Calcium phosphate/collagen composite biologic ceramic material and preparation method thereof

A technology of composite bioceramics and calcium phosphate ceramics, applied in the field of biomedical materials, to achieve the effect of enhancing bone connection and healing function, excellent bone formation ability, and material stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

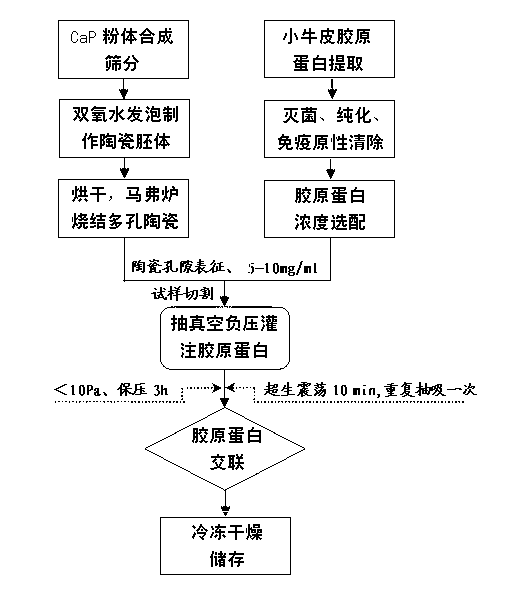

Method used

Image

Examples

Embodiment 1

[0035] Using hydroxyapatite powder as raw material, a 5×5×20 mm cuboid porous calcium phosphate ceramic product was prepared. Product pore structure requirements: the overall porosity is 85%±5%, the macropore diameter is 400±50μm, and the interpenetrating micropore diameter is 80±20μm. Specific steps are as follows:

[0036] 1) The hydroxyapatite powder prepared by the wet reaction is screened with a standard type sieve to screen out the dry hydroxyapatite powder with a diameter of 80-160 μm, and then the porous ceramic embryo is prepared by the hydrogen peroxide foaming method, and the low temperature is <100 ℃ drying;

[0037] 2) Put the ceramic body into a muffle furnace for sintering, raise the temperature from room temperature to 1100 °C at a rate of 5 °C / min for 2 hours for sintering, and then cool with the furnace. Then the obtained porous hydroxyapatite ceramics were cut into cuboids of 5×5×20 mm;

[0038] 3) Dilute the sterilized, purified and deimmunized type I ca...

Embodiment 2

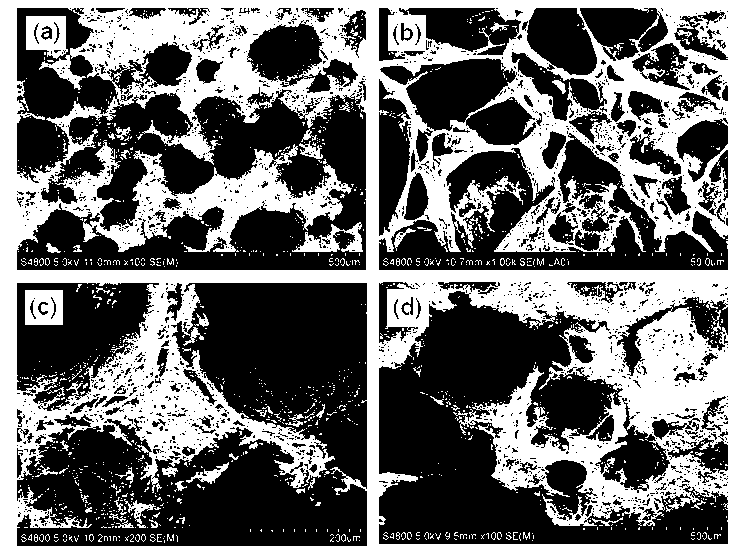

[0043] A tricalcium phosphate / collagen (TCP / Collagen) composite ceramic material was prepared using porous β-tricalcium phosphate ceramics as a matrix. The overall porosity of the ceramic is 85%±5%, the macropore diameter is 400±50 μm, and the interpenetrating micropore diameter is 80±20 μm. The rest of the product preparation process and steps are the same as in Example 1. The scanning electron microscope picture of the obtained tricalcium phosphate / collagen composite bioceramic material is as follows: image 3 As shown, its maximum compressive strength measured by a universal material testing machine is 5.4 MPa, which is about 2.9 times higher than the mechanical properties of the porous β-tricalcium phosphate ceramic material before compounding collagen, and is higher than that of hydroxyapatite in Example 1. The compressive strength of HA / Collagen composite ceramics is 3.8 MPa lower, because the mechanical properties of pure tricalcium phosphate ceramics are worse than pur...

Embodiment 3

[0045] A biphasic calcium phosphate / collagen (BCP / Collagen) composite ceramic material was prepared with porous biphasic calcium phosphate ceramics as the matrix. The overall porosity of the ceramic is 85%±5%, the macropore diameter is 400±50 μm, and the interpenetrating micropore diameter is 80±20 μm. The rest of the product preparation process and steps are the same as in Example 1. The scanning electron microscope picture of the resulting biphasic calcium phosphate / collagen composite bioceramic material is as follows: image 3 As shown, its maximum compressive strength measured by a universal material testing machine is 6.7 MPa, which is about 3.0 times higher than the mechanical properties of the porous biphasic calcium phosphate ceramic material before the composite collagen, and compared with the hydroxyapatite / calcium phosphate ceramic material in Example 1. The compressive strength of collagen (HA / Collagen) composite ceramics is low, but the compressive strength height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com