Patents

Literature

1671 results about "Sulfamic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

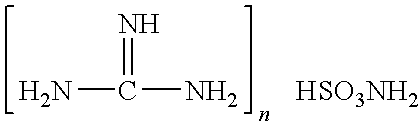

Sulfamic acid, also known as amidosulfonic acid, amidosulfuric acid, aminosulfonic acid, and sulfamidic acid, is a molecular compound with the formula H₃NSO₃. This colorless, water-soluble compound finds many applications. Sulfamic acid melts at 205 °C before decomposing at higher temperatures to water, sulfur trioxide, sulfur dioxide and nitrogen.

Concentrated aqueous bromine solutions and their preparation

Described is a process of producing a concentrated liquid biocide formulation. Mixed together are (a) bromine chloride or bromine and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the solution is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine from (a) and (b) is greater than 1 when bromine is used and is greater than 0.93 when bromine chloride is used. Use of bromine chloride as the source of the active bromine in the process is preferred because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine as the active bromine content of the biocidal composition.

Owner:ALBEMARLE CORP

Biocidal applications of concentrated aqueous bromine chloride solutions

Methods for disinfecting surfaces and for sanitizing bodies of water using a single-feed, bromine-based biocide are described. These methods use concentrated liquid biocide compositions comprising biocidally active bromine as the biocide. Also described is a process of producing the concentrated liquid biocide composition: mixed together are (a) bromine chloride and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the composition is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine in the composition is greater than 0.93. Use of bromine chloride as the source of the active bromine in the process is advantageous because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine as the active bromine content of the biocidal composition.

Owner:ALBEMARLE CORP

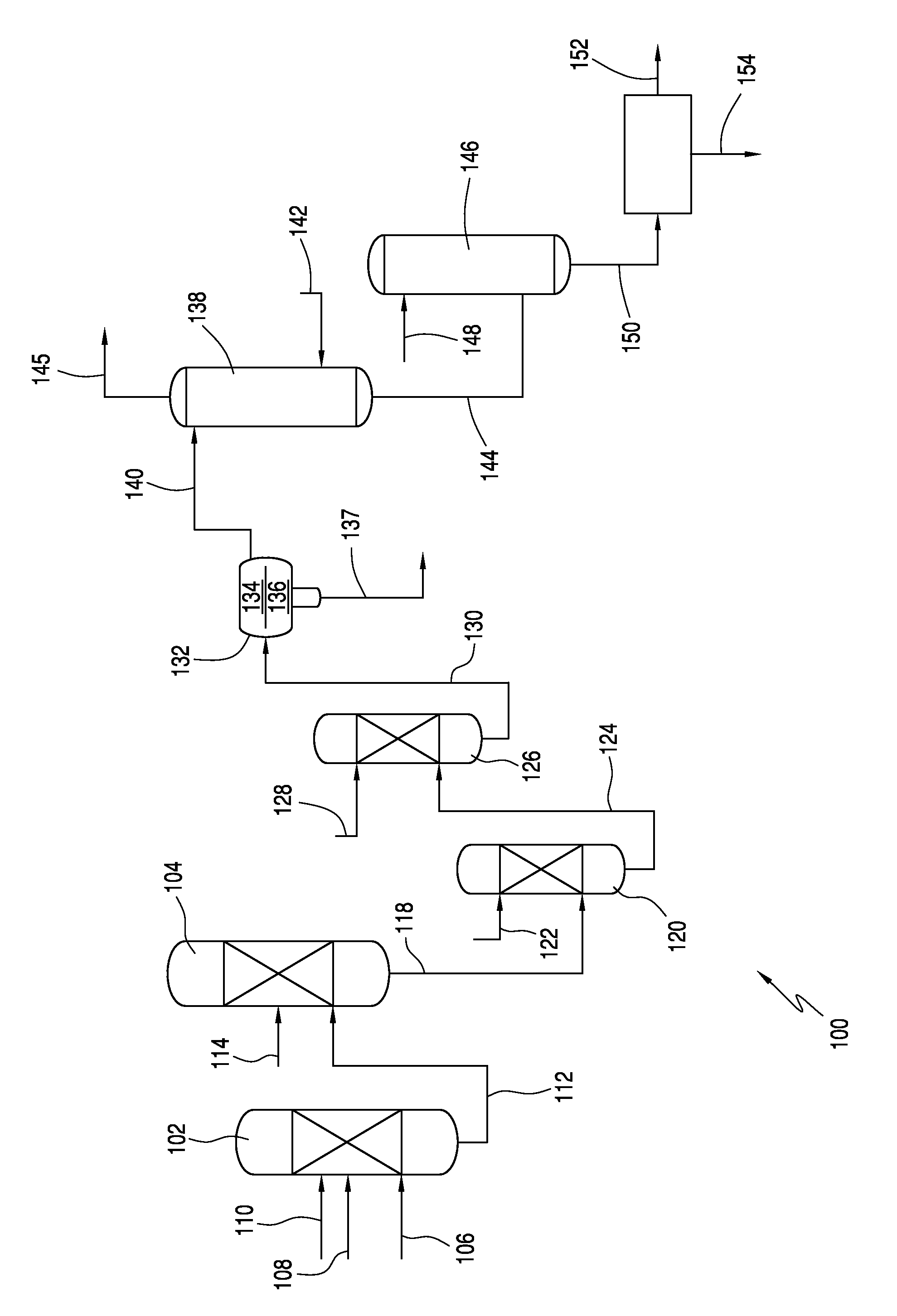

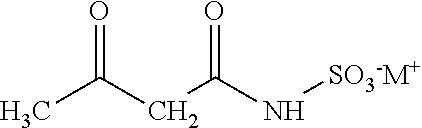

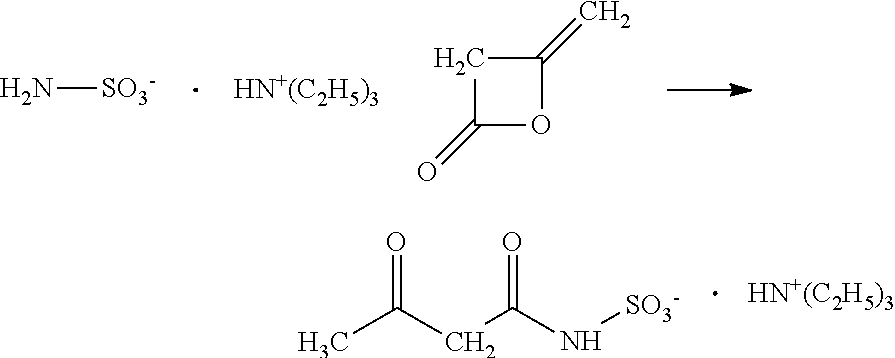

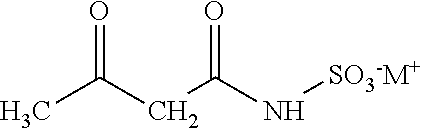

Process for producing acesulfame potassium

ActiveUS9024016B2Organic compound preparationSulfuric acid amide preparationAcetic acidSulfamic acid

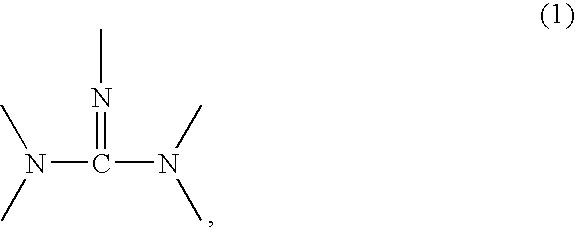

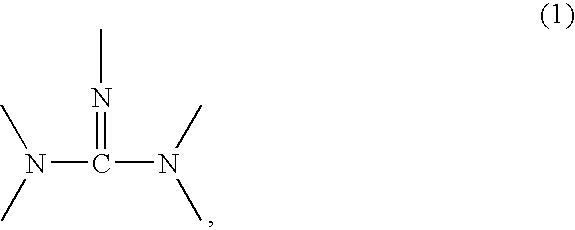

In one embodiment, the invention relates to processes for producing acesulfame potassium. In one embodiment, the process comprises the step of reacting a first reaction mixture to form an amidosulfamic acid salt such as a trialkyl ammonium amidosulfamic acid salt. The first reaction mixture comprises sulfamic acid, an amine, and smaller amounts, if any, acetic acid, e.g., less than 1 wt % (10000 wppm). In terms of ranges, the first reaction mixture may comprise from 1 wppm to 1 wt % acetic acid. The process further comprises the step of reacting the amidosulfamic acid salt with diketene to form an acetoacetamide salt. In preferred embodiments, the amidosulfamic acid salt formation reaction is conducted at pH levels from 5.5 to 7.0. The process further comprises the step of deriving the acesulfame-K from the acetoacetamide salt.

Owner:CELANESE SALES GERMANY

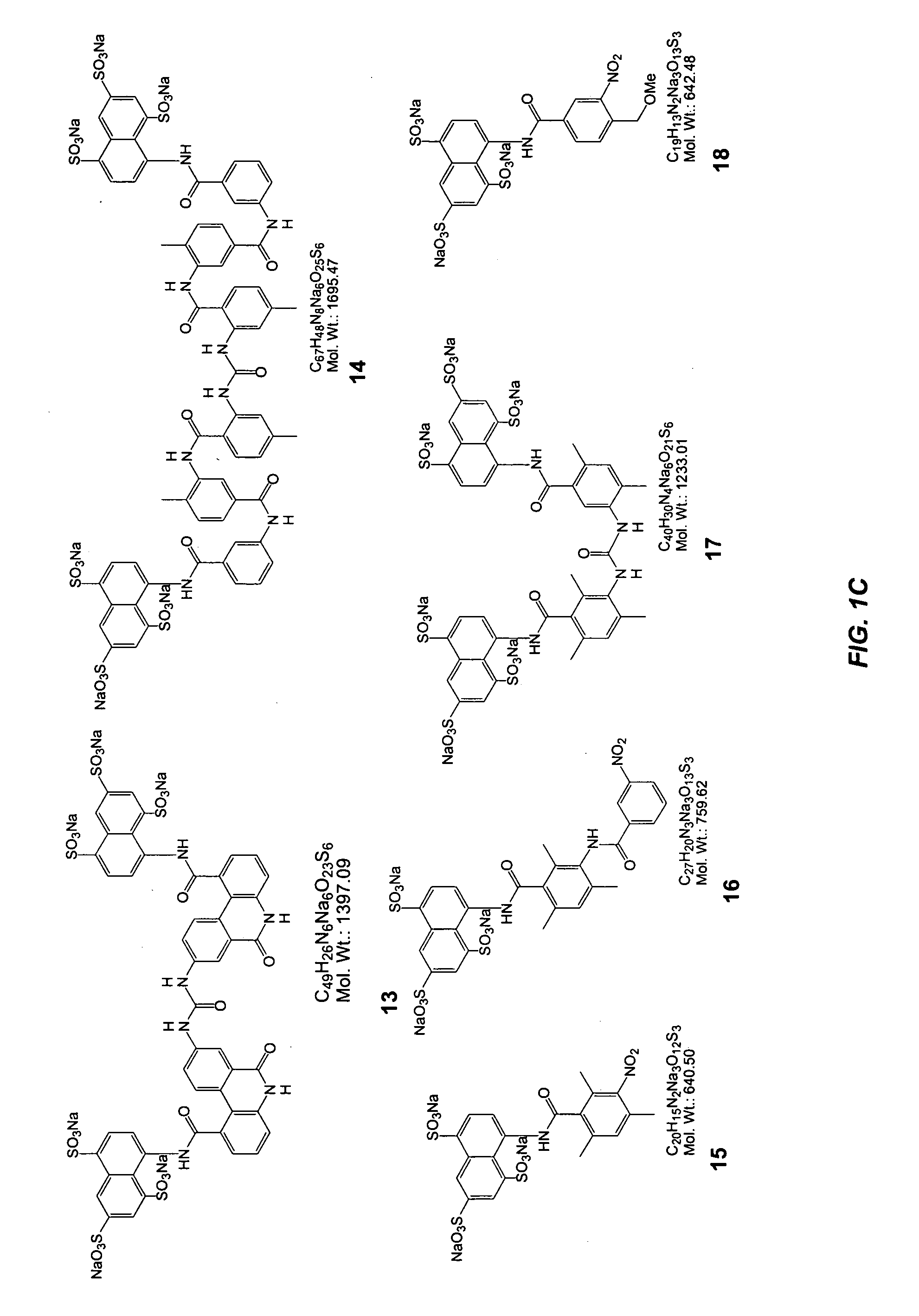

N-acyl sulfamic acid esters useful as hypocholesterolemic agents

PCT No. PCT / US97 / 06725 Sec. 371 Date Aug. 10, 1998 Sec. 102(e) Date Aug. 10, 1998 PCT Filed Apr. 21, 1997 PCT Pub. No. WO97 / 44314 PCT Pub. Date Nov. 27, 1997The instant invention is new compounds of Formula I their use as cerebrovascular agents in diseases such as stroke, peripheral vascular disease, restenosis, and as agents for regulating plasma cholesterol concentrations, for treating hypercholesterolemia and atherosclerosis, and for lowering the serum or plasma level of Lp(a). A pharmaceutical composition is also claimed.

Owner:WARNER-LAMBERT CO

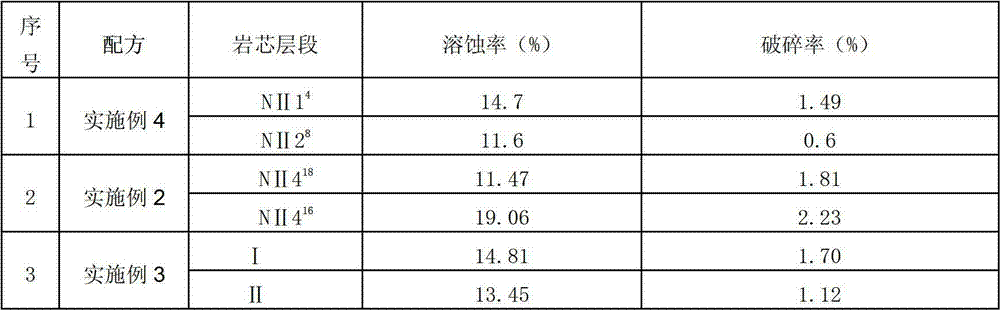

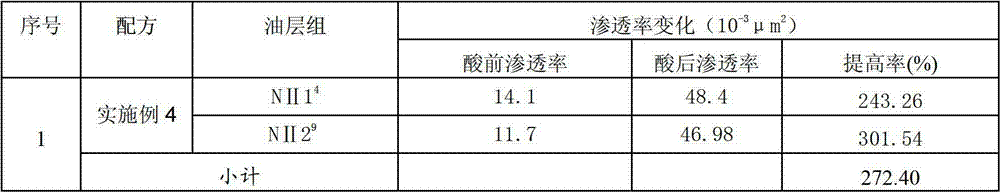

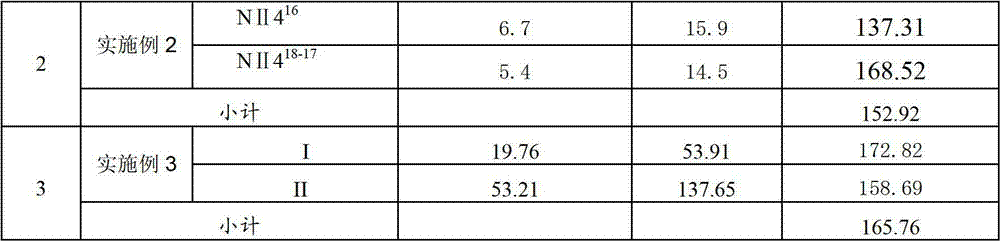

Acidizing block remover suitable for complex lithologic reservoir

ActiveCN102775980ASuppressed ionizationRestore permeabilityDrilling compositionSolventFluoboric acid

The invention relates to an acidizing block remover suitable for a complex lithologic reservoir. The acidizing block remover suitable for the complex lithologic reservoir comprises the following components by weight: 0-12% of hydrochloric acid, 0-3% of ammonium bifluoride, 0-10% of sulfamic acid, 0-5% of fluoboric acid, 0-3% of boric acid, 0-4% of alcohol, 0-2% of triethanolamine, 3% of glacial acetic acid, 4.0-6.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 0.5-1.0% of penetrating agent, 2.0% of clay stabilizer and 45-88.5% of water. The problems that the lithologic and physical property differences of oil fields are large, the oil fields are in staggered distribution, and the acidizing debugging construction effect of a common water injection well is not ideal are mainly solved. The acidizing block remover suitable for the complex lithologic reservoir can effectively corrode the strata minerals and obstruent, does not destroy a rock skeleton, can prevent secondary precipitation caused by sensitive mineral, improves the water absorbing capacity of the reservoir, and increases the daily increasing water injection rate of an average single-well measure.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

Process for Producing Acesulfame Potassium

ActiveUS20130331565A1Organic compound preparationSulfuric acid amide preparationAcetic acidSulfamic acid

In one embodiment, the invention relates to processes for producing acesulfame potassium. In one embodiment, the process comprises the step of reacting a first reaction mixture to form an amidosulfamic acid salt such as a trialkyl ammonium amidosulfamic acid salt. The first reaction mixture comprises sulfamic acid, an amine, and smaller amounts, if any, acetic acid, e.g., less than 1 wt % (10000 wppm). In terms of ranges, the first reaction mixture may comprise from 1 wppm to 1 wt % acetic acid. The process further comprises the step of reacting the amidosulfamic acid salt with diketene to form an acetoacetamide salt. In preferred embodiments, the amidosulfamic acid salt formation reaction is conducted at pH levels from 5.5 to 7.0. The process further comprises the step of deriving the acesulfame-K from the acetoacetamide salt.

Owner:CELANESE SALES GERMANY

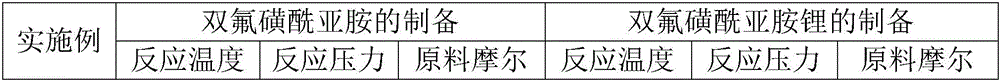

Preparation method of difluoro-sulfimide and lithium difluoro-sulfimide

InactiveCN106365132AFew reaction stepsSimple processNitrosyl chlorideAmidosulfonic acidChemical synthesisDistillation

The invention relates to a preparation method of difluoro-sulfimide and lithium difluoro-sulfimide, and belongs to the field of fluorine chemical synthesis. The preparation method comprises the steps that difluoro-sulfimide is obtained by adding fluoro-sulfoxide into a mixture of sulfamic acid or amino sulfonyl fluoride and fluorosulfuric acid for reacting and then subjected to recrystallization and filtration which are conducted at the temperature of minus 100 DEG C to 16 DEG C and / or reduced / normal-pressure distillation and purification which are conducted at the temperature of 60 DEG C to 169 DEG C; difluoro-sulfimide and a lithium-containing substance react in a solvent to obtain lithium difluoro-sulfimide, and then recrystallization, filtration and purification are conducted. According to the preparation method, difluoro-sulfimide can be prepared through one step, lithium difluoro-sulfimide is obtained through lithiation, and the prepared products can be purified; few steps are needed, the technology is simple, the process is easy to control, the requirement on production devices is low, the production efficiency, the product yield and the purity are high, and large-scale production and application can be achieved.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

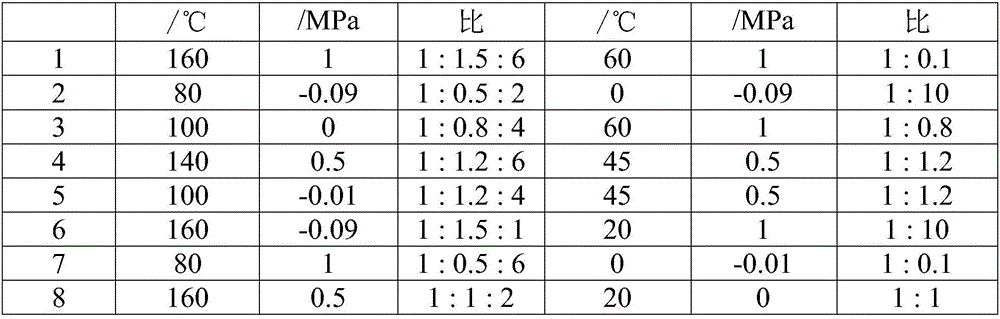

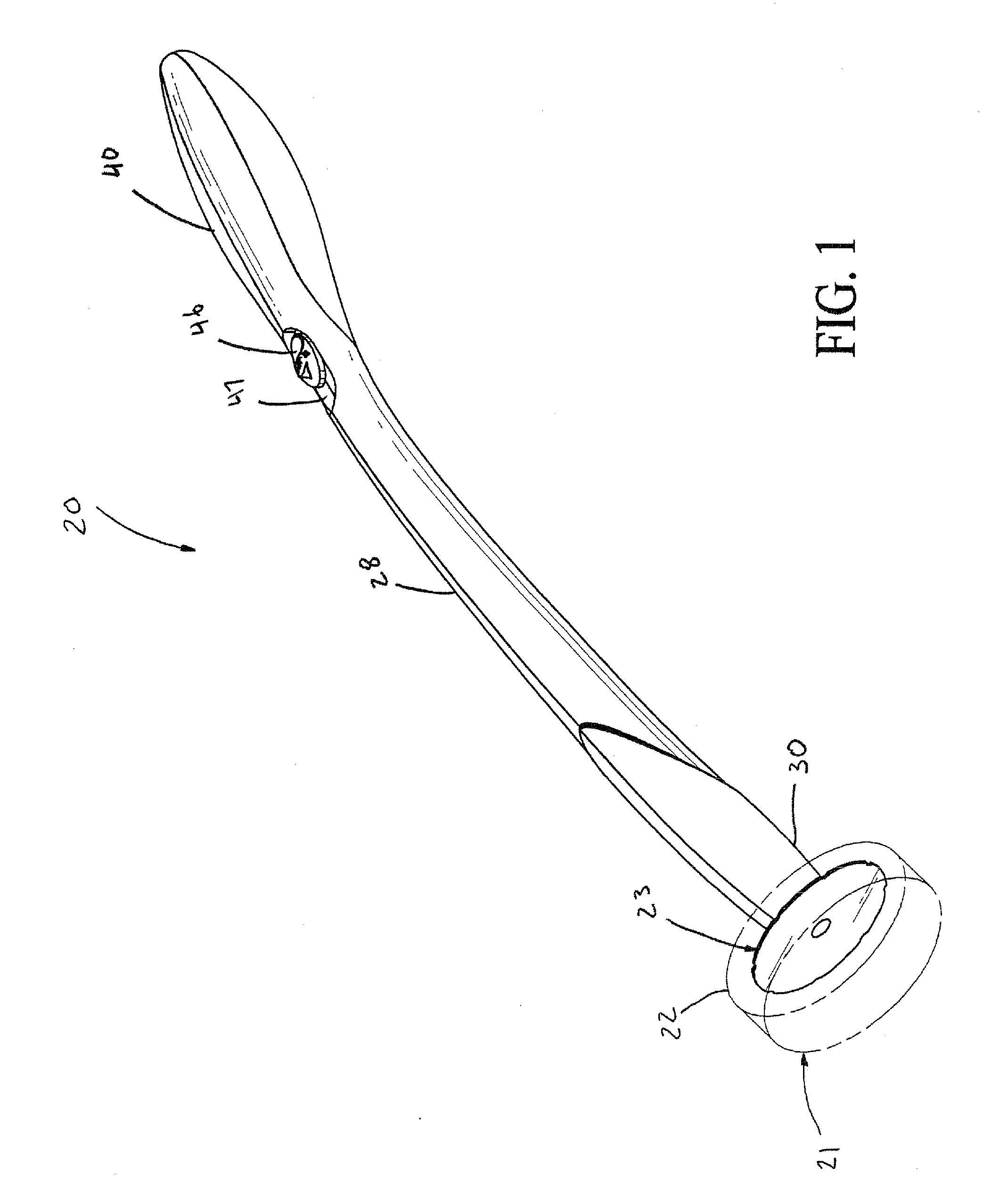

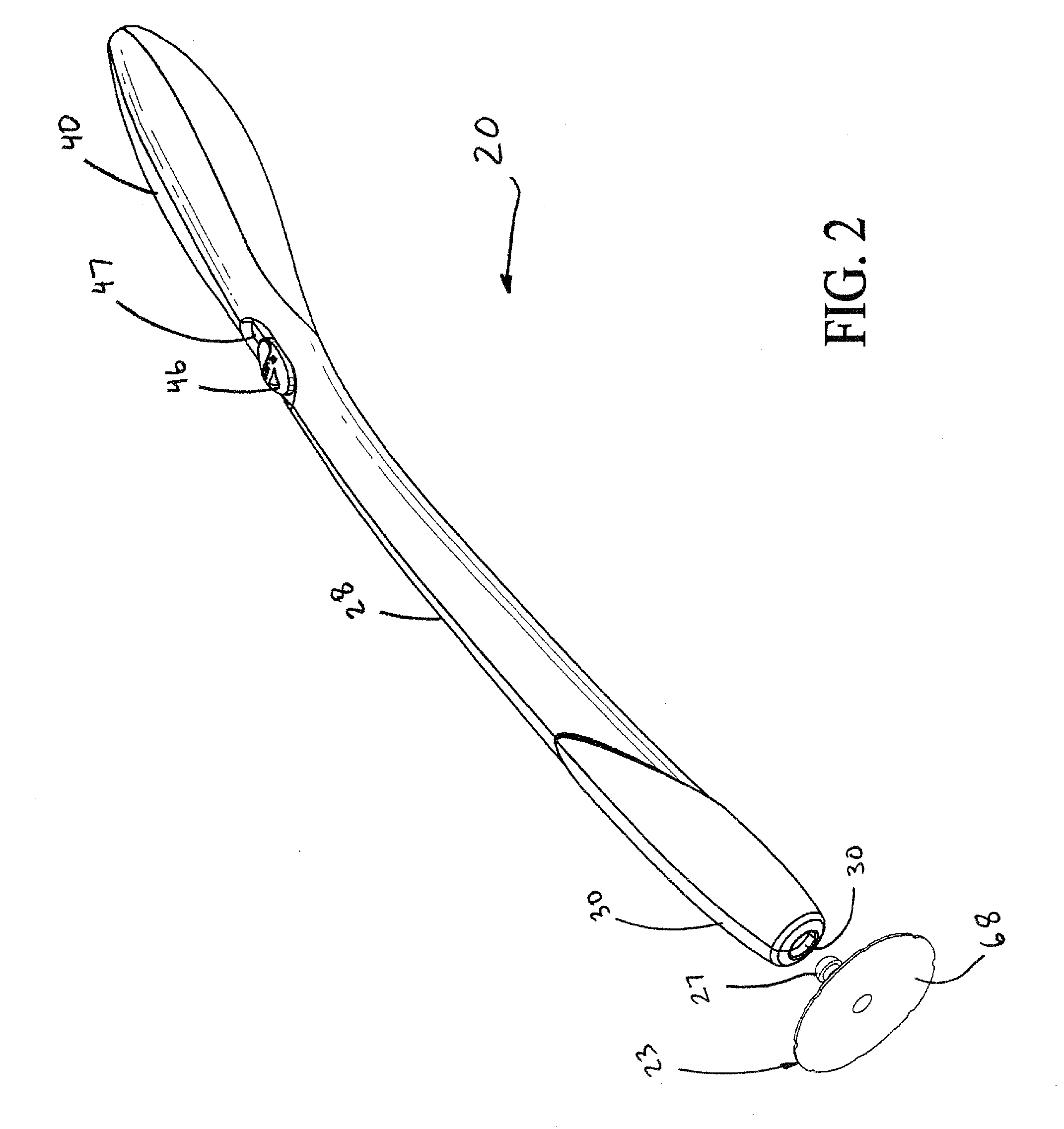

Cleaning Tool With Disposable Cleaning Head and Composition

InactiveUS20080115302A1Reduce stiffnessAvoid flowBoard cleaning devicesCarpet cleanersWater dispersibleSulfamic acid

A cleaning tool with a handle having a manual release device actuator and a removable cleaning head having a cleaning substrate can be used to effectively clean surfaces. The cleaning substrate can have a fitment for attachment to the handle. The cleaning substrate can be impregnated with a cleaning composition having a solid inorganic acid, such as sulfamic acid. The cleaning substrate can be water-soluble or water-dispersible. Examples of suitable cleaning tools include a hard surface floor mop, a carpet mop, an auto cleaning device, a toilet cleaning device, a bathroom cleaning device, and a shower cleaning device.

Owner:THE CLOROX CO

Concentrated aqueous bromine solutions and their preparation and use

InactiveUS6652889B2Improve solubilityMinimize extentBiocideSpecific water treatment objectivesChloride saltNitrogen

Described is a process of producing a concentrated liquid biocide formulation. Mixed together are (a) bromine chloride or bromine and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the solution is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine from (a) and (b) is greater than 1 when bromine is used and is greater than 0.93 when bromine chloride is used. Use of bromine chloride as the source of the active bromine in the process is preferred because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine in the biocidal composition as active bromine capable of providing biocidal activity.

Owner:ALBEMARLE CORP

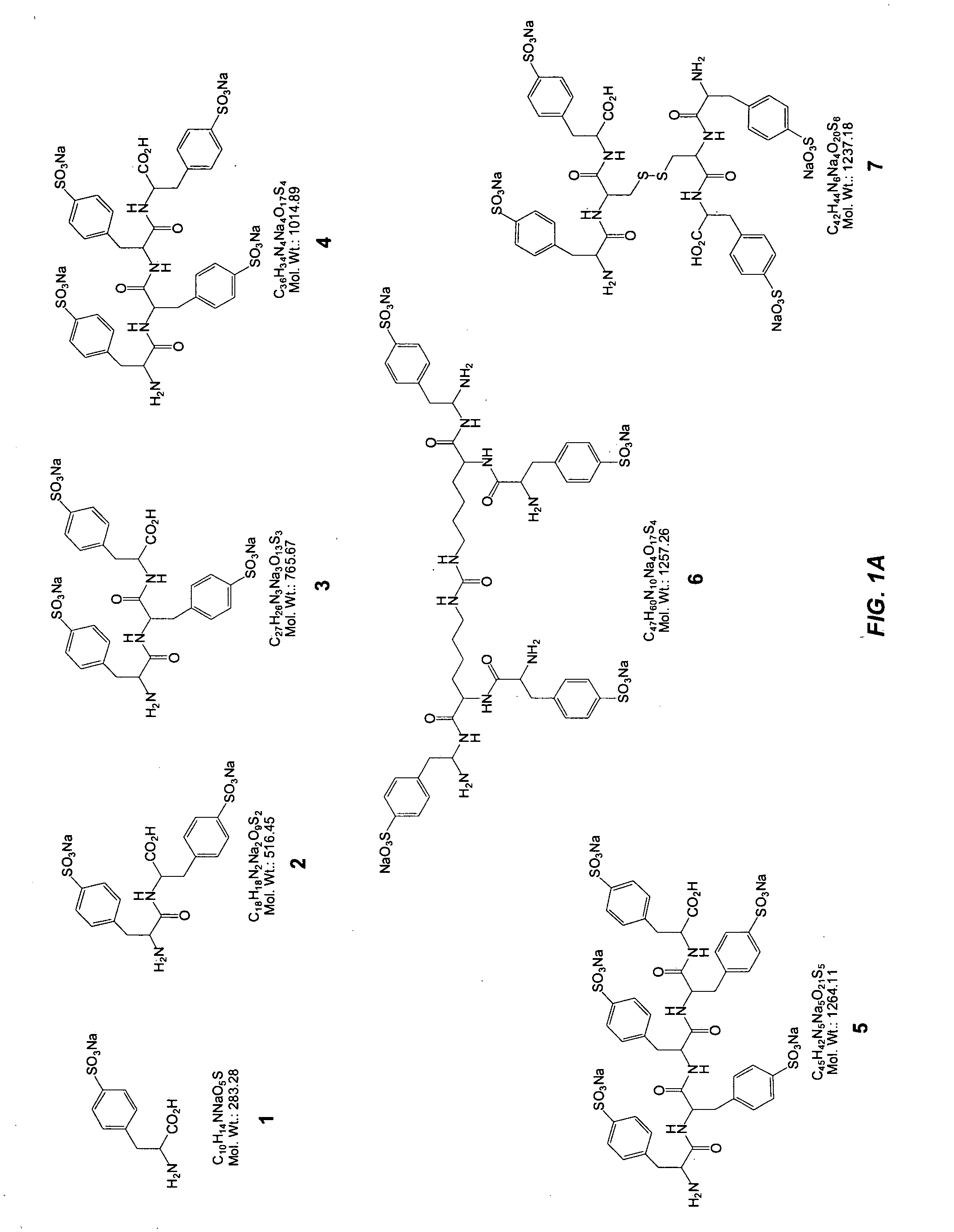

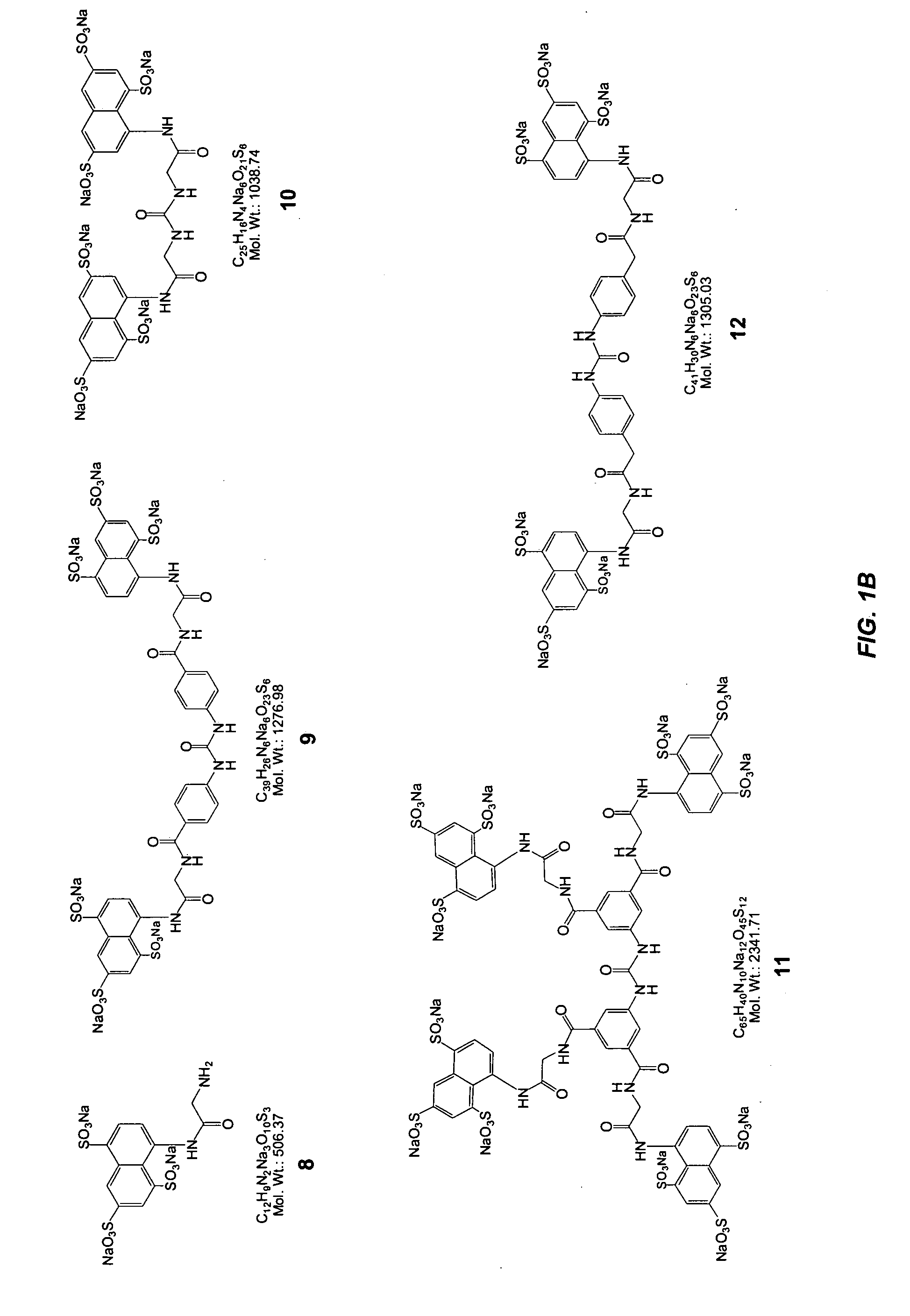

Glycomimetic antagonists for both E-and P-selectins

Compounds and methods are provided for modulating in vitro and in vivo processes mediated by selectin binding. More specifically, selectin modulators and their use are described, wherein the selectin modulators that modulate (e.g., inhibit or enhance) a selectin-mediated function comprise particular glycomimetics linked to a member of a class of compounds termed BASAs (Benzyl Amino Sulfonic Acids).

Owner:GLYCOMIMETICS

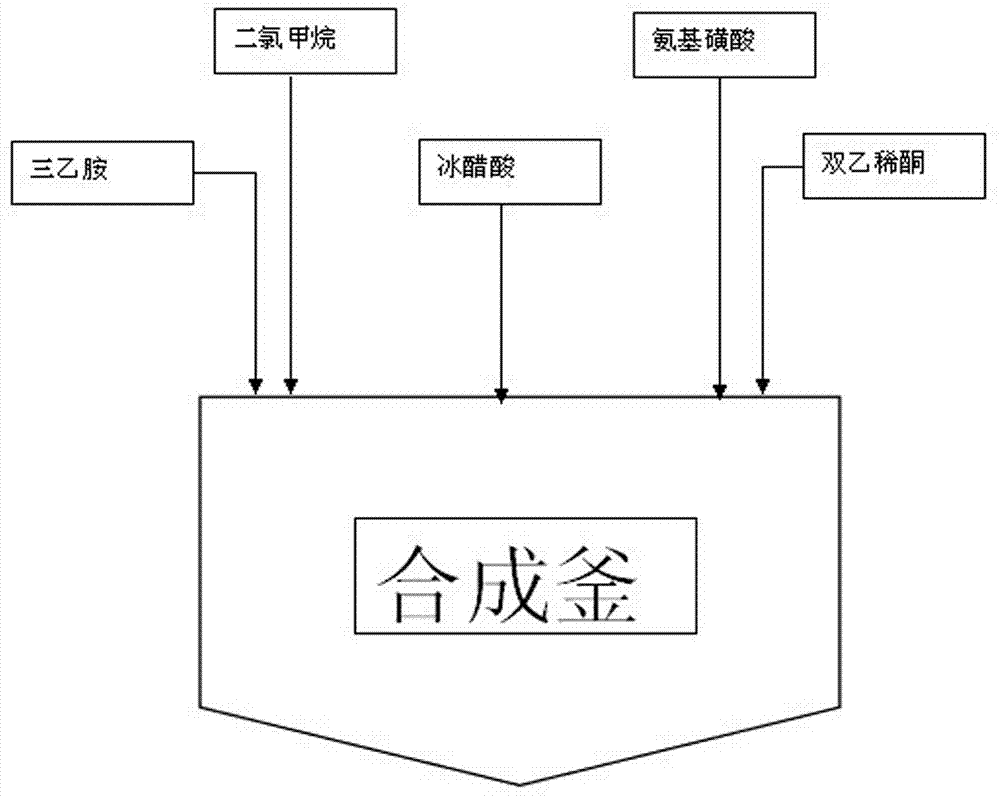

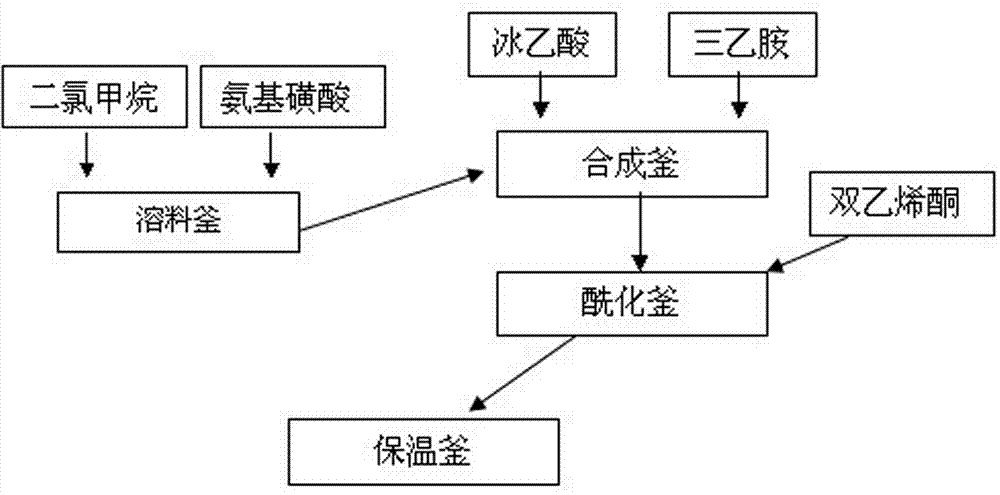

Acesulfame synthesis and acylation production process

InactiveCN103570592AReduce labor intensityImprove continuitySulfuric acid amide preparationAcetic acidEconomic benefits

The invention relates to an acesulfame synthesis and acylation production process, which comprises the following steps of a, putting a sulfamic acid and dichloromethane into a dissolving kettle, and pumping a mixture into a synthesis kettle; b, adding dropwise triethylamine into the synthesis kettle, adding dropwise a glacial acetic acid, and performing natural reaction for 1 hour after the glacial acetic acid is added dropwise; c, placing reactants in the synthesis kettle into an acylation kettle, and adding dropwise diketene for an acylation reaction; and d, after the diketene is added dropwise, circulating a product subjected to the acylation reaction for 1 hour in the acylation kettle, placing into a heat-preservation kettle, performing natural reaction for 1 hour to generate an acetoacetyl-N-sulfonate intermediate, and feeding the acetoacetyl-N-sulfonate intermediate to a sulfonation section for use. The acesulfame synthesis and acylation production process has the advantages that 1, a stepwise reaction mode is adopted, so that compared with a conventional single-kettle production process, the method has the characteristics of production operation continuity and high reaction stability; 2, a multi-kettle stepwise production mode is adopted, so that the production efficiency is greatly improved, the reaction efficiency of the whole production flow is optimized, and the economic benefits of an enterprise are significantly improved.

Owner:ANHUI JINGHE IND

Method for preparing novel sulfamic acid high-efficiency concrete water reducing agent

The invention relates to a method for preparing novel sulfamic acid high-efficiency concrete water reducing agent, which is carried out according to the steps of: (1) hydroxymethylation: adding formaldehyde with the mass ratio of 3-6 with melamine into melamine solution, adjusting the pH value to be 10-12, and carrying out heat preservation for 1-5h at the temperature of 65-95 DEG C; wherein the formaldehyde is polyformaldehyde or 30-40% of formaldehyde water solution; (2) sulfonation: adding p-amino benzene sulfonic acid sodium with the mass ratio of 1-3 with melamine into the melamine solution treated by hydroxymethylation, maintaining the pH value to be 10-12, and keeping the temperature of 70-85 DEG C for 1-3h; (3) etherification reaction: adjusting the pH value to be 3.5-6, and reacting for 1-6h at the temperature of 70-95 DEG C; and (4) neutralization: adding alkali and adjusting the pH value to be 7-9. The high-efficiency concrete water reducing agent prepared by the method can be separately used when the solid doping quantity is 4%, has the water reducing rate of 24% and increases the later period strength of concrete to be 140%.

Owner:JIANG SU TMS CONCRETE ADDITION AGENT

Concentrated aqueous bromine solutions and their preparation

InactiveUS6511682B1Reduced pHRaise the pHBiocideSpecific water treatment objectivesChloride saltBromine

Described is a process of producing a concentrated liquid biocide formulation. Mixed together are (a) bromine chloride or bromine and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the solution is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine from (a) and (b) is greater than 1 when bromine is used and is greater than 0.93 when bromine chloride is used. Use of bromine chloride as the source of the active bromine in the process is preferred because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine in the biocidal composition as active bromine capable of providing biocidal activity.

Owner:ALBEMARLE CORP

Active bromine containing biocidal compositions and their preparation

InactiveUS20040022874A1Reduce shipping costsReduce storage space costsBiocideSpecific water treatment objectivesChemical compositionBromine

Described are highly concentrated liquid biocidal solutions formed in water from (a) specified bromine sources (e.g., BrCl or mixtures of BrCl and Br2) and (b) alkali metal salt of sulfamic acid and / or sulfamic acid and alkali metal base, wherein the solution contains >160,000 ppm of active bromine. Solutions of this type have been found to have greater stability than a commercially-available solution made from the same components containing 148,600 ppm of active bromine. Also described are new, water-soluble, solid state biocidal products formed by removing the water from solutions made in water from (a) and (b) irrespective of the initial concentration of active bromine. Removal of water can be accomplished by flashing or distillation at reduced pressure or preferably by spray drying. Such solid state products are typically in the form of powders or small particles, but can be compacted into larger forms preferably with the aid of one or more suitable binding agents.

Owner:ALBEMARLE CORP

Water soluble composite potassium monopersulfate powder disinfectant

The invention relates to a water soluble compound potassium monopersulfate powdered disinfecting agent comprising sodium chloride, potassium monopersulfate, sulfamic acid, malic acid, lemon acid, sodium hexametaphosphate, sodium dodecanesulphonate and sodium silicate by weight percentage.

Owner:BEIJING DABEINONG ANIMAL HEALTH TECH +1

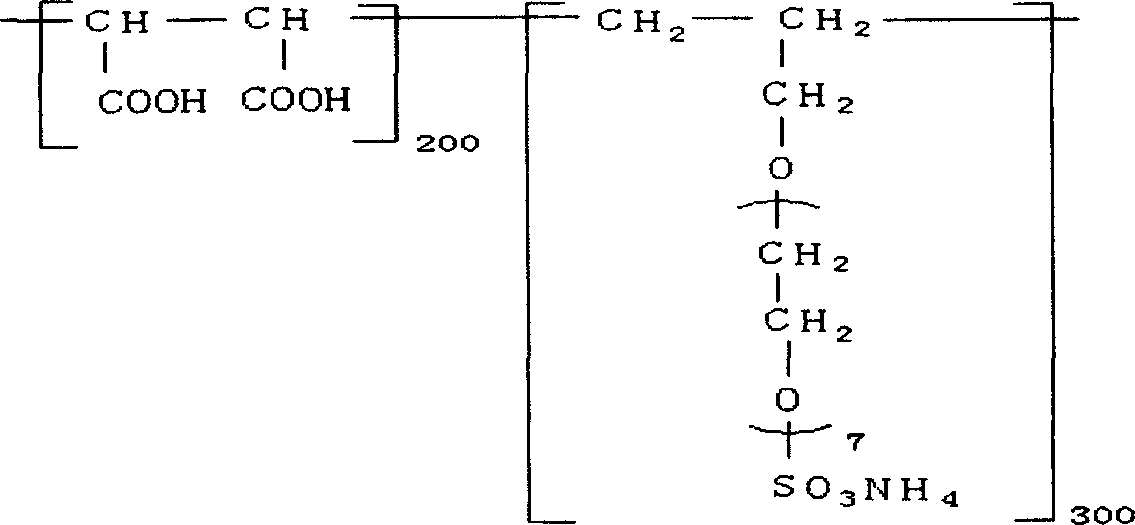

Cleaning agent for electronic materials

InactiveUS20110245127A1Improve device reliabilityHigh yieldOrganic detergent compounding agentsOrganic chemistryActive agentSulfamic acid

Provided is a cleaning agent for electronic materials, which enables very efficient advanced cleaning such that yield in the production of the electronic materials is improved and cleaning in a short period of time becomes possible, the cleaning agent having excellent cleaning power for fine-grained particles and organic matter and being able to reduce metallic contamination on the substrate. The cleaning agent for electronic materials comprises sulfamic acid (A), an anionic surfactant having at least one sulfonic acid group or a salt thereof in the molecule (B), a chelating agent (C), and water, wherein the pH at 25 C is preferably not more than 3.0 and the (B) is preferably a polymeric anionic surfactant (B1) having a weight average molecular weight of 1,000 to 2,000,000.

Owner:SANYO CHEM IND LTD

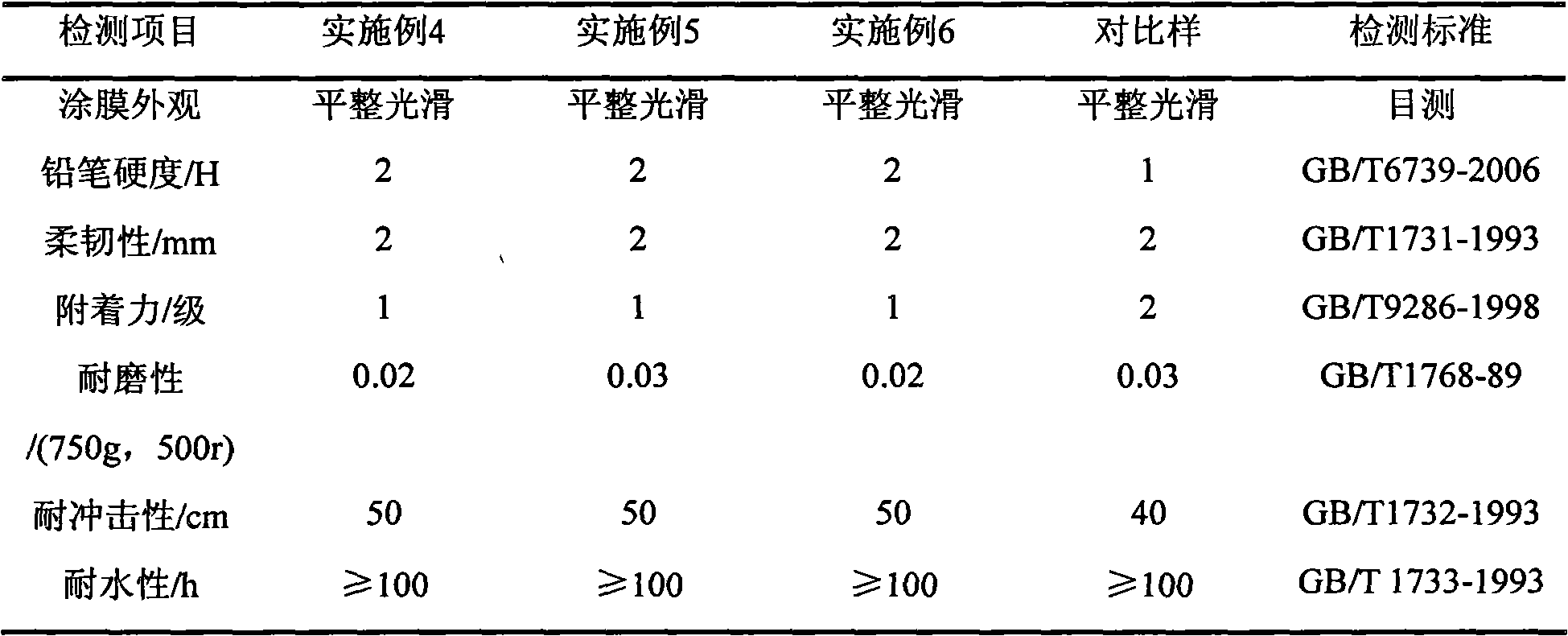

Acrylic modified epoxy resin emulsion and preparation method thereof

InactiveCN101921373AAvoid stabilityAvoid the adverse effects of later film formationCoatingsEpoxyFatty alcohol

The invention discloses an acrylic modified epoxy resin emulsion and a preparation method thereof. The preparation method comprises the following steps of: mixing epoxy resin, fatty alcohol-polyoxyethylene ether and triphenylphosphine and reacting the mixture at the temperature of between 90 and 110 DEG C for 3 to 5 hours to obtain epoxy resin polyethenoxy ether monoester; controlling the temperature of the obtained epoxy resin polyethenoxy ether monoester within a range from 70 to 90 DEG C; adding sulfamic acid into the epoxy resin polyethenoxy ether monoester, reacting the two materials for 2 to 4 hours, adding aqueous solution of NaOH into the mixture for neutralizing and dispersing, and adjusting the pH to be 7 to 8 after the dispersion to obtain a reactive type anionic and nonionic epoxy resin emulsifier; and polymerizing the emulsifier with epoxy resin and acrylic acid series monomer emulsion to obtain stable environment-friendly acrylic grafted epoxy resin emulsion. The method avoids the influence of the emulsifier on storage stability and later-stage filming of the emulsion; and compared with pure acrylic emulsion, the obtained product has the advantages that the film has more superior wear resistance, adhesion and chemical resistance, and can be applied to metal corrosion-resistant paint, road mark paint, indoor and outdoor floor paint and the like.

Owner:SOUTH CHINA UNIV OF TECH

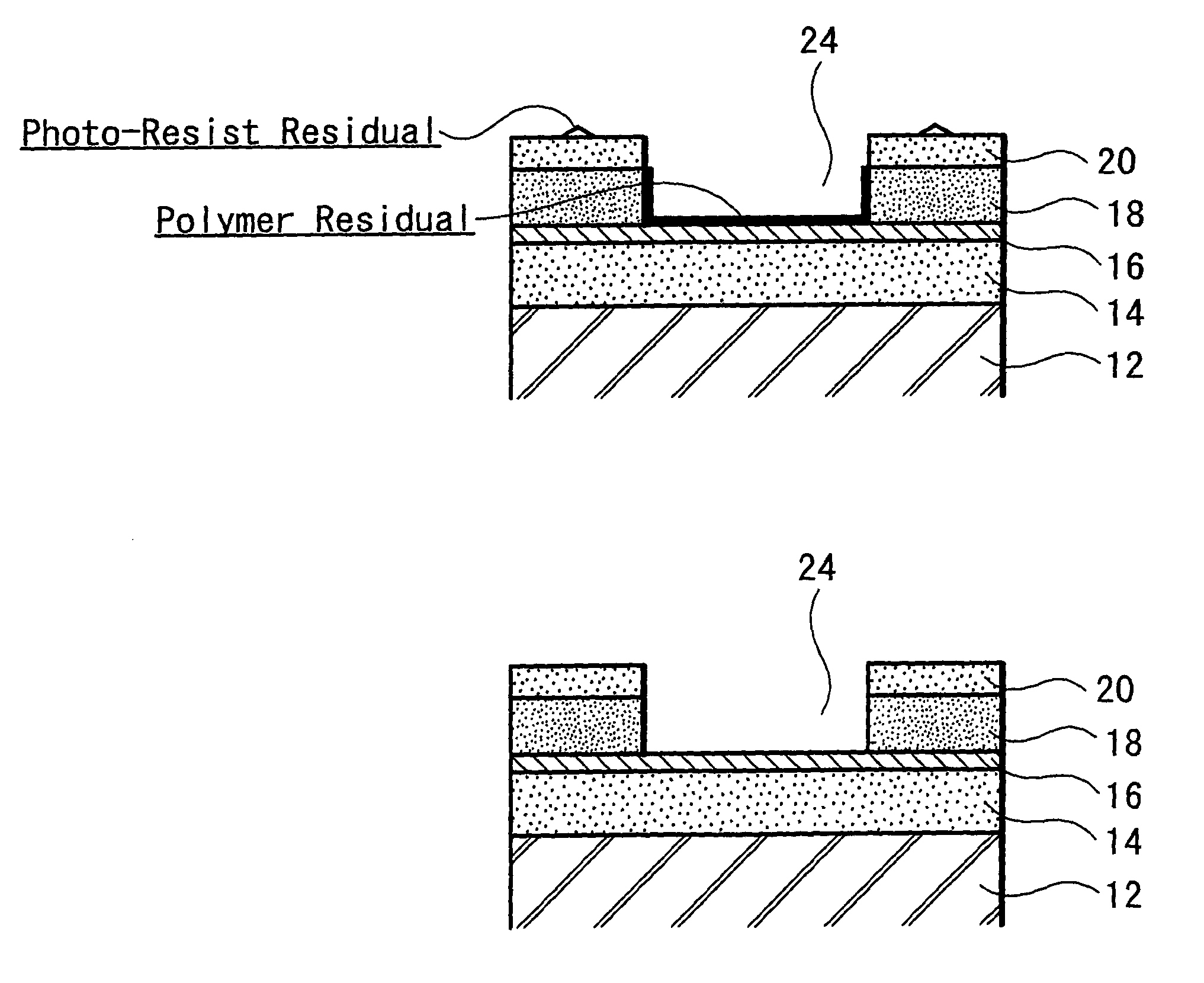

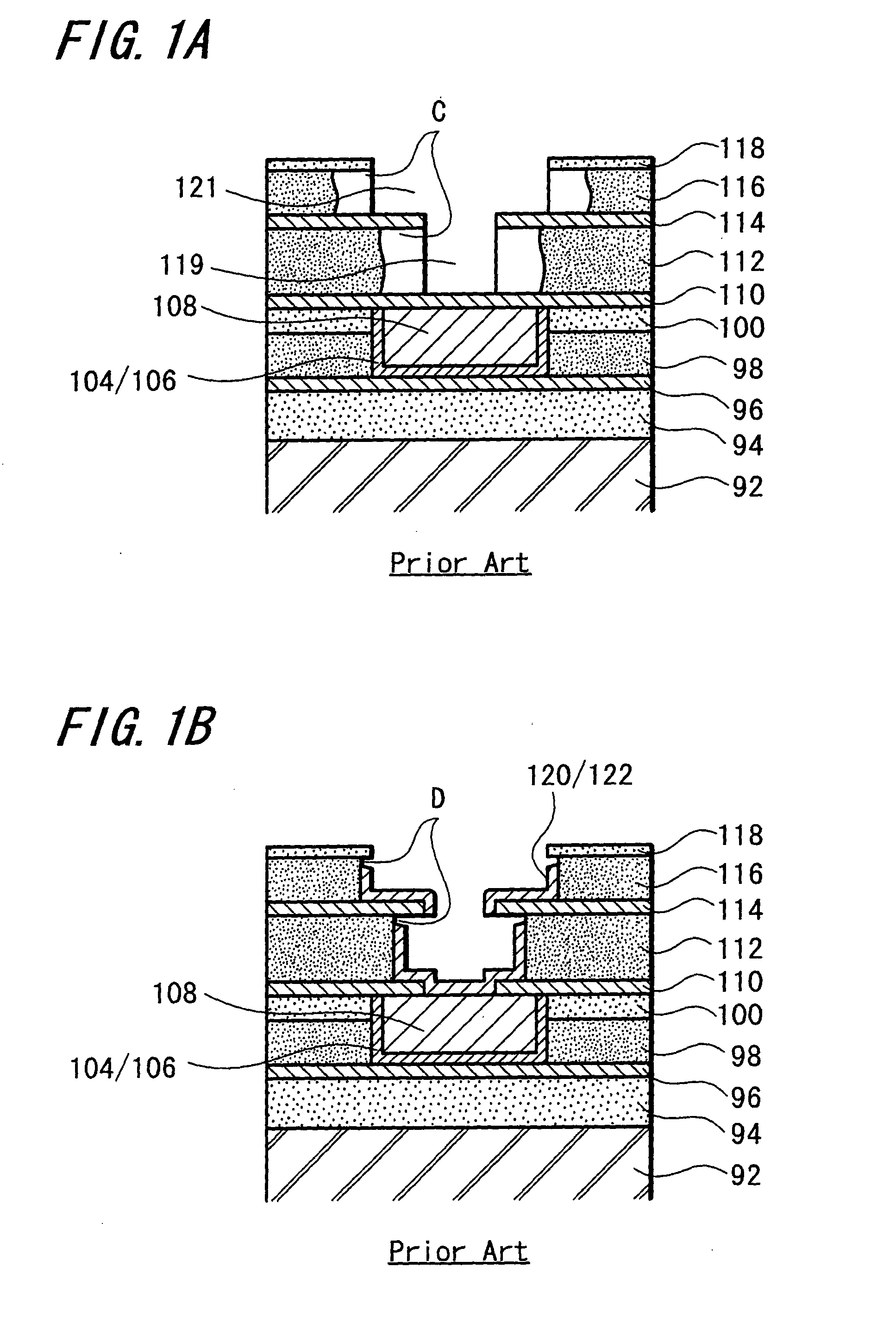

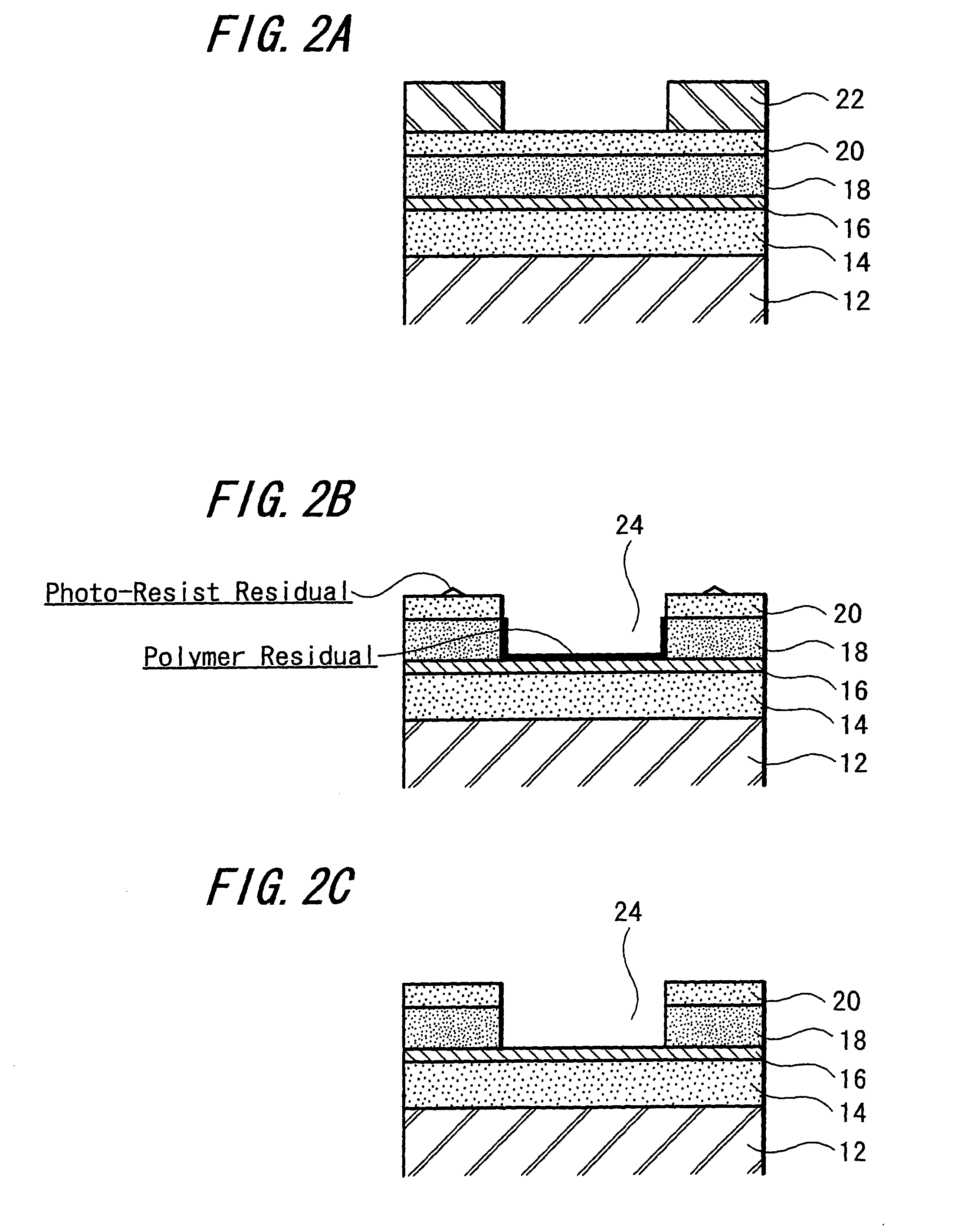

Separation-material composition for photo-resist and manufacturing method of semiconductor device

InactiveUS20040038154A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistPolymer chemistry

One example of a separation-material composition for a photo-resist according to the present invention comprises 5.0 weight % of sulfamic acid, 34.7 weight % of H2O, 0.3 weight % of ammonium 1-hydrogen difluoride, 30 weight % of N,N-dimethylacetamide and 30 weight % of diethylene glycol mono-n-buthyl ether. Another example of a separation-material composition for a photo-resist according to the present invention comprises 1-hydroxyethylidene-1, 3.0 weight % of 1-diphosphonic acid, 0.12 weight % of anmonium fluoride, 48.38 weight % of H2O and 48.5 weight % of diethylene glycol mono-n-buthl ether. The separation-material composition for the photo-resist is mainly used for a medicinal liquid washing liquid / scientific liquid in order to remove the photo-resist residuals and the by-product polymer after an ashing process of a photo-resist mask. It can propose a separation-material composition for a photo-resist such that the photo-resist residuals and the by-product polymer are easily removed after a dry etching process and at the same time the low dielectric-constant insulation film is avoided from erosion and oxidization.

Owner:EKC TECH +1

Water quality purifying agent

ActiveCN105217802ASolve the suspension reuse problemSolve the problem of substrate hardeningBiological water/sewage treatmentSodium bicarbonateMicrobial agent

The invention discloses a water quality purifying agent. A formula of the water quality purifying agent comprises the following components in parts by weight: 15 to 55 parts of potassium hydrogen persulfate composite salt, 0 to 5 parts of sulfamic acid, 5 to 20 parts of citric acid, 1 to 12 parts of sodium carbonate, 0 to 10 parts of sodium bicarbonate, 0 to 0.5 part of magnesium carbonate, 0 to 9 parts of sodium hexametaphosphate, 15 to 30 parts of calcium peroxide, 0 to 1 part of sodium dodecyl benzene sulfonate, 0 to 2 parts of lauryl sodium sulfate, 0.05 to 0.1 part of polyethylene glycol, 5 to 15 parts of anhydrous sodium sulphate and 15 to 25 parts of composite microbial agent. In the formula of the water quality purifying agent, a composite potassium hydrogen persulfate product detoxifying technology and a sewage treatment technology beneficial for microorganisms to restore the micro-ecological balance are used for substituting the existing product capable of leading to the secondary pollution, the advantages such as fast onset of action and lasting effect can be realized, and the water quality purifying agent can take effect within half an hour; the water modification, detoxifying, bacteriostat and water purifying effect can last for 7 to 10 days, and the treatment on the water pollution and the restoration of the ecological balance can be realized in 7 days to 1 month.

Owner:上海泰缘生物科技股份有限公司

Process for producing bis(fluorosulfonyl)imide anion compound, and ion-pair compound

InactiveCN102046523AHigh purityLow costNitrosyl chloridePhysical/chemical process catalystsIonic liquidIon pairs

A process for producing a bis(fluorosulfonyl)imide anion compound by substituting a bis(chlorosulfonyl)imide anion compound, obtained from sulfamic acid, chlorosulfonic acid, and a halogenating agent, with fluorine is used as a process for producing a fluorine compound for use, for example, in the synthesis of battery electrolytes and ionic liquids. According to the above process, the inclusion of impurities can be reduced, and a high-purity fluorine compound of a bis(fluorosulfonyl)imide compound can be efficiently produced at a high yield. A base catalyst can be used in the reaction for substituting the bis(chlorosulfonyl)imide anion with fluorine. The base catalyst is preferably a nitrogen-containing compound.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

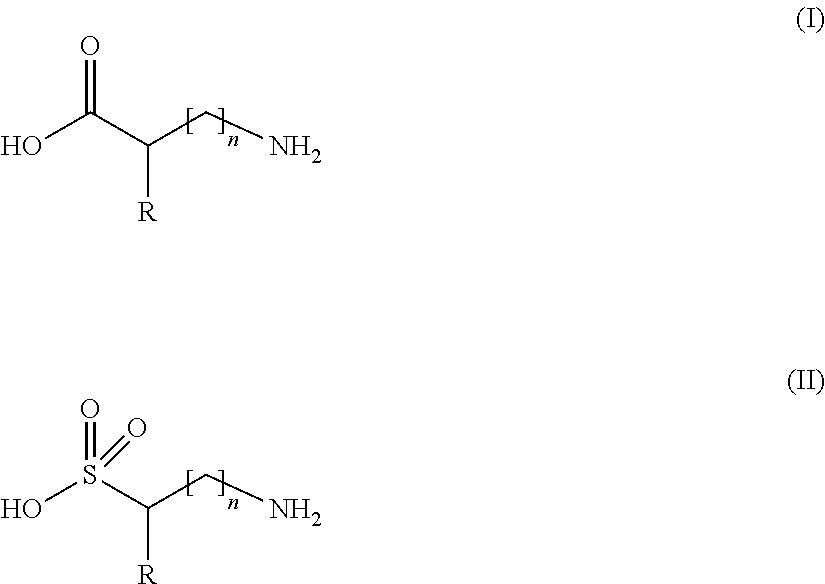

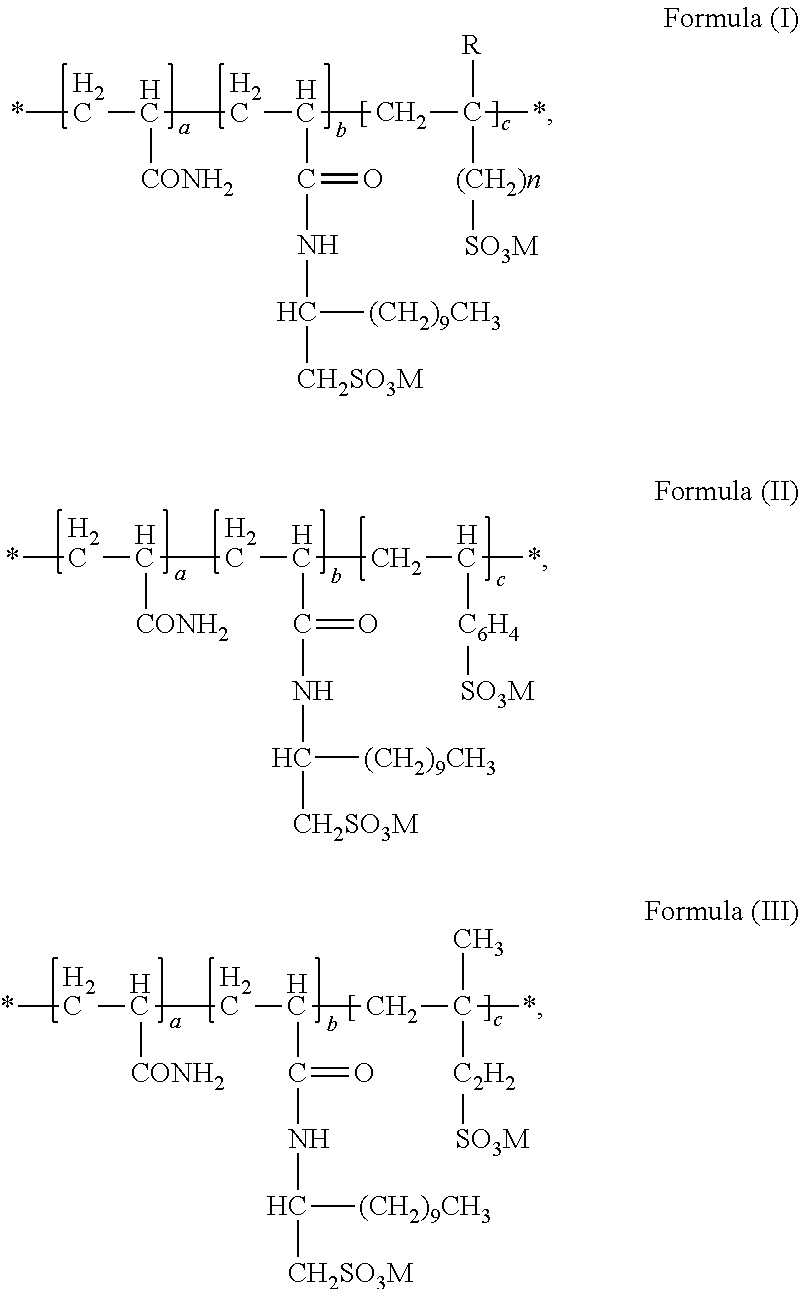

Hair-treatment compositions

PendingUS20180280270A1Condition protectProtection from damageCosmetic preparationsHair cosmeticsPolymer scienceTricarboxylic acid

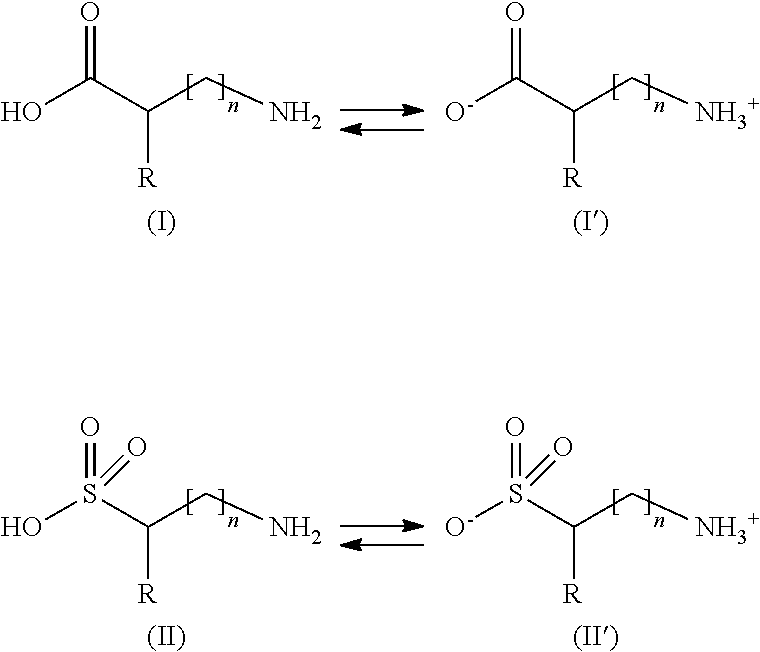

The present disclosure relates to hair-treatment compositions, which are particularly useful for repairing, strengthening, and protecting hair from damage. The hair-treatment composition include at least 0.5 wt. % of at least one amino acid or amino sulfonic acid, and / or a salt thereof, and optionally, at least 0.5 wt. % of at least one non-polymeric mono, di, or tricarboxylic acid, and / or a salt thereof. Additional components such as surfactants and water may also be included. The unique components of the hair-treatment compositions restructure the hair fibers and result in the hair exhibiting improved properties such as increased hair fiber strength, better discipline, and more curl definition.

Owner:LOREAL SA

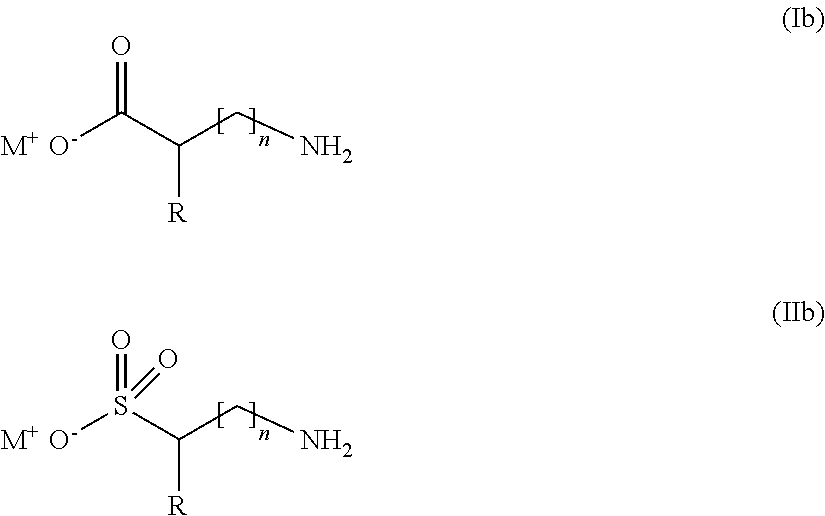

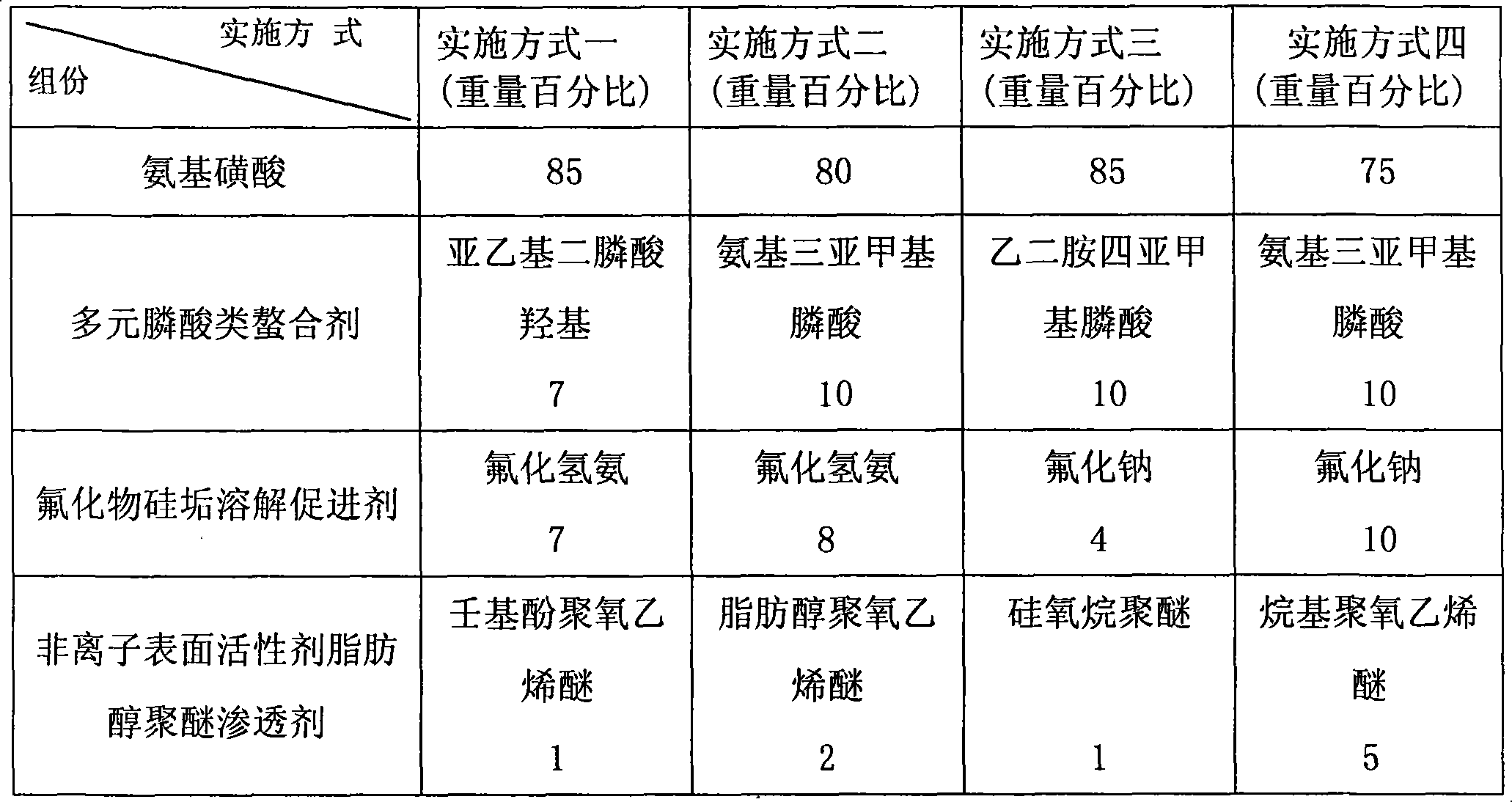

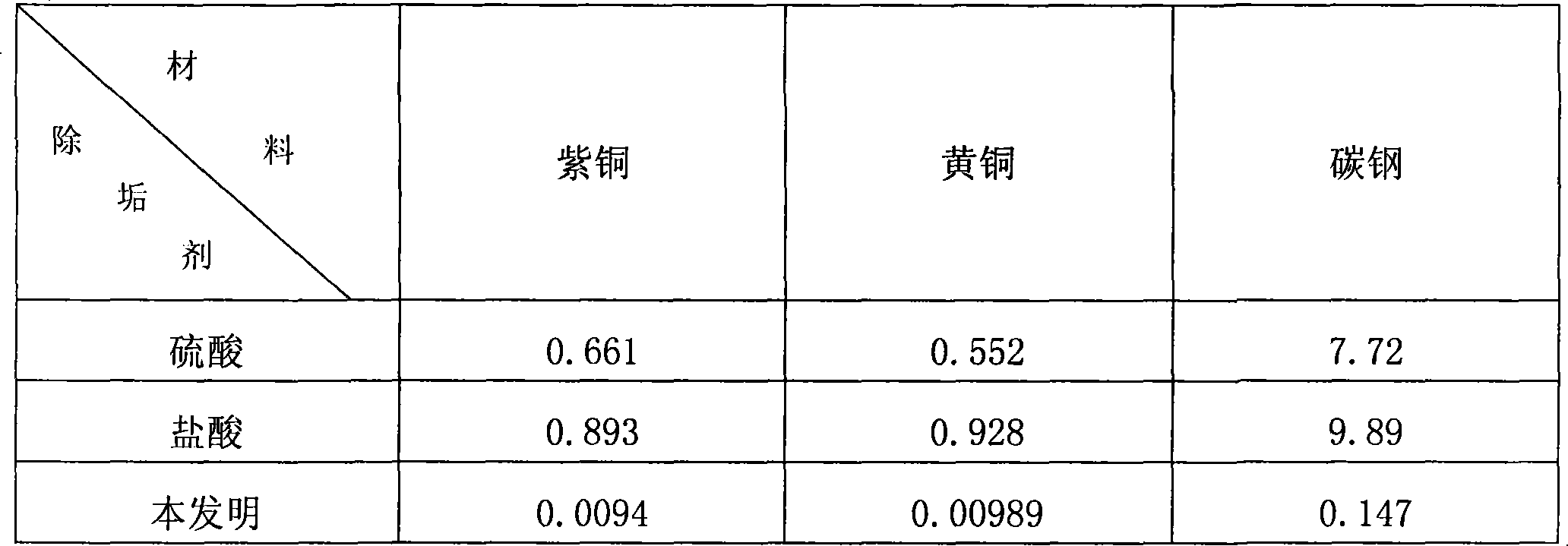

Descaling agent for cleaning central air conditioner main machine

InactiveCN101086065ASolve cleaning problemsStrong acidity of solid organic acidPolyesterHexamethylenetetramine

The invention relates to a scale and rust remover used for cleaning main frame of central air-conditioner. It is characterized in that it comprises solid mixture and liquid inhibitor; said solid mixture comprises amidosulfonic acid, polyphosphinic acid chelating agent, silicofluoride scale and rust dissolution promotor, non-ionic surface activator aliphatic alcohol polyester penetrant, their weight proportions in order are as follows: 75%-85%, 5%-10%, 5%-10%, 1%-5%; said inhibitor is liquid and comprises hexamethylene tetramin, aniline and methyl azimido-benzene according to weight proportion of 2: 2: 1. Said inhibitor is added into acidic washing solution with its weight amount being 0.3% of that of water amount. The product can dissolve carbonate, silicate, sulfate and iron oxide, the descaling speed at room temperature is fast, and is increased within 60 Deg. C, the corrosive rate to metal is pretty low, and there is no acid mist and harmful gas generation during desaling process.

Owner:长沙科惠洁水质处理服务有限公司

Microbiological control in animal processing

InactiveUS6919364B2Reduce Microbial ContaminationProduced economicallyOrganic active ingredientsBiocideWater chlorinationZoology

Fecal bacterial contamination in an animal is reduced by providing it with drinking water containing a microbiocidally-effective amount of halogen-based microbiocide resulting from mixing with water (A) a product formed in water from (i) bromine, chlorine, or bromine chloride, or any two or more thereof, (ii) a water-soluble source of sulfamate anion, and (iii) a water-soluble base; (B) at least one 1,3-dihalo-5,5-dialkylhydantoin in which one of the halogen atoms is a chlorine atom and the other is a chlorine or bromine atom, and in which each alkyl group, independently, contains in the range of 1 to about 4 carbon atoms; (C) at least one 1,3-dibromo-5,5-dialkylhydantoin in which one of the alkyl groups is a methyl group and the other alkyl group contains in the range of 1 to about 4 carbon atoms; or (D) any two or more of (A), (B), and (C).

Owner:ALBEMARLE CORP

Blocking remover for reservoir of oil well

The invention discloses a blocking remover for a reservoir of an oil well. The blocking remover is applied to the technical field of oil extraction in an oil field, comprises an agent A and an agent B, and is characterized in that the weight percentage of the agent A is 25-35%; the weight percentage of the agent B is 65-75%; the agent A comprises the following components by weight: 45-50% of petroleum mixed xylene, 1-2% of nonyl phenol polyoxyethylene (4) ether, and the balance of 0# diesel oil; the agent B comprises the following components by weight: 6-10% of glacial acetic acid or sulfamic acid, 2-2.5% of ammonium bifluoride, 2% of ammonium chloride, 1-2% of citric acid, 1.5-2% of corrosion inhibitor 7801, 3-5% of tertiary butanol, 0.5-1% of octyl phenol polyoxyethylene (10) ether and the balance of water. The blocking remover has the following effects that: the agent A and the agent B are respectively prepared so as to be beneficial to storing the blocking remover for a long time, the agent A of the blocking remover has strong dissolving capacity on crude oil heavy components, such as wax colloid asphalt, and the washing oil efficiency on oil sand is more than 90%. The dissolving rate of the agent B of the blocking remover on carbonate is more than 80%, and the corrosion speed on N80 steel is low and is smaller than 2 g / m<2>.h.

Owner:PETROCHINA CO LTD

Production process for electroplated abrasive material on surface of metal wire

InactiveCN102191525AImprove adsorption capacityUniform adsorptionElectrolytic coatingsSulfamic acidMaterials science

The invention relates to a production process for electroplated abrasive material on the surfaces of a metal wire. The production process comprises the following steps: 1. carrying out chemical nickel plating treatment on the surface of a diamond; 2. preparing impactive nickel electroplating solution; 3. preparing sulfamic acid nickel plating solution and nickel-plated diamond mixed electroplating solution; 4. cleaning; 5. carrying out impactive nickel electroplating; 6. electroplating the nickel-plated diamond on the surface of the metal wire; 7. reinforcing nickel-plated diamond granules; and 8. carrying out post-electroplating treatment. The invention employs the diamond and the metal wire the surfaces of which are chemically nickel-plated as raw materials, and realizes high-speed production by using sulfamic acid nickel plating solution. The binding of the nickel-plated diamond and a nickel plating layer is identical nickel-material binding, and belongs to identical nickel-metal atomic force binding, so that the diamond has high firmness, long service life and high sawing capability.

Owner:NV BEKAERT SA

Flame retardant aqueous liquid composition, use thereof for producing flame retardant polyurethane foam, and flame retardant polyurethane foam article

A flame retardant aqueous liquid composition containing water, guanidine sulfamate, a citric acid compound including a metal salt of citric acid, and a water soluble polymer. A flame retardant polyurethane foam is produced by a process including the steps of providing a mixture of the above flame retardant aqueous liquid composition with a polyol and an isocyanate, and reacting the mixture in the presence of a catalyst.

Owner:NANKYO EFUNIKA

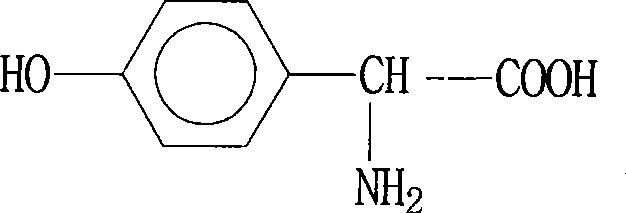

P-hydroxybenzene glycine synthesis technology

InactiveCN101362703AOrganic compound preparationAmino-carboxyl compound preparationSulfite saltHydroxylamine Hydrochloride

The invention belongs to the field of pharmaceutical chemical engineering intermediate production, which relates to a synthesis technology of p-hydroxyphenylglycine (HPG). The purpose of the invention is achieved by the following steps: phenol, glyoxylic acid, water and sulfamic acid carry out the one-pot braise reaction under the action of catalysts such as benzene sulfonic acid, p-toluenesulfonic acid, o-toluenesulfonic acid, and the like; after the reaction is finished, a small amount of reducing substances such as sodium sulfite, sodium bisulfite, hydroxylamine hydrochloride, and the like, are added; finally, the PH value is adjusted by alkali, the mother liquor separation is washed by large amount of water and then washed by organic solvents such as methanol, ethanol, acetone, glacial acetic acid, and the like; the obtained product HPG is white powder, wherein, the content of NPLC is equal to or more than 98.5, which can meet the requirement of splitting. The method has the advantages of low production cost, simple operation, stable quality, etc.

Owner:谢建中

Agent of anti dirt of allylloxy polyether, and preparation method

InactiveCN101003410AHigh inhibitory effectGood compatibilityScale removal and water softeningDouble bondSulfonic acid

This invention relates to a method for preparing allyloxy polyether scale inhibitor, which is a stable, phosphorus-free, biodegradable and environmentally friendly scale inhibitor. The scale inhibitor is a mixture of free radical copolymerization product of allyloxy polyether monomer and vinyl-containing monomer 80-90 wt.%, and graft-copolymerization product of allyloxy polyether monomer and maleic anhydride-acrylic acid copolymer 10-20 wt.%. The method comprises: (1) reacting allyloxy polyethoxy ether, amino sulfonic acid and urea under nitrogen protection to obtain allyloxy polyethoxy ammonia sulfonate; (2) mixing with maleic anhydride-acrylic acid copolymer, and adding water to obtain an aqueous solution; (3) adding initiator solution and maleic anhydride solution at a uniform speed; (4) reacting for 0.5-5 h to obtain the product.

Owner:SOUTHEAST UNIV +1

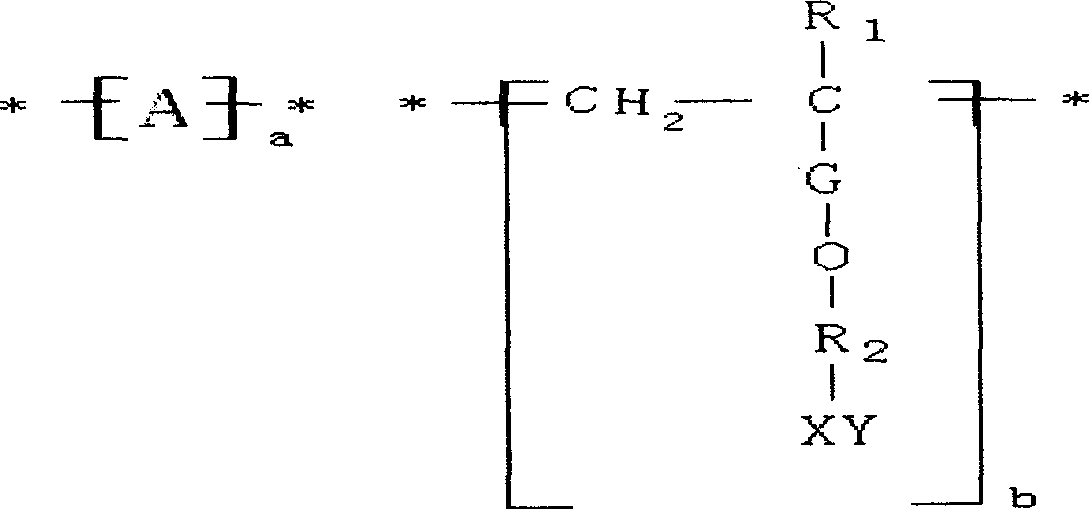

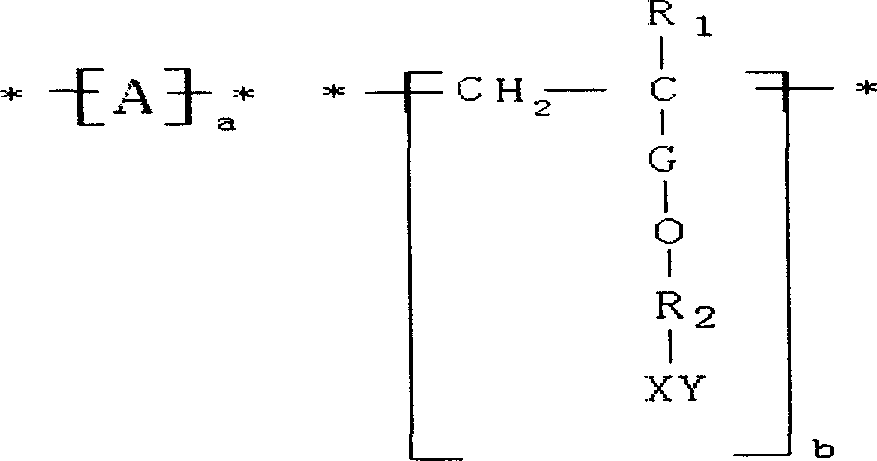

Dispersant and a drilling fluid containing the same

InactiveUS20130079257A1Low viscosityEliminate the effects ofTransportation and packagingMixingFiltrationSulfamic acid

The present invention provides a dispersant and a drilling fluid containing the dispersant. The dispersant comprises the product obtained from the reaction of water, lignin, phenol, sulfonating agent, telogen and catalyst at 140-220° C., preferably at 160-180° C.; the catalyst is one or more selected from the group consisting of sulfamic acid, p-toluenesulfonic acid and benzenesulfonic acid. The dispersant provided by the present invention not only can significantly lower the viscosity of the drilling fluid but also plays a role in reducing filtration loss.

Owner:CHINA PETROCHEMICAL CORP +1

Polyurethane dispersions

The invention relates to aqueous polyurethane dispersions with an acid number of 5 to 60 mg KOH / g of the polyurethane solid, a hydroxyl group content of 0.25 to 6.5% by weight and 2 to 25% by weight of urethane groups (calculated as -NH-CO-O-) based on the polyurethane solid. The inventive dispersions are characterized in that the polyurethanes are the reaction products of a) 10 to 80% by weight of at least one dimer diol, b) 10 to 80% by weight of at least one dimer diol carboxylic acid and / or dimer diol ether, c) 1 to 10% by weight of at least one acidic component that consists of I) hydroxycarboxylic acids, ii) aminocarboxylic acids, iii) aminosulfonic acids and iv) hydroxysulfonic acids, d) 0 to 20% by weight of a low-molecular component that consists of compounds of the molecular weight range of 60 to 300 and that carry at least two hydroxyl and / or amino groups, e) 0 to 20% by weight of at least one hydrophilic, mono- or polyvalent alcohol of the molecular weight range of 350 to 3,000 that carries ethylene oxide moieties, and f) 5 to 40% by weight of an isocyanate component. The reaction products are at least partially base-neutralized and the percentages indicated add up to 100.

Owner:COGNIS DEUT GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com