High-concentration wastewater resource utilization method

A high-concentration wastewater and resource-recycling technology, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc. Treatment cost, effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

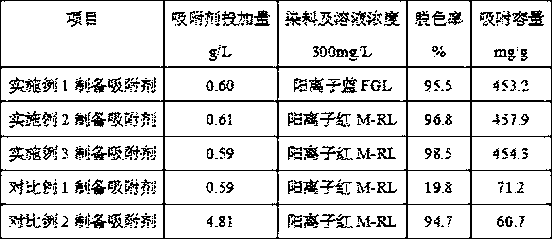

Examples

Embodiment 1

[0028] (1) Add strong acidic hydrogen-type cation exchange resin to high-concentration water-based ink printing wastewater, and stir the reaction to reduce the solubility of the water-soluble polymer binder and destroy the stability of the binder, so that the extractable substances in the wastewater just condense into Insoluble fine solid particles;

[0029] (2) Separating the cation exchange resin, slowly adding an appropriate amount of potassium bicarbonate powder to the wastewater, reacting with the wastewater to generate micro-bubbles, making the bubbles adhere to the fine solid particles in the wastewater, and forming gas, liquid and solid particles between the fine solid particles. Contact interface;

[0030] (3) Heating to a temperature higher than 25°C above the softening point of the binder, gradually making the fine solid particles bond to each other to form a large solid extract with tiny air bubbles and water inside;

[0031](4) Keep warm for 25 minutes, use the f...

Embodiment 2

[0037] (1) Add weakly acidic hydrogen-type cation exchange resin to high-concentration water-based ink printing wastewater, and stir the reaction to reduce the solubility of the water-soluble polymer binder and destroy the stability of the binder, so that the extractable substances in the wastewater just condense into Insoluble fine solid particles;

[0038] (2) Separating the cation exchange resin, slowly adding an appropriate amount of sodium bicarbonate powder to the wastewater, reacting with the wastewater to generate micro-bubbles, making the bubbles adhere to the fine solid particles in the wastewater, and forming gas, liquid and solid particles between the fine solid particles. Contact interface;

[0039] (3) Heating to a temperature 20°C higher than the softening point of the binder, gradually making the fine solid particles bond to each other to form a large solid extract with tiny air bubbles and water inside;

[0040] (4) Keep warm for 30 minutes, use the force suc...

Embodiment 3

[0046] (1) Add strong acidic hydrogen-type cation exchange resin to high-concentration water-based ink printing wastewater, and stir the reaction to reduce the solubility of the water-soluble polymer binder and destroy the stability of the binder, so that the extractable substances in the wastewater just condense into Insoluble fine solid particles;

[0047] (2) Separate the cation exchange resin, slowly add appropriate amount of sodium carbonate powder to the wastewater, react with the wastewater to generate micro-bubbles, make the bubbles adhere to the fine solid particles in the wastewater, and form three phases of gas, liquid and solid between the fine solid particles contact interface;

[0048] (3) Heating to a temperature 15°C higher than the softening point of the binder, gradually making the fine solid particles bond to each other to form a large solid extract with tiny air bubbles and water inside;

[0049] (4) Keep warm for 30 minutes, use the force such as the curl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com