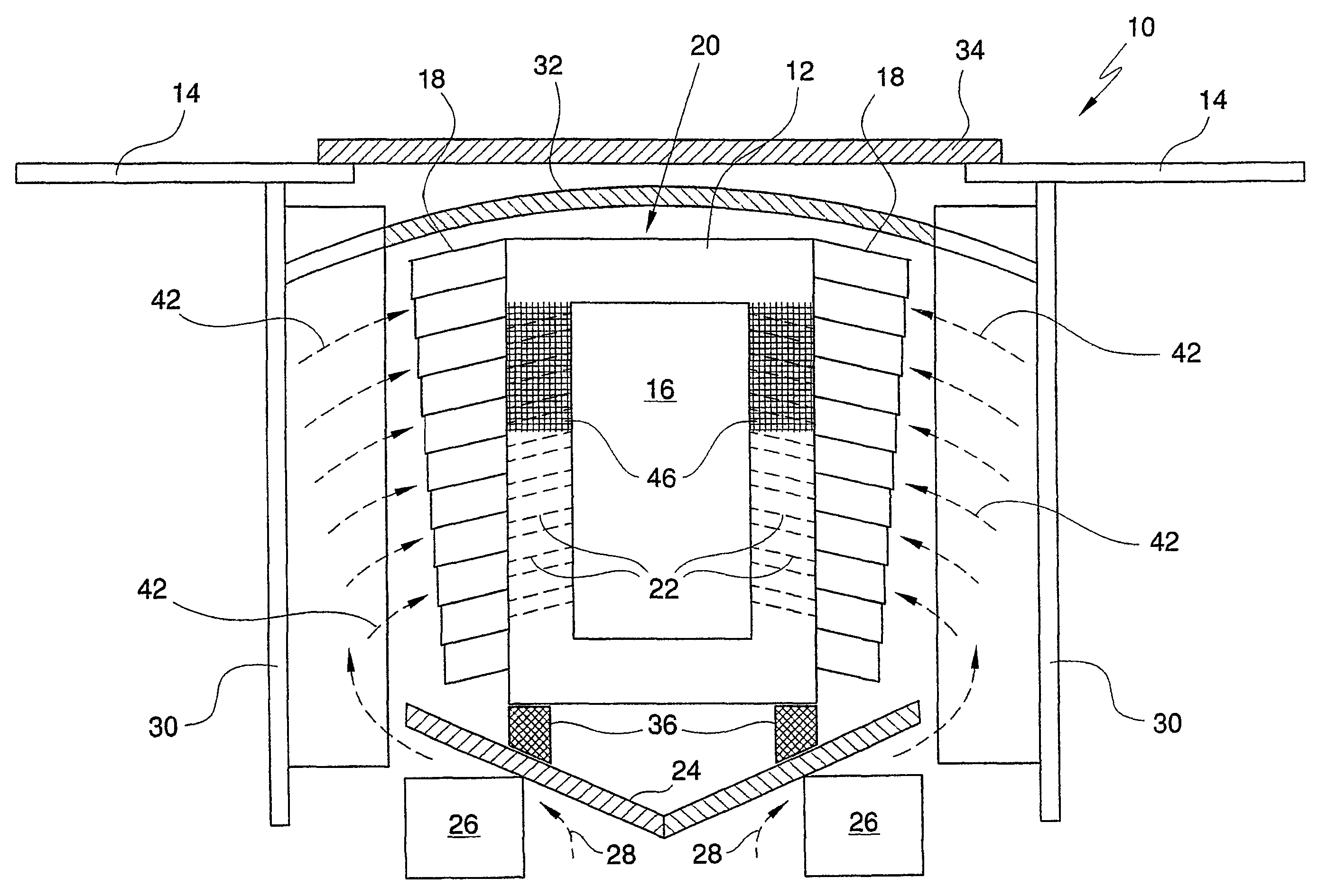

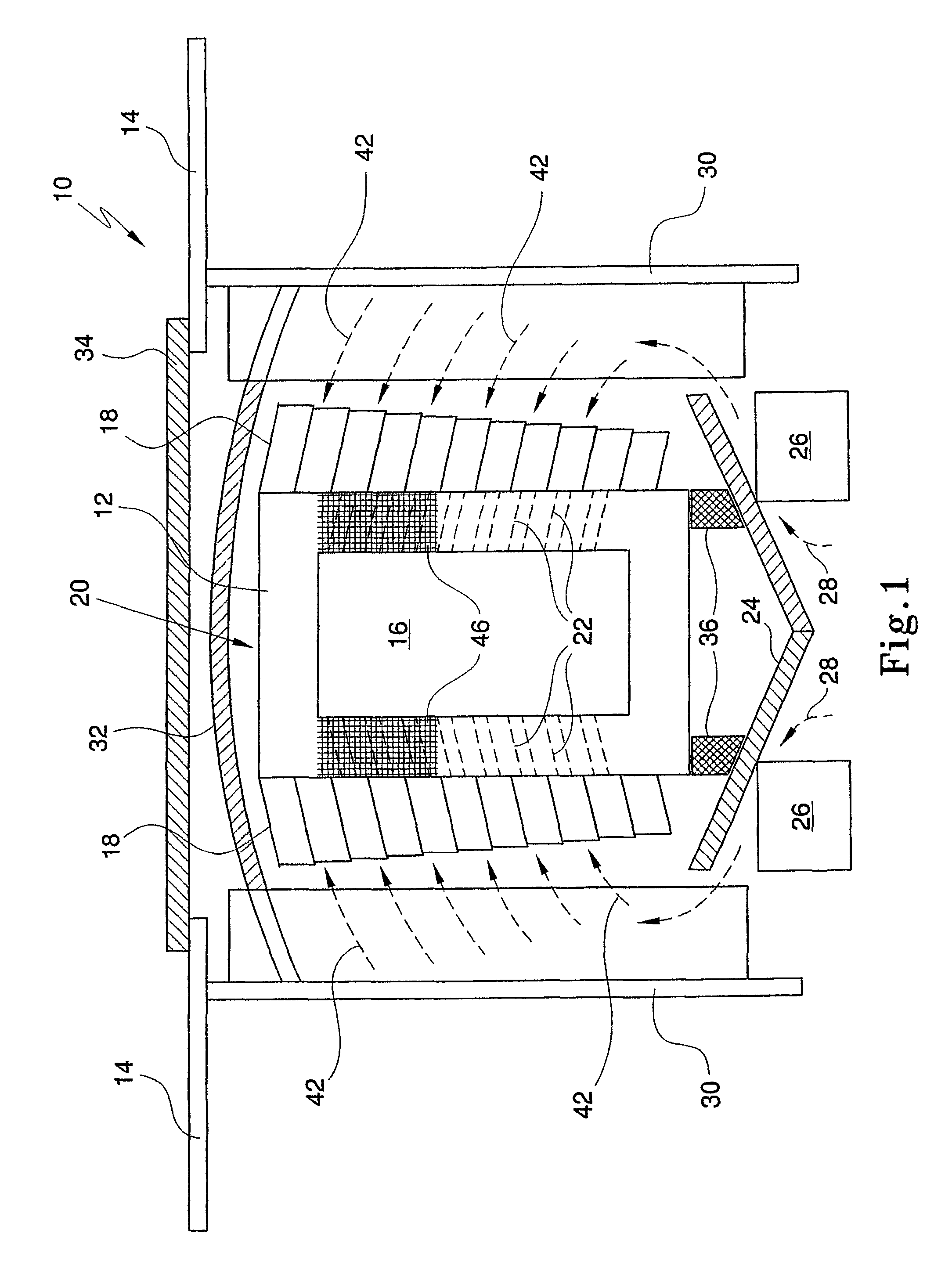

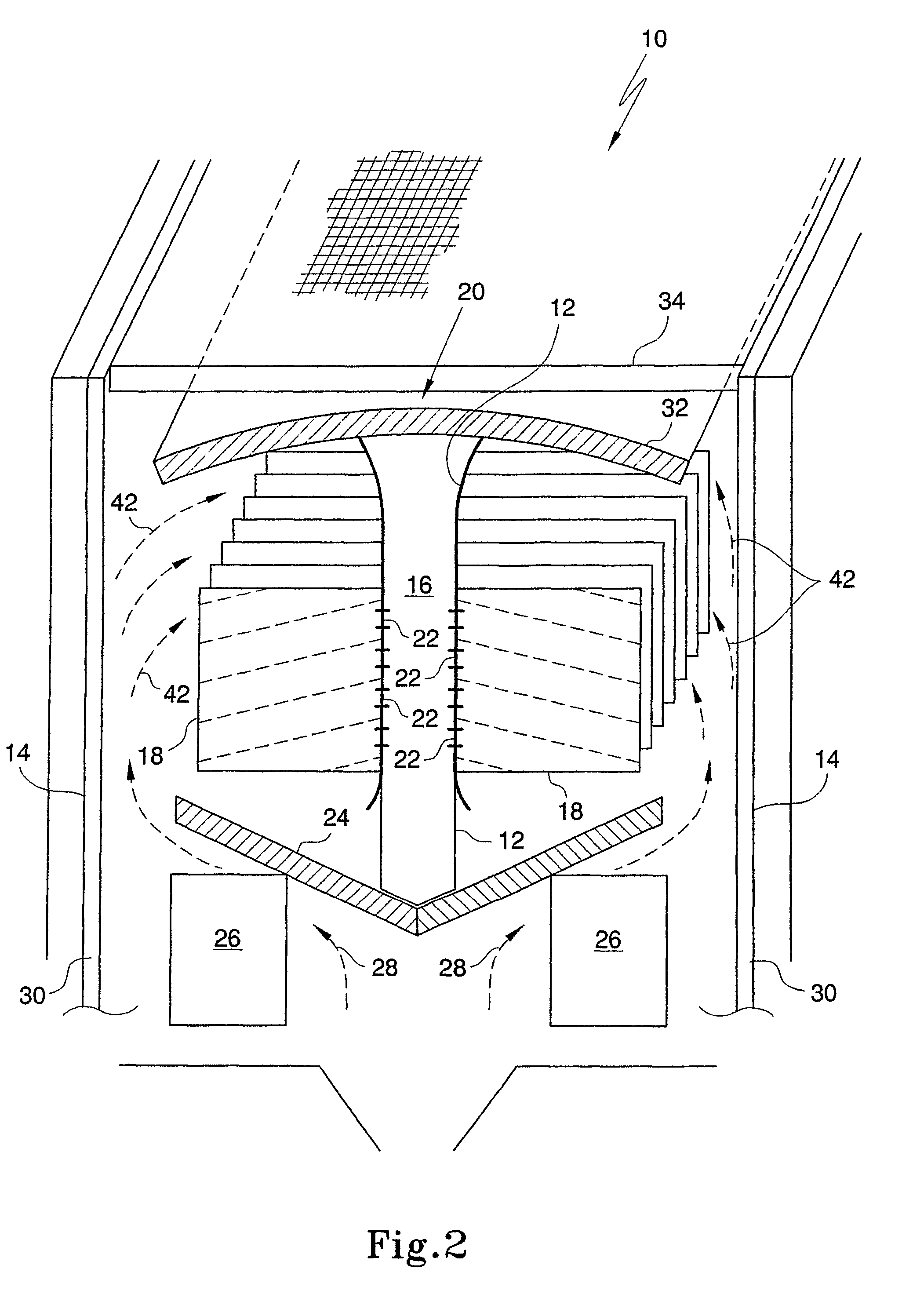

Heat exchanger

ActiveUS7901617B2Lower overall pressure dropImprove heat transfer performanceBlast furnace detailsManufacturing convertersEngineeringCooling fluid

A heat exchanger 10 includes a conduit 12 for conveying cooling fluid relative to a body to be cooled. A heat transfer arrangement 62 is arranged in communication with an interior of the conduit 12, the heat transfer arrangement 62 and the conduit 12 together defining an assembly that is mountable adjacent the body to be cooled, convective heat exchange occurring, in use, due to movement of the cooling fluid relative to the body and the heat transfer arrangement 62 of the assembly and radiant heat exchange occurring between the body and at least part of the heat transfer arrangement 62 of the assembly.

Owner:ENPOT HLDG LTD

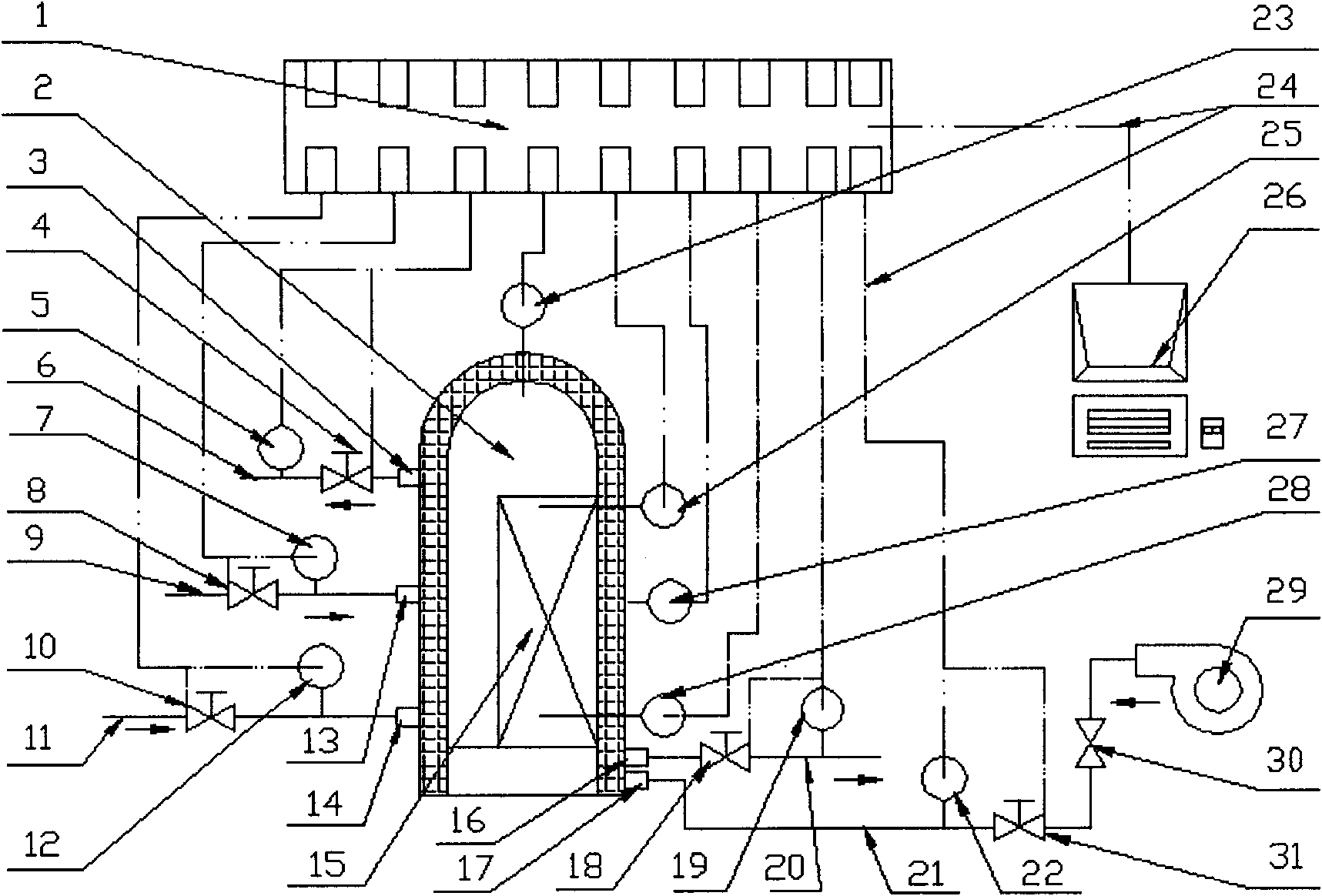

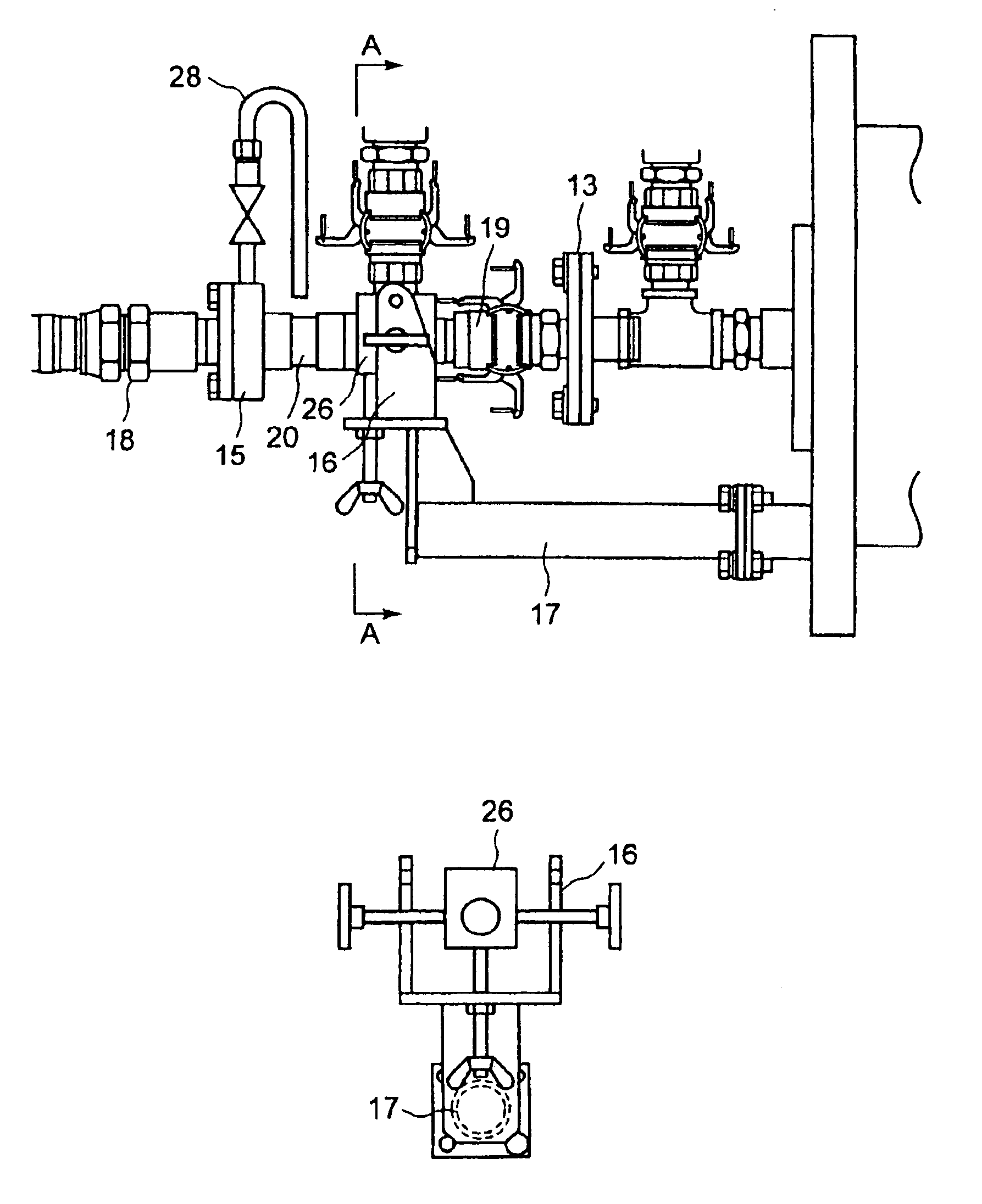

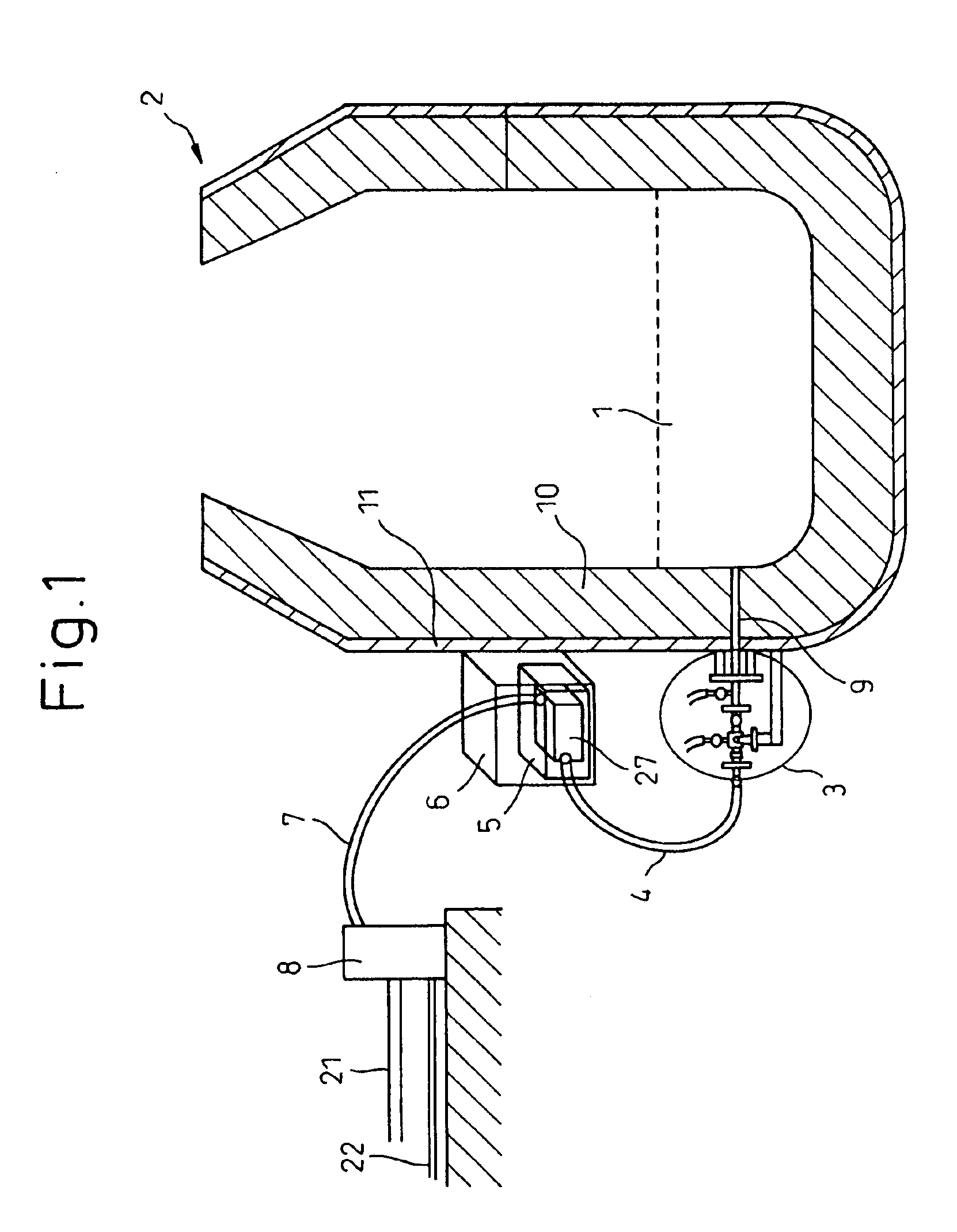

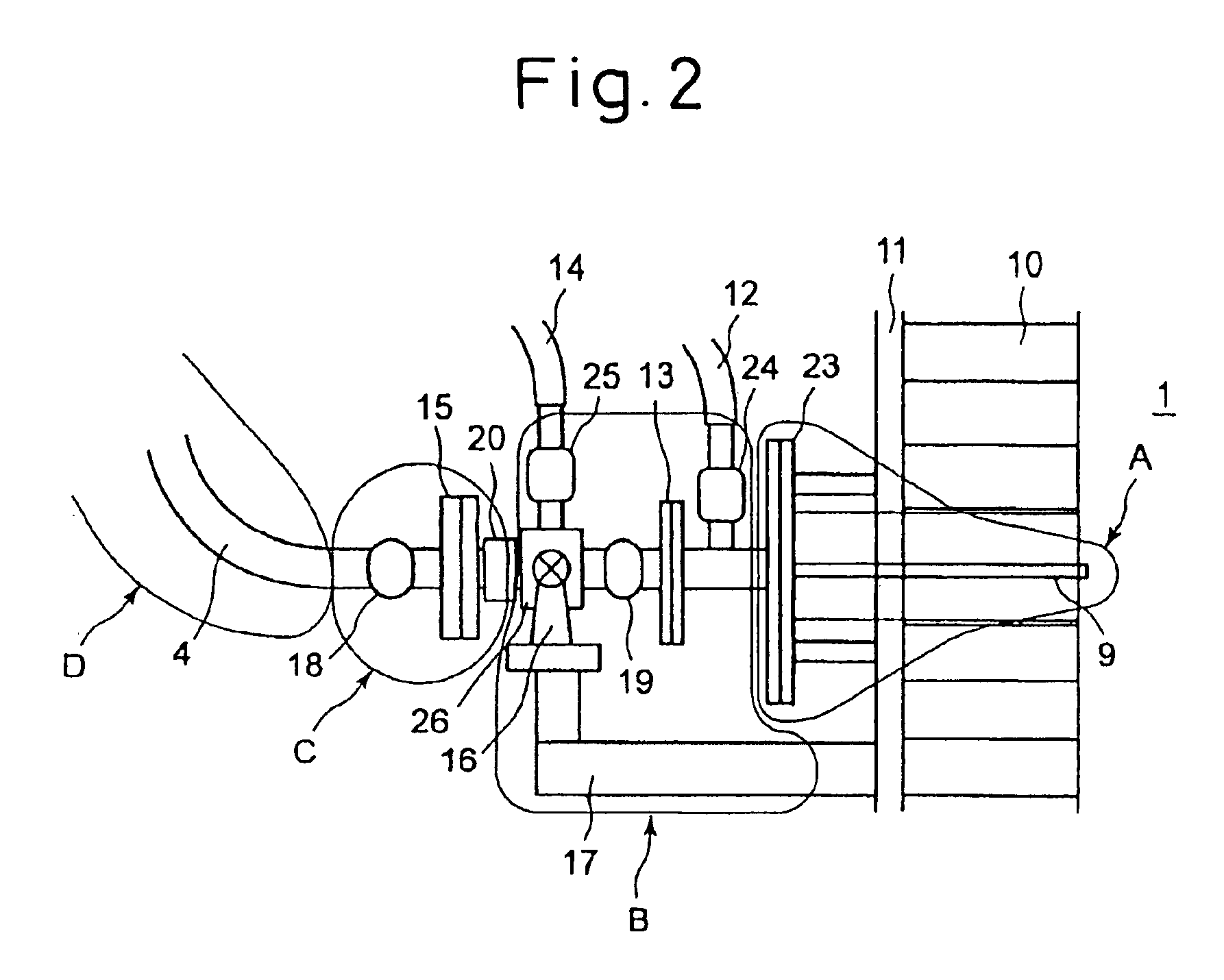

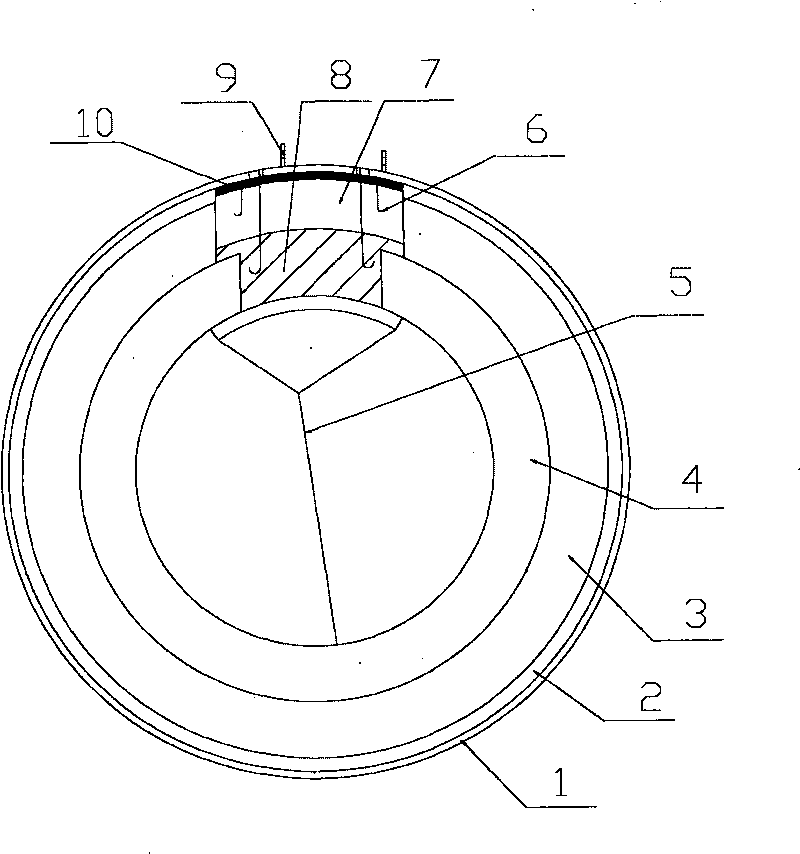

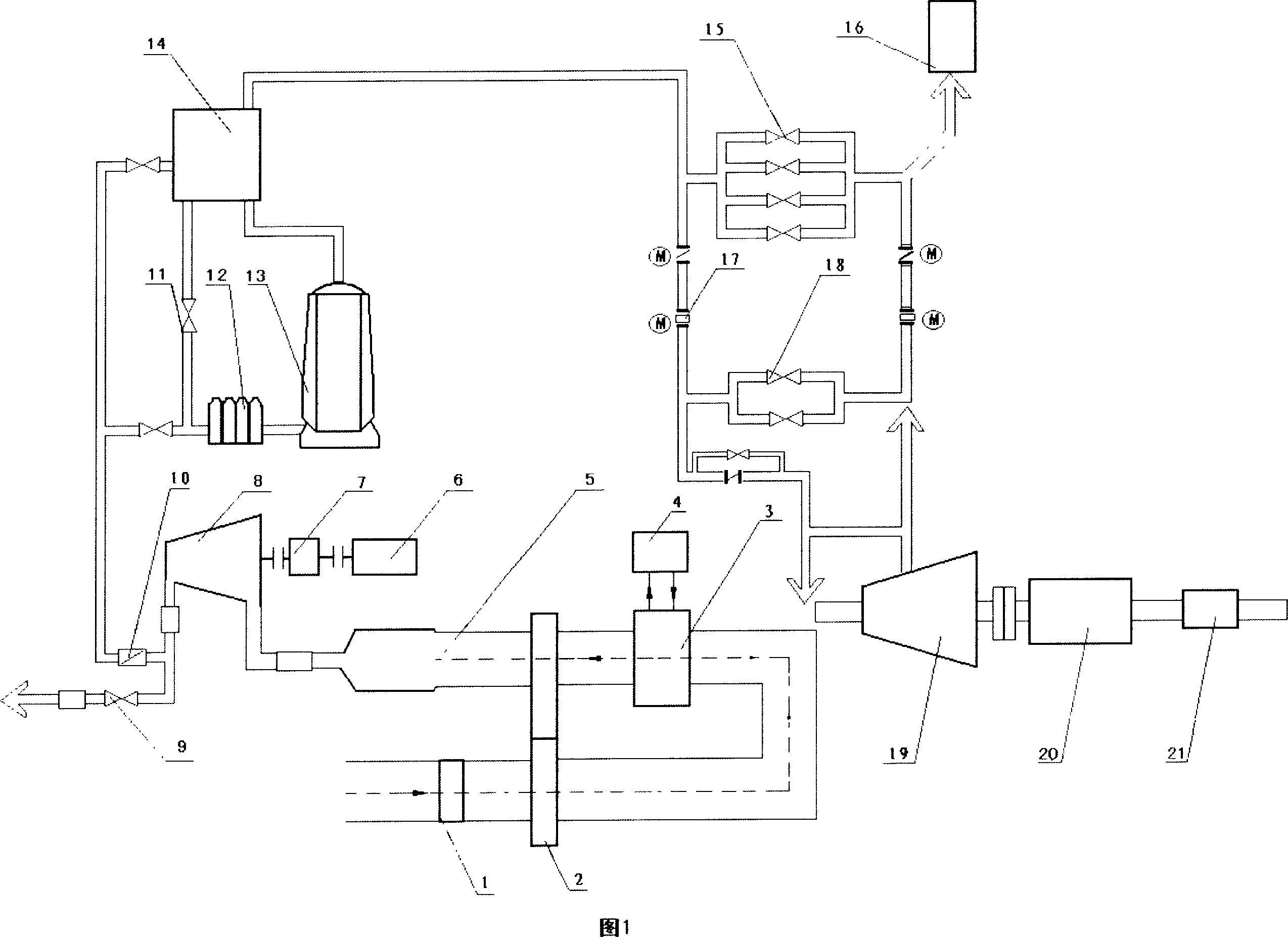

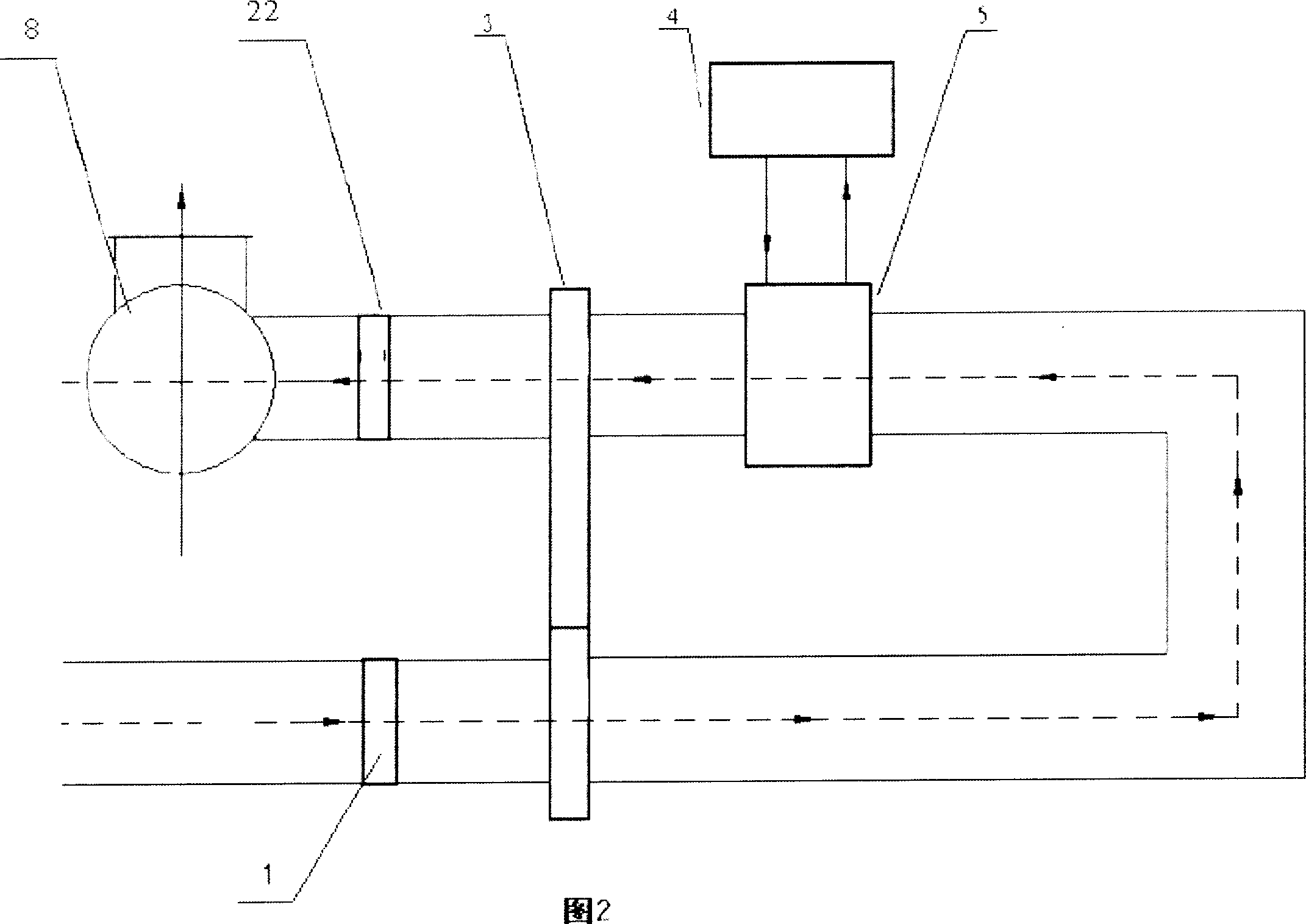

Constant wind temperature control system for hot blast stove

ActiveCN101892338ARegulating pressureAdjustable temperatureBlast furnace detailsHeating stovesBrickAir volume

The invention provides a constant wind temperature control system for a hot blast stove, comprising the hot blast stove (2), a detection element, a regulating valve, a data acquisition unit (1) and a computer (26). The control method of the control system comprises the following processes: detection of fluid parameters and valve location signals, data acquisition, data transmission, data comparison and data correction and control adjustment, wherein the detection element and the regulating valve are arranged in a pipeline, and temperature measuring equipment is arranged on the surface of a stove body. Specific steps are as follows: dynamically calculating parameters such as the heat storage capacity of checker bricks, temperature-rise ratio, theoretical wind temperature and the like during the combustion process, and carrying out on-line adjustment of parameters such as combustion air and gas flow, preheating temperature and the like; controlling direction change of the hot blast stove by the highest setting temperature of the checker bricks, a stove top and fume; and during the air supply period, taking hot blast temperature control as a target to determine an air supply curve and air supply time. The method based on calculation of dynamic balance of on-line energy of the hot blast stove effectively controls the heat storage capacity of the checker bricks of the hot blast stove, adjusts air supply quantity and air supply time, and ensures stable output of wind temperature of the hot blast stove.

Owner:SHOUGANG CORPORATION

Slag washing water steam recycling and white fog removing system and recycling method

PendingCN107815514ADesaturationAvoid it happening againBlast furnace detailsDischarge devicesSlagDihydrogen oxide

The invention provides a slag washing water steam recycling and white fog removing system and a recycling method. The slag washing water steam recycling and white fog removing system comprises a slagwashing water steam chimney close to a blast furnace, at least one cooling spraying device and a hot air furnace assembly; the lower portion of the slag washing water steam chimney can contain waste slag discharged out of the blast furnace and carries out slag washing operation, the cooling spraying devices are arranged in the middle of the slag washing water steam chimney and spray atomized waterto the lower portion of the slag washing water steam chimney, the hot air furnace assembly is communicated with the blast furnace and the upper portion of the slag washing water steam chimney, the hot air furnace assembly can convey generated hot air into the blast furnace, and conveys the treated waste gas to the upper portion of the slag washing water steam chimney, the mist spraying cooling direct heat exchange manner is adopted, the cooling efficiency is high, in combination with the humidity and condensation effect of atomized water, a small amount of water is sprayed, and therefore a large amount of water steam can be recycled, water steam which is not condensed is subject to waste gas temperature rise dilution, the water steam saturability is reduced, and white smoke is prevented from being generated.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

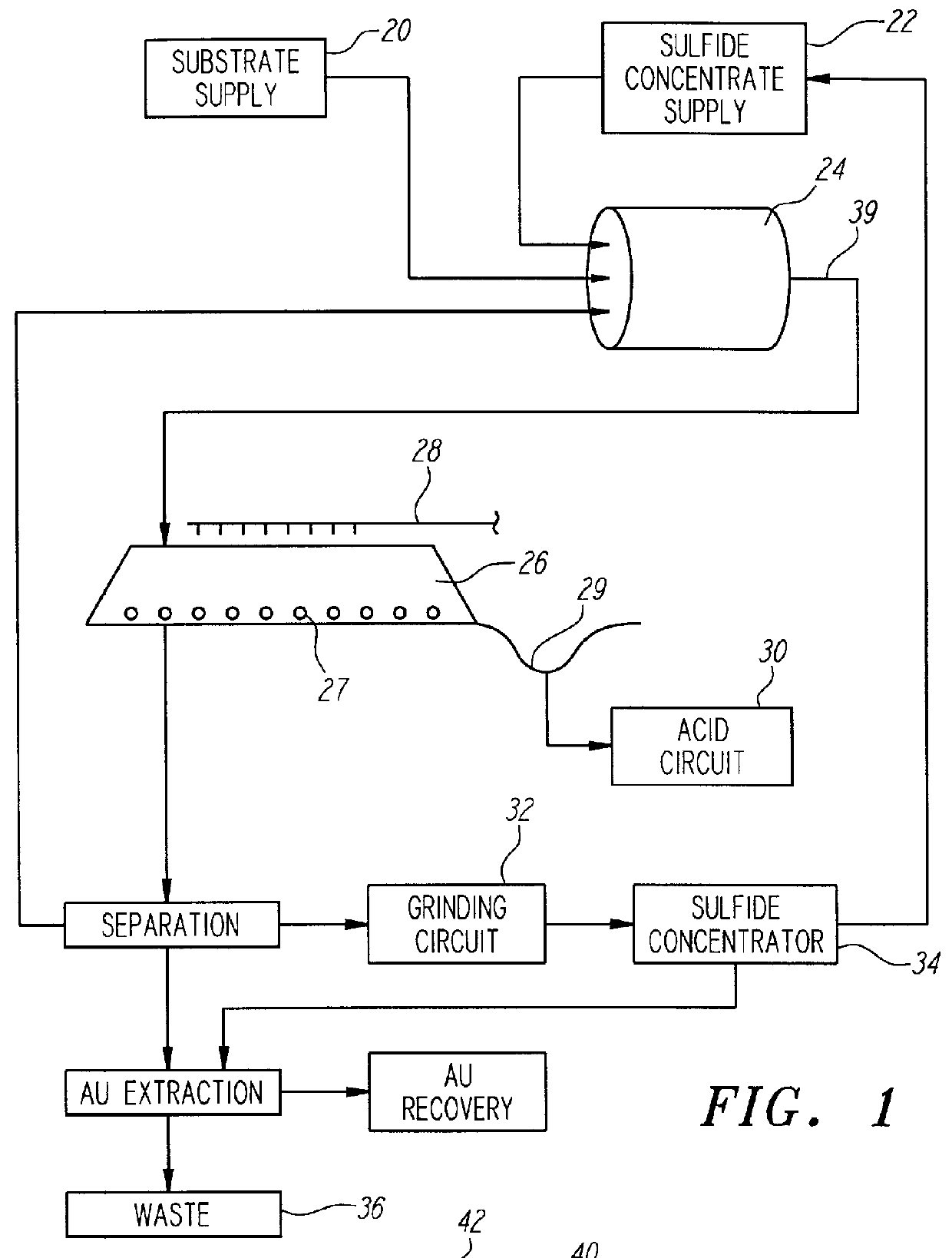

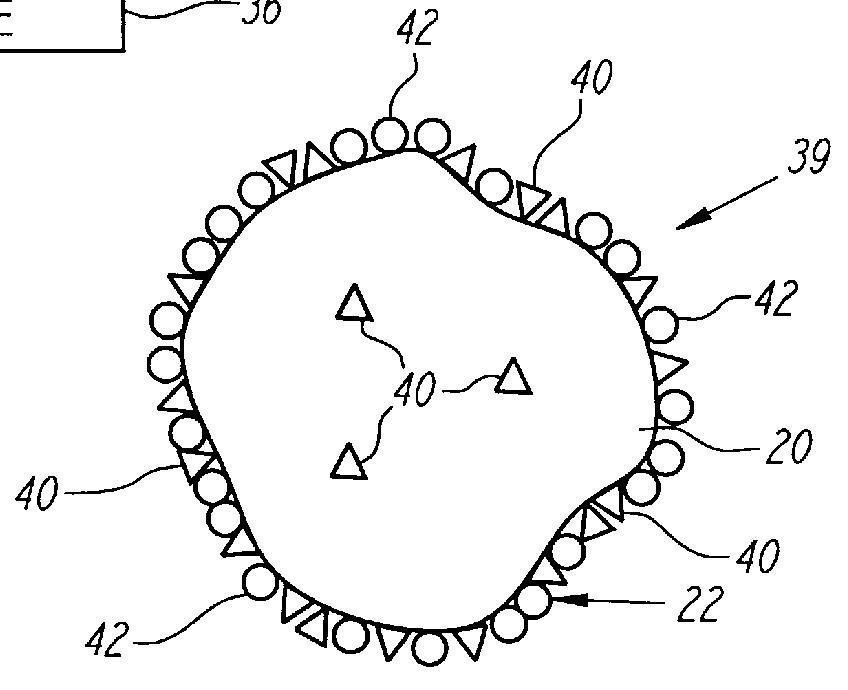

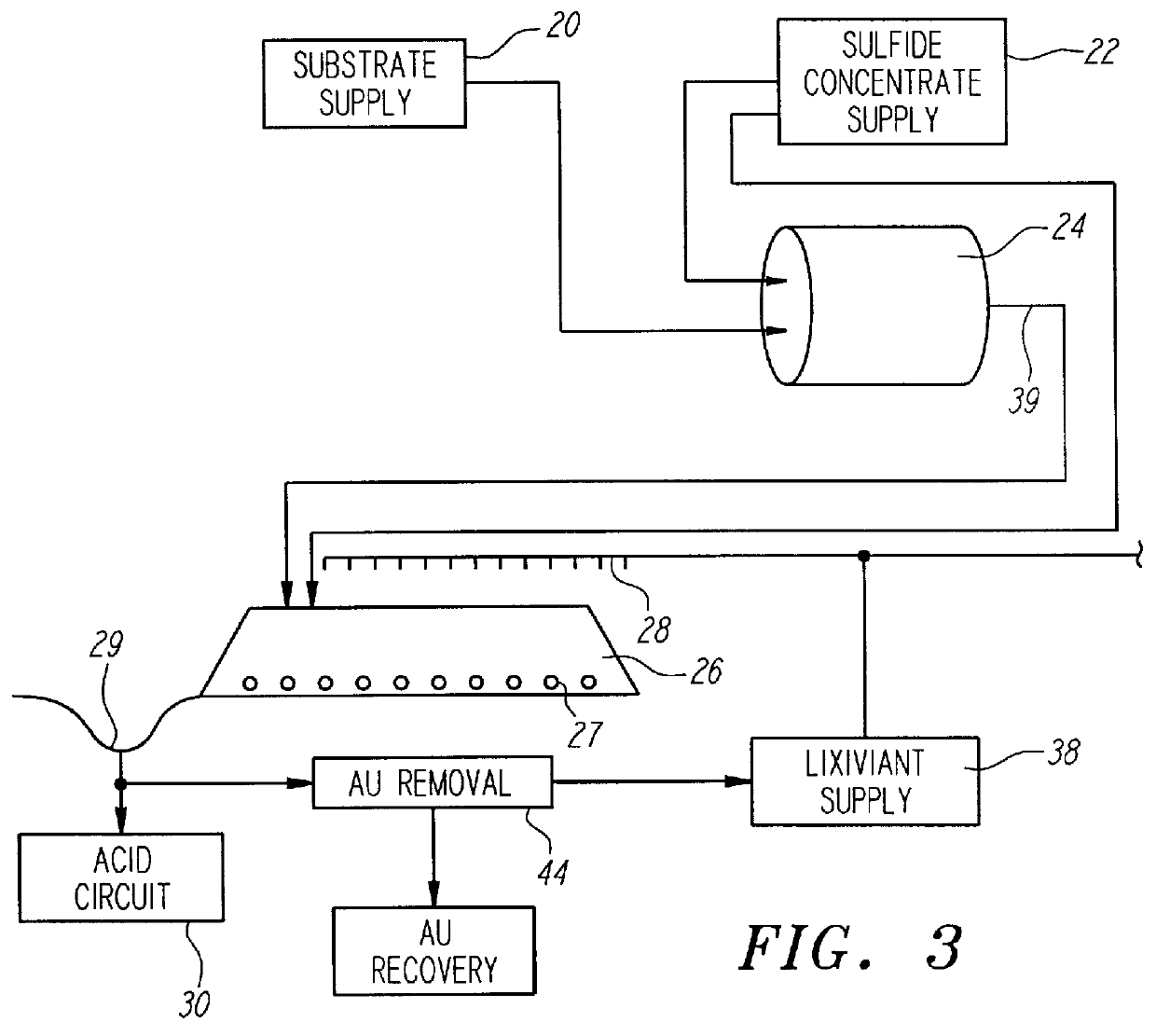

Nonstirred bioreactor for processing refractory sulfide concentrates and method for operating same

InactiveUS6083730AReduced pHIncrease equipment costSolvent extractionContaminated soil reclamationSulfide mineralsMetallic sulfide

A method of biooxidizing sulfide minerals in a nonstirred bioreactor is provided. According to the disclosed method, a concentrate of sulfide minerals is coated onto a substrate, such as coarse ore particles, lava rock, gravel or rock containing mineral carbonate as a source of CO2 for the biooxidizing bacteria. After the sulfide minerals are coated onto the substrate, a heap is formed with the coated substrates or the coated substrates are placed within a tank. The sulfide minerals are then biooxidized to liberate the metal value of interest. Depending on the particular ore deposit being mined, the sulfide mineral concentrates used in the process may comprise sulfide concentrates from precious metal bearing refractory sulfide ores or they may comprise sulfide concentrates from metal sulfide type ores, such as chalcopyrite, millerite or sphalorite. The distinction being that in the former, the metal of interest is a precious metal occluded within the sulfide minerals, whereas in the latter, the metal to be recovered is copper, nickel or zinc and is present as a metal sulfide in the sulfide concentrate.

Owner:GEOSYNFUELS LLC (US)

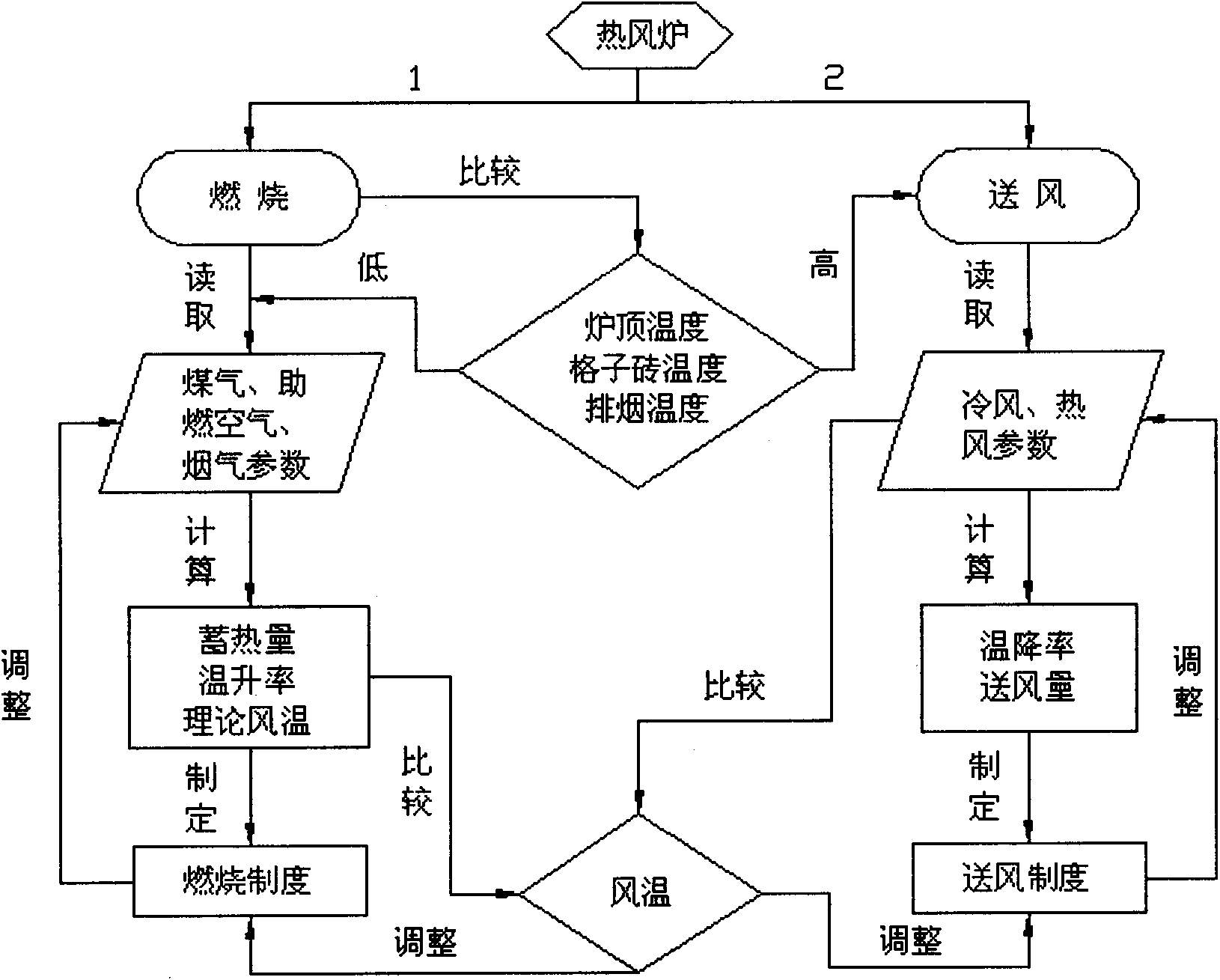

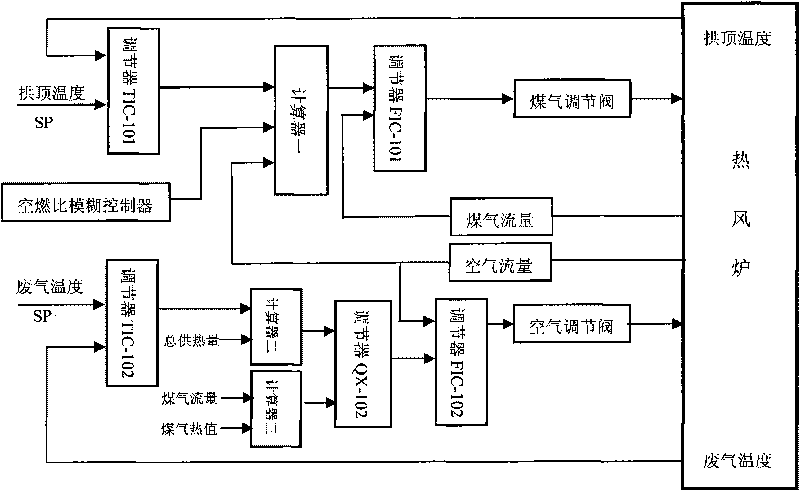

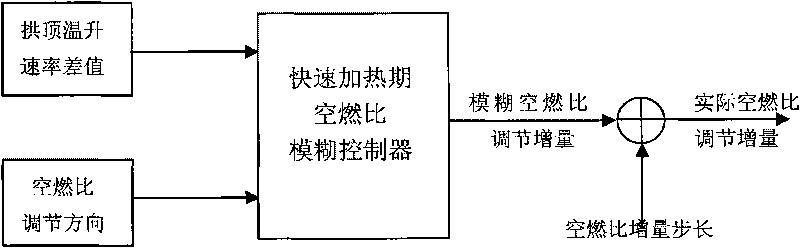

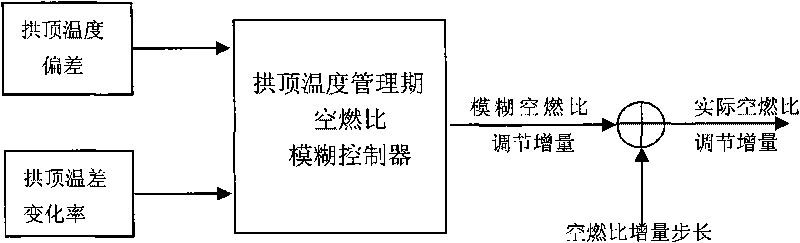

Intelligent control method for automatic optimization combustion of hot-blast stove

InactiveCN101736111AImproved combustion controlTake advantage ofFuel supply regulationBlast furnace detailsEngineeringAir conditioning

The invention provides an intelligent control method for automatic optimization combustion of a hot-blast stove. Based on computation of total heat supply amount, by setting the target values of the temperature of a combustion arch top and the temperature of exhaust gas, an air-fuel ratio fuzzy controller optimizes optimal air-fuel ratio coefficients in a combustion period in real time to regulate the flow of combustion-supporting air and mixed gas in real time; the control of the flow of the combustion-supporting air is completed by an exhaust gas temperature regulator, a heat supply amount regulator and a combustion-supporting air regulator; the control of the flow of the mixed gas is completed by an arch top temperature regulator and a mixed gas regulator; and the control of the air-fuel ratio is completed by the air-fuel ratio fuzzy controller. The invention can improve the combustion control level of the hot-blast stove and has the advantages of high combustion efficiency, full utilization of energy sources and strong heat storage capacity.

Owner:WISDRI ENG & RES INC LTD

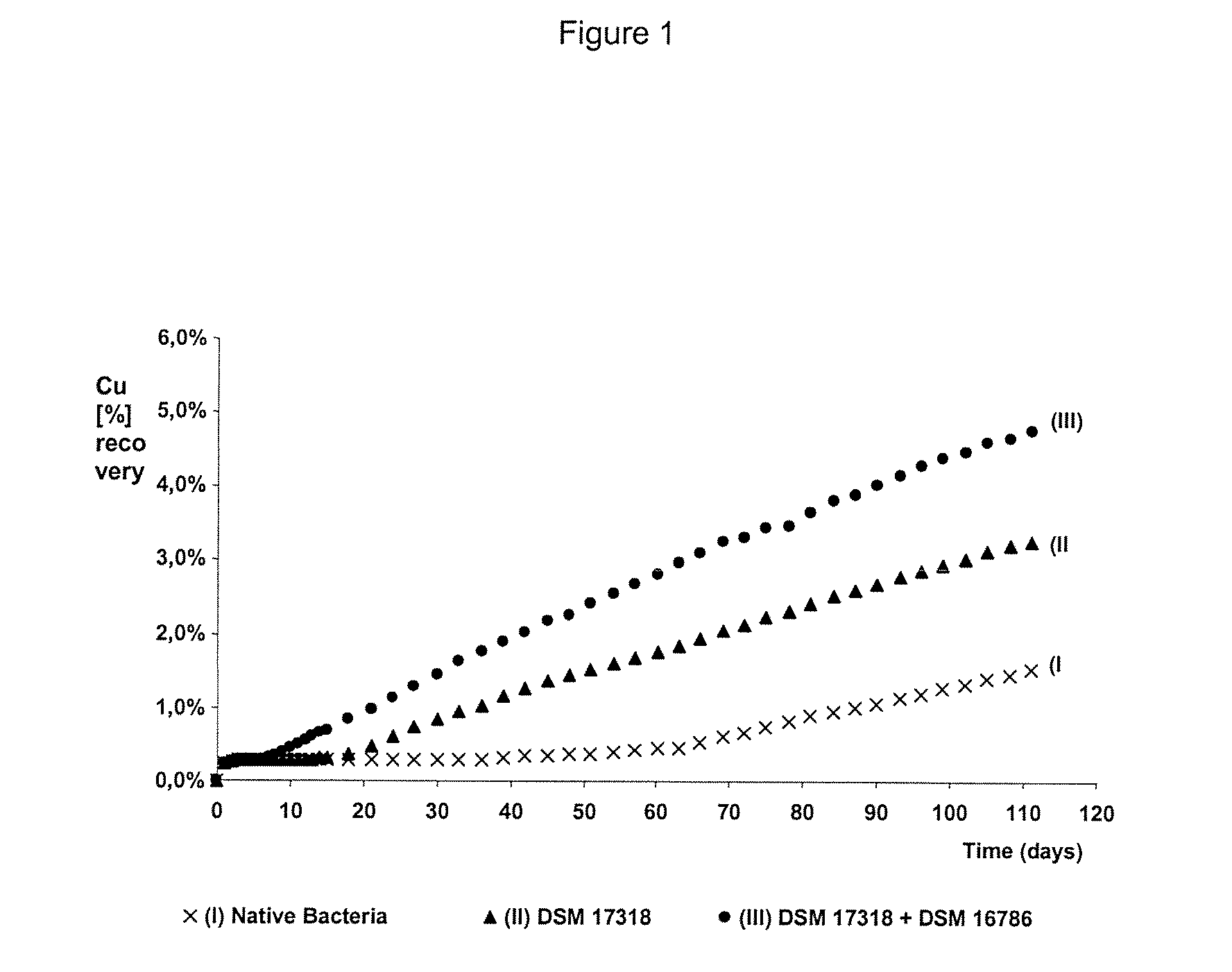

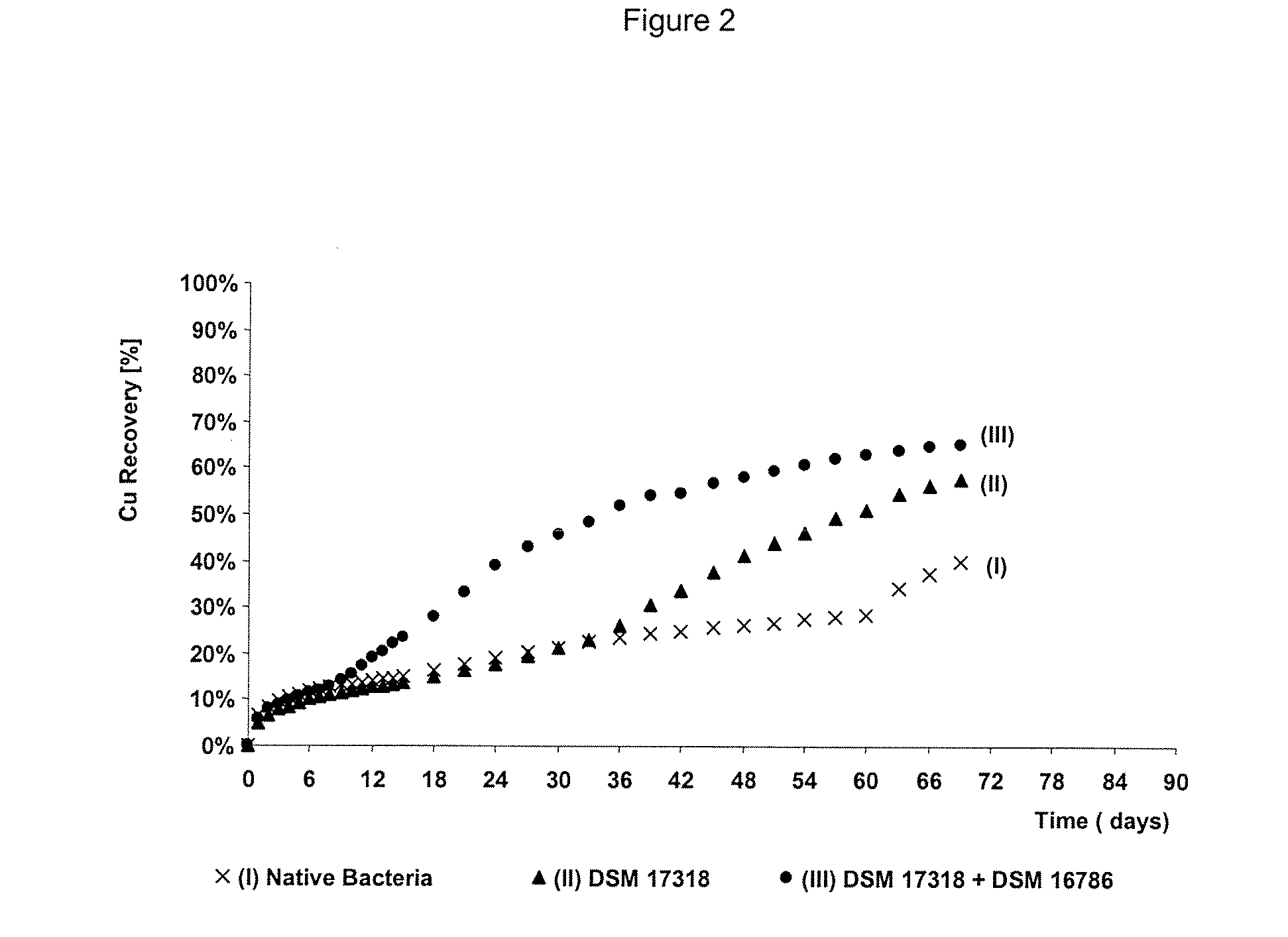

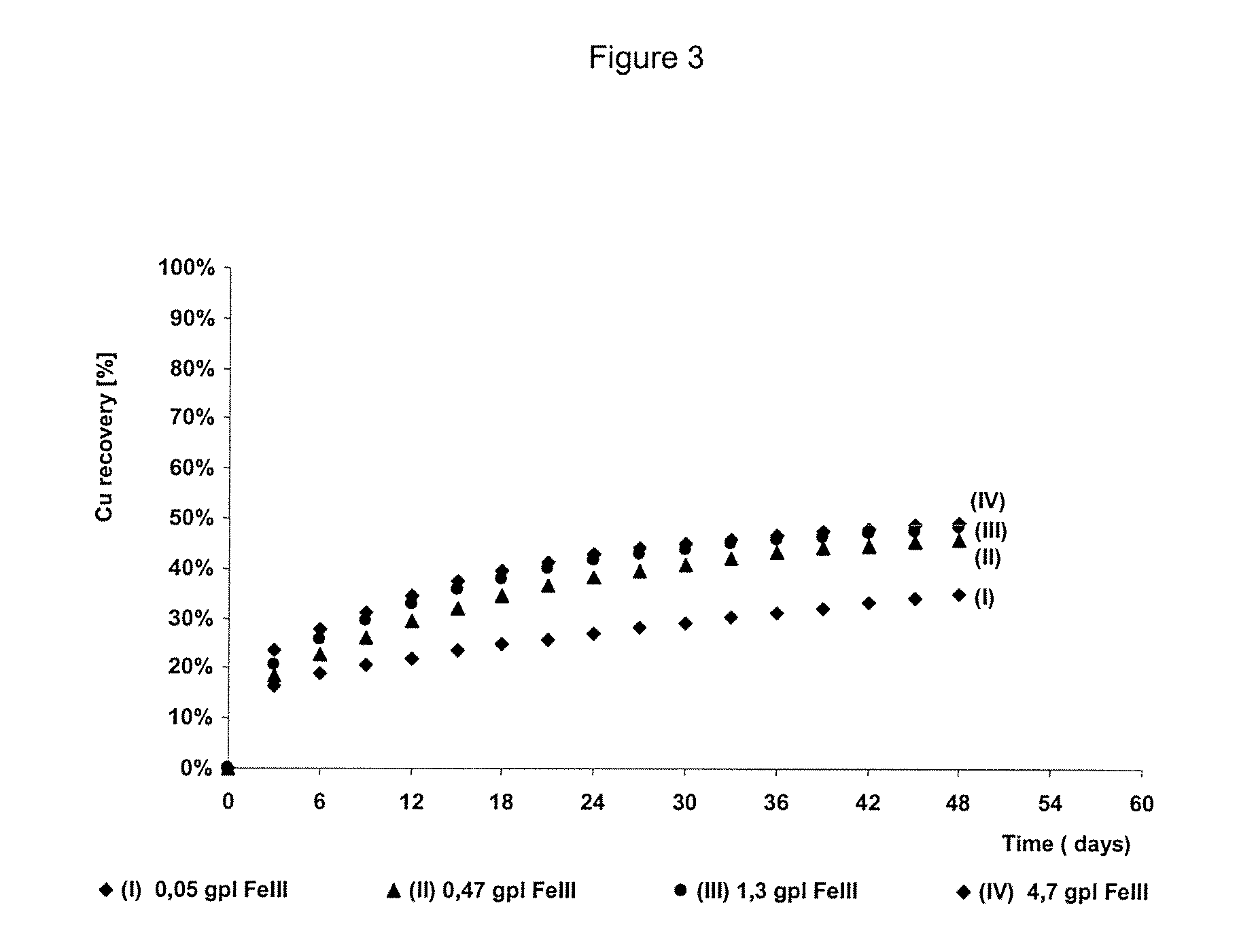

Process to increase the bioleaching speed of ores or concentrates of sulfide metal species, by means of continuous inoculation with leaching solution that contains isolated microorganisms, with or without presence of native microorganisms

ActiveUS20080127779A1Decrease ore bioleaching timeImprove bioleaching conditionSolvent extractionGold compoundsTailings damPotassium

The invention publishes a process to increase the bioleaching speed of ores or concentrates of sulfide metal species in heaps, tailing dams, dumps, or other on-site operations. The process is characterized by the continuous inoculation of the ores or concentrates with isolated microorganisms of the Acidithiobacillus thiooxidans type, together with isolated microorganisms of the Acidithiobacillus ferrooxidans type, with or without native microorganisms, in such a way that the total concentration of microorganisms in the continuous inoculation flow is of around 1×107 cells / ml to 5,6×107 cells / ml. In particular, the invention publishes the continuous inoculation of Acidithiobacillus thiooxidans Licanantay DSM 17318 together with Acidithiobacillus ferrooxidans Wenelen DSM 16786 microorganisms, or with other native microorganisms at a concentration higher than 5×107 cells / ml. In addition to the inoculation of isolated bacteria, the invention includes the addition of oxidizing agents such as the ferric ion produced externally, together with nutrients in the shape of salts of ammonium, magnesium, iron, potassium, as well as air enriched continuously with carbon dioxide to promote bacterial action in the bioleaching process of ores or concentrates.

Owner:BIOSIGMA

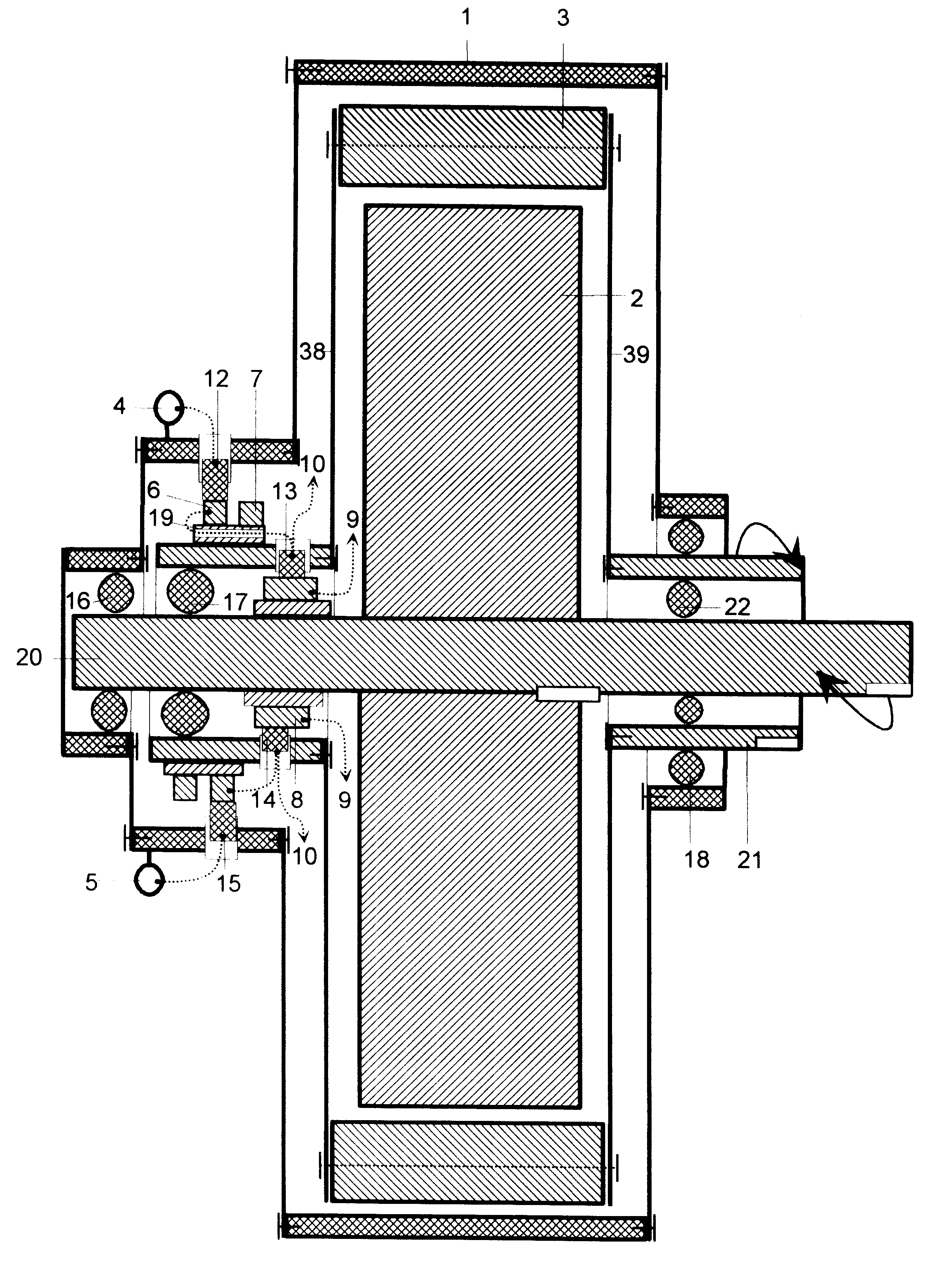

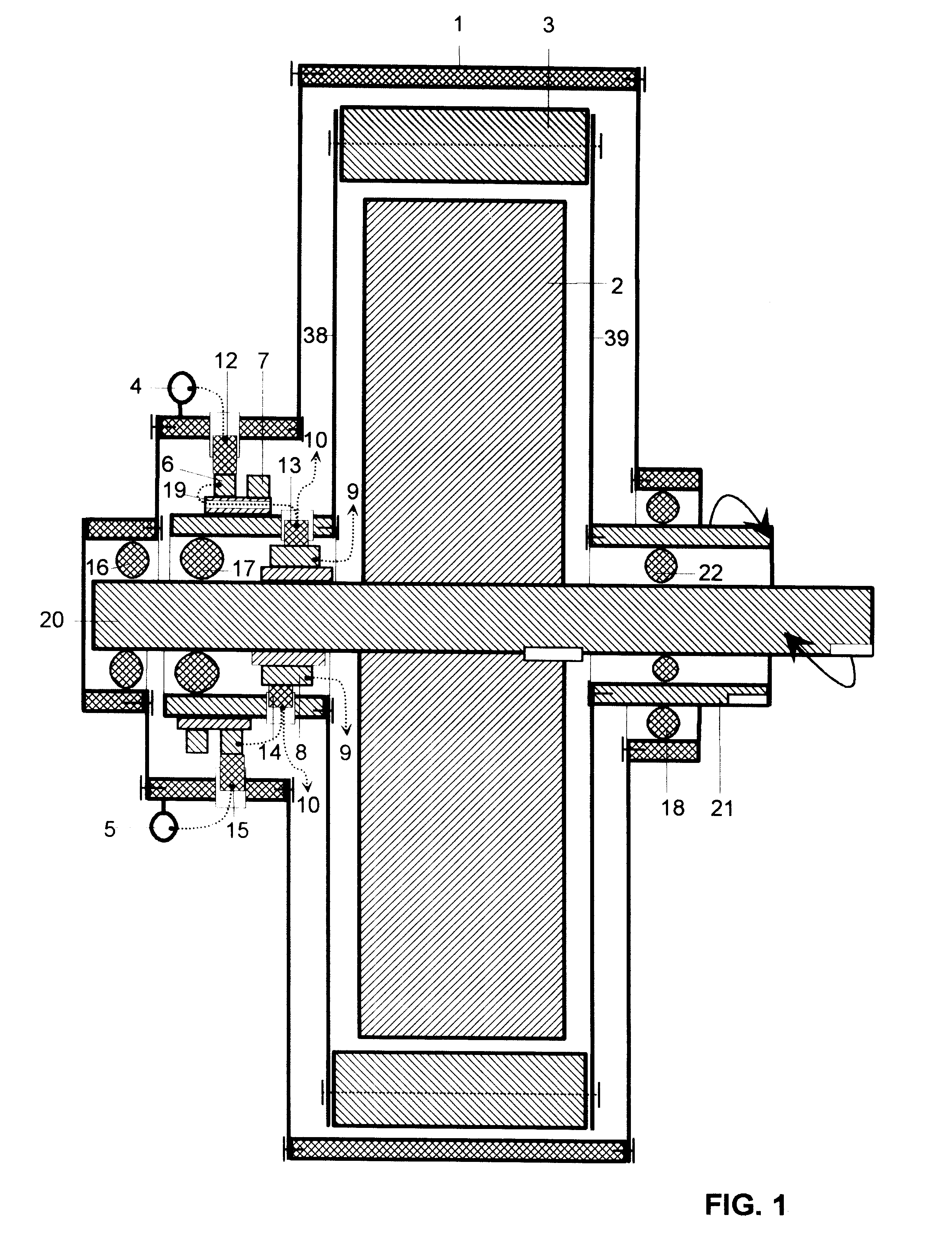

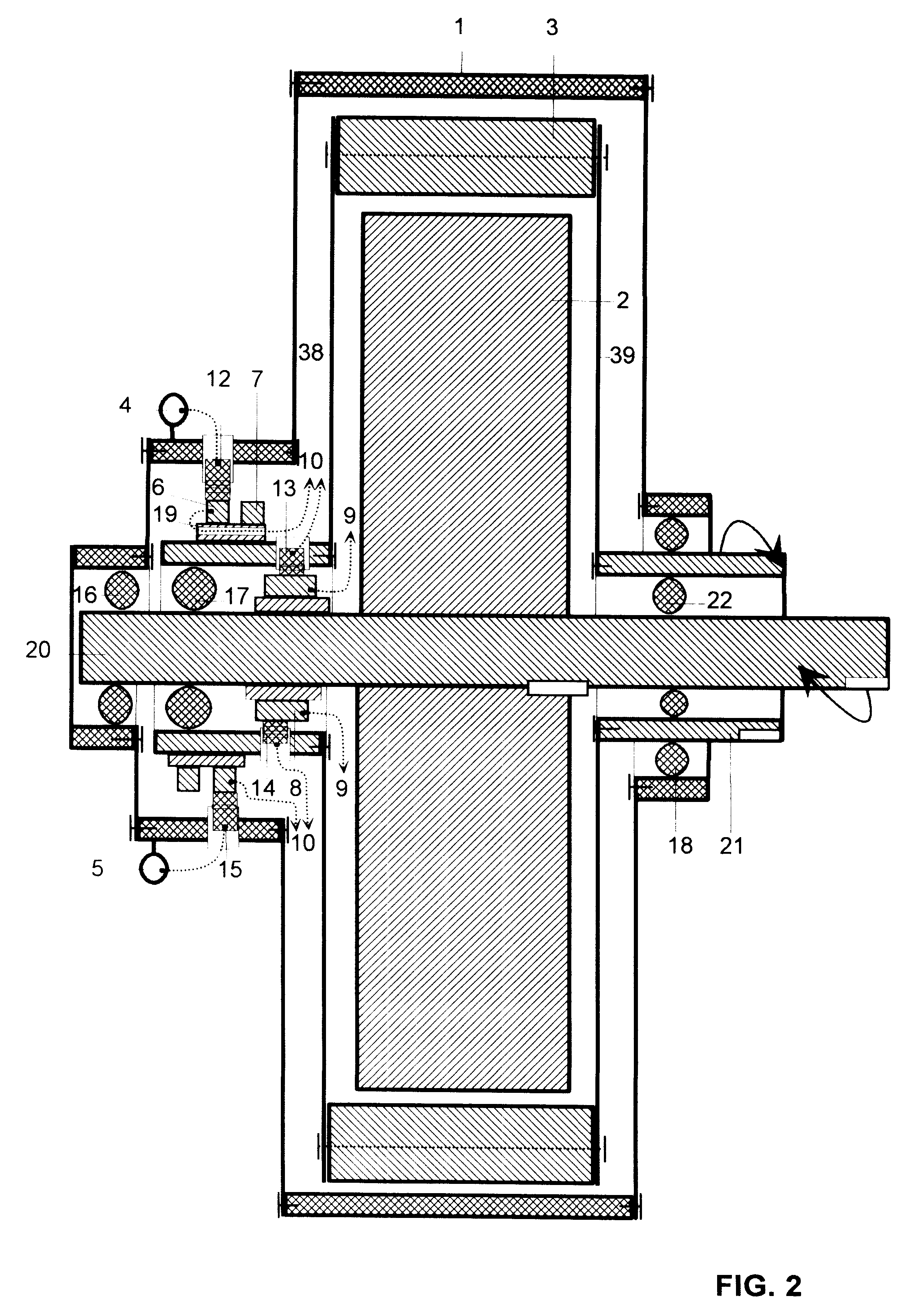

Method and electric motor with rotational stator

An electric composite rotating machine haveing two rotors, capable of developing mechanical power and of runing on two rotational direction at selfadjutable speeds, of differential type, with 40% increase of output, doubling the torque at 30% reduction of used electrical energy.

Owner:CHERCIU TRAIAN

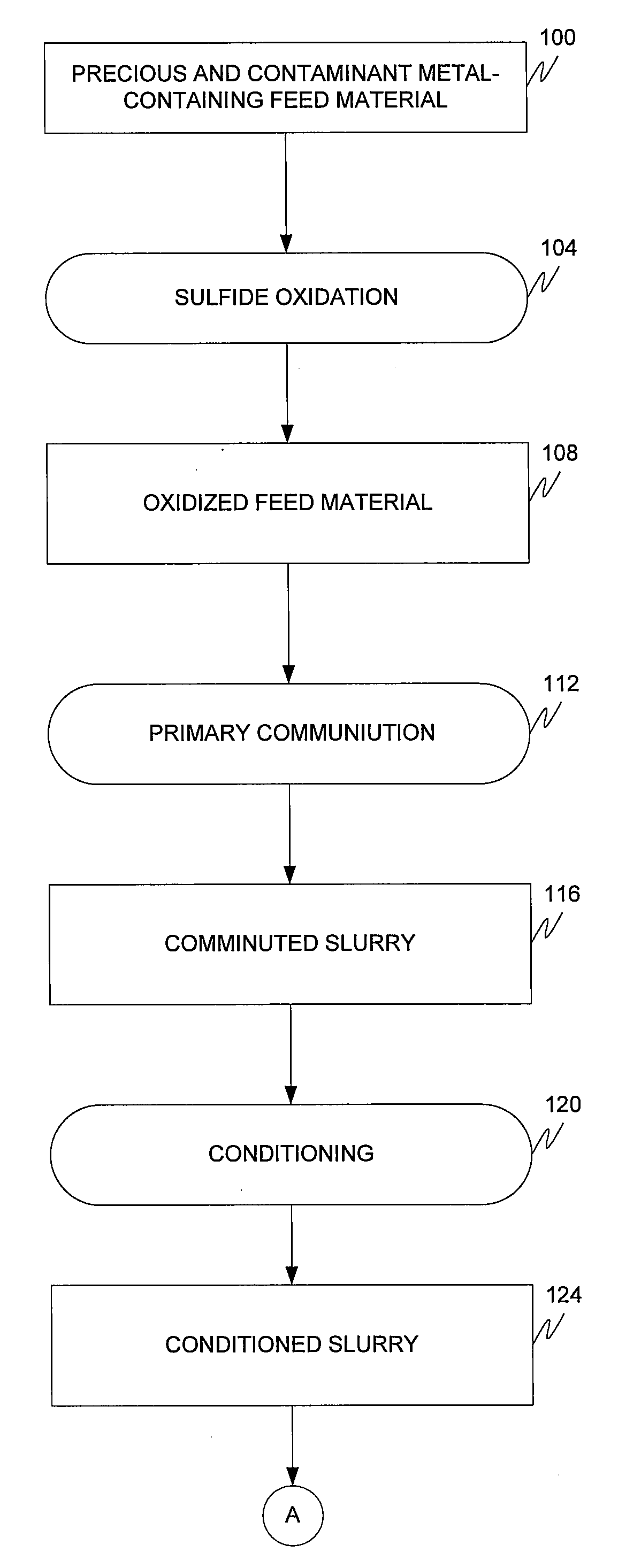

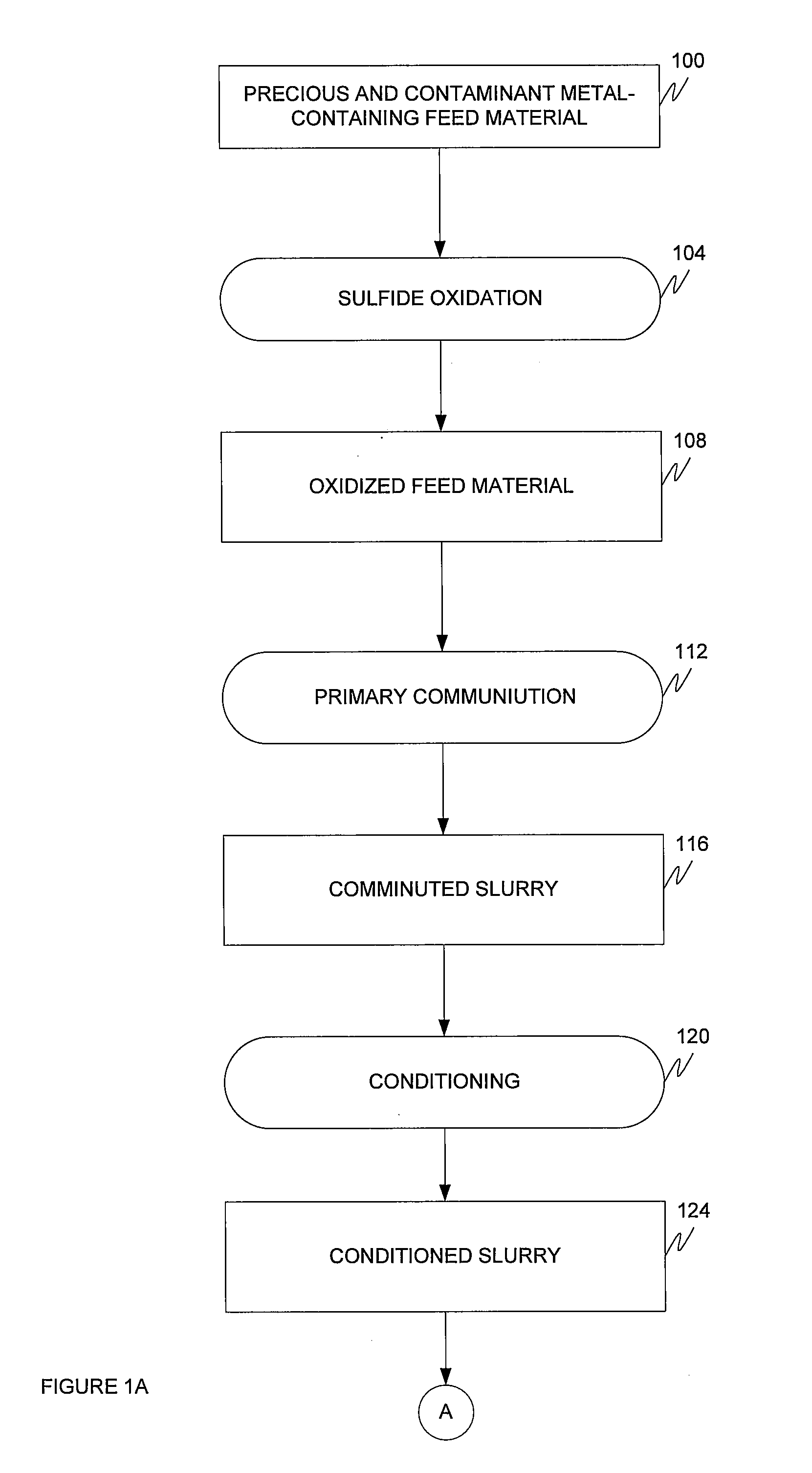

Method to improve recovery of gold from double refractory gold ores

ActiveUS20090071295A1Liberation of additionalReducing gold lossBlast furnace detailsFlotationSulfideGold ore

The present invention is directed to a precious metal recovery process in which carbonaceous material, such as preg robbing carbon, is floated after sulfide oxidation to separate the carbonaceous material from the precious metal.

Owner:BARRICK GOLD

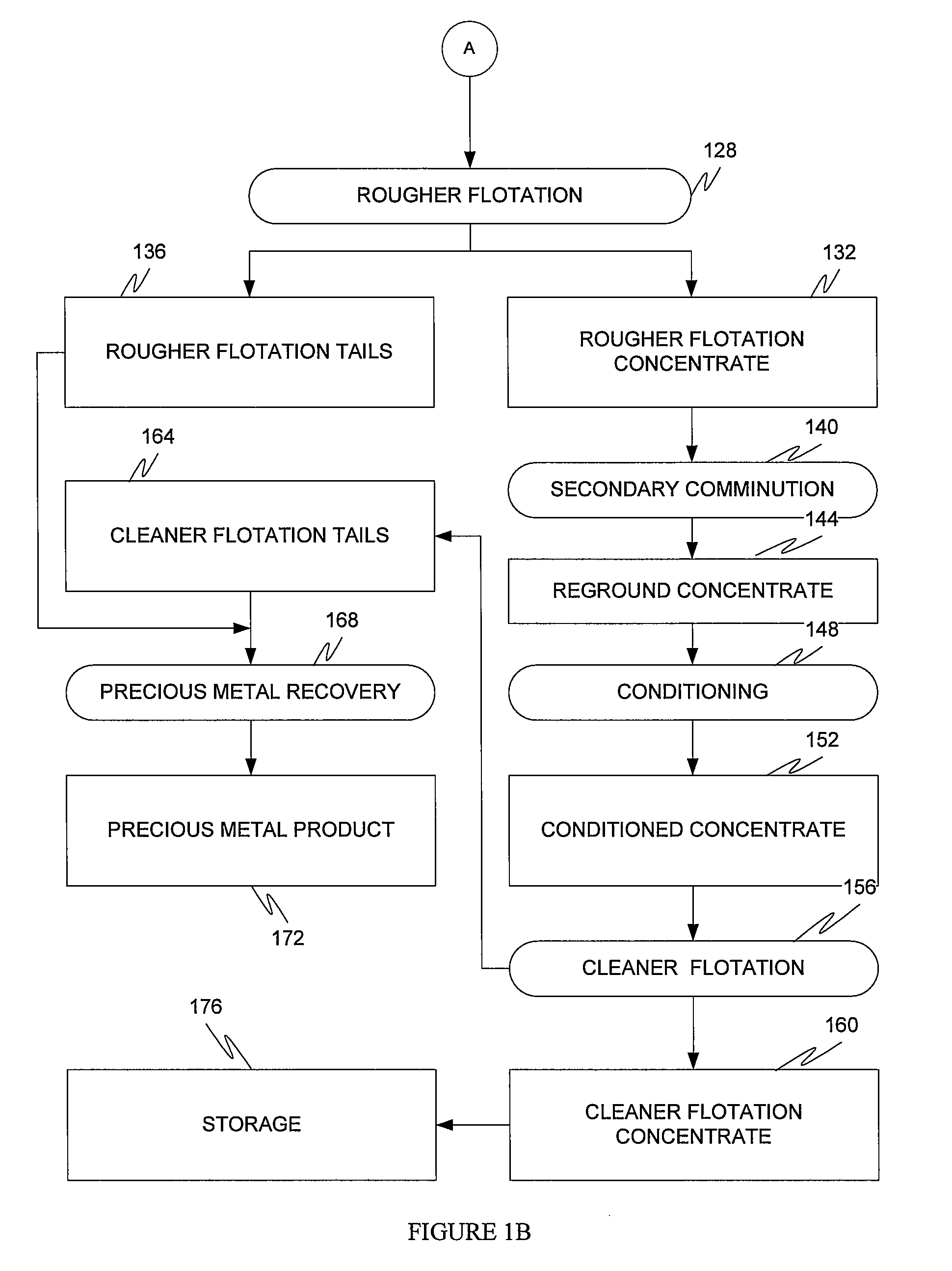

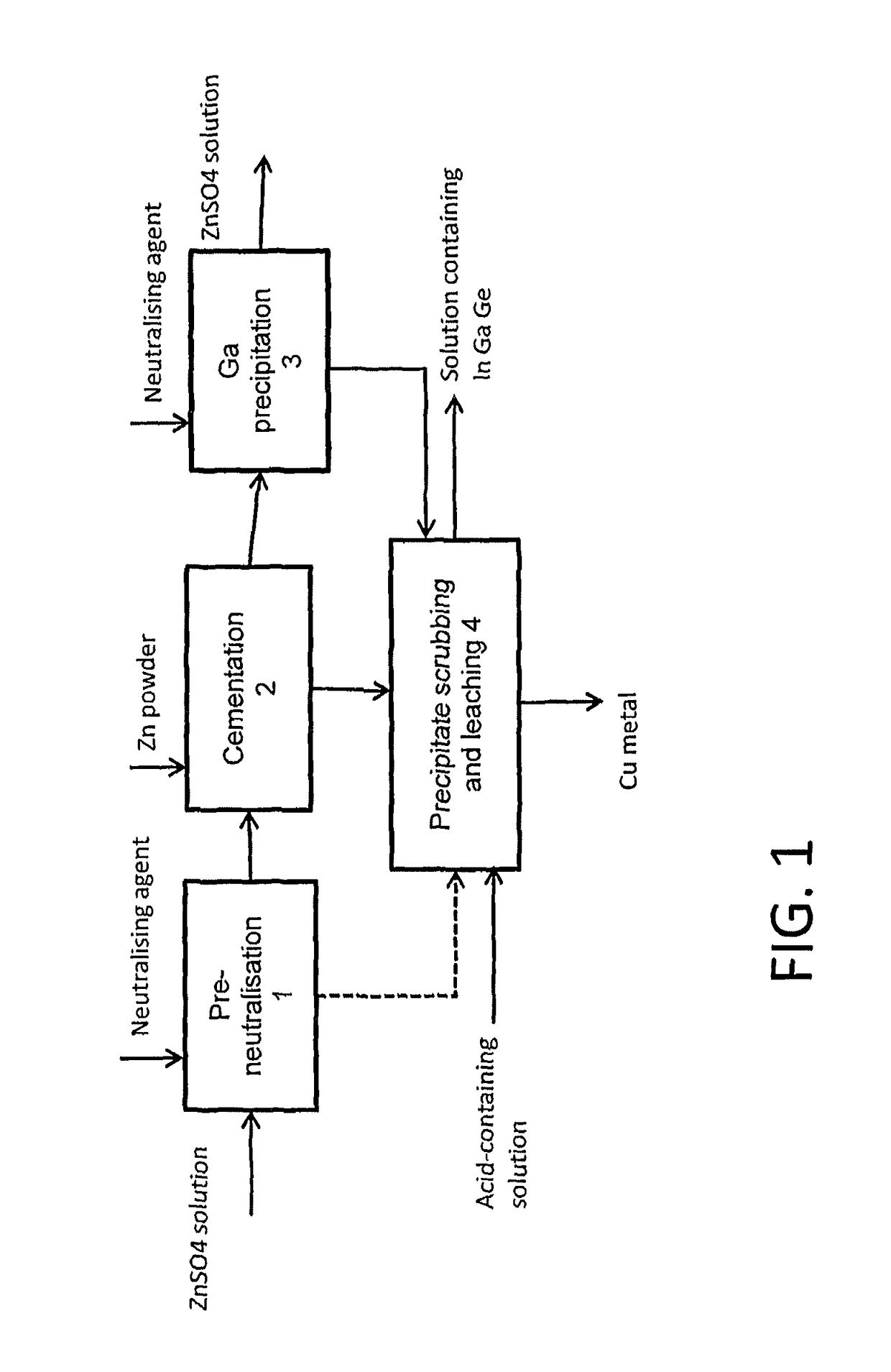

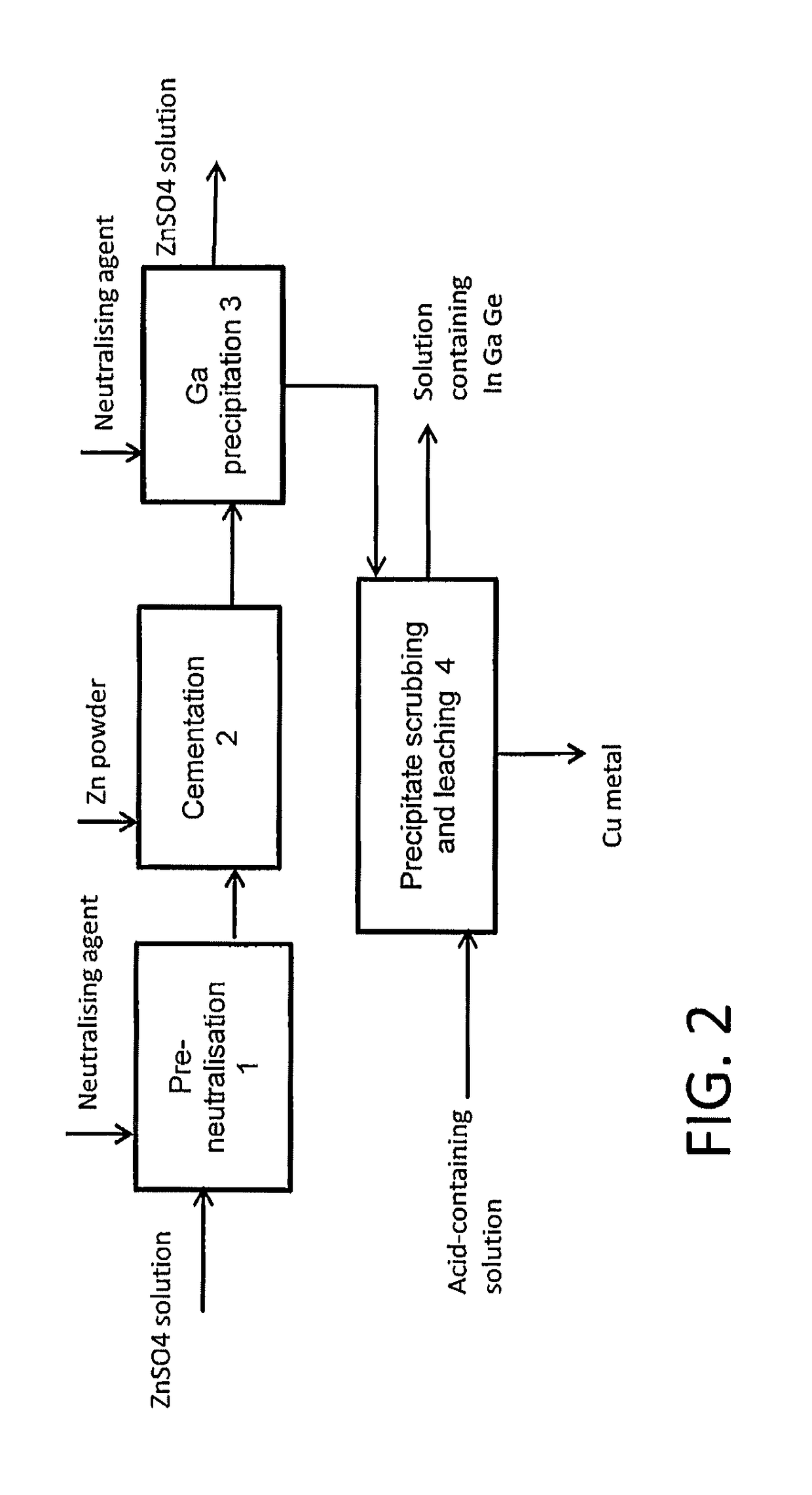

Method for treating a solution containing zinc sulphate

The invention relates to a method for treating a solution containing zinc sulphate, so that at least one of the rare metals such as indium, gallium and germanium can be separated from it. A portion of the metals to be separated can be precipitated from zinc sulphate solution by neutralizing the acidic solution and at least a portion is cemented by means of metal powder. The solid precipitates that are formed can be combined and treated subsequently in some suitable way to leach out the desired metals.

Owner:METSO OUTOTEC (FINLAND) OY

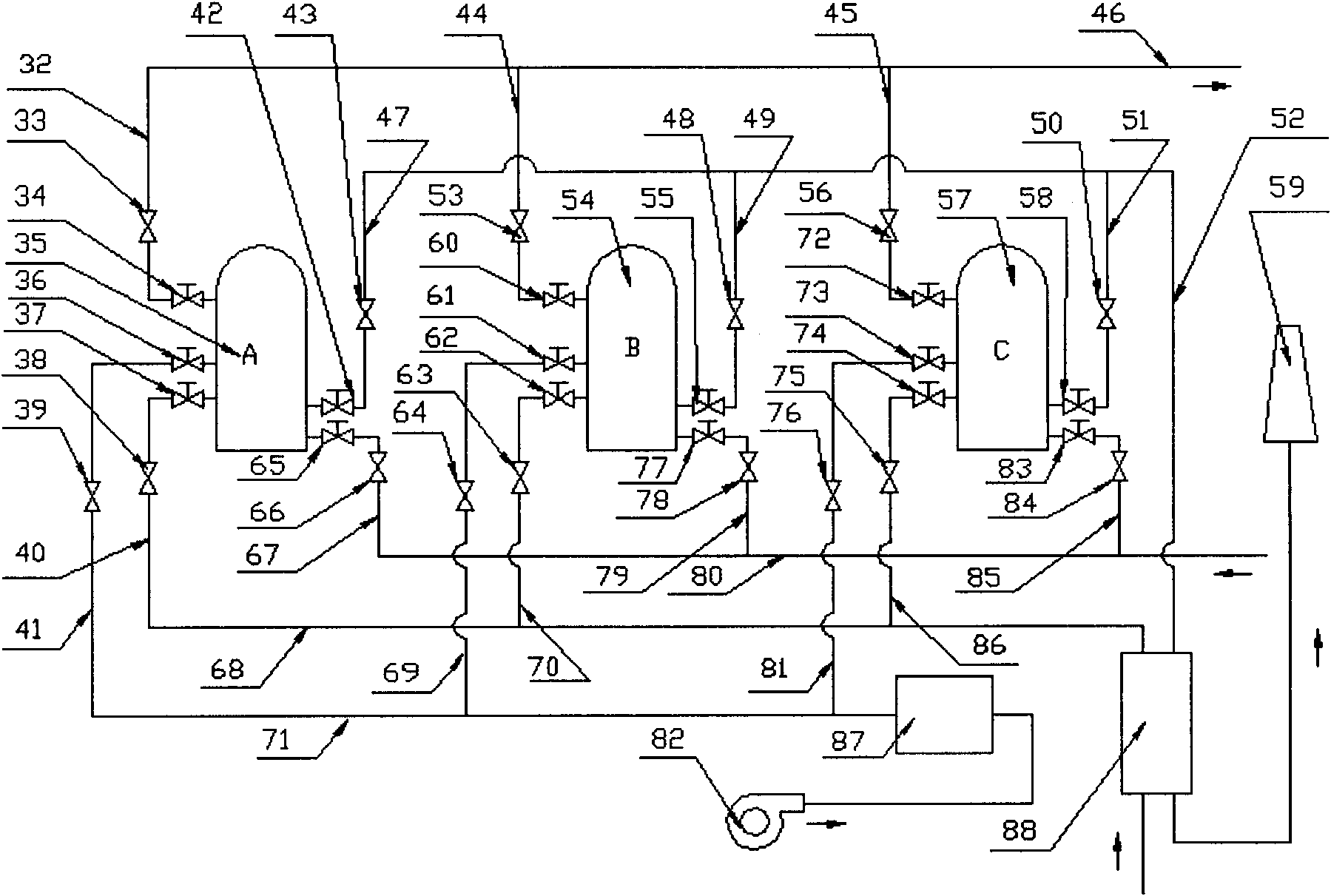

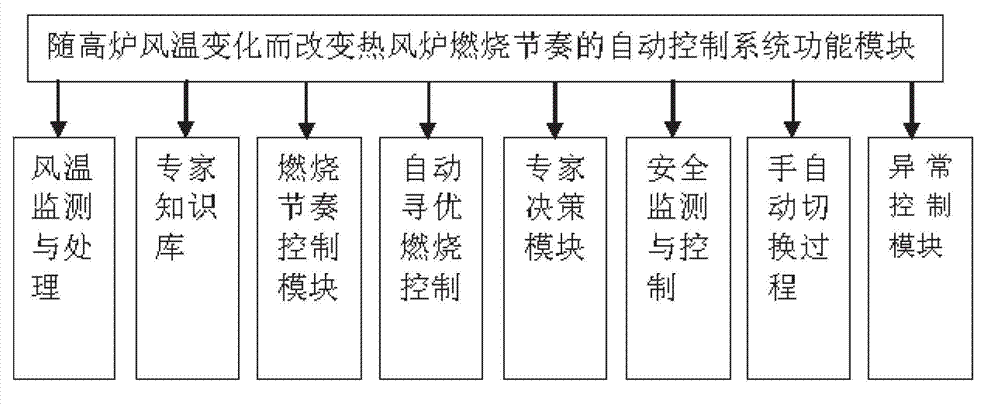

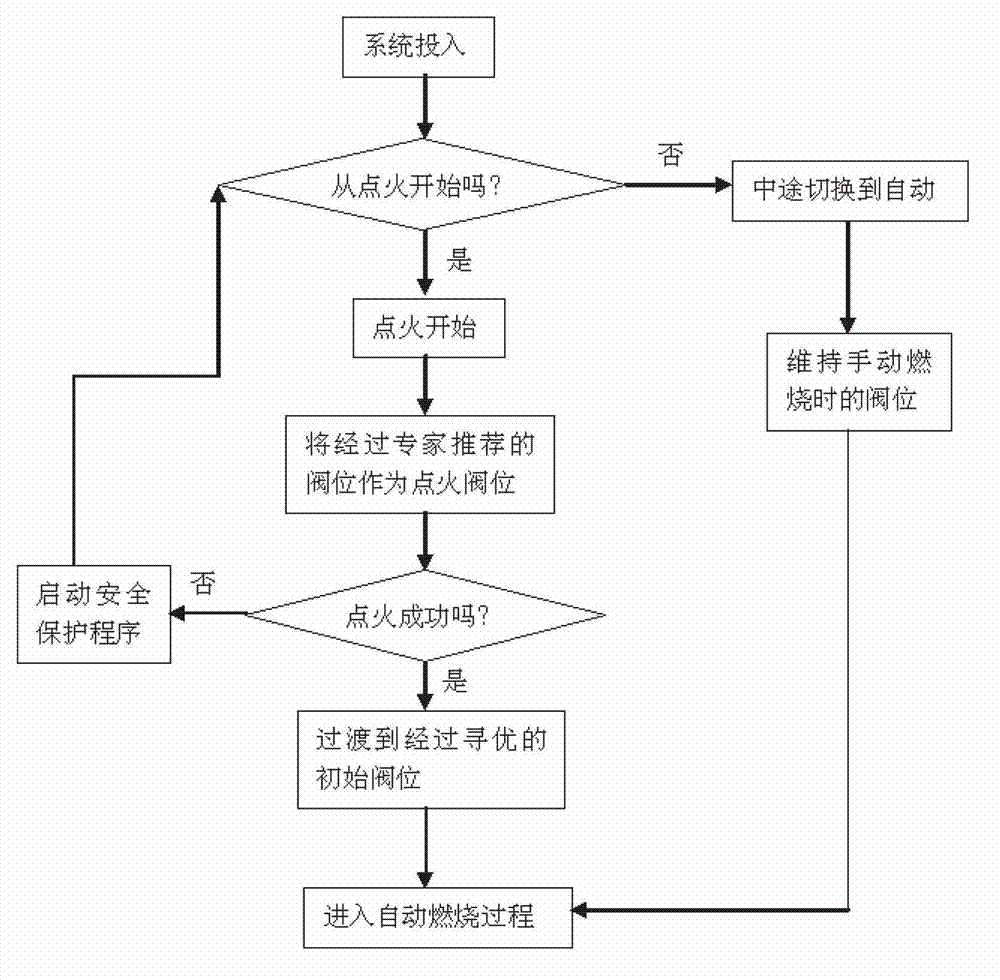

Automatic control system for changing combustion rhythm of hot blast furnace along with blast temperature of high furnace

InactiveCN102888479ADynamic MonitoringDynamicsBlast furnace detailsHeating stovesAutomatic controlAutomated control system

The invention relates to an automatic control system for changing the combustion rhythm of a hot blast furnace along with the blast temperature of a high furnace, belonging to the technical field of automatic control on a hot blast furnace of a high furnace. The automatic control system is composed of an air / coal gas regulating valve, a PLC (programmable logic controller), an industrial control computer and intelligent control software, wherein the air / coal gas regulating valve is used for controlling the flow of air or coal gas; the PLC is used for collecting pressure and flow information of coal gas and air, realizing logic linkage and protection and simultaneously outputting a given valve position to control the action of the regulating valve; the industrial control computer is used as a hardware carrier of the intelligent control software, and is used for acquiring coal gas pressure, air pressure, coal gas flow, air flow, coal gas regulating valve signals and air regulating valve signals from the PLC, calculating the appropriate valve position through the intelligent control software and transmitting the valve position to the PLC; and the intelligent control software is the core of the automatic control system, and is used for realizing the automatic control on the combustion process in the situation that the external conditions are changed. The automatic control system has the advantage that the problems on the automatic combustion of a hot blast furnace and the dynamic control on the combustion rhythm of the hot blast furnace are solved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH +1

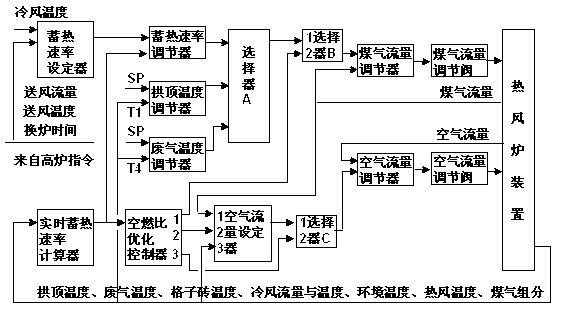

Intelligent optimization control system of blast furnace hot-blast stove

ActiveCN102912055AIncrease profitGuaranteed energy savingBlast furnace detailsHeating stovesHeat balanceTrial and error

The invention discloses an intelligent optimization control system of a blast furnace hot-blast stove, which relates to the technical field of blast furnace ironmaking optimization control and can reduce coal gas consumption, ensure equipment safety and prolong the service life on the premise of ensuring that the required hot-blast temperature and flow of a blast furnace are satisfied. The system is technically characterized in that the on-line calculation of a heat accumulation rate is realized based on heat balance, a reasonable heat accumulation rate setting curve is set according to the required total heat amount of blast and heating time of the blast furnace and the heat accumulation rate characteristic of a hot-blast stove, the amount of fuel in the heating stage is controlled in real time according to the heat accumulation rate, and the calculated amount of fuel is limited according to accepted upper limits of arch crown temperature and exhaust gas temperature processes. The system fully meets the demands of the blast furnace for hot blast, reduces lost heat carried away by waste gas and simultaneously ensures the equipment safety; and furthermore, the air-fuel ratio is optimized by taking the heat accumulation rate as the optimization target value and using a trial-and-error self-optimization algorithm, so that the fuel utilization is maximized, and the energy saving of the device is ensured at multiple levels.

Owner:北京和隆优化科技股份有限公司

Apparatus and method for measuring temperature of molten metal

InactiveUS6923573B2Image degradationReduce lightThermometer detailsFurnace componentsFiberOptoelectronics

The invention provides a cooling system for protecting an image fiber and an imaging device from thermal influences and a temperature measurement apparatus, for a molten metal, capable of being easily controlled and stably measuring the temperature. The temperature measurement apparatus for a molten metal comprises four connectable portions of a nozzle portion a purge / cooling gas introduction portion, an image fiber fitting portion with a window glass and an image fiber to a double pipe nozzle protection tube. A distance from a nozzle distal end as an introduction portion of thermal radiation light to a light reception portion at an image fiber distal end becomes short so that a greater amount of thermal radiation light can be received.

Owner:NIPPON STEEL CORP +1

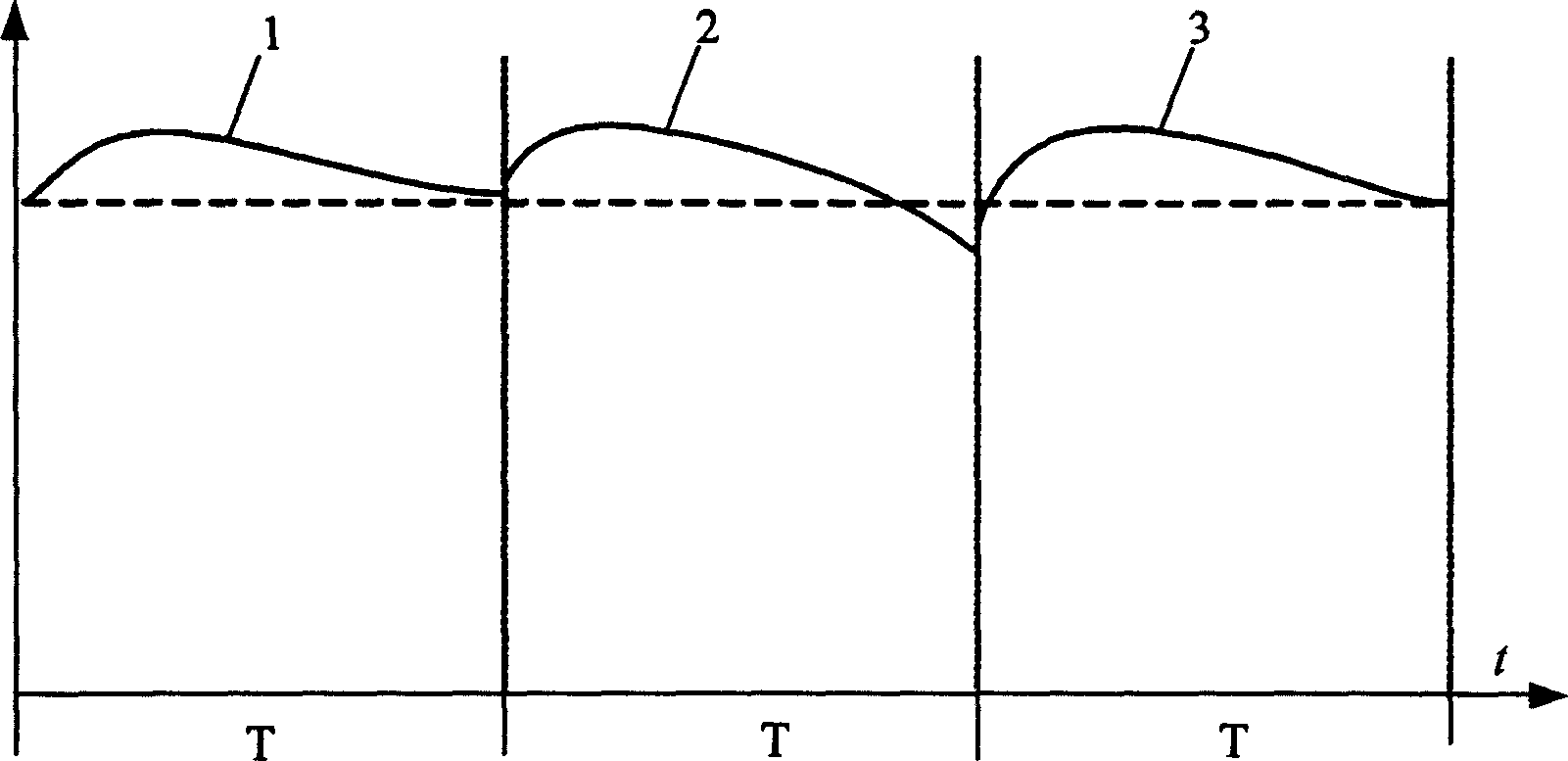

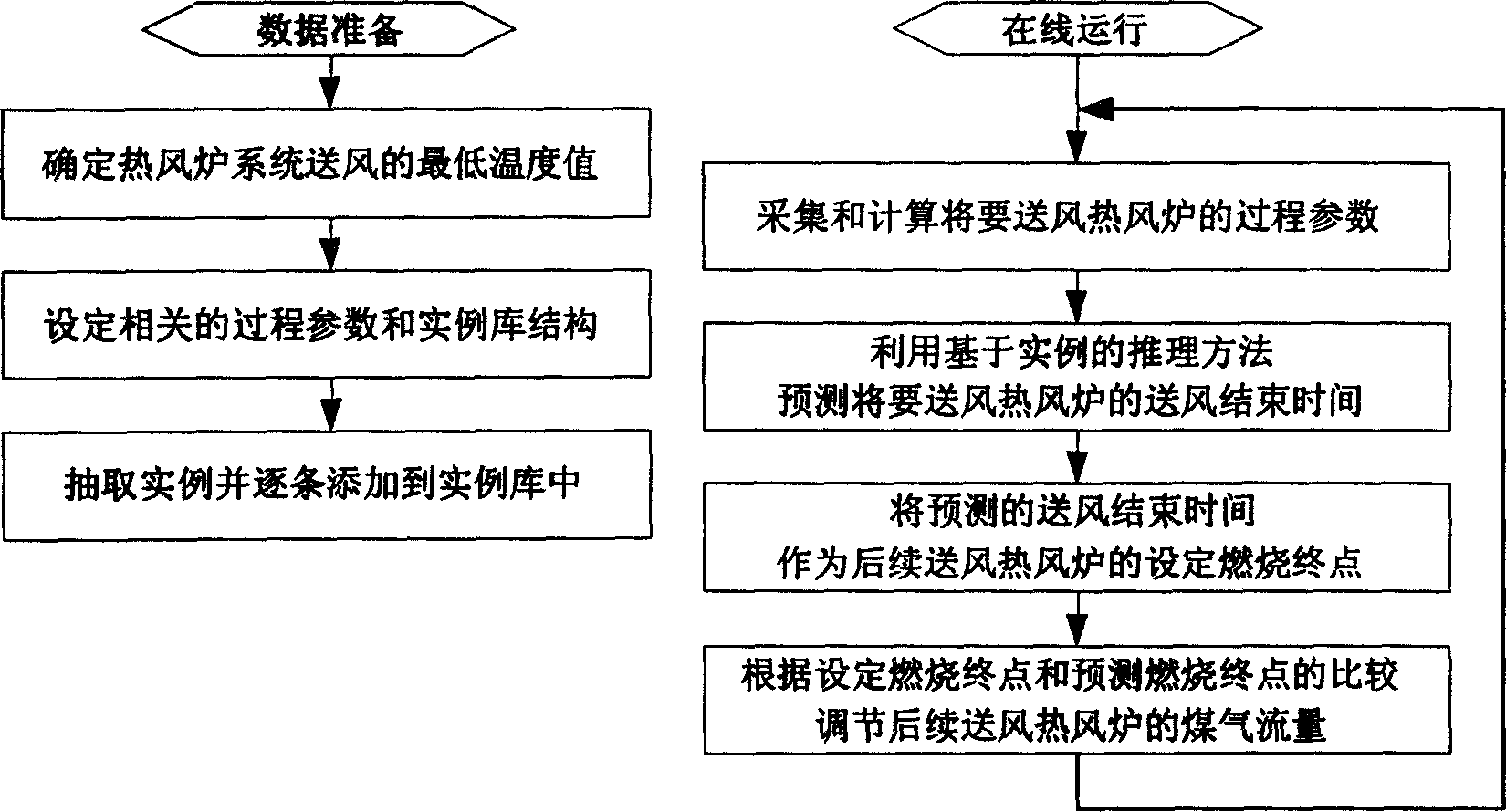

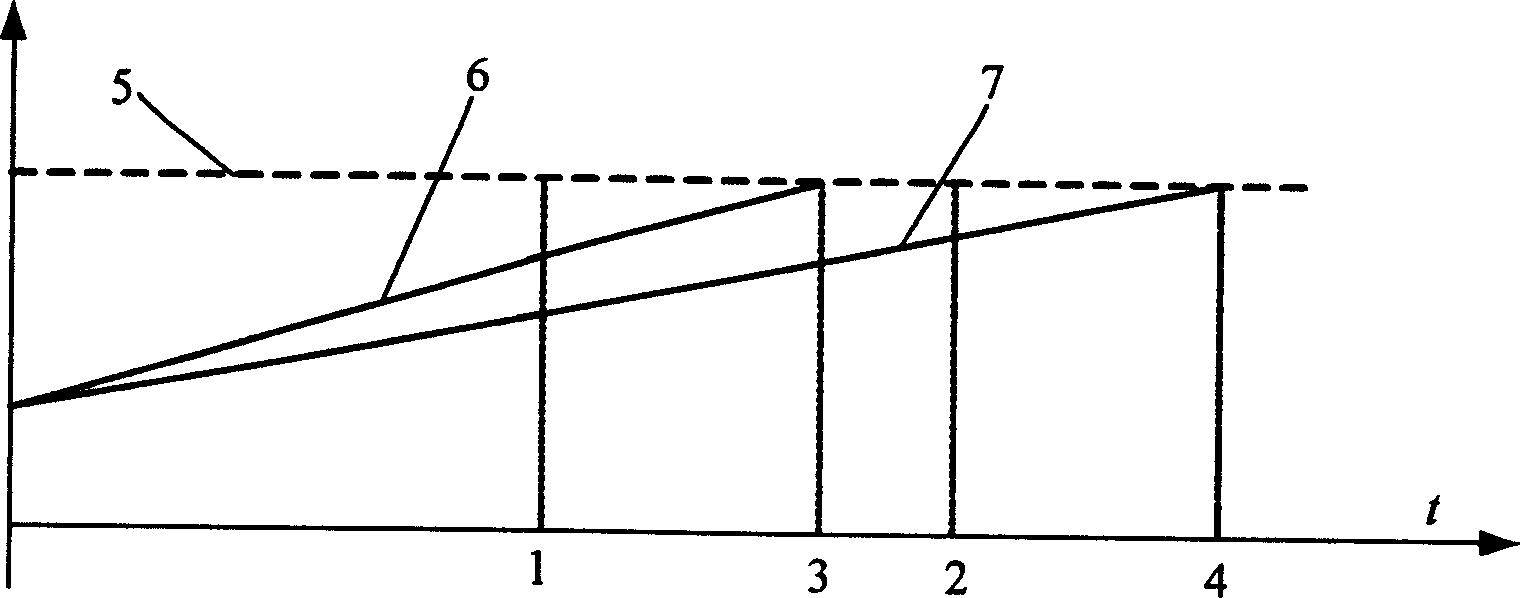

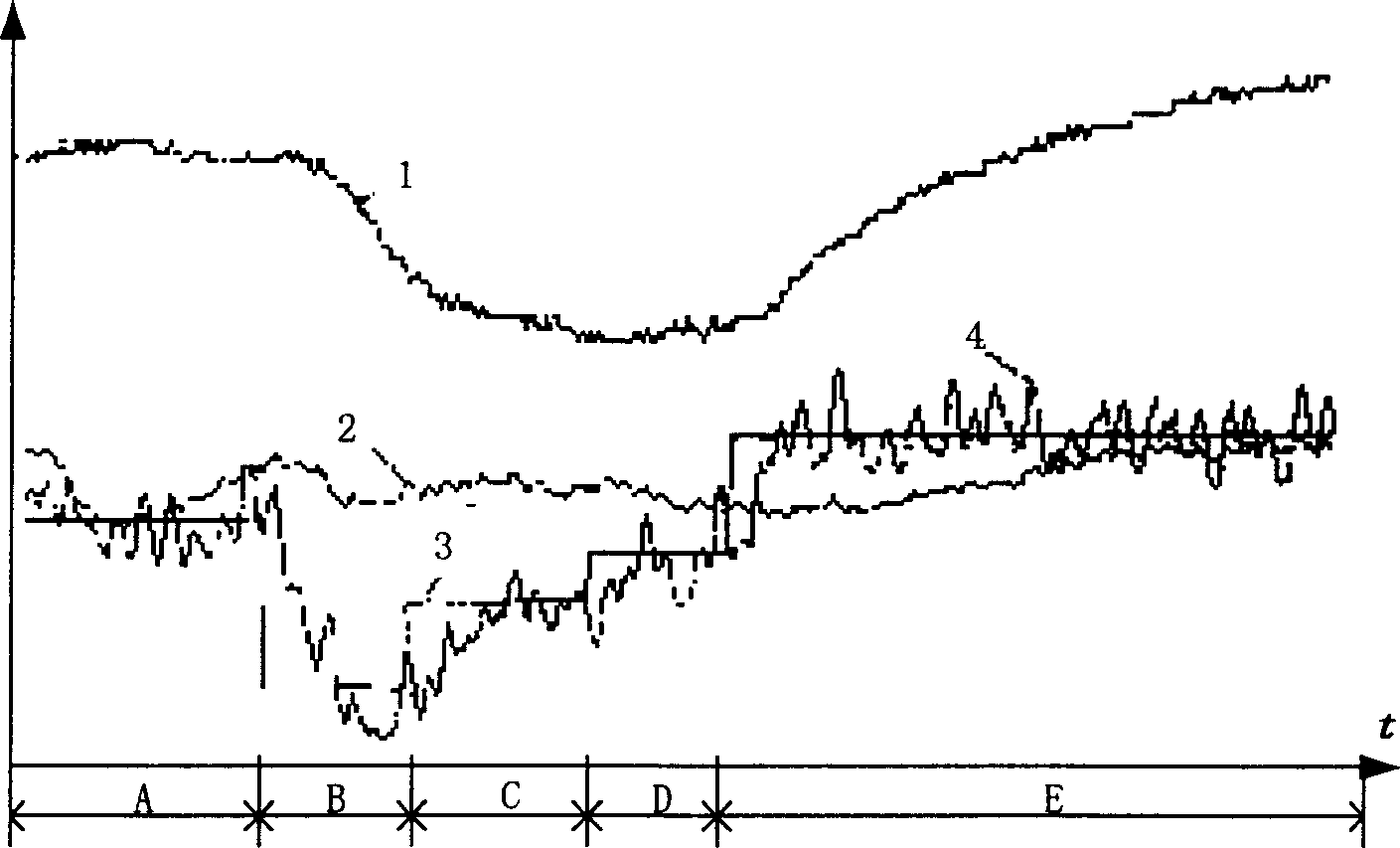

Harmonization control method for blast furnace hot blast stove system

InactiveCN1766130ARaise the supply air temperatureReduce supply air temperature fluctuationsTemperatue controlBlast furnace detailsAutomatic controlEngineering

The invention relates to compatible control method for hot-blast stove of blast furnace, which comprises: determining the lowest blast temperature, designing correlated process parameters and constructing case database; extracting burning data to add into database; obtaining real-time process parameters; with case-base inference method, predicting the time that blast temperature drops down to lowest temperature as the blast end time and the burning terminal time of successive furnace; comparing the predicted time with preset terminal time of successive furnace; according to result, changing gas supply to achieve the waste gas temperature upper limit with set terminal; repeating said steps to realize the variable-period running. This invention increases total blast temperature, and reduces blast temperature.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

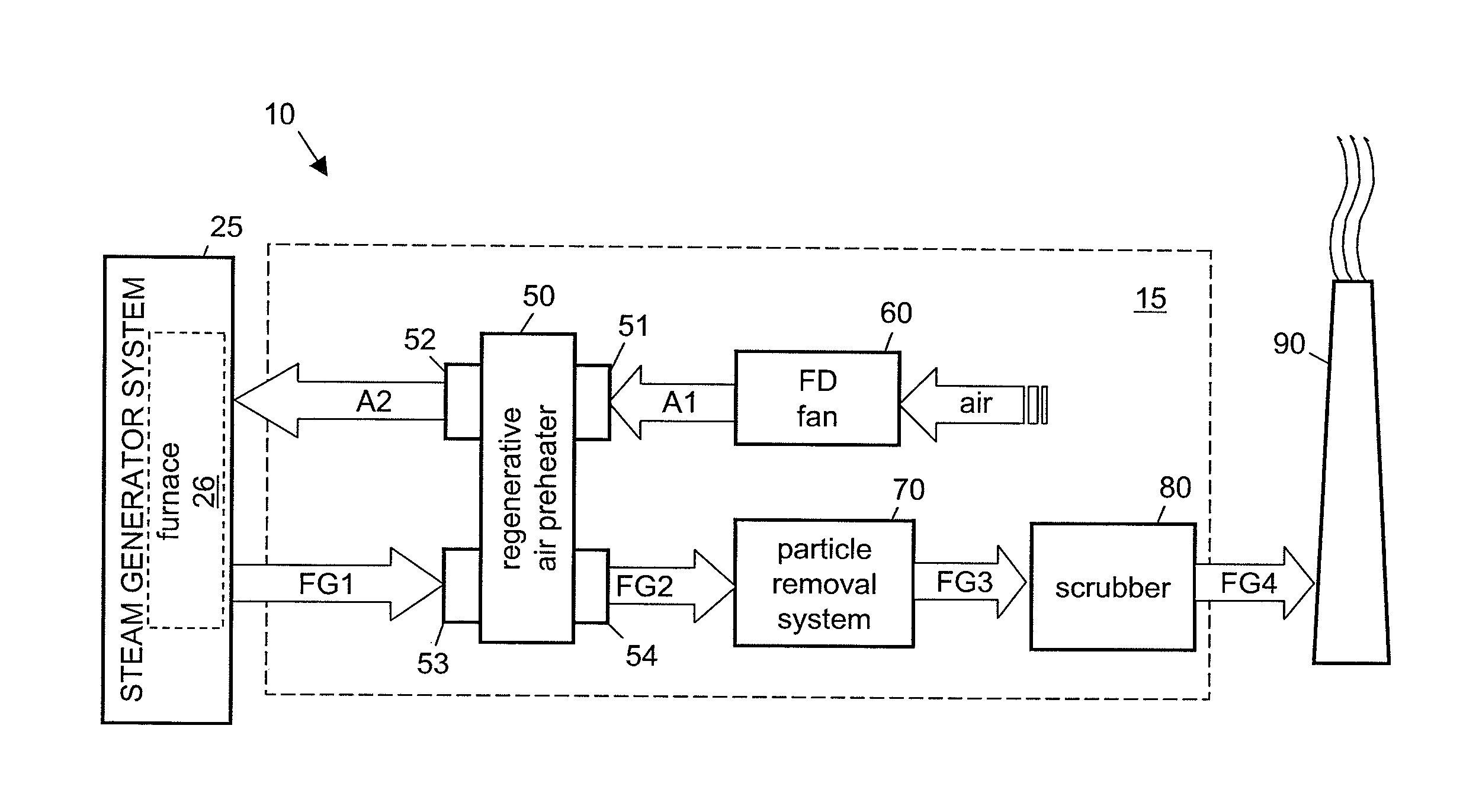

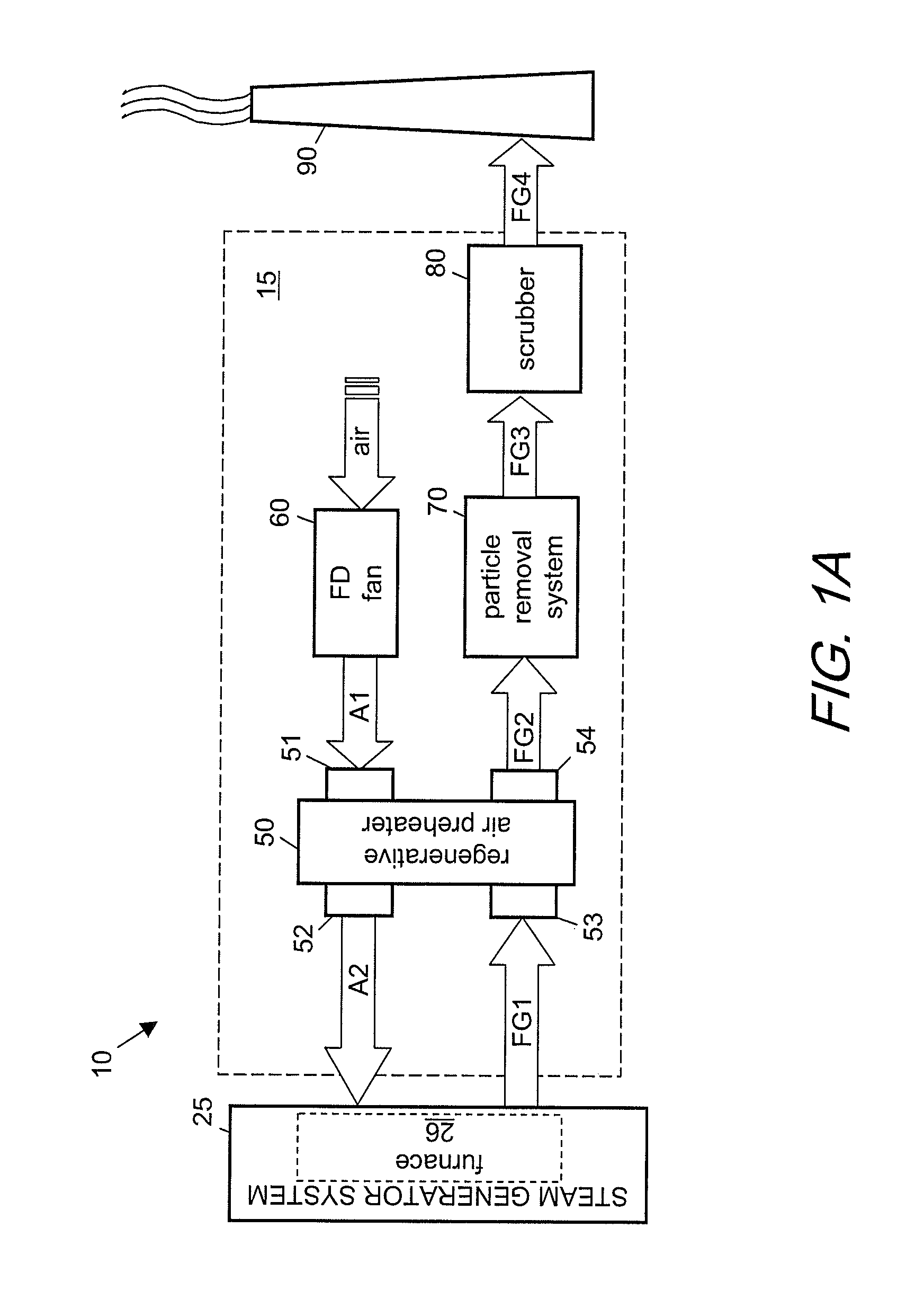

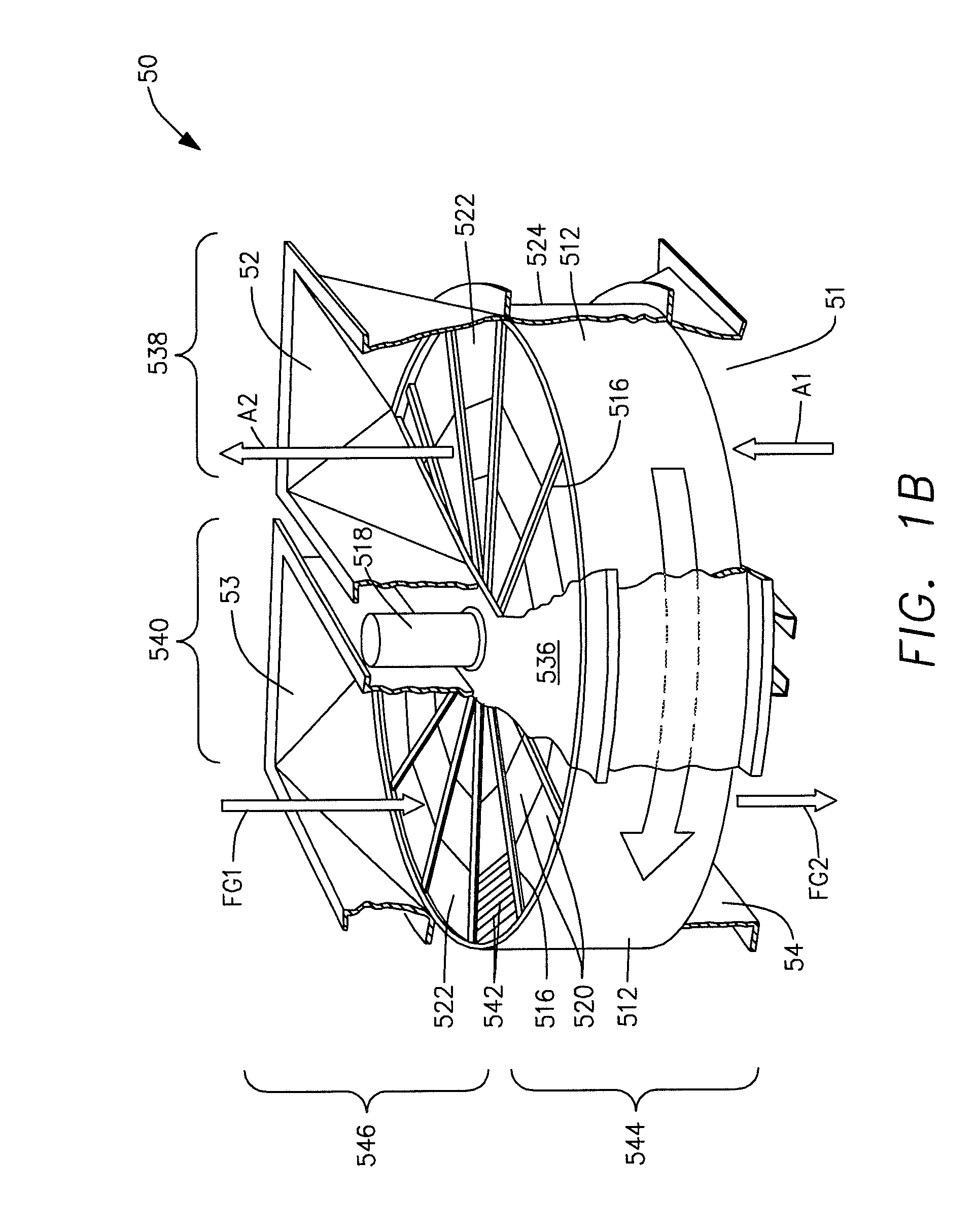

Exhaust processing and heat recovery system

InactiveUS20110073023A1Reduce accumulationImprove thermal efficiencyBurnersBlast furnace detailsThermal energyAir preheater

A thermally efficiency regenerative air preheater 250 extracts more thermal energy from the flue gas exiting a solid fuel fired furnace 26 by employing an alkaline injection system 276. This mitigates acid fouling by selectively injecting different sized alkaline particles 275 into the air preheater 250. Small particles provide nucleation sites for condensation and neutralization of acid vapors. Large particles are injected to contact and selectively adhere to the heat exchange elements 542 and neutralize liquid acid that condenses there. When the deposit accumulation exceeds a threshold, the apparatus generates and utilizes a higher relative percentage of large particles. Similarly, a larger relative percentage of small particles are used in other cases. Mitigation of the fouling conditions permits the redesign of the air preheater 250 to achieve the transfer of more heat from the flue resulting in a lower flue gas outlet temperature without excessive fouling.

Owner:ALSTOM ENERGY TECH AG

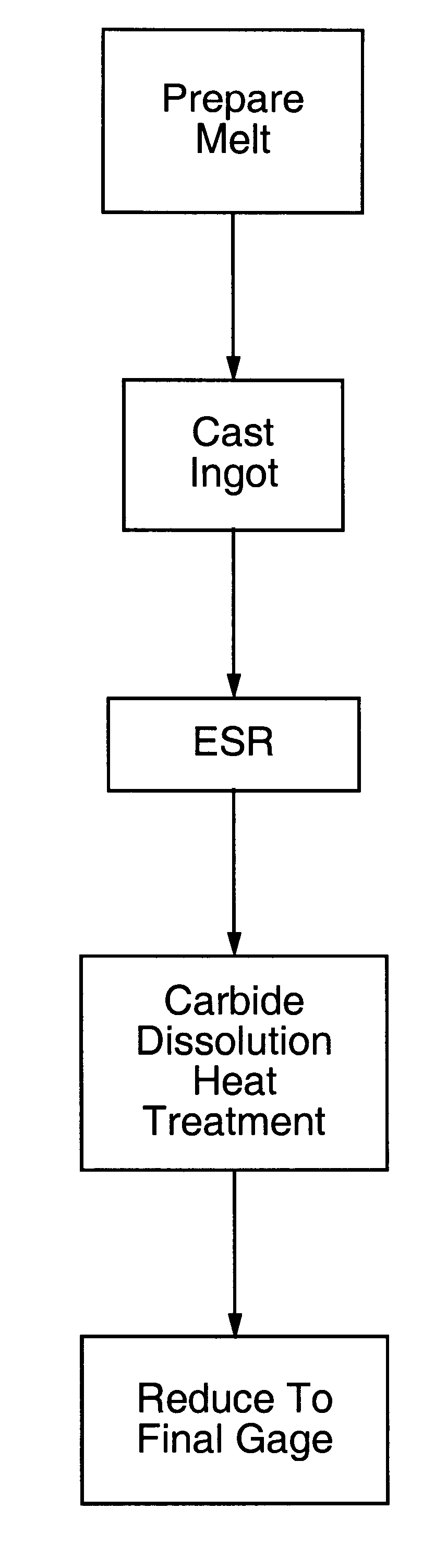

Steelmaking process

InactiveUS6273973B1Avoid breakingInhibit unacceptable checkingBlast furnace detailsMoulding machinesSteelmakingManganese

A process for producing a steel includes subjecting at least a portion of a melt of the steel to electroslag remelting and, in a subsequent step, heating the steel to a temperature at least as great as the lowest temperature at which all carbides that can form in the remelted steel will dissolve and no greater than the nil ductility temperature of the of the remelted steel, and maintaining the temperature for a period of time sufficient to dissolve primary and clustered carbide particles in the remelted steel greater than 15 micrometers in length. A novel martensitic stainless steel also is disclosed including 0.65 to 0.70 carbon; 0 to 0.025 phosphorus; 0 to 0.020 sulfur; 0.20 to 0.50 silicon; at least one of greater than 0.0004 boron and greater than 0.03 nitrogen; 0.45 to 0.75 manganese; 12.7 to 13.7 chromium; and 0 to 0.50 nickel.

Owner:ATI PROPERTIES

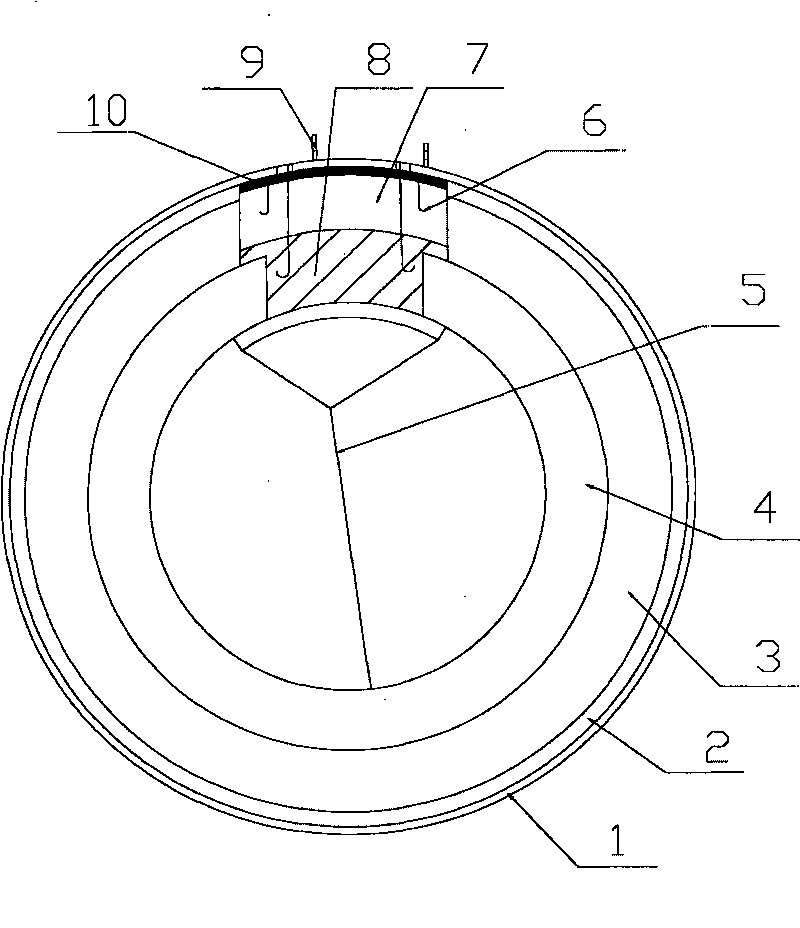

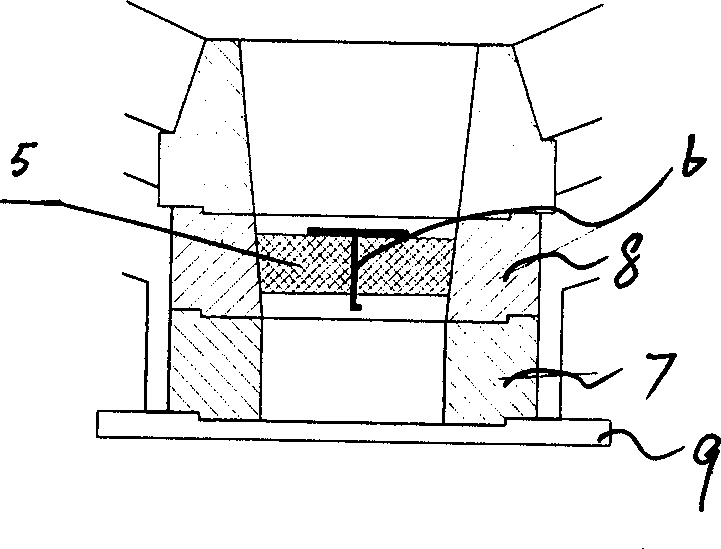

Repatching method for top liner of blast furnace hot-wind pipeline

ActiveCN101760576AResume production earlyEarly productionBlast furnace detailsHeating stovesEmergency situationsBlast furnace

The invention discloses a repatching method for the top liner of a blast furnace hot-wind pipeline. According to the damage condition of the liner of the pipeline, a pipeline steel housing (1) is provided with a hole, and the periphery of the inner surface of the pipeline steel housing (1) is welded with lifting hooks (6) and a wood mould supporting is supported well (5), and then a working layer pouring material (8) and a warm keeping pouring material (7) are poured, and then the pipeline steel housing (1) is welded well; a pipeline skin is welded with more than two mudjacking holes (9), and mudjacking material is pressed into the gap between the steel housing (1) and the warm-keeping pouring material (7), and the construction pressure is kept between 2 to 3kg / cm2. The invention resolves the emergency gusty repatching problem for the damage of the blast furnace hot-wind pipeline, so that the liner of the blast furnace hot-wind pipeline is repaired fast , thus improving the construction effect of the pipeline repatching.

Owner:BEIJING SHOUGANG CO LTD

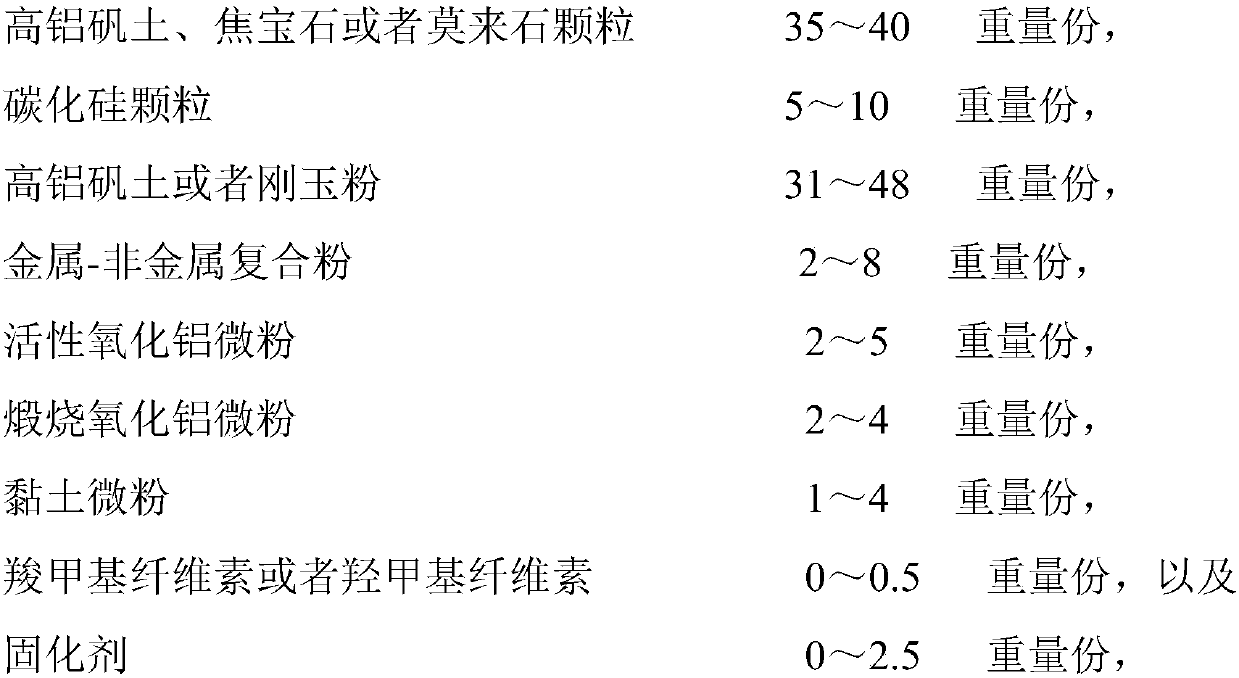

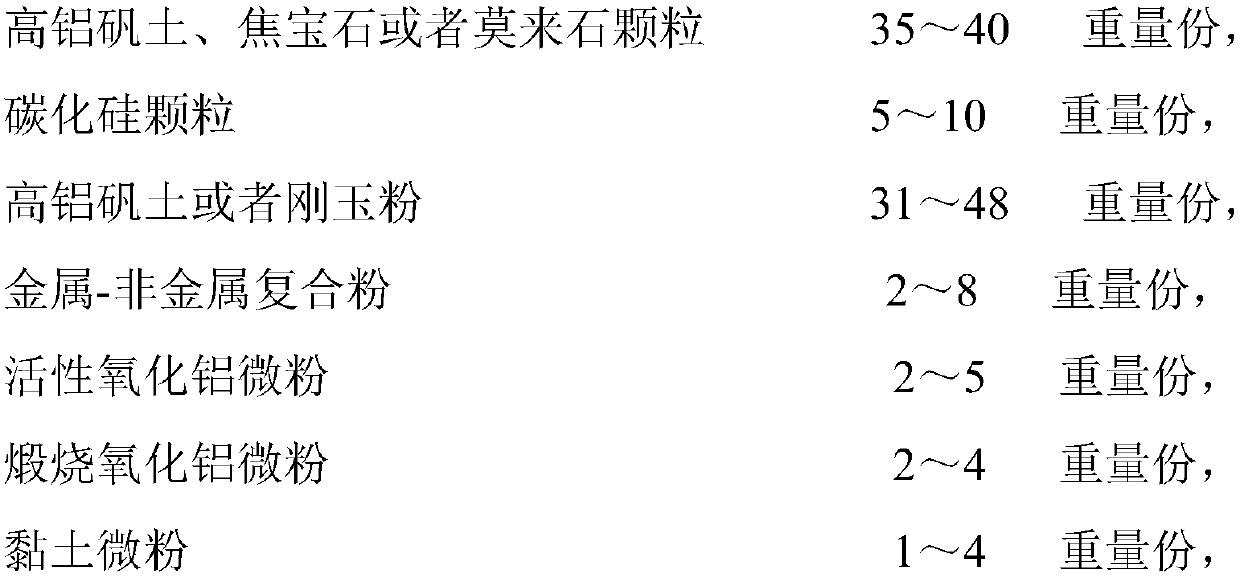

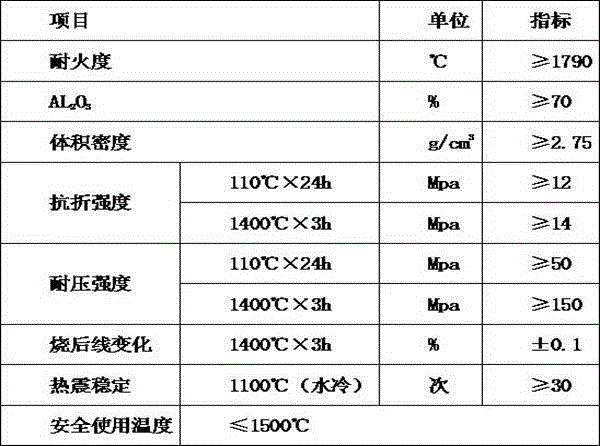

Hot-blast furnace pipe packing material and preparation method therefor

ActiveCN107698266AImprove high temperature performanceGood solid state sintering propertiesBlast furnace detailsProcess efficiency improvementResource utilizationMullite

The invention discloses a hot-blast furnace pipe packing material and a preparation method therefor. The packing material is prepared from the ingredients in parts by weight: 100 parts of dry mattersand 10-25 parts of silica sol, wherein the 100 parts of dry matters comprise high bauxite, flint clay or mullite particles, silicon carbide particles, high bauxite or corundum powder, metal-nonmetal composite powder, activated alumina micropowder, calcined alumina micropowder, clay micropowder, carboxymethyl cellulose or hydroxymethyl cellulose and a curing agent. The packing material disclosed bythe invention is pollution-free to environments, is good in fluidity in construction time, is not prone to settlement, can be thoroughly packed into small slits during pressed-in repair, can be constructed at high temperatures and can also be cured at normal temperatures; the packing material can be tightly bonded to a material of a pressed-in area; the packing material has good strength propertyat all temperatures; the packing material has low linear shrinkage in service temperature intervals and has good thermal shock stability; and industrial wastes of other industries are utilized, so that the utilization ratio of resources is increased.

Owner:CHINA JINGYE ENG +2

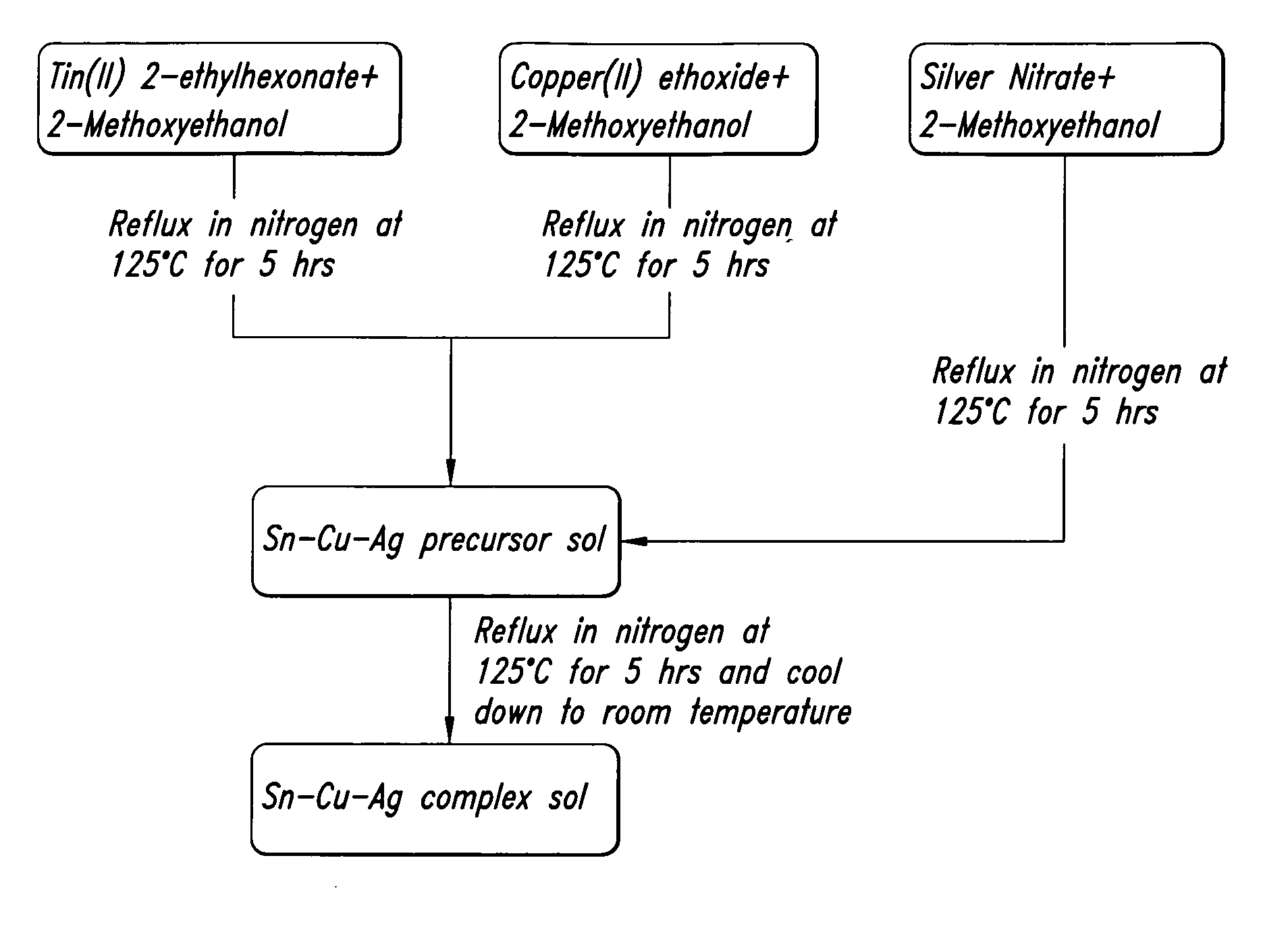

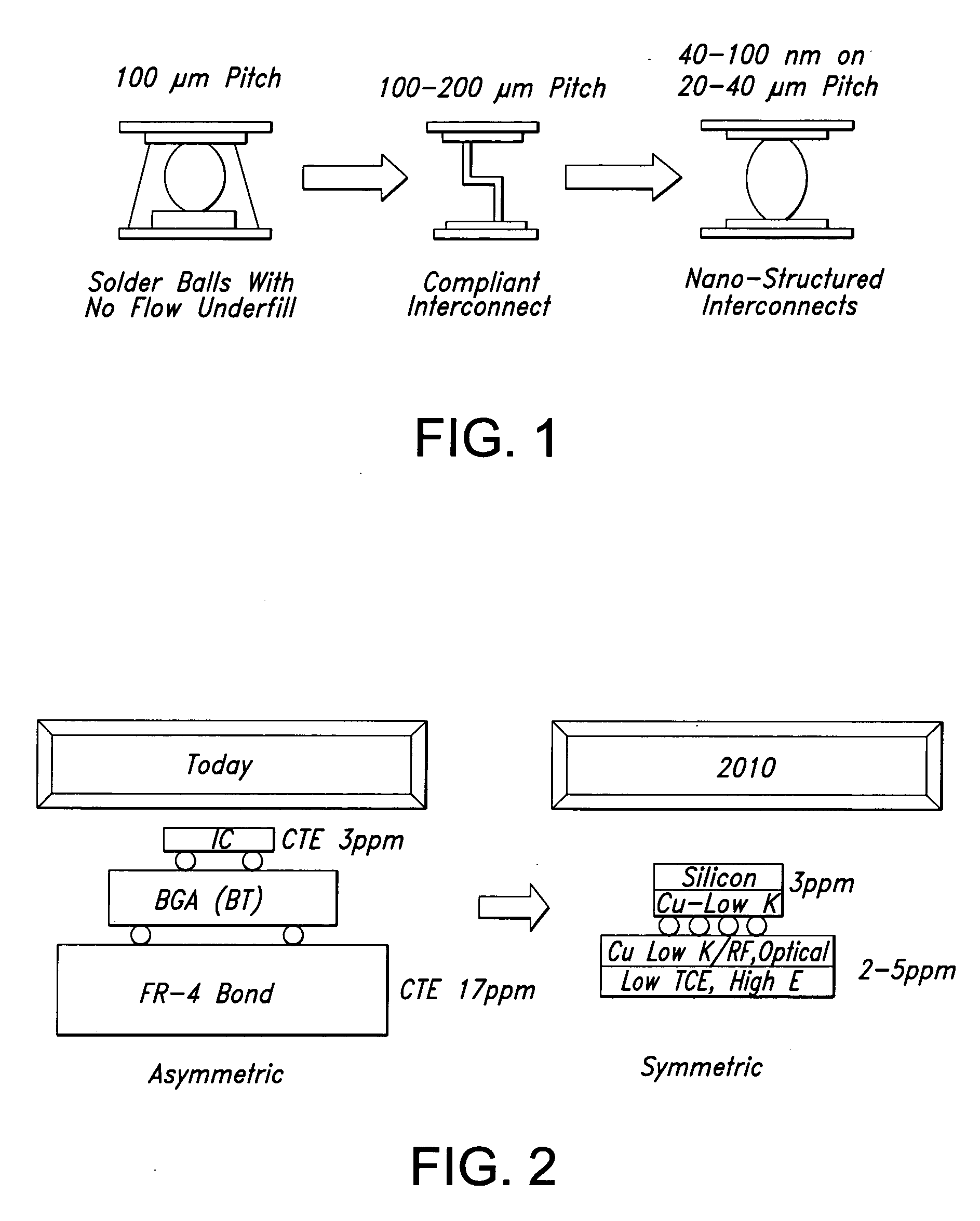

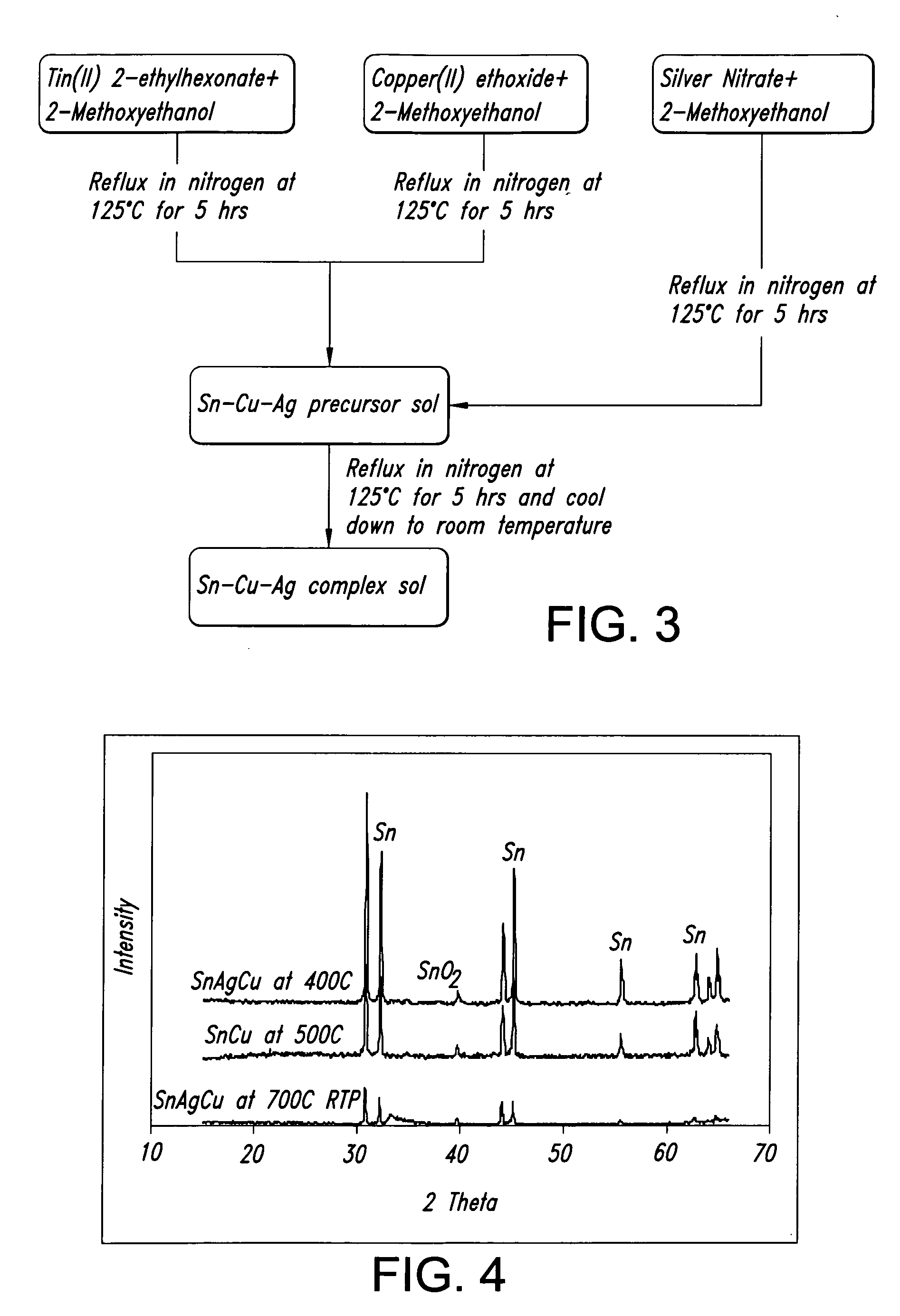

Lead-free bonding systems

InactiveUS20050274227A1Improve mechanical propertiesHigh bandwidthMolten spray coatingVacuum evaporation coatingBonding processHermetic packaging

Nano-structured interconnect formation and a reworkable bonding process using solder films. Large area fabrication of nano-structured interconnects is demonstrated at a very fine pitch. This technology can be used for pushing the limits of current flip chip bonding in terms of pitch, number of I / Os, superior combination of electrical and mechanical properties as well as reworkability. Sol-gel and electroless processes were developed to demonstrate film bonding interfaces between metallic pads and nano interconnects. Solution-derived nano-solder technology is an attractive low-cost method for several applications such as MEMS hermetic packaging, compliant interconnect bonding and bump-less nano-interconnects.

Owner:GEORGIA TECH RES CORP

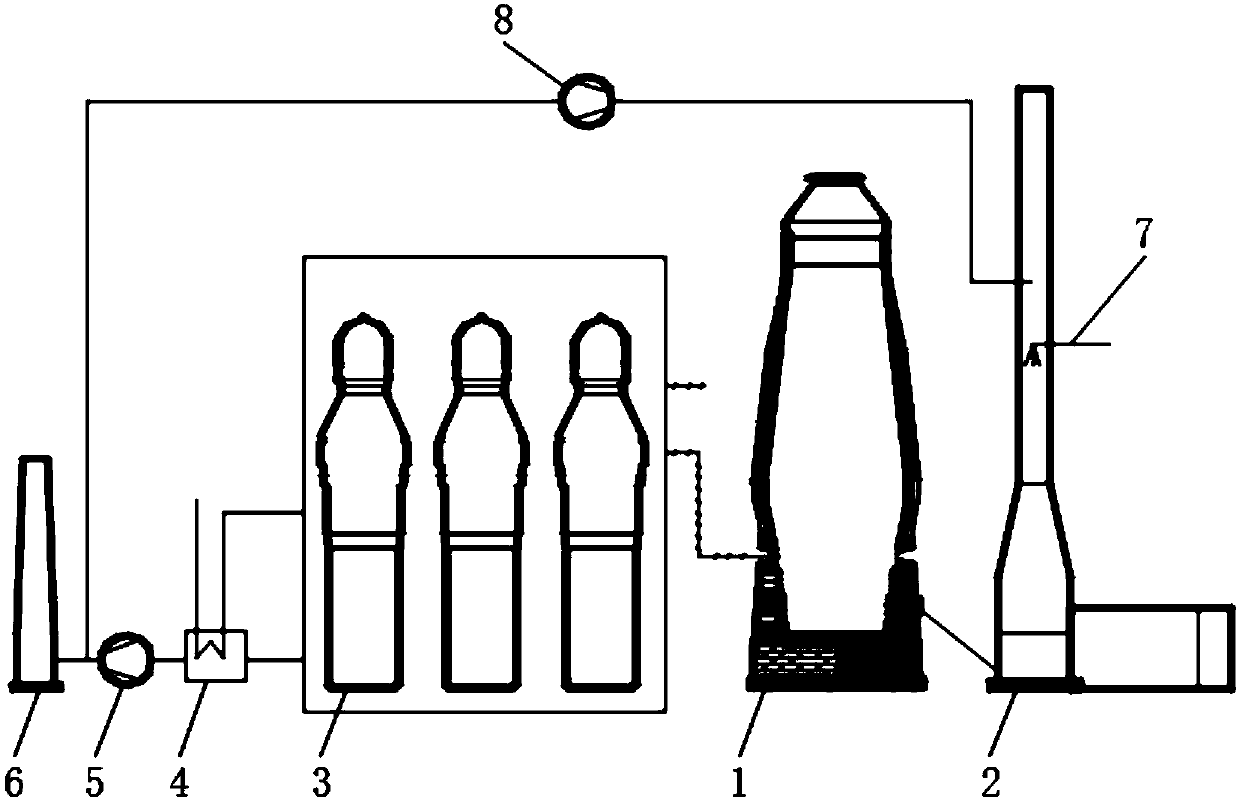

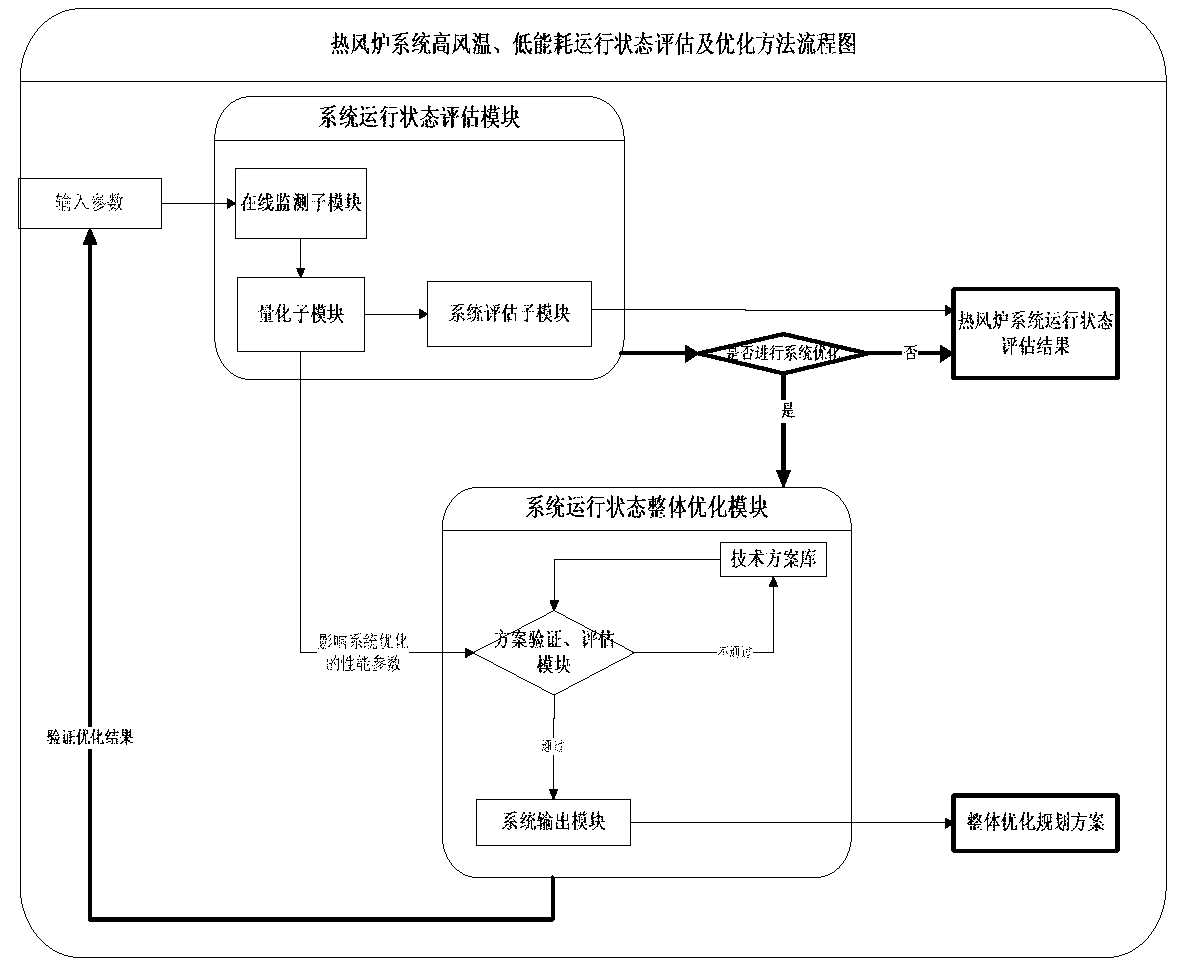

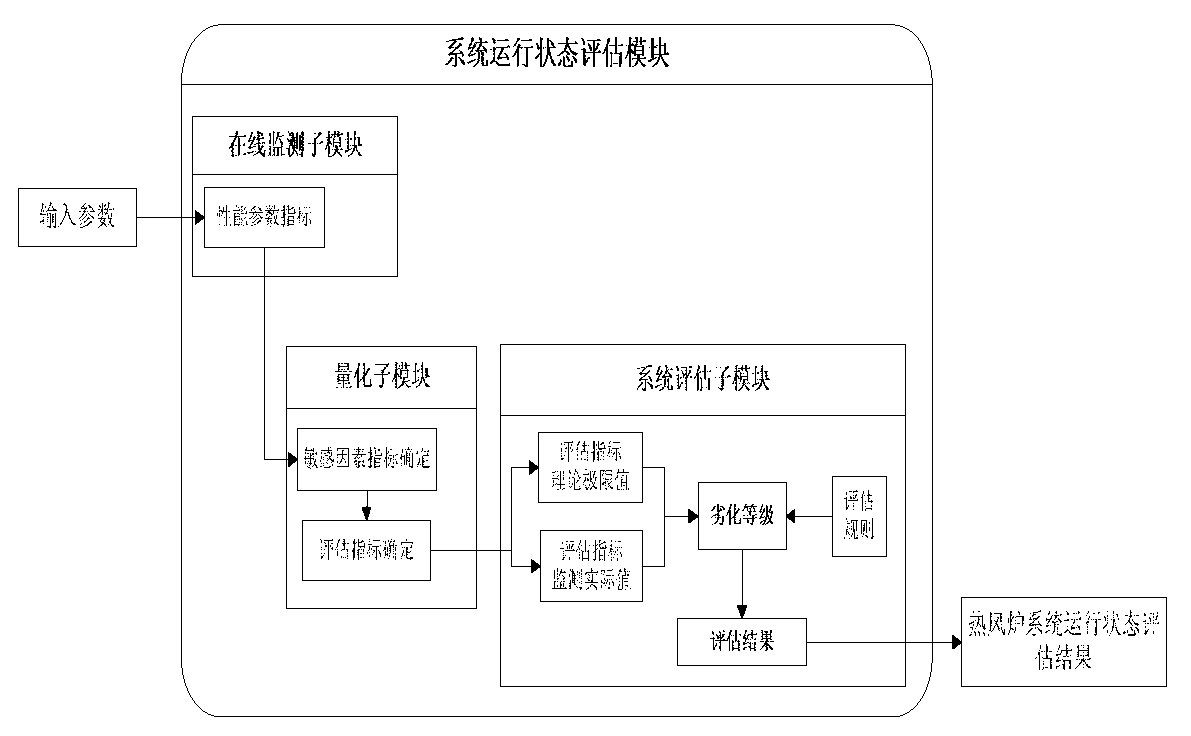

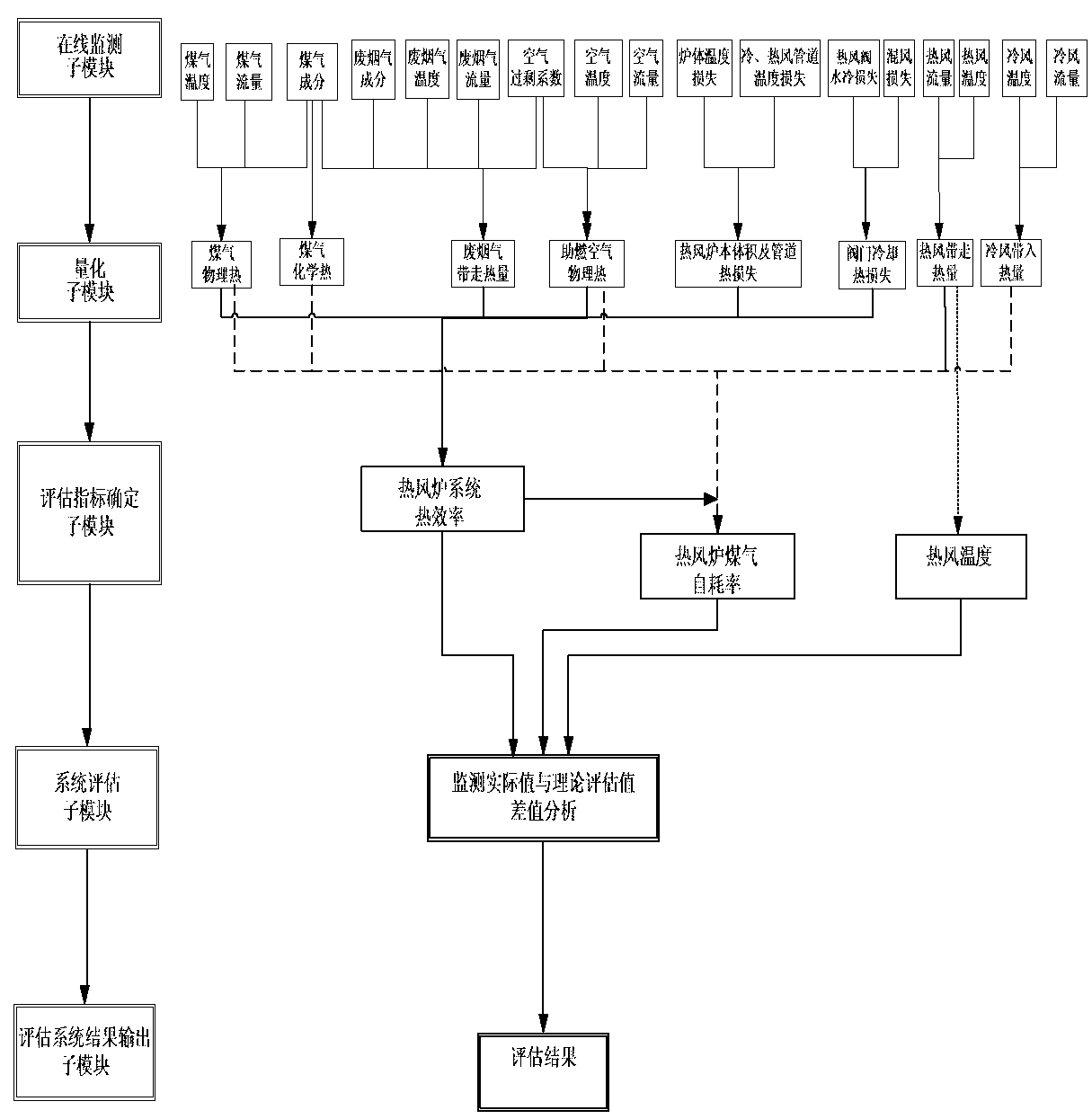

High-temperature and low-energy-consumption running state estimation and optimization method for hot air furnace system

ActiveCN103305647AGuaranteed uptimeReduce energy consumptionBlast furnace detailsHeating stovesHot air ovenProcess engineering

The invention relates to a high-temperature and low-energy-consumption running state estimation and optimization method for a hot air furnace system. The high-temperature and low-energy-consumption running state estimation and optimization method comprises the following steps of: a, setting a preset running estimation index of the hot air furnace system; b, acquiring real-time monitored running state data of the hot air furnace system; c, quantifying the monitored data, and determining the on-line heat efficiency and the coal gas self-consumption rate of the hot air furnace and the hot air temperature; d, determining the degradation degree and the degradation grade of the hot air furnace system according to a difference between a theoretical extreme value of the index and an on-line monitored actual value; e, determining the type of sensitivity parameters influencing the optimization of the hot air furnace system; and f, optimizing the hot air furnace system according to optimized sensitivity parameters and a corresponding technical scheme called from a technical scheme library according to the type of the sensitivity parameters. According to the high-temperature and low-energy-consumption running state estimation and optimization method, estimation, forecasting and optimization for the production running state of the hot air furnace system are integrated, the running state of the hot air furnace system can be estimated, whether the hot air furnace system runs in a high air temperature and low energy consumption state can be judged, and a scientific and effective technical scheme is supplied to the low-energy-consumption and high-efficiency running of the hot air furnace system.

Owner:SICHUAN CHUANGUO BOILER

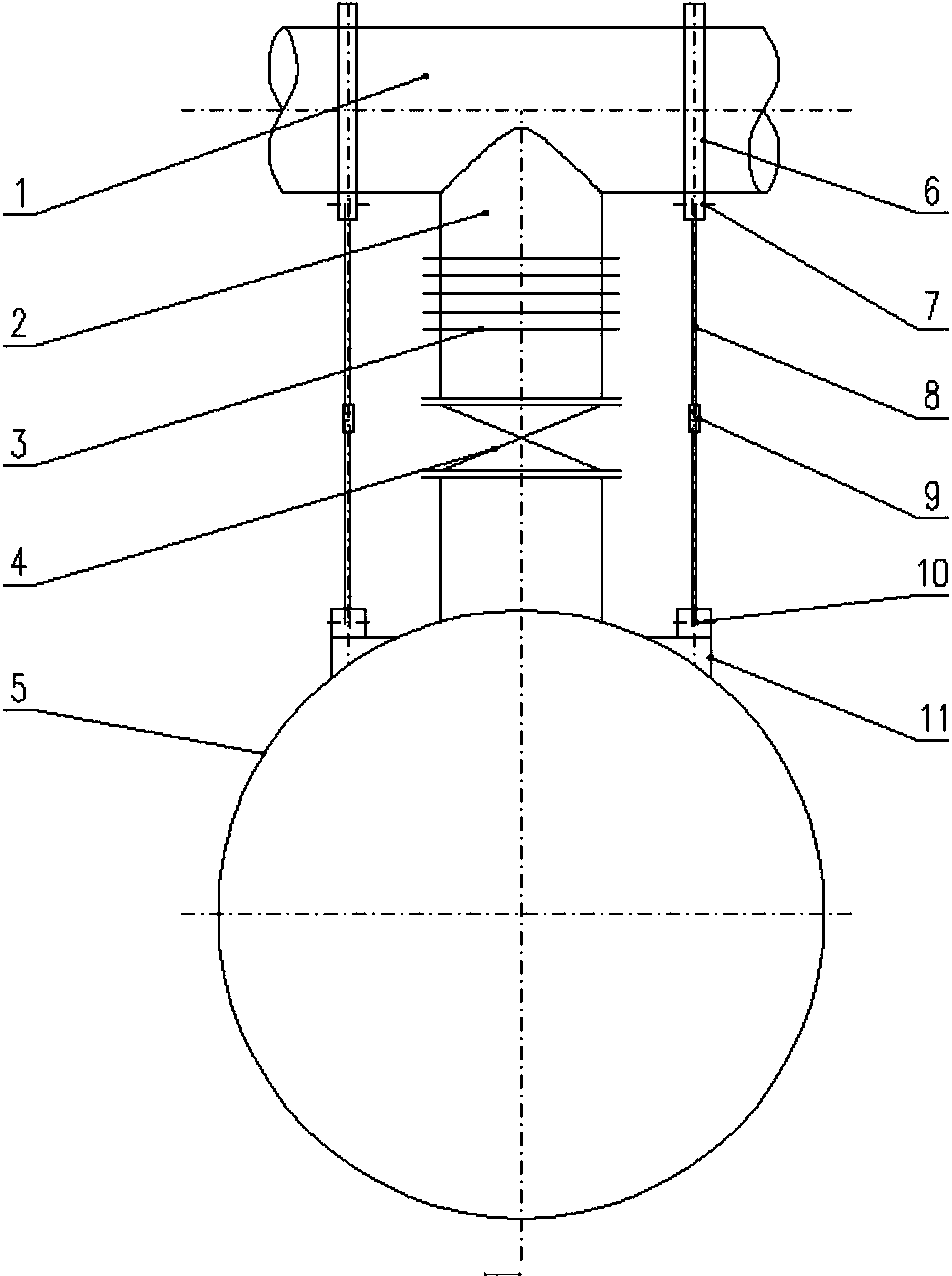

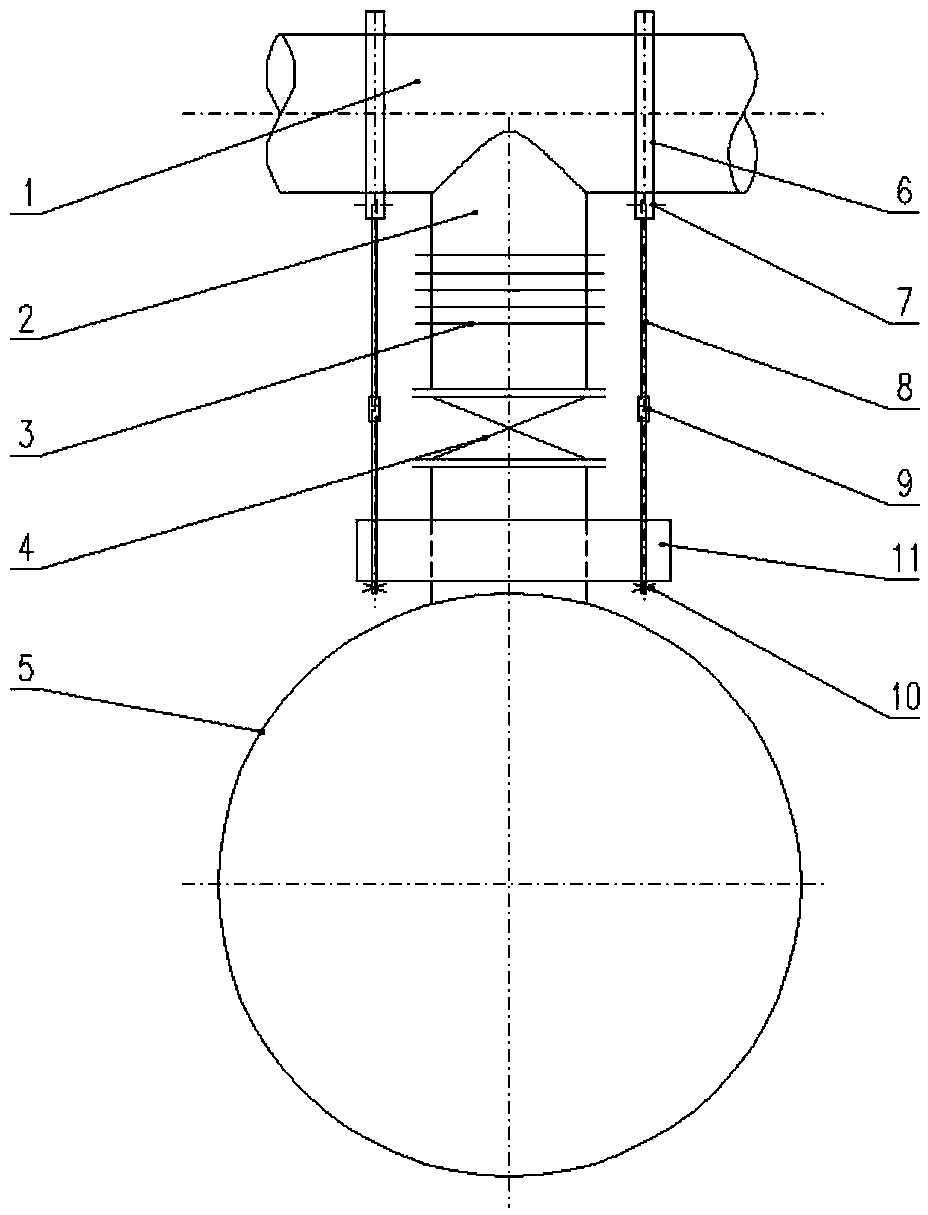

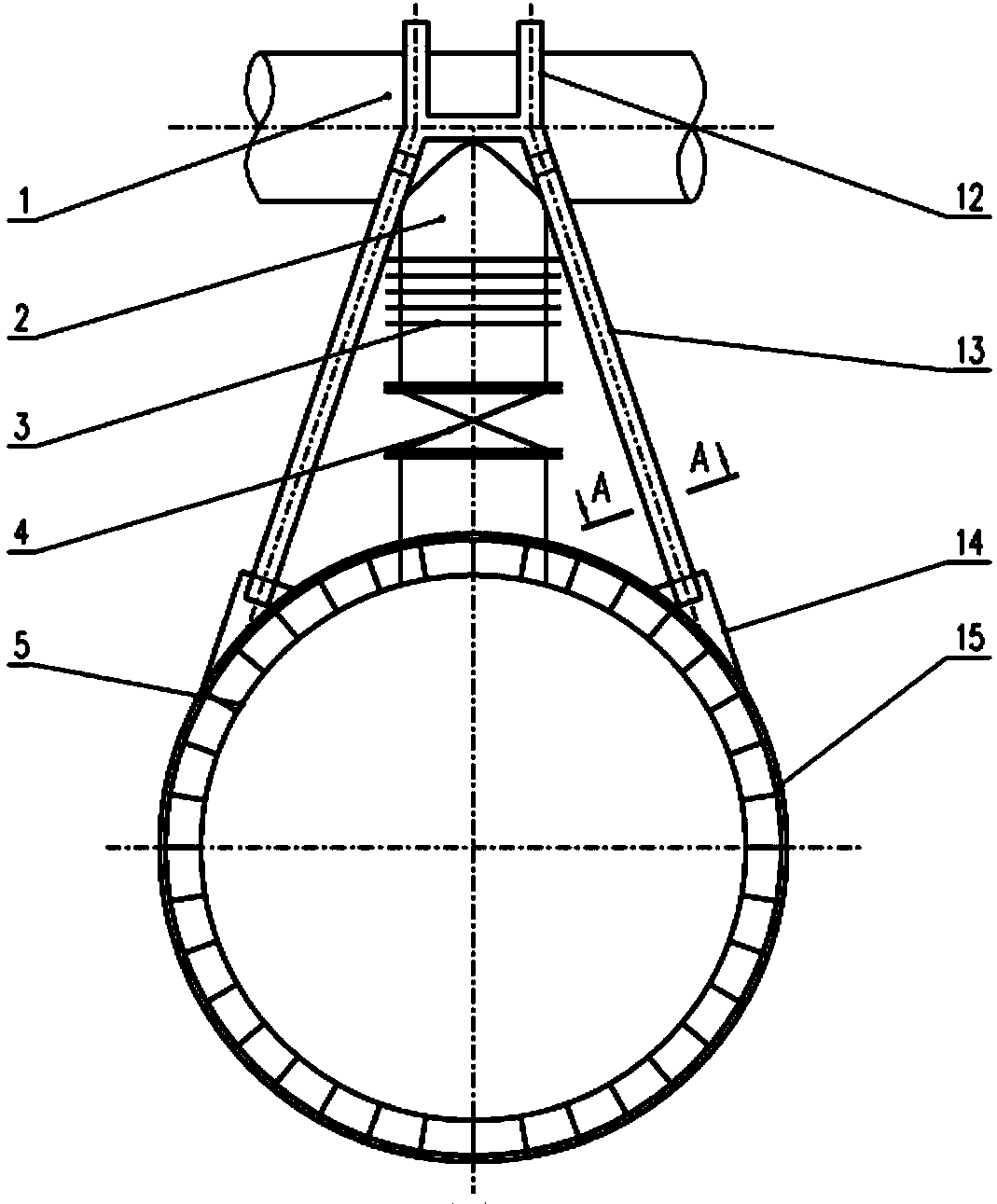

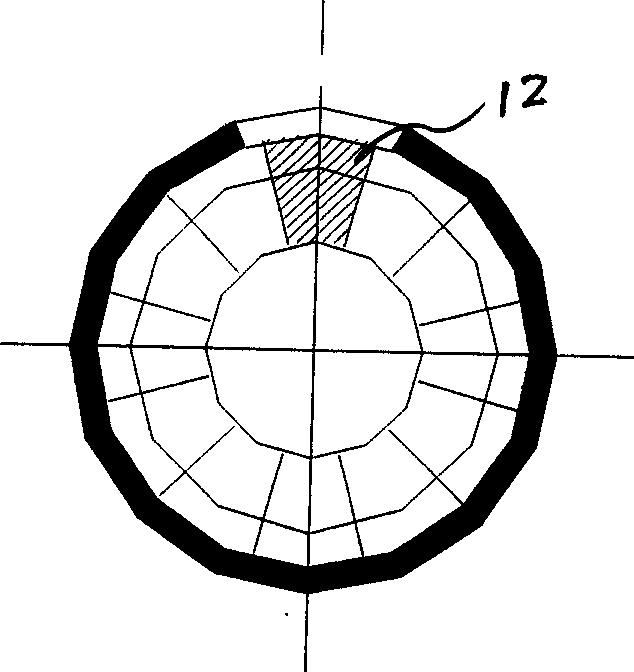

Triangular flexible large pull rod device with hot air pipelines

The invention discloses a triangular flexible large pull rod device hot air pipelines, which belongs to the technical field of blast furnace top combustion type hot air furnaces. The device comprises a hot air main pipe, a hot air branch pipe, a hot air branch pipe compensator, a hot air valve and a hot air furnace shell, wherein a hot air furnace shell reinforcing ring is arranged on the hot air furnace shell, an upper hot air pipeline large pull rod support base is arranged in a cross position where the hot air branch pipe is connected with the hot air main pipe; two groups of triangularly arranged flexible large pull rods are adopted to integrally connect the hot air furnace shell reinforcing ring with a flexible large pull rod support base in a connection manner of welding or bolt connection. To connect conveniently, a connecting plate can be arranged. The device has the advantages that the raising of the hot air furnace shell can be effectively absorbed, the stress of the pipe shell and the furnace shell is reduced, the security of the hot air furnace and the pipelines is improved, and the device is particularly applicable to top combustion type hot air furnaces of which the hot air outlet is relatively high and the furnace shell raising amount is relatively large.

Owner:BEIJING SHOUGANG INT ENG TECH

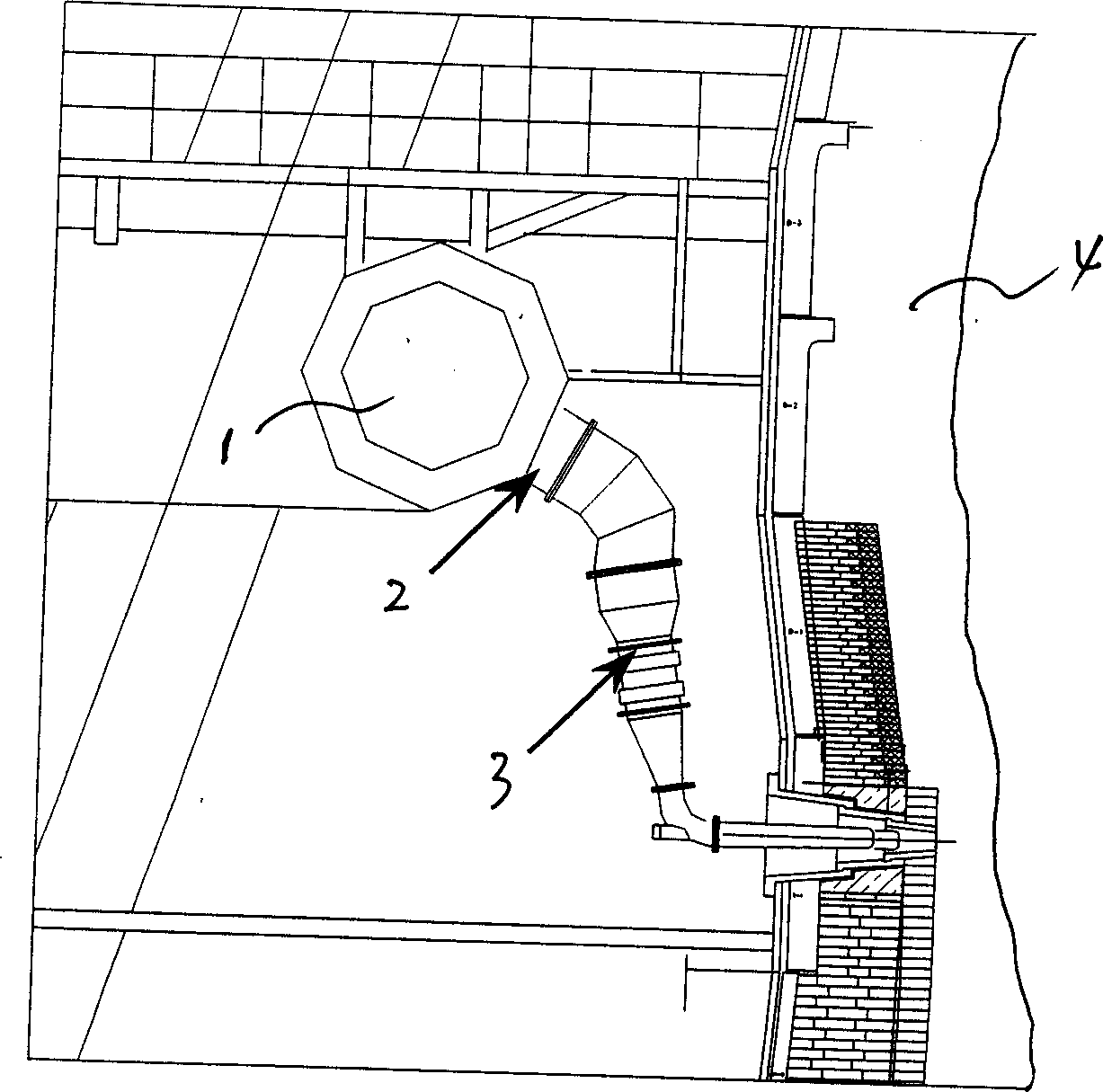

Thermal state method for restoring branch pipe orifice of blast furnace bustle pipe

A technology of repairing inner lining material of blast furnaces, especially thermally repairing bustle pipes. It comprises: a. clogging and insulating the ceramic fiber layer containing metallic framework ; b. dissembling the firebricks in inner walls; c. supporting and fixing flatiron onto iron housing of the pipe;d. selecting firebricks. The invention is mainly used to repair inner linings ofblast furnaces.

Owner:BAOSHAN IRON & STEEL CO LTD +1

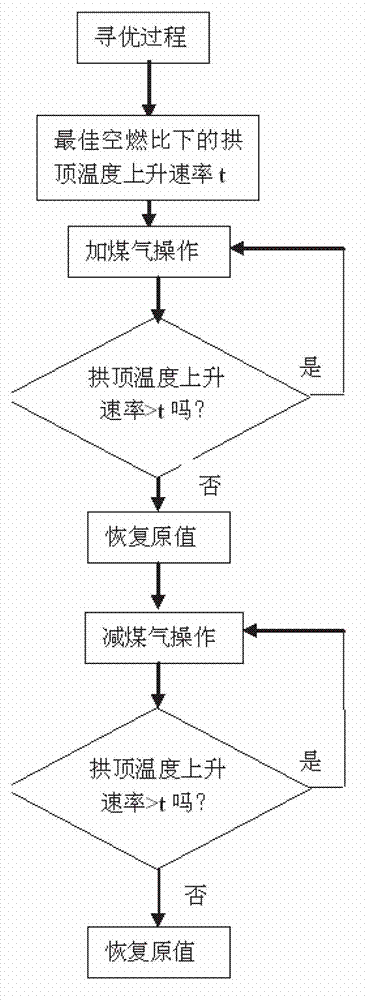

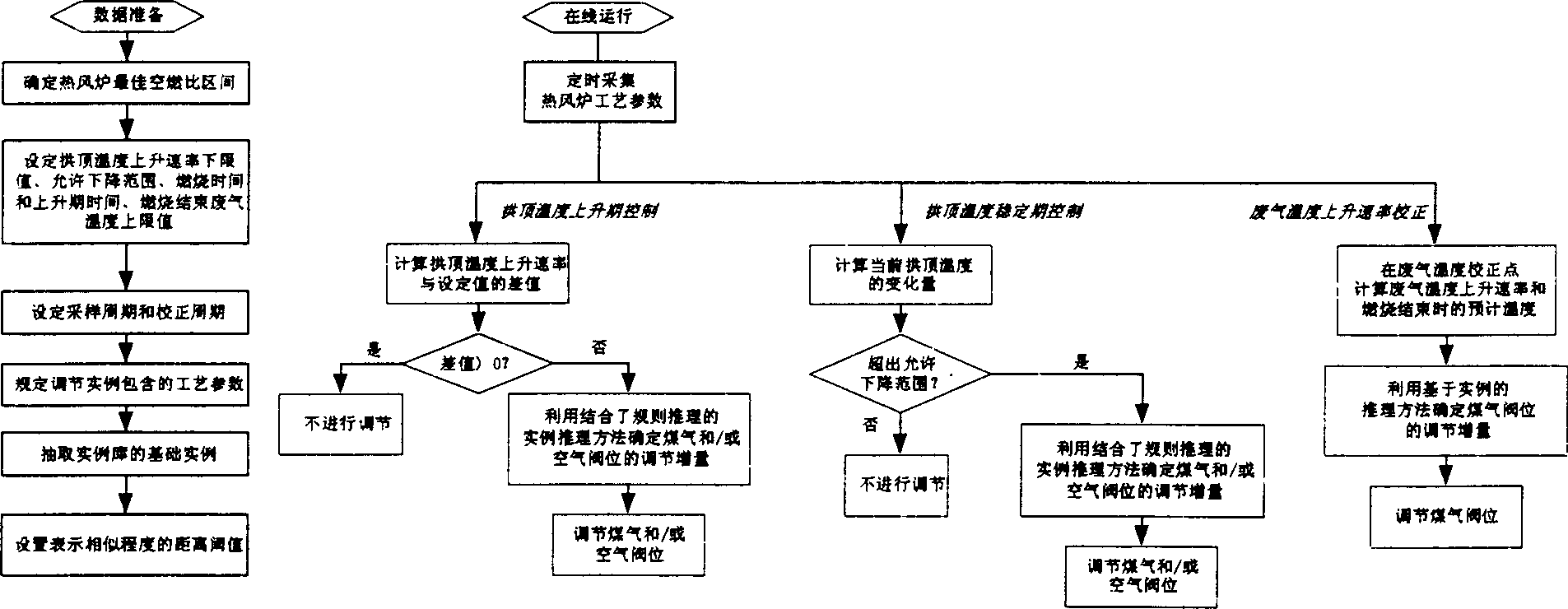

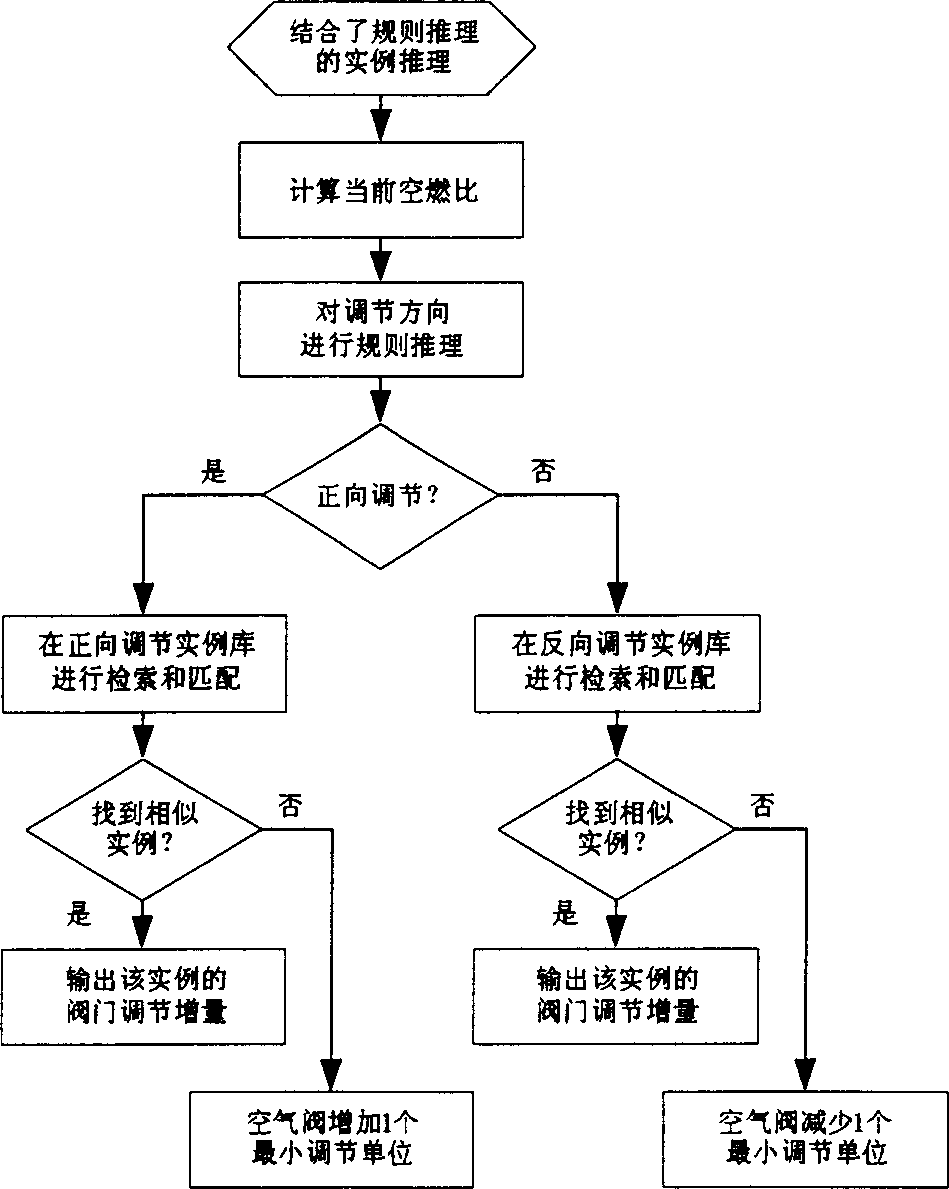

Blast furnace hot-blast stove combustion automatic control method based on example inference

InactiveCN1676619AReduce the number of adjustmentsTroubleshoot scaling issuesFuel supply regulationBlast furnace detailsAutomatic controlEngineering

This invention relates to blast furnace air-stove automatic control method based on example reasoning. At first assure the best skip area of air-stove, and prescribe a technique parameter contained in the example and relating to the burning procedure, and then extract several successful adjusting examples to be the basic examples of the database during the line-functioning phase; according the real time technique parameter during the functioning procedure, calculate the speed or variable amount of the temperature raising of the arch, if it is lower than the rising speed value or more than the allowable falling range, adjust the air burning ratio combining with the example reasoning method to speed up the temperature rising and restrain the arch temperature falling; this invention does not depend on the mathematic model of furnace air-stove, does not detect the residue amount, and confirm the output of controlling decision according to example reasoning to realize the automatic control of the furnace air-stove.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Efficient economical dust collecting method and dust collector for iron-smelting blast furnace

InactiveCN101074453AImprove the efficiency of waste heat recovery and utilizationIncrease temperatureBlast furnace detailsCooling devicesCombustionHeat transfer efficiency

An efficient energy-saving dust-collecting method and its apparatus for iron-smelting blast furnace are disclosed. The procedure is carried out by pre-cooling wet air before entering them into air blower, re-cooling, lowering temperature below saturated temperature, coagulating while precipitating for water content in wet air, re-cooling, delivering into blast furnace by air blower, discharging smoke from blast furnace, heat-exchanging, recovering partial tailed heat, lowering temperature, bagged collecting dust, storing or generating. It's cheap and simple, has higher heat-transfer rate, long utilizing life, less apparatus, full combustion and recovery and better high-temperature resistance for bagged dust collector.

Owner:童裳慧

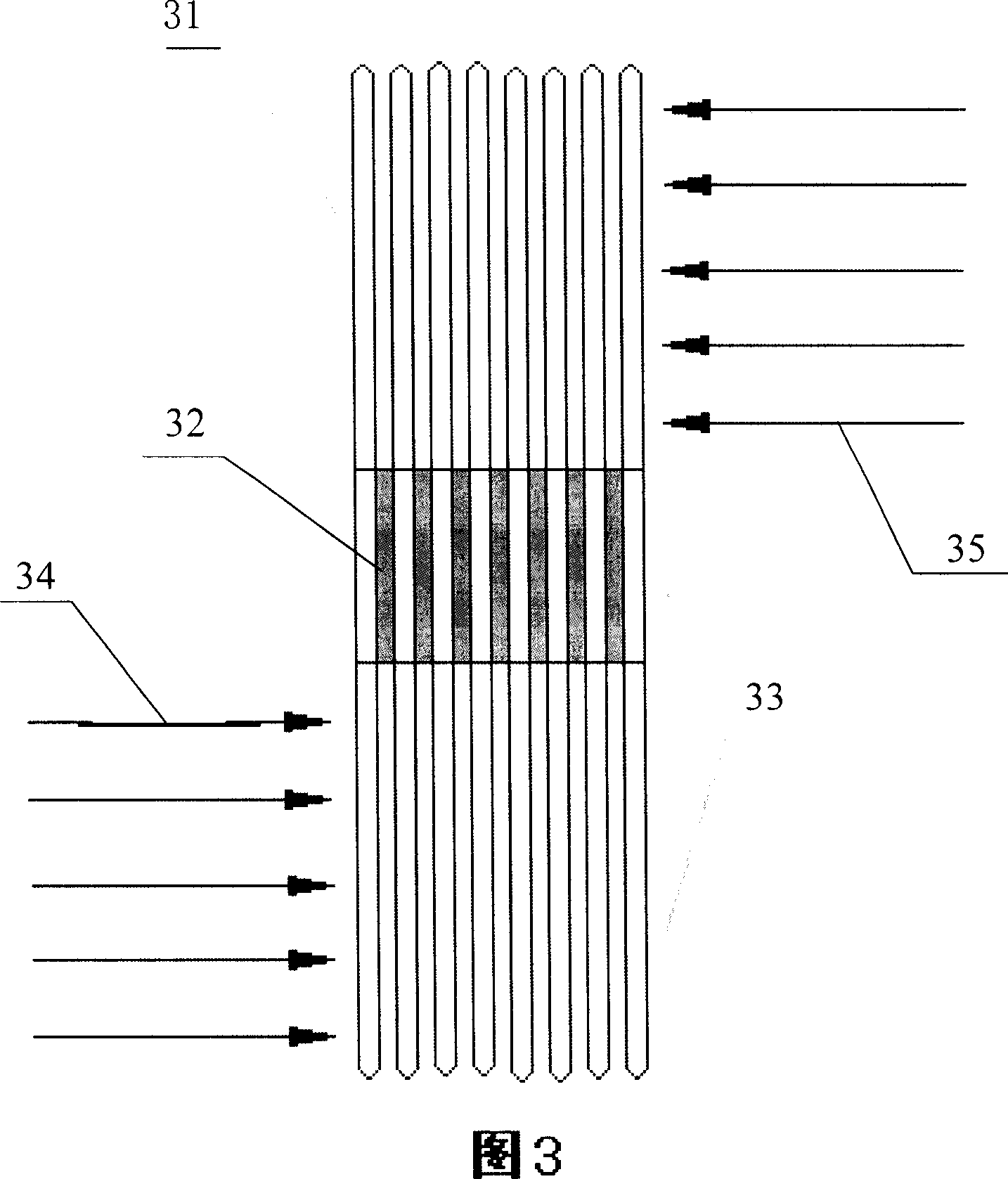

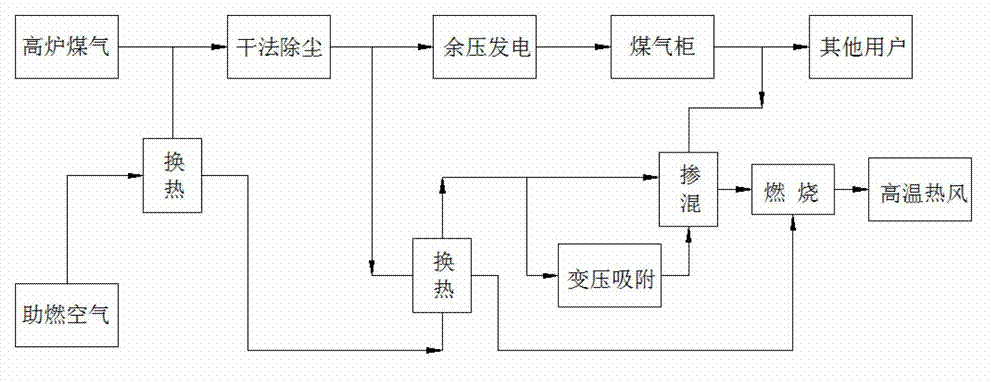

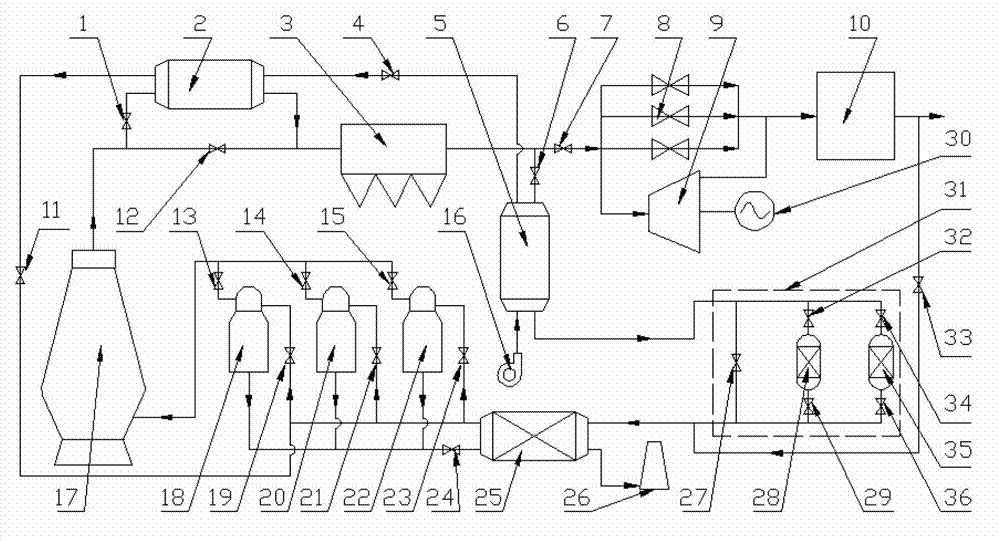

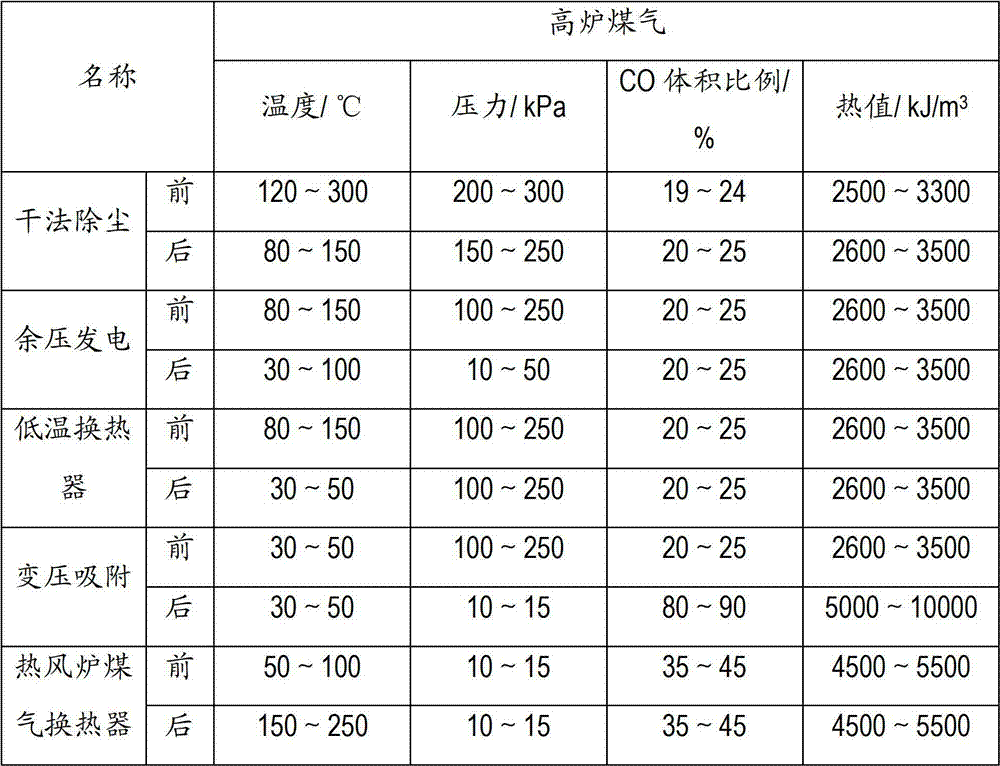

Method for guaranteeing high blast temperature by using blast furnace gas

ActiveCN102876824AHigh calorific valueIncreased CO concentrationBlast furnace detailsIncreasing energy efficiencyCold airCombustion

The invention discloses a method for guaranteeing high blast temperature by using blast furnace gas, and belongs to the technical field of utilization of blast furnace gas of iron making and combustion of hot-blast furnaces. The method is particularly suitable for being used under the conditions that high heating value gas is in short, and blast furnace gas is rich. The method aims to solve the problem that high blast temperature cannot be guaranteed due to low heating value of the blast furnace gas, and an additional combustion furnace is adopted to guarantee the high blast temperature, and the blast furnace gas is comprehensively utilized; and the method comprises the steps of: utilizing the residual heat of the blast furnace gas, removing dust by a dry method, and performing pressure swing adsorption and mixing and combusting to guarantee high blast temperature. The residual heat of the blast furnace gas and the residual heat produced after the dust is removed by the dry method are used for heating air from an air blower, and the heated air is used as combustion air for combustion of the hot blast furnace and cold air blast at an inlet of the hot-blast furnace; the low heating value blast furnace gas which is obtained after the dust is removed by the dry method and of which the volume proportion is 10 to 40 percent is cooled to enter a pressure swing adsorption device, so that the low heating value blast furnace gas is changed into the high heating value gas, and the high heating value gas and low heating value blast furnace gas obtained after top pressure power generation is mixed and combusted; and under the condition that a hot-blast furnace system is not provided with the additional combustion furnace, the hot blast at the high temperature of between 1,250 and 1,350 DEG C can be provided for a blast furnace for use.

Owner:SHOUGANG CORPORATION

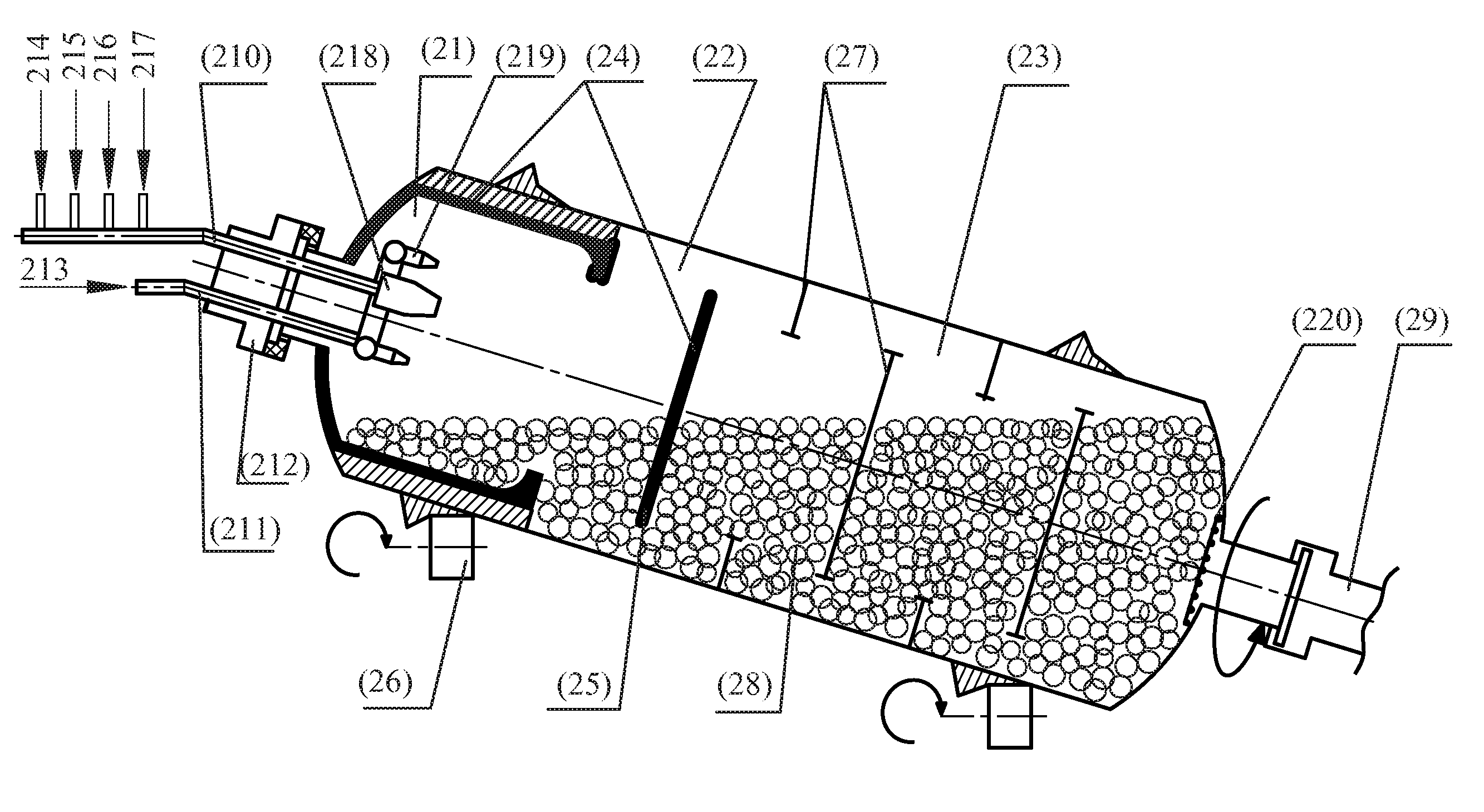

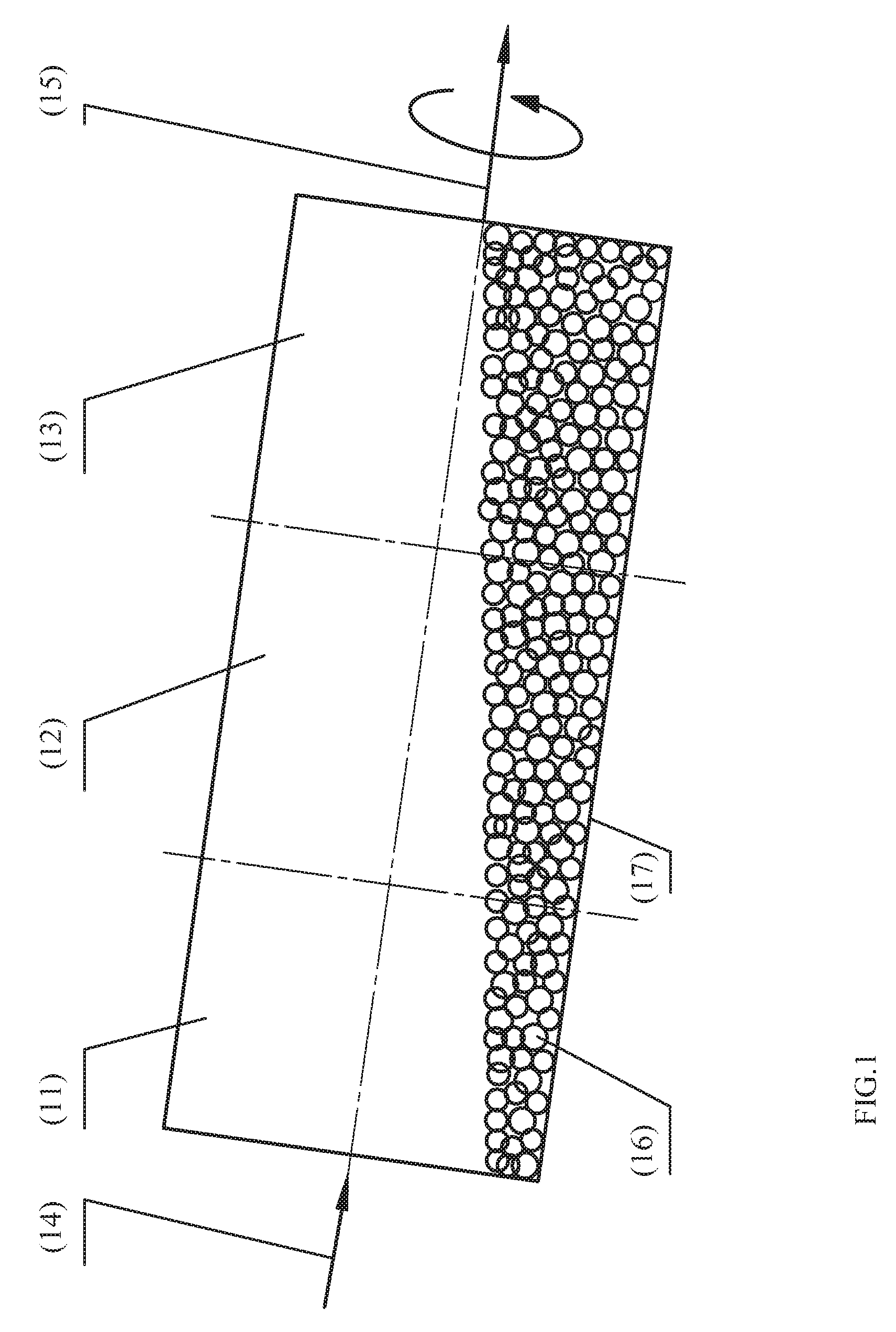

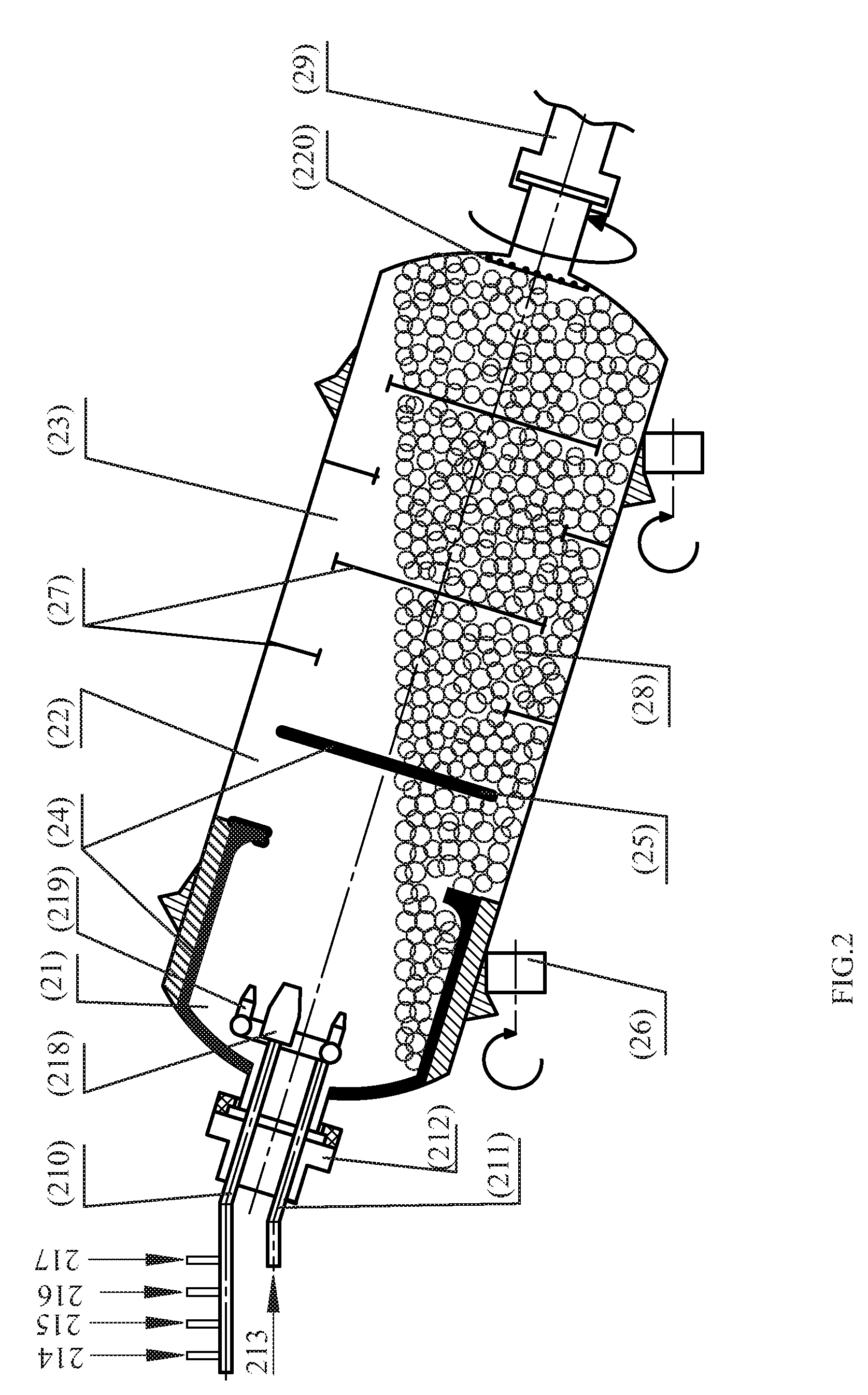

Reaction chamber for a direct contact rotating steam generator

InactiveUS7814867B2Lower the volumeEliminate needBoiler water tubesRotary drum furnacesCombustionProduct gas

Owner:EX TAR TECH

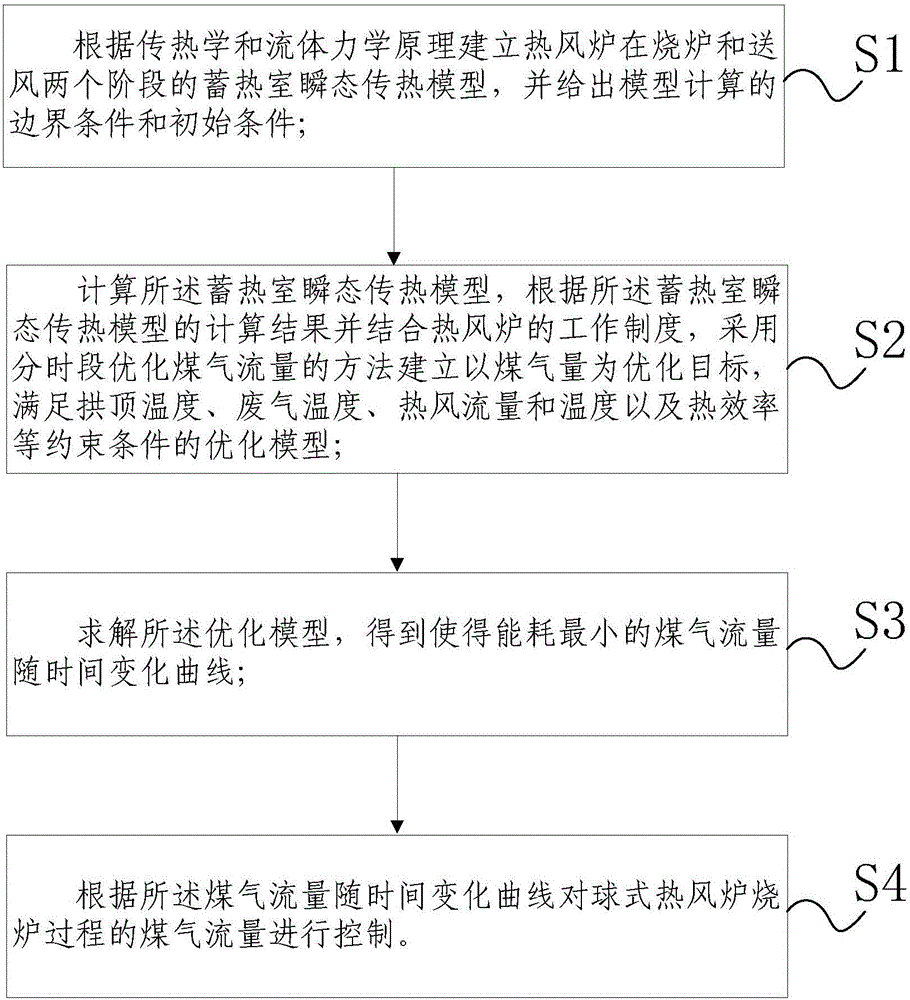

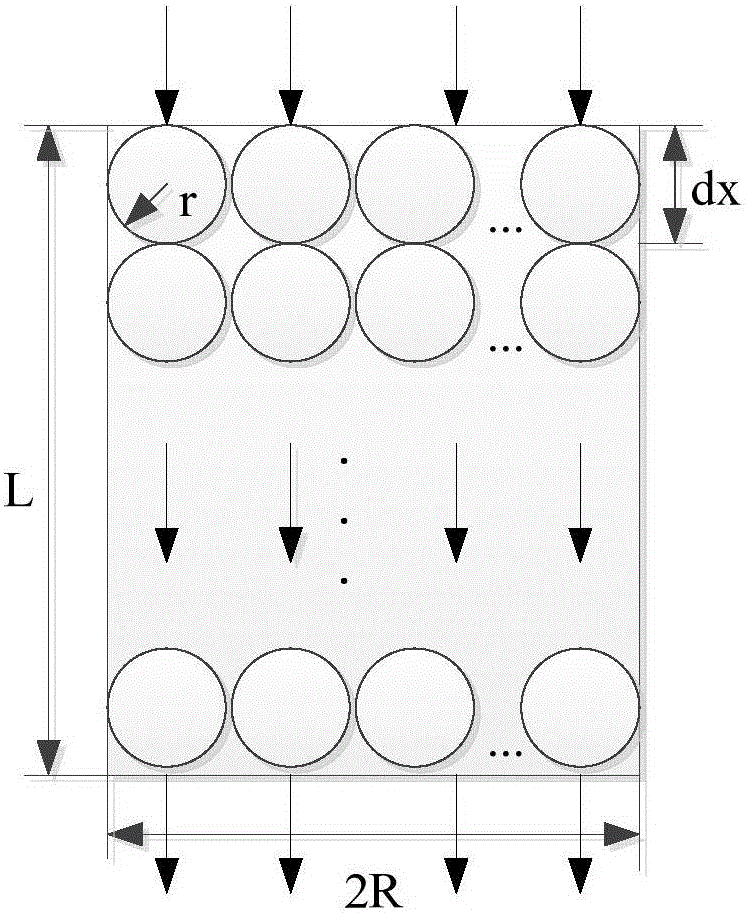

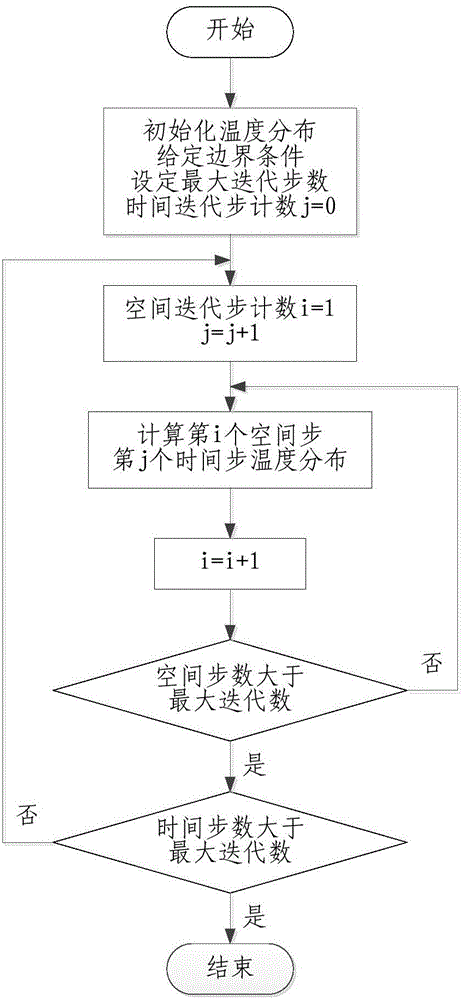

Method and system for ball type hot blast furnace sintering process modeling and energy consumption optimization

ActiveCN105907906ARealize automatic burning furnaceForecast temperatureSteel manufacturing process aspectsBlast furnace detailsTransient heat transferHot blast

The invention discloses a method and system for ball type hot blast furnace sintering process modeling and energy consumption optimization, and can realize purposes of energy saving and cost reduction. The method includes the steps: S1, according to heat transfer and fluid mechanics principles, establishing a regenerative chamber transient heat transfer model of a hot blast furnace in two stages of furnace sintering and air feeding, and providing boundary conditions and initial conditions for model calculation; S2, calculating the regenerative chamber transient heat transfer model, according to the calculated results of the regenerative chamber transient heat transfer model and with combination of a working system of the hot blast furnace, establishing an optimization model taking the coal gas volume as an optimized target and meeting the dome temperature, the exhaust gas temperature, the hot air flow quantity and temperature, the thermal efficiency and other constraint conditions by a method of time-dividing optimization of the coal gas flow quantity; S3, solving the optimization model, to obtain a change curve of the coal gas flow quantity having minimum energy consumption along with the time; and S4, controlling the coal gas flow quantity of the ball type hot blast furnace sintering process according to the change curve of the coal gas flow quantity along with the time.

Owner:CENT SOUTH UNIV

Rapid repairing technology of blast furnace hot blast stove pipeline

ActiveCN105018664AResume production as soon as possibleGood high temperature and high pressure resistanceBlast furnace detailsHeating stovesHot blastHigh pressure

The invention relates to a rapid repairing technology of a blast furnace hot blast stove pipeline. The technology comprises the steps that firstly, imperfect ports are cleaned; secondly, modes are arranged; thirdly, a fish skeleton frame is manufactured; fourthly, high-abrasion-resisting ceramic pouring is conducted; fifthly, a zirconium-contained ceramic fiber blanket is laid fully, and a steel shell is recovered; and finally, mudjacking is conducted. The hot blast stove pipeline can be put into operation after the steps are conducted. To achieve the solidifying effect, it is better to follow the progressive principle when the temperature and pressure of supplied air of a hot blast stove are improved. After the repaired hot blast stove pipeline is put into operation, a daily monitoring checking rule should be established for the part. The rapid repairing technology has the beneficial effects that maintaining is easy and convenient, cost is low, the requirement for rapid repairing can be met, a blast furnace can resume production as soon as possible, and after the hot blast stove pipeline breaks down, production is recovered rapidly, and the production cost is reduced; and refractory needed for repairing has good high-temperature and high-pressure resisting performance and can meet the requirement for normal air supplying of the hot blast stove.

Owner:SGIS SONGSHAN CO LTD

Popular searches

Solid fuel combustion Indirect carbon-dioxide mitigation Gaseous fuel burner Combustion using gaseous and pulverulent fuel Combustion using liquid and pulverulent fuel Glass furnace apparatus Glass melting apparatus Firebridges Non-combustible gases/liquids supply Combustion using lump and gaseous fuel

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com