Patents

Literature

538 results about "Alkali salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali salts or basic salts are salts that are the product of the neutralization of a strong base and a weak acid. Rather than being neutral (as some other salts), alkali salts are bases as their name suggests. What makes these compounds basic is that the conjugate base from the weak acid hydrolyzes to form a basic solution. In sodium carbonate, for example, the carbonate from the carbonic acid hydrolyzes to form a basic solution. The chloride from the hydrochloric acid in sodium chloride does not hydrolyze, though, so sodium chloride is not basic.

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS20050142211A1Facilitated releaseTo promote metabolismBiocideSurgical adhesivesO-Phosphoric AcidPowder mixture

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS6840251B2Reduce Microbial ContaminationReduce removalDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

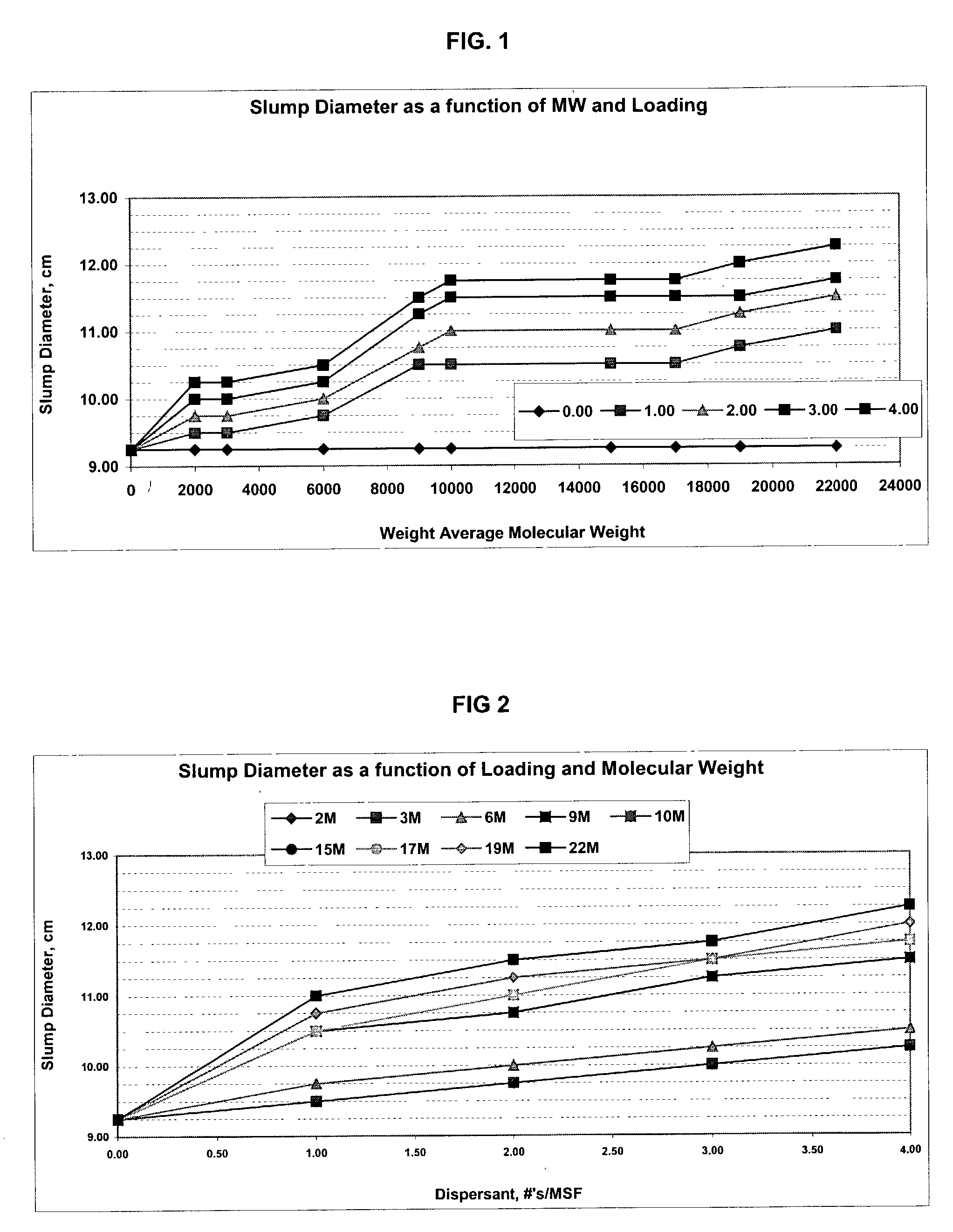

Dispersant and foaming agent combination

InactiveUS20040028956A1Low densityReduce weightConstruction materialOther chemical processesAlkaline earth metalAir entrainment

The present invention provides a dispersant and foaming agent combination that is useful in the production of gypsum wallboard and other aqueous cementitious products, a method of forming a gypsum wallboard and a gypsum wallboard. The dispersant in the combination according to the invention is a naphthalene sulfonate-aldehyde condensate alkali salt polymer having a weight average molecular weight of from about 17,000 to about 47,000. The alkali is preferably an alkali metal and / or an alkaline earth metal. The aldehyde is preferably formaldehyde. The foaming agent used in the combination according to the invention is a soap, preferably an alkali salt of an alkyl ether sulfate and / or an alkyl sulfate. The combination of a high molecular weight dispersant and a foaming agent produces a gypsum wallboard core effect that more efficiently entrains air (i.e., creates void space), thereby lowering overall board weight without detrimentally affecting strength. A gypsum wallboard formed using the dispersant and foaming agent combination according to the invention exhibits a higher nail pull value than gypsum wallboard formed using a conventional dispersant and a foaming agent at the same solids loading ratio.

Owner:GEO SPECIALTY CHEM

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS7273523B2Facilitated releaseTo promote metabolismBiocideSurgical adhesivesPowder mixturePhosphate

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

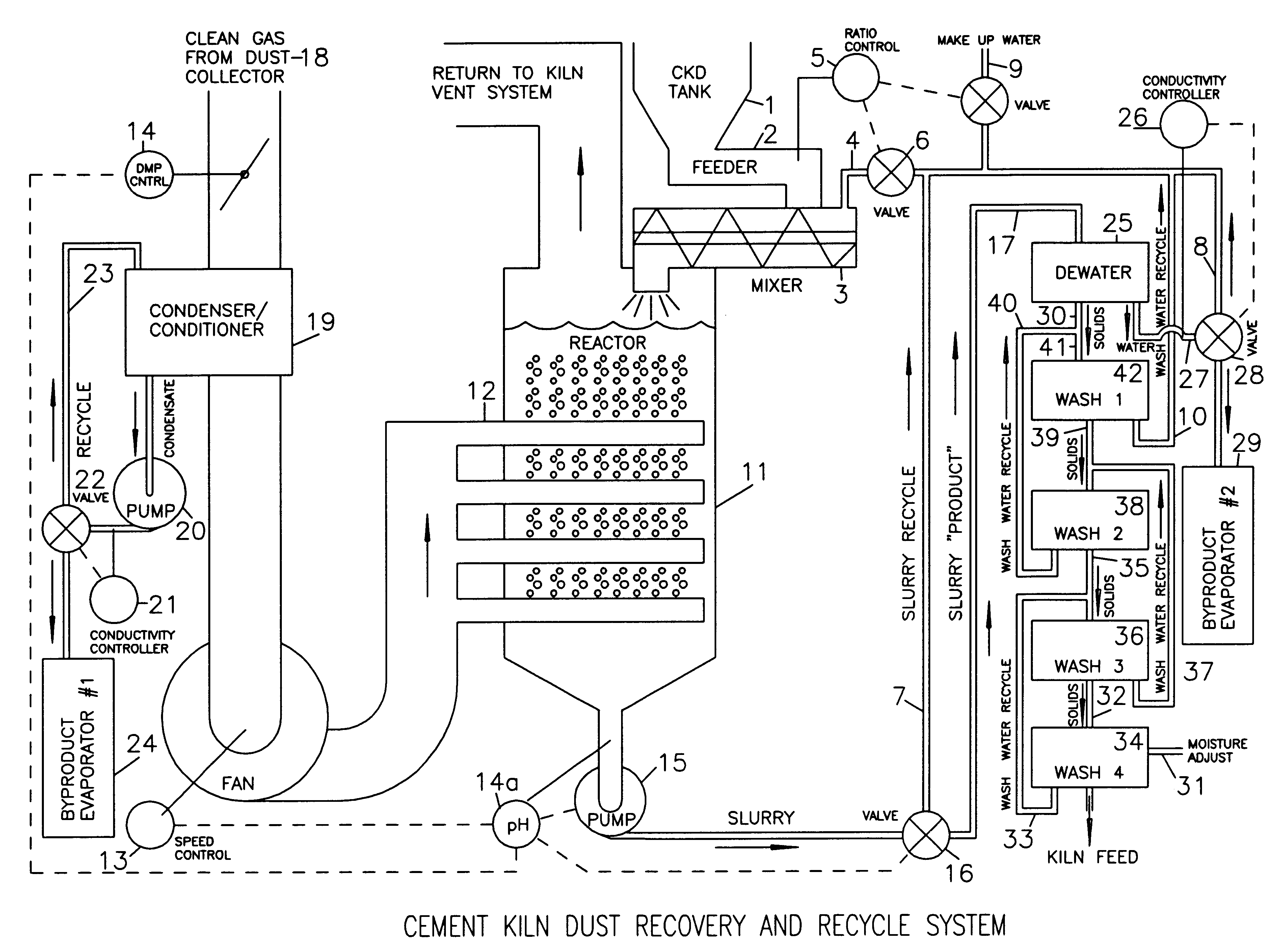

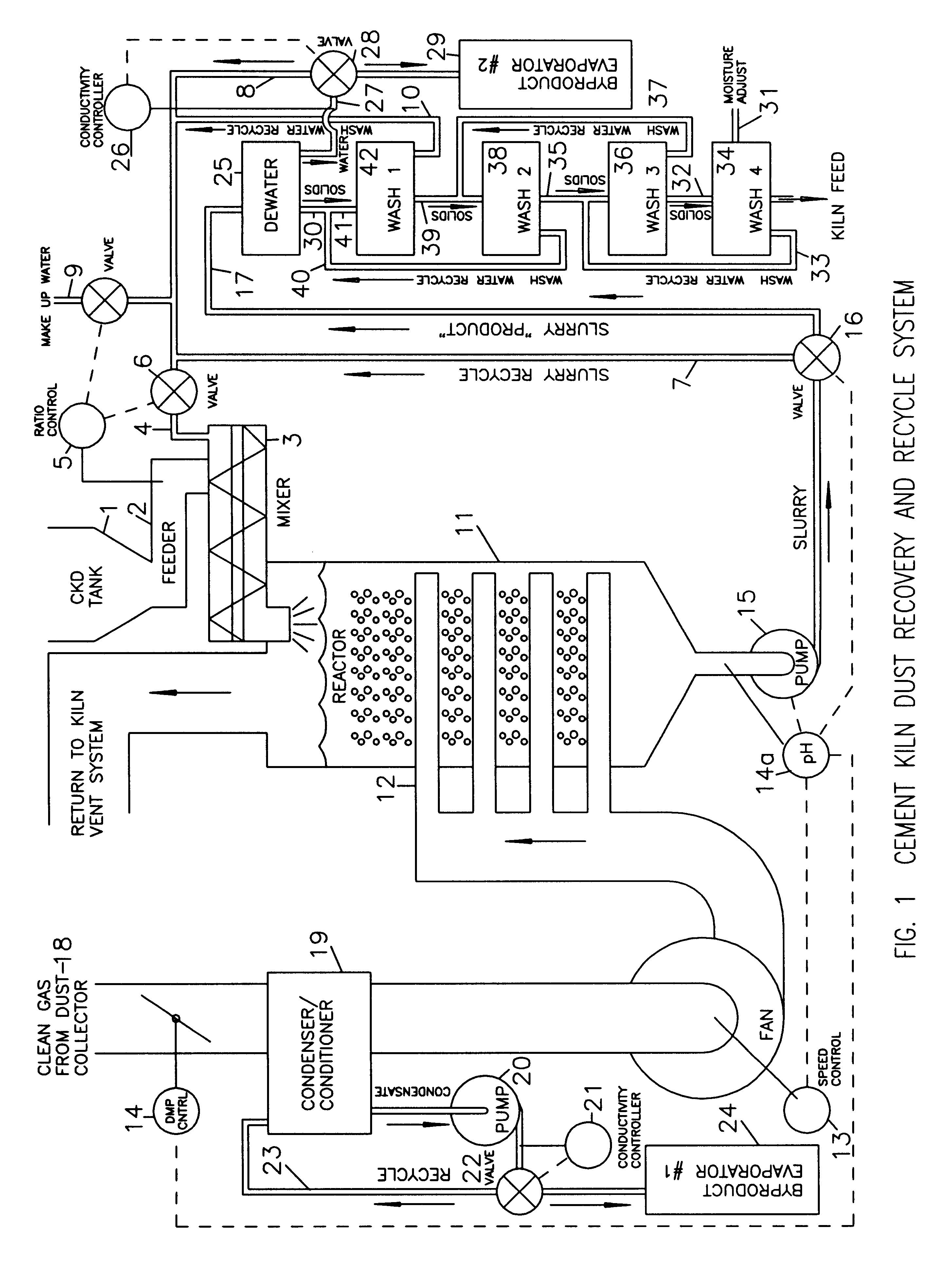

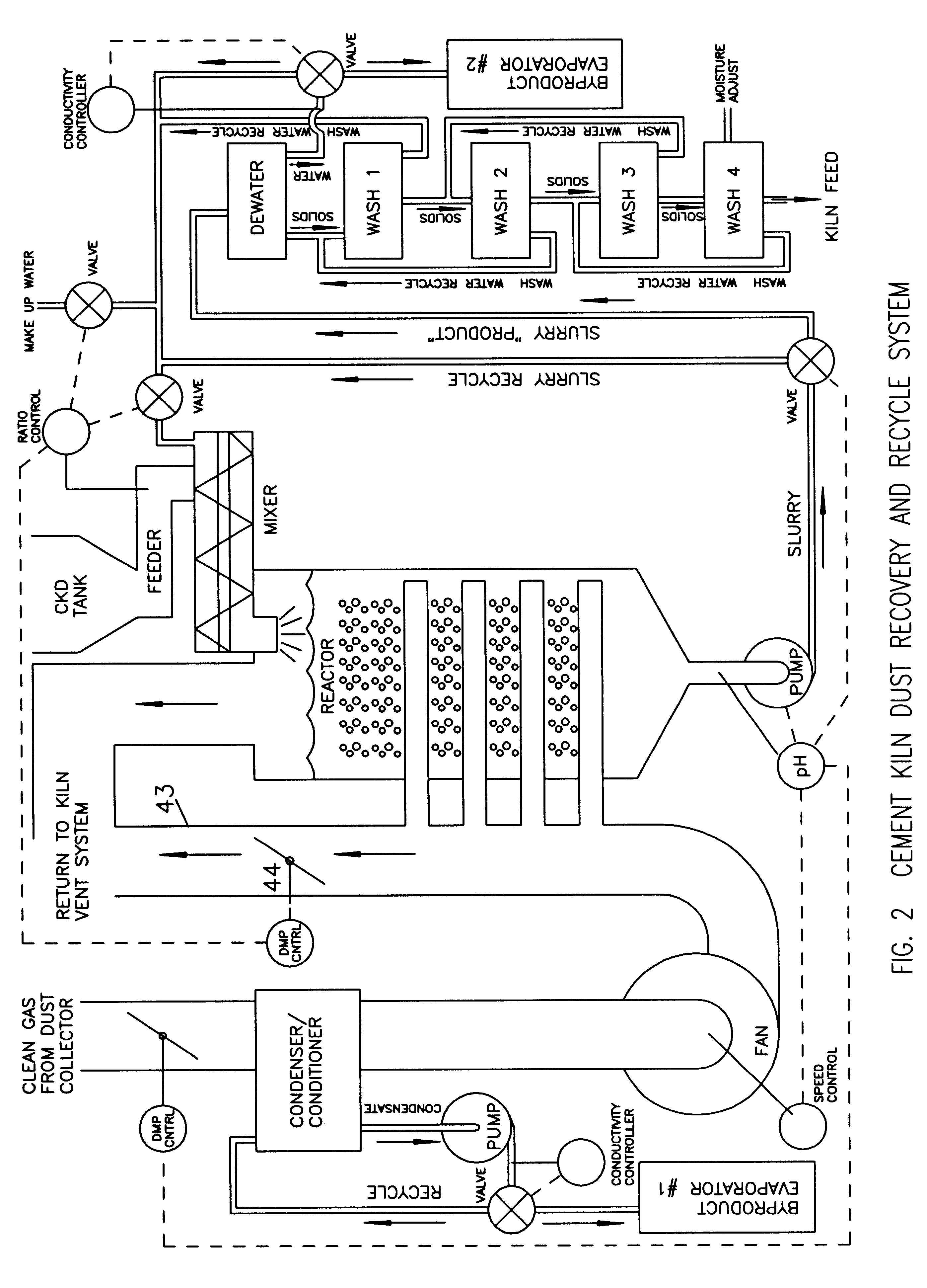

Method of treating cement kiln dust for recovery and recycle

Fresh or stockpiled cement kiln dust is moistened with sufficient water so that the amount of total free and combined water relative to dust is about 3 parts water to 1 part dust by mass, or less. The wet solids are treated with carbon dioxide to convert compounds, such as calcium hydroxide, to carbonates, such as calcium carbonate. The degree of carbonation is controlled so that the solubility of calcium becomes minimum for the dust being treated; this is also when hydroxyl and bicarbonate ions in solution are about at their minima. As the carbonation reactions occur, the water combined in hydroxides is released as free water so that the mixture becomes a slurry and the potentially soluble alkalies and sulfate (and any chlorides present) are released to the liquid phase. The solids are separated from the liquid, and the solids, which may be washed, provide a material suitable for return as feed to the kiln. The liquid, which contains the dissolved alkali compounds, is recycled to reclaim additional dust or treated to recover alkali salts when the alkali salts are sufficiently concentrated.While any source of carbon dioxide may be used, the preferred source is exit gases from the kiln. The gases are conditioned by condensation of water and removal of ammonium compounds, such as sulfate and chloride. The conditioning condensate may be treated to recover useful byproduct salts.

Owner:GEBHARDT RONALD FR

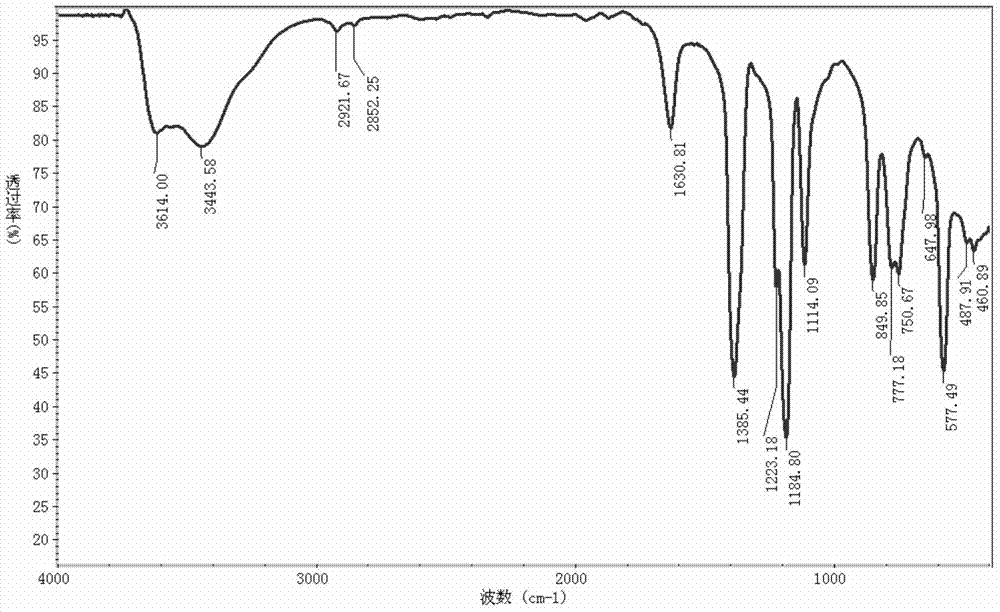

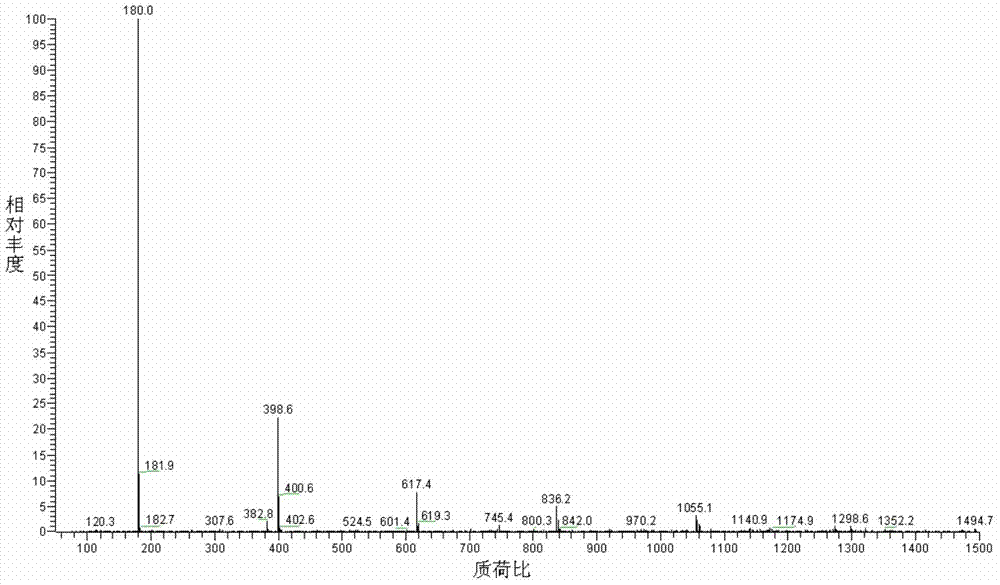

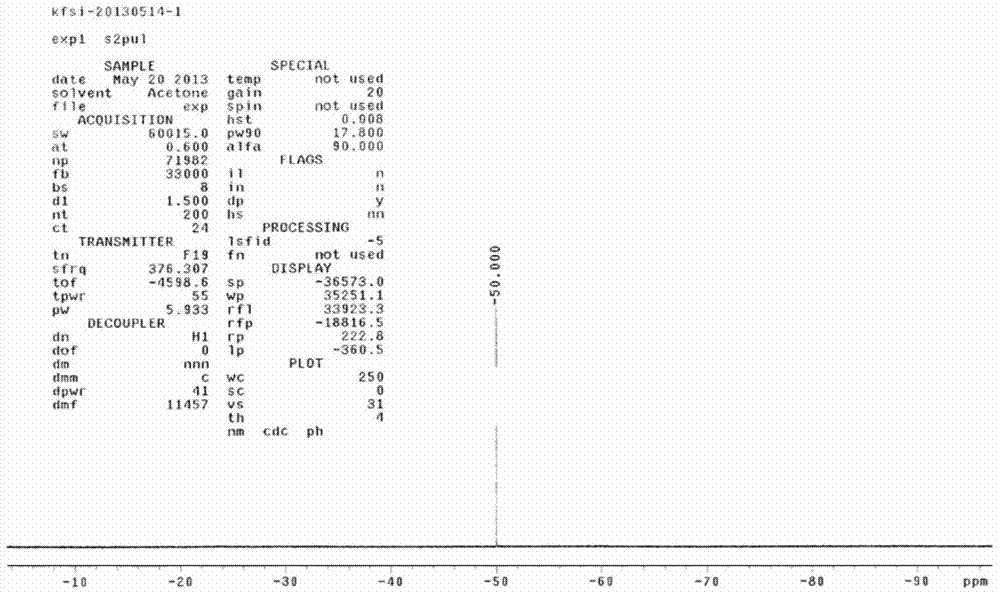

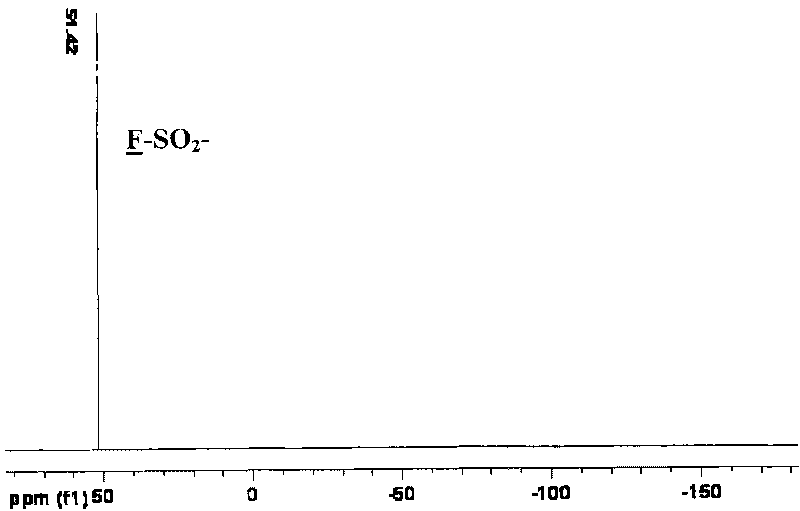

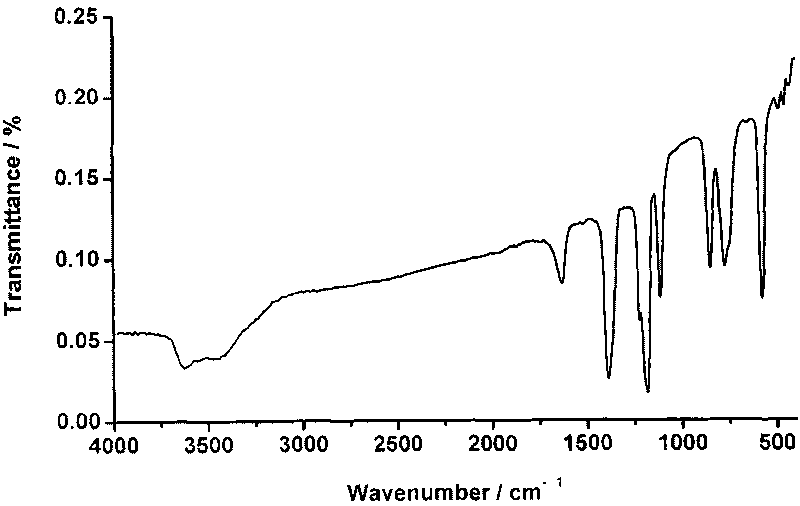

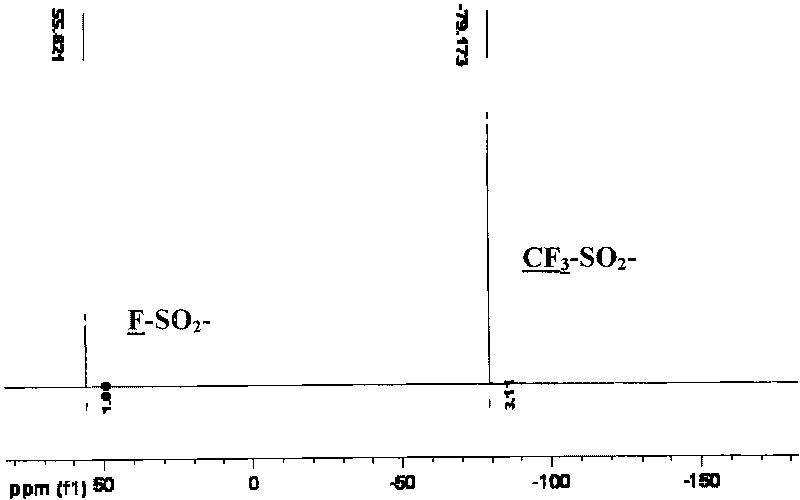

Preparation method of lithium bis(fluorosulfonyl)amide

The present invention provides a preparation method of lithium bis(fluorosulfonyl)amide. The method comprises the following steps: A) reacting chlorosulfuric acid with ammonia in the presence of an organic base to obtain organic alkali salt of bis(fluorosulfonyl)amide; B) mixing the bis(fluorosulfonyl)amide obtained in the step A) with HF for a fluorinated reaction to obtain an organic alkali salt of bis(fluorosulfonyl)amide; C) mixing the organic alkali salt of bis(fluorosulfonyl)amide obtained in the step B) with an alkaline substance for a neutralization reaction to obtain a bis(fluorosulfonyl)amid metal salt crude product; D) purifying the bis(fluorosulfonyl)amid metal salt crude product obtained in the step C) to obtain bis(fluorosulfonyl)amid metal salt; and E) mixing the bis(fluorosulfonyl)amid metal salt obtained in the step D) with a lithium reagent for a replacement reaction, so as to obtain lithium bis(fluorosulfonyl)amide. The preparation method provided by the invention has the characteristics of low raw material cost, low impurity content in the product and high yield of lithium bis(fluorosulfonyl)amide.

Owner:湖南福邦新材料有限公司

Ionic liquid prepared through diimine (vikane) and (perfluoroalkglsulfonyl fluorosulfonyl group) imine alkali salt

InactiveCN101747243APromote hydrolysisLow melting pointElectrolytic capacitorsGroup 5/15 element organic compoundsSulfoniumLithium-ion battery

The invention provides an ionic liquid consisting of the anions of diimine (vikane) and (perfluoroalkglsulfonyl fluorosulfonyl group) imine and the cation of sulfonium salt, ammonium salt or phosphor salt, as well as method for preparing the ionic liquid through diimine (vikane) and (perfluoroalkglsulfonyl fluorosulfonyl group) imine alkali salt. The ionic liquid can be used as an electrolyte material and applied on the fields like secondary lithium ion batteries, super capacitors, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

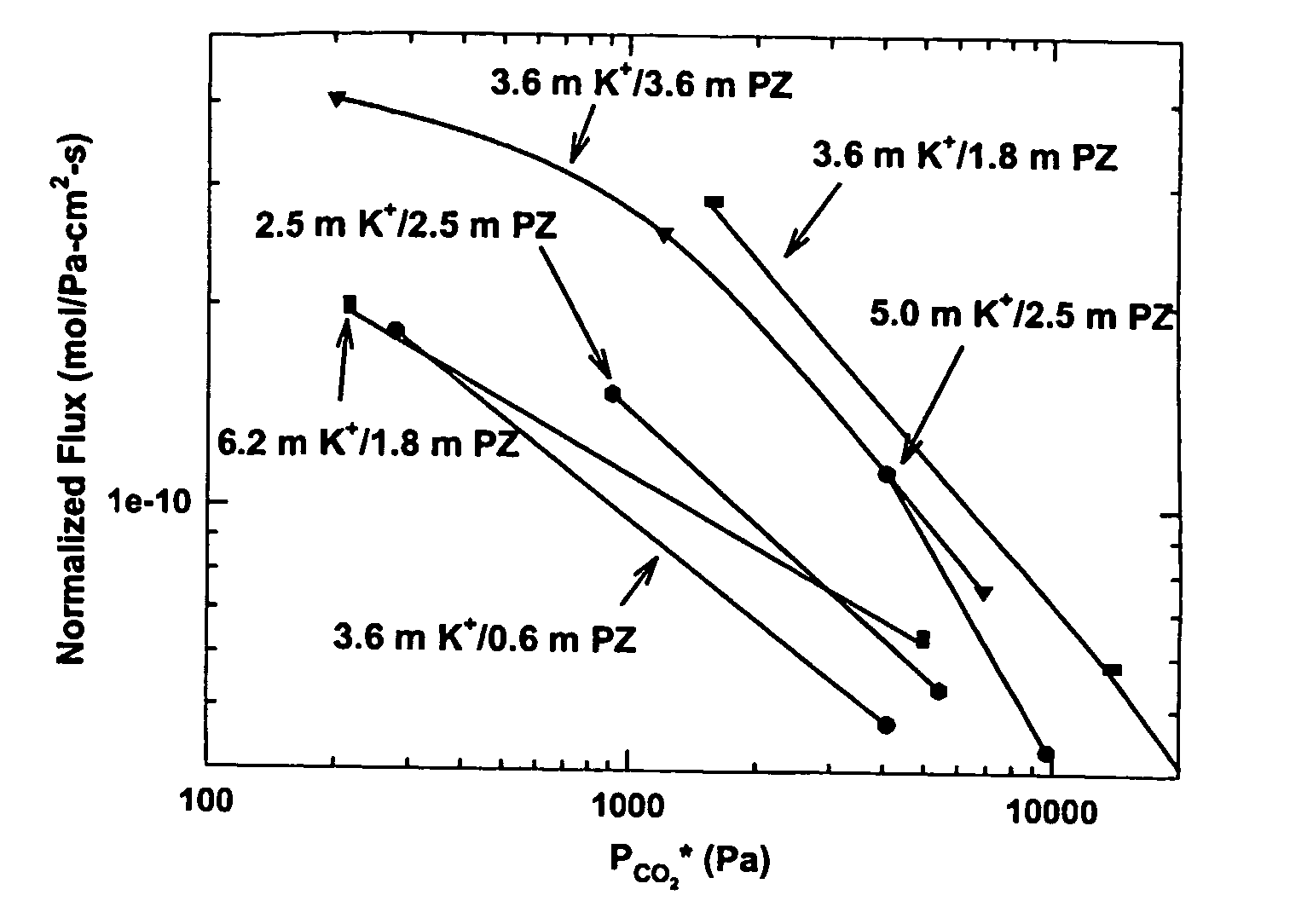

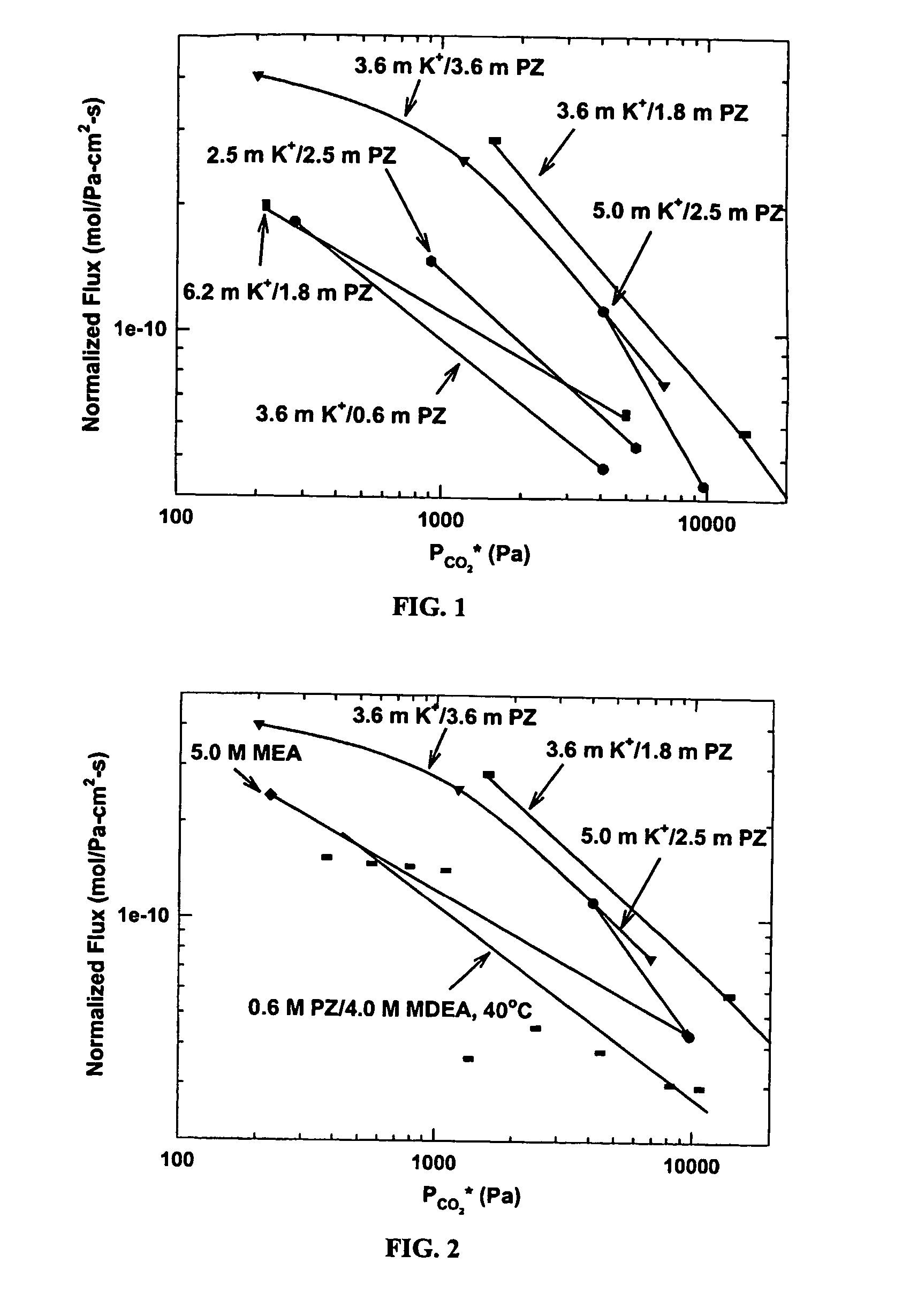

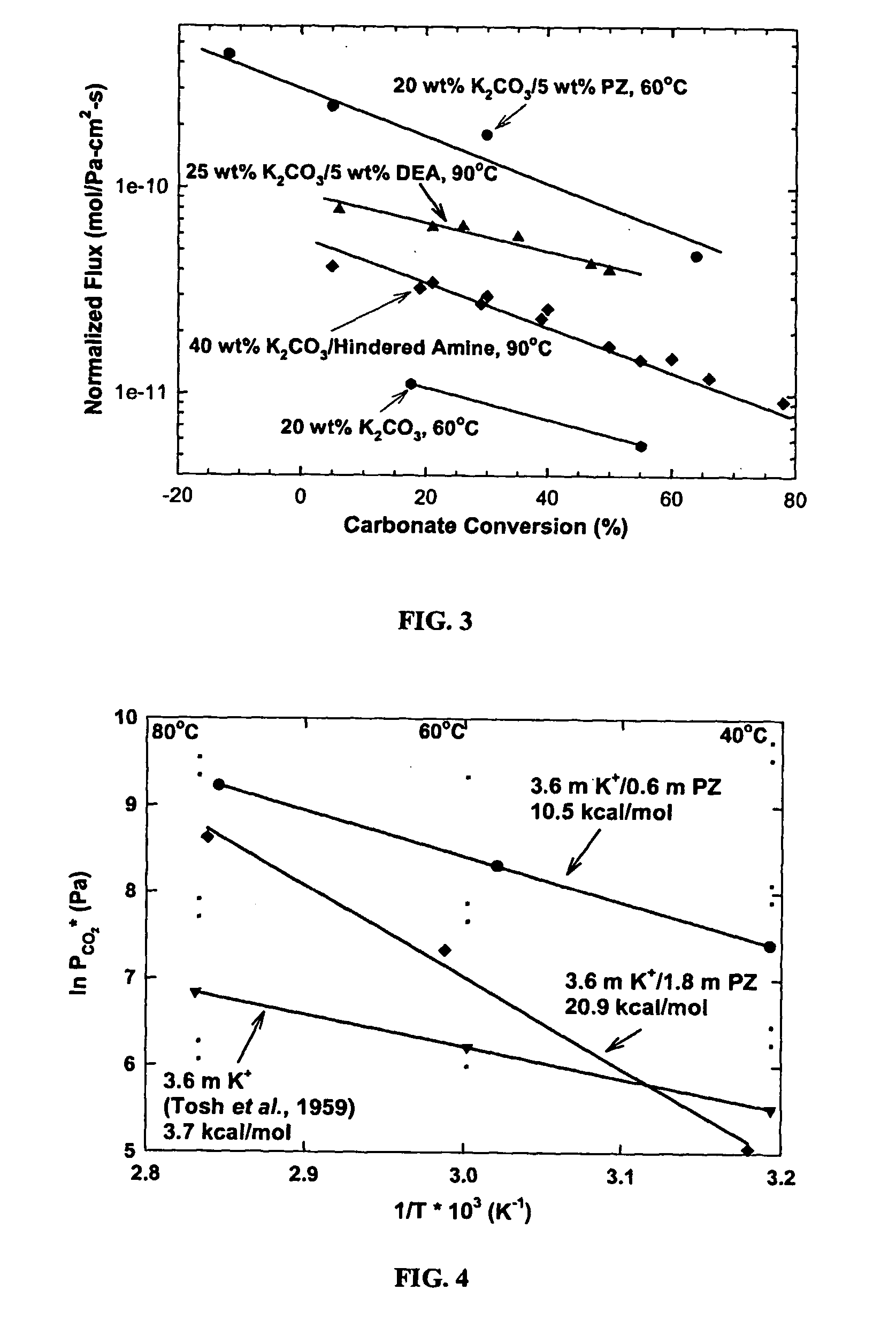

Polyamine/alkali salt blends for carbon dioxide removal from gas streams

InactiveUS20070044658A1Increase chanceReduce absorptionProductsGas treatmentSolventPotassium carbonate

Novel solvents and methods of use for the removal of CO2 from flue gas, natural gas, hydrogen gas, synthesis gas, and other process and waste gas streams are provided. The solvent contains an alkali salt such as potassium carbonate and a polyamine such as piperazine (PZ) where the polyamine concentration is at least 1.5 equivalents / Kg H2O and the alkali salt concentration is at least 0.5 equivalents / Kg H2O. The preferred alkali salt / polyamine ratio is from approximately 1:2 to 2:1, and no additional alcohol is required for solubilizng the PZ. This chemical solvent and method of use provides efficient and effective removal of CO2 from gaseous streams and other sources.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

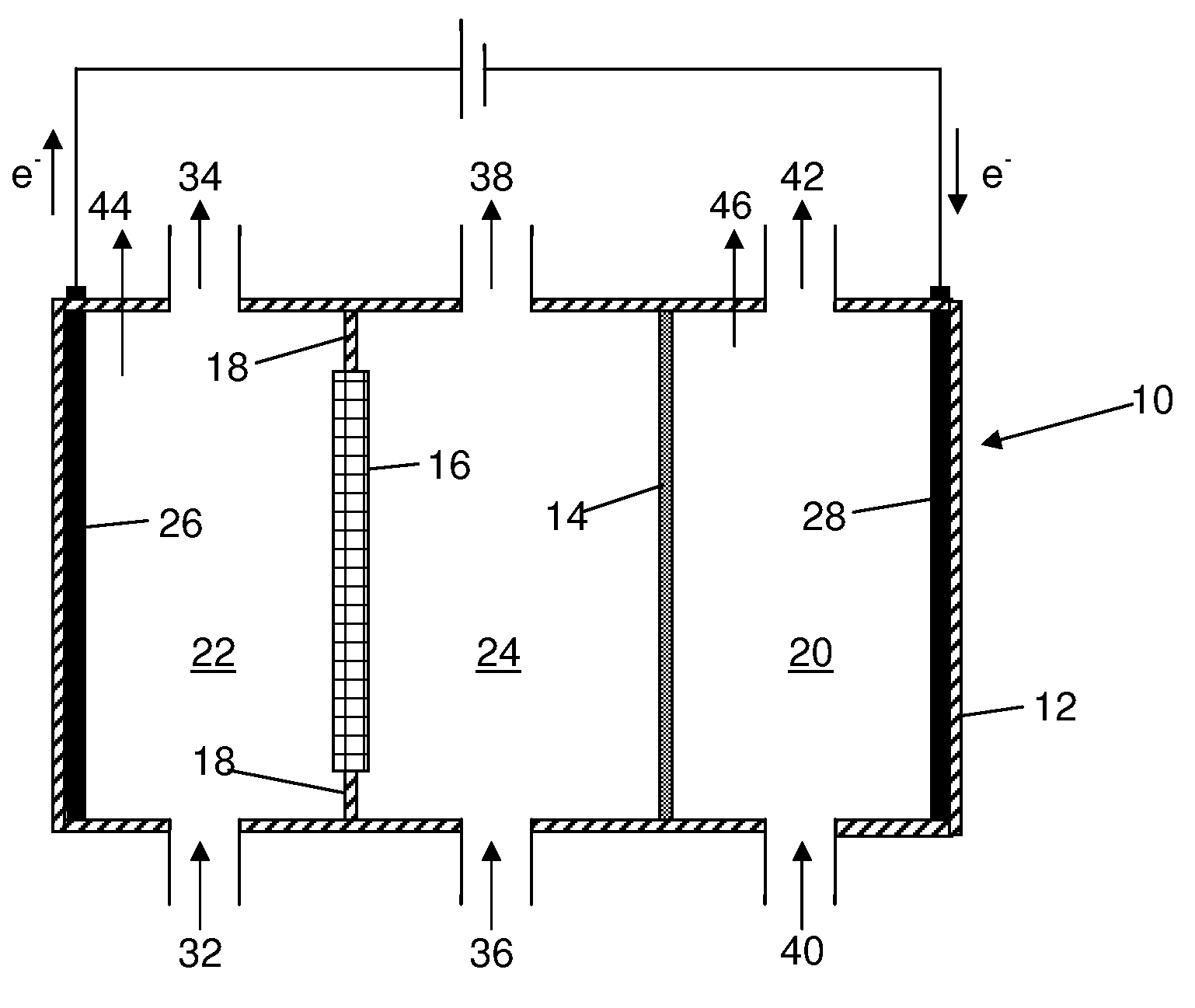

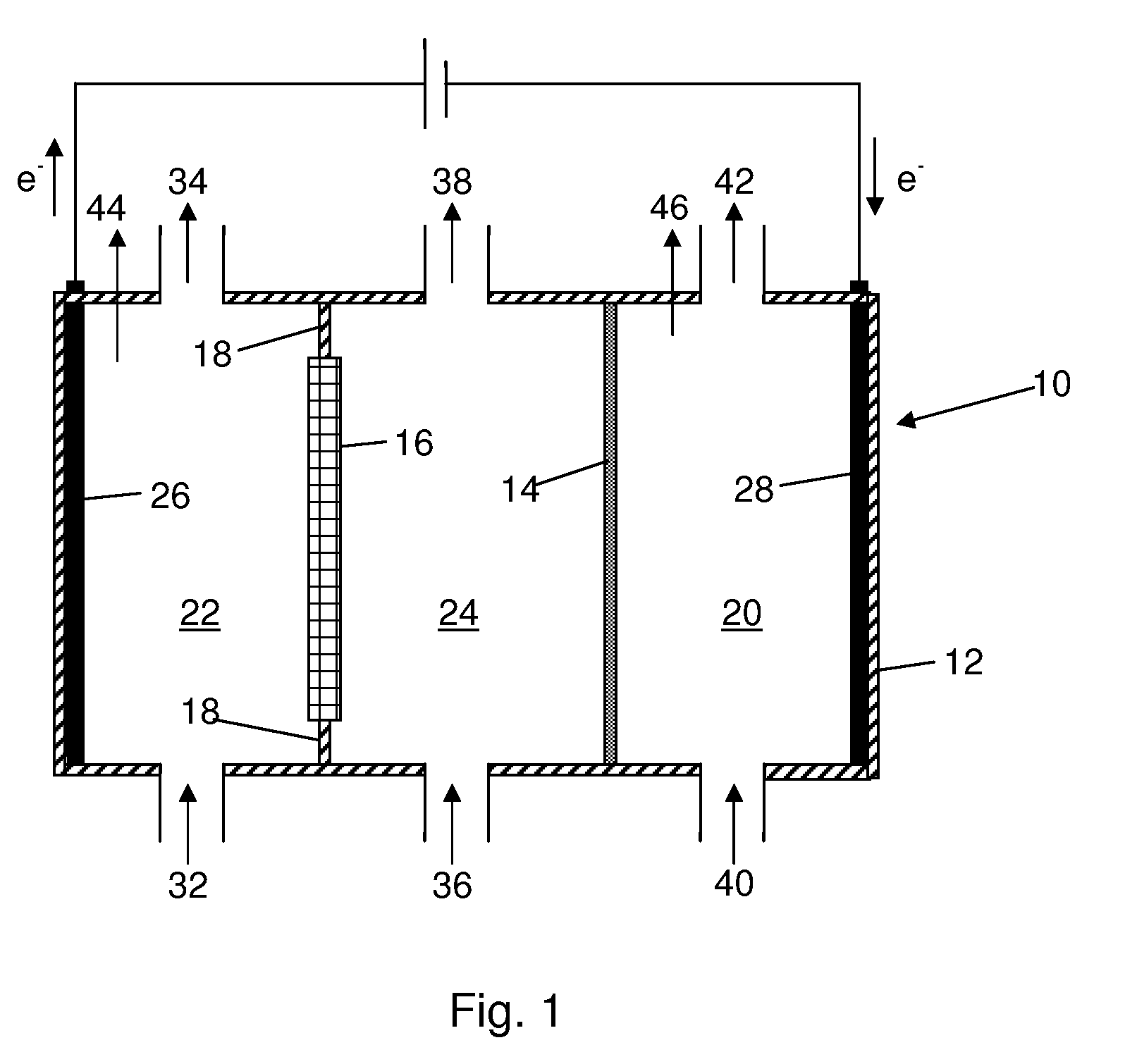

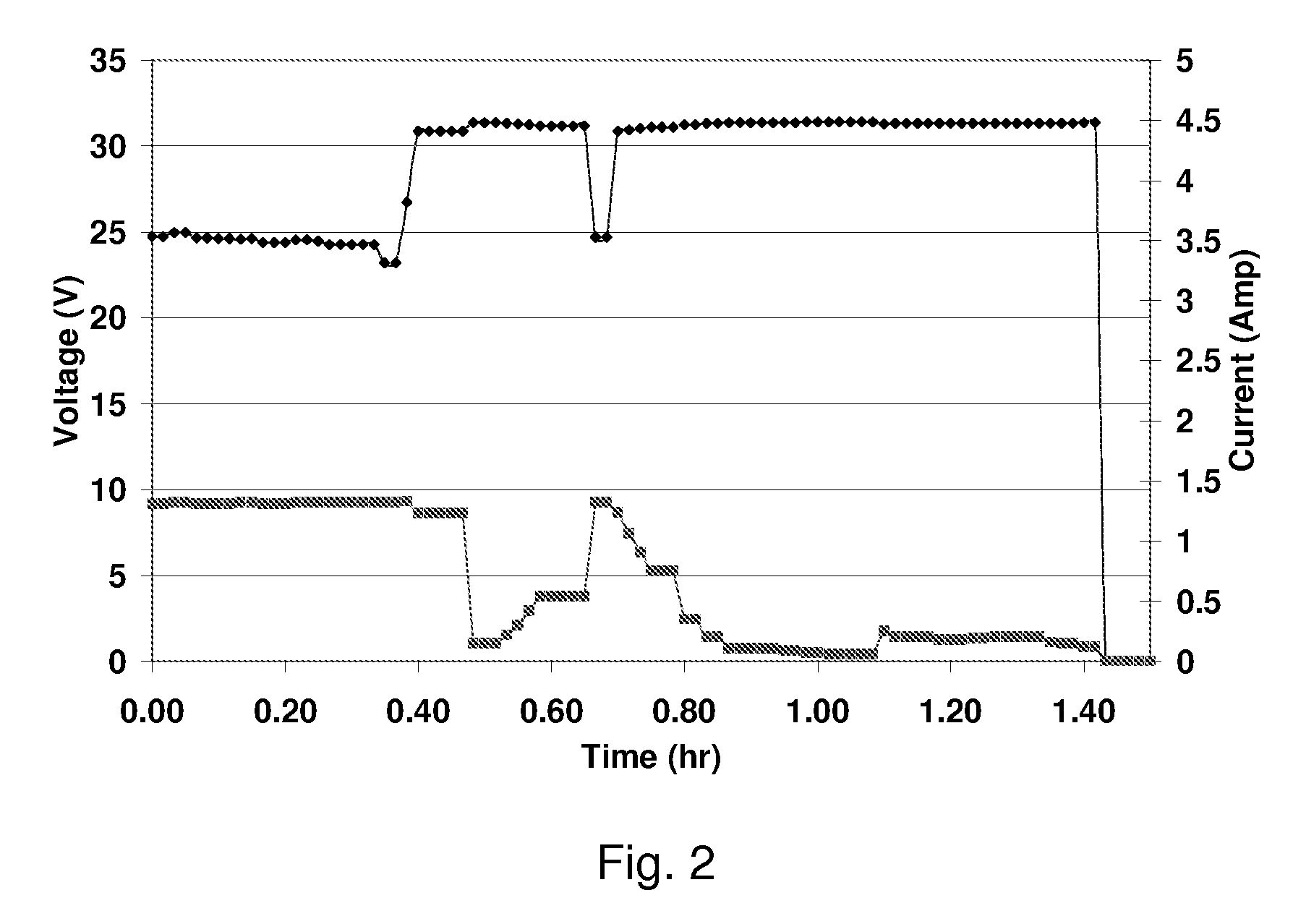

Electrolytic method to make alkali alcoholates using ion conducting alkali electrolyte/seperator

ActiveUS20080142373A1Efficient executionElectrolysis componentsElectrolytic organic reductionAlkali ionsAlcohol

Alkali alcoholates, also called alkali alkoxides, are produced from alkali metal salt solutions and alcohol using a three-compartment electrolytic cell. The electrolytic cell includes an anolyte compartment configured with an anode, a buffer compartment, and a catholyte compartment configured with a cathode. An alkali ion conducting solid electrolyte configured to selectively transport alkali ions is positioned between the anolyte compartment and the buffer compartment. An alkali ion permeable separator is positioned between the buffer compartment and the catholyte compartment. The catholyte solution may include an alkali alcoholate and alcohol. The anolyte solution may include at least one alkali salt. The buffer compartment solution may include a soluble alkali salt and an alkali alcoholate in alcohol.

Owner:ENLIGHTEN INNOVATIONS INC

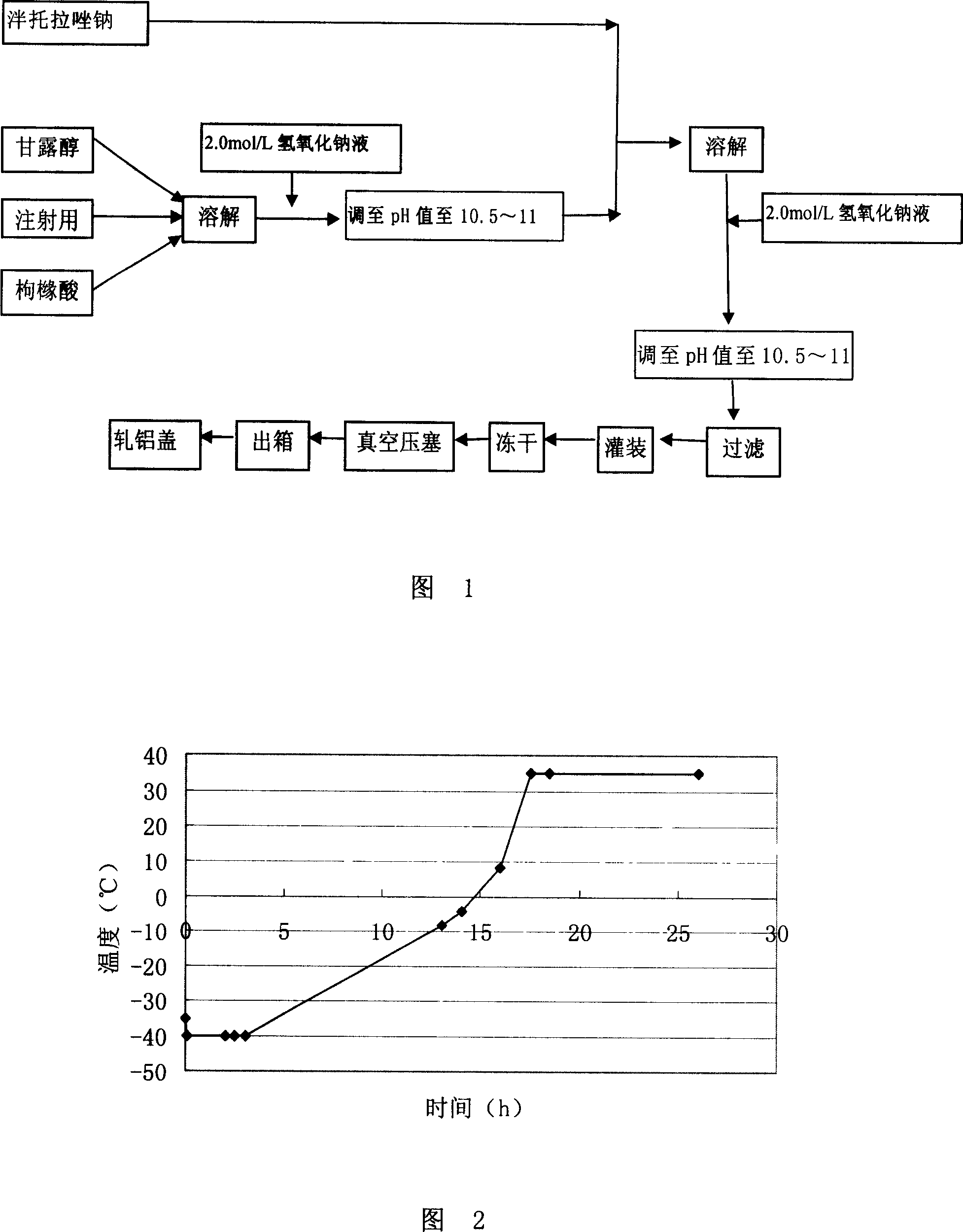

Pantoprazole sodium freeze dried injection and preparation method thereof

InactiveCN101011397AReduce dosageIncrease dosagePowder deliveryOrganic active ingredientsInorganic saltsFreeze-drying

The invention relates to a method for preparing batoracosodium freeze dried, whose pH value is 9.5-11.5. And the invention comprises 1 deal of batoracosodium, 0.5-1 deals of supporting agent, 0-0.06 deals of weak-acid strong-alkali salt, and some inorganic alkali. And the preparation comprises that 1, preparing materials; 2, dissolving the supporting agent and weak-acid strong-alkali salt via injection water, using inorganic salt to adjust the pH value to 9.5-11.5, adding batoracosodium, dissolving and using inorganic salt to adjust the pH value to 9.5-11.5; 3, filtering; 4, freezing and drying to obtain the final product. The invention can be used treat peptic ulcer, ulcer bleed, or the like.

Owner:LIVZON PHARM GRP INC

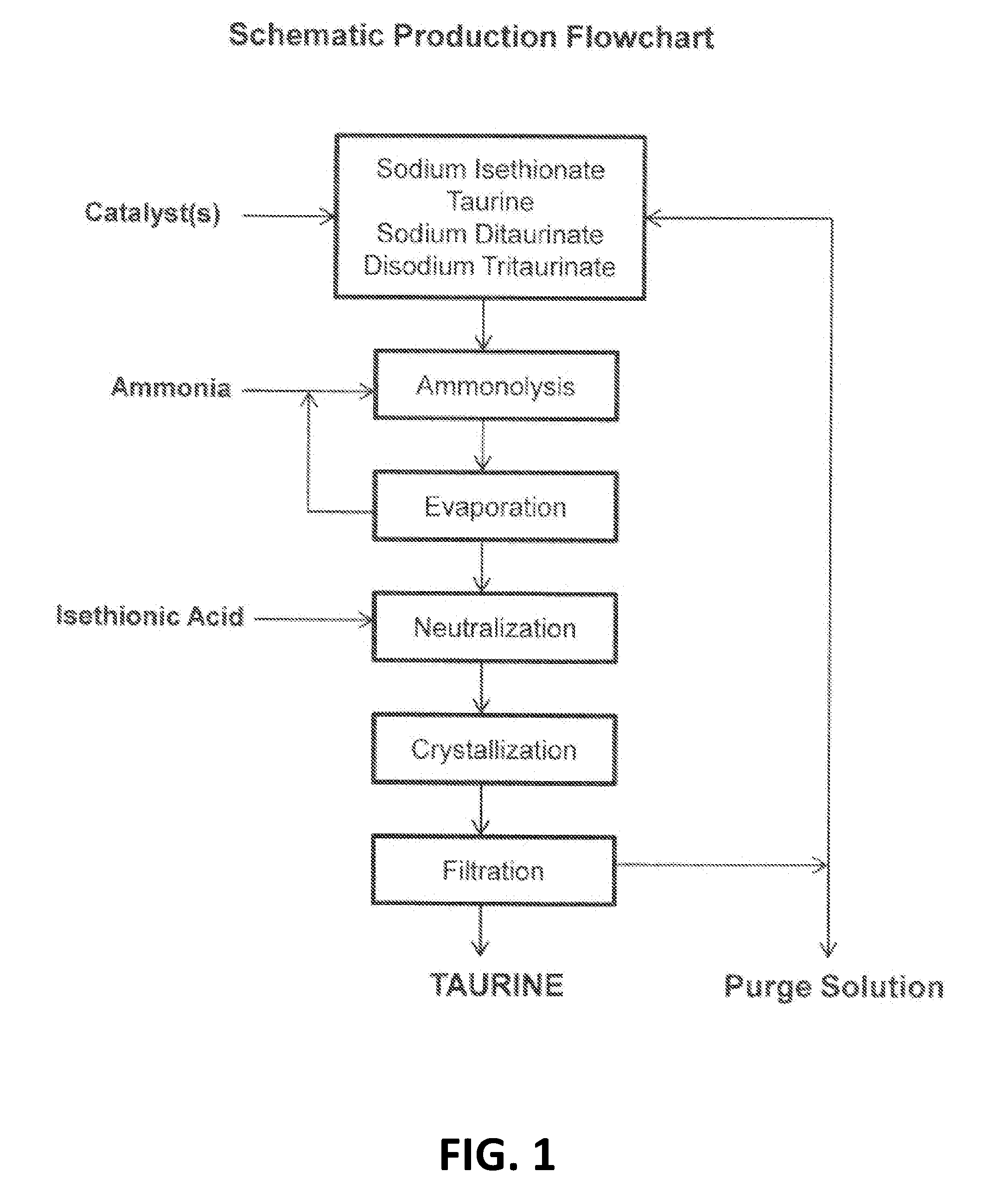

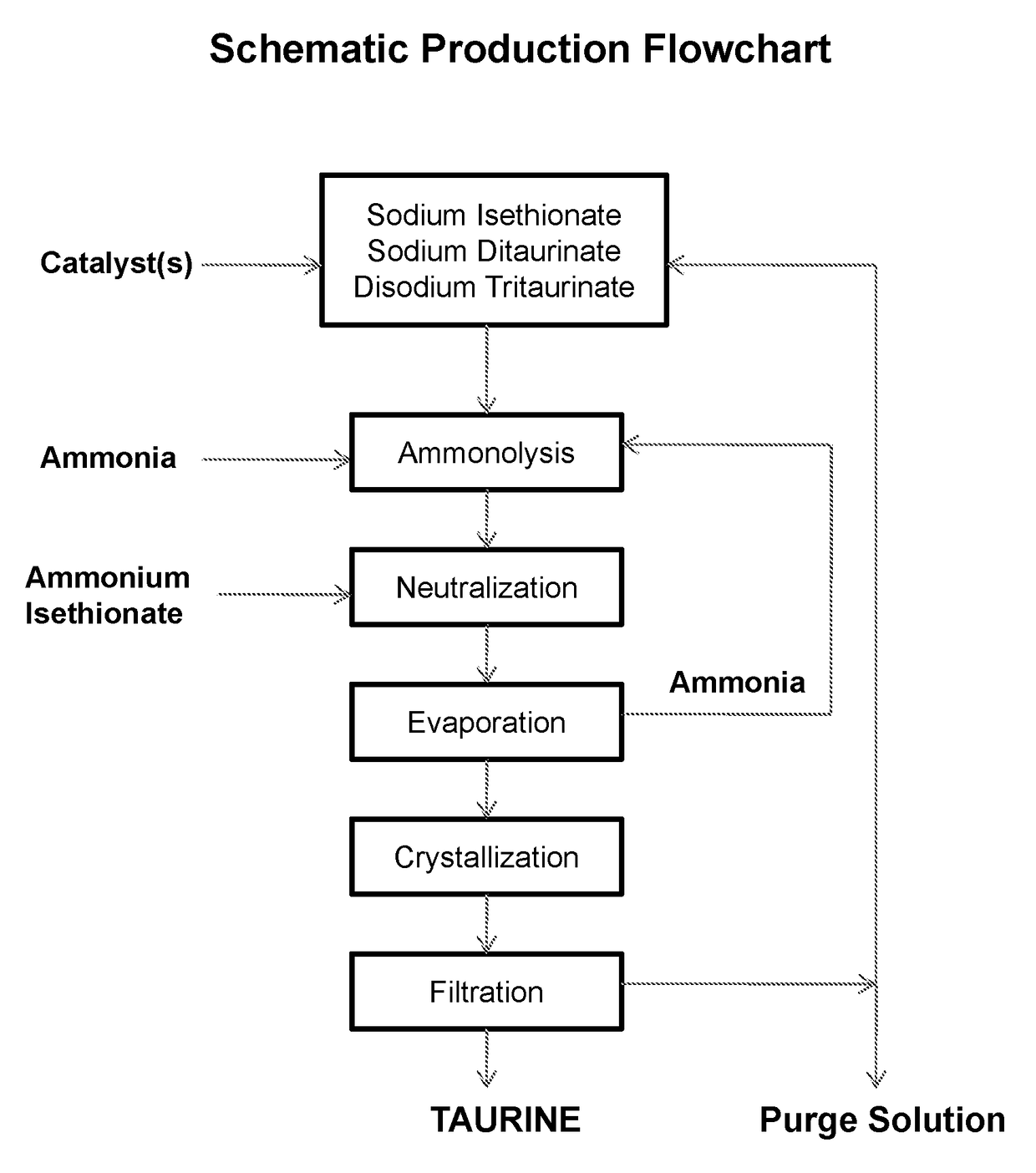

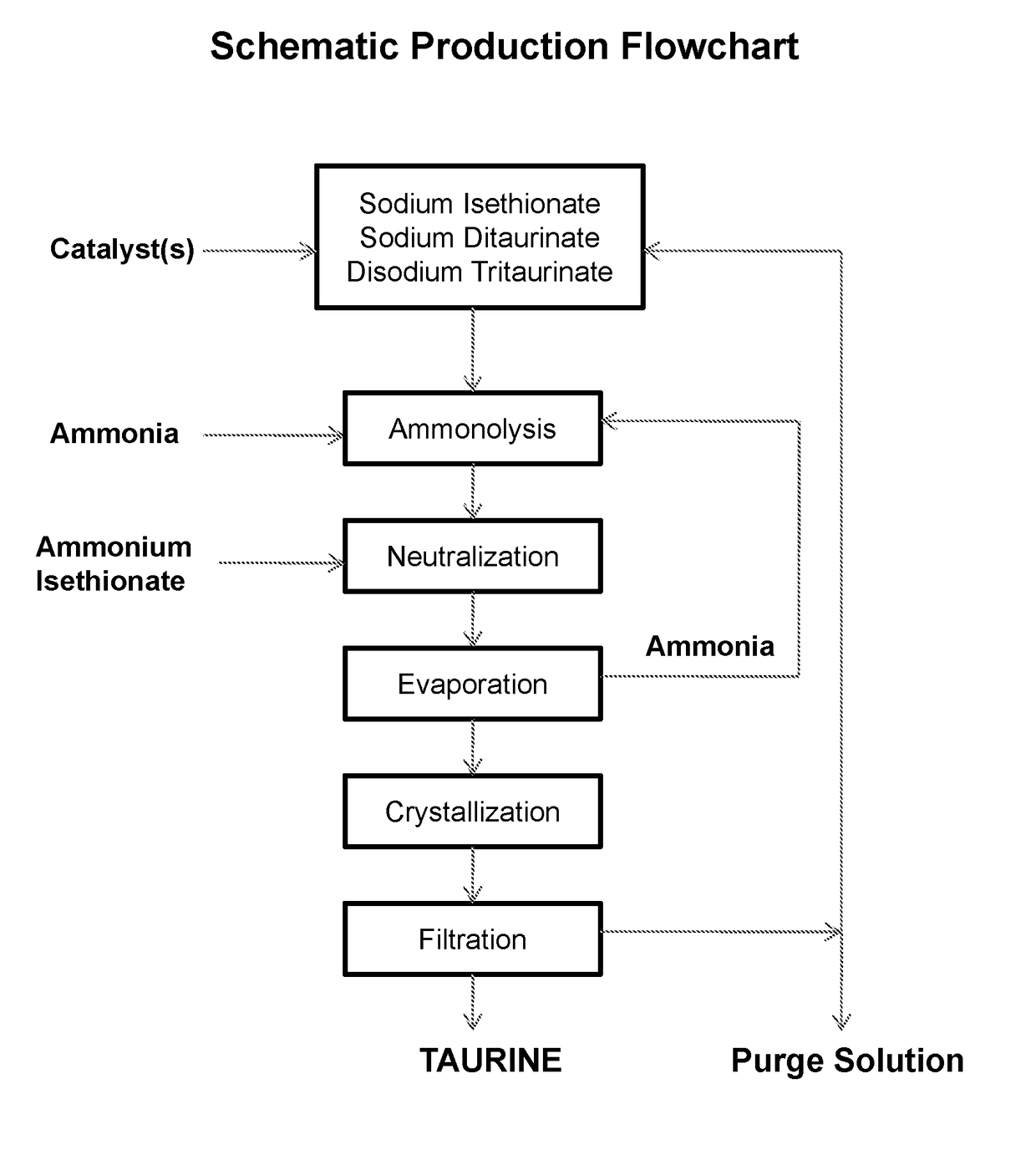

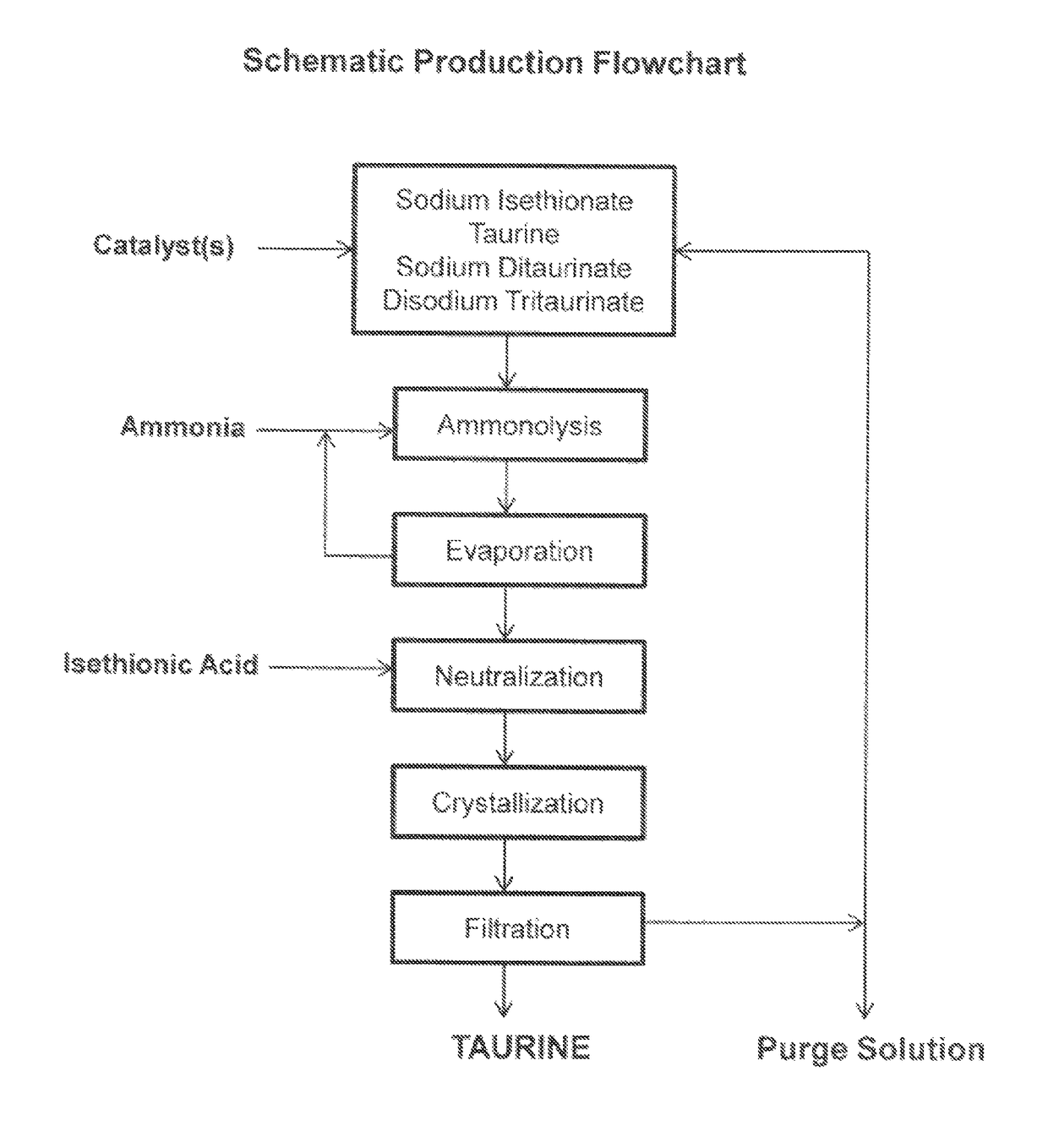

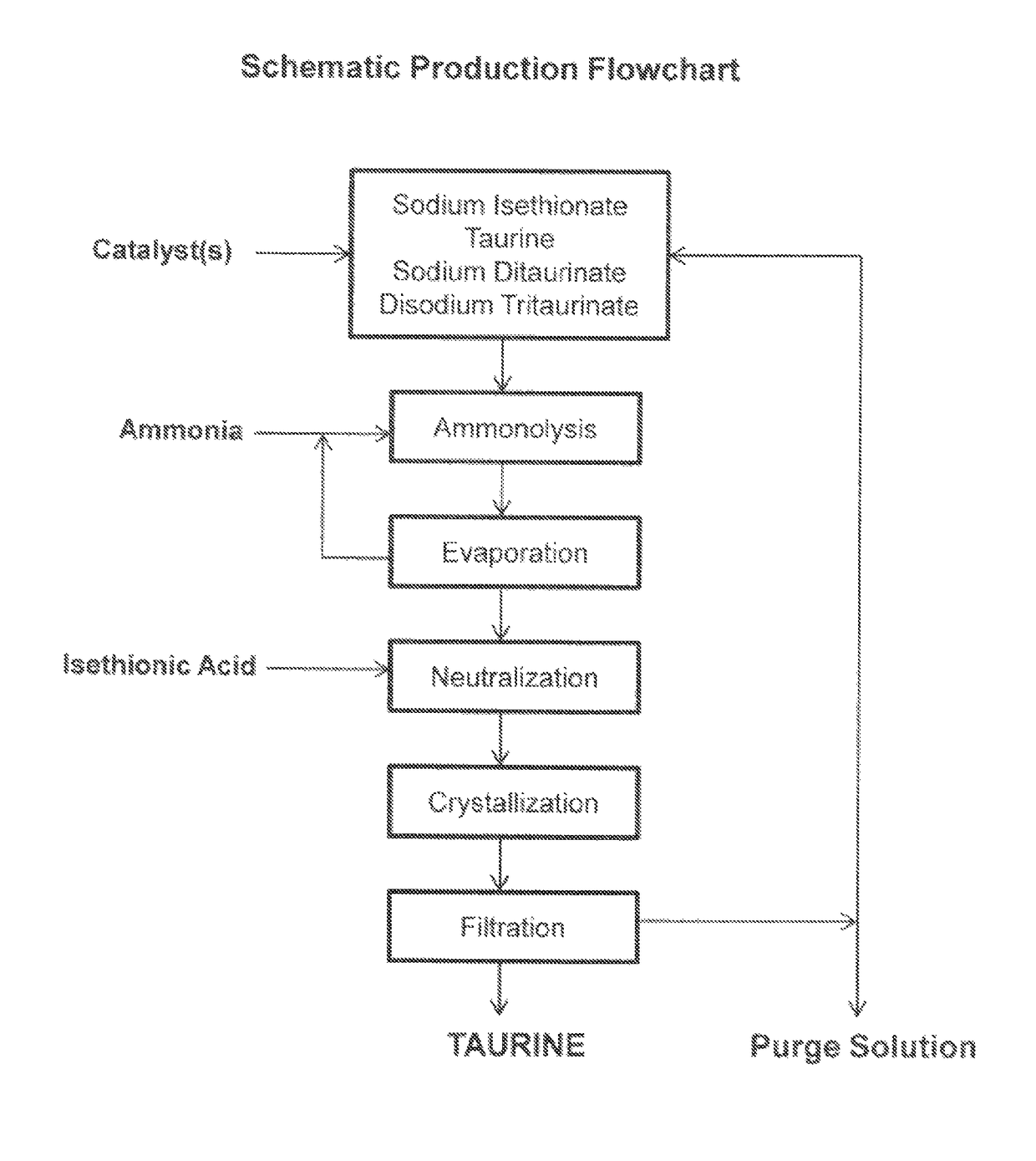

Cyclic process for producing taurine

ActiveUS20160355470A1Reduce wasteImprove production yieldOrganic compound preparationSulfonic acids salts preparationAlkali saltSulfite

There is disclosed a process for producing taurine by the ammonolysis of alkali isethionate in the presence of alkali ditaurinate or alkali tritaurinate, or their mixture, to inhibit the formation of byproducts and to continuously convert the byproducts of the ammonolysis reaction to alkali taurinate. Alkali taurinate is neutralized with isethionic acid to obtain taurine and to regenerate alkali isethionate. The production yield is increased to from 90% to nearly quantitative. The ammonolysis reaction is catalyzed by alkali salts of hydroxide, sulfate, sulfite, phosphate, or carbonate.

Owner:VITAWORKS IP LLC

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS20050150520A1Reduced pHDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

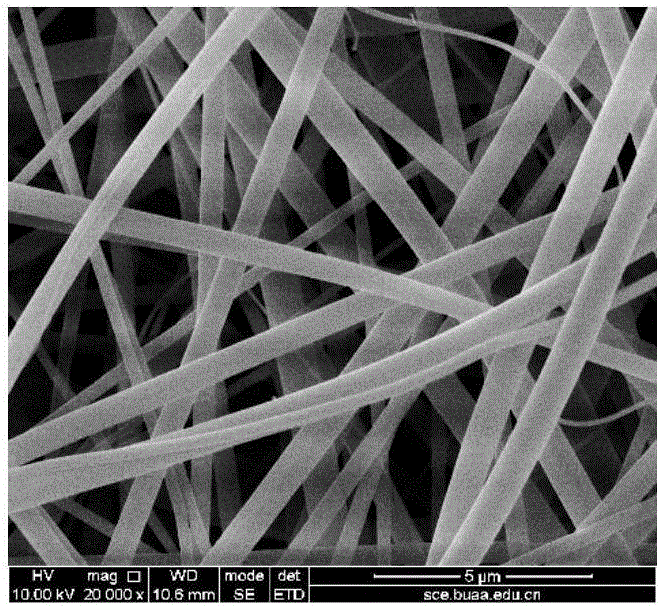

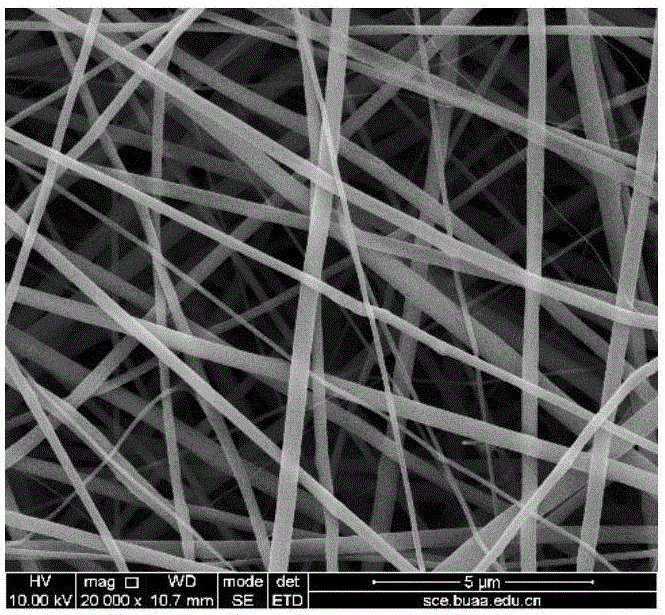

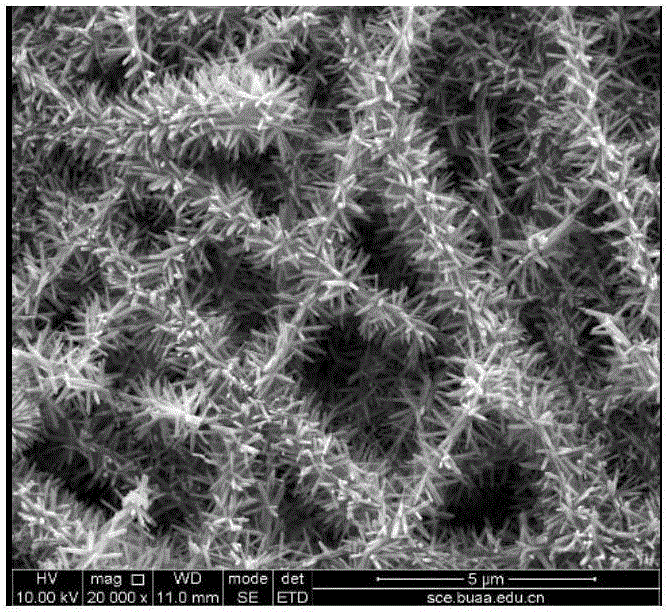

Preparation method of super wetting titanium dioxide nanorod porous membrane and application of super wetting titanium dioxide nanorod porous membrane to emulsion separation

ActiveCN106731012AGood environmental stabilityRealize the separation functionMembranesSemi-permeable membranesFiberMicro nano

The invention discloses a preparation method of a super wetting titanium dioxide nanorod porous membrane and application of the super wetting titanium dioxide nanorod porous membrane to emulsion separation, and belongs to the technical field of function materials. The method comprises the following steps: preparing a PVP / TiO2 composite fiber membrane through an electrospinning technology, and drying the composite fiber membrane in a drying oven; laying the dried composite fiber membrane in a muffle furnace for calcining the composite fiber membrane for a certain period, removing organic carbon in the composite fiber membrane, calcining the composite fiber membrane to form an inorganic TiO2 fiber membrane, vertically laying the calcined inorganic TiO2 fiber membrane into a hydrothermal polymeric pecursor solution in a polytetrafluoroethylene liner, and performing a hydrothermal reaction, so as to obtain a super-hydrophilicity and underwater super-oleophobicity porous super wetting micro-nano composite structure membrane. The obtained membrane has high environmental stability, namely acid resistance, alkali resistance and salt resistance, and can be applied to sewage treatment in harsh acid and alkali salt environments, so that the efficient separation of a corrosive emulsion is realized, and e the application value is high. The preparation method is simple, and is convenient, efficient and rapid for emulsion separation.

Owner:BEIHANG UNIV

Salt of leonurine and its preparation

InactiveCN1415603ALess irritatingGuaranteed stabilityOrganic active ingredientsOrganic chemistryLeonurineOrganic acid

Owner:李晓祥

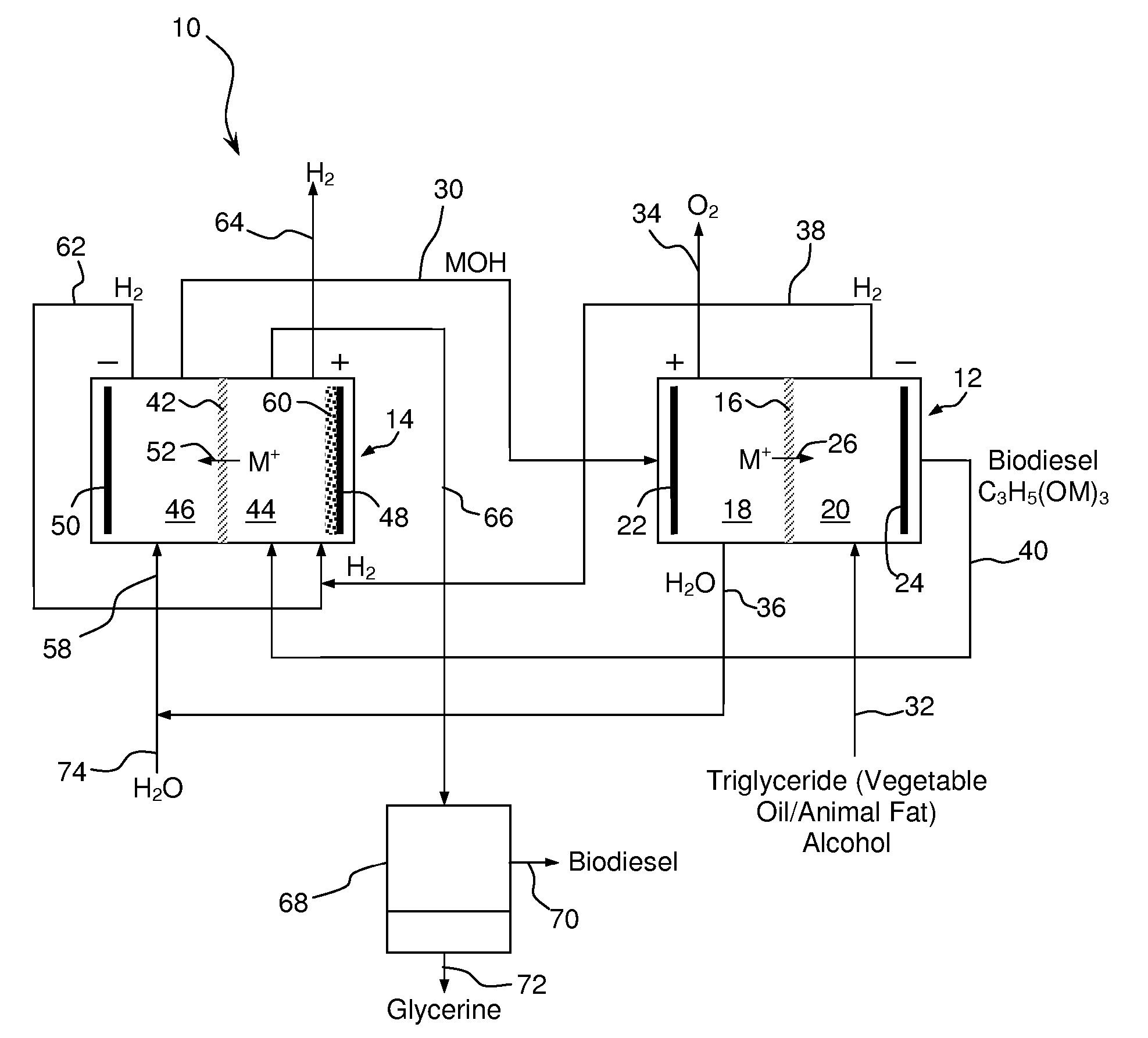

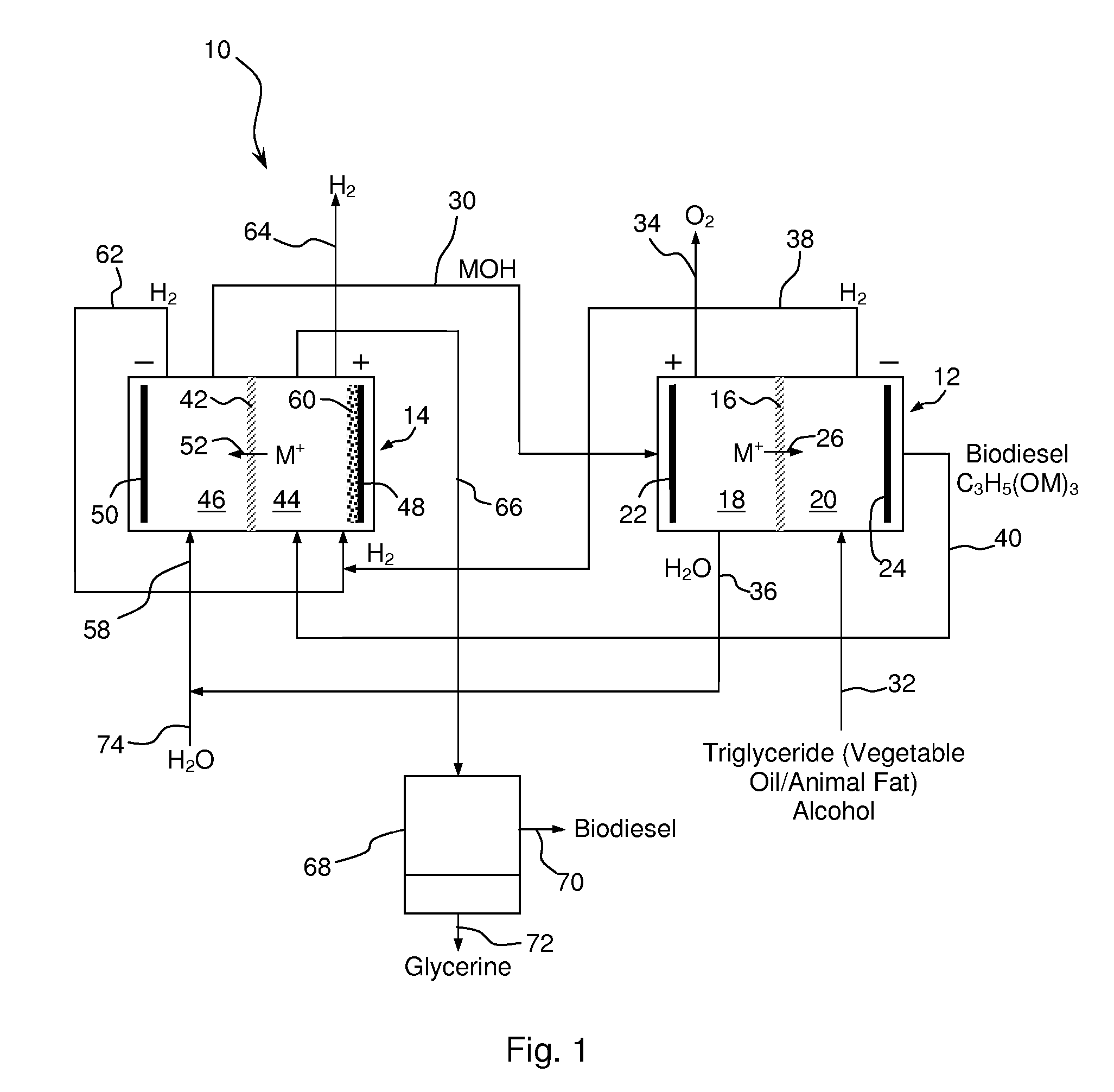

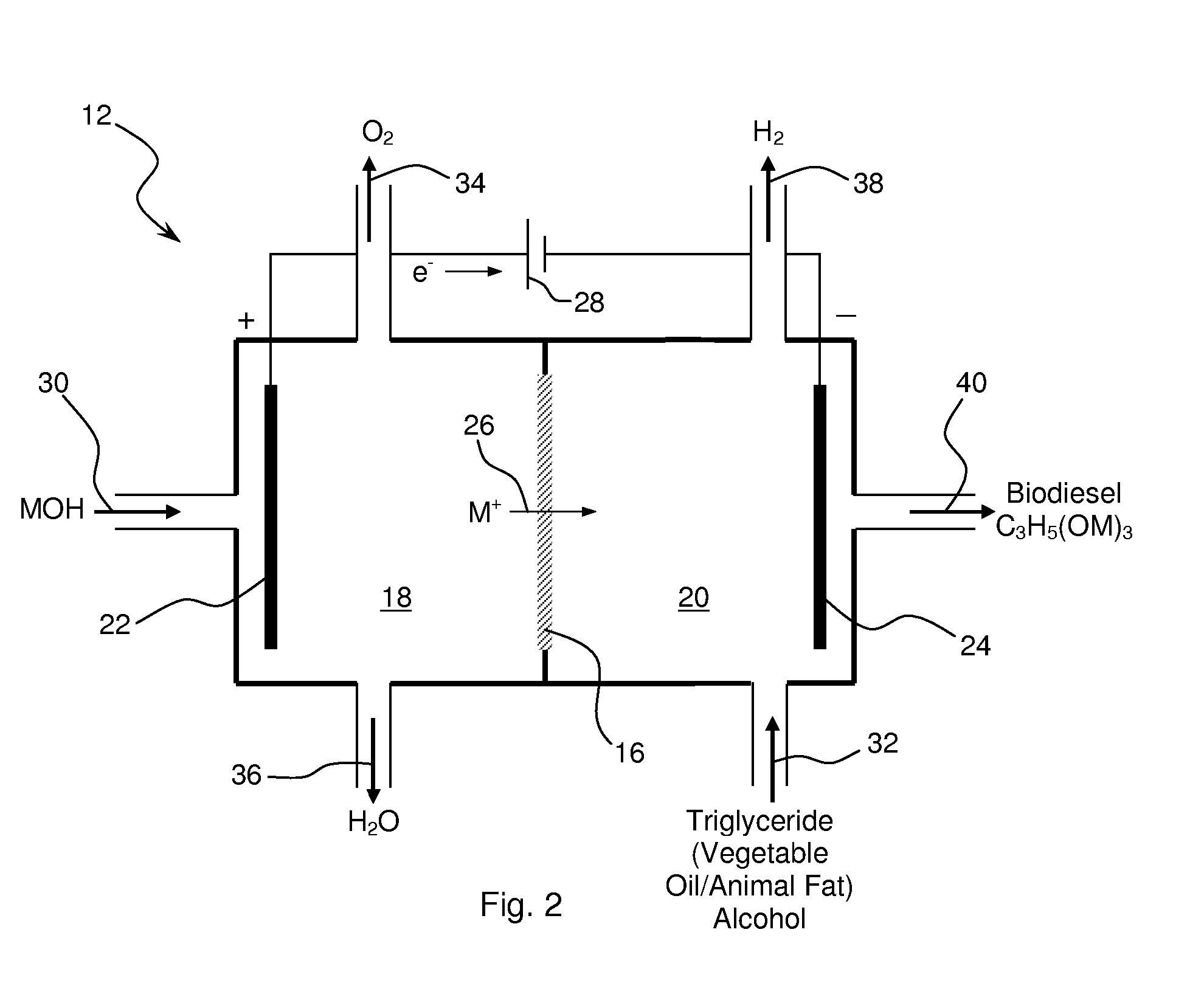

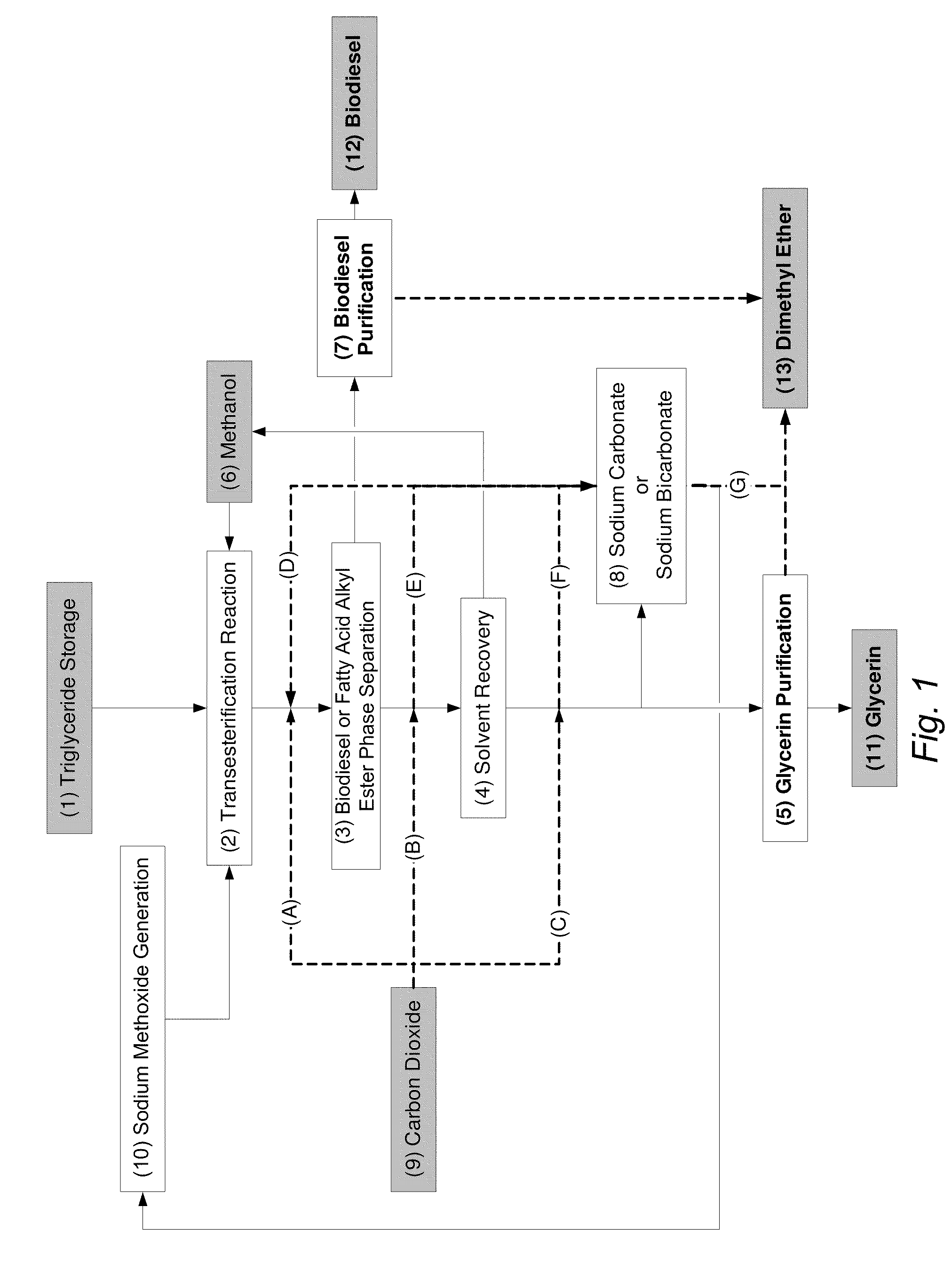

Synthesis of Biodiesel Using Alkali Ion Conductive Ceramic Membranes

InactiveUS20070158205A1Easy to separateImprove responseCellsFinal product manufactureAlkali ionsBiodiesel

Methods and apparatus for synthesizing biodiesel using alkali alkoxide generated on-site using an electrochemical process are disclosed. The apparatus and methods are disclosed to converting alkali salts of glycerine into glycerine and thereby facilitate the separation of clean glycerine from biodiesel. These methods are enabled by the use of alkali ion conductive ceramic membranes in electrolytic cells.

Owner:CERAMTEC

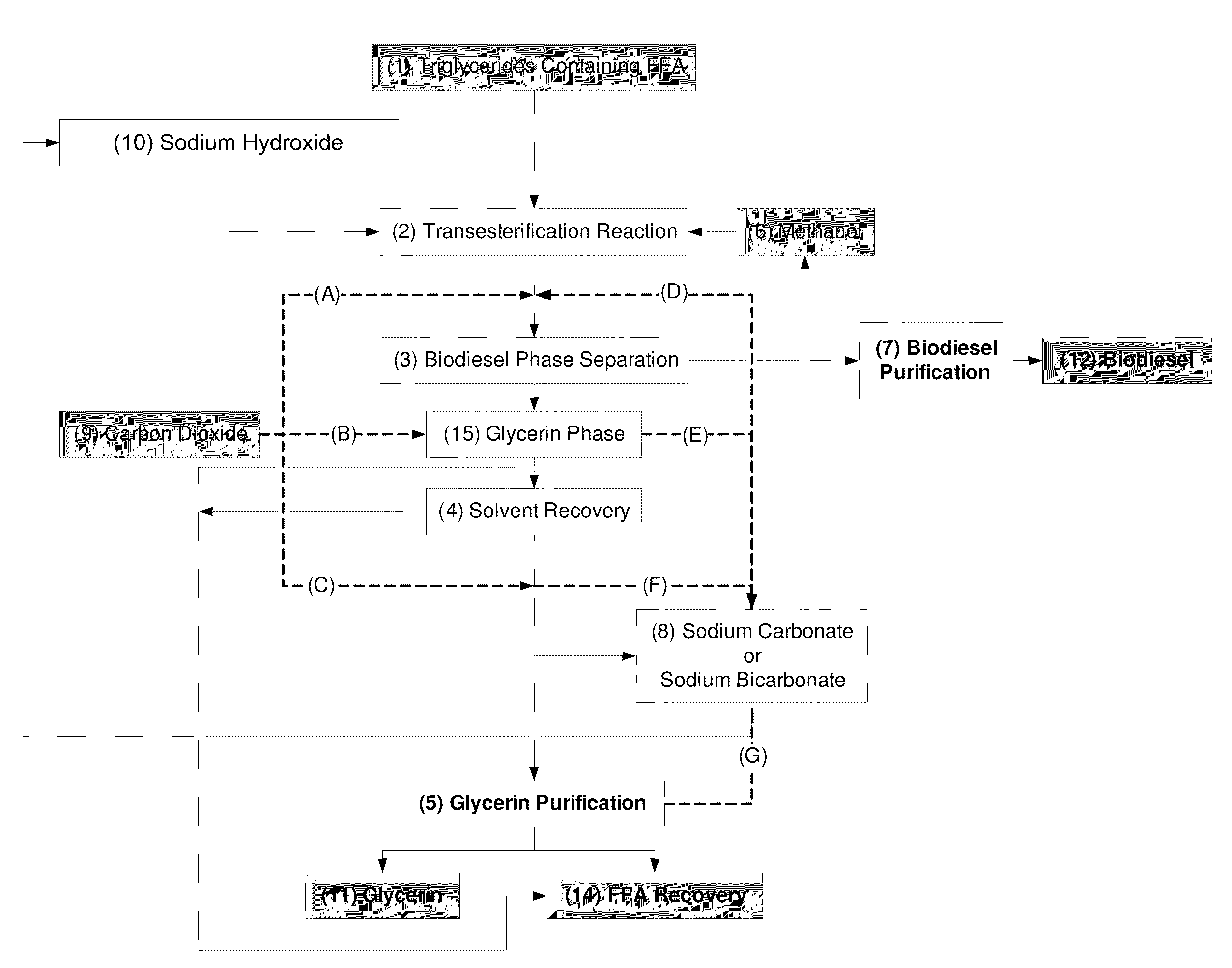

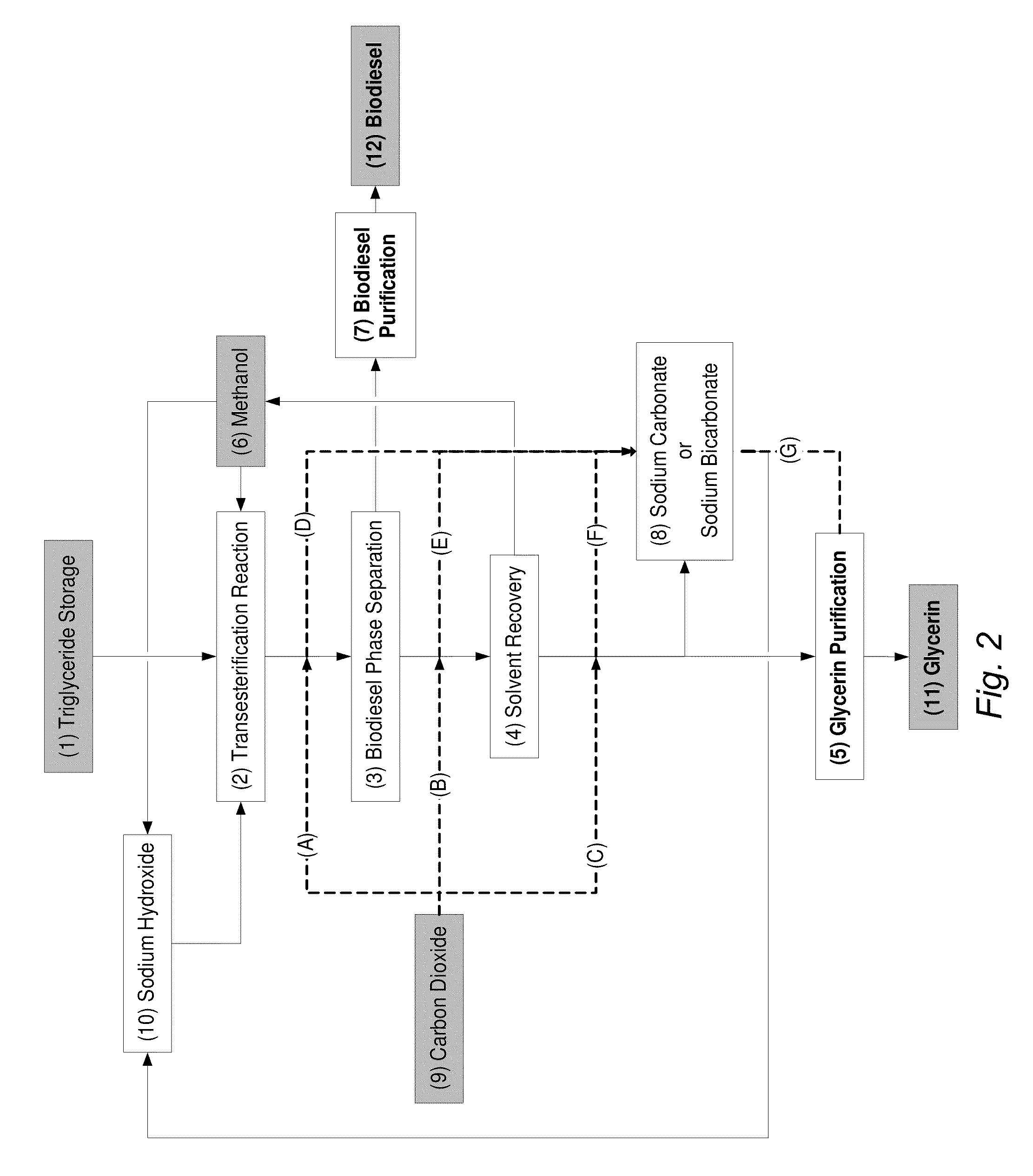

Systems and methods for removing catalyst and recovering free carboxylic acids after transesterification reaction

ActiveUS20110015419A1Low costFatty oils/acids recovery from wasteFatty acid esterificationAlcoholTransesterification

Systems and methods for using carbon dioxide to remove an alkali catalyst and to recover free carboxylic acids after a transesterification reaction are disclosed. Generally, the methods include first providing a mixture resulting from the transesterification of an ester, wherein the mixture includes substances selected from the alkali catalyst, an alcohol, and a transesterification reaction product such as biodiesel. Second, the methods generally include adding carbon dioxide to the mixture. In some cases, adding the carbon dioxide to the mixture causes the alkali catalyst to convert into an alkali carbonate and / or an alkali bicarbonate. In other cases, adding the carbon dioxide to the mixture causes the carboxylic acid alkali salt to convert into a free carboxylic acid. In either case, the alkali carbonate, the alkali bicarbonate, and / or the free carboxylic acid can be separated from the mixture in any suitable manner.

Owner:ENLIGHTEN INNOVATIONS INC

Resin solution for preparing melamine formaldehyde resin foam plastics and preparation method thereof

The invention discloses resin solution for preparing melamine formaldehyde resin foam plastics and a preparation method thereof. The preparation method for melamine formaldehyde resin solution comprises the following steps: adding weak-acid-strong-alkali salts into the resin solution, and evenly mixing to prepare the melamine formaldehyde resin solution, wherein the resin solution is a reaction product of melamine and formaldehyde. The melamine formaldehyde resin solution has good storage stability, and has shelf life of above 72 hours when preparing the melamine formaldehyde resin foam plastics so as to greatly facilitate preparing the melamine formaldehyde resin foam plastics. Experiments show that the melamine formaldehyde resin flexible foam plastics prepared from the melamine formaldehyde resin solution have good mechanical property, physiochemical performance and flame resistance.

Owner:SHANGHAI HAOHAI CHEM

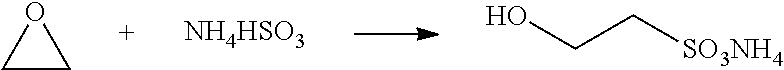

Cyclic process for producing taurine

ActiveUS9745258B1Quality improvementImprove production yieldOrganic compound preparationSulfonic acids salts preparationCyclic processPhosphate

There is disclosed a process for producing taurine from ammonium isethionate by the ammonolysis of alkali isethionate in the presence of alkali ditaurinate or alkali tritaurinate, or their mixture, to inhibit the formation of byproducts and to continuously convert the byproducts of the ammonolysis reaction to alkali taurinate. Alkali taurinate is reacted with ammonium isethionate to obtain taurine and to regenerate alkali isethionate. The production yield is increased to from 90% to nearly quantitative. The ammonolysis reaction is catalyzed by alkali salts of hydroxide, sulfate, sulfite, phosphate, or carbonate.

Owner:VITAWORKS IP LLC

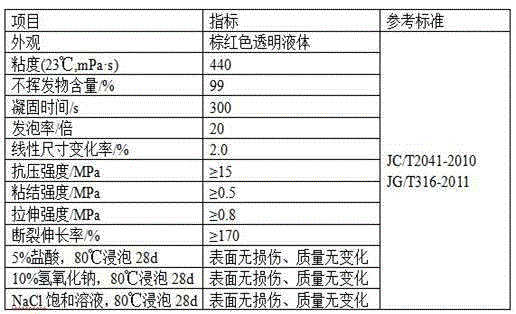

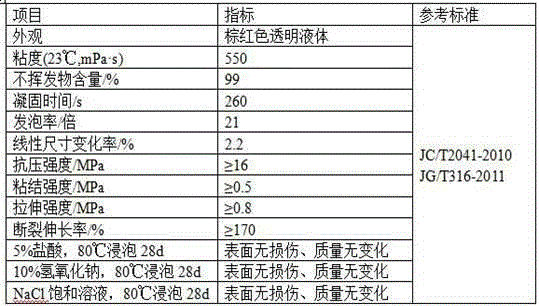

High-performance environment-friendly single-component hydrophobic polyurethane grouting material and preparation method thereof

The invention relates to a high-performance environment-friendly single-component hydrophobic polyurethane grouting material. The high-performance environment-friendly single-component hydrophobic polyurethane grouting material comprises the following substances: 100 parts of a polyurethane prepolymer, 1-10 parts of diatomaceous earth powder, 5-25 parts of polyurethane plasticizer, 5-25 parts of environment-friendly plasticizer, 10-35 parts of an environment-friendly solvent, 2-10 parts of a foam stabilizer, 0.2-2 parts of a catalyst and 0-0.2 part of a storage stabilizer. During construction, the hydrophobic polyurethane grouting material is single liquid grouting, the grouting material is environmentally friendly and free of pollution and can permeate inside various leakage water channels by virtue of grouting pressure and low viscosity, is in contact with water in the leakage gaps to rapidly absorb moisture by virtue of a porous filler and rapidly react with water for foaming. The grouting material and water are rapidly reacted and cured, the more excellent mechanical properties of the grouting material is ensured and the grouting material is high in dimensional stability so that the acid, salt alkali salt corrosion resistance of a product and engineering durability are increased to an utmost extent.

Owner:JIANGSU SOBUTE NEW MATERIALS

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS7252096B2Detergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

Pumpable geopolymer composition for well sealing applications

Three pumpable geopolymer compositions for well sealing application is disclosed herein. One pumpable geopolymer composition comprises: (i) less reactive aluminosilicate; (ii) more reactive aluminosilicate; (iii) alkaline silicate activator solution with a very low SiO2 / M2O. Another pumpable geopolymer composition comprises: (i) less reactive aluminosilicate; (ii) more reactive aluminosilicate; (iii) alkaline silicate-free activator solution that may contain an alkali salt; and (iv) powdered alkali silicate glass. The third pumpable geopolymer composition comprises (i) less reactive aluminosilicate; (ii) more reactive aluminosilicate; (iii) alkaline low silicate activator solution; and (iv) powdered alkali silicate glass.

Owner:CATHOLIC UNIV OF AMERICA

Sprayable dry wash and wax composition comprising a silicone blend and acrylic-based polymer

ActiveUS7399738B1Equal and good performanceGood colorInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWaxCentistokes

A composition for simultaneously cleaning and waxing non-porous surfaces without the need for additional rinsing of the treated surface with water, has a pH of from about 6 to about 7 and contains by weight: (a) from about 0.04 to about 0.12% of an acrylic-based polymer, wherein the acrylic-based polymer is a hydrophobically modified, crosslinked polyacrylate powder which has been crosslinked with a polyalkenyl polyether or is an acrylic polymer containing acid groups and which dissolves and swells immediately when neutralized with an alkali salt (b) from about 0.5 to about 5.0% of a silicone blend composed of: (i) from about 70 to about 95% of a first polydiorganosiloxane fluid having a viscosity of from about 0.65 to about 60,000 centistokes at 25° C., and (ii) from about 5 to about 30% of a polydiorganosiloxane fluid mixture having a viscosity of from about 500 to about 2000 centistokes at 25° C., the polydiorganosiloxane fluid mixture being composed of a second polydiorganosiloxane fluid and a silicone resin; (c) wax; and (d) water. The composition can be used to simultaneously clean and wax non-porous surfaces such as the exterior surfaces of automobiles and other vehicles, windows, and the like.

Owner:ENERGIZER AUTO INC

Biodegradable scale and corrosion inhibitor composition

ActiveUS7241391B1Other chemical processesSpecific water treatment objectivesNatural sourceAlkali salt

A biodegradable scale and corrosion inhibiting composition includes between about 50 and about 90% by weight of a protein polymer that is derived from a natural source, and between about 10 and about 20% by weight of the alkali salts of gluconic acid.

Owner:CORTEC

Process for producing taurine

ActiveUS9573890B2Reduce wasteImprove production yieldOrganic compound preparationSulfonic acids salts preparationPhosphateAlkali salt

There is disclosed a process for producing taurine by the ammonolysis of alkali isethionate in the presence of alkali ditaurinate or alkali tritaurinate, or their mixture, to inhibit the formation of byproducts and to continuously convert the byproducts of the ammonolysis reaction to alkali taurinate. The production yield is increased to from 90% to nearly quantitative. The ammonolysis reaction is catalyzed by alkali salts of hydroxide, sulfate, sulfite, phosphate, or carbonate.

Owner:VITAWORKS IP LLC

Cyclic process for producing taurine

ActiveUS9593076B2Reduce wasteImprove production yieldOrganic compound preparationSulfonic acids salts preparationCyclic processPhosphate

There is disclosed a process for producing taurine by the ammonolysis of alkali isethionate in the presence of alkali ditaurinate or alkali tritaurinate, or their mixture, to inhibit the formation of byproducts and to continuously convert the byproducts of the ammonolysis reaction to alkali taurinate. Alkali taurinate is neutralized with isethionic acid to obtain taurine and to regenerate alkali isethionate. The production yield is increased to from 90% to nearly quantitative. The ammonolysis reaction is catalyzed by alkali salts of hydroxide, sulfate, sulfite, phosphate, or carbonate.

Owner:VITAWORKS IP LLC

Geopolymer foamed concrete, foamed concrete sandwich composite thermal insulation wallboard and preparation method

ActiveCN105967535APromote energy saving and emission reductionRapid development of strengthSolid waste managementCement productionFoam concretePolymer science

The invention provides inorganic geopolymer foamed concrete, a composite wallboard prepared by the inorganic geopolymer foamed concrete, and a preparation method thereof. The inorganic geopolymer foamed concrete comprises the following components in parts by weight: 400 to 500 parts of inorganic geopolymer cementing material and 0.5 to 10 parts of foaming agent, wherein the inorganic polymer cementing material comprises 2 to 20 parts by weight of active silica-alumina material, 4 to 30 parts by weight of alkali salt aqueous solution, 1 to 20 parts of inorganic filler, and 0.05 to 3 parts of setting agent. The lightweight and high-strength inorganic geopolymer foamed concrete sandwich composite thermal insulation wallboard can be prepared from the inorganic geopolymer foamed concrete provided by the invention. The preparation method provided by the invention has the advantages of simple process and high production efficiency, and the thermal insulation and decoration integrated construction of exterior walls of buildings can be realized.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Slow-release alkaline microcapsule for buccal tobacco product and preparation method and application thereof

ActiveCN102940307AImprove inner qualityMeet comfort requirementsTobacco treatmentMicroballoon preparationWater bathsBULK ACTIVE INGREDIENT

The invention discloses a slow-release alkaline microcapsule for a buccal tobacco product and a preparation method thereof. The microcapsule particularly is a microcapsule prepared by encapsulating alkali salt active ingredients with a microcapsule coating raw material; and the percentage by weight of the microcapsule coating raw material is 10 to 90 percent. The preparation method comprises the following steps of: in constant-temperature water bath with a temperature of 60 DEG C to 70 DEG C, adding the coating raw material with continuous stirring; after completely dissolving the coating raw material, adding alkali salt; and finally, carrying out high-speed dispersion on the mixture to obtain emulsion, and carrying out spray-drying on the emulsion to obtain the capsule, wherein the mass content of solid substances in the emulsion is 40 to 80 percent. The prepared microcapsule can slowly release alkalinity; the internal quality of the buccal tobacco product is promoted; and the requirement of consumers on the comfort of a smokeless tobacco product is met.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Saline-resistant multifunctional water-preserving agent and method for preparing same

InactiveCN1699508ALow costImprove water absorptionOrganic fertilisersSoil conditioning compositionsCross-linkAlkali salt

The invention discloses a saline-resistant multifunctional water-preserving agent and method for preparation, wherein the water-loss reducer is prepared by using Attaplgite clay, starch, acrylamide, humic acid, cross linking agent and initiating agent as the raw material through the process of cross bonding polymerization. The water-loss reducer has the multifunction of organic-inorganic hybridization alkali-salt resistance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel surfactants and use thereof

InactiveUS20060062751A1Improve abilitiesQuality improvementCosmetic preparationsHair cosmeticsEmulsionPotassium

The invention relates to a novel surfactant which is obtained by blending an N—C8-24 acylamino acid and an alkali salt of an amino acid, and also relates to a detergent composition comprising this surfactant as a cleansing component and an emulsion composition comprising this surfactant as an emulsifying component. In the alkali salt of an amino acid, a suitable amino acid is an acidic or neutral α-amino acid, and a suitable alkali is sodium, potassium, triethanolamine, or N-methyltaurine sodium. In the N—C8-24 acylamino acid, a suitable amino acid is acidic or neutral, and a suitable C8-24 acyl is a C12-18 acyl. This surfactant can provide a detergent composition which ensures good lathering ability and foam quality and which does not cause stiff hair or taut skin after use. The surfactant can also provide an emulsion composition which ensures a good emulsion state.

Owner:P&PF

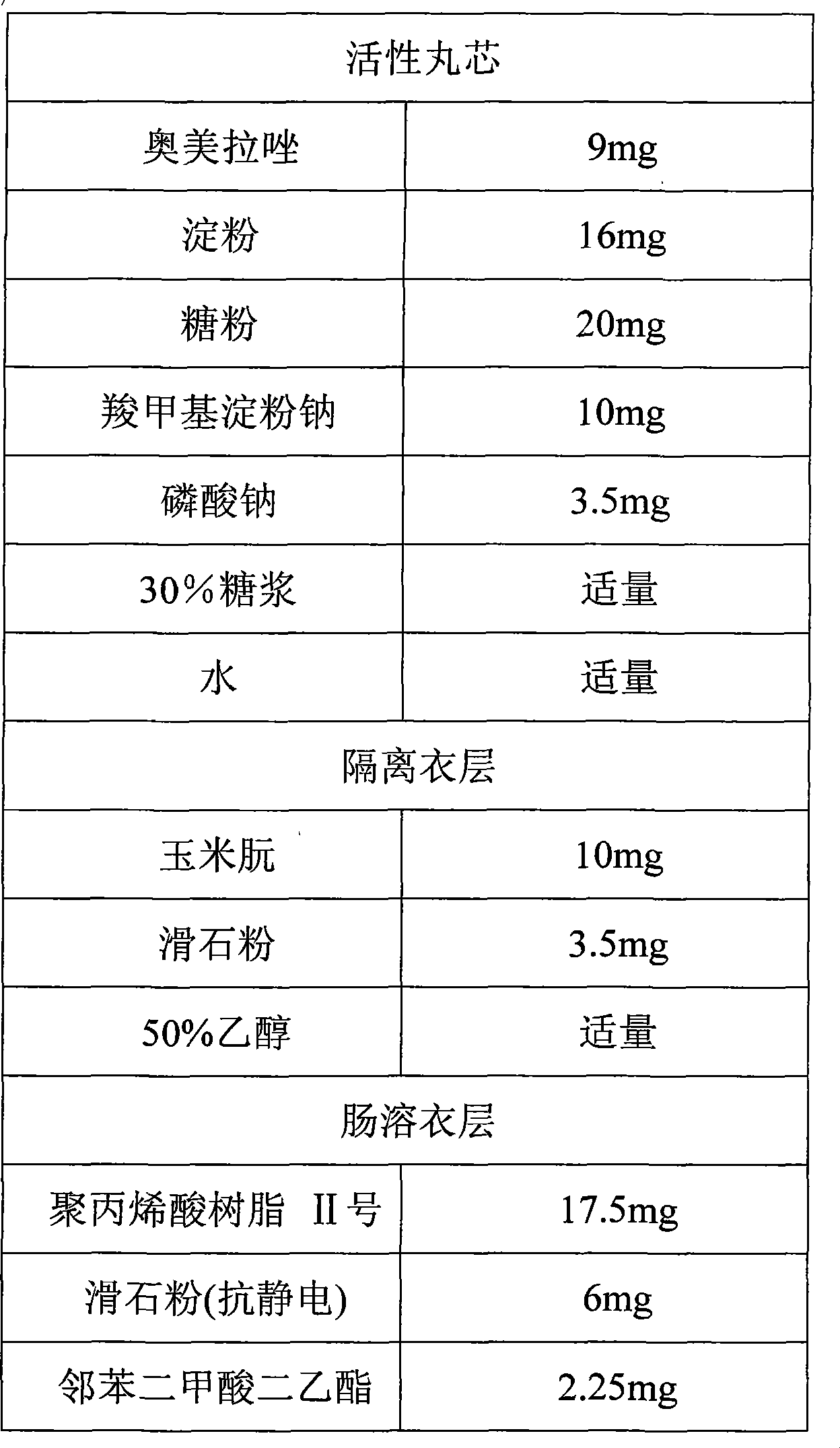

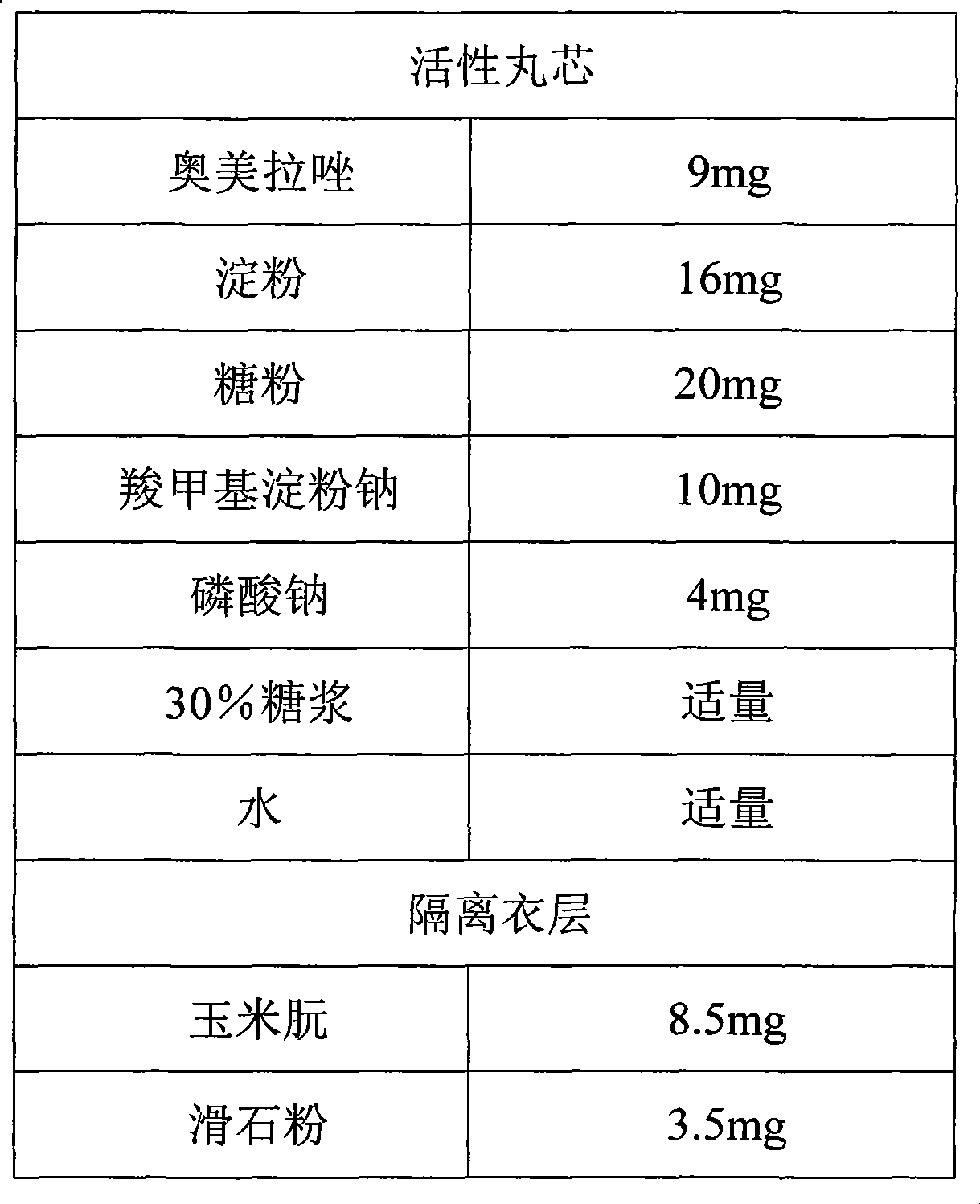

Omeprazole enteric coated pellets formulation and preparation method

The invention discloses an omeprazole enteric micropill preparation and a preparation method thereof. The preparation takes alkali salt containing omeprazole or a single antimer of the omeprazole as an active pill core, and contains a film isolating and coating layer and an enteric coating layer. The preparation takes zein as an isolating and coating material, thereby improving the stability of micropills. The preparation method uses alcohol as menstruum, thereby further improving the stability of the omeprazole micropills.

Owner:SHOUGUANG FUKANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com