Patents

Literature

797 results about "Sodium diacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium diacetate is a compound with formula NaH(C₂H₃O₂)₂. It is a salt of acetic acid. It is a colorless solid that is used in seasonings and as an antimicrobial agent.

Modified nano mineral powder-containing aerated brick

The invention discloses a modified nano mineral powder-containing aerated brick. The aerated brick is prepared from the following raw materials by the conventional process for preparing the aerated brick: 25 to 30 weight parts of carbide slag, 5 to 10 weight pars of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano mineral powder, 5 to 10 weight parts of shell powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.002 to 0.008 weight part of lauryl sodium sulfate, 0.03 to 0.08 weight part of tea seed cake powder, 0.3 to 0.5 weight part of soda ash, 0.5 to 0.8 weight part of expanded vermiculite powder, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of aluminum hydroxide, 0.05 to 0.1 weight part of sodium diacetate and an appropriate amount of water. By adding the nano mineral powder, the volume weight of the brick, and the energy consumption are reduced; the brick is high in thermal insulation performance and sound insulation performance; compared with the conventional aerated brick, the aerated brick has the advantages that the thermal insulation performance and the sound insulation performance are improved obviously; the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:广东合盛建筑工程有限公司

Methods of preparation and using antimicrobial products

InactiveUS6123973AEliminate bad tasteLower decomposition temperatureBiocideDough treatmentPropanoic acidSodium sorbate

Novel antimicrobial products and methods of making and using the same are shown, whereby the products can be used in the same or greater percentages as conventional microbial growth inhibitors without imparting an off-flavor, taste, color or odor to the products in which they are used. The antimicrobial products are formed by reacting azodicarbonamide or an ammonia gas with a compound selected from the group consisting of benzoic acid, sodium benzoate, calcium benzoate, potassium benzoate, acetic acid, sodium diacetate, paraben, niacin, calcium acetate, calcium diacetate, citric acid, lactic acid, fumaric acid, sorbic acid, sodium sorbate, calcium sorbate, potassium sorbate, propionic acid, sodium propionate, calcium propionate, potassium propionate and mixtures thereof. In one embodiment, the product is prepared by placing a layer of azodicarbonamide on a substrate and covering the layer with a gas permeable separator. The antimicrobial compound is then added on top of the separator, and the combination is heated to form the final product. In another embodiment, the product is prepared by exposing the antimicrobial compound to an ammonia gas. The ammonia gas reacts with free acids in the antimicrobial compound to convert the free acids into ammonium salts, thereby eliminating off-flavor and off-odor of the resulting antimicrobial product. The antimicrobial products prepared according to the present invention are suitable for use in foodstuffs, sanitation products, cosmetics, pharmaceuticals, and so forth.

Owner:TILLIN

Waterproof rubber material

InactiveCN105384989AImprove thermal conductivityImprove conductivityPolyethylene glycolMaterials science

The invention discloses a waterproof rubber material. The waterproof rubber material is prepared from the following raw materials by weight: 7 to 8 parts of polyethylene glycol terephthalate, 3 to 4 parts of trioctyl citrate, 1 to 2 parts of rosin, 24 to 27 parts of polyacrylonitrile, 1 to 2 parts of sodium diacetate, 12 to 13 parts of graphite, 3 to 4 parts of fly ash bead, 0.7 to 1 part of sodium dodecyl sulfate, 42 to 55 parts of liquid acrylonitrile-butadiene rubber, 0.6 to 1 part of methacrylic acid, 52 to 60 parts of acrylonitrile-butadiene rubber, 20 to 255 parts of butadiene styrene rubber, 5 to 6 parts of nanometer silica sol, 3 to 4 parts of tetramethyl-thiuram disulfide, 2 to 3 parts of diglycol, 6 to 8 parts of VAE emulsion, 14 to 16 parts of activated clay, 5 to 7 parts of barium titanate, 7 to 9 parts of magnesium hydroxide and 0.2 to 0.3 part of calcium propionate. The waterproof rubber material prepared in the invention has good waterproof performance and acid resistance, oil resistance and flame retardation performance, can perfectly meet requirements of production and is worth popularization.

Owner:安徽创奇乐智能游乐设备有限公司

Attapulgite fruit and vegetable fresh-keeping coating

The invention discloses an attapulgite fruit and vegetable fresh-keeping coating. The technical scheme comprises the essential that the attapulgite fruit and vegetable fresh-keeping coating consists of pasty attapulgite clay, chitosan, superfine polyvinyl alcohol, sodium hexametaphosphate, sodium diacetate, super water absorbent resin and de-ionized water. A production method of the attapulgite fruit and vegetable fresh-keeping coating comprises the steps of mixing materials, stirring, comminuting, grinding, stirring, degasifying and packing to obtain a finished product of the attapulgite fruit and vegetable fresh-keeping coating. The attapulgite fruit and vegetable fresh-keeping coating has good film-forming property. When coated on surfaces of fruits and vegetables, the attapulgite fruitand vegetable fresh-keeping coating forms a protective layer of a sealing film quickly to inhibit and kill various midew, bacteria and other putrefying bacteria, effectively prevent nutritive materials and moisture of fruits and vegetables from running off and keep the original taste of the fruits and vegetables with the fresh-keeping period of more than 60 days. The attapulgite fruit and vegetable fresh-keeping coating can be sprayed, painted and dipped to cover the surfaces of the fruits and vegetables.

Owner:南通丁布儿海苔食品有限公司

Handwork-dough-modeling and plasticine dual-purpose material

ActiveCN103651654AGood moisturizing effectImprove toughnessDough treatmentOrnamental structuresBiotechnologyKaolin clay

The invention relates to a handwork-dough-modeling and plasticine dual-purpose material. The handwork-dough-modeling and plasticine dual-purpose material comprises, by weight, 8 parts of wheat flour, 5 parts of glutinous rice flour, 1 part of malt sugar, 0.5 part of refined salt, 0.5 part of condensed milk, 2 parts of fresh milk, 0.8 part of honey, 2 parts of diatom soil, 2 parts of modified starch, 1 part of waxiness corn starch, 1.5 parts of kaolin, 0.5 part of bone glue, 1 part of calcium carbonate, 0.8 part of glycerin, 0.2 part of sodium diacetate, 0.5 part of potassium hydrogen tartrate, 0.5 part of food colorant, 1.5 parts of aloe gel, 0.1 part of olive oil, 0.2 part of sun screen and 5 parts of water. When children make handwork artware, the handwork-dough-modeling and plasticine dual-purpose material can be used as a dough modeling material so that dough modeling handwork artware can be made, and can also be used as a plasticine material for playing, multiple kinds of modeling can be made in a pinched mode, and the handwork-dough-modeling and plasticine dual-purpose material has the advantages of being green, nontoxic, harmless, free of cracking, antibacterial, long in retention time, good in modeling and proper in rigidity.

Owner:启东市清源环境检测技术有限公司

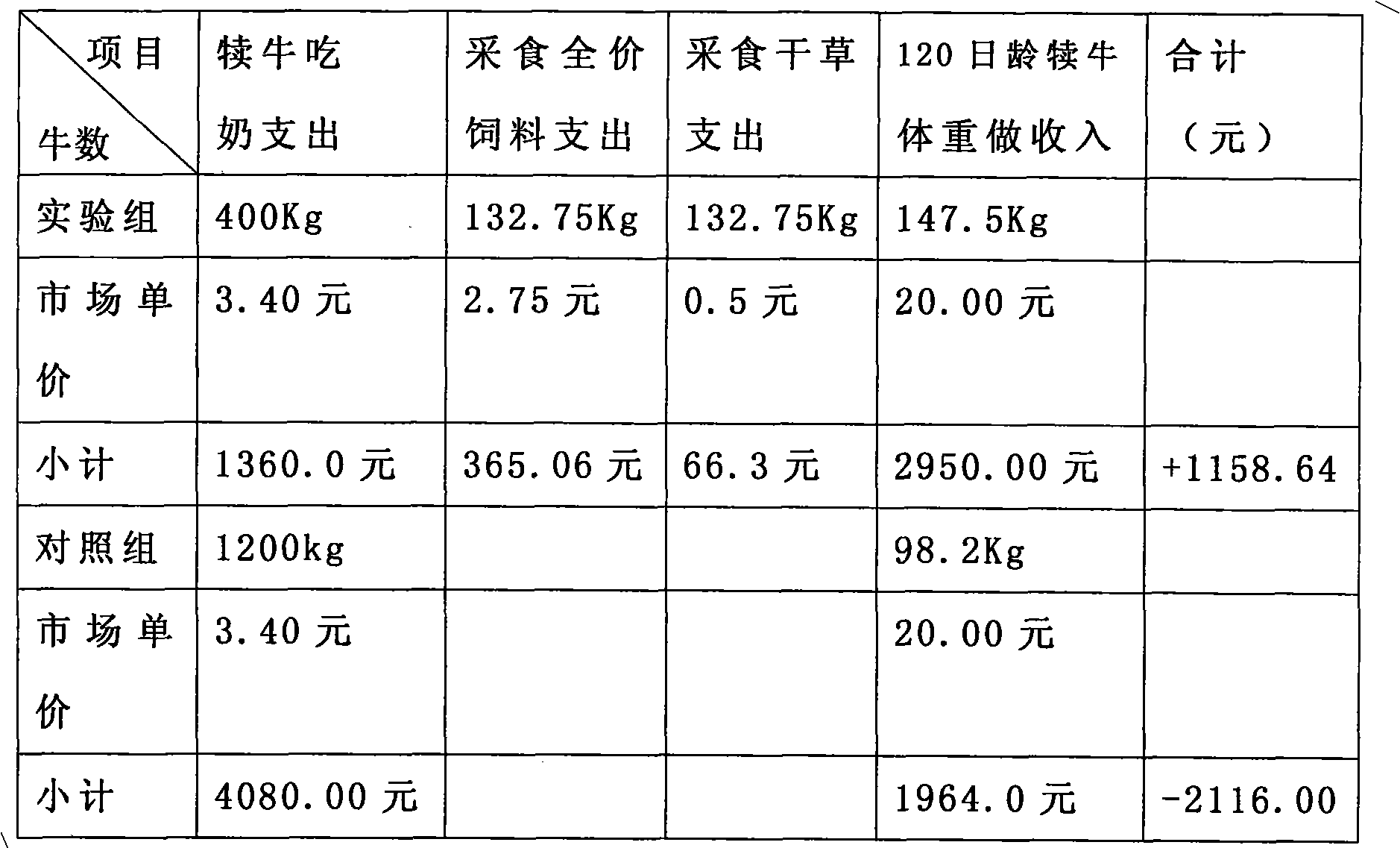

Concentrated calf fodder and use method thereof

InactiveCN101623059APromote growth and developmentComprehensive nutritionFood processingAnimal feeding stuffWeight gainingManganese

The invention relates to fodder and a use method, in particular to concentrated calf fodder and a use method thereof. The fodder comprises protein fodder and a premix compound, wherein the protein fodder is prepared from raw materials of bean cakes, corn protein powder, cotton dregs, complex enzymes, and the like; and the premix compound is prepared from common salt, fluorspar powder, magnesium sulfate, sodium diacetate, calcium hydrogen phosphate, soda, sodium humate, monensin, vitamins and trace elements of copper, iron, manganese, zinc, cobalt, and the like. The use method comprises the following steps: manually feeding calves at age of 3-5 days with a mixture of the concentrated calf fodder and a certain amount of milk; and stopping feeding the milk when the calves are at age of 60 days; and coming into a fatting period when the calves are at age of 120 days. The calf fodder has complete nutrients, reasonable proportion and low cost and is fed to the calves in a suckling period to substitute a great amount of milk, improve the commodity rate of the milk, facilitate the growth and the development of the calves, shorten the suckling period by 50 percent, increase the weight-gaining speed by about two times, shorten the deliver time by one half, increase the current fertility rate of milk cows by about two times, realize perennial milking, facilitate mechanical milking and scaled stabling management and remarkably improve the economic benefits, the social benefits and ecological benefits of cattle rearing in a plurality of aspects.

Owner:好毕斯嘎拉吐 +2

Additive of feed and preparing method thereof.

InactiveCN101366450AGrowth inhibitionImprove the immunityAnimal feeding stuffAccessory food factorsAnimal scienceMycotoxin

The invention relates to a feed additive for livestock and a method for preparing the same. The feed additive consists of modified montmorillonite, sodium diacetate, Chinese traditional medicine extract and glucose oxidase. If reasonably used, the feed additive can adsorb mycotoxin, inhibit the growth of molds, eliminate the influence of mycotoxin on physiology of animals, improve the capability of animals of resisting illnesses, obviously improve feed returns, improve the immunity effect of vaccine injection, improve the mating fertility rate and improve the number born.

Owner:GUANGDONG GALLOPER VETERINARY PHARMA

Liquid-based cell preservation liquid composite and preparation method thereof

InactiveCN102318597AKeep shapeImprove diagnostic accuracyDead animal preservationFood additiveSodium diacetate

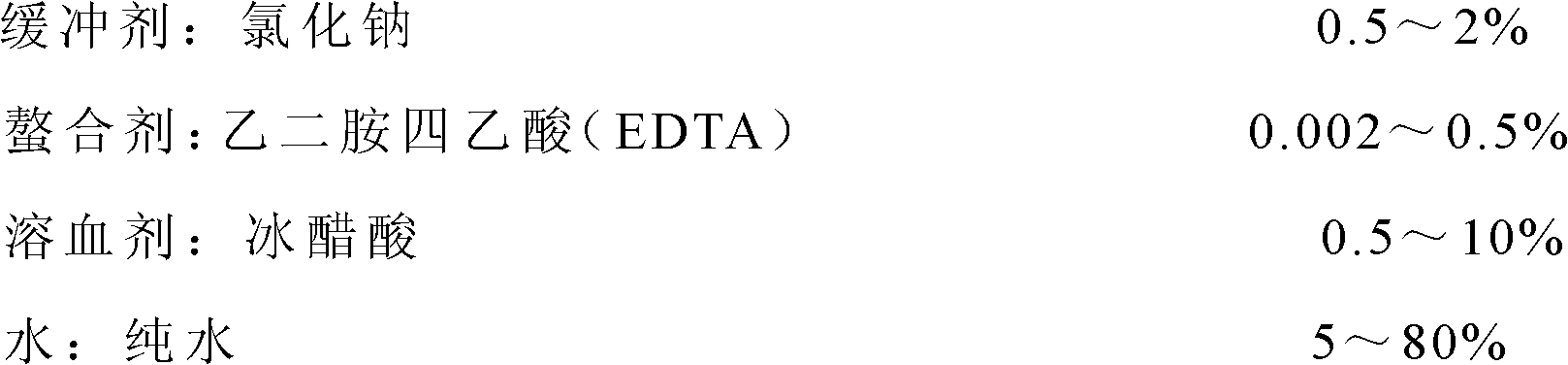

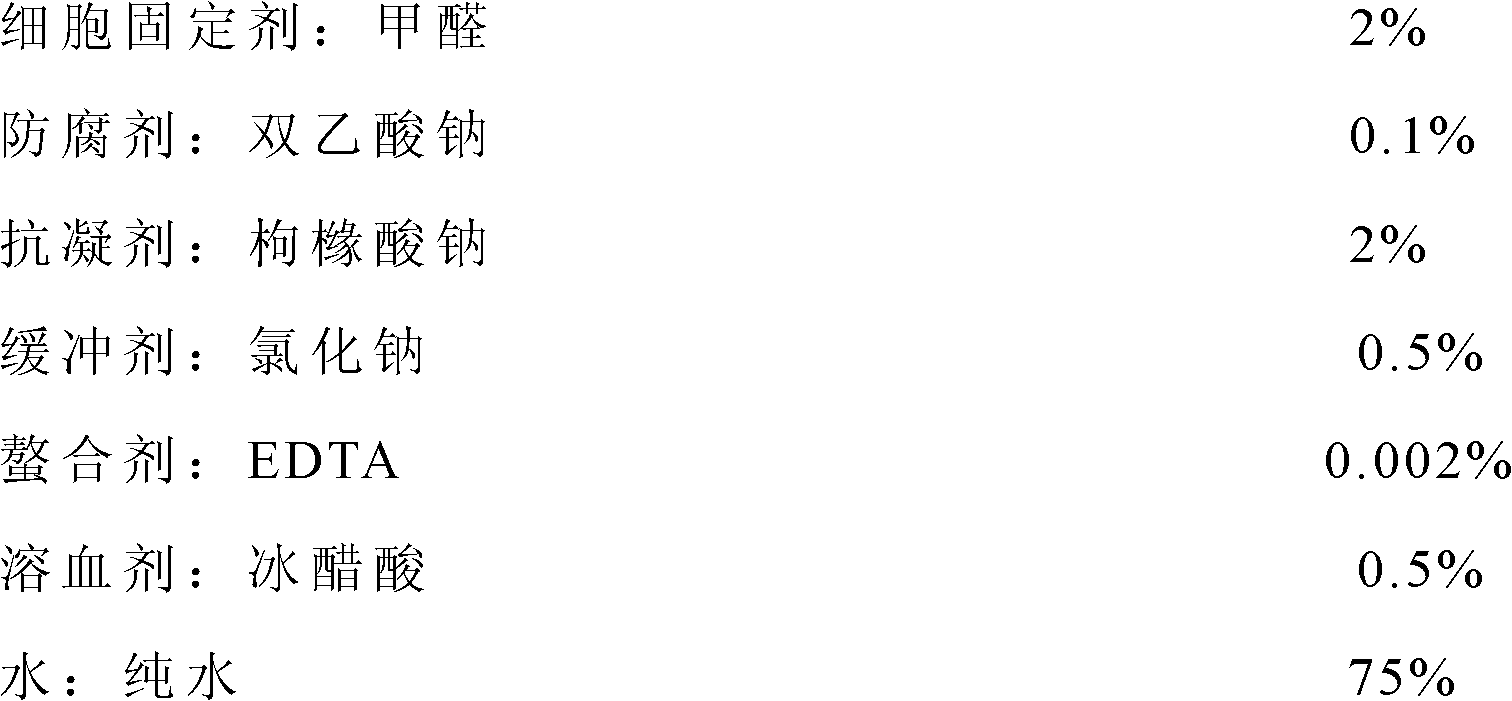

A liquid-based cell preservation liquid composite is characterized by comprising the following components in percentage by weight: cell fixing agent: 2-15% of formaldehyde, preservative: 0.1-5% of sodium diacetate, anticoagulant: 2-10% of sodium citrate, buffering agent: 0.5-2% of sodium chloride, chelating agent: 0.002-0.5% of ethylene diamine tetraacetic acid (EDTA), hemolytic agent: 0.5-10% ofglacial acetic acid, and water: 5-80% of pure water, wherein the formaldehyde is the analytical reagent, and accounts for 37-40%; the sodium diacetate is the food additives; the sodium citrate and the sodium chloride are analytical reagents, and NaCl is more than 99.5%; and the EDTA and the glacial acetic acid are analytical reagents, and H2COOH is more than 99.5%. The invention has the advantages that the liquid-based cell preservation liquid composite can keep the cell form to the maximum extent, can improve the diagnosis accuracy and can prevent the cell form of a specimen from significantdifference at room temperature for at least three months.

Owner:上海鎏轶生物技术中心

A kind of Cantonese black pepper sausage and its preparation method

The invention relates to a Cantonese black pepper sausage and a preparation method thereof. The Cantonese black pepper sausage is prepared from No. II and No. IV fresh and frozen pork and pork fat meat which serve as raw materials and auxiliary materials, wherein the auxiliary materials comprise potato starch, isolated soy protein, ice water, table salt, white granulated sugar, monosodium glutamate, composite phosphate, carrageenan, D-sodium erythorbate, sodium nitrite, monascus haematochrome, temptation haematochrome, white pepper, mashed black pepper, meat flavor essence, sodium lactate, nisin and sodium diacetate. The invention also provides a preparation method for the Cantonese black pepper sausage. The Cantonese black pepper sausage is high in meat quality, full in meat fragrance, hot spicy, palatable and abundant in nutrition.

Owner:TIANJIN CHUNFA BIO TECH GRP

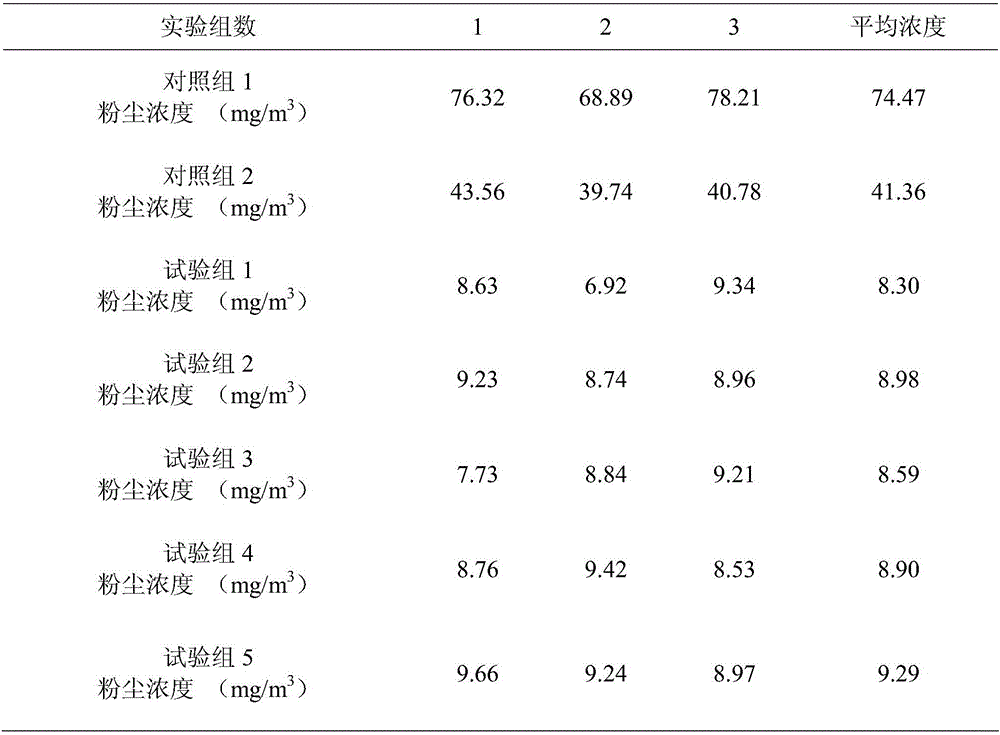

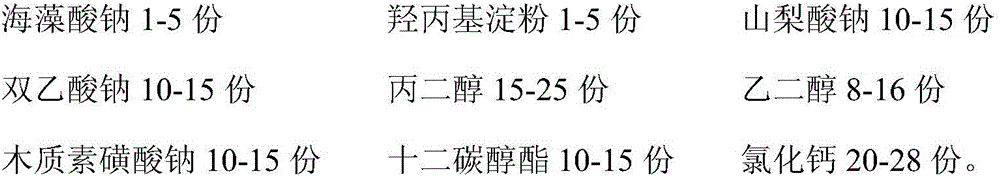

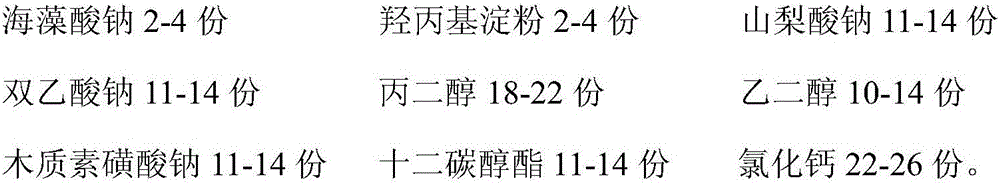

Dust suppressant and preparing method thereof

ActiveCN105885795AConvenient sourceLow costBiocideOther chemical processesSodium sorbateSodium diacetate

The invention provides a dust suppressant and a preparing method thereof, and relates to the field of environment protection. The dust suppressant is prepared from sodium alginate, hydroxypropyl starch, propylene glycol, ethylene glycol, sodium sorbate, sodium diacetate, sodium lignin sulfonate, 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate) and calcium chloride. By means of the dust suppressant, the surface tension of dust can be reduced, dust can be rapidly wetted, gathered and settled, cured films with certain strength and tenacity can be formed on the surfaces of dust, and dust is prevented from rising along with wind and effectively prevented from polluting the environment. According to the dust suppressant, as the calcium chloride is used as an anti-freezing assistant, and the sodium diacetate and the sodium sorbate are used as sterilizing agents, the freezing problem of a dust suppressant in winter can be solved, and harmful bacteria in dust surrounding air can be killed; in addition, the adopted raw materials can be easily degraded, secondary pollution is avoided, the dust suppressing effect is obvious, the application range is wide, and the dust suppressant and the preparing method are worthy of application and popularization.

Owner:深圳市卡普瑞环境科技有限公司

Compound feed for Scylla serrata, preparation and application method thereof

The invention relates to a compound feed for Scylla serrata, a preparation method, and an application method thereof. The compound feed comprises a solid part and a liquid part, wherein the solid part is composed of fish meal, strong flour, soybean meal, peanut meal, beer yeast, fish oil, shrimp shell powder, cuttlefish paste, phospholipids, plasma protein powder, choline chloride, compound vitamins, compound mineral substances, a decladding element, sodium diacetate, betaine, butylated hydroxyanisole, phytase and beta-carotene. The preparation method of the invention comprises the steps of raw material smashing and sifting, mixing, conditioning, granulating, drying and packaging, ant the like. The feed prepared by the method of the invention has the advantages of good food calling effect, good palatability, high feed utilization, rich and overall nutrient, a raised feed utilizing rate of the Scylla serrata, reduced pool pollution, and significant environmental protection effect.

Owner:ZHEJIANG MARINE DEV RES INST

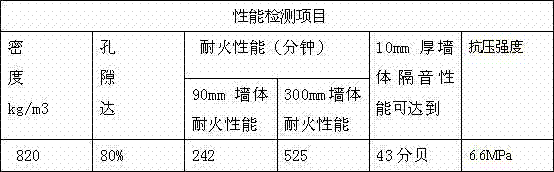

Oil shale residue aerated brick and preparation method thereof

ActiveCN102875184AGood heat insulationImprove sound insulationSolid waste managementCeramicwareCelluloseCalcium bicarbonate

The invention provides an oil shale residue aerated brick. The oil shale residue aerated brick is prepared from the following raw materials: 20 to 30 weight parts of oil shale residue, 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 4 to 6 weight parts of modified attapulgite, 5 to 10 weight parts of mica powder, 5 to 10 weight parts of ceramics factory waste, 5 to 10 weight parts of calcium carbonate powder, 10 to 15 weight parts of lime, 0.1 to 0.3 weight percent of triethanolamine lime, 4 to 5 weight parts of gypsum, 0.02 to 0.08 weight part of aluminum powder, nekal which is 3 to 5 percent based on weight of aluminum powder, 0.01 to 0.02 weight part of calcium bicarbonate, 2 to 3 weight parts of volcanic rock, 1 to 2 weight parts of lignocellulose, 0.3 to 0.5 weight part of soda ash, 0.03 to 0.05 weight part of borax, 1 to 2 weight parts of sodium diacetate, 1 to 2 weight parts of hydroxypropyl methyl cellulose sodium, and 1 to 2 weight parts of superfine polyvinyl alcohol. The oil shale residues are added into the raw materials of the aerated brick, other conventional aids and modified nano aids are added, and the aerated brick which is processed by an appropriate process is low in cost and high in performance, achieves the cyclic economy effect of changing waste into wealth, and reduces pollution; and the processed aerated brick has the characteristics of light volume weight, high thermal insulation property, good sound absorption effect, and high intensity and can be used for a non-load bearing wall body or a load-bearing wall body.

Owner:深圳市嘉能新型环保建材有限公司

Durable air-added brick

The invention discloses a durable air-added brick. The durable air-added brick is prepared from the following raw materials in parts by weight: 10-20 parts of CFB desulfurized coal ash, 1-2 parts of sodium carbonate, 3-5 parts of limestone powder, 3-6 parts of hollow glass bead, 1-2 parts of sugar calcium, 20-30 parts of cement, 15-35 parts of gypsum, 8-15 parts of hydrogen peroxide with the concentration being 10-20%, 2-4 parts of alum, 1-2 parts of jade powder, 1-2 parts of sodium diacetate, 1.5-2.8 parts of polypropylene fiber, 1-2 parts of calcium chloride and 35-48 parts of modified filler. The durable air-added brick disclosed by the invention has the advantages that the firm and durable effects are achieved, simultaneously the volume weight is low and the service life is long.

Owner:ANHUI SHENGREN NEW BUILDING MATERIAL

Alanine compound mildew preventive and preparation method thereof

InactiveCN101647595AImprove performanceLow priceFood preservationAnimal feeding stuffSolid componentPropanoic acid

The invention discloses an alanine compound mildew preventive consisting of propionic acid, alanine, sodium diacetate, potassium sorbate, a sorbent and a carrier. A preparation method of the mildew preventive comprises the following steps: a, alanine synthesis; b, liquid mixture adsorption; c, solid component mixing. The invention is used for preventing mildew pollution, removing mildew toxin andimproving the safety performance of feed and feed raw materials, thereby increasing feed return and use ratio.

Owner:南通中牧生物科技有限公司

High-efficiency broad-spectrum food composite preservative

The invention provides a high-efficiency broad-spectrum food composite preservative and aims to solve the technical problem that most of the food preservatives now used in food processing are potassium sorbate and sodium benzoate, cannot achieve ideal preservation effect when use alone due to certain limitation to antibacterial spectrum and suffers certain limitation on use. The key point of the preservative lies in that the preservative contains nisin, natamycin, potassium sorbate, sodium diacetate and sodium dehydroacetate or also one or all of d-sodium erythorbate and d-glucono-delta-lactone. The use of the preservative is to be added in various foods.

Owner:SHENYANG HONGMEI BIOTECH

Chicken feed

InactiveCN102550840AGreat tasteIncrease egg productionAnimal feeding stuffBenzoic acidPropanoic acid

The invention relates to chicken feed. The chicken feed comprises: by weight, 40 to 55% of corn, 5 to 15% of soybean meal, 2 to 5% of dry earthworm, 5 to 8% of earthworm manure, 2 to 4% of xanthophyll, 4 to 6% of tenebrio molitor, 1 to 2% of calcium hydrogen phosphate, 0.1 to 0.5% of table salt, 3 to 8% of stone flour, 3 to 10% of wheat bran flakes, 5 to 15% of additives, 2 to 6% of mildew inhibitors and 3 to 8% of one or more feed attractants. The mildew inhibitors comprise: by weight, 0.5 to 1.5% of sodium diacetate, 0.1 to 0.3% of ethoxyquin, 0.5 to 1.5% of eugenol, 0.5 to 1.5% of propionic acid, 1 to 2% of benzoic acid and 2 to 3% of vermiculite powder. The chicken feed can improve chicken immunity, reduce a disease incidence rate, improve a chicken laying rate and egg quality, prolong a laying fastigium and increase the weight of a single egg.

Owner:李健

Compound acidifier for feed, and preparation method and application of acidifier

InactiveCN103005160APromote digestion and absorptionPromote growthAnimal feeding stuffAbsorption capacityPhosphoric acid

The invention discloses a compound acidifier for feed, and a preparation method and application of the acidifier. The preparation method of the compound acidifier comprises the following steps of: mixing and stirring phosphoric acid with weight percentage of 40%-50% with citric acid or fumaric acid with weight percentage of 30%-40% at 40 DEG C to 60 DEG C, thus obtaining a uniform compound acid solution; and adding sodium diacetate with weight percentage of 10%-30% to the compound acid solution, thus obtaining the compound acidifier for the feed after sufficiently dissolving and uniformly mixing the sodium diacetate. The compound acidifier for the feed provided by the invention has the simple preparation method and stable quality, is convenient to popularize and apply, can be applied to livestock and in particular early-weaning piglets, and can make up the shortage of gastric acid secretion and improve the digestive absorption capacity of animals to promote the growth of the animals and improve the production performance of the animals.

Owner:ZHEJIANG UNIV

Nitrite-free Chinese-style sausage and production method

The invention relates to a nitrite-free Chinese-style sausage and a production process. The production process comprises the steps of selecting and preprocessing raw meat, mixing materials and salting, filling and bundling sausages, putting the sausages on a bar, putting the sausages in an oven, baking the sausages, cooling, packaging and warehousing, thereby obtaining the nitrite-free Chinese-style sausage. By using monascus color, tert-butylhydroquinone, sodium erythorbate, nisin and sodium diacetate to substitute for nitrite and nitrate and by adjusting the original material mixing and salting and baking process, effects of colorizing, anti-oxidation and anticorrosion are taken in the nitrite-free Chinese-style sausage, and the nutrient, delicious and healthy nitrite-free Chinese-style sausage is produced. According to physical and chemical inspection, the results show that the sausage does not contain residual nitride, the color and the flavor of the nitride-free sausage are superior to the color and the flavor of a nitride-containing sausage and the color of the nitride-free sausage is not changed after the nitride-free sausage is stored for one month in a incubator at 37 DEG C.

Owner:湖南唐人神肉制品有限公司

Safe and efficient composite mildew preventive for feed

ActiveCN102488076AImprove palatabilityLess irritatingAnimal feeding stuffAnimal fodder preservationPropanoic acidMildew

The invention relates to a feed additive and specially, relates to a safe and efficient composite mildew preventive for feed and a preparation method thereof. The safe and efficient composite feed mildew preventive comprises: by weight, 15 to 30% of litseacubeba oil, 5 to 15% of allicin, 2 to 8% of propionic acid, 2 to 10% of sorbic acid, 1 to 10% of fumaric acid, 5 to 15% of sodium diacetate, 1 to 5% of mannosan and 30 to 65% of carriers. The preparation method comprises the following steps of adding litseacubeba oil, propionic acid, sorbic acid and fumaric acid into a reactor according to the ratios, heating the mixture in the reactor to a temperature of 45 to 60 DEG C with stirring to obtain a liquid mixture after uniform mixing, well mixing allicin, sodium diacetate, mannosan, the carriers and the liquid mixture in a mixer, cooling, taking out the cooled mixture from the mixer, crushing, sieving, and carrying out examination and packaging to obtain the safe and efficient compositefeed mildew preventive. Compared with the prior art, the safe and efficient composite feed mildew preventive has less irritation, greatly improved safety, good mildew-proof effects and antibacterial effects, and strong palatability and satisfies environmental protection requirements.

Owner:CHAOYANG SHENGFENG ANIMAL IND

Environment-friendly stainless steel substrate plating stripping agent

The invention discloses an environment-friendly stainless steel substrate plating stripping agent. Nitrate is optimally selected as an oxidizing agent for stripping nickel, chromium, copper, tin, and other plating on a stainless steel substrate, and as generally, nitrate is relatively stable in property and relatively low in toxicity, so that when the stripping agent provided by the invention is used, exhaust gases and waste water are not generated, and the stripping agent is non-corrosive to a device and highly friendly to the environment; at the same time nitrate is matched with citrate, potassium sodium tartrate and a proper amount of polyhydroxyl aldehyde, so that the speed for stripping the nickel plating on the stainless steel substrate is effectively increased, the plating stripping is achieved in a short time, and the production cycle is shortened while the substrate is not damaged; and the stripping rate of the nickel plating on the stainless steel substrate can be effectively increased through the combination of mannitol and sodium diacetate. Relative to the prior art, the stripping agent has the advantages of being free of corrosion, poisonous gases and pollution, high in efficiency, environment-friendly in use, easy and convenient to maintain, and the like.

Owner:HUIZHOU CITY HIROMI CHEM CO LTD

Spice flavoring agent capable of retaining freshness and use thereof

InactiveCN102138668AImprove taste qualityReduce manufacturing costFood preservationFood preparationPhosphatePotassium

The invention discloses a spice flavoring agent capable of retaining freshness, which comprises the following components in percentage by weight: 8-20% of potassium cinnamate, 2-3% of nisin, 10-20% of D-sodium erythorbate, 20-30% of sodium diacetate, 15-25% of composite phosphate, 15-25% of potassium sorbate and 5-10% of citric acid. The shelf life of chicken feet with pickled peppers can be prolonged, the fishy smell of the chicken feet can be removed, and the taste quality of the chicken feet with pickled peppers can be improved through adding the flavoring agent capable of retaining the freshness during the pickling process of the chicken feet with pickled peppers; and the pickling liquid can be recycled for 2-3 times; therefore, the production cost of an enterprise is greatly reduced.

Owner:湖北远成赛创科技有限公司

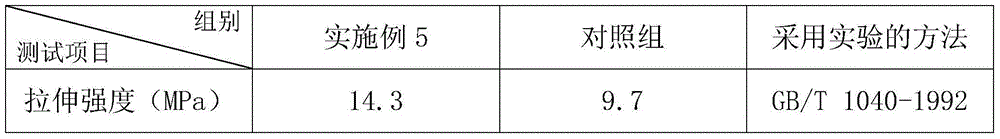

Environment-friendly plastic material

The invention discloses an environment-friendly plastic material which comprises the following raw materials in parts by weight: 20-25 parts of polycaprolactone PCL, 65-70 parts of modified poly-beta-hydroxybutyric acid PHB, 13-18 parts of peanut protein flour, 1.5-1.8 parts of jute fiber, 3-4 parts of wood fiber, 1.1-1.3 parts of a silane coupling agent KH, 2-3 parts of sodium lactate, 1.1-1.6 parts of sodium diacetate, 2-2.2 parts of diisononyl phthalate, 5-7 parts of epoxy tall oil acid butyl ester, 2-4 parts of oxidized starch, 20-23 parts of nano white carbon black, 6-8 parts of light calcium carbonate, 3-5 parts of sea-foam stone powder and 1-1.4 parts of an antioxidant 1010, wherein the modified poly-beta-hydroxybutyric acid PHB is prepared by blending and modifying poly-beta-hydroxybutyric acid PHB and high cis-butadiene rubber. The environment-friendly plastic material can be degraded by microbes and is low in decomposition rate, high in oxidation resistance and impact resistance and low in water-absorbing quality.

Owner:汕头市纳川塑胶制品有限公司

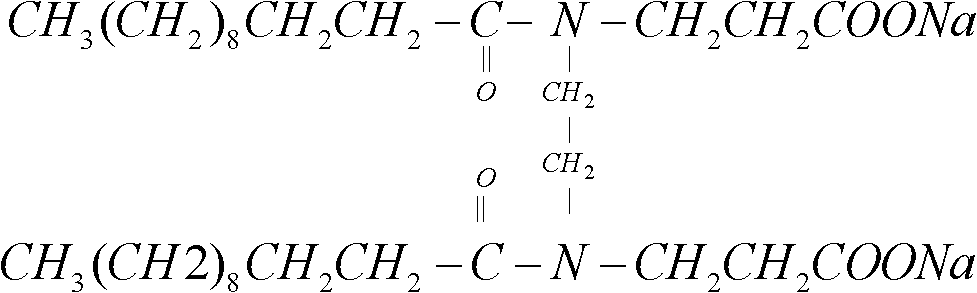

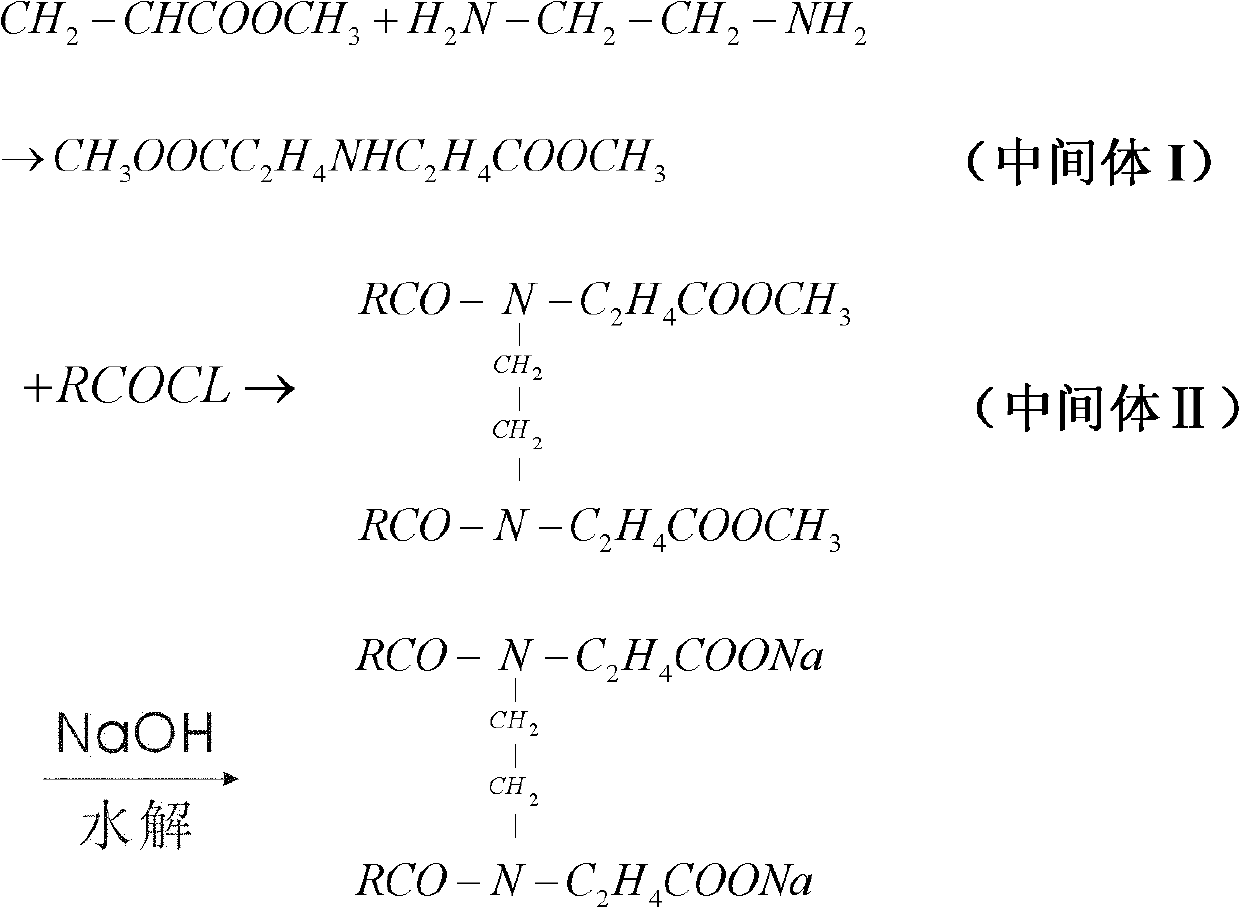

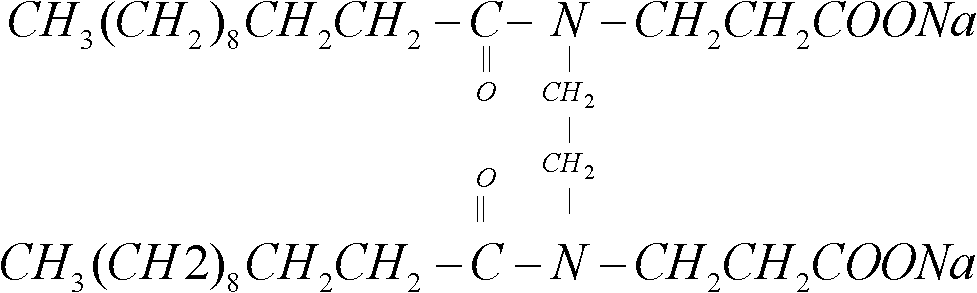

Oil displacement agent

InactiveCN102146282AFulfil requirementsDrilling compositionChromatographic separationEthylenediamine

The invention provides an oil displacement agent which is a Gemini type dianionic surfactant N,N'-dilauroyl-ethylenediamine-sodium diacetate of which the molecular structural formula is disclosed in the specification. The oil displacement agent effectively avoids the phenomenon of chromatographic resolution, and has an ideal use effect.

Owner:SHANXI HUASHENG ELECTRIC ENG

Compound pig feed and preparation method thereof

InactiveCN104824346APromote growthImprove the immunityFood processingAnimal feeding stuffDiseaseToxic material

The invention discloses a compound pig feed and a preparation method thereof. The compound pig feed comprises the following raw materials: maize flour, bean cake, bone meal, sorghum meal, edible salt, pumpkin, wheat bran, grain stillage, fish meal, lucerne meal, wheat straw, silkworm chrysalis, barley, peanuts, calcium hydrogen phosphate, a microelement additive, a vitamin additive, citric acid, sodium diacetate and an amino-acid additive. The preparation method comprises the steps of preparation of a traditional Chinese medicine additive, milling, mixing and drying. The compound pig feed provided by the invention has the benefits as follows: the compound pig feed contains the traditional Chinese medicine additive with the efficacies of eliminating dampness, reducing phlegm, clearing heat, dissolving phlegm, depressing qi, removing fullness, removing dampness, strengthening the spleen, harmonizing the stomach, helping digestion to remove accumulation and clearing away heat and toxic material, can be used for strengthening body resistance and eliminating evil, and has the advantages of good curative effect, no medicine residue, low cost and the like; and the traditional Chinese medicine additive mutually cooperates and interacts with the other raw materials, so that the compound pig feed not only can be used for curing the yellow fat disease in pig, but also can meet the nutritional requirement of pigs.

Owner:袁春梅

Composite fresh keeping agent of waxberry and its application method

InactiveCN1729802APrevent mildewInhibition of decayFruits/vegetable preservation by freezing/coolingPropionateCooling down

The invention discloses a composite fresh keeping agent of waxberry and its application method, which comprises dissolving sodium diacetate, calcium propionate and citric acid into water, whose mass percents are 0.05-0.15%, 0.1-0.2% and 0.1-0.3%, selecting red bayberry and cooling down to 1-3 deg. C, submerging in the composite fresh-keeping liquid for 3-5 minutes, weathering in cold air, boxing and storing 25-30 days at the temperature of 0-2 deg C.

Owner:ZHEJIANG UNIV

Hot-pot crispy sausage and production method thereof

The invention relates to a hot-pot crispy sausage and a production method thereof. The crispy sausage is characterized in that the crispy sausage is produced from the following raw materials, by weight: 30-40 parts of chicken, 20-25 parts of chicken skin, 25-30 parts of ice water, 1-2 parts of salt, 0.5-1 part of sugar, 0.7-1.2 parts of glucose, 0.1-0. 2 parts of monosodium glutamate, 0.3-0.7 parts of sodium tripolyphosphate, 0.1-0.2 parts of sodium hexametaphosphate, 0.05-0.1 parts of sodium isoascorbate, 0.05-0.1 parts of white pepper, 2-2.5 parts of soy protein isolate, 5-10 parts of tapioca modified starch, 0.5-1.0 parts of carrageenan, 1.5-2 parts of sodium lactate, 0.3-0.6 parts of sodium diacetate, 0.005-0.01 parts of monascus red, 0.001-0.005 parts of cochineal, 0.01-0.05 parts of sodium nitrite, 0.1-0.5 parts of chicken paste, 0.1-0.5 parts of pork fine paste, 1-2 parts of star anise, 0.5-0.8 parts of fennel, 1-2 parts of fermented beans, and 1-2 parts of onion. Specific production method comprises the steps of raw material cutting, meat mincing, emulsifying, filling, smoking and steaming, heat dissipating, packaging, and sterilizing, such that finished product is obtained. The method provided by the invention has the advantages of simple steps, convenient processing, and suitability for industrialized productions. The product can be safely applied by consumers, and is safe and healthy.

Owner:ANHUI BAODI MEAT FOODS

Mildewproof anti-staling agent for rice

The invention provides a mildewproof anti-staling agent for rice, which consists of the following components by weight portion: 10 to 15 portions of sodium diacetate, 5 to 8 portions of vitamin C, 5 to 8 portions of trehalose and 1 to 2 portions of rice flavoring agent. The components are dissolved in clear water and made into 10 percent anti-staling agent solution. The mildewproof anti-staling agent for rice can be used only when the moisture content of rice is required to be below 16 percent, and is added as a polishing agent when the rice is polished. Two kilograms of the anti-staling agent solution is used for per ton of rice. In contrast to the common rice which mildews and goes bad till mid-April, the rice which is treated by use of the mildewproof anti-staling agent for rice and placed at room temperature does not mildew till mid-July, and is normal in color, odor and taste.

Owner:天津市农作物研究所

High-temperature-resistant composite calcium carbonate and preparation method thereof

InactiveCN106349759AImprove high temperature resistanceTake advantage ofPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPoly ether ether ketoneMixed materials

The invention discloses a high temperature resistant composite calcium carbonate and a preparation method thereof, which comprises the following raw materials: calcium carbonate, polyimide, polyether ether ketone resin, perlite powder, sodium diacetate, polyester resin, xylene, diacetate Alcohol ether, n-butanol, modifying agent, and appropriate amount of water; the preparation method comprises the following steps: (1) preparing a premix for use; (2) preparing a mixed solution; (3) preparing a modifying agent; (4) Mix the premix, the mixed liquid and the modifier, stir evenly, grind, dry and crush into superfine powder. The present invention improves the production process by combining calcium carbonate with sodium diacetate, polyimide, polyether ether ketone resin, polyester resin and other materials with better comprehensive properties, and effectively increases the composition by using modifiers and the like. Excellent high temperature resistance; its production process is simple, the production cycle is short, the quality is stable, the production cost is low, and the application value is high.

Owner:中玺新材料(安徽)有限公司

Method for producing sodium diacetate

InactiveCN104892397AWhite appearanceHigh purityOrganic compound preparationCarboxylic acid salt preparationAcetic acidGas phase

The invention discloses a method for producing sodium diacetate by taking a gas phase reaction as a main mode, which comprises the following steps: placing the metered sodium carbonate in a reactor and stirring, then slowly dropping glacial acetic acid in a reactor according to mass ratio of 1: 2.125 at temperature of 40 DEG C, controlling the temperature to 75-90 DEG C while dropping; after feeding, insulating and reacting for 30 minutes at 75-90 DEG C during a reaction process; after gas phase reaction is completed, drying under negative pressure, and cooling to obtain the sodium diacetate crystallization particles. According to the invention, sodium diacetate is produced during the gas phase reaction in a horizontal reactor, a solvent medium is not required, the crystallization product has the advantages of uniform particles, good dispersibility, simple production process, easily available raw materials, low production cost, no three waste discharge during the reaction process, high product purity and simple operation.

Owner:秦健

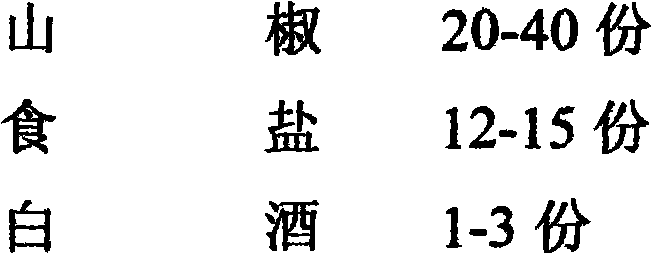

Production process for boiling chicken feet

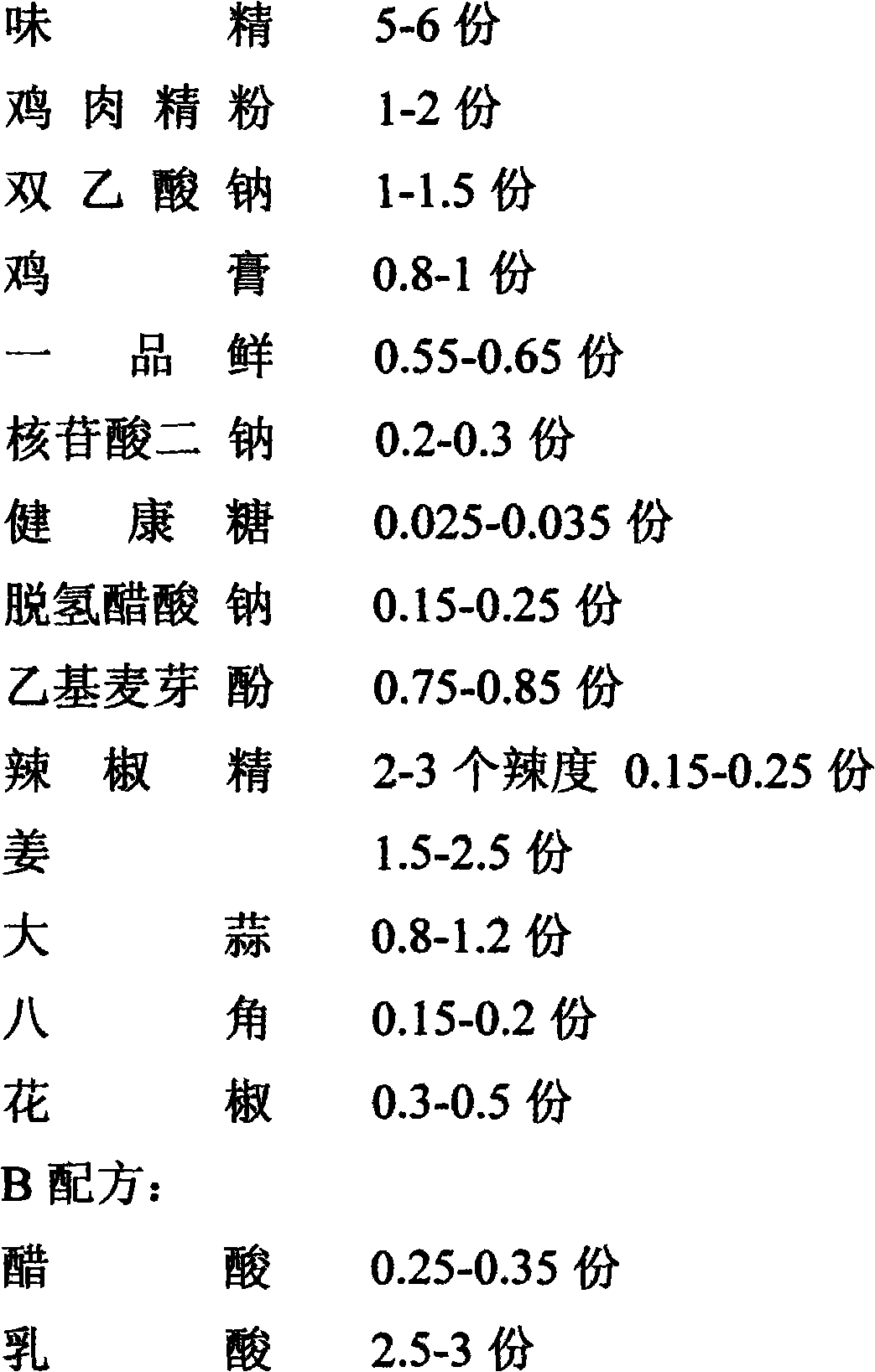

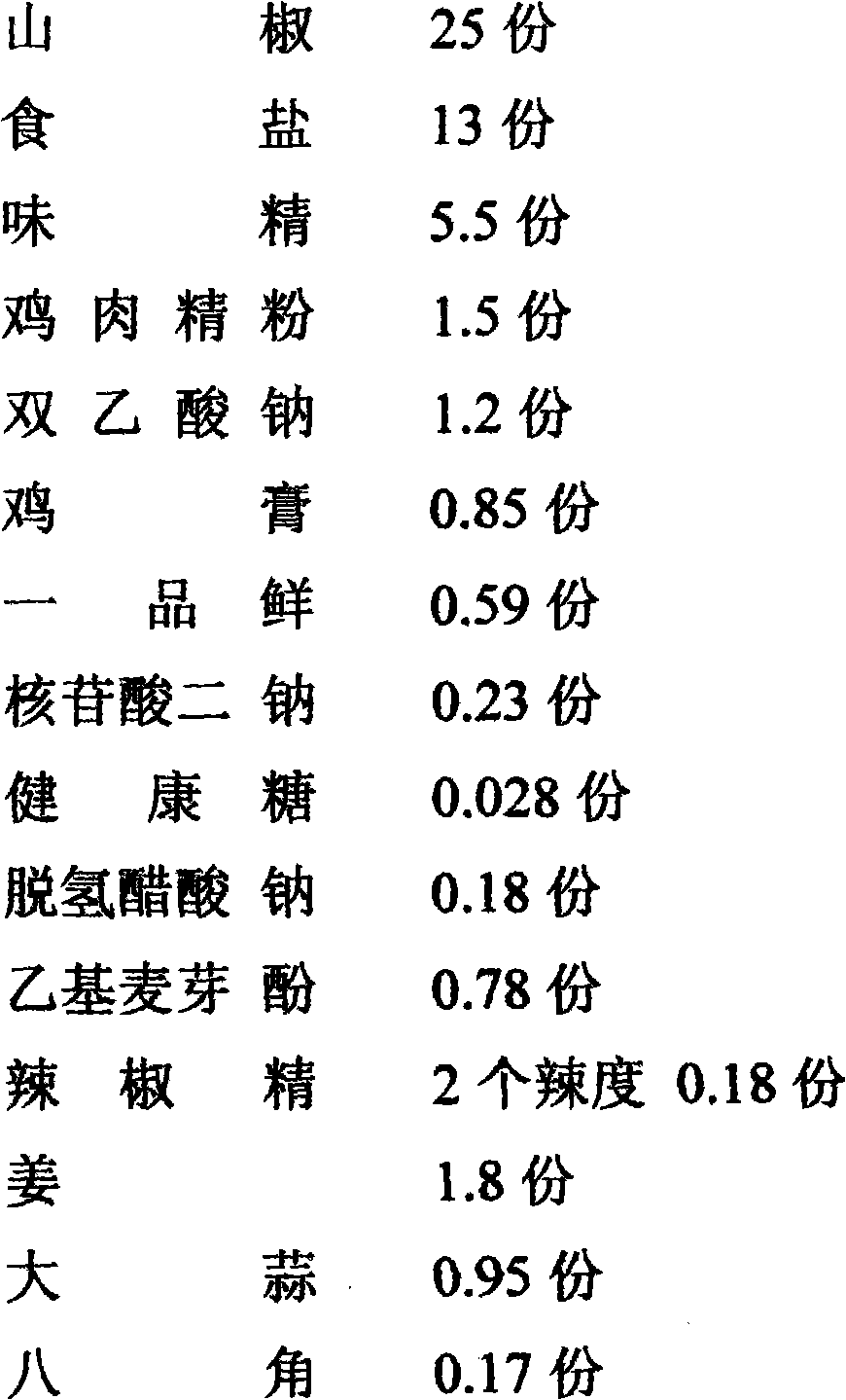

The invention relates to a production process for boiling chicken feet. Chicken feet are used as the main material, and maintain pepper, edible salt, white wine, monosodium, chicken flavor powder, chicken cream, sauce, sodium diacetate, disodium ribonucleotide, health sugar, sodium dehydroacetate, ethyl maltol, chilli extract, ginger, garlic, anise, pepper, acetic acid, lactate and the like are used as pickling liquid raw materials. The chicken feet are processed by the steps of boiling soup, selecting materials, defrosting, disinfecting, boiling, pickling, packaging, and the like. The chicken feet boiled with the production process have rich nutrients, bright color, crisp skin and fragrant meat. The chicken feet embody the best color, fragrance and flavor characteristics of Chinese food.

Owner:HUNAN HAPPY TO DASH FORWARD FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com