Patents

Literature

578 results about "Ultrasonic guided wave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

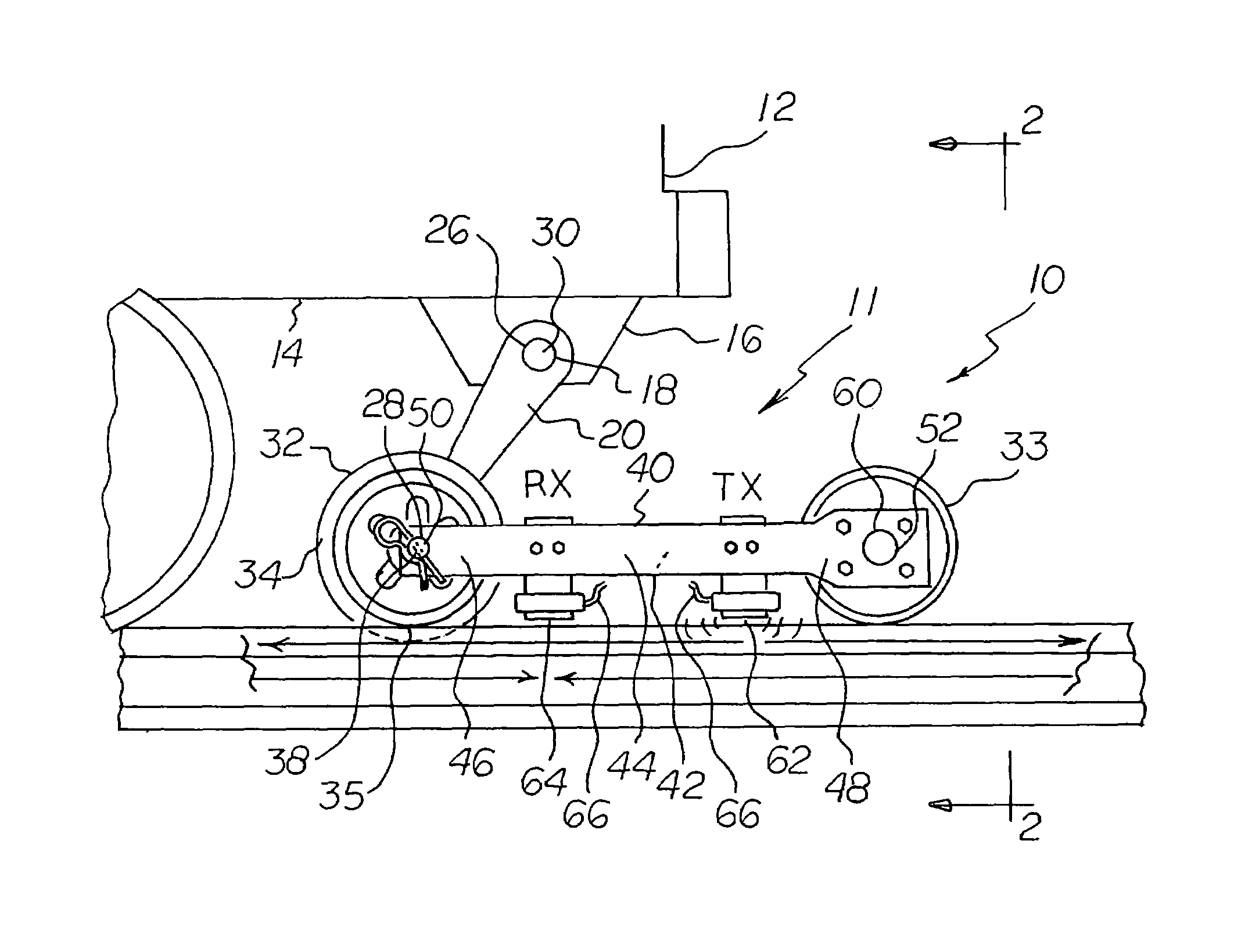

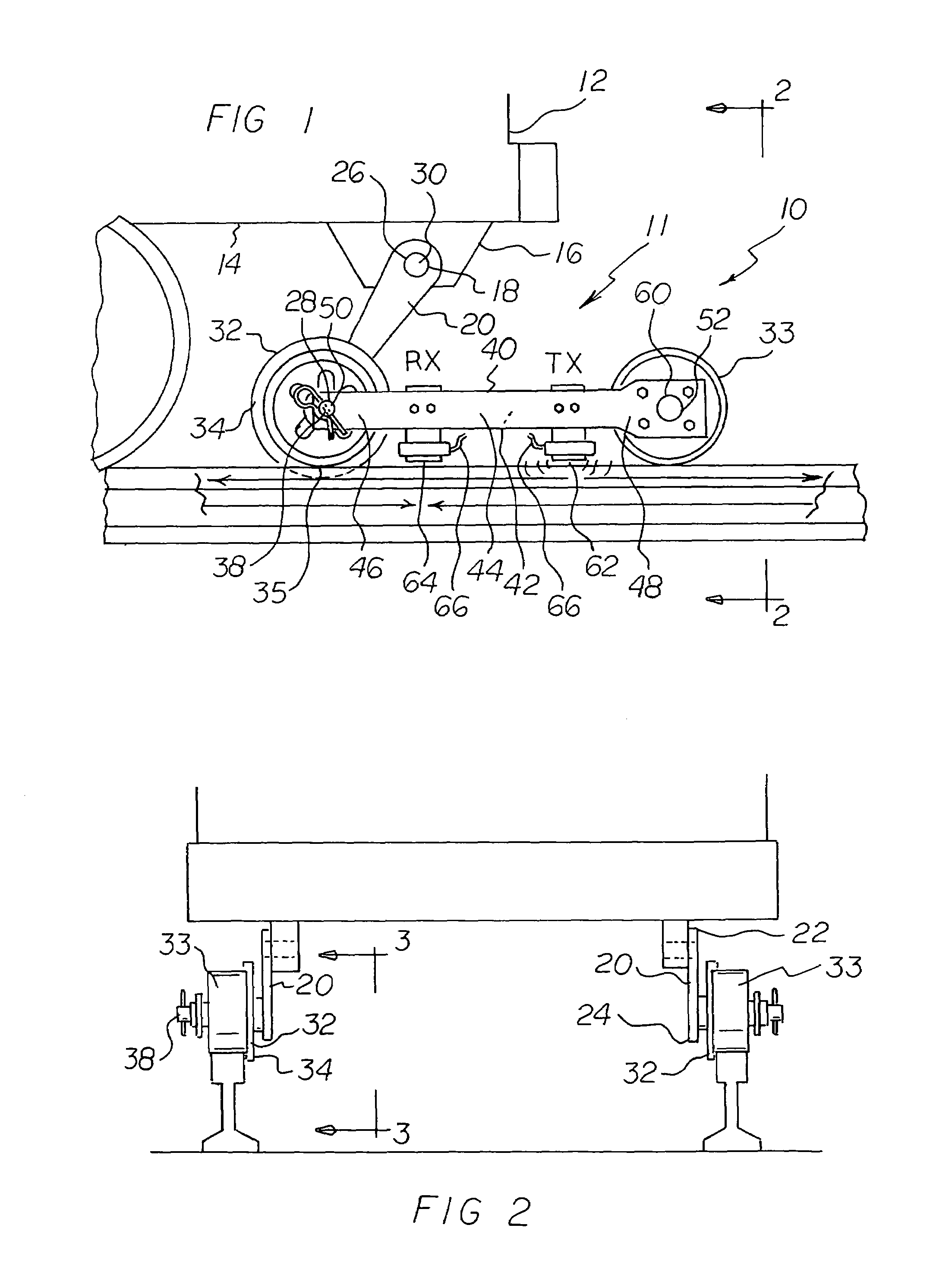

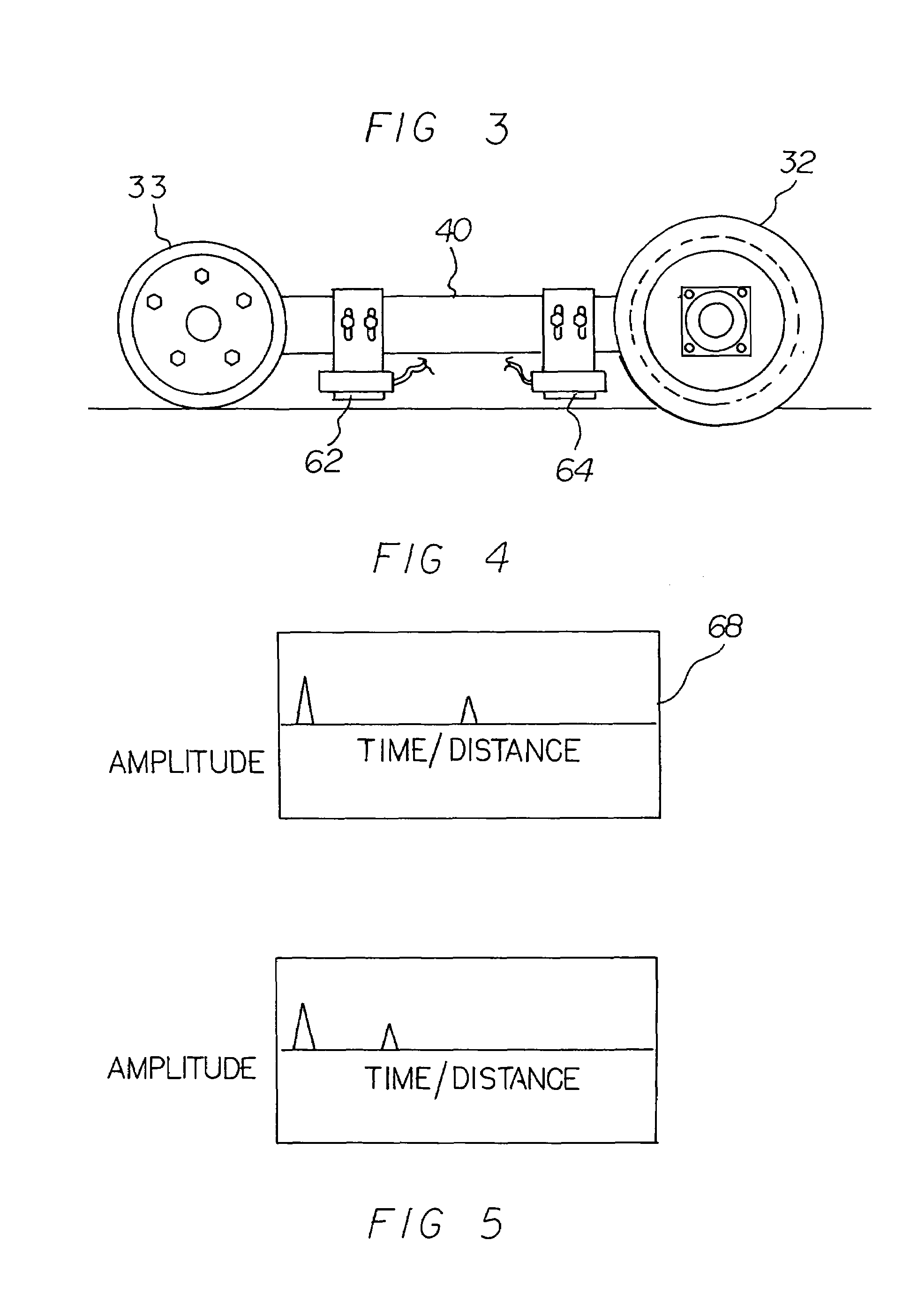

Rail inspection system

InactiveUS7389694B1Easily and efficiently manufactured and marketedDurable and reliable constructionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesRail inspectionEngineering

An apparatus rides along a rail of a railroad track. A transmitter transmits ultrasonic guided waves bidirectionally along the rail while the apparatus and transmitter are moving along the railroad track. A sensor detects flaws in response to the transmitted ultrasonic guided waves while the apparatus, transmitter and sensor are moving along the railroad track. An electronic coupler operatively couples the sensor to monitoring equipment.

Owner:WAVESINSOLIDS

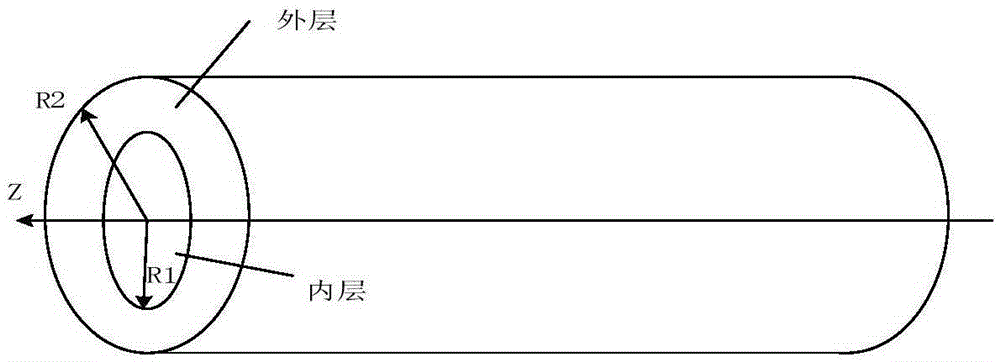

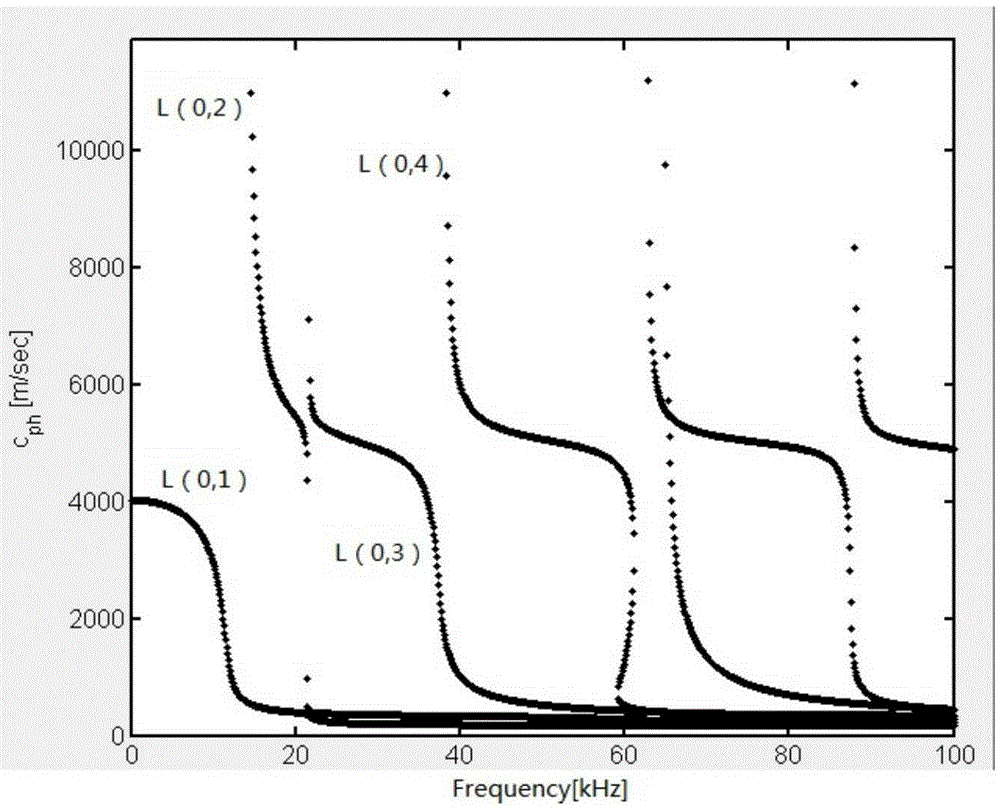

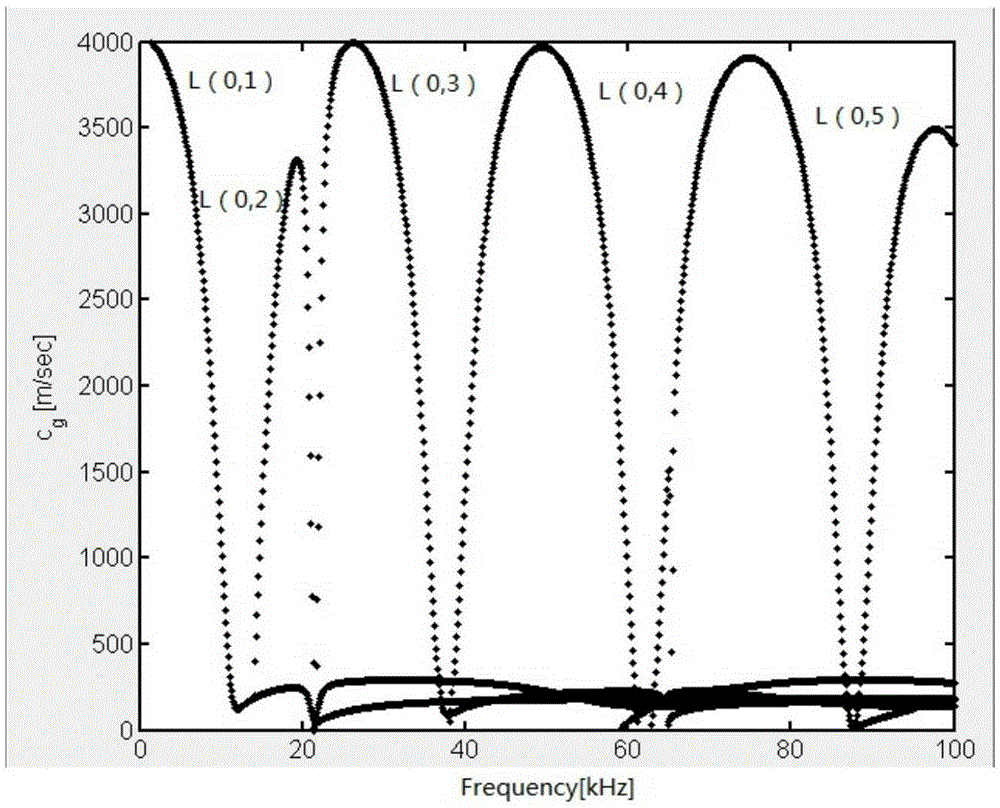

Power station thick-walled pipeline ultrasonic guided wave detecting method

ActiveCN101726541AQuick checkReliable detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSize measurementPower station

The invention belongs to the field of nondestructive detection, and particularly relates to a power station thick-walled pipeline ultrasonic guided wave detecting method, wherein the method comprises the following steps of: selecting an ultrasonic guided wave detecting probe; selecting an ultrasonic guided wave detecting instrument; manufacturing a sensitivity test block; making a distance-amplitude curve; scanning; carrying out flaw size measurement; and verifying and grading detecting results. The detecting method is suitable for comprehensively detecting the flaws of pipelines with different pipe diameters and thicknesses, and is particularly suitable for comprehensively detecting power station thick-walled pipelines. The detecting method has the characteristics of rapidness, simpleness, safety and reliability, can overcome some limitations of a conventional nondestructive detection method, lowers the manual detection intensity and saves human and material resources.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

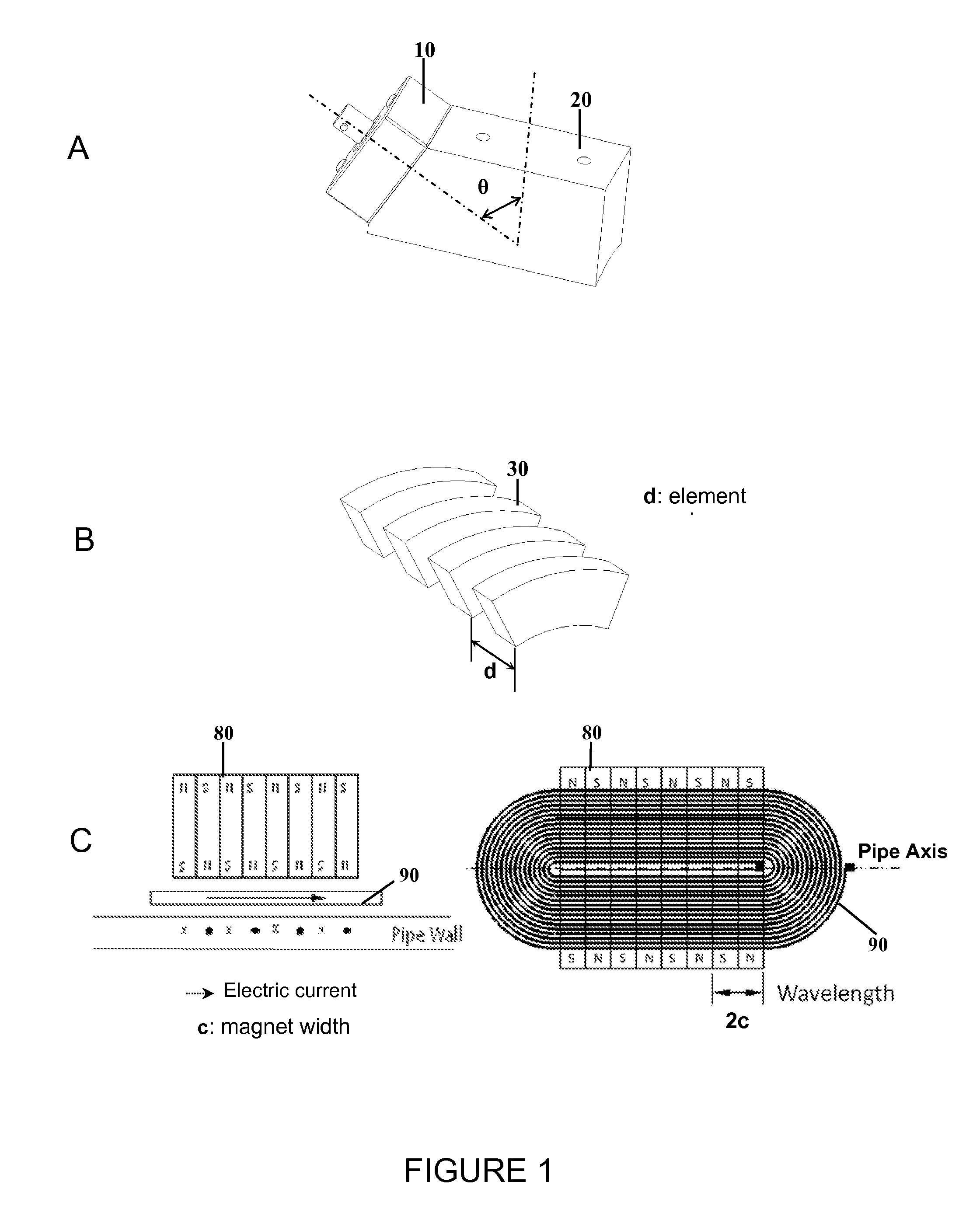

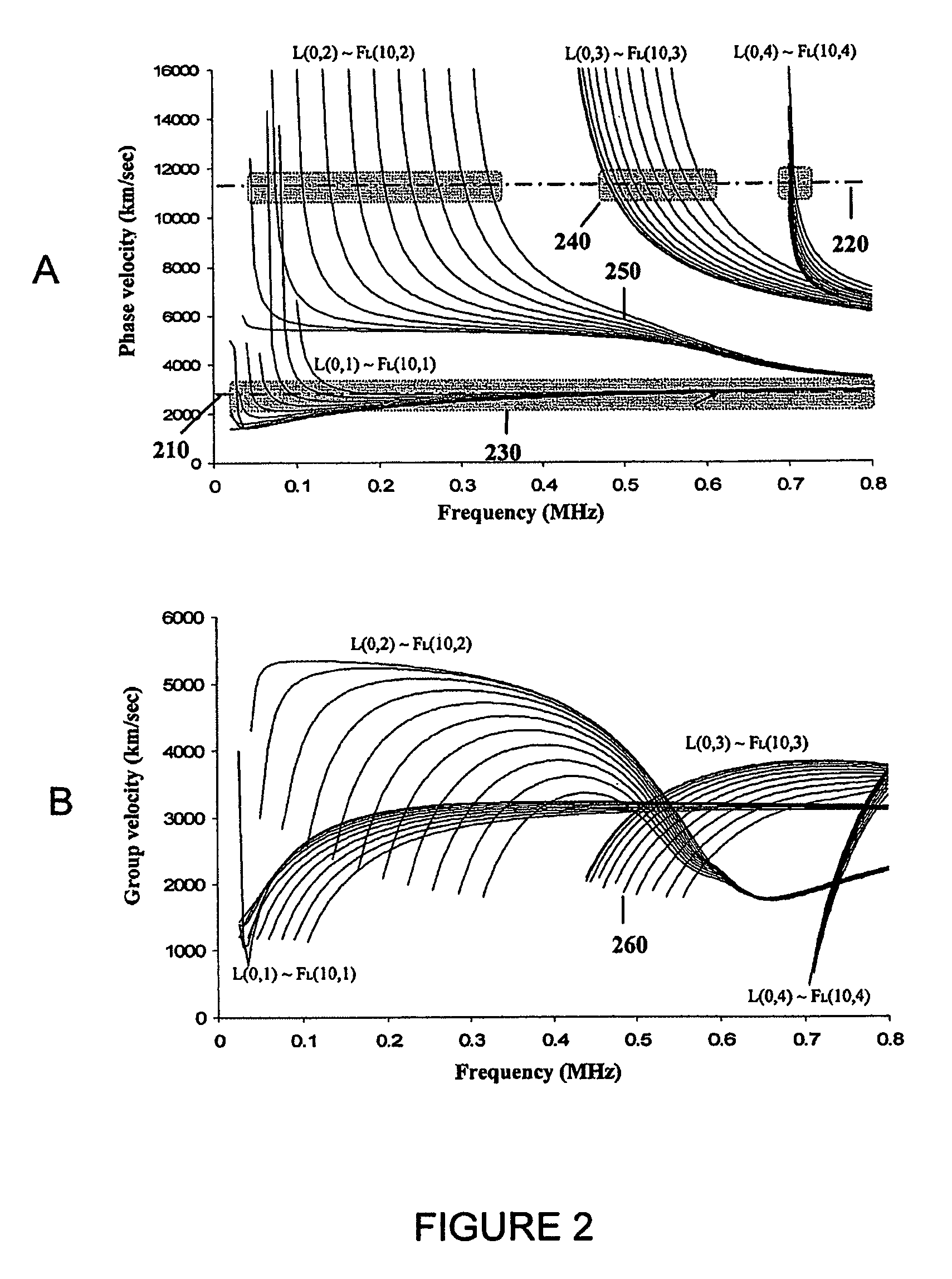

Guided wave pipeline inspection system and method with enhanced natural focusing techniques

InactiveUS20090139337A1The method is accurate and reliableVibration measurement in solidsVibration measurement in fluidNon destructiveTransducer

A method for the nondestructive inspecting of coated or uncoated pipeline, using ultrasonic guided waves excited on the outer or inner pipe surface, wherein at least one or more transducers are individually or simultaneously excited to generate ultrasound, wherein multiple received signals with different focal spot positions are processed and combined to produce a reduced number of final waveforms that show defect axial positions in the pipe, wherein a data calibration scheme is utilized to adjust velocity variability for all the guided wave modes at different frequencies, and wherein the hardware arrangement has at least one pulser channel and one receiver channel for the collection and storage of signals.

Owner:FUKUOKA BROADCASTING CORPORATION

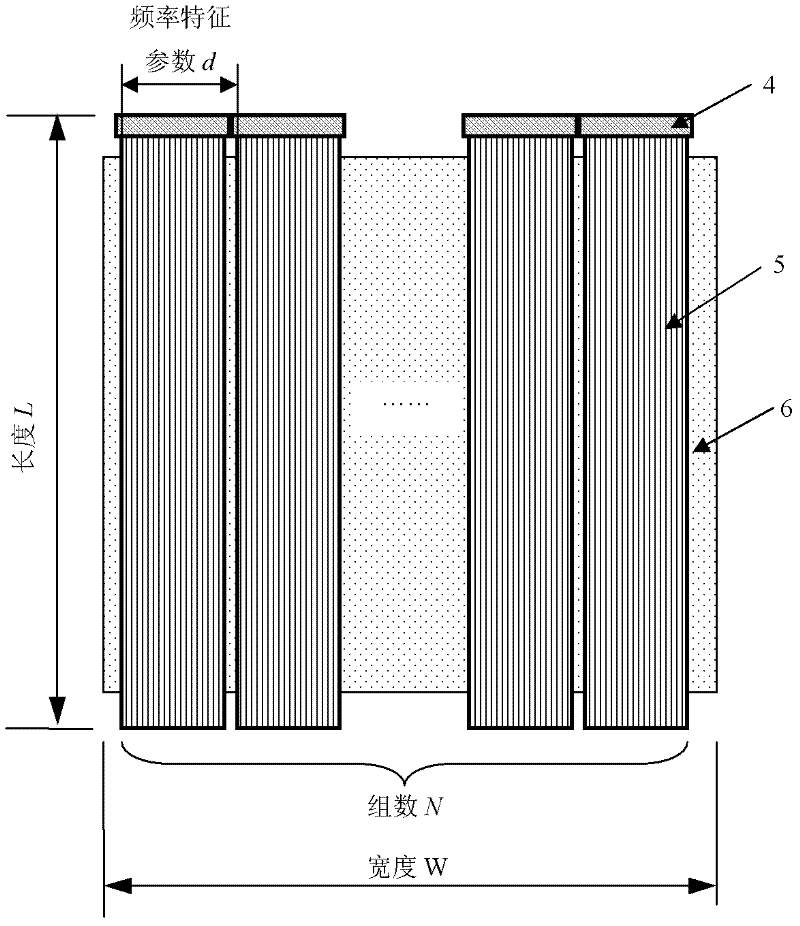

Ultrasonic guided wave detection device for quality evaluation of composite laminated plate

InactiveCN101571513AAchieve non-destructive quality assessmentAvoid destructionAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansSonificationDesign software

The invention provides an ultrasonic guided wave detection device for quality evaluation of a composite laminated plate. In the device, ultrasonic guided wave is taken as a detection means for accurately and conveniently evaluating quality of the composite laminated plate. The detection means is achieved by the following steps: (a) performing time-frequency analysis on guided wave signals of the composite laminated plate, comparing a time-frequency distribution diagram of the signals with a theoretical time-frequency distribution curve of the guided wave, and providing a mode separation method; (b) obtaining accurate time delay information in a time-frequency domain based on good characteristics of a Gabor wavelet, combining optimal sensor placement and multi-path positioning, broadening the range of defect positioning, introducing cluster analysis and then improving accuracy and reliability of two-dimensional positioning; and (c) improving rationality and accuracy for extracting signal characteristics, and effectively separating various mode components from ultrasonic guided wave signals by adopting an improved HTT method, and taking instantaneous components as a characteristic parameter according to linear regression analysis; and (d) constructing a detection device of the ultrasonic guided wave signals, improving detection steps, designing software architecture and programming for processing the guided wave signals based on the time-frequency analysis.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Ultrasonic guided wave combined type nondestructive testing method and ultrasonic guided wave combined type nondestructive testing device

InactiveCN101666783AHigh sensitivityMaterial analysis using acoustic emission techniquesEngineeringUltrasonic guided wave

The invention provides an ultrasonic guided wave combined type nondestructive testing method. The method tests an object to be tested by allowing ultrasonic guided waves to transmit in the object to be tested and then testing reflection echo, and is characterized in that: the method for generating the ultrasonic guided wave by excitation adopts an electromagnetic excitation mode; and the mode of receiving the reflection echo is using a piezoelectric element for testing. The invention also claims the protection of the testing device corresponding to the ultrasonic guided wave combined type nondestructive testing method. The device of the invention can realize the defect test at greater distance and with higher sensitivity under a condition that the prior pipeline has a damping effect on theultrasonic guided wave. The technique can be used for nondestructive testing of components such as common pipes, steel rails, special pipes / rods, wire ropes, tank bottoms of oil tanks and the like. The method of the invention creatively combines two big technical advantages, so that the method has more obvious and better technique effect, and predicable huge economic values and social values.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

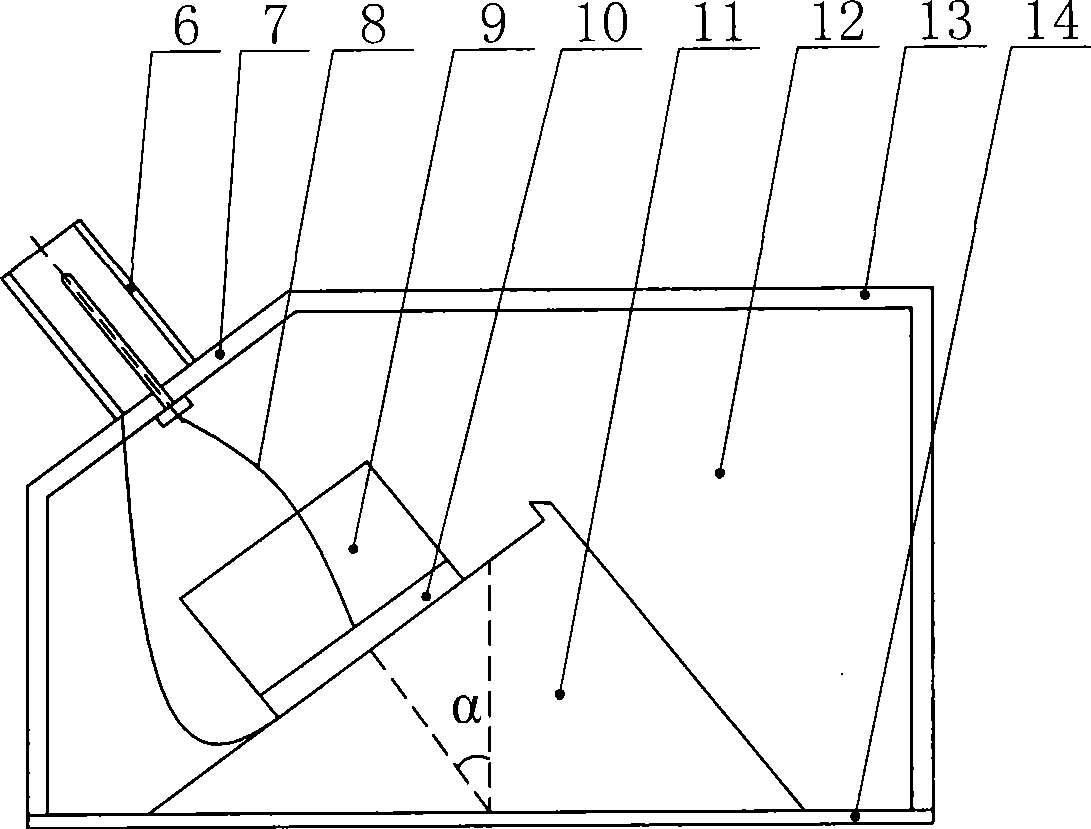

Gas pipeline crack electromagnetical ultrasonic oblique wave guide detecting method

InactiveCN101424663AAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorCoupling

The invention discloses an electromagnetic ultrasonic inclined guiding wave checking method of natural gas pipeline cracks, which is characterized in that electromagnetic ultrasonic energy exchanger units are composed of split-type broken line coils and permanent magnet blocks, and are arranged on an inner checking device in the pipeline along the inclined direction, and generated ultrasonic guiding waves have a certain checking sensitivity on cracks of each direction on the spreading route of the ultrasonic guiding waves. The inclined ultrasonic guiding wave and the supporting guiding wave after crack action of a single emitting electromagnetic ultrasonic energy exchanger unit are received by two annular receiving energy exchangers arranged on both sides of the emitting electromagnetic ultrasonic energy exchanger. A plurality of emitting energy exchanger units are arranged into an annular set, and orderly generate inclined guiding waves so as to cover the entire circumference of the pipeline wall according to time, and the positions and the sizes of the crack defects are fixed according to the received guiding wave signals and the arranging condition of the energy exchangers. The invention realizes the non-contact purpose of the cracks in the natural gas pipeline without liquid coupling check, and can be used for the crack defects of each direction.

Owner:TSINGHUA UNIV

Rail destruction detection device and method based on magnetostriction and longitudinal ultrasonic guided wave

ActiveCN102520068AImproving the efficiency of early identification of damageEnabling non-contact damage detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringElectromotive force

The invention discloses a rail damage detection device and method based on magnetostriction and longitudinal ultrasonic guided wave, which are applied in the field of railway traffic nondestructive detection. The rail damage detection device comprises a shell, wherein an inner wire support, an inner coil, an outer wire support, an outer coil, a yoke and a permanent magnet are arranged in the shell; a current input port, an inner coil current input electric wire and an inner coil current output electric wire are arranged at one end of the shell; an outer coil current output electric wire, an outer coil current loop electric wire and a voltage output port are arranged at the other end of the shell; and the upper part of the shell is fixedly connected with a rail detection vehicle. The rail damage detection method comprises the following steps of: exciting induced electromotive force by utilizing magnetostriction and longitudinal ultrasonic guided wave, and indirectly measuring time and strength generated by a defect reflective waveguide signal according to the induced electromotive force, and further determining the destruction position and the destruction size. The rail damage detection device and method can be used for carrying out accurate detection on trace destruction inside and outside the rail, and have the advantages of long detection distance and high detection efficiency.

Owner:JINAN UNIVERSITY

Damage detection method based on instantaneous phase changing degree

InactiveCN101995435AAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationRandom noise

The invention discloses a damage detection method based on instantaneous phase changing degree in the technical field of mechanical structural detection, comprising the following steps: fixing an energy converter on the surface of an object to be detected or inlaying the energy converter in the structure of the object to be detected and constructing a detection area; detecting and calculating the objected to be detected in a non-damage state by utilizing ultrasonic guided wave to obtain the flight time of the wave signal scattered by the damage; calculating to obtain the damaged coordinate position by adopting a triangle positioning method according to the flight time, and drawing multiple coordinate tracks by combining ToF assessed by each sensing path in a sensing network, wherein the converging area of the coordinate tracks is the area in which the damage can appear. The method of the invention has preferable ability of resisting the random noise interference; even though signal noise ratio (SNR) of the collected wave signal is lower, the method still can be used for accurately assessing the ToF scattered by the damage in a basic order symmetrical (S0) mode, and further successfully identifies and positions the damage by combining a triangle positioning method.

Owner:GARBSEN ELECTRIC SHANGHAI CO LTD

Ultrasonic guided-wave detecting system for defect of composite insulator and detecting method of ultrasonic guided-wave detecting system

InactiveCN105424802ALow costReduce sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesComposite insulatorsSonification

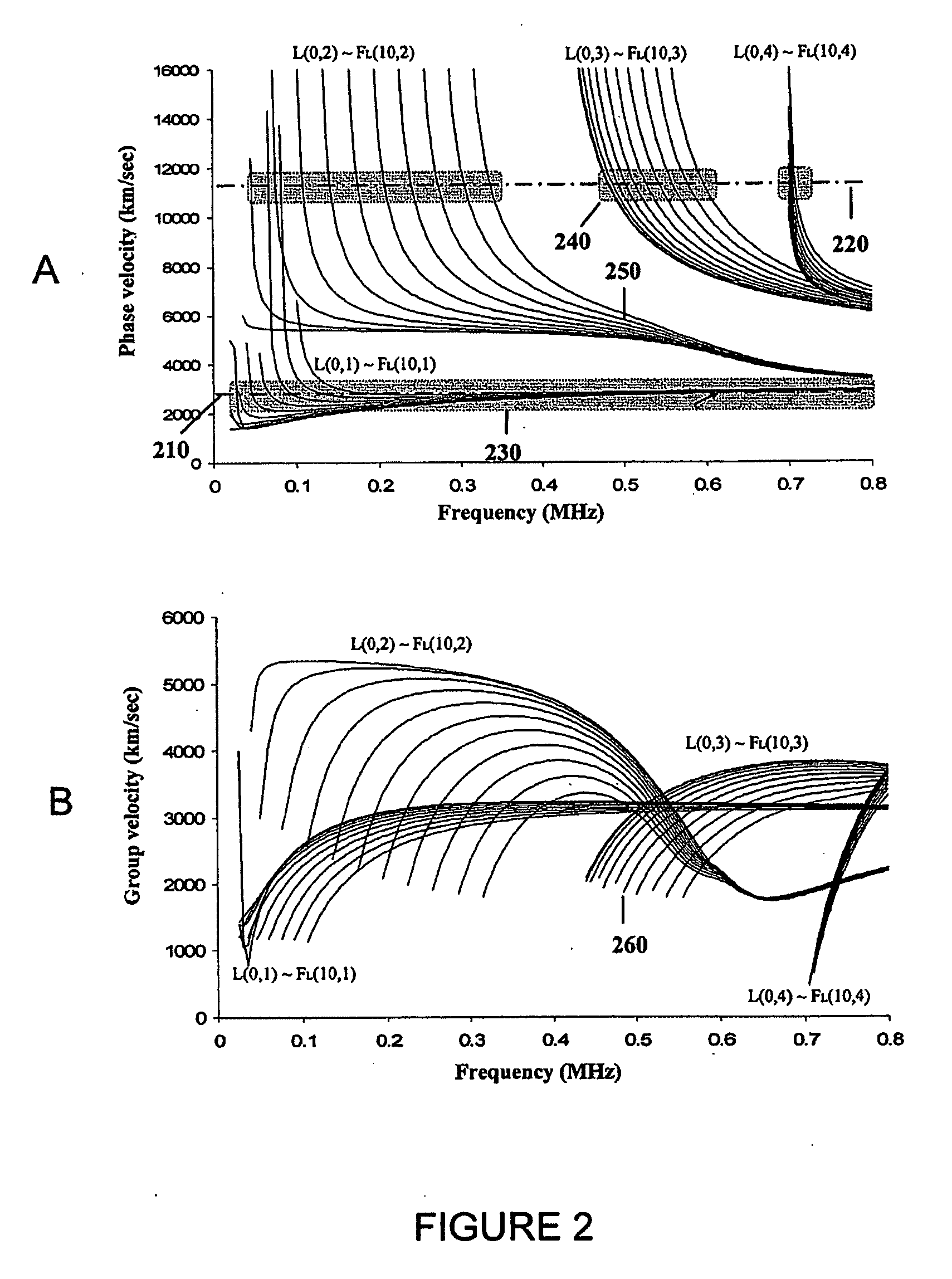

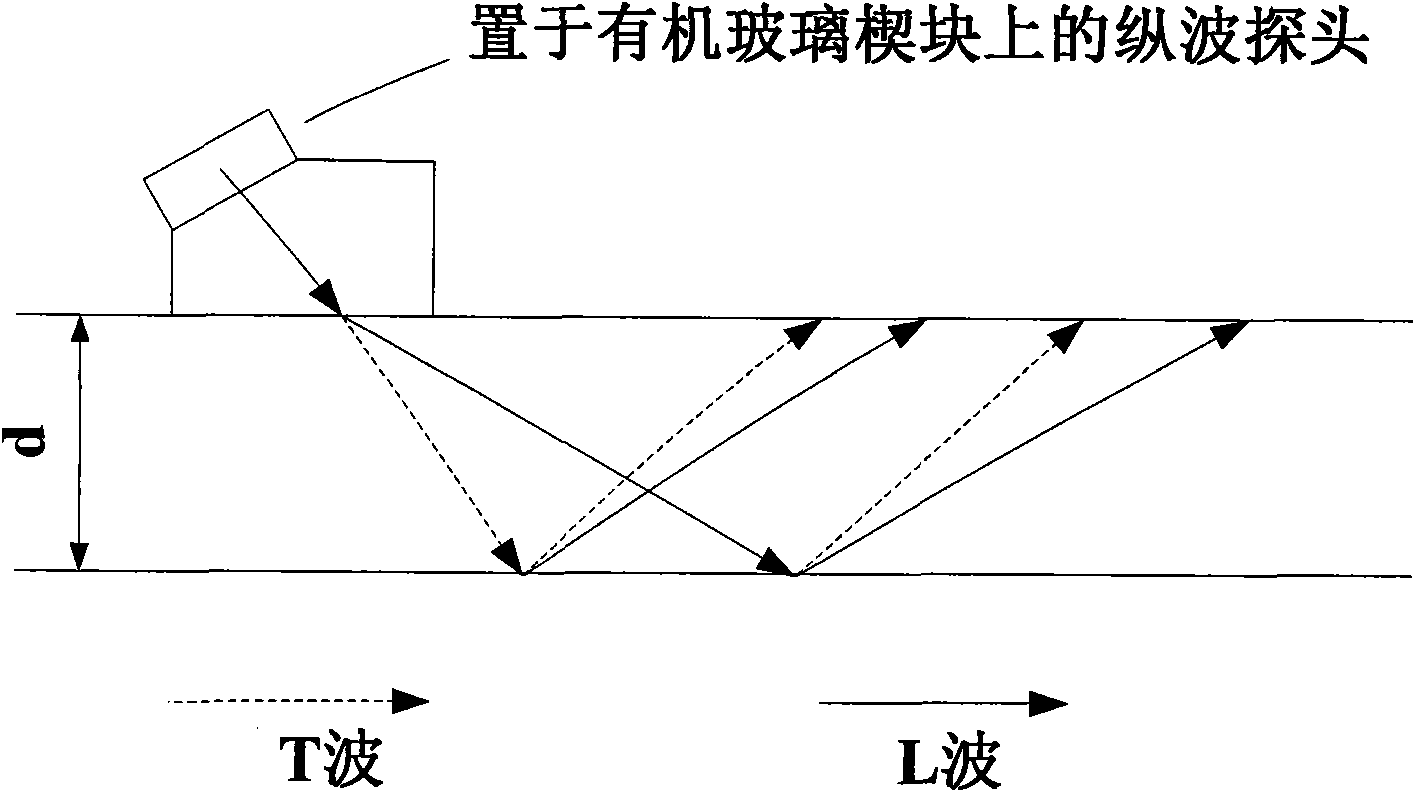

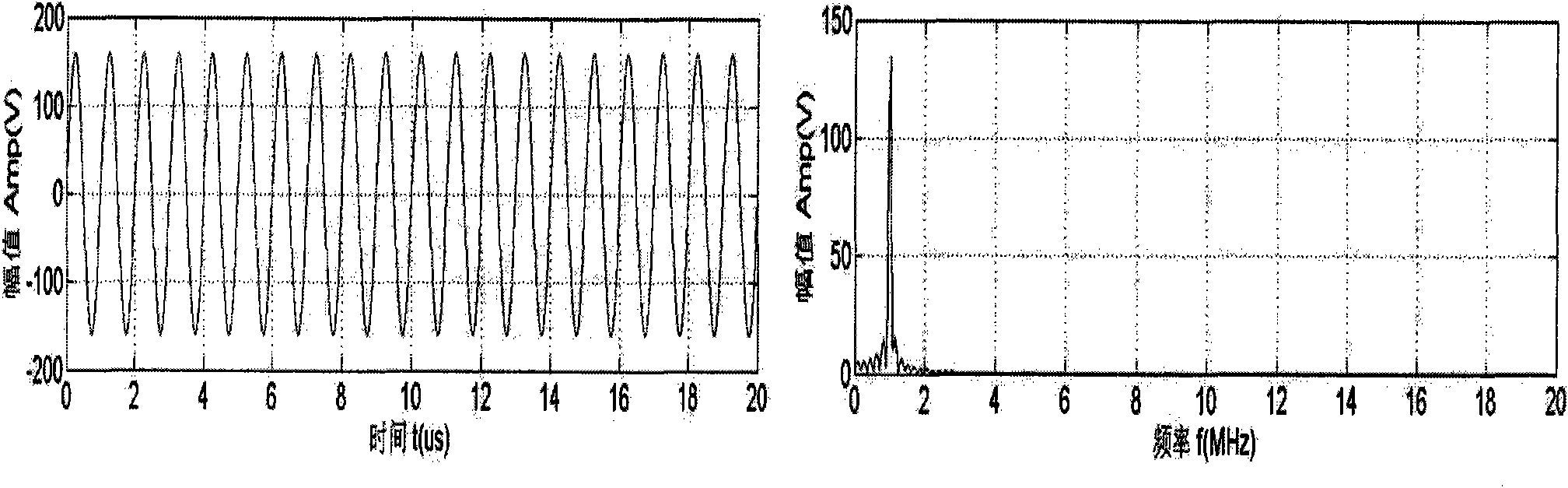

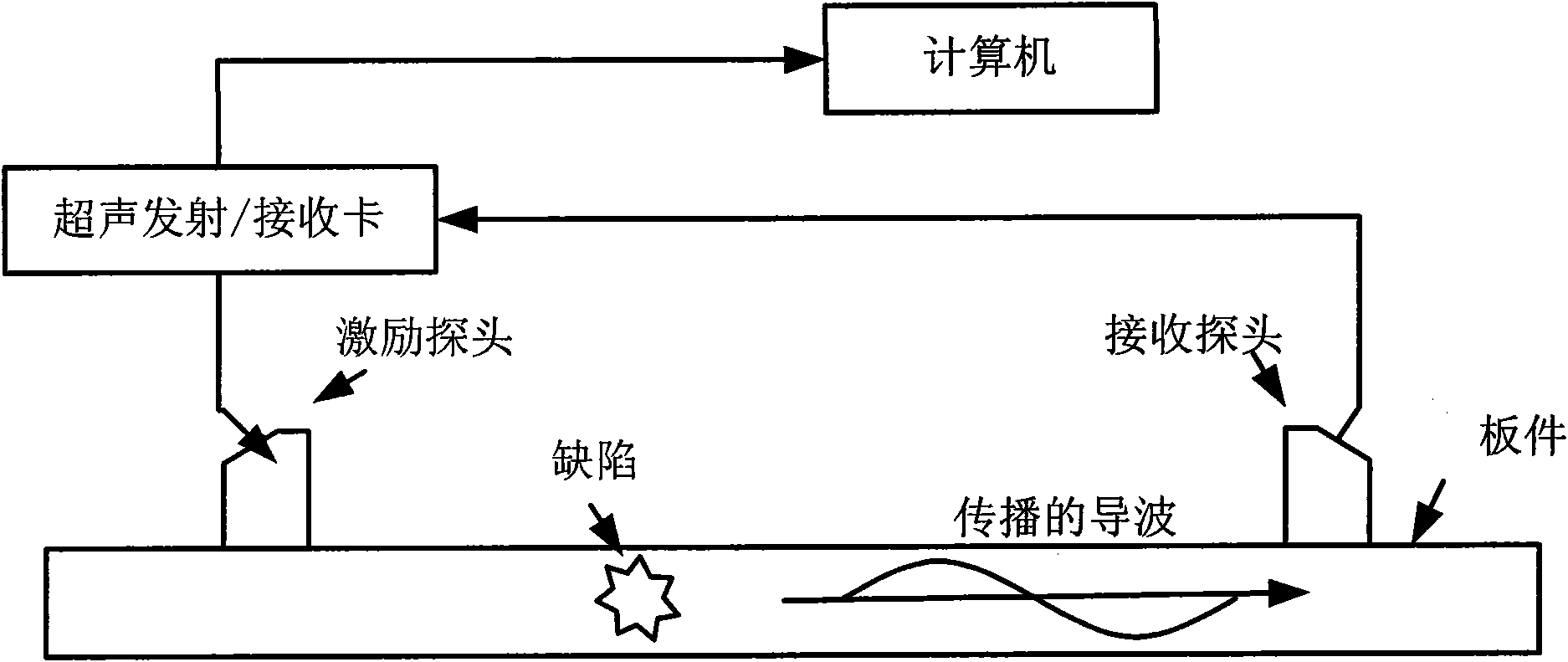

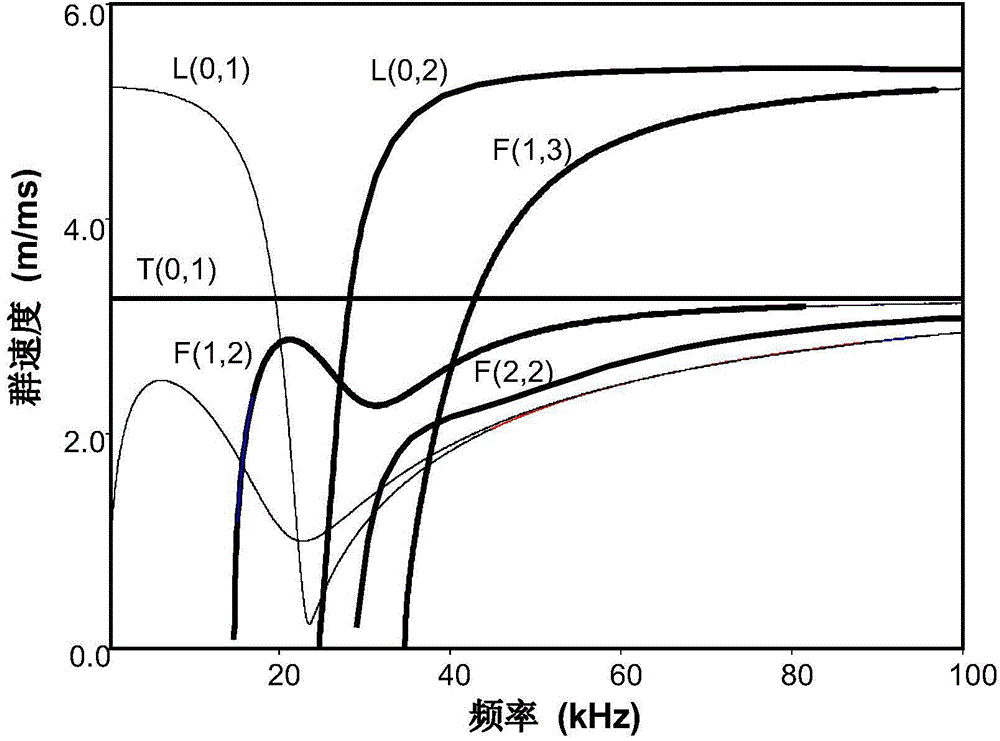

The invention discloses an ultrasonic guided-wave detecting system for the defect of a composite insulator. The ultrasonic guided-wave detecting system comprises a system master control computer, a signal generator, a power amplifier, a piezoelectric paster and a digital oscilloscope. The invention further discloses a detecting method applied to the ultrasonic guided-wave detecting system for the defect of the composite insulator. The detecting method comprises the following steps that 1, the frequency dispersion equation of propagation of guided waves in a composite insulator model is determined; 2, a corresponding frequency dispersion curve is obtained through insulator test piece related parameters tested through experiments; 3, stimulation guided wave frequency, periods and modal are determined according to a frequency dispersion curve conclusion; 4, stimulation and receiving points are selected, and defect detection of guided waves is achieved; 5, a guided wave detecting waveform is placed in a computer for data analysis processing, whether the defect exits or not it judged, and the size and type of the defect are judged. The detecting advantages of being accurate, fast, long in distance, large in range, low in cost and the like are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Guided wave pipeline inspection system and method with enhanced natural focusing techniques

InactiveUS7997139B2The method is accurate and reliableVibration measurement in solidsVibration measurement in fluidNon destructiveTransducer

A method for the nondestructive inspecting of coated or uncoated pipeline, using ultrasonic guided waves excited on the outer or inner pipe surface, wherein at least one or more transducers are individually or simultaneously excited to generate ultrasound, wherein multiple received signals with different focal spot positions are processed and combined to produce a reduced number of final waveforms that show defect axial positions in the pipe, wherein a data calibration scheme is utilized to adjust velocity variability for all the guided wave modes at different frequencies, and wherein the hardware arrangement has at least one pulser channel and one receiver channel for the collection and storage of signals.

Owner:FUKUOKA BROADCASTING CORPORATION

Flexible magnetostriction and magnetoelastic integrated sensor for detecting stress and defect of wire rope

ActiveCN102435357ALight structureEasy to disassembleControlForce measurement by measuring magnetic property varationEngineeringUltrasonic guided wave

The invention discloses a flexible magnetostriction and magnetoelastic integrated sensor for detecting stress and defect of a wire rope. The integrated sensor comprises an inner flexible printing coil and an outer flexible printing coil, wherein the structure of the flexible printing coil can be curled and attached to the surface of the wire rope to form a single-layer or multi-layer solenoid coil which is locked by a connector and then mounted on the detected wire rope; and after the locked state is released, the solenoid coil is removed from the surface of the wire rope. The integrated sensor can work as a magnetostriction sensor and excite a longitudinal modal ultrasonic guide wave in the wire rope to perform long-distance defect detection of the wire rope or to measure the average stress of the wire rope in a certain distance based on the acoustoelastic effect of the ultrasonic guide wave; and the integrated sensor also can work as a magnetoelastic sensor and calculate the stress value of a section of the wire rope based on the magnetoelastic effect by measuring the magnetic conductivity of the material of the wire rope, or scan along the length direction of the wire rope to obtain the change of the magnetic conductivity of the material of the wire rope along the length direction and reflect the size and position of the defect.

Owner:BEIJING UNIV OF TECH

Ultrasonic detecting method for electric power pylon steel angle

ActiveCN101509899AFast NDTAccurate NDTAnalysing solids using sonic/ultrasonic/infrasonic wavesElectrical steelUltrasonic guided wave

The invention provides an ultrasonic guided wave testing method aiming at the angle steel of an electric steel tower, which belongs to the field of ultrasonic guided wave testing. The testing method is mainly and technically characterized by comprising the steps of: selecting an ultrasonic flaw detector, an ultrasonic guided wave probe and a reference block, and manufacturing an artificial defective groove on the reference block; manufacturing a distance-amplitude curve by the reference block; polishing a smooth probe movement area on the surface of the angle steel to be tested and coating a coupling agent; using the ultrasonic guided wave probe to transversely move along the probe movement area for scanning; and judging whether the angle steel to be tested is qualified or not according to the relationship between the echo signal amplitude and the distance-amplitude curve. The testing method uses the ultrasonic detector by matching with the special ultrasonic guided wave probe for exciting the ultrasonic guided wave with designated mode, is used for the nondestructive testing of the angle steel of the electric steel tower, is characterized by simpleness, fastness, safety and reliability, and has great significance in ensuring the safe and stable operation of the electric steel tower and power transmission lines.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

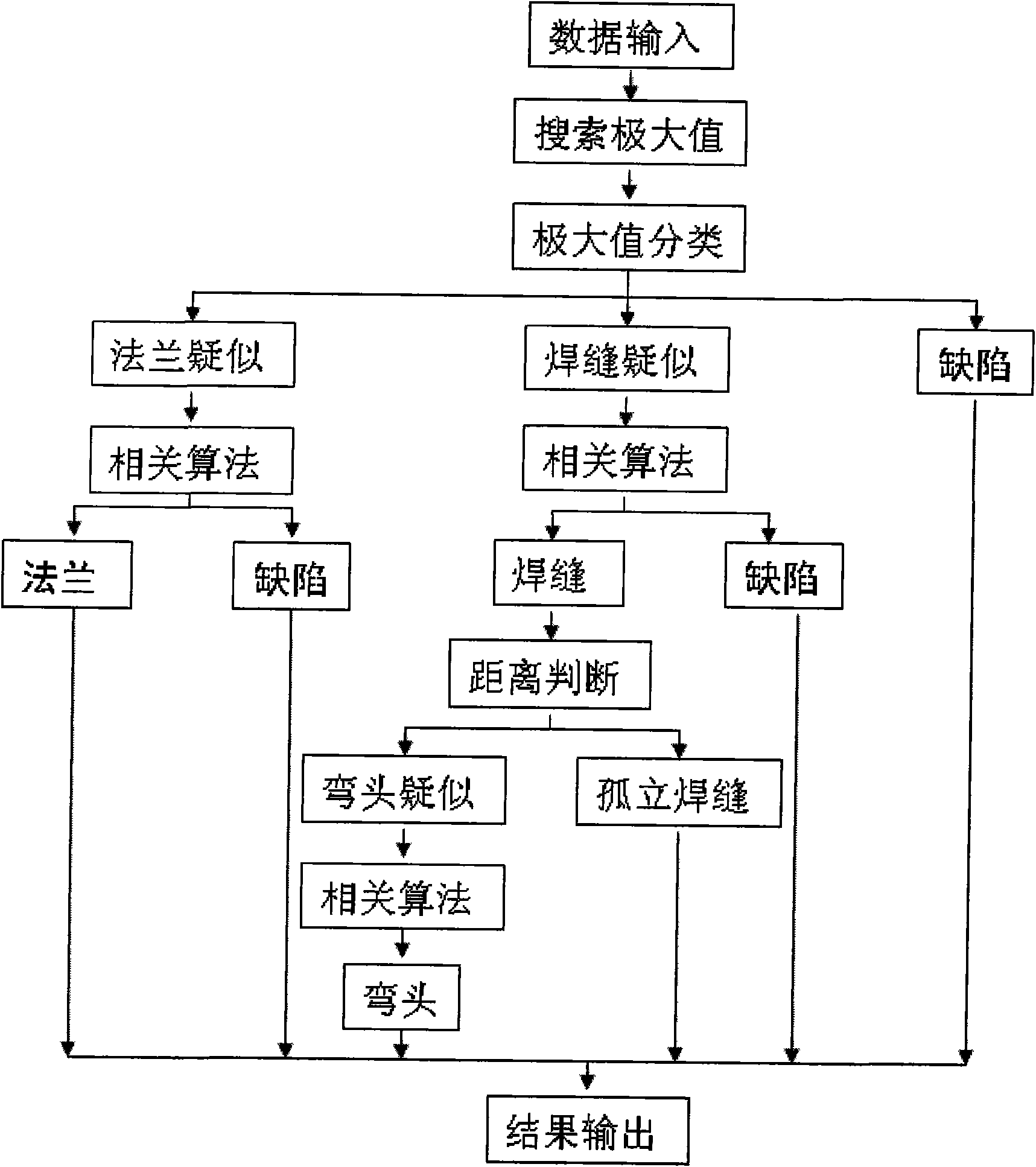

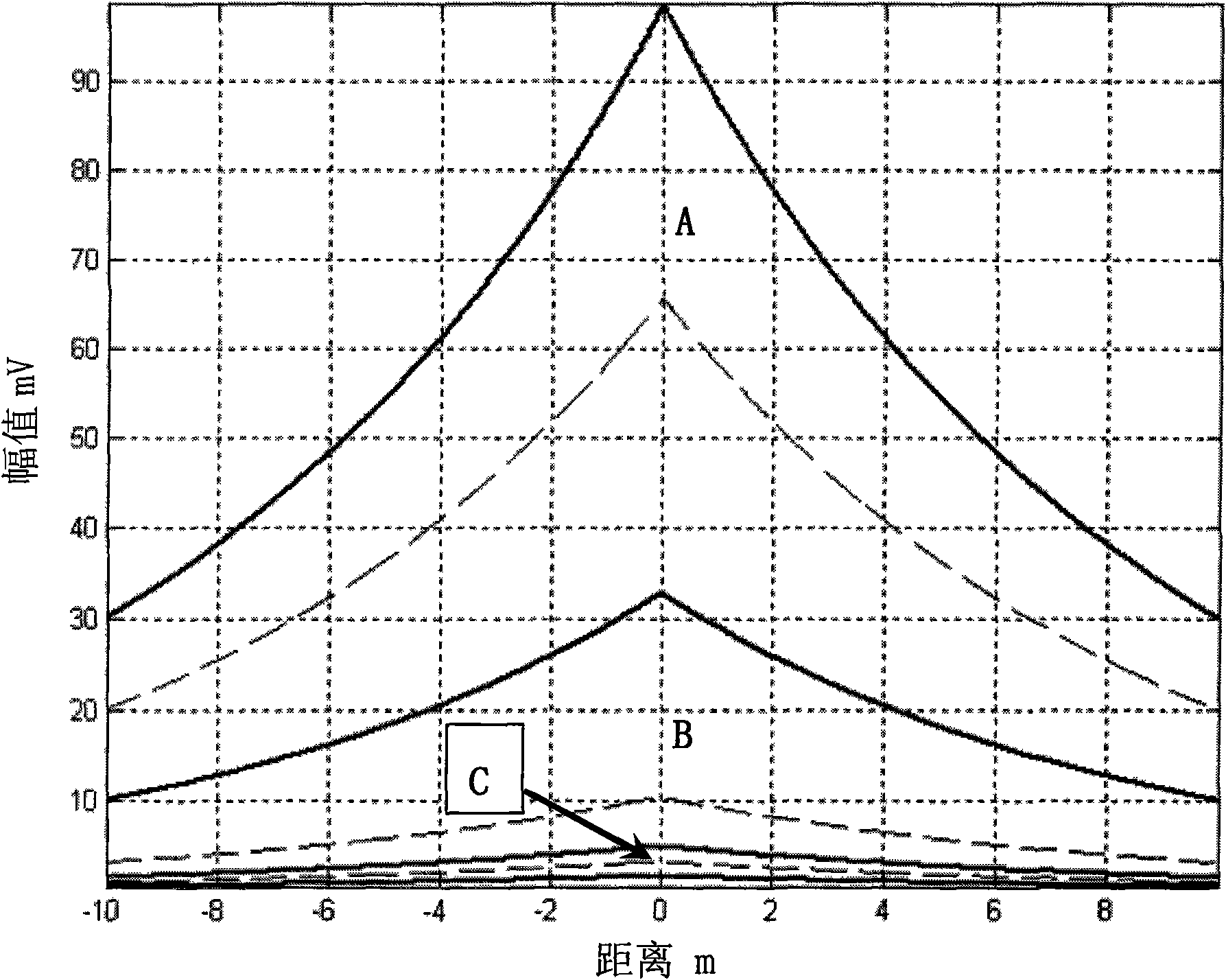

Pipeline feature intelligent recognition method based on correlation analysis

ActiveCN101571233ARealize fully automatic intelligent classificationRealize analysisAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsPattern recognitionNon destructive

The invention relates to a pipeline feature intelligent recognition method based on correlation analysis, belonging to the field of non-destructive detection signal analysis. The method classifies detection signals according to amplitude, shape similarity and relative size relationship between symmetric and asymmetric signals based on the correlation analysis of ultrasonic guided wave detection signals. The corresponding relationship between the categories and the pipeline features is established through tests, thereby being capable of rapidly and accurately classifying the ultrasonic guided wave detection signals.

Owner:BEIJING UNIV OF TECH +1

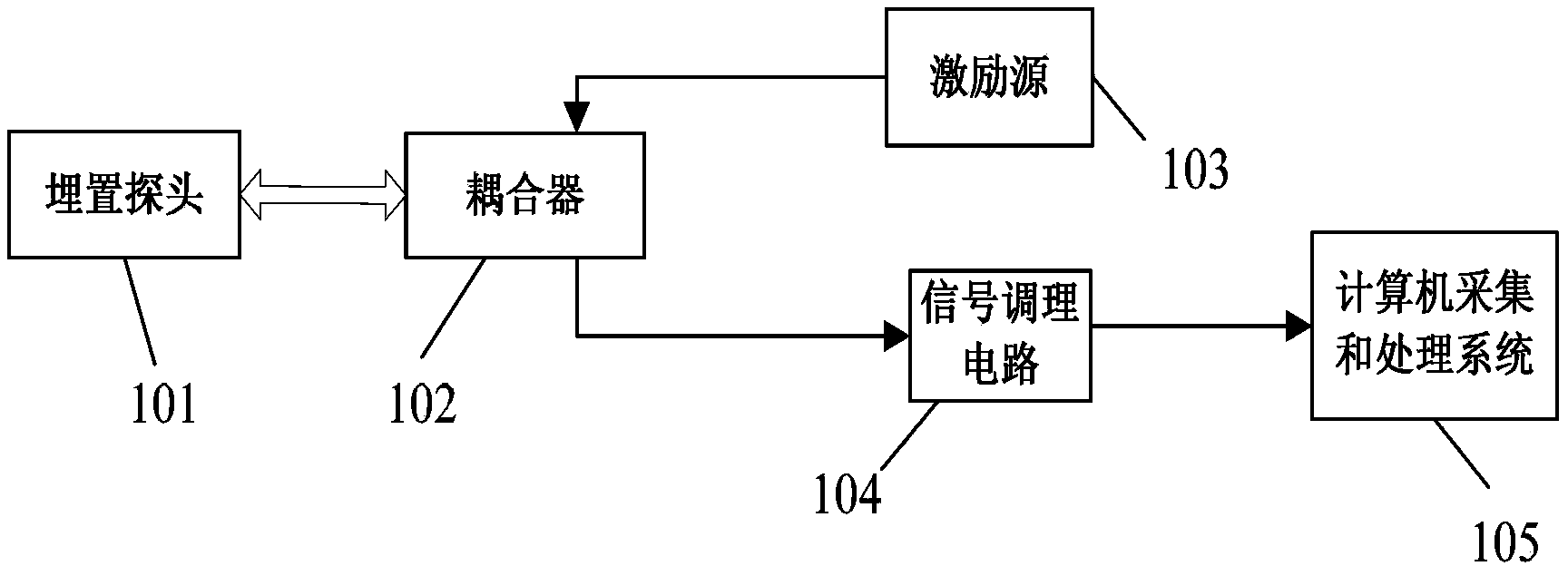

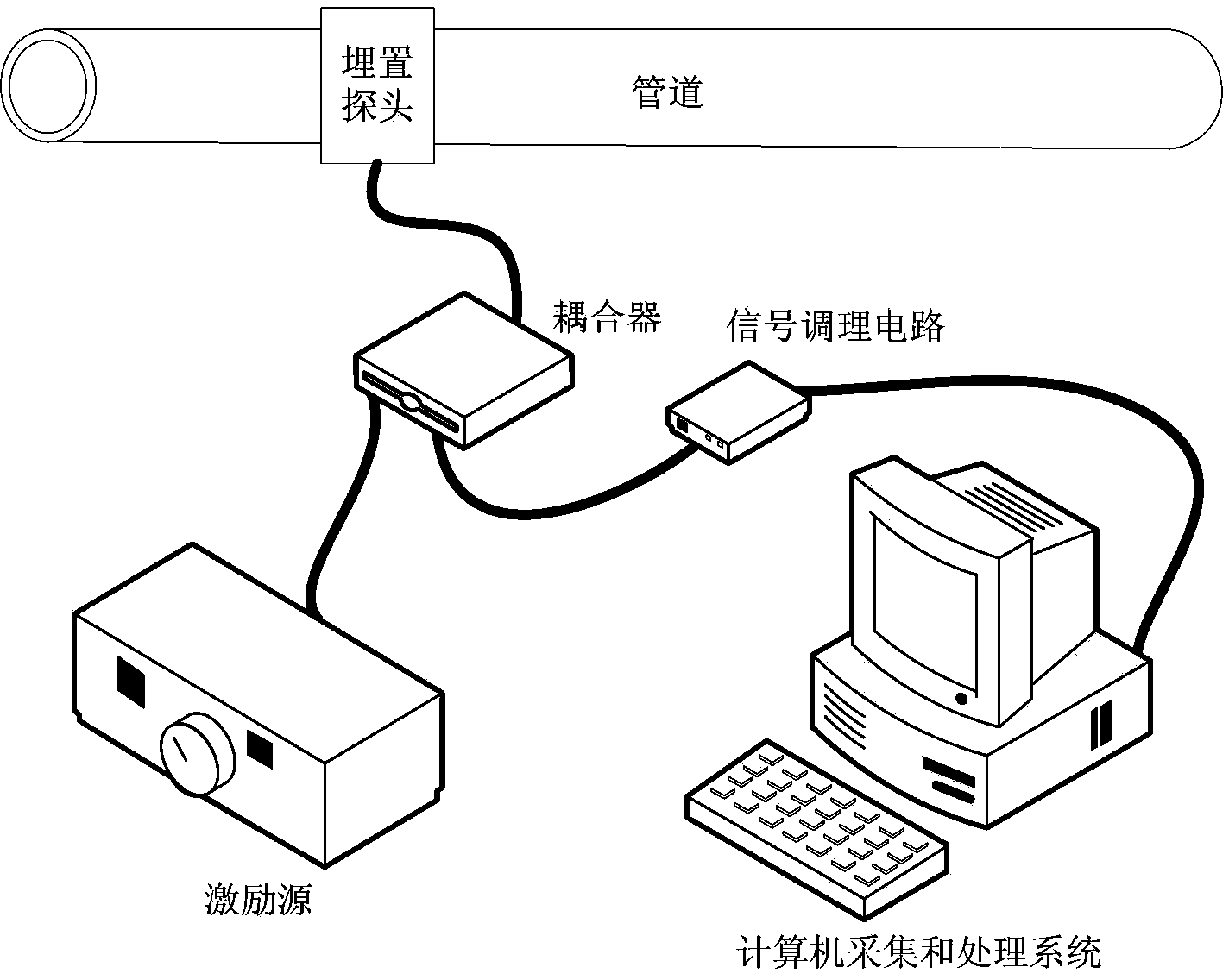

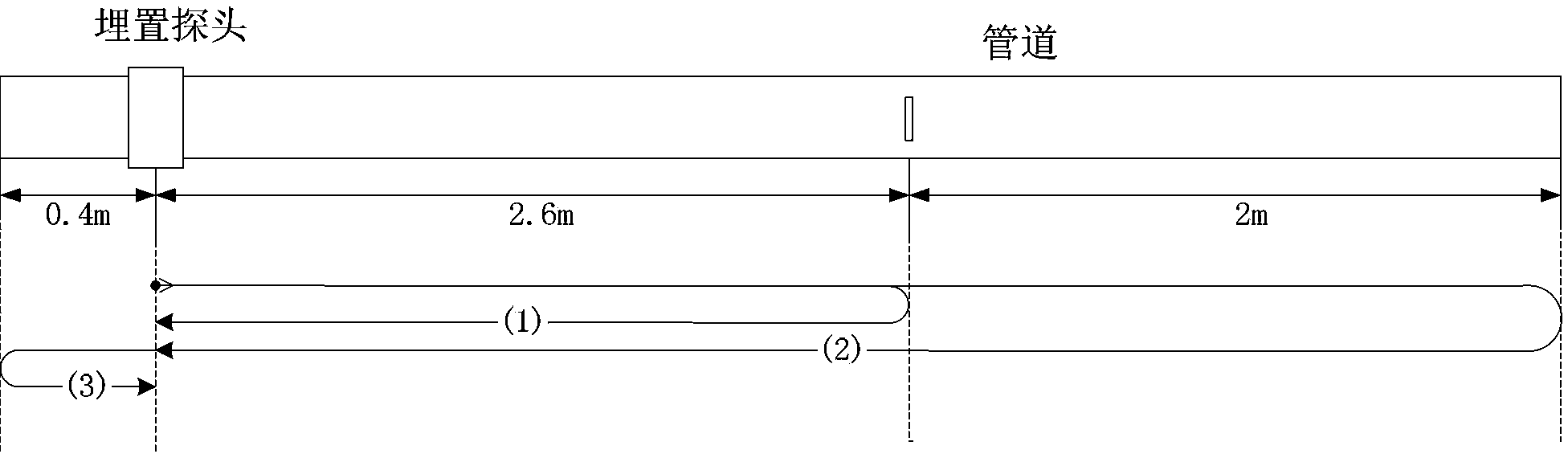

Method for monitoring defects of high-temperature steam injection pipeline

ActiveCN103412049AEasy to detectEnable long-term monitoringAnalysing solids using sonic/ultrasonic/infrasonic wavesSignal conditioning circuitsSonification

The invention discloses a method for monitoring defects of a high-temperature steam injection pipeline. An embedded probe is connected with a probe interface of a coupler; an exciting circuit is connected with an excitation source interface of the coupler; an input end of a signal conditioning circuit is connected with a signal conditioning interface of the coupler, and an output end of the signal conditioning circuit is connected with a data acquisition card interface of a computer acquisition and processing system; the excitation source inputs a pulsed excitation signal to the embedded probe through the coupler, excites ultrasonic guided-waves in the pipeline, and generates ultrasonic echoes when encountering the defects, the ultrasonic echoes are transmitted to the embedded probe and are converted into voltage signals through the embedded probe; the voltage signals are transmitted to the signal conditioning circuit to be processed through the coupler and are output to the computer acquisition and processing system which acquires, processes and displays the ultrasonic echo signals containing defect information. The embedded probe can be embedded in an insulating layer of the pipeline, and the insulating layer of the high-temperature steam injection pipeline does not need to be damaged basically, but online detection and long-term monitoring for the defects of the pipeline can be realized, and the defects of the pipeline can be simply and accurately positioned.

Owner:TSINGHUA UNIV

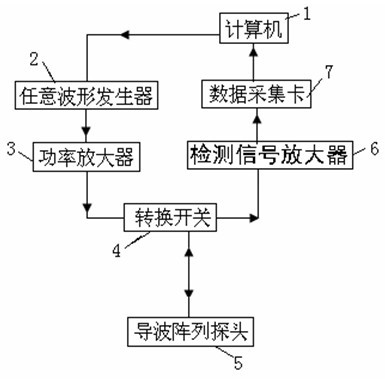

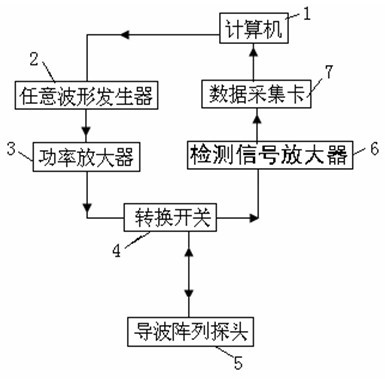

Ultrasonic guided wave device and method for detecting defect at rail bottom of steel rail at long distance

InactiveCN102043015AAccurate judgmentSolve the problem that rapid non-destructive testing cannot be performedAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesSonificationAudio power amplifier

The invention discloses an ultrasonic guided wave device for detecting a defect at the rail bottom of a steel rail at a long distance, which comprises a computer, a data acquisition card, a detection signal amplifier, an arbitrary waveform generator, a power amplifier, a change-over switch and a guided wave array probe. The ultrasonic guided wave device is characterized in that: the computer serves as a control center of the device, and controls the arbitrary waveform generator to generate a single-audio frequency signal of which central frequency is selected detection frequency; the single-audio frequency signal is transmitted to the guided wave array probe after passing through the power amplifier to excite guided waves of a vertical bending mode in the rail bottom of the steel rail; and under the regulation and control of the change-over switch, the guided wave array probe receives a defect reflection echo signal which is transmitted to the computer for processing and display after passing through the detection signal amplifier and the data acquisition card. The ultrasonic guided wave device realizes the rapid nondestructive detection of the defect at the rail bottom of the steel rail.

Owner:NANCHANG HANGKONG UNIVERSITY

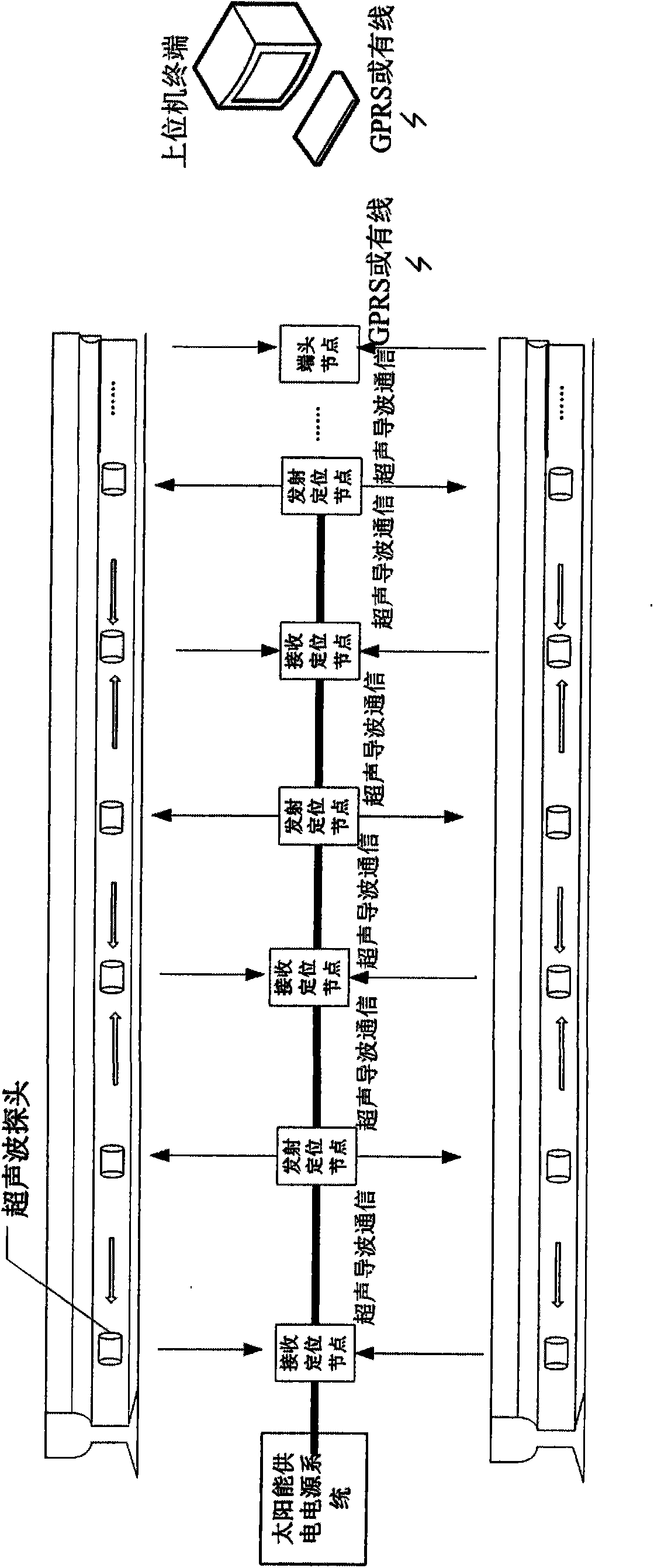

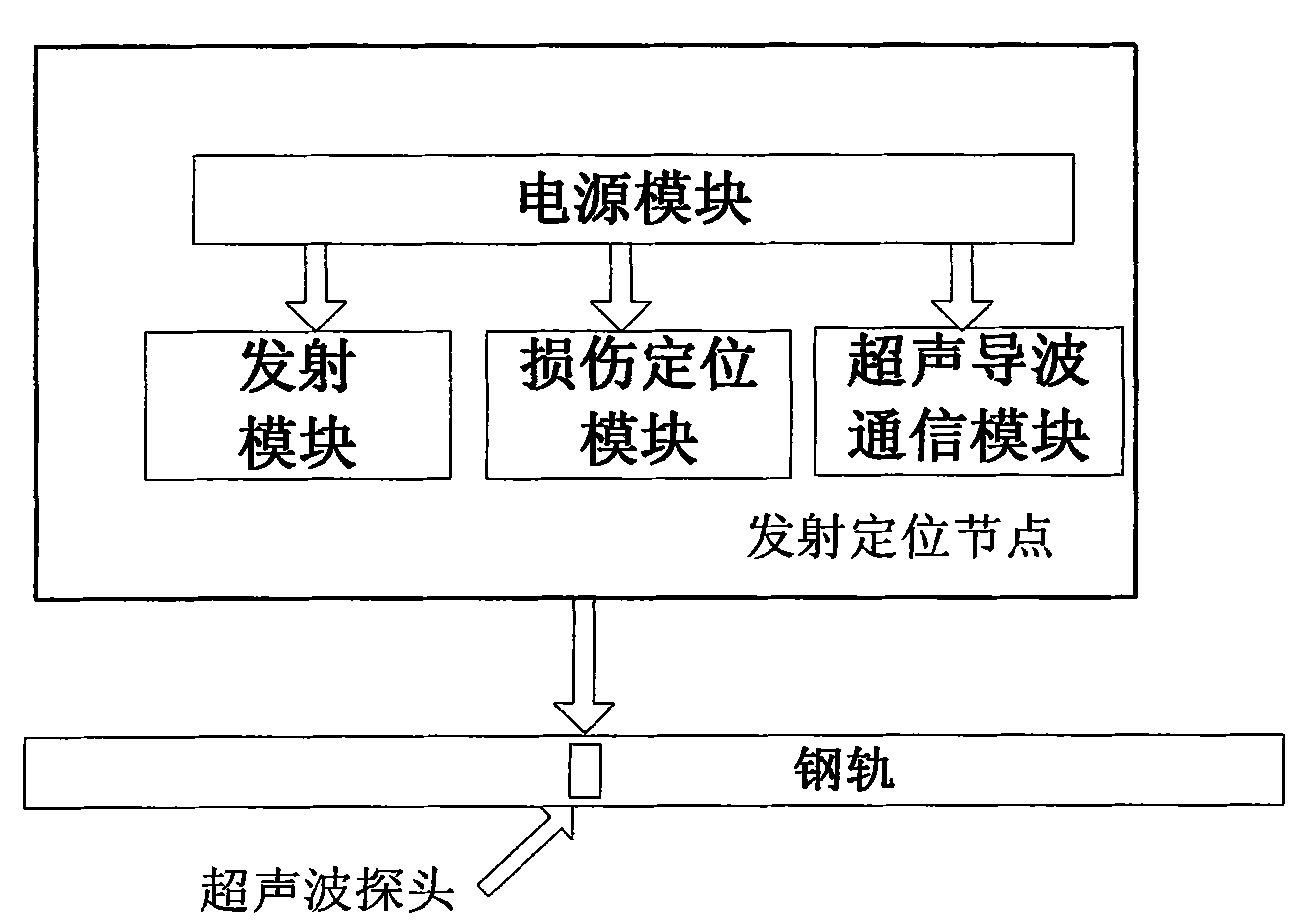

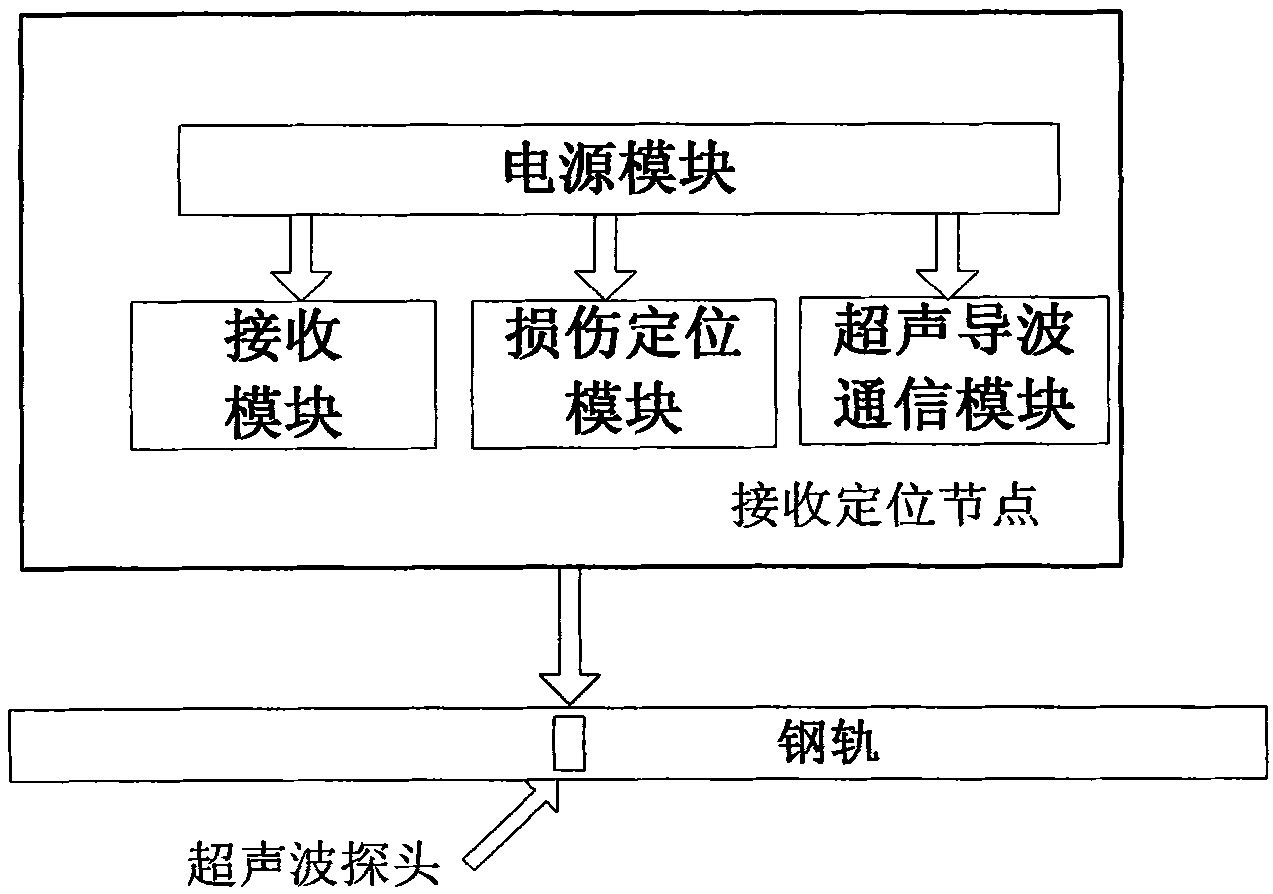

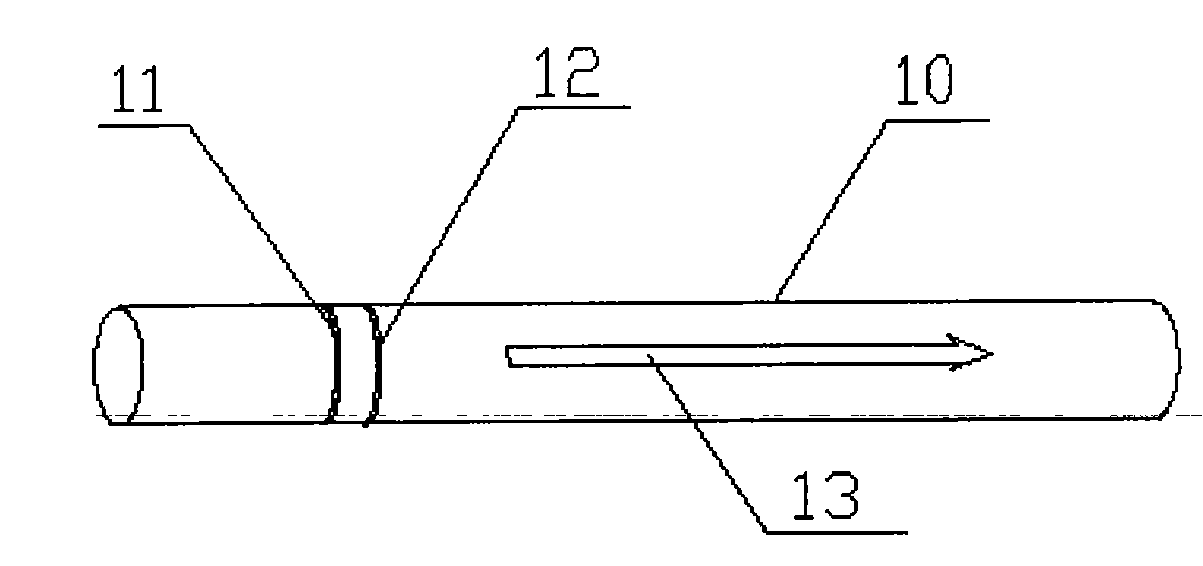

Real-time broken-rail detecting and positioning system based on ultrasonic guided waves

ActiveCN104020221ASettlement feeAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic wave reradiationSonificationSimulation

The invention discloses a real-time broken-rail detecting and positioning system based on ultrasonic guided waves. The real-time broken-rail detecting and positioning system based on ultrasonic guided waves is composed of a solar power supply or wired power supply system, an ultrasonic probe, a transmission positioning node, a receiving positioning node, an end node and an upper computer terminal. By using the system, whether a long-distance steel rail is damaged or broken can be detected in real time, the accurate position and damage size of a broken rail can be detected, and the problem that the long-distance broken rail cannot be detected or positioned in real time in the prior art is solved; in addition, the transmission of alarm data of all of the nodes is realized by adopting ultrasonic guided wave signals based on a steel rail transmission medium, and the problems of poor signals and high cost of the existing communication technology are solved.

Owner:杨媛

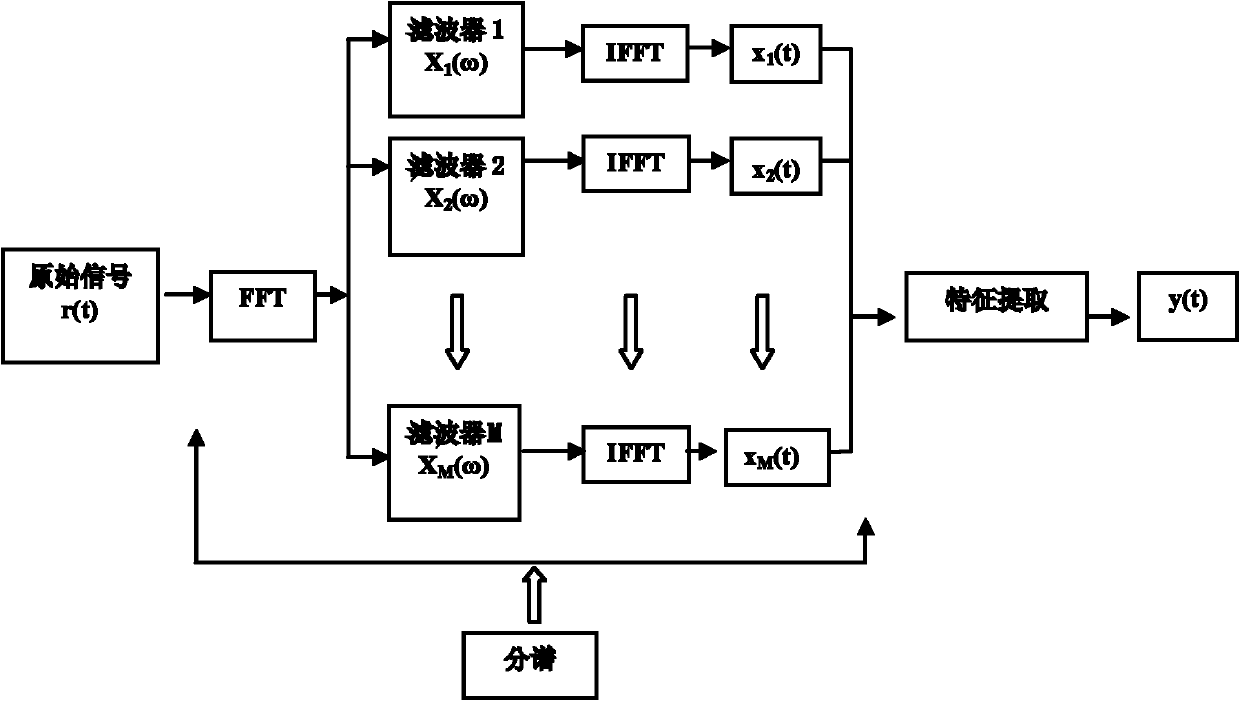

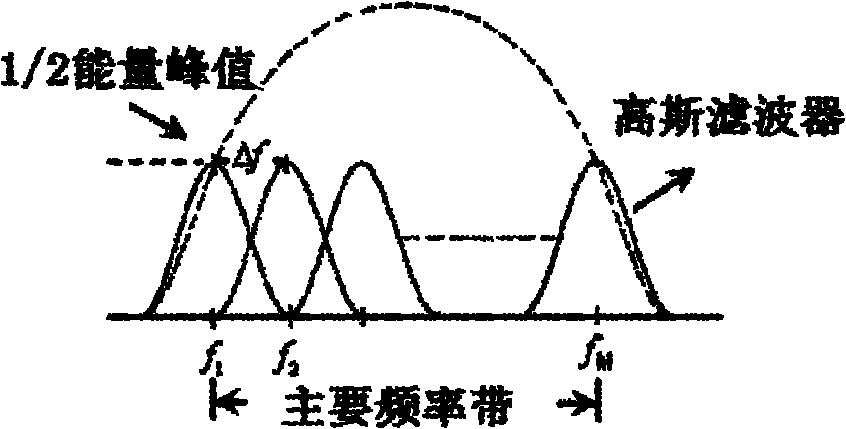

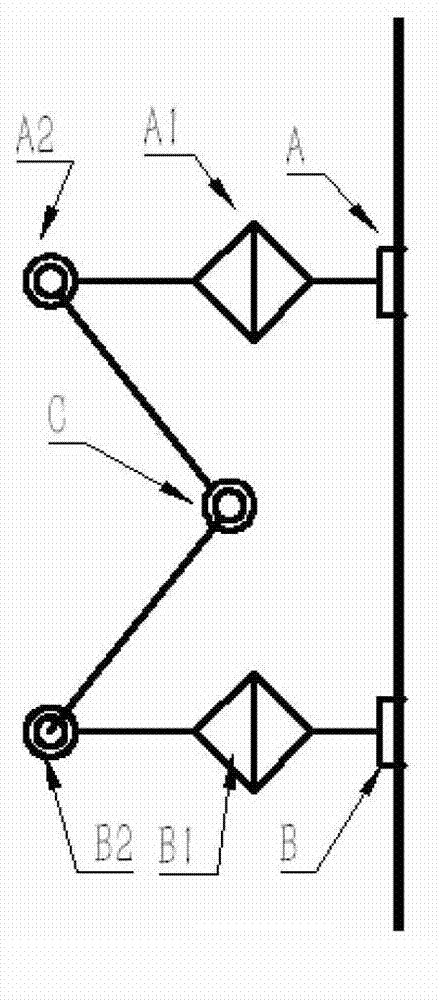

Guided wave signal analyzing method based on time delay

ActiveCN101782555ALower requirementAchieve separationProcessing detected response signalSonificationUltrasonic guided wave

The invention discloses a guided wave signal analyzing method based on time delay. The time delay and the linear superposition are carried out on the basis of multiple groups of original signals for detecting ultrasonic guided wave, and multiple groups of original signals are separated in directions and combined into two detection result curves finally. The method comprises the steps of: mounting N sensors, wherein each sensor group corresponds to one channel, the sensors are divided into an A-ring and a B-ring and respectively set in odd number and even number, and the interval between the A-ring and the B-ring is 1 / 4 of the wavelength of exciting signal central frequency; selecting M windowing modulation sine waves with different central frequencies and the certain periodicity as the exciting signals, wherein the M turns of exciting signals have respective central frequency and bandwidth in the frequency domain, each turn of exciting signals covers a certain frequency range, and M*N*N groups of data are obtained by exciting and changing the central frequencies for many times; and obtaining a final pipeline detection curve graph by the calculation to realize the separation in the direction of detection and the separation of symmetrical and unsymmetrical signals, which is convenient to find out defects on the pipeline.

Owner:BEIJING UNIV OF TECH

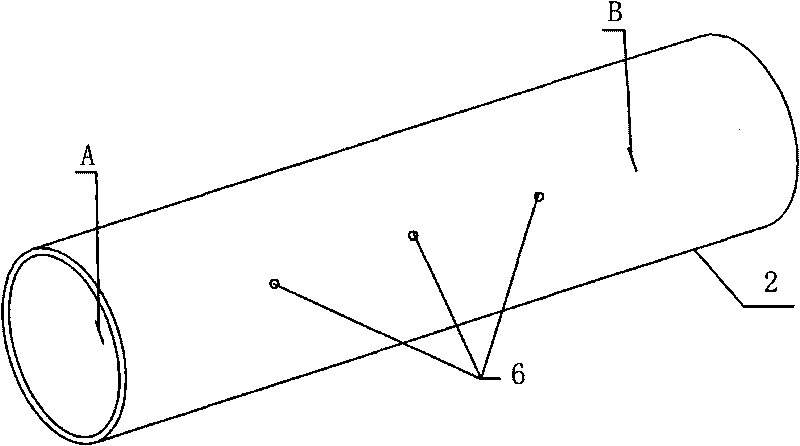

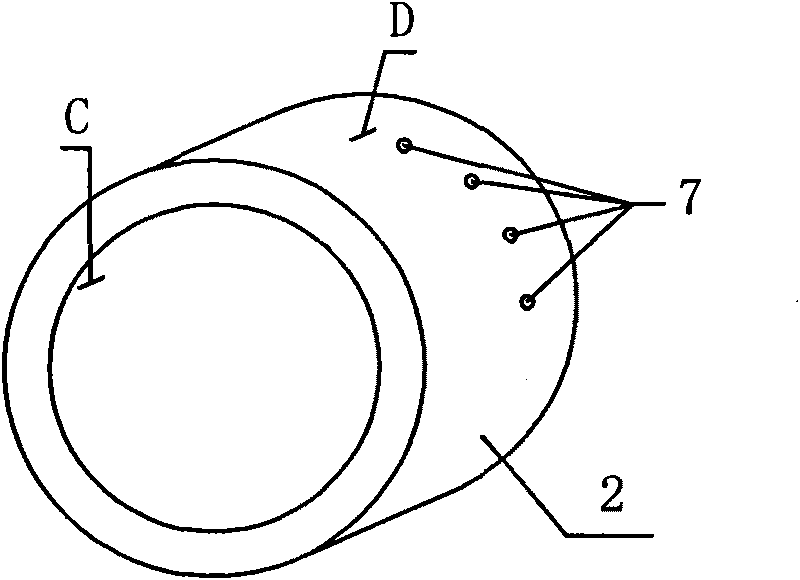

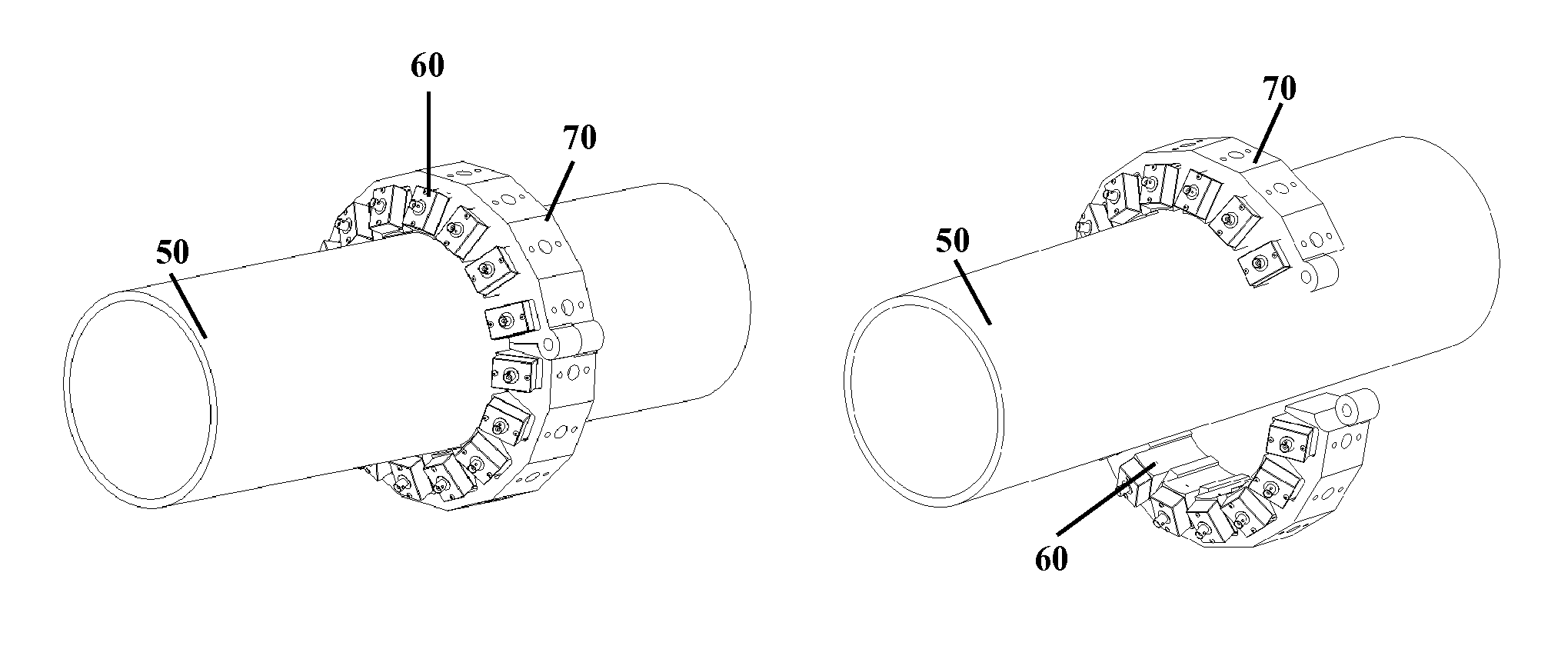

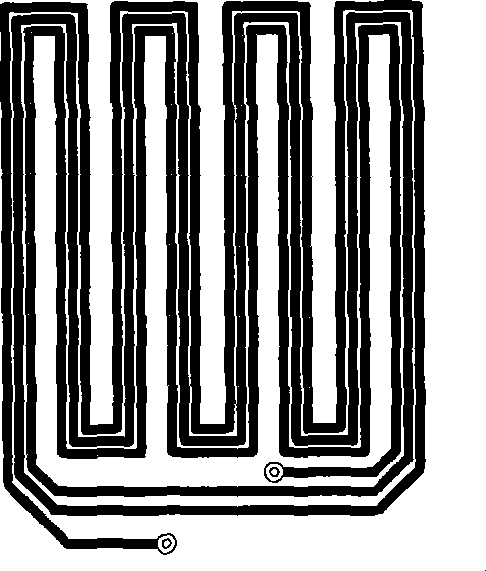

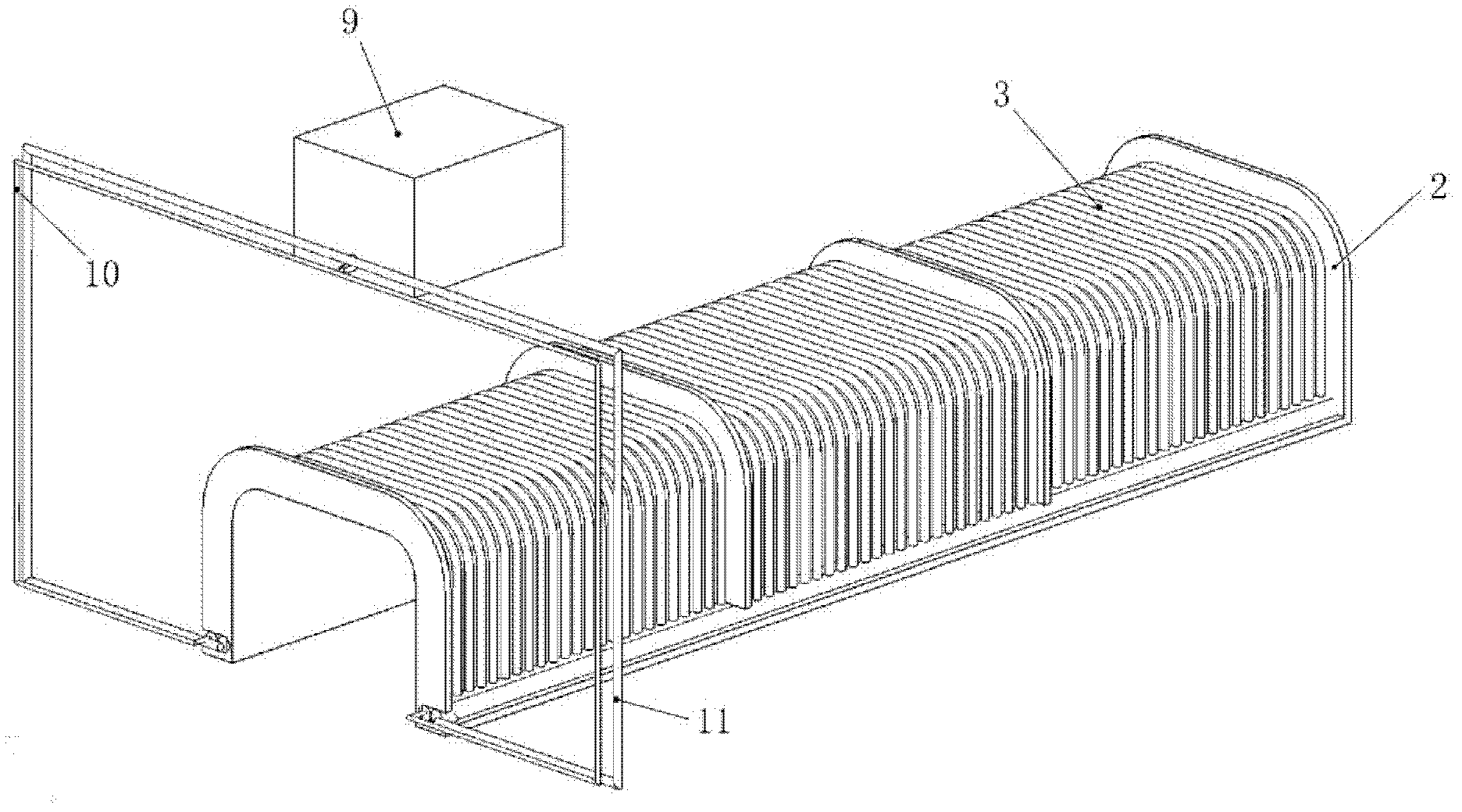

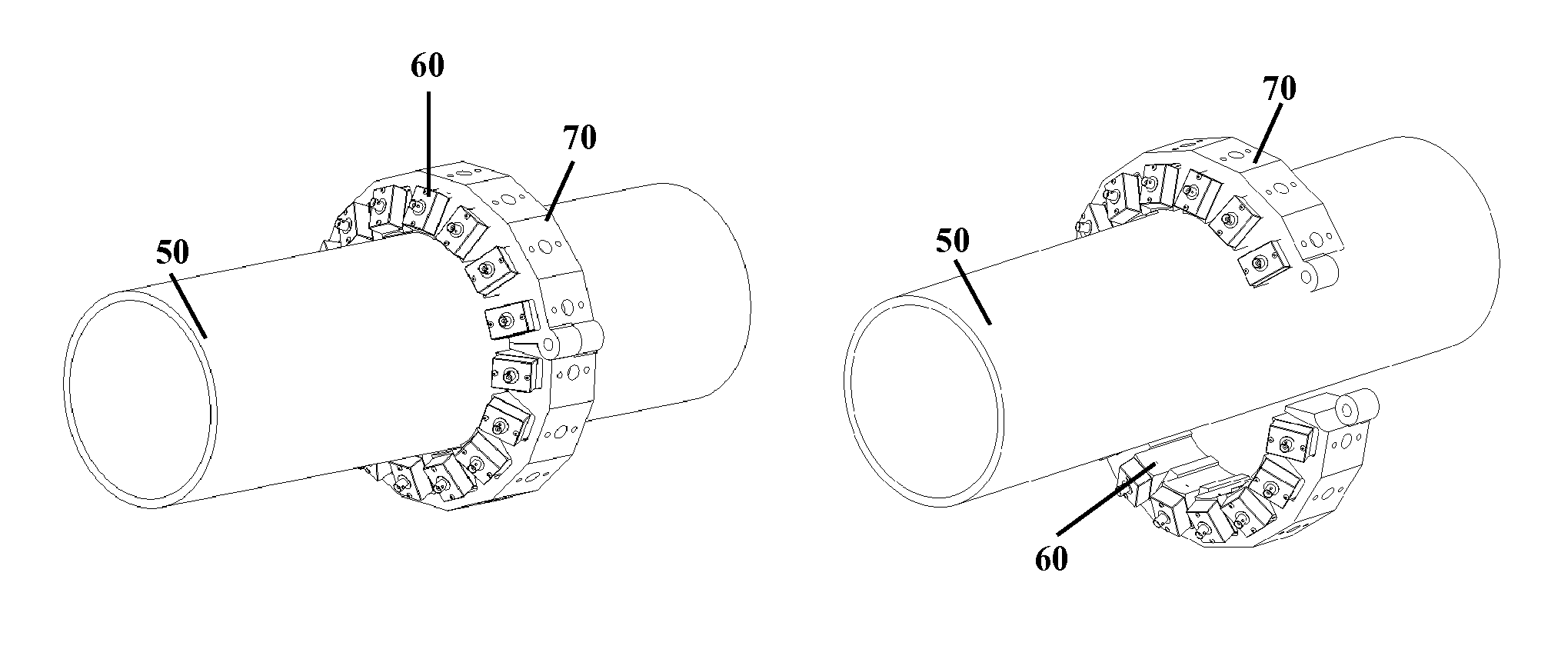

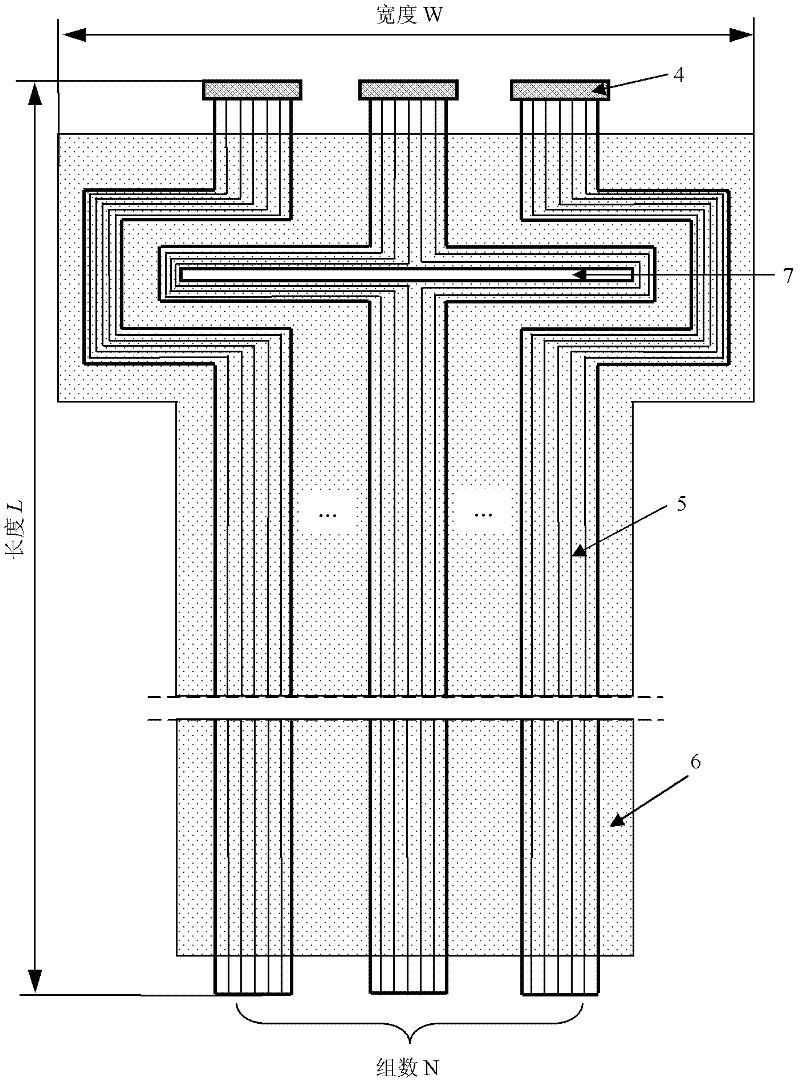

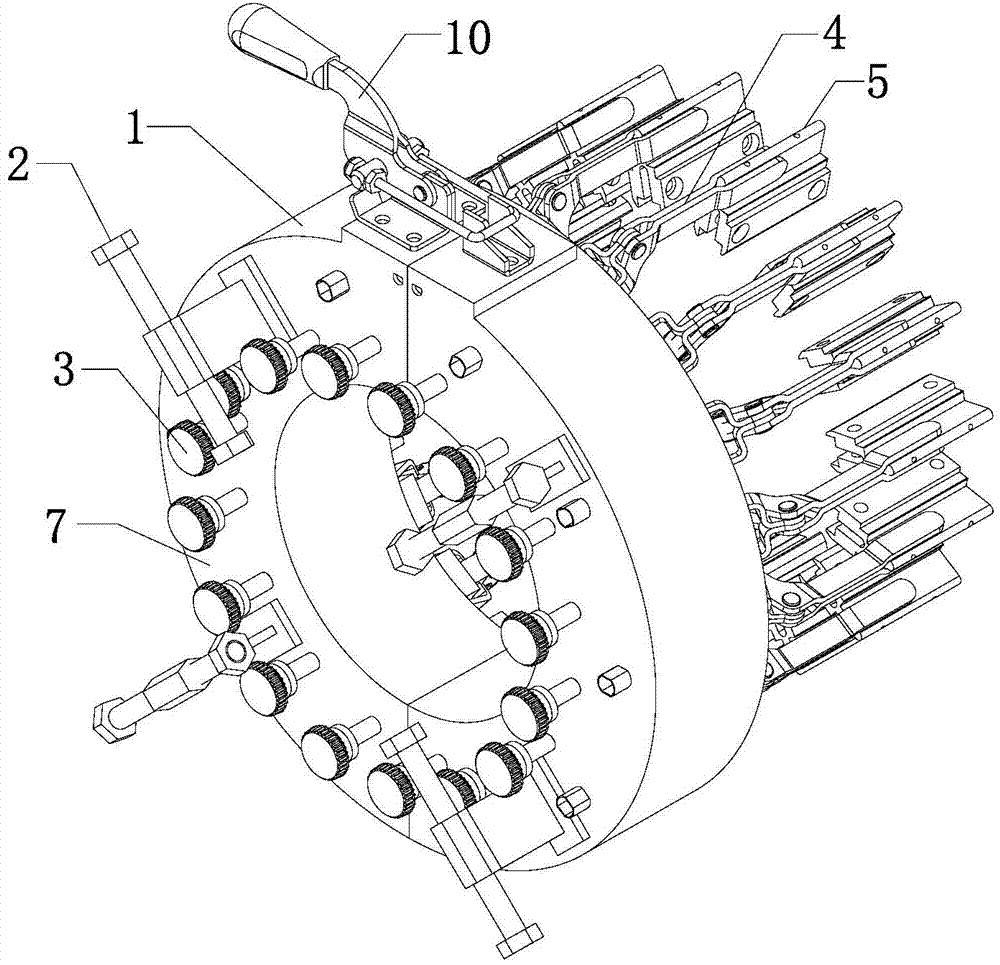

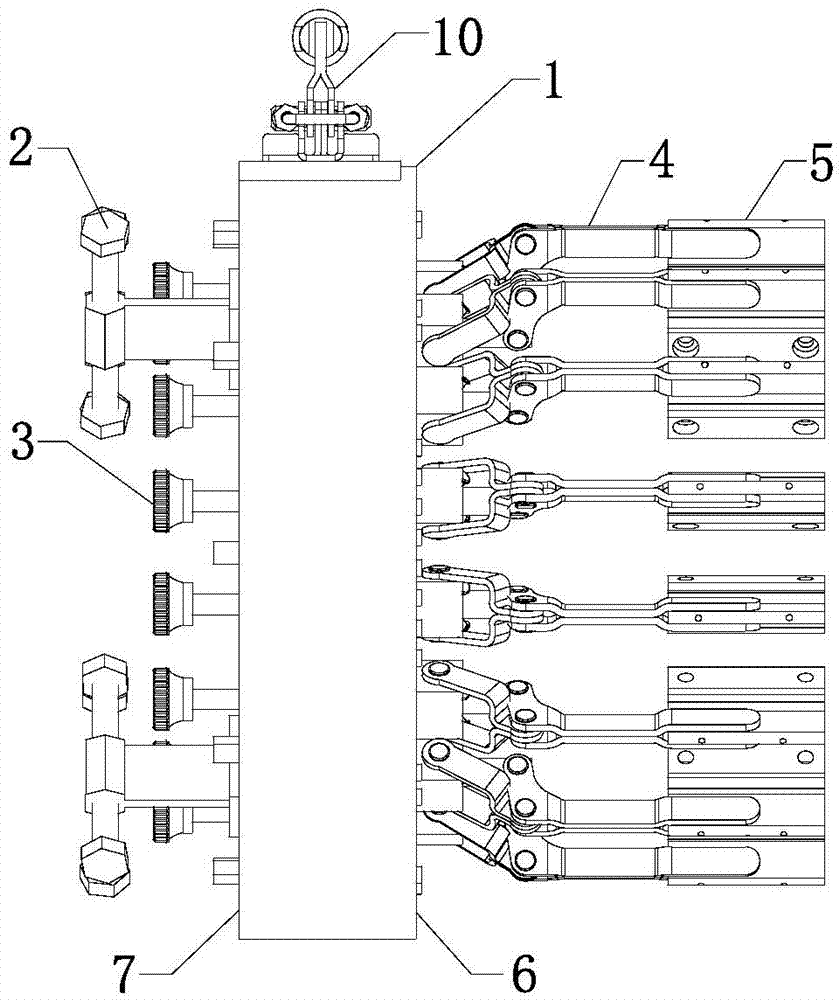

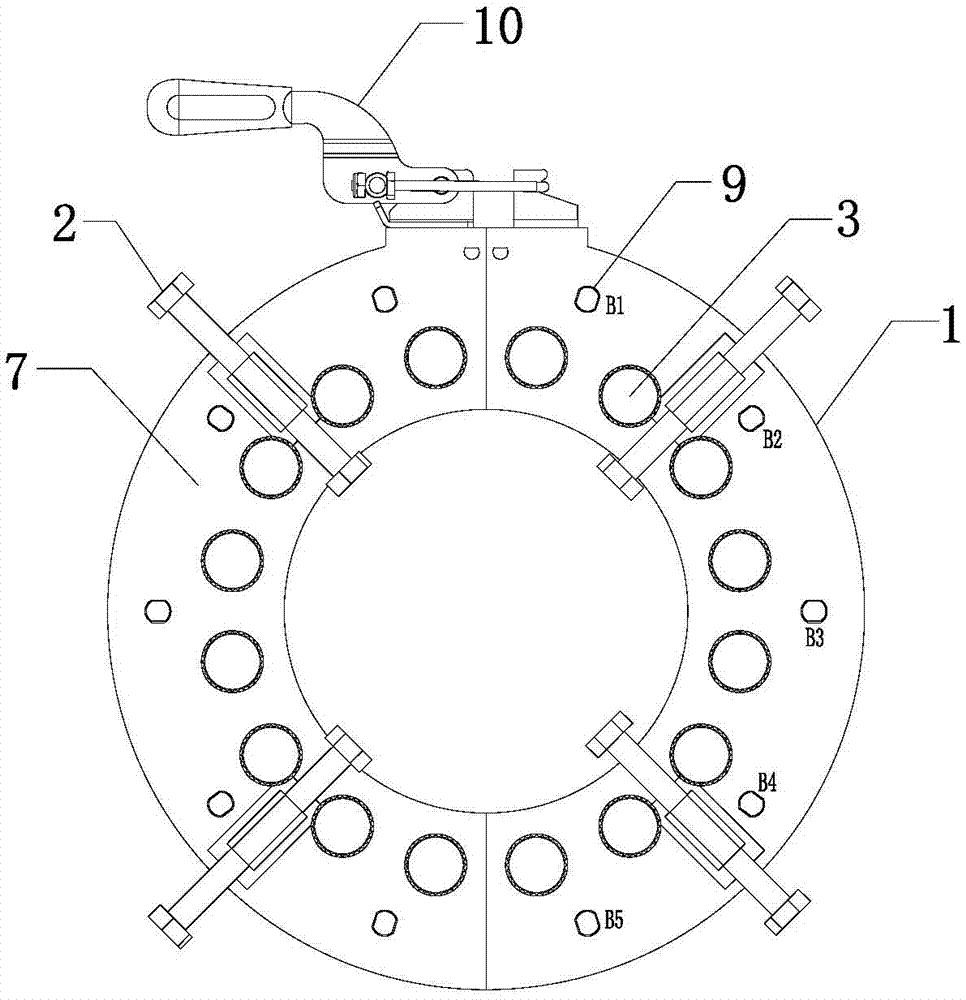

Ultrasonic guided-wave probe array fixing device used for tube fitting detection

ActiveCN104749258AImprove versatilityOvercome the defect that only a single outer diameter pipe can be detectedMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic guided waveBiomedical engineering

The invention discloses an ultrasonic guided-wave probe array fixing device used for tube fitting detection. The ultrasonic guided-wave probe array fixing device comprises a mechanical part and a signal circuit part, wherein the mechanical part comprises a circular-ring-shaped base, a plurality of positioning bolts, a plurality of spiral telescopic components, a plurality of swing rods and a plurality of probe bases; the inner diameter of the circular-ring-shaped bases is larger than the outer diameter of a detected tube fitting; two side panels of the circular-ring-shaped bases are respectively a panel A and a panel B; the positioning bolts are mounted on the panel B; each spiral telescopic component penetrates through the panel B and the panel A in sequence and then is correspondingly connected with one end of each swinging rod to regulate the opening and the closing of the swinging rod, the other end of each swinging rod is correspondingly connected with each probe base; a structure consisting of the spiral telescopic component, the swinging rods and the probe bases is uniformly distributed on the circular-ring-shaped base. The ultrasonic guided-wave probe array fixing device used for tube fitting detection, disclosed by the invention, is simple in structure, quick and convenient to operate, and capable of adapting to detection needs of tube fittings with different outer diameters within a design range.

Owner:JINAN UNIVERSITY

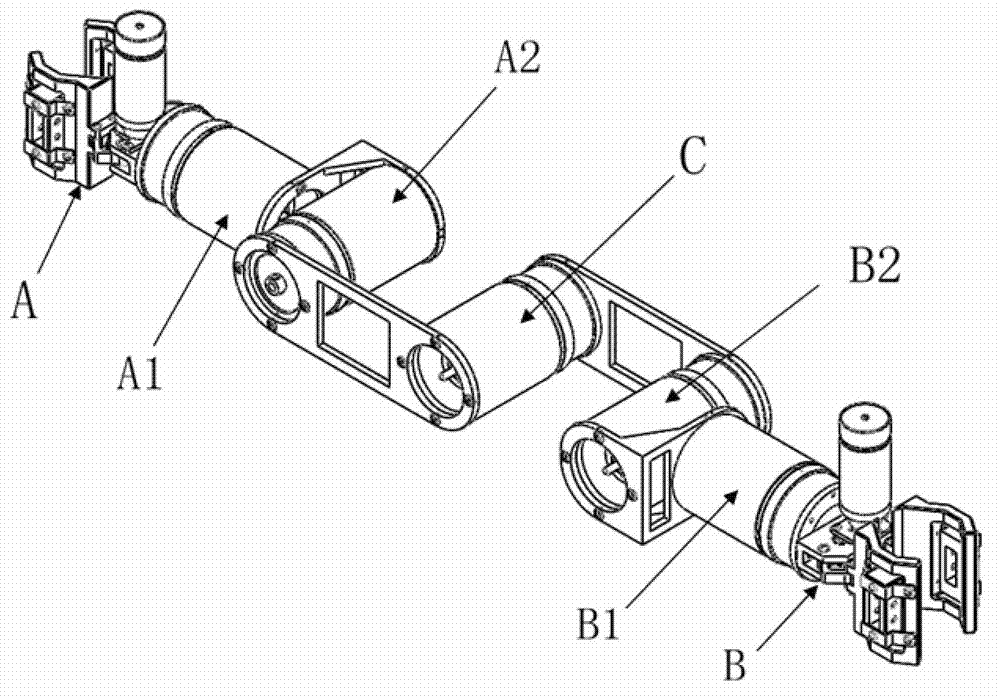

Rack pipe detection robot based on ultrasonic guided wave technology

ActiveCN103395064AAdaptable to pipe diameterEasy to buildPipeline systemsManipulatorRemote controlControl system

The invention relates to a rack pipe detection robot based on the ultrasonic guided wave technology. The robot is mainly characterized in that five rotary modules and two clamps are connected in a series manner on the basis of modular structure; the two clamps can be changed according to different pipe diameters, and a claw of each clamp is provided with a guided-wave probe clamping component on which guided-wave probes different in structure and quantity can be mounted; the rotary modules expand and retract to adjust the pose of terminal clamps, the two claws hold alternately to coordinate with the rotary modules to allow for various climbs. A control system based on PC / 104 bus technology is used and comprises a servo motor, an embedded computer main board, a sensor and a remote control system. The robot has the advantages of small size, light weight, simple structure and high flexibility, can detect in such manners of creeping on straight pipes and bent pipes and creeping among the pipes, and allows for rack pipe nondestructive detection on the basis of the ultrasonic guided wave technology by integrating the guided wave detection technology and the robot technology.

Owner:WUHAN UNIV

Two-way time reversal damage imaging method based on ultrasonic guided-wave

ActiveCN105510444AIncrease signal amplitudeImprove signal-to-noise ratioAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationElement model

The invention discloses a two-way time reversal damage imaging method based on ultrasonic guided-wave. The method comprises the following steps: carrying out active stress wave detection on a damaged object by the use of a modulated excitation signal, and synchronously acquiring signals at a transmission end and a reflective end of a detected area; carrying out frequency dispersion compensation separation on the acquired signals, and separating longitudinal mode guided wave and bending mode guided wave; extracting the longitudinal mode guided wave in the separated signals, carrying out time reversal treatment, and amplifying the reversed signal; carrying out simulation reversal by importing the reversed signal into a finite element model, extracting displacement values of all point clouds and moments in the model, and carrying out time and space focusing treatment to obtain a vibration cloud map; and defining a space curve to convert the vibration cloud map into a three-dimensional color map, and carrying out damage imaging by three-dimensional color point cloud. According to the method, characteristics of damages are analyzed from an overall perspective, and different mode guided waves are innovatively extracted to carry out time reversal analysis of transmission and reflective ends simultaneously. The method of the invention has important academic value and practical significance.

Owner:SOUTH CHINA UNIV OF TECH +1

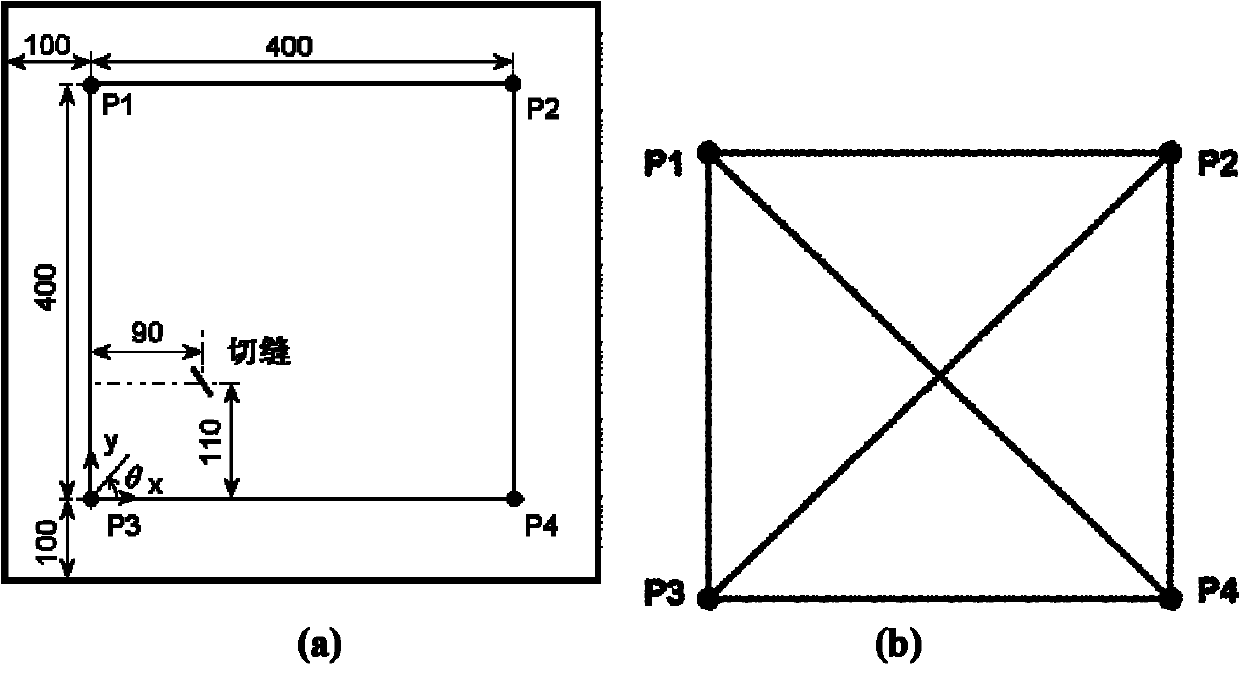

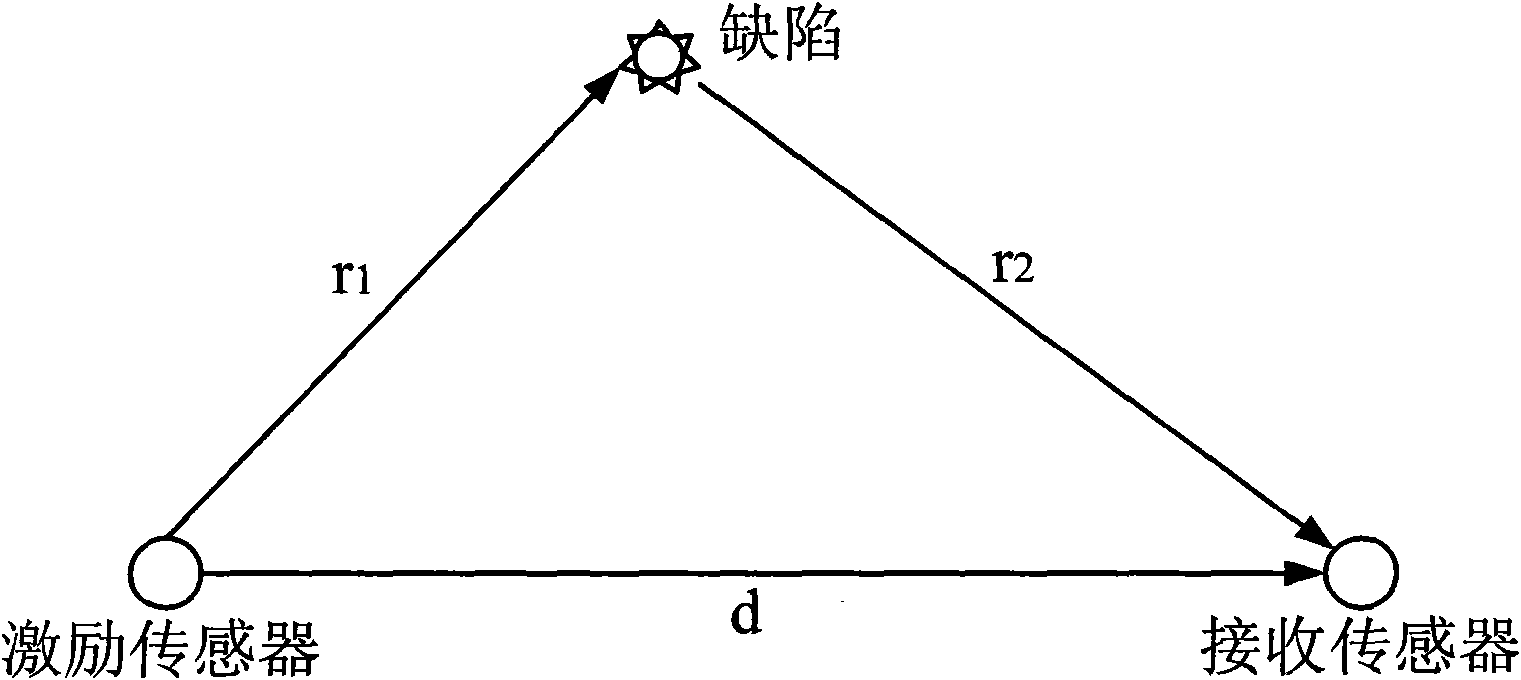

Ultrasonic guided wave detection technology for positioning defects of composite laminated plate

InactiveCN101571514AImprove positioning reliabilityReduce mistakesAnalysing solids using sonic/ultrasonic/infrasonic wavesPosition fixationTime delaysEngineering

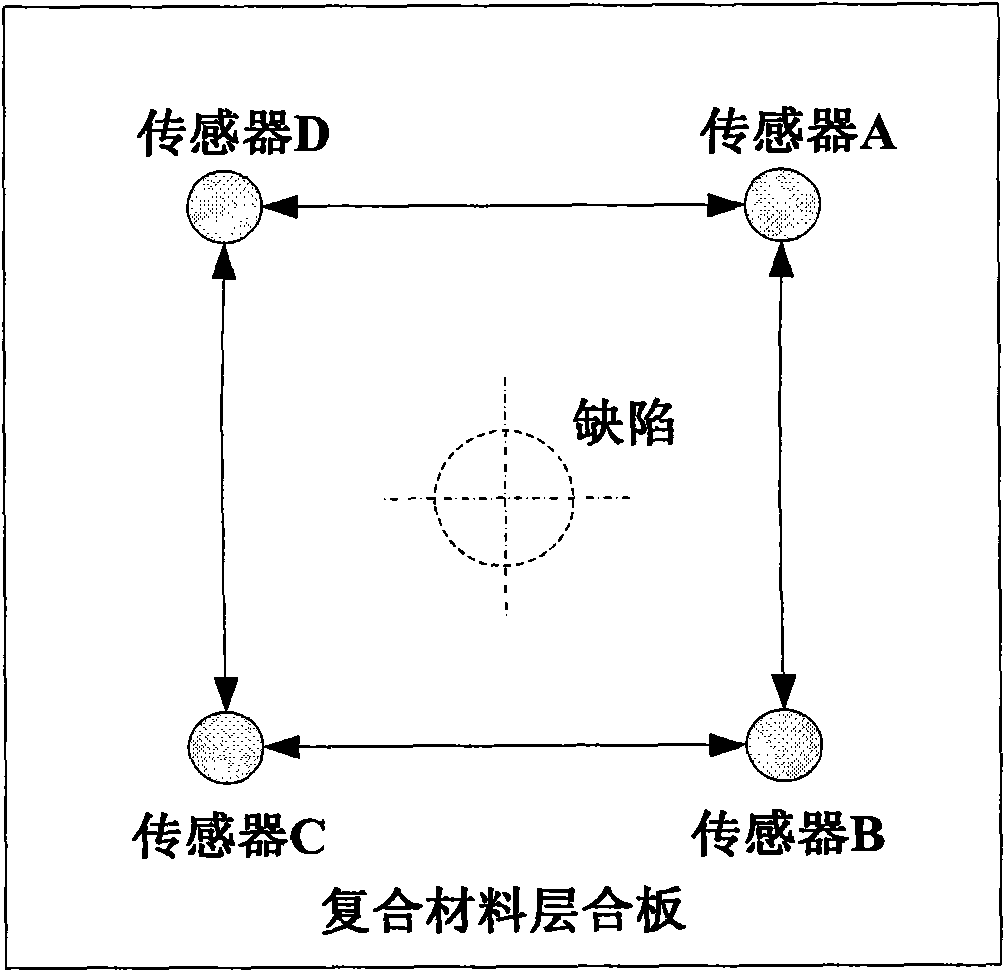

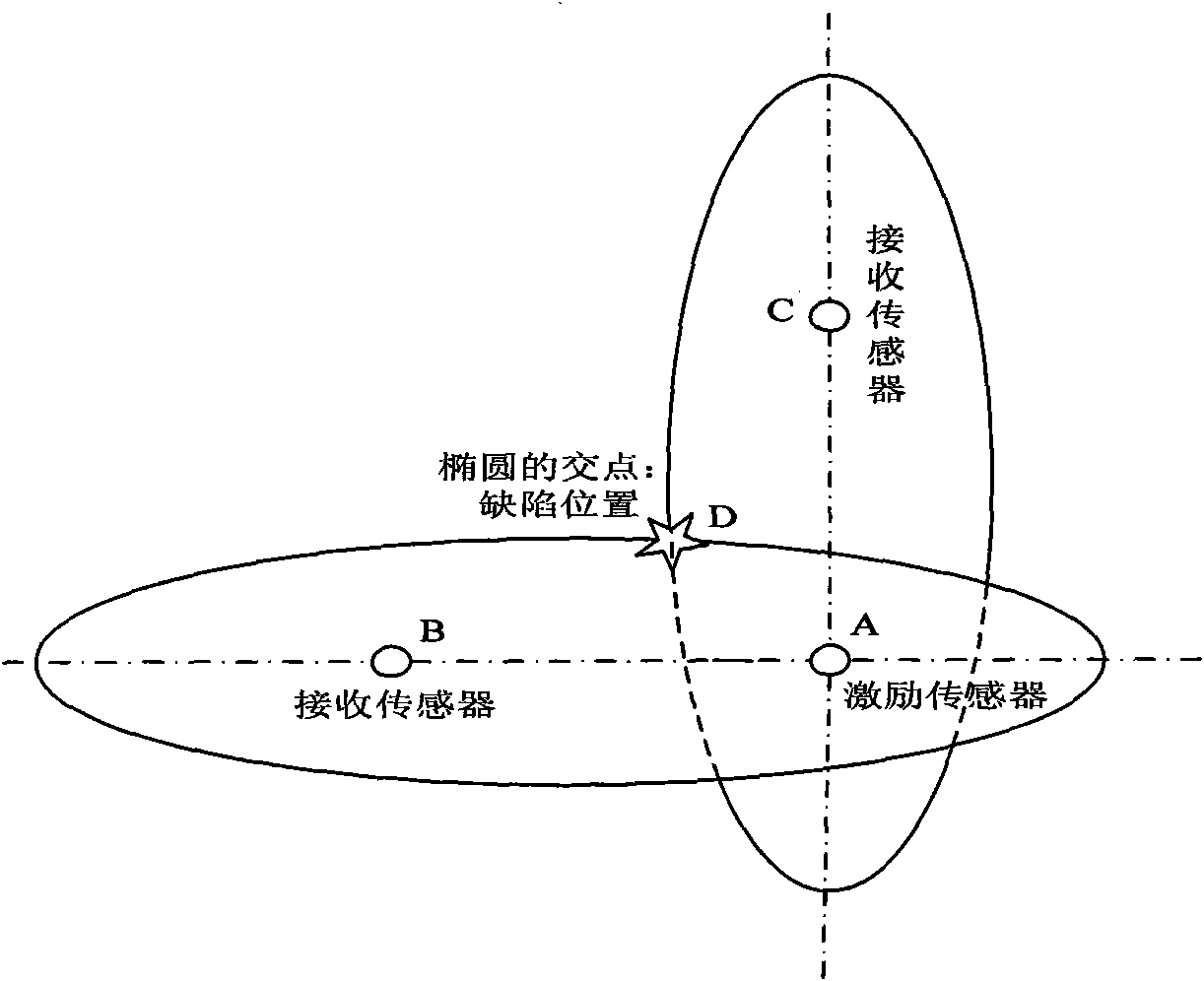

The invention provides a nondestructive test method for positioning defects of a composite laminated plate. The method is characterized in that a multi-probe detection mode is adopted to accurately and conveniently perform two-dimensional positioning on interfacial defects of the composite laminated plate. The method comprises the following steps: (a) arranging four sensors in a square at a certain spacing on the surface of the composite laminated plate; (b) taking each sensor in the square arrangement as an excitation sensor sequentially and two sensors adjacent to the excitation sensors as receiver sensors, thus forming a multiplex defect positioning system; (c) performing cluster analysis on position information of a plurality of groups of the defects, keeping effective data and eliminating information with obvious deviation; and (d) calculating to obtain position information of the defects based on an elliptic positioning method according to time delay, and further reducing errors by an averaging method for centering, thus performing accurate two-dimensional positioning on the defects of the composite laminated plate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Ultrasonic guided-wave based calculation method for separating flexural mode reflected signal

ActiveCN104833729AGet reflection coefficientSave human effortProcessing detected response signalWave structureSonification

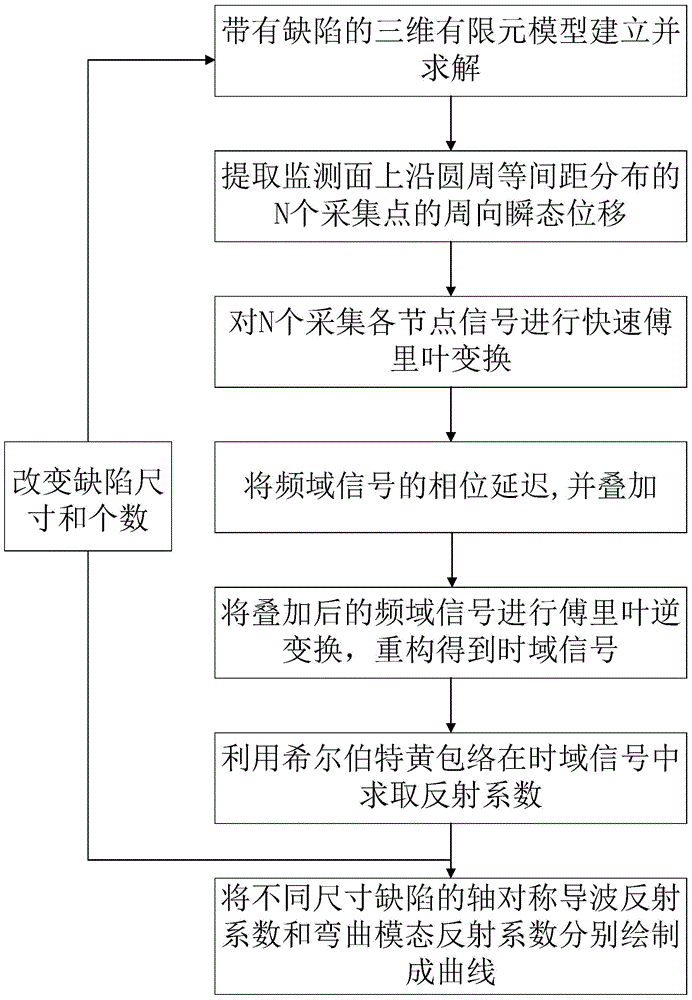

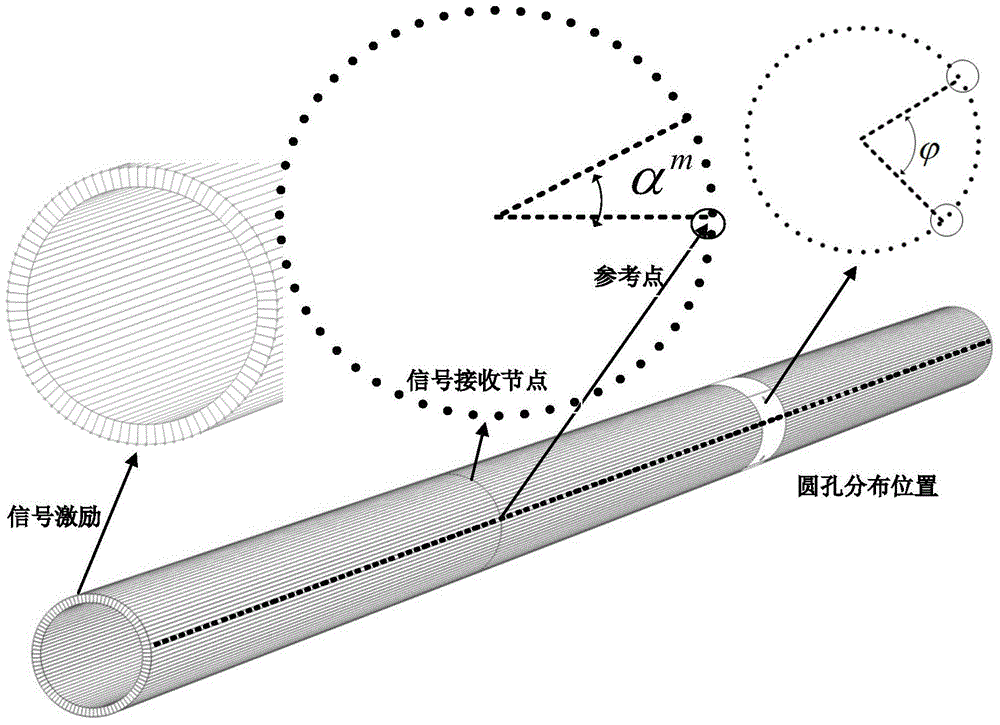

The present invention discloses a calculation method for separating symmetric and flexural mode wave packet and extracting weak signal of the bending mode. Based on the wave structure characteristic theory of axisymmetric mode and bending mode, the method uses finite element software to establish correlative model, extracts transient displacement signal of signal acquisition nodes of a guided-wave monitoring surface, and conducts delay superimposing on the collected signals on the frequency domain in accordance with relative formula; then the superimposed frequency domain signal is subjected to the inverse Fourier transform to obtain guided-wave mode wave packet of each order after separation; and Hilbert-Huang envelope is employed to calculate reflection coefficient for each mode. The method uses secondary development function of finite element software to compile the secondary development program, quantitatively analyze the influence degree of the parameters such as characteristics of defect size, location distribution, the number of defects and the center excitation frequency on the amplitude value of the flexural mode reflection echo generated from the defect locations through modal conversion, thereby integrally utilize reflection coefficients of axisymmetric mode and bending mode to evaluate the distribution of defect locations.

Owner:BEIJING UNIV OF TECH

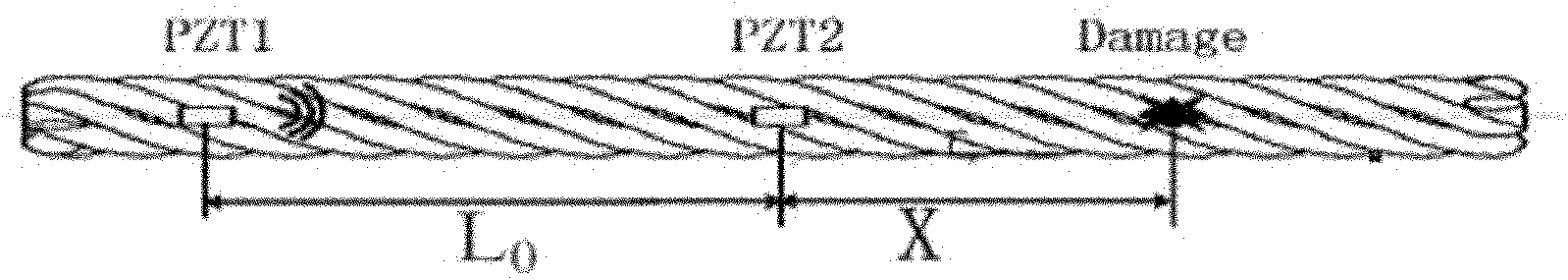

Damage positioning method for ultrasonic detection of transmission line

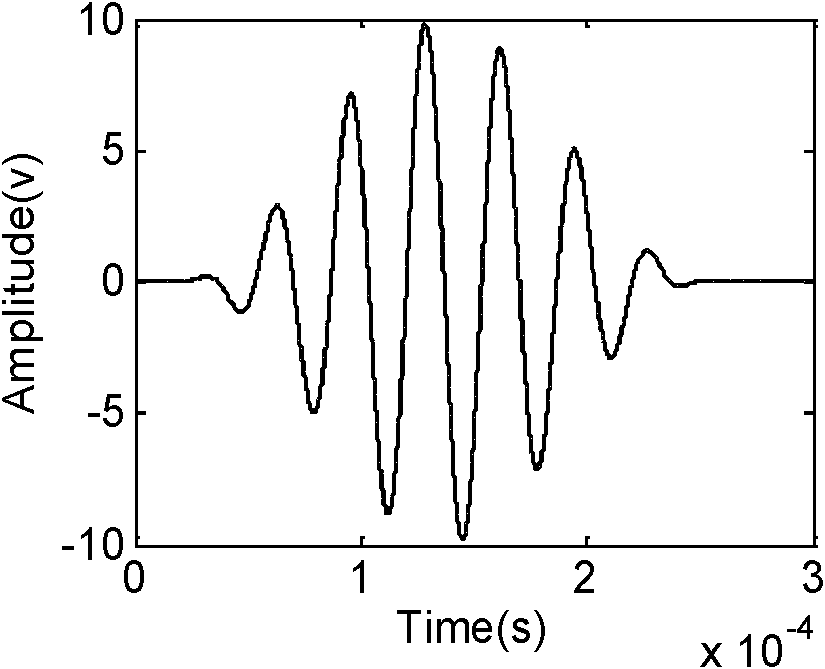

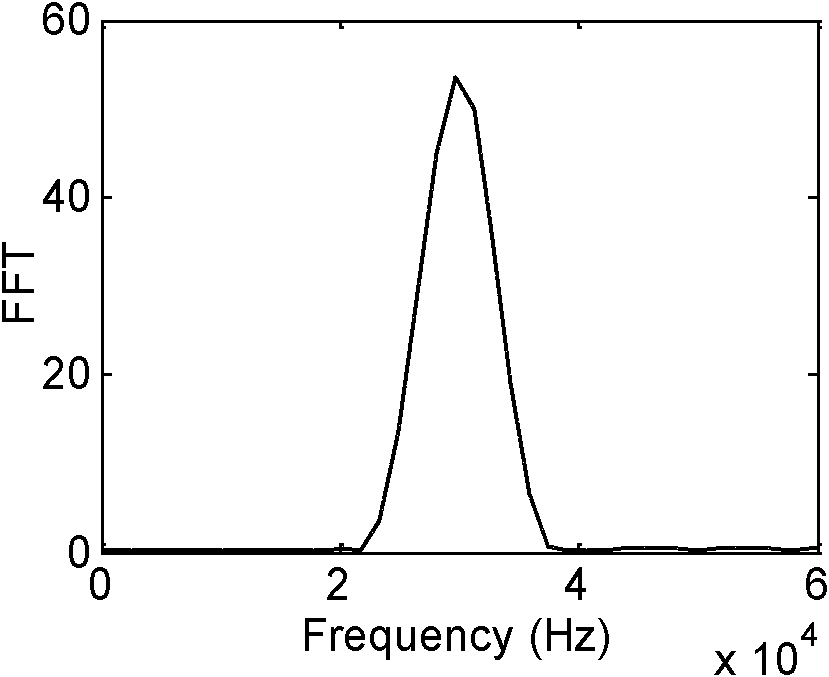

ActiveCN101975822AAchieving Single Mode PropagationGood time delayAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalTime domainSonification

The invention discloses a damage positioning method for the ultrasonic detection of a transmission line. The time delay of an ultrasonic guided wave signal between a driving point and a damage point is calculated by acquiring a time domain signal of the ultrasonic guided wave detection signal and adopting the technology of wavelet transform to obtain the damage position in the transmission line. The damage positioning method has the advantages of strong generality and accurate positioning, and can be suitable for various ultrasonic guided wave-based detection devices.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

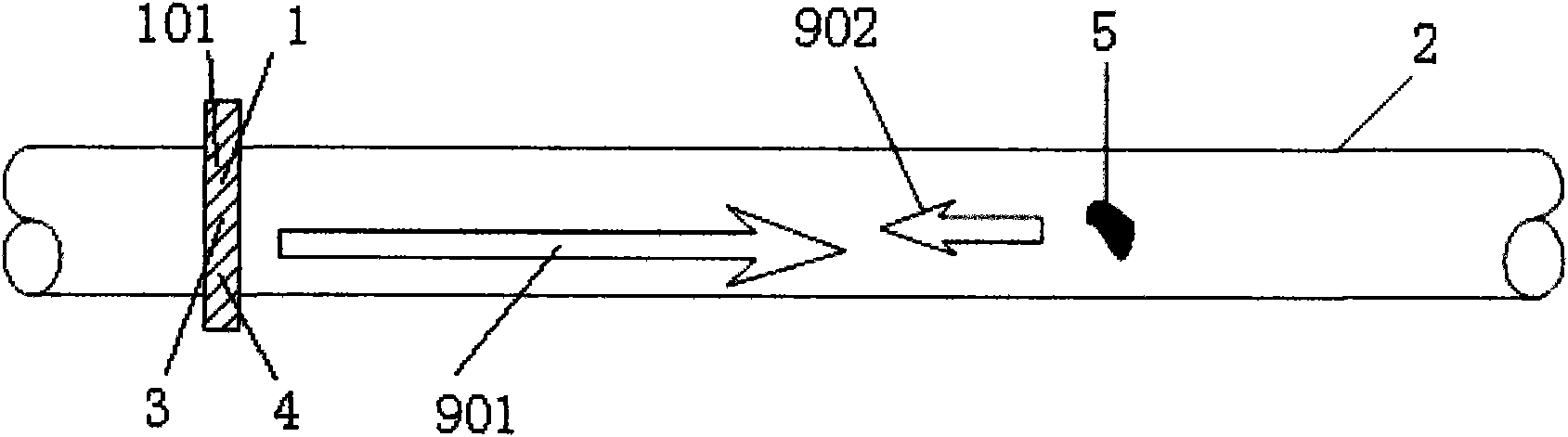

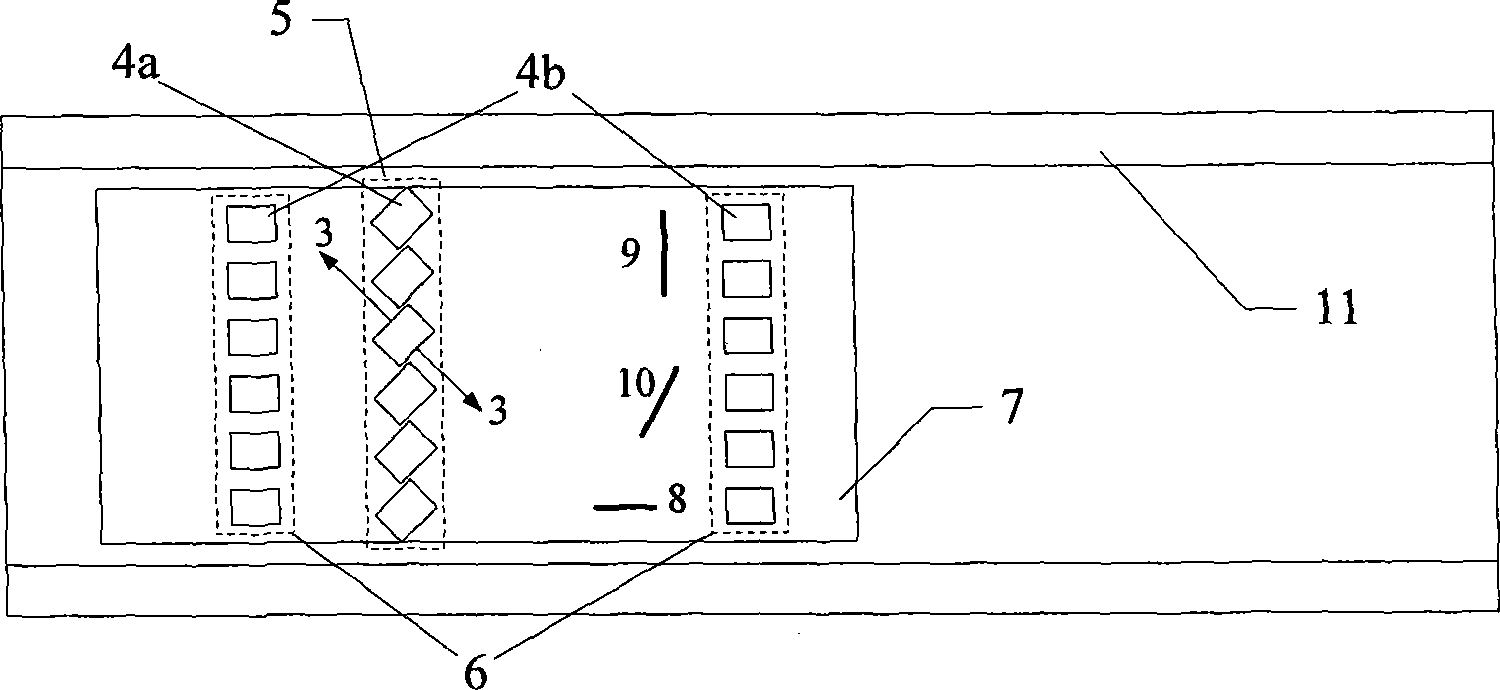

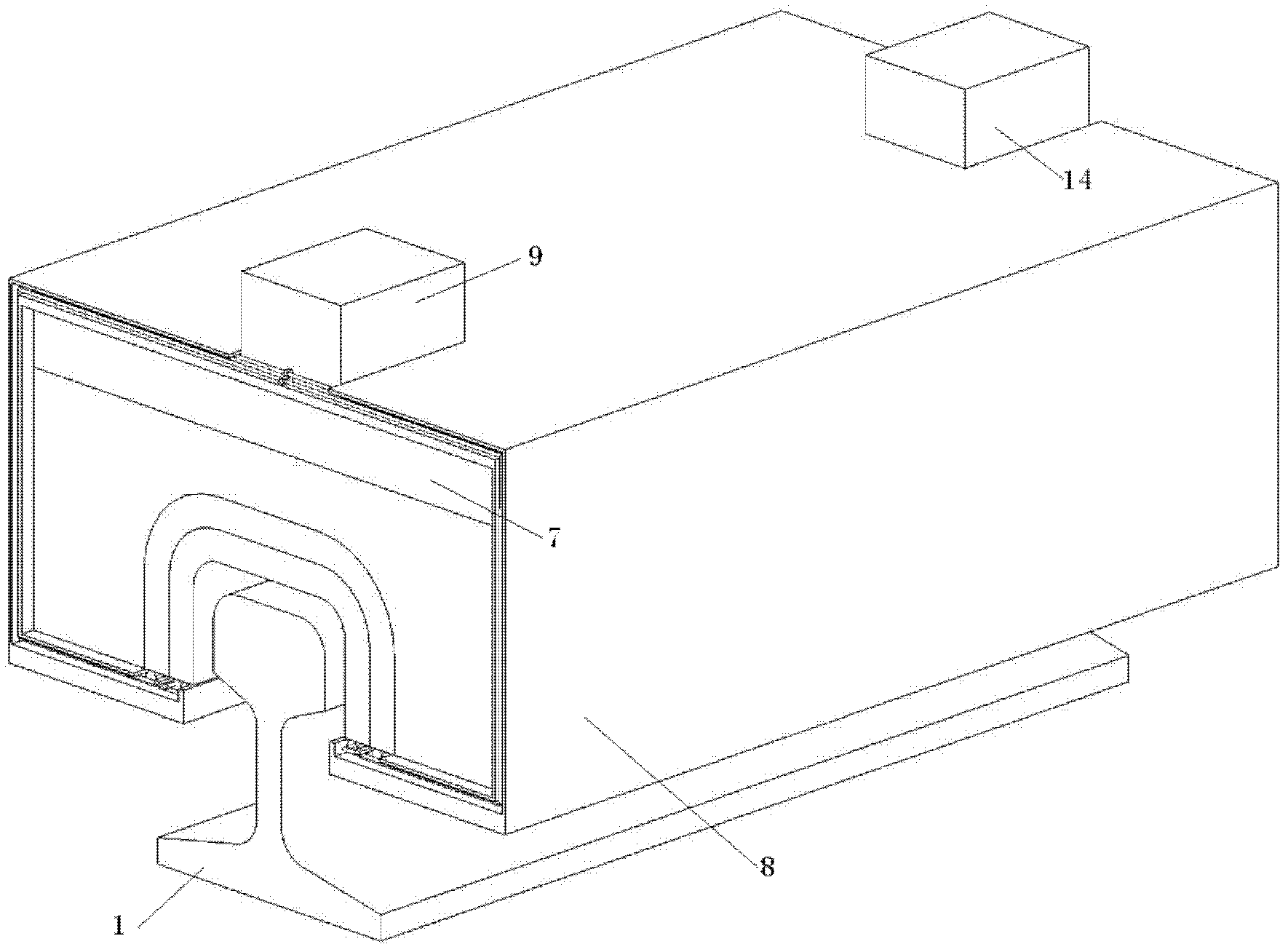

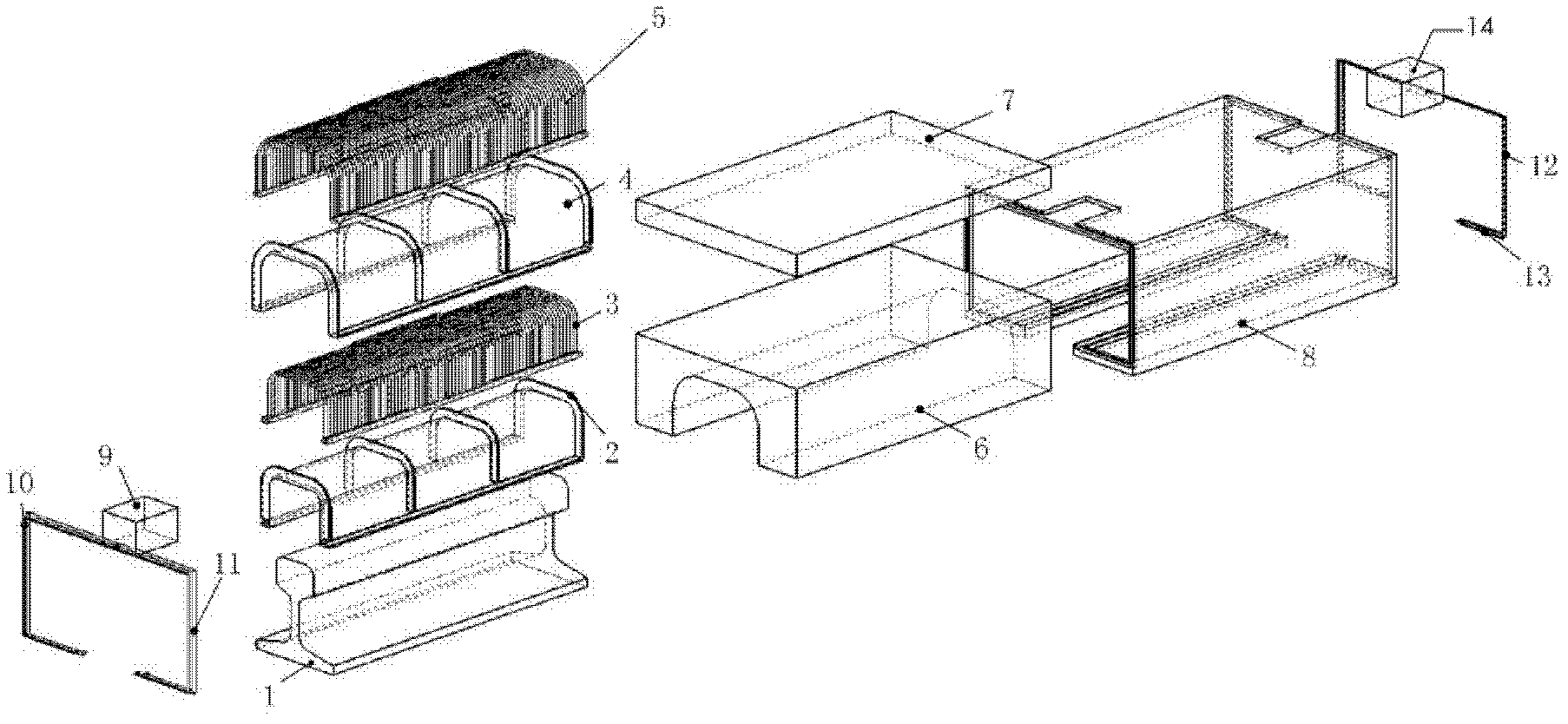

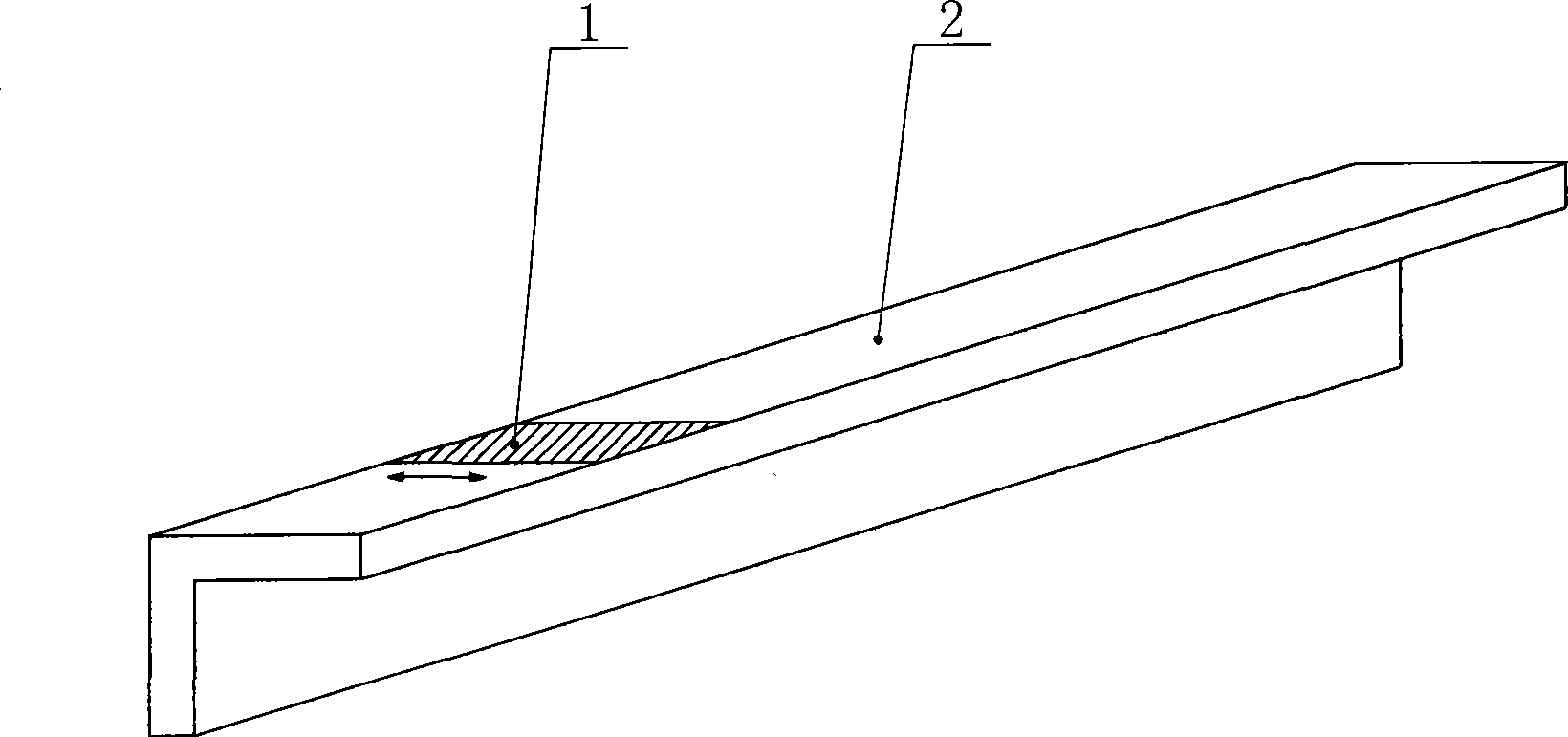

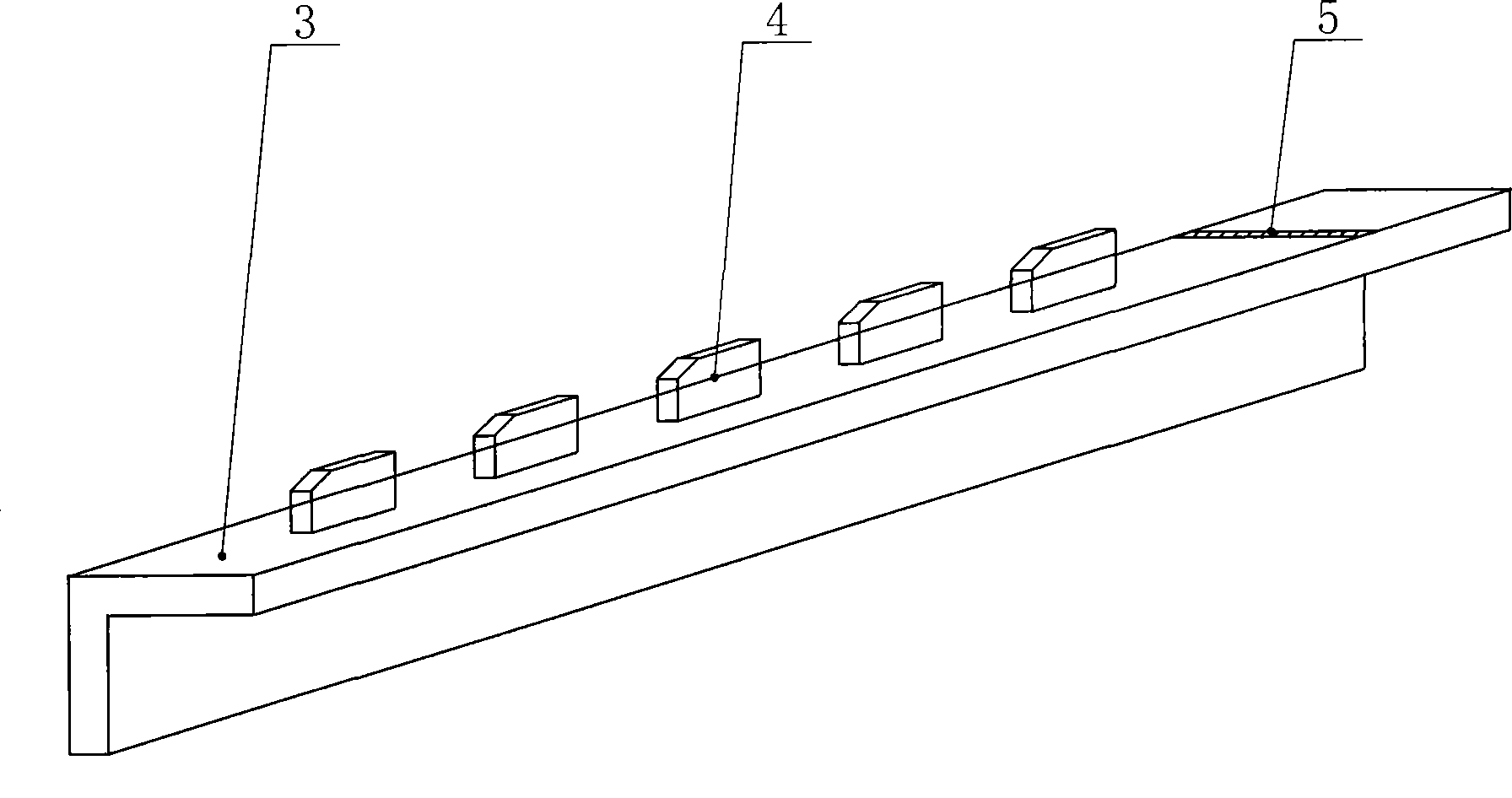

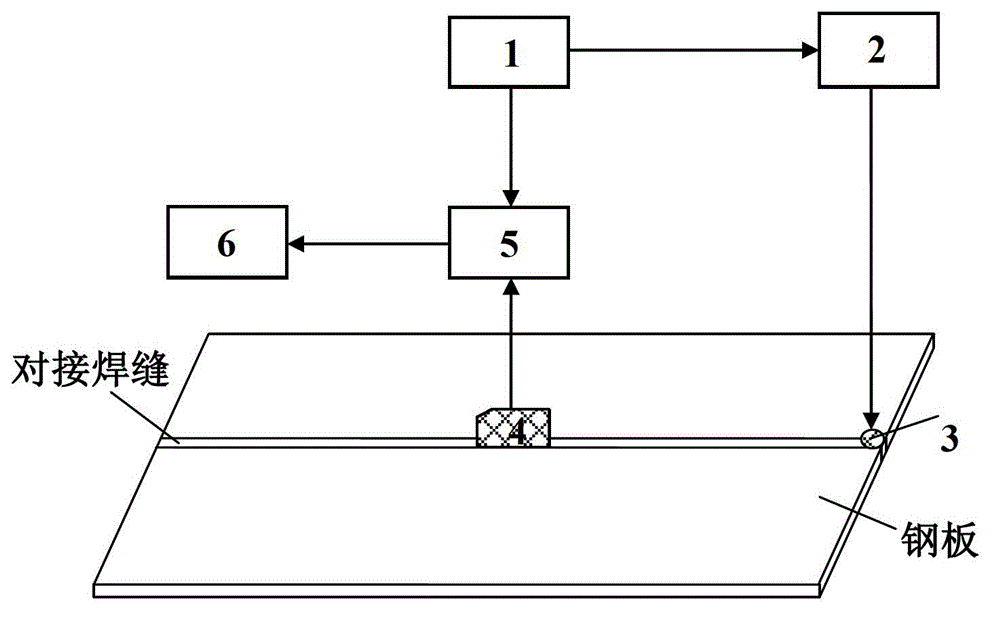

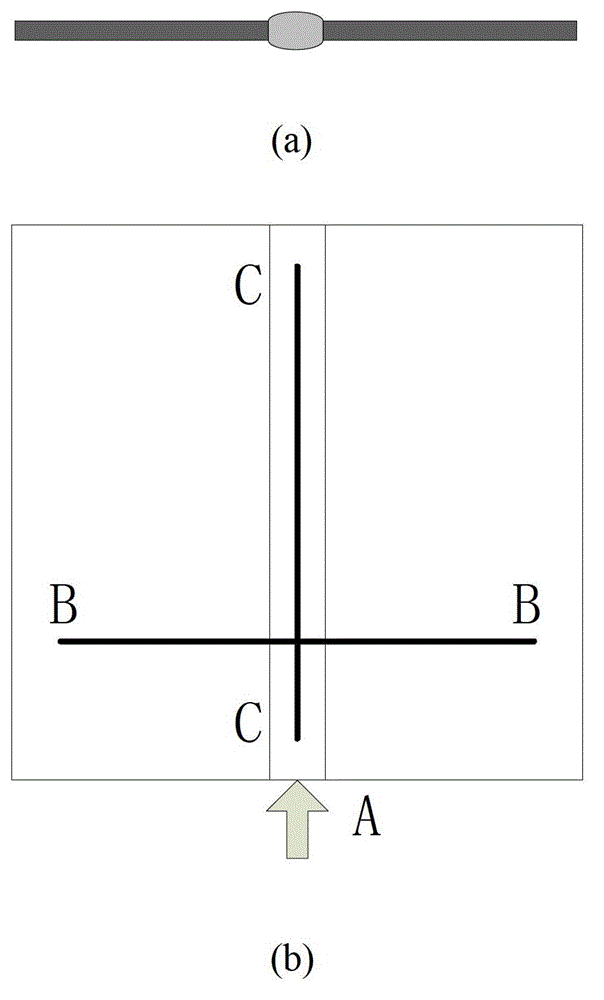

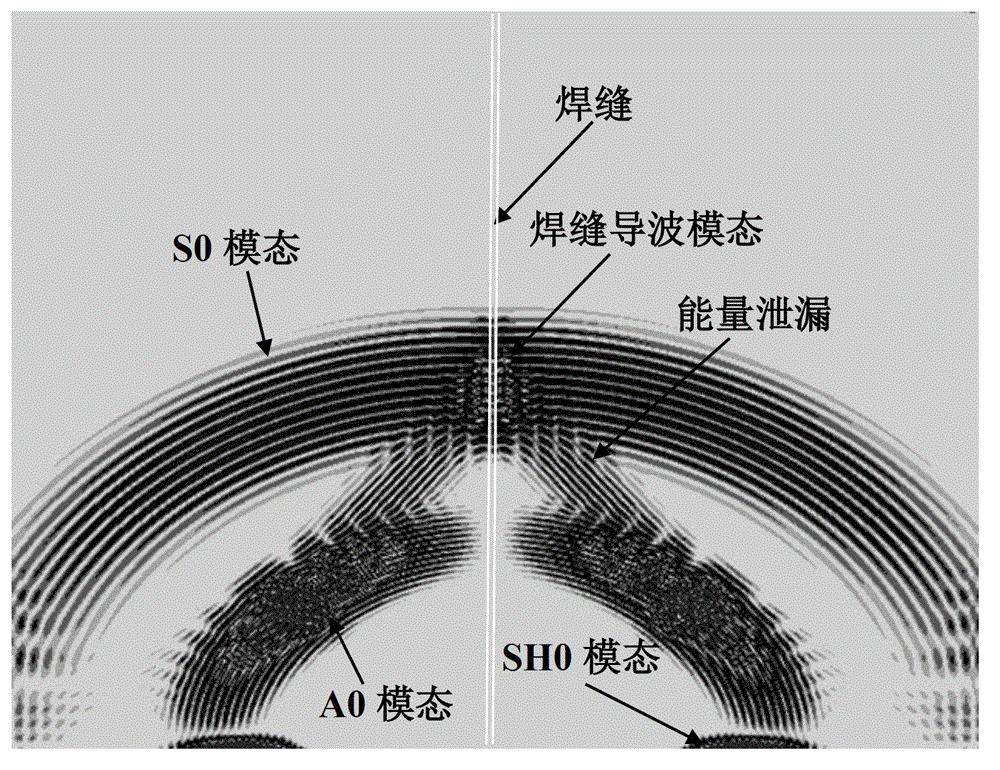

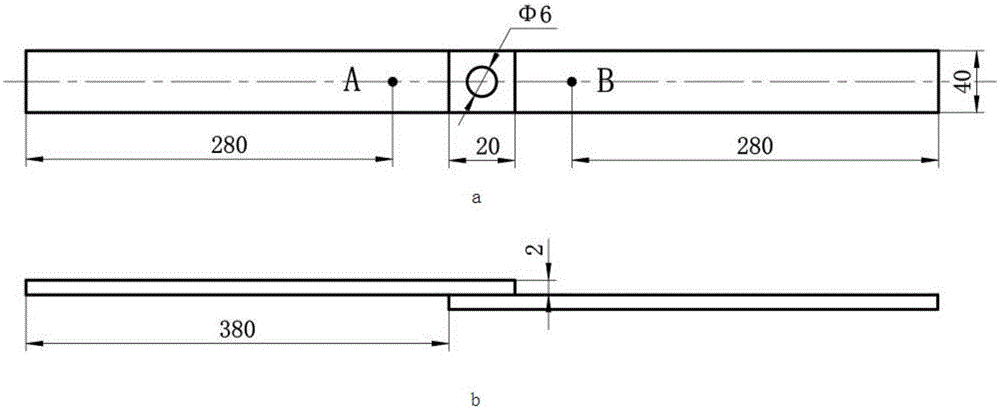

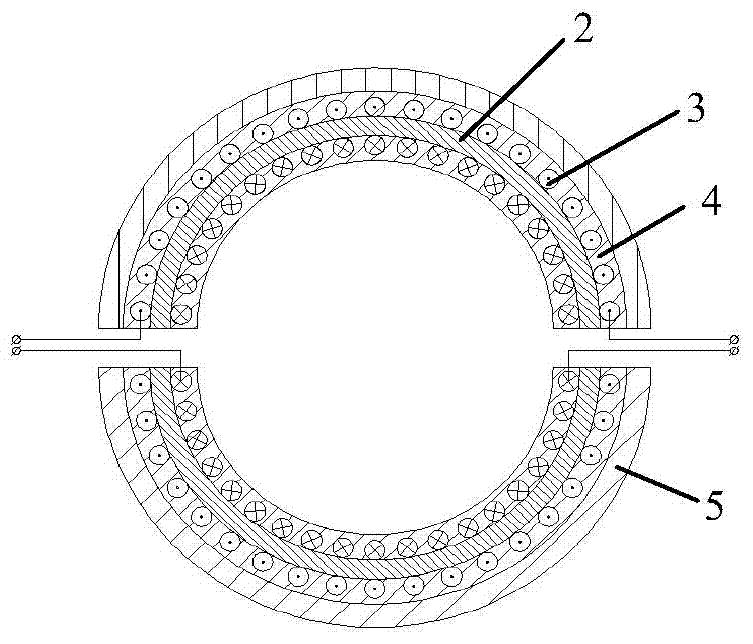

Ultrasonic Lamb wave-based butt weld nondestructive testing method

ActiveCN103336054AHigh energyEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalHigh energyFunction generator

The invention concretely relates to an ultrasonic Lamb wave-based butt weld nondestructive testing method and belongs to the ultrasonic guided-wave nondestructive testing field. An excitation source is loaded at the end of a weld joint. Two piezoelectric patches are pasted on the upper surface and the lower surface of a plate symmetrically and excited. The generated weld joint guided-wave mode propagating along the weld joint has high energy and slow attenuation, and the long-distance testing problem can be solved. The testing system is shown in the figure, and composed of a function generator (1), a power amplifier (2), piezoelectric patches (3), an oblique incidence-type piezoelectric ultrasonic sensor (4), an oscilloscope (5) and a computer (6). By utilizing the testing system, when the ultrasonic Lamb wave encounters flaws of the weld joint, flaw echoes are generated. According to the time difference between the excitation waveforms and the waveforms of flaw echoes and the group velocity of the weld joint guided-wave mode, the distance from the flaws to the excitation source can be obtained, and therefore the effective locating of weld joint flaws can be achieved.

Owner:BEIJING UNIV OF TECH

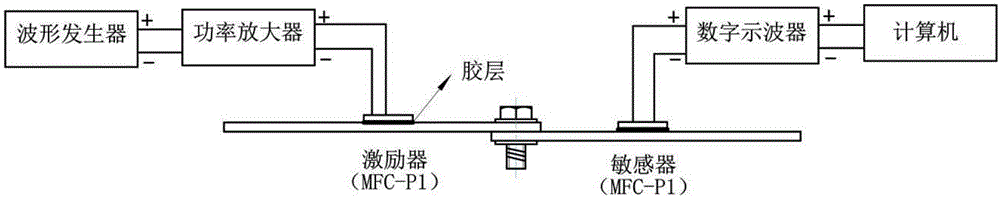

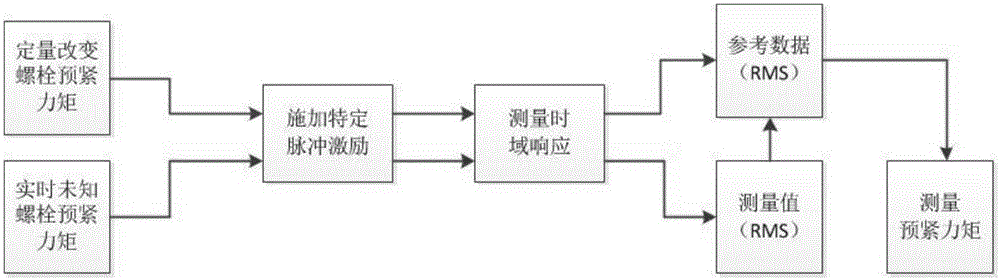

Method for quantified monitoring bolt pre-tightening torque through active ultrasonic guided wave

InactiveCN105115652AMonitor tightnessLower assembly costsMeasurement of torque/twisting force while tighteningElectricityFiber

The invention discloses a method for quantified monitoring bolt pre-tightening torque through active ultrasonic guided wave. MFC (Macro-Fiber Composite) material elements serve as an exciter and a sensor to conduct directional excitation, acquire fluctuation response and establish a bolt pre-tightening torque reference and comparison database. In this way, on-line monitoring bolt pre-tightening torque based on the reference database is carried out. The tightness of a bolt can be rapidly monitored without disassembling a structure, the assembling cost is reduced, and the efficiency is improved. The method is simple in operation, and quantified monitoring precision for single-bolt torque value is relatively high. The MFC material elements are thin (about 0.2mm), and may not affect structure performance after being pasted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

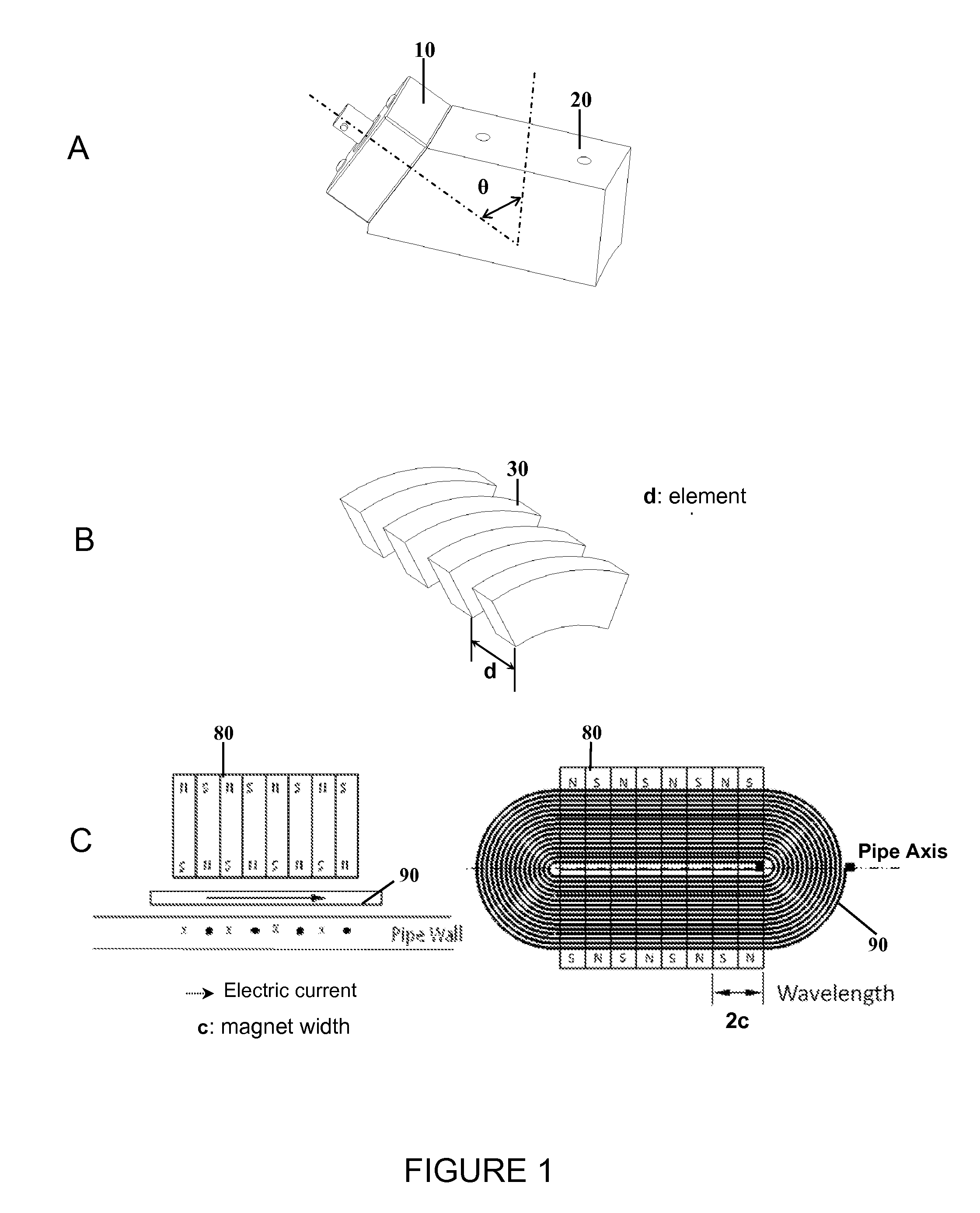

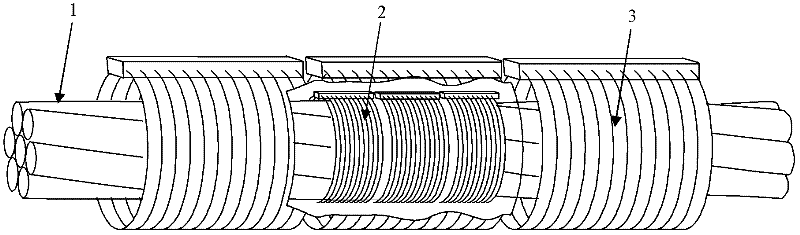

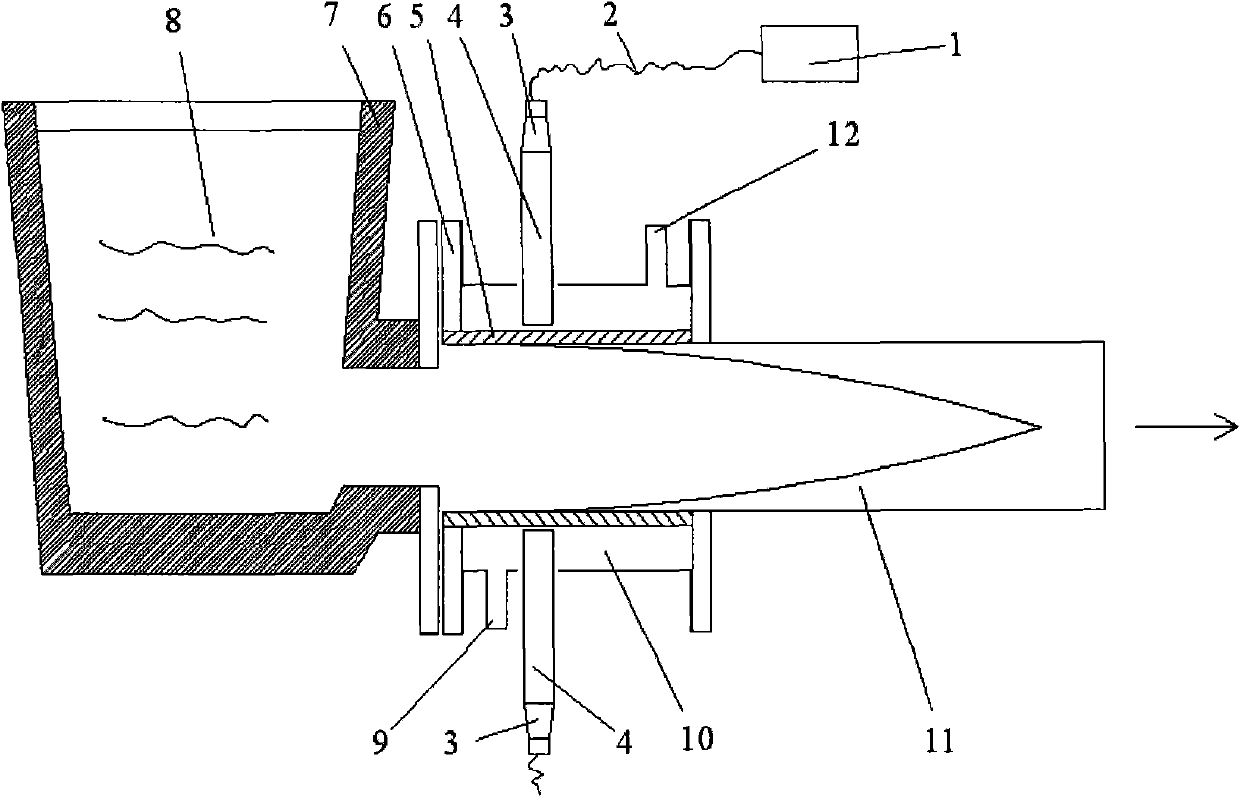

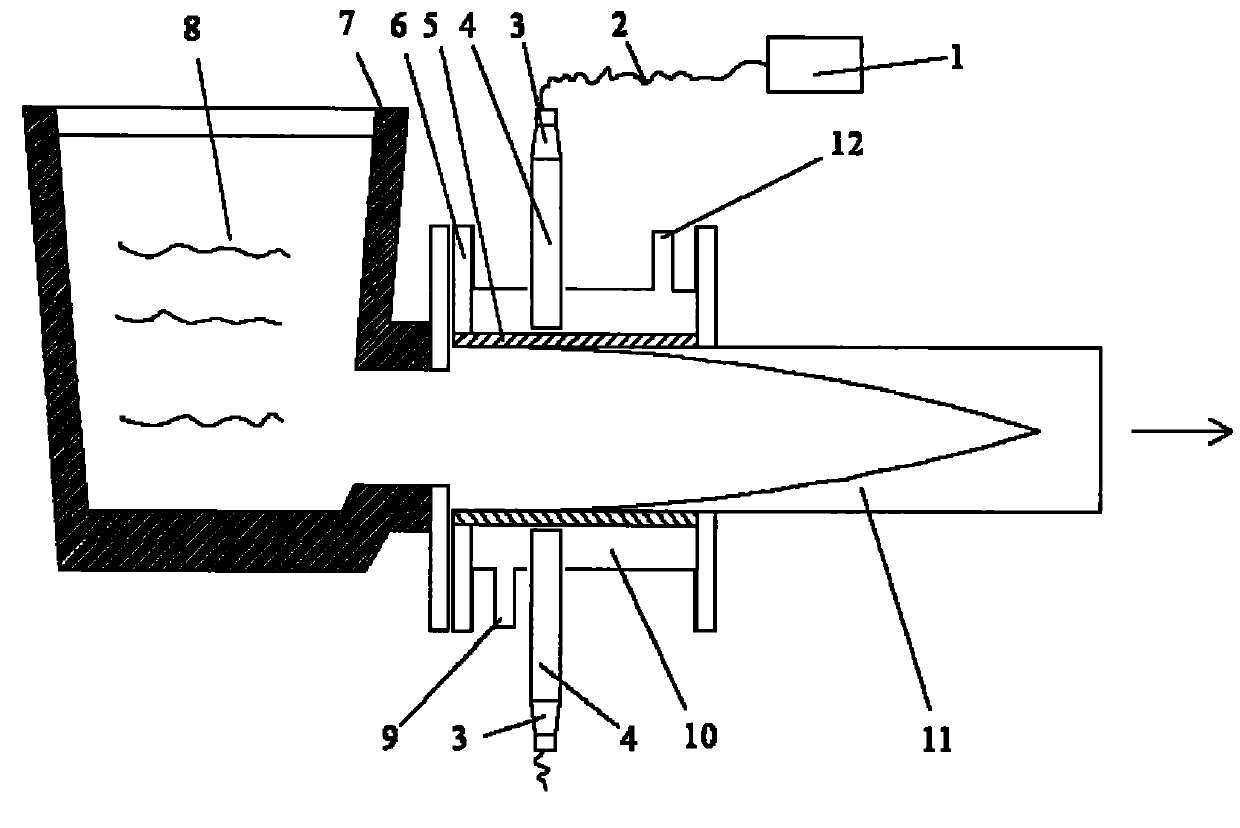

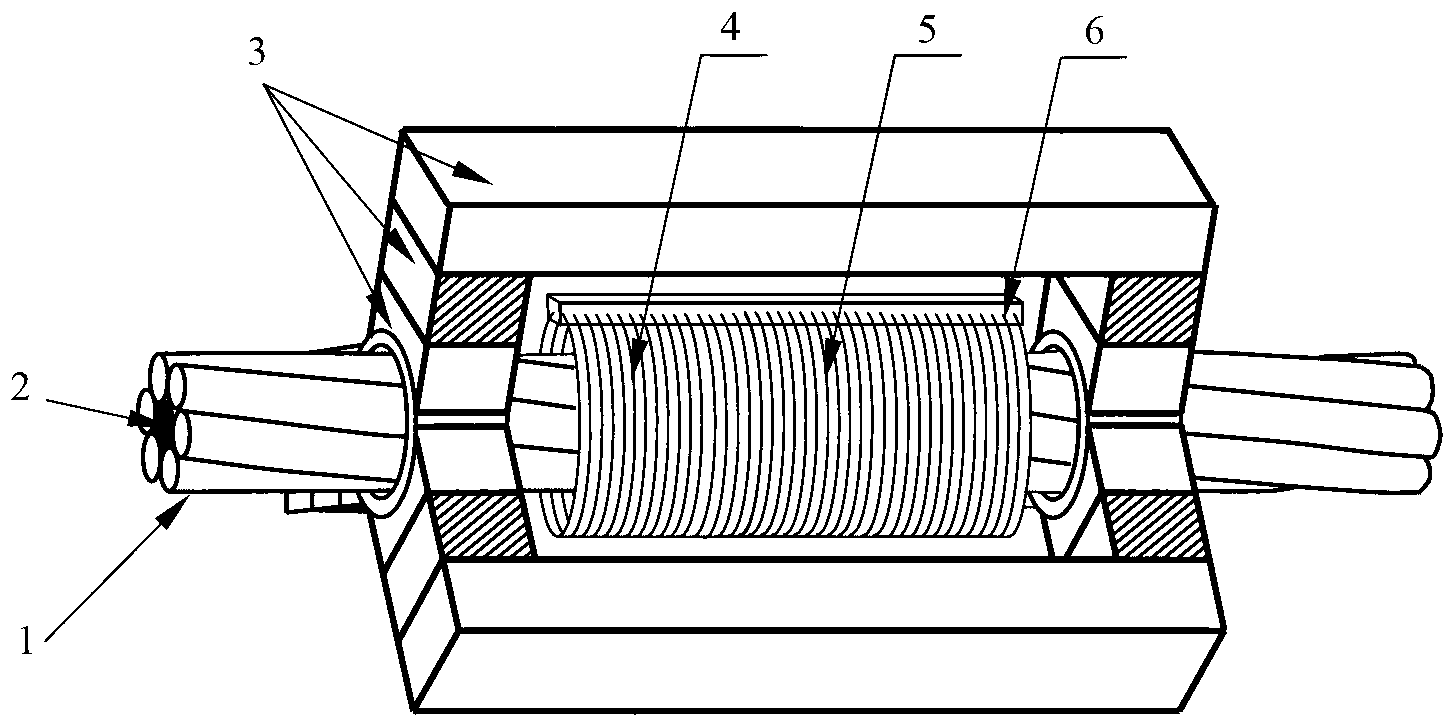

Nonlinear ultrasonic guided wave detection method and device for pipeline micro damage

InactiveCN103969339AEfficient receptionStable under pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesHarmonicNonlinear ultrasound

The invention discloses a nonlinear ultrasonic guided wave detection method and a nonlinear ultrasonic guided wave detection device for pipeline micro damage. An exciting transducer capable of exciting single guided wave modal state and a matched receiving transducer are adopted, the transducers can wind a pipeline to excite axisymmetric modal states, the receiving efficiency of a second order harmonic signal is improved by a matching and corresponding receiving probe, the detection capacity of the system on second order harmonic waves of the guided waves is improved. The nonlinear change of a material is characterized by detecting the ratio of nonlinear response to propagation distance, nonlinear interference of instruments is effectively reduced, nonlinear ultrasonic guided wave evaluation of the pipeline material is realized, and nonlinear ultrasonic high sensitivity can be used for early detection of the pipeline micro defects.

Owner:XIAMEN UNIV

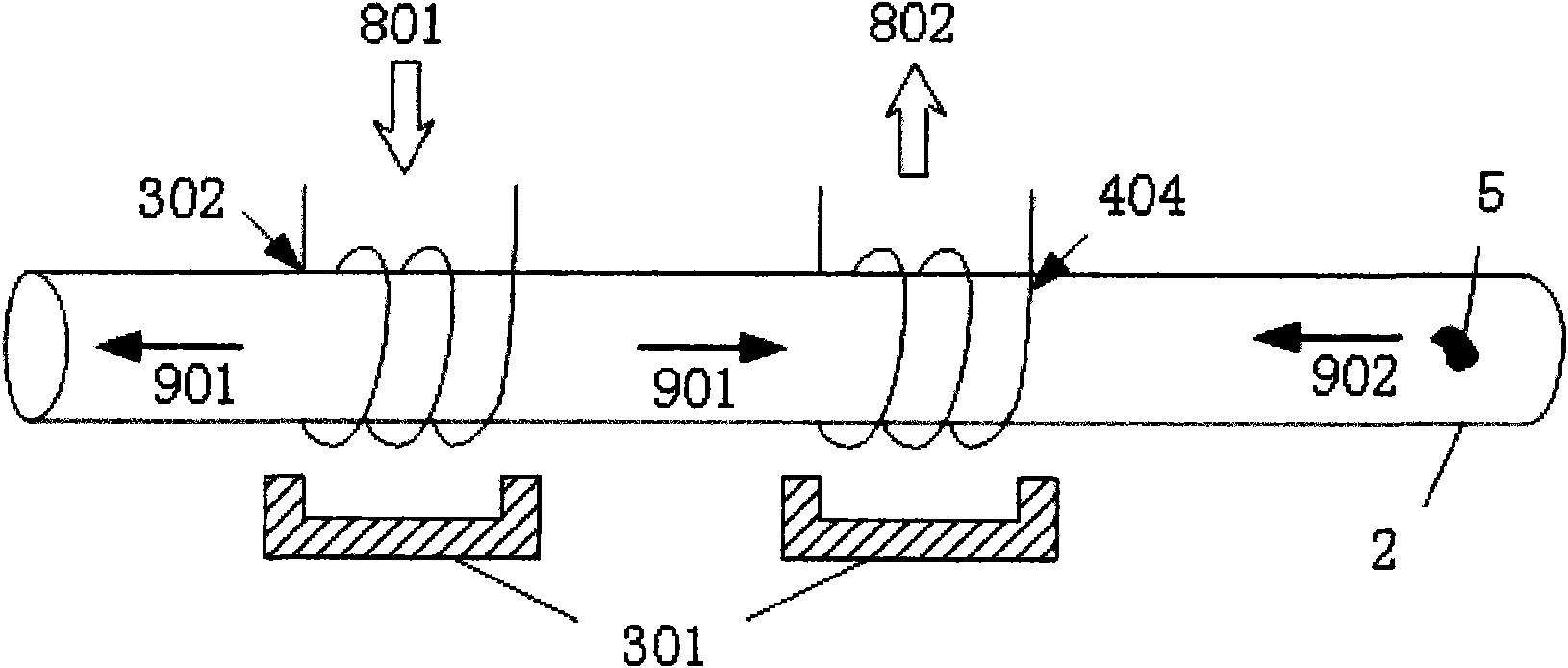

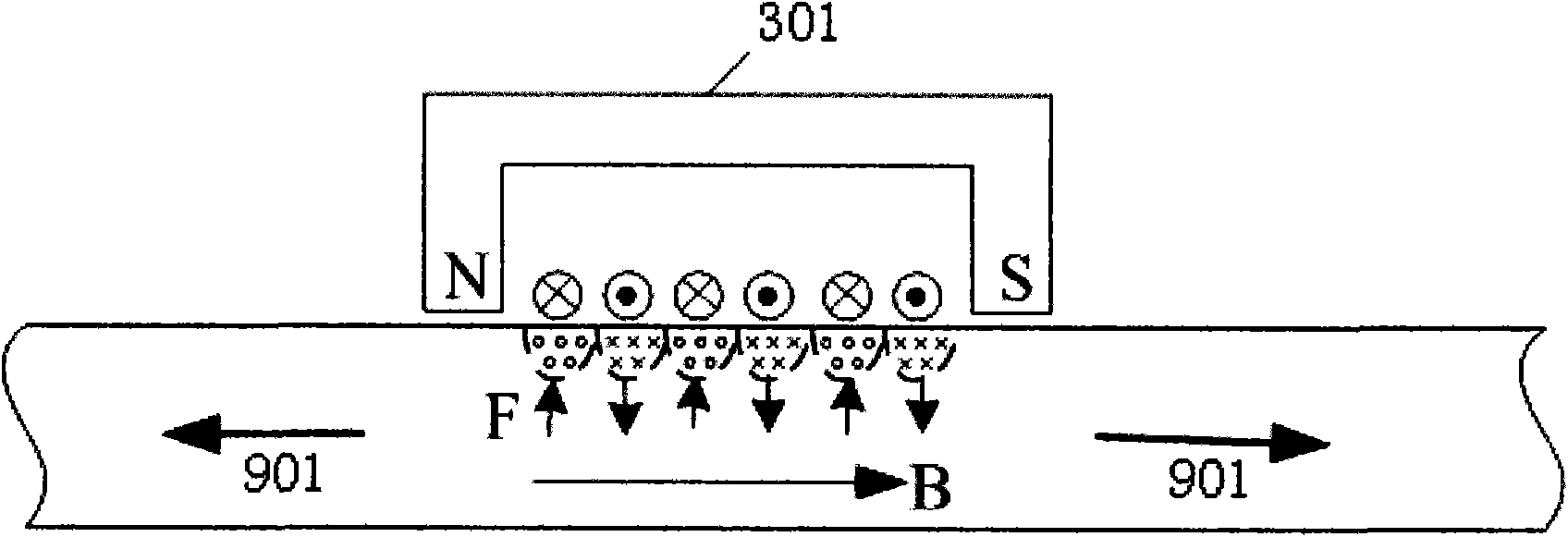

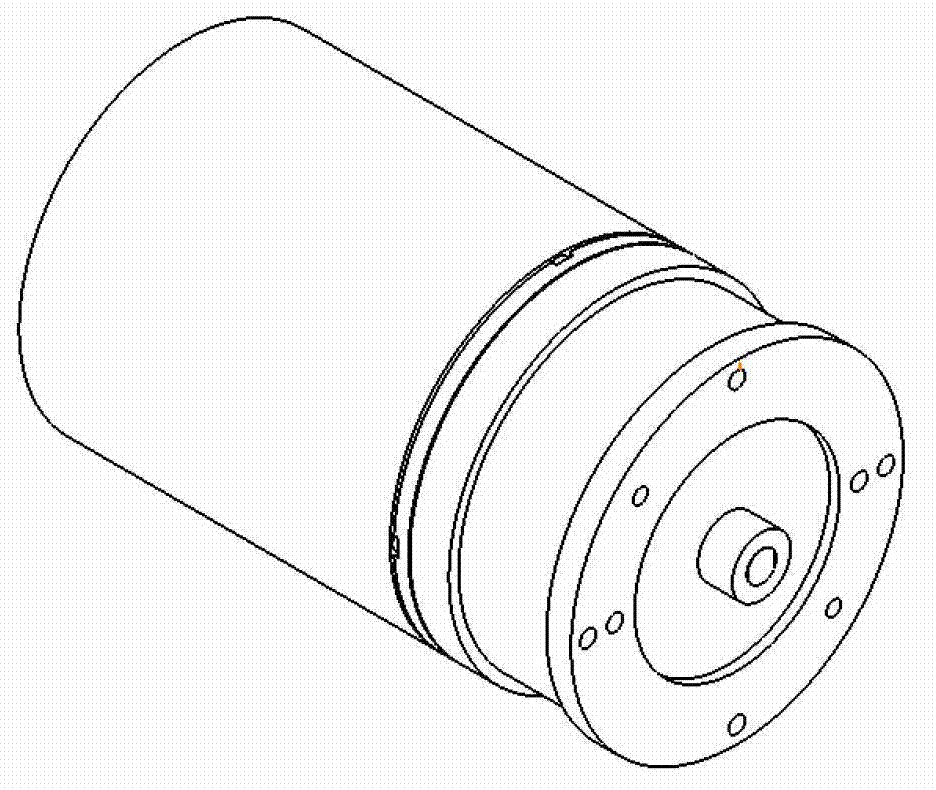

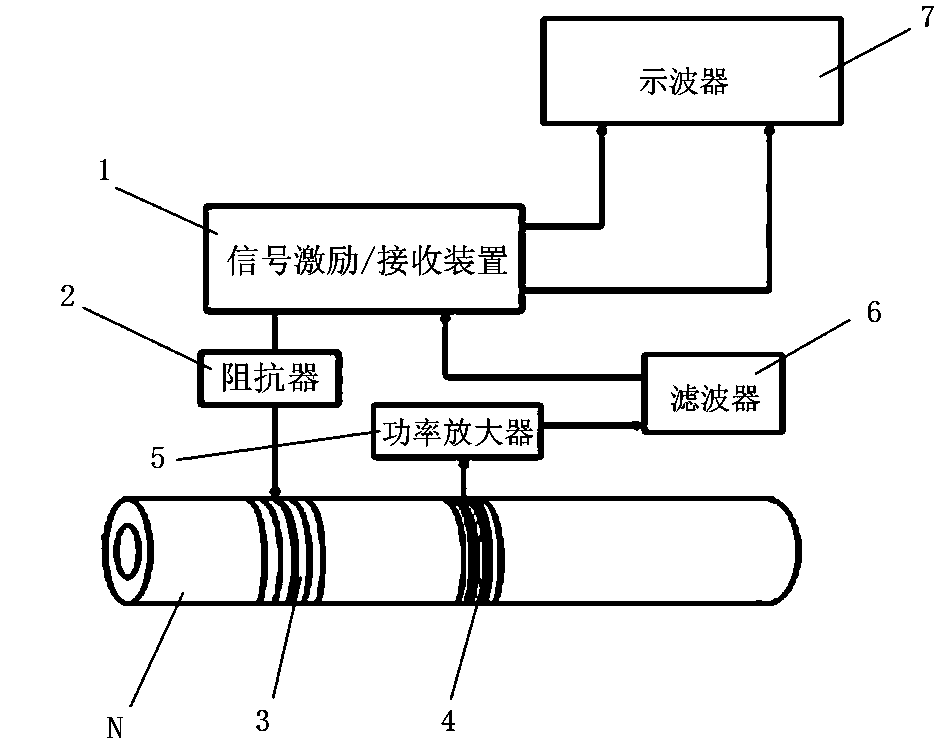

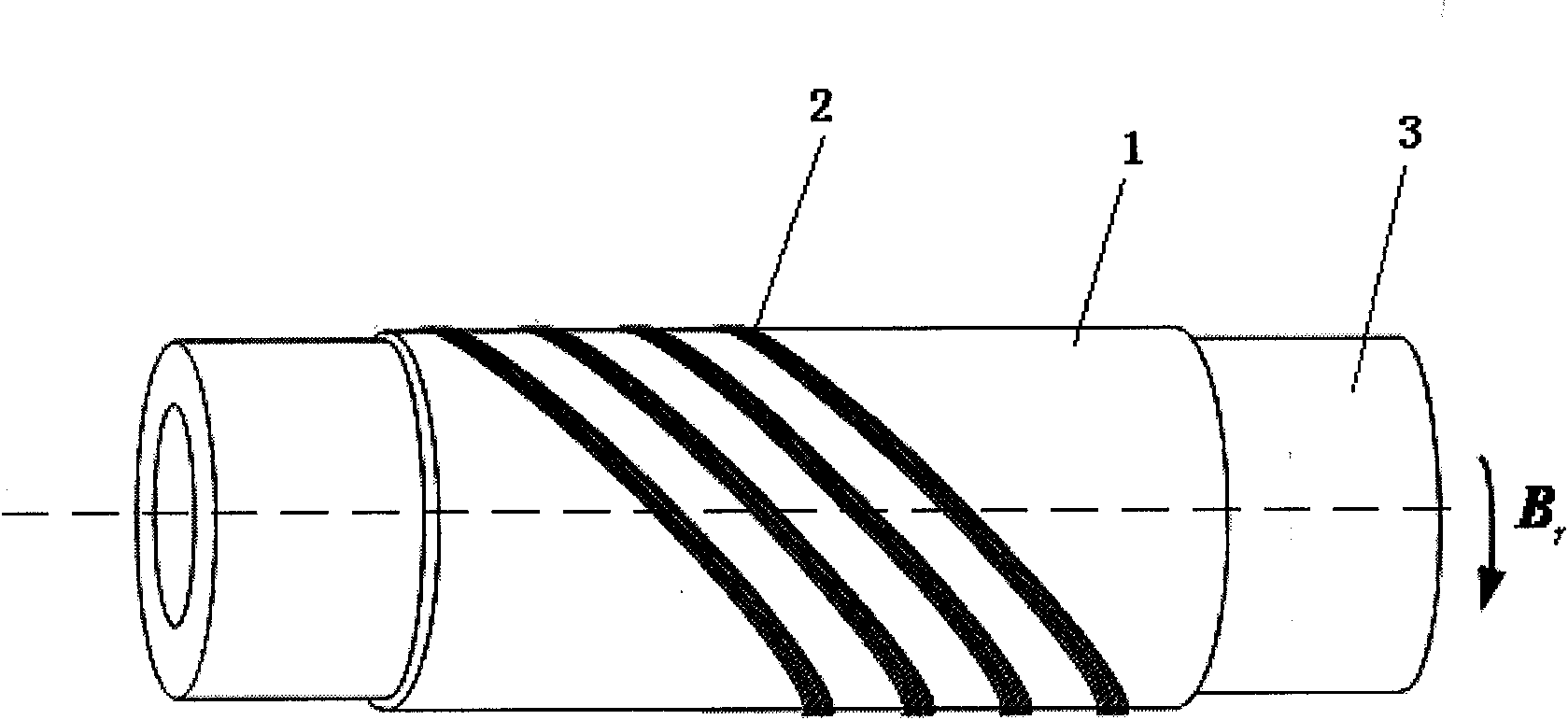

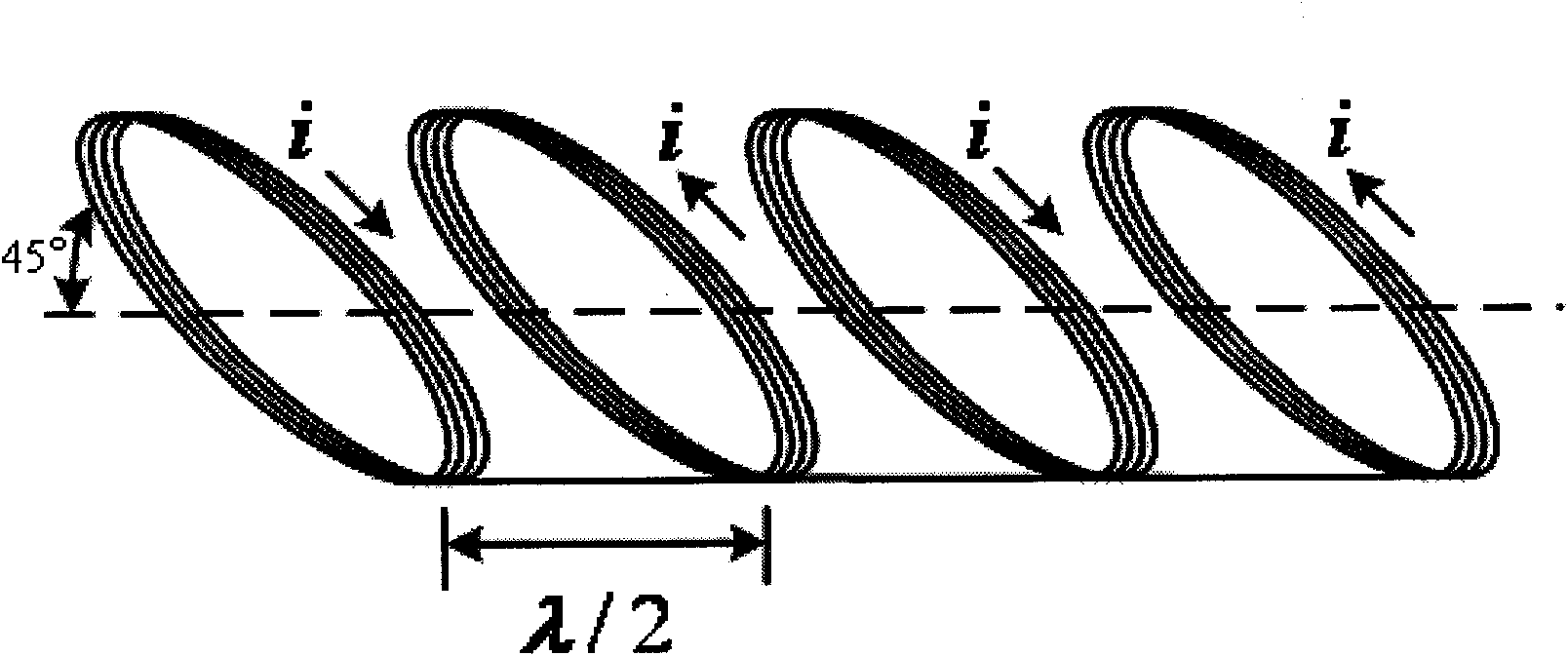

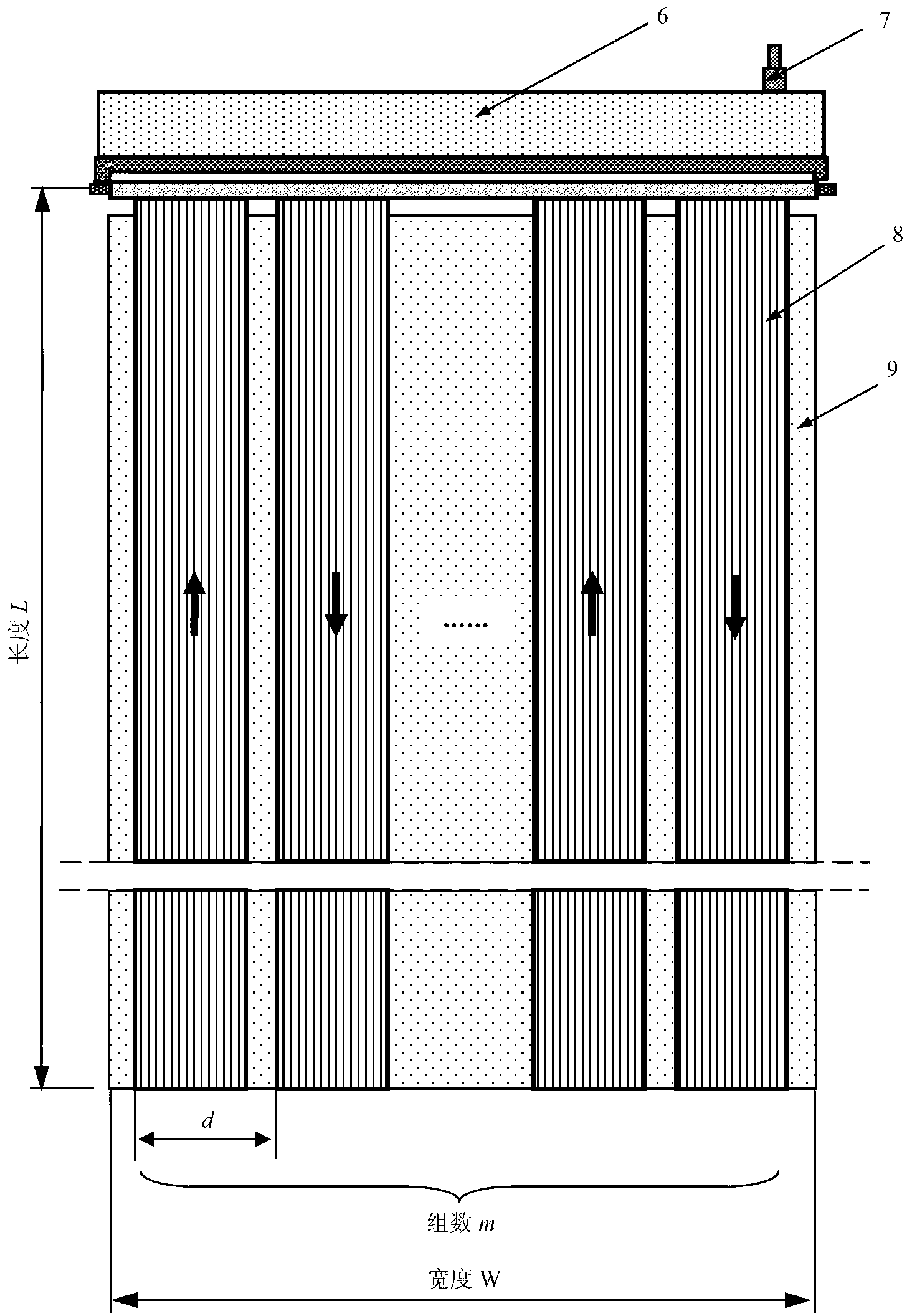

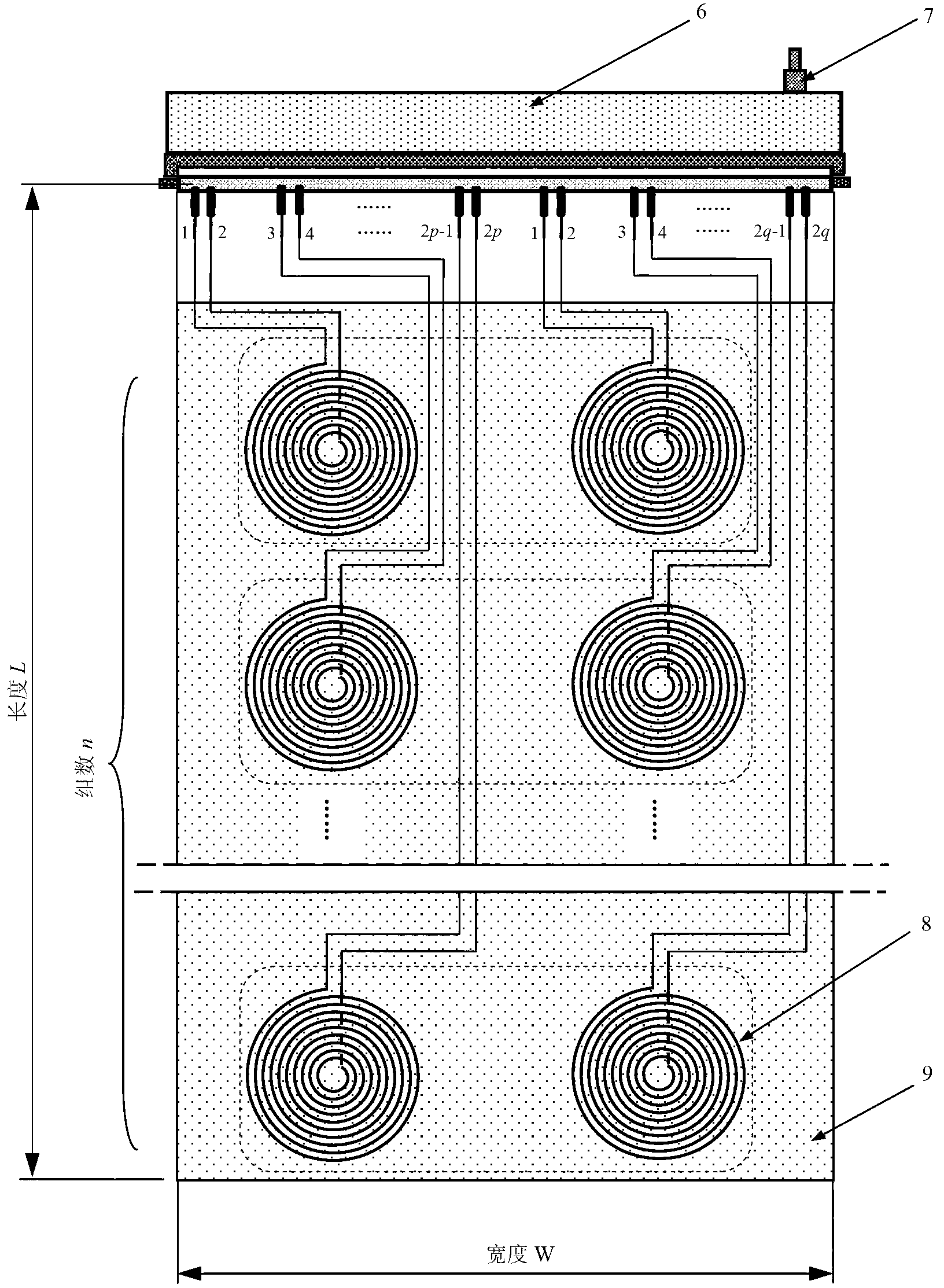

Pipeline axial ultrasonic guided wave energy exchange probe

InactiveCN101813670ALong distanceWith frequency selection functionAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsAlloyUltrasonic guided wave

The invention relates to a pipeline axial ultrasonic guided wave energy exchange probe, which is characterized in that the pipeline axial ultrasonic guided wave energy exchange probe comprises a premagnetized nickel-iron alloy sheet and a plurality of groups of coil belts, wherein the nickel-iron alloy sheet is tightly fixed on the outer wall of a pipeline to be detected in the circumferential direction of the pipeline to be detected, the rest magnetic flux density on the nickel-iron alloy sheet is distributed along the circumferential direction of the pipeline to be detected, a plurality of groups of coil belts are a plurality of groups of coil belts formed by winding a conducting wire on the premagnetized nickel-iron alloy fixed on the outer wall of the pipeline to be detected, the two adjacent groups of coils have the same center distance, and in addition, the two adjacent groups of coils have the opposite winding directions. A pulse power amplifier is connected with the starting end of the conducting wire for winding a plurality of groups of coil belts, and the tail end of the conducting wire for winding a plurality of groups of coil belts is sequentially connected with a wave filter amplification circuit and an oscilloscope. The invention can be widely applied to the field of nondestructive detection of the pipeline.

Owner:TSINGHUA UNIV

Continuous casting crystallizer device using ultrasonic vibration

InactiveCN101905295AEliminate stickingEliminate surface defectsUltrasonic vibrationUltrasonic guided wave

The invention provides a continuous casting crystallizer device using ultrasonic vibration, which belongs to the technical field of metallurgical casting. The device of the invention comprises a trough, a crystallizer, a crystallizer copper plate, ultrasonic guide rods, an energy converter and an ultrasonic power supply, wherein the crystallizer is directly connected with the trough; the ultrasonic guide rod is arranged on each reverse side of the crystallizer copper plate and connected with the energy converter; the energy converter is connected with the ultrasonic power supply; the ultrasonic guide rod passes through a cooling water tank and is vertically connected with the crystallizer copper plate; and the length of the ultrasonic guide rod is an integral multiple of the wavelength or half-wavelength of the used ultrasonic. The vibration mode of the ultrasonic vibration crystallizer provided by the invention breaks through the traditional mechanical vibration limit, and the continuous casting crystallizer device using the ultrasonic vibration is favorable for promoting the production of deflect-less continuous casting blanks without surface defects such as vibration marks and improving the quality of the casting blanks and steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

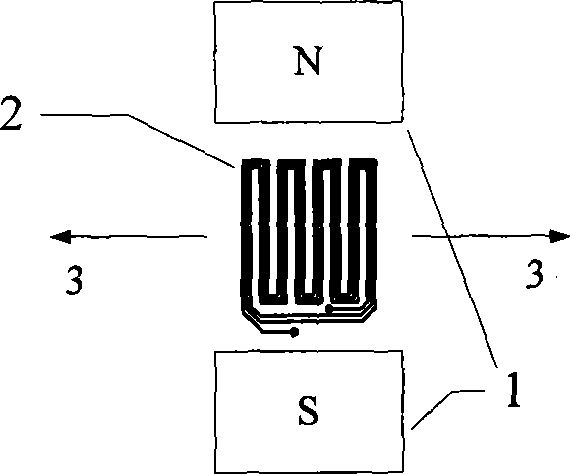

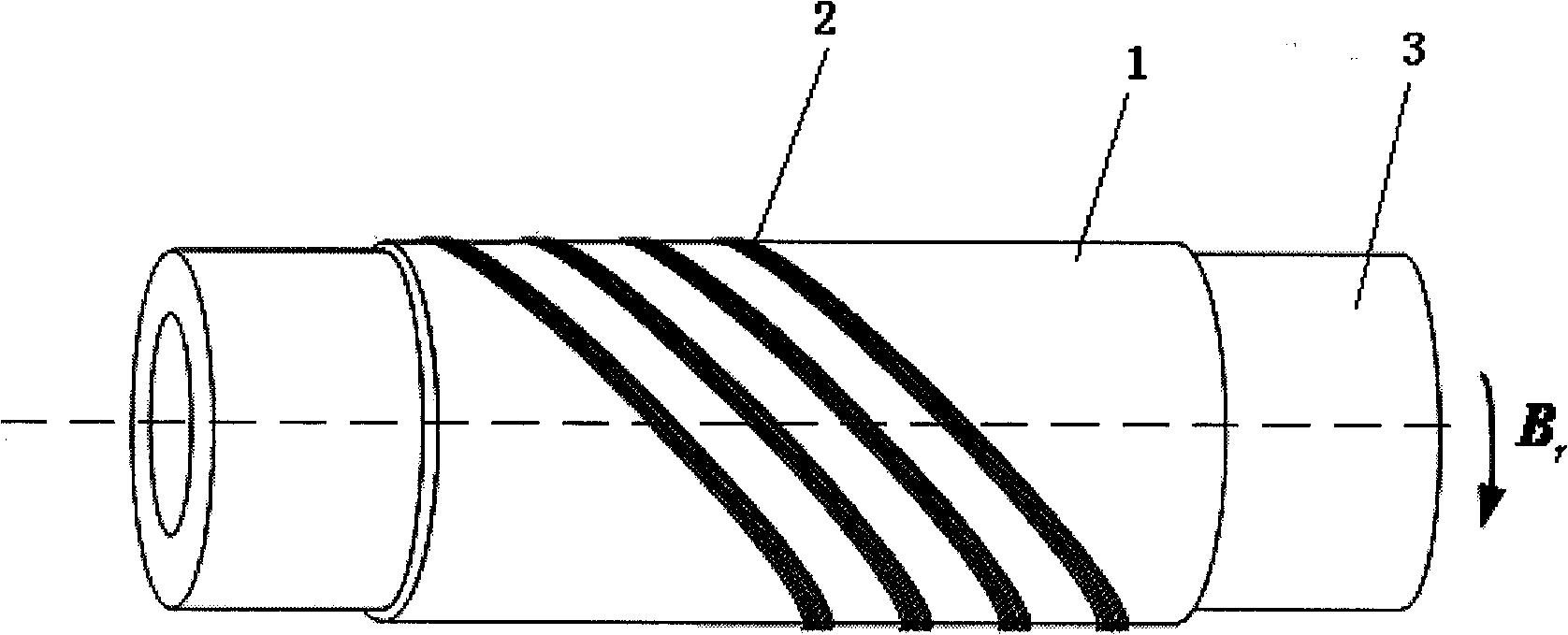

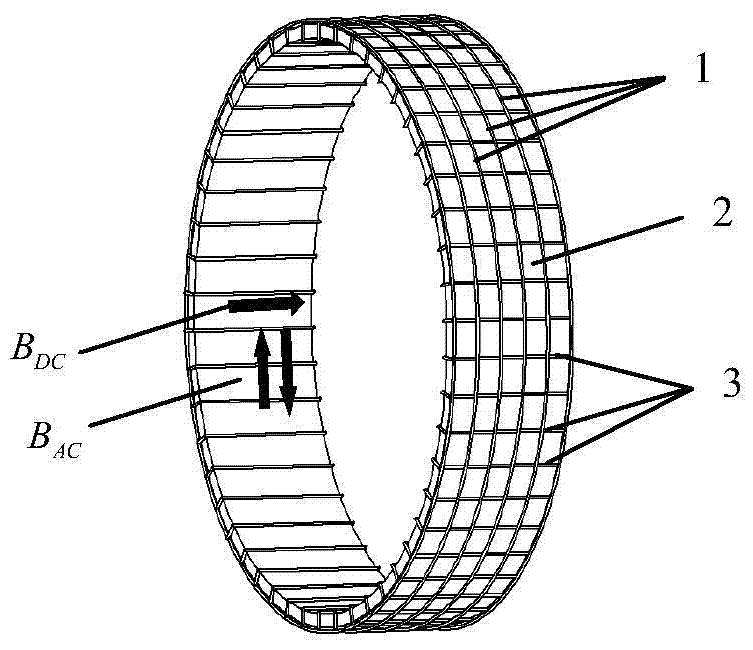

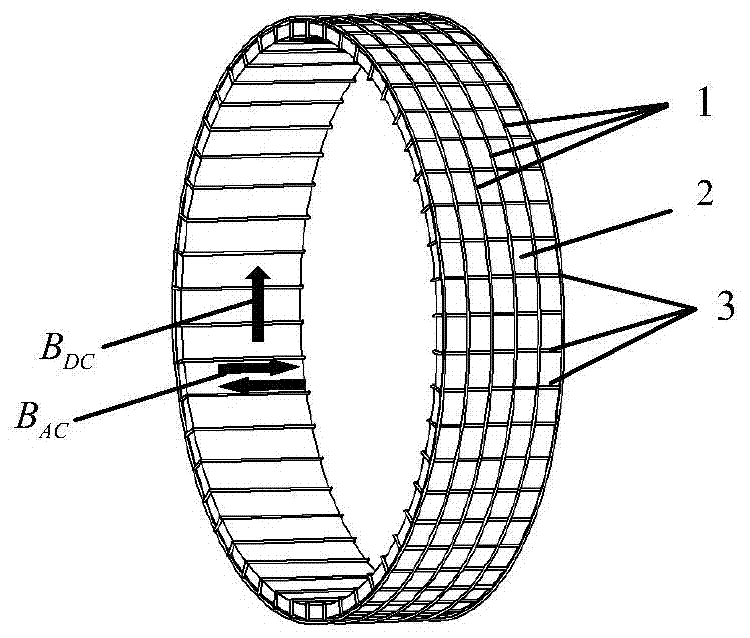

Circular-array-type magnetostriction sensor based on orthogonal encircling coil

InactiveCN104502443AUniform static magnetic field distributionHigh magnetostriction coefficientMaterial magnetic variablesEpoxyHigh energy

The invention relates to a circular-array-type magnetostriction sensor based on an orthogonal encircling coil. The circular-array-type magnetostriction sensor comprises a ferrocobalt band, a rectangular coil, a circular coil and a mechanical clamping device, wherein the rectangular coil and the circular coil are orthogonally encircled on the ferrocobalt band. The rectangular coil is preliminarily encircled on the ferrocobalt band, bonded through epoxy resin and solidified with an outside rubber layer to form a semi-cylindrical-shell detection unit. Two detection units are directly buckled or stuck to the surface of a structure such as a circular pipe and a circular rod by adopting epoxy resin and form an access after being connected through a conducting plug pin. The bar-type circular coil is encircled outside each detection unit and penetrates through the mechanical clamping device to form an access by adopting an adaptor; the mechanical clamping device can be used for applying radial load onto the circular coil and the detection units. The circular-array-type magnetostriction sensor can be used for exciting and receiving a torsional-mode ultrasonic guide wave in the circular pipe and the circular rod structure and has higher energy exciting efficiency; moreover, the structure is simple, multichannel excitation and receiving of the torsional-mode ultrasonic guide wave can be realized, and a foundation is provided for a focus imaging algorithm of the pipeline detection.

Owner:BEIJING UNIV OF TECH

Flexible magnetostriction and eddy integrated sensor for detecting defects of high-voltage transmission line

ActiveCN102841132ARealize full structural defect detectionAchieve axial positioningOptically investigating flaws/contaminationMaterial magnetic variablesEngineeringHigh pressure

The invention relates to a flexible magnetostriction and eddy integrated sensor for detecting defects of a high-voltage transmission line and belongs to the technical field of an electromagnetic acoustic sensor. An outer-layer magnetostriction sensor is printed on a substrate through a flexible printing coil and an inner-layer eddy sensor is printed on the substrate through the flexible printing coil; the flexible printing coil can be coiled into a cylindrical shape and clung to the surface of the high-voltage transmission line so as to form a solenoid coil; after the solenoid coil is clamped and fixed by a connector, the solenoid coil is mounted on a detected transmission line so as to detect the defects; and after the clamped and fixed state is released, the solenoid coil can be detached from the surface of the transmission line. The integrated sensor can be used for stimulating a longitudinal modal ultrasonic guide wave from the transmission line and detecting the defects of the whole structure of the transmission line on the basis of a magnetostriction effect; the integrated sensor also can be used for detecting complex impedance change of a sensor detecting coil due to the defects of the transmission line by utilizing a multi-channel eddy sensor and realizing the peripheral positioning for the defects on the basis of an eddy effect; and meanwhile, the deep positions of the defects in the transmission line can be confirmed on the basis of a surface action of an eddy field.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com