Fractional-slot concentrated winding permanent magnet synchronous motor and design method thereof for improving reluctance torque

A permanent magnet synchronous motor, concentrated winding technology, applied to synchronous motors with stationary armatures and rotating magnets, shapes/styles/structures of winding conductors, magnetic circuit rotating parts, etc. Low resistance torque, etc., to reduce the risk of short-circuit between phases, reduce losses, and achieve the effect of phase-to-phase isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

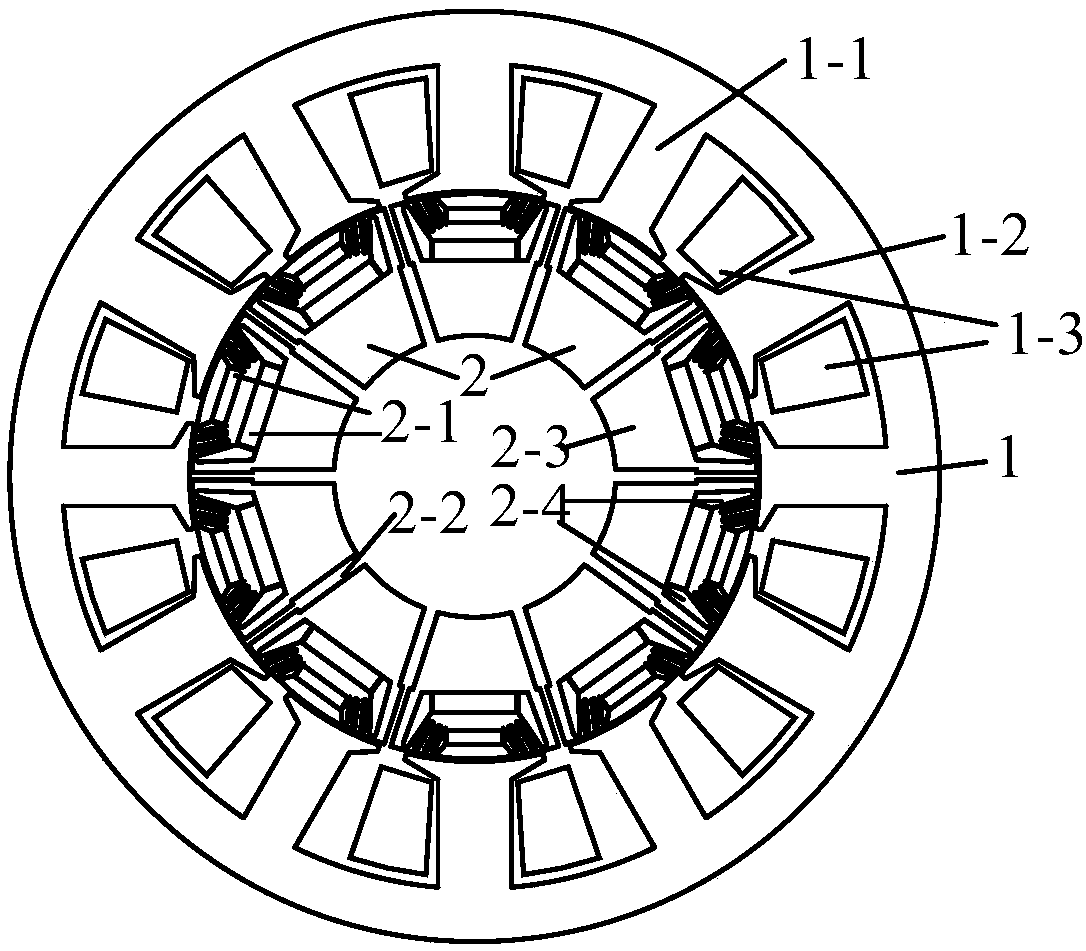

[0031] Please refer to figure 1 , the present invention is a method for increasing the reluctance torque of a fractional slot concentrated winding permanent magnet synchronous motor with high reluctance torque ratio, mainly by increasing the reluctance of the direct-axis magnetic circuit and reducing the direct-axis inductance to achieve the design purpose. The structure of the present invention includes a stator 1 and a rotor 2. There is an air gap between the stator 1 and the rotor 2, and the length of the air gap is selected according to the motor structure and actual requirements.

[0032] Take a 12-slot 10-pole motor as an example, figure 1 It is a structural schematic diagram of a new fractional slot concentrated winding permanent magnet synchronous motor. The stator 1 includes two structures of a fault-tolerant tooth 1-1 and an armature tooth 1-2. The armature winding 1-3 is wound on the armature teeth 1-2. The tooth width ratio of the armature tooth and the toleranc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com