Magnetic ultrasonic wave on-line scale-preventing-removing all-in-one machine

An all-in-one, prevention technology, applied in the direction of cleaning methods using liquids, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of low efficiency, high labor intensity of workers, loss of downtime, etc., to increase the pulse beam and mechanical Energy, enhance synergistic effect, prevent the effect of new scale formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The best embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

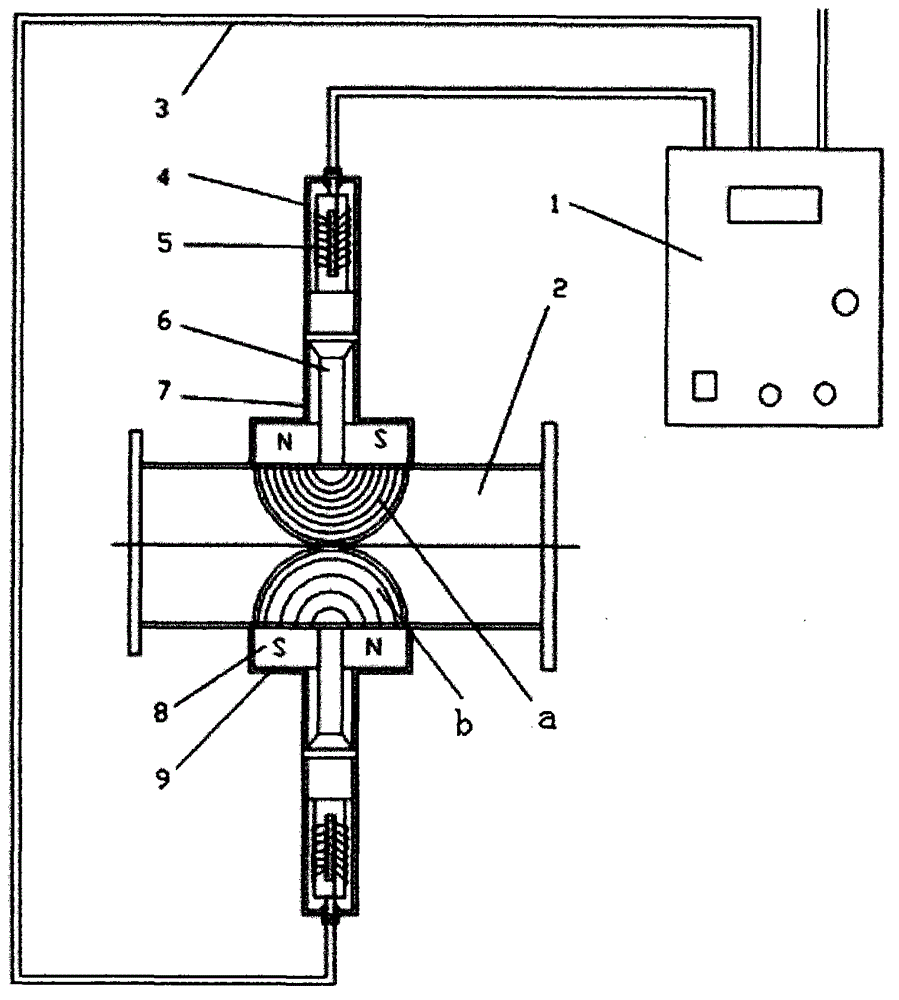

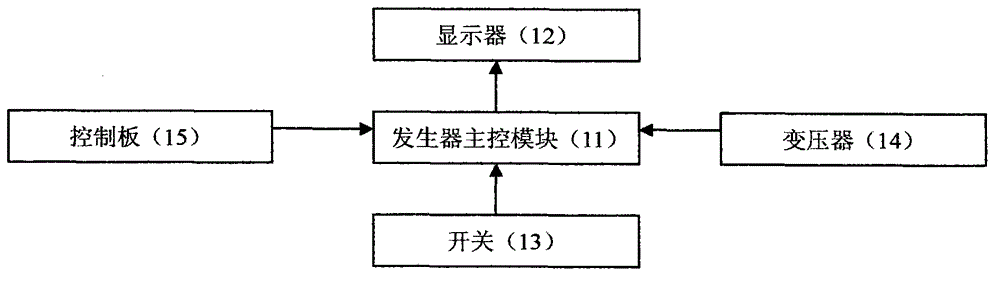

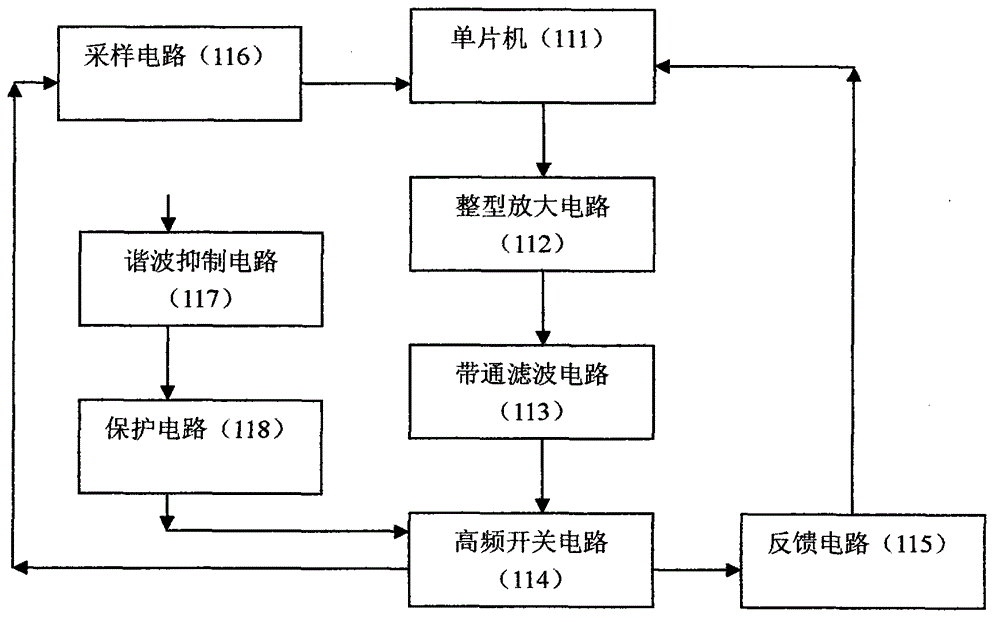

[0027] Such as figure 1As shown, the magnetic ultra-online anti-scaling integrated machine of the present invention includes a high-strength transducer, a high-strength transducer shielding cover 4, a strong magnet 8, a strong magnet protection device 9 and an ultrasonic generator 1, and the high-strength transducer is installed In the high-strength transducer shielding protective cover 4 and connected to the ultrasonic generator 1 through the shielding conductive cable 3, the bottom end of the high-strength transducer shielding protective cover 4 contacts the surface of the metal pipeline 2, and the strong magnet 6 Installed on the bottom of the high-strength transducer shielding cover 4 and on both sides of the bottom of the high-strength transducer, the strong magnet protection device 9 is installed on the surface of the strong magnet 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com