Patents

Literature

2676 results about "Thick wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

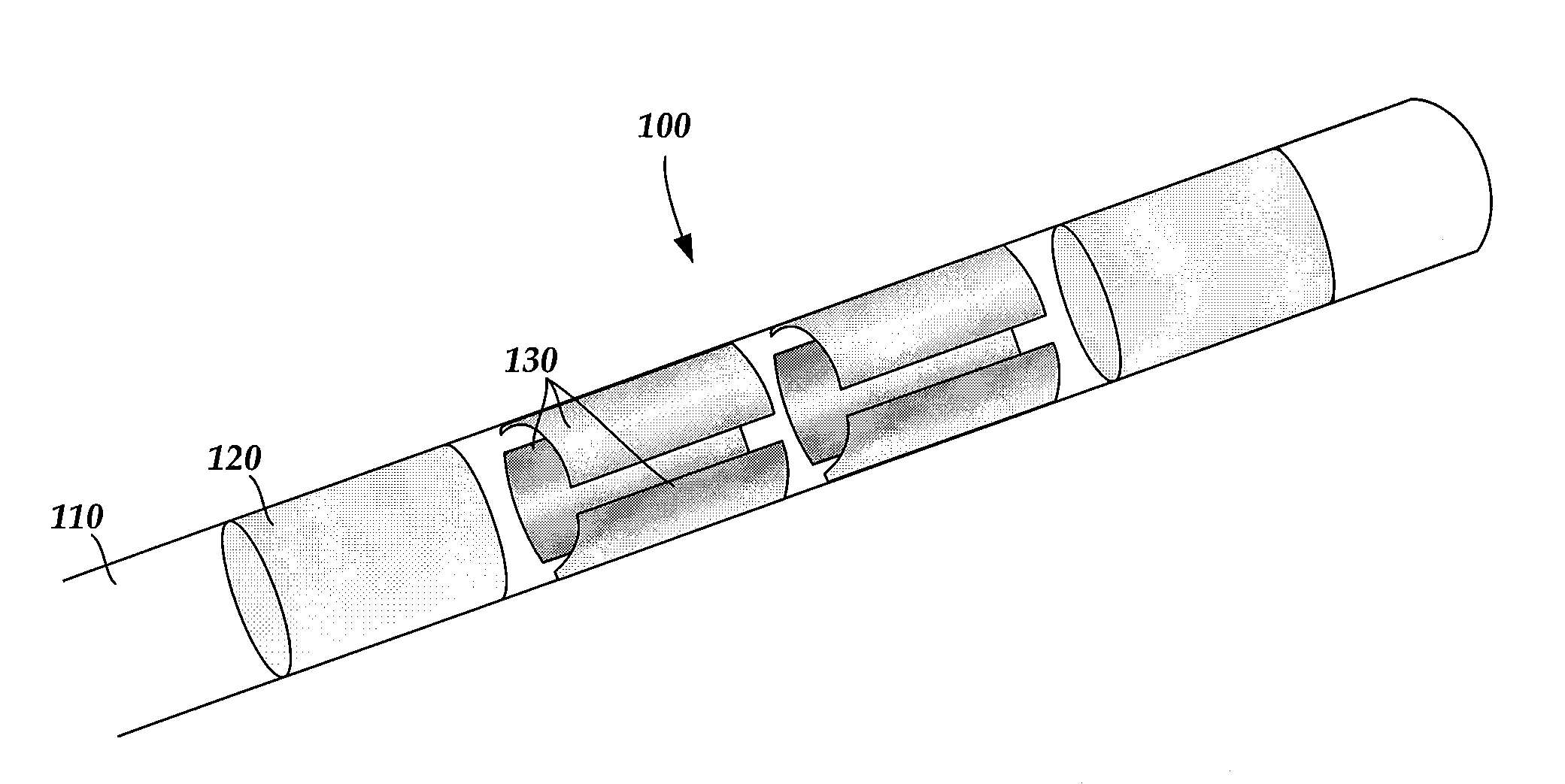

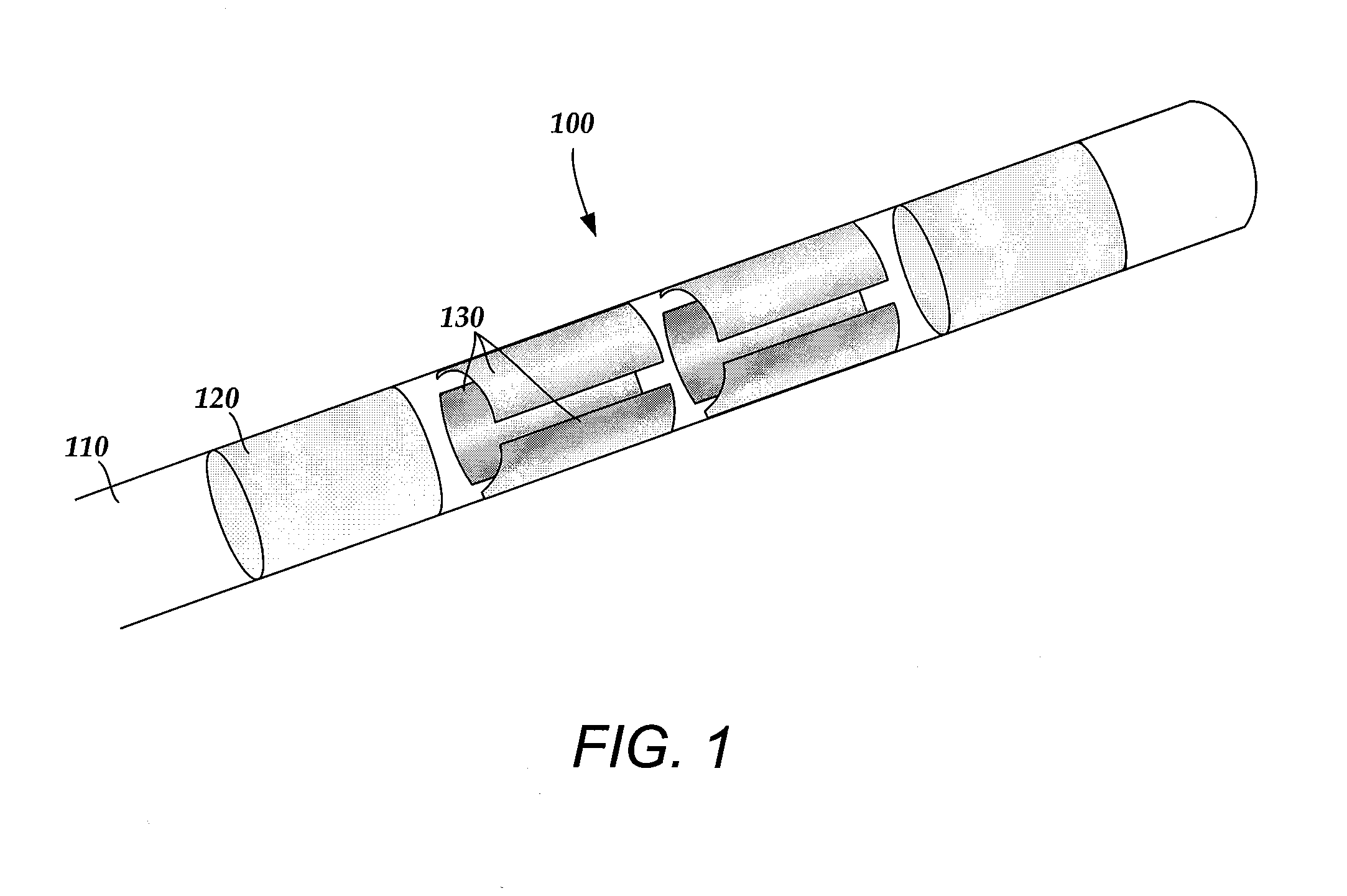

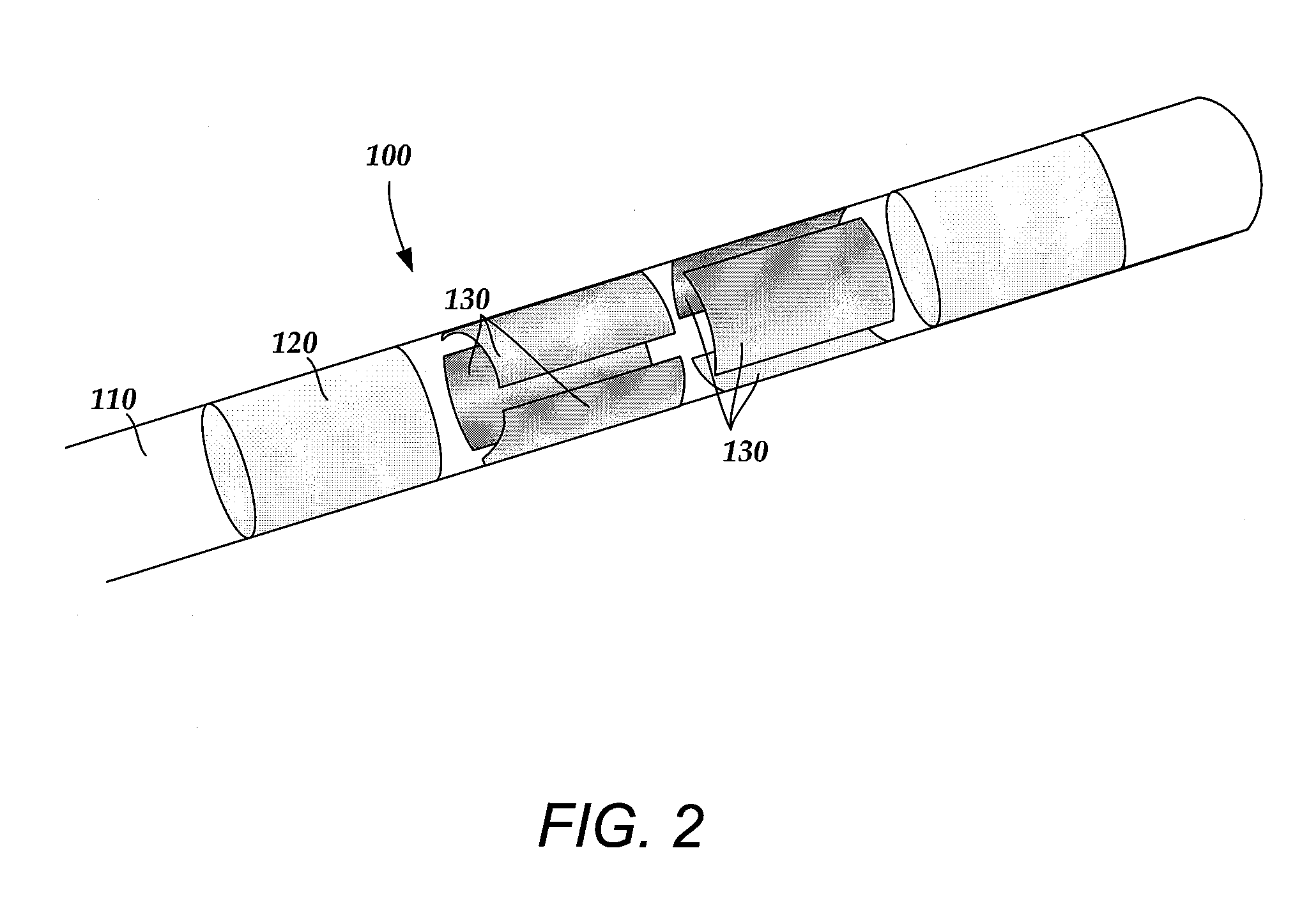

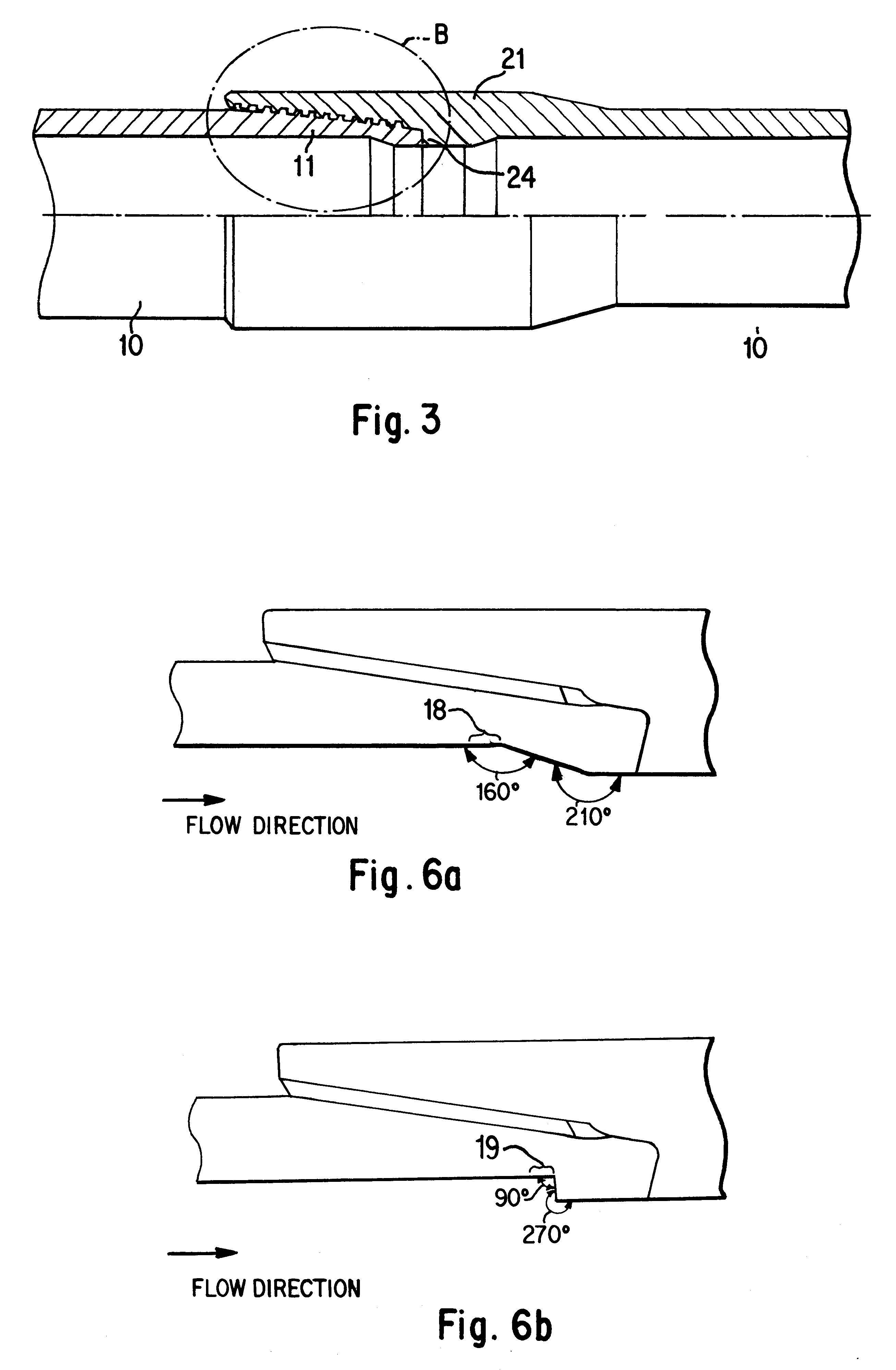

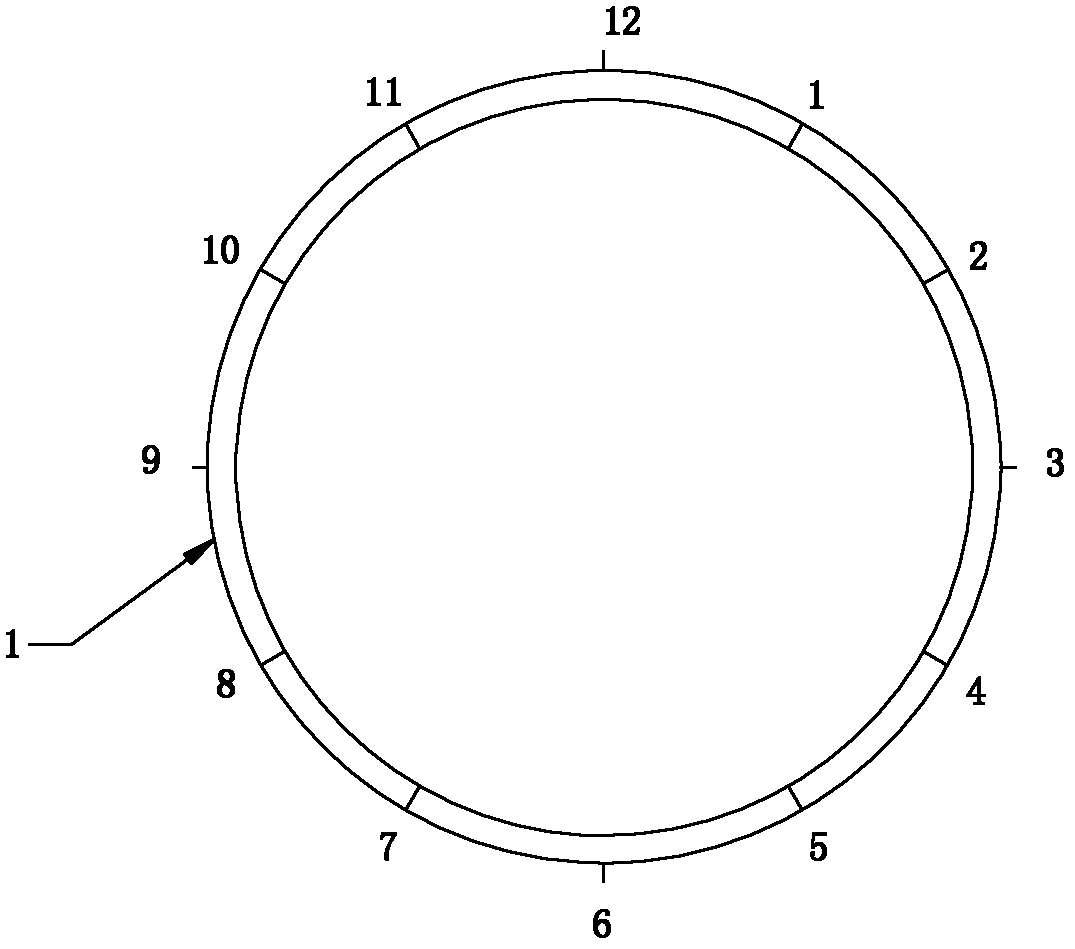

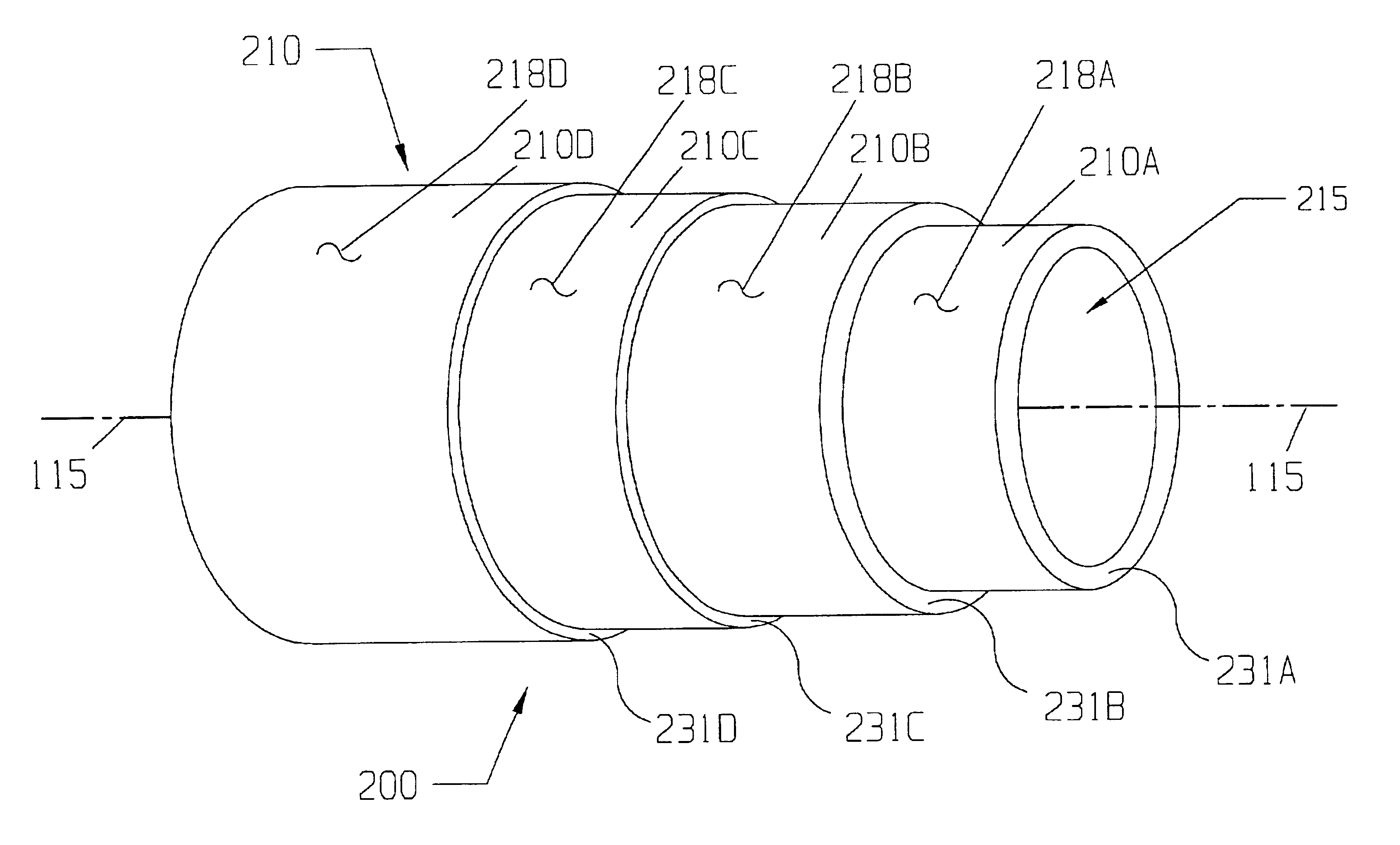

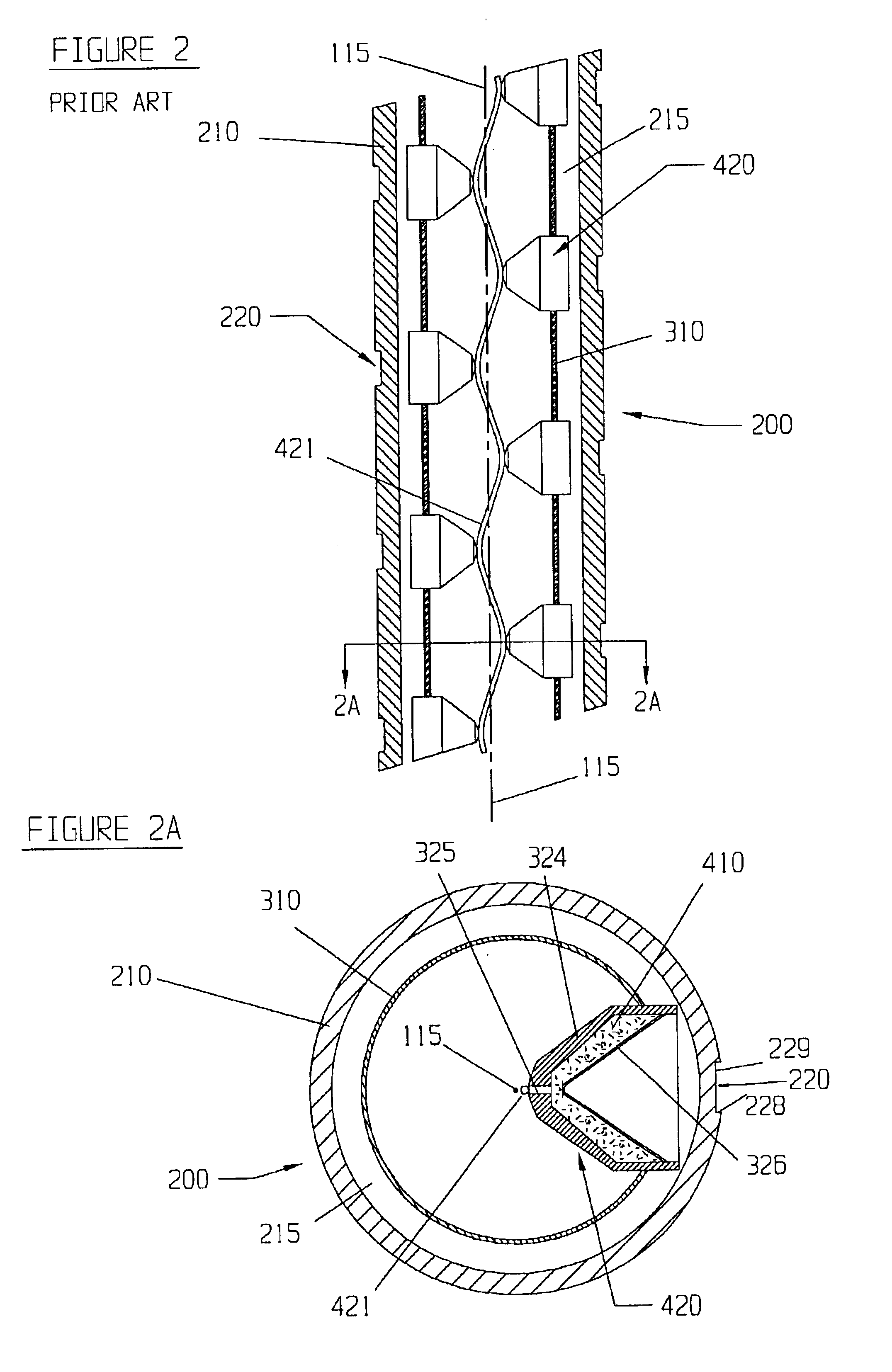

Systems and leads with a radially segmented electrode array and methods of manufacture

A method of making a lead for a stimulation device includes forming at least one pre-electrode in the shape of a ring, the at least one pre-electrode comprises at least two thin-walled portions separated by at least two thick-walled portions; disposing the at least one pre-electrode near a distal end of a lead body; joining at least one conductor to each thick-walled portion of the at least one pre-electrode; and grinding the lead body and the at least one pre-electrode to remove the thin-walled portions of the at least one pre-electrode to form segmented electrodes from the thick-walled portions of the at least one pre-electrode.

Owner:BOSTON SCI NEUROMODULATION CORP

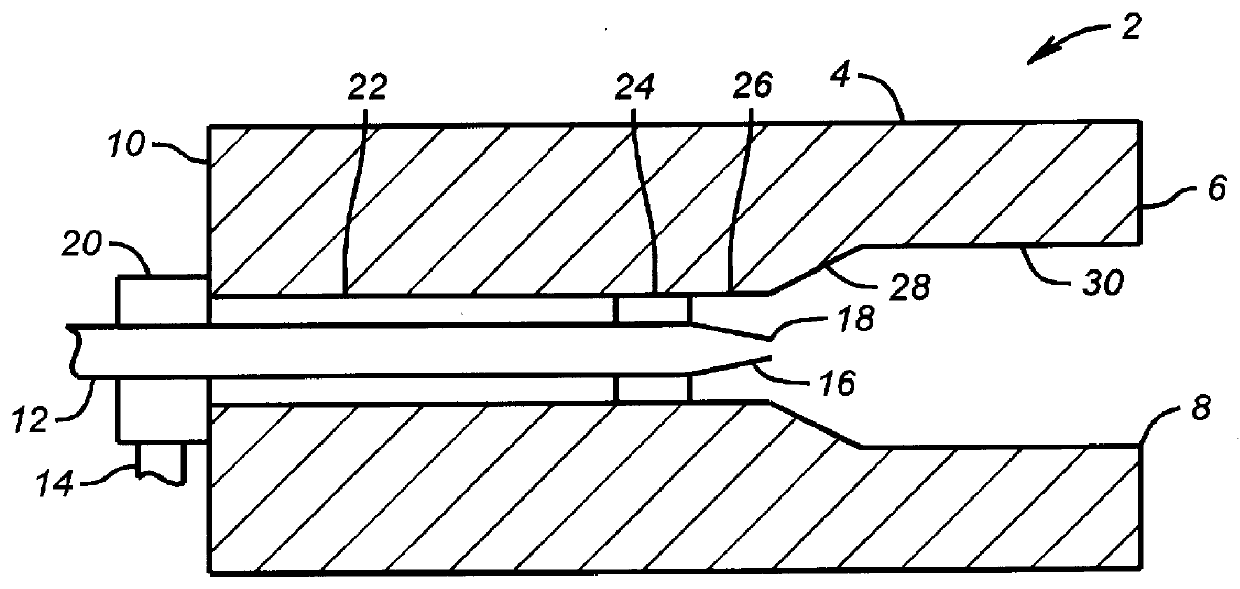

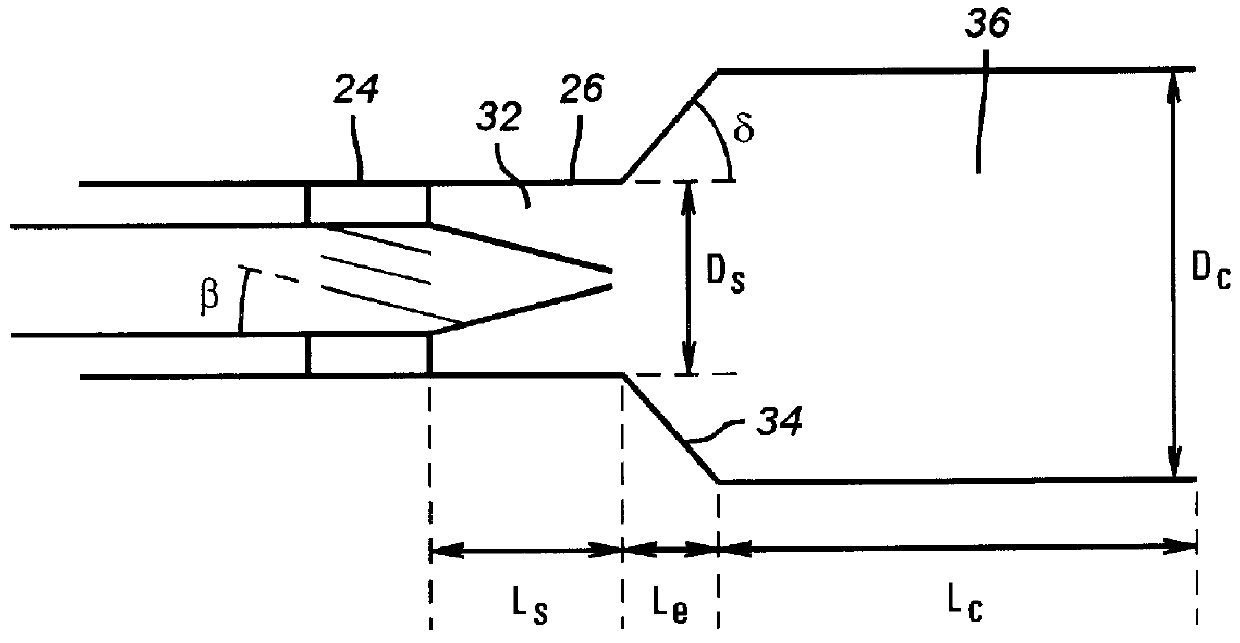

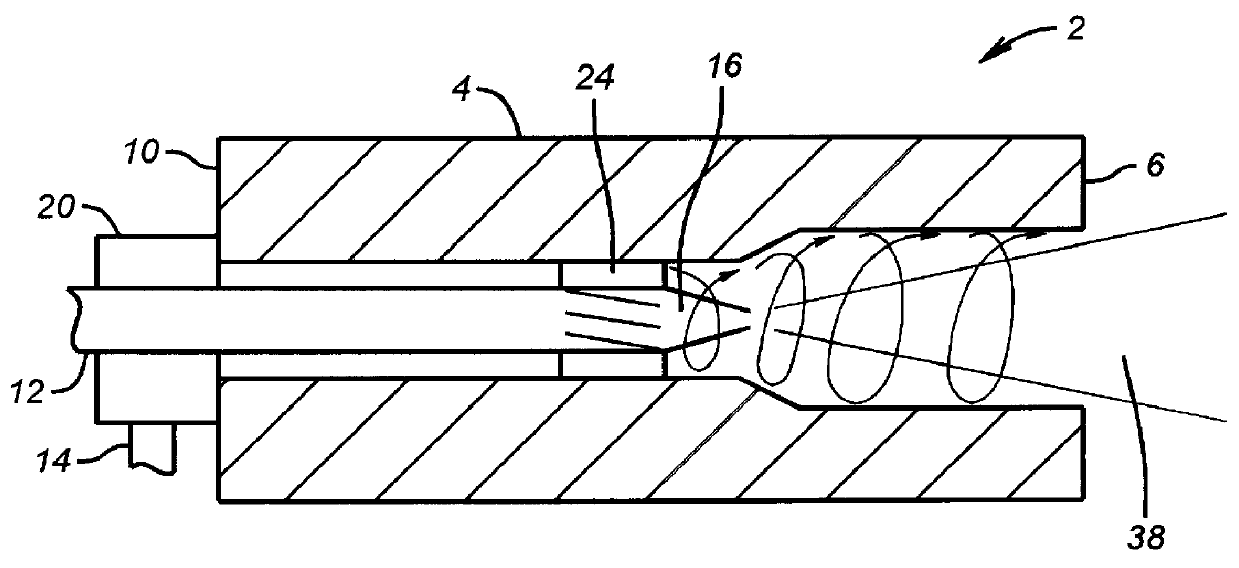

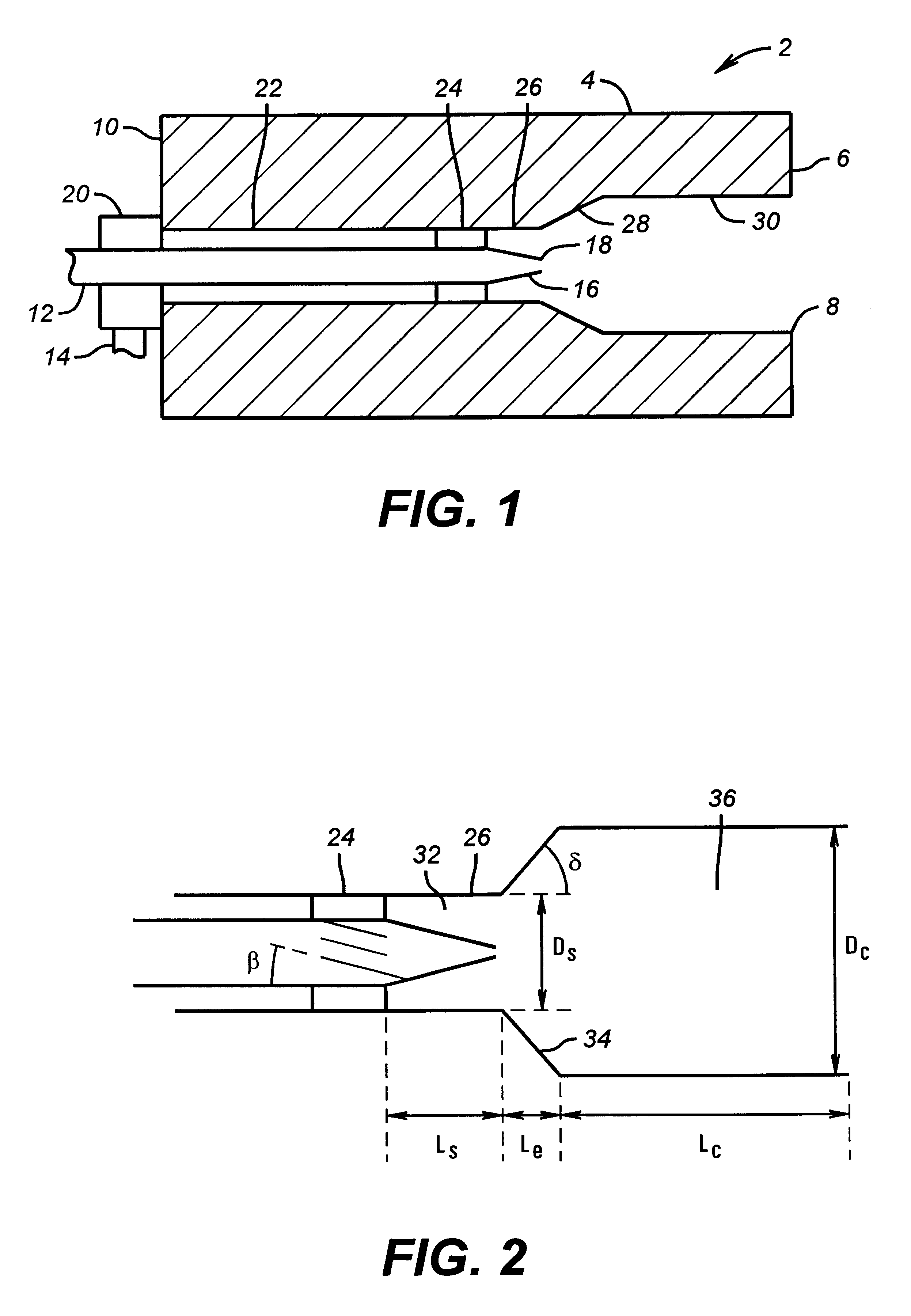

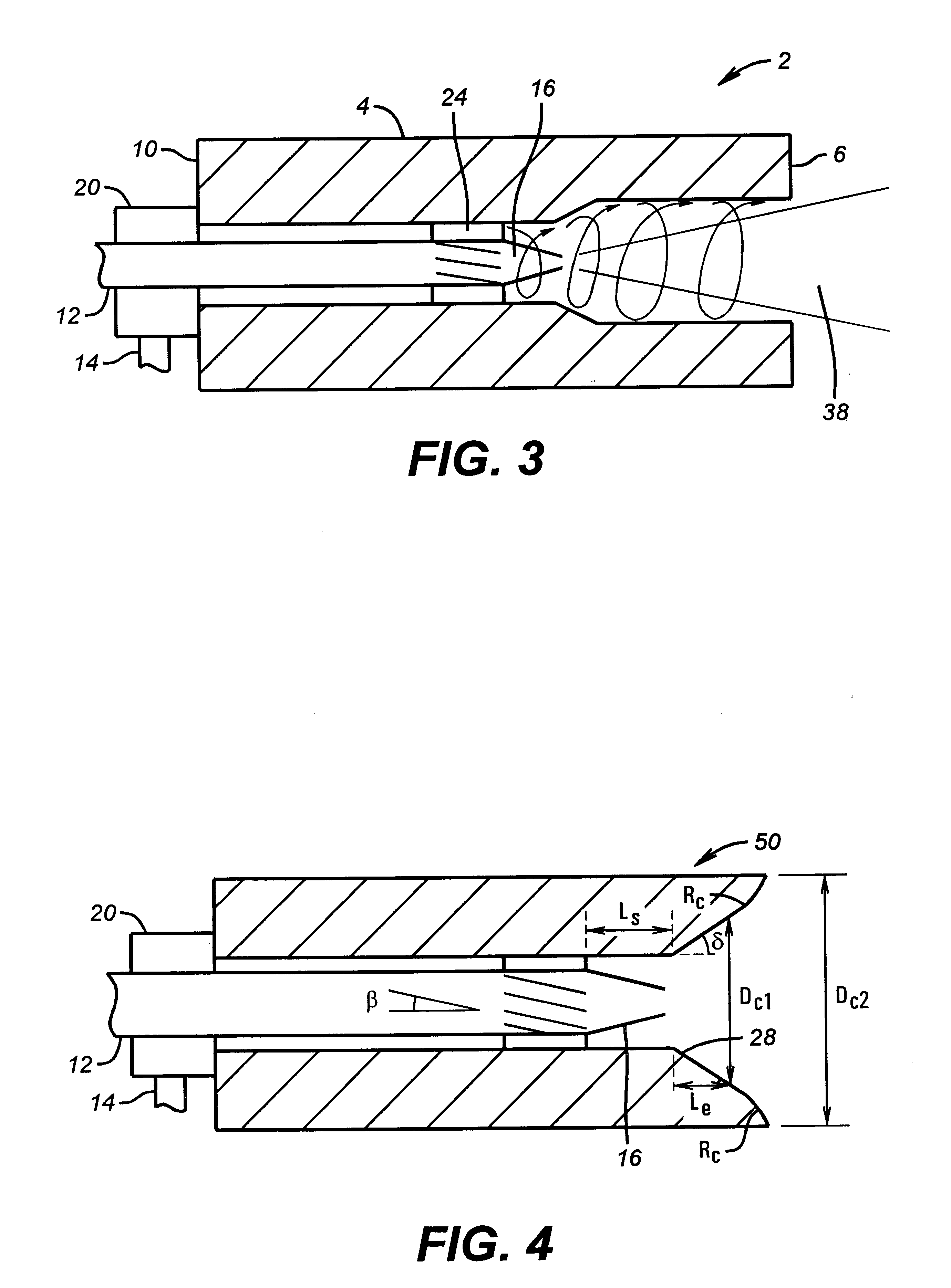

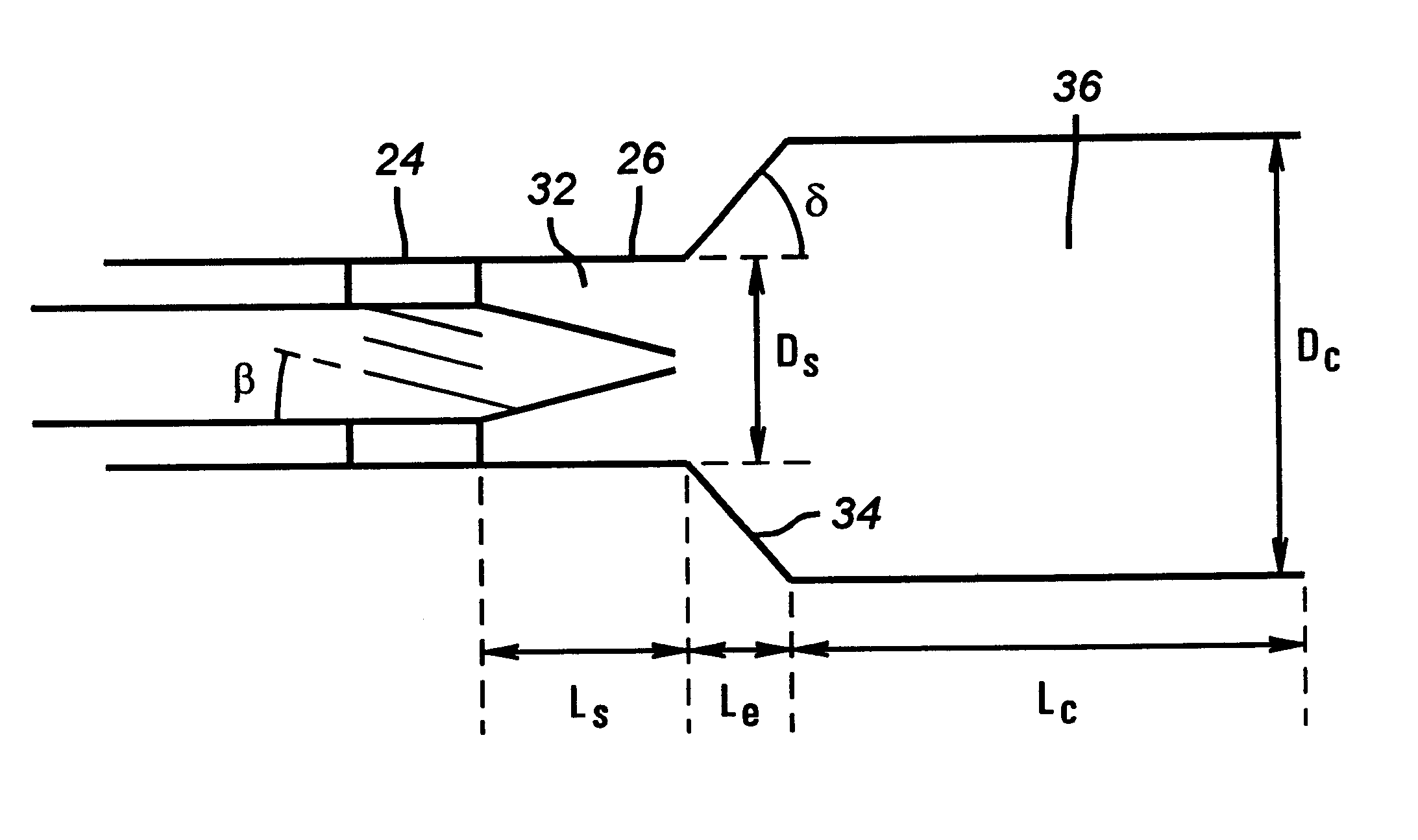

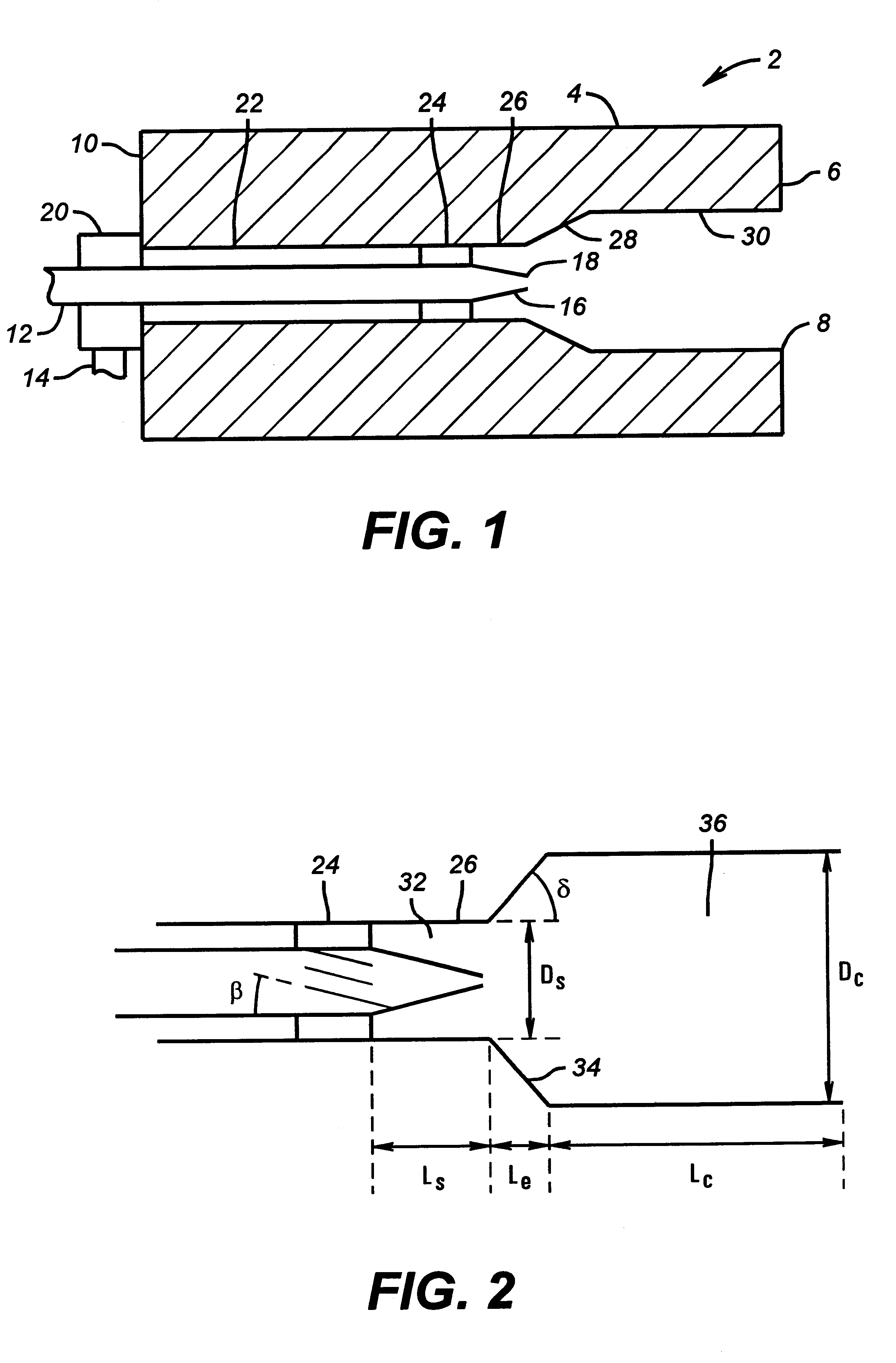

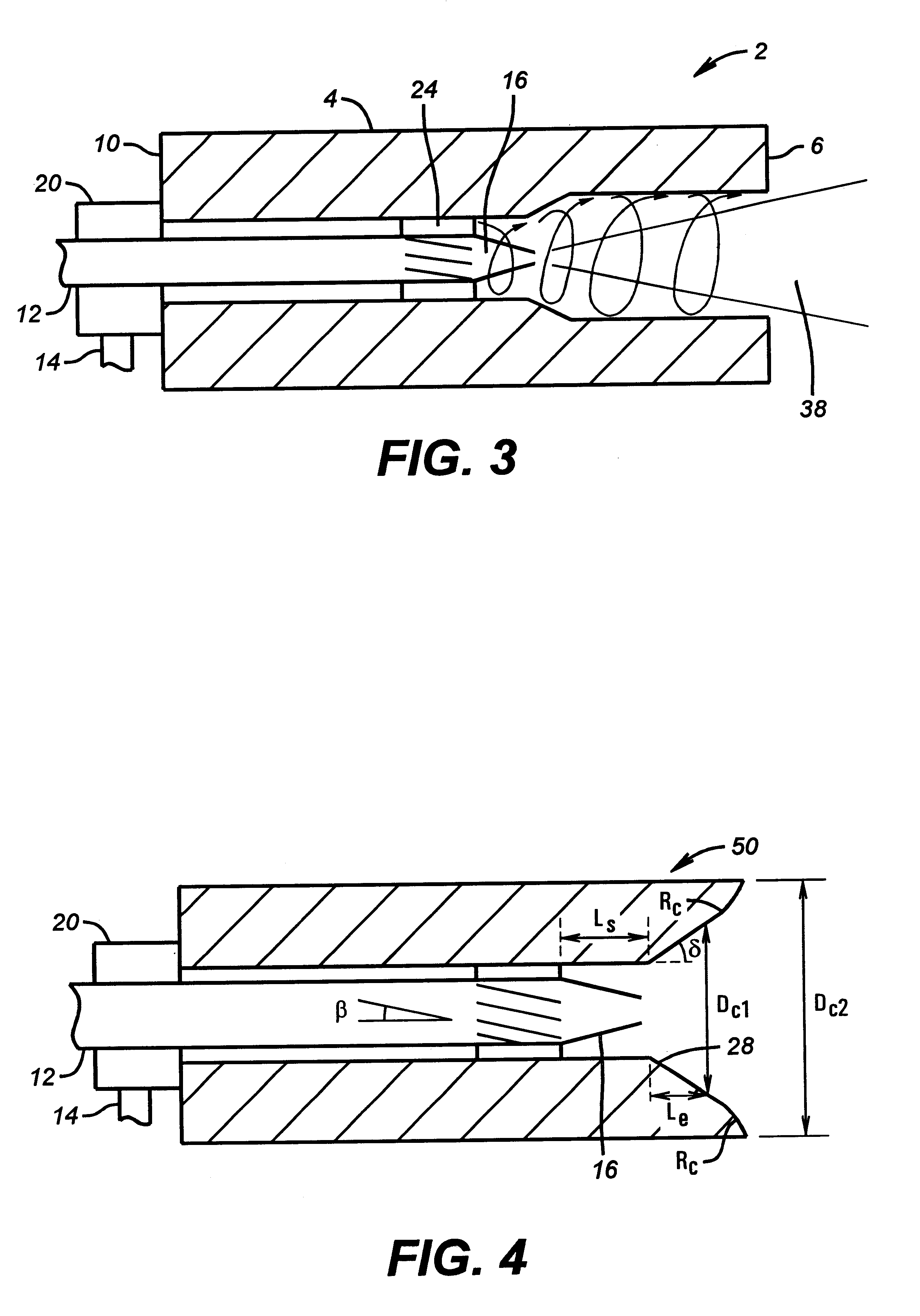

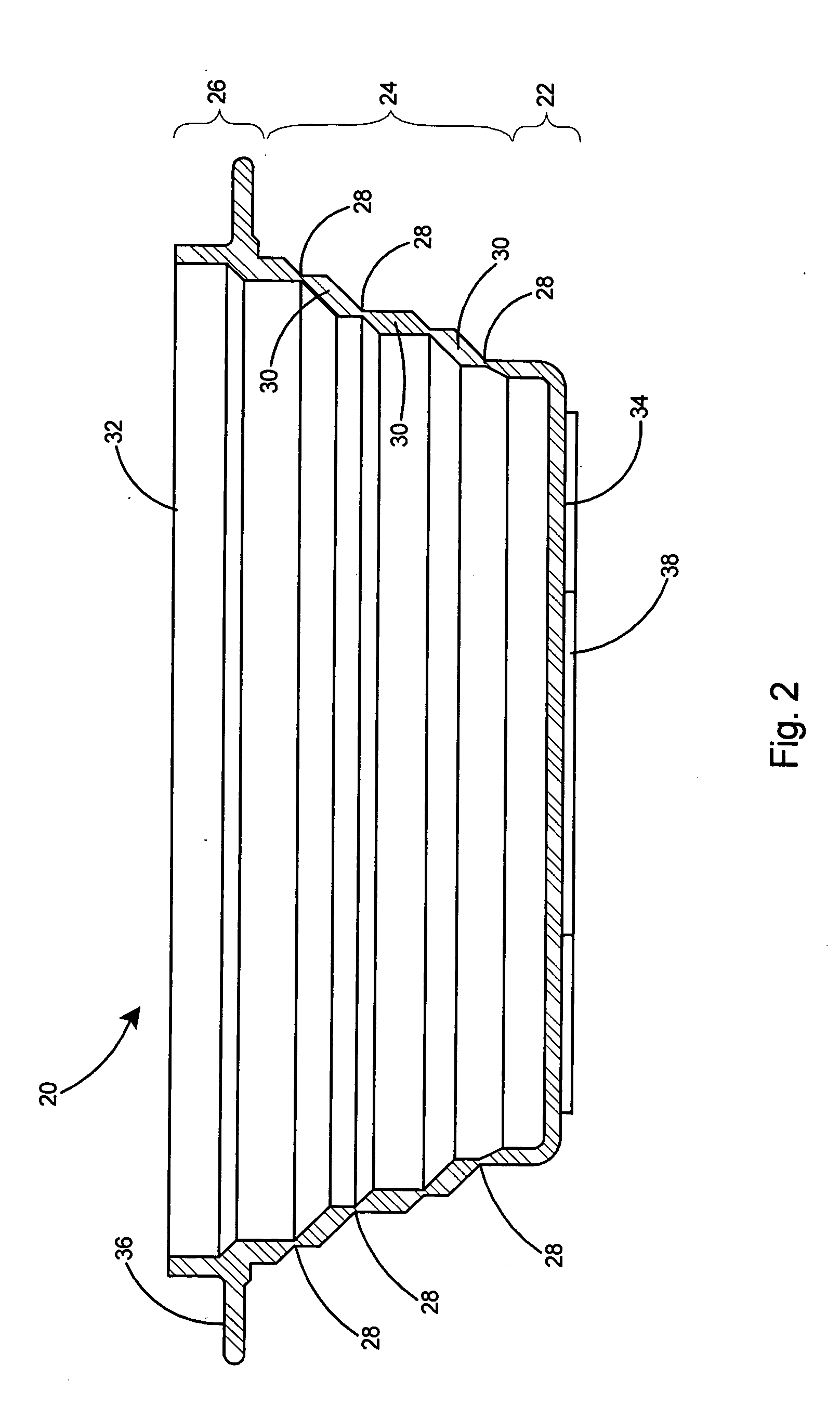

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6123542AAvoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200 DEG F. to 3000 DEG F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:LAIR LIQUIDE SA POUR L ETUD ET LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

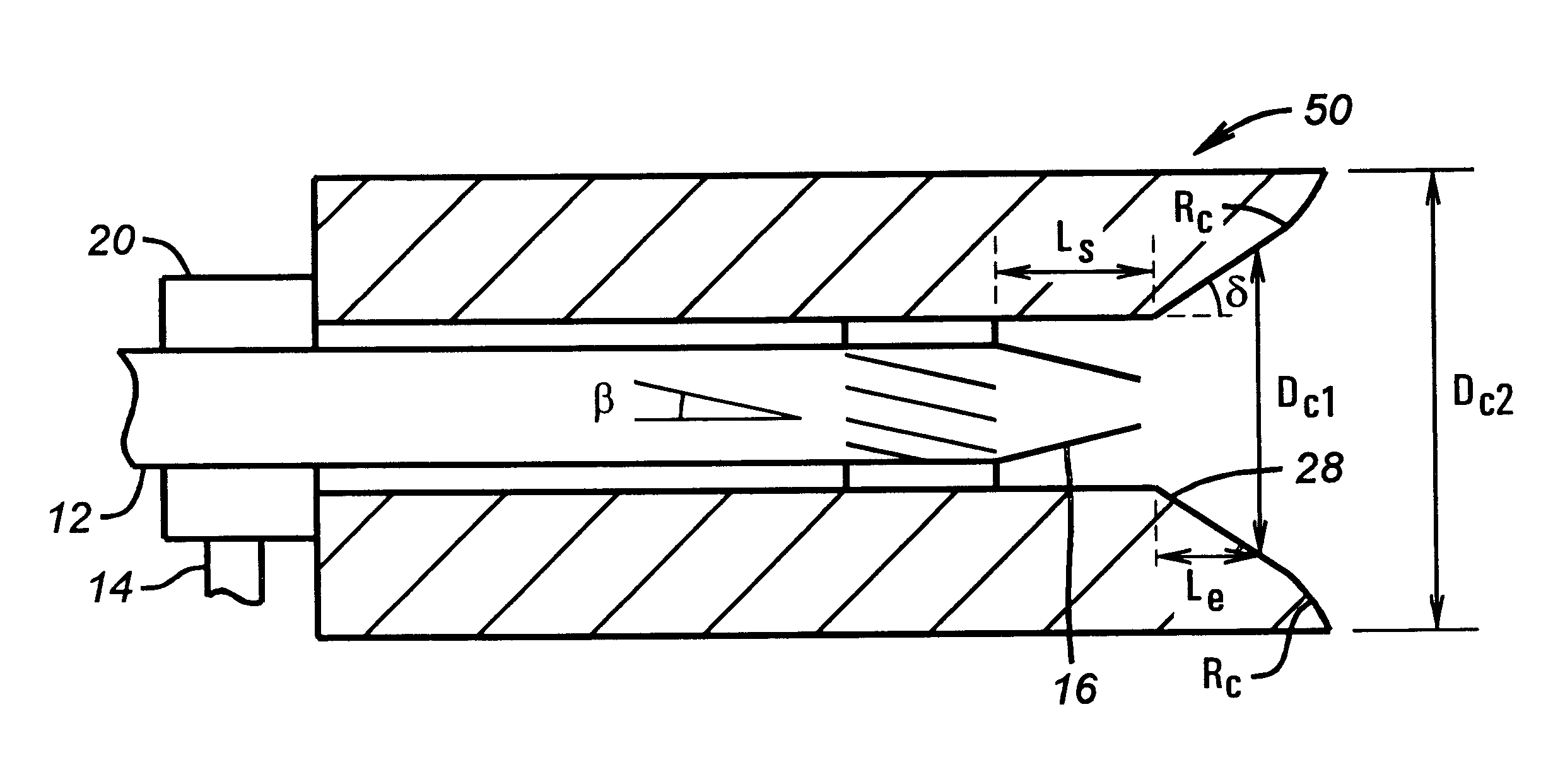

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

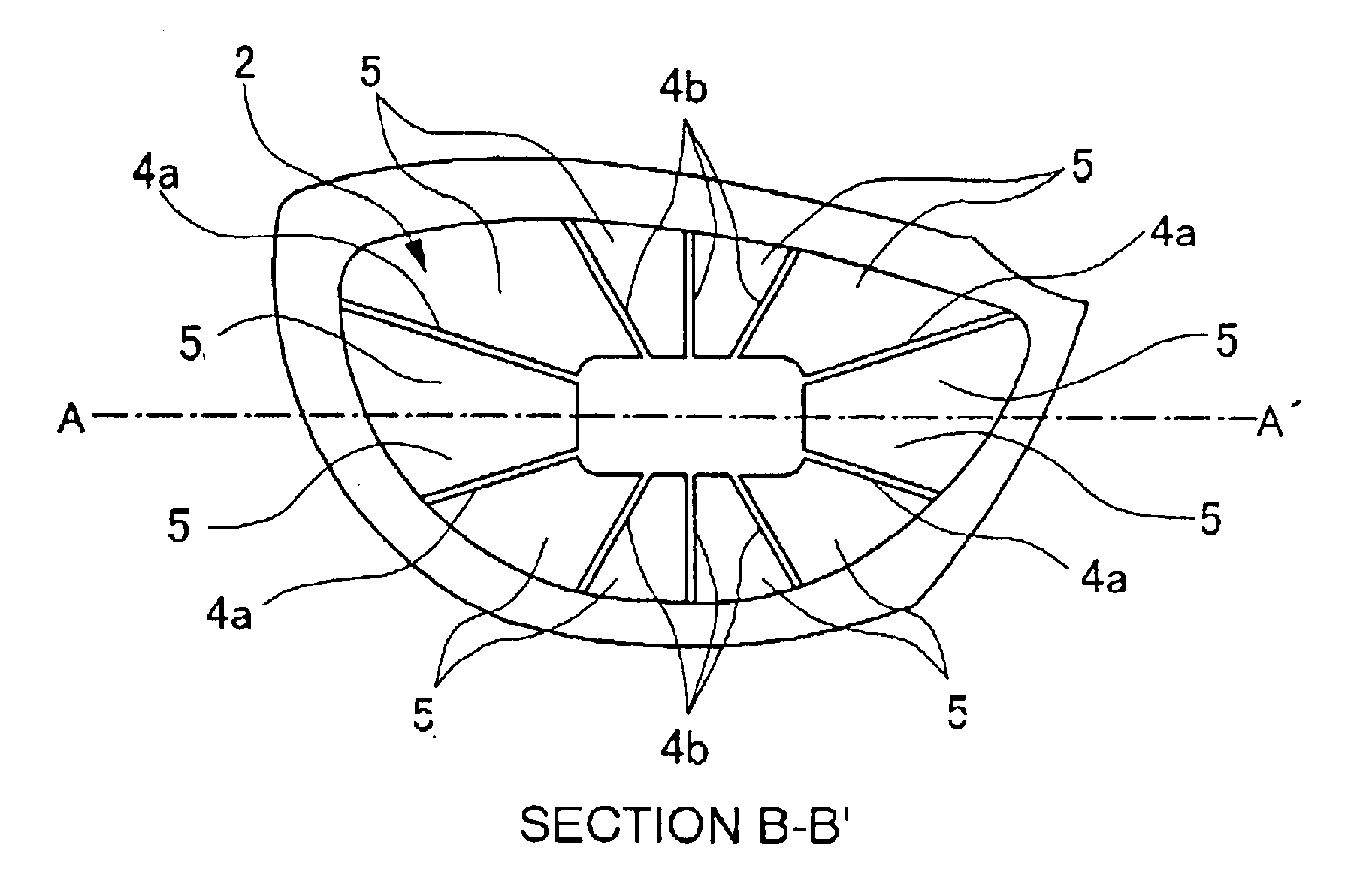

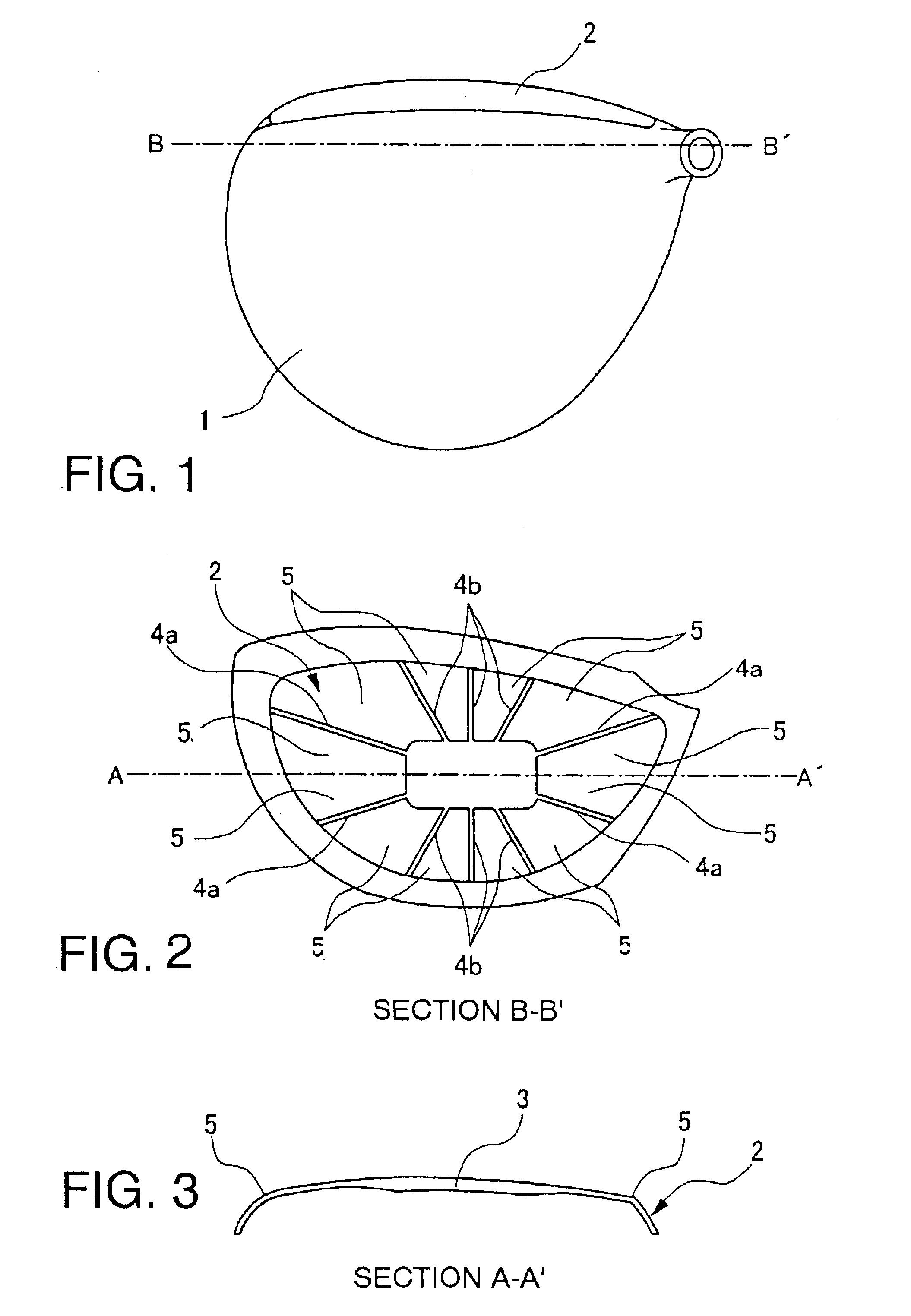

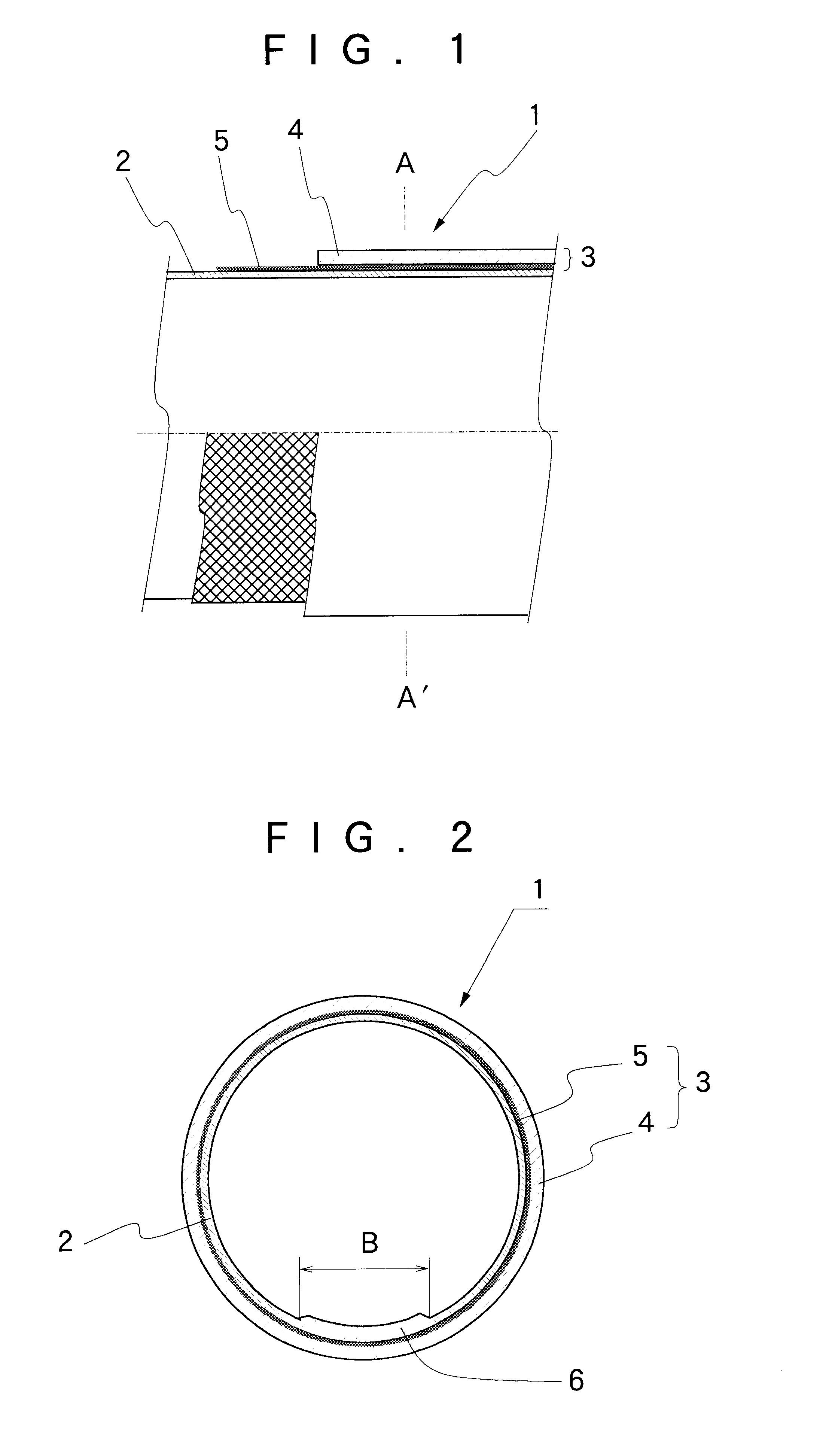

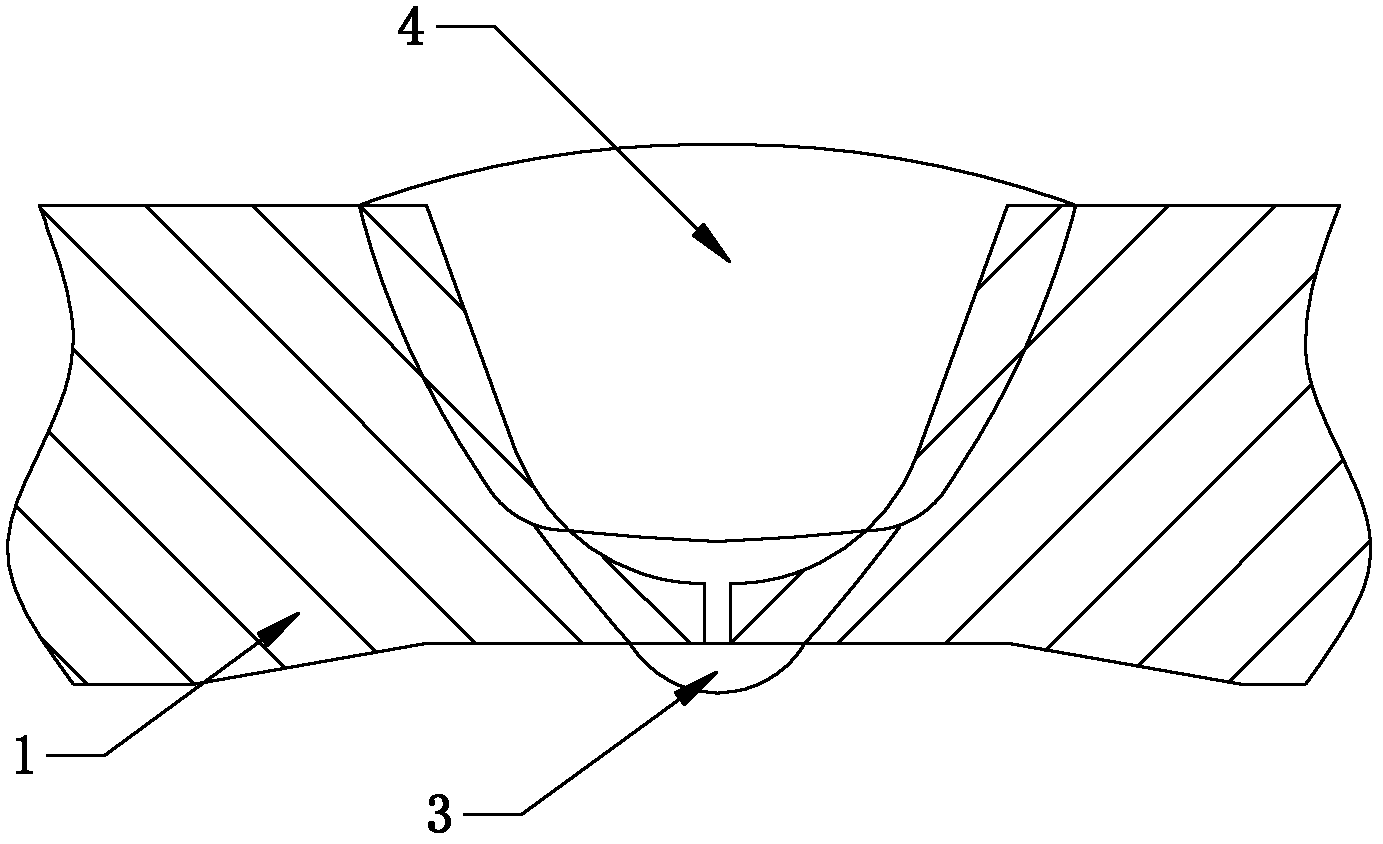

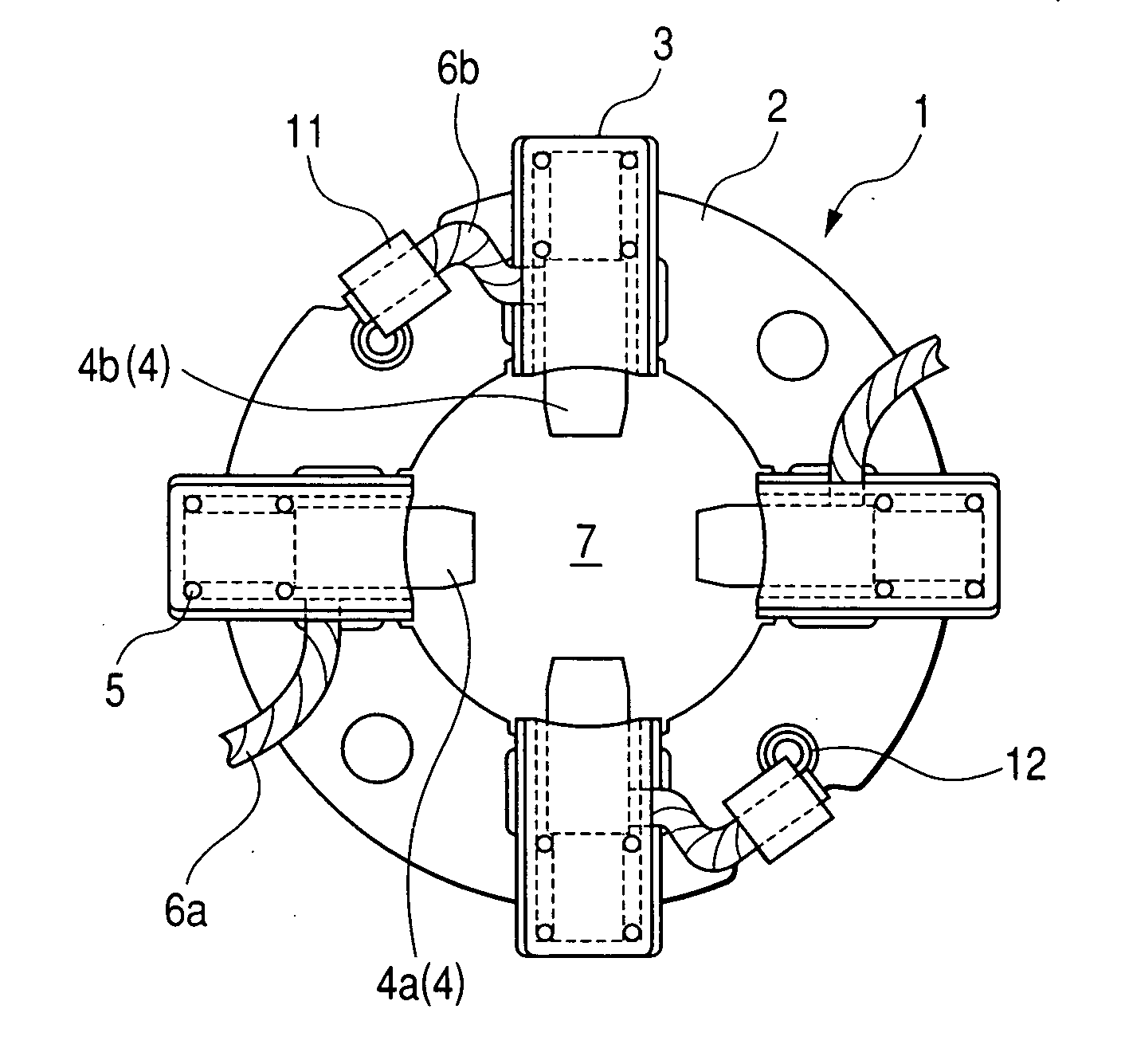

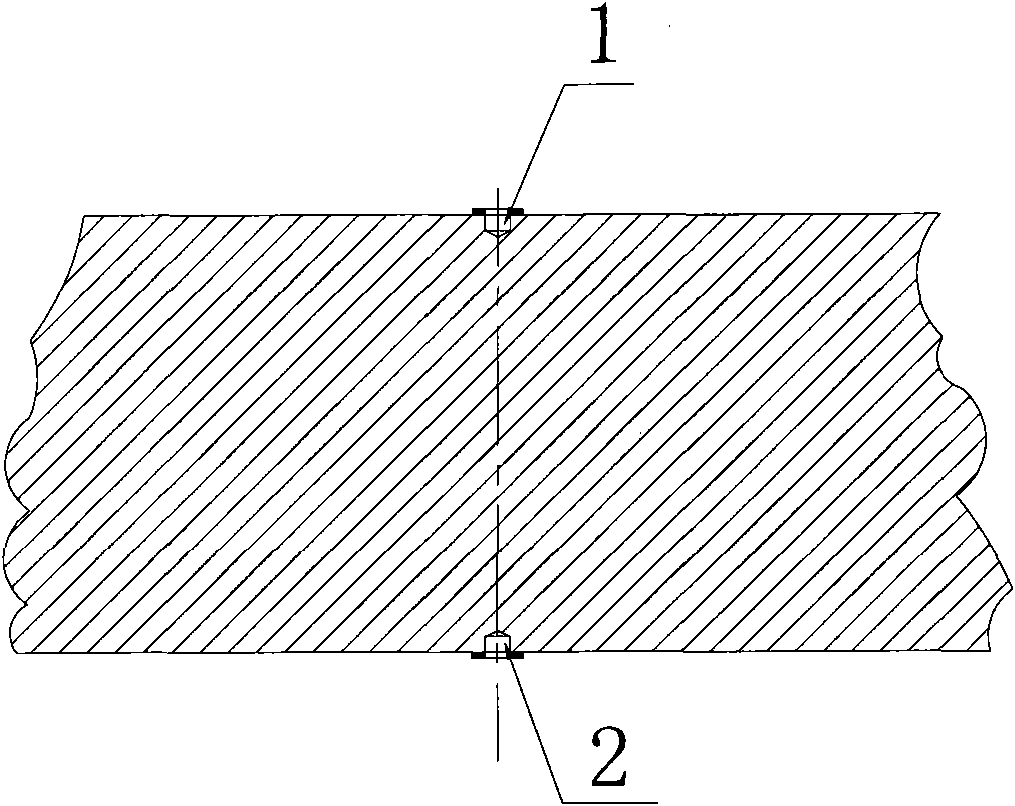

Golf club head

A golf club head has a face plate of high strength and high resilience and which provides excellent directional stability of the ball trajectory. The golf club head comprises a thick-walled portion 3 at the center of the face plate 2, and at least four narrow ribs 4a and 4b. Each of the ribs is formed with a thickness not substantially exceeding the thickness of the thick-walled portion, and extends radially from the thick-walled portion toward the perimeter of the face plate. Thin-walled portions 5 are formed between the thick-walled portion and the narrow ribs.

Owner:YONEX CO LTD

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

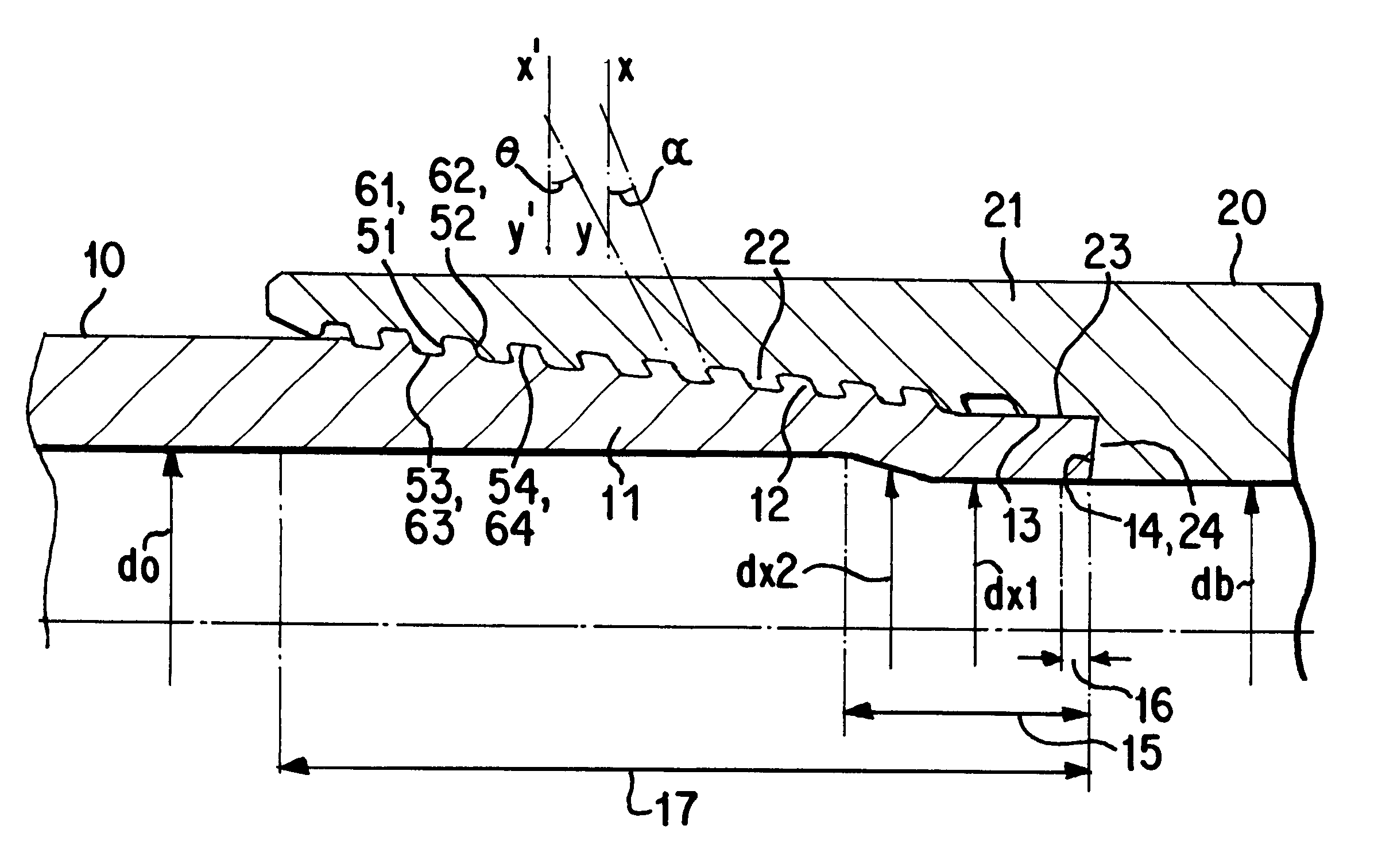

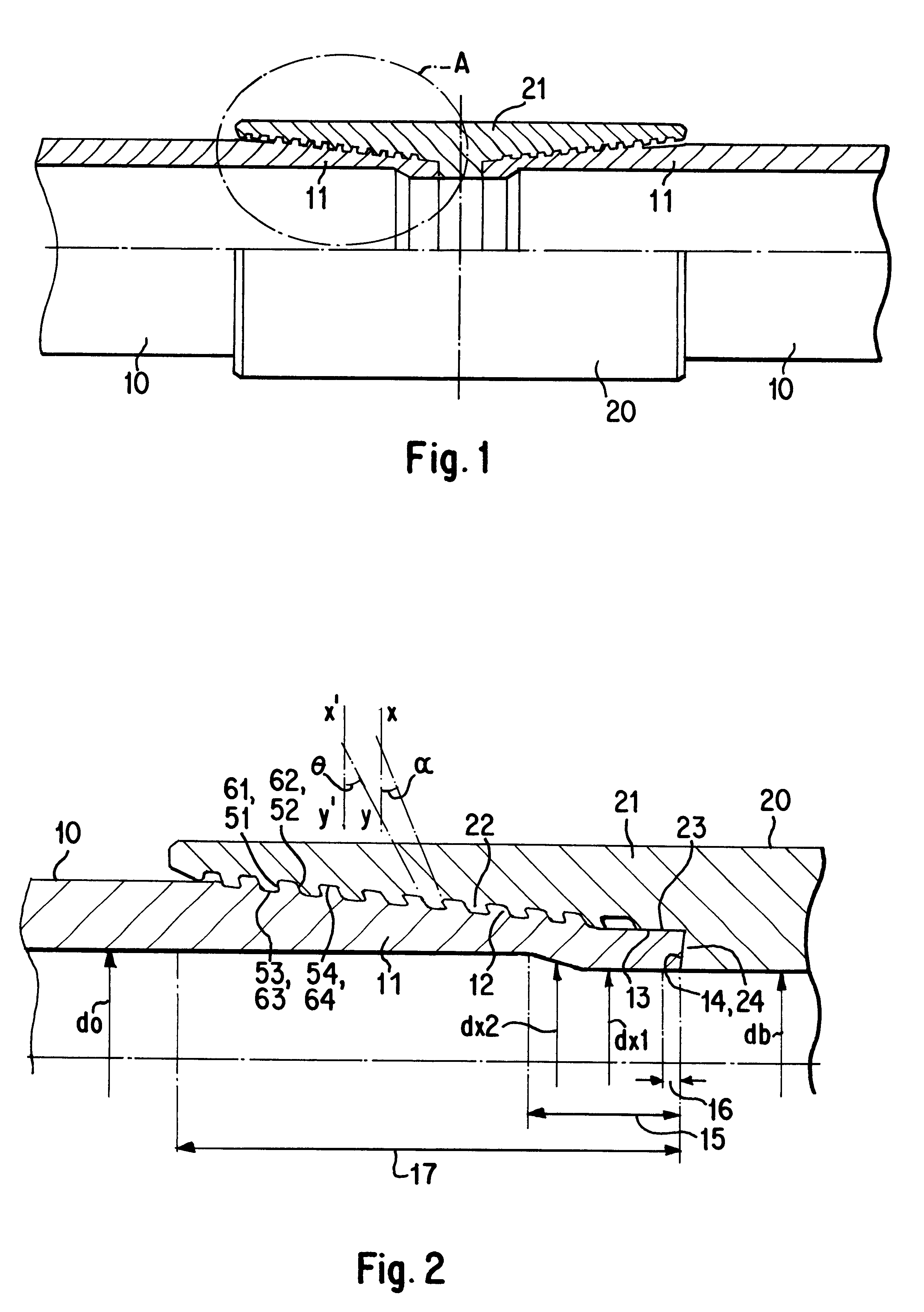

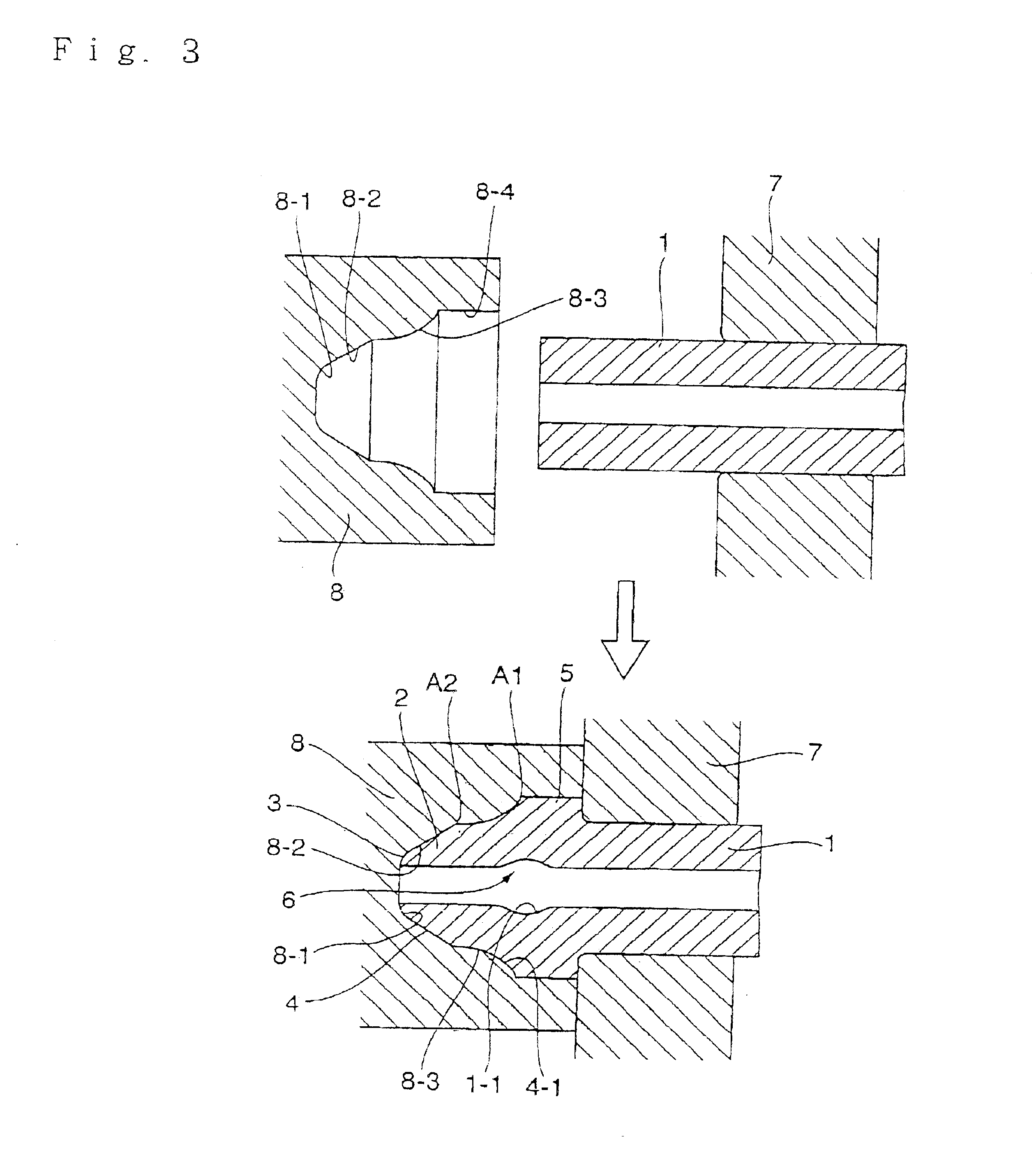

Threaded connection for oil country tubular goods and its method of manufacturing

[Purpose]To provide a threaded connection capable of preventing deterioration of gas tightness from occurring when a tensile stress acts thereon after a compressive force in the direction of the axis of a pipe is applied.[Means of Solving Problems](1) A threaded connection for oil country tubular goods wherein a length (15) of a thick walled portion with a diameter defined in the formula (1), is longer than the length (16) from seal contact to the extremist of the pin section, shorter than a half of the length (17) of the pin section, the rest of inside diameter is equal to the inside diameter of pipe proper, having smooth tapered inner wall between thick walled portion and pipe proper. The inside diameter of the box section of torque shoulder section is the same as inside diameter of thick wall.Where dx(mm)=inside diameter of the thick walled portion of the pin section, and d0(mm)=inside diameter of the pipe proper.

Owner:SUMITOMO METAL IND LTD +1

Multimodal polyethylene pipe resins and process

ActiveUS20100092709A1Improve the immunitySolve low usageLayered productsThin material handlingCrack resistancePolymer science

Multimodal polyethylene resins having improved stress crack resistance and melt strength rendering them useful for the manufacture of thick-walled pipe are produced in a process wherein the second stage of the process is a copolymerization conducted at a high temperature with a low comonomer to ethylene ratio and a low hydrogen to ethylene ratio.

Owner:EQUSR CHEM LP

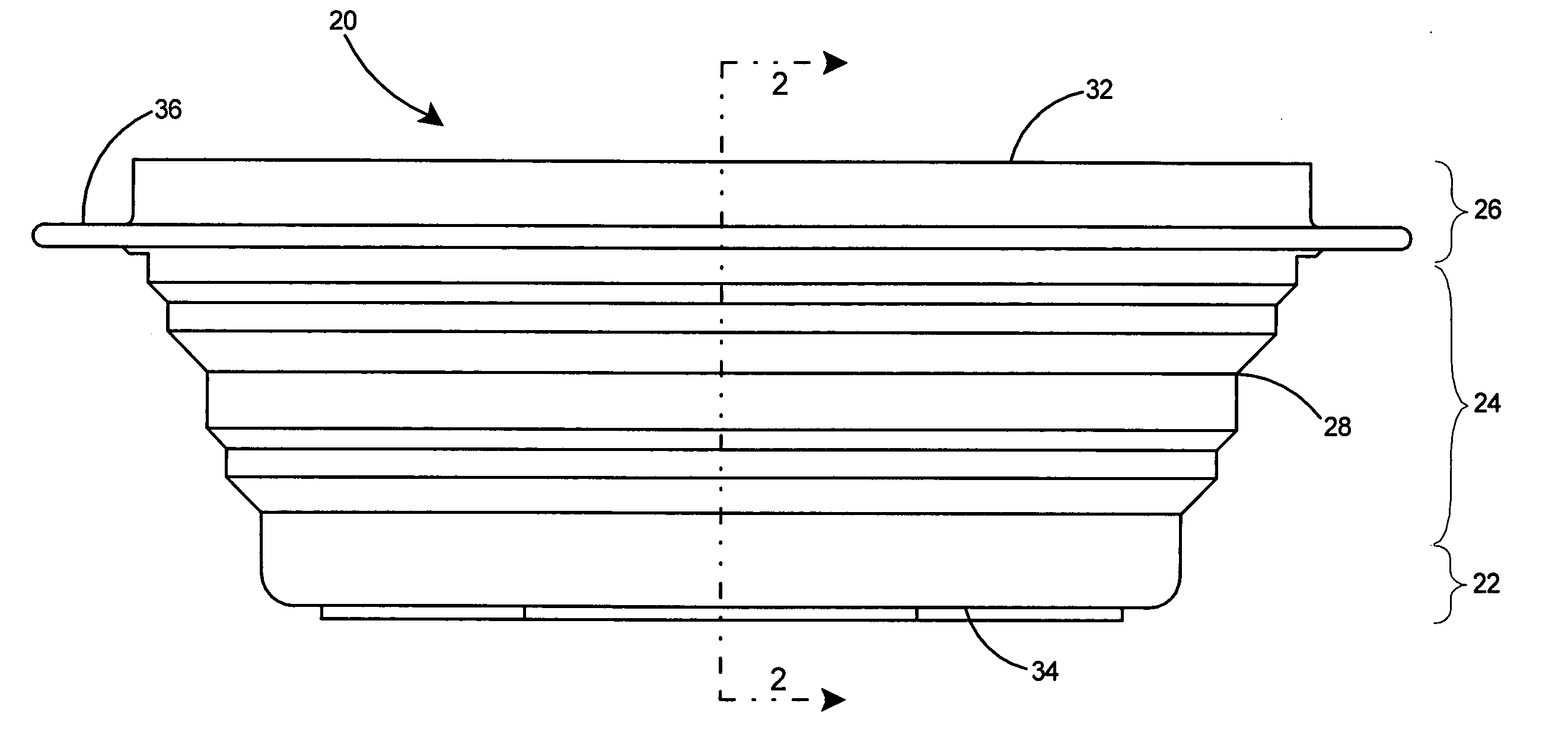

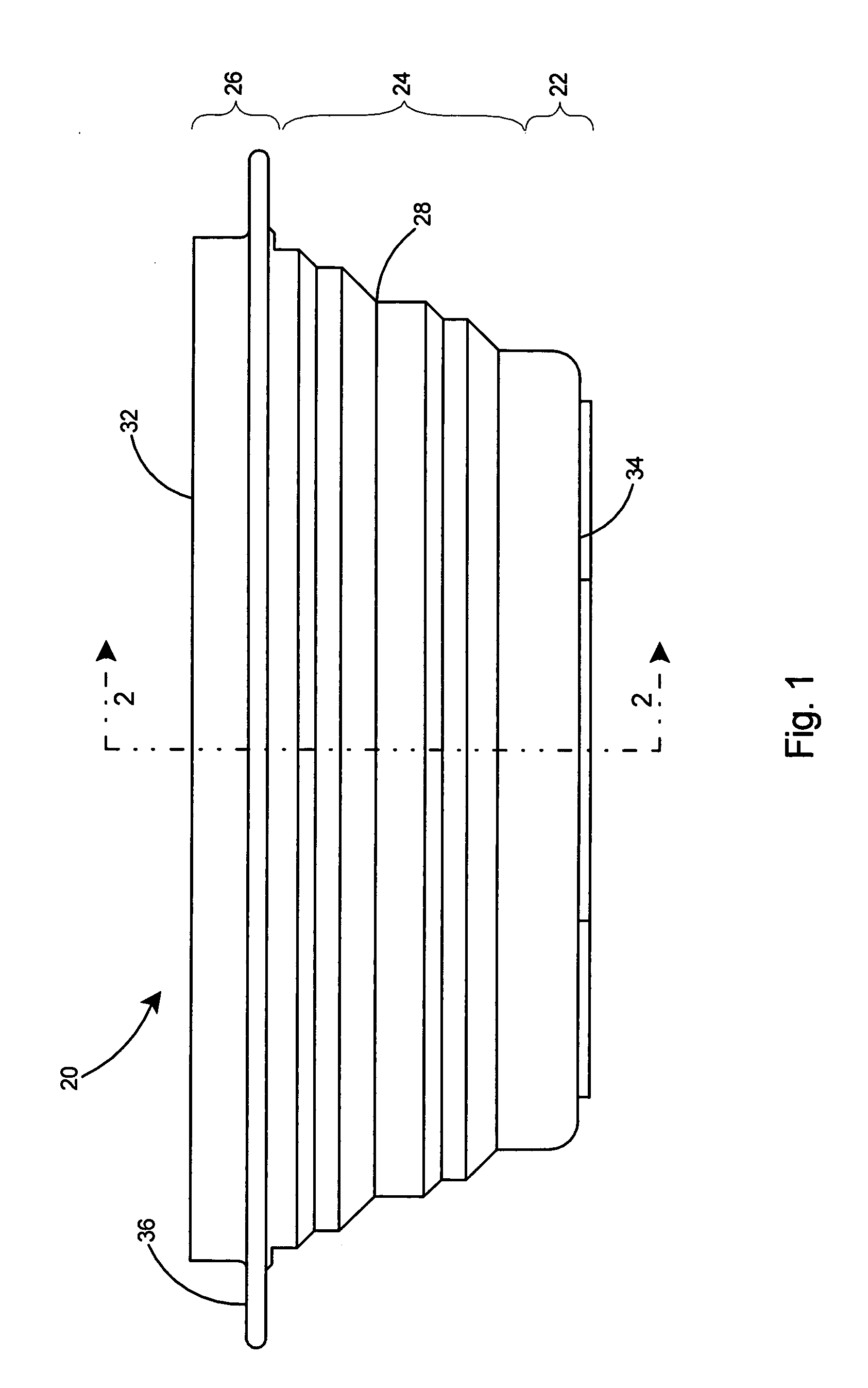

Foldable ovenware container and method of production

A foldable or collapsible ovenware container that maintains a rigid shape while in use and can be folded into a smaller size for storage. The ovenware container includes rigid top and bottom portions separated by a flexible middle portion. The flexible middle portion includes thick and thin wall sections. Pressure applied to the top portion causes the flexible middle portion to collapse in an orderly manner toward the bottom portion, with the middle portion folding at each of the thin wall sections to create a plurality of folds or pleats in the middle portion in the collapsed configuration.

Owner:FUNG DUNCAN C

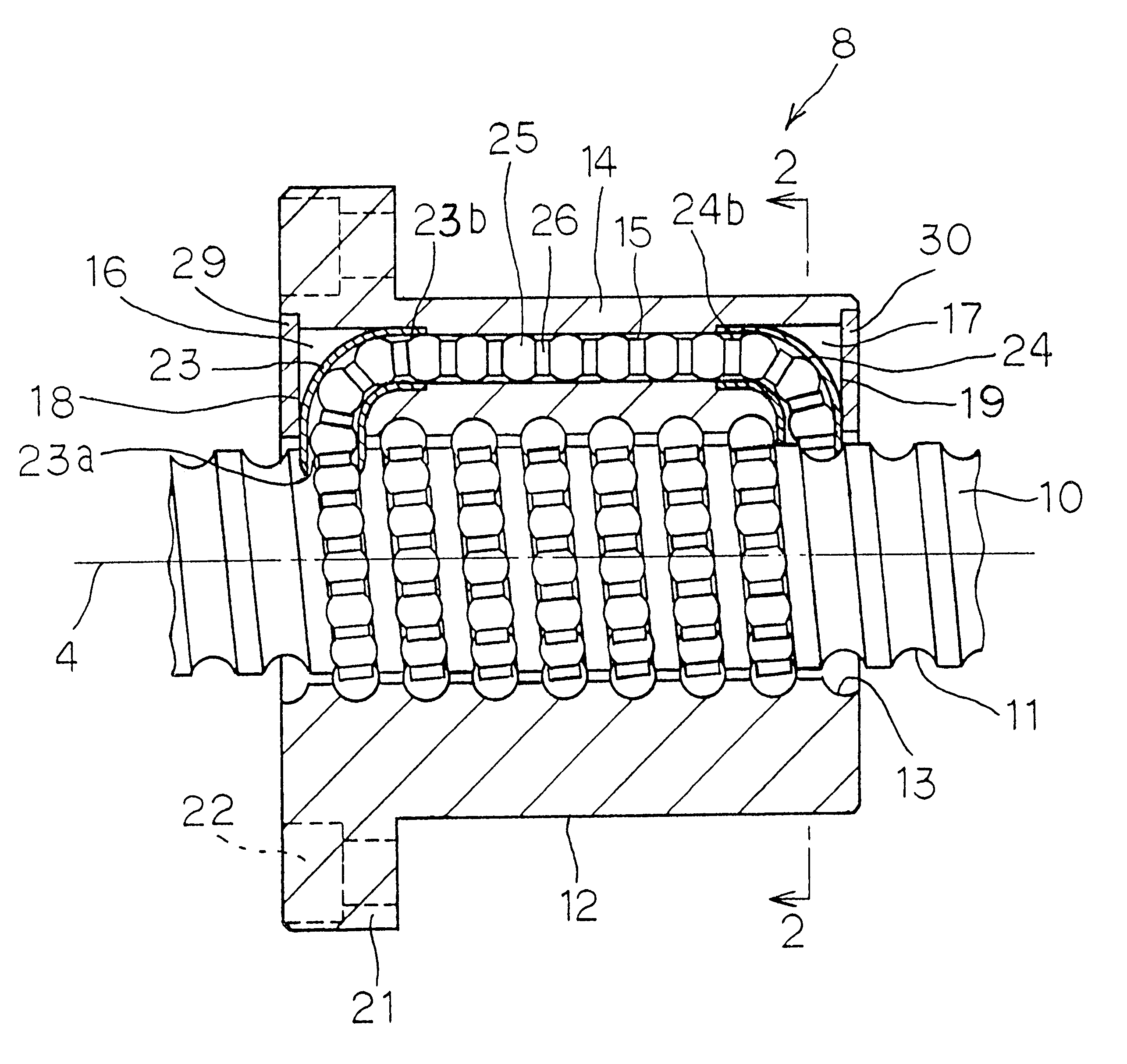

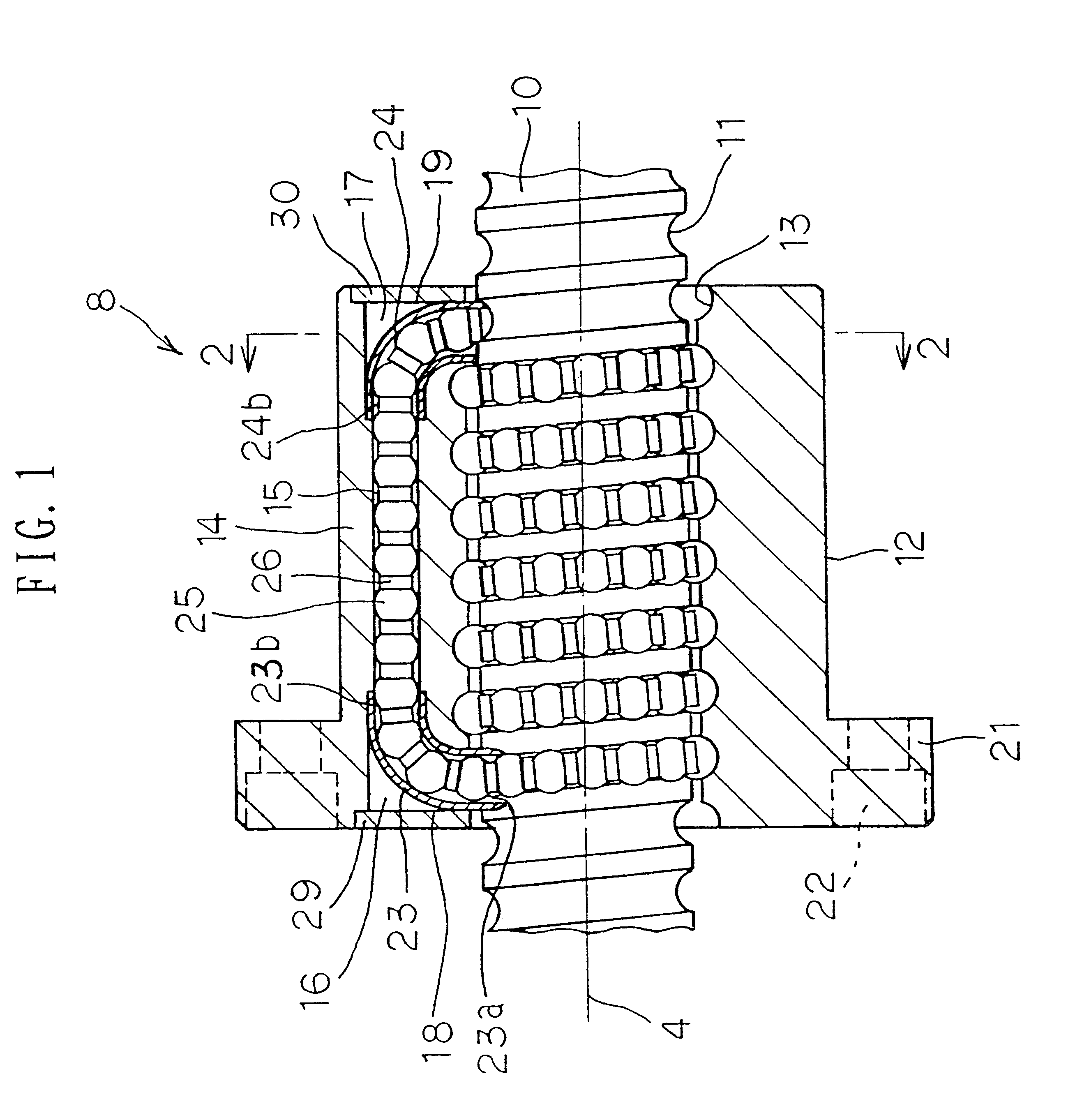

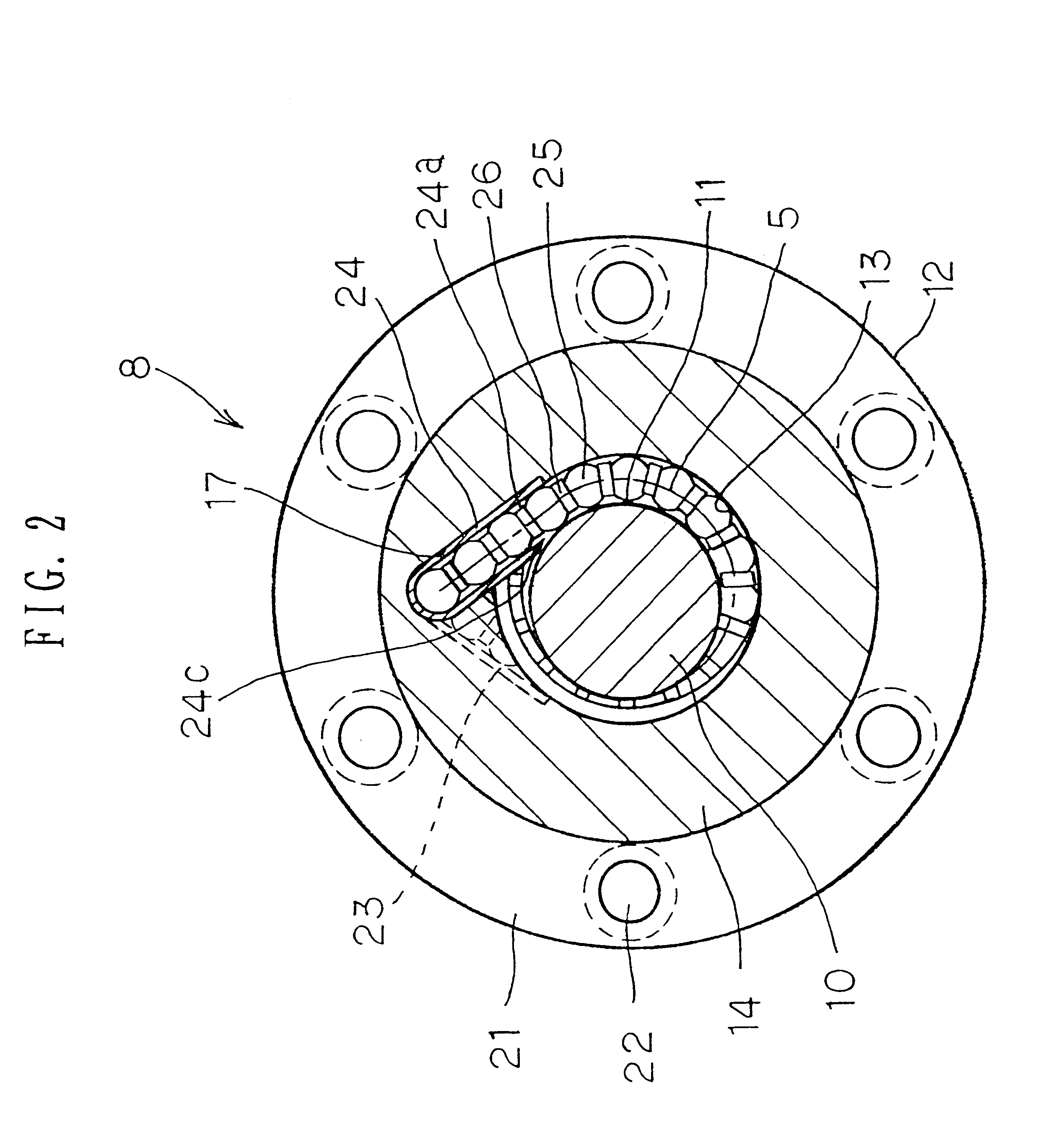

Ball screw having spacers

InactiveUS6176149B1Improve carrying capacityIncrease stiffnessControlling membersLinear bearingsCarrying capacityReciprocating motion

Spacers 26 each of which has a concave surface 27 complementary to the spherical surface of a ball 25 at each end thereof are disposed at areas between the adjacent balls 25, 25. A ball circulation mechanism comprises; a through hole 15 which extends in parallel to an axial line 4 of the ball nut 12 inside a thick wall part 14 of the ball nut 12; and adapters 23, 24 having open ends 23a, 24a provided with tongue portions 23c, 24c for scooping up or returning balls 25 between a ball screw groove 11 of a ball shaft 10 and a ball screw groove 13 of the ball nut 12, and the other open ends 23b, 24b being connected to be in communication with the through hole 15, and each adapter being fitted into recesses 16, 17 provided on both axial ends in the thick wall part 14 of the ball nut 12. Therefore, there is no need of upsizing a ball screw, and thus a compact ball screw which has a high load-carrying capacity and is suitable for a reciprocating movement can be provided.

Owner:TSUBAKI NAKASHIMA

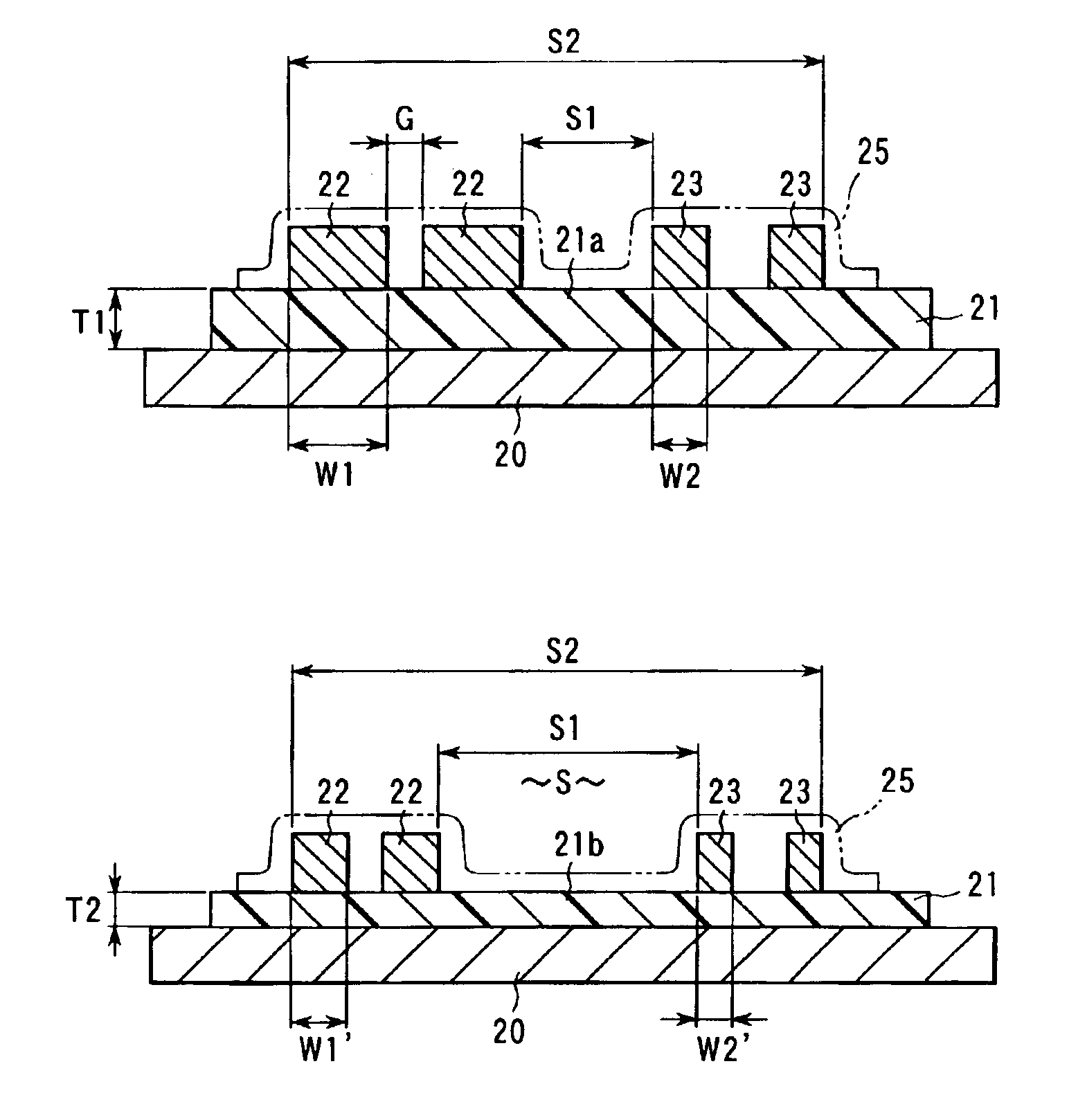

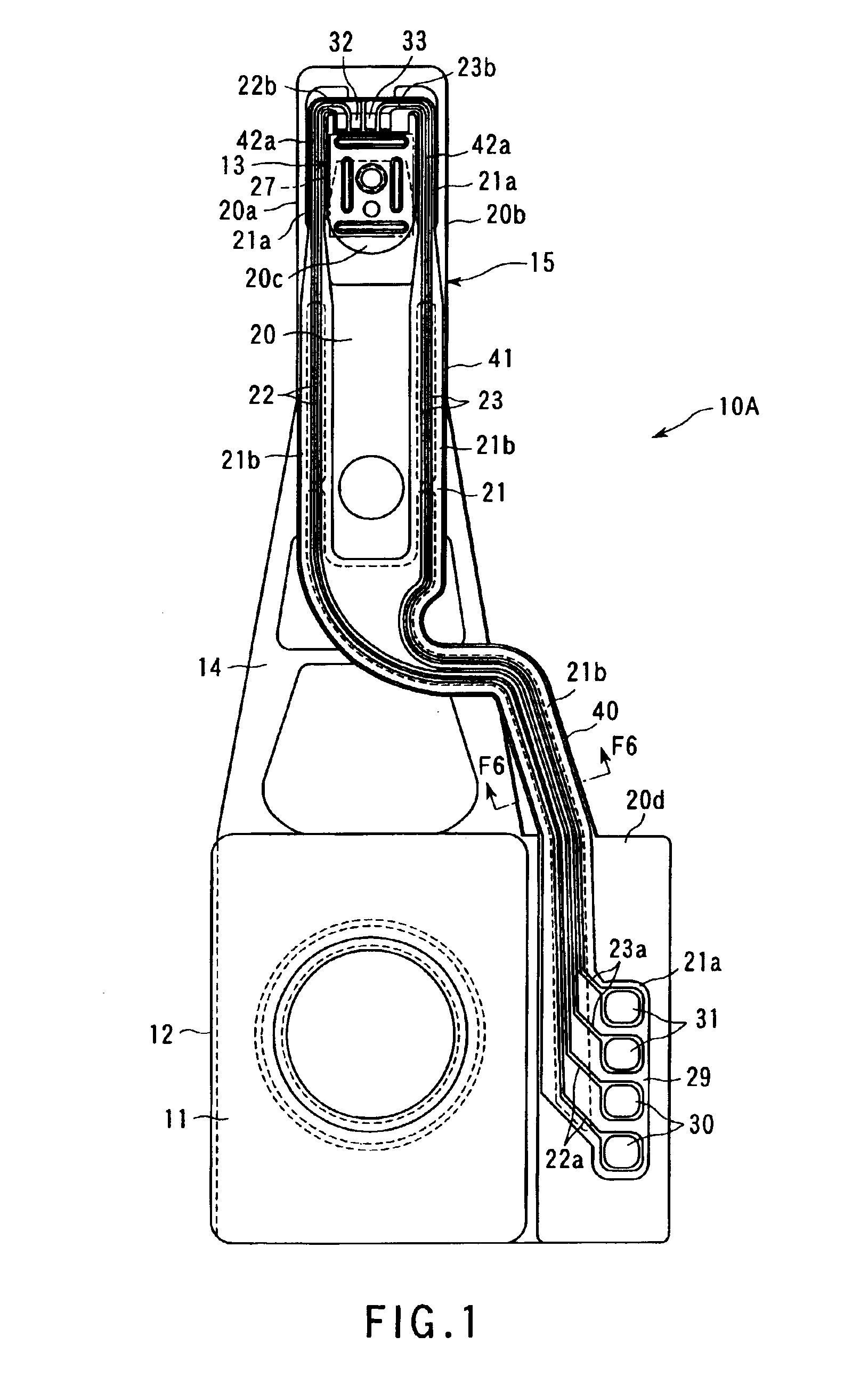

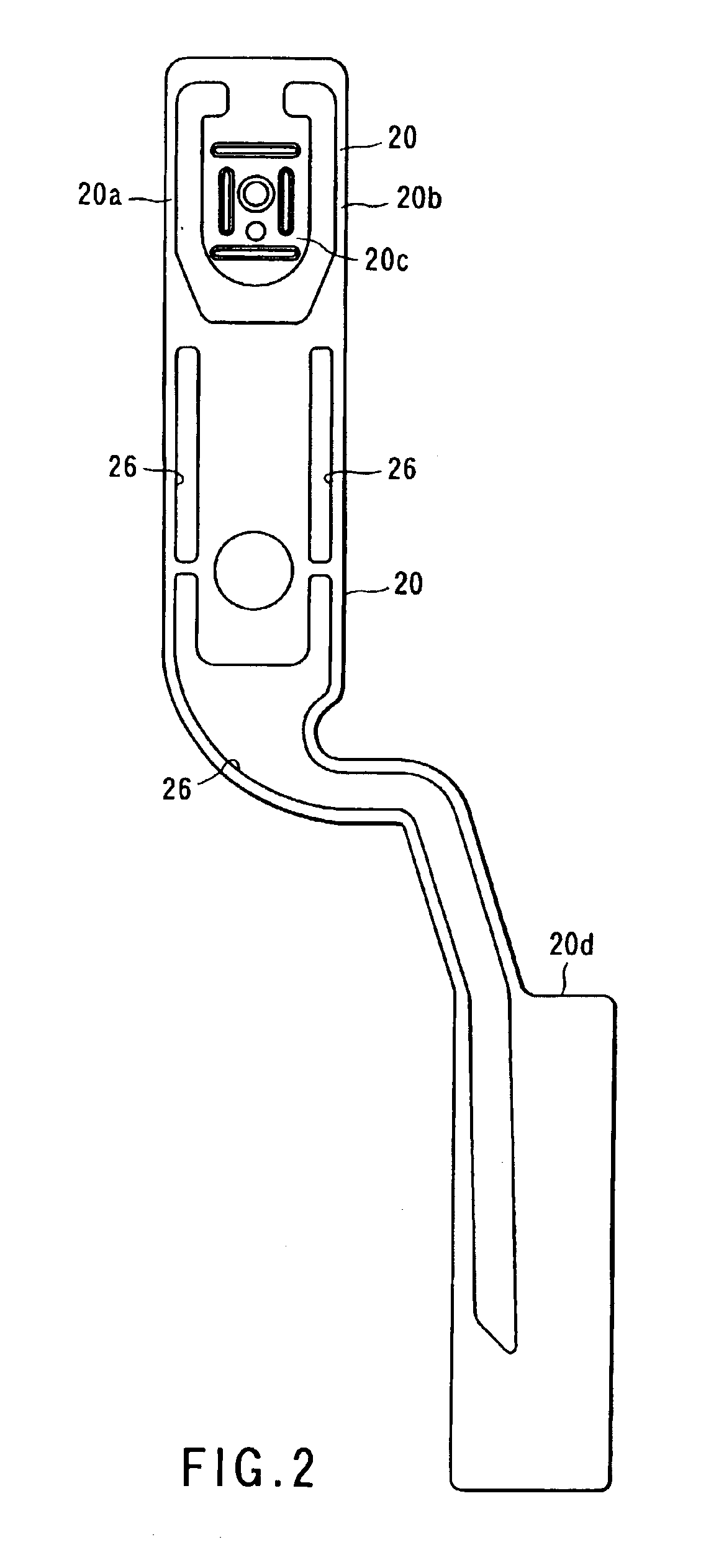

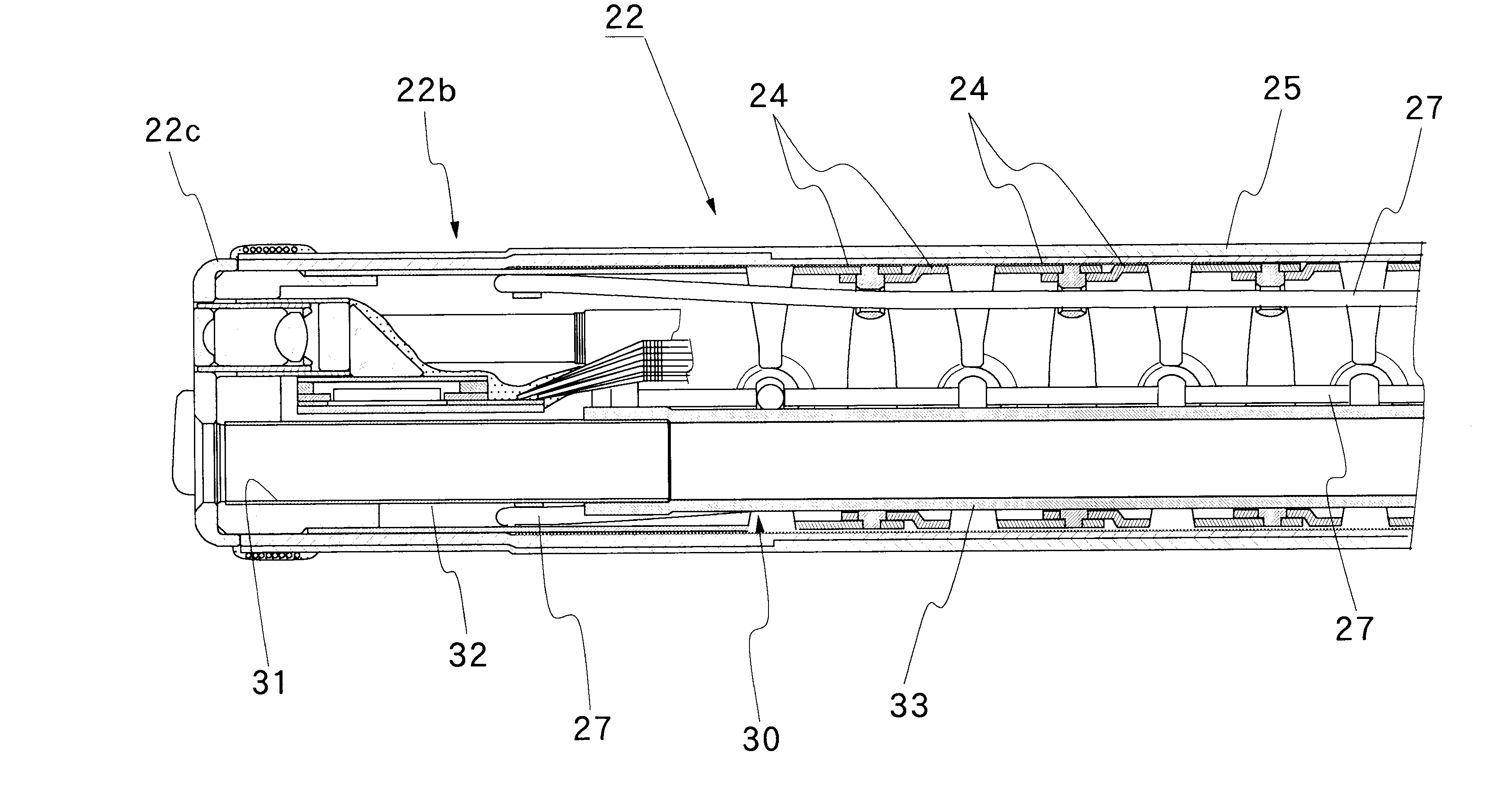

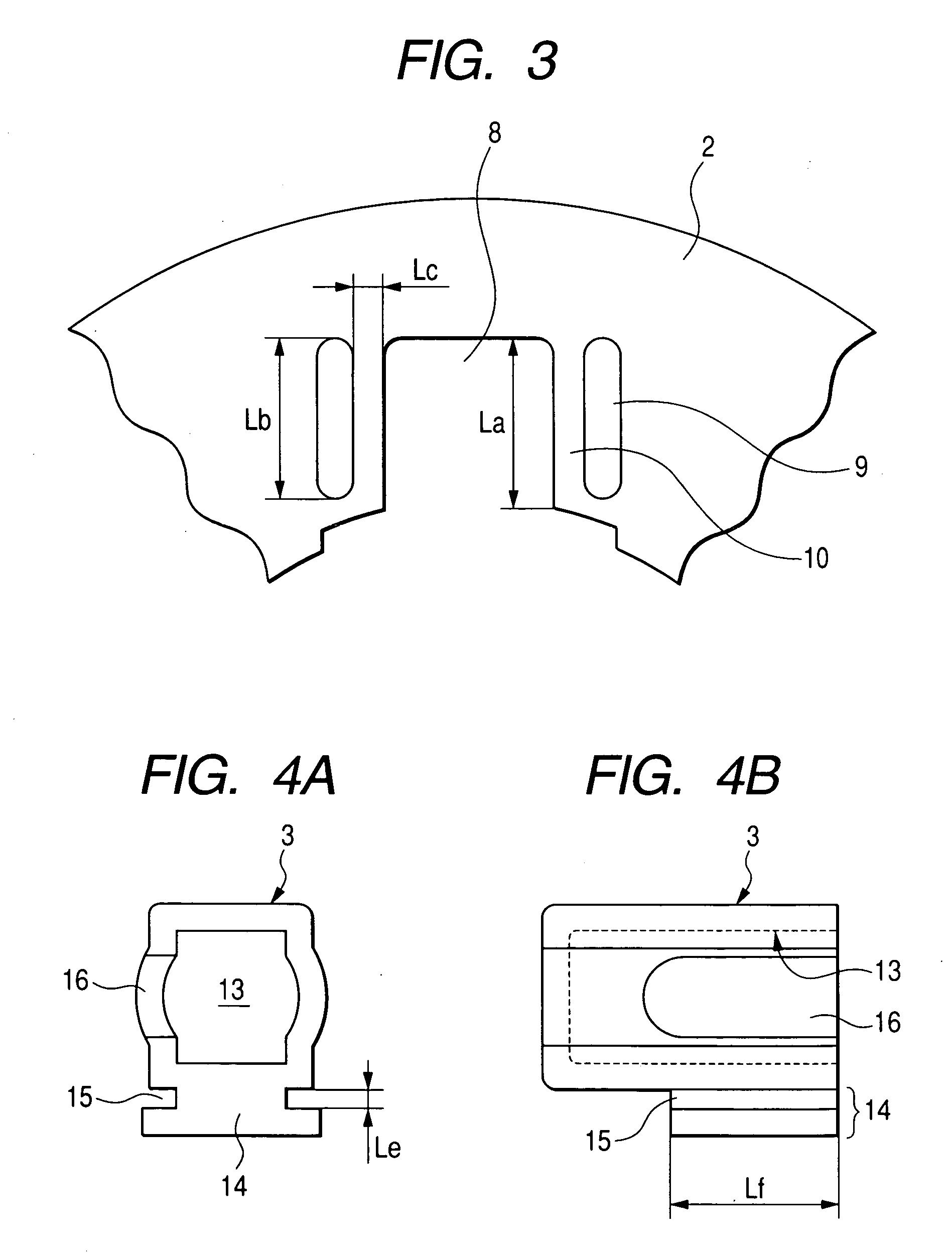

Wiring member of a disc drive suspension having an insulating layer with thick-walled and thin-walled portions

ActiveUS6963471B2Mechanical strength is securedImproved cross talk characteristicFluid-dynamic spacing of headsRecord information storageElectrical conductorThick wall

A wired flexure comprises a metallic substrate, a polyimide layer formed on the metallic substrate, and read conductors and write conductors formed on the polyimide layer. The polyimide layer has a thick-walled portion and a thin-walled portion that are different in thickness. The read and write conductors extend covering the thick- and thin-walled portions. In order to obtain a desired impedance, the width of the conductors in the thin-walled portion is smaller than that of the conductors in the thick-walled portion.

Owner:NHK SPRING CO LTD

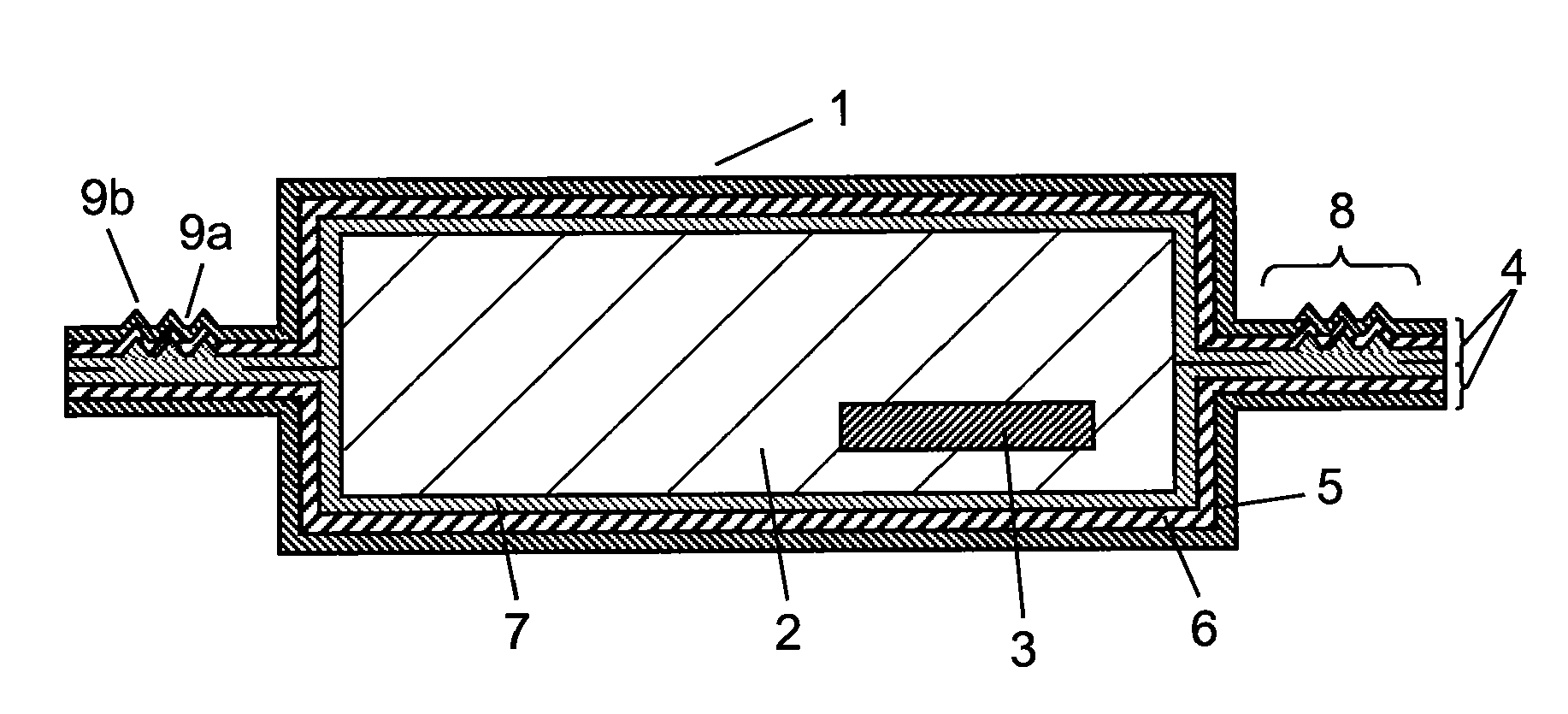

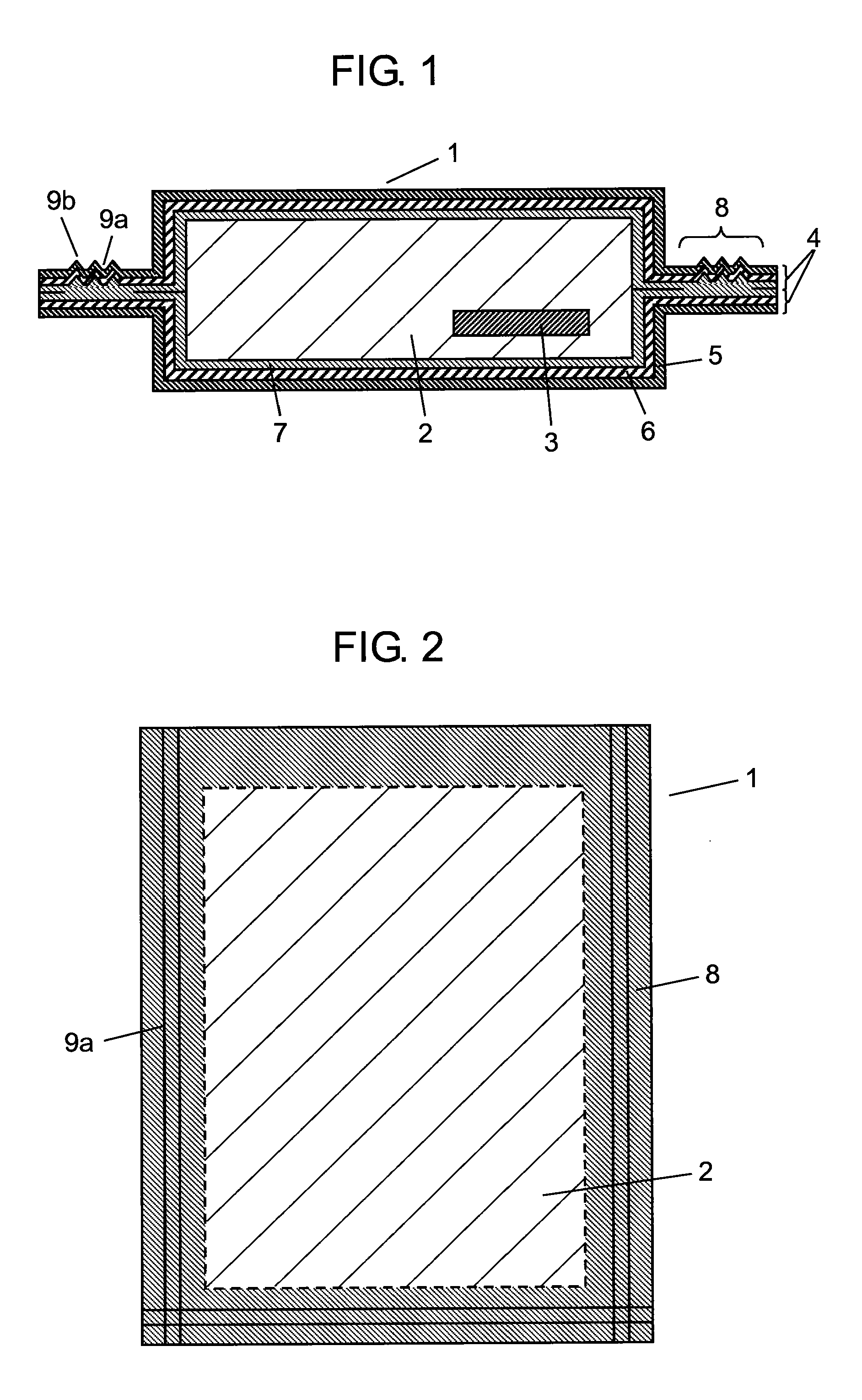

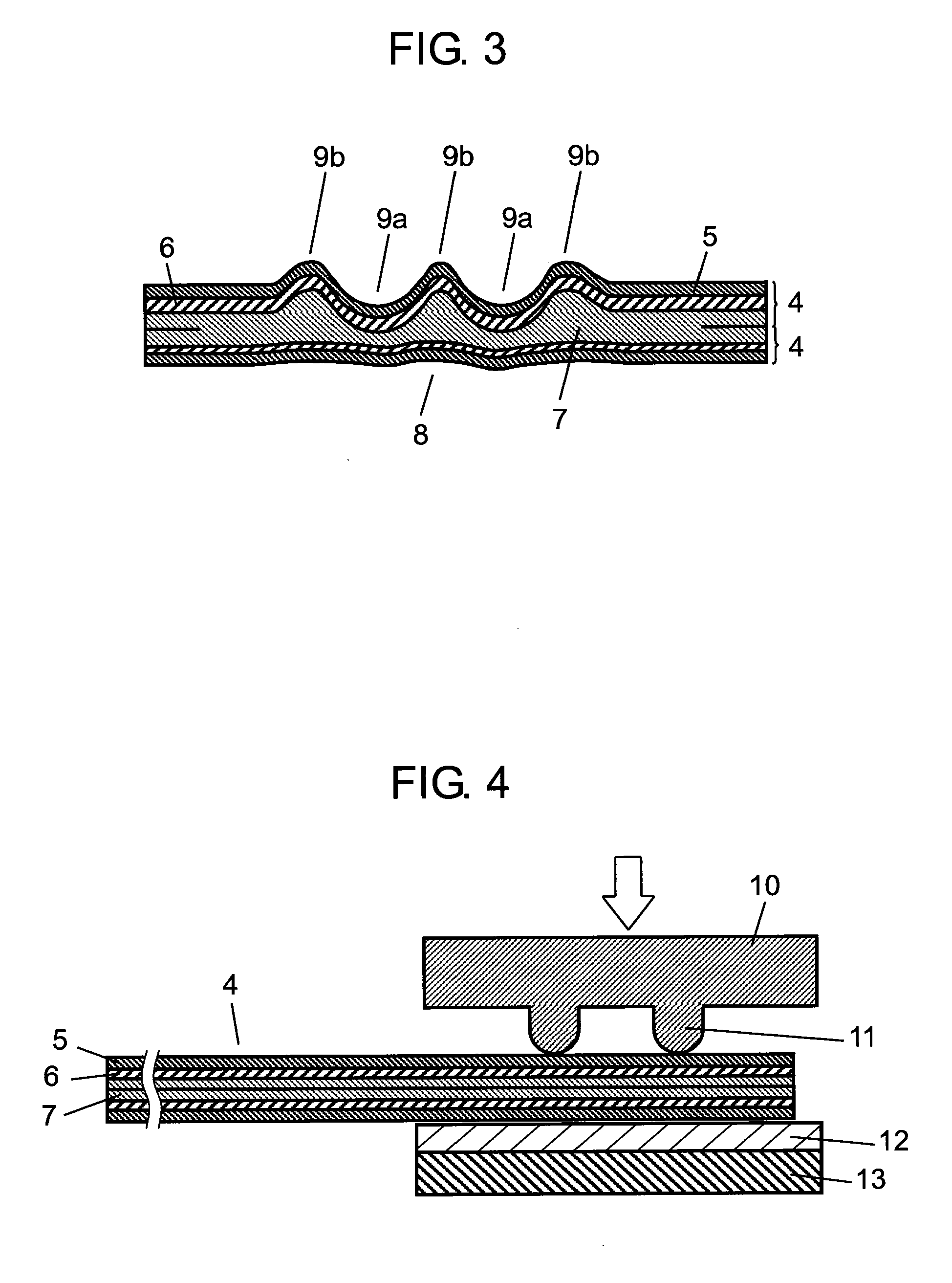

Vacuum heat insulation material and manufacturing method therefor

ActiveUS20110165367A1Avoid it happening againLimited amountThermal insulationClimate change adaptationThick wallEngineering

A plurality of thin-wall parts (9a) of a sealant layer (7) are formed in a portion continuously changed in the interval of one sealing part (8) and a gas barrier layer (6) of other laminate film (4). At the inner circumferential side between the adjacent thin-wall parts (9a) and the thin-wall part (9a) at the innermost circumferential side and at the outer circumferential side of the thin-wall part (9a) of the outermost circumferential side, a thick-wall part (9b) of the sealant layer (7) is formed. All of the opposing sealant layers (7) between the two adjacent thin-wall parts (9a) are mutually heated and fused, so that an excellent adiabatic performance is maintained for a long period.

Owner:PANASONIC CORP

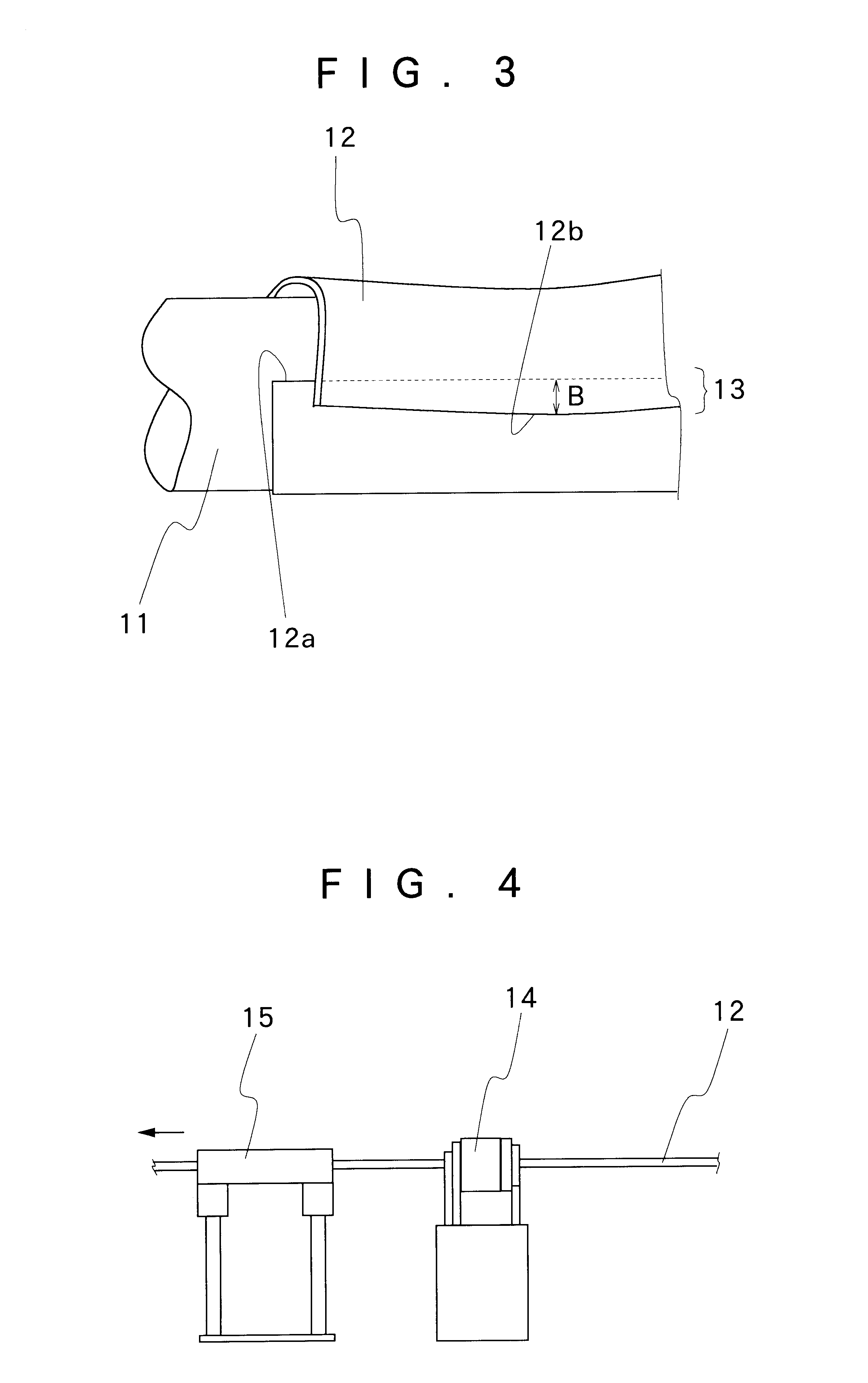

Flexible tube, and method for manufacturing same

InactiveUS6565507B2Reduce the overall diameterWithout sacrificing propertySurgeryEndoscopesThick wallEngineering

A flexible tube having a laminated multi-layer structure including an outer layer composed of a main tube body layer formed of thermoplastic synthetic resin in a predetermined thickness and a reinforcing layer provided on the inner side of the main tube body layer, and an inner layer formed of a thin film sheet of air tight and low friction material. The inner layer is formed by rolling an elongated strip of a thin film sheet into a tubular form such that opposite lateral sides of the thin film sheet are overlapped one on the other to provide a thick wall portion extending longitudinally of and at one angular position of the inner layer.

Owner:FUJI PHOTO OPTICAL CO LTD

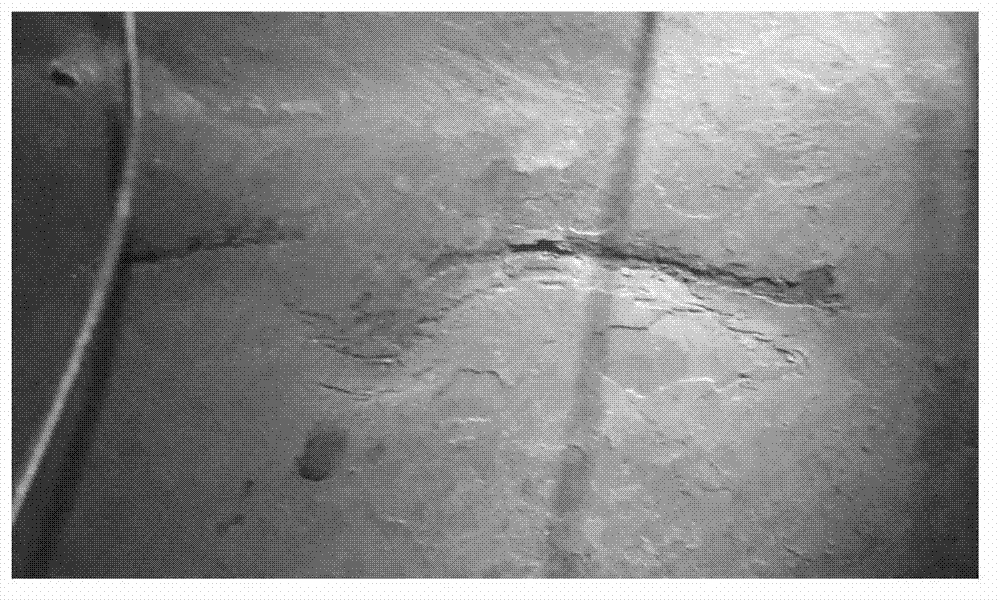

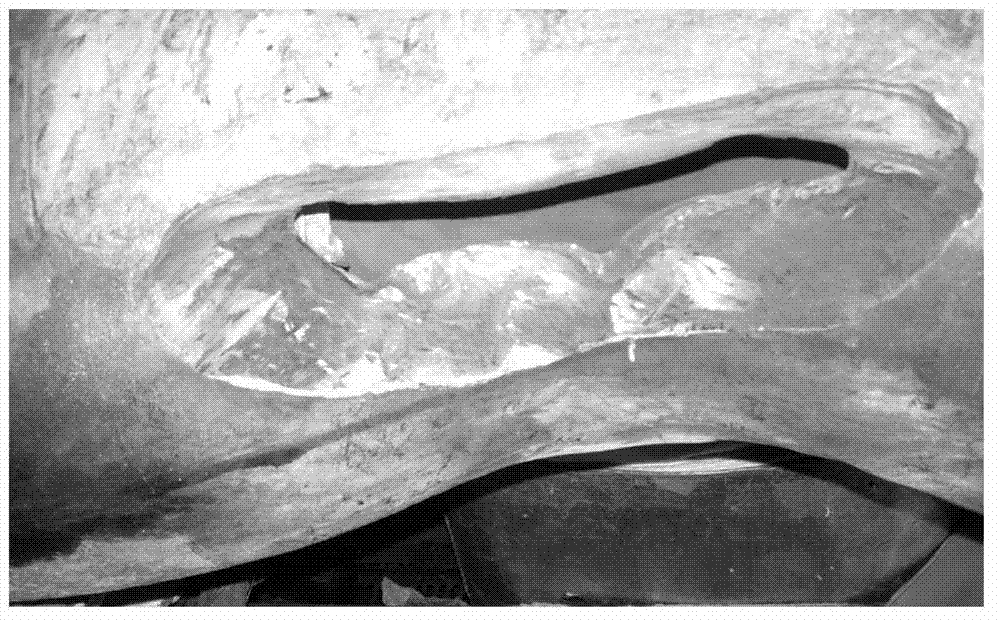

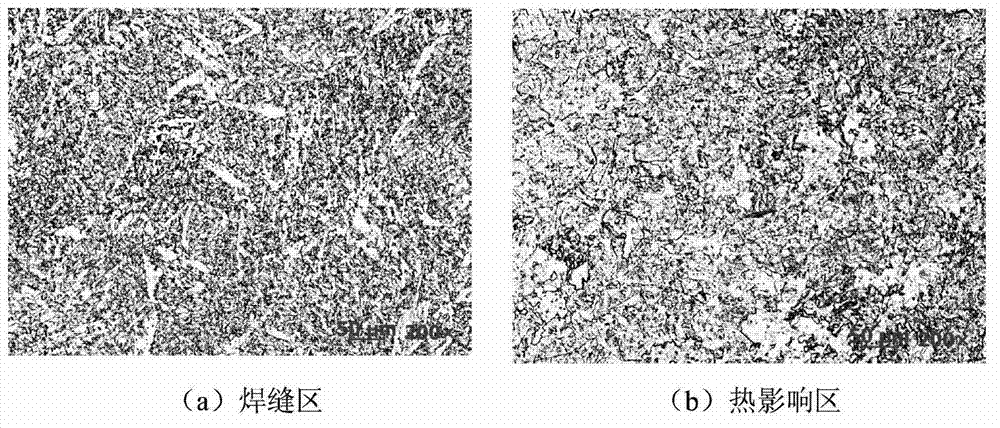

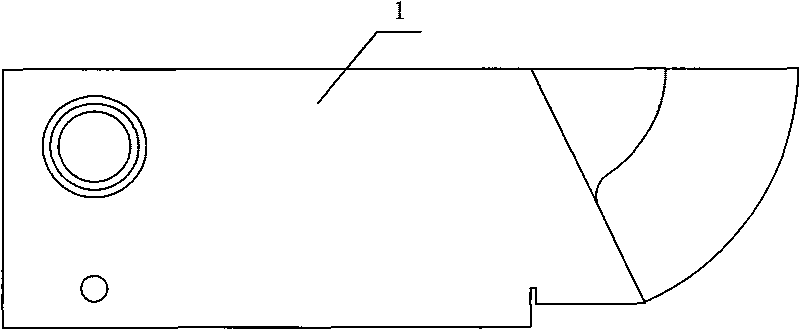

Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

The invention relates to a field welding repair method especially for larger and penetrating defects in a steel casting with heavy wall thickness. The method comprises a pre-welding preparation process, a welding repair process and a post-welding quality inspection process, wherein the welding repair process comprises the steps of (1) preheating; (2) carrying out 1 to 2 layers of backing weld for all positions of a groove by adopting TIG weld, and filling the whole bottom of the groove with solid wire materials; (3) warming up to 220 to 330 DEG C, carrying out constant thermal insulation for 3 to 8 hours, adopting manual arc welding to implement the filler welding for the groove, hammering the welded bead immediately with an air hammer, and ensuring the dense and uniform traces of the hammer; (4) carrying out dehydrogenation heat treatment; (5) carrying out post-welding treatment: carrying out stress annealing at the temperature of 500 to 550 DEG C, then carrying out high tempering at the temperature of 700 to 750 DEG C, and finally, cooling at the speed of 65 to 150 DEG C / h to the room temperature. After welding repair, a welding seam is tested to be good in quality, and have low possibility of cracking again.

Owner:SUZHOU NUCLEAR POWER RES INST +4

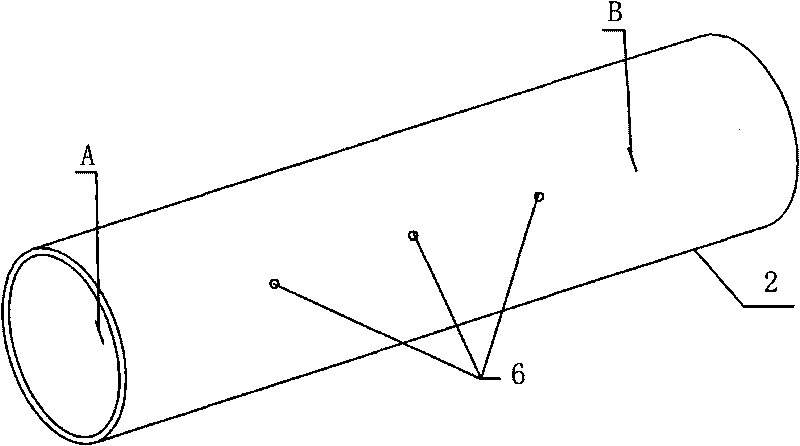

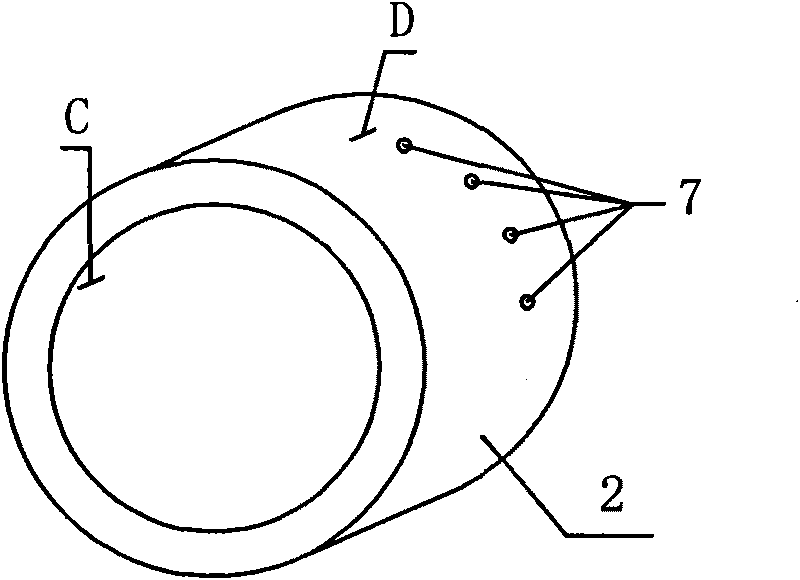

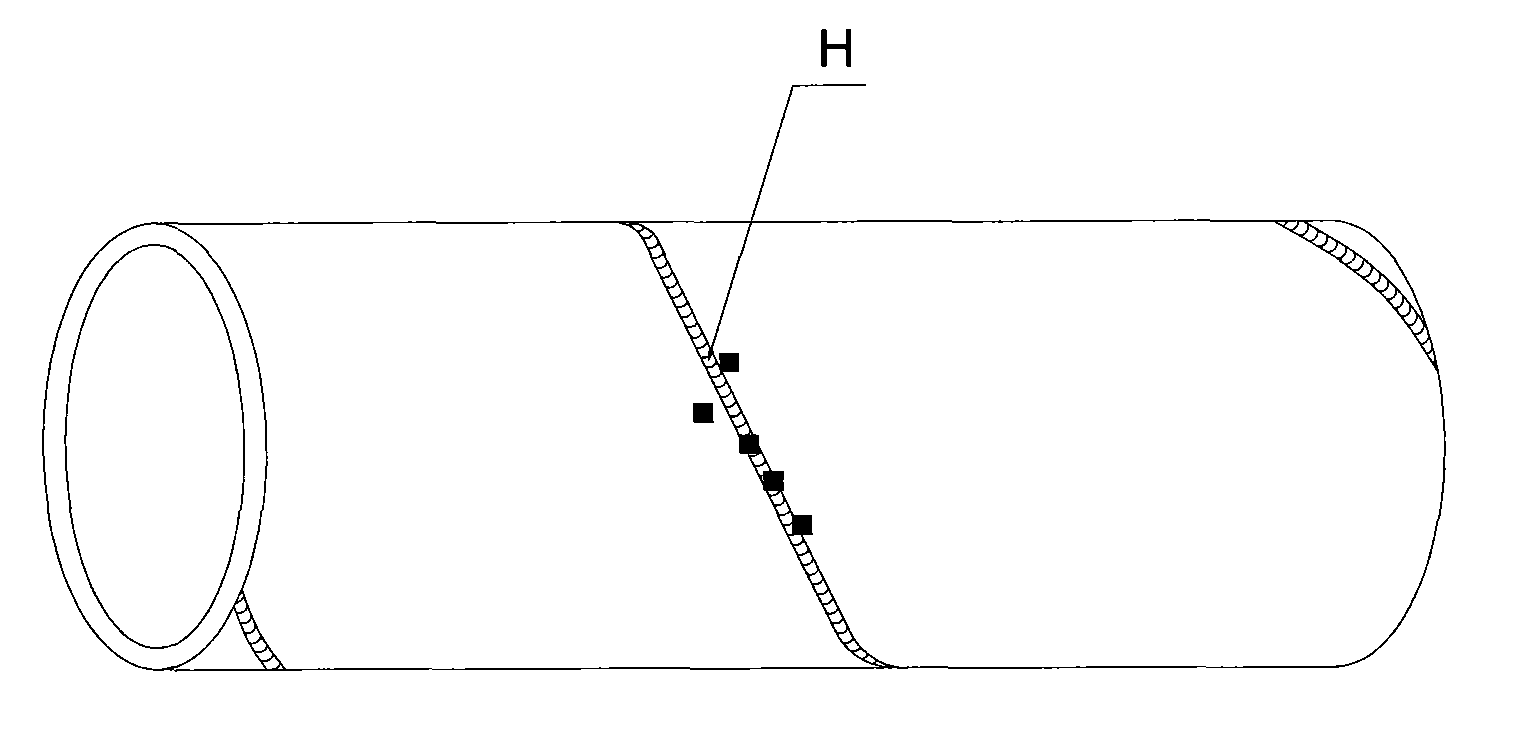

Power station thick-walled pipeline ultrasonic guided wave detecting method

ActiveCN101726541AQuick checkReliable detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSize measurementPower station

The invention belongs to the field of nondestructive detection, and particularly relates to a power station thick-walled pipeline ultrasonic guided wave detecting method, wherein the method comprises the following steps of: selecting an ultrasonic guided wave detecting probe; selecting an ultrasonic guided wave detecting instrument; manufacturing a sensitivity test block; making a distance-amplitude curve; scanning; carrying out flaw size measurement; and verifying and grading detecting results. The detecting method is suitable for comprehensively detecting the flaws of pipelines with different pipe diameters and thicknesses, and is particularly suitable for comprehensively detecting power station thick-walled pipelines. The detecting method has the characteristics of rapidness, simpleness, safety and reliability, can overcome some limitations of a conventional nondestructive detection method, lowers the manual detection intensity and saves human and material resources.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

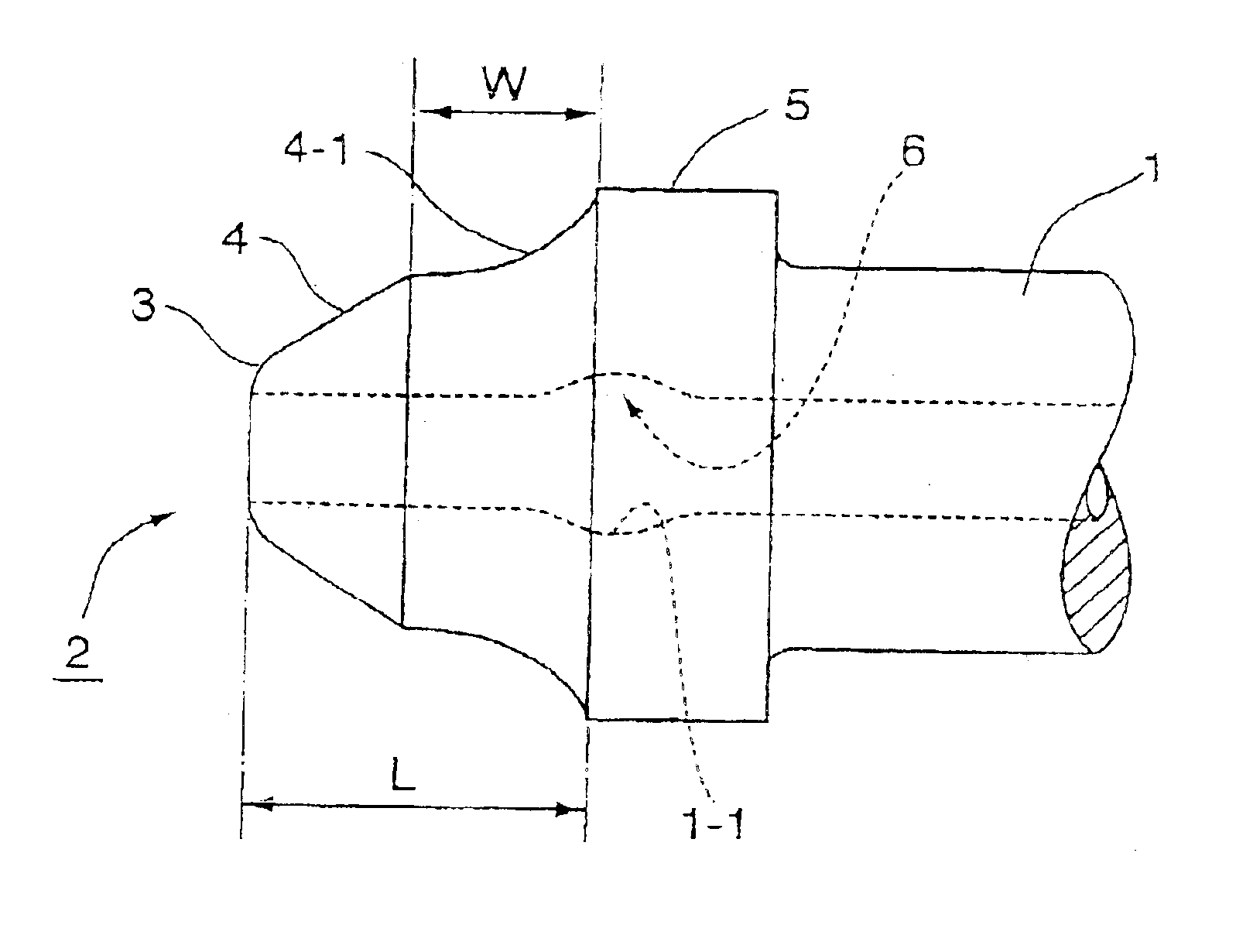

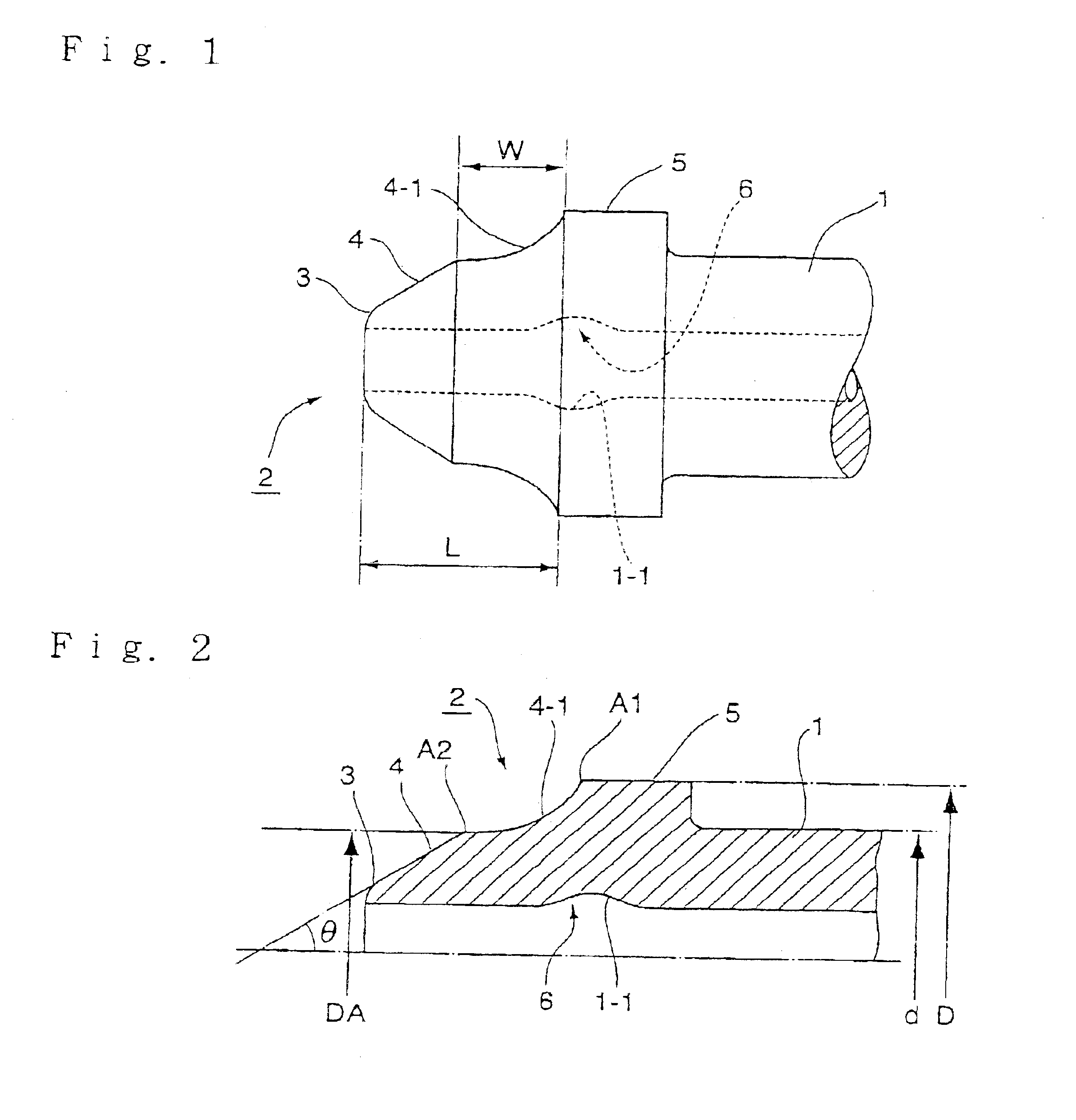

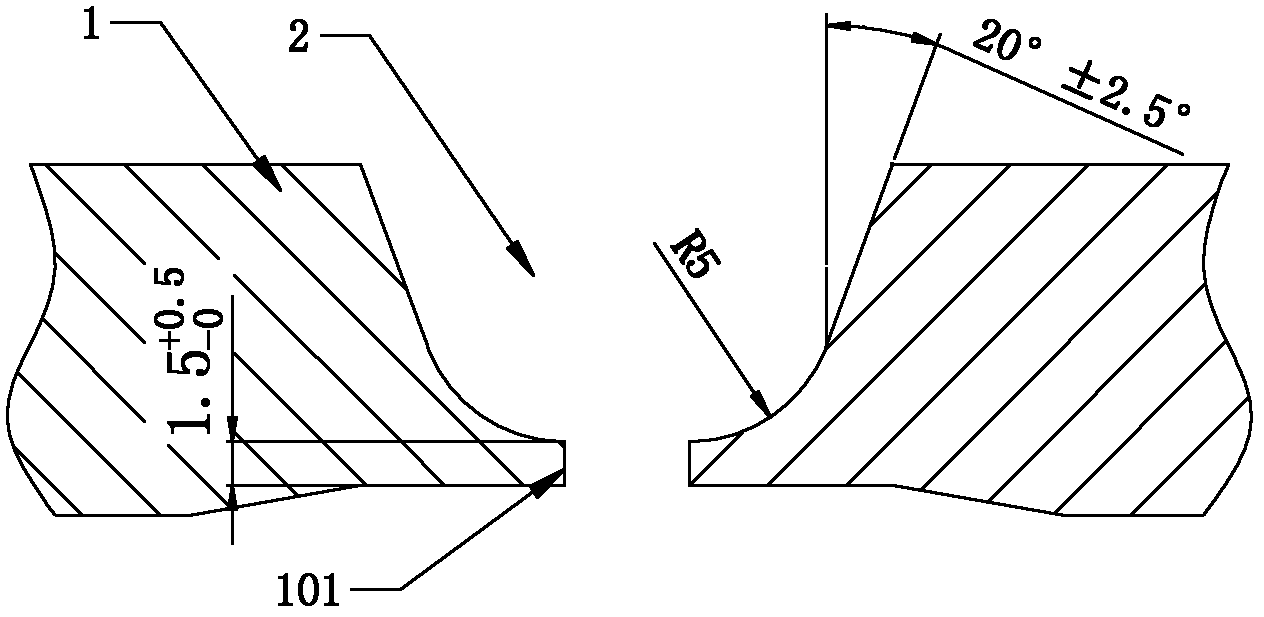

High-pressure fuel injection pipe having connecting head portion

InactiveUS6840283B2Eliminate fearReduce fatigue failureJoints with sealing surfacesMetal-working apparatusThick wallEngineering

A high-pressure fuel injection pipe having connecting head portion is provided which is capable of eliminating a fear of the occurrence of cavitation erosion of the inner surface of the connecting head portion and a fatigue failure of the same head portion by having a contour of a cross section of an annular pocket occurring in an inner part of the connecting head portion during a head portion processing operation extend shallowly and gently. This fuel injection pipe has at a connecting end portion of a thick-walled steel pipe having a relatively small diameter, including a seat surface, an annular flange formed so that the flange is axially spaced from the seat surface, and a conical surface connected to the seat surface, extending therefrom to the annular flange and tapering off to a free end of the connecting head portion, wherein the conical surface is provided at a part thereof with an annular, shallow, cross-sectionally curved recess.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes

ActiveCN102554402AReduce labor intensityEnsure continuous weldingArc welding apparatusFurnace typesNuclear technologyNuclear engineering

The invention discloses welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes, which are suitable for welding and heat treatment of large-diameter and thick-wall pipes. The pipes welded by the welding and heat treatment processes are steady and reliable in the quality of welding lines, and can completely meet the quality requirement of nuclear technology.

Owner:江苏利柏特股份有限公司

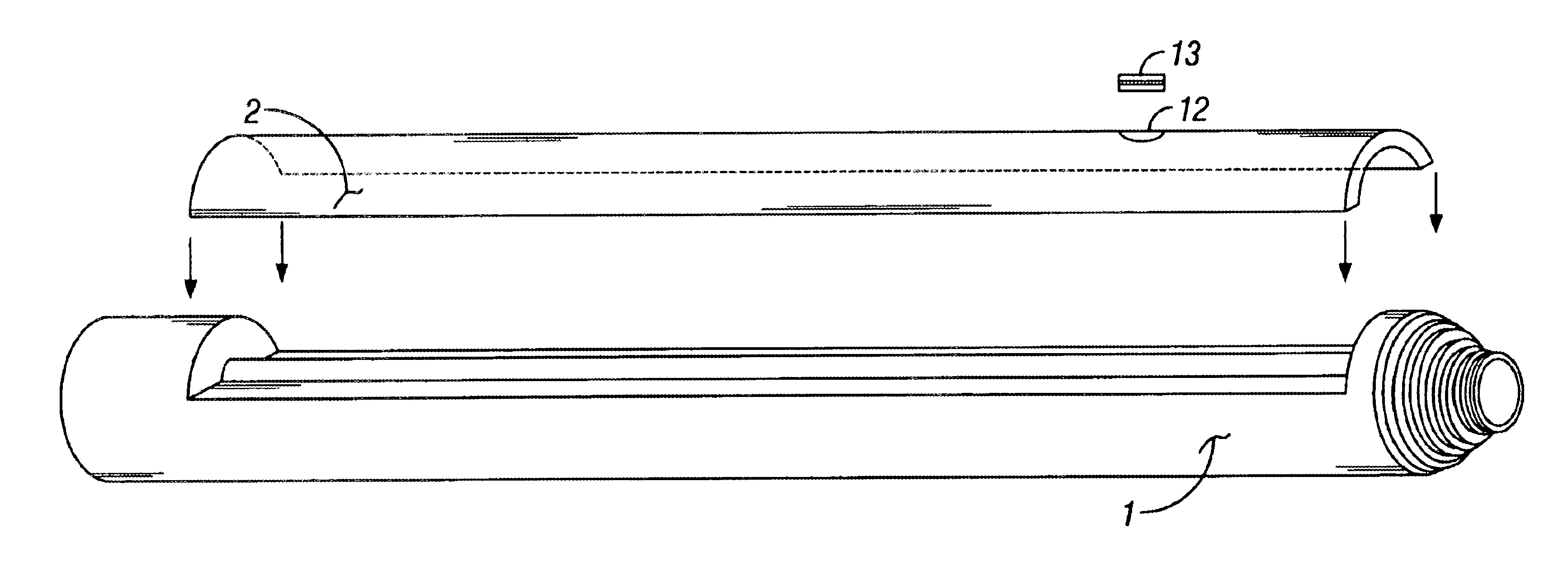

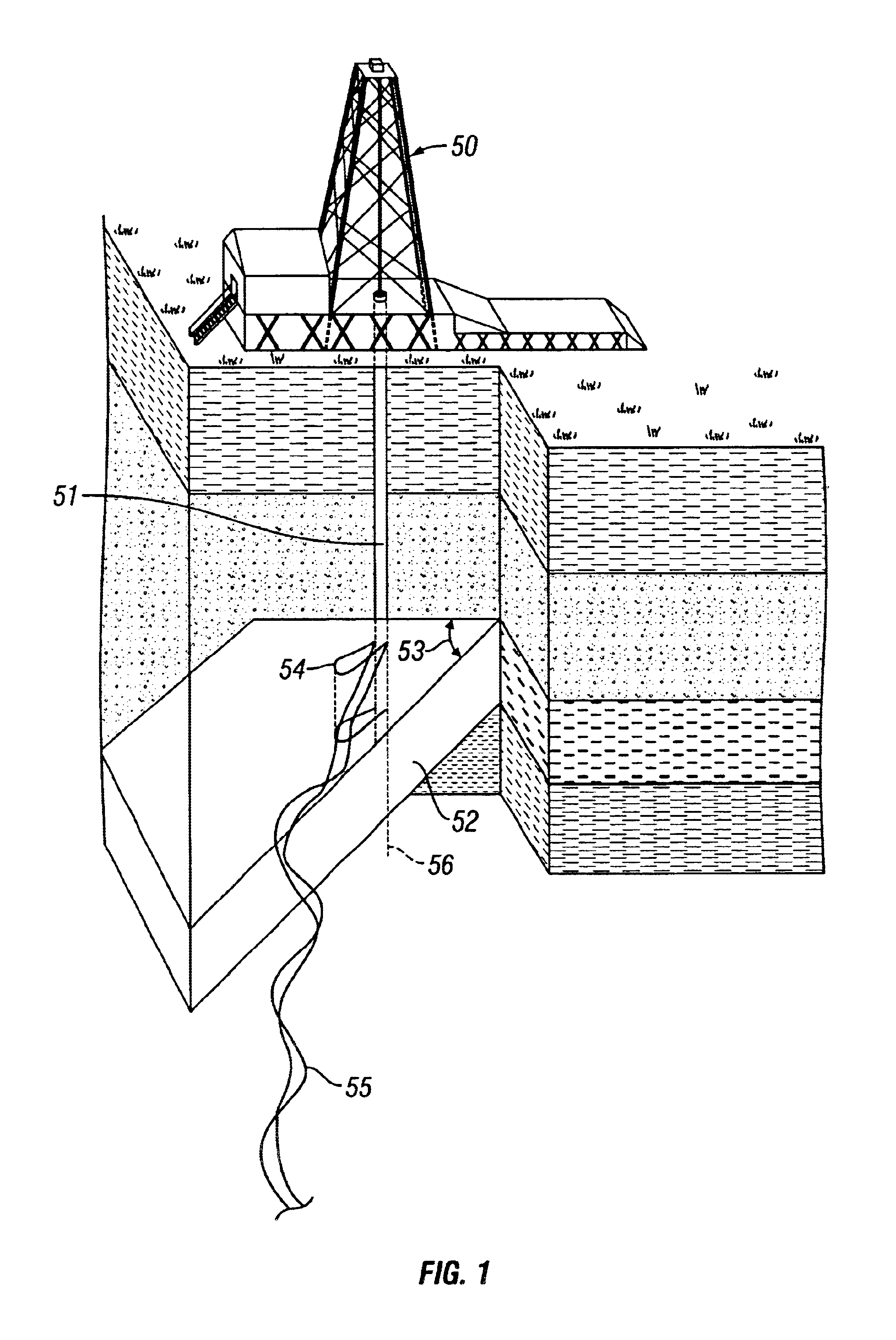

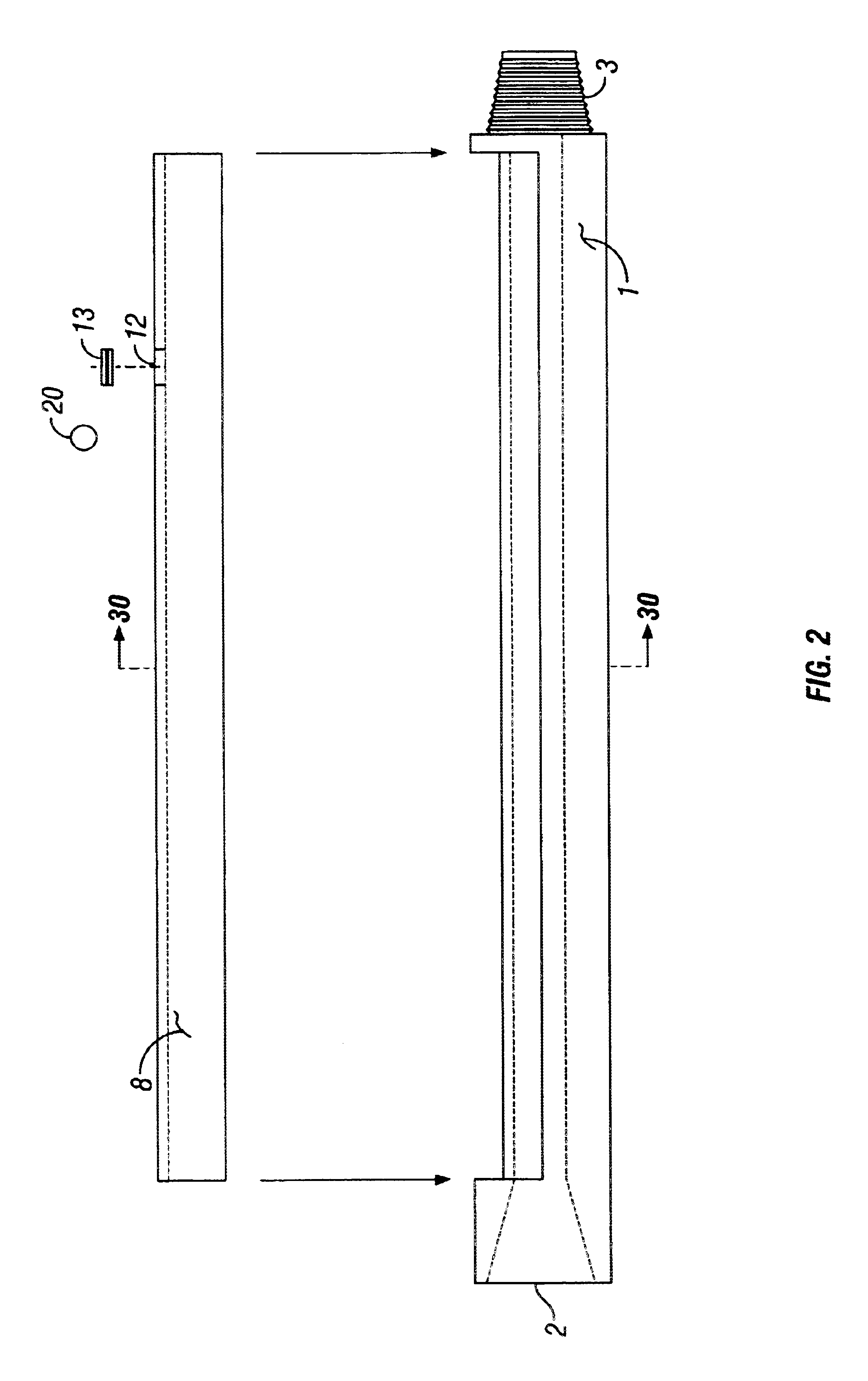

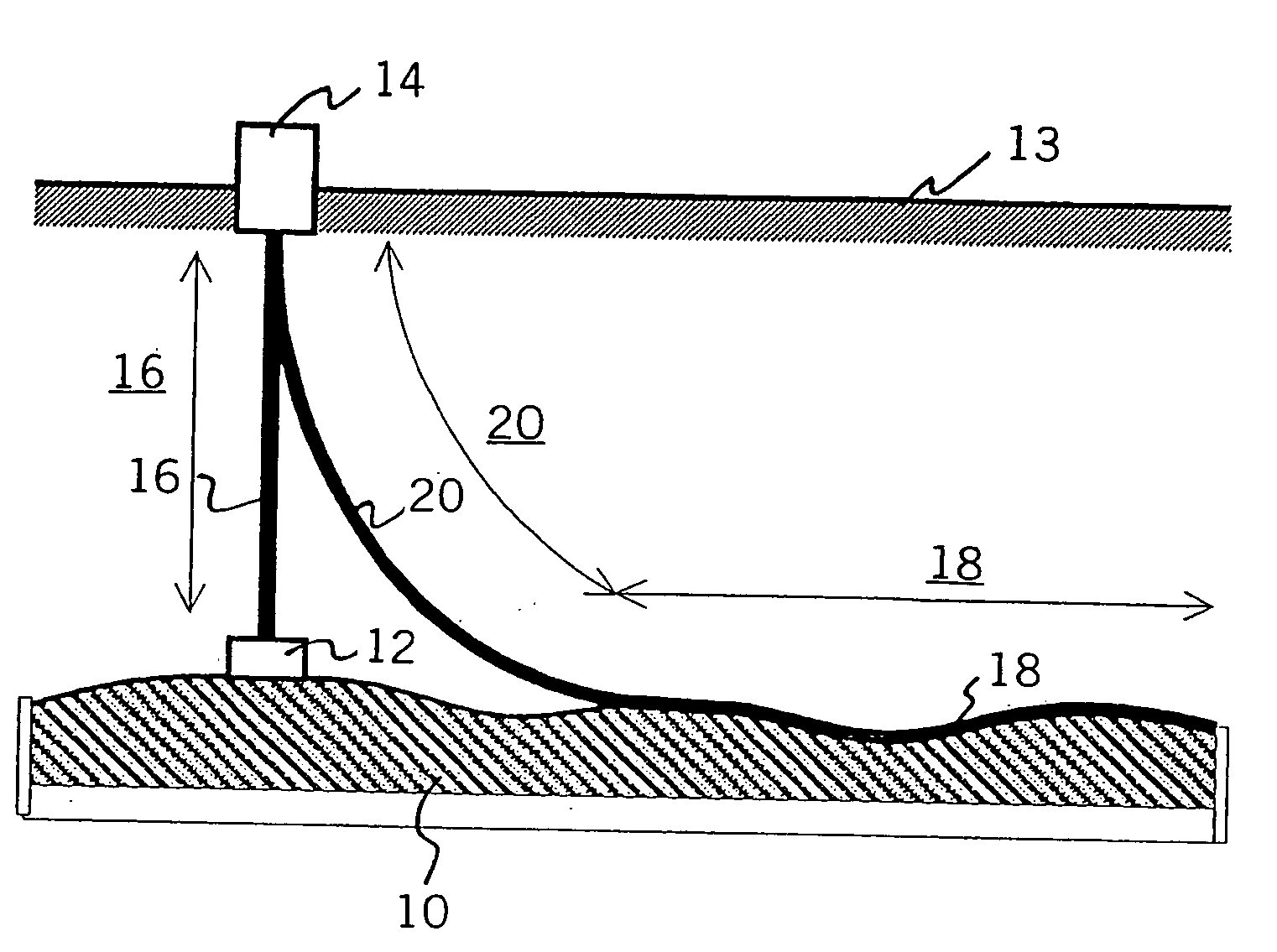

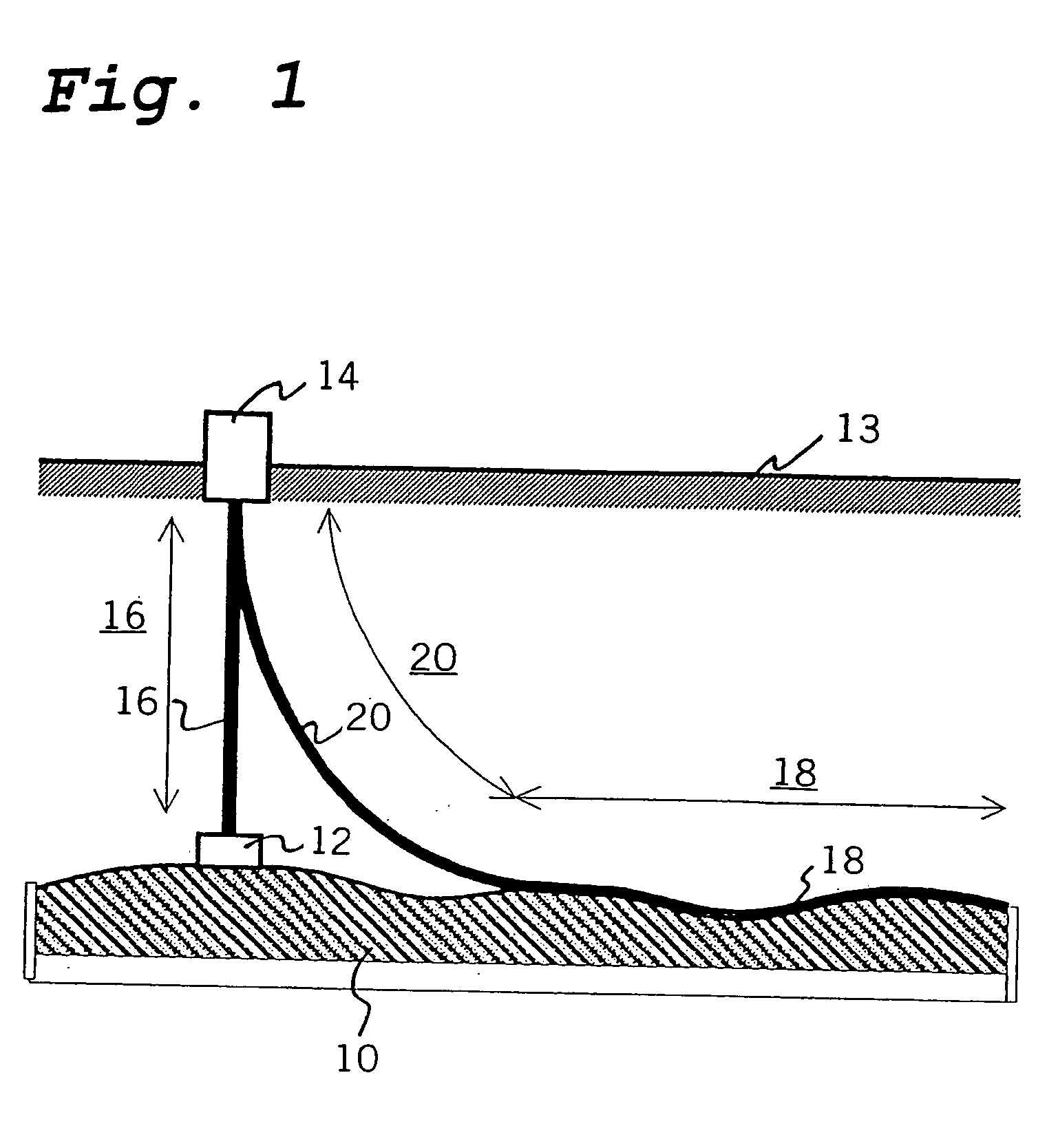

Method and apparatus for drilling wells

A well borehole is prevented from deviating from its intended vertical path as it is being drilled by use of a sub assembly which is eccentrically weighted with respect to its axis of rotation. Such a sub assembly can comprise a straight tubular member weight relieved along one side by, for example, forming a cavity within the heavy walls of the tubular member along the side of the collar. Thus, the eccentric weight is imposed upon the drill bit without providing any protrusions or elbows which are designed to bear on the wall of the borehole. Additionally, as the cavity is contained within the heavy walls of the tubular member, drilling fluids containing various debris cannot inhabit the cavity, thus maintaining a constant eccentric weight upon the drill bit.

Owner:MATTHEWS FIRM THE

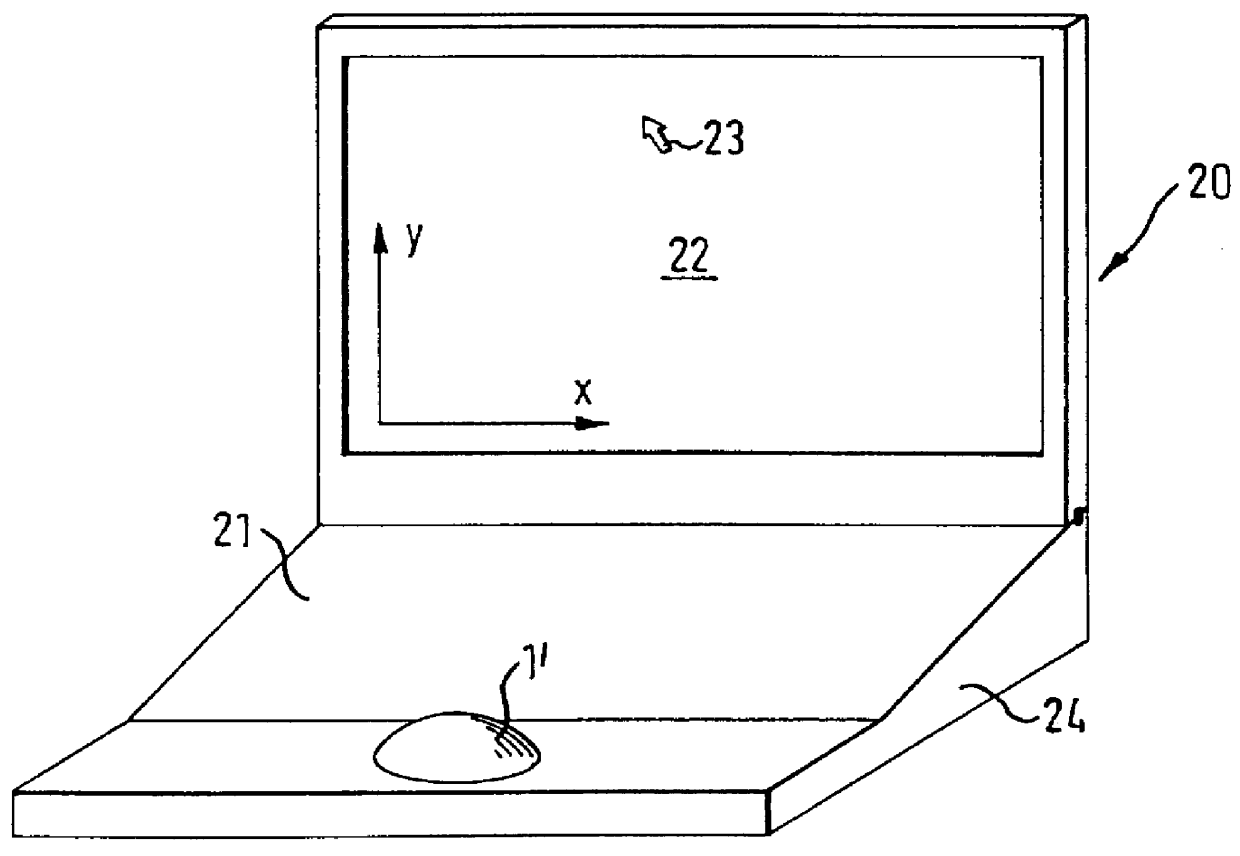

Device for controlling a position indicator on a visual display

InactiveUS6094190AEasy constructionMiniaturizationCathode-ray tube indicatorsInput/output processes for data processingMotion detectorDisplay device

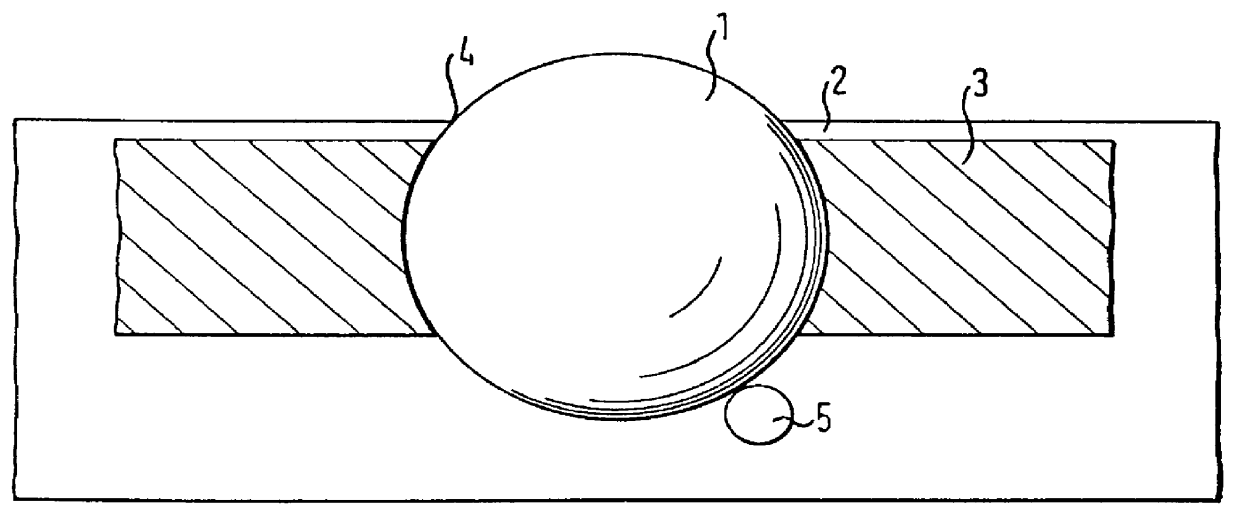

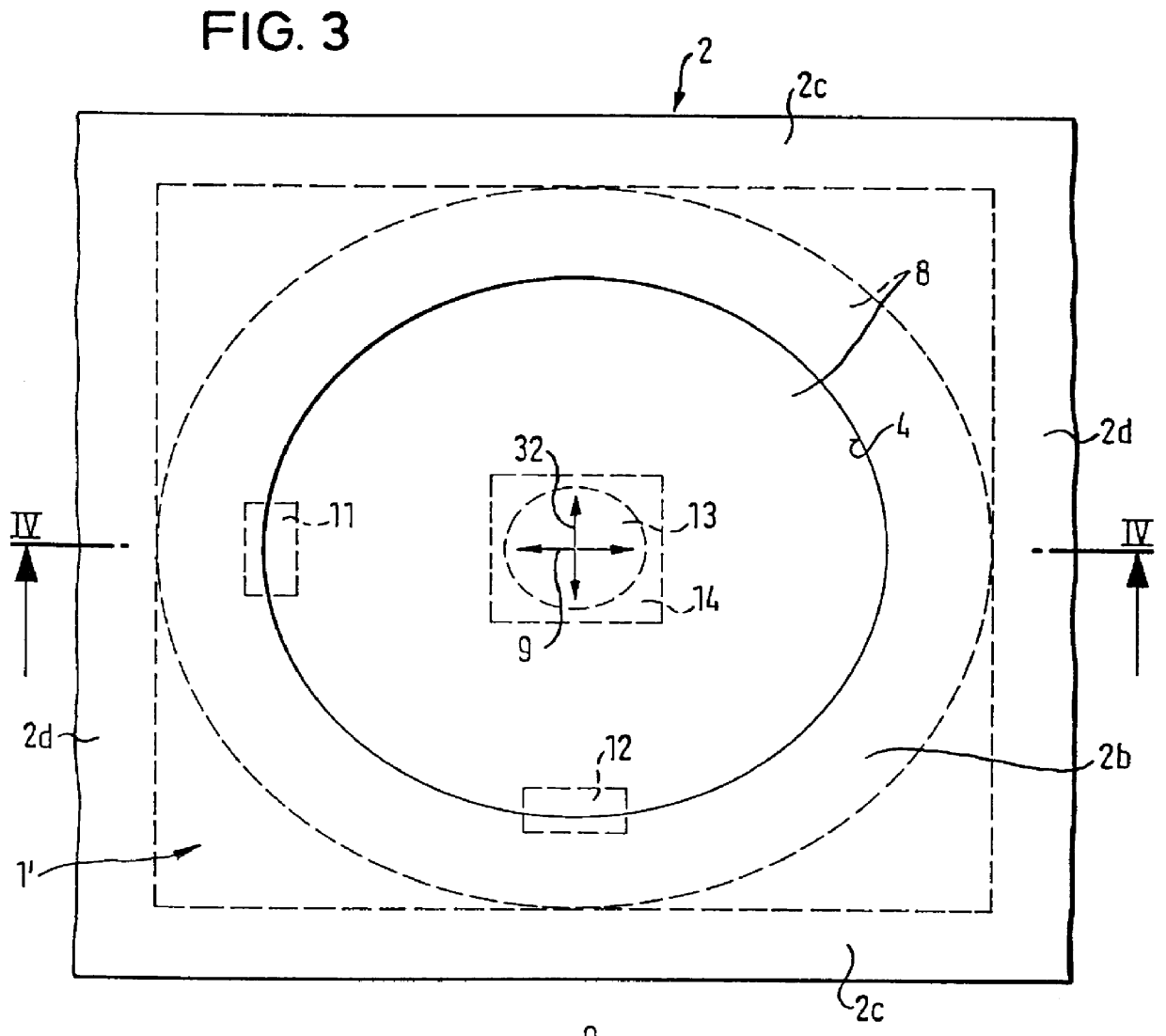

For controlling a position indicator, e.g. a cursor, on a visual display, e.g. the monitor screen associated with a personal computer or a laptop computer screen, a position indicator controlling device (1) comprises an indicator position controller (6) in the form of a continuous membrane of elastomeric material (8) stretched, in wrinkle-free manner, around a solid form-keeping core (7) held captive in a housing (2) so that by applying finger pressure in a generally horizontal direction to an uppermost exposed, part-spheroidal, portion of the membrane, the membrane can slide on the core to produce a corresponding output signal from one or more motion detectors (11, 12). The indicator position controller gives the appearance to a user of a spherical ball device (such as is commonly used in a laptop computer), but the special shape of the form-keeping core is such as to reduce the overall height requirement and leads to a heightwise compact construction for the position indicator controlling device (1'). According to two modifications (FIGS. 5 and 6), the indicator position controller (6) is realized by a normally spheroidal thick-walled elastomeric ball (8'), or by a solid elastomeric ball (8'') held in a deformed state by the housing (2). The position indicator controlling device (1) can be designed for use as a ball-type device for a laptop computer or as a mouse for a personal computer.

Owner:BLACKBERRY LTD

Magnetic grinding and polishing method and device of inner surface of thick-wall ceramic pipe

InactiveCN103624634AHigh precision grinding and polishingIncrease grinding pressureReciprocating motionMagnetic poles

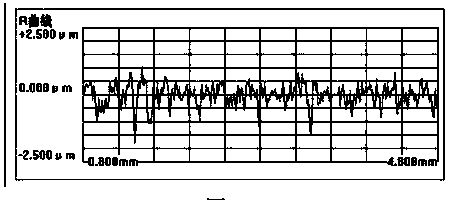

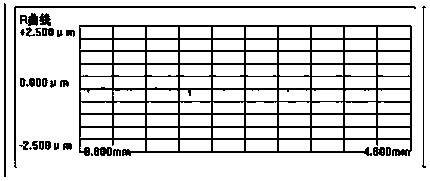

The invention discloses a magnetic grinding and polishing method and device of the inner surface of a thick-wall ceramic pipe. The method includes the steps that the thick-wall ceramic pipe is clamped to a three-claw chuck; one permanent magnet is placed at one end of a magnetic pole frame in an N-S mode, and another permanent magnet is placed at the other end of the magnetic pole frame in an S-N mode; magnetic grinding materials are prepared; the prepared magnetic materials are adsorbed to a V-type magnet, and the V-type magnet to which the magnetic materials are adsorbed is placed into the thick-wall ceramic pipe; magnetic grinding particles collide with one another and are squeezed mutually on the inner surface of a ceramic pipe body to polish the inner surface. The magnetic grinding and polishing device comprises a base, a variable-speed motor, a cam, a connecting rod, the permanent magnets, the magnetic pole frame, the three-claw chuck, a connecting shaft, a connecting shaft bearing, an adjustable-speed motor, a variable-speed stating switch, an adjustable-speed starting switch, a moving platform, a guide rail, the magnetic grinding materials and the V-type magnet. Linear reciprocating motion and magnetic abrasive finishing processing are adopted, and high-precision grinding and polishing of the inner surface of the ceramic pipe can be achieved through the flexibility of a magnetic abrasive finishing brush.

Owner:UNIV OF SCI & TECH LIAONING

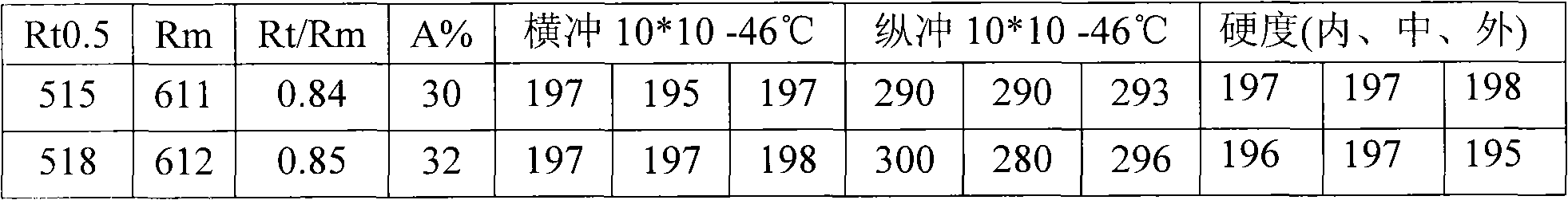

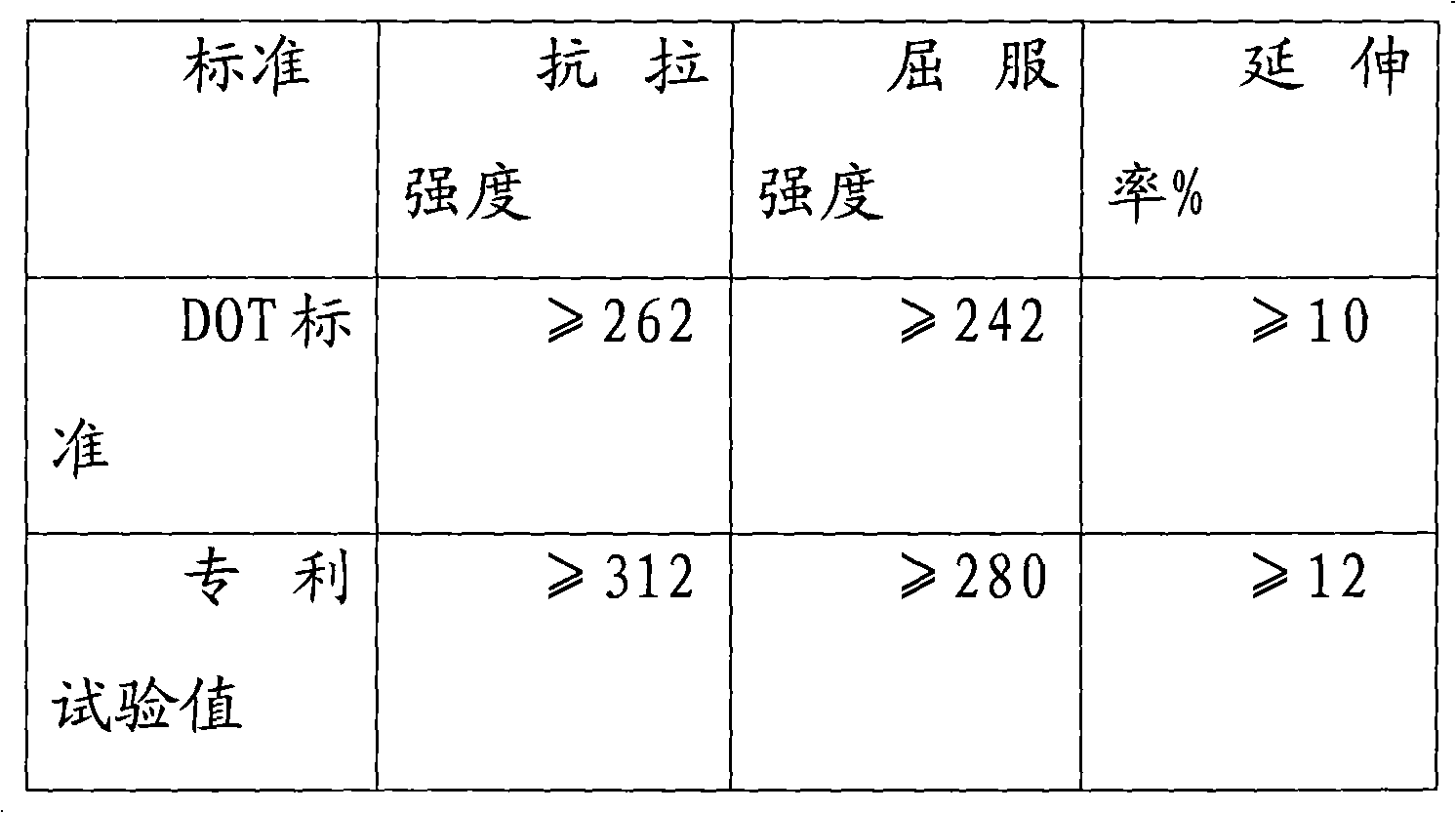

High-strength high-ductility X70 thick-wall seamless pipeline steel and manufacturing method

ActiveCN101343715AImprove hardenabilityFulfil requirementsFurnace typesHeat treatment furnacesCold weatherThick wall

The invention provides a high-intensity and high-toughness X70 thick-walled seamless pipeline steel. The steel comprises the following elements, in weight percentage: 0.04 to 0.12 percent of C, 0.17 to 0.35 percent of Si, 1.20 to 1.60 percent of Mn, 0.015 percent or less than 0.015 percent of P, 0.010 percent or less than 0.010 percent of S, 0.10 to 0.30 percent or less than 0.10 to 0.30 percent of Mo, 0.005 to 0.045 percent of Al, 0.02 to 0.06 percent of Nb, 0.02 to 0.10 percent of V, 0.10 to 0.25 percent of Cu, 0.10 to 0.30 percent of Ni, 0.010 to 0.030 percent of Ti, 0.20 percent or less than 0.20 percent of Cr, 0.43 percent or less than 0.43 percent of CE, 0.22 percent or less than 0.22 percent of Pcm, balance iron and trace impurity element. The invention also provides a seamless pipeline steel rolling and manufacturing method. The invention has the advantages that micro-alloy steel is adopted, the seamless pipeline steel is suitable for the production of the thick-walled pipeline with the wall thickness of less than 36 mm, the overall structure of the pipe adopts an even Bainite structure, the carbon equivalent is low, the welding performance is good, the impact performance at low temperature is good, the requirements of the thick-walled pipeline used in deep sea and under other cold weather are satisfied, the mechanical property of the pipeline is enhanced, the steel hardness penetration when in water quenching is improved, and the difficult problem of thick-walled pipe machining by a chamfering machine is solved.

Owner:TIANJIN PIPE GROUP CORP

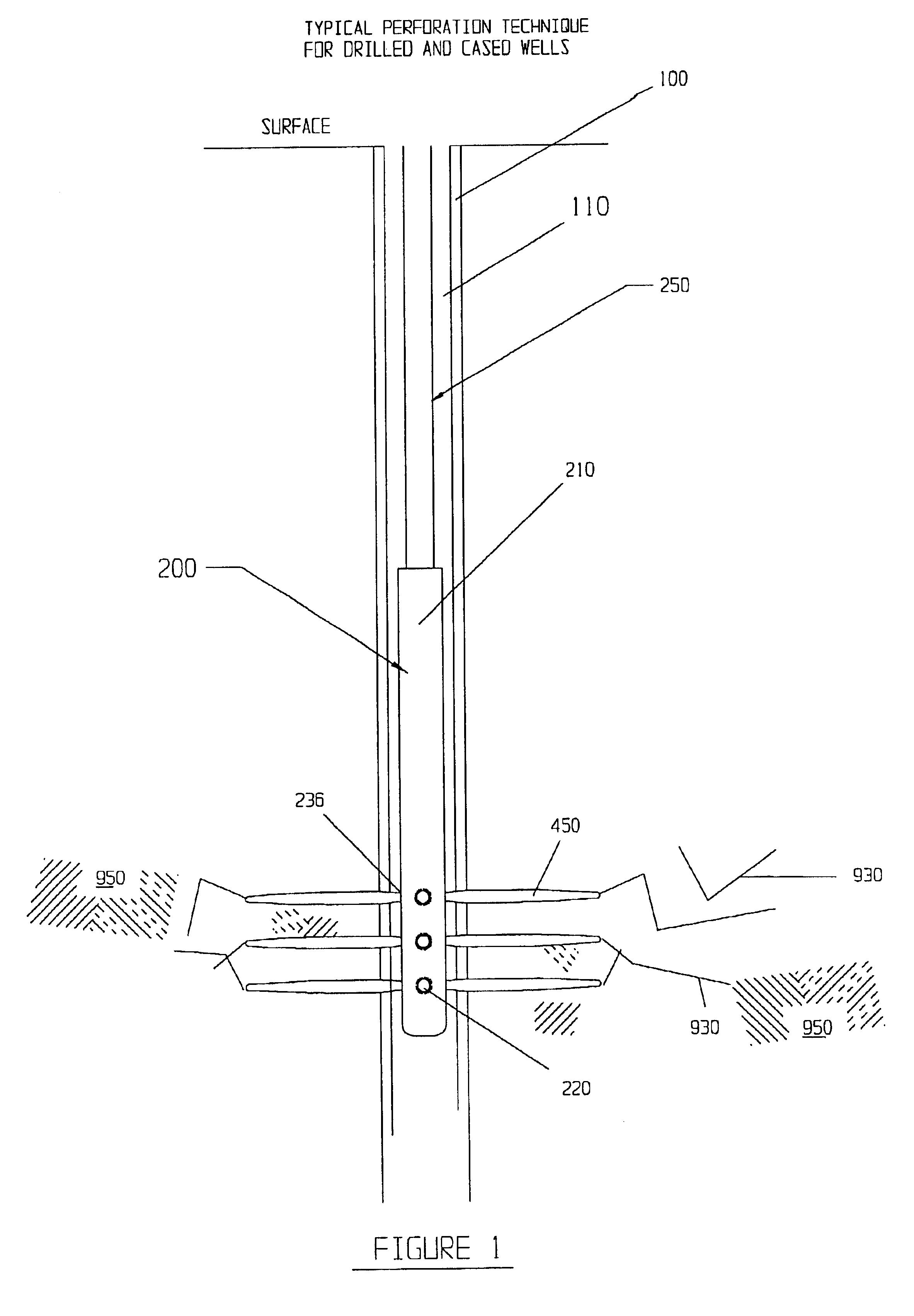

Well perforating gun

InactiveUS6865978B2Minimize failureMinimizes problemExplosive chargesAmmunition projectilesTectonicsThick wall

Owner:KASH EDWARD CANNOY

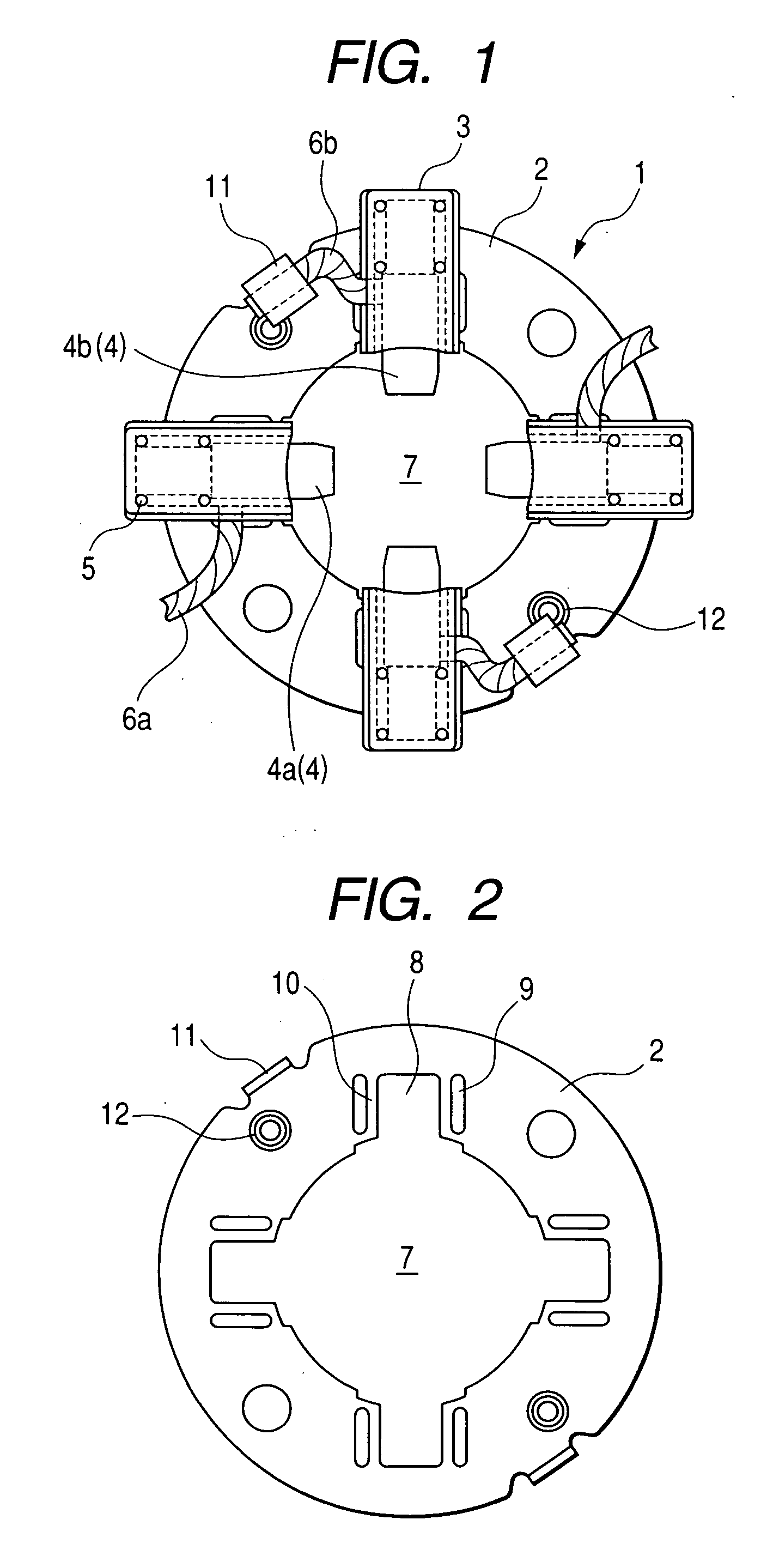

Brush holding device

ActiveUS20070007846A1High strengthLarge fixing forceRotary current collectorDynamo-electric machinesThick wallMechanical engineering

The brush holding device includes a brush holder having a brush-housing chamber, and a holder plate to which the brush holder is attached. The holder plate is formed with a center hole at a center portion thereof, the center hole having a size allowing a commutator to path therethrough, and a pair of elongated holes opposing to each other with respect to the opening portion, the elongated holes defining bridge portions with the opening hole. The brush holder has a thick-wall portion integral with a bottom wall of the brush-housing chamber, the thick-wall portion being formed with fitting grooves at lateral sides thereof. The bridge portions are inserted into the fitting grooves so that the brush holder is fitted to the holding plate in such a state that the thick-wall portion is caught between the bridge portions.

Owner:DENSO CORP

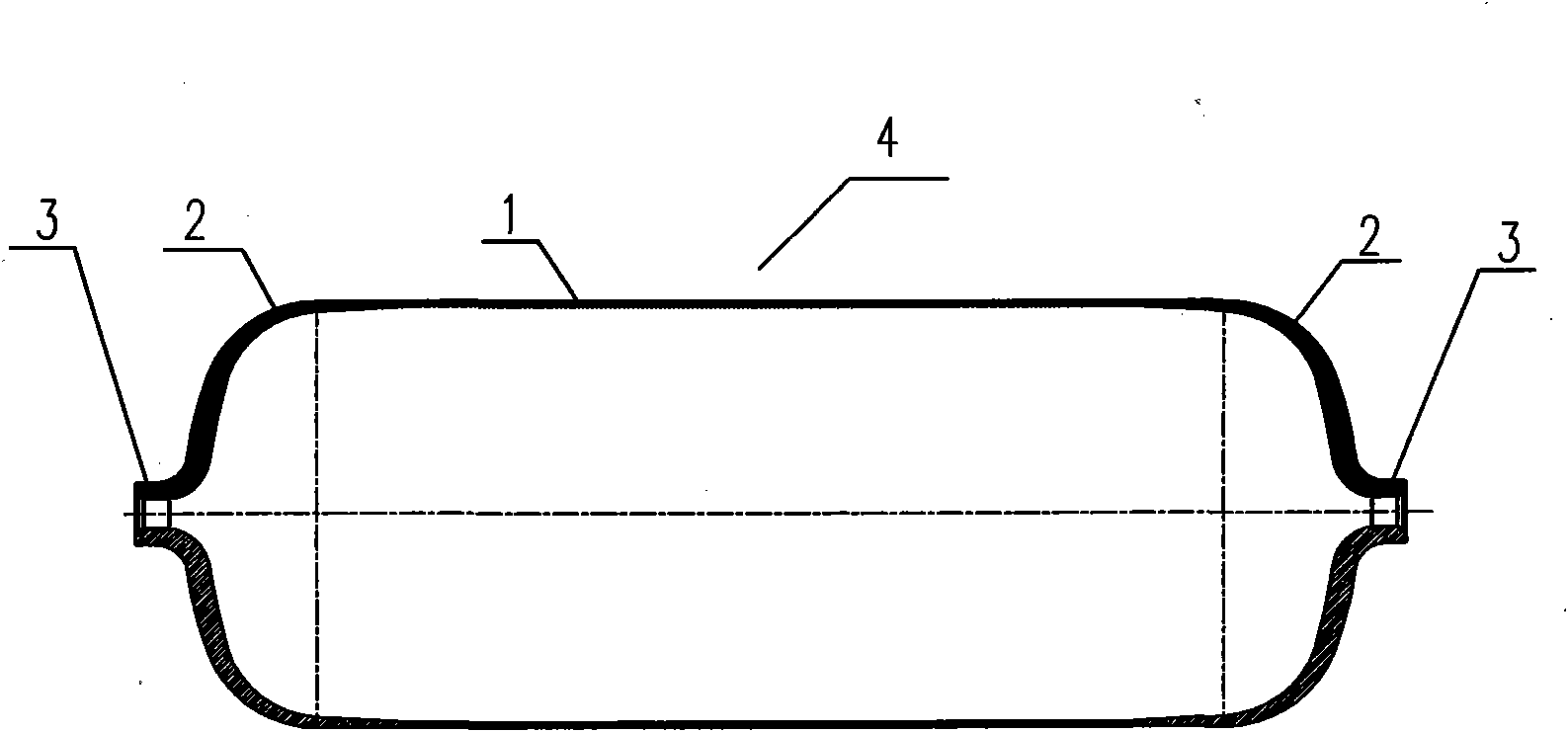

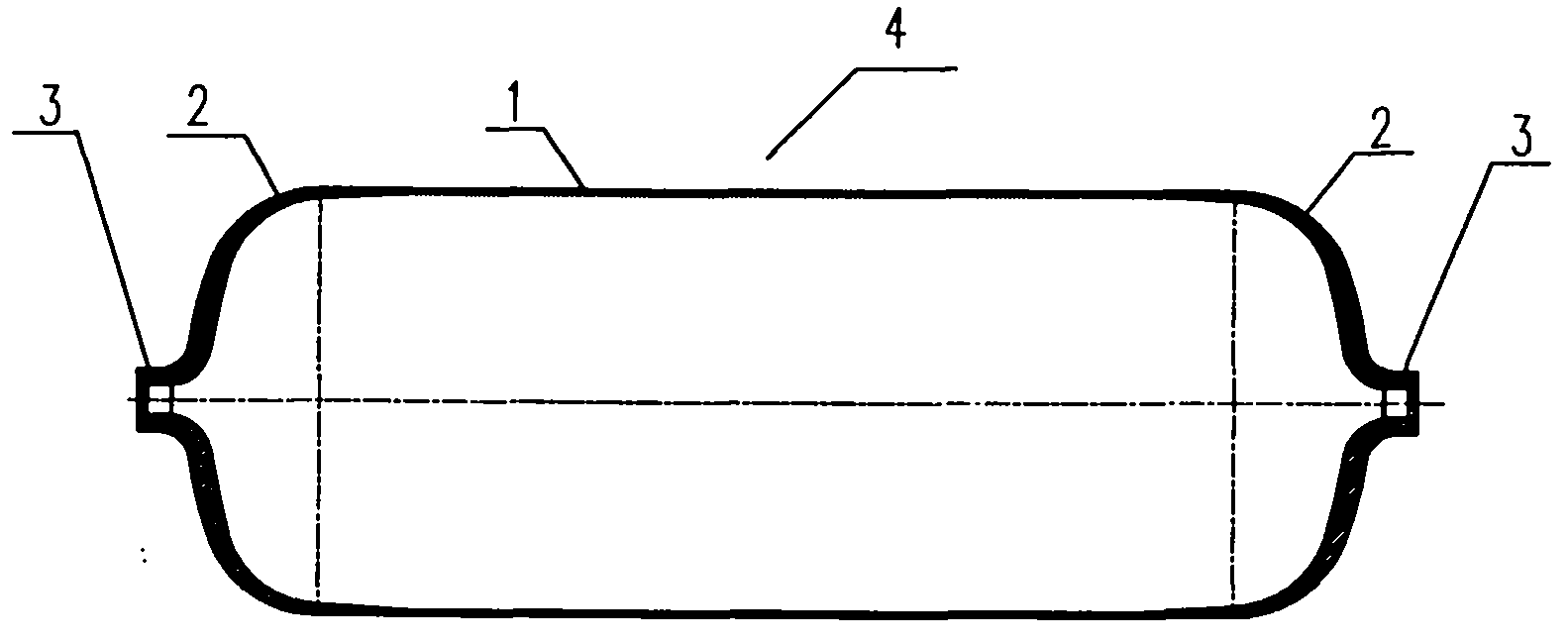

Method for manufacturing aluminum liner of vehicular composite cylinder

The invention discloses a method for manufacturing an aluminum liner of a vehicular composite cylinder, which is used for manufacturing the aluminum liner of the vehicular composite cylinder. The aluminum liner consists of a thin-walled cylinder body of the aluminum liner, an end enclosure gradually thickening part and an opening part. The aluminum liner is manufactured by adopting a method of reducing the wall thickness of a thick-wall aluminum pipe by over 60 percent by one time of rotary pressing by a 450 strong spinning reduction machine, forming the end enclosure part and the opening part by using a 412 spinning necking machine, and machining the connecting threads on the opening part after solution ageing heat treatment. The aluminum liner of the vehicular composite cylinder has the advantages of high quality, large diameter, thin wall thickness, small weight capacity ratio (weight / capacity), high geometric dimensioning accuracy, high quality of inner and outer surfaces and the like, and has the excellent application and market prospects.

Owner:BEIJING TIANHAI IND

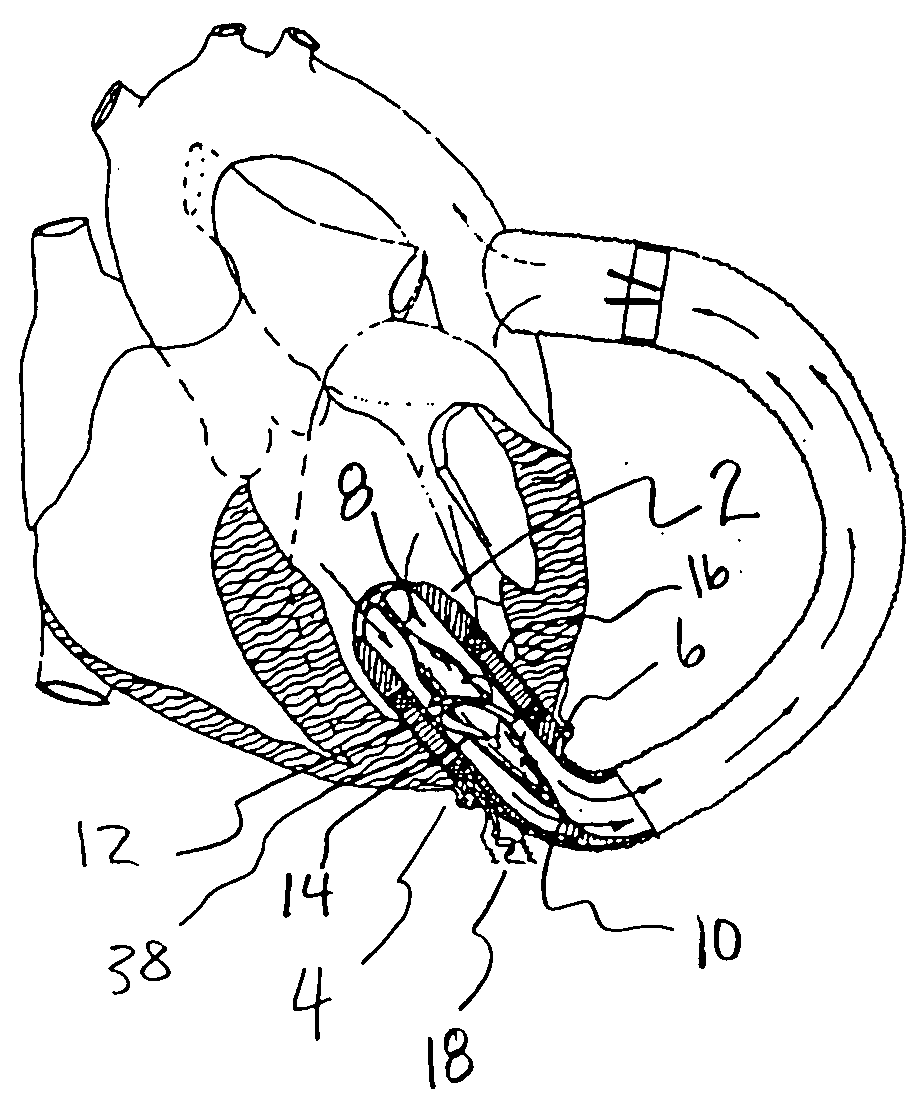

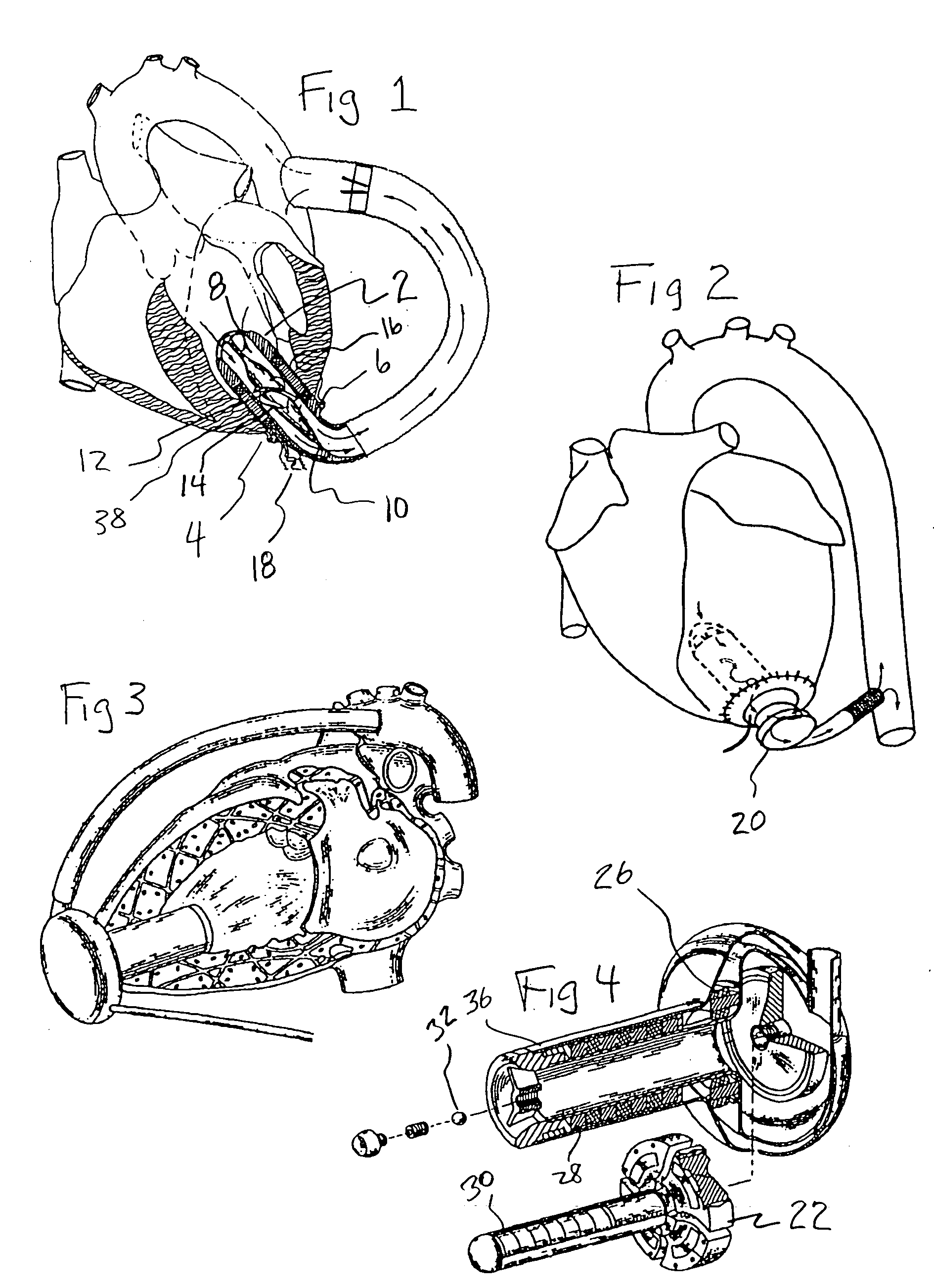

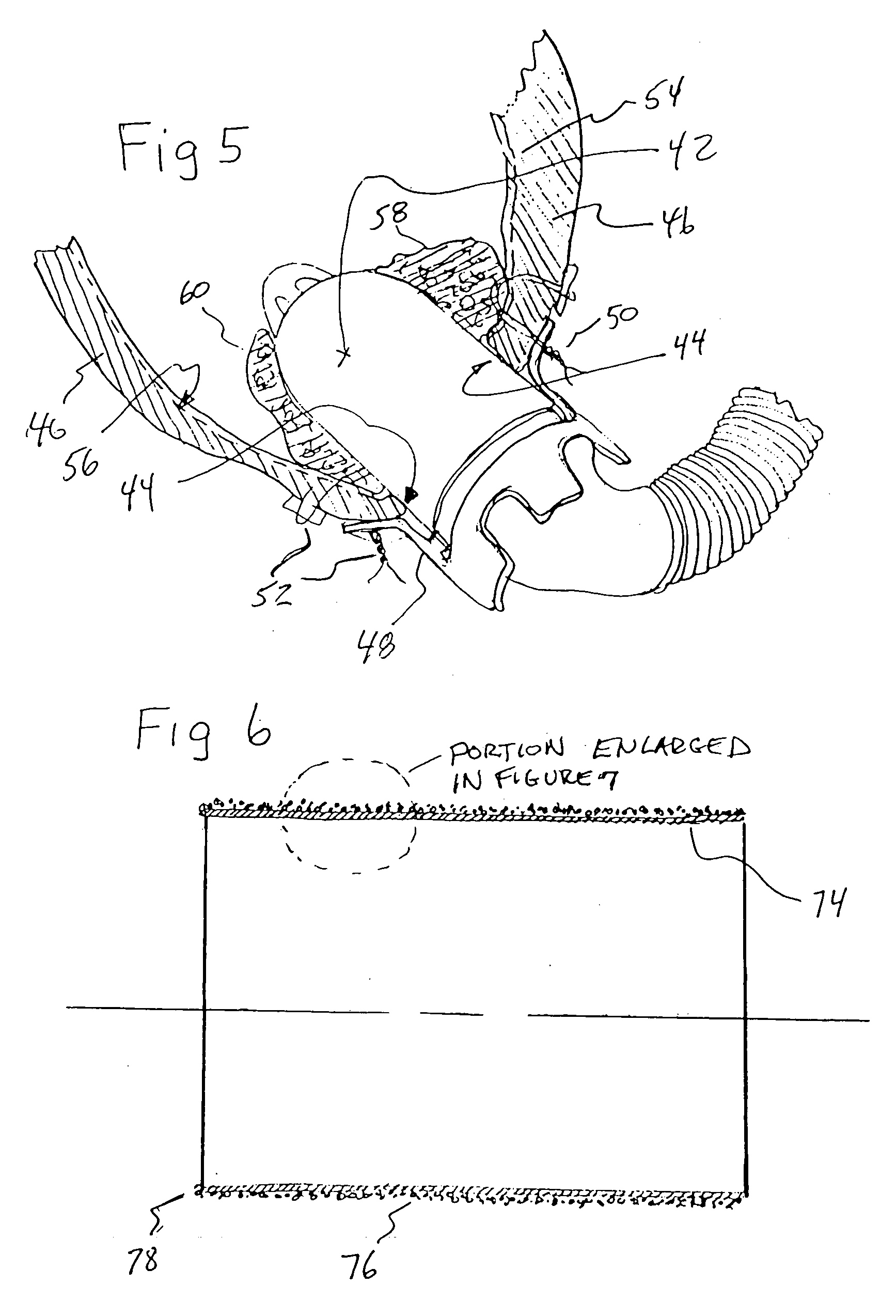

Textured conforming shell for stabilization of the interface of precision heart assist device components to tissues

InactiveUS20070299297A1Quantity minimizationPrevent thrombosisBlood pumpsMedical devicesMicrospherePolymer insulation

The blood contacting surfaces of heart assist devices must avoid excessive thrombus formation, which can break off and cause thromboembolism, become infected and cause other problems. Certain textured surface coatings, such as sintered titanium microsphere coatings, form a thin layer of living cells on the surface that becomes endothelized and is highly resistant to thrombus generation. Some of these coatings require high processing temperatures. Simple thick wall conduit tubes, which do not require high precision, coated with sintered microspheres, have been used successfully as inlet cannulae. Thick wall titanium pump components have also been successfully coated with sintered microspheres, using methods to retain their shape in the furnace and avoid excessive deformation. Blood pumps or portions of blood pumps that utilize high precision components subject to damage or warping if exposed to high temperatures cannot be directly coated. This applies to intraventricular and other blood pumps with precision heat sensitive components, such as polymer insulated wires, placed at least partly within an organ of the cardiovascular vascular system. The present invention provides a thin wall textured surface shell that is coated at high temperature and then, after finish machining, is affixed over the heat sensitive precision blood pump to serve as the interface with biological tissues.

Owner:JARVIK ROBERT

Seamless steel pipe for line pipe and a process for its manufacture

ActiveUS20080219878A1Stable supplyHigh strengthFurnace typesHeat treatment furnacesChemical compositionHigh intensity

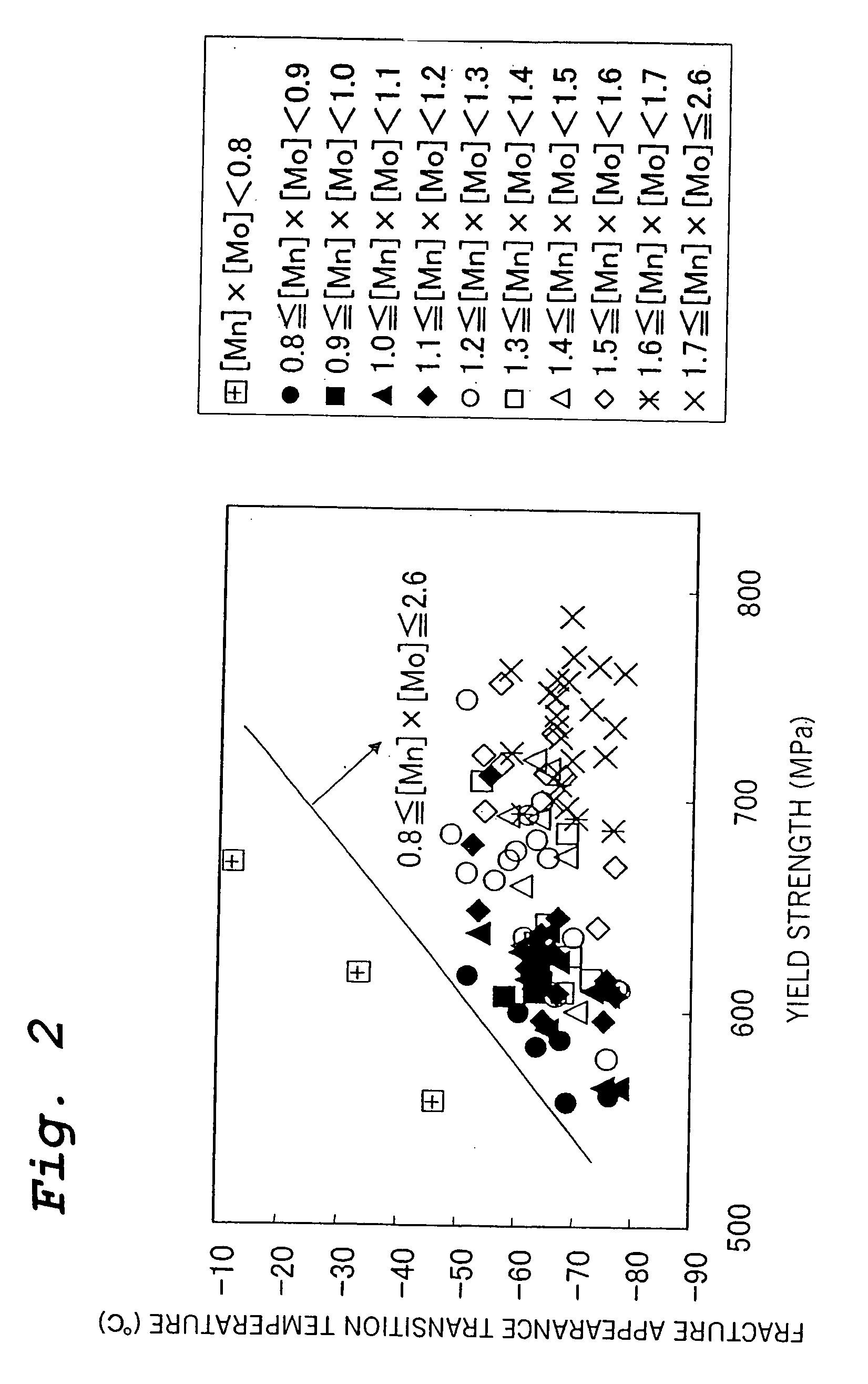

A thick-walled seamless steel pipe for line pipe which has a high strength and improved toughness and corrosion resistance in spite of the thick wall and which is suitable for use as a riser and flow line has a chemical composition comprising, in mass percent, C: 0.02-0.08%, Si: at most 0.5%, Mn: 1.5-3.0%, Al: 0.001-0.10%, Mo: greater than 0.4%-1.2%, N: 0.002-0.015%, at least one of Ca and REM in a total amount of 0.0002-0.007%, and a remainder of Fe and impurities, with the impurities having the content of P: at most 0.05%, S: at most 0.005%, and O: at most 0.005%, the chemical composition satisfying the inequality: 0.8≦[Mn]×[Mo]≦2.6, wherein [Mn] and [Mo] are the numbers equivalent to the contents of Mn and Mo, respectively, in mass percent.

Owner:NIPPON STEEL CORP

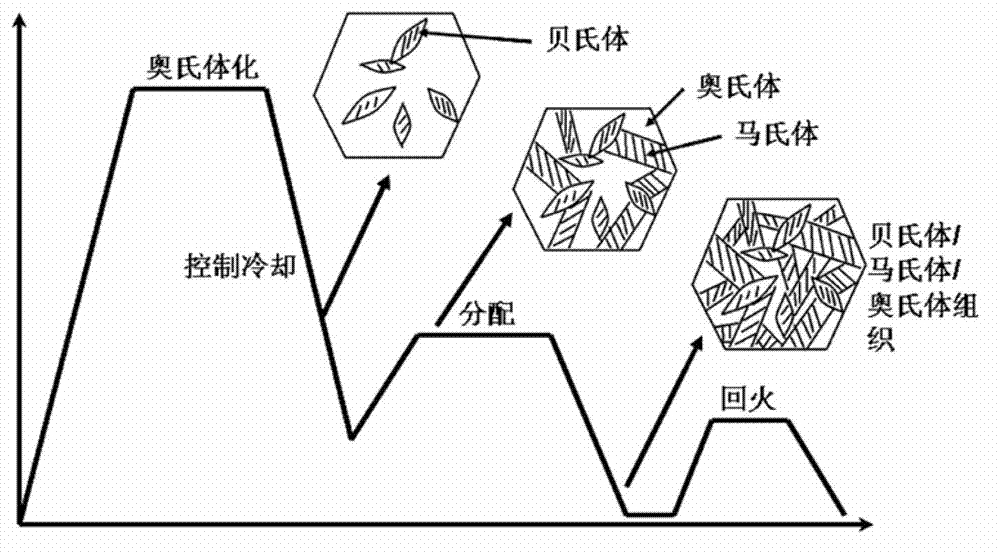

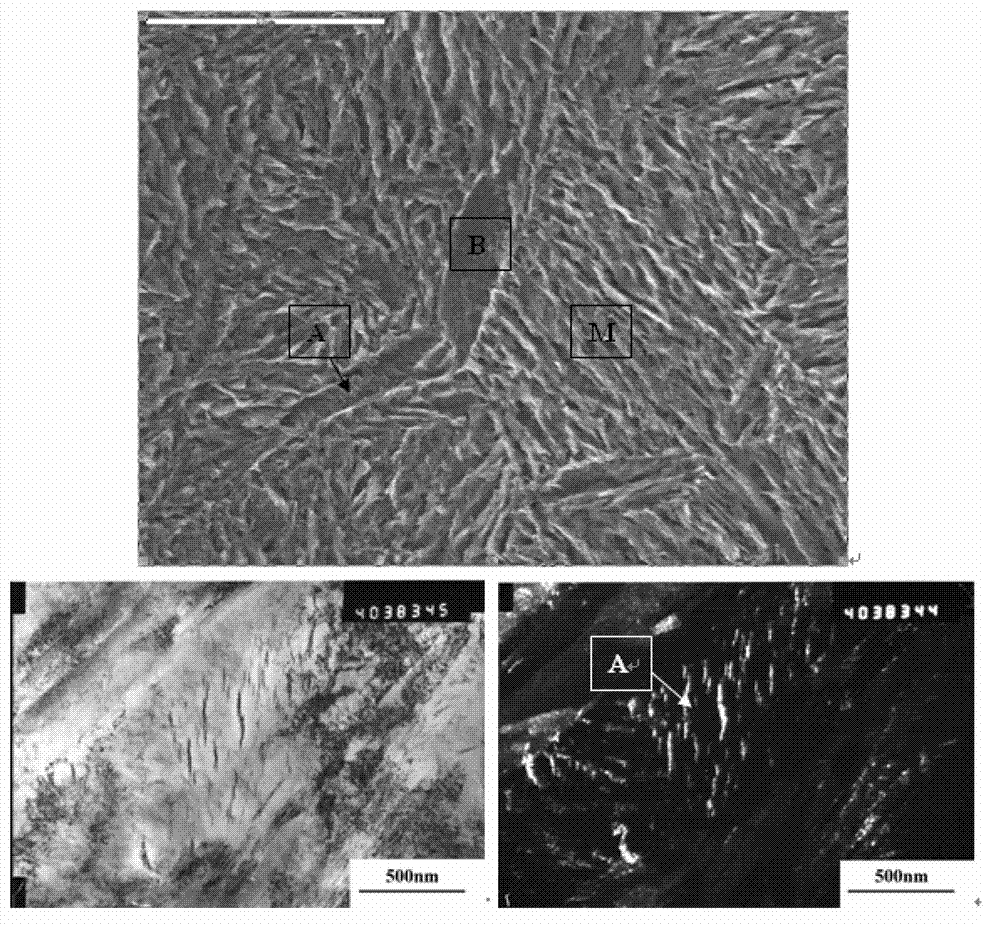

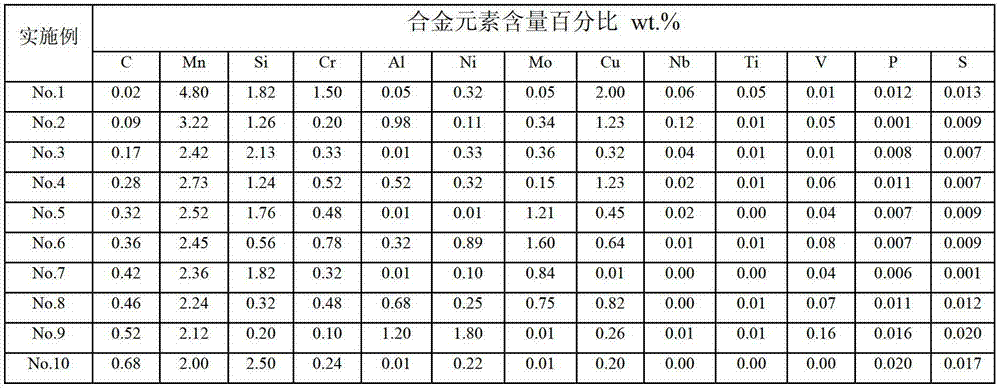

Preparation method of bainite/martensite/austenite composite high-strength steel

InactiveCN103243275AImprove stabilityOvercome the disadvantage of high costHeat treatment process controlSmelting processThick wall

The invention discloses a preparation method of bainite / martensite / austenite composite high-strength steel, belonging to the field of low-alloy high-strength steel. According to the composite high-strength steel, C, Mn, Si and Cr are used as main alloy elements, Al, Ni, Mo, Cu, Nb, Ti, V and the like are added, and the balance is Fe. The preparation method comprises the following steps: smelting, casting, forging or rolling to prepare rails, thick-wall pipes, large-section bars or thick pipes and the like by adopting a conventional steel-smelting process; carrying out austenitizing; controlling cooling by adopting different cooling media to obtain a part of bainite tissue in the cooling process; instantly carrying out distribution treatment and low-temperature tempering treatment so as to finally obtain a bainite / martensite / austenite composite tissue which is good in strong plasticity and toughness coordination, wherein the distribution time is 30-360 minutes. For a component which is large in size and easy to crack in quenching, the bainite / martensite / austenite composite high-strength steel has wide application prospect.

Owner:BEIJING JIAOTONG UNIV

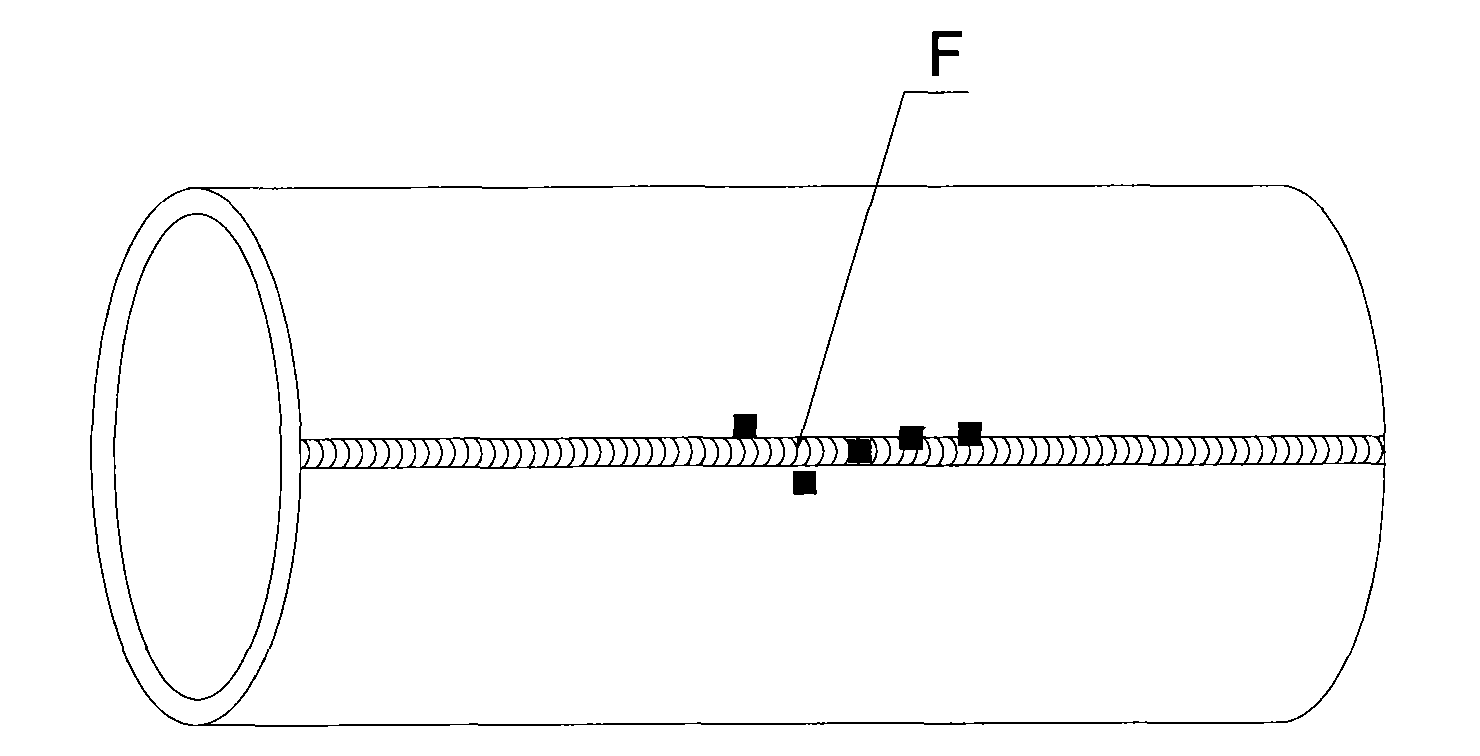

Blind hole measurement method for value and distribution of residual stress of thick-wall and large-diameter welded steel pipe

The invention relates to a blind hole measurement method for the value and distribution of residual stress of a thick-wall and large-diameter welded steel pipe. In the method, the cut length of a measured pipe body is no less than 2m; the same number of measuring points are distributed on the inner and outer surfaces of the measured pipe, and the distance between the measuring points on the same surface is no less than 40nm; the measuring points in a welded area are distributed in an area which covers half of the cut pipe segment and uses a welded joint cross point as the centre; measuring resistance strain gauges are X, Y and 45 degree three-way resistance strain rosettes; when the resistance strain rosettes are adhered, the X and Y directions are parallel and vertical to the welded joints of the measured pipe body, and the blind hole has a diameter Phi of 1.2 to 1.5mm and a depth of 2 to 2.5mm; and the size and direction of the residual stress value of each measuring point can be obtained by substituting the measured data together with the marked stress release coefficient in a blind hole stress measure equation. Thus, the blind hole measurement method can measure the value and the distribution of the residual stress of three types of thick-wall and large-diameter welded steel pipes including spiral pipes, UOE pipes and JCOE pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

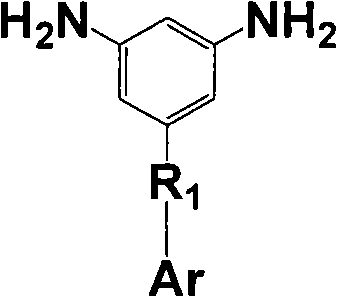

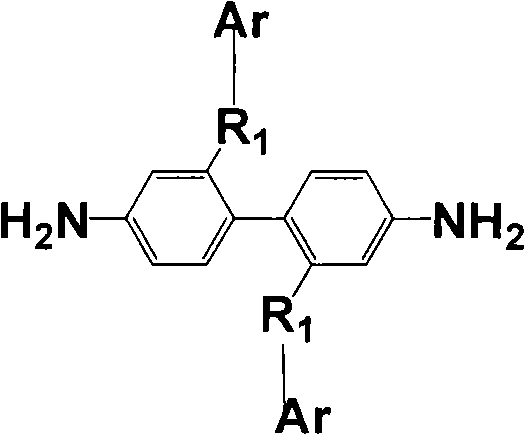

Aromatic diamine with phthalonitrile pendant group, preparation method thereof and polyimides or polyamide prepared therefrom

InactiveCN101307013ARegulating processabilityRegulatory usabilityPreparation by carboxylic acid amide dehydrationFiberSide chain

The invention discloses an aromatic diamine containing o-phthalonitrile side group. The structure formula of the aromatic diamine is shown as the right formula. The invention also discloses a method for preparing the aromatic diamine and polyimide and daiamid which are prepared by taking the aromatic diamine containing the o-phthalonitrile side group as one of raw materials. The o-phthalonitrile side group in the aromatic diamine is positioned on the side chain, thereby adjusting the degree of crosslinking with adjusting the polymer molecular weight and widening the application of the polyimide and the daiamid in a thick-wall composite material or a composite material element with a complicated shape and the fields of membrane material and fiber.

Owner:SICHUAN UNIV

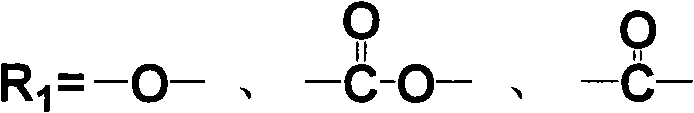

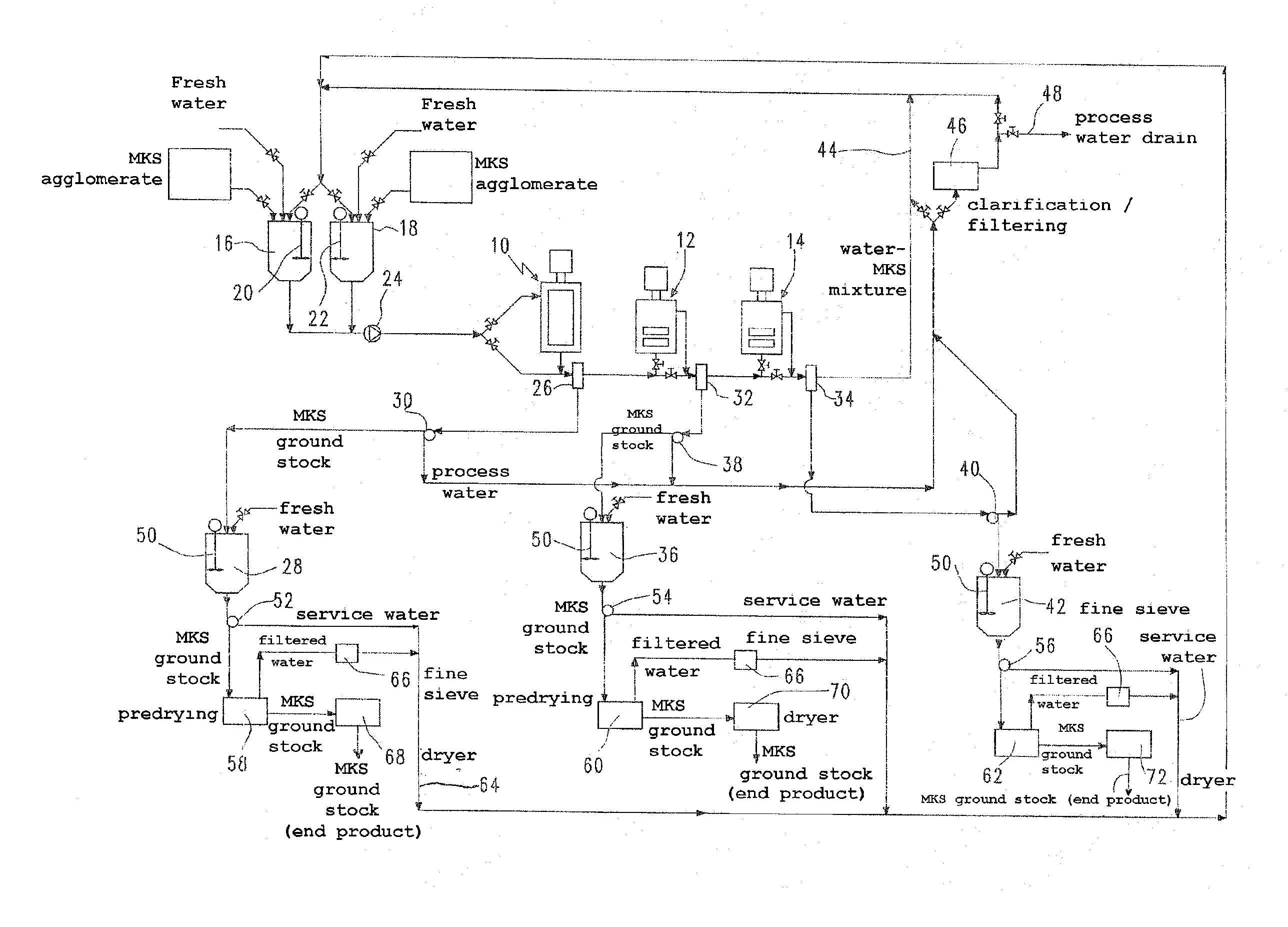

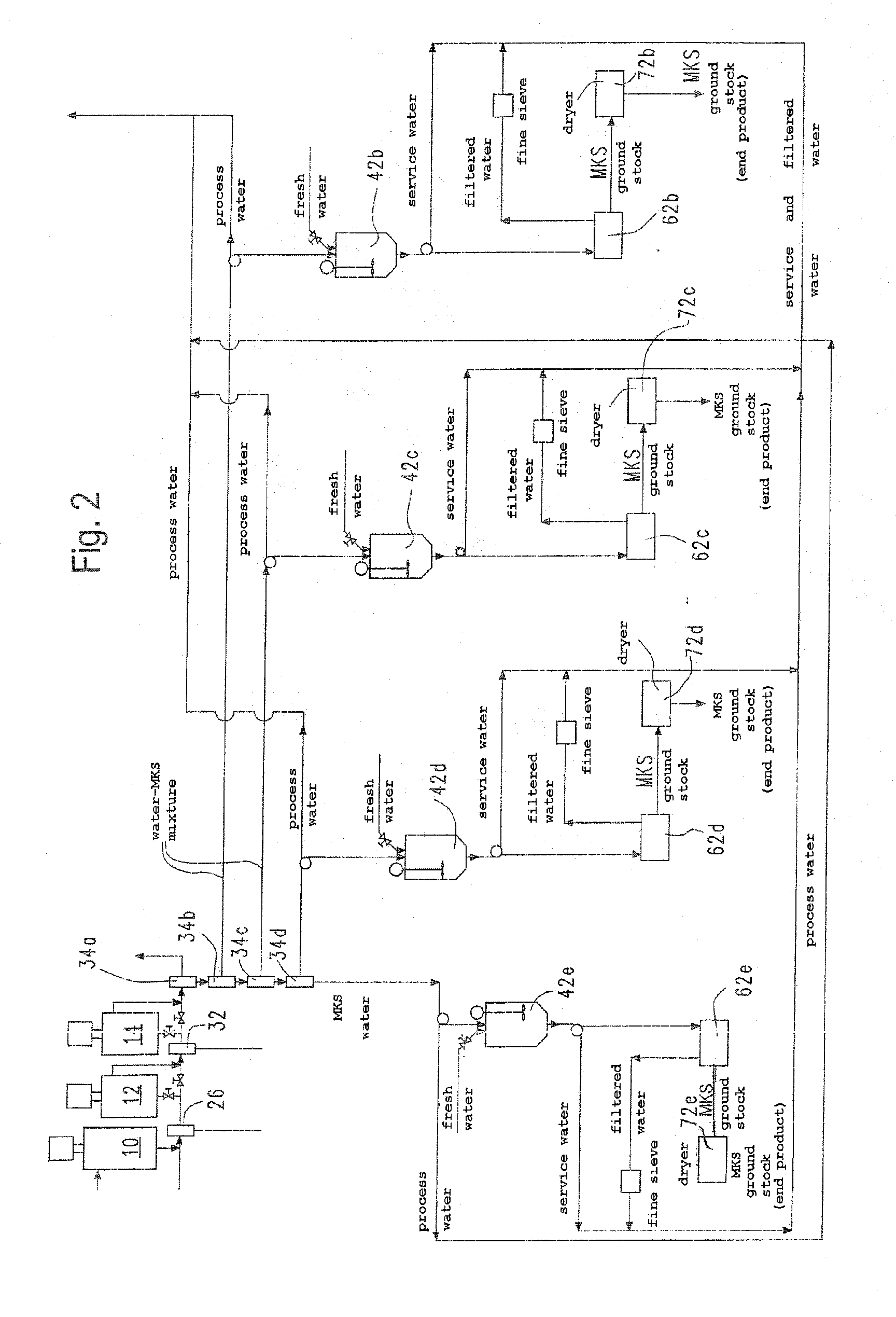

Method and Apparatus for Comminuting and Cleaning of Waste Plastic

InactiveUS20080191069A1Improve consistencyHigh material yieldSolid waste disposalWood working apparatusThick wallFine grain

Method for comminuting and cleaning waste plastic, in particular, mixed plastic (MKS) with the following steps: a compacted material, especially, an agglomerate is produced from film scraps or film remnants comminuted into flakes and / or thick-walled plastic parts chopped up into chips, the compacted material is introduced into a disc or drum refiner and is ground therein in the presence of water, wherein the portion of compacted material of the goods located in the refiner amounts to at least 10 percent by weight, a fine grain fraction is removed from the ground stock exiting from the refiner, the remaining ground stock is washed and either mechanically dewatered and dried, or pulverized again in a further refiner stage in the presence of water, and subsequently dewatered and dried.

Owner:CVP CLEAN VALUE PLASTICS GMBH

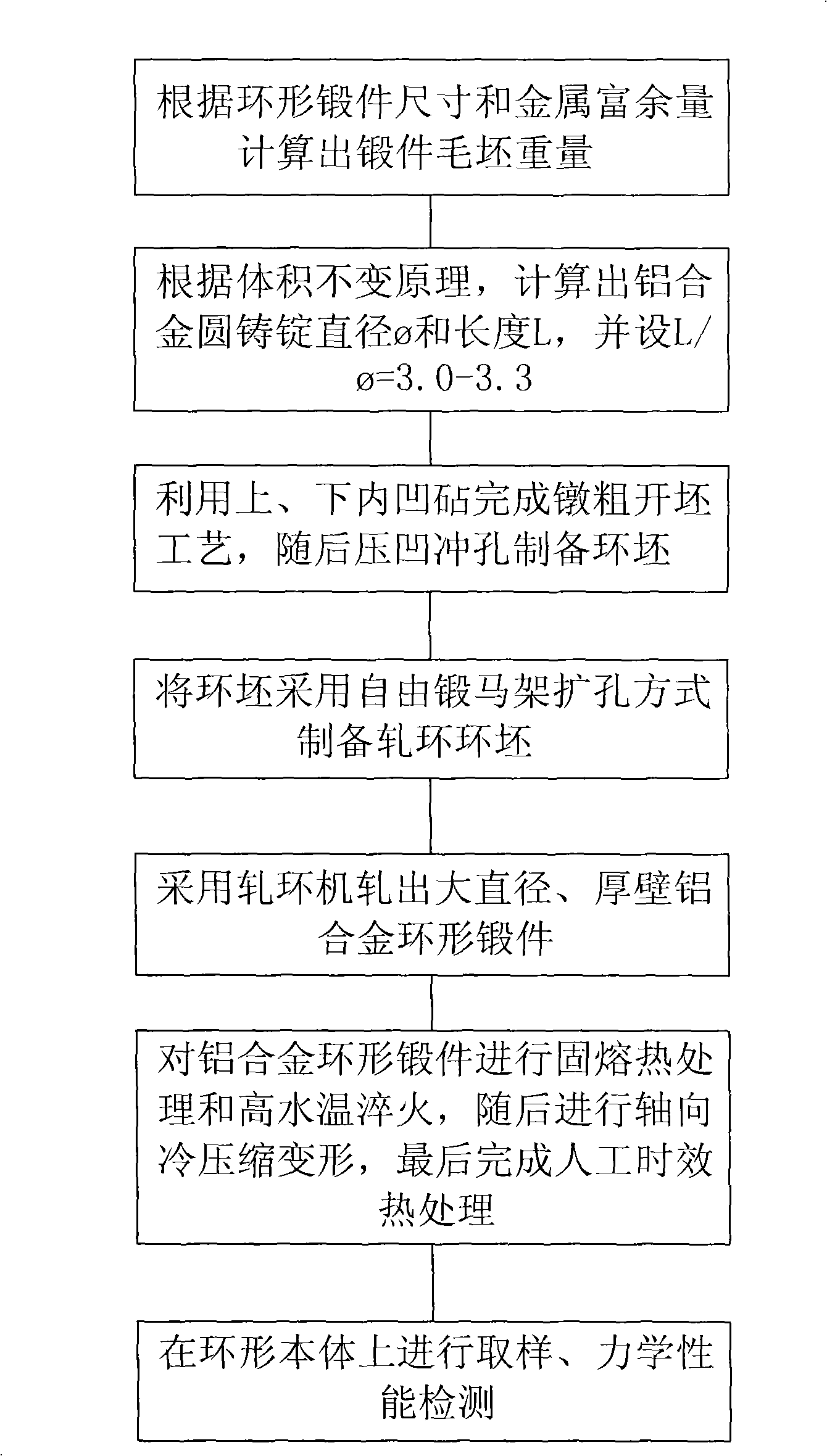

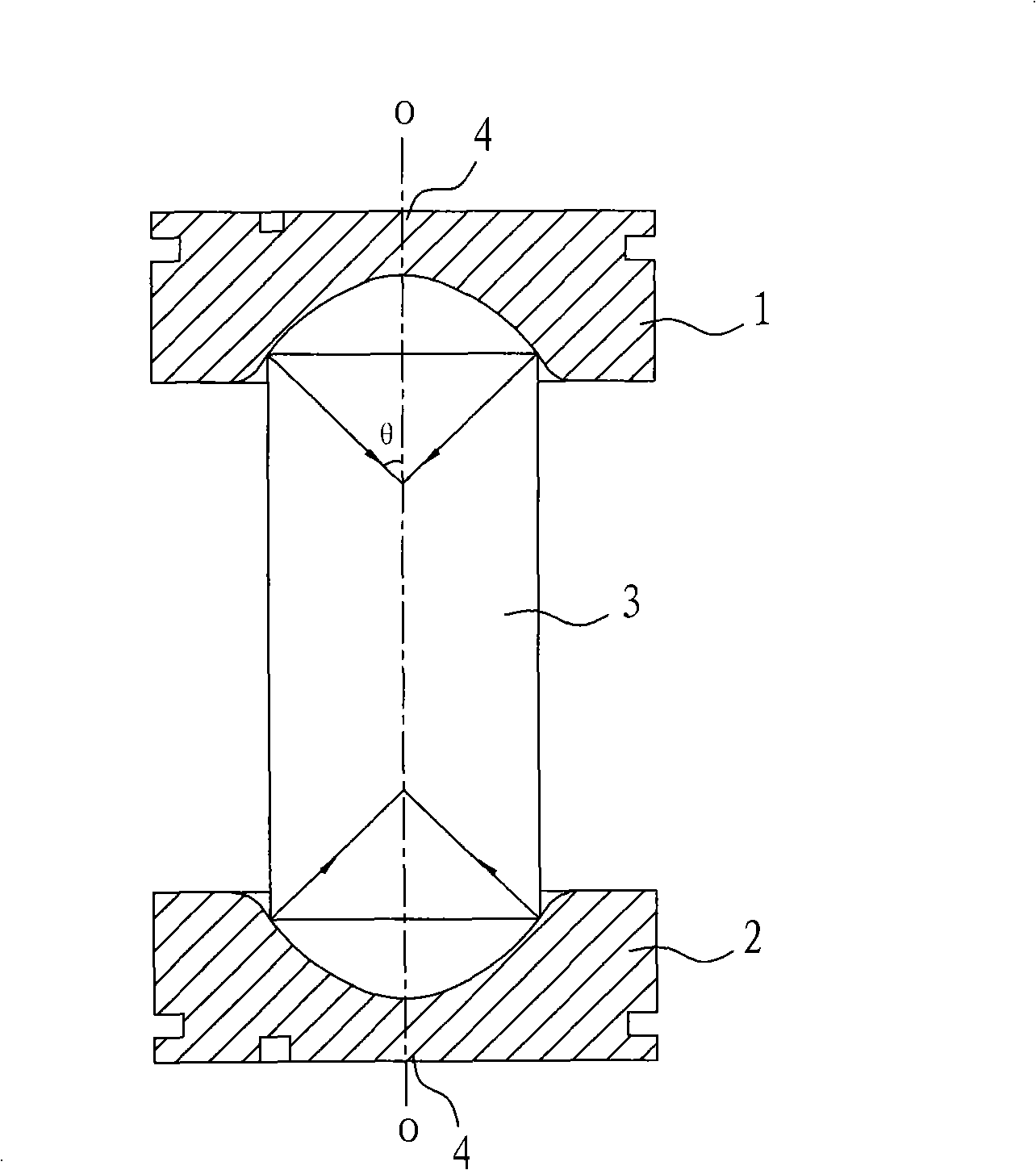

Method for manufacturing aluminium alloy rings with high performance and low residual stress

ActiveCN101537466AImprove performanceFully deformedRoll mill control devicesMetal rolling arrangementsThick wallQuenching

The invention discloses a method for manufacturing aluminium alloy rings with high performance and low residual stress, comprising the following technical steps: 1) calculating blank weight of forgings according to size and metal residual content of ring forgings; 2) calculating the diameter Phi and length L of aluminium alloy round ingots according to the volume constancy principle; 3) finishing the upsetting and cogging processes by using upper and lower recessed anvils, and preparing ring blank by shallow recessing and punching; 4) preparing rolling ring blank by using flat-die forging trestle broaching on the ring blank; 5) rolling out aluminium ring forgings with big diameter and thick wall by using a ring rolling mill; 6) carrying out solution heat treatment and high water temperature quenching, then carrying out axial cold compression and deformation, and finally finishing artificial aging heat treatment; and 7) carrying out crack detection on the ring by using ultrasonic according to the standard requirement, and carrying out sampling and mechanic performance detection on the main body of the ring complying with the standard requirement. The method has the advantages of high metal utilization rate, complete and uniform deformation from the surface to the core of the ring, high performance, low residual stress and the like.

Owner:SOUTHWEST ALUMINUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com