Patents

Literature

47results about How to "Suppressed ionization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor light emitting device capable of suppressing silver migration of reflection film made of silver

ActiveUS20050211989A1Suppress generationInhibit migrationSolid-state devicesSemiconductor devicesAlloyLight emitting device

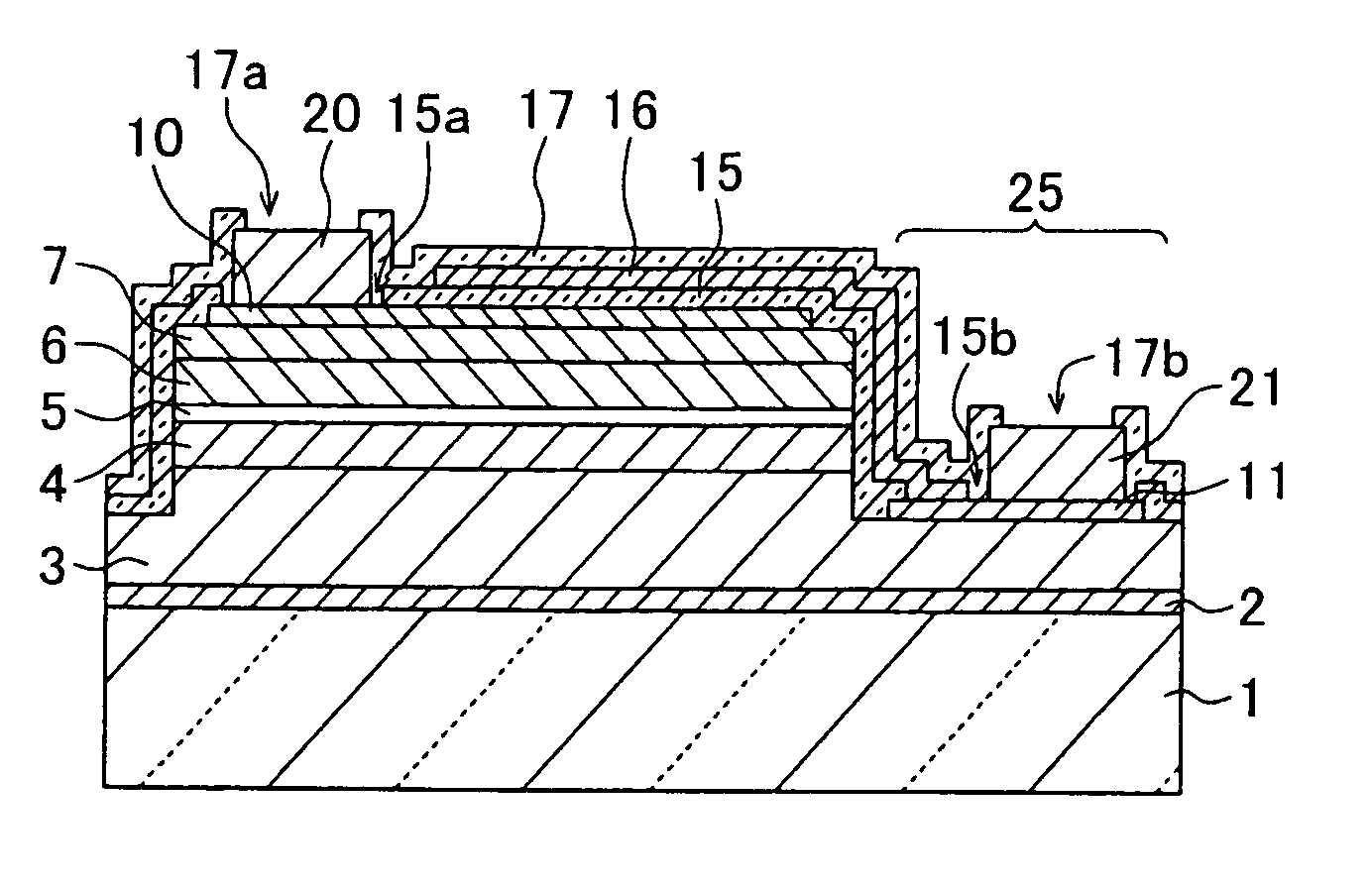

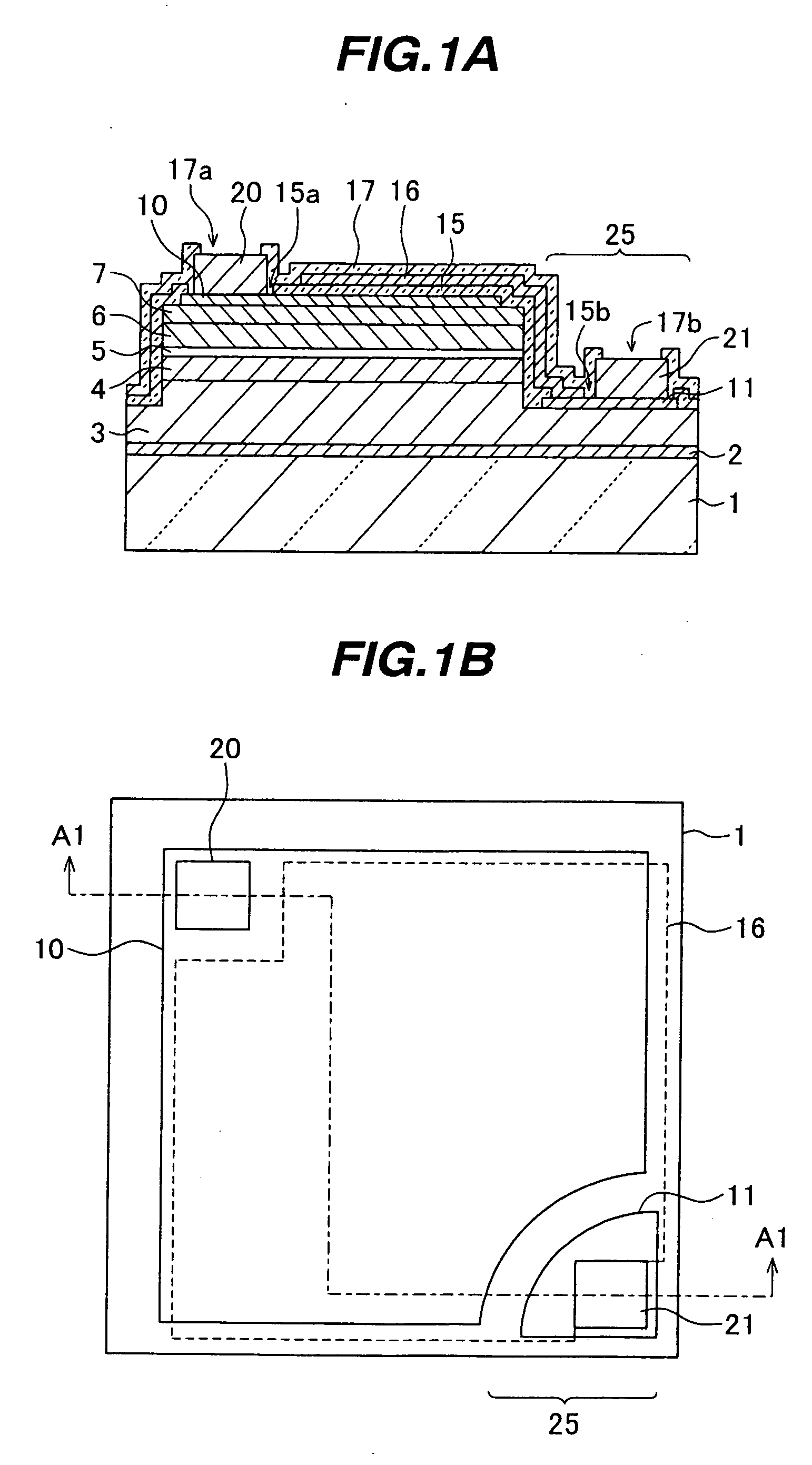

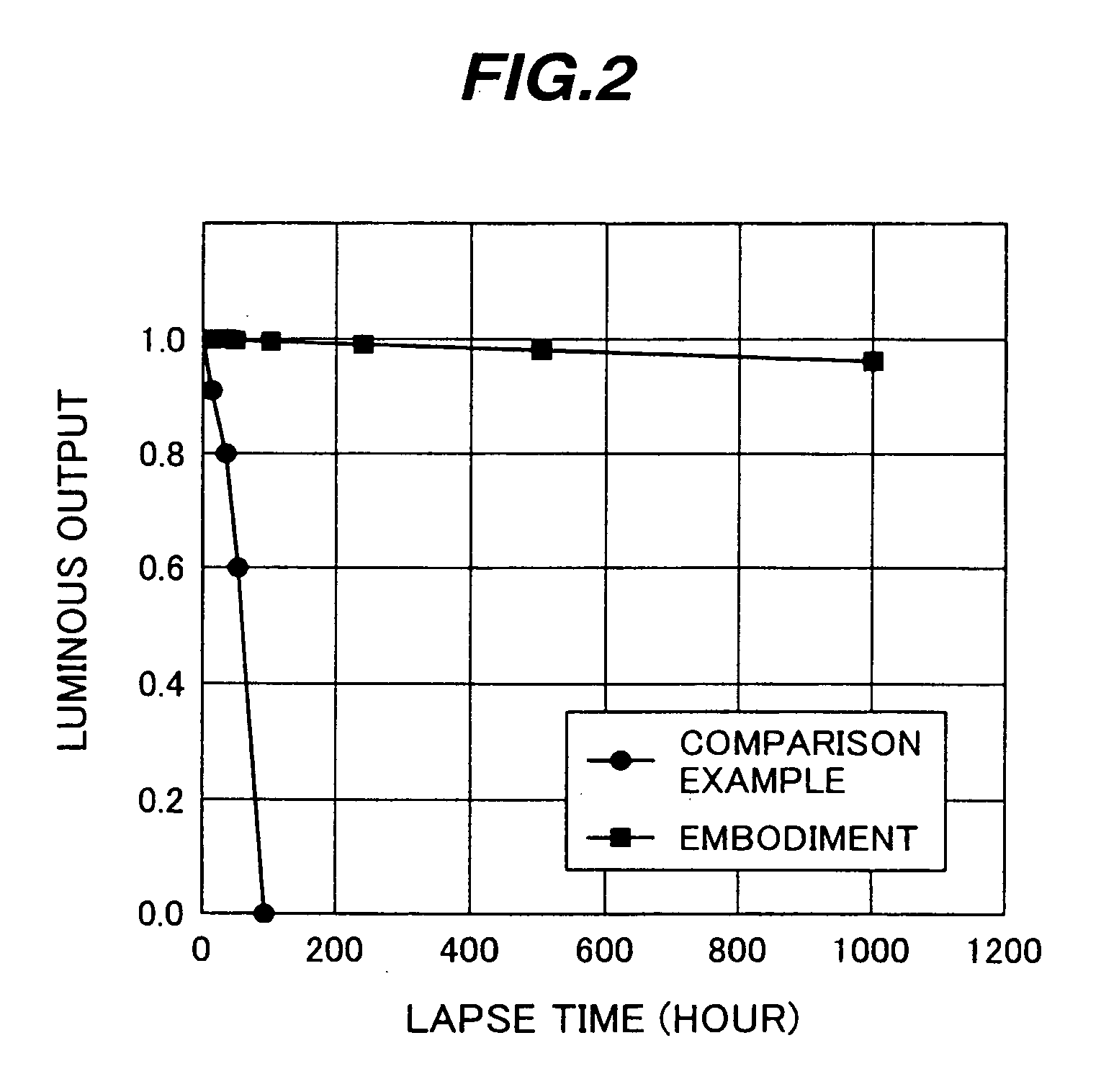

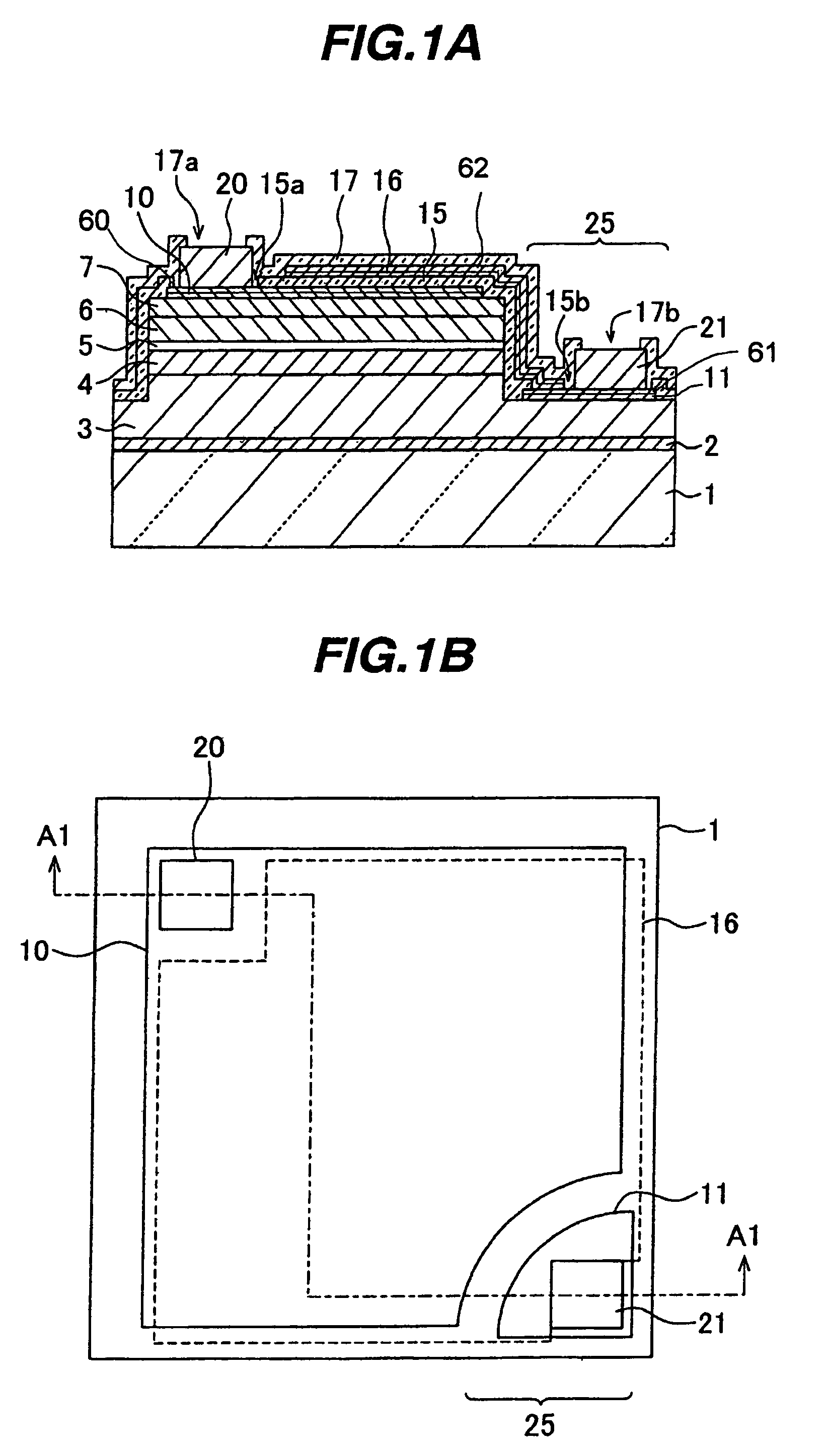

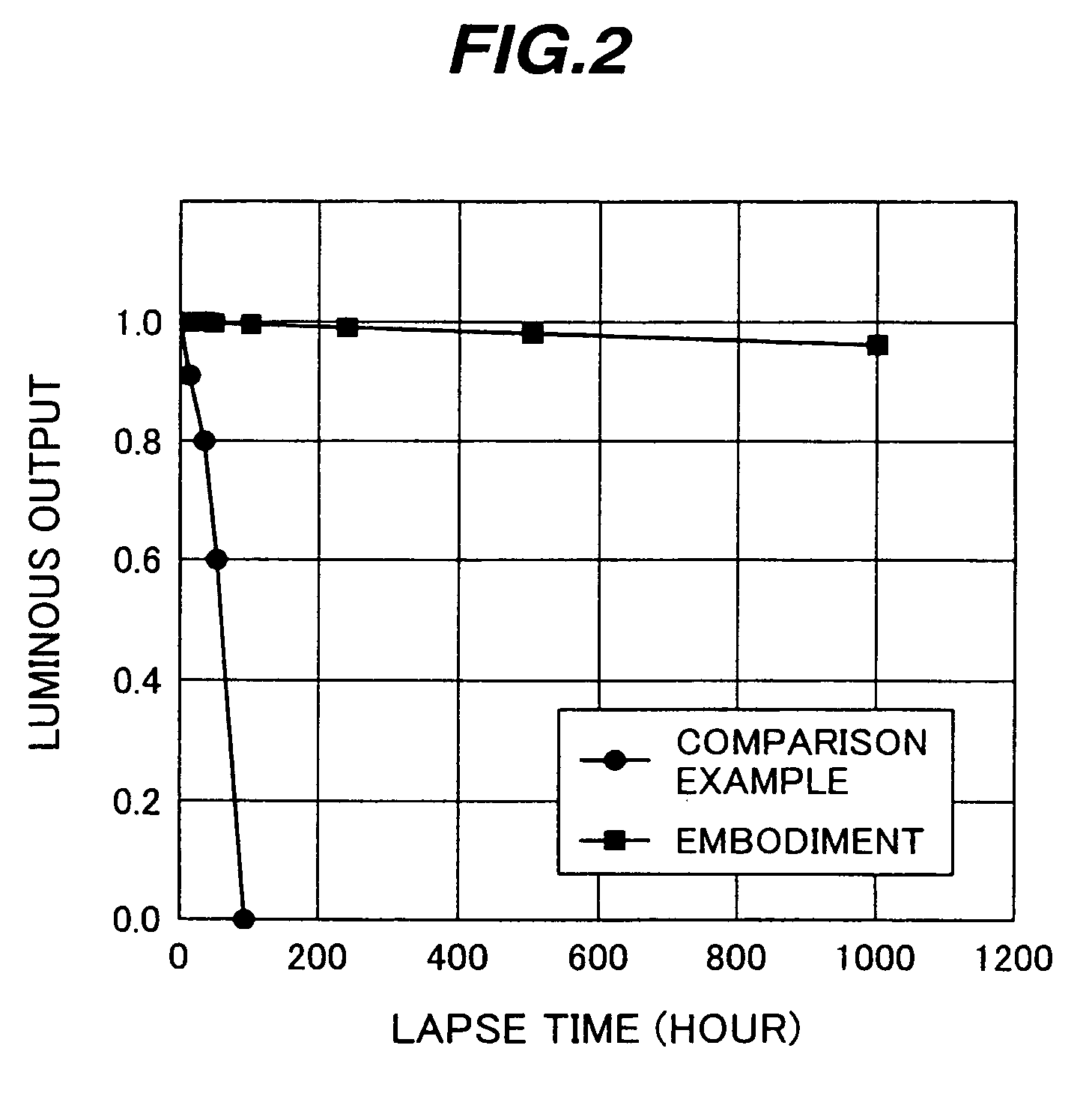

A luminous lamination structure includes a first layer made of n-type nitride semiconductor and a second layer made of p-type nitride semiconductor and disposed over the first layer wherein a luminous region is defined between the first and second layers. The second layer is removed to expose the first layer in a first area which is a partial surface of the first layer. A p-side electrode is disposed on a surface of the second layer and electrically connected to the second layer. An insulating film covers the p-side electrode. An n-side electrode electrically connected to the first layer is disposed in the first area. A reflection film disposed on the insulating film extends to the n-side electrode and electrically connected to the n-side electrode. The reflection film is made of silver containing alloy or silver.

Owner:STANLEY ELECTRIC CO LTD

Semiconductor light emitting device capable of suppressing silver migration of reflection film made of silver

ActiveUS7141825B2Inhibit migrationImprove reliabilitySolid-state devicesSemiconductor devicesAlloyLight emitting device

A luminous lamination structure includes a first layer made of n-type nitride semiconductor and a second layer made of p-type nitride semiconductor and disposed over the first layer wherein a luminous region is defined between the first and second layers. The second layer is removed to expose the first layer in a first area which is a partial surface of the first layer. A p-side electrode is disposed on a surface of the second layer and electrically connected to the second layer. An insulating film covers the p-side electrode. An n-side electrode electrically connected to the first layer is disposed in the first area. A reflection film disposed on the insulating film extends to the n-side electrode and electrically connected to the n-side electrode. The reflection film is made of silver containing alloy or silver.

Owner:STANLEY ELECTRIC CO LTD

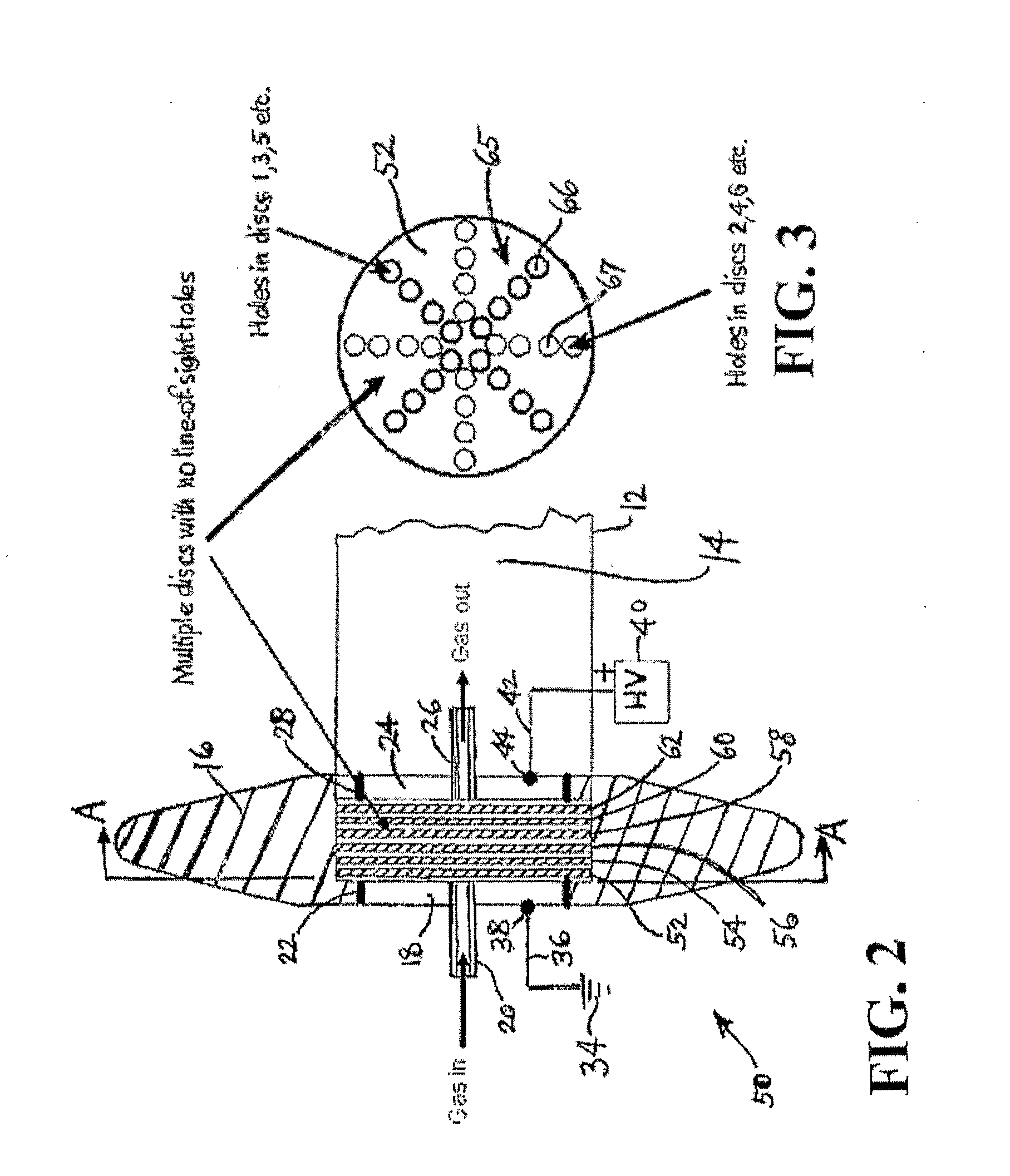

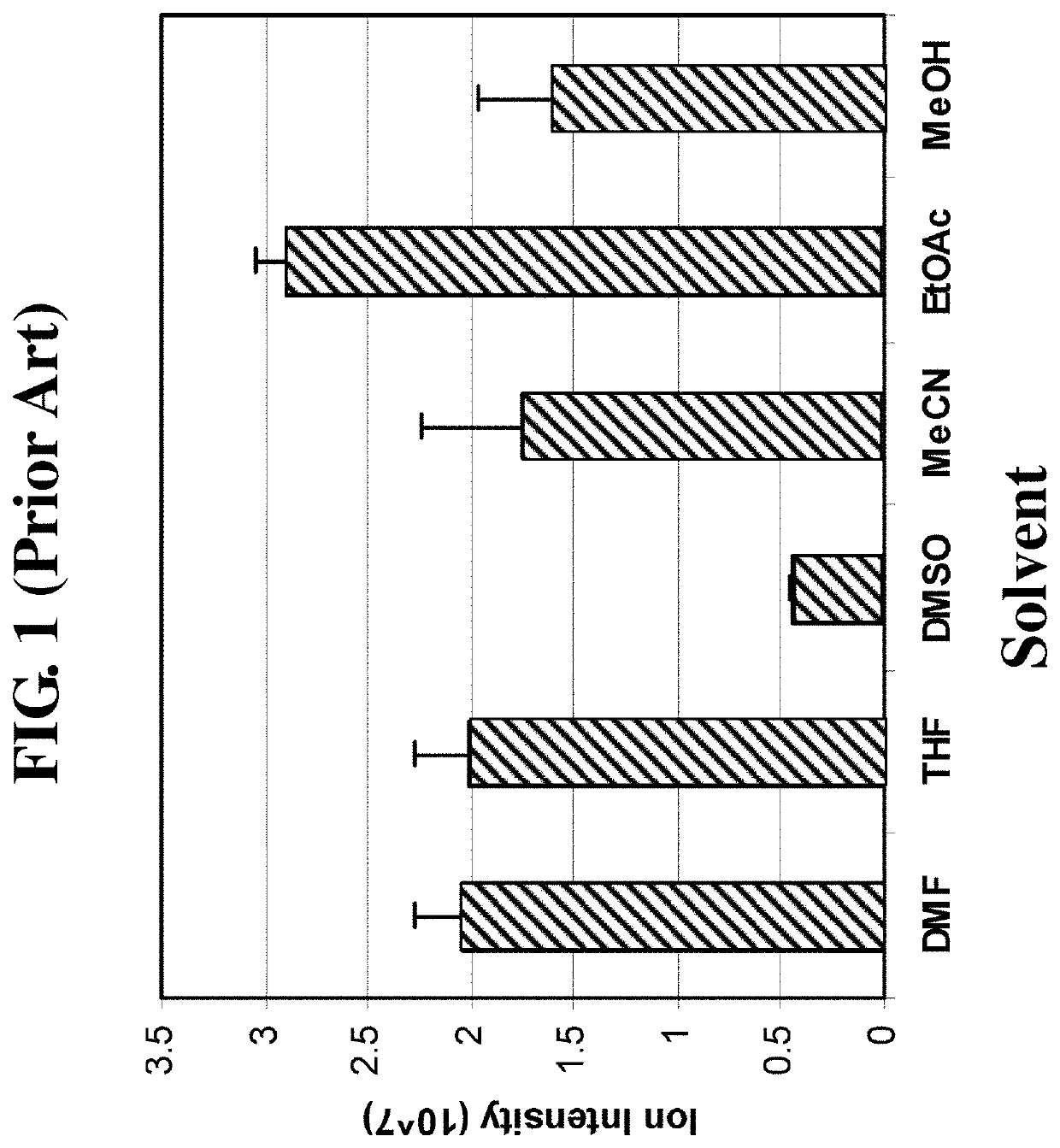

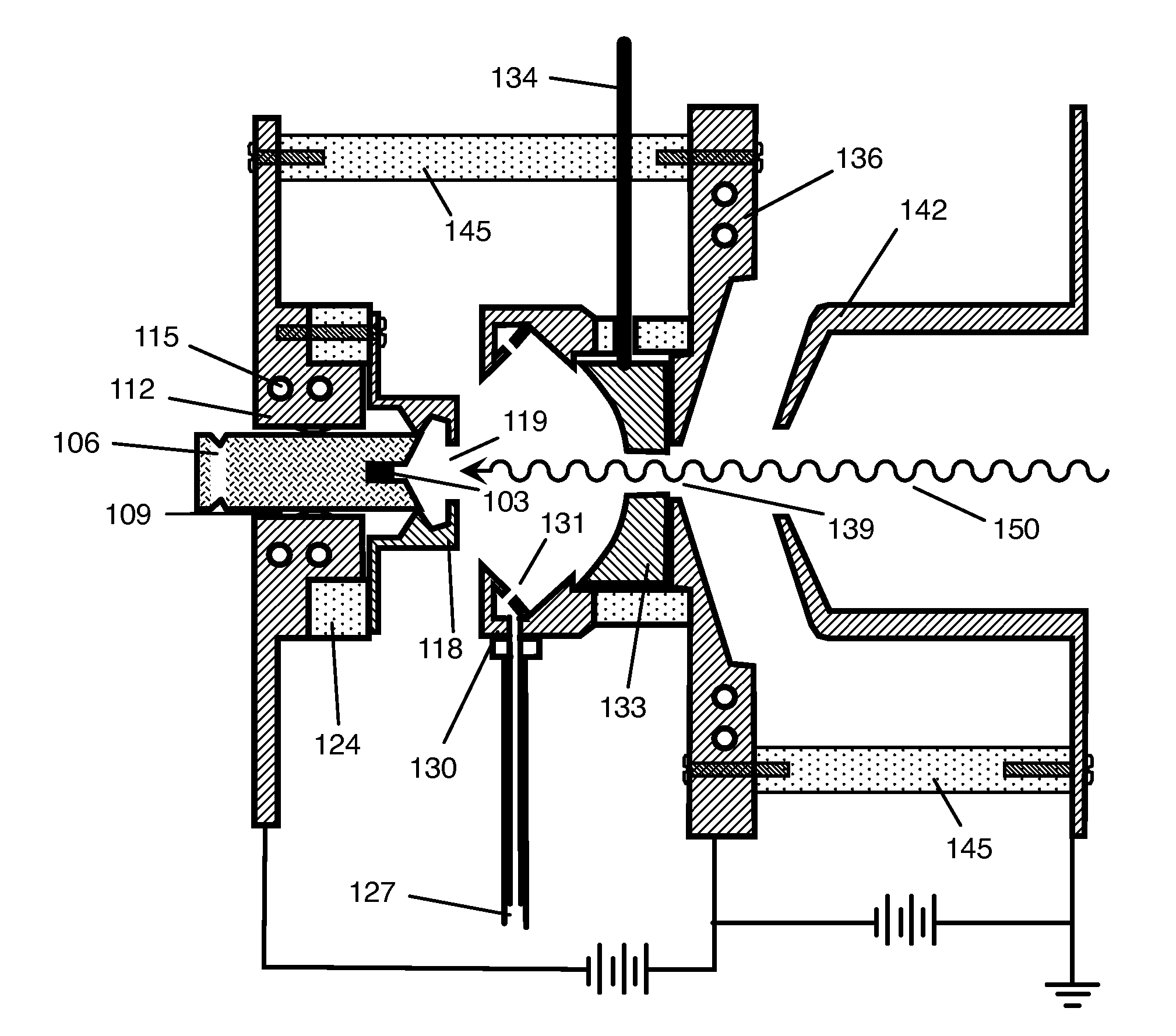

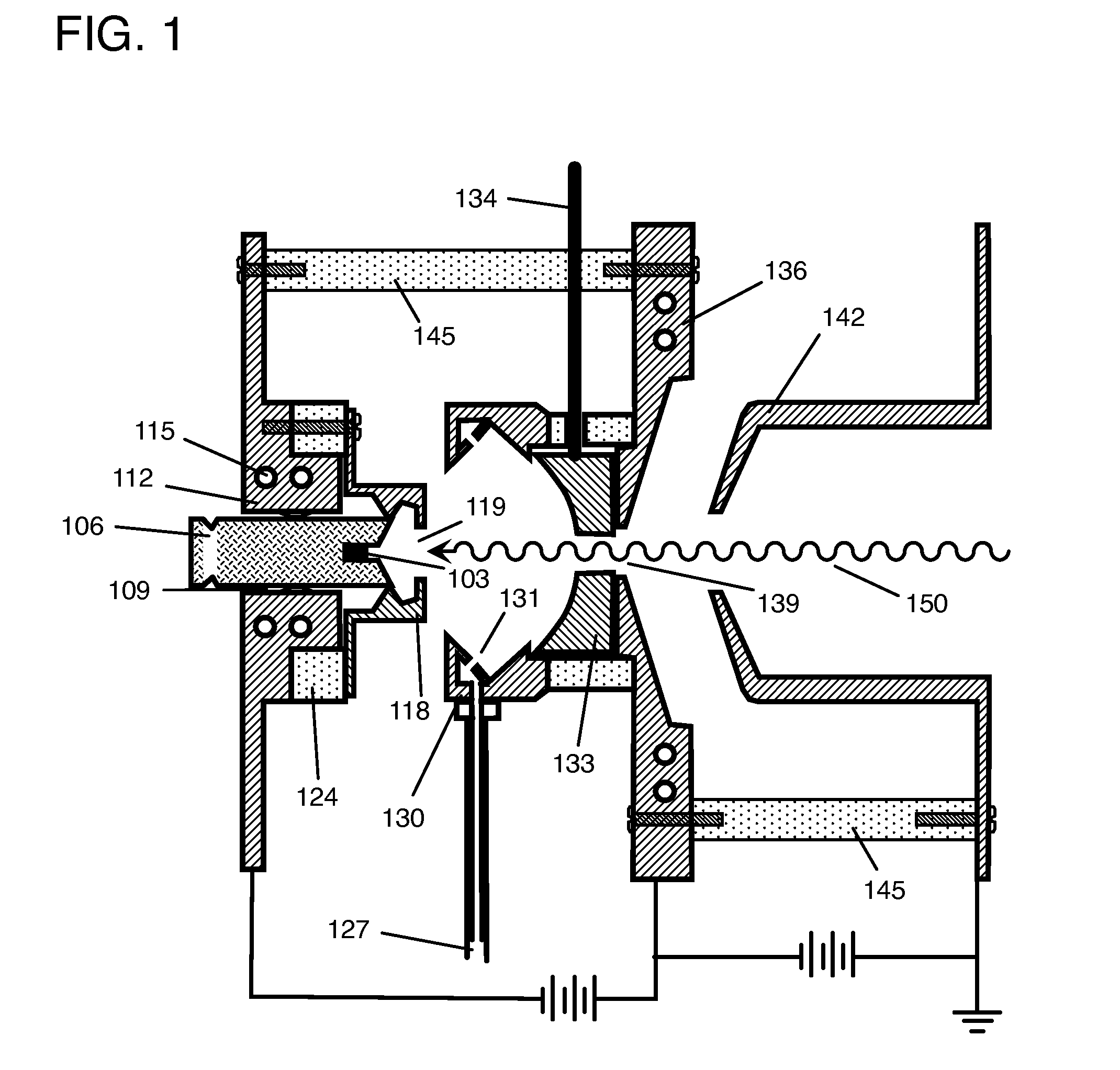

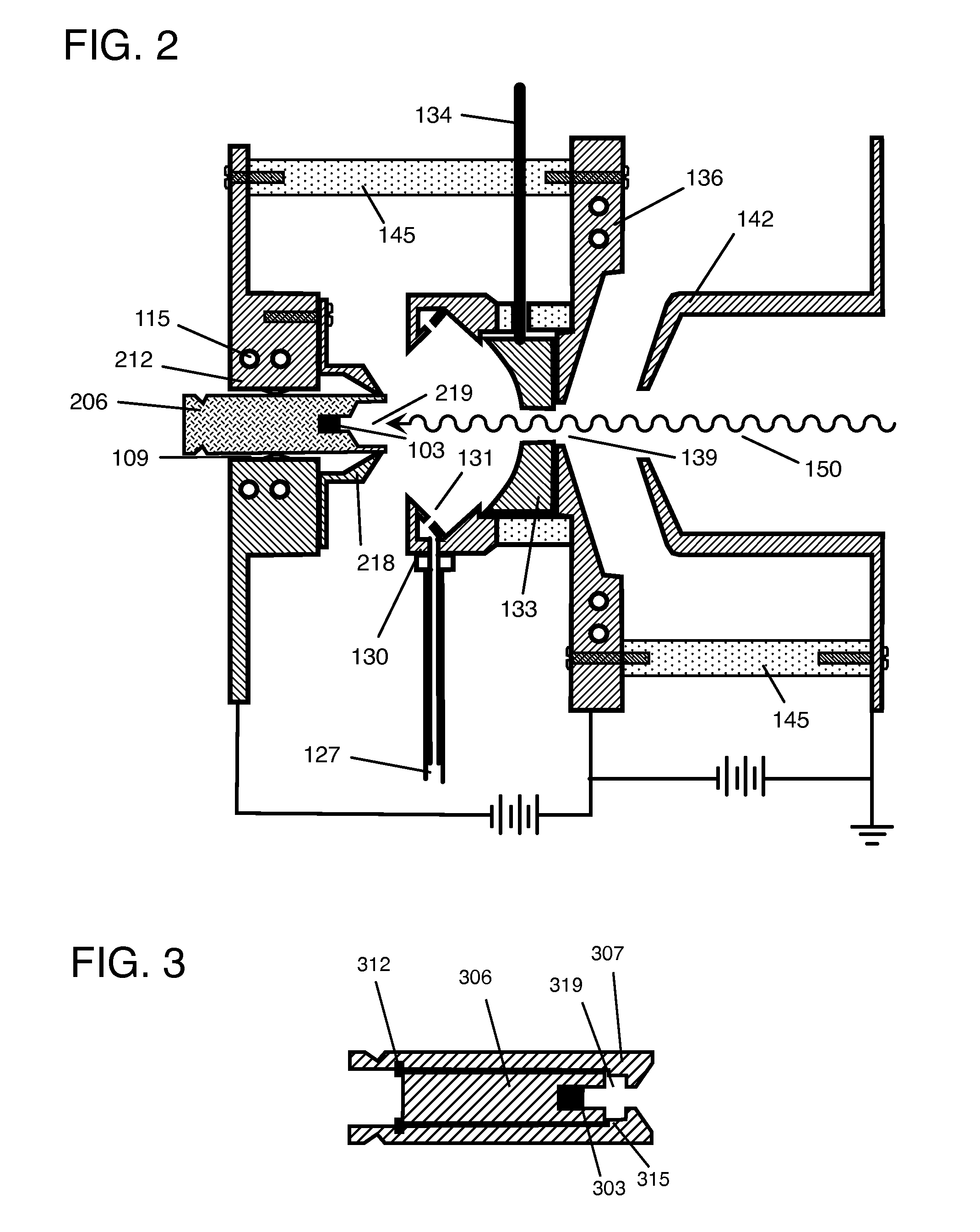

Delivery of Low Pressure Dopant Gas to a High Voltage Ion Source

InactiveUS20080220596A1Ionization suppressionReduce the impactMaterial analysis by optical meansSemiconductor/solid-state device manufacturingDelivery systemHigh voltage

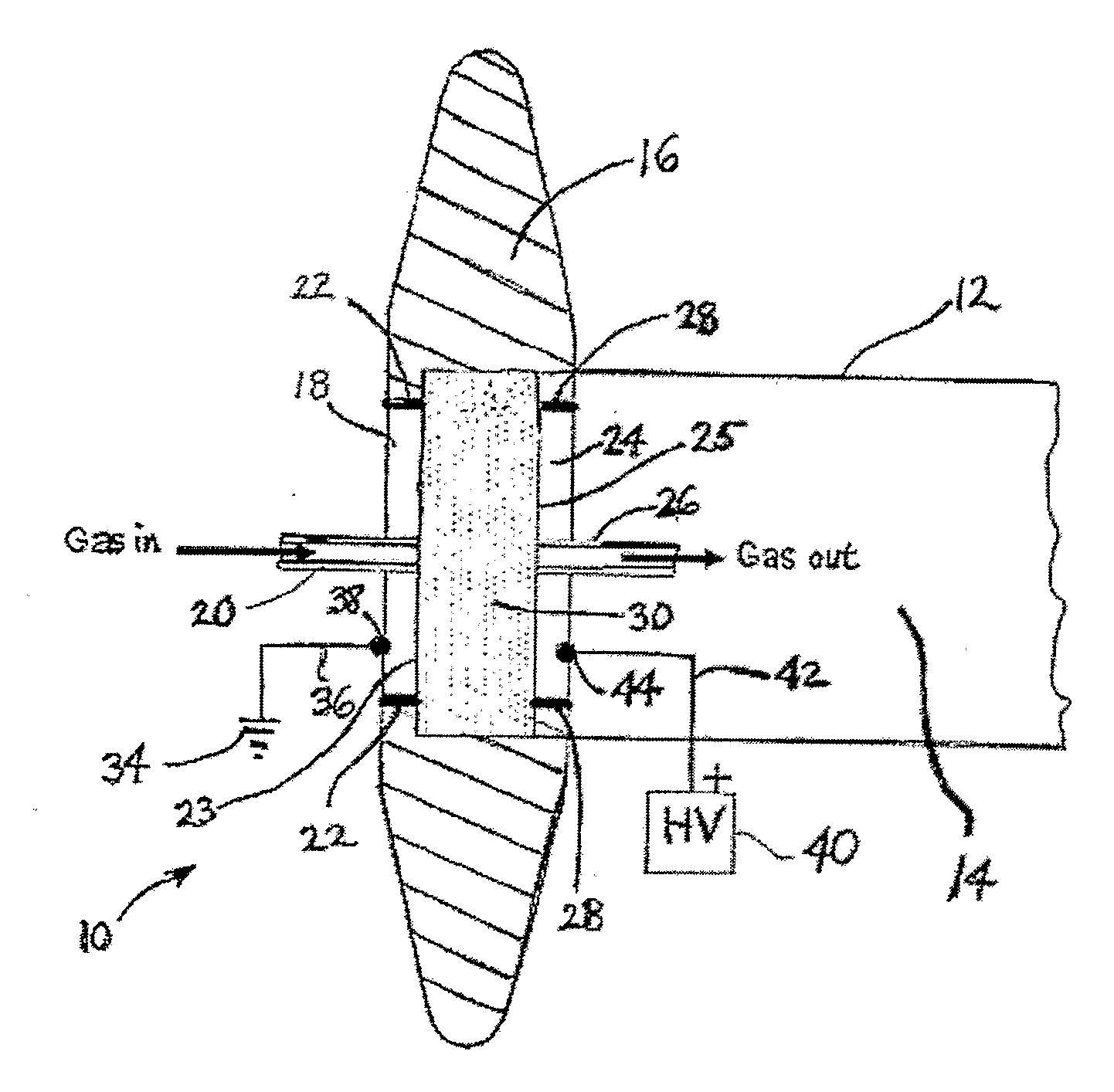

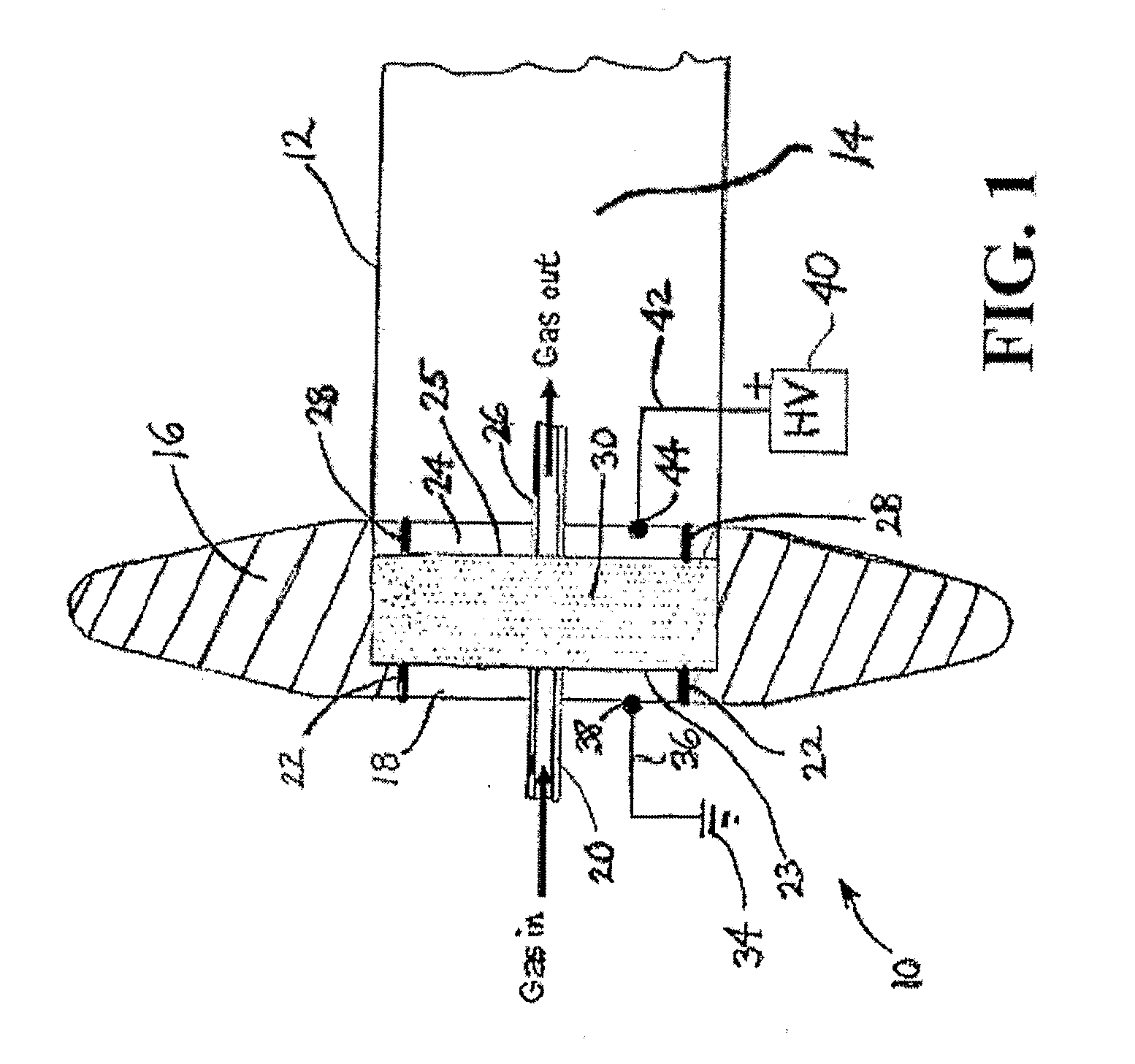

A system for delivery of low-pressure dopant gas to a high-voltage ion source in the doping of semiconductor substrates, in which undesired ionization of the gas is suppressed prior to entry into the high-voltage ion source, by modulating electron energy upstream of the high-voltage ion source so that electron acceleration effects are reduced to below a level supporting an electronic ionization cascade. The gas delivery system in a specific application includes a gas flow passage, a voltage generator electrically coupled with at least a portion of the gas flow passage to impose an electric field thereon, and an obstructive structure that is deployed to modulate acceleration length of electrons of the low-pressure gas in relation to ionization potential of the gas, to suppress ionization in the gas flow passage.

Owner:ENTEGRIS INC

Flaky iron phosphate, and preparation method and application thereof

ActiveCN110357057AModerate particle size distributionEasy to processPhosphorus compoundsPhosphoric acidSlurry

The invention discloses flaky iron phosphate, and a preparation method and application thereof. The microscopic morphology of the flaky iron phosphate is a primary particle in a sheet shape with a thickness of 10 to 50 nm, a length of 100 nm to 3 [mu]m and a width of 100 nm to 3 [mu]m. The preparation method comprises the following steps of: weighing a ferrous ion solution and adding phosphoric acid and a crystal modifier; weighing a phosphorus salt solution and adding an oxidizing agent; carrying out mixing to obtain a mixed solution C, controlling the pH value of the mixed solution C to be 1.5-2.2, and carrying out a reaction to obtain pale yellow iron phosphate slurry; converting the iron phosphate slurry into white or pink-white iron phosphate slurry containing crystal forms under theconditions of stirring and heating, reducing a stirring speed by 20%-50% after the completion of the conversion, and carrying out ageing and heat preservation; performing solid-liquid separation, andcollecting a solid portion to obtain a crystalline iron phosphate precipitate; and washing the precipitate and then performing calcination to obtain the flaky iron phosphate. The iron phosphate of theinvention can be used for preparing lithium iron phosphate with high compaction density.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

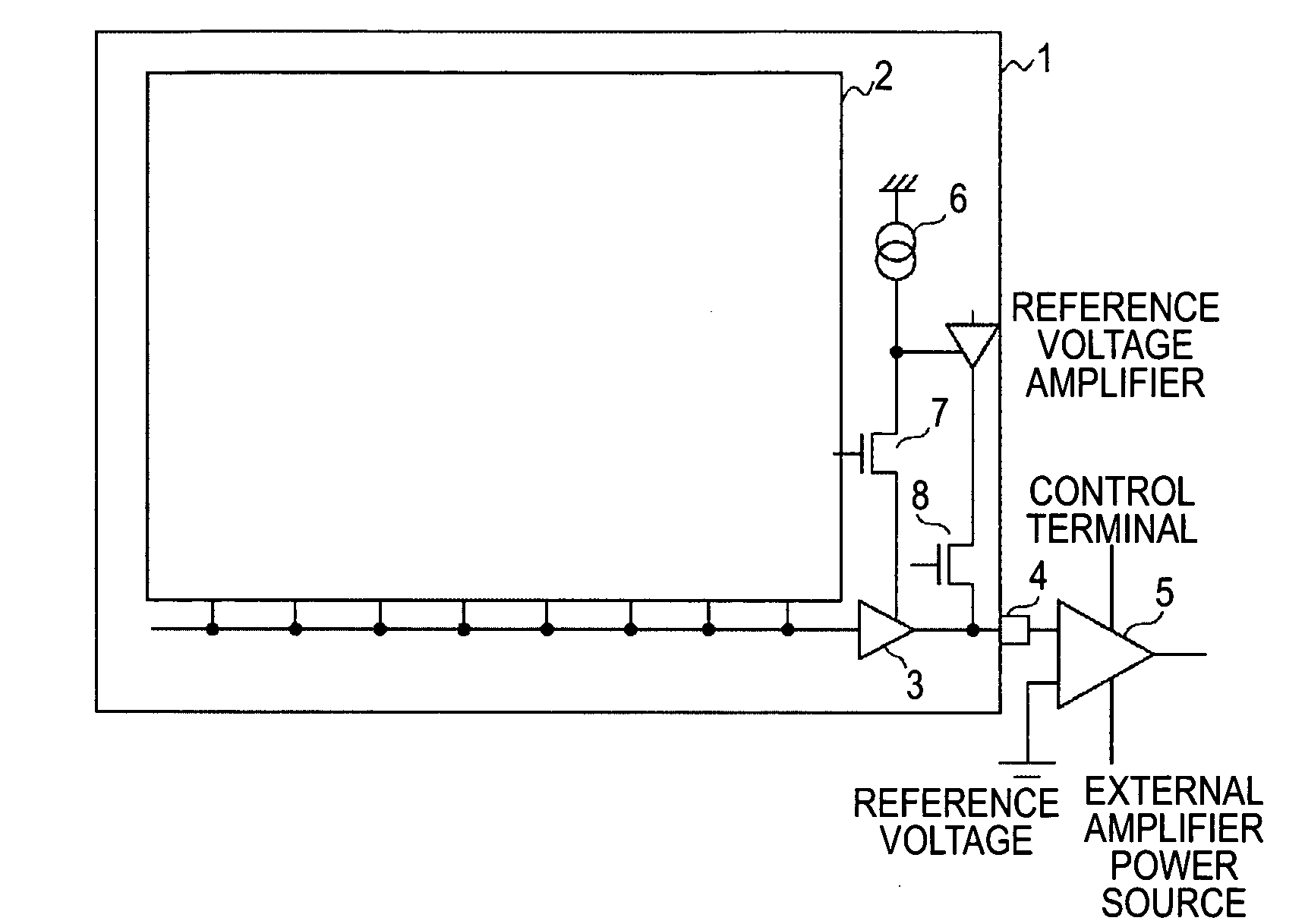

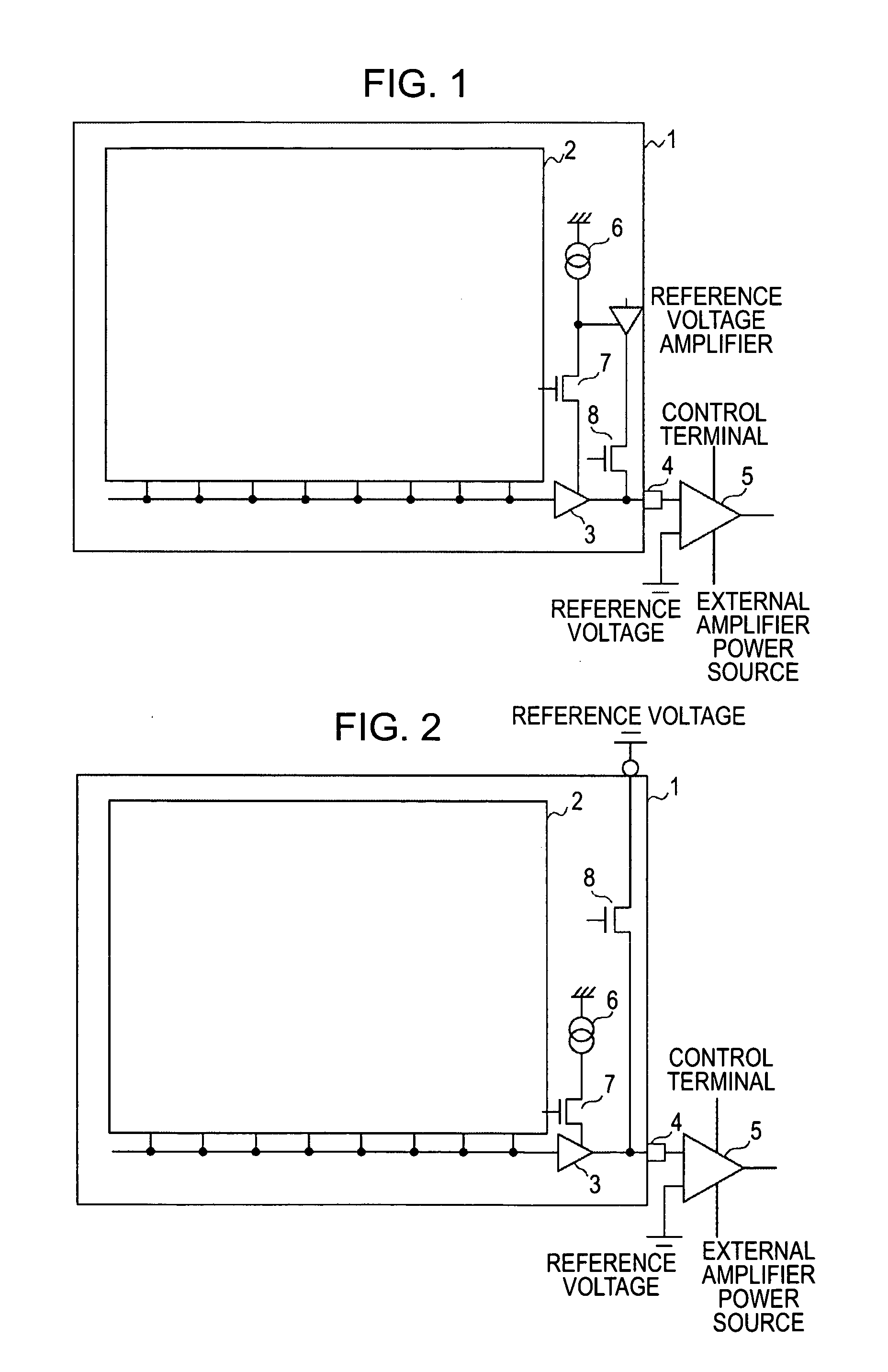

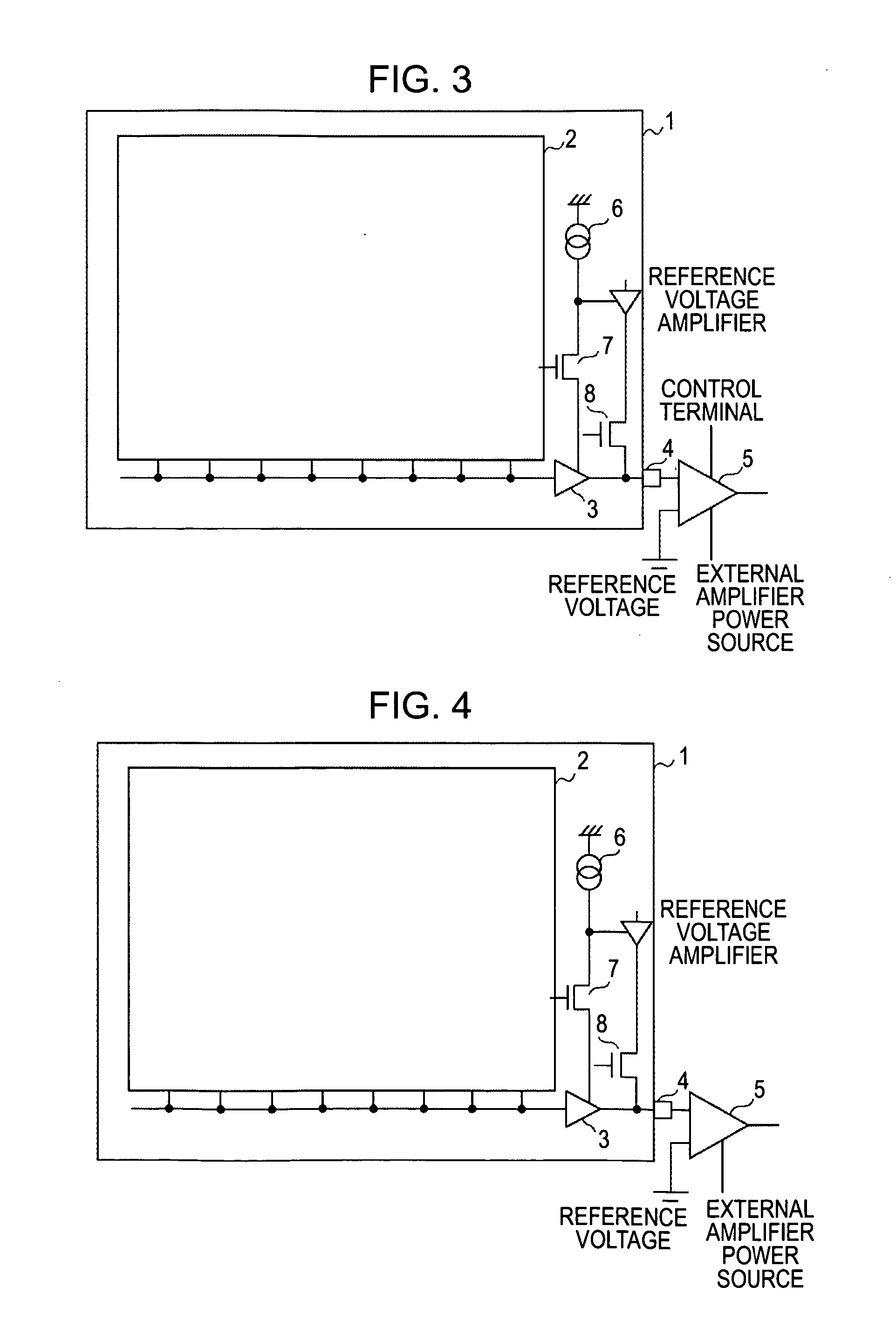

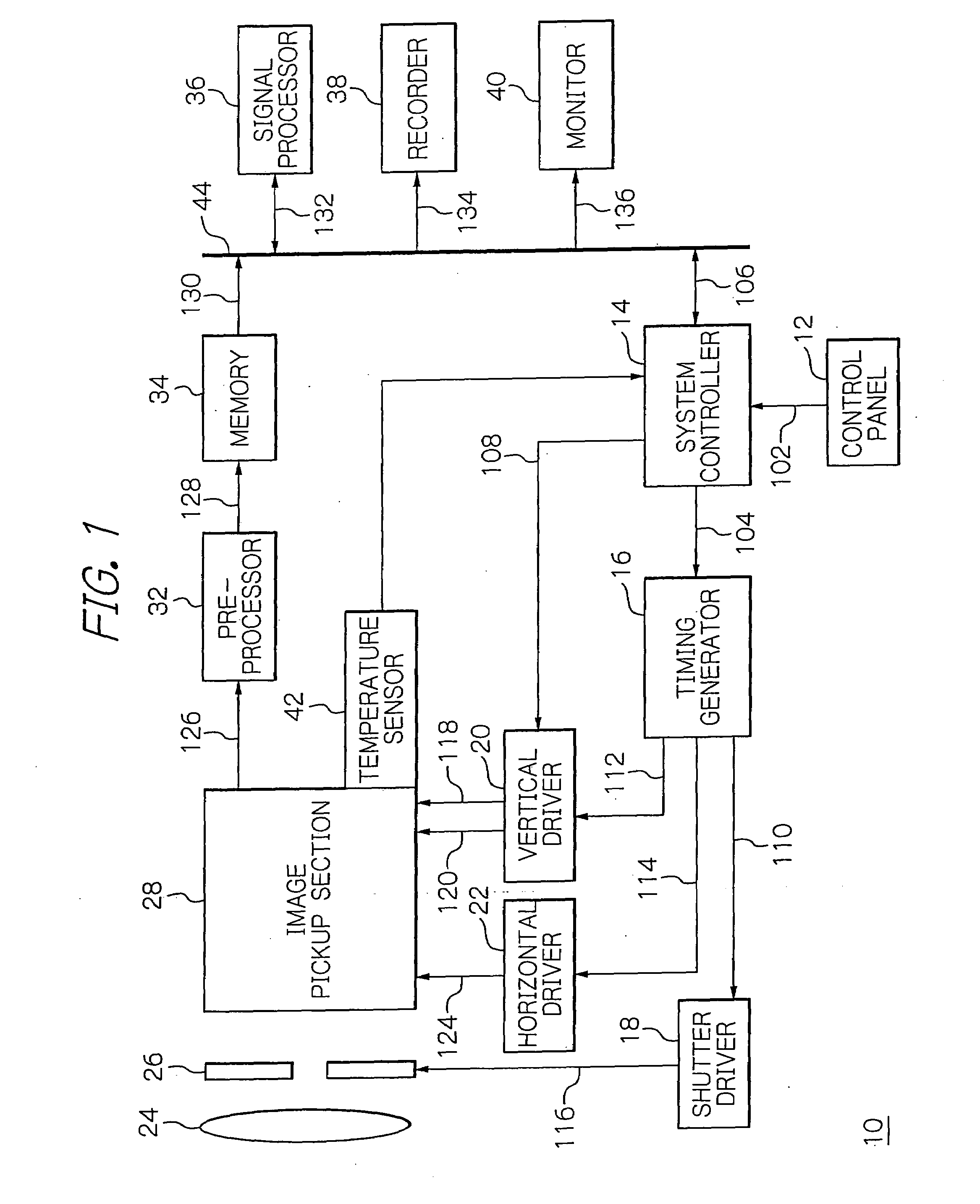

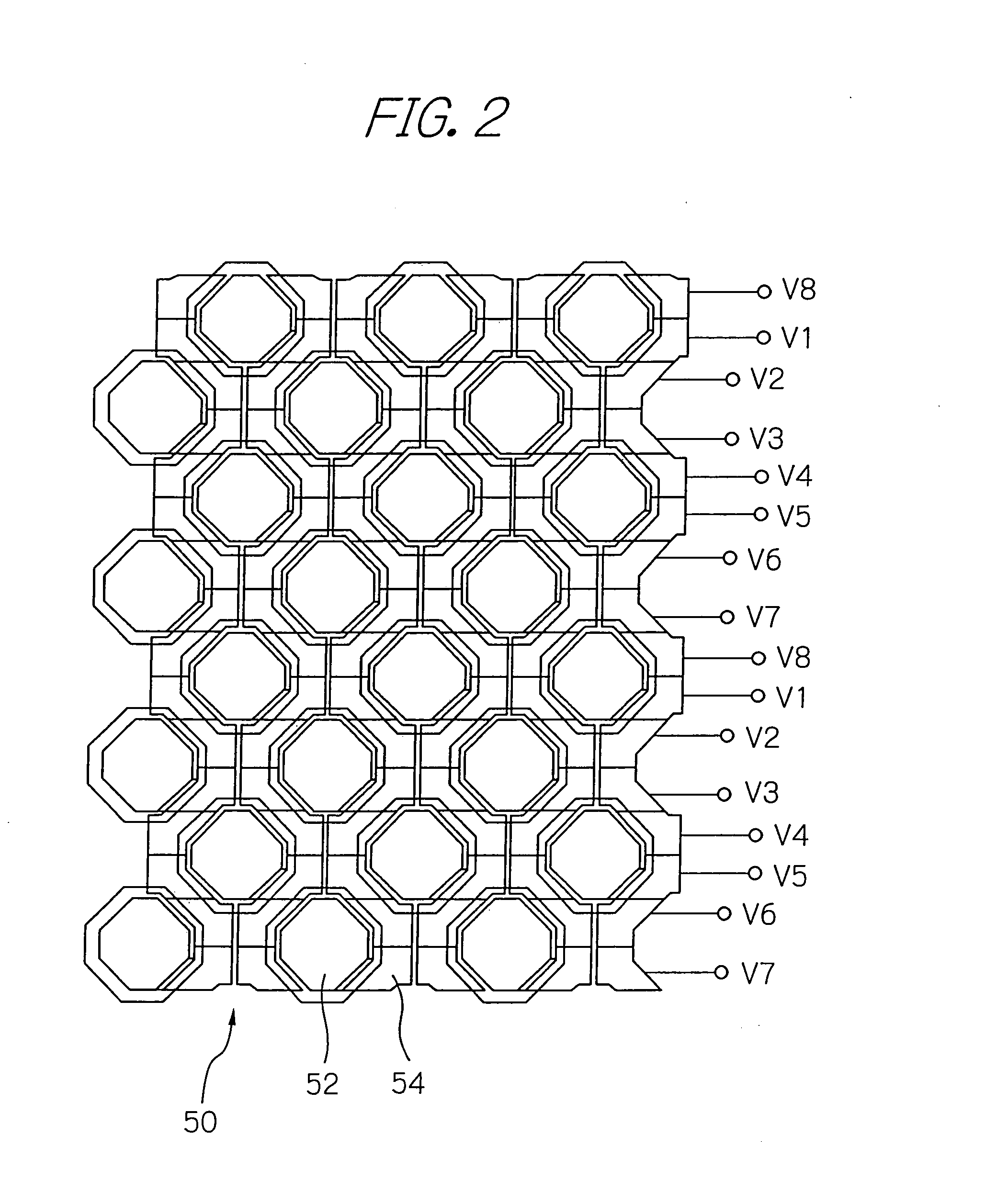

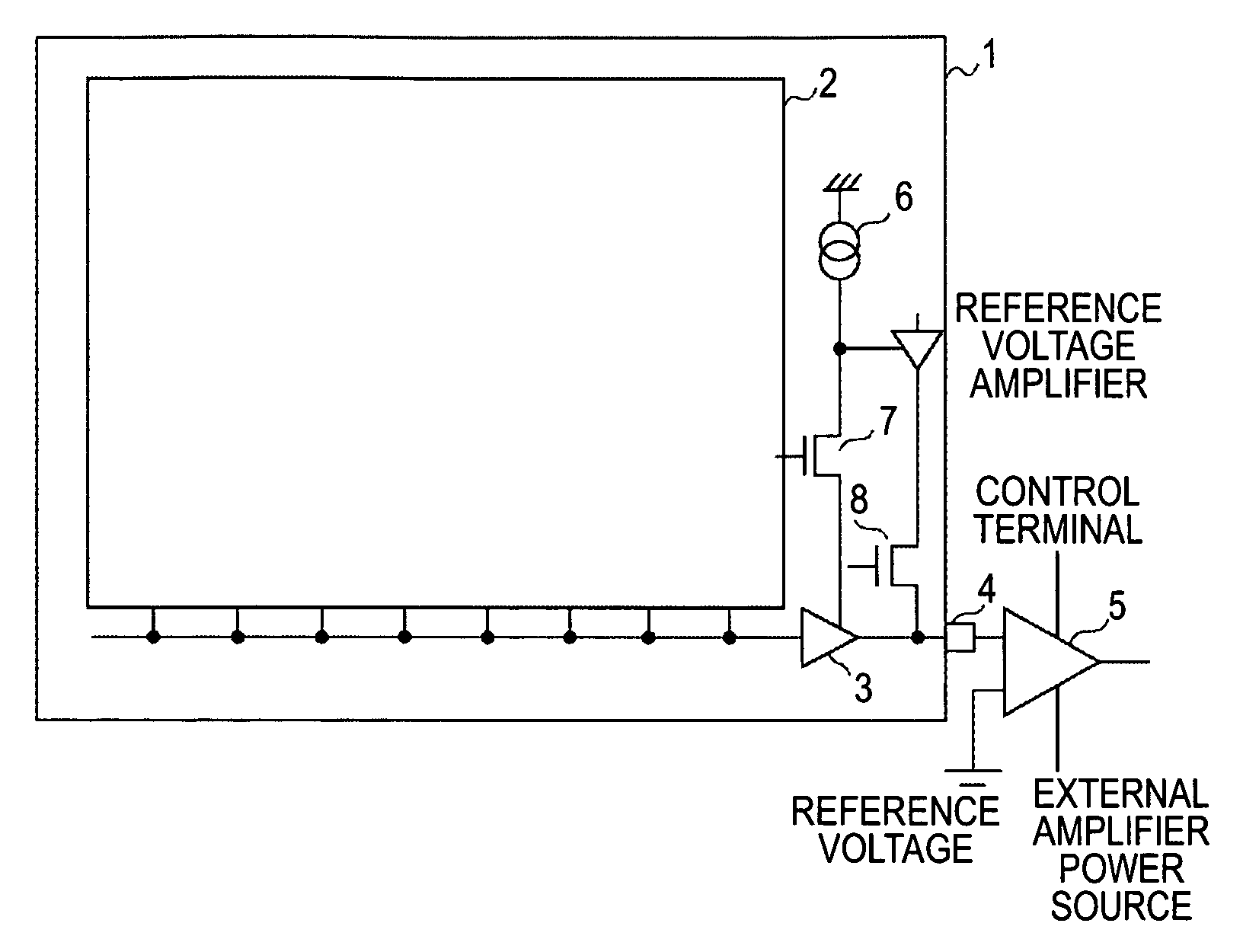

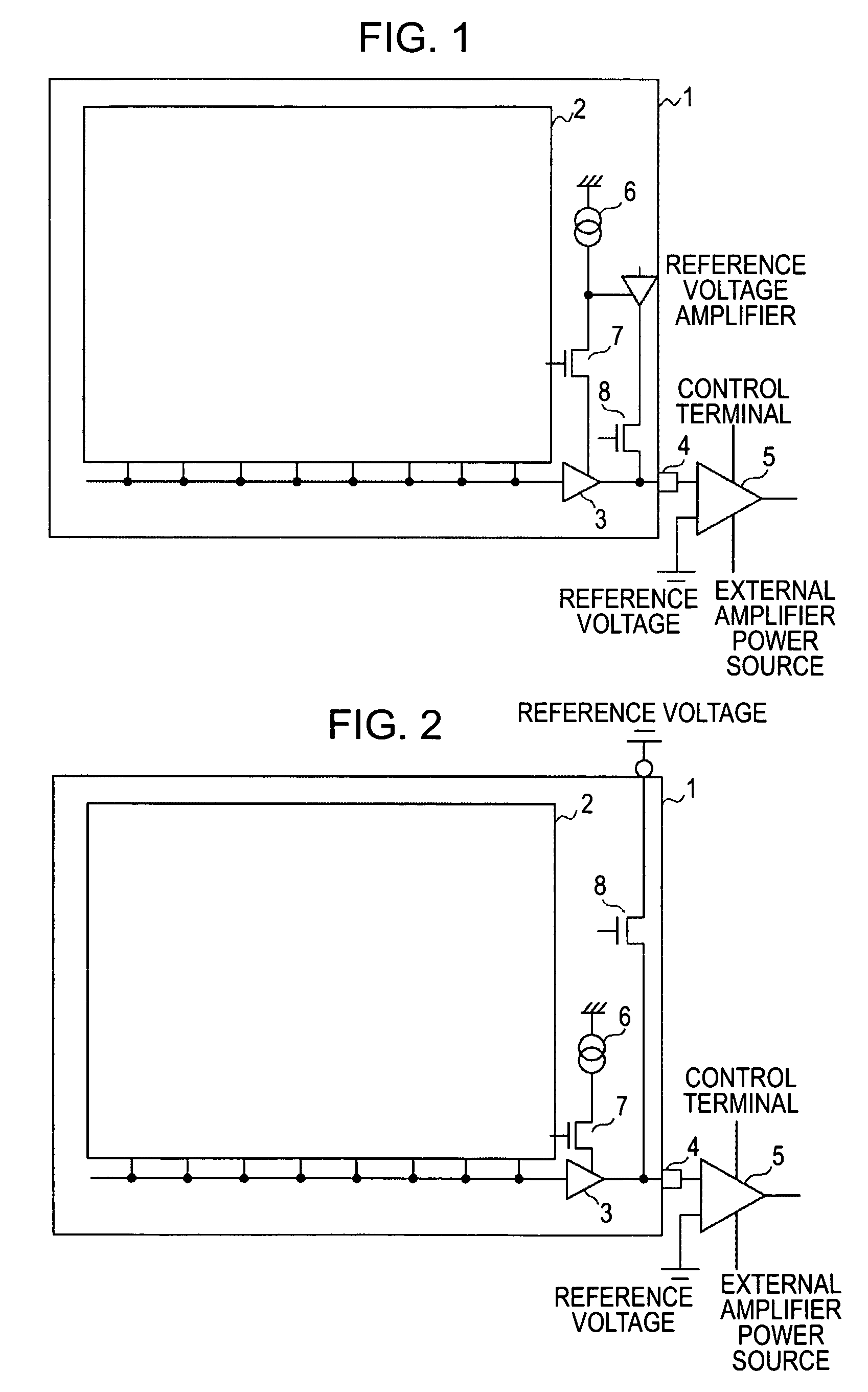

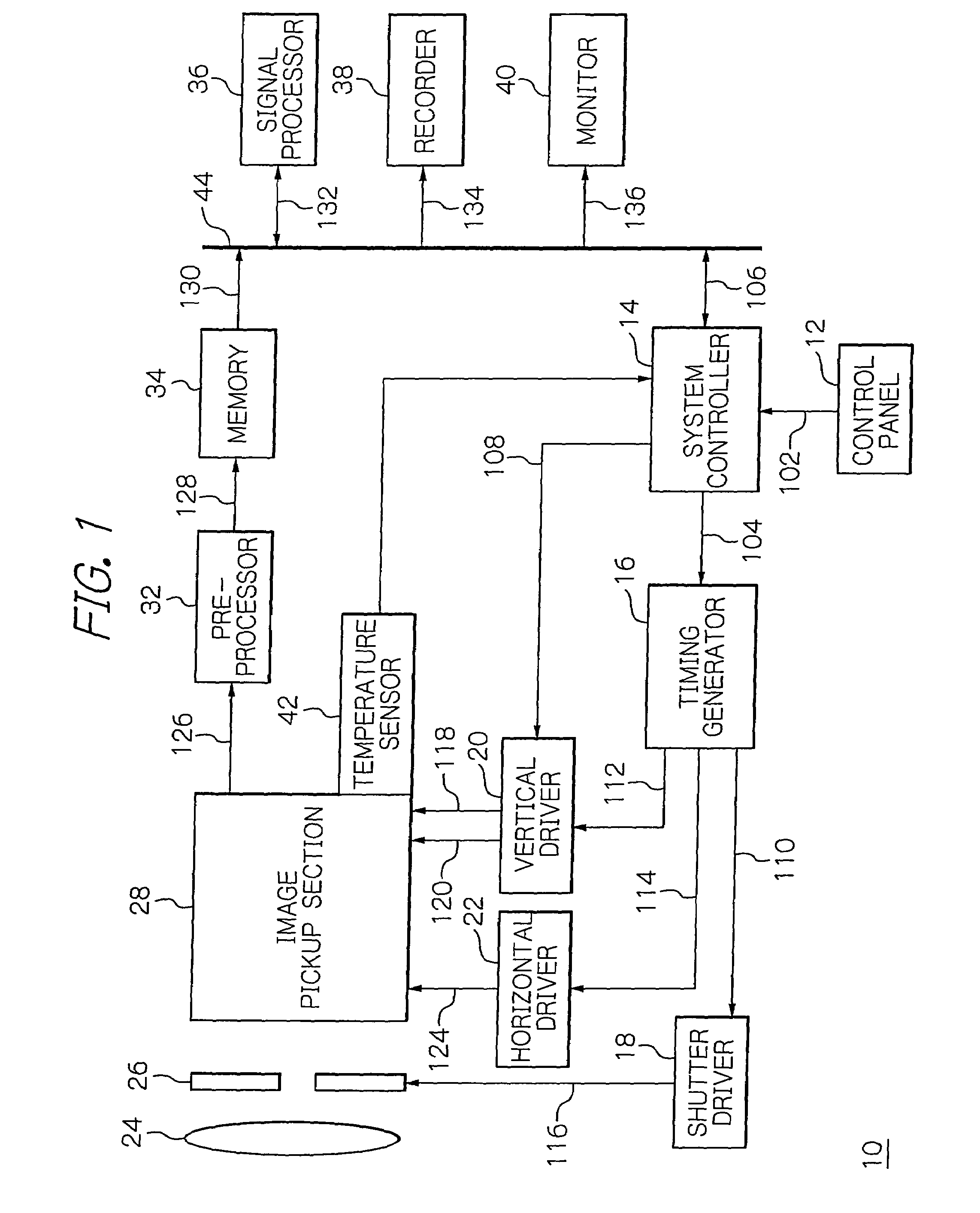

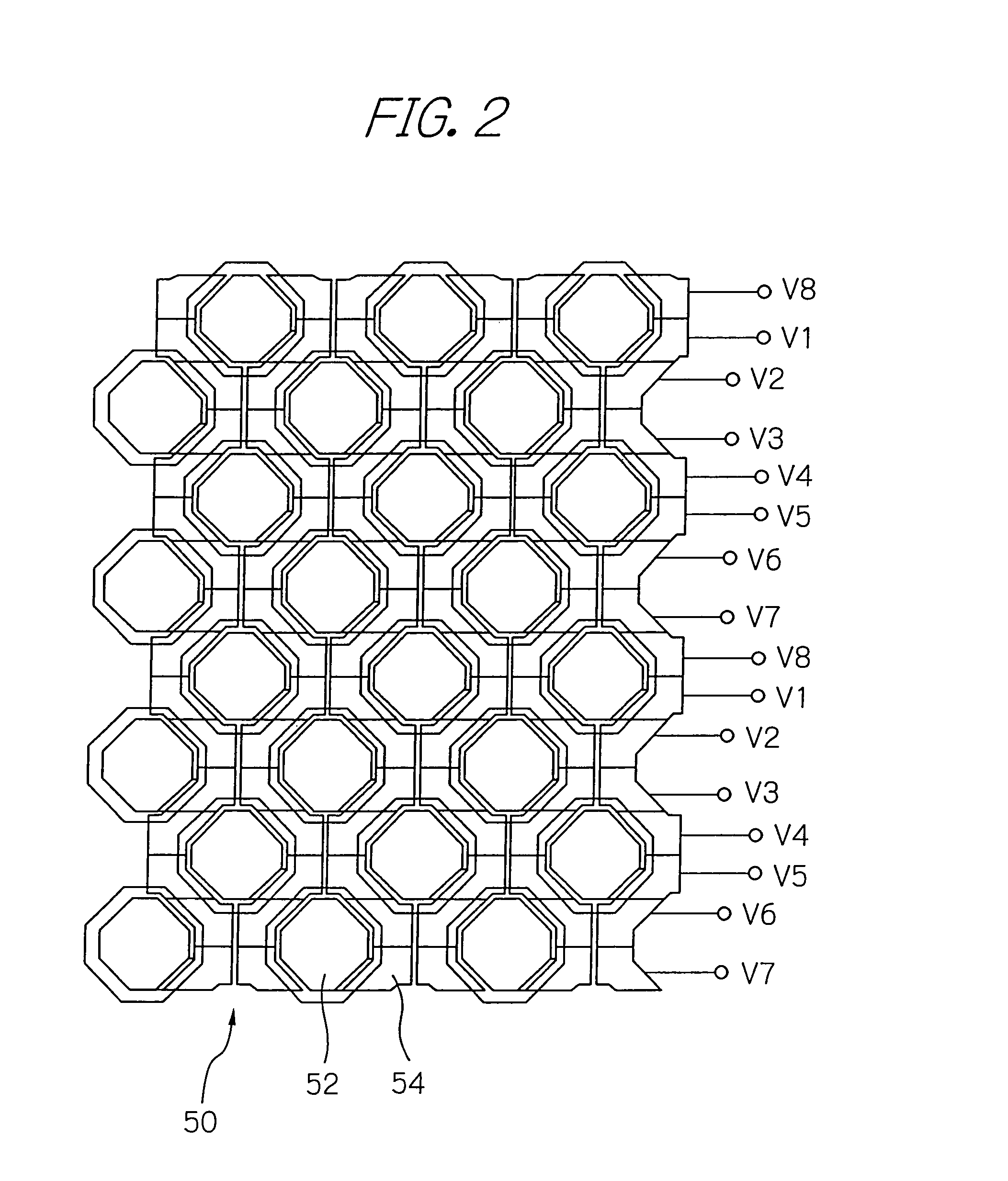

Solid-state image device and camera including solid-state image device

InactiveUS20060109360A1Quality improvementTotal current dropTelevision system detailsTelevision system scanning detailsAudio power amplifierEngineering

A solid-state image device including pixels arranged two-dimensionally, the pixels each including a photoelectric converter for converting incident light into an electric signal, is provided. The solid-state image device includes an output amplifier configured to amplify a photoelectric conversion output from each of the pixels, and a reference voltage amplifier configured to output a reference voltage. The solid-state image device selectively outputs the photoelectric conversion output and the reference voltage.

Owner:CANON KK

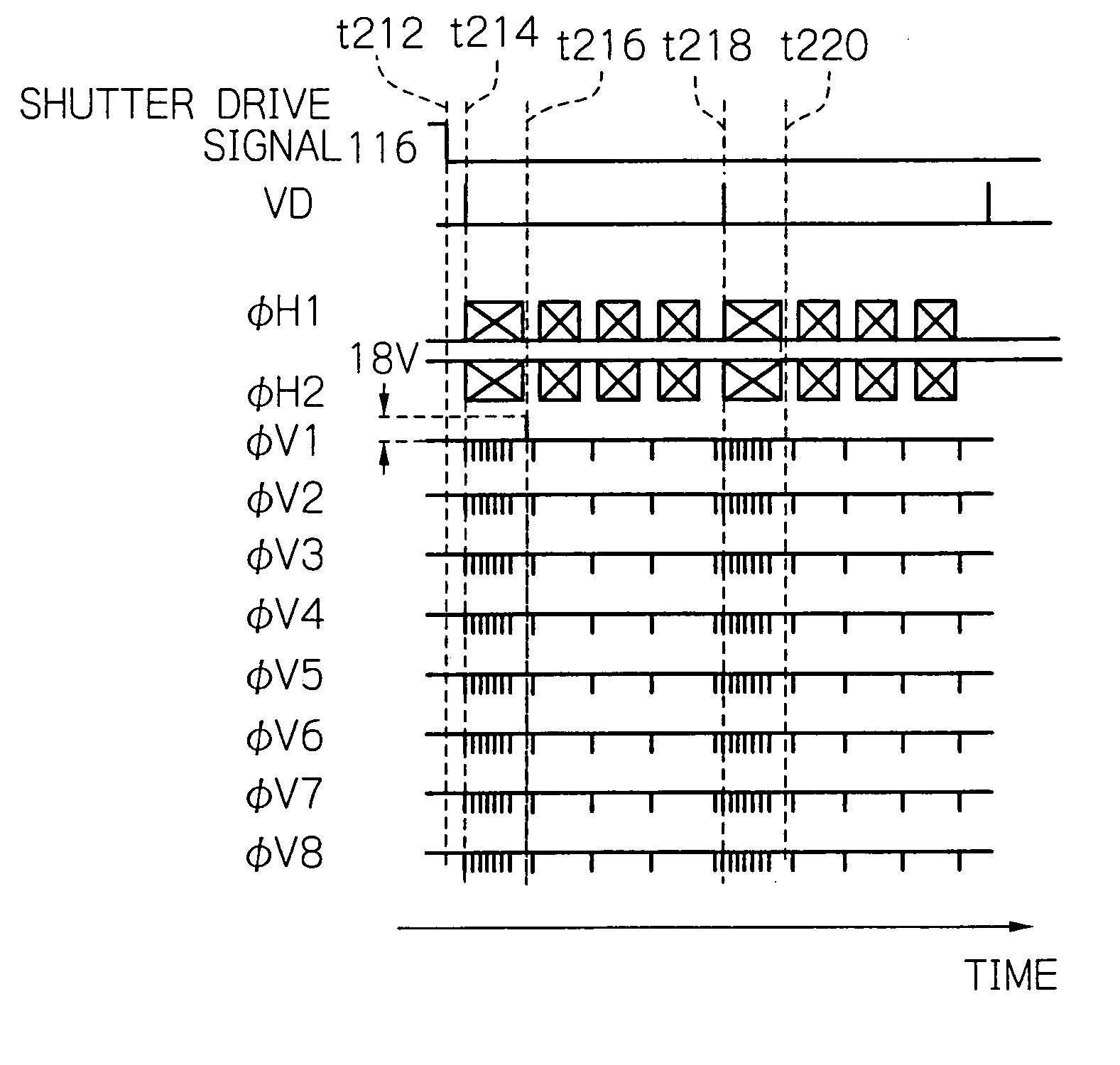

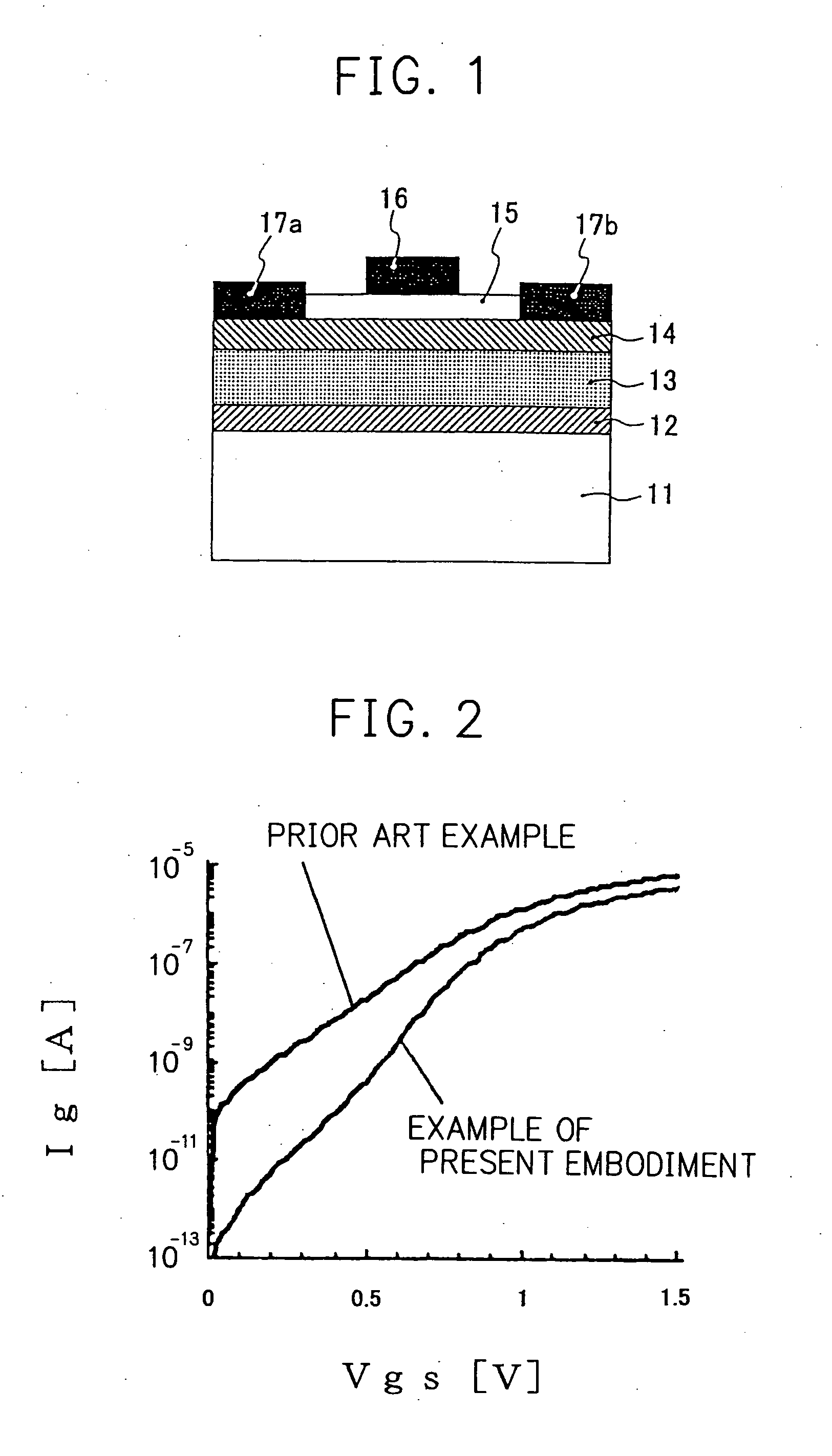

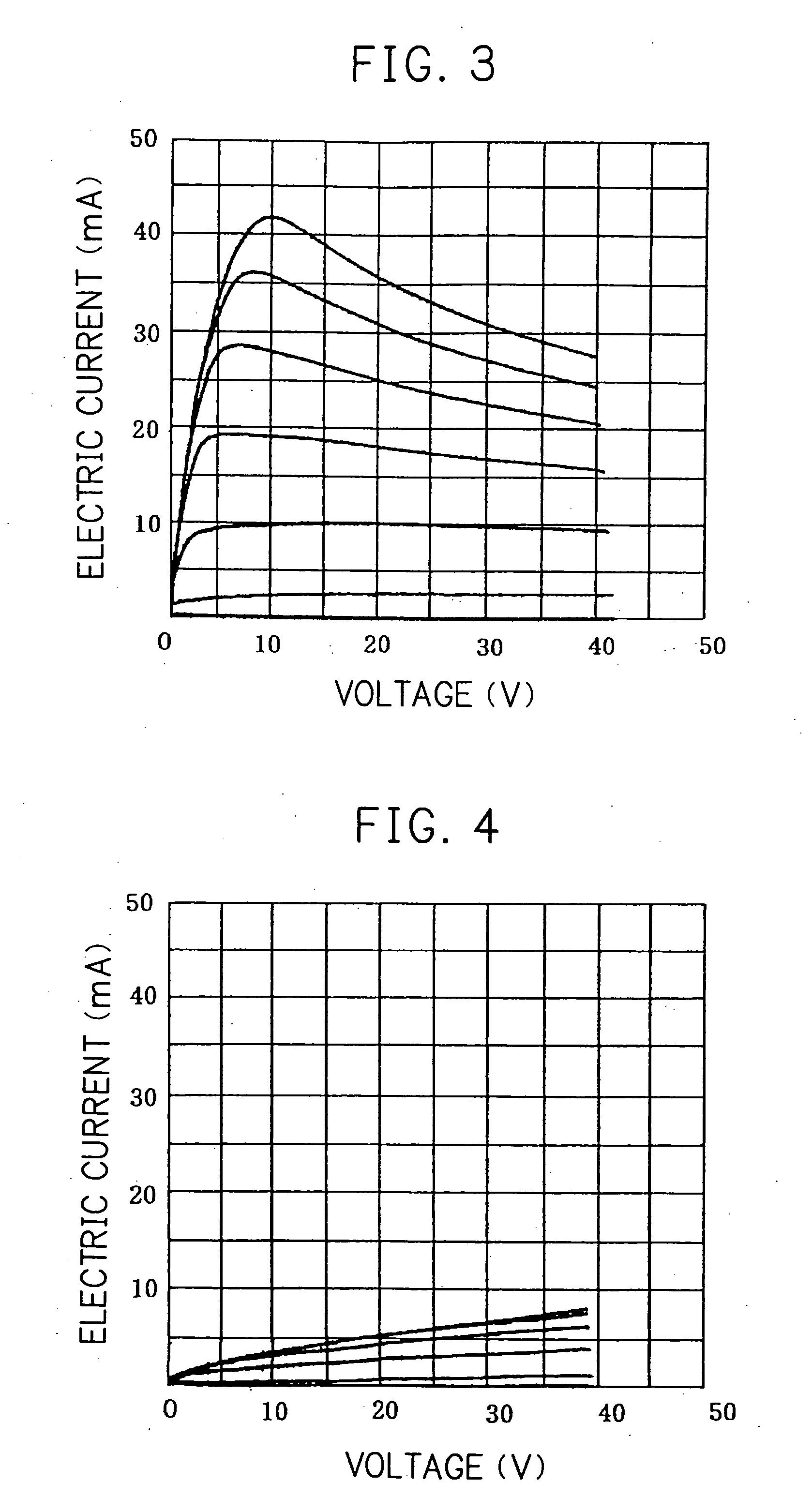

Solid-state image pickup apparatus multiplying signal charges depending on image circumstances

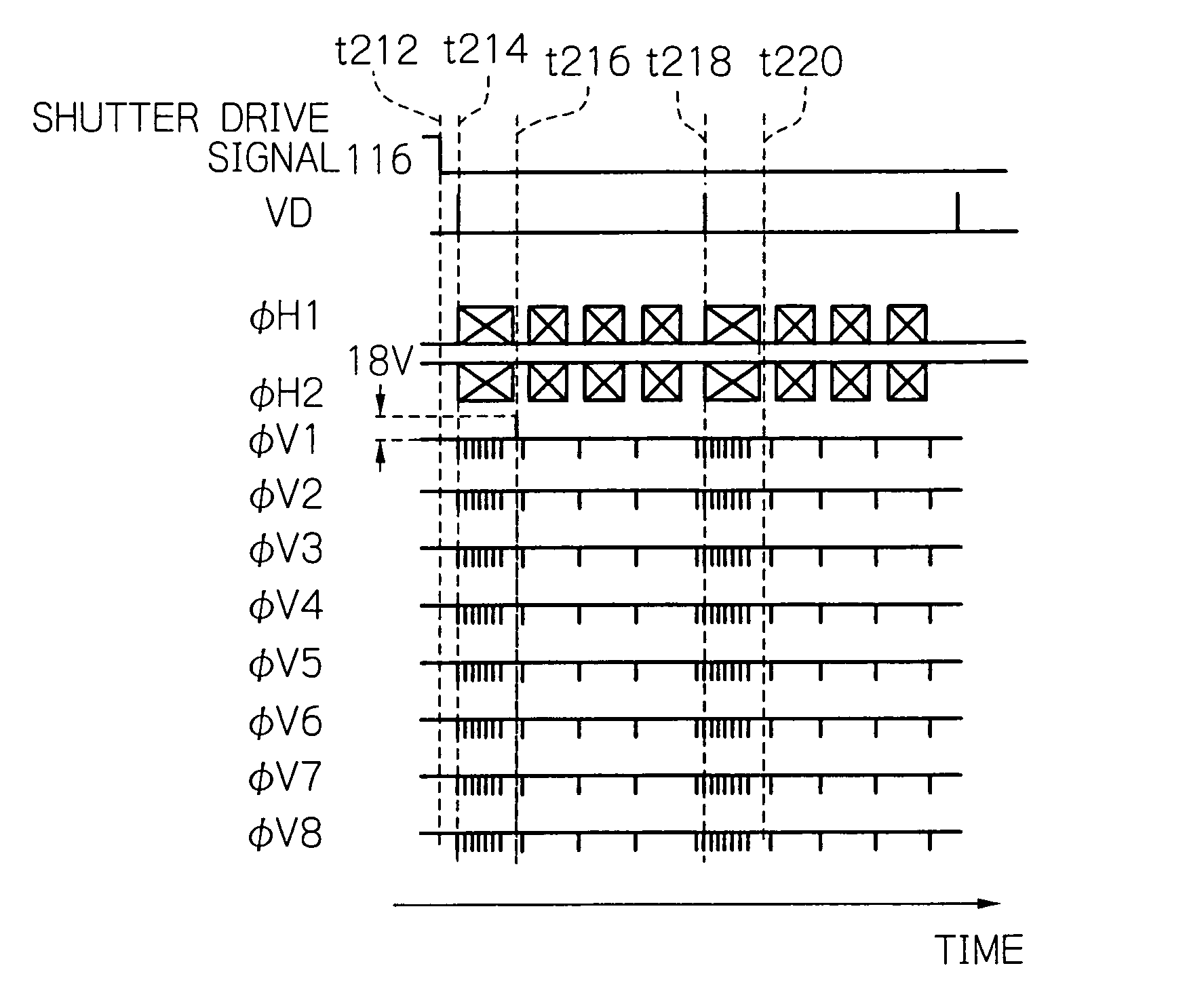

InactiveUS20080079831A1Big lossSuppressed ionizationTelevision system detailsTelevision system scanning detailsSensor arrayPotential well

A solid-state image pickup apparatus selects, in a first image pickup circumstance in which dark current is liable to occur in vertical transfer paths of an array of photo-sensors, a first transfer mode in which the potential well capacity in the vertical transfer paths is relatively small, and, in a second image pickup circumstance in which the dark current is small in quantity, a second transfer mode which is greater in potential well capacity than the first transfer mode. As a positive voltage applied to the read-out gates of the photo-sensors, a first voltage mode indicating a relatively low positive voltage that suppresses impact ionization is set in the first image pickup circumstance, and, a second voltage mode indicating a positive voltage higher than in the first voltage mode is set in the second image pickup circumstance so as to cause the impact ionization.

Owner:FUJIFILM CORP

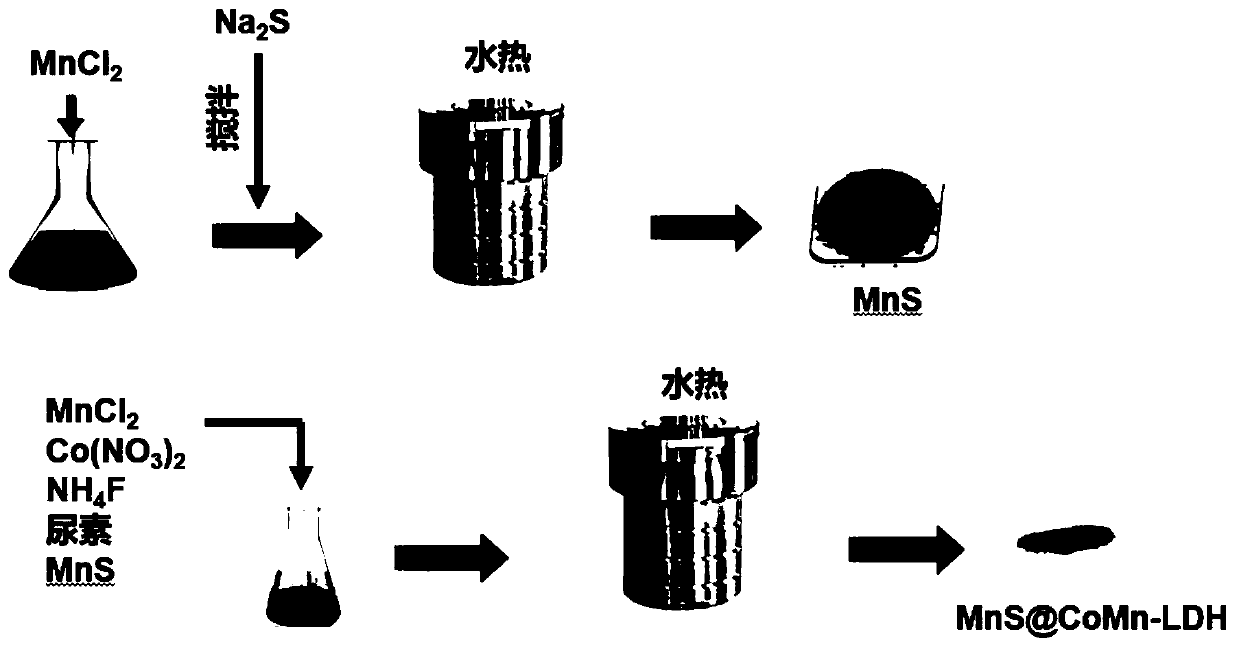

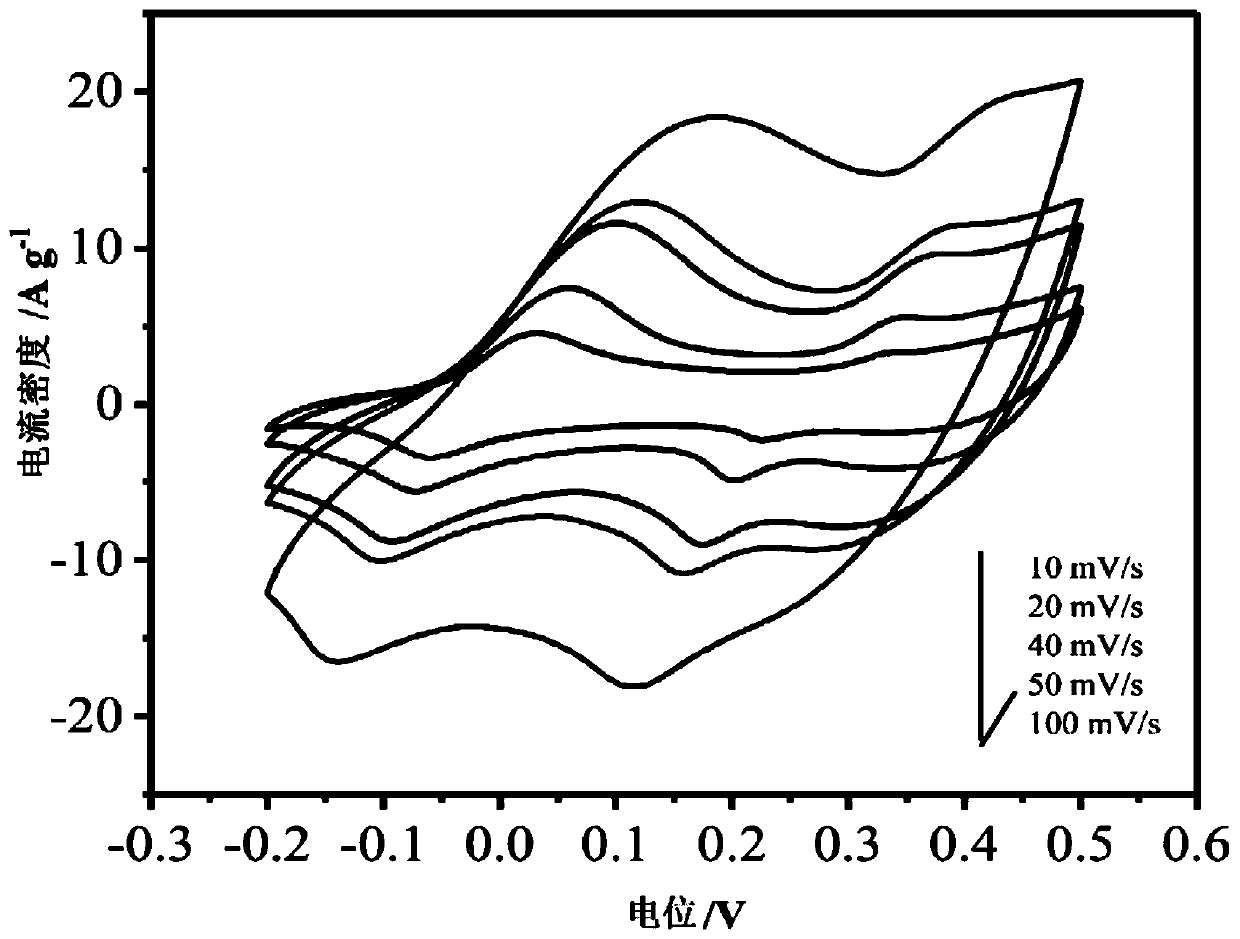

MnS@CoMn-LDH composite material, and preparation method and application thereof

ActiveCN110211812AEase of mass productionHigh purityMaterial nanotechnologyHybrid capacitor electrodesCobalt saltManganese

The invention relates to an MnS@CoMn-LDH composite material, and a preparation method and an application thereof. The preparation method of the composite material comprises the steps of 1) dissolvingsoluble manganese salt in water, then adding sulfide, carrying out a primary hydrothermal reaction, and carrying out centrifuging, washing and drying to obtain MnS; and 2) dissolving the soluble manganese salt, soluble cobalt salt, ammonium fluoride and urea in the water, then adding the MnS, carrying out a secondary hydrothermal reaction, and carrying out cooling, centrifuging, washing and dryingto obtain the MnS@CoMn-LDH composite material. The composite material is prepared into a working electrode for a supercapacitor. Compared with the prior art, the MnS@CoMn-LDH composite material is synthesized through the two-step hydrothermal reactions; the composite material contains rich mesopores and micropores so as to achieve good electrochemical performance; the preparation method of the composite material is simple and environment-friendly; the synthesis time is greatly shortened; and the large-scale production of high-purity MnS@CoMn-LDH composite materials is facilitated.

Owner:SHANGHAI INST OF TECH

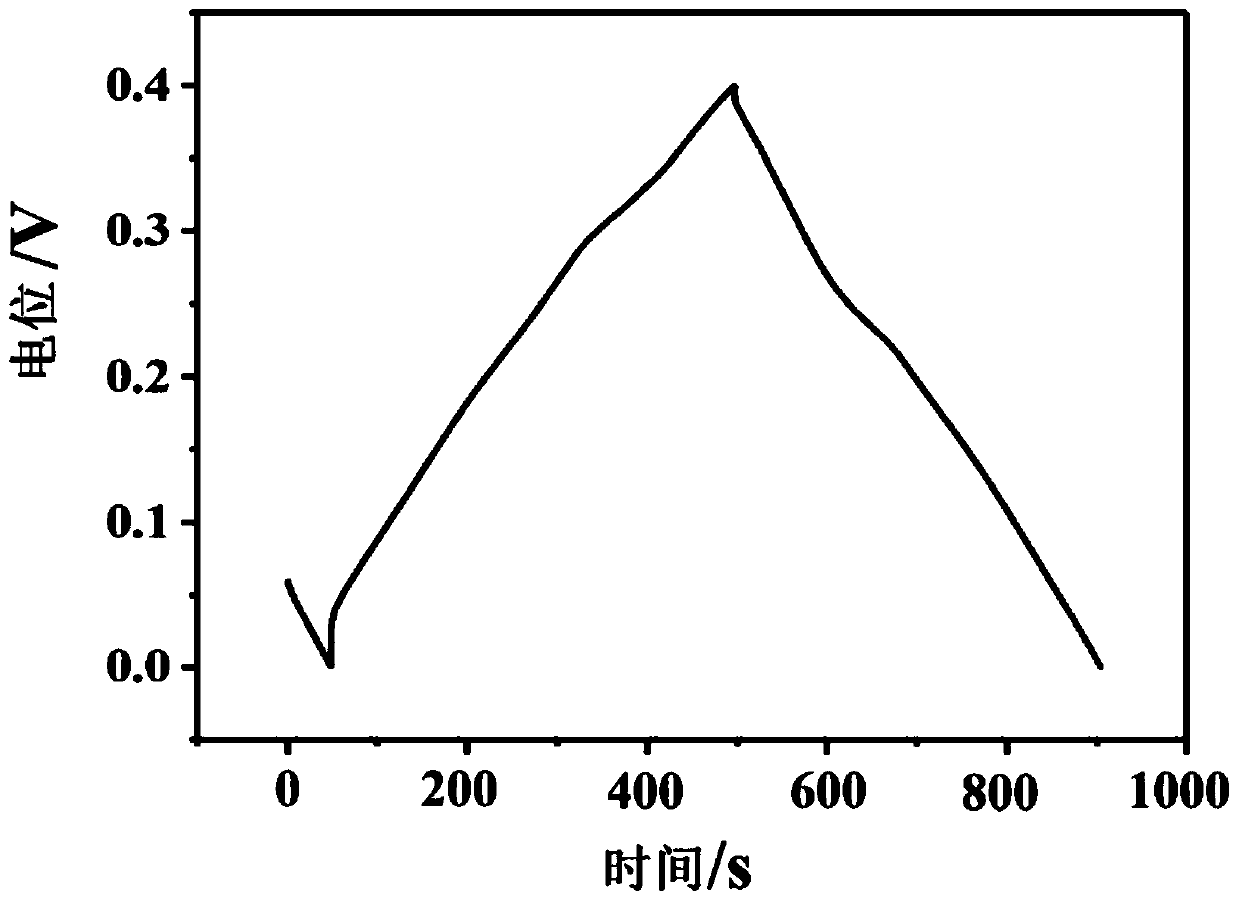

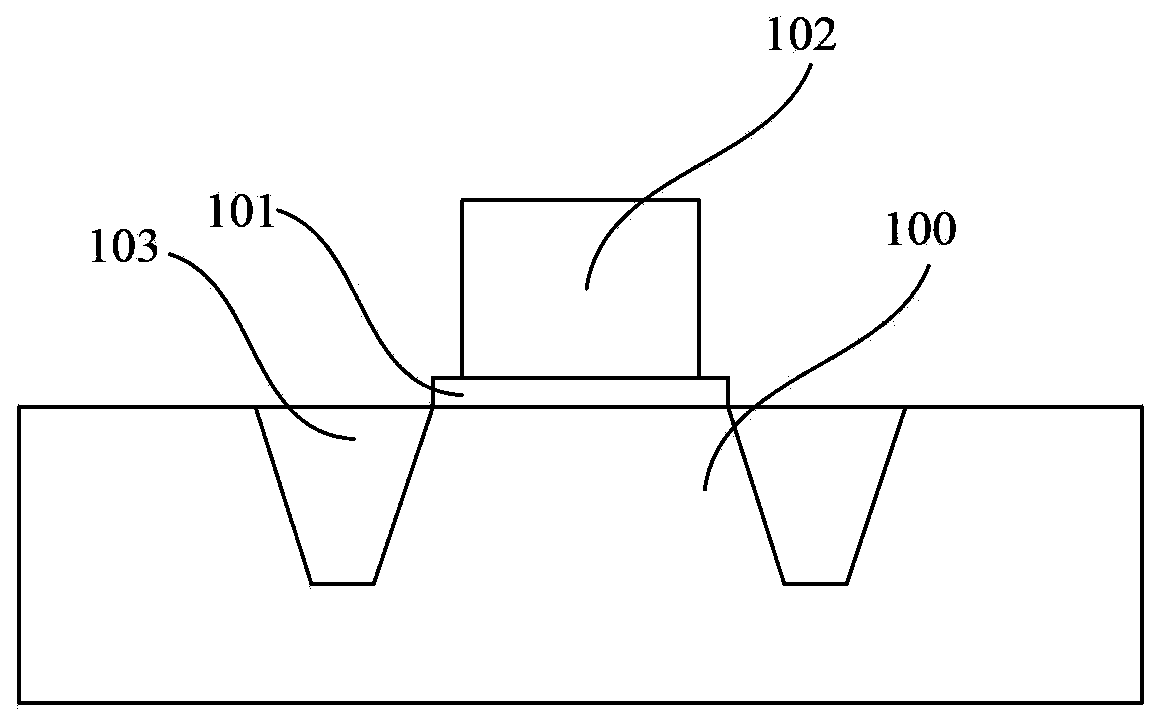

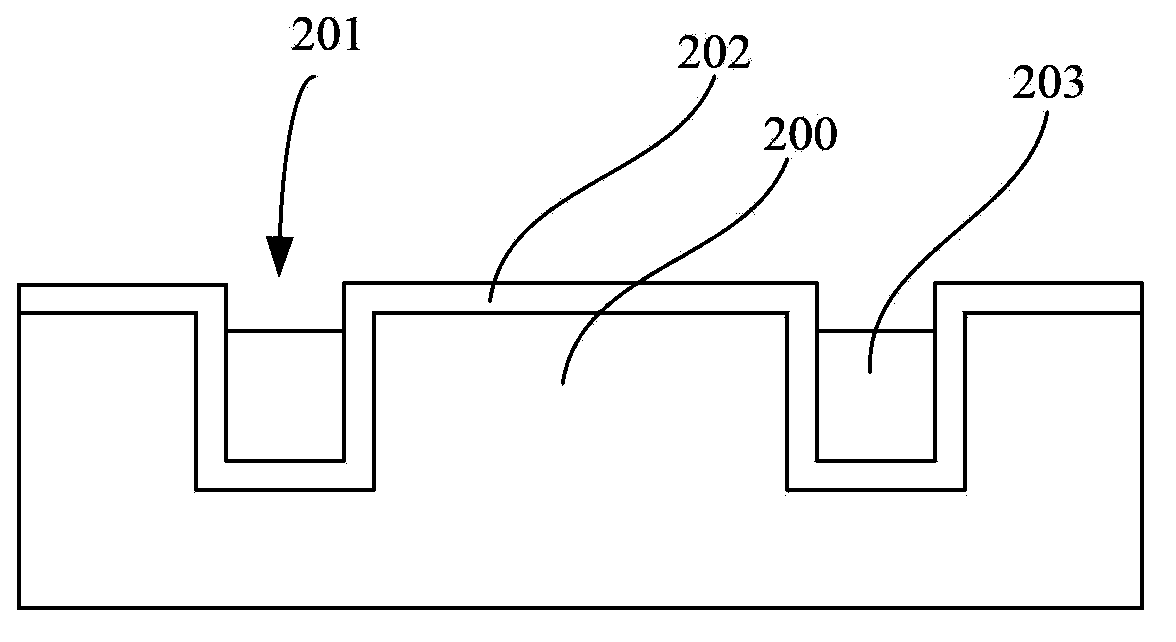

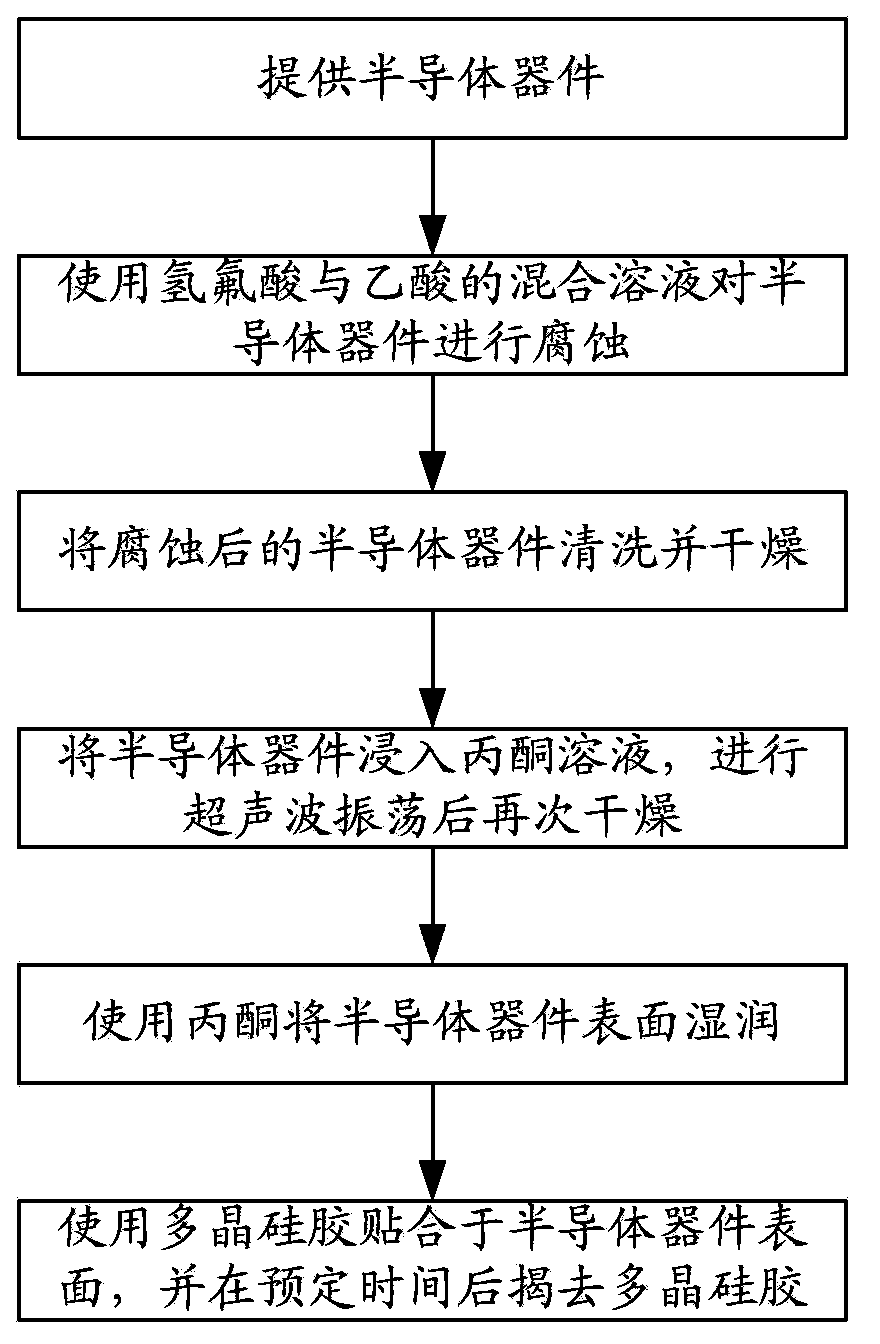

Preparation method of active region failure analysis sample of semiconductor device

ActiveCN103776668AAvoid damageEasily damagedPreparing sample for investigationSemiconductor/solid-state device manufacturingLayer removalHydrogen ion

The invention provides a preparation method of an active region failure analysis sample of a semiconductor device. A mixed solution of hydrofluoric acid and acetic acid replaces hydrofluoric acid simply used in the prior art to remove an oxidation layer; compared with strong corrosion of hydrofluoric acid simply used, acetic acid in the mixed solution also ionizes hydrogen ions, ionizing of hydrofluoric acid can be inhibited, and excessive fluorine ions are prevented from participating in reaction in a corrosion process, so that damages to an active region of the semiconductor device can be reduced or avoided in the corrosion process; ultrasonic waves are used for oscillating the semiconductor device to allow a polycrystalline silicon layer lower than the surface of the active region to be protruded; removal of the polycrystalline silicon layer with polycrystalline silicon glue subsequently is facilitated; and the damages to the active region of the semiconductor device in a polycrystalline silicon layer removal process are avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

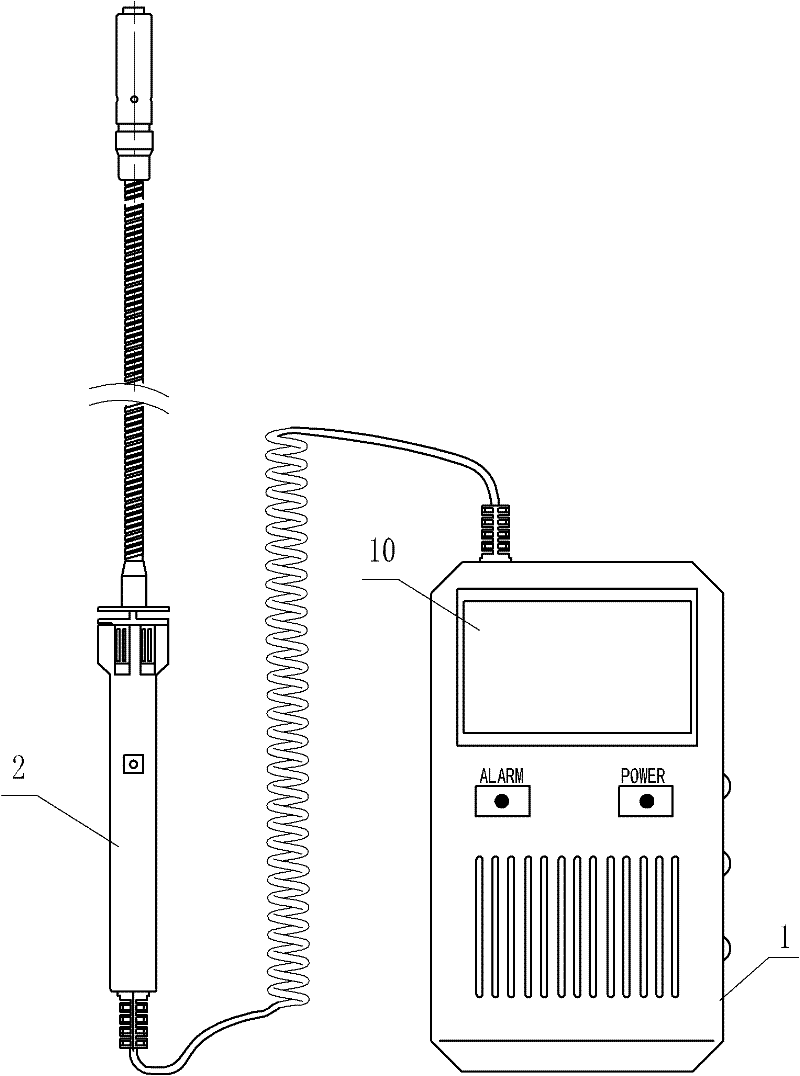

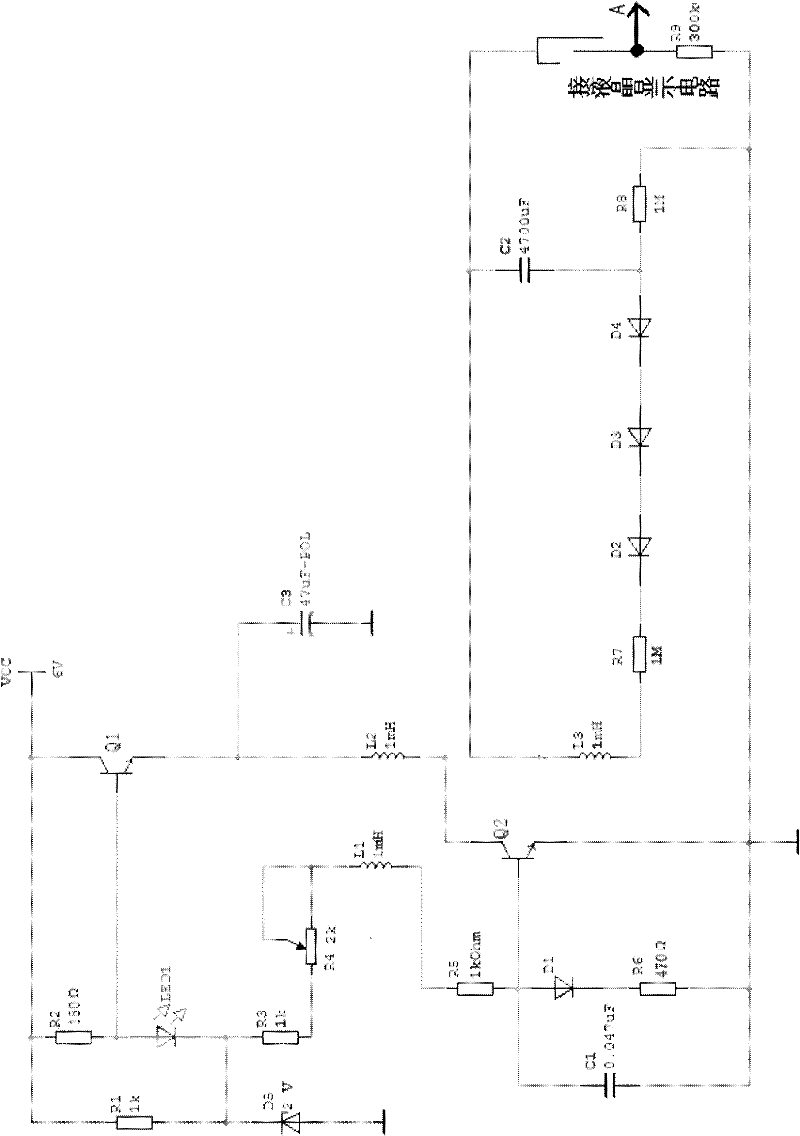

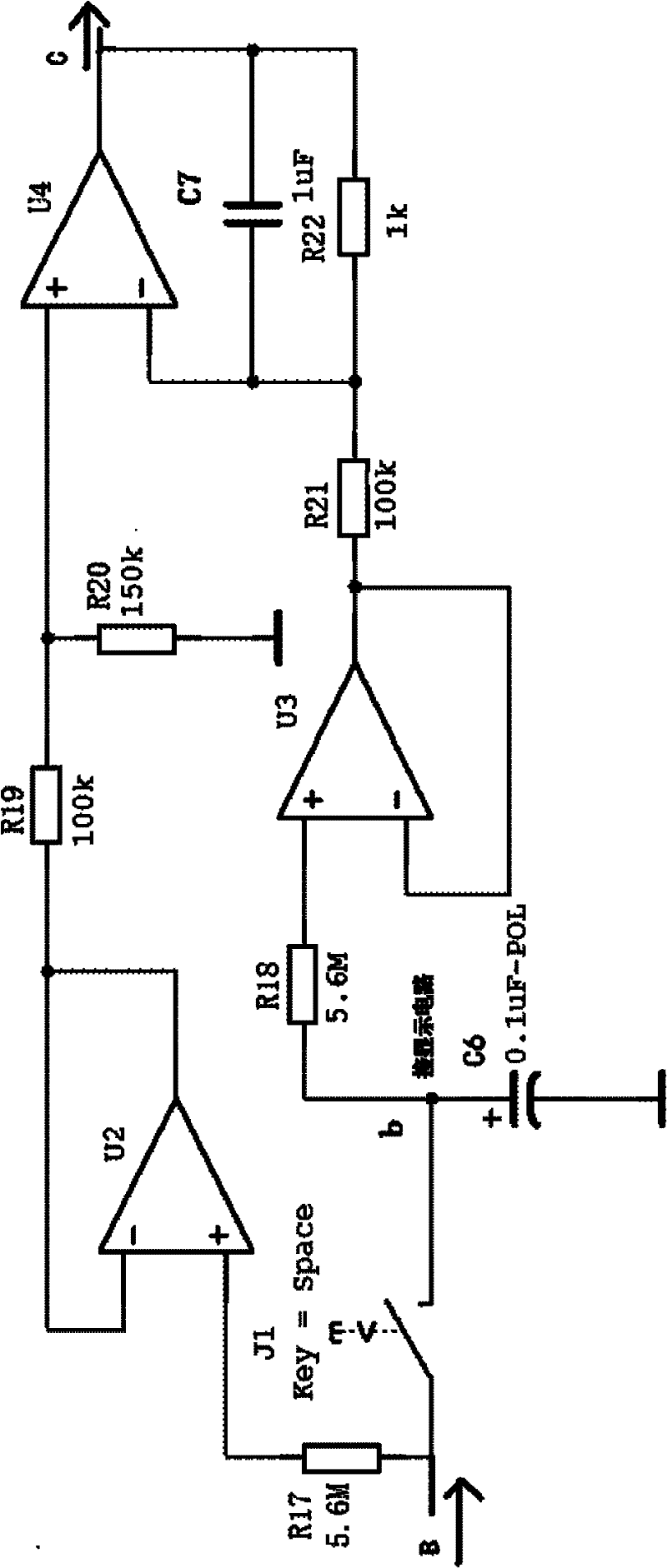

Portable sulfur hexafluoride leak detector

InactiveCN102243128ASuppressed ionizationChange intensityDetection of fluid at leakage pointHigh concentrationSulfur hexafluoride

The invention relates to a portable sulfur hexafluoride leak detector. The leak detector comprises a probe, an inverter and booster circuit, a signal amplification circuit, a data processing circuit and an acousto-optic alarm circuit, wherein the data processing circuit comprises a memory unit and a comparer. The data processing circuit of the portable sulfur hexafluoride leak detector comprises the memory unit and the comparer, the comparer compares a detected real-time sulfur hexafluoride signal value with a value stored in the memory unit, and the real-time value is stored in the memory unit and the acousto-optic alarm circuit is controlled to send an alarm only when the real-time value is greater than the value stored, so that a detecting person can be guided to move to a place with high concentration of the sulfur hexafluoride, and a leaking point can be quickly found.

Owner:WENZHOU UNIVERSITY

Solid-state image device and camera including solid-state image device for selective outputs

InactiveUS7619667B2Quality improvementTotal current dropTelevision system detailsTelevision system scanning detailsAudio power amplifierPhotoelectric conversion

A solid-state image device including pixels arranged two-dimensionally, the pixels each including a photoelectric converter for converting incident light into an electric signal, is provided. The solid-state image device includes an output amplifier configured to amplify a photoelectric conversion output from each of the pixels, and a reference voltage amplifier configured to output a reference voltage. The solid-state image device selectively outputs the photoelectric conversion output and the reference voltage.

Owner:CANON KK

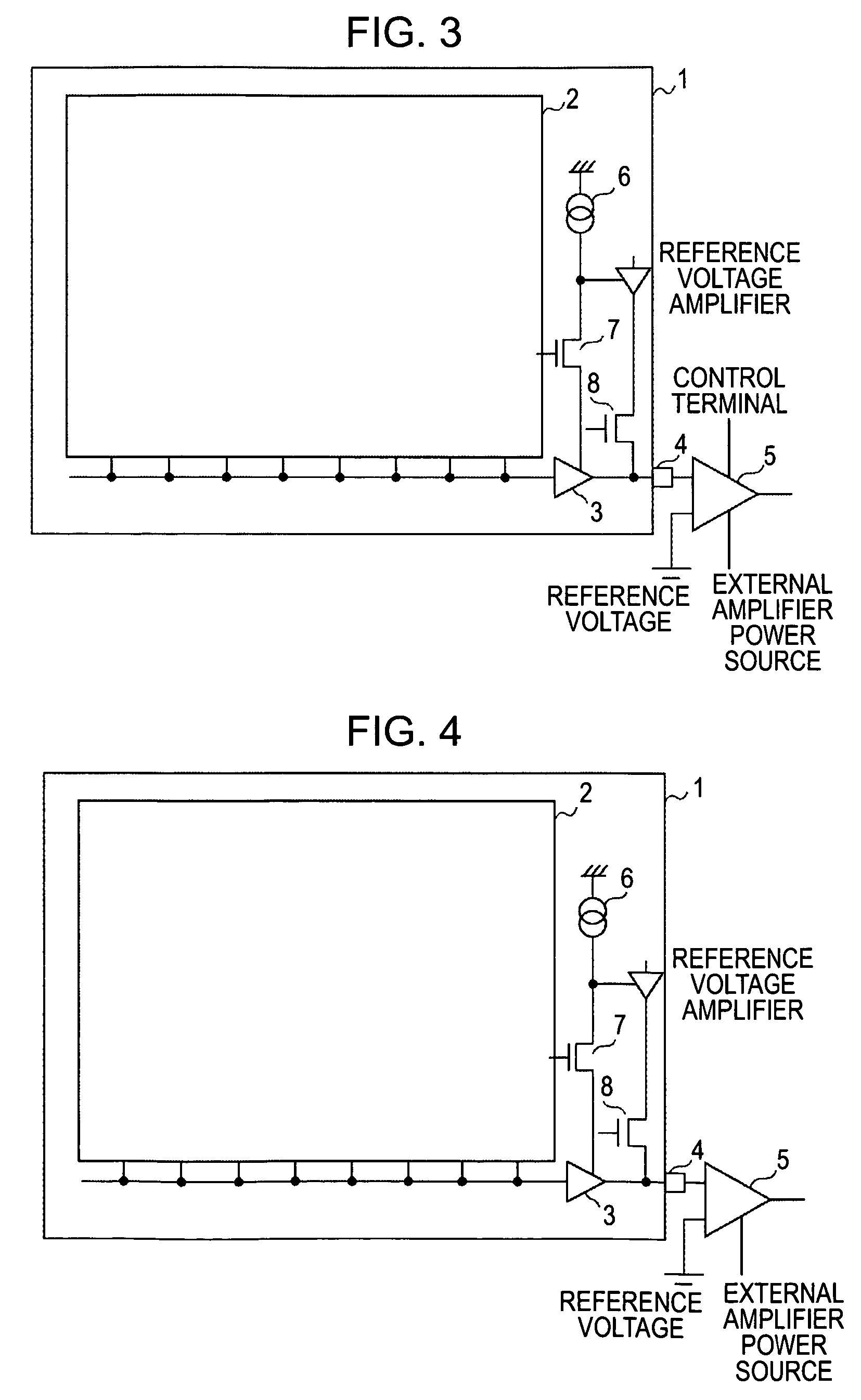

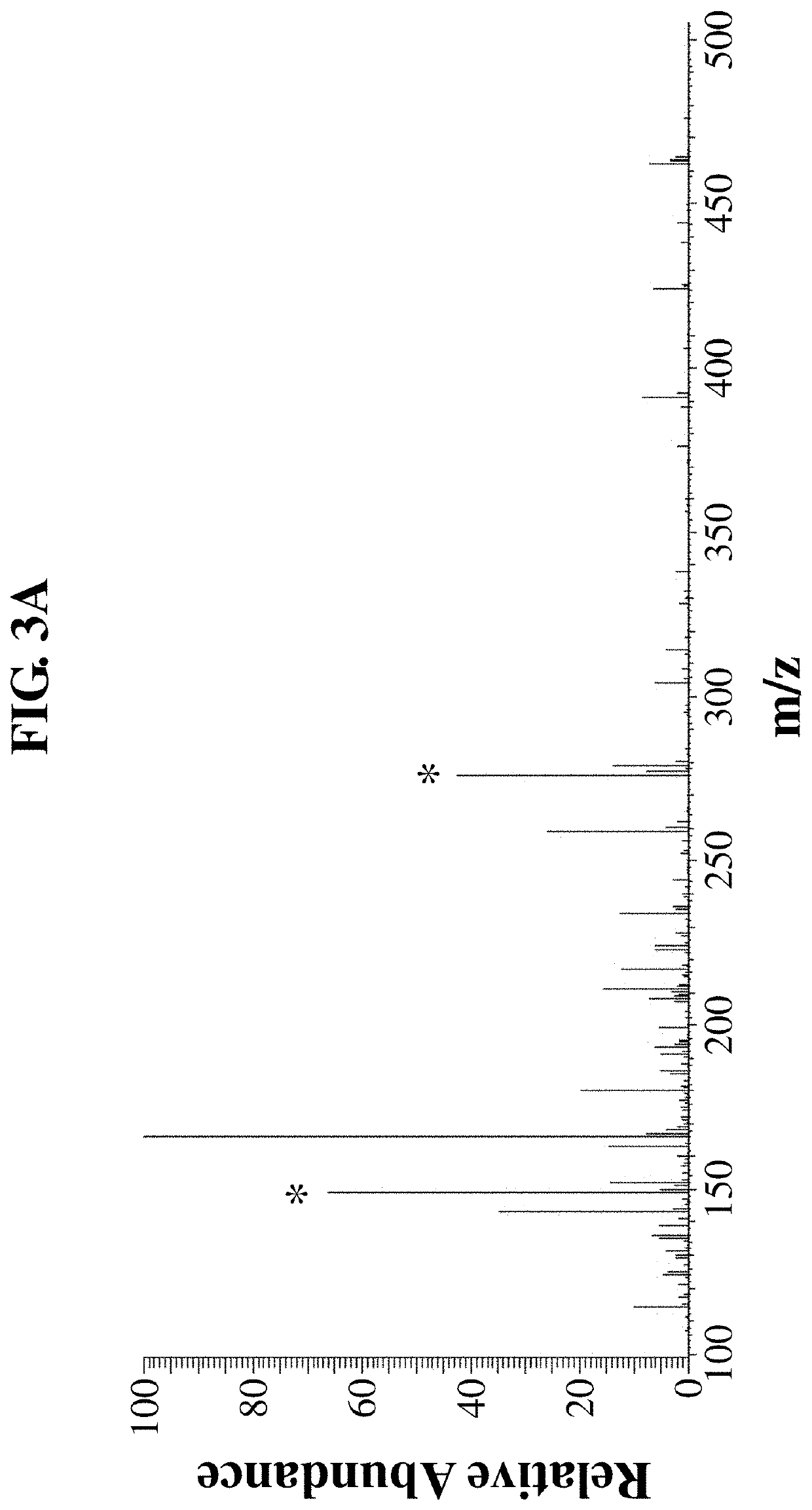

Apparatus and method for reducing matrix effects

ActiveUS20190371592A1Reduce inhibitionReduce decreaseSamplingIon sources/gunsAtmospheric pressureNatural abundance

In an embodiment of the present ambient ionization experiment, the abundance of background chemicals relative to ions of interest is decreased by reducing the overall abundance of background chemicals introduced into the ionizing region. In an embodiment of the present invention, the reduction of unwanted background chemicals in the ionization region can be effected by limiting the area which the sample volume is deposited. In an embodiment of the present invention, the reduction of unwanted background chemicals in the ionization region can be effected by decreasing the duration of time that the sample is exposed to the atmospheric pressure ionization source. In an embodiment of the present invention, the reduction of unwanted background chemicals in the ionization region can be effected by limiting the sample volume. In an embodiment of the present invention dilution of the sample with water can be used to reduce the contribution of the background chemicals. In an embodiment of the present ambient ionization experiment, an ion intensifier is used to suppress ionization of background chemicals to permit more efficient ionization and detection of the molecules of interest.

Owner:BRUKER SCI LLC

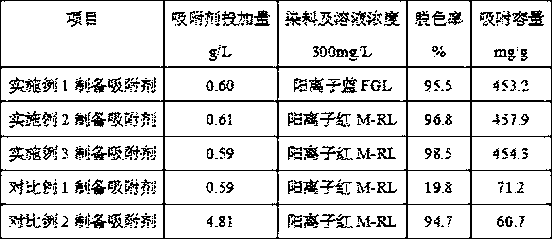

High-concentration wastewater resource utilization method

InactiveCN109126701AHigh decolorization rateReduce pollution loadOther chemical processesWater contaminantsHigh concentrationSorbent

The invention discloses a high-concentration wastewater resource utilization method. The high-concentration wastewater resource utilization method comprises the following steps: adding a cation exchanger in wastewater, and carrying out stirring reaction to enable extractable substances in the wastewater to be exactly condensed into insoluble fine and small solid particles; separating out the cation exchanger, slowly adding a proper amount of chemical agent in the wastewater to generate small air bubbles, and enabling the air bubbles to adhere to the fine and small solid particles in the wastewater so as to reduce viscosity of the wastewater; heating to the temperature which is higher than a connecting material softening point by 0-30 DEG C, and enabling the fine and small solid particles to adhere to one another so as to form large-particle solids; carrying out insulation treatment for a certain time so that a blocky extract is formed; cooling the extract with a saturated potassium hydroxide solution; and carbonizing and activating the pulverized and dried blocky extract at one step for 1-4 h at the temperature of 700 DEG C under the protection of nitrogen, and breaking the blockyextract to obtain an adsorbent. The adsorption capacity of the adsorbent prepared by the method to cationic dyestuff can reach 450 mg / g or above.

Owner:QINGDAO UNIV

High-concentration wastewater pollutant extracting and utilizing method

InactiveCN109126705AHigh decolorization rateReduce pollution loadSludge treatment by de-watering/drying/thickeningOther chemical processesHigh concentrationSorbent

The invention discloses a high-concentration wastewater pollutant extracting and utilizing method. The high-concentration wastewater pollutant extracting and utilizing method comprises the following steps: adding a proper amount of cation exchange material in wastewater, and carrying out stirring reaction to enable an extractable substance in the wastewater to be exactly condensed into insoluble fine and small solid particles; separating out the cation exchange material, adding a proper amount of chemical agent in the wastewater while stirring to generate small air bubbles, and enabling the air bubbles to adhere to the fine and small solid particles in the wastewater so as to reduce viscosity of the wastewater; carrying out ultrasonic treatment, heating to the temperature which is higher than a connecting material softening point by 0-20 DEG C, and enabling the fine and small solid particles to adhere to one another so as to form large-particle solids; carrying out ultrasonic insulation treatment for a certain time so that a blocky extract is formed; cooling the extract with a saturated potassium hydroxide solution; and carbonizing and activating the dried blocky extract at one step for 1-4 h at the temperature of 700 DEG C under the protection of nitrogen, and breaking the dried blocky extract to obtain an adsorbent. The adsorption capacity of the adsorbent prepared by the method to cationic dyestuff can reach 450 mg / g or above.

Owner:QINGDAO UNIV

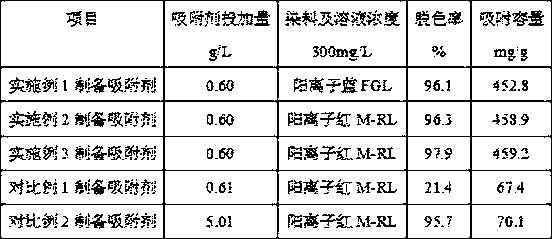

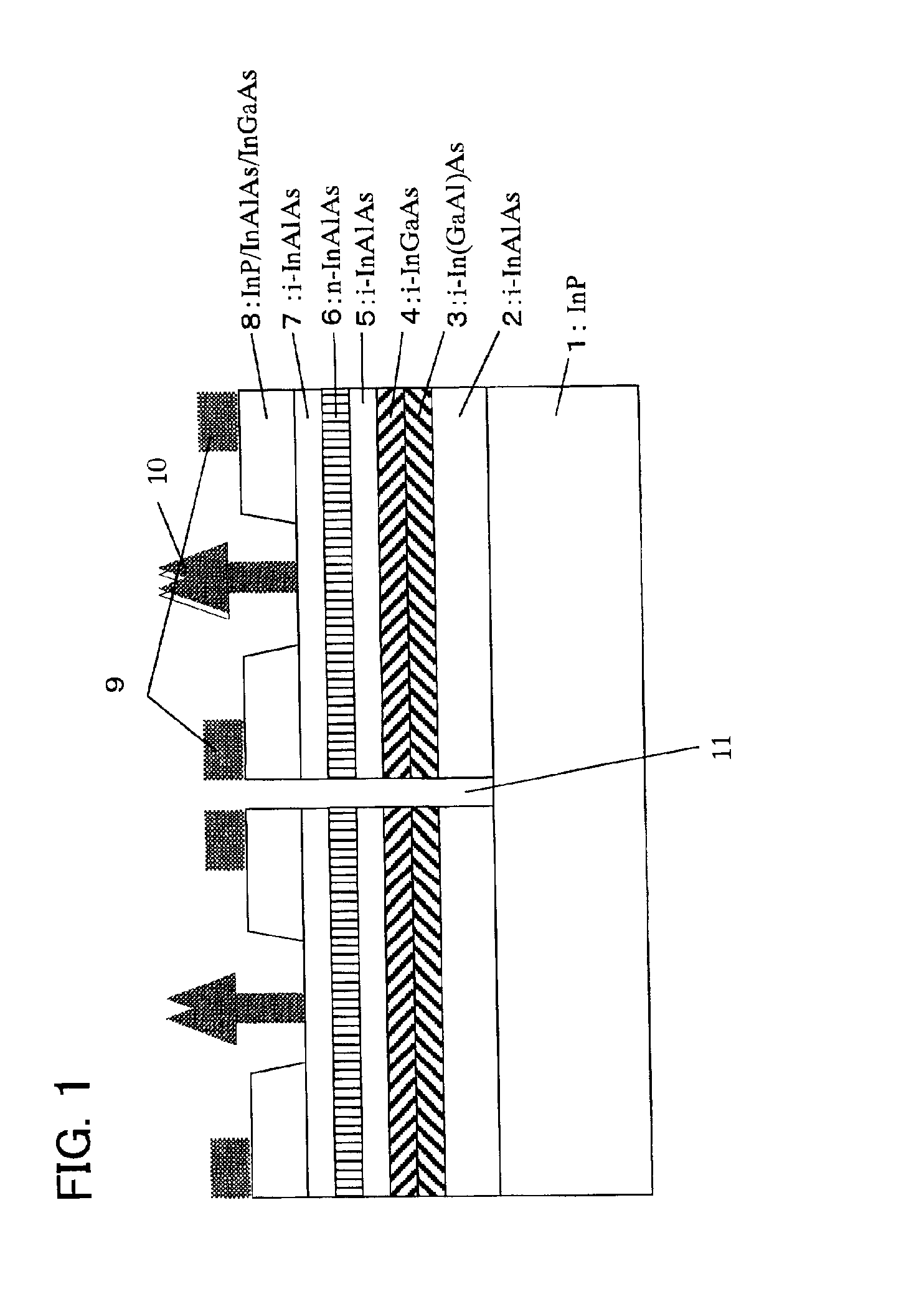

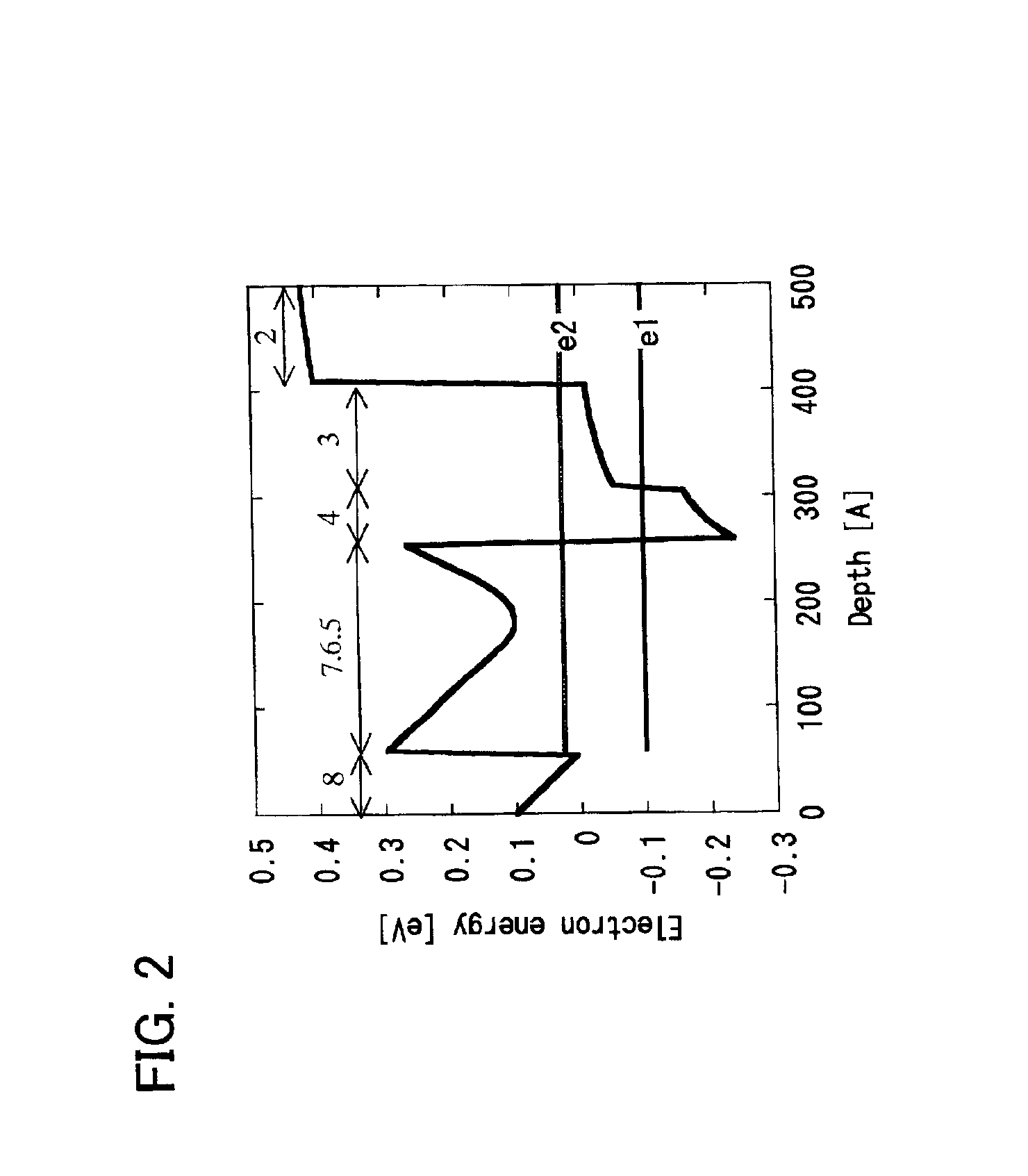

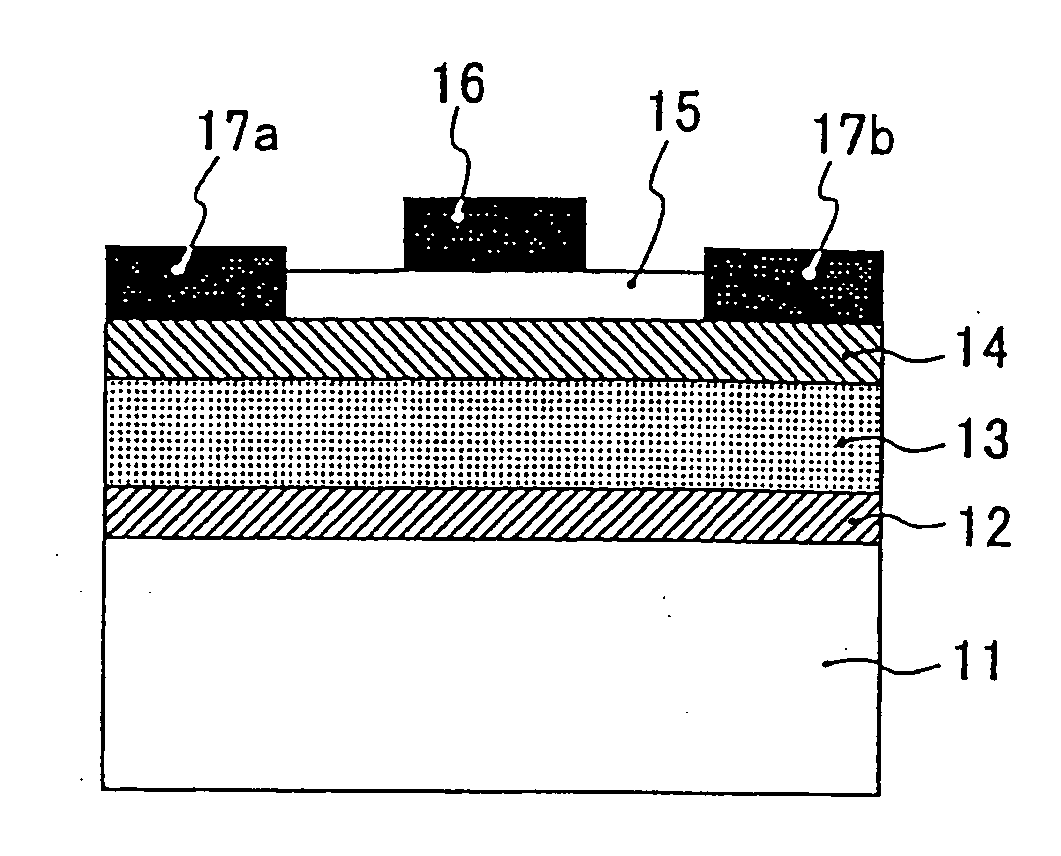

Field-effect transistor using a group III-V compound semiconductor

InactiveUS6867439B2High composition ratioLow composition ratioTransistorSolid-state devicesConduction bandField-effect transistor

A high electron mobility transistor using a Group III-V compound semiconductor comprises an undoped second channel layer laminated on an InP substrate via a buffer layer, an undoped first channel layer laminated on the second channel layer, and a doped electron-supplying layer laminated on the first channel layer. The first channel layer is composed of In1-xGaxAs and has an energy level of conduction band lower than that of the electron-supplying layer at the interface. The second channel layer is composed of a Group III-V compound semiconductor using a Group V element other than P, has an energy level of conduction band higher than that of the first channel layer, and has a band gap wider than that of the first channel layer.

Owner:FUJITSU LTD

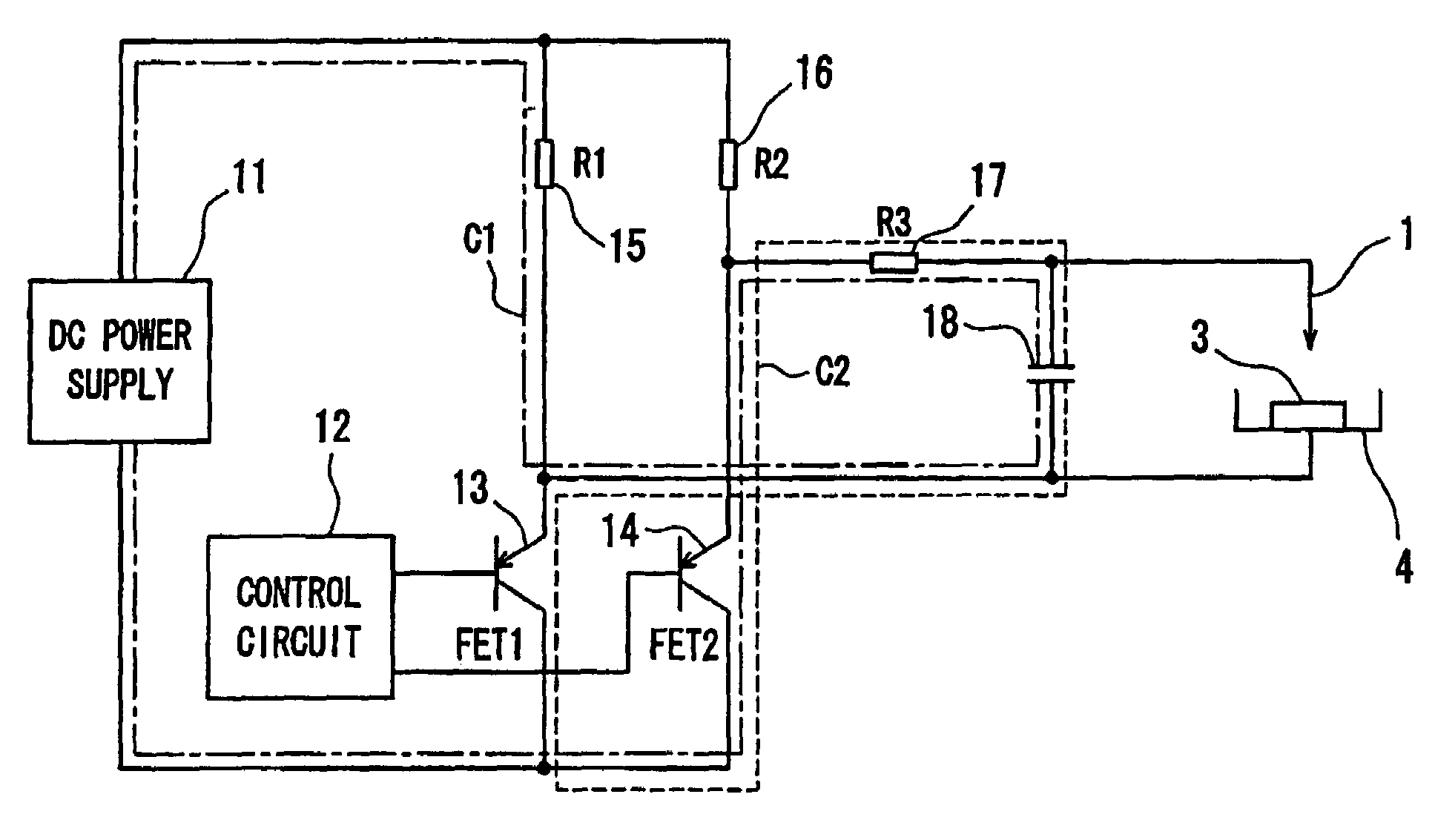

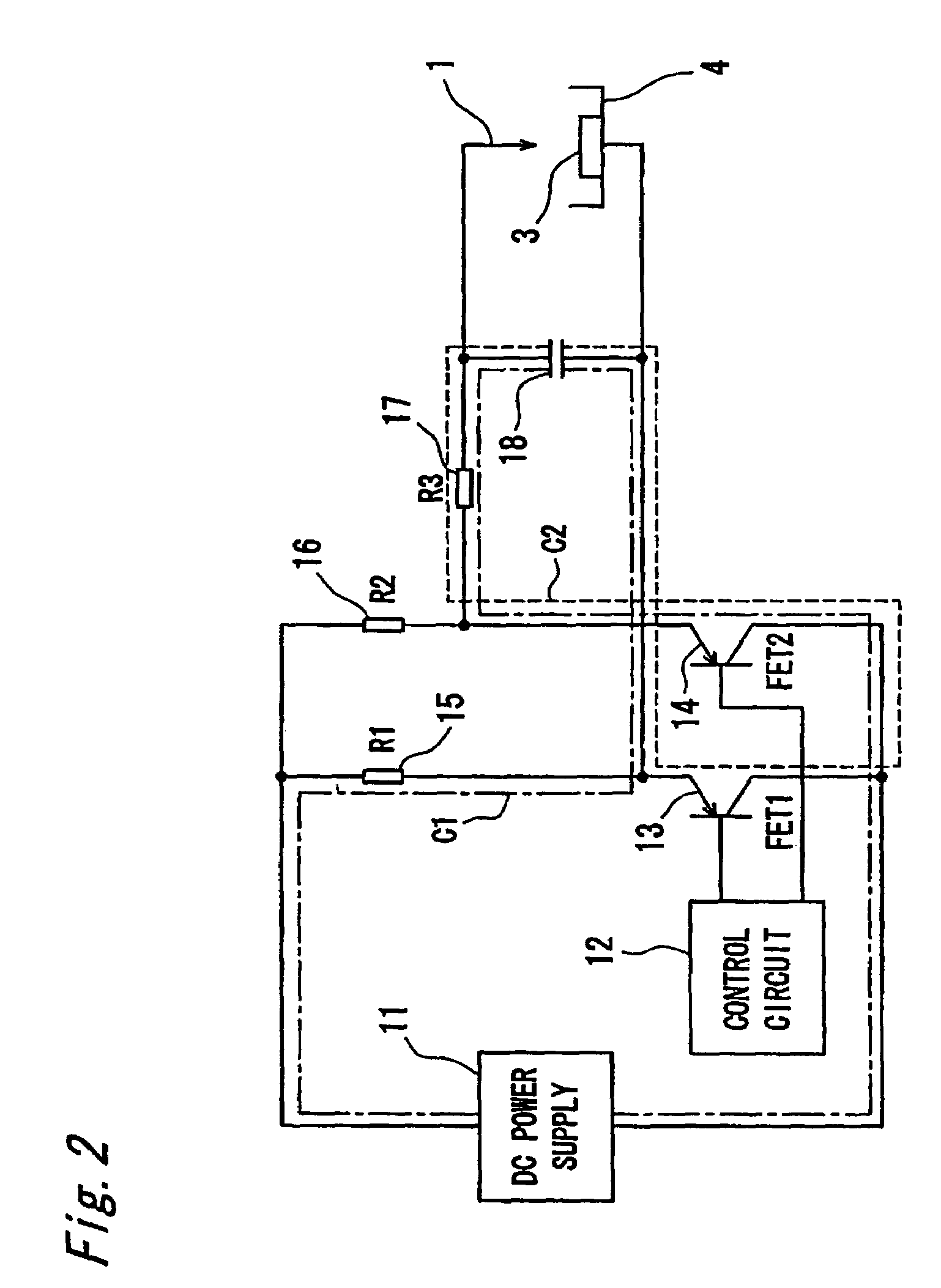

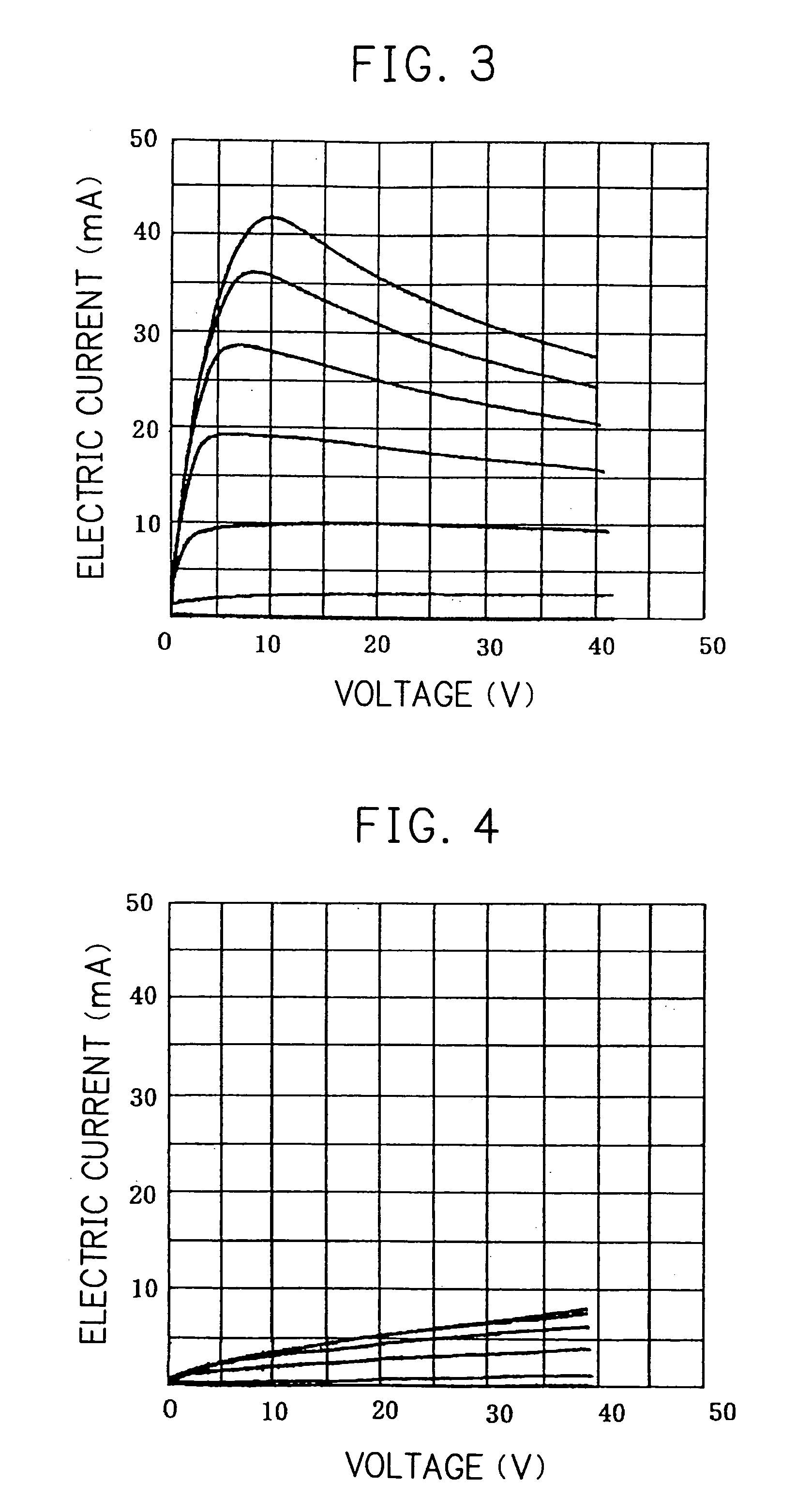

Electrical discharge machine power supply

InactiveUS7214900B2Shorten application timeIonization of the working fluid can be suppressedElectric circuitsLeading edgeWorking fluid

An electrical discharge machining apparatus includes a work electrode adapted to support a work immersed in a working fluid, a tool electrode located opposing the work electrode with a predetermined gap therebetween, a capacitor that is connected between the work electrode and the tool electrode to provide a series of voltage pulses, a charging circuit having a power supply and a first switching element which are connected in series to the capacitor, a charge regulating circuit having a second switching element connected in series to the capacitor, and a control unit that controls the first and second switching elements, such that the first switching element turns on, and then the second switching element turns on before the first switching element turns off. Then, one voltage pulse, having a leading edge corresponding to the turning on of the first switching element and a trailing edge corresponding to the turning on of the second switching element, is generated.

Owner:PANASONIC CORP

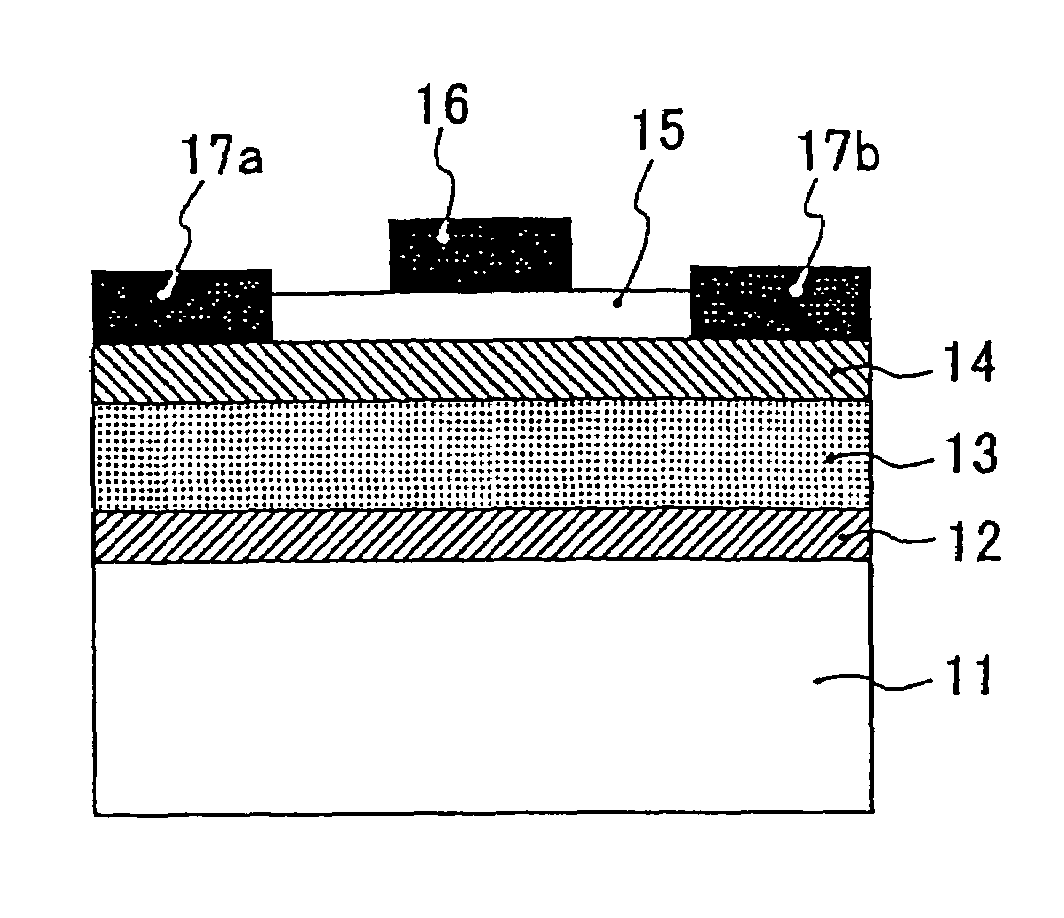

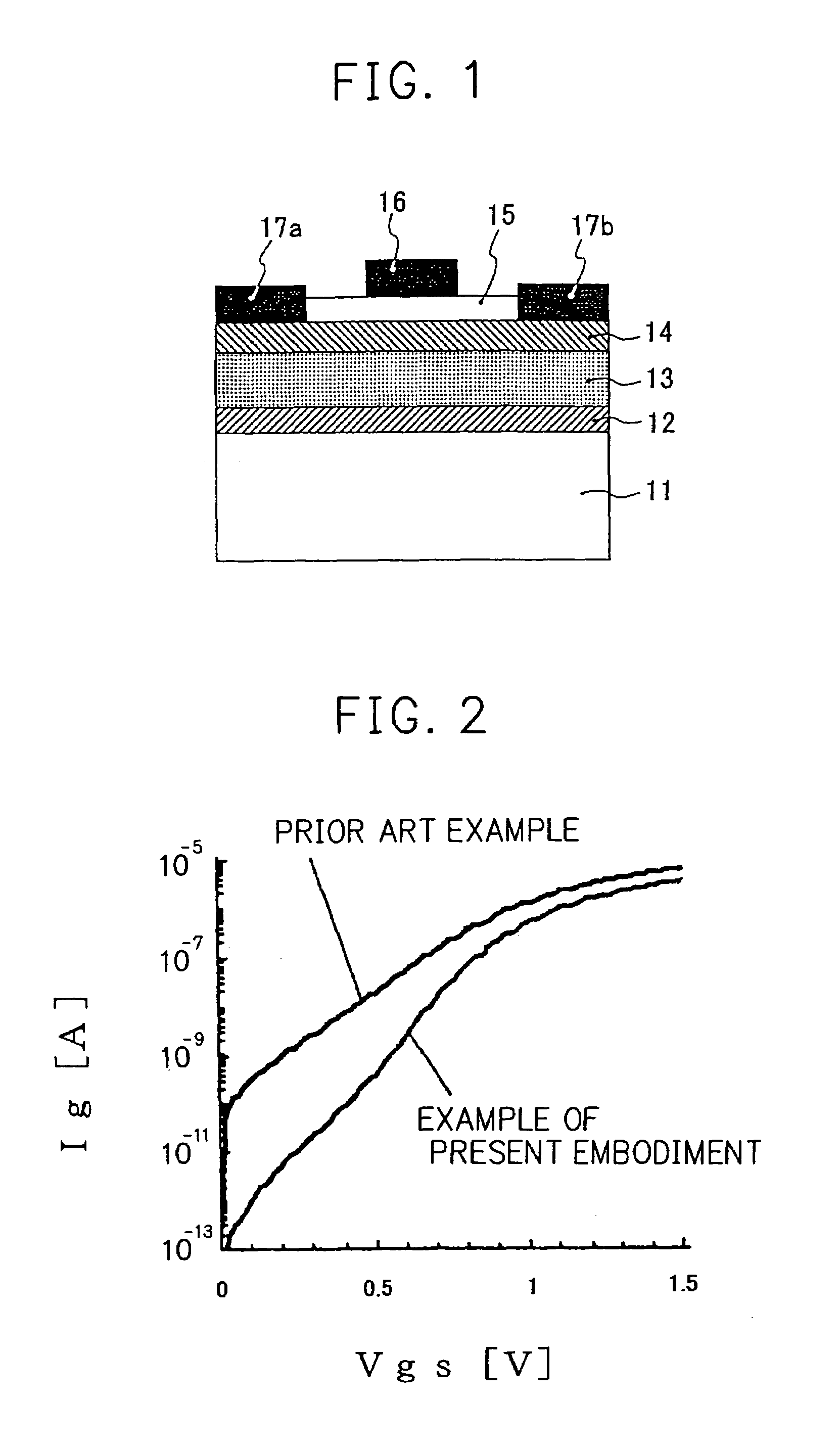

Nitride semiconductor device

ActiveUS7304330B2Suppressed ionizationImprove leakage currentTransistorSemiconductor/solid-state device manufacturingIndiumNitrogen

Owner:NEW JAPAN RADIO CORP

Acidizing block remover suitable for complex lithologic reservoir

ActiveCN102775980BSuppressed ionizationRestore permeabilityDrilling compositionSolventFluoboric acid

The invention relates to an acidizing block remover suitable for a complex lithologic reservoir. The acidizing block remover suitable for the complex lithologic reservoir comprises the following components by weight: 0-12% of hydrochloric acid, 0-3% of ammonium bifluoride, 0-10% of sulfamic acid, 0-5% of fluoboric acid, 0-3% of boric acid, 0-4% of alcohol, 0-2% of triethanolamine, 3% of glacial acetic acid, 4.0-6.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 0.5-1.0% of penetrating agent, 2.0% of clay stabilizer and 45-88.5% of water. The problems that the lithologic and physical property differences of oil fields are large, the oil fields are in staggered distribution, and the acidizing debugging construction effect of a common water injection well is not ideal are mainly solved. The acidizing block remover suitable for the complex lithologic reservoir can effectively corrode the strata minerals and obstruent, does not destroy a rock skeleton, can prevent secondary precipitation caused by sensitive mineral, improves the water absorbing capacity of the reservoir, and increases the daily increasing water injection rate of an average single-well measure.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

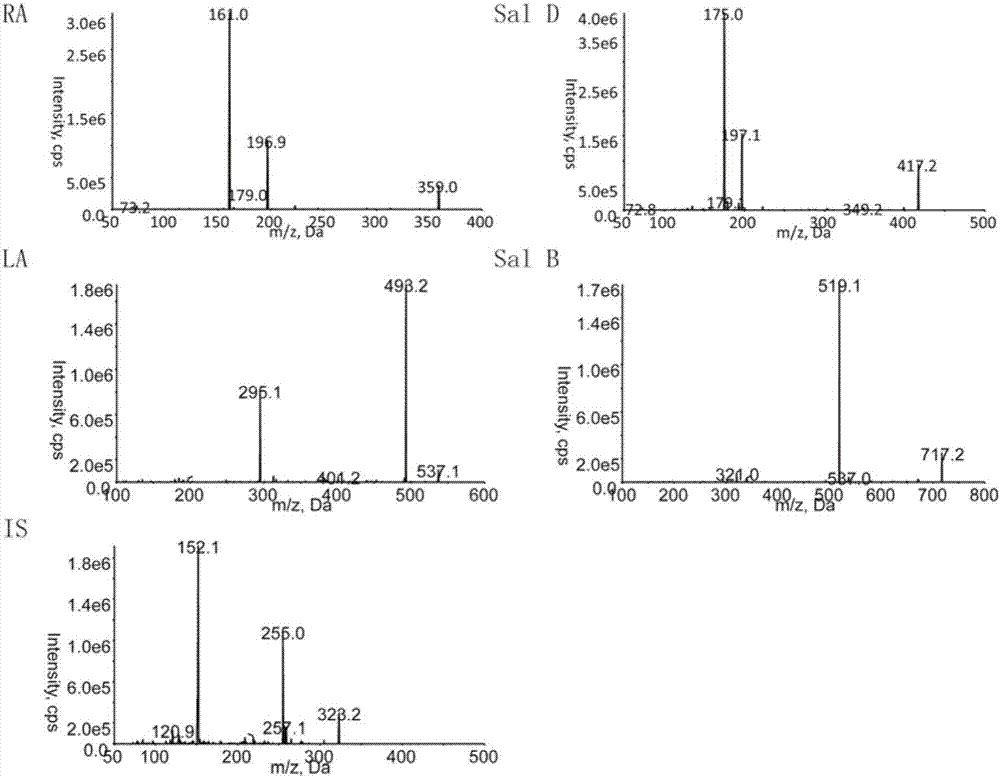

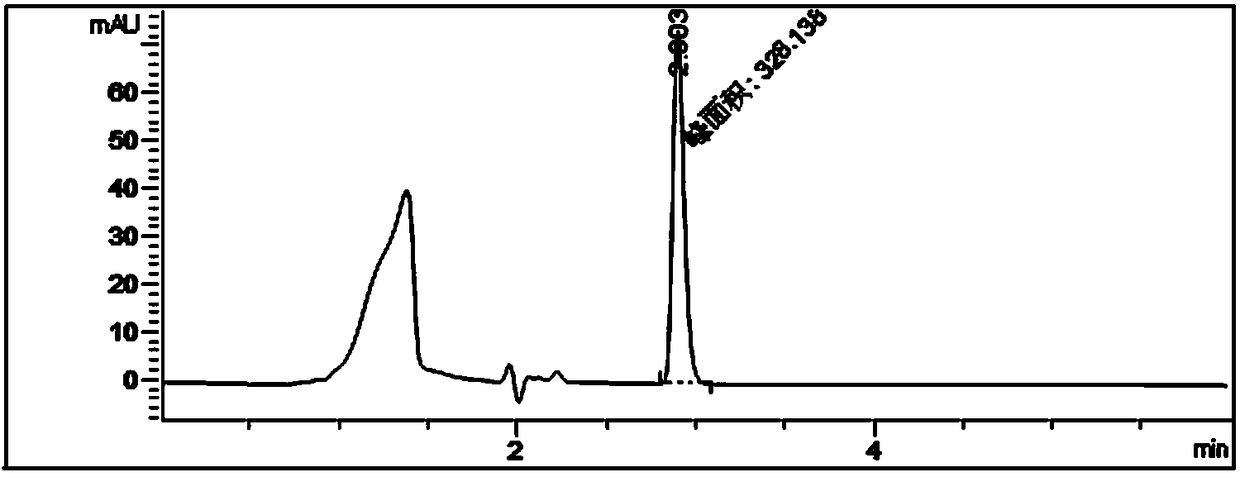

Method for detecting phenolic acid substances in blood plasma

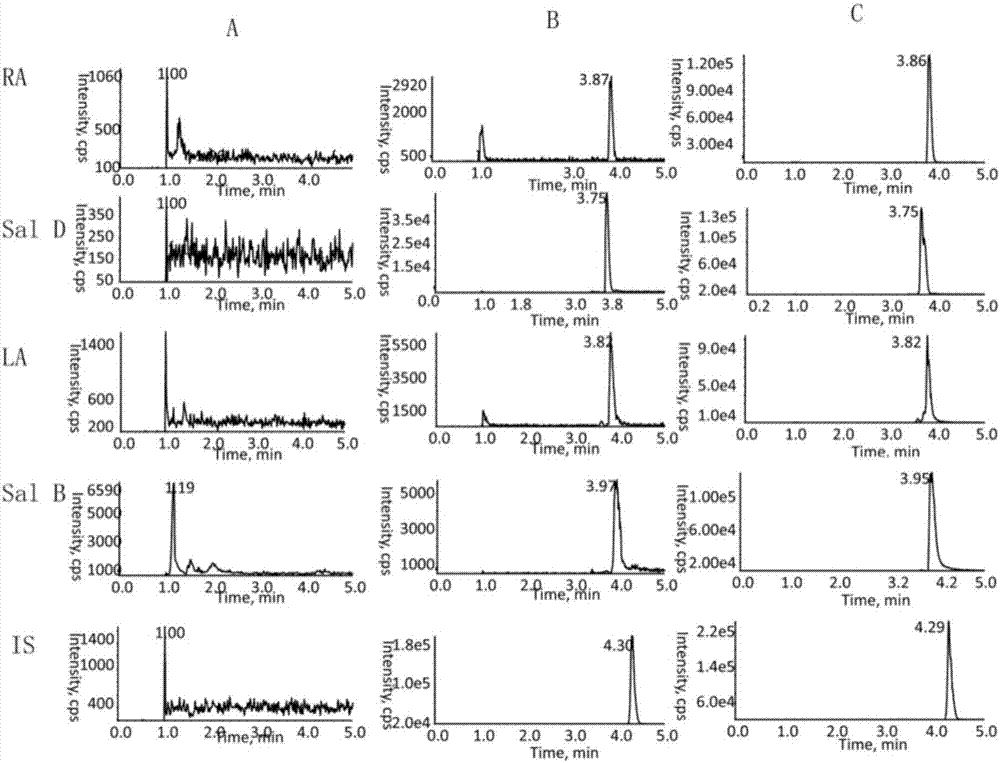

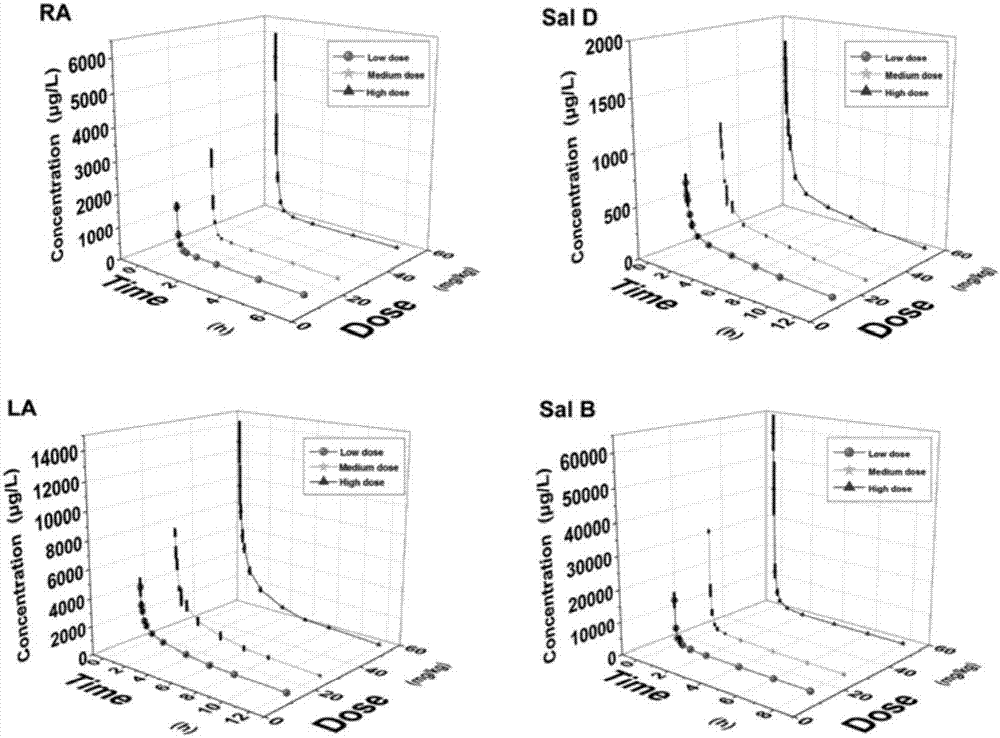

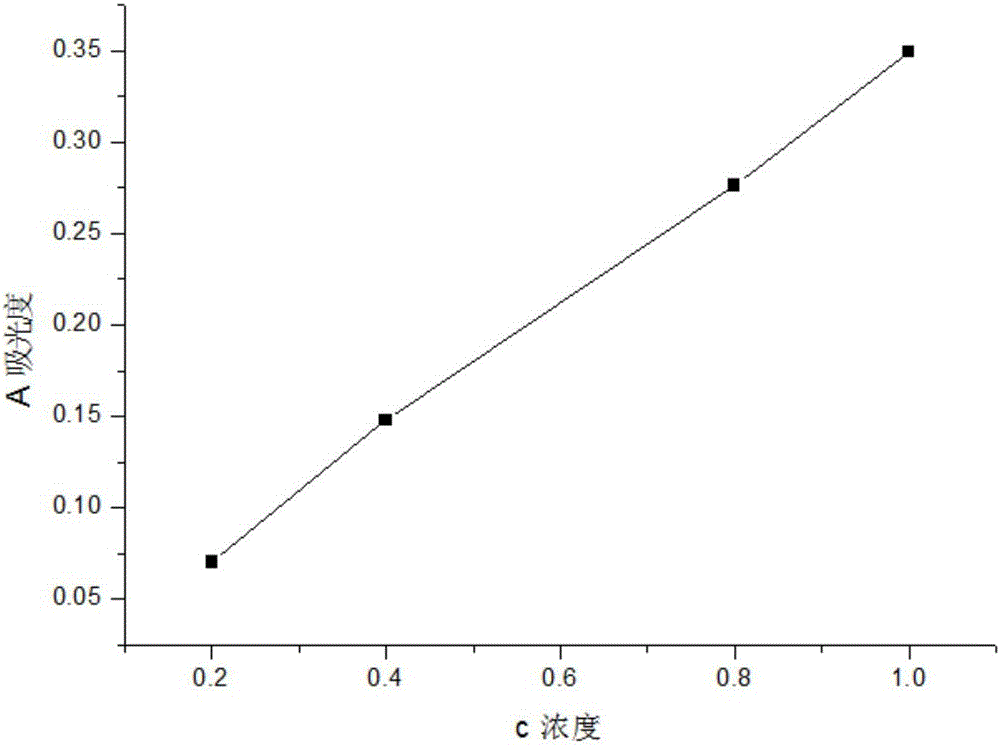

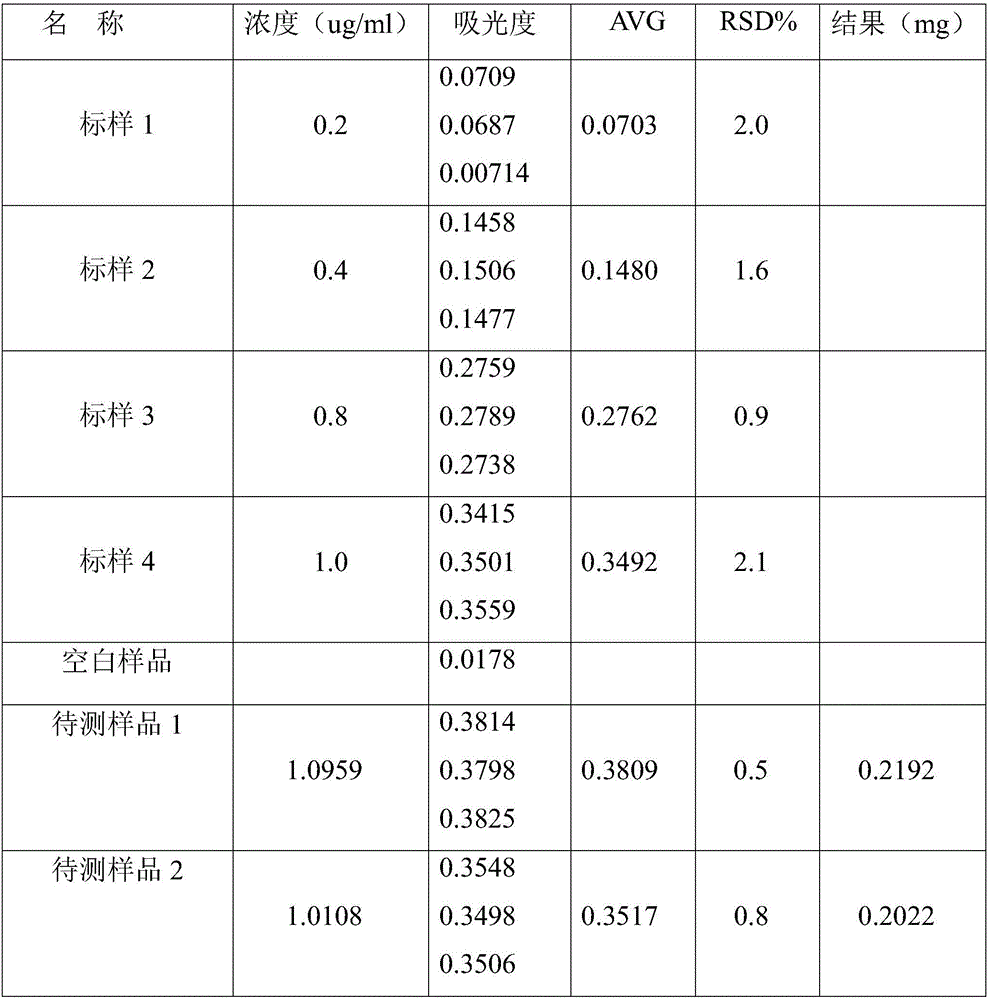

PendingCN107957452ASuppressed ionizationLittle effect on separationComponent separationSalvianolic acid BBlood plasma

The invention relates to a method for detecting phenolic acid substances in blood plasma. The method includes steps of 1, preparing standard reference solution; 2, preparing internal standard solution; 3, preparing quality control (QC) samples; 4, treating medicated blood plasma samples; 5, carrying out detection. The method has the advantages that the plasma concentration of salvianolic acid B, salvianolic acid D, rosmarinic acid and lithospermic acid in blood plasma of rats is measured by the inventor by the aid of simple, convenient and sensitive LC-MS / MS (liquid chromatography-mass spectrometry / mass spectrometry) processes with high specificity after administration injection salvianolic acids are injected to the rats, and research is carried out on elimination relations of main effective components of different doses of the injection salvianolic acids in mammals.

Owner:TIANJIN TASLY PHARMA CO LTD

Sample processing method for determining residual lithium salt on surface of battery shell in flame atomic absorption spectroscopy method

ActiveCN106769917AImprove solubilityAvoid interferenceColor/spectral properties measurementsLithiumOrganic solvent

The invention discloses a sample processing method for determining residual lithium salt on a surface of a battery shell in a flame atomic absorption spectroscopy method. The method comprises the following steps: cleaning and extracting the surface of a battery shell by using dimethyl carbonate, continuously performing ultrasonic immersion for a battery eluted by the dimethyl carbonate by using a nitric acid solution to extract the lithium salt, concentrating a dimethyl carbonate extract solution, adding a nitric acid solution, performing oscillation extract, and transferring a nitric acid phase into the nitric acid extract solution; heating to remove the acid, transferring the residual solution into a volume bottle after the acid removal, adding 1ml of 1 percent cesium chloride, fixing the volume by using deionized water to obtain a solution to be detected; and performing the blank treatment by adopting a same method, and determining the sample to be detected and the blank sample by directly using the flame atomic absorption spectroscopy method. By adopting a combined pretreatment means for dissolving the residual lithium salt on the surface of the battery shell by using the dimethyl carbonate and the nitric acid solution, and the lithium salt in the dimethyl carbonate is extracted into the nitric acid solution by using a liquid-liquid extraction method, so that the interference of organic solvents is effectively avoided.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

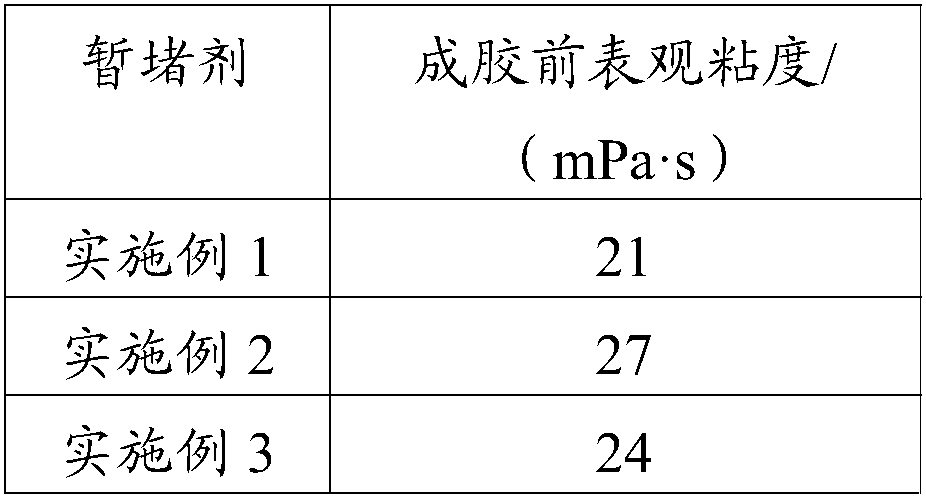

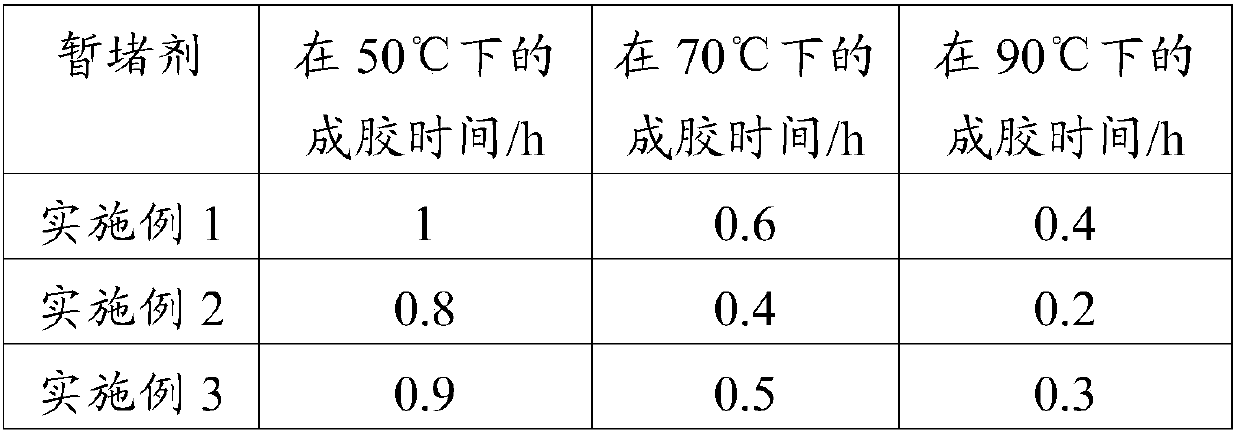

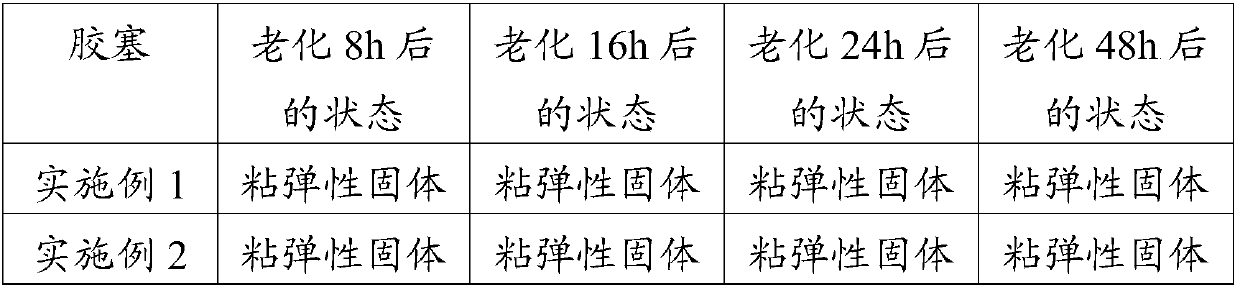

Temporary plugging agent for well killing and preparation method thereof

The invention discloses a temporary plugging agent for well killing and a preparation method thereof, and belongs to the field of oilfield chemistry. The temporary plugging agent for well killing is obtained by crosslinking the following components in percentage by mass: 1.0%-5.0% of a crosslinking monomer, 1.0%-5.0% of oil, 0.5%-2.0% of a dispersing agent, 2.0%-5.0% of a crosslinking agent, 2.0%-10.0% of polyol, and 0.05%-1.0% of a gel breaker, with the balance being water, and the crosslinking monomer being plant gum. The temporary plugging agent is low in viscosity before gelling, easy to pump and inject, high in viscosity after gelling, wide in applicable temperature range, capable of resisting high temperature of 120 DEG C, capable of quick gel breaking after being in contact with acidic substances, short in plug removal time and small in damage to a reservoir after plant gum breaking.

Owner:PETROCHINA CO LTD

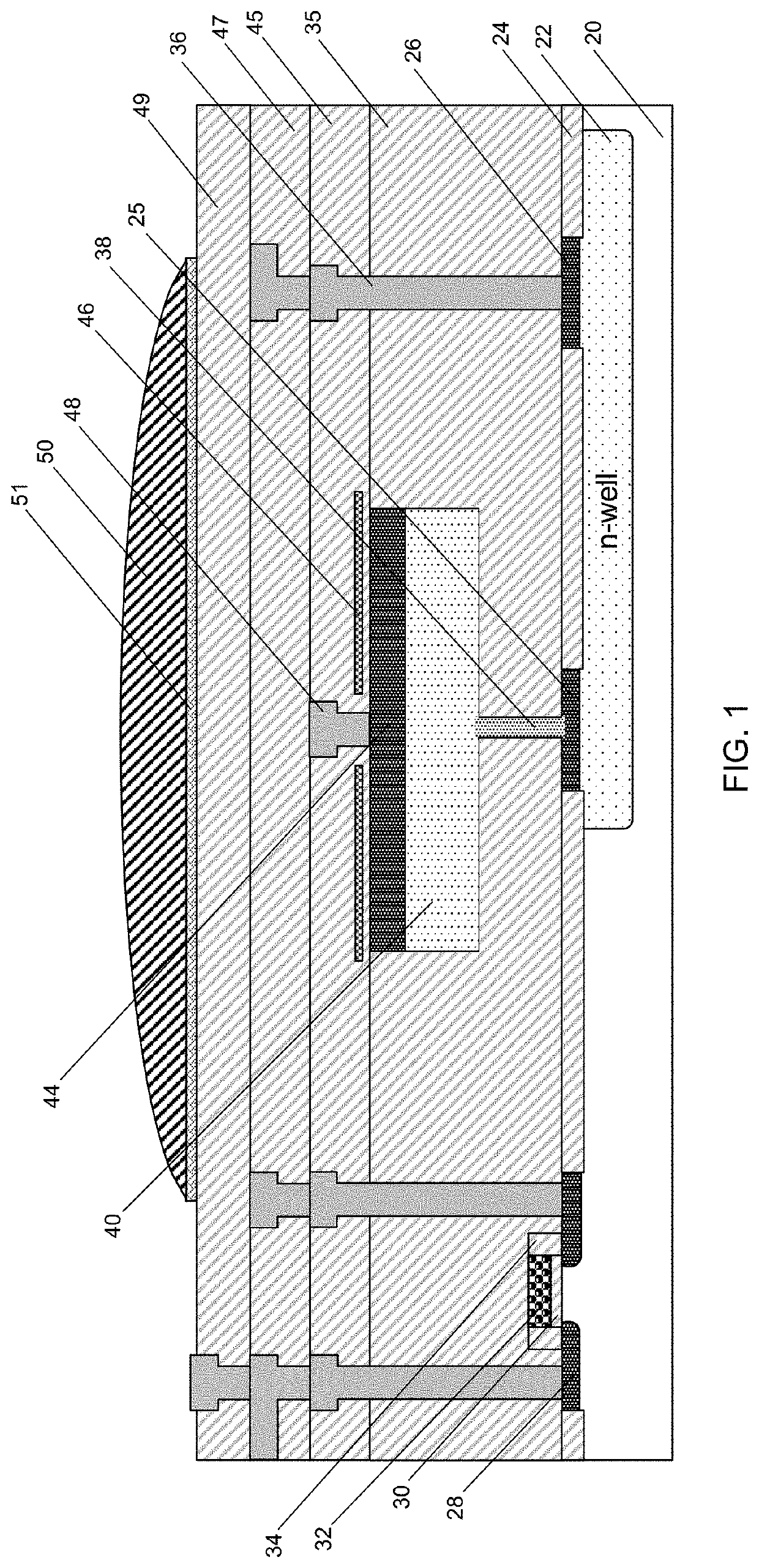

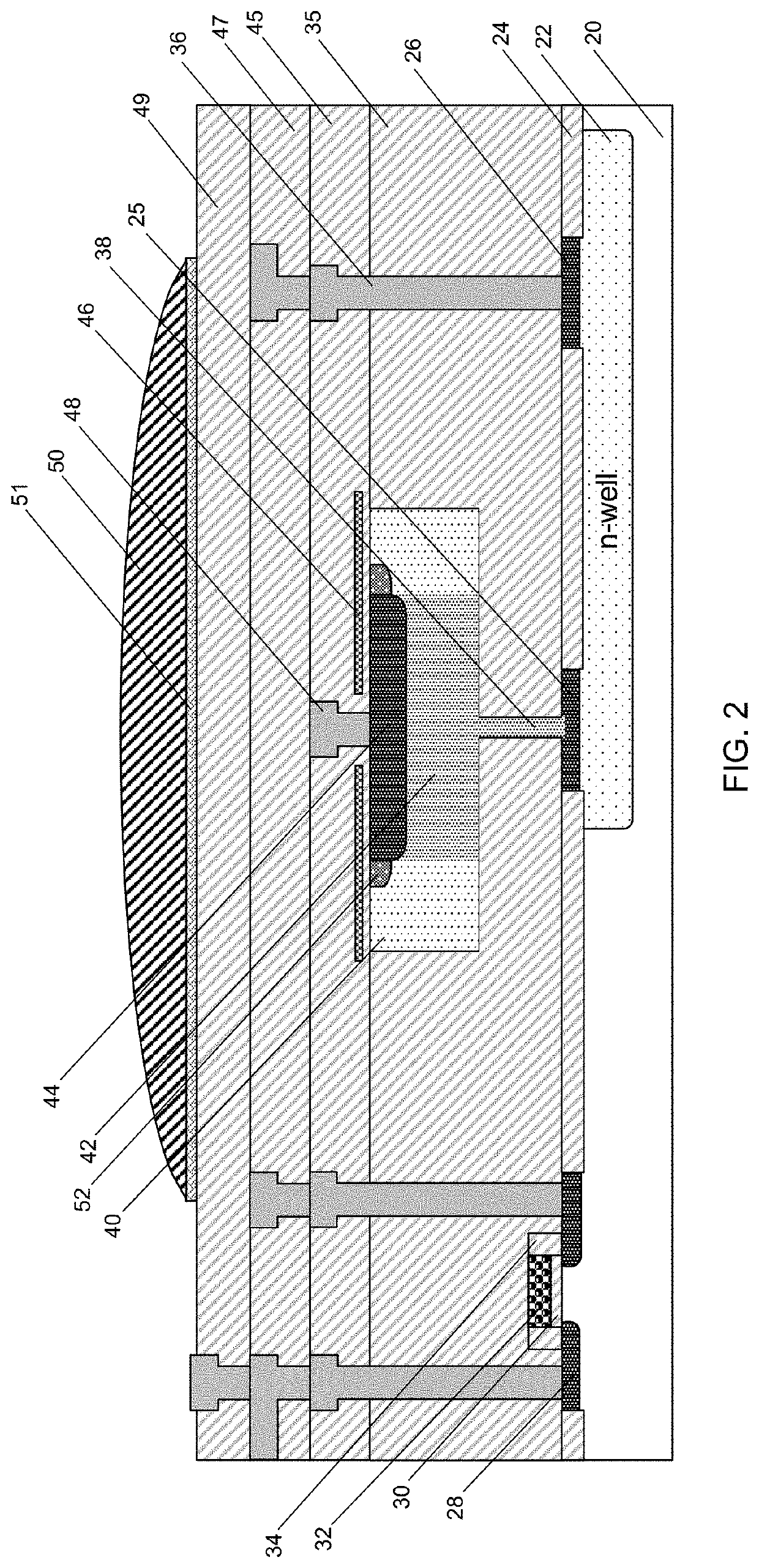

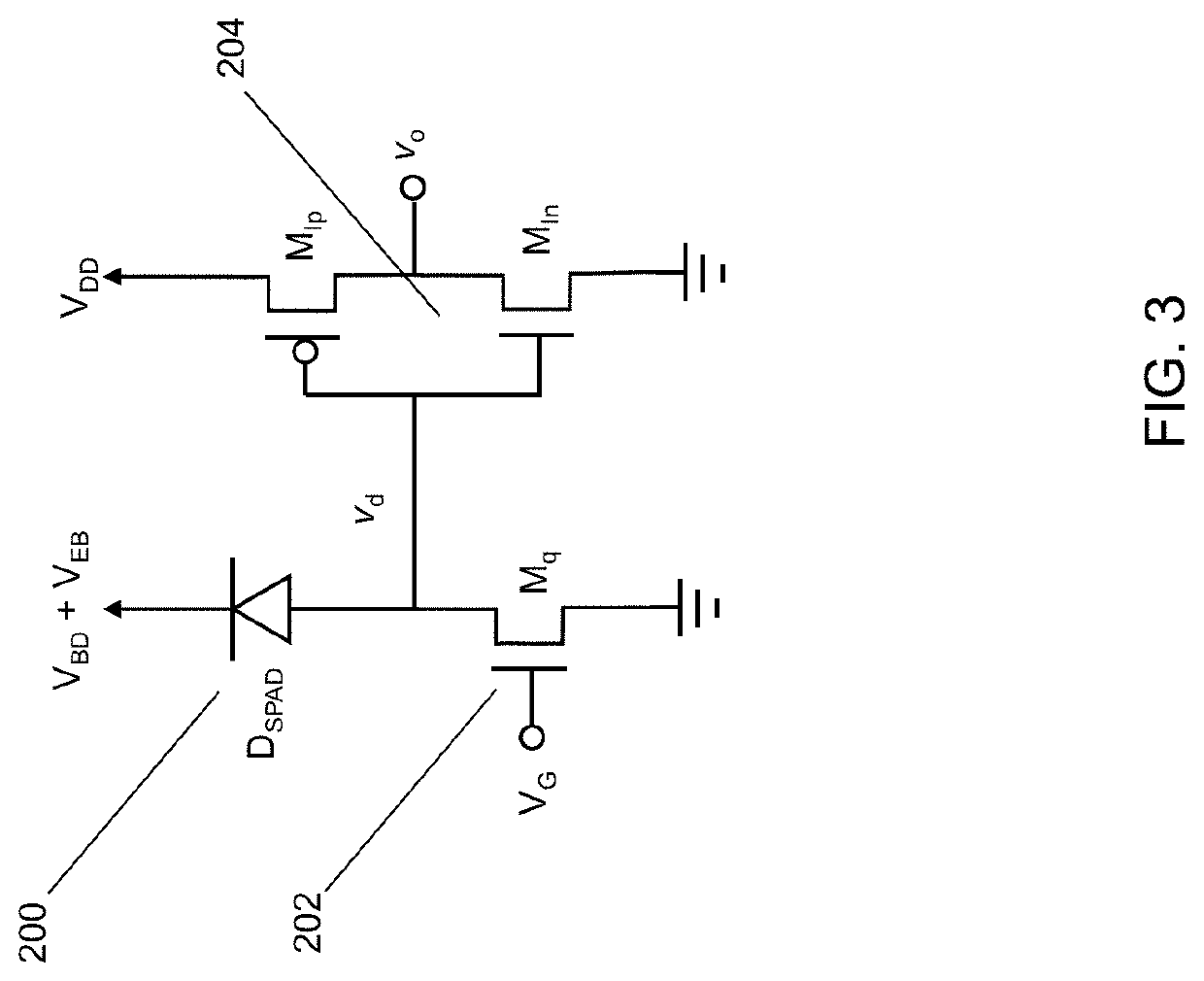

High Dynamic Range Single Photon Avalanche Detector Array on Silicon with Circuitry for Light Detection and Ranging

PendingUS20210341619A1Increase dynamic rangeReduce probabilityTransistorTelevision system detailsImage sensorHigh dynamic range

An image sensor array includes a substrate and a plurality of pixels. Each pixel includes a single photon avalanche detector (SPAD), a quench device coupled to a respective SPAD and configured to quench an avalanche current, and time measurement circuitry configured to measure a time-of-flight of a photon. The SPAD has a trench coupled to the substrate and having a lattice mismatch with the substrate, and a substantially defect-free region coupled to the trench and configured to generate the avalanche current when the photon is detected in the defect-free region, wherein the trench and the defect-free region form an electrode. An imaging system includes an infrared laser configured to provide a pulse of light, and the image sensor array configured to receive the pulse from the infrared laser.

Owner:SEMIKING LLC

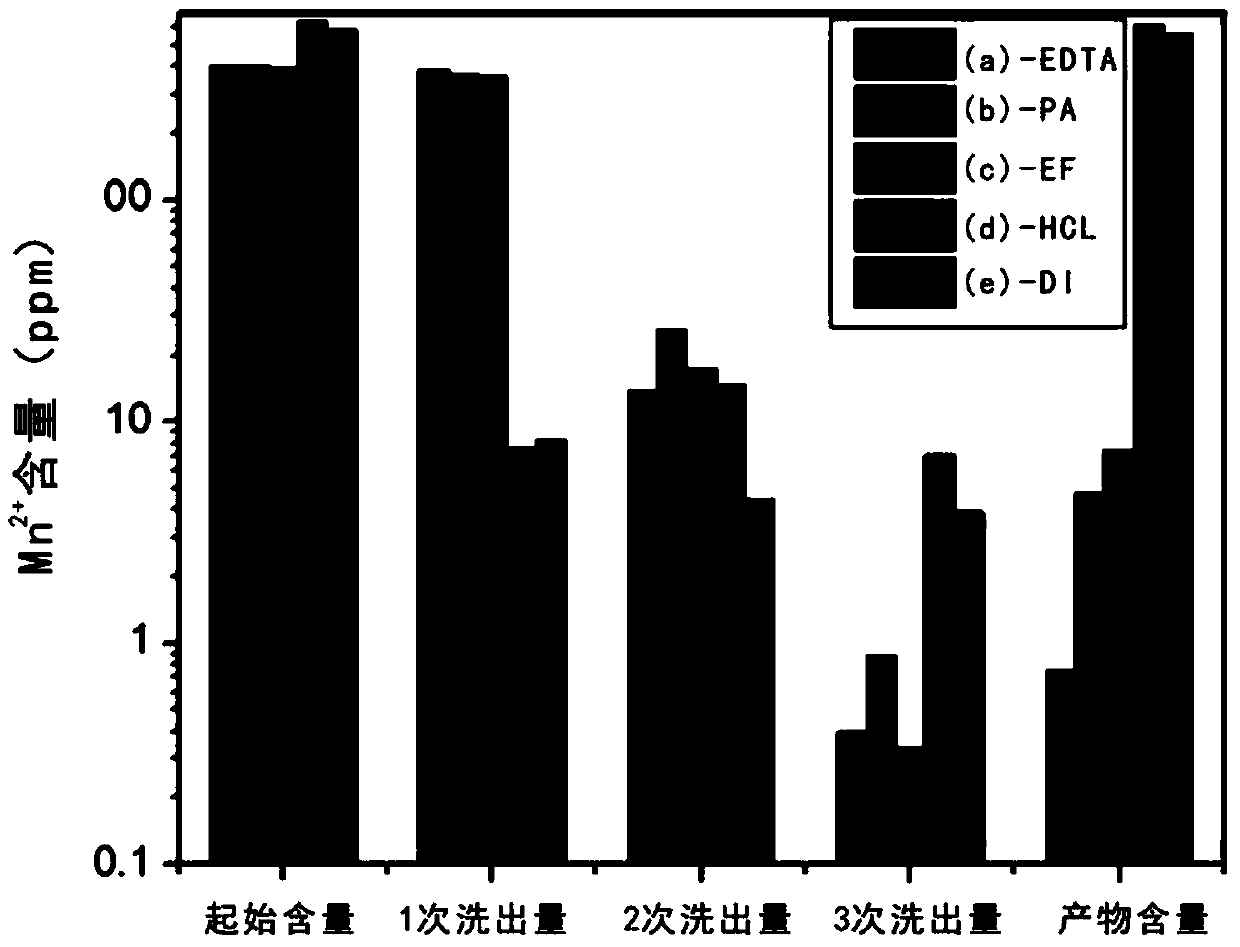

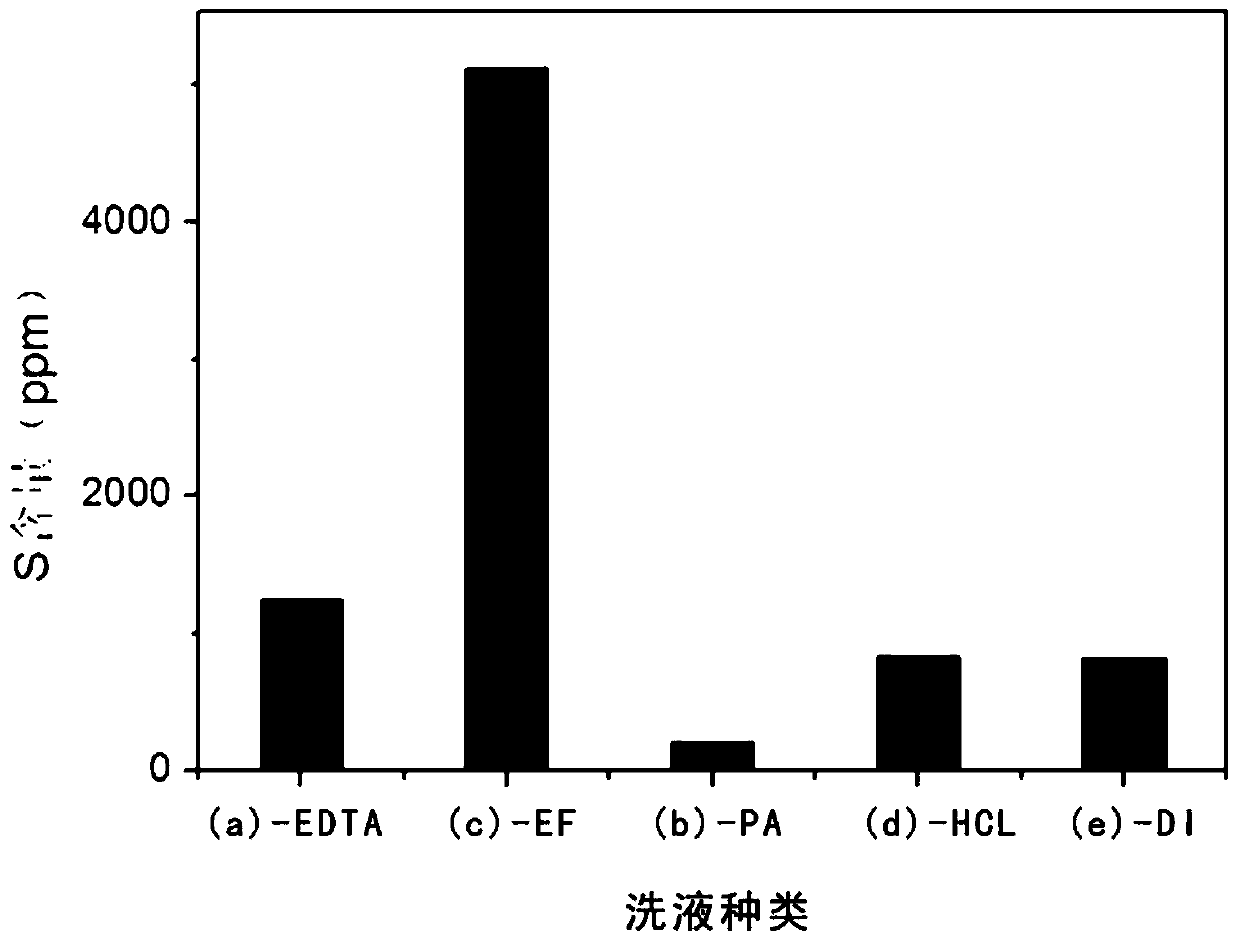

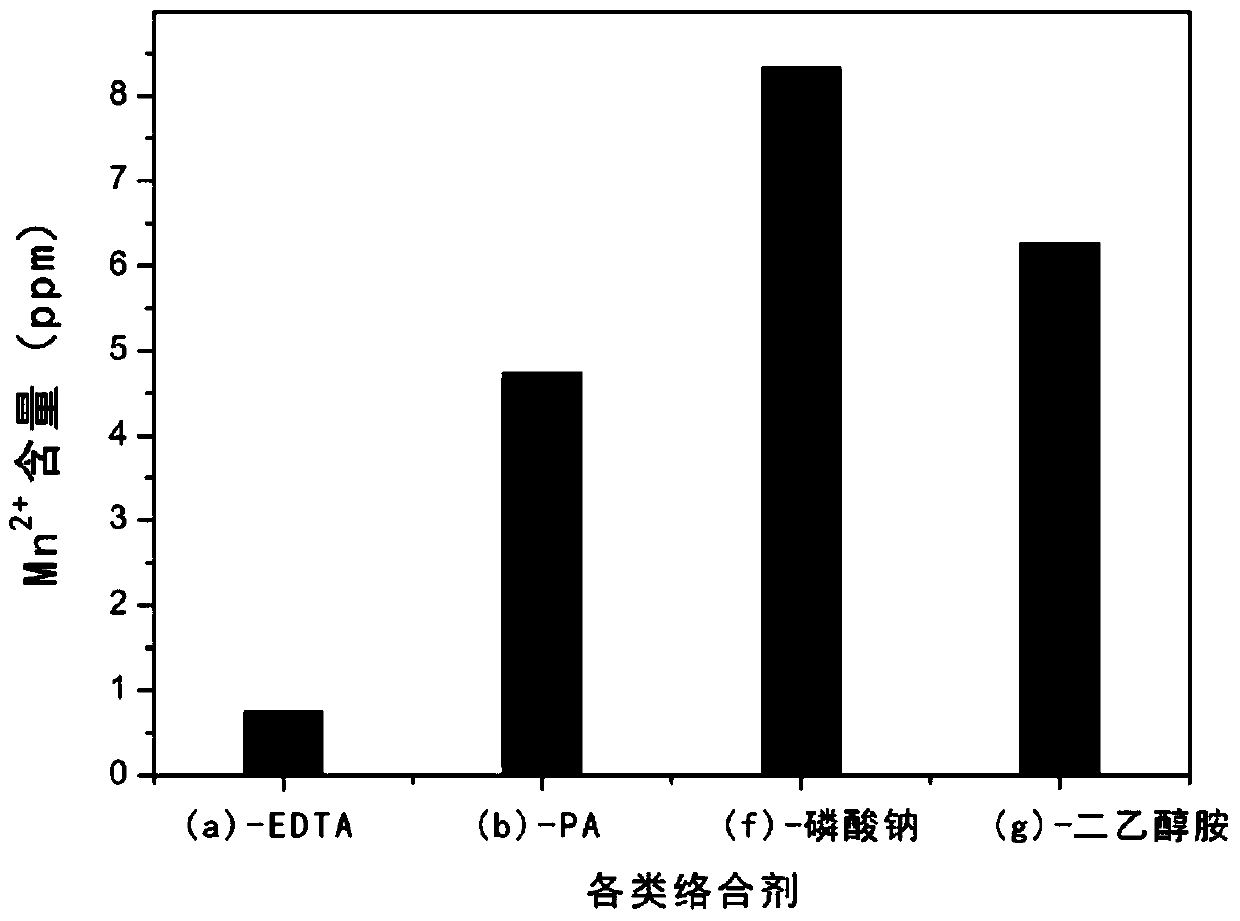

Method for removing metal ions in graphite oxide

Owner:SICHUAN UNIV +1

Method of Anion Production from Atoms and Molecules

InactiveUS20120280139A1Increase ionic strengthGood precisionMaterial analysis by optical meansIon beam tubesIon beamIon source

Owner:VOGEL JOHN

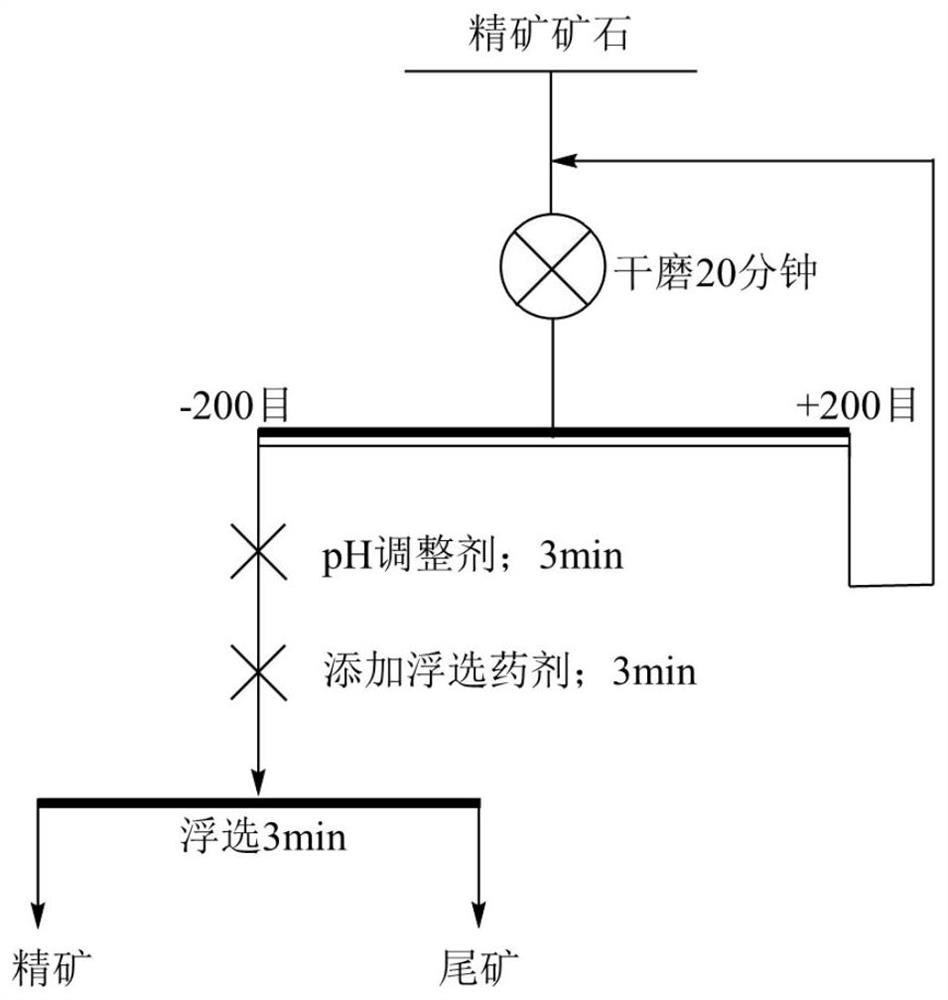

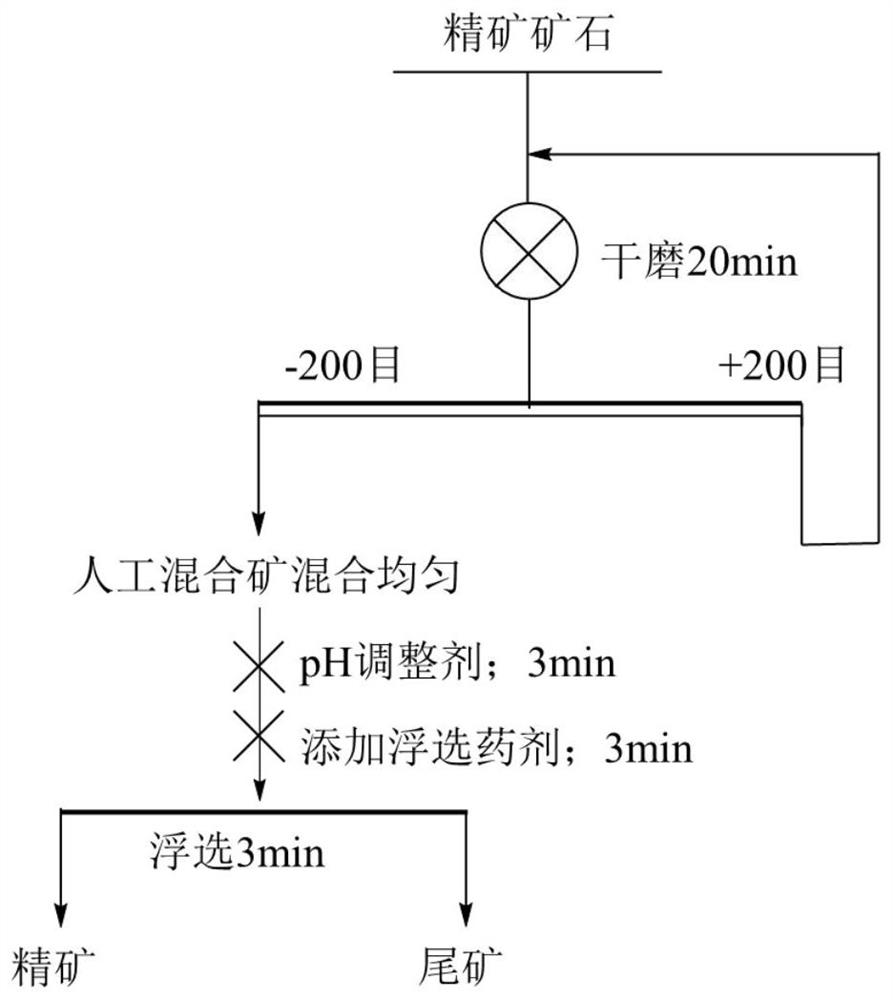

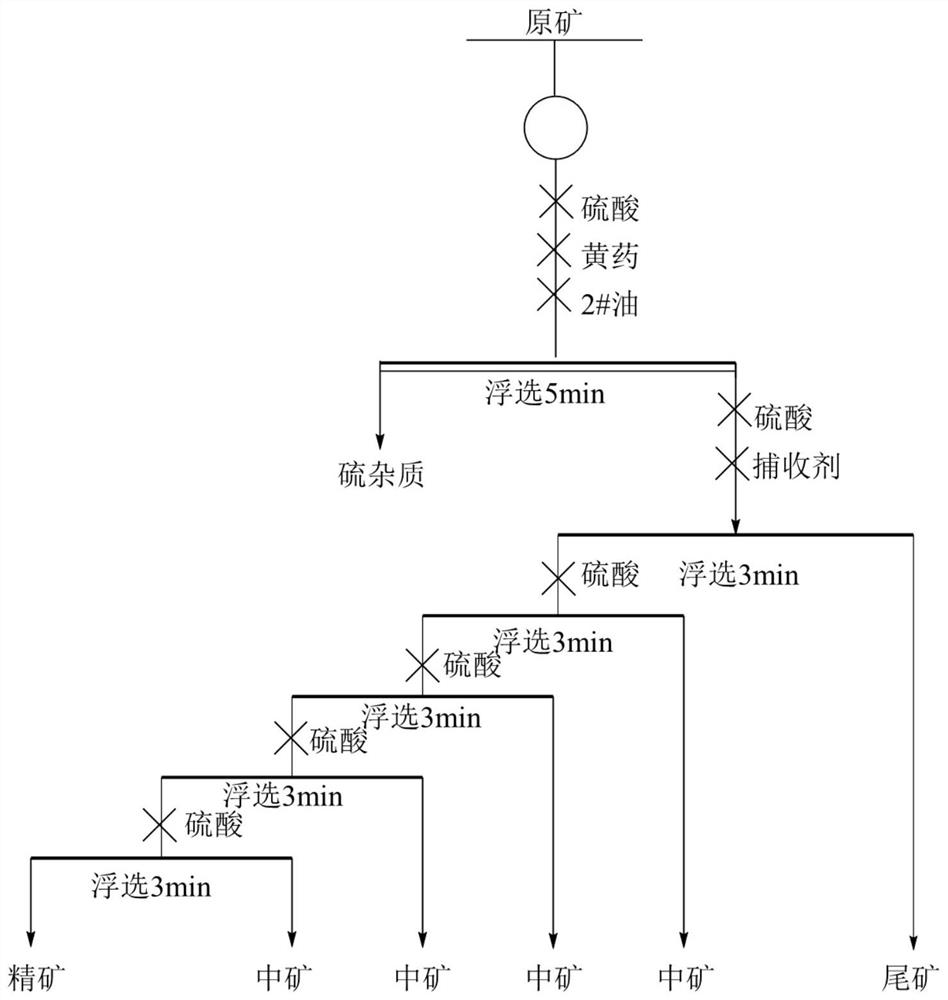

Flotation collecting agent, flotation reagent and flotation method for improving separation efficiency of ilmenite and gangue of ilmenite

The invention provides a flotation collecting agent, a flotation reagent and a flotation method for improving the separation efficiency of ilmenite and gangue of ilmenite.The flotation collecting agent comprises a collecting agent A, the collecting agent A has a formula shown in the specification. In the formula, R1 is C1-C15 alkyl, C4-C15 cycloalkyl, allyl, ethynyl, phenyl, benzyl or benzyloxy; and R2 is hydrogen, C1-C15 alkyl, C4-C15 naphthenic base, propenyl, ethynyl, phenyl or benzyl. The collecting agent A serves as the flotation collecting agent of the ilmenite, benefited from the special synergistic effect of the benzene ring and the phosphate group, the collecting agent A shows good flotation selectivity and recovery rate, and the recovery rate and grade of the ilmenite can be improved.

Owner:CENT SOUTH UNIV

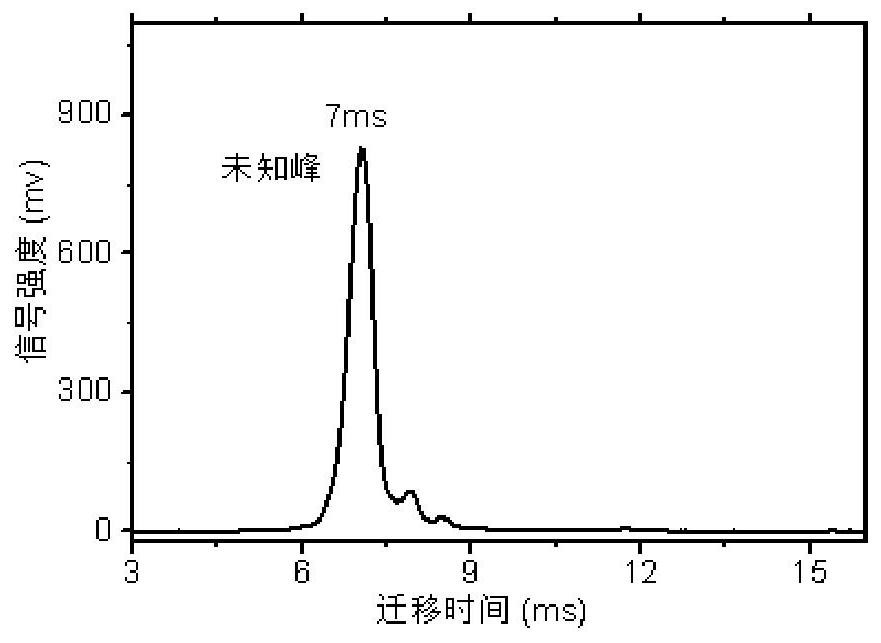

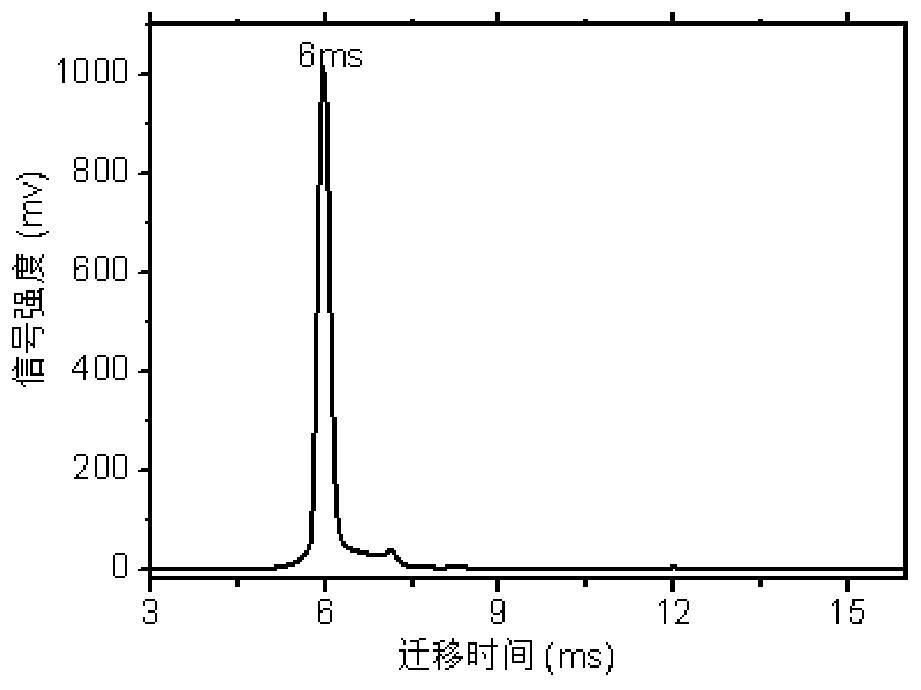

Dopant cartridge and method for stably controlling concentration of ion mobility spectrometry chemical dopant

InactiveCN112071738AExtend the life cycleHigh detection sensitivityParticle spectrometer methodsMaterial analysis by electric/magnetic meansDopantHigh signal intensity

The invention discloses a method for stably controlling the concentration of an ion mobility spectrometry chemical dopant. According to the invention, the method comprises the steps: employing a photoionization ion mobility spectrometry technology as a basic detection technology; in a positive ion high-voltage mode, optimizing the types of dopants, employing a combined adding mode of mixed dopants, and then selecting a dopant control mode to effectively control the release concentration of the dopant. therefore, signals can be remarkably enhanced under the low-concentration condition of dopan,the service life of dopan can be effectively prolonged, and meanwhile, nodes needing to be replaced by reagents are judged by utilizing peak pattern changes caused by reagent concentration changes; according to the method, high signal intensity under the low-concentration condition of dopant can be realized, and the detection sensitivity of a target sample can be improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Dephenolization extraction agent as well as preparation method and application thereof

ActiveCN112811500AImprove removal efficiencyEfficient removalWaste water treatment from ceramic industriesWater contaminantsQuinoneKetone

The invention provides a dephenolization extraction agent as well as a preparation method and application thereof. The dephenolization extraction agent comprises a combination of methyl isobutyl ketone, a synergistic extraction agent and an antioxidant, wherein the antioxidant comprises C6-C9 saturated aliphatic ketone and / or C7-C9 saturated aliphatic alcohol. According to the dephenolization extraction agent, through compounding of specific components, on one hand, synergistic interaction is achieved on the dephenolization efficiency, on the other hand, ionization and oxidation of phenolic substances in the extraction process can be effectively inhibited, and the content of pollutants such as phenoxy anions, quinones and derivatives thereof which are higher in removal difficulty and higher in toxicity in wastewater is remarkably reduced. The dephenolization extraction agent is used for treating phenol-containing wastewater, the volume ratio range and the pH application range are wide, industrial operation is easy to achieve, the extraction efficiency of monohydric phenol and polyhydric phenol is high, the single-stage total phenol extraction efficiency reaches 97.4% or above, the concentration of an oxidation product benzoquinone in the extracted wastewater is extremely low, the biotoxicity of the wastewater is reduced, and the subsequent biochemical treatment is facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

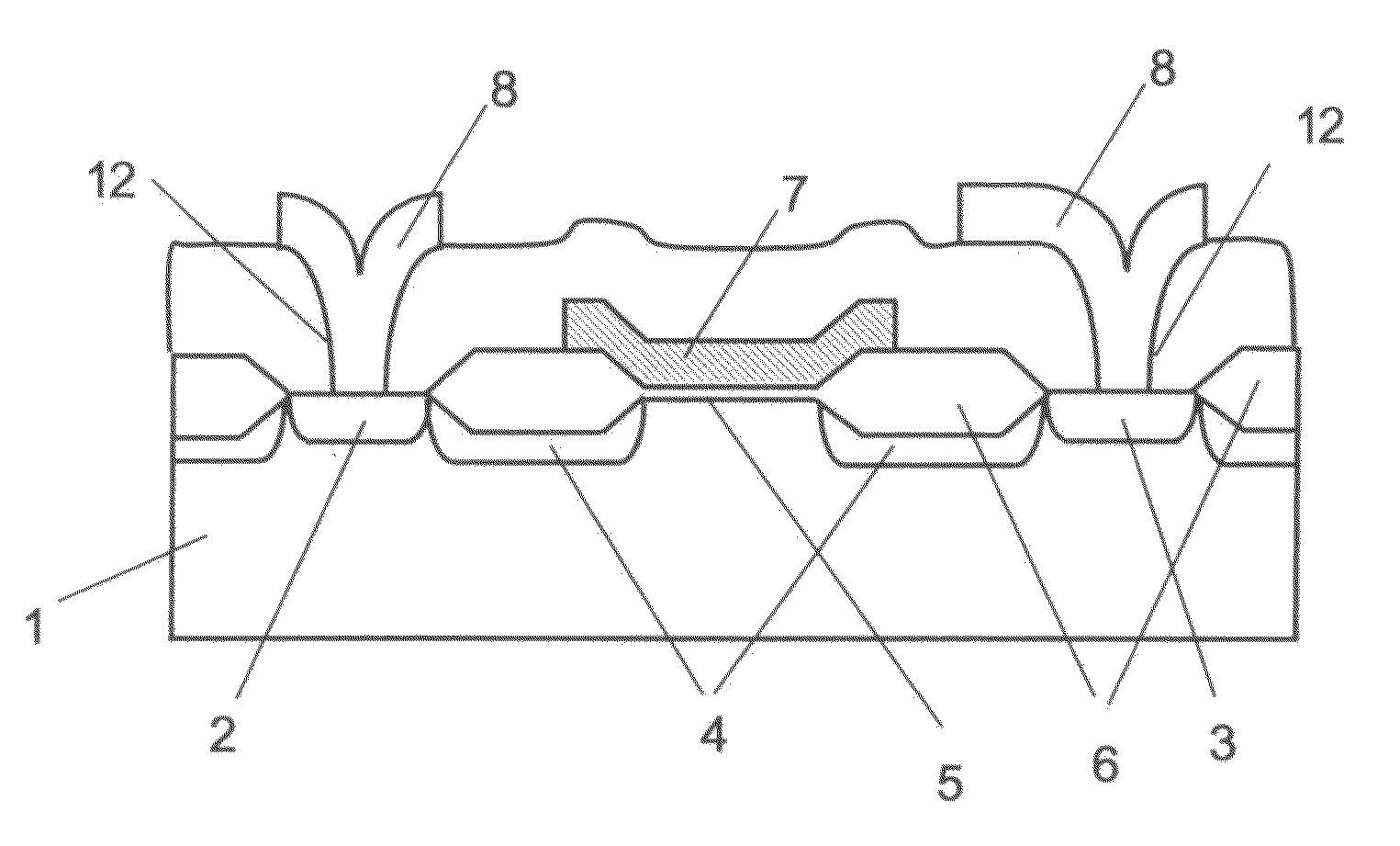

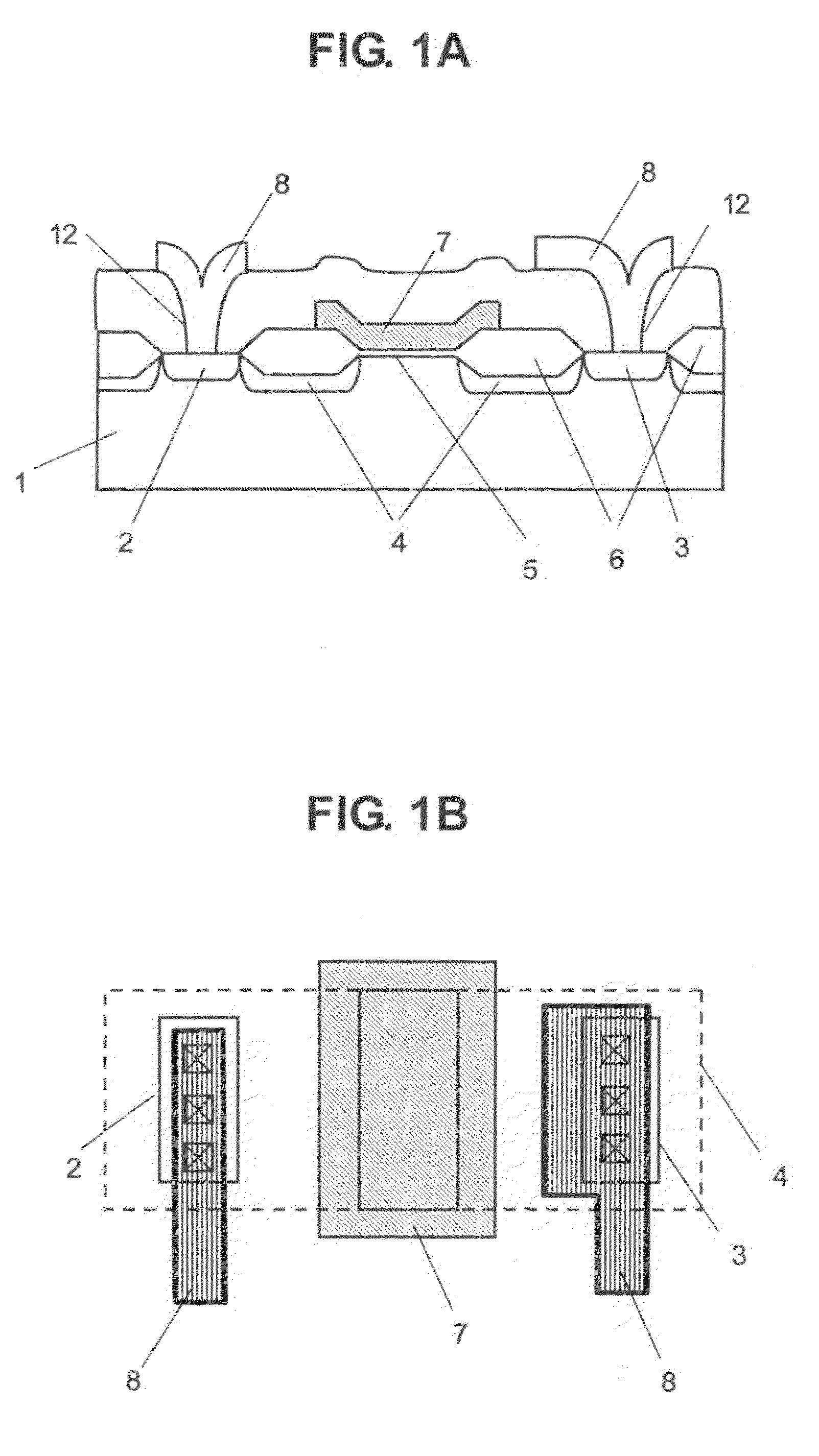

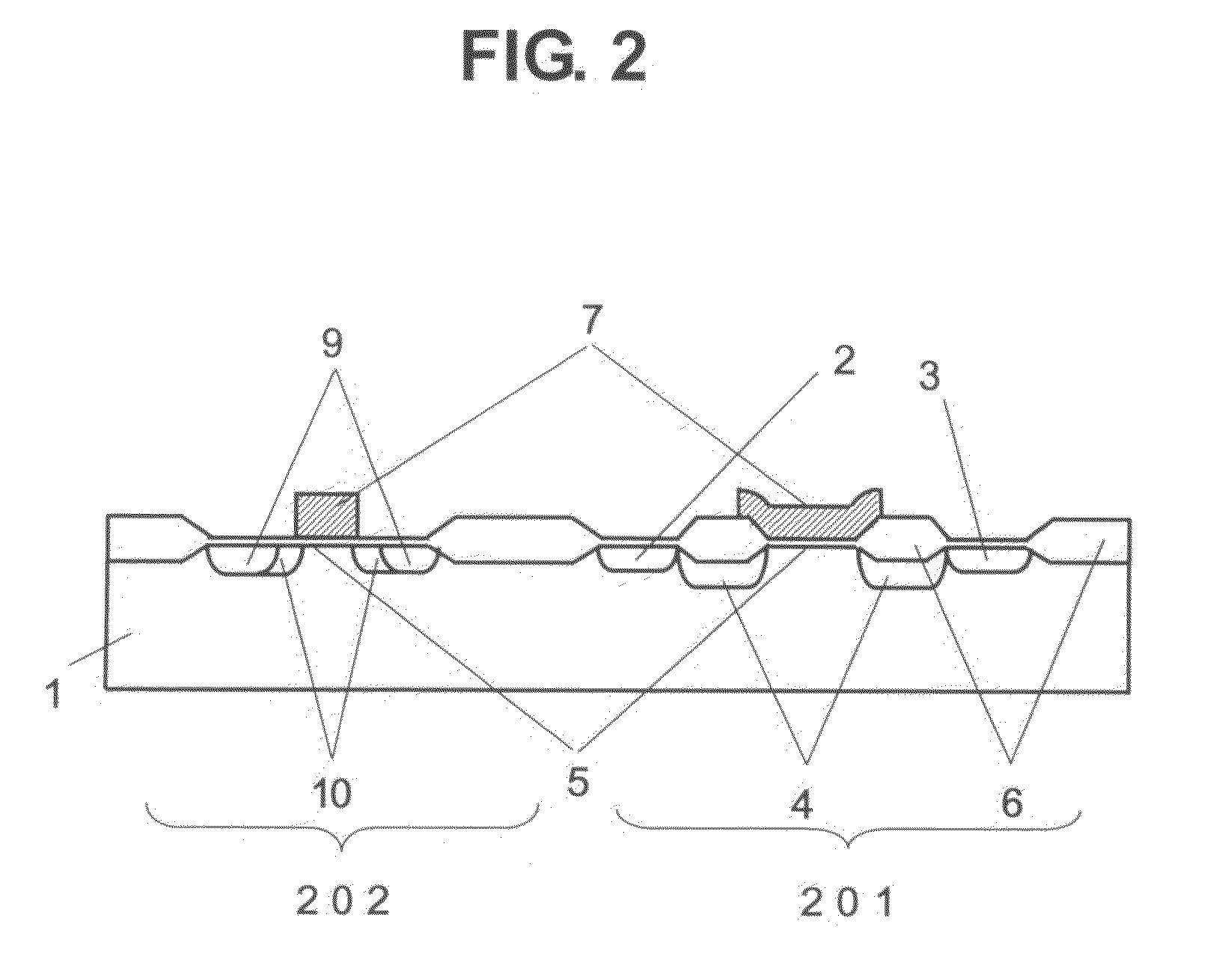

Nitride semiconductor device and production process thereof

ActiveUS20050116248A1Suppressed ionizationImprove leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumNitrogen

A nitride semiconductor device, which includes a III-V Group nitride semiconductor layer being composed of a III Group element consisting of at least one of a group containing of gallium, aluminum, boron and indium and V Group element consisting of at least nitrogen among a group consisting of nitrogen, phosphorus and arsenic, including a first nitride semiconductor layer including the III-V Group nitride semiconductor layer being deposited on a substrate, a second nitride semiconductor layer including the III-V Group nitride semiconductor layer being deposited on the first nitride semiconductor and not containing aluminum and a control electrode making Schottky contact with the second nitride semiconductor layer wherein the second nitride semiconductor layer includes a film whose film forming temperature is lower than the first nitride semiconductor layer.

Owner:NEW JAPAN RADIO CORP

Solid-state image pickup apparatus multiplying signal charges depending on imaging circumstances

InactiveUS7880781B2Big lossSuppressed ionizationTelevision system detailsColor signal processing circuitsSensor arrayPotential well

A solid-state image pickup apparatus selects, in a first image pickup circumstance in which dark current is liable to occur in vertical transfer paths of an array of photo-sensors, a first transfer mode in which the potential well capacity in the vertical transfer paths is relatively small, and, in a second image pickup circumstance in which the dark current is small in quantity, a second transfer mode which is greater in potential well capacity than the first transfer mode. As a positive voltage applied to the read-out gates of the photo-sensors, a first voltage mode indicating a relatively low positive voltage that suppresses impact ionization is set in the first image pickup circumstance, and, a second voltage mode indicating a positive voltage higher than in the first voltage mode is set in the second image pickup circumstance so as to cause the impact ionization.

Owner:FUJIFILM CORP

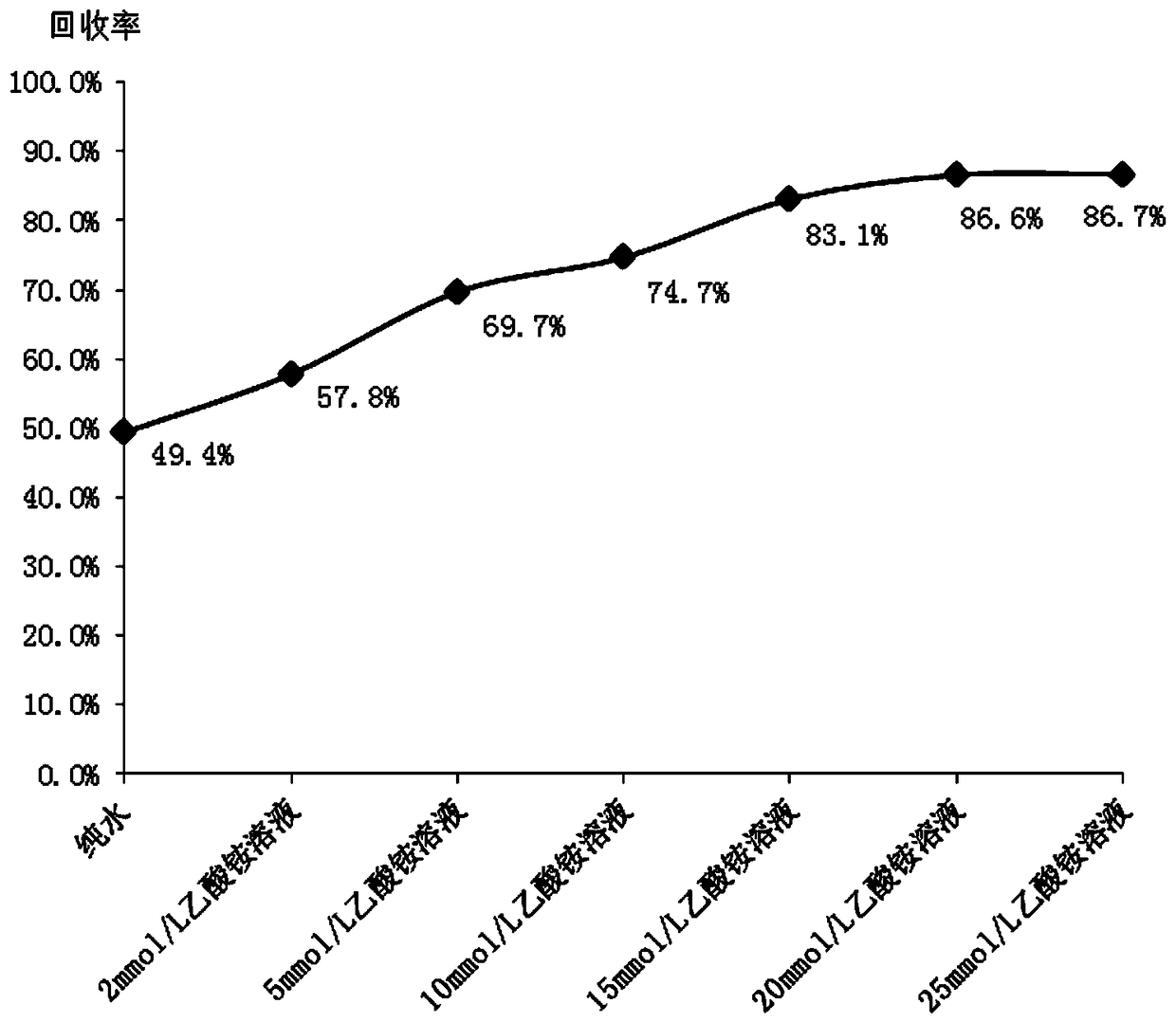

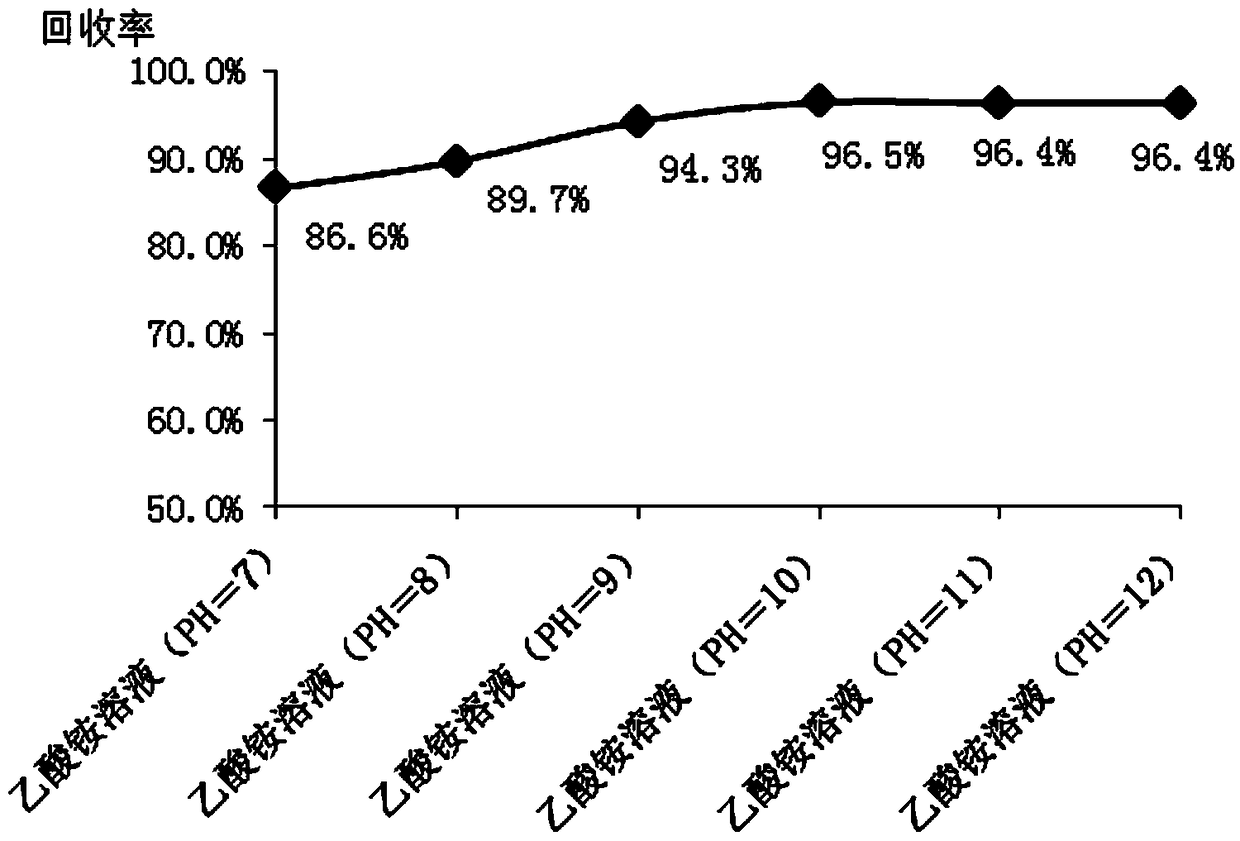

Method for measuring urotropine content of rice and flour and rice-flour product

InactiveCN108802244ASuppressed ionizationIncreased O contentComponent separationMicrofiltration membraneHexamethylenetetramine

The invention provides a method for measuring urotropine content of rice and flour and a rice-flour product. The method comprises the following steps: 1, making a product to be measured into a sample;2, weighing the sample to a centrifuging tube, adding ammonium acetate for performing ultrasonic extraction and centrifuging, and placing supernatant into a volumetric flask; 3, continuously adding the ammonium acetate into the centrifuging tube, performing ultrasonic extraction and centrifuging, placing the supernatant into the volumetric flask used in step 2, and metering the volume of the supernatant to 10 mL with the ammonium acetate to obtain a clear sample liquid; 4, performing filtering with a water-phase microfiltration membrane to obtain a sample liquid to be measured; 5, measuring peak areas of a urotropine standard working liquid and the sample liquid to be measured with an efficient liquid phase chromatograph to obtain a standard curve equation; 6, calculating the urotropine content in the product to be measured. The method has the characteristics of high urotropine extraction efficiency, easiness in operation, high accuracy, high stability and high repeatability, so thata stable and reliable method for detecting urotropine in the rice-flour product is provided.

Owner:GUANGZHOU INST FOR FOOD INSPECTION(GUANGZHOU INSPECTION CENT FOR WINE & SPIRITS)

Semiconductor device

InactiveUS20100224933A1Suppress impact ionizationHigh withstand voltageSemiconductor/solid-state device detailsSolid-state devicesElectric fieldN channel

Provided is a semiconductor device including an N-channel high-voltage MOS transistor, in which wiring metal connected to a drain region is laid above a boundary portion between an oxide film formed by LOCOS process or the like on a low impurity concentration region and a high impurity concentration region forming the drain region, to thereby alleviate an electric field concentration at the boundary portion which is a contact portion between the low impurity concentration region and the high impurity concentration region by an electric field generated from the wiring metal toward a semiconductor substrate.

Owner:SEIKO INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com