Nano-carbon material dispersion liquid and preparation method and equipment thereof

A nano-carbon material and dispersion technology, applied in nanotechnology and other directions, can solve the problems of inability to completely solve the problem of nanomaterial particle agglomeration, unfavorable for storage and transportation, and unable to exist stably for a long time, achieving better dispersion effect and easy storage. and transport, long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

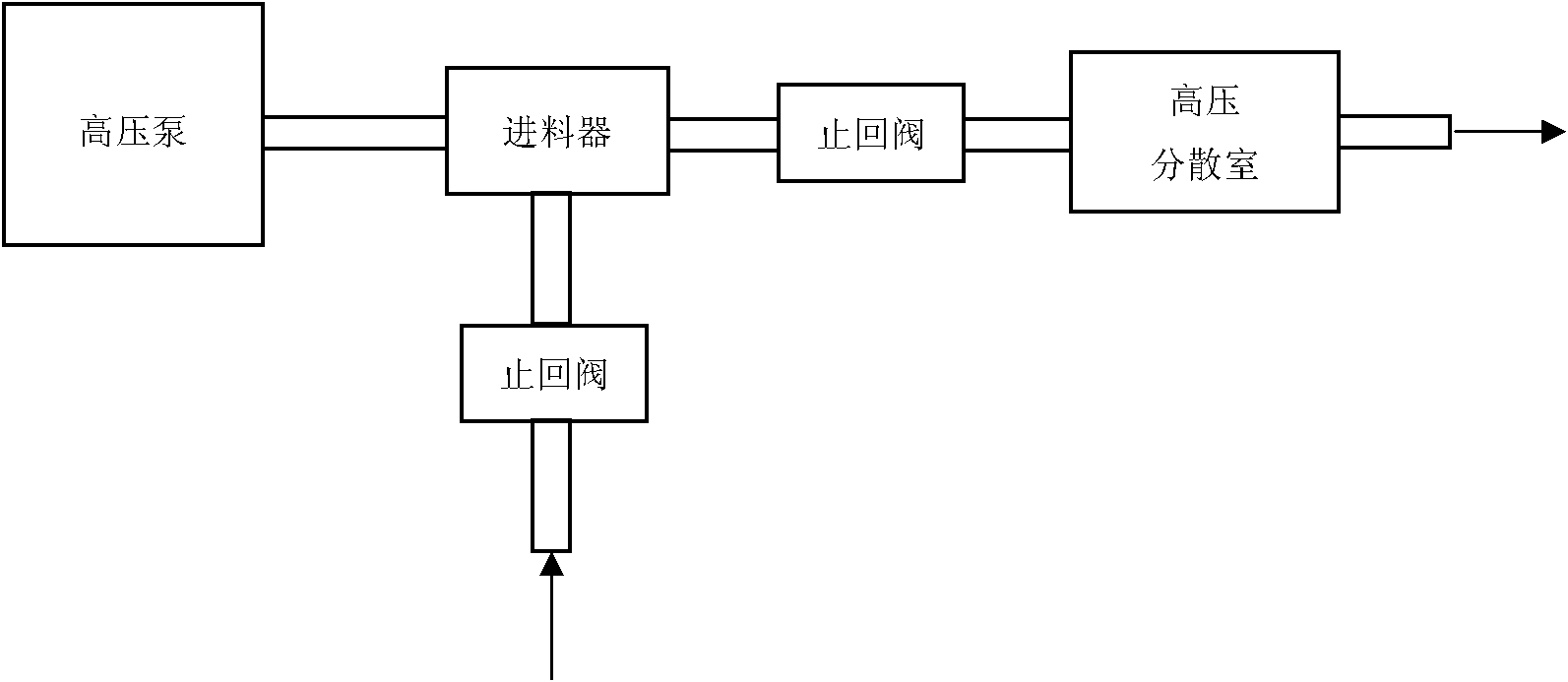

[0030] The preparation method of nano carbon material dispersion liquid of the present invention, comprises the following steps:

[0031] 1. Pre-dispersion treatment. According to the mass ratio of the final nano-carbon material dispersion liquid, 0.5-20% of the nano-carbon material, 0-10% of the dispersion aid, 0-5% of the stabilizer, and the rest are dispersion solvents. The dispersion aid, The stabilizer is dissolved in the dispersing solvent, and pre-dispersed after adding the nano-carbon material. Pre-dispersion adopts high-speed stirring, grinding, mixing or ultrasonic oscillation physical methods, high-speed stirring speed 2000-8000rmp, time 1-6h; ball milling speed 30-120rpm, time 2-48h; internal mixer rotor speed 15-80rpm, time 0.5 -5h; ultrasonic oscillation frequency 20-40KHz, power density 100-300W / cm 2 , time 0.5-8h. A predispersed suspension is obtained in the manner described above. The purpose of pre-dispersion is to preliminarily disperse nano-carbon materi...

Embodiment 1-12

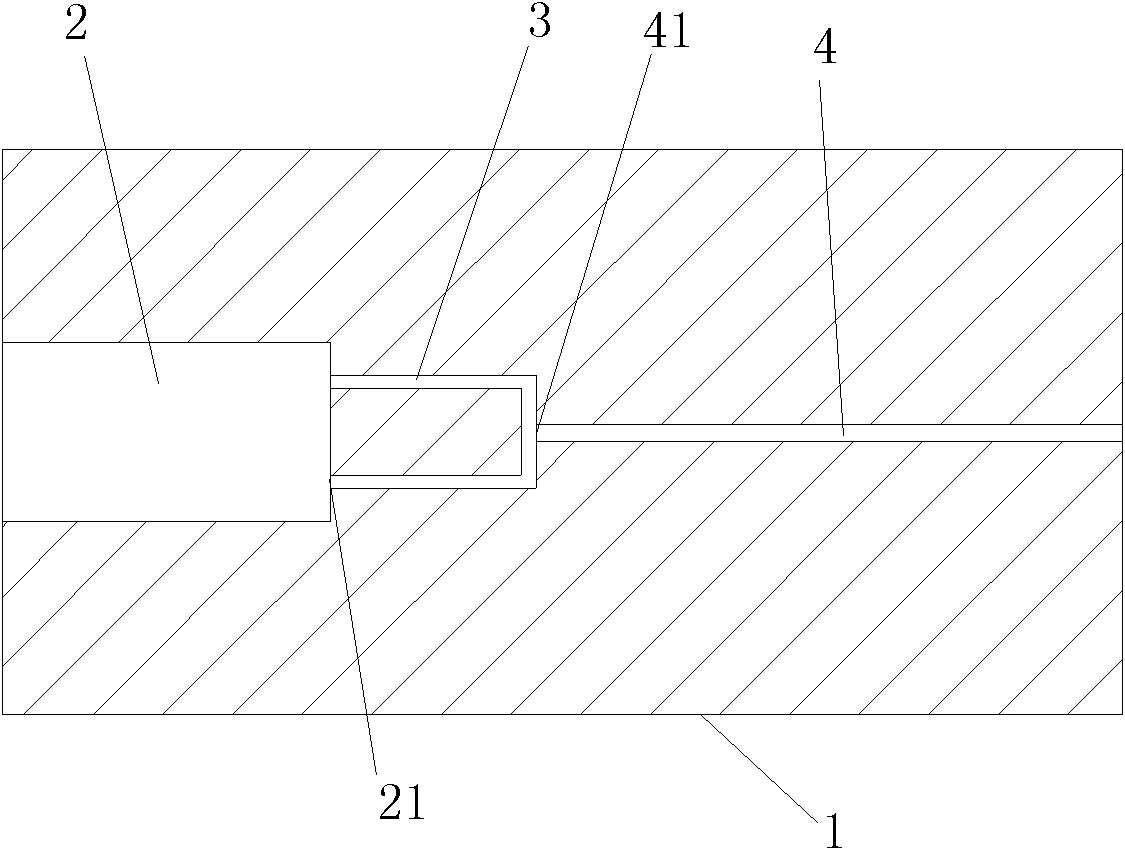

[0040] Embodiment 1-12 The high-pressure pump adopts the QUANTUM ESP 77S type high-pressure pump of Techni Waterjet Company of Australia, and the first check valve and the second check valve all adopt the B-6929 type check valve of Harwood Engineering Company of the United States. The cavity diameter is the same as that of the piston rod of the high-pressure pump. The diversion channel, diversion channel, and confluence channel of the high-pressure dispersion chamber are all cylindrical, with diameters of 5-20mm, 0.1-0.5mm, and 0.5-1mm respectively, and the steering angle is 90° .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Steering angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com