Irpex lacteus capable of efficiently degrading lignin

A technology of albacodon and lignin, which is applied in the field of microbial engineering, can solve the problems of high economic cost and poor depolymerization effect, and achieve the effect of short degradation time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

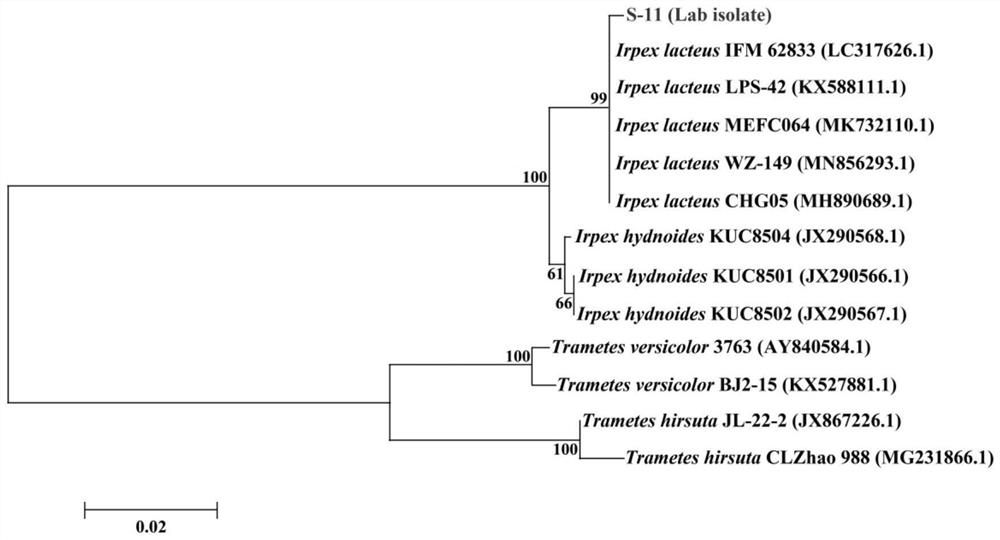

[0051] Example 1: Isolation, screening and species identification of Irpex lacteus S-11 strain

[0052] 1. Separation and screening

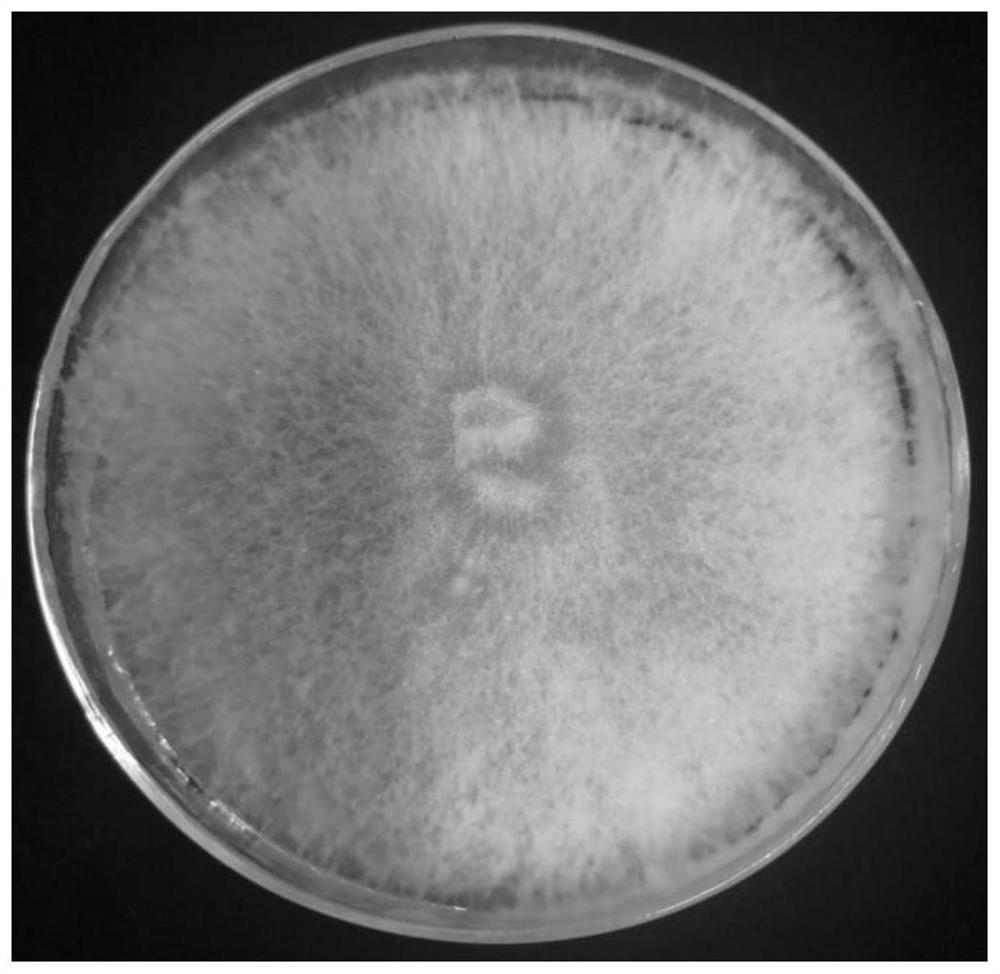

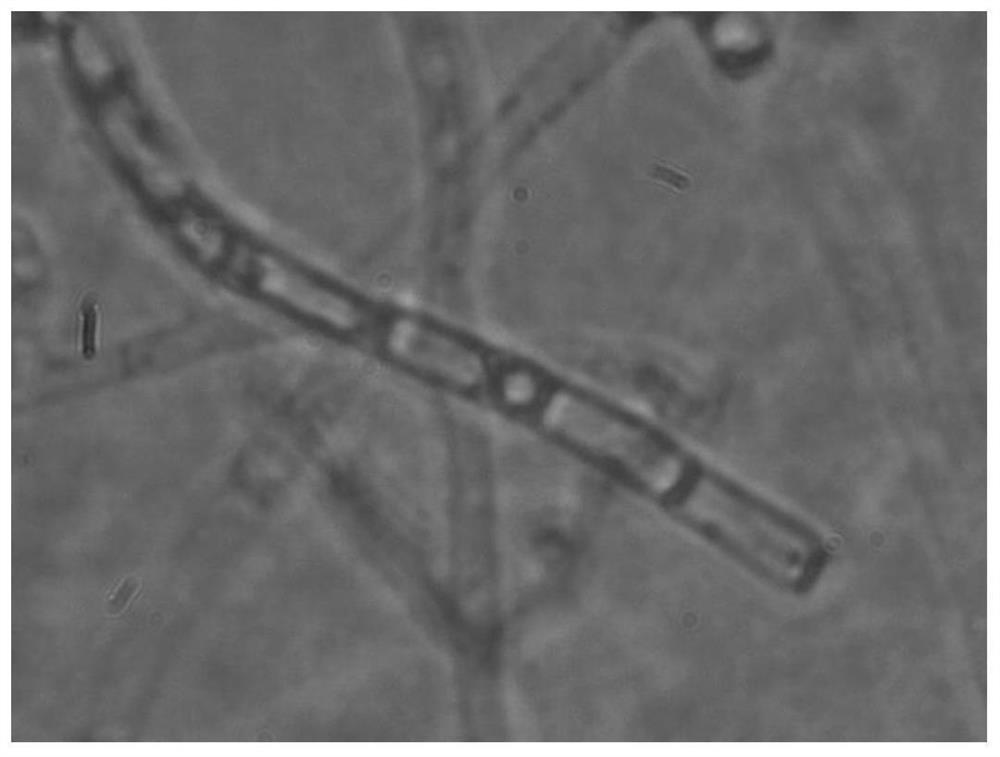

[0053] The fruiting body of the fungus taken from dead standing trees or fallen trees with good growth potential in Yuelu Mountain, Hunan Province was cleaned with sterile water and wiped with 75% alcohol, and then the fruiting body of the fungus was cut into pieces The 0.5cm×0.5cm bacterial block is connected to the PDA agar medium and cultured in a constant temperature incubator at 28°C.

[0054] After the fungal mycelium grows on the PDA agar medium, cut off the 0.5cm×0.5cm mycelium with a thin layer of medium with an inoculation spatula, and connect it in a new PDA agar medium.

[0055] Obtain pure colonies of microorganisms after repeated inoculation and culture for 2 to 3 generations, inoculate the isolated pure colonies on PDA-aniline blue agar medium and PDA-guaiacol agar medium respectively, and place them in a constant temperature inc...

Embodiment 2

[0061] Example 2: Detection of lignin-degrading enzyme produced by Irpex lacteus S-11

[0062] Inoculate the Irpex lacteus S-11 mycelia obtained in Example 1 onto the PDA-guaiacol agar medium, then place the PDA-guaiacol agar medium upside down at a constant temperature of 28°C In the incubator, cultivate for 3 to 5 days, observe and record the discoloration of the medium around the colony.

[0063] Such as Figure 4~5 As shown, compared with the control without strain inoculation, there is a larger and clear reddish-brown color circle around and at the bottom of the colony on the PDA-guaiacol agar medium inoculated with the bacteria, and the diameter of the color circle is is: 32mm, indicating that the strain has a strong ability to produce lignin-degrading enzymes.

Embodiment 3

[0064] Example 3: Detection of peroxidase produced by Irpex lacteus S-11 strain

[0065] The Irpex lacteus (Irpex lacteus) S-11 mycelium obtained in Example 1 was inoculated on the PDA-aniline blue agar medium, and then the PDA-aniline blue agar medium was placed upside down in a constant temperature incubator at 28°C, After culturing for 3 to 5 days, observe and record the decolorization of the culture medium around the colony.

[0066] Such as Figure 6-Figure 7 As shown, compared with the control, there is a large and clear fading circle around and at the bottom of the PDA-aniline blue agar medium inoculated with the bacterium. The diameter of the fading circle is: 53mm, and the mycelium still presents natural color, This shows that the strain can utilize and metabolize aniline blue, and that the strain has a strong ability to produce lignin peroxidase or manganese peroxidase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com