Patents

Literature

177results about How to "Increased reluctance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

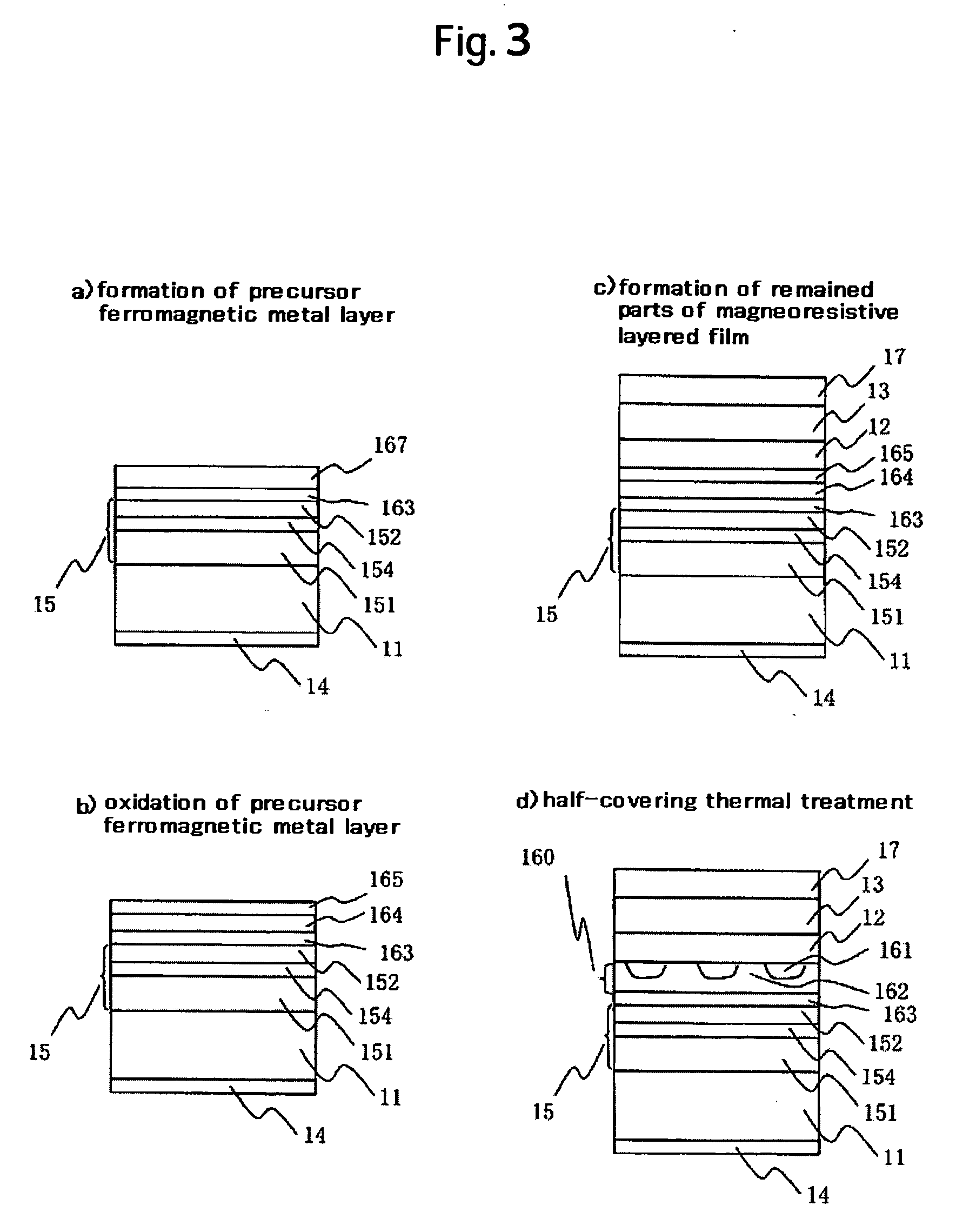

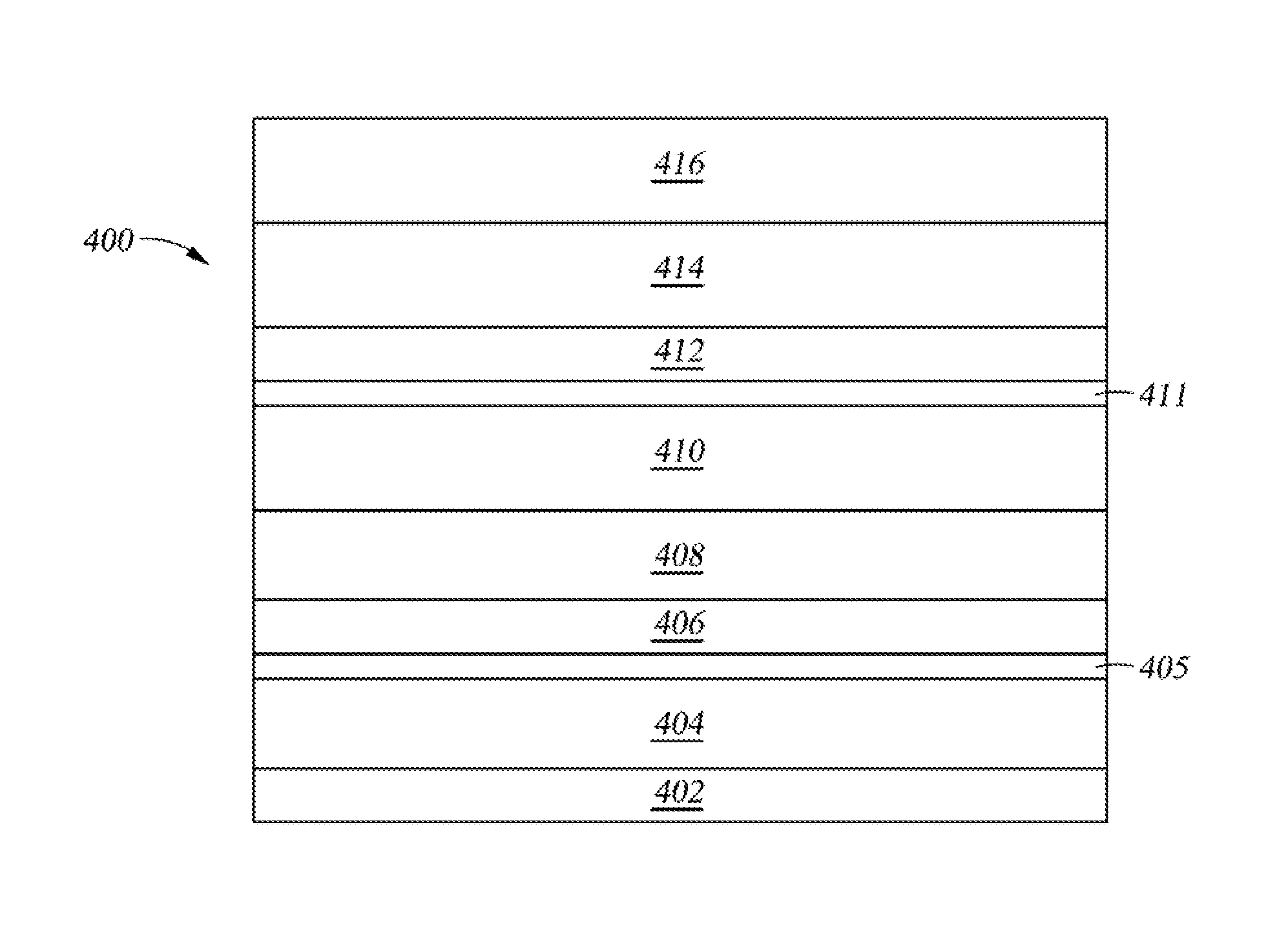

Apparatus and process for manufacturing ST-MRAM having a metal oxide tunnel barrier

ActiveUS9136464B1Improved breakdown distributionReduce in quantityNanoinformaticsGalvano-magnetic device detailsBreakdown voltageMetal

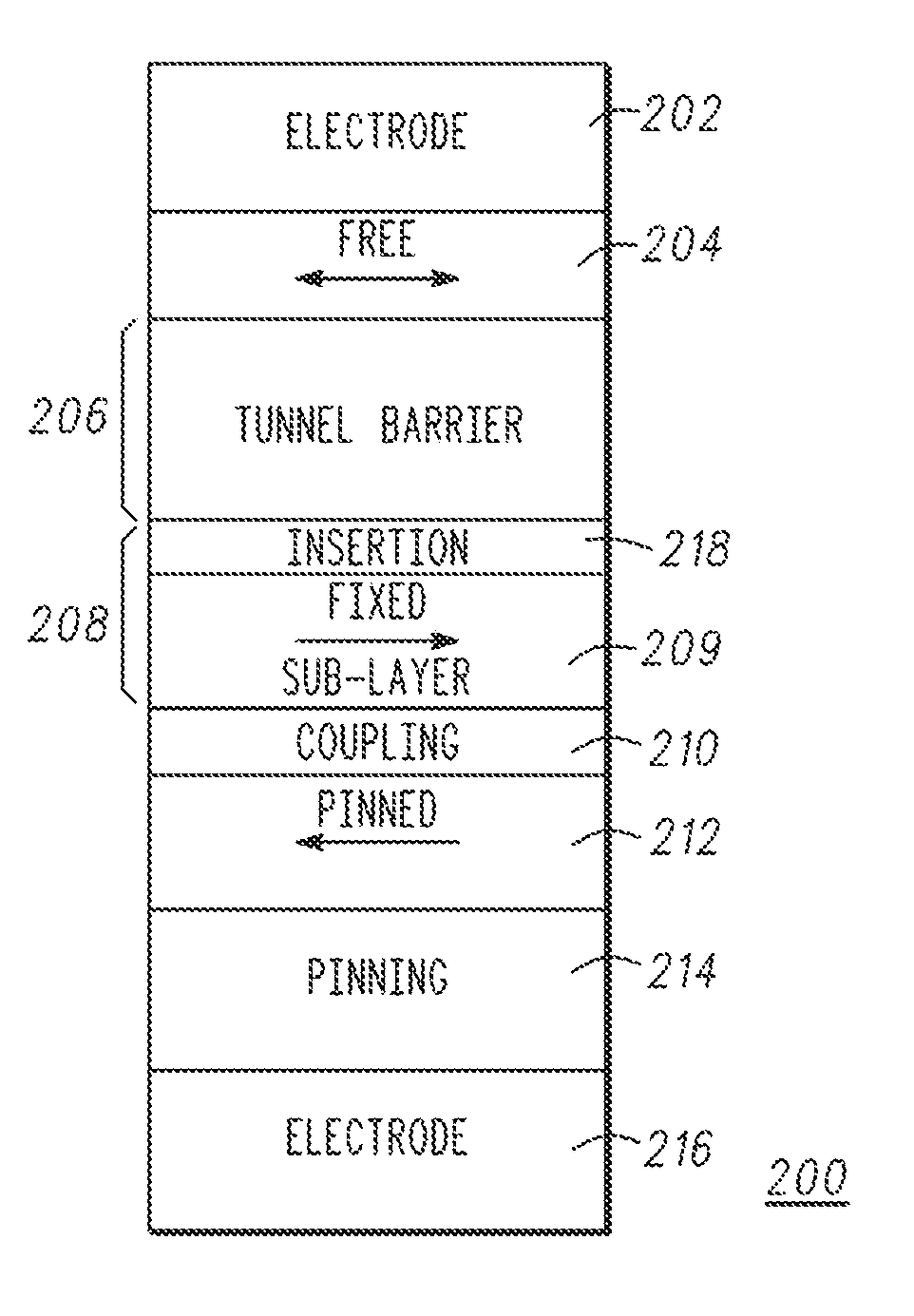

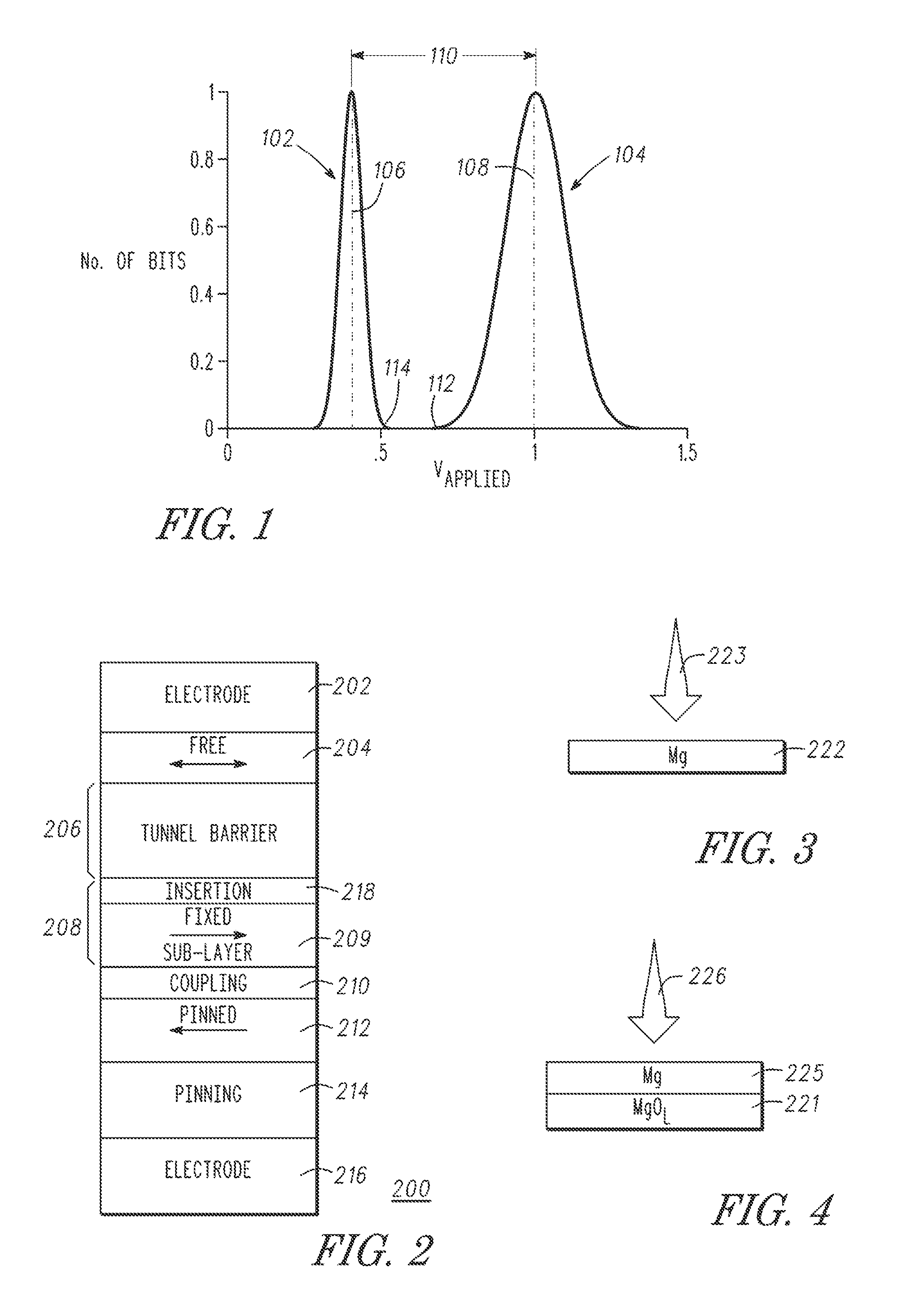

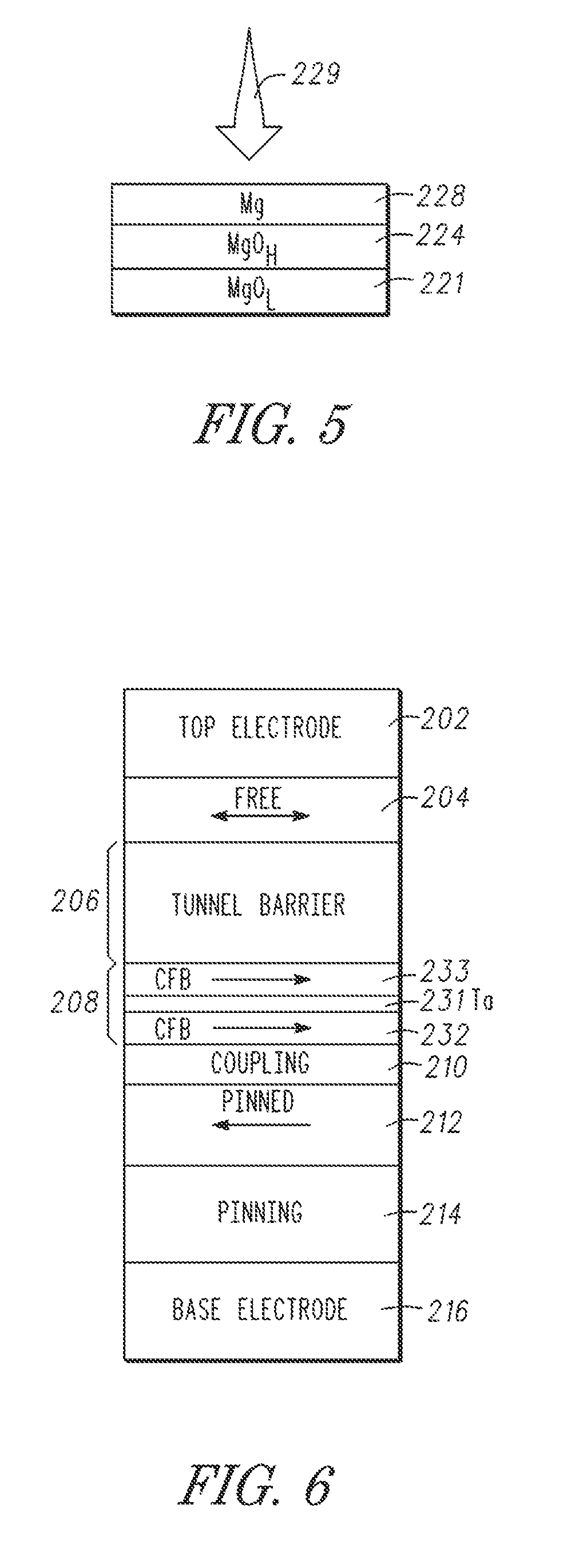

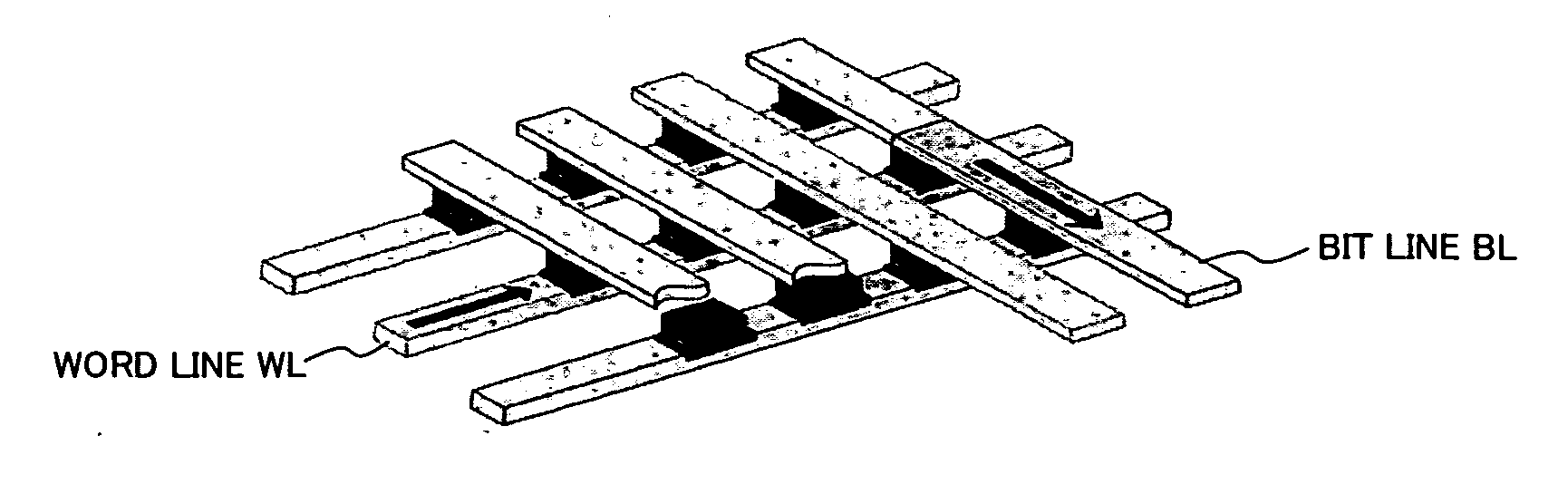

An MRAM device, and a process for manufacturing the device, provides improved breakdown distributions, a reduced number of bits with a low breakdown voltage, and an increased MR, thereby improving reliability, manufacturability, and error-free operation. A tunnel barrier is formed between a free layer and a fixed layer in three repeating steps of forming a metal material, interceded by oxidizing each of the metal materials. The oxidization of the third metal material is greater than the dose of the first metal, but less than the dose of the second metal. The fixed layer may include a discontinuous layer of a metal, for example, Ta, in the fixed layer between two layers of a ferromagnetic material.

Owner:EVERSPIN TECHNOLOGIES

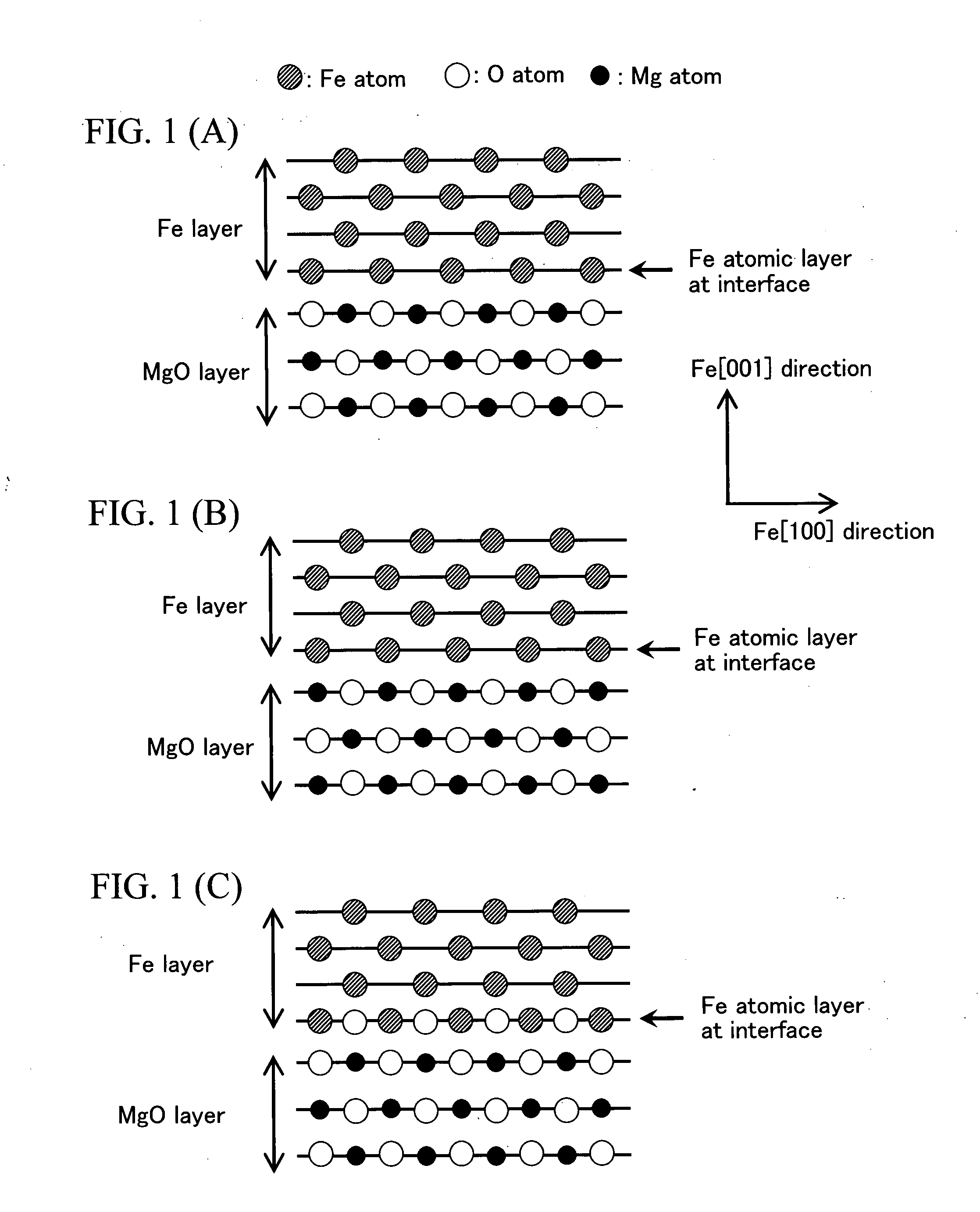

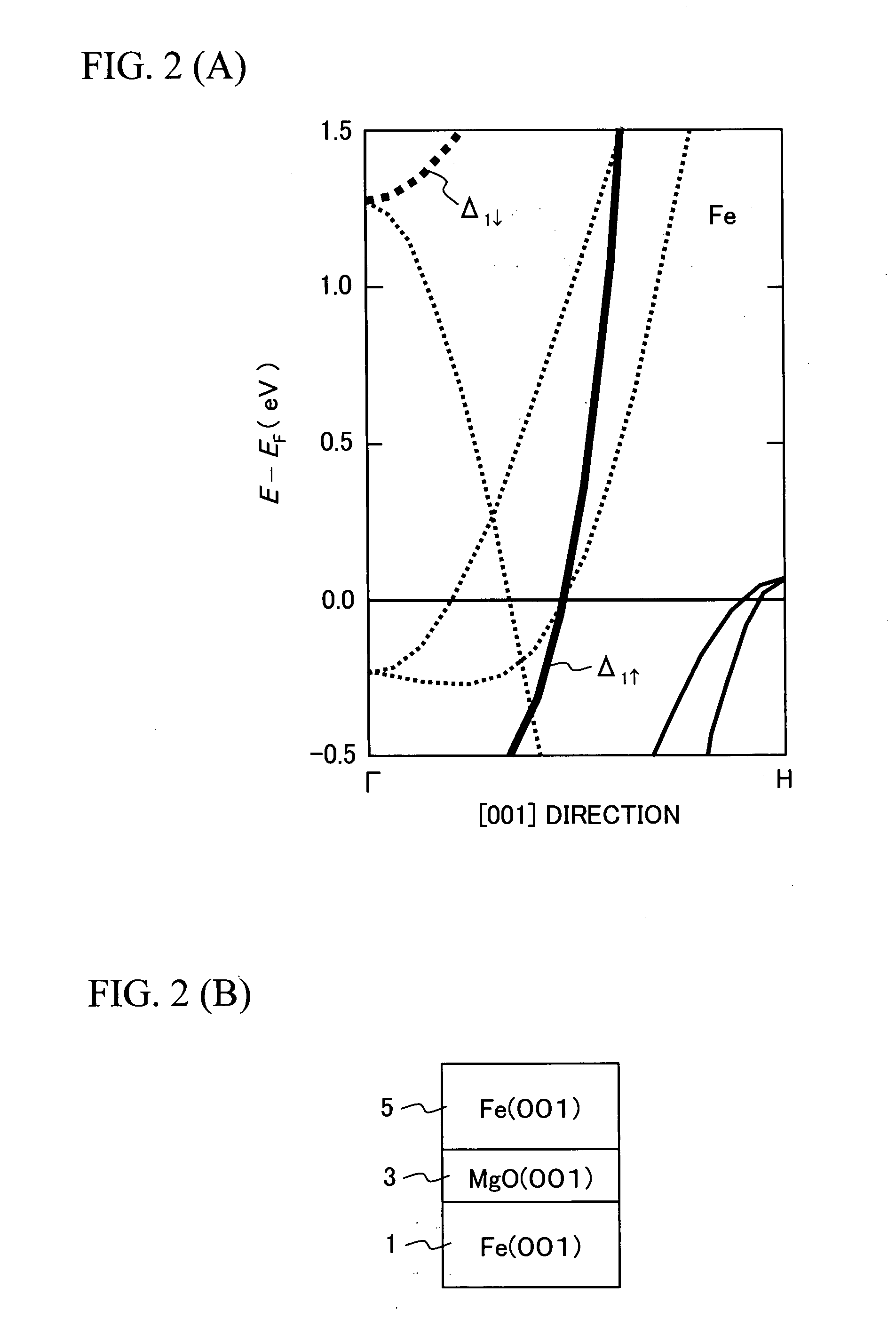

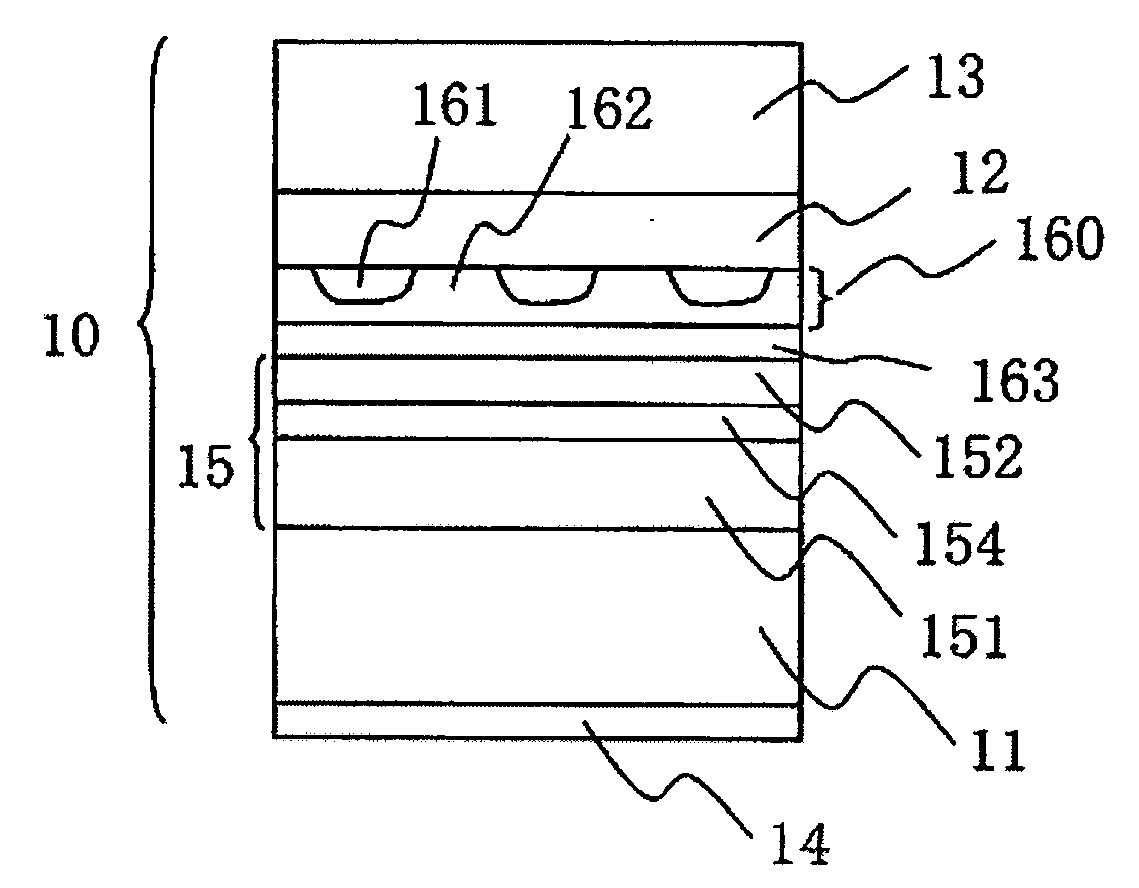

Magnetic tunnel junction device and method of manufacturing the same

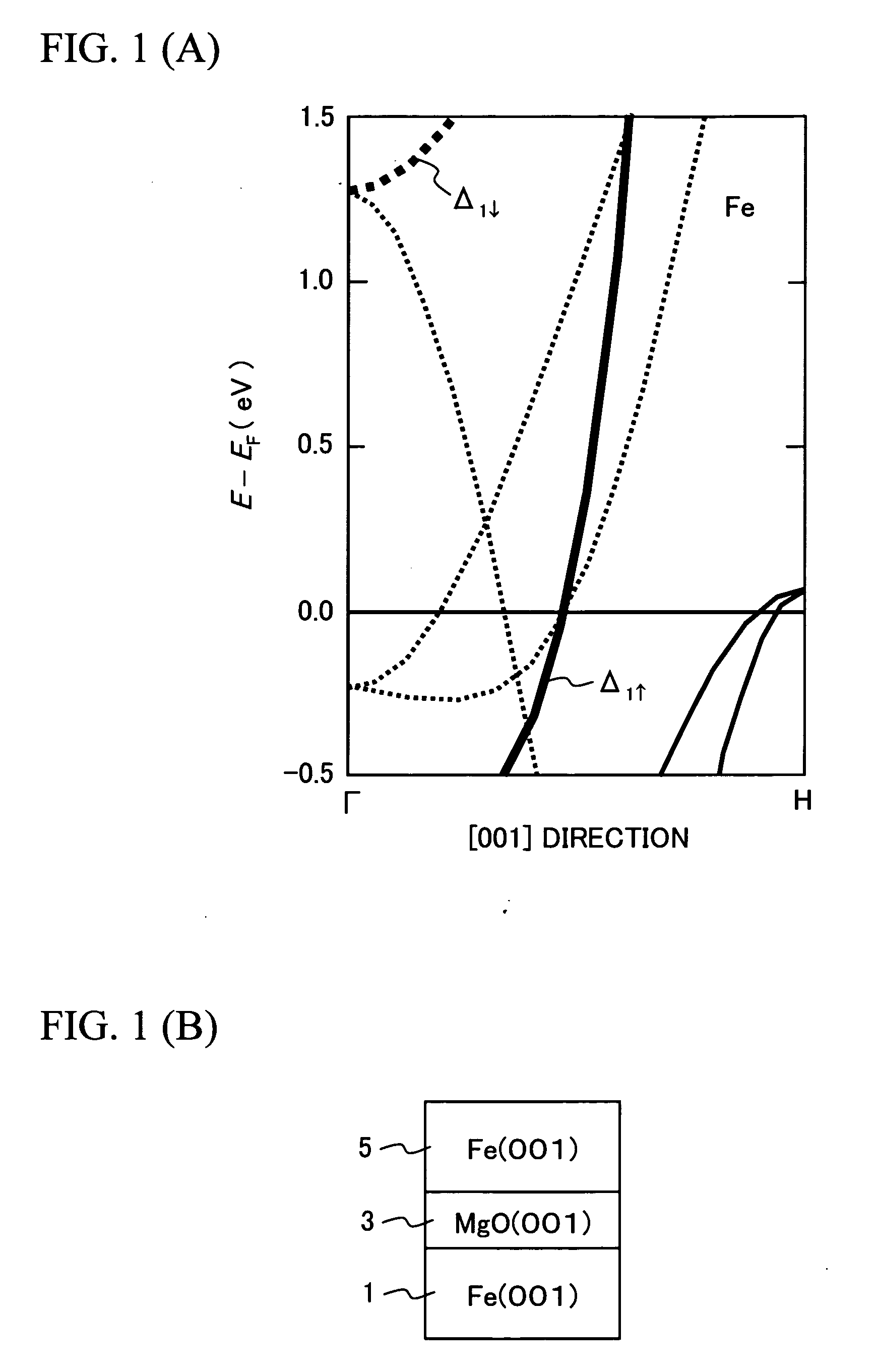

ActiveUS20070195592A1Increase magnetoresistanceIncrease output voltageNanomagnetismNanoinformaticsVoltageOptoelectronics

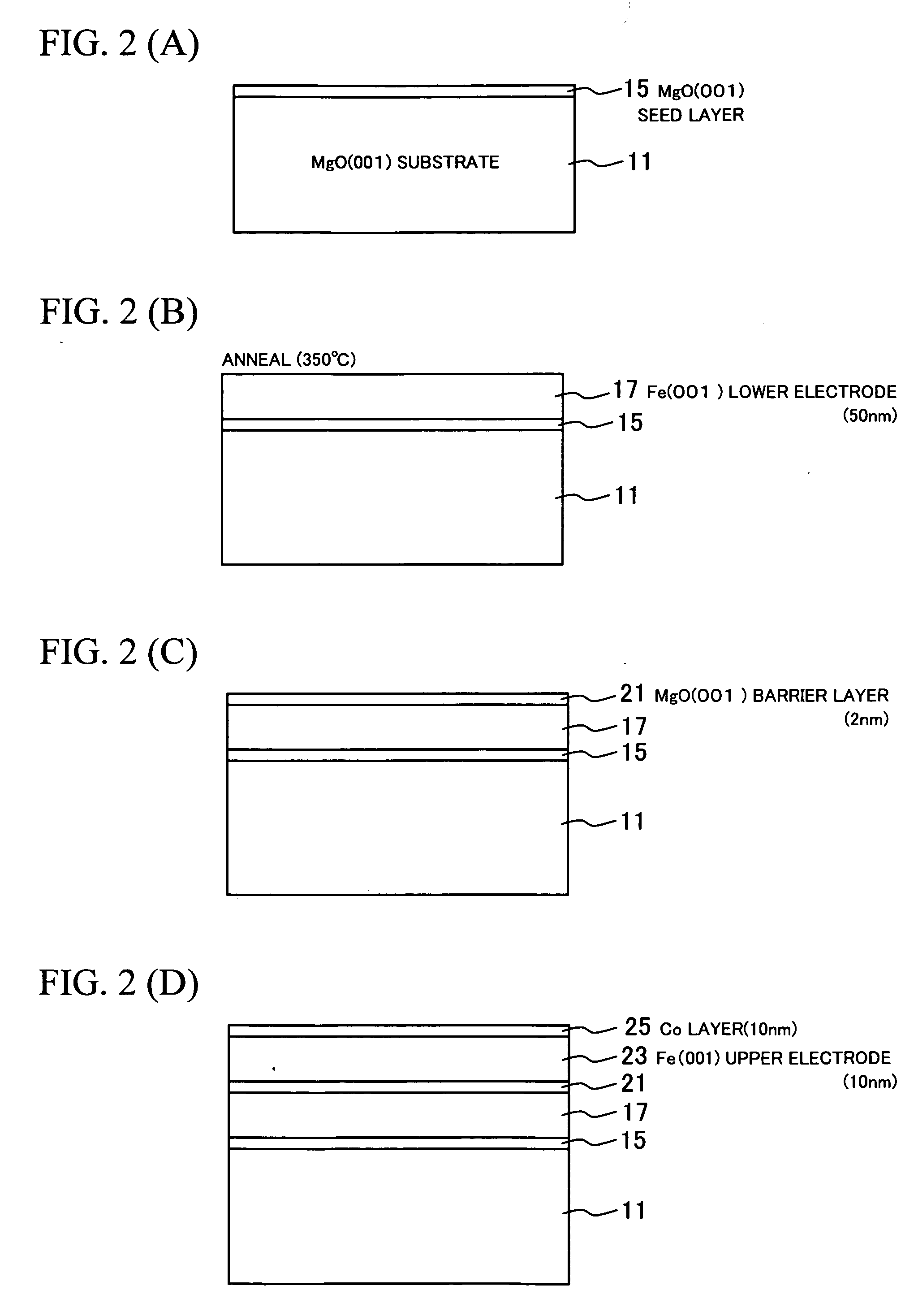

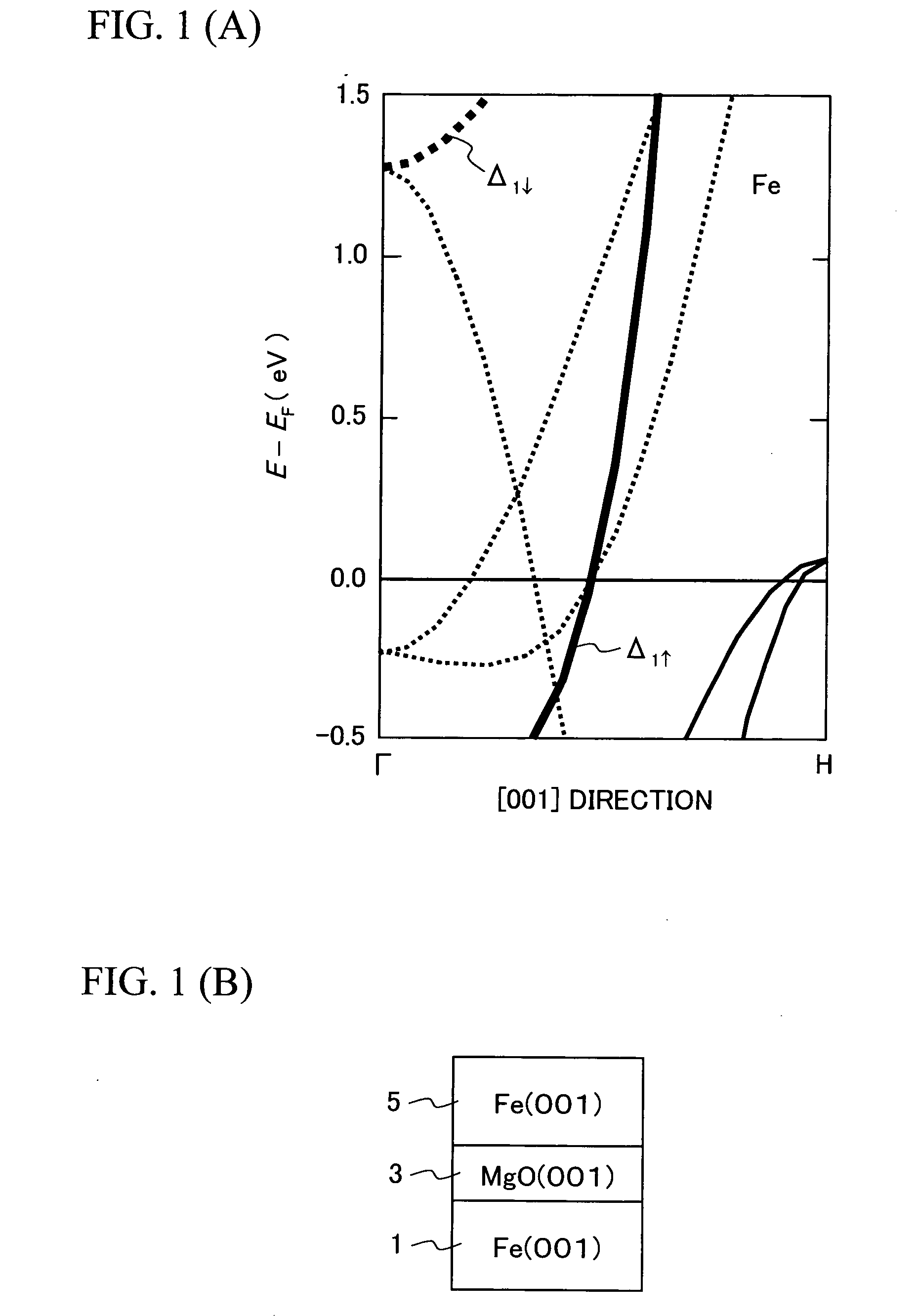

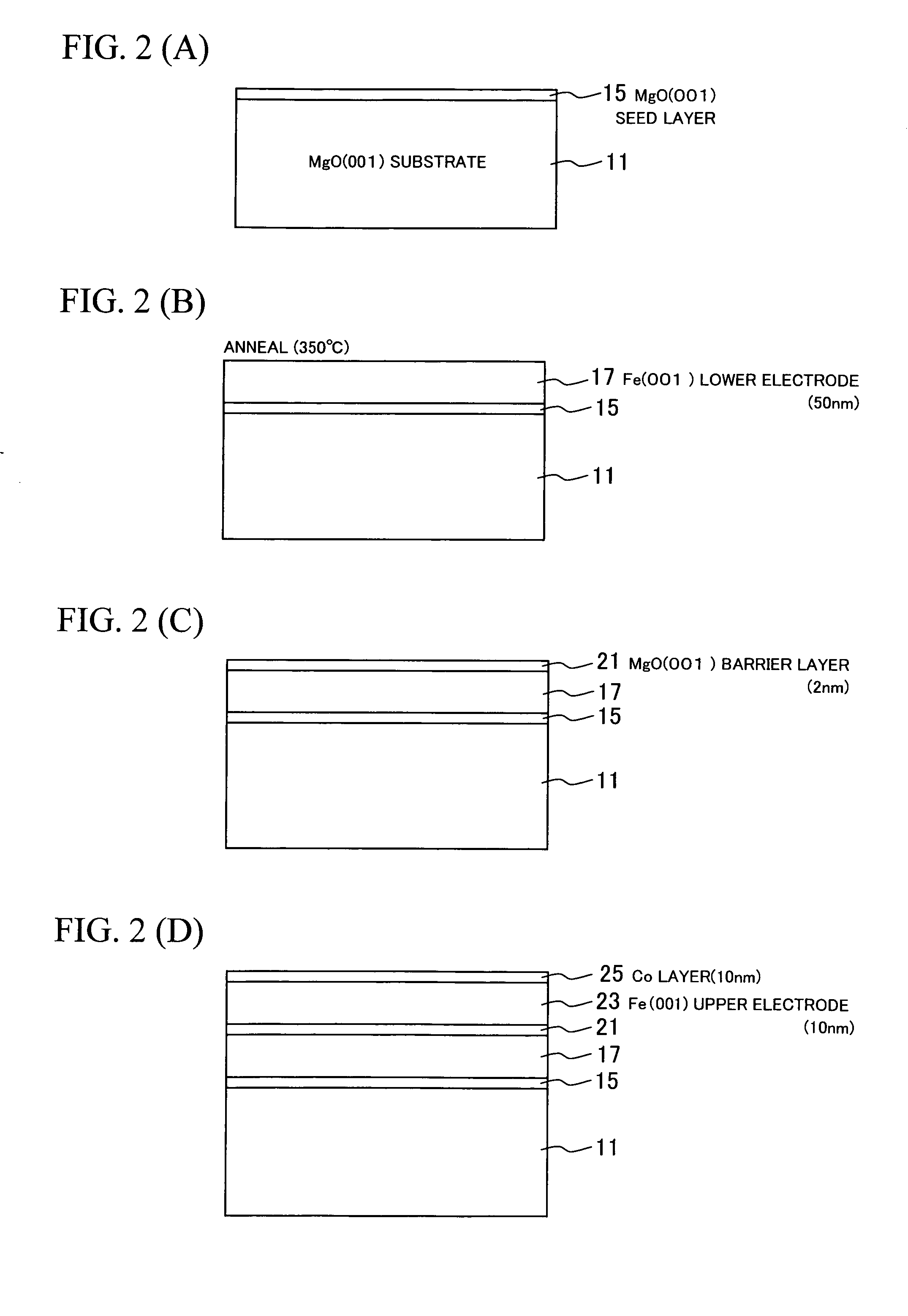

The output voltage of an MRAM is increased by means of an Fe(001) / MgO(001) / Fe(001) MTJ device, which is formed by microfabrication of a sample prepared by the following steps. A single-crystalline MgO(001) substrate 11 is prepared. An epitaxial Fe(001) lower electrode (a first electrode) 17 with the thickness of 50 nm is grown on a MgO(001) seed layer 15 at room temperature, followed by annealing under ultrahigh vacuum (2×10−8 Pa) and at 350° C. A MgO(001) barrier layer 21 with the thickness of 2 nm is epitaxially formed on the Fe(001) lower electrode (the first electrode) at room temperature, using a MgO electron-beam evaporation. A Fe(001) upper electrode (a second electrode) with the thickness of 10 nm is then formed on the MgO(001) barrier layer 21 at room temperature. This is successively followed by the deposition of a Co layer 21 with the thickness of 10 nm on the Fe(001) upper electrode (the second electrode) 23. The Co layer 21 is provided so as to increase the coercive force of the upper electrode 23 in order to realize an antiparallel magnetization alignment.

Owner:GK BRIDGE 1

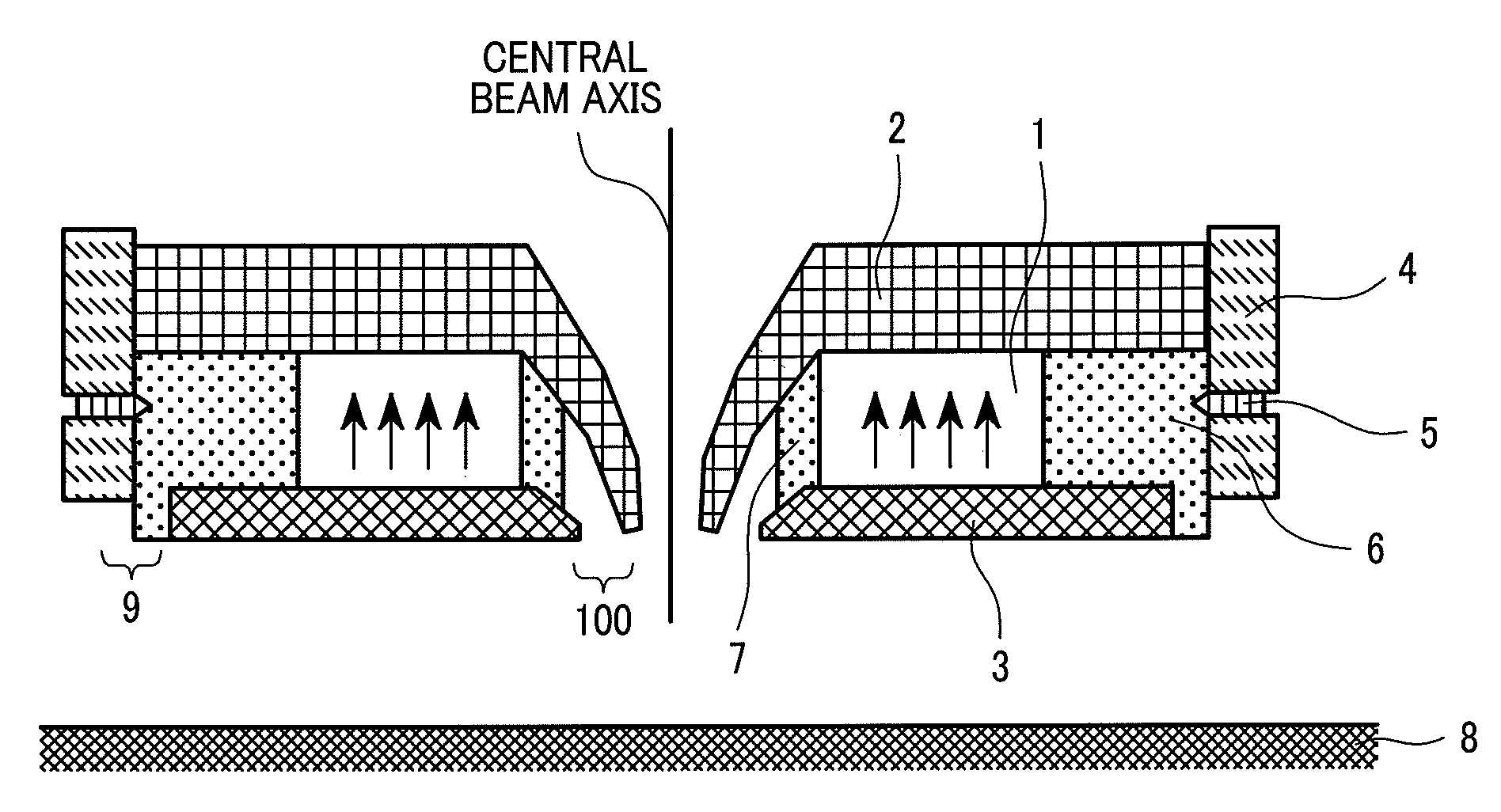

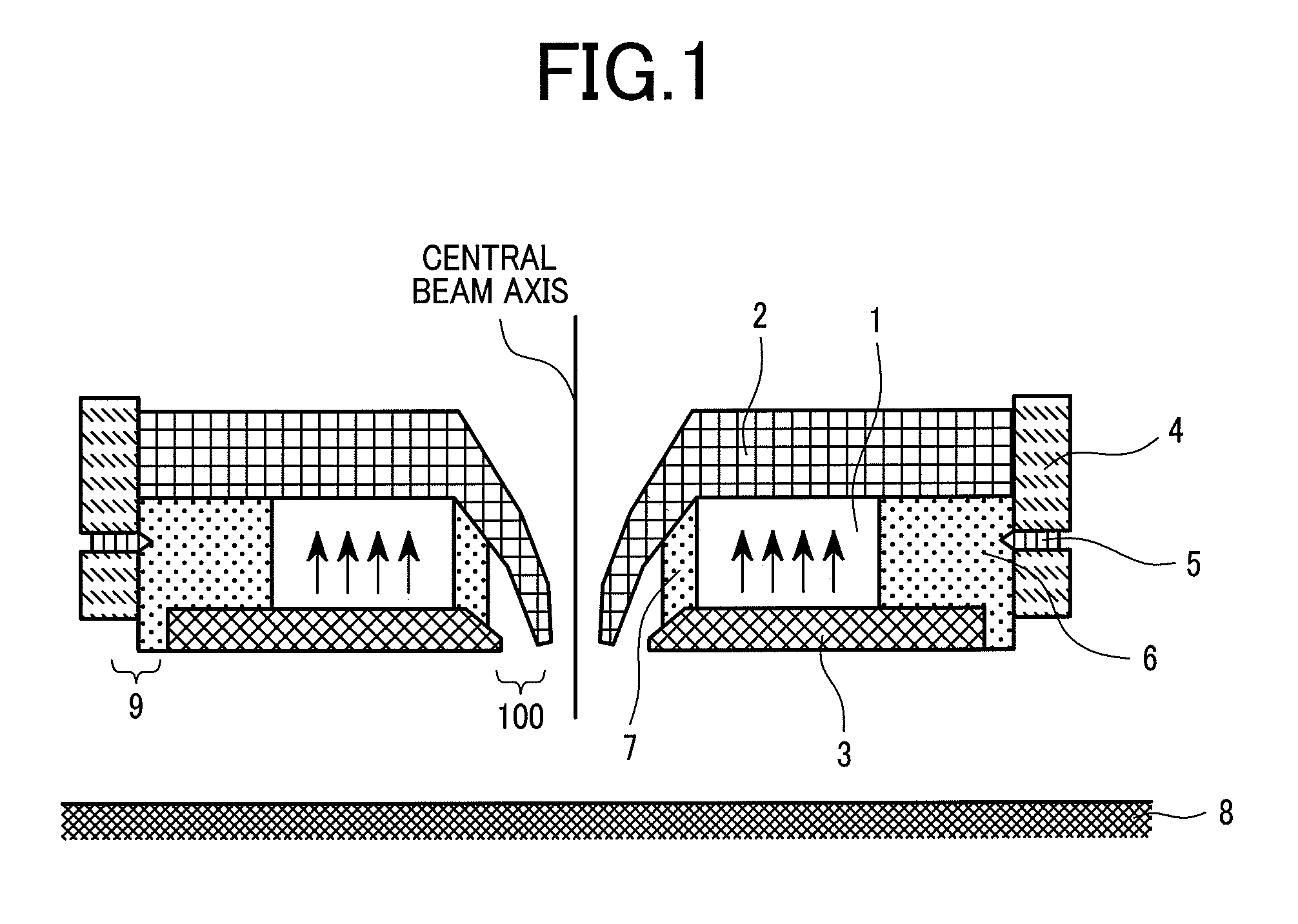

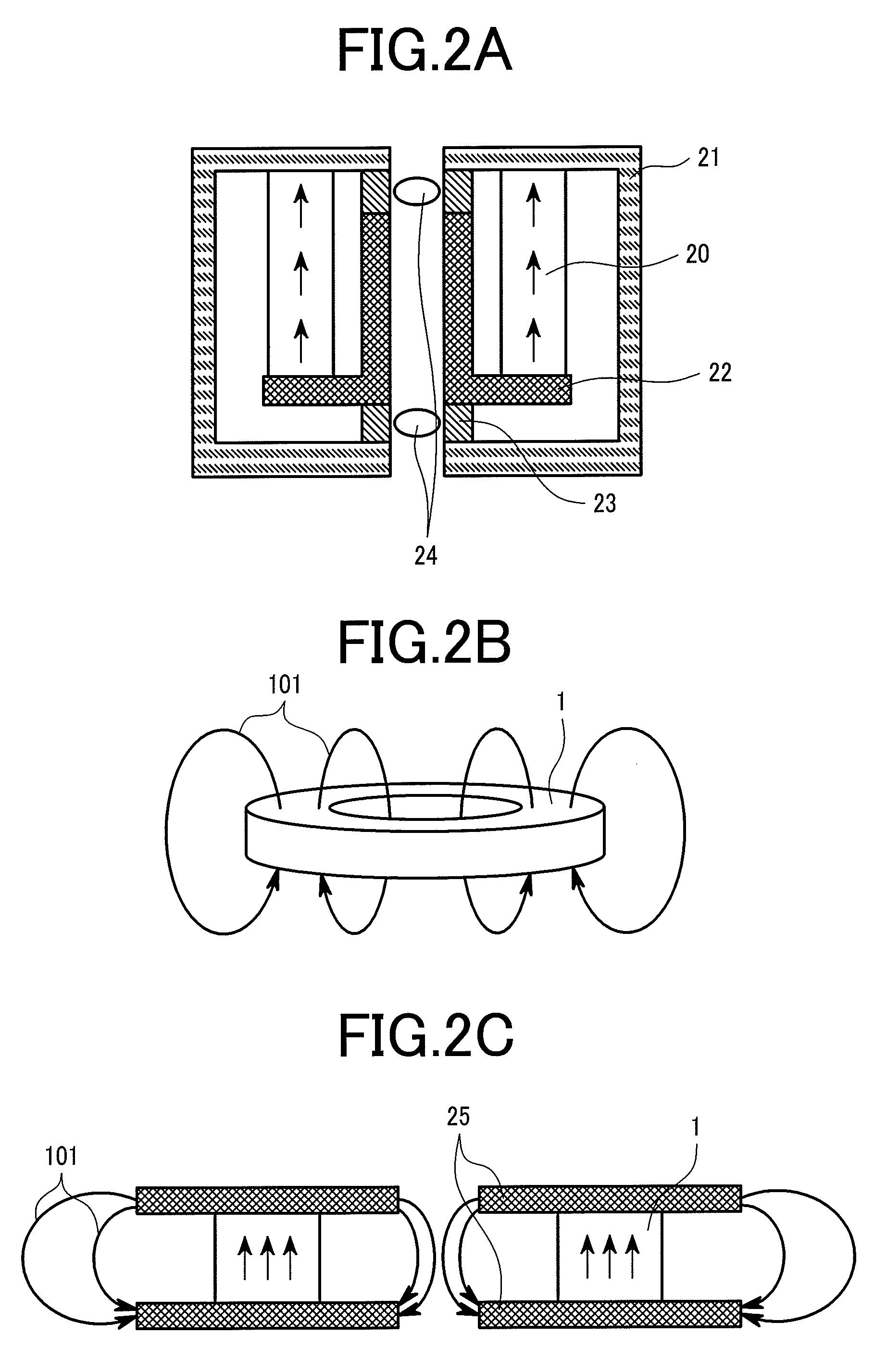

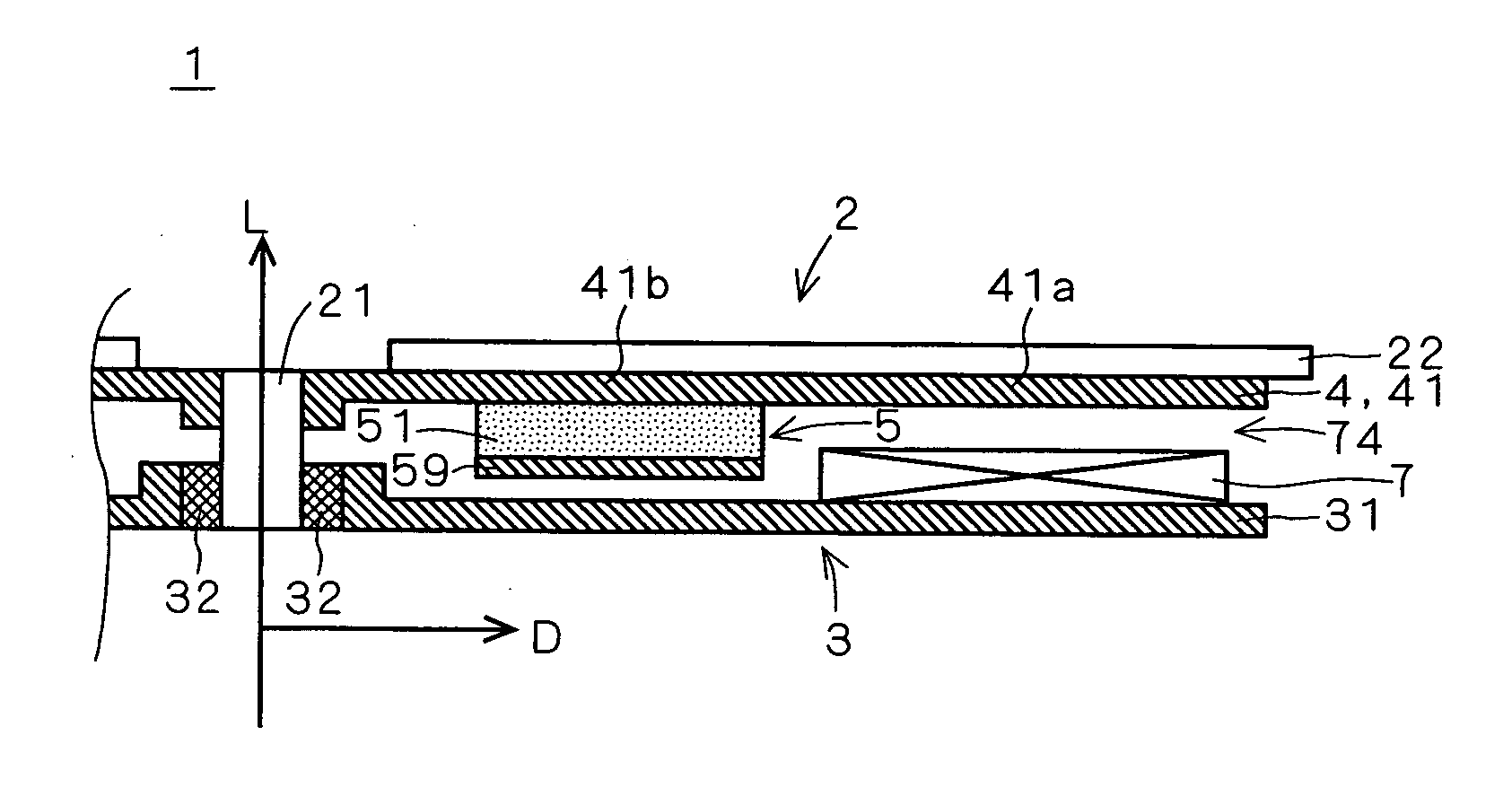

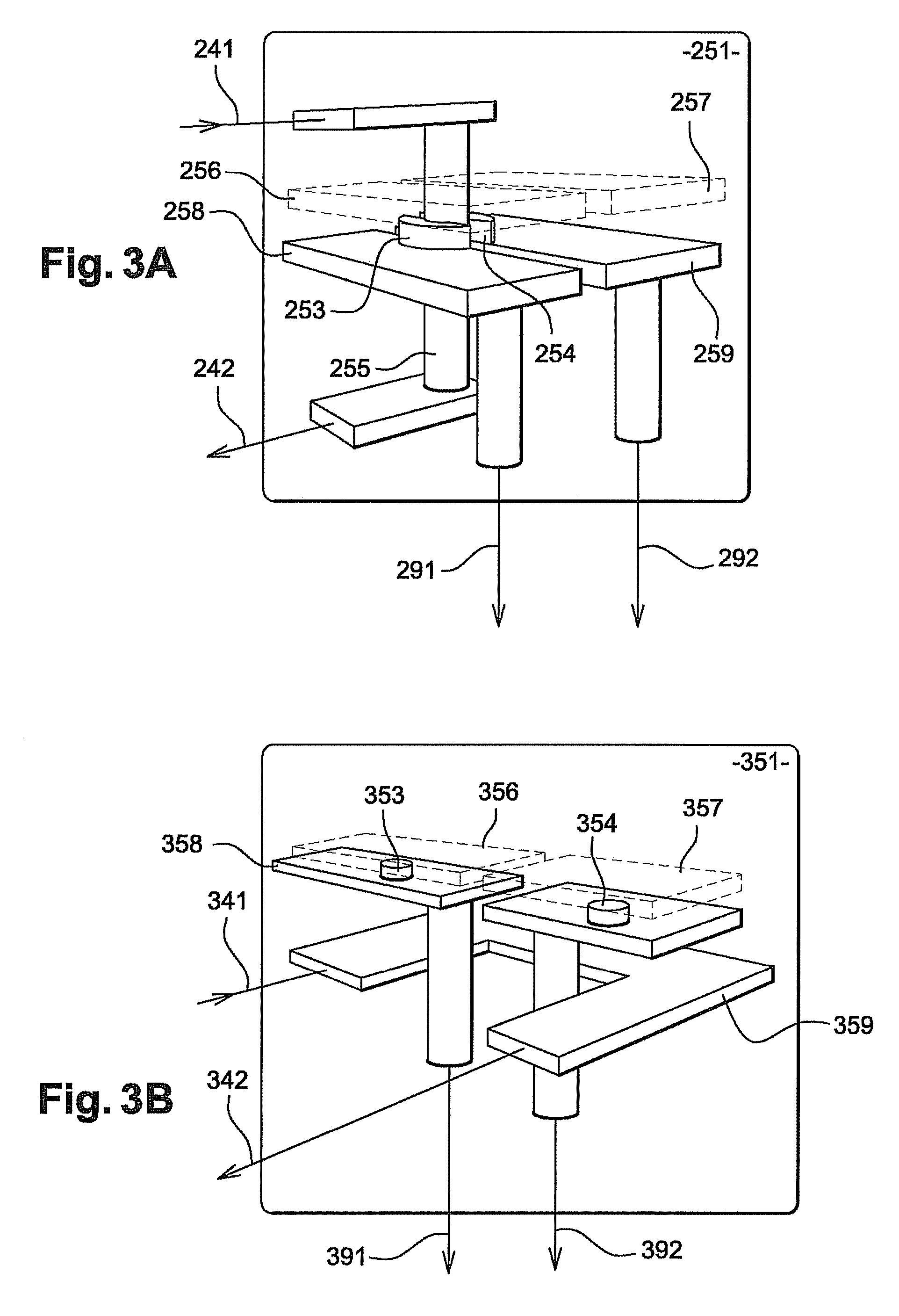

Electron Lens and Charged Particle Beam Apparatus

InactiveUS20080067396A1High resolutionSmall aberrationElectric discharge tubesMaterial analysis by optical meansRare earthMagnetic poles

The present invention provides a compact electron lens causing little aberration, and a charged particle beam apparatus such as a scanning electron microscope that is super compact and offers a high resolution. An upper magnetic pole and a sample-side magnetic pole are magnetically coupled to the respective poles of a permanent magnet that is made of a highly strong magnetic material such as a rare-earth cobalt system or a neodymium-iron-boron system, that is axially symmetrical, and that has a hole in the center thereof. An inner gap is created on the side of a center axis. Thus, a magnetic lens is formed axially. Moreover, a semi-stationary magnetic path that shields an outside magnetic field and has the magnetic reluctance thereof regulated is disposed outside. The sample-side magnetic pole and magnetic path defines a region where magnetic reluctance is the highest outside the permanent magnet. A space defined by the permanent magnet, upper magnetic pole, sample-die magnetic pole, and semi-stationary magnetic path is filled with a filling made of a non-magnetic material. Thus, an objective lens is constructed.

Owner:HITACHI HIGH-TECH CORP

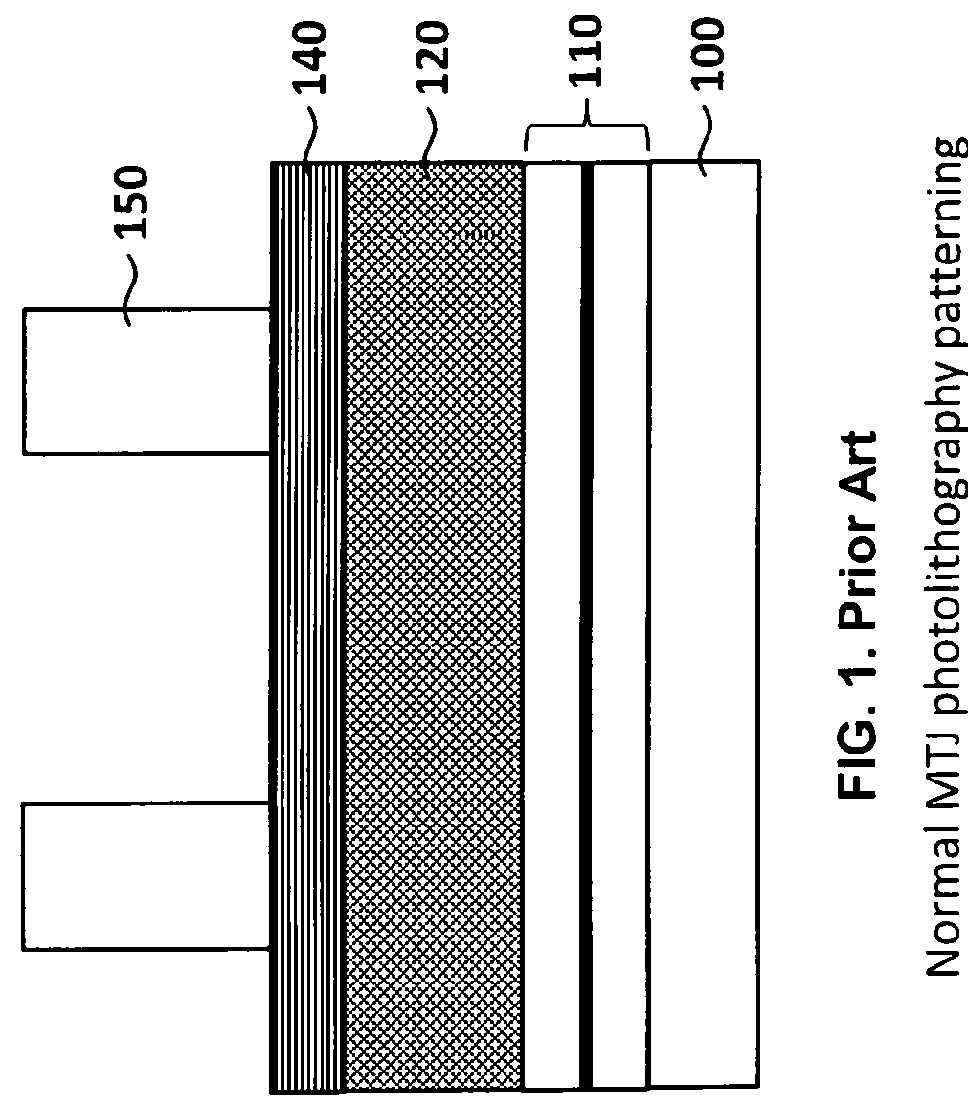

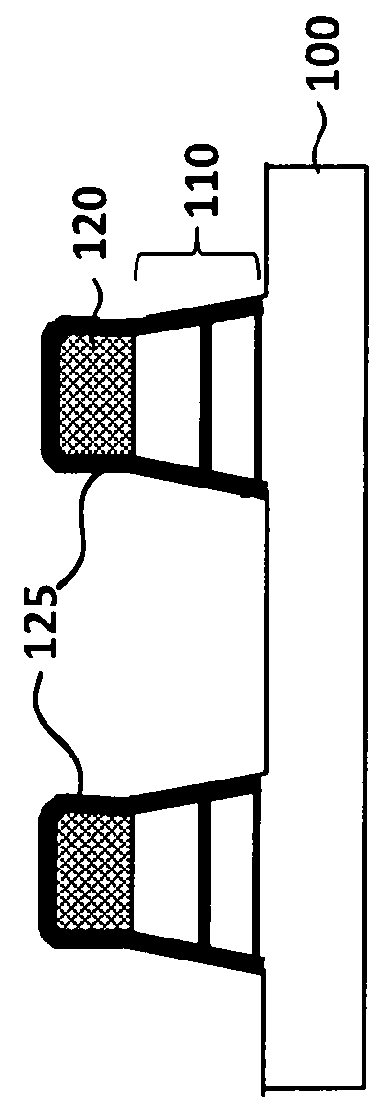

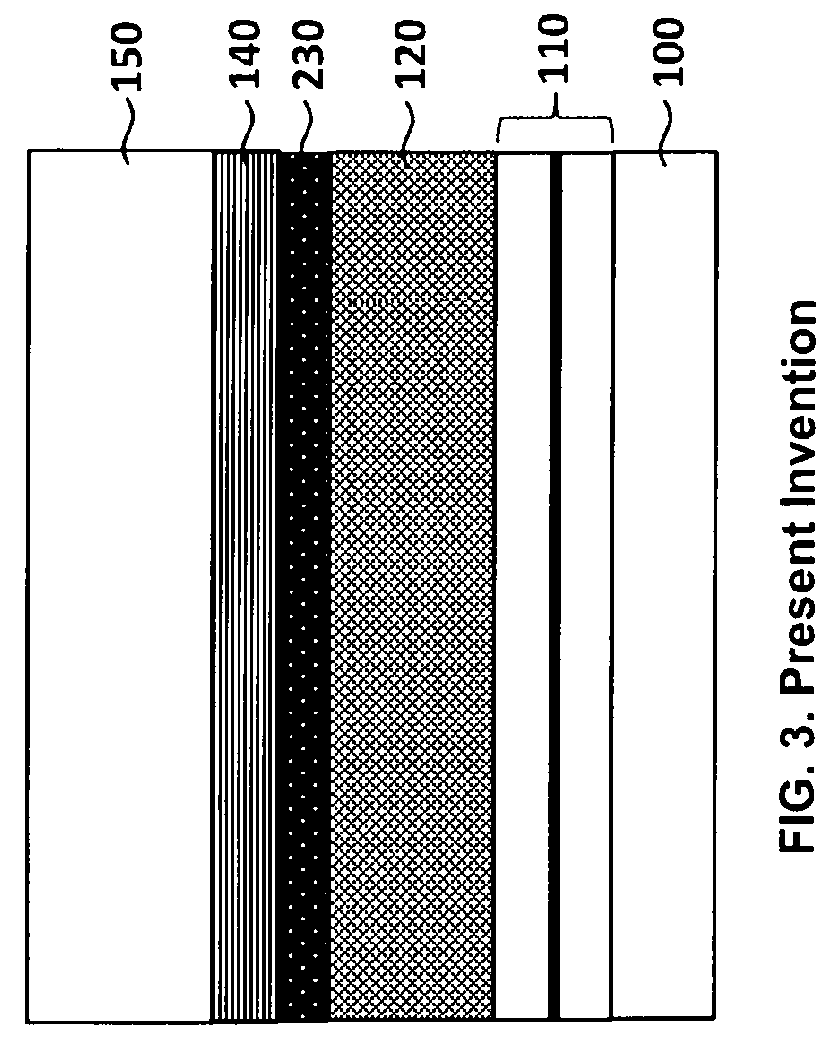

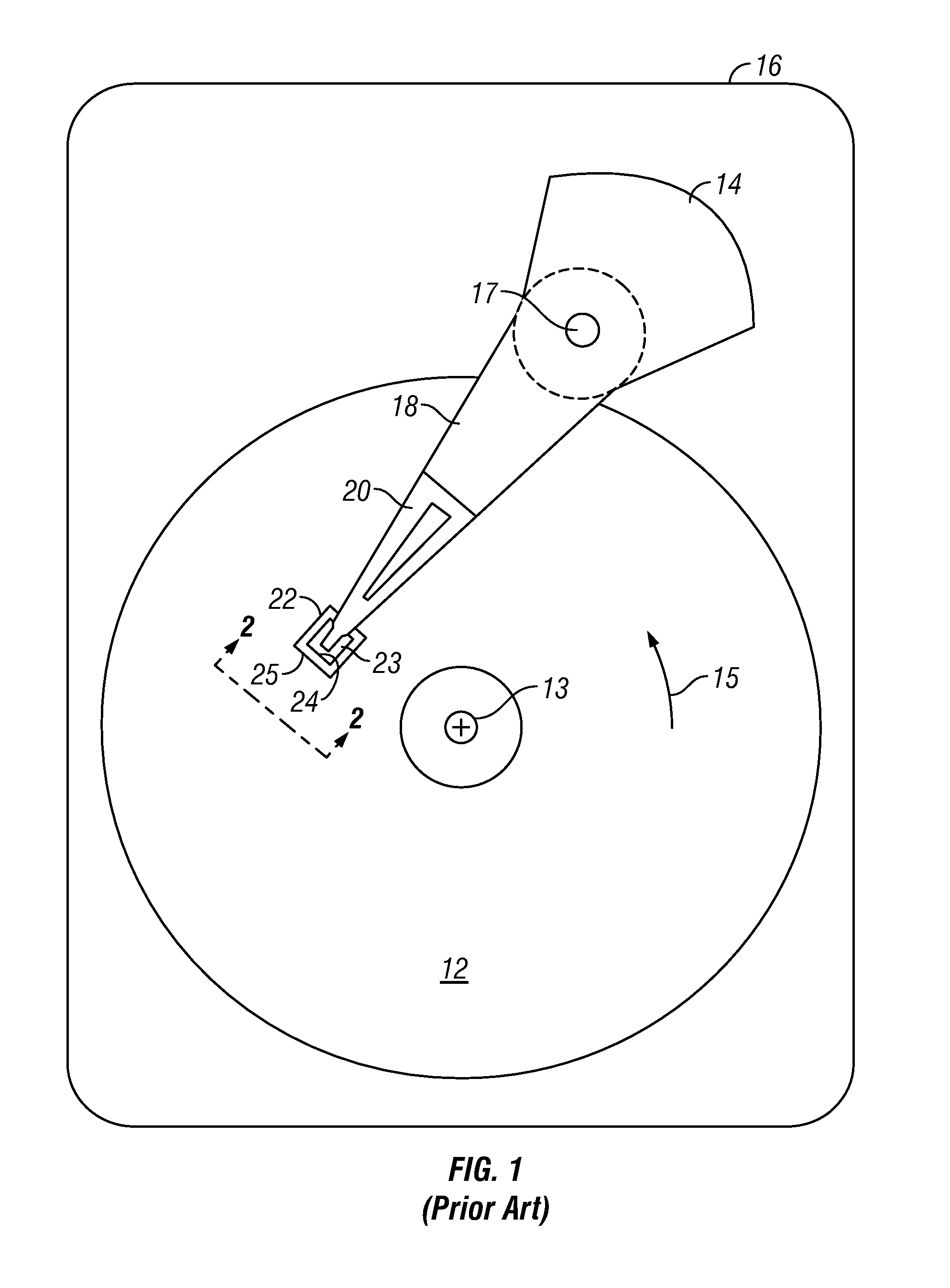

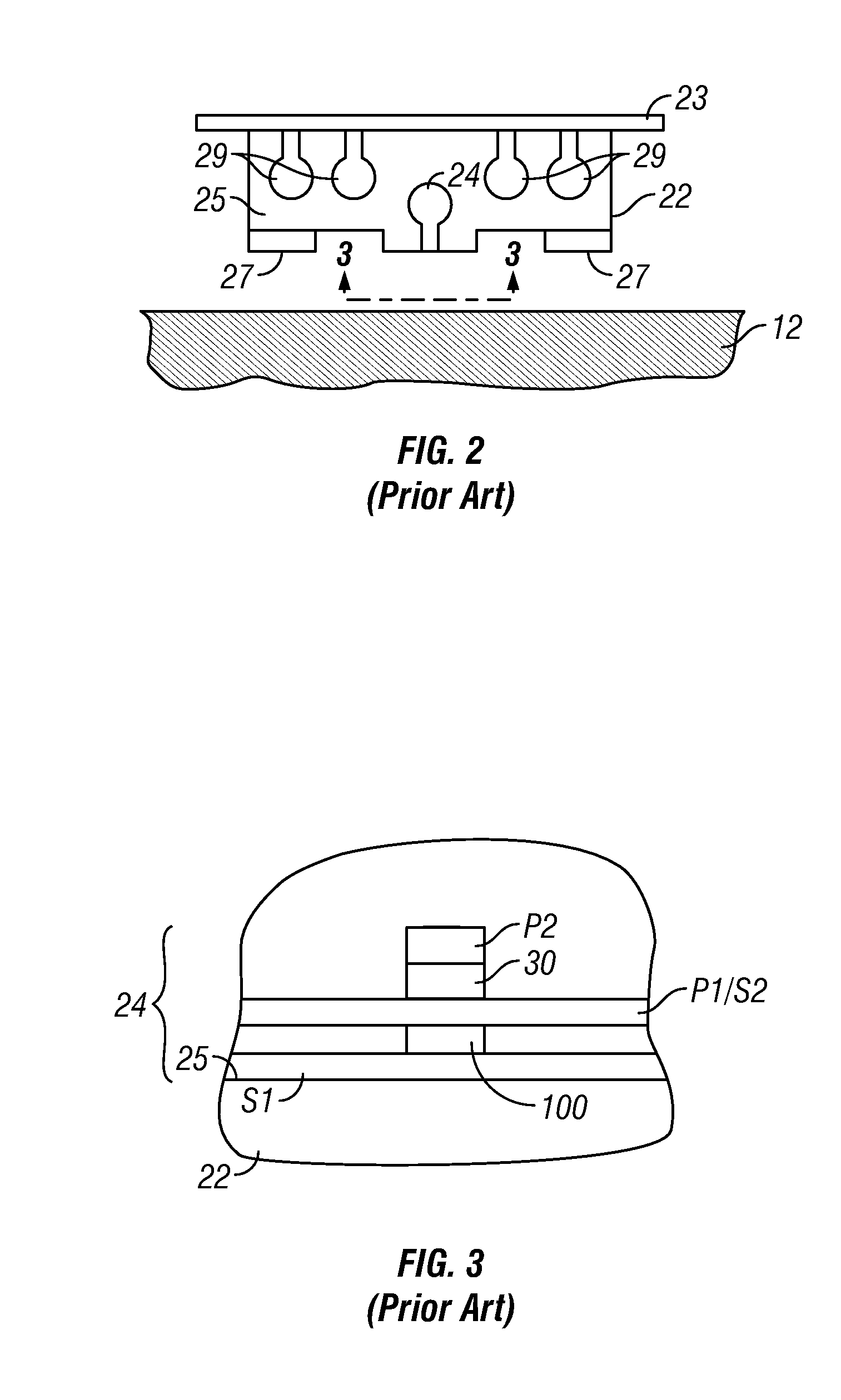

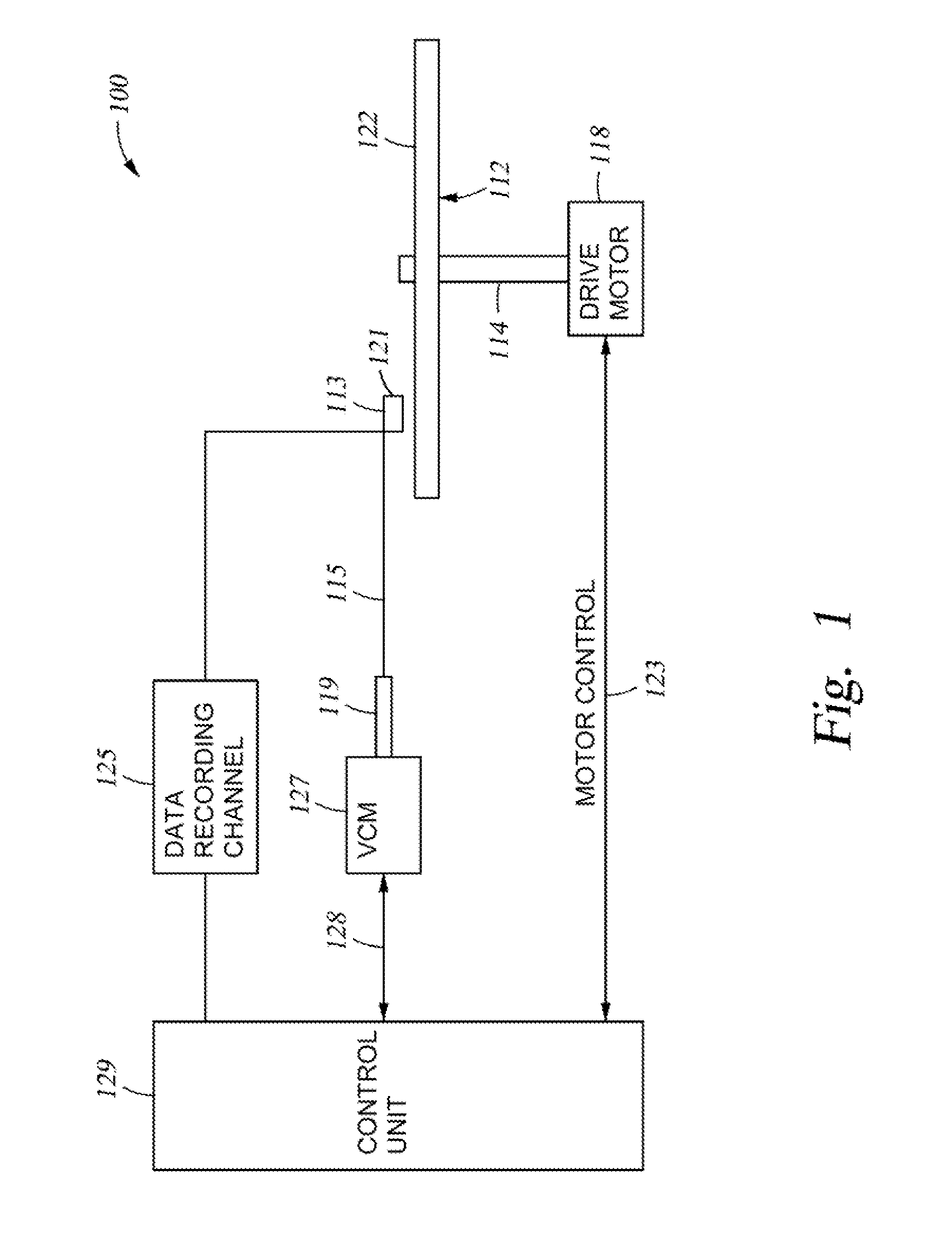

Method of patterning MTJ cell without sidewall damage

ActiveUS9362490B1Increased reluctanceImprove device performanceMagnetic-field-controlled resistorsGalvano-magnetic device detailsIonMagnetoresistance

A method of removing a damaged magnetic layer at the sidewall of MTJ edge is provided to form damage-free MRAM cell. In this method, the MTJ film stack outside the Ta hard mask protected area is first etched by high-power magnetic reactive ion etch (RIE) using methanol (CH3OH) or Co & NH3 as etchant gases. Then a very mild chemical vapor trimming (CVT) process is used to remove a damaged layer (by the high power RIE) from the MTJ sidewall followed by an in-situ edge passivation with Si nitride (SiN) layer formed by PECVD. The MRAM cell formed by such method will have higher magnetoresistance with good device performance and better reliability.

Owner:XIAO RONGFU

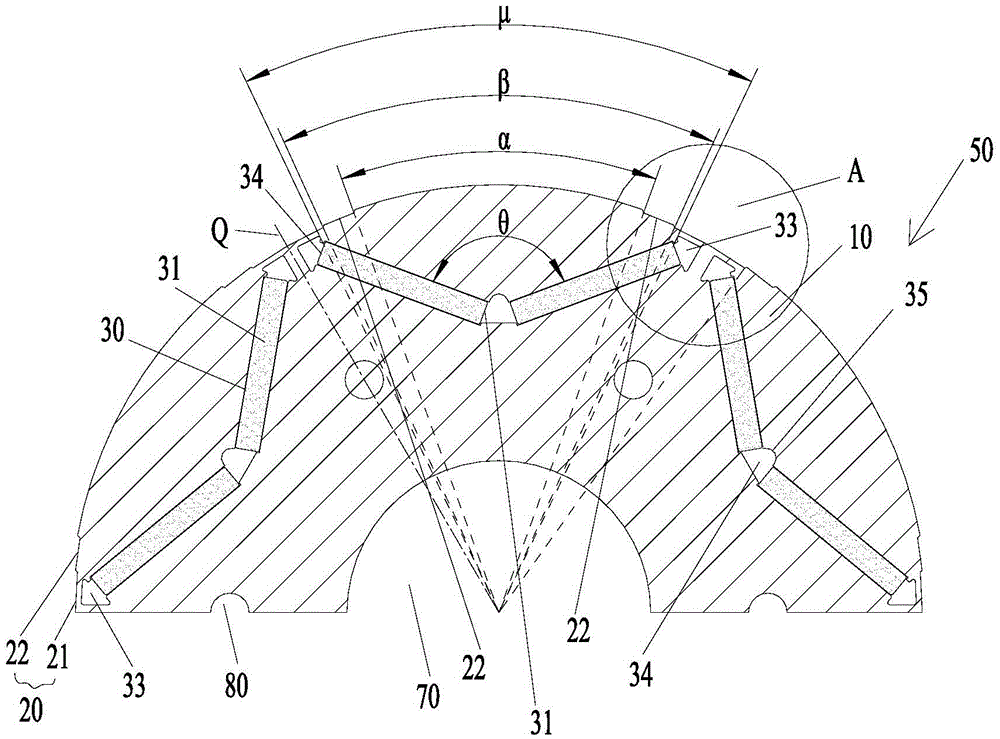

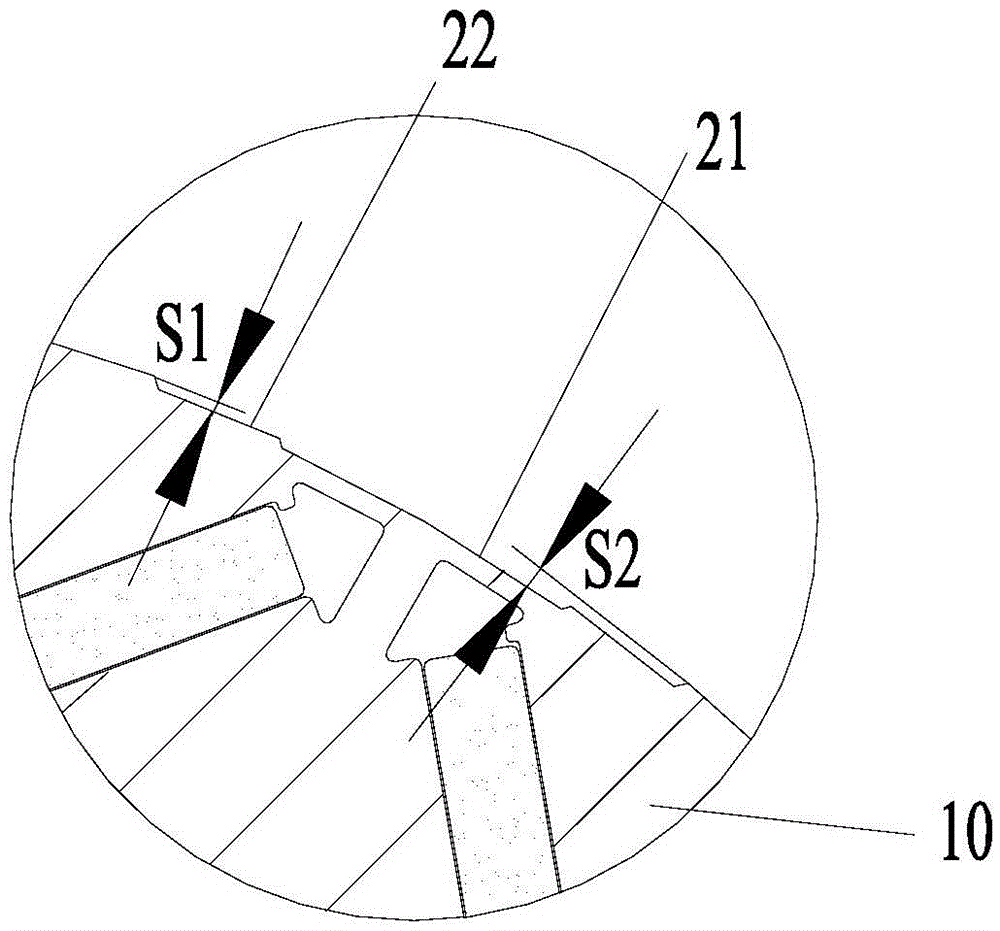

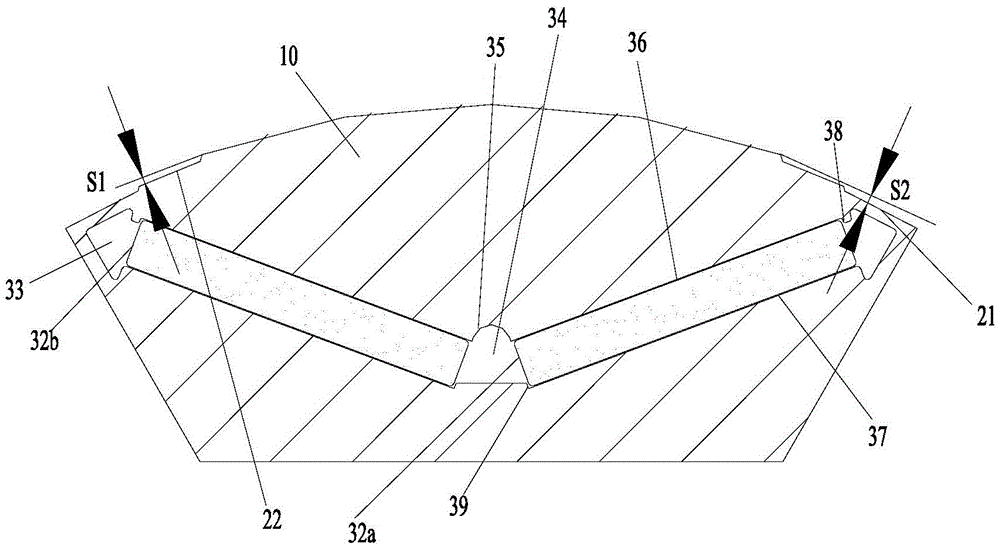

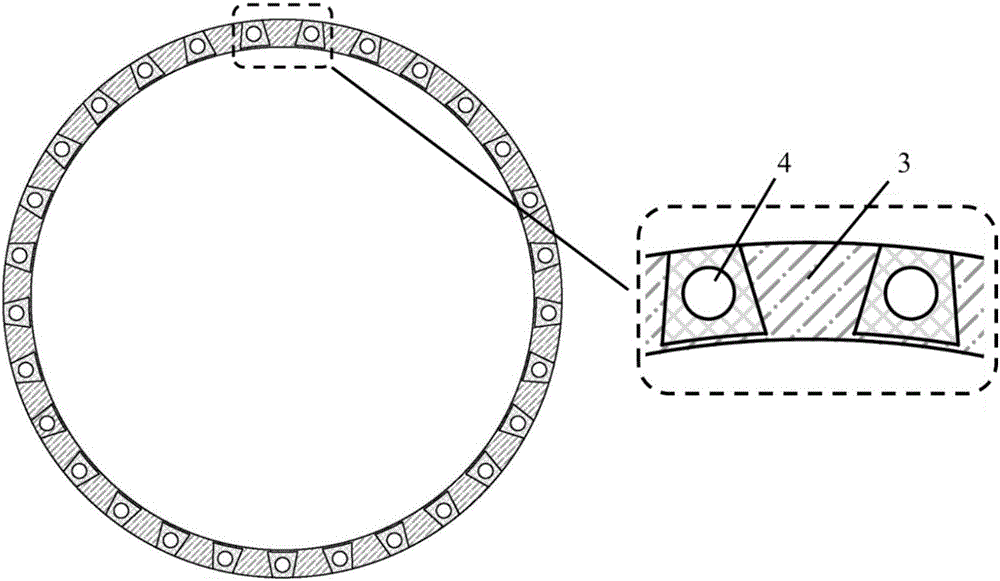

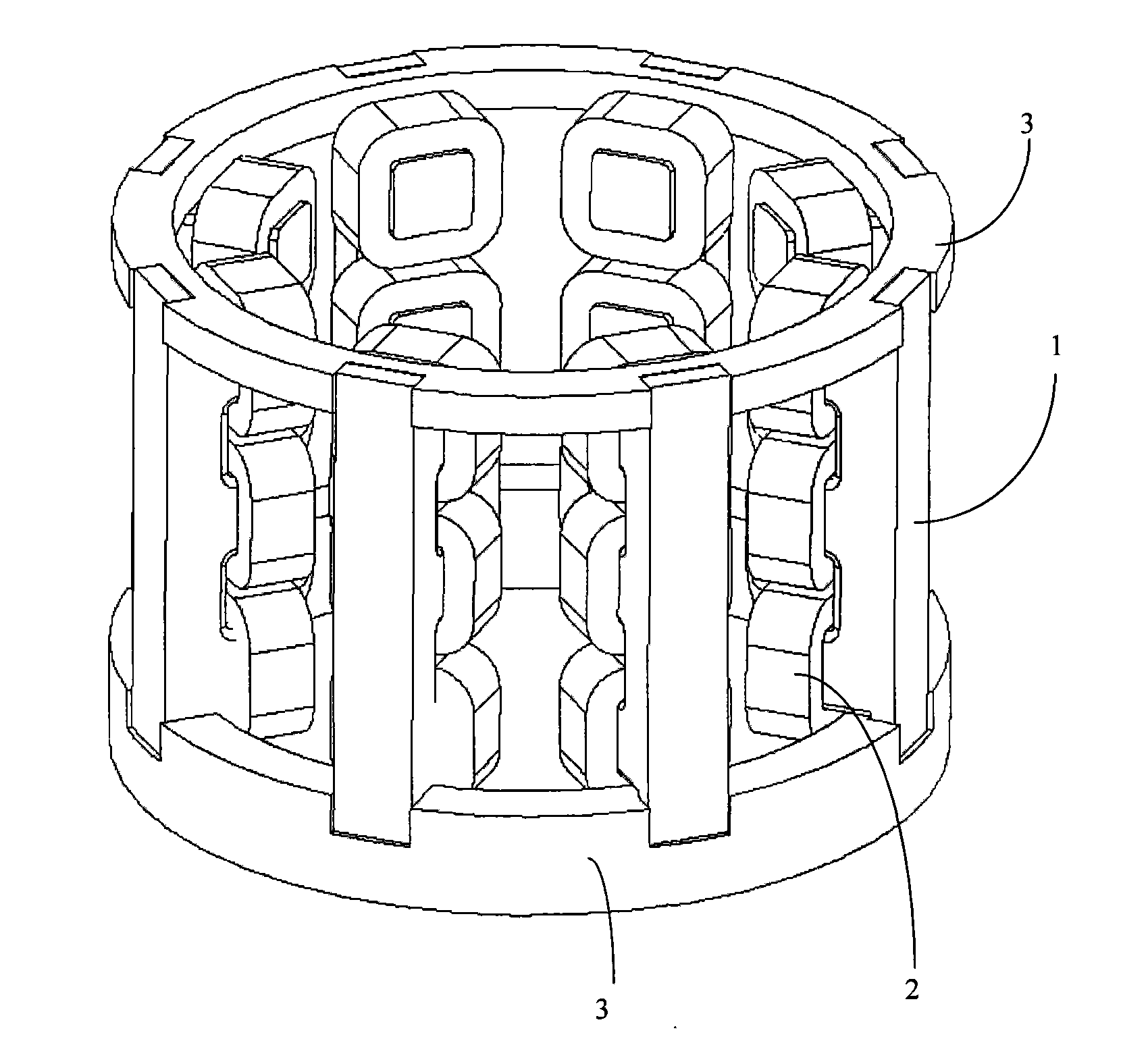

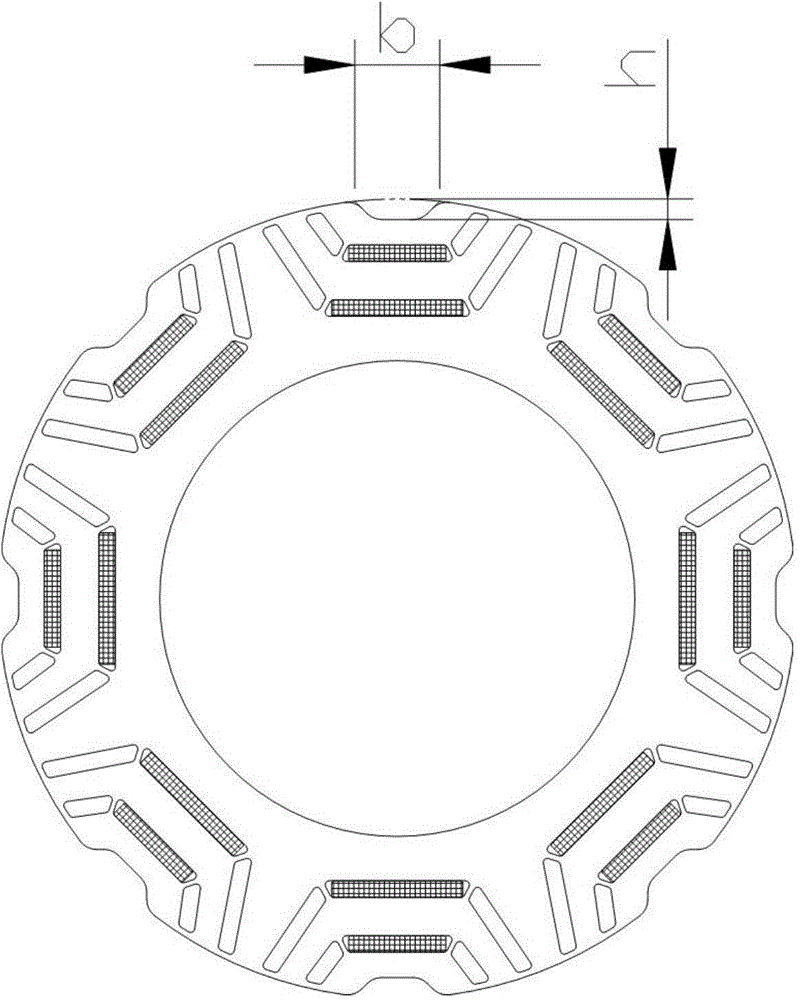

Rotor iron core and permanent magnet synchronous motor with same

ActiveCN105553143AGreat effortHarmonic reductionMagnetic circuit rotating partsSynchronous machinesHarmonicPermanent magnet synchronous motor

The invention provides a rotor iron core and a permanent magnet synchronous motor with the same. The rotor iron core comprises an iron core body, wherein grooves are formed on the peripheral wall of the iron core body in an axial direction of the iron core body; the grooves comprise a first groove and a second groove which are communicated mutually; and a depth of the first groove in a radial direction of the iron core body is greater than that of the second groove in the radial direction of the iron core body. At the position of the first groove, an air gap is the largest, magnetic resistance is high, an air gap flux density is small, and an applied moment fluctuation with a stator tooth socket is reduced; the first groove and the second groove have different depths; by transition of the second groove, a fundamental wave magnetic field is increased and is closer to sine; a torque of the tooth socket is reduced, so that a motor output is increased, a harmonic wave is reduced, and an electromagnetic force and operation vibration voice of the motor are reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

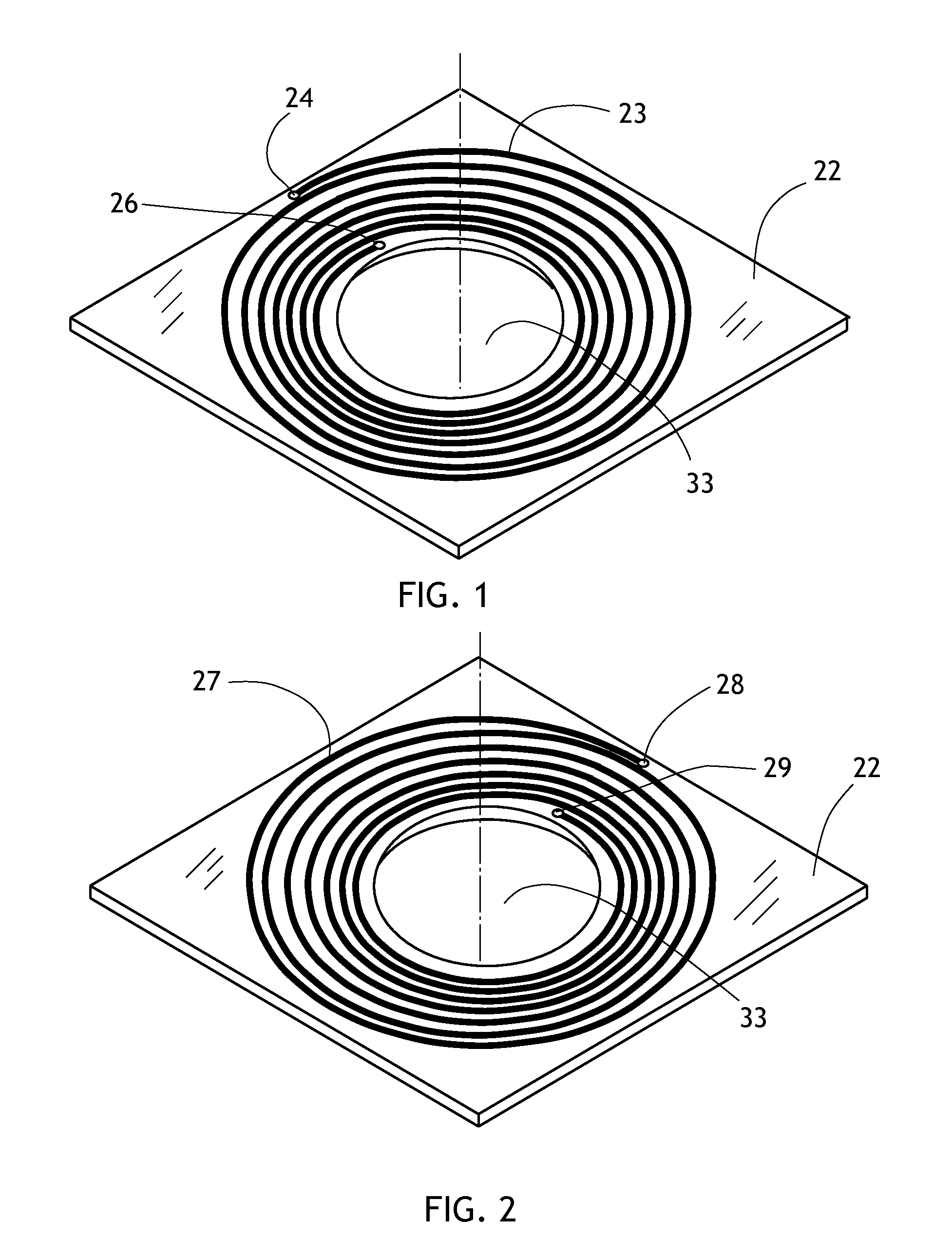

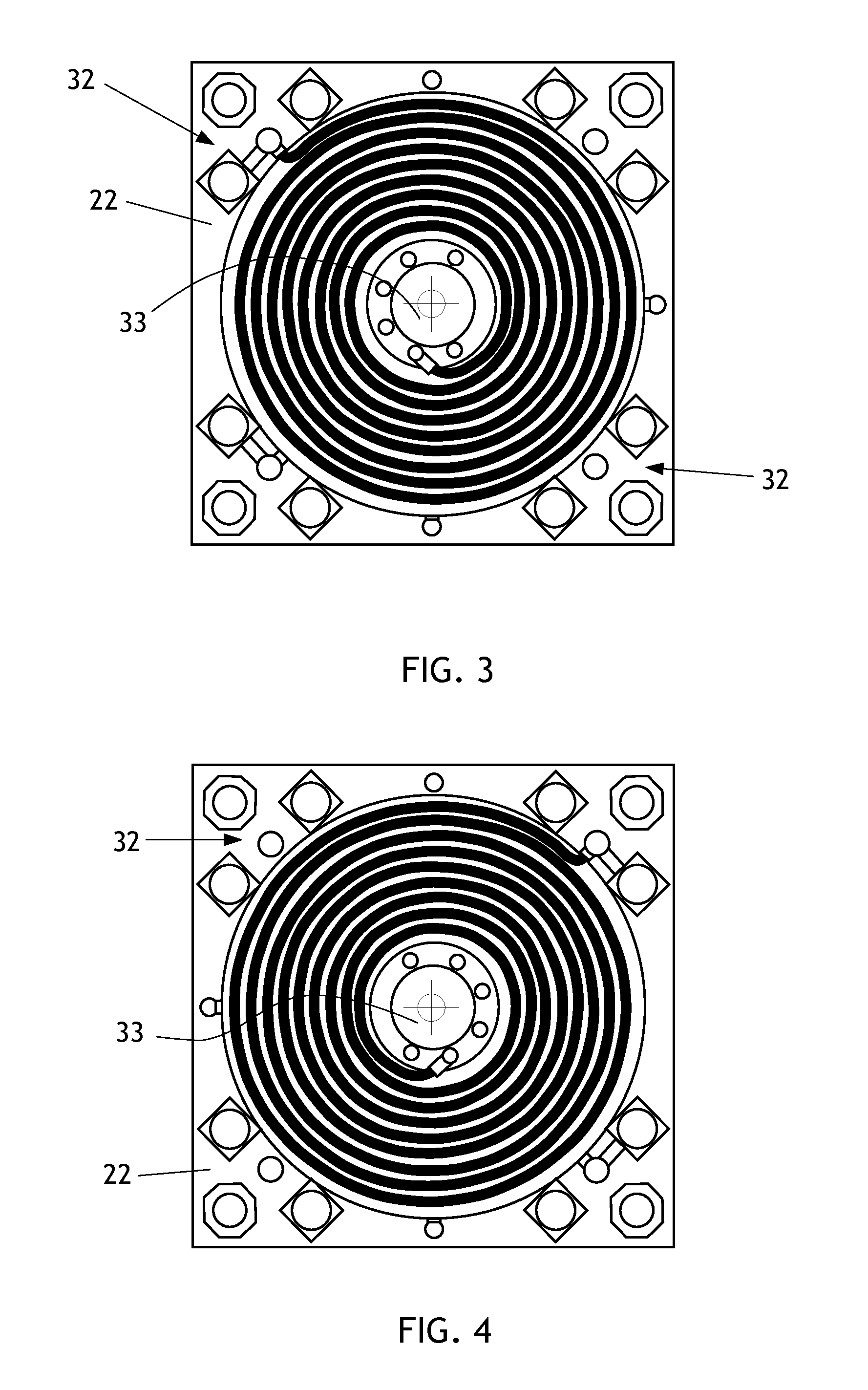

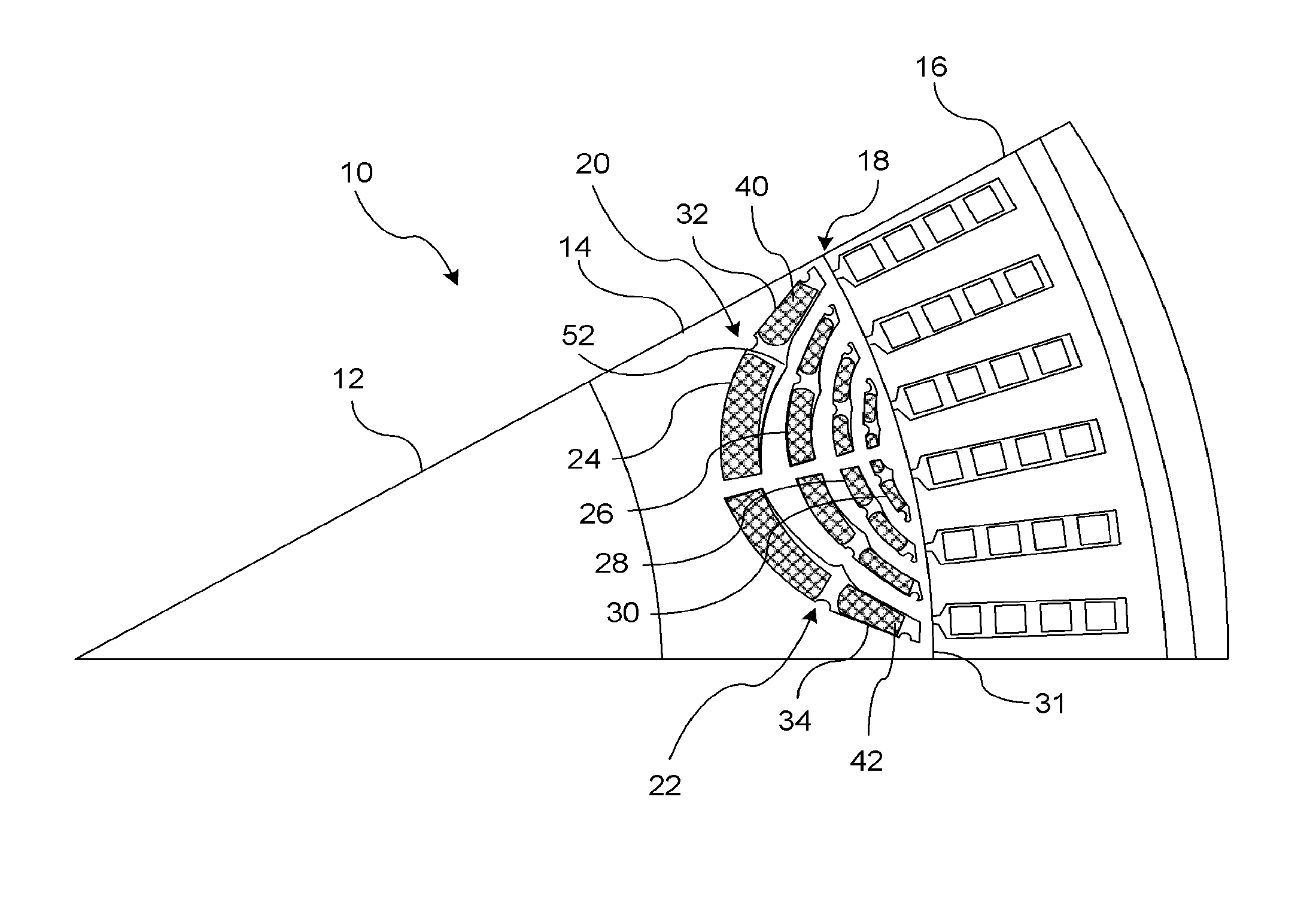

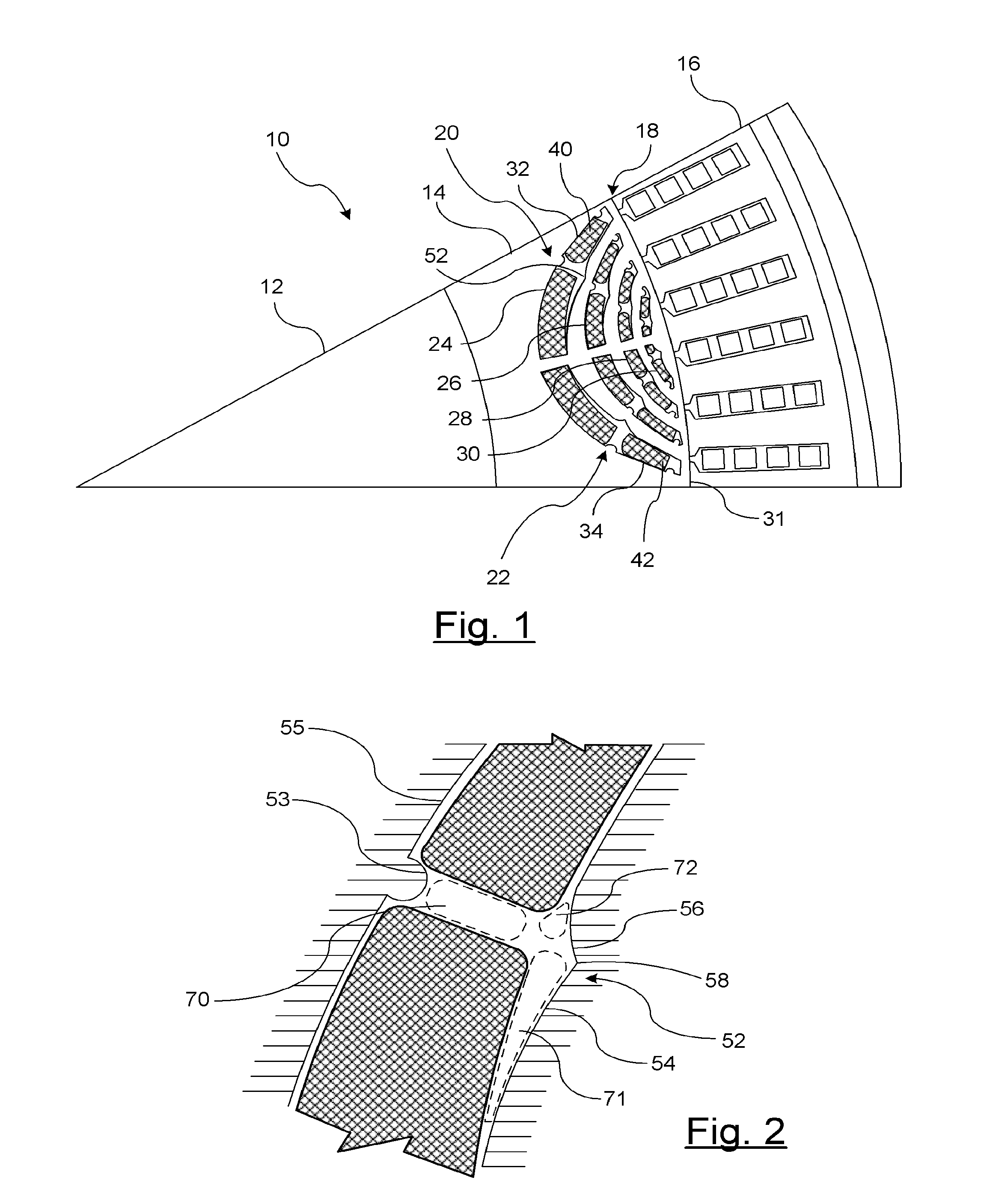

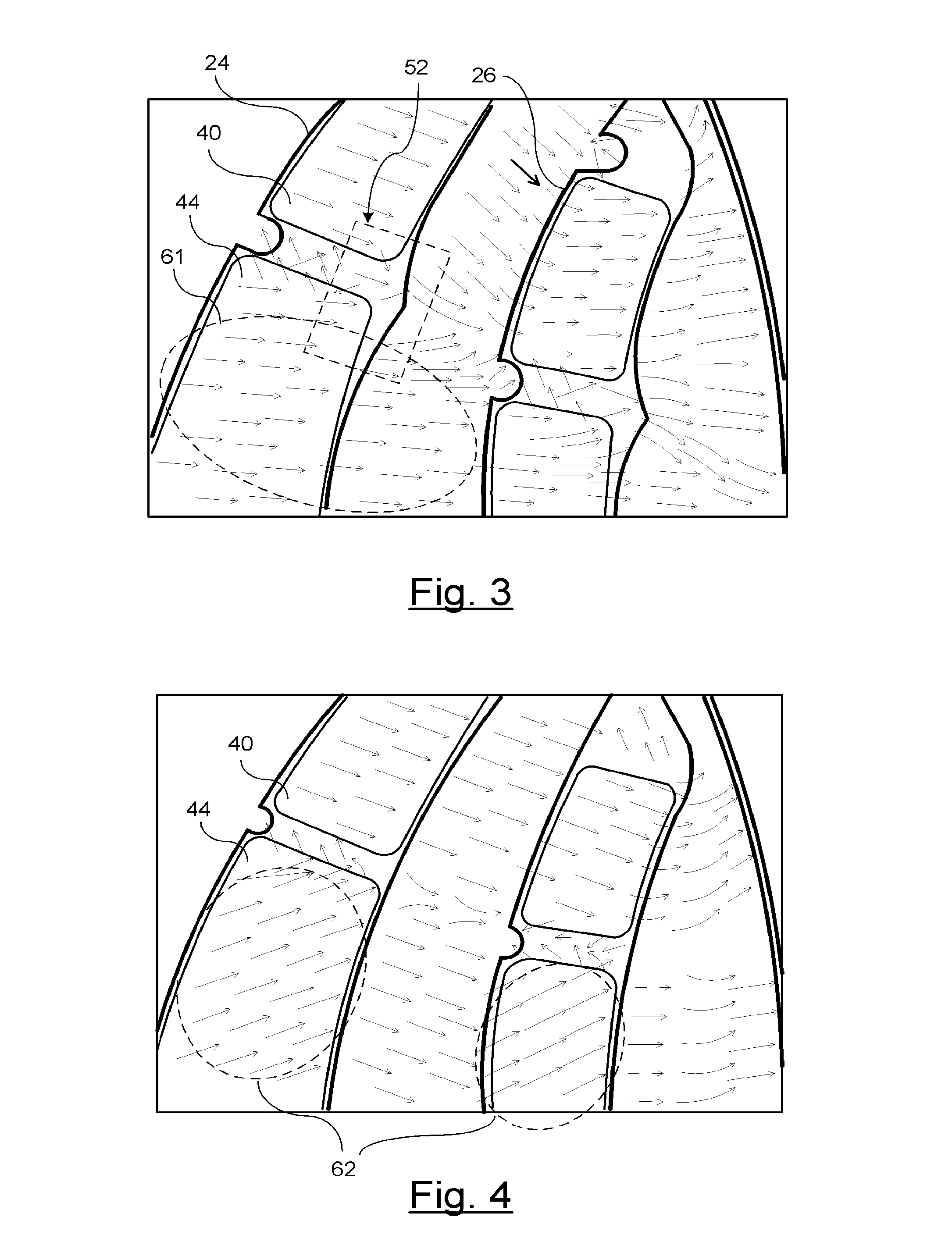

Magnetic barrier for minimizing demagnetization in bi-permanent magnet synchronous machines

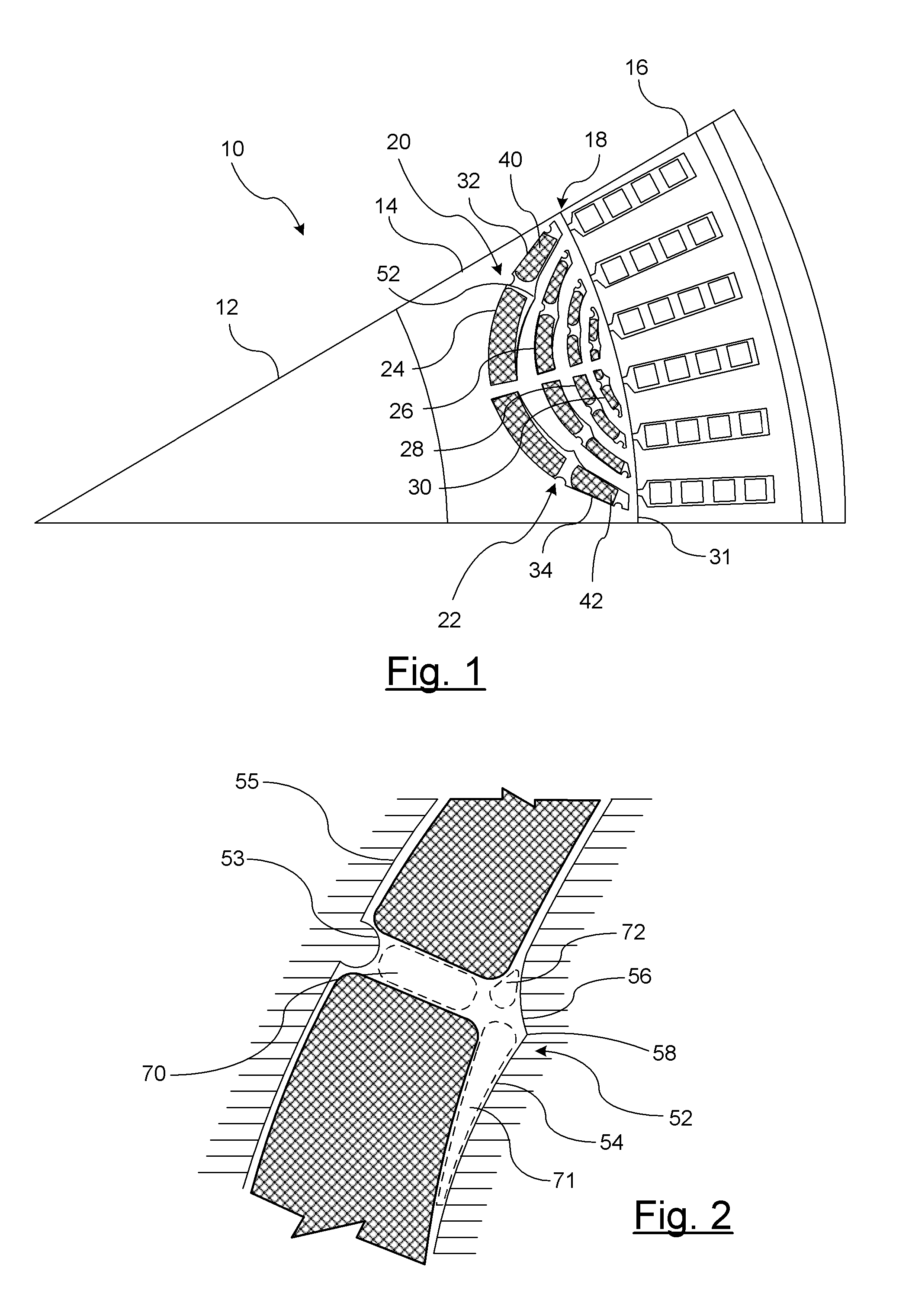

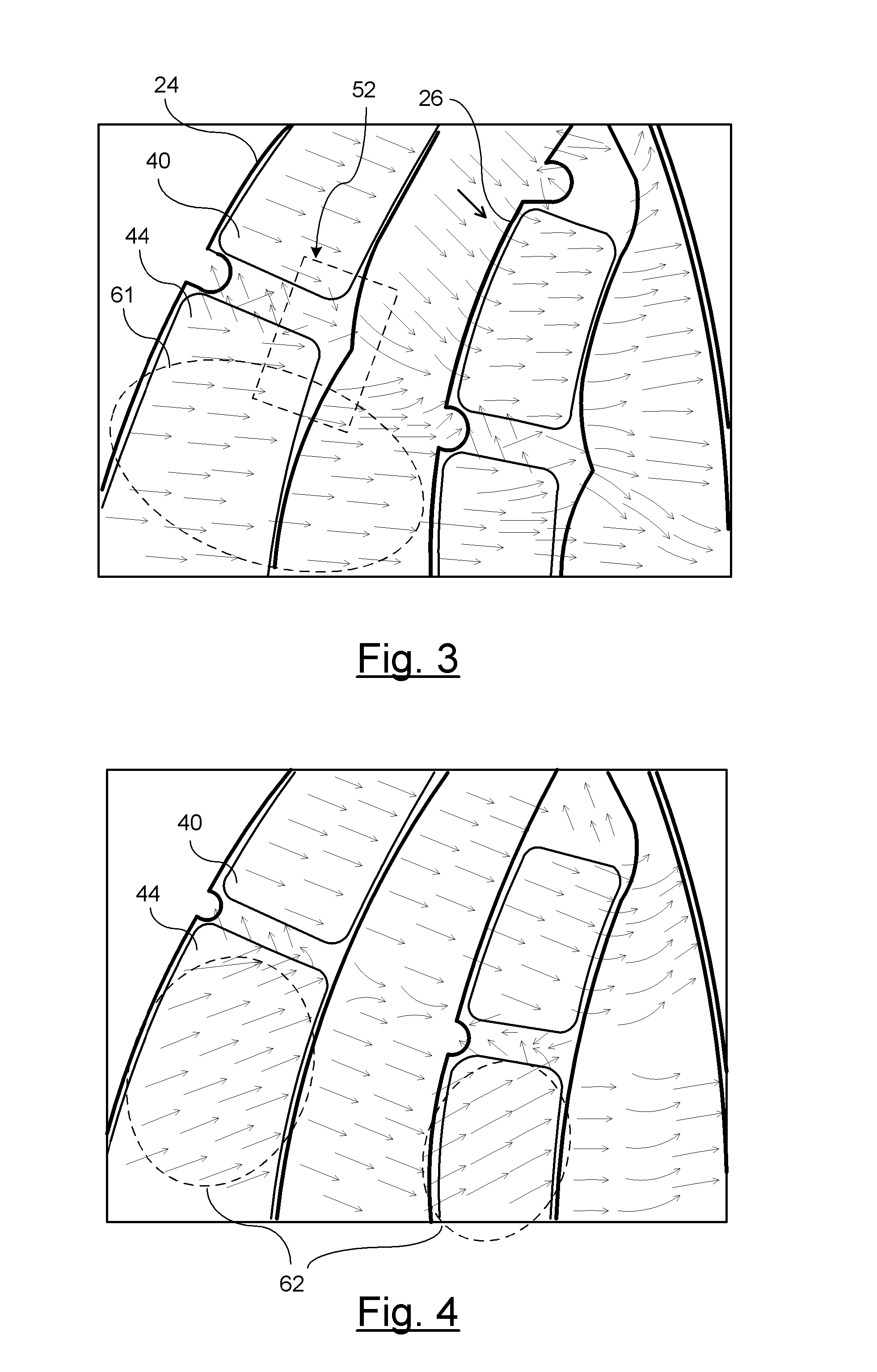

ActiveUS20130320797A1Low costReduce in quantityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic barrierPermanent magnet synchronous machine

A rotor for a permanent synchronous machine includes a rotor having a plurality of arcuately-shaped cavities formed within a rotor core structure. The plurality of arcuately-shaped cavities substantially concentrically layered with respect to an outer cylindrical wall of the rotor core structure. A plurality of permanent magnets is inserted within the plurality of arcuately-shaped cavities. Each cavity layer retains a permanent magnet of a first magnetic field strength disposed in end sections and a permanent magnet of a second magnetic field strength in a center section of each cavity layer. Each respective cavity includes an air barrier formed between the magnets having different magnetic field strengths. The air barrier generates a reluctance within an air barrier gap for directing a flow of flux generated by each third permanent magnet in a preceding layer in a direction toward each third permanent magnet in a succeeding layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

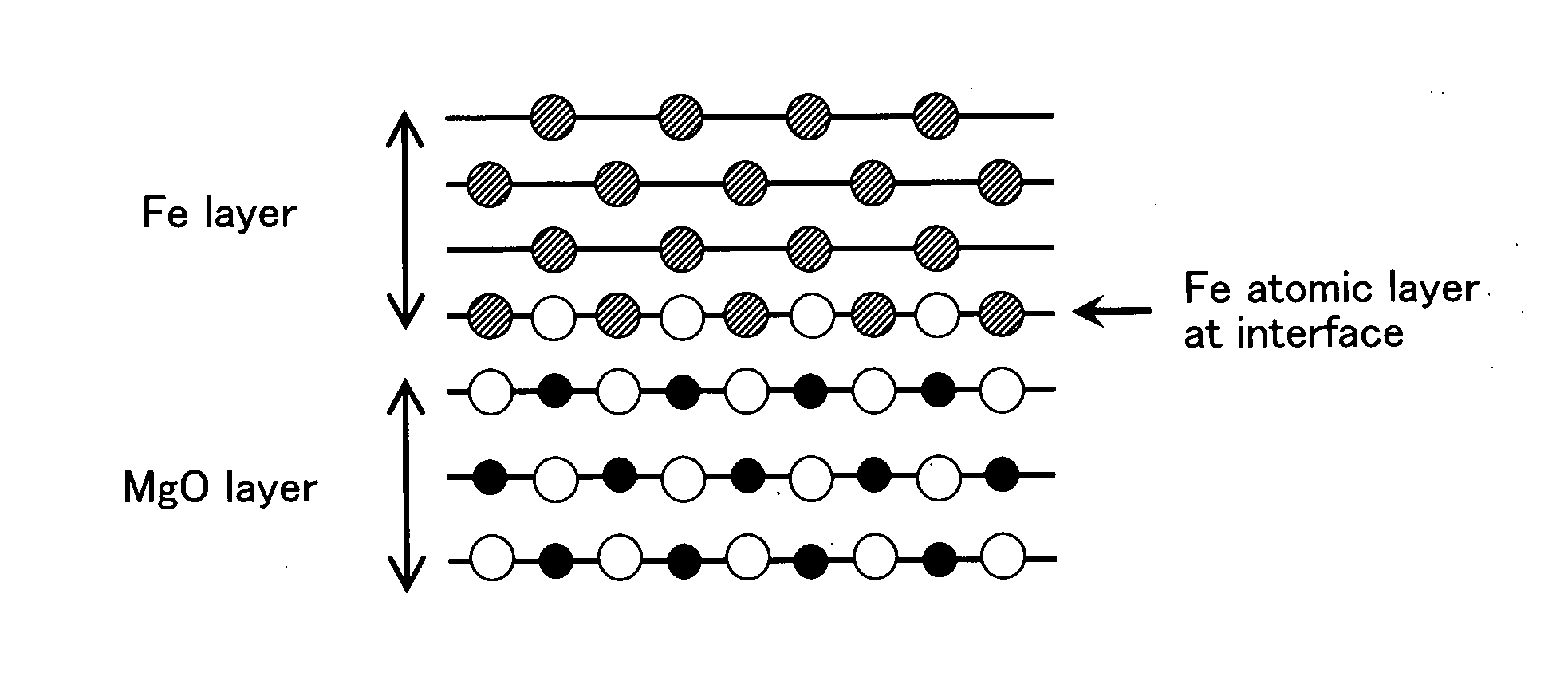

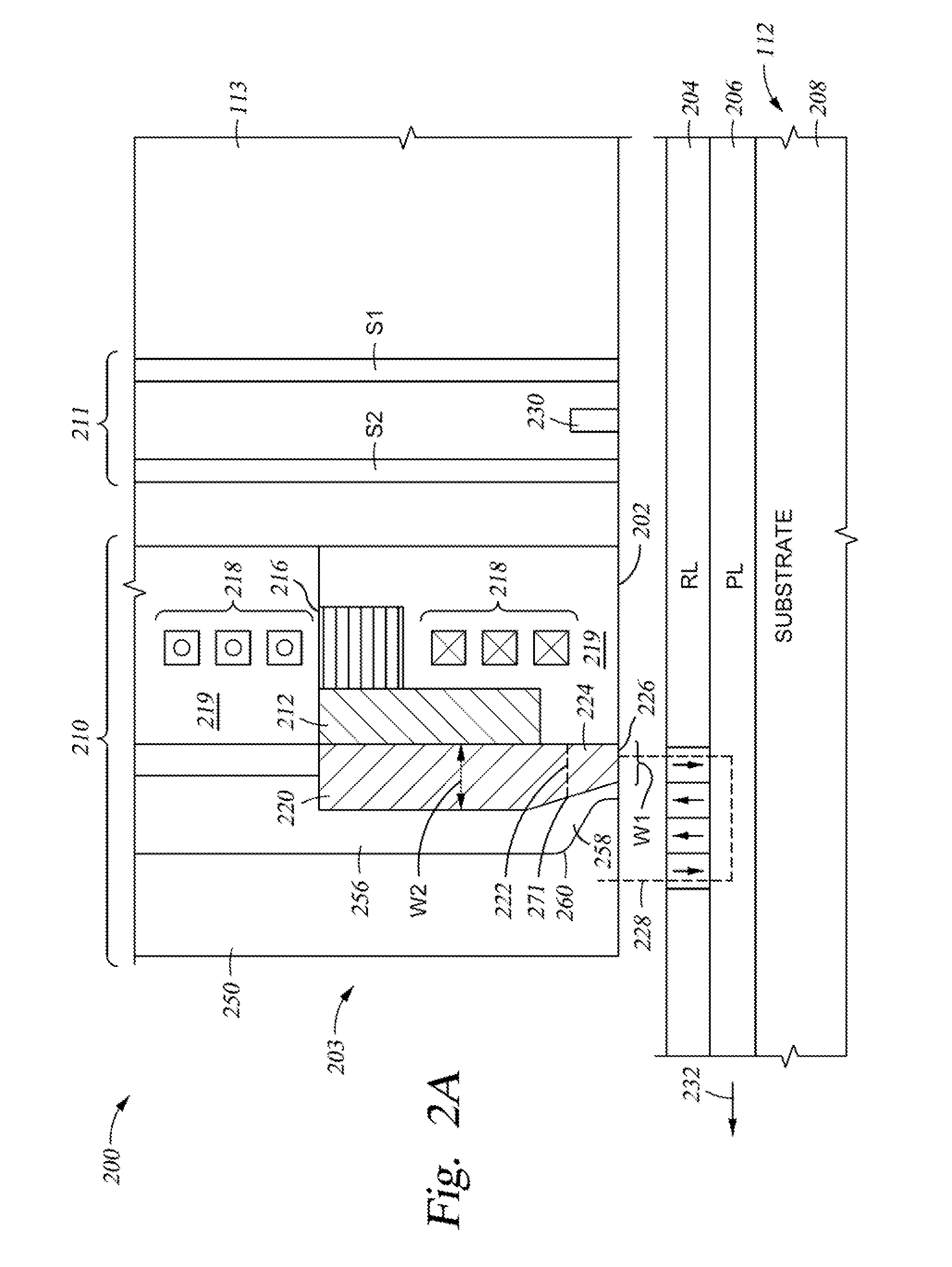

Magnetic Tunnel Junction Device and Method of Manufacturing the Same

InactiveUS20070258170A1Increases tunneling probabilityIncreased reluctanceMagnetic-field-controlled resistorsSolid-state devicesMagnetizationRoom temperature

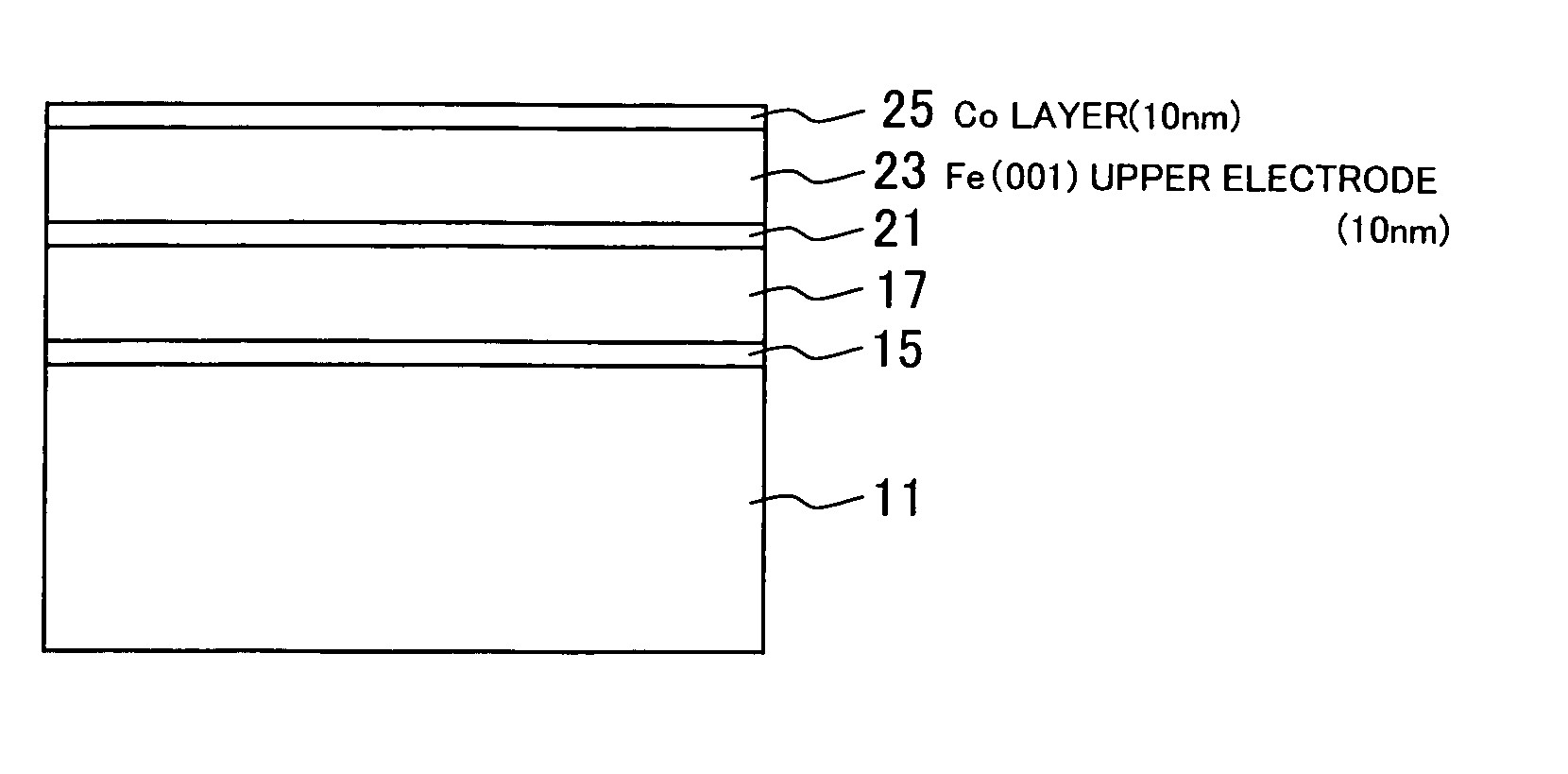

A single-crystalline MgO (001) substrate 11 is prepared, and then an epitaxial Fe (001) lower electrode (first electrode) 17 with a thickness of 50 nm is grown on a MgO (001) seed layer 15 at room temperature. Annealing is then performed in ultrahigh vacuum (2×10−8 Pa) at 350° C. A 2-nm thick MgO (001) barrier layer 21 is epitaxially grown on the Fe (001) lower electrode (first electrode) 17 at room temperature, using electron beam evaporation of MgO. A Fe (001) upper electrode (second electrode) 23 with a thickness of 10 nm is then grown on the MgO (001) barrier layer 21 at room temperature, successively followed by the deposition of a IrMn layer 25 with a thickness of 10 nm on the Fe (001) upper electrode (second electrode) 23. The IrMn layer 25 is used for realizing an antiparallel magnetization alignment by giving an exchange-biasing field to the upper electrode 23. Thereafter, the above-prepared sample is subjected to microfabrication so as to obtain a Fe (001) / MgO (001) / Fe (001) MTJ device with an enhanced MR ratio.

Owner:JAPAN SCI & TECH CORP +1

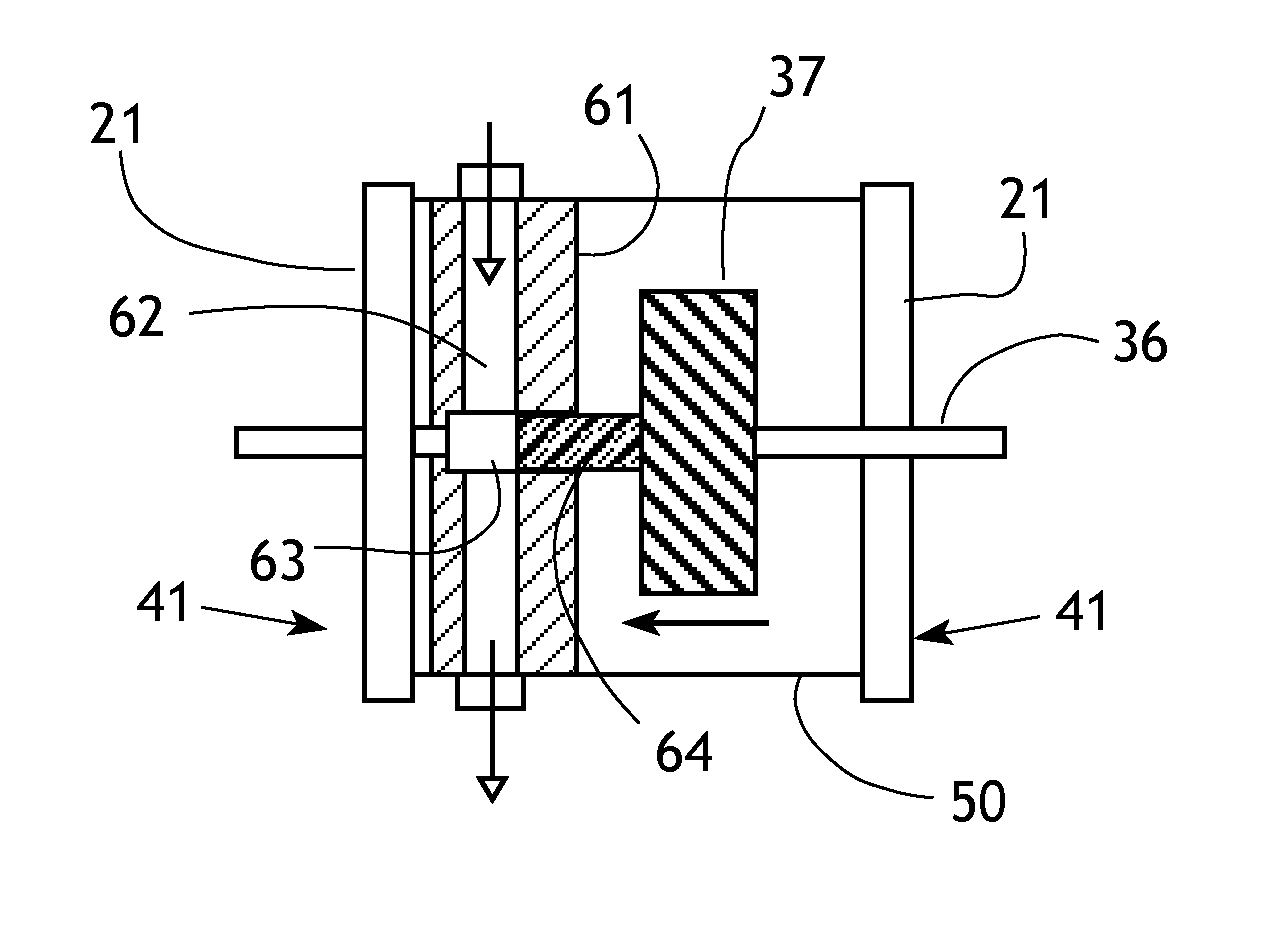

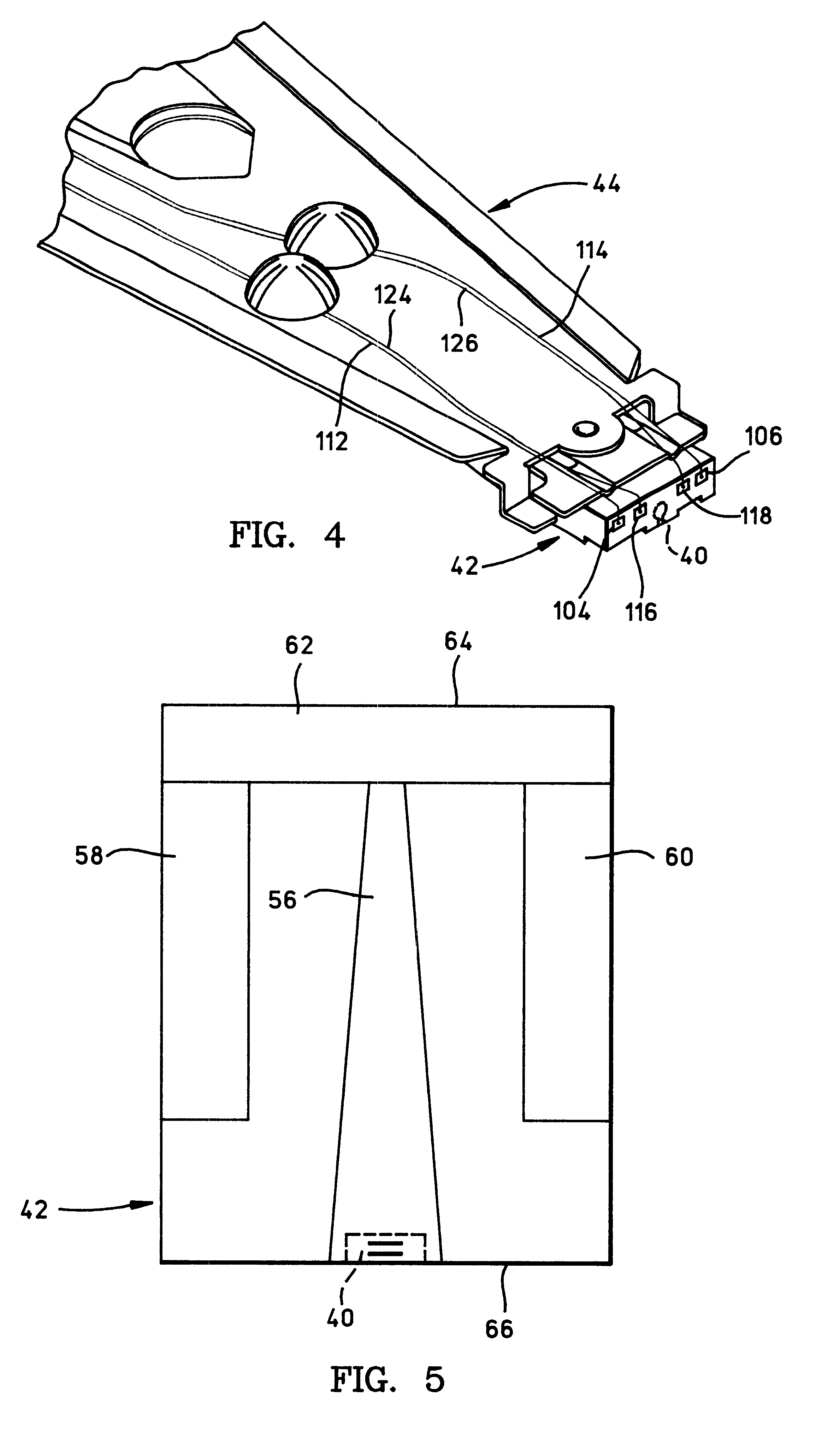

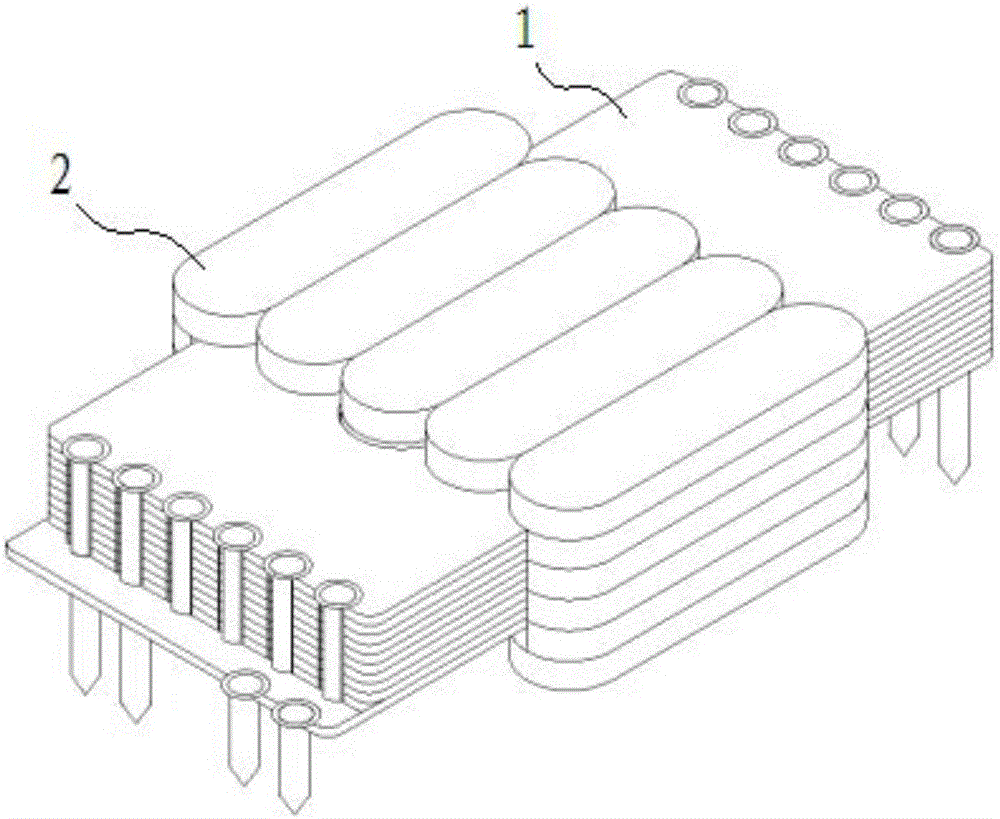

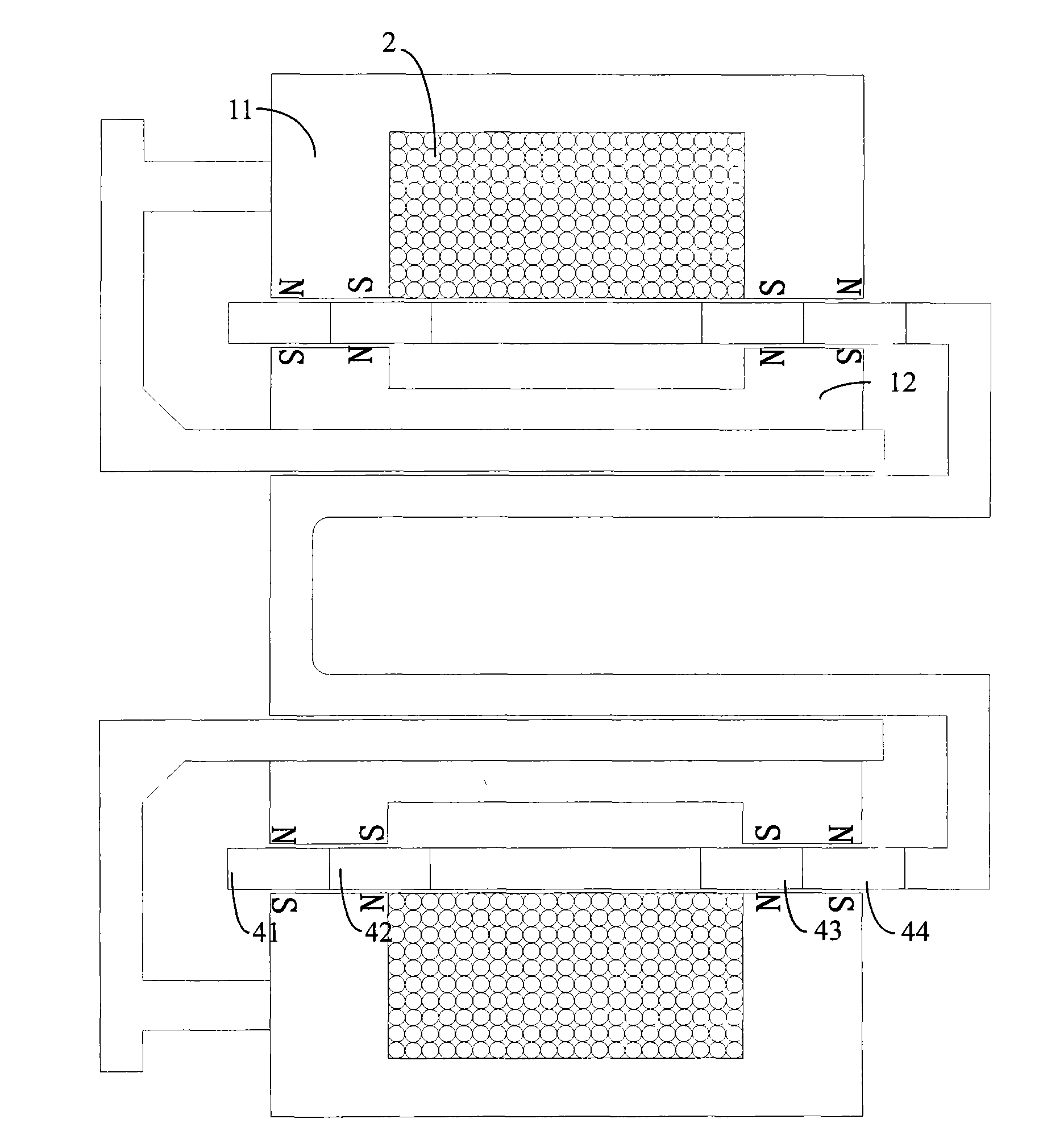

Solenoid actuators using embedded printed circuit coils

InactiveUS20130236337A1Inexpensive to manufactureEasy to assembleOperating means/releasing devices for valvesFlexible member pumpsElectromagnetMagnetic field

A magnetomotive device has an embedded electromagnetic coil formed of multiple printed conductor segments on multiple lamina of a multilayer PCB. A shaft extends through an opening in the PCB, and a permanent magnet with axially opposed poles is secured to the shaft. Energizing the embedded electromagnet generates a magnetic field that attracts or repels the permanent magnet, driving the shaft to do useful work. A pair of embedded PCB coils may be employed, the shaft extending through both coils with the permanent magnet disposed therebetween, and the coils energized so that one repels the permanent magnet while the other attracts it, and the shaft may be driven reversibly to do useful work.

Owner:GUMMIN MARK A +2

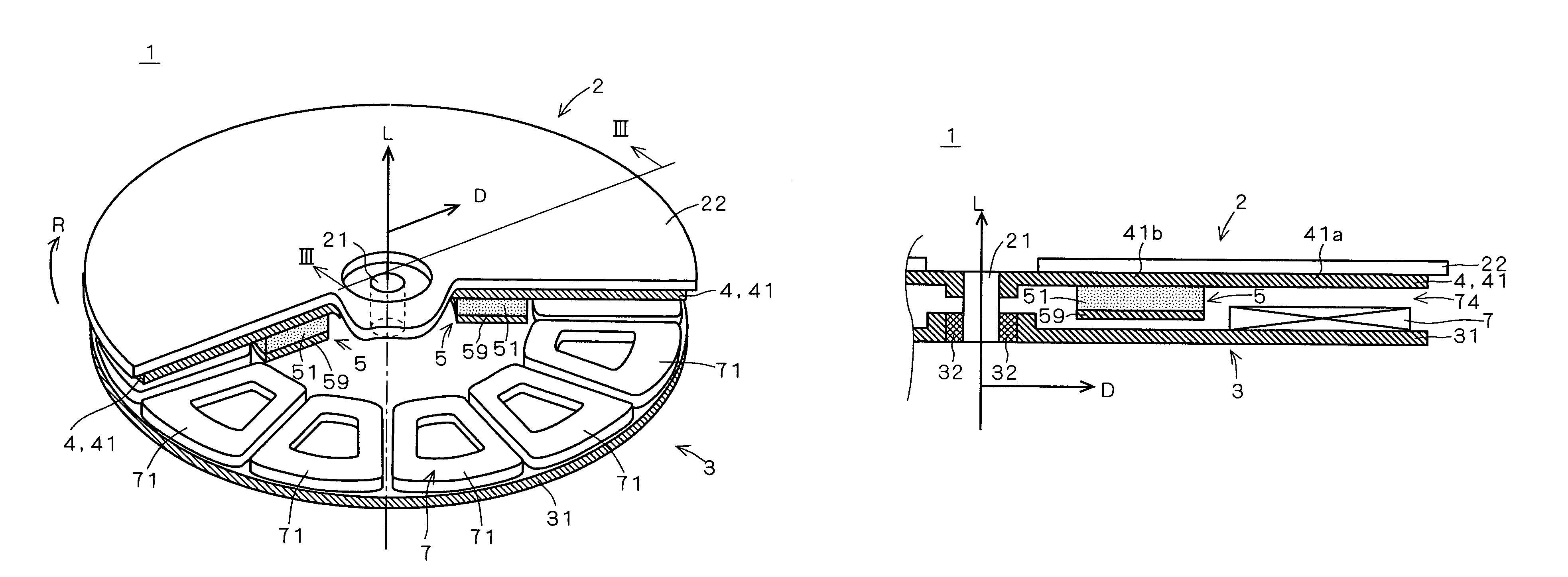

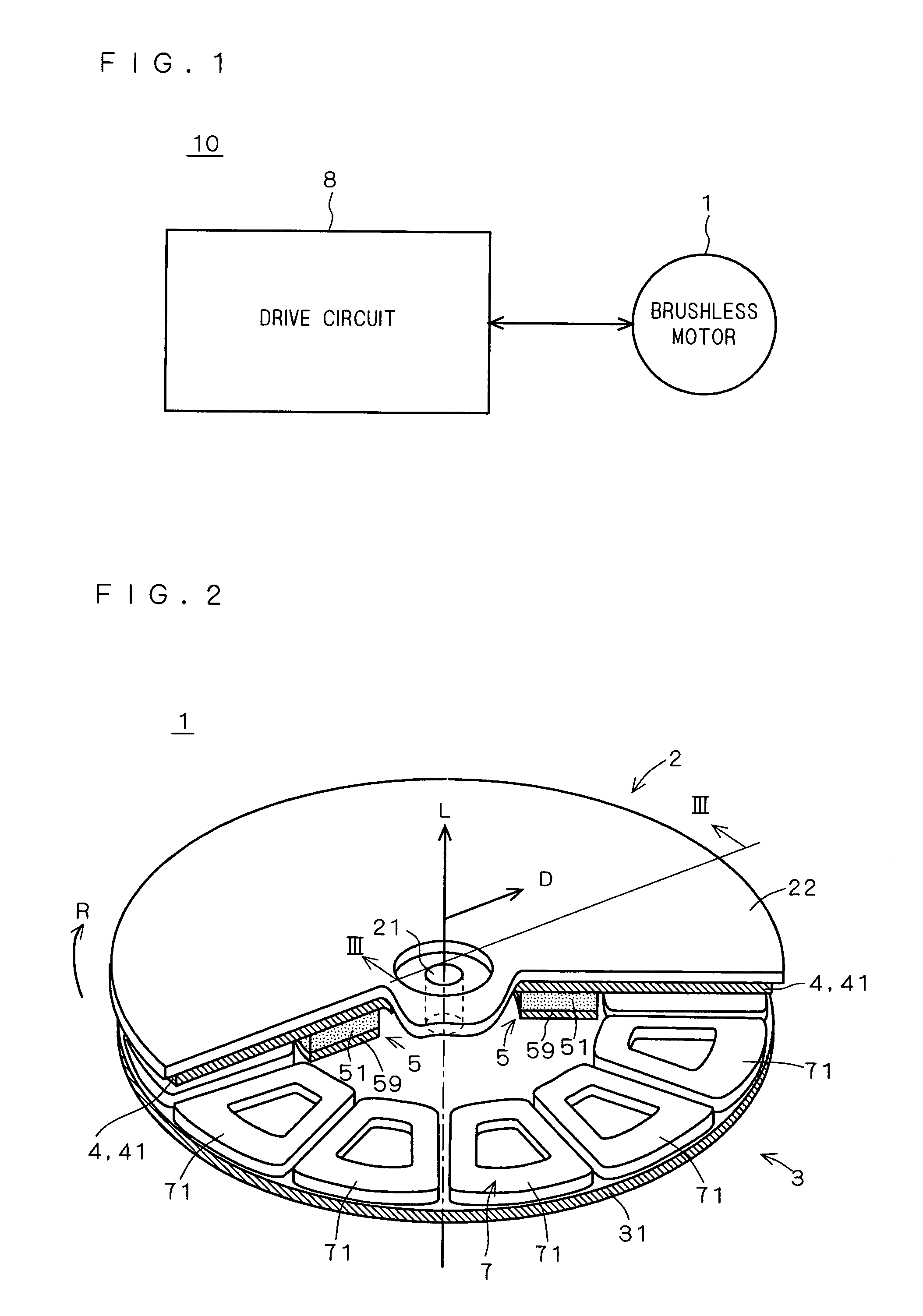

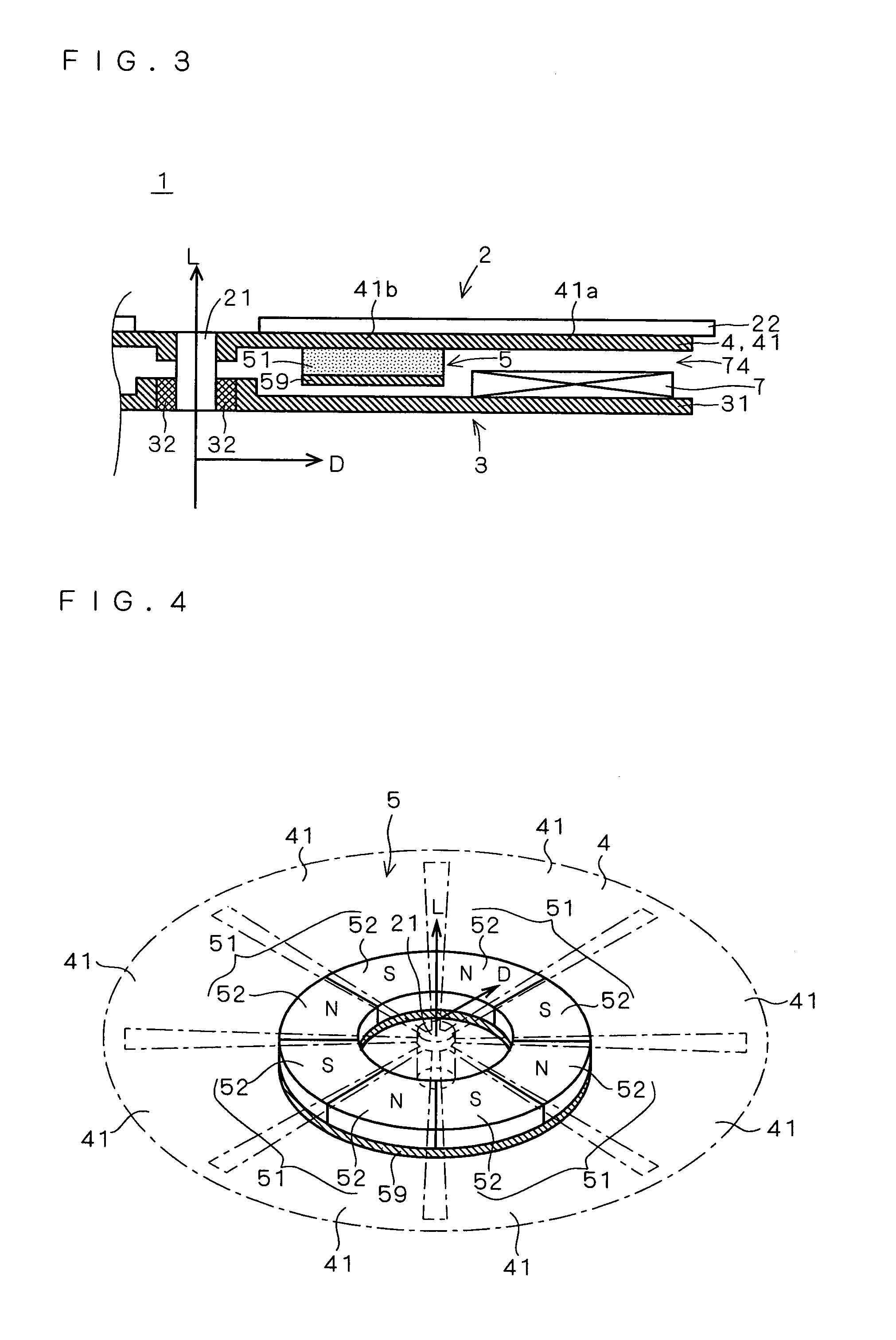

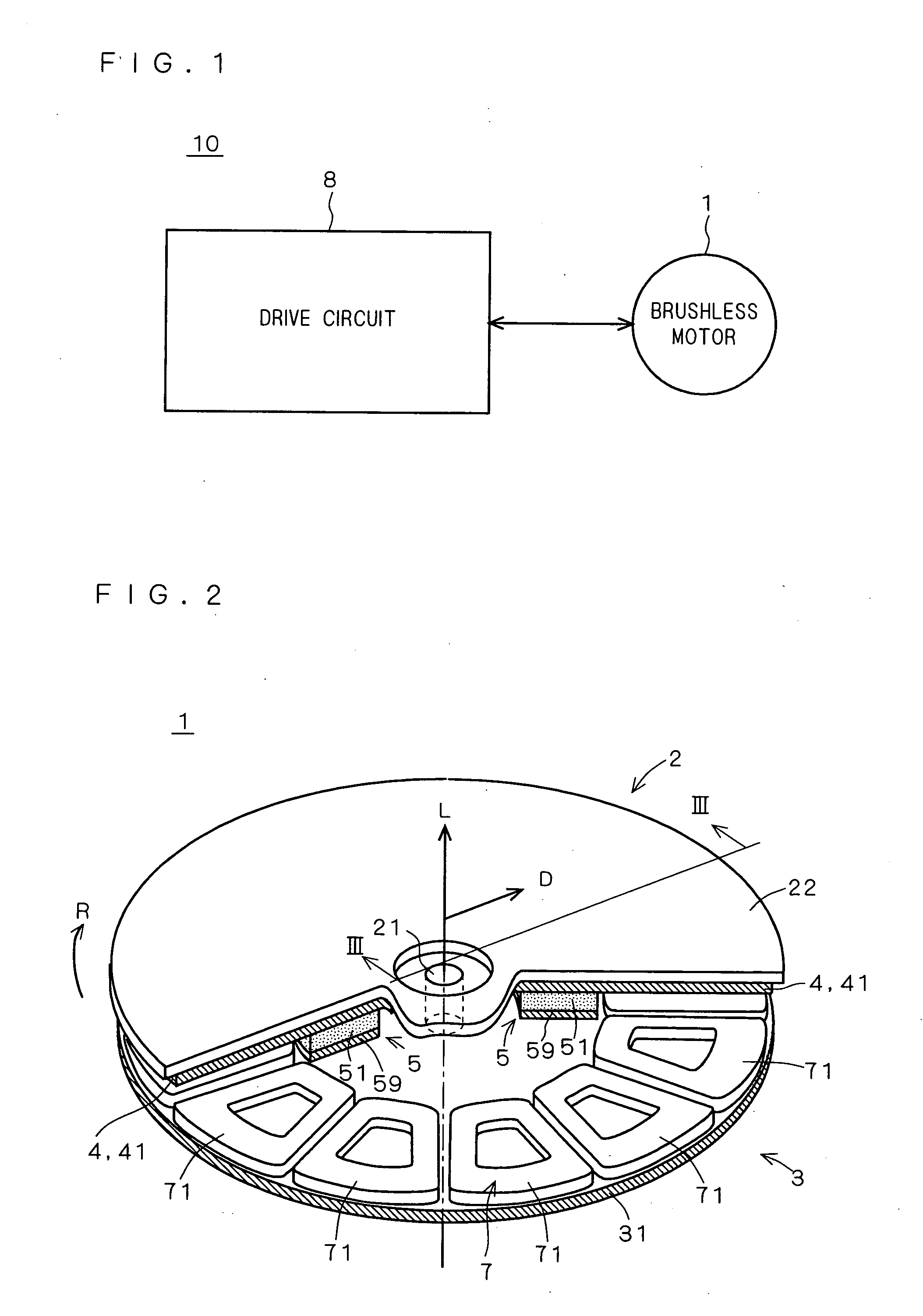

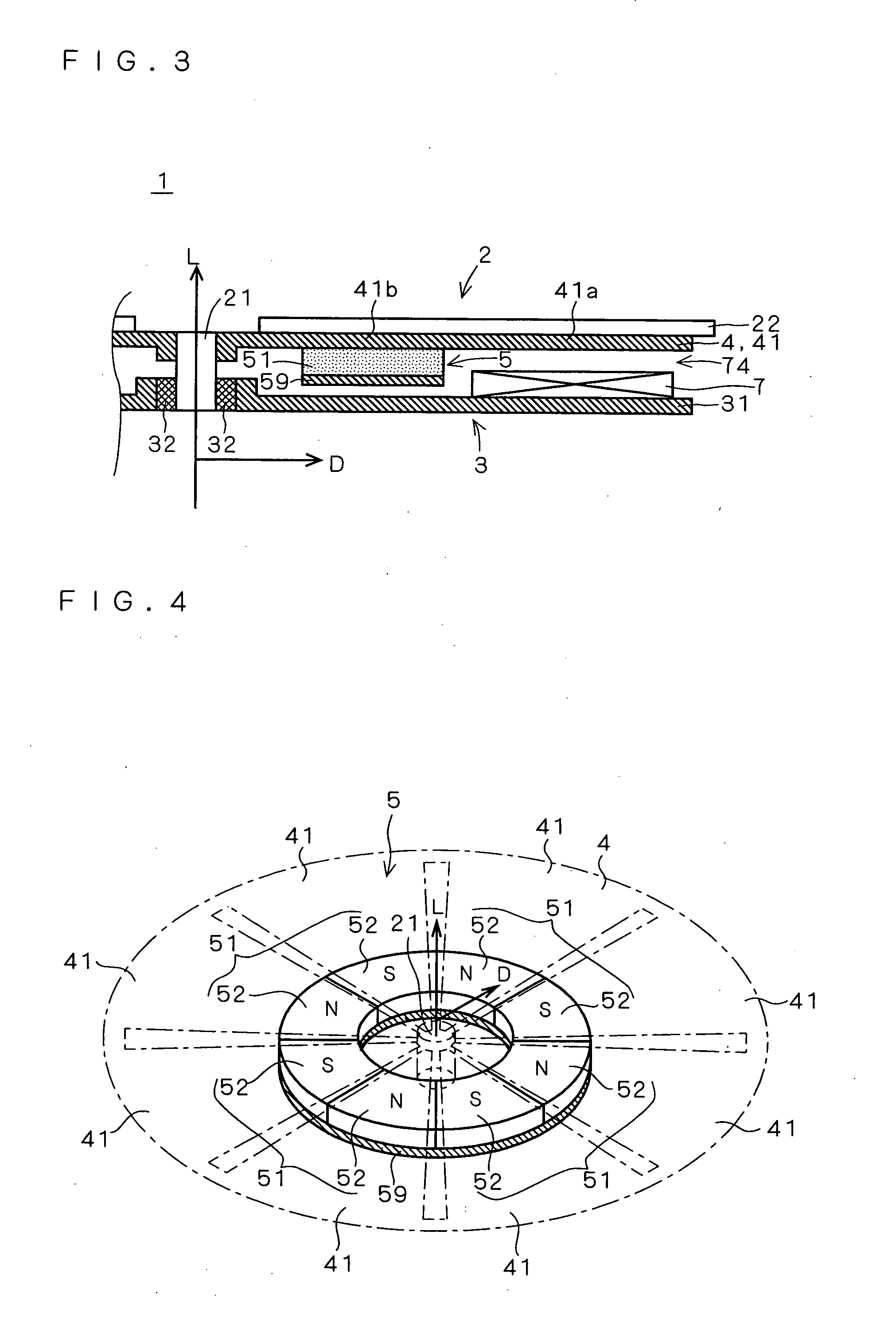

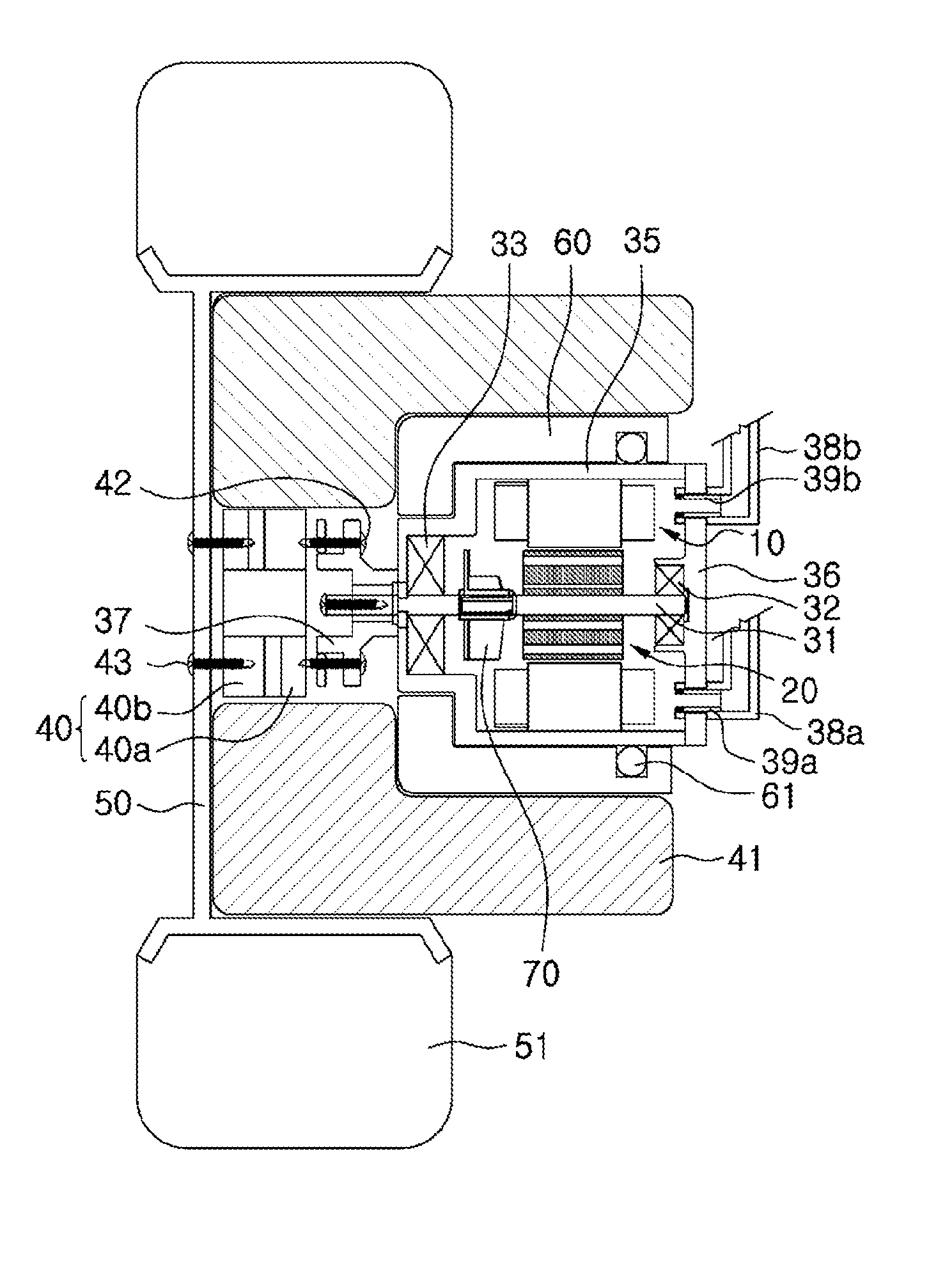

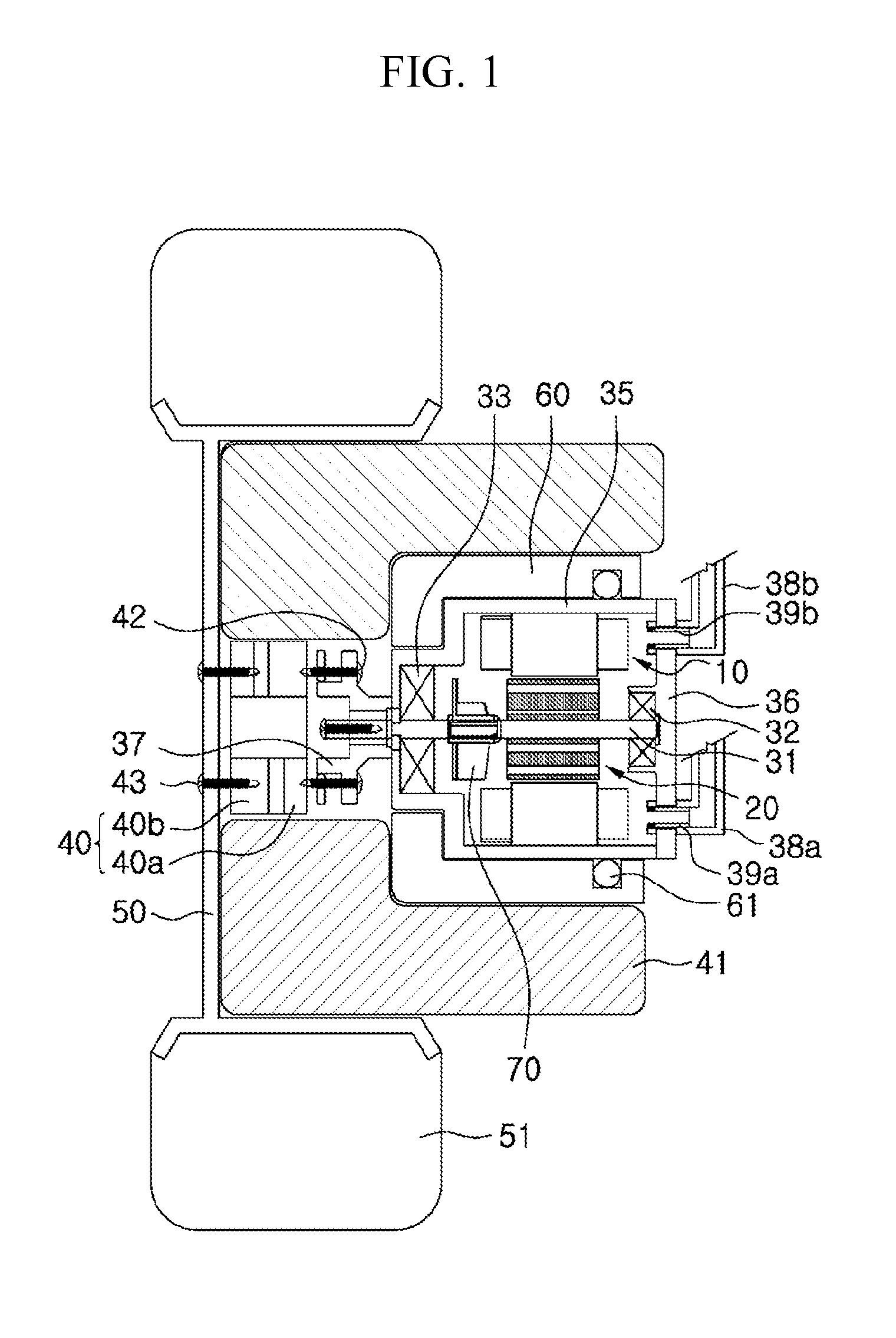

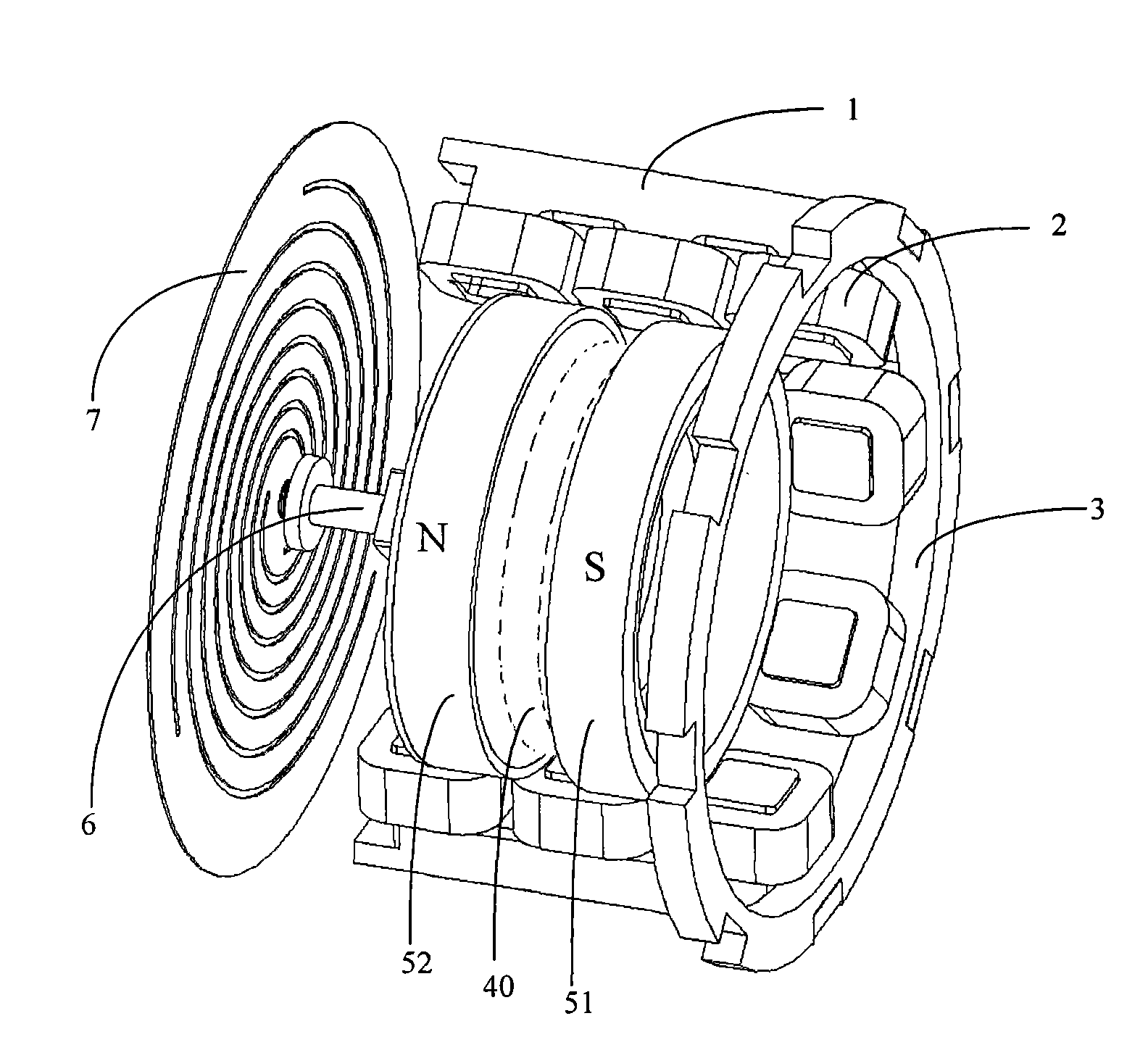

Motor, blower, compressor, and air conditioner

InactiveUS7608964B2Increase the lengthIncrease in sizeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic reluctance

It is an object of the present invention to provide techniques for improving efficiency and torque of a motor while achieving thinning of the motor. In a brushless DC motor, a rotor includes a magnetic-field creating magnet and a stator includes an armature winding. The magnetic-field creating magnet and the armature winding are placed to locally face in a radial direction orthogonal to an axial direction. This reduces a thickness of the brushless DC motor which extends in the axial direction. Also, a short-circuit yoke plate for joining and magnetically short-circuiting the north pole and the south pole of a permanent magnet is placed on a negative side in the axial direction with respect to the magnetic-field creating magnet. By provision of the short-circuit yoke plate, a magnetic path on a negative side in the axial direction with respect to the magnetic-field creating magnet can be shortened. Accordingly, magnetic reluctance occurring during rotational movement of the brushless DC motor can be reduced, to thereby improve efficiency and torque of the brushless DC motor.

Owner:DAIKIN IND LTD

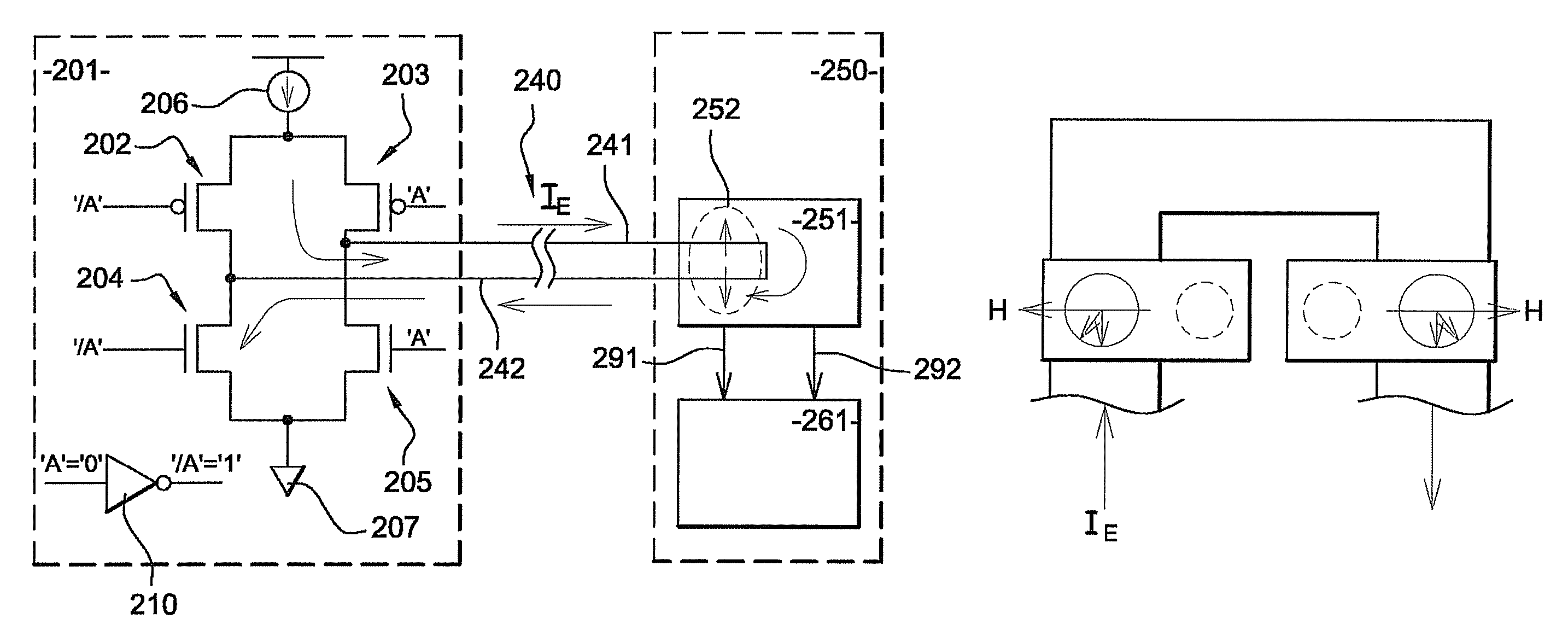

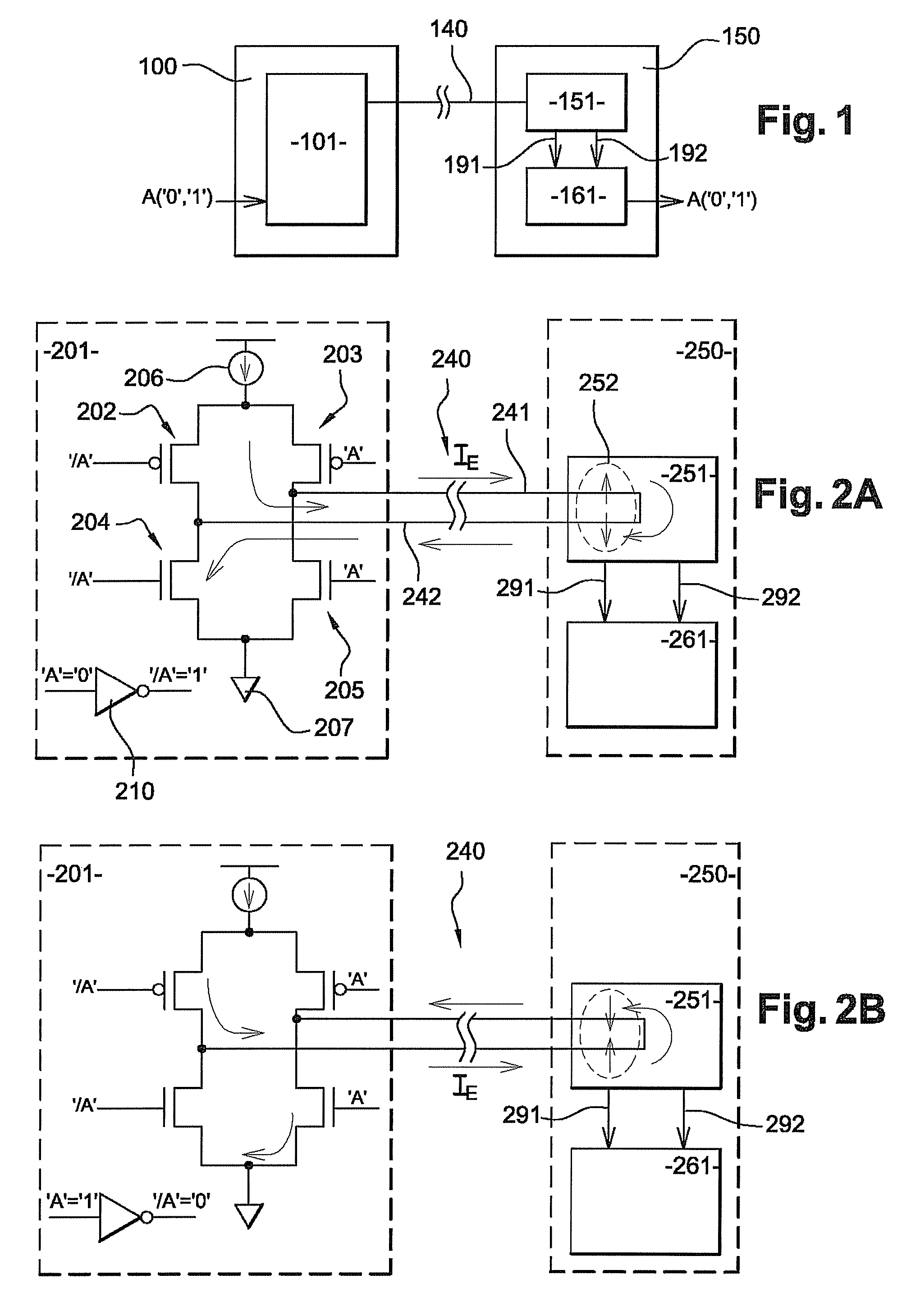

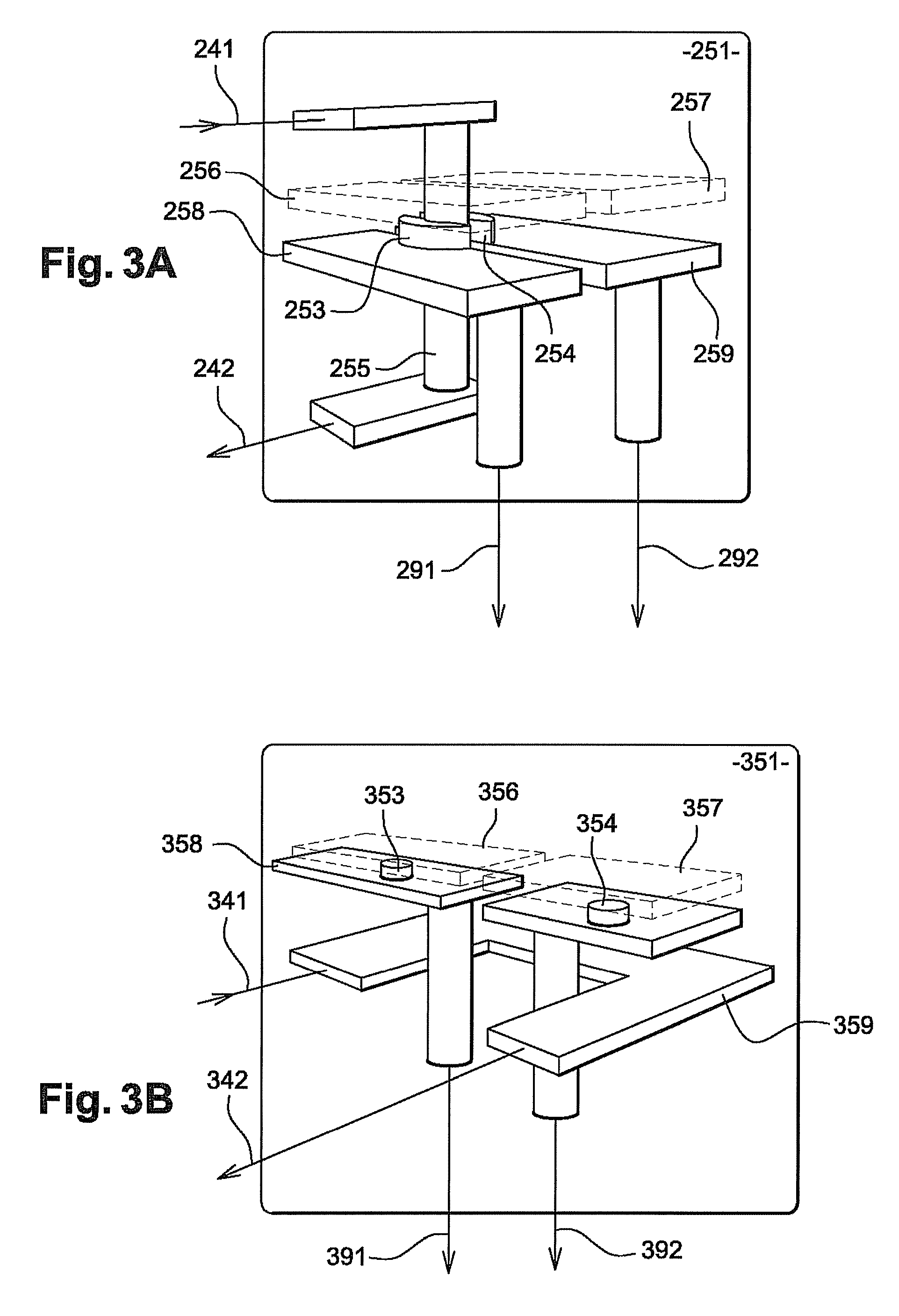

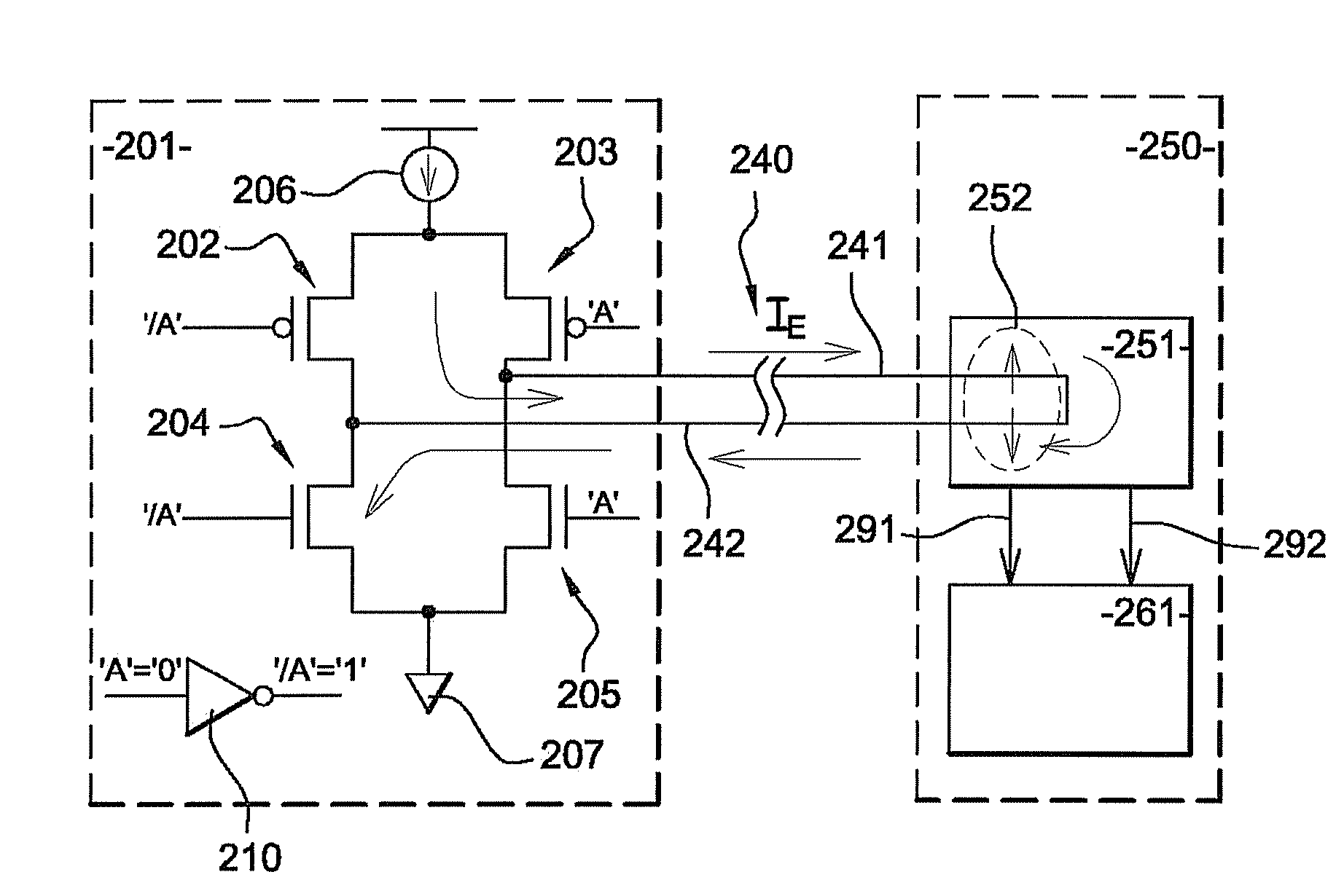

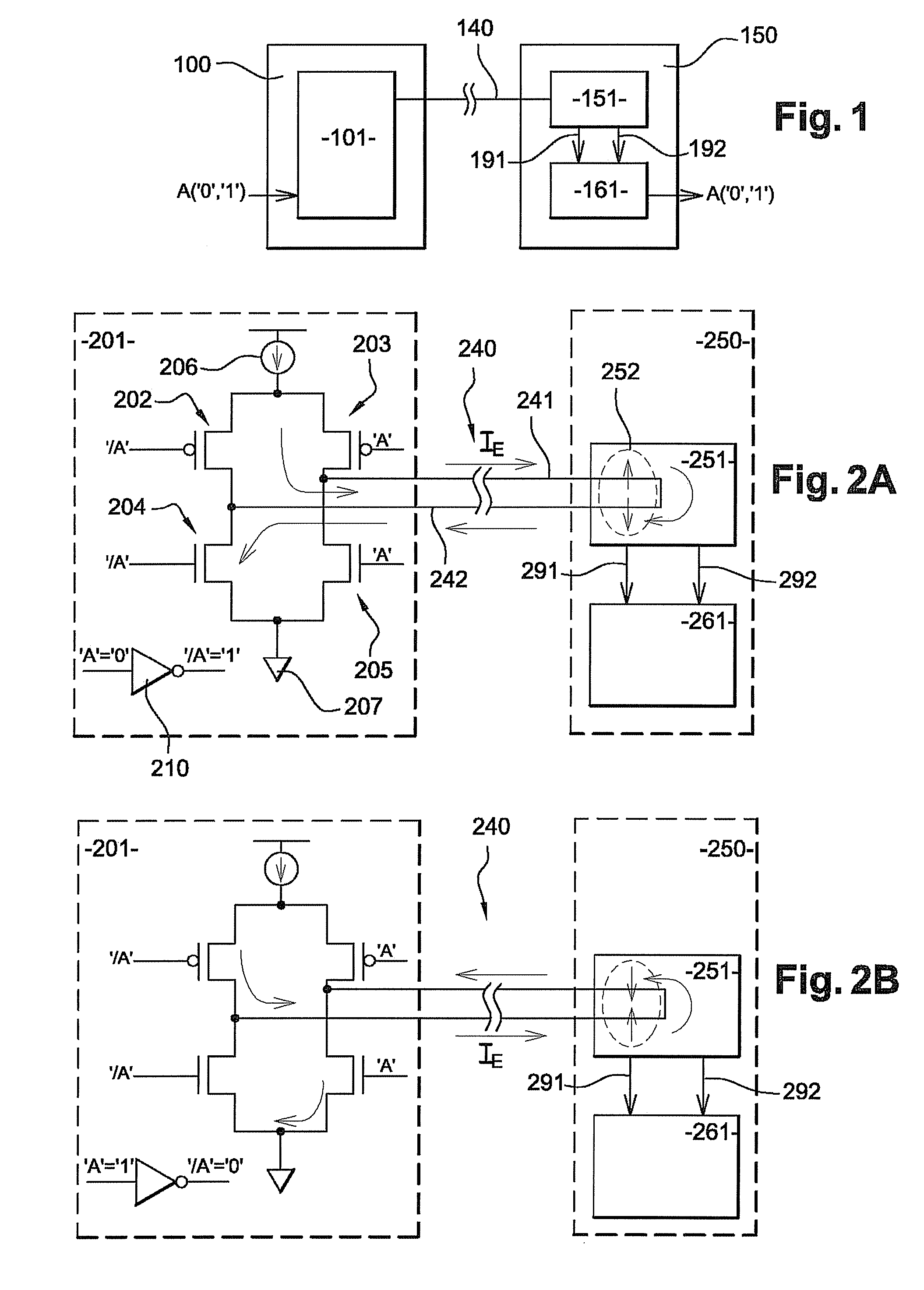

Electronic device for the transport of numerical information

InactiveUS7944231B2Maximise variationReduce areaReliability increasing modificationsSolid-state devicesElectricityElectrical resistance and conductance

An electronic device designed to transport digital information (“0”, “1”) over long distances, including a transmitter generating current pulses and at least one assembly of receivers converting the received current pulses into logic pulses which are compatible with the operation of standard electronic logic circuits. Each receiver includes a pair of magnetoresistive stacks containing at least one hard ferromagnetic layer and one soft ferromagnetic layer separated by a non-ferromagnetic interlayer, the hard layer of each of the magnetoresistive stacks being pinned in a magnetic orientation perpendicular to an easy-magnetization axis which is used as a reference for the soft layer of the same stack. The soft layer of each magnetoresistive stack has a magnetic orientation which can be modulated by the magnetic field generated by current pulses delivered by the transmitter so as to cause modification of the transverse resistance of the stack sufficient to trigger an electrical signal.

Owner:CENT NAT DE LA RECH SCI 15

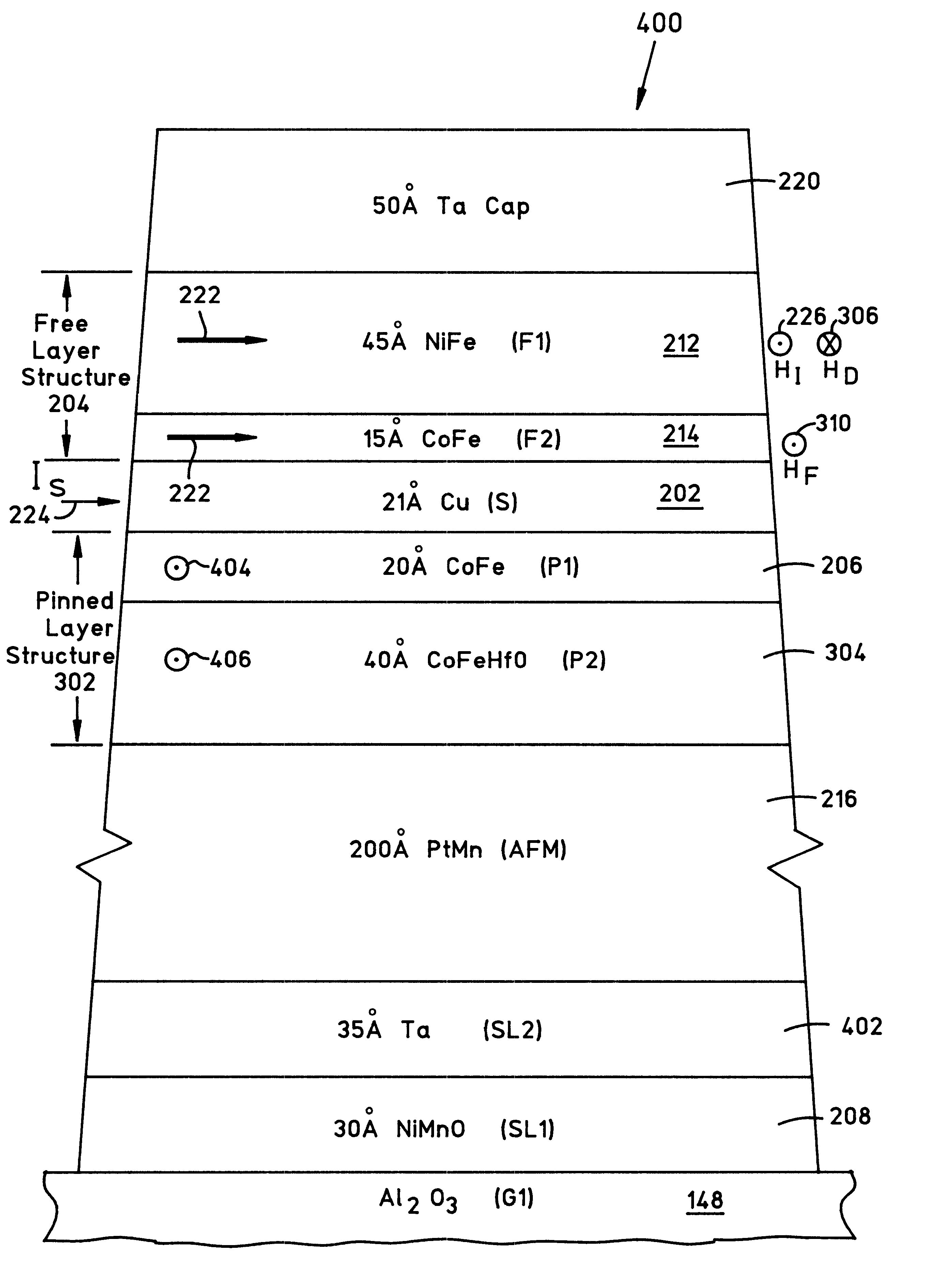

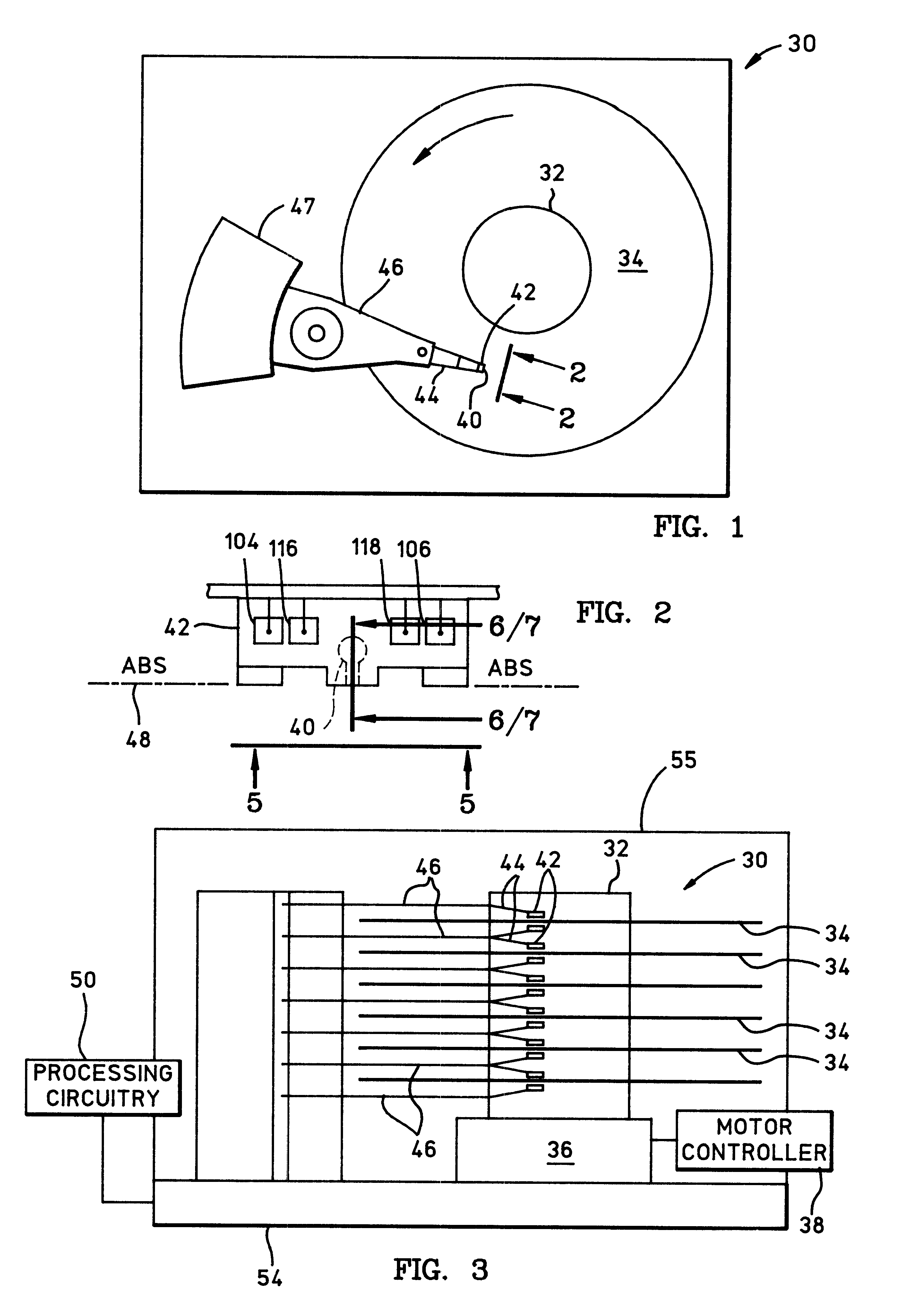

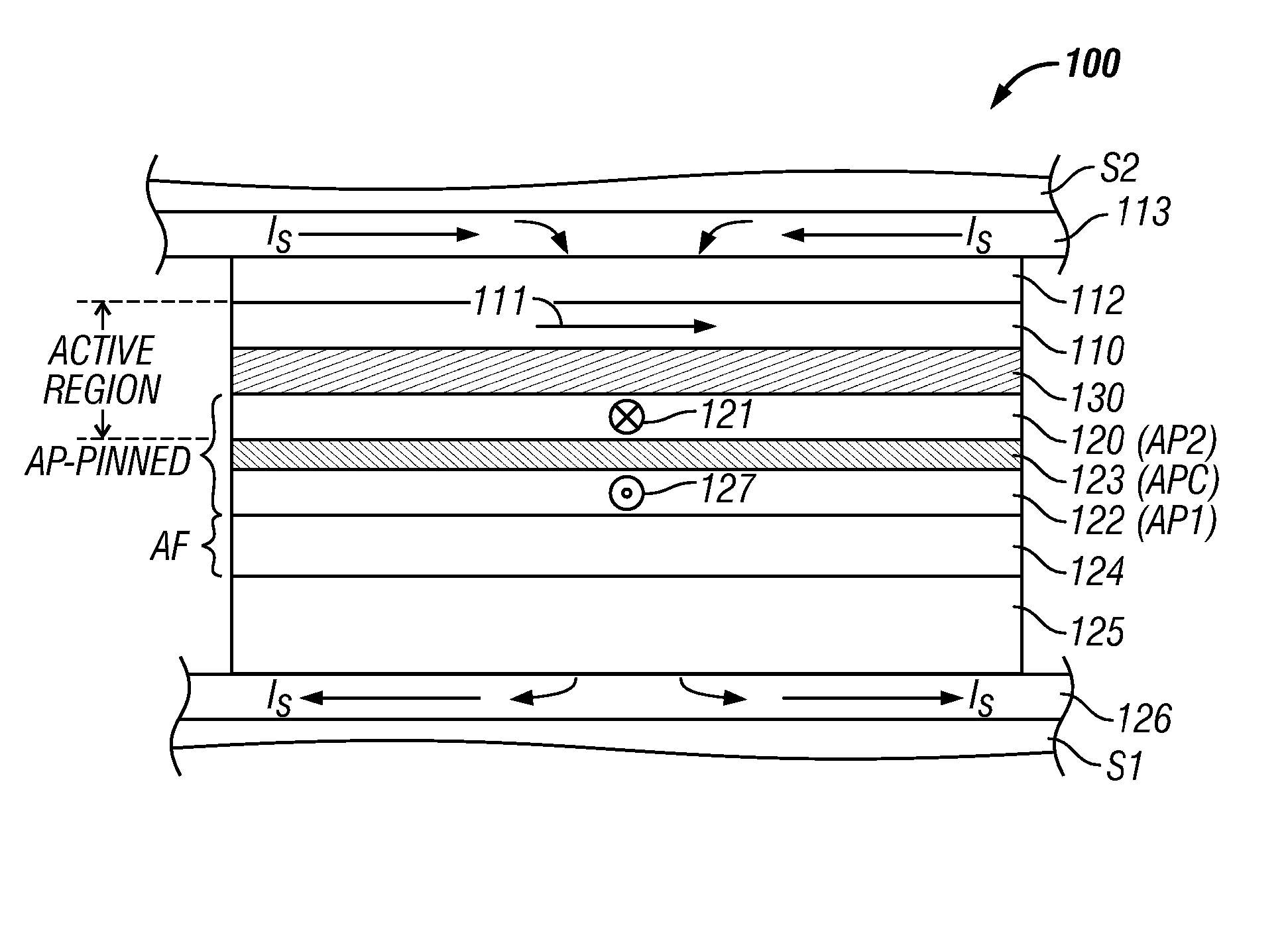

Spin valve sensor with composite pinned layer structure for improving biasing of free layer structure with reduced sense current shunting

InactiveUS6519121B1Increased reluctanceMagnetoresistance of a spin valve sensor is increasedNanoinformaticsRecord information storageHigh resistanceMagnetic reluctance

A cobalt iron hafnium oxide (CoFeHfO) layer is employed in a pinned layer structure of a top or bottom simple pinned or antiparallel (AP) pinned spin valve sensor for increasing a demagnetization field from the pinned layer structure which will improve biasing of a free layer structure in the spin valve sensor with minimal shunting of the sense current IS through the spin valve sensor because of its high resistance. The demagnetization field from the pinned layer structure opposes a typically high sense current field due to the sense current so as to zero bias the spin valve sensor with a magnetic moment of the free layer structure oriented parallel to an air bearing surface of the sensor. The cobalt iron (CoFe) content in the cobalt iron hafnium oxide (CoFeHfO) layer increases the magnetoresistance of the sense current due to its proximity to the spacer layer and the oxygen content in the layer causes specular reflection of conduction electrons through the sensor for still further increasing the magnetoresistance.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Motor rotor and permanent magnet motor

PendingCN108023421AReduce the difficulty of charging and demagnetizingImprove operational efficiencyWindingsMagnetic circuit rotating partsElectric machineMagnetic poles

Owner:GREE ELECTRIC APPLIANCES INC

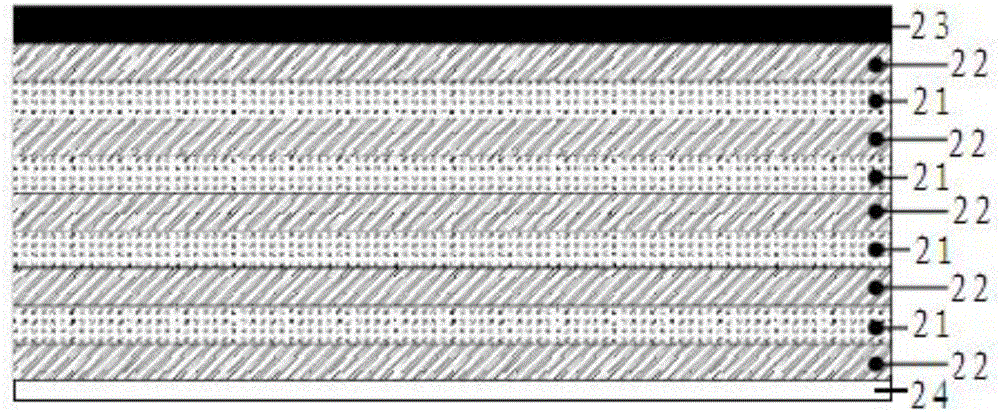

Magnetic tunnel junction device and method of manufacturing the same

InactiveUS20060176735A1Great magnetoresistanceThe implementation process is simpleMagnetic-field-controlled resistorsDigital storageMagnetizationEvaporation

The MR ratio of an MTJ device is increased. A single-crystalline MgO (001) substrate 11 is prepared, and then an epitaxial Fe (001) lower electrode (first electrode) 17 with a thickness of 50 nm is grown on a MgO (001) seed layer 15 at room temperature. Annealing is then performed in ultrahigh vacuum (2×10−8 Pa) at 350° C. A 2-nm thick MgO (001) barrier layer 21 is epitaxially grown on the Fe (001) lower electrode (first electrode) 17 at room temperature, using electron beam evaporation of MgO. A Fe (001) upper electrode (second electrode) 23 with a thickness of 10 nm is then grown on the MgO (001) barrier layer 21 at room temperature, which is successively followed by the deposition of a Co layer 21 with a thickness of 10 nm on the Fe (001) upper electrode (second electrode) 23. The Co layer 21 is used for realizing an antiparallel magnetization alignment by enhancing an exchange bias magnetic field of the upper electrode 23. Thereafter, the above-prepared sample is subjected to microfabrication so as to obtain a Fe (001) / MgO (001) / Fe (001) MTJ device. The density of dislocation defects that exist at the interface between one of the first or the second Fe (001) layer and the single-crystalline MgO (001) layer is not more than 25 to 50 defects / μm.

Owner:JAPAN SCI & TECH CORP +1

Motor, Blower, Compressor, And Air Conditioner

InactiveUS20070200445A1Increase the lengthIncrease in sizeMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic reluctanceConductor Coil

It is an object of the present invention to provide techniques for improving efficiency and torque of a motor while achieving thinning of the motor. In a brushless DC motor, a rotor includes a magnetic-field creating magnet and a stator includes an armature winding. The magnetic-field creating magnet and the armature winding are placed to locally face in a radial direction orthogonal to an axial direction. This reduces a thickness of the brushless DC motor which extends in the axial direction. Also, a short-circuit yoke plate for joining and magnetically short-circuiting the north pole and the south pole of a permanent magnet is placed on a negative side in the axial direction with respect to the magnetic-field creating magnet. By provision of the short-circuit yoke plate, a magnetic path on a negative side in the axial direction with respect to the magnetic-field creating magnet can be shortened. Accordingly, magnetic reluctance occurring during rotational movement of the brushless DC motor can be reduced, to thereby improve efficiency and torque of the brushless DC motor.

Owner:DAIKIN IND LTD

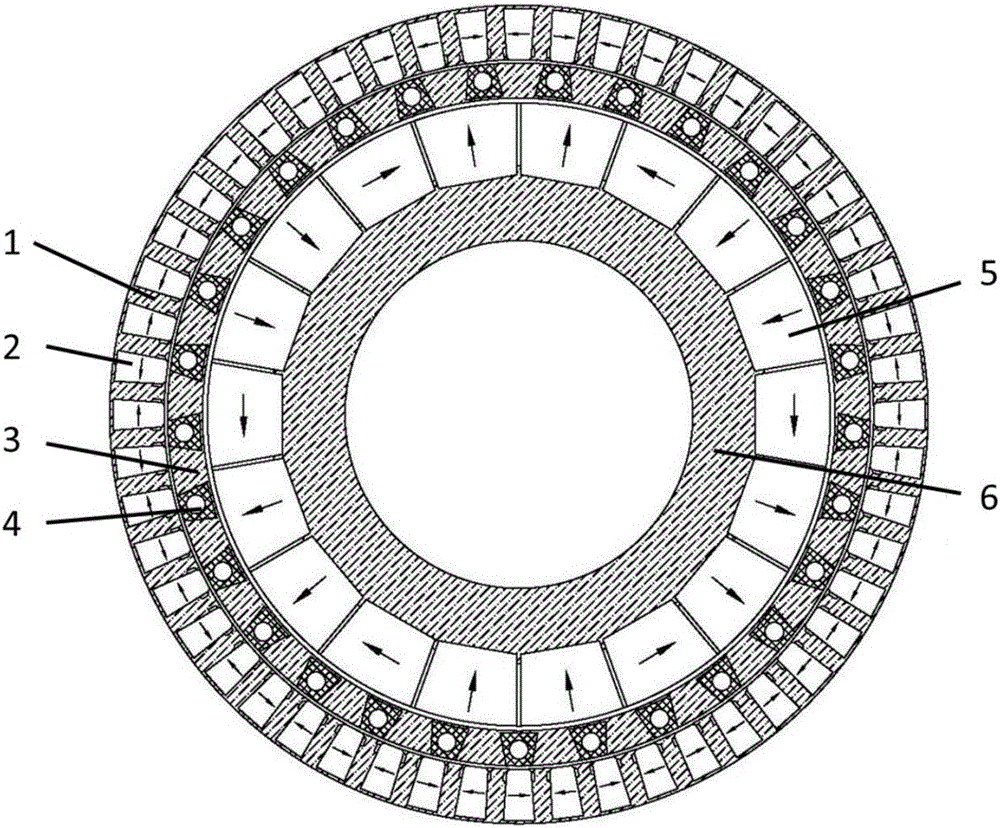

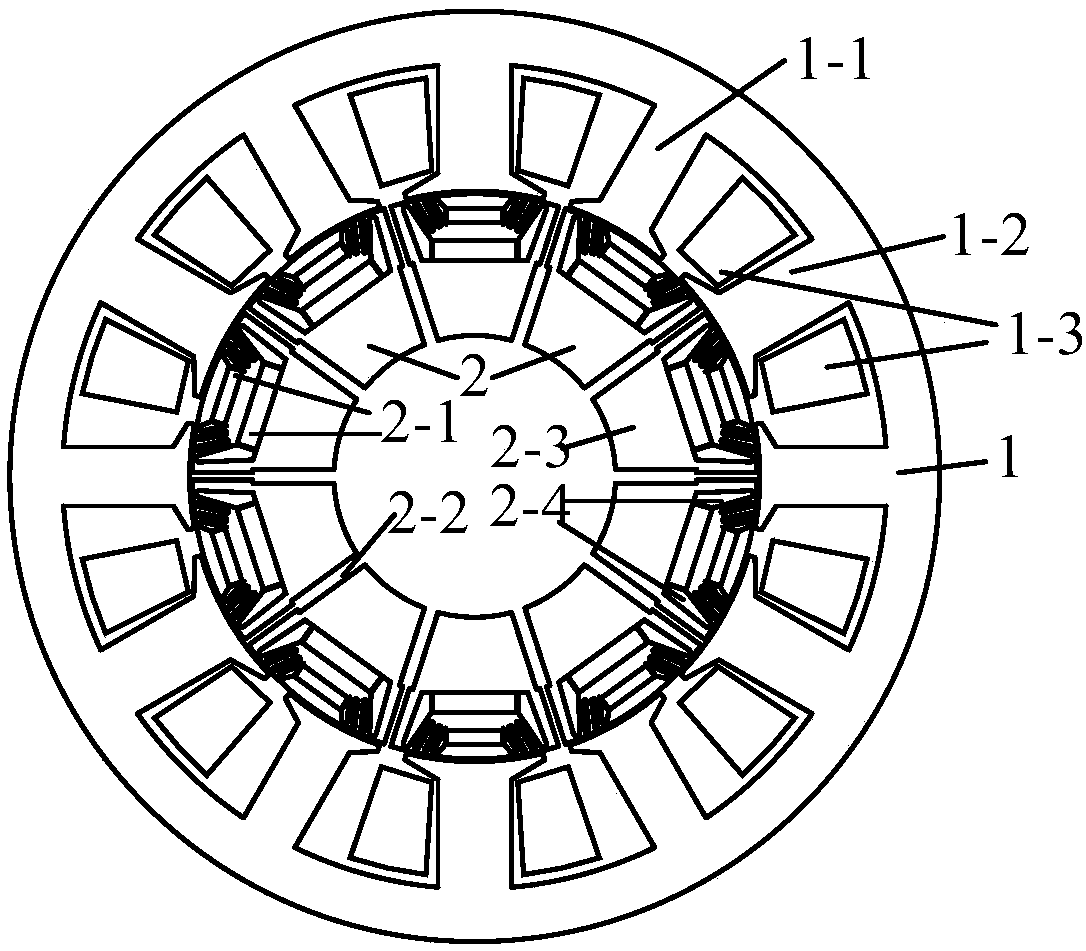

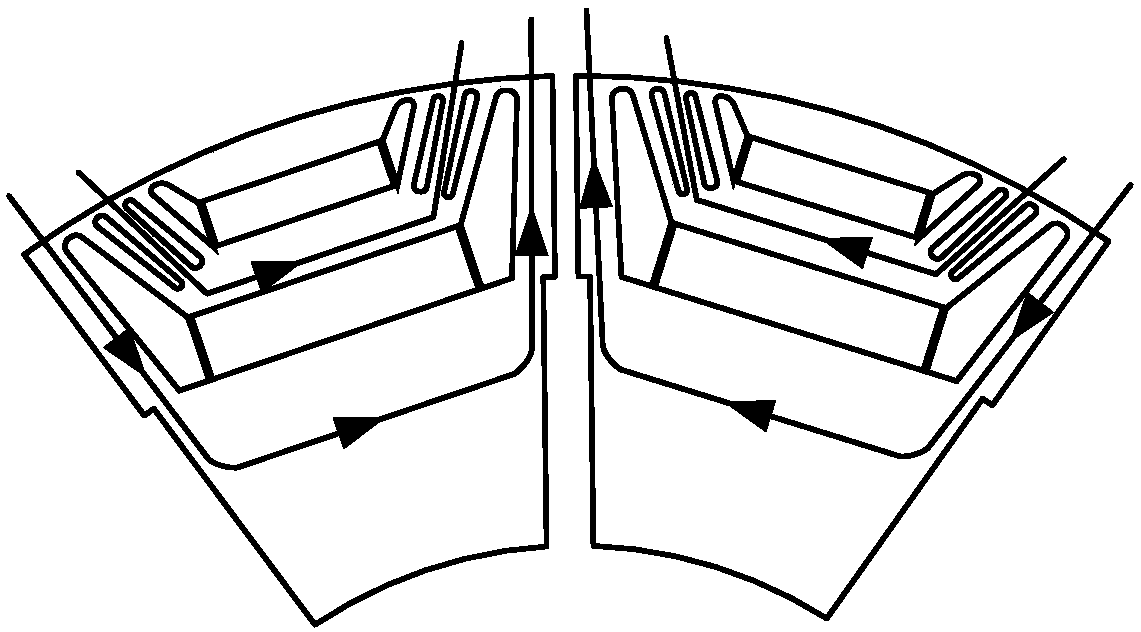

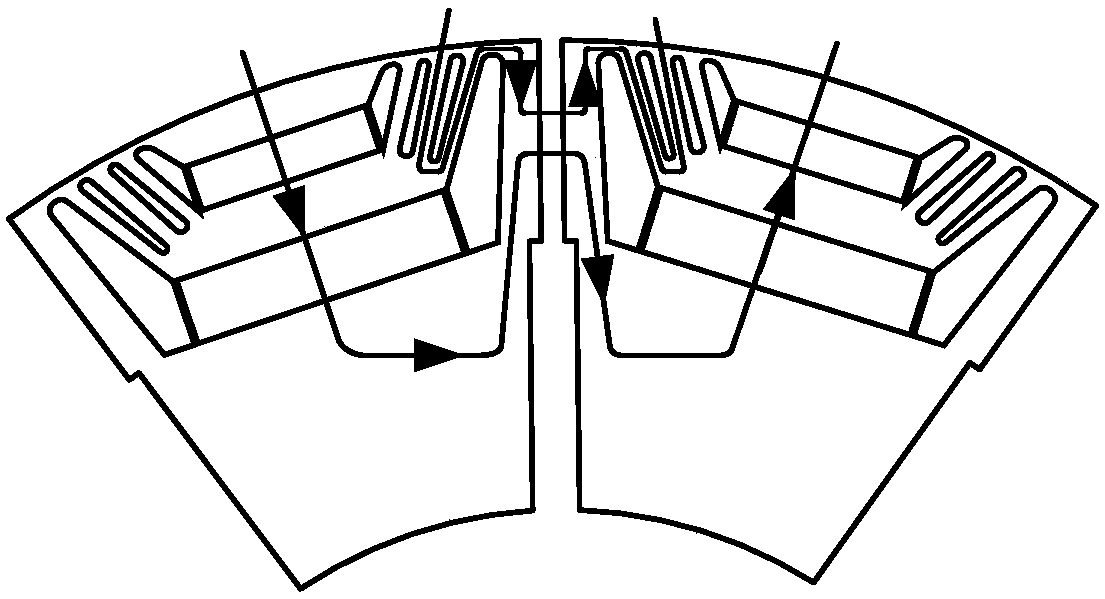

High torque density magnetic field modulation type magnetic gear

ActiveCN106787609AIncreased torque densityLow harmonic content of magnetic fieldPermanent-magnet clutches/brakesMagnetic tension forceTorque density

The invention discloses a high torque density magnetic field modulation type magnetic gear, which comprises a permanent magnetic outer stator, a modulation rotor and a permanent magnetic inner rotor which are concentrically nested to one another and arranged sequentially from outside to inside; air gaps are formed between the permanent magnetic outer stator and the modulation rotor as well as between the modulation rotor and the permanent magnetic inner rotor respectively; a trapezoidal groove is formed in the inner surface of an outer stator iron core of the permanent magnetic outer stator; demagnetization inhibition grooves are formed in the two sides of the inner end of the trapezoidal groove respectively; a tangentially polarized inverted trapezoidal outer stator permanent magnet is embedded in the trapezoidal groove; the demagnetization inhibition grooves have the action of inhibiting local demagnetization of the outer stator permanent magnet; the modulation rotor is composed of a plurality of magnet regulating yokes and a plurality of non-magnetic conductive materials embedded with punched holes respectively; the non-magnetic conductive materials embedded with the punched holes are embedded between two adjacent magnet regulating yokes respectively; the permanent magnetic inner rotor is composed of inner rotor permanent magnets and an inner rotor iron core which are concentrically nested to one another sequentially from outside to inside; and the inner rotor permanent magnets have a simplified Halbach structure. According to the magnetic field modulation type magnetic gear provided by the invention, higher torque density is realized under low torque ripples.

Owner:HUAZHONG UNIV OF SCI & TECH

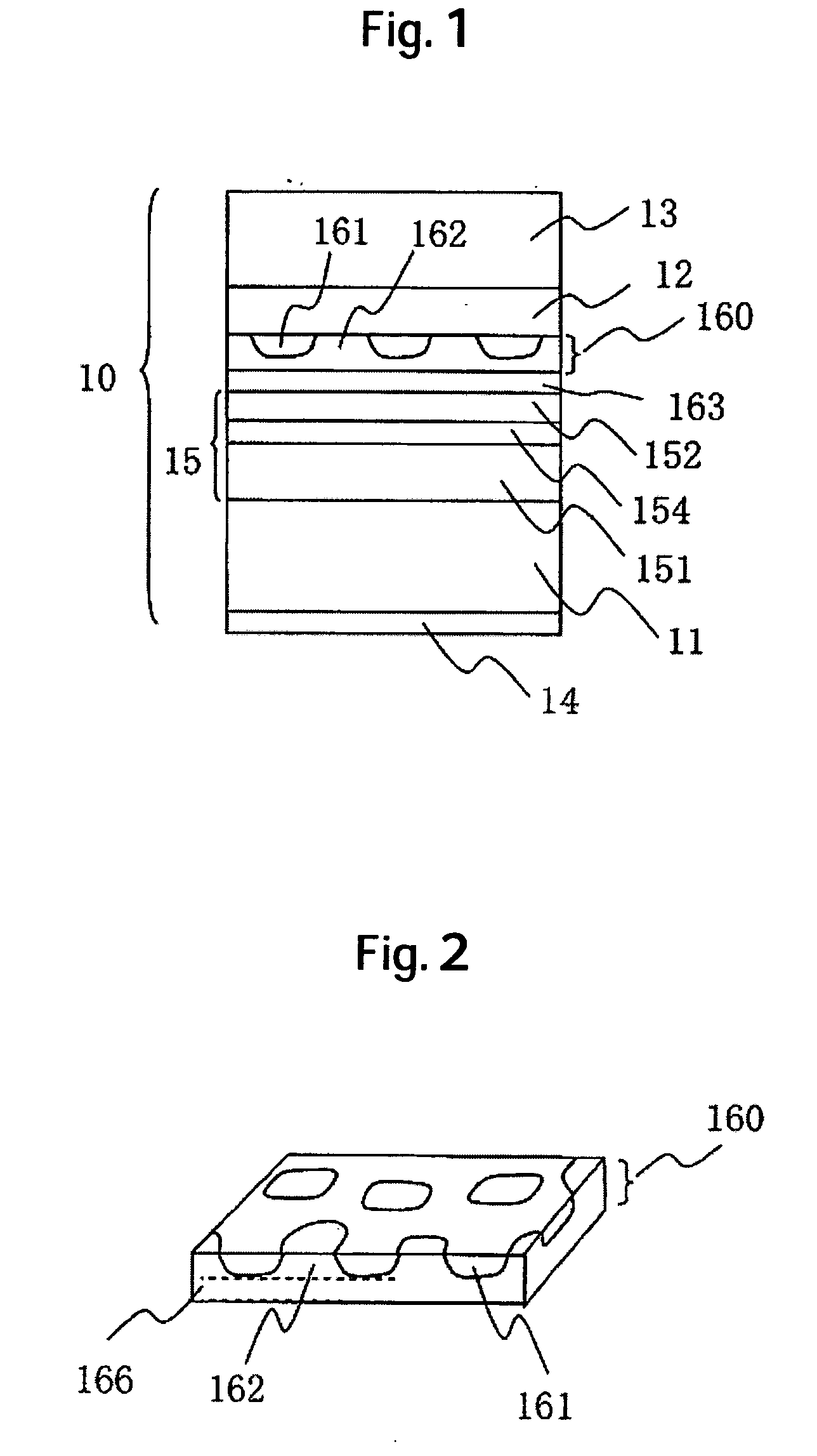

CPP-GMR magnetic head having GMR-screen layer

InactiveUS20070091511A1Efficiently effectedHigh magnetoresistanceNanomagnetismNanoinformaticsEngineeringOxide

A spin-valve type magnetic head which has sufficiently high output is provided. In one embodiment, a structure in which high output coexists with high stability is achieved by letting a GMR-effect and a current-path-confinement effect manifest themselves at the same time in a GMR-screen layer consisting of a ferromagnetic metal spike-like part and a half-covering oxide layer.

Owner:WESTERN DIGITAL TECH INC

Current-perpendicular-to-the-plane (CPP) magnetoresistive sensor with antiparallel-free layer structure and low current-induced noise

InactiveUS20070253119A1Reduction in susceptibilityCurrent-induced noiseNanomagnetismMagnetic measurementsPhysicsElectron scattering

A current-perpendicular-to-the-plane (CPP) magnetoresistive sensor has an antiparallel free (APF) structure as the free layer and a specific direction for the applied bias or sense current. The (APF) structure has a first free ferromagnetic (FL1), a second free ferromagnetic layer (FL2), and an antiparallel (AP) coupling (APC) layer that couples FL1 and FL2 together antiferromagnetically with the result that FL1 and FL2 have substantially antiparallel magnetization directions and rotate together in the presence of a magnetic field. The thicknesses of FL1 and FL2 are chosen to obtain the desired net free layer magnetic moment / area for the sensor, and the thickness of FL1 is preferably chosen to be greater than the spin-diffusion length of the electrons in the FL1 material to maximize the bulk spin-dependent scattering of electrons and thus maximize the sensor signal. The CPP sensor operates specifically with the conventional sense current (opposite the electron current) directed from the pinned ferromagnetic layer to the APF structure, which results in suppression of current-induced noise.

Owner:WESTERN DIGITAL TECH INC

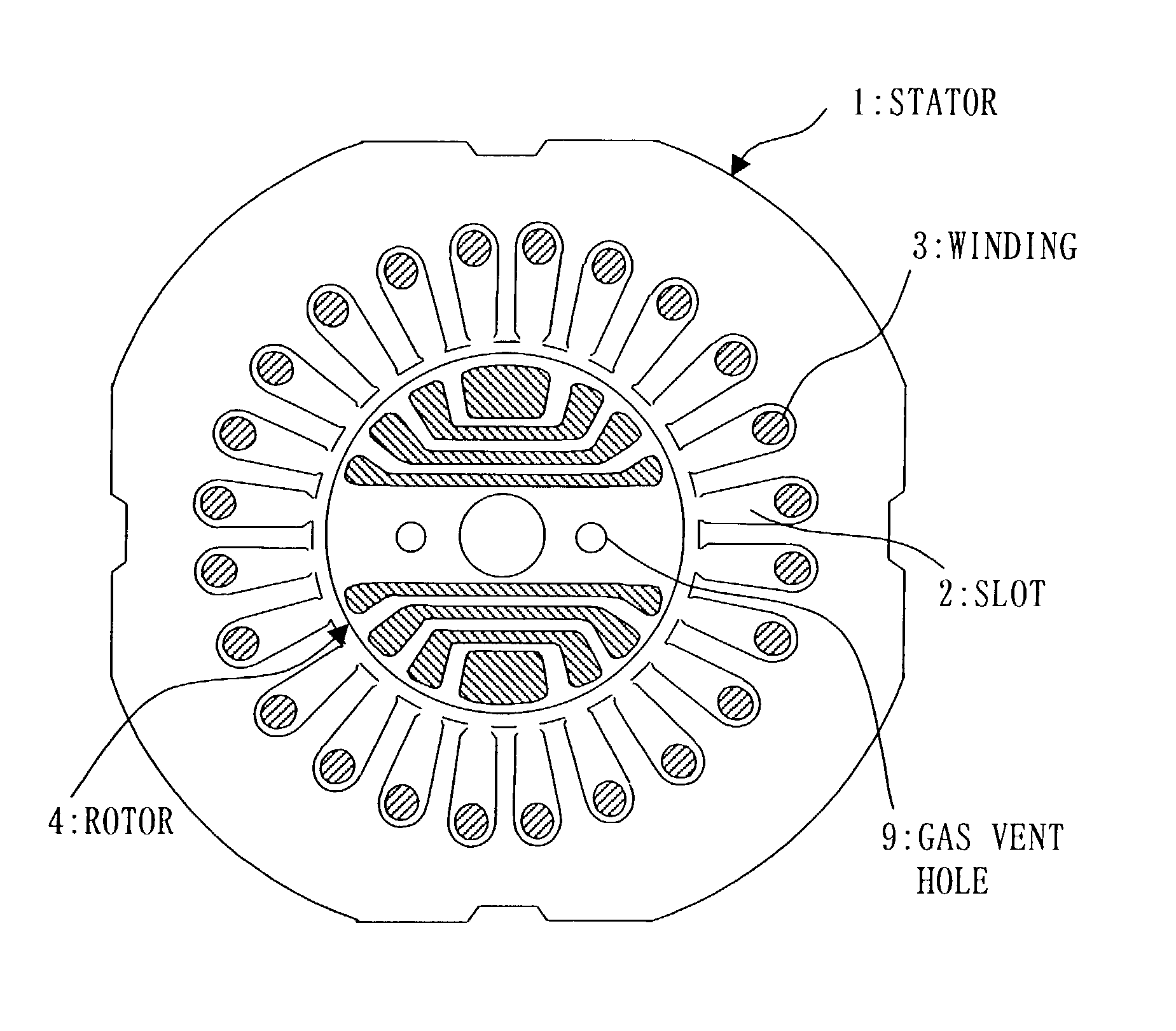

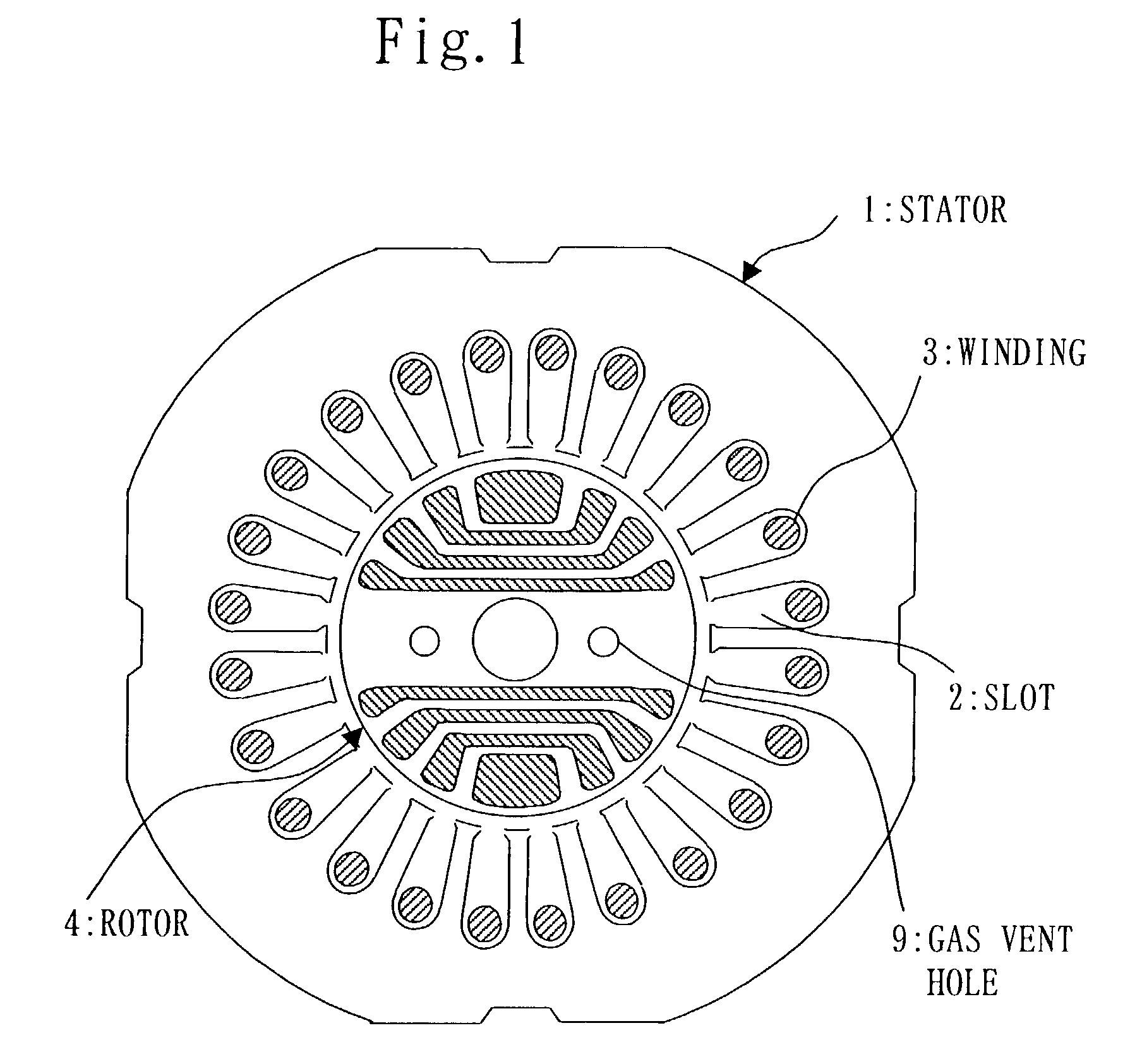

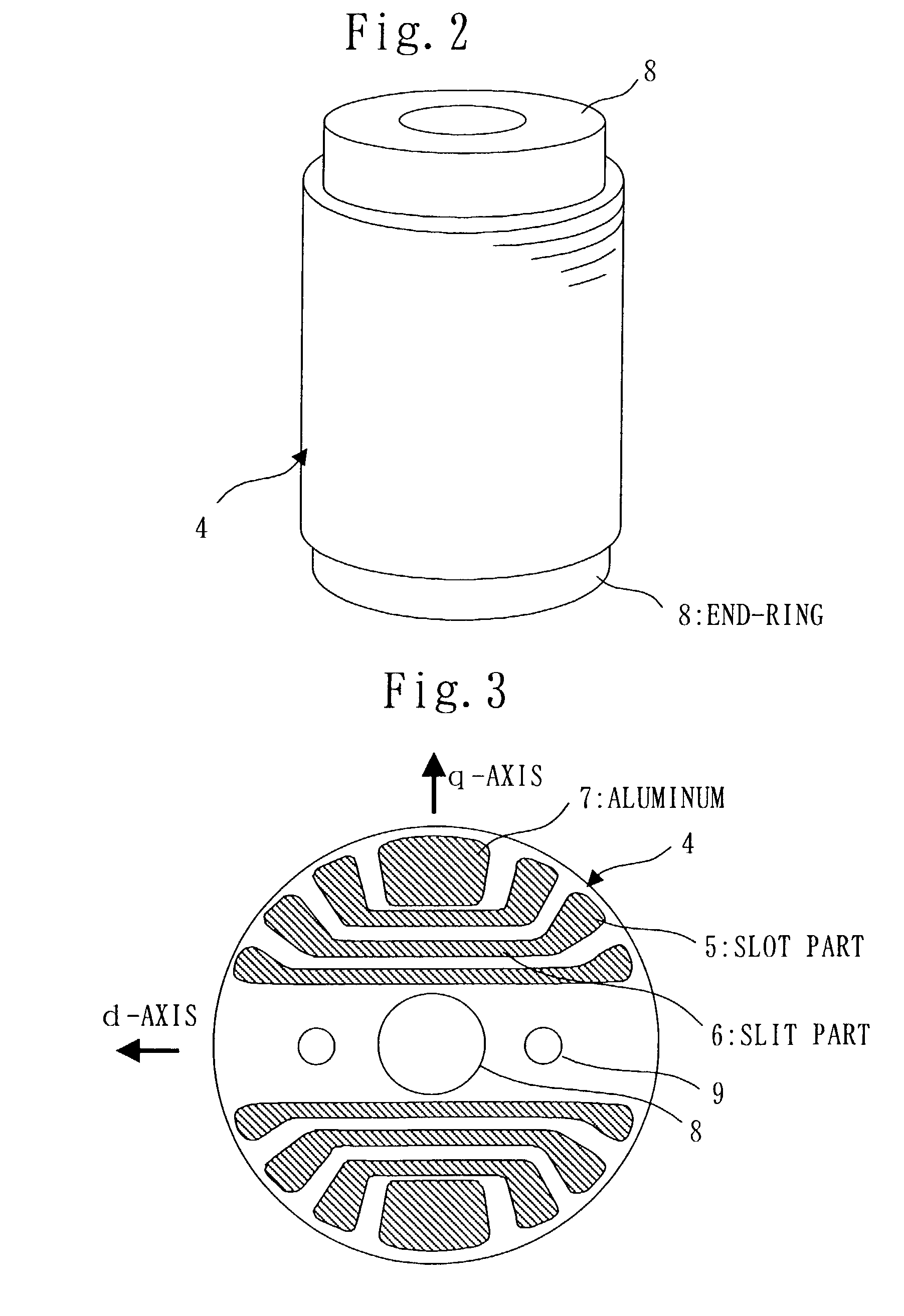

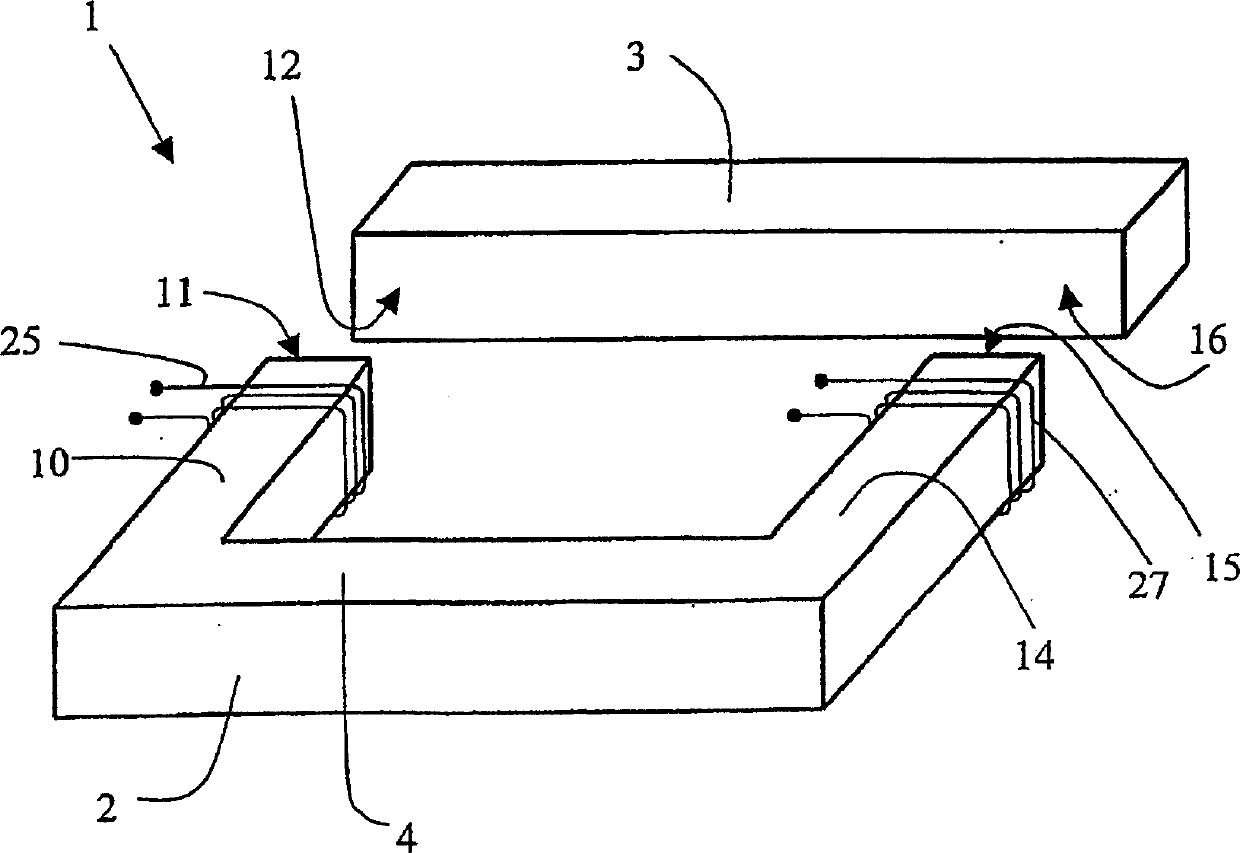

Rotor of a synchronous induction electric motor

InactiveUS7102259B2Increased reluctanceLow efficiencyMagnetic circuit rotating partsPositive displacement pump componentsRotational axisInduction motor

A rotor of a synchronous induction electric motor according to the present invention includes a slot for generating induction torque and a slit for generating reluctance torque. The slot and the slit are filled up with aluminum which is short-circuited by an end-ring at each of both ends of the rotor, and the slit includes a non-filling part penetrating in the direction of the rotational axis and not filled up with the aluminum.

Owner:MITSUBISHI ELECTRIC CORP

Bulk amorphous metal inductive device

InactiveCN1735948AEliminate difficultiesRemove complexityTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureTransformerSwitching frequency

A bulk amorphous metal inductive device comprises a magnetic core having plurality of low-loss bulk ferromagnetic amorphous metal magnetic components assembled in juxtaposed relationship to form at least one magnetic circuit and secured in position, e.g. by banding or potting. The device has one or more electrical windings and may be used as a transformer or inductor in an electronic circuit. Each component comprises a plurality of similarly shaped layers of amorphous metal strips bonded together to form a polyhedrally shaped part. The low core losses of the device, e.g. a loss of at most about 12 W / kg when excited at a frequency of 5 kHz to a peak induction level of 0.3 T, make it especially useful for application in power conditioning circuits operating in switched mode at frequencies of 1 kHz or more. Air gaps are optionally interposed between the mating faces of the constituent components of the device to enhance its energy storage capacity for inductor applications. The inductive device is easily customized for specialized magnetic applications, e.g. for use as a transformer or inductor in power conditioning electronic circuitry employing switch-mode circuit topologies and switching frequencies ranging from 1 kHz to 200 kHz or more.

Owner:METGLAS INC

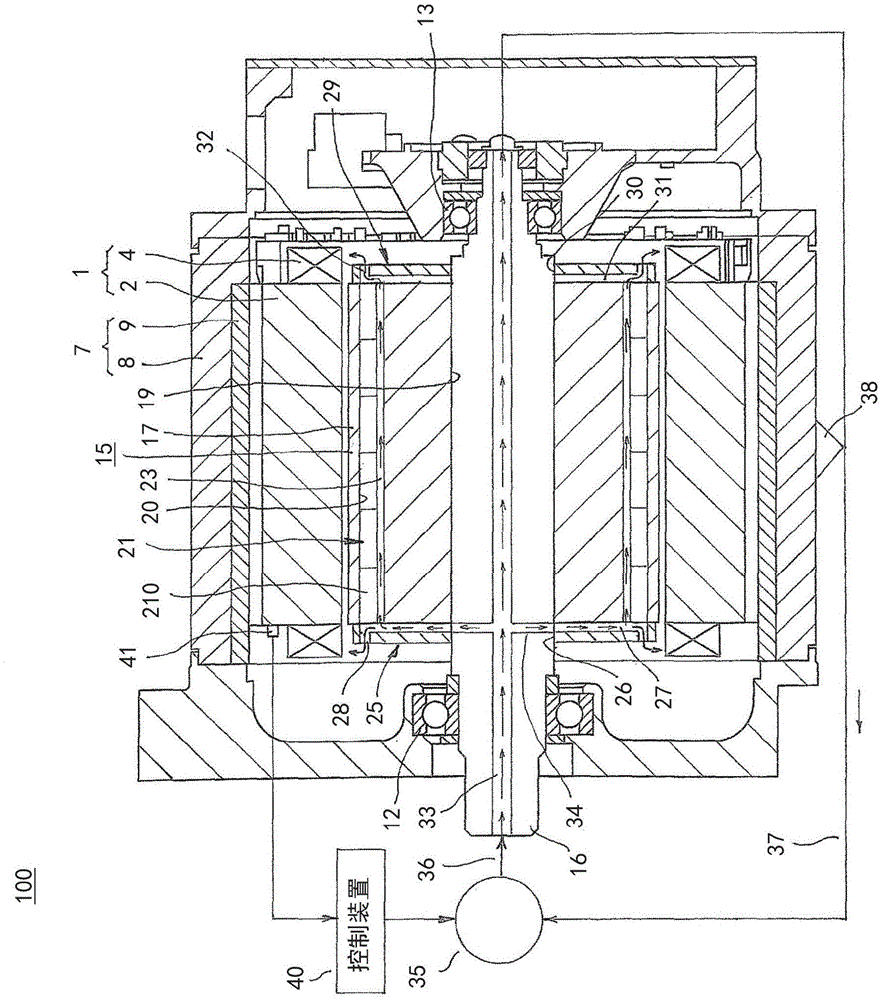

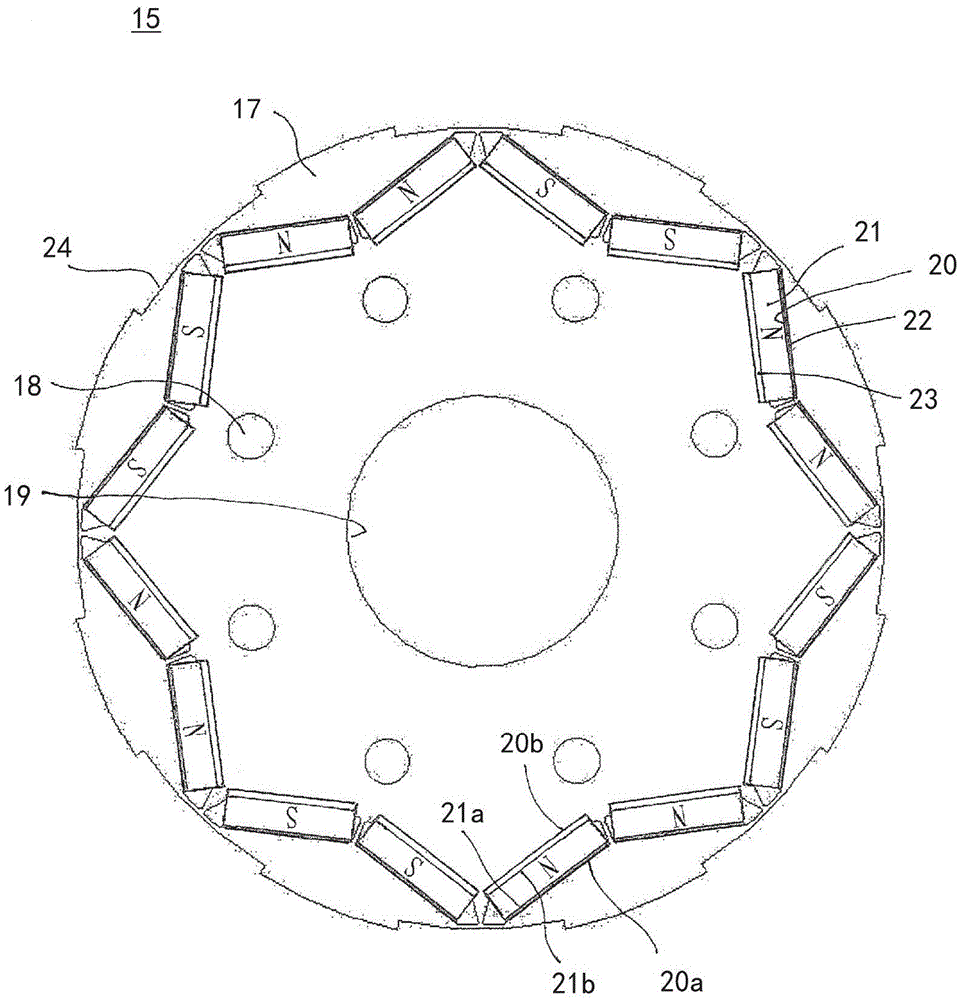

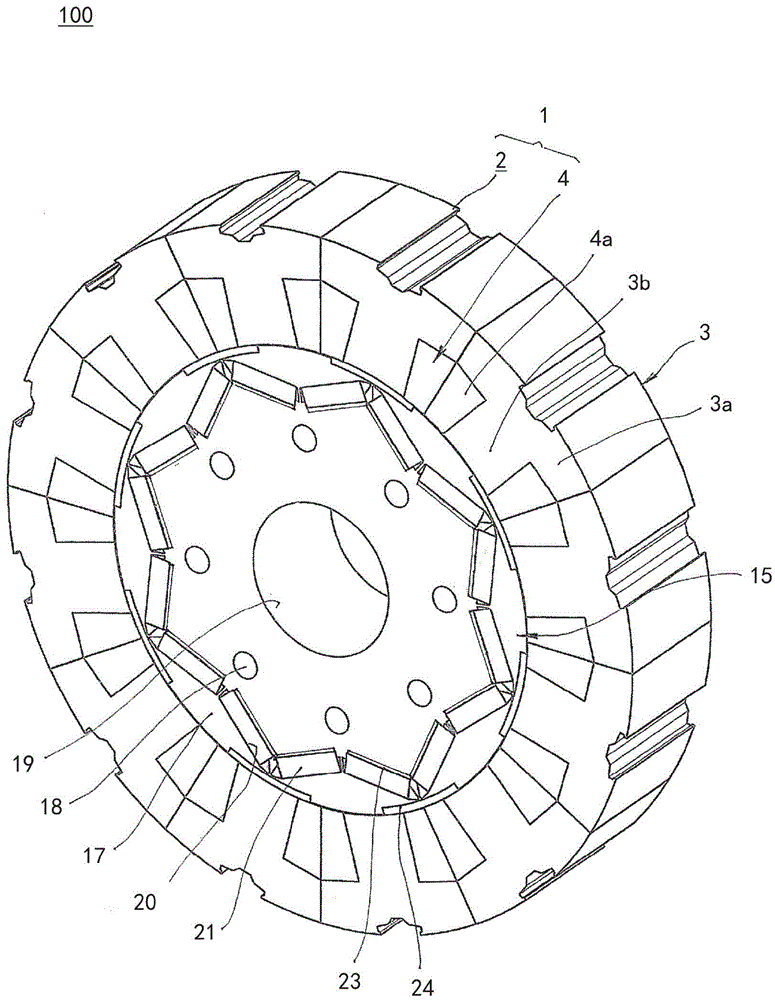

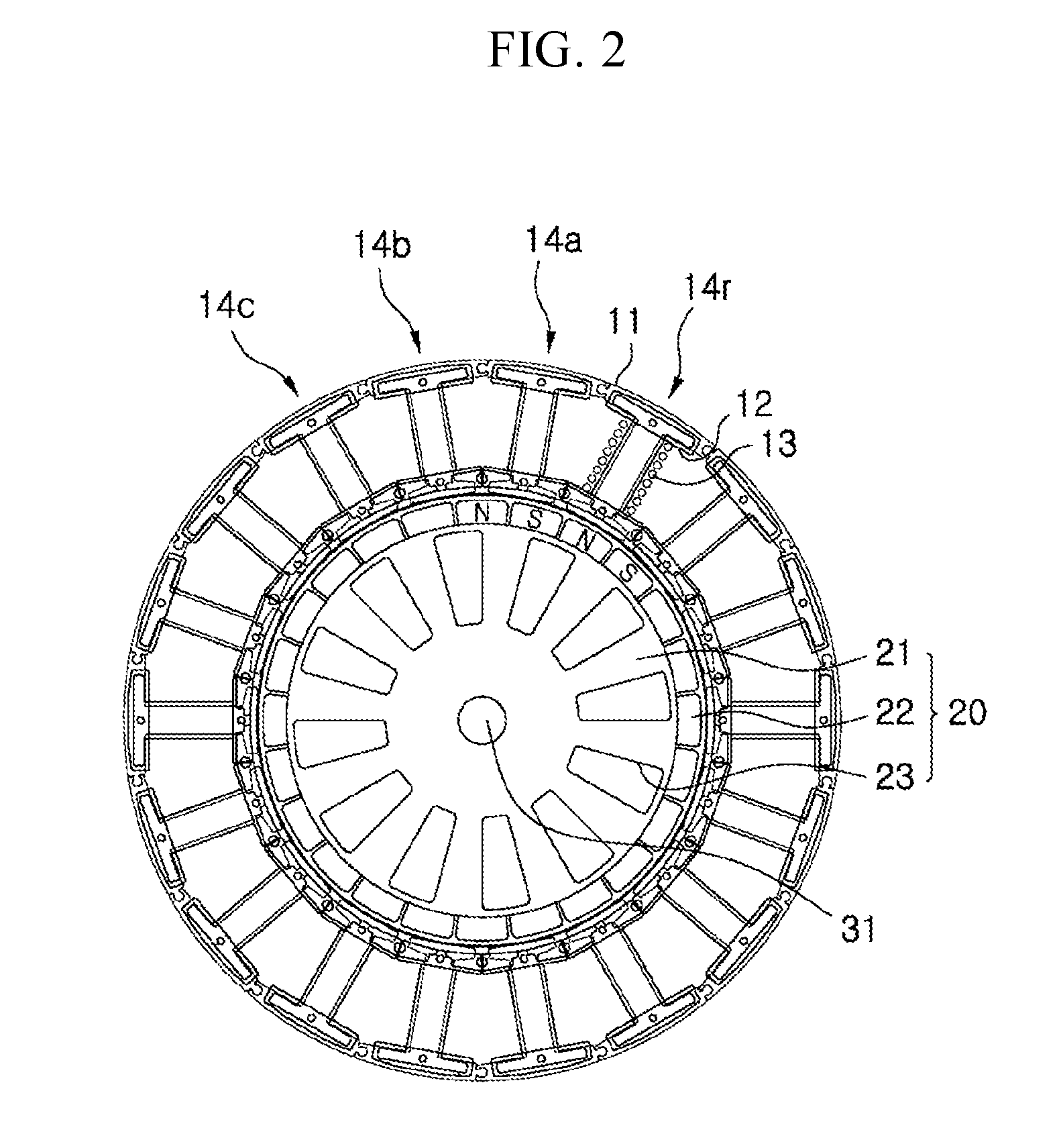

Permanent magnet embedded type rotating electric machine

ActiveCN105453387ALess quantityReduce the cross-sectional areaMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic flux

The purpose of this invention is to obtain a permanent magnet embedded type rotating electric machine in which the amount of magnetic flux of a permanent magnet can be prevented from reducing and the permanent magnet can be effectively cooled. In the permanent magnet embedded type rotating electric machine, a rotor (15) has: a rotor iron core (17) constructed by laminating and integrating magnetic steel sheets and firmly fixed to a shaft; a plurality of magnet housing openings (20) each formed so as to penetrate in an axial direction on the outer circumferential side of the rotor iron core (17) and disposed in a circumferential direction; and permanent magnets (21) housed in the respective magnet housing openings (20). An adhesive agent (22) is disposed only between the outside wall surface (20a) of the inner wall surfaces of each of the magnet housing openings (20), which is positioned outward in the radial direction, and the outside surface (21a) of the surfaces of each of the permanent magnets (21), which is positioned outward in the radial direction. The permanent magnets (21) are each disposed one-sided to the outside wall surface (20a) of each of the magnet housing openings (20) and fixed. A cooling flow path (23) through which a refrigerant flows is constituted by the inside surface (21b) of the surfaces of each of the permanent magnets (21), which is positioned inward in the radial direction, and the inside wall surface (20b) of the inner wall surfaces of each of the magnet housing openings (20), which is positioned inward in the radial direction.

Owner:MITSUBISHI ELECTRIC CORP

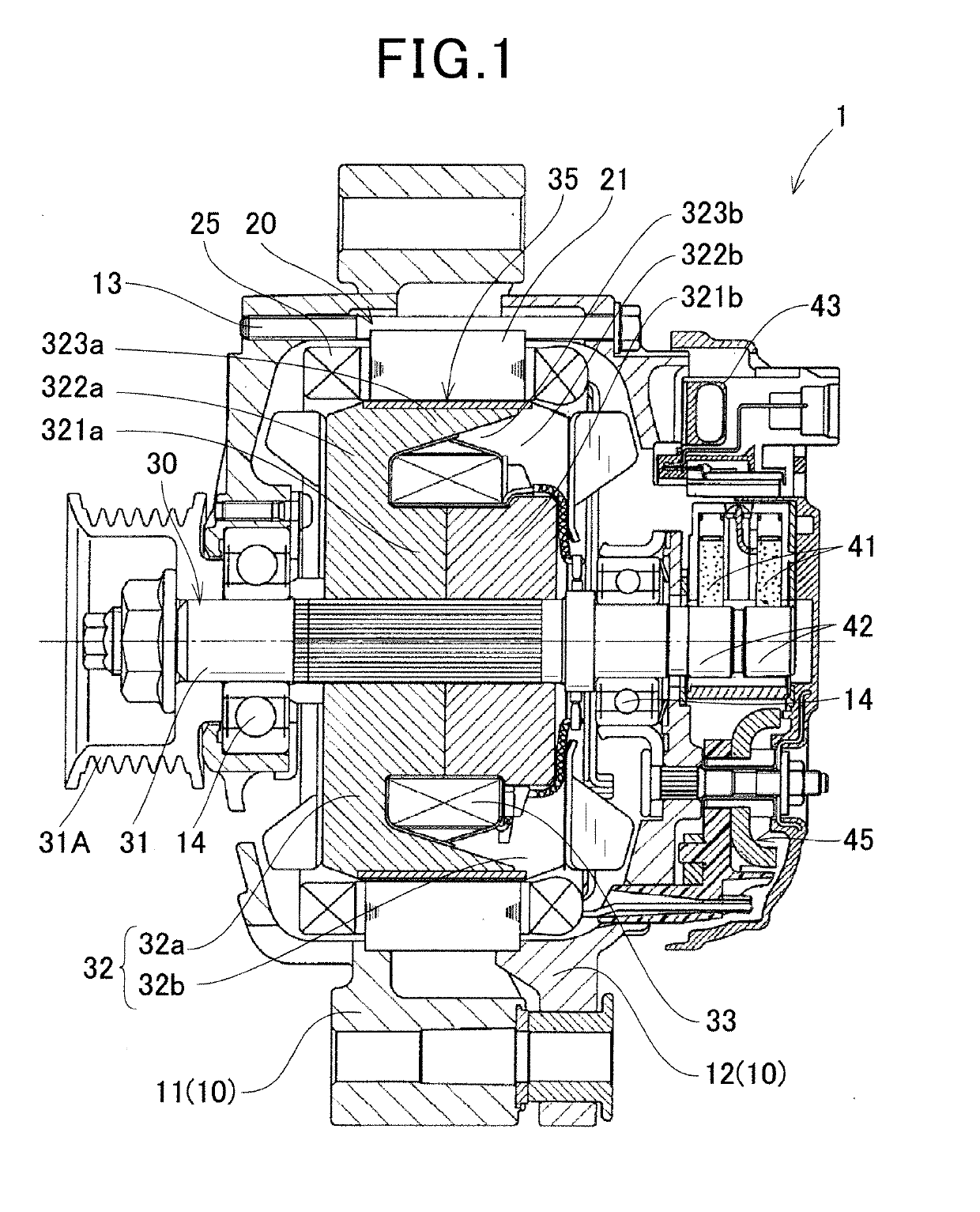

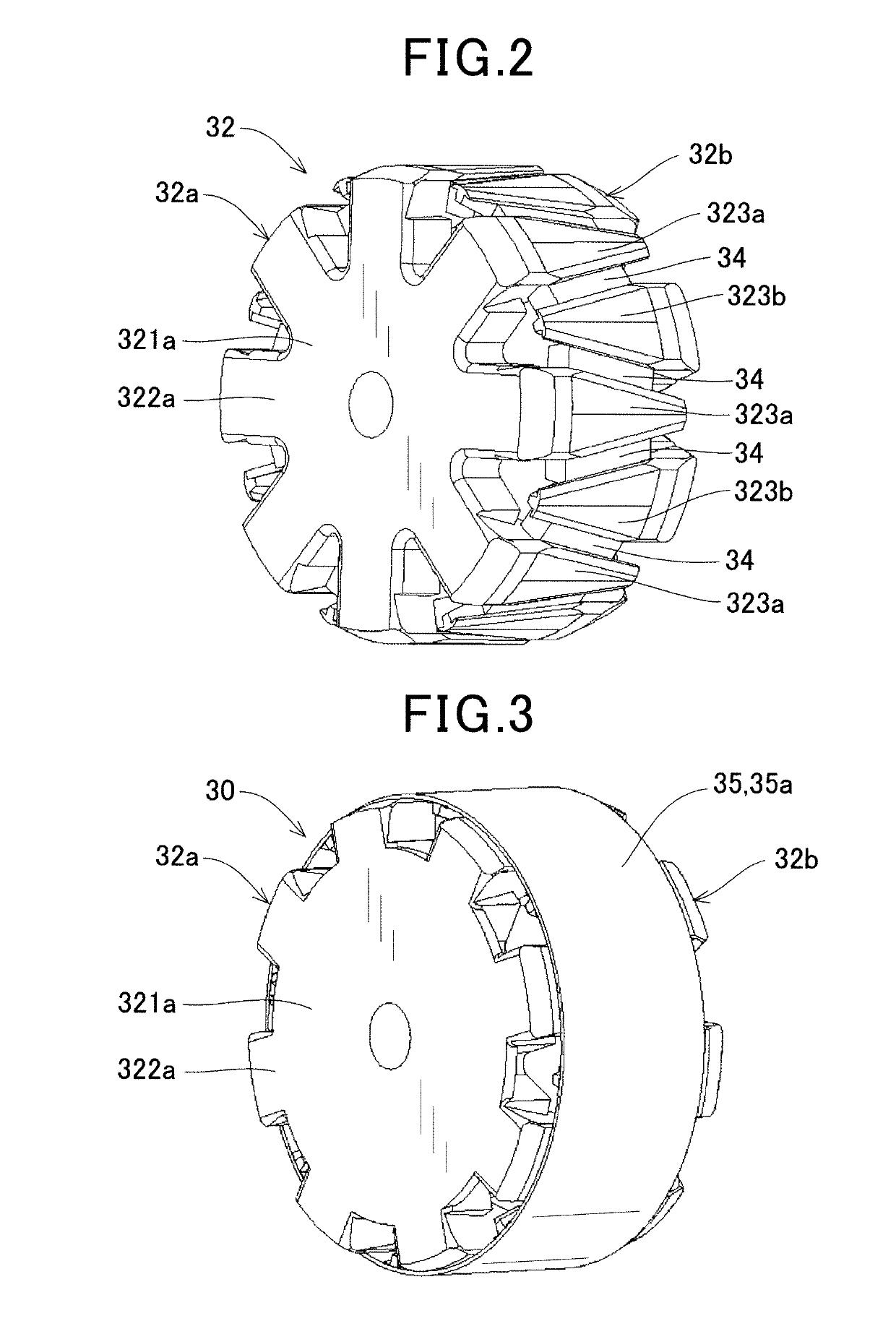

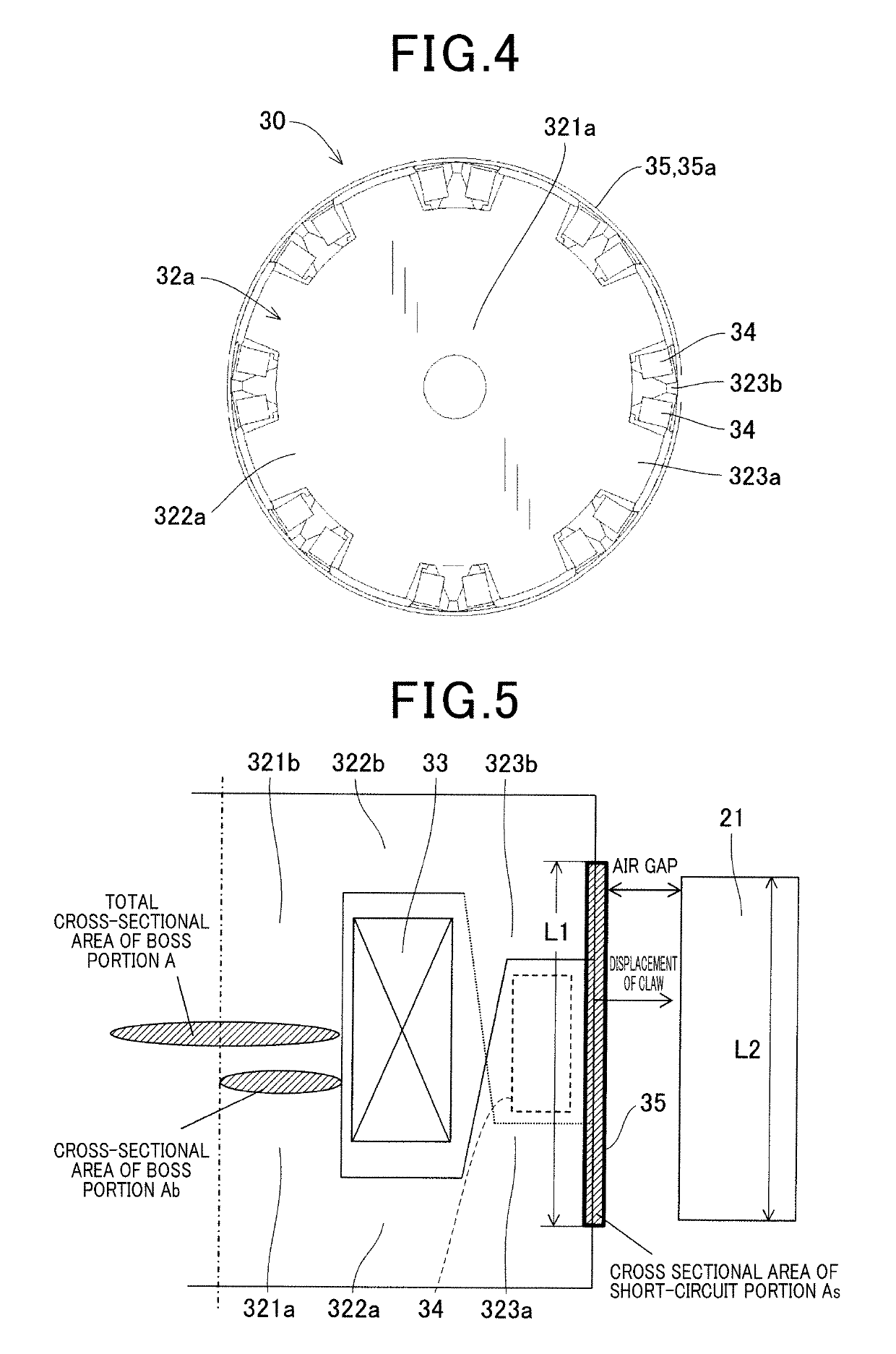

Rotating electric machine

ActiveUS20190157954A1Lower capability requirementsIncrease productionSynchronous machine detailsMagnetic circuitMagnetomotive forceElectric machine

A rotor of a rotating electric machine includes a field core having a cylindrical boss portion, and a plurality of claw-shaped magnetic pole portions that are arranged on the outer side of the boss portion and form poles of alternately different polarities in the circumferential direction, a field winding that is wound around the outer periphery of the boss portion and generates a magnetomotive force by energization, a permanent magnet disposed between the circumferentially adjacent claw-shaped magnetic pole portions so as to have its easy axis of magnetization oriented in the circumferential direction and have its polarity coincide with the polarity of the claw-shaped magnetic pole portions which alternately appears by excitation, and a magnetic flux short circuit member having a short circuit portion that magnetically connects the claw-shaped magnetic pole portions circumferentially arranged to have different polarities.

Owner:DENSO CORP

Amorphous magnetic component, electric motor using same and method for manufacturing same

InactiveUS20130264894A1Simple moldingExcellent soft magnetic propertiesMagnetic circuit rotating partsTransportation and packagingCompression moldingMetal powder

An amorphous magnetic component for use in a high-power, high-speed electric motor, in which amorphous metal materials are powdered, compressed, and molded, to be easily molded into magnetic components of a complex shape, and crystalline metal powder of excellent soft magnetic properties is added to the amorphous alloy powder, to promote improvement of a magnetic permeability and improvement of a packing density at the time of compression molding. A method of manufacturing the amorphous magnetic component; includes the steps of: pulverizing ribbons or strips of amorphous alloys to obtain plate-shaped amorphous alloy powder; classifying the amorphous alloy powder, and mixing the amorphous alloy powder with spherical soft magnetic powder, in order to improve magnetic permeability and packing density, to obtain mixed powder; mixing the mixed powder with a binder, to be molded into a shape of the magnetic components; and sintering the molded magnetic components to implement magnetic properties.

Owner:AMOTECH

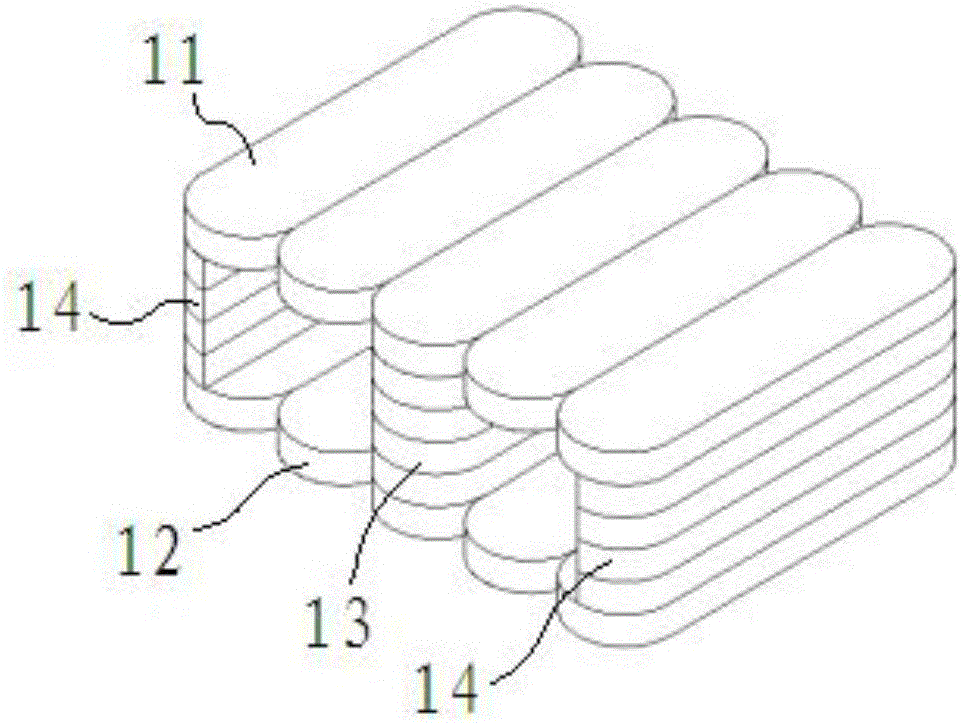

Planar transformer

ActiveCN105914011AEasy to produceIncreased reluctanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMagnetic reluctanceMiniaturization

The invention discloses a planar transformer which comprises a magnetic core and a coil winding; the magnetic core comprises a top plate, a bottom plate, a middle column and two edge columns, the middle column and the two edge columns are located between the top plate and the bottom plate, the coil winding and the magnetic core are assembled together, the top plate and the bottom plate are composed of a whole magnetic block or formed by laying and splicing a plurality of unit magnetic block bodies, and the middle column and the edge columns are formed by stacking multiple unit magnetic block bodies; each unit magnetic block body is a flat strip-shaped block body, and a preset gap is formed between the two ends of the two adjacent unit magnetic block bodies which are laid and spliced. The whole magnetic core is formed by piling multiple unit magnetic block bodies, the transformer can still maintain high efficiency under high frequency, the unit magnetic block body is the flat strip-shaped block body, it is convenient to produce the magnetic core, it is beneficial to miniaturization and planarizartion, and a piled production mode is more beneficial to automated generation; the preset gap is formed between the two ends of the two adjacent unit magnetic block bodies which are laid and spliced, magnetic resistance between every two unit magnetic block bodies is increased, an edge magnetic line can be drawn close to the magnetic core, and thus diffusion flux is reduced.

Owner:SHENZHEN MAIJIRUI TECH CO LTD

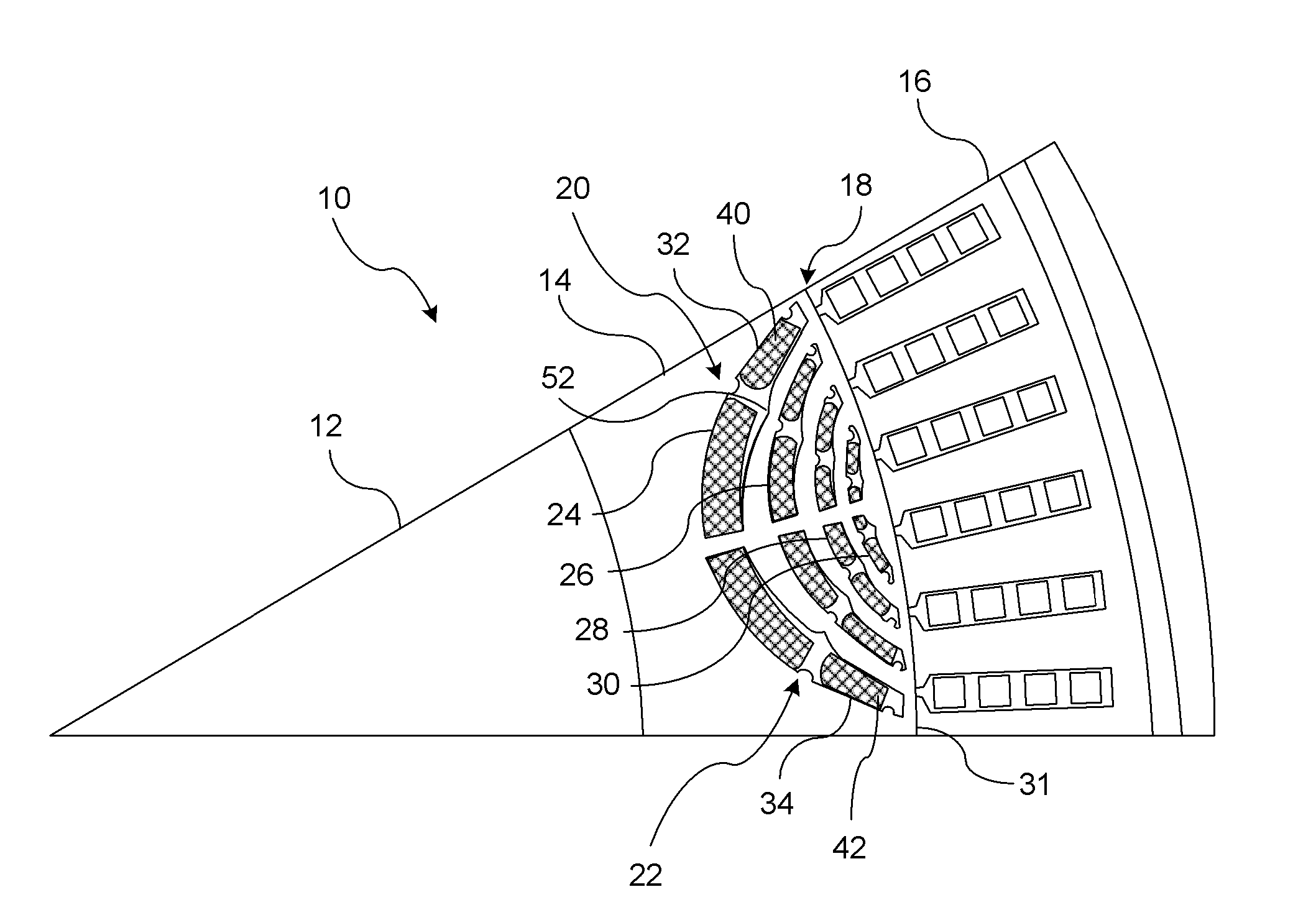

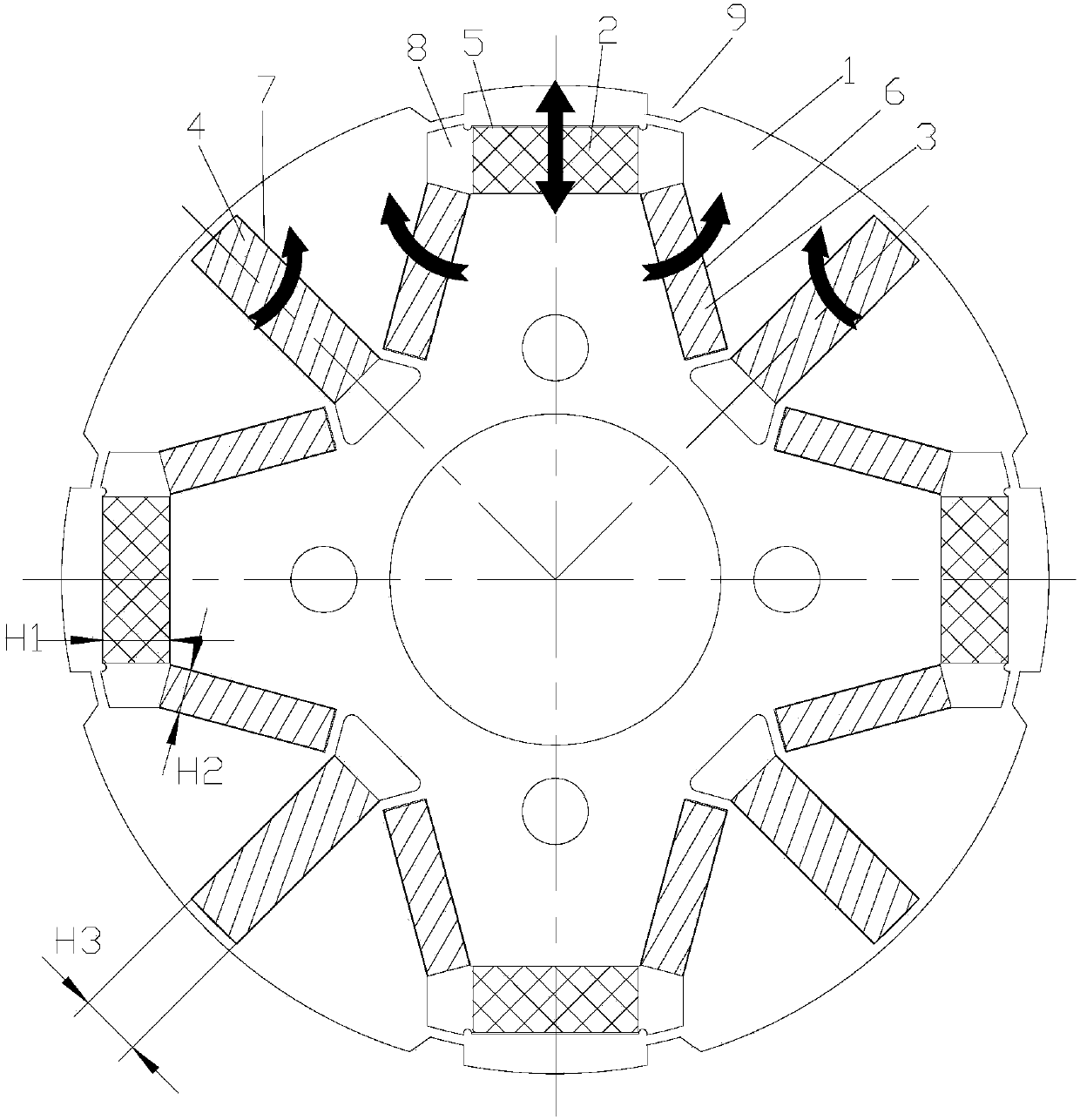

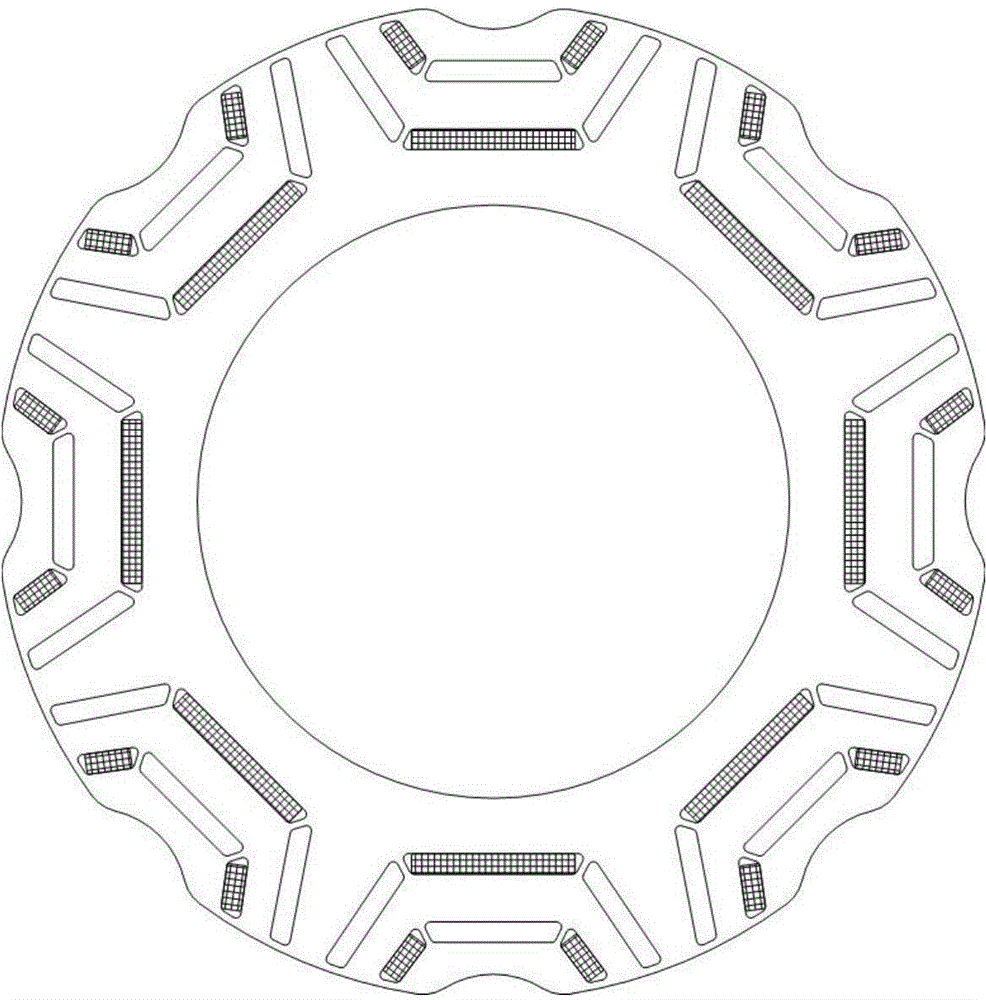

Magnetic barrier for minimizing demagnetization in bi-permanent magnet synchronous machines

ActiveUS8664823B2Low costReduce in quantityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic barrierPermanent magnet synchronous machine

A rotor for a permanent synchronous machine includes a rotor having a plurality of arcuately-shaped cavities formed within a rotor core structure. The plurality of arcuately-shaped cavities substantially concentrically layered with respect to an outer cylindrical wall of the rotor core structure. A plurality of permanent magnets is inserted within the plurality of arcuately-shaped cavities. Each cavity layer retains a permanent magnet of a first magnetic field strength disposed in end sections and a permanent magnet of a second magnetic field strength in a center section of each cavity layer. Each respective cavity includes an air barrier formed between the magnets having different magnetic field strengths. The air barrier generates a reluctance within an air barrier gap for directing a flow of flux generated by each third permanent magnet in a preceding layer in a direction toward each third permanent magnet in a succeeding layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

Moving-magnetic type linear motor

InactiveCN101621244AImprove cooling effectIncrease flux leakageMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesLinear motor

The invention provides a moving-magnetic type linear motor which mainly comprises a stator and a rotor, wherein the stator comprises two yoke supporting rings in the shape of a circular ring, and at least four strip-shaped stator yokes which are uniformly distributed along the circular ring are arranged between the two yoke supporting rings; the inner surface of each stator yoke is in a tooth socket structure which comprises N stator teeth; a coil is coiled on the tooth socket structure; after the coil is electrified, adjacent stator teeth form opposite magnetic poles; the rotor is positioned in a cylindrical cavity surrounded by the stator yokes; for each stator yoke, the rotor has N-1 magnetic poles which are axially arranged in parallel, the magnetic lines of the magnetic poles are distributed in the radial direction, and the polarities of adjacent magnetic poles which are arranged at intervals are opposite; and the rotor is connected with a plate spring through a connection shaft. The moving-magnetic type linear motor reduces the magnetic leakage loss, improves the permanent magnet efficacy, has good radiating effect and simple and compact structure, and is convenient in installation and maintenance.

Owner:HUAZHONG UNIV OF SCI & TECH

Underlayer for reference layer of polycrystalline CPP GMR sensor stack

ActiveUS9412399B2Increased reluctanceImproved magnetic headMagnetic measurementsMagnetic-field-controlled resistorsComputer scienceMagnetoresistance

Owner:WESTERN DIGITAL TECH INC

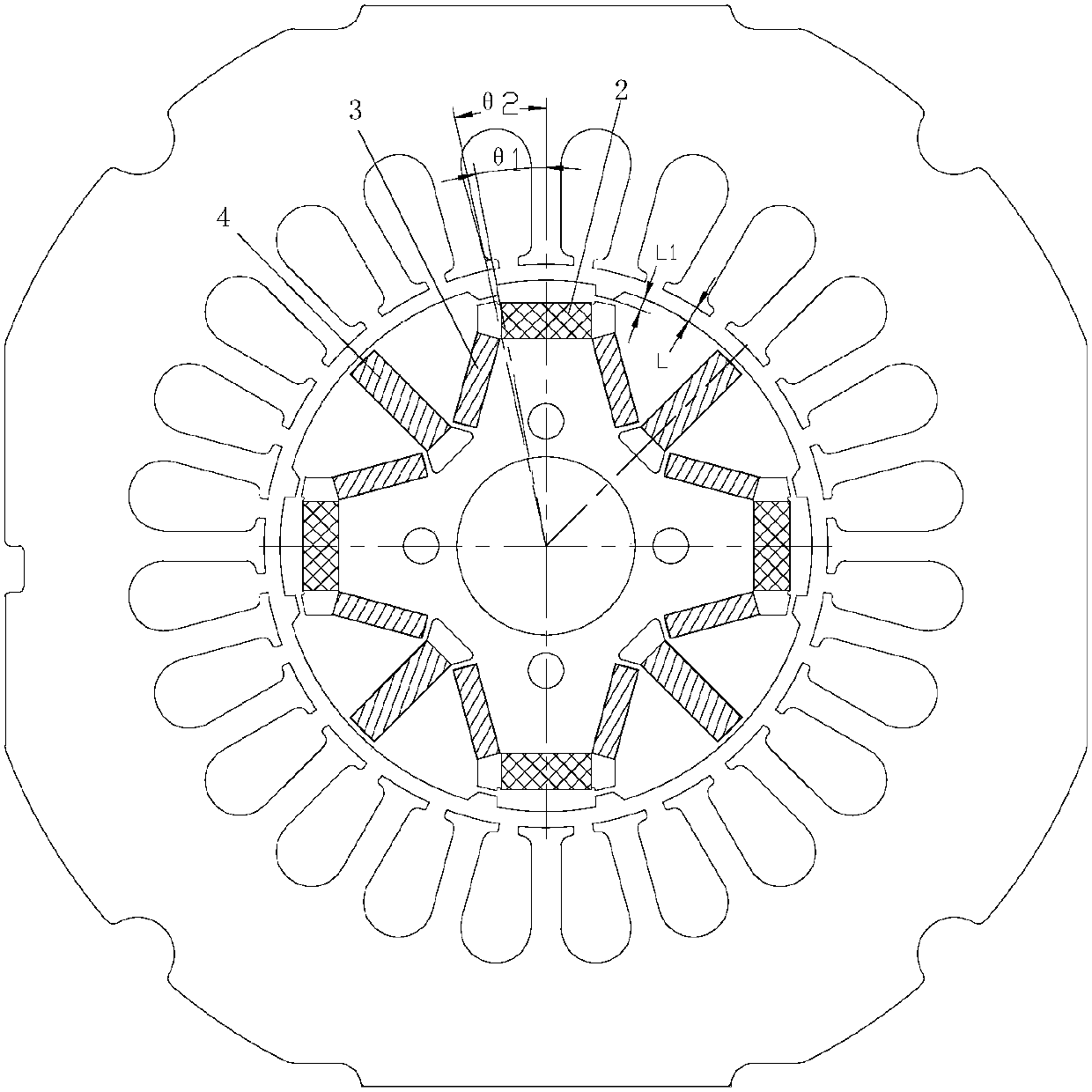

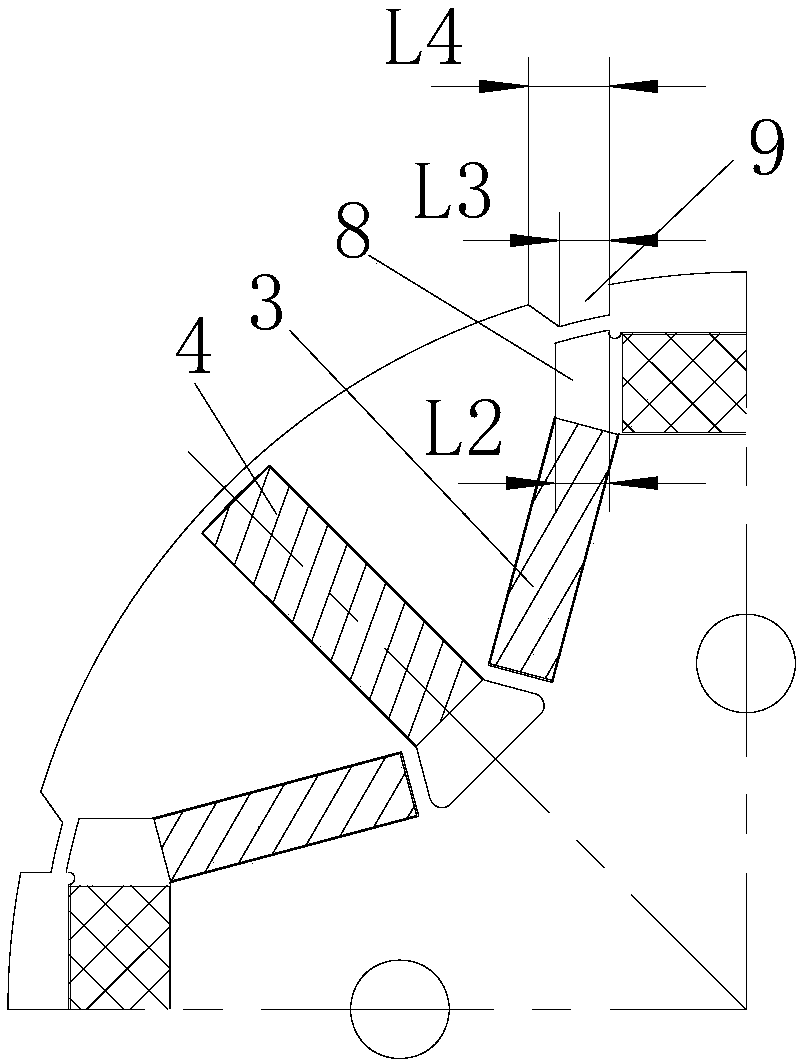

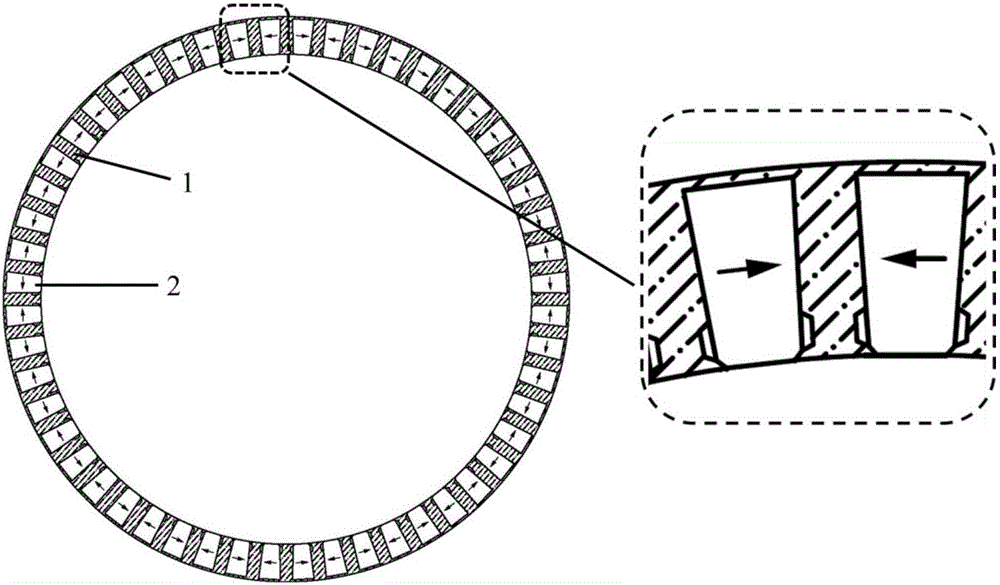

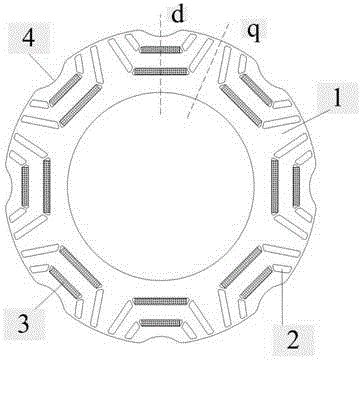

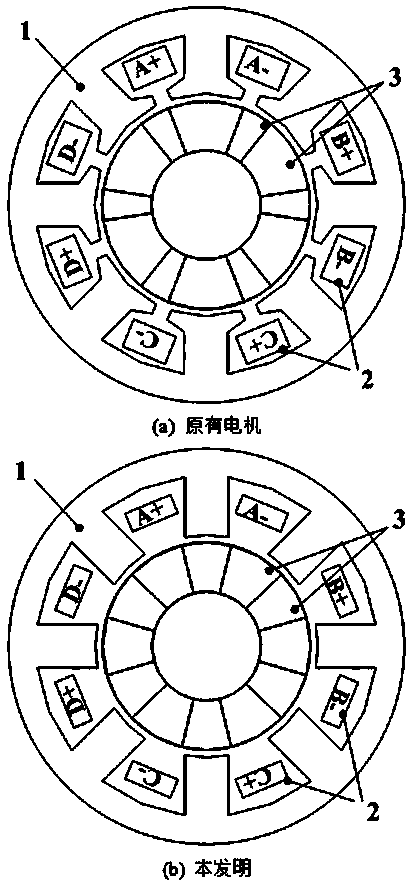

Fractional-slot concentrated winding permanent magnet synchronous motor and design method thereof for improving reluctance torque

InactiveCN108199509ALow failure rateReduce temperature riseMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorMetallic materials

The invention discloses fractional-slot concentrated winding permanent magnet synchronous motor and a design method thereof for improving reluctance torque. The fractional-slot concentrated winding permanent magnet synchronous motor comprises a stator and a rotor, wherein the stator is slotted along the peripheral direction to form fault-tolerant teeth and armature teeth arranged alternately; an armature winding is wound on the armature teeth, the fault-tolerant teeth and the armature teeth are different in widths, and the widths of the armature teeth are wider than those of the fault-tolerantteeth; the rotor consists of a permanent magnet, a rotor core and a magnetic obstacle, the permanent magnet is a double-layer permanent magnet, the rotor core is composed of a plurality of independent units, and during machining, the rotor is wrapped with a non-metal material to form a compact structure. The rotor core is segmented along the axis pole direction of the permanent magnet, and the width of the upper part of the magnetic obstacle during segmentation is narrower than that of the lower part. The permanent magnet synchronous motor has the advantages that the direct-axis inductance can be reduced through the special magnetic obstacle design, the influence on quadrature axis inductance can also be reduced as much as possible, and the subharmonic of the motor is free of obvious inhibition. Therefore, the reluctance torque of the motor can be improved effectively, and the iron loss and eddy-current loss of the motor are reduced.

Owner:JIANGSU UNIV

Synchronous reluctance motor rotor applied to hybrid power system

InactiveCN104810945AReduce usageLow costMagnetic circuit rotating partsSynchronous machine detailsSynchronous reluctance motorPunching

The invention discloses a synchronous reluctance motor rotor applied to a hybrid power system. The synchronous reluctance motor rotor applied to the hybrid power system comprises a rotor core and magnetic steel. The rotor core is formed by rotor punching sheets in an overlying mode. Each rotor punching sheet comprises a plurality of symmetrical magnetic poles, and the polarities of every two adjacent magnetic poles are opposite. Each magnetic pole comprises a plurality of layers of grids, wherein the magnetic steel is placed in the grids. Grooves are formed in the excircle of the rotor in the straight axes in the direction facing the circle center of the rotor.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

Electronic device for the transport of numerical information

InactiveUS20080232479A1Maximise variationReduce areaReliability increasing modificationsSolid-state devicesElectricityElectrical resistance and conductance

An electronic device designed to transport digital information (“0”, “1”) over long distances, including a transmitter generating current pulses and at least one assembly of receivers converting the received current pulses into logic pulses which are compatible with the operation of standard electronic logic circuits. Each receiver includes a pair of magnetoresistive stacks containing at least one hard ferromagnetic layer and one soft ferromagnetic layer separated by a non-ferromagnetic interlayer, the hard layer of each of the magnetoresistive stacks being pinned in a magnetic orientation perpendicular to an easy-magnetization axis which is used as a reference for the soft layer of the same stack. The soft layer of each magnetoresistive stack has a magnetic orientation which can be modulated by the magnetic field generated by current pulses delivered by the transmitter so as to cause modification of the transverse resistance of the stack sufficient to trigger an electrical signal.

Owner:CENT NAT DE LA RECH SCI 15

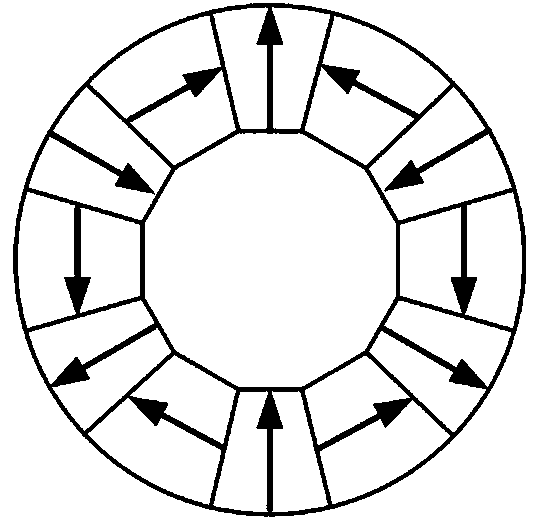

High slot-fill factor high-performance permanent magnet motor with open slots and straight teeth

InactiveCN103647421ACompact structureReduce usageMagnetic circuit rotating partsMagnetic circuit stationary partsThermal isolationFill factor

The invention discloses a high slot-fill factor high-performance permanent magnet motor with open slots and straight teeth, the motor including a stator and a rotor. The stator includes a stator core and stator windings. Stator teeth are made into straight teeth with equal tooth width and can be used for improving the slot-fill factor. As for the stator windings, single layer concentrated windings are employed, and each slot is wound by a winding. The rotor is composed of permanent magnets and a rotating shaft, and an air gap exists between the stator and the rotor. The permanent magnets are composed of permanent magnets arranged in a Halbach array, and are divided into radial permanent magnets and tangential permanent magnets according to different magnetizing directions, and each permanent magnet is of fan-shaped structure. The fan-shaped permanent magnets are arranged in an actinoid manner around an axial lead. The Halbach-type permanent magnet array can improve power density and reduce torque ripple. The motor provided by the invention is simple in structure, high in slot-fill factor, high in no-load back EMF sinusoidal degree, small in torque ripple and high in mechanical robustness, and is conducive to reducing positioning torque of the motor. In addition, physical isolation, thermal isolation and decoupling of a magnetic circuit are arranged between phases of the motor.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com