Extruding processing technology of aluminium alloy tubing with large diameter

An aluminum alloy pipe and extrusion processing technology, which is applied in the field of aluminum alloy extrusion, can solve the problems of difficult production of large-caliber aluminum alloy pipe, small diameter of aluminum alloy pipe production, and large consumption of auxiliary equipment, etc., to eliminate long production cycle, Effect of improving strength characteristics and reducing device failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

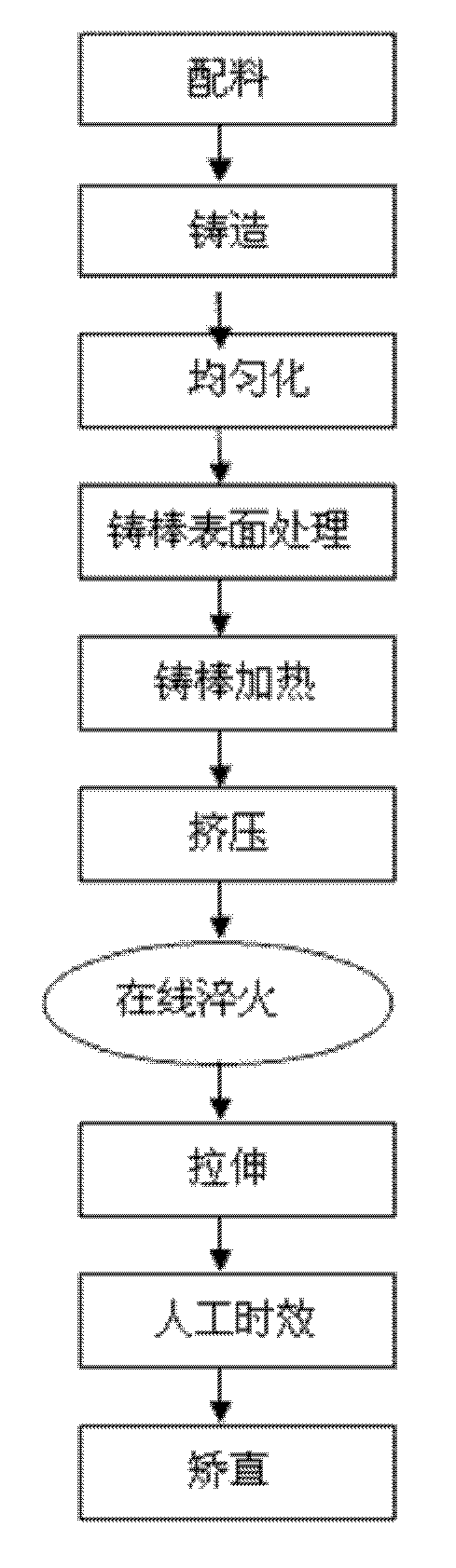

[0022] Embodiment 1: a large-diameter aluminum alloy pipe extrusion process, comprising the following steps:

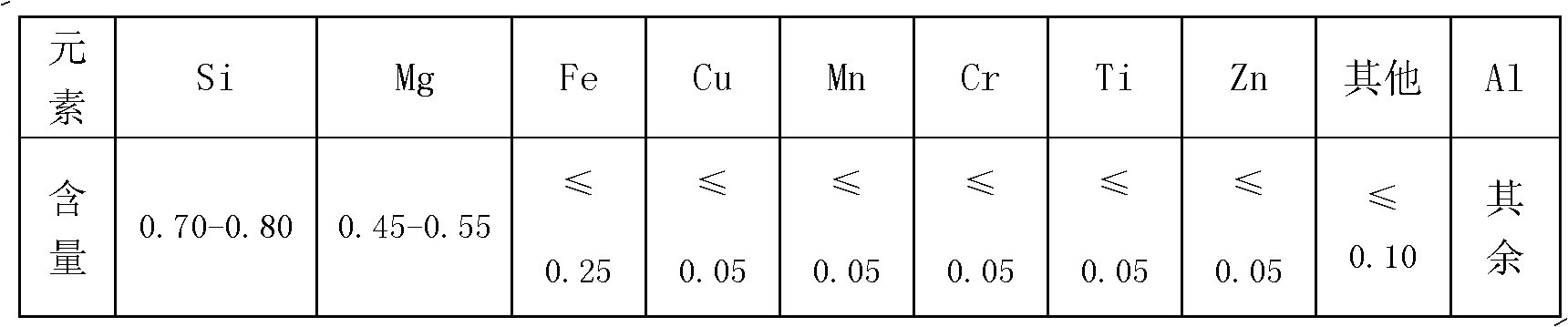

[0023] a. Ingredients: This profile adopts 6005A alloy, and the mass percentage ratio of each element meets the following requirements;

[0024] the element

Si

Mg

Fe

Cu

mn

Cr

Ti

Zn

other

Al

content

0.70

0.55

0.25

0.05

0.05

0.05

0.05

0.05

0.10

the remaining

[0025] The ingredients can follow the following process: First, put the ingredients into the melting furnace for smelting. The furnace is controlled at 740°C, and the flux is used for refining and covering. After feeding, when molten aluminum appears in the furnace, start stirring, and after refining and slag removal to obtain qualified components, inject molten aluminum from the melting furnace into the holding furnace, keep the furnace temperature at 730°C for 20 minutes, and then use ar...

Embodiment 2

[0035] Embodiment 2: a large-diameter aluminum alloy pipe extrusion process, comprising the following steps:

[0036] a. Ingredients: This profile adopts 6005A alloy, and the mass percentage ratio of each element meets the following requirements;

[0037] the element

Si

Mg

Fe

Cu

mn

Cr

Ti

Zn

other

Al

content

0.80

0.45

0.25

0.05

0.05

0.05

0.05

0.05

0.10

the remaining

[0038] The ingredients can follow the following process: put the ingredients into the melting furnace for smelting in turn, control the temperature in the furnace at 740 ° C, and use flux to refine and cover; After qualified components, pour the aluminum liquid from the melting furnace into the holding furnace, keep the furnace temperature at 740°C for 30 minutes, and then use argon to bring the hydrogen and fine impurities in the aluminum liquid to the surface, thereby reducing the hydrog...

Embodiment 3

[0048] Embodiment 3: A large-diameter aluminum alloy pipe extrusion process, comprising the following steps:

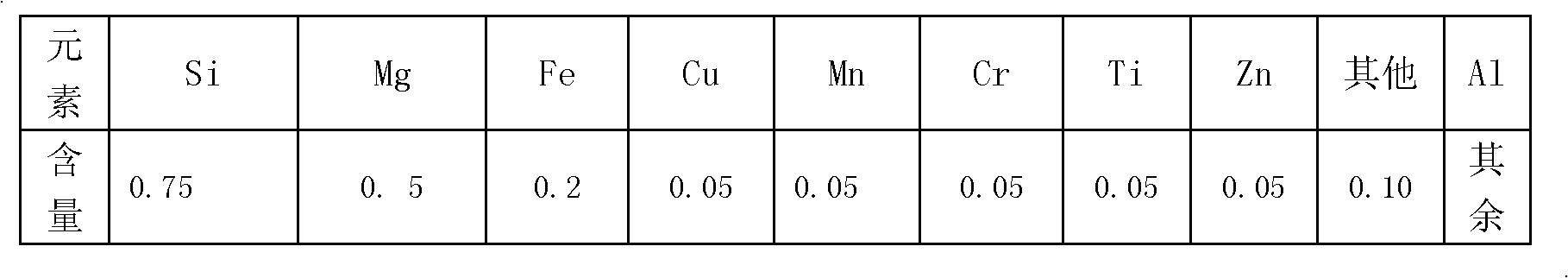

[0049] a. Ingredients: This profile adopts 6005A alloy, and the mass fraction ratio of each element meets the following requirements:

[0050]

[0051]The ingredients can follow the following process: First, put the ingredients into the melting furnace for smelting. The furnace is controlled at 740°C, and the flux is used for refining and covering. After feeding the materials, when molten aluminum appears in the furnace, start stirring, and after refining and slag removal to obtain qualified components, pour the molten aluminum from the smelting furnace into the holding furnace, keep the furnace temperature at 735°C for 25 minutes, and then use argon gas to Bring the hydrogen and fine impurities in the aluminum liquid to the surface, thereby reducing the hydrogen content in the aluminum liquid;

[0052] b. Casting: This method adopts oil-slip casting, the casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com