Motor rotor and permanent magnet motor

一种电机转子、永磁体的技术,应用在磁路、电气元件、机电装置等方向,能够解决永磁电机难以兼顾高频和低频效率、限制电机最高运行频率、降低电机运行效率等问题,达到降低充退磁难度、减小充退磁电流大小、电机运行效率最优的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

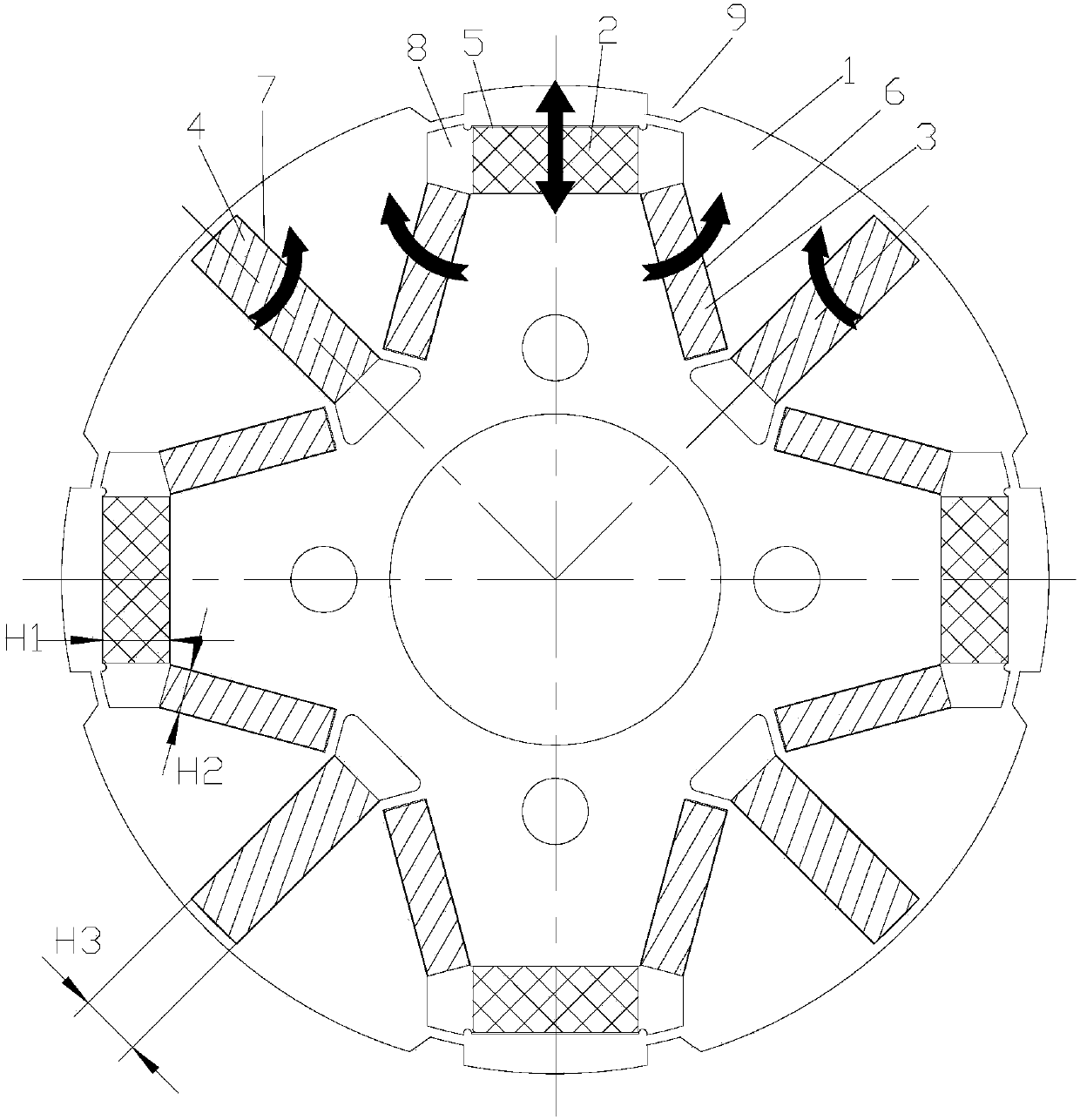

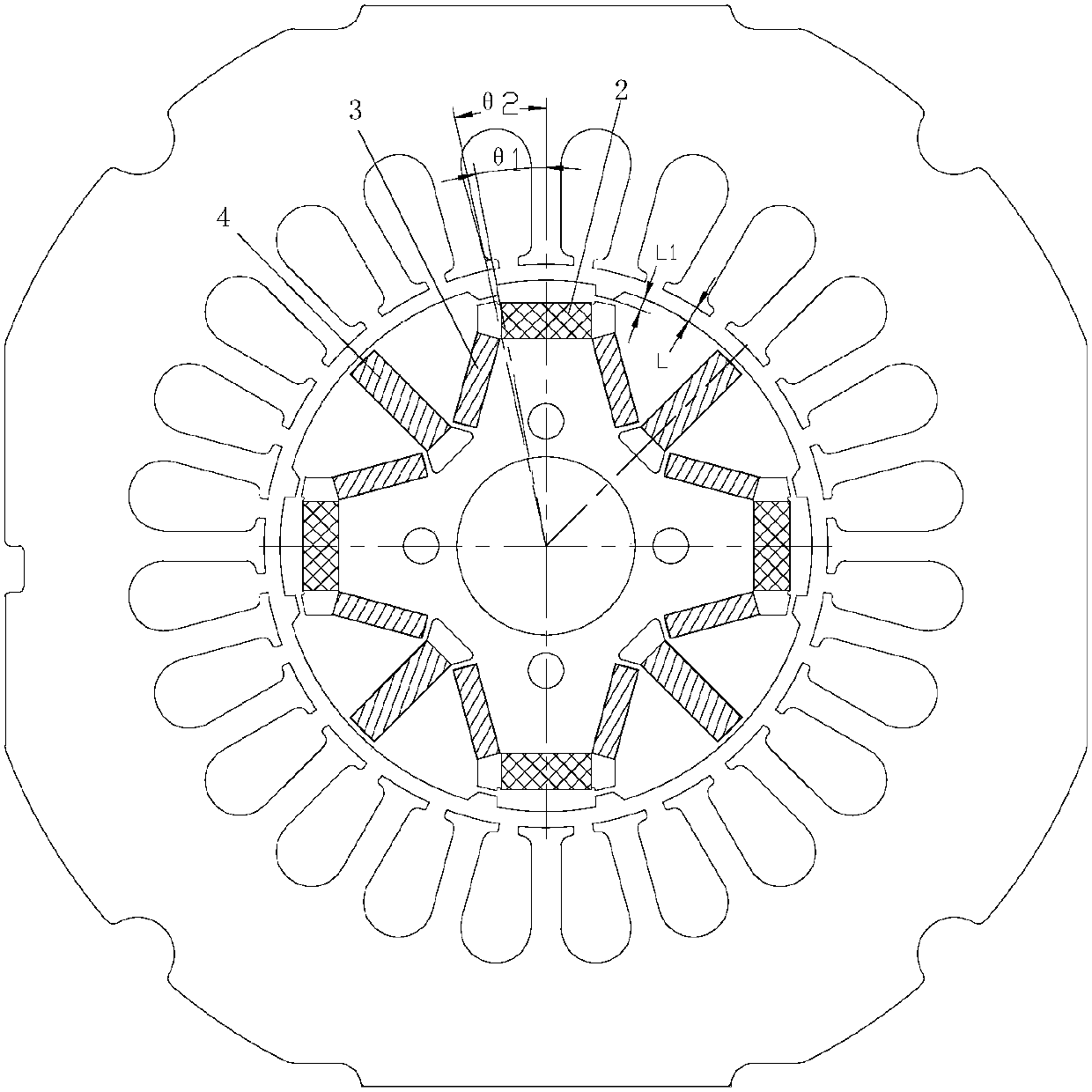

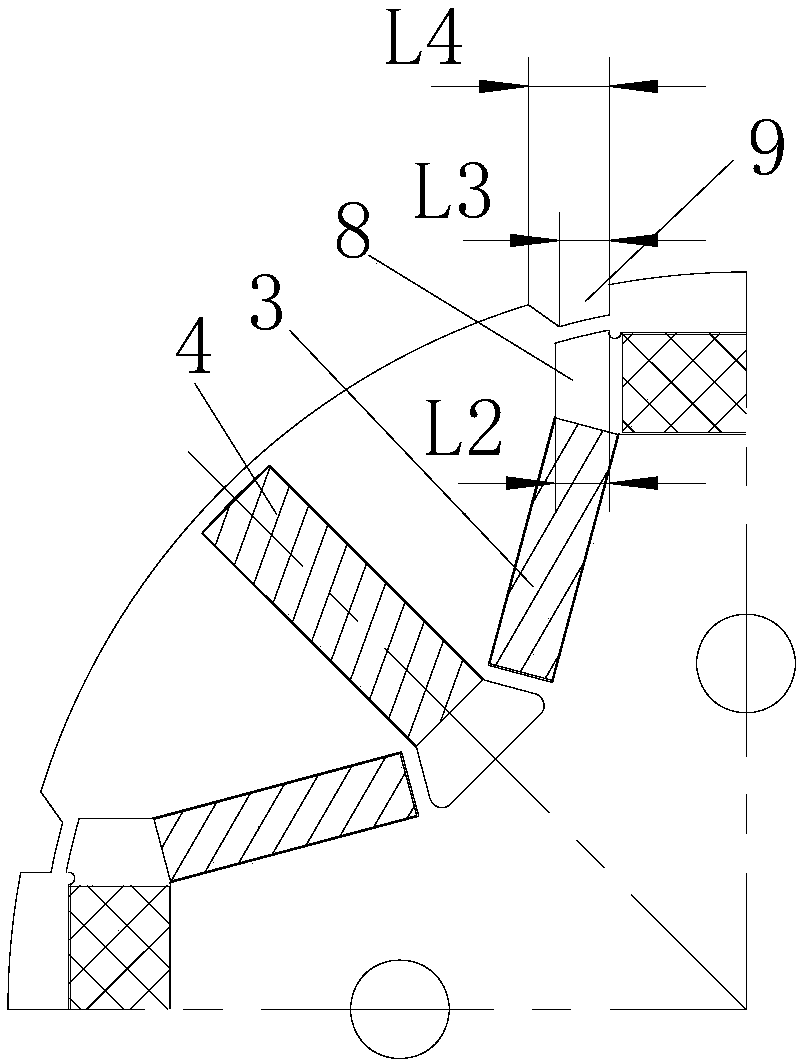

[0039] see in conjunction Figures 1 to 12 As shown, according to the embodiment of the present invention, the motor rotor includes a rotor core 1 and a plurality of magnetic poles arranged in the rotor core 1, and the magnetic poles include a first permanent magnet 2, a second permanent magnet 3 and a third permanent magnet 4, The first permanent magnet 2 is arranged on the central position of its magnetic pole, the second permanent magnet 3 is arranged on both sides of the first permanent magnet 2, and the third permanent magnet 4 is arranged on one side of the second permanent magnet 3 away from the first permanent magnet 2. On the side, the coercive force of the first permanent magnet 2 is smaller than the coercive force of the second permanent magnet 3 and the coercive force of the third permanent magnet 4, and the third permanent magnet 4 is arranged on the q-axis of the motor.

[0040]When the motor rotor is running, the motor control strategy adopts magnetization contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com