Power station thick-walled pipeline ultrasonic guided wave detecting method

An ultrasonic guided wave and detection method technology, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of difficult to obtain guided waves, low detection frequency, and difficult tasks, achieve obvious economic and safety benefits, and reduce detection. Cost and effect of reducing on-site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

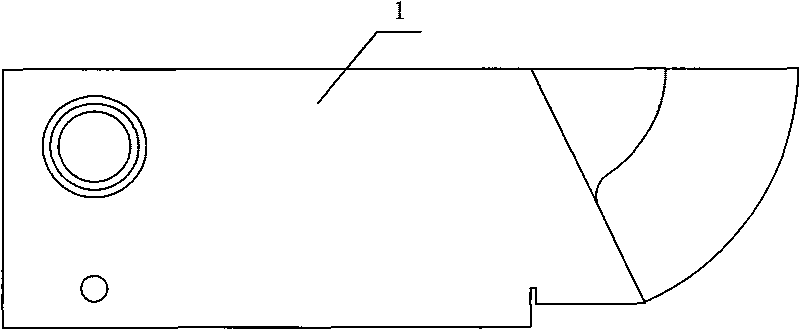

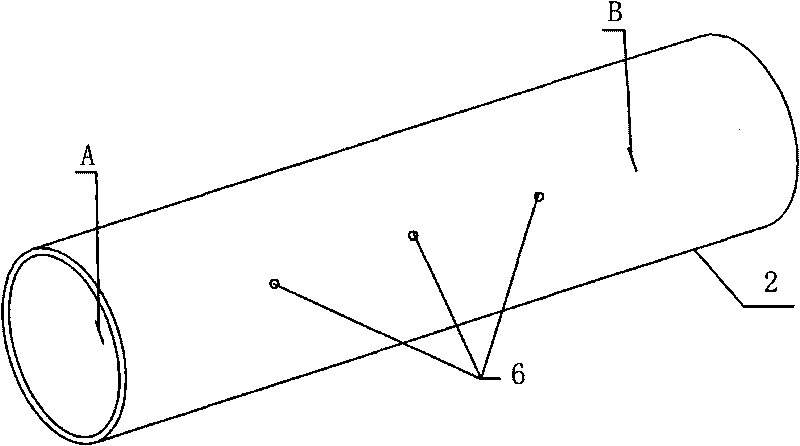

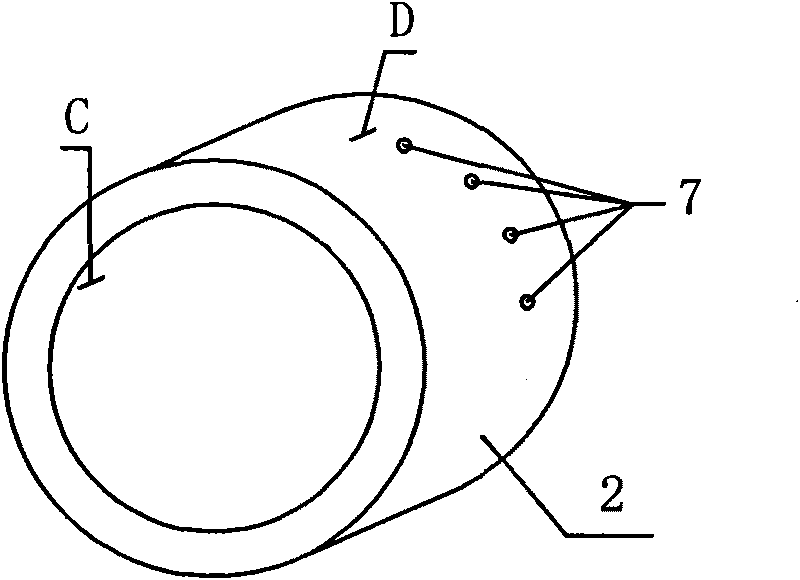

[0031] The present invention is aimed at the ultrasonic guided wave detection method of the thick-walled pipeline of the power station, which is a kind of non-destructive detection method. It mainly uses an ultrasonic detector and an ultrasonic guided wave sensor (probe) for detection. The specific steps are as follows:

[0032] (1) Select the probe for detection: according to the outer diameter, thickness, and material of the pipeline to be inspected, select a special ultrasonic guided wave probe, select the detection frequency as 1MHz±0.5MHz, the size of the probe chip is 20mm×20mm, 27.5°±2°, the probe incident angle, the horizontal deviation angle of the probe sound beam axis should not be greater than 2°, there should be no obvious double peaks in the vertical direction of the main sound beam, and the ultrasonic guided wave probe is required to detect the length × width at a distance of 400mm The signal-to-noise ratio of simulated cracks with a depth of 20mm×0.4mm×1.5mm is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com