Patents

Literature

77results about How to "Good magnetic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of metal soft magnetic powder core

InactiveCN103247403ASimple preparation processEasy to useInorganic material magnetismMagnetic stabilityOrganic solvent

The invention discloses a preparation method of a metal soft magnetic powder core, which aims at solving the technical problems of high pollution, high cost and poor magnetic stability in the prior art. The method comprises the steps of raw material sieving, insulation coating, to-be-formed magnetic powder preparation, pressure forming, heat treatment and surface spraying. The method has the technical benefits that a preparation technique is simple; used equipment is simple; the insulation coating is conducted on magnetic powder with nano oxide dispersion liquid; a using effect is good; an environment is not polluted; the raw material cost is low; an organic solvent and an organic binder are not used in a preparation process; soaking and solidification treatment is not conducted; the method is low in cost and pollution-free; and the metal soft magnetic powder core prepared by the method has good magnetic stability, a higher quality factor and lower magnetic core loss.

Owner:HEFEI UNIV OF TECH +1

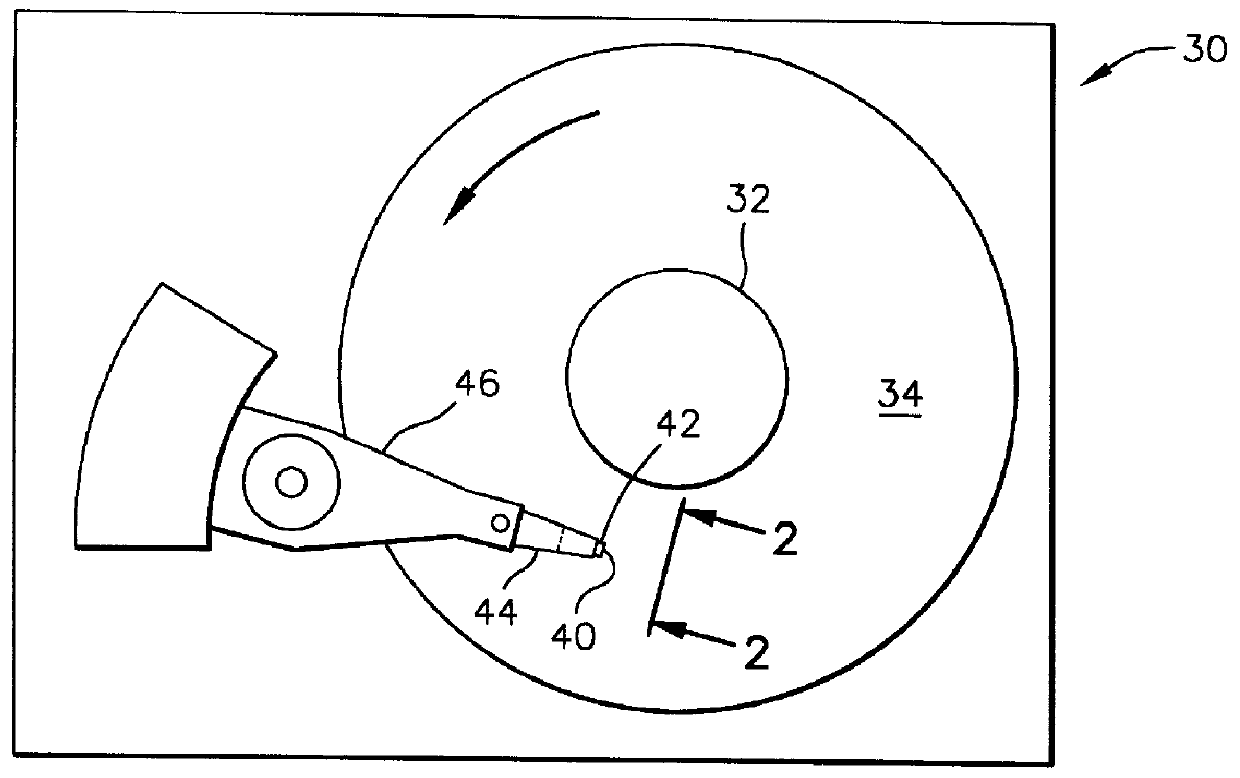

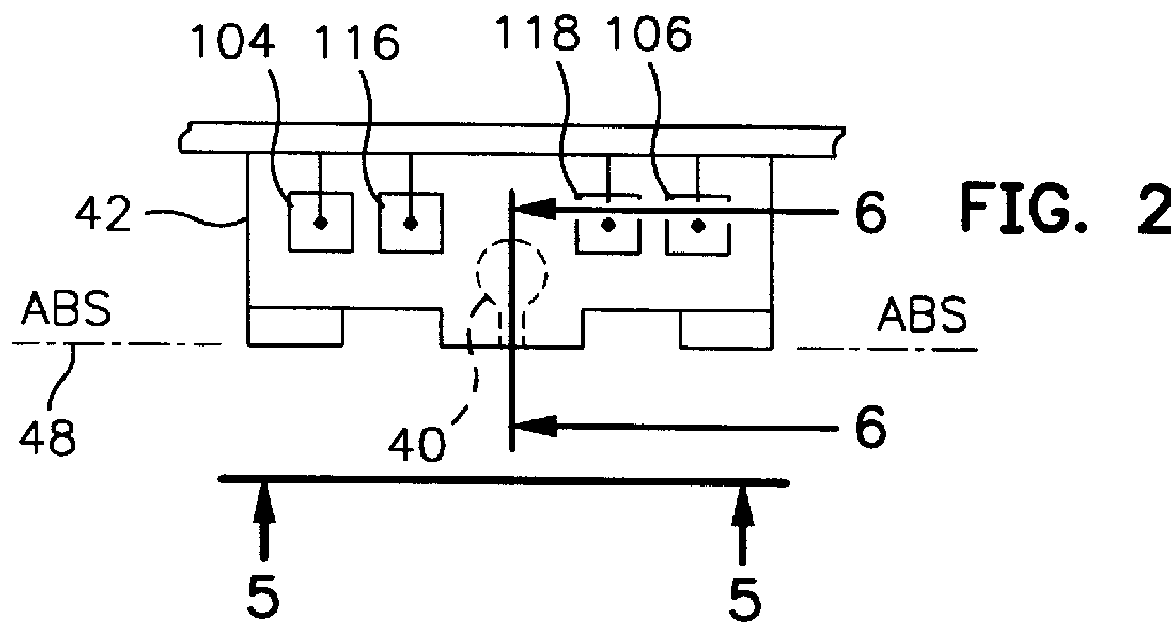

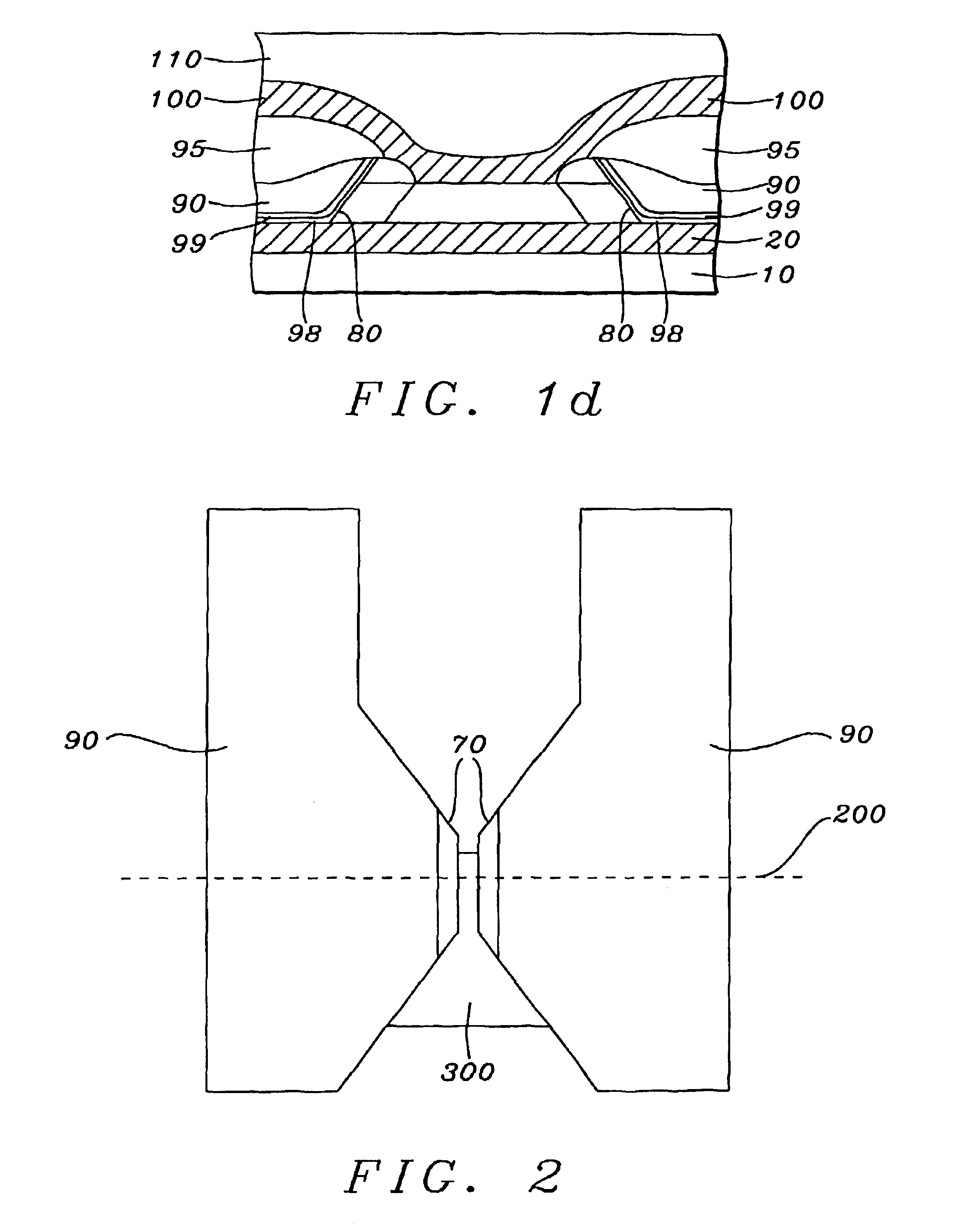

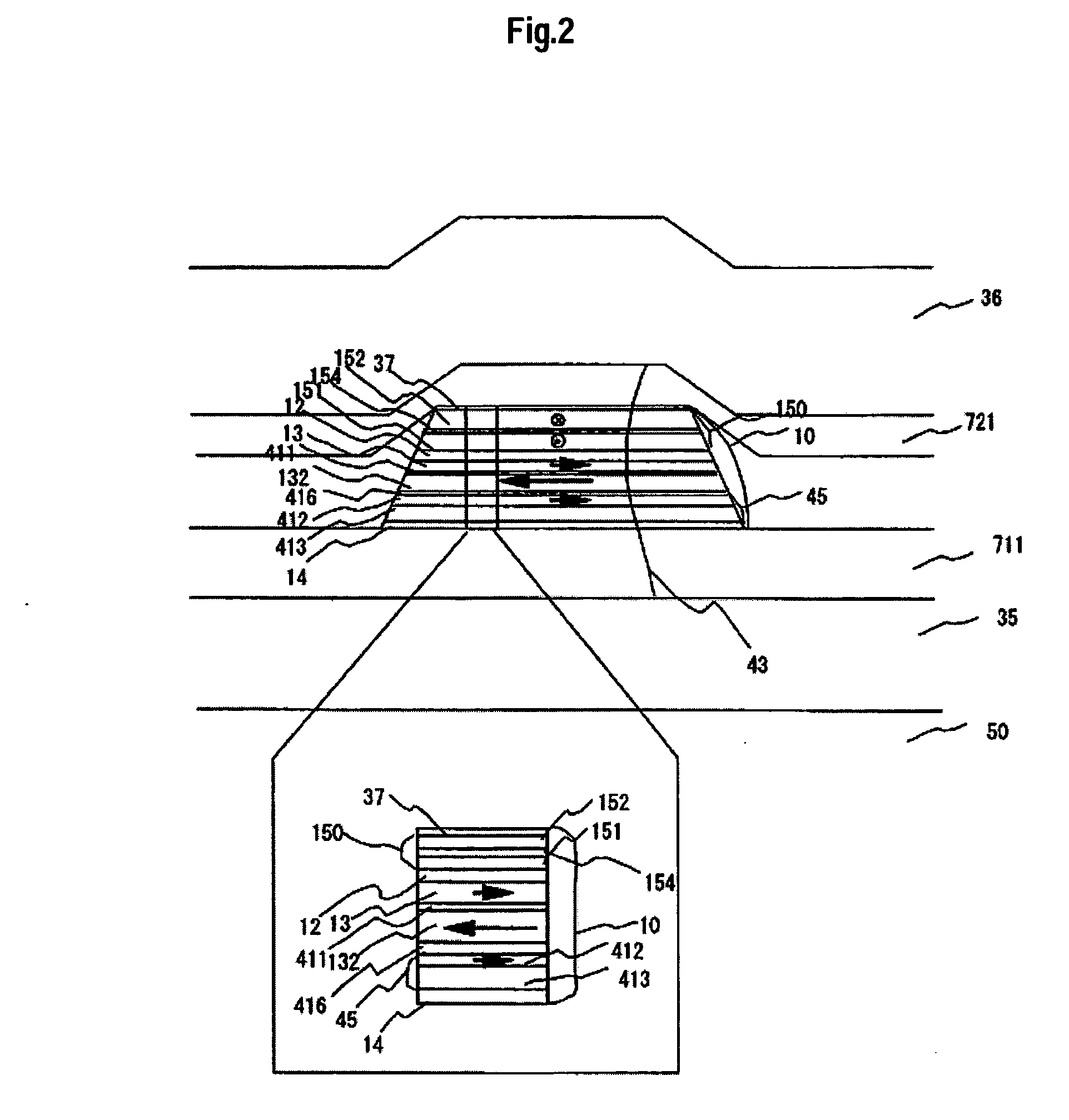

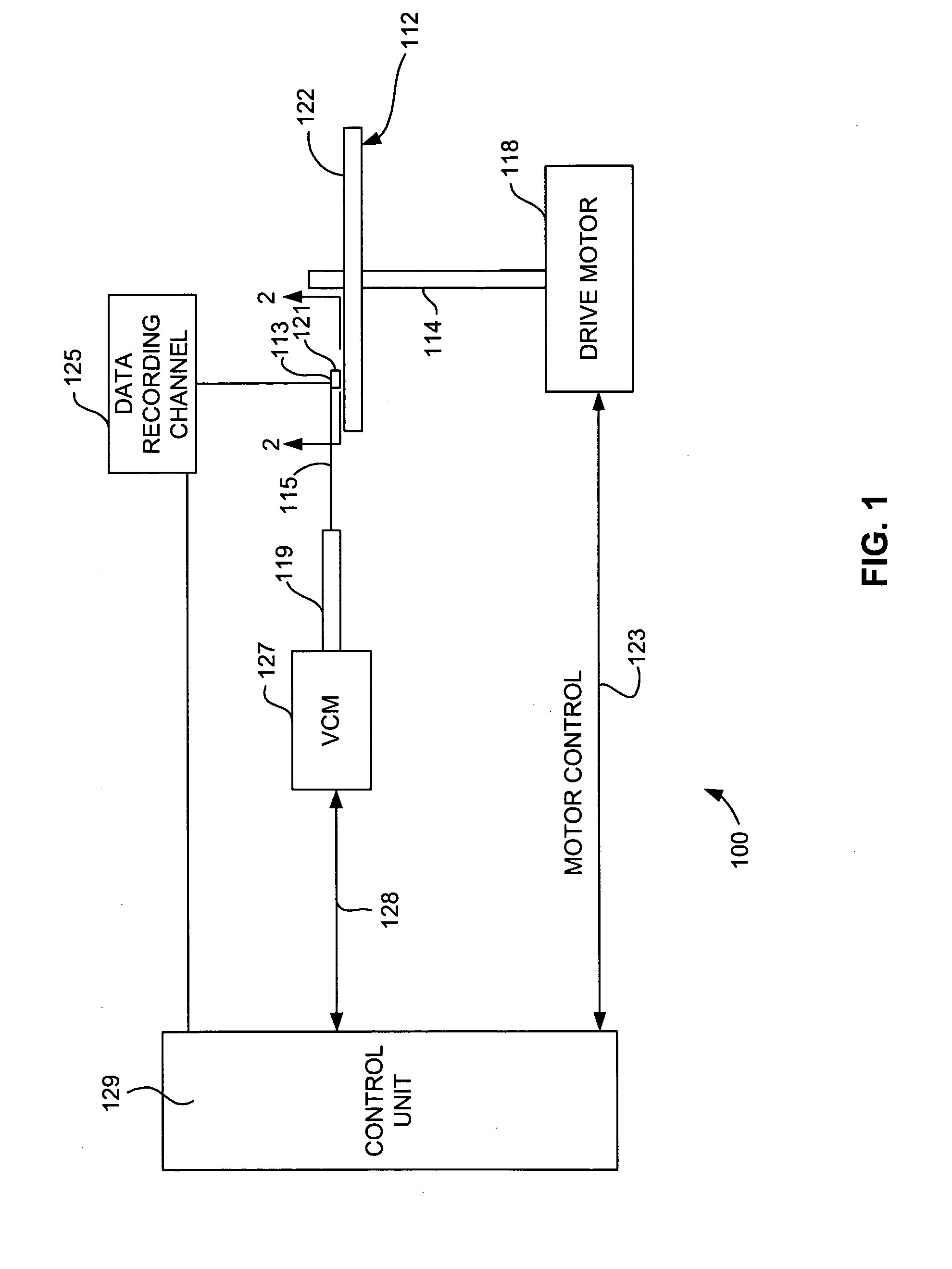

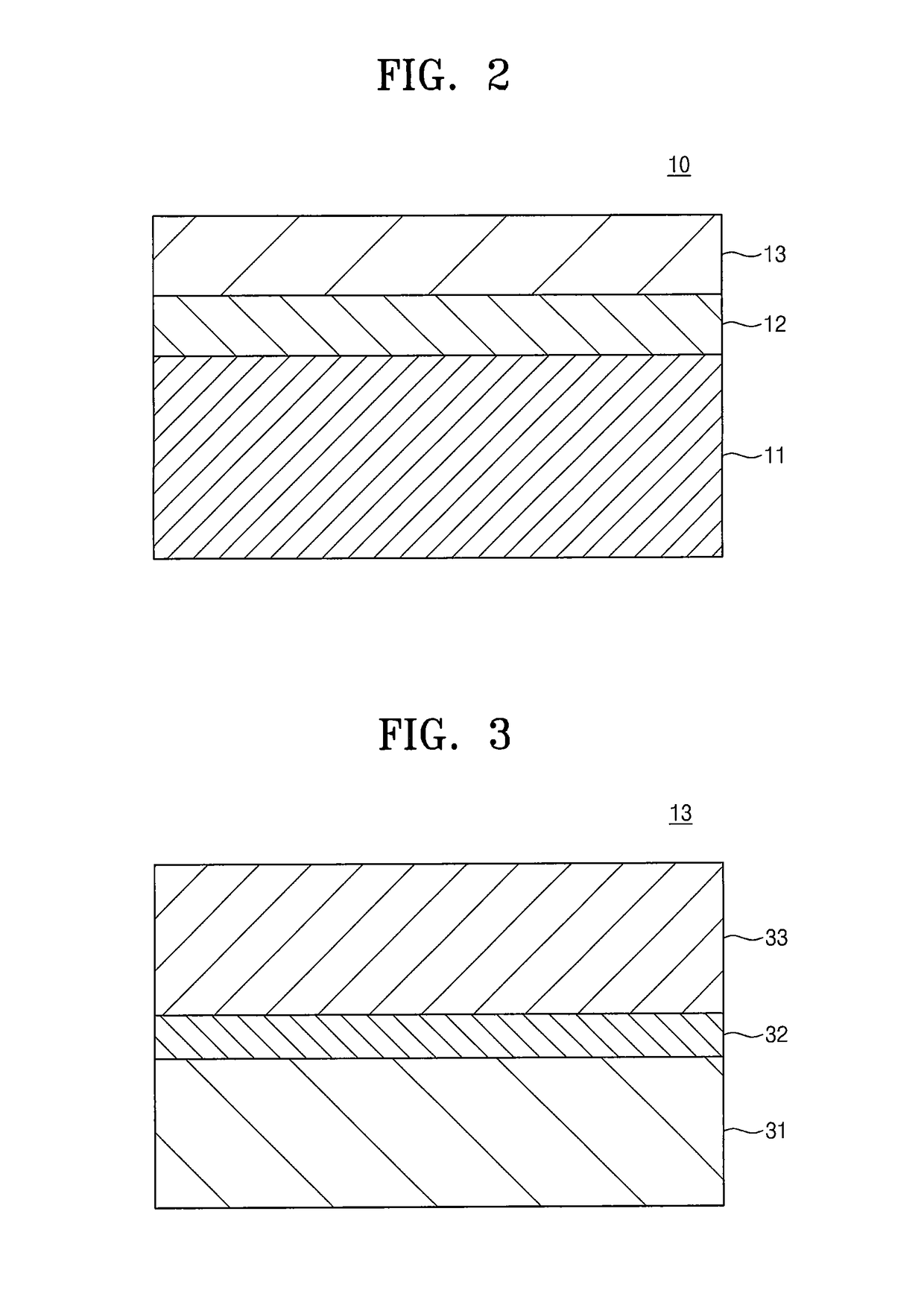

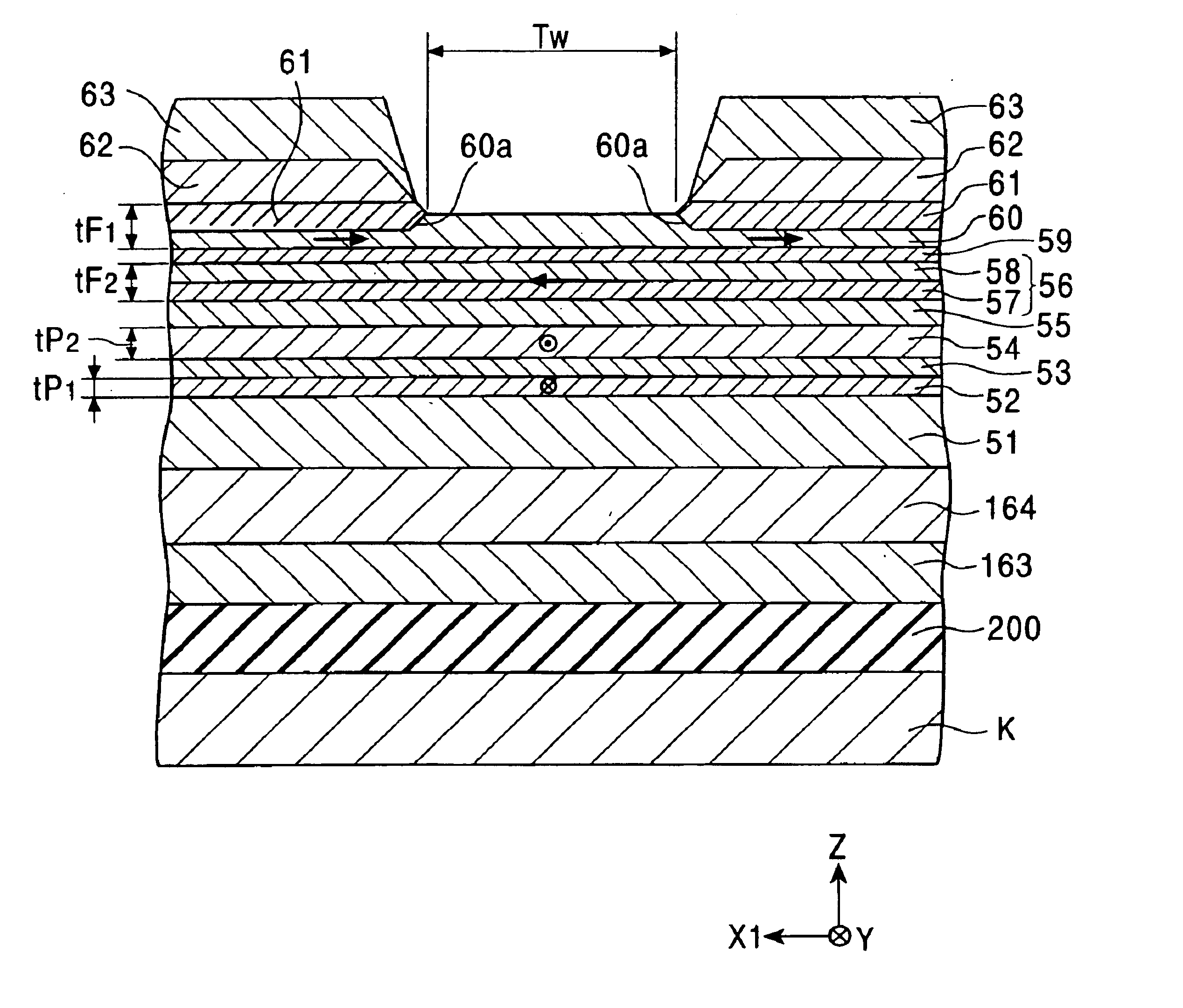

High moment bilayer first pole piece layer of a write head with high magnetic stability for promoting read signal symmetry of a read head

InactiveUS6163442AGood magnetic stabilityHigh strengthHeads using thin filmsRecord information storageIron nitridePhysics

A high moment bilayer first pole piece layer of a write head has high magnetic stability for promoting read signal symmetry of a read sensor of a read head. The bilayer first pole piece layer has a first layer of nickel iron and a second layer of iron nitride. The iron nitride has a high magnetic moment for conducting more flux per volume than the nickel iron first layer. In a first aspect of the invention, the nickel iron first layer is highly stabilized by providing it with a negative magnetostriction so that a stress induced anisotropy (HK) supports an intrinsic uniaxial anisotropy (HK) of the nickel iron first layer. The iron nitride second layer is formed directly on the nickel iron first layer so that by magnetic coupling the iron nitride second layer has significantly improved magnetic stability. In a second aspect of the invention the iron nitride second layer is provided with a positive magnetostriction which still further increases the magnetic stability of the bilayer first pole piece layer. In a preferred embodiment a net magnetostriction is zero or near zero. Each aspect of the invention improves the asymmetry sigma of the read head.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

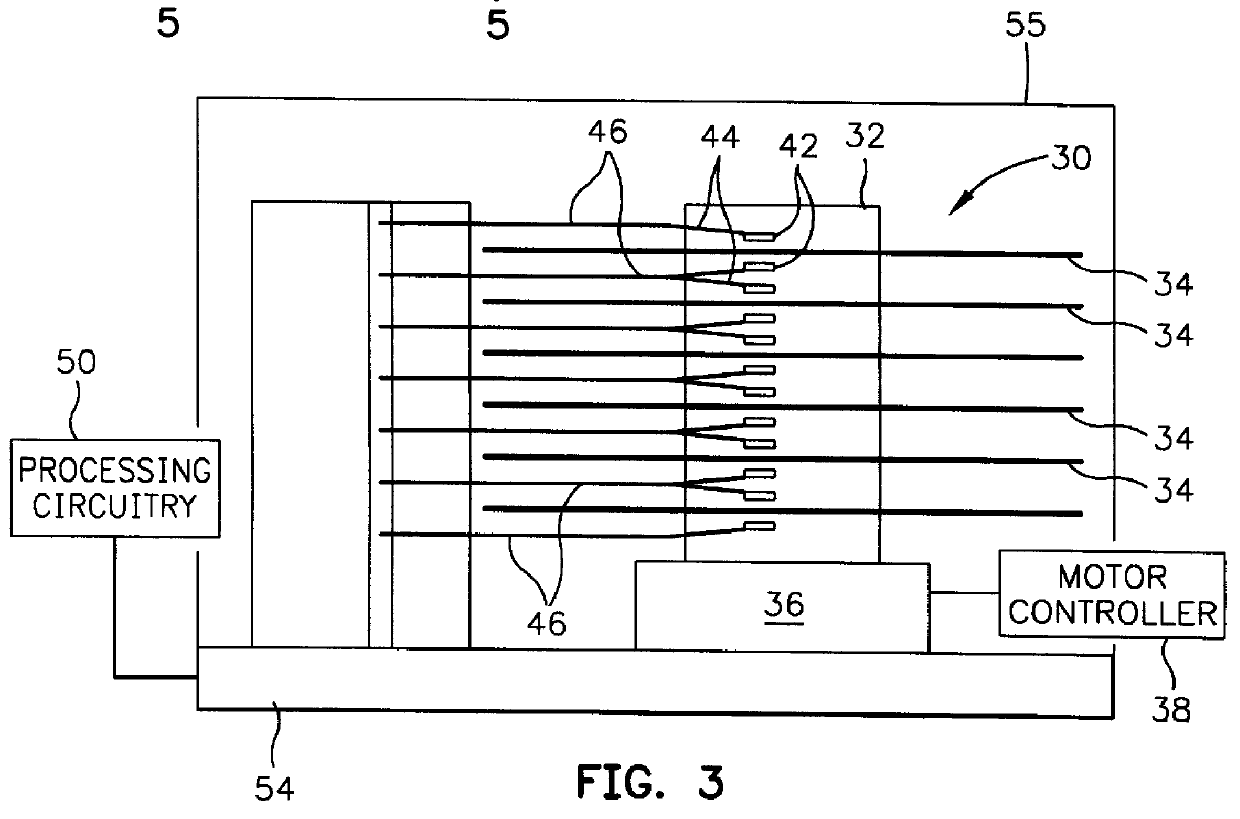

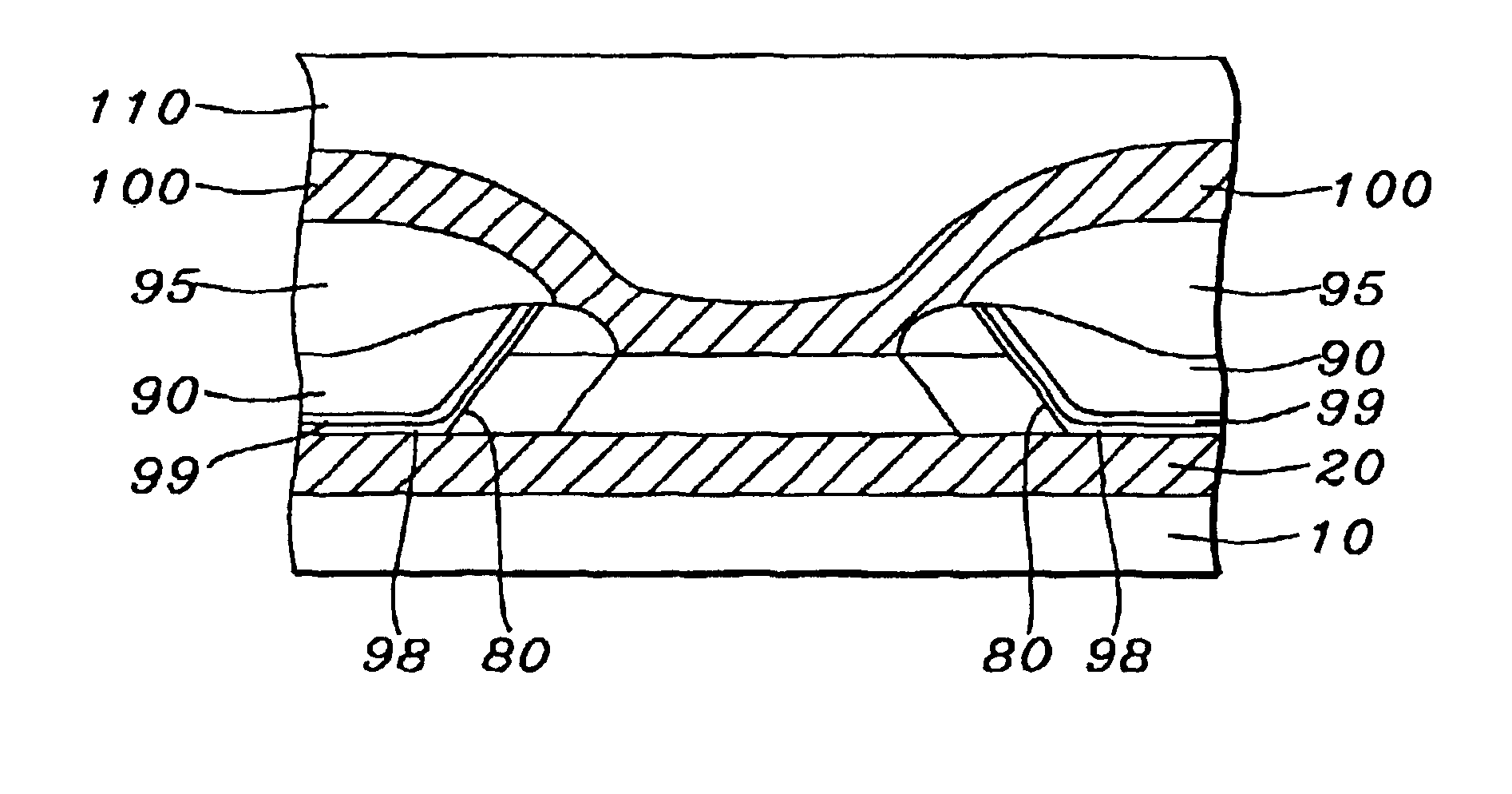

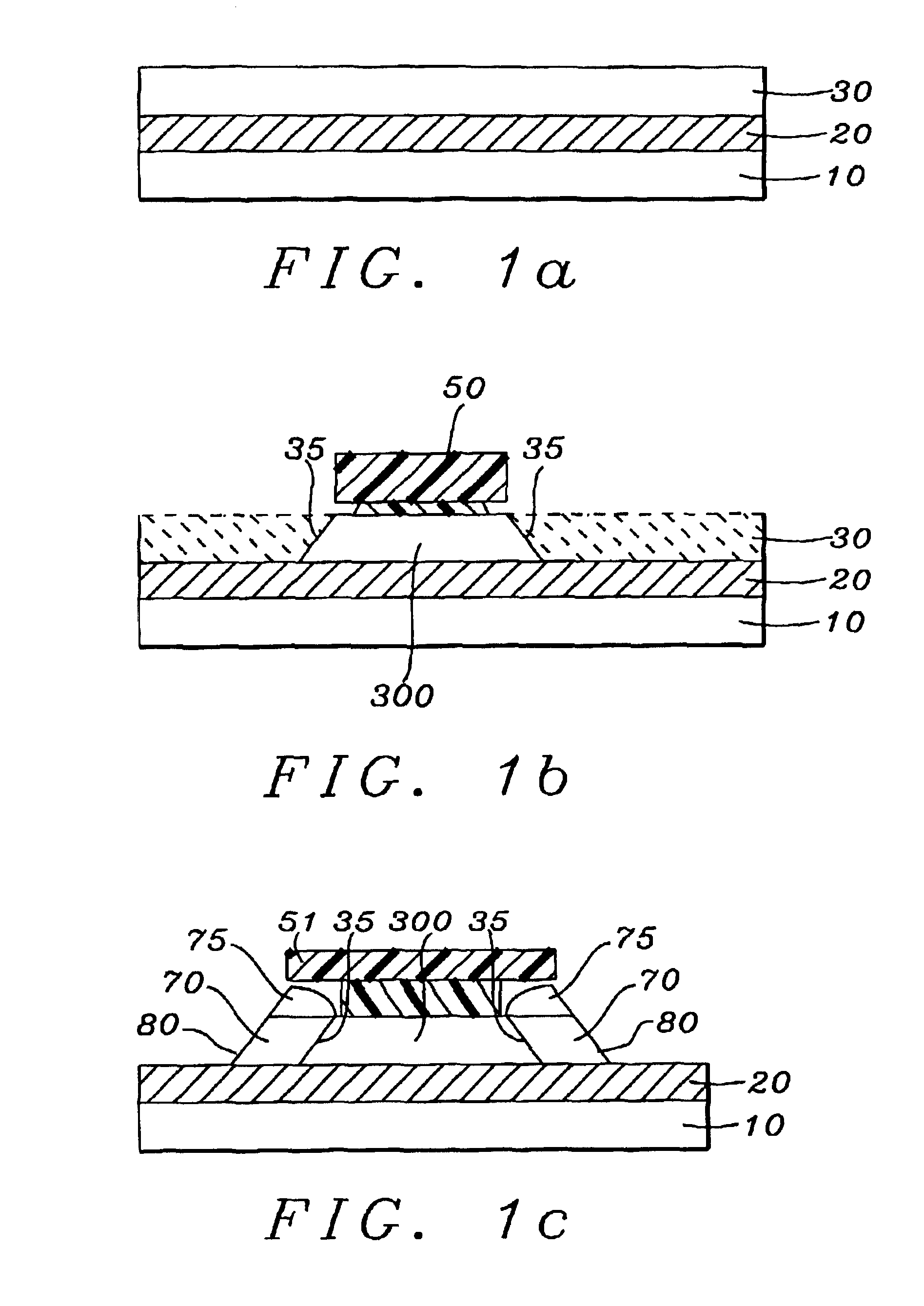

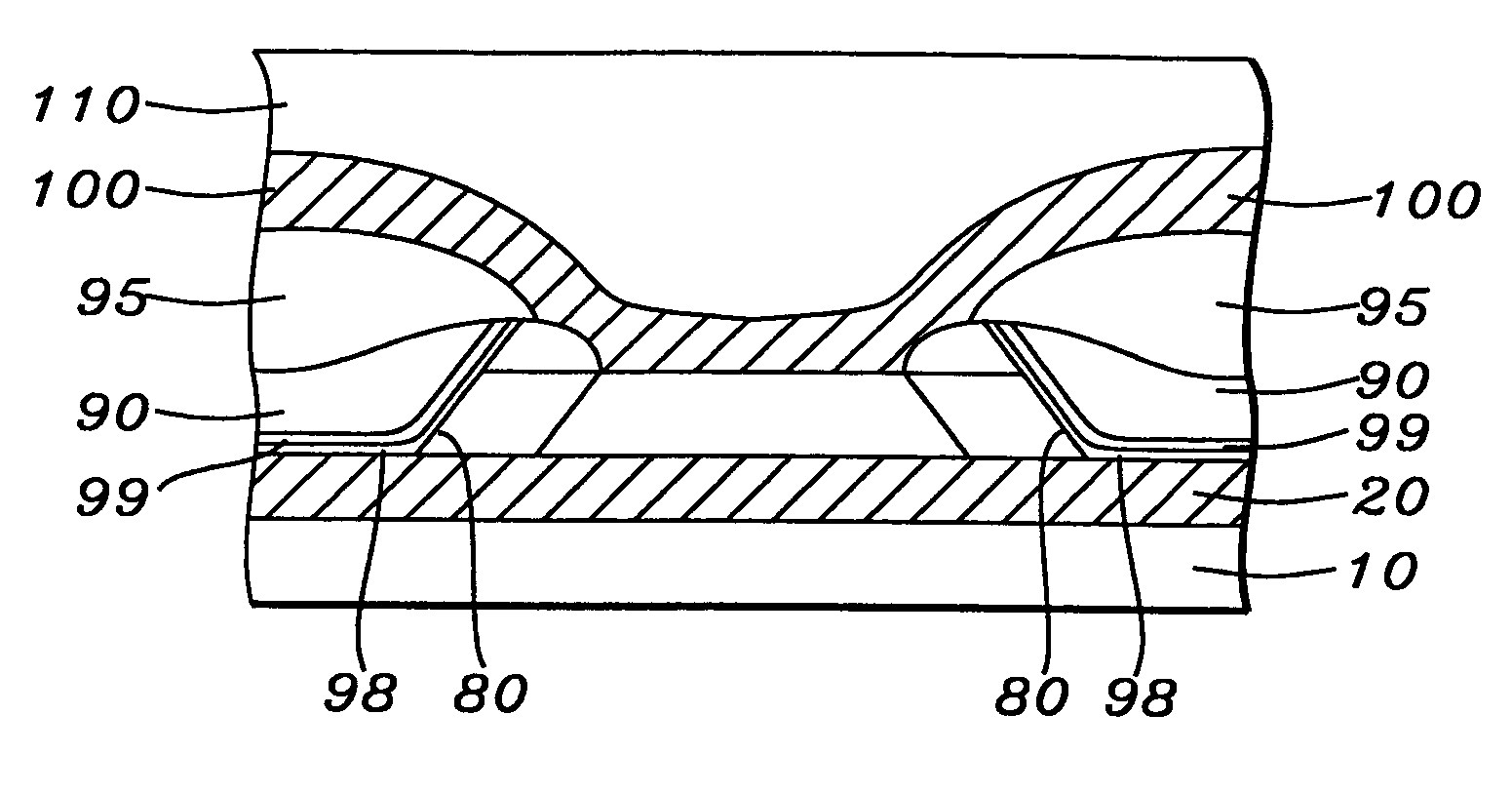

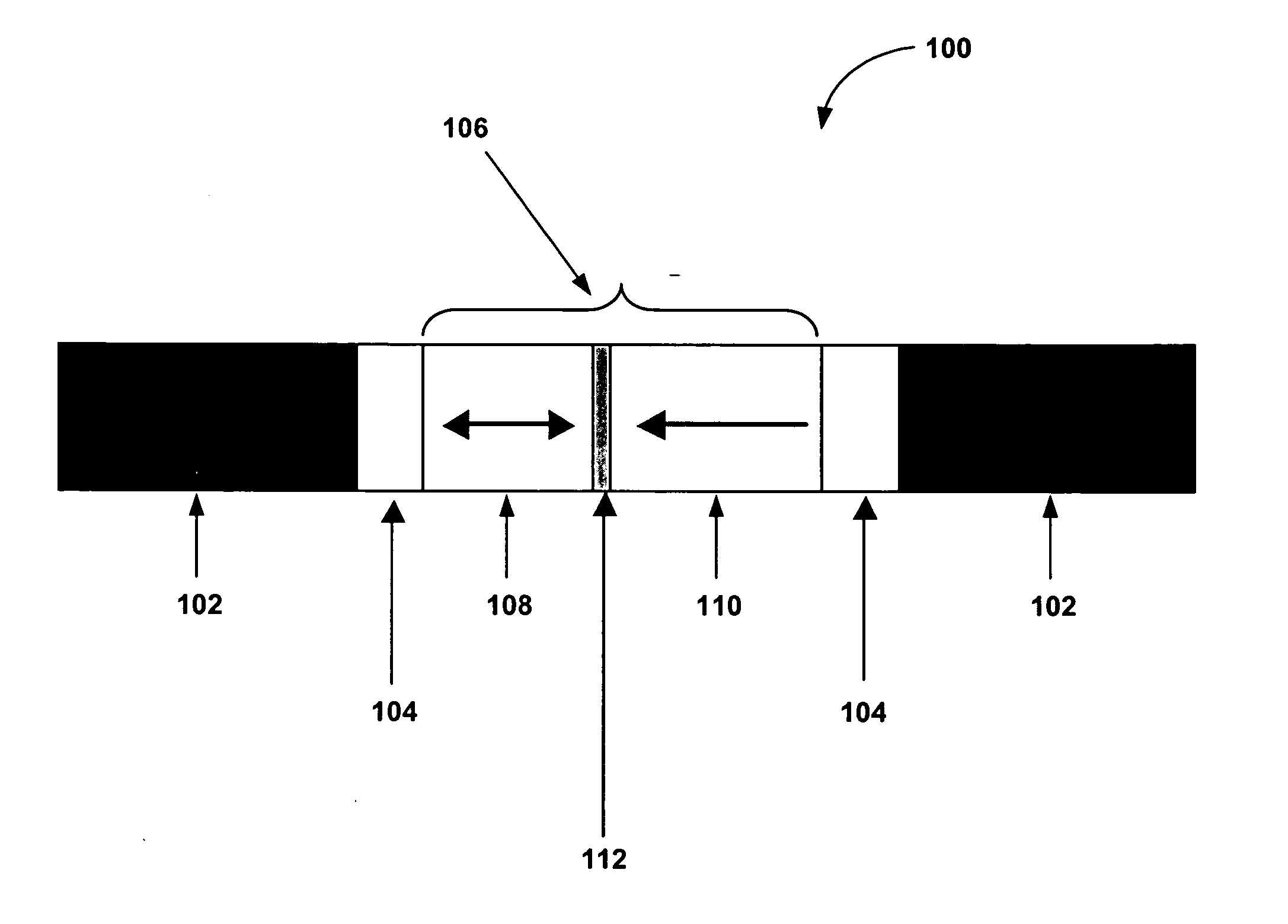

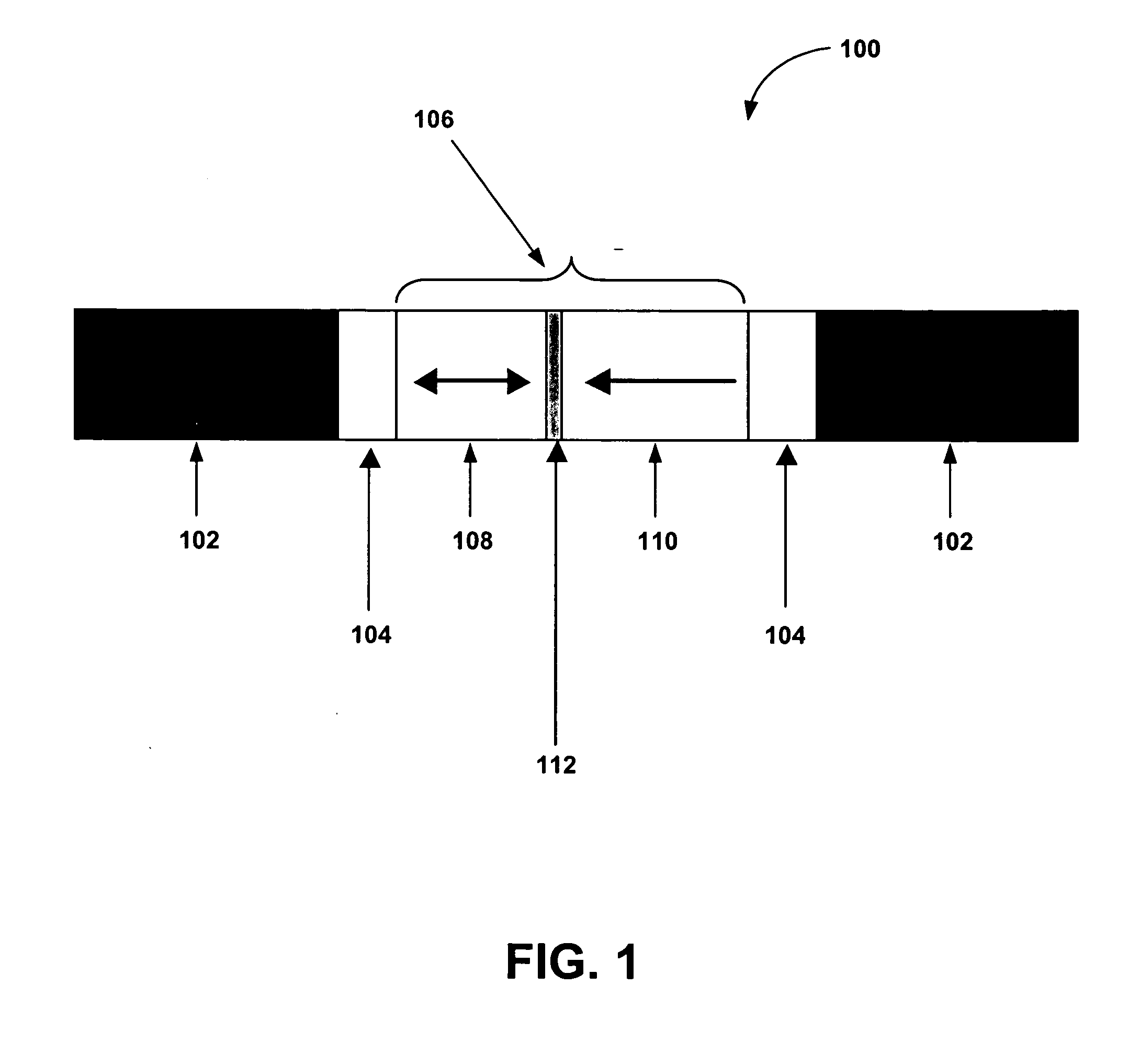

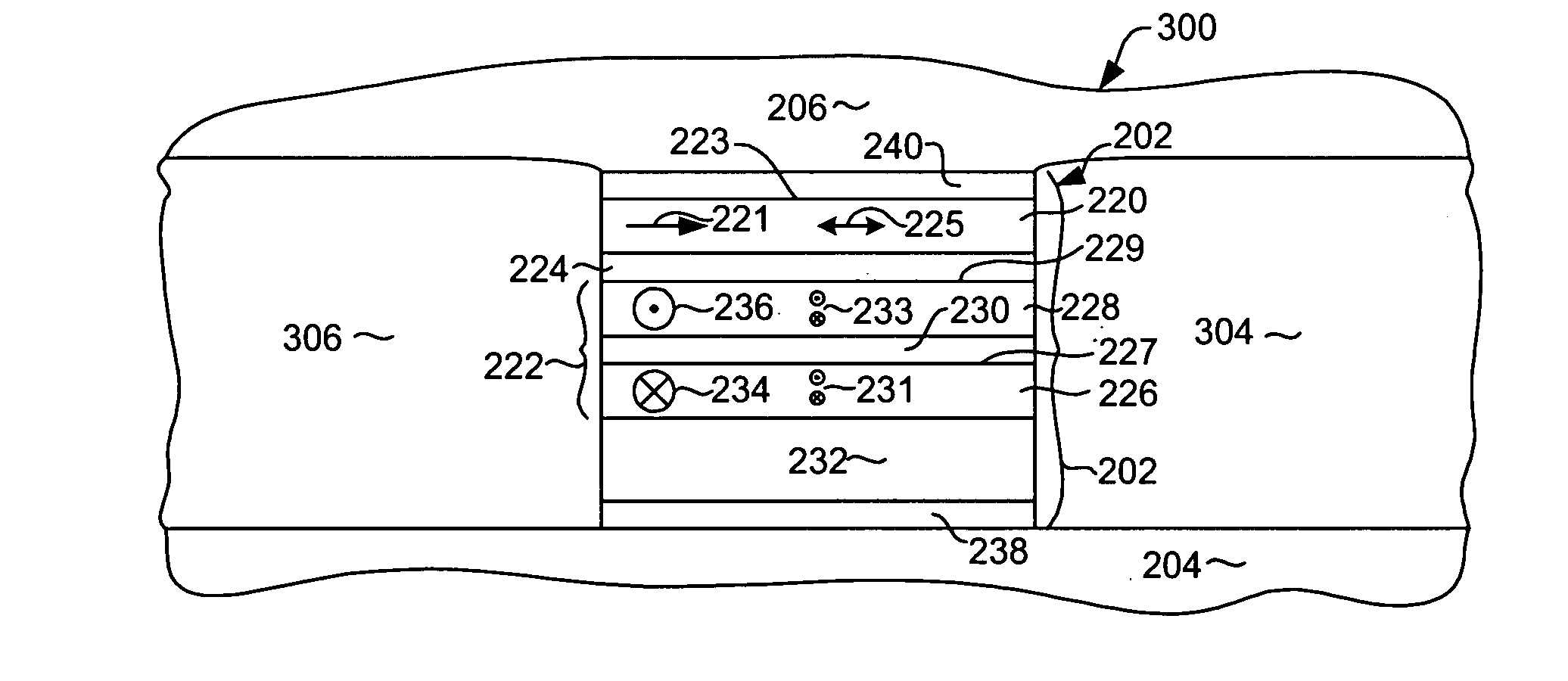

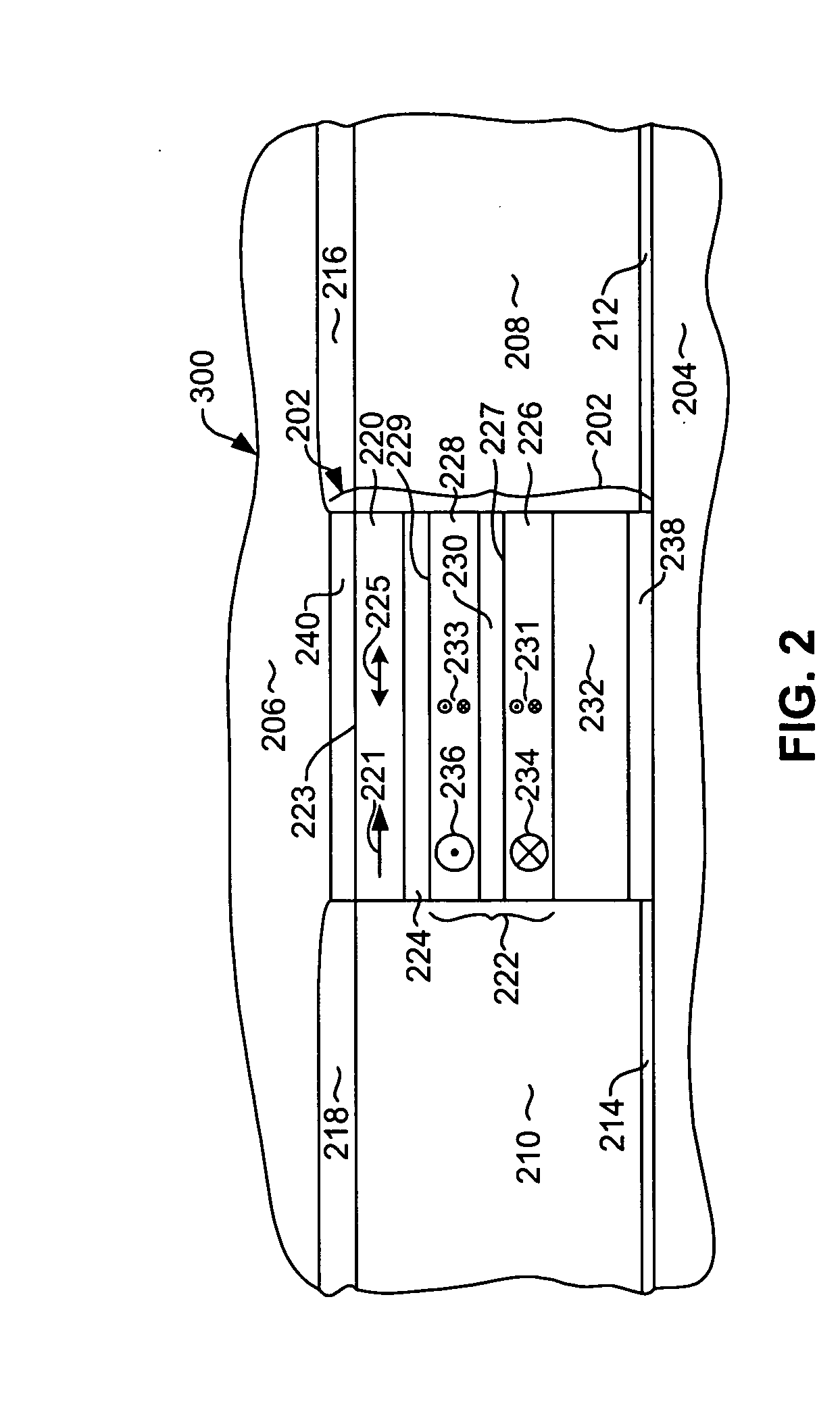

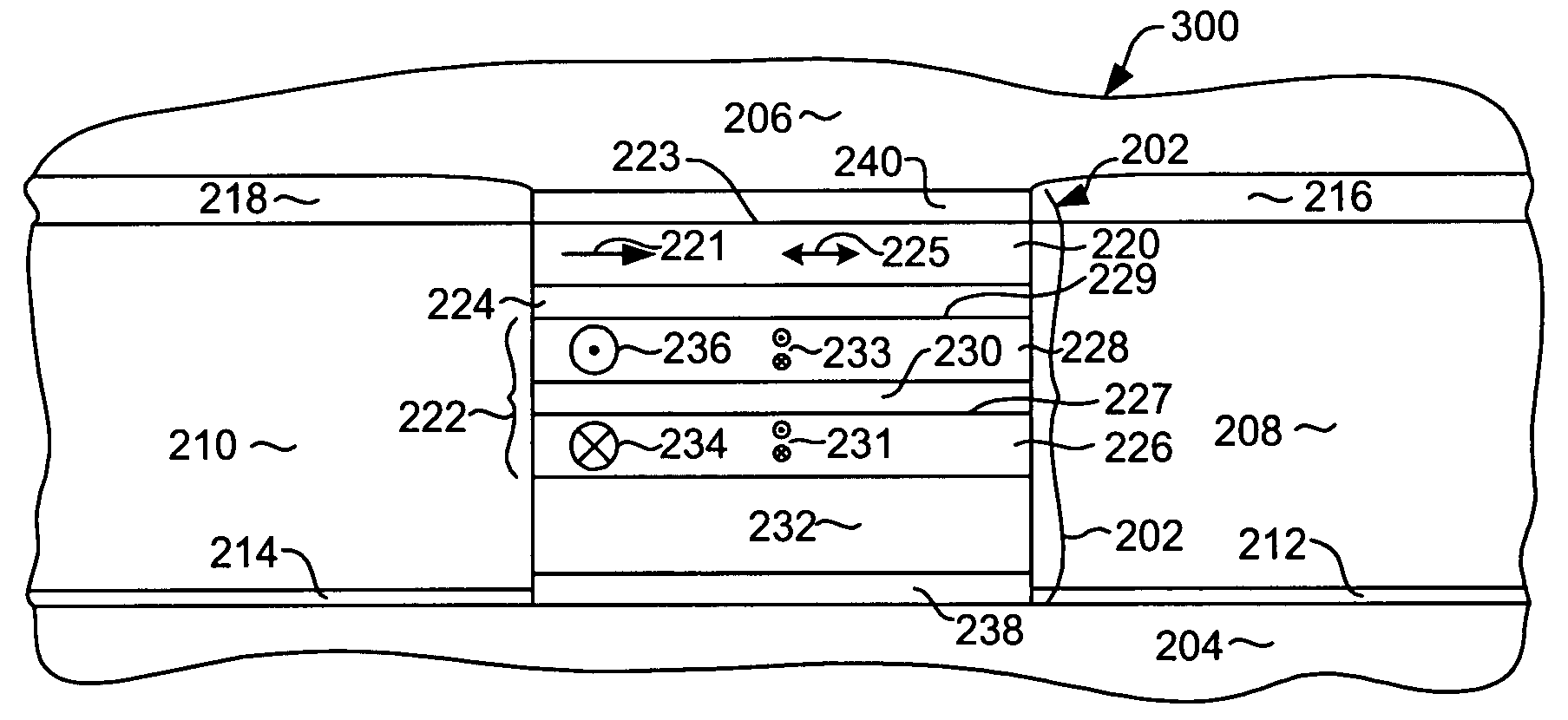

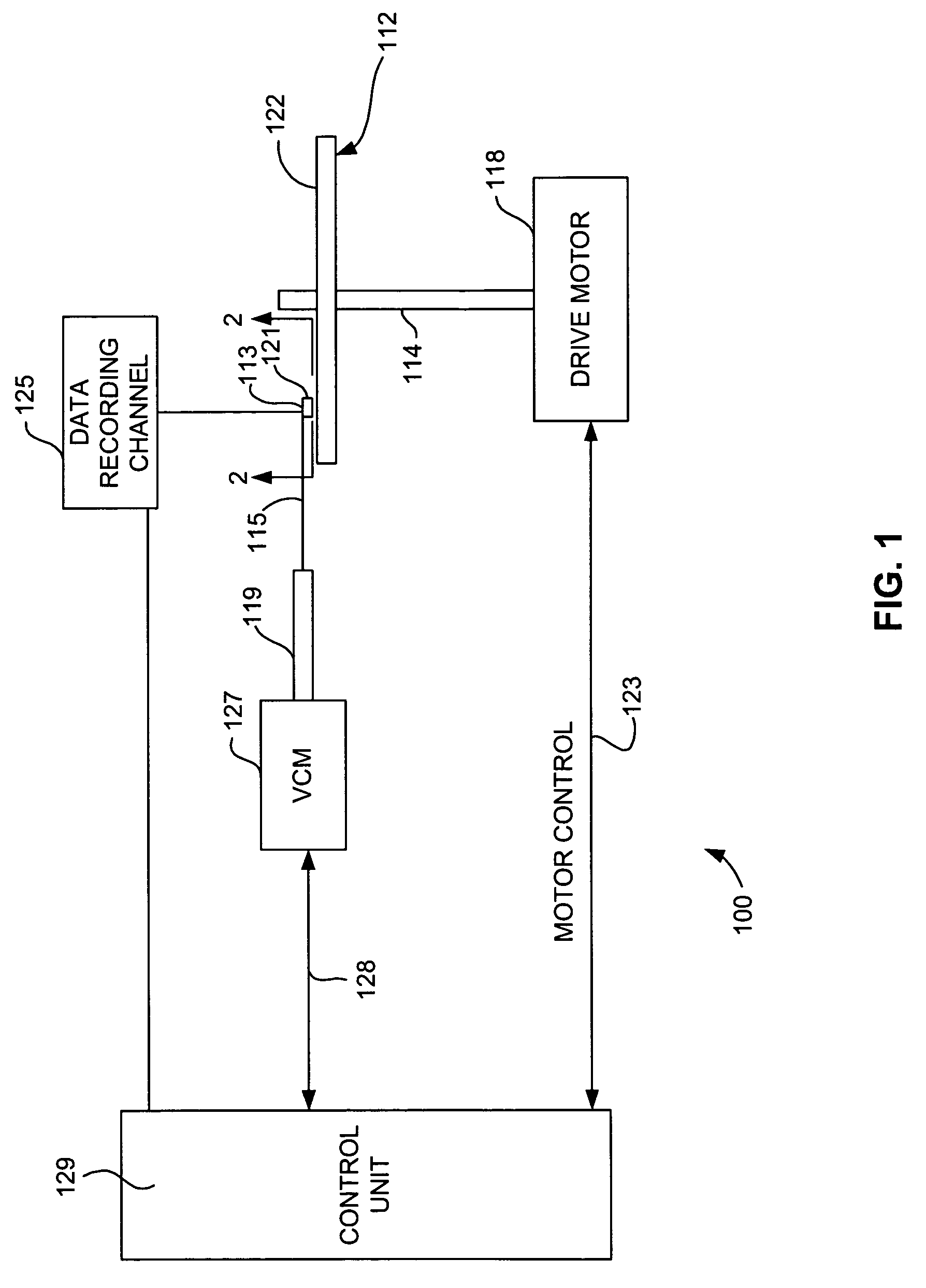

Method for forming a GMR sensor having improved longitudinal biasing

InactiveUS6944939B2Good magnetic stabilityEasily and efficiently fabricatedNanomagnetismElectrical transducersEngineeringMagnetic layer

A GMR sensor having improved longitudinal biasing is provided as is a method of forming it. The improved biasing is provided by longitudinal biasing structures in which a soft magnetic layer is interposed between a hard magnetic biasing layer and the lateral edge of the GMR sensor element. The soft magnetic layer eliminates the need for a seed layer directly between the hard magnetic layer and the GMR element and provides improved coupling to the free layer of the GMR element and a substantial reduction in random domain variations.

Owner:HEADWAY TECH INC

Preparation method of Fe-based metal soft magnetic powder core

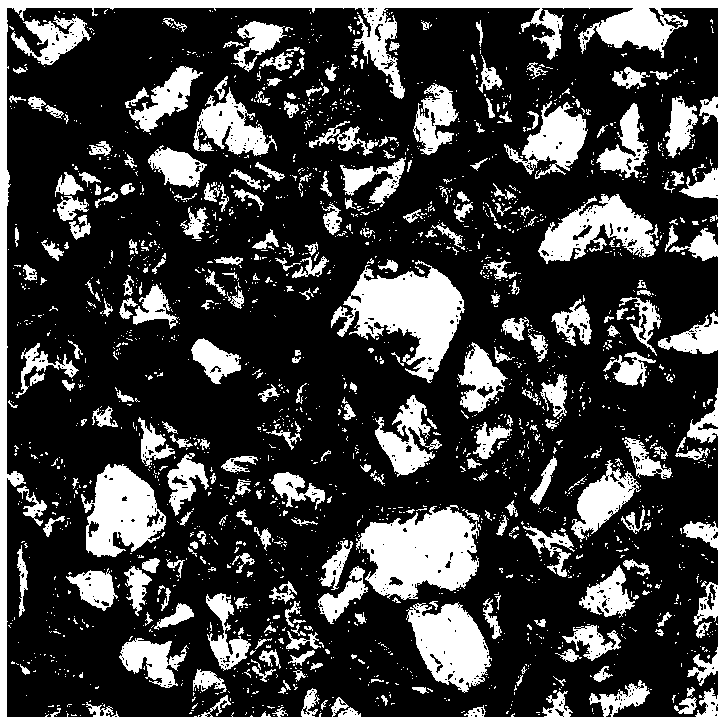

ActiveCN105185560APowder moldingEasy to shapeInorganic material magnetismInductances/transformers/magnets manufactureEpoxyMaterials preparation

The invention relates to a preparation method of a Fe-based metal soft magnetic powder core, and belongs to the technical field of magnetic material preparation. The method comprises the following steps: with Fe-based flake-like metal soft magnetic powder as raw material powder, carrying out annealing treatment; carrying out passivation and insulated coating treatment on the annealed powder; carrying out drying treatment on the passivated and insulated powder; pressing the dried metal powder into a magnetic powder core blank, and adopting zinc stearate powder as a releasing agent; and carrying out annealing treatment on the molded magnetic powder core blank and spraying a layer of epoxy resin insulating paint on the surface of the magnetic powder core blank, so as to obtain the metal soft magnetic powder core. The density of the magnetic powder core prepared by the method is greatly improved; the density distribution is even; the magnetic powder core has relatively high compactness and good mechanical strength; and meanwhile, the magnetic powder core has relatively high magnetic conductivity and relatively low magnetic loss. In addition, the prepared magnetic powder core also has the characteristics of high magnetic conductivity, high quality factor and low loss.

Owner:有研增材技术有限公司

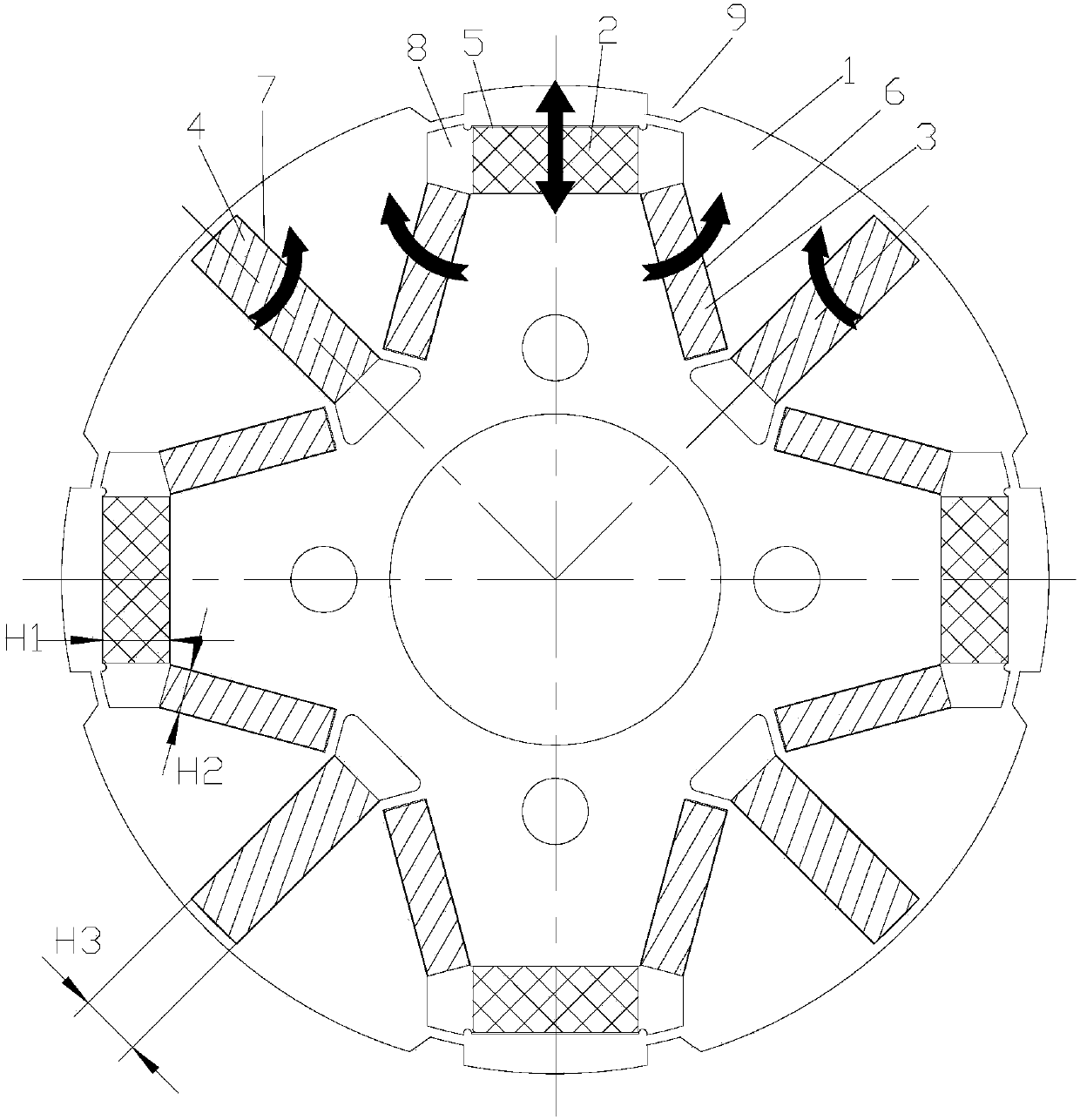

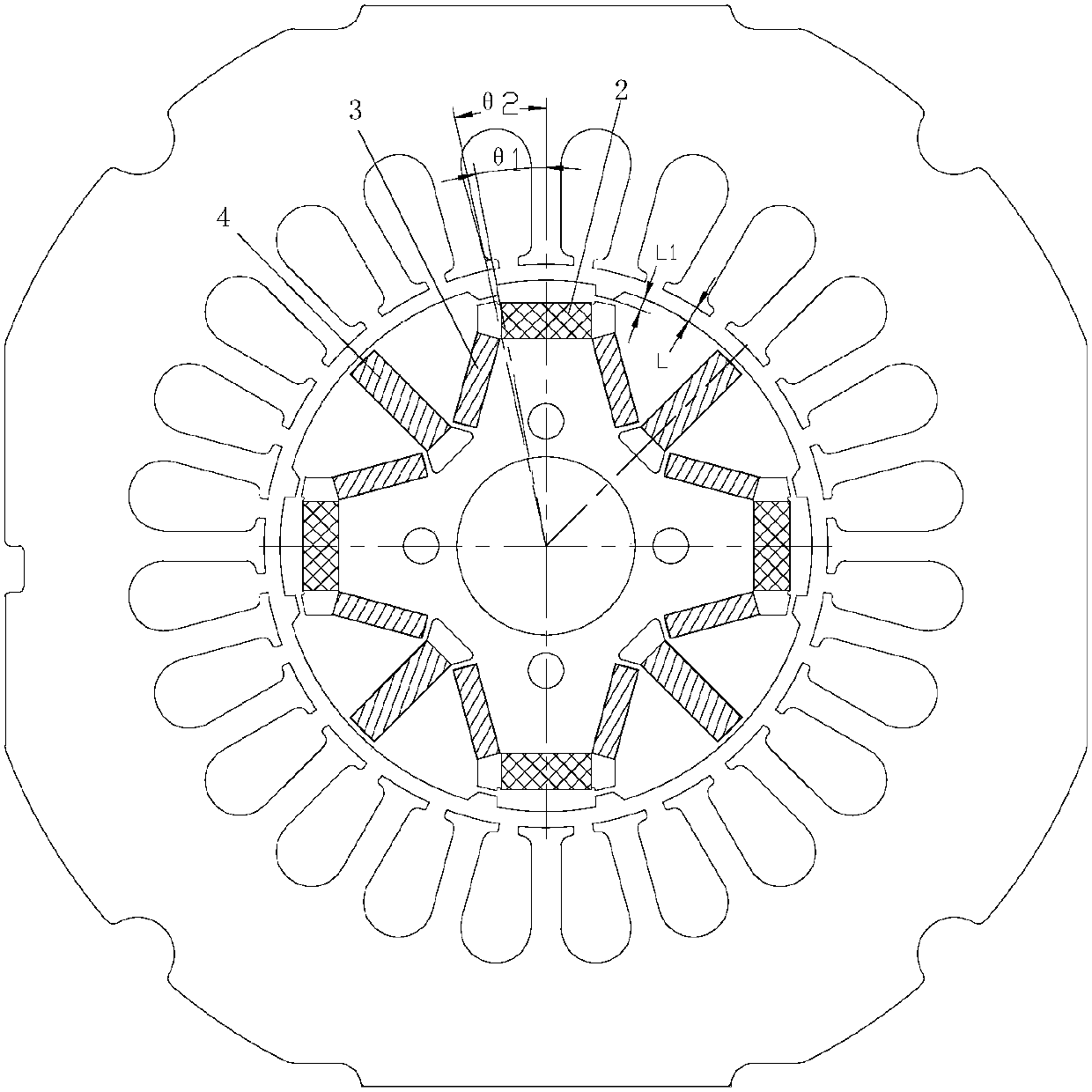

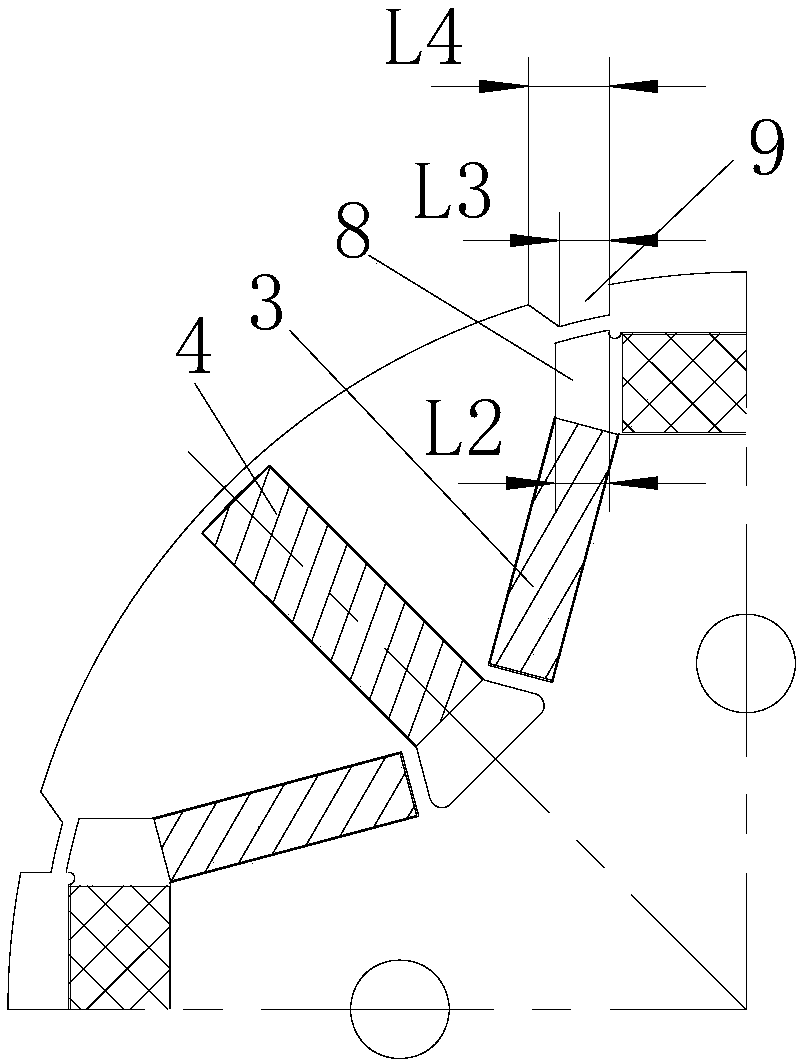

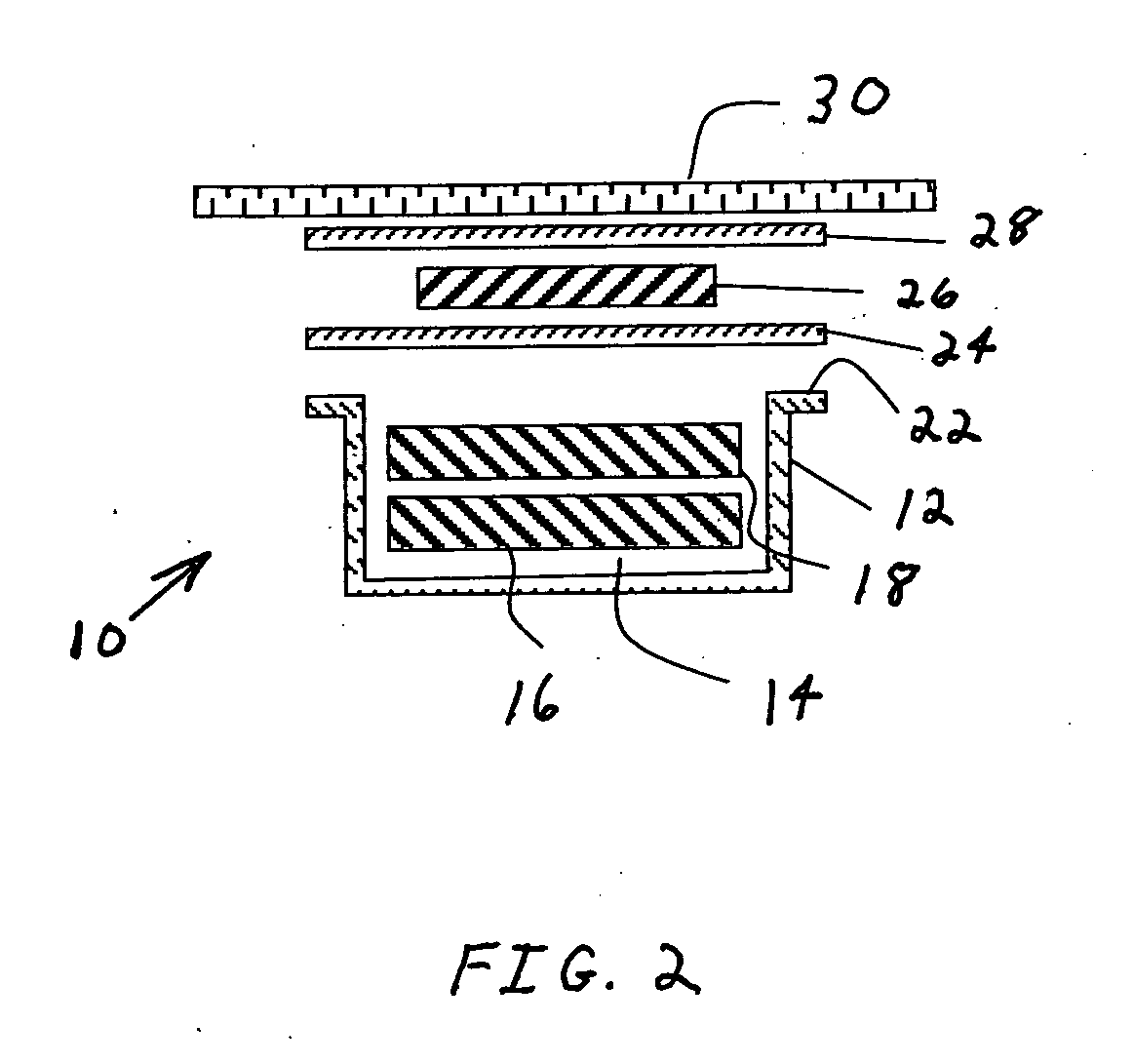

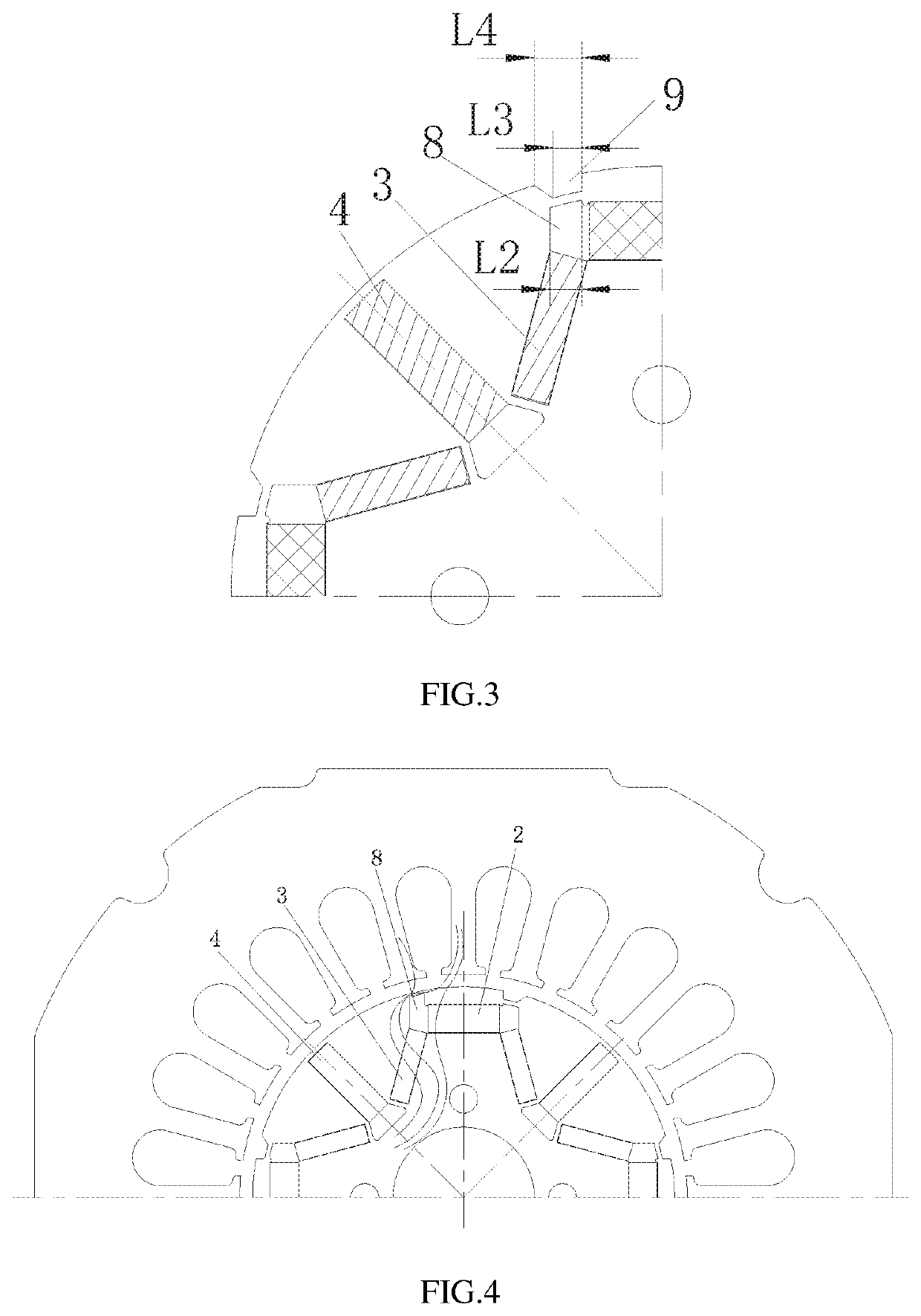

Motor rotor and permanent magnet motor

PendingCN108023421AReduce the difficulty of charging and demagnetizingImprove operational efficiencyWindingsMagnetic circuit rotating partsElectric machineMagnetic poles

Owner:GREE ELECTRIC APPLIANCES INC

NdFeB magnet and preparation method thereof

ActiveCN104064301ARefine the grain sizeRaise the sintering temperaturePermanent magnetsInductances/transformers/magnets manufactureIngotCopper

The invention provides an NdFeB magnet which comprises, by mass, 29% to 33% of Pr-Nd, 0.97% to 1.5% of B, 0.4% to 0.6% of Dy, 0.2% to 0.8% of Al, 0.6% to 0.8% of Co, 0.01% to 0.5% of Cu, 0.01% to 0.2% of Zr and the balance Fe. The invention further discloses a preparation method of the NdFeB magnet. The method includes the steps that firstly, Pr-Nd alloy, Zr-Fe alloy, B-Fe alloy, Dy-Fe alloy, aluminum, cobalt, copper and iron are molten to prepare an NdFeB cast ingot; secondly, the obtained NdFeB cast ingot is milled into NdFeB powder; finally, the NdFeB powder is sintered into the NdFeB magnet. The NdFeB magnet prepared through the method has a more refined magnet grain size and higher magnet stability.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

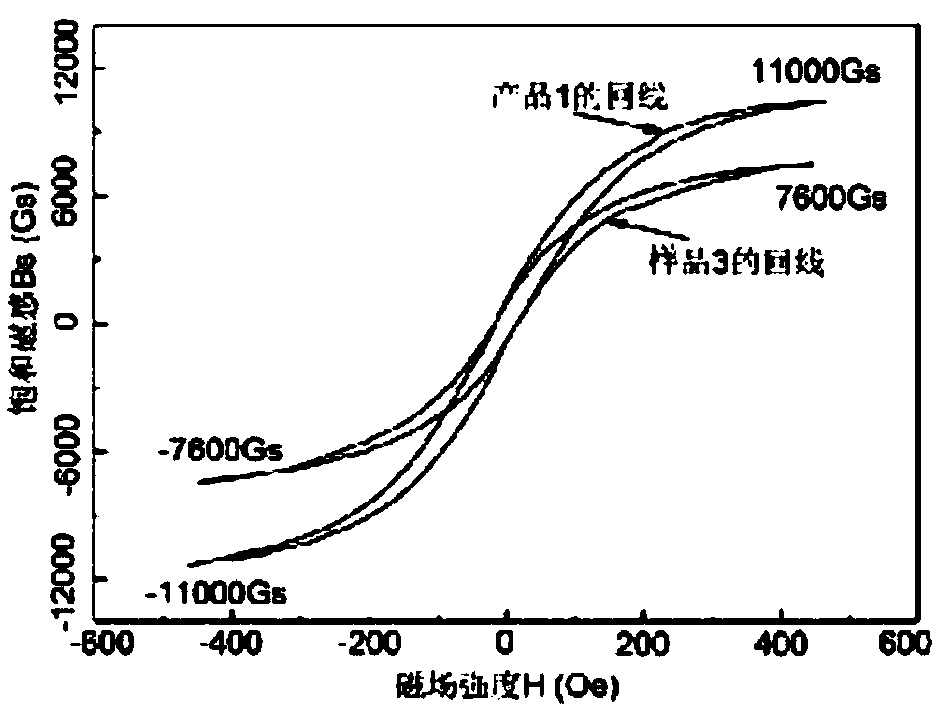

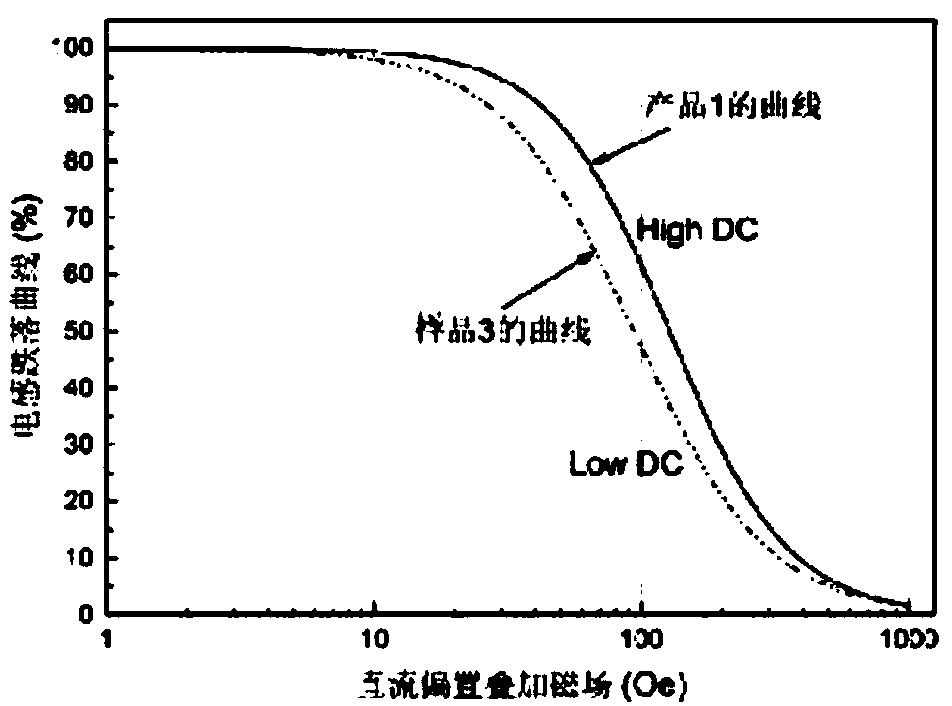

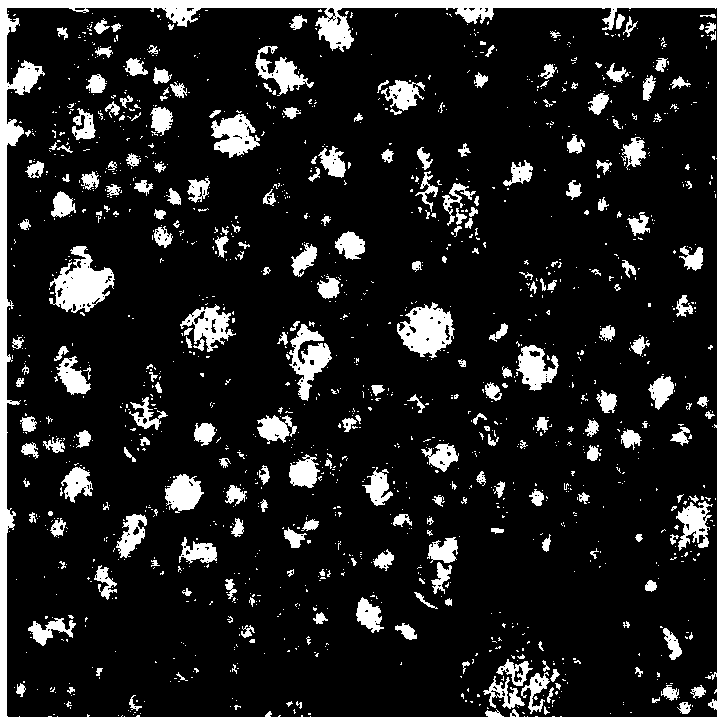

Material preparation method capable of improving direct current biasing characteristic and preparation method of magnetic powder core

ActiveCN108242309ASimple preparation processEasy to useTransportation and packagingMetal-working apparatusMaterials preparationBall mill

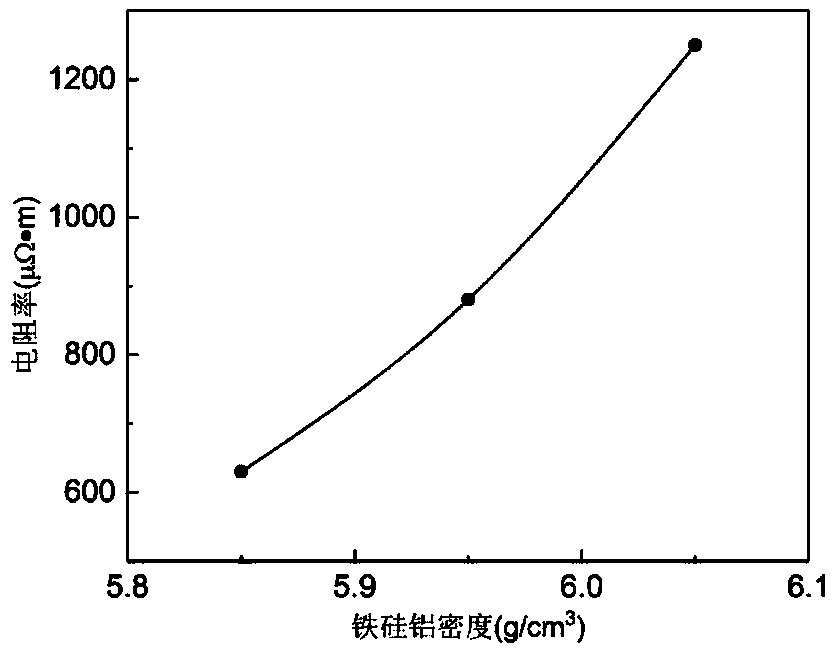

The invention relates to a material preparation method capable of improving direct current biasing characteristic. The material preparation method is characterized by comprising the following steps: (1) sieving Fe-Si-Al magnetic powder by adopting a sieve with 140 meshes, thus obtaining a first kind of Fe-Si-Al magnetic powder; sieving the Fe-Si-Al magnetic power by adopting a sieve with 300 meshes, thus obtaining a second kind of Fe-Si-Al magnetic powder; (2) mixing the first kind of Fe-Si-Al magnetic powder and the second kind of Fe-Si-Al magnetic powder in a mass ratio of 1.5:4 to obtain amixed powder material, putting the mixed powder material into a ball mill, and carrying out ball milling for 0.25-2.0 hours; and (3) insulating and coating, thus obtaining the coated magnetic powder.The magnetic powder material is simple in preparation technology, environmentally friendly, and the direct current biasing characteristic of the prepared magnetic powder core can be improved.

Owner:NBTM NEW MATERIALS GRP

Quantum ceramic and formulation, making method and application thereof

InactiveCN107266056AReasonable ratioGood health benefitsWatch chainsOrnamental chainsNitrogen atmosphereMagnesium

The invention relates to quantum ceramic and a formulation, a making method and application thereof and relates to the field of materials. The formulation of the quantum ceramic comprises tourmaline, meteorite, stone needle, medical stone, germanite, silicon dioxide, titanium dioxide, calcium oxide, kaolin, iron sesquioxide, zinc oxide, neodymium, boron and magnesium oxide and is reasonable in proportioning, so that performance of the quantum ceramic which is finally obtained is improved effectively. The making method includes: mixing raw materials according to the above formulation; sintering and then cooling in a nitrogen atmosphere. The making method is simple to operate and convenient for industrial production. The quantum ceramic made by the method releases micro magnetism and infrared light waves, thereby having excellent healthcare efficacy. By applying the quantum ceramic in accessories, functionality of the accessories can be improved effectively, and value of the accessories can be increased.

Owner:雷永泉 +2

High-frequency magnetic material and method for producing the same

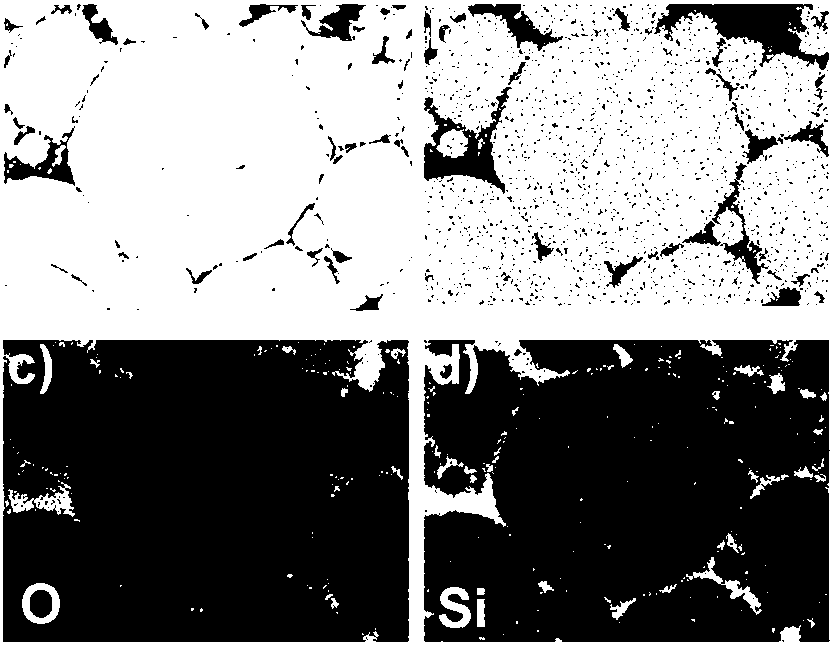

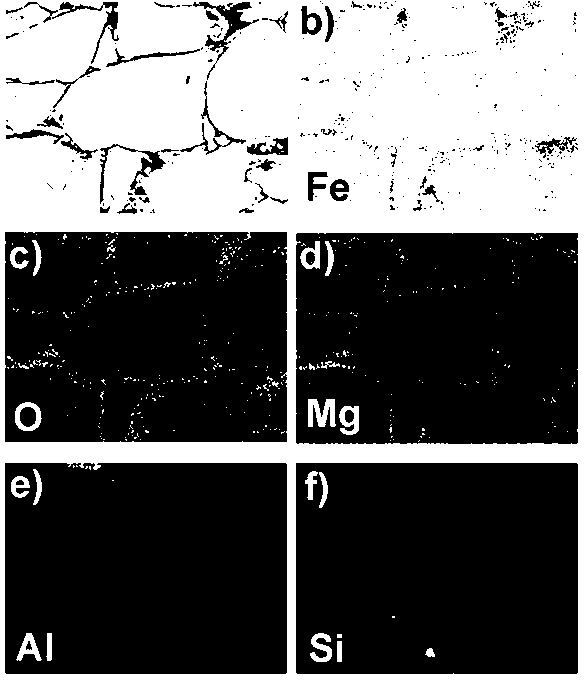

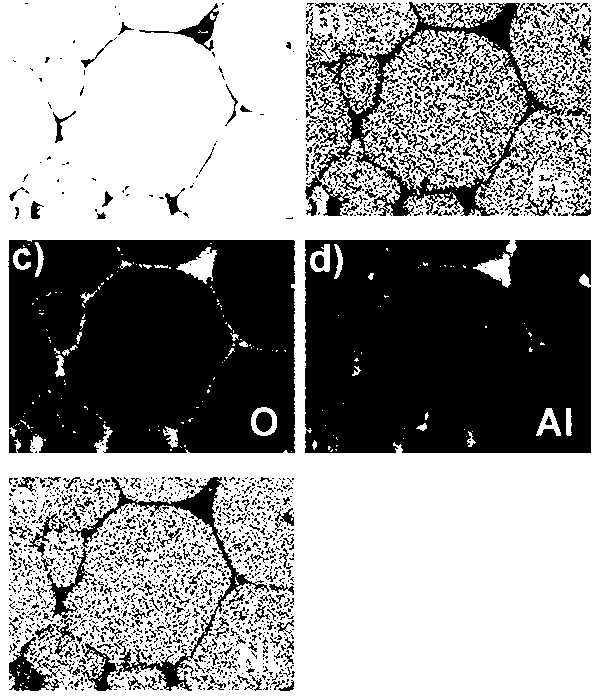

ActiveUS20080226899A1Improve thermal stabilityGood magnetic stabilityMaterial nanotechnologyIron compoundsRare-earth elementMetal particle

A high-frequency magnetic material is provided and includes: an oxide phase including: a first oxide of a first element being at least one selected from the group consisting of Mg, Al, Si, Ca, Zr, Ti, Hf, Zn, Mn, a rare-earth element, Ba, and Sr, and a second oxide of a second element being at least one selected from the group consisting of Li, Na, K, Rb, Cs, Be, Mg, Ca, Sr, Ba, and Zn, the first oxide and at least a part of the second oxide being formed into a solid solution; and magnetic metal particles including at least one of Fe and Co and having a particle size of 1 to 100 nm, the magnetic metal particles being deposited on a surface and inside of the oxide phase, the magnetic metal particles occupying 50% of a volume of the high-frequency magnetic material exclusive of a void.

Owner:KK TOSHIBA

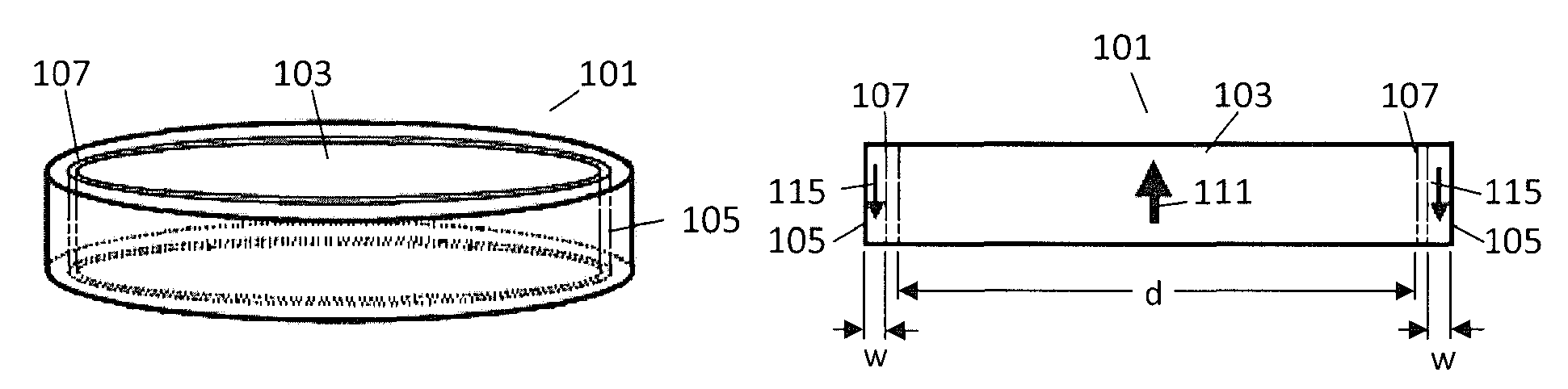

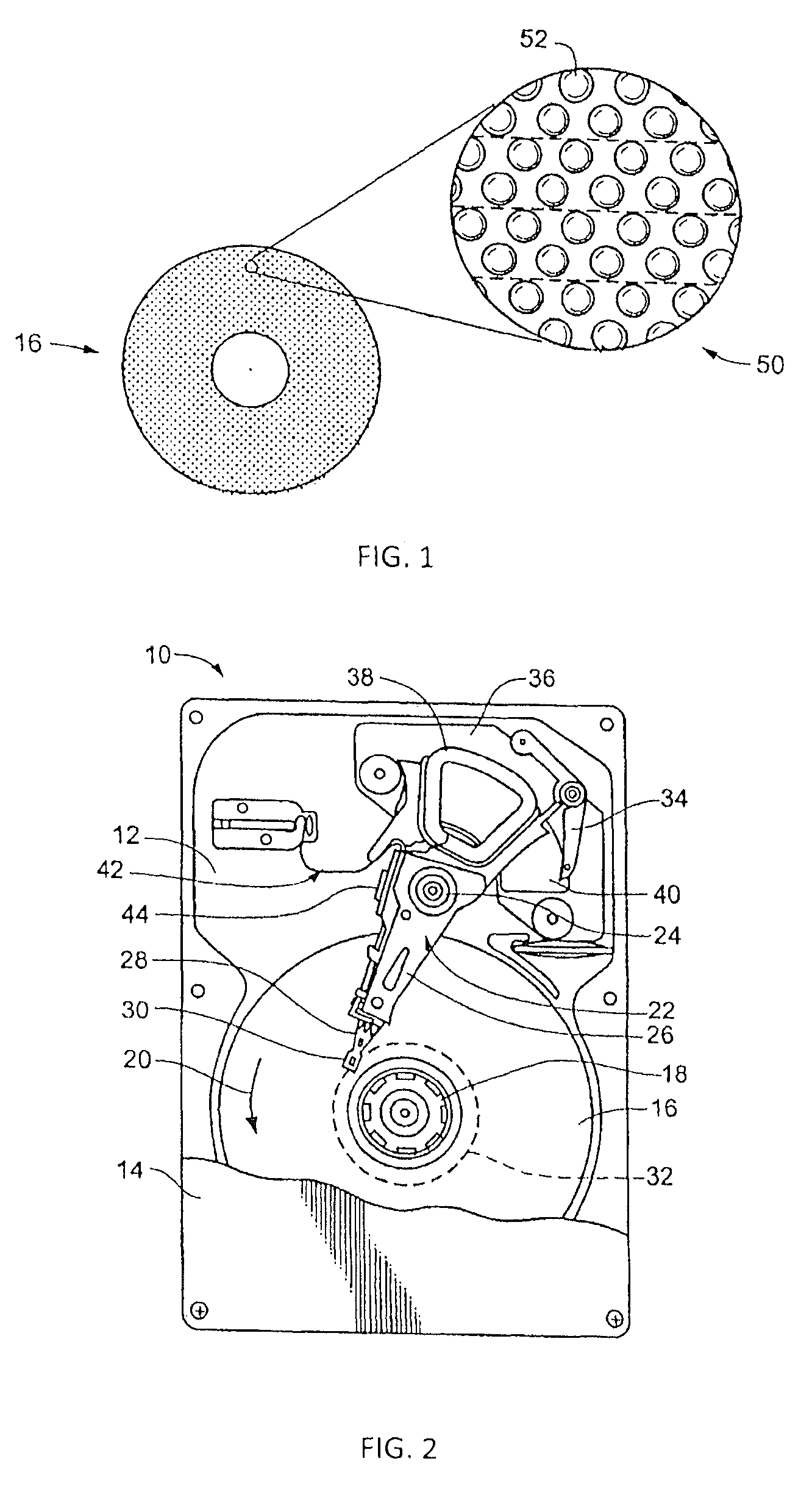

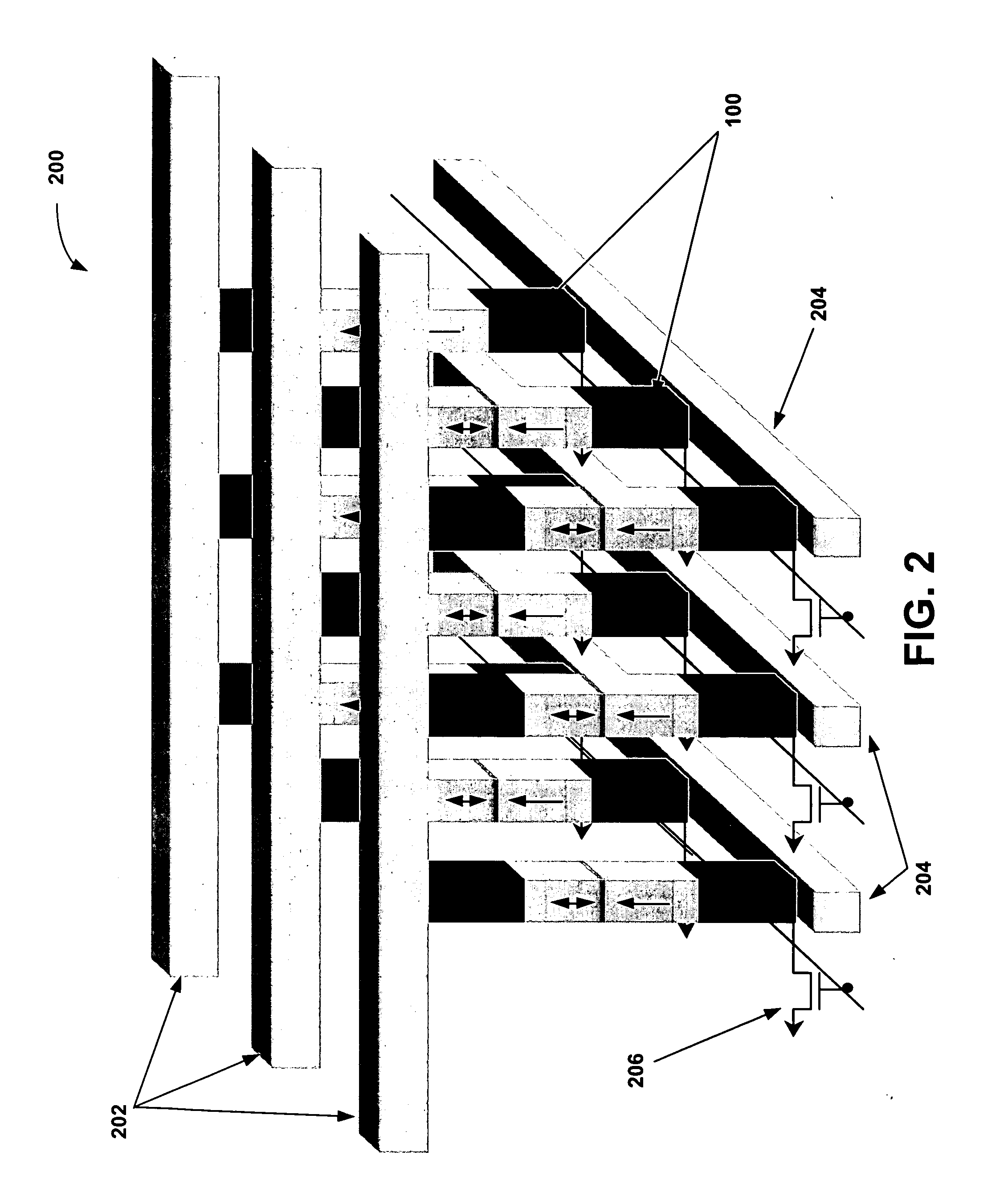

Patterned media bits with cladding shell

InactiveUS8147995B2Simple structureGood magnetic stabilityDecorative surface effectsPatterned record carriersSignal-to-noise ratio (imaging)Magnetic dots

A bit patterned media (BPM) includes many magnetic dots arranged in tracks on a substrate. The magnetic dots each have a hard magnetic core, a soft magnetic cladding surrounding the core and a thin non-magnetic layer that separates the hard magnetic core from the soft magnetic ring. The soft magnetic cladding stabilizes the magnetization at the edges of the hard magnetic core to improve the signal to noise ratio of the magnetic dots. The soft magnetic rings also narrow the magnetic field of the dots which reduces the space requirements and allows more dots to be placed on the substrate.

Owner:SEAGATE TECH LLC

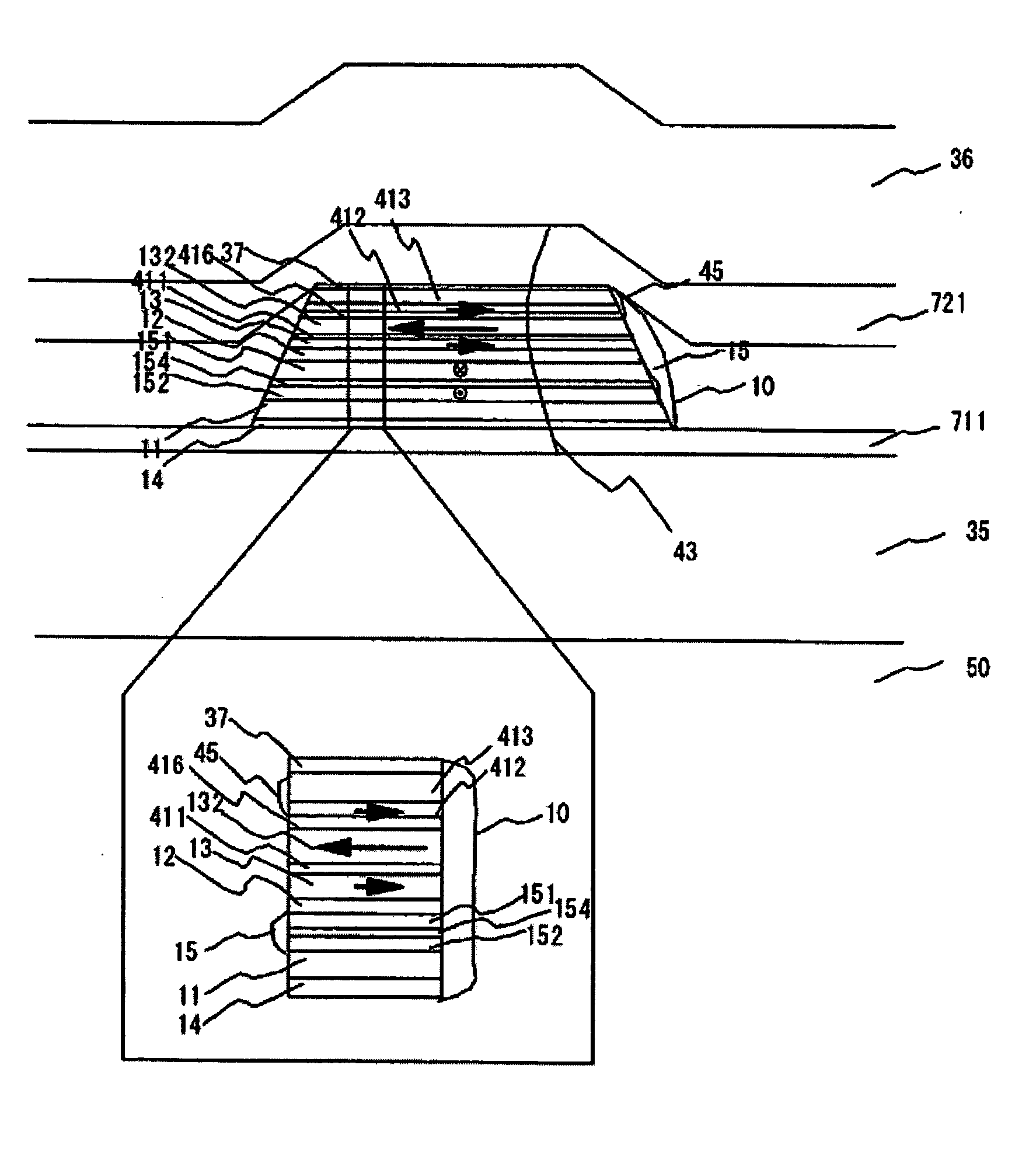

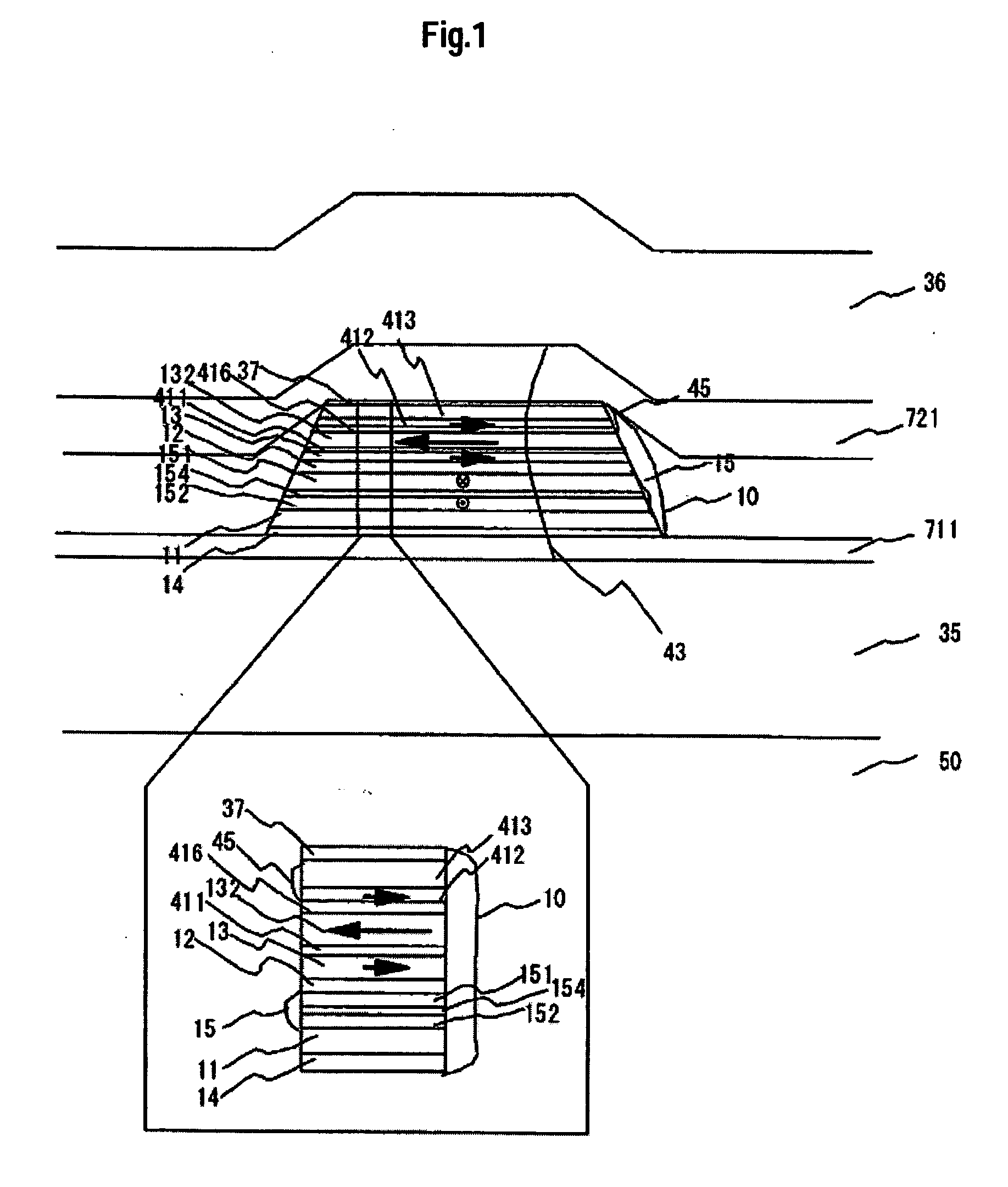

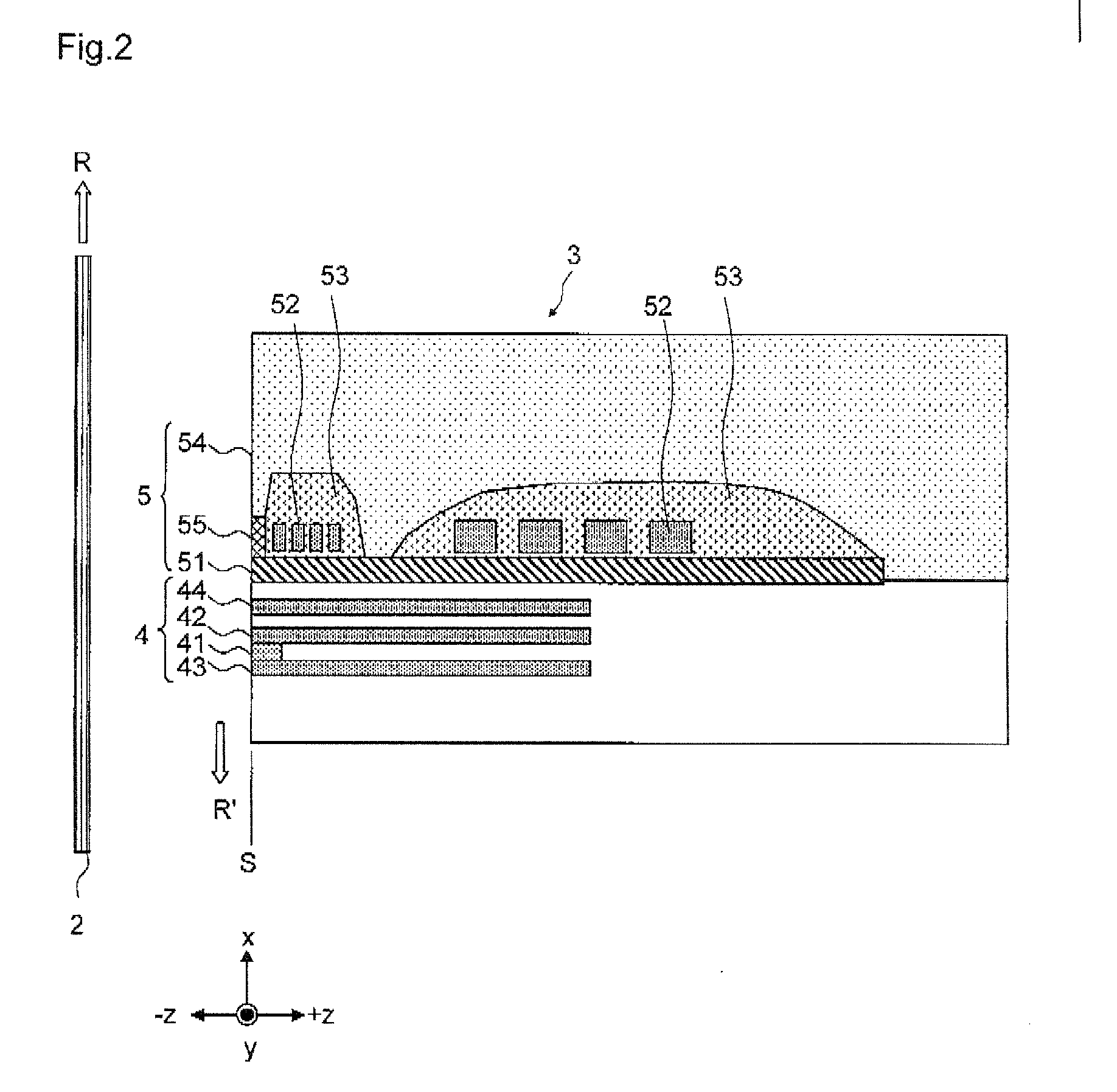

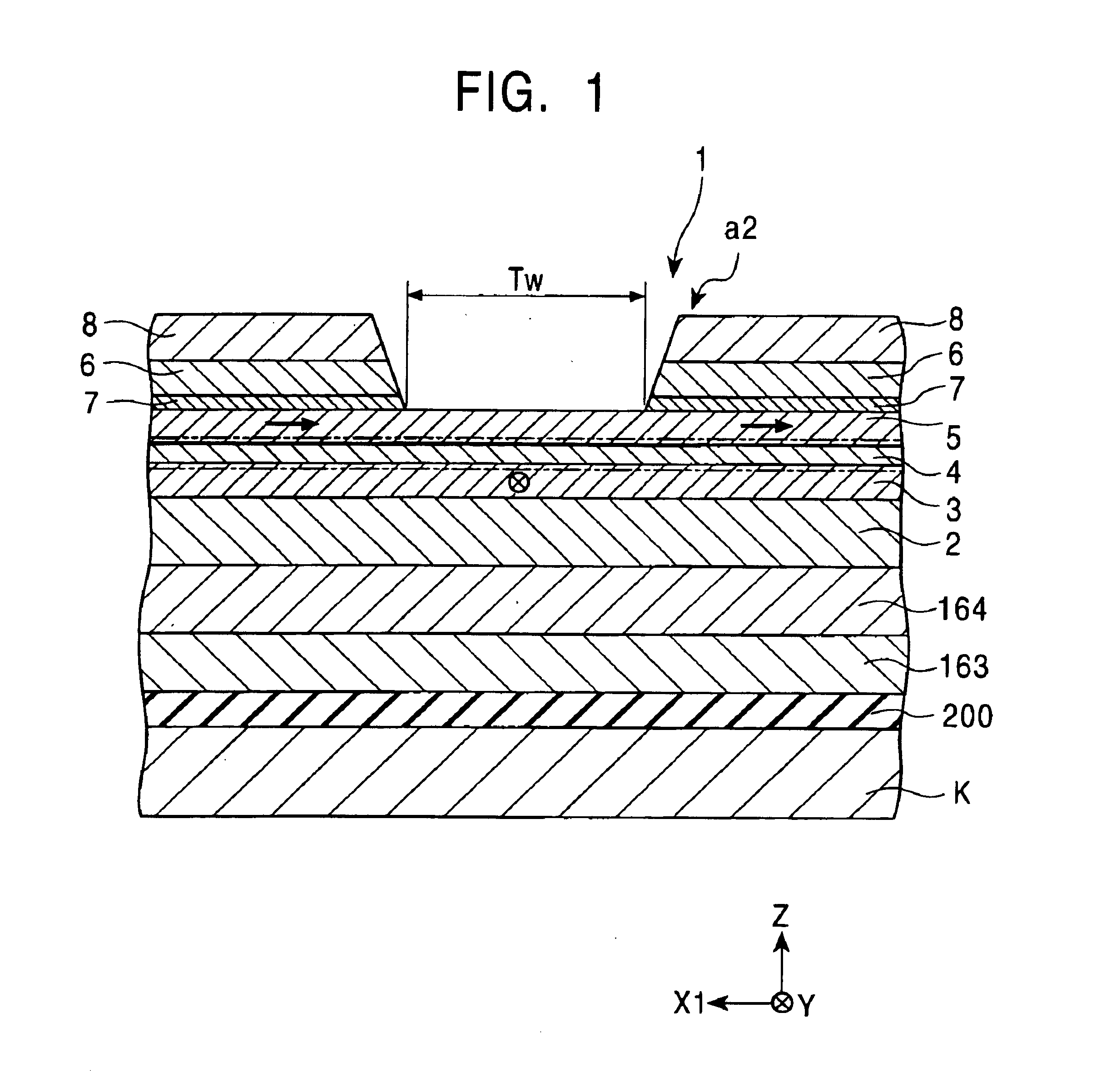

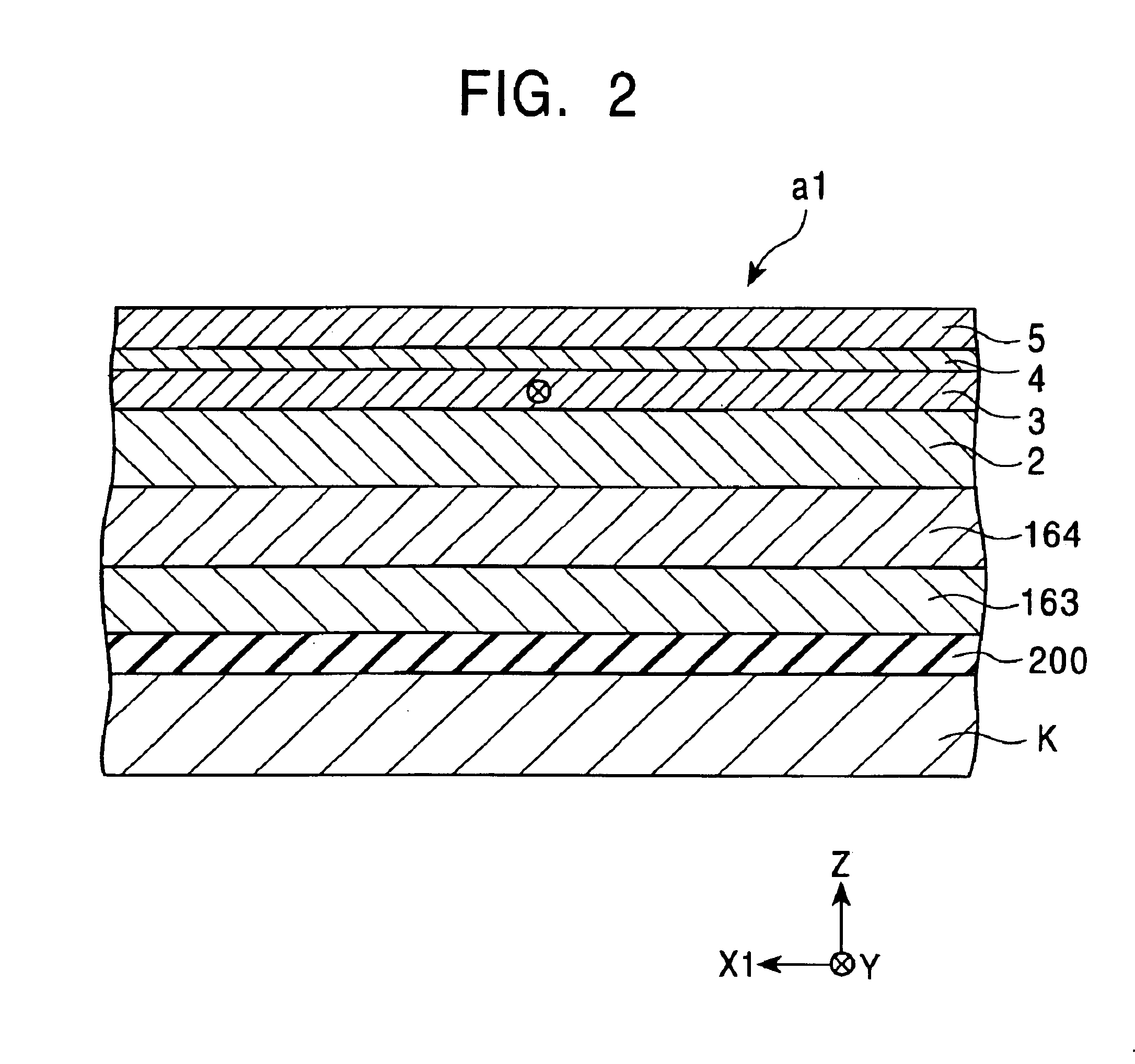

Magnetic head with domain stabilization and magnetic recording/reproducing apparatus using the same

InactiveUS20050225907A1High outputImprove stabilityNanoinformaticsMagnetic-field-controlled resistorsMagnetic reluctanceA domain

Embodiments of the invention provide a spin-valve type magnetic head that satisfies the requirements of both high read output and stability with narrow tracks. In one embodiment, a domain control film is formed on a magnetoresistive layered film in the same track width. A double closed flux path structure that uses three magnetic layers is employed with magnetic coupled structure in both ends of the track. The three magnetic layers are a soft magnetic free layer, a domain-stabilization ferromagnetic layer, and a soft magnetic anti-parallel layer.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

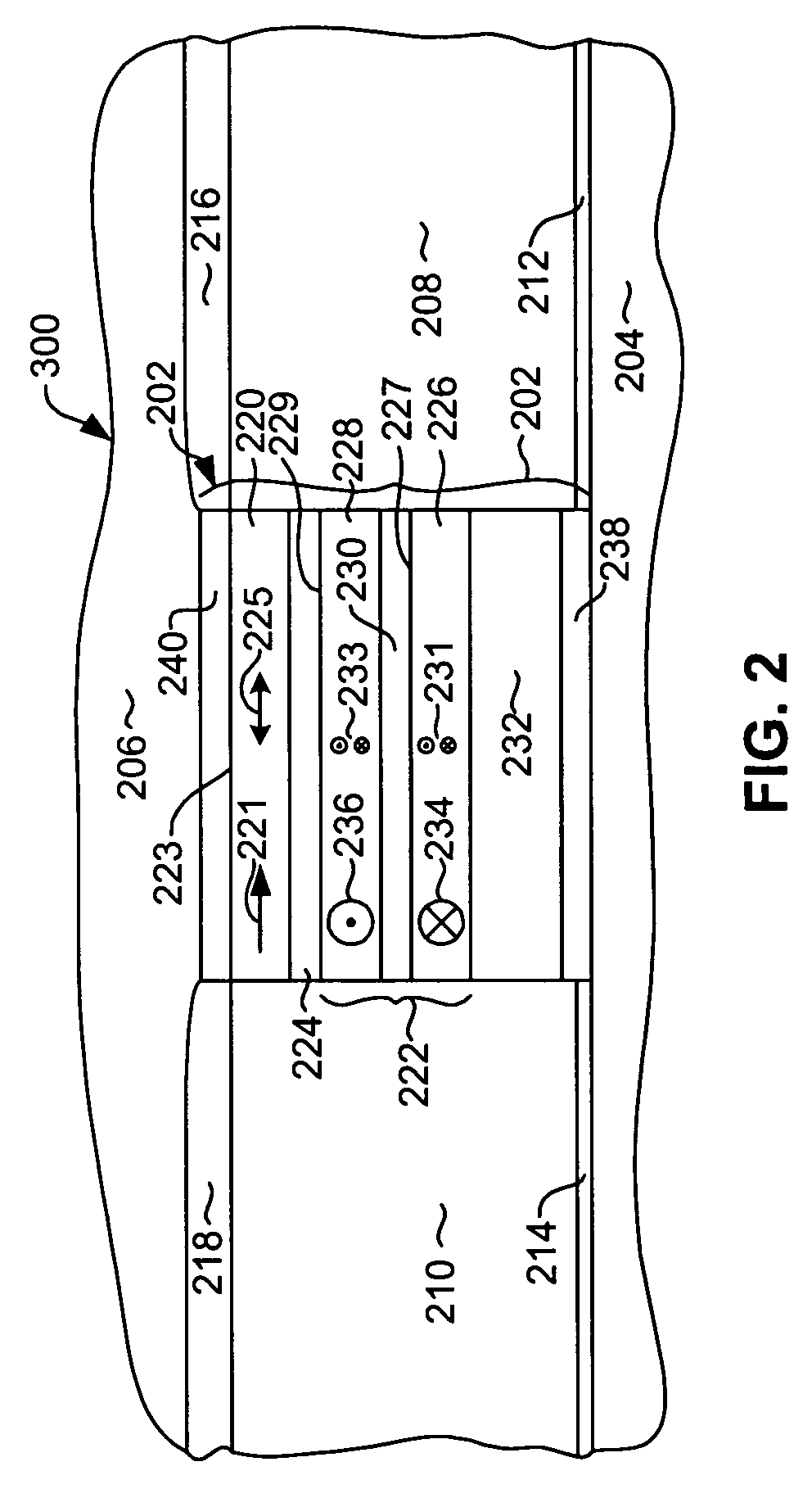

Longitudinal bias structure with improved magnetic stability

InactiveUS20050280959A1Good magnetic stabilityEasily and efficiently fabricatedNanomagnetismElectrical transducersMagnetic stabilityEngineering

A GMR sensor having improved longitudinal biasing is provided as is a method of forming it. The improved biasing is provided by longitudinal biasing structures in which a soft magnetic layer is interposed between a hard magnetic biasing layer and the lateral edge of the GMR sensor element. The soft magnetic layer eliminates the need for a seed layer directly between the hard magnetic layer and the GMR element and provides improved coupling to the free layer of the GMR element and a substantial reduction in random domain variations.

Owner:HEADWAY TECH INC

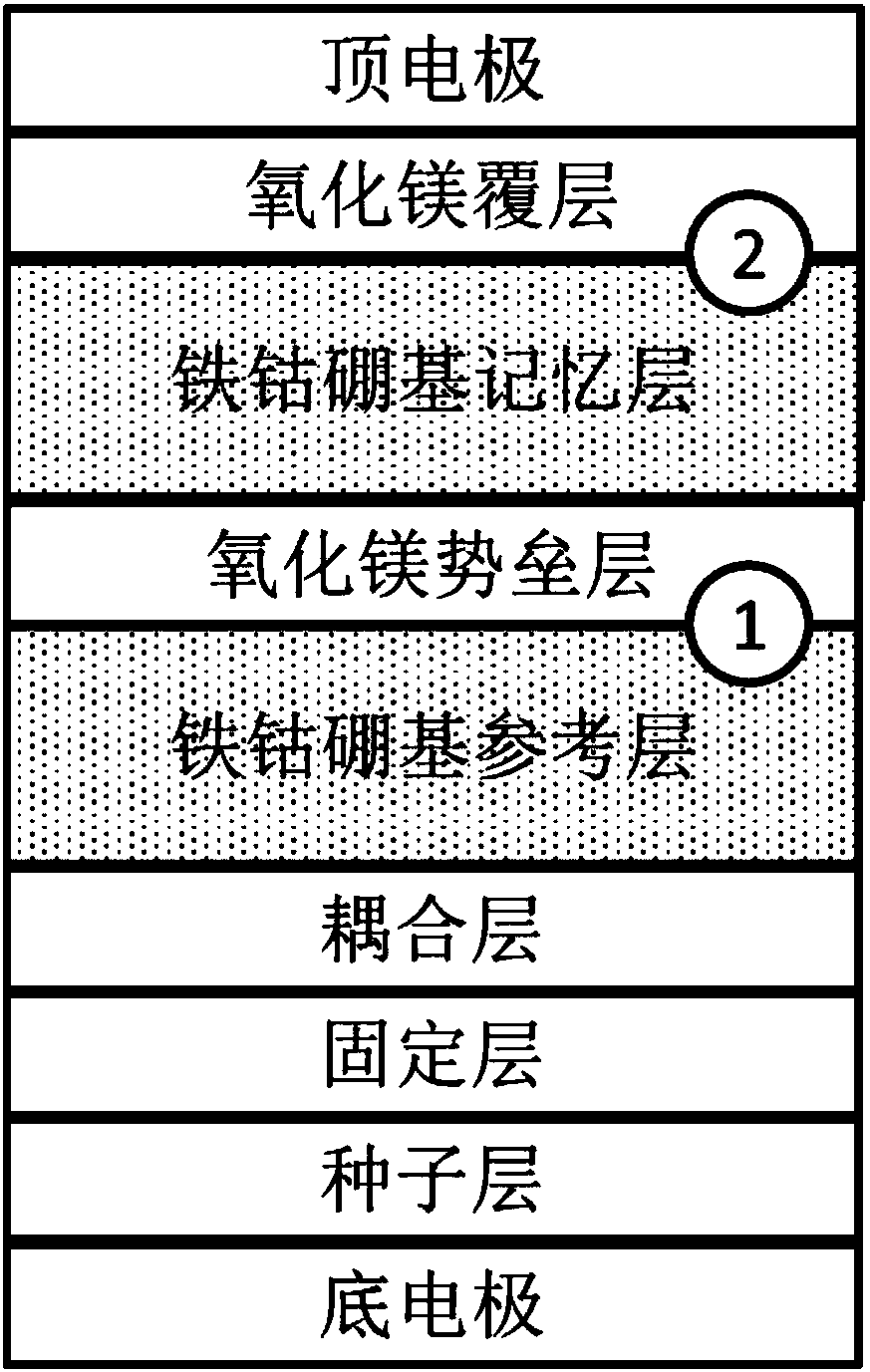

Perpendicular MRAM with high magnetic transition and low programming current

InactiveUS20050105328A1High magnetic transition stabilityReduce programming currentDigital storageMagnetic transitionsBit line

An invention is provided for a magnetic random access memory (MRAM) cell. The MRAM cell includes a first wordline and a first bitline perpendicular to the wordline. Disposed at an intersection of the first wordline and the first bitline is an MTJ device having a perpendicular magnetic orientation. To program the MRAM cell, current is driven through the two bitlines and two wordlines that are adjacent to the memory cell. As a result, the MRAM cell has a high magnetic transition and low programming current.

Owner:MACRONIX INT CO LTD

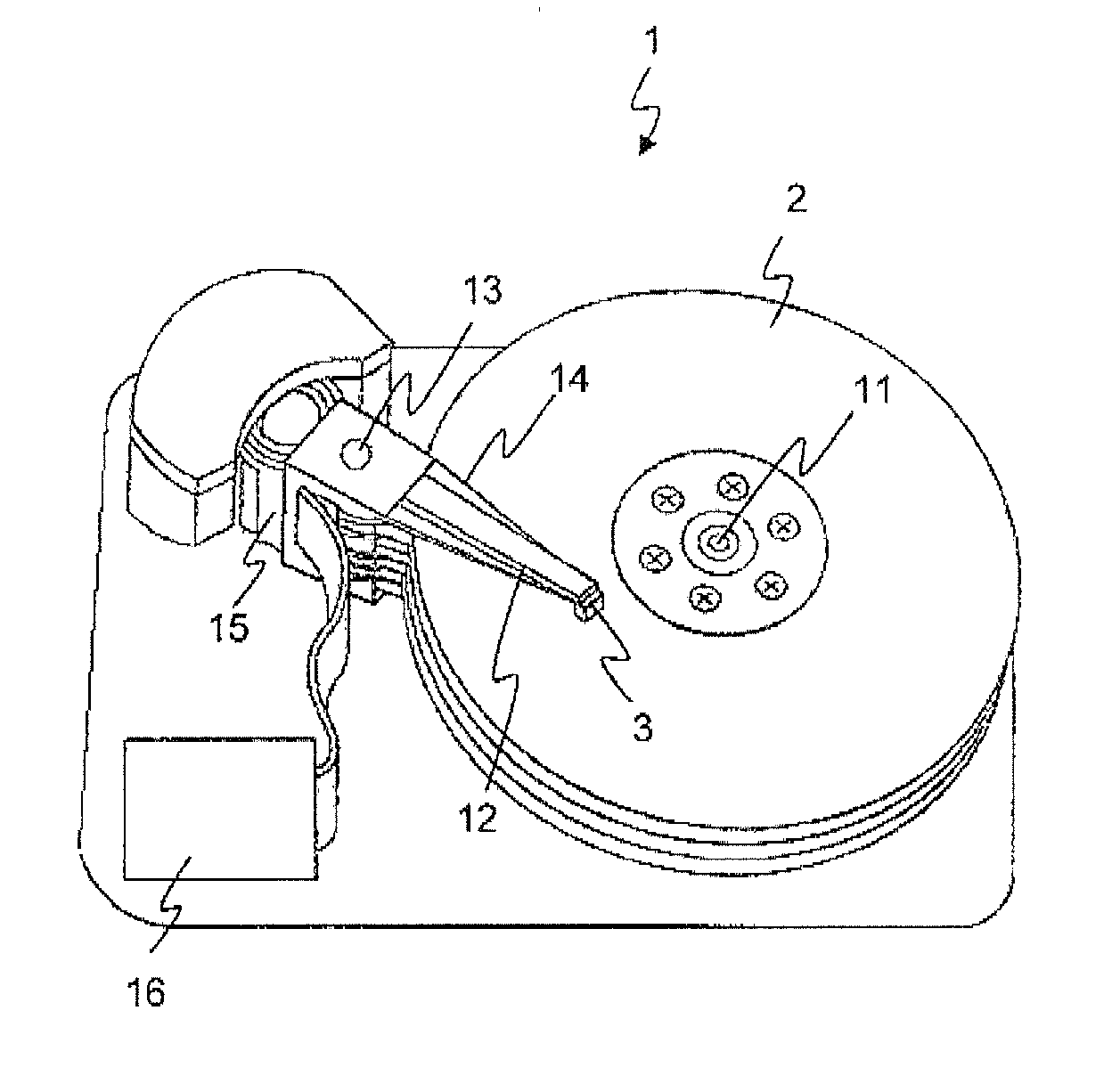

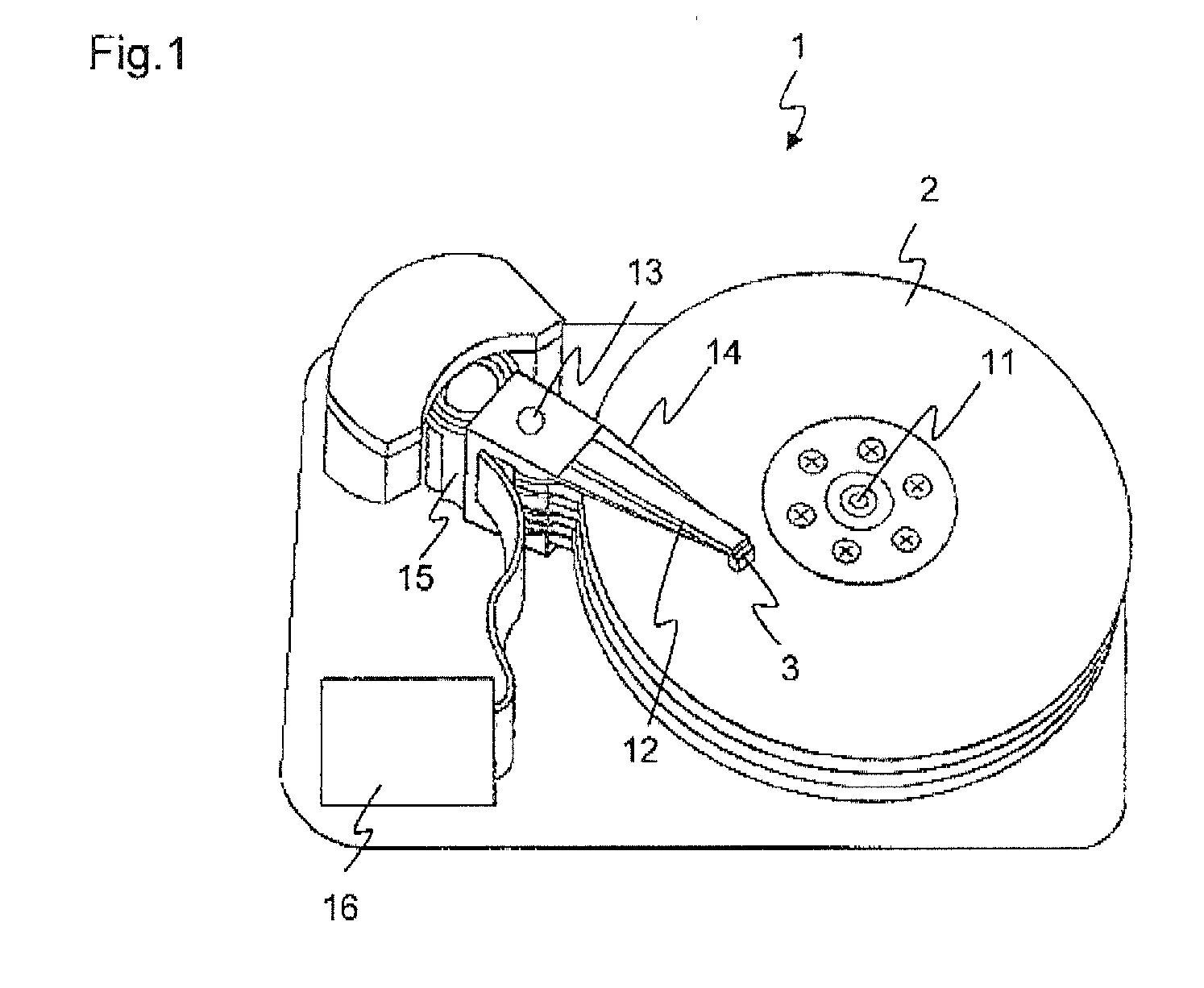

Magnetic recording apparatus

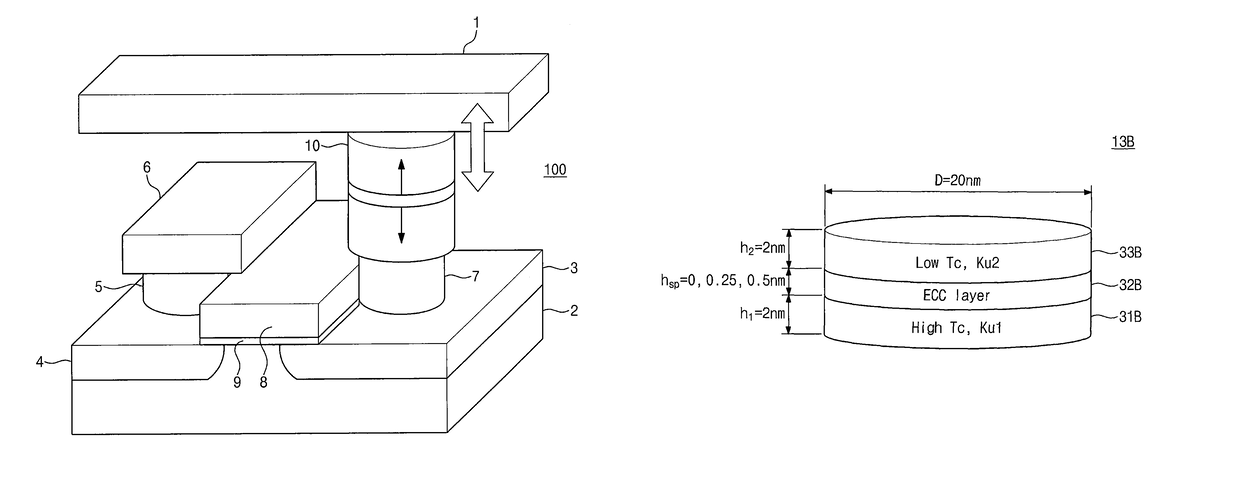

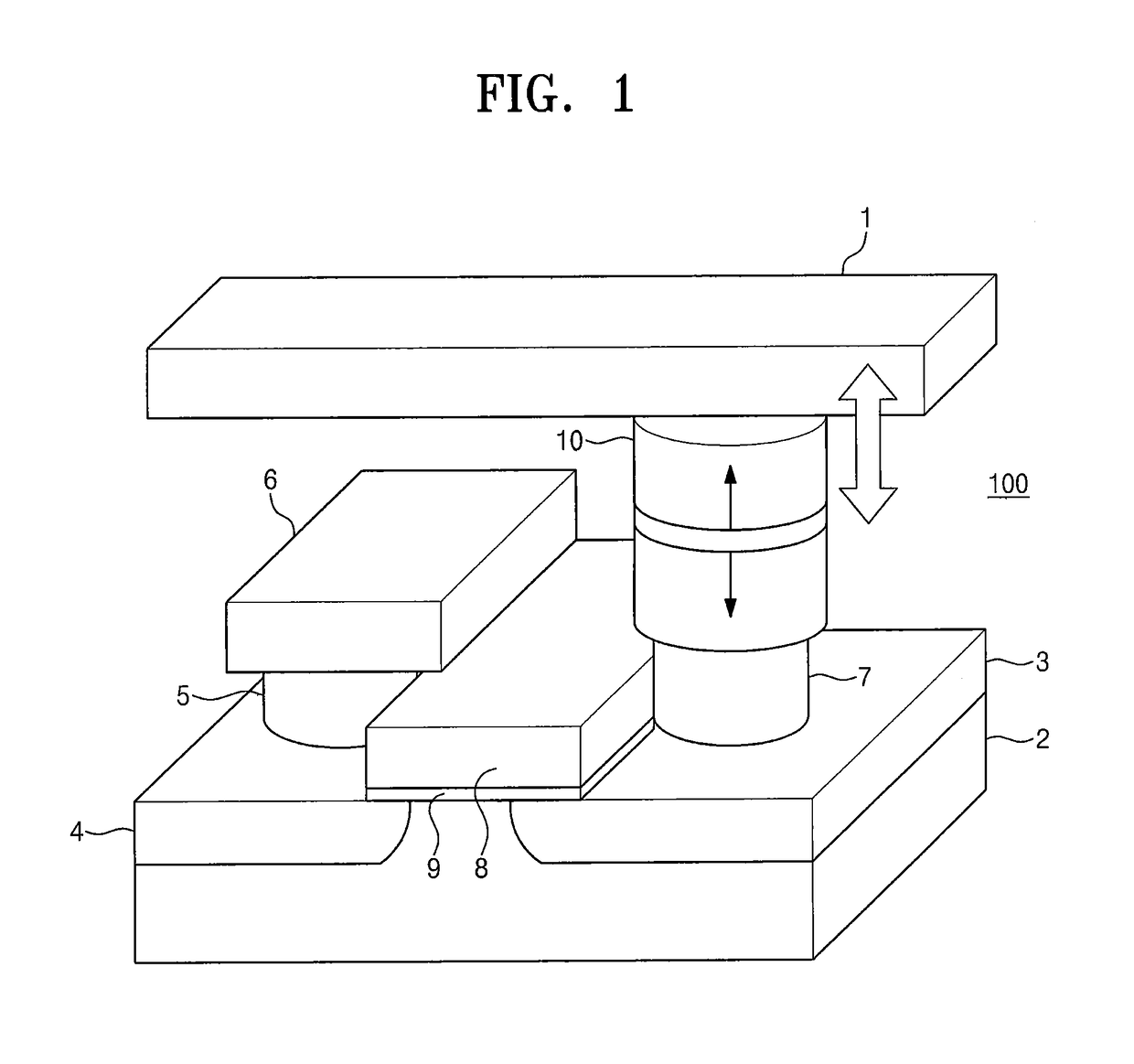

ActiveUS20130083428A1Large recording densitySmall recordingRecord information storageMagnetic recordingAlternating currentMagnetocrystalline anisotropy

A magnetic recording apparatus includes a magnetic recording medium that is provided with a first magnetic layer with magneto crystalline anisotropy energy, a second magnetic layer with magneto crystalline anisotropy energy that is smaller than the magneto crystalline anisotropy energy of the first magnetic layer, and a nonmagnetic metal layer that is positioned between the first magnetic layer and the second magnetic layer and that provides coupling force between the first magnetic layer and the second magnetic layer; and a magnetic head that includes a main pole that applies a recording magnetic field in a direction perpendicular to a film surface of the magnetic recording medium to the magnetic recording medium, and an alternate current (AC) magnetic field generator that applies an AC magnetic field with a frequency of 1-40 GHz to the magnetic recording medium.

Owner:TDK CORPARATION

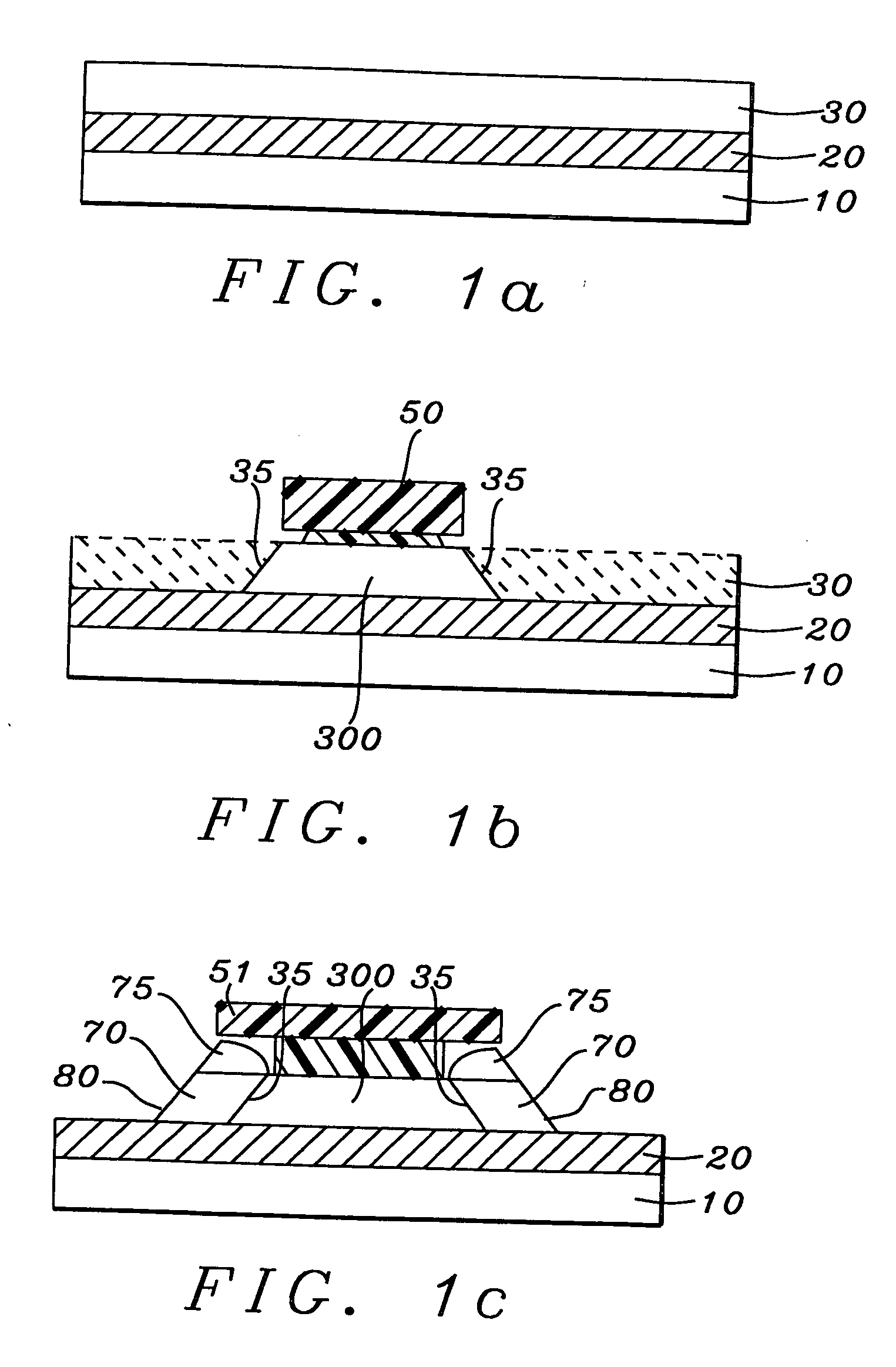

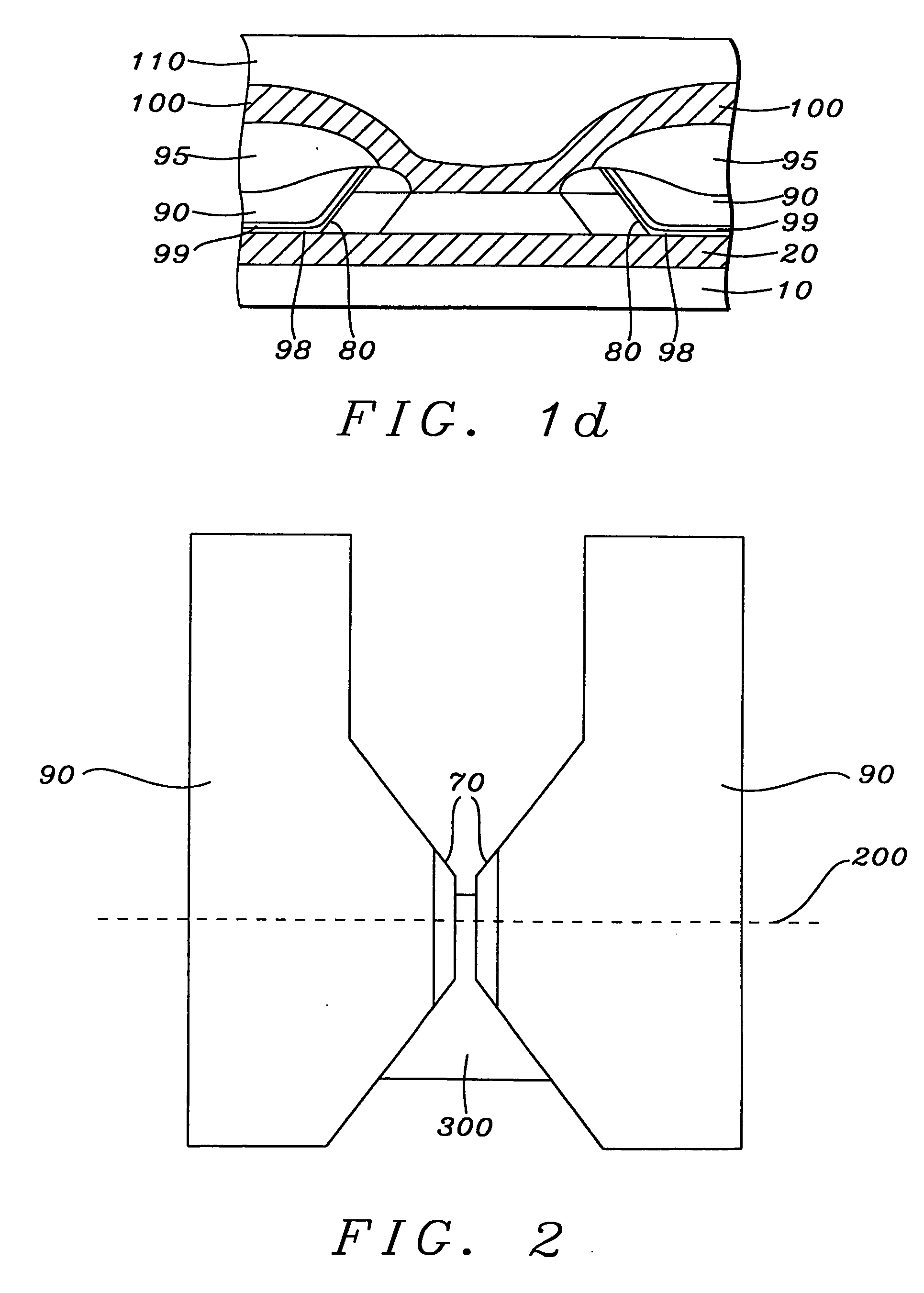

Magnetoresitive sensor having magnetic layers with tailored magnetic anisotropy induced by direct ion milling

InactiveUS20070133132A1Improve coercive forceGood magnetic stabilityRecord information storageManufacture of flux-sensitive headsMagnetic anisotropyAtomic physics

A magnetoresistive sensor having a magnetic anisotropy induced in one or both of the free layer and / or pinned layer. The magnetic anisotropy is induced by a surface texture formed in the surface of the magnetic layer of either or both of the free layer or pinned layer. The surface texture is formed by a direct, angled ion mill performed on the surface of the magnetic layer while holding the wafer on a stationary chuck. By applying this ion milling technique, the magnetic anisotropy of the pinned layer can be formed in a first direction (eg. perpendicular to the ABS) while the magnetic anisotropy of the free layer can be formed perpendicular to that of the pinned layer (eg. parallel to the ABS).

Owner:WESTERN DIGITAL TECH INC

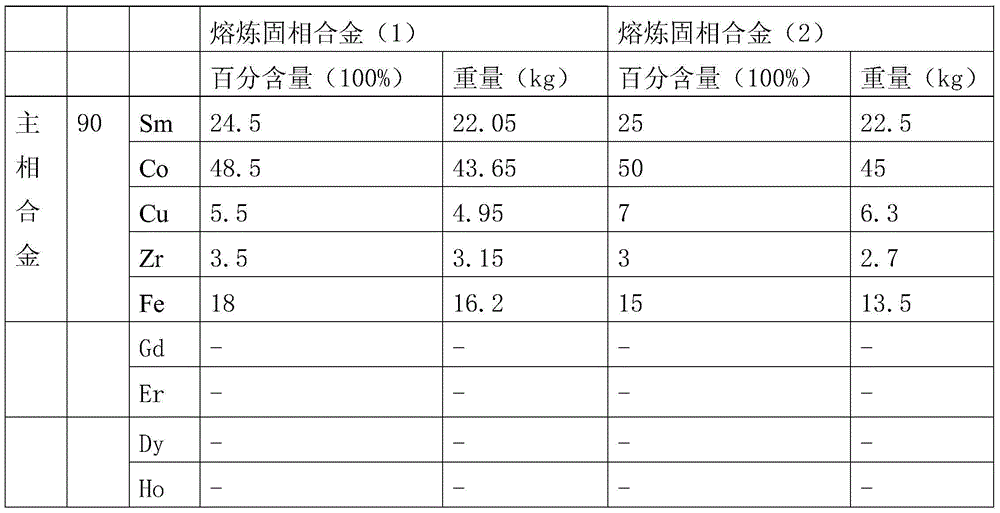

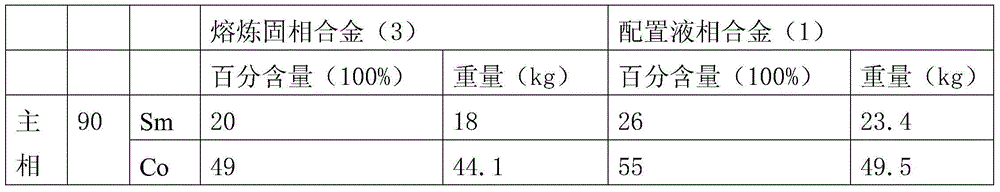

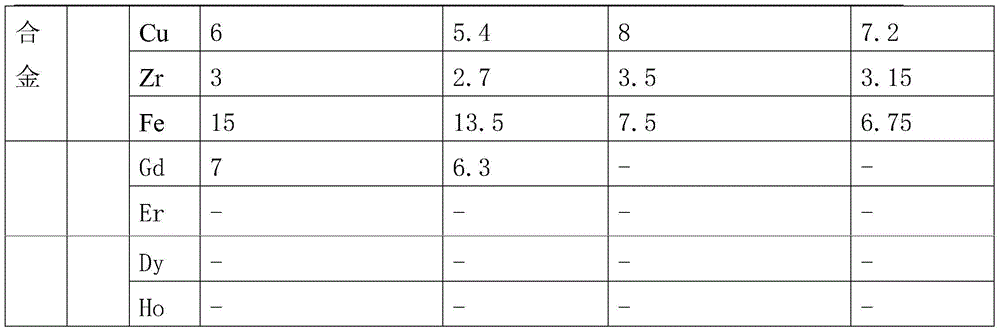

Rare earth permanent magnetic material Sm2(CoFeCuZr)17 and preparation method thereof

The invention provides a rare earth permanent magnetic material Sm2(CoFeCuZr)17 which comprises the following components by weight percentage: 87-100% of main phase alloy, 0-10% of Gd or Er, and 0-3% of Dy or Ho, wherein the main phase alloy is a 2:17 sintered samarium cobalt based rare earth permanent magnetic material and comprises the following components by atomic weight percentage: 20-40% of Sm, 40-65% of Co, 0-10% of Cu, 0-5% of Zr and 10-20% of Fe. Compared with the prior art, the rare earth permanent magnetic material Sm2(CoFeCuZr)17 has the benefits that all properties can be covered by a preparation method according to different material property requirements of users without changing pulverization, forming, sintering or aging treatment, the production cycle is shortened, and the raw material cost and labor cost are lowered as compared with the common sintered 2:17 permanent magnet.

Owner:CHENGDU 899 SCI & TECH

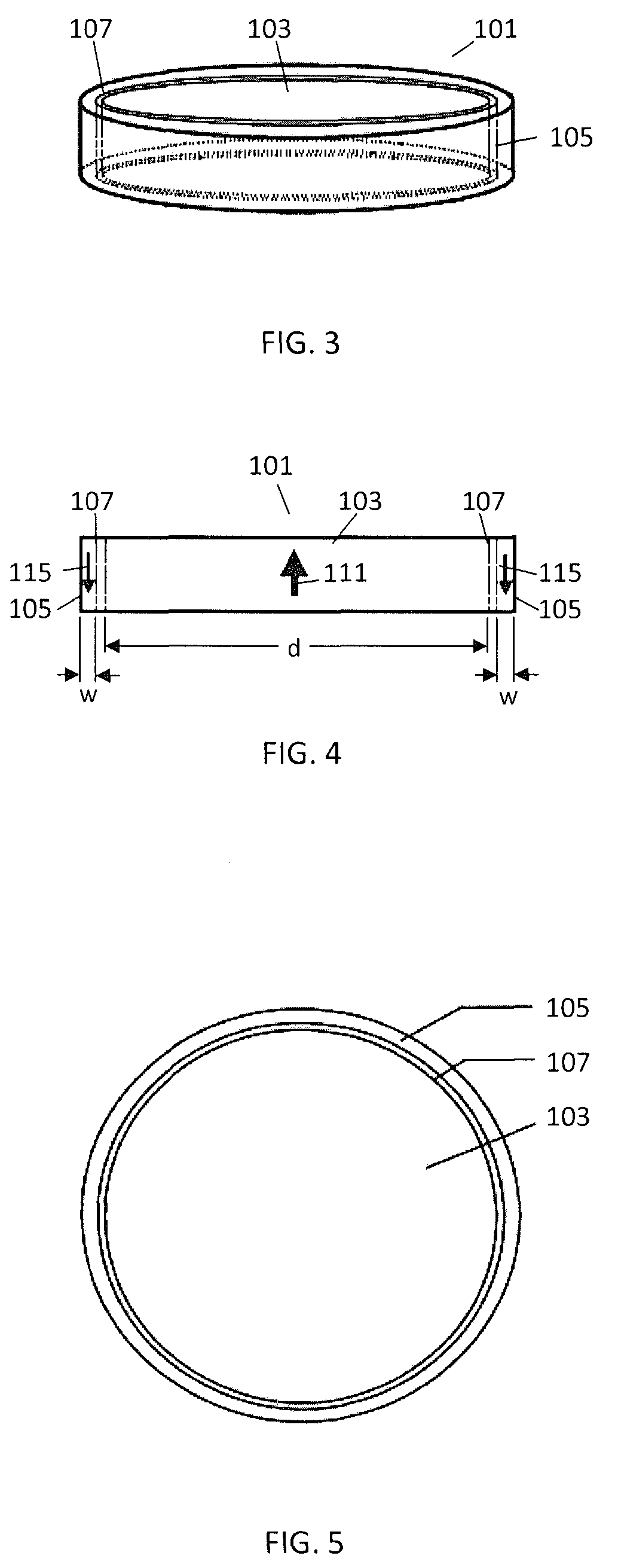

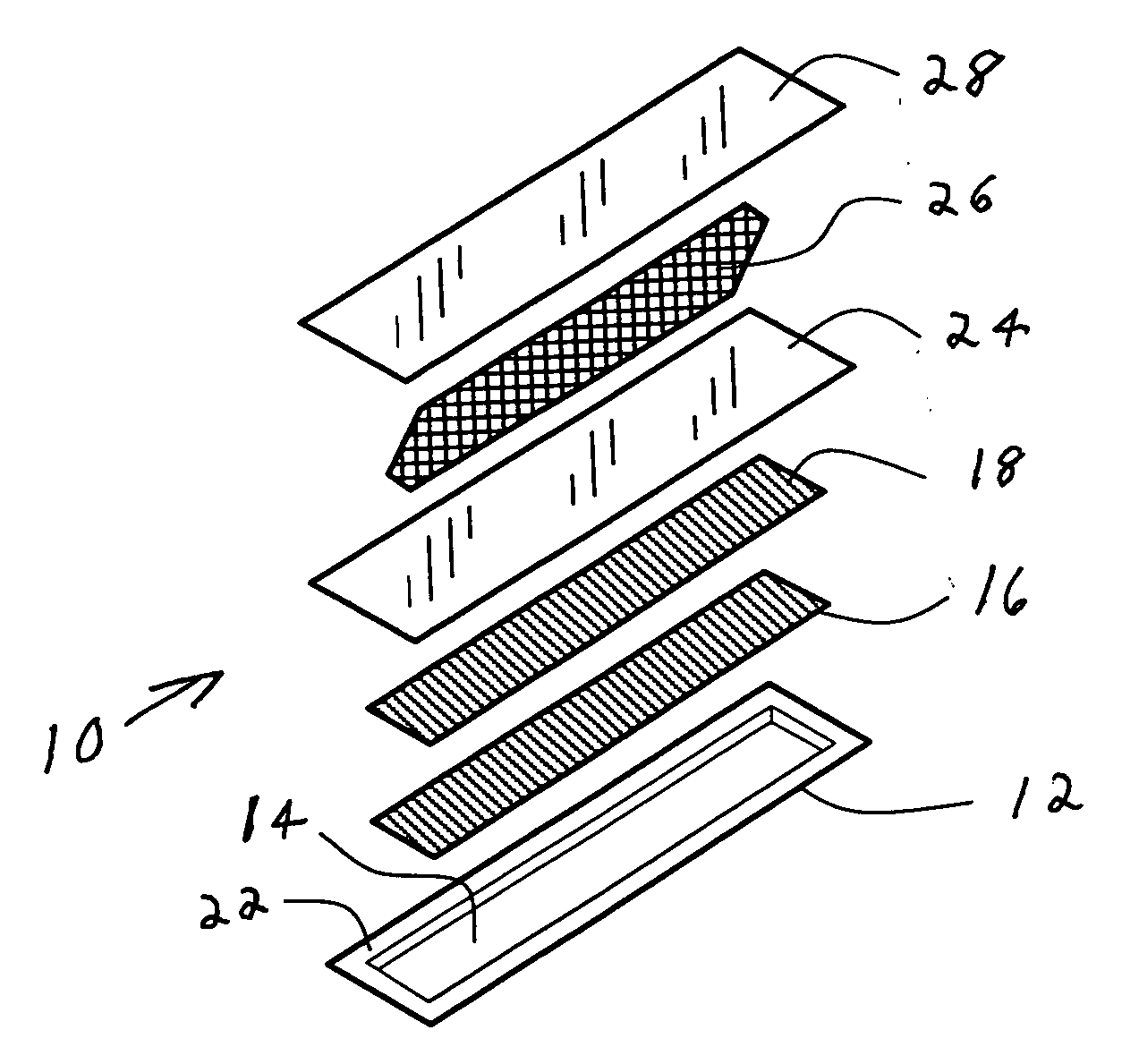

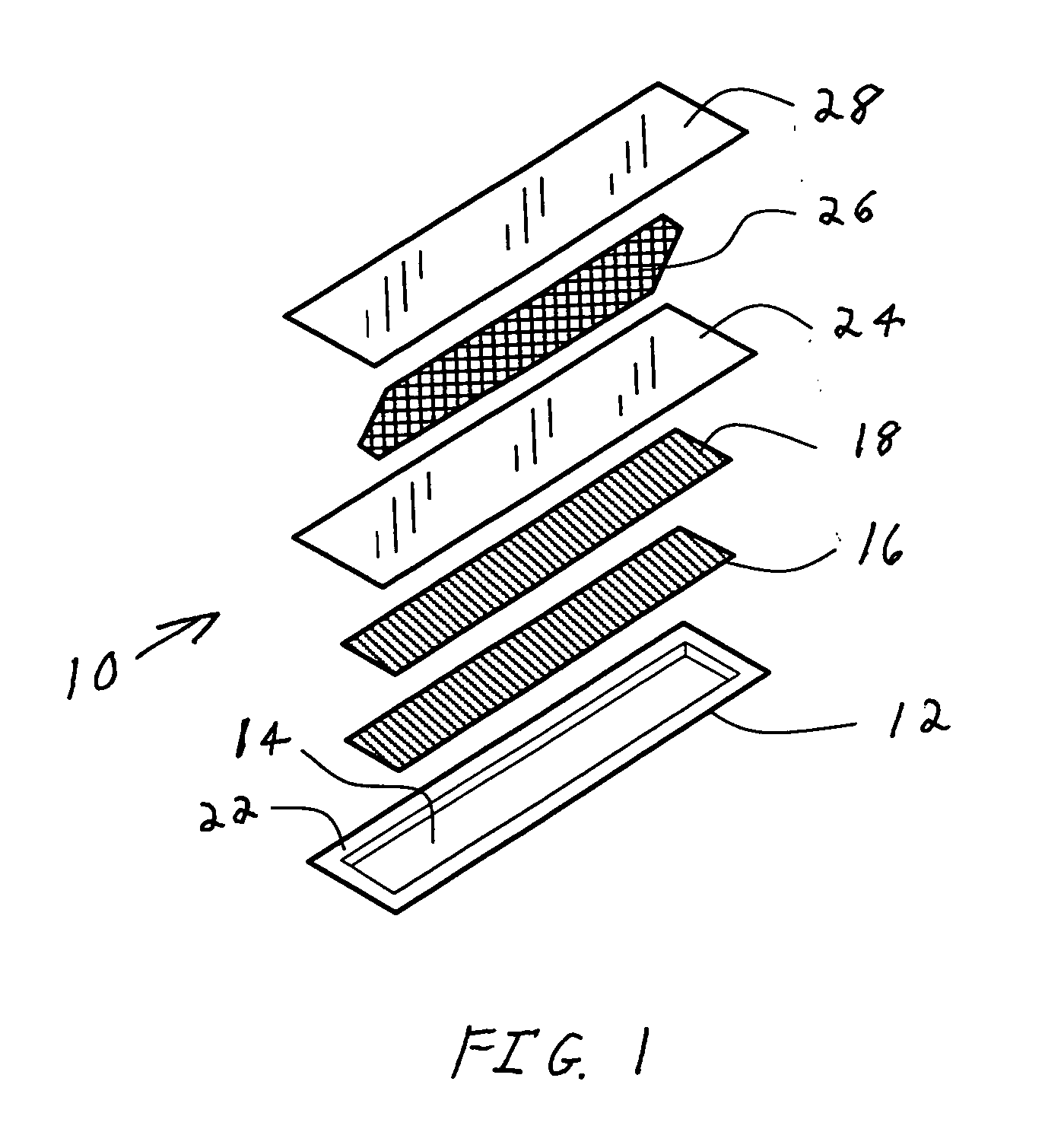

Electronic article surveillance marker

InactiveUS20080030339A1Enhanced deactivationGood magnetic stabilityBurglar alarm by hand-portable articles removalMonitoring systemAmorphous metal

A magnetomechanical marker for use in an electronic article surveillance system comprising a magnetomechanical element, a bias magnet and a housing. The magnetomechanical element comprises first and second resonator strips composed of an unannealed magnetostrictive amorphous metal alloy having a resonant frequency response including a resonant frequency minimum in response to the incidence thereon of an electromagnetic interrogating field. The bias magnet has a bias point to magnetically bias the magnetomechanical element so that the magnetomechanical element resonates at a predetermined frequency in the presence of an electromagnetic interrogating field. The housing has a cavity sized and shaped to accommodate the first and second resonator strips positioned in the cavity in registration and to allow the first and second resonator strips to mechanically vibrate, wherein the first resonator strip has a first weight and first shape and is positioned proximate the second resonator strip so that the first weight and the first shape mechanically interfere with the second resonator strip to impart a stress on the second resonator strip which shifts the resonant frequency minimum to the bias point.

Owner:TCI LTD

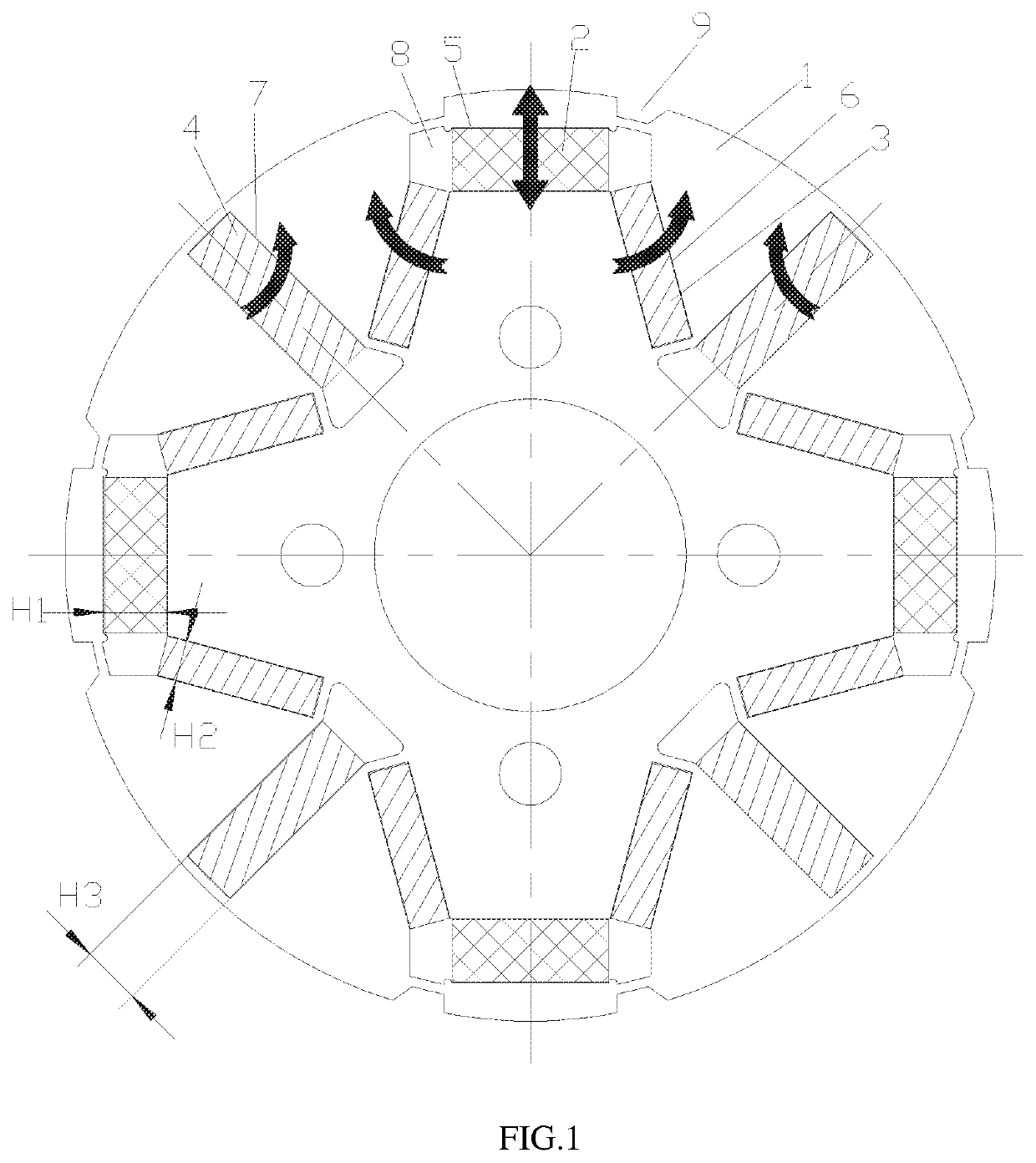

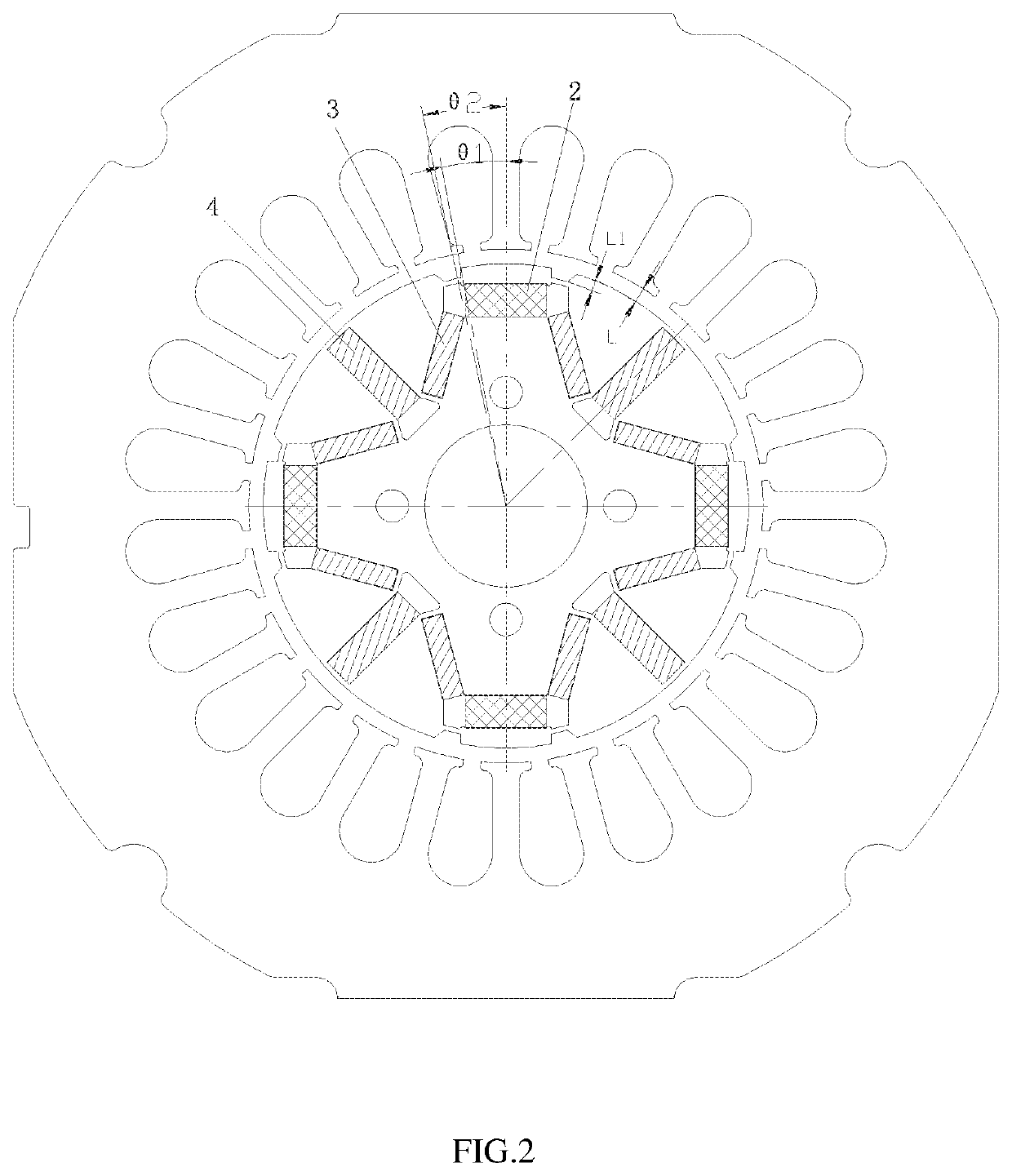

Motor rotor and permanent magnet motor

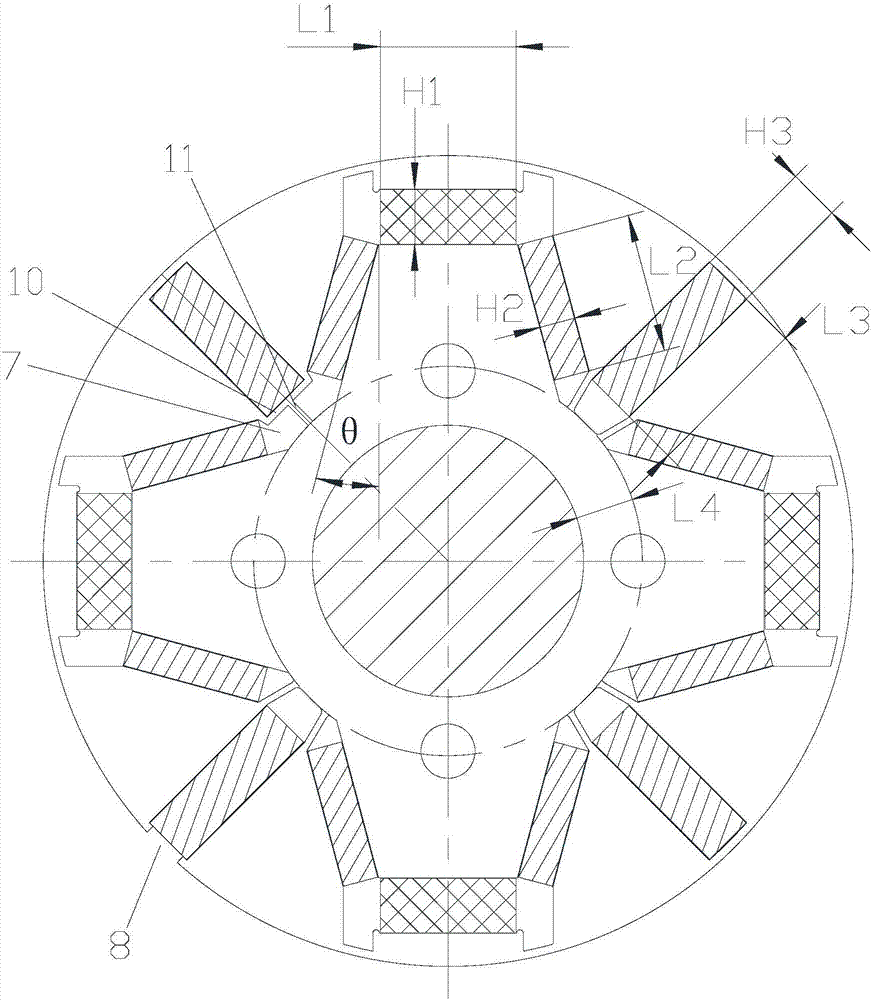

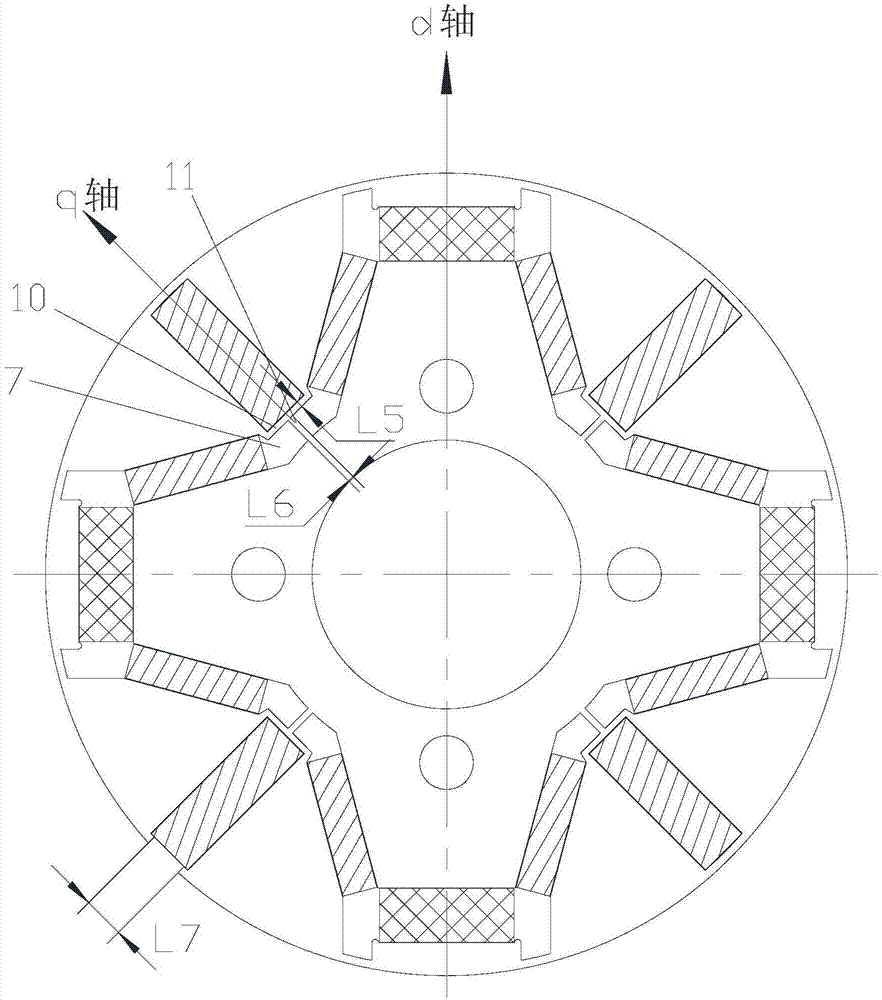

ActiveCN107994702AReduce the difficulty of charging and demagnetizingReduce charge and demagnetization currentMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsMagnetic polesPermanent magnet motor

The invention provides a motor rotor and a permanent magnet motor. The motor rotor comprises a rotor core and a plurality of magnetic poles arranged in the rotor core, each magnetic pole comprises a first permanent magnet, a second permanent magnet and a third permanent magnet, and the dimension relation of the first permanent magnet, the second permanent magnet and the third permanent magnet on the cross section of the rotor core meets m / 2>H1*Hcj1*L1 / [(H2*Hcj2*L2+1 / 2H3*Hcj2*L3)]>m / 10; wherein m is a multiple of the motor magnetism adjustment range, L1 is the length of the first permanent magnet, H1 is the width of the first permanent magnet, Hcj1 is the intrinsic coercive force of the first permanent magnet, L2 is the length of the second permanent magnet, H2 is the width of the second permanent magnet, Hcj2 is the intrinsic coercive force of the second permanent magnet, L3 is the length of the third permanent magnet, H3 is the width of the third permanent magnet, and Hcj3 is the intrinsic coercive force of the third permanent magnet. According to the motor rotor, the magnetizing and demagnetizing difficulty can be effectively reduced, the motor adjustment range is increased, andthe operation efficiency of the motor in magnetizing control is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Magneto-resistive devices including a free layer having different magnetic properties during operations

ActiveUS9715915B2Low Power FeaturesImprove data retentionMagnetic-field-controlled resistorsSolid-state devicesCurie temperatureTunnel junction

Owner:SAMSUNG ELECTRONICS CO LTD

Magnetoresistive sensor having magnetic layers with tailored magnetic anisotropy induced by direct ion milling

InactiveUS7529066B2Good magnetic stabilityIncrease in coercivityRecord information storageManufacture of flux-sensitive headsMagnetic anisotropyMagnetic layer

A magnetoresistive sensor having a magnetic anisotropy induced in one or both of the free layer and / or pinned layer. The magnetic anisotropy is induced by a surface texture formed in the surface of the magnetic layer of either or both of the free layer or pinned layer. The surface texture is formed by a direct, angled ion mill performed on the surface of the magnetic layer while holding the wafer on a stationary chuck. By applying this ion milling technique, the magnetic anisotropy of the pinned layer can be formed in a first direction (eg. perpendicular to the ABS) while the magnetic anisotropy of the free layer can be formed perpendicular to that of the pinned layer (eg. parallel to the ABS).

Owner:WESTERN DIGITAL TECH INC

A material and a method for improving the density of a magnetic powder core insulating layer

ActiveCN109103010ASimple preparation processEasy to useInorganic material magnetismInductances/transformers/magnets manufactureFerrosiliconSlurry

A method for preparing a metal soft magnetic powder core comprises the following steps: step 1) selecting a metal magnetic powder, wherein the metal magnetic powder is ferrosilicon aluminum magnetic powder or ferrosilicon magnetic powder, and the particle size is 30-77 mum, accounting for more than 95%; 2) dissolving the metal surface conditioner in water, wherein the weight ratio of solute to solvent is 1:10 to 1:4; after the solution is prepared, adding the solution to metal magnetic powder, performing stirring, and leaving the powder for later use after drying, wherein the adding quantity is 1 to 5 percent of the mass of the metal magnetic powder; 3) performing insulation coating: continuously carrying out insulation coating on the metal magnetic powder treated by the surface regulatingagent; 4) pouring the inorganic insulating powder into the slurry obtained in the step 3), mixing and stirring, drying, and grinding the dried magnetic powder to obtain coating magnetic powder; 5) adding demoulding agent accounting for 0.3 to 1.0 percent of the weight of the coating magnetic powder and uniformly mixing the demoulding agent to obtain the magnetic powder to be made; 6) pressing andmolding: the magnetic powder to be molded is made into a magnetic powder core blank by a press, wherein the press applied by the press is 14 to 24 ton / cm<2>.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

High-frequency magnetic material comprising an oxide phase and method for producing the same

ActiveUS7700194B2Improve thermal stabilityKeep for a long timeMaterial nanotechnologyIron compoundsRare-earth elementMetal particle

A high-frequency magnetic material is provided and includes: an oxide phase including: a first oxide of a first element being at least one selected from the group consisting of Mg, Al, Si, Ca, Zr, Ti, Hf, Zn, Mn, a rare-earth element, Ba, and Sr, and a second oxide of a second element being at least one selected from the group consisting of Li, Na, K, Rb, Cs, Be, Mg, Ca, Sr, Ba, and Zn, the first oxide and at least a part of the second oxide being formed into a solid solution; and magnetic metal particles including at least one of Fe and Co and having a particle size of 1 to 100 nm, the magnetic metal particles being deposited on a surface and inside of the oxide phase, the magnetic metal particles occupying 50% of a volume of the high-frequency magnetic material exclusive of a void.

Owner:KK TOSHIBA

Compound immune magnetic beads for separation and purification of hepatic stellate cells and preparation method of compound immune magnetic beads

The invention relates to the technical field of cell separation and purification materials and particularly relates to compound immune magnetic beads for separation and purification of hepatic stellate cells and a preparation method of the compound immune magnetic beads. The compound immune magnetic beads are prepared by grafting antibodies on magnetic bead granules of which the granule sizes are50-1500nm, wherein the antibodies include CD11b and CD146 antibodies, and the inner cores of the magnetic bead granules are Fe3O4 micro-spheres including carboxylated graphene layers, modified chitosan layers and sodium alginate layers from inside to outside. The antibodies are grafted on the magnetic bead granules to obtain the compound immune magnetic beads; the magnetic bead granules contain more carboxyl functional groups, have good dispersion properties in solutions and can not aggregate easily; the antibodies have a higher grafting ratio on the magnetic bead granules and have higher binding stability; and the compound immune magnetic beads can be used for separation and purification of hepatic stellate cells so as to obtain hepatic stellate cells with higher purity and better activity.

Owner:ARMY MEDICAL UNIV

Spin-valve type magnetoresistive sensor and method of manufacturing the same

InactiveUS6913836B1Highly reliable magnetoresistiveIncreased durabilityNanomagnetismMagnetic measurementsManganeseAlloy

A spin-valve type magnetoresistive sensor with a bias structure enabling a magnetization direction of a free magnetic layer to be uniformly arranged with certainty. The spin-valve type magnetoresistive sensor comprises an antiferromagnetic layer; a pinned magnetic layer having a magnetization direction made stationary; a nonmagnetic electrically conductive layer formed between the pinned magnetic layer and a free magnetic layer; soft magnetic layers that are arranged on the free magnetic layer while a spacing corresponding to a track width is left between the soft magnetic layers and that fill recesses in the free magnetic layer on both sides of an area corresponding to the track width; bias layers formed on the soft magnetic layers; and electrically conductive layers. The antiferromagnetic layer and the bias layers are each made of an alloy containing at least one or more elements selected from among Pt, Pd, Rh, Ru, Ir, Os, Au, Ag, Cr, Ni, Ne, Ar, Xe and Kr, as well as Mn.

Owner:TDK CORPARATION

Mn-Zn ferrite, transformer magnetic core and transformer

InactiveUS6905629B2Little deteriorationImprove reliabilityMagnetsInorganic material magnetismMagnetic stabilityHigh temperature storage

An Mn—Zn ferrite wherein 0 to 5000 ppm of a Co oxide in a Co3O4 conversion is contained in a basic component constituted by Fe2O3: 51.5 to 57.0 mol % and ZnO: 0 to 15 mol % (note that 0 is not included) wherein the rest is substantially constituted by MnO; and a value α in a formula (1) below in said ferrite satisfies α≧0.93.α=((Fe2+−Mn3+−Co3+)×(4.29×A+1.91×B+2.19×C+2.01×D)) / ((A−B−C−D)×100) formula (1).Note that in the formula (1), (Fe2+−Mn3+−Co3+): [wt %], A: Fe2O3 [mol %], B: MnO [mol %], C: ZnO [mol %] and D: CoO [mol %]. According to the present invention, a highly reliable Mn—Zn ferrite used as a magnetic core of a power supply transformer, etc. of a switching power supply, etc., having a small core loss in a wide temperature range, furthermore, exhibiting a little deterioration of core loss characteristics under a high temperature (in a high temperature storage test) and having excellent magnetic stability, a transformer magnetic core and a transformer can be provided.

Owner:TDK CORPARATION

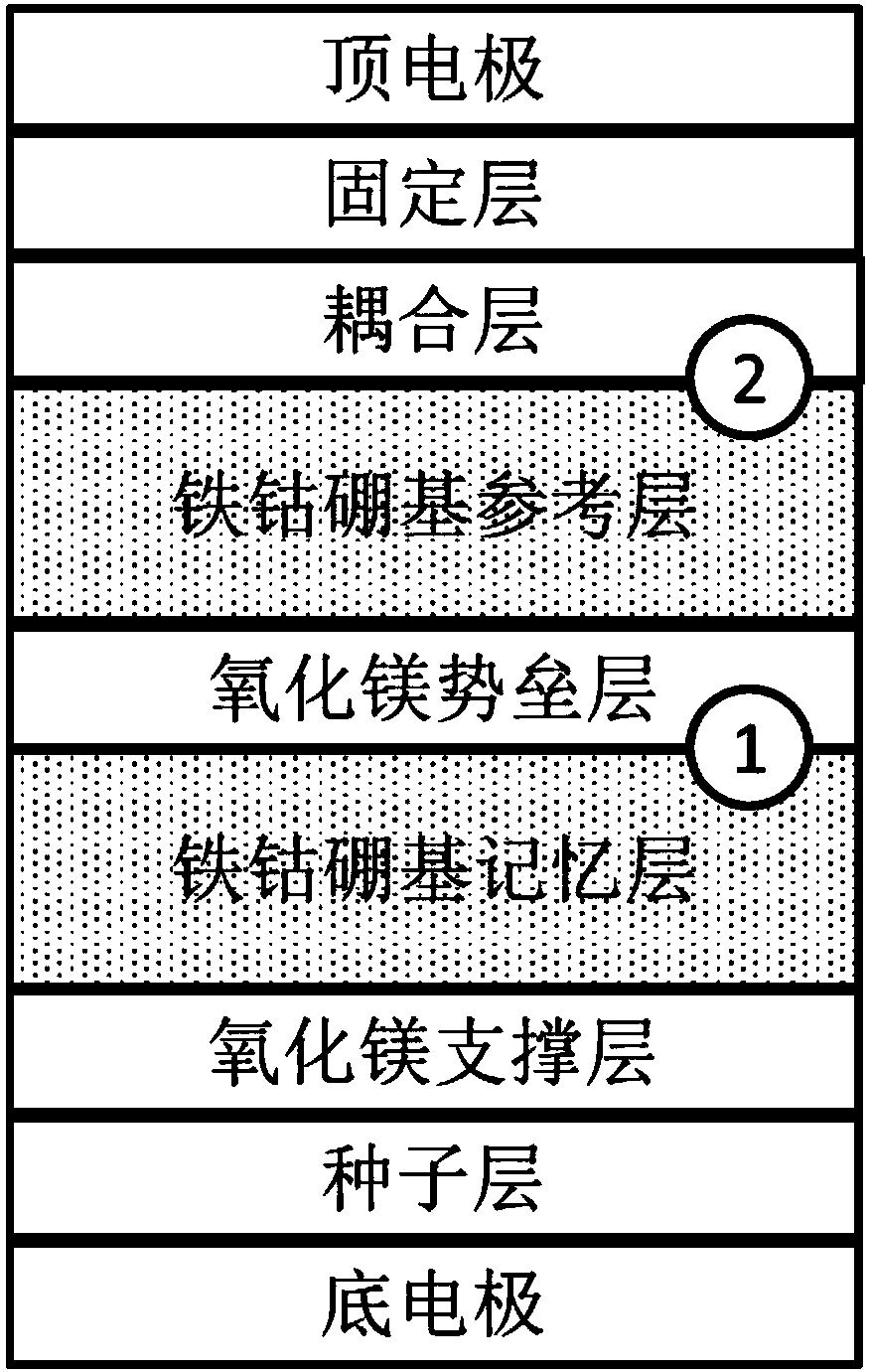

Planarization method of magnetic tunnel junction

ActiveCN108695431ALarge magnetoresistance performanceGood Magnetic StabilityMagnetic-field-controlled resistorsGalvano-magnetic device manufacture/treatmentAmorphismAmorphous silicon

The invention provides a planarization method of a magnetic tunnel junction. The magnetic tunnel junction comprises an amorphous iron-cobalt-boron layer. The method is characterized in that the methodcomprises the step that ion or plasma beams are adopted to bombard the amorphous iron-cobalt-boron layer. According to the planarization method of the invention, low-power ion or plasma beam bombardment is adopted, so that surface atoms can acquire a certain kinetic energy but cannot escape, and therefore, a material can be shifted from rough protrusions to troughs, and an MTJ (magnetic tunnel junction) multilayer film deposition of atomic-level smoothness can be obtained.

Owner:SHANGHAI CIYU INFORMATION TECH

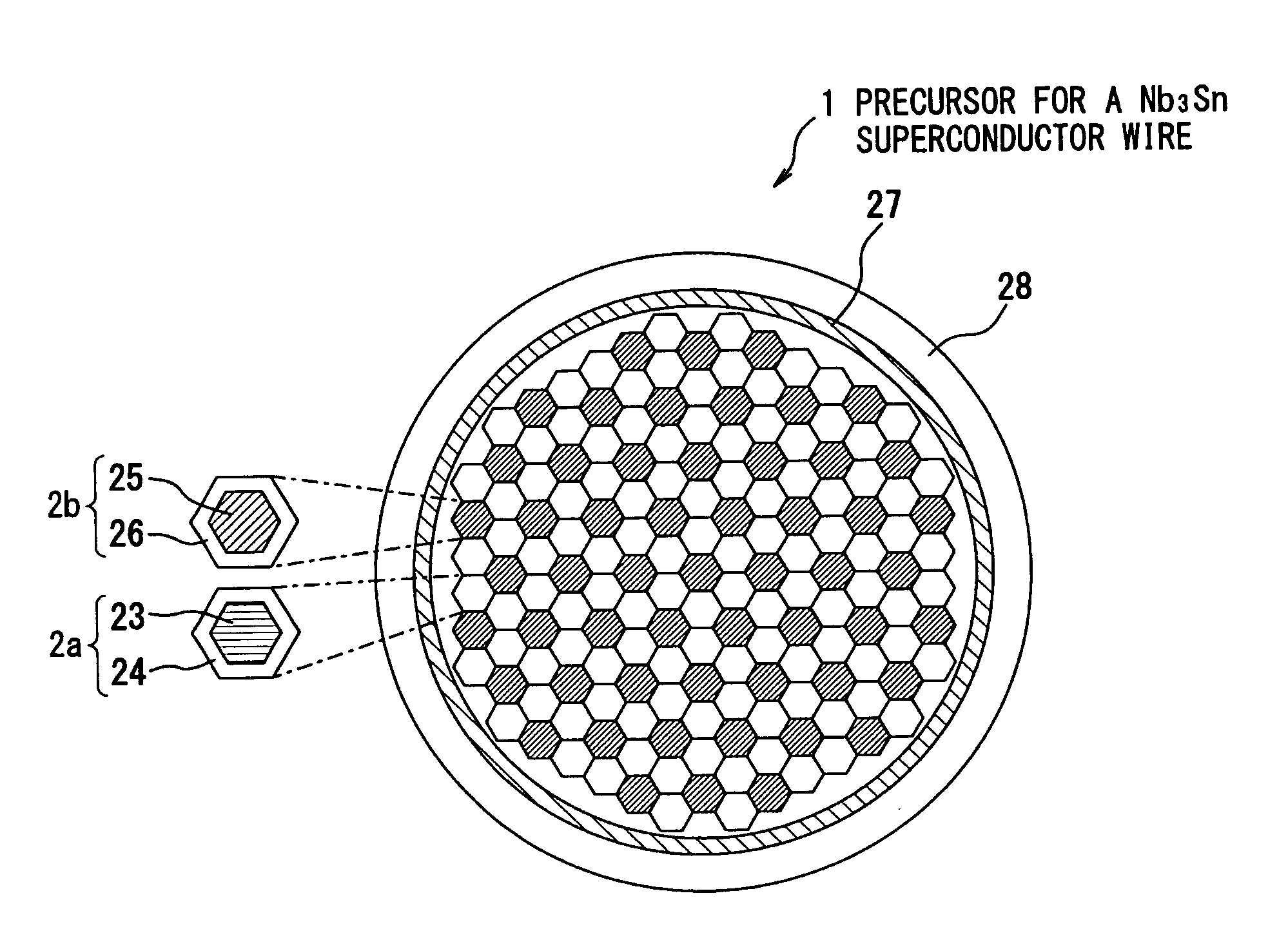

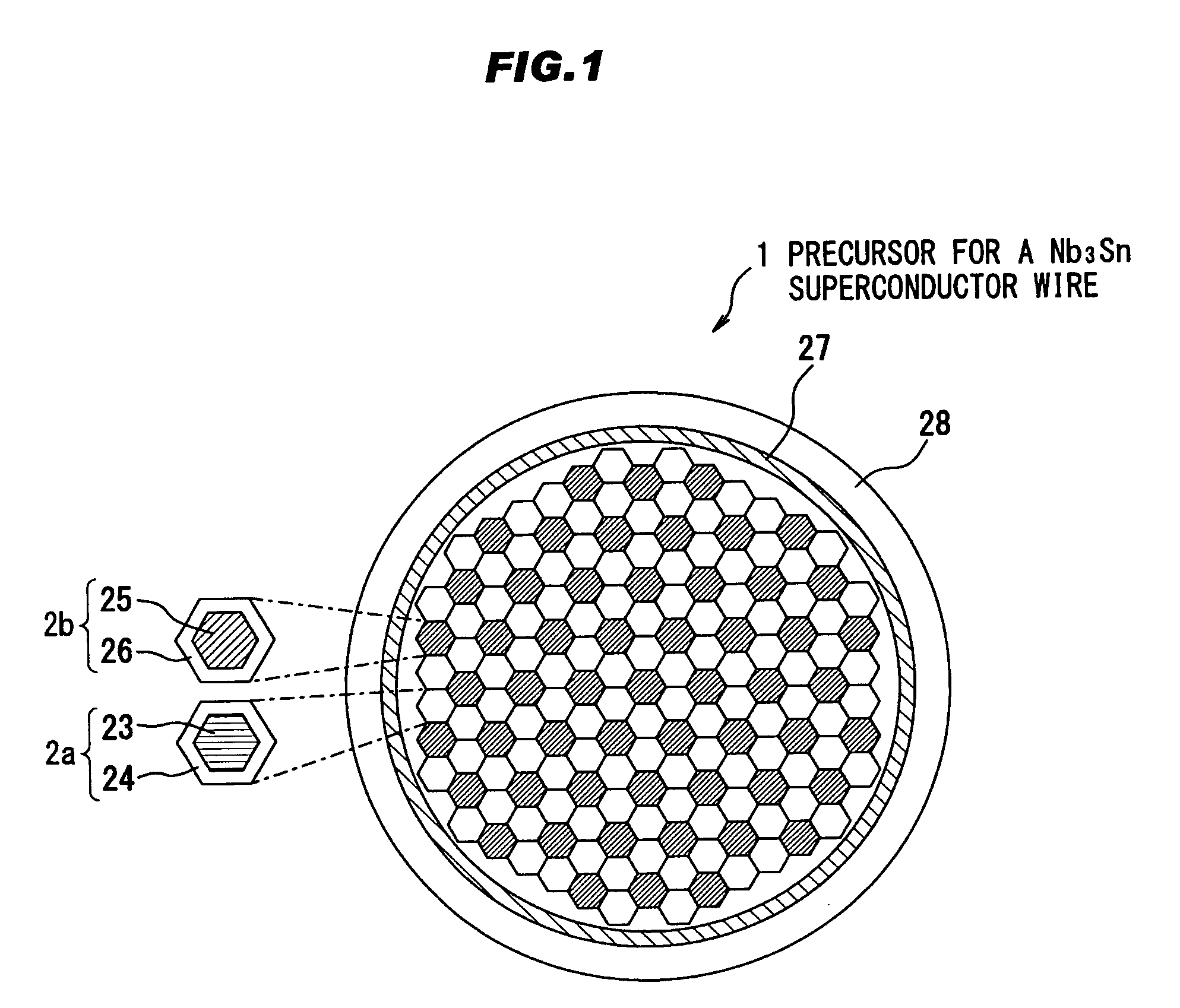

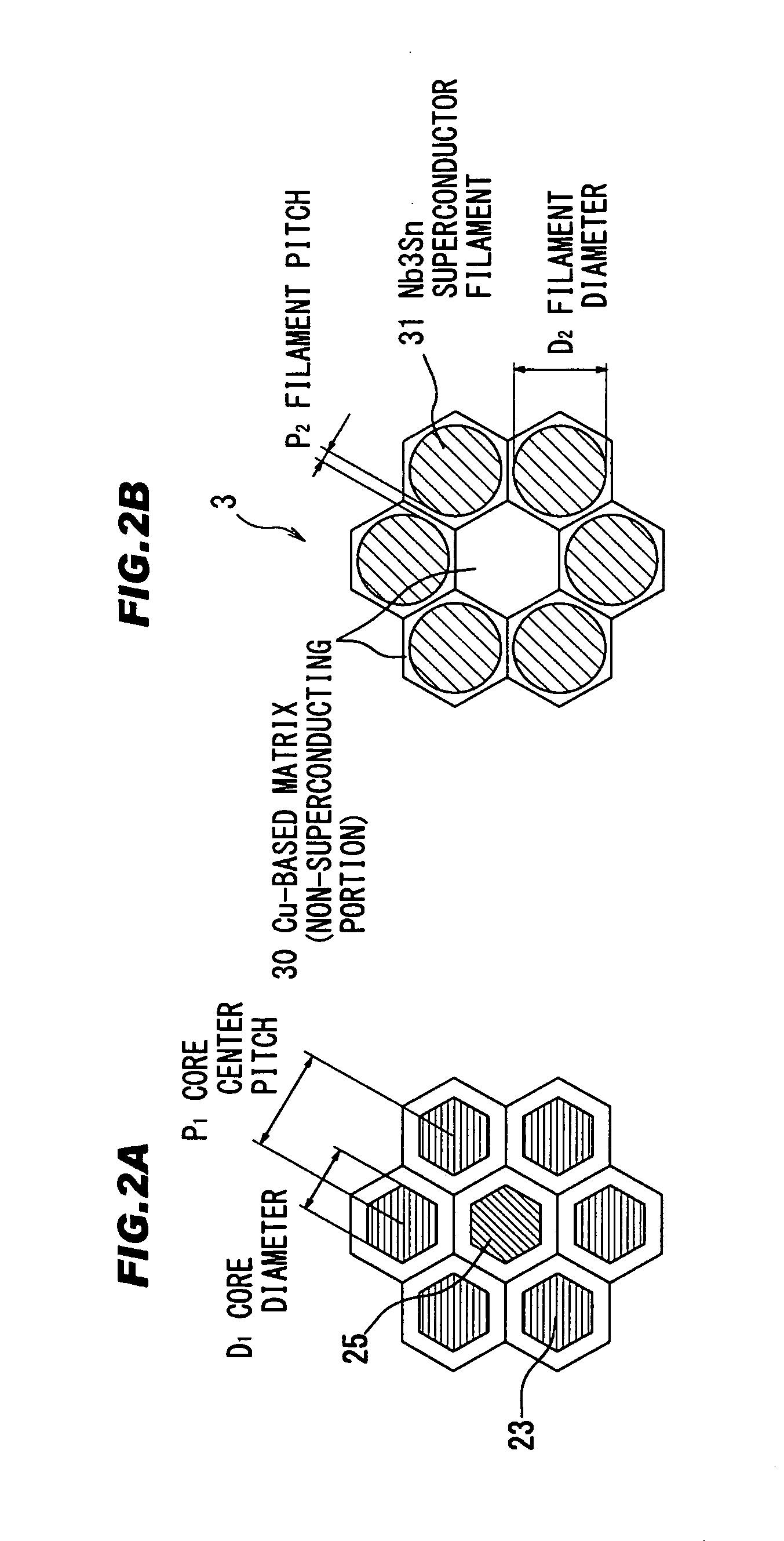

Precursor for a Nb3Sn superconductor wire, method for manufacturing the same, Nb3Sn superconductor wire, and superconducting magnet system

ActiveUS20120149579A1High currentGood magnetic stabilitySuperconductors/hyperconductorsSuperconductor detailsSuperconducting magnetDiffusion barrier

Owner:SH COPPER PROD CO LTD

Vacuum reaction intensity refining method and application of vacuum reaction intensity refining method to prepare nickel-based and iron-based alloys

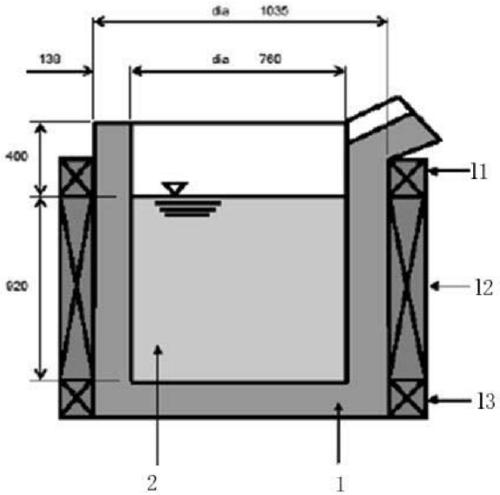

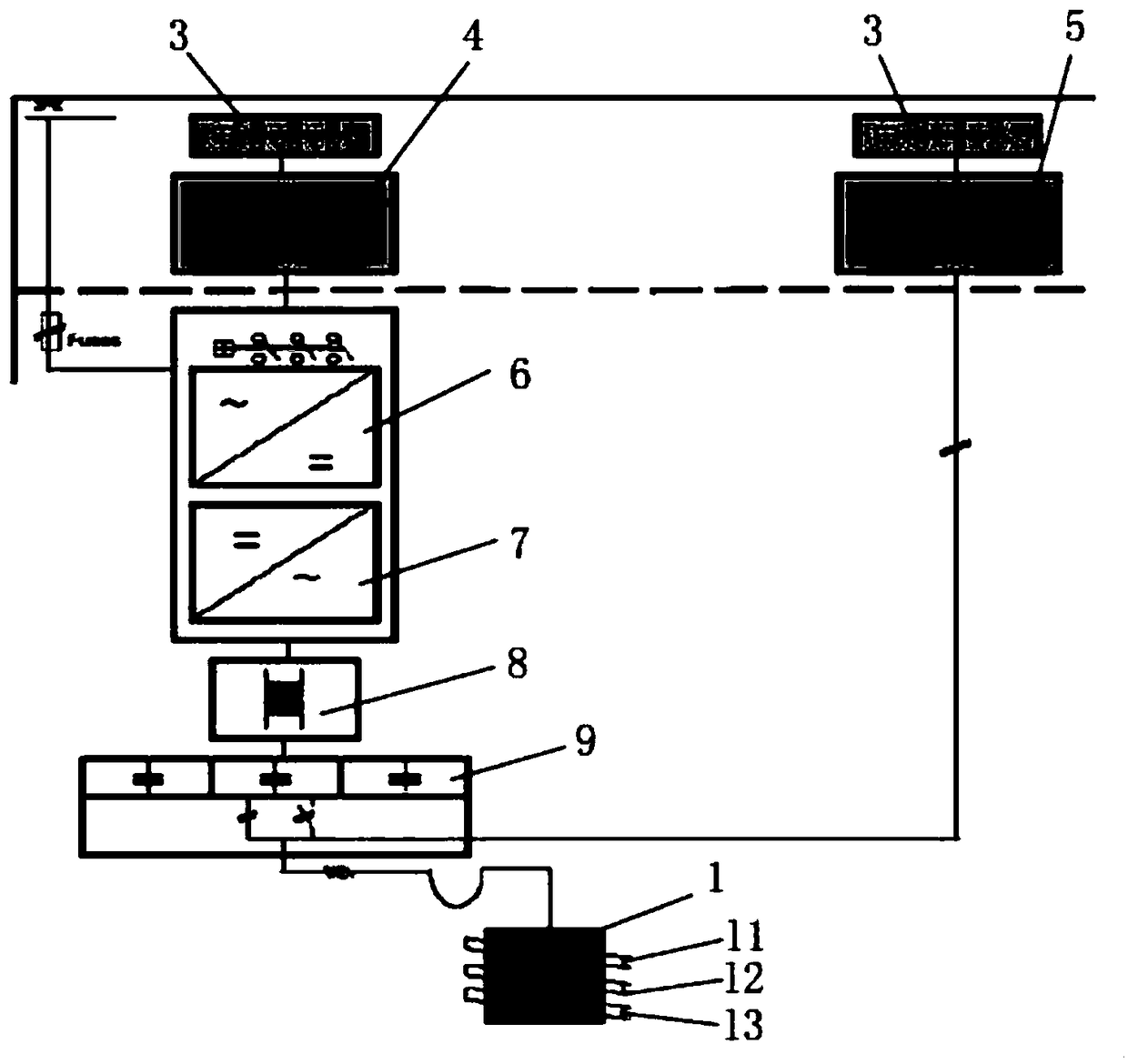

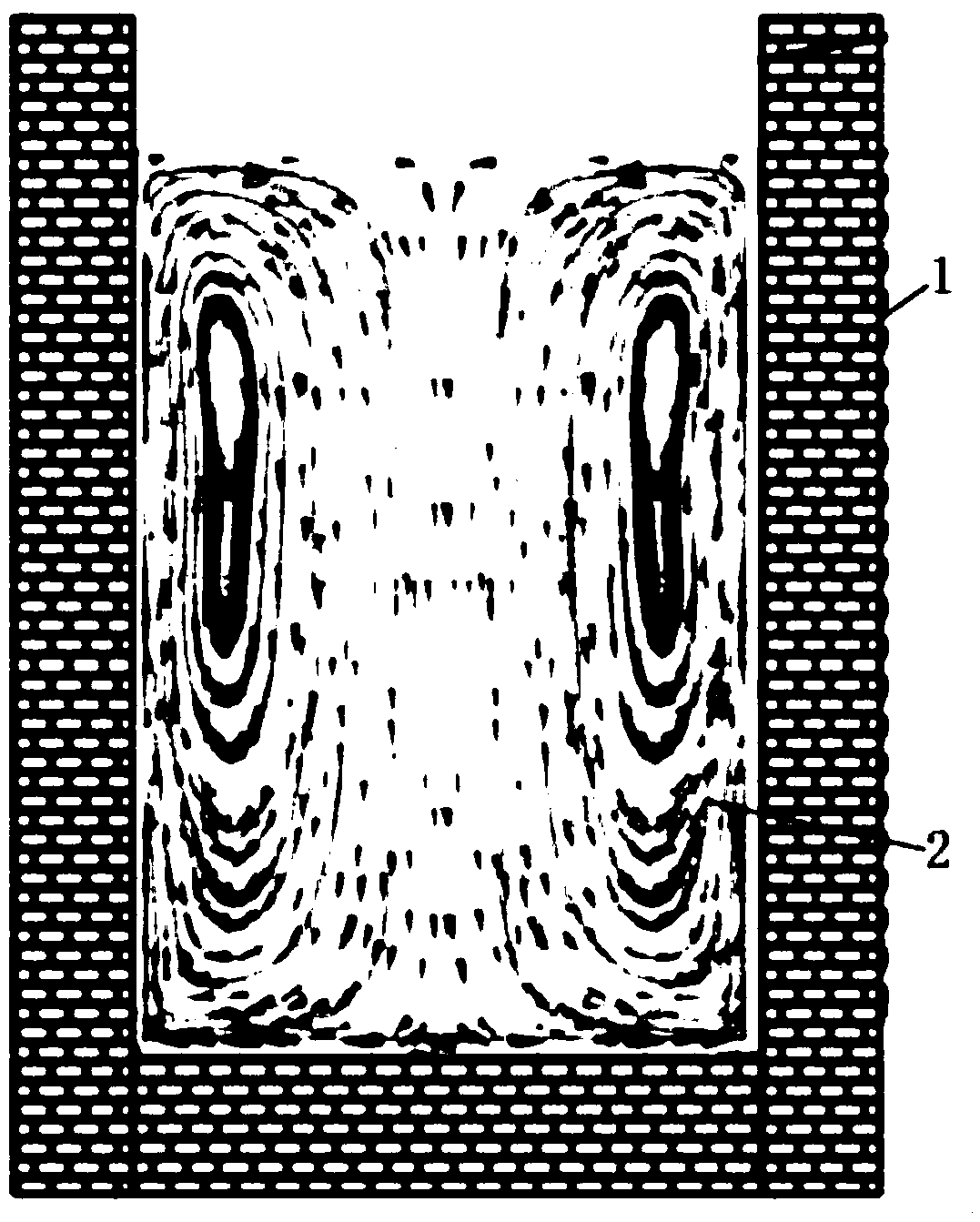

InactiveCN108950228AReduce segregationImprove toughnessIncreasing energy efficiencyUltrasound attenuationAtomic group

The invention relates to a vacuum reaction intensity refining method and application of the vacuum reaction intensity refining method to prepare nickel-based and iron-based alloys. The vacuum reactionintensity refining method is technically characterized in that raw materials are thrown into a vacuum induction smelting furnace with a magnetic stirring function to be smelted, in the smelting process, melt generates the complete circulation in the vertical direction, in other words, the melt at the bottom of a furnace body is rapidly overturned to the top, accordingly, all atomic groups of themelt in the furnace circularly make contact with the upper vacuum face of the furnace body, and the melt is refined through enough vacuum reaction intensity. Through vacuum energy, an alloy deep-layermicrostructure is changed, the conventional alloy performance extreme is broken through, the vacuum induction smelting furnace prepares high-end nickel-based alloy and iron-based alloy materials through the vacuum reaction intensity refining method, and accordingly the strict requirements of the high-end alloy materials for the service life, deformation recovery precision, performance attenuation, corrosion resistance, magnetism and the like are met.

Owner:沈阳金纳新材料股份有限公司

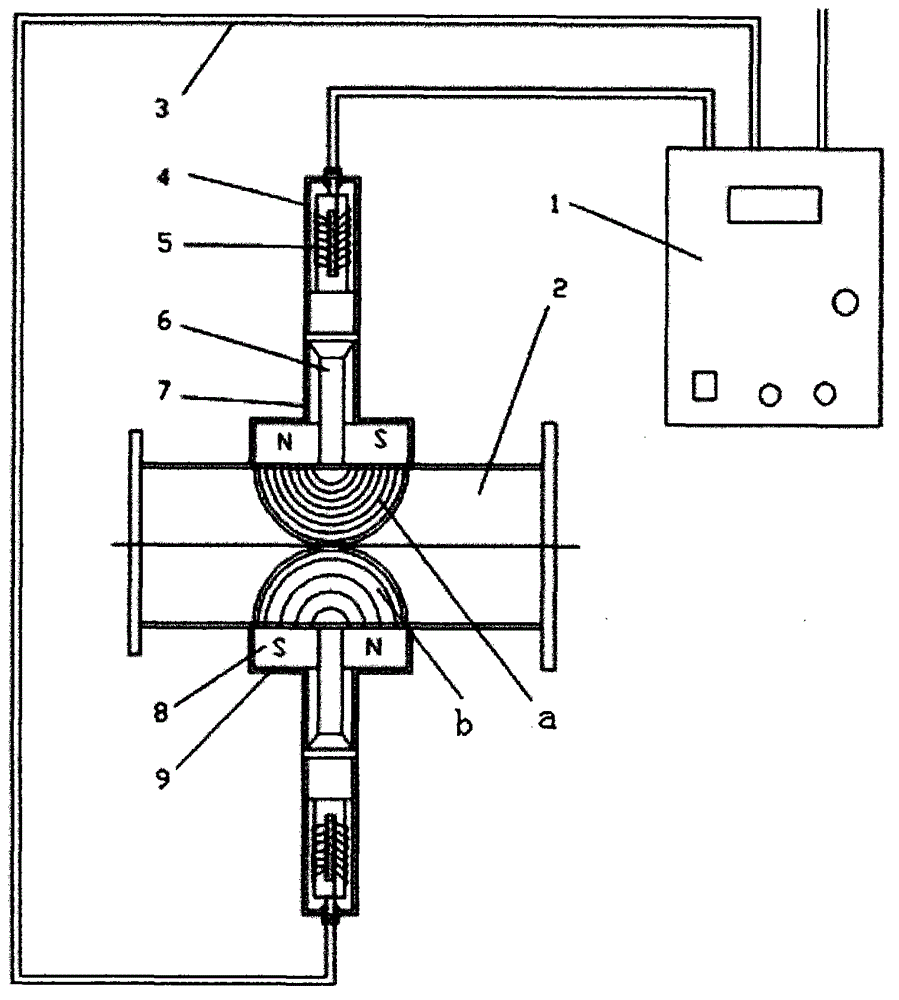

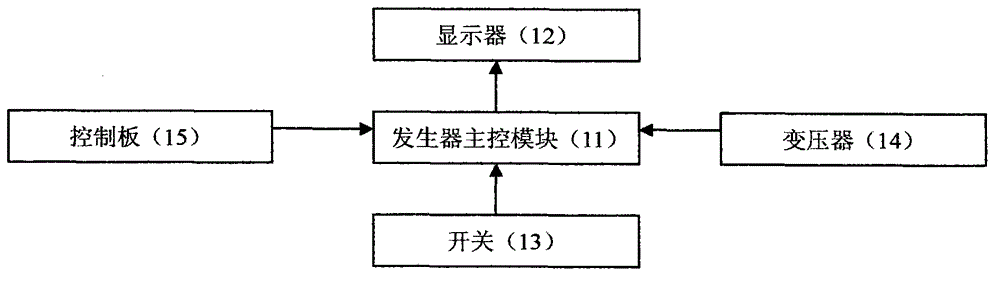

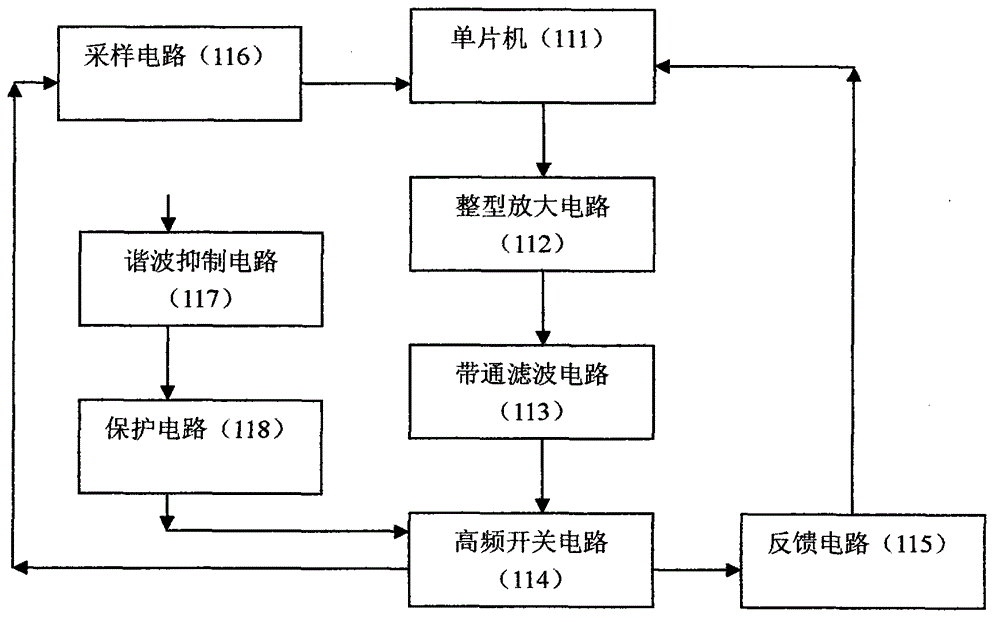

Magnetic ultrasonic wave on-line scale-preventing-removing all-in-one machine

InactiveCN104001698AIncrease pulse beam and mechanical energyReduce enable lossHollow article cleaningCleaning using liquidsUltrasonic generatorMagnet

The invention discloses a magnetic ultrasonic wave on-line scale-preventing-removing all-in-one machine which comprises a high-intensity transducer, a high-intensity transducer shielding protecting cover, strong magnets, strong magnet protecting devices and an ultrasonic wave generator. The high-intensity transducer is arranged in the high-intensity transducer shielding protecting cover and is connected with the ultrasonic wave generator through an electric cable. The bottom end of the high-intensity transducer extends out of the high-intensity transducer shielding protecting cover and is in contact with the surface of a metal pipeline. The strong magnets are arranged on the bottom of the high-intensity transducer shielding protecting cover and are placed on the two sides of the bottom of the high-intensity transducer. The strong magnet protecting devices are arranged on the surfaces of the strong magnets. The high-intensity transducer and the strong magnets are combined, ultrasonic pulse resonance waves generated by the high-intensity transducer and a magnetic field generated by the strong magnets have effect on a metal pipeline, synergistic effect is formed, wave-like impact waves are generated, a scale layer of the pipe wall of the metal pipeline is impacted and hammered ceaselessly, stress is generated between scale layer molecules, so that scale layer fracturing, loosening and falling off happen, and the scale layer sinks deep into an impounding reservoir with water flow.

Owner:广州正森一辰科技有限责任公司

Motor rotor and permanent magnet motor

ActiveUS20200328638A1Increase magnetizing rangeOperation efficiency can be improvedWindingsMagnetic circuit rotating partsMagnetic polesElectric machinery

The present invention discloses a motor rotor and a permanent magnet motor. The motor rotor includes a rotor core and a plurality of magnetic poles provided in the rotor core, wherein each magnetic pole includes a first permanent magnet, a second permanent magnet and a third permanent magnet; the first permanent magnet being arranged on a central position of the magnetic pole on which said first permanent magnet is located, the second permanent magnet being arranged at two sides of the first permanent magnet, the third permanent magnet being arranged at one side of the second permanent magnet far away from the first permanent magnet; the coercivity of the first permanent magnet is smaller than that of the second permanent magnet and that of the third permanent magnet; and the third permanent magnet is arranged on a q axis of the motor.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com