Nano-carbon-reinforced wear-resistant composite material

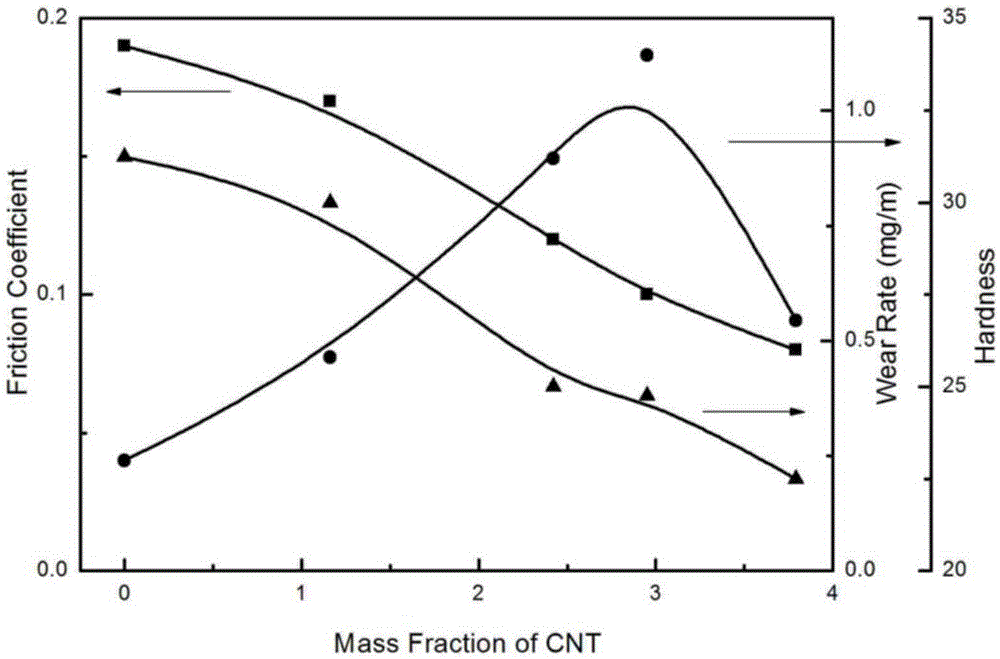

A composite material and nano-carbon technology, which is applied in the field of wear-resistant composite materials reinforced by nano-carbon materials, to achieve the effects of stabilizing the friction coefficient, improving thermal conductivity, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

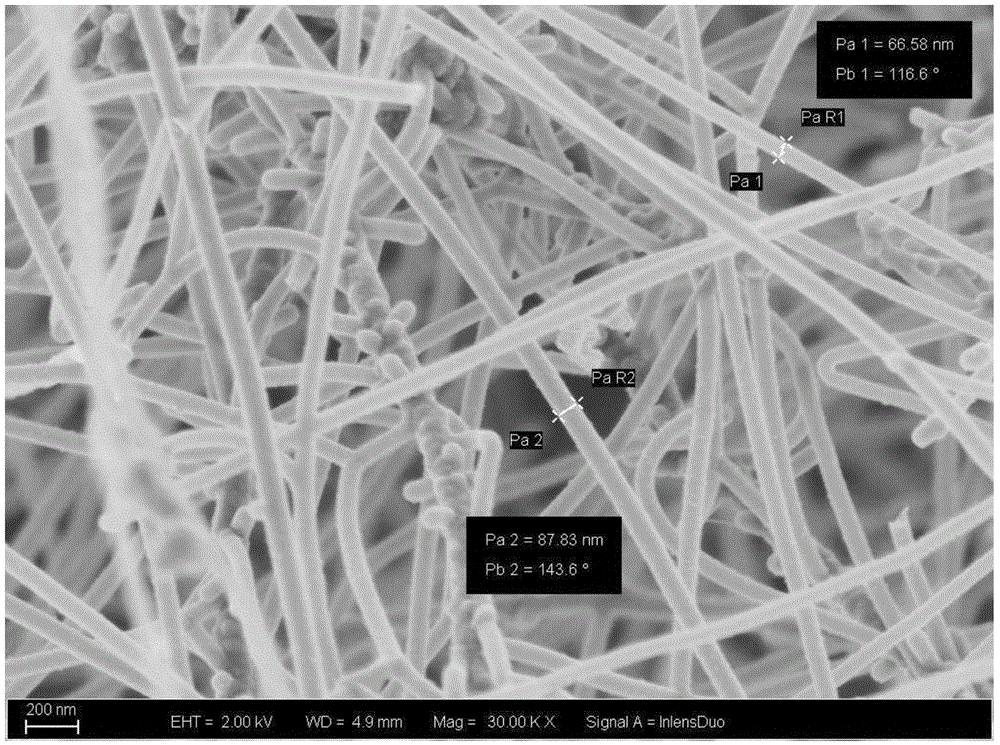

[0029] The nanocarbon-reinforced wear-resistant composite material involved in this embodiment includes: a copper matrix with a particle size of 5 to 10 microns; ceramic powder of silicon carbide and molybdenum disulfide with a particle size of 300 to 3 microns; The nano-carbon is selected from multi-walled carbon nanotubes, the outer diameter of which is 50-80 nanometers, and the length is 3-5 microns. The composite material formula includes 75% of copper powder, 10% of silicon carbide, 12% of molybdenum disulfide, and 3% of carbon nanotubes in weight ratio. In order to compare the application effect of CNT, in this example, 1000-mesh flake graphite powder (with a particle size of about 13um) of the same weight was used instead of carbon nanotubes, and a comparative sample was prepared under the same conditions. The specific preparation method is as follows:

[0030] 1) Dry the powders of carbon nanotubes, silicon carbide, molybdenum disulfide and other components at 85°C, a...

Embodiment 2

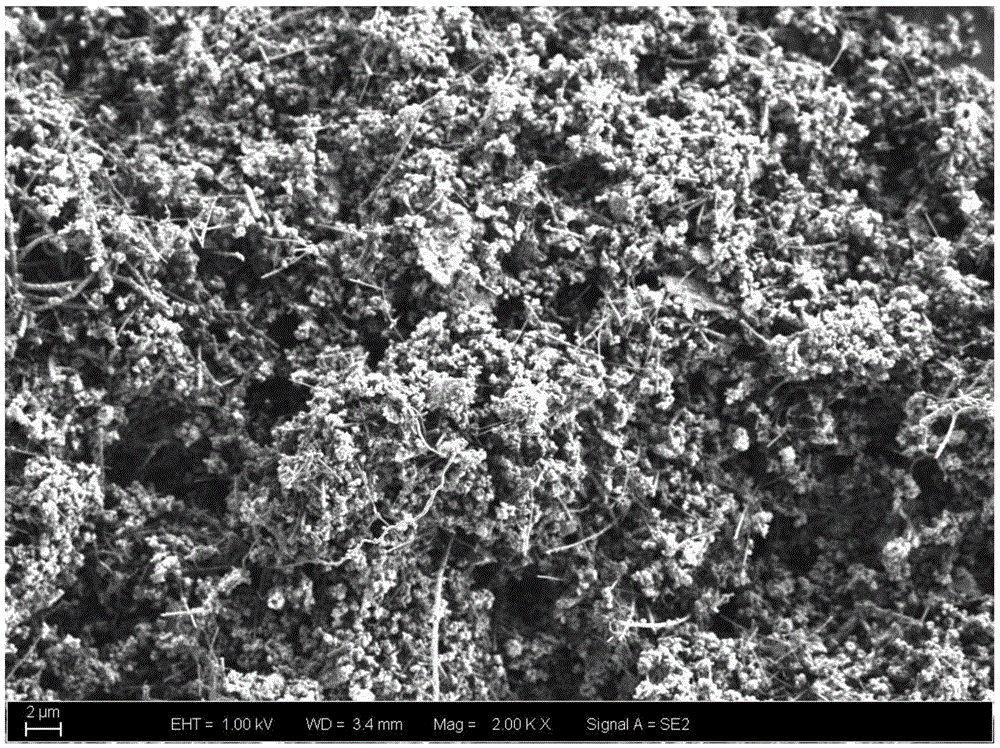

[0038] The nano-carbon reinforced wear-resistant composite material involved in this embodiment includes: iron powder (70-100 microns in particle size), copper powder (50-100 microns in particle size), manganese powder (50-100 microns in particle size ), chromium powder (50-100 microns in particle size), molybdenum disulfide powder (50-100 microns in particle size), and a 4:1 mixture of single-walled carbon nanotubes and multi-walled carbon nanotubes for nano-carbon, among which single-walled carbon The outer diameter of the nanotube is 2 nanometers, and the length is 10-30 micrometers, and the outer diameter of the multi-walled carbon nanotube is 30-60 nanometers, and the length is 5-15 micrometers. The formula of the composite material includes 70% of iron powder, 16% of copper powder, 8% of manganese powder, 4% of chromium powder, 7% of molybdenum disulfide and 1% of carbon nanotube according to the weight ratio. In order to compare the application effect of CNT, an equal w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com