Patents

Literature

54results about How to "High magnetostriction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

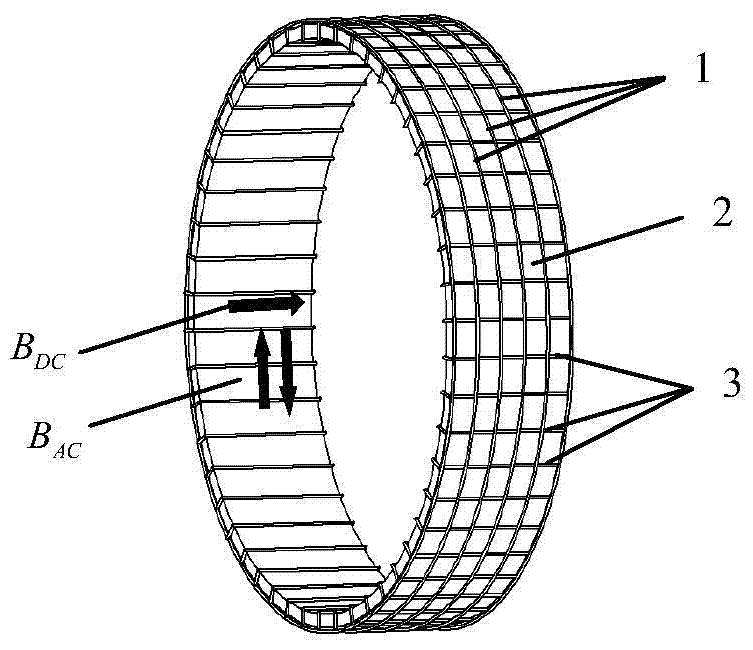

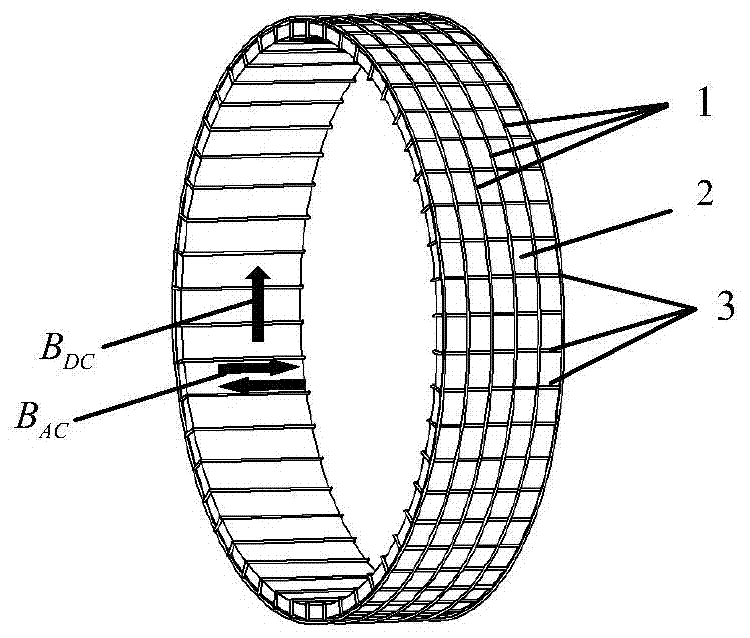

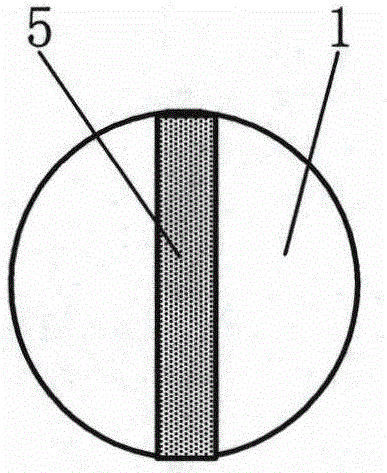

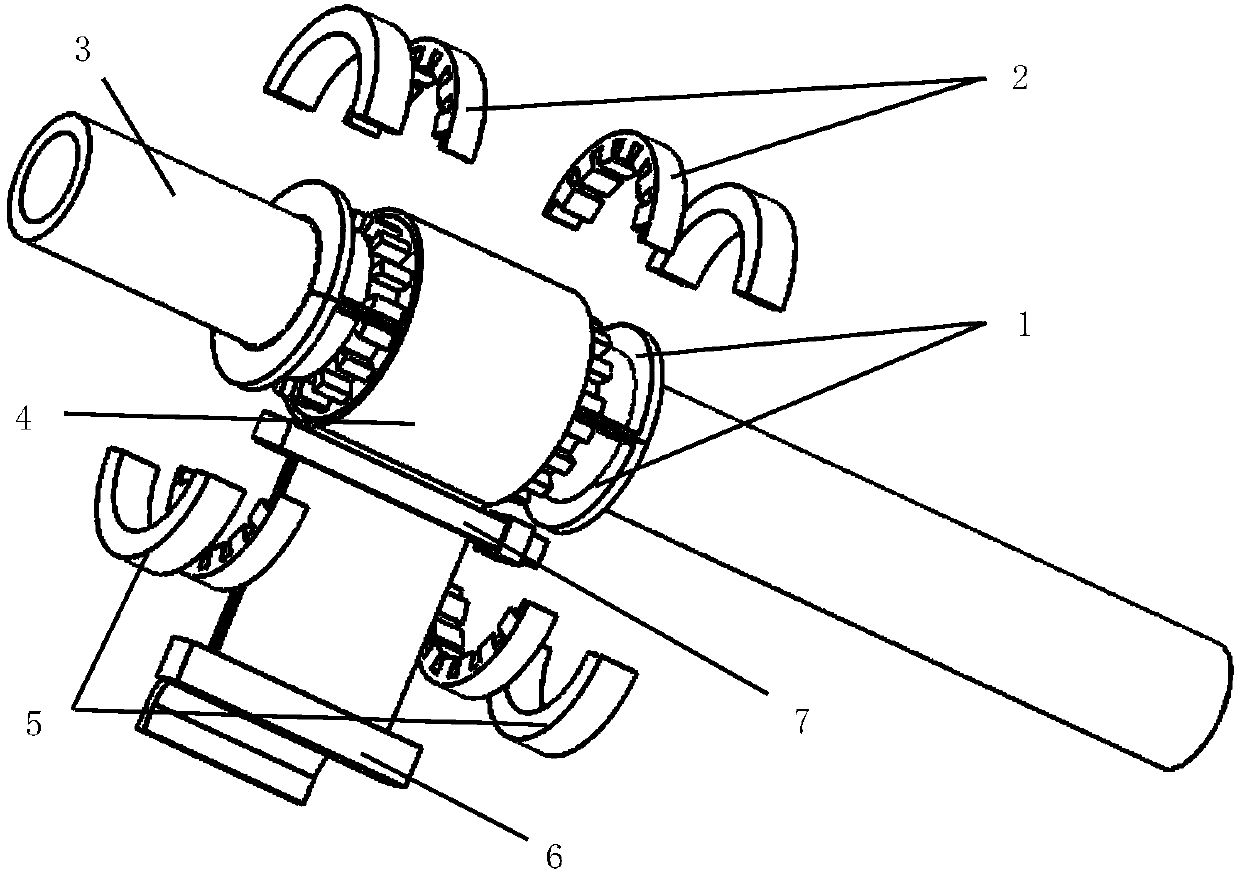

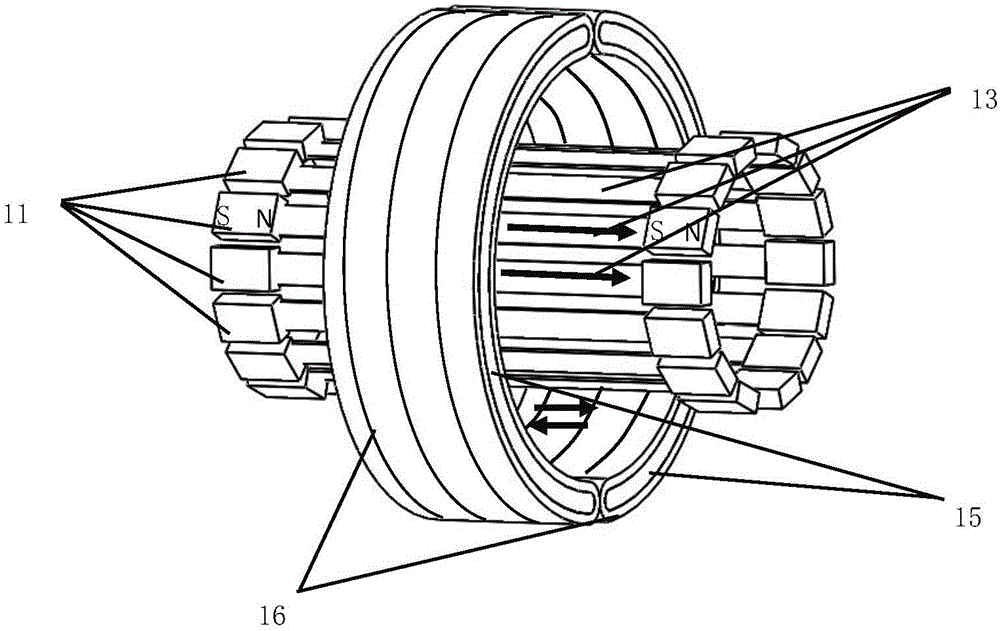

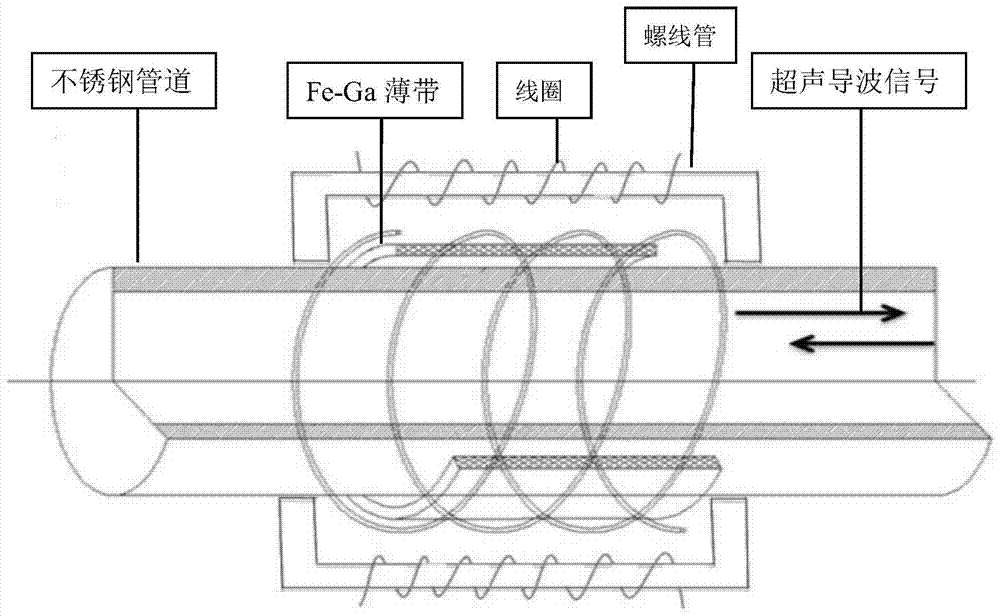

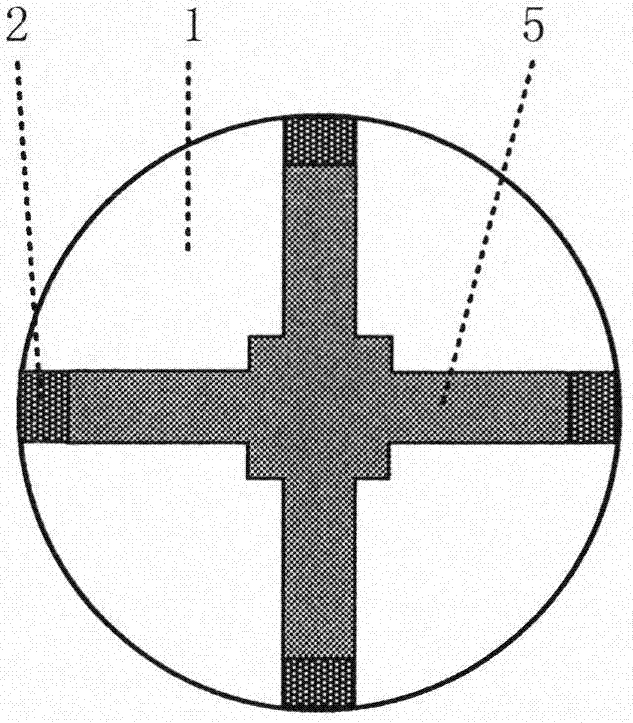

Circular-array-type magnetostriction sensor based on orthogonal encircling coil

InactiveCN104502443AUniform static magnetic field distributionHigh magnetostriction coefficientMaterial magnetic variablesEpoxyHigh energy

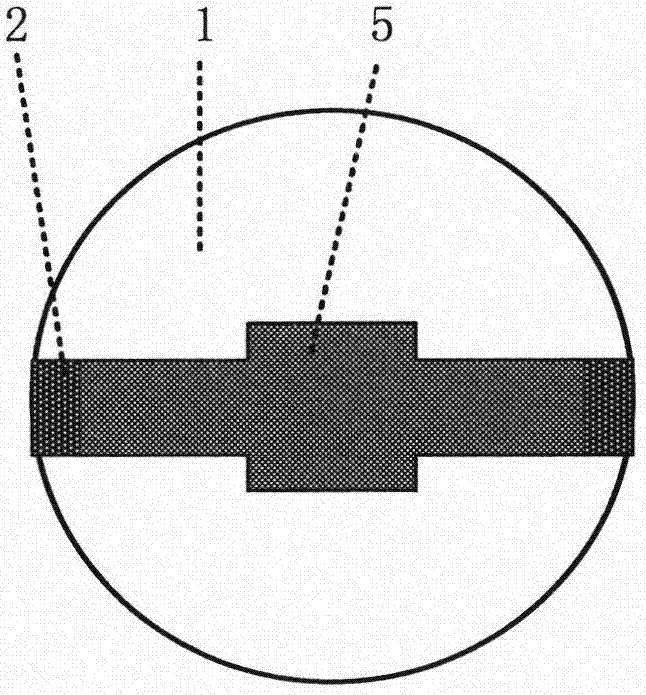

The invention relates to a circular-array-type magnetostriction sensor based on an orthogonal encircling coil. The circular-array-type magnetostriction sensor comprises a ferrocobalt band, a rectangular coil, a circular coil and a mechanical clamping device, wherein the rectangular coil and the circular coil are orthogonally encircled on the ferrocobalt band. The rectangular coil is preliminarily encircled on the ferrocobalt band, bonded through epoxy resin and solidified with an outside rubber layer to form a semi-cylindrical-shell detection unit. Two detection units are directly buckled or stuck to the surface of a structure such as a circular pipe and a circular rod by adopting epoxy resin and form an access after being connected through a conducting plug pin. The bar-type circular coil is encircled outside each detection unit and penetrates through the mechanical clamping device to form an access by adopting an adaptor; the mechanical clamping device can be used for applying radial load onto the circular coil and the detection units. The circular-array-type magnetostriction sensor can be used for exciting and receiving a torsional-mode ultrasonic guide wave in the circular pipe and the circular rod structure and has higher energy exciting efficiency; moreover, the structure is simple, multichannel excitation and receiving of the torsional-mode ultrasonic guide wave can be realized, and a foundation is provided for a focus imaging algorithm of the pipeline detection.

Owner:BEIJING UNIV OF TECH

Optical fiber cantilever beam magnetic field sensing probe based on giant magnetostrictive film

InactiveCN106569152AMiniaturizationImprove detection accuracyMagnetic field measurement using magneto-optic devicesResonant cavityCantilever

The invention discloses an optical fiber cantilever beam magnetic field sensing probe based on a giant magnetostrictive film, and belongs to the technical field of optical fiber sensors. The optical fiber cantilever beam magnetic field sensing probe comprises an optical fiber, a fixing and supporting end, an optical fiber cantilever beam, a chromium metal film and the giant magnetostrictive film. The optical fiber cantilever beam is arranged on the optical fiber end surface. The optical fiber cantilever beam is connected with the optical fiber end surface through the fixing and supporting end. The optical fiber cantilever beam and the optical fiber end surface form a Fabry-Perot resonant cavity. The chromium metal film and the giant magnetostrictive film are plated on the external surface of the optical fiber cantilever beam in turn. In a magnetic field to be measured, telescoping of the giant magnetostrictive film results in the deflection of the optical fiber cantilever beam or the change of the resonant frequency, and the deflection of the optical fiber cantilever beam or the change of the resonant frequency is detected by the Fabry-Perot resonant cavity so as to measure the size of the external magnetic field.

Owner:CHINA JILIANG UNIV

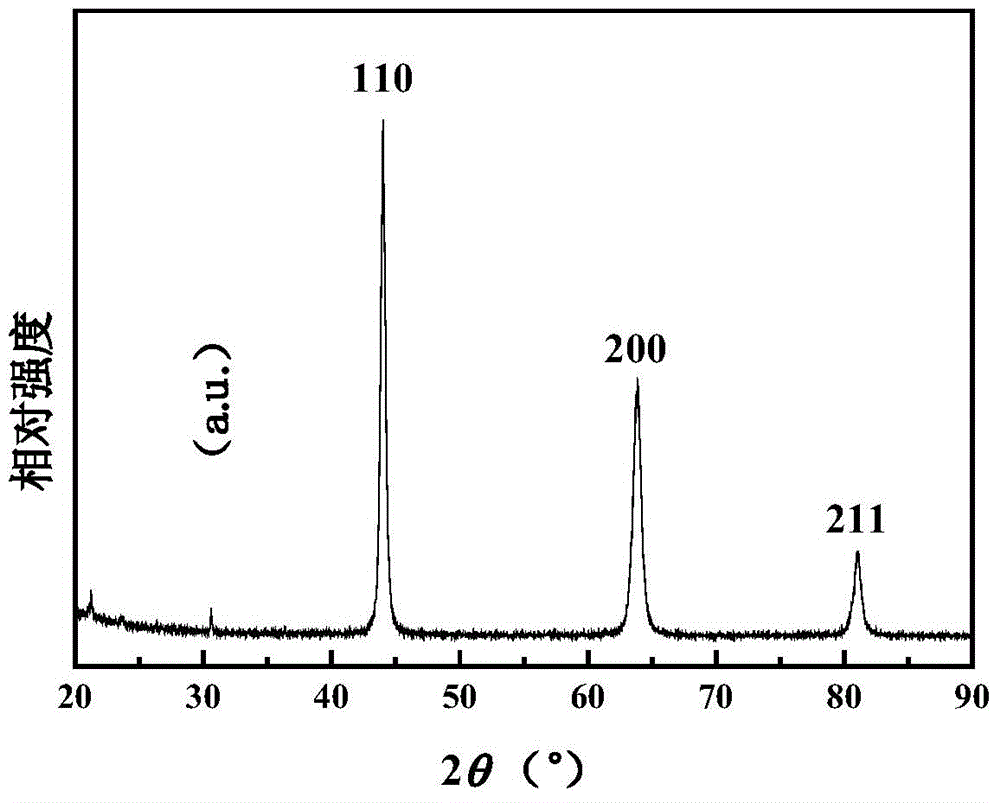

Magnetostrictive material and preparation method thereof

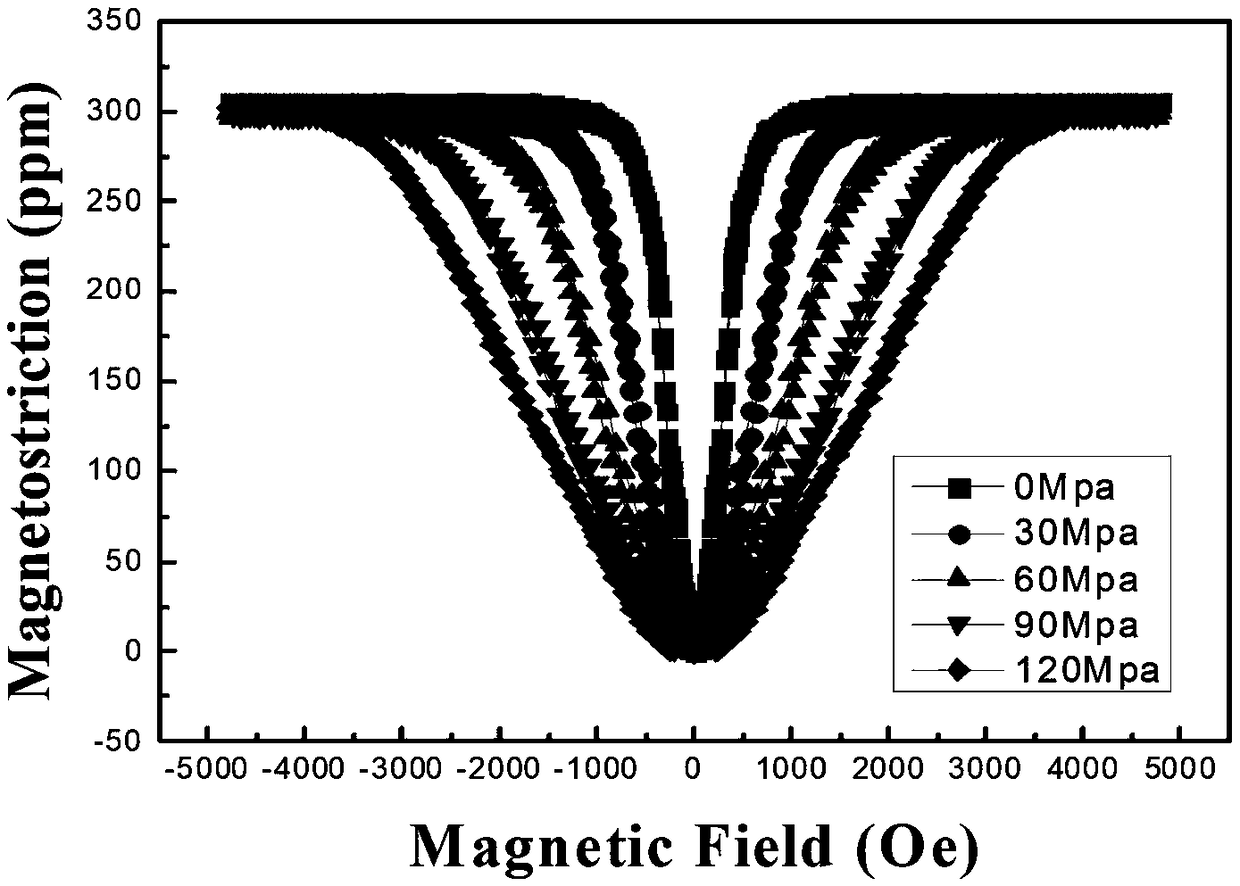

ActiveCN104947194AAchieve <100> single crystal orientationRaise the temperature gradientPolycrystalline material growthFrom frozen solutionsRare earthShielding gas

The invention provides a magnetostrictive material and a preparation method thereof. The composition of the magnetostrictive material is (Fe[]1-x]Gax)[100-y]REy, wherein 0.17<=x<=0.19, 0.01<=y<=0.2, and RE is selected from one or more of Tb, La, Sm, Dy, Lu, Ho, Er and Tm. The preparation method comprises the following steps: smelting the Fe Ga and RE prepared according to the composition requirements into a mother alloy cast ingot, preparing a mother alloy bar, putting the mother alloy bar and a <100>-oriented FeGa monocrystal seed in a directional solidification apparatus, vacuumizing the directional solidification apparatus, charging protective gas, heating to melt all the mother alloy bar and melt the upper part of the FeGa monocrystal seed, and drawing the molten material into a coolant along the lower part of the FeGa monocrystal seed to carry out directional solidification, wherein the temperature gradient is controlled at 1*10<5>-9*10<5> K / m, and the growth rate is 1000-20000 mm / hour. The magnetostrictive material prepared by the method is a <100>-oriented monocrystal material in which the RE elements are completely dissolved in the FeGa matrix; the saturated magnetic field is only 100-5000e, and the magnetostriction coefficient is up to 300-1500 ppm; and the magnetostrictive material has favorable comprehensive usability and wide application prospects.

Owner:BEIHANG UNIV

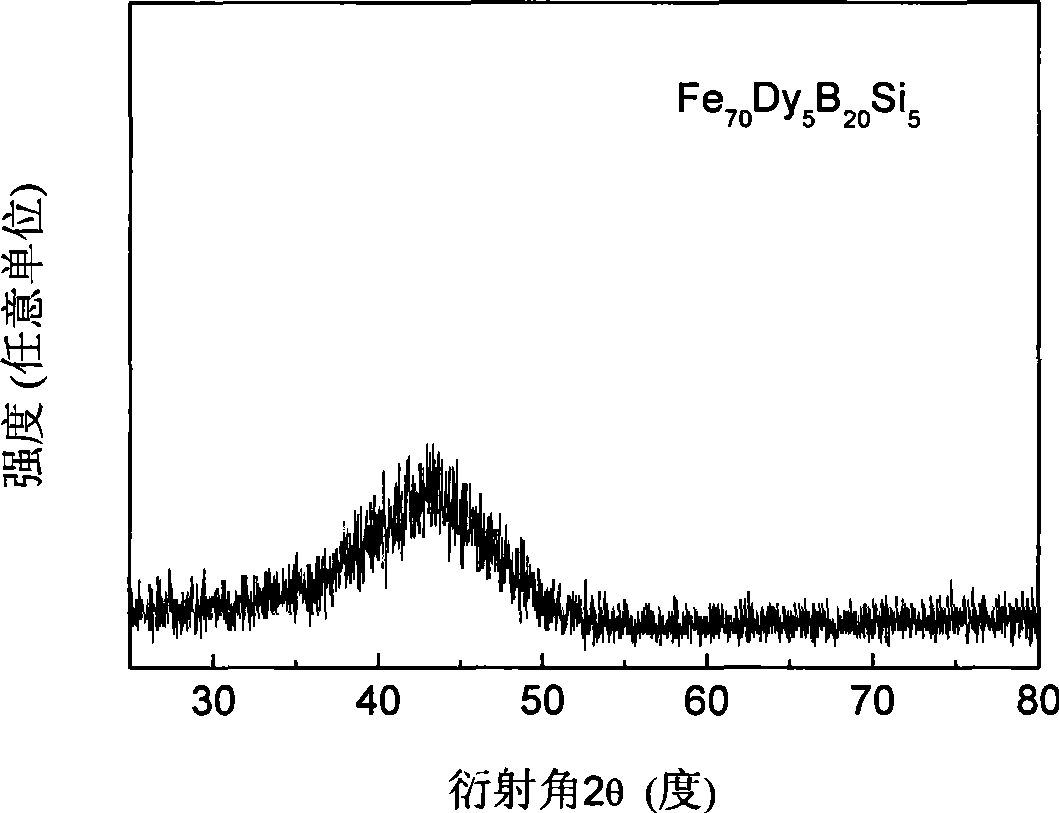

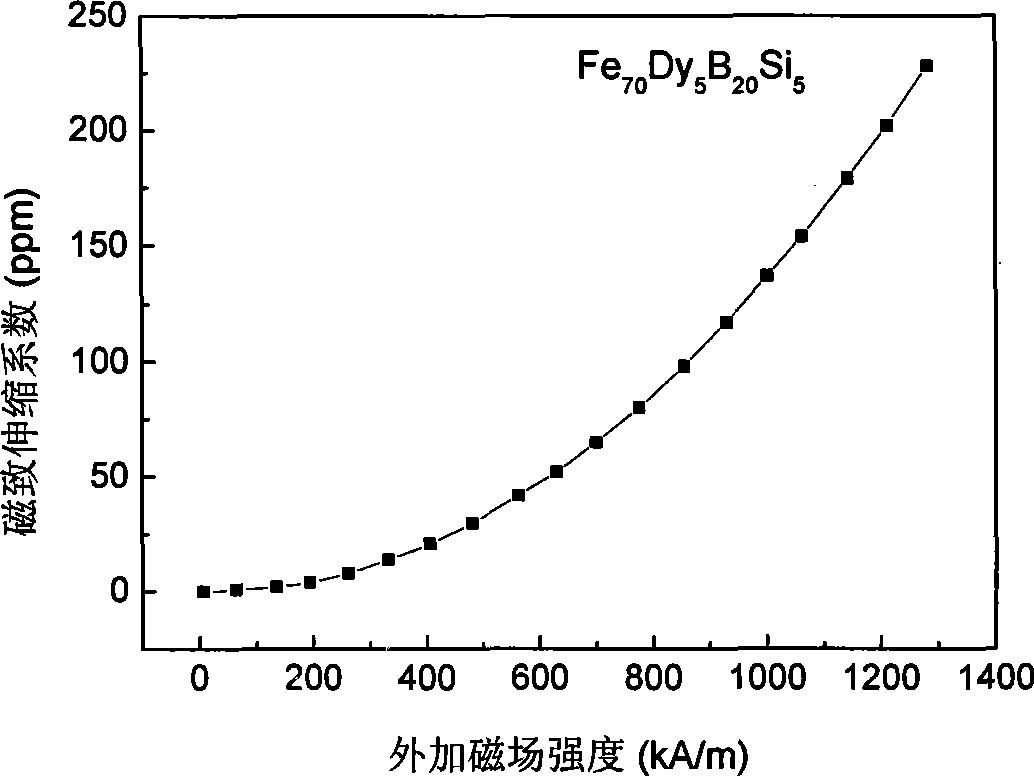

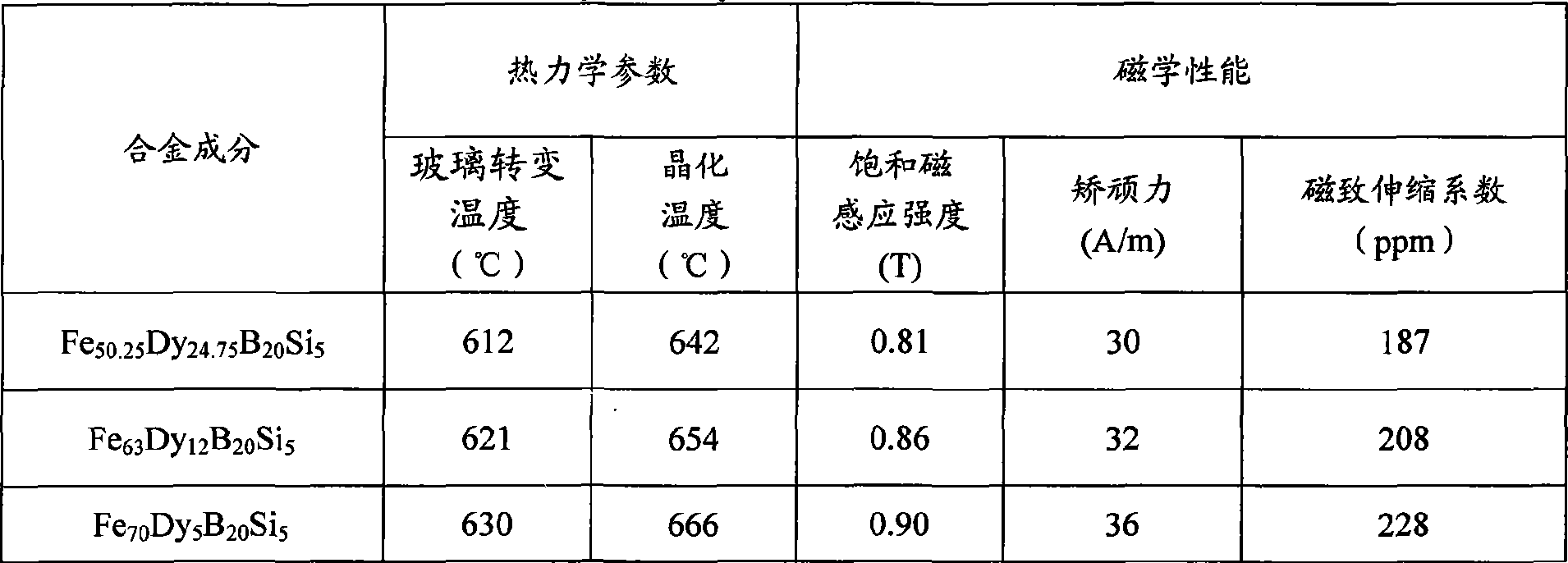

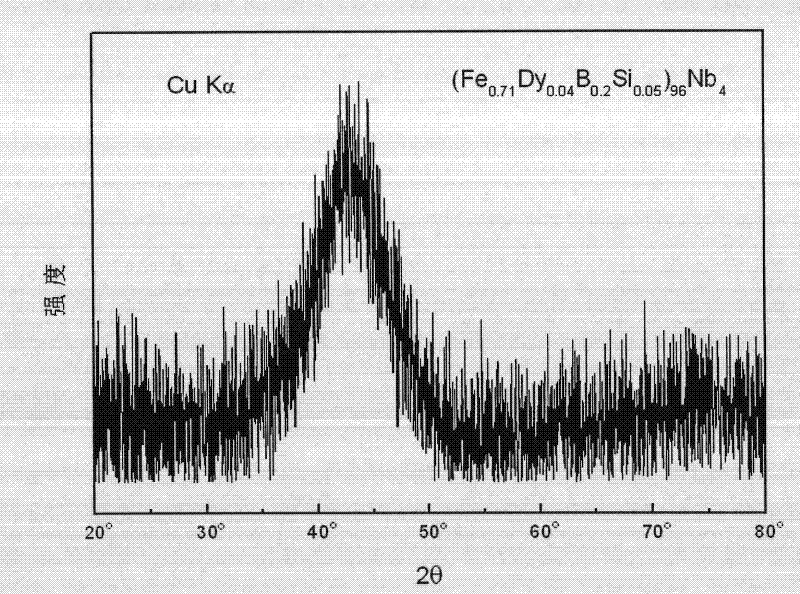

High magnetostriction iron based amorphous alloy and preparation thereof

InactiveCN101503784AHigh magnetostriction coefficientImprove thermal stabilityMagnetizationThermal stability

The invention discloses a high magnetostriction iron base amorphous alloy and a preparation method thereof. The high magnetostriction iron base amorphous alloy has the following chemical molecular formula: Fe100-x-y-zDyxBySiz, wherein x, y and z are the atom percent of a Dy element, a B element and a Si element respectively, 100-x-y-z is the atom percent of a Fe element, x is more than or equal to 5 and less than or equal to 25, y is more than or equal to 20 and less than or equal to 25, and z is more than or equal to 0 and less than or equal to 10. The preparation method comprises the following steps: mixing industrial pure metal raw materials and an FeB alloy according to an alloy formulation, carrying out the magnetic suspension induction smelting on the raw materials and the FeB alloy to obtain a mother alloy, and then preparing an amorphous thin belt through a single roller melt-spun method. The iron base amorphous alloy material has a high magnetostriction coefficient of 228 ppm, excellent soft magnetization performance, high thermal stability, and a good amorphous formation capability. Simultaneously, the alloy material has simple preparation method and can be widely applied to the aspects of soft magnetization materials and structural materials in the fields of information, communication, computer, and the like.

Owner:ZHEJIANG UNIV +1

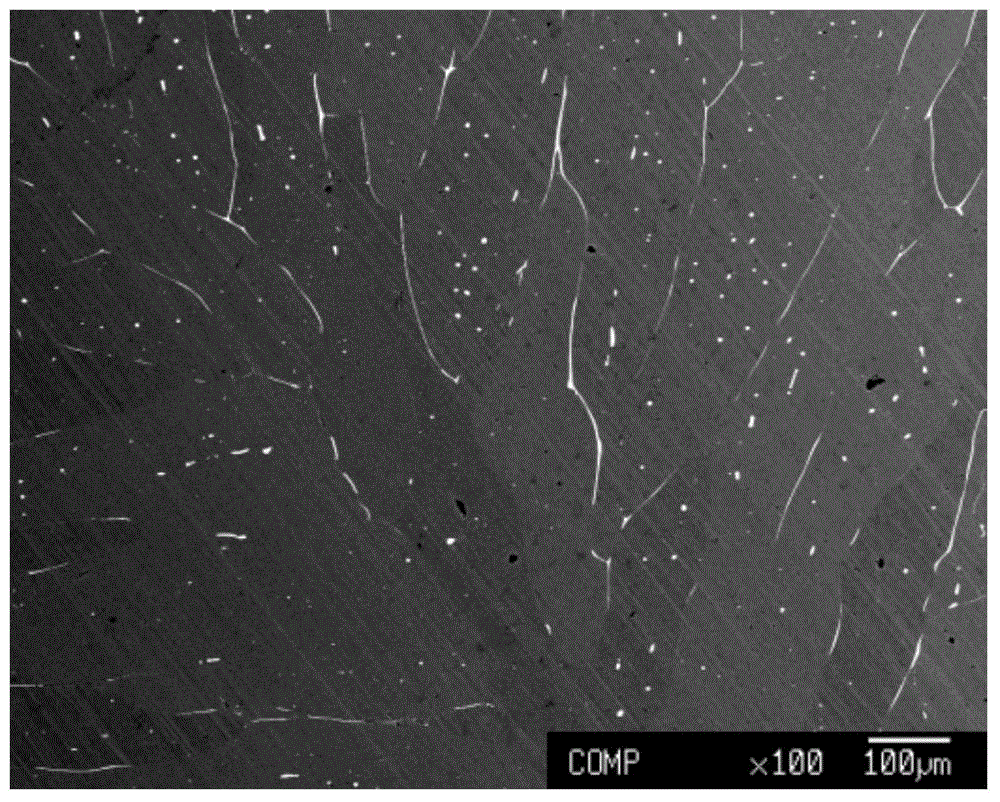

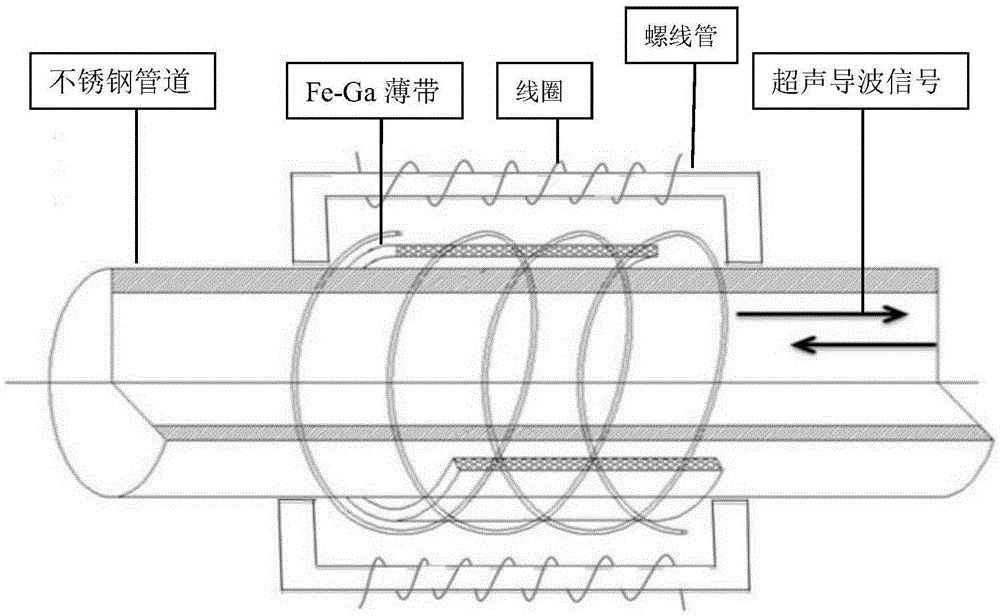

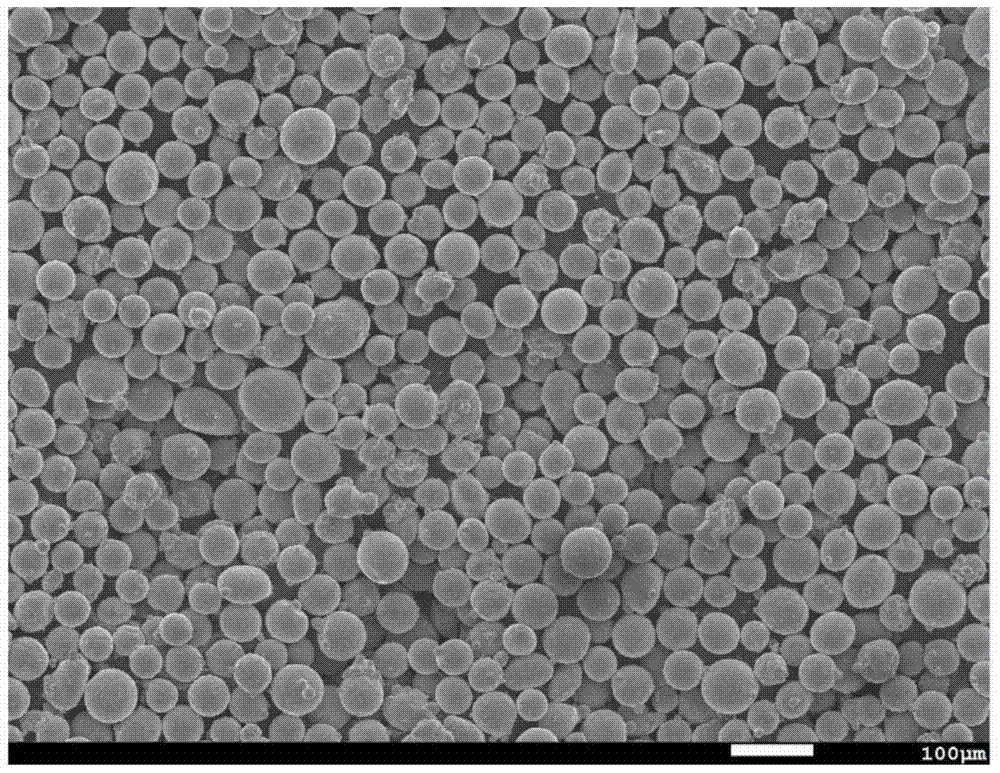

Method for manufacturing iron-based magnetostrictive coating through thermal spraying technology

ActiveCN105252011AHigh magnetostriction coefficientNot easily oxidizedMolten spray coatingPorosityThermal spraying

The invention provides a method for manufacturing an iron-based magnetostrictive coating through the thermal spraying technology and belongs to the field of magnetic materials. An iron-based magnetostrictive material is manufactured into spherical gasified and atomized powder, a metal material serves as a substrate, the spherical gasified and atomized powder is sprayed to the metal substrate in a plasma spraying manner, and the iron-based magnetostrictive coating is manufactured. The method includes the specific steps that the iron-based magnetostrictive material is smelted into a cast ingot in a vacuum smelting furnace, oxide skin on the surface is removed in a machining manner, the cast ingot is then conveyed to a high-pressure atomization powder making device, and molten alloy flow is crushed into small drops through high-speed argon flow and then condensed into powder. Plasma spraying is adopted in the thermal spraying technology, plasma gas is mainly nitrogen, hydrogen is auxiliary gas, the iron-based magnetostrictive gasified and atomized powder is conveyed into a plasma chamber, and through heating, smelting, flight, base body impact, cooling and solidification, the coating is formed. The method has the beneficial effects that the coating combination strength is high, the structure is dense, the porosity is low, and included oxide slag is reduced due to the addition of alloy elements.

Owner:UNIV OF SCI & TECH BEIJING

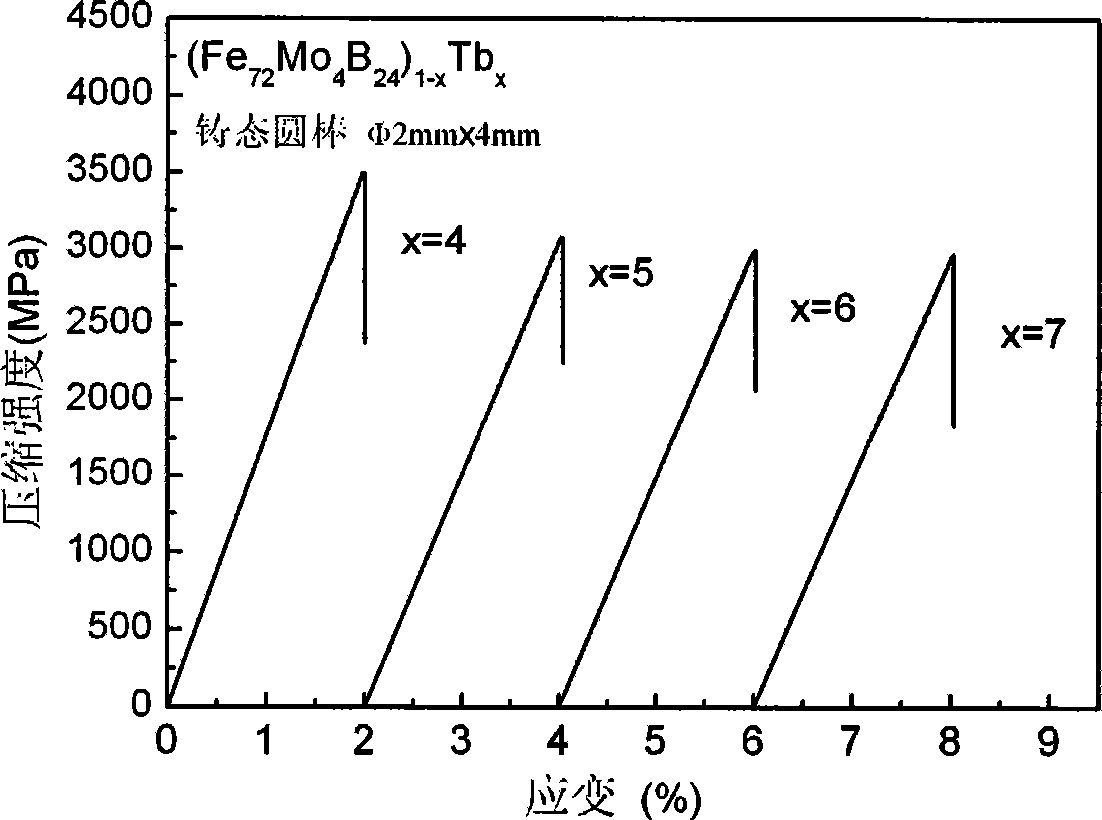

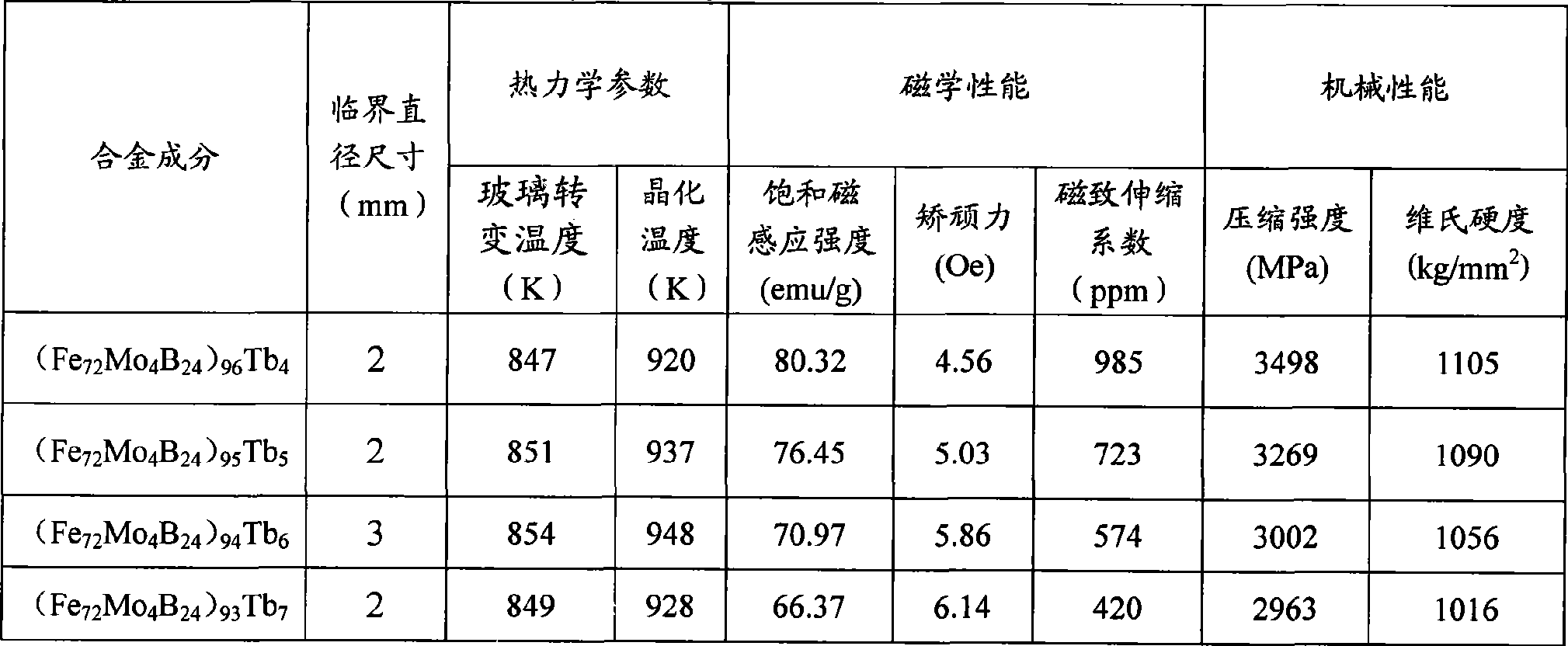

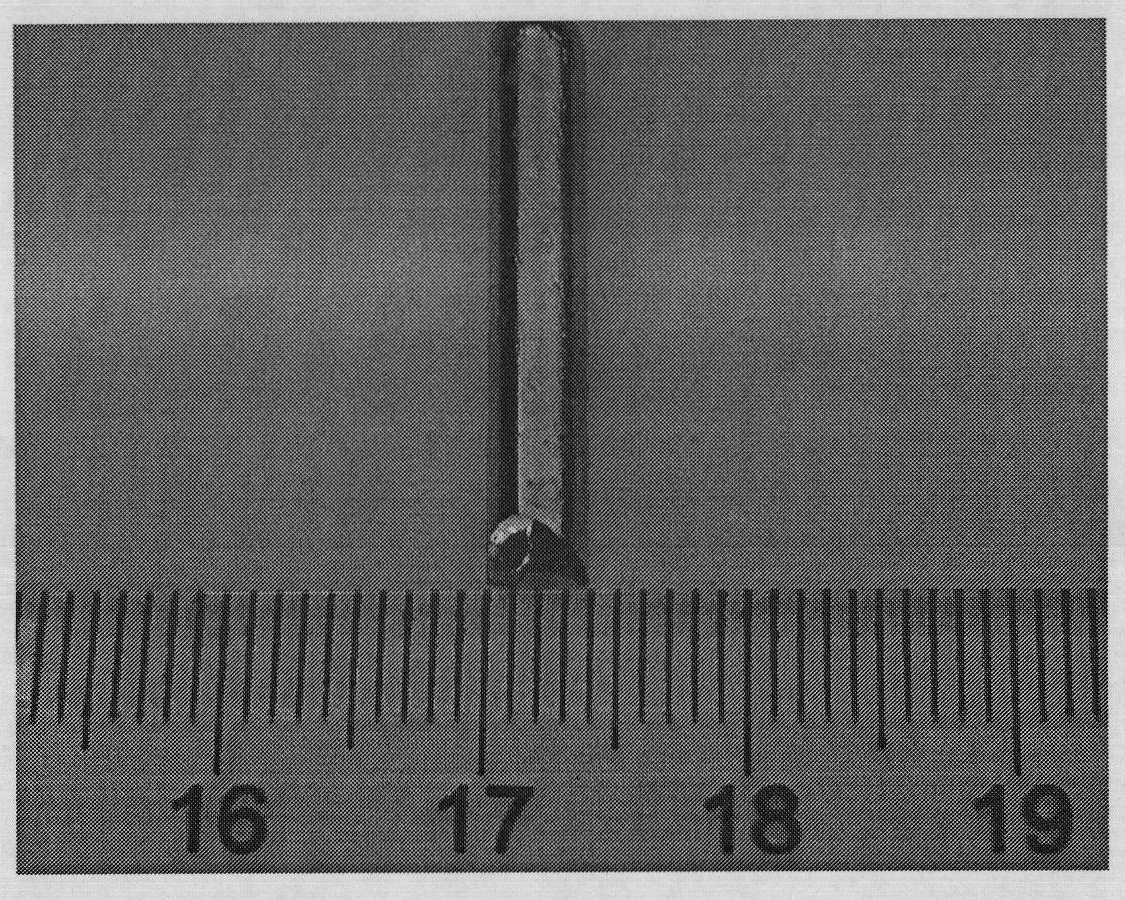

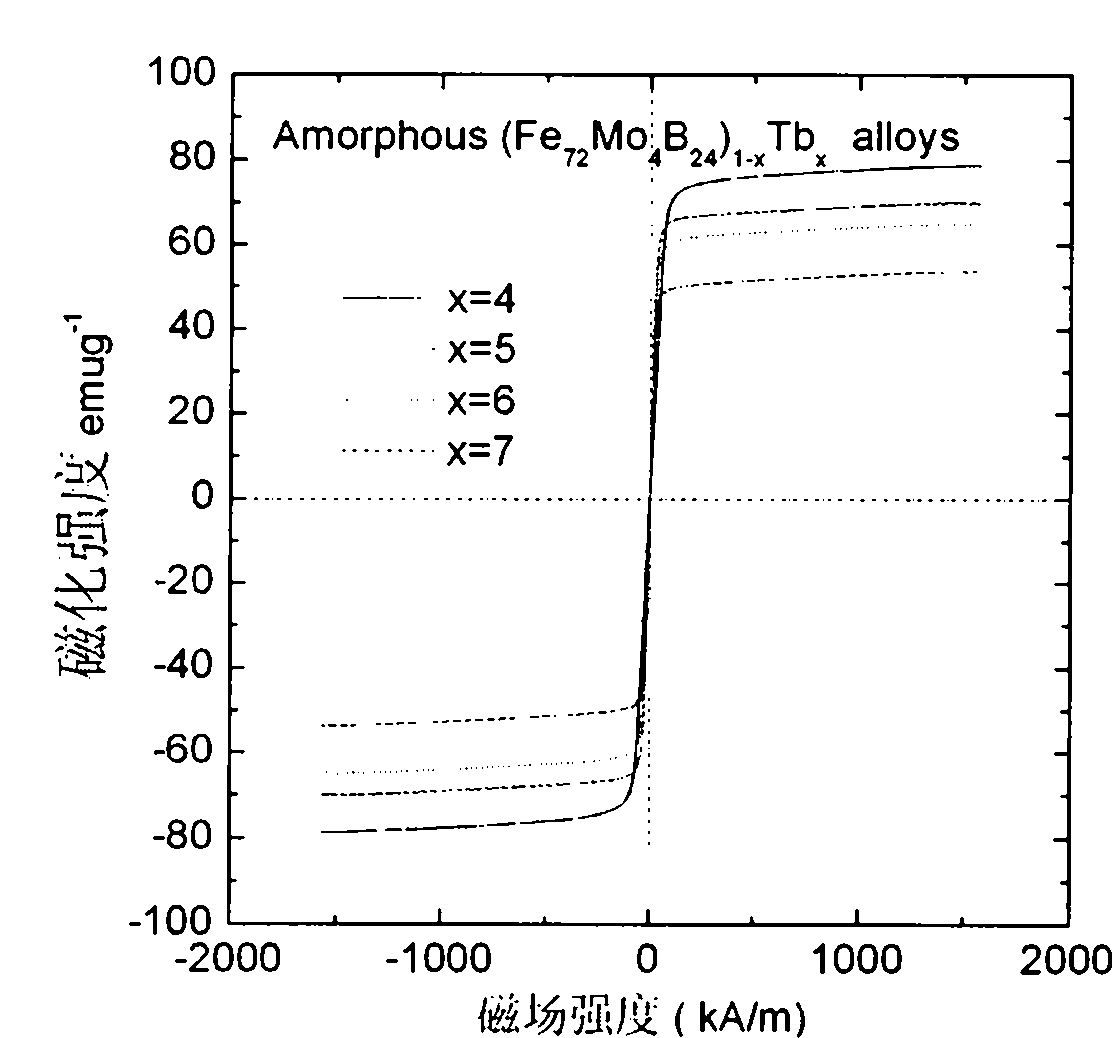

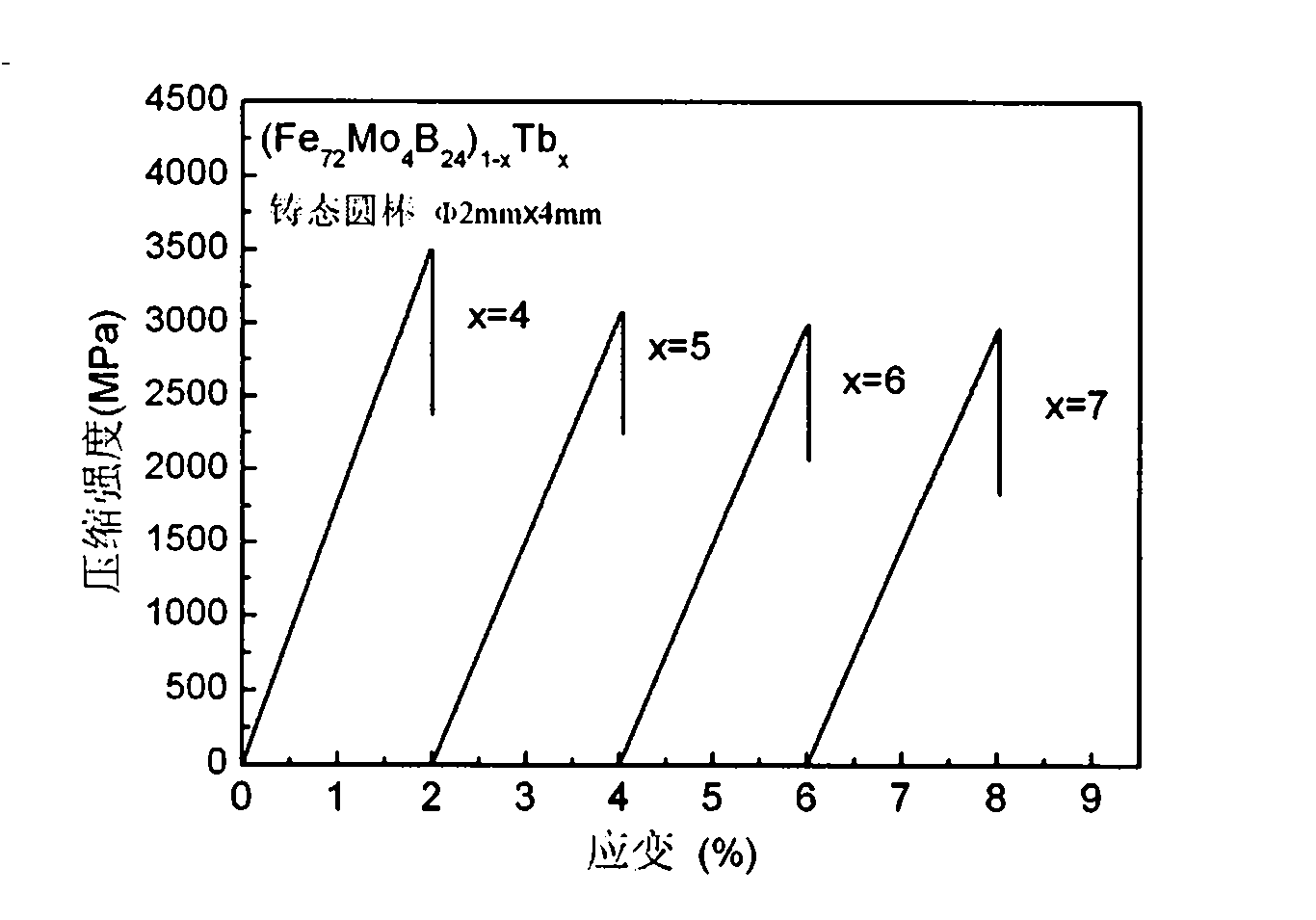

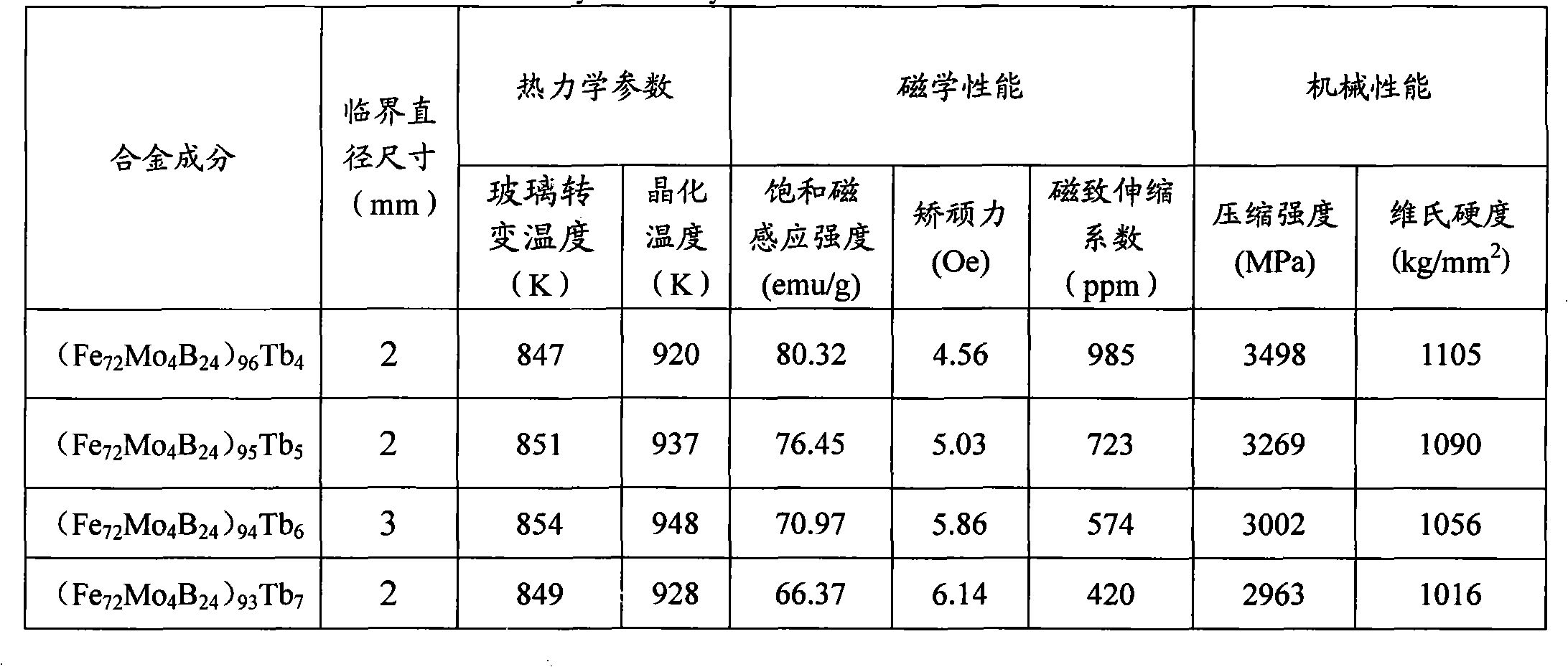

High magnetic striction iron based metallic glass magnetic material and preparation thereof

InactiveCN101487106APurity requirements are not very highHigh magnetostriction coefficientSimple componentTransducer

The invention discloses a high magnetostrictive Fe-based metal glass magnetic material and a preparation method thereof. The chemical formula of the high magnetostrictive Fe-based metal glass alloy is Fe100-x-y-zMozByTbx, wherein, x, y and z are respectively the atomic percents of Tb, B and Mo, 100-x-y-z is the atomic percent of Fe, x is more than 0 and less than or equal to 10, y is more than or equal to 20 and less than or equal to 25, z is more than 0 and less than or equal to 10. The preparation method of the alloy is as follows: the industrial pure metals Fe, Mo, Tb and FeB alloy are proportioned according to the alloy formula and melted repeatedly by induction-arc under the protection of argon to make master alloy, then the high magnetostrictive Fe-based metal glass magnetic material is obtained through casting by using the copper mold spray-casting method. The magnetostrictive coefficient of the magnetic material is 420 ppm to 985 ppm, and the magnetic material has simple components, high thermal stability, and good mechanical properties and amorphous forming ability. The high magnetostrictive Fe-based metal glass magnetic material can be widely applied to the fields of sonar transducer, sensor, ultrasonic technology, communication technology, and the like.

Owner:ZHEJIANG UNIV +1

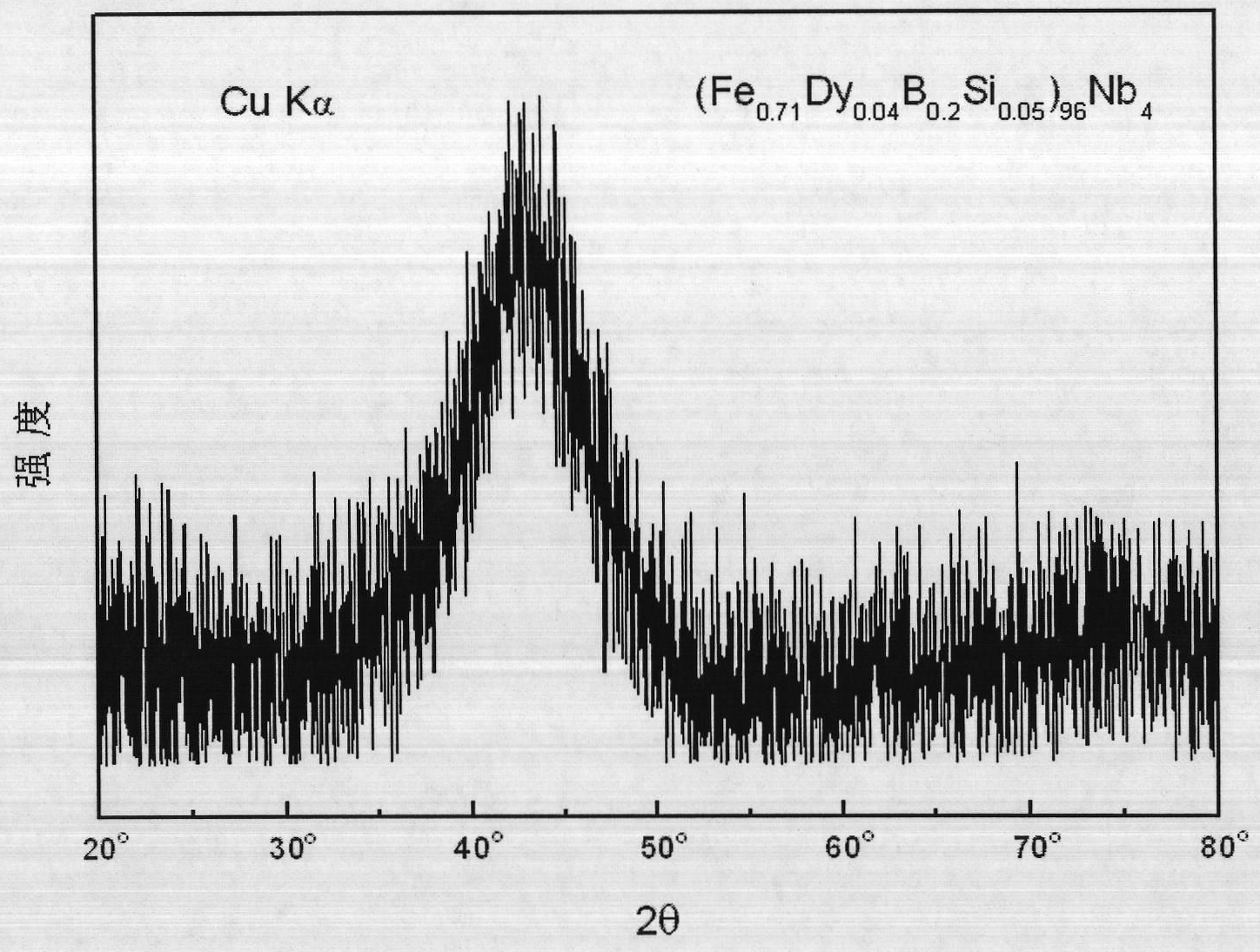

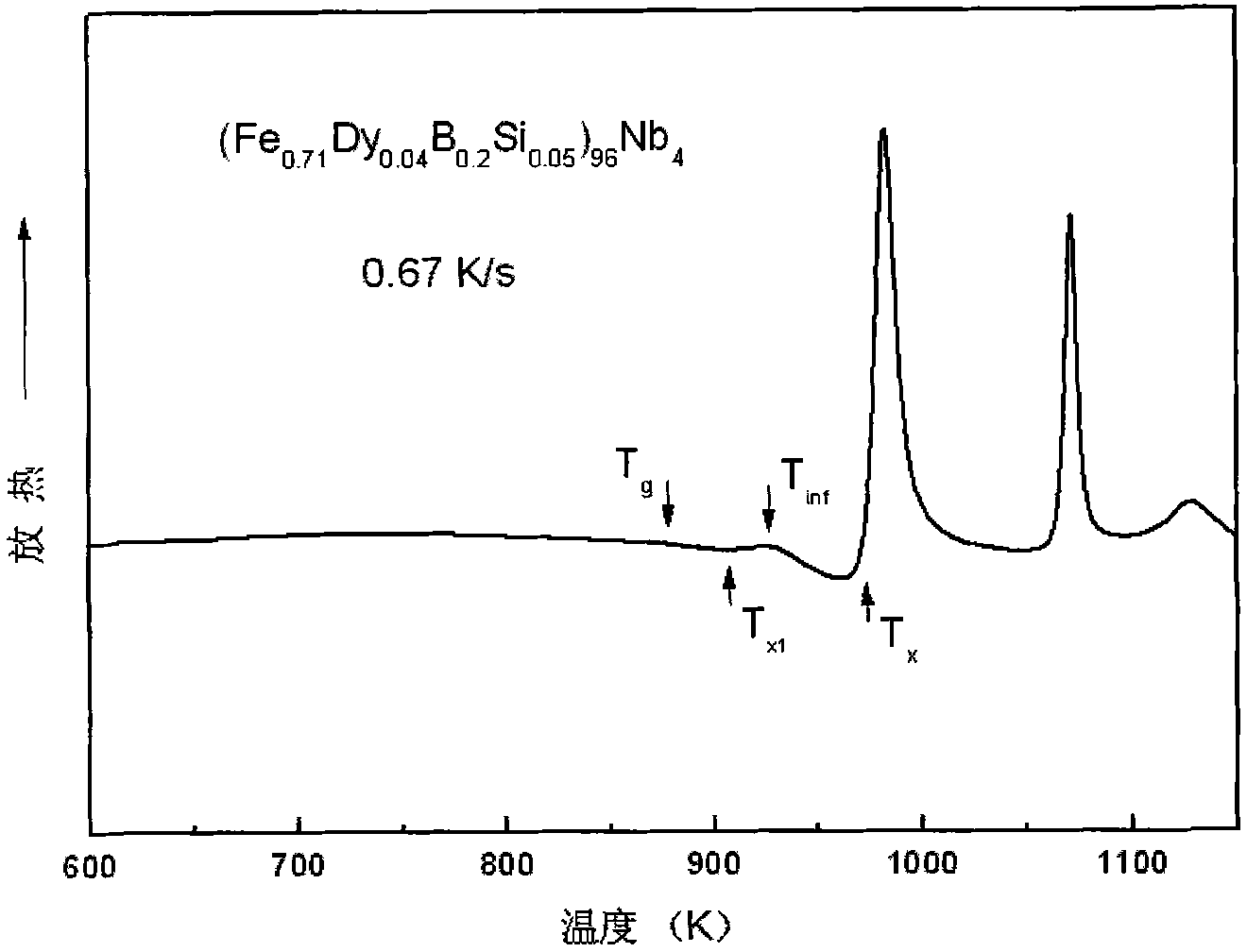

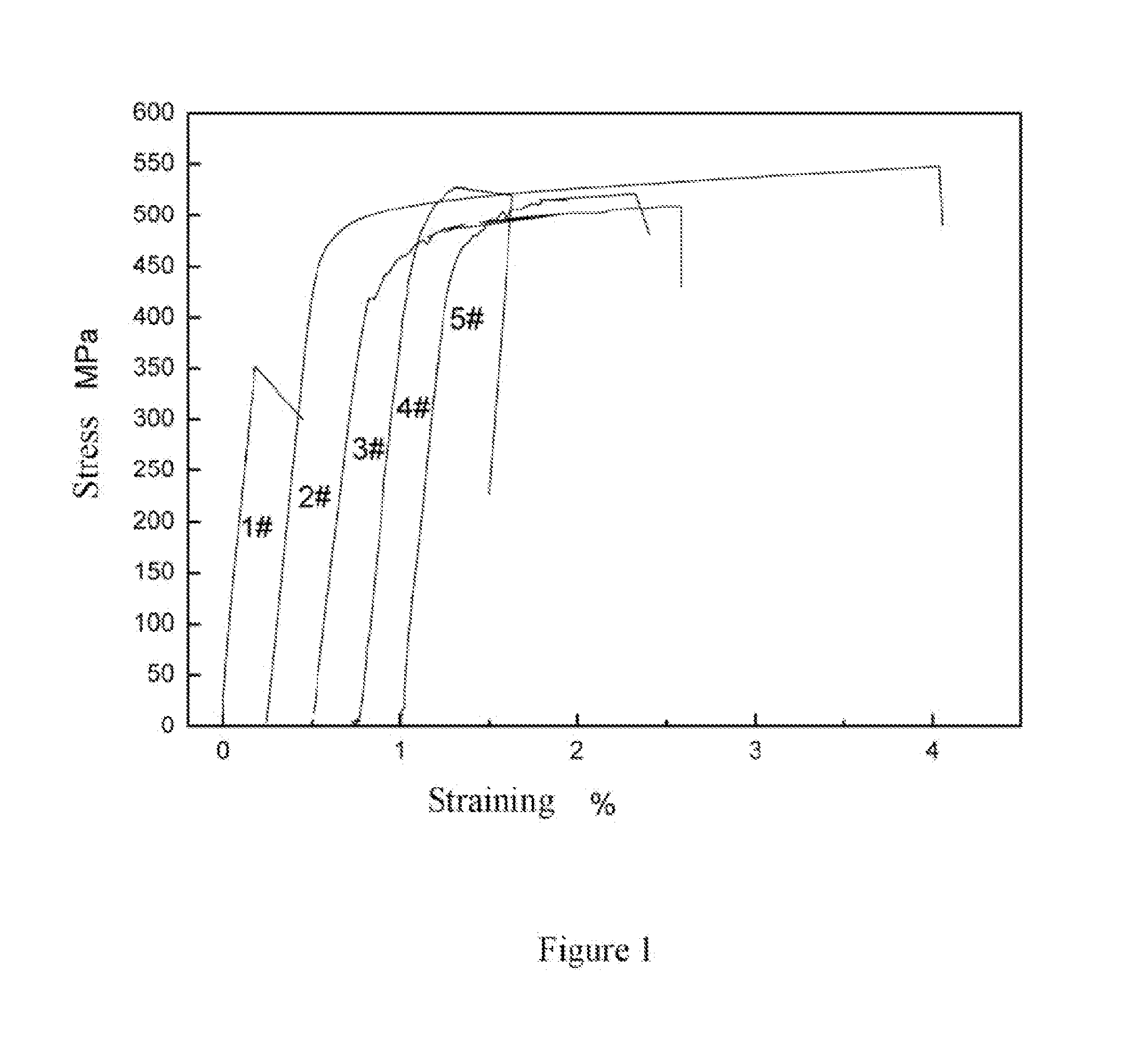

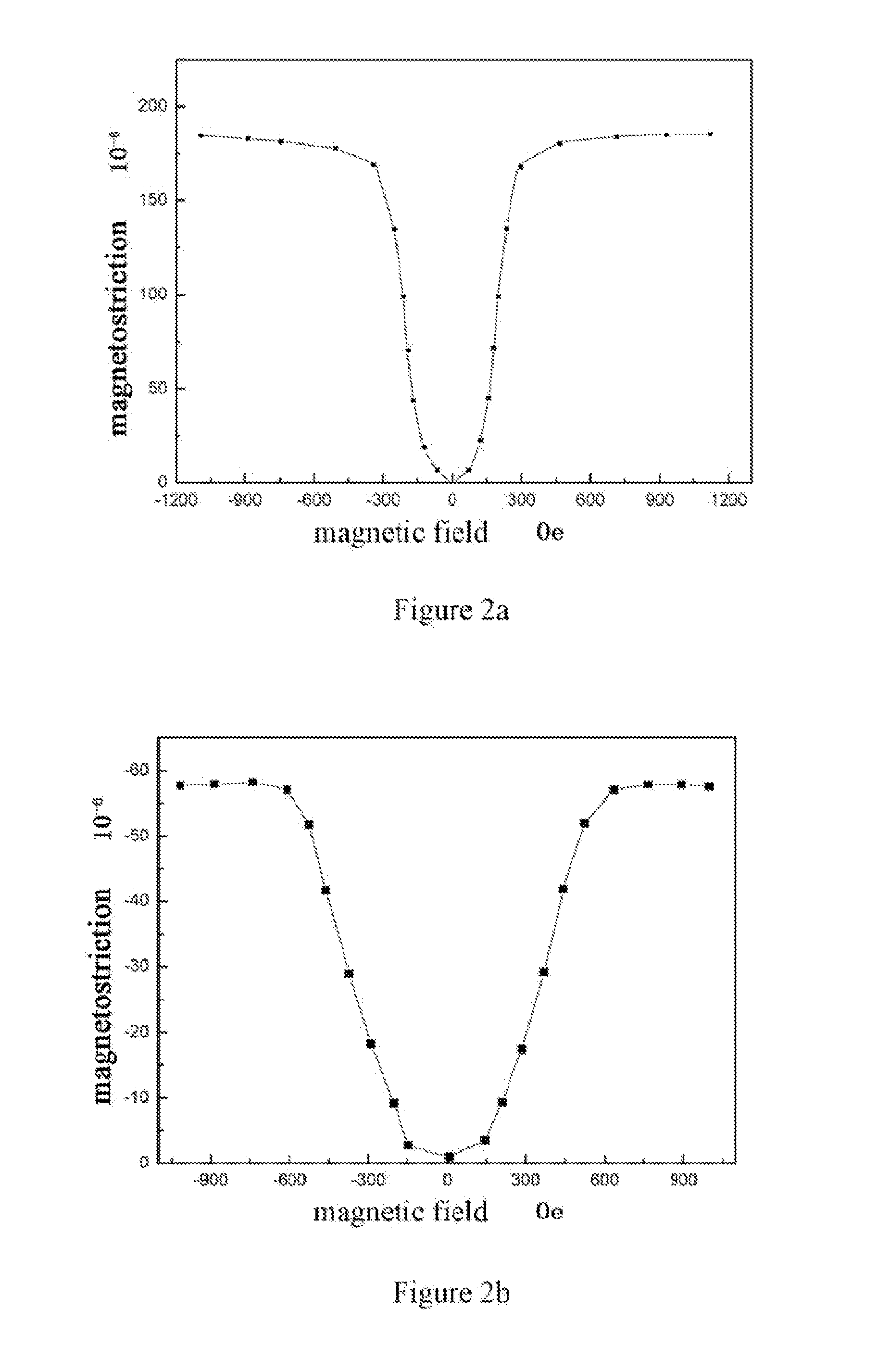

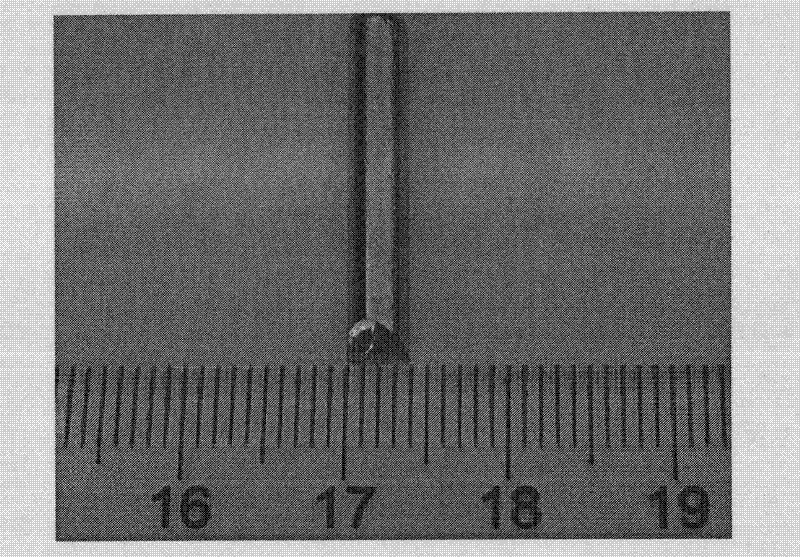

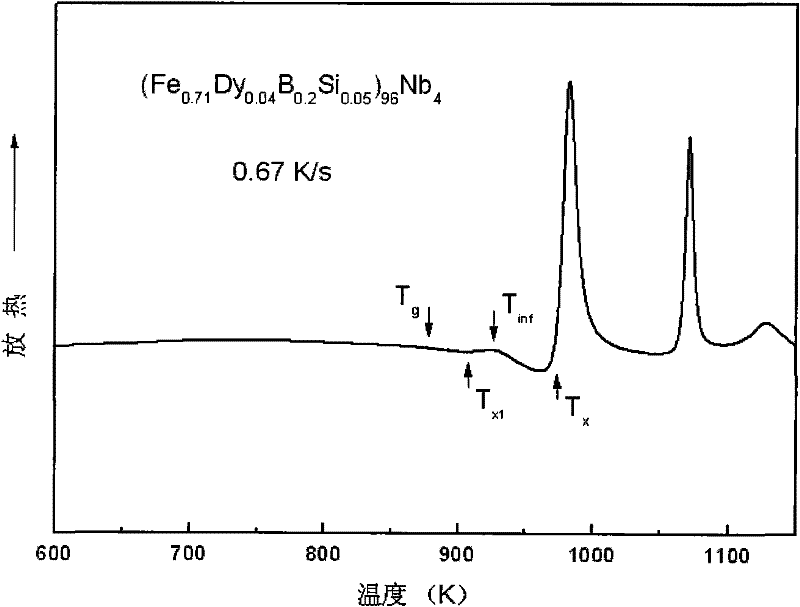

Large-amorphous forming capacity iron-based block amorphous magnetic alloy material and preparation method thereof

ActiveCN101928896AEnhanced Amorphous Formation AbilityHigh magnetostriction coefficientMagnetic materialsTransformerGlass transition

The invention discloses a large-amorphous forming capacity iron-based block amorphous magnetic alloy material and a preparation method thereof. The molecular formula of the large-amorphous forming capacity iron-based block amorphous magnetic alloy material is (Fe0.75-aMaB0.25-bSib) 1-cNbc, wherein M is one or more elements of Dy, Tb, Sm, Er, Ga and Y, a, b and c are atom percentages, a is not less than 0.005 and not greater than 0.1, b is not less than 0.03 and not greater than 0.07, and c is not less than 0.02 and not greater than 0.06. Compared with the prior art, the alloy material in the invention has the advantages of large amorphous forming capacity, favorable magnetostrictive coefficient and excellent soft magnetic performance, the reduced glass transition temperature of the alloy material reaches 0.5-0.7, the magnetostrictive coefficient reaches -50*10<-6> to 200*10<-6>, the alloy material can be prepared into amorphous bars with the diameters of 0.5mm-6mm due to the large amorphous forming capacity, thereby the alloy material can be widely applied in the fields of transformers, magnetic sensors and the like.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

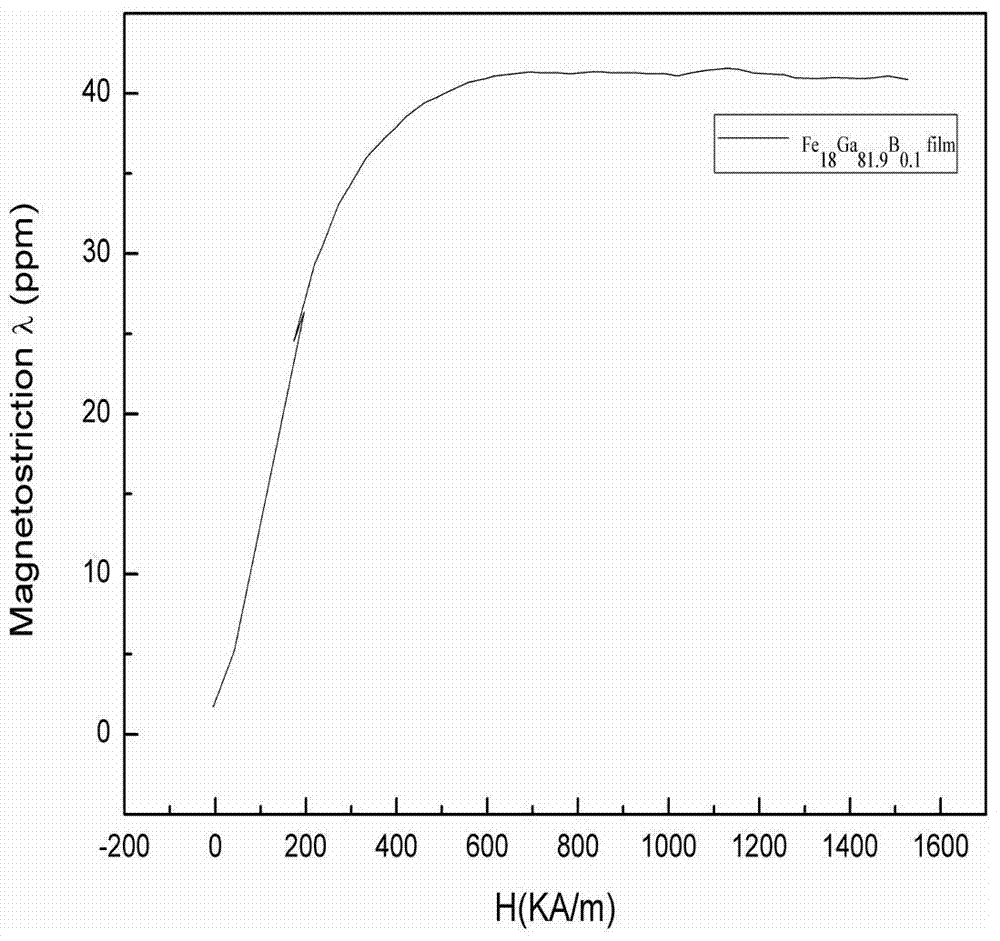

Magnetostrictive material and preparation method thereof

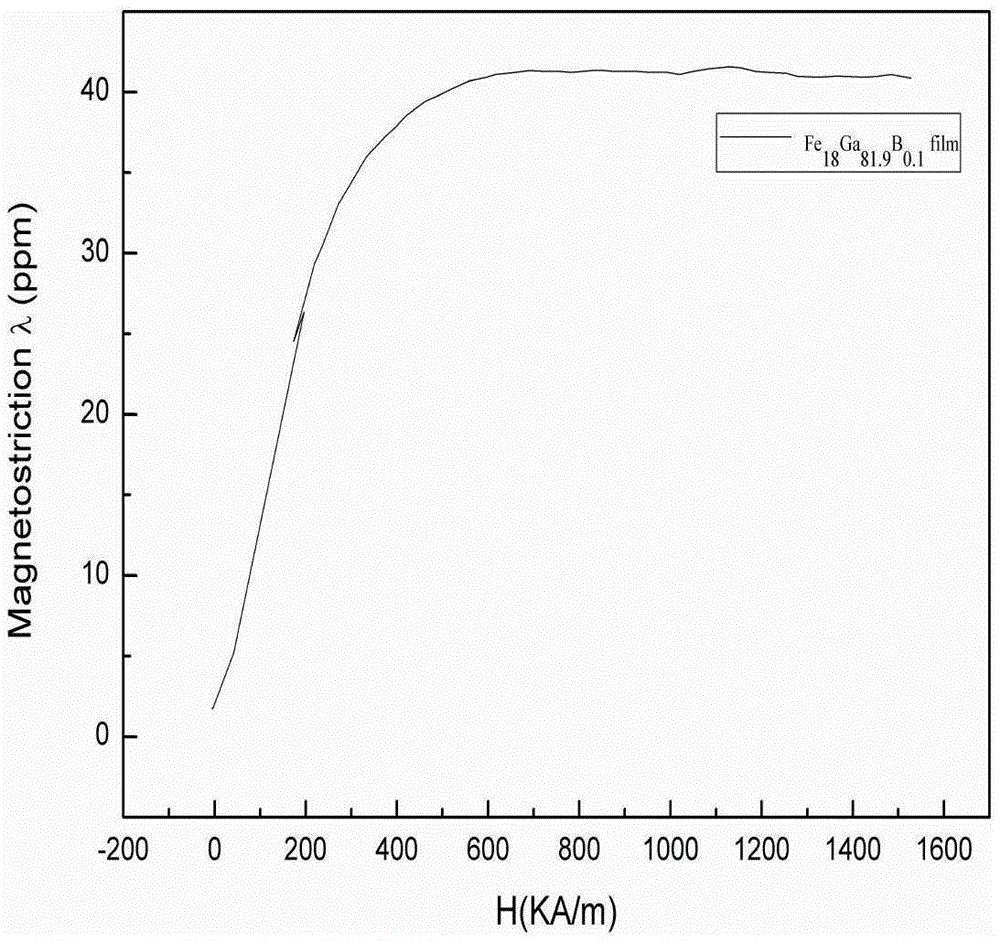

ActiveUS20110192508A1High magnetostriction coefficientImprove mechanical propertiesMagnetostrictive material selectionMagnetic layersThin sheetMaterials science

The present invention relates to a Fe—Ga—Al-based magnetostrictive thin-sheet material and a process for preparation thereof. The raw materials used for production of the thin-sheet material is composed of the components according to the general Formula, Fe100-x-y-zGaxAlyMz, wherein x=10-30, y=1-10, and z=0.1-5, and M is any one, or more elements selected from V, Cr, Zr, Sb, Sn, Ti, SiC.

Owner:BEIJING MAGORIENTAL MATERIALS TECH CO LTD

F-P structure-based optical fiber micro-suspension bridge magnetic field sensing probe

ActiveCN106932739ASimple structureWon't interfereMagnetic field measurement using magneto-optic devicesResonant cavityParticle physics

The present invention relates to the magnetic field measurement in a narrow space and provides an F-P structure-based optical fiber micro-suspension bridge magnetic field sensing probe. The sensing probe structurally comprises an optical fiber, a fixed support end, an optical fiber micro-suspension bridge, an intermediate reflector, a Fabry-Perot resonant cavity, a chromium metal film and a giant magnetostrictive film. The optical fiber micro-suspension bridge is arranged at the end surface of the optical fiber and is connected with the optical fiber through the fixed support end. The optical fiber micro-suspension bridge and the end surface of the optical fiber together form the Fabry-Perot resonant cavity. The chromium metal film and the giant magnetostrictive film are sequentially plated on the outer surface of the optical fiber micro-suspension bridge. According to the technical scheme of the invention, the requirements of a high-precision detection magnetic field can be met based on the Fabry-Perot resonant cavity. The two pole plates of the Fabry-Perot resonant cavity are effectively ensured to be parallel to each other by the intermediate reflector. Meanwhile, the measurement range is increased.

Owner:CHINA JILIANG UNIV

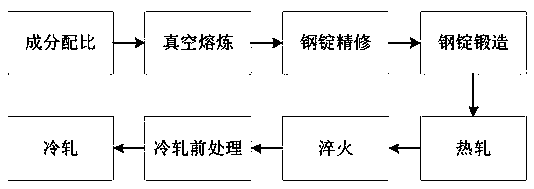

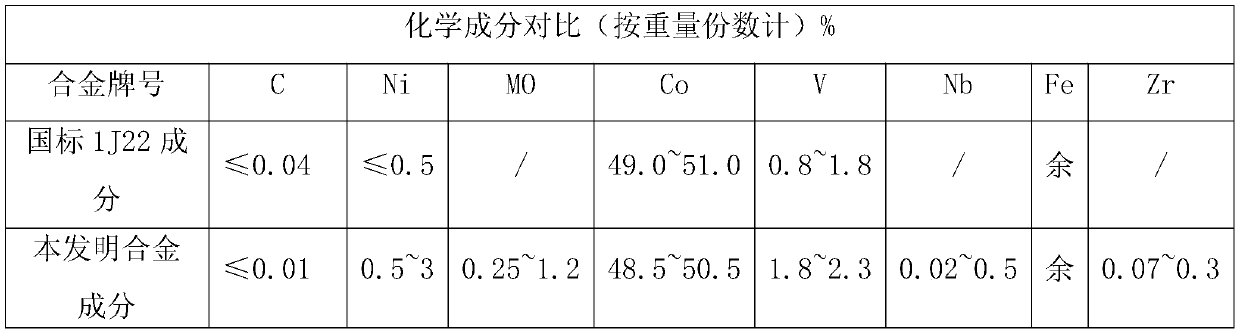

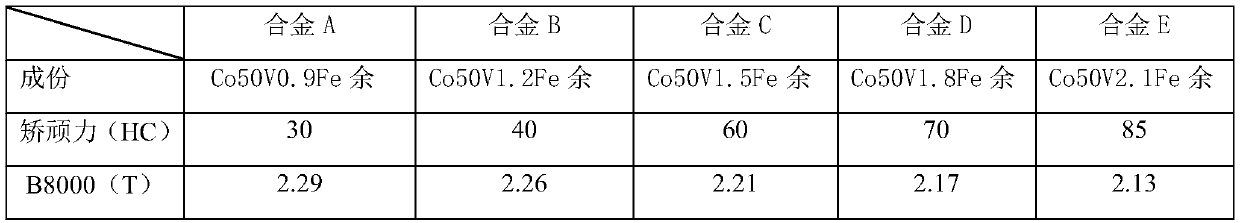

High-strength high-saturation magnetically soft alloy for generator and strip preparation method thereof

InactiveCN110499469AReduce size and weightGuaranteed flexibilityFurnace typesHeat treatment furnacesSurface finishingChemical composition

The invention provides high-strength high-saturation magnetically soft alloy for a generator and a strip preparation method thereof. The high-strength high-saturation magnetically soft alloy comprisesthe following chemical components of 47.5%-50.8% of Co, 1.8%-2.3% of V, 0.02%-0.5% of Nb, 0.5%-3% of Ni, 0.25%-1.2% of Mo and 0.07%-0.3% of Zr, and the rest component is Fe. The strip preparation method comprises the following process steps that firstly, matching is conducted according to the chemical components; secondly, smelting is conducted with a vacuum induction method; thirdly, finishing and forging are conducted on a smelted steel ingot; fourthly, a processed-forged square billet forms a hot-rolled strip billet through hot rolling; fifthly, surface treatment is conducted through pickling and polishing during cold rolling, and cold rolling cogging is conducted; and sixthly, rolling is conducted through a cluster mill till cold rolling total deformation is not lower than 90%. According to the high-strength high-saturation magnetically soft alloy material special for the high-power aerogenerator, the lowest strip coercivity can reach 100 A / m, magnetic induction intensity reaches2.3 T, with the higher saturation magnetic induction intensity, the size and weight are reduced greatly when a same-power motor is made, and flexibility of the complete machine is ensured.

Owner:陕西航空精密合金有限公司

High-performance rare-earth-iron-based giant magnetostrictive material and preparation method thereof

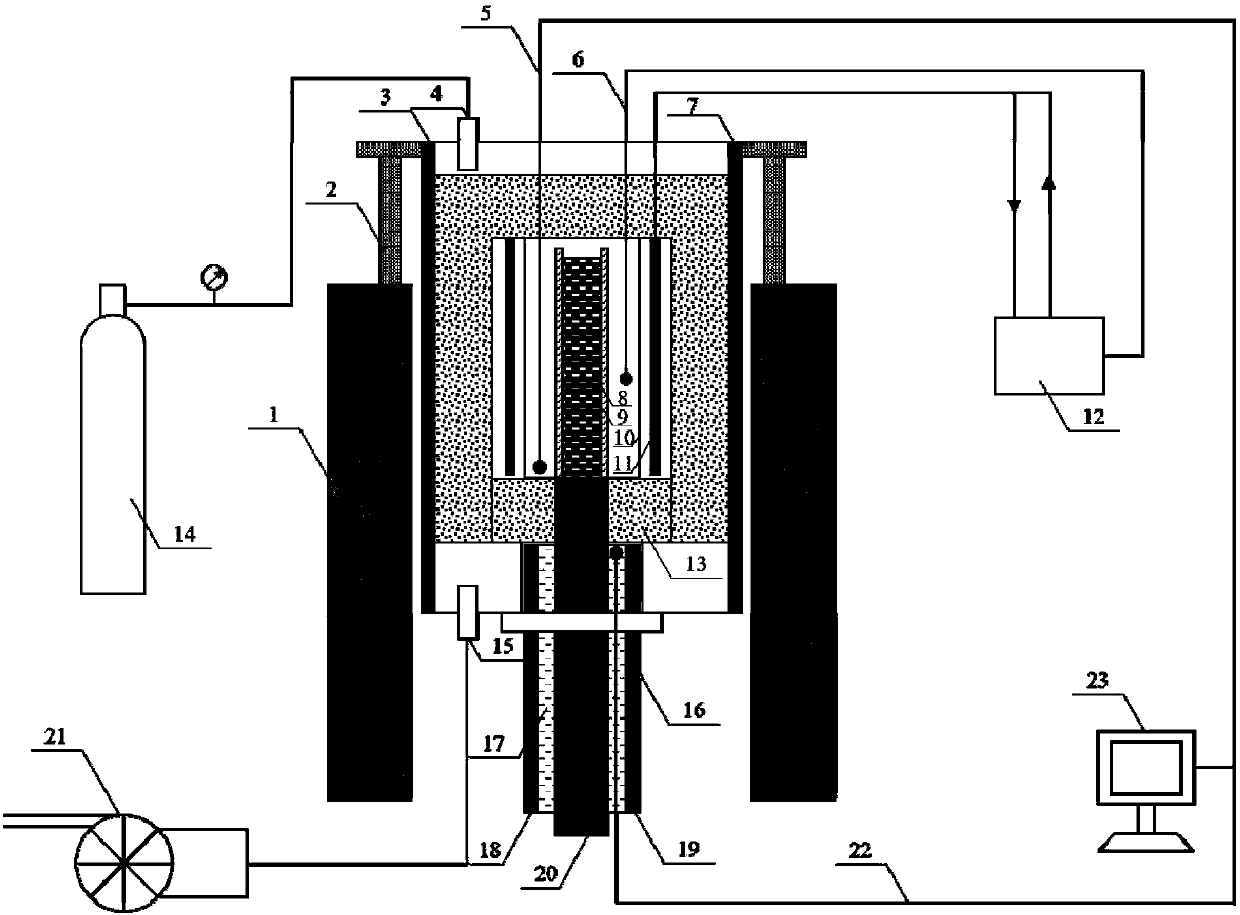

InactiveCN108018483AHigh magnetostrictive performanceGood magnetostrictive performanceRare earthLiquid metal

The invention discloses a high-performance rare-earth-iron-based giant magnetostrictive material and a preparation method thereof, and belongs to the technical field of magnetic functional materials.The method comprises the following steps that 1, induction smelting is carried out on a (TB1-XMX) fey alloy, M is equal to at least one of Dy, Sm, Ce, Pr, Nd, Ho and Er, X is equal to 0 to 0.70, and Yis equal to 1.75-2.25; 2, the alloy is placed in an inert gas and gradient strong magnetic field environment, and the alloy is at least heated to 150 DEG C above the liquidus temperature, and the temperature is kept for at least 8 minutes; and 3, the rate of 5-120 microns per second is taken, then an alloy liquid is pulled into a liquid metal cooling liquid to achieve directional solidification,and after the temperature of a heating chamber is cooled to the room temperature, the sample is taken out. The prepared magnetostrictive material has the advantages of high mechanical property, the large magnetostriction coefficient and the like; and the method has the advantages that operation is simple, control is accurate, the product performance is excellent, and the high-performance magnetostriction material can be produced in batches.

Owner:NORTHEASTERN UNIV

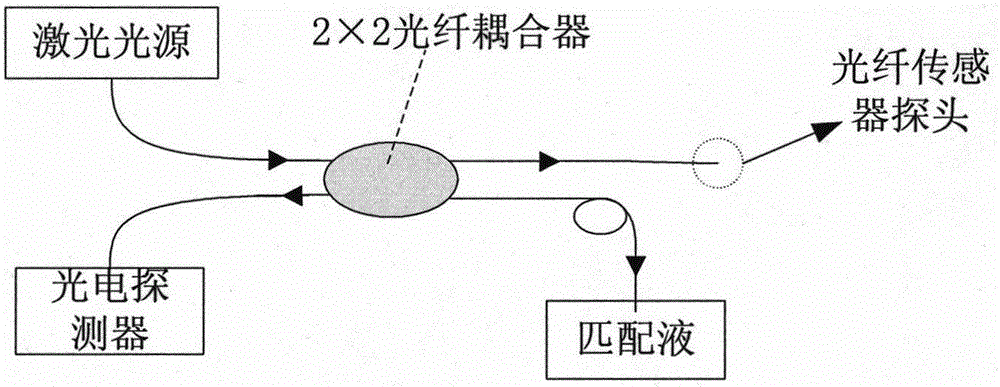

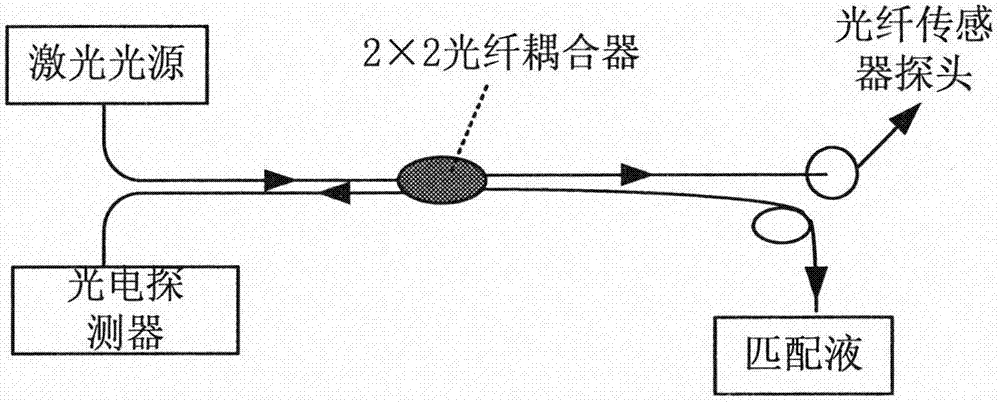

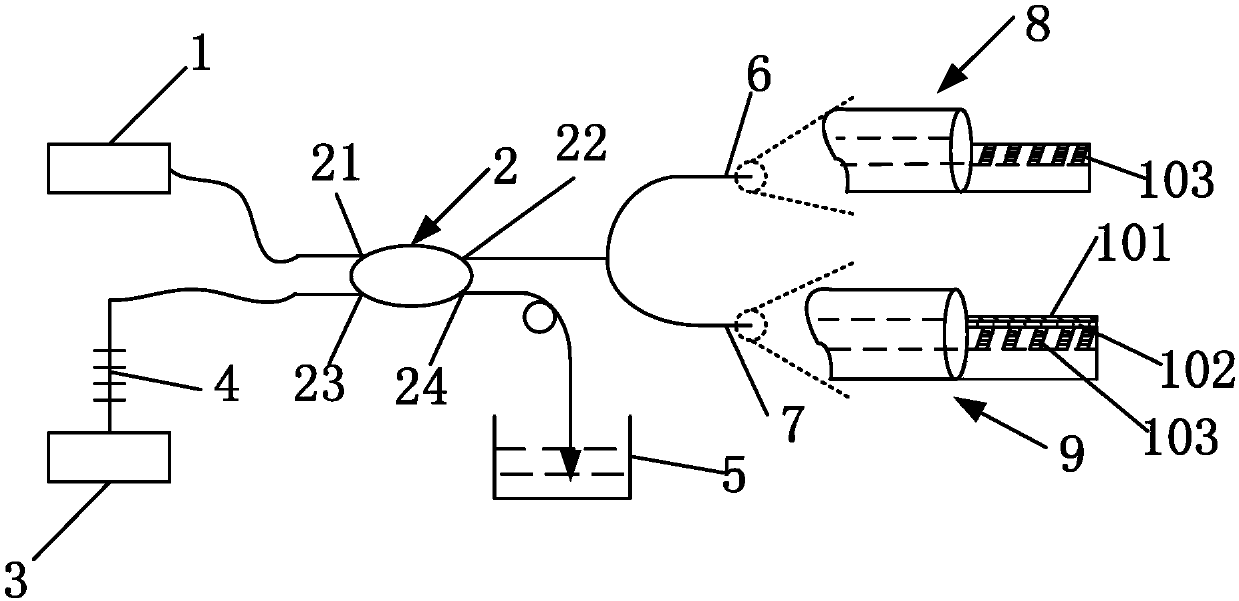

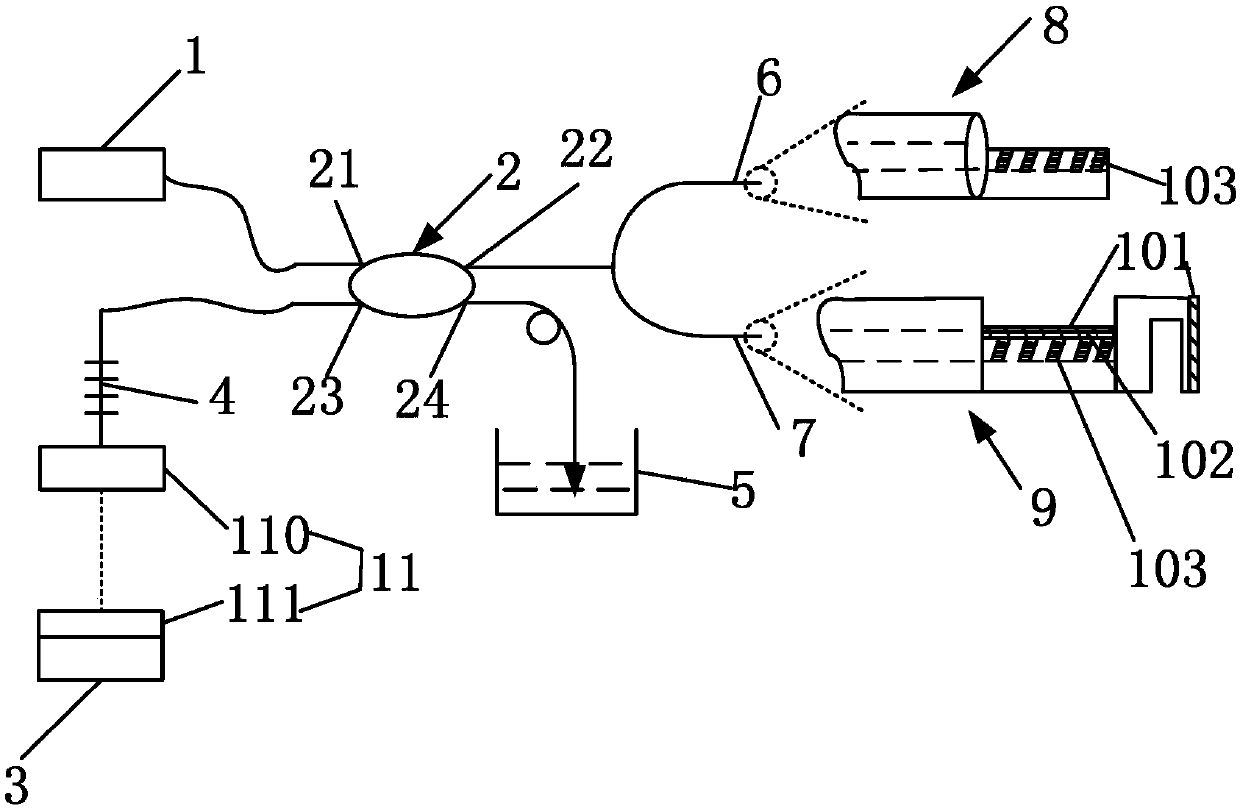

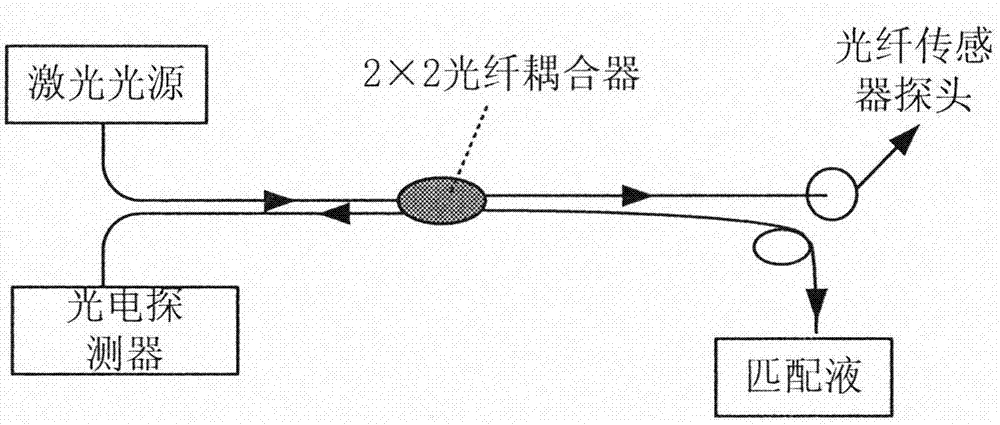

Magnetic field detection system based on giant magnetostrictive film

InactiveCN107632276AWon't interfereReduce volumeMagnetic field measurement using magneto-optic devicesPhotovoltaic detectorsFiber gratings

The invention provides a magnetic field detection system based on a giant magnetostrictive film and relates to the technical field of a fiber sensor. The system comprises an LD light source, a fiber directional coupler, a photoelectric detector, matching liquid, a Y-shaped fiber body and a magnetic field sensor, wherein the magnetic field sensor comprises a first sensing probe and a second sensingprobe, the first sensing probe is directly constructed at a first end portion of the Y-shaped fiber body and is used for detecting temperature in the magnetic field as temperature compensation basis,the second sensing probe comprises a D-type fiber grating suspension beam, a metal film and the giant magnetostrictive film, the D-type fiber grating suspension beam is directly constructed at a second end portion of the Y-shaped fiber body, the metal film is coated at an upper surface of the D-type fiber grating suspension beam, and the giant magnetostrictive film is arranged at the surface of the metal film to induct intensity of the induction magnetic field. The system is advantaged in that the system works under all-optical excitation conditions, interference on the to-be-detected magnetic field is avoided, the volume is small, and the system is suitable for being used in the narrow space.

Owner:于盟盟

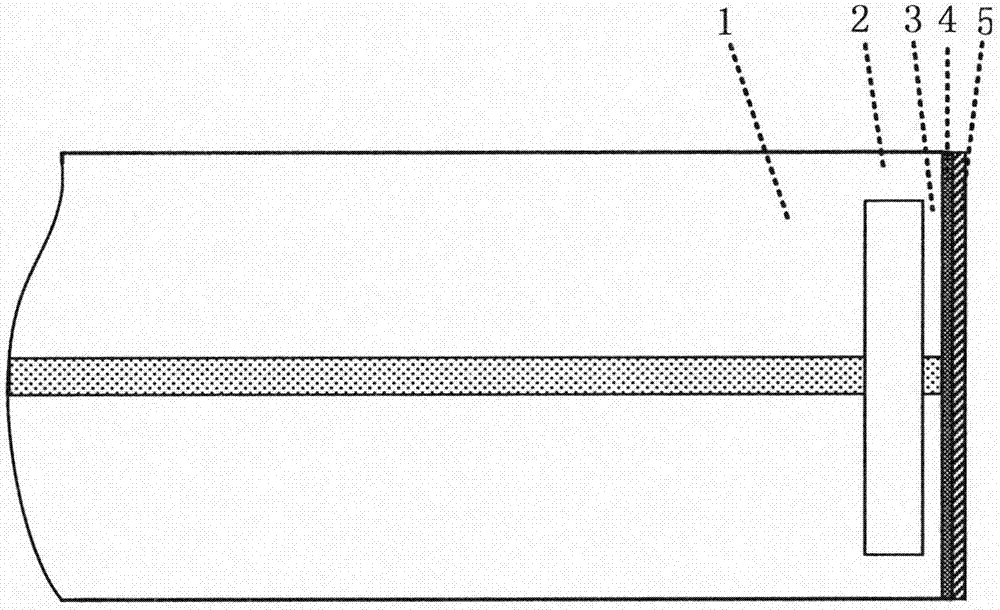

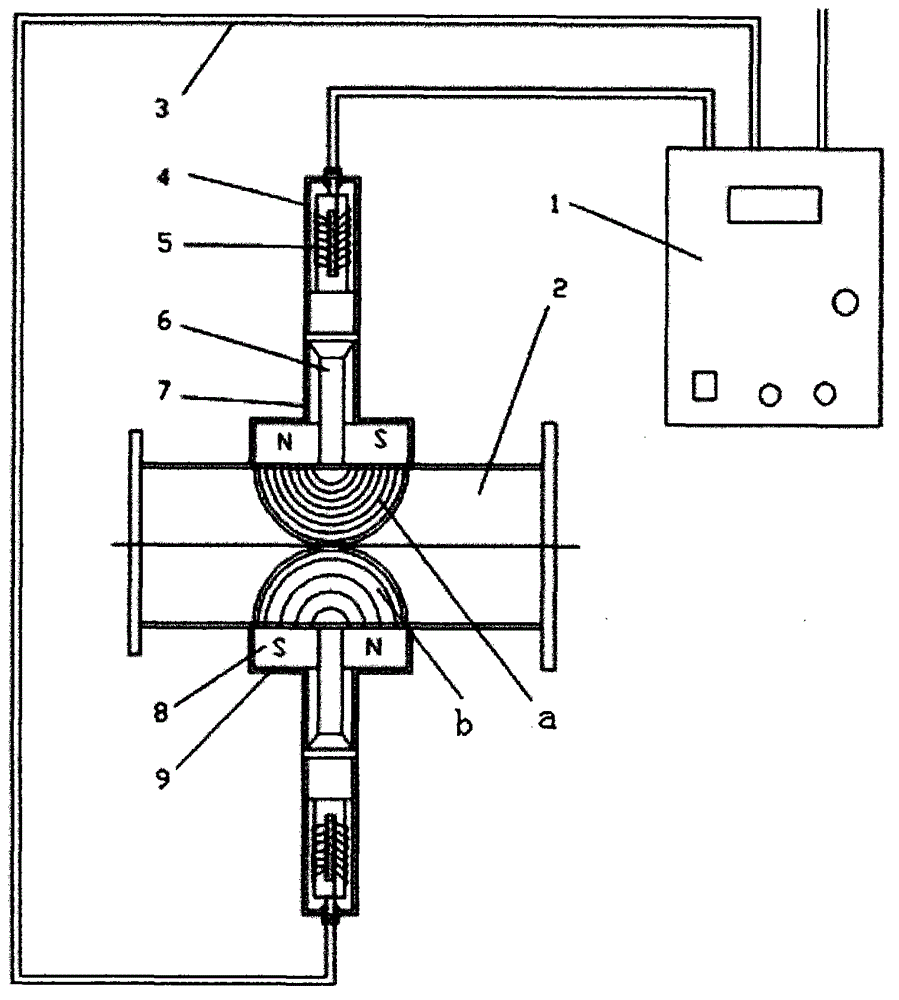

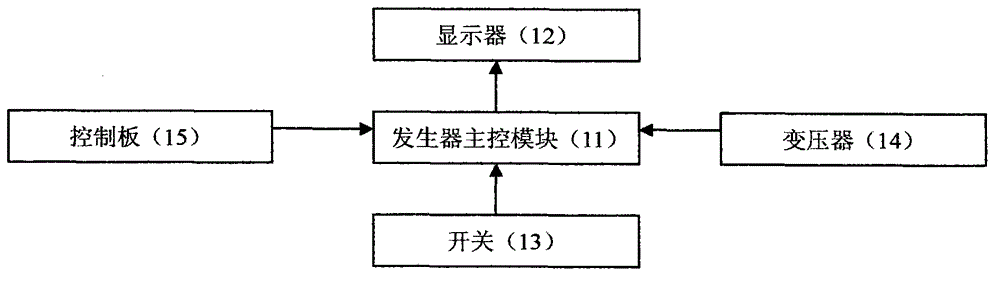

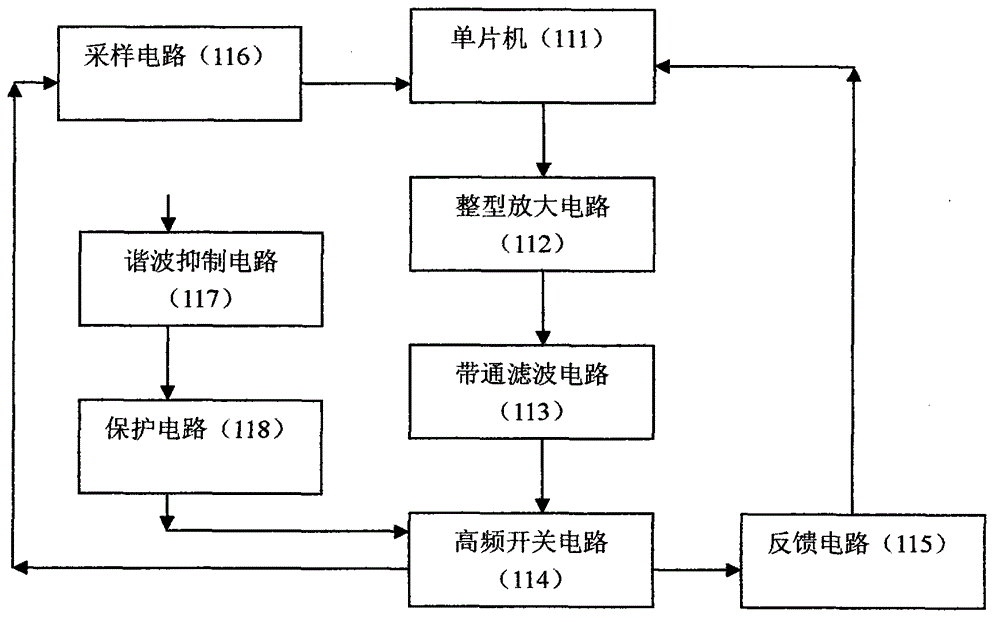

Magnetic ultrasonic wave on-line scale-preventing-removing all-in-one machine

InactiveCN104001698AIncrease pulse beam and mechanical energyReduce enable lossHollow article cleaningCleaning using liquidsUltrasonic generatorMagnet

The invention discloses a magnetic ultrasonic wave on-line scale-preventing-removing all-in-one machine which comprises a high-intensity transducer, a high-intensity transducer shielding protecting cover, strong magnets, strong magnet protecting devices and an ultrasonic wave generator. The high-intensity transducer is arranged in the high-intensity transducer shielding protecting cover and is connected with the ultrasonic wave generator through an electric cable. The bottom end of the high-intensity transducer extends out of the high-intensity transducer shielding protecting cover and is in contact with the surface of a metal pipeline. The strong magnets are arranged on the bottom of the high-intensity transducer shielding protecting cover and are placed on the two sides of the bottom of the high-intensity transducer. The strong magnet protecting devices are arranged on the surfaces of the strong magnets. The high-intensity transducer and the strong magnets are combined, ultrasonic pulse resonance waves generated by the high-intensity transducer and a magnetic field generated by the strong magnets have effect on a metal pipeline, synergistic effect is formed, wave-like impact waves are generated, a scale layer of the pipe wall of the metal pipeline is impacted and hammered ceaselessly, stress is generated between scale layer molecules, so that scale layer fracturing, loosening and falling off happen, and the scale layer sinks deep into an impounding reservoir with water flow.

Owner:广州正森一辰科技有限责任公司

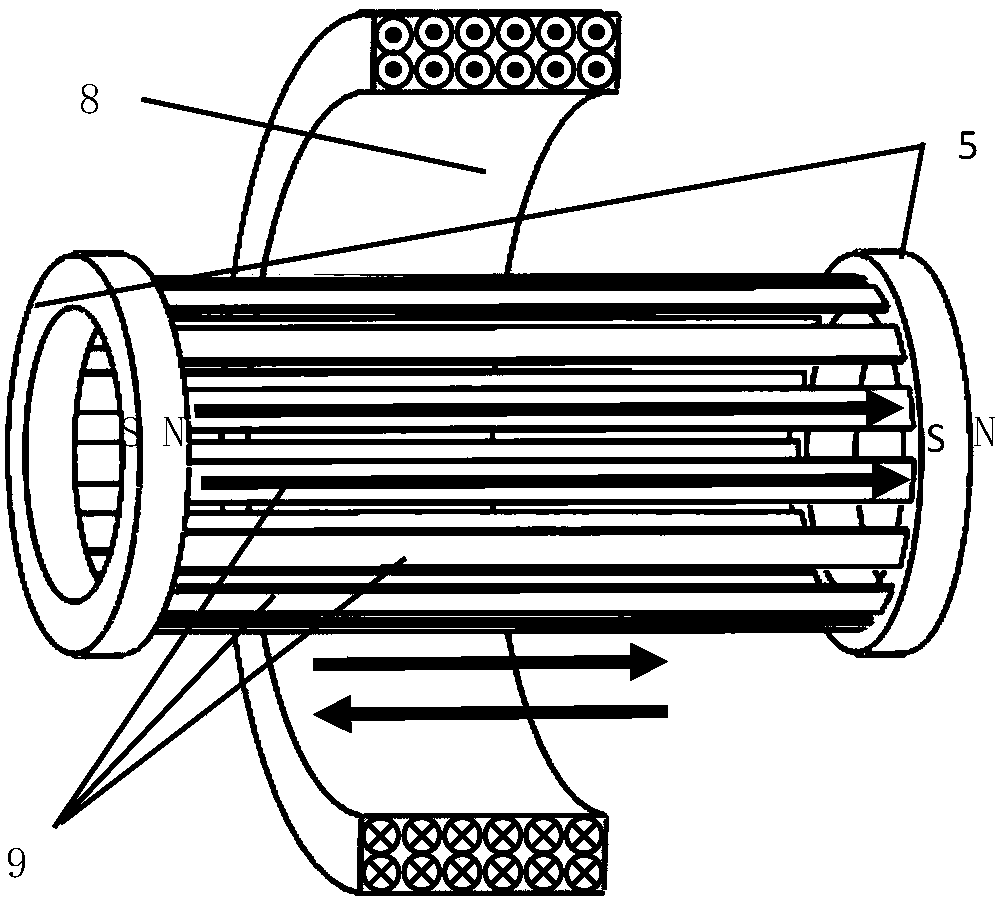

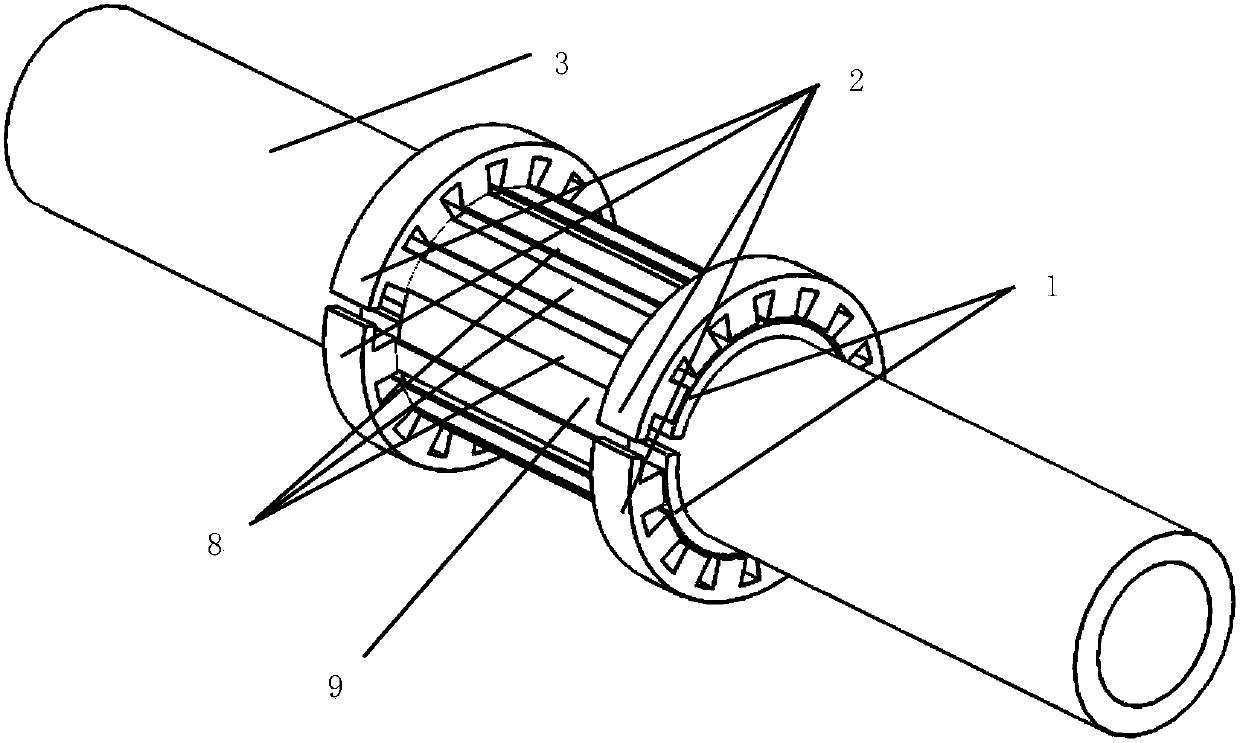

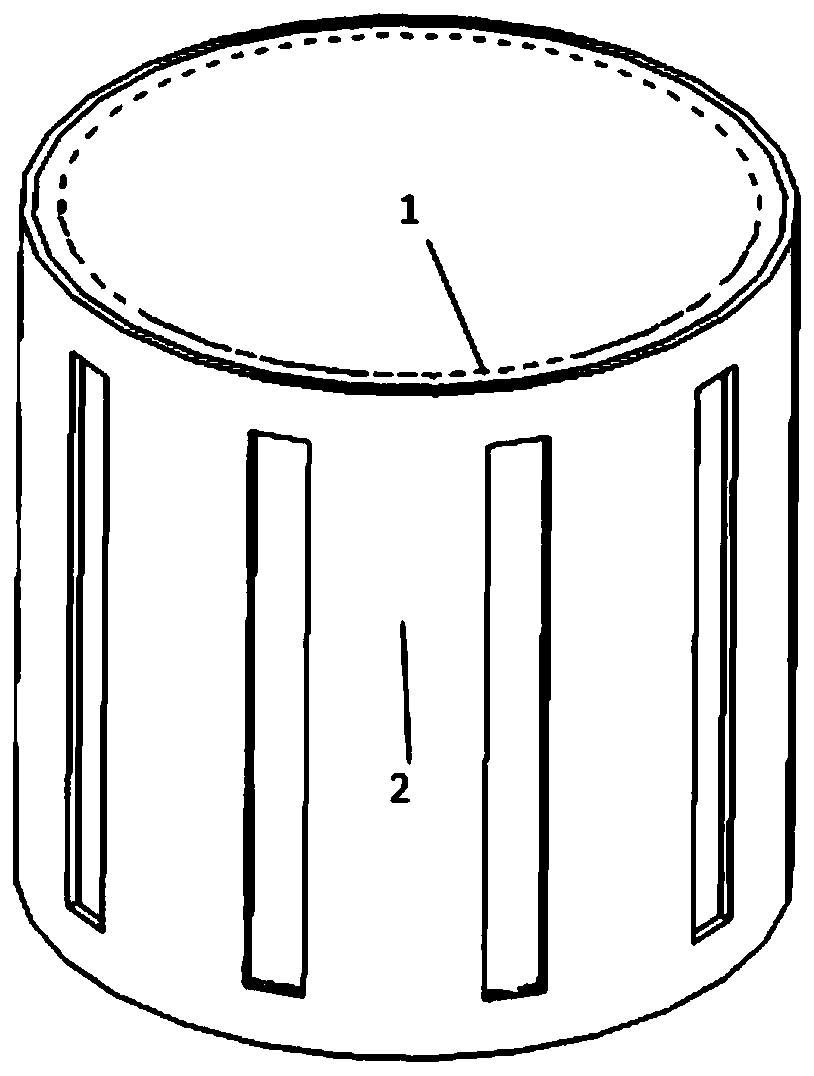

Mouse cage type magnetostrictive longitudinal mode guided wave detection sensor

ActiveCN107607623AHigh magnetostriction coefficientImprove incentive efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesWave detectionElectrical connection

The invention discloses a mouse cage type magnetostrictive longitudinal mode guided wave detection sensor. The two ends of each iron cobalt alloy thin strip are embedded into a groove of a toothed rubber layer; and end pressing buckles fix the toothed rubber layer and the plurality of iron cobalt alloy thin strips. The middle section of each iron cobalt alloy thin strip is spin-coated with a curedepoxy resin layer and is used for being in contact with the surface of a measured micro-tube. Two permanent magnetic rings are formed by splicing C-shaped permanent magnets, the two permanent magnetic rings are arranged at the two ends of an iron cobalt alloy cylindrical shell cage in a magnetic pole dissimilar mode and maintain coaxial with the iron cobalt alloy cylindrical shell cage, and the iron cobalt alloy thin strips are subjected to same-direction bias magnetization. A flexible coil is wound at the middle section of the iron cobalt alloy cylindrical shell, and electrical connection isconducted by a coil adapter, so that an alternating magnetic field in the length direction of the measured micro-tube is stimulated or received, and longitudinal mode guided wave is stimulated and received. The mouse cage type magnetostrictive longitudinal mode guided wave detection sensor can realize on-site rapid assembling and disassembling and can perform magnetostrictive guided wave detection on defects.

Owner:北京中盈盘古智能技术有限公司

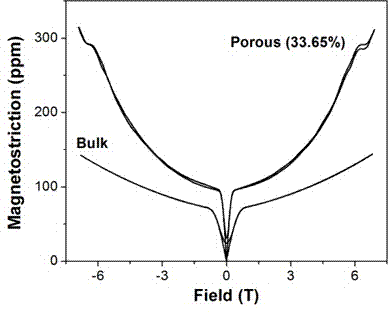

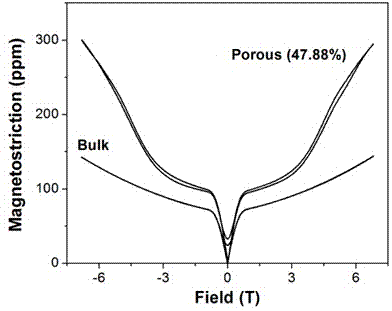

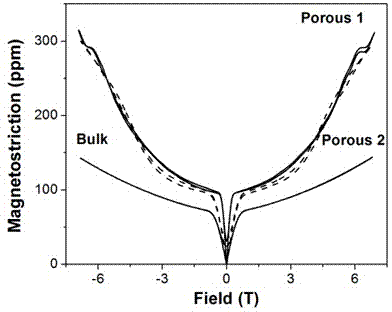

High-performance macroscopic foam-state Fe73Ga27 magnetostrictive material and preparation process thereof

InactiveCN104775068AGood magnetostrictive performanceHigh magnetostrictive performanceMagnetostrictive material selectionSodium aluminateAlloy

The invention discloses a high-performance macroscopic foam-state Fe73Ga27 magnetostrictive material and a preparation process thereof. Holes are introduced into an Fe73Ga27 alloy by preparing a porous sodium metaaluminate precursor so as to ensure that the magnetostrictive performance of the Fe73Ga27 alloy can be improved; the pore size is 20-100 microns, and the porosity is 30-50%; and the preparation process comprises the following step: performing spray casting in a copper mold by using a vacuum spray casting furnace. According to the high-performance macroscopic foam-state Fe73Ga27 magnetostrictive material and the preparation process thereof disclosed by the invention, the hindering effect of magnetic domain rotation in Fe73Ga27 can be reduced based on introduced pores, the macroscopic foam-state Fe73Ga27 magnetostrictive material can be developed, and large magnetic-induced strain, low driving fields and relatively high mechanical performance can be achieved; and a foam material prepared by using a method disclosed by the invention is uniform in pore, ensures that the magnetostrictive coefficient exceeds 300ppm, also is simple and convenient in process and high in finished product rate, and is beneficial to popularization and application.

Owner:ZHEJIANG UNIV +1

Large-amorphous forming capacity iron-based block amorphous magnetic alloy material and preparation method thereof

ActiveCN101928896BEnhanced Amorphous Formation AbilityHigh magnetostriction coefficientMagnetic materialsTransformerGlass transition

The invention discloses a large-amorphous forming capacity iron-based block amorphous magnetic alloy material and a preparation method thereof. The molecular formula of the large-amorphous forming capacity iron-based block amorphous magnetic alloy material is (Fe0.75-aMaB0.25-bSib) 1-cNbc, wherein M is one or more elements of Dy, Tb, Sm, Er, Ga and Y, a, b and c are atom percentages, a is not less than 0.005 and not greater than 0.1, b is not less than 0.03 and not greater than 0.07, and c is not less than 0.02 and not greater than 0.06. Compared with the prior art, the alloy material in the invention has the advantages of large amorphous forming capacity, favorable magnetostrictive coefficient and excellent soft magnetic performance, the reduced glass transition temperature of the alloy material reaches 0.5-0.7, the magnetostrictive coefficient reaches -50*10<-6> to 200*10<-6>, the alloy material can be prepared into amorphous bars with the diameters of 0.5mm-6mm due to the large amorphous forming capacity, thereby the alloy material can be widely applied in the fields of transformers, magnetic sensors and the like.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

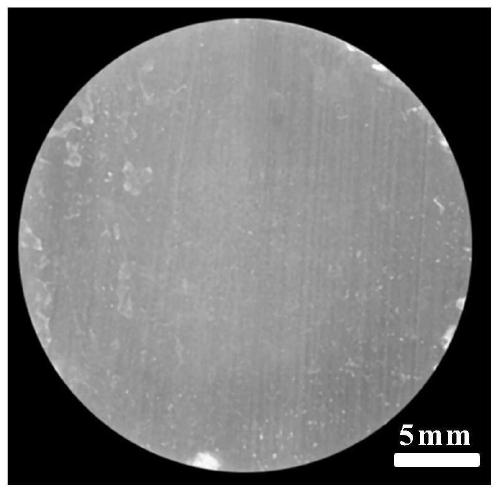

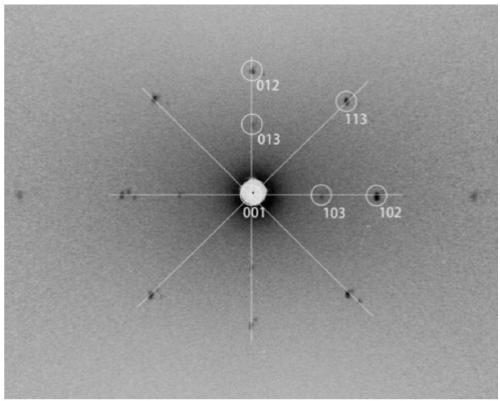

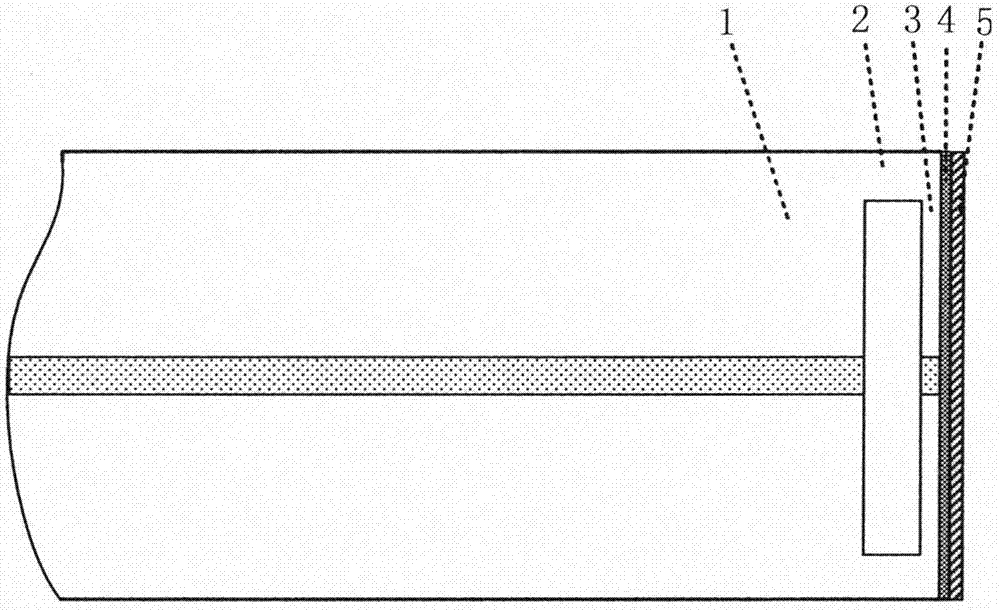

Method for controlling large-size FeGa magnetostrictive single crystal to grow on solid-liquid interface

ActiveCN109868508AEnhanced one-way heat conductionStable temperature fieldPolycrystalline material growthFrom frozen solutionsSeed crystalDirectional solidification

The invention provides a method for controlling a large-size FeGa magnetostrictive single crystal to grow on a solid-liquid interface. The method comprises the following steps: 1) carrying out proportioning according to target components; 2) smelting a mother alloy by using a vacuum non-consumable electric arc smelting furnace; 3) melting a mother alloy ingot by utilizing a magnetic suspension induction smelting furnace, and carrying out casting to form mother alloy bars; and 4) placing the mother alloy bars and FeGa single-crystal seed crystals in a double-layer crucible, placing the double-layer crucible into directional solidification equipment, carrying out heating to completely melt the mother alloy bars and melt the upper part of the FeGa single-crystal seed crystals, and pulling thelower part of the melted material into a cooling liquid along the lower part of the FeGa single-crystal seed crystals to carry out directional solidification, so that the large-size FeGa magnetostrictive material is prepared. The method is simple in process equipment and is convenient to operate, a prepared FeGa single crystal saturated magnetic field is only 500 Oe, the magnetostrictive coefficient is up to 300-320 ppm, comprehensive usability is good, and the application prospect is wide.

Owner:BEIHANG UNIV +1

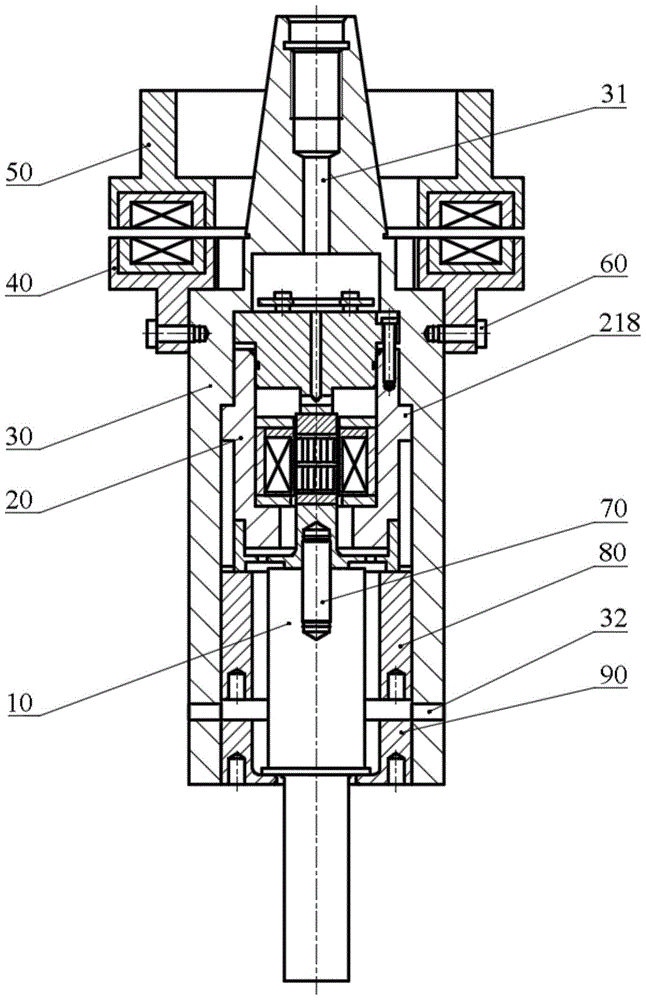

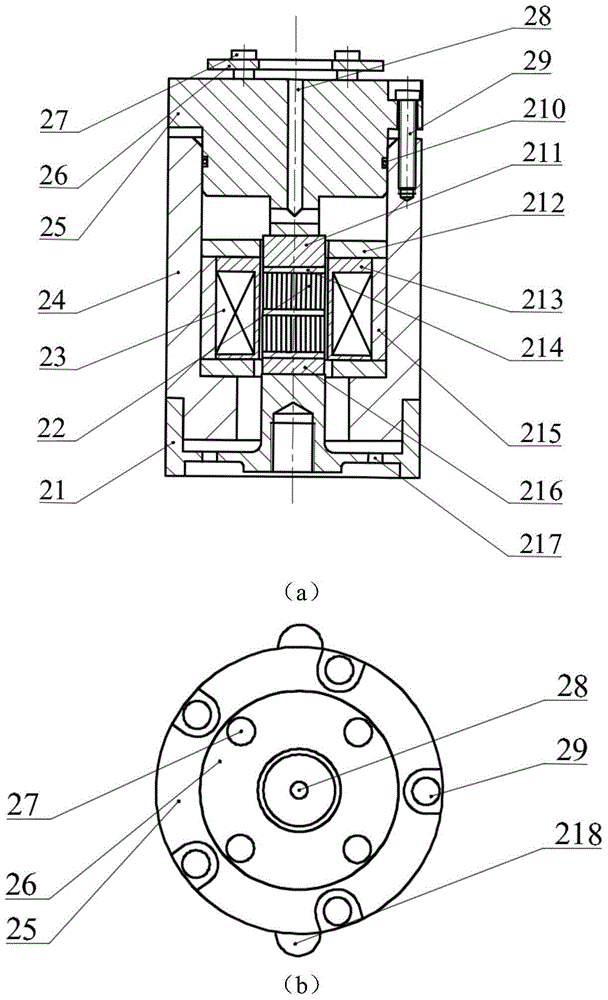

Giant Magnetostrictive Rotary Ultrasonic Vibration Tool Holder

ActiveCN105397920BHigh magnetostriction coefficientIncrease output powerMechanical vibrations separationStone-like material working toolsTransducerUltrasonic vibration

The invention relates to a giant magnetostrictive rotary ultrasonic vibration knife handle and belongs to the technical field of ultrasonic precise special machining. The knife handle comprises an amplitude-change pole, a giant magnetostrictive ultrasonic transducer, a hollow knife handle body, an auxiliary side component, a primary side component and a threaded pressing block, wherein the giant magnetostrictive ultrasonic transducer is connected with the amplitude-change pole through a threaded rod and installed in a cavity in the lower portion of the knife handle body; an ultrasonic vibrator formed by connecting the giant magnetostrictive ultrasonic transducer with the amplitude-change pole makes contact with the inner wall of the knife handle body, the lower end of the giant magnetostrictive ultrasonic transducer is tightly pressed onto the knife handle body through the threaded pressing block, and the threaded pressing block is connected with the knife handle body through threads; the lower end of the amplitude-change pole is tightly pressed through the threaded pressing block, and the threaded pressing block is connected with the knife handle body; the lower end of the auxiliary side component is fixed to the knife handle body through a screw, and the primary side component is fixed to the end face of a machine tool spindle. According to the giant magnetostrictive rotary ultrasonic vibration knife handle, the problem of heating of the transducer is effectively solved by means of a giant magnetostrictive material of a slice structure and an air cooling system. By the adoption of the knife handle, the machining efficiency can be improved. In addition, the knife handle can be suitable for any knife handle connection standards.

Owner:TSINGHUA UNIV

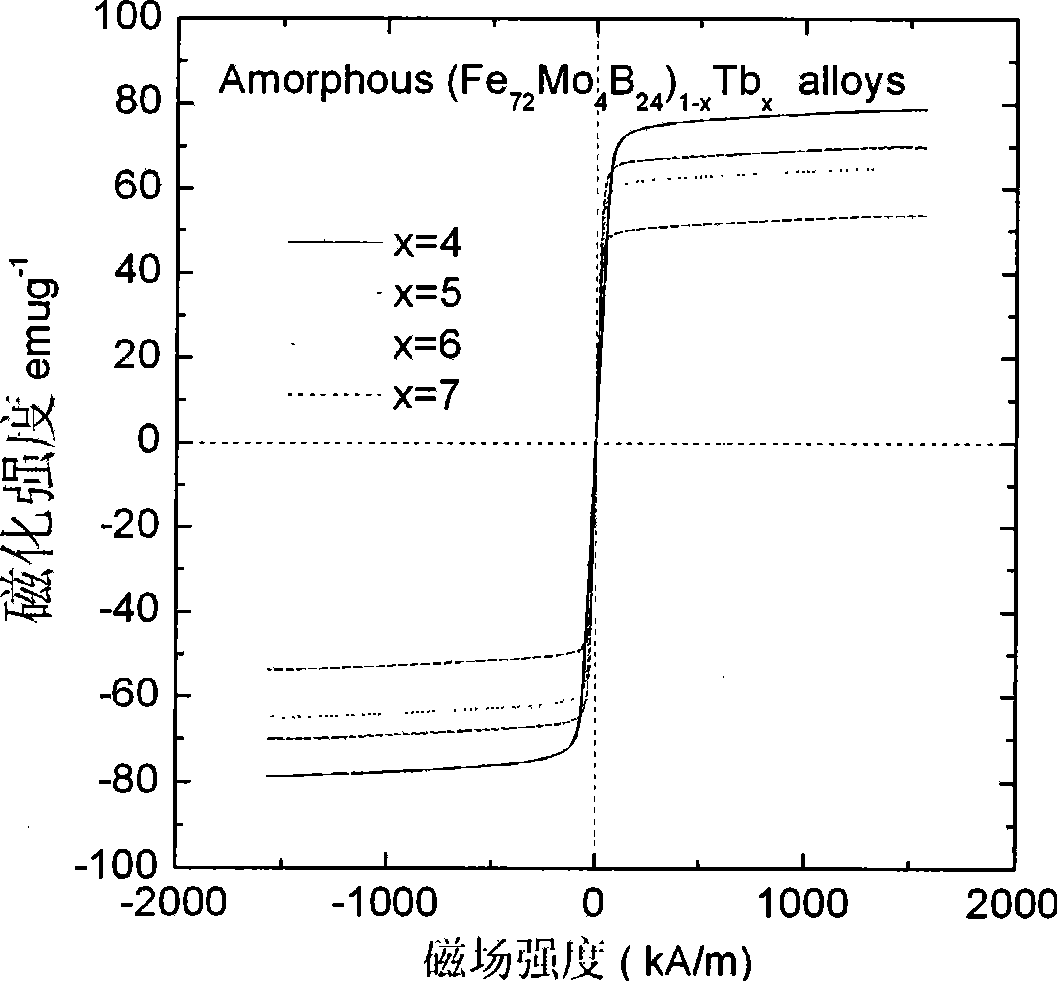

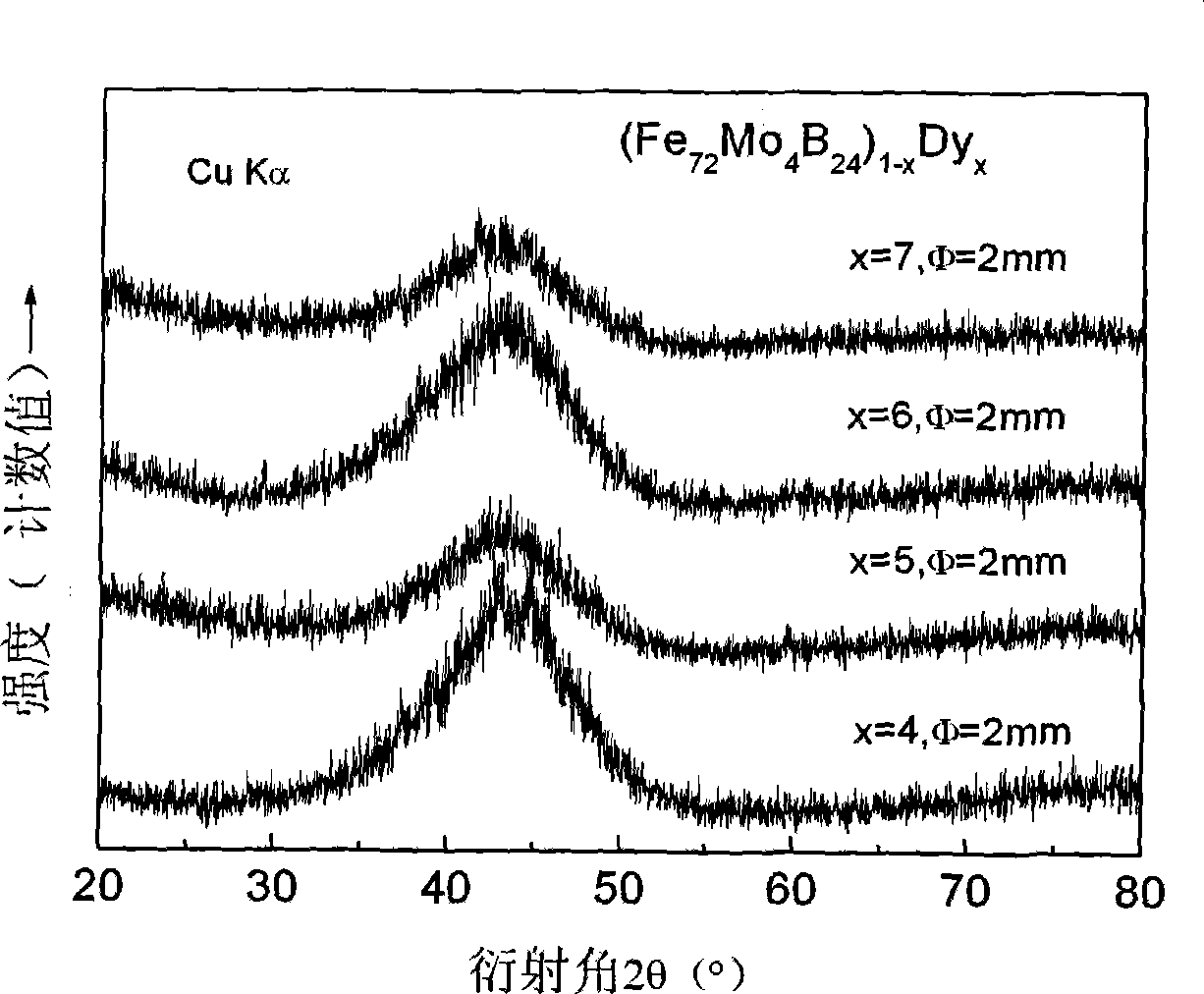

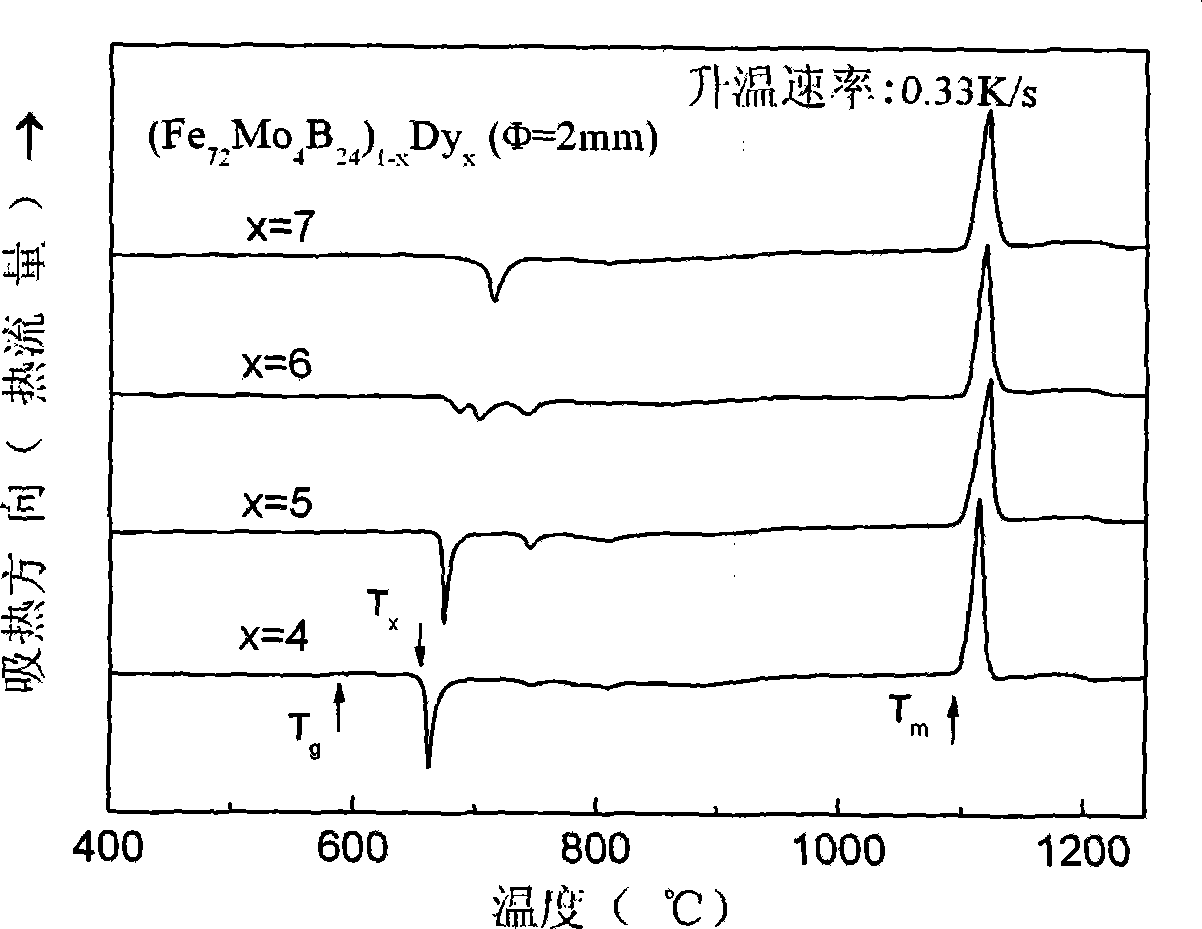

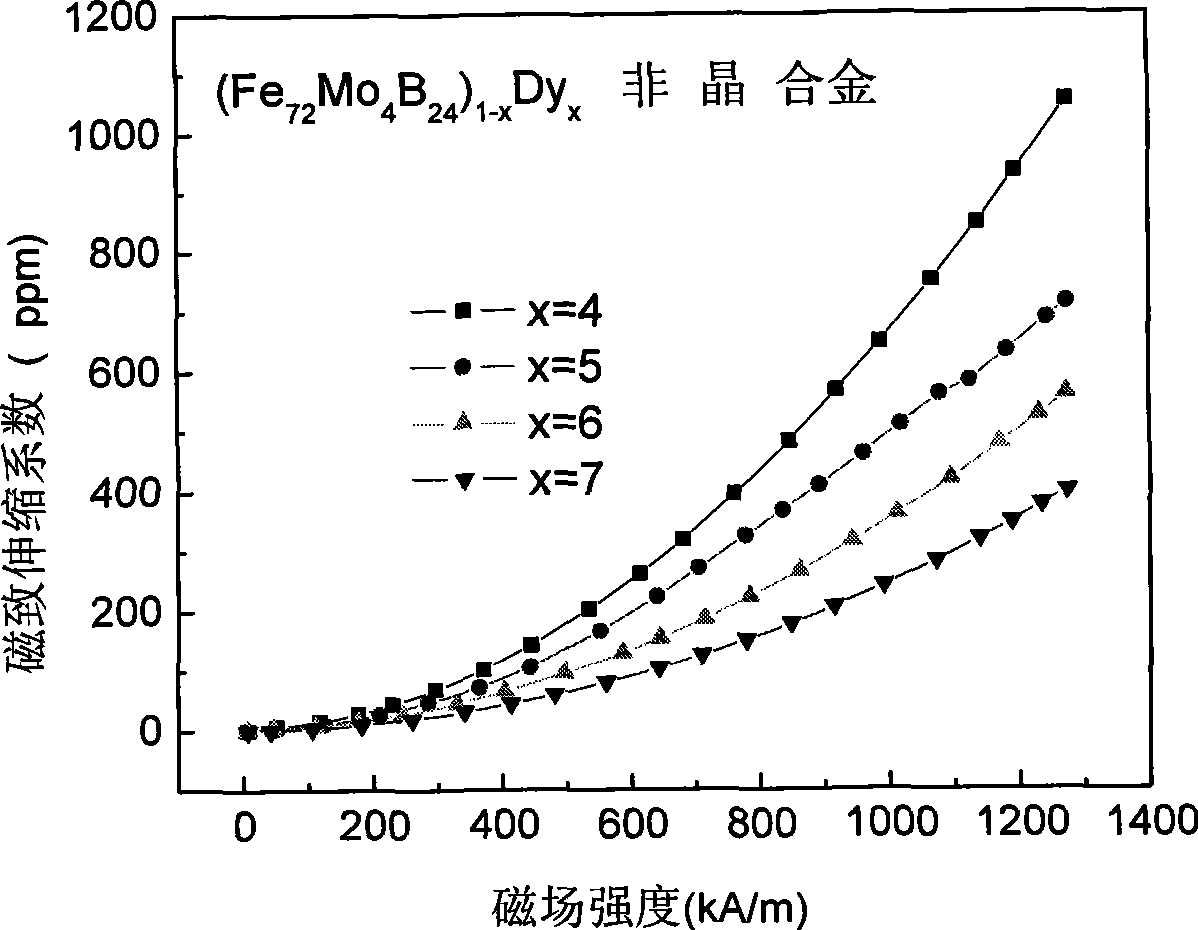

Bulk amorphous alloy magnetostriction material and method of producing the same

The invention discloses a block amorphous alloy magnetostriction material and a preparation method thereof. The block amorphous alloy magnetostriction material has the following chemical formula: (FeaMobBc) 1-xDyx, wherein, a is more than or equal to 65 and less than or equal to 75, b more than or equal to 2 and less than or equal to 8, c is more than or equal to 20 and less than or equal to 25, x is more than or equal to 1 and less than or equal to 10, and a plus b plus c equals 100. The preparation method of the block amorphous alloy has the following steps: firstly, materials are mixed by following the general formula of FeaMobBc; FeaMobBc is melted into master alloy; then a master alloy spindle is ground to small pieces; according to atomic ratio of (FeaMobBc) 1-xDyx, Dy metal is added; a bar-shaped alloy sample is obtained by putting the raw materials to a silica tube for smelting and carrying out direct spray casting; as a result, volatilization of rare earth element Dy can be reduced. The block amorphous alloy magnetostriction material of the invention has very high magnetostriction coefficient and wide supercooling liquid phase region. Moreover, the thermal stability thereof is high and the glass transition temperature and crystallization temperature thereof are relatively high, thus contributing to the application of the material at relatively high temperature. Therefore, the amorphous alloy enjoys potential application prospect.

Owner:ZHEJIANG UNIV

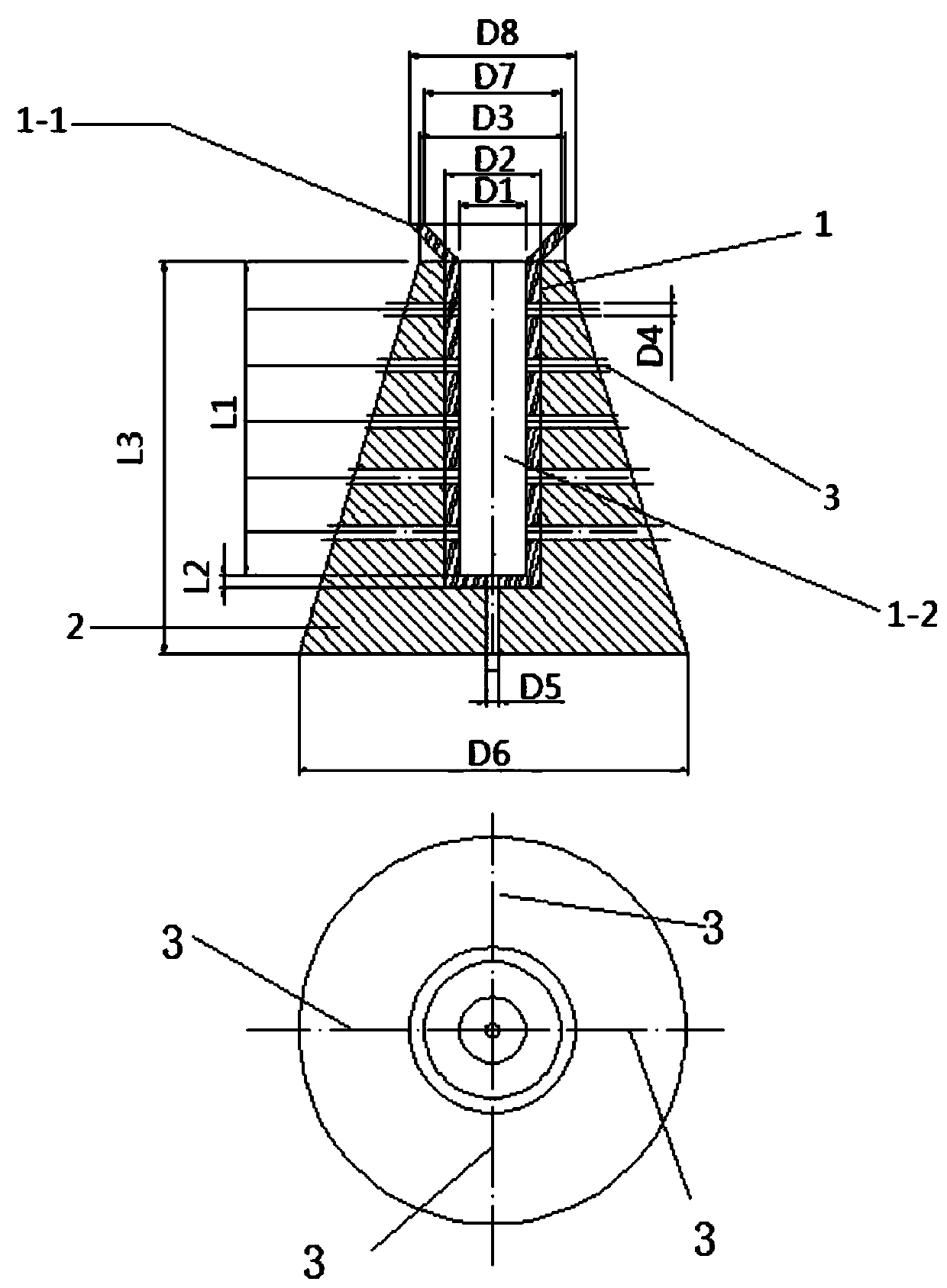

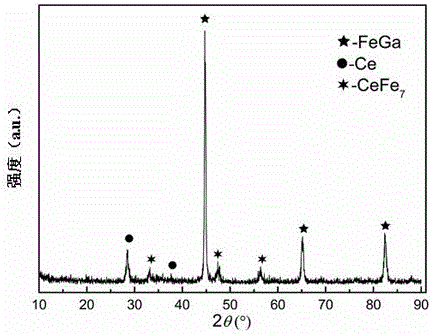

Fe-Ga-Ce-B alloy bar and preparation method thereof and cooling copper mold

InactiveCN110218934AAmplify the intensityAchieving stacking effectsMaterials preparationChemical composition

The invention provides a Fe-Ga-Ce-B alloy bar and a preparation method thereof and a cooling copper mold, and relates to the technical field of functional material preparation. The chemical composition of the Fe-Ga-Ce-B alloy bar is Fe(100-(x+y+z))GaxCeyBz, wherein x ranges from 17 to 19, y ranges from 0.2 to 1.5, z ranges from 0.8 to 1.2, and the length-diameter ratio of the Fe-Ga-Ce-B alloy barranges from 7 to 14. The Fe-Ga-Ce-B alloy bar is an alloy bar with the largest length-diameter ratio, double elements of Ce and B are doped with an iron and gallium alloy, and the magnetostrictive property, the plasticity and the strength of the alloy can be effectively improved. The cooling copper mold is composed of a molding copper mold with vent holes and a taper cooling cooler, the iron and gallium alloy rod with the large length-diameter ratio can be directionally crystallized, and the magnetostriction coefficient and casting property of the alloy can be improved.

Owner:NANCHANG INST OF TECH

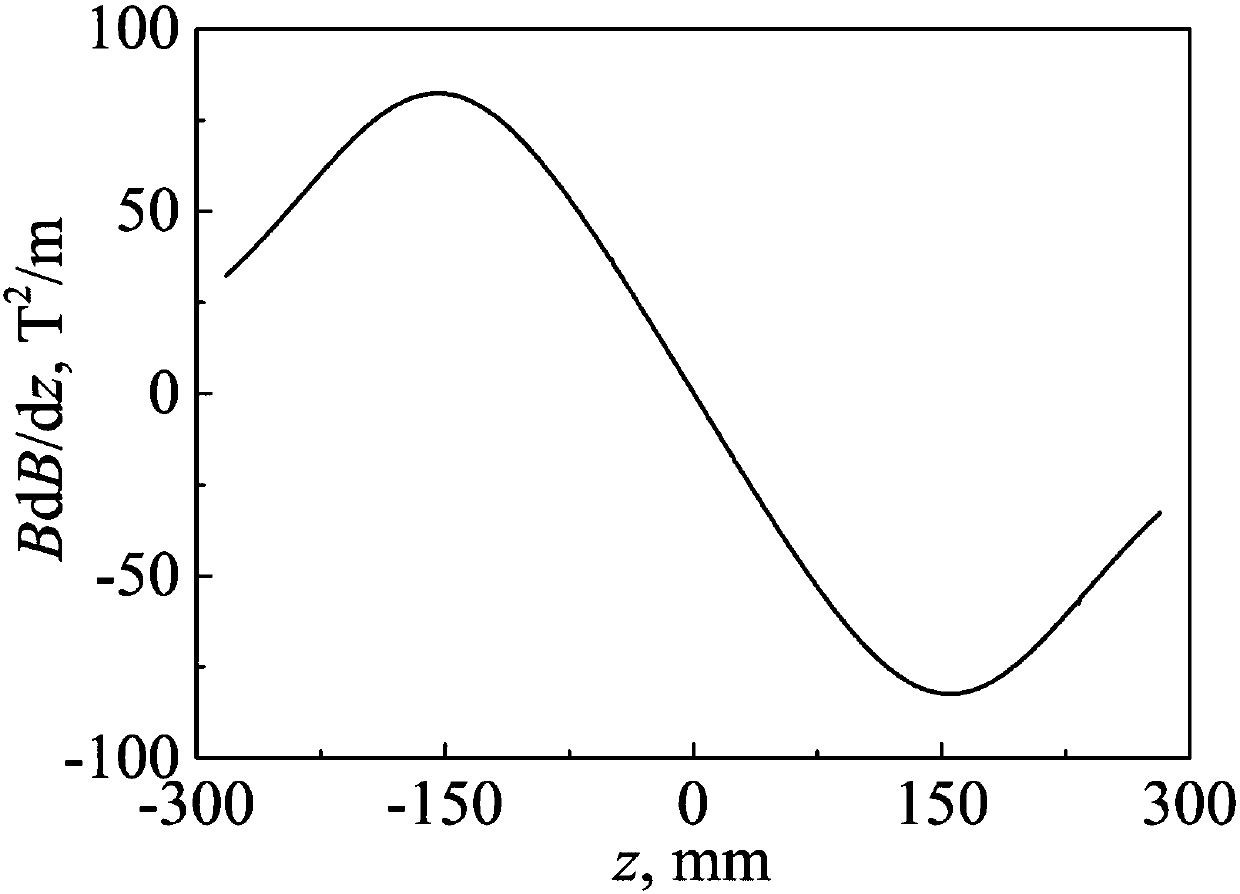

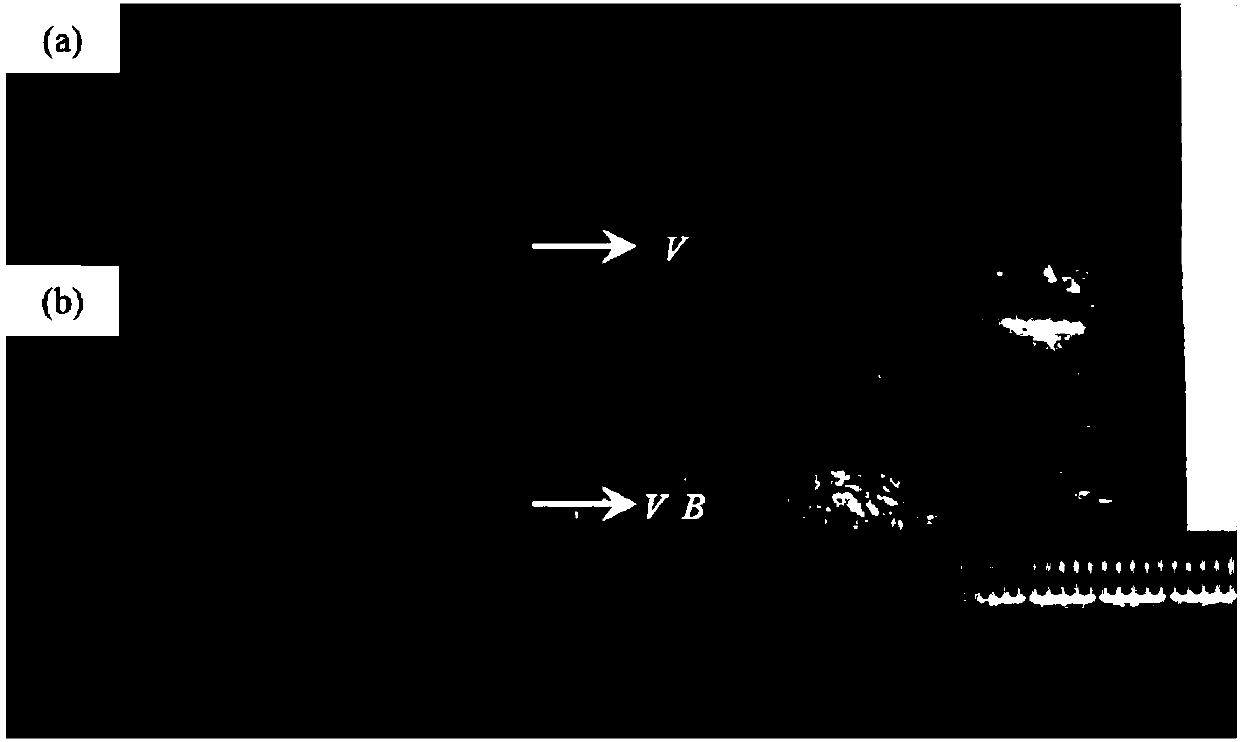

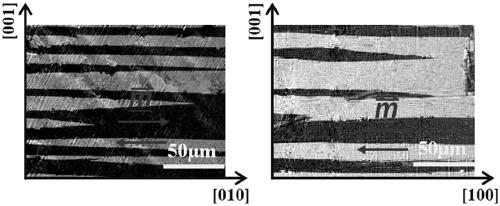

Method for regulating magnetic domain of FeGa magnetostrictive alloy by using unidirectional solidification stress

ActiveCN109023505ALarge saturation magnetostrictive performanceSimple process equipmentPolycrystalline material growthFrom frozen solutionsBridgman methodShielding gas

The invention discloses a method for regulating the magnetic domain of a FeGa magnetostrictive alloy by using unidirectional solidification stress. The method is a liquid metal cooling Bridgman method. According to the invention, unidirectional thermal stress generated by unidirectional heat conduction parallel to a growth direction in the directional solidification process of the liquid metal cooling Bridgman method is utilized to allow initial magnetic domains in the FeGa alloy to be arrayed along a direction perpendicular to the growth direction, so a saturation magnetostriction value of 300 to 320 ppm can be obtained without pre-compressive stress. The nominal composition of the FeGa alloy is Fe100-xGax, wherein x is no less than 17 and no more than 20. After melting of Fe and Ga proportioned according to composition requirements into a master alloy ingot and the master alloy ingot is cast into a master alloy rod, the FeGa master alloy rod is placed in directional solidification equipment; the directional solidification equipment is vacuumized and filled with protection gas; the mother alloy rod is completely melted by heating; then a molten material is drawn into a liquid metal coolant for directional solidification; and a temperature gradient is controlled to be 5*10<4>-9*10<4> K / m, and a growth rate is controlled to be 1 to 100 mm / h.

Owner:BEIHANG UNIV

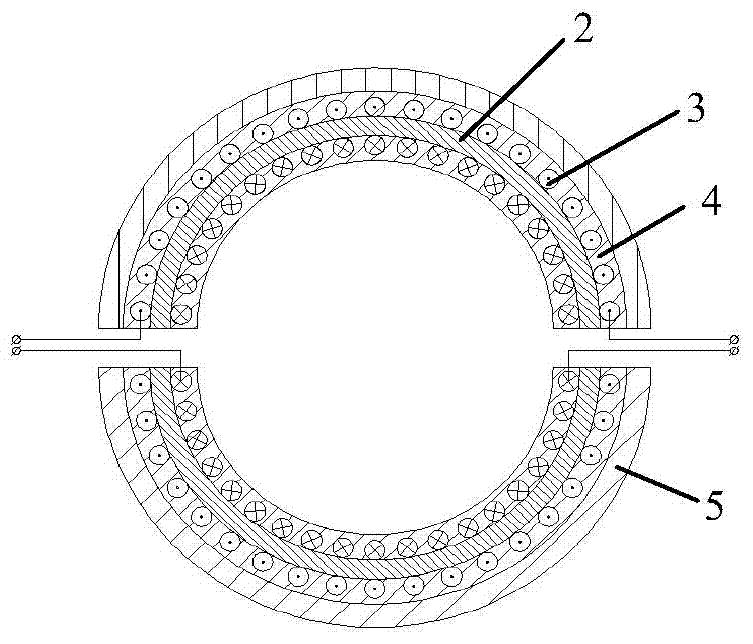

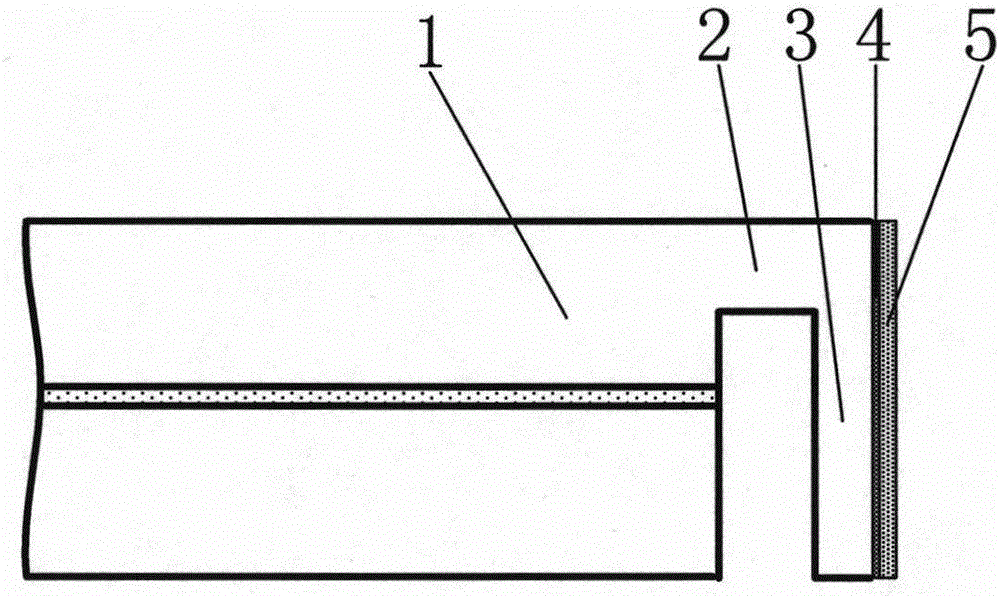

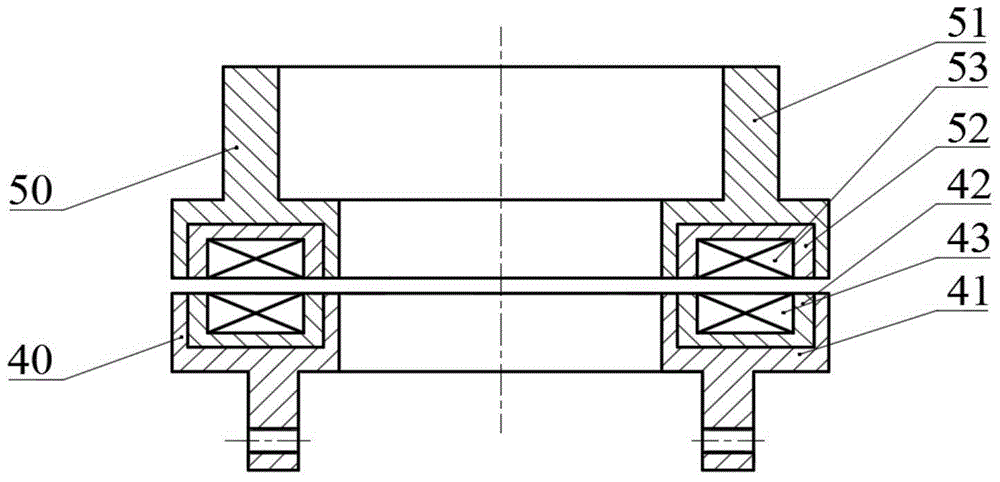

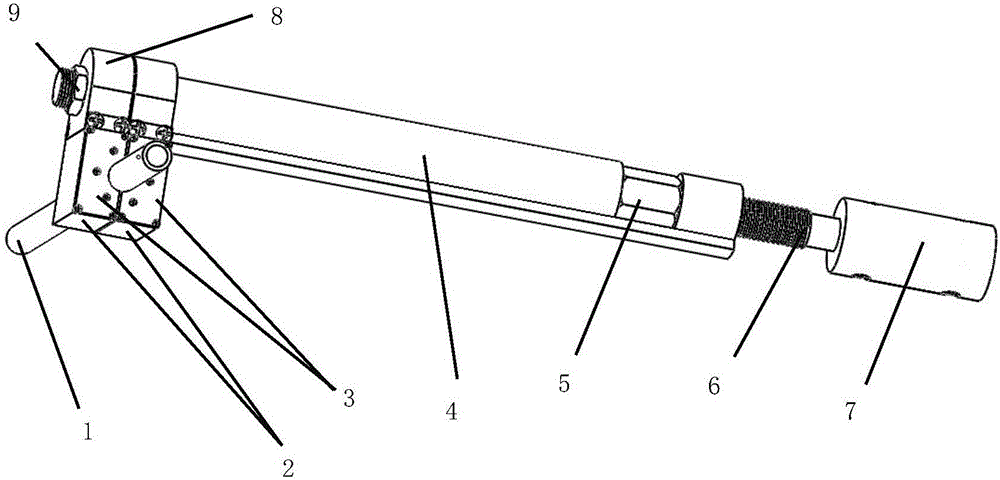

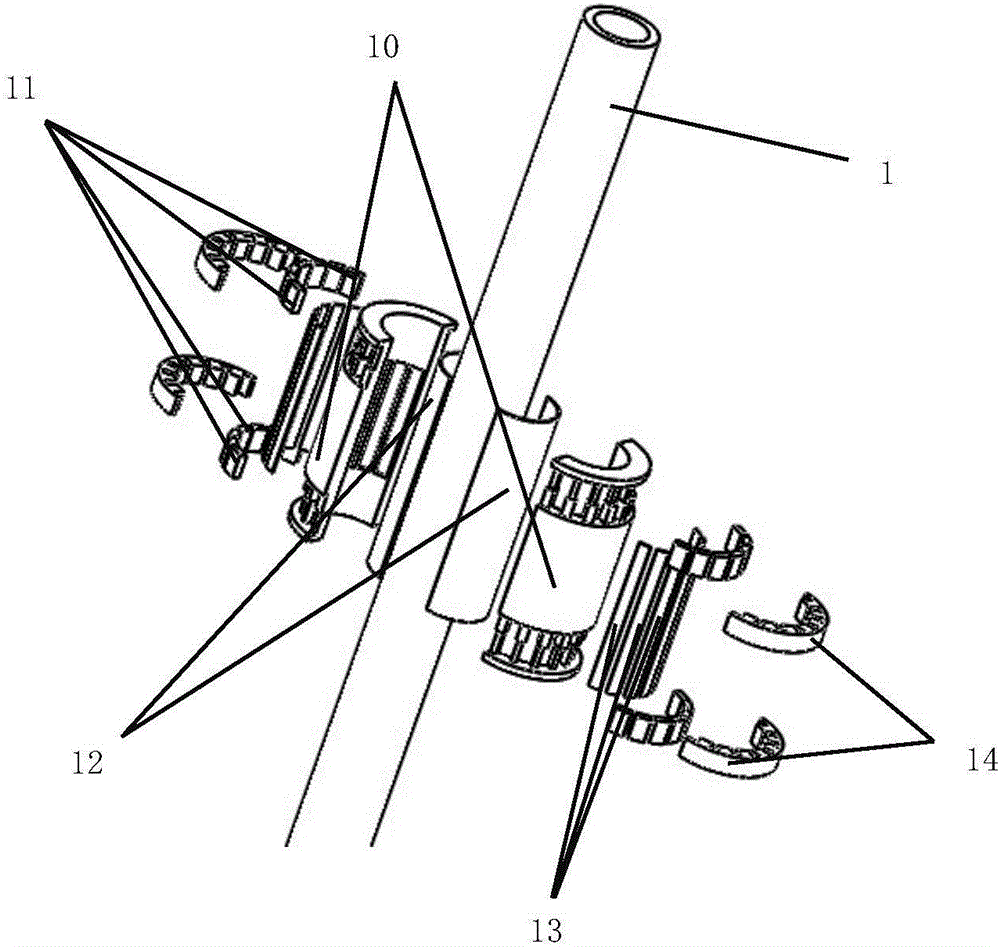

Demountable longitudinal mode guided wave magnetostrictive sensor based on operating cane

ActiveCN107525851AConsistent and uniform static magnetic field distributionHigh magnetostriction coefficientAnalysing solids using sonic/ultrasonic/infrasonic wavesSelenodontEngineering

The invention provides a demountable longitudinal mode guided wave magnetostrictive sensor based on an operating cane. The demountable longitudinal mode guided wave magnetostrictive sensor mainly comprises two parts, namely, the operating cane and a squirrel-cage magnetostrictive sensor, wherein the squirrel-cage magnetostrictive sensor comprises two symmetric C-type elements; a moving track and a connecting rod are connected through a displacement adjusting nut, and a pipe is clamped or the sensor is dismounted from the pipe when the displacement adjusting nut is rotated to move forwards and backwards along the connecting rod. Each single C-type element of the squirrel-cage magnetostrictive sensor mainly comprises an iron cobalt alloy shell cage, a block permanent magnet hoop array and selenodont detection coil. After the squirrel-cage magnetostrictive sensor is clamped on the to-be-measured pipe, the squirrel-cage magnetostrictive sensor can be stimulated to produce longitudinal mode ultrasonic guided waves, the longitudinal mode ultrasonic guided waves penetrate through epoxy resin cured on the inner surfaces of the C-type elements to be coupled to the pipe.

Owner:BEIJING UNIV OF TECH

High magnetic striction iron based metallic glass magnetic material and preparation thereof

InactiveCN101487106BPurity requirements are not very highHigh magnetostriction coefficientSimple componentTransducer

The invention discloses a high magnetostrictive Fe-based metal glass magnetic material and a preparation method thereof. The chemical formula of the high magnetostrictive Fe-based metal glass alloy is Fe100-x-y-zMozByTbx, wherein, x, y and z are respectively the atomic percents of Tb, B and Mo, 100-x-y-z is the atomic percent of Fe, x is more than 0 and less than or equal to 10, y is more than orequal to 20 and less than or equal to 25, z is more than 0 and less than or equal to 10. The preparation method of the alloy is as follows: the industrial pure metals Fe, Mo, Tb and FeB alloy are proportioned according to the alloy formula and melted repeatedly by induction-arc under the protection of argon to make master alloy, then the high magnetostrictive Fe-based metal glass magnetic material is obtained through casting by using the copper mold spray-casting method. The magnetostrictive coefficient of the magnetic material is 420 ppm to 985 ppm, and the magnetic material has simple components, high thermal stability, and good mechanical properties and amorphous forming ability. The high magnetostrictive Fe-based metal glass magnetic material can be widely applied to the fields of sonar transducer, sensor, ultrasonic technology, communication technology, and the like.

Owner:ZHEJIANG UNIV +1

Preparing method of magnetostriciton material

The invention relates to a preparing method of a magnetostriciton material, and belongs to the technical field of preparation of magnetostriciton materials. Aimed at the problem that in the current prepared resin matrix magnetostriciton material, interface bonding is bad and usability performance of the materials is reduced due to the fact that magnetostriciton particles have low wetting with resin, and the particles are prone to clustering and segregation when being mixed together, the magnetostriciton material is provided. According to the preparing method of the magnetostriciton material, magnetic ceramic powder is prepared, and the magnetic ceramic powder is then combined with epoxy resin; under the action of a coupling agent, magnetic ceramic is uniformly recombined to the inner part of the resin; under a magnetic action of an external permanent magnet, bonding strength between modified resin matrix and magnetic-induced particles is strengthened, sedimentation speed of particles among the resin is lowered; under the action of a magnetic field system, a controllable oriented magnetic field is determined, and a stable compound system is formed. The magnetostriciton material has a high combination degree, particles have good dispersity, and magnetostriction coefficient improved by 5-8% compared with similar products; meanwhile, the preparing method is simple, the raw material is green and safe, and the prepared magnetostriciton material does not cause environment pollution.

Owner:ZHEJIANG JIAYUDA MACHINERY CO LTD

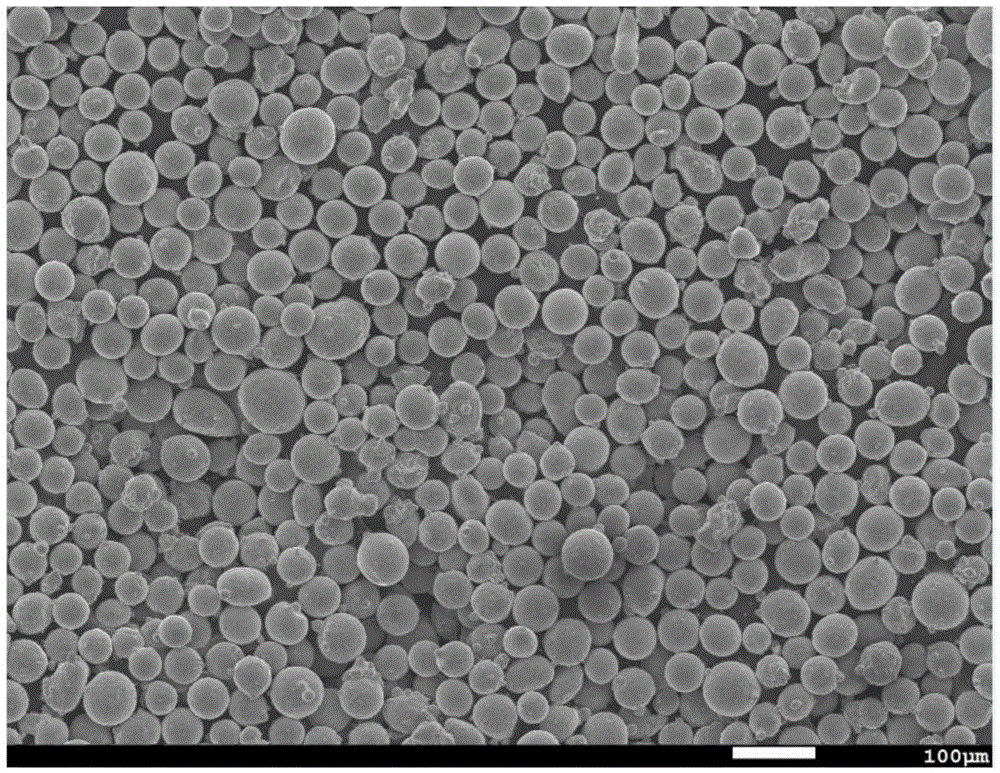

A method for preparing iron-based magnetostrictive coatings using thermal spraying technology

ActiveCN105252011BHigh magnetostriction coefficientNot easily oxidizedMolten spray coatingPorosityThermal spraying

The invention discloses a method for preparing an iron-based magnetostrictive coating by using a thermal spraying technology, which belongs to the field of magnetic materials. The iron-based magnetostrictive material is firstly prepared into spherical gas-atomized powder, and then the metal material is used as the substrate, and the spherical gas-atomized powder is sprayed onto the metal substrate by plasma spraying to prepare the iron-based magnetostrictive coating. The specific steps are to first melt the iron-based magnetostrictive material into an ingot in a vacuum melting furnace, remove the scale on the surface by machining, and then send the ingot to a high-pressure atomization powder making device, and melt the ingot through a high-speed argon gas flow. The alloy stream breaks up into small droplets and condenses into powder. Thermal spraying technology adopts plasma spraying. The plasma gas is mainly nitrogen, supplemented by hydrogen. The iron-based magnetostrictive gas atomized powder is sent into the plasma chamber, and the coating is formed by heating, melting, flying, impacting the substrate, cooling and solidification. Its advantages are: high bonding strength of the coating, fine structure, low porosity, and the addition of alloying elements reduces oxide slag inclusions.

Owner:UNIV OF SCI & TECH BEIJING

Li-Fi-based all-optical transmission magnetic field detection system

ActiveCN107607889AInterfereReduce volumeMagnetic field measurement using magneto-optic devicesGratingLight source

The present invention provides a Li-Fi-based all-optical transmission magnetic field detection system and relates to the technical field of optical fiber sensors. The system of the invention includesan optical fiber directional coupler, an LD light source, a magnetic field sensor, a matching liquid and a Li-Fi module. The optical fiber directional coupler is configured as a 2*2 optical fiber directional coupler and is provided with a first port, a second port, a third port and a fourth port. The LD light source is used to emit the modulated laser of a preset frequency to the magnetic field detection system. The output end of the LD light source is connected with the first port. The magnetic field sensor is connected with the second port through a y-type optical fiber body and is used fordetecting the strength of the magnetic field. The Li-Fi module comprises a Li-Fi transmitting unit and a Li-Fi receiving unit. The Li-Fi transmitting unit is connected with the third port through a matched grating. The Li-Fi receiving unit is connected with a photoelectric detector. In this way, a wireless transmission network between the magnetic field sensor and the photoelectric detector is established. According to the invention, in the full-light excitation mode, a to-be-tested magnetic field is not influenced at all. The system is small in size, and is suitable for being used in a narrowspace.

Owner:蚌埠高灵传感系统工程有限公司

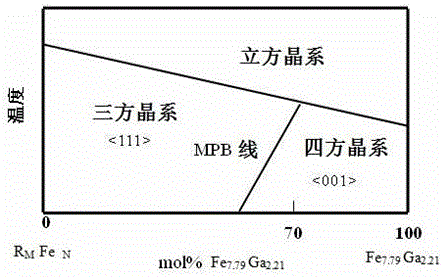

Novel polycrystal magnetostriction material based on morphotropic phase boundary and preparation method of novel polycrystal magnetostriction material based on morphotropic phase boundary

InactiveCN106480505AExcellent magnetostriction coefficientHigh magnetostriction coefficientPolycrystalline material growthMagnetostrictive material selectionRare-earth elementNew materials

The invention relates to the technical field of new materials, in particular to a novel polycrystal magnetostriction material based on a morphotropic phase boundary and a preparation method of the novel polycrystal magnetostriction material based on the morphotropic phase boundary. The novel polycrystal magnetostriction material is shown as a molecular formula (Fe7.79Ga2.21)x(RMFeN)100-x, wherein mole percentage content of x is not less than 50 and not more than 80; R refers to at least one of Ce, Pr, Nd and Sm; M refers to 1 or 2, N is 7 when M is 1, and N is 7 when M is 2. The novel polycrystal magnetostriction material is made from light rare earth elements rather than expensive heavy rare earth, thereby being low in material cost. The preparation method is simple and low in preparation cost, and the novel polycrystal magnetostriction material is excellent in performance and is of great significance to promotion of application and development of magnetostriction materials.

Owner:XIHUA UNIV

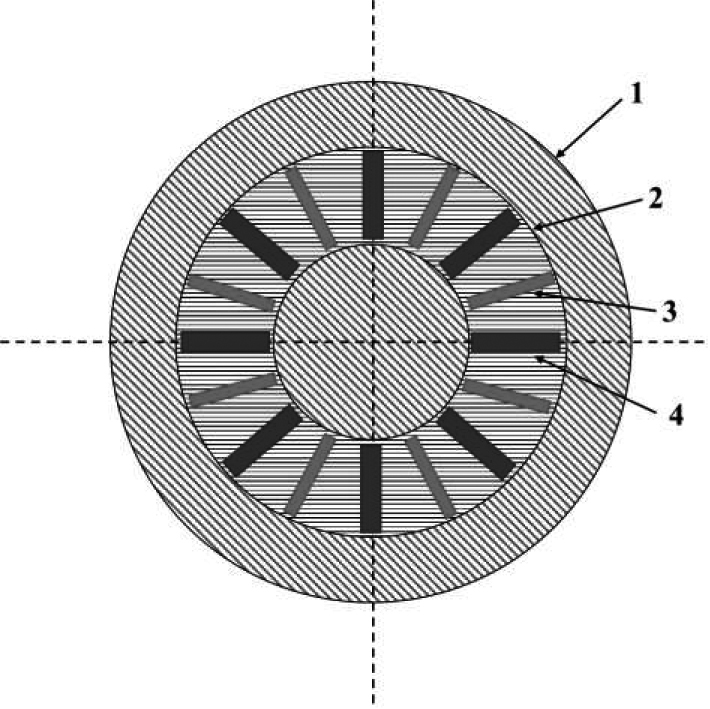

Cross microbridge fiber magnetic field sensing probe based on giant magnetostrictive effect

ActiveCN107247243ARealize an integrated structureIncrease the areaMagnetic field measurement using magneto-optic devicesFiberChrome plating

The invention relates to a cross microbridge fiber magnetic field sensing probe based on the giant magnetostrictive effect and belongs to the technical field of a fiber sensor. The cross microbridge fiber magnetic field sensing probe comprises a fiber, a fixing end, a cross microbridge, an intermediate reflector, a fabry-perot resonator, a chrome metal film and a giant magnetostrictive film, wherein the cross microbridge is arranged at a fiber end surface and is connected with the fiber through the fixing end, the cross microbridge and the fiber end surface form the fabry-perot resonator, and an outer surface of the cross microbridge is sequentially plated by the chrome metal film and the giant magnetostrictive film. The cross microbridge fiber magnetic field sensing probe is advantaged in that demands of a high precision detection magnetic field can be realized through employing the fabry-perot resonator, two pole plates of the fabry-perot resonator can be effectively guaranteed by the cross microbridge to be parallel, and measuring range increase is further guaranteed.

Owner:CHINA JILIANG UNIV

Magnetostrictive film target material structure and preparation method thereof

PendingCN114318252ALow saturation fieldHigh magnetostriction coefficientVacuum evaporation coatingSputtering coatingIndiumDysprosium

The invention discloses a magnetostrictive film target material structure which comprises a circular iron target and a concentric etching ring arranged on the iron target, dysprosium sheets and terbium sheets are alternately arranged on the etching ring in the radial direction, the terbium sheets and the dysprosium sheets are fixed through indium, the ratio of the sum of the surface areas of the terbium sheets and the dysprosium sheets to the surface area of the iron target is 1: 2alpha, wherein alpha is the ratio of the sputtering rates of the terbium target, the dysprosium target and the iron target under the same sputtering condition; the invention further discloses a preparation method. The sizes, the number and the placing positions of the terbium sheets and the dysprosium sheets can be rapidly estimated, the method is simple, the proportion of all the components in the film is adjusted conveniently and rapidly, and the magnetostrictive film which is low in saturation field, high in magnetostriction coefficient and excellent in performance is prepared.

Owner:HUAZHONG PHOTOELECTRIC TECH INST (CHINA SHIPBUILDING IND CORP THE NO 717 INST)

Heat treatment method for improving magnetostrictive property of Tb<x>Dy<1-x>Fe<y> alloy bars with <112> axial alignment

InactiveCN101775565AHigh magnetostriction coefficientHigh magnetostrictive performanceRoom temperatureAlloy

The invention discloses a heat treatment method for improving the magnetostrictive property of Tb<x>Dy<1-x>Fe<y> alloy bars with <112> axial alignment, comprising the following steps: 1) after polishing the surface and two ends of Tb<x>Dy<1-x>Fe<y> alloy with <112> axial alignment, cutting the Tb<x>Dy<1-x>Fe<y> alloy into alloy bars with specification of phi5*30-10*50mm3; 2) encapsulating the alloy bars in a vacuum quartz glass tube with vacuum degree being about 10<-1>Pa, placing the encapsulated quartz glass tube in the middle part of a furnace tube for magnetic heat treatment, uniformly raising the temperature to 400-900 DEG C in the absence of external magnetic fields, preserving the heat for 10min-2h and then cooling the furnace, simultaneously applying external magnetic fields with strength of 0.1-1.2T, cooling the furnace to the room temperature and then taking out the alloy bars, wherein the magnetic field direction forms an angle of 0-90 degrees with the alloy bars axially. Through magnetic heat treatment, the magnetostriction coefficient lambda and the piezomagnetic coefficient d33 of the Tb<x>Dy<1-x>Fe<y> alloy bars with <112> axial alignment are respectively improved by 45-65% and 240% in the absence of compressive prestress. The magnetostrictive property is further improved after the compressive prestress is applied.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com