Patents

Literature

4299 results about "Nano carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

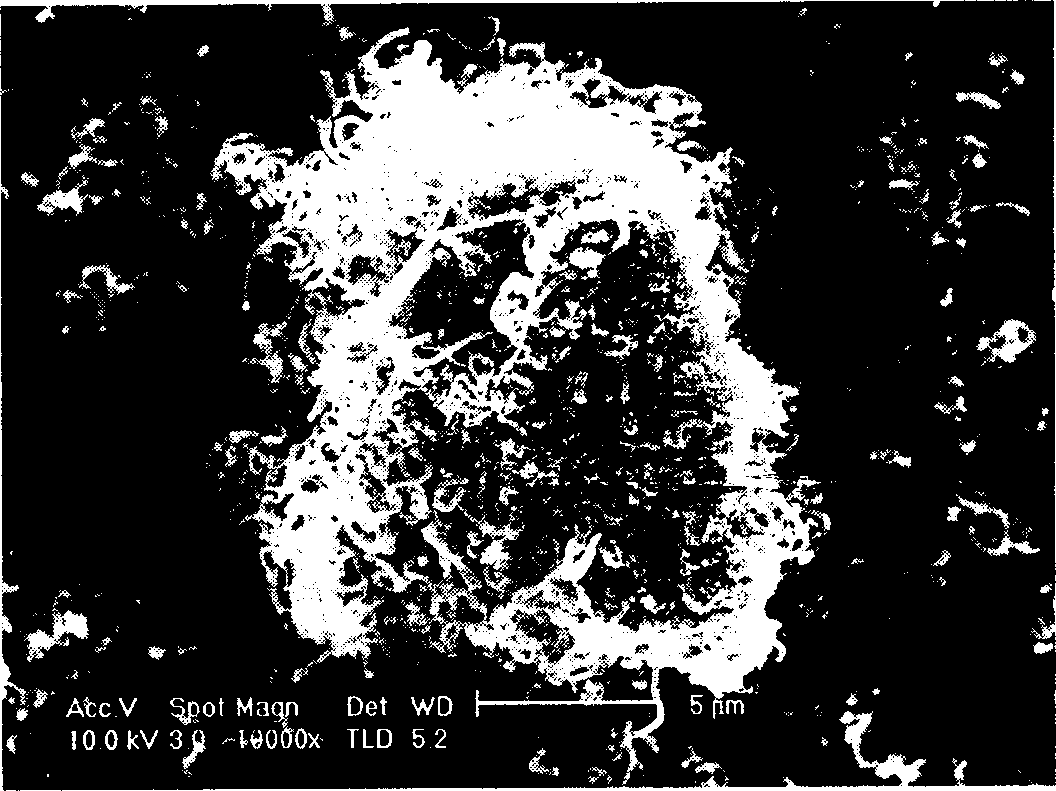

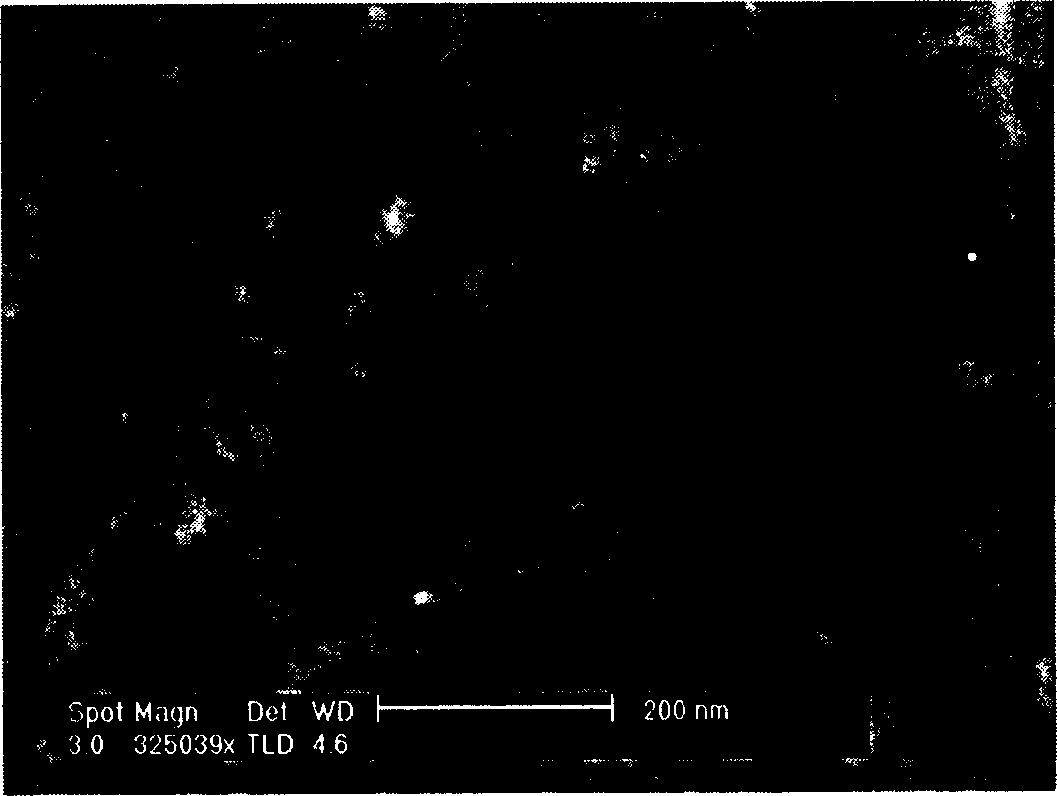

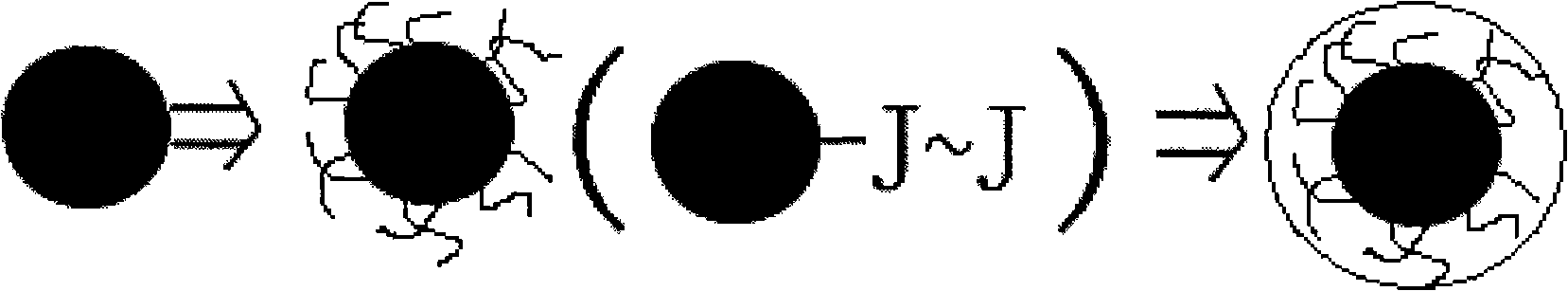

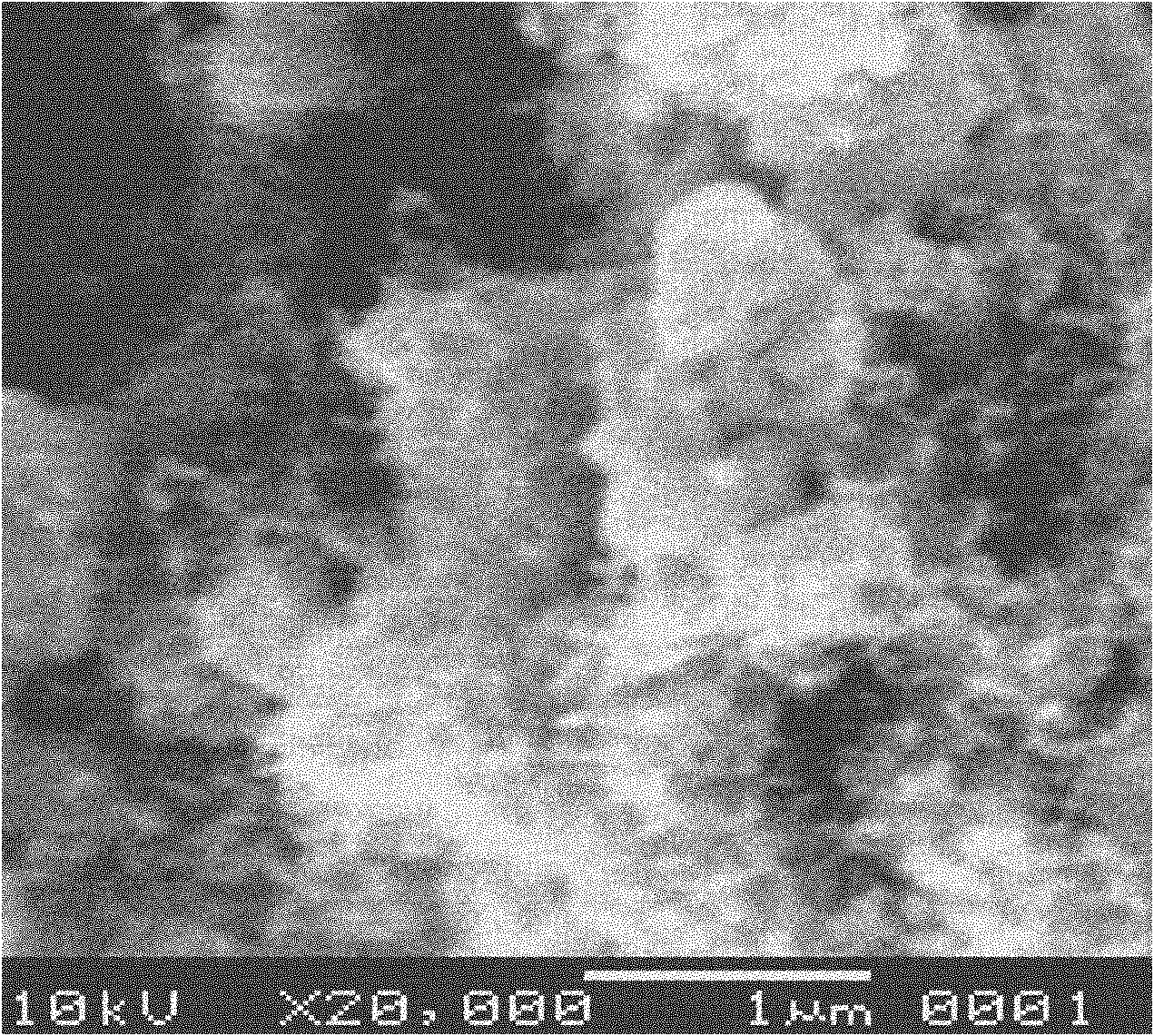

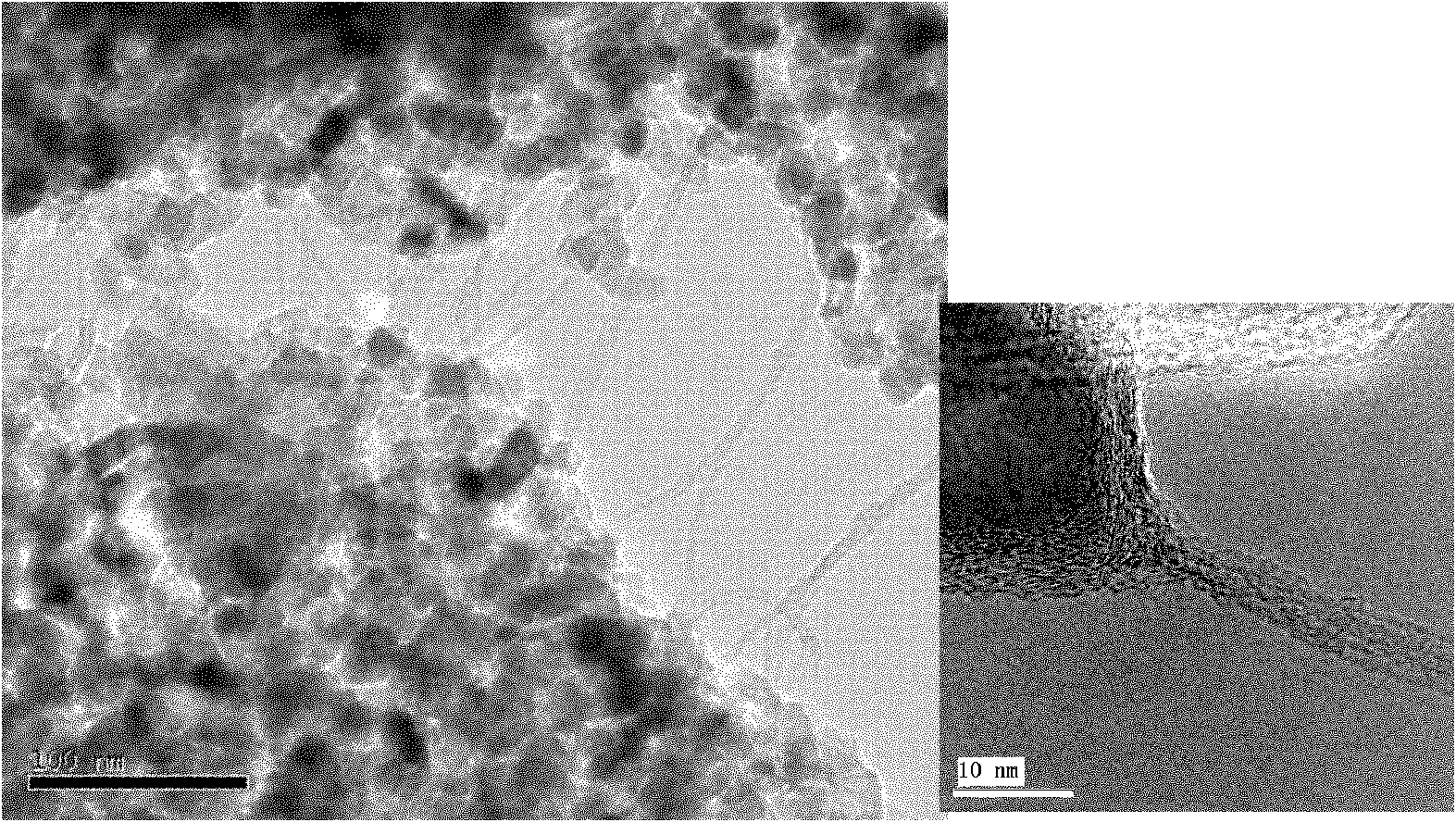

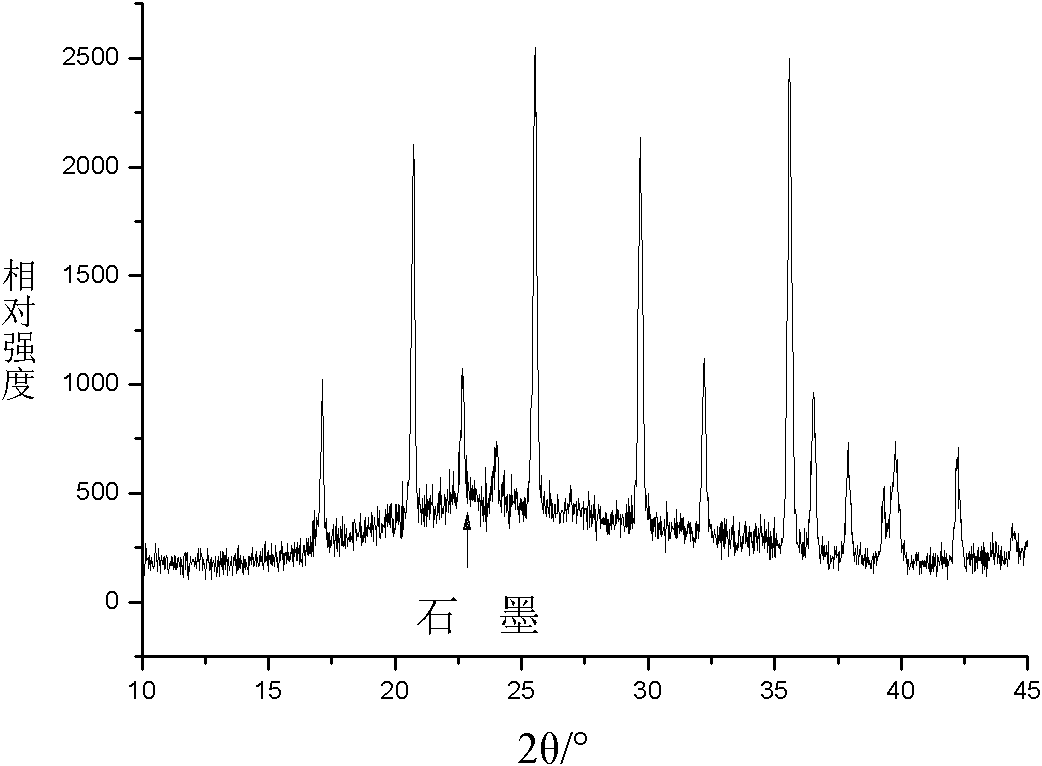

Carbon/silicon/carbon nano composite structure cathode material and preparation method thereof

The invention discloses a carbon / silicon / carbon nano composite structure cathode material and a preparation method thereof, belonging to the technical field of electrochemical power supply technologies. The cathode material consists of a carbon-based conductive substrate, nano silicon and a nano carbon coating layer, wherein the nano silicon is uniformly distributed on the carbon-based conductive substrate; the nano carbon coating layer is arranged on the surface of the nano silicon; the carbon-based conductive substrate is porous carbon, a carbon nanotube or graphene; the nano silicon exists in the state of nanoparticles or nano films; the weight percentage of the nano silicon in the cathode material is 10-90 percent; and the thickness of the nano carbon coating layer is 0.1-10 nanometers. The preparation method comprises the following steps of: depositing nano silicon on the carbon substrate in a reaction space in oxygen-free atmosphere by adopting a chemical vapor deposition process; and coating nano carbon on the surface of the nano silicon by adopting the chemical vapor deposition process. In the obtained carbon / silicon / carbon composite cathode material, the volume change of a silicon electrode material is controlled effectively in the charging and discharging processes, the electrode structure is kept complete, the circulation volume is large, the circulation service life is long, and the electrochemical performance is high.

Owner:TSINGHUA UNIV

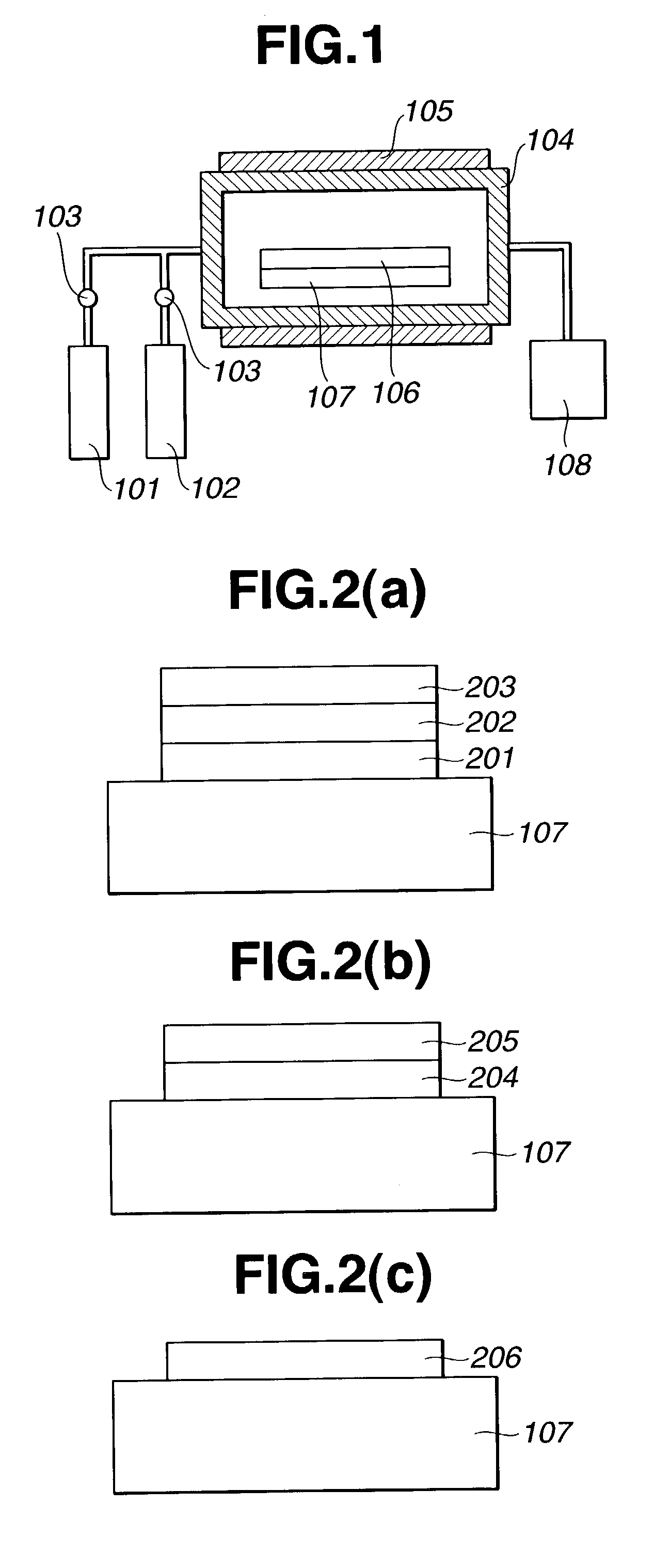

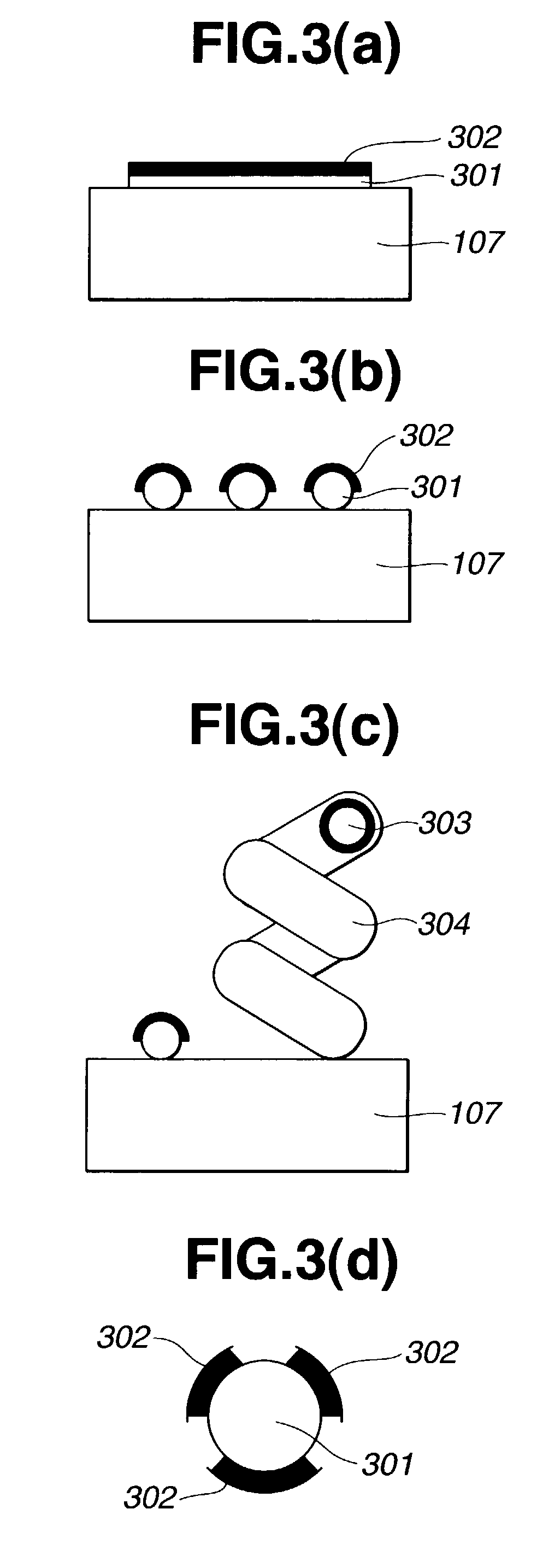

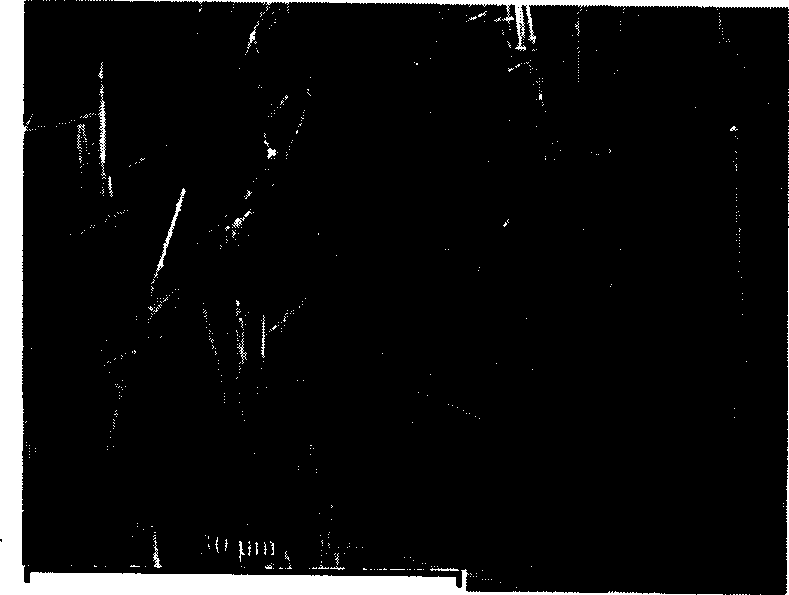

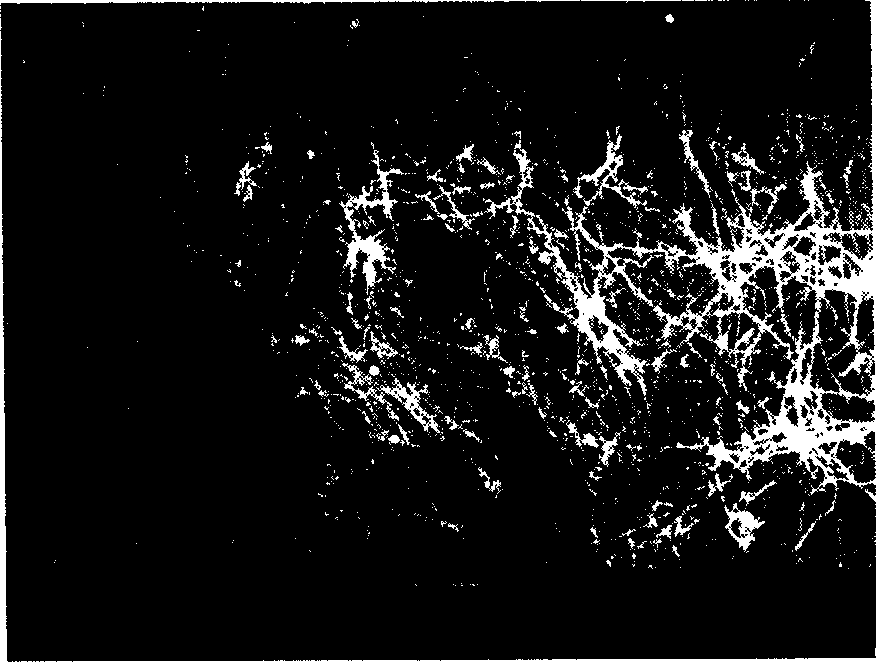

Method for preparing nano-carbon fiber and nano-carbon fiber

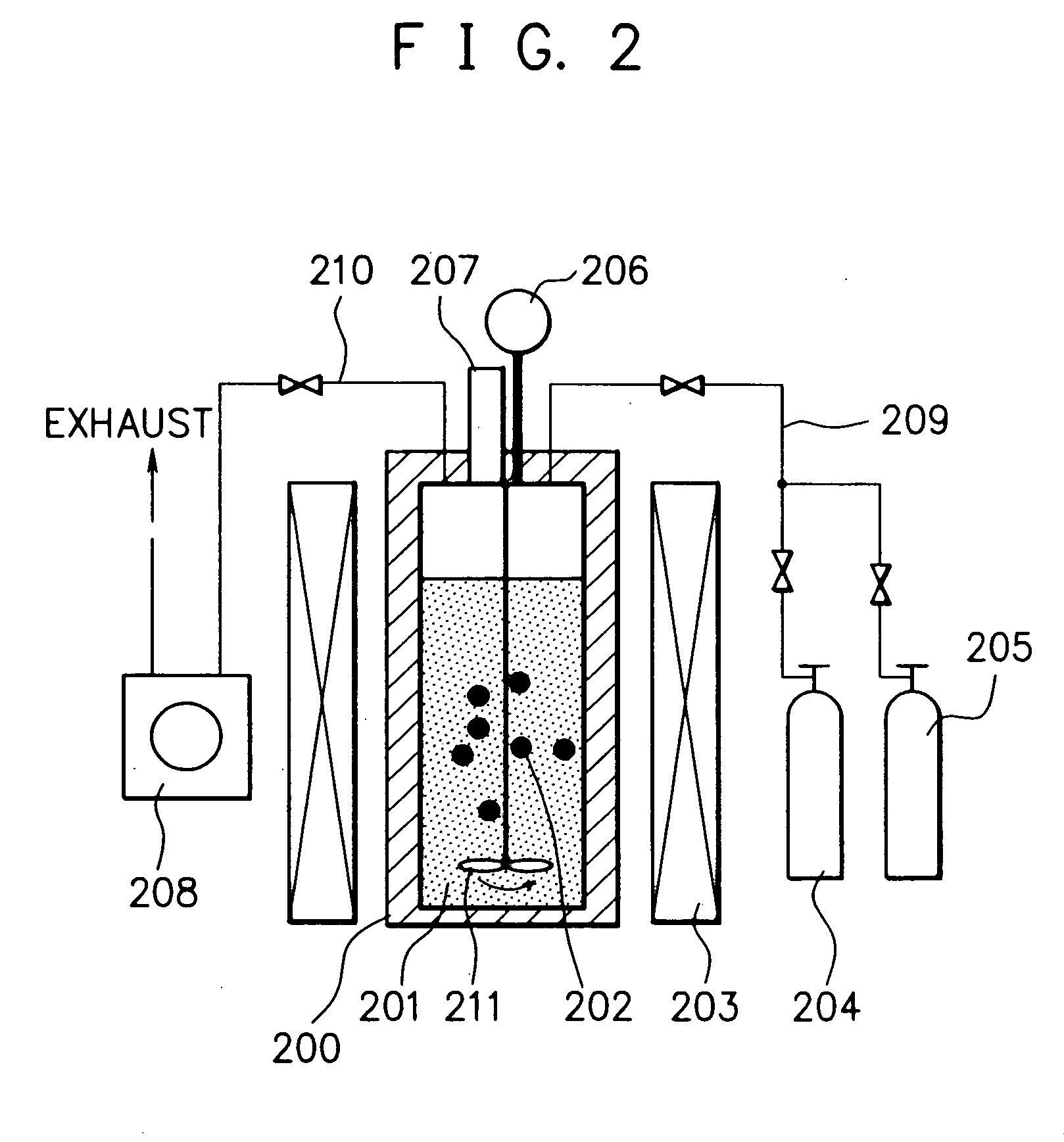

A carbon nano-fiber, particularly twisted carbon nano-fiber such as a carbon nano-coil, carbon nano-twist, carbon nano-rope is produced by means of a catalyst CVD method using carbon-containing gas as a raw material and a catalyst comprising one or plural components selected from the group consisting of Cr, Mn, Fe, Co, Ni and oxide thereof and one or plural components selected from the group consisting of Cu, Al, Si, Ti, V, Nb, Mo, Hf, Ta, W and oxide thereof is used.

Owner:FUTABA CORPORATION

Nano carbon materials for enhancing thermal transfer in fluids

InactiveUS6695974B2Improve thermal conductivityImprove heat transfer performanceMaterial nanotechnologyNanostructure manufactureOrganic groupElectrical polarity

A novel fluid heat transfer agent suitable for use in a closed heat transfer system, for example, wherein energy is transferred between an evaporator and a condenser in heat exchange relationship with the heat transfer agent that is caused to flow from one to the other. The novel heat transfer agent is a complex comprising a body of heat transfer fluid, for example, ethylene glycol or water, having suspended therein carbon nanoparticles in a quantity sufficient to enhance the thermal conductivity of the body of heat transfers fluid, per se. The carbon nanoparticles are selected from carbon in the form of sp<2 >type and sp<3 >type bonding and preferably comprise nanotubes or fullerenes and may have a coupling agent bonded thereto or enclosed therein when the nanotube or fullerene forms a hollow capsule. The coupling agent may be a polar organic group covalently bonded to the carbon nanoparticles and miscible in the fluid medium.

Owner:MATERIALS & ELECTROCHEM RES

Composite lithium titanate electrode material and preparation method thereof

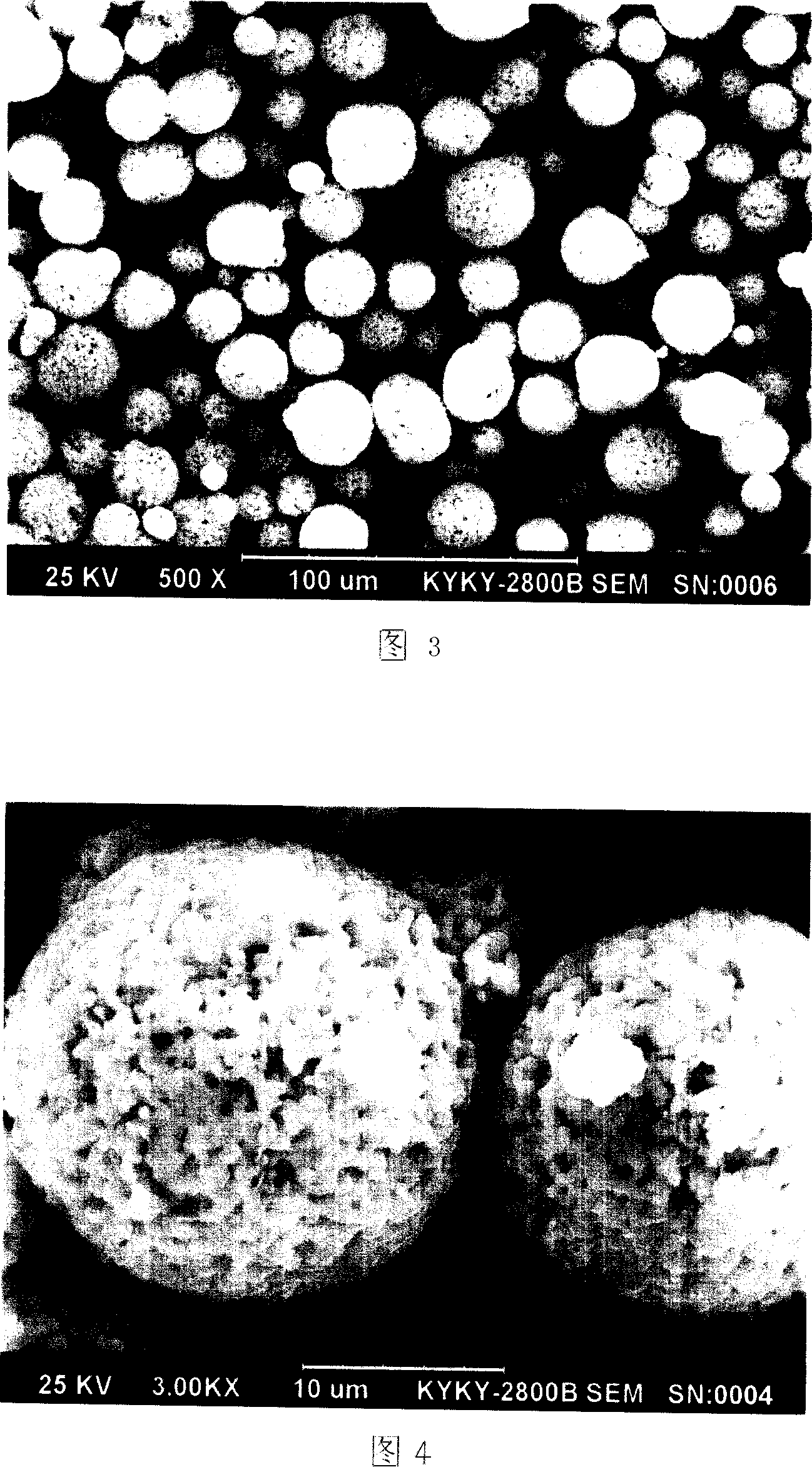

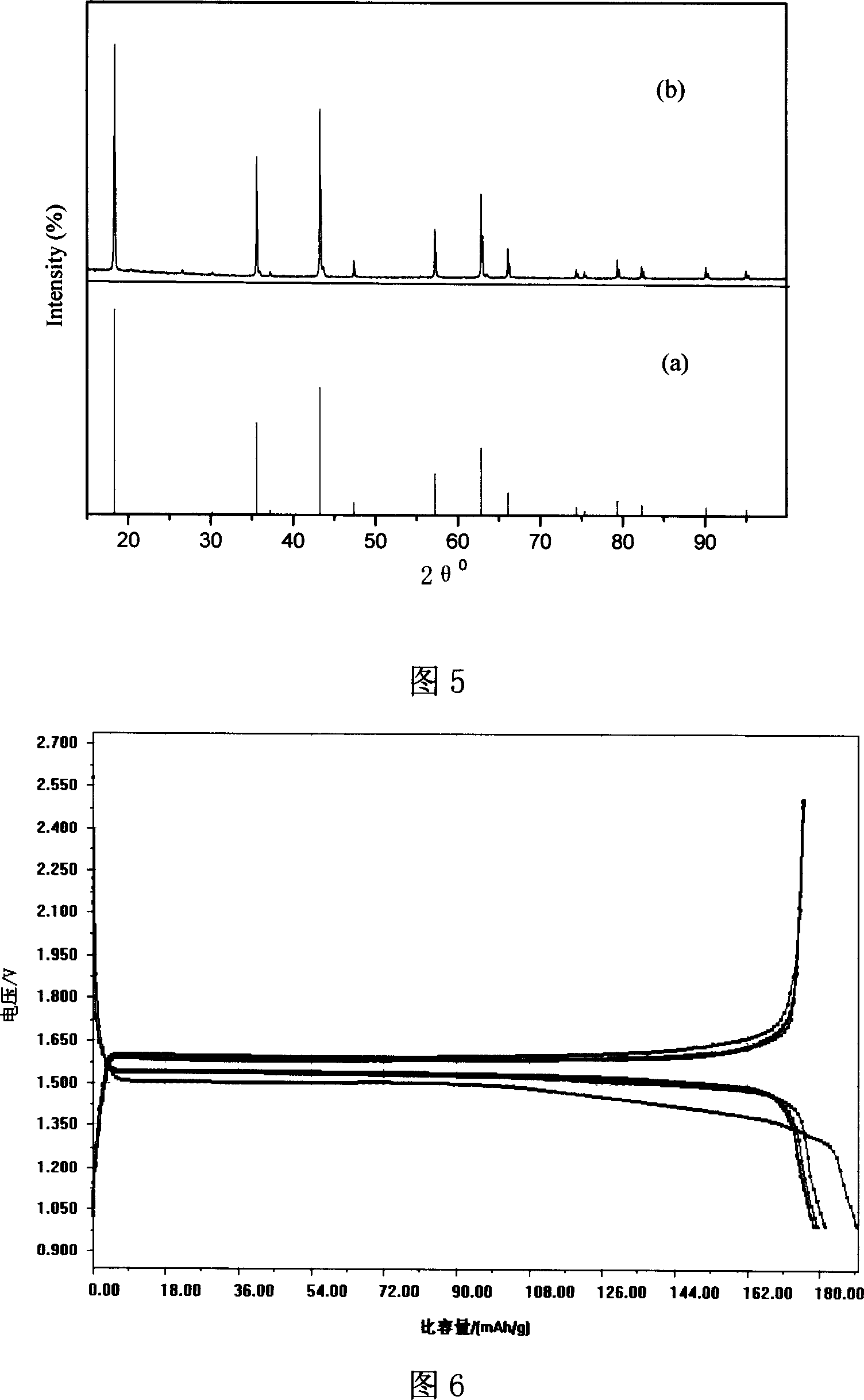

ActiveCN101000960AHigh reversible electrochemical capacityImproved magnification performanceElectrode manufacturing processesChemical/physical/physico-chemical processesHigh rateSpherical shaped

The invention discloses an electrode material of composite lithium titanate and its preparation method, which is secondary particles with spherical or similar spherical shape and porous nanometer channels, which is made from lithium titanate particles, nano-carbon coated materials and doped modifier. The preparation method includes: milling the inorganic lithium salt, titanium dioxide, nano-carbon coated material or doped modifier, scattering them into the organic solvent for further drying, processing heat treatment, and cooling. Comparing with the existing technologies, this electrode material has the high-rate performance, highly reversible electrochemical capacity, and smaller surface area to enhance its first Coulomb efficiency and cycle stability, applying to rechargeable and once-use lithium-ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

Nano carbon materials for enhancing thermal transfer in fluids

InactiveUS20020100578A1Improve thermal conductivityImprove heat transfer performanceMaterial nanotechnologyNanostructure manufactureElectrical polarityOrganic group

A novel fluid heat transfer agent suitable for use in a closed heat transfer system, for example, wherein energy is transferred between an evaporator and a condenser in heat exchange relationship with the heat transfer agent that is caused to flow from one to the other. The novel heat transfer agent is a complex comprising a body of heat transfer fluid, for example, ethylene glycol or water, having suspended therein carbon nanoparticles in a quantity sufficient to enhance the thermal conductivity of the body of heat transfers fluid, per se. The carbon nanoparticles are selected from carbon in the form of sp2 type and sp3 type bonding and preferably comprise nanotubes or fullerenes and may have a coupling agent bonded thereto or enclosed therein when the nanotube or fullerene forms a hollow capsule. The coupling agent may be a polar organic group covalently bonded to the carbon nanoparticles and miscible in the fluid medium.

Owner:MATERIALS & ELECTROCHEM RES

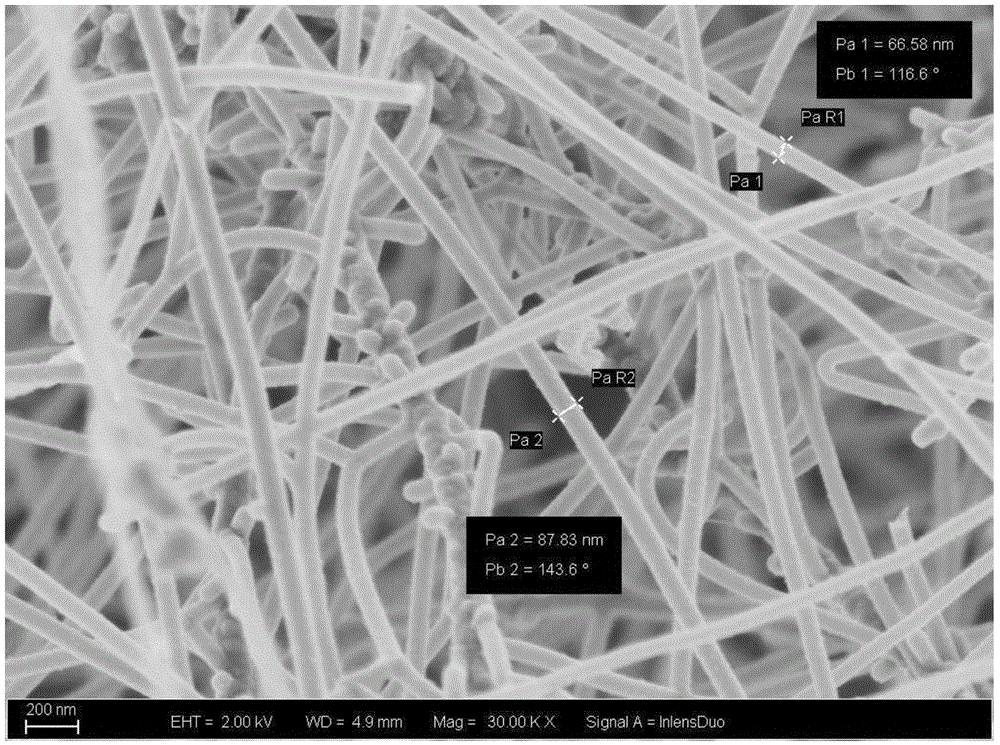

Carbon silicon composite material, its preparation method and use

InactiveCN1903793AStable structureLarge specific surface areaElectrode manufacturing processesFuel cellsSilicon matrixCarbon fibers

The present invention relates to a carbon-silicon composite material. It includes silicon matrix and carbon nano tube or nano carbon fibre grown on the matrix. The average grain size of the described silicon matrix is 100 nm-100 micrometer, the diameter of the described carbon nano tube or nano carbon fibre is 1-200 nm and its length is 1 nm-100 micrometer. The described carbon nano tube is single-wall, double-wall or multiwall. Said invention also provides its preparation method and concrete steps.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

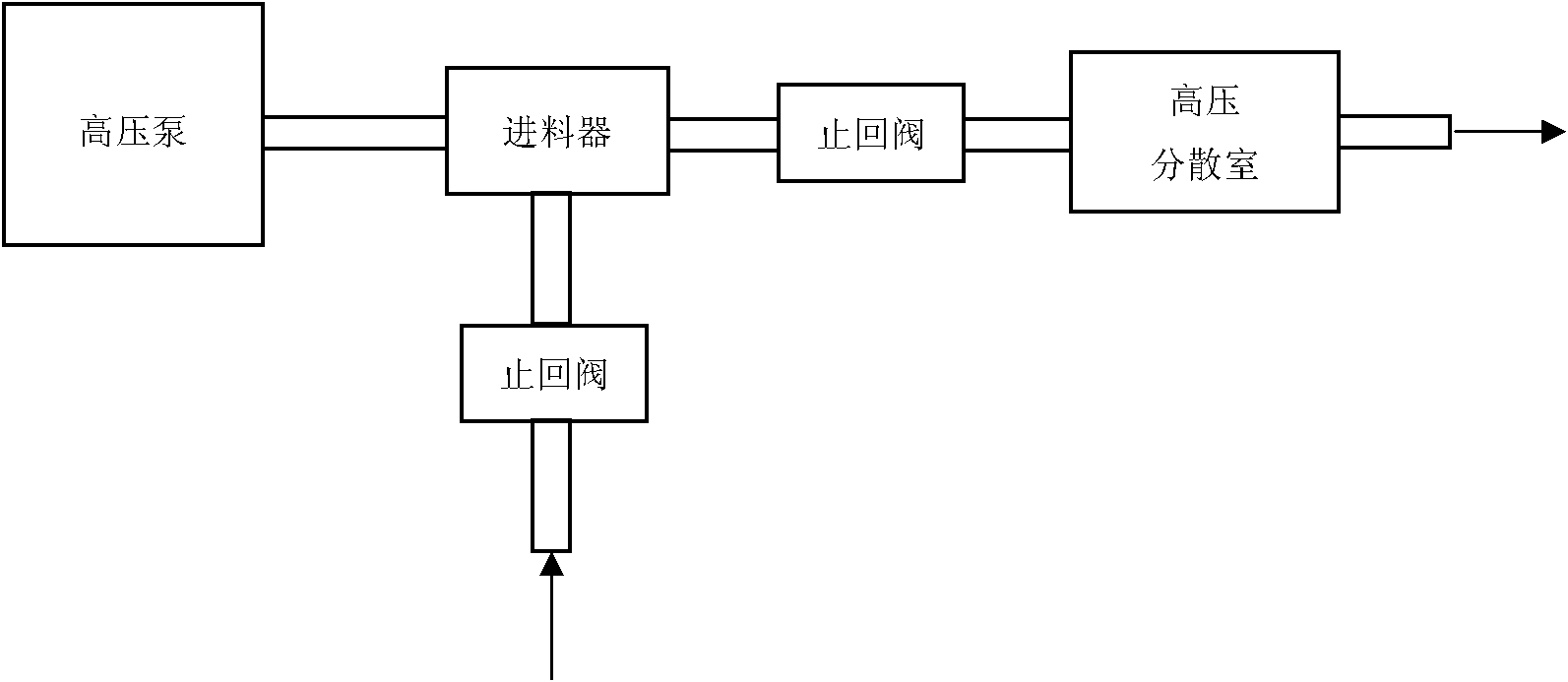

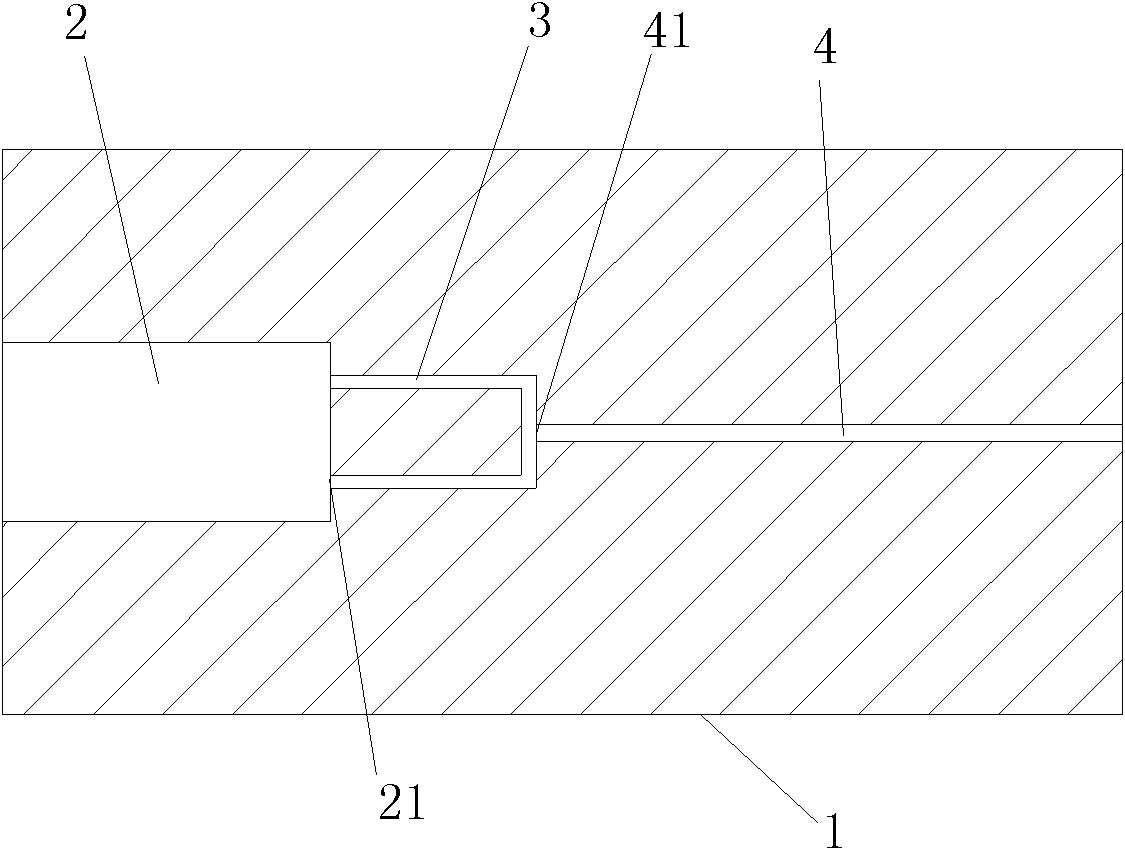

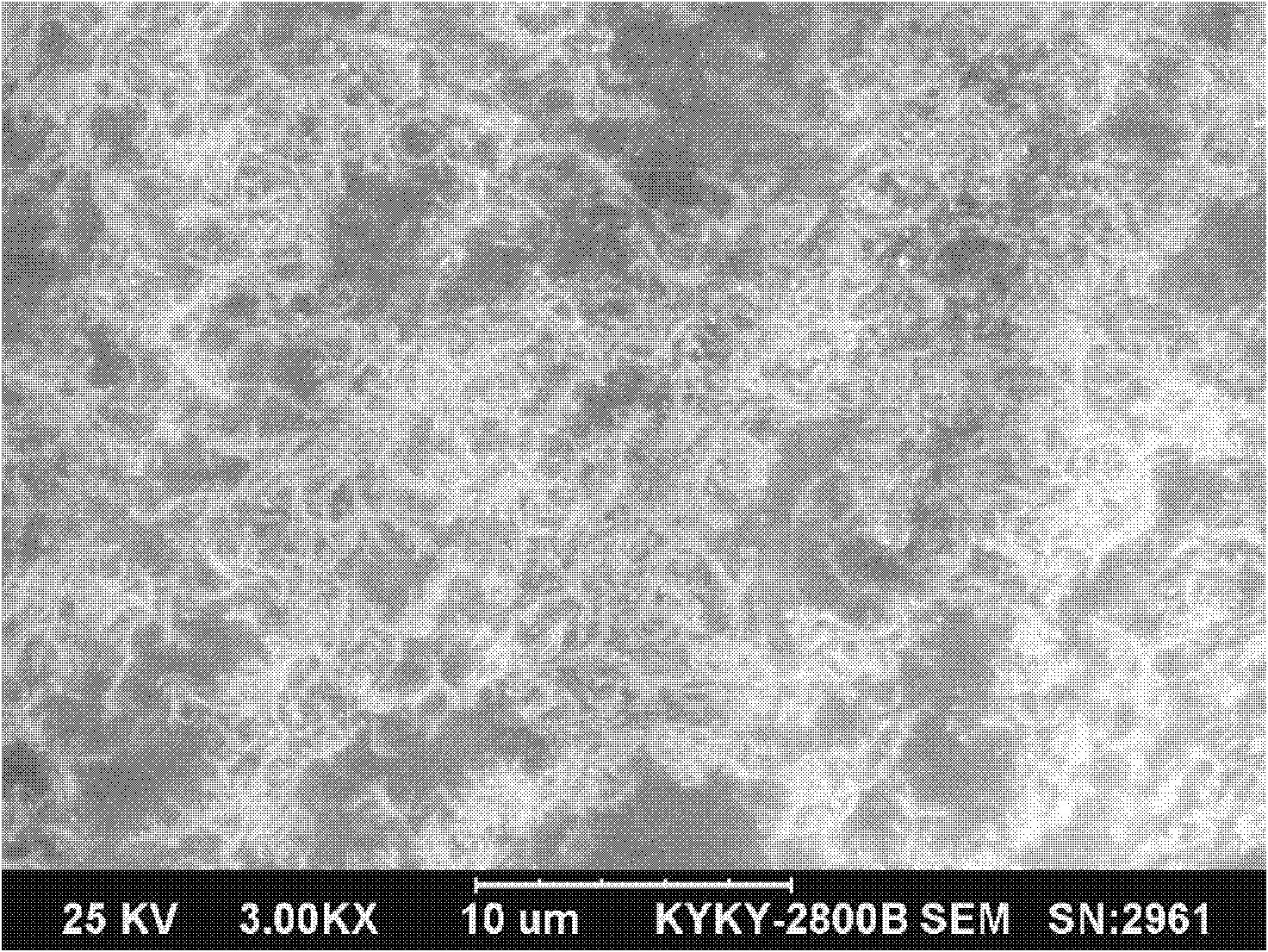

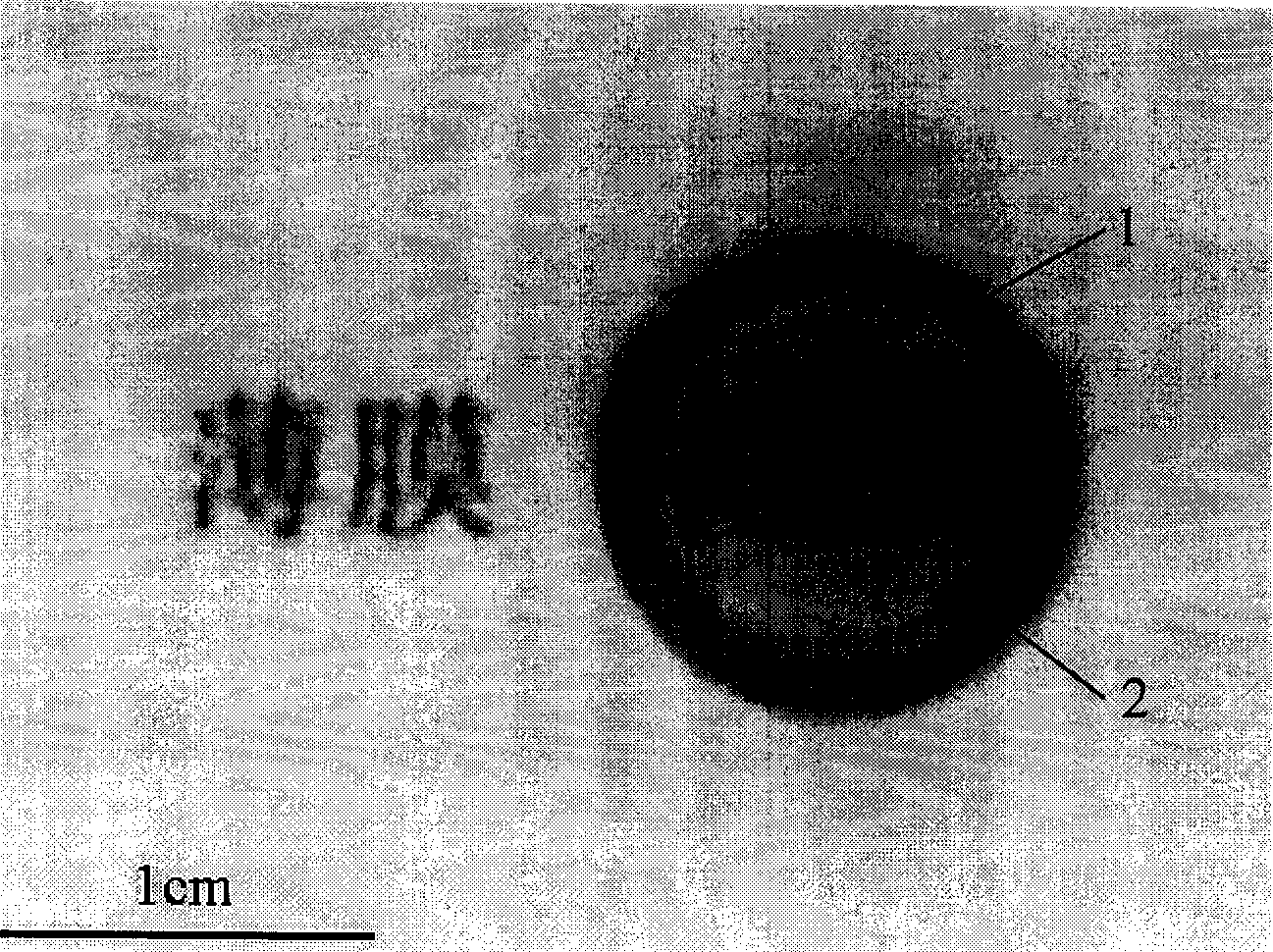

Nano-carbon material dispersion liquid and preparation method and equipment thereof

The invention discloses a nano-carbon material dispersion liquid, and a preparation method and preparation equipment of the nano-carbon material dispersion liquid, and aims to prepare a nano-carbon material dispersion system which contains uniformly distributed nano-carbon particles and is stable. The dispersion liquid comprises the following components in percentage by mass: 0.5 to 20 percent ofthe nano-carbon material, and the balance of dispersion solvent. The preparation method comprises the steps of pre-dispersion and high-pressure dissociation dispersion. The preparation equipment consists of pre-dispersion equipment and high-pressure dissociation dispersion equipment. Compared with the prior art, a high-pressure dispersion method is introduced into the preparation method, and morethan two paths of 50 to 500MPa high-pressure liquid flows are guided to one place and converged together to ensure that the high-pressure liquid flows generate violent collision to fully dissociate the nano-carbon material in the high-pressure liquid flows, so that the nano-carbon material is uniformly distributed in the dispersion solvent to achieve a more effective dispersion effect of the nanomaterial; besides, the obtained nano-carbon material dispersion liquid is better in dispersion effect, can exist stably for a long time, and is convenient to store and transport.

Owner:深圳市贝特瑞新能源技术研究院有限公司

Large-area ultra-thin carbon nanotube film and its preparation process

The large-area untrathin nano carbon tube film with well feature in microcosmic level comprises nano carbon tubes with centimeter-level length and more then 90wt% purity. Wherein, the least thickness of single-layer film can achieve 20nm with near transparent color and more then 10cm2 film area; there are multiple functional groups on tube surface. It also discloses the opposite preparation technique: with the macroscopic body of nano carbon tube, oxidating the macroscopic body in air; then, dipping into hydroperoxide; adding strong acid to poach till the liquid shows neutrality; finally, adding alcohol or acetone into the liquid to float the tube and form the film.

Owner:TSINGHUA UNIV +1

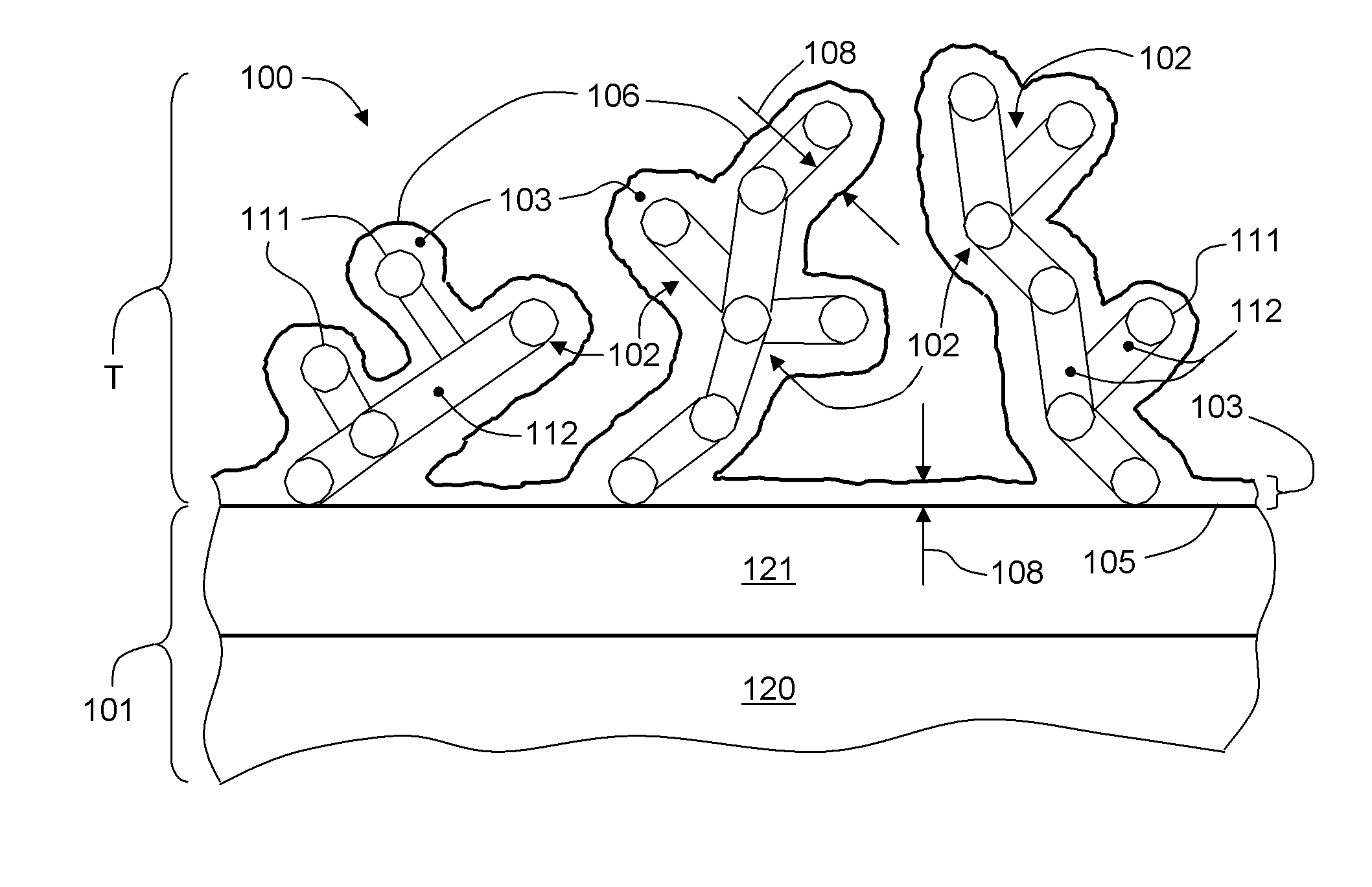

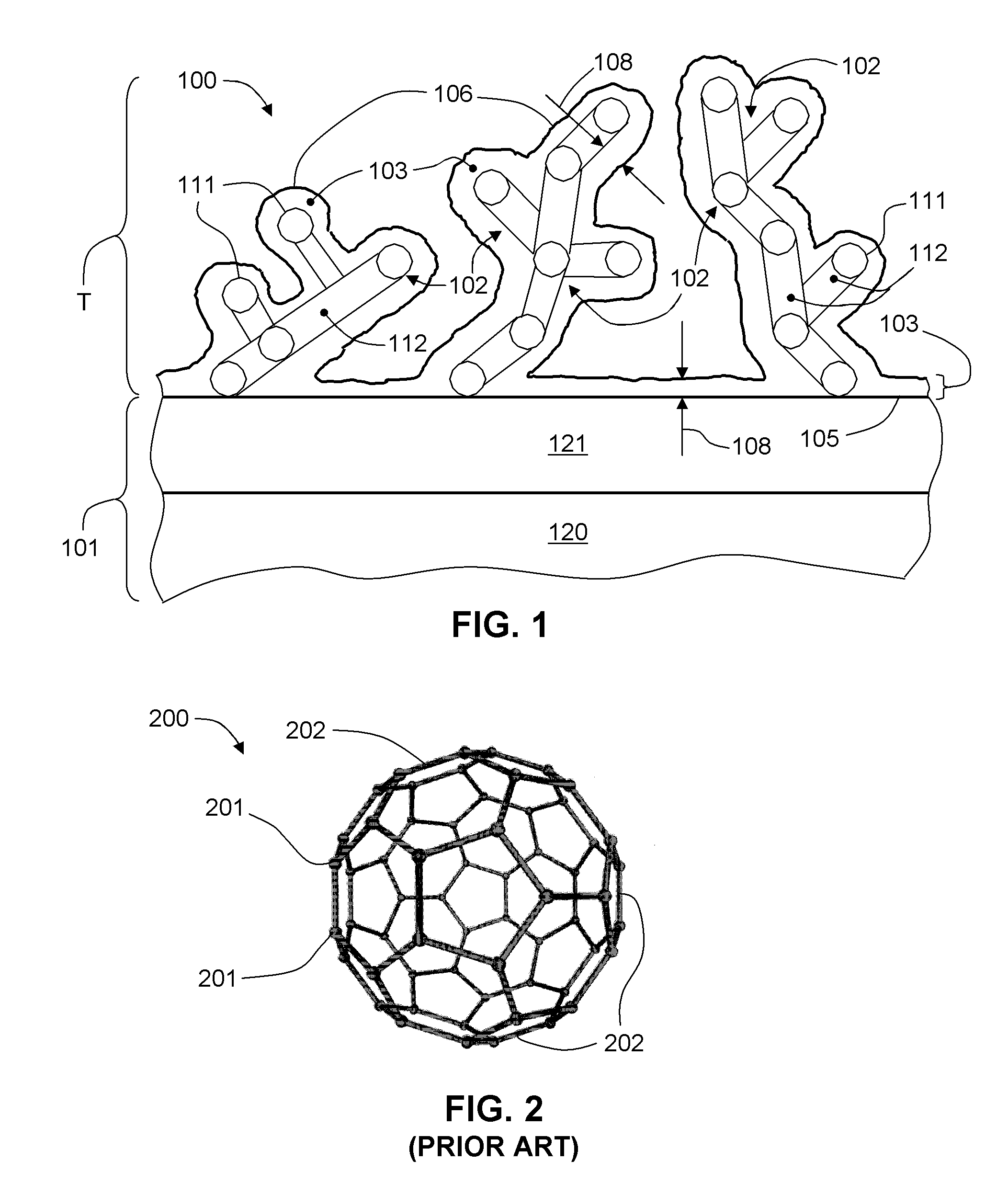

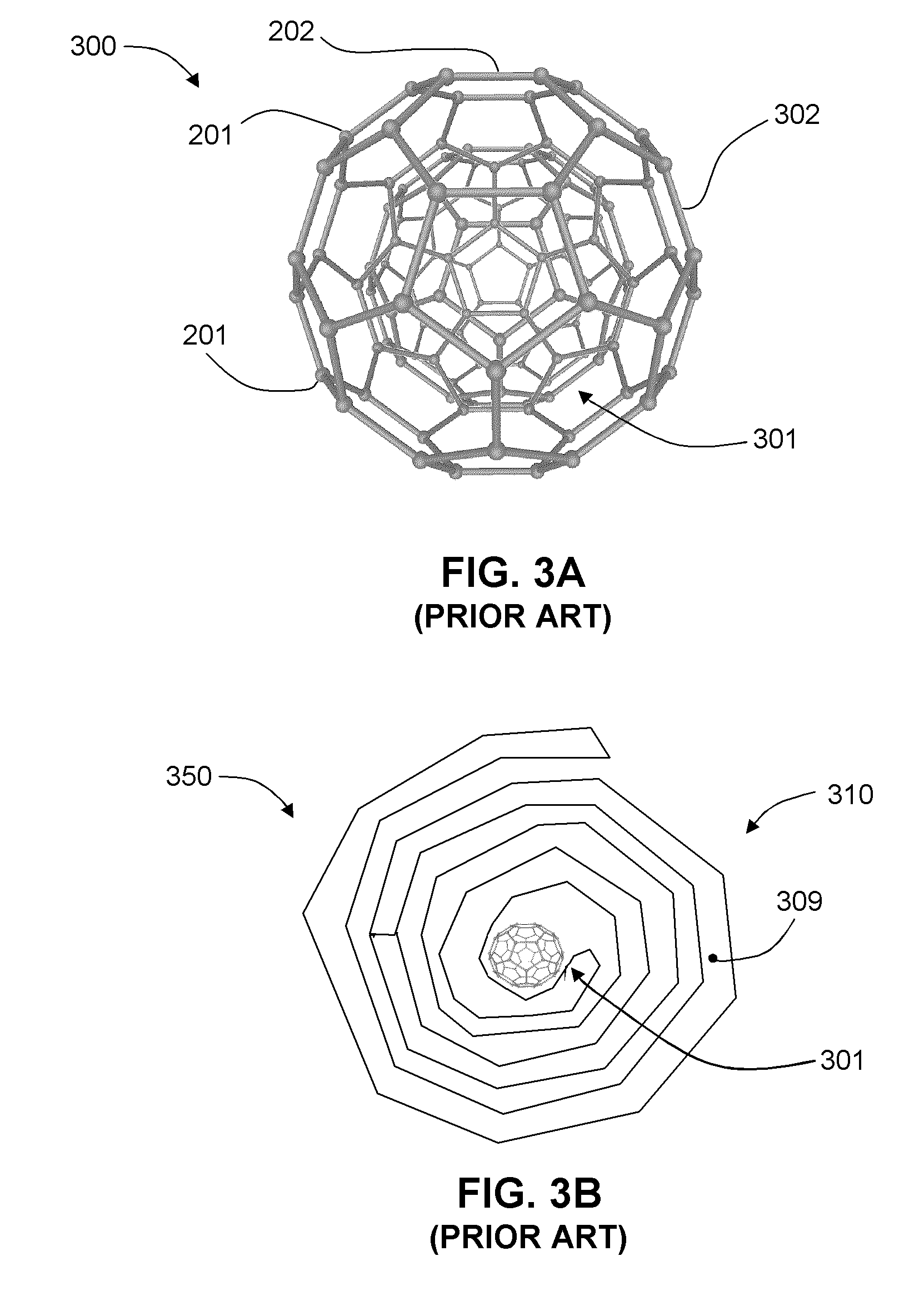

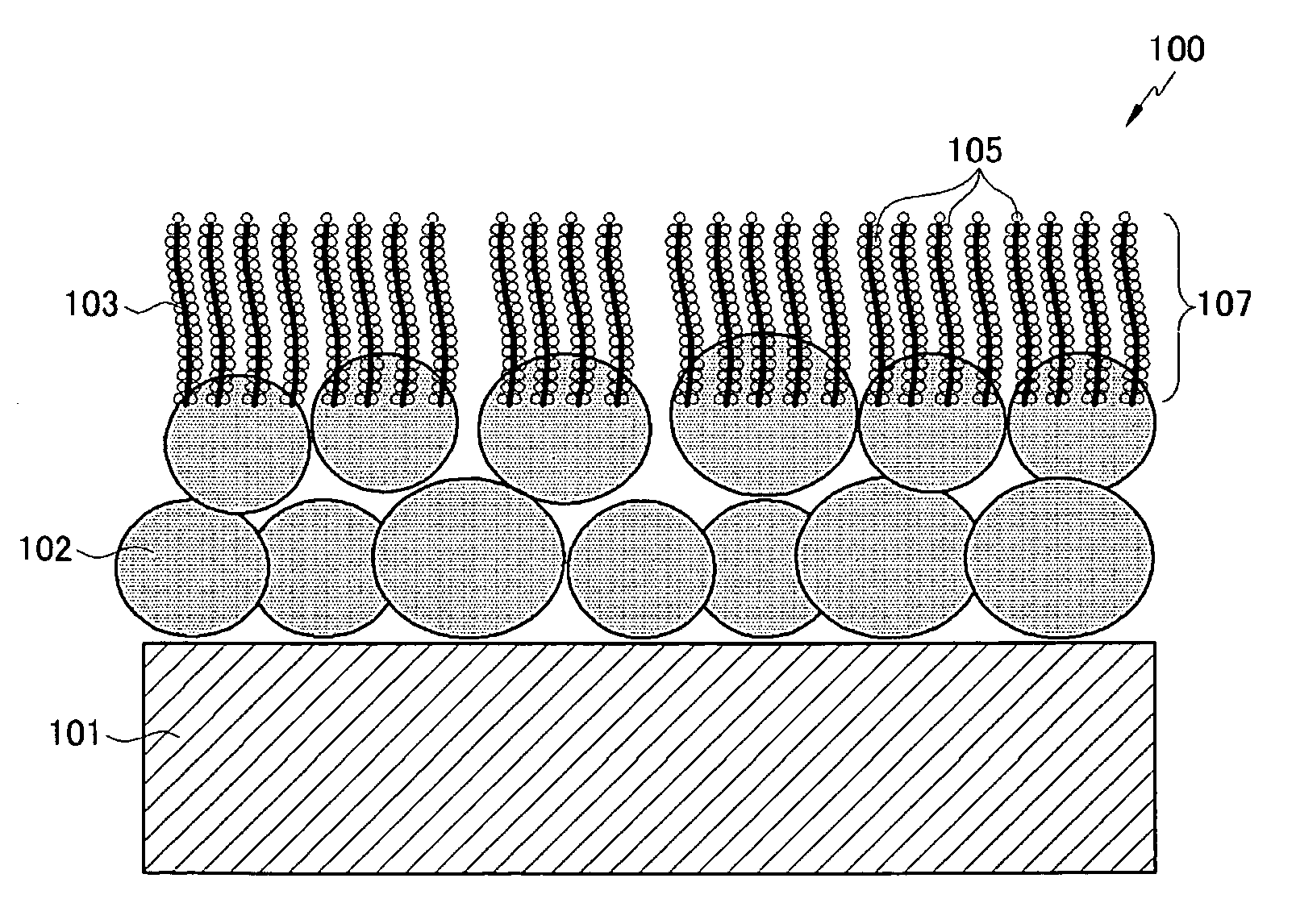

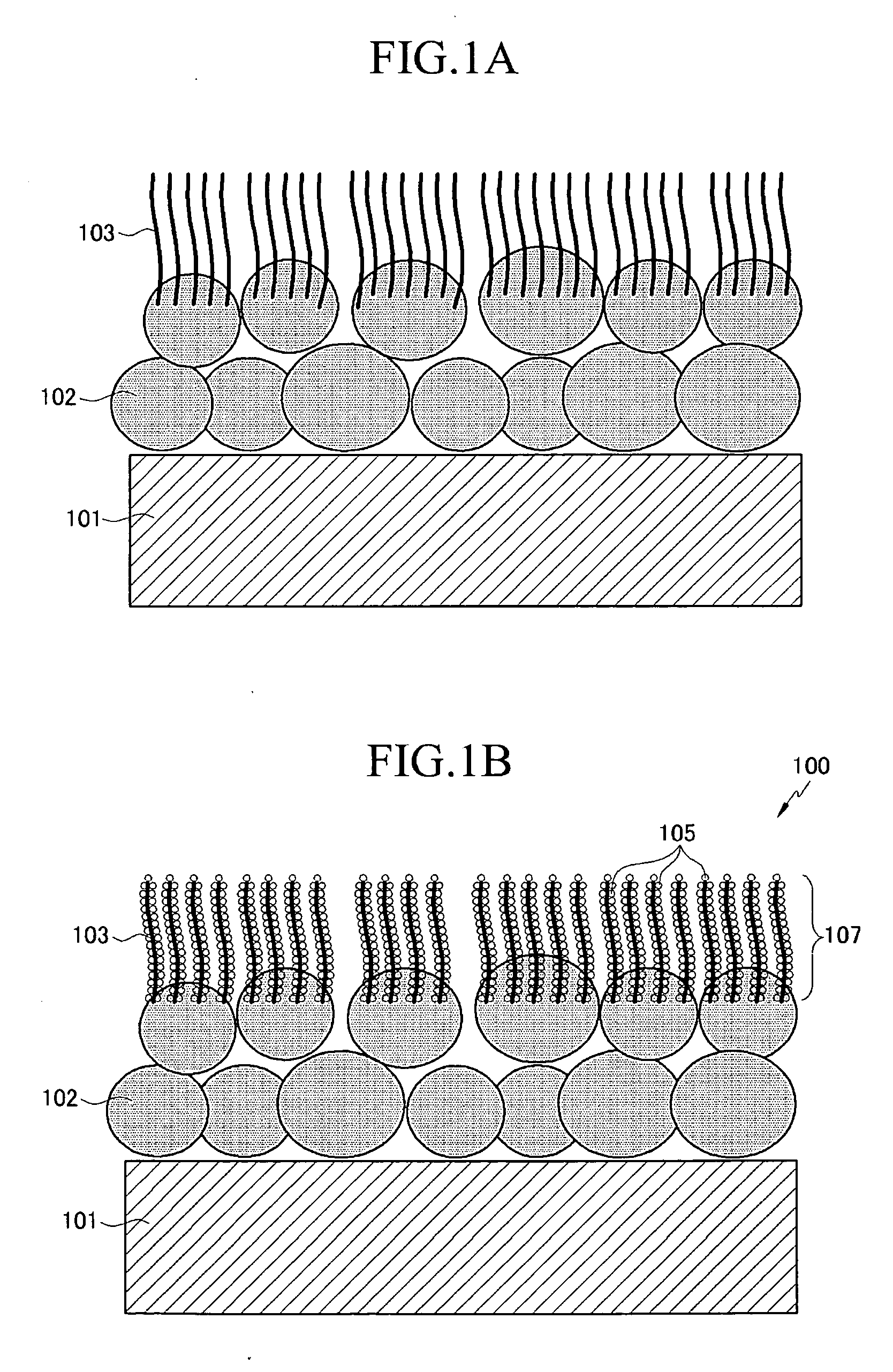

Three-dimensional battery with hybrid nano-carbon layer

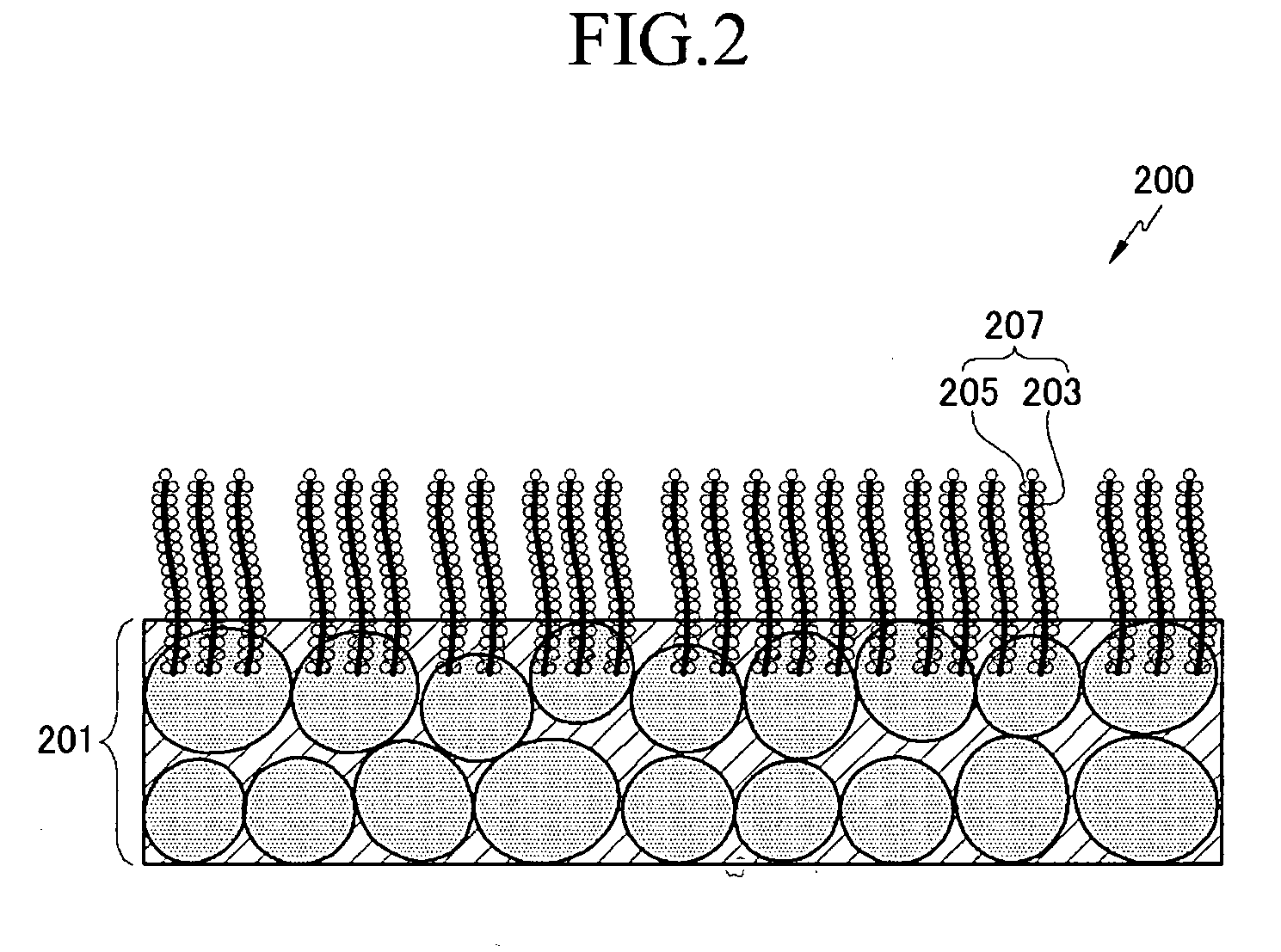

InactiveUS20100151318A1Good electrical contactMaterial nanotechnologyNanostructure manufactureCarbon nanotubeHigh surface area

A Li-ion battery cell is formed from deposited thin-film layers and comprises a high-surface-area 3-D battery structure. The high-surface-area 3-D battery structure includes a fullerene-hybrid material deposited onto a surface of a conductive substrate and a conformal metallic layer deposited onto the fullerene-hybrid material. The fullerene-hybrid material is made up of chains of fullerene “onions” linked by carbon nanotubes to form a high-surface-area layer on the conductive substrate and has a “three-dimensional” surface. The conformal metallic layer acts as the active anode material in the Li-ion battery and also has a high surface area, thereby forming a high-surface-area anode. The Li-ion battery cell also includes an ionic electrolyte-separator layer, an active cathodic material layer, and a metal current collector for the cathode, each of which is deposited as a conformal thin film.

Owner:APPLIED MATERIALS INC

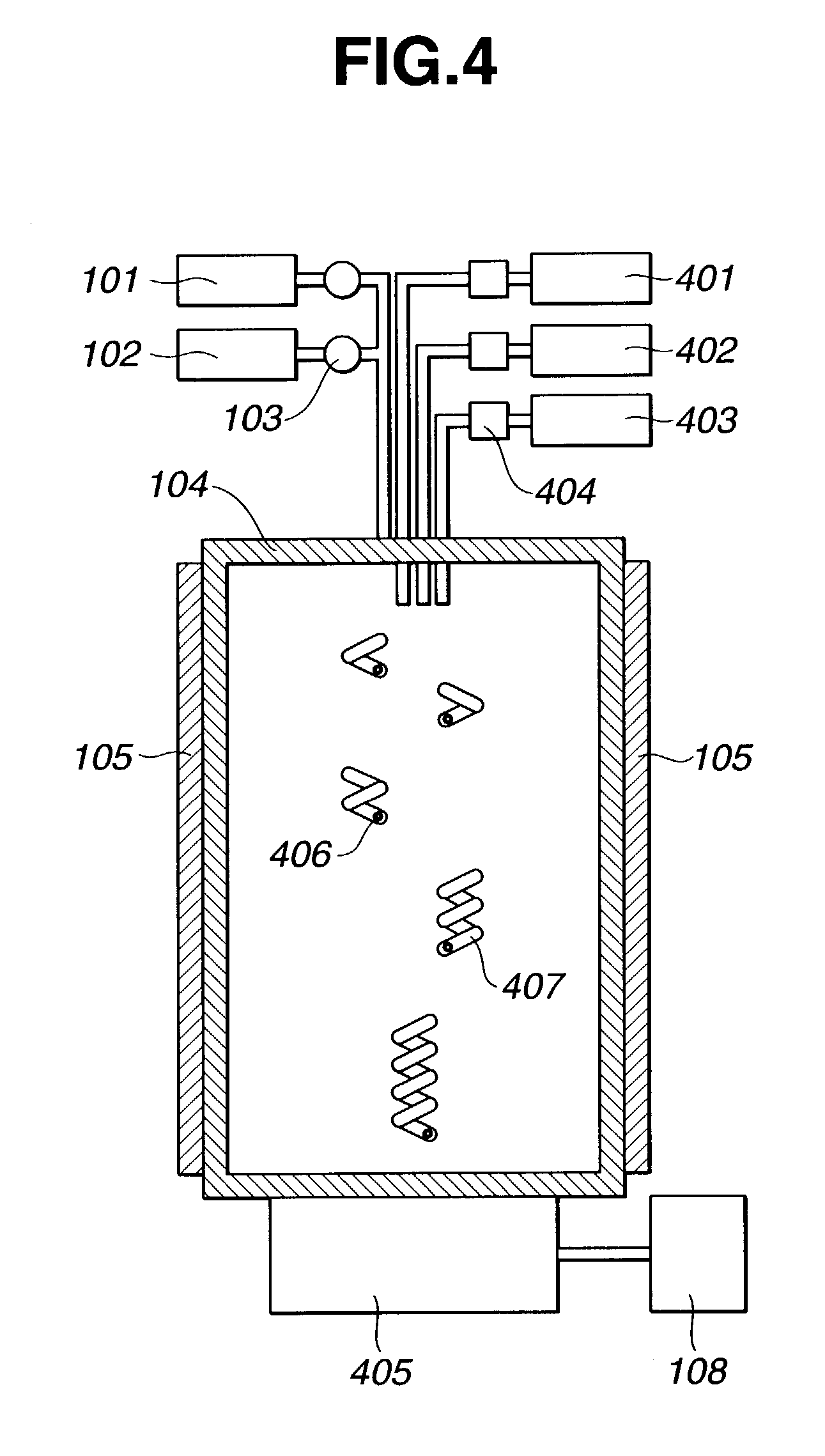

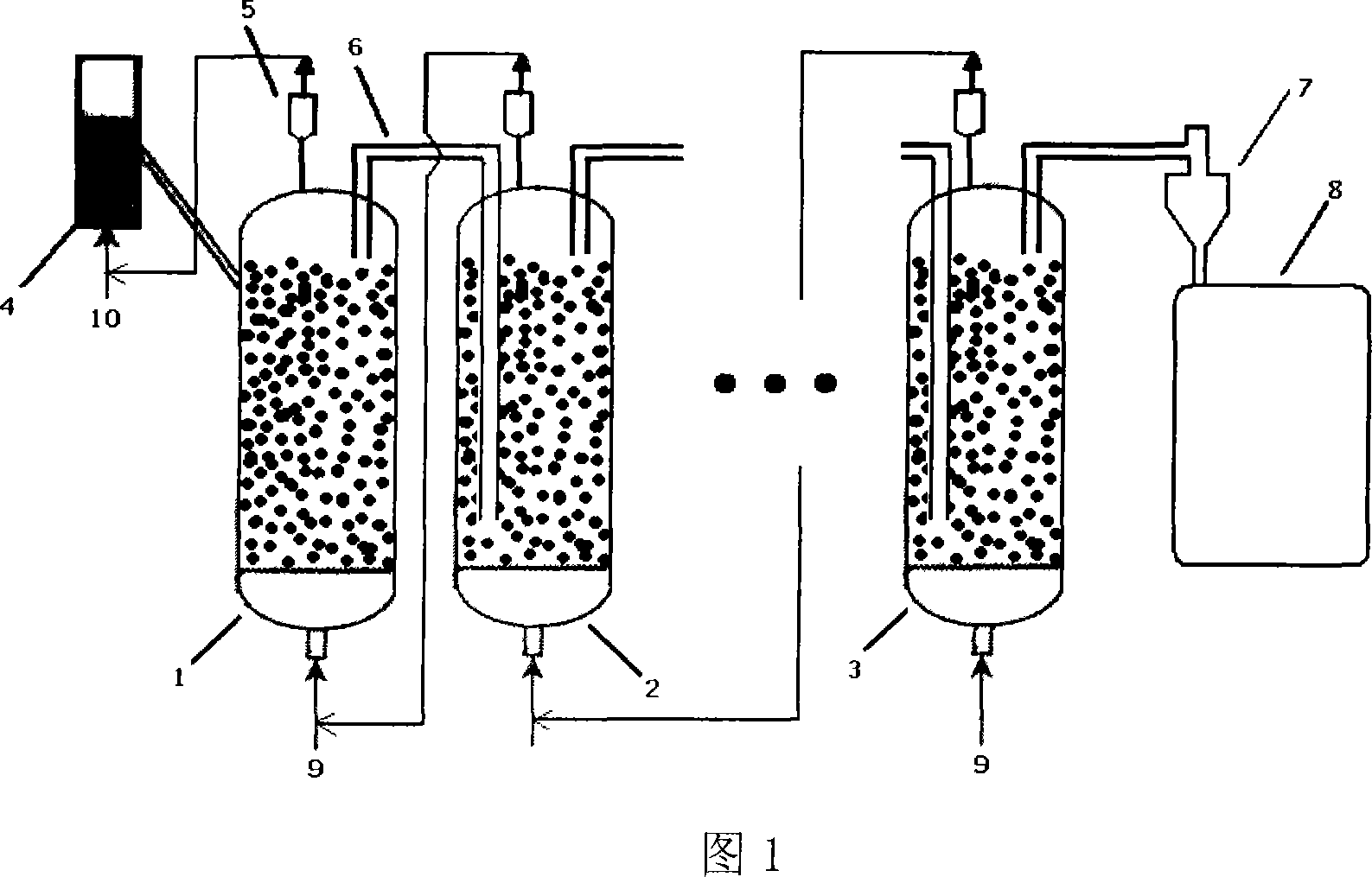

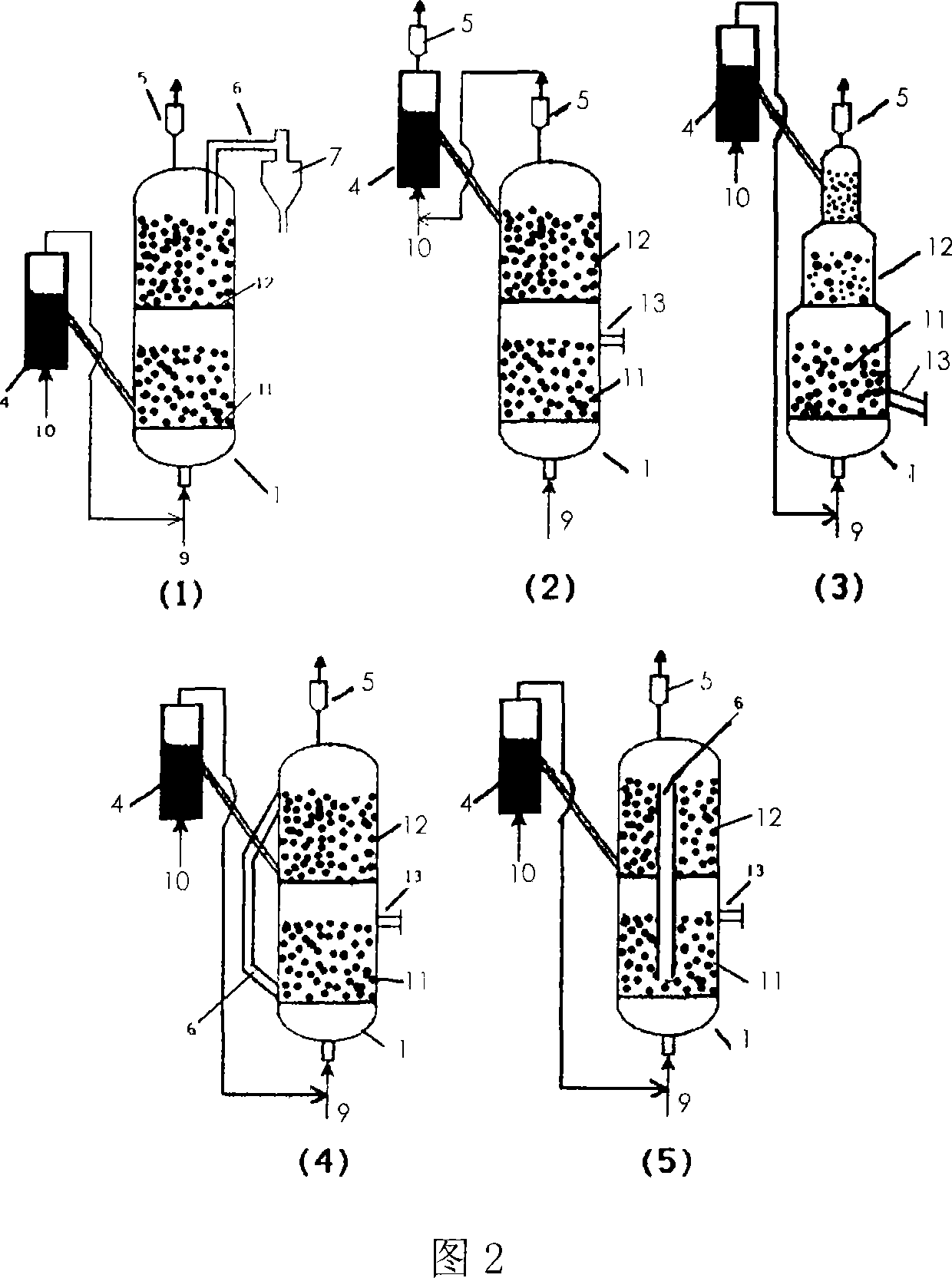

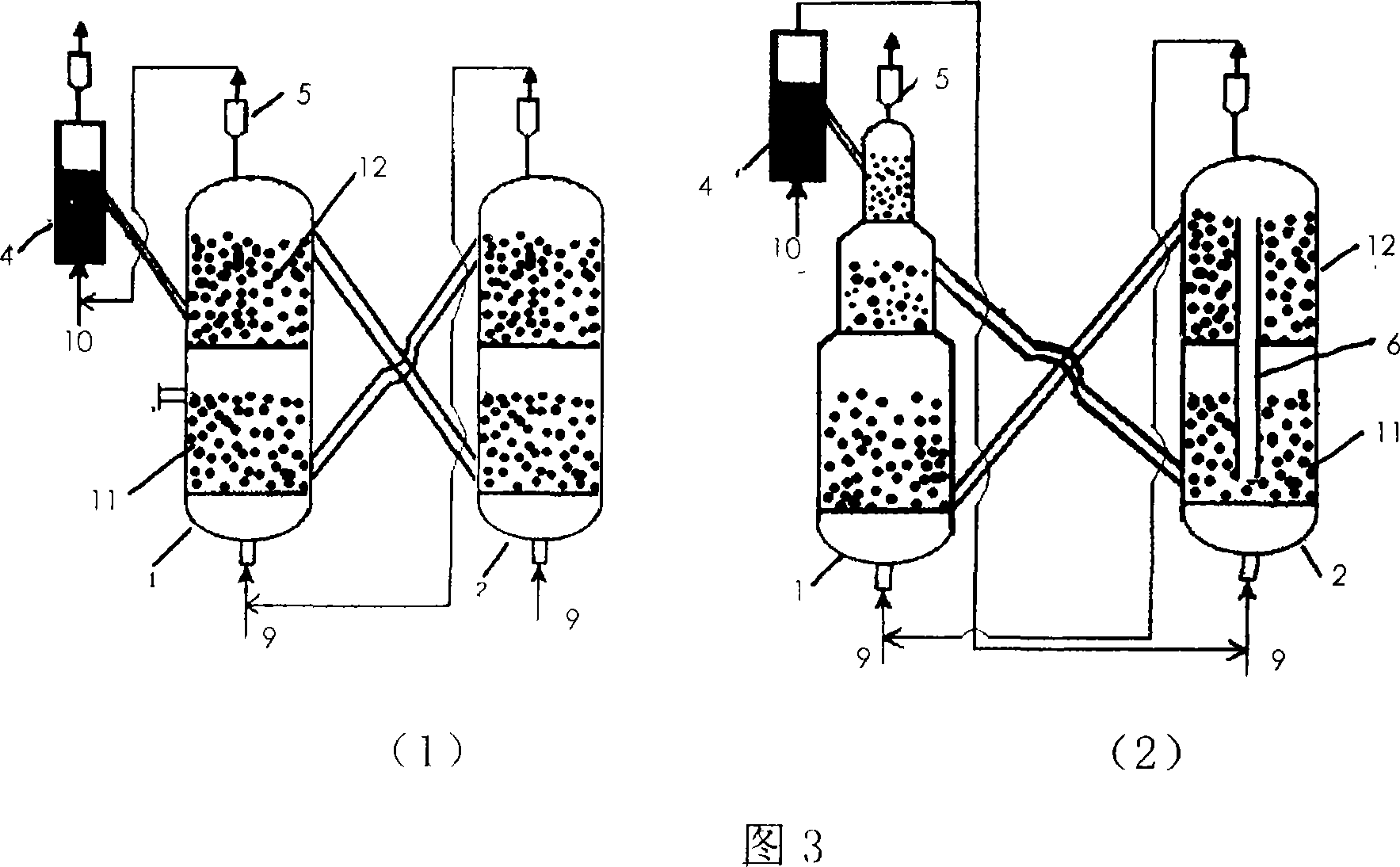

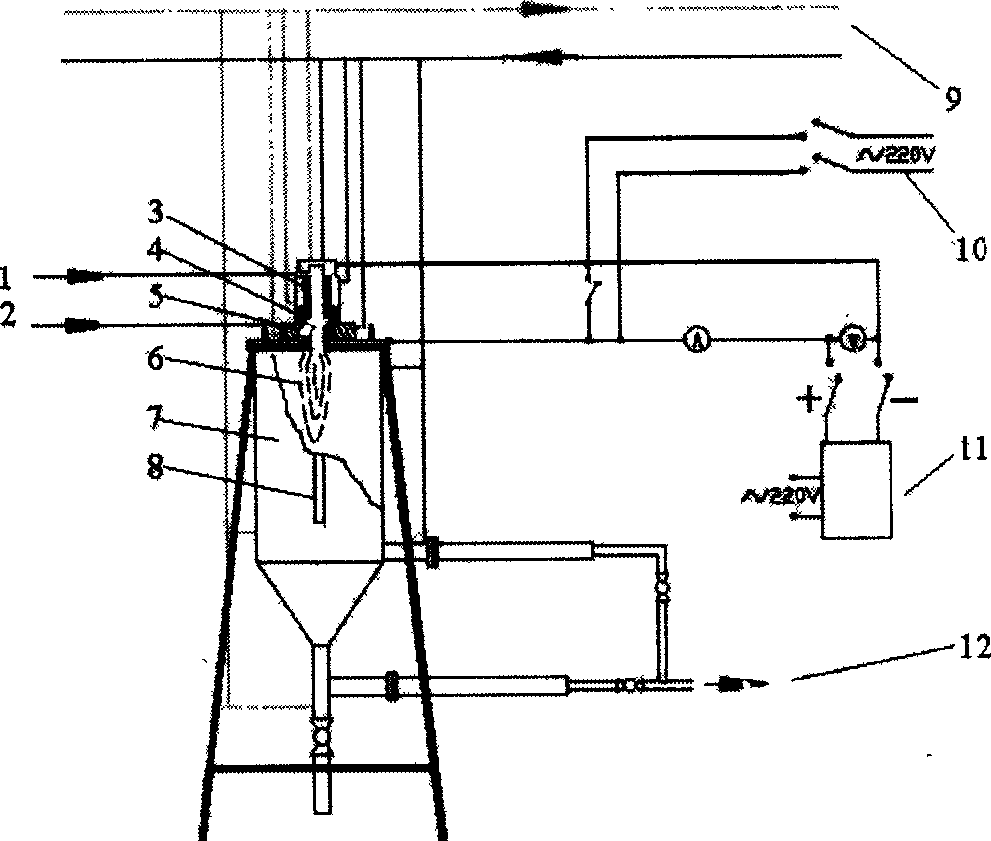

Method for producing Nano carbon tubes continuously and equipment

ActiveCN101049927AEfficient separationImprove stabilityMaterial nanotechnologyMulti-walled nanotubesCarbon nanotubeProduct gas

This invention discloses high-efficiency method and apparatus for continuously producing carbon nanotubes. The apparatus is a multi-stage counter-current reaction apparatus. The method comprises: placing the catalyst in the pre-reactor or the main reactor, introducing mixed gases of H2 or CO, and N2 or Ar, reducing, then introducing raw material gas, reacting to obtain carbon nanotubes, and sending the expanded solid raw material to the next stage reactor for reaction. The gas flow and the solid raw material are arranged in counter-current contact mode in the reactors, which can increase the conversion rate of the solid raw material. This invention has such advantages as simple apparatus and easy operation, and is suitable for industrial production on the scale of tens of thousands of tons per year.

Owner:TSINGHUA UNIV

Process for synthesizing nano linear carbon array

InactiveCN1382626ASimple preparation conditionsLow costSilicon compoundsHydrofluoric acidNano carbon

A process for synthesizing linear nano carbon array includes putting monosilicon wafer in a hydrothermal reactor containing the reacting solution of hydrofluoric acid (0.2-15 mol / L) and silver nitrate (0.05-0.10 mol / L), and reaction at 30-80 deg.C for 30-150 min to generate large-area linear nano carbon array on the monosilicon wafer. Its advantages are low reaction temp and low cost.

Owner:TSINGHUA UNIV

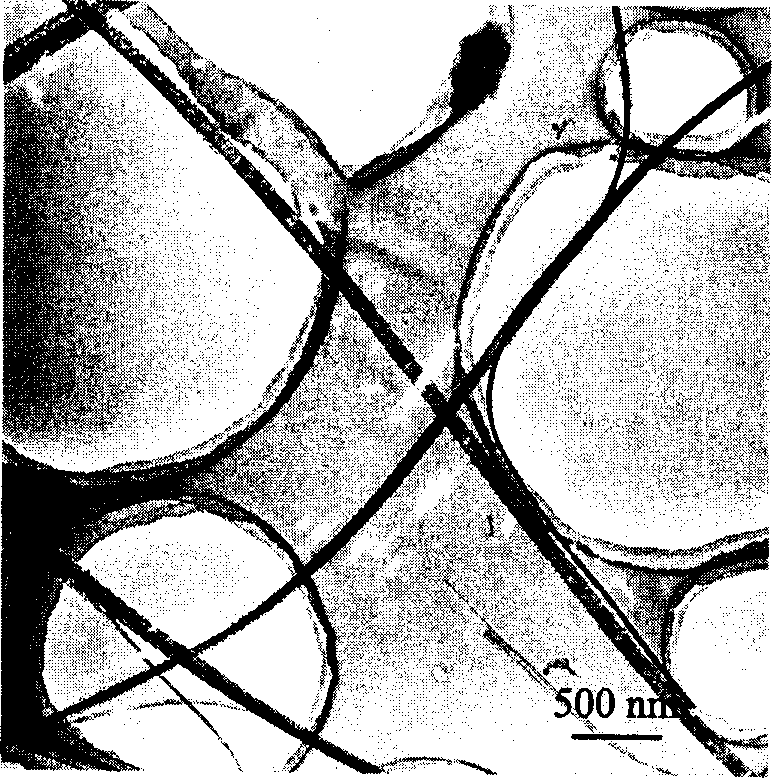

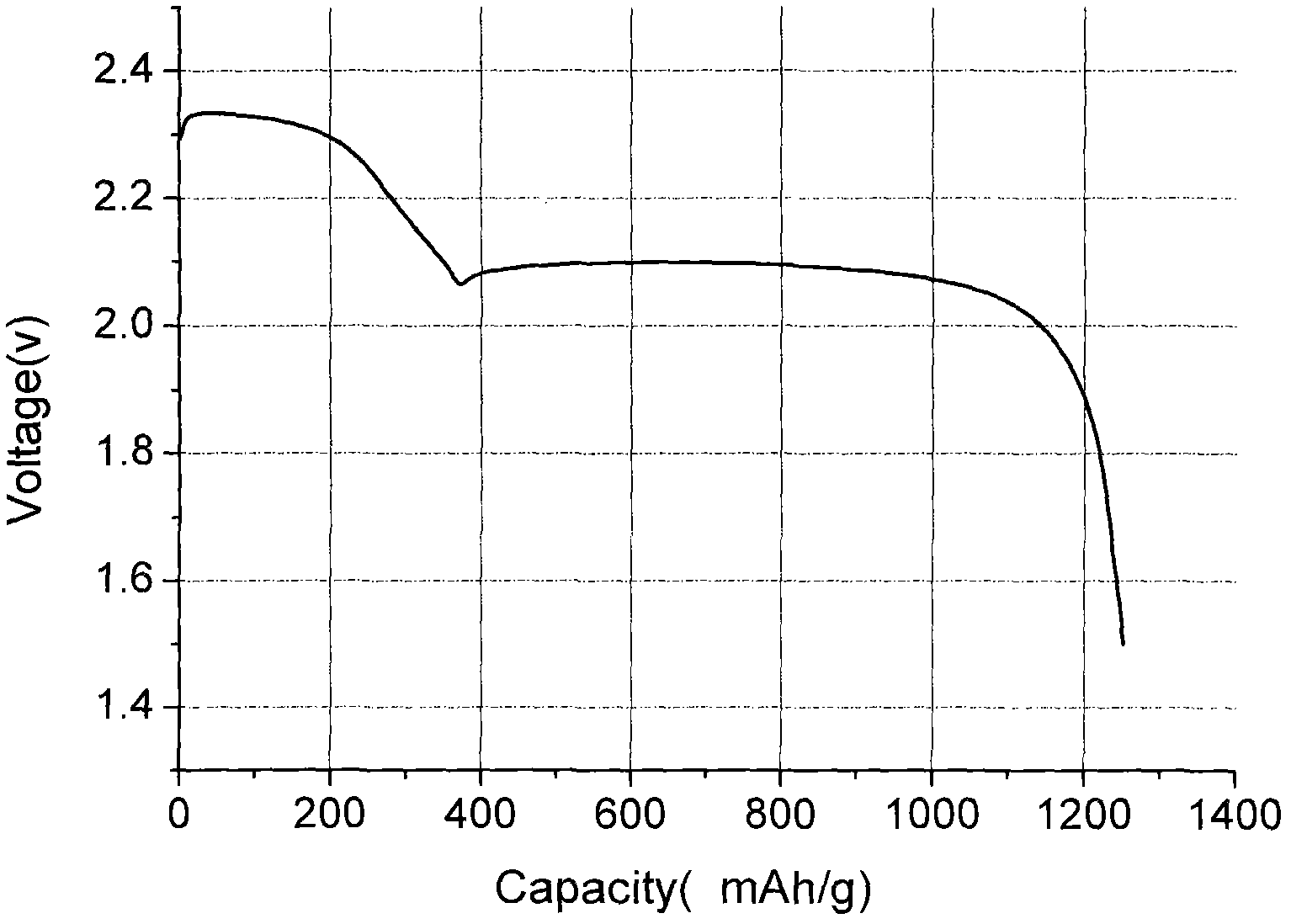

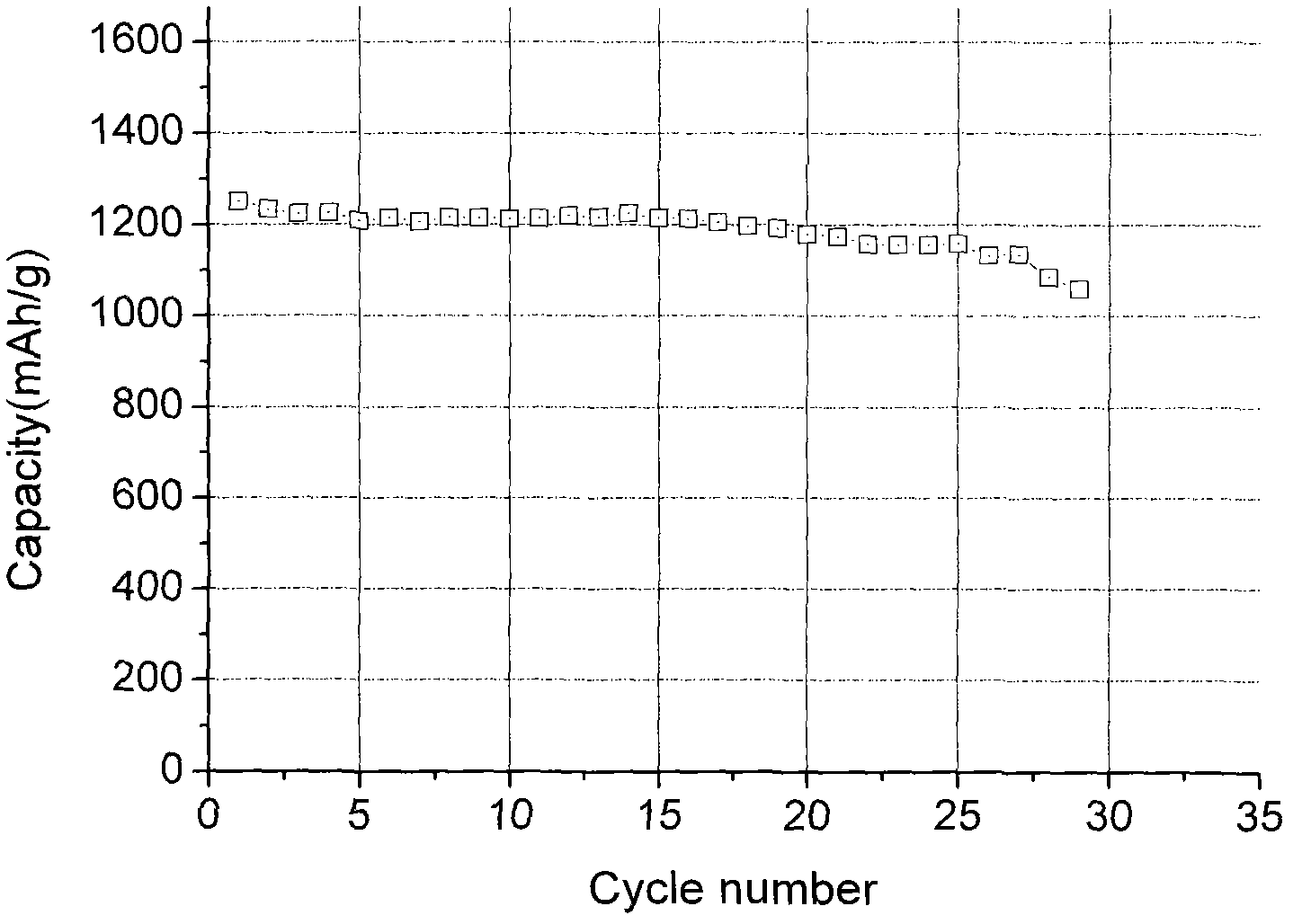

Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

InactiveCN102142554AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCross-linkPorosity

The invention relates to a nano carbon material with a network structure consisting of polymer chains, in particular to a nano carbon sulfur composite material with a network structure suitable to be used in a secondary lithium sulfur battery anode and a preparation method thereof. The carbon sulfur composite material is formed by adopting the following steps of: introducing functional groups onto carbon particles by adopting the electric conductivity and the porosity of a carbon material and the reaction capacity of similar condensed aromatics of the carbon material and by means of an irreversible chemical reaction; introducing the polymer chains, wherein the polymer chains are stretched, bent and cross-linked on the surfaces of the carbon particles to form a cross-linked network structure; and compounding a sulfur element or a polysulfide (m is more than 2) containing -Sm- structure into the network structure to form the nano carbon sulfur composite material with the network structure. The carbon sulfur composite material has a rich cross-linked network structure, nano-scale network pores constrain the sulfur element or the polysulfide (m is more than 2) containing the -Sm- structure in the network, and the active substances are limited in a certain region to react, so that the composite material has predominant electrochemical performance.

Owner:NO 63971 TROOPS PLA

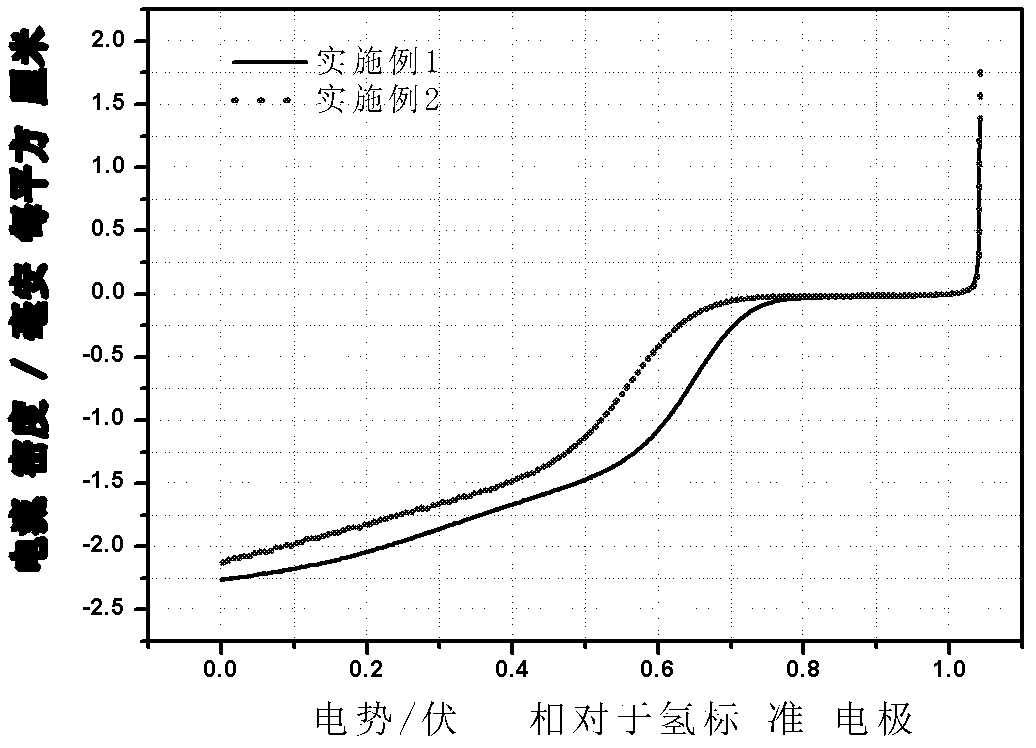

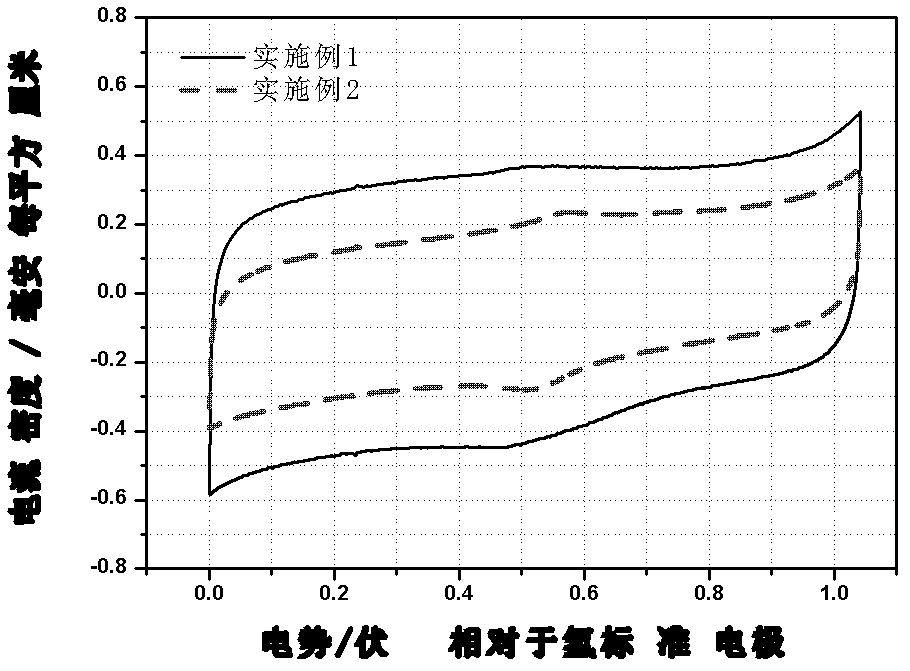

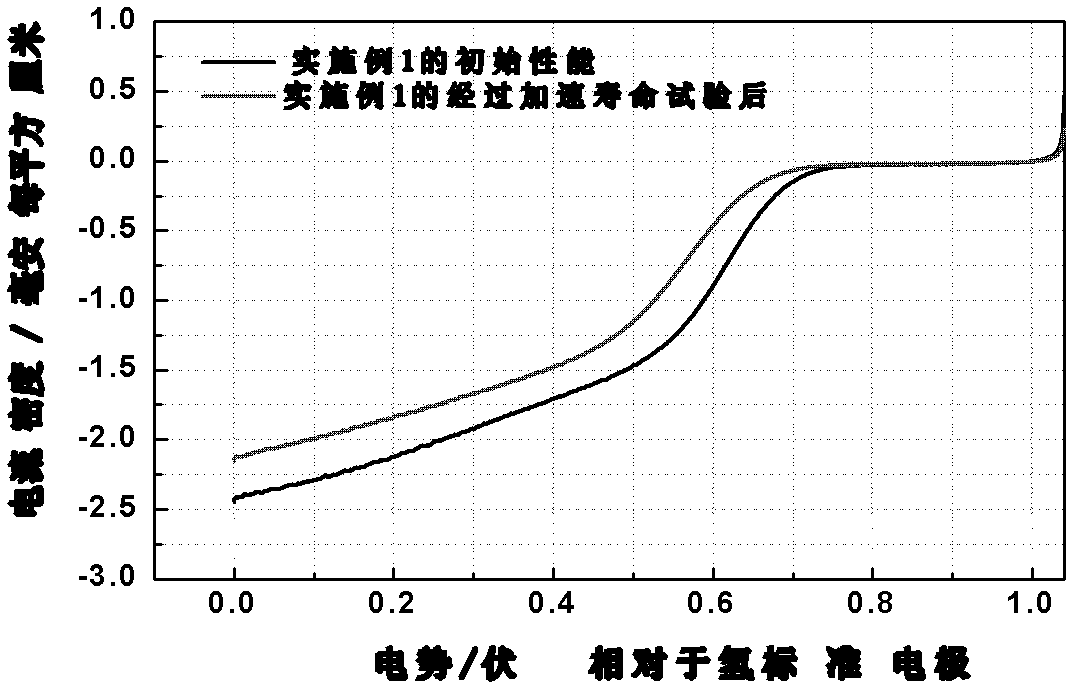

Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

InactiveCN103050714AChange the microstructureChange Edge Face DefectsPhysical/chemical process catalystsCell electrodesMicrowave radiometryHigh heat

The invention relates to a nano carbon doped electrocatalyst for a fuel cell, and application of the nano carbon doped electrocatalyst. The electrocatalyst is prepared by adopting the steps of: complexing a nitrogen-containing and / or boron-containing organic precursor and a transition metal salt to form a composite; adding nano carbon as a carrier, and heating and reacting a mixture by adopting a microwave radiation method; and after the reaction is complete, filtering and drying, placing a product obtained after the reaction in an inert atmosphere and / or reducing atmosphere, and treating at a high temperature of 500-1500 DEG C to obtain the nano carbon doped electrocatalyst. The nano carbon doped electrocatalyst is very low in cost, high in activity and stability and excellent in anti-poisoning capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

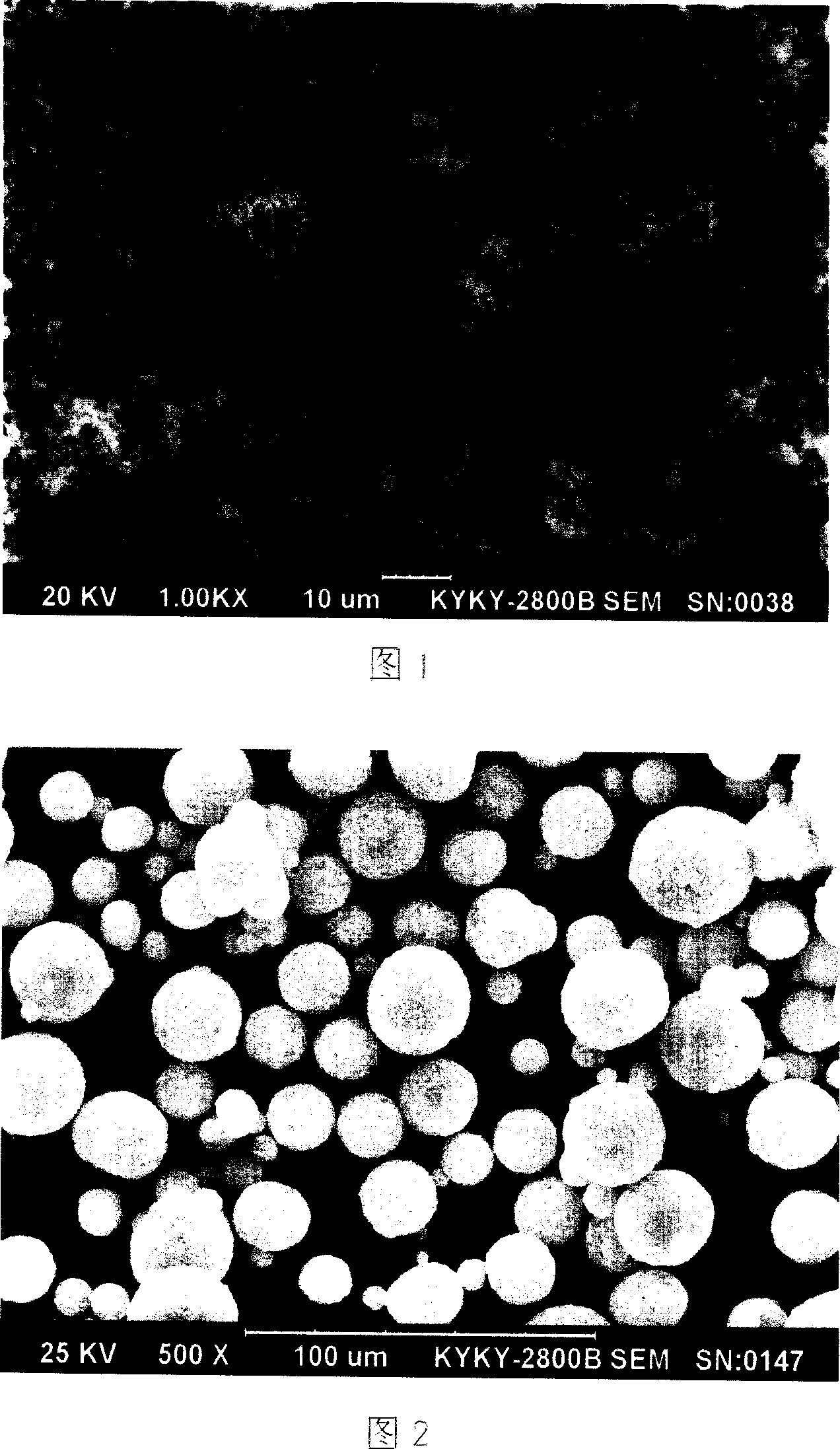

Plasma method for preparing nano carbon material using coal liquefied residue as raw material

The invention discloses an arc plasma torch preparing nanometer charcoal fibrous material method, which comprises the following steps: placing untreated leavings of liquefying coal directly in direct current arc plasma torch to carry on heat-treatment; using nitrogen for arc working gas under atmosphere pressure; getting nanometer charcoal fibrous material after 120-175 seconds, wherein there is no need to add in any activators in preparing process. The method is characterized by the following: the craft route is simple; the raw material is the waste of coal hydrogenant liquefaction craft; it's a good way to use coal liquification leavings to prepare high-added value, functional carbon material; the nanometer charcoal fibrous material can be used for accelerating agent, catalyst carrier, lithium ion secondary cell anode material, double-layer capacitor electrode, highly effective active solid, release agent and construction reinforced materials.

Owner:DALIAN UNIV OF TECH

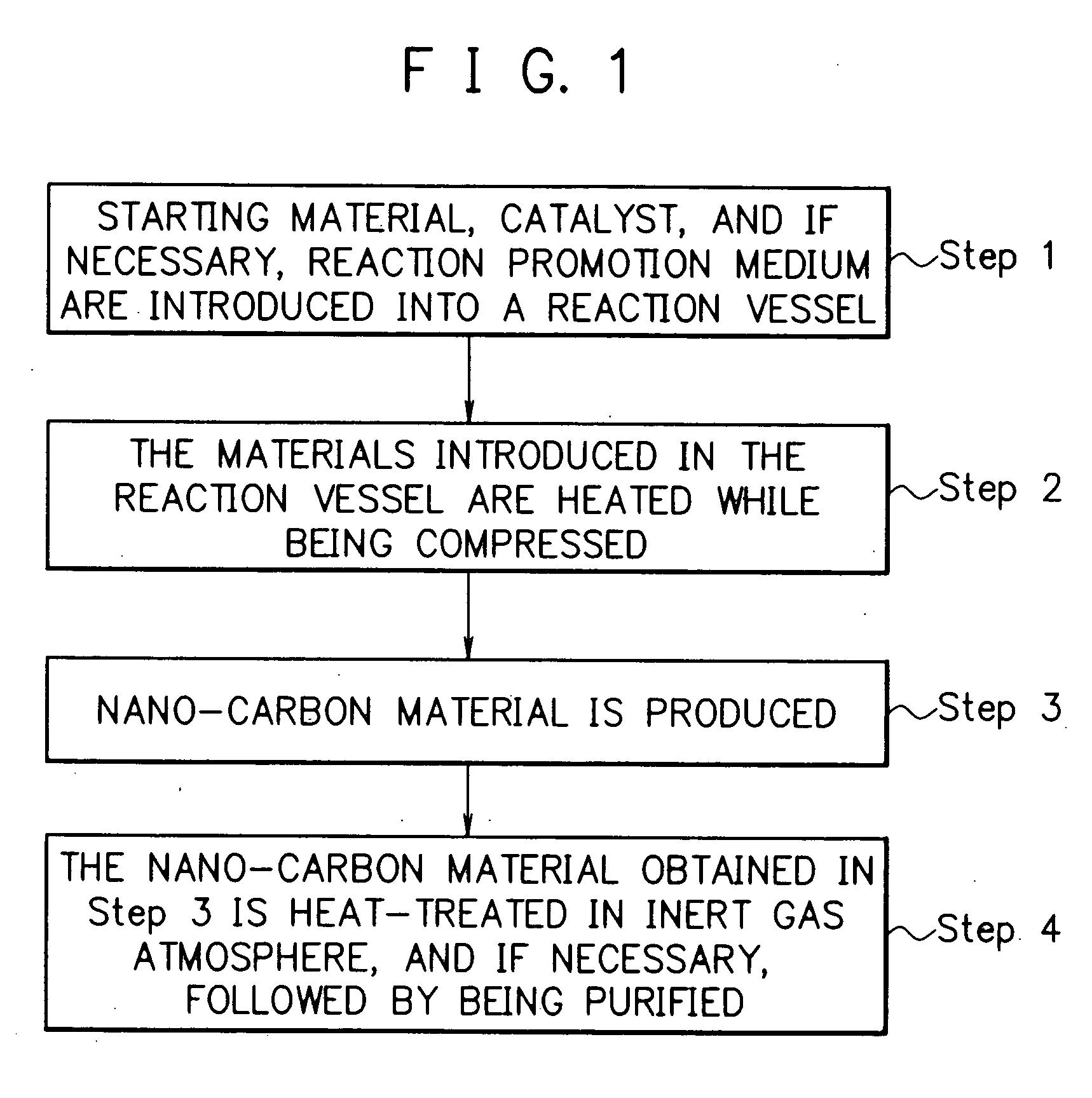

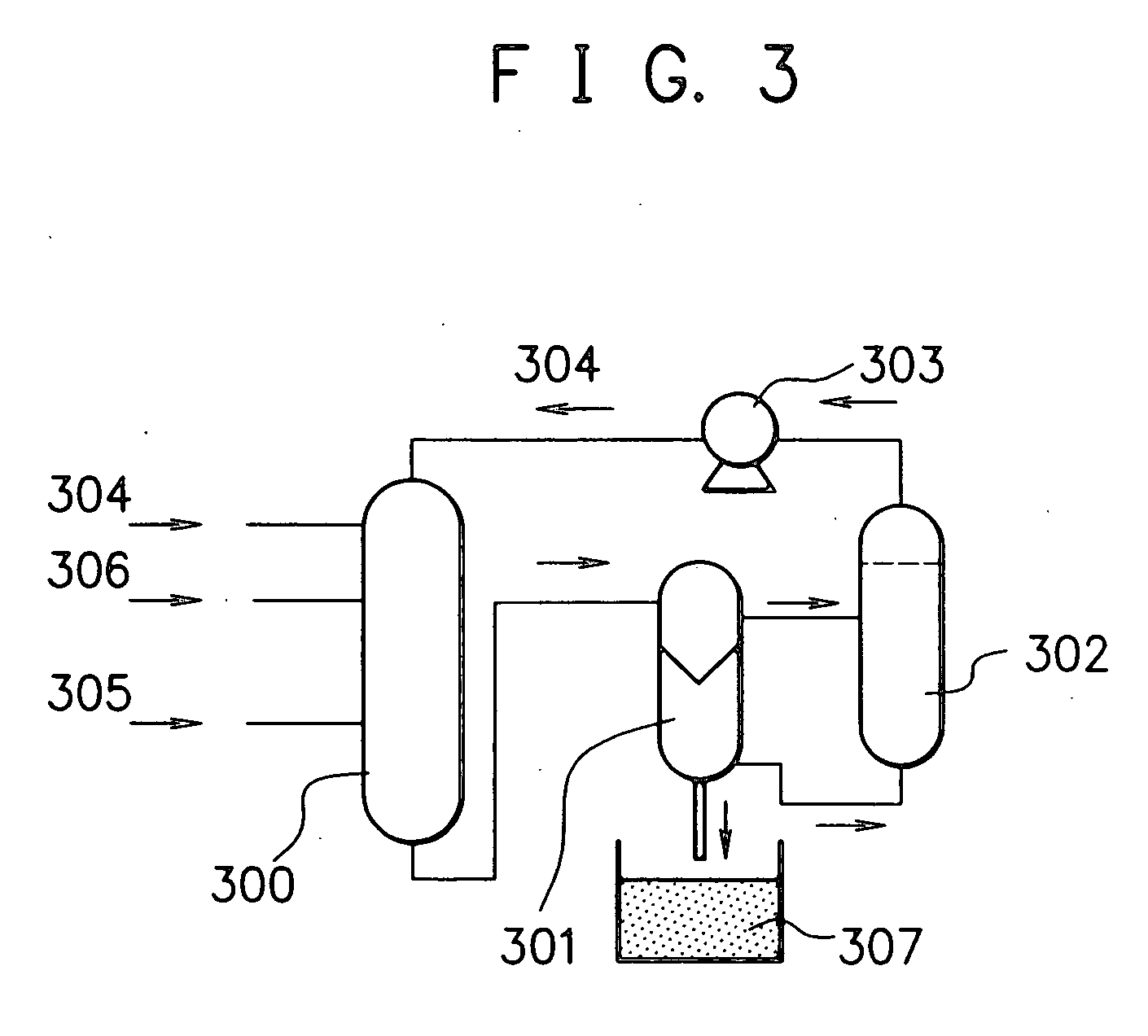

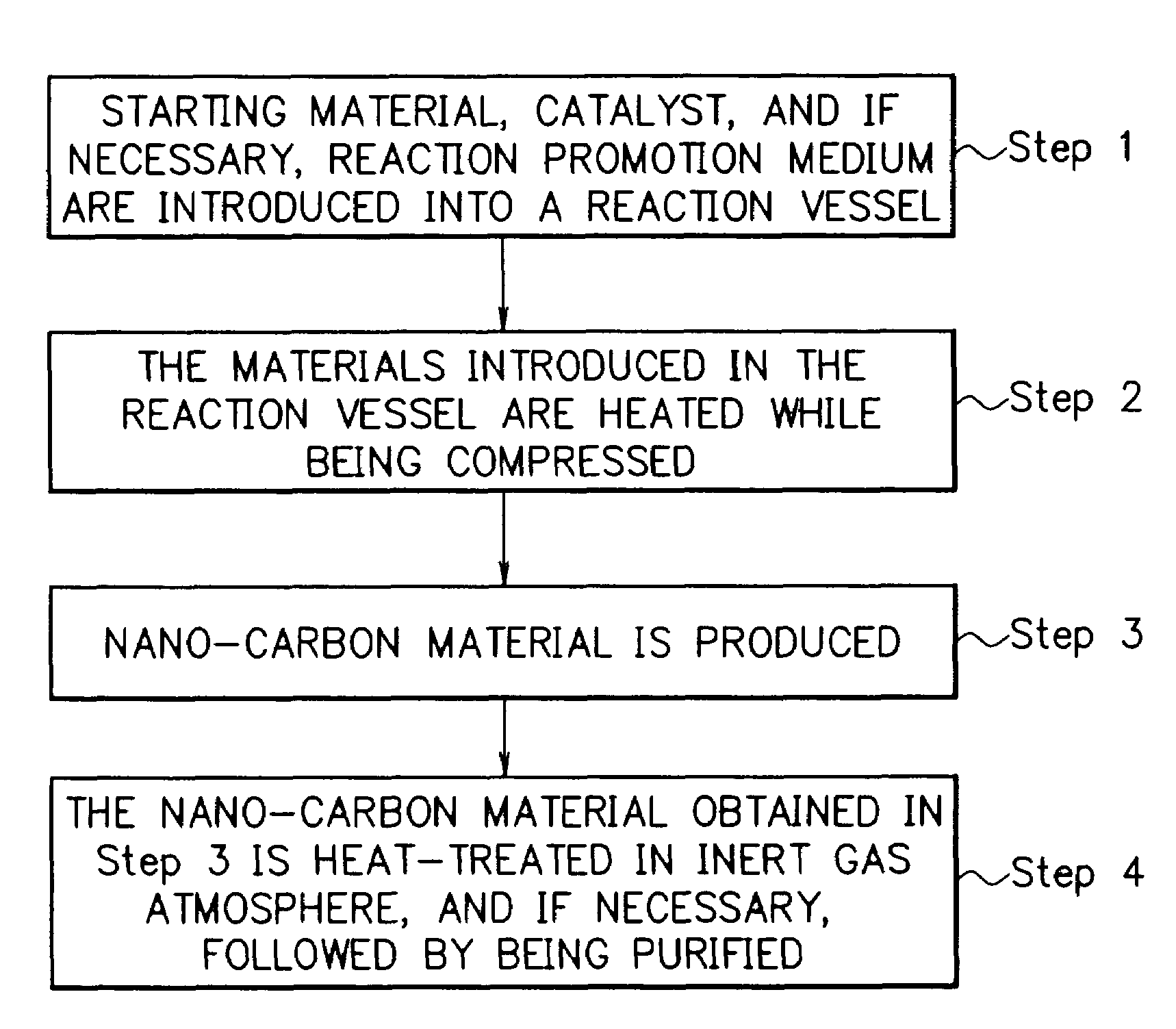

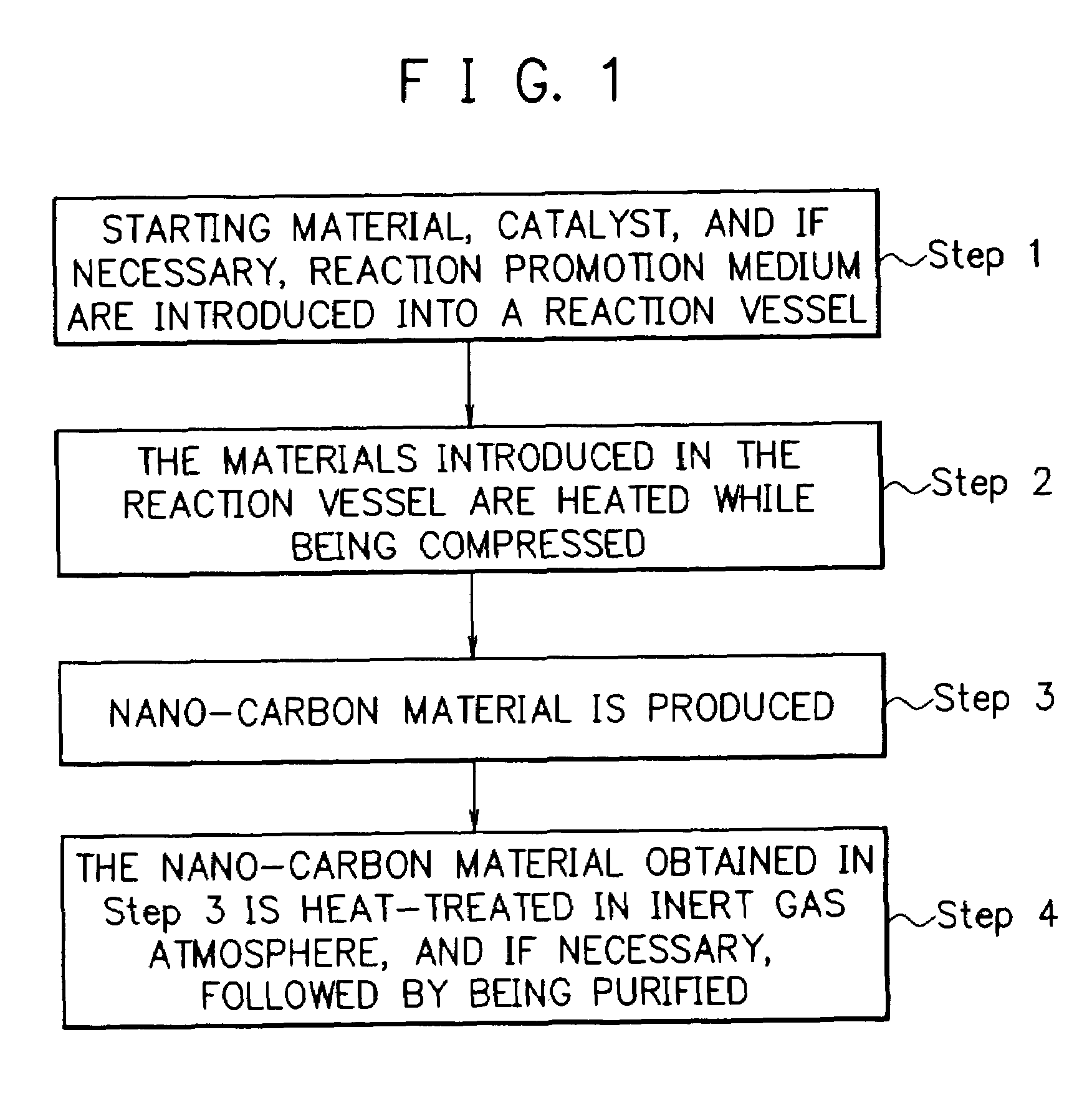

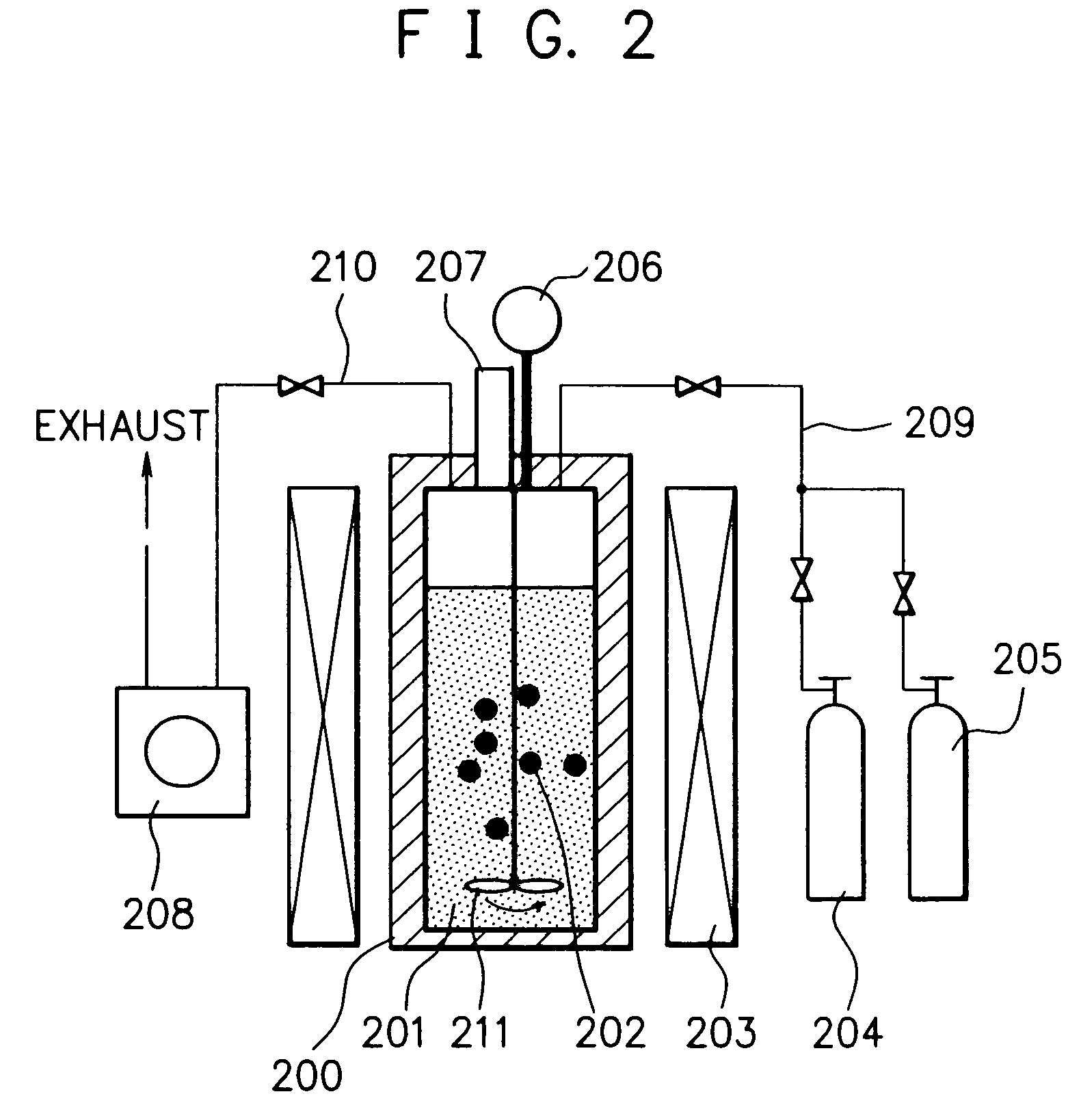

Method for producing nano-carbon materials

InactiveUS20050079119A1Efficiently and quantitatively produceLow production costMaterial nanotechnologyNanostructure manufacturePtru catalystUnsaturated hydrocarbon

A method for producing nano-carbon materials, having a step wherein a starting material comprising one or more kinds of compounds selected from the group consisting saturated hydrocarbons, unsaturated hydrocarbons, saturated cyclic hydrocarbons, and alcohols whose atomic ratio of the component carbon to the component oxygen is more than 2.0 and a catalyst are together treated at a temperature in a range of from 100 to 800° C. while being compressed at a pressure in a range of from 0.2 to 60 MPa, where said starting material is converted into a supercritical fluid or a subcritical fluid while said supercritical fluid or said subcritical fluid being contacted with said catalyst, or a step wherein said starting material, said catalyst and a supplementary material capable of functioning as a reaction promotion medium are together treated at a temperature in a range of from 100 to 800° C. while being compressed at a pressure in a range of from 0.2 to 60 MPa, where at least said supplementary material is converted into a supercritical fluid or a subcritical fluid and said starting material is contacted with said supercritical fluid or said subcritical fluid formed from said supplementary material while being contacted with said catalyst.

Owner:CANON KK

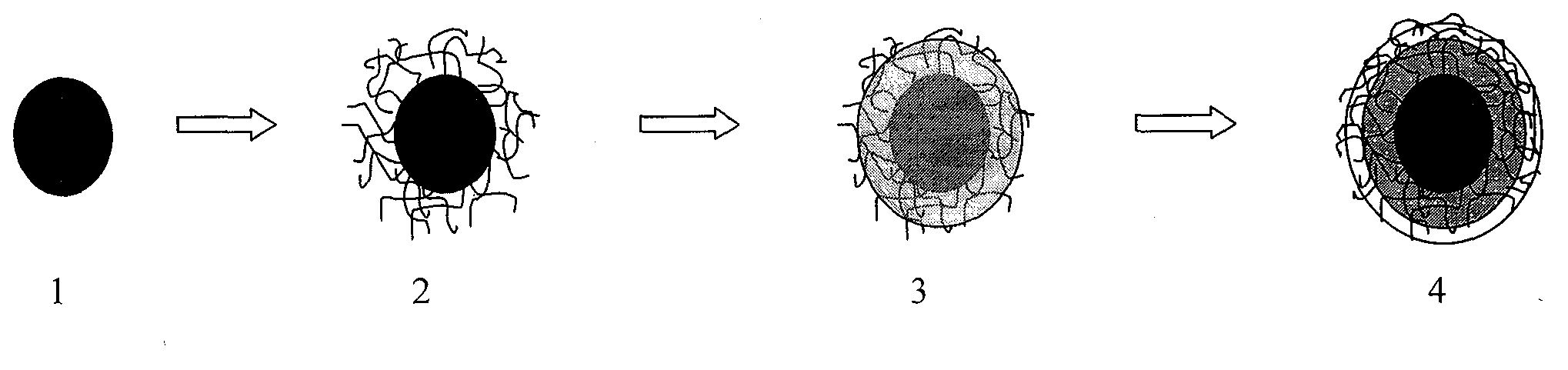

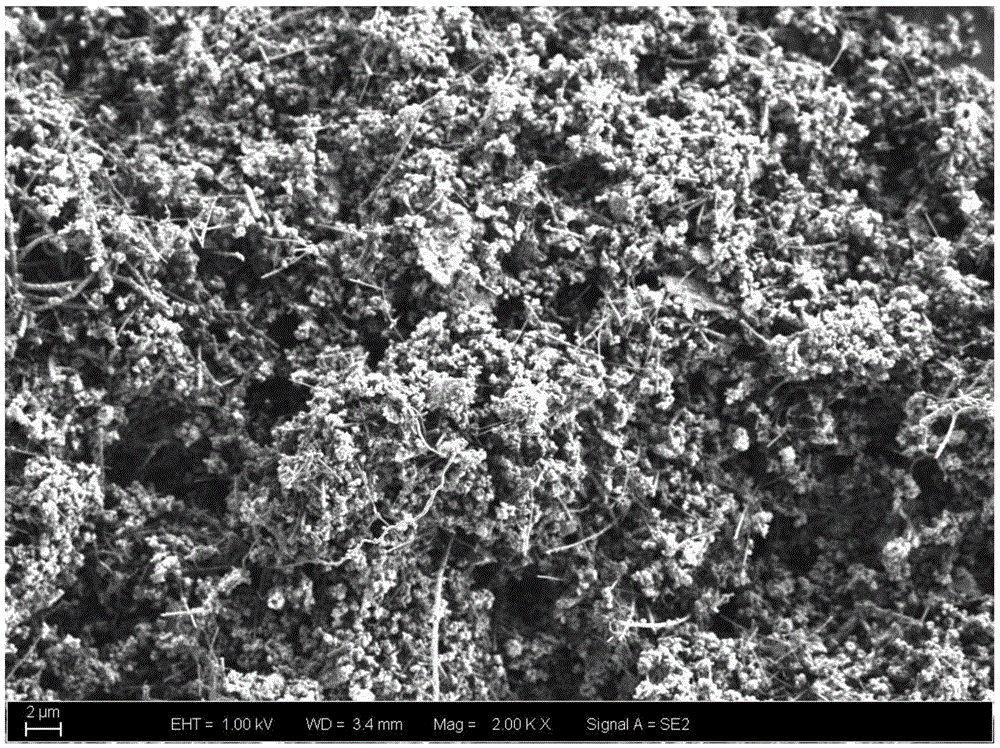

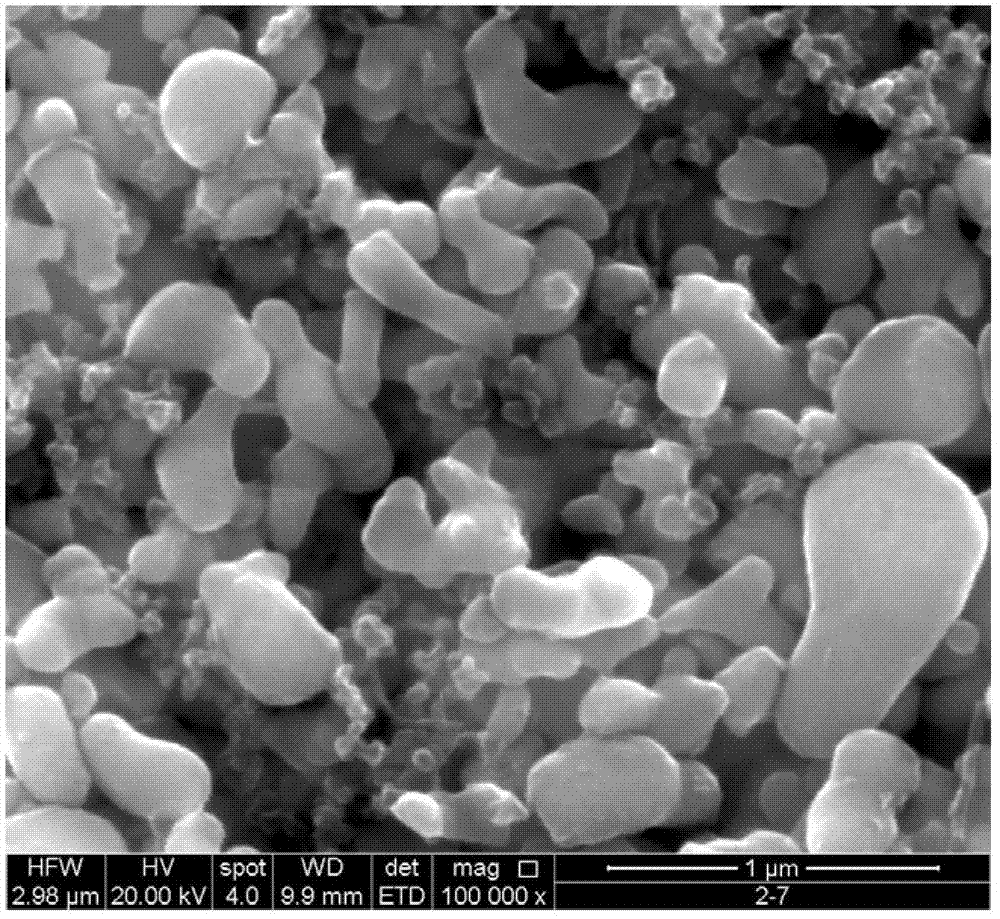

Silicon carbon composite negative electrode material for lithium ion battery as well as preparation method and applications of material

ActiveCN102903896AImprove securityImprove cycle performanceCell electrodesCarbon compositesElectrical battery

The invention is applicable to the field of novel materials, and provides a silicon carbon composite negative electrode material for a lithium ion battery, as well as a preparation method and applications of the material. The negative electrode material is of a nuclear-shell-type composite structure, and consists of nano silicon in the core, amorphous carbon at the middle layer and a one-dimensional nano carbon material at the outermost layer, wherein the amorphous carbon at the middle layer forms an elastic loose surface structure, and thus the circulating performance and multiplying performance of silicon are improved; a network structure built by the one-dimensional nano carbon material at the outermost layer not only plays a role in buffering mechanical stress, but also provides a rapid electric conducting channel for active silicon particles, and improves the circulating performance and multiplying performance of silicon further; and meanwhile, a three-dimensional electric-conducting heat-conducting network formed by the one-dimensional nano carbon material can conduct heat generated by a battery during the discharging process to the space around, and the safety performance of the battery is improved. The preparation method of the silicon carbon composite negative electrode material for the lithium ion battery is simple and feasible in process, environment-friendly and energy-saving, low in cost, and easy for industrialization.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Electrode for fuel cell, fuel cell comprising the same, and method for preparing the same

InactiveUS20060115711A1Increase surface areaImprove reaction efficiencyMaterial nanotechnologyFuel cell auxillariesFuel cellsEngineering

An electrode for a fuel cell of the present invention includes an electrode substrate, a microporous layer formed on the surface of the electrode substrate, and a nano-carbon layer formed on the surface of the microporous layer with a catalyst layer coated on the surface of the nano-carbon layer. Alternatively, an electrode for a fuel cell includes an electrode substrate in which carbon particles are dispersed, a nano-carbon layer on the electrode substrate, and a catalyst layer on the nano-carbon layer.

Owner:SAMSUNG SDI CO LTD

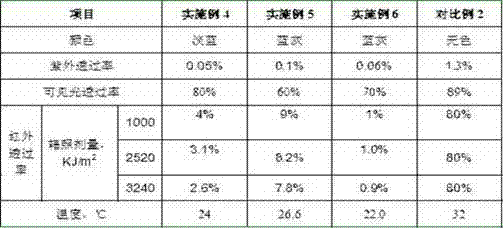

PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and preparation method thereof

ActiveCN104262874AHas the effect of heat insulation and UV protectionPlay the effect of energy saving and environmental protectionPolyvinyl butyralInfrared

The invention discloses a PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and a preparation method thereof. The functional PVB film comprises cesium tungsten bronze, antimony indium oxide, indium tin oxide, titanium dioxide, nano carbon spheres, zirconium carbide, PVB resin powder, a plasticizer, a trace improver and the like. The preparation method comprises the following steps: dispersing the cesium tungsten bronze composite nanoparticles with a solvent, adding the plasticizer, stirring uniformly, adding the PVB resin powder and trace improver, thoroughly mixing, and carrying out film formation on the mixture by running to obtain the heat-insulation ultraviolet-resistant PVB film. The ultraviolet rejection ratio of the PVB film is greater than 99.0%, the visible light transmittance is adjustable within the range of 60-85%, and the infrared rejection ratio is up to 80-99%; and the PVB film can be directly used for producing heat-insulation infrared / ultraviolet-resistant safety laminated glass, can be widely used in architectural curtain walls, doors / windows, zeniths, automobile windshields and the like, and is a novel energy-saving film material.

Owner:SUZHOU POLIMA MACROMOLECULE MATERIAL CO LTD

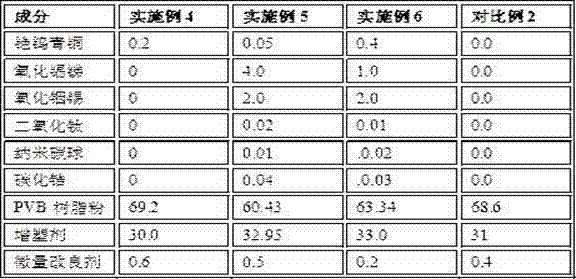

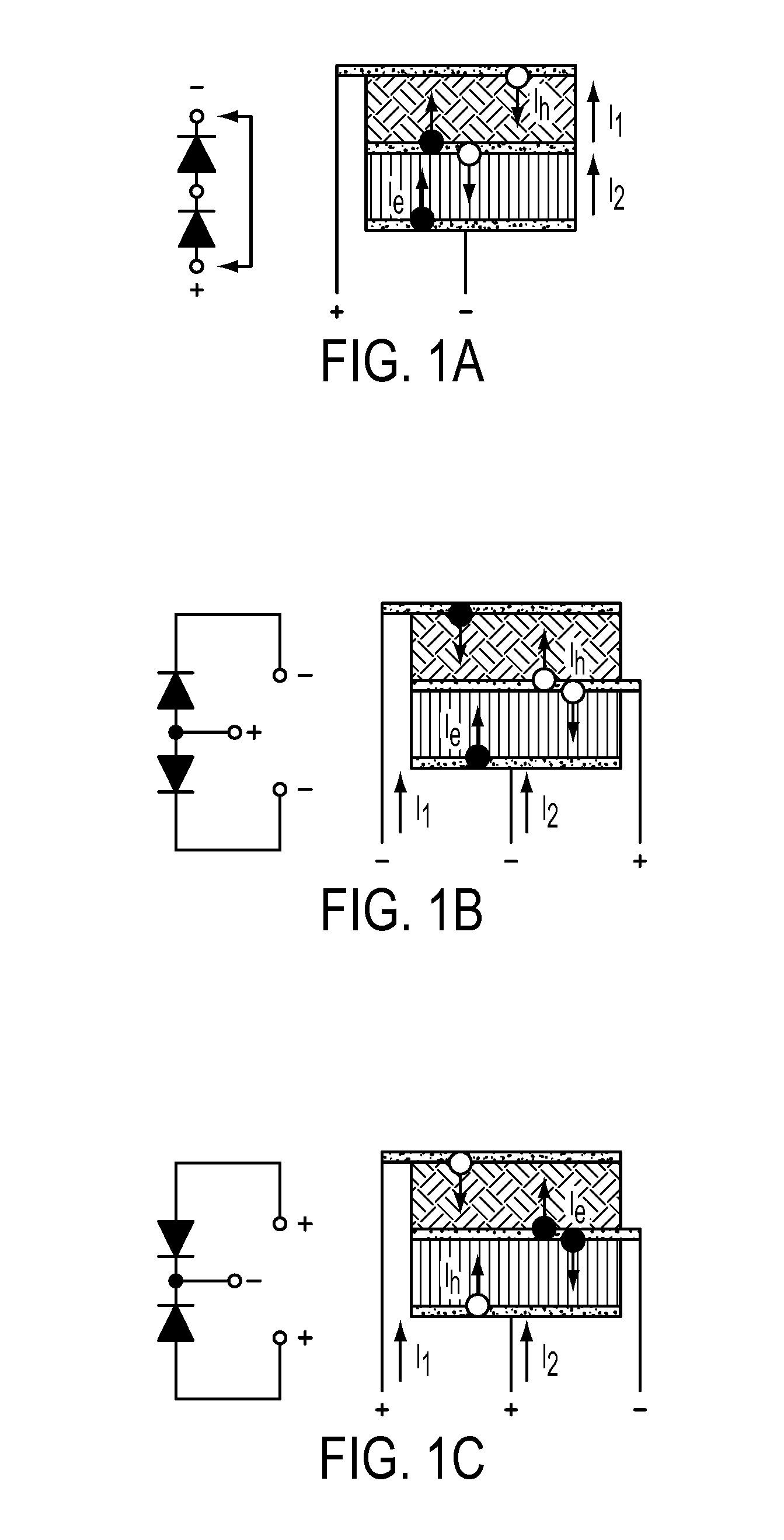

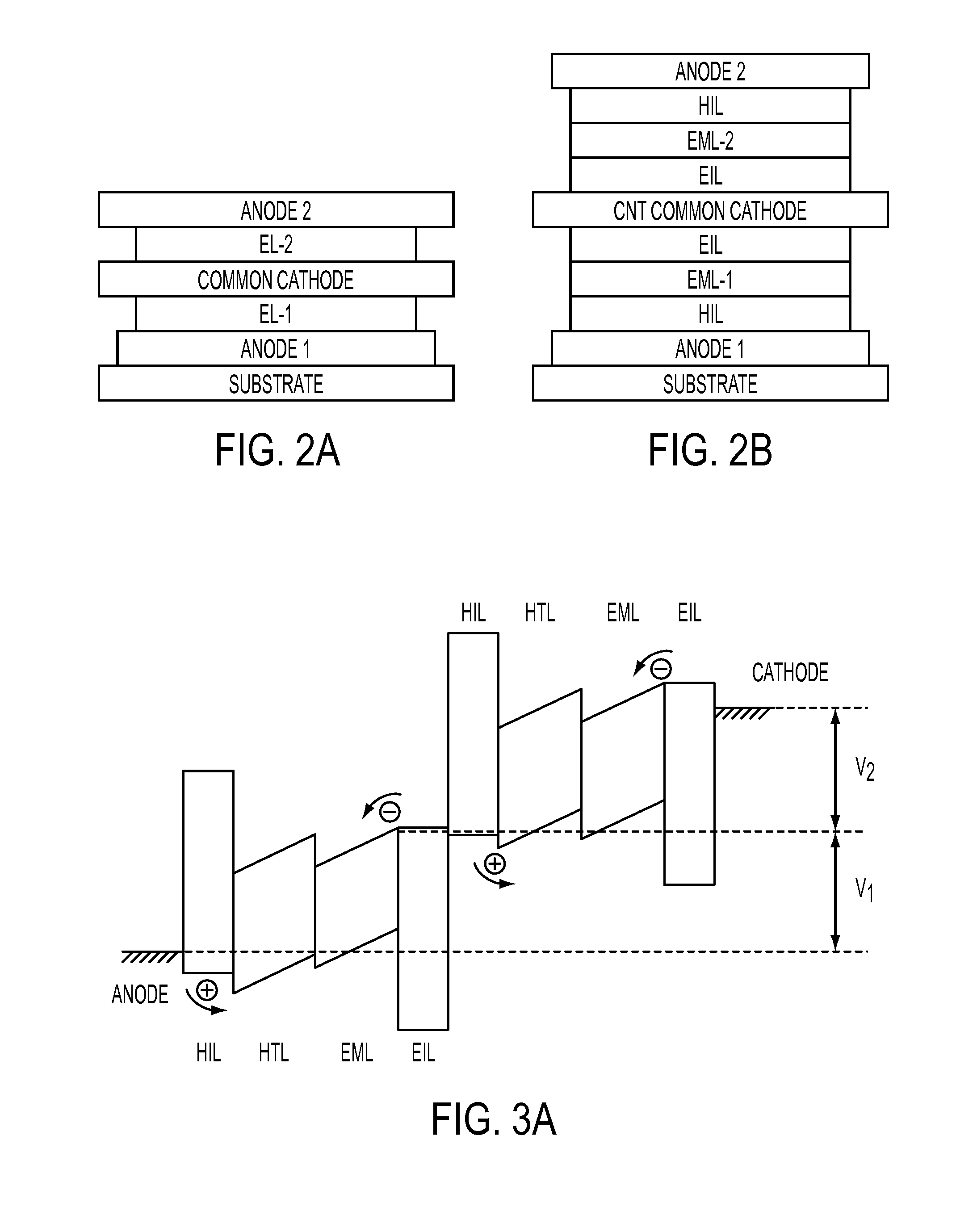

Monolithic parallel multijunction OLED with independent tunable color emission

InactiveUS20130240847A1Improve Charge Injection EfficiencyImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingCharge injectionInter layer

A tandem organic light emitting diode (OLED) device comprised of multiple stacked single OLEDs electrically connected in parallel via transparent interlayer is recited herein. Transparent interlayers are coated by charge injection layers in order to enhance the charge injection efficiency and decrease the operation voltage. Transparent nanomaterials, such as carbon nanotube sheets (or graphene, graphene ribbons and similar conductive transparent nano-carbon forms) are used as Interlayers or outer electrodes. Furthermore, functionalization of carbon nanotubes inter layers by n-doping (or p-doping) converts them into common cathode (or common anode), further decreasing operation voltage of tandem. The development of these alternative interconnecting layers comprised of nanomaterials simplifies the process and may be combined with traditional OLED devices. In addition, novel architectures are enabled that allow the parallel connection of the stacked OLEDs into monolithic multi-junction OLED tandems.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

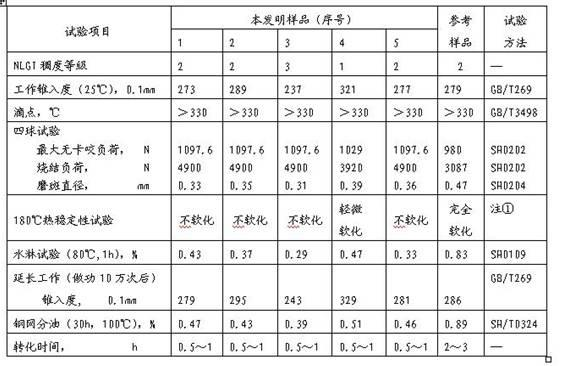

Nano calcium carbonate-containing calcium sulfonate complex grease and production method thereof

InactiveCN101993767AImprove thermal stabilityImprove extreme pressure and anti-wear performanceLubricant compositionMetallurgyPhysical chemistry

The invention relates to nano calcium carbonate-containing calcium sulfonate complex grease and a production method thereof. The grease comprises the following components in percentage by weight: 10 to 40 percent of high base-value calcium alkylbenzenesulfonate, 50 to 85 percent of base oil, 1 to 10 percent of nano calcium carbonate, 0.5 to 5 percent of boric acid, 0.5 to 5 percent of saturated fatty acid with 12 to 22 carbon atoms, 0.1 to 5 percent of anti-oxidant additive and 1 to 5 percent of composite transformation accelerator HBS. The grease and the production method have the advantages that: a nano calcium carbonate material is added into the formula of the calcium sulfonate complex grease for the first time, so that the thermal stability and extreme pressure wearing resistance of the ordinary calcium sulfonate complex grease are enhanced and a preparation and operation process is simplified. Simultaneously, the composite transformation accelerator is adopted, so that transformation speed and transformation rate are increased and production cost is lowered.

Owner:WUXI HUIYUAN PACKAGING TECH +1

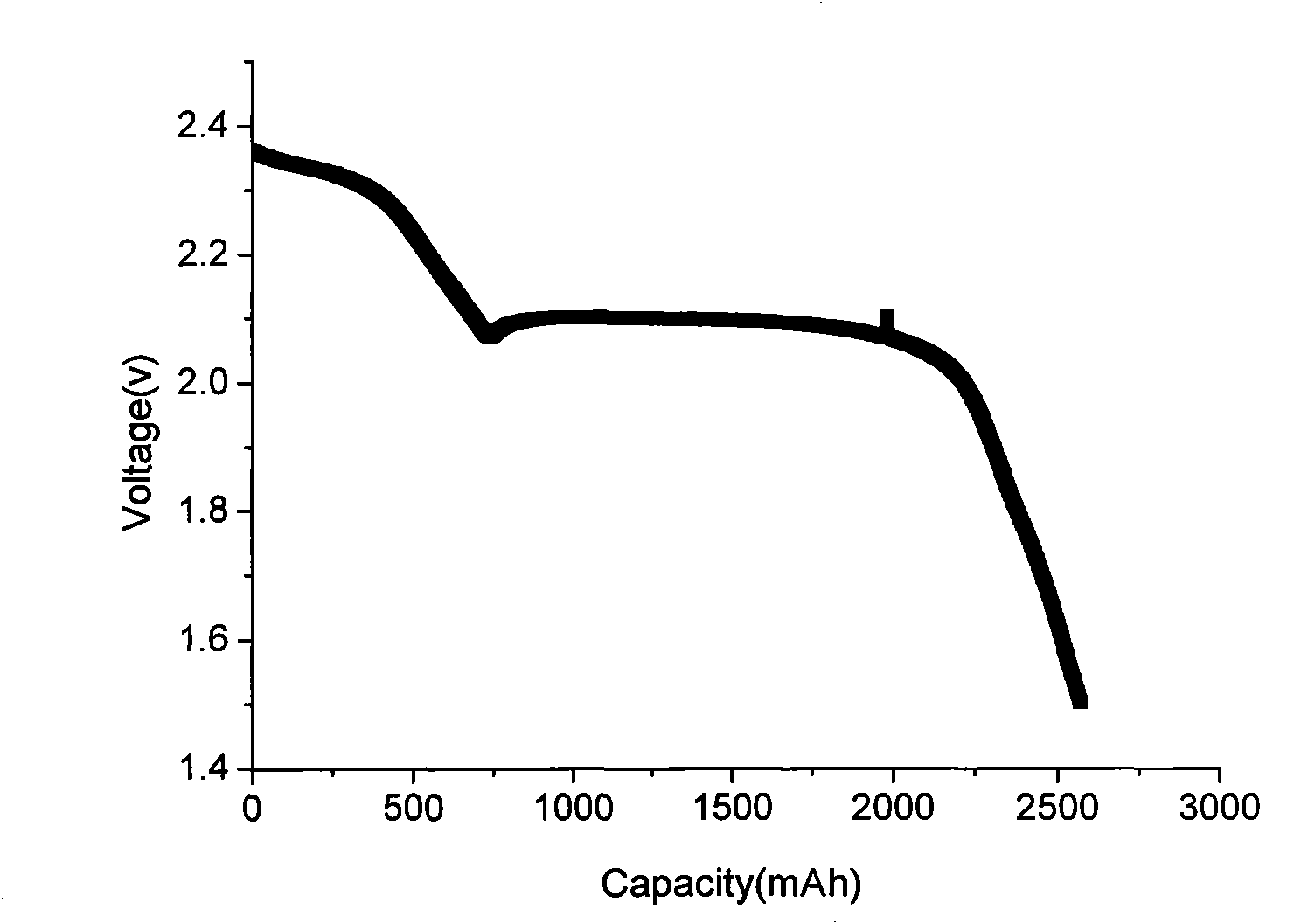

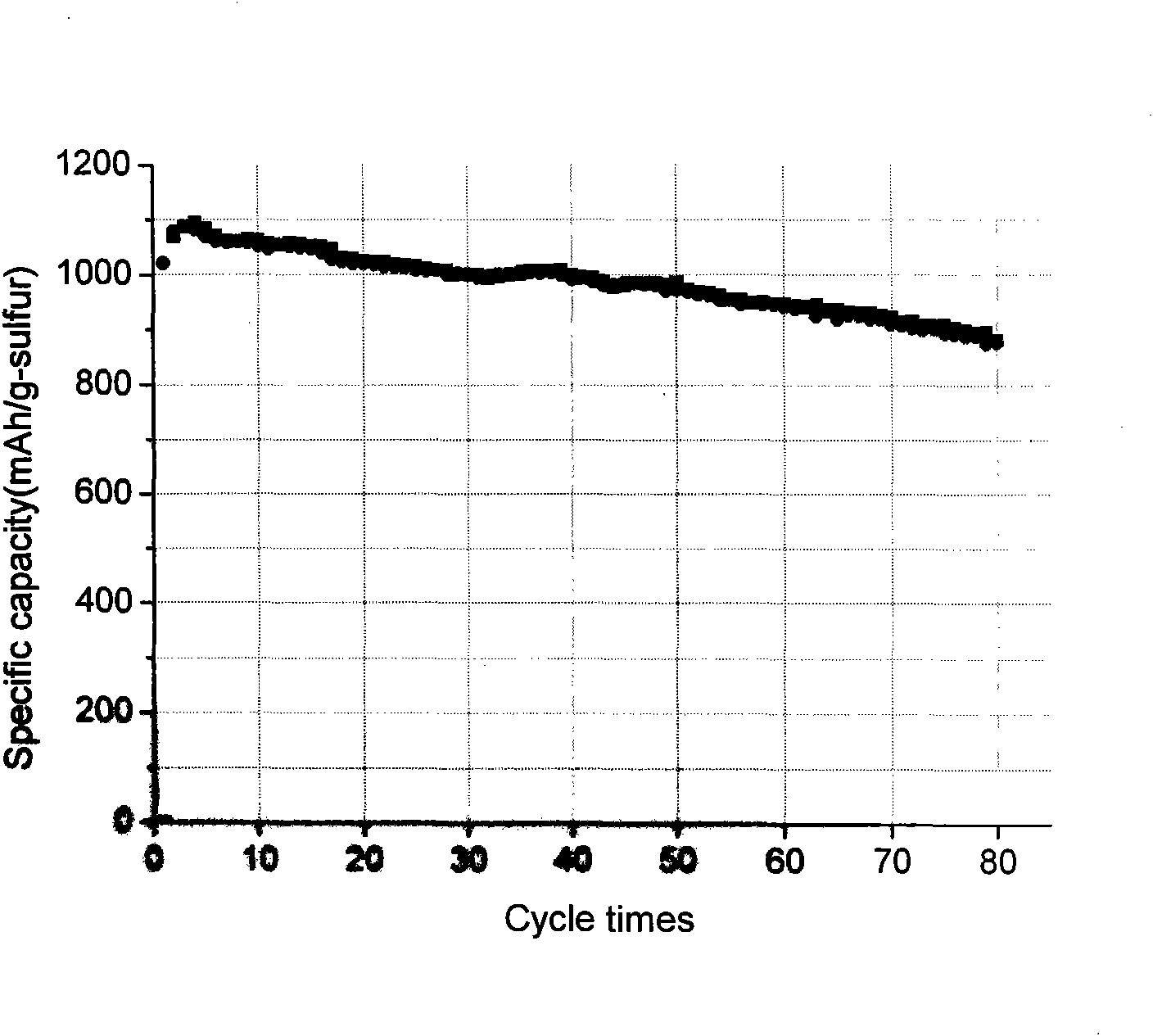

Carbon-sulfur-shell matter composite material having network dual-core shell structure and preparation method thereof

InactiveCN103474633AInhibition of dissolution and diffusion lossIncrease profitMaterial nanotechnologyElectrode manufacturing processesPolycyclic aromatic hydrocarbonLithium–sulfur battery

The invention relates to a carbon-sulfur-shell matter composite material having a network dual-core shell structure and a preparation method thereof. The carbon-sulfur-shell matter composite material has a carbon-sulfur-shell three layer structure, a central core (inner core) is nano carbon particles, sulfur elemental or a polysulfide containing-Sm-structure (m>2) is directly deposited on the nano carbon particles, or functional groups are introduced onto the nano carbon particles by use of polycyclic aromatic hydrocarbon like reaction capacity of the carbon material and through an irreversible chemical reaction, polymeric chains are introduced in, a crosslinked network structure is formed through stretching, bending and crosslinking of the polymeric chains on the surface of the nano carbon particles, the sulfur elemental or the polysulfide containing the-Sm-structure (m>2) is composited onto the crosslinked network structure to form a nano sulfur layer having a network structure, then a mono-core shell nano composite material having a network structure is obtained and is used as a second layer (outer core) of the carbon-sulfur-polymer composite material having the network dual-core shell structure, an outermost layer is a shell matter layer, electronic and / or ionic conductivity of the material are / is improved, dissolving loss of discharge products can be further inhibited, and structural stability of the material is improved. The material is suitable for positive poles of lithium sulfur batteries, and has a prominent effect on improvement of cycle stability of the lithium sulfur batteries.

Owner:NO 63971 TROOPS PLA

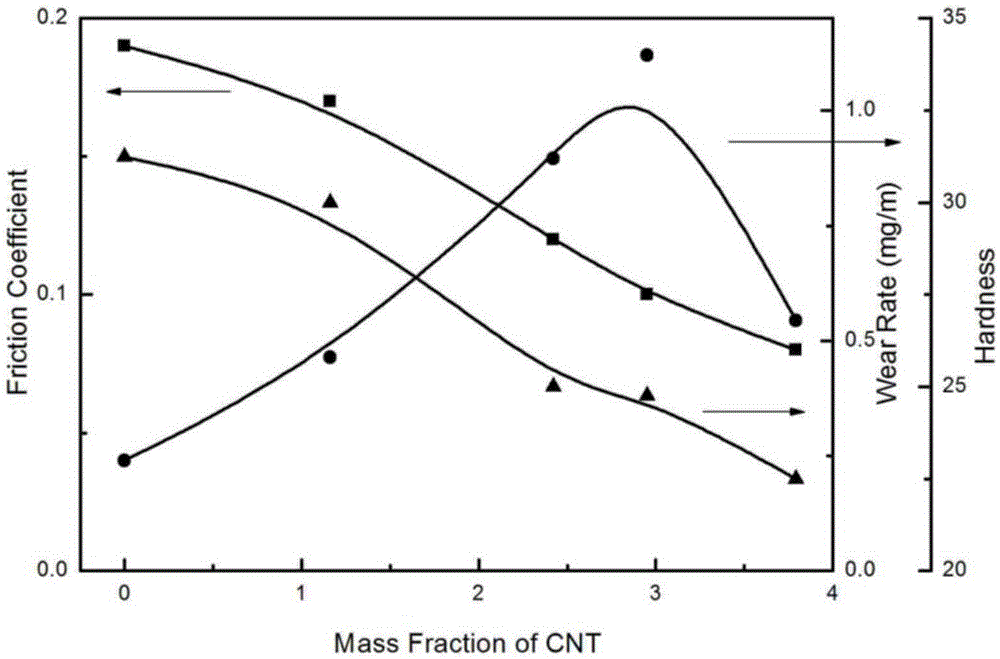

Nano-carbon-reinforced wear-resistant composite material

The invention belongs to the technical field of materials, and specifically relates to a nano-carbon-reinforced wear-resistant composite material. The nano-carbon-reinforced wear-resistant composite material comprises the following components in percentage by mass: 55-99% of metal powder, 0.1-35% of ceramic powder, and 0.01-15% of nano-carbon, wherein the metal powder is used as a composite material matrix; the ceramic powder is used as a wear-resistant filling material; and the nano-carbon comprises single-wall carbon nano-tubes, multi-wall carbon nano-tubes and other materials, and is mainly used for improving the heat-conducting performance, strength, toughness, wear resistance and other performances of the composite material. The wear-resistant composite material disclosed by the invention can keep a stable friction coefficient and a low wear rate under the conditions of a heavy load, a high speed, and long-time braking.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Method for producing nano-carbon materials

InactiveUS7270795B2Efficiently and quantitatively produceLow production costMaterial nanotechnologyNanostructure manufactureAlcoholUnsaturated hydrocarbon

A method for producing nano-carbon materials, having a step wherein a starting material comprising one or more kinds of compounds selected from the group consisting saturated hydrocarbons, unsaturated hydrocarbons, saturated cyclic hydrocarbons, and alcohols whose atomic ratio of the component carbon to the component oxygen is more than 2.0 and a catalyst are together treated at a temperature in a range of from 100 to 800° C. while being compressed at a pressure in a range of from 0.2 to 60 MPa.

Owner:CANON KK

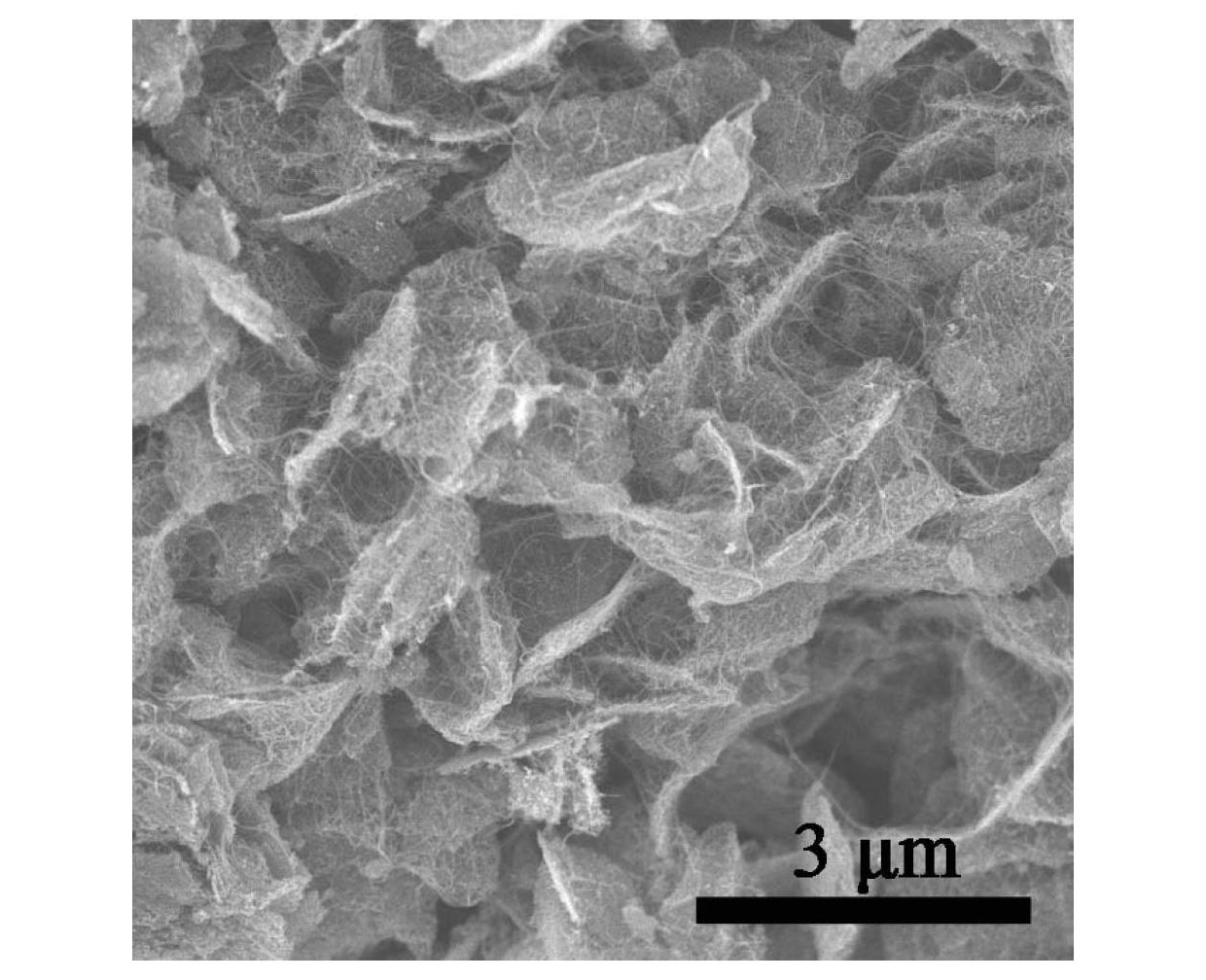

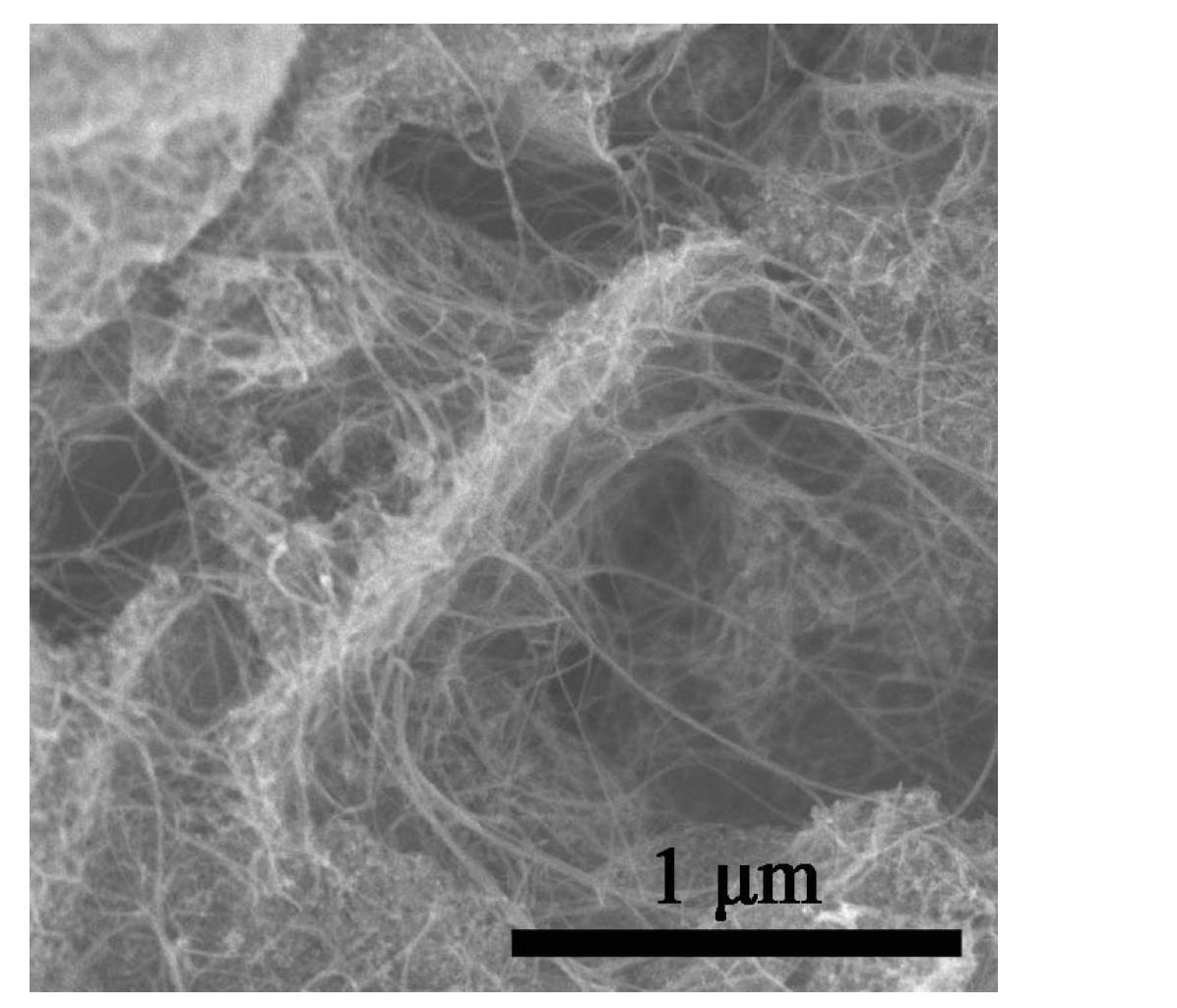

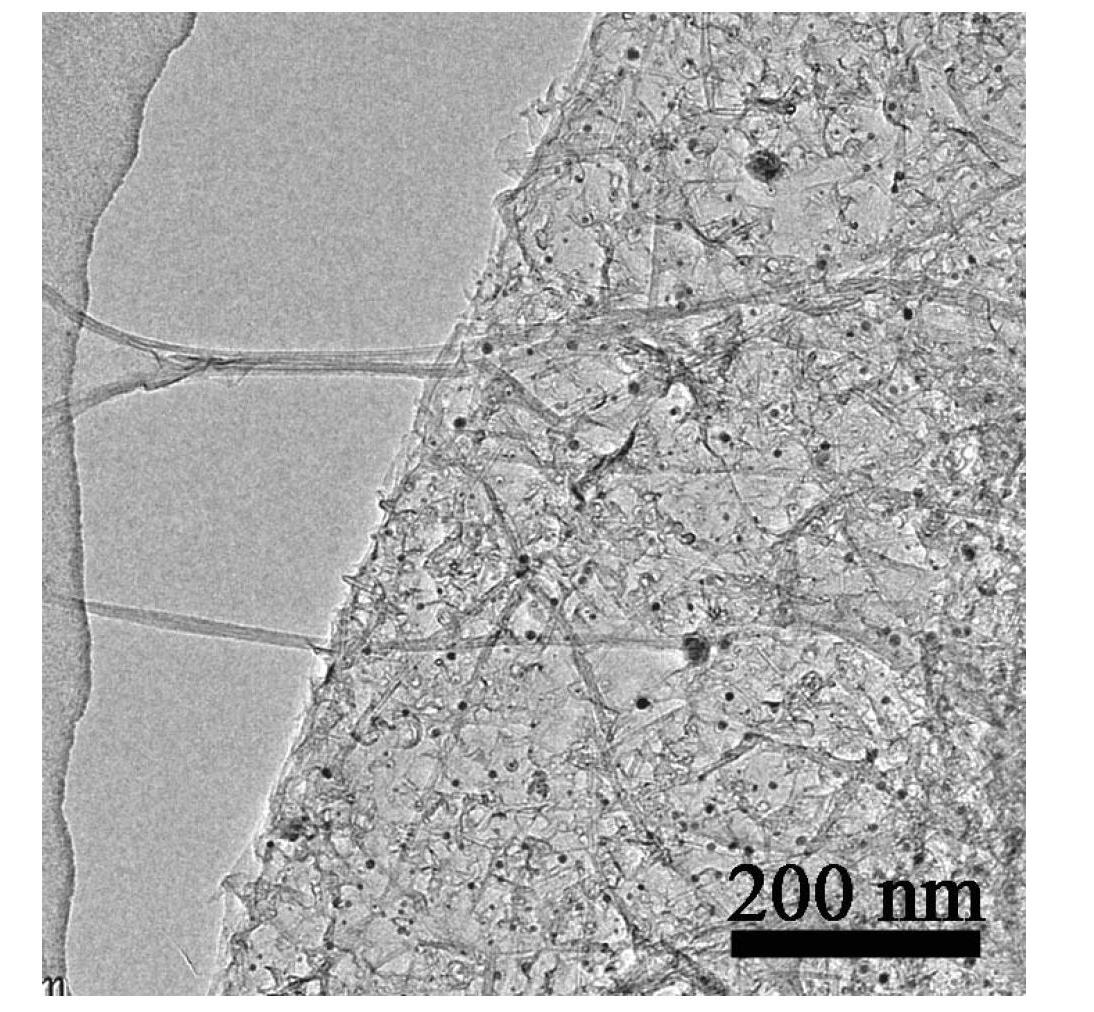

Method for preparing composition of carbon nano tube and graphene by using sheet material

ActiveCN102674316AIncrease production capacityMaterial nanotechnologyGrapheneGas phaseActive component

The invention relates to a method for preparing composition of a carbon nano tube and graphene by using a sheet material; the composition comprises the carbon nano tube and the graphene material, wherein the carbon nano tube directly grows on the surface of graphene. According to the preparation method, the sheet material loaded with a catalyst active component is used as a catalyst, the carbon nano tube and the graphene are deposited on the sheet material by chemical vapor deposition, and the composition of carbon nano tube and graphene can be obtained after purification. The method enriches the variety of nano carbon materials; and the method can be easily applied to industrial production to realize batch production, thus promoting the application study of the composition of carbon nano tube and graphene.

Owner:TSINGHUA UNIV

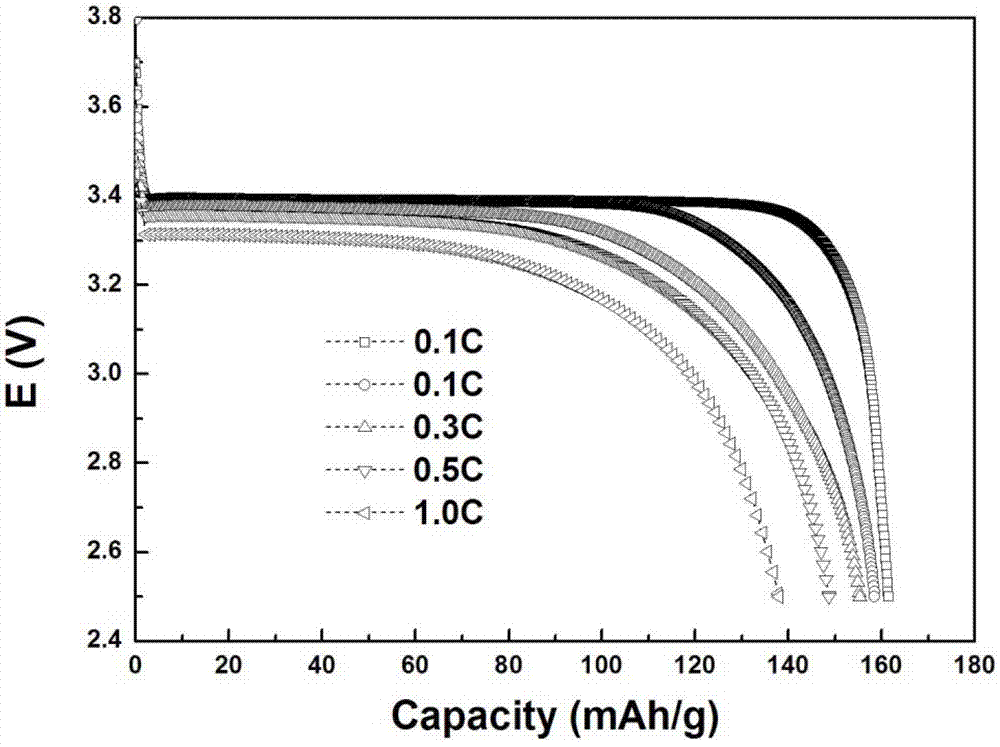

Cathode material of lithium ion battery, preparation method of cathode, and lithium ion battery

ActiveCN103199258APromote accumulationEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryNano carbon

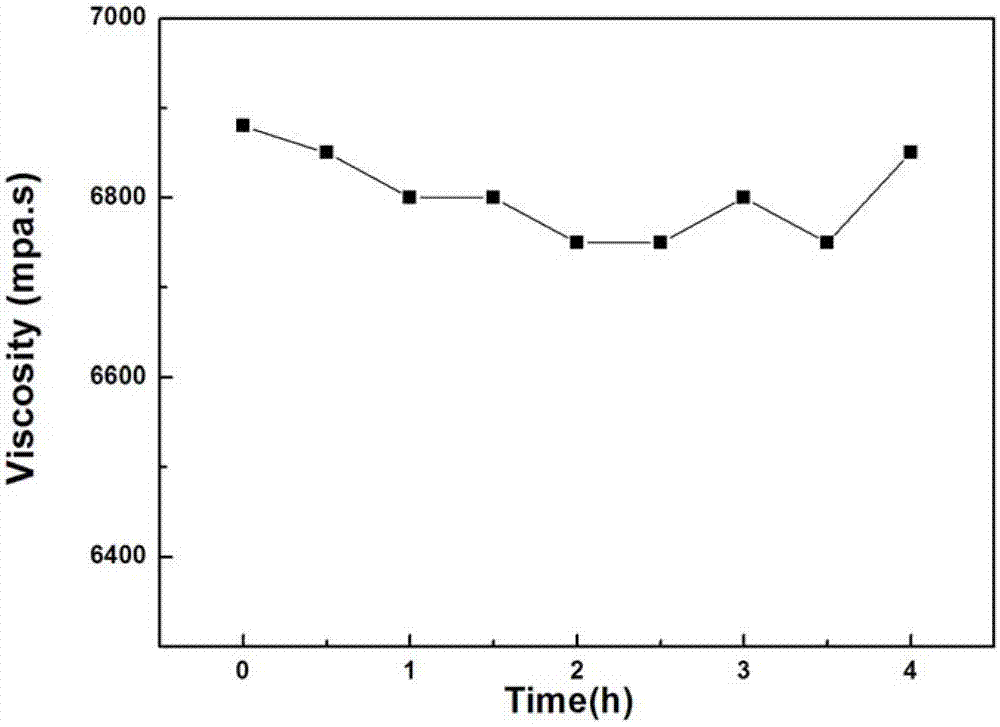

The invention discloses a cathode material of a lithium ion battery, a preparation method of the cathode, and the lithium ion battery using the cathode material, belonging to the technical field of energy material. According to the invention, a chemical dispersant is added into the cathode of an aqueous lithium-ion battery, thereby solving problems of uniform dispersion for active materials of positive electrode and a nano-carbon mixed conductive agent; and a mechanical dispersion method is combined, preferably with a revolution speed of the mechanical dispersion being 15-35 HZ and a rotation speed being 10-30 HZ, thereby realizing uniform dispersion of the nano-active substances in a relatively short time. The cathode material of a lithium ion battery and the preparation method provide technical approach for solving uniform dispersion of the aqueous nano-active substances, and are high in production efficiency and low in cost; the prepared battery is high in discharge capacity, and is significantly improved in low temperature, multiplying power and cycling performances; and a new approach is provided for a large scale application of the nanometer lithium batteries which are limited to a high cost and a high-polluting oil system in the field.

Owner:中创新航科技(江苏)有限公司

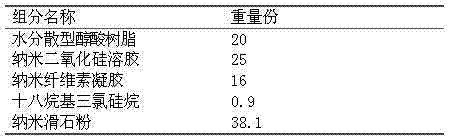

Water-based polyurethane functional coating material and preparation method thereof

InactiveCN105153906AMeet high concentration dispersionHigh volume compoundPolyurea/polyurethane coatingsPolymer scienceNano carbon

The invention discloses a water-based polyurethane functional coating material and a preparation method thereof. The coating material comprises the following basic ingredients by weight percent: 10 to 40 percent of water-based polyurethane matrix resin, 1 to 10 percent of water-soluble acrylic acid resin, 1 to 5 percent of nano carbon material, 0.1 to 5 percent of silica sol, 0.5 to 2 percent of dispersing agent, 0.1 to 5 percent of moisturizing agent, 0.1 to 5 percent of leveling agent, 1 to 20 percent of butyl cellosolve, 0.1 to 10 percent of normal butanol, 0.1 to 10 percent of ethanol and the balance of water. By adopting the water-based coating material, the high-volume content addition of the nano carbon material can be realized, the conductivity and heat conduction performance of the coating can be effectively controlled, and high heat conduction performance and high conductivity characteristics can be obtained. The volatilization rate of solvent is reasonably controlled by virtue of flexible mixing, different construction coating process requirements can be met, and the applicability is wide. The novel functional coating material formula system can be used as a conducting coating material (ink), a radiation heat radiation coating material, an electric thermal coating material (ink), an antistatic coating material and an electromagnetic shielding coating material and has an important commercial value.

Owner:JINAN QINGNA MATERIAL TECH CO LTD

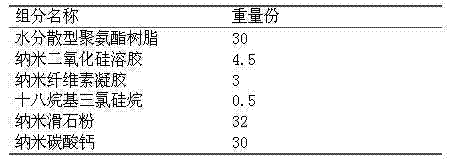

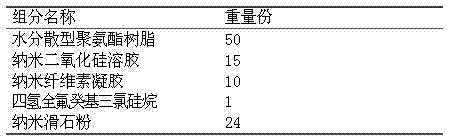

Transparent super-hydrophobicity wood coating and preparation method thereof

InactiveCN103756541AParticle size controllableHydrophobic hasPolyurea/polyurethane coatingsPolyester coatingsOctadecyltrichlorosilanePolymer science

The invention discloses a transparent super-hydrophobicity wood coating which comprises the following components in parts by weight: 20-50 parts of water dispersive polyurethane resin or water dispersive alkyd resin, 4.5-25 parts of nano silica sol, 3-16 parts of nano cellulose gel, 0.1-1 part of octadecyl trichlorosilane or tetrahydroperfluorodecyltrichlorosilane or stearic acid and 0-45 parts of nano talc powder or nano calcium carbonate. A preparation method of the transparent super-hydrophobicity wood coating comprises the following steps: adding matrix resin and filler into a stirring kettle, and stirring uniformly to obtain slurry; grinding the slurry with a sand mill; adding a low-surface energy substance and supported nano silica sol; performing ultrasonic sufficient mixing for 30 minutes to obtain the transparent super-hydrophobicity coating. The transparent super-hydrophobicity wood coating disclosed by the invention has the advantages of low cost, controllable process, adjustable size and good applicability and is suitable for a preparation method of large-area preparation of transparent super-hydrophobicity surface; the prepared super-hydrophobicity film has good self-cleaning property, antifouling property, hydrophobic property, oleophobic property and the like.

Owner:GUANGDONG YIHUA TIMBER IND +1

Lithium iron phosphate-carbon nanotube composite material, preparation method, and application thereof

ActiveCN102427130AThe phase is pure and the crystal form is goodLow resistivityCell electrodesLithium iron phosphateCarbon nanotube

The present invention discloses a lithium iron phosphate-carbon nanotube (LiFePO4-CNTs) composite material. The composite material comprises LiFePO4 particles, a nano-carbon layer and CNTs, wherein the nano-carbon layer is positioned outside the LiFePO4 particles, and the CNTs grow in the nano-carbon layer in an in situ growth manner by a chemical vapor deposition (CVD) process. In addition, the present invention further discloses a preparation method for the composite material. The method comprises: uniformly mixing and coating the prepared LiFePO4 precursor powder, a catalyst and liquid carbon source to prepare into the slurry; adopting a spraying feeding device to convey the slurry to a high-temperature reaction furnace to form a floating CVD process; carrying out heat insulation calcination for the resulting mixture so as to complete the treatments of granulation of the LiFePO4 precursor, in situ growth and coating of the CNTs and synthesis sintering of the LiFePO4 in one step, such that the uniform nano-carbon layer and the CNTs are formed on the surfaces of the LiFePO4 particles. In addition, the present invention further discloses an application of the composite material in battery preparation. According to the composite material of the present invention, the nano-carbon layer and the CNTs have good crystallization, the total carbon content is low, the electrical conductivity and the specific capacity are high so as to substantially increase the rate performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

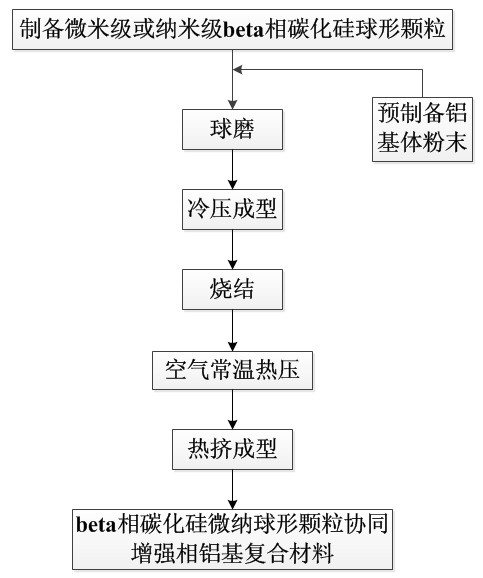

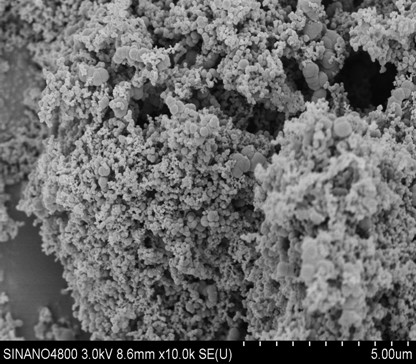

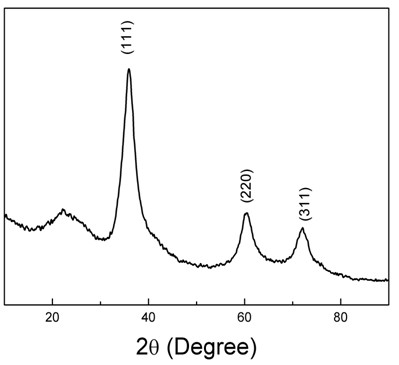

Silicon carbide reinforced aluminum-based composite material and its preparation method

The invention relates to a silicon carbide reinforced aluminum-based composite material and its preparation method. The composite material is characterized by being composited by micron-scale and nano-scale beta-phase silicon carbide spherical particles and an aluminum substrate, with the beta-phase silicon carbide spherical particles distributed in the aluminum substrate to form a synergistic reinforced phase. The preparation method is summarized to be mainly composed of: pre-preparing beta-phase silicon carbide spherical particles, adding aluminum substrate powder and the beta-phase silicon carbide spherical particles accounting for 0-25wt% of the composite material into a ball mill for ball milling treatment, and conducting cold press molding, sintering, as well as air hot pressing sequentially, and finally carrying out hot extrusion molding to obtain a molded product of the composite material. Specifically, the particle size of the aluminum substrate powder is 1micrometer to 100micrometers. The technical scheme of the invention innovatively uses spherical particulate beta-phase silicon carbide and makes use of the synergistic reinforcement effect of the micron and nano-silicon carbide particles, substantially improves the strength, toughness, abrasion resistance and others of the aluminum-based composite material. The preparation process is simple, and the cost input is effectively reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

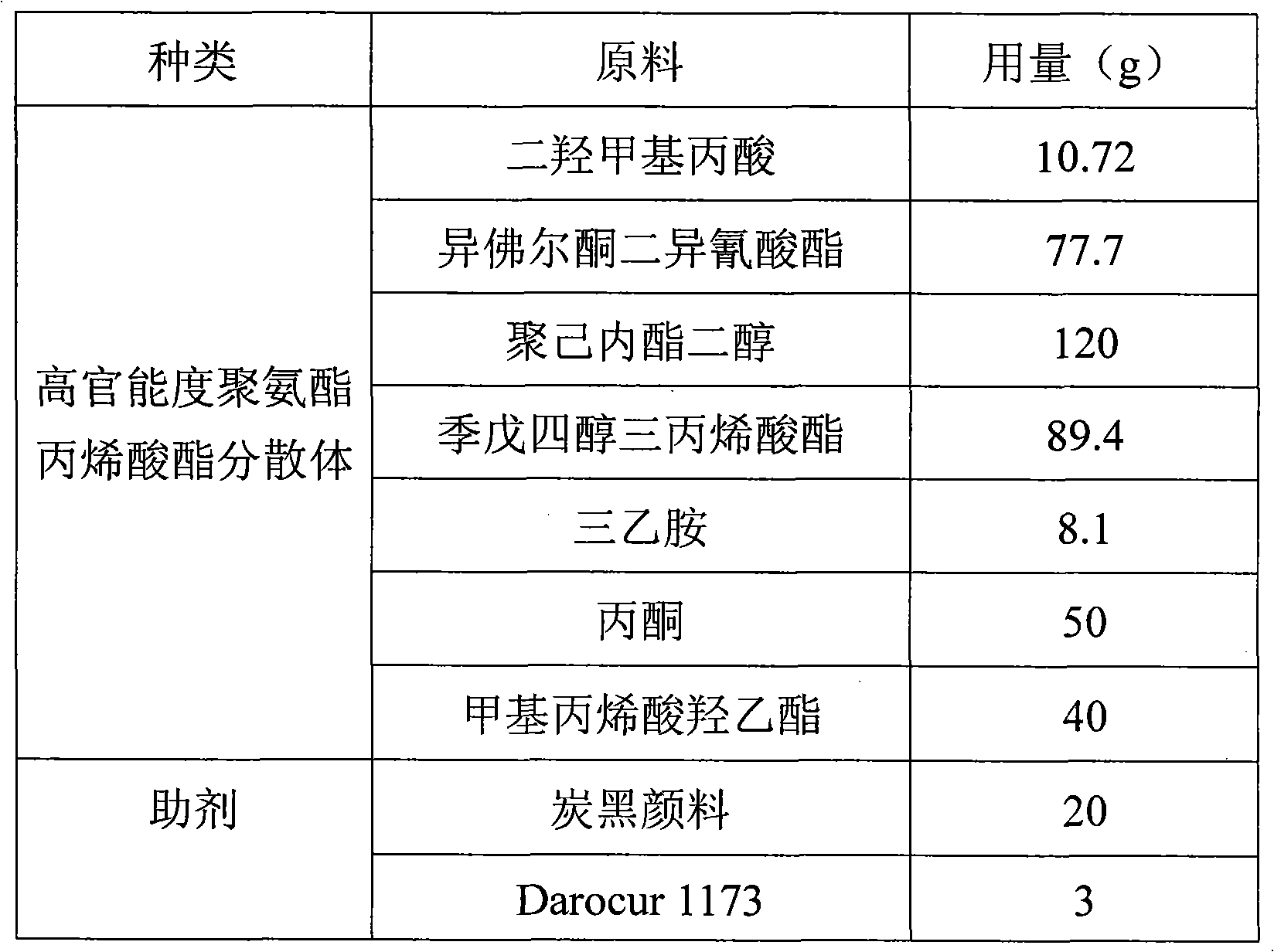

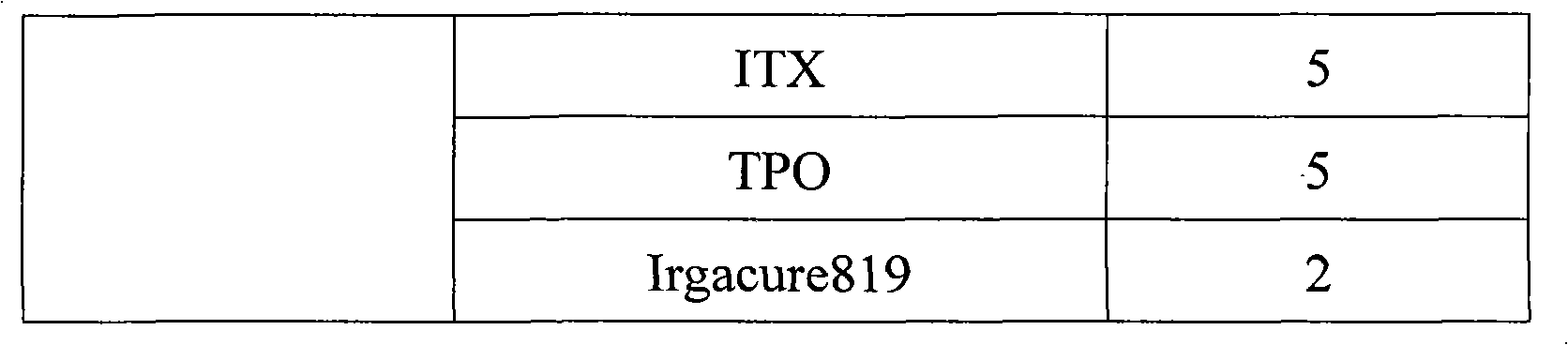

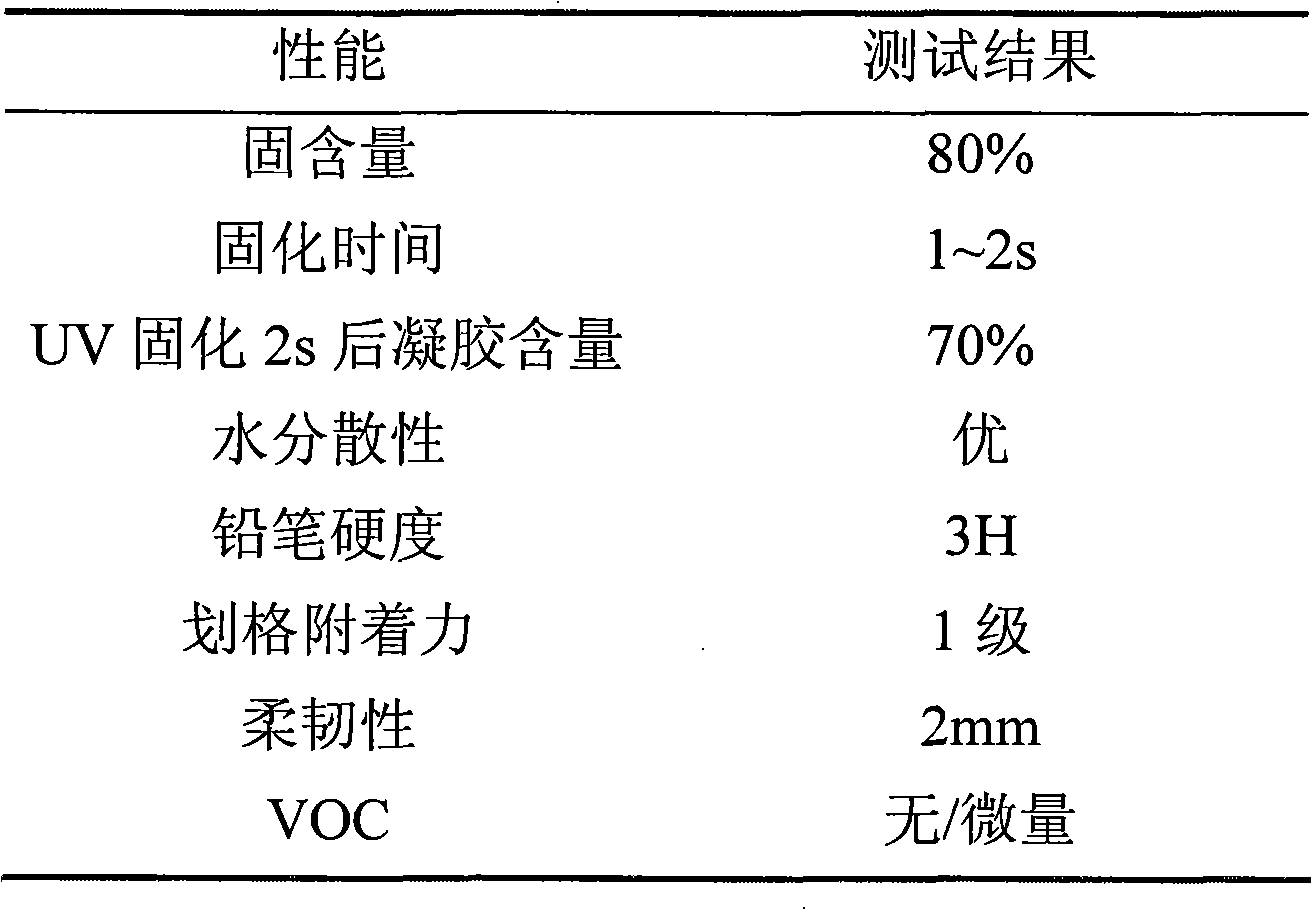

Water-based UV black ink with super-high solid content and preparation method thereof

InactiveCN101659809AEmissions are environmentally friendly and non-toxicHealthy littleInksWater basedPliability

The invention discloses water-based UV black ink with super-high solid content and a preparation method thereof. The black ink comprises the following components in percentage by weight: 20%-60% of high-functionality water-based polyurethane acrylate, 5%-8% of compound photoinitiator, 15%-35% of hydrophilic acrylate diluted body or prepolymer, 10%-25% of solvent and 5%-15% of nano-carbon black pigment. The light curing time of the water-based UV black colored paint of the invention is shorter than 5 seconds, the bottom layer can be completely cured, the comprehensive properties of adhesive force, hardness, toughness and the like are excellent, and the water-based UV black colored paint can be widely applied to the fields of ink, wood paint and the like; the solid content is as high as 80%;and the water-based UV black ink has short drying and curing time, simple construction technology and high production efficiency, can be diluted by water or ethanol or other nontoxic solvents for regulating the viscosity, is suitable for various production modes and production requirements, and is environment-friendly and nontoxic.

Owner:FOSHAN CITY SHUNDE DISTRICT DEMEI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com