Ultrasonic guided wave detection device for quality evaluation of composite laminated plate

A composite material layer and ultrasonic guided wave technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, and using sound waves/ultrasonic/infrasonic waves to analyze solids, etc., can solve problems such as operational limitations and difficulty in ensuring detection accuracy, and avoid The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

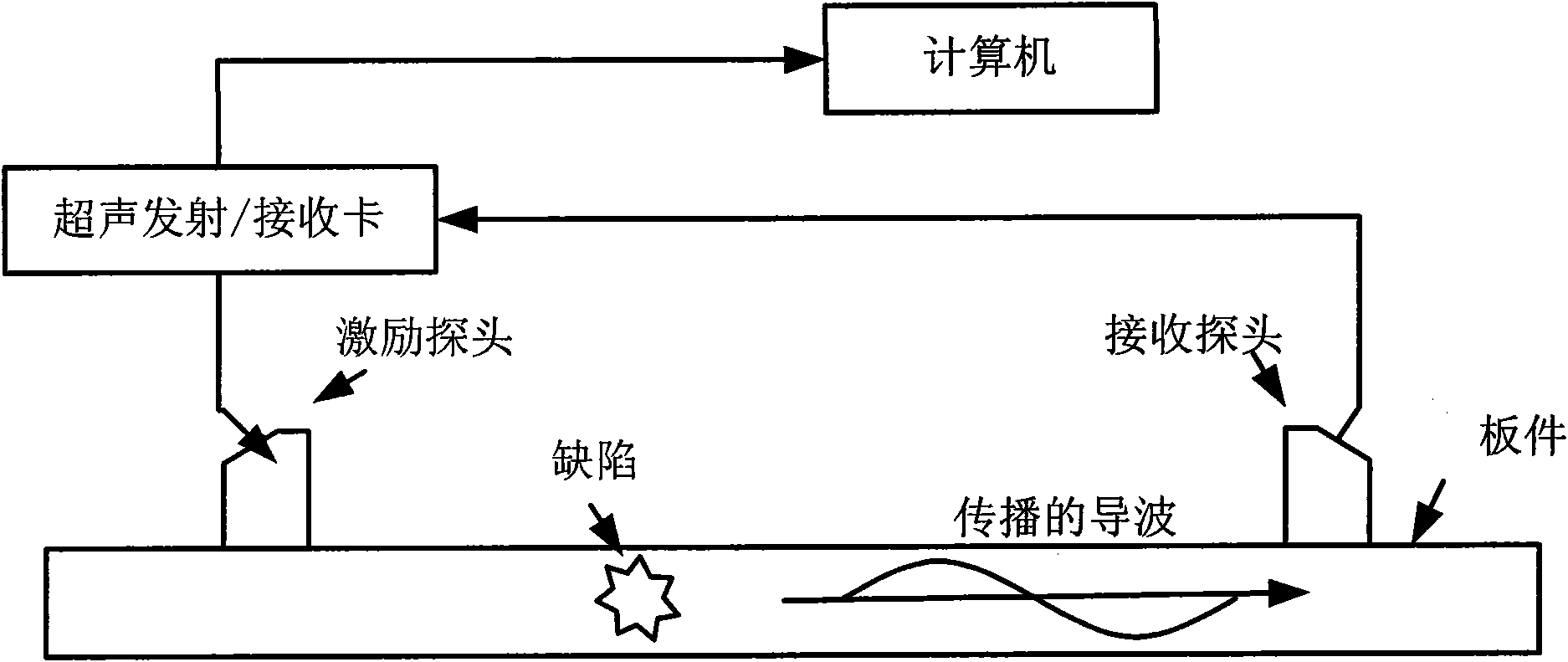

[0010] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

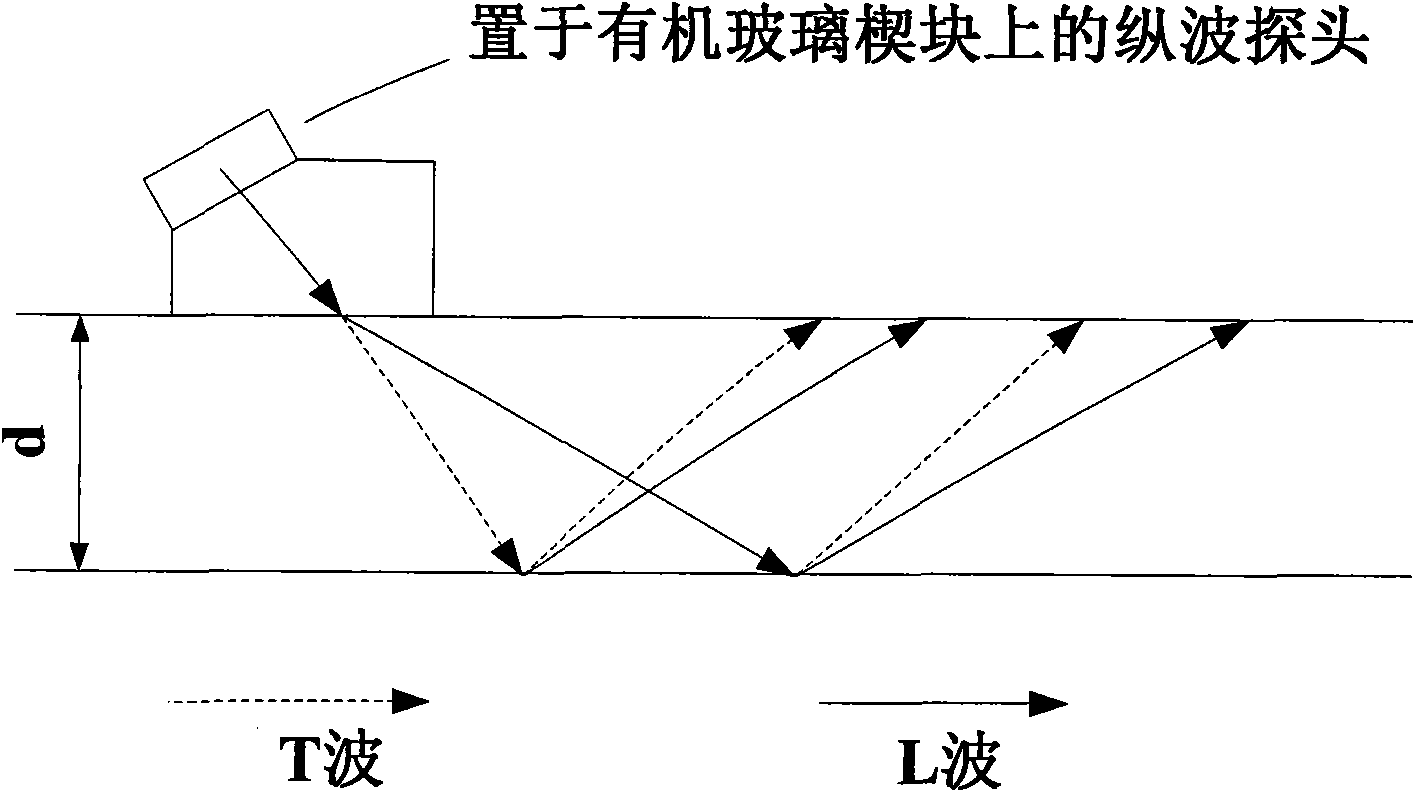

[0011] There are many methods to excite guided waves, among which the use of longitudinal-wave oblique probes is an accurate and effective method, and the generation of guided waves has been gained insight from physics. figure 1 The generation of guided waves with a longitudinal wave probe on a plexiglass wedge is described. The longitudinal wave is incident at a certain incident angle and velocity. According to Snell's theorem, the wave will undergo wave mode conversion, reflection and refraction at the interface. At a certain distance from the probe, the waves will no longer be clearly discernible, but appear as superimposed wave packets. For a certain situation, given the angle of incidence, thickness d and material properties, the guided wave will propagate in the plate.

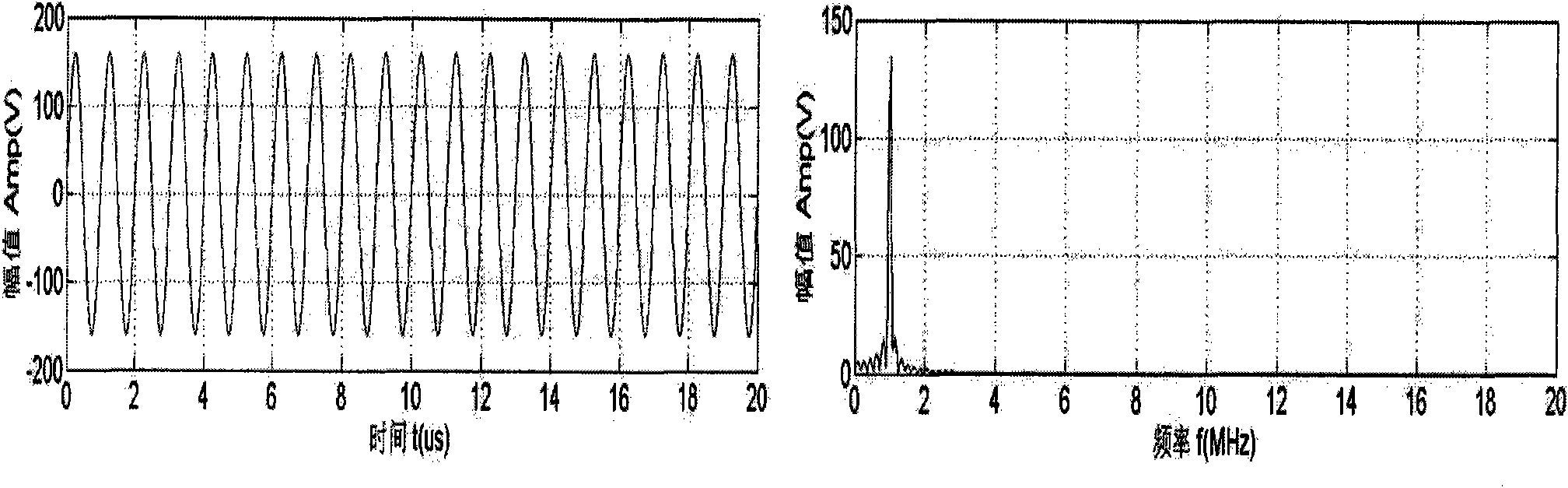

[0012] Various combinations of thickness d, incident angle, and mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com