Patents

Literature

209 results about "Circular coil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

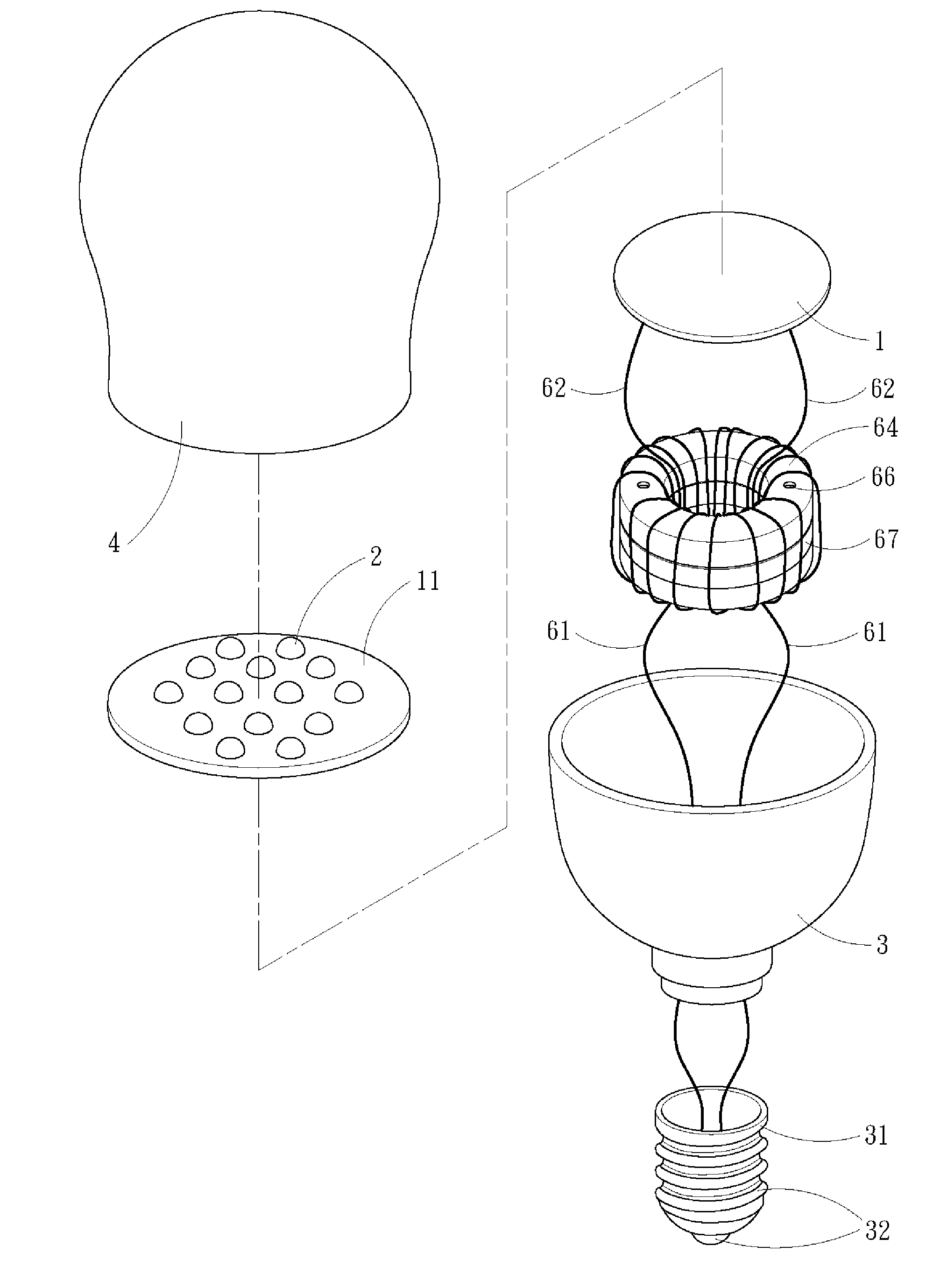

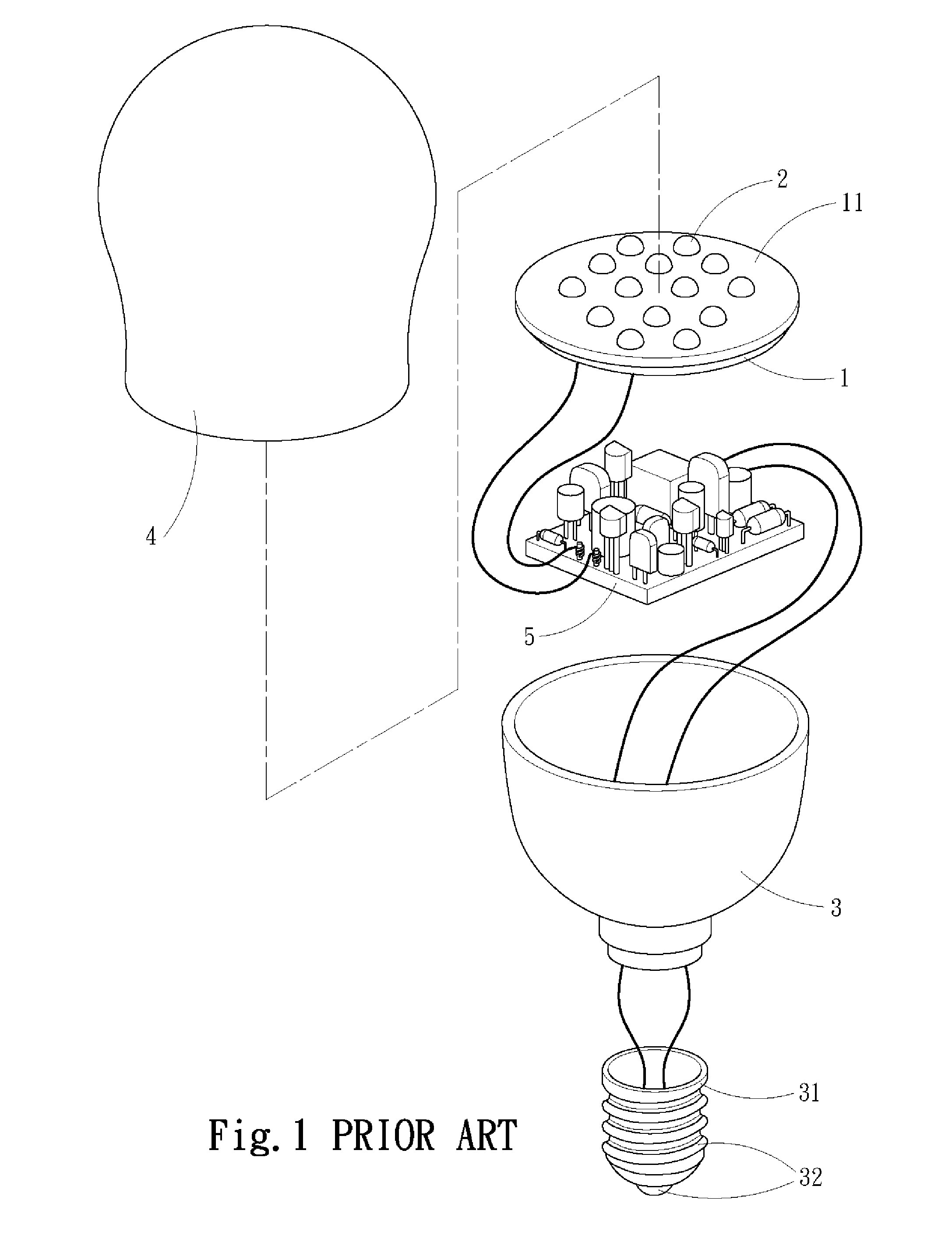

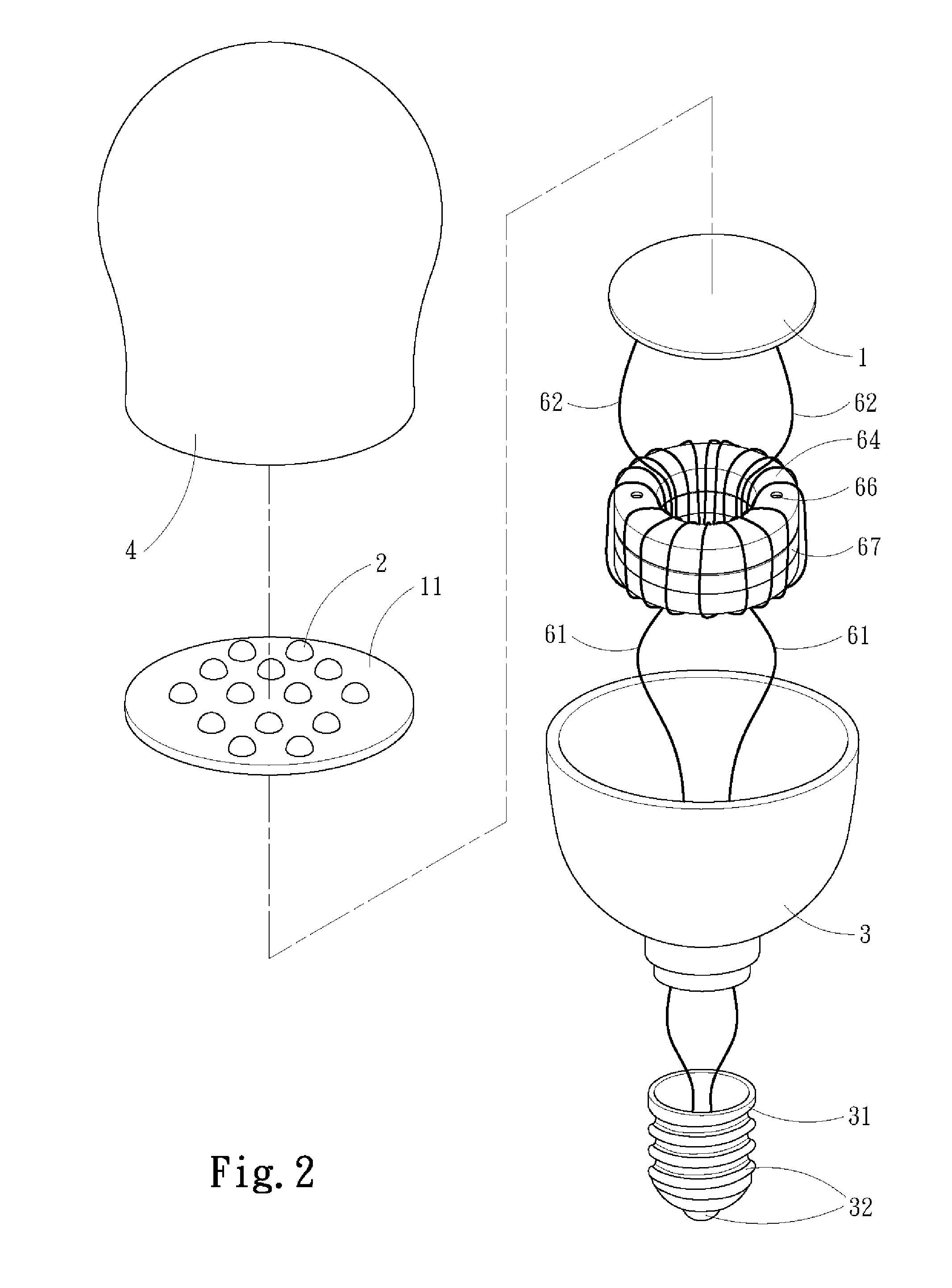

LED lamp structure

InactiveUS20080315784A1Extended service lifeImprove power qualityElectrical apparatusElectroluminescent light sourcesEngineeringAlternating current

The present invention provides an LED lamp structure, including a circuit board, a circular coil, and a lamp housing. The circuit board has one or more LED light bulb mounted thereon, and the circular coil includes an iron core, a primary winding and a secondary winding, wherein the primary winding of the circular coil is connected with the lamp housing for conducting an AC power, and then, the secondary winding, which is connected with the circuit board, is induced to produce a DC power for transmitting to the circuit board, thereby lighting up the LED light bulb on the circuit board.

Owner:TSENG JUI KAI

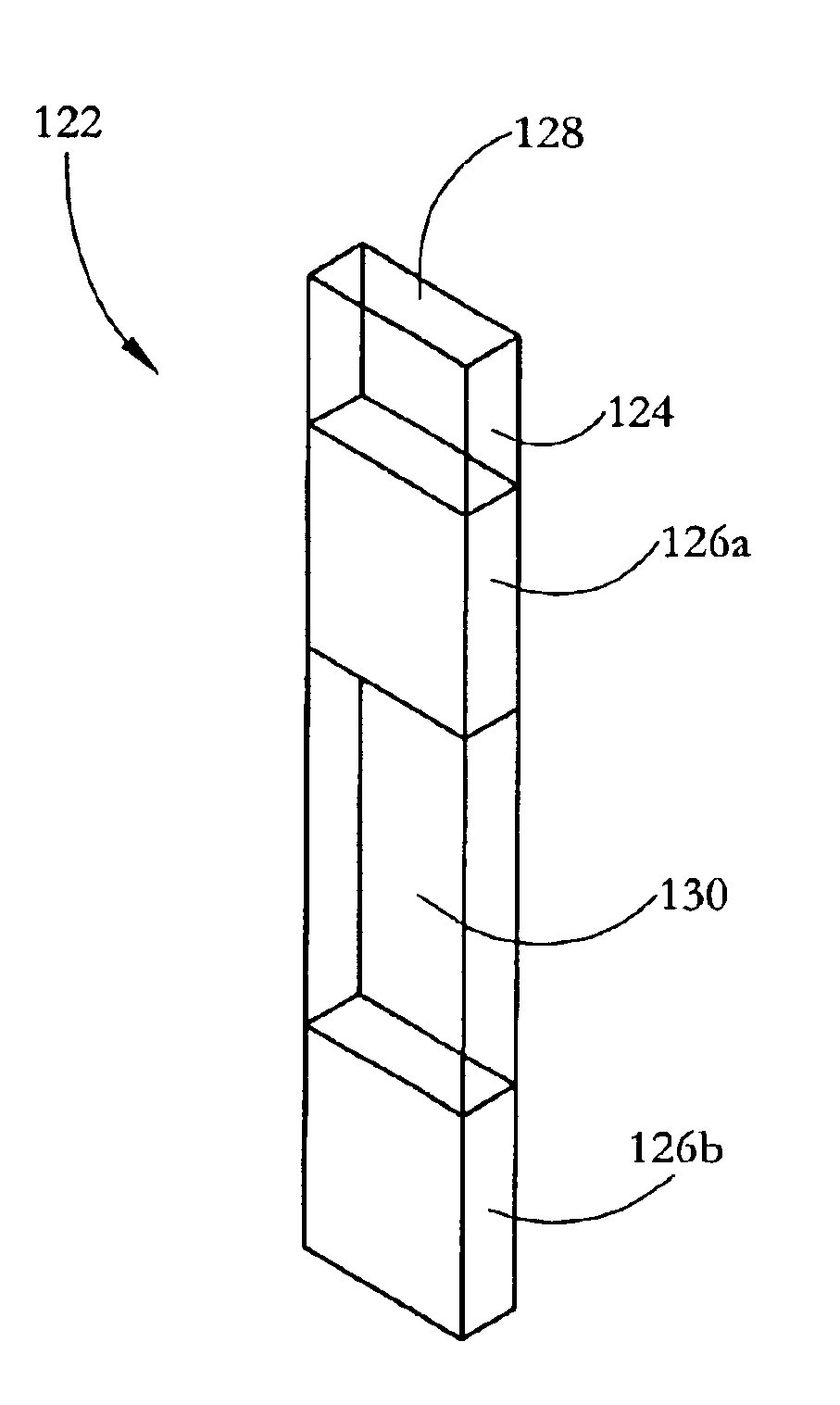

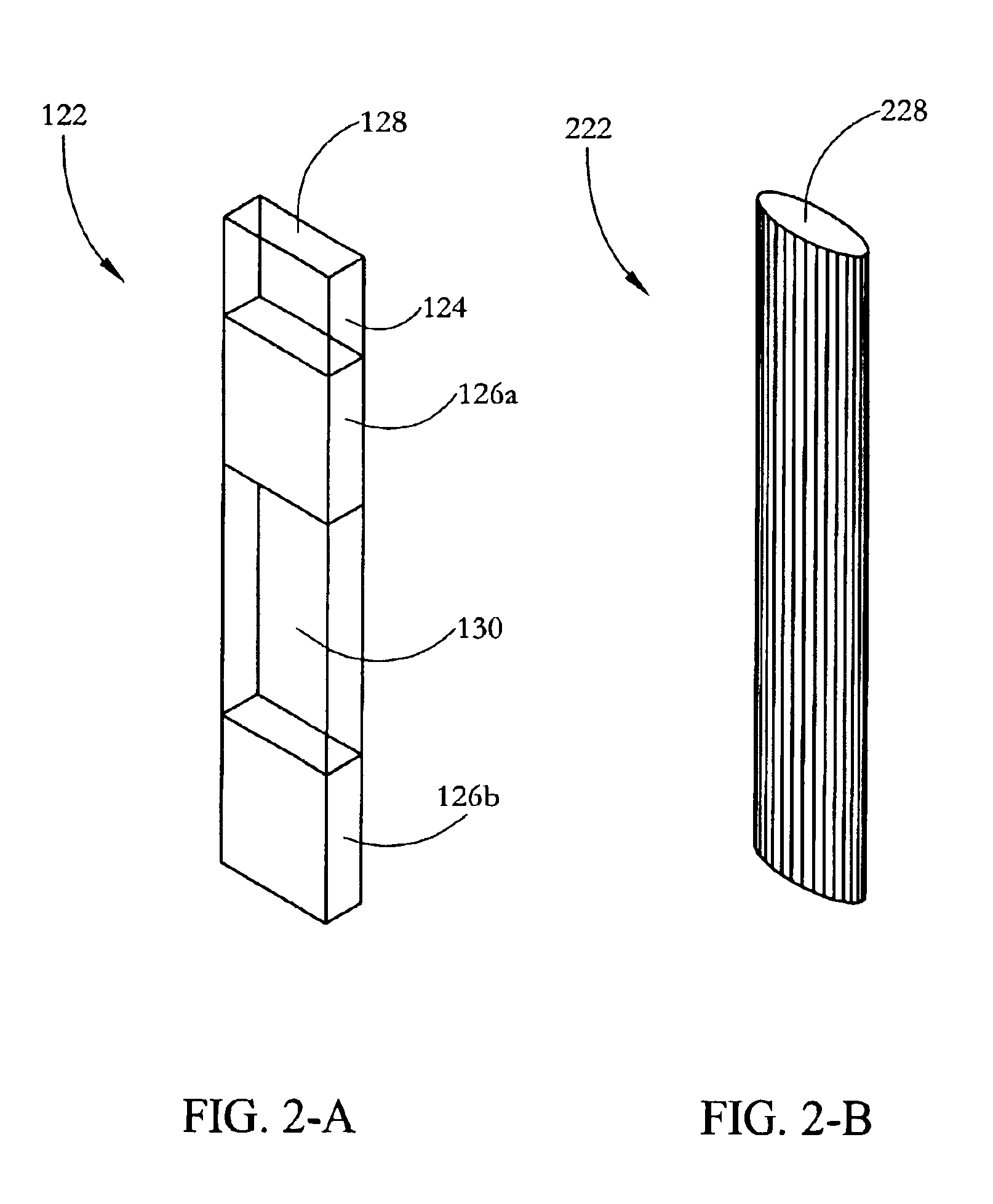

Squashed liquid NMR sample tubes and RF coils

InactiveUS6917201B2Laboratory glasswaresElectric/magnetic detectionNMR - Nuclear magnetic resonanceSaddle shape

Nuclear magnetic resonance (NMR) systems and methods employing squashed (transversely-elongated) sample vessels (sample tubes or flow cells) for holding liquid NMR samples, and matching squashed saddle-shaped RF coils allow reducing sample and / or coil losses and increasing the RF circuit quality factors (Q). In a present implementation, the RF coils and sample vessels have rectangular cross-sections. Rounded (e.g. ellipsoidal) or other squashed cross-sections may also be used. The coil corresponding to the highest sample losses is positioned such that the magnetic field generated by the coil is along the major axis of the sample vessel. Squashed sample vessels may also be used with conventional circular coils, particularly for low-temperature measurements where sample losses dominate.

Owner:AGILENT TECH INC

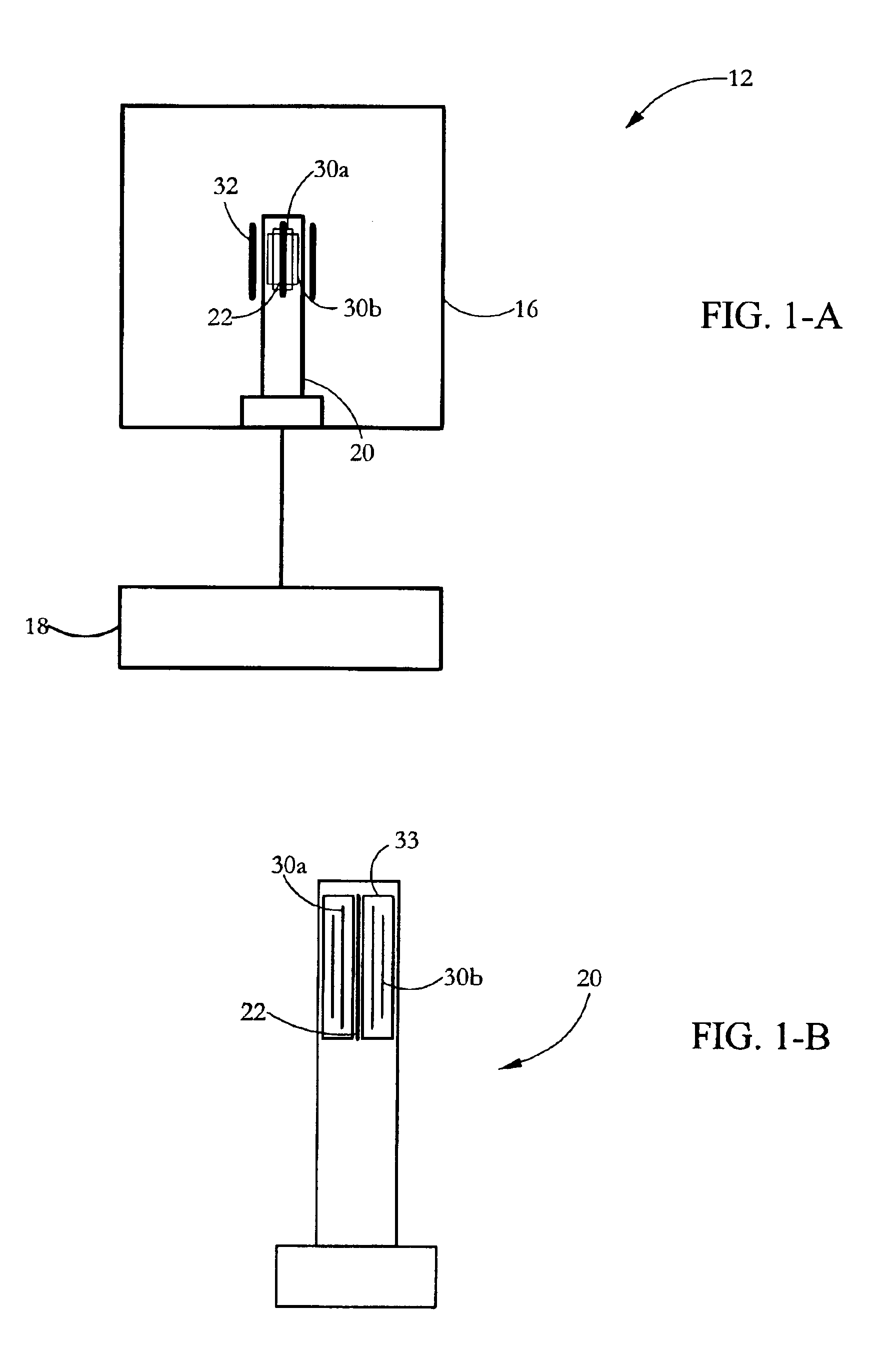

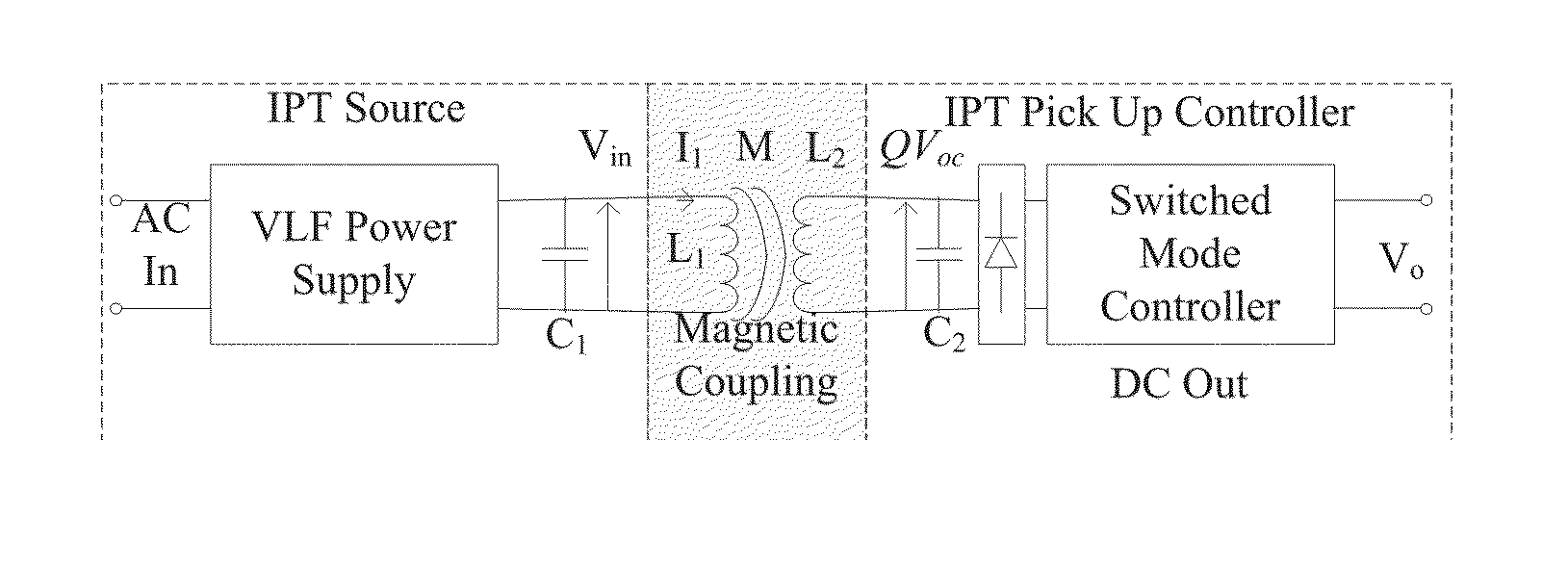

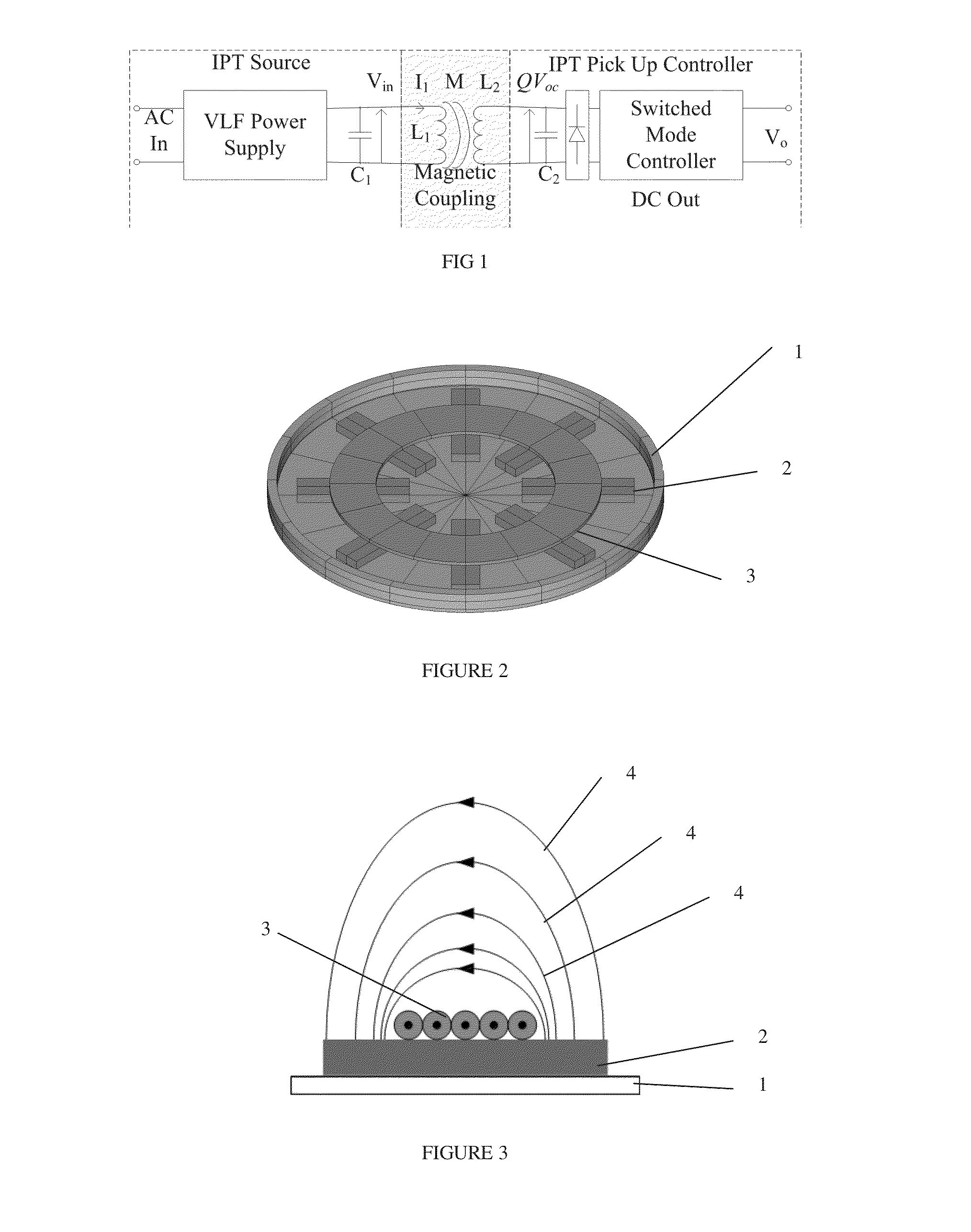

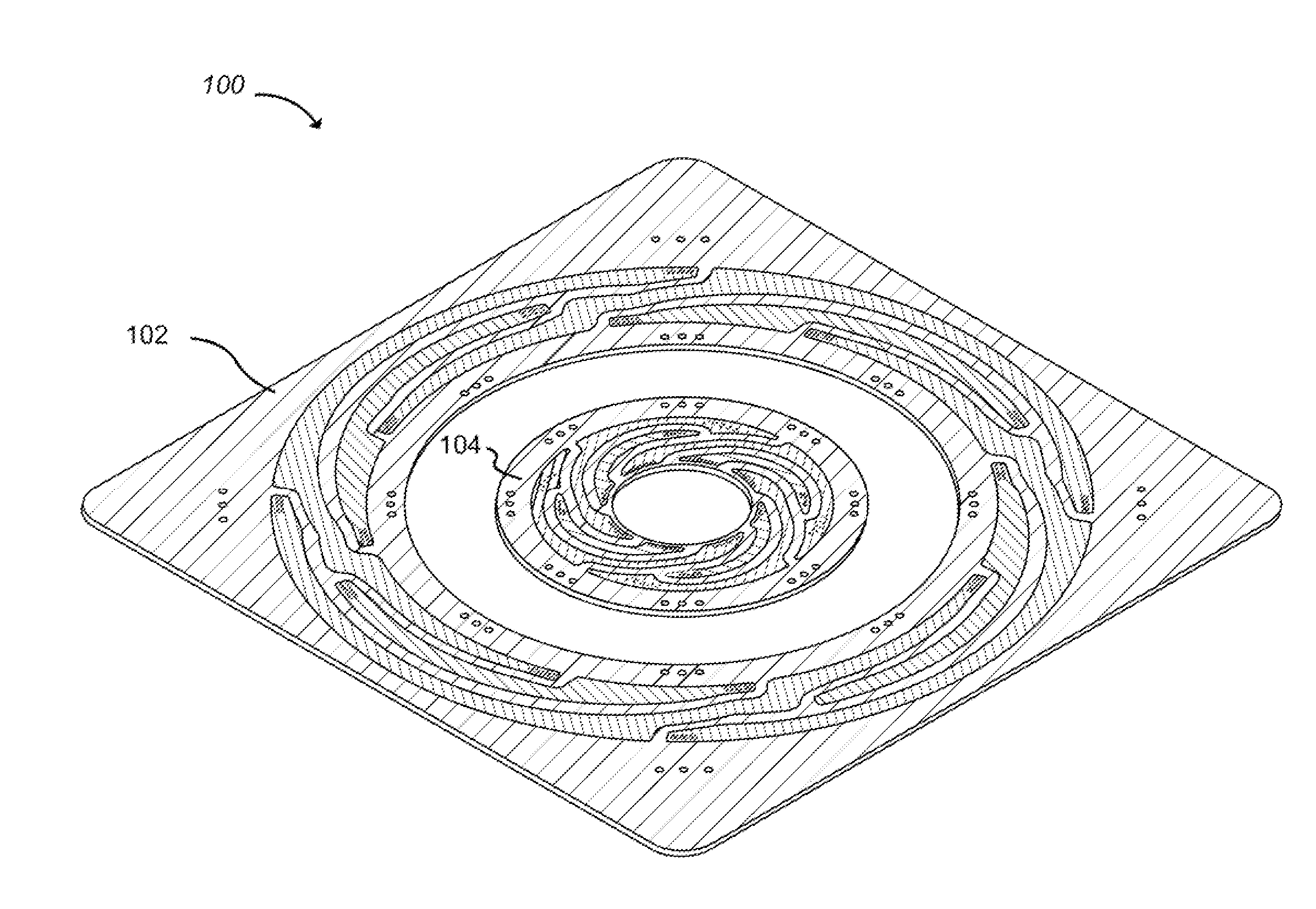

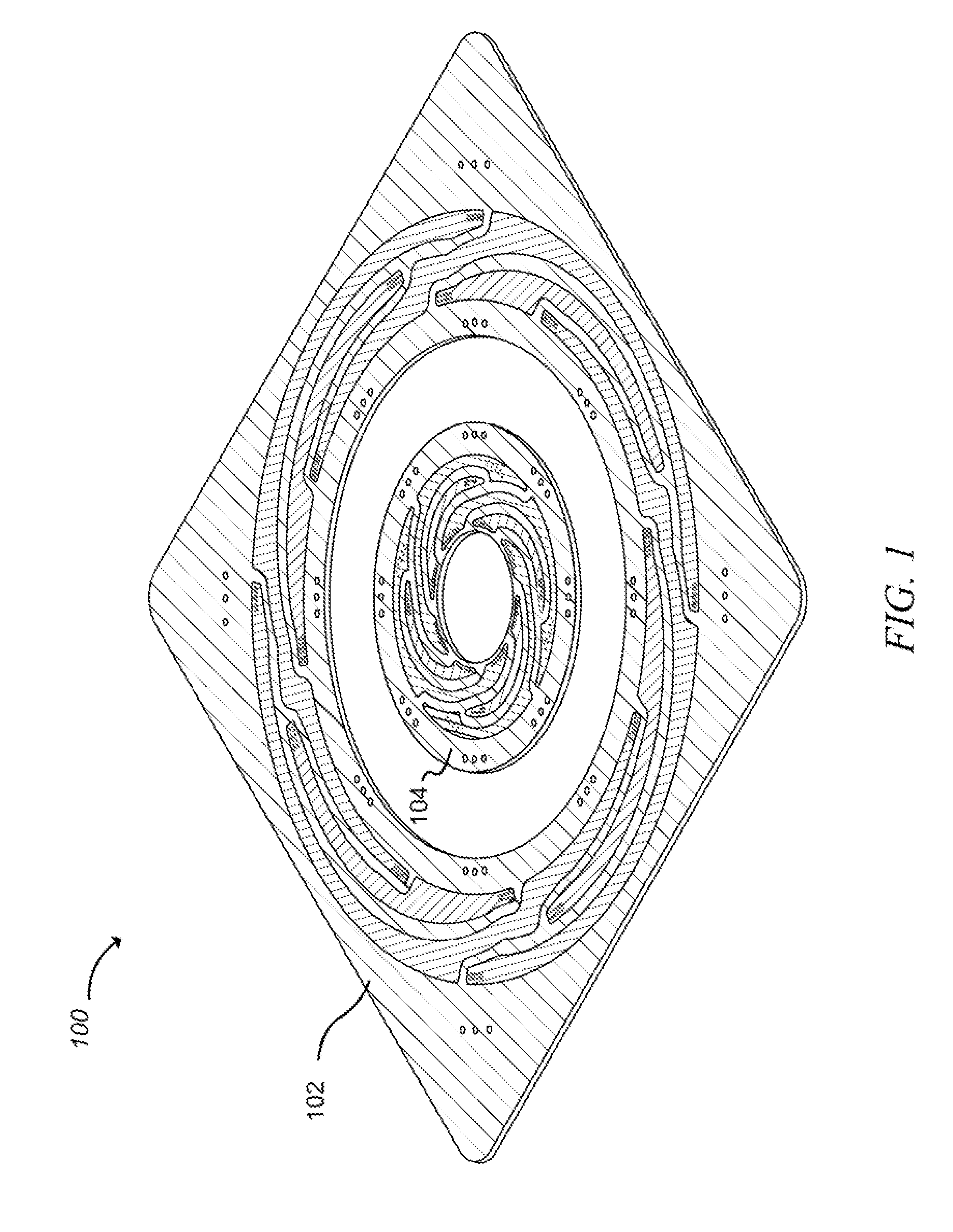

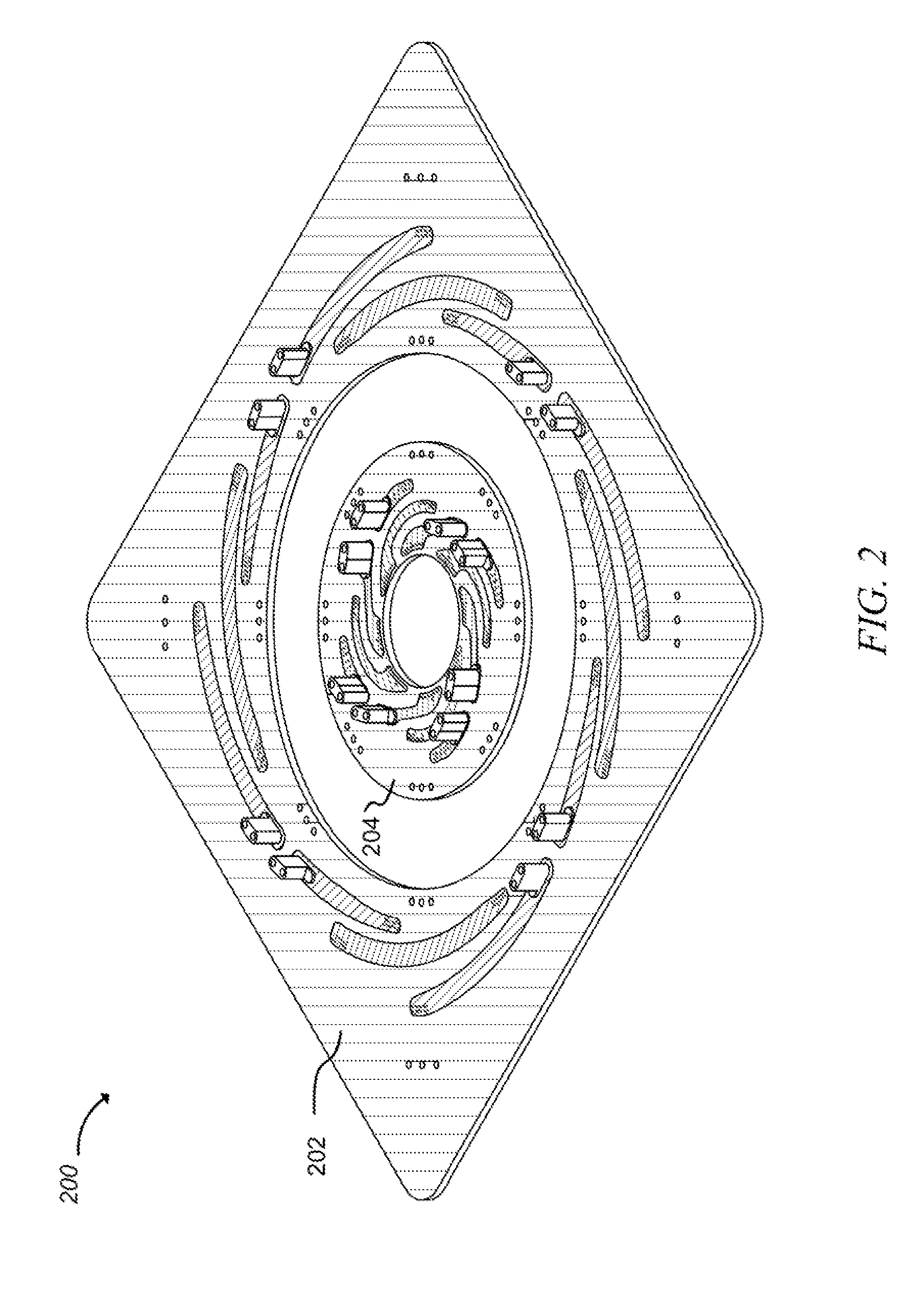

Interoperability of magnetic structures for inductive power transfer systems

Inductive power transfer apparatus has a first magnetic coupling structure and a second magnetic coupling structure, the structures being adapted to generate and / or receive magnetic flux to thereby transfer power inductively, the first structure comprising a substantially circular coil, and the second magnetic structure comprising an arrangement of at least two coils associated with a magnetically permeable core.

Owner:AUCKLAND UNISERVICES LTD

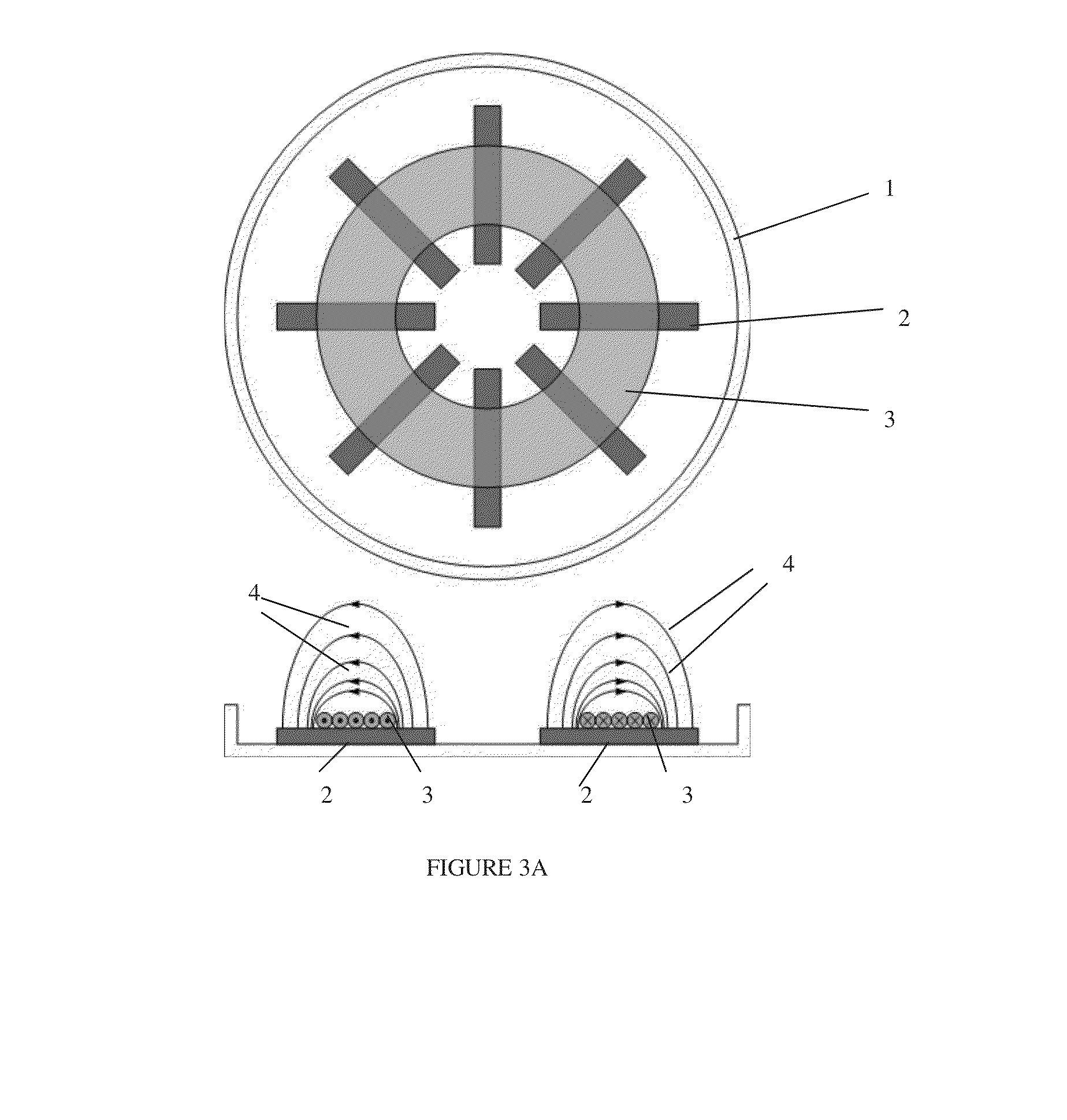

Methods and apparatus for an induction coil arrangement in a plasma processing system

InactiveUS20110253310A1Electric discharge tubesSemiconductor/solid-state device manufacturingAzimuth directionPlasma processing

An antenna arrangement in a plasma processing system for providing plasma uniformity across a substrate during substrate processing is provided. The arrangement includes a plurality of circular antenna assemblies. Each circular antenna assembly of the plurality of circular antenna assemblies includes a set of non-circular coils. Each non-circular coil of the set of non-circular coils is offset at a predetermined angle in an azimuthal direction. The arrangement also includes a set of power generators for powering the plurality of circular antenna assemblies.

Owner:LAM RES CORP

Cable tunnel inspection robot equipped with wireless charging equipment and charging method for robot

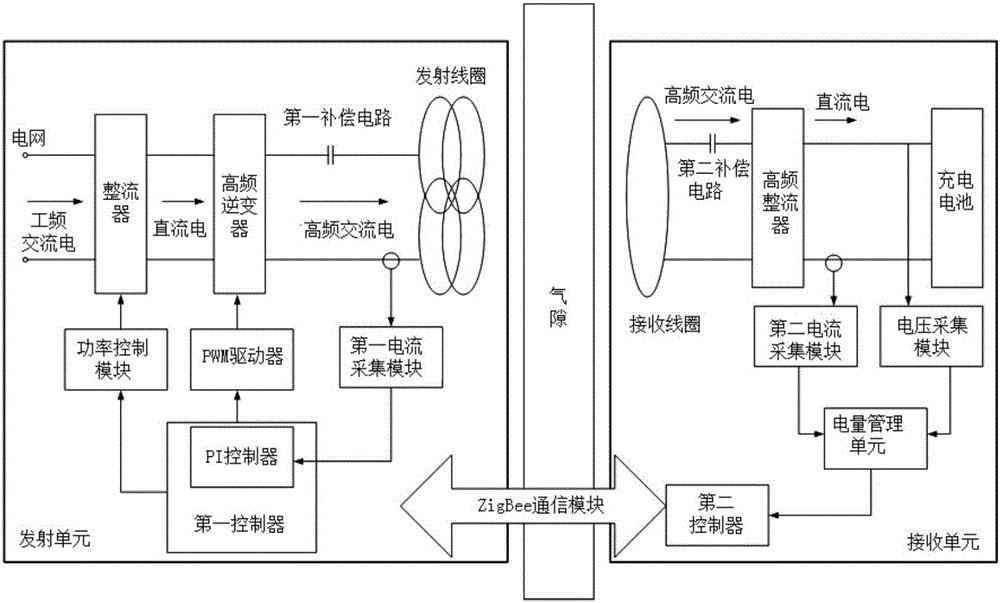

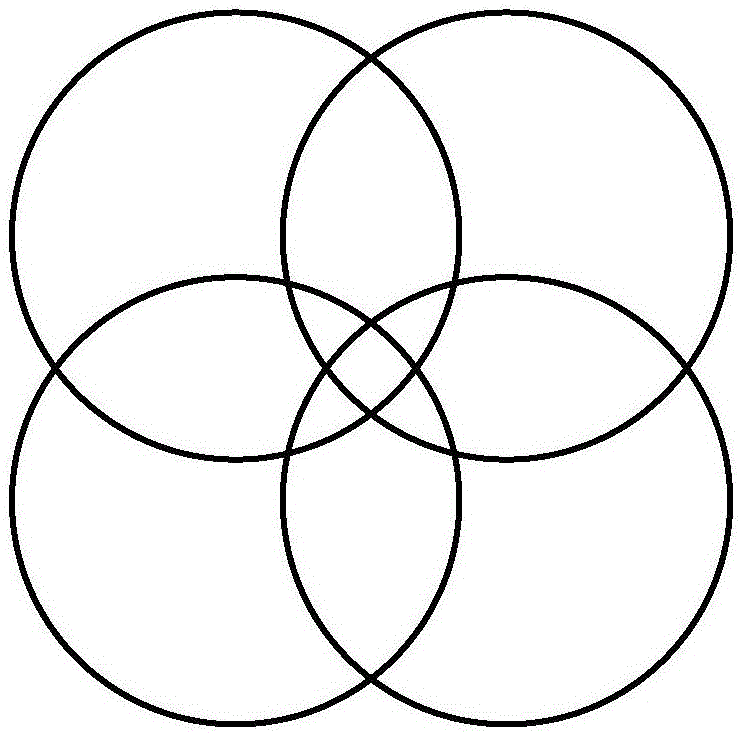

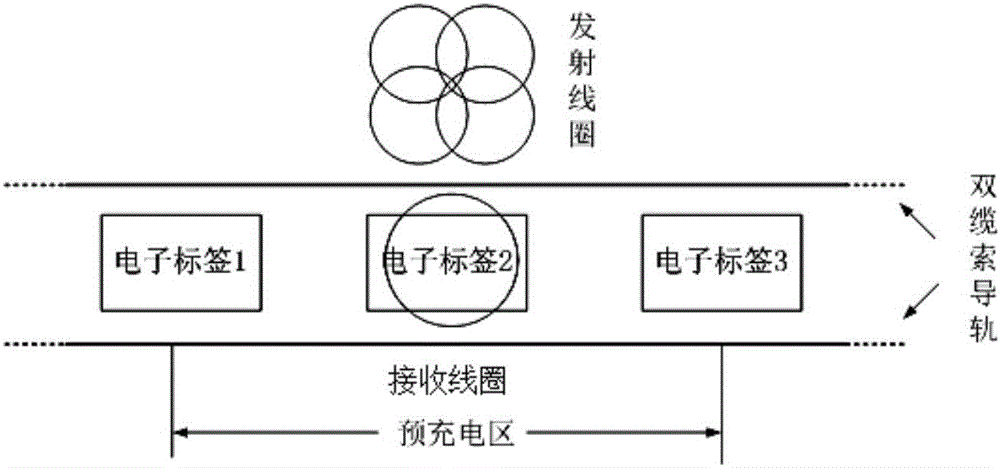

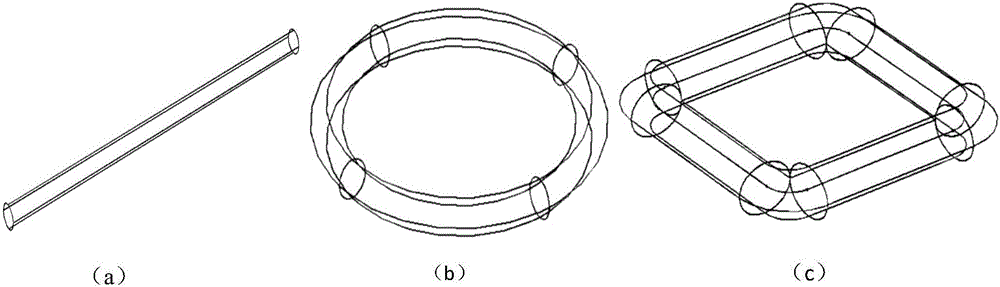

InactiveCN106787233AFast wireless chargingIncrease magnetic inductionCircuit arrangementsEngineeringElectron

The invention discloses a cable tunnel inspection robot equipped with wireless charging equipment and a charging method for the robot. The wireless charging equipment comprises a transmitting unit, a receiving unit and a ZigBee communication module, wherein the receiving unit is mounted on the cable tunnel inspection robot; the transmitting coils in the transmitting unit are four equal-size circular coils which are arranged on the same plane and are connected in series mutually; a square is formed by the centers of the circular coils in a surrounding manner, and the circular coils are partially overlapped mutually; a charging battery in the receiving unit is used for supplying electric energy for the cable tunnel inspection robot; and a first controller in the transmitting unit and a second controller in the receiving unit are in wireless connection through the ZigBee communication module. According to the charging method disclosed by the invention, an RFID electronic tag is adopted to realize accurate positioning of the cable tunnel inspection robot, so that quick wireless charging of a dual-cable-rope guiding rail type cable tunnel inspection robot is realized.

Owner:WUHAN UNIV

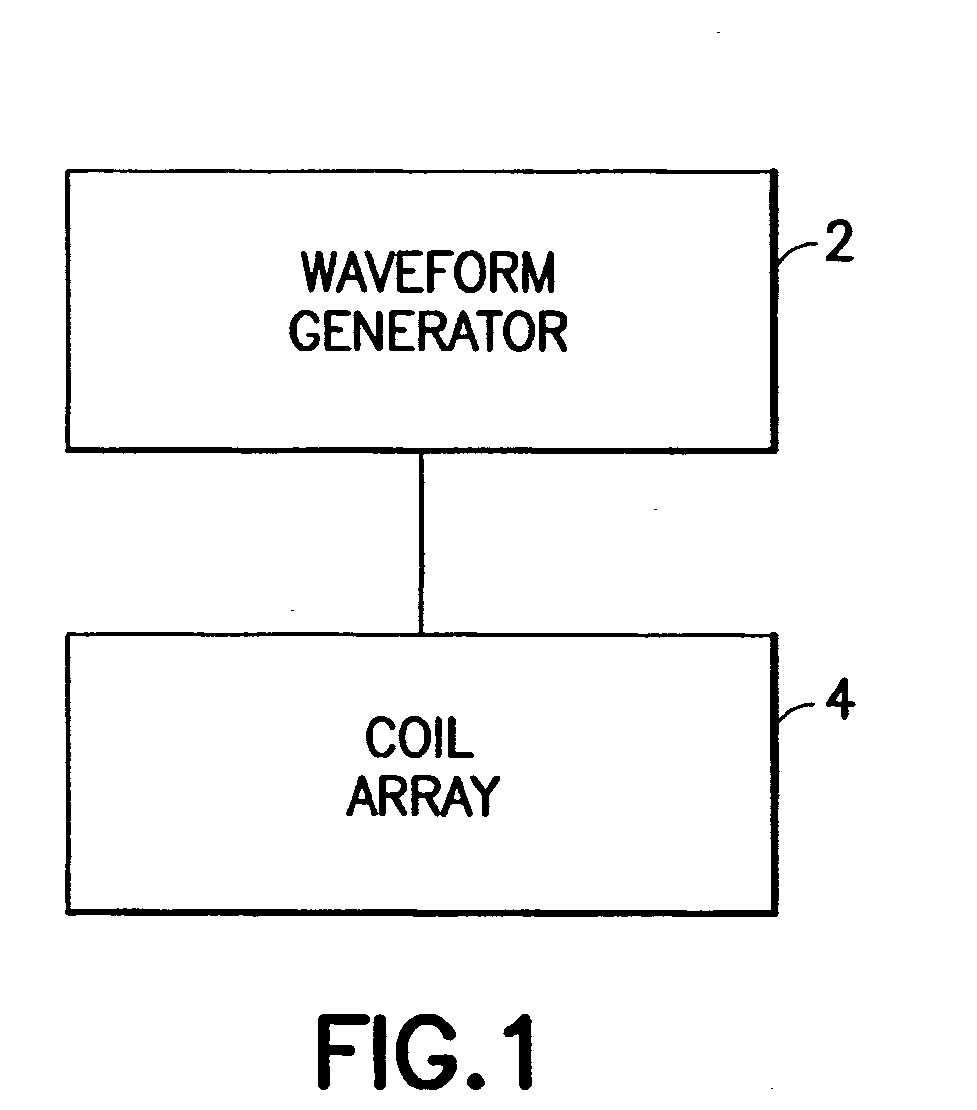

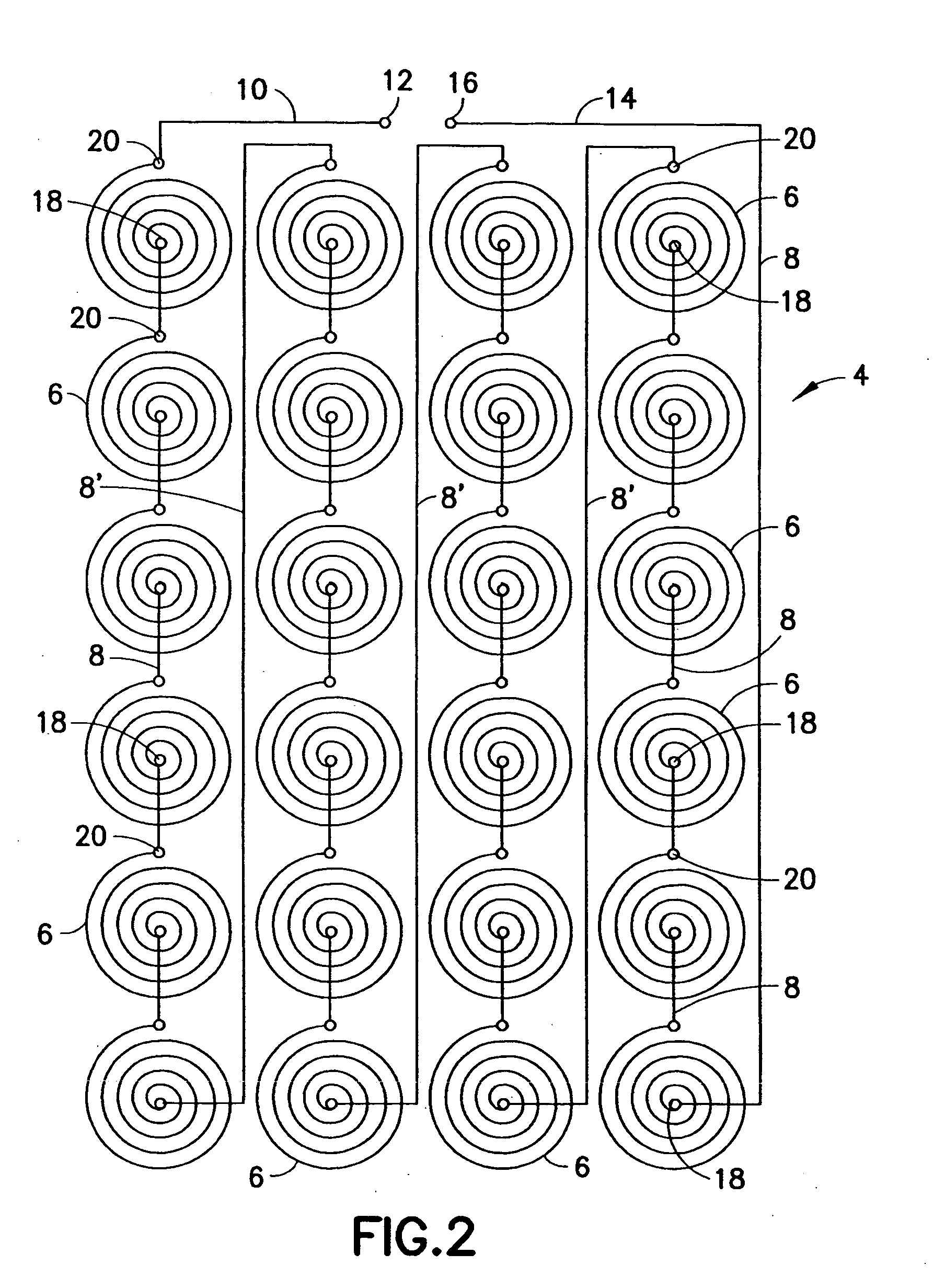

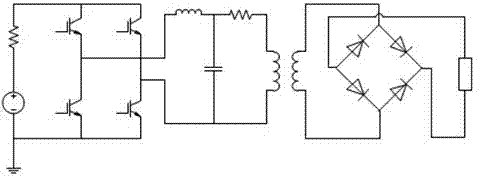

Method and apparatus for treatment of amyotrophic lateral sclerosis patients

InactiveUS20070282388A1Improving and ameliorating symptomDelay progressElectrotherapyMagnetotherapy using coils/electromagnetsSquare waveformMedicine

A method for treating patients with Amyotrophic Lateral Sclerosis (ALS), also known as Lou Gehrig's disease. In accordance with the method of treatment, transcranial AC pulsed electromagnetic fields (EMFs) in substantially square waveforms in particular frequency and amplitude ranges and picotesla quantities are applied to the patient's brain. EMFs are applied via a transducer array containing a plurality of flexible circular coils in an arrangement placed over the scalp of an ALS patient. The treatment method ameliorates symptoms associated with the disease state and slows the progression of the disease.

Owner:SANDYK REUVEN

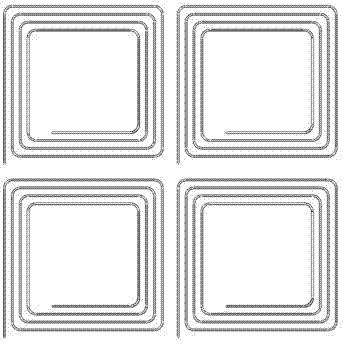

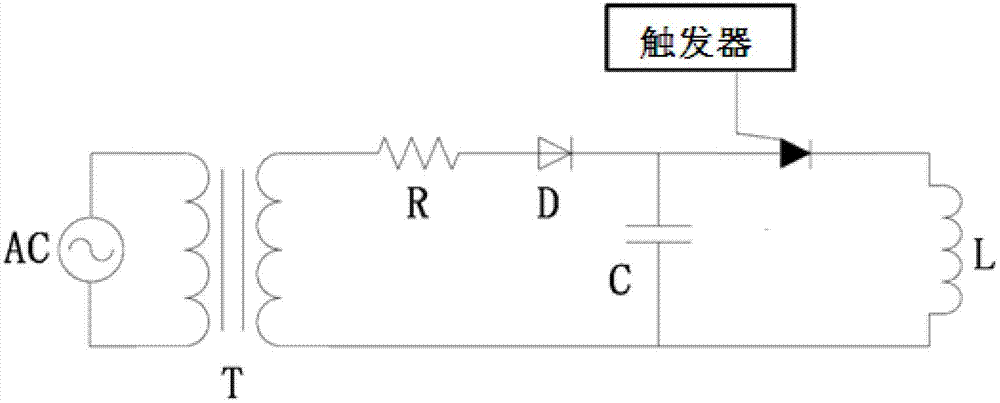

Wireless magnetic-resonance charging device based on array coils

InactiveCN103532255AEvenly distributedDistribution rulesElectromagnetic wave systemCircuit arrangementsResonanceElectromagnetic field

The invention relates to a wireless charging device, in particular to a wireless magnetic-resonance charging device based on array coils. The wireless magnetic-resonance charging device comprises a power supply, a control circuit, a driving circuit and a transmitting terminal, which are sequentially connected, and a receiving terminal and an electric energy converting circuit, which are sequentially connected, wherein the transmitting terminal comprises a plurality of spiral coils; the receiving terminal is a spiral coil. The wireless magnetic-resonance charging device has the advantages as follows: 1, different from conventional circular coils, the coils adopting efficient array structures can enable an electromagnetic field to be distributed uniformly to a certain extent; 2, the distribution of the electromagnetic field generated by the efficient array coils compared with conventional coils is more regular; 3, under a certain external environmental condition, the distribution of the efficient array coils can be regulated so as to efficiently transmit electric energy; 4, the transmitting array coils and the receiving array coil can have the same or different structures and can be flexibly regulated.

Owner:WUHAN UNIV

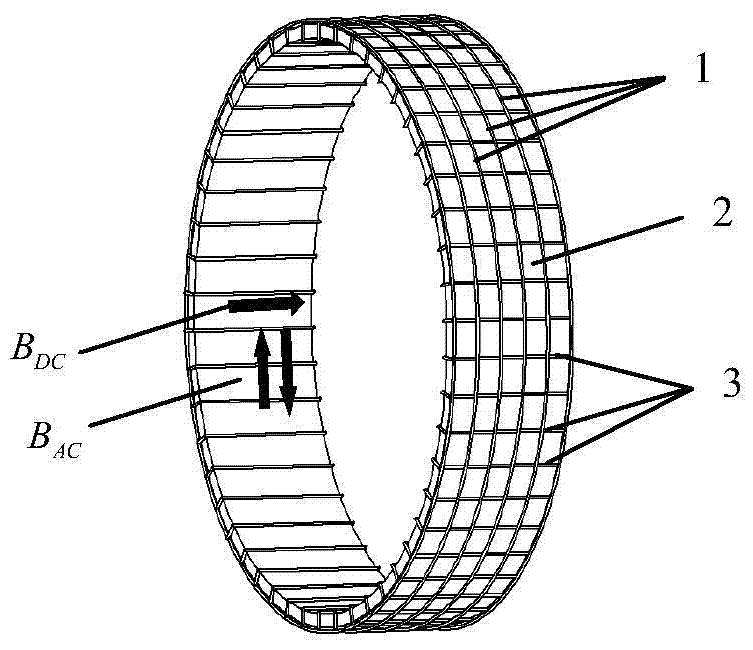

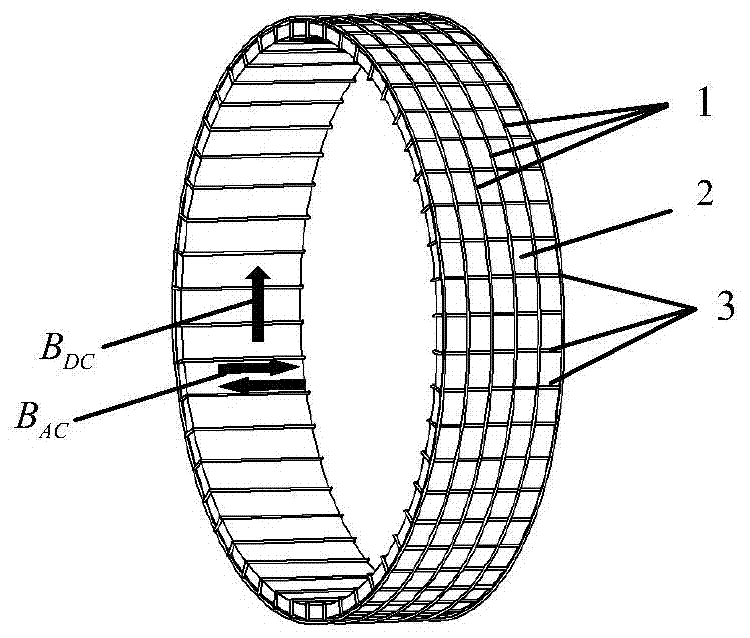

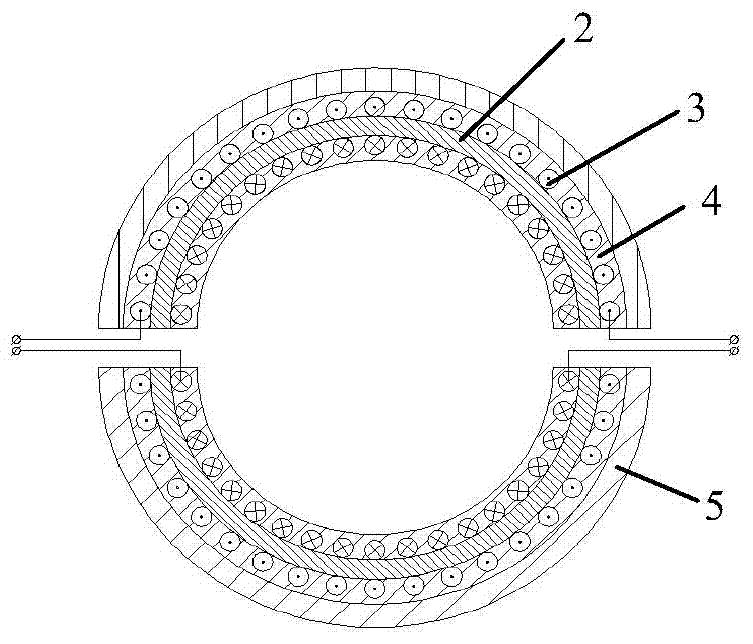

Circular-array-type magnetostriction sensor based on orthogonal encircling coil

InactiveCN104502443AUniform static magnetic field distributionHigh magnetostriction coefficientMaterial magnetic variablesEpoxyHigh energy

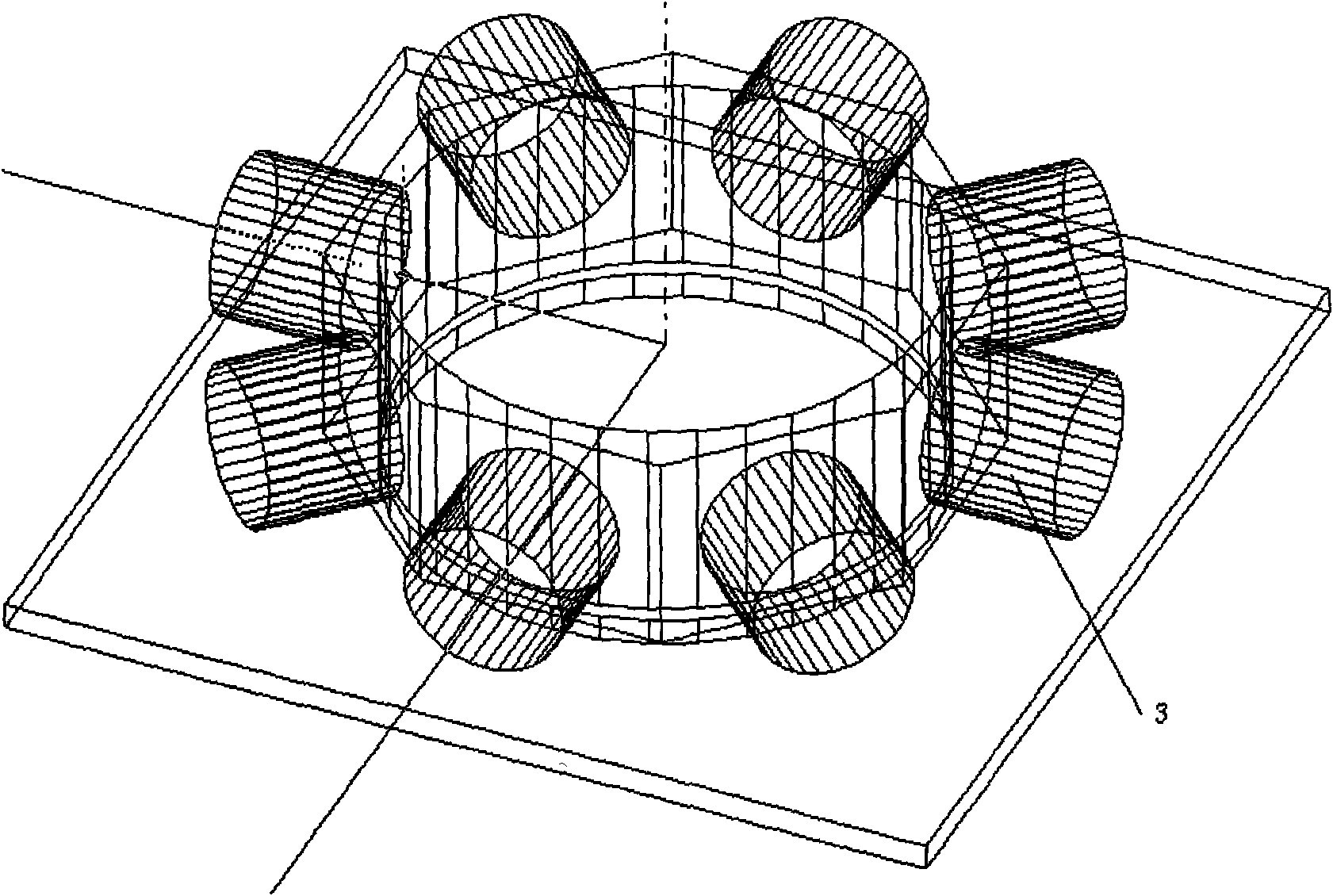

The invention relates to a circular-array-type magnetostriction sensor based on an orthogonal encircling coil. The circular-array-type magnetostriction sensor comprises a ferrocobalt band, a rectangular coil, a circular coil and a mechanical clamping device, wherein the rectangular coil and the circular coil are orthogonally encircled on the ferrocobalt band. The rectangular coil is preliminarily encircled on the ferrocobalt band, bonded through epoxy resin and solidified with an outside rubber layer to form a semi-cylindrical-shell detection unit. Two detection units are directly buckled or stuck to the surface of a structure such as a circular pipe and a circular rod by adopting epoxy resin and form an access after being connected through a conducting plug pin. The bar-type circular coil is encircled outside each detection unit and penetrates through the mechanical clamping device to form an access by adopting an adaptor; the mechanical clamping device can be used for applying radial load onto the circular coil and the detection units. The circular-array-type magnetostriction sensor can be used for exciting and receiving a torsional-mode ultrasonic guide wave in the circular pipe and the circular rod structure and has higher energy exciting efficiency; moreover, the structure is simple, multichannel excitation and receiving of the torsional-mode ultrasonic guide wave can be realized, and a foundation is provided for a focus imaging algorithm of the pipeline detection.

Owner:BEIJING UNIV OF TECH

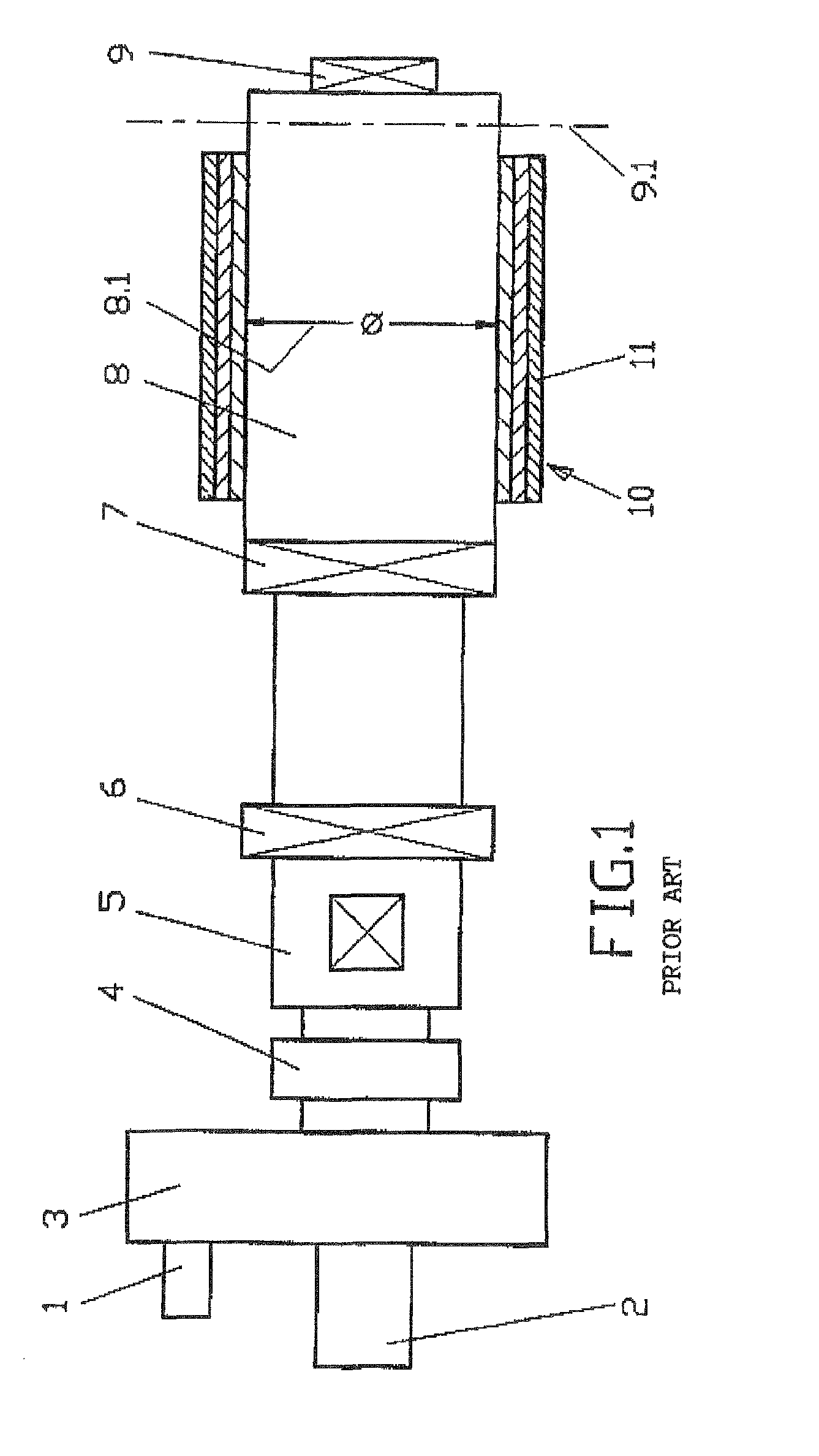

External ball passage detecting method and device for ball-bed high temperature gas cooled reactor

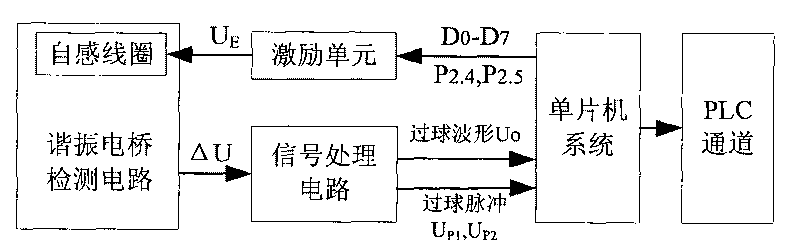

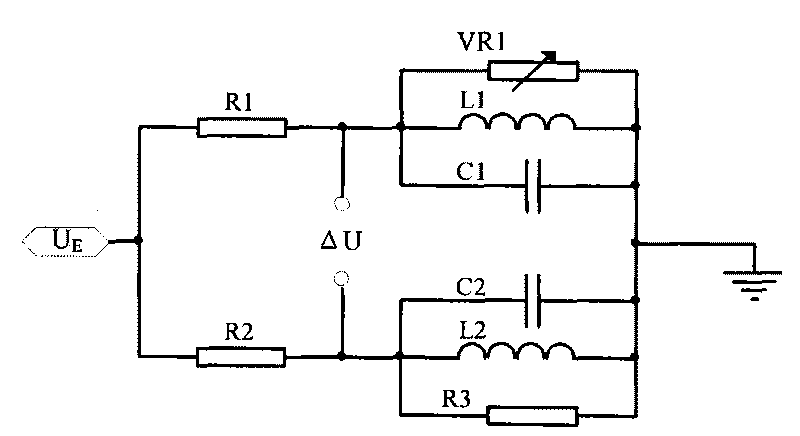

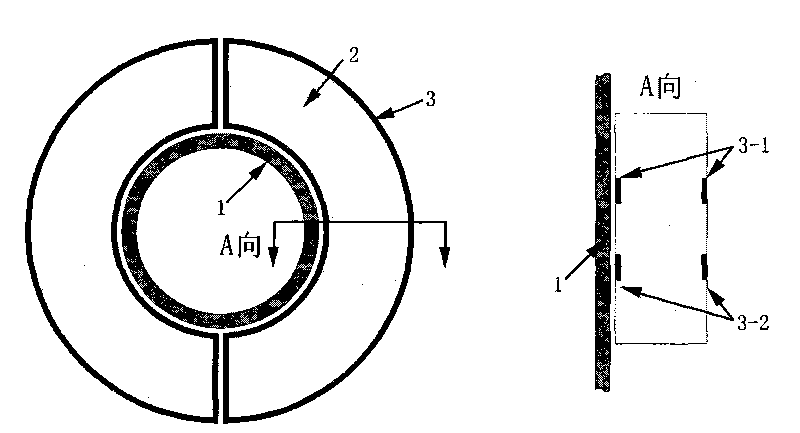

ActiveCN101719387AEffective controlGuaranteed uptimeNuclear energy generationNuclear monitoringMicrocontrollerSignal processing circuits

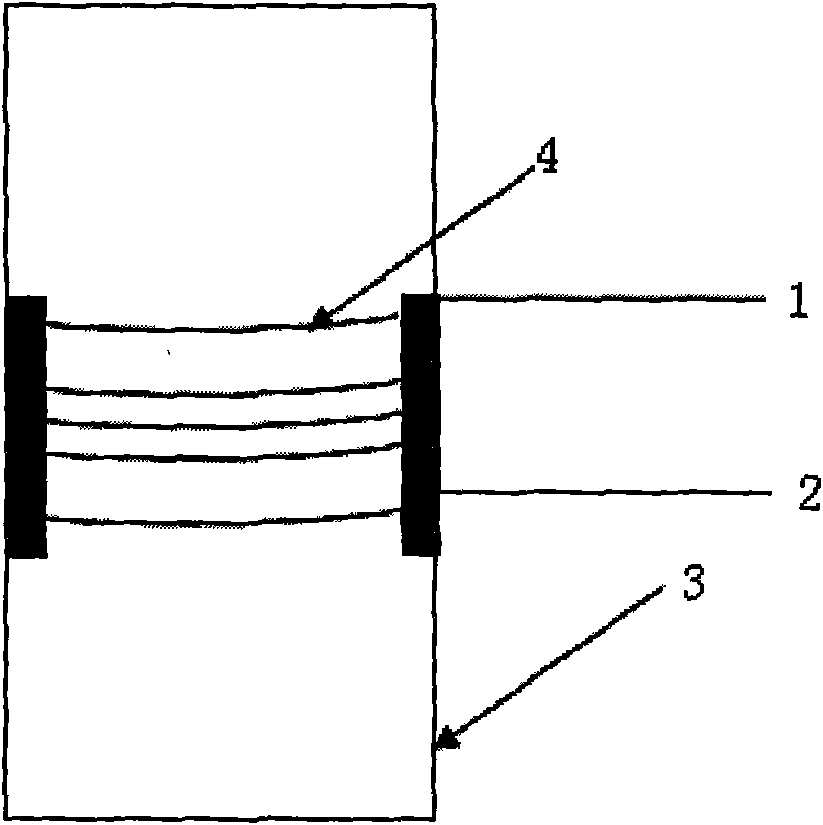

The invention relates to external ball passage detecting method and device for a ball-bed high temperature gas cooled reactor, which belong to the technical field of fuel element detection of the ball-bed high temperature gas cooled reactor. The method is characterized by comprising the following steps of: inducing the pass of balls by two self induction coils in a resonance bridge detecting circuit, and outputting sinusoidal alternating voltage delta U; sequentially amplifying, rectifying and filtering the sinusoidal alternating voltage delta U by a signal processing circuit, then extracting a ball passing waveform UO, and outputting a wave crest pulse UP1 and a wave trough pulse UP2 after passing through a comparator; and inputting the data into a singlechip, and judging whether a ball passes according to conditions, wherein the resonance bridge detecting circuit comprises the two self induction coils, two oppositely installed semicircular columns surrounding at the outer side of a pipeline are used as the frameworks of the self induction coils, two semicircular coils are respectively up and down wound on the framework at each side, the two semicircular coils on the same plane of the frameworks at both sides are used as a group, and each group is equivalent to a single circular coil through external connection. The detecting device has the advantages of simple structure, high accuracy, good reliability and the like.

Owner:TSINGHUA UNIV

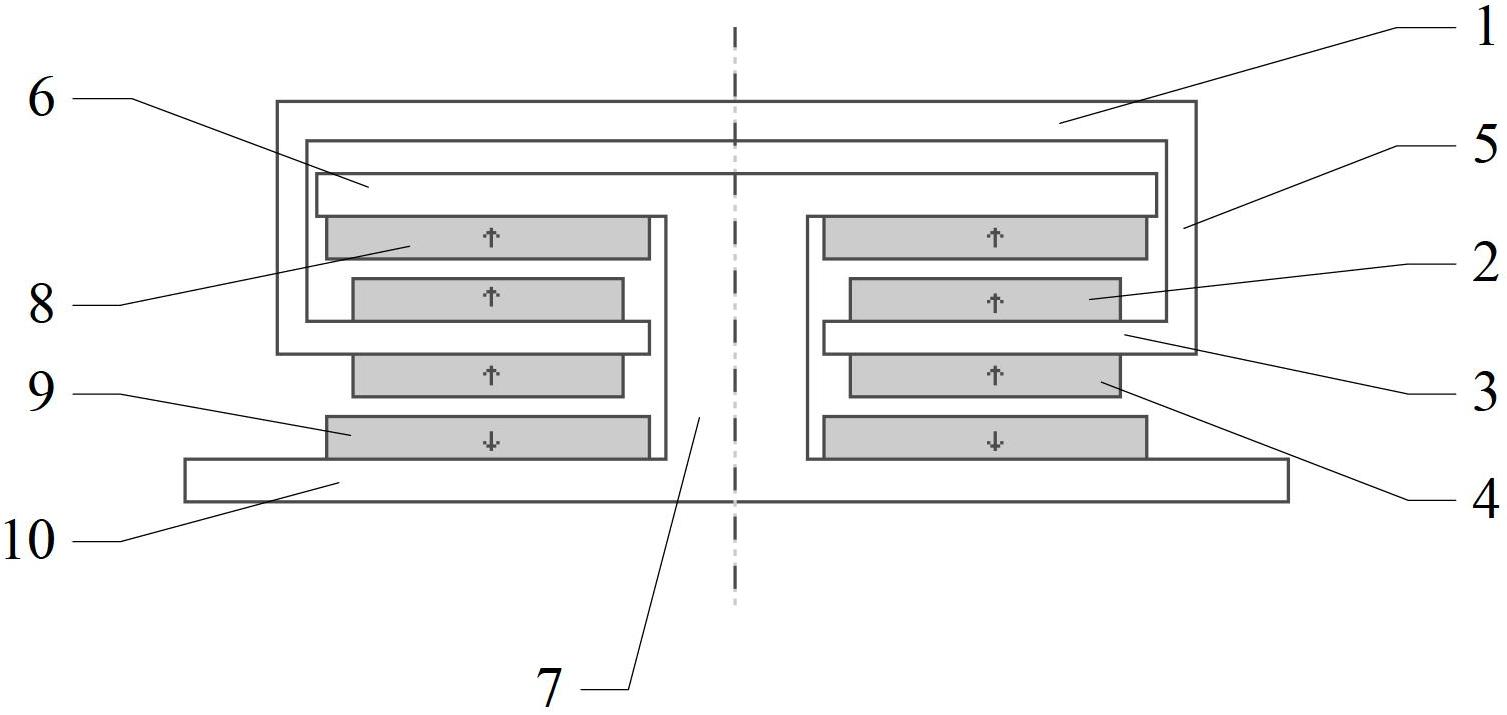

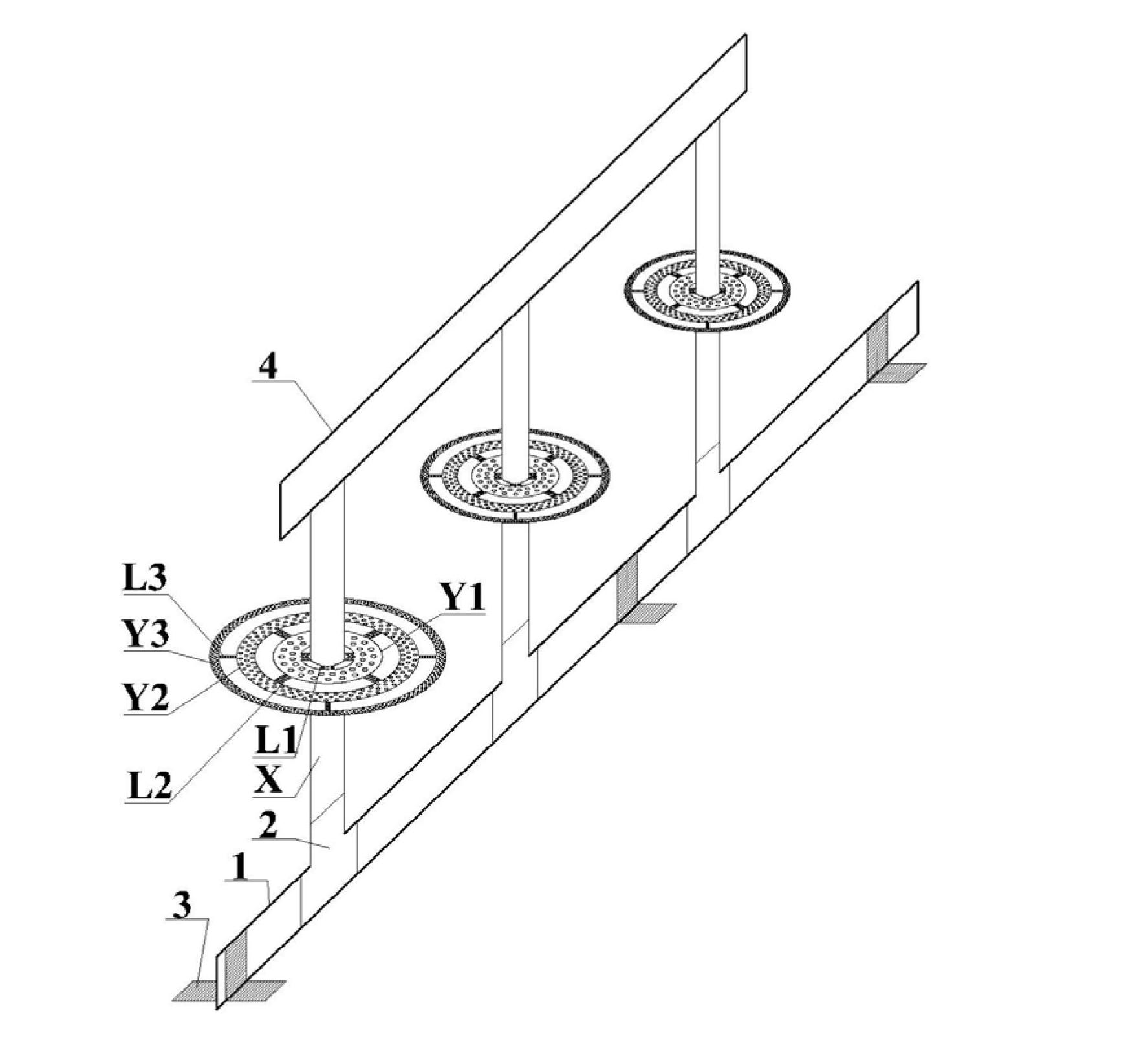

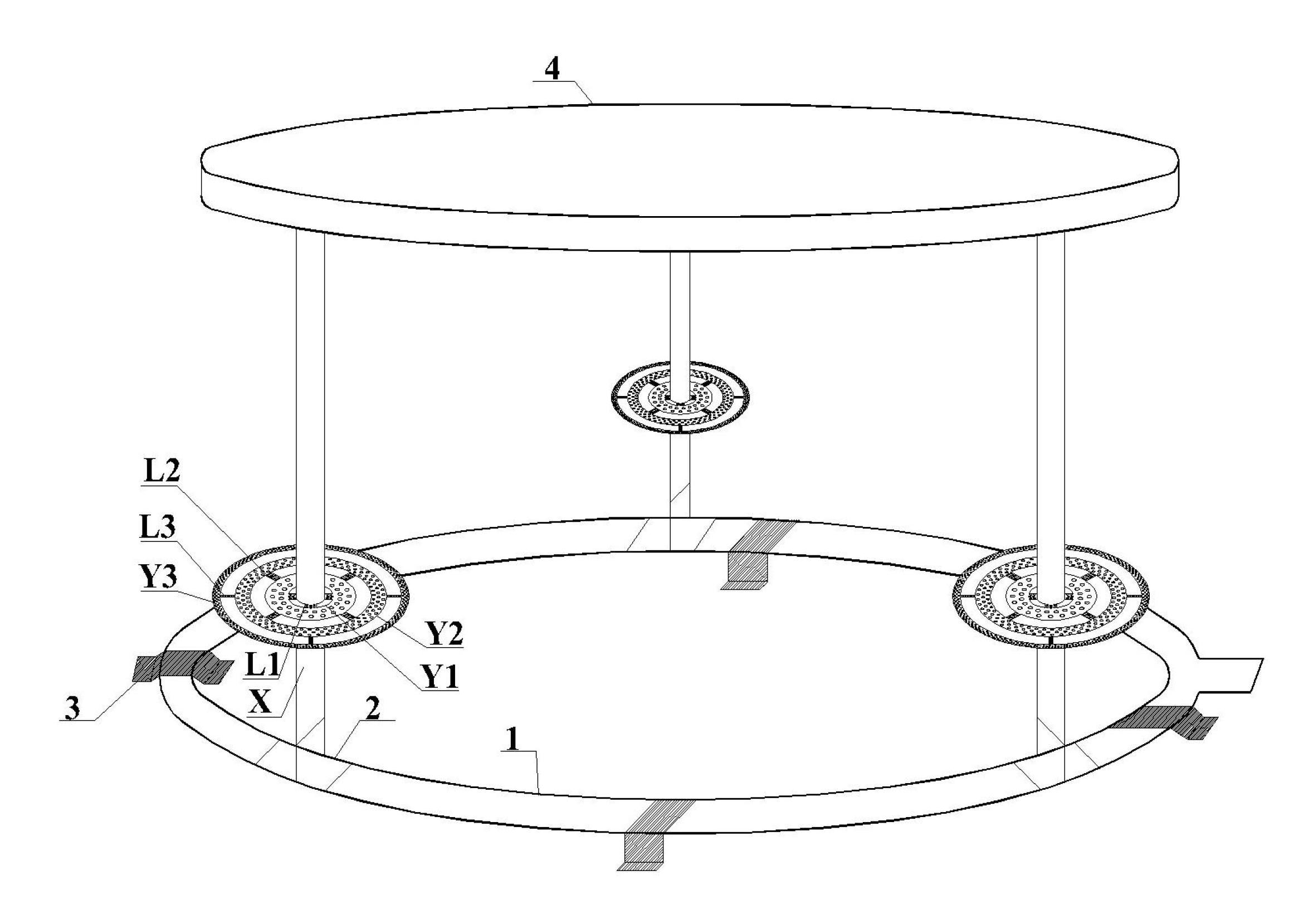

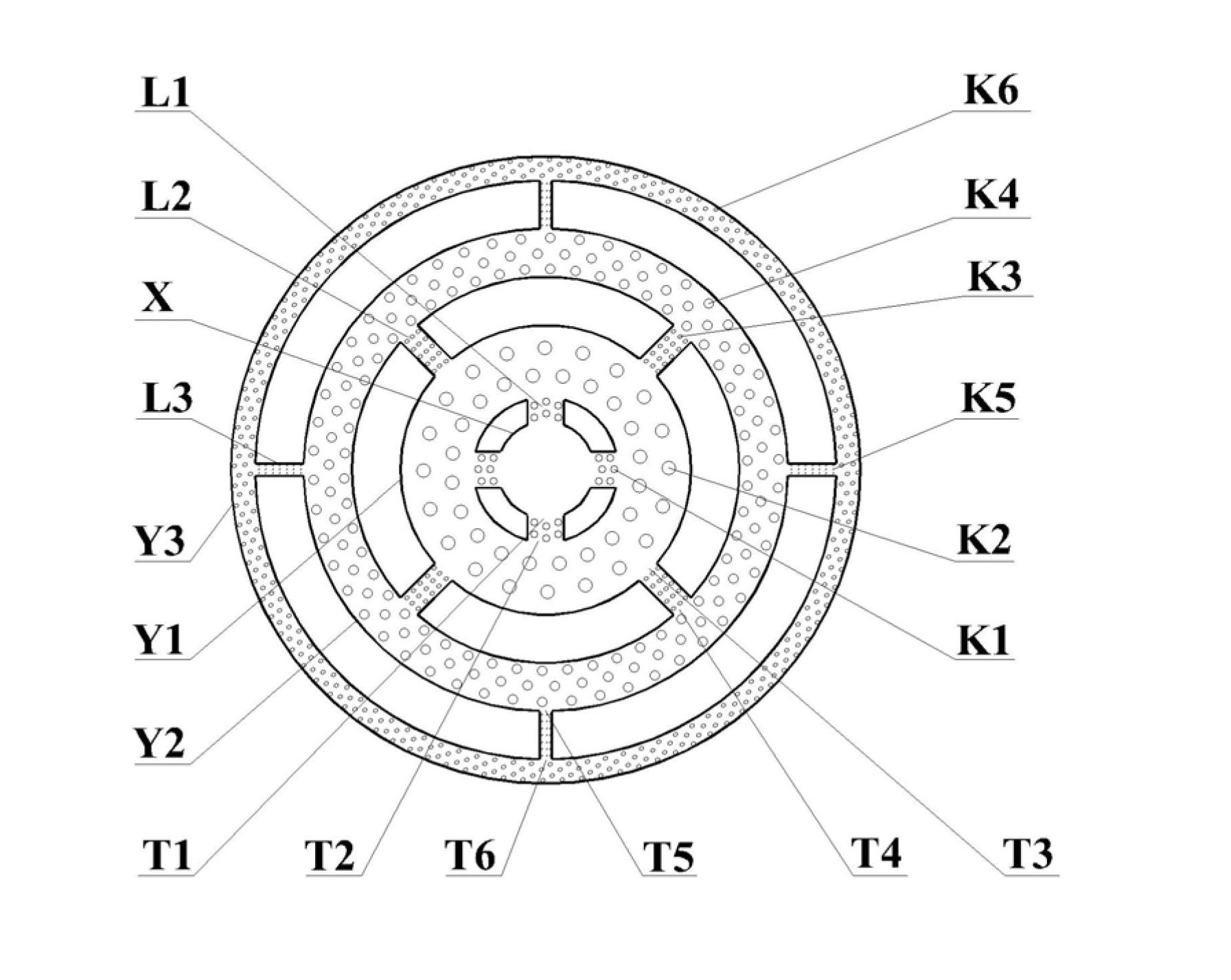

Magnetic levitation vibration isolation platform

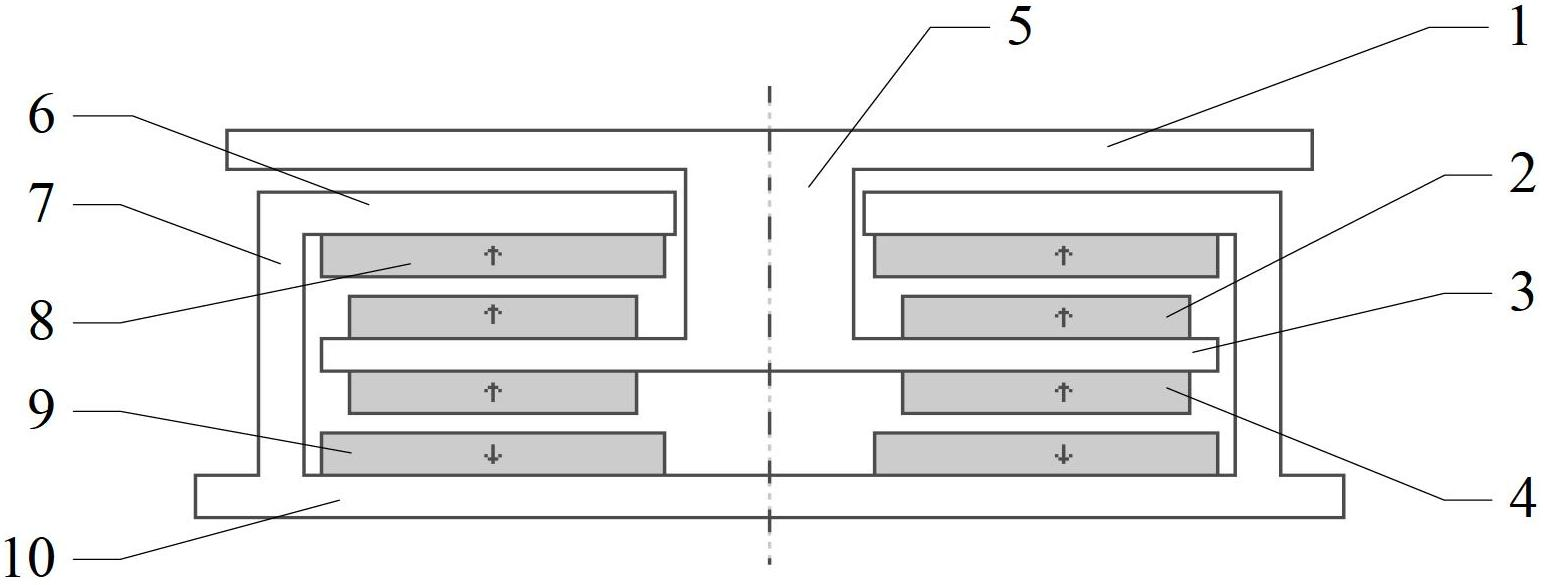

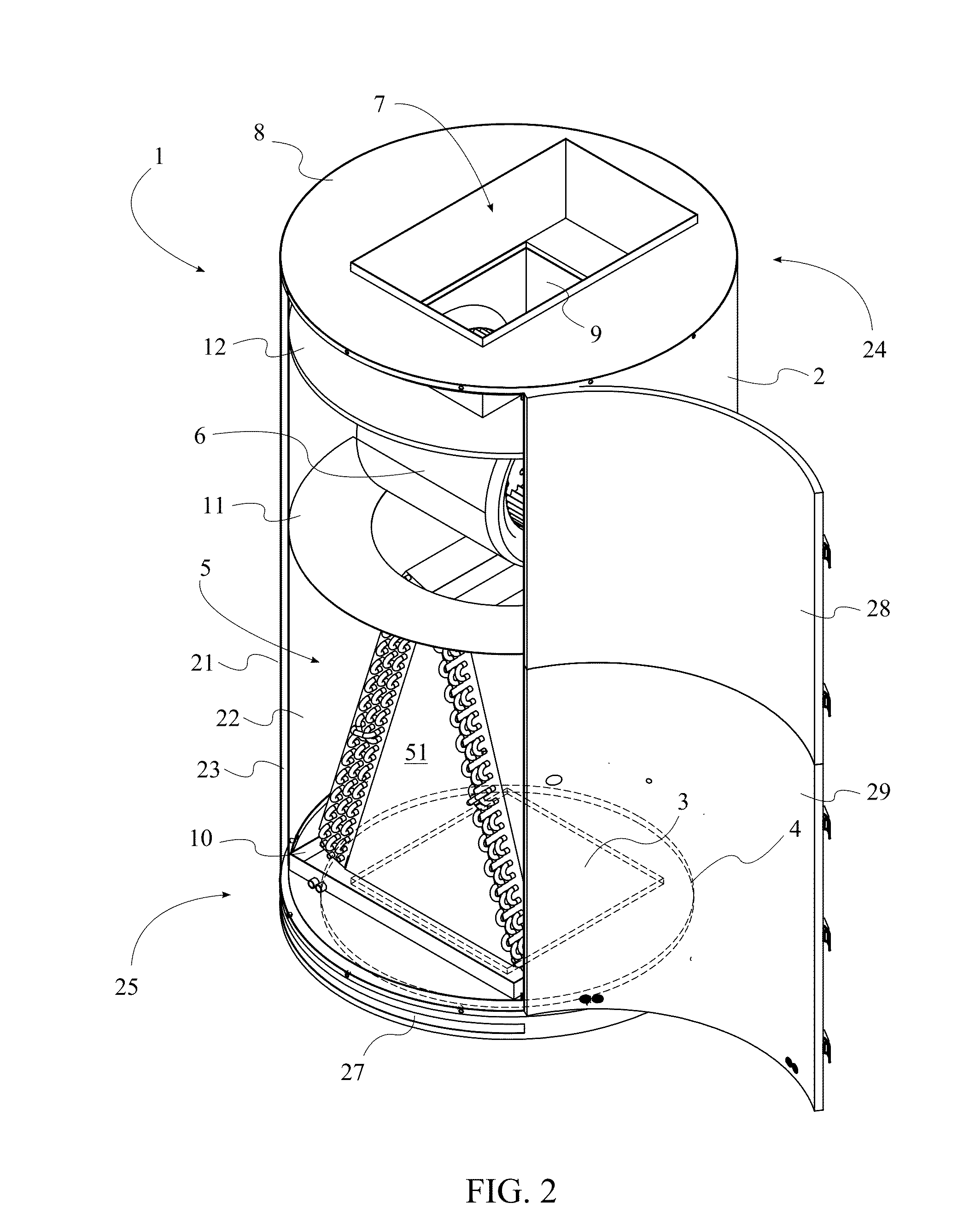

InactiveCN102691747ASimple structureGood vibration isolationNon-rotating vibration suppressionEngineeringVibration isolation

The invention discloses a magnetic levitation vibration isolation platform, relating to the technical field of a magnetic levitation vibration isolation platform. Through the invention, the shortcoming that the existing vibration isolation platform has a natural frequency is overcome. In the vibration isolation platform disclosed by the invention, a static bearing unit comprises a rotor and a stator; the primary level of a Z-direction adjustment unit is formed by coaxially connecting multiple circular coils in series sequentially along the Z direction, and the secondary level is in a bilateral structure; and an X-direction adjustment unit comprises a primary level and a secondary level. The rotors of multiple static bearing units, the secondary level of the Z-direction adjustment unit, the secondary level of the X-direction adjustment unit and the secondary level of the Y-direction adjustment unit are fixed on the bottom surface of a moving substrate; the stators of multiple static bearing units, the primary level of the Z-direction adjustment unit, the primary level of the X-direction adjustment unit and the primary level of the Y-direction adjustment unit are fixed on a fixed substrate; and the planes of the moving substrate and the fixed substrate are parallel to each other, and an air gap exists between the two. The magnetic levitation vibration isolation platform disclosed by the invention easily forms a large magnetic levitation vibration isolation platform, has simple structure and high vibration isolation precision, is easy to control and can be applied to vacuum environment.

Owner:HARBIN INST OF TECH

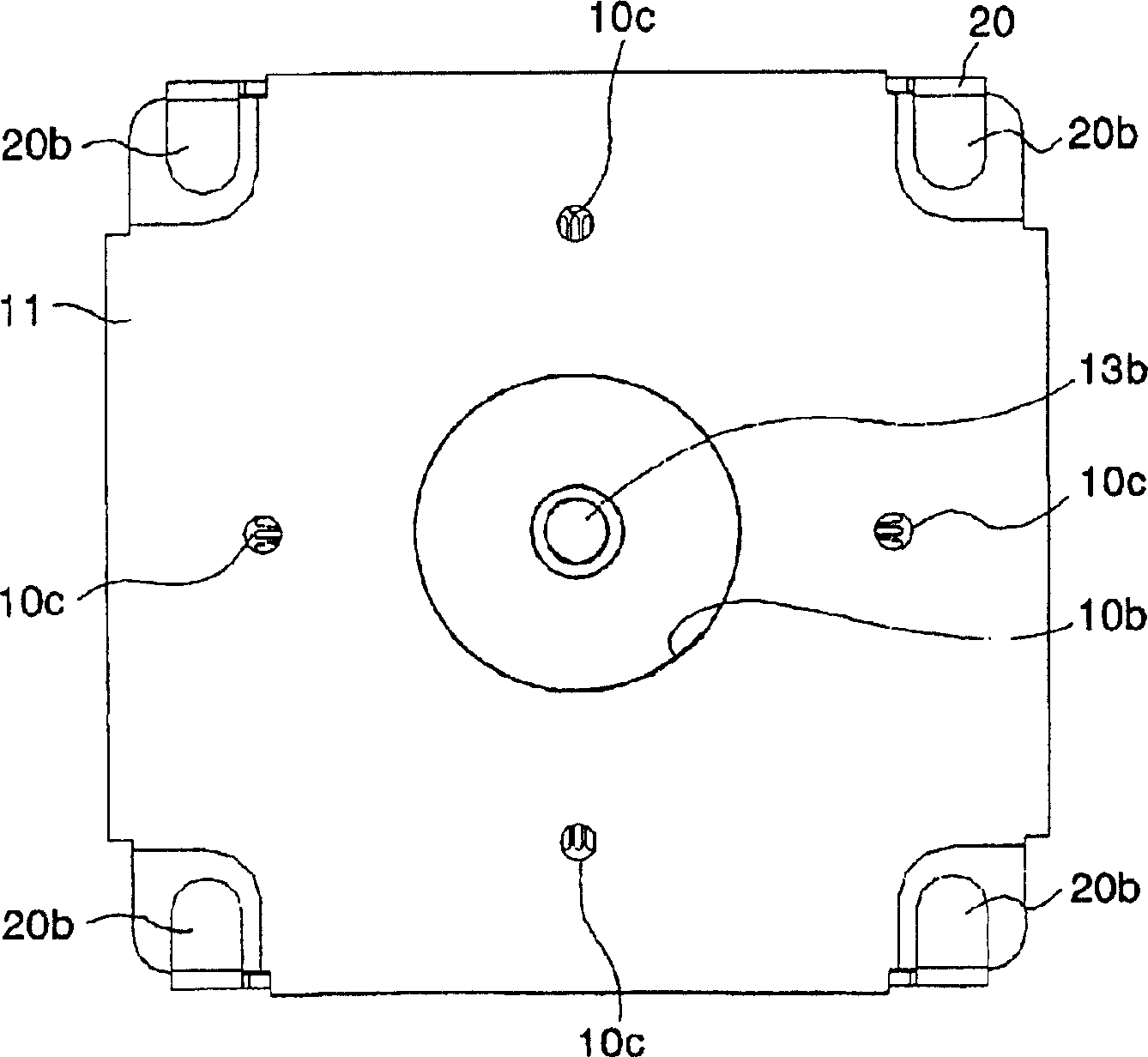

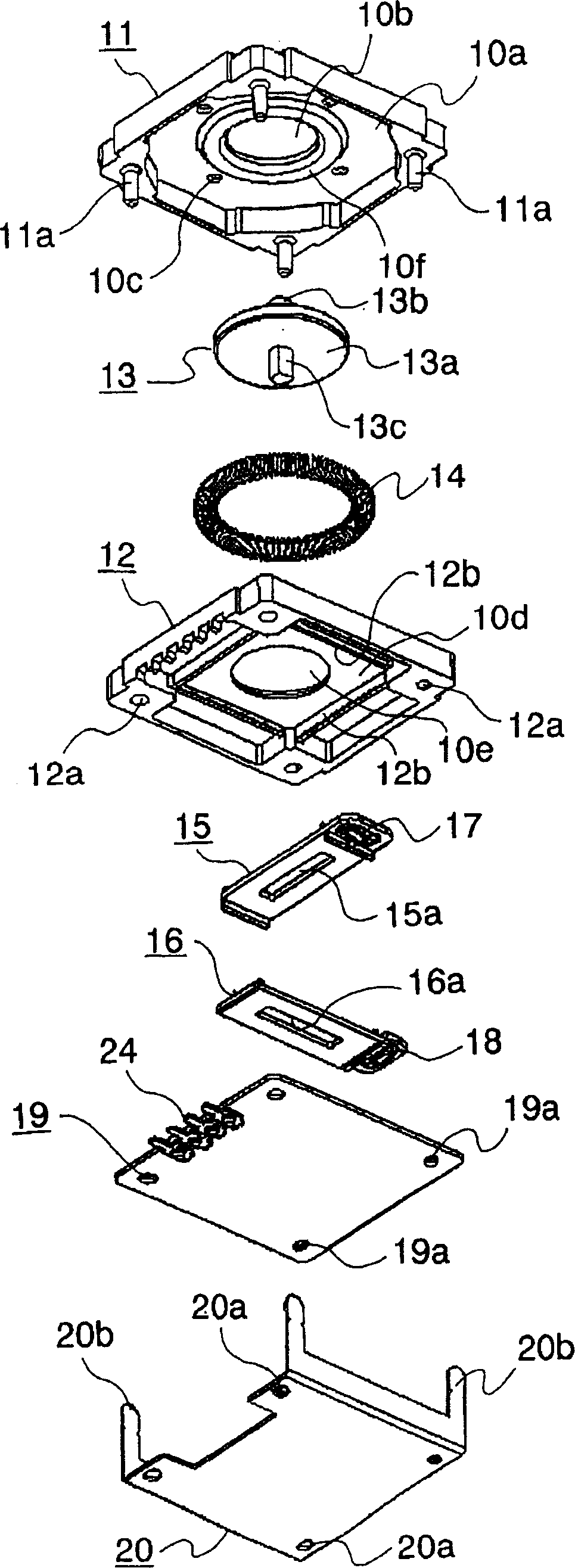

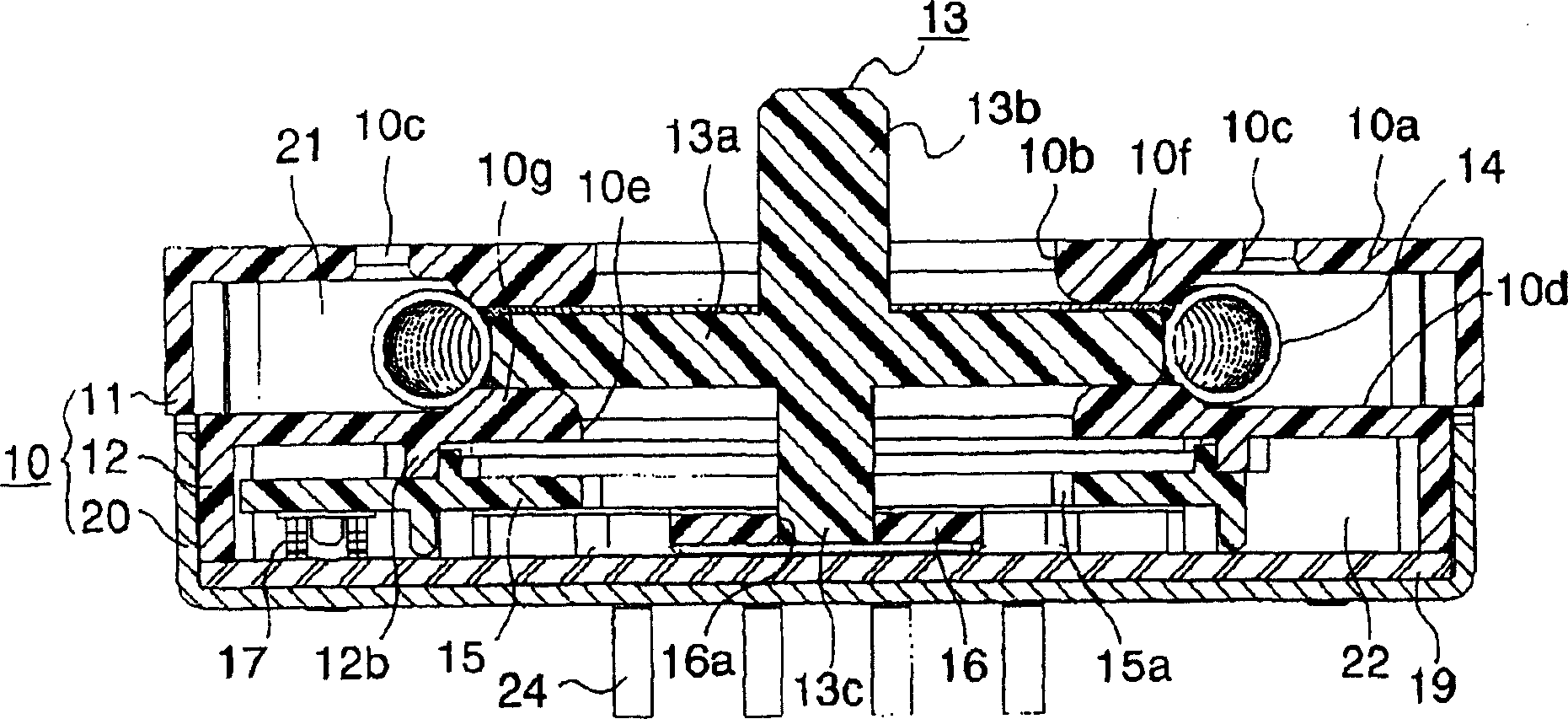

Multiway input device

The invention provides a multidirectional input device capable of automatically resetting an operating body making a slide operation, with an excellent operability and high reliability. A barrier rib 10d provided in a chassis 10 is partitioned into a first hollow part 21 and a second hollow part 22, in which former, a circular coil spring 14 for automatically resetting an operating body 13 is built in, and in which latter, a detection means including a pair of sliders 15, 16 capable of sliding in directions crossing each other is built in. The operating body 13 is provided with a large-diameter part 13a arranged at the first hollow part 21, a protruded part 13b protruded from an outside opening 10b to be given an operating force, and a driving part 13c extended to the second hollow part 22 for driving the sliders 15, 16. At slide operation, the large-diameter part 13a pushes in the circular coil spring 14 in the sliding direction to extend (elastically deform) it.

Owner:ALPS ALPINE CO LTD

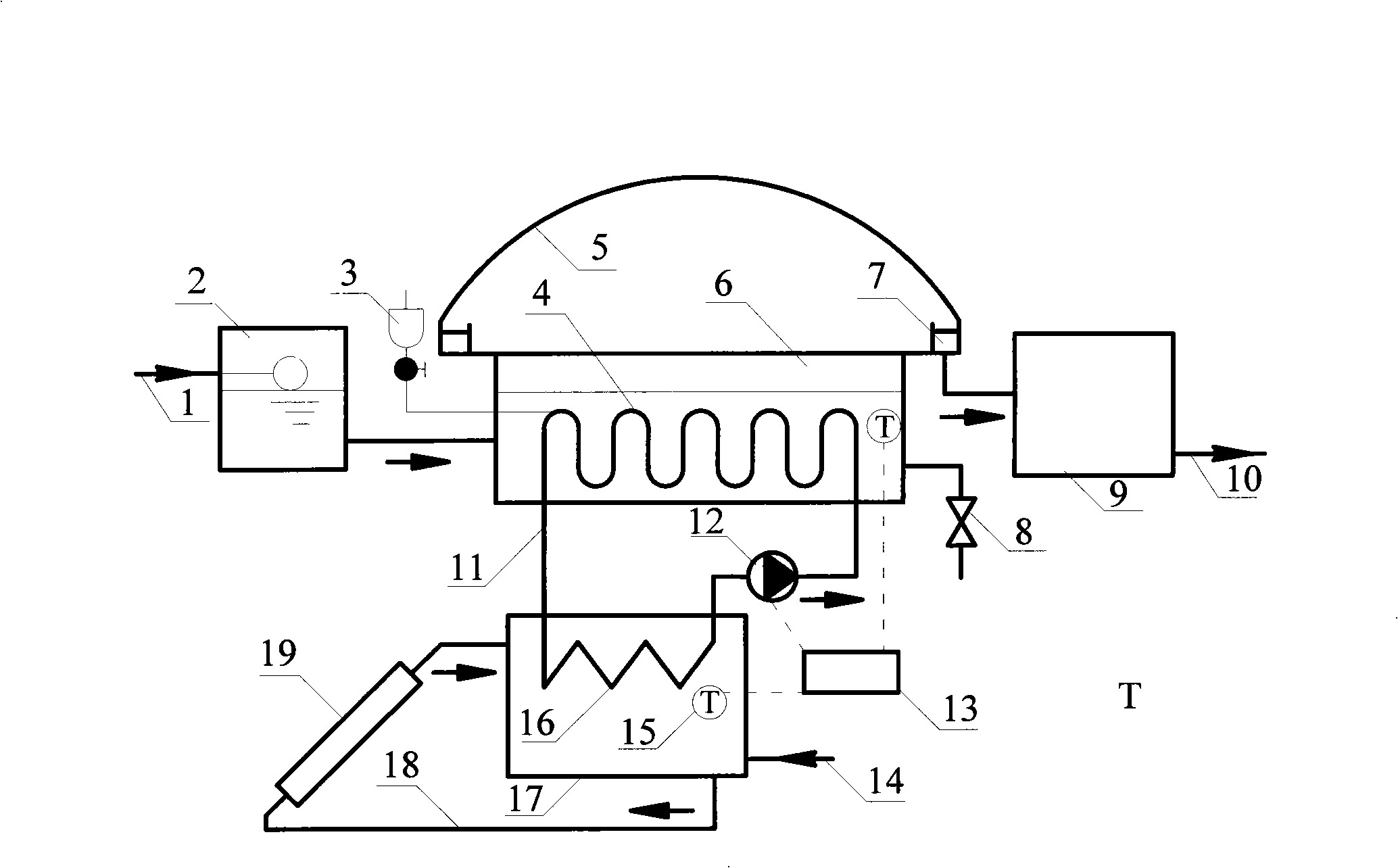

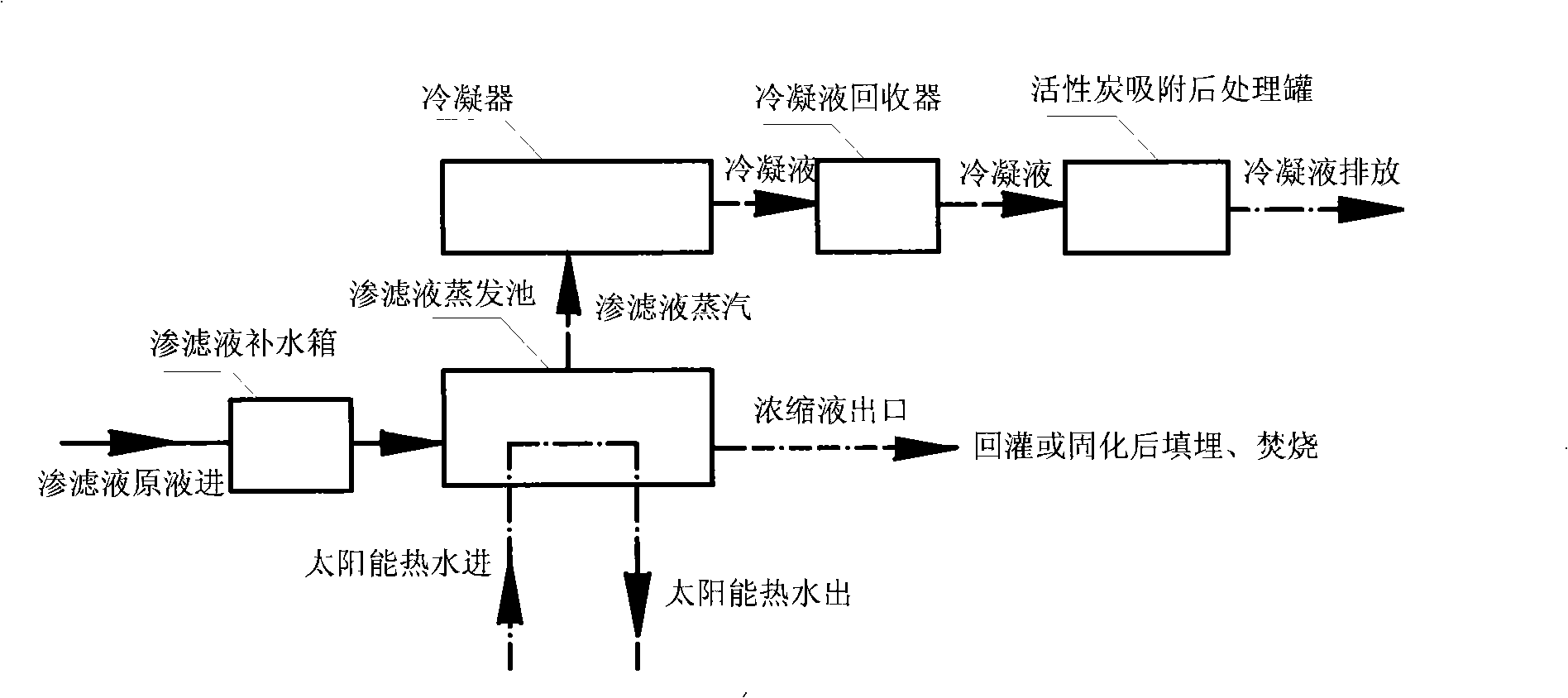

Solar heating evaporation treatment process and apparatus for garbage

InactiveCN101318751ASave conventional energyLow running costGeneral water supply conservationEnergy based wastewater treatmentWater dischargeEnvironmental engineering

The invention relates to a process and a device for treating a landfill leachate by solar energy heating and evaporation. The process comprises the following steps that: a landfill leachate in a thermal heating tank is collected by utilizing a solar thermal collector, heated, evaporated and condensed in a condenser; and a condensate is reclaimed by a condensate recoverer and enters an active carbon adsorption posttreatment tank for carrying out posttreatment. The evaporation treatment device consists of the solar thermal collector, a hot water storage tank, a water replenishing pipe of the hot water storage tank, a circular coil tube type heat exchanger, a water replenishing tank, a leachate evaporation tank, a parallel calandria type heat exchanger, a condenser, the condensate recoverer, the active carbon adsorption posttreatment tank, an effluent water discharge pipe, etc. The process and the device for treating the landfill leachate by solar energy heating and evaporation use solar energy as main energy and have the advantages of low energy consumption and low operating cost.

Owner:KUNMING UNIV OF SCI & TECH

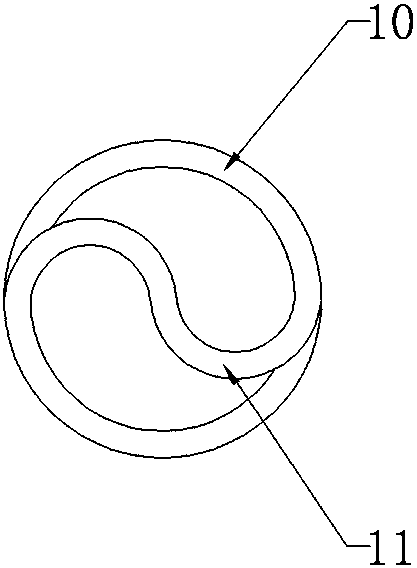

Taichi type graphene filter choke and manufacturing method thereof

InactiveCN107871594AReduce lossReduce lossesShielding materialsTransformers/inductances coils/windings/connectionsWire rodEngineering

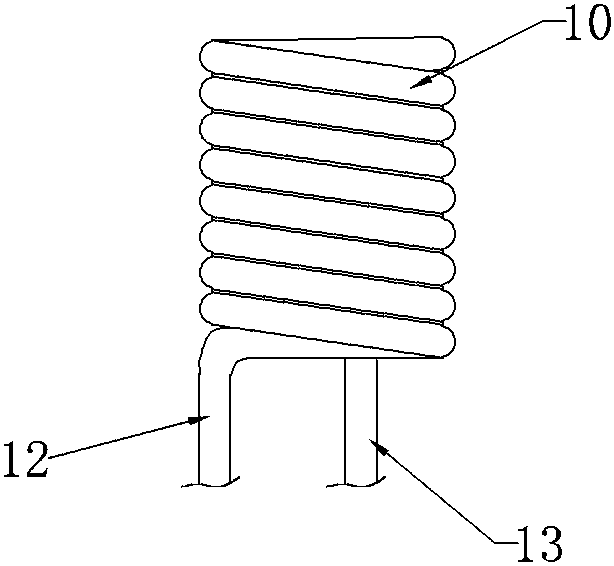

The invention discloses a Taichi type graphene filter choke and a manufacturing method thereof. The choke comprises a plurality of groups of circular coils, an S-shaped coil, a positive pin and a negative pin, wherein one end of the S-shaped coil is connected with the first group of circular coils, the other end of the S-shaped coil is connected with the second group of circular coils, the first group of circular coils is connected with the third group of circular coils, the second group of circular coils is connected with the fourth group of circular coils, successively, the M-th group of circular coils is connected with the (M+2)-th group of circular coils, the (M+1)-th group of circular coils is connected with the (M+3)-th group of circular coils, and the M is greater than or equal to 3; the (M+2)-th group of circular coils is connected with the positive pin, and the (M+3)-th group of circular coils is connected with the negative pin; the first group of circular coils to the (M+3)-th group of circular coils are the same in semidiameters, and are arranged in parallel successively to form a tubular choke structure; the choke consisting of the groups of circular coils and the S-shaped coil is formed by circling a wire rod, and the surface of the wire rod is uniformly coated with a filter layer.

Owner:洪豪立 +5

Fixture for zinc-spraying of circular coil

ActiveCN104492635AEasy to operateMeet the needs of different external zinc sprayingMagnetic/electric field screeningSpraying apparatusEngineeringMechanical engineering

The invention relates to a fixture for zinc-spraying of a circular coil and aims to provide a fixture, simple in structure, quick to mount and demount, reliable to fix and convenient to use. The fixture is characterized by comprising a circular turnplate; the middle of the turnplate is provided with a hole in which a non-spray part of the circular coil is placed in; a connecting rack which is square and has one end opened is fixed to an opening in the rear of the turnplate; the open end of the connecting rack is fixed to the turnplate; a rear plate of the connecting rack is provided with a pinhole concentric to the turnplate; the non-spray part of the circular coil is fixed to the hole through a connector; the turnplate and the connecting rack are rested on an underframe and can rotate on the same; the underframe comprises an L-shaped frame support; a fixing plate which is vertical is fixed on a horizontal part of the L-shaped frame support; two sides of the inside of the fixing plate are provided with rollers, respectively, used for resting the turnplate; a pin block is fixed to a vertical part of the L-shaped frame support; the pin block is provided with a positioning hole equal to the pinhole in center and diameter; a pin is inserted into the pinhole and the positioning hole.

Owner:JIASHAN SUNKING POWER EQUIPMENT TECHNOLOGY CO LTD

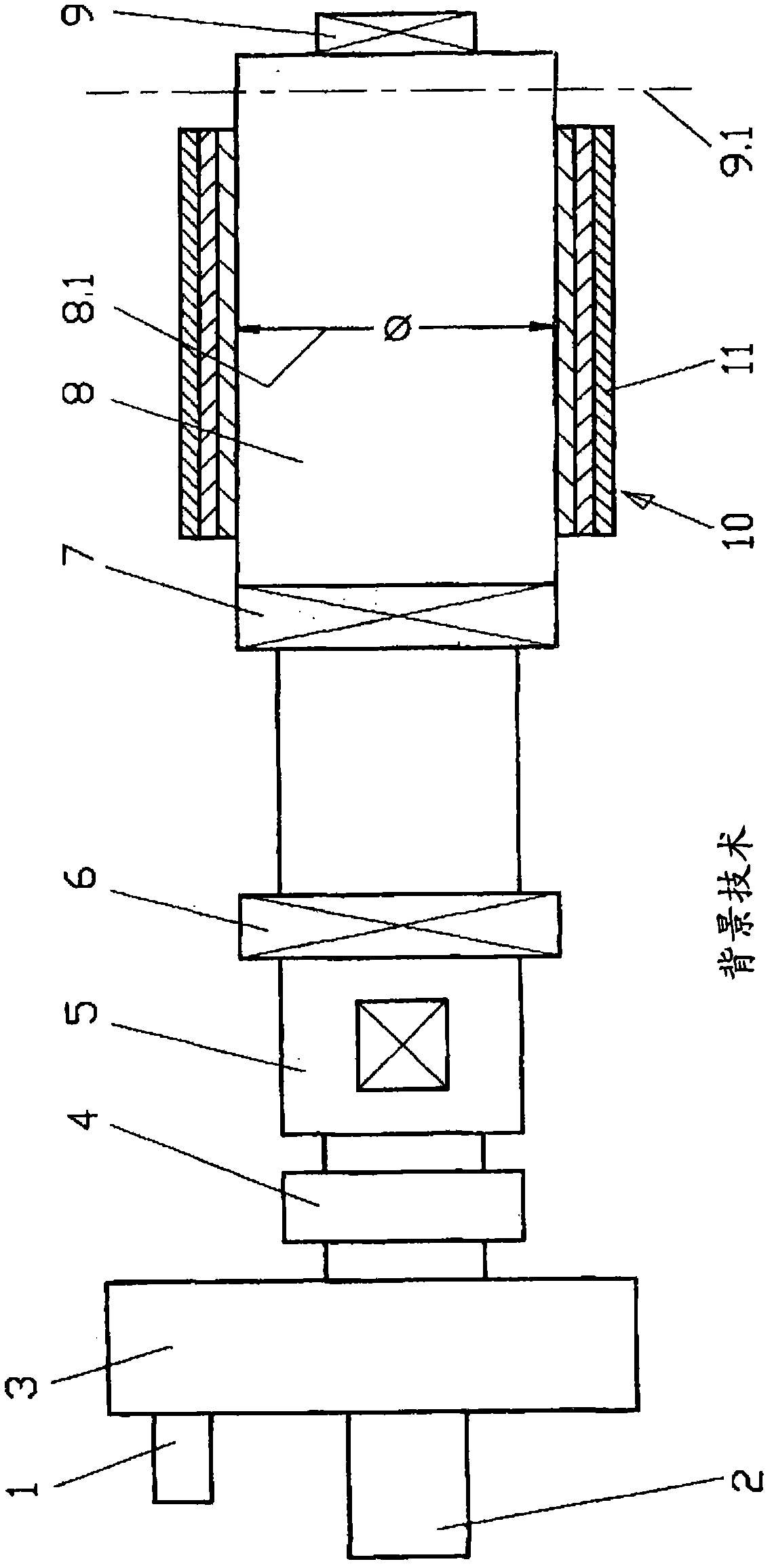

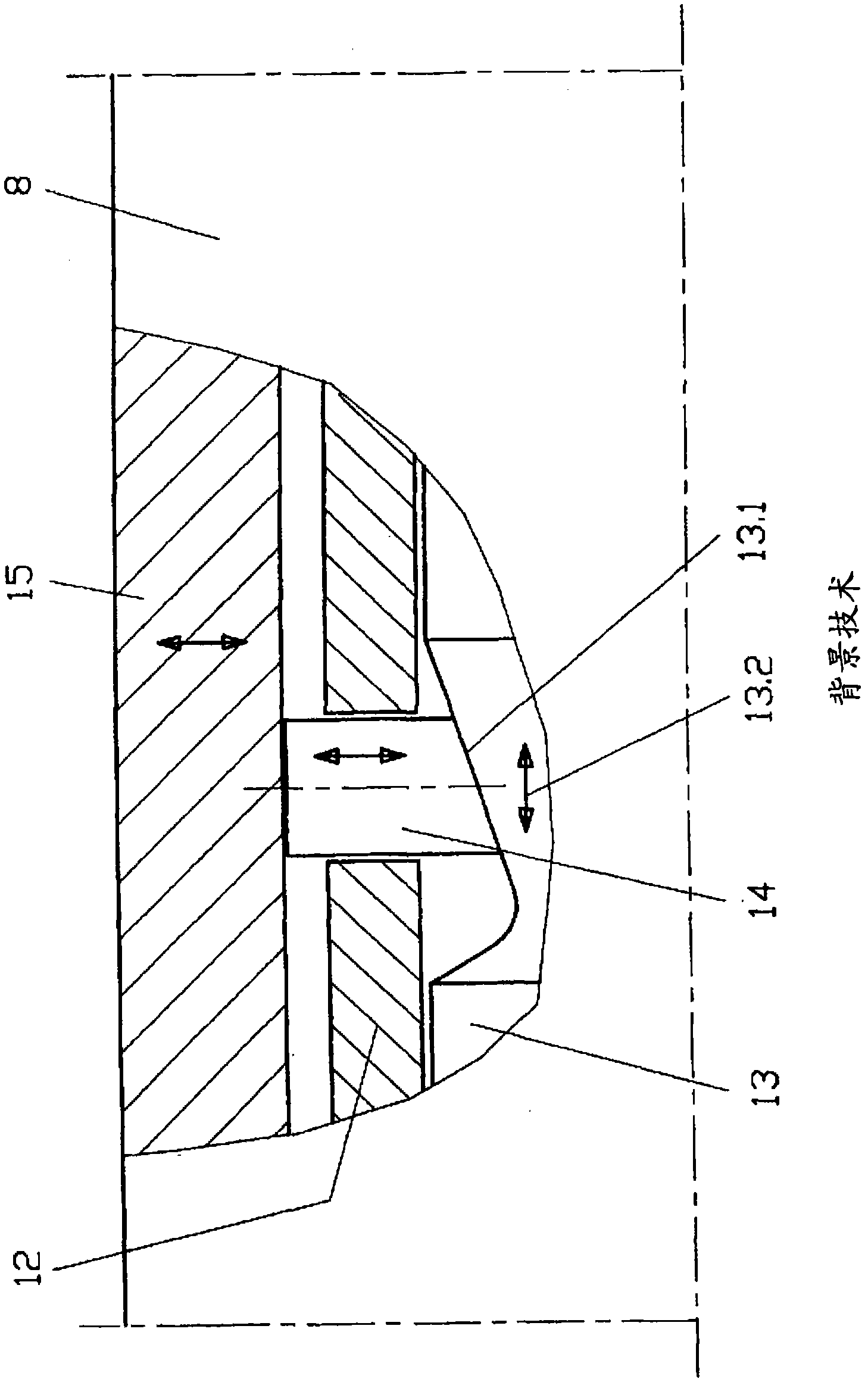

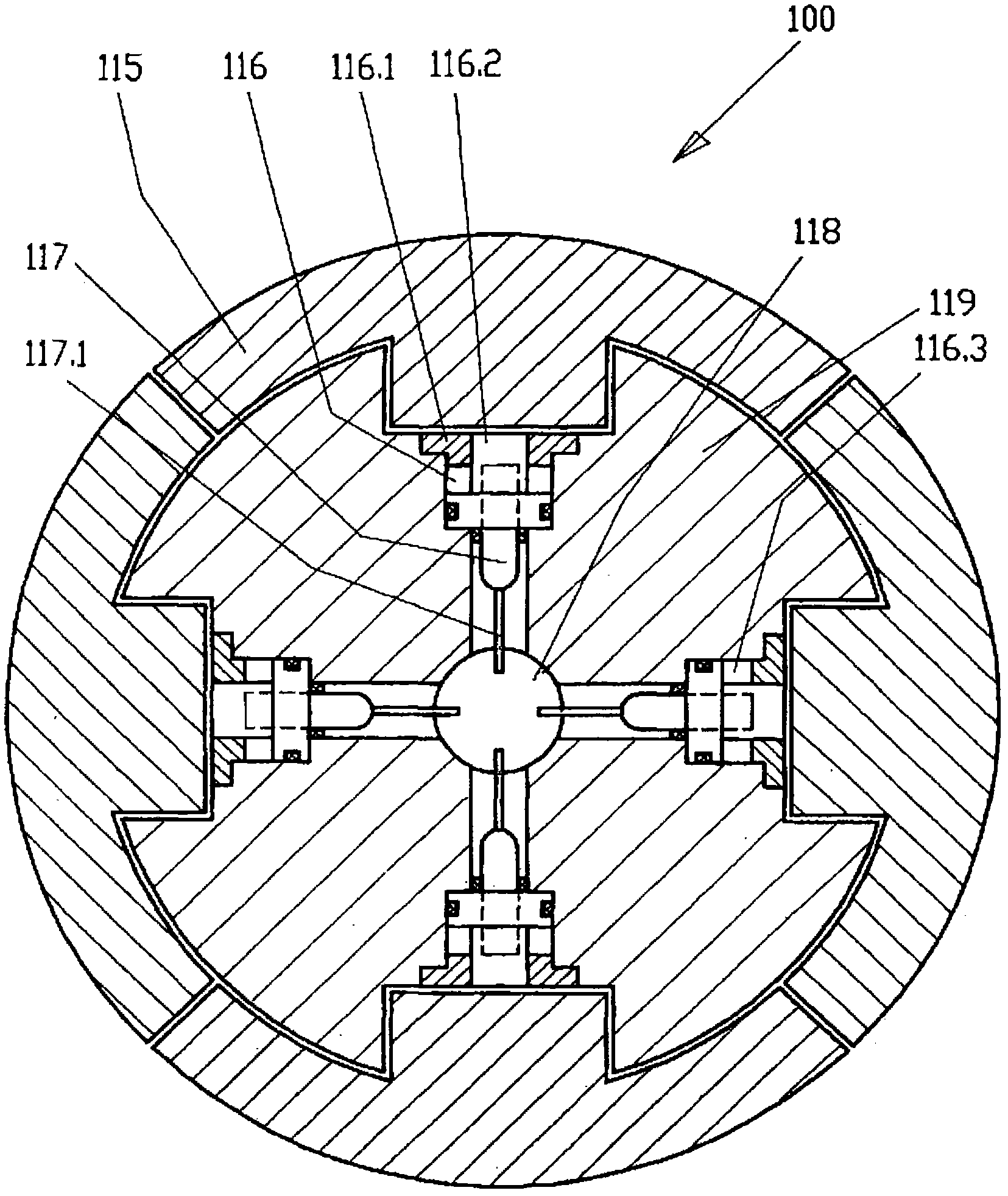

Method and device for winding metal strip material

InactiveCN102076587AAvoid damageExtend your lifeSleeve/socket jointsWebs handlingHydraulic cylinderMetal strips

The invention relates to a method and a decoiler mandrel for winding metal strip material (110), wherein the decoiler mandrel (100) comprises a mandrel body (120), a plurality of radially spreadable segments (115) being disposed about the mandrel body (120), and a plurality of hydraulic cylinders (116) through which the segments (115) are moved radially. In order to also be able to wind the metal strip material utilizing a circular coil eye when the friction is different in the individual cylinders, the invention provides that each cylinder (116) of the plurality is controlled individually.

Owner:SMS DEMAG AG

High-speed pre-inspection system

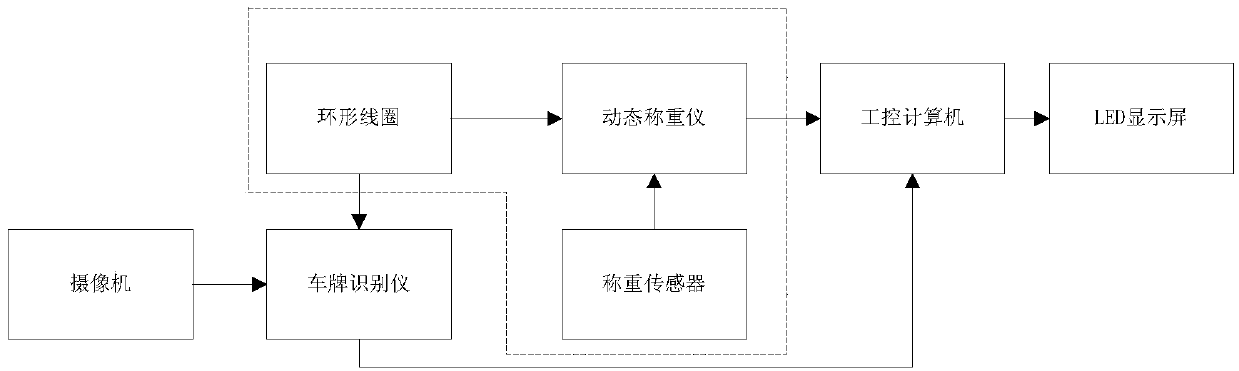

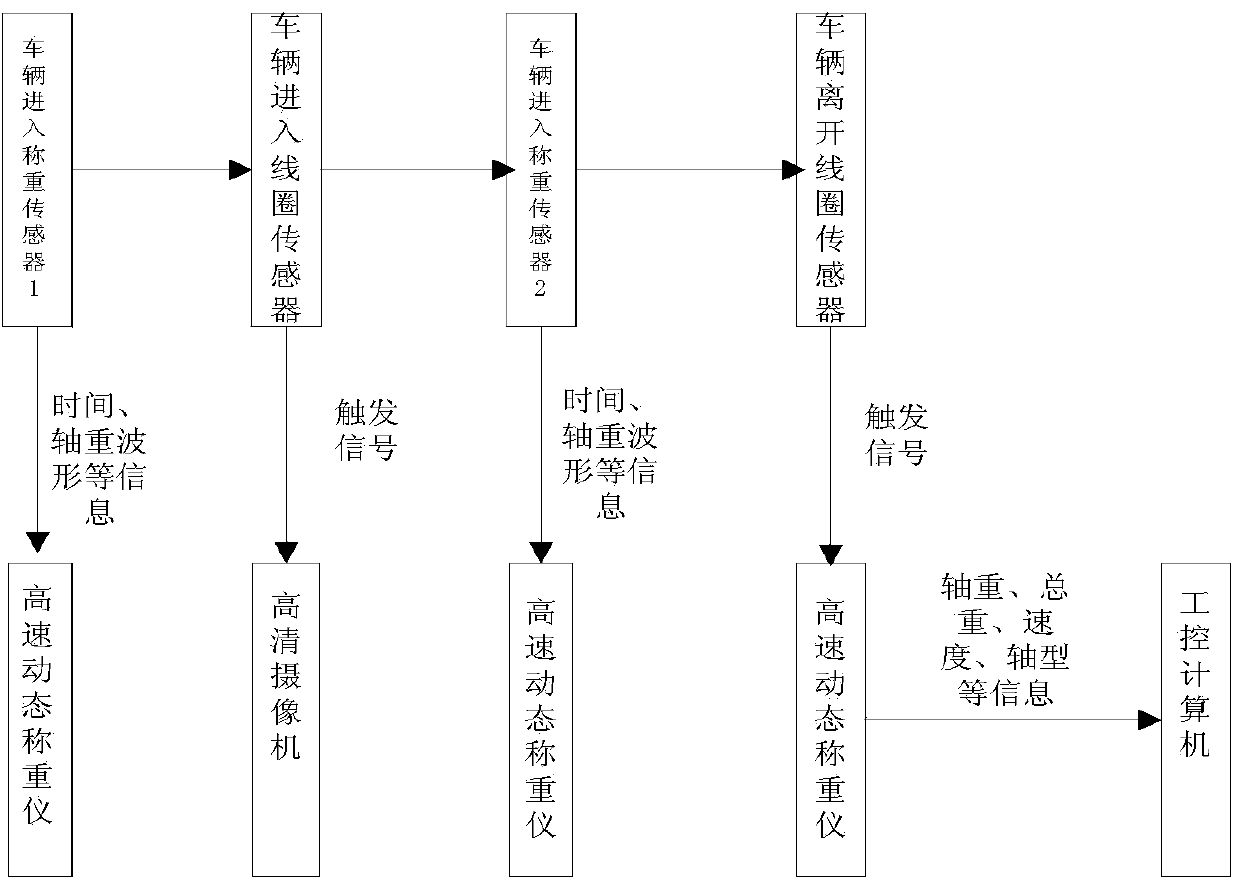

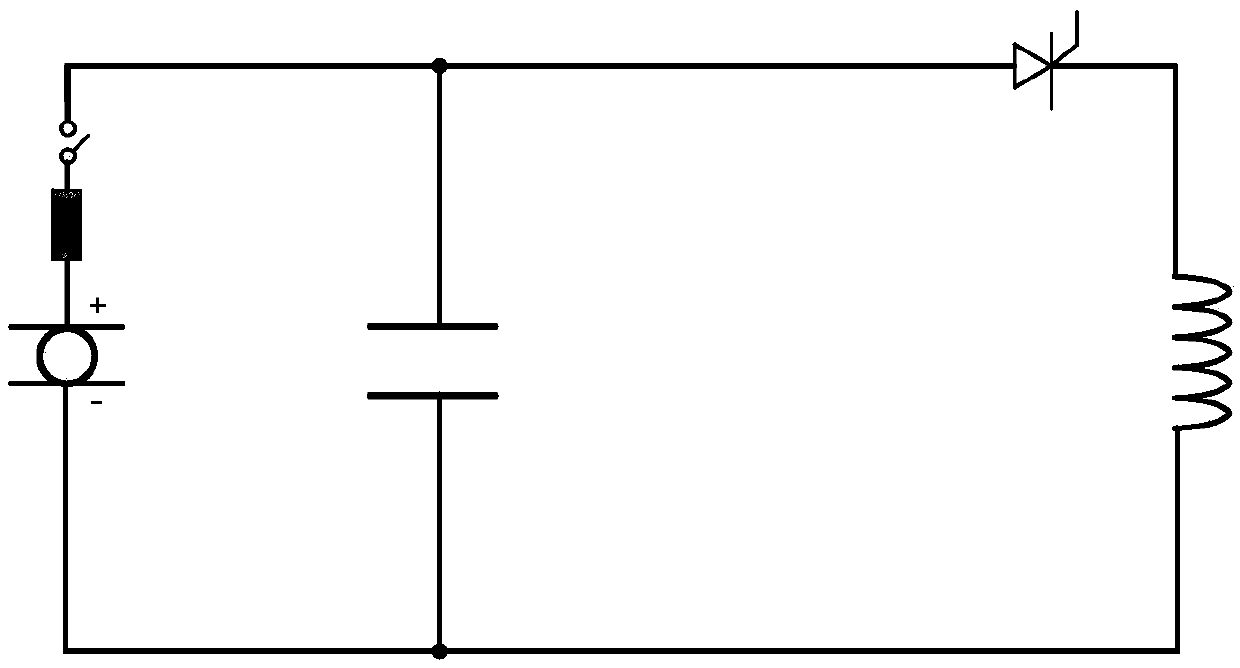

InactiveCN104200663ACalculation speedQuickly Calculate Gross WeightDetection of traffic movementLED displayRoad surface

The invention discloses a high-speed pre-inspection system comprising a high-speed dynamic weighing system, a camera, a license plate recognizer, an LED variable information board and an industrial personal computer. The high-speed dynamic weighing system is connected with the license plate recognizer and the industrial personal computer. The camera is connected with the license plate recognizer which is connected with the industrial personal computer. The industrial personal computer is connected with a LED display screen. The high-speed dynamic weighing system comprises a weighing sensor, a circular coil and a dynamic weigher; the circular coil is connected with the dynamic weigher and the license plate recognizer; the weighing sensor is connected with the dynamic weigher; the dynamic weigher is connected with the industrial personal computer. The high-speed pre-inspection system has the advantages that calculation speed is high, test precision is high, installation time is short and small damage is caused to the road surface.

Owner:重庆市华驰交通科技有限公司

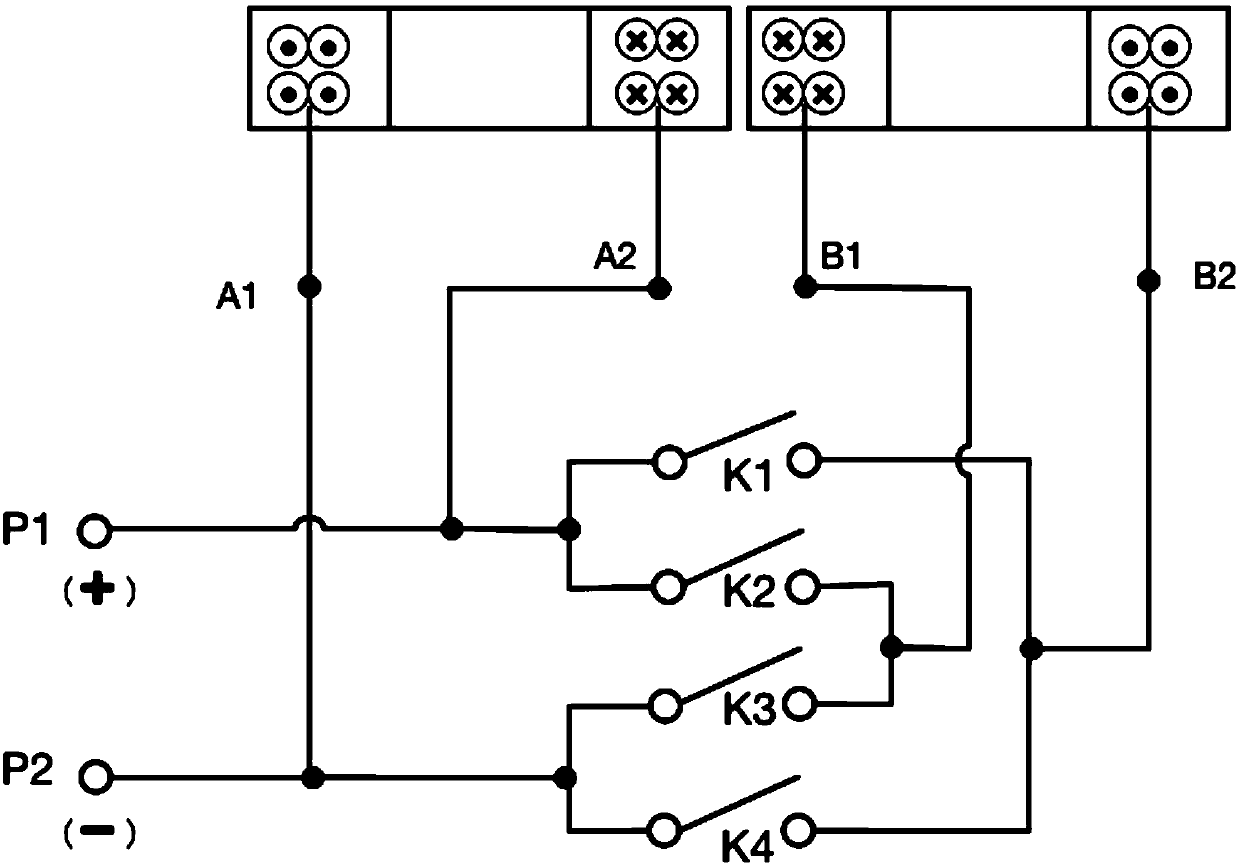

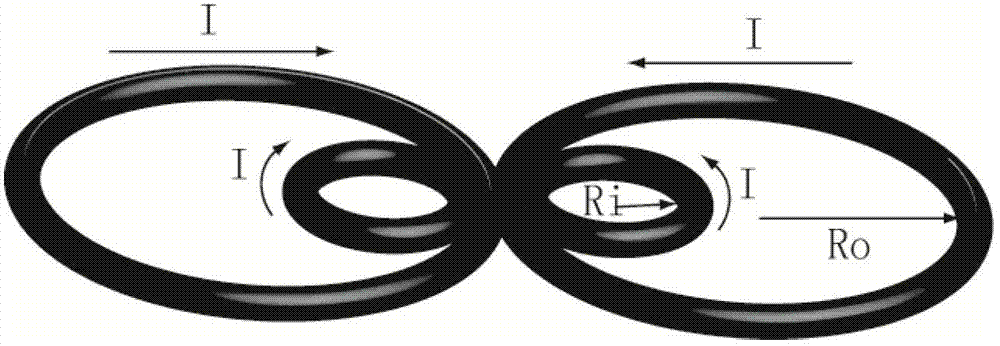

8-shaped coil for transcranial magnetic stimulation contrast experiment and configuration management method of coil

PendingCN109621210AAchieve stimulationDouble-blind effectElectrotherapyMagnetotherapy using coils/electromagnetsPower flowComputer module

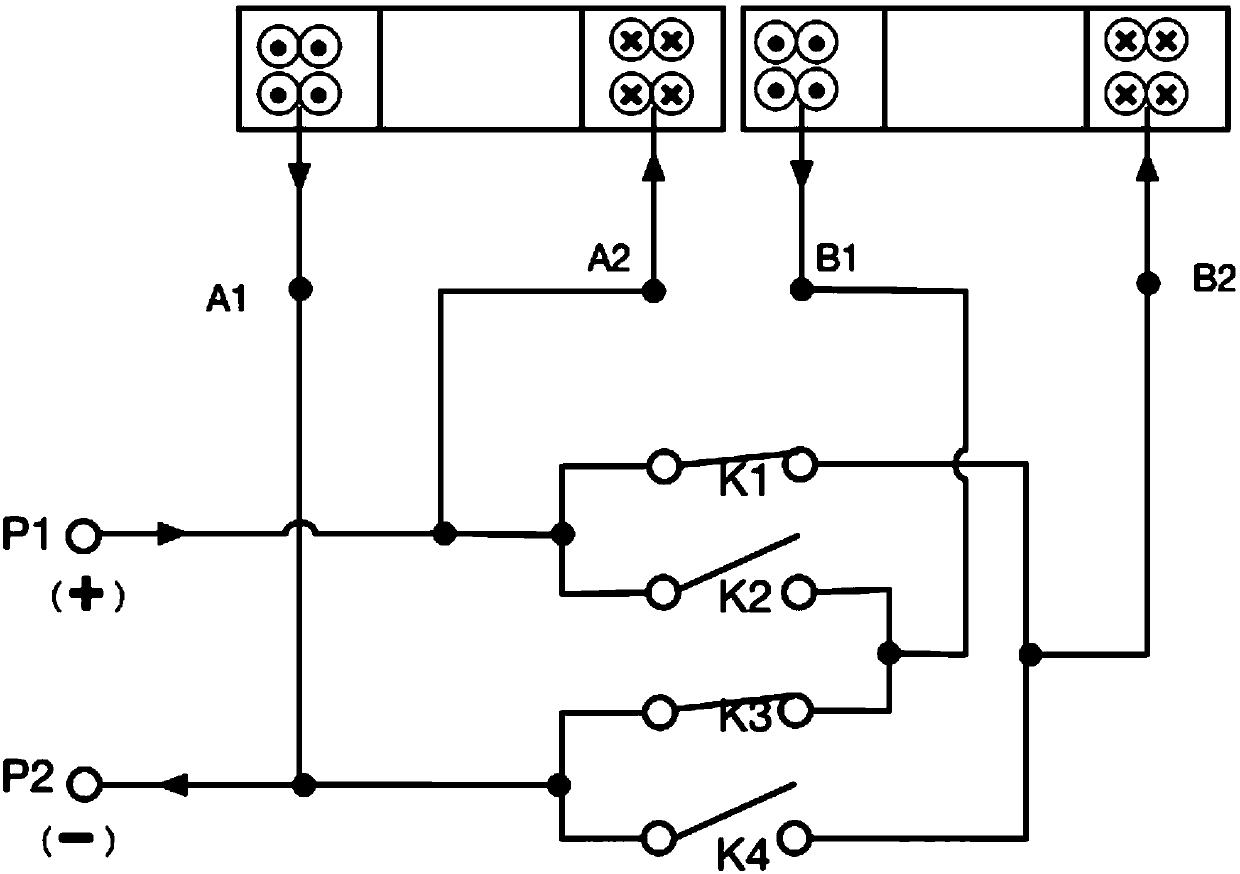

The invention provides an 8-shaped coil for a transcranial magnetic stimulation contrast experiment. The coil comprises a first circular coil body and a second circular coil body, the first circular coil body is wound anticlockwise, the input end is A2, and the output end is A1; the second circular coil is wound clockwise, the input end is B1, and the output end is B2; the input ends and the output ends of the two circular coils are connected and combined through four single switches K1, K2, K3 and K4 to form different configuration states that the current directions at the intersections of the two circular coil bodies are the same or opposite; the on-off states of the single switches K1, K2, K3 and K4 are controlled through a control module. The invention further provides a configurationmanagement method of the 8-shaped coil. The 8-shaped coil is configured by controlling the on-off states of the single switches K1, K2, K3 and K4, and normal stimulation or pseudo-stimulation is freely realized. When the contrast experiment is carried out, a double-blind effect can be achieved on an operator and an experimenter.

Owner:宋锦

Molten steel flow-speed measurement method and device based on electromagnetic tomography

InactiveCN101566639AImprove cleanlinessImprove qualityFluid speed measurementMeasurement deviceLiquid state

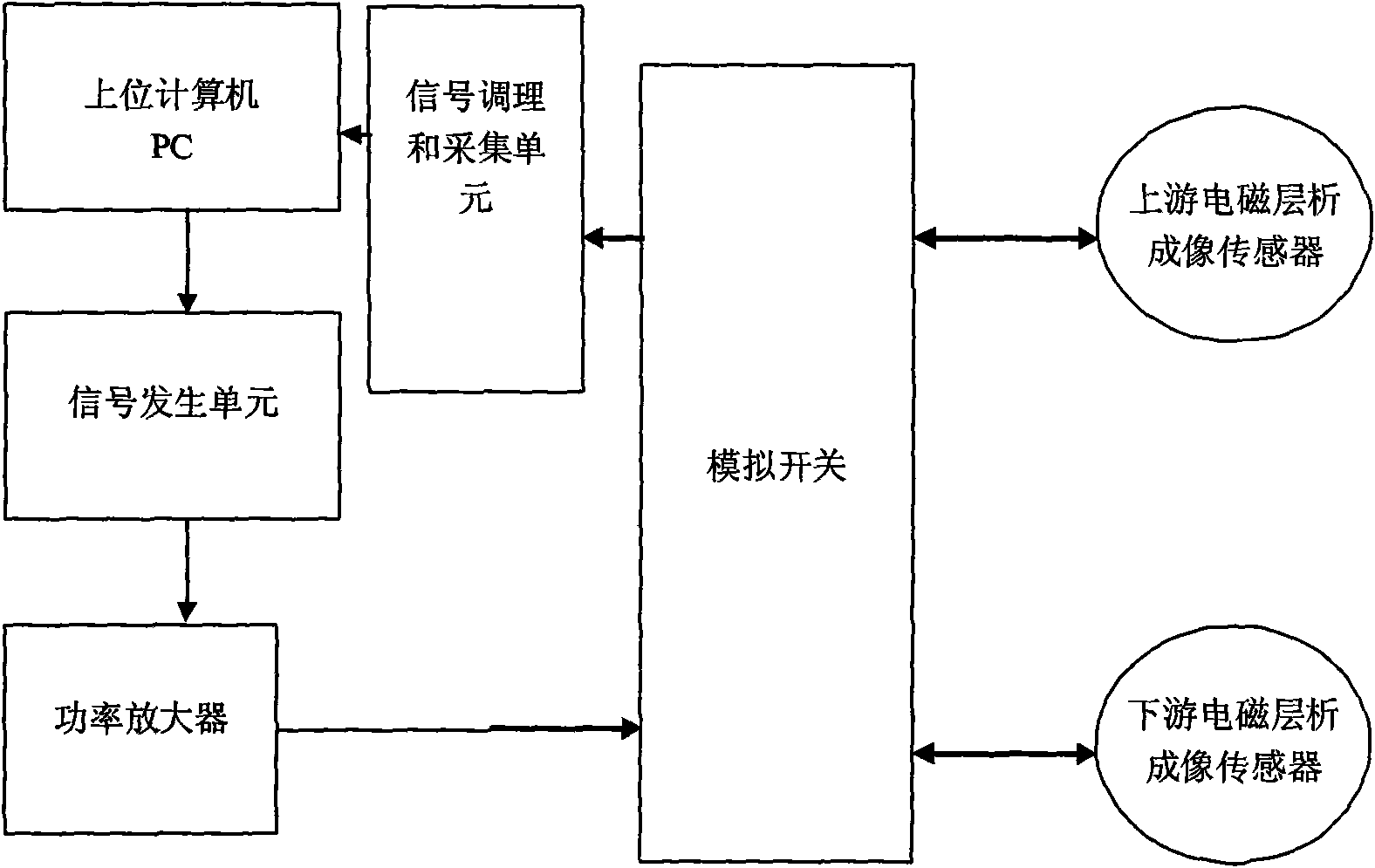

The invention belongs to the technical field of fluid flow-speed detection and relates to a molten steel flow-speed measurement device based on electromagnetic tomography. The measurement device comprises an upstream sensor and a downstream sensor, a signal conditioning and collecting unit, a power amplifier and an upper computer. The upstream sensor and the downstream sensor are respectively composed of circular coil arrays. For each sensor, a coil is gated as an exciting coil sequentially, other coils are taken as receiving coils, an exciting signal is exerted on the exciting coil and induced signals of all the receiving coils are collected. The upper computer conducts image reconstruction respectively according to the upstream measurement data and downstream measurement data to obtain the respective electrical conductivity distribution image, and then conducts cross-correlation computation on two electrical conductivity distribution images based on pixel, thus obtaining the flow-speed distribution of molten steel. The invention provides a measurement method used for the device simultaneously. Under a non-contact situation, the device and the method can acquire the flow state of high temperature molten steel and has great realistic significance to the optimization of steel making process.

Owner:TIANJIN UNIV

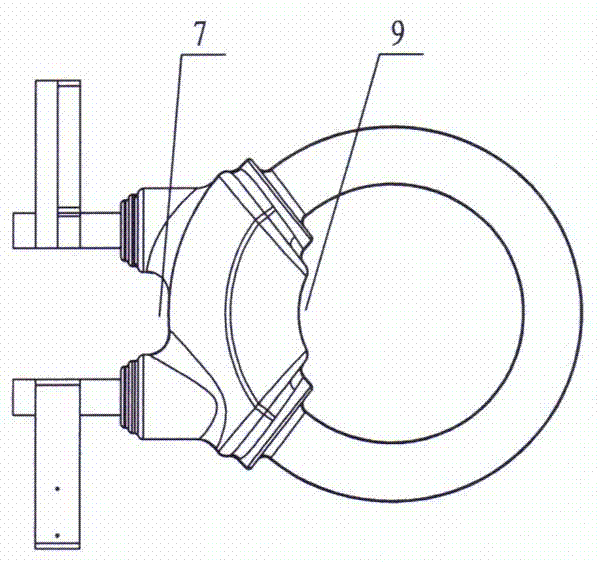

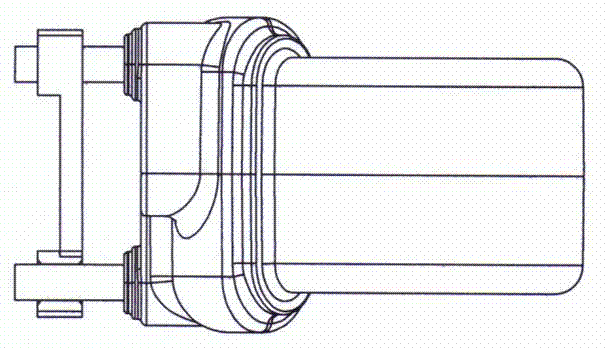

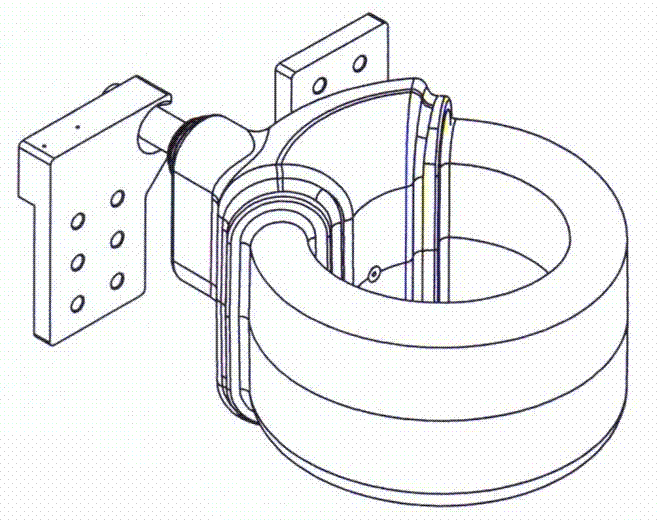

Rotary microporous aeration circular coil system for treating sewage

ActiveCN102674533ARealize high-efficiency and low-consumption operationDissolved oxygen is quickly and evenly distributed laterallyTreatment using aerobic processesSustainable biological treatmentSewageOxygen

The invention relates to a rotary microporous aeration circular coil system for treating sewage, belonging to the field of microporous aeration pipe equipment for treating the sewage. The rotary microporous aeration circular coil system is characterized in that: each microporous concentric circular coil group consists of a vertical rotating main pipe and a horizontal microporous concentric coil, wherein the horizontal microporous concentric coil is an integral coil which is formed by connecting a plurality of microporous concentric circular pipes from the inside out with microporous communicating pipes which are radially and uniformly arranged between the adjacent inner circular pipes and outer circular pipes at intervals; the central inner circular pipes of the coil are communicated with the vertical rotating main pipe through the microporous communicating pipes which are radially arranged at intervals; a plurality of microporous concentric circular coil groups are arranged intervals; and the upper ends of the rotating main pipes in all groups are connected with rotation drivers and control mechanisms respectively, and the lower ends of the rotating main pipes are communicated with gas transmission branch pipes respectively to form the rotary microporous aeration circular coil system. The rotary microporous aeration circular coil system greatly improves the aeration efficiency, ensures that oxygen dissolved in water bodies in a whole aeration tank is more uniformly distributed, reduces the operating cost of the aerobic process, and realizes the high-efficient and low-energy consumption operation of the aeration tank.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

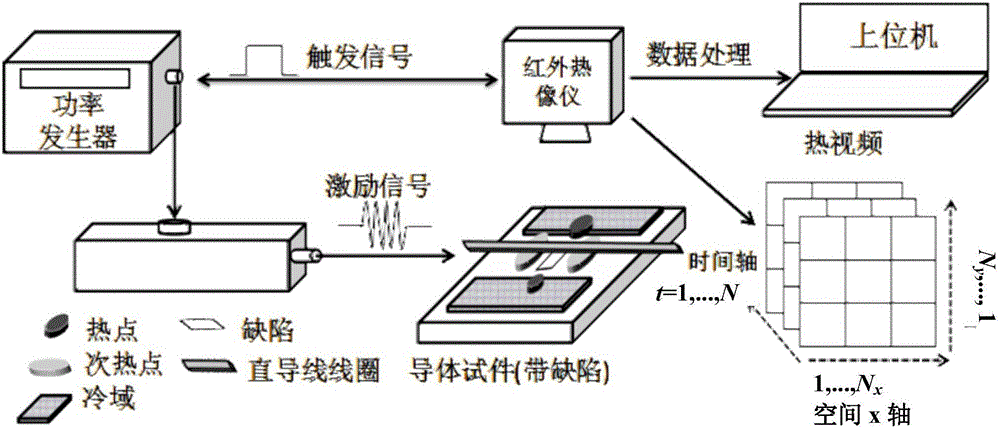

Inductive thermal image nondestructive testing device based on commensal type magnet yoke coil

ActiveCN105823797AHeating evenlyIncrease temperature contrastMaterial flaws investigationElectrical conductorRelative permeability

The invention discloses an inductive thermal image nondestructive testing device based on a commensal type magnet yoke coil.On the basis of the prior art, a coil generating an alternating magnetic field is improved, and in other words, the brand-new commensal type magnet yoke coil is adopted to replace a traditional straight wire coil, a rectangular coil and a circular coil to generate the alternating magnetic field.Due to the fact that the relative permeability of a magnet yoke is much higher than that of air, the magnet yoke can efficiently 'collect' a magnetic field excited by an exciting coil in a space and 'inject' the magnetic field into a conductor test piece.In other words, by means of the commensal type magnet yoke coil, a magnetic field higher in intensity can be excited in the conductor test piece through the alternating magnetic field excited by the exciting coil more efficiently, furthermore a vortex filed which is larger in area and uniform is generated to heat the conductor test piece, the temperature contrast ratio of a defective area and a non-defective area in a heat map is effectively raised, and the purpose of improving the efficiency of detecting defects is finally achieved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

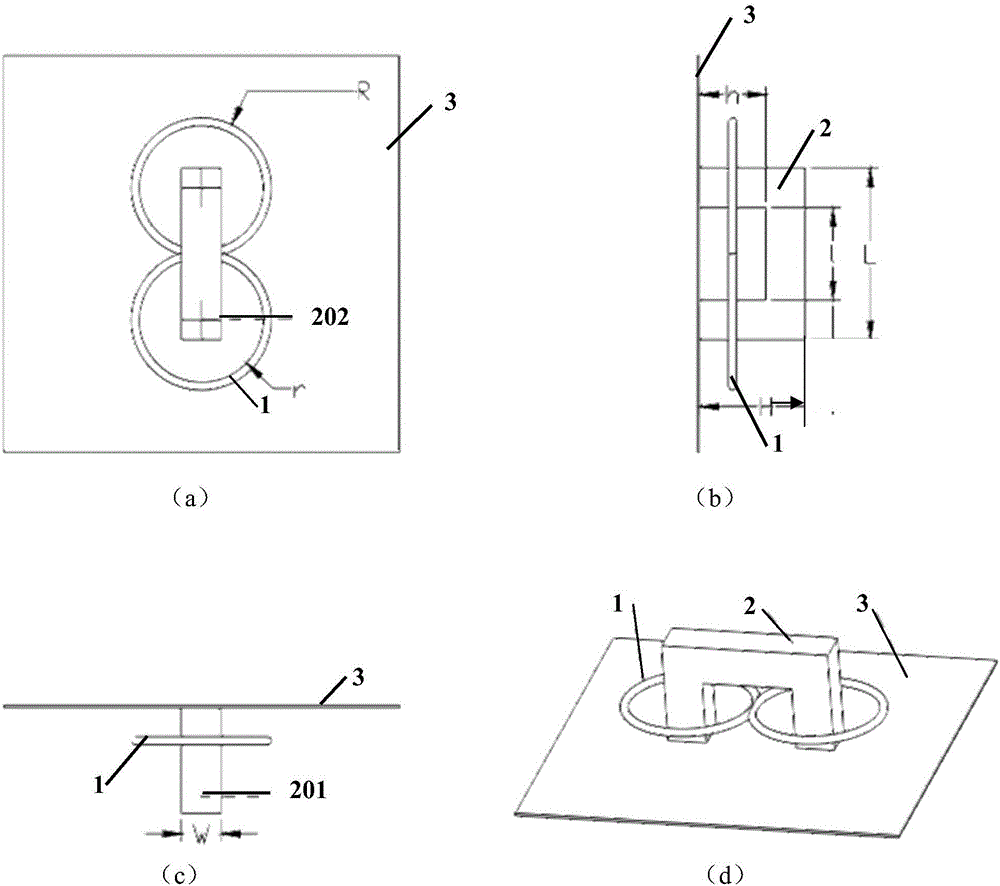

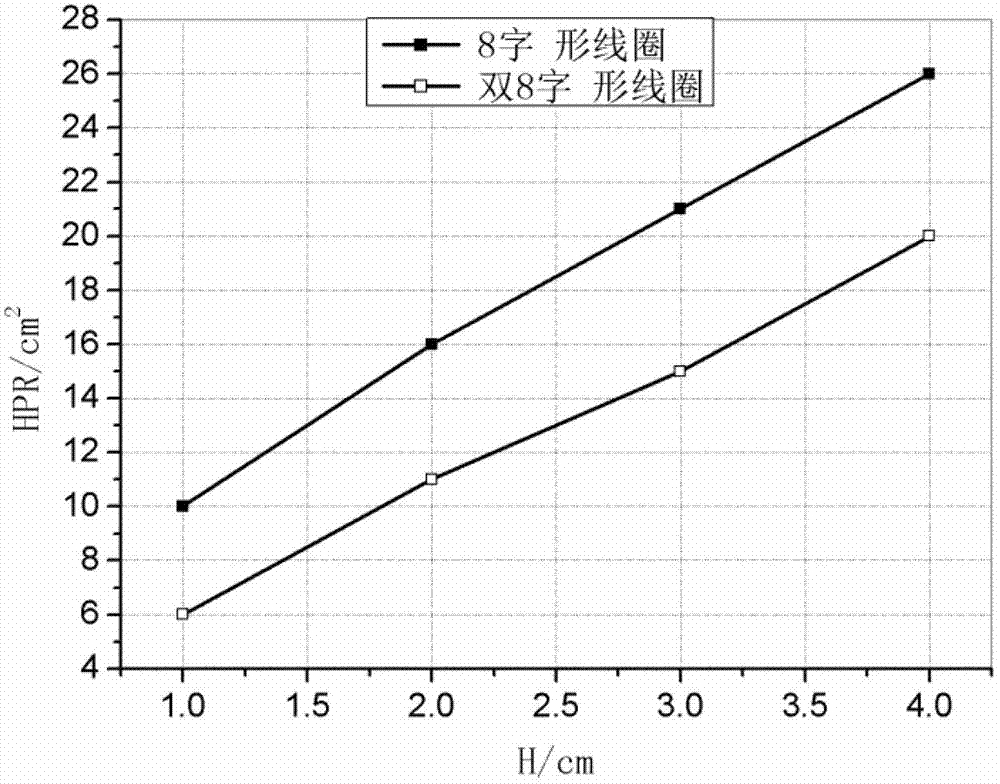

Double butterfly transcranial magnetic stimulation coil

InactiveCN102727997AFocusLess likely to be irritatedElectrotherapyMagnetotherapyElectrical conductorOuter coil

The invention relates to a double butterfly transcranial magnetic stimulation coil. The coil is formed by connecting a first butterfly coil and a second butterfly coil; the center of the first butterfly coil is coincided with the center of the second butterfly coil in space; two circular coils, of which the radii are Ri, of the second butterfly coil are positioned in two circular coils, of which the radii are Ro, of the corresponding first butterfly coil; and the Ro is greater than the Ri. According to the double butterfly transcranial magnetic stimulation coil, the two circular coils of which the radii are small are arranged inside the traditional butterfly coil, the spatial position of a conductor, and the radii of inner and outer coils and number of turns of the inner and outer coils are set, so that focusing degree of coil stimulation is improved; and the double butterfly transcranial magnetic stimulation coil is concentrated in stimulation range and high in pertinence, and the possibility of stimulating unrelated nervous tissues is obviously reduced.

Owner:XI AN JIAOTONG UNIV

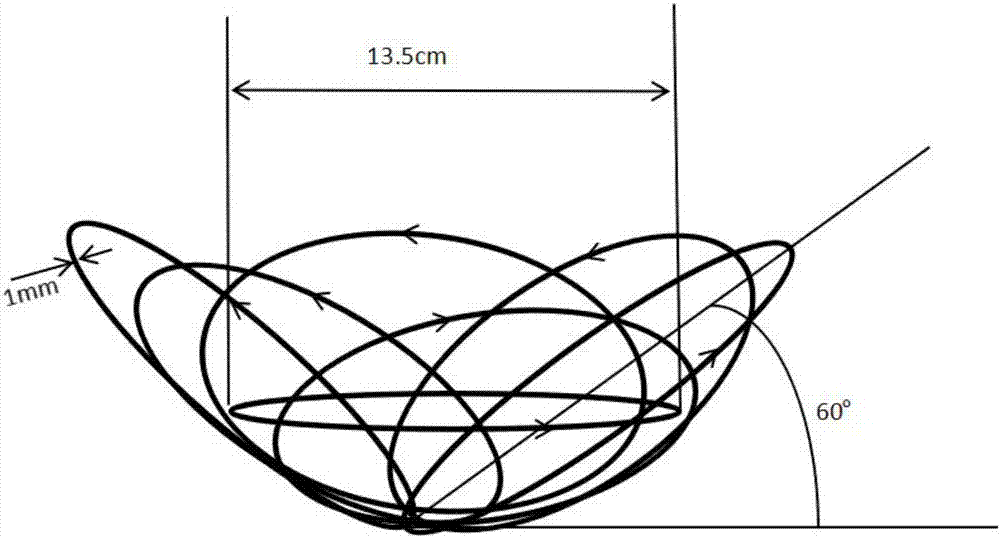

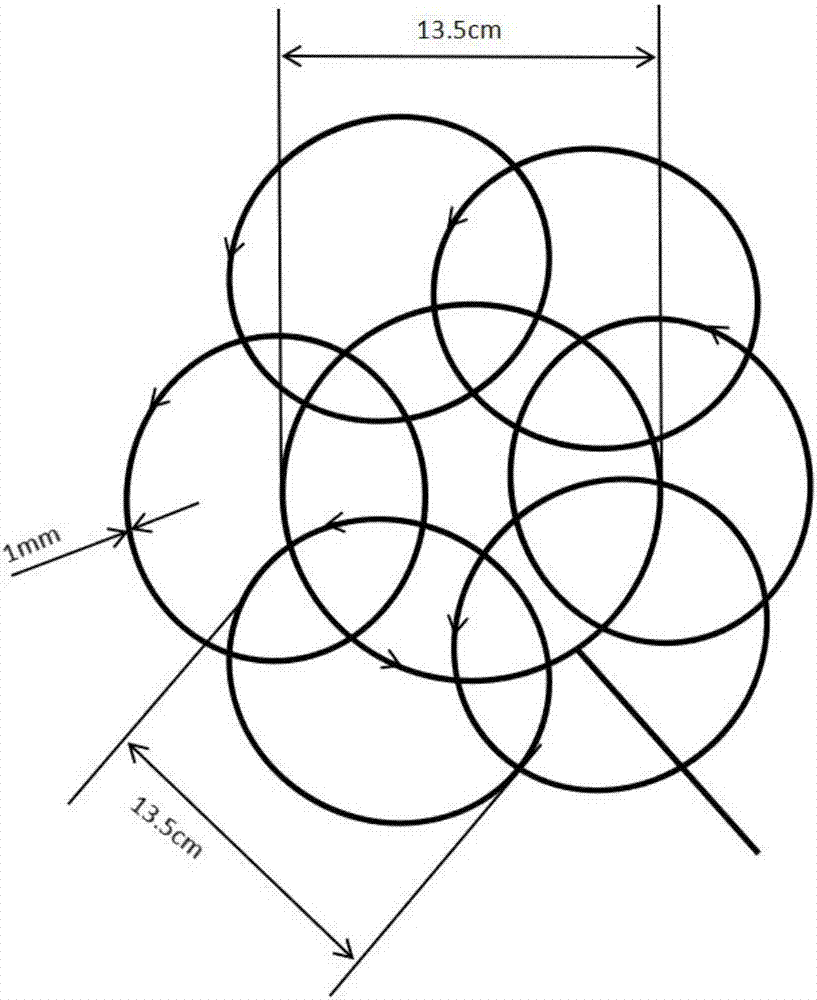

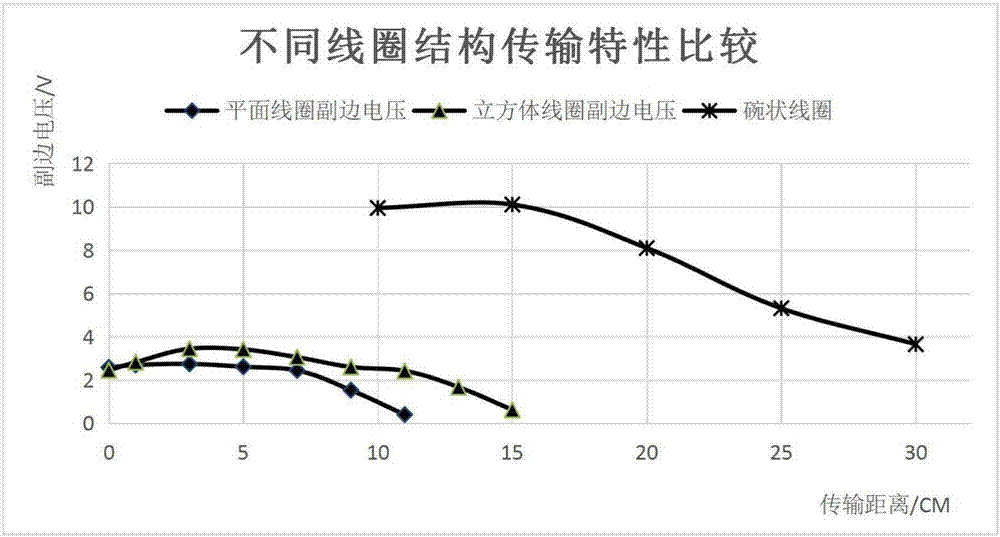

Magnetic coupling resonant-type wireless power transmitting bowl-shaped primary coil

InactiveCN107276249AImprove experienceImprove featuresBatteries circuit arrangementsTransformersConductor CoilInductive charging

The invention discloses a magnetic coupling resonant-type wireless power transmitting bowl-shaped primary coil. Seven identical planar circular coil groups are in lap winding to form a bowl-shaped three-dimensional structure; the seven identical planar circular coil groups are in mutual serial connection; each planar circular coil group is in clockwise winding, and after winding, directions of magnetic induction lines formed by coil current all face the same side. According to the bowl-shaped coil, in a condition of a long transmission distance of a charging platform, the voltage transmission characteristics and the distance transmission characteristics are greatly improved; while a bowl-shaped transmitting coil keeps various advantages of wireless charging, improvement of the voltage transmission characteristics and the distance transmission characteristics provides better user experience for actual application of later small-power wireless charging; and through actual measurement, the voltage transmission characteristics and the distance transmission characteristics of the 3D bowl-shaped coil are obviously better than existing other schemes.

Owner:ZHEJIANG UNIV

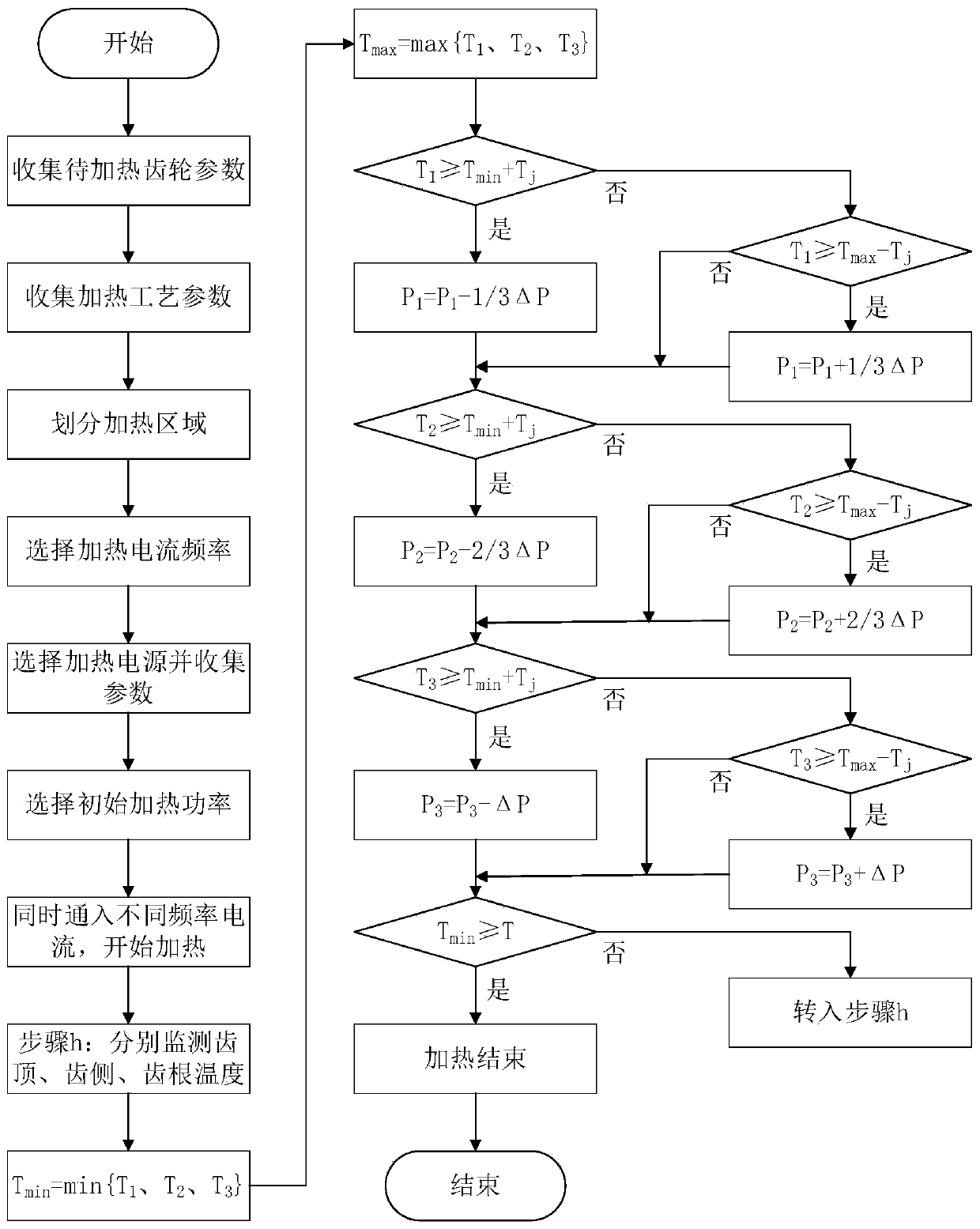

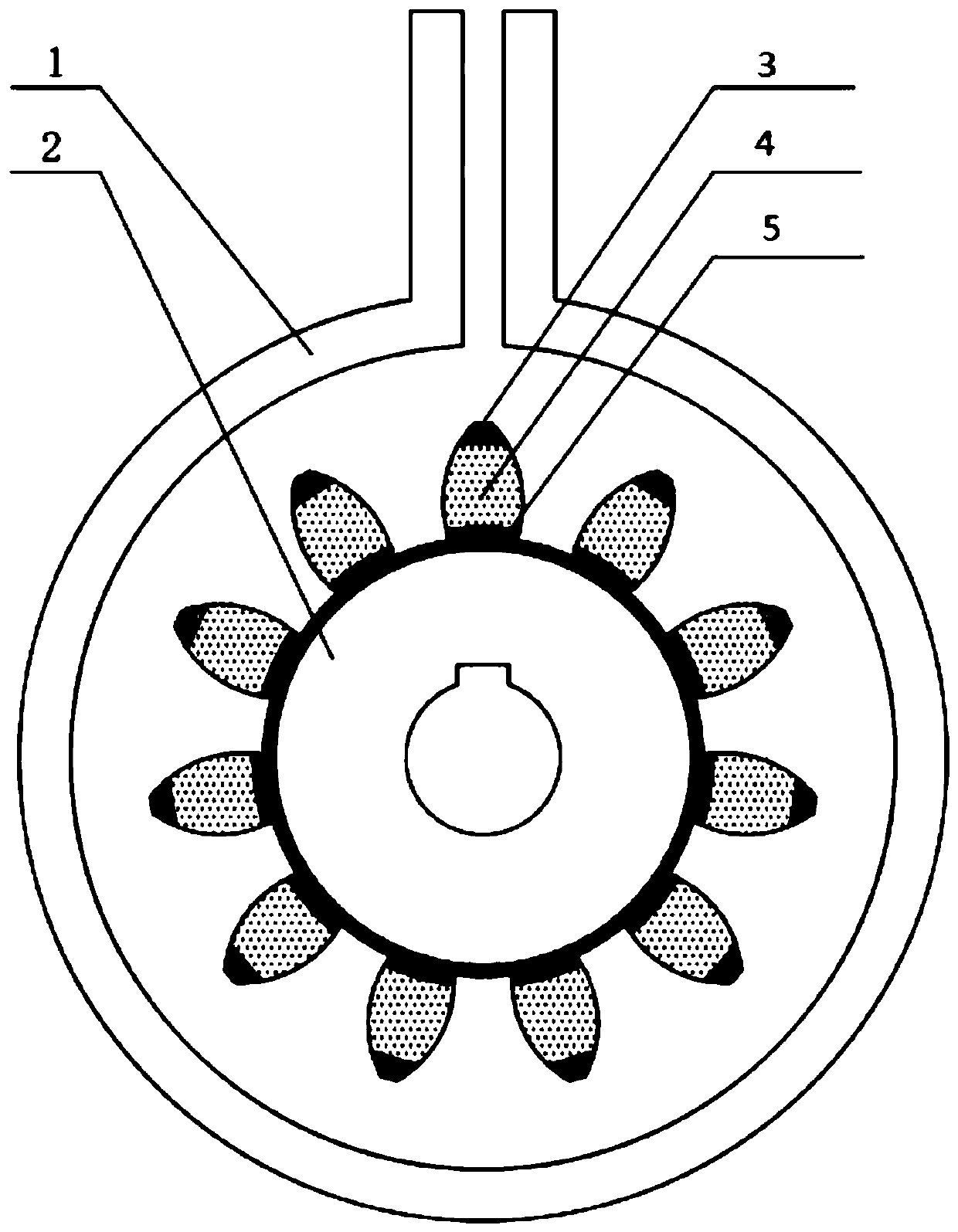

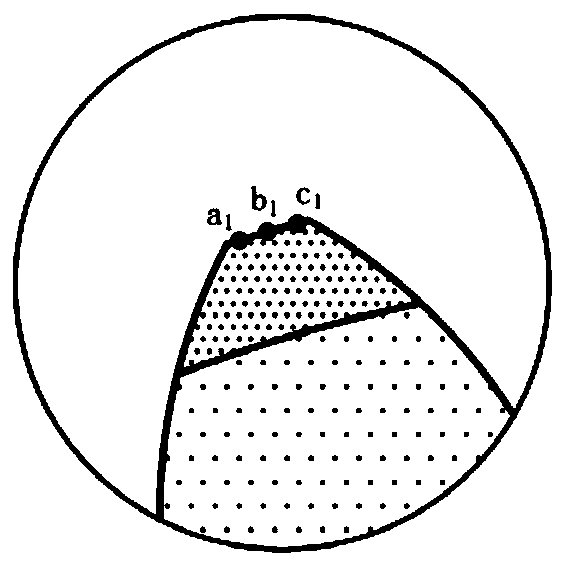

Control method for heating weathering steel gear

ActiveCN111424158AMethods for Realizing Partition ControlUniform temperatureFurnace typesIncreasing energy efficiencyThermodynamicsGear wheel

The invention relates to a control method for heating a weathering steel gear, and belongs to the technical field of gear production. The technique uses the characteristic that different frequency currents have different penetration depths to divide the teeth of the gear to be heated into three different heating areas, and uses three single-frequency power supplies to synchronously switch on current of three different frequencies, which are respectively high, medium and medium frequencies, to a circular coil, so as to heat the operation parts including the tooth top, tooth side and tooth rootof the gear to be heated. Meanwhile, the temperature monitoring of the tooth top, tooth side and tooth root is carried out in real time, the temperature difference of the respective parts is calculated, and the power supply heating power regulation corresponding to the respective parts is carried out based on the temperature difference feedback of the respective parts to realize high-precision gradient heating control of the gear to be heated. The temperature difference is controlled within the temperature accuracy, the production cost is reduced under the condition of meeting the requirementsof production quality, and the best economic benefit can be achieved for the enterprise.

Owner:YANSHAN UNIV

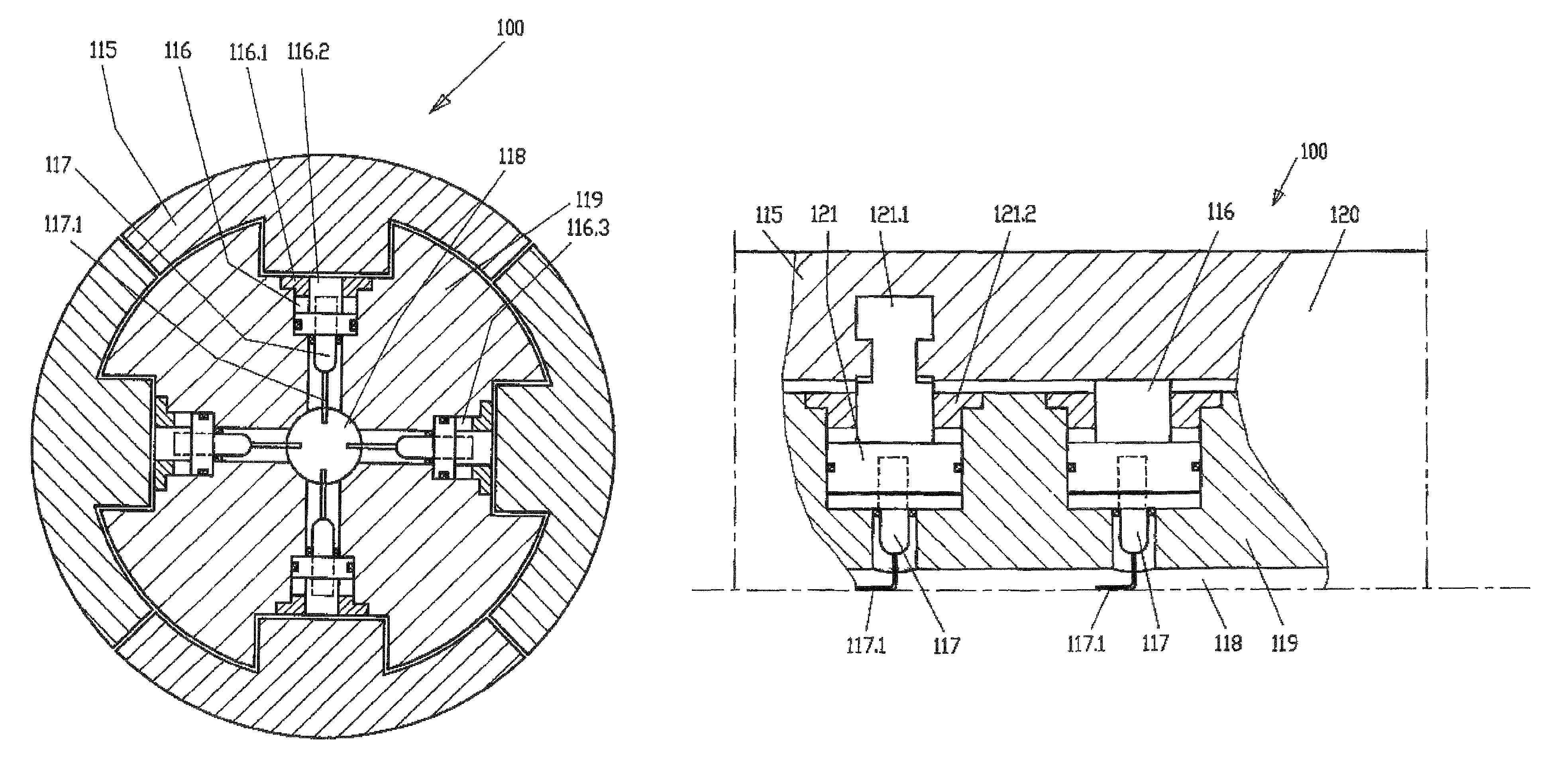

Method and device for winding metal strip material

InactiveUS8523099B2Reliable startMinimize damageSleeve/socket jointsForging/hammering/pressing machinesHydraulic cylinderMetal strips

The invention concerns a method and a coiler mandrel for coiling metal strip (110), wherein the coiler mandrel (100) comprises a mandrel body (120), a plurality of radially expandable segments (115) arranged around the mandrel body (120), and a plurality of hydraulic cylinders (116) by which the segments (115) can be moved in the radial direction. To be able to coil the metal strip with a circular coil eye even when the friction varies in the individual cylinders, the invention proposes that each cylinder (116) of the plurality of cylinders be individually controlled.

Owner:SMS DEMAG AG

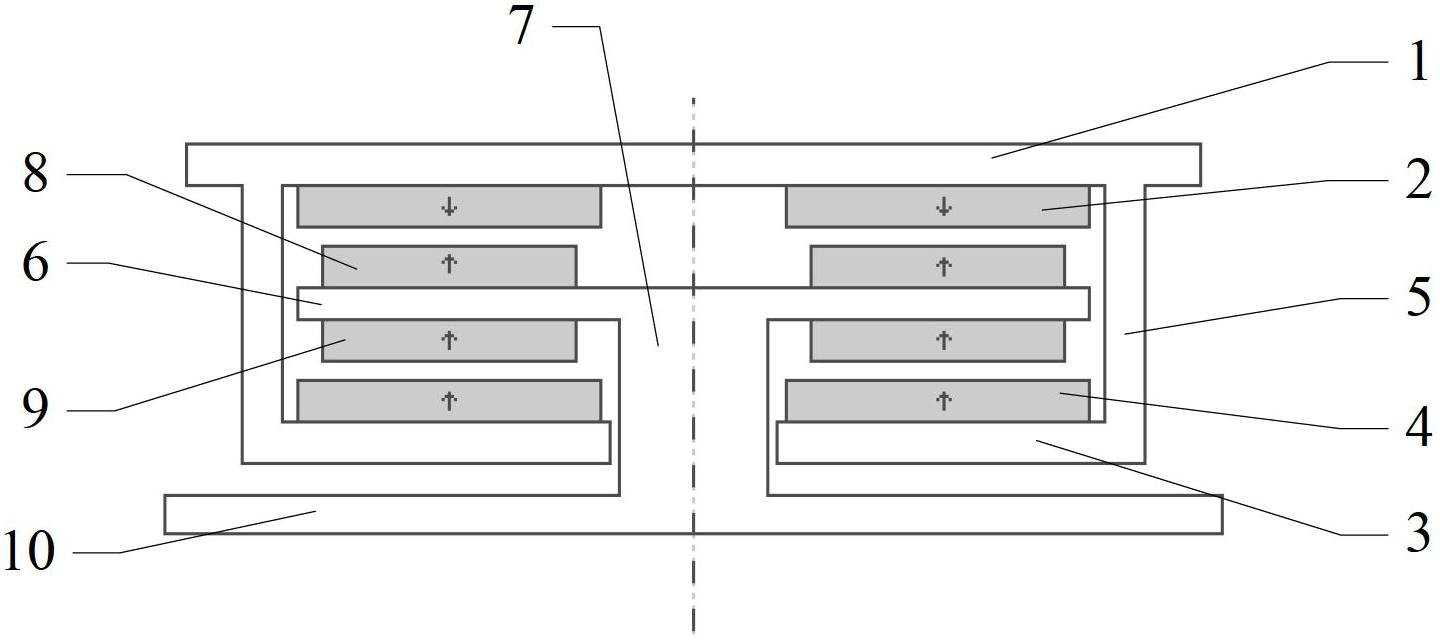

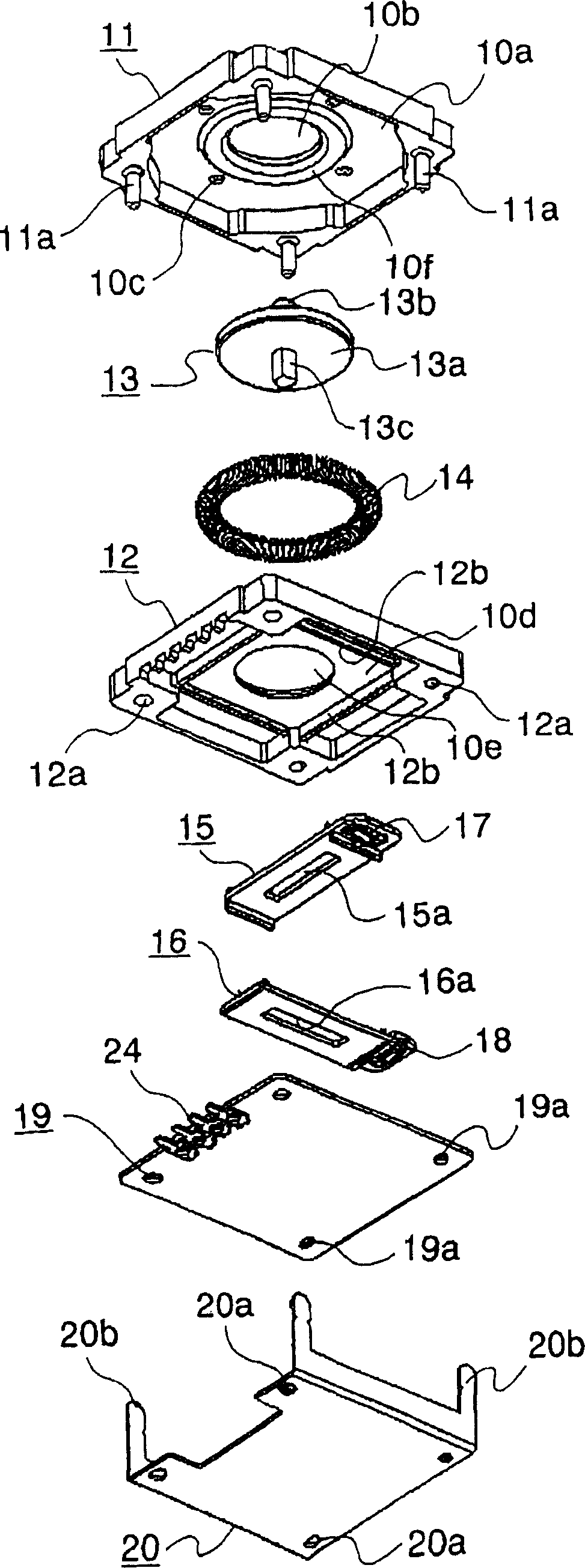

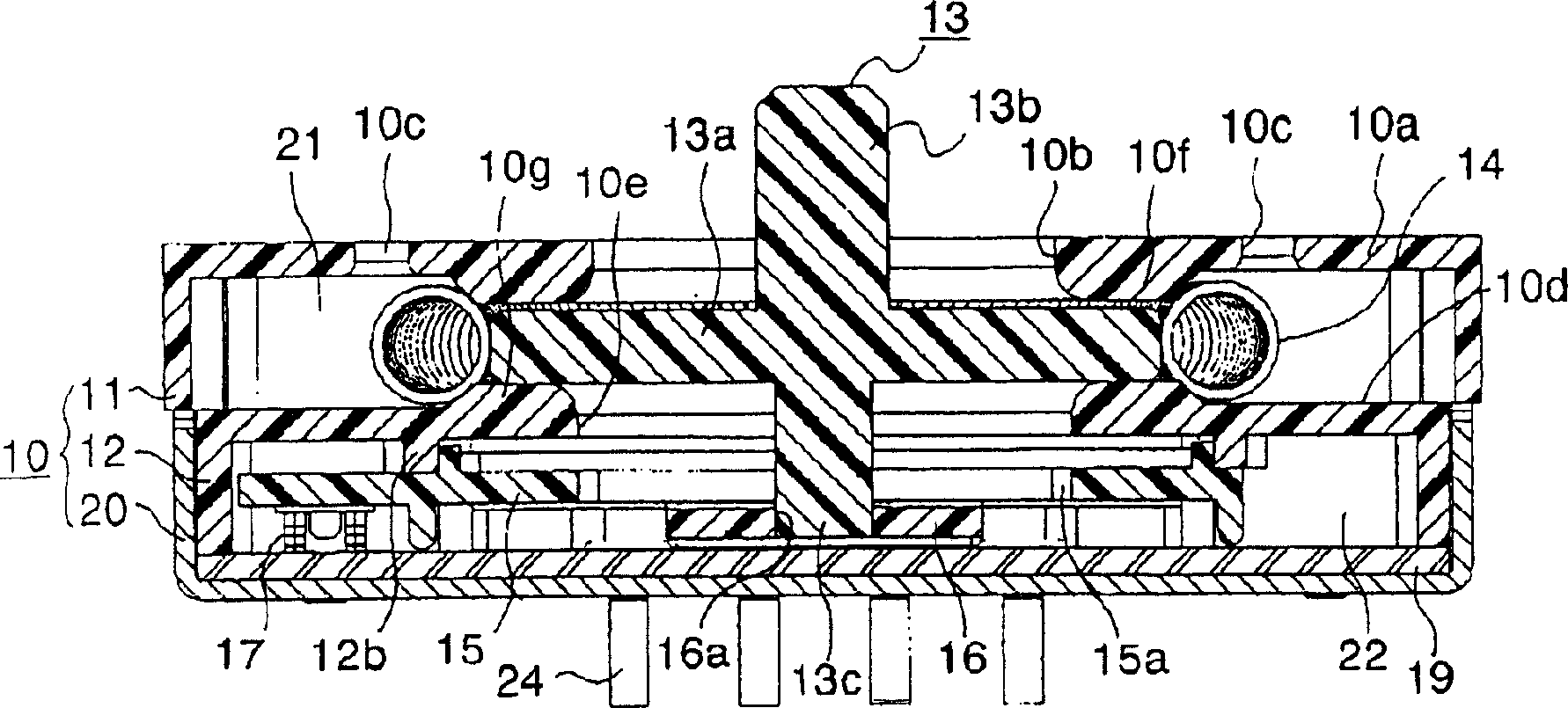

Multiway input device and assembling method therefor

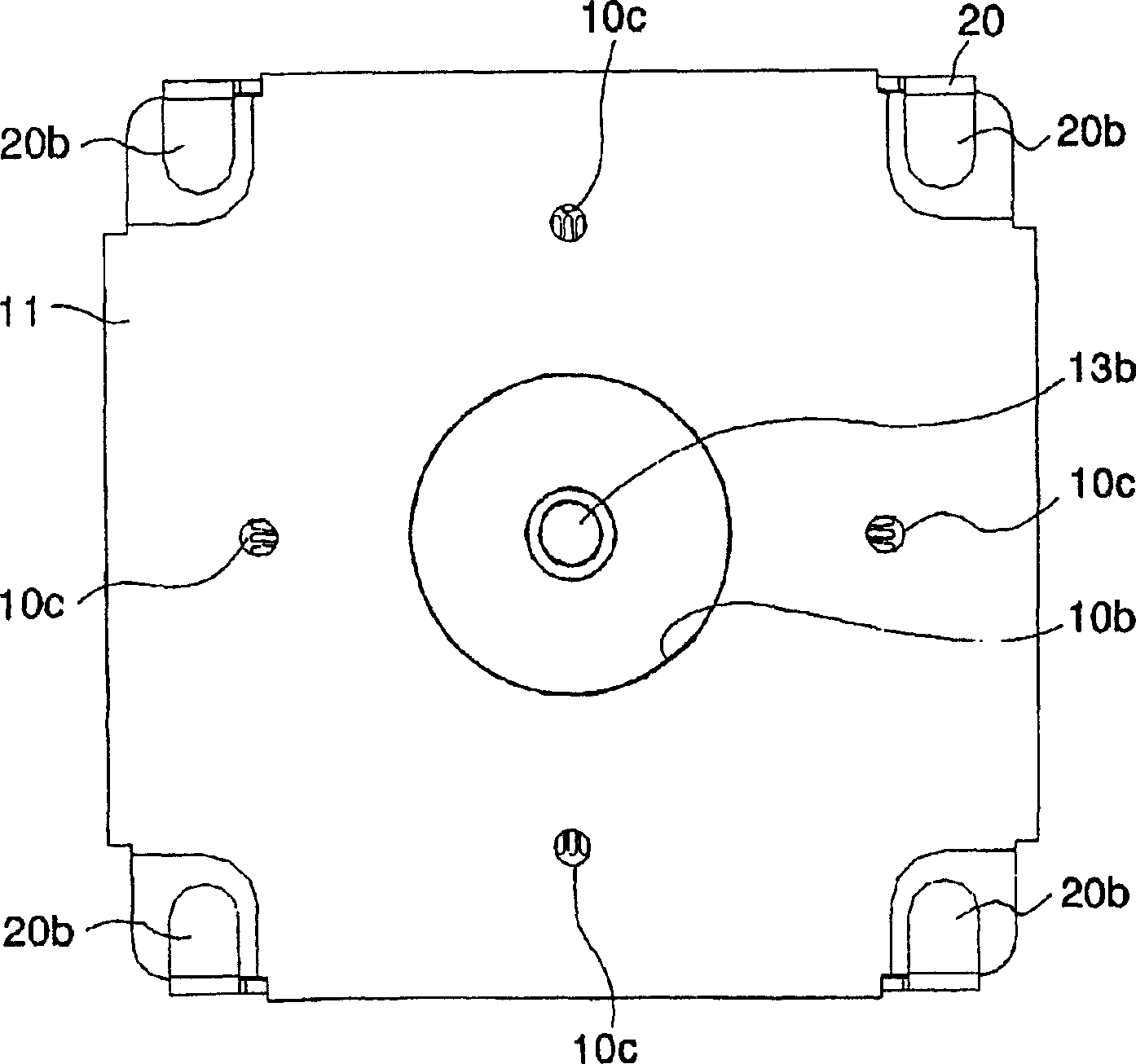

ActiveCN1691237AEasy to assembleExcellent operating forceElectric circuit arrangementsElectric switchesEngineeringRestoring force

To provide a multidirectional input device, and its assembly method, capable of automatically resetting an operating body making a slide operation, with an operation area widely taken with little deviation of operating force by operating directions, and that, with an excellent assembling property. Inside a chassis 10, a large-diameter part 13a of the operating body 13, a circular coil spring 14 surrounding the large-diameter part 13a, and detection means such as sliding pieces 17, 18 detecting a slide direction and a slide volume of the operating body 13. A jig insertion hole 10c for letting in an assembling jig 30 for preliminarily retaining the circular coil spring 14 at assembly is provided beforehand at a chassis 10. When the operating body 13b is operated to slide through a protruded part 13b protruded from an opening 10b of the chassis 10, the large-diameter part pushes in the circular coil spring located in its sliding direction to extend it, so that, when the operating force is removed, the operating body automatically returns to the initial position by the restoring force of the circular coil spring.

Owner:ALPS ALPINE CO LTD

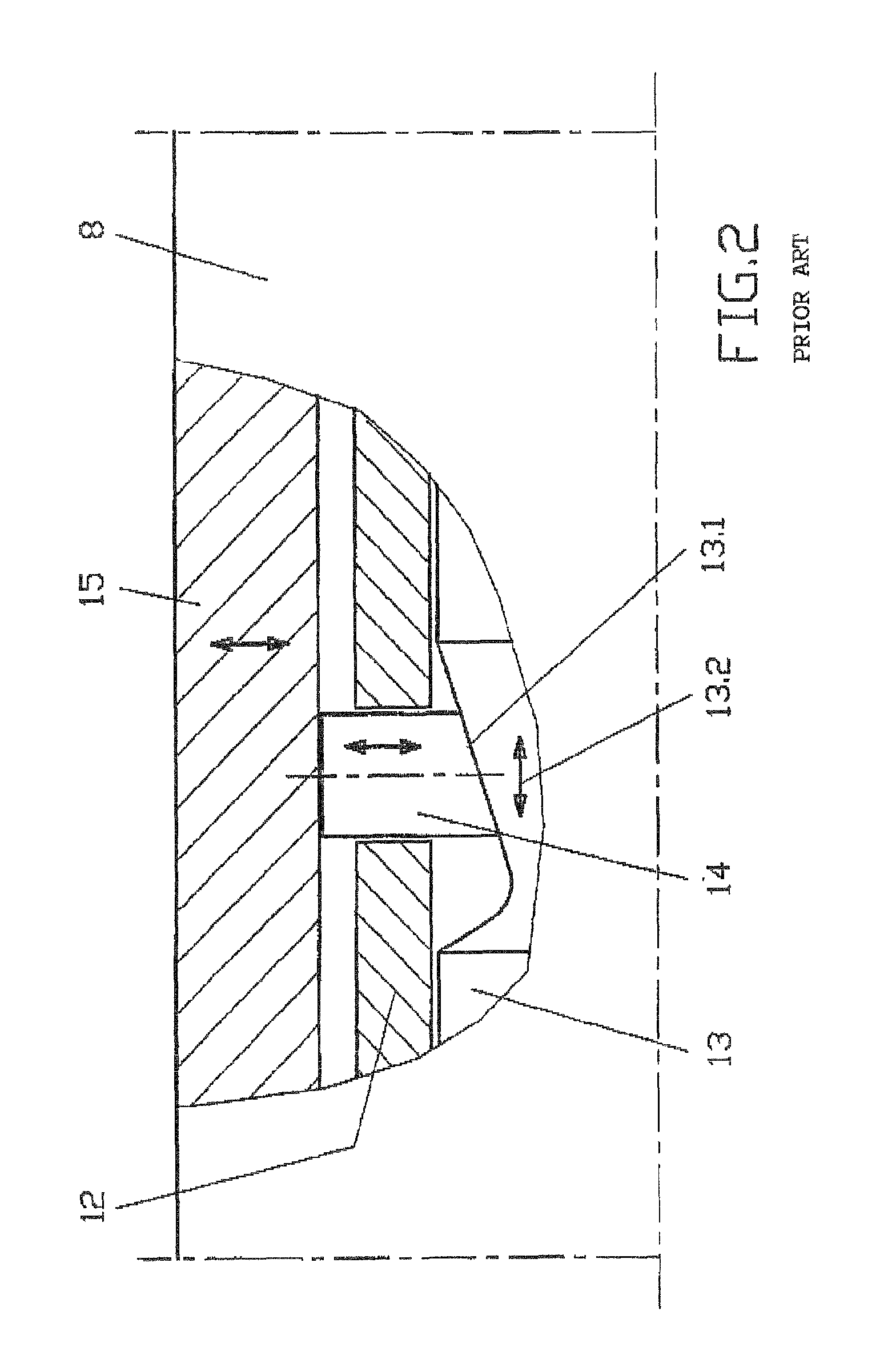

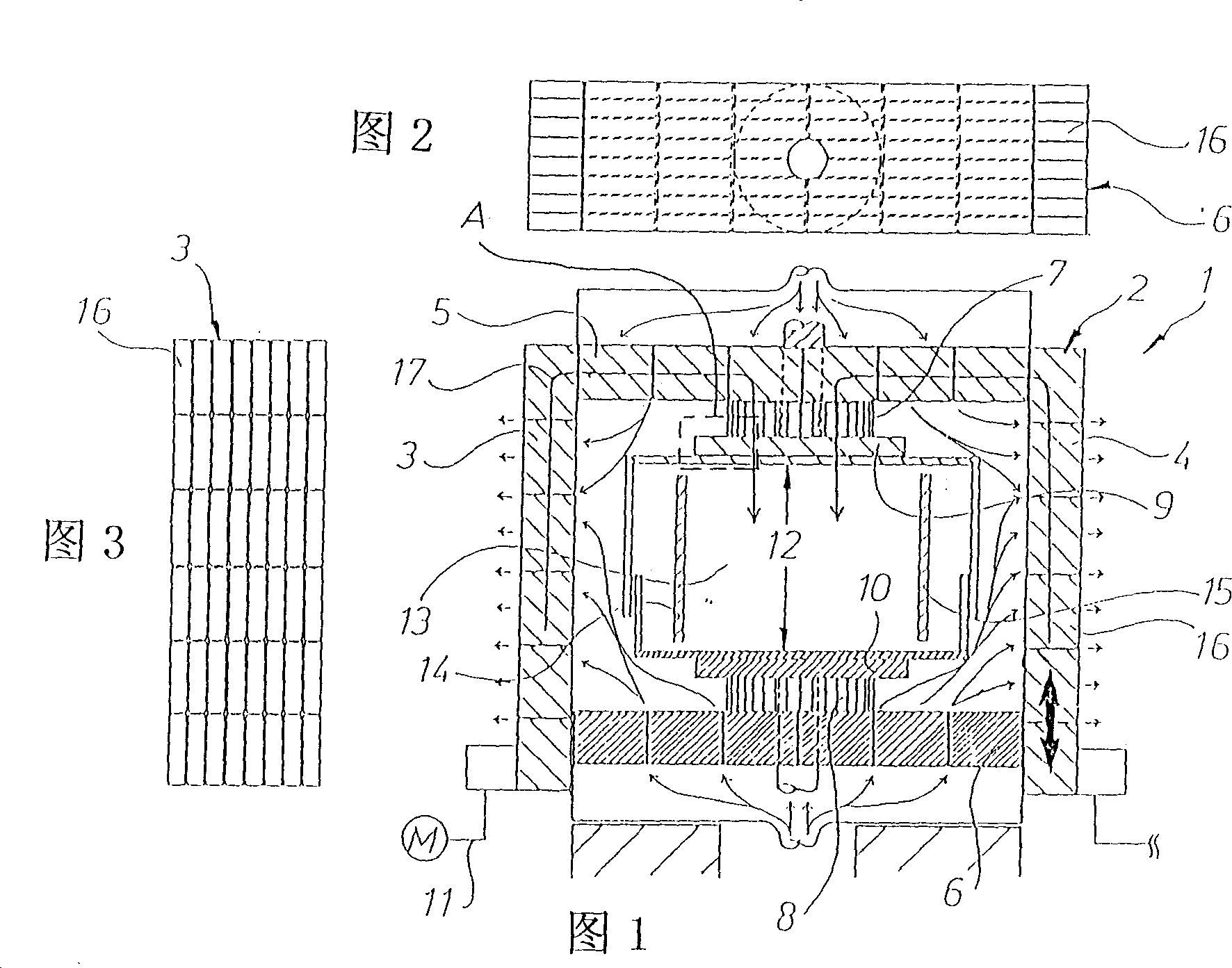

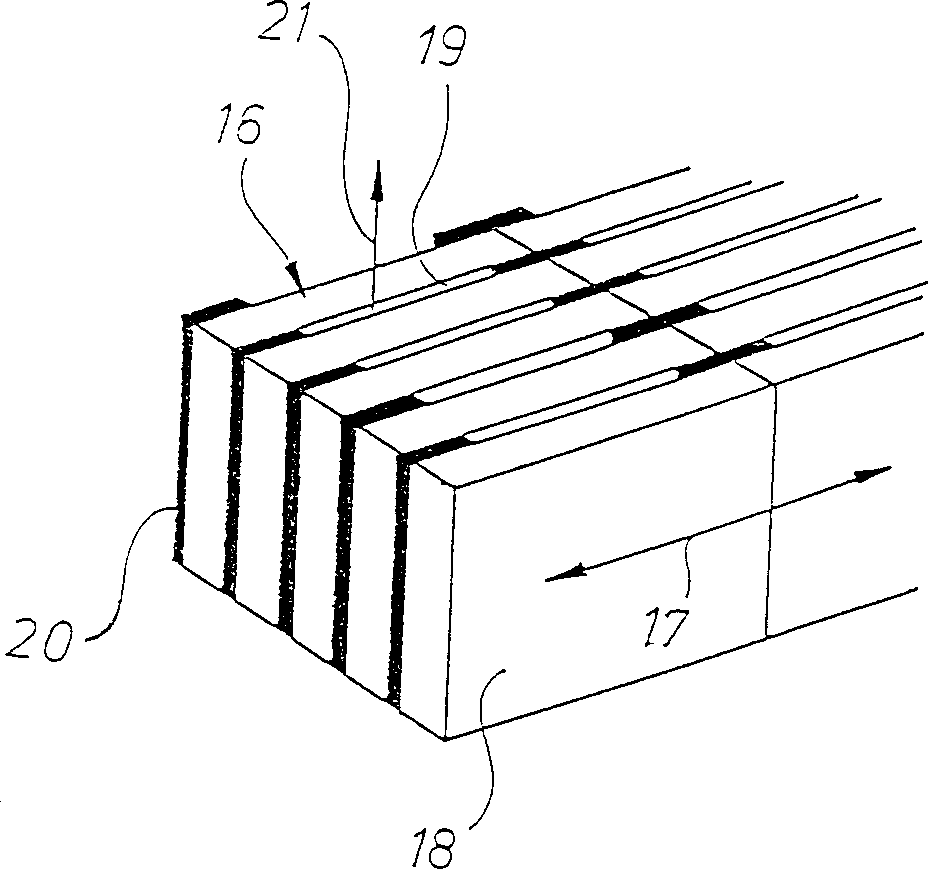

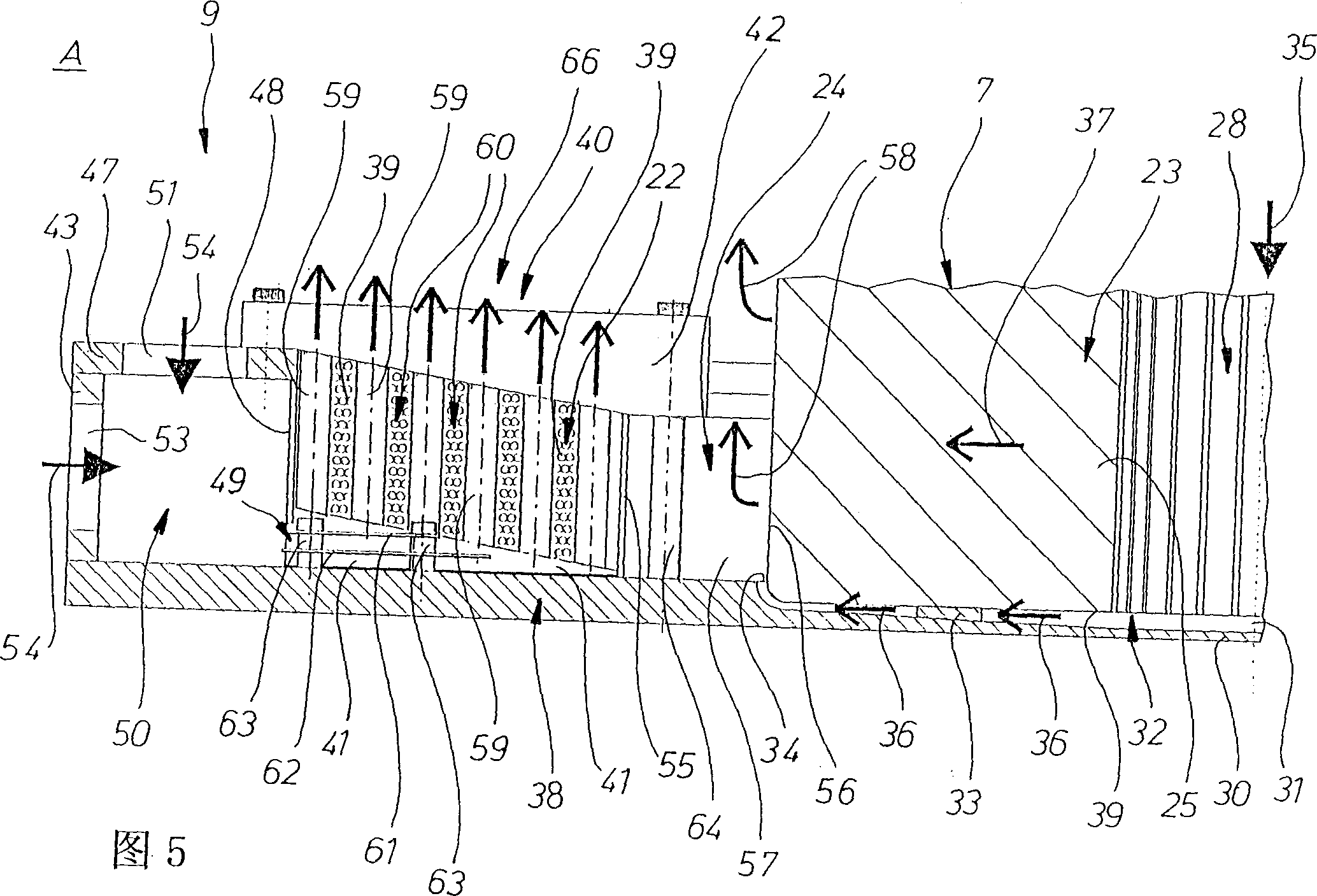

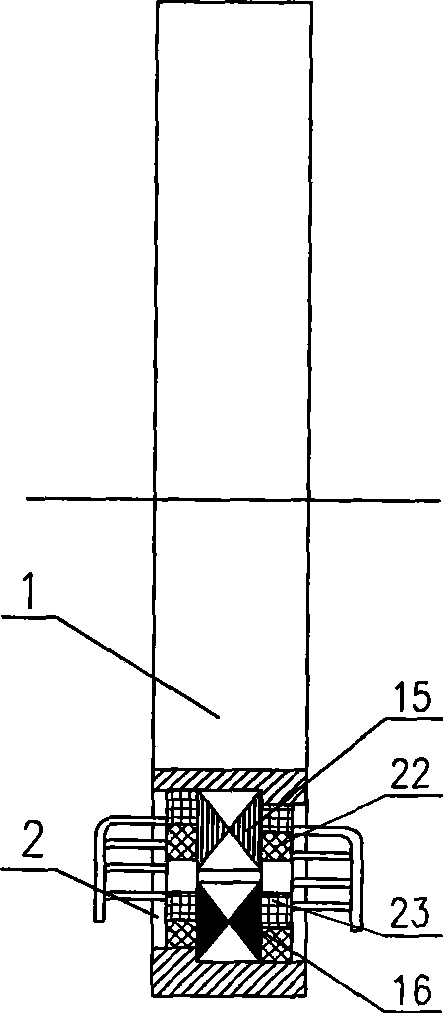

Magnetic coil of magnetic field generator for heating magnetic material in biological organism

InactiveCN1371753AEasy to shapeLow costElectrotherapyMagnetotherapy using coils/electromagnetsLow magnetic fieldBiological tissue

The invention relates to a magnetic coil structure of a magnetic field generator for heating magnetic or magnetizable materials or solids in biological tissues. It has a coolable magnetic yoke (2) and two mutually opposite magnetic yoke (2). , pole pieces (7, 8) separated by a field forming gap (12), wherein in order to generate an alternating magnetic field, two magnetic coils (22) respectively assigned to one pole piece (7, 8) are designed to have The disk coils of the spirally advancing coil windings, and the pole shoe ends of the respective pole shoes (7, 8) are annularly surrounded by a magnetic coil / pole shoe gap (57) that runs between them. According to the invention, the magnetic coils (22) are respectively installed in a coil box annularly surrounded by corresponding pole pieces (7, 8), and the coil box (9, 10) has at least one cold air outlet for connecting to the cold air pump. - inlet holes (51, 52, 53) and at least one cold air-outlet hole (57, 66).

Owner:MFH控制体温系统有限公司

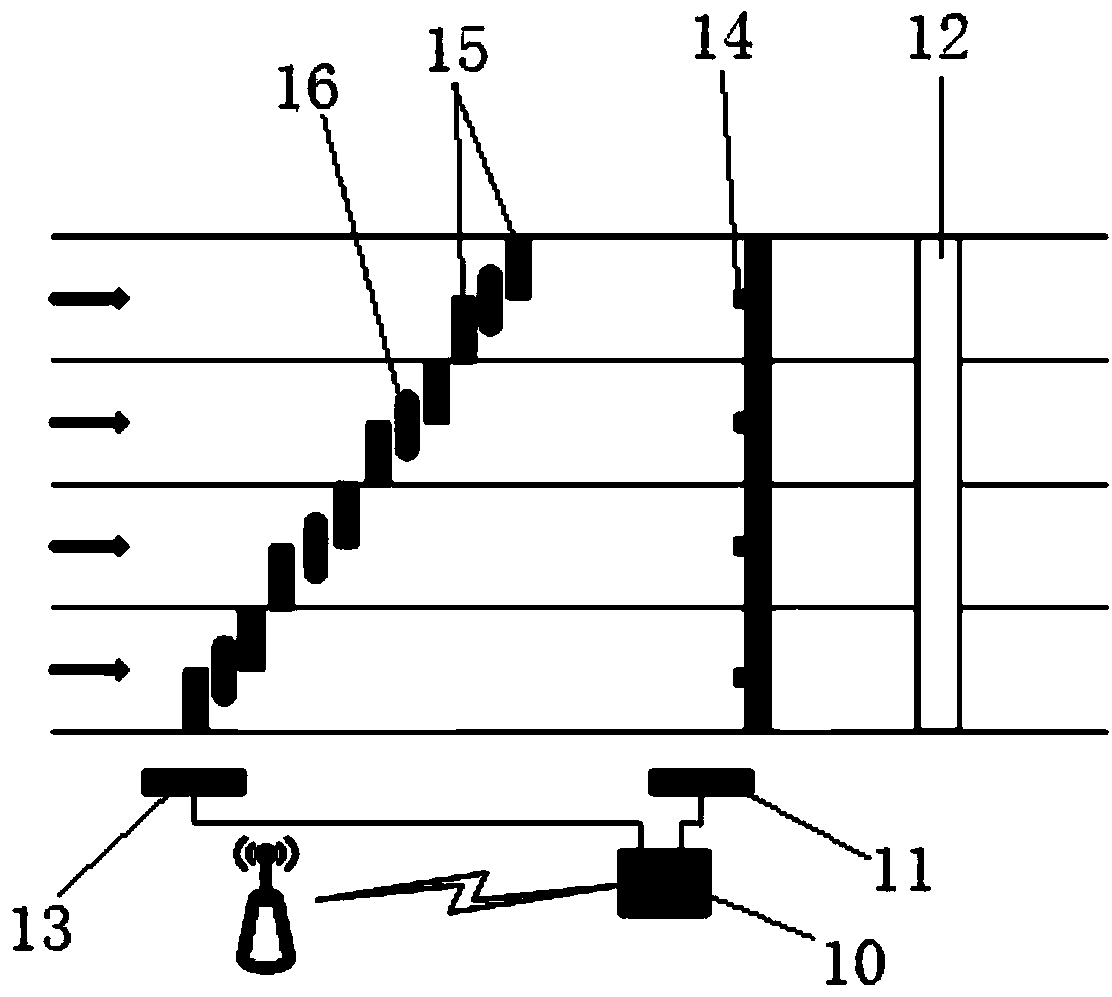

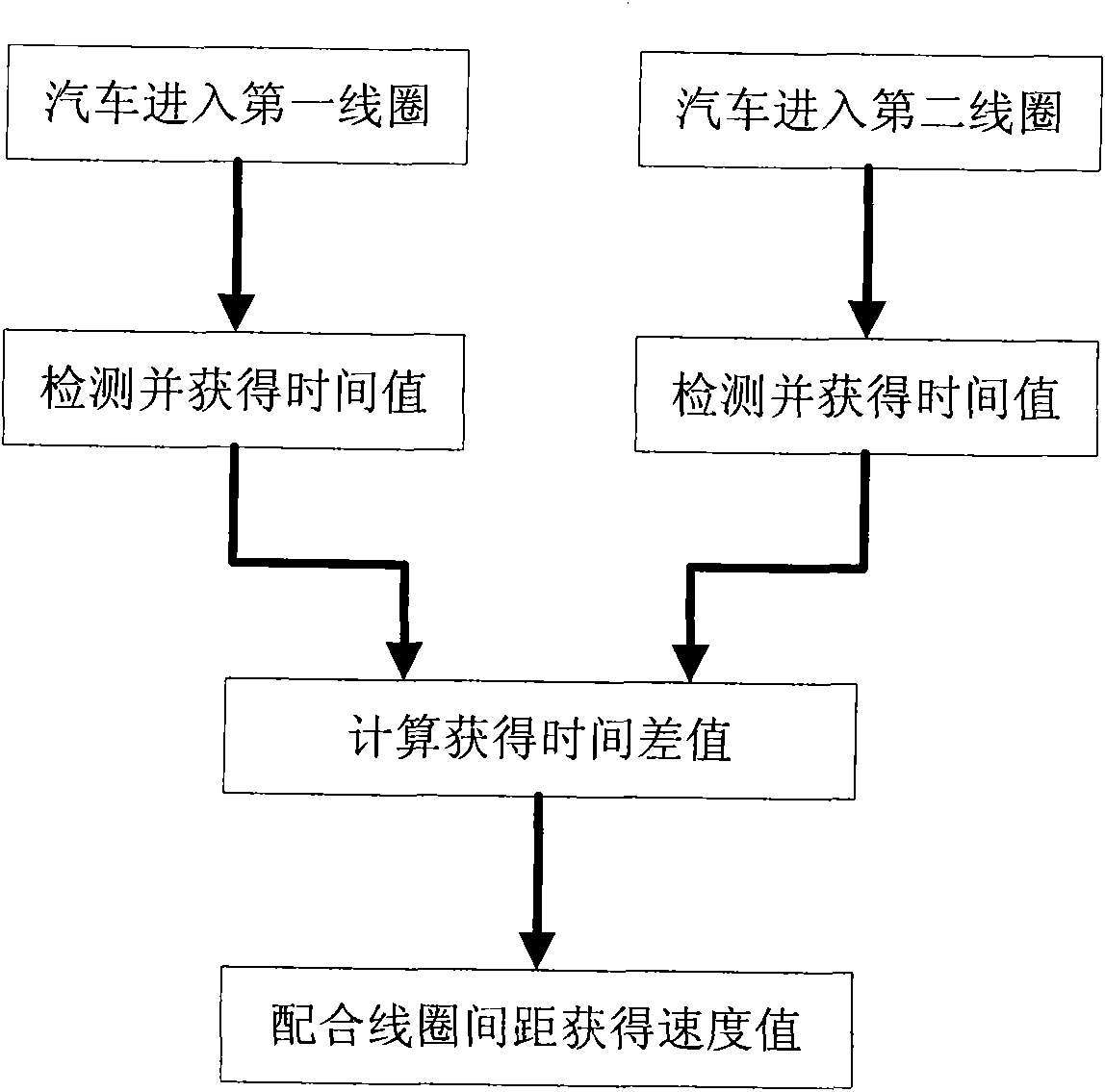

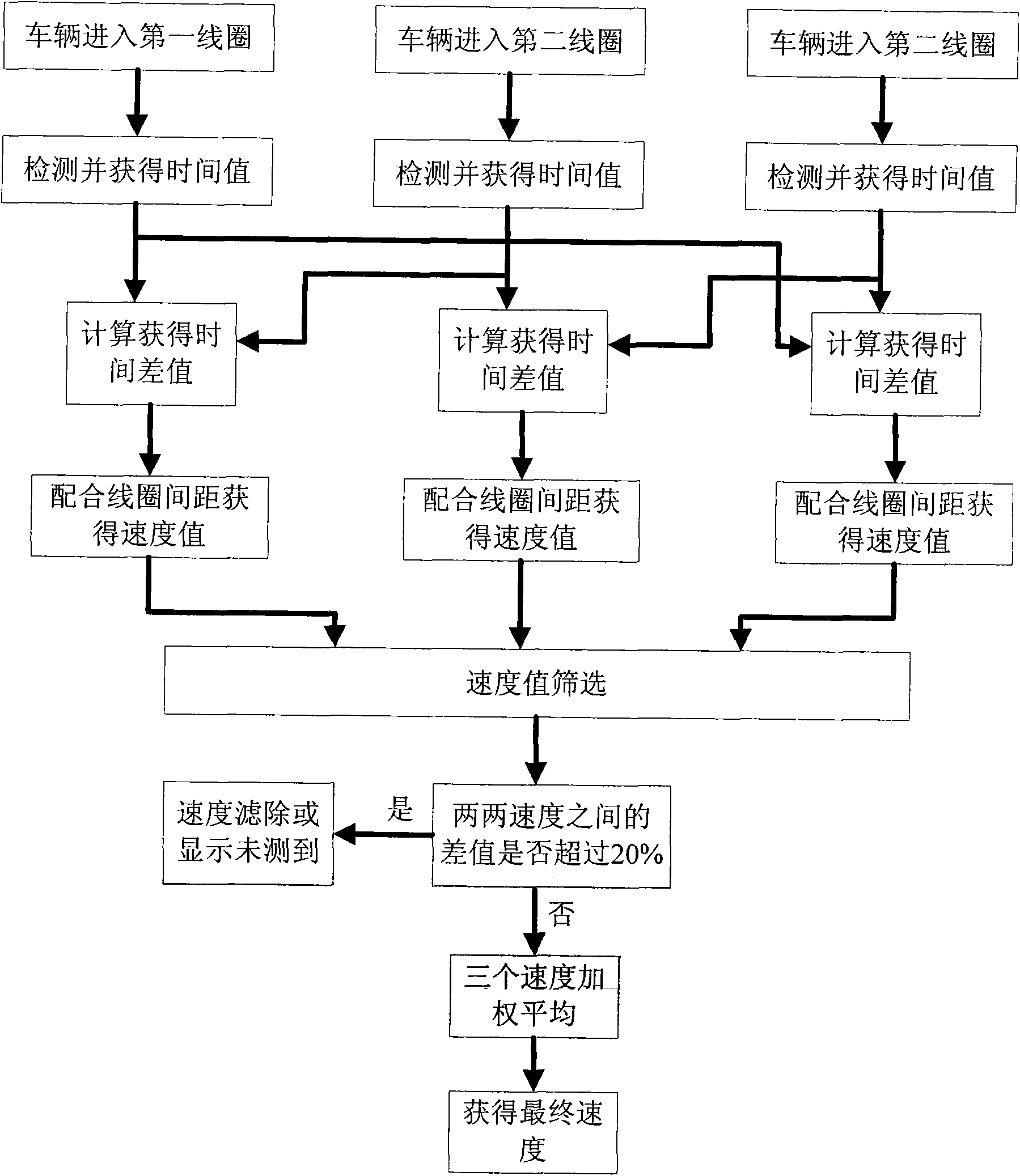

Measuring method with circular coils

ActiveCN101526548AAccurate speedRoad vehicles traffic controlDevices using time traversedTime differenceComputer science

The invention relates to measuring method with circular coils, which comprises the following steps: allowing a vehicle to pass through n coils and recording time values when the vehicle passes through each coil; measuring the distance between each two coils respectively; solving speeds by a formula V=S / T respectively, wherein S is the distance between each two coils, T is the time difference between the vehicle passing through a first coil and a second coil, and V is the speed of the vehicle; and screening speed values to determine whether the difference value between two speeds is always less than 20 percent, if one of the difference value is more than 20 percent, filtering the speed or displaying that the speed is not detected; and if the difference value is always less than 20 percent,performing weighted average on the obtained speeds so as to obtain the final speed. The measuring method can obtain the actual speed of the vehicle as much as possible.

Owner:SHANGHAI BAOKANG ELECTRONICS CONTROL ENG

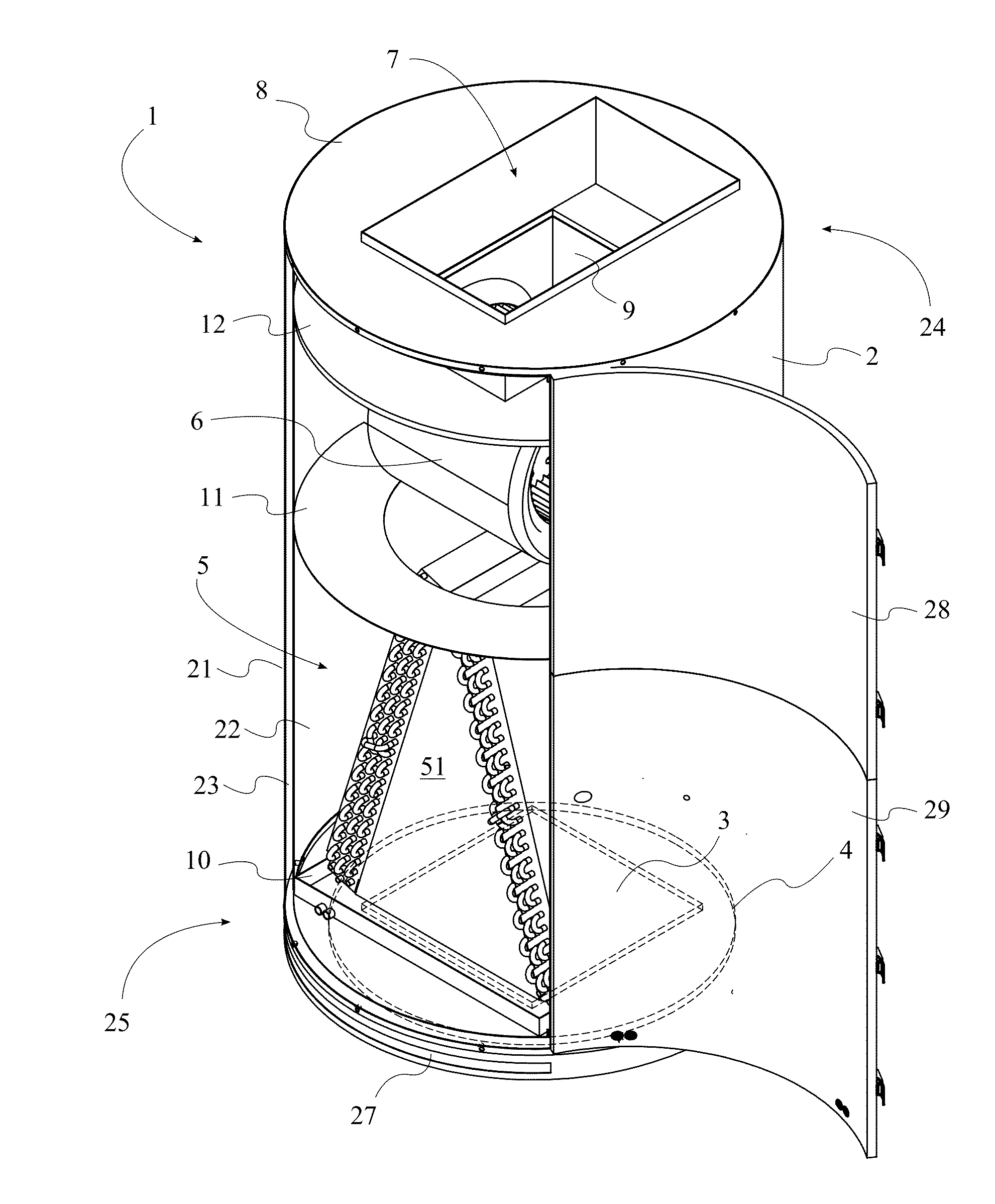

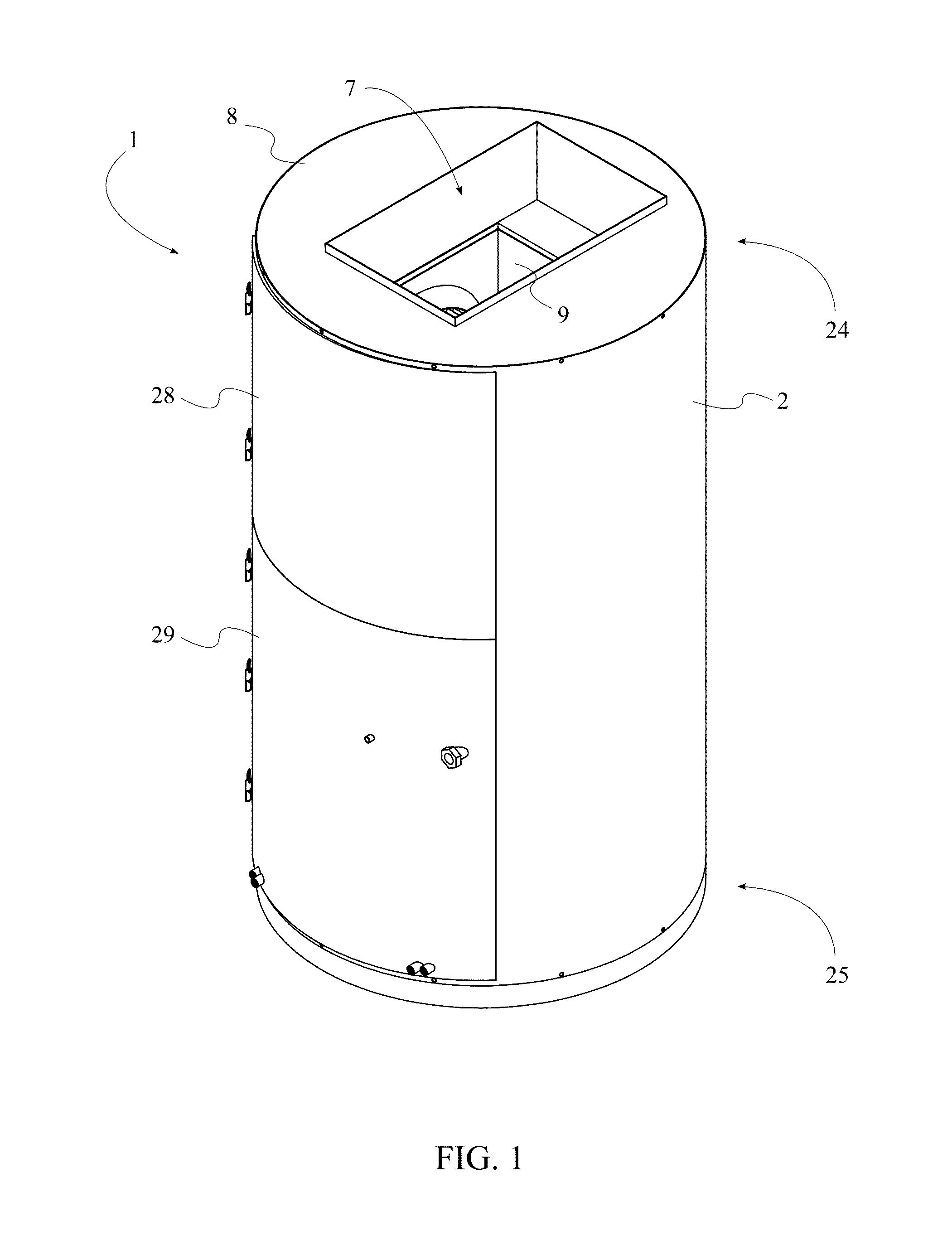

Air Handling Unit That Eliminates Corner Singularities and Eddies for High Energy Efficiency and Its Evaporator Heat Exchanger Coil Arrangements

InactiveUS20160084266A1Improve performanceImprove efficiencyPump componentsHeating and ventilation casings/coversHigh energyEngineering

An air handling unit with a cross-sectional profile of continuous curvature eliminates corner singularities and eddies for high energy efficiency in comparison to rectangular air handling units. A housing has an outer shell, an inner shell, and an insulation shell between the outer and inner shells. A blower and motor assembly forces air through an air intake opening over a heat exchanger, and out through an air discharge opening. An upper door and a lower door in the wall of the housing allow maintenance access to the blower and motor assembly and the heat exchanger. Three heat exchanger coil arrangements are also disclosed: an A-coil arrangement, a parallel coil arrangement, and a circular coil arrangement.

Owner:SHOWOLE RASCHID ALANI

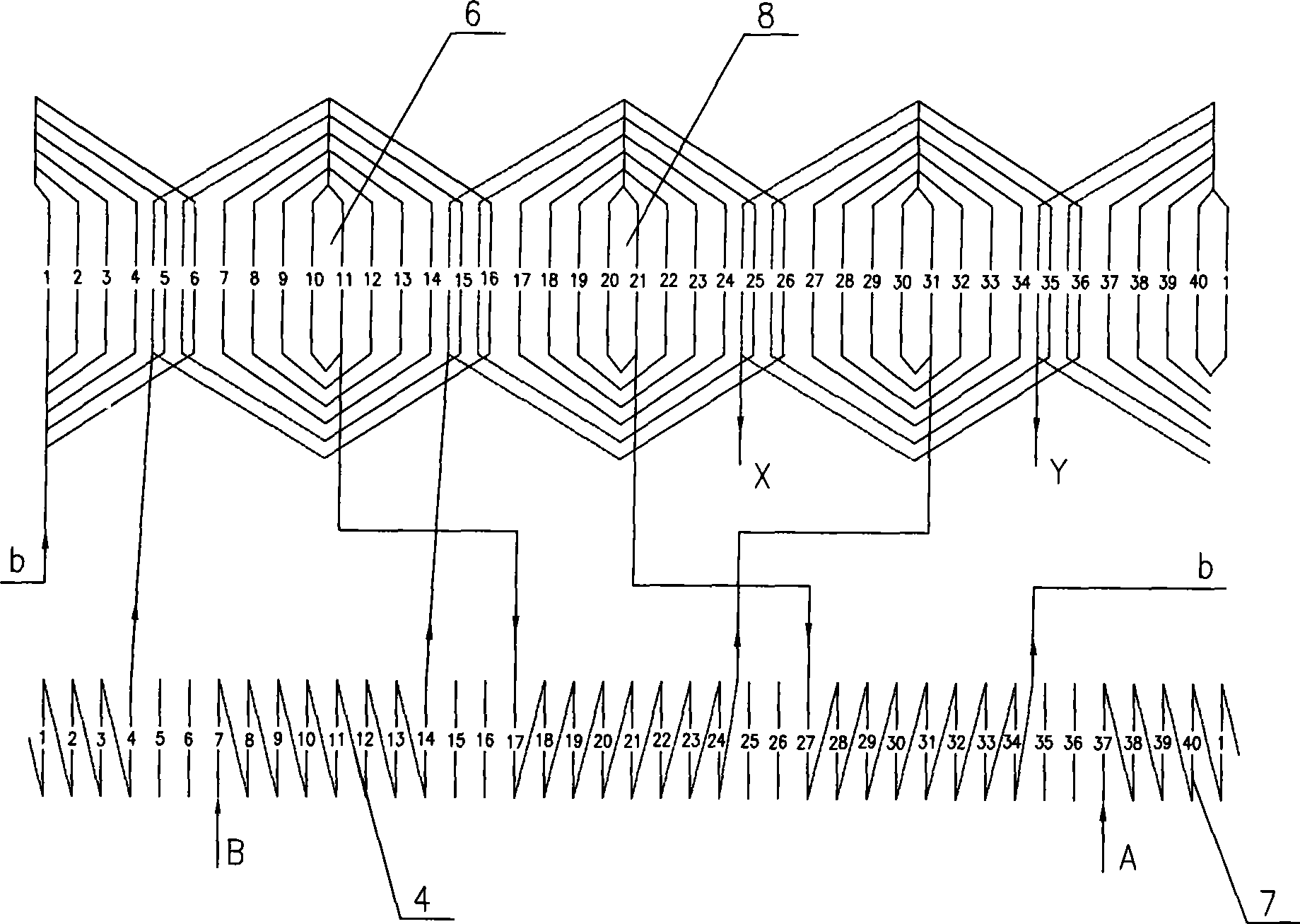

Rotary transformer with relatively small output common ground error

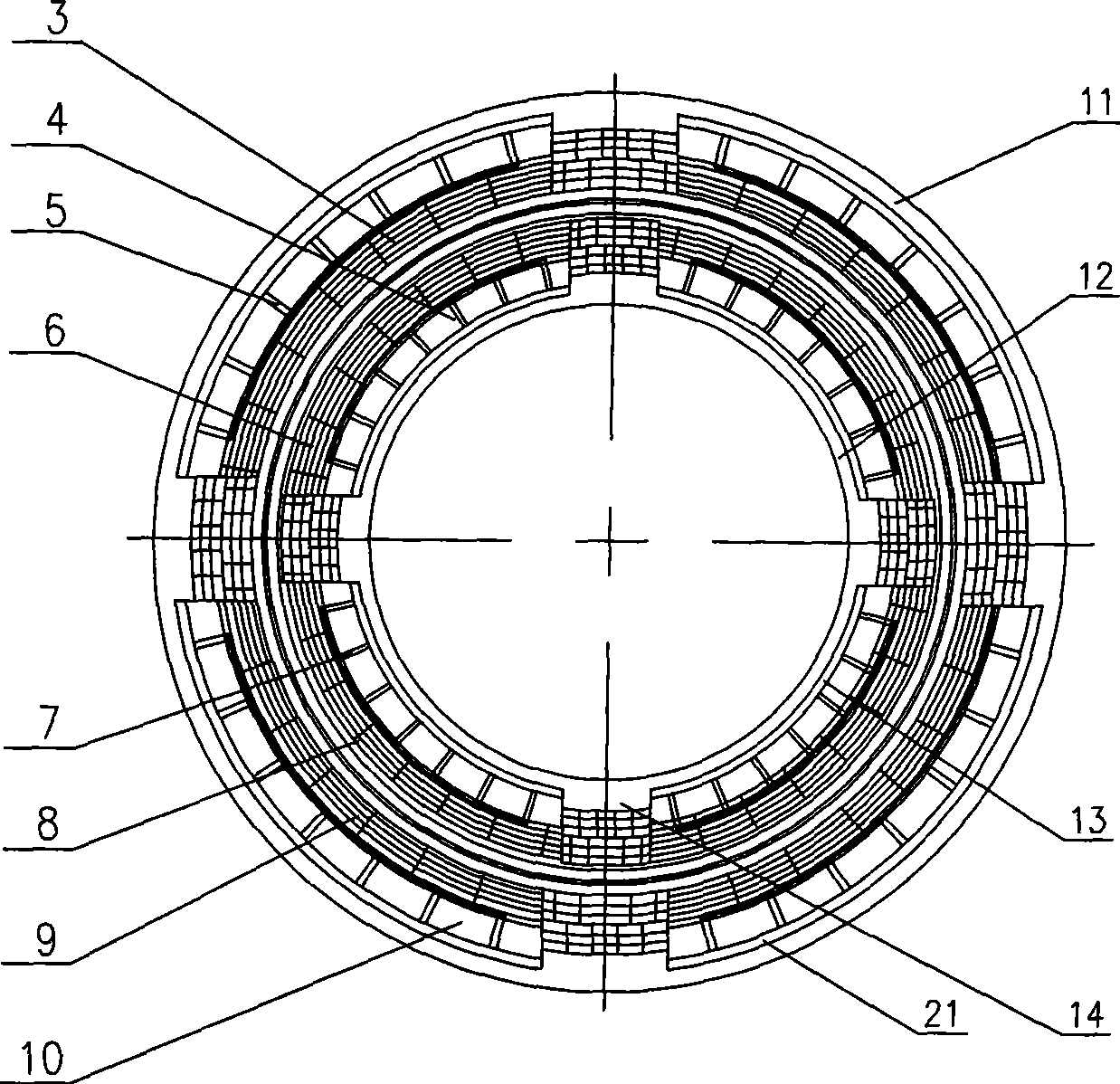

ActiveCN101521102AReduce interphase distributed capacitanceReduce mistakesTransformersTransformers/inductances coils/windings/connectionsCapacitanceToroidal coil

The invention relates to a rotary transformer with relatively small output common ground error, which is composed of a stator and a rotor and exists in two structural forms, namely, segmental type andintegral type. The stator comprises a stator case, a stator iron core and a stator winding wound thereon, and the rotor comprises a rotor shaft sleeve, a rotor iron core and a rotor winding wound the reon, wherein two phase windings of the rotor winding and / or stator winding are all formed by the alternate arrangement of a circular coil assembly and a concentric coil assembly; and the circular coil assembly and the concentric coil assembly under the two poles of the two phase windings are both symmetrically arranged. The capacitance of the rotary transformer is greatly reduced due to the alternative distribution of the output windings, and the output common ground quadrature error and null voltage are also greatly reduced, thus lowering the system angle measurement error, improving the system precision, and simultaneously widening the excitation frequency application range of the rotary transformer, satisfying the application requirements of certain special systems on high excitation frequency and small output common ground error of the rotary transformer.

Owner:TIANJIN NAVIGATION INSTR RES INST

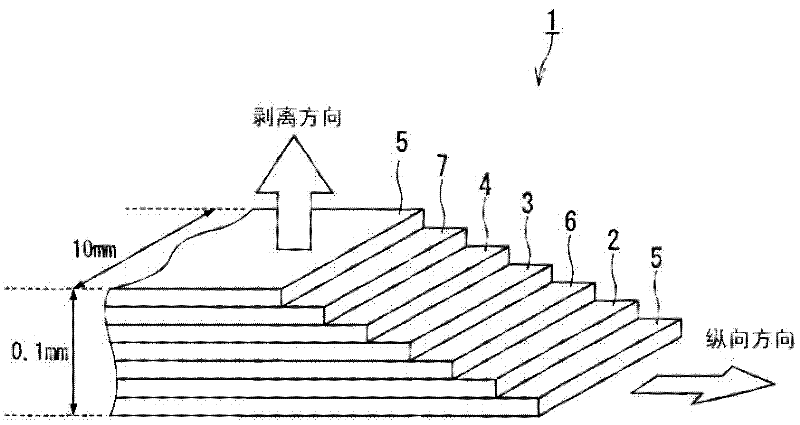

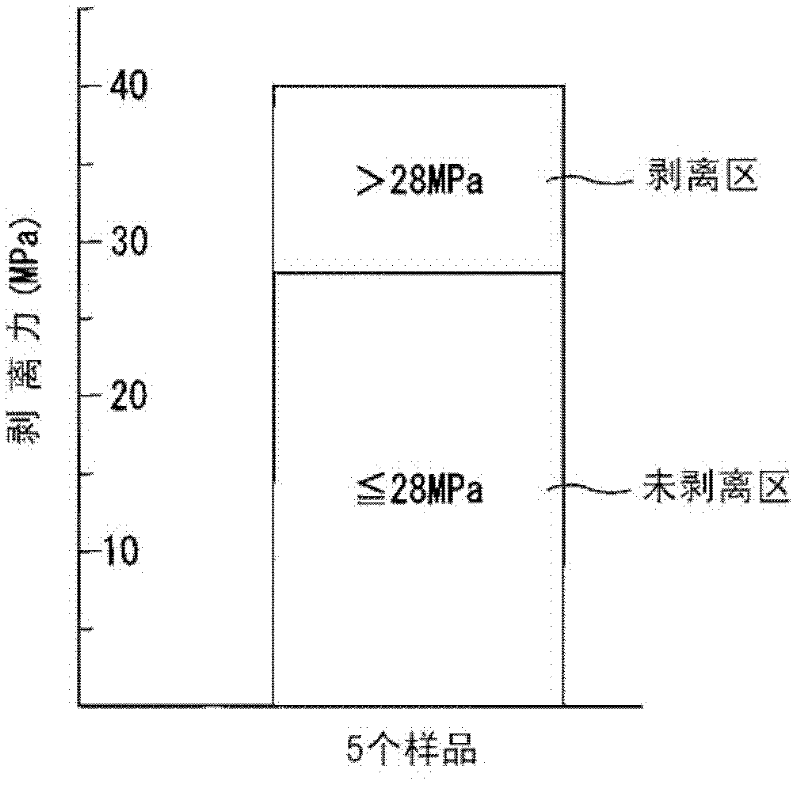

Superconducting coil

ActiveCN102468029ASmall peeling forceDegradation of superconducting propertiesSuperconducting magnets/coilsFiberPeel force

A superconducting coil 40 comprises a plurality of superconducting coil layer portions 43a, 43b, 43c which are formed by winding a thin-film superconducting wire and an insulating material into a multiple layer structure, wherein the coil layer portions 43a, 43b, 43c are adjacent to each other at boundary portions 45 having adhesive forces that are less than those of other portions of the coil 40. The coil 40 may be a non-circular shape such as: racetrack, saddle, ellipse, oval or rectangle. The coil portions 43a, 43b, 43c may be arranged to have an outer to inner diameter ratio of less than 3.1. The boundary portions 45 may be non-bonded or involve an insulating material subjected to a mould release treatment. The release agents involved may be fluorocarbon tape, paraffin, grease and / or silicon oil. A cooling member or plate, subjected to an insulating treatment, may be used in the boundary potions 45. The coil 40 may include a fibre reinforced plastic core 19. The coil 40 arrangement may reduce the peeling forces experienced by the thin-film superconductive wires such that there is less coil degradation and there is improved stability of the coil performance.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com