Patents

Literature

2682 results about "Ultrasonic oscillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ultrasonic oscillation could occur when part of the output signal is fedback to the input (of the pre or power) such that it enhances bonafide input (of the pre or power).

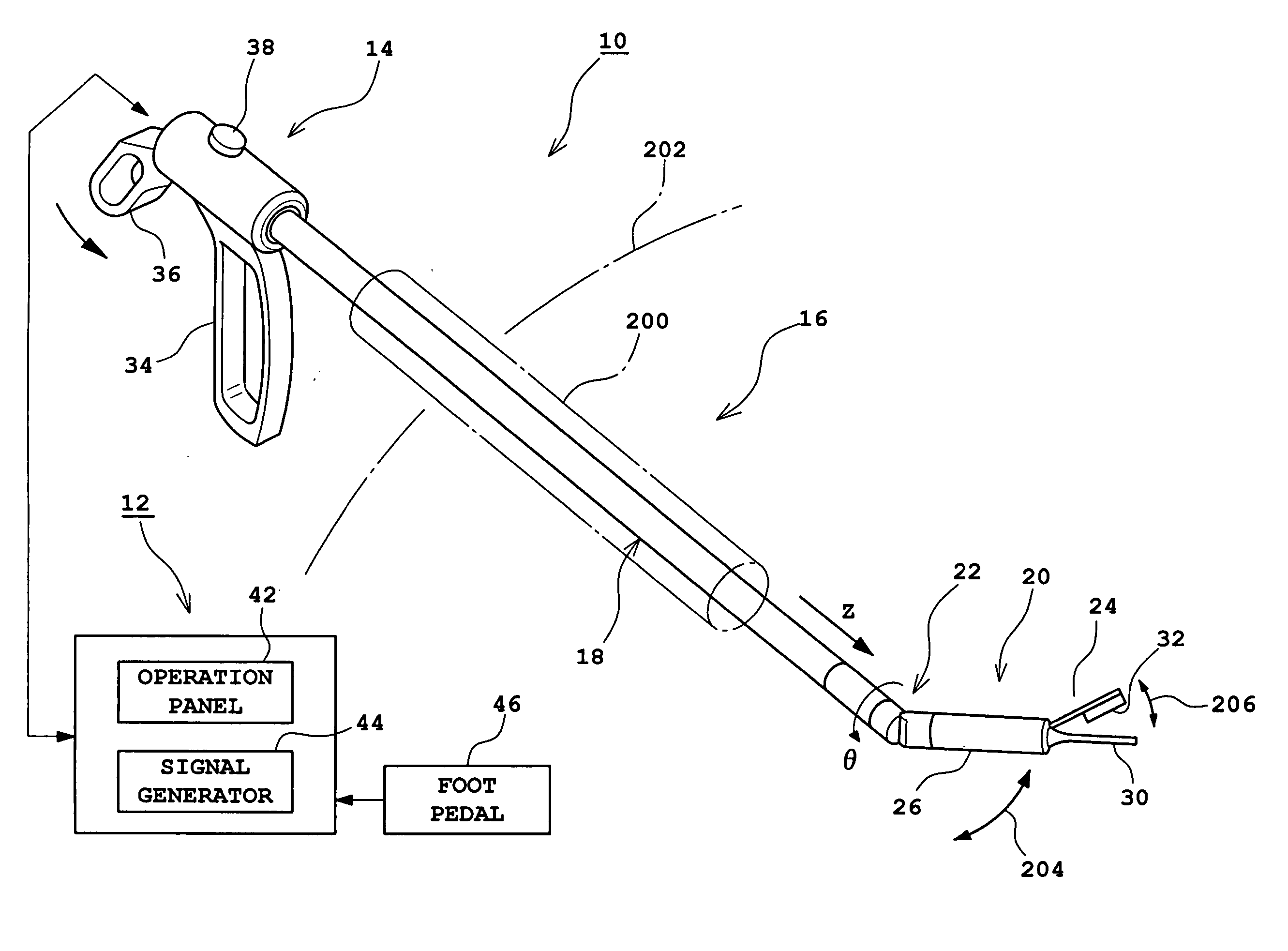

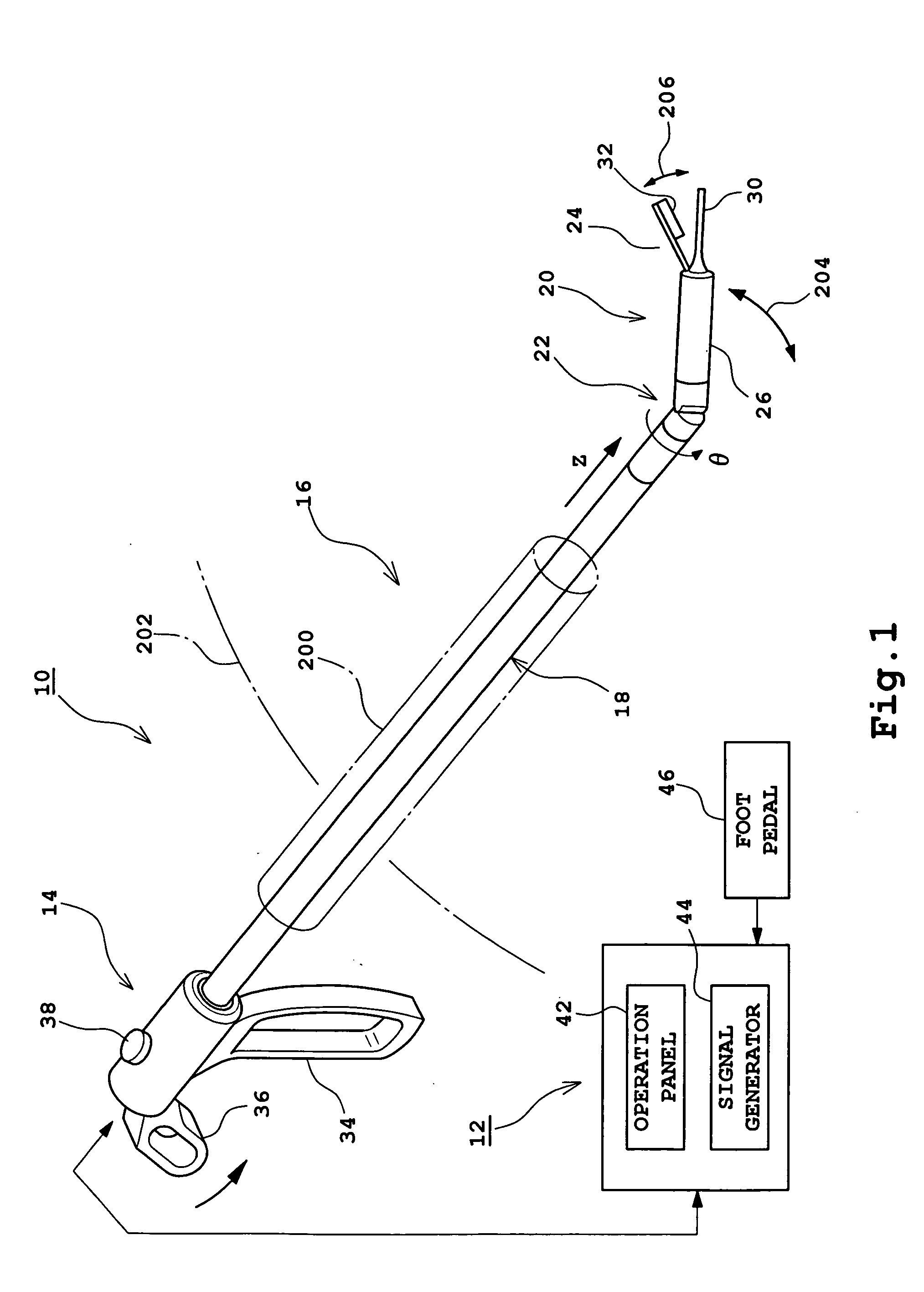

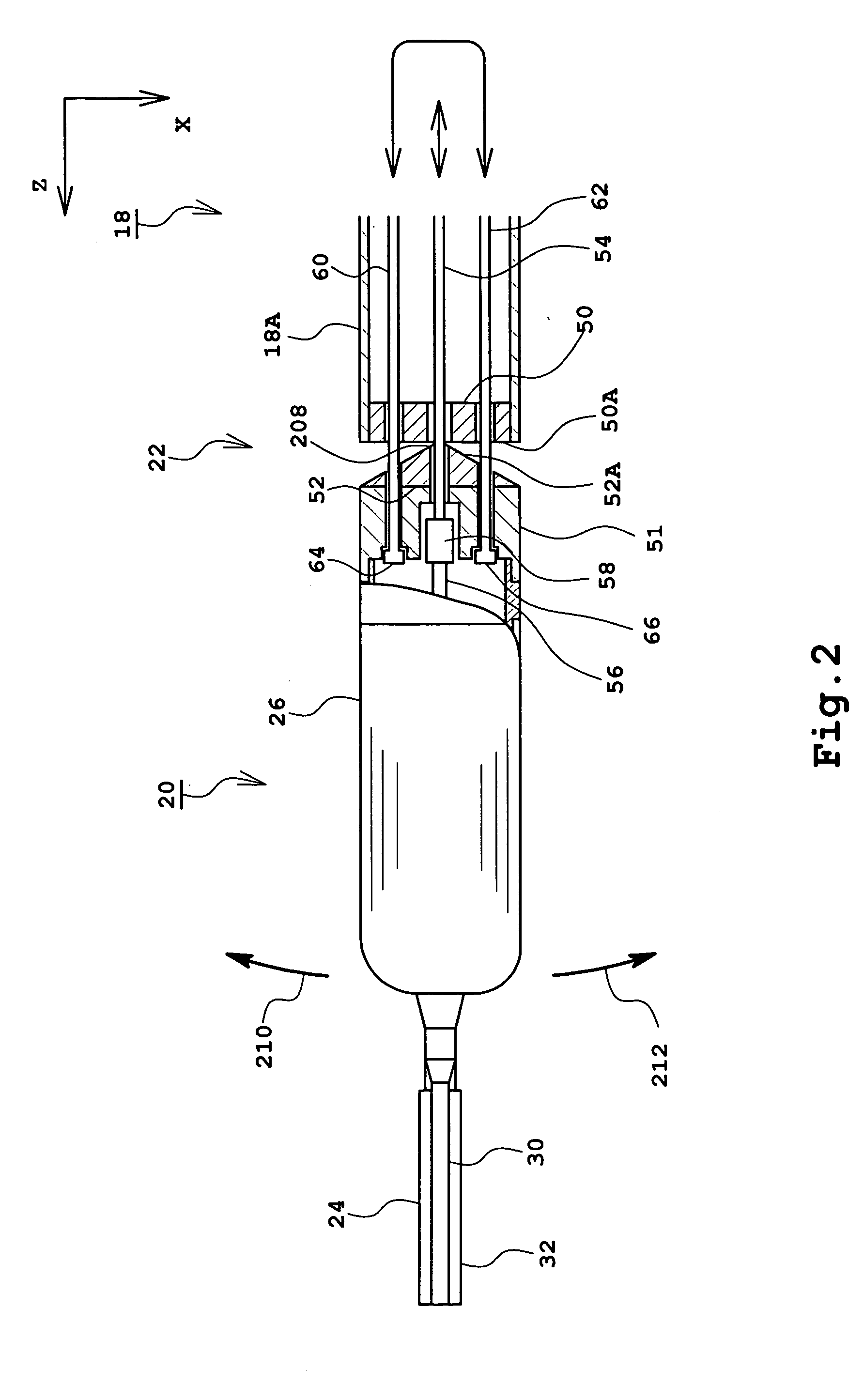

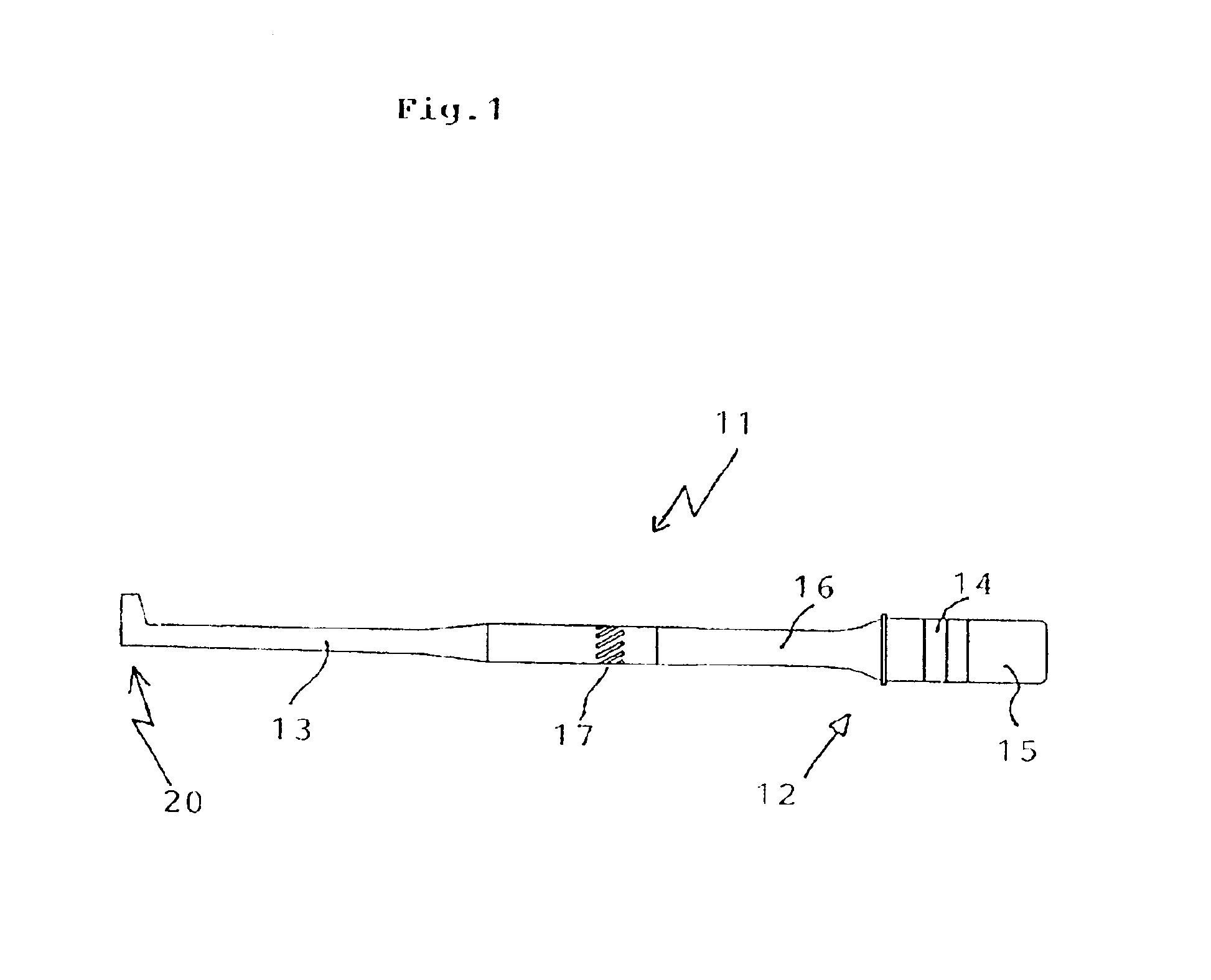

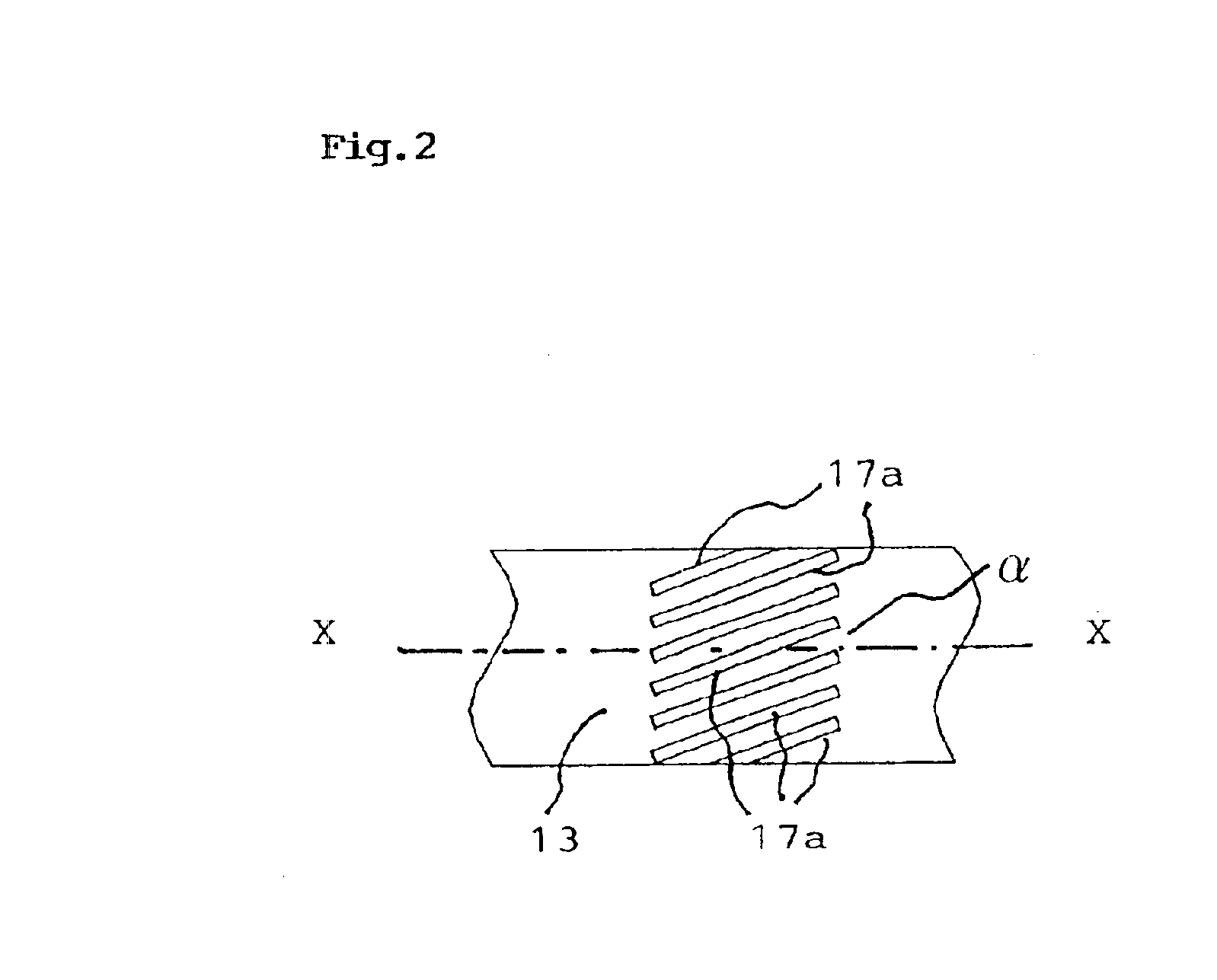

Ultrasonic surgical apparatus

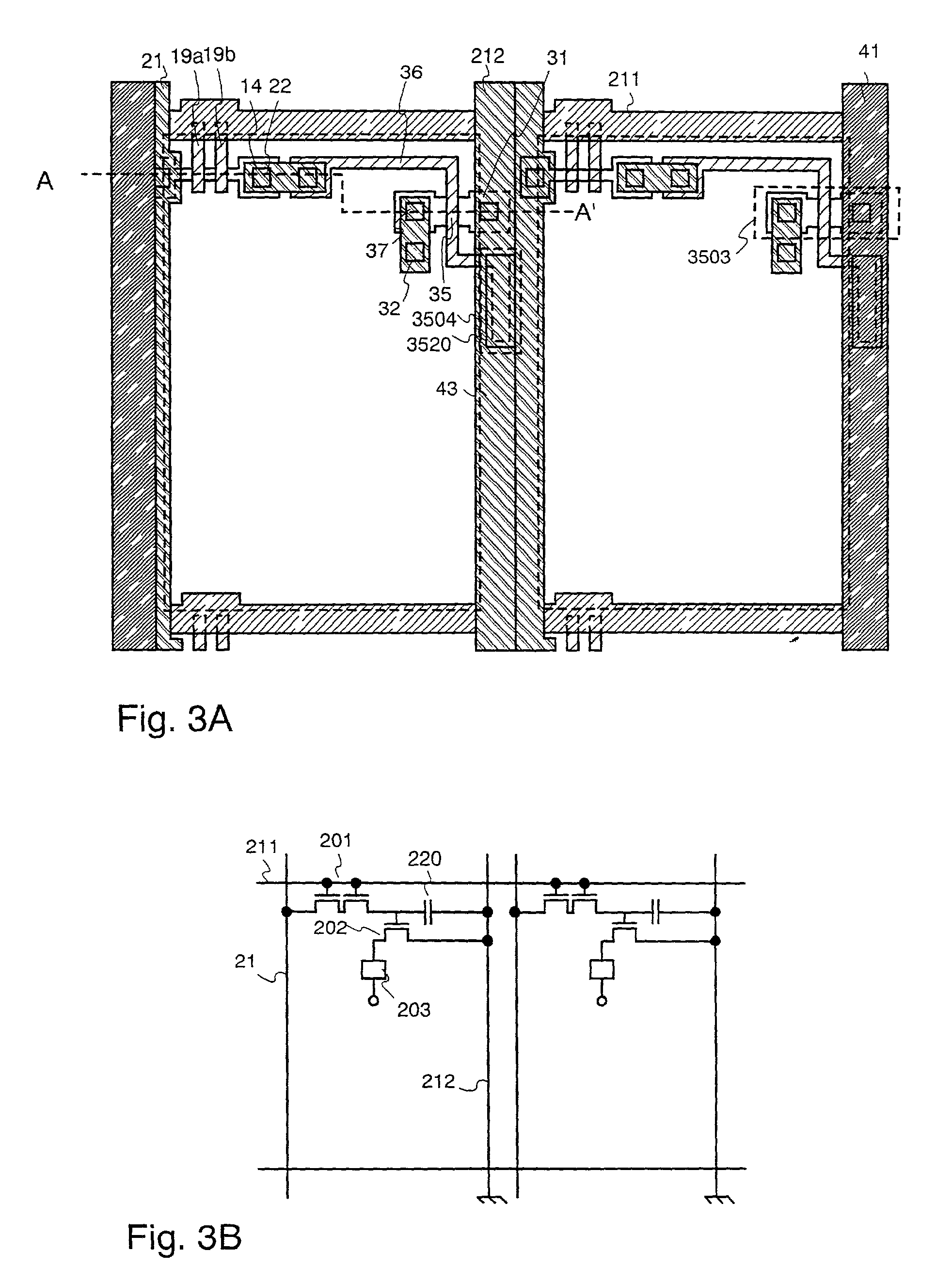

InactiveUS20060058825A1Easy to operateImprove security levelEndoscopic cutting instrumentsSurgical forcepsTransducerExtremity Part

An ultrasonic surgical apparatus which can be used in laparoscopic surgery. The ultrasonic surgical apparatus includes an inserting unit and an operation unit. The inserting unit is inserted into a guide member called a trocar. The inserting unit includes an elongated member, a tip portion, and also a joint section provided between the elongated member and the tip portion. The tip portion includes a transducer unit and an oscillation member, and preferably further includes a clamp member and an open / close mechanism. The joint section enables the tip portion to be slanted with respect to the elongated member. The operation unit includes a mechanism for operating the joint section, and preferably further includes a mechanism for operating the clamp member. The direction of the oscillation member can be varied by the joint section. Because ultrasonic oscillation is generated in the tip portion, effective transmission of the ultrasonic oscillation to the oscillation member can be achieved.

Owner:ALOKA CO LTD

Coupling vibration ultrasonic hand piece

ActiveUS6955680B2Shorten speedReduce vibrationUltrasonic/sonic/infrasonic diagnosticsSurgical instrument detailsRotation velocityLongitudinal vibration

Problems to be SolvedSurgical operation or others excellent in operability, safety, operation efficiency and precision are realized by outputting a vertical-torsional composite vibration through conversion processing of the longitudinal vibration from an ultrasonic oscillation mechanism and reducing the displacement speed of the non-working plane in a female portion less than the speed of the working plane.Means to Solve the ProblemA configuration, comprising an ultrasonic oscillation mechanism composed of a longitudinal vibration element, a backing plate and a front plate for generating an ultrasonic vibration, a horn coupled with the ultrasonic oscillation mechanism for amplifying the vibration transmitted from said ultrasonic oscillation mechanism, a vibration conversion mechanism for converting the vibration transmitted from said ultrasonic oscillation mechanism into a composite vibration composed of a longitudinal vibration in the horn central axial direction and a torsional vibration having the horn central axis as fulcrum, and a female portion provided with a working plane and disposed at said horn tip, wherein said ultrasonic oscillation mechanism is composed of one or more groove portions formed on the circumferential surface of the horn or said backing plate, and a speed variation mechanism of torsional vibration in said composite vibration is formed in the female portion, in order to reduce the reciprocating rotation speed of the non-working plane less than the speed of the working plane.

Owner:STRYKER CORP

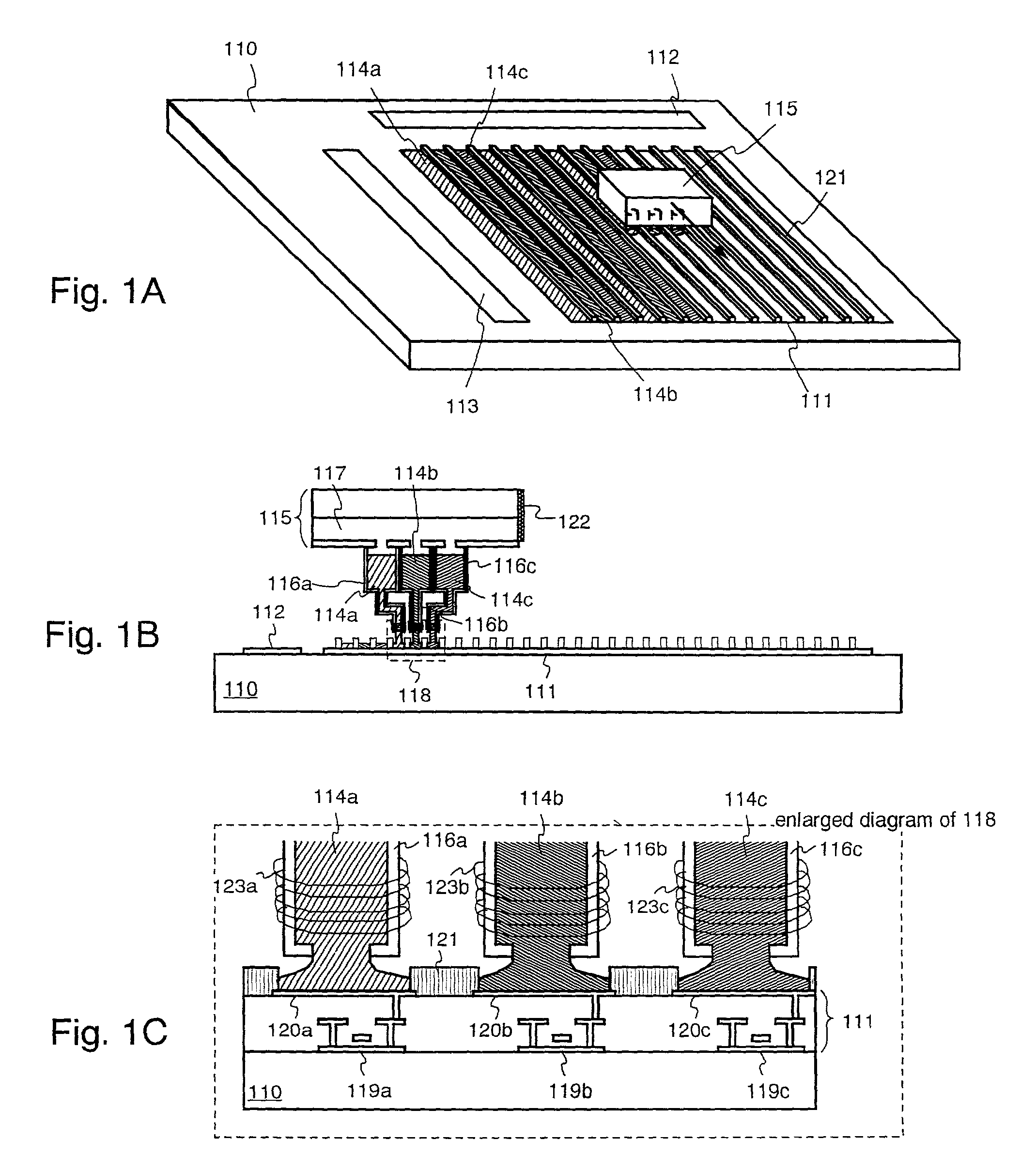

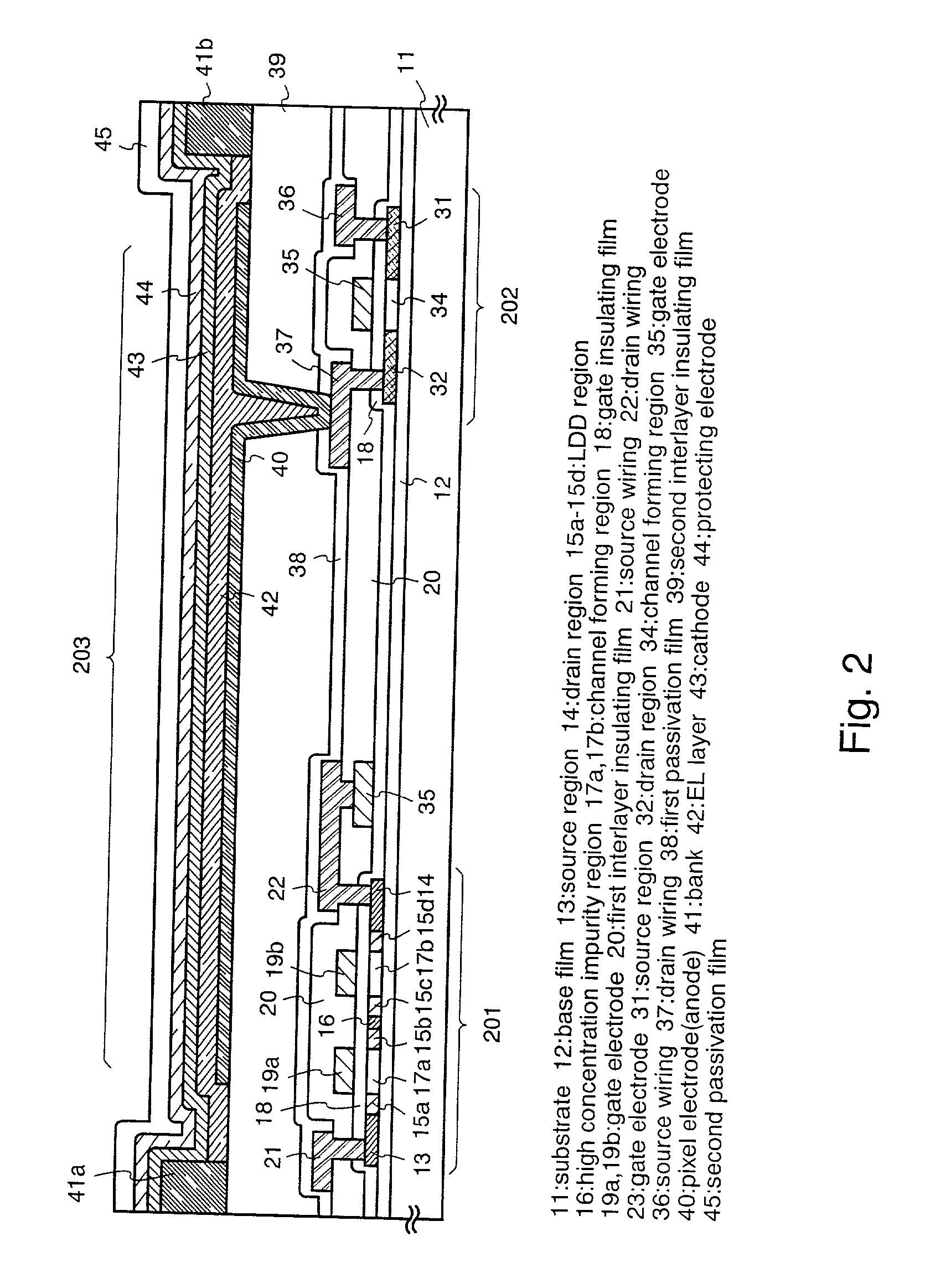

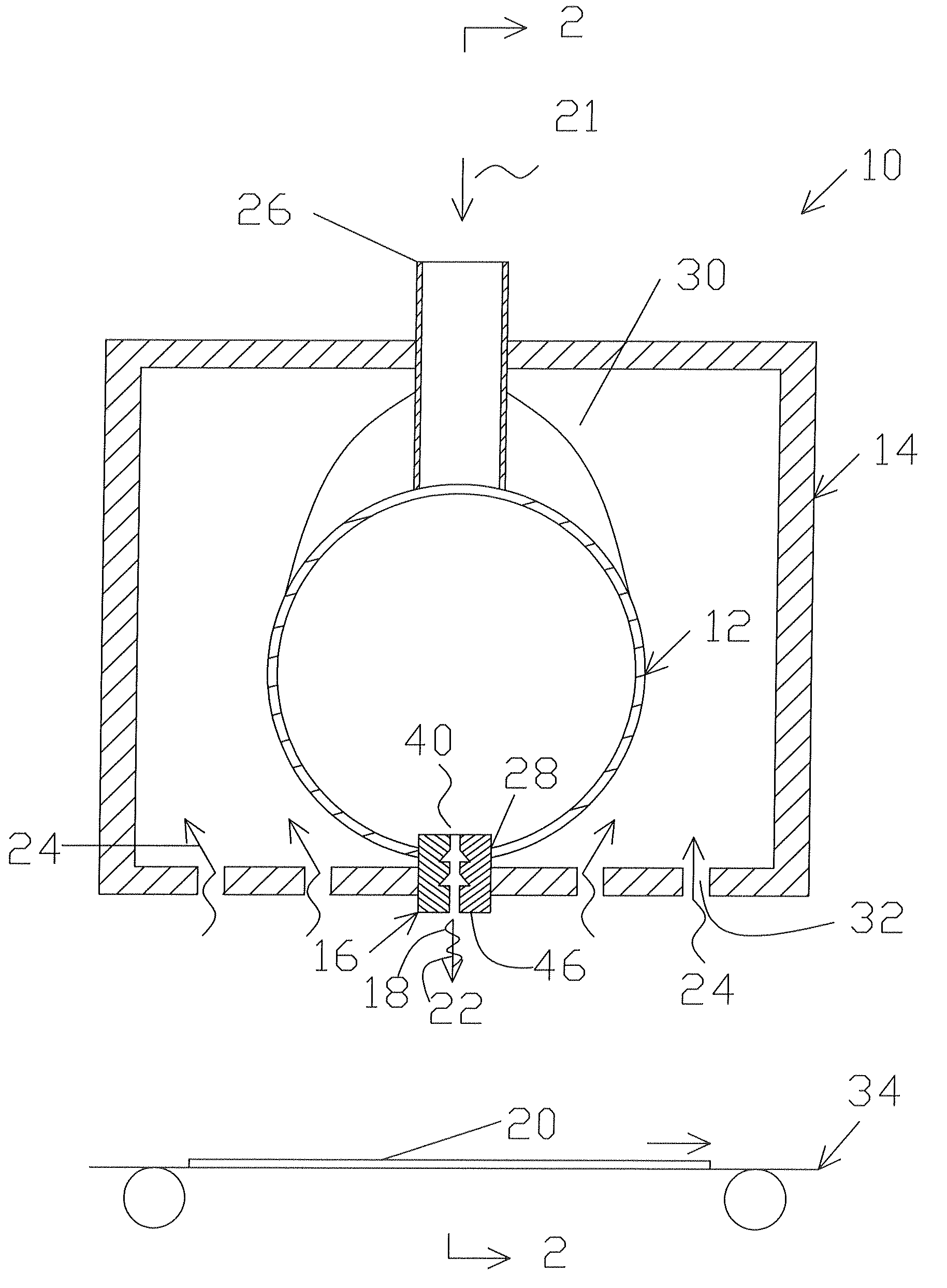

Thin film formation apparatus and method of manufacturing self-light-emitting device using thin film formation apparatus

InactiveUS20010023661A1Solve the real problemLarge diameterFuel elementsSolid-state devicesEngineeringLight emitting device

A means of effectively applying an organic EL material application liquid with good application liquid cut-off is provided. A heater and an ultrasonic oscillator are formed in a thin film formation apparatus when applying the application liquid, and heat and ultrasonic oscillations are imparted to the application liquid. Defective application liquid cut-off and liquid clogging can thus be resolved.

Owner:SEMICON ENERGY LAB CO LTD

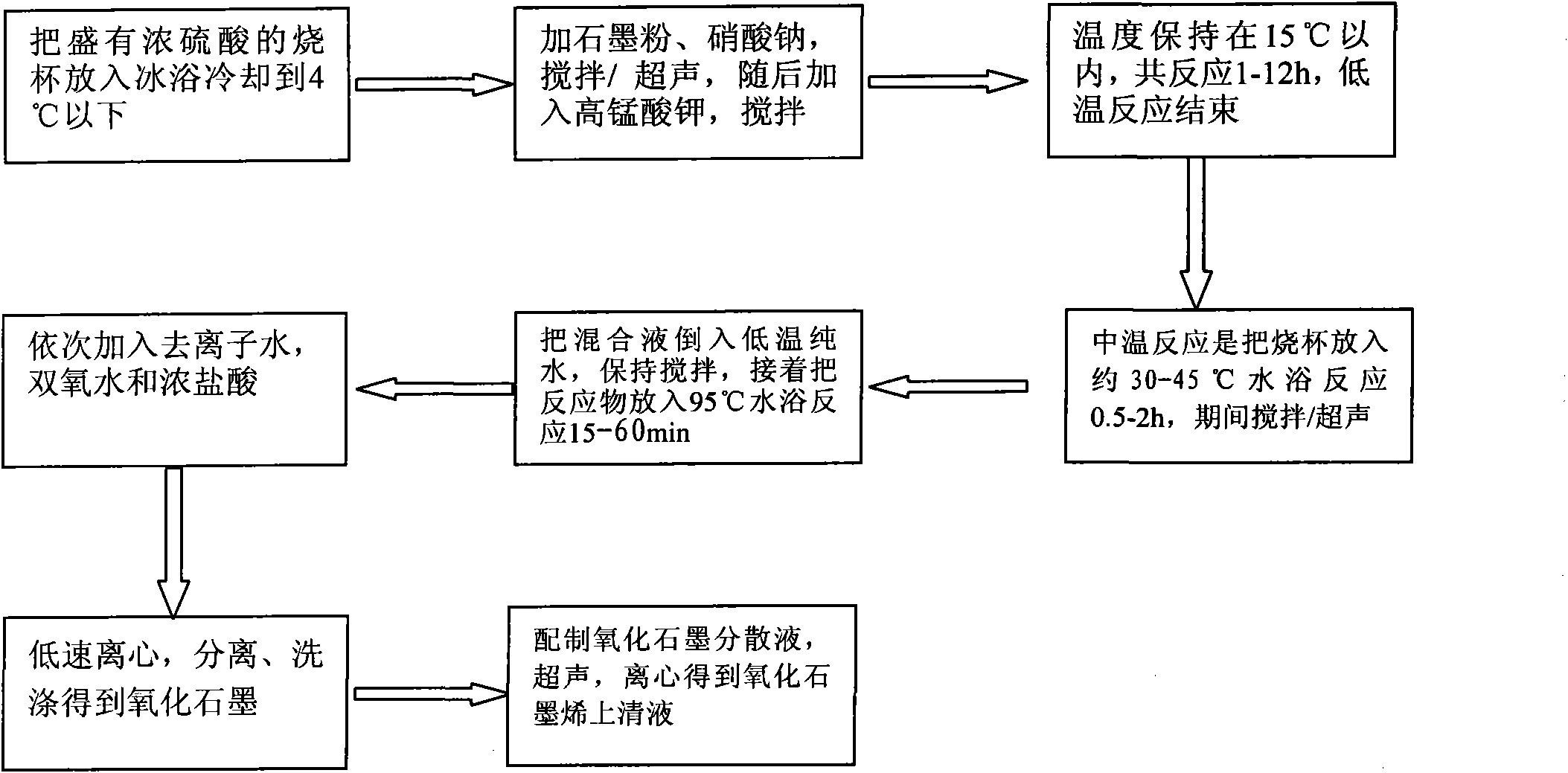

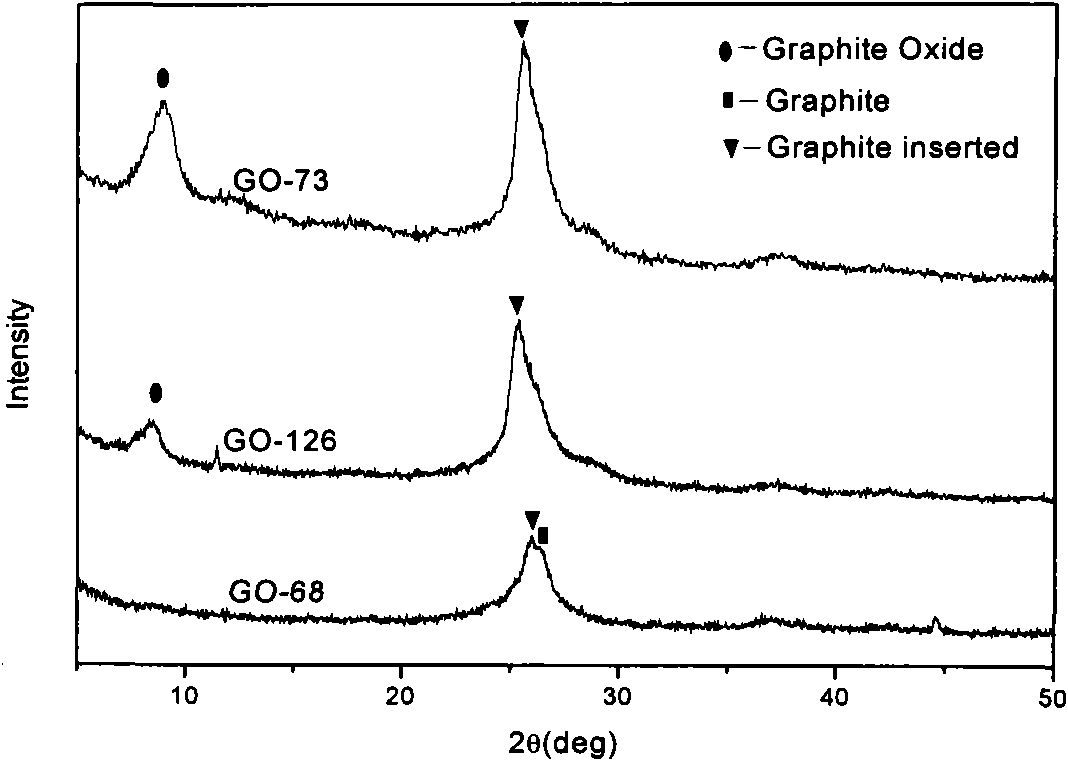

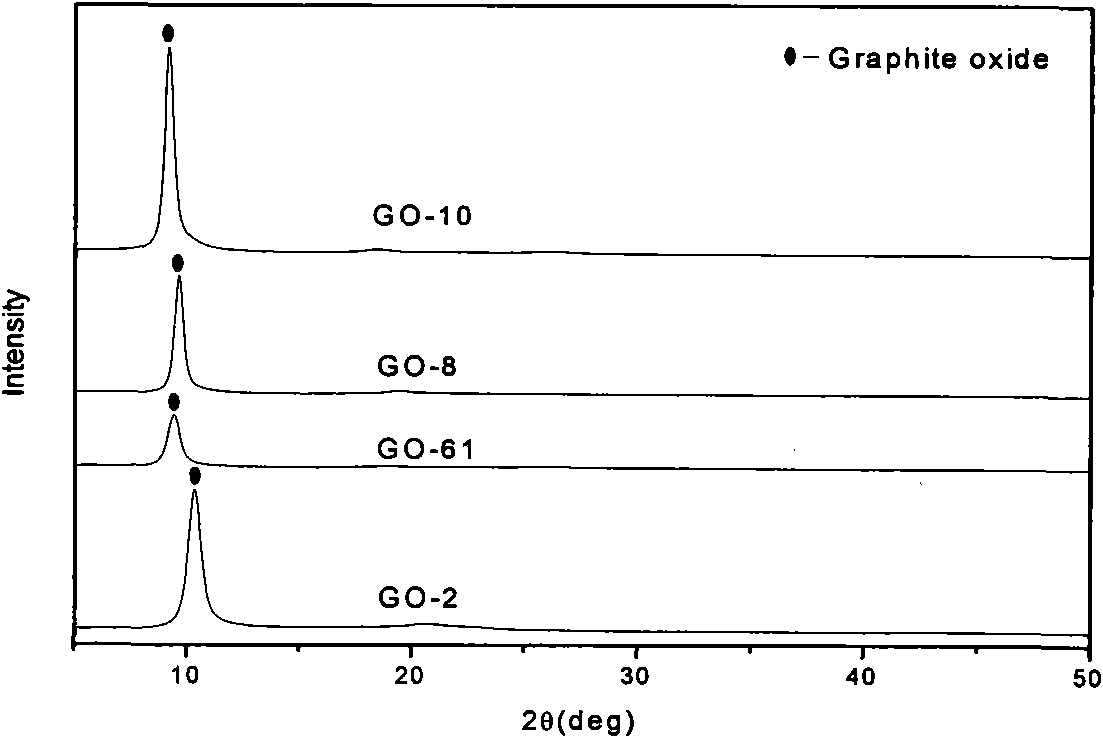

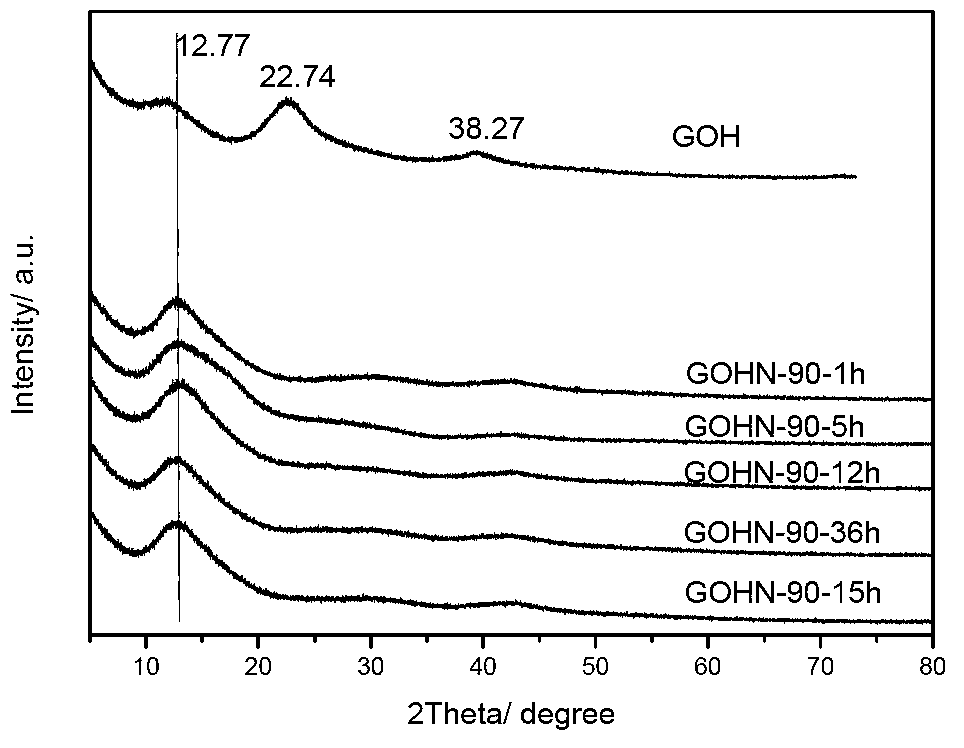

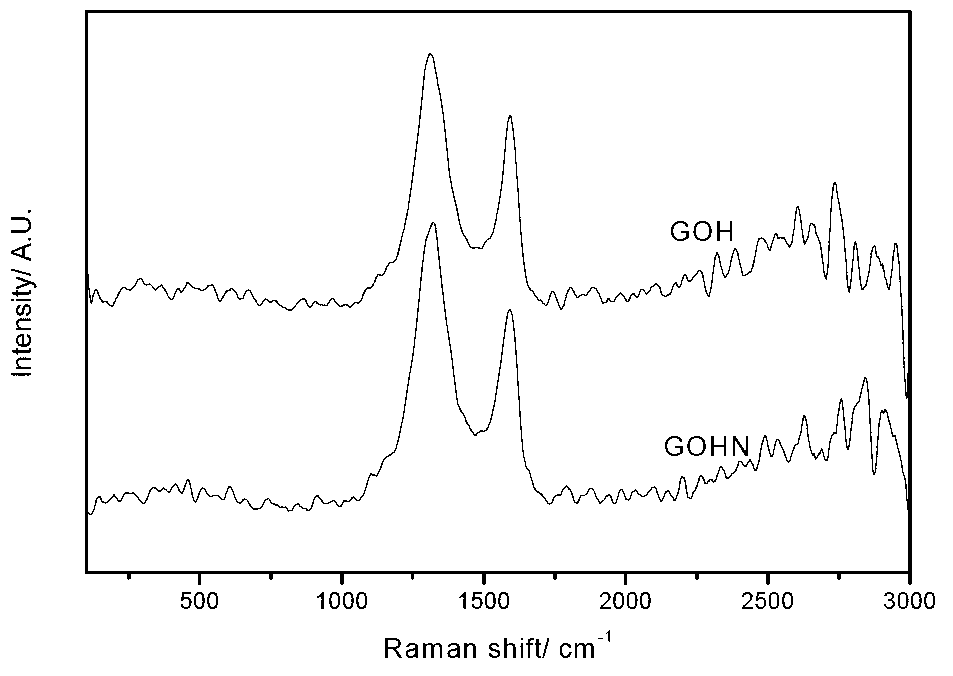

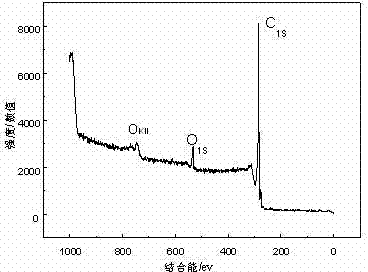

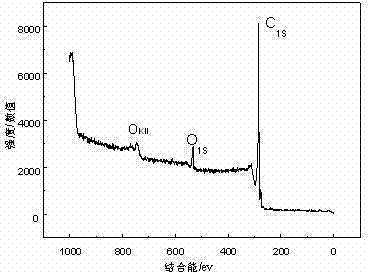

Method for synthesizing graphene oxide by ultrasonic assistance Hummers method

InactiveCN102153075AImprove efficiencyHigh degree of oxidationUltrasonic oscillationMechanical property

The invention relates to a method for synthesizing graphene oxide by an ultrasonic assistance Hummers method. The method for synthesizing the graphene oxide includes the steps as follows: firstly adding ultrasonic oscillation in low-temperature and middle-temperature reaction stages of the Hummers method to improve the intercalation efficiency and the oxidation degree of graphite oxide; secondly slowly dropping mixed liquor containing concentrated sulphuric acid into low-temperature deionized water to increase temperature when high-temperature reaction begins, thus effectively preventing intercalated materials such as sulphuric acid molecules and the like from rapidly escaping from graphite layers due to overhigh local temperature; and finally obtaining the graphite oxide through low-speed centrifugation. The method for synthesizing the graphene oxide by using the ultrasonic assistance Hummers method is convenient and fast, saves resources, and can effectively increase spacings of graphite oxide layers. The prepared graphene oxide can serve as a wild phase of a composite material and papyraceous laminated graphite oxide based composite material with high mechanical property and the like can be prepared. The reduction product graphene can be used for preparing graphene-based composite materials such as transparent electrodes, super capacitors, hydrogen storage materials, chemical / biological sensors, thin film transistors and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

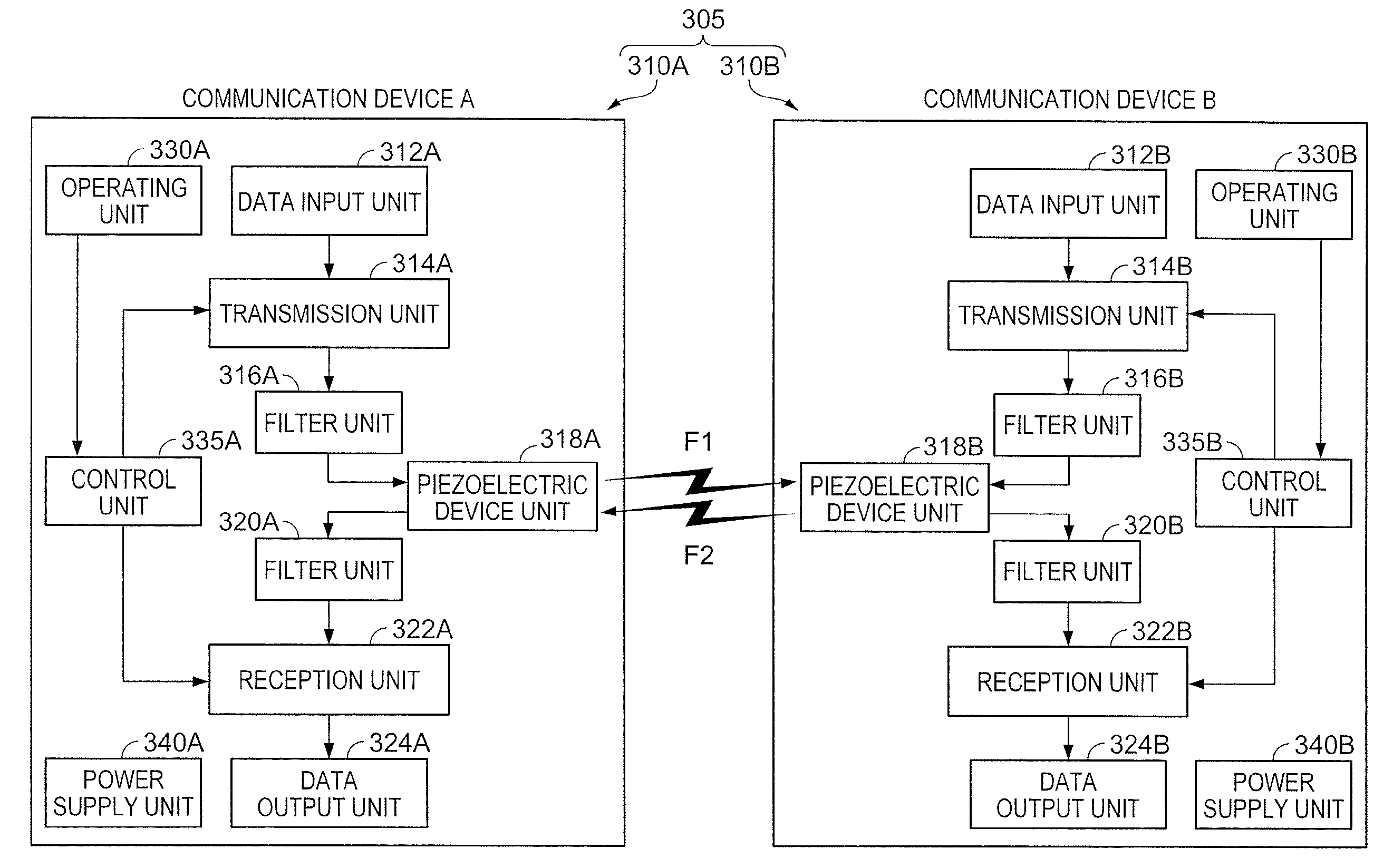

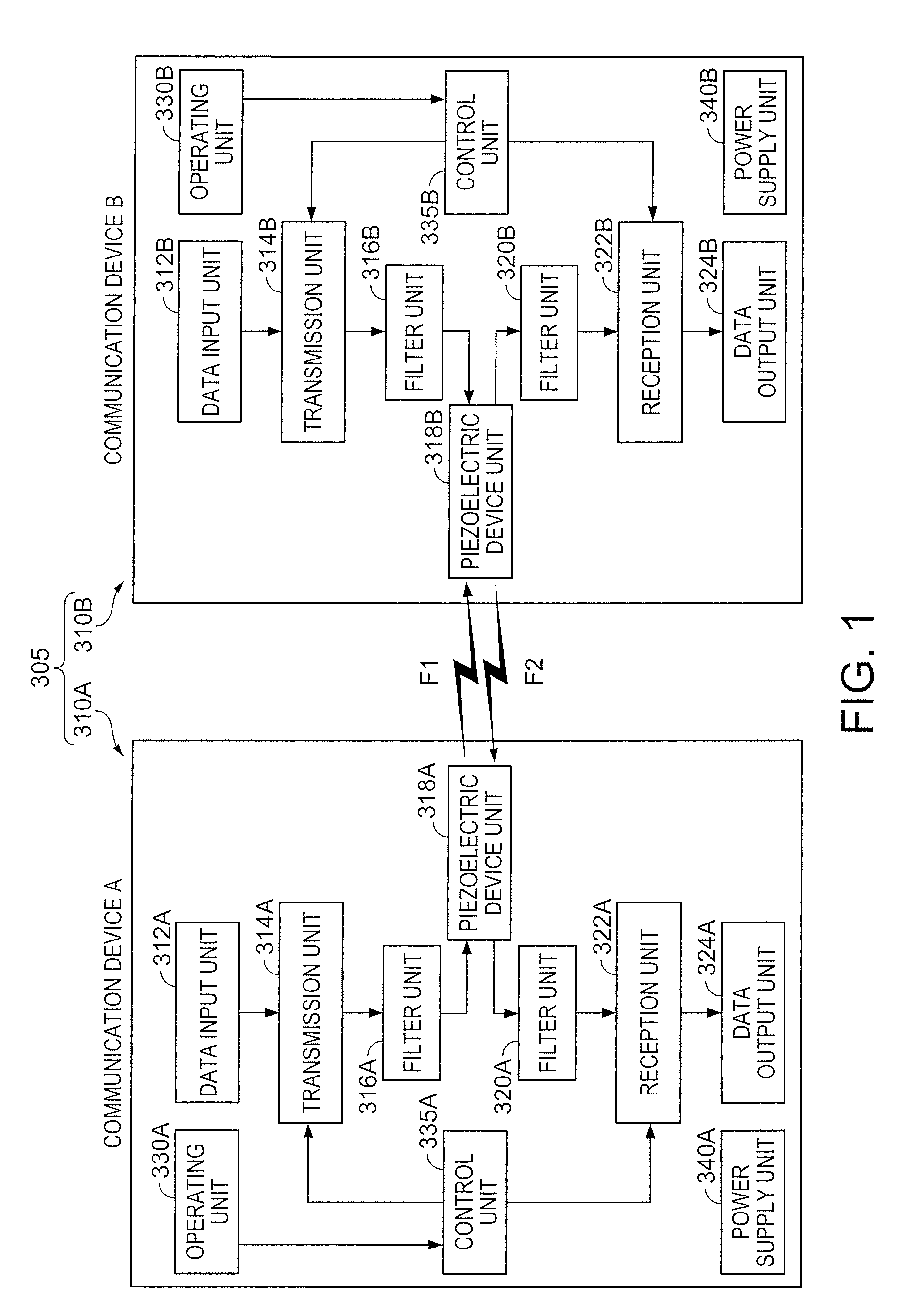

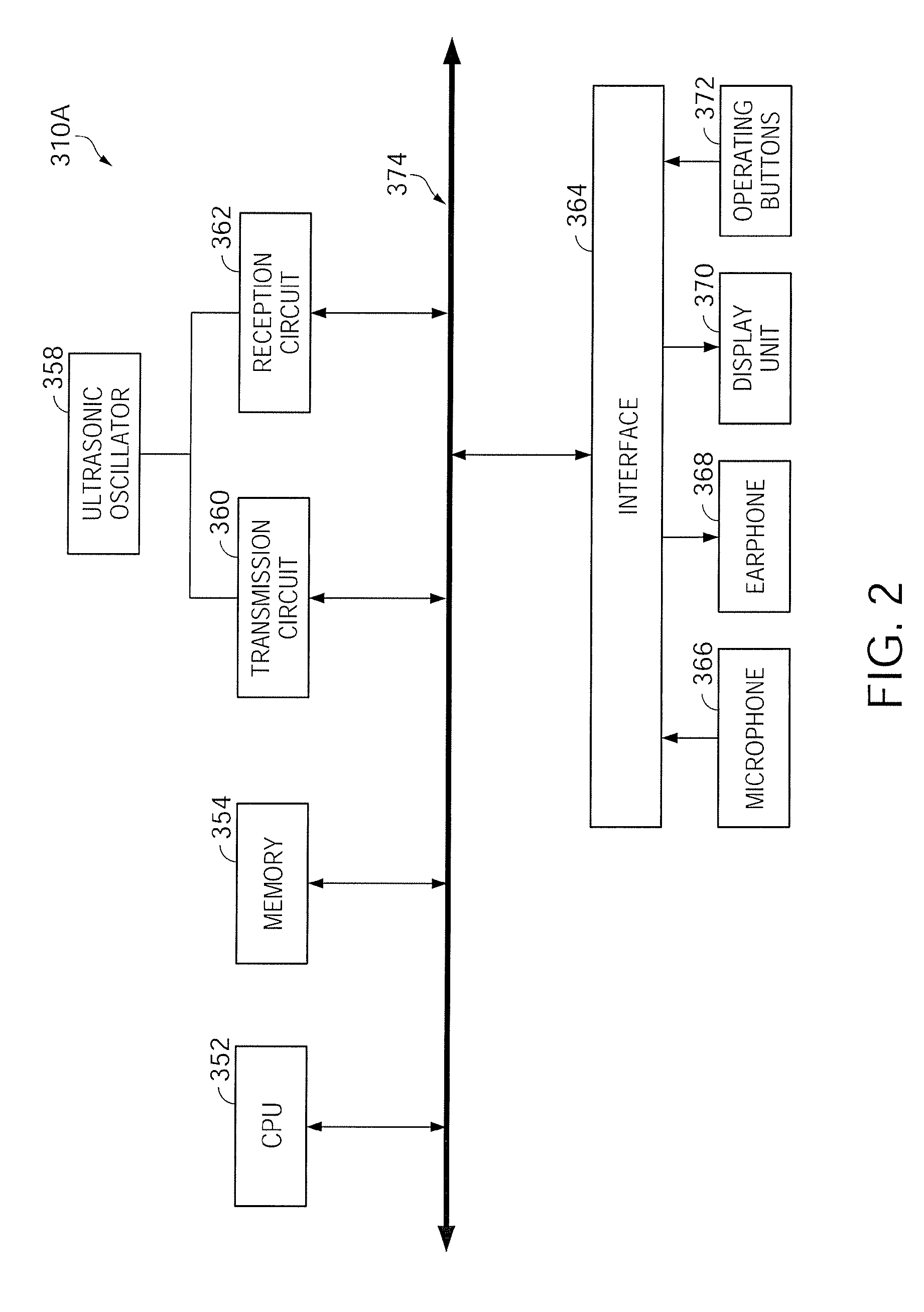

Ultrasonic signal communication device, communication device, communication device for divers, communication system, and communication method

InactiveUS20090279389A1Simple configurationDirection finders using ultrasonic/sonic/infrasonic wavesSonic/ultrasonic/infrasonic transmissionCommunications systemResonance

An ultrasonic signal communication device that has an ultrasonic oscillation unit that has at least two resonance frequencies according to the oscillation mode, a transmission unit that generates a first ultrasonic signal at one of the two resonance frequencies and transmits the generated first ultrasonic signal from the ultrasonic oscillation unit, and a reception unit that receives from the ultrasonic oscillation unit a second ultrasonic signal that is transmitted at the other of the two resonance frequencies.

Owner:SEIKO EPSON CORP

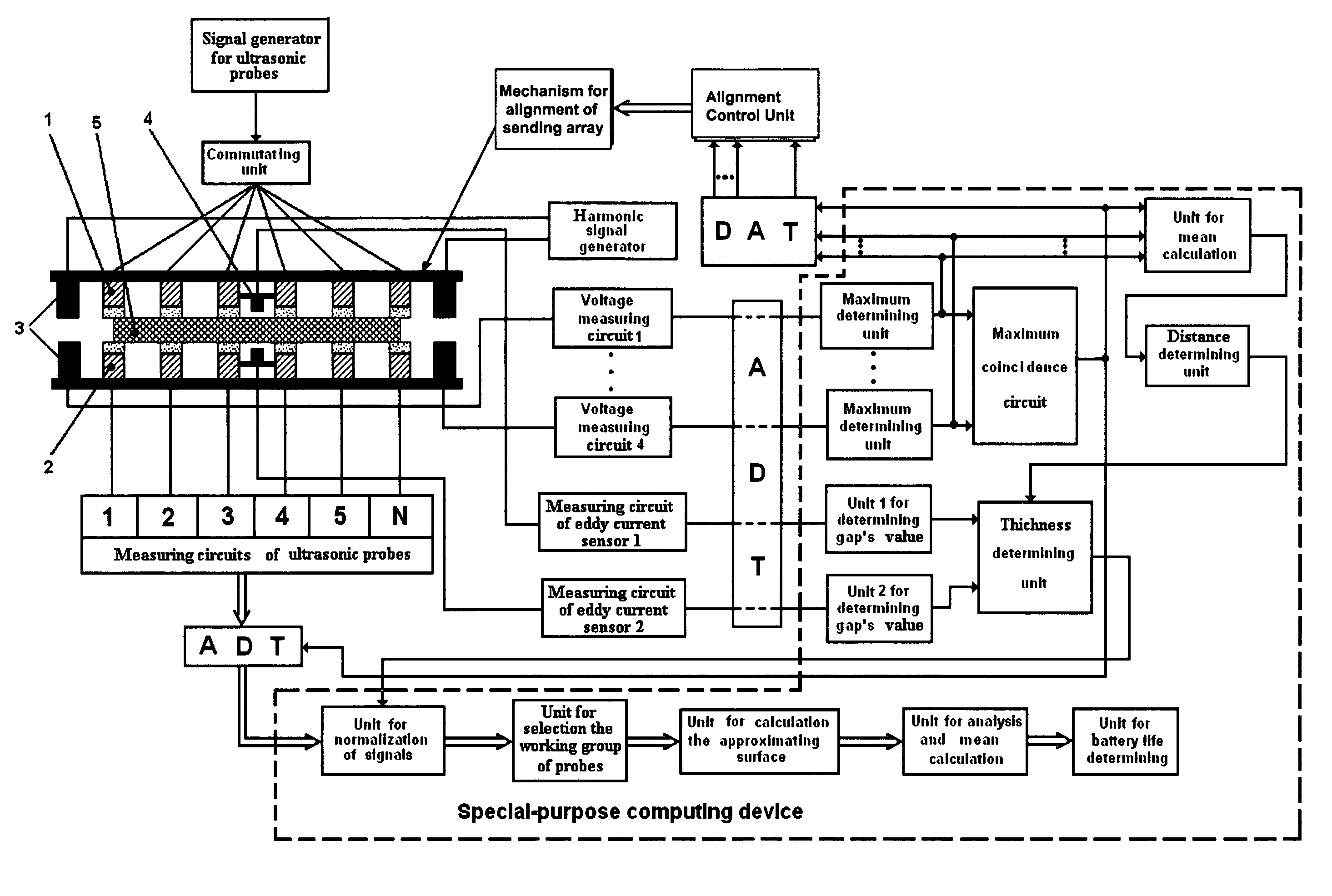

Apparatus and method for determining service life of electrochemical energy sources using combined ultrasonic and electromagnetic testing

InactiveUS20080028860A1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMeasurement testSonification

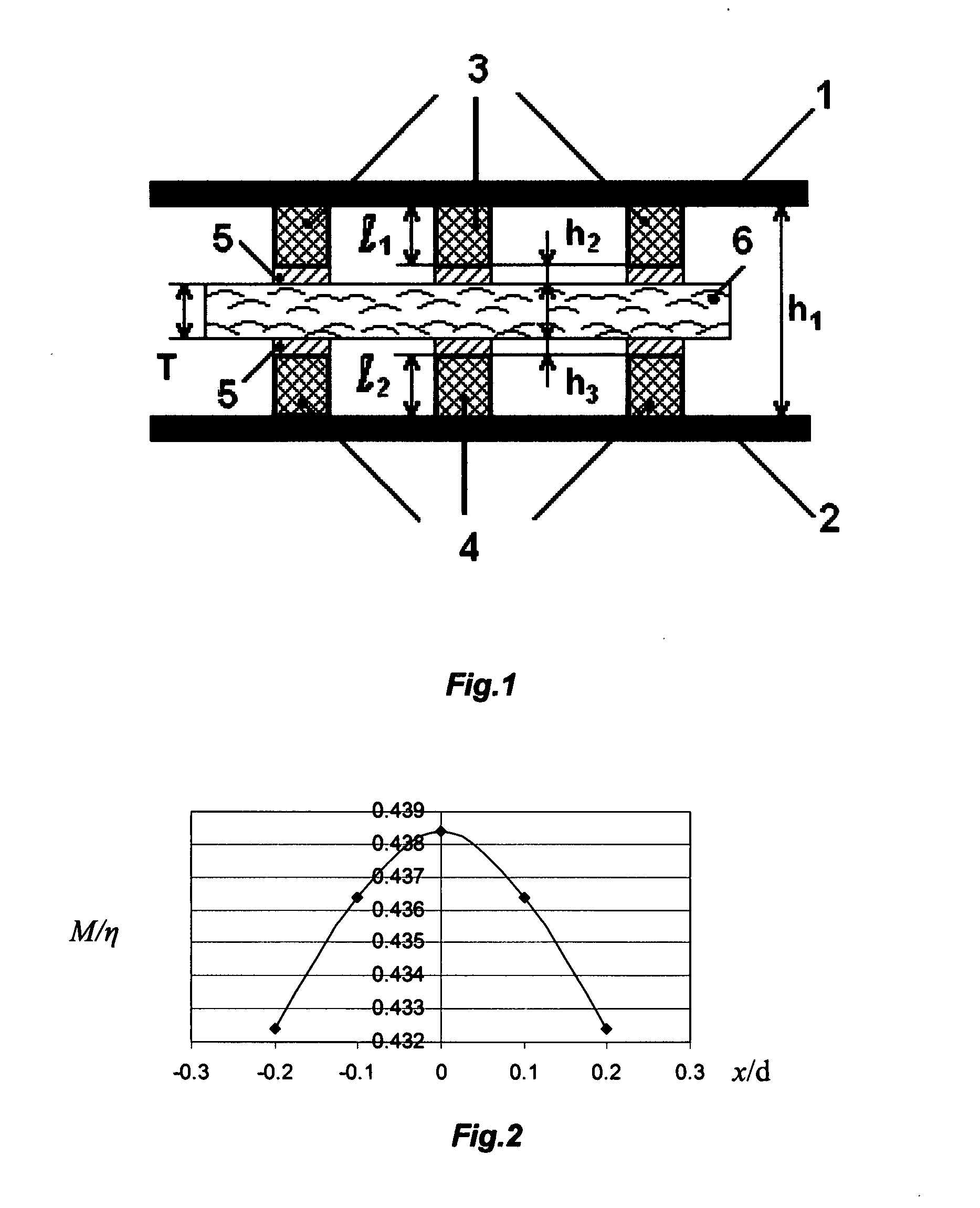

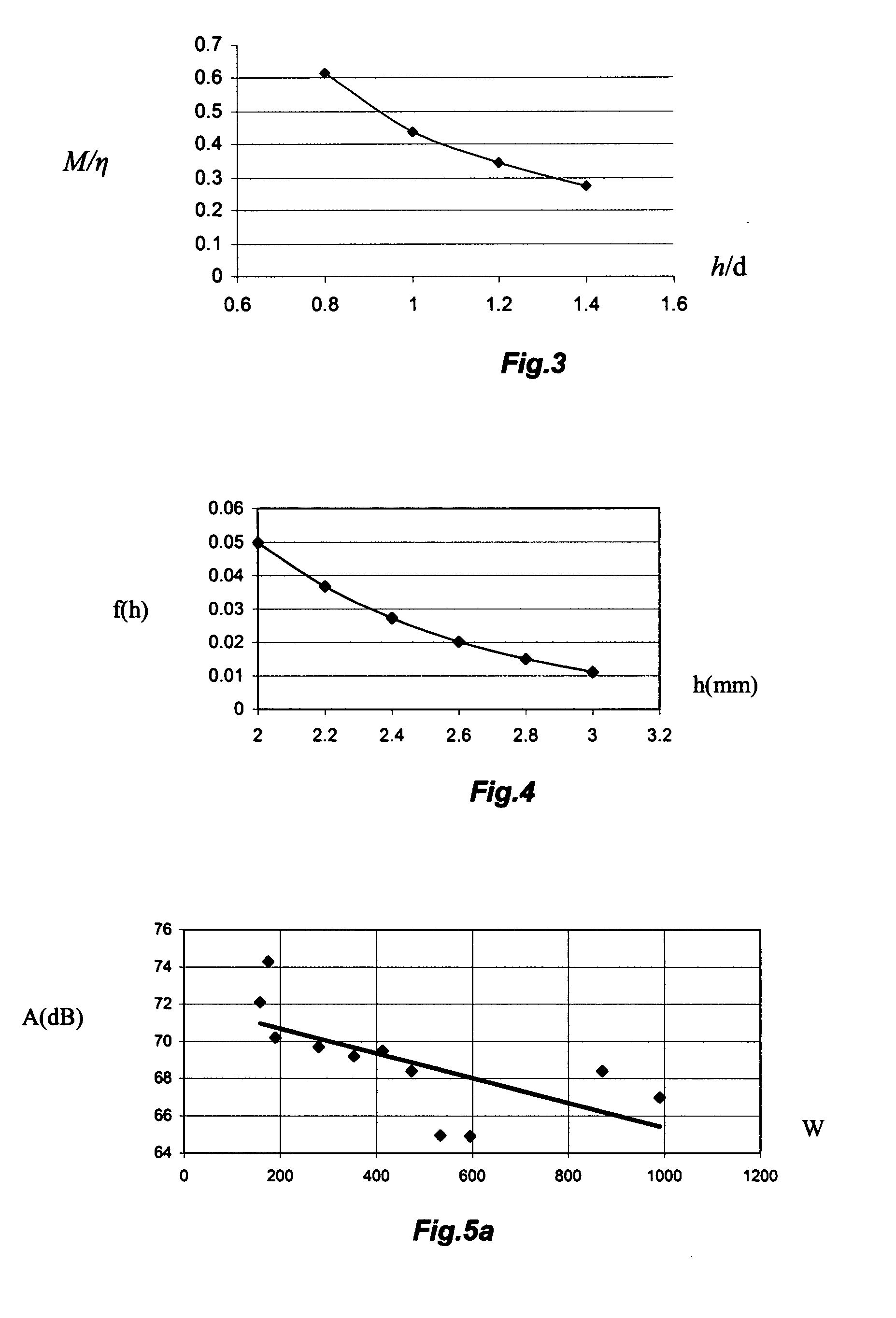

The present invention is an apparatus and method for determining the remaining service life of electrochemical energy generation and storage device including batteries, supercapacitors, DSSC solar cells and fuel cell. Measurements are performed by passing ultrasonic oscillations through the test object. The apparatus of the present invention comprises two arrays of transmitting and receiving ultrasonic probes between which the object being tested is affixed. Polyurethane tips are used for matching the acoustic resistance of the probes with the test object body. The apparatus includes means for positioning the transmitting and the receiving probe arrays relative to each other. The apparatus includes an electromagnetic means for measuring the test object thickness. The calibration characteristic for determining the remaining service life of a the test object are established from the signal values from the ultrasonic probes related to the number of charge-discharge cycles obtained at various charge values. A three-dimensional approximating dependence surface is constructed using the normalized signals from the receiving probes. The average value of this surface is determined. The remaining service life of the test object is determined using a calibration curve based on the average level of the surface

Owner:ENERIZE CORP

Development method of flexible pressure-sensitive element based on carbon nano-tube filled high polymer composite material

InactiveCN101885463ALarge aspect ratioHigh sensitivityDecorative surface effectsChemical vapor deposition coatingCarbon nanotubeCopper foil

The invention relates to a development method of a flexible pressure-sensitive element based on a carbon nano-tube filled high polymer composite material, which belongs to the technical field of sensors. The method comprises the following steps of: 1. pressure-sensitive material preparation: dispersing carbon nano-tubes into polydimethylsiloxane by utilizing ultrasonic vibration and mechanical stirring methods, and preparing a thin and flexible pressure-sensitive material by using tetraethoxysilane as a crosslinking agent and dibutyltin dilaurate as a catalyst with a spin coating method; 2. pressure-sensitive element packaging, wherein a two-stage sandwich structure is adopted, the first-stage sandwich structure comprises two layers of packaging films and the pressure-sensitive material positioned in the middle; and in the second-stage sandwich structure, each layer of packaging film comprises two layers of polyimide films as well as a copper foil electrode and a lead which are embedded in the two layers of polyimide films. The pressure-sensitive element developed by the invention has good flexibility, high precision, thin thickness, simple process and low cost and is applicable to the fields of pressure monitoring of structures between narrow curved surface layers in the fields of military industry and civil use and artificial electronic skin development and the like.

Owner:NORTHEASTERN UNIV

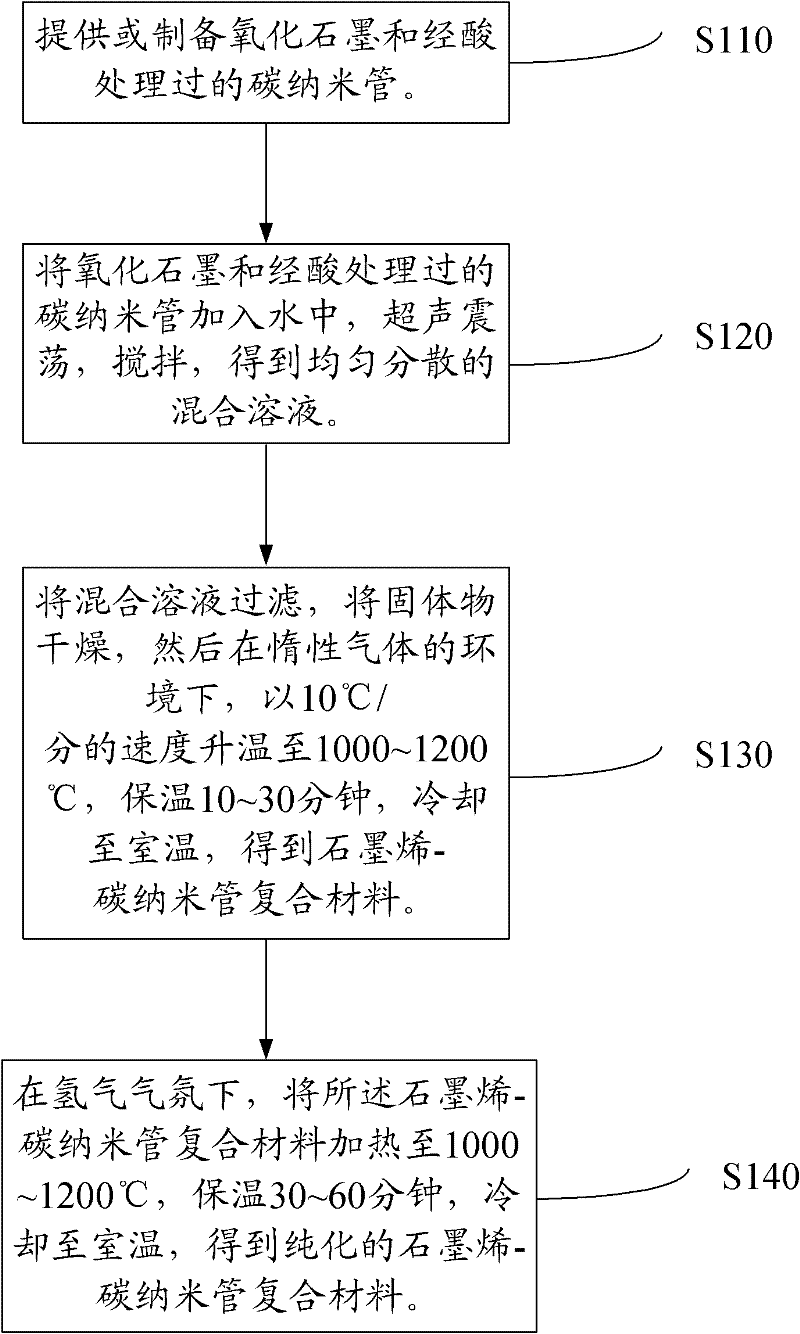

Method for preparing graphene-carbon nano tube composite material

InactiveCN102530913AReduce pollutionSimple processMaterial nanotechnologyCarbon compoundsRoom temperatureCarbon nanotube

The invention discloses a method for preparing a graphene-carbon nano tube composite material. The method comprises the following steps of: 1, adding graphite oxide and carbon nano tubes treated by using acid into water, performing ultrasonic oscillation, and stirring to obtain a uniformly dispersed mixed solution; and 2, filtering the mixed solution, drying the solid, heating the dried solid to the temperature of between 1,000 and 1,200 DEG C at the velocity of 10 DEG C per minute under an inert gas environment, preserving the heat for 10 to 30 minutes, cooling to room temperature, and thus obtaining the graphene-carbon nano tube composite material. The method has the advantages of simple process and low cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

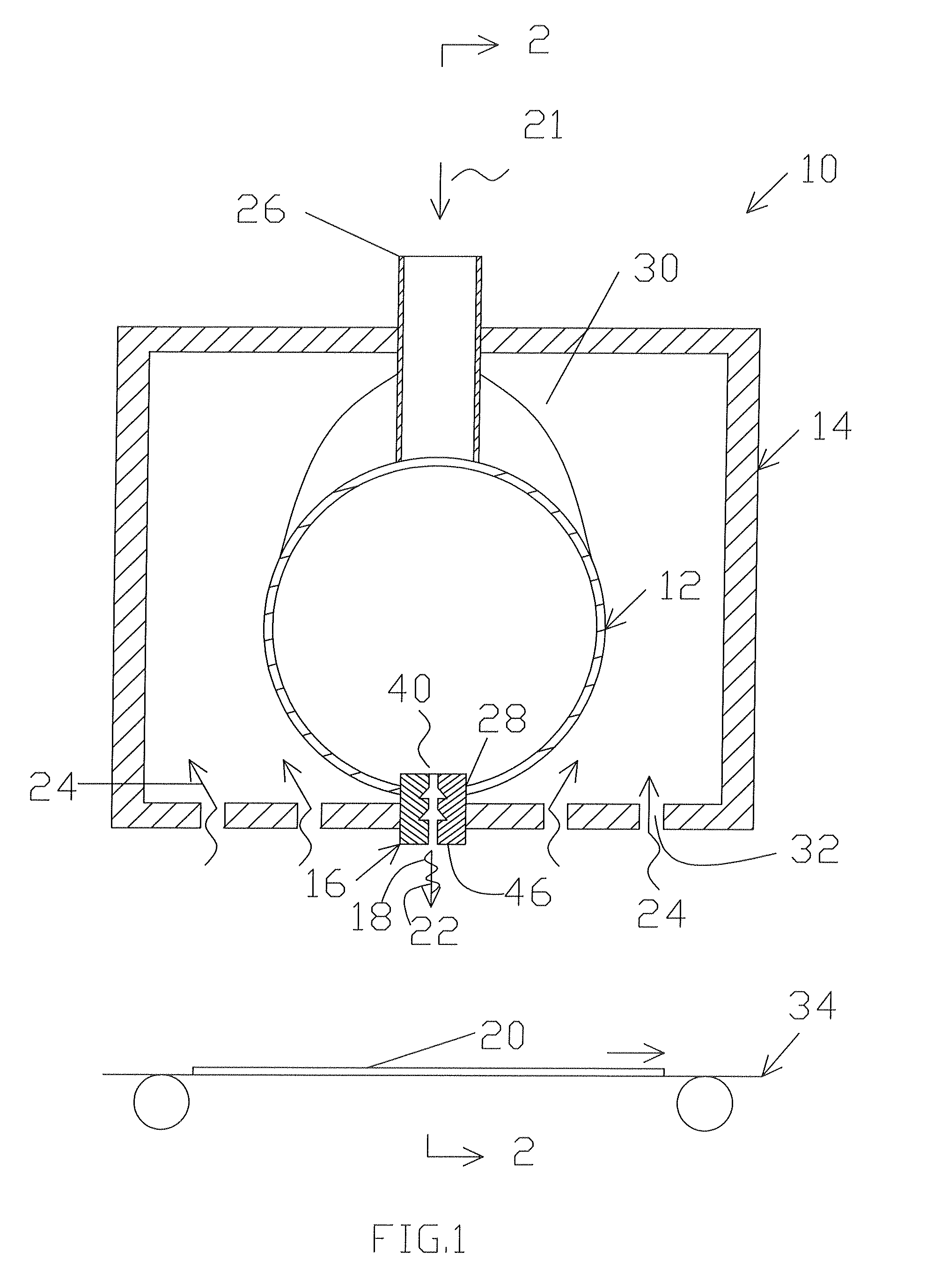

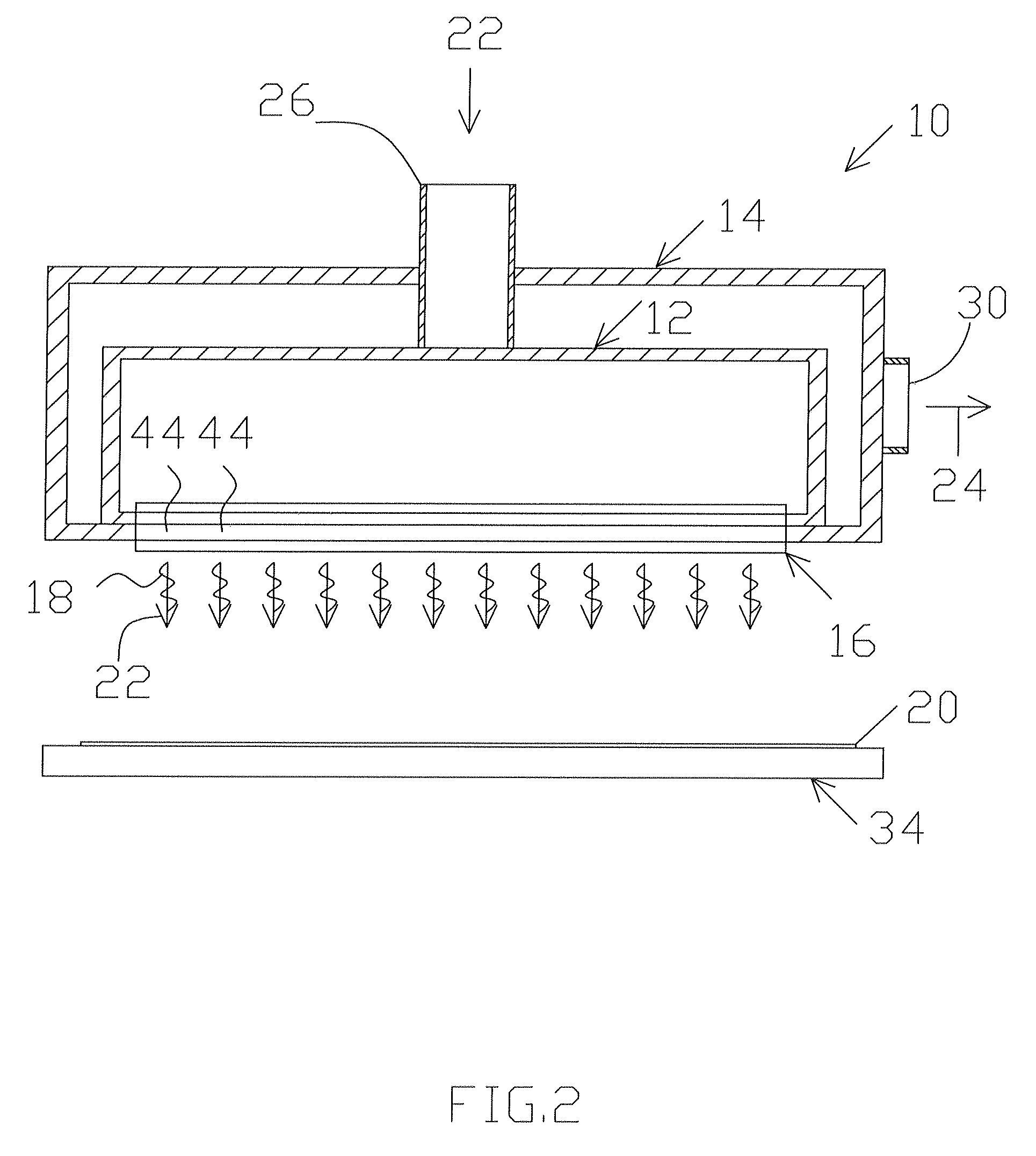

Ultrasonic drying system and method

ActiveUS20100199510A1Reduce heat lossEfficiently disruptedDrying using combination processesDrying solid materials with heatSonificationLength wave

A drying apparatus and method including heated airflow and ultrasonic transducers. The ultrasonic transducers are arranged and operated for effectively breaking down the boundary layer to increase the heat transfer rate. The ultrasonic transducers are spaced from the material to be dried a distance of about (λ)(n / 4), where λ is the wavelength of the ultrasonic oscillations and n is an odd integer (i.e., 1, 3, 5, 7, etc.). In this way, the amplitude of the ultrasonic oscillations is maximized to more-effectively agitate the boundary layer. In addition, the ultrasonic transducers are operated to produce about 120-190 dB (preferably, about 160-185 dB) at the interface surface of the material to be dried. In one embodiment, the ultrasonic transducers are of a pneumatic type. In another embodiment, the ultrasonic transducers are of an electric type. And in other embodiments, infrared and / or UV light devices are included for further boundary layer disruption.

Owner:HEAT TECH

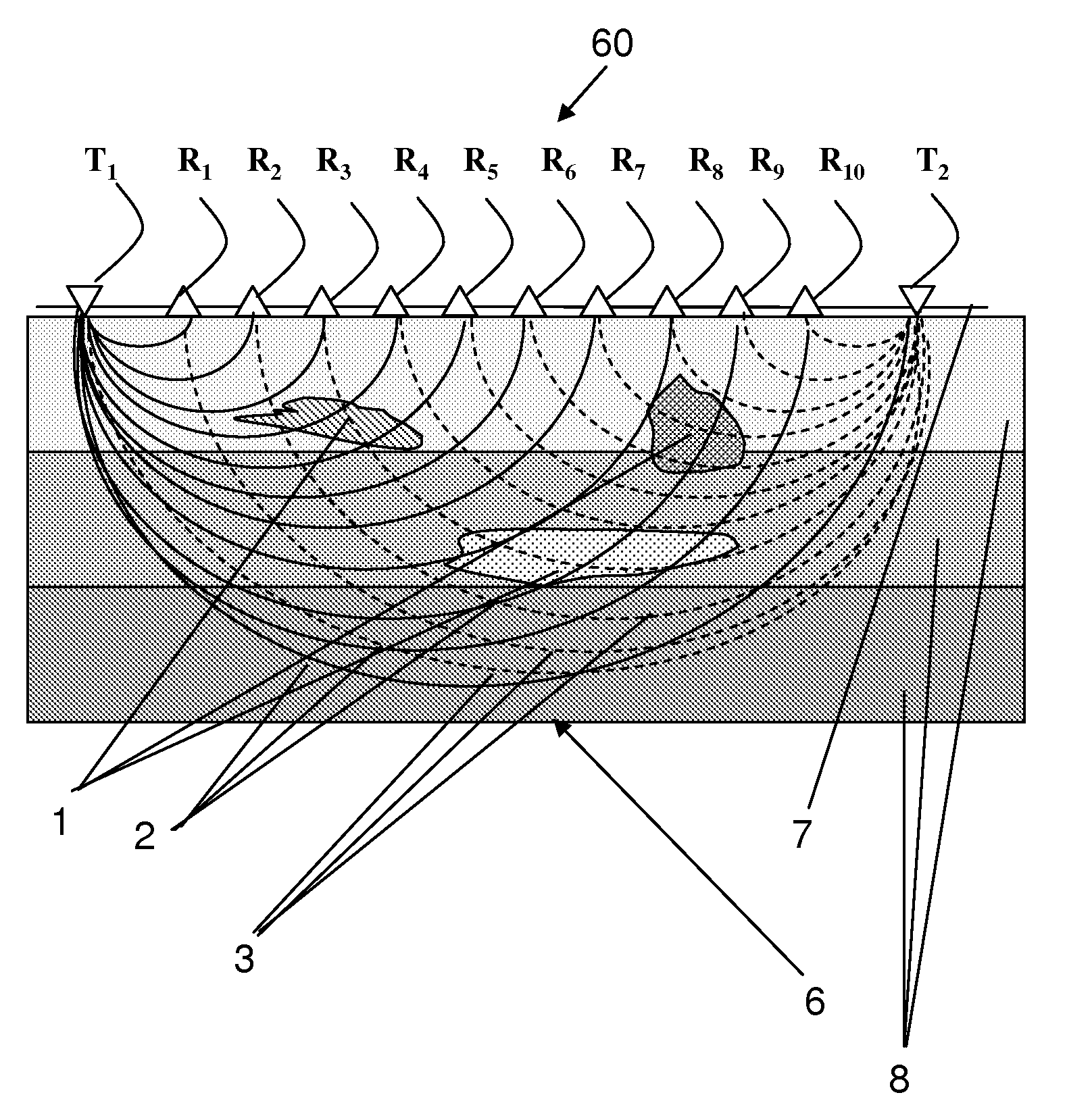

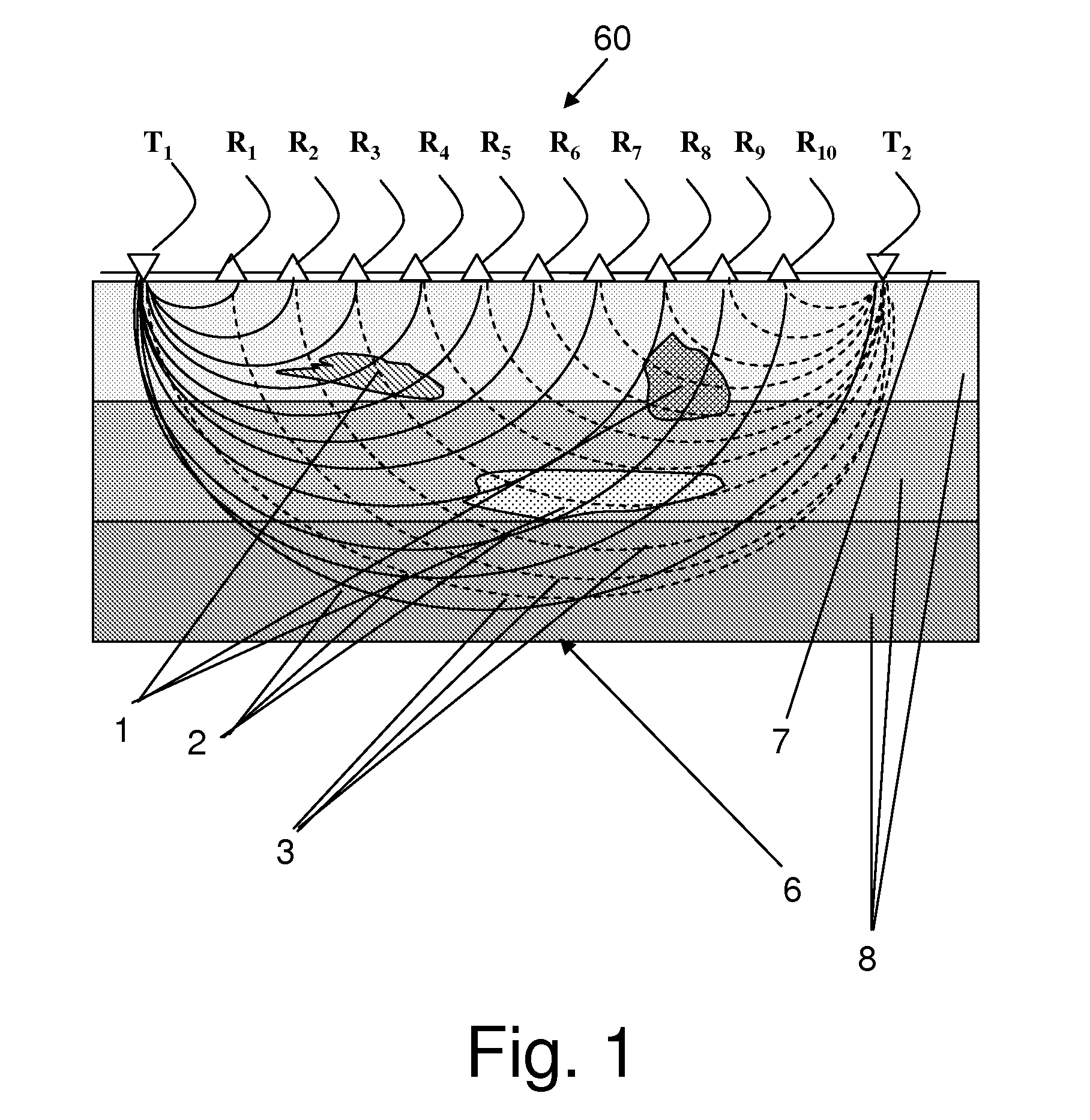

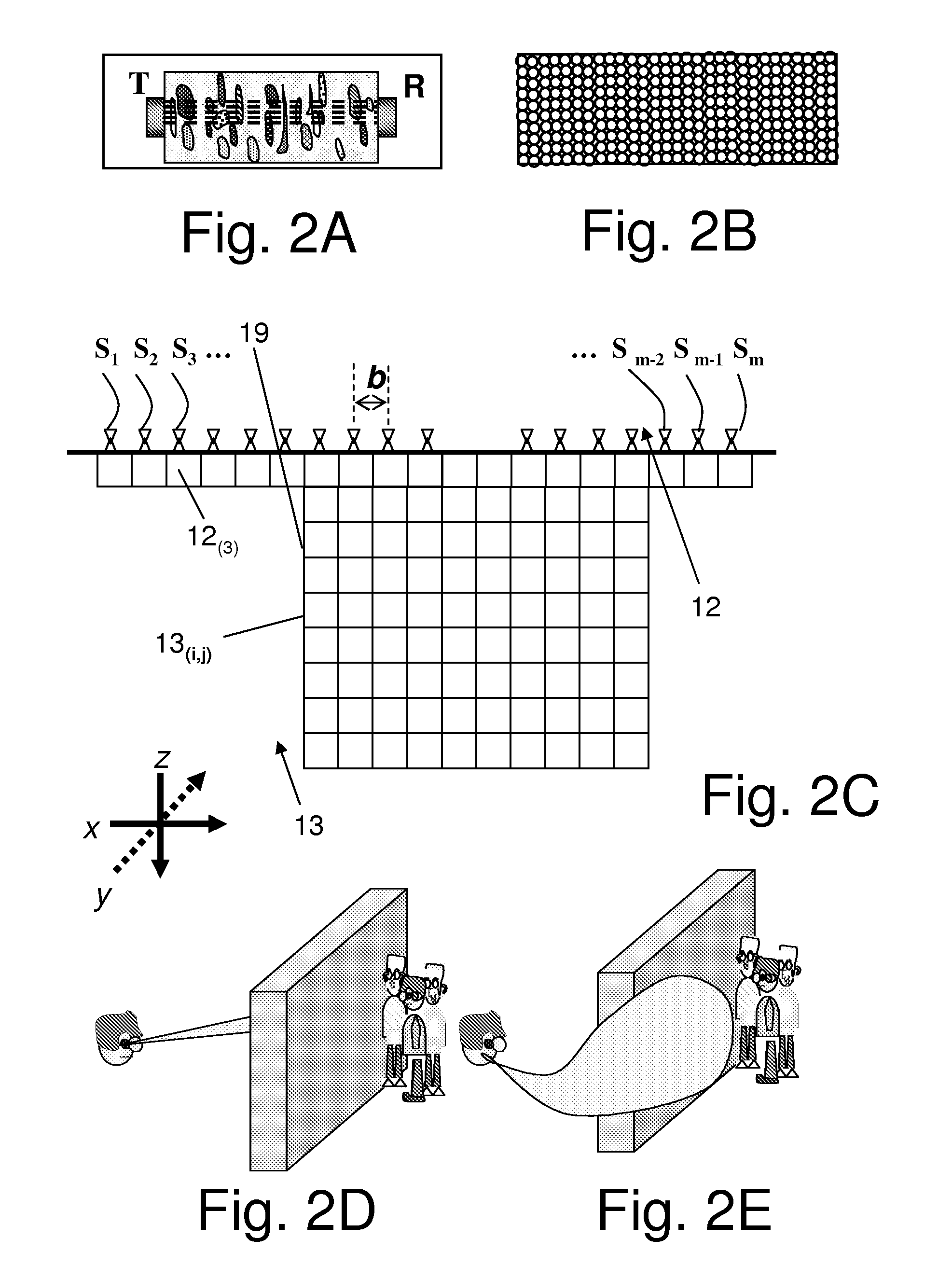

3-d quantitative-imaging ultrasonic method for bone inspections and device for its implementation

InactiveUS20110112404A1Enabling useUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsPorositySonification

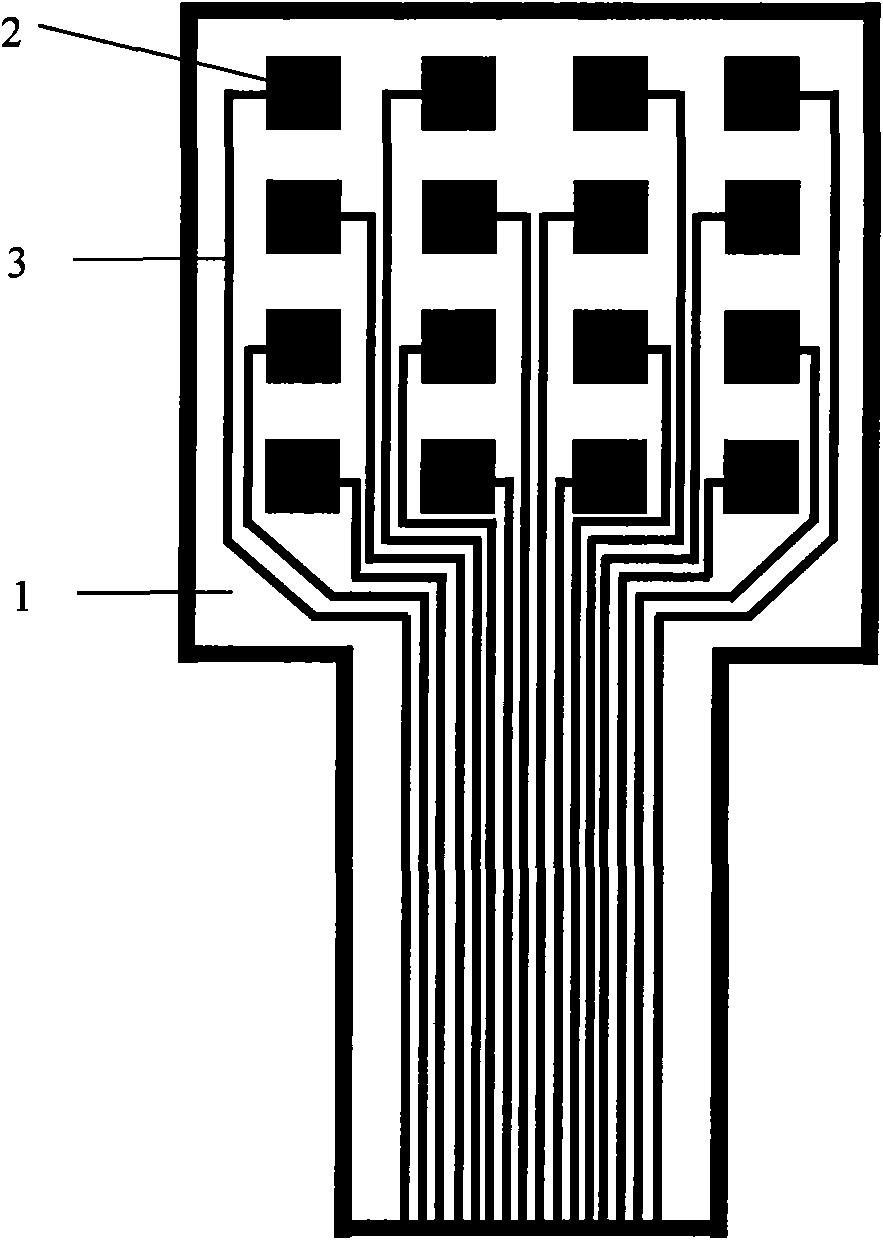

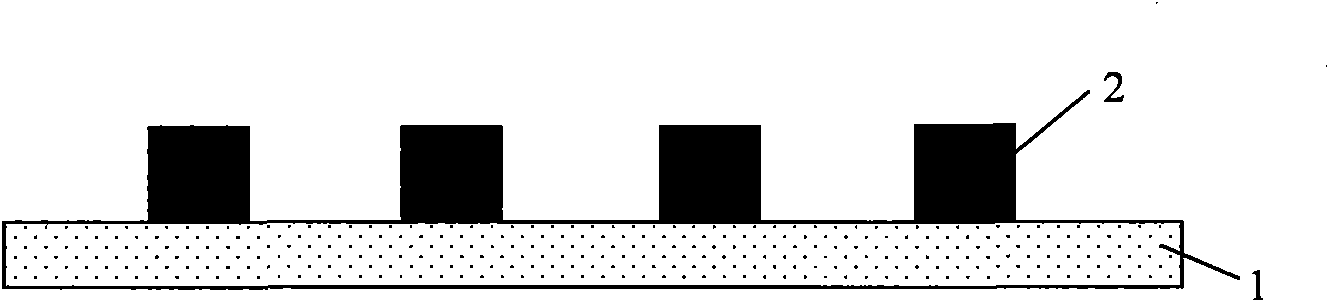

The invention is a differential 3D Quantitative-Imaging Ultrasonic Tomography method for inspecting a layered system that is comprised of a heterogeneous object embedded in a volume of space that comprises layers having an acoustic impedance gradient between the layers providing non-linear beams travels. A transducer grid is attached to the surface of the layered system in a unilateral manner. By sequentially changing the distance between transmitter and receiver the fastest travel times of the ultrasonic oscillations are measured. A differential approach provides from the data the longitudinal wave velocities values for each elementary volume that make up an inspected volume. These values are used to construct two and three-dimensional maps of the longitudinal wave velocity values distribution in the inspected volume and the porosity values distribution in the heterogeneous object. By applying statistical treatment to the obtained data the longitudinal wave velocity in the inspected material matrix part is estimated.

Owner:GOUREVITCH ALLA

Method for preparing silk fibroin hydrogel

InactiveCN101502670AImprove work efficiencyLow biocompatibilityOn/in organic carrierProsthesisProtein solutionBiocompatibility Testing

The invention discloses a method for preparing fibroin protein hydrogel, comprising the following steps: obtaining fibroin protein solution with mass concentration of 1-30% by degumming, dissolving and dialyzing domestic silkworm silk; carrying out ultrasonic oscillation treatment on the fibroin protein solution at the temperature of 0-60 DEG C with ultrasonic power being 10-2000 watt and treatment time being 30-600 seconds; carrying out standing for 0-6 hours, thus obtaining the fibroin protein hydrogel. With the method of ultrasonic oscillation treatment adopted, no chemical cross linking agent is added and the fibroin protein solution can be turned into the hydrogel in a short time, thus greatly improving work efficiency; meanwhile, the obtained fibroin protein hydrogel features good biocompatibility and adaptability to biological and medical fields such as artificial skin, artificial cartilage, cell culture brackets, bioreactors, enzyme immobilization materials and the like.

Owner:SUZHOU UNIV

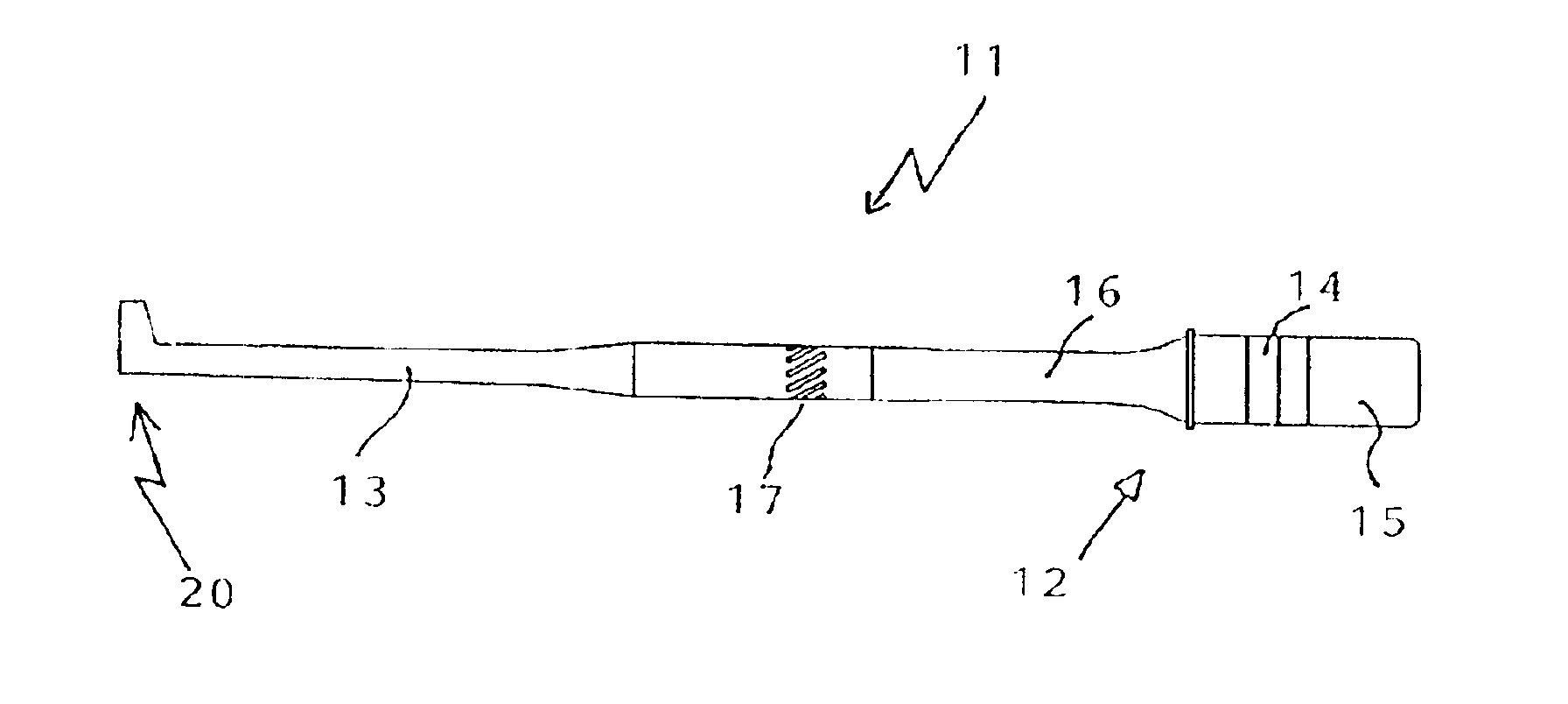

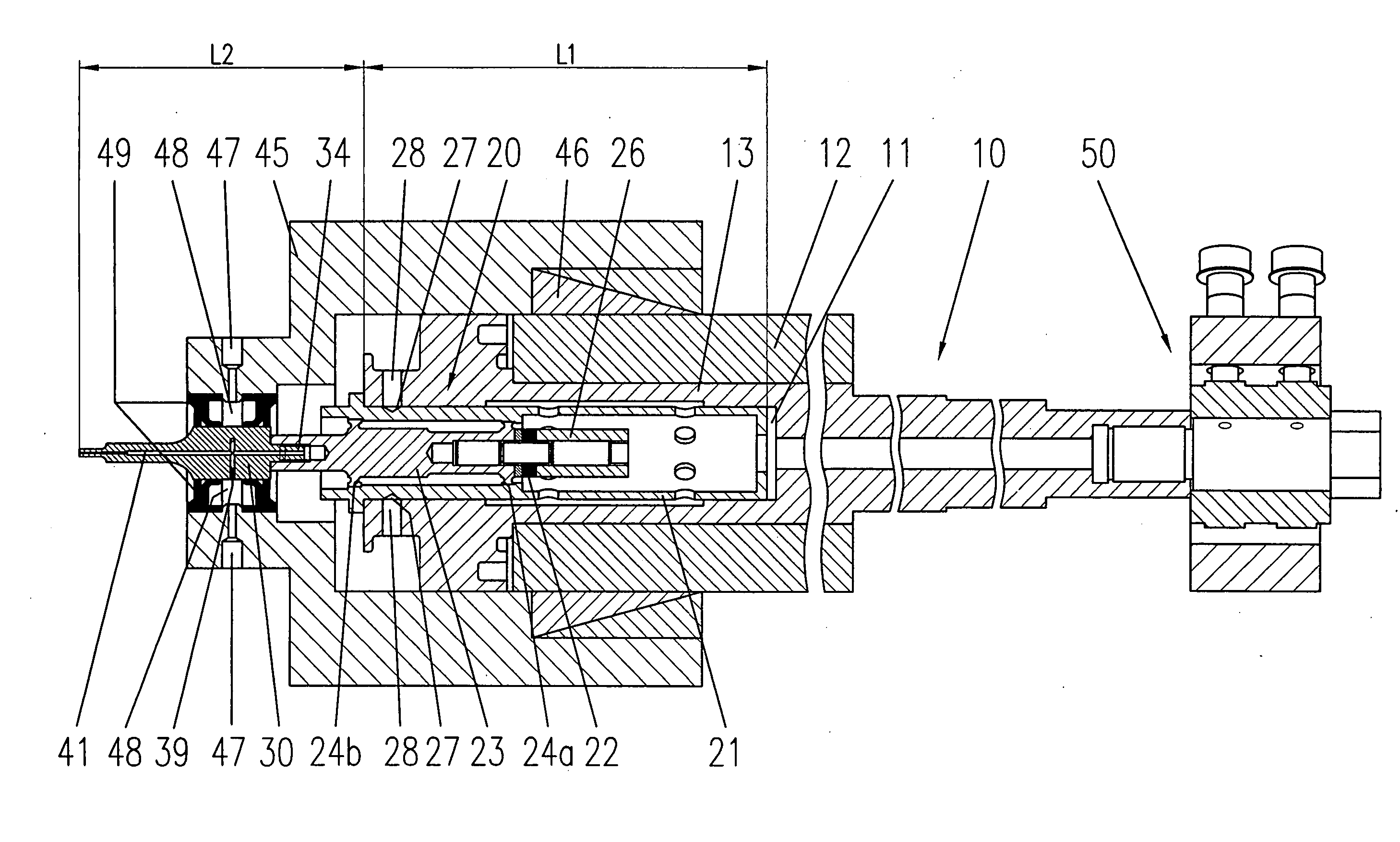

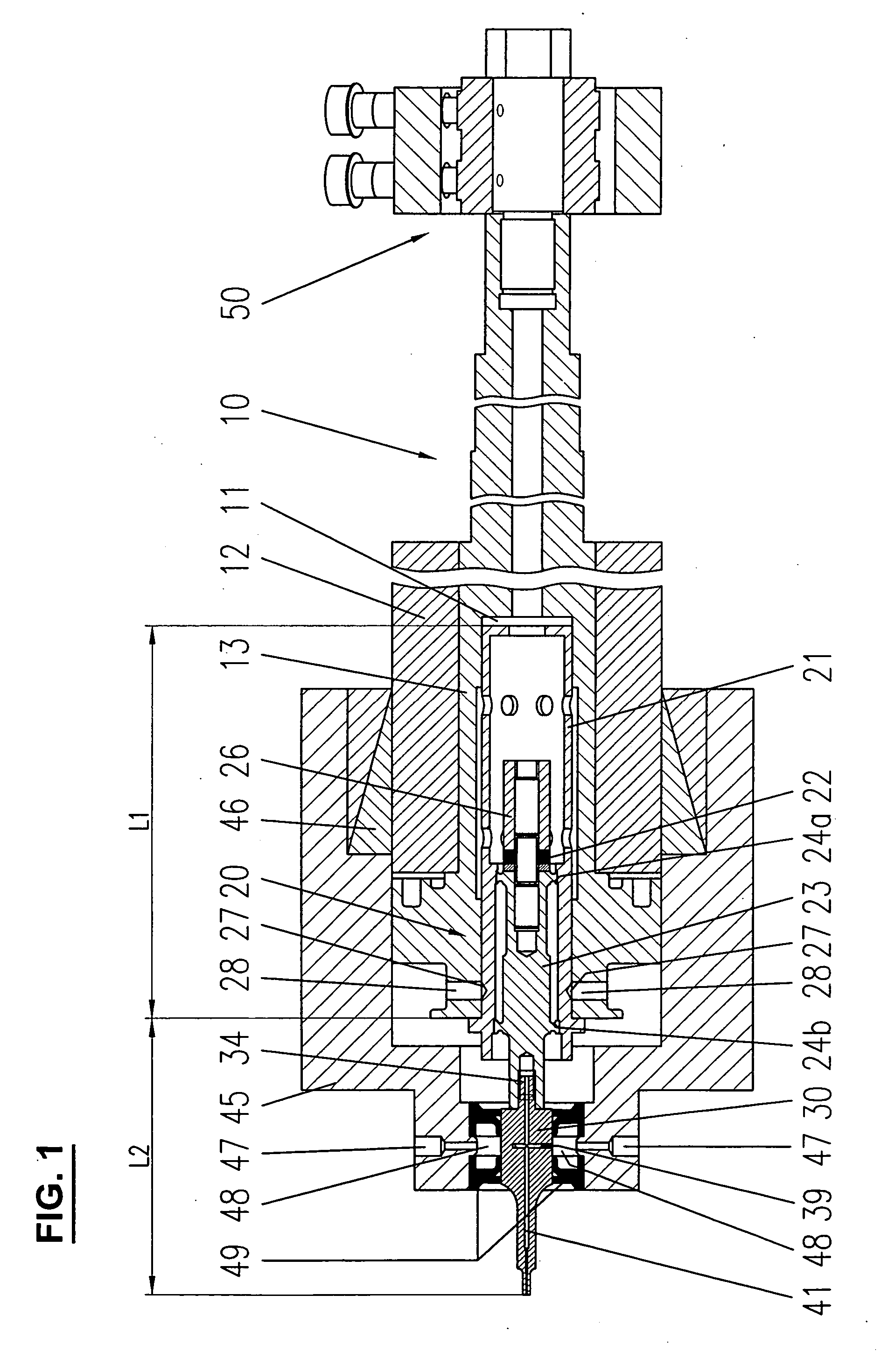

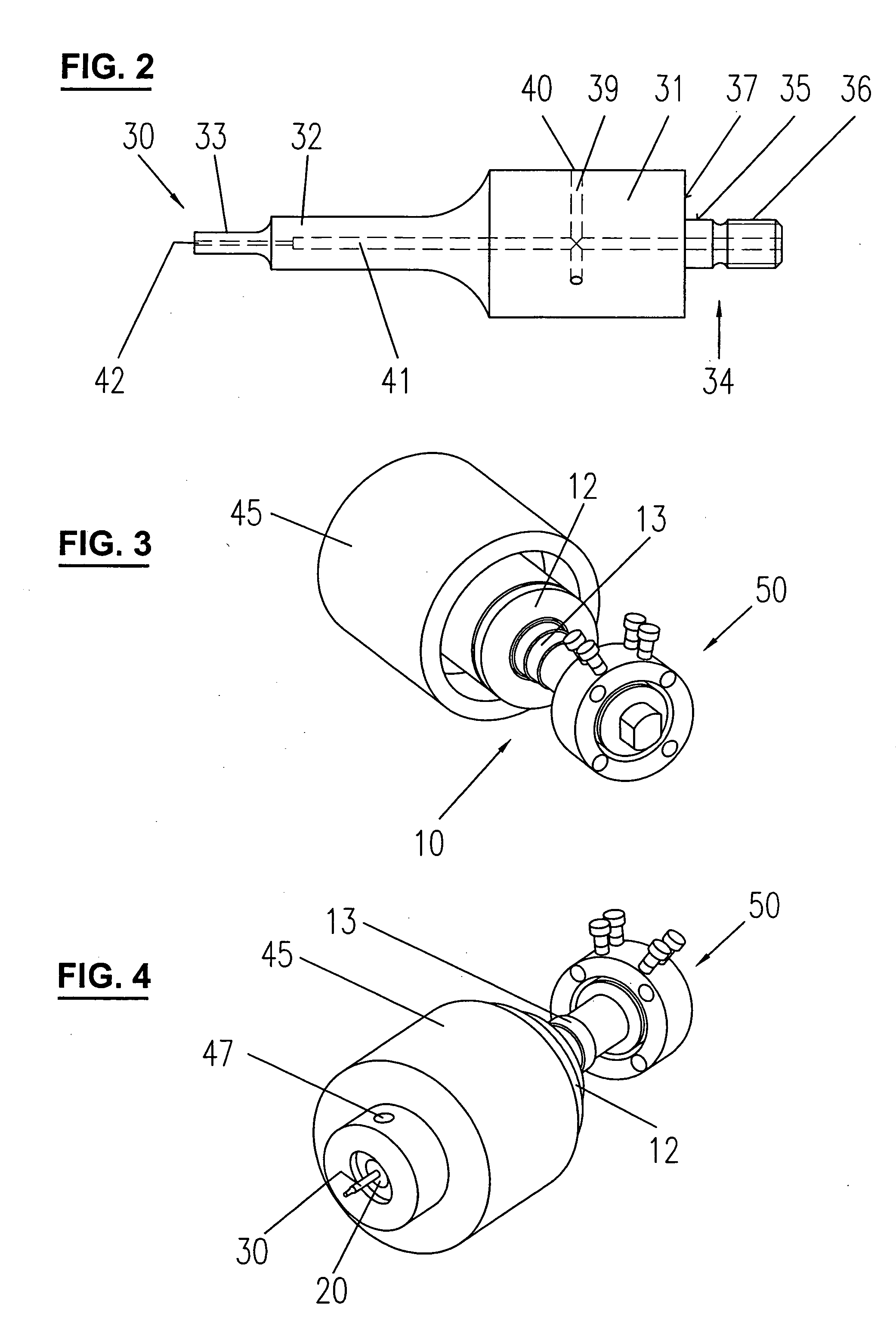

Tool unit for ultrasonically assisted rotary machining

ActiveUS20060128283A1Easy to replaceCompact designEdge grinding machinesTurning machine accessoriesUltrasonic assistedTransducer

The tool unit for the ultrasonically assisted rotary machining of a workpiece comprises a converter (23) including at least one electroacoustic transducer (22) for generating and transmitting ultrasonic oscillations, a tool (30) that is coupled to the converter, and a holder (21) in which the converter including the transducer is arranged and which is insertable at least partially in the retainer (11) of a tool spindle (10) and connectable thereto by means of a detachable connection (27).

Owner:FRITZ STUDER AG

Method for preparing high-strength graphite oxide aerogel

InactiveCN102887508AHigh mechanical strengthEasy to makeCarbon compoundsUltrasonic oscillationMaterials science

The invention discloses a method for preparing high-strength graphite oxide aerogel. The method is characterized by comprising the following processes of: 1) matching graphite oxide powder and deionized water into a water solution with the concentration being 0.1-10mg / ml, carrying out ultrasonic oscillation for 0.1-5 hours, and obtaining a graphite oxide water solution with good dispersion; 2) adding 10-500ml graphite oxide water solution which is allocated in a water heat kettle, treating for 1-24 hours under the temperature of being 90-200 DEG C, and preparing the graphite oxide aerogel; and 3) putting the prepared graphite oxide aerogel into ammonia water, dipping for 1-36 hours under the temperature being 0-150 DEG C, freezing and drying, and obtaining the high-strength graphite oxide aerogel. The method disclosed the invention has the advantages that the preparing method is simple, the mechanical strength of the graphite oxide aerogel can be increased through simple ammonia water treatment on the basis of the graphite oxide aerogel, the energy consumption is low, no pollution exists, a microcosmic porous structure is matched, and the graphite oxide aerogel has a great application prospect in adsorption and catalysis.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of multidimensional hybrid composite of glass fibre/ grapheme- carbon nano tube/ epoxy resin

InactiveCN102304274AIncreased interlaminar shear strengthImprove interface strengthCarbon nanotubeResin matrix

The invention relates to a preparation method of multidimensional hybrid composite of glass fibre / grapheme-carbon nano tube / epoxy resin. In the method, after grapheme-carbon nano tube network structure is subjected to surface carboxylation, diamine or polyamine is introduced on the grapheme-carbon nano tube network structure; the grapheme-carbon nano tube connected with the amino is modified by micromolecule aromatic polybasic anhydride compound to prepare the carbon nano tube carried with an anhydride group; the grapheme-carbon nano tube is dispersed in the epoxy resin matrix by ultrasonic oscillation and high-speed stirring; organic acid anhydride curing agent is adopted for curing; and the obtained epoxy resin polymer containing the grapheme-carbon nano tube serves as the matrix to be compounded with glass fiber processed by silane coupling agent to form a multifunctional hybrid composite structure connected by covalent bonds. The multidimensional hybrid composite is convenient to prepare, the application range of the glass fiber, the grapheme, the carbon nano tube and the epoxy resin is widened, so that the hybrid composite can be widely applied on the aspects of aerospace, traffic transportation, electronic industry, civil facilities, building, chemical engineering and the like, can be industrially produced on a large scale, has low cost and is friendly to environment.

Owner:TONGJI UNIV

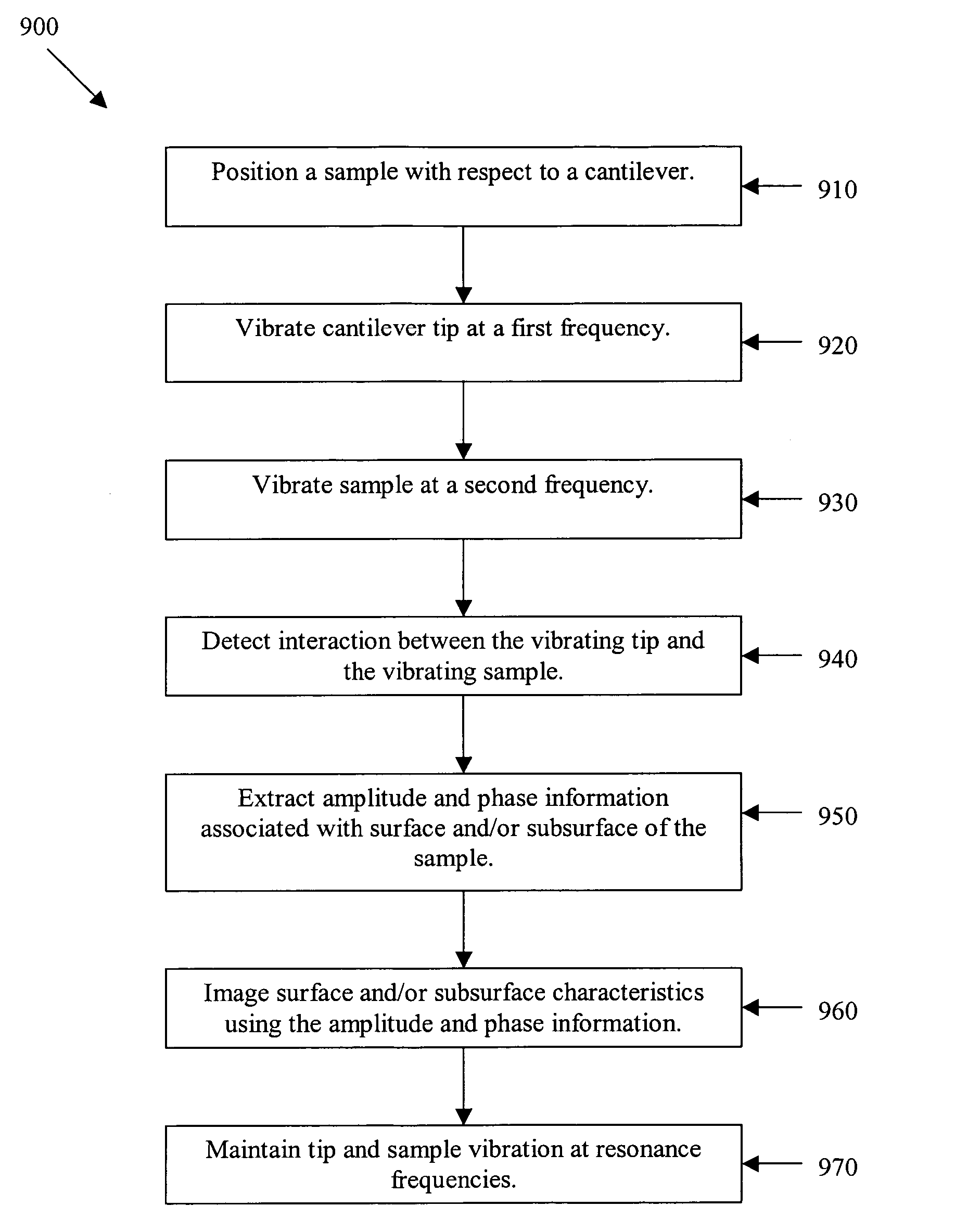

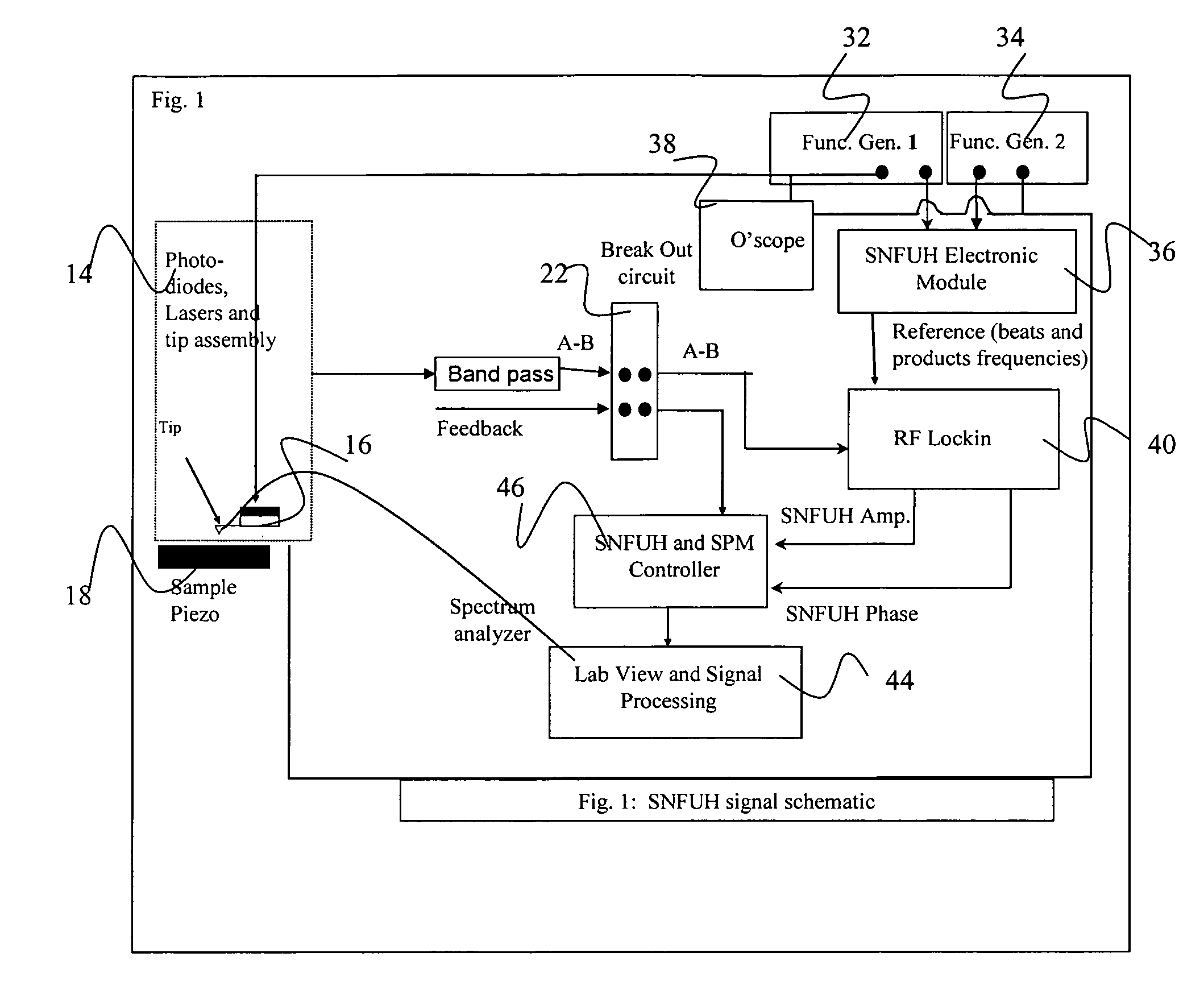

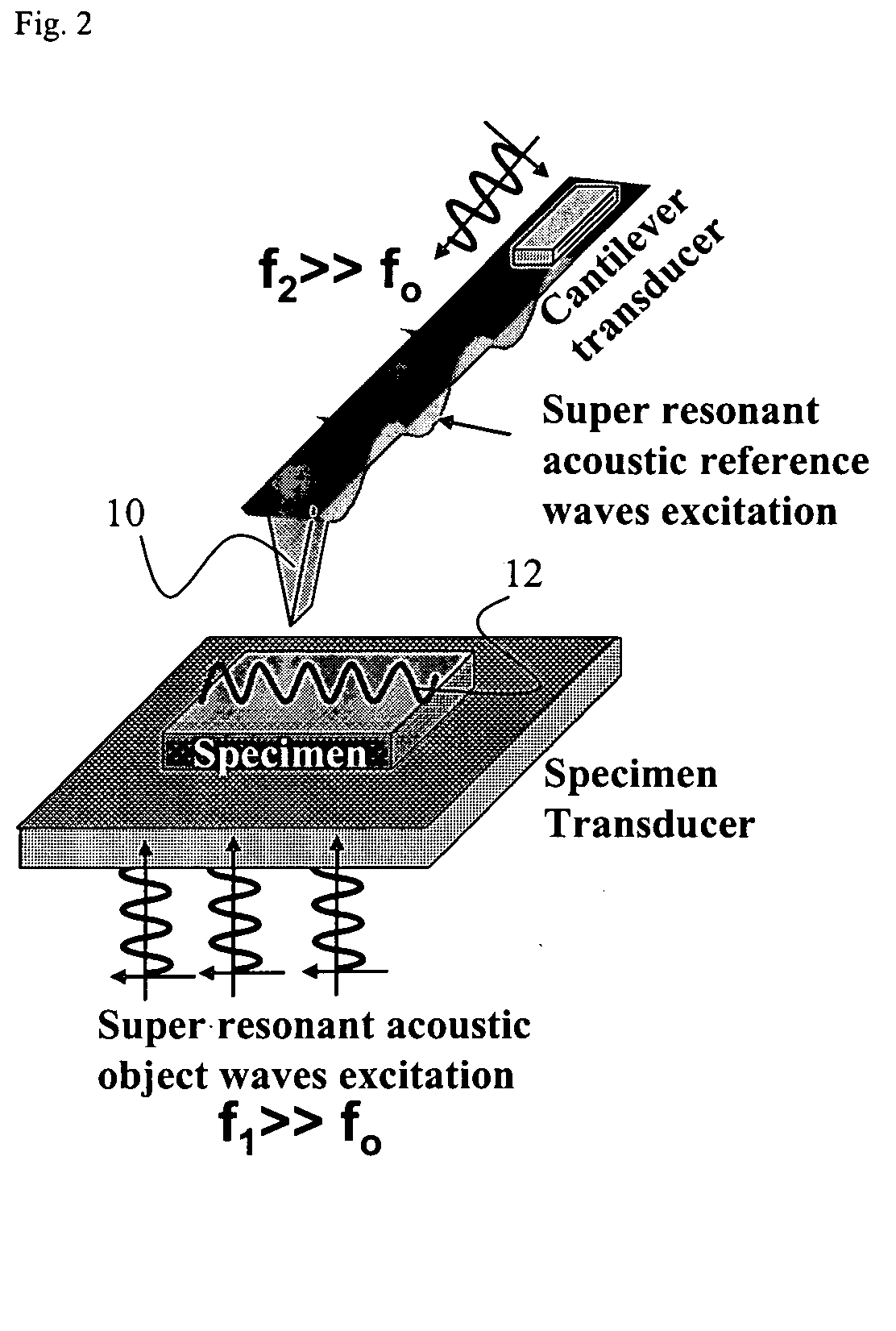

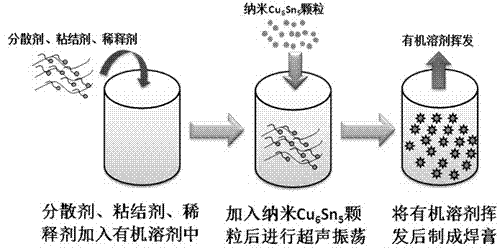

Scanning near field ultrasound holography

InactiveUS20060037401A1Improve spatial resolutionEliminate needAnalysing solids using sonic/ultrasonic/infrasonic wavesSurface/boundary effectSonificationHigh spatial resolution

A high spatial resolution phase-sensitive technique employs a scanning near field ultrasound holography (SNFUH) methodology for imaging elastic as well as viscoelastic variations across a sample surface. SNFUH uses a near-field approach to measure time-resolved variations in ultrasonic oscillations at a sample surface. As such, it overcomes the spatial resolution limitations of conventional phase-resolved acoustic microscopy (i.e. holography) by eliminating the need for far-field acoustic lenses.

Owner:NORTHWESTERN UNIV

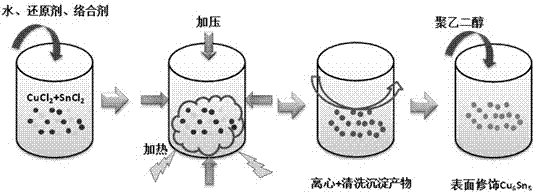

Nano intermetallic compound soldering paste and preparation method thereof

ActiveCN102922177ALow costHigh purityWelding/cutting media/materialsSoldering mediaSolid componentSolvent

The invention discloses nano intermetallic compound soldering paste and a preparation method thereof, belonging to the field of material technologies. The nano intermetallic compound soldering paste disclosed by the invention comprises the following materials in mass ratio: 80-90 of nano intermetallic compound particles, 2-8 of dispersant, 2-8 of binder, 2-8 of thinner and 2-8 of soldering flux. The specific method comprises the following steps of: preparing the nano intermetallic compound particles by using a co-precipitation hydrothermal reduction method; mixing the prepared nano intermetallic compound particles with the dispersant, the binder, the thinner and the soldering flux; uniformly dispersing the obtained mixture in an organic solvent by using an ultrasonic oscillation, manual stirring or mechanical stirring method; and volatilizing an excess solvent, so that the nano intermetallic compound soldering paste is prepared. The soldering paste takes nano intermetallic compound particles as solid components, and by using the size effect of nano materials, an interconnection process at a temperature lower than the melting point temperature of a block is realized, thereby avoiding the high-temperature damages to components, avoiding the overreaction of a connection interface, achieving an effect of long-term high-temperature serving, and reducing the packaging cost.

Owner:HARBIN INST OF TECH

Titanium dioxide and graphene oxide composite nano-grade sheet material and preparation method thereof

ActiveCN102492313AThickness is continuously controllableMeet different requirements of thicknessPigment physical treatmentOxide compositeVacuum drying

The invention relates to a titanium dioxide and graphene oxide composite nano-grade sheet material and a preparation method thereof. A structural layer of the titanium dioxide and graphene oxide composite nano-grade sheet comprises a graphene oxide layer, and two titanium dioxide layers respectively positioned on the upper and lower sides of the graphene oxide layer. The preparation method comprises steps that: step 1, graphene oxide is subject to ultrasonic oscillation under a normal temperature, such that graphene oxide is uniformly dispersed in distilled water, and a graphene oxide dispersed liquid is obtained; step 2, the graphene oxide dispersed liquid is diluted by using absolute alcohol; step 3, a proper amount of tetrabutyl titanate is dissolved in absolute alcohol, such that an alcohol solution of tetrabutyl titanate is obtained; step 4, the alcohol solution of tetrabutyl titanate with a different concentration is gradually dropped into the alcohol diluent of graphene oxide with a temperature of 20-60 DEG C while stirring; step 5, a reaction is carried out, such that a dispersed liquid of an amorphous titanium dioxide and graphene oxide composite nano-grade sheet materialis obtained; step 6, the dispersed liquid is subject to centrifugal washing by using distilled water and absolute alcohol, and is subject to normal-temperature vacuum drying, such that powder is obtained. The powder is the amorphous titanium dioxide and graphene oxide composite nano-grade sheet material obtained with the initial reaction.

Owner:SICHUAN UNIV +1

Preparation method of functional nano-graphene

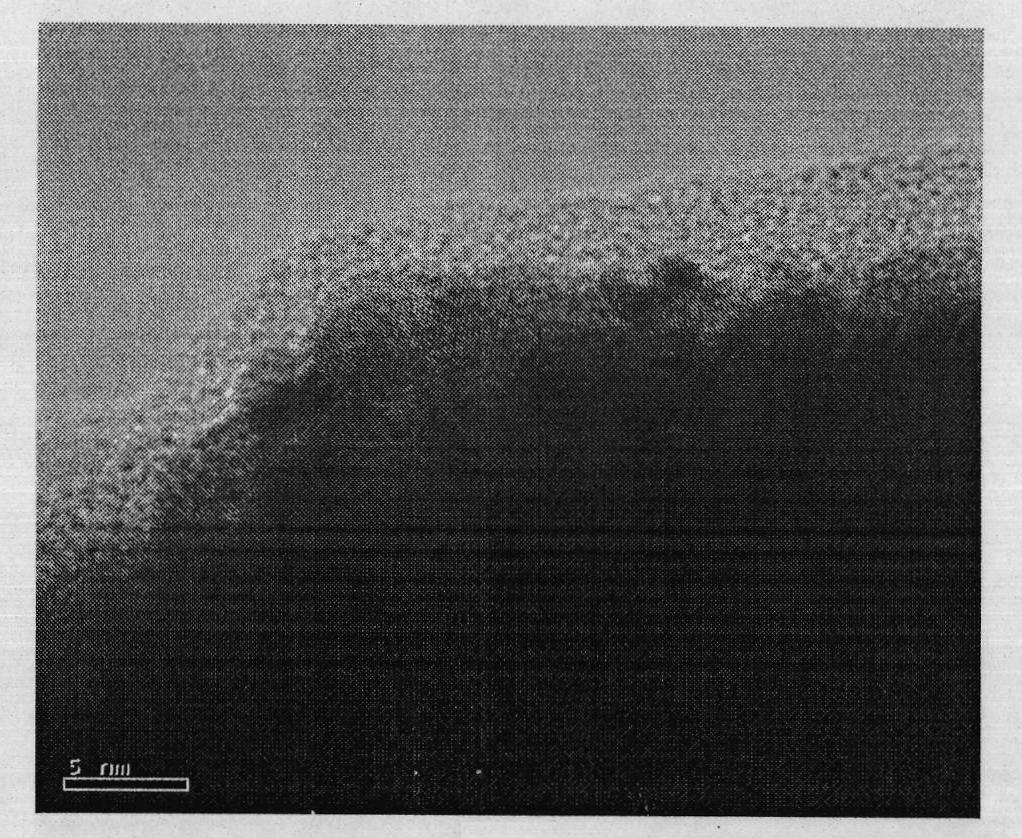

The invention relates to a preparation method of functional nano-graphene, belonging to the technical field of nano-graphene functional material. The method comprises the following steps: adding graphite oxide in water while adding one or more kinds of penetrants, stirring with ultrasonic wave or a rapid machine to form brown or black uniform suspension, heating to 70-100 DEG C, refluxing, washingwith water and drying to obtain the nano-graphene containing monolayer or multilayer graphene, wherein in the mixing process, graphite oxide absorbs penetrants and performs interlaminar swelling andthe swelled graphite oxide becomes loose and performs dissociation under the ultrasonic oscillation or the mechanical agitation of the rapid machine. The analysis of TEM finds that the nano-graphene has fold property and high radius-thickness ratio, simple technological process, reliable production principle, accessible raw material, low cost, good nanometer functionality, stable structural performance and good application effect.

Owner:QINGDAO UNIV

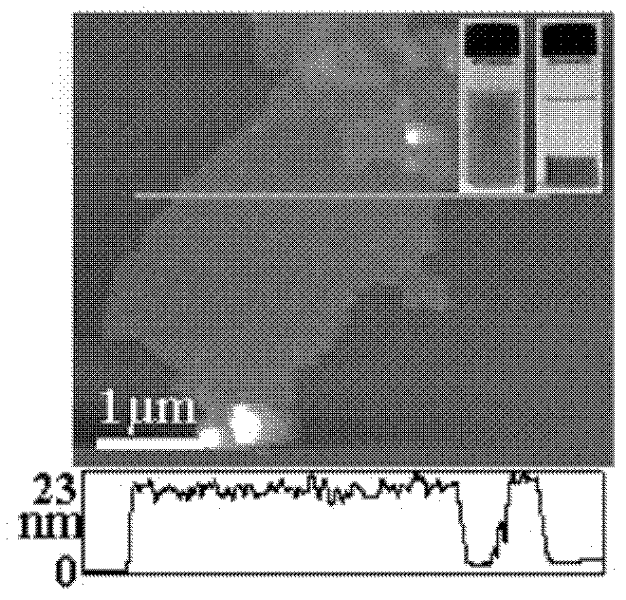

Calcium phosphate/collagen composite biologic ceramic material and preparation method thereof

InactiveCN103055352AImprove mechanical propertiesPromote repair and regenerationProsthesisCalcium biphosphateBone tissue engineering

The invention relates to a CaP (Calcium Phosphate) / collagen composite biologic ceramic material and a preparation method thereof. The composite biologic ceramic is prepared by adopting a porous calcium phosphate ceramic as the substrate and I-type collage as the toughening reinforcing phase in a vacuum negative pressure pouring and crosslinking mode. The process is as follows: firstly, preparing the first type through porous calcium phosphate ceramic, wherein the porosity is 60-95%; dipping the porous calcium phosphate ceramic into a collagen solution of which the concentration is 5-20mg / ml; and vacuuming to 0-10Pa at normal temperature and pouring, keeping the pressure for 1-3 hours and carrying out ultrasonic oscillation. The vacuum negative pressure pouring process can be repeated according to demands. The calcium phosphate ceramic poured with the collagen is frozen and dried to prepare the composite biologic ceramic after being subjected to crosslinking. The prepared biologic ceramic has good biocompatibility and biological activity, and at the same time has a mechanical strength better than that of a pure calcium phosphate ceramic material, so that the biologic ceramic can be used as artificial bones and bone tissue engineering bracket materials, and has wide clinical application prospects in orthopedics.

Owner:SICHUAN UNIV

Preparation method for graphene conductive slurry

The invention discloses a preparation method for graphene conductive slurry. The preparation method comprises the steps of dissolving a dispersing agent into a solvent firstly, and performing ultrasonic oscillation to form a uniform solution; then adding graphene and a conductive carbon material into the solution to be mixed and stirred; next, performing full dispersion through a way of ultrasonic oscillation; and finally transferring the well-dispersed slurry to a high-speed shearing emulsification homogenizing machine to be sheared and dispersed to obtain the uniform and consistent and fully-dispersed graphene conductive slurry. The preparation method is simple and easy to implement and applicable to engineering production.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Graphene/silicone/carbon nano tube composite material and preparation method and application thereof

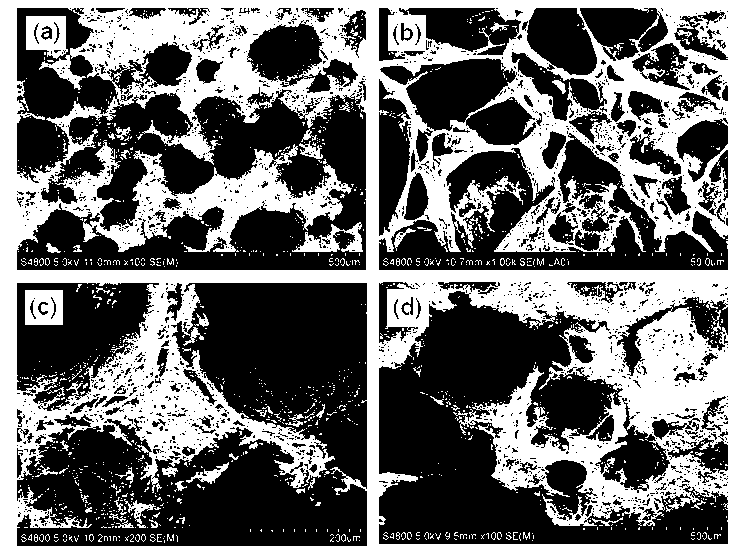

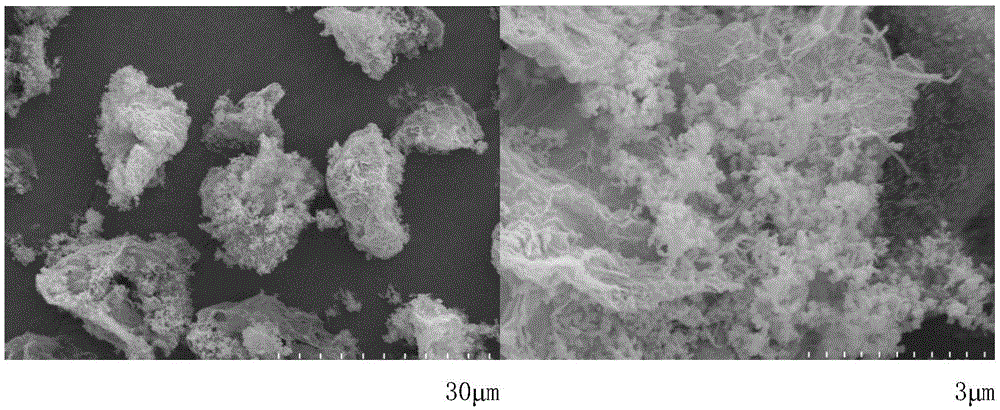

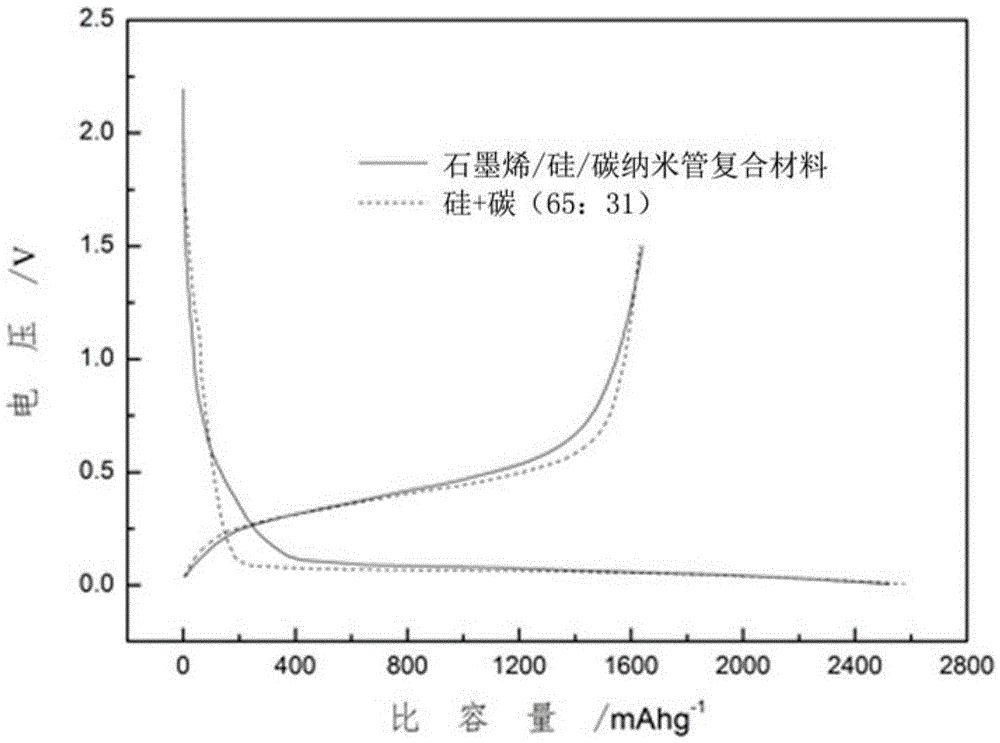

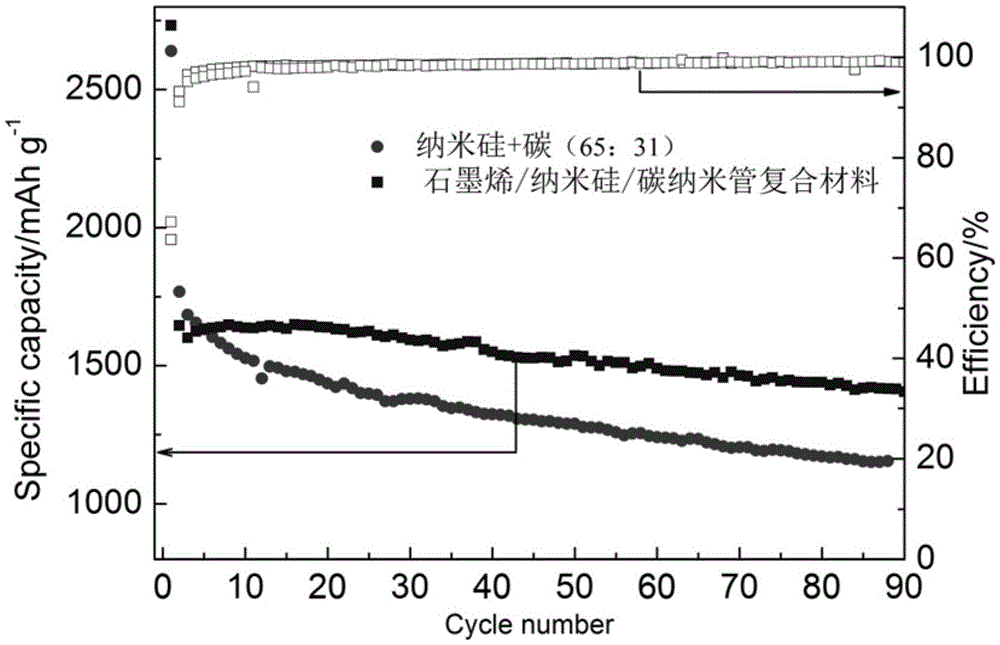

InactiveCN105576203AIncrease capacityImprove efficiencyMaterial nanotechnologyCell electrodesCarbon compositesCarbon nanotube

The invention discloses a graphene / silicone / carbon nano tube composite material and a preparation method and application thereof and relates to lithium ion battery silicone cathode materials. The graphene / silicone / carbon nano tube composite material is a silicone-carbon composite material compositing graphene, a silicone material and carbon nano tubes. The preparation method includes: adding graphene powder and the carbon nano tubes into an NMP solution, adopting ultrasonic oscillation to enable uniform dispersion of the graphene powder and the carbon nano tubes, adding nano silicone powder, and adopting ultrasonic oscillation to enable uniform dispersion; drying, stoving and grinding a mixed solution obtained to obtain the graphene / silicone / carbon nano tube composite material. The graphene / silicone / carbon nano tube composite material can serve as a cathode material to be applied in lithium ion batteries and has characteristics of high capacity, high efficiency and good circulating performance. Graphene, the silicone material and the carbon nano tubes are composited through simple steps, volume effect of the silicone material in the process of charging and discharging is improved through graphene and special structure of a novel material, and electroconductivity of the silicone material is improved.

Owner:XIAMEN UNIV +1

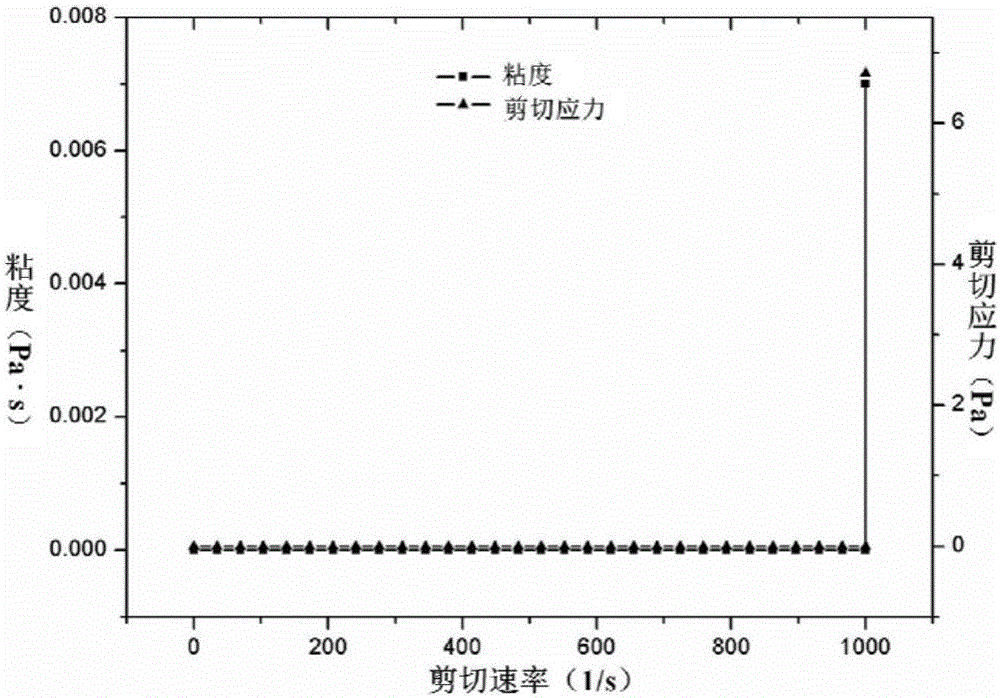

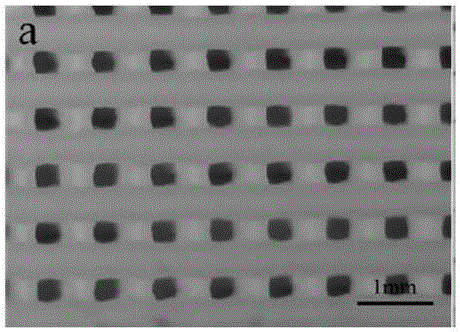

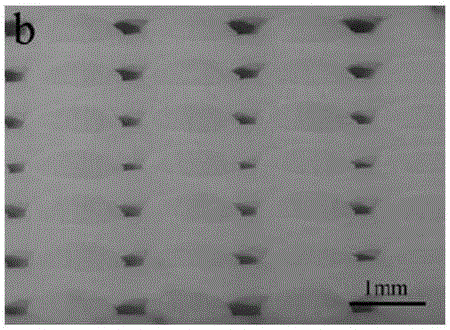

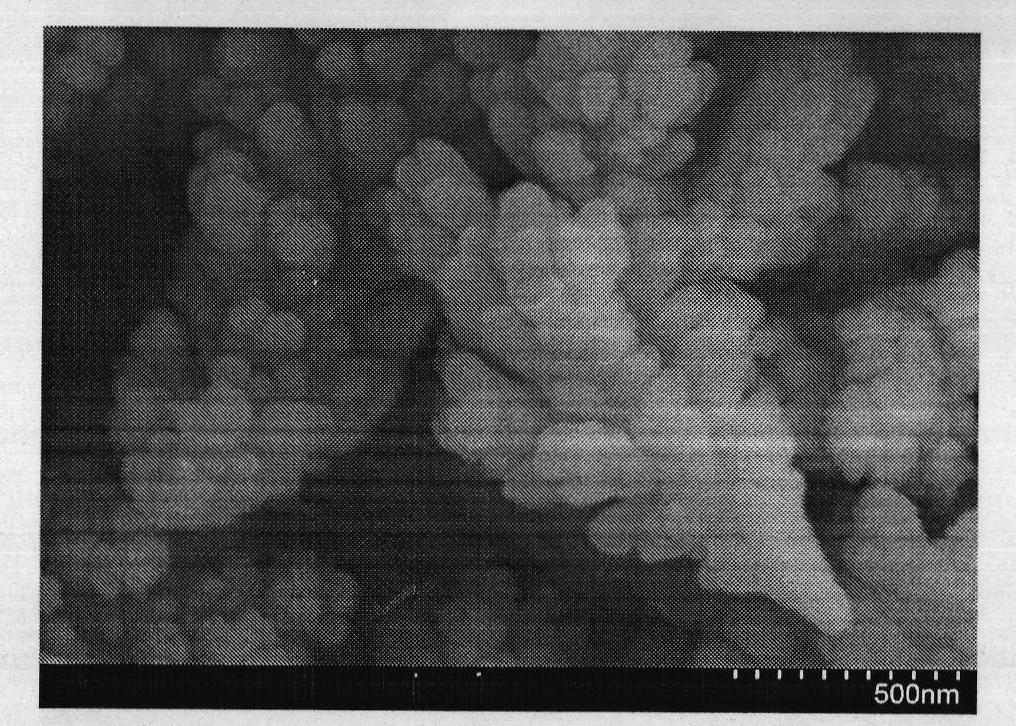

Preparation methods of ceramic slurry for air pressure extrusion type three-dimensional printing and biological ceramic bracket

ActiveCN105196398AImprove liquidityHigh standardAdditive manufacturing apparatusCeramic shaping apparatusCeramic bracketsWater soluble

The invention discloses a preparation method of ceramic slurry for air pressure extrusion type three-dimensional printing. The preparation method comprises the following steps: (11) adding biological active ceramic powder into a solvent, performing ball grinding by a planetary ball grinder for 3 to 12 hours, and obtaining slurry, wherein the solid phase content of the slurry is 35 to 55 vol%; (12) adding a water-soluble rheological additive into the slurry obtained in the step (11), performing ball grinding by the planetary ball grinder for 0.5 to 3 hours, then transferring the slurry into a material feeding barrel, performing ultrasonic oscillation and low-temperature debubbling in sequence, and obtaining the ceramic slurry for air pressure extrusion type three-dimensional printing. The invention further discloses a preparation method of a biological active ceramic bracket by adopting an air pressure extrusion type three-dimensional printing forming technology. The ceramic slurry prepared by the preparation method disclosed by the invention is high in solid phase content and good in printing performance and coagulability; the prepared biological active ceramic bracket can be connected by 100 percent, and the appearance structure and the internal size of the biological active ceramic bracket can be controlled.

Owner:广州康睿医疗器械有限公司

Chemical separating method for aluminum foil in waste lithium ion battery positive plate

ActiveCN102412430AImprove solubilityLoose surface compositionSolid waste disposalWaste accumulators reclaimingActive agentEngineering

The invention discloses a chemical separating method for an aluminum foil in a waste lithium ion battery positive plate. The method comprises the following steps of: (1) adding the waste lithium ion battery positive plate into a surfactant solution, performing ultrasonic oscillation treatment to loosen surface components of the positive plate, washing, drying, filtering and recovering the positive plate; (2) putting the positive plate treated in the step (1) into a mixed solution of N, N-dimethylacetamide and N-methylpyrrolidone, heating, taking the positive plate out, and washing with water; (3) putting positive plate treated in the step (2) into water, performing ultrasonic oscillation till the aluminum foil as well as active substances of an anode, a conducting agent and a bonding agent; and (4) filtering a solution obtained in step (3), washing to obtain a mixture containing the active substances, the conducting agent, the bonding agent and the aluminum foil, and screening to obtain a dissociative aluminum foil sheet. In the method, the aluminum foil sheet can be recovered directly; and compared with the conventional method for extracting an aluminum foil after dissolving with alkali, the chemical separating method has the advantages: the process is simplified, and cost is lowered.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

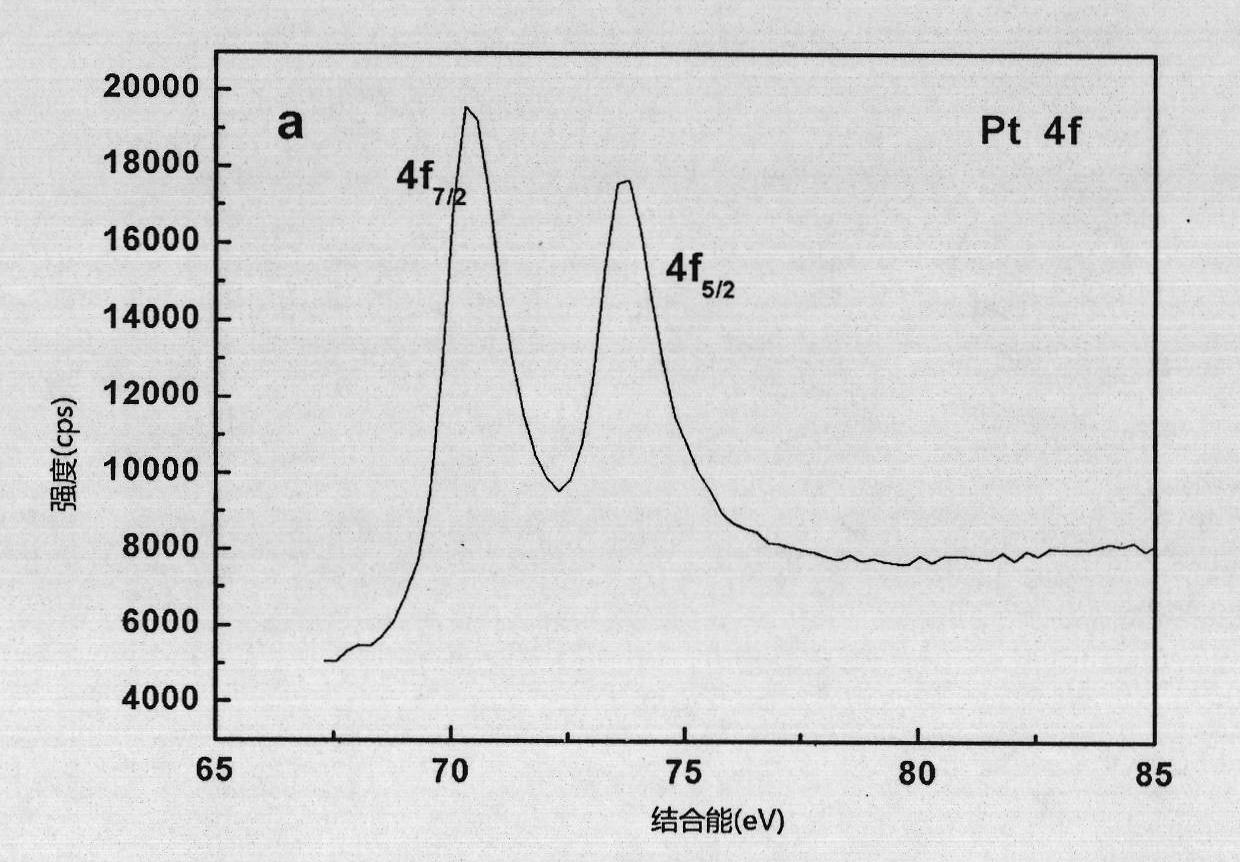

Three-dimensional Pt-Pb nano floricome type enzyme-free glucose sensor electrode as well as preparation and application thereof

ActiveCN101975807AElectrode area is smallHigh sensitivityMaterial electrochemical variablesGlucose sensorsPhosphate

The invention relates to a three-dimensional Pt-Pb nano floricome type enzyme-free glucose sensor electrode as well as preparation and application thereof. The electrode consists of a three-dimensional Pt-Pb nano floricome array on a stainless steel acupuncture needle substrate, wherein three-dimensional Pt-Pb nano floricomes exist on the surface of the electrode in a good crystallization form, and the diameter of the single nano floricome is 50-80nm. The preparation method comprises the following steps of: polishing a stainless steel acupuncture needle on deerskin; after the stainless steel acupuncture needle is repeatedly washed through secondary distilled water and processed through ultrasound, putting the stainless steel acupuncture needle in a PBS (Phosphate Buffer Solution) of whichthe pH is 7.0 to scan and activate for 10 circles through cyclic voltammetry; putting the stainless steel acupuncture needle into a hydrochloric acid electrolyte of 0.5mol / L, which consists of chloroplatinic acid and lead acetate by a ratio of 1:1; and preparing an electrode sample through an ultrasonic oscillation electro-deposition method. The three-dimensional Pt-Pb nano floricome type enzyme-free glucose sensor electrode has good electro-catalysis activity, wide linear response range and high sensitivity and selectivity.

Owner:苏州盛泽科技创业园发展有限公司

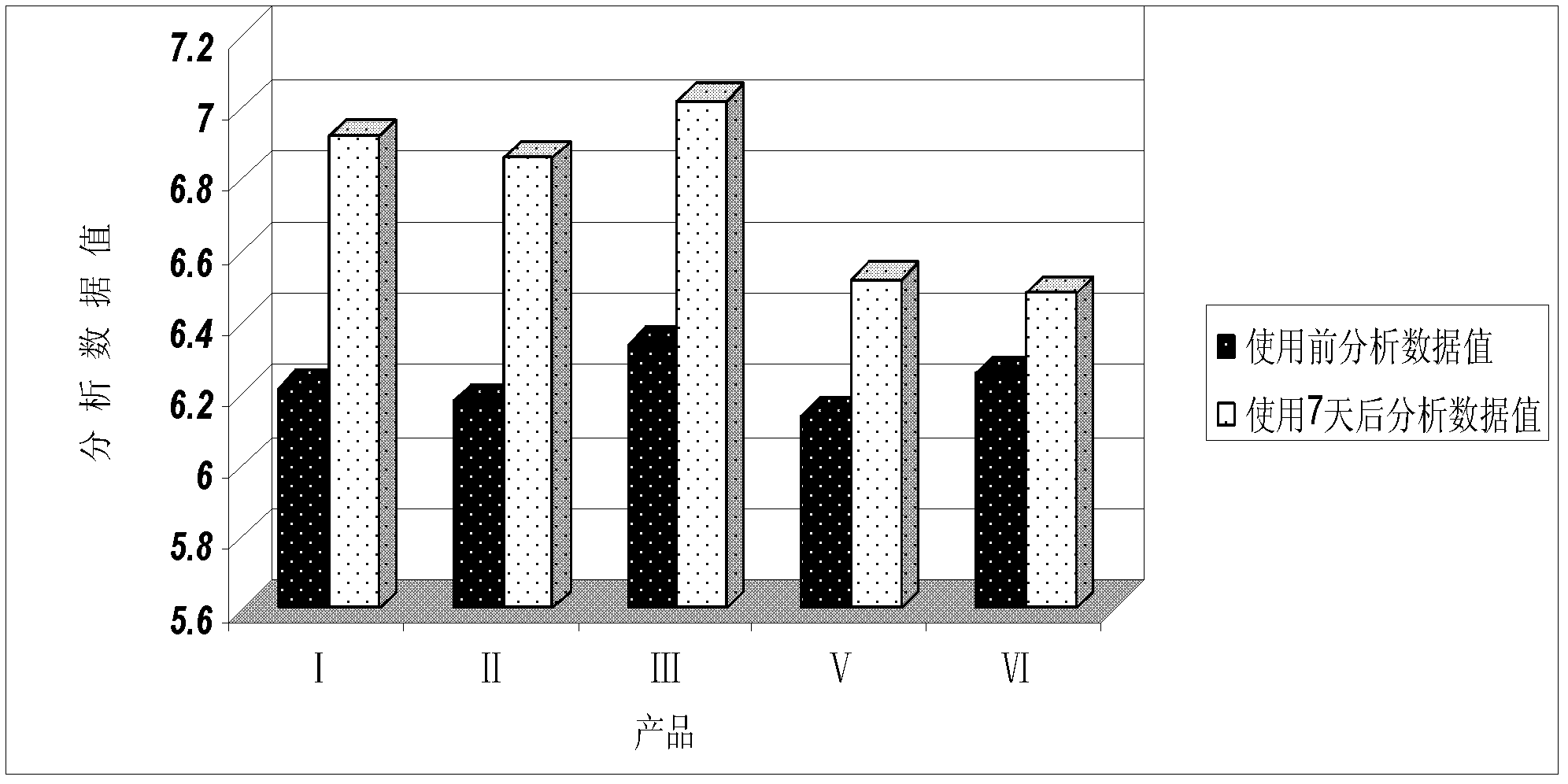

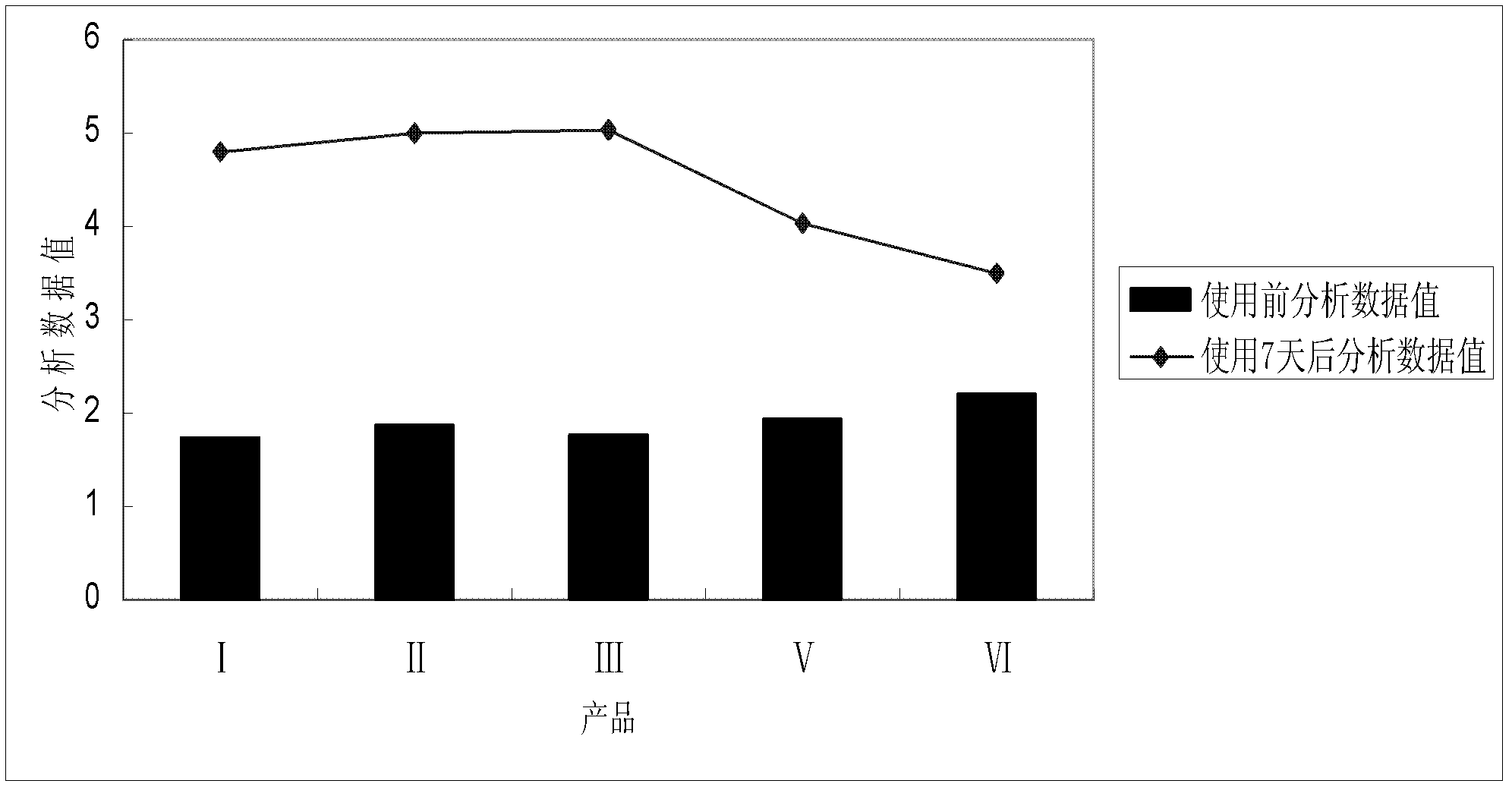

Essential oil added type skin care product

ActiveCN102600056APromote absorptionImprove absorption rateCosmetic preparationsToilet preparationsLiquid productIrritation

The invention provides an essential oil added type skin care product which is prepared from the following raw materials in percent by weight: 15-20 percent of lavender essential oil, 1-5 percent of sweet orange essential oil, 1-2 percent of rose flower essential oil, 2-4 percent of clary sage essential oil, 3-5 percent of rosemary essential oil, 2-4 percent of chamomile essential oil, 1-2 percentof arabian Jessamine essential oil, 10-15 percent of vitamin E and the balance of jojoba oil. According to the invention, the raw materials are mixed, and are subjected to ultrasonic oscillation to obtain a uniform liquid product with small oil drop diameter, so that the essential oil added type skin care product is obtained. The essential oil added type skin care product provided by the invention has the advantages of little irritation, good permeability and capability of remarkably improving the sub-health state of the skin within a short time to recover the skin health from inside to outside.

Owner:GUANGZHOU FRASLANE COSMETIC

Conductive graphite cream and preparation method thereof

ActiveCN102618107AReduce carbon additionDoes not affect conductivityCellulose coatingsConjugated diene hydrocarbon coatingsConductive polymerGraphite

The invention discloses conductive graphite cream and a preparation method thereof, which solve the technical problem of improving dispersibility of graphite cream. The conductive graphite cream comprises materials including, in weight percent, 10-30% of conductive graphite, 1-30% of matrix resin, 0.1-5% of conductive polymer auxiliaries, 0.1-5% of dispersing auxiliaries and the balance solvents. The preparation method includes the steps: adding the conductive polymer auxiliaries into the solvents to obtain solution 1; adding the matrix resin into the solvents to obtain solution 2; adding the conductive graphite into the solution 2; adding the dispersing auxiliaries into the solution 2 for ball-milling; adding the solution 1 into solution 3; and performing ultrasonic oscillation, high-pressure dispersion and stirring to obtain the conductive graphite cream. Compared with the prior art, the conductive graphite cream and the preparation method have the advantages that nano carbon materials are added, ball-milling, ultrasonic oscillation and high-pressure dispersion are performed for assisting so that the conductive graphite cream is uniformly dispersed, and the preparation method is simple and low-cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Method for improving teflon adhesive property and method for producing pressure-sensitive adhesive tape

The invention discloses a method for improving a teflon adhesive property. The method comprises the following steps of washing, wherein at least one kind of methyl alcohol, methyl alcohol, isopropanol, acetone and methylbenzene is adopted, and teflon base materials are washed through ultrasonic oscillation; normal-pressure low-temperature plasma processing, wherein a normal-pressure low-temperature plasma technology based on barometric pressure glow is used for carrying out the normal-pressure low-temperature plasma processing on the washed teflon base materials. The invention further discloses a method for producing pressure-sensitive adhesive tape. The method for improving the teflon adhesive property has the advantages that the adhesive property of the teflon base materials can be effectively improved, the contact angle of the surfaces of the processed materials is 86 degrees, and the adhesive strength is larger than 5.0MPa.

Owner:成都同明创新科技有限公司

Silk fibroin gel microneedle system and manufacturing method thereof

ActiveCN103800998ASimple methodDoes not affect biocompatibilityMicroneedlesMedical devicesBrute forceBiocompatibility Testing

The invention discloses a silk fibroin gel microneedle system and a manufacturing method of the silk fibroin gel system microneedle system. Silk fibroin solution with the mass concentration between 3 percent to 15 percent is processed through ultrasonic oscillation and then is poured on a polydimethylsiloxane film needle hole die array obtained through laser boring, dies are placed in a vacuum drying box and vacuumized, the solution is made to enter holes, the vacuum degree is kept, the dies are dried to constant weight, and then the silk fibroin gel microneedle system is obtained. The microneedle system is an insoluble gel microneedle and has certain brute force to puncture into the skin, the microneedle system swells after making contact with body fluid in the skin, and medicine in the microneedle system is released. The gel microneedle system is good in biocompatibility, easy to prepare, moderate in condition and capable of biodegradation, and the system can be used in the aspects of cosmetology, transdermal drug absorption devices and the like.

Owner:PHARSUN MEDICAL BIOTECHNICS (SHANGHAI) CO LTD

Gradient wear-resistant coating and method for preparing same

ActiveCN105543839AImprove wear resistanceHigh temperature resistantSuperimposed coating processWear resistantUltrasonic oscillation

Provided are a gradient wear-resistant coating and a method for preparing the same. Co50+0.15% CeO2 powder, Co50+0.25% CeO2+6% Ni / Wc powder and Co50+0.4% CeO2+12% Ni / WC powder are used for preparing the gradient wear-resistant coating with the structure of a bottom layer, a transition layer and a wear-resistant layer on the surface of a workpiece in a coaxial powder supply manner and a laser cladding manner, and the wear resisting performance of the work surface of a part is improved. An ultrasonic vibration device and a contour tracing electromagnetic induction heating device are adopted in the cladding process. Ultrasonic oscillation of a certain degree is applied to the area close to a cladded area of the workpiece, the grain size of a cladding layer can be remarkably refined, residual stress can be remarkably eliminated, and therefore generated cracks are reduced, and a cladding layer structure with good performance is obtained. The contour tracing electromagnetic induction heating device can be utilized for effectively reducing thermal stress brought by the temperature gradient of the cladding layer and relieving the cracking tendency. According to the technological parameters of the ultrasonic vibration device, the work frequency ranges from 10 kHz to 20 kHz, the maximum output power is 1,000 W, and the pneumatic pressure ranges from 0.3 MPa to 0.6 MPa. According to the technological parameters of the contour tracing electromagnetic induction heating device, the voltage is 380 V, the frequency is 60 Hz, and the heating temperature ranges from 150 DEG C to 1,000 DEG C.

Owner:CHANGCHUN UNIV OF SCI & TECH

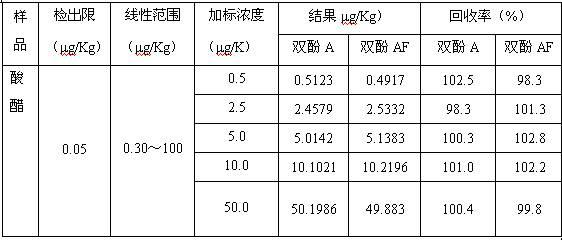

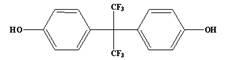

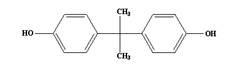

Method for rapidly detecting bisphenol A and bisphenol AF in food

The invention relates to a method for detecting bisphenol A and bisphenol AF in food, belonging to technical field of analytical chemistry determination method. With ionic liquid (1-butyl-3-methylimidazole hexafluorophosphate) as an extractant and TritonX-100 or acetone as an dispersant, ultrasonic oscillation is carried out to form emulsion; after centrifugal separation, extraction drops at the lower layer are directly subjected to HPLC (high performance liquid chromatography) quantitative analysis. The method disclosed by the invention has the advantages of simpleness in detection steps, easiness in operation, low detection limit and high enrichment multiple, greatly reduced detection cost. The method disclosed by the invention is a rapid, efficient and environmentally friendly pre-treatment technology and has a wider application prospect in the field of food analysis.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com