Patents

Literature

488results about "Firebridges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

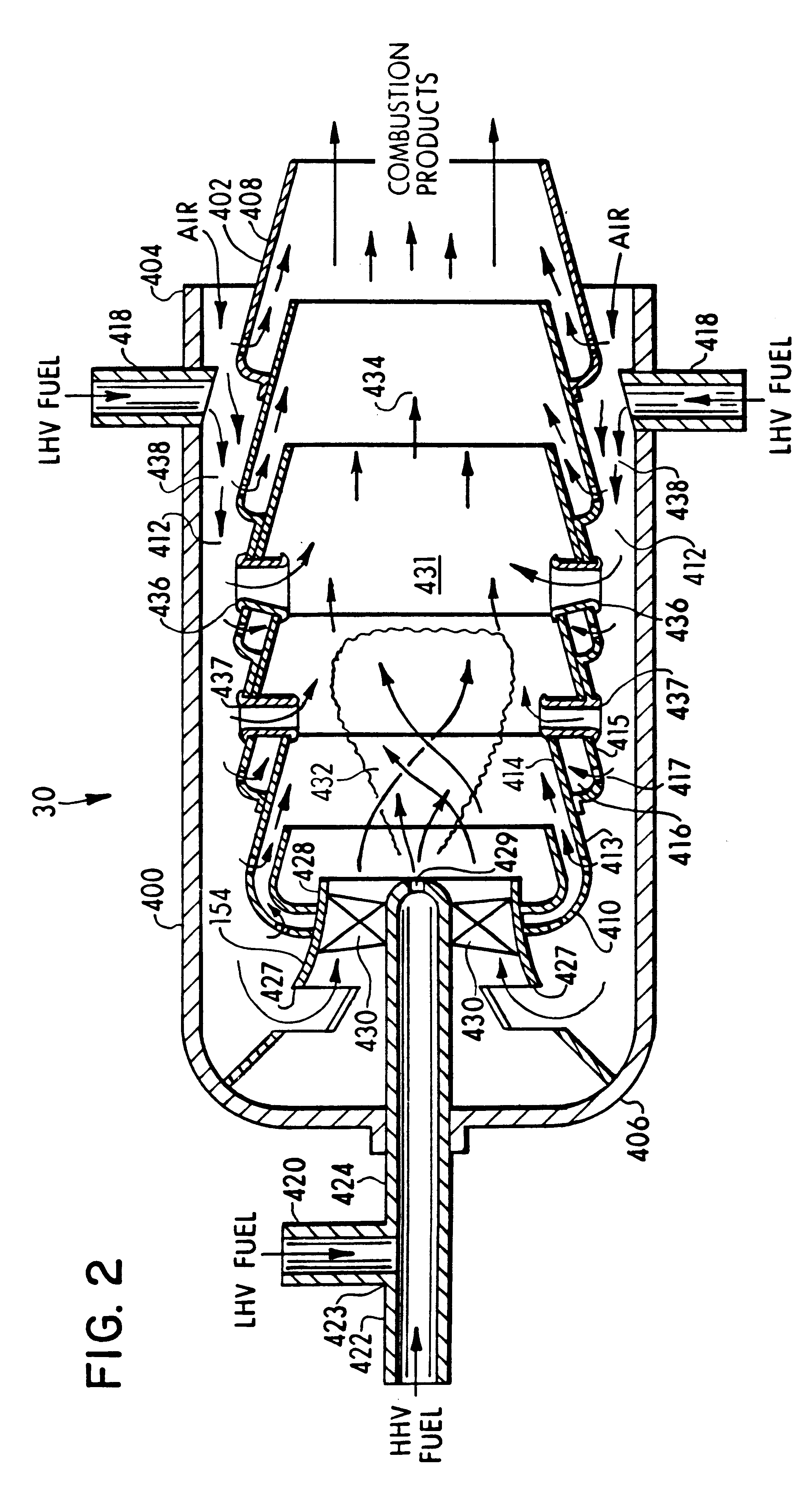

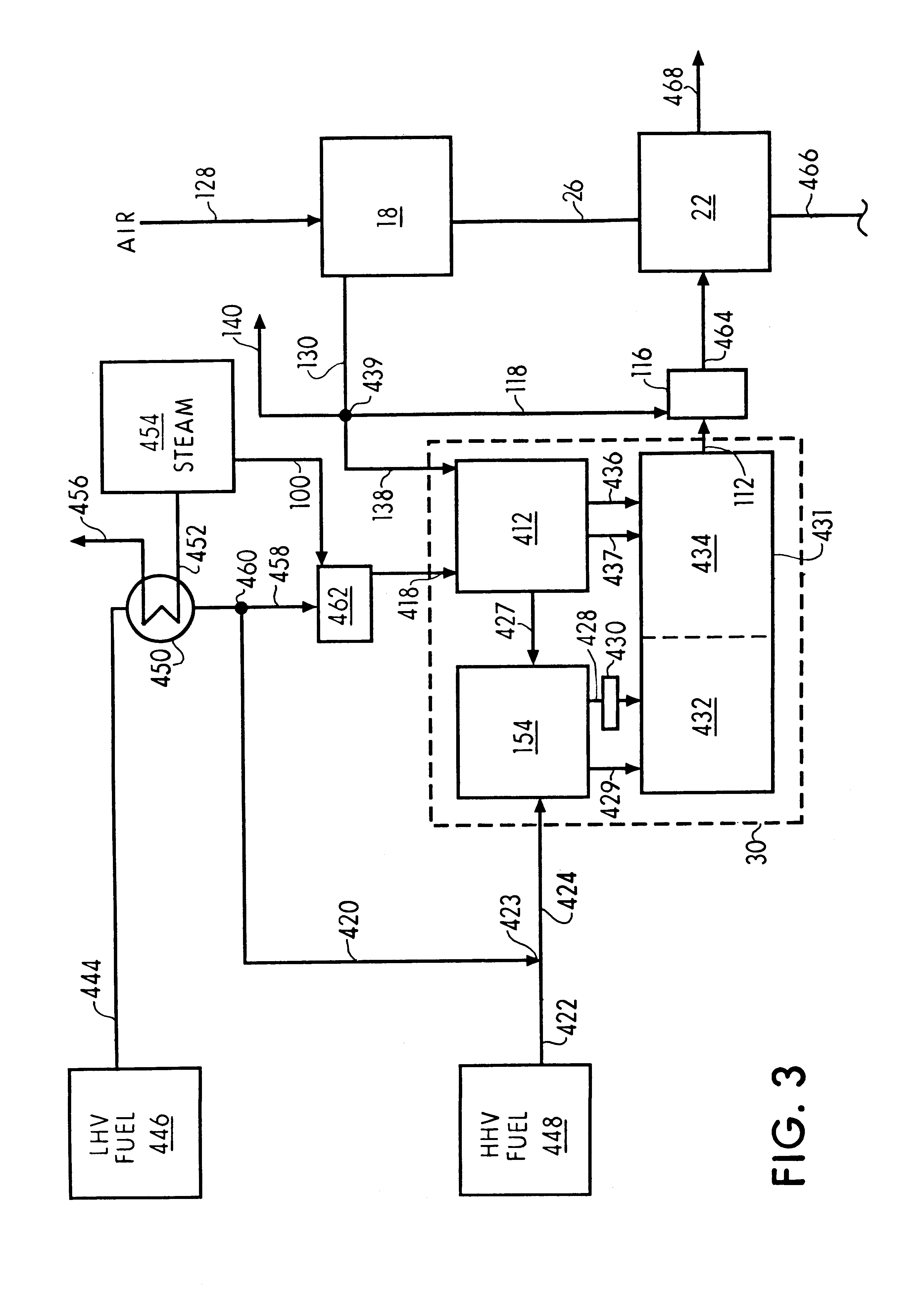

Staged combustion of a low heating value fuel gas for driving a gas turbine

A process is provided for combusting a low heating value fuel gas in a combustor to drive an associated gas turbine. A low heating value fuel gas feed is divided into a burner portion and a combustion chamber portion. The combustion chamber portion and a combustion air are conveyed into a mixing zone of the combustor to form an air / fuel mixture. The burner portion is conveyed into a flame zone of the combustor through a burner nozzle while a first portion of the air / fuel mixture is conveyed into the flame zone through a burner port adjacent to the burner nozzle. The burner portion and first portion of the air / fuel mixture are contacted in the flame zone to combust the portions and produce flame zone products. The flame zone products are conveyed into an oxidation zone of the combustor downstream of the flame zone while a second portion of the air / fuel mixture is also conveyed into the oxidation zone. The second portion is combusted in the oxidation zone in the presence of the flame zone products to produce combustion products. The combustion products are conveyed into the associated gas turbine and drive the gas turbine.

Owner:MARATHON OIL CO +1

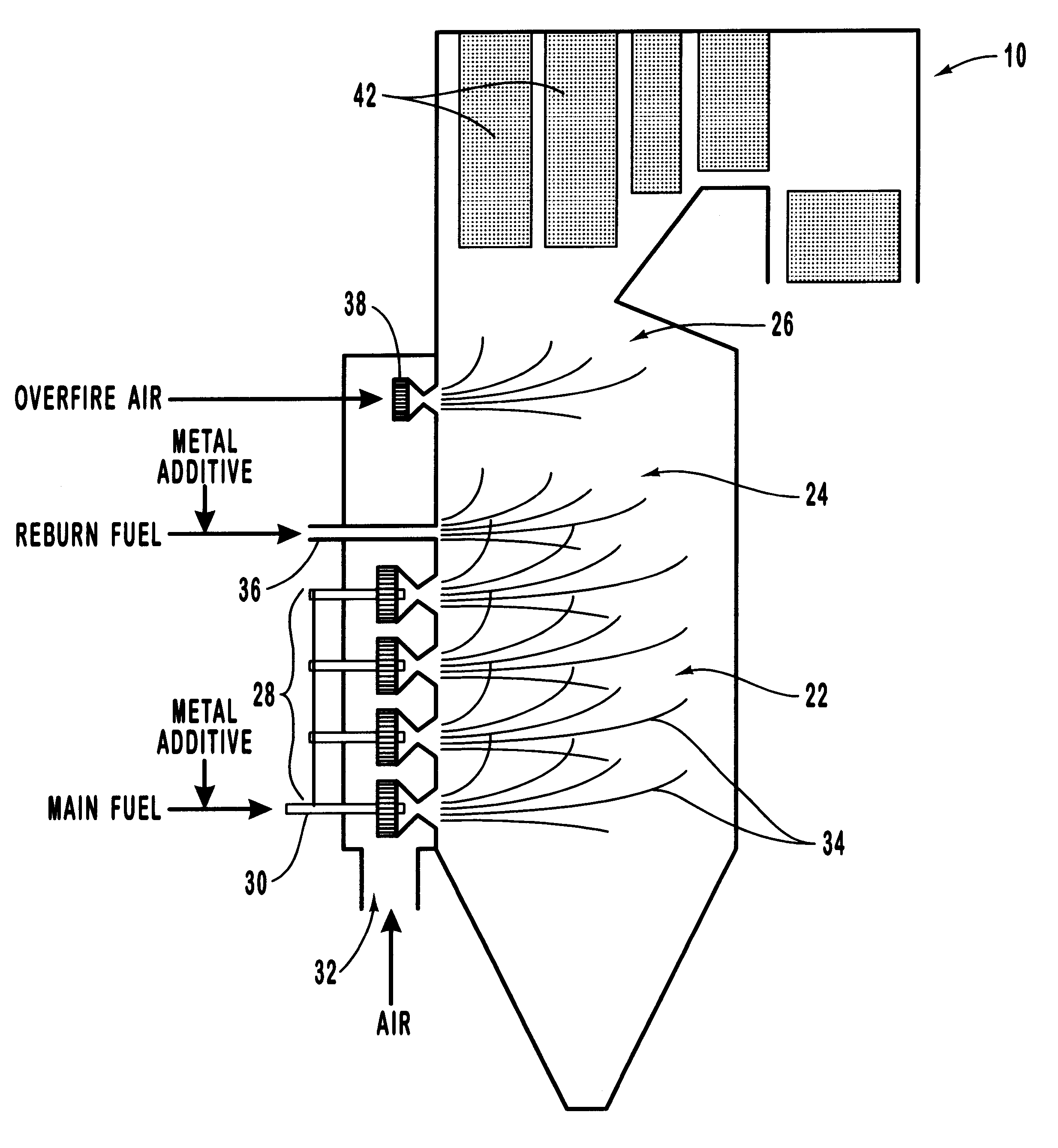

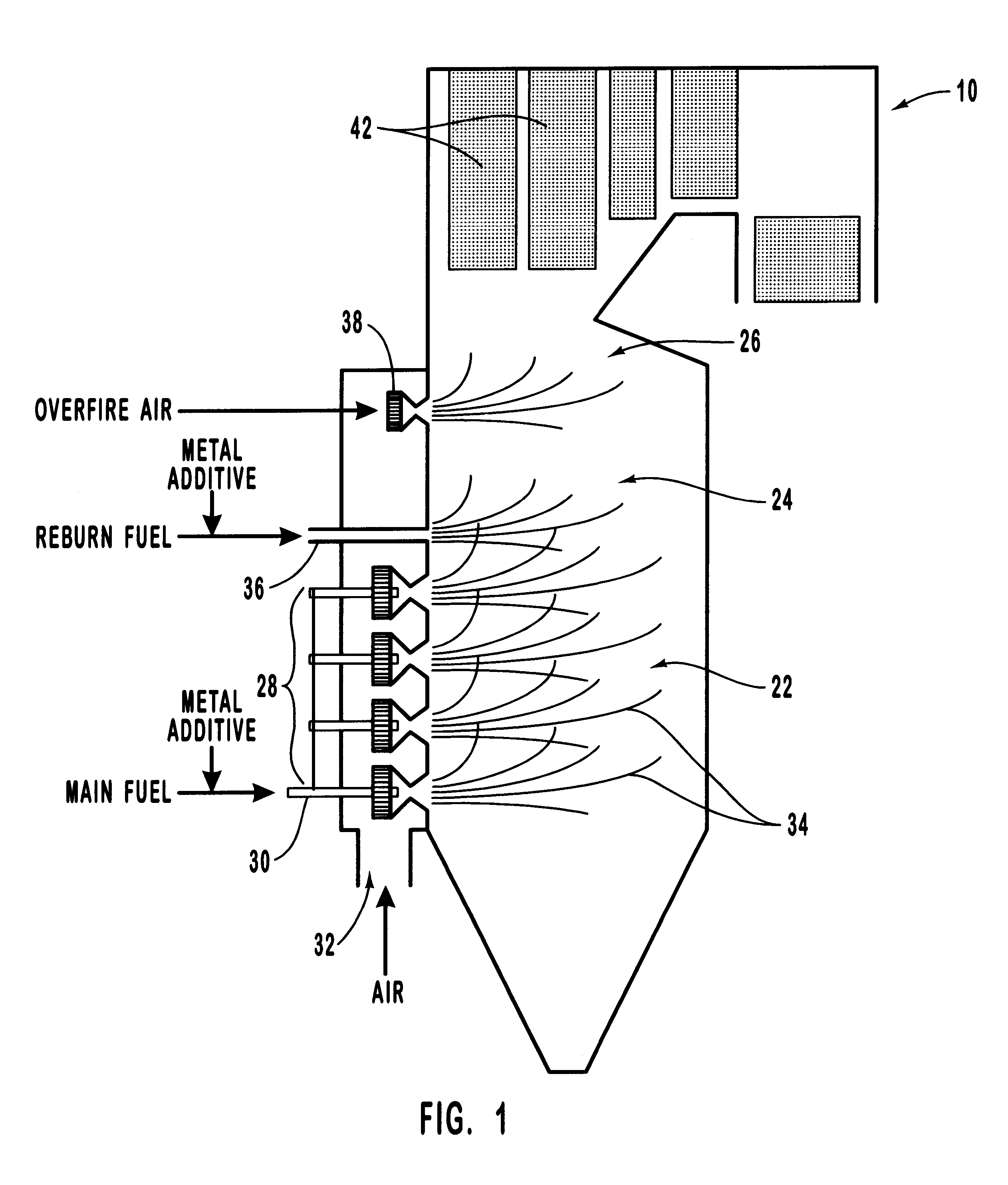

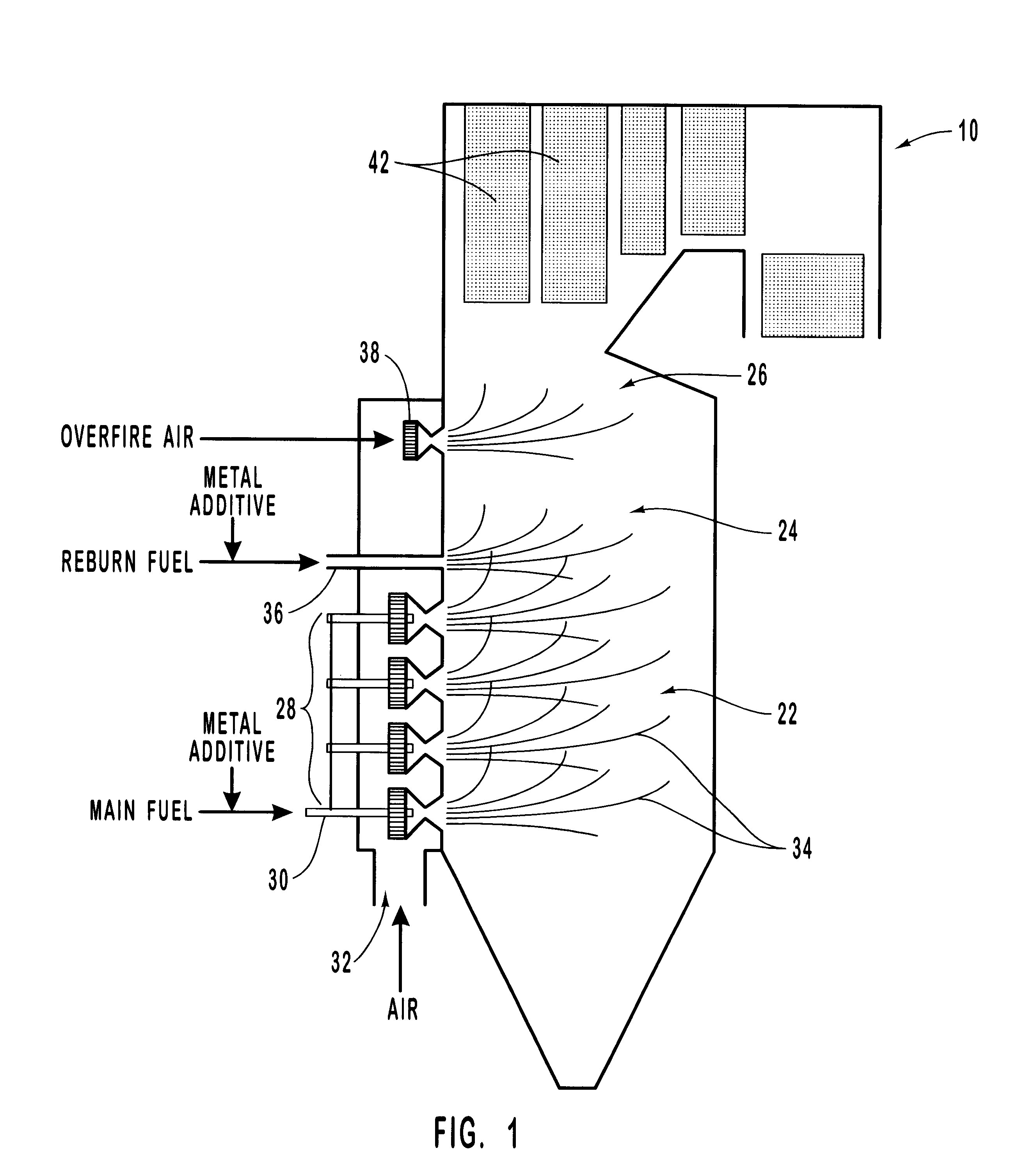

Method for reducing NOX in combustion flue gas using metal-containing additives

InactiveUS6206685B1Improved control deviceSure easyDispersed particle separationSolid fuel combustionAtmospheric airNitric oxide

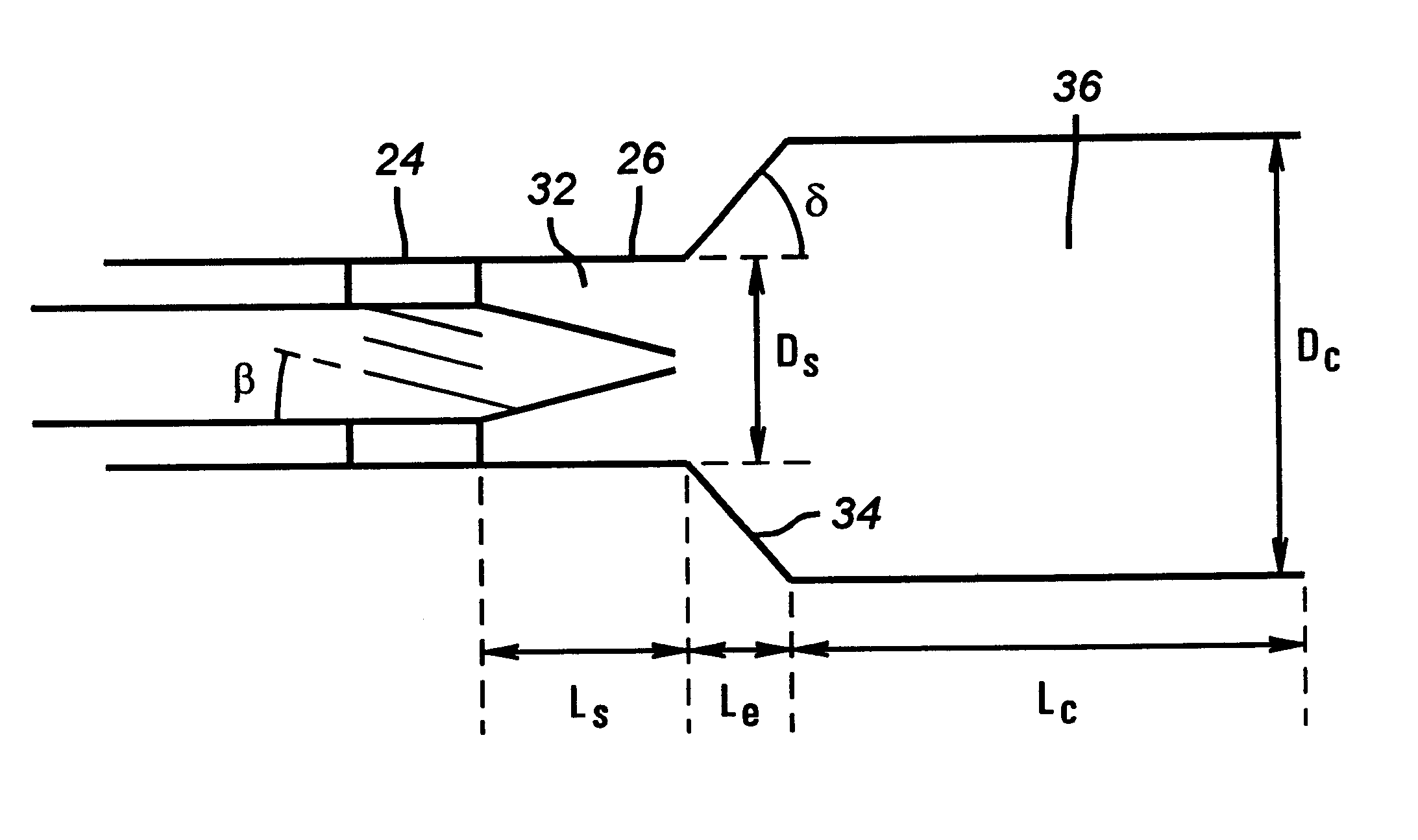

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

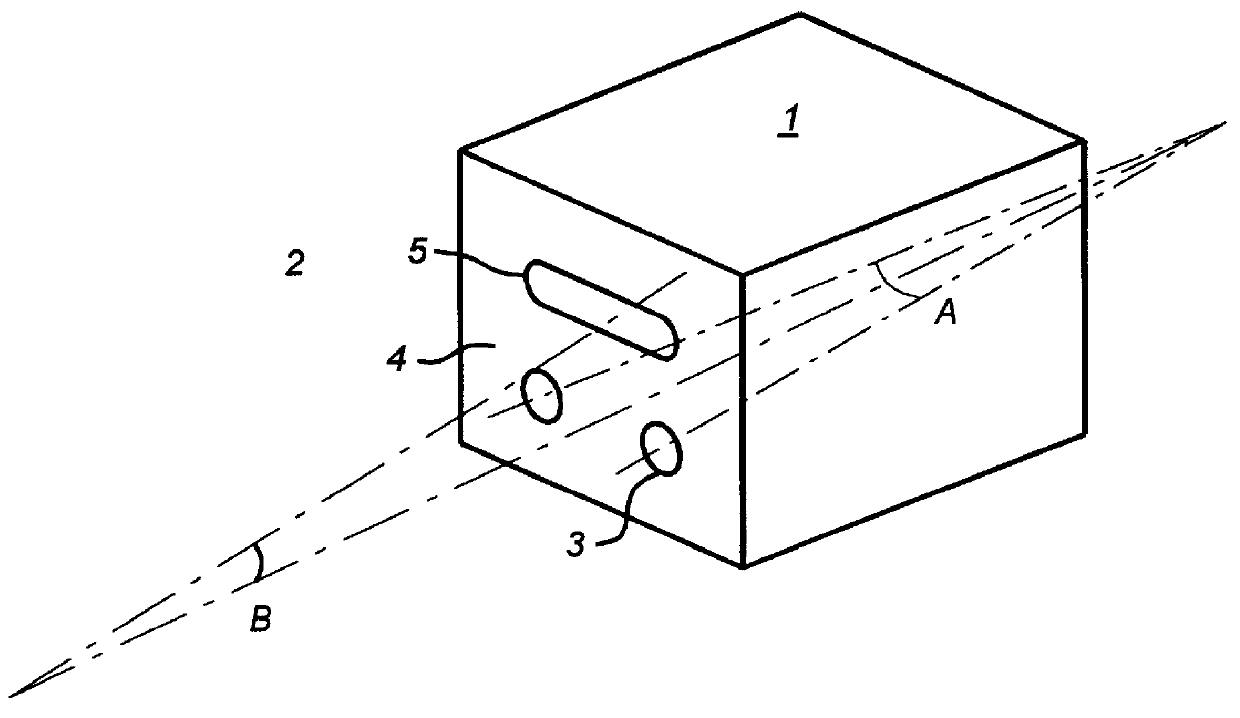

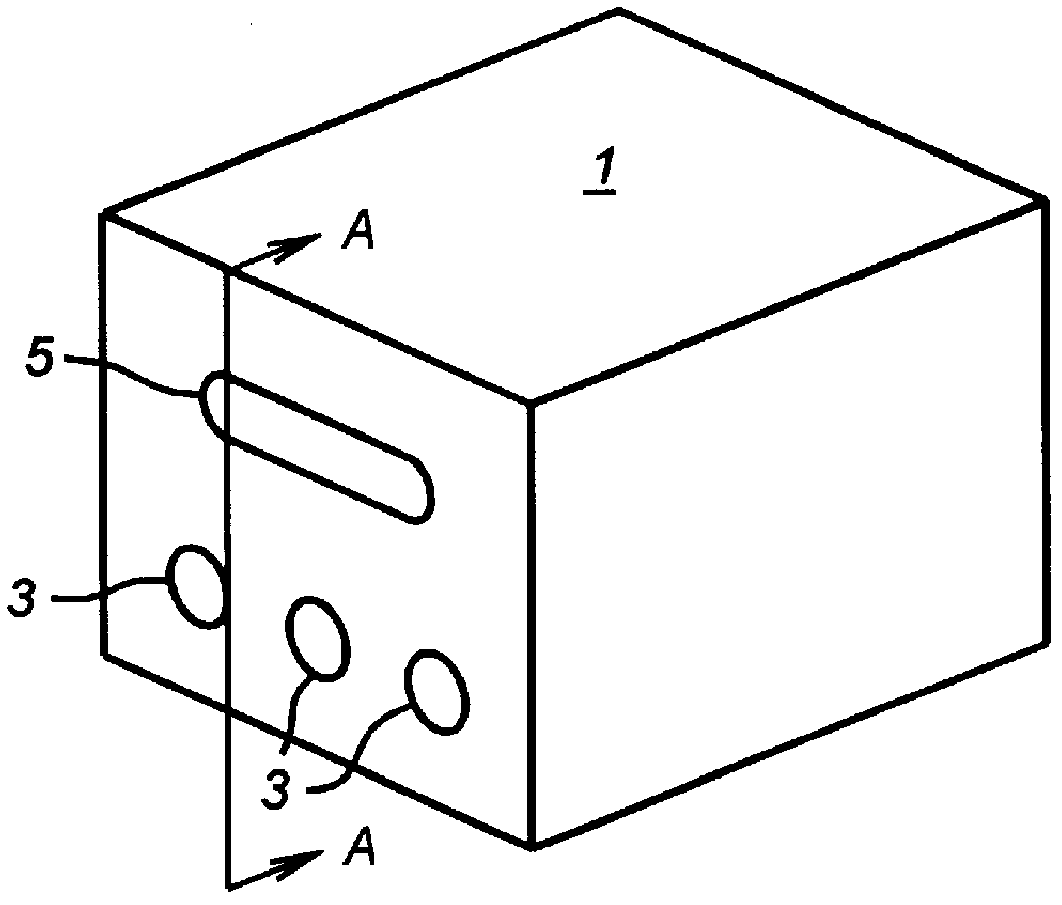

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6074197AReduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

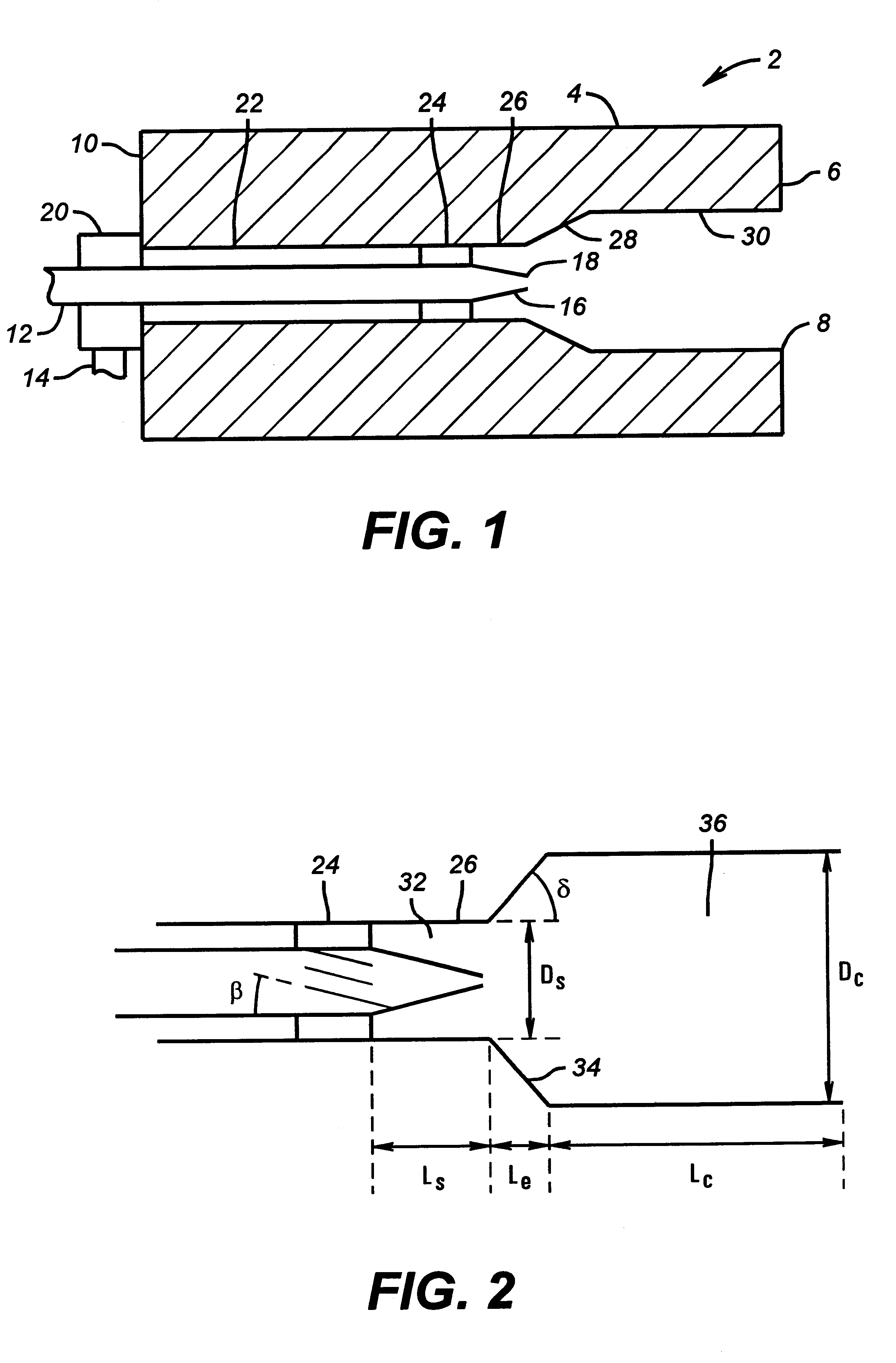

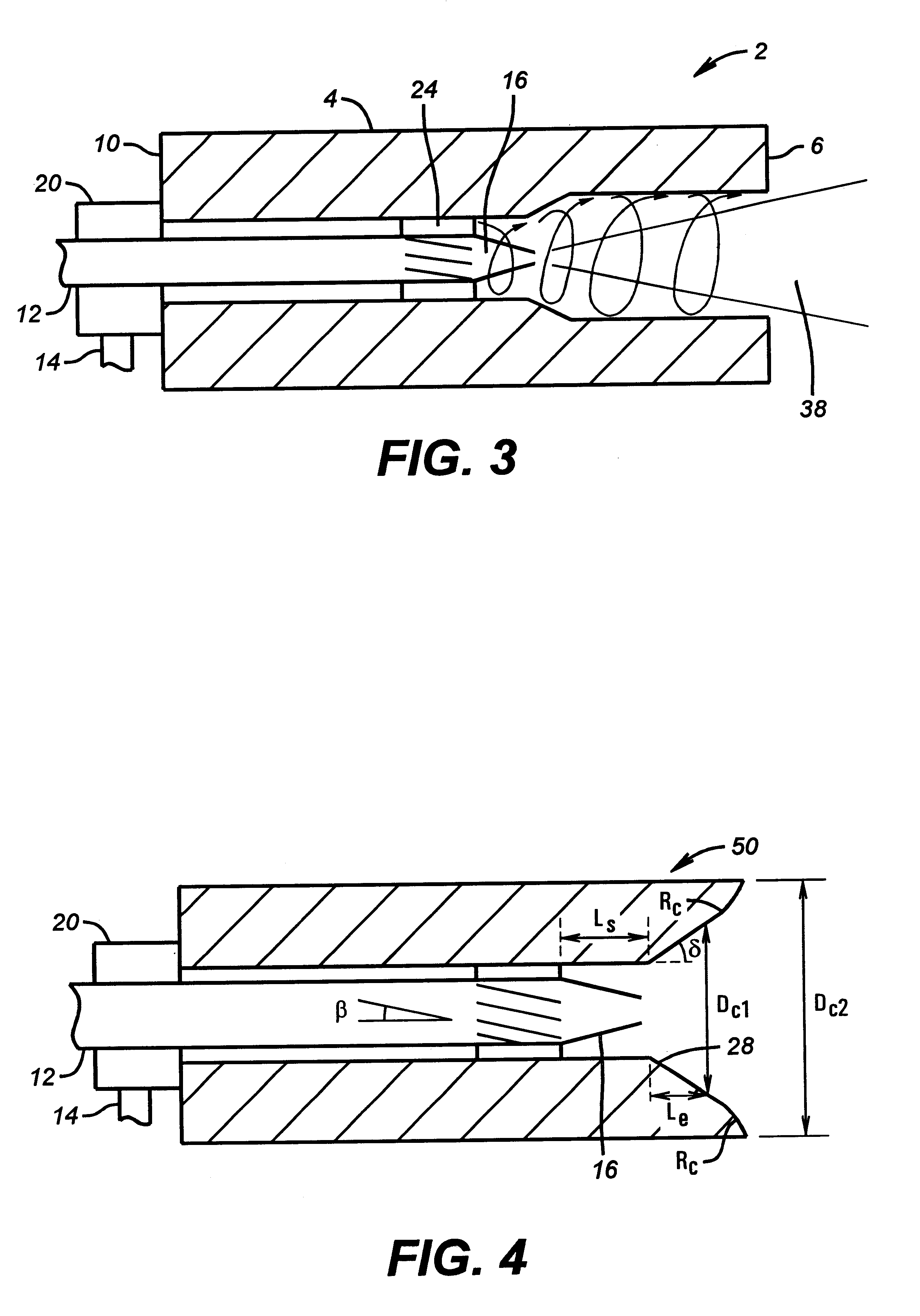

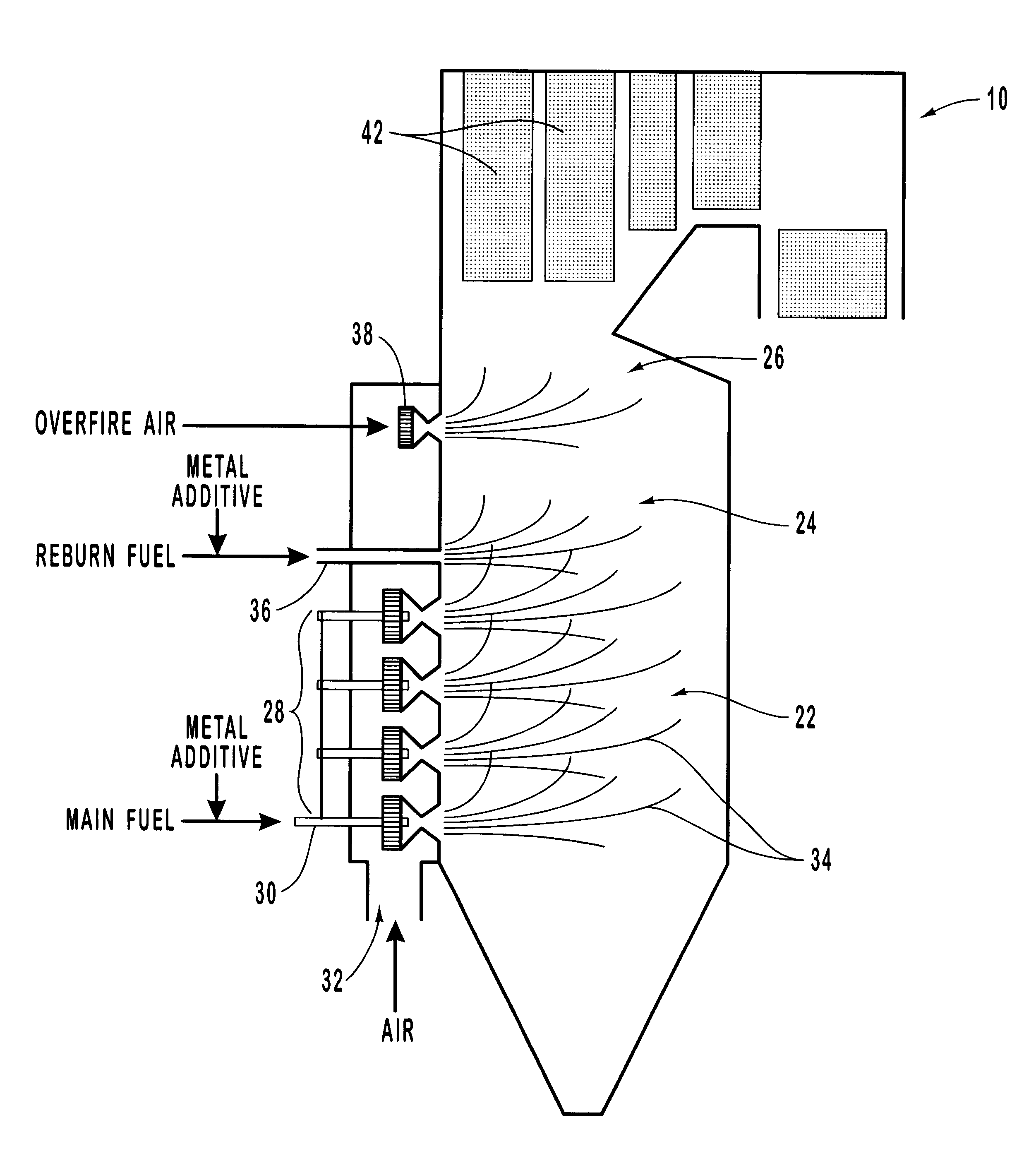

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

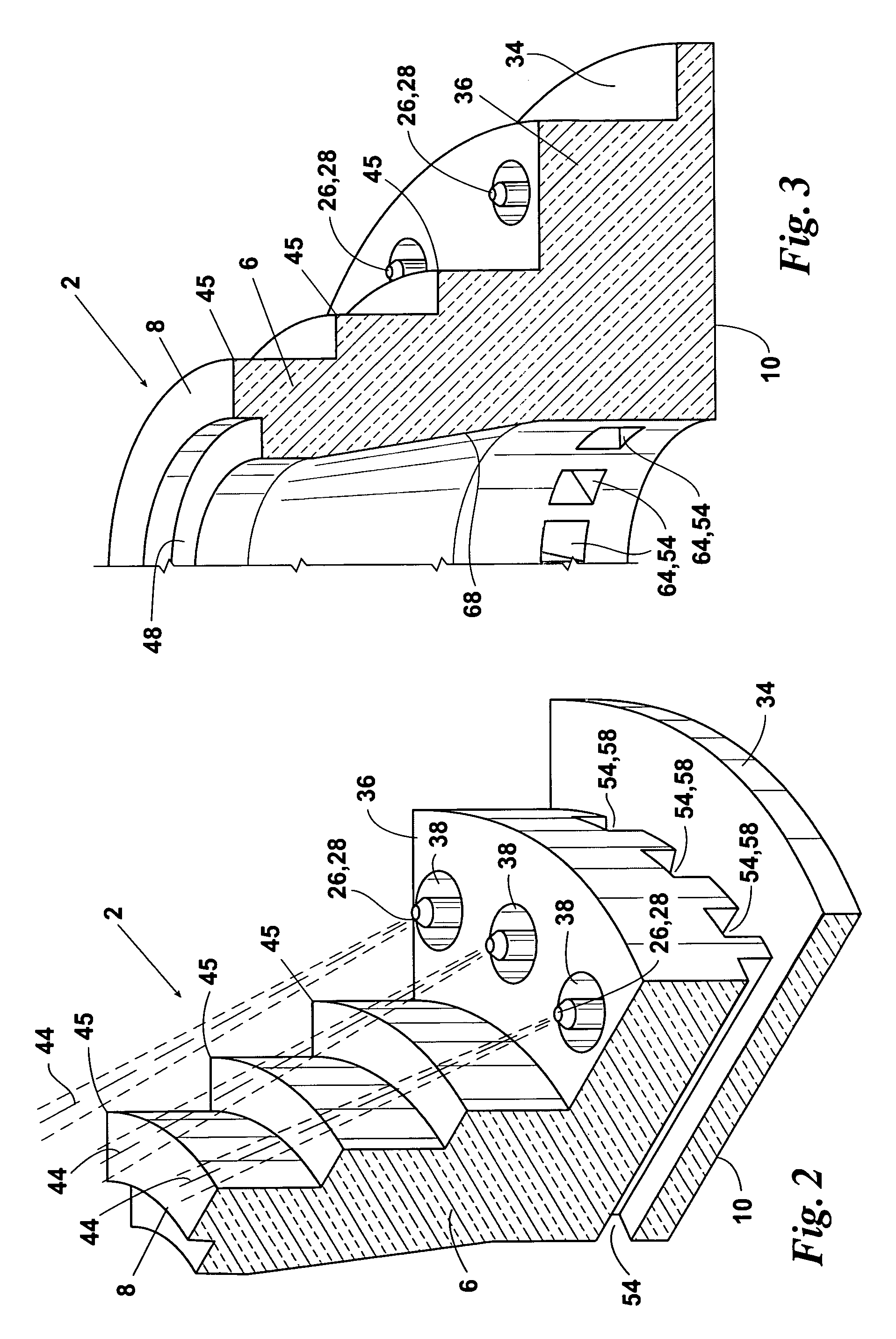

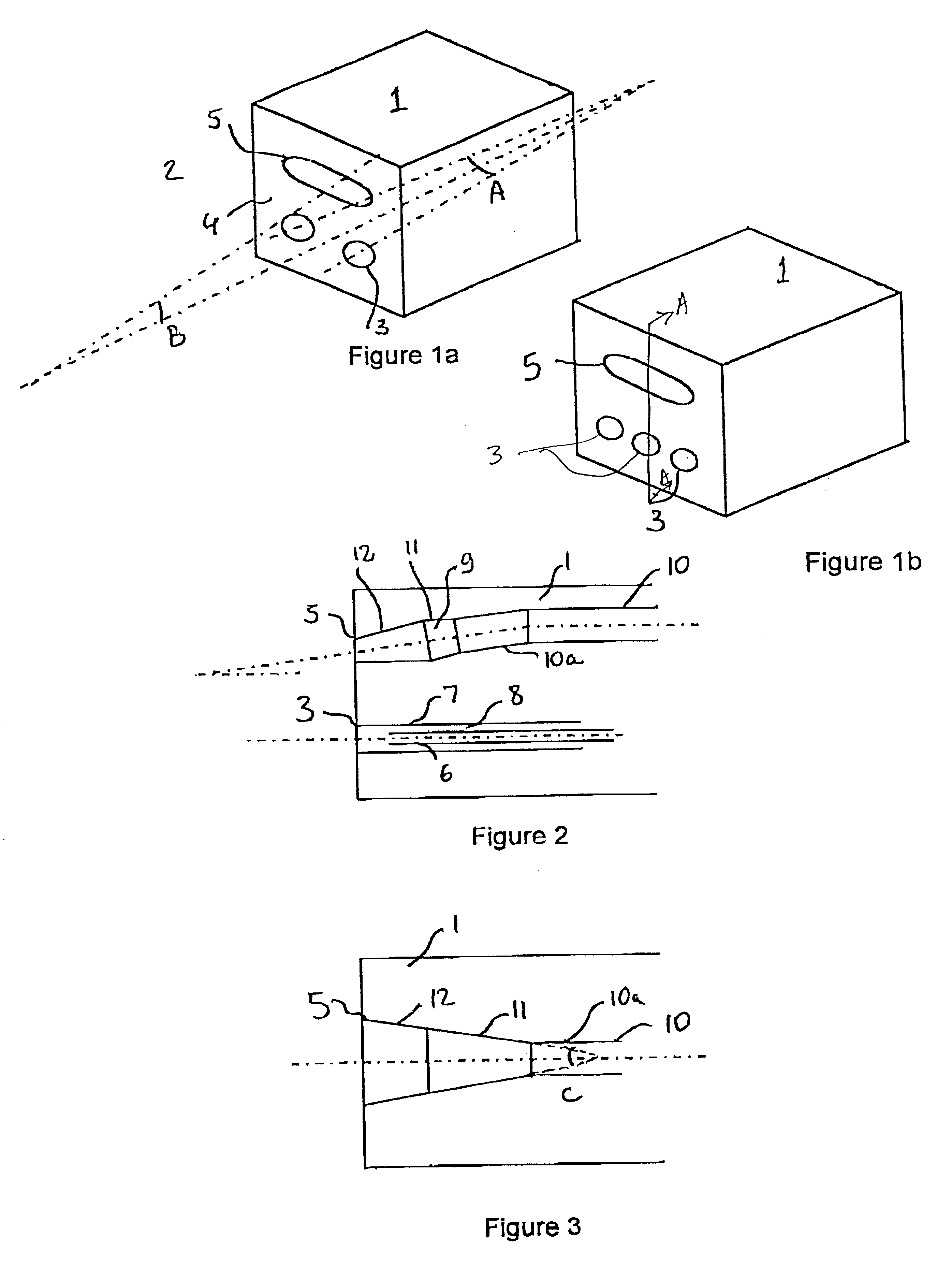

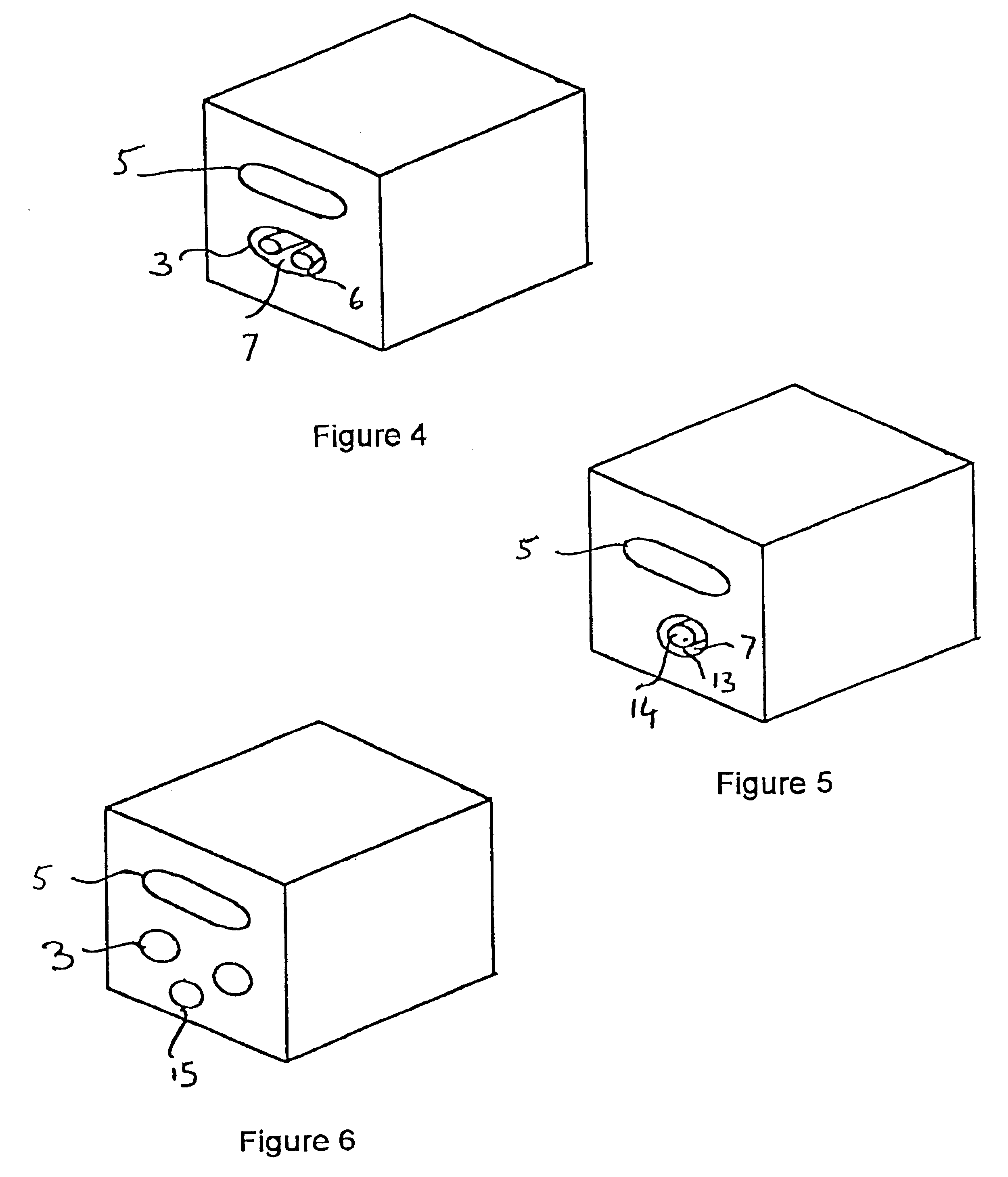

Refractory block for use in a burner assembly

InactiveUS6068468ACombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets-, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

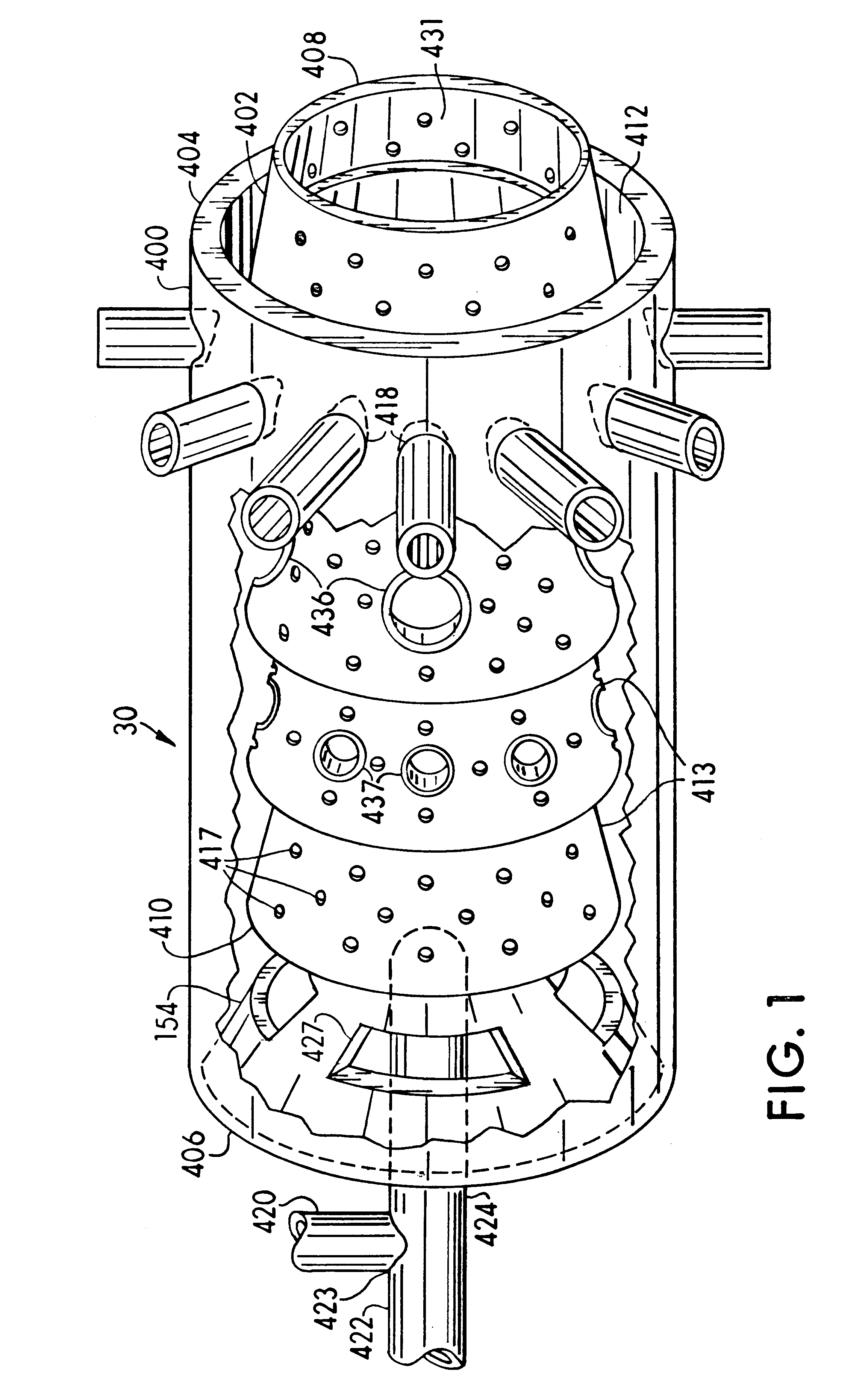

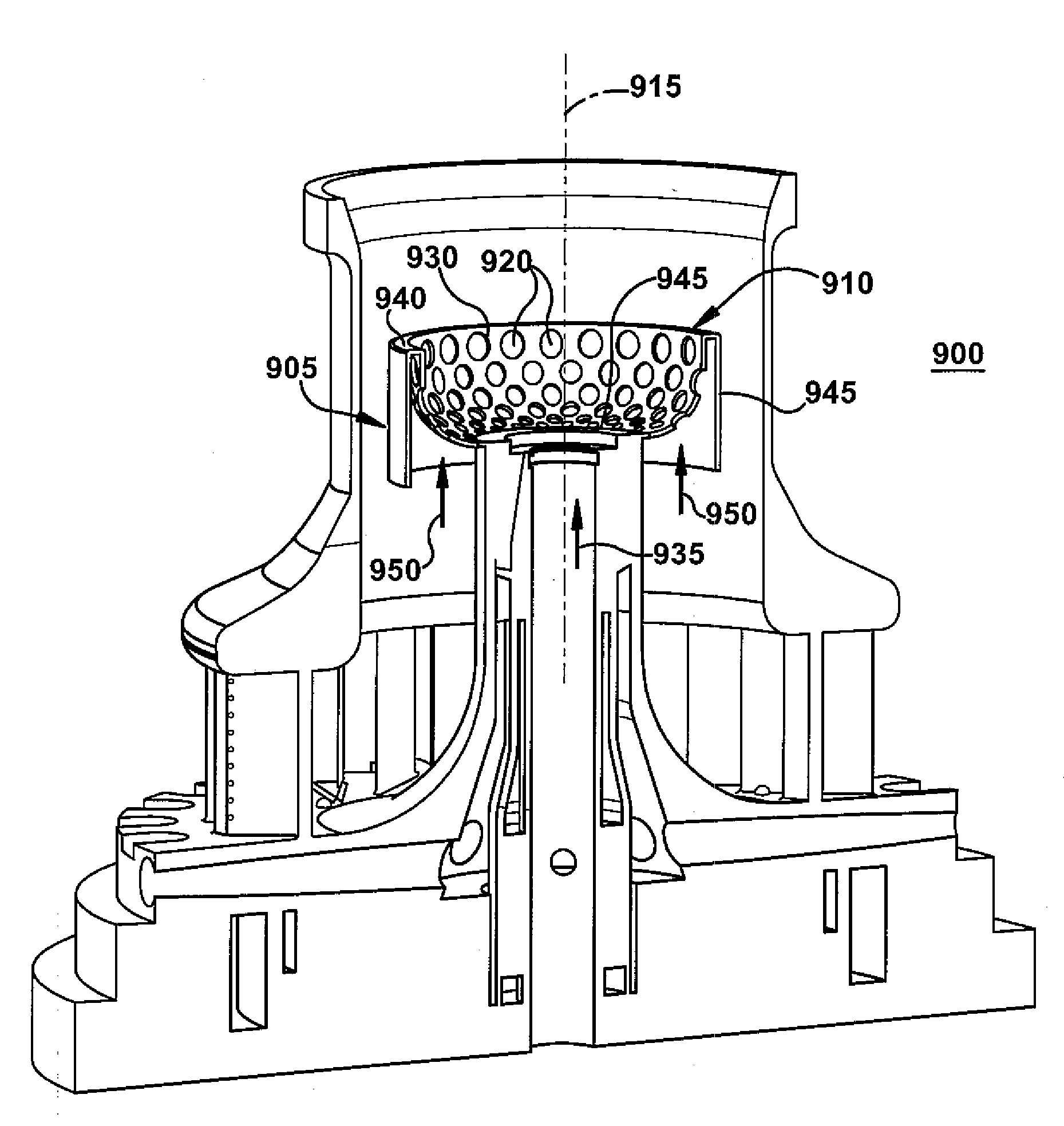

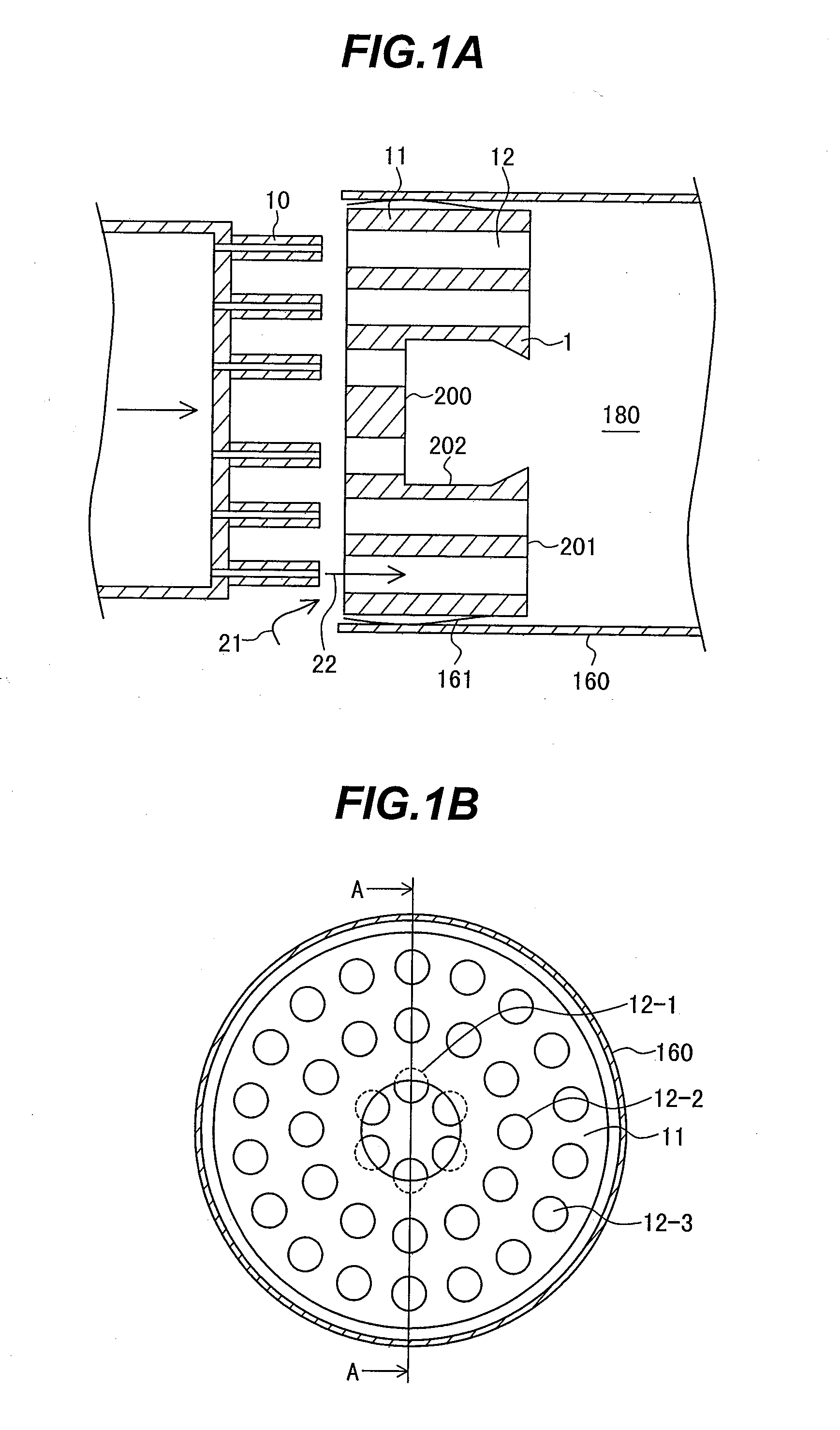

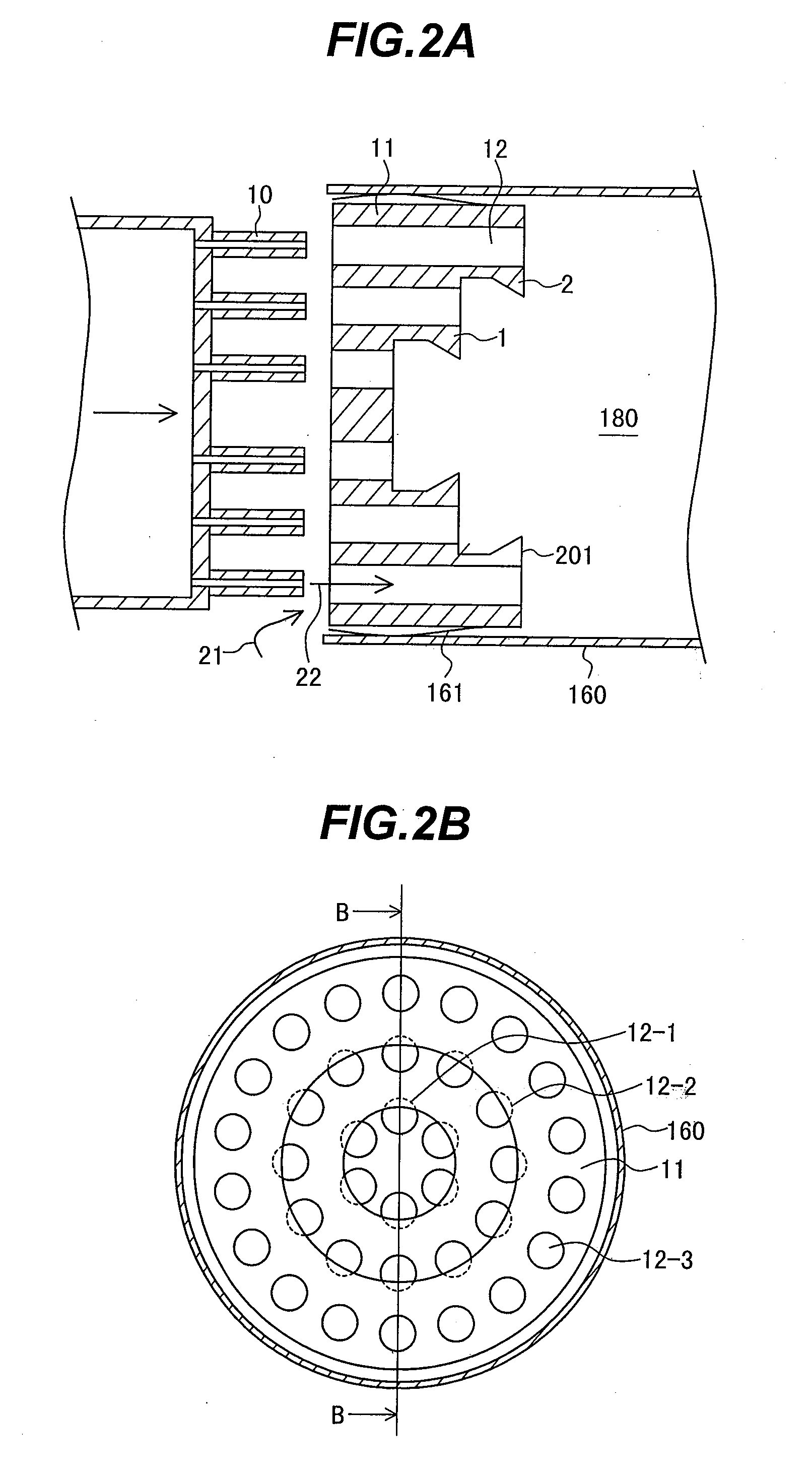

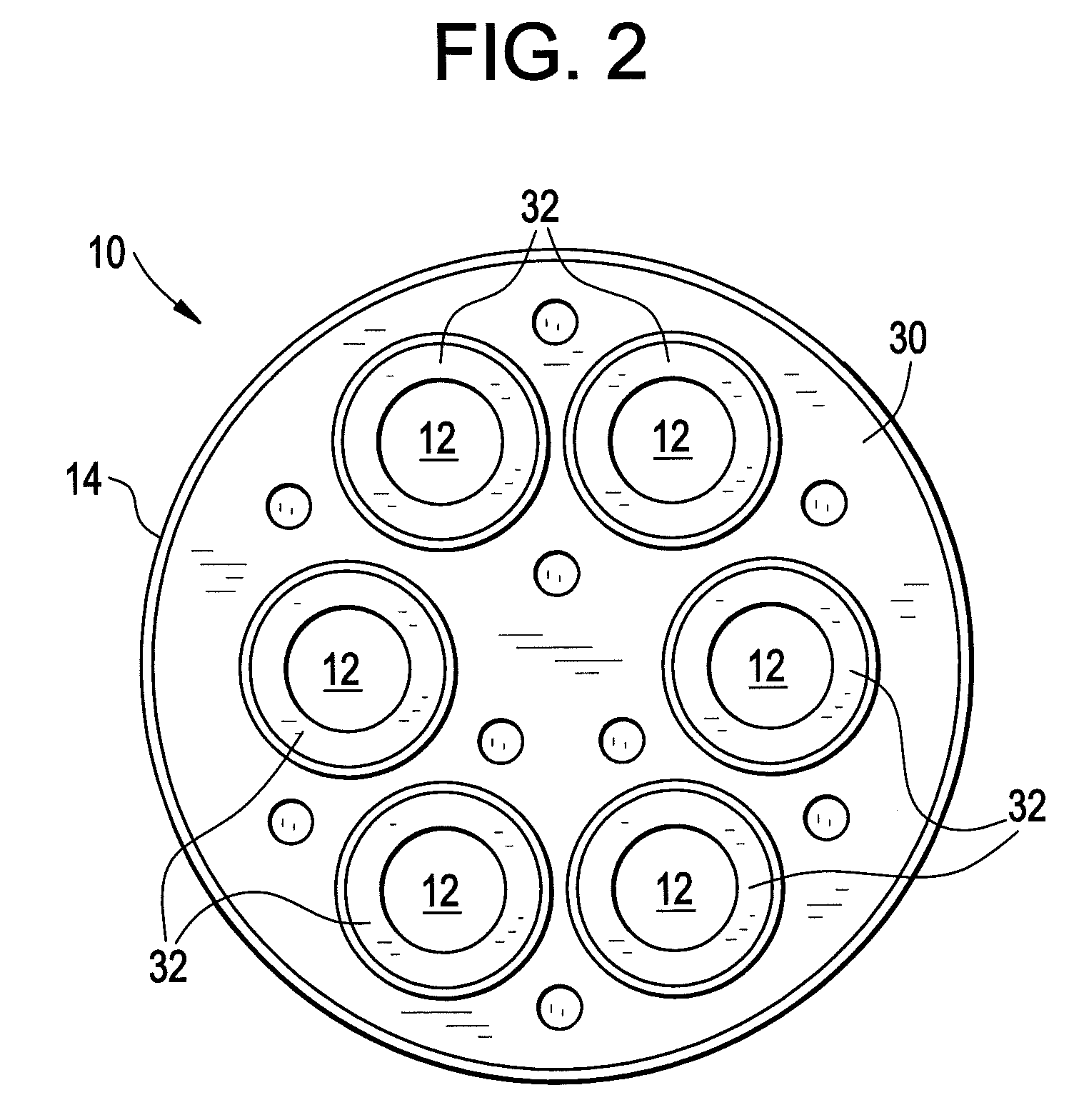

Lean premixed, radial inflow, multi-annular staged nozzle, can-annular, dual-fuel combustor

InactiveUS20090111063A1Stable combustionEmission reductionCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorNuclear engineering

A lean premixed, radial inflow, multi-annular staged nozzle for creating three independent combustion zones within a can-annular, dual-fuel gas turbine combustor is provided. The nozzle includes a pilot zone fueled by a gas pilot nozzle and center cartridge; a flame holder zone fueled by an inner main gas fuel; a main flame zone fueled by an outer main gas fuel; a main radial swirler for mixing a portion of incoming air to the nozzle with the inner main gas fuel supply and the outer main gas fuel supply; an endcover; and means for controlling the ratio of an inner main gas fuel supplied and an outer main gas fuel supplied.

Owner:GENERAL ELECTRIC CO

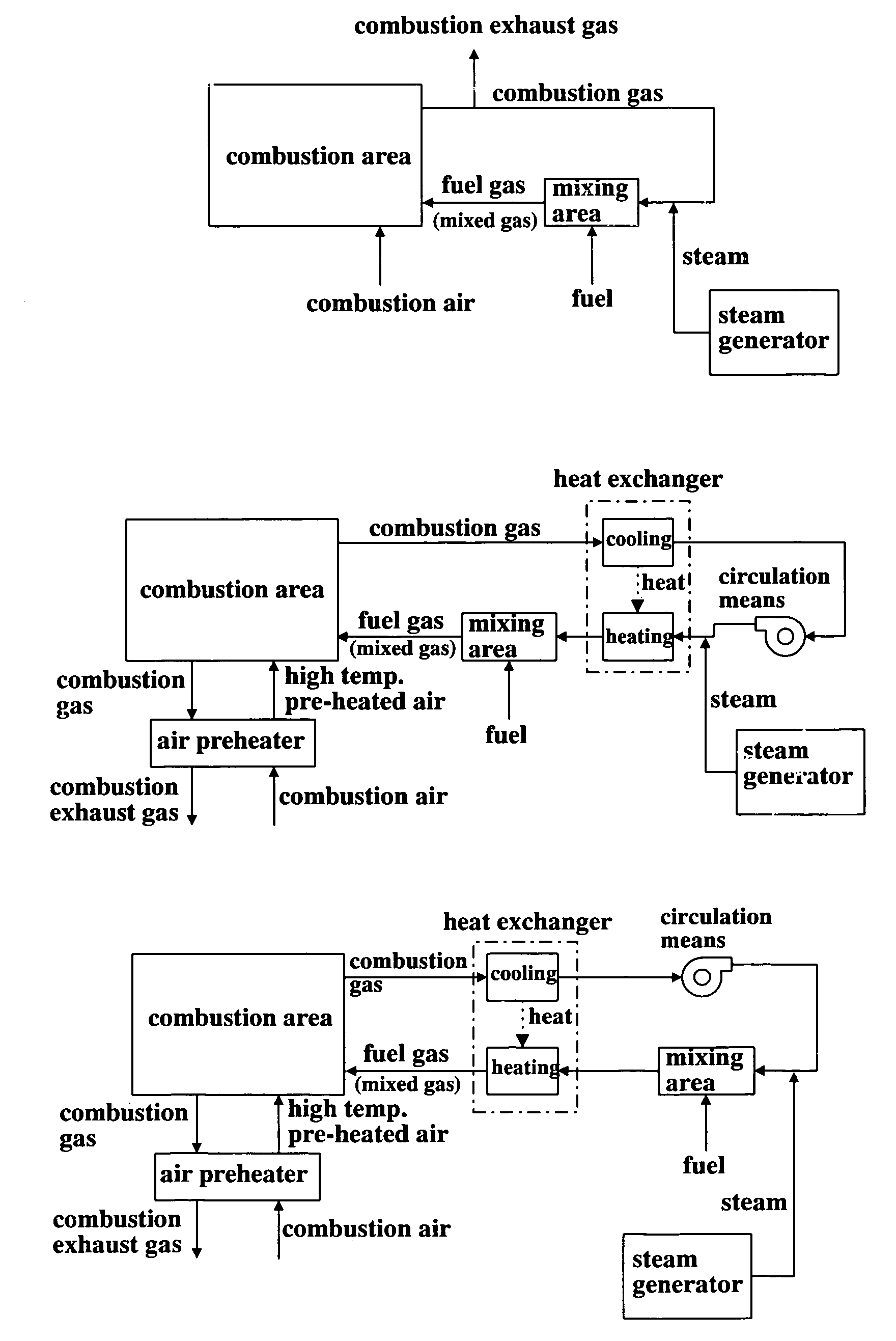

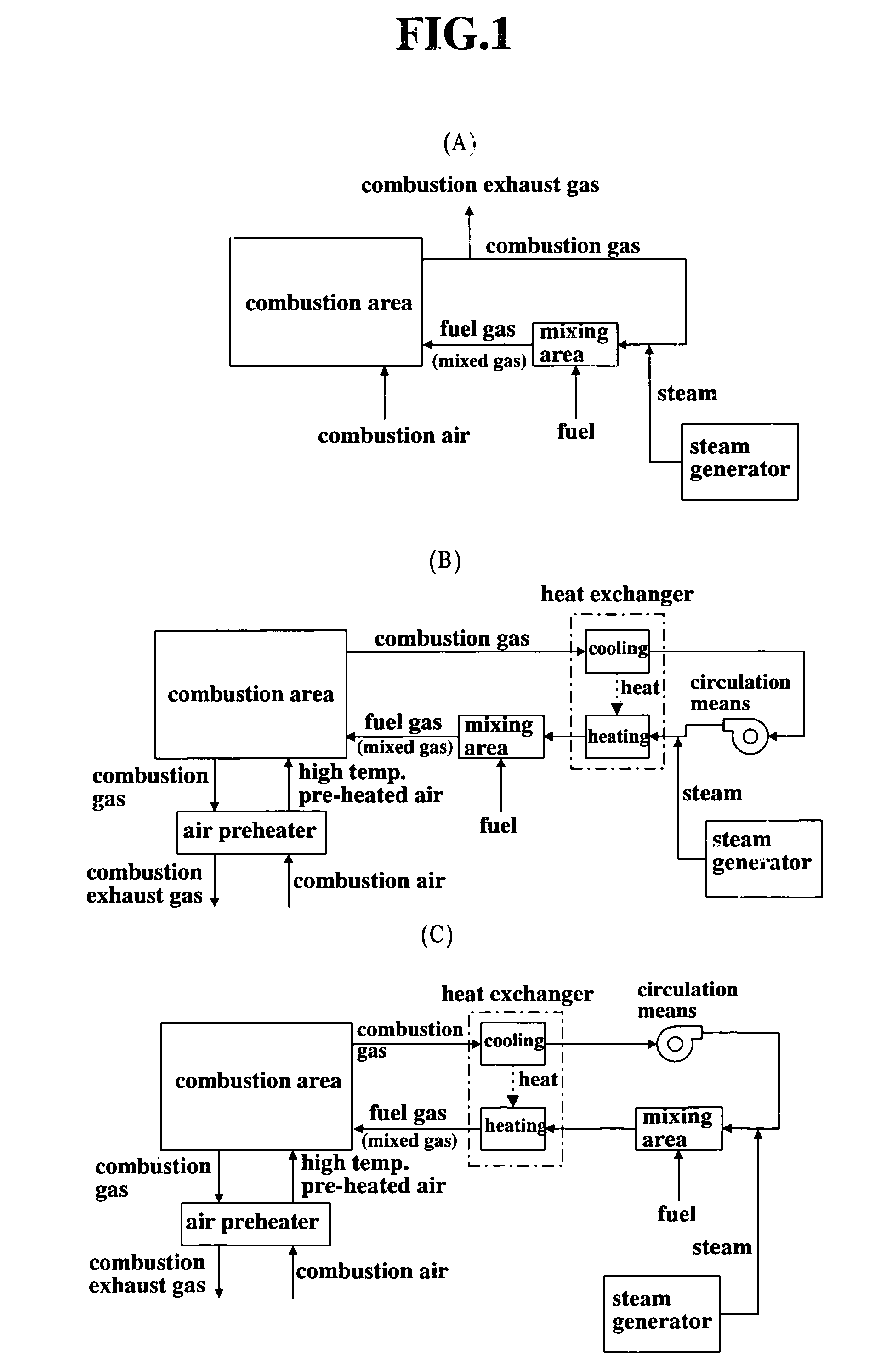

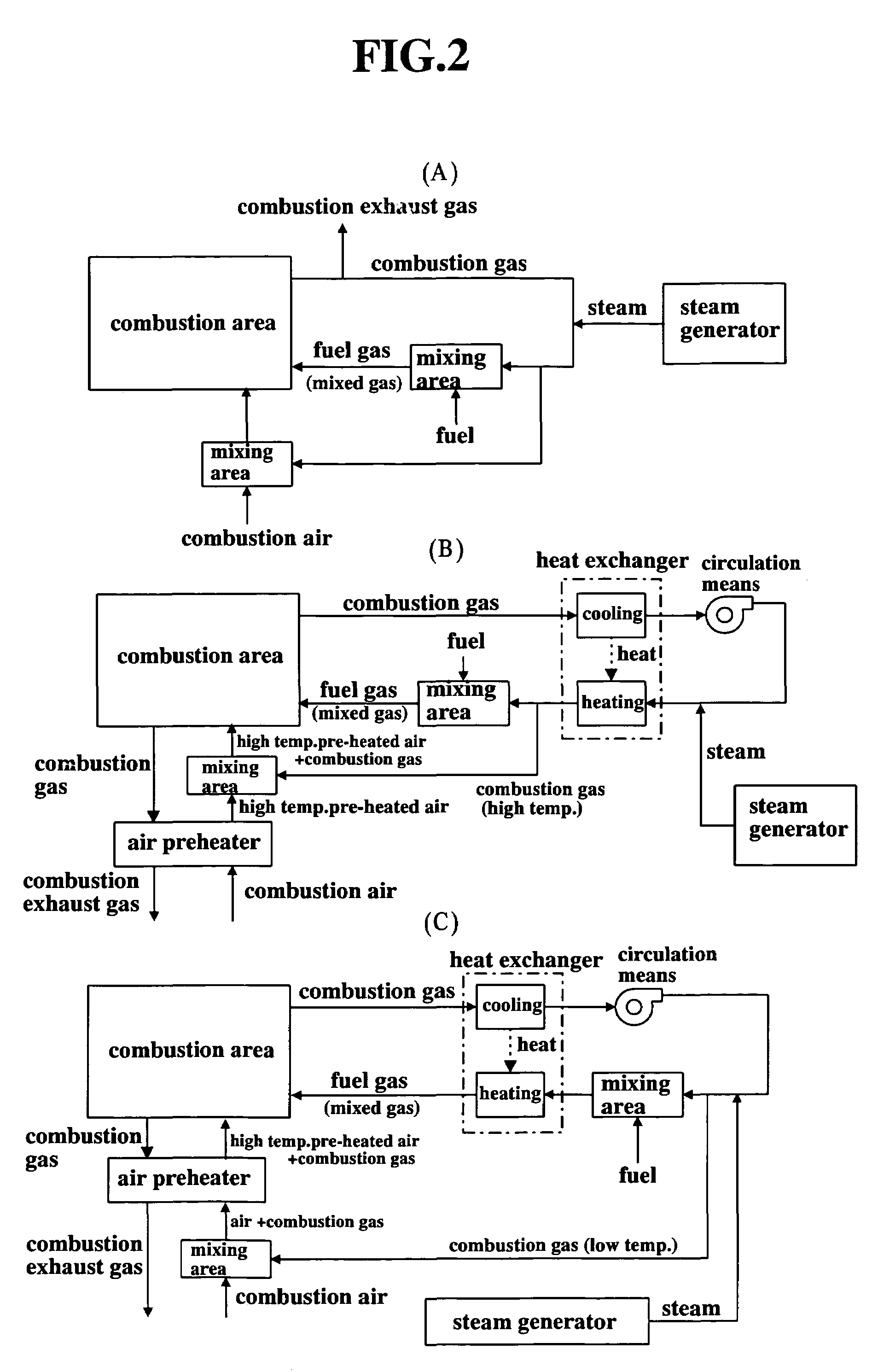

Device and method for feeding fuel

InactiveUS7104784B1Control of combustionReduced flexibilityGaseous fuel pretreatmentCombustion using multiple fuelsCombustion systemProduct gas

The present invention provides a fuel feeding apparatus and method for improving the controllability of mixing process and mixing ratio of fuel and combustion air, and a combustion system and method for effecting new combustion properties. The fuel feeding apparatus of the combustion system has fuel feeding means, combustion gas extraction means, steam supply means, mixing means and fuel gas introduction means. The combustion gas extraction means extracts combustion gas of a combustion area therefrom. The mixing means mixes the fuel of fuel feeding means with at least one of combustion gas extracted from the furnace and steam of a steam generator. The fuel gas introduction means introduces a mixed fluid of combustion gas, steam and fuel to the combustion area as a fuel gas, and allows the fuel gas to be mixed with the combustion air. A step of mixing the fuel with the combustion gas after extracted from the furnace and a step of mixing the fuel gas with the combustion air are stepwisely carried out, so that the controllability of mixing process and ratio of the air and fuel is improved. Such a control of fuel gas flow enables control of characteristics of flame and production of flame with new properties in the combustion area.

Owner:NFK HLDG

Swirling flashback arrestor

InactiveUS6179608B1Performance maximizationPipeline systemsGaseous fuel burnerEngineeringGas turbines

A structure is disclosed that will quench a flame front during a flashback event in a gas turbine while simultaneously providing a mixing function during normal operations. The device disclosed consists of two monoliths one upstream of the other. In the basic embodiment of the invention the downstream monolith acts as a mixer while the combination of the upstream monolith and the downstream monolith act as the flashback arrestor. Other embodiments of the device also allow the downstream monolith to be a flameholder.

Owner:PRECISION COMBUSTION

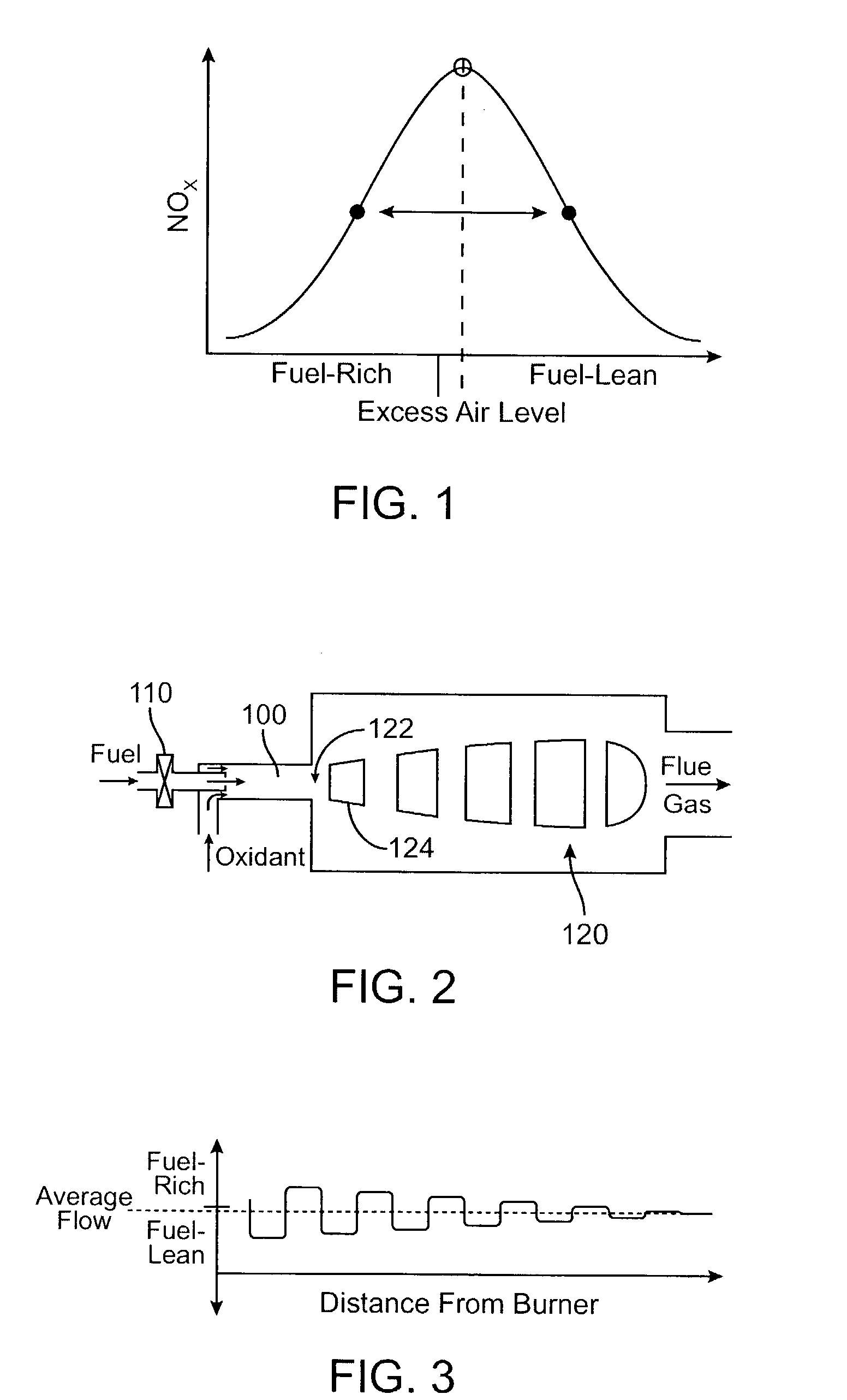

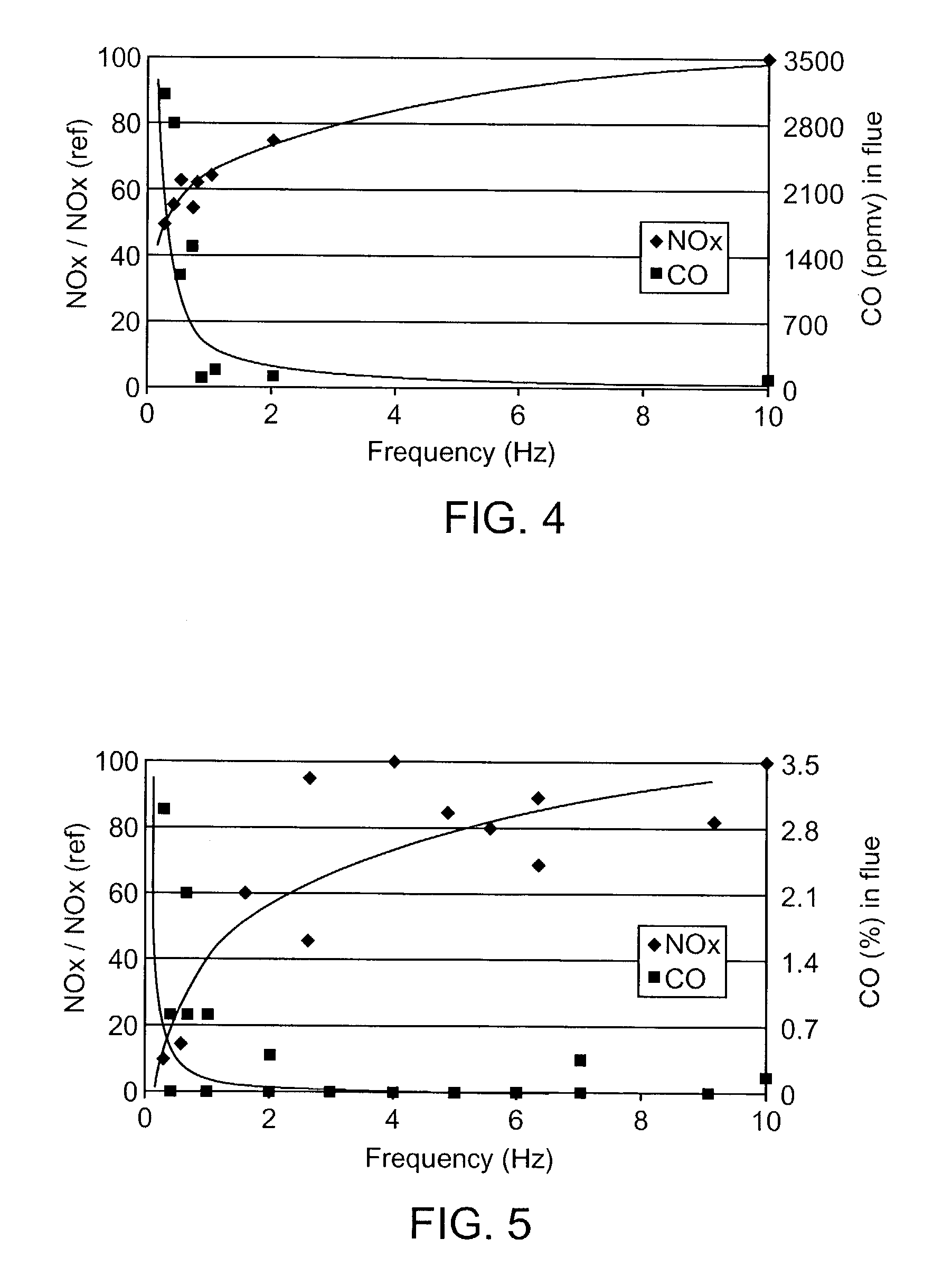

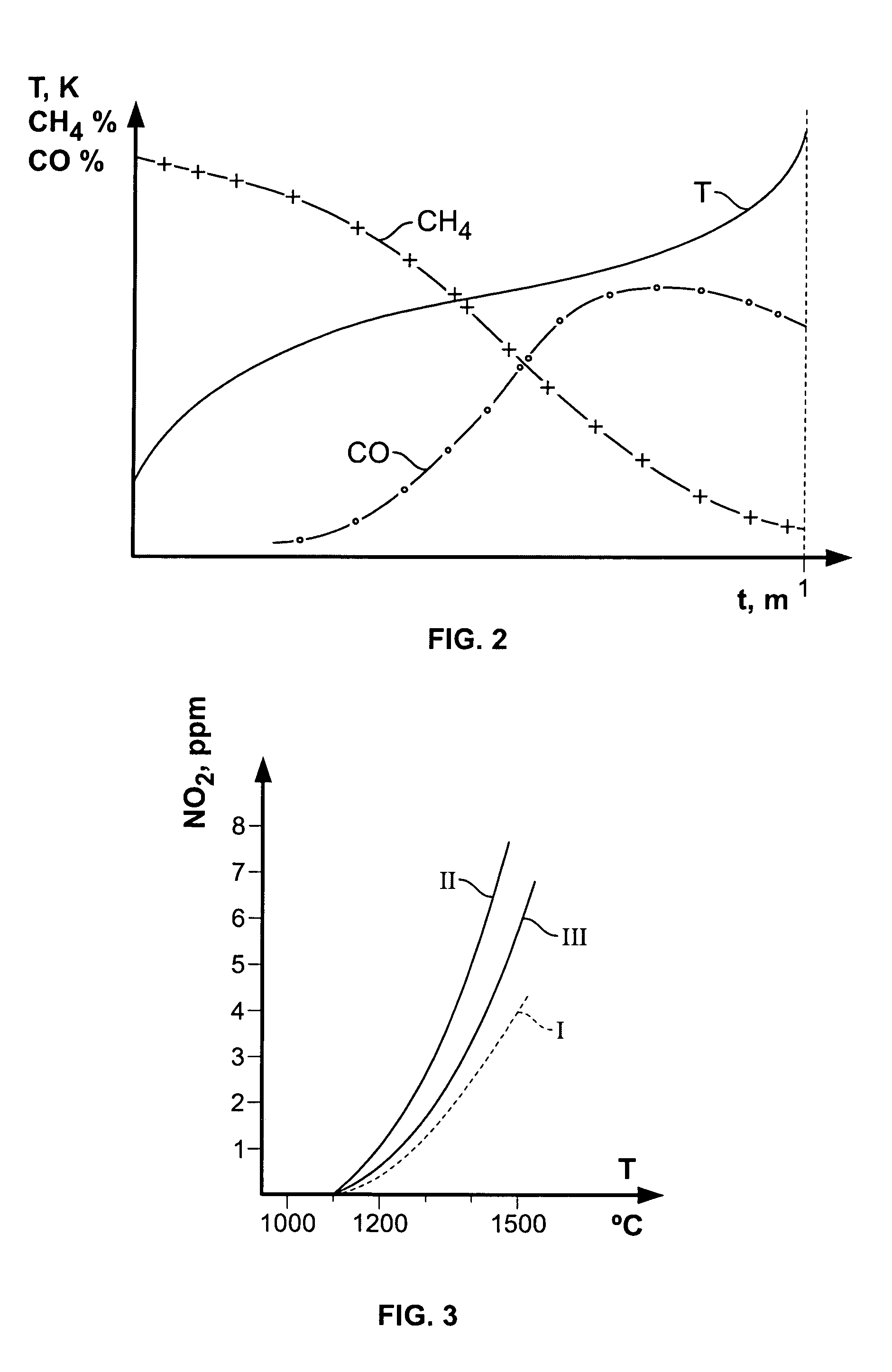

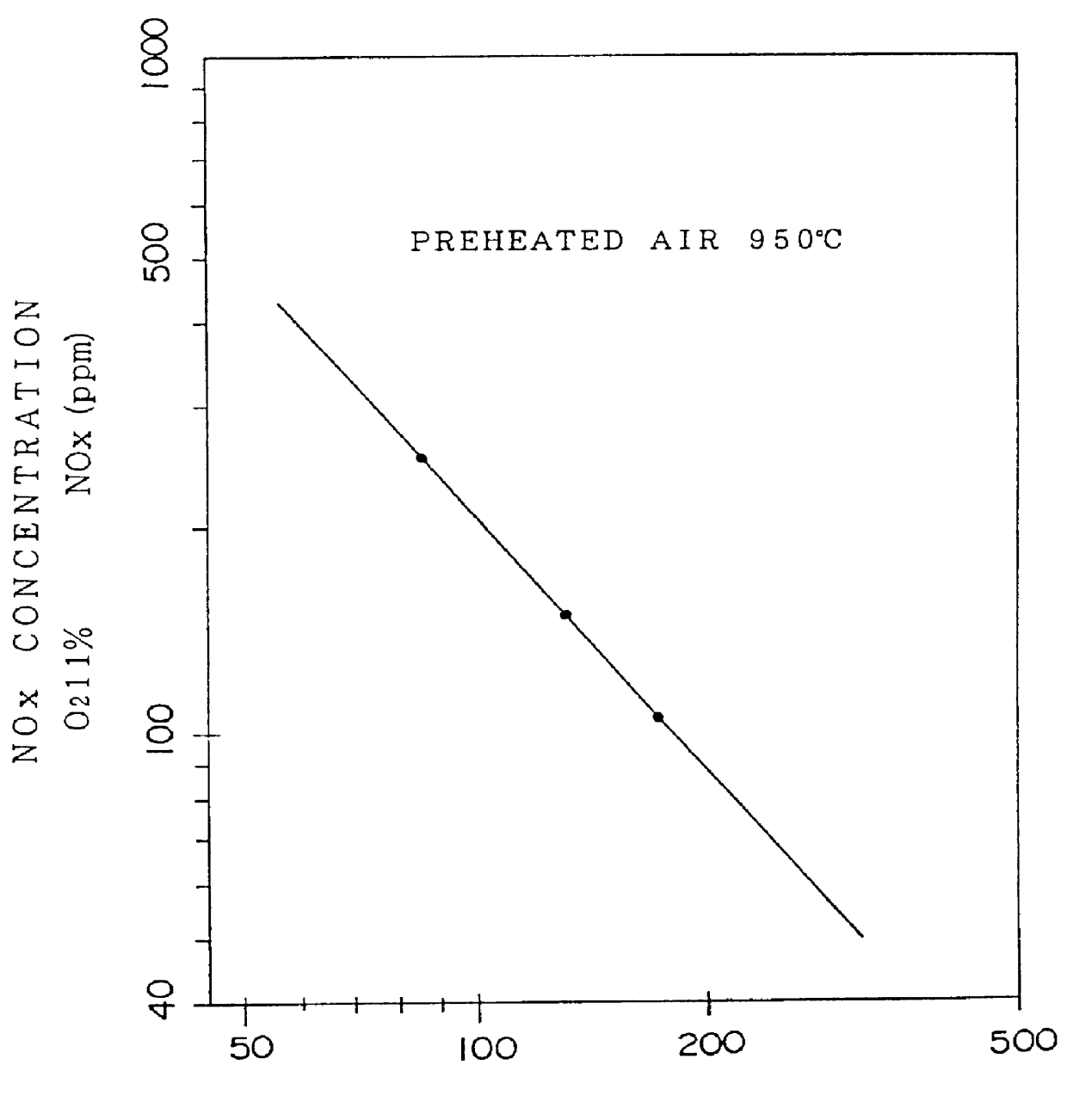

Process and apparatus of combustion for reduction of nitrogen oxide emissions

InactiveUS20030134241A1Special fuel supply arrangementsIndirect carbon-dioxide mitigationNitrogen oxidesControl system

A combustion control system allows the dramatic reduction of NOx emission levels from industrial combustion processes without having recourse to expensive flue gas clean up methods. The system combines the technique of oscillating combustion with an adapted system for post combustion burn out of the excess of CO resulting from the low-NOx combustion zone. A process for fuel combustion includes generating an oscillating combustion zone by oscillating at least one of the fuel flow and the oxidant flow to achieve a reduced nitrogen oxide emission, selecting oscillating parameters and furnace operating parameters to maximize nitrogen oxide reduction efficiency to the detriment of carbon monoxide production, and combusting carbon monoxide downstream of the oscillating combustion zone by injecting a post combustion oxidant.

Owner:MARIN OVIDIU +3

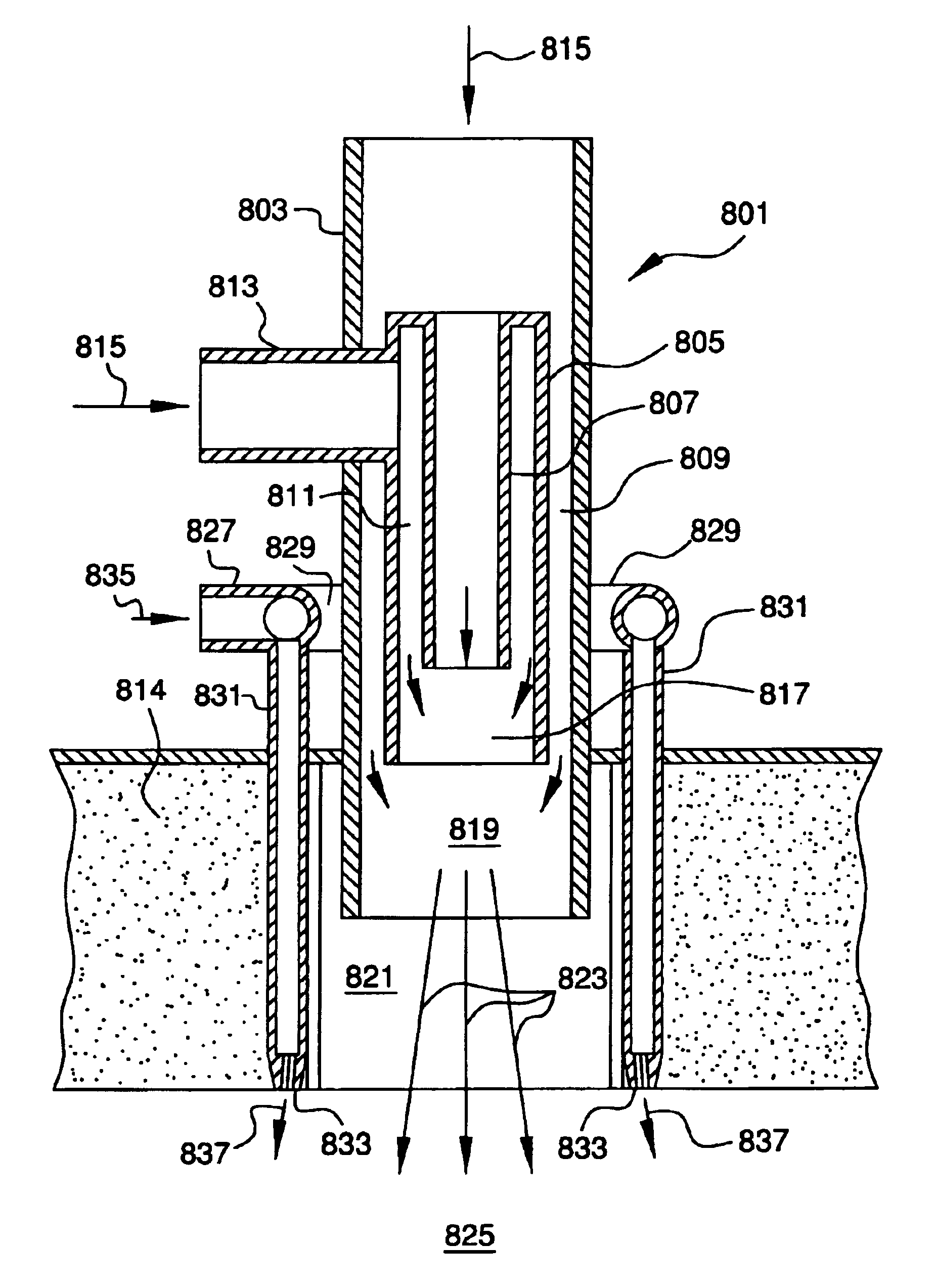

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

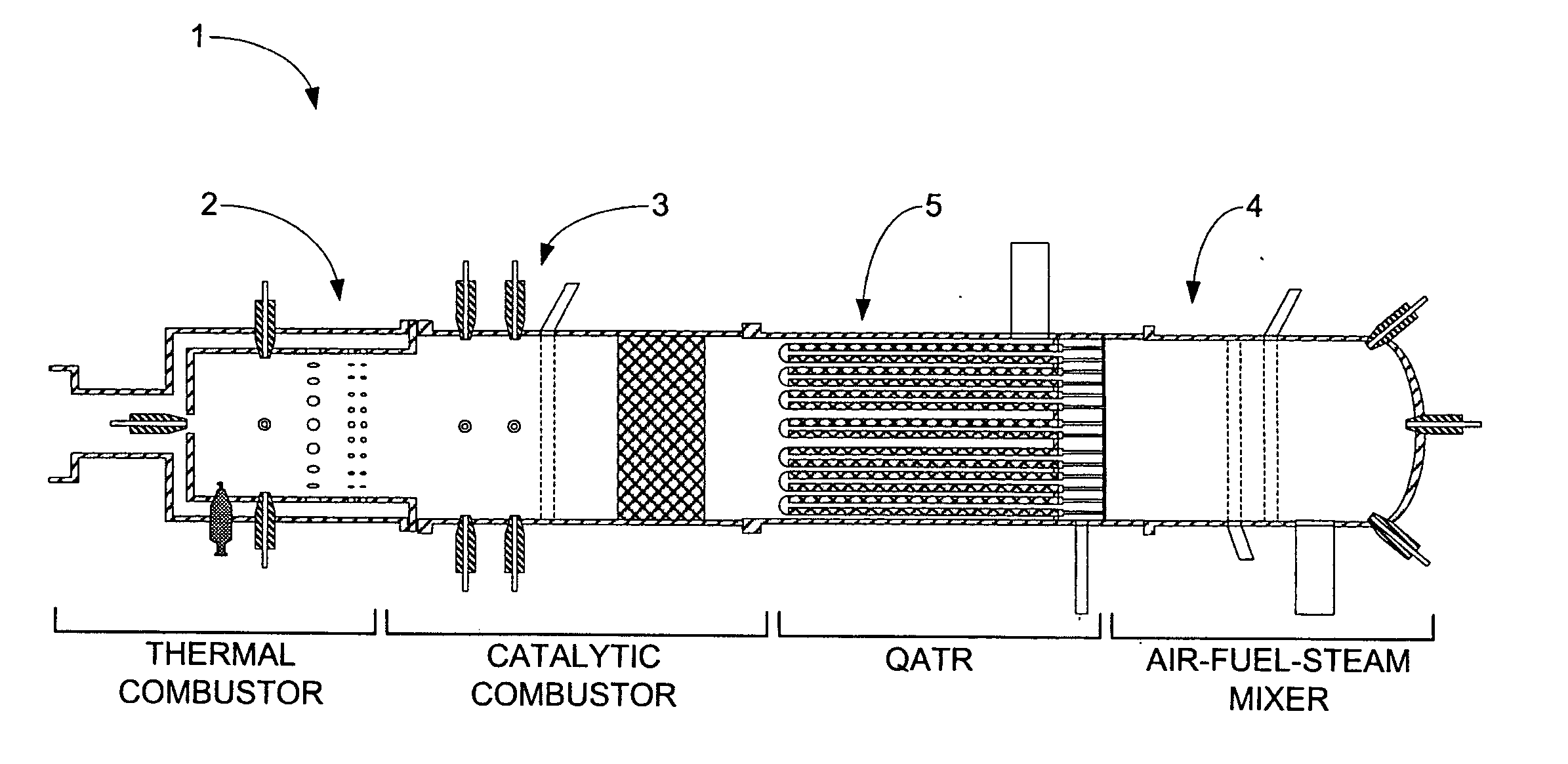

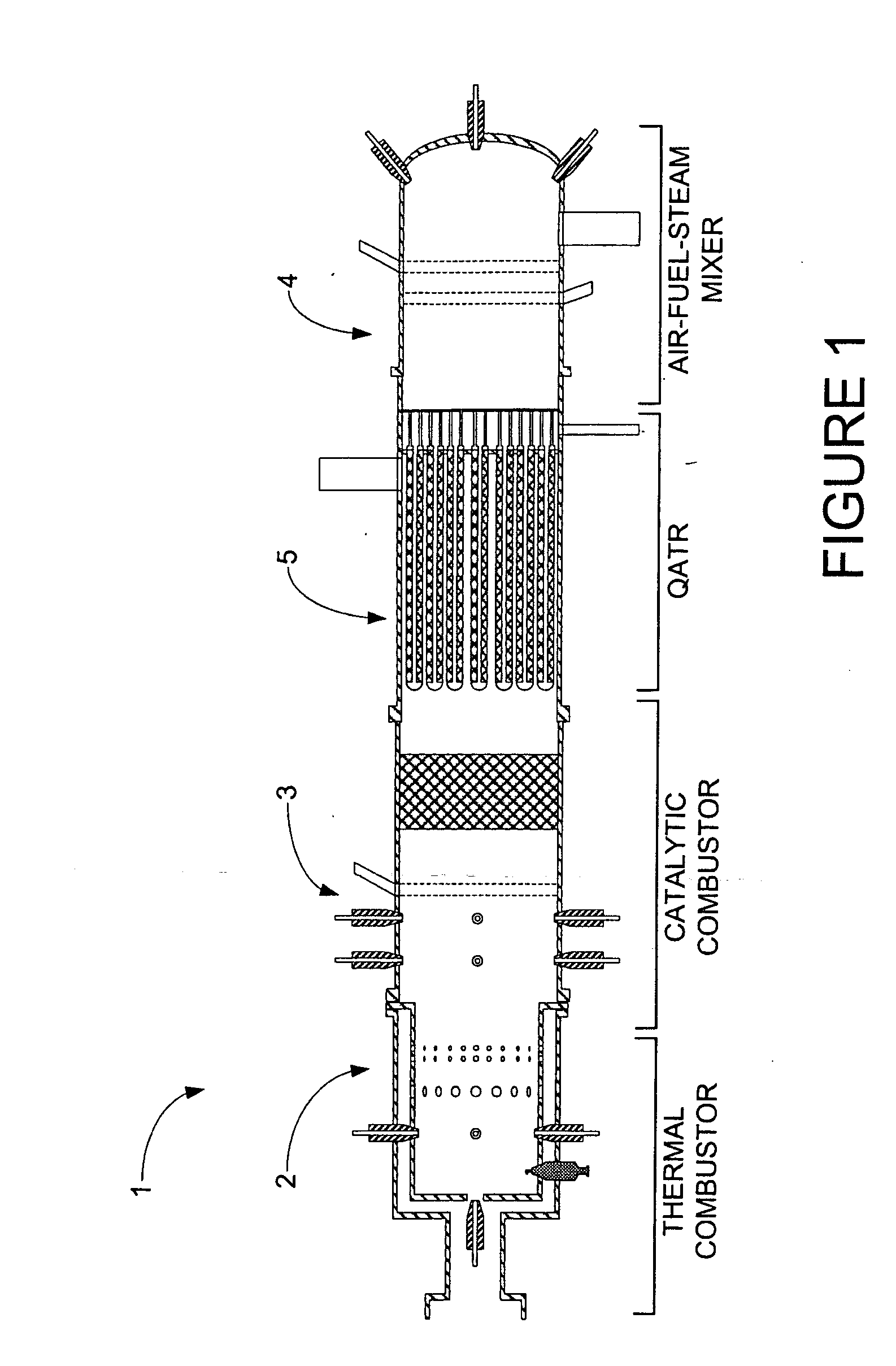

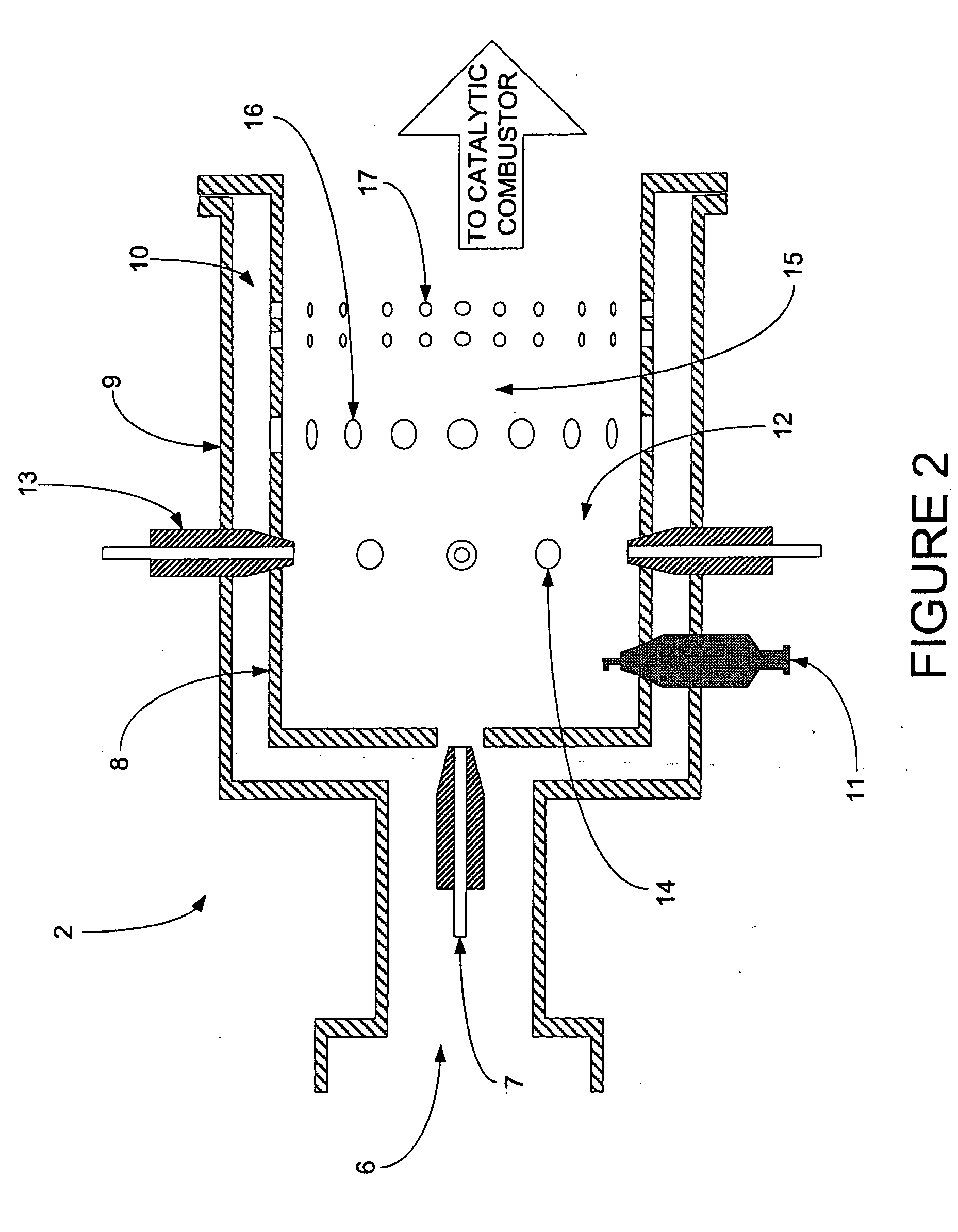

Integrated fuel processor subsystem with quasi-autothermal reforming

InactiveUS20050188615A1Provide flexibilitySufficient flexibilityReciprocating combination enginesExhaust apparatusSteam reformingFuel treatment

The present invention includes an integrated fuel processor subsystem incorporating a thermal combustor, a catalytic combustor, a quasi-autothermal reactor (QATR) and a air-fuel-steam (AFS) mixer to provide a range of operating modes exhibiting performance between that of a pure steam reformer and a pure autothermal reformer to increase the flexibility of the fuel processor to handle transient system demands such as cold starts, suppress emissions and carbon formation and improve efficiency.

Owner:FLARION TECH +1

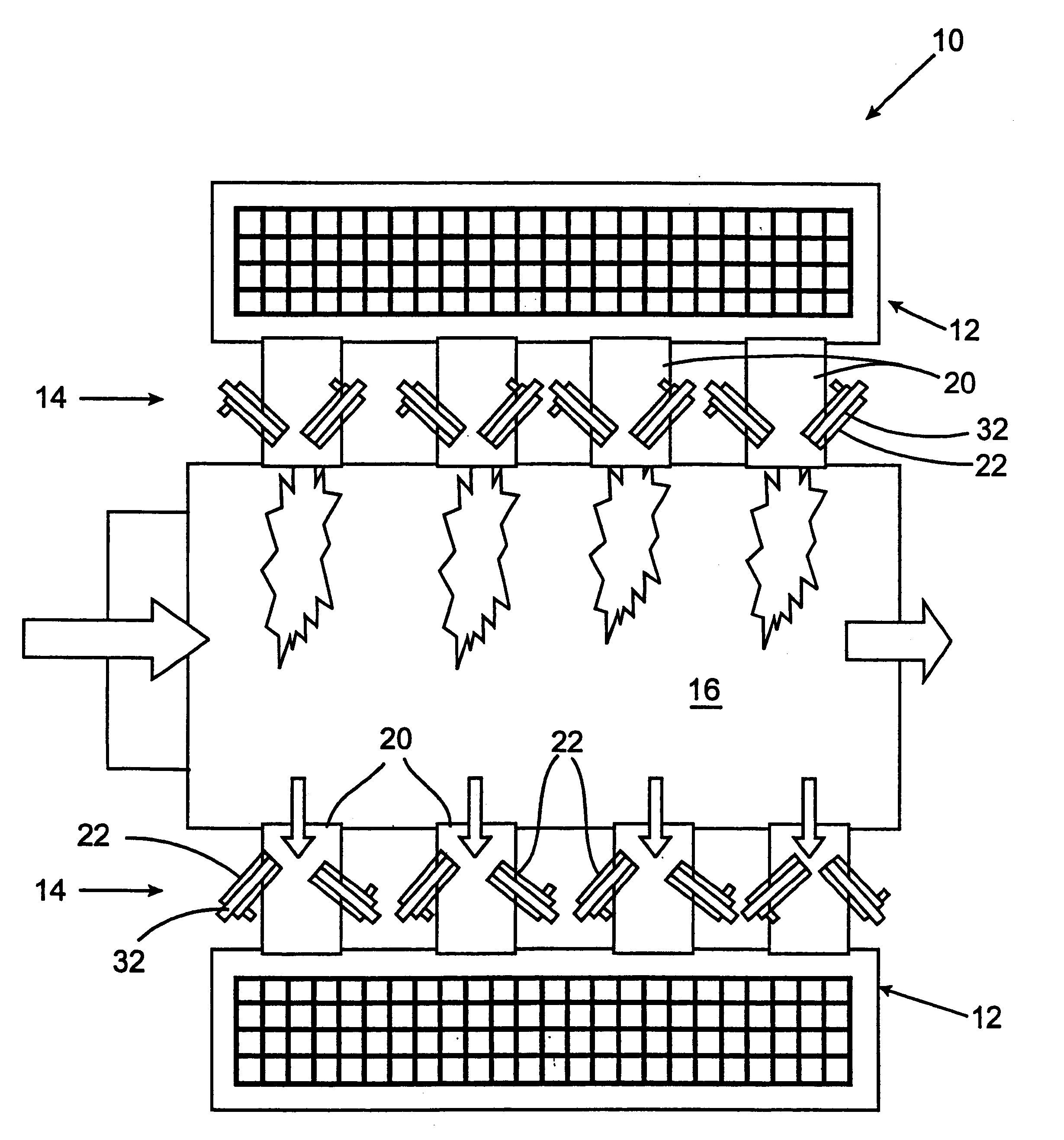

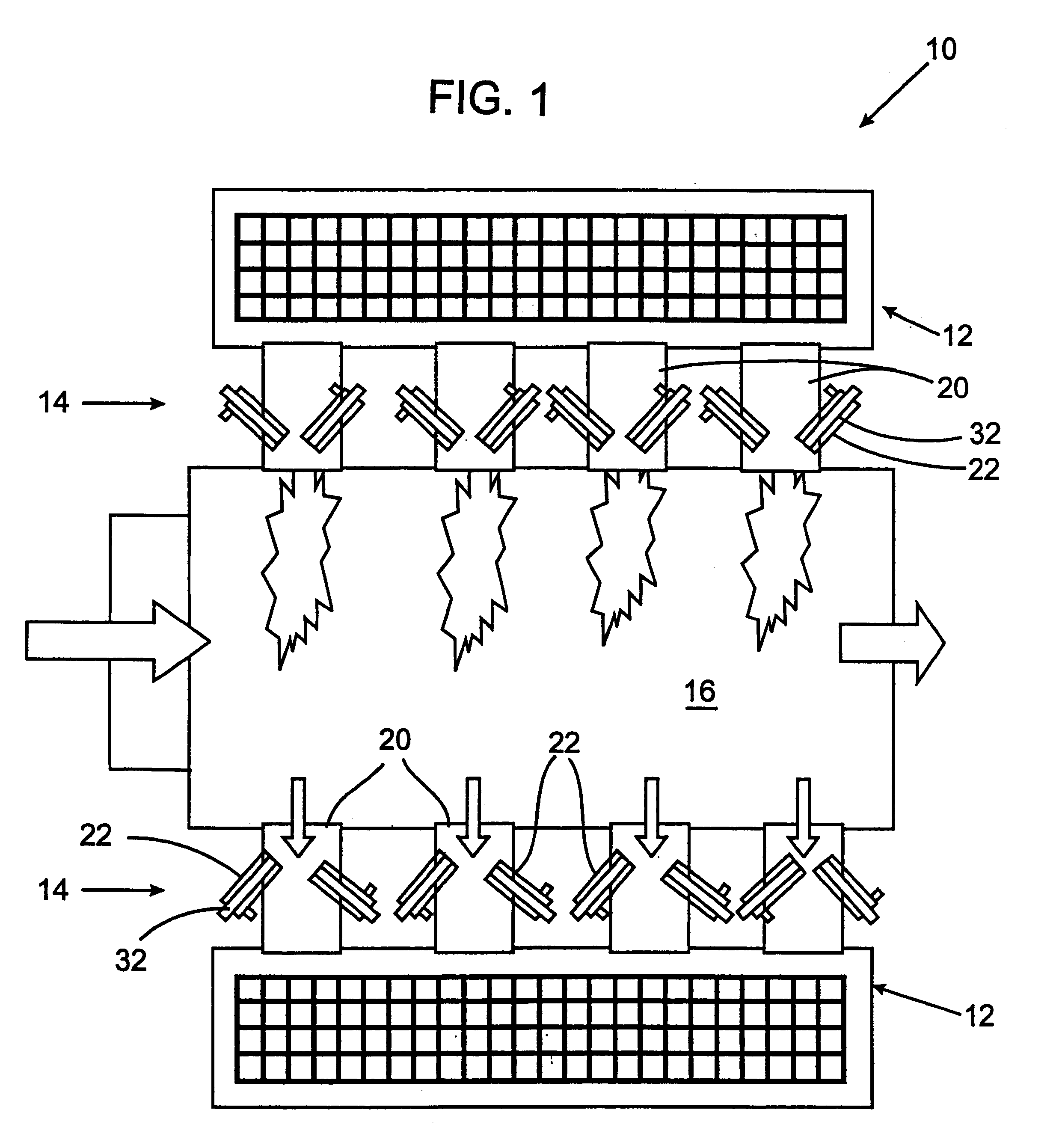

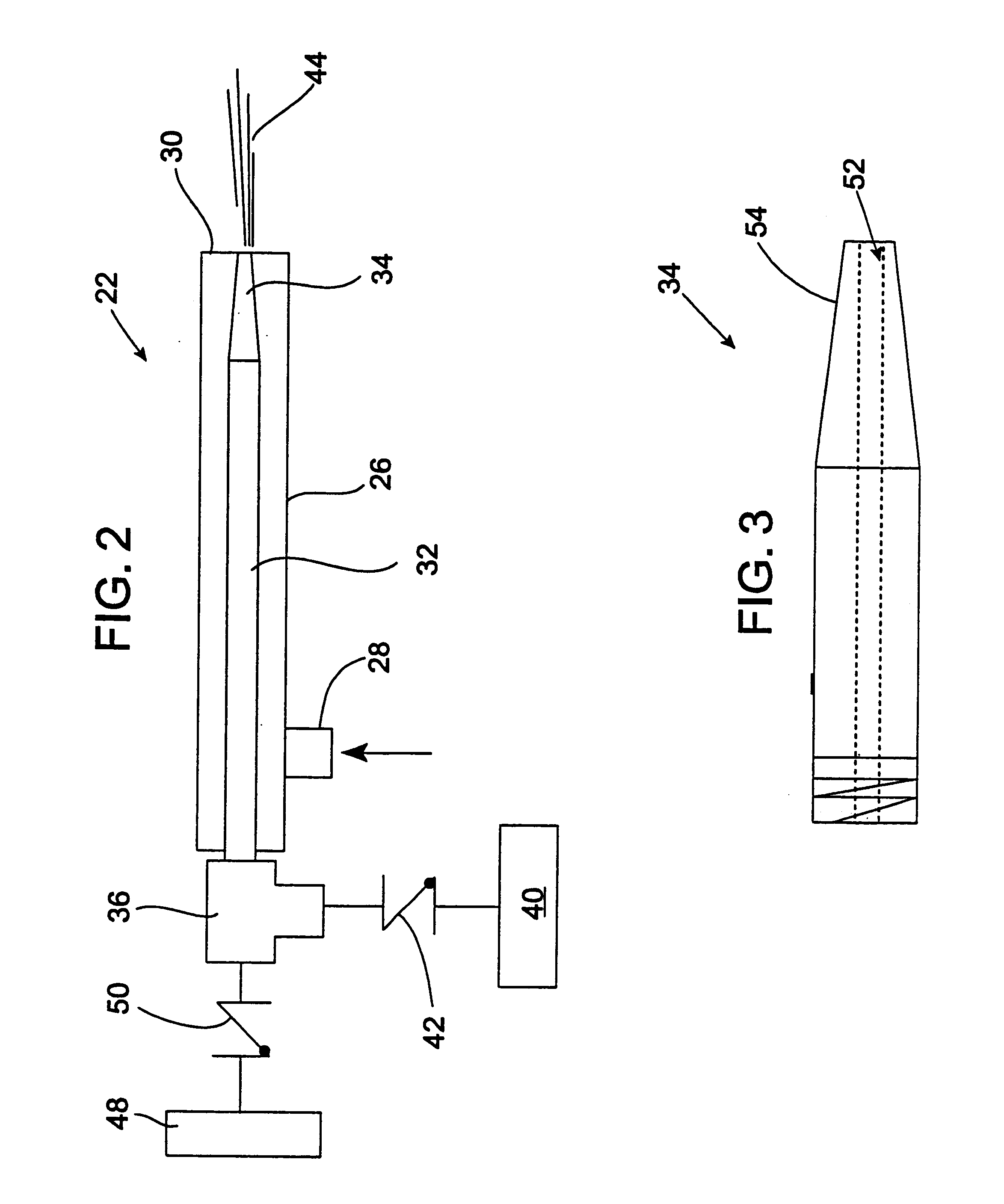

Burner and method for induction of flue gas

ActiveUS7670135B1Reduce nitrogen oxide emissionsEfficient drawingFluegas recirculationCasings/liningsCombustorFlue gas

A low NOx burner and method wherein (a) combustion air flows through the interior of the burner in a manner effective for drawing an amount of inert flue gas diluent from the fired heating system into the combustion air stream, preferably via one or more induction channels provided through the burner wall, and / or (b) air or an inert gas is discharged into the induction channel(s) in a manner effective for delivering flue gas into the combustion air stream.

Owner:ZEECO

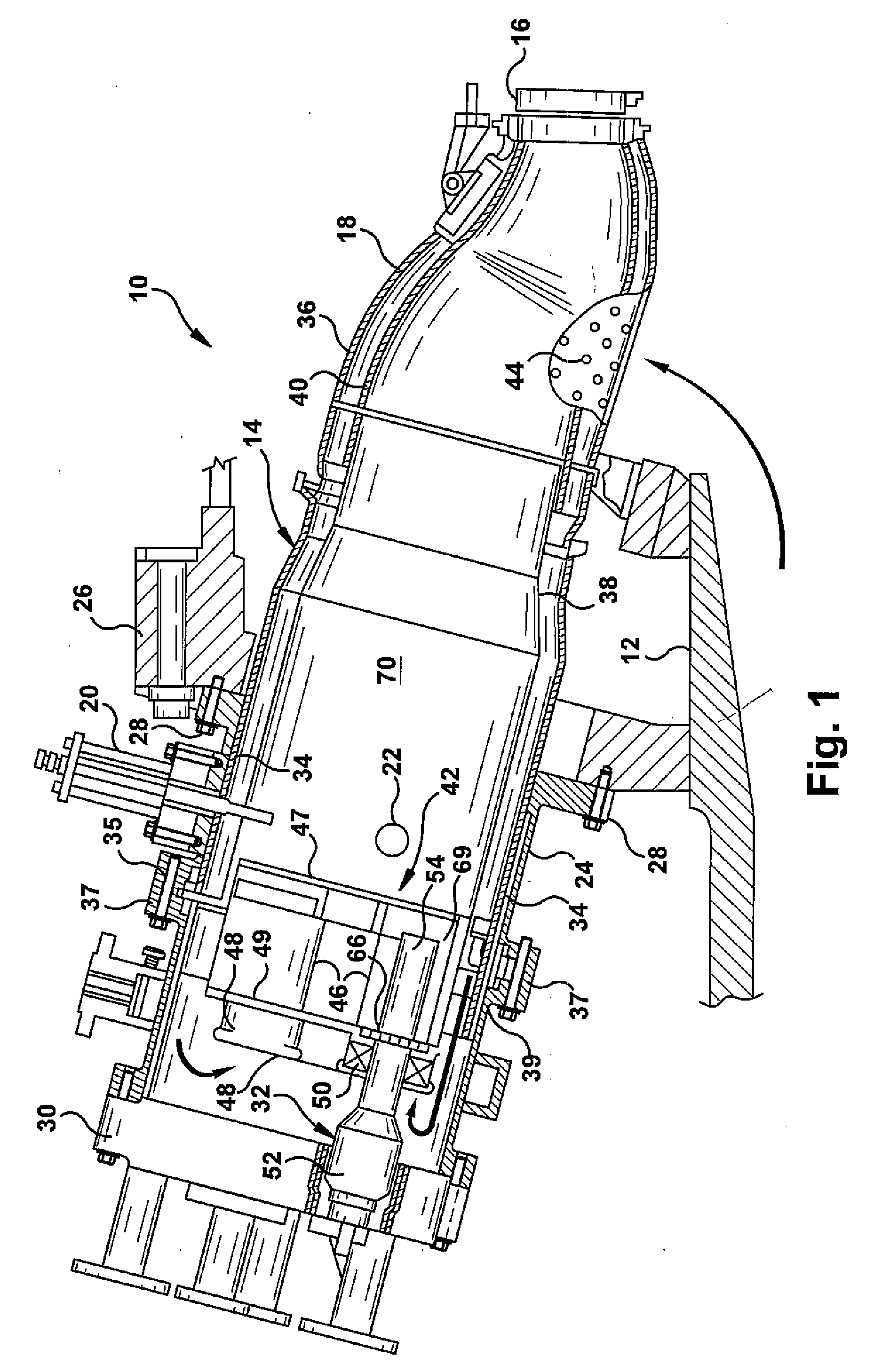

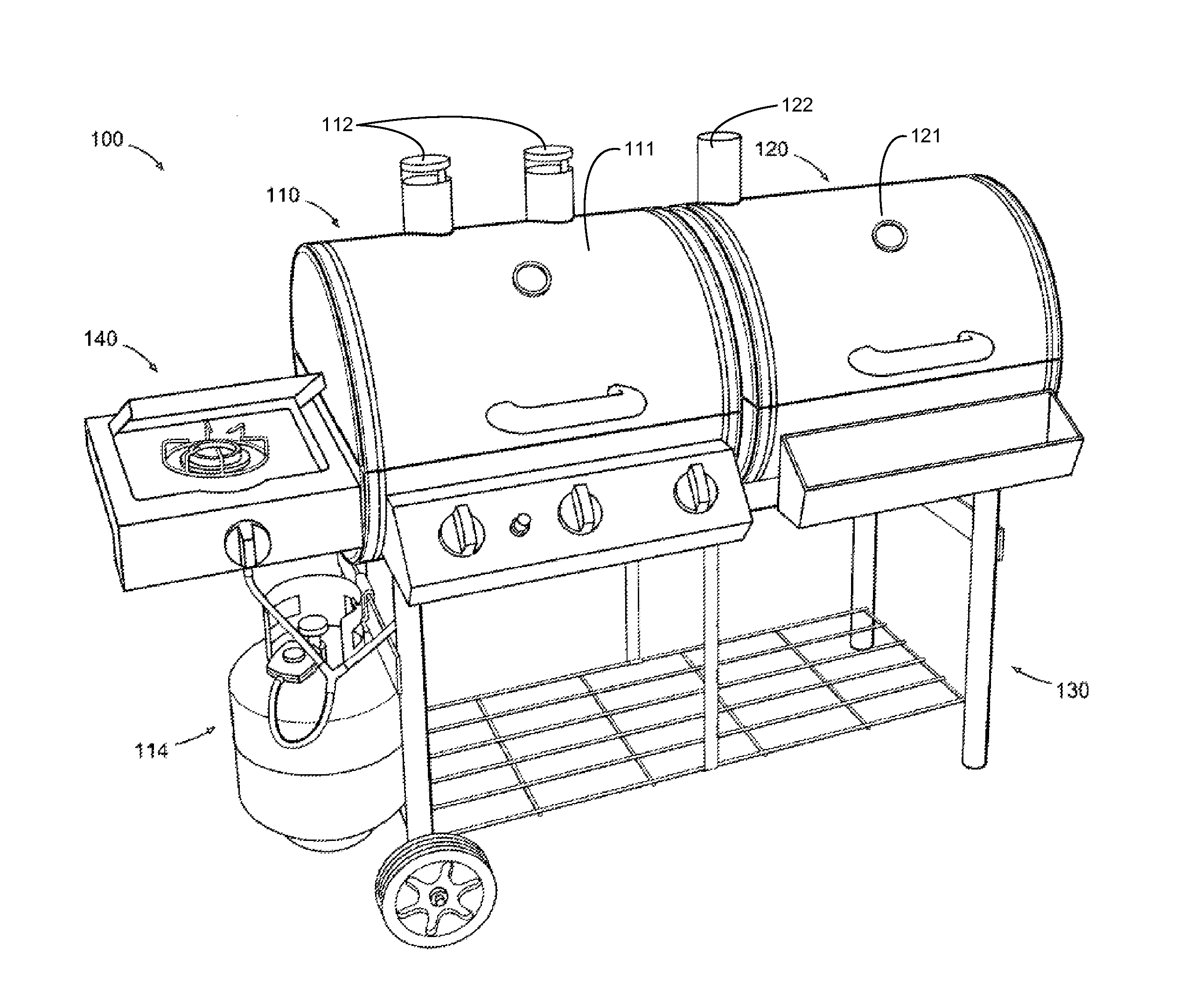

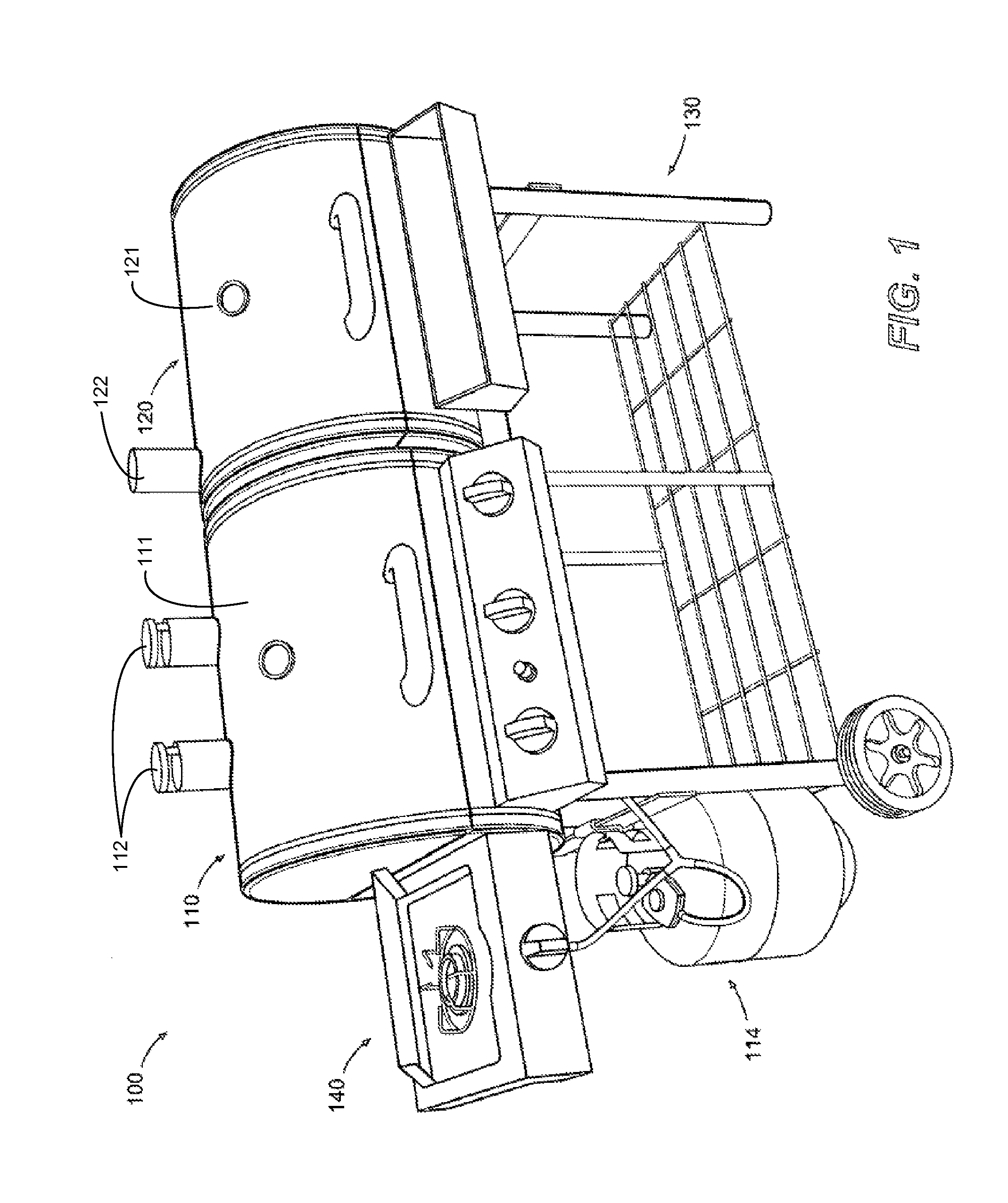

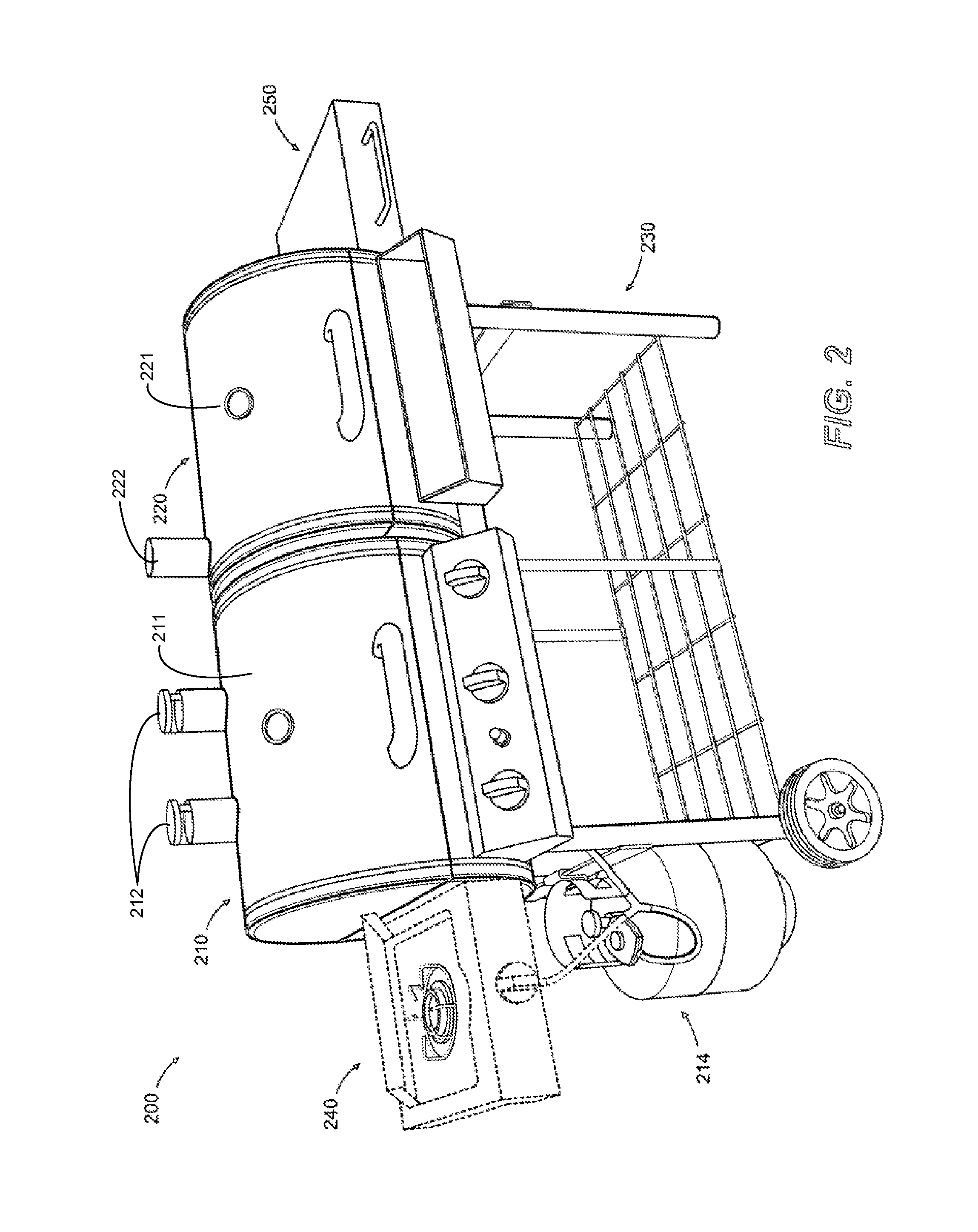

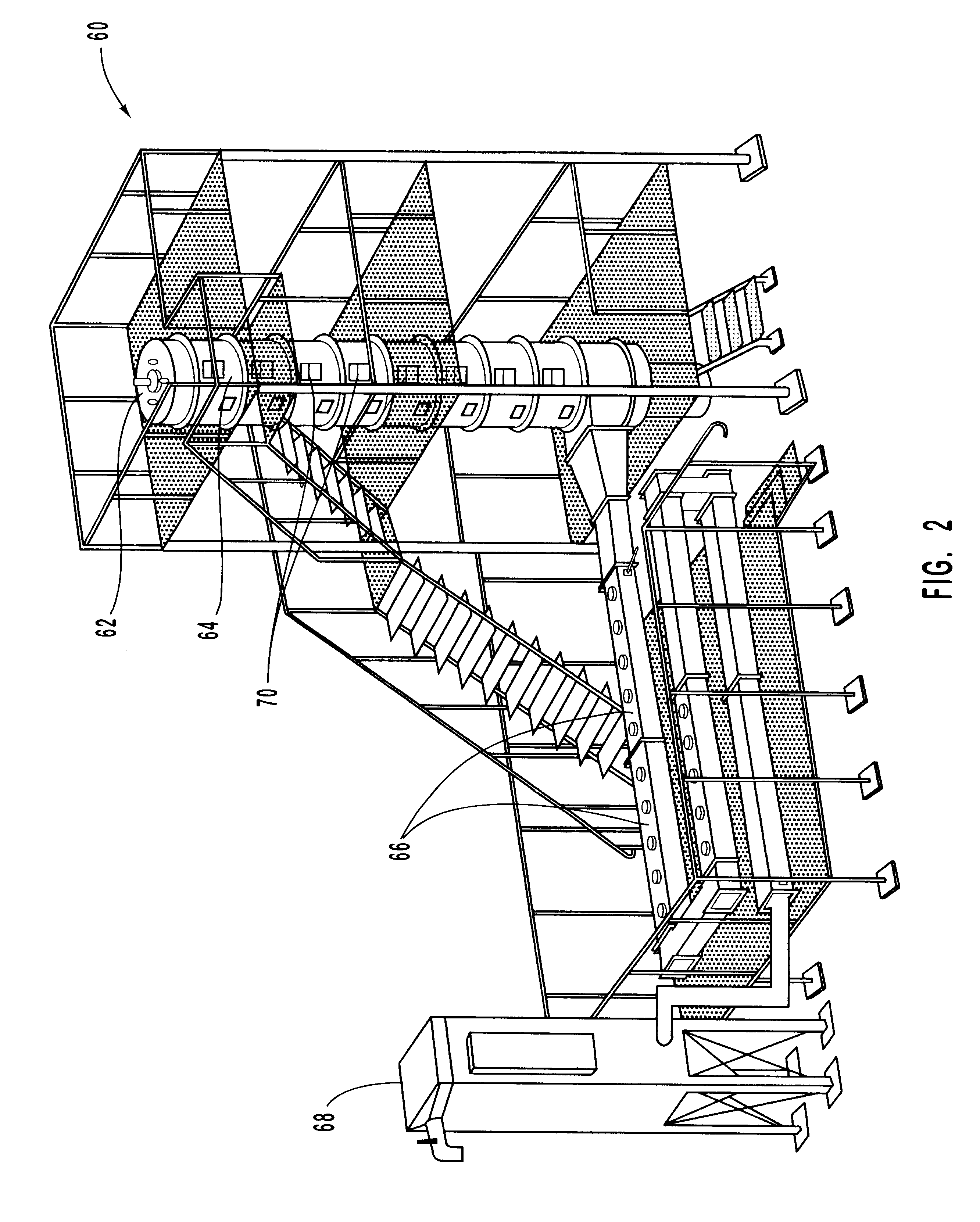

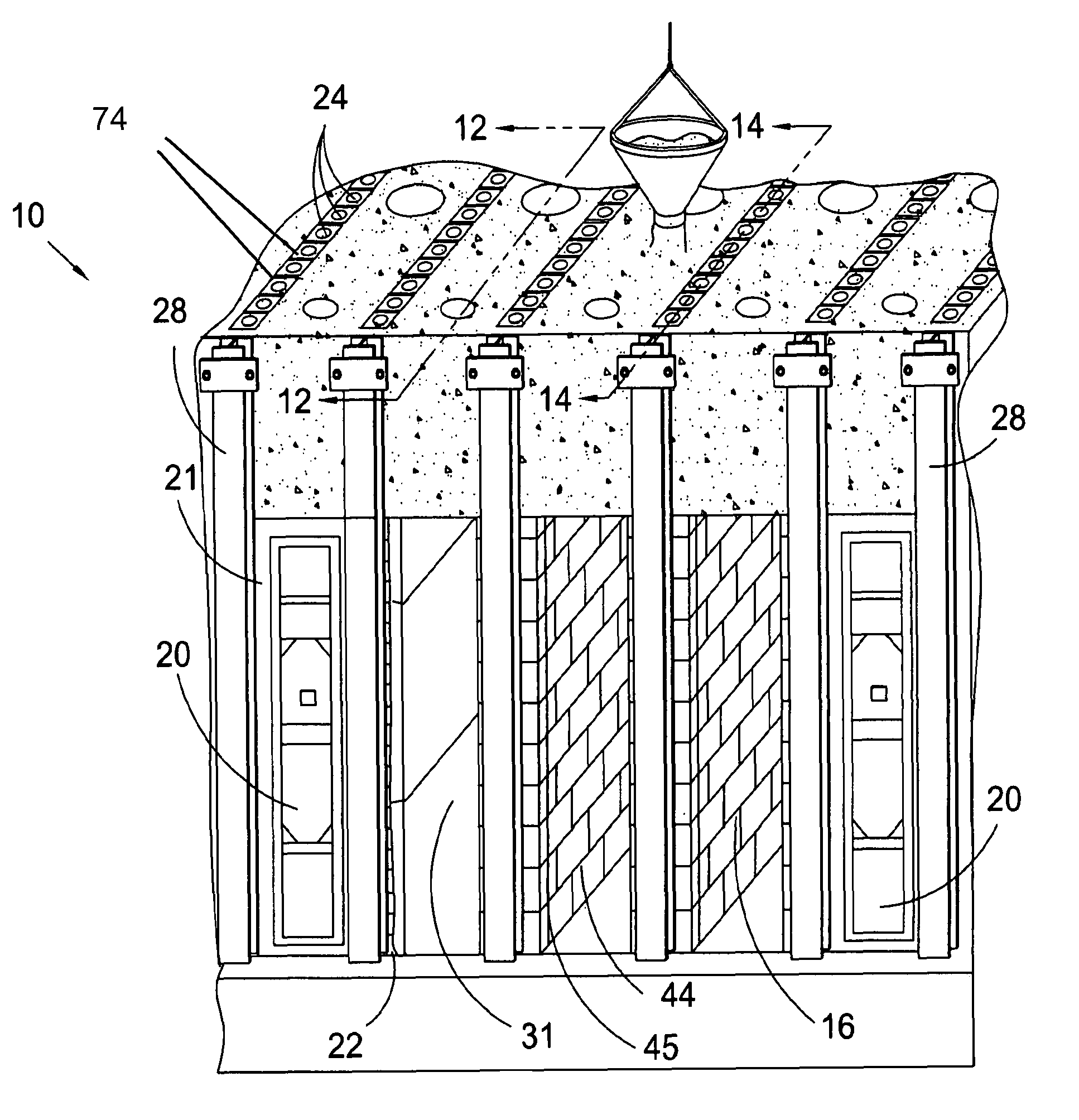

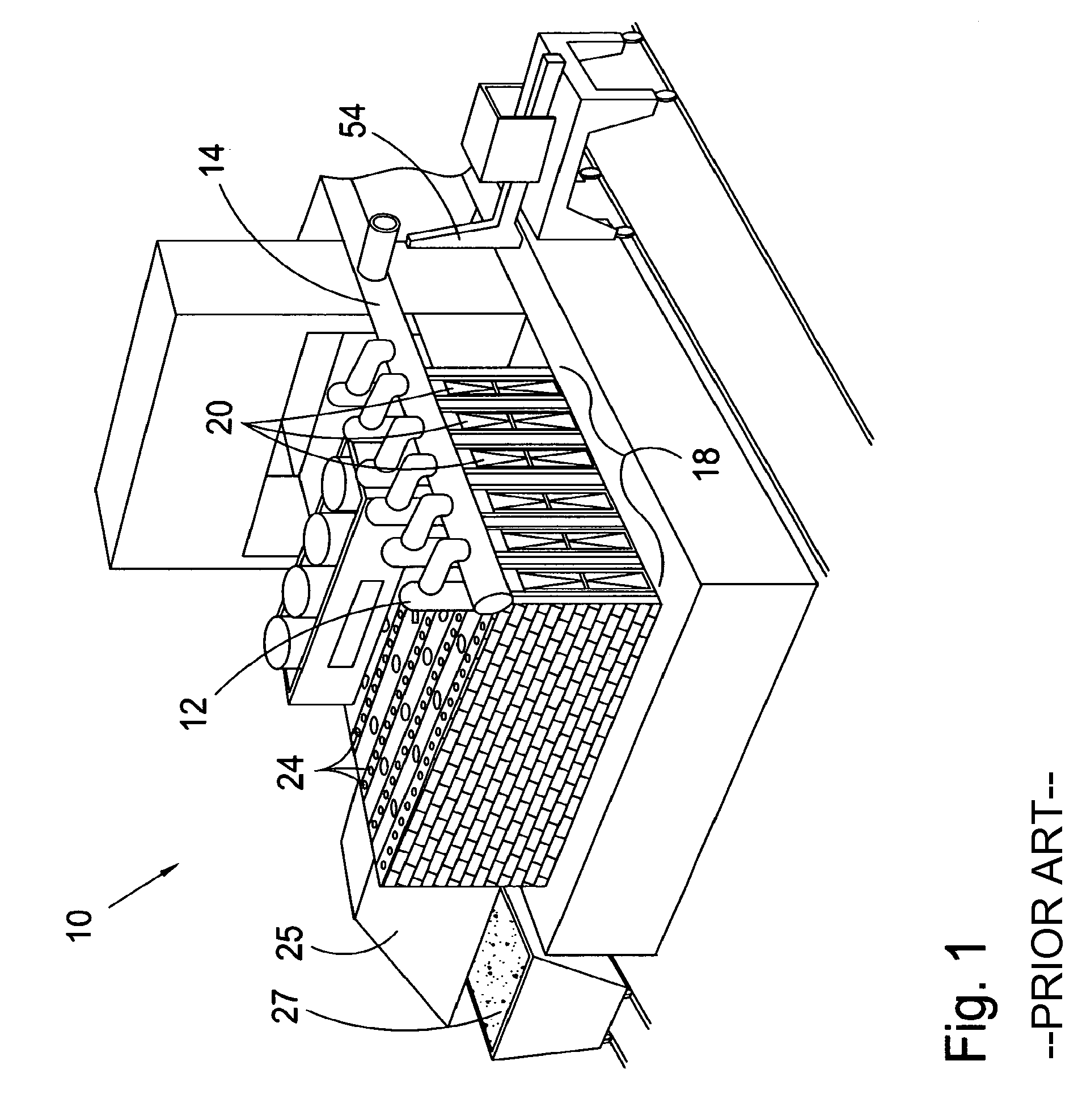

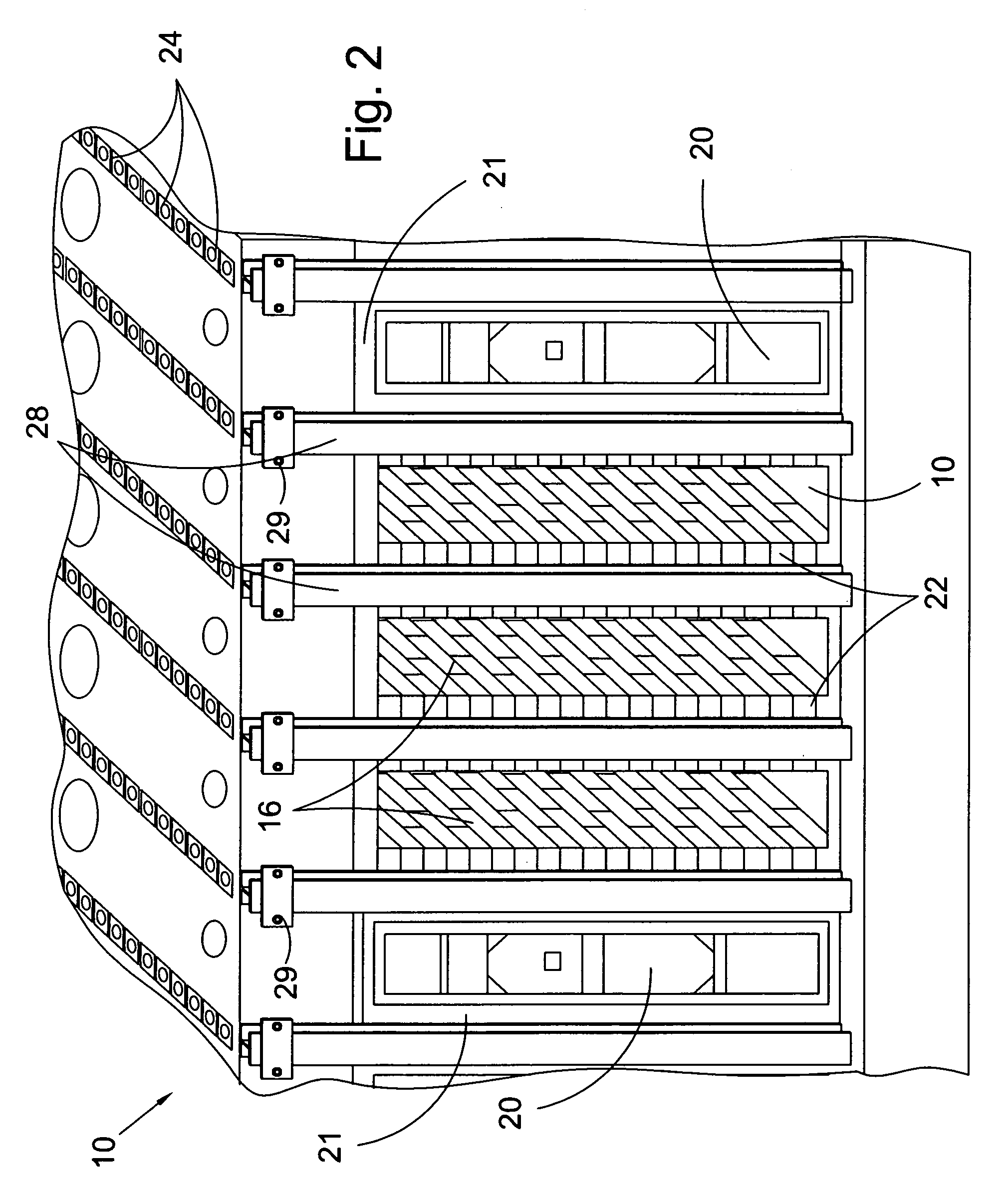

Simultaneous multiple cooking mode barbecue grill

ActiveUS8381712B1Effectively and conveniently prepareStoves/ranges foundationsDomestic stoves or rangesProcess engineering

A simultaneous multiple cooking mode barbecue grill that includes a first cooking mode unit configured to prepare food in a first cooking mode, a second cooking mode unit configured to prepare food in a second cooking mode, and a supporting structure that supports the first cooking mode unit and the second cooking mode unit so that the first and second cooking mode units can be moved securely and operated simultaneously to prepare food using multiple cooking modes.

Owner:A&J MFG

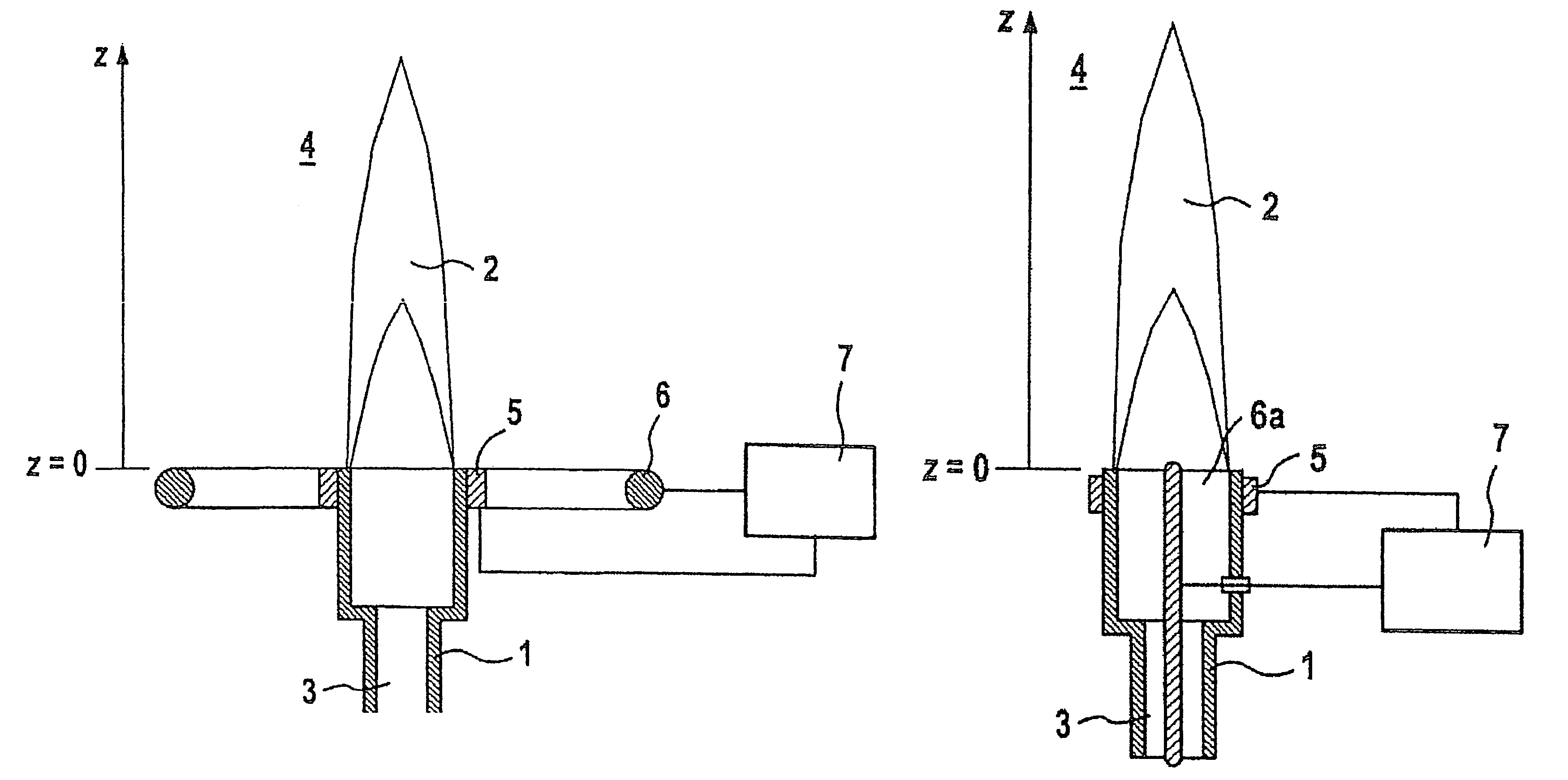

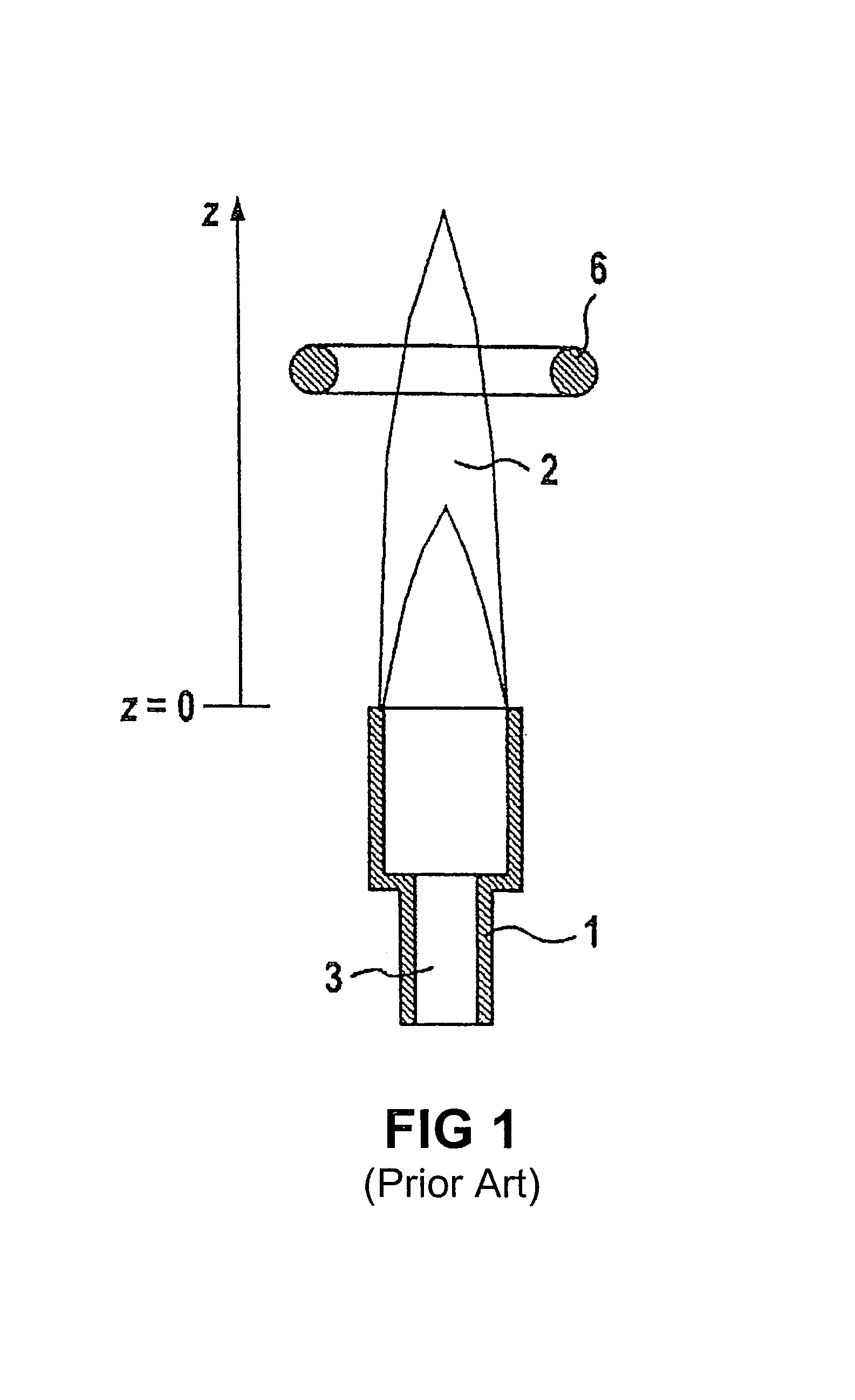

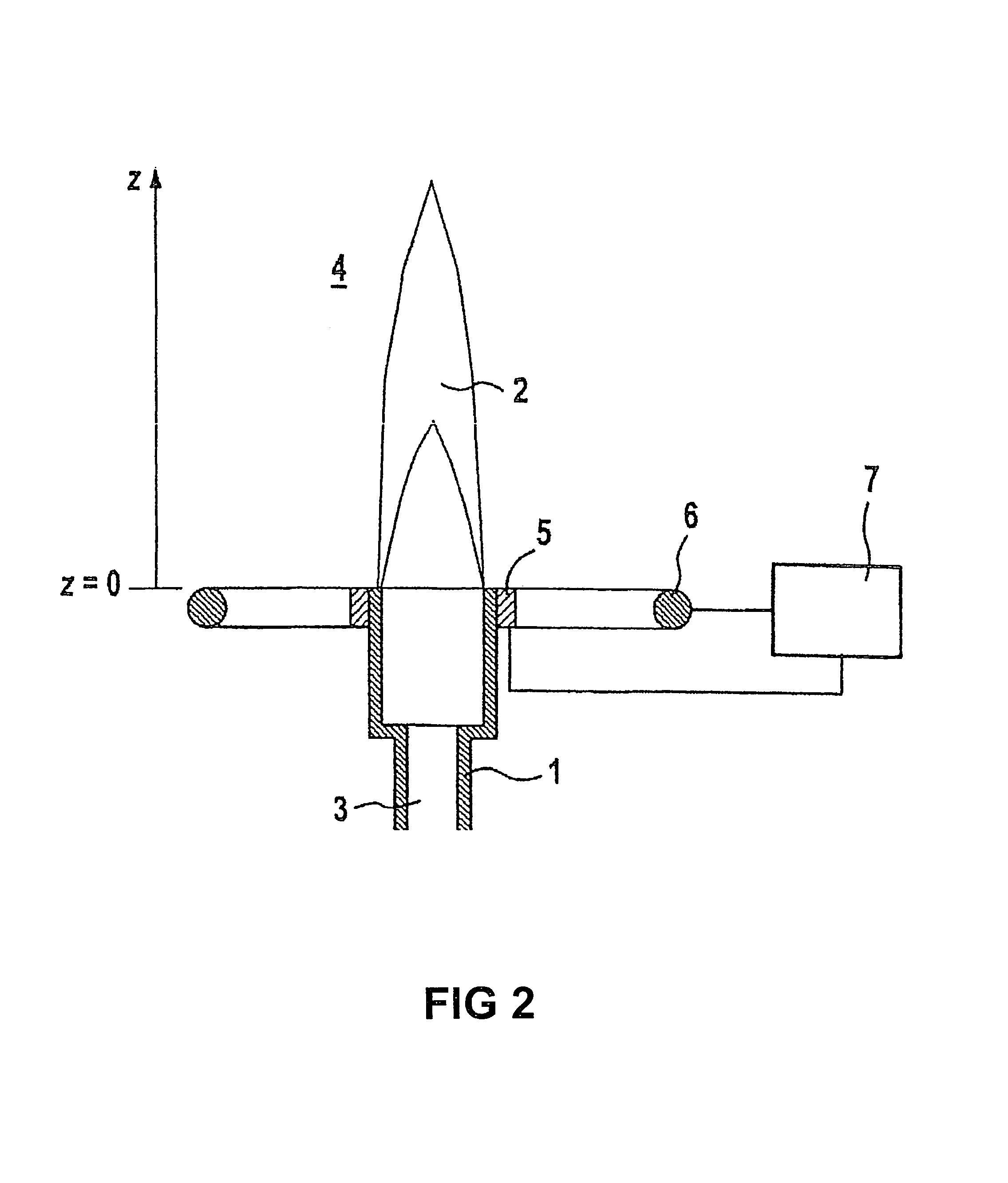

Method and device for influencing combustion processes involving combustibles

InactiveUS7137808B2Increase influenceEconomical and simpleCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHazardous substance

A method and device are for influencing combustion processes, and include an electrical device. The electrical device engages with the flame front so that the electrical field thus produced, only penetrates areas of the flame front in which a stabilizing and harmful-substance-reducing effect is produced. The electrodes of the burner are arranged outside the region of the flame in the associated device.

Owner:SIEMENS AG

Combustion equipment and burner combustion method

InactiveUS20080268387A1Reduce nitrogen oxide emissionsIncrease flow rateCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustion chamberCombustor

Combustion equipment of a coaxial jet combustion scheme is provided that includes: a burner plate in which fuel and air are mixed with each other while the fuel and air pass through an air hole; a burner plate extension which is a portion of the burner plate and extends toward a combustion chamber side spaced apart from the air hole; and a protrusion disposed on the combustion chamber side of the burner plate extension so as to protrude in a direction where flow of the fuel moves. In the combustion equipment, a gap between opposite portions of the protrusion is greater than a diameter of the air hole and a flame source forming area is defined between the burner plate, the burner plate extension and the protrusion. The combustion equipment of a coaxial jet combustion scheme can achieve a further reduction in NOx emissions.

Owner:HITACHI LTD

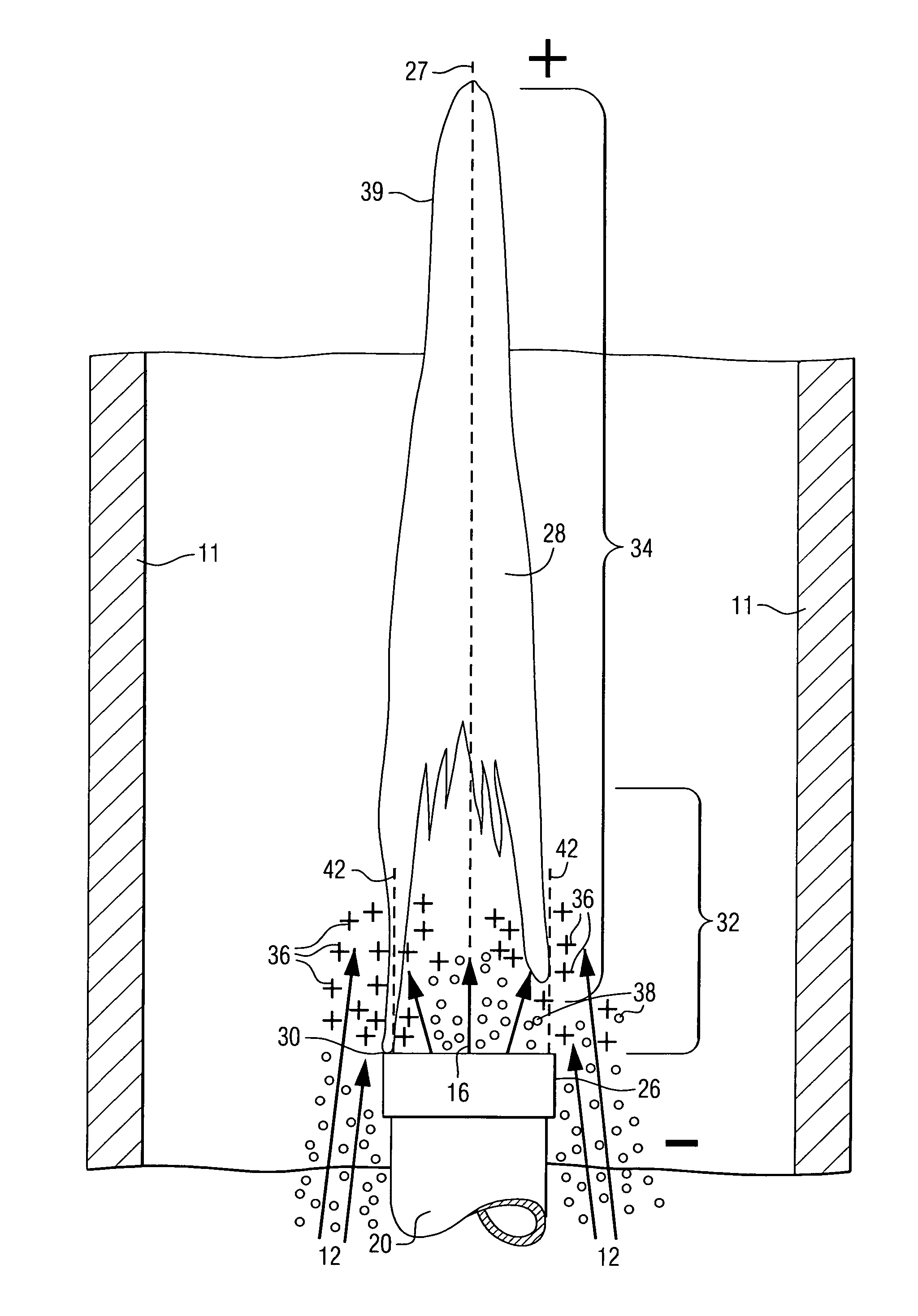

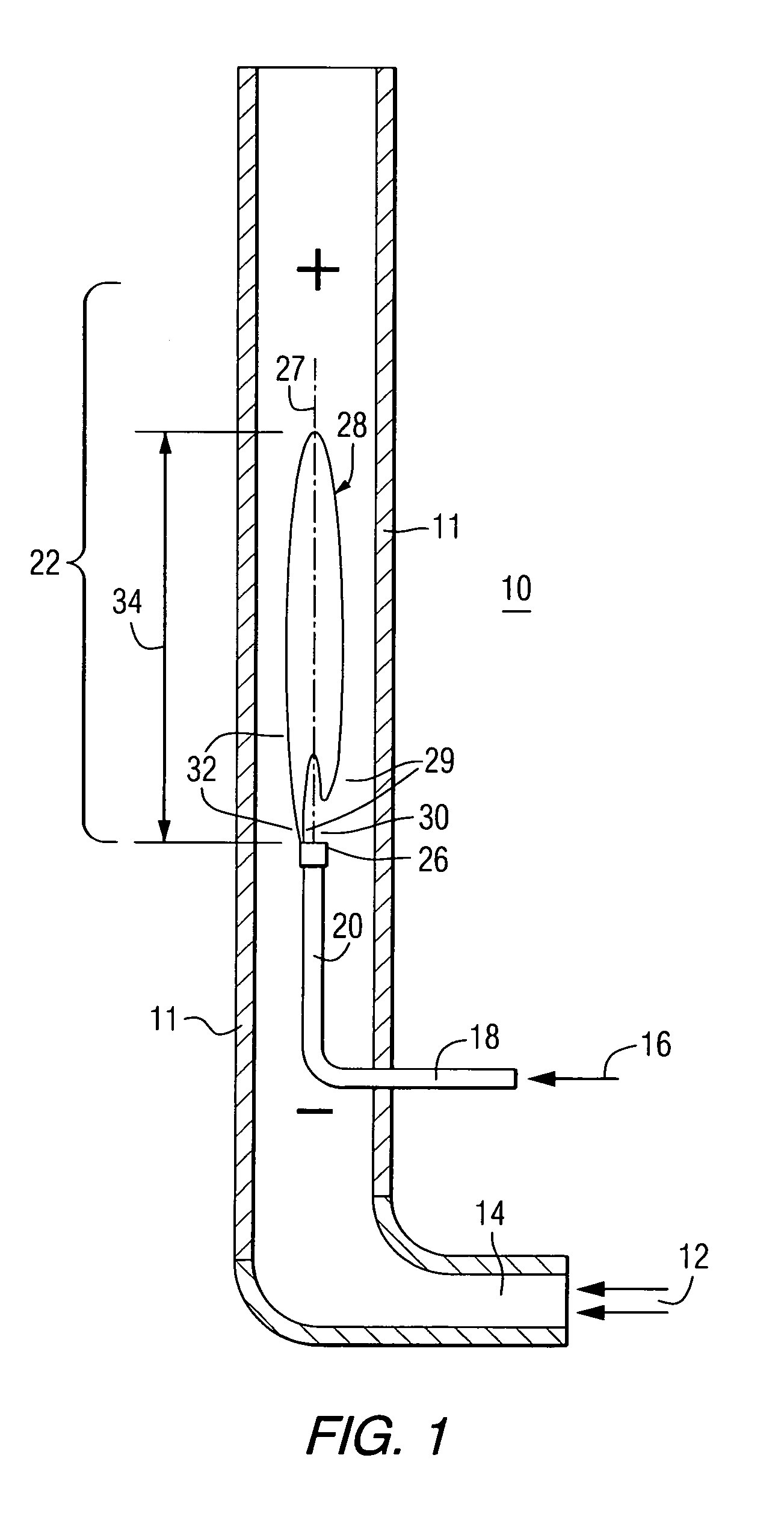

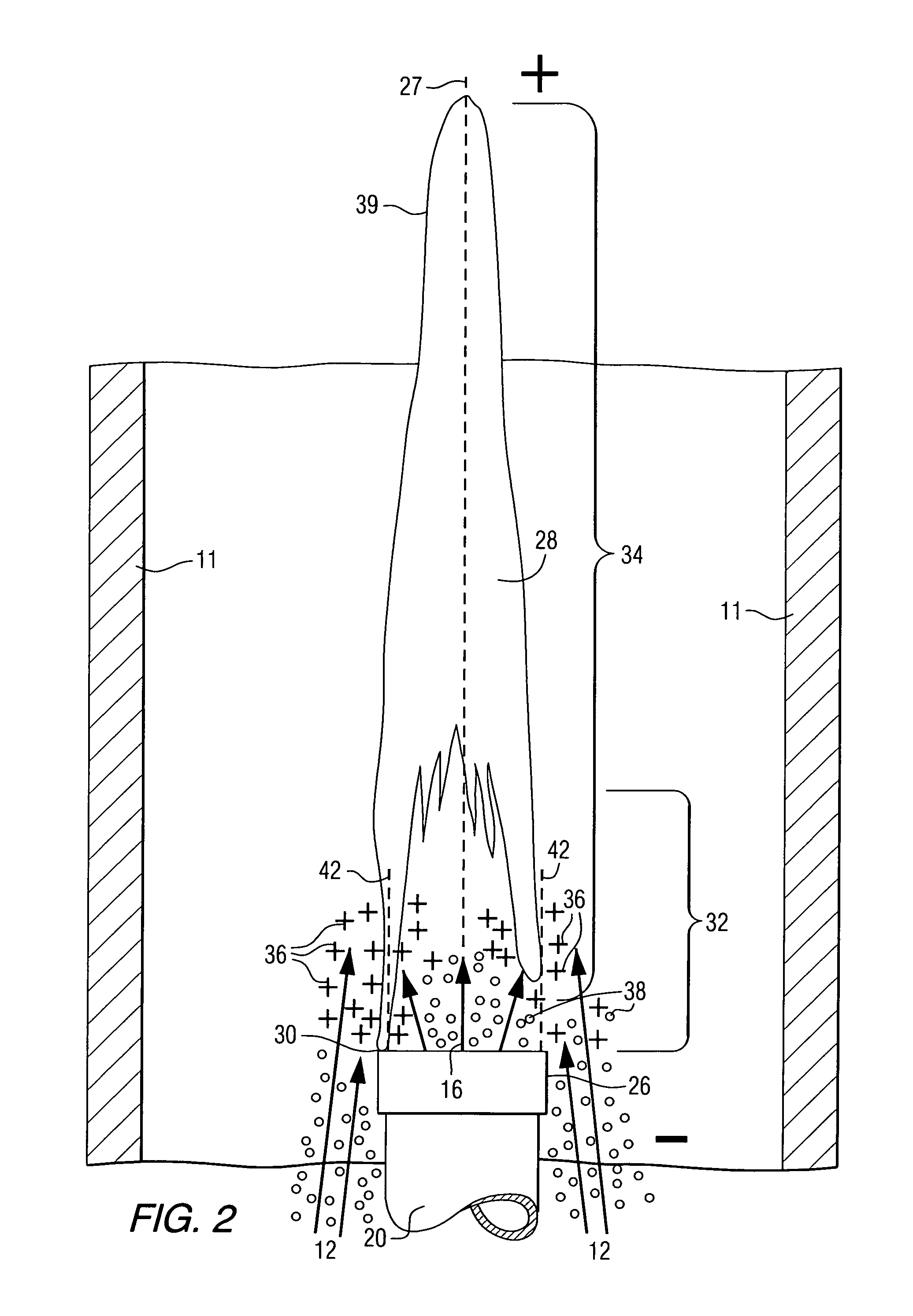

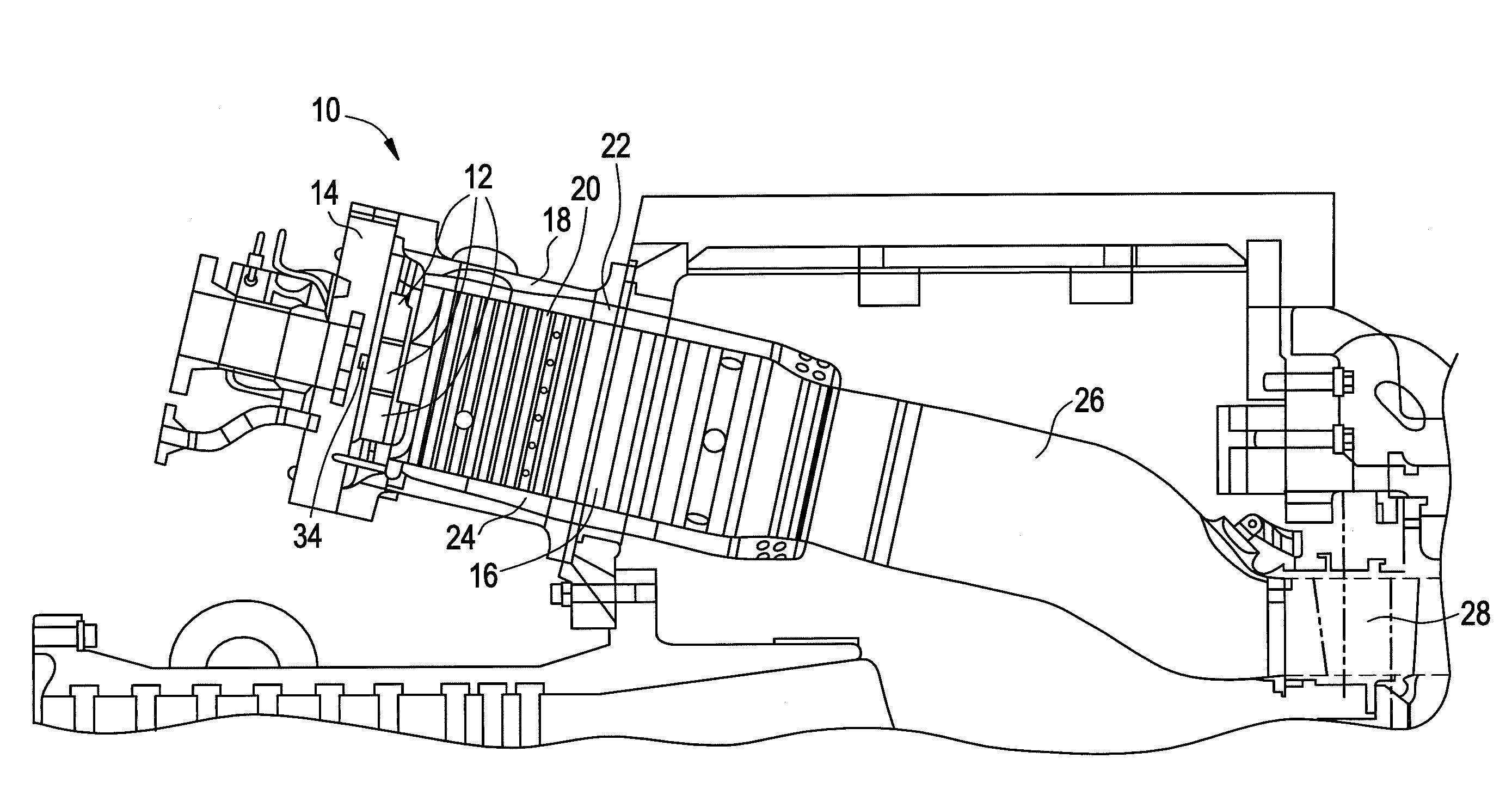

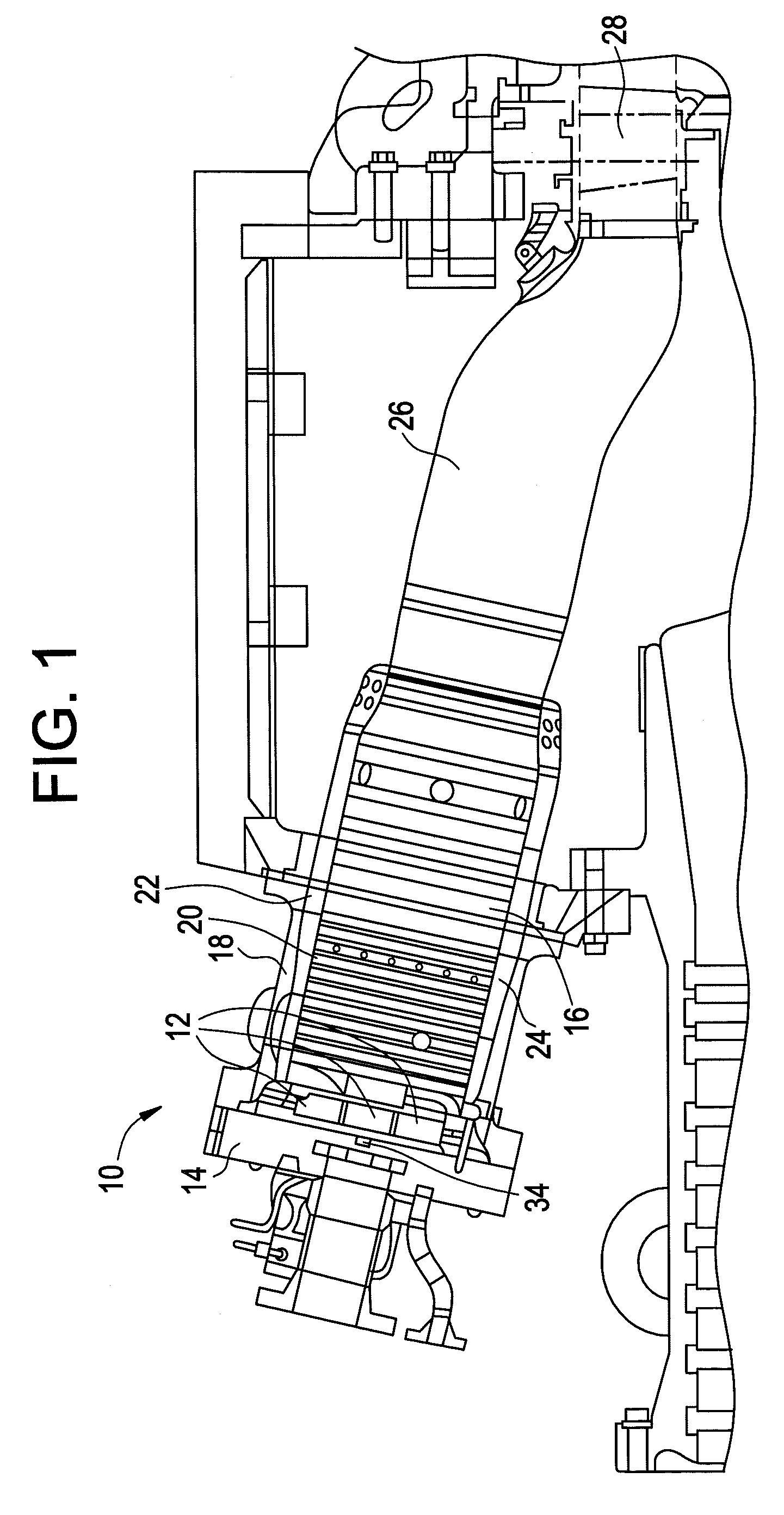

Electric flame control using corona discharge enhancement

InactiveUS7243496B2Increased ionizationPromote combustionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionElectricityCombustor

A method of operating a combustor (10), to provide intimately mixed hot combusted gas (44) for a gas turbine (46), includes feeding gaseous oxidant (12) and gaseous fuel (16) into the combustor (10) near a combustion flame (28) which has a tip end (39) and a root end (29), where corona discharge occurs through adjustment of an electric field (34), and where the corona discharge causes ionized particles (36) to form and also causes intimate turbulent mixing of the gases.

Owner:SIEMENS ENERGY INC

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

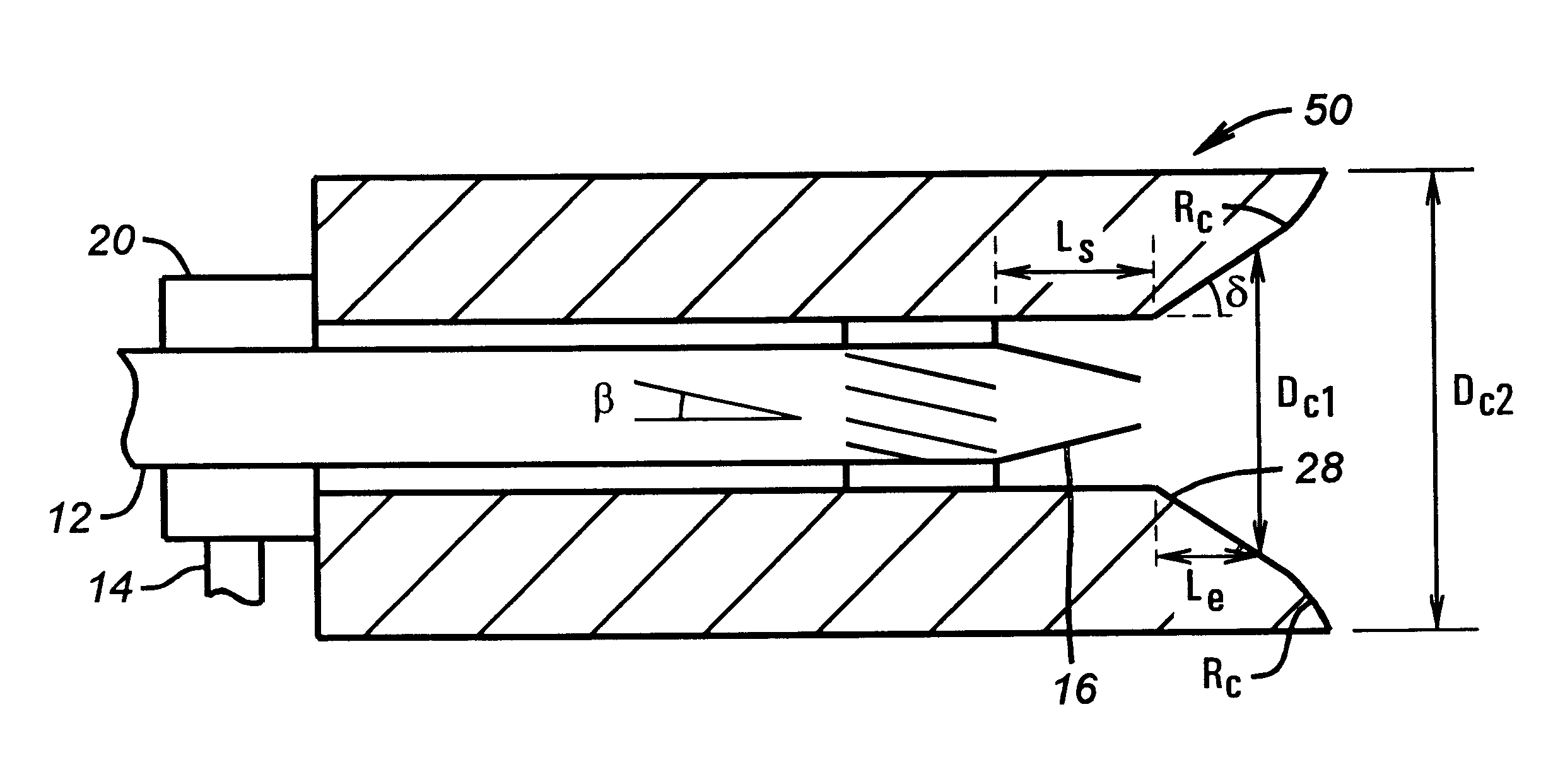

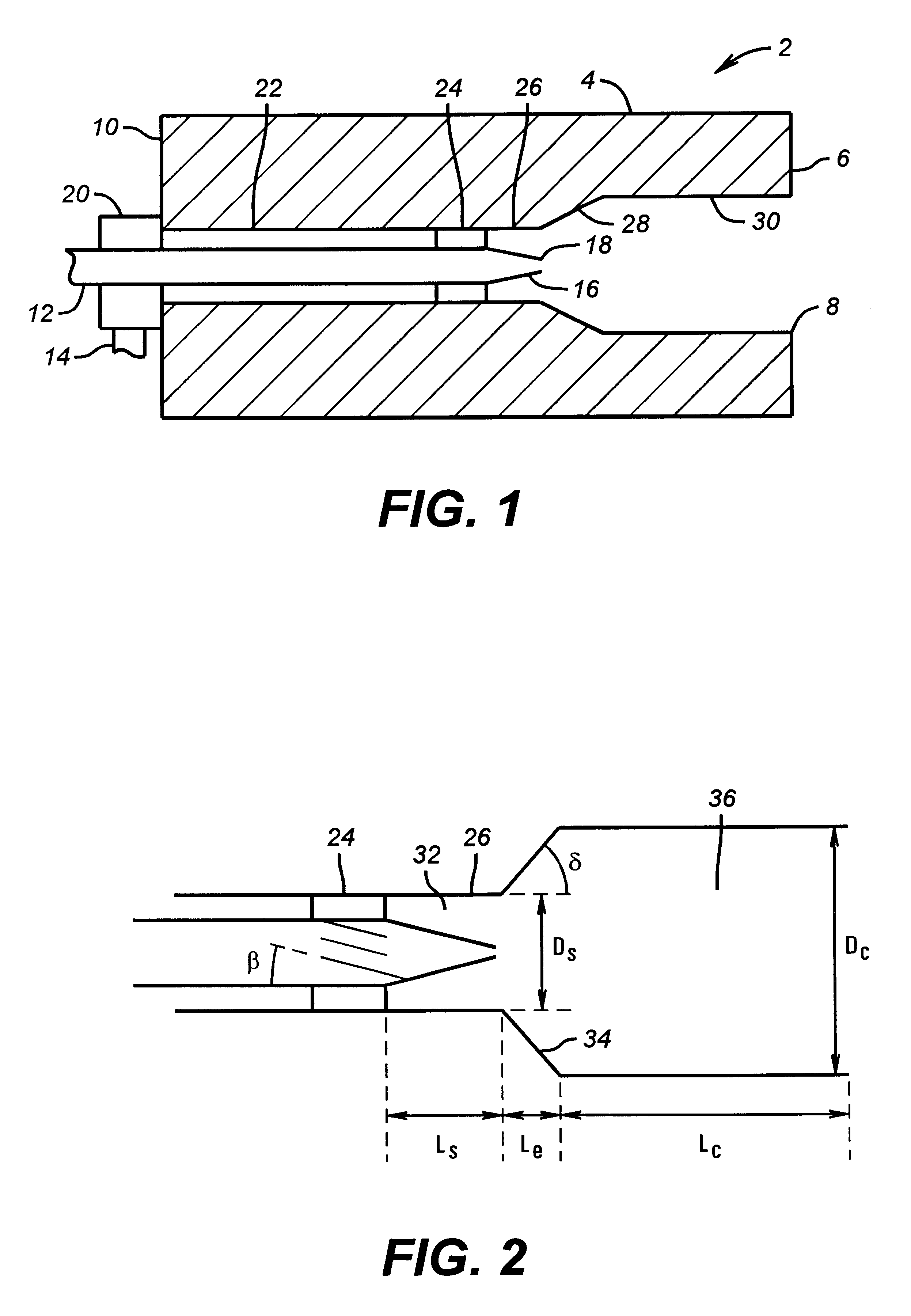

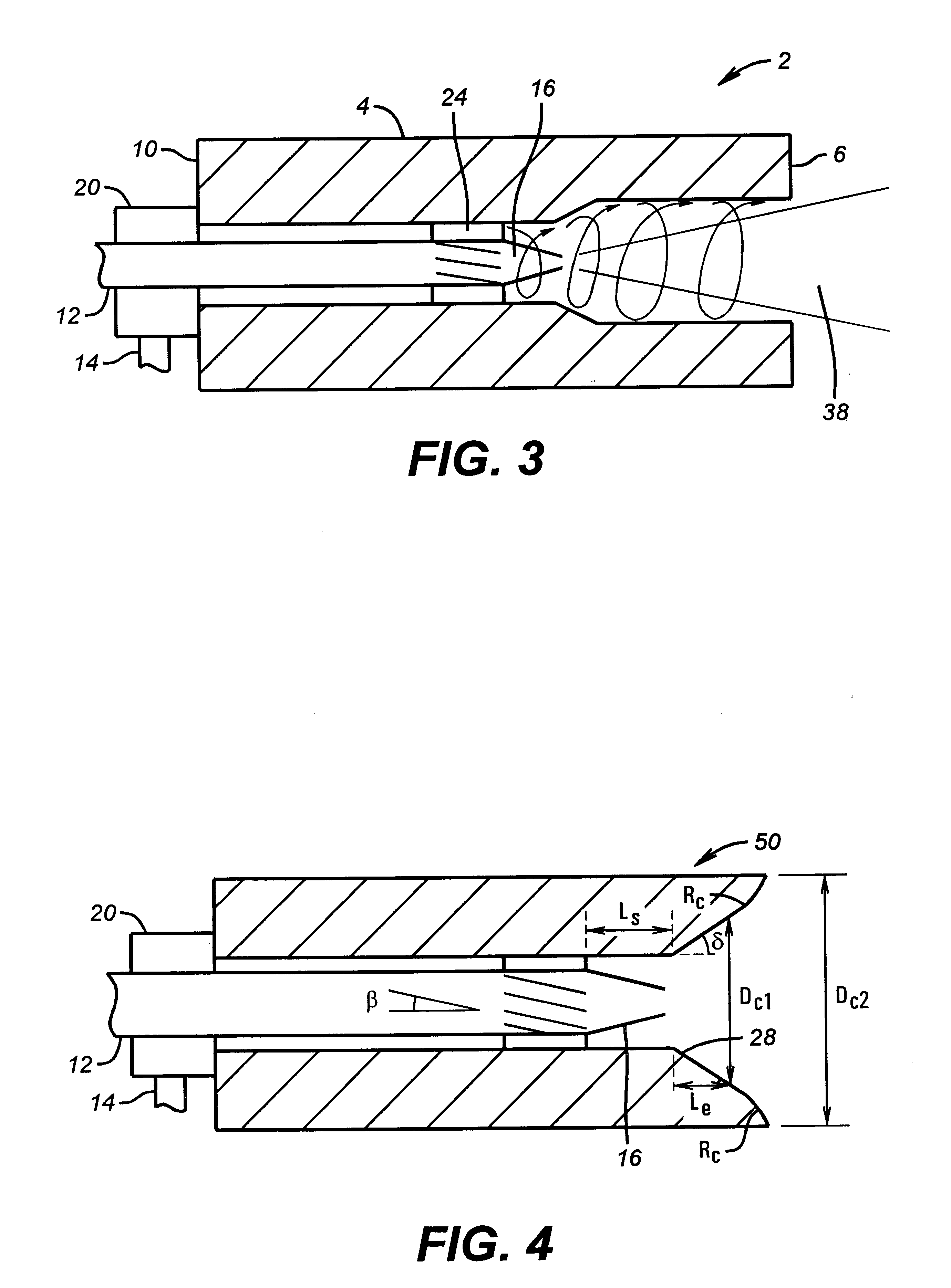

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

Methods for reducing NOx in combustion flue gas using metal-containing additives

InactiveUS6471506B1Simple and inexpensive methodReduce penetrationDispersed particle separationIncinerator apparatusAtmospheric airMolecular nitrogen

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

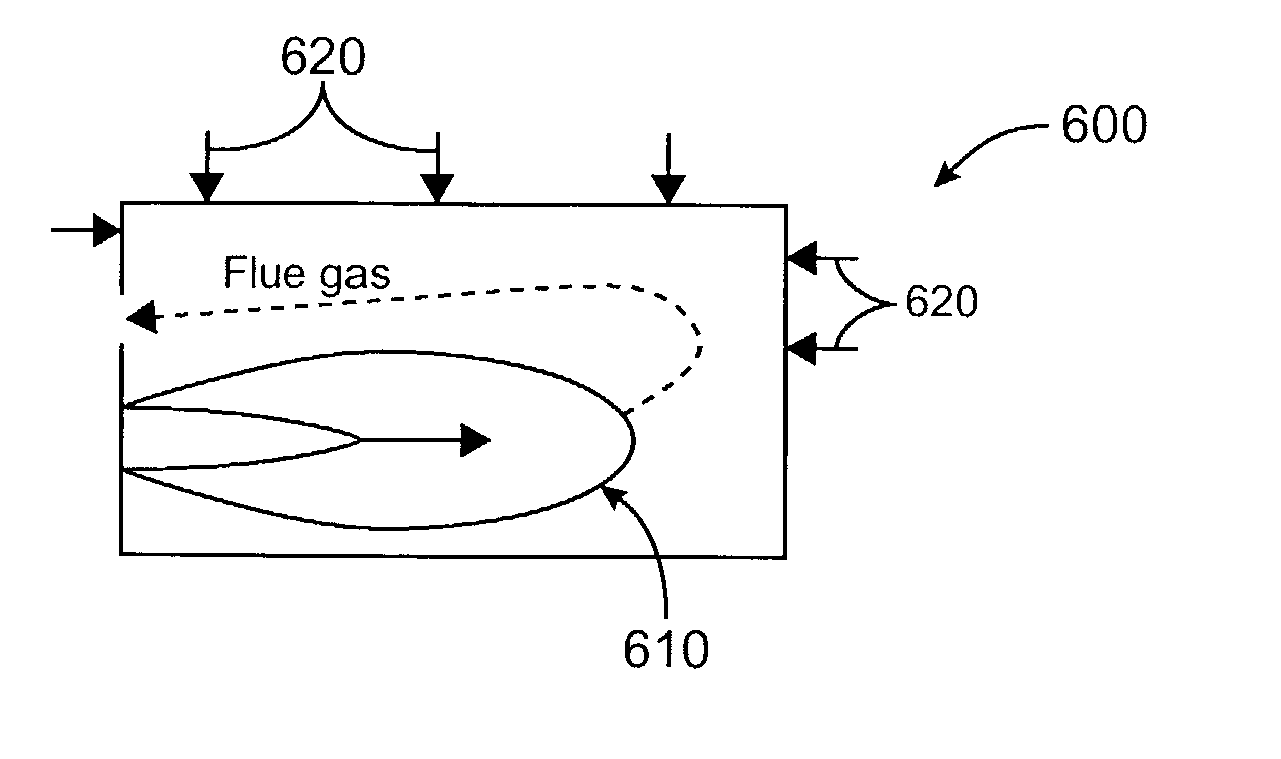

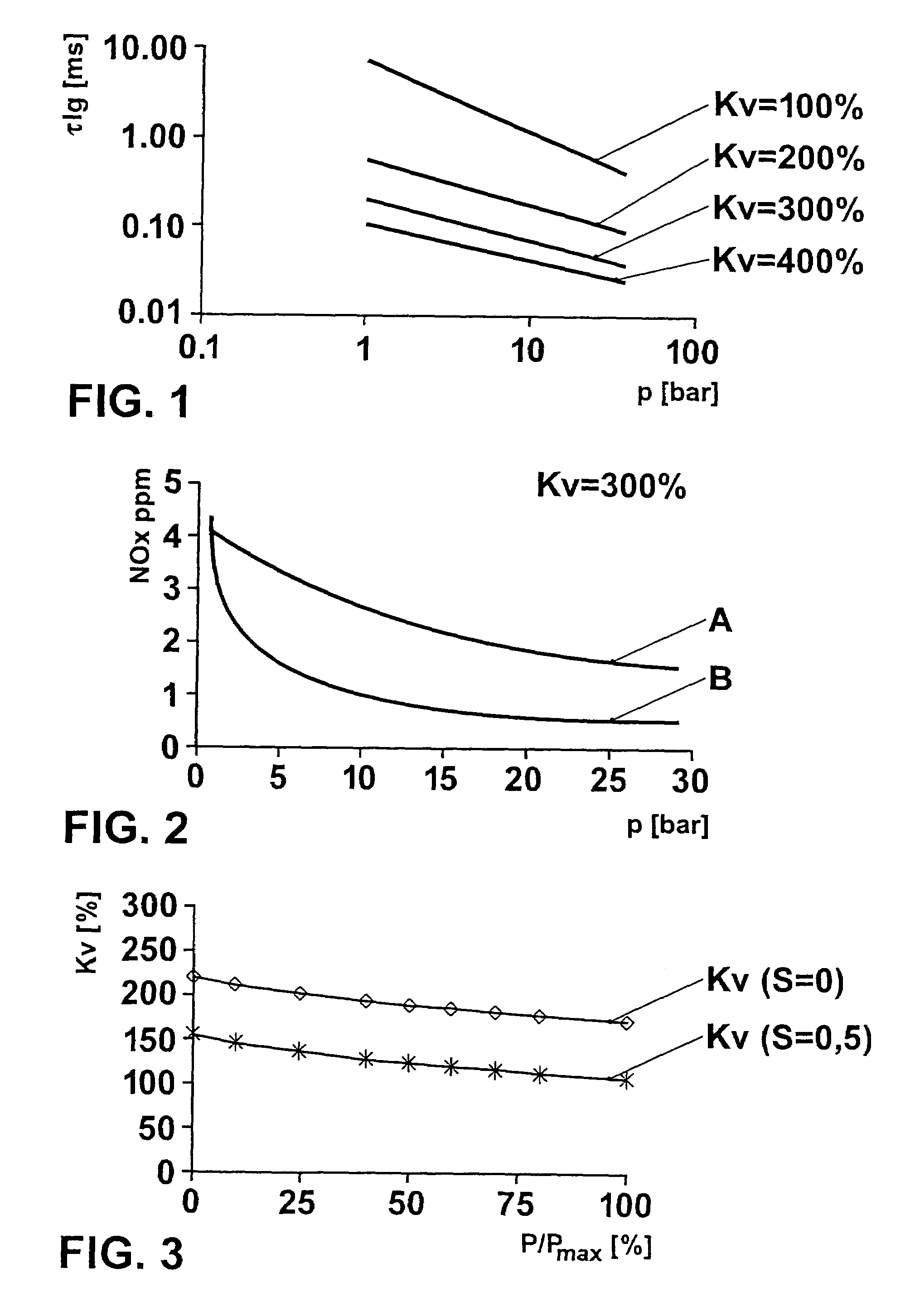

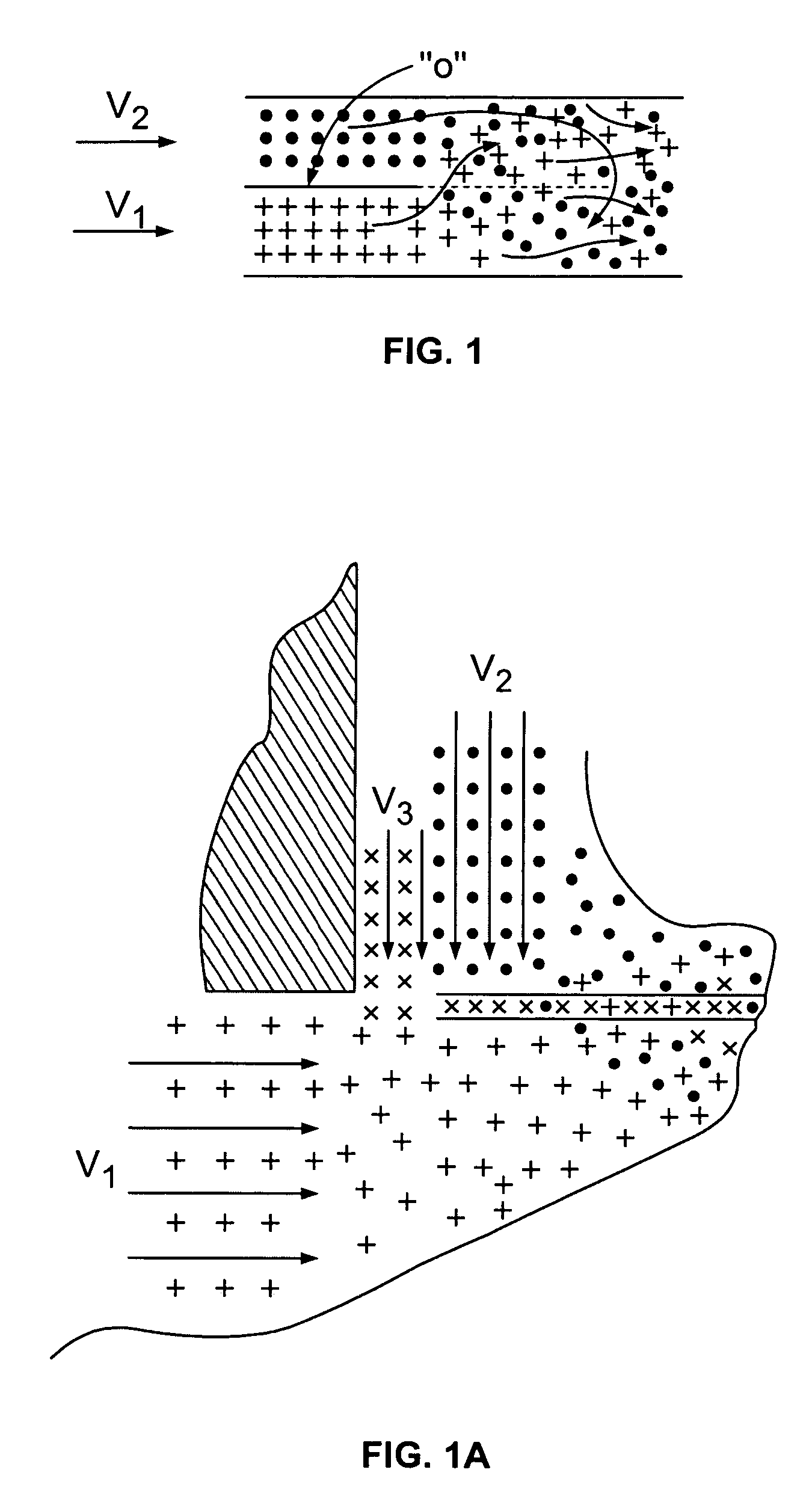

Method for combustion of a fuel

InactiveUS7363756B2Increase speedAccelerated dilutionContinuous combustion chamberGas turbine plantsCombustion chamberFront velocity

In a method for the combustion of a fuel, a fuel or a premixed combustible mixture is introduced into a combustion space as a combustible fluid open jet. The velocity of the open jet is selected in such a way that it is impossible for a stable flame front to form, i.e. is in any event greater than the flame front velocity, and that, on account of a jet pump effect, flue gas is mixed into the combustible fluid jet from the combustion chamber in a jet-induced recirculation internally within the combustion chamber. The admixed flue gas dilutes and heats the combustible fluid. The heating causes the spontaneous ignition temperature to be exceeded, and a low-pollutant volumetric flame is formed in a highly dilute atmosphere.

Owner:ANSALDO ENERGIA SWITZERLAND AG

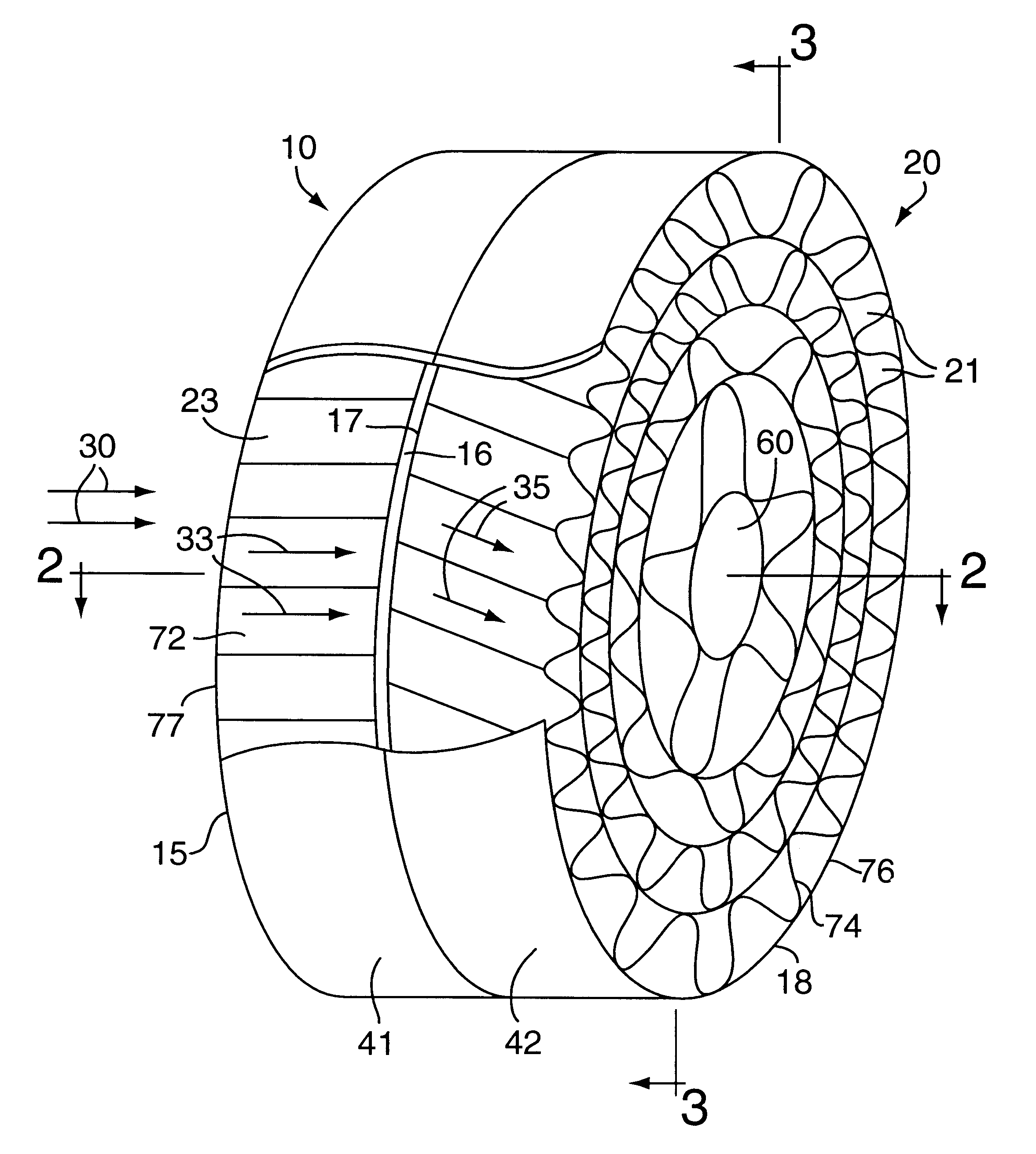

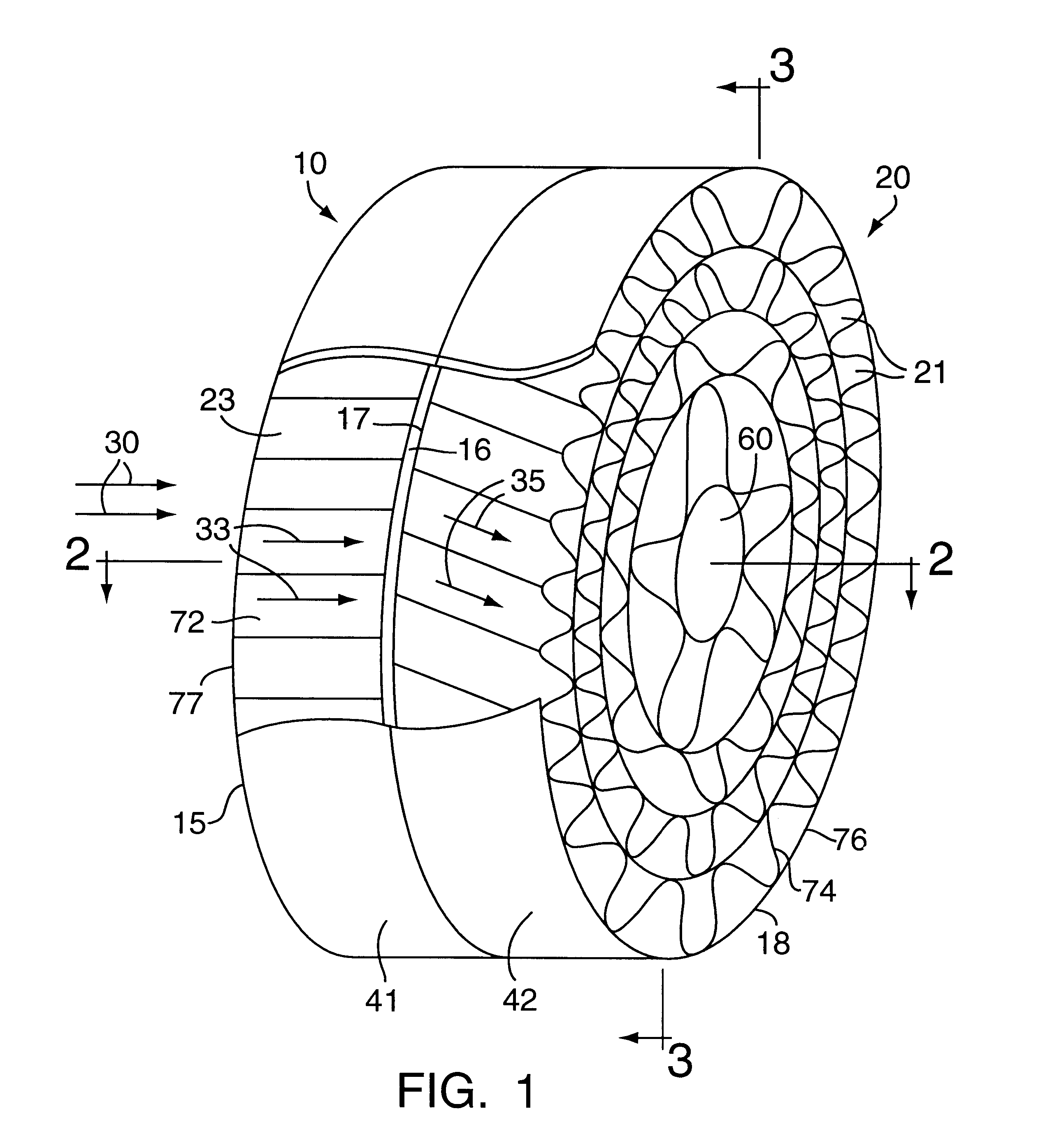

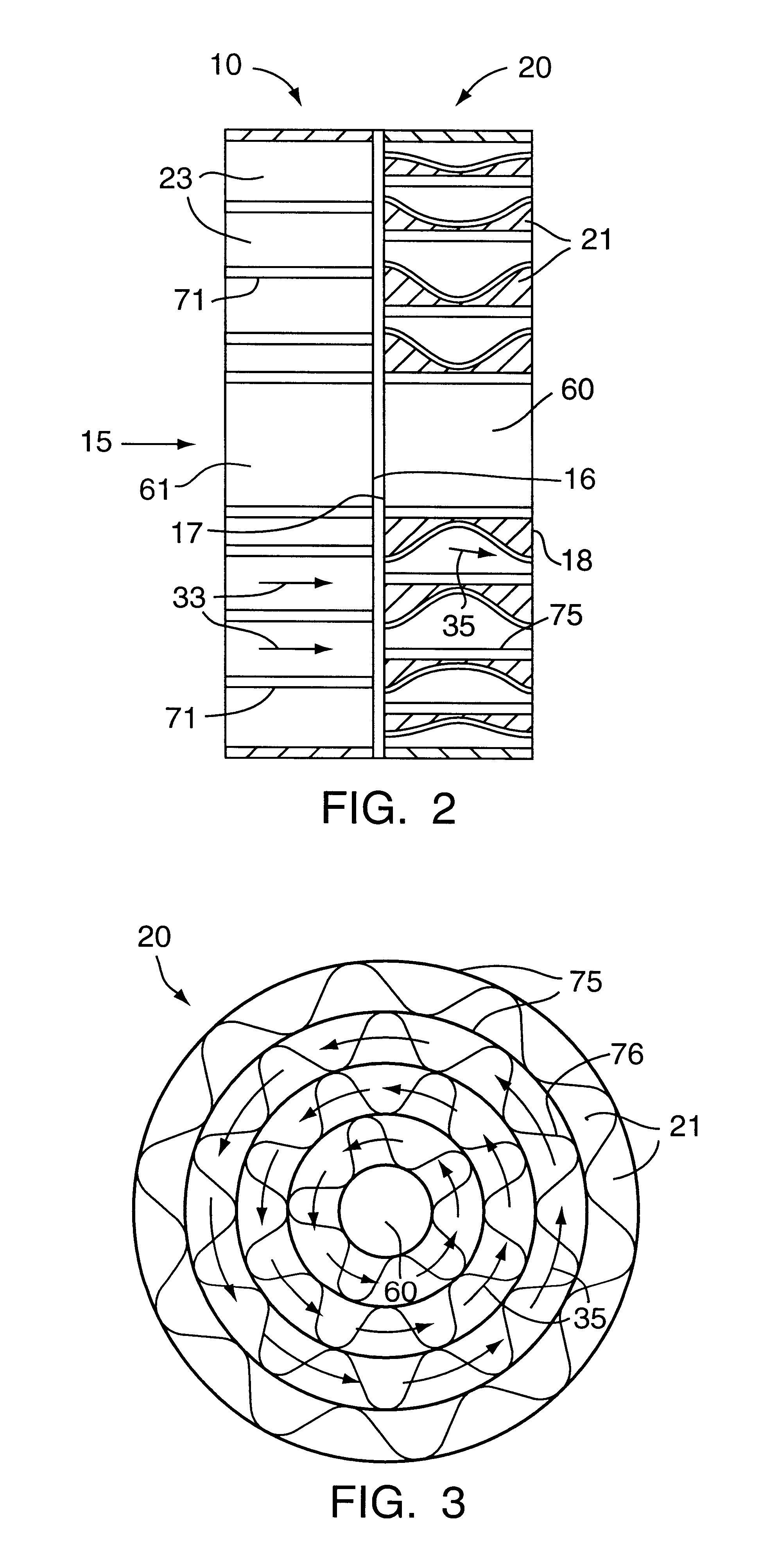

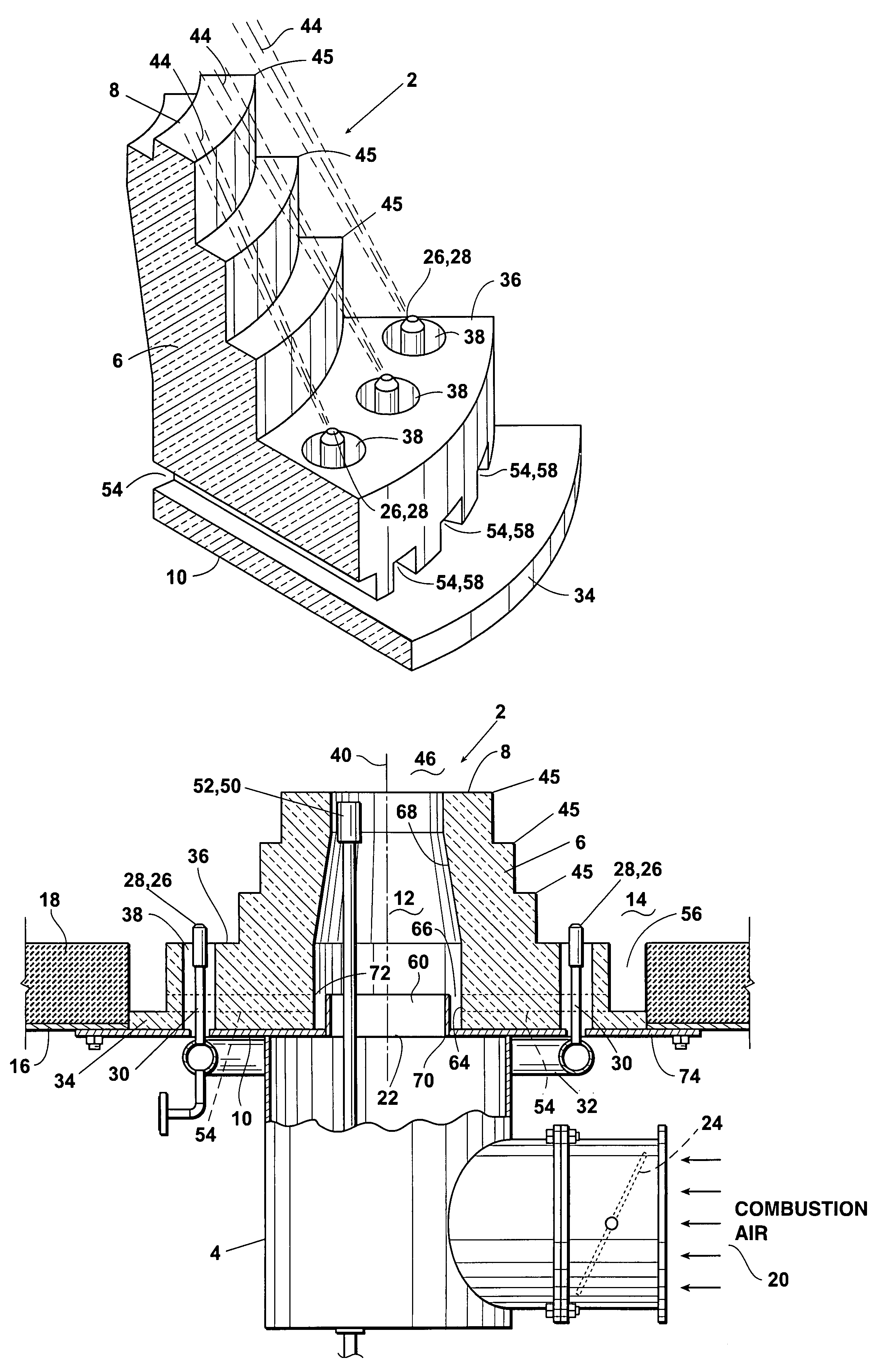

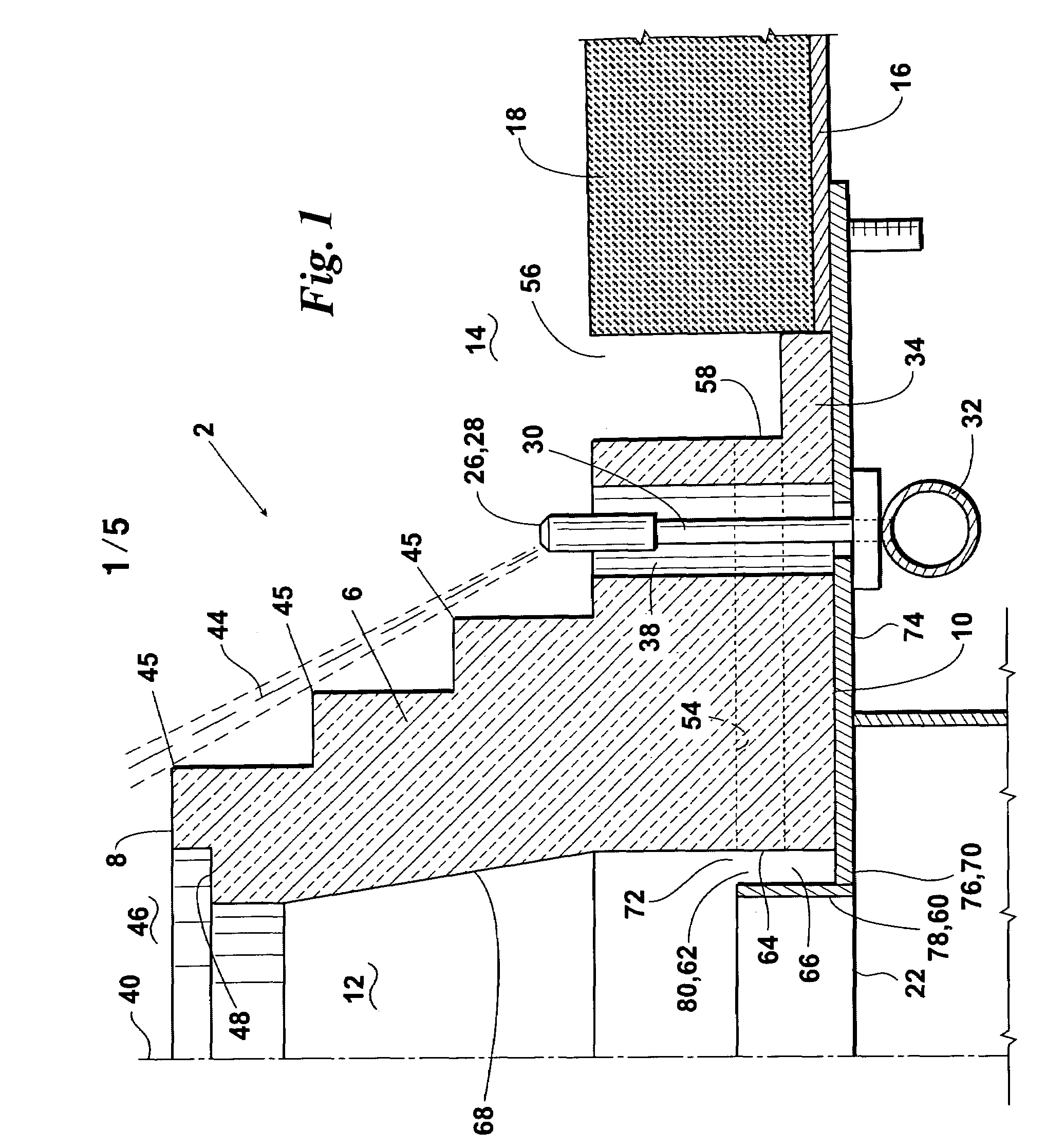

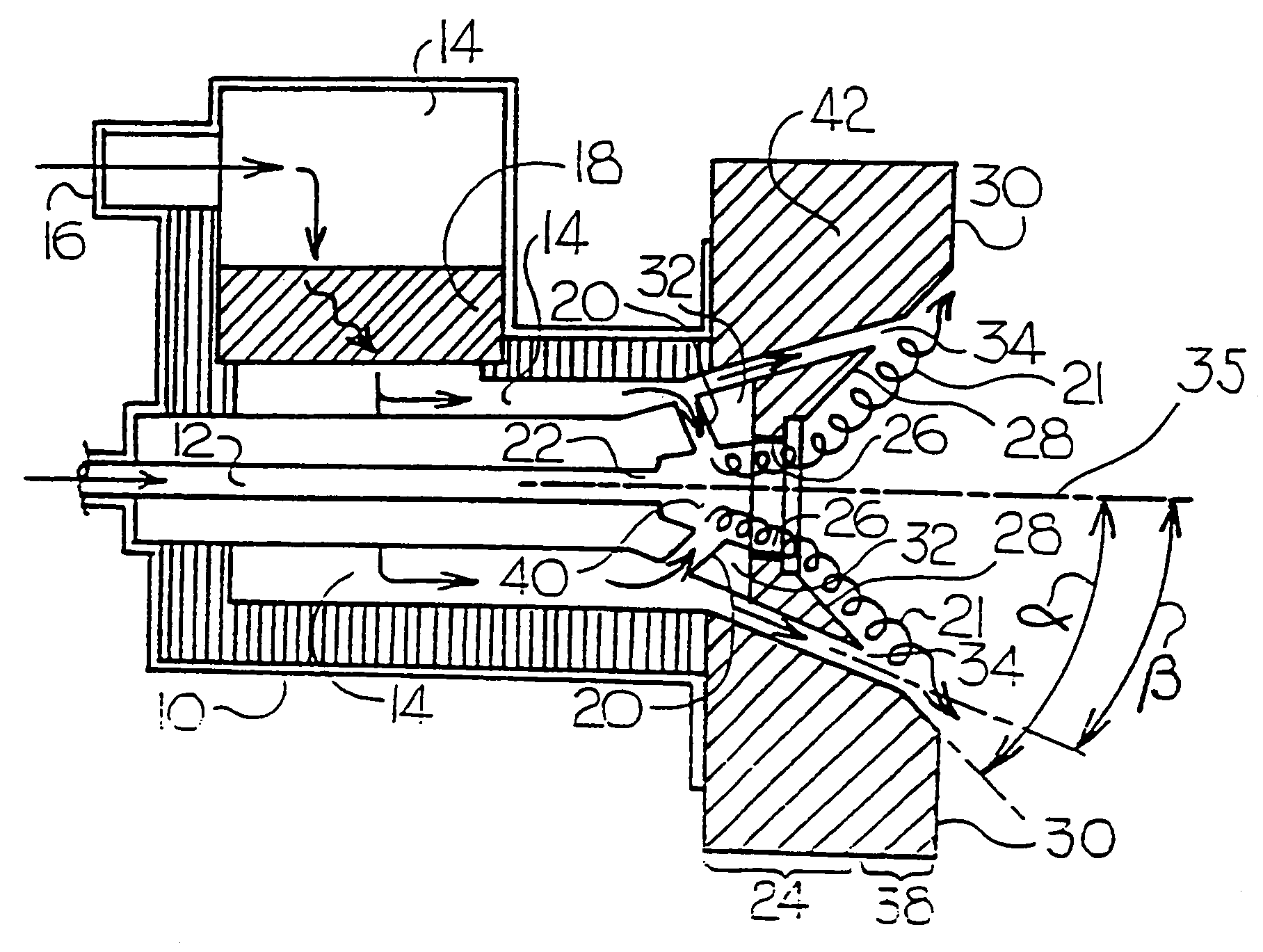

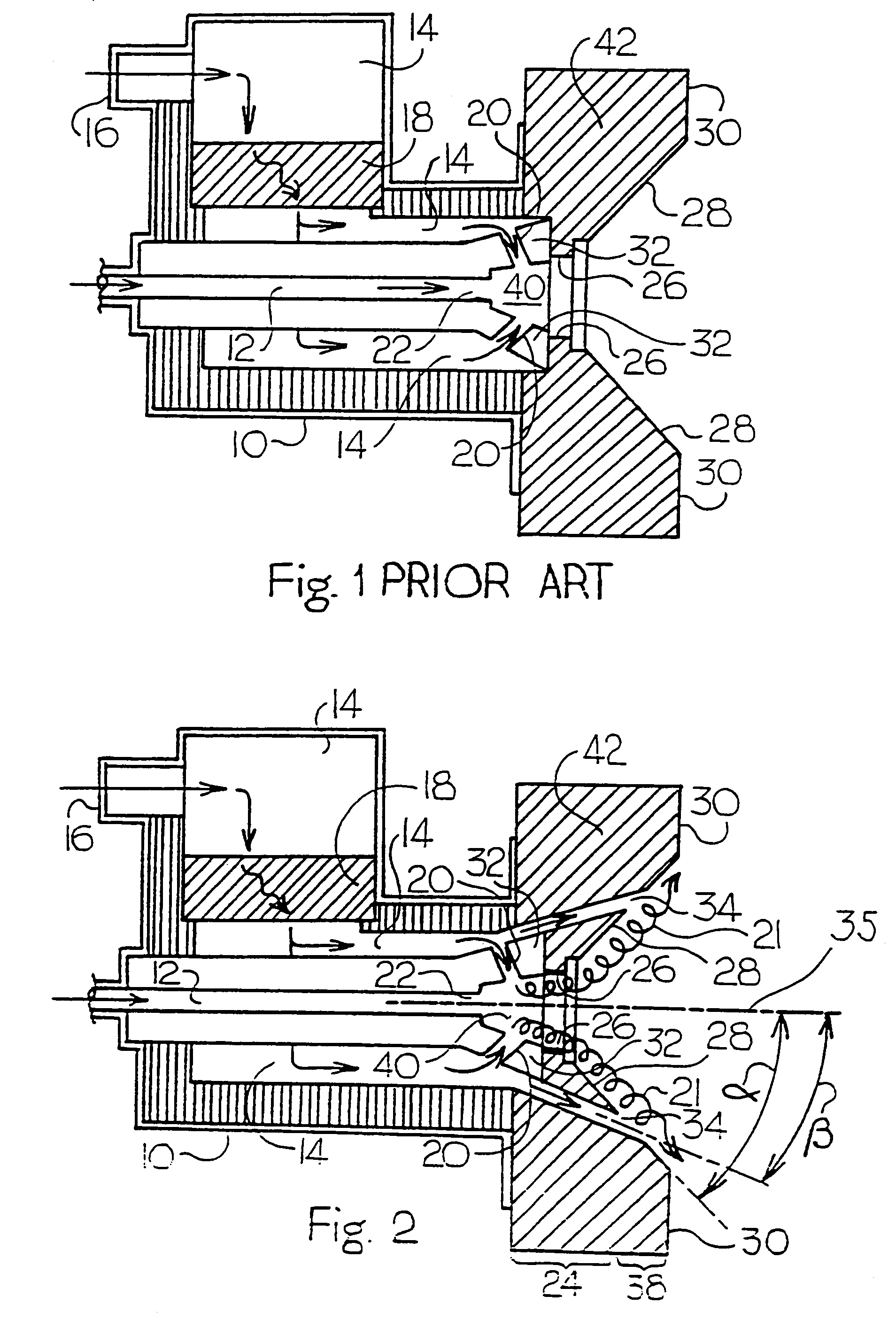

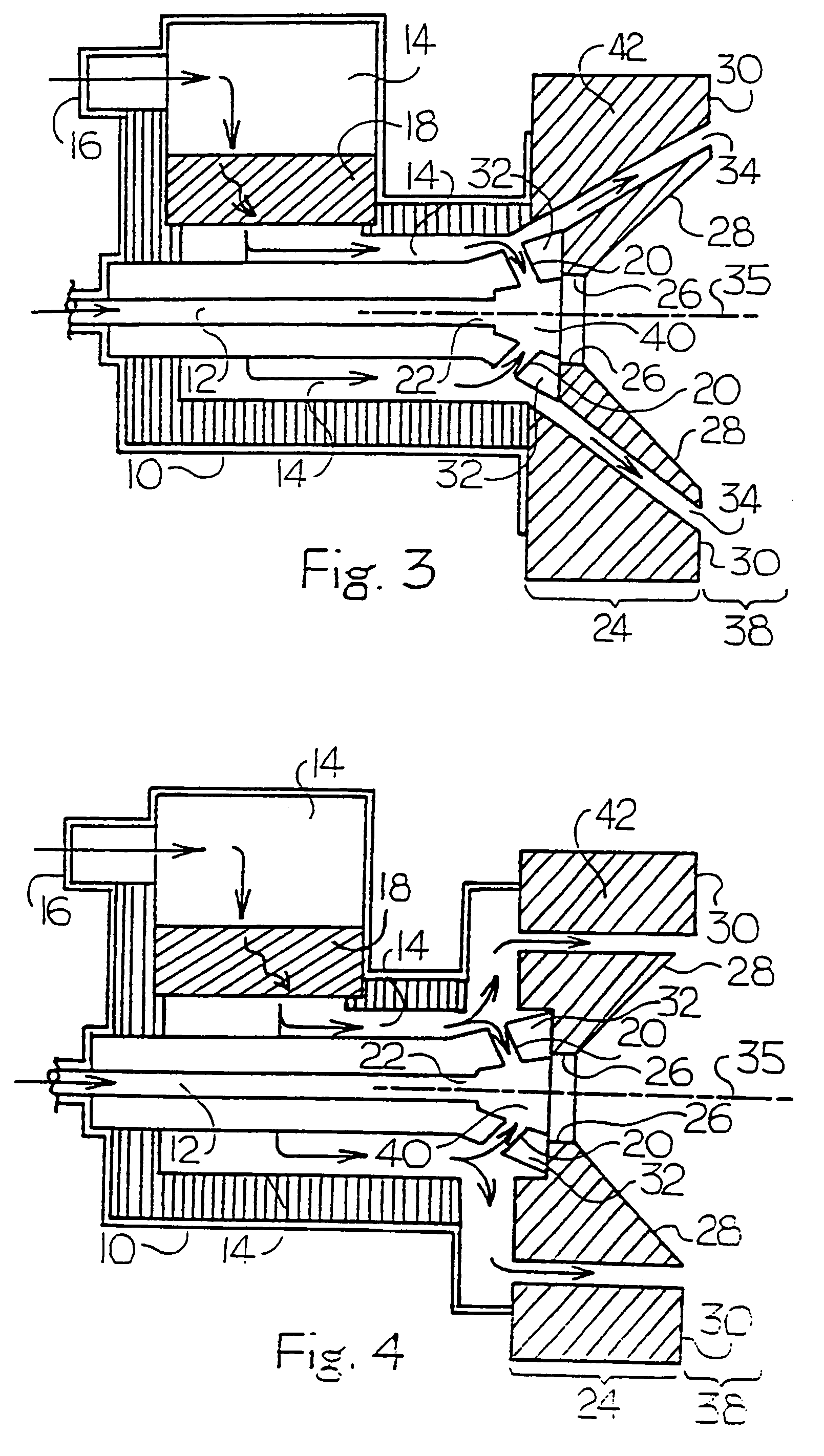

Air staged low-NOx burner

InactiveUS7175423B1Reduce the production of nitrogen oxidesReduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

An apparatus and method for using staged air combustion. The apparatus includes a burner body (10) secured to a port block (42), and a fuel passageway (12) extending through the burner body (10), terminating in a fuel nozzle (22), which injects fuel into the burner throat (40). Primary air jets (20) are configured to inject primary air into a primary combustion region (24), which is normally in the burner throat (40). A dish with a dish surface (28) is connected to the burner throat (40); the dish surface (28) extending in a divergent angle with respect to a burner centerline (35). Secondary air jets (34) are connected to the air passageway (14) and extend through the port block (42). The secondary air jets (34) inject secondary air into a secondary combustion region (38), which may be at the dish surface (28) or the hot face (30) of the burner.

Owner:BLOOM ENG

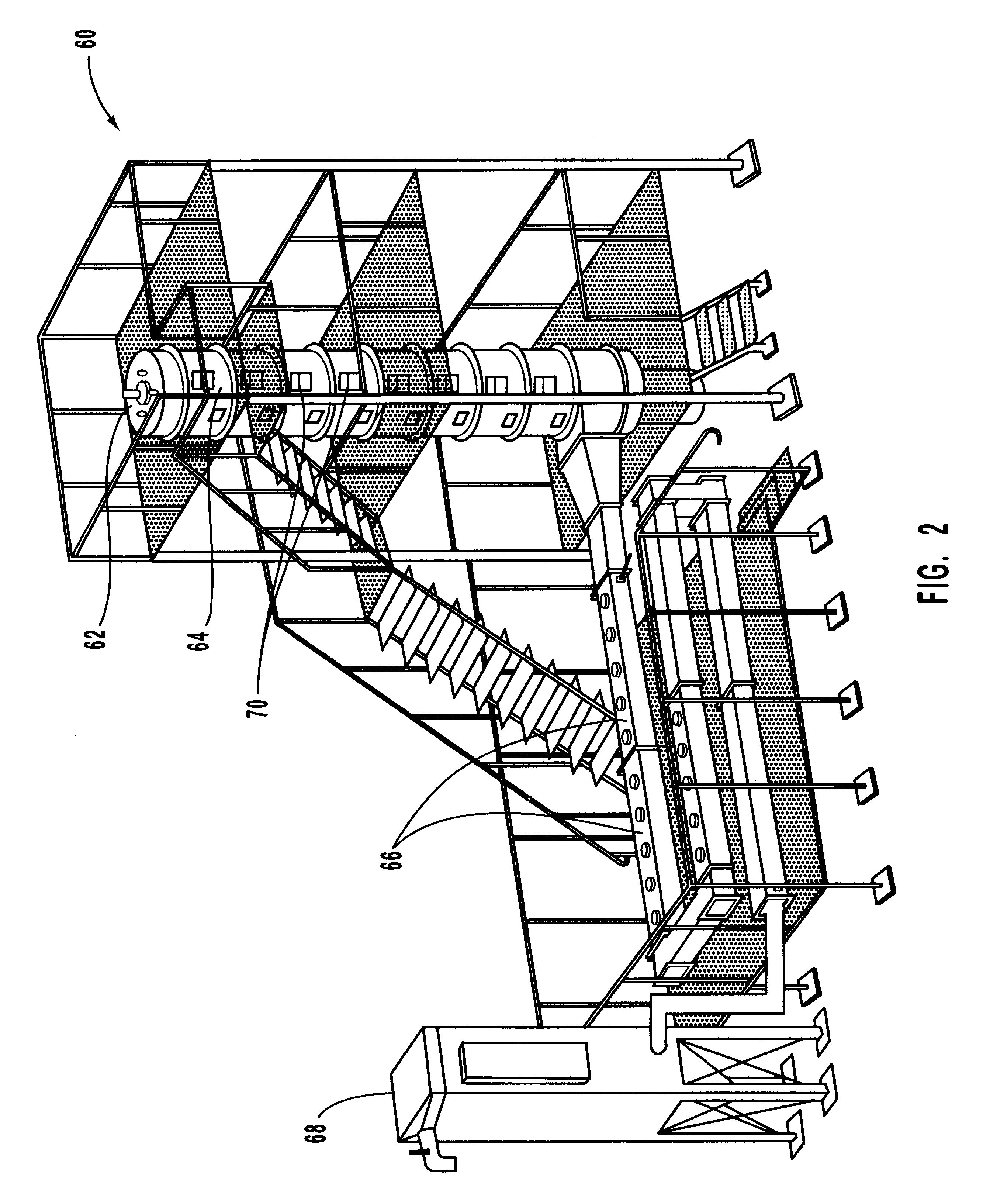

Coke oven reconstruction

ActiveUS7827689B2Good dimensional stabilityNegligible heatingConstruction materialCoke oven brickworkComputer moduleEngineering

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

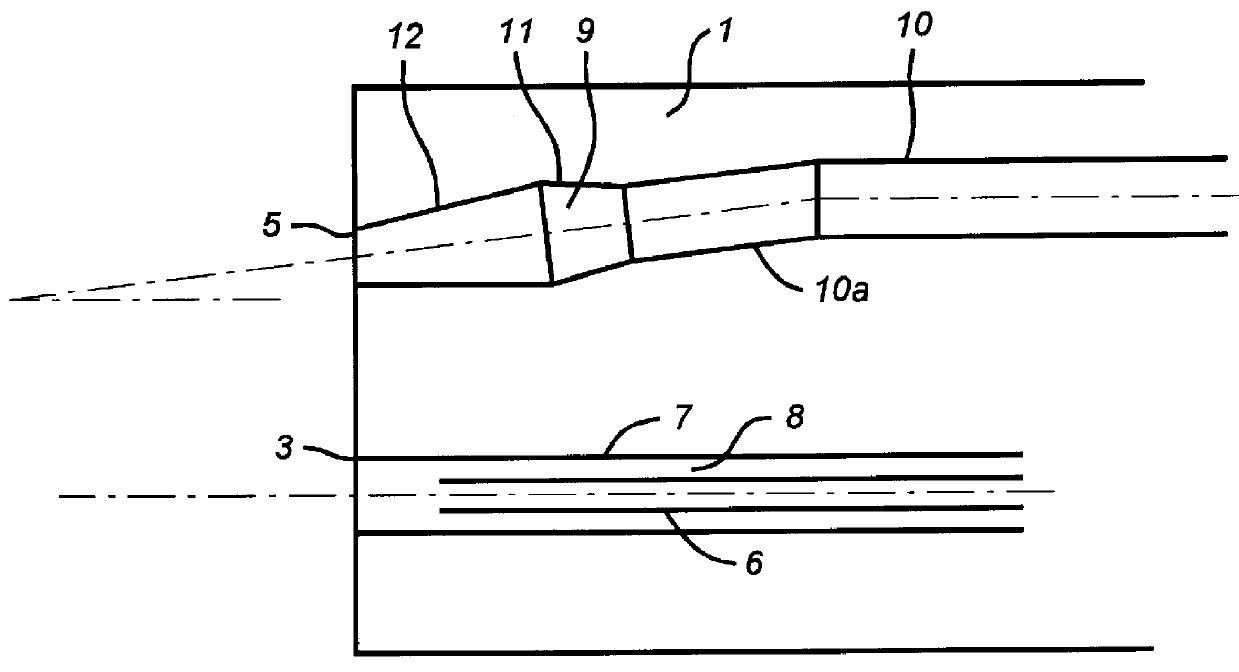

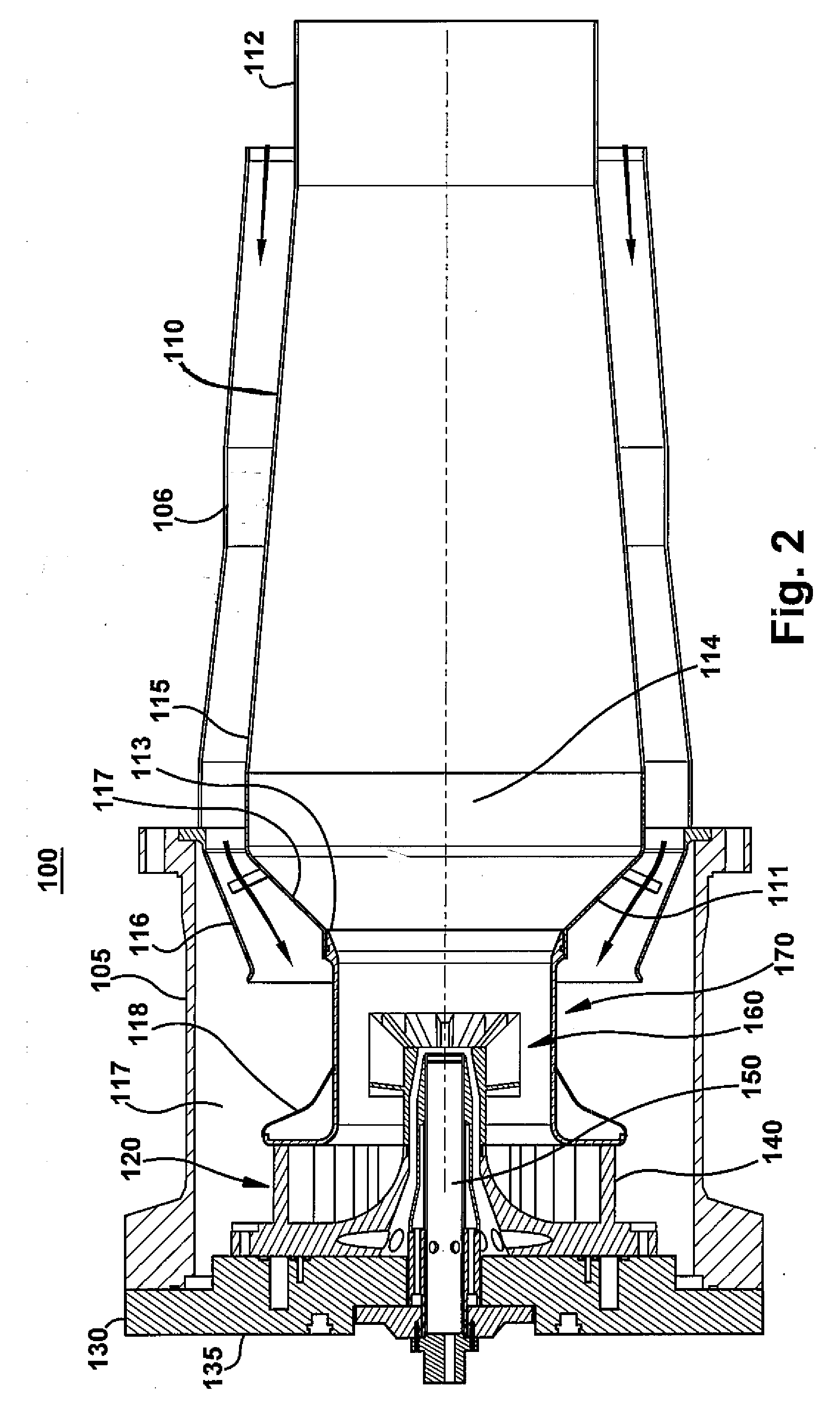

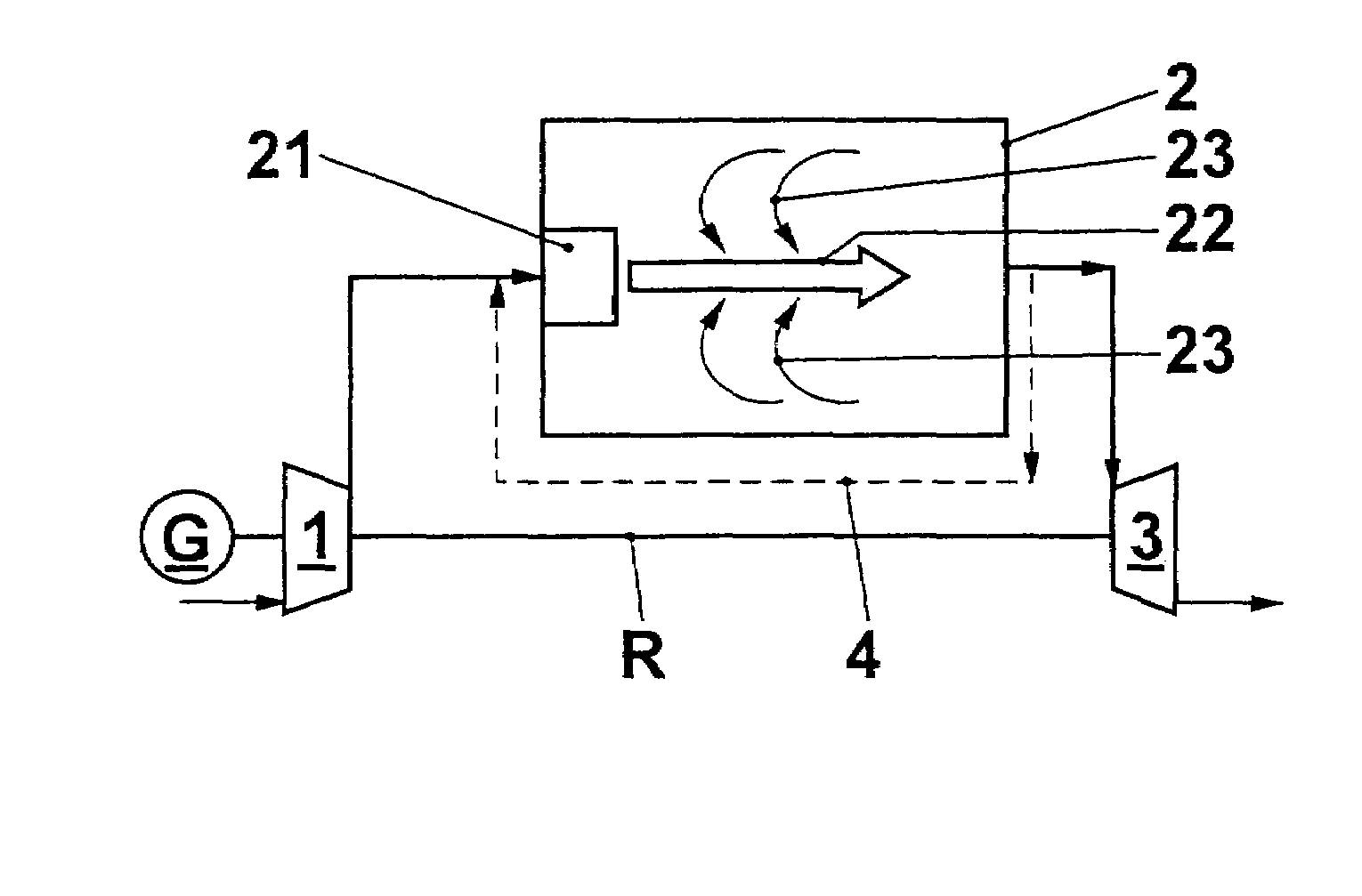

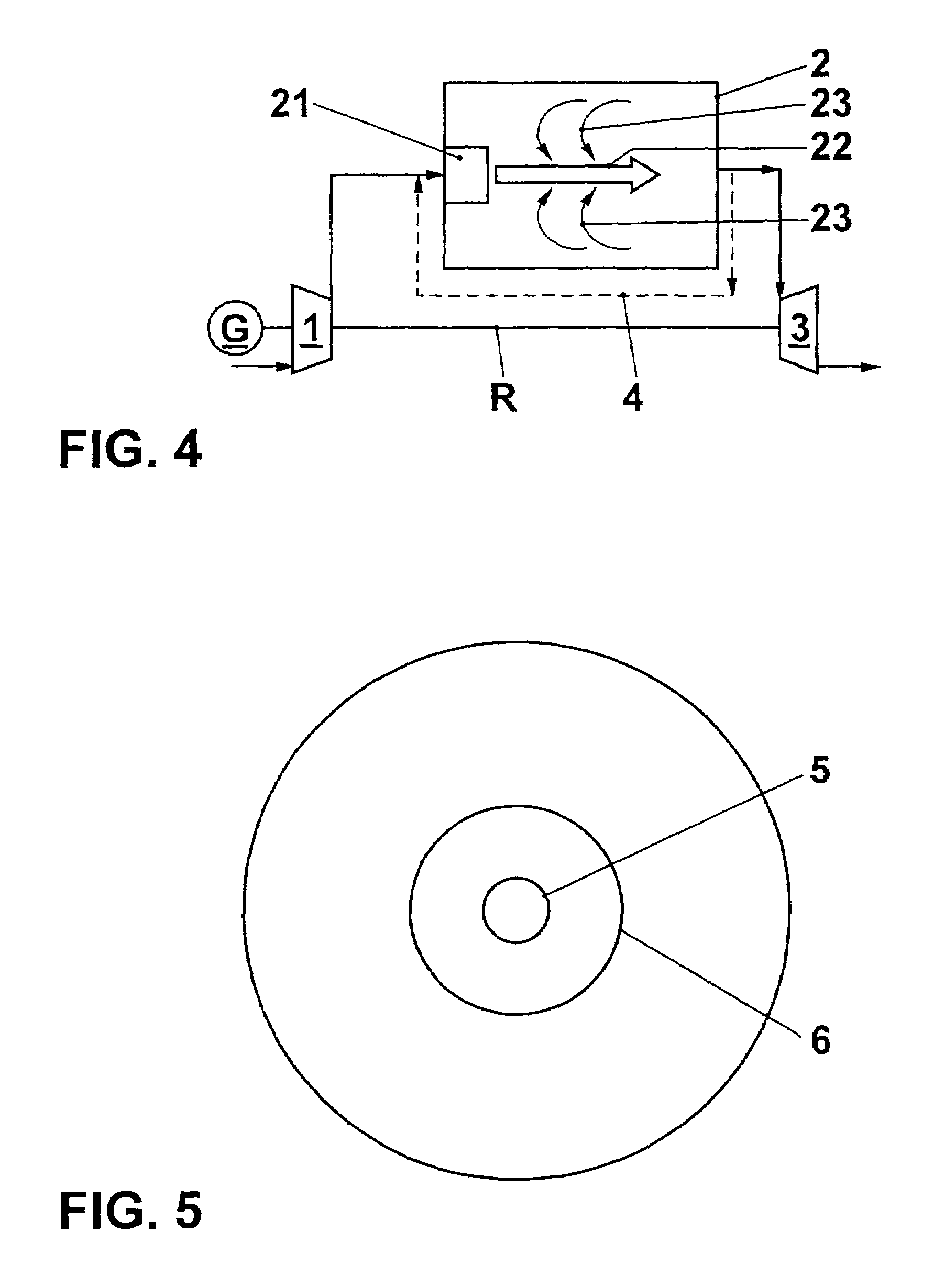

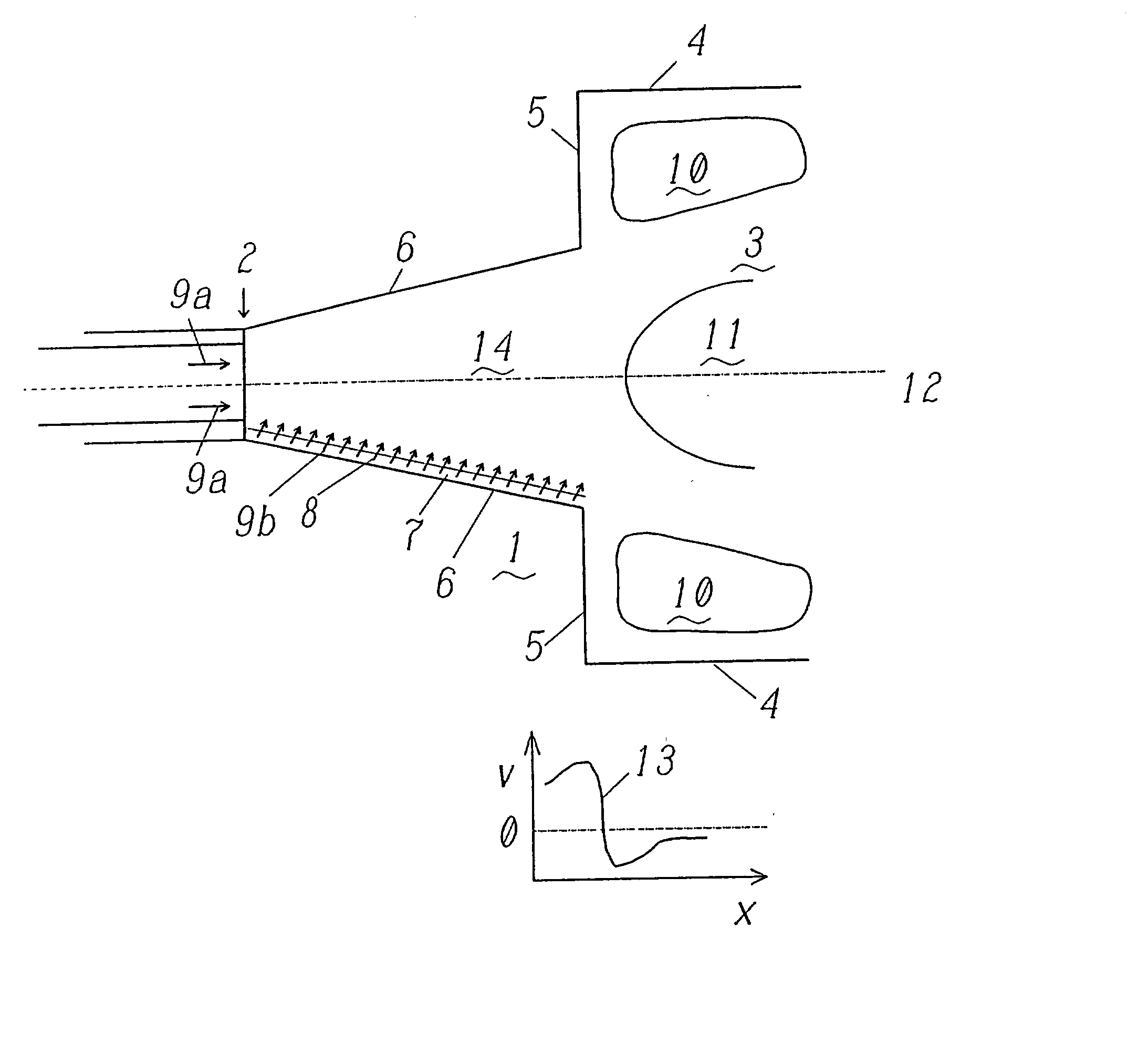

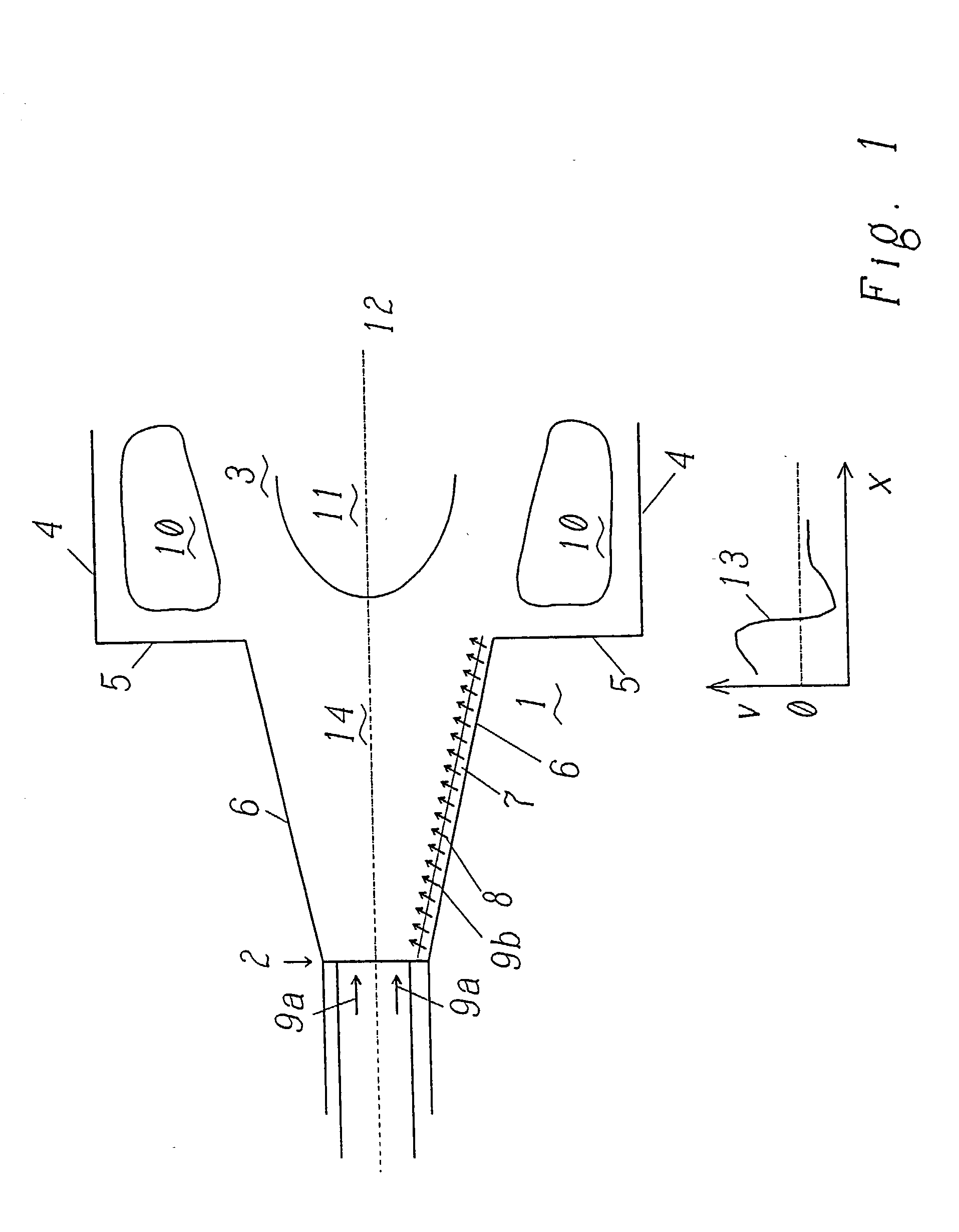

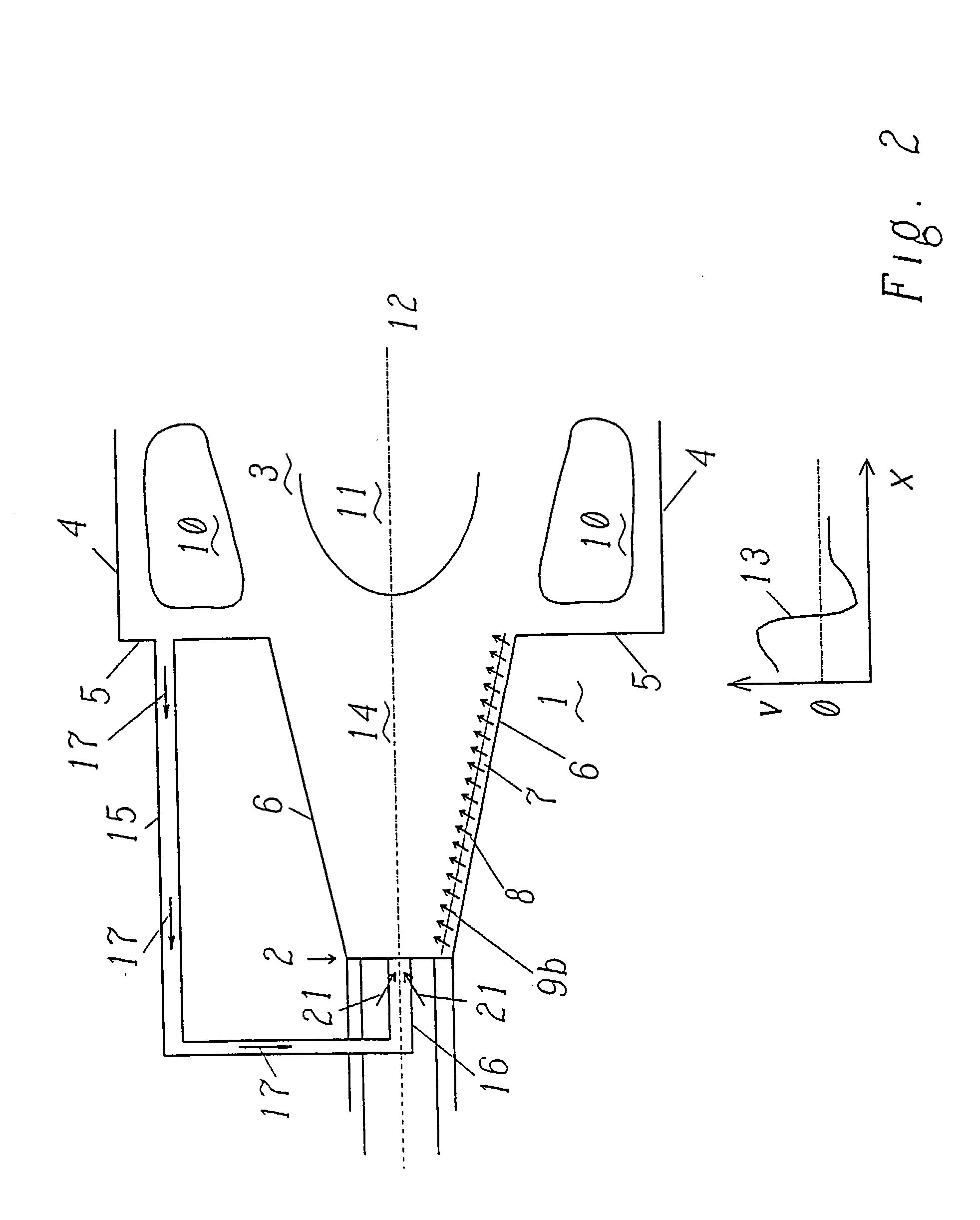

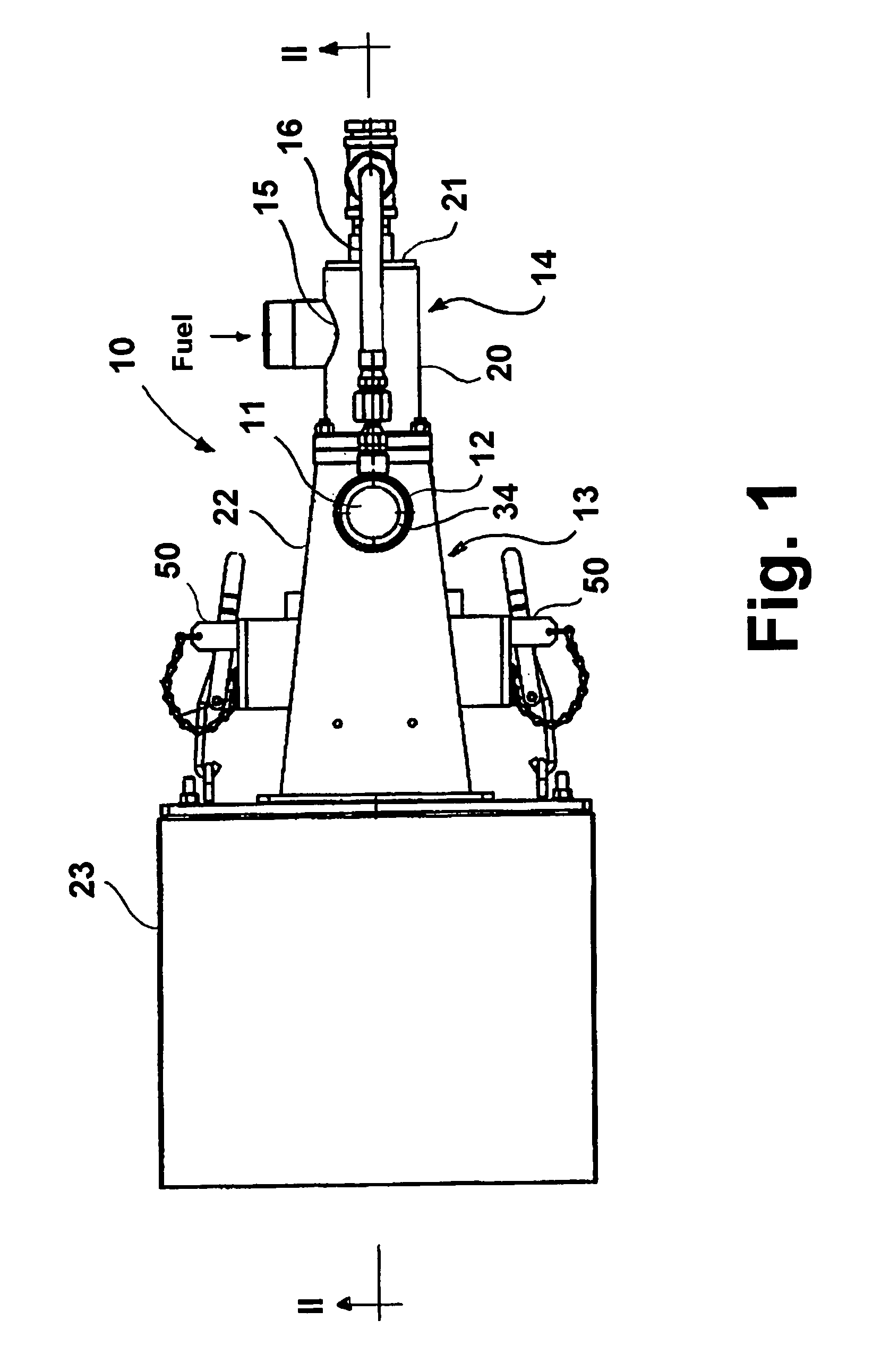

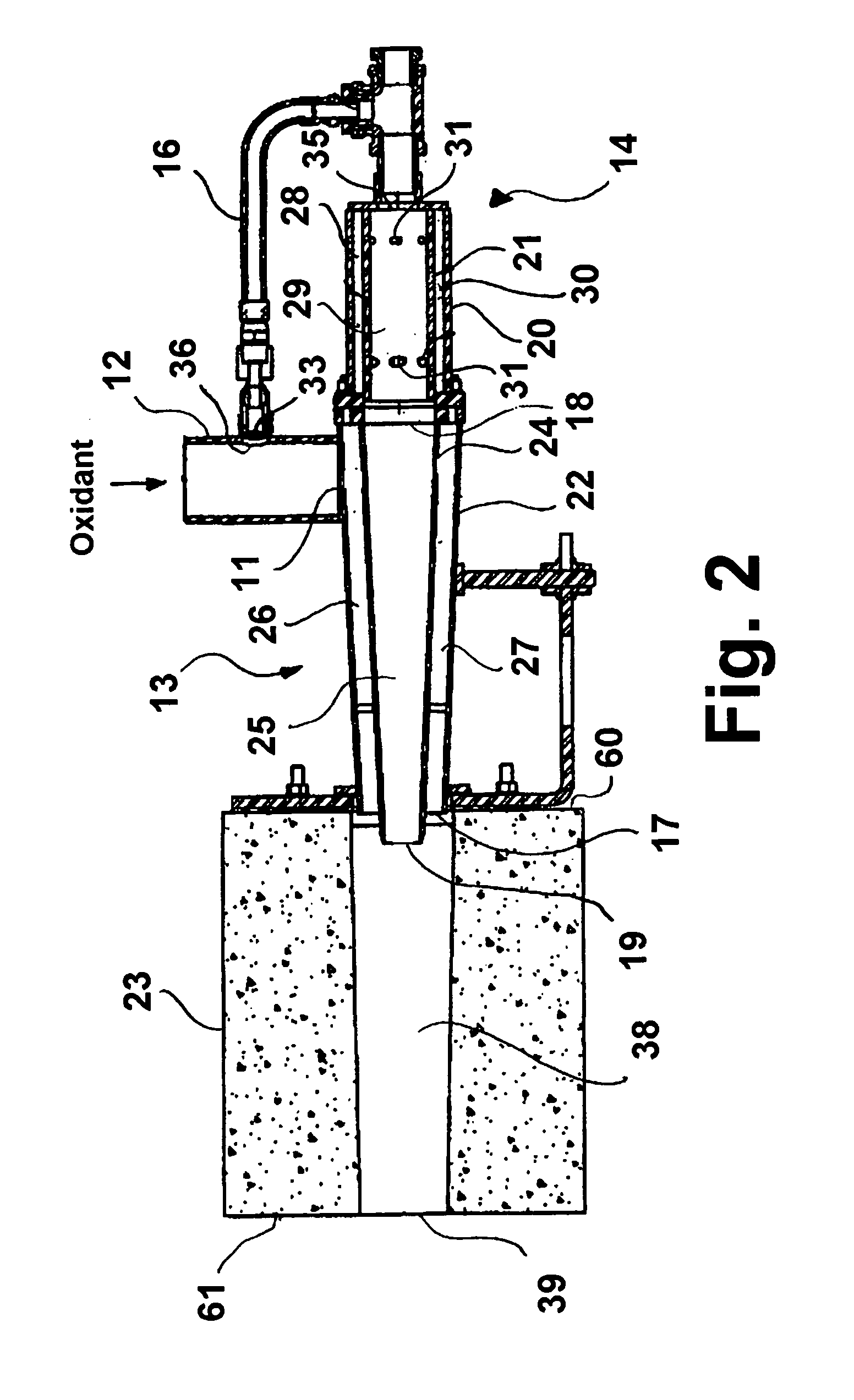

Burner with exhaust gas recirculation

InactiveUS20020187449A1Reduce power outputEffective and stableFirebridgesGaseous fuel burnerCombustion chamberCombustor

In a premixing burner (1) for a gas turbine or hot-gas generation for the combustion of liquid or gaseous fuel, in which fuel is mixed with combustion air (9a, 9b) in a burner interior (14), is fed to a combustion chamber (3) and is burnt in this combustion chamber (3), stabilization in the part-load mode is achieved in a simple and efficient way in that means (15) are provided which make it possible to recirculate hot exhaust gas (17) out of the combustion chamber (3) into the burner interior (14) and to stabilize the flame by means of selfignition processes. The means (15) are preferably a recirculation line which picks up hot exhaust gas (17) from the outer backflow zone (10) and feeds it to the burner interior (14) in the region of a burner tip (2) facing away from the combustion chamber (3), additional fuel (pilot fuel 21) being admixed with the exhaust gas (17) in the recirculation line upstream of the feed to the burner interior (14).

Owner:ALSTOM TECH LTD

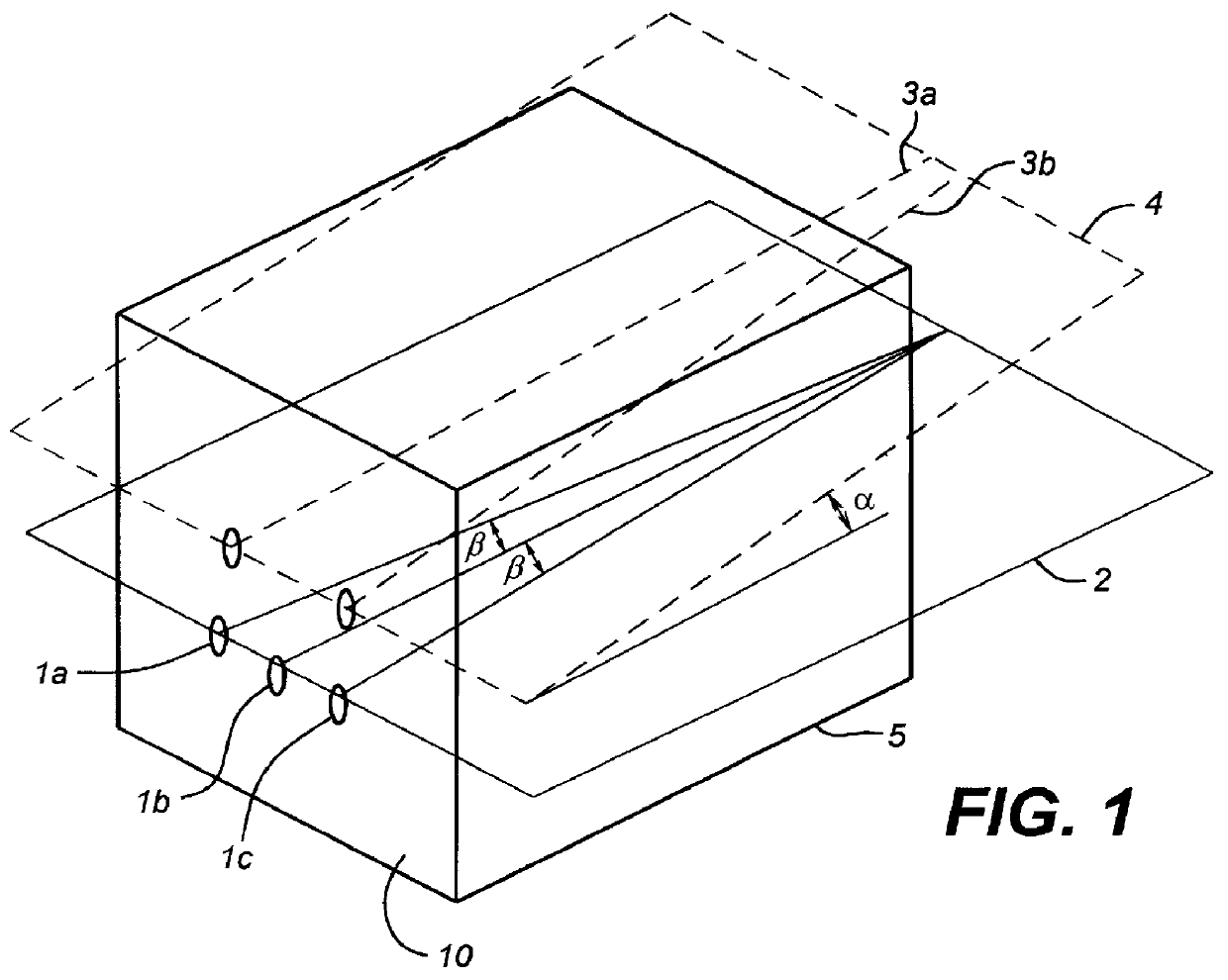

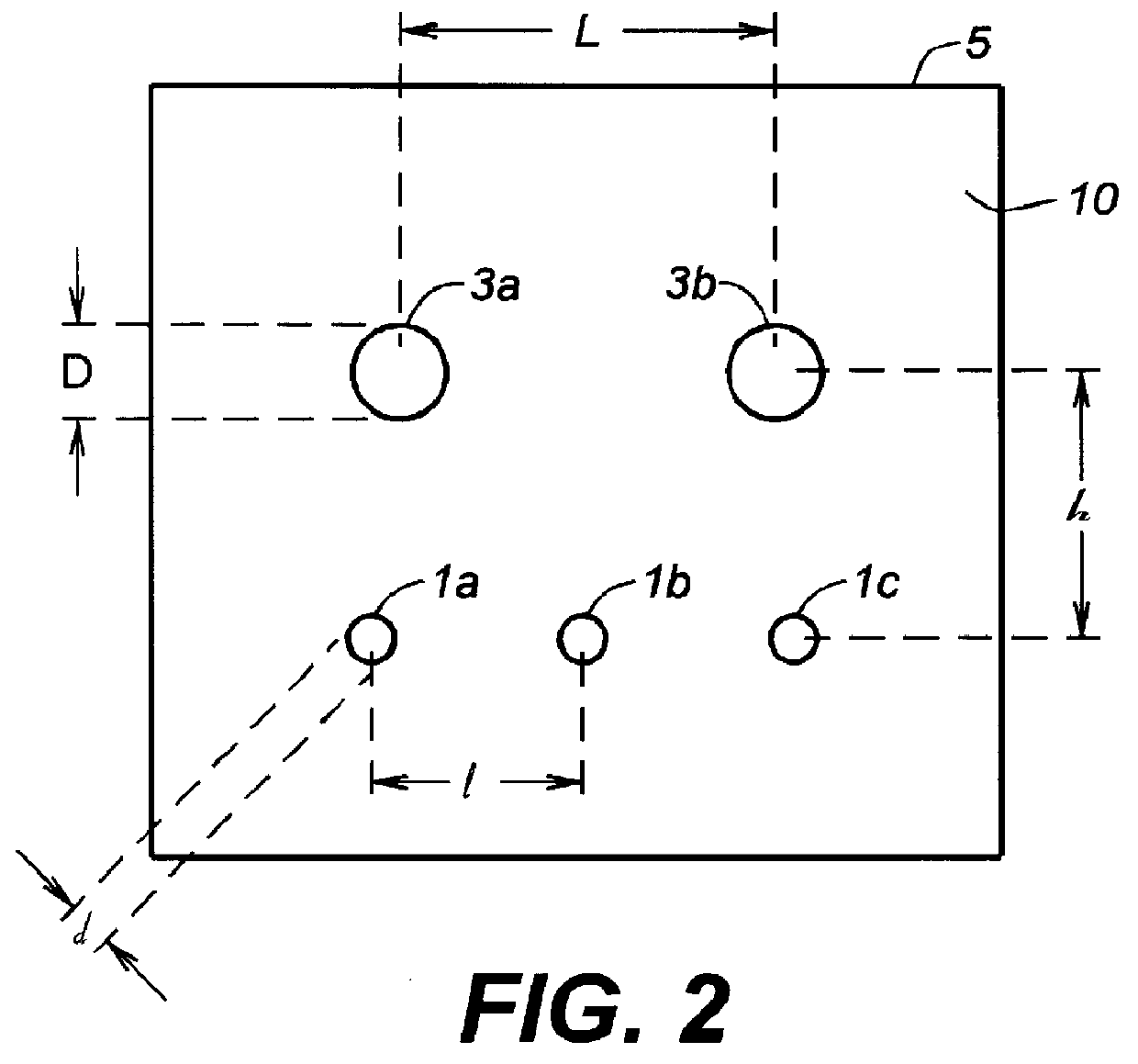

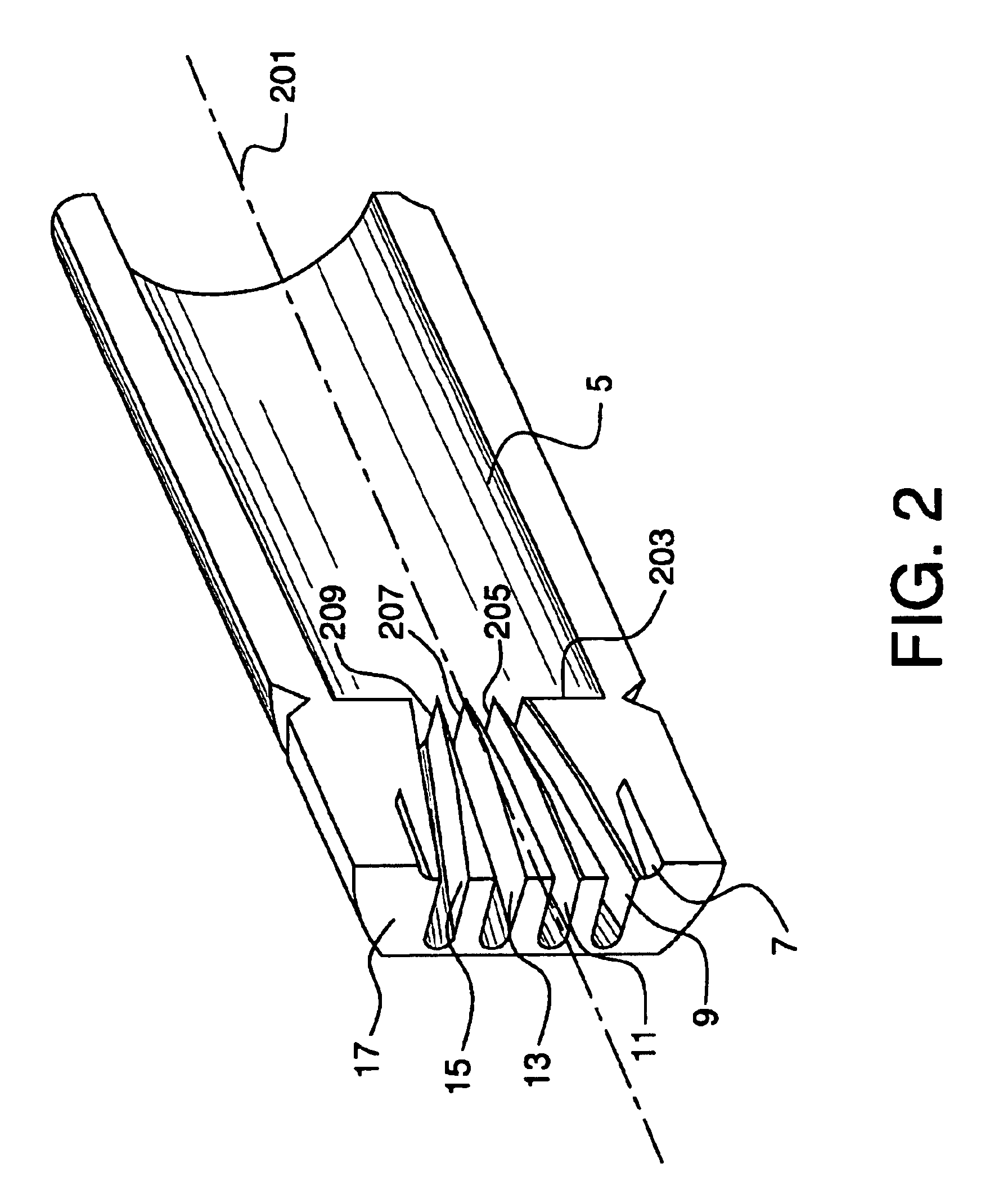

Slotted injection nozzle and low NOx burner assembly

InactiveUS6866503B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A nozzle comprising a nozzle body having an inlet face, an outlet face, and an inlet flow axis passing through the inlet and outlet faces, and two or more slots extending through the nozzle body from the inlet face to the outlet face. Each slot has a slot axis and the slot axis of at least one of the slots is not parallel to the inlet flow axis of the nozzle body. In another embodiment, the nozzle comprises a nozzle body having an inlet face, an outlet face, and an inlet flow axis passing through the inlet and outlet faces, and two or more slots extending through the nozzle body from the inlet face to the outlet face, each slot having a slot axis, wherein none of the slots intersect other slots and all of the slots are in fluid flow communication with a common fluid supply conduit. The nozzles may be used to inject secondary fuel in a burner system having a central burner combusting a primary fuel surrounded by secondary fuel injection nozzles.

Owner:AIR PROD & CHEM INC

Diluent shroud for combustor

Owner:GENERAL ELECTRIC CO

Device and method for flame stabilization in a burner

InactiveUS7467942B2Improve design flexibilityAccelerate emissionsFuel supply regulationContinuous combustion chamberCombustion chamberCombustor

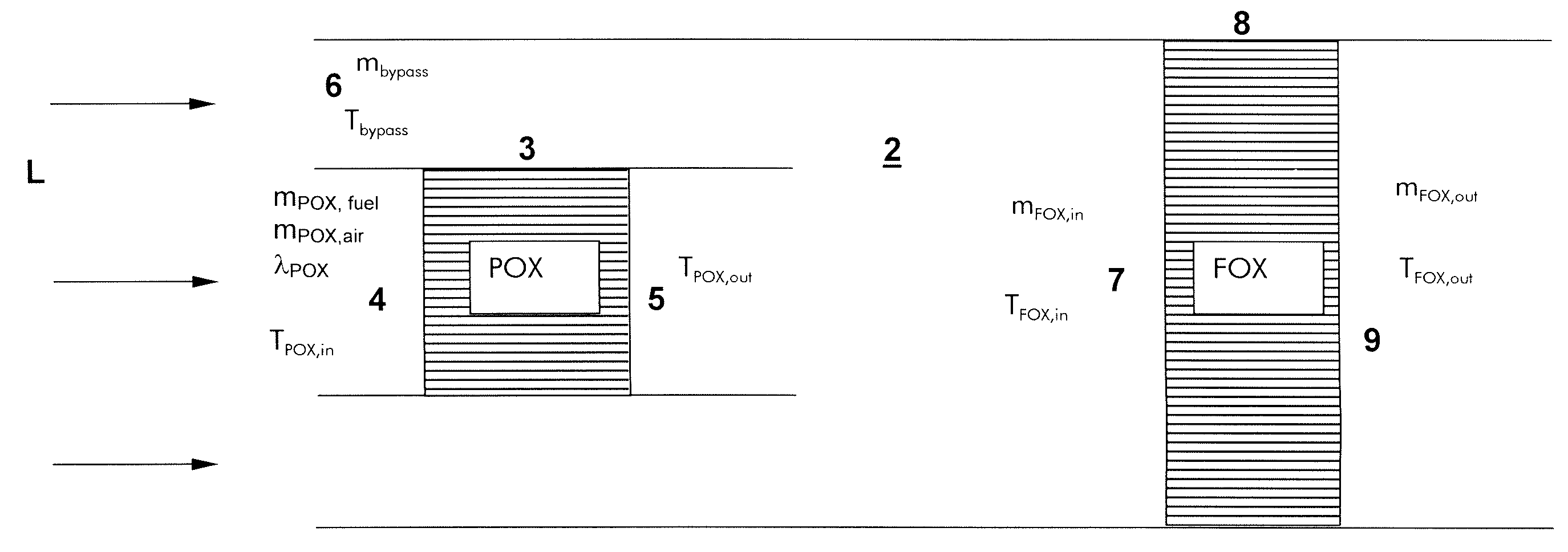

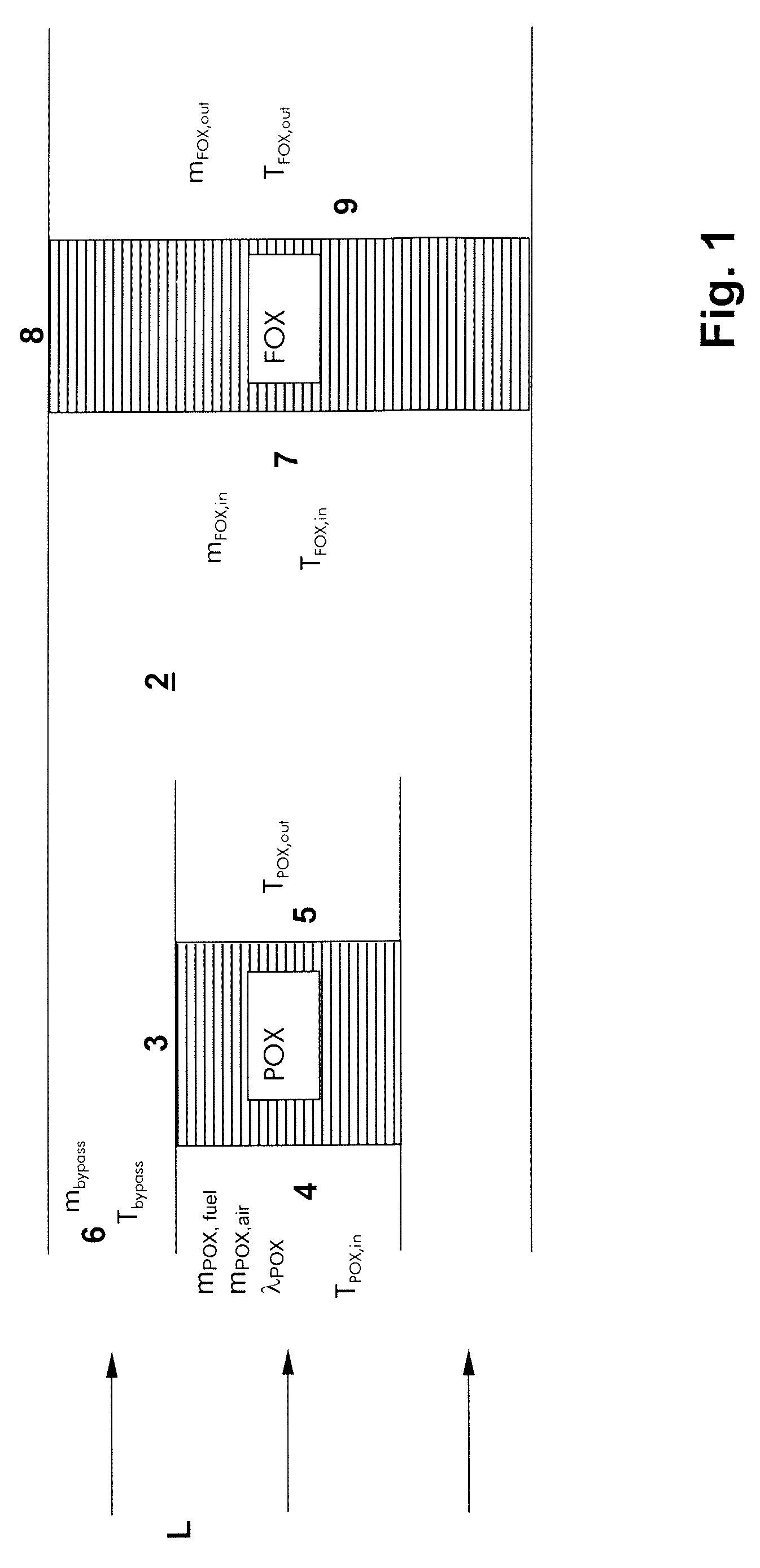

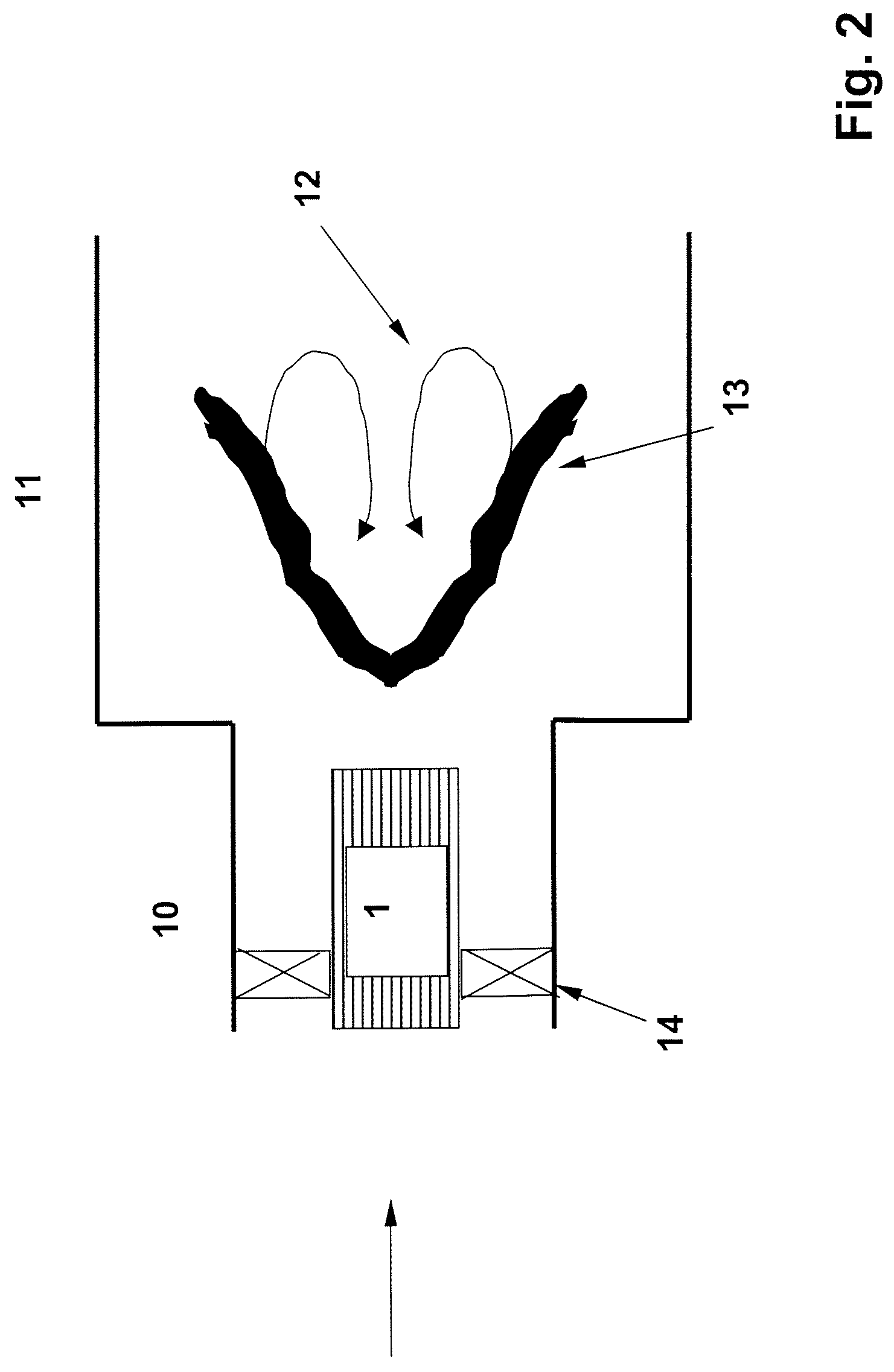

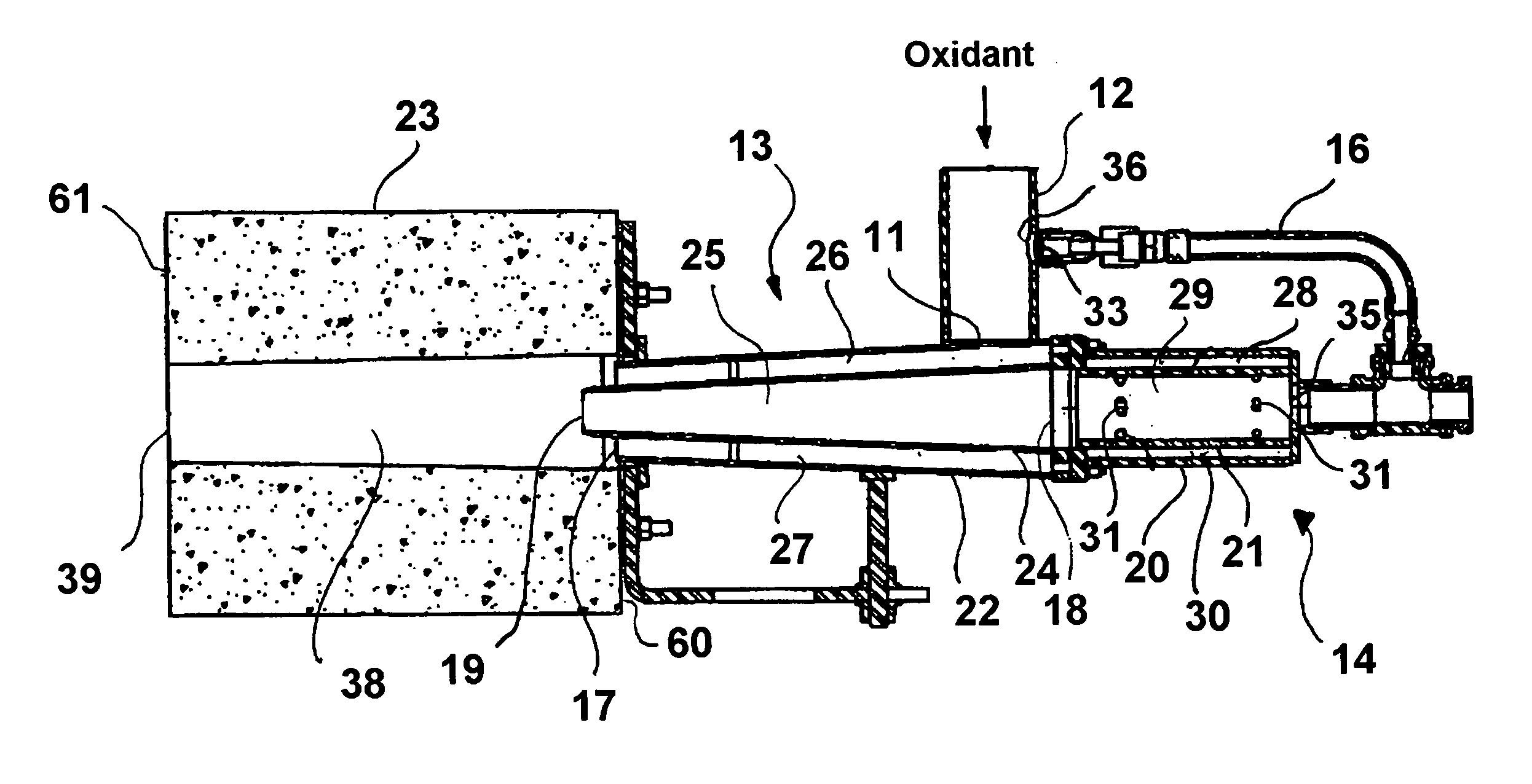

A device and a method for flame stabilization in a burner (10), includes a burner housing at least partially enclosing a burner volume, into which may be introduced via at least one fuel line, fuel, and via at least one air feed means, air, forming an air / fuel mixture spreading in a preferred flow direction, which may be ignited in a combustion chamber (11) connecting downstream of the burner housing to form a stationary flame (13). Upstream of the flame (13), a catalyst arrangement (1) is provided through which an air / pilot fuel mixture (4), separate from the air / fuel mixture, is flowable. The catalyst arrangement (1) has at least two catalyst stages which are located one behind the other in the through-flow direction, of which the catalyst stage (3) located upstream, the so-called POX-catalyst, is flow-washable by the air / pilot fuel mixture (4) with an air / pilot fuel mixture ratio λ<1, by which catalyst stage (3) the air / pilot fuel mixture (4) is partially oxidized, and of which catalyst stages the downstream catalyst stage (8), the so-called FOX-catalyst, is flow-washable by a leaned air / pilot fuel mixture (7) with a mixture ratio λ>1, by which the leaned air / pilot fuel mixture is completely oxidized forming an inert hot gas flow (9).

Owner:ALSTOM TECH LTD

High-heat transfer low-NOx combustion system

ActiveUS6939130B2Lower NO<sub>xIncrease brightnessCombustion using gaseous and pulverulent fuelBurner safety arrangementsCombustion systemVertical plane

Owner:GAS TECH INST

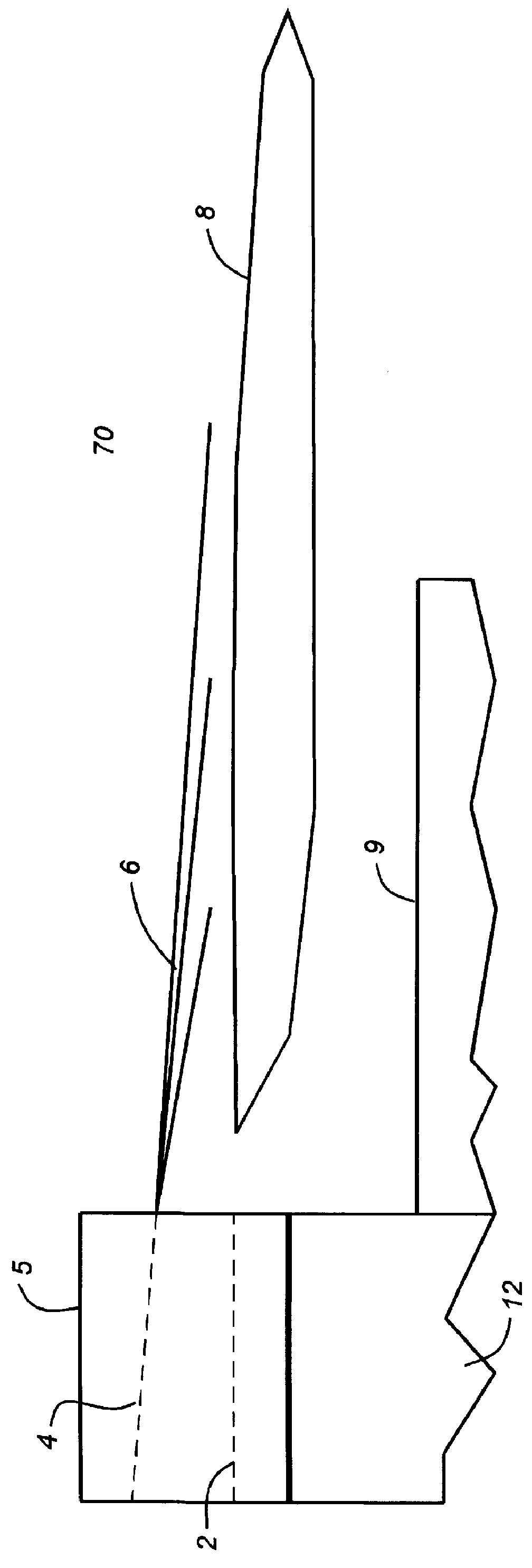

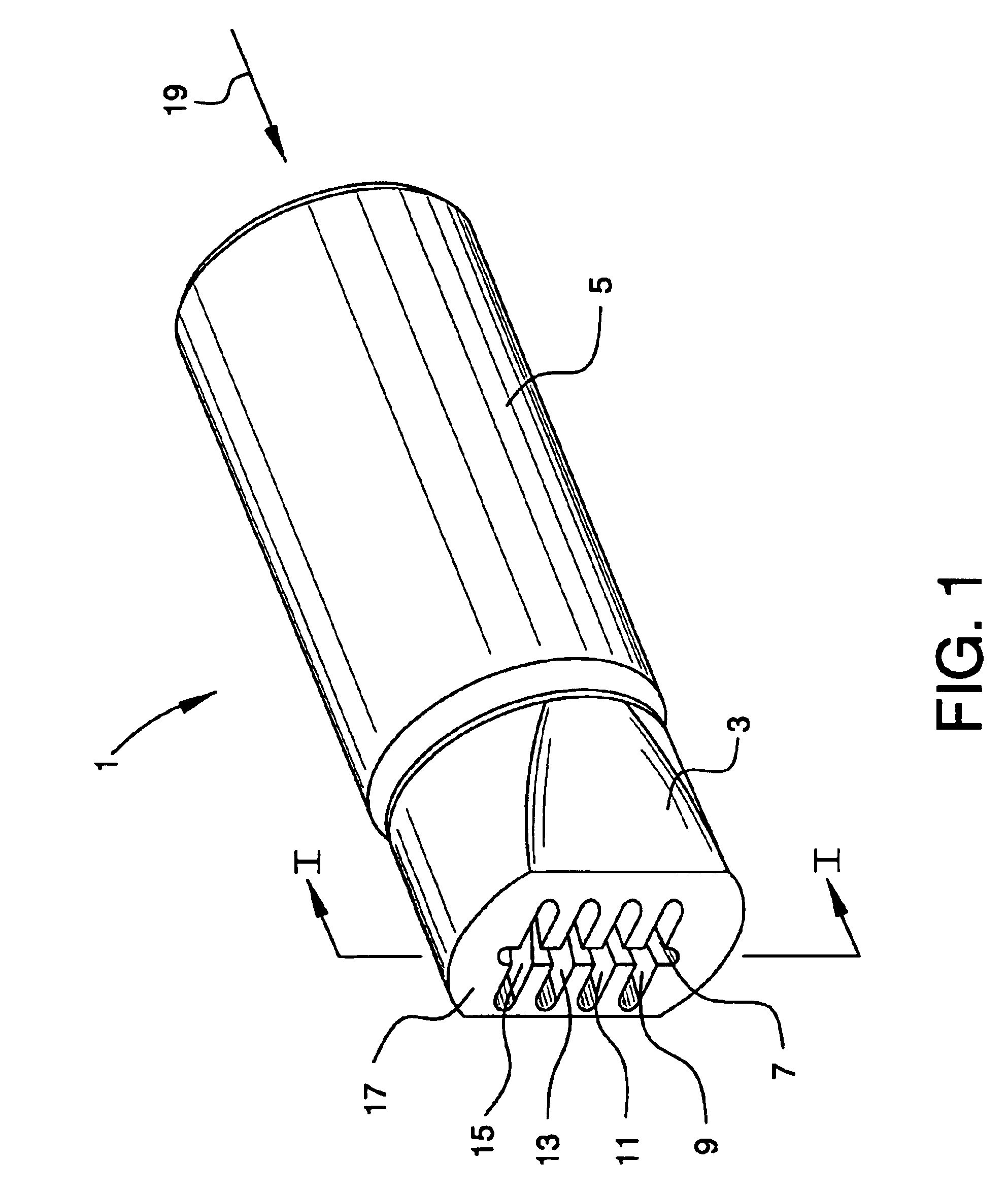

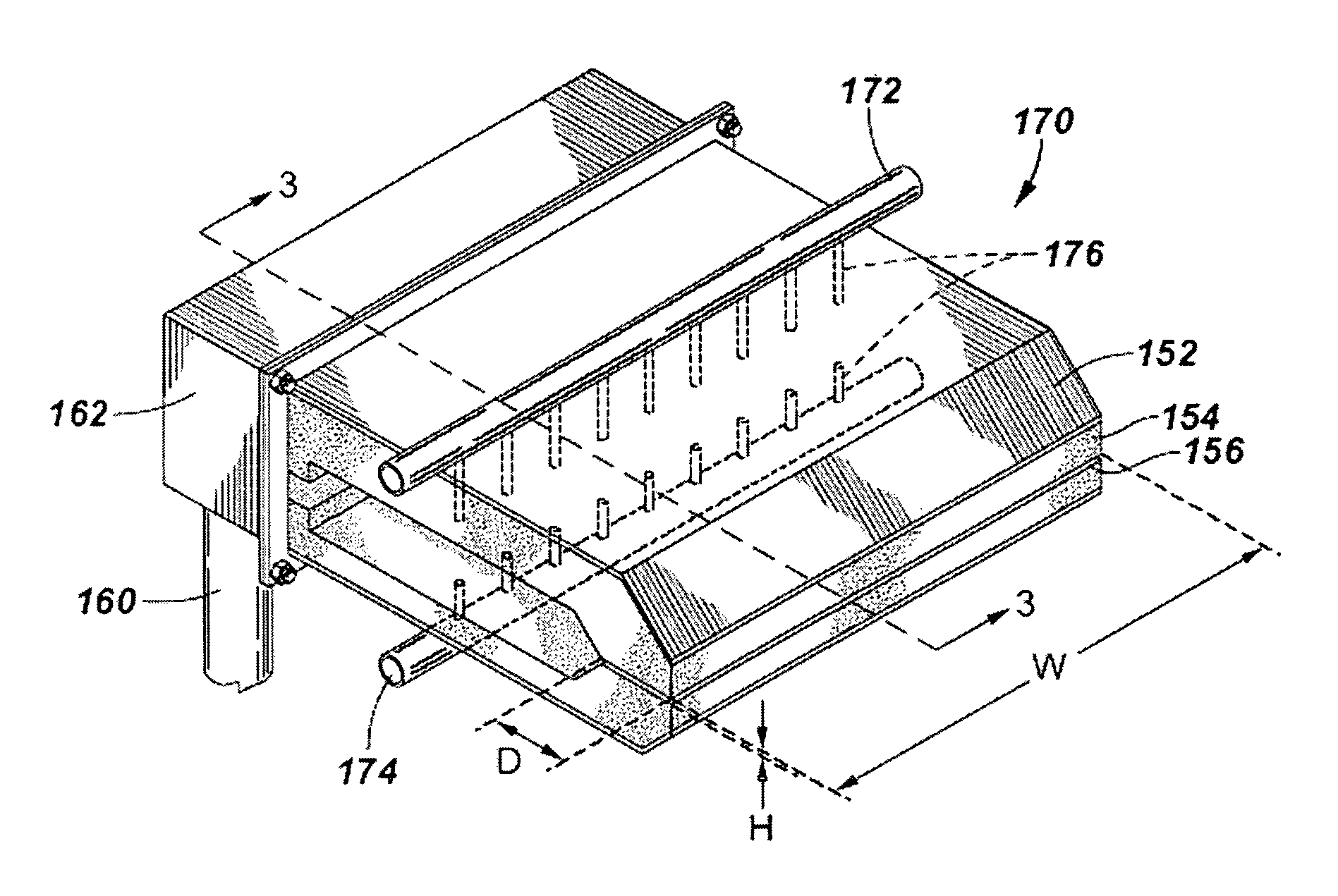

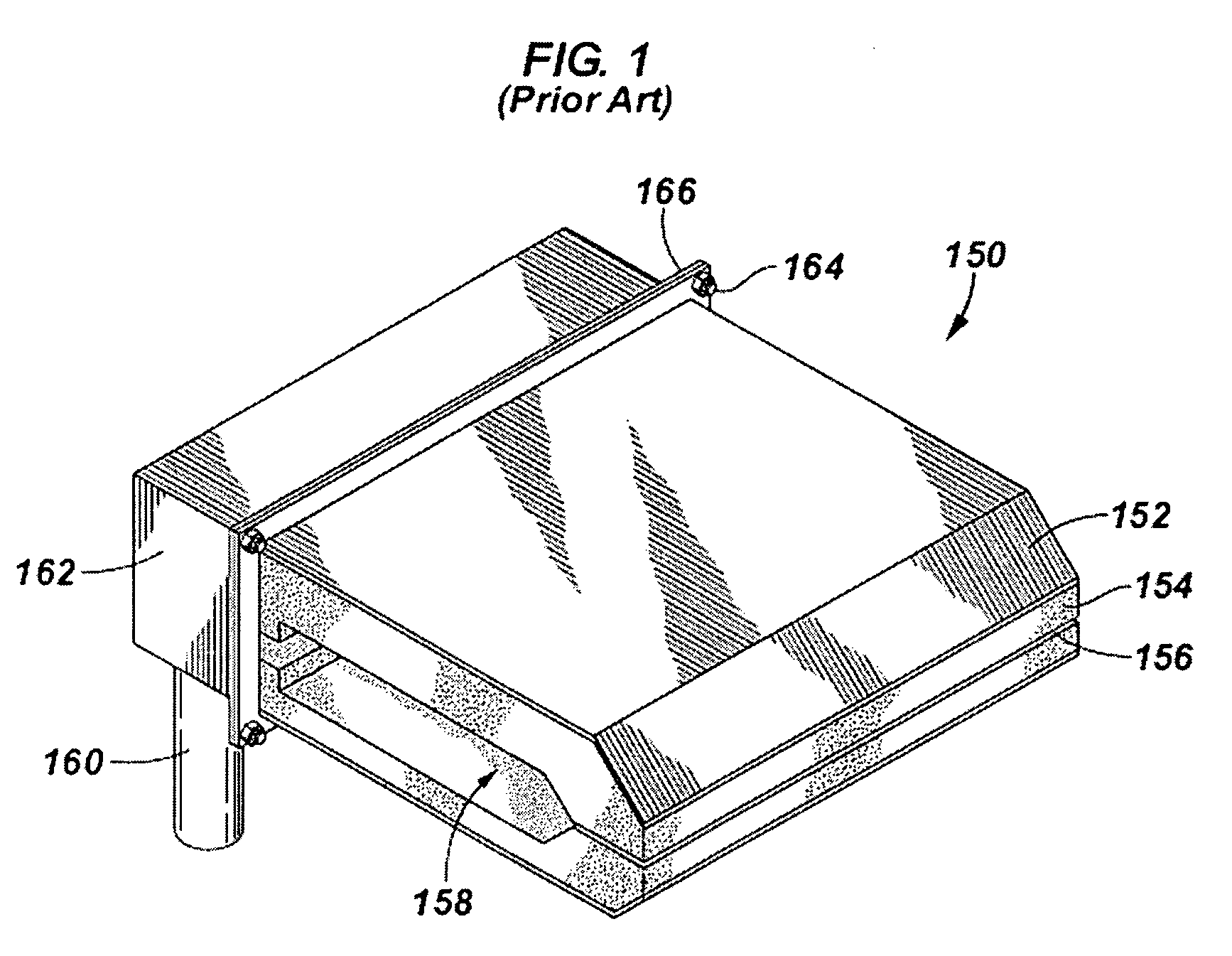

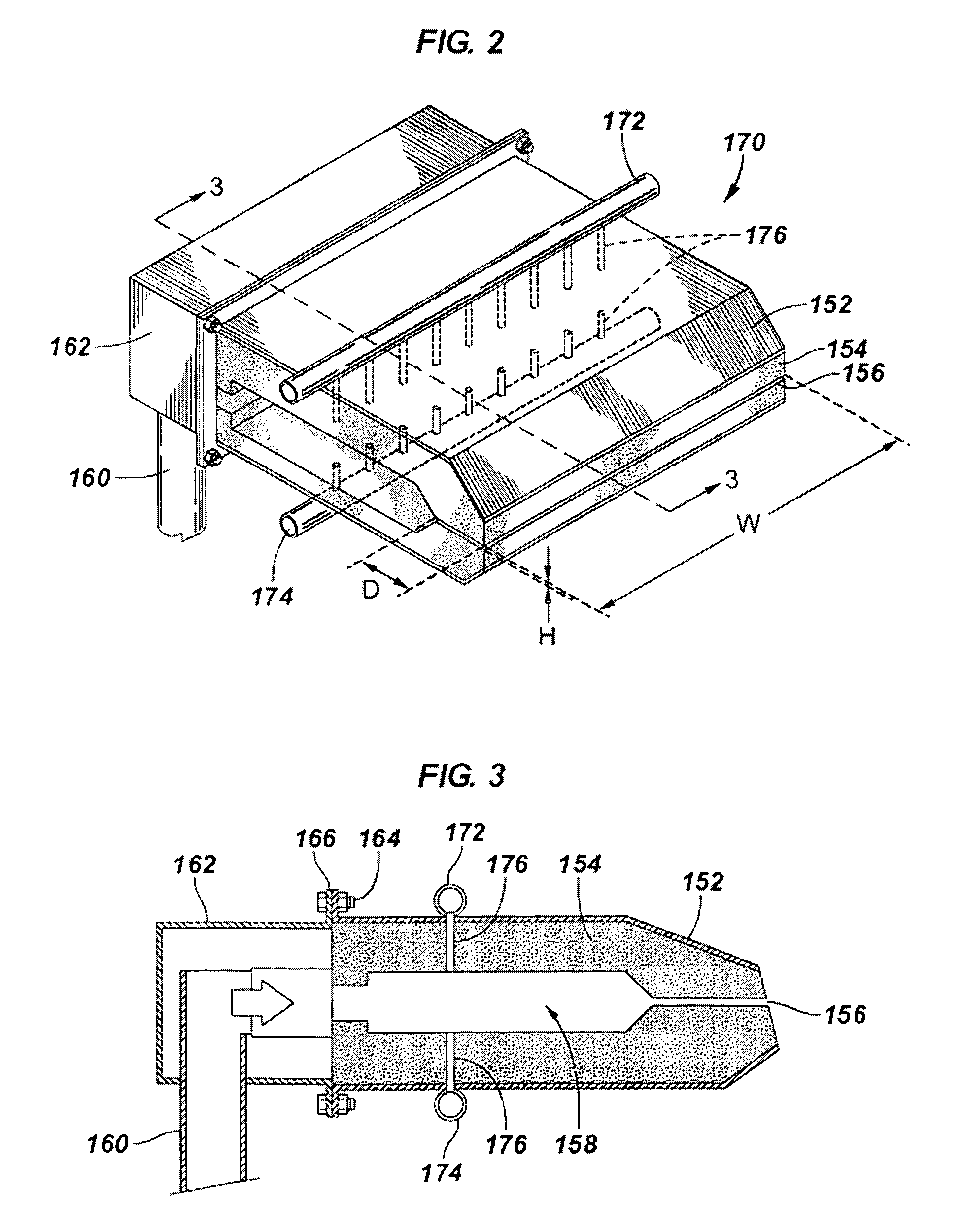

Burner apparatus and methods for making inorganic fibers

Inorganic fiber production burner apparatus and methods of use are disclosed. One burner includes a refractory block adapted to be in fluid connection with sources of primary oxidant and fuel, the refractory block having a fuel and primary oxidant entrance end and a flame exit end, the flame exit end having a substantially rectangular flame exit having a width greater than its height, the refractory block defining a combustion chamber and a second chamber fluidly connecting the combustion chamber and the flame exit end; and an oxygen manifold fluidly connected to the combustion chamber and adapted to route oxygen to the combustion chamber through a plurality of passages through the refractory block. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:JOHNS MANVILLE CORP

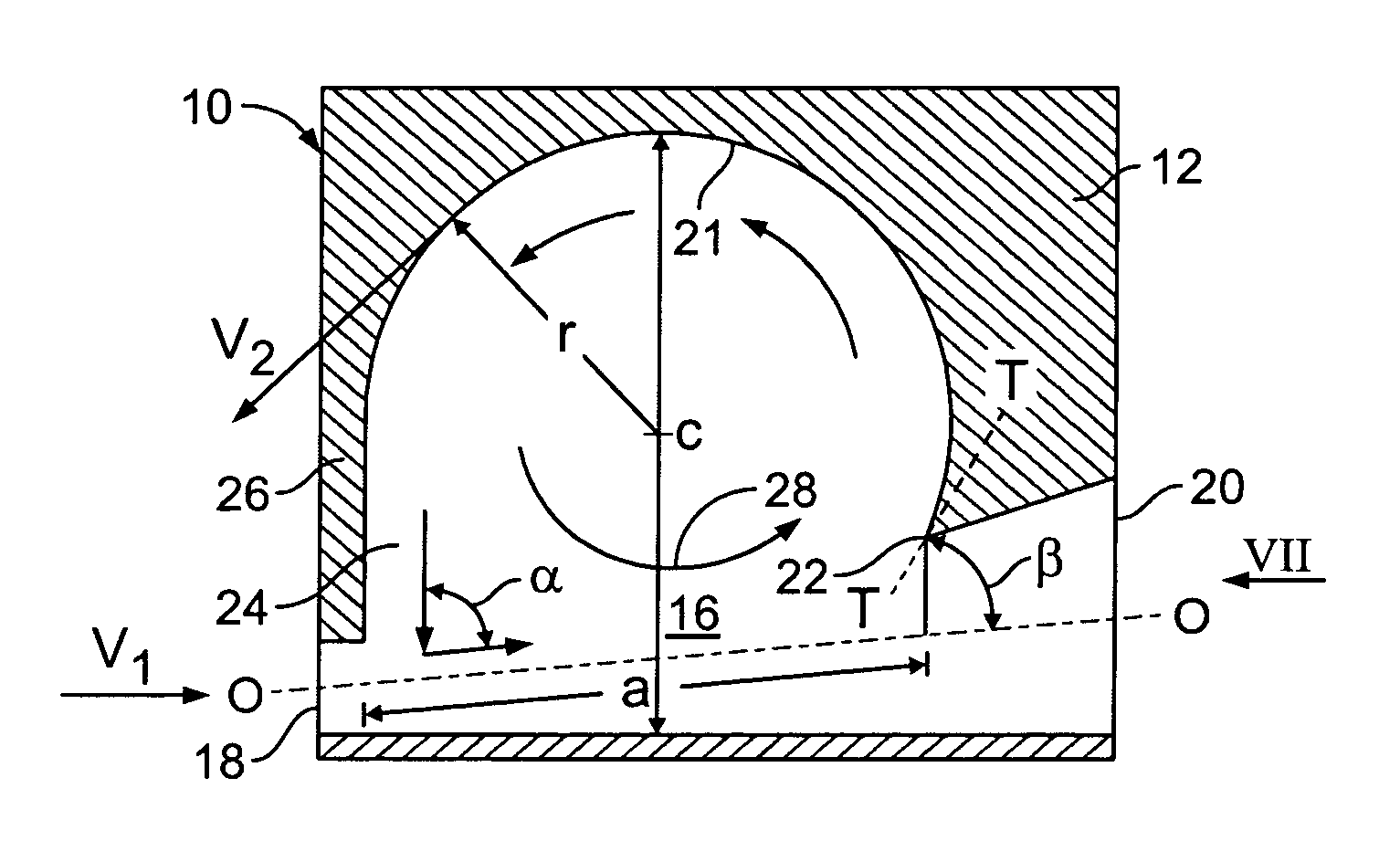

Combustion method and apparatus for carrying out same

InactiveUS7086854B2Increase speedTransfer is bulkyContinuous combustion chamberGas turbine plantsChemical reactionCombustor

The invention relates to recirculation flow combustors having a generally curved recirculation chamber and unobstructed flow along the periphery of the boundary layer of the vortex flow in this chamber, and methods of operating such combustors. Such combustors further have a border interface area of low turbulence between the vortex flow and the main flow in the combustor, in which chemical reactions take place which are highly advantageous to the combustion process, and which promote a thermal nozzle effect within the combustor. A combustor of this type may be used for burning lean and super-lean fuel and air mixtures for use in gas turbine engines, jet and rocket engines and thermal plants such as boilers, heat exchanges plants, chemical reactors, and the like. The apparatus and methods of the invention may also be operated under conditions that favor fuel reformation rather than combustion, where such a reaction is desired.

Owner:LEAN FLAME INC

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6331107B1Reduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC

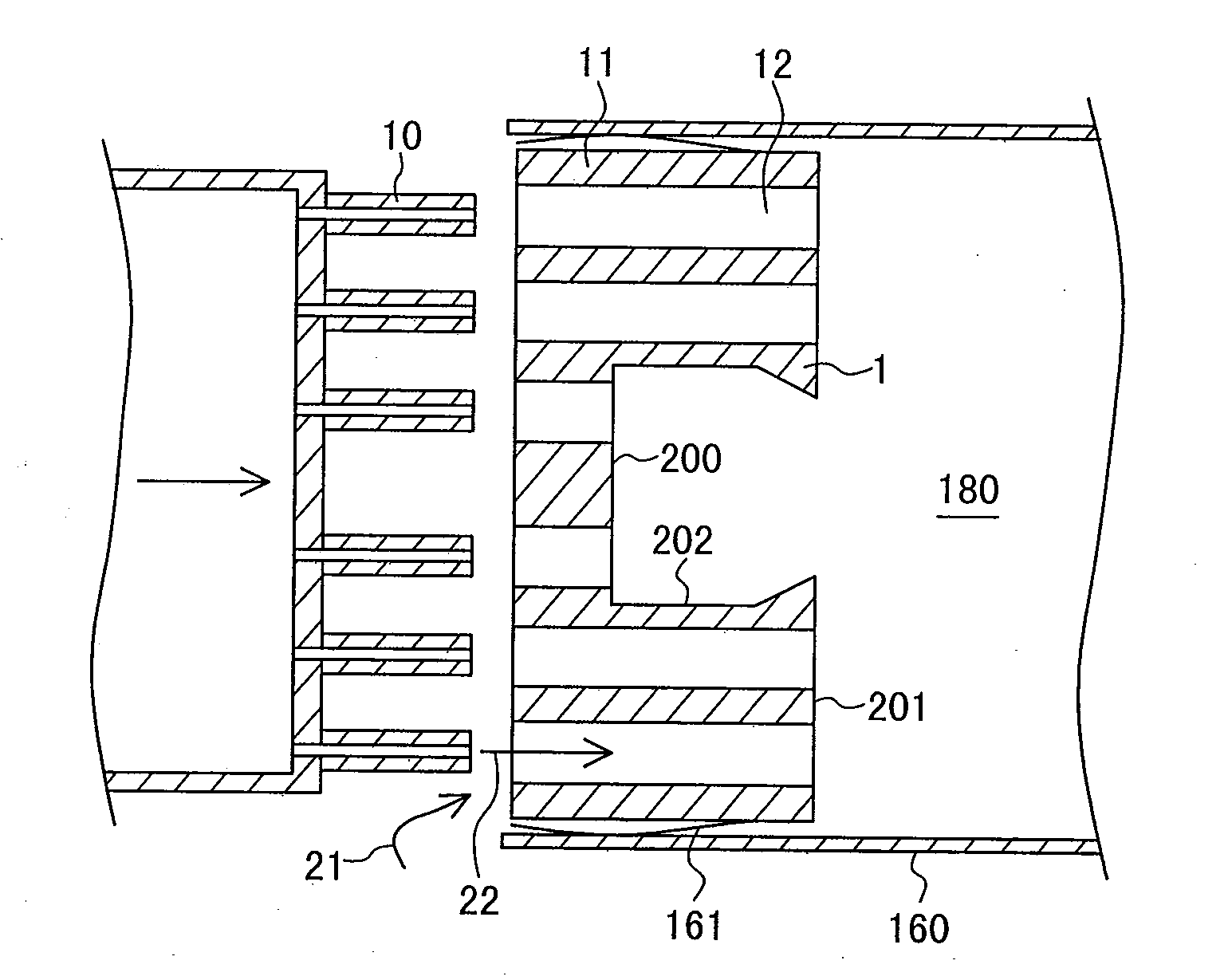

Radiant tube burner

PCT No. PCT / JP95 / 01916 Sec. 371 Date May 23, 1996 Sec. 102(e) Date May 23, 1996 PCT Filed Sep. 22, 1995 PCT Pub. No. WO96 / 09496 PCT Pub. Date Mar. 28, 1996With respect to a radiant tube burner to be used for heating a heating furnace or the like, to suppress the generation of NOx accompanying combustion, to make the structure thereof fit for a radiant tube burner equipment, to simplify the control of a fuel supply system and an air supply system, and to prevent the coking. Furthermore, to provide a combustion control scheme appropriate to a radiant tube burner. For these purposes, the present invention placed the respective tips of a fuel nozzle, e.g., pilot burner joint-use nozzle (11), and an air throat (13) in the end of a radiant tube (3) and moreover has a combustion air injection port (33) of the air throat (13) provided to be deviated in contact with or near to the inner circumferential wall surface of the radiant tube (3). In addition, a control device (307) for making a burner burn alternately.

Owner:NIPPON KOKAN KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com