Sugar juice decoloring agent and sugar juice purification decoloring method

A technology of decolorizing agent and sugar juice, applied in the direction of using adsorbent purification, etc., can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

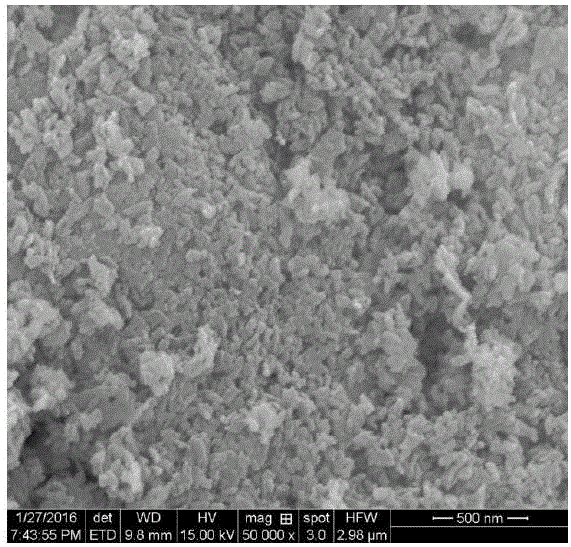

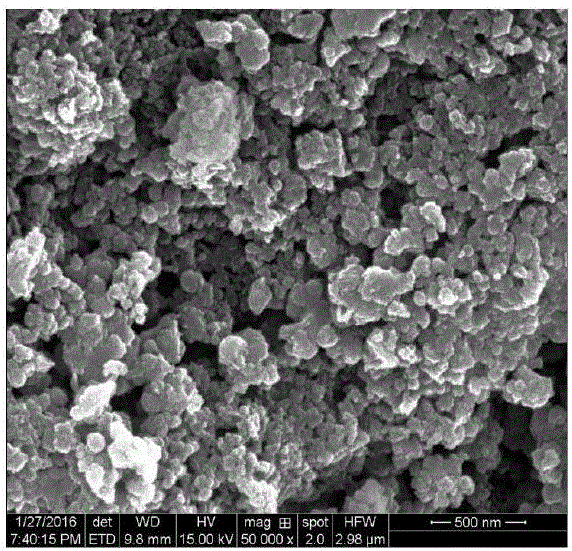

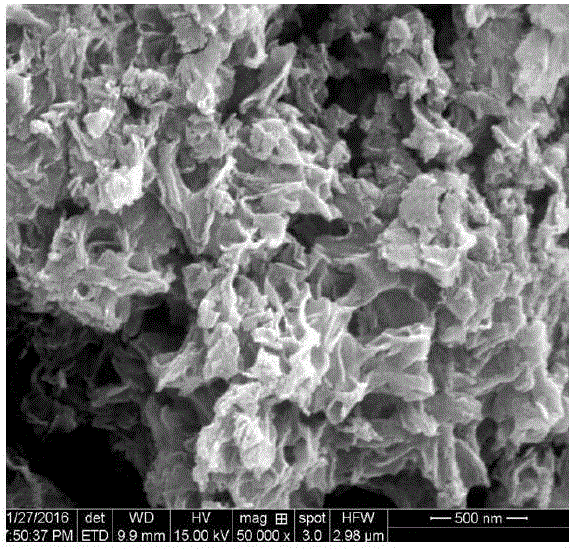

[0021] Embodiment 1: a kind of syrup decolorizing agent, it is prepared by following method:

[0022] (1) Pre-lime the brown sugar back-dissolving syrup (10°Bx) with milk of lime (10°Bé) to pH=6.80, heat the brown sugar re-dissolving syrup to 65°C in a constant temperature magnetic stirrer, and then add phosphoric acid ( 210 mg / kgBx, that is, the content of phosphoric acid in the red granulated sugar redissolving syrup is 210ppm per hammer), adjusted to neutrality with calcium hydroxide, heated to 100°C for the second time after stirring for 5 minutes, and added polyacrylamide (2 mg / kg , that is, add 2 mg of polyacrylamide to 1 kg of brown sugar redissolving syrup) flocculation and sedimentation, after standing for cooling for 30 minutes, recover the flocs to obtain calcium phosphate flocculation sediments;

[0023] (2) Calcium phosphate flocculation sediments were burned at a high temperature of 550°C for 3 hours, and the organic matter wrapped and adsorbed in the flocs was b...

Embodiment 2

[0024] Embodiment 2: A kind of method for the quiet decolorization of sugar juice, get the red granulated sugar redissolving syrup 100mL of 6.00 ° of Bx, add the macroporous calcium phosphate sugar juice decoloring agent that 0.2g embodiment 1 prepares, then adjust the pH value to 6.0 , reacted for 30 minutes at a temperature of 80°C, and the decolorization rate of macroporous calcium phosphate to sugar juice reached 38.15%.

Embodiment 3

[0025] Embodiment 3: A kind of method for the quiet decolorization of sugar juice, get the red granulated sugar redissolving syrup 100 mL of 6.00 ° of Bx, add the macroporous calcium phosphate sugar juice decoloring agent that 0.2g embodiment 1 prepares, then adjust the pH value to 5.0 , reacted for 30 minutes at a temperature of 80°C, and the decolorization rate of macroporous calcium phosphate to sugar juice reached 37.36%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com