Ionic liquid prepared through diimine (vikane) and (perfluoroalkglsulfonyl fluorosulfonyl group) imine alkali salt

A technology of ionic liquids and alkali metal salts, applied in the field of H[RfFSI], can solve the problems of fluorosulfonic anhydride's high toxicity, difficult product separation, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

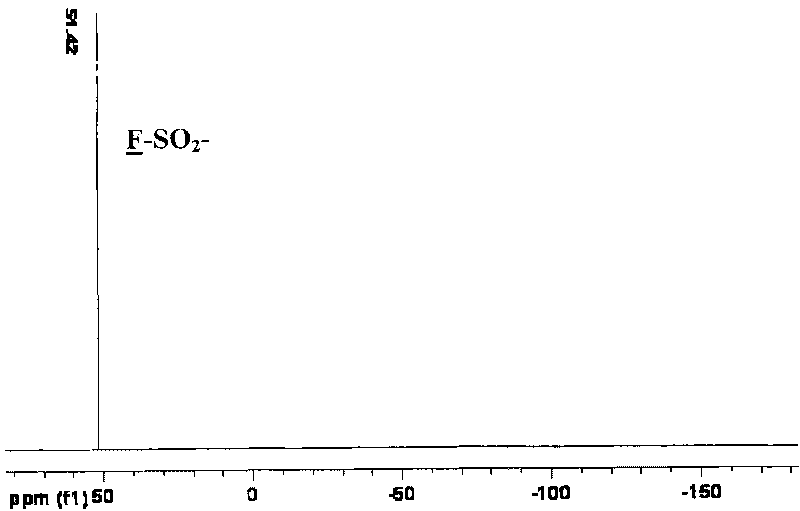

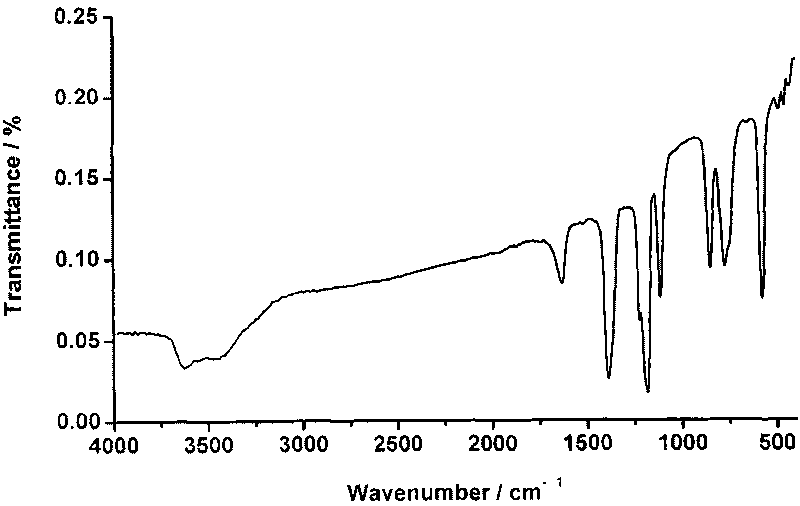

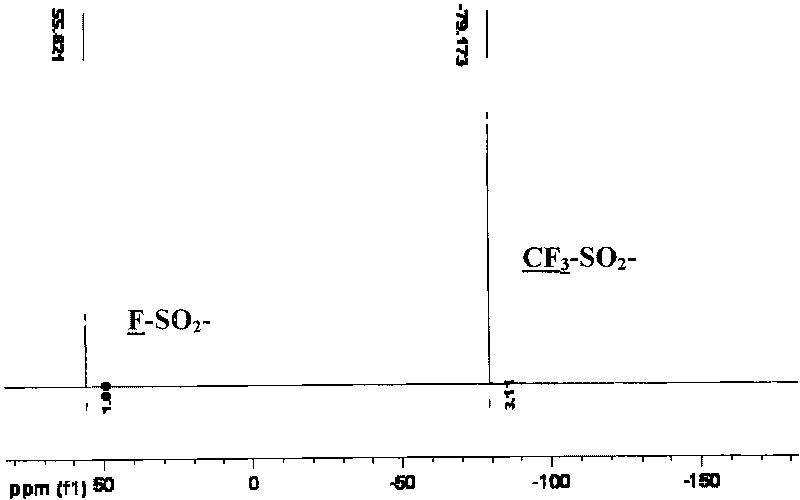

Image

Examples

Embodiment 1-9

[0060] Examples 1-9 relate to H[FSI] and H[R f FSI] Preparation of Alkali Metal Salts

Embodiment 1

[0061] Example 1: Preparation of potassium bis(fluorosulfonyl)imide (K[FSI])

[0062] The synthesis reaction scheme is as follows:

[0063] HOSO 2 NH 2 +SOCl 2 +HOSO 2 Cl→H[N(SO 2 Cl) 2 ]+SO 2 ↑+HCl↑

[0064]

[0065] Under the protection of nitrogen, add 480 grams (5mol) of sulfamic acid, 1780 grams (15mol) of thionyl chloride, and 580 grams (0.5mol) of chlorosulfonic acid into a 5000mL reaction flask in sequence, and stir and react at 130°C for 24 hours , Atmospheric pressure distillation removes excessive low-boiling point reactant, then carries out vacuum distillation, collects the cut of 112-114 ℃ / 2mmHg, obtains two (chlorosulfonyl)imides (HN(SO 2 Cl) 2 ) 880 g (4.1 mol) of colorless crystals, yield 82%.

[0066] Under magnetic stirring and nitrogen protection, 96 grams (0.45mol) of bis(chlorosulfonyl)imide and 54 grams (0.3mol) of anhydrous antimony trifluoride were placed in a 500mL three-necked flask, and stirred at room temperature After reacting for 12 ...

Embodiment 2

[0068] Embodiment 2: Preparation of bis(fluorosulfonyl)imide cesium (Cs[FSI])

[0069] The synthesis reaction scheme is as follows:

[0070]

[0071] Under magnetic stirring and nitrogen protection, 9.6 grams (0.045mol) of bis(chlorosulfonyl)imide (prepared according to the operation of Example 1), and 5.4 grams (0.03mol) of anhydrous antimony trifluoride were placed in 100mL In a three-necked flask, after stirring for 12 hours at room temperature, 40 mL of acetonitrile was added to the reaction flask. After most of the solids were dissolved, 8.9 g (0.03 mol) of anhydrous cesium carbonate was added in portions under stirring, and the reaction was continued for 12 hours after the addition was complete. Then, the pH value of the system was adjusted to neutral with 2M HCl. Filter under reduced pressure to remove solid insoluble matter, concentrate the filtrate to about 7-10 mL, add an equal volume of CH 2 Cl 2Perform recrystallization. After filtering, washing and drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com