Patents

Literature

1530 results about "Calcium pidolate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

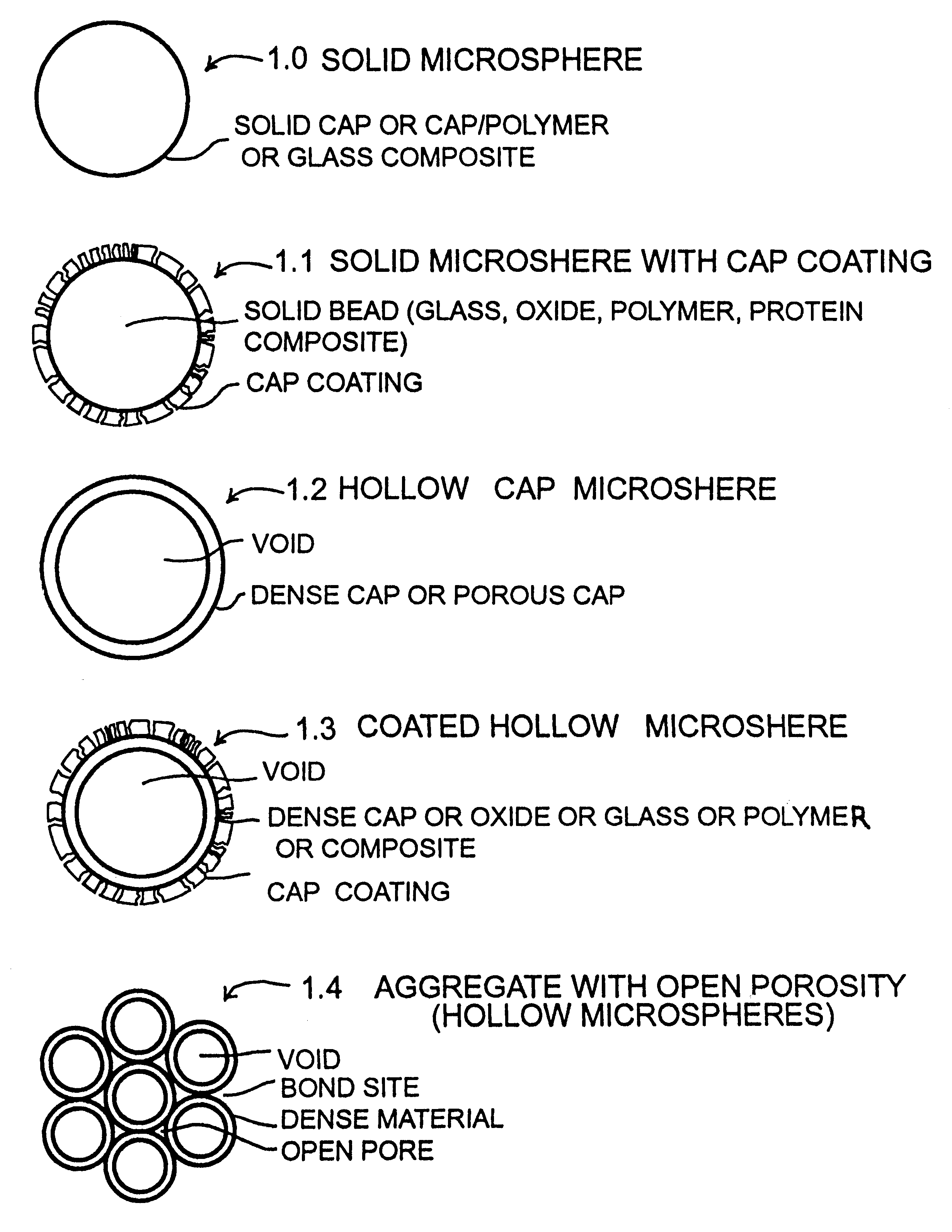

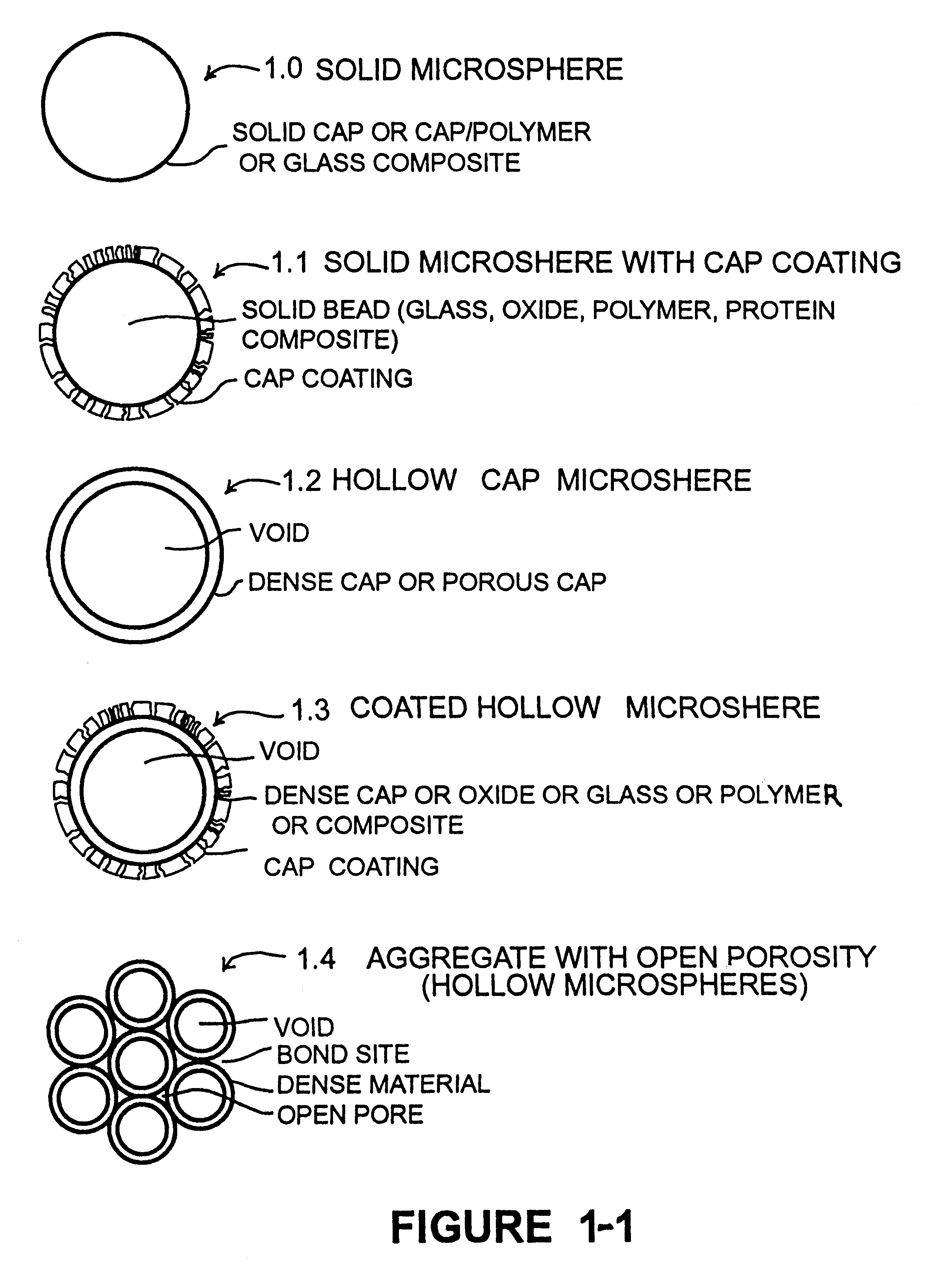

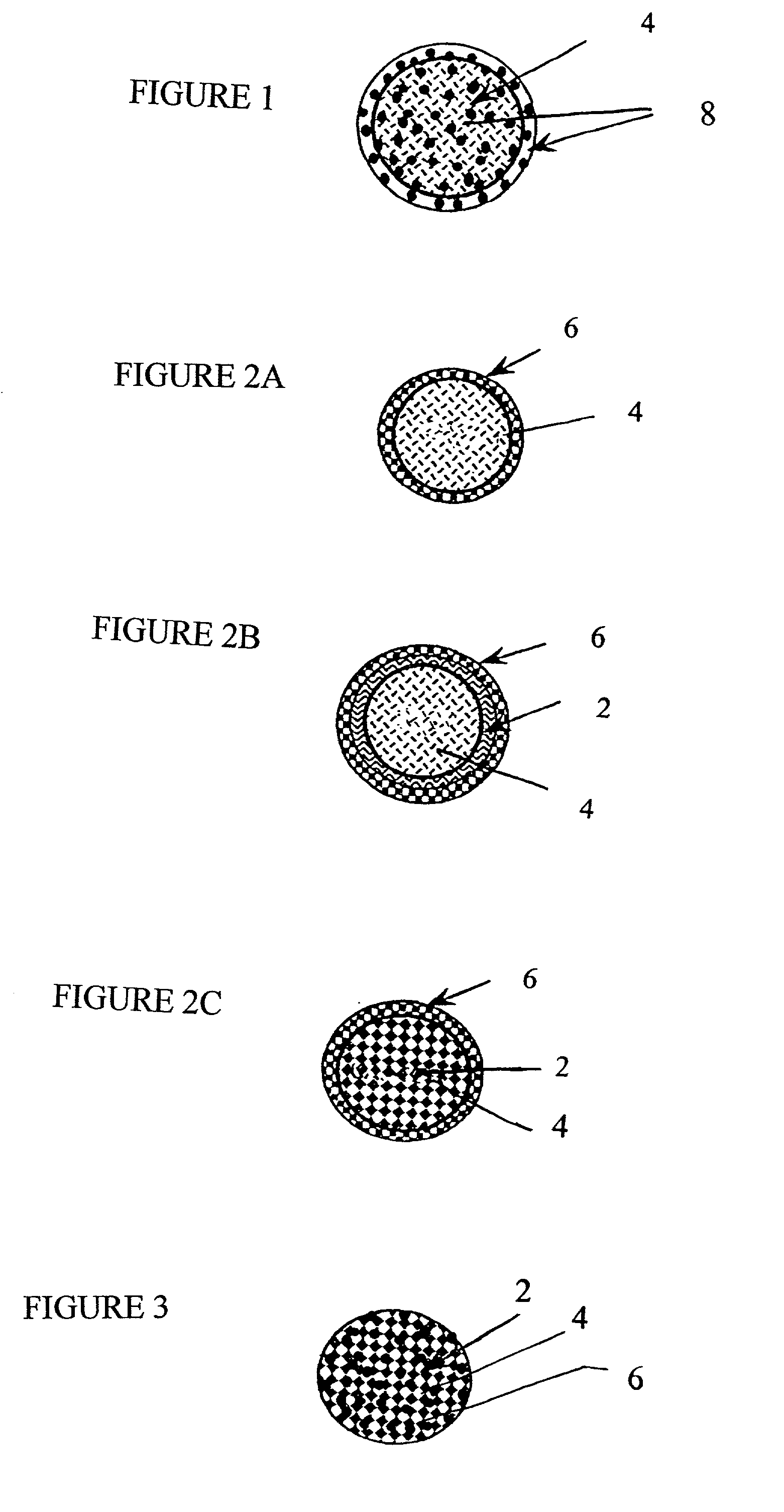

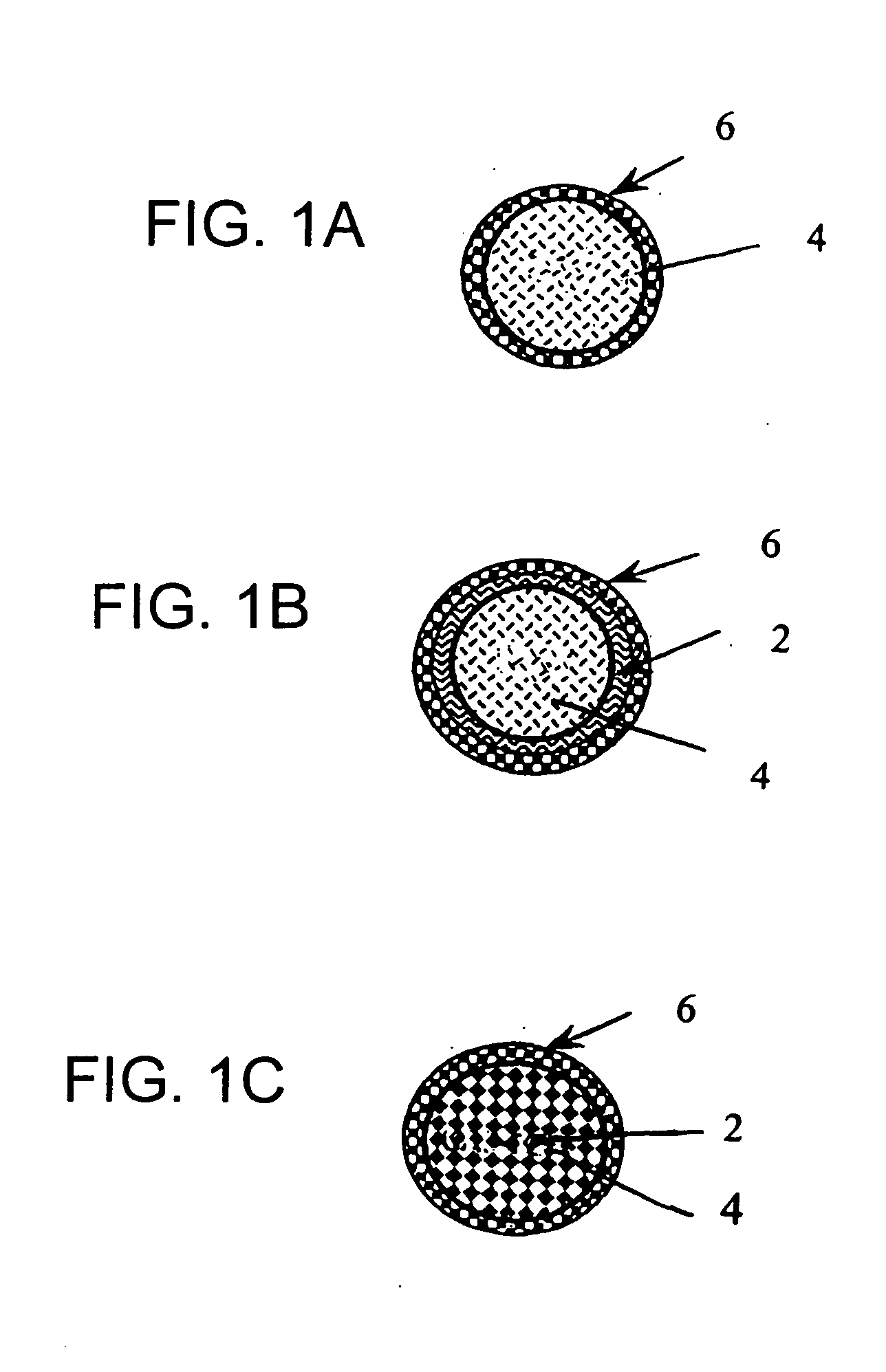

Calcium phosphate microcarriers and microspheres

InactiveUS6210715B1Increase resorbabilityCompressive strengthPowder deliveryBiocideChemistryCalcium biphosphate

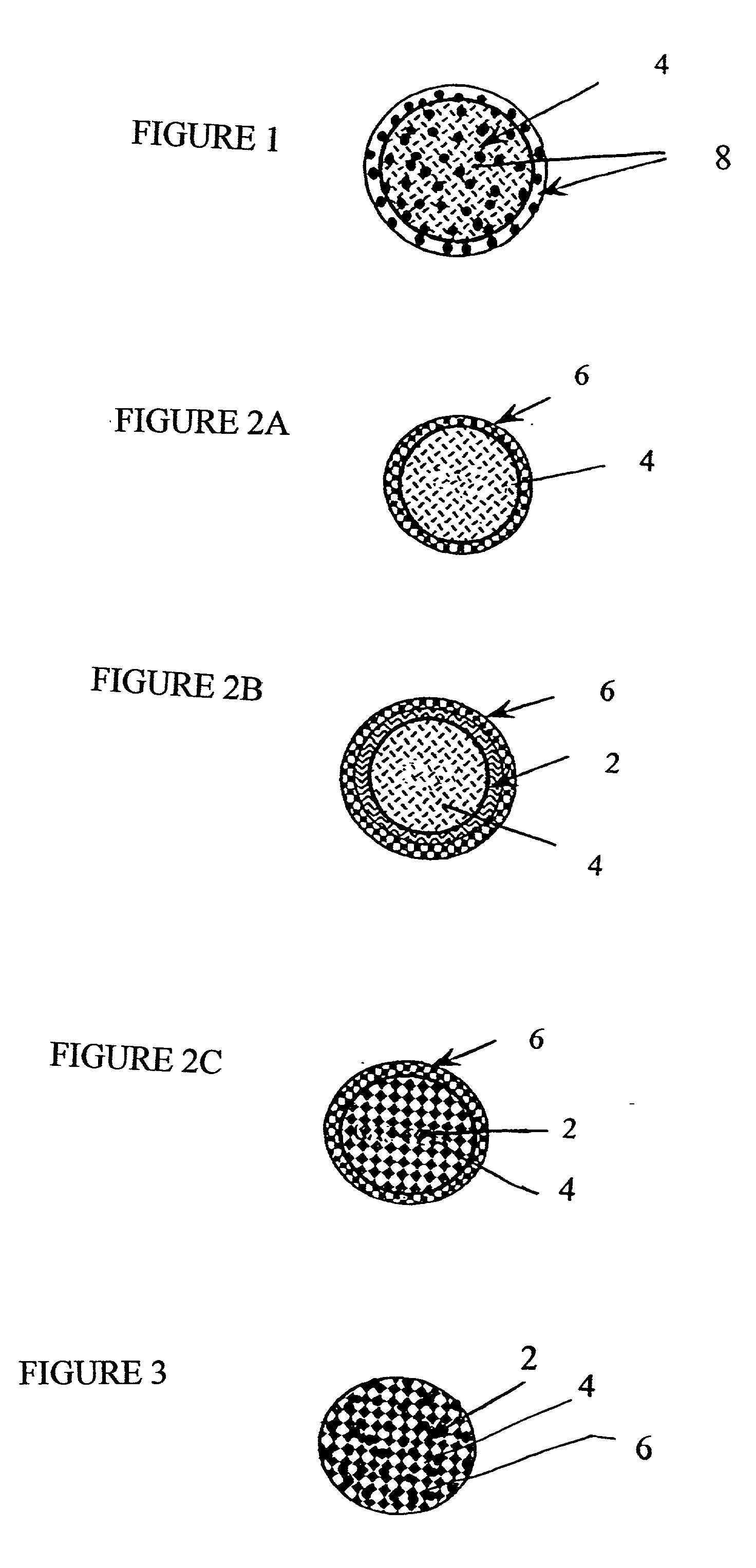

The present invention provides calcium phosphate-based (CAP) microcarriers and microspheres and their use in cell culturing systems, chromatography and implantable biomedical materials.

Owner:CAP BIOTECH

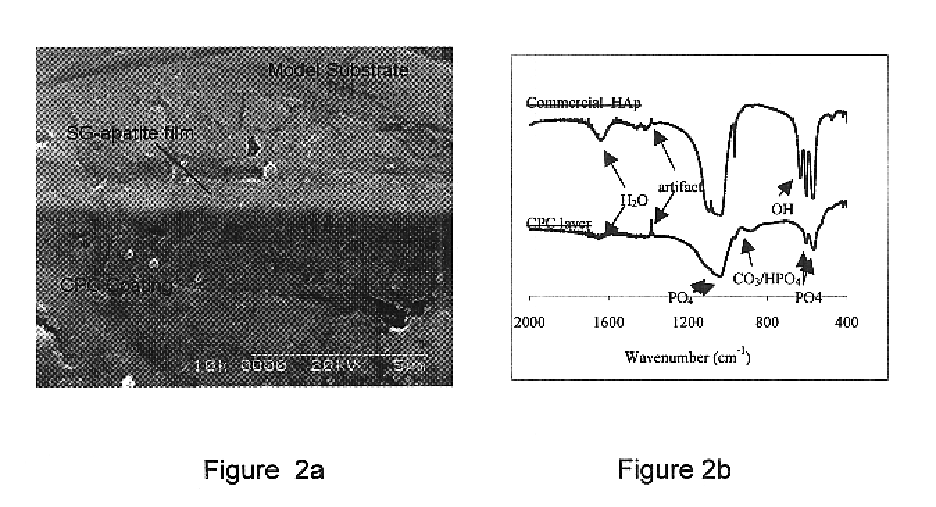

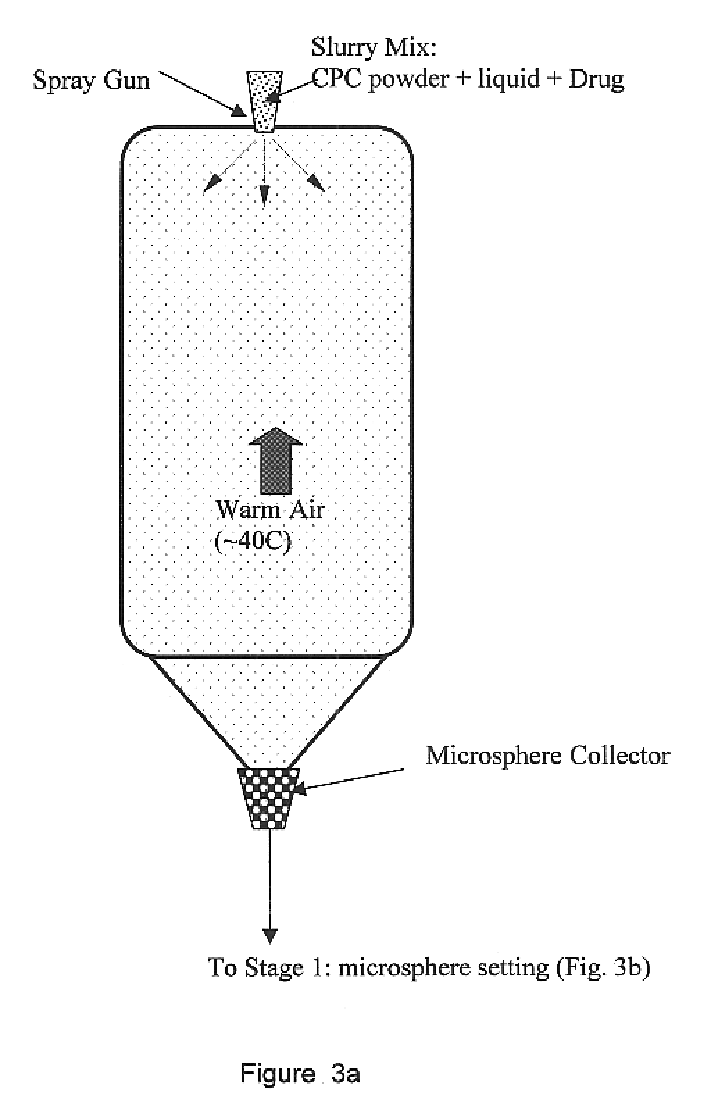

Biofunctional hydroxyapatite coatings and microspheres for in-situ drug encapsulation

InactiveUS6730324B2High strengthEasy to makePowder deliveryOrganic active ingredientsGene deliverySide effect

This invention relates to novel room-temperature process for obtaining calcium phosphate, in particular hydroxyapatite, coatings and microspheres that encapsulate drugs, proteins, genes, DNA for therapeutical use. The coatings and microspheres are designed to perform a defined biological function related to drug delivery, such as gene therapy through gene delivery. A novel method for encapsulation, and subsequent controlled release of therapeutically active agents from such biofunctional coatings and microspheres is disclosed. Such coatings and microspheres are useful for side-effects free, long-term, targeted, controlled release and delivery of drugs, proteins, DNA, and other therapeutic agents.

Owner:THE UNIV OF BRITISH COLUMBIA

Calcium phosphate cement composition and a method for the preparation thereof

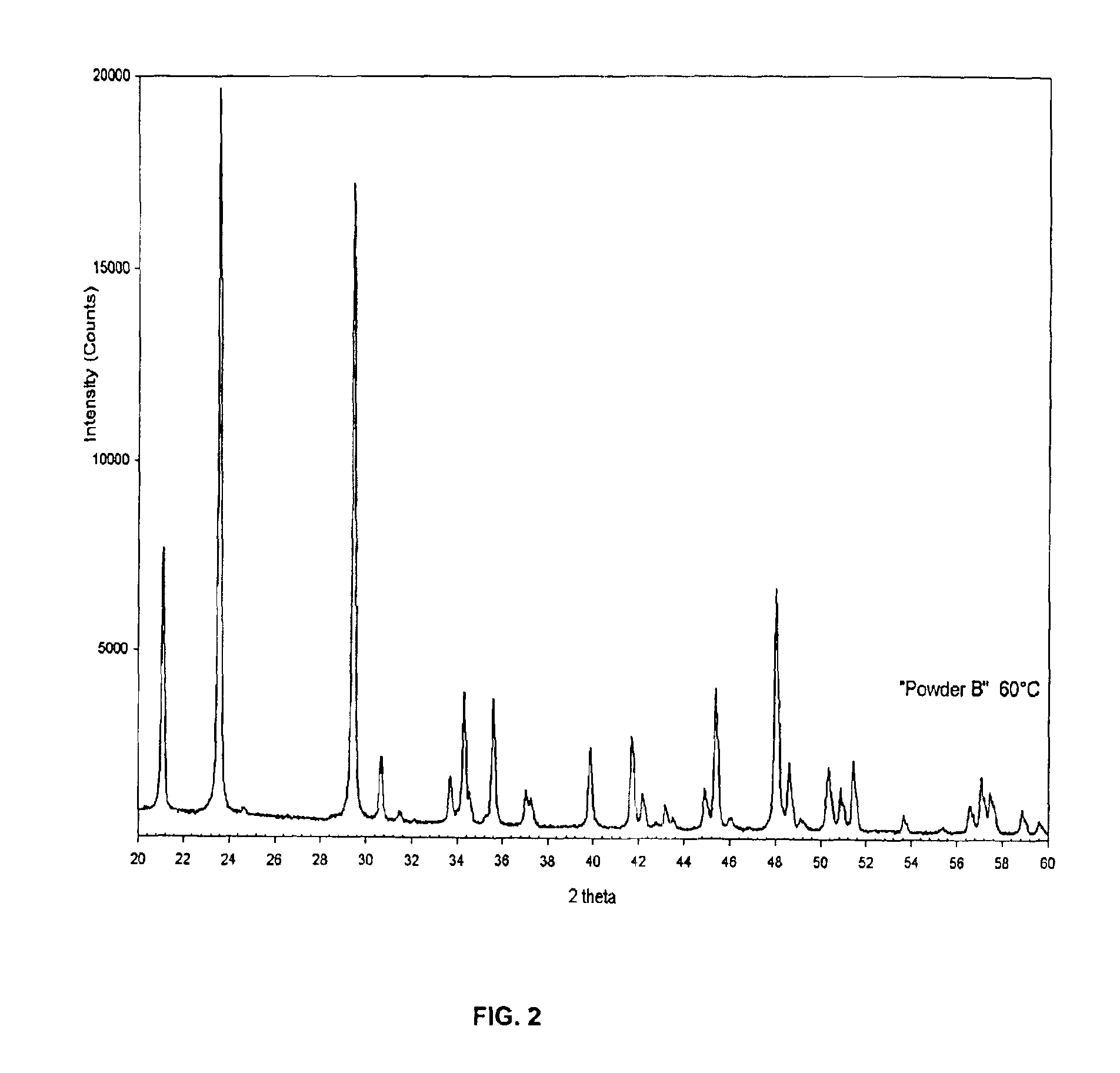

ActiveUS6929692B2Good water solubilityIncreased formationOther chemical processesBone implantChemical synthesisCalcium biphosphate

The invention describes a new calcium phosphate cement powder, whose composition can best be described over the Ca / P molar ratio range of 1.35 to 1.40, most preferably 1.39, and whose two components were prepared by wet chemical synthesis procedures. One component is chemically-synthesized, bi-phasic alpha-TCP (Ca3(PO4)2, 95 wt %)+HA (Ca10(PO4)6(OH)2, 5 wt %) powder, while the second component is again a chemically-synthesized, single-phase DCPD (CaHPO4·2H2O) powder. A setting solution (Na2HPO4·2H2O) is used to form a self-setting calcium phosphate cement from the powder mixture. This cement can be used as bone filler or bone substitute in applications, which require higher rates of resorption.

Owner:DR AHMET CUNEYT TAS

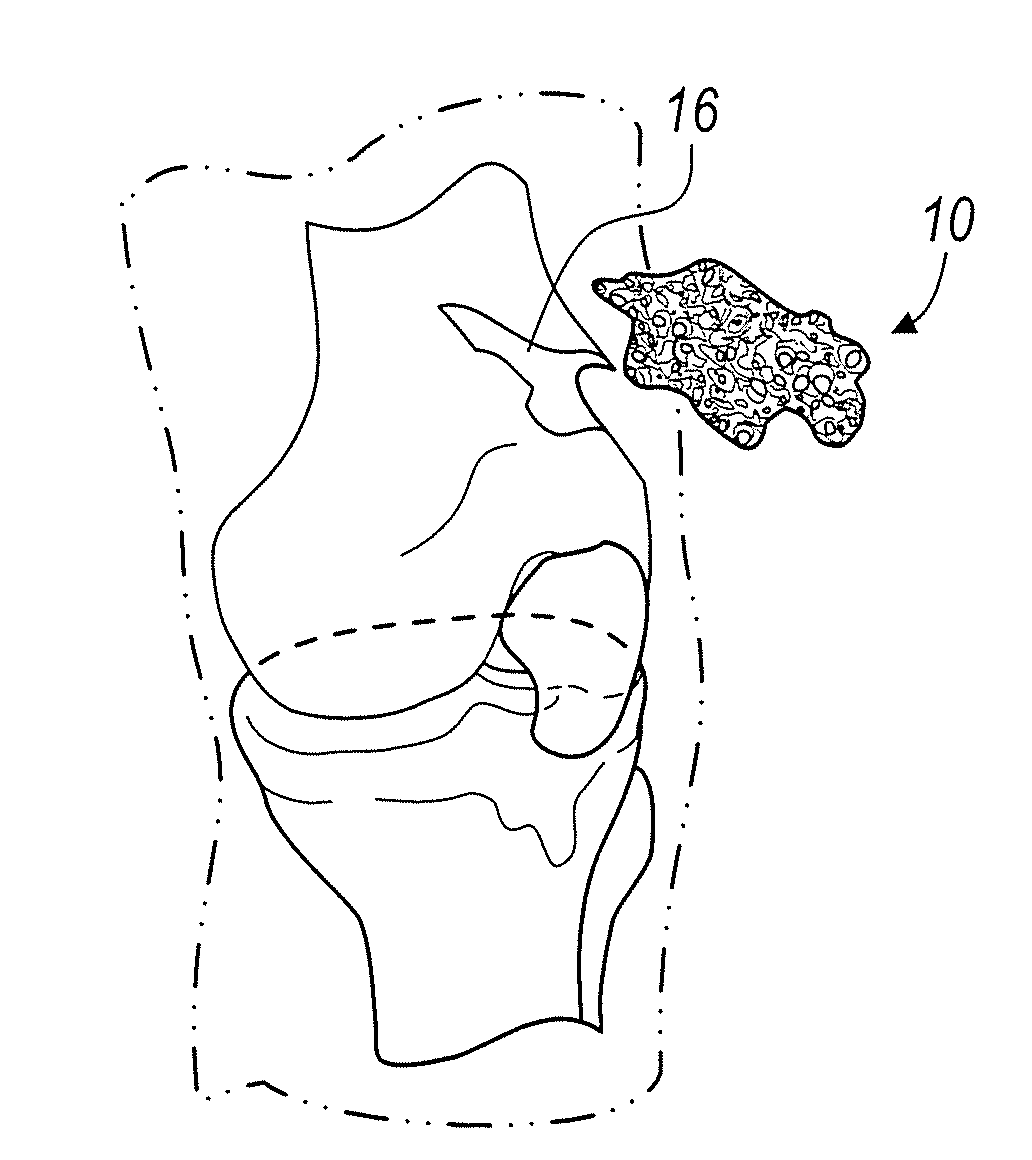

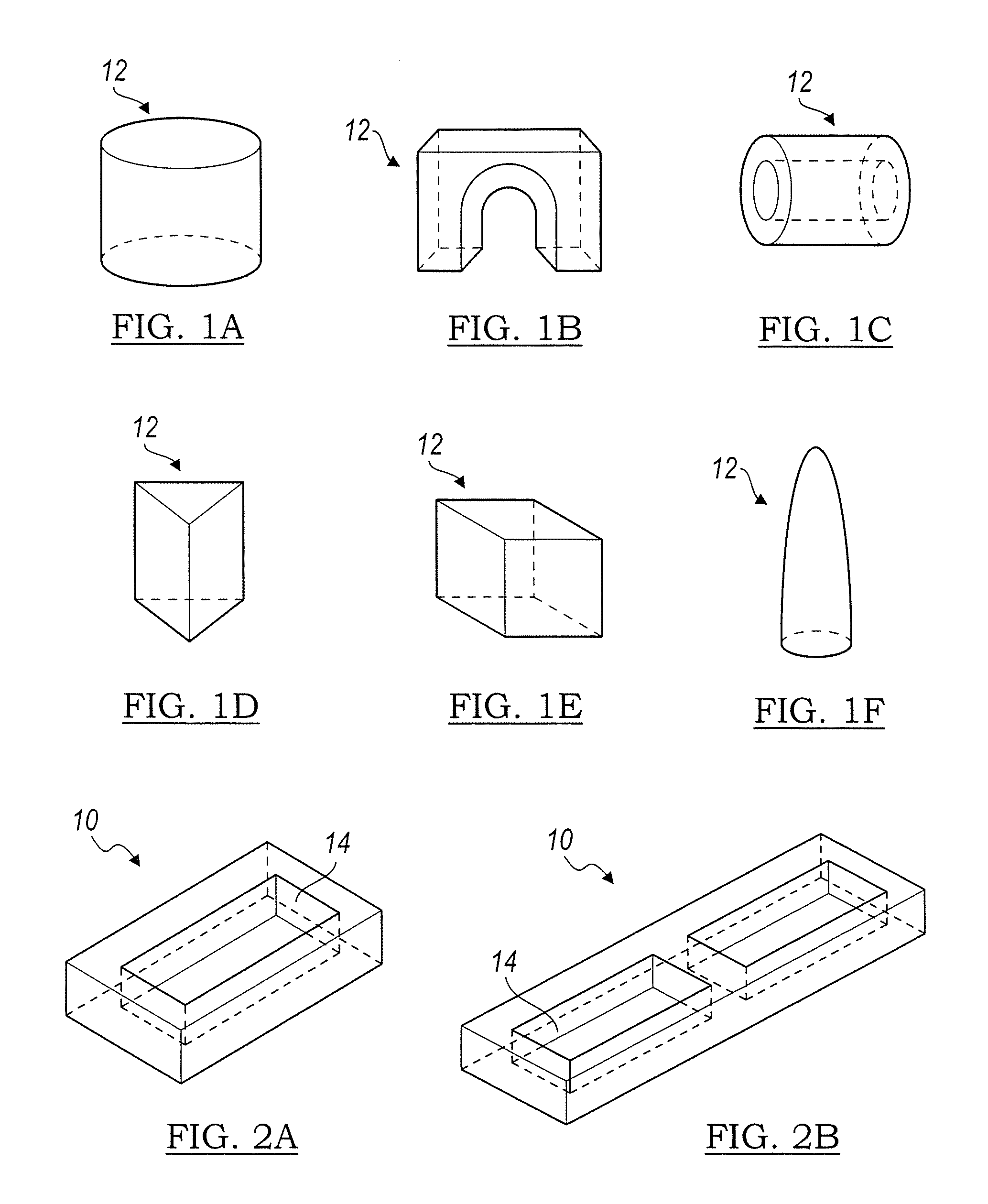

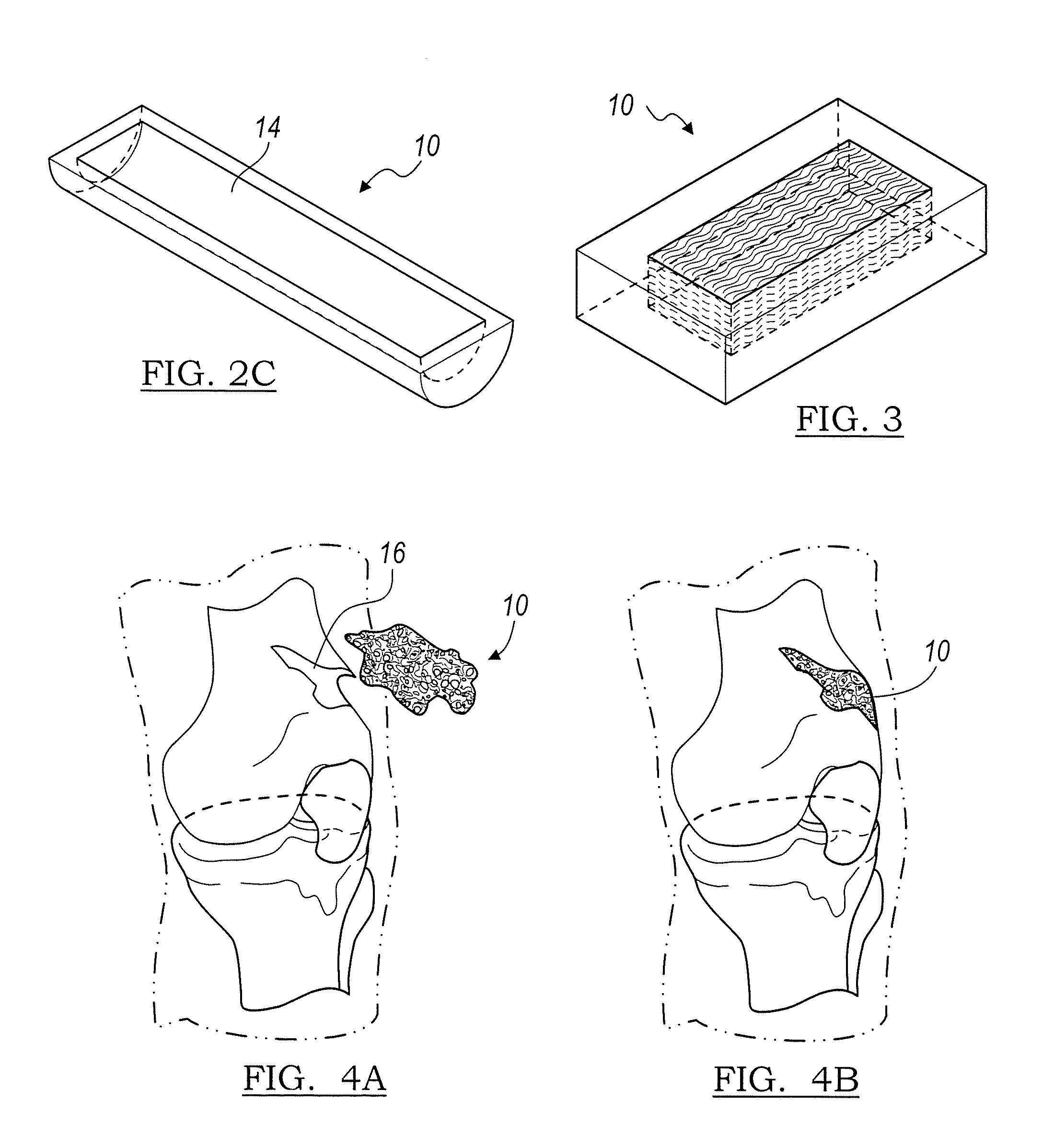

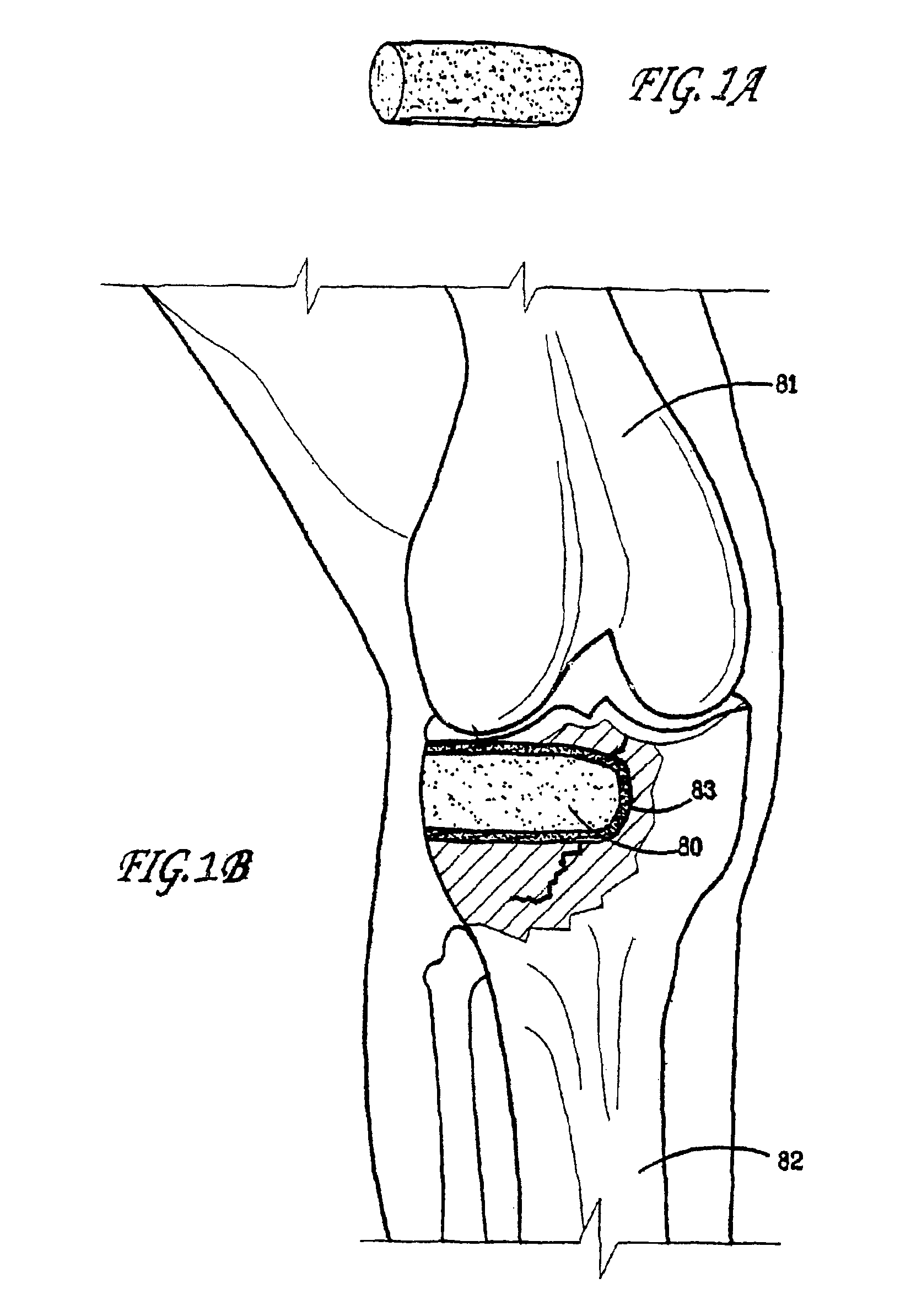

Osteoinductive bone material

ActiveUS20050084542A1Sufficient amountMaximize formabilityBiocideInorganic phosphorous active ingredientsNatural boneBone implant

Osteogenic bone implant compositions that approximate the chemical composition of natural bone are provided. The organic component of these implant compositions is osteoinductive despite the presence of the inorganic component and, further, is present in an amount sufficient to maximize the regenerative capabilities of the implant without compromising its formability and mechanical strength. The composition may be an osteoinductive powder, including demineralized bone matrix (DBM) particles, a calcium phosphate powder, and, optionally, a biocompatible cohesiveness agent. The powder may be combined with a physiologically-acceptable fluid to produce a formable, osteoinductive paste that self-hardens to form a poorly crystalline apatitic (PCA) calcium phosphate having significant compressive strength. The bone implant materials retain their cohesiveness when introduced at an implant site and are remodeled into bone in vivo. Methods for using these implant materials to repair damaged bone and a method of assaying the content of DBM particles, by weight, in a bone implant material are also provided.

Owner:ETEX

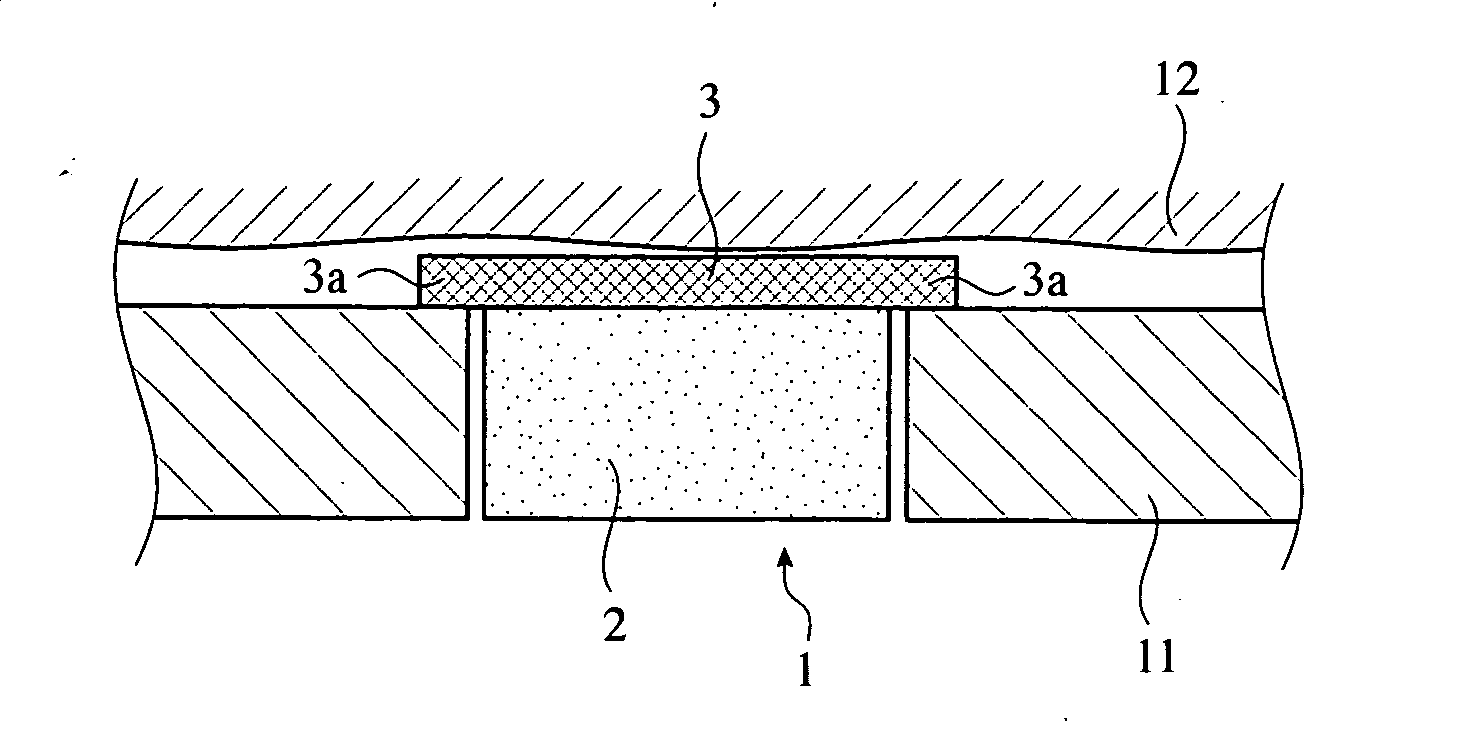

Biomaterial

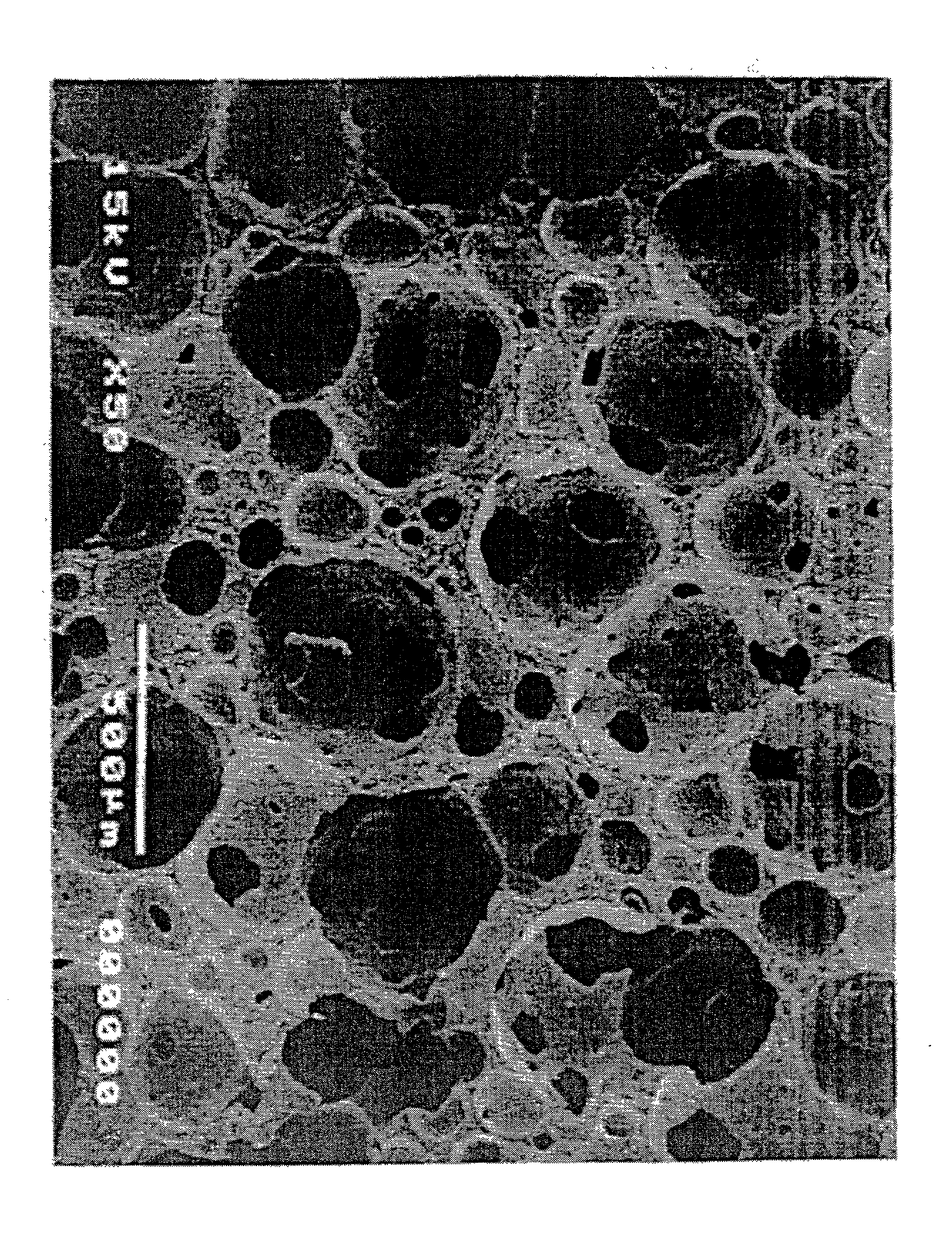

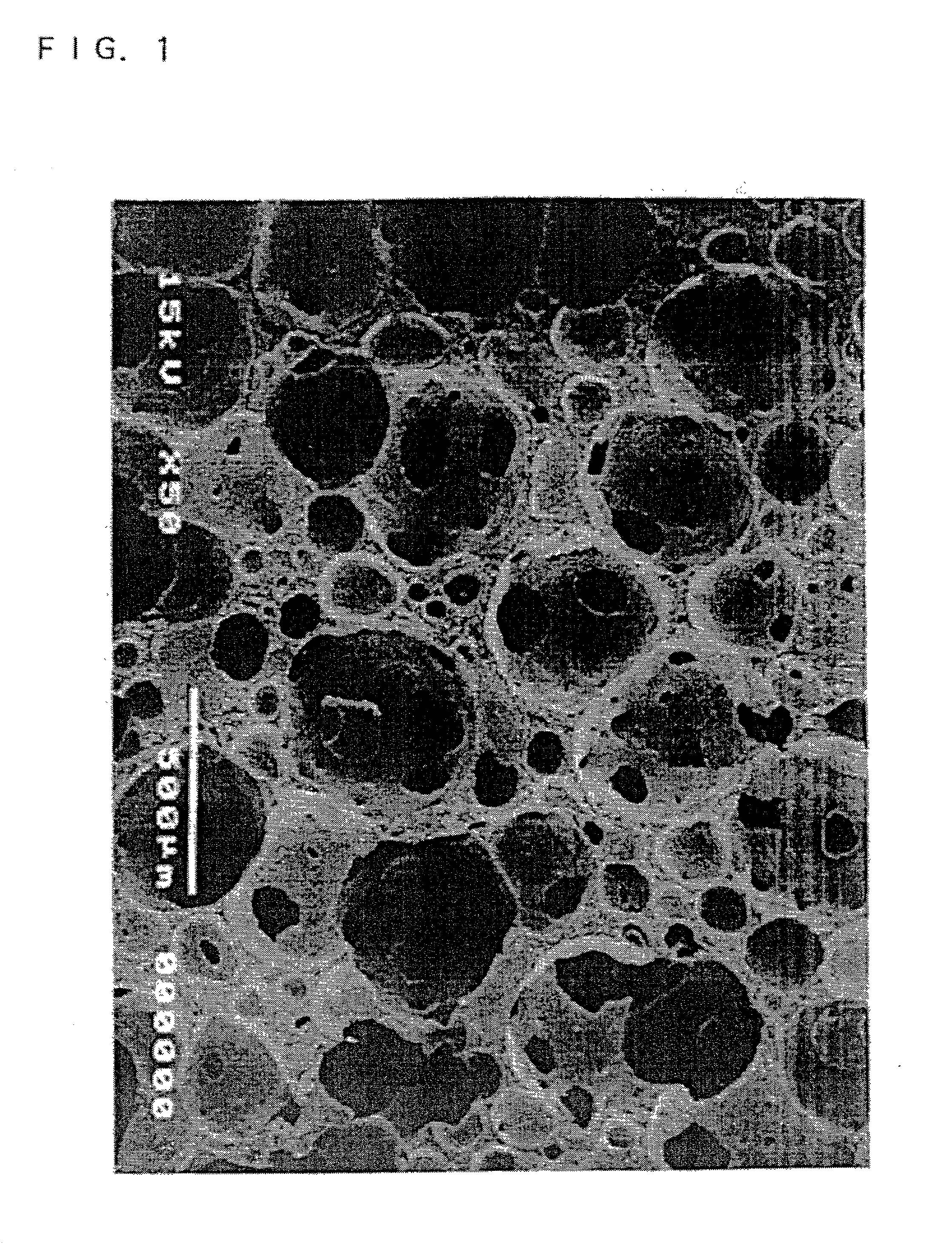

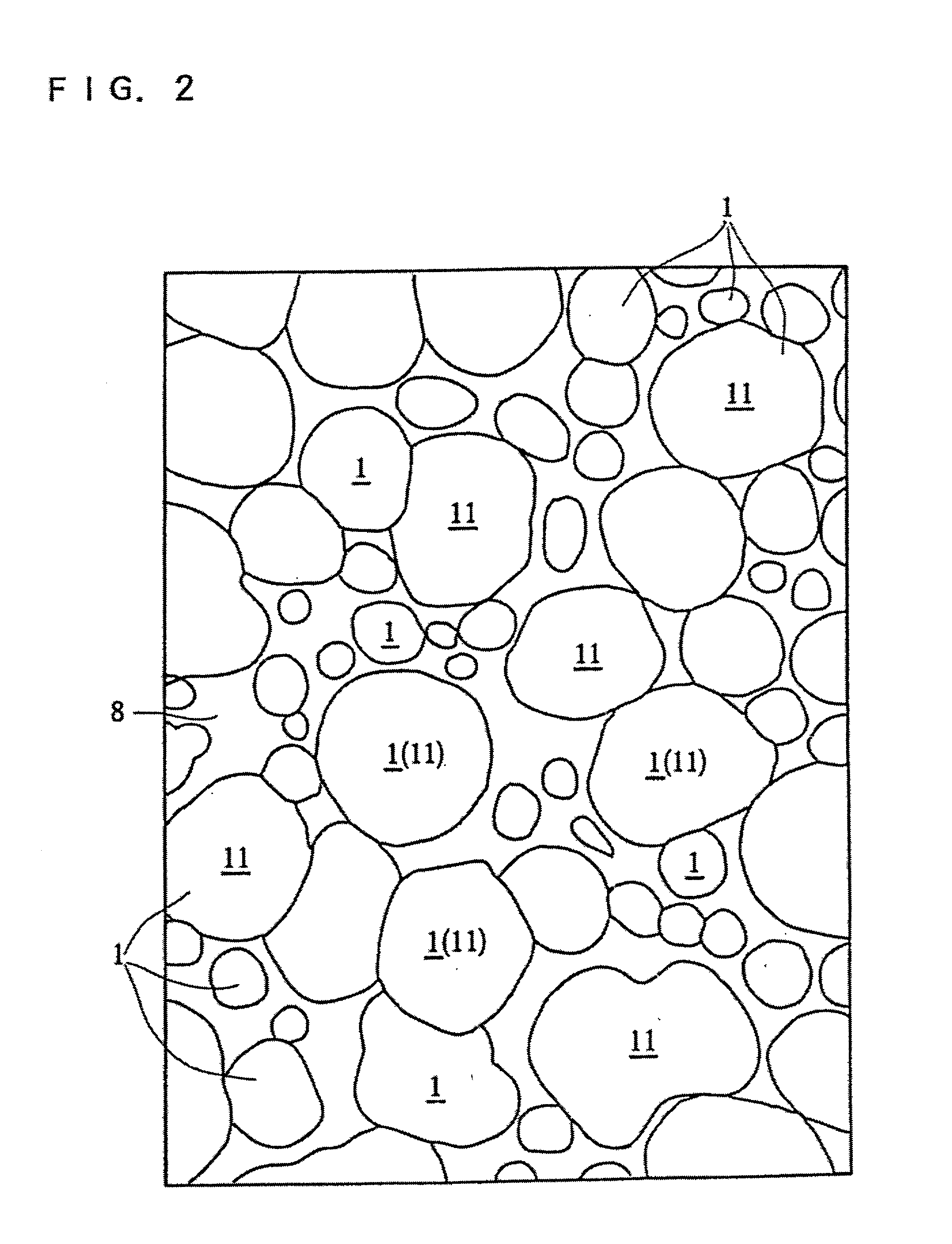

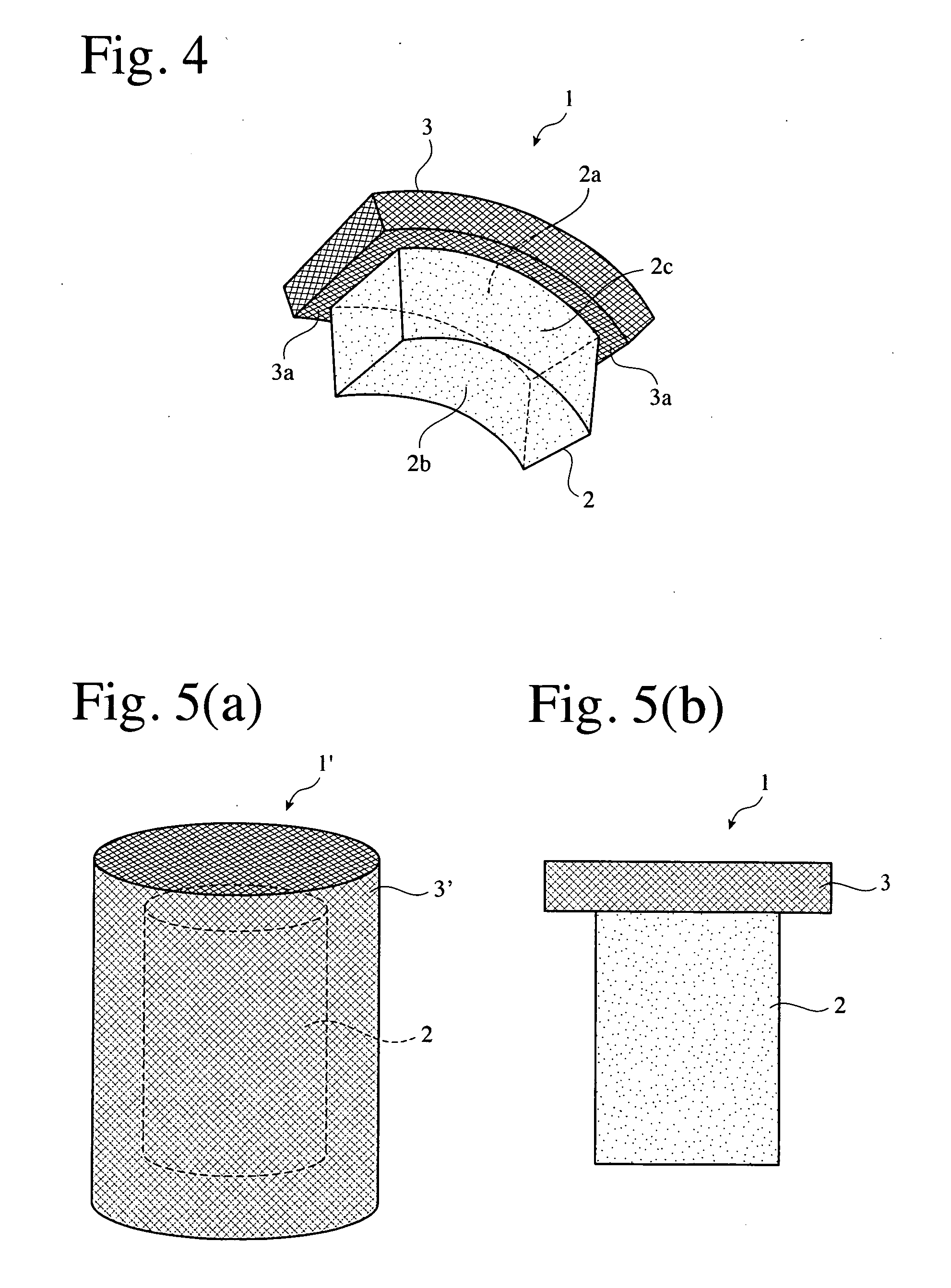

InactiveUS20020022885A1Cell infiltration into an inner surface is very fastBone implantCalcium biphosphatePore diameter

A porous body is a calcium phosphates sintered body having a number of substantially globular pores 1. A porosity is not less than 55% and not more than 85%, and simultaneously, and a mean pore diameter is not less than 50 mum and not more than 800 mum. A pore 11 having a size larger than the mean pore diameter has at least three communicating pores 2 having a diameter of not less than 5 mum, on the average, and simultaneously, a pore having at least the three communicating pores 2 has at least one communicating pore 2 having a diameter of not less than 25 mum, on the average. The total opening area of the communicating pore 2 which is possessed by the pore 11 having a size larger than the mean pore diameter occupies the ratio of not more than 50% of the pore surface area. In a dry state, it is possible to wet the whole the porous body by dropping water and blood.

Owner:OCHI TAKAHIRO +2

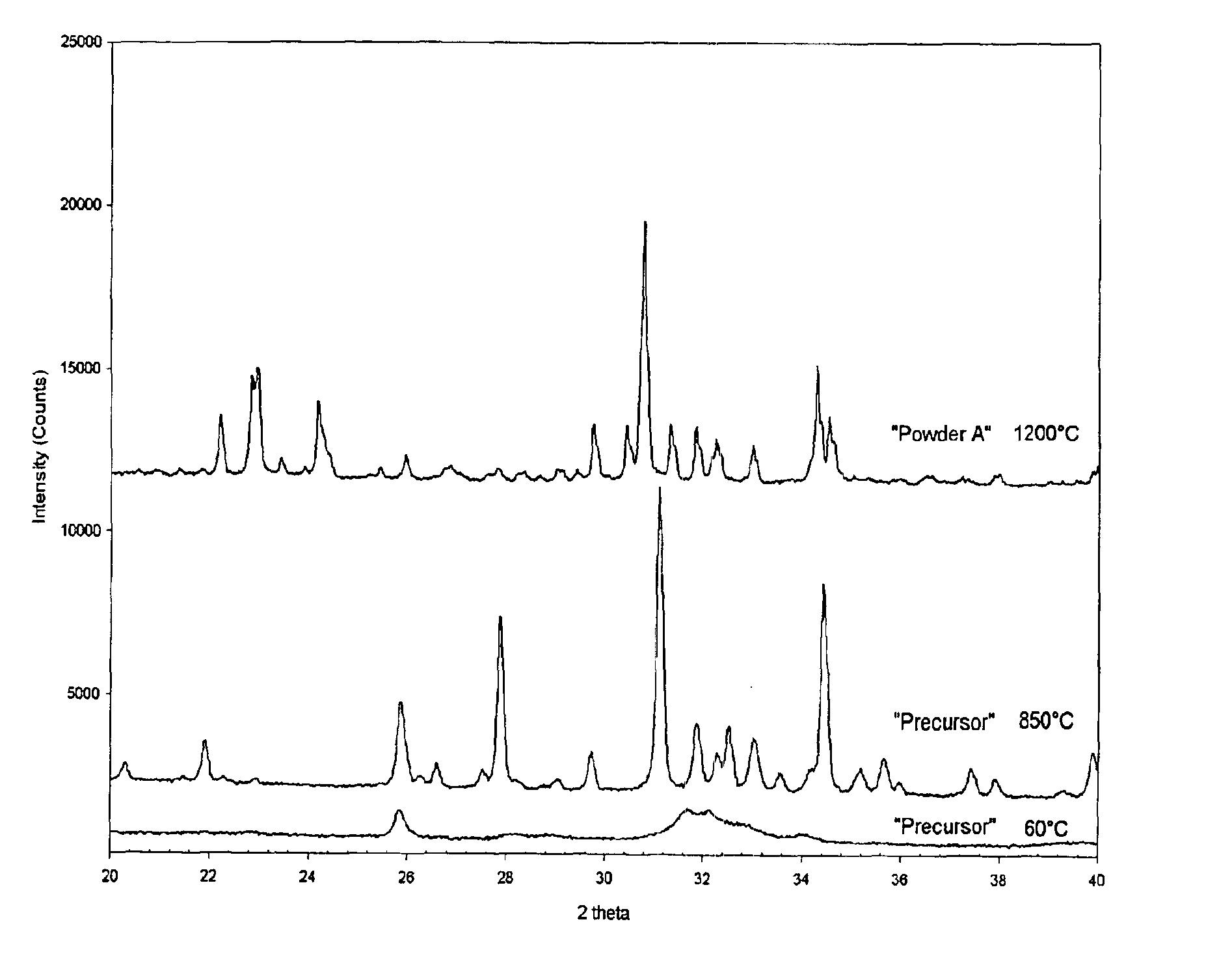

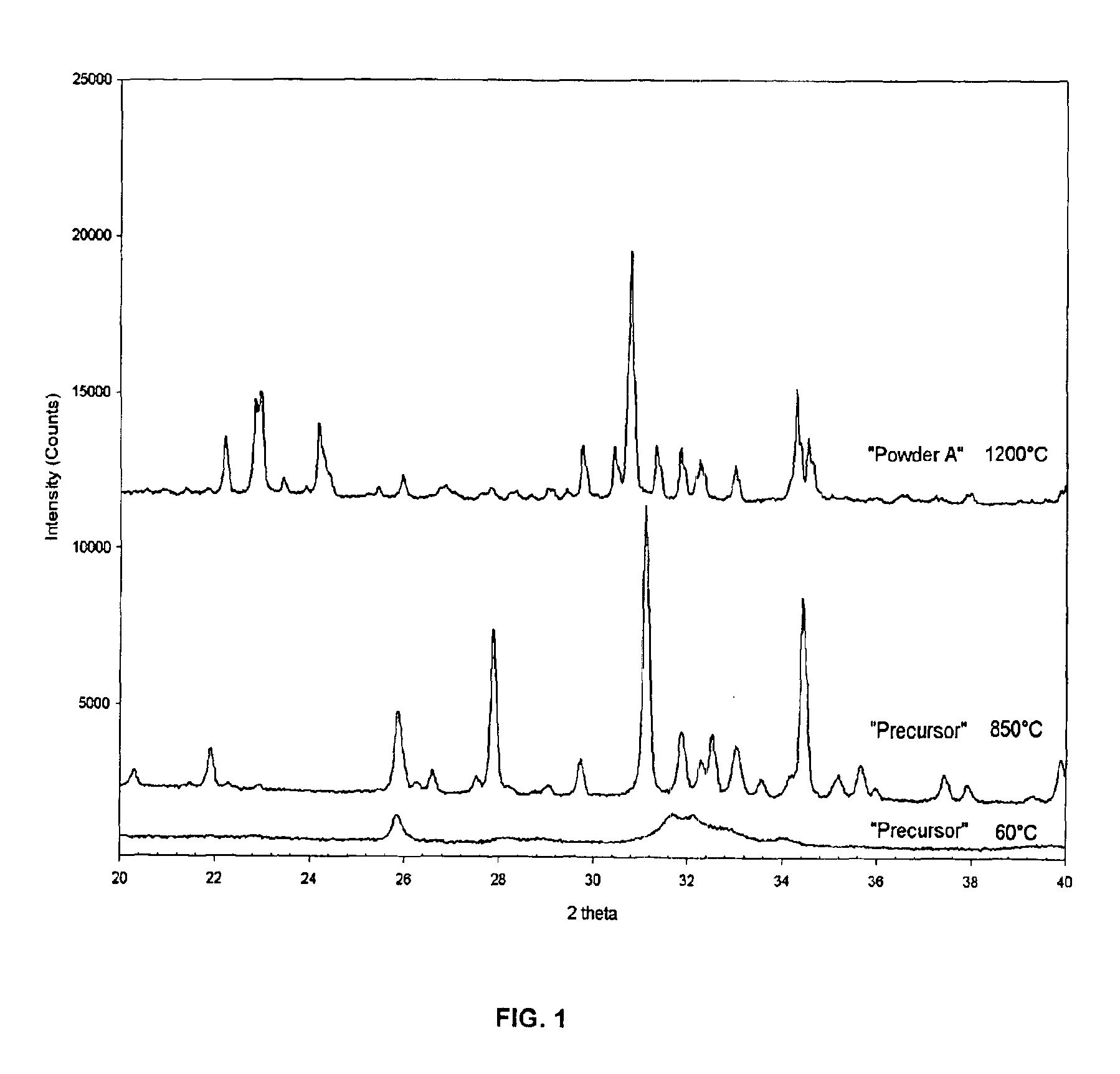

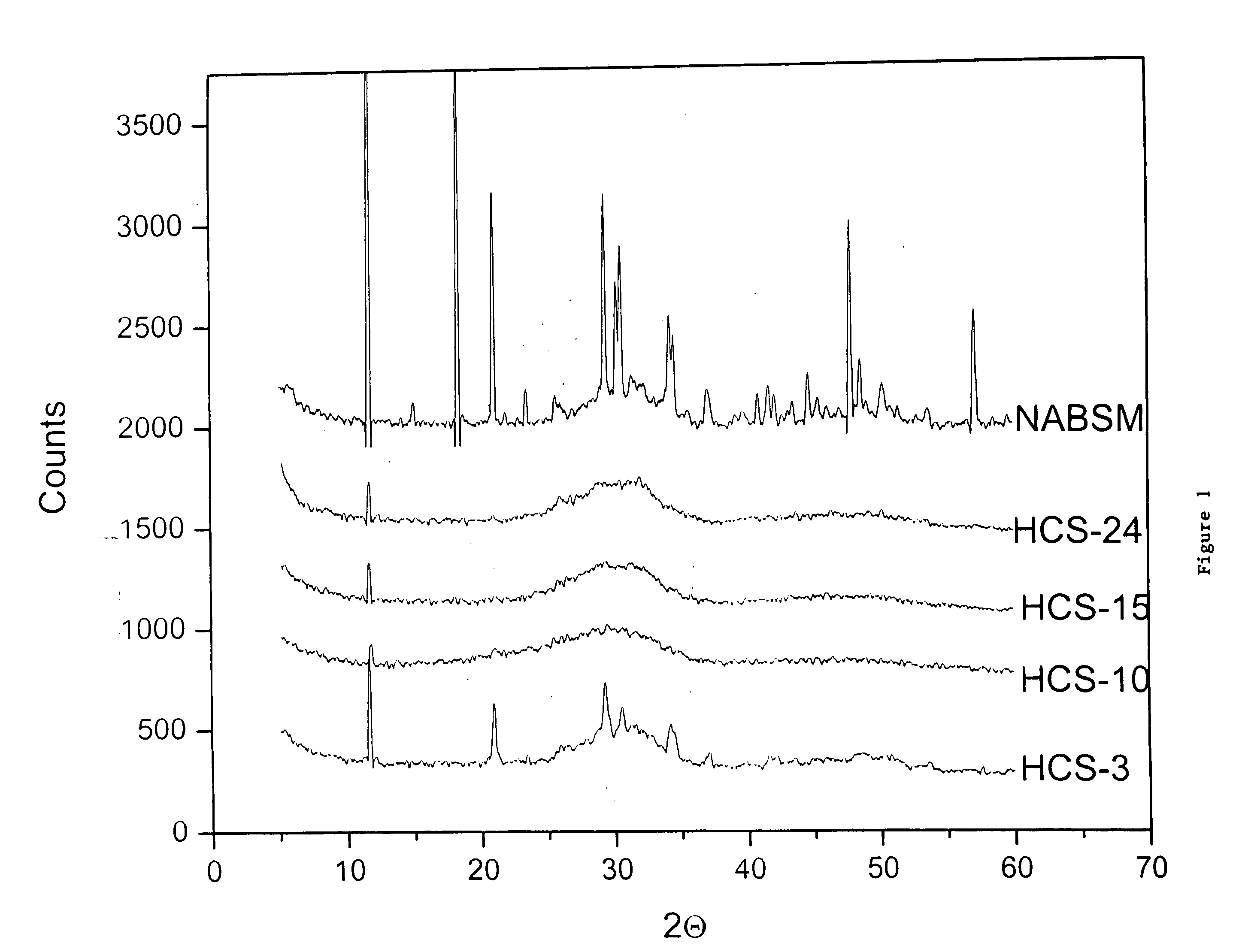

Method of preparing a poorly crystalline calcium phosphate and methods of its use

InactiveUS7517539B1Readily injectableHigh strengthBiocideSurgical adhesivesOsteoporotic boneIntervertebral spaces

The present invention provides a novel process for producing a calcium phosphate cement or filler which hardens in a temperature dependent fashion in association with an endothermic reaction. In the reaction a limited amount of water is mixed with dry calcium phosphate precursors to produce a hydrated precursor paste. Hardening of the paste occurs rapidly at body temperature and is accompanied by the conversion of one or more of the reactants to poorly crystalline apatitic calcium phosphate. The hardened cements, fillers, growth matrices, orthopedic and delivery devices of the invention are rapidly resorbable and stimulate hard tissue growth and healing. A composite material is provided including a strongly bioresorbable, poorly crystalline apatitic calcium phosphate composite and a supplementary material. The supplementary material is in intimate contact with the hydroxyapatite material in an amount effective to impart a selected characteristic to the composite. The supplemental material may be biocompatible, bioresorbable or non-resorbable. A method for treating a bone defect also is provided by identifying a bone site suitable for receiving an implant, and introducing a strongly resorbable, poorly crystalline apatitic calcium phosphate at the implant site, whereby bone is formed at the implant site. The implant site may be a variety of sites, such as a tooth socket, non-union bone, bone prosthesis, an osteoporotic bone, an intervertebral space, an alveolar ridge or a bone fracture.

Owner:LIFE SCI ENTERPRISES

Resorbable bone graft materials

Ceramic materials operable to repair a defect in bone of a human or animal subject comprising a porous ceramic scaffold having a bioresorbable coating, and a carrier comprising denatured demineralized bone. The ceramic may contain a material selected from the group consisting of hydroxyapatite, tricalcium phosphate, calcium phosphates, calcium carbonates, calcium sulfates, and combinations thereof. The compositions may also contain a bone material selected from the group consisting of: bone powder, bone chips, bone shavings, and combinations thereof. The bioresorbable coating may be, for example, demineralized bone matrix, gelatin, collagen, hyaluronic acid, chitosan, polyglycolic acid, polylactic acid, polypropylenefumarate, polyethylene glycol, or mixtures thereof.

Owner:BIOMET MFG CORP

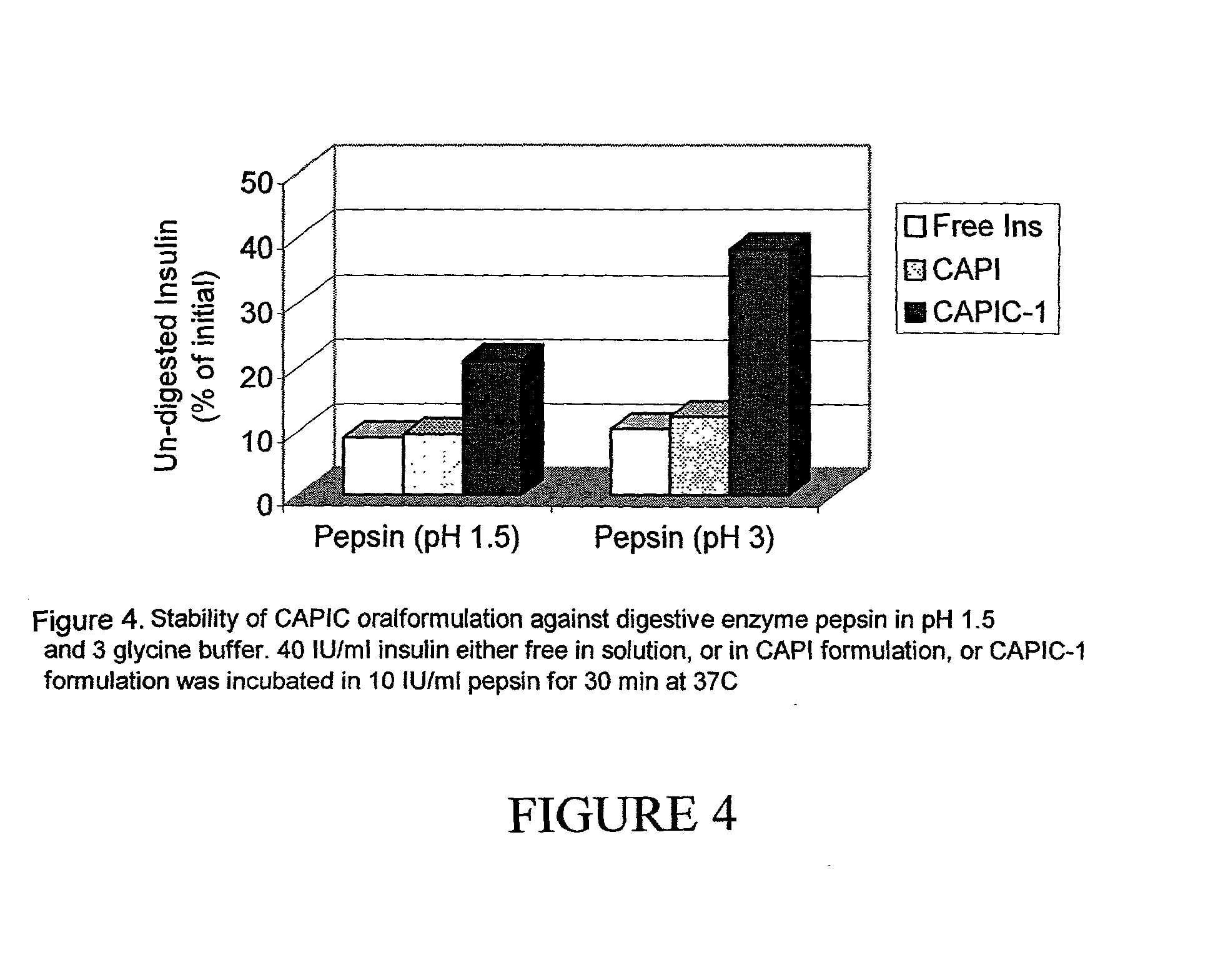

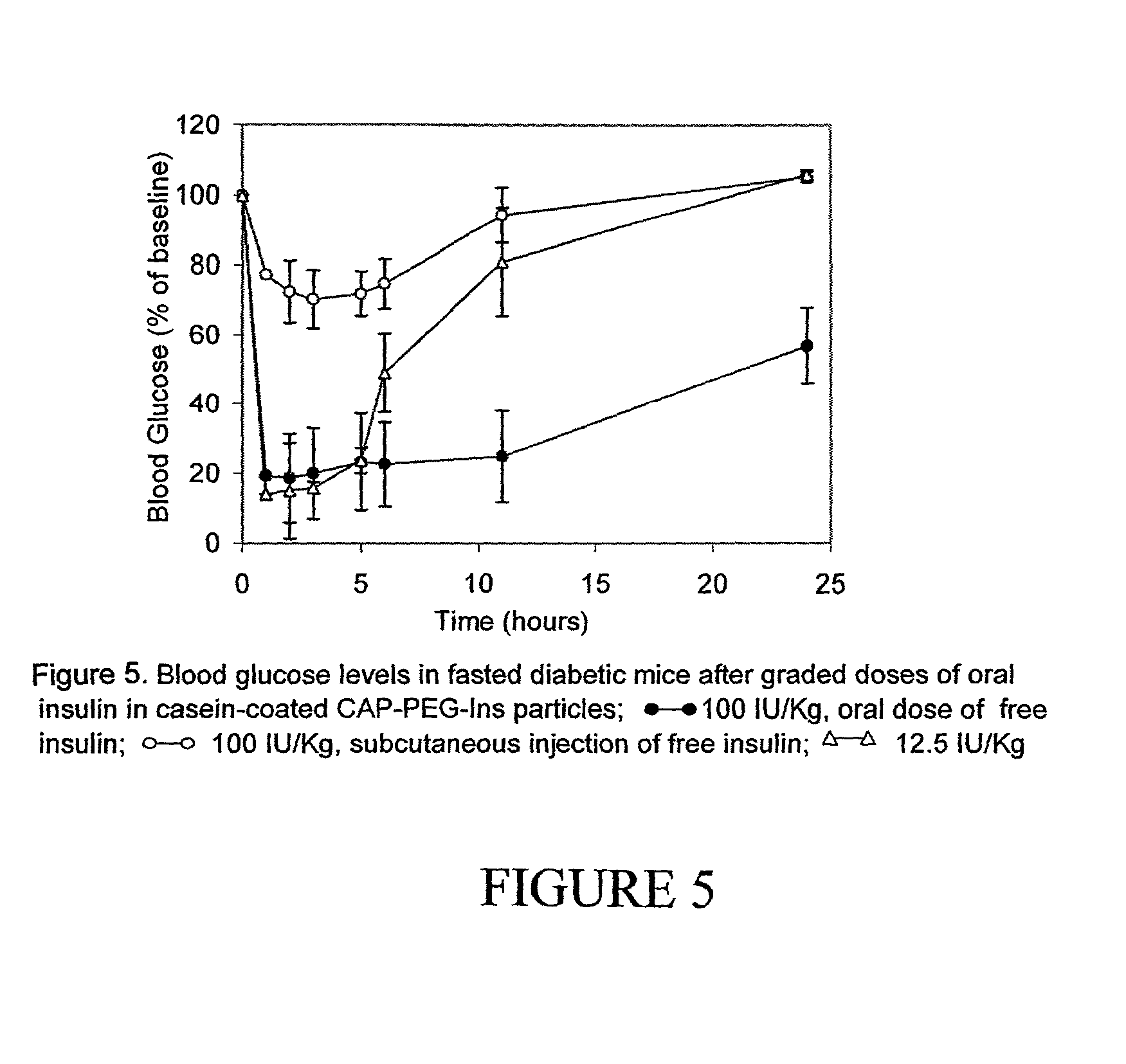

Compositions and methods for therapuetic agents complexed with calcium phosphate and encased by casein

InactiveUS20020054914A1Improve bioavailabilityBiocideOrganic active ingredientsBiologic AgentsMedicine

The present invention relates generally to an oral drug delivery system which incorporates a therapeutic bioactive agent with biodegradable calcium phosphate particles, the particles then encapsulated by casein. The resulting particles provide a carrier designed to protect the therapeutic agent in the harsh, acidic environment of the stomach before releasing the agent into the small intestine. The therapeutic agent may be any therapeutically effective agent, such as a natural isolate or synthetic chemical or biological agent, such as a therapeutic agent, and in particular, may be a protein or a peptide such as insulin. Also incorporated with the particles may be additional surface modifying agents to assist binding, controlled release, or to otherwise modify the particles. The particles generally support the therapeutic agent to form controlled- or sustained-release particles for the oral or mucosal delivery of the therapeutic agent over time, wherein the therapeutic agent is incorporated into the structure of the particle core, disposed on the surface of the particle, or both.

Owner:CAPTIVATE PHARMACEUTICALS LLC

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS7273523B2Facilitated releaseTo promote metabolismBiocideSurgical adhesivesPowder mixturePhosphate

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

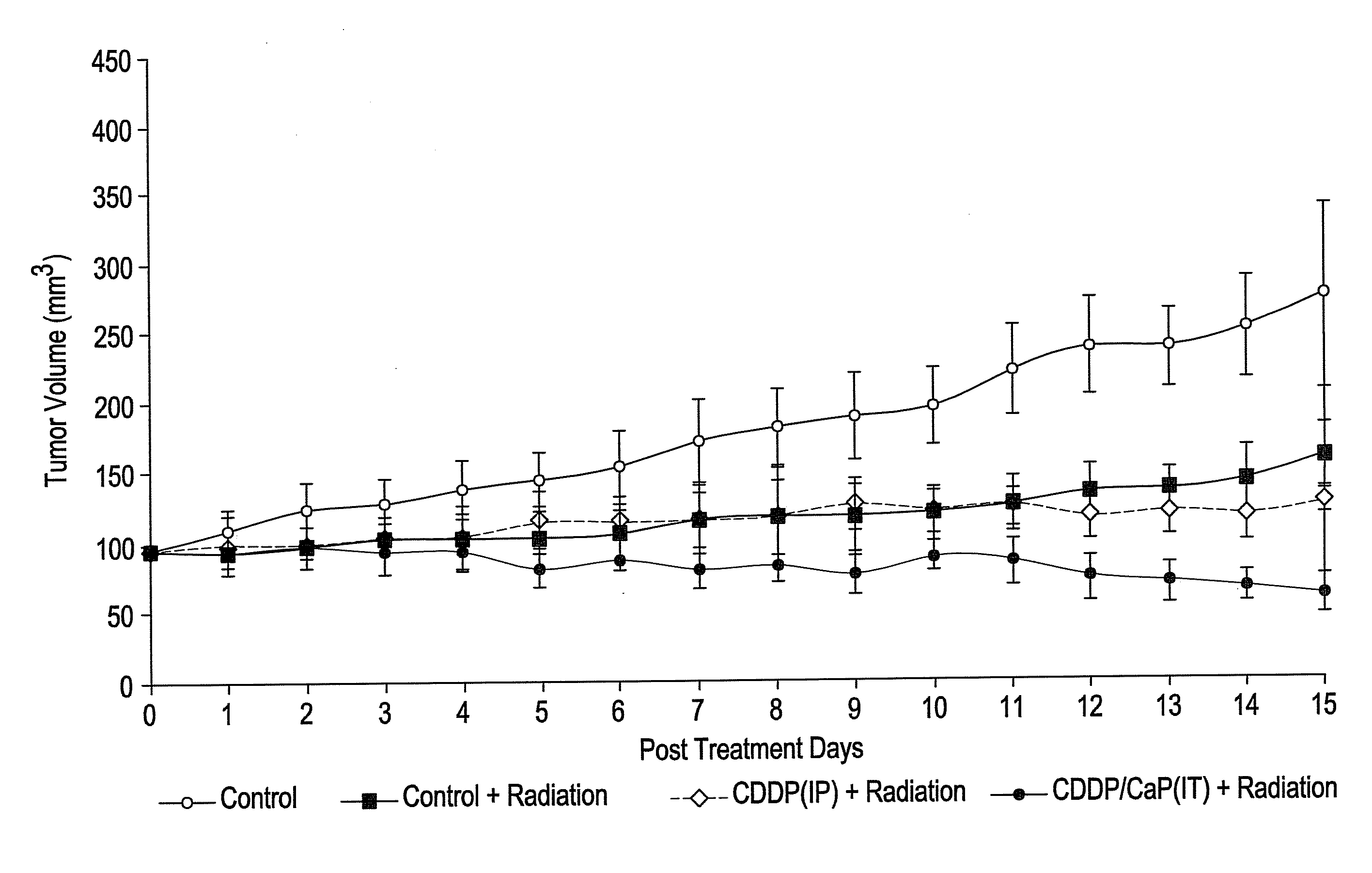

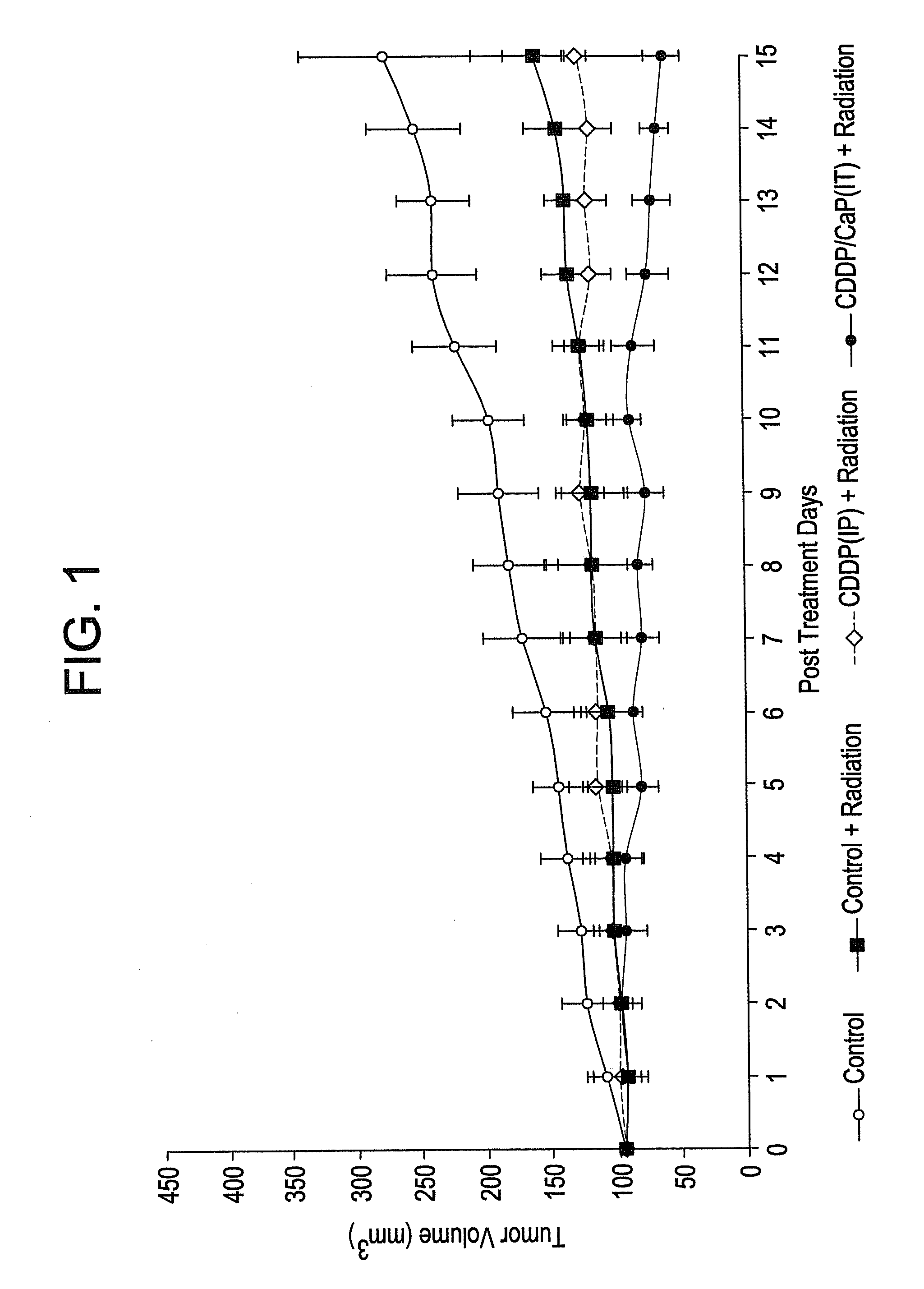

Targeted active agent delivery system based on calcium phosphate nanoparticles

InactiveUS20080241256A1Organic active ingredientsHeavy metal active ingredientsActive agentCalcium biphosphate

Calcium phosphate nanoparticle active agent conjugates are described. Specifically, anticancer agent conjugates are prepared which are suitable for targeted active agent delivery to tumor cells and lymphatics for the treatment of cancer and the treatment or prevention of cancer metastasis.

Owner:UNIV OF CONNECTICUT

Machinable preformed calcium phosphate bone substitute material implants

InactiveUS6840961B2Process stabilitySlows natural bone growthBiocideSurgical adhesivesCalcium biphosphateNatural bone

The present invention provides machinable calcium phosphate bone substitute material implants having mechanical properties comparable to those of natural bone. The implants include intimately mixed solid precursor materials that react under physiological conditions to form poorly-crystalline hydroxyapatite and eventually are remodeled into bone in vivo. The implants can include a biocompatible polymer to increase density and strength and control resorbability.

Owner:ETEX

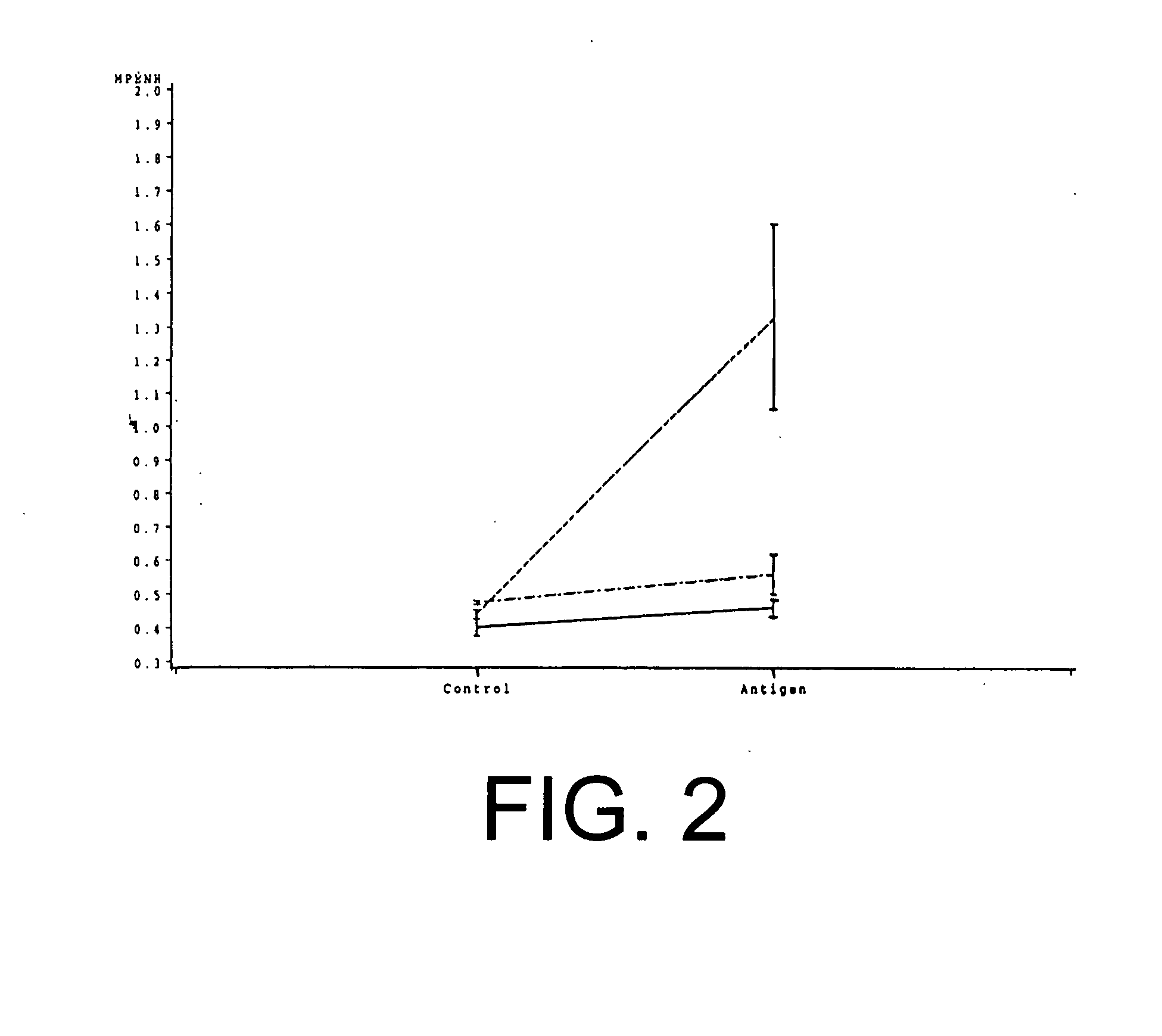

Methods of manufacture and use of calcium phosphate particles containing allergens

The present invention relates to the use of calcium phosphate particles in formulation with allergens for allergic desensitization. Particularly, the invention relates to novel calcium phosphate core particles, particularly nano- and micron-sized particles, as allergen adjuvants and in compositions for inducing allergic desensitization. Methods of making such particles and to methods of inducing a specific immune response using the particles of this invention are also provided.

Owner:CAPTIVATE PHARMACEUTICALS LLC

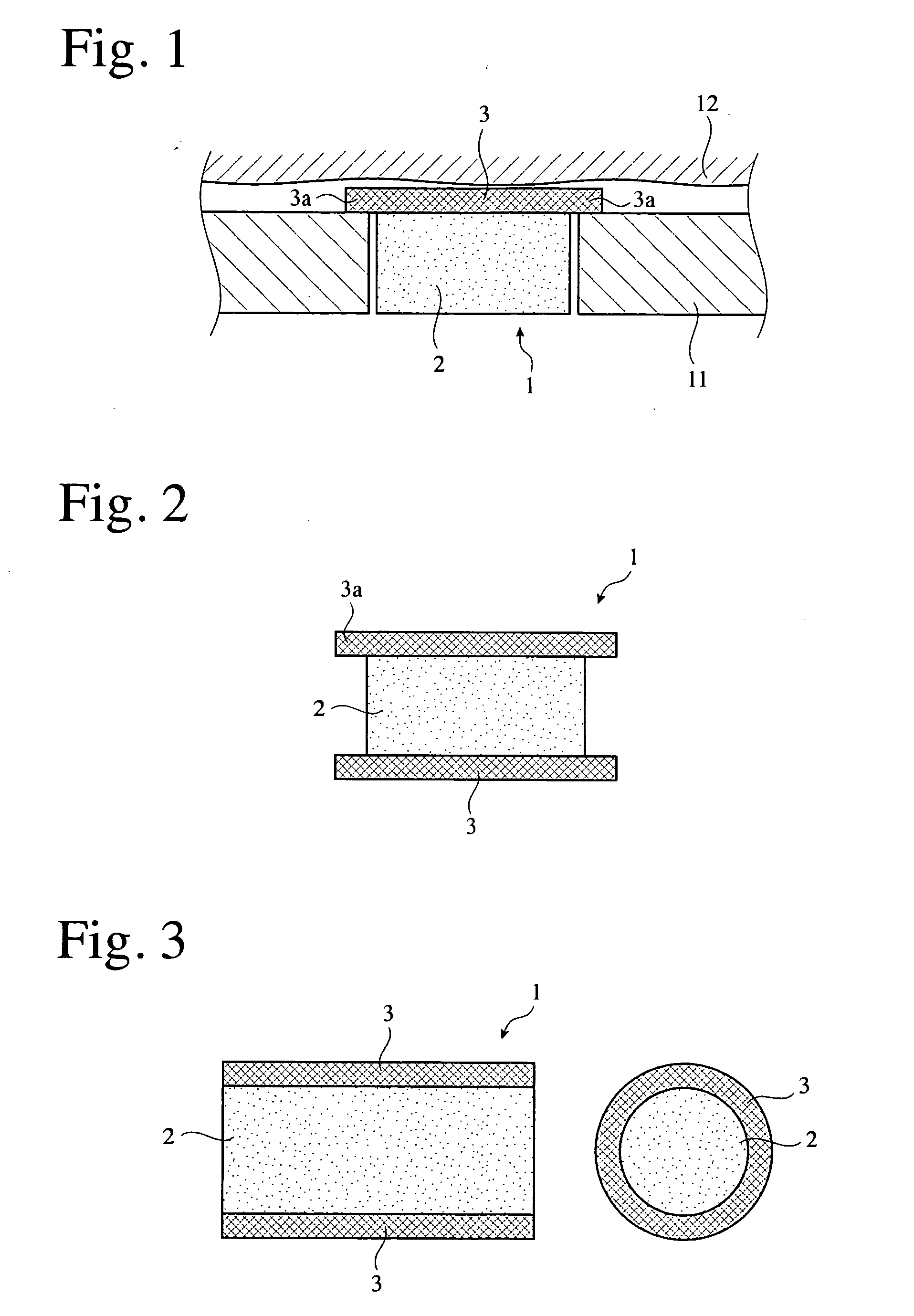

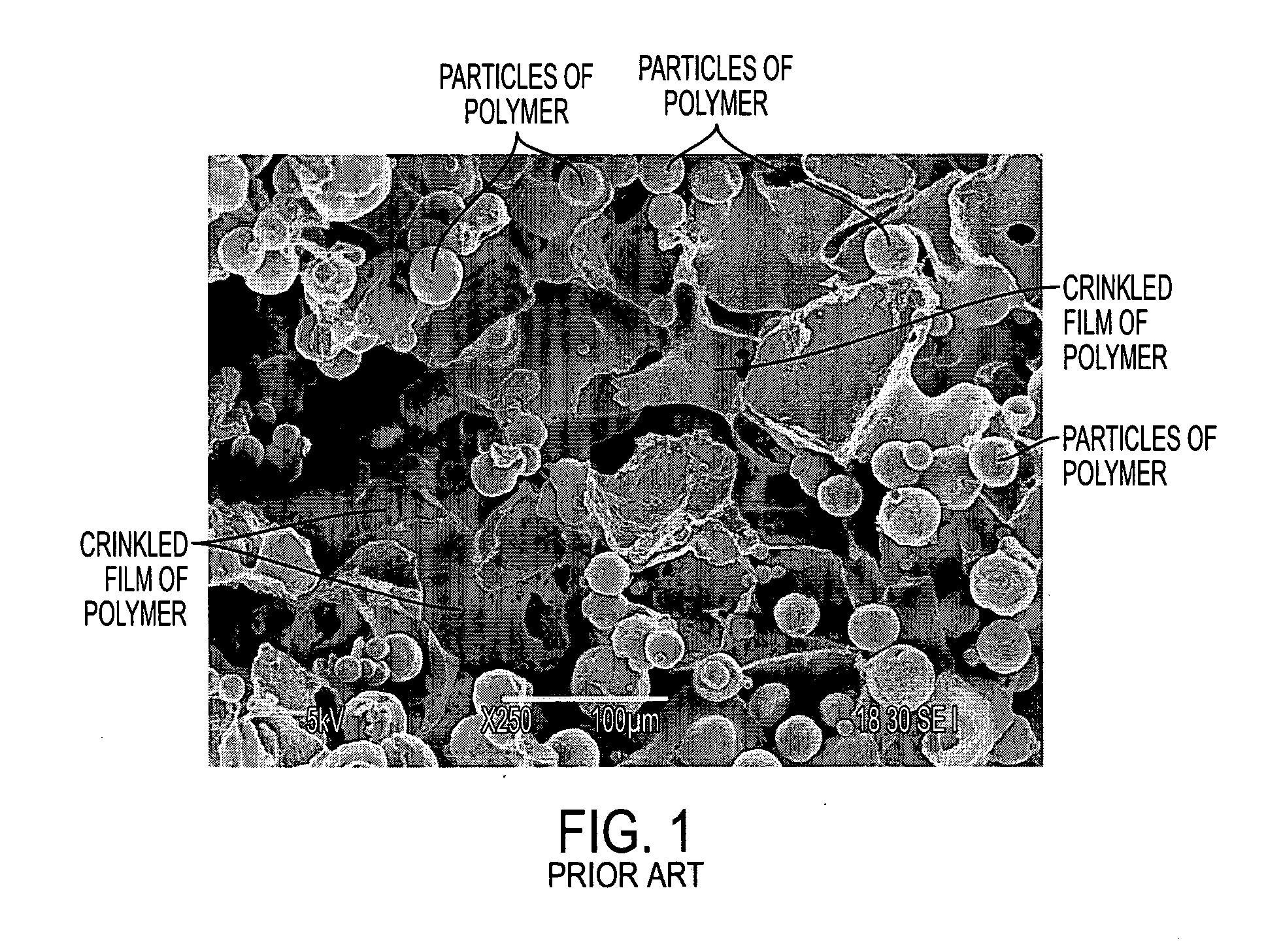

Porous composite containing calcium phosphate and process for producing the same

ActiveUS20060292350A1Small apertureImprove thermal conductivityImpression capsSynthetic resin layered productsLinking collagenCalcium biphosphate

A porous composite comprising a porous layer containing a calcium phosphate ceramic, and a dense layer formed on part of the porous layer and having a smaller average pore size than that of the porous layer. The porous composite can be produced by (1) introducing a slurry containing a calcium phosphate ceramic / collagen composite and collagen into a molding die having a high thermal conductivity, (2) rapidly freezing and drying the slurry in the molding die, to form a porous body comprising a porous layer and a dense layer formed on the porous layer, (3) cross-linking collagen in the porous body, and (4) removing the dense layer except for a portion thereof on a surface coming into contact with a soft tissue when implanted in a human body, so that the porous layer is exposed.

Owner:NAT INST FOR MATERIALS SCI +1

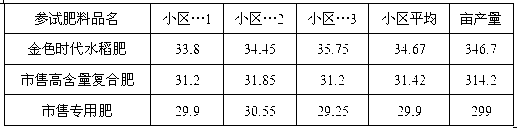

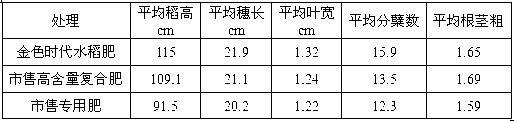

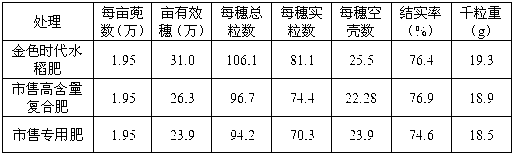

Rice fertilizer capable of improving resistance, quality and yield of rice

InactiveCN102701853AIncrease productionThe effect of increasing production is obviousFertilizer mixturesMagnesium phosphateMagnesium orthophosphate

The invention relates to rice fertilizer capable of improving the resistance, quality and yield of rice. The rice fertilizer consists of the following raw materials in percentage by weight: 20.0 to 27.0 percent of urea, 7.0 to 20.0 percent of ammonium sulfate, 5.0 to 13.0 percent of monoammonium phosphate, 9.8 to 17.5 percent of potassium chloride, 10.0 to 18.5 percent of calcium superphosphate, 3.0 to 6.0 percent of calcium-magnesium phosphate, 2.0 to 8.0 percent of soluble silicon, 0.1 to 0.9 percent of amino acid, 5.0 to 30.0 percent of humic acid, 0.5 to 6.0 percent of other trace elements (zinc, manganese, boron, ferrum, copper, molybdenum, selenium and the like), 0.2 to 0.5 percent of activating agent and less than or equal to 2.5 percent of water. The rice fertilizer has the advantages of comprehensively providing the nutrient required by growth of rice, improving the yield and the quality of rice, activating the nutrient of soil, enhancing the capacity of absorbing nutrient by crops, improving a soil structure, enhancing soil fertility, promoting development, and improving the resistance of the crops (disease resistance, pest resistance, drought resistance, flooding resistance, cold resistance, saline-alkaline resistance, lodging resistance and the like).

Owner:王豫希

Scaffold for tissue engineering cartilage having outer surface layers of copolymer and ceramic material

InactiveUS6656489B1High mechanical strengthEfficient transportBiocideJoint implantsCartilageComposite scaffold

A biodegradable, biocompatible porous matrix as a scaffold for tissue engineering cartilage is formed of a copolymer of a polyalkylene glycol and an aromatic polyester such as a polyethylene glycol / polybutylene terephtalate copolymer. A ceramic coating such as a calcium phosphate coating may be provided on the scaffold by soaking the scaffold in a solution containing calcium and phosphate ions. A composite scaffold which is preferably a two-layer system may be formed having an outer surface of a layer of the porous matrix formed of the copolymer, and an outer surface of a layer of a ceramic material. The composite scaffold may be prepared by casting the copolymer on top of the ceramic material in a mould. Cells are preferably seeded on the scaffold prior to implanting, and the scaffold may contain bioactive agents that are released on degradation of the scaffold in vivo.

Owner:OCTOPLUS SCI

Method for making a porous calcium phosphate article

InactiveUS20050186449A1Improves bioresorbabilityLayered productsPretreated surfacesCalcium biphosphateCompressive strength

The present invention discloses a method for making a porous calcium phosphate article including i) preparing a shaped article from a paste containing a calcium phosphate cement, a pore-forming powder and a setting liquid; ii) immersing the shaped article in an immersing liquid for a period of time so that the pore-forming powder is dissolved in the immersing liquid, creating pores in said shaped article; and iii) removing the resulting porous shaped article from the immersing liquid, wherein the resulting porous shaped article has an improved compressive strength. The porous shaped calcium phosphate article of the present invention may be used as a tissue-engineered scaffold, medical implant or a reinforcing constituent of a composite.

Owner:CALCITEC

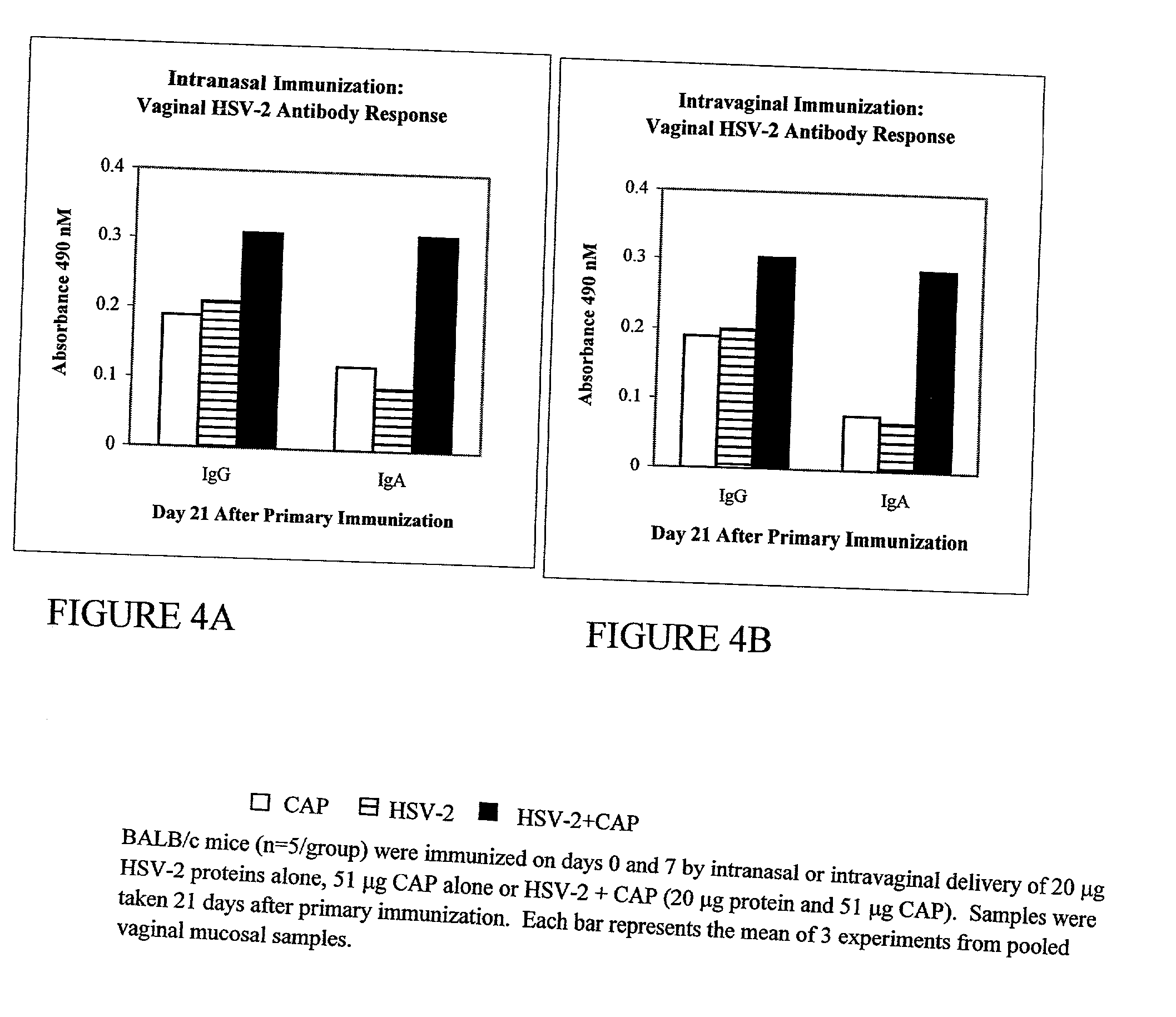

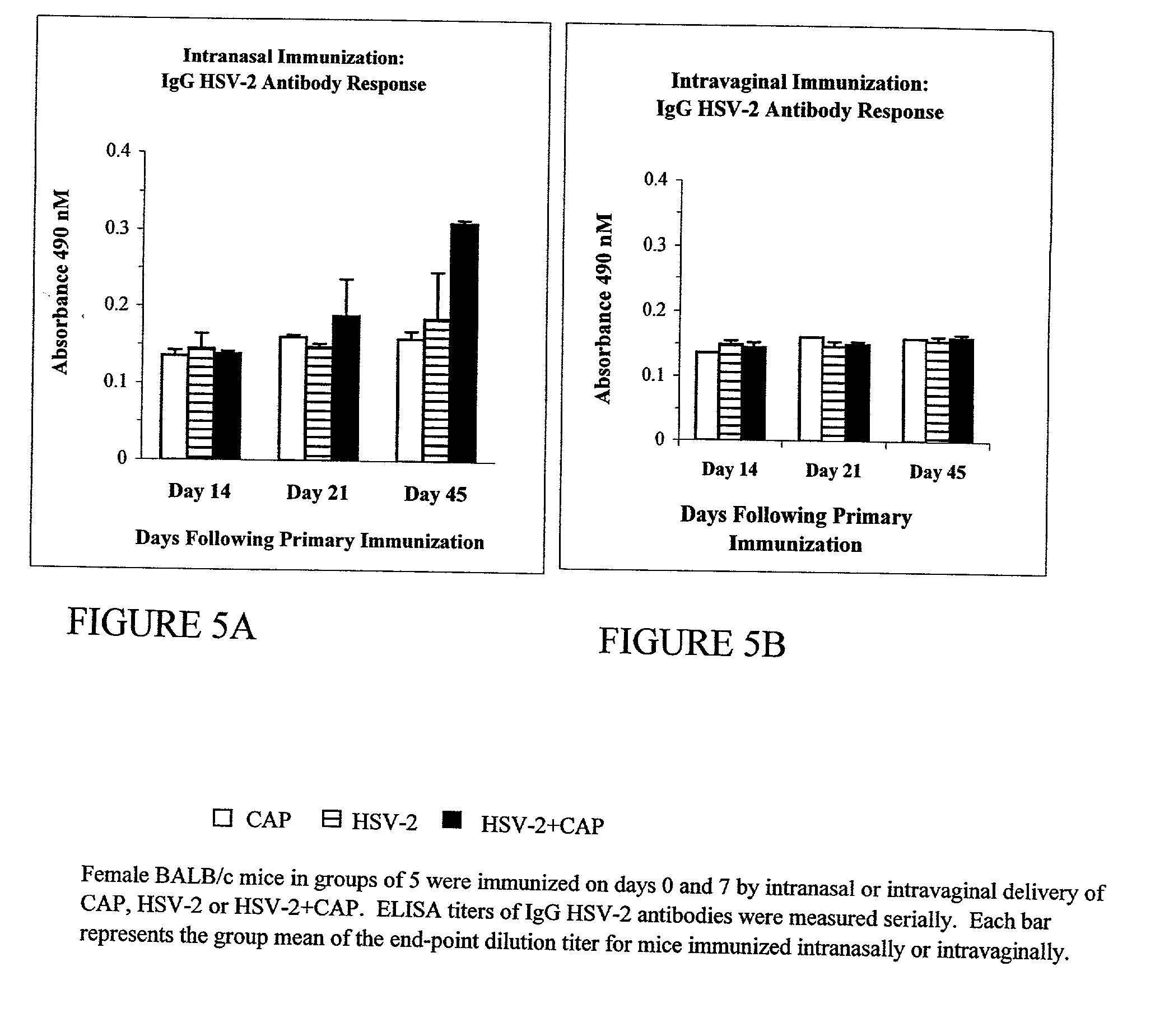

Calcium phosphate particles as mucosal adjuvants

The present invention relates to mucosal immune protection, mucosal vaccine delivery, and mucosal drug delivery. Novel calcium phosphate core particles, particularly nanoparticles are used as vaccine adjuvants and compositions for inducing protective mucosal immunity. Methods of inducing an immune response to an antigen by delivering the antigen to a mucosal surface using the particles of this invention, and to methods of making such particles are also provided. The particles of this invention are also useful for delivering compositions, such as a pharmacologically active agent, to the mucosal surfaces of a patient in need thereof, to methods of delivering such compositions, and to methods of making such particles.

Owner:CAPTIVATE PHARMACEUTICALS LLC

Bioactive bone graft substitute

Owner:STRYKER CORP

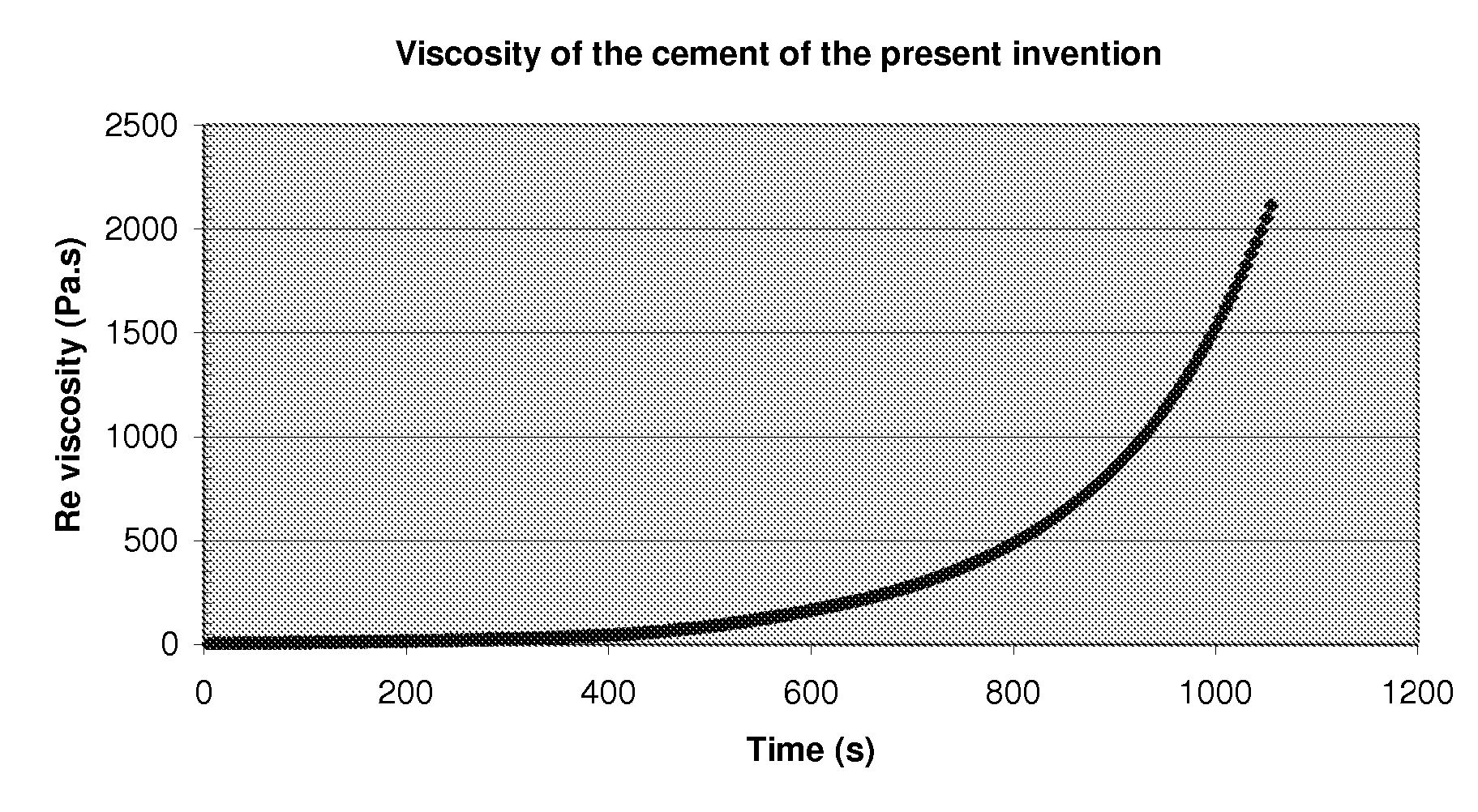

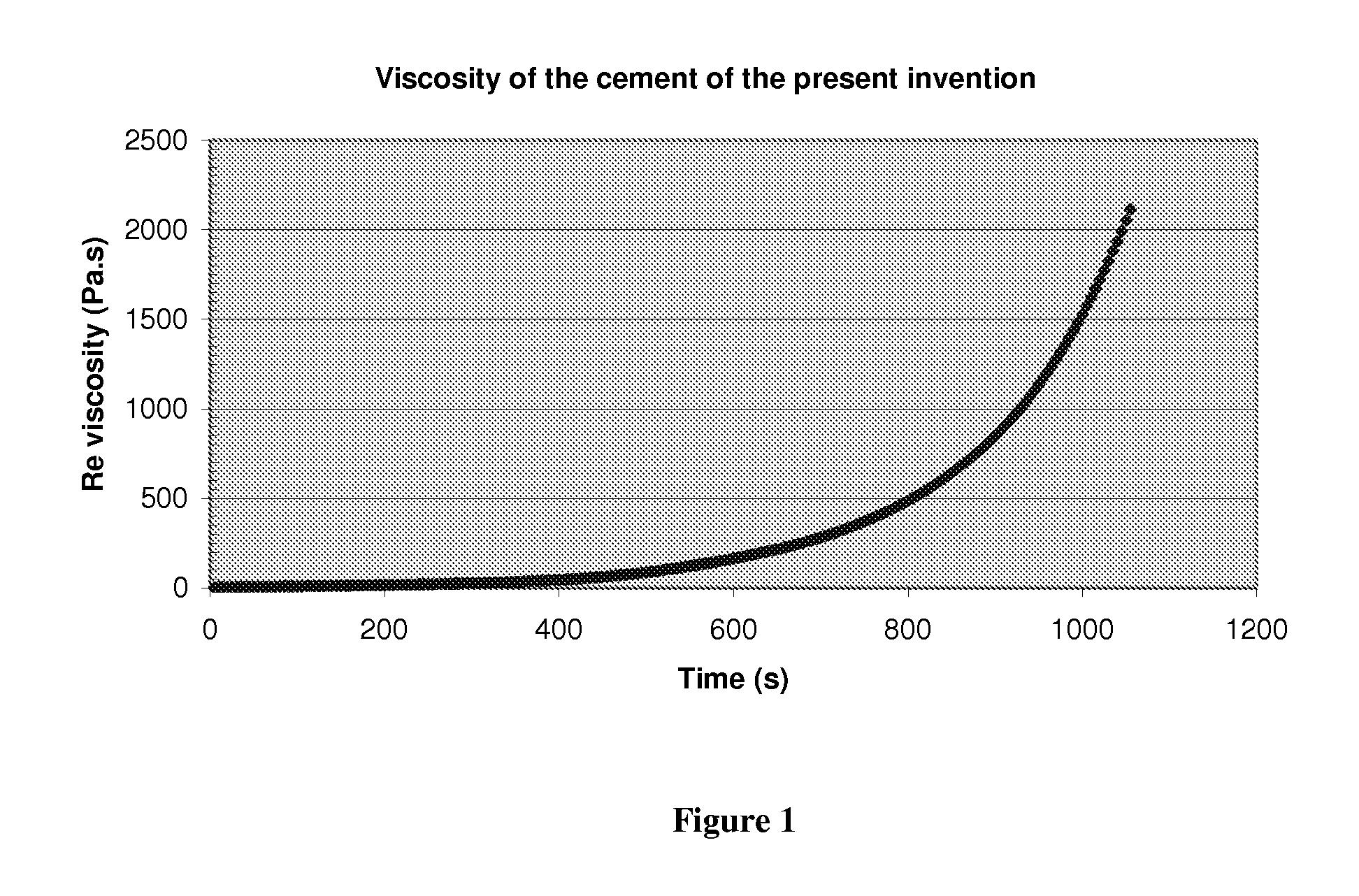

Polymer cement for percutaneous vertebroplasty and methods of using and making same

The invention provides a fluid cement for medical use for bone reconstruction, in particular for filling the vertebral body, and a binary composition which is intended for the preparation of such a cement. The invention also provides a device for conditioning the binary composition, and a method of preparing a bone cement from a binary composition. The fluid cement according to the invention comprises: a) approximately 60% to 85% by weight of a polymer comprising a polymethylmethacrylate and a methylmethacrylate monomer and b) approximately from 15 to 40% by weight of a radio-opaque composition. Preferably, the radio-opaque composition comprises a radio-opacifier, such as barium sulfate and zirconium dioxide, in a mixture with a calcium phosphate, for example apatite hydroxide.

Owner:TEKNIMED SAS

Methods and devices for delivering orthopedic cements to a target bone site

InactiveUS20050058717A1BiocideInorganic phosphorous active ingredientsSubject matterBiomedical engineering

Methods and devices are provided for delivery an orthopedic, e.g., calcium phosphate cement to a target bone site. In practicing the subject methods, a flowable cement composition is delivered to a target bone site in conjunction with vibration. Also provided are the devices that deliver a flowable cement to a target bone site according to the subject methods. Introducing a flowable cement to a target bone site in conjunction with vibration in accordance with the subject methods provides for highly controlled penetration of the delivered cement throughout the target bone site without the use of substantial pressure. The subject devices and methods find use in a variety of different applications, and are particularly suited for use in applications where a calcium phosphate cement is to be delivered to cancellous tissue, e.g., as found in a vertebral body.

Owner:SKELETAL KINETICS

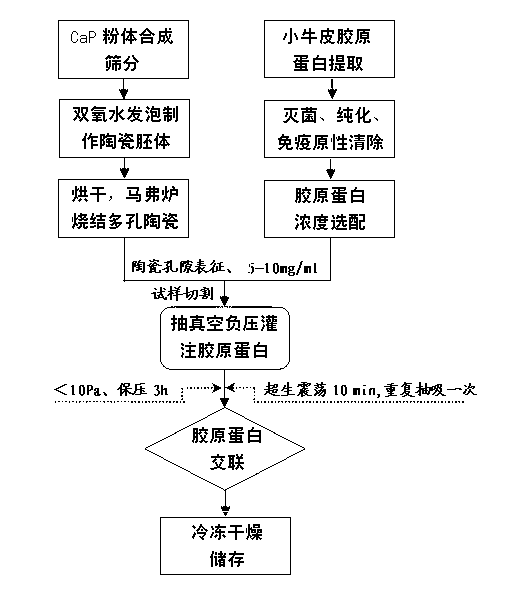

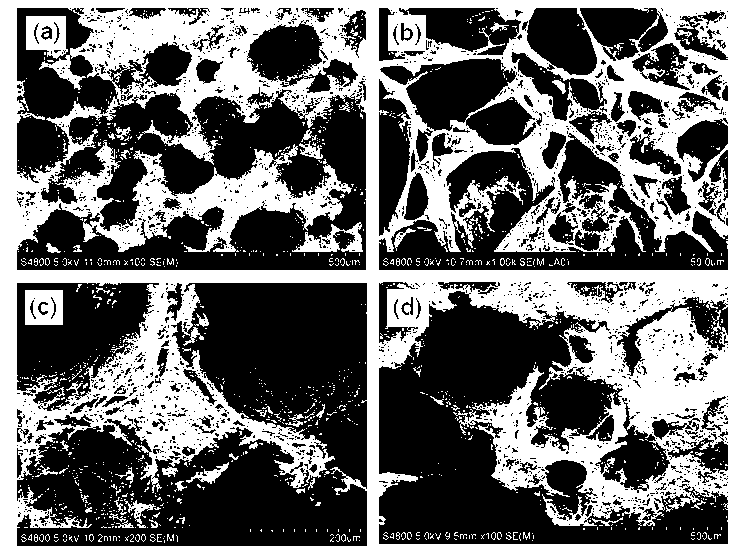

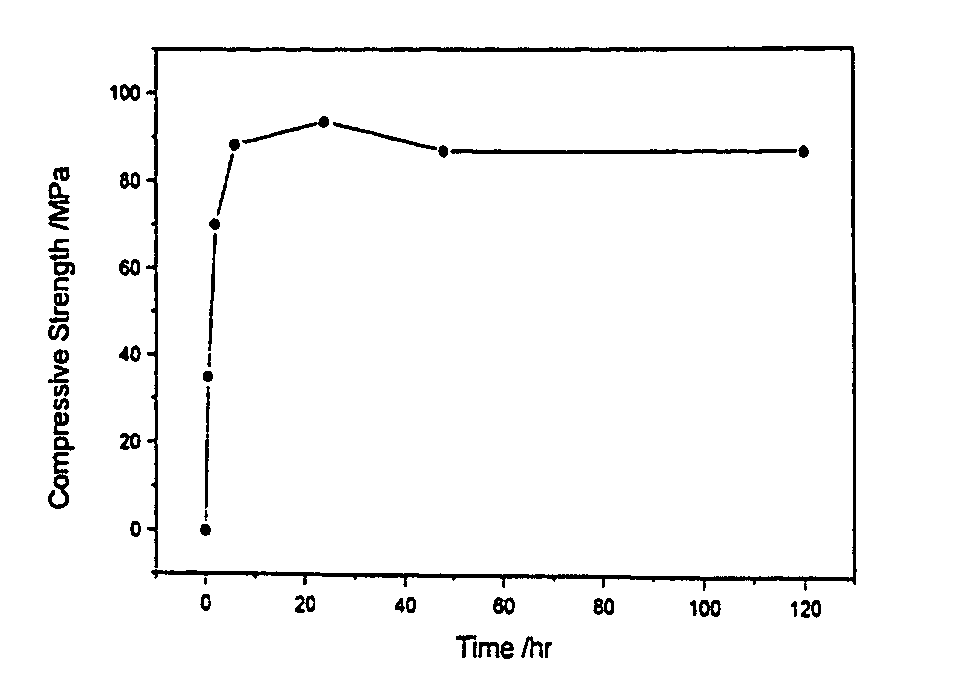

Calcium phosphate/collagen composite biologic ceramic material and preparation method thereof

InactiveCN103055352AImprove mechanical propertiesPromote repair and regenerationProsthesisCalcium biphosphateBone tissue engineering

The invention relates to a CaP (Calcium Phosphate) / collagen composite biologic ceramic material and a preparation method thereof. The composite biologic ceramic is prepared by adopting a porous calcium phosphate ceramic as the substrate and I-type collage as the toughening reinforcing phase in a vacuum negative pressure pouring and crosslinking mode. The process is as follows: firstly, preparing the first type through porous calcium phosphate ceramic, wherein the porosity is 60-95%; dipping the porous calcium phosphate ceramic into a collagen solution of which the concentration is 5-20mg / ml; and vacuuming to 0-10Pa at normal temperature and pouring, keeping the pressure for 1-3 hours and carrying out ultrasonic oscillation. The vacuum negative pressure pouring process can be repeated according to demands. The calcium phosphate ceramic poured with the collagen is frozen and dried to prepare the composite biologic ceramic after being subjected to crosslinking. The prepared biologic ceramic has good biocompatibility and biological activity, and at the same time has a mechanical strength better than that of a pure calcium phosphate ceramic material, so that the biologic ceramic can be used as artificial bones and bone tissue engineering bracket materials, and has wide clinical application prospects in orthopedics.

Owner:SICHUAN UNIV

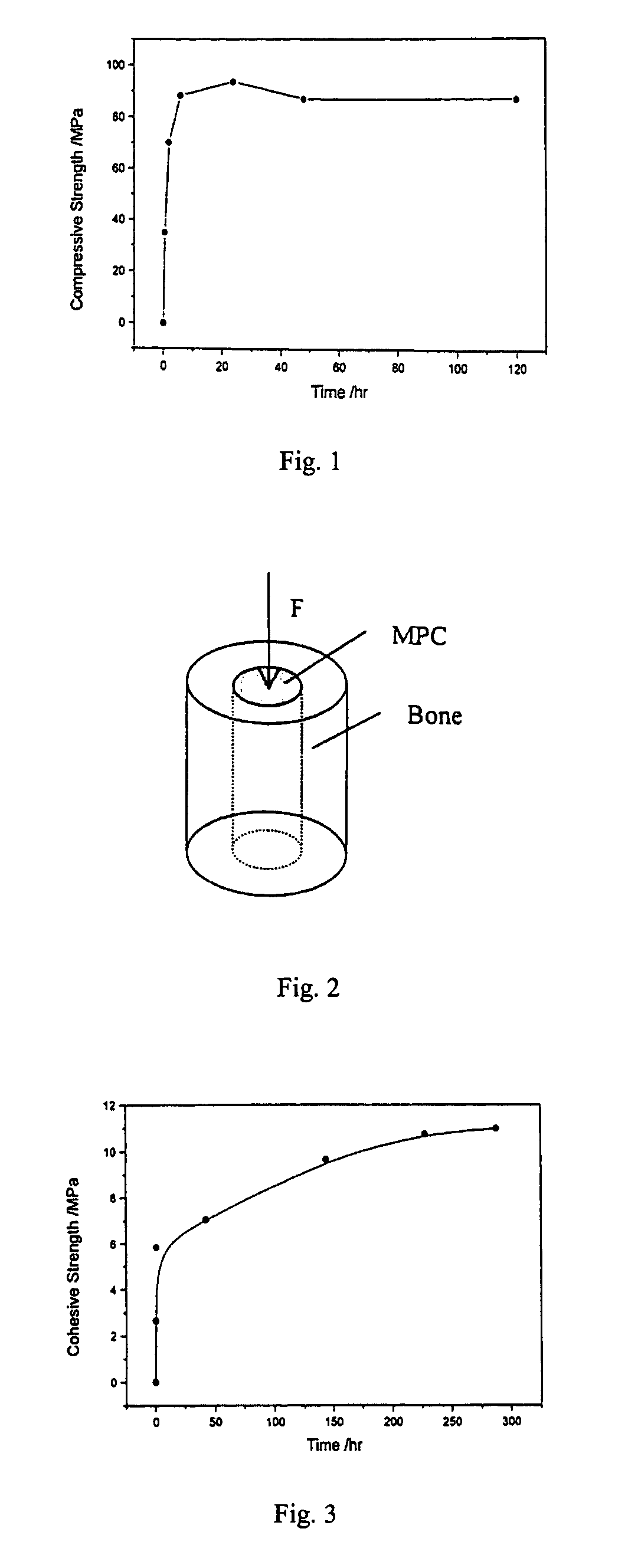

Inorganic bone adhesion agent and its use in human hard tissue repair

InactiveUS7094286B2High strengthGood biocompatibilityBiocideSurgical adhesivesHydration reactionMagnesium phosphate

The present invention discloses an inorganic bone adhesive and its use in human hard tissue repairs. The inorganic bone adhesive comprises basic compound, phosphate, calcium phosphate bone cement and retarder with the characteristics of rapid hydration rate and high early strength. Inorganic Bone adhesive can be widely used in the artificial joints fixation, screw fixation as well as comminuted fracture fixation. It is a kind of safe and effective adhesive material and beneficial for the fast postoperative recovery. The final hydration reaction products contains the composition of magnesium phosphate, bio-mineral containing ammonium and apatite-like materials, which has excellent biocompatibility and can be gradually absorbed by surrounding tissues after being implanted in vivo, which benefits the in-growth of the new bone.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for treating complexed chemical nickel electroplating wastewater

InactiveCN103833123AImprove processing efficiencyGood effectWaste water treatment from metallurgical processWater/sewage treatment by oxidationPotassium ferrateAdsorption effect

The invention provides a method for treating complexed chemical nickel electroplating wastewater and aims at the problem in the existing complexed chemical nickel electroplating wastewater treatment processes that the nickel ion removal efficiency is inadequate. The method comprises the main processes of firstly adding calcium hydroxide into the wastewater, adjusting the pH to 8-9 so as to form calcium phosphate precipitates, adding sulfuric acid into a supernatant liquid so as to adjust the pH of the liquid to 4-5, then, adding a potassium ferrate liquid with strong oxidizing power so as to decomplex in a strong oxidizing manner and change complexed nickel ions into free-state nickel ions, then, adding calcium hydroxide, adjusting the pH to 10-11 so as to enable the free-state nickel ions to form precipitates to be removed from the wastewater, enabling trivalent ferric ions with excellent flocculation function generated after oxidation of ferric acid radical ions to have flocculation with hydroxide precipitates with an adsorption effect, and finally, adding polyacrylamide (PAM) to coagulate and precipitate, thereby removing nickel ions from the electroplating wastewater. The method has the advantages that the condition that the nickel ions obtained after the complexed chemical nickel electroplating wastewater is treated reach the national standards can be effectively guaranteed, the treatment efficiency is high, and the requirements on emission are met.

Owner:陈瀚翔

Desulfurization and novel sorbents for same

InactiveCN1384770AOctane dropReduce hydrocarbon contentRefining with metalsOther chemical processesAluminateCalcium silicate

Particulate sorbent compositions which are suitable for the removal of sulfur from streams of cracked-gasoline or diesel fuel are provided which have increased porosity, improved resistance to deactivation through the addition of a calcium compound selected from the group consisting of calcium sulfate, calcium silicate, calcium phosphate or calcium aluminate to the support system comprised of zinc oxide, silica and alumina having thereon a promotor wherein the promotor is metal, metal oxide or metal oxide precursor with the metal being selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium or mixtures thereof and wherein the valence of such promotor has been substantially reduced to 2 or less. Process for the preparation such sorbent systems as well as the use of same for the desulfurization of cracked-gasolines and diesel fuels are also provided.

Owner:CHINA PETROLEUM & CHEM CORP

Powdery saline-alkali soil water-retention slow-release fertilizer

The invention discloses a powdery saline-alkali soil water-retention slow-release fertilizer. The technical scheme of the powdery saline-alkali soil water-retention slow-release fertilizer has the key point that the ingredients of the powdery saline-alkali soil water-retention slow-release fertilizer consist of high-viscosity attapulgite clay powder, acidized attapulgite clay powder, ardealite, ammonia sulfate, calcium superphosphate, potassium sulphate, sulfuric acid, super absorbent resin and microelement mixture, and the ingredients of the powdery saline-alkali soil water-retention slow-release fertilizer are smashed after being stirred and are packed as the finished product of the powdery saline-alkali soil water-retention slow-release fertilizer. The powdery saline-alkali soil water-retention slow-release fertilize is acidic, the alkalinity of soil can be lowered, calcium ions contained in the fertilizer can be used for replacing sodions on a saline alkali soil colloid, so that the content of the soil exchangeable sodions is lowered, and a purpose of improving the saline-alkali soil is achieved. The powdery saline-alkali soil water-retention slow-release fertilizer contains a great quantity of nitrogen, phosphorus and potassium and various trace elements, has the functions on slow release of fertilizer efficiency and water retention and is suitable for topdressing on the saline-alkali soil, and necessary nutritional ingredients for plant growth can be provided.

Owner:江苏农盛废弃物循环再利用有限公司 +1

Therapeutic calcium phosphate particles and methods of making and using same

InactiveUS20120128767A1Improve packaging efficiencyImprove encapsulation efficiencyOrganic active ingredientsPowder deliveryCalcium biphosphateMedicine

The present invention provides novel calcium phosphate nanoparticles suitable for efficient encapsulation of biologically active molecules. The invention further provides pharmaceutical compositions comprising these nanoparticles, as well as methods of making such nanoparticles and using them as carriers for therapeutic delivery of biologically active macromolecules.

Owner:NOD PHARMA

Polysaccharide/calcium orthophosphate composite bone cement and preparation method thereof

InactiveCN101496909AGood biocompatibilityNo adverse reactionBone implantCalcium biphosphateBiocompatibility Testing

The invention discloses a polysaccharide / autosolidification calcium phosphate composite bone cement composition, which comprises the following components in percentage by weight: 10 to 95 weight percent of autosolidification calcium phosphate bone cement and 5 to 90 weight percent of polysaccharide. The bone cement composition can obtain bone cement with high strength, good toughness, strong plasticity, quick solidification, and good biocompatibility and degradability, thereby overcoming the defects of inadequate toughness and slow degradation in human bodies existing in the prior calcium phosphate bone cement materials and the defects existing in a plurality of enhancement methods in the prior art, and better meeting the requirement of operation use.

Owner:EAST CHINA UNIV OF SCI & TECH

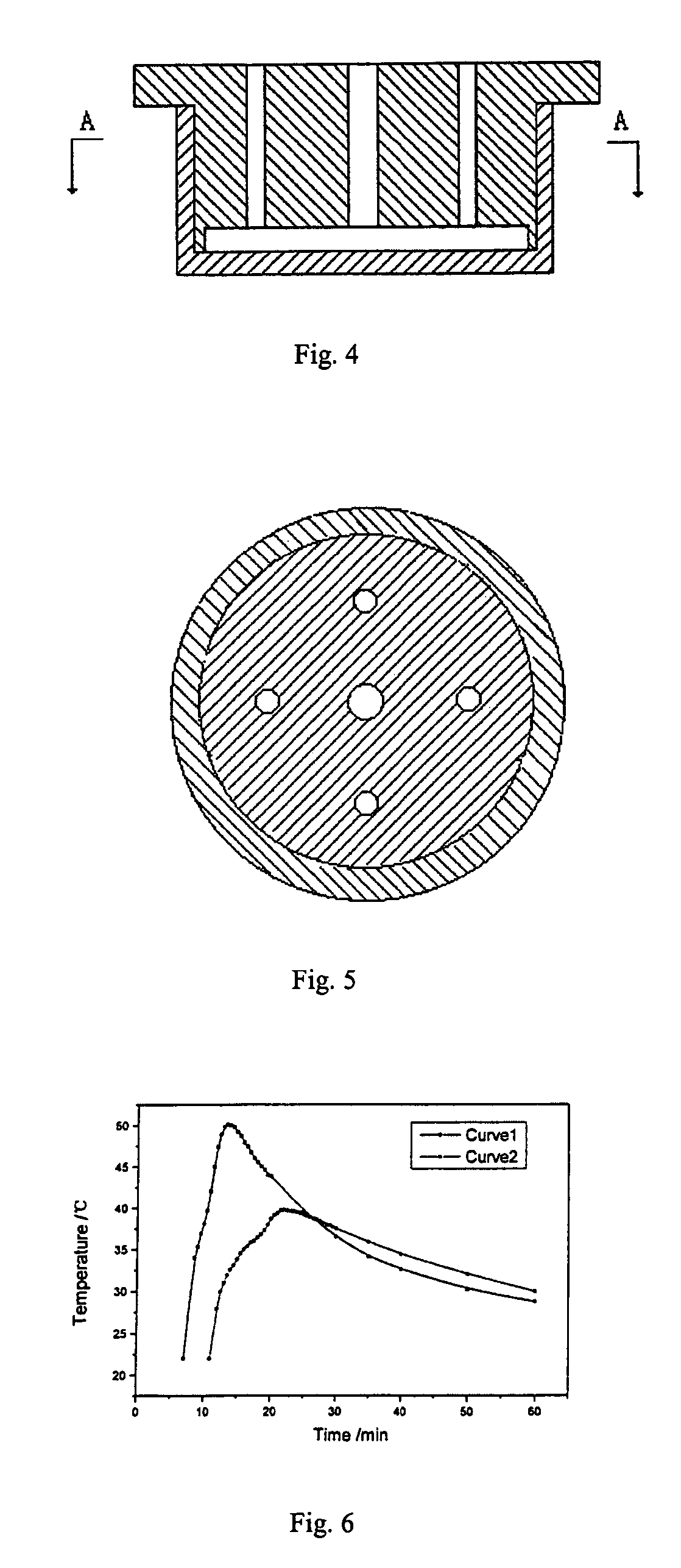

Bone growth particles and osteoinductive composition thereof

InactiveUS7718616B2Reduce deliveryEnhance in vivo formationPowder deliveryCosmetic preparationsCalcium biphosphateFiber

A biocompatible synthetic bone growth composition comprising a fibrillar collagen component and a calcium phosphate component. The composition is formed into particles, and then formed into a unitary article that may be provided at the site of a skeletal defect. An osteoinductive component may be further added, either before or after forming the unitary article. The composition may be formulated as a paste or putty and facilitates bone growth and / or repair.

Owner:ZIMMER ORTHOBIOLOGICS

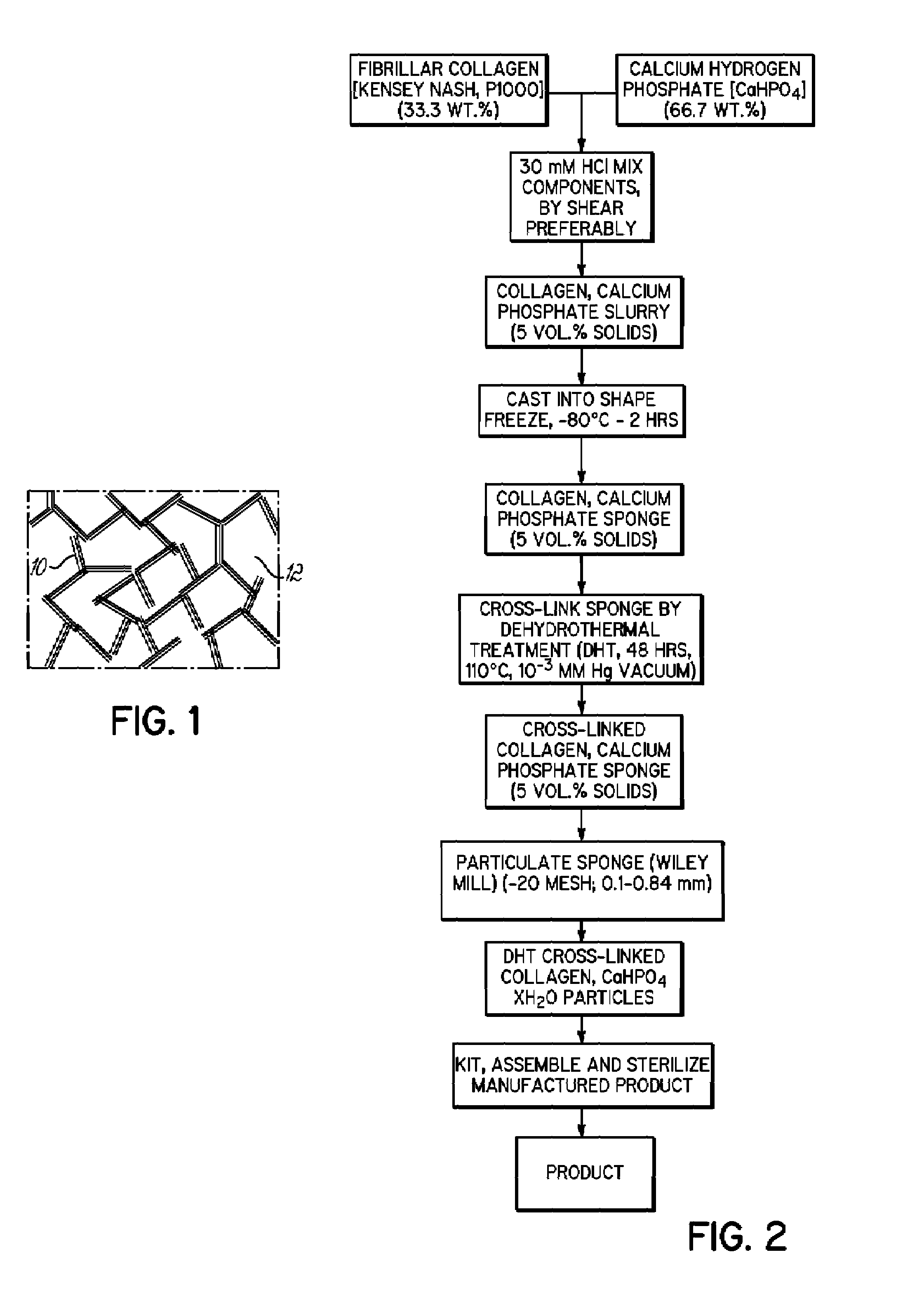

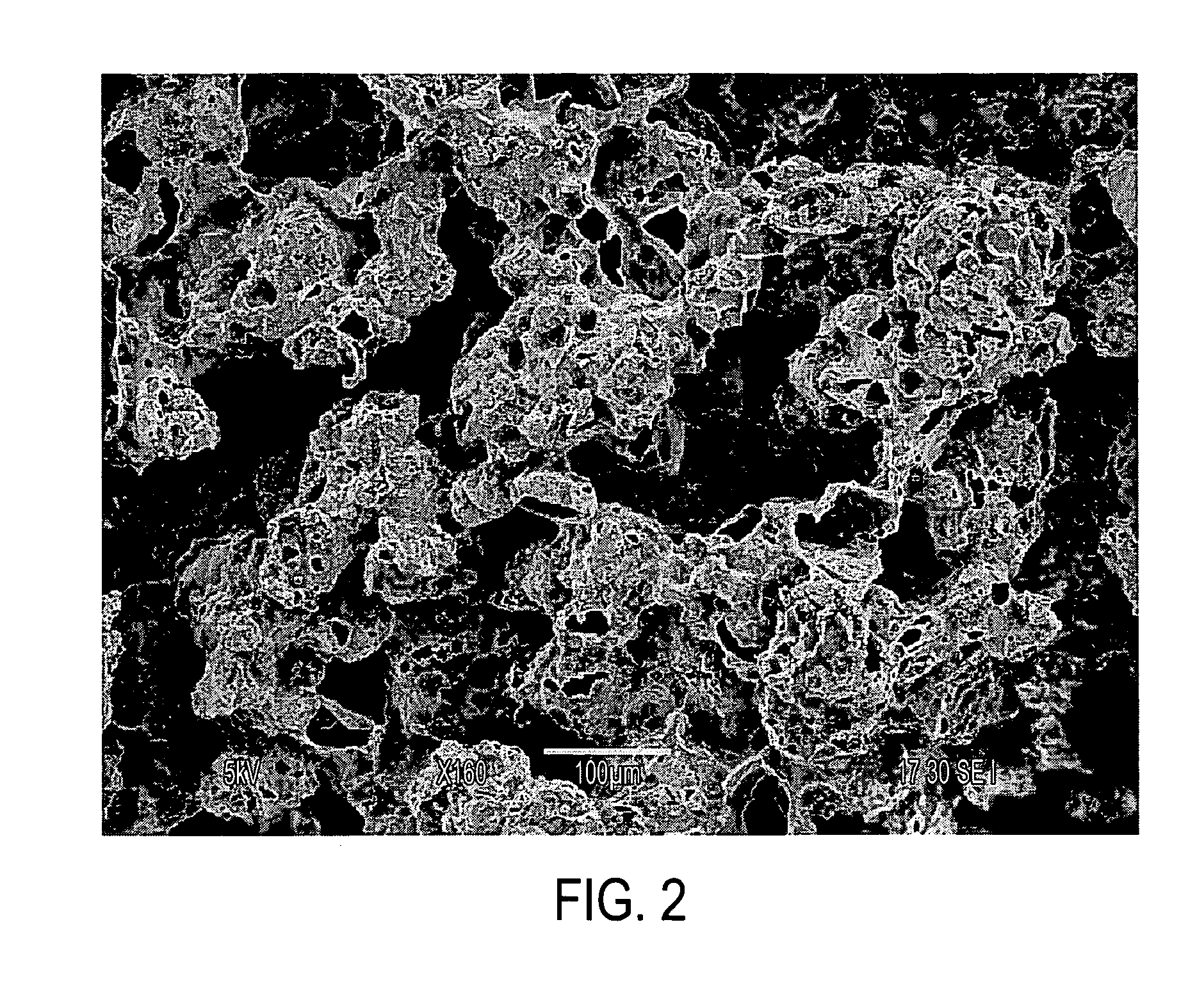

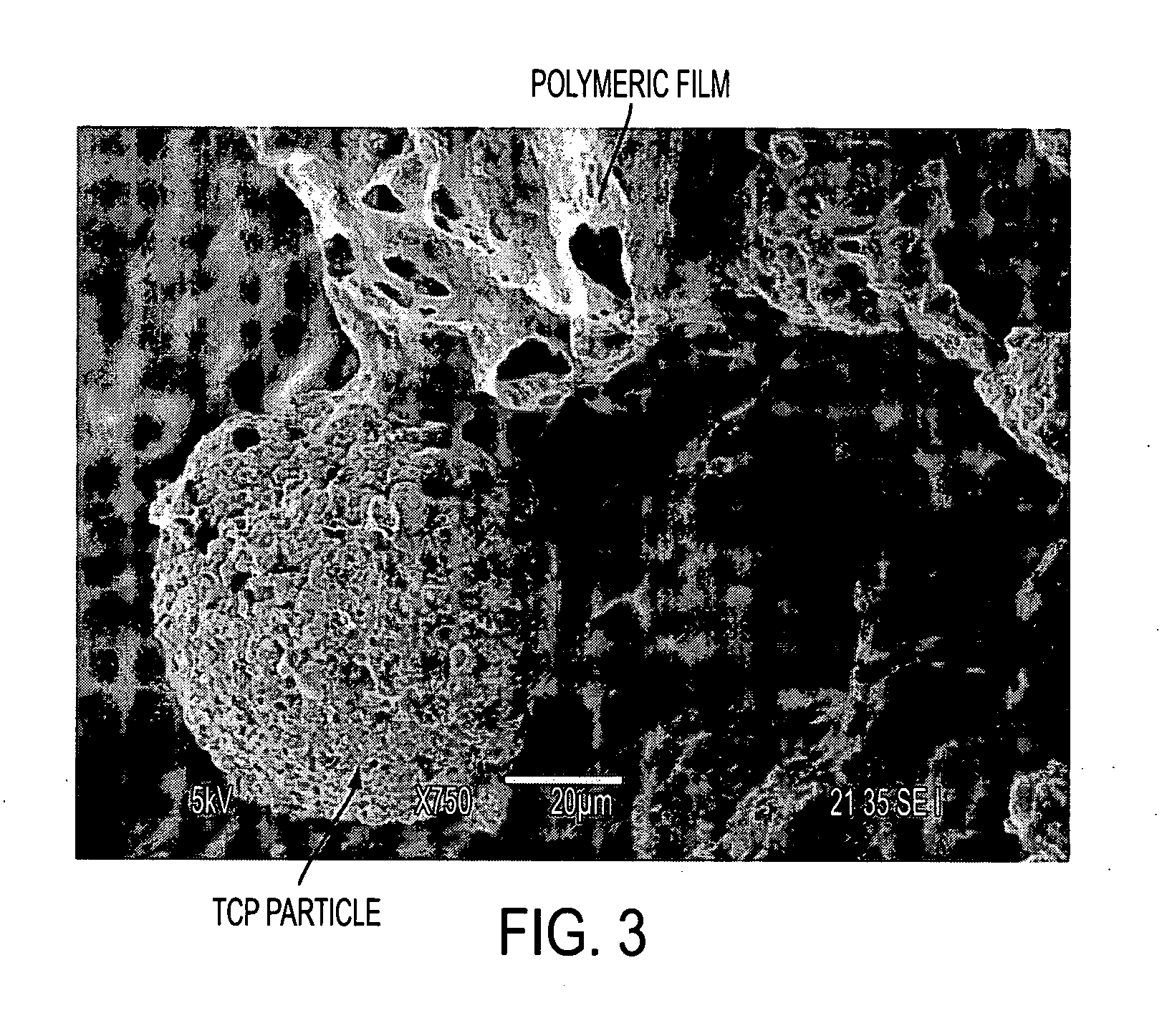

Manufacturing process, such as three dimensional printing, including binding of water-soluble material followed by softening and flowing and forming films of organic-solvent-soluble material

InactiveUS20070009606A1Effectively osteoinductiveHigh porosityAdditive manufacturing apparatusPhotosensitive materialsManufacturing technologyAdditive ingredient

The invention includes biostructures which may be characterized as having substantially all of the organic-solvent-soluble material in the form of a network of irregularly shaped perforated films. The biostructure may further include particles of a substantially-insoluble material, which may be a member of the calcium phosphate family. The biostructure may be osteoconductive. The biostructure may further contain an Active Pharmaceutical Ingredient or other bioactive substance. The API may be a substance which stimulates the production of bone morphogenetic protein, such as Lovastatin or related substances, thereby making the biostructure effectively osteoinductive. One or more of the polymers may have a resorption rate in the human body such as to control the release of the API. Methods of manufacture are also disclosed.

Owner:MASSACHUSETTS INST OF TECH +1

Composite bracket made of multialdehyde sodium alginate crosslinked calcium polyphosphate/chitosan and preparation and use thereof

InactiveCN101301491AGood biocompatibilityPromote degradationPharmaceutical non-active ingredientsProsthesisDefect repairBiocompatibility Testing

The invention discloses a composite frame of multi-aldehyde sodium alginate cross-linked polyethylene / chitosan for bone or cartilage repair and treatment, as well as preparation and application of the material of the framework. The framework is made from Calcium polyphosphate, chitosan and multi-aldehyde sodium alginate. As organic matrix multi-aldehyde sodium alginate cross-linked chitosan derived from nature which is the main component of the composite frameworks of the invention, therefore the composite framework is safe and non-toxic, has good biocompatibility and biodegradability, and cell identificaton signal existed on the surface provides physical support and the best chemical environment for bone or cartilage regeneration and reconstruction, the network structure makes the mechanical properties improved greatly. In addition, the components of the inorganic strengthened calcium polyphosphate are consistent with those of human bone tissue, has the property of activity which promotes bone or cartilage growth and the controllable degradation. The composite of the invention can be used as defect repair of bone or cartilage and tissue engineering, drug delivery carrier.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com