Patents

Literature

1070 results about "Ethyl maltol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl maltol is an organic compound that is a common flavourant in some confectioneries. It is related to the more common flavorant maltol by replacement of the methyl group by an ethyl group. It is a white solid with a sweet smell that can be described as caramelized sugar and cooked fruit.

Essence for cigarette blasting bead and application thereof

InactiveCN105925376AImprove aroma qualityEnhance fullnessTobacco preparationEssential-oils/perfumesCyclopenteneSweet flavor

The invention discloses an essence for a cigarette blasting bead and application thereof. The essence comprises the following components: 2,3-dimethylpyrazine, clove bud oil, lactic acid, ethyl maltol, ethyl cyclopentene alcohol ketone, vanillin, 2,6-syringol and medium chain triglyceride (MCT). The essence 15-20 mu l is wrapped in a capsule in the manner of injection perfuming and then is put into a middle part of a filter tip of a cigarette. The essence for the cigarette blasting bead has bake, coke and sweet flavor fully coordinated with the cigarette smoke flavor feature and is accompanied with slight flowery flavor. The essence applied to the cigarette blasting bead can obviously increase the smoke flavor quality, reinforce the satiated feel and richness of the smoke and reduce the sensory stimuli of the smoke.

Owner:HONGTA LIAONING TOBACCO

Method for preparing tobacco-characteristic-taste tobacco flavor material and electronic cigarette fluid containing tobacco flavor material

ActiveCN105595411ACapture completelyImprove qualityTobacco treatmentEssential-oils/perfumesDistillationLiquid smoke

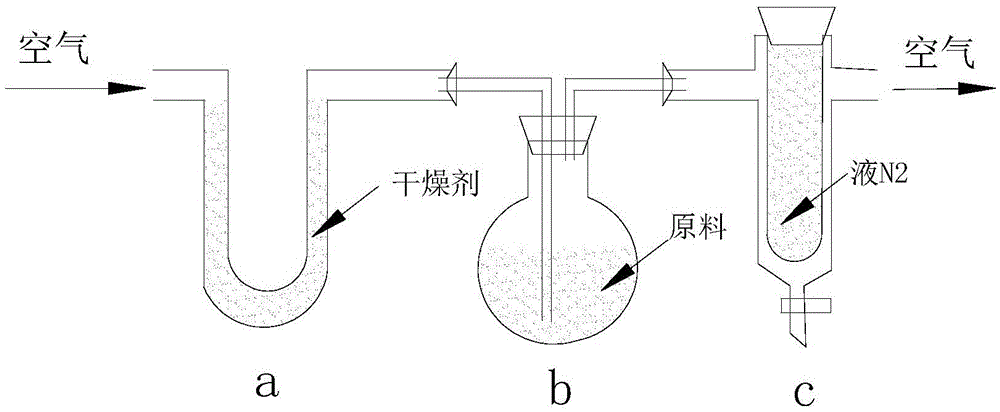

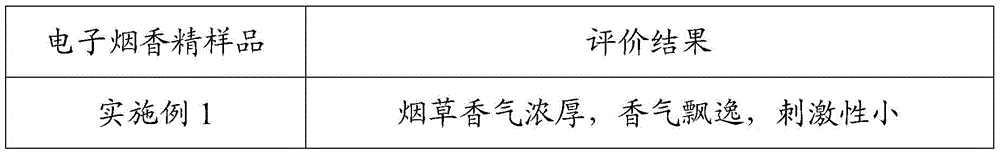

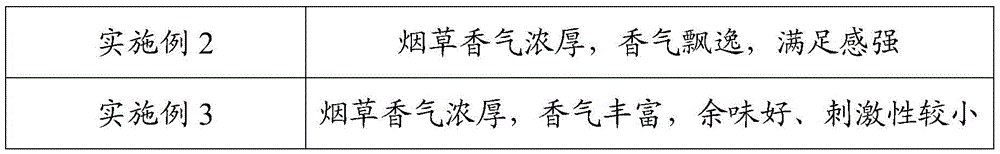

The invention provides a method for preparing a tobacco-characteristic-taste tobacco flavor material. The method comprises the following steps of choosing a raw tobacco material as a backing material, evenly spraying an atomizing agent on the surface of the raw tobacco material, standing, putting the backing material into a dry distilling device after the backing material is fully infiltrated by the atomizing agent, distilling the backing material under the temperature between 150 DEG C and 300 DEG C to obtain aromatic components, inducing dry air into the dry distilling device in distillation and catching the aromatic components through a condensing device to obtain the tobacco flavor material. The invention further provides electronic tobacco fluid which comprises basic tobacco fluid formed by essences, nicotine, glycerinum and propylene glycol in a mixing manner. The flycerinum and the propylene glycol serve as solvents, the tobacco flavor material and tobacco extracts are added into the basic tobacco fluid, the tobacco extracts comprise a red sun-cured tobacco reactant and a Zimbabwe tobacco extractive, and the essences comprise ethyl maltol and 2(H) beta-ionone. According to the tobacco flavor material prepared through a dry distilling-condensing catching method, a preparing process of the tobacco flavor material is closer to a burning and smoking process of traditional cigarettes, and the smoking taste of the tobacco flavor material is closer to the smoking taste of the traditional cigarettes.

Owner:HUBEI CHINA TOBACCO IND

Quick-frozen fish tofu and processing method thereof

The invention discloses quick-frozen fish tofu and a processing method thereof. The quick-frozen fish tofu comprises a meat material part and a soybean part; the meat material part comprises the following components in part by weight: 600-800 parts of minced fish meat, 300-500 parts of chicken breast meat, 200-500 parts of pork fat, 50-150 parts of cassawa starch, 100-200 parts of maize meal, 100-300 parts of monoacetate starch, 200-300 parts of water, 100-150 parts of egg white, 40-60 parts of edible salt, 40-60 parts of white granulated sugar, 10-30 parts of glucose, 10-30 parts of gourmet powder, 10-30 parts of cooking wine, 1-2 parts of freshener, 1-2 parts of fish essence, 4-5 parts of moisture retention agent, 3-4 parts of xylitol, 0.1-0.3 part of ethyl maltol, 1-2 parts of sorbitol, and 1-3 parts of guar gum; and the soybean part comprises the following components in part by weight: 200-300 parts of isolated soy protein, 1000-1500 parts of ice water, 4-6 parts of transglutaminase, 1-2 parts of Beta-cyclodextrine, and 2-4 parts of gourmet powder. The quick-frozen fish tofu has the advantages of mellow outline, golden color, pure flavor, dense scent, elasticity and crisp, and is oily but not greasy.

Owner:NANJING DADI REFRIGERATION FOOD

Flavoring essence used for tobacco

InactiveCN101606752AImprove the sense of convergenceReduce stimulationTobacco treatmentDaidzeinFlavoring essences

The invention relates to essence, in particular to flavoring essence used for tobacco. The flavoring essence is formed by mixing the following raw material components in percentage by weight: 1 to 3 percent of 10 percent vanillin, 2 to 4 percent of 10 percent damascenone, 2 to 4 percent of 10 percent ethyl maltol, 5 to 8 percent of stachyurus extract, 2 to 4 percent of Peru concrete, 1 to 3 percent of five-flavor ketone, 0.5 to 2 percent of 10 percent furaneol, 1 to 3 percent of 10 percent oak chip extract, 0.5 to 2 percent of 10 percent cassia leaf oil, 0.5 to 2 percent of elecampane extract, 1 to 3 percent of 10 percent clove bud oil, 2 to 4 percent of Xianning orange osmanthus extract, 1 to 3 percent of 1 percent valerian oil, 1.5 to 3 percent of trigonella tincture, 0.5 to 2 percent of 10 percent geranium oil, 15 to 20 percent of white hyacinth bean tincture, 1 to 3 percent of 10 percent acetic ether, 5 to 8 percent of lonicera confusa extract, 1 to 3 percent of ribes burejeuse extract, 8 to 51.5 percent of 70 percent ethanol, and 1 to 3 percent of daidzein. The flavoring essence used for the tobacco overcomes the defects that the prior cigarette has burr feeling at the throat and astringent feeling at the oral cavity, and has quite obvious effect of improving the comfort of the cigarette.

Owner:HUBEI CHINA TOBACCO IND

Barbecue essence and production process thereof

The invention discloses a barbecue essence, which is prepared from the following raw materials: ethyl maltol, 4-hydroxyl-2,5-dimethyl-3(2H)-furanone, 2,5-dimethyl-2,5-diyhydroxyl-1,4-dithiacyclo-hexane, methyl cyclopentenotone, 2-acetylpyrazine, 2-methyl tetrahydrofuran-3-mercaptan, bis(2-methyl-3-furyl) disulfide, propyl2-methyl-3-furyl disulfide, 4-methyl-5- hydroxyethyl-thiazole, 2-methylpyrazine, 2,3,5-trimethylpyrazine, 3-methylmercaptopropionaldehyde, difurfuryl disulfide, 4-methyl-4-furfurylthio-2-pentanone, 2,4,5-trimethylthiazole, 2,4,6-triisobutyl-1,3,5-dithiazine, beta-phenylethylmercaptan, 1,6-ethanthiol, 2-pentylthiophene, furfuryl mercaptan, 4,5-dimethyl-2-isobutyl-3-thiazoline, guaiacol, delta-dodecalactone, 2,4-decadienealdehyde, trans,trans-2,4- nonadienal, anisic aldehyde, butanoic acid, acetic acid, black pepper essential oil ginger essential oil, clove oil, cassia oil and an oil-soluble solvent. The invention also discloses a barbecue essence production process.

Owner:厦门市顶味兴业香料发展有限公司

Electronic cigarette liquid

InactiveCN105455190ALow sweetnessSmooth tasteTobacco treatmentEssential-oils/perfumesLiquid smokeIrritation

The invention provides an electronic cigarette liquid. The electronic cigarette liquid comprises basic cigarette liquid formed by mixing tobacco extract, tobacco essence, glycerin solvent, propylene glycol and water. The electronic cigarette liquid is characterized in that nicotine salt or a mixture thereof or a mixture of the nicotine salt and nicotine is added to the basic cigarette liquid, the nicotine salt comprises citric acid nicotine, dipicric acid nicotine salt, tartaric acid nicotine salt and nicotine hydrochloride, the tobacco extract comprises red sun-cured tobacco reactants and Zimbabwe tobacco extract, and the tobacco essence comprises ethyl maltol and dihydro ionone beta. According to the electronic cigarette liquid, the nicotine salt or the mixture thereof or the mixture of the nicotine salt and the nicotine is added to the electronic cigarette liquid, strong irritation brought by only adding the nicotine to mucosa can be avoided on the condition that the same physiological intensity is provided, the red sun-cured tobacco reactants, the Zimbabwe tobacco extract, the ethyl maltol and the dihydro ionone beta can provide characteristic flavor of tobacco, and the smoking flavor of the electronic cigarette liquid can be made close to traditional cigarettes.

Owner:HUBEI CHINA TOBACCO IND

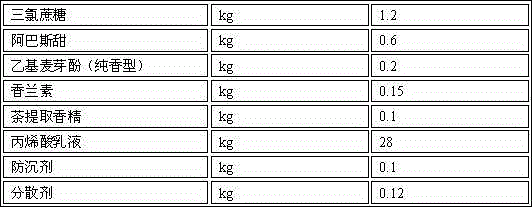

Fragrant and sweet taste cigarette tipping paper production method

ActiveCN104372719AIncrease the fragranceDifferent pumping sensationSpecial paperPaper coatingHot stampingSucrose

The invention relates to a fragrant and sweet taste cigarette tipping paper production method, which specifically comprises: 1, completely mixing alcohol and an acrylic acid emulsion, then sequentially adding chlorosucrose and aspartame, stirring for 10-20 min, then adding an anti-sedimentation agent and a dispersant, stirring for 5-10 min, adding ethyl maltol (pure flavor type), vanillin and tea extraction essence, stirring for 5-10 min to prepare a fragrant and sweet taste ink, and carrying out sealed storage; 2, printing on a gravure printing machine, wherein the printing plate adopts the laser engraving gravure, the ground color ink adopts the inorganic ink, dilution is performed with alcohol, the final color adopts the fragrant and sweet taste ink to coat, and the printing plate with the mesh depth of 35 [mu]m is adopted; 3, the fragrant and sweet taste ink prepared in the step 1 is coated on the surface of tipping paper, and carrying out sealed storage, wherein the printing speed is 100-120 m / min, and the temperature is 80-100 DEG C; and 4, carrying out hot stamping, slitting and perforating on the tipping paper. With the production method, the cigarette tipping paper is endowed with the sweet taste effect, and the fragrance of the cigarette tipping paper is increased.

Owner:QINGDAO JUSTO PACKAGING +1

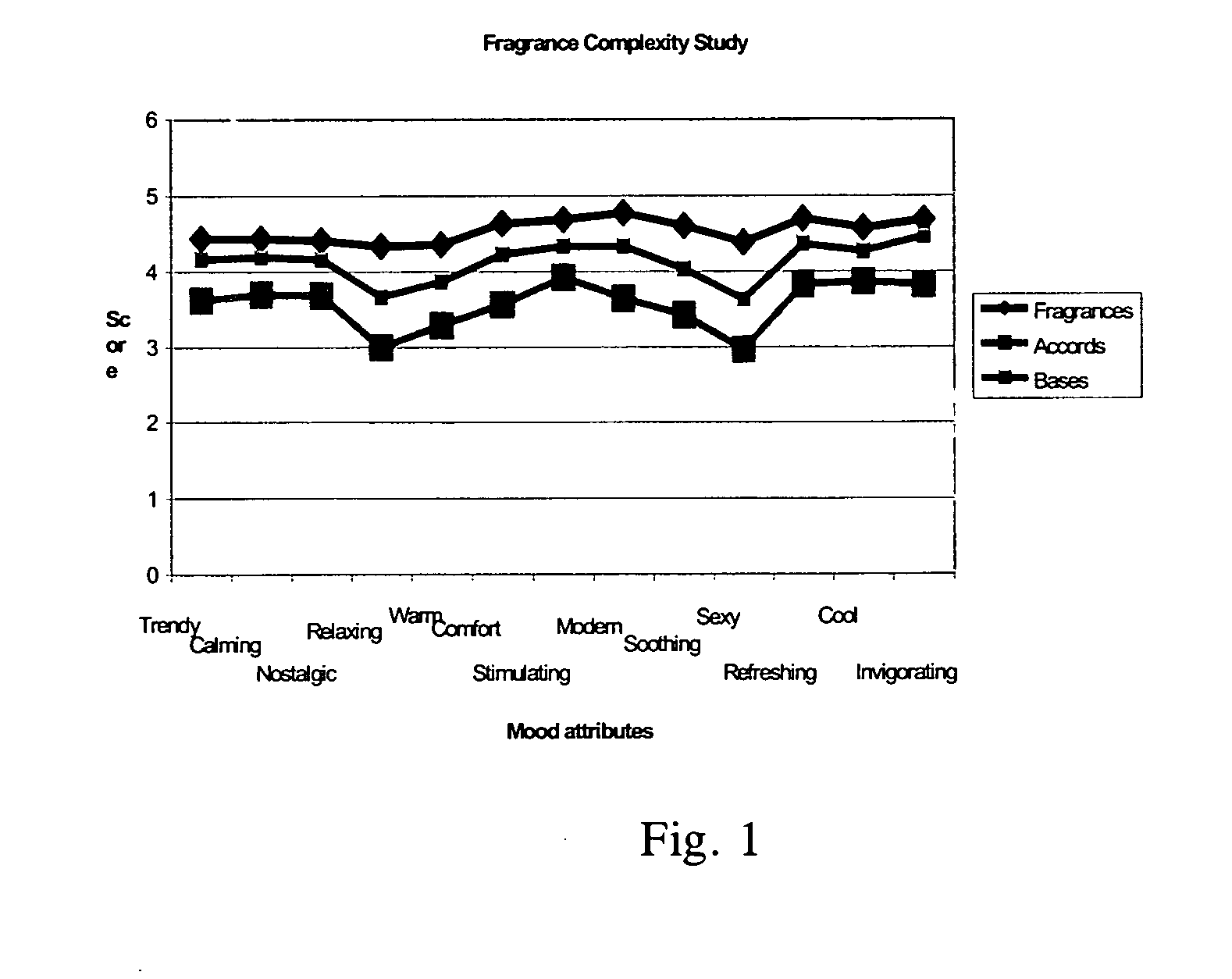

Fragrance compositions

InactiveUS20080096790A1Minimally disruptiveEasy to moveCosmetic preparationsToilet preparationsHexyl acetateLemon oil

A method of promoting activated, pleasant moods through the inhalation of energising, non-stressing fragrances (invigorating fragrances) comprising at least 75% by weight, preferably 85% by weight of perfume materials drawn from the following groups:A) At least 10% by weight in total of at least three materials drawn from Group ‘IMP’ comprising: allyl amyl glycolate; benzyl salicylate; bergamot oil; coriander oil; cyclamen aldehyde; 1-(2,6,10-trimethylcyclododeca-2,5,9-trien-1-yl)ethanone; allyl (cyclohexyloxy)acetate; Damascenia 185 SAE; 2,4-dimethylheptan-1-ol; fir balsam; fir needle oil; 3-(4-ethylphenyl)-2,2-dimethylpropanal; ginger oil; guaiacwood; linalyl acetate; litsea cubeba oil; methyl 2,4-dihydroxy-3,6-dimethylbenzoate; nutmeg oil; olibanum oil; orange flower oil; Ozonal AB 7203C; patchouli oil; rose oxide; rosemary oil; sage clary oil; spearmint oil; Tamarine AB 8212E; tarragon oil;B) Optionally up to 90% of materials from the following groups:Group ‘HMR’ comprising:allyl ionone; benzyl acetate; cis-jasmone; citronellol; ethyl linalol; ethylene brassylate; 4-methyl-2-(2-methylpropyl)tetrahydro-2H-pyran-4-ol; geraniol; geranium oil; isoeugenol; lemon oil; 2,4-dimethylcyclohex-3-ene-1-carbaldehyde; 3-(4-hydroxy-4-methylpentyl)cyclohex-3-ene-1-carbaldehyde; 4-(4-hydroxy-4-methylpentyl)cyclohex-3-ene-1-carbaldehyde; alpha-iso-methyl ionone; 3-methylcyclopentadec-2-en-1-one; cyclopentadecanone; cyclohexadecanolide; gamma-undecalactone.Group ‘HMI’ comprising:1-{[2-(1,1 -dimethylethyl)cyclohexyl]oxy}butan-2-ol; 3a,6,6,9a-tetramethyldodecahydronaphtho[2,1 -{b}]furan; alpha-damascone; dihydromyrcenol; eugenol; 3-(1,3-benzodioxol-5-yl)-2-methylpropanal; 2,4-dimethylcyclohex-3-ene-1-carbaldehyde; mandarin oil; orange oil; 2-(1,1-dimethylethyl)cyclohexyl acetate.Group ‘HMP’ comprising:1-(2,6,6,8-tetramethyltricyclo[5.3.1.0 {1,5}]undec-8-en-9-yl)ethanone; allyl cyclohexyl propionate; allyl heptanoate; Apple Oliffac S pcmf; 7-methyl-2H-1,5-benzodioxepin-3(4H)-one; cassis base; cis-3-hexenyl salicylate; damascenone; gamma-decalactone; ethyl acetoacetate; ethyl maltol; ethyl methyl phenylglycidate; hexyl acetate; (3E)-4-methyldec-3-en-5-ol; 2,5,5-trimethyl-6,6-bis(methyloxy)hex-2-ene; 4-(4-hydroxyphenyl)butan-2-one; styrallyl acetate; 2,2,5-trimethyl-5-pentylcyclopentanone; ylang oil. Group ‘RMP’ comprising: anisic aldehyde; (2Z)-2-ethyl-4-(2,2,3-trimethylcyclopent-3-en-1-yl)but-2-en-1-ol; benzoin siam resinoid; ethyl vanillin; oxacyclohexadec-12(13)-en-2-one; hexyl salicylate; hydroxycitronellal; jasmin oil; 3-methyl-5-phenylpentan-1-ol; 2-(phenyloxy)ethyl 2-methylpropanoate; alpha-terpineol; vanillin;Group ‘GEN’ comprising:cyclopentadecanolide; oxacyclohexadecan-2-one; hexyl cinnamic aldehyde; ionone beta; isobornyl cyclohexanol; 1-(2,3,8,8-tetramethyl-1,2,3,4,5,6,7(8),8(8a)-octahydronaphthalen-2-yl)ethanone; 4-(1,1-dimethylethyl)phenyl]-2-methylpropanal; linalol; methyl dihydrojasmonate; 2-phenylethanol;provided the following conditions are met:(a) IMPs>=HMPs+HMRs(b) IMPs+HMIs+GENs>=70%(c) (IMP+HMI) / (IMP+HMI+RMP+HMR)>=0.7(d) IMPs / (HMPs+RMPs+IMPs)>=0.5(e) IMPs / [(HMPs+RMPs+IMPs)+(100−TOTAL)]>=0.3wherein ‘IMPs’ indicates the sum of the percentages of materials within Group IMP, and similarly for the remaining groups, the symbol ‘>=’ indicates ‘at least equal to’, and ‘TOTAL’ is the sum of HMPs, HMRs, HMIs, IMPs, RMPs and GENs, provided also that low odour or no odour solvents are excluded from the calculation of these sums is provided which have an invigorating effect when inhaled by a subject.

Owner:GIVAUDAN NEDERLAND SERVICES

Yoghourt ice cream power and ice cream preparation method using same

InactiveCN1919031AWith health functionRich Fermented Yogurt FlavorMilk preparationFrozen sweetsSodium CaseinateWhole milk

The invention discloses a yoghourt and ice cream power comprising the following constituents (by weight portions): refined granulated sugar 30-50 parts, yoghourt powder 10-40 parts, whole milk powder 5-20 parts, plant grease powder 5-20 parts, guar gum 0.4-1.2 parts, xanthan gum 0.1-0.6 part, propylene glycol alyinate 0.2-1.2 parts, sodium caseinate 0.2-1.2 parts, milk essence 0.05-0.6 part, ethyl maltol 0.001-0.006 part. The invention also discloses the process for preparing ice-cream by utilizing the powder.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

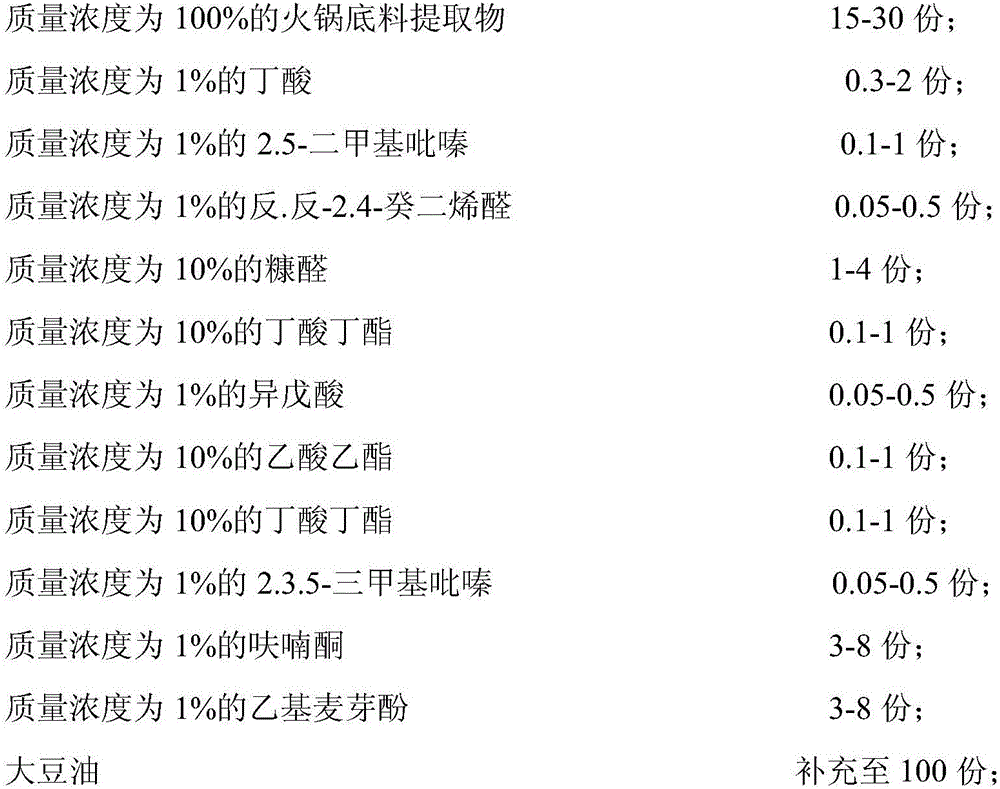

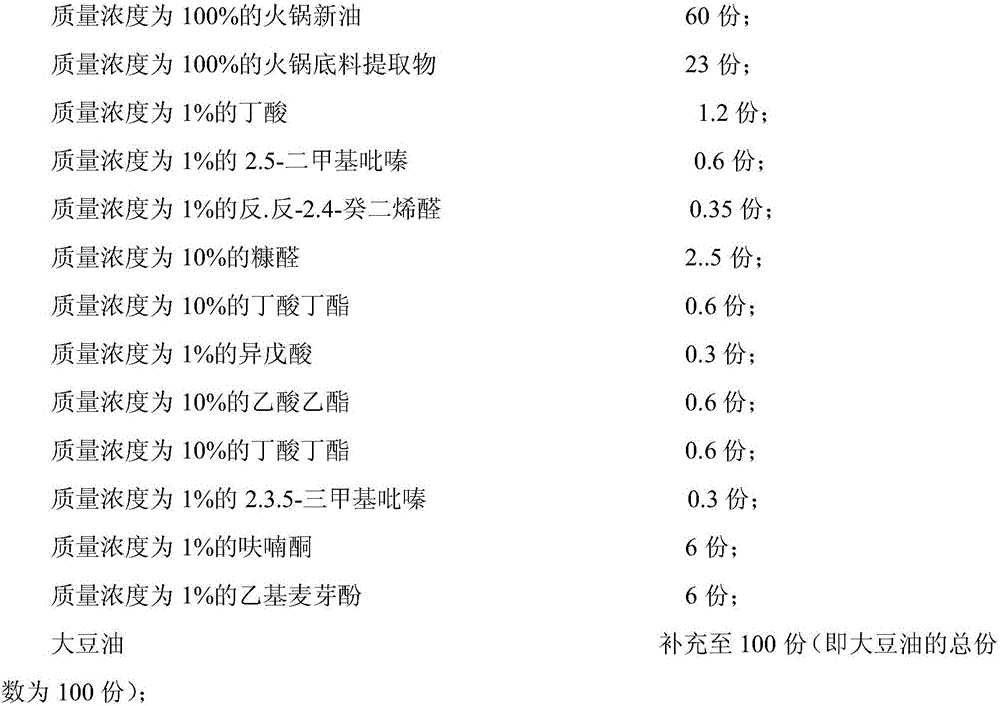

Old oil hotpot flavor essential oil and preparation method thereof

The invention relates to old oil hotpot flavor essential oil. The oil is prepared from, by weight, 40-80 parts of hotpot fresh oil, 15-30 parts of hotpot condiment extracts, 0.3-2 parts of butyric acid with mass concentration of 1%, 0.1-1 part of 2,5-dimethylpyrazine, 0.05-0.5 part of trans,trans-2,4-decadienal, 1-4 parts of furfural with mass concentration of 10%, 0.1-1 part of butyric acid butylester, 0.05-0.5 part of isovaleric acid with mass concentration of 1%, 0.1-1 part of ethyl acetate with mass concentration of 10%, 0.1-1 part of butyric acid butylester, 0.05-0.5 part of 2,3,5-trimethylpyrazine with mass concentration of 1%, 3-8 parts of furanone, 3-8 parts of ethyl maltol and the balance soybean oil supplemented till 100 parts. The essential oil is natural, safe and healthy, customers can enjoy the delicious taste, and meanwhile the requirement for ensuring body health can be met.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

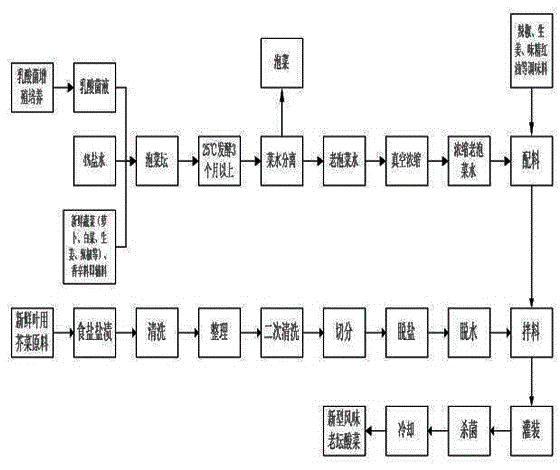

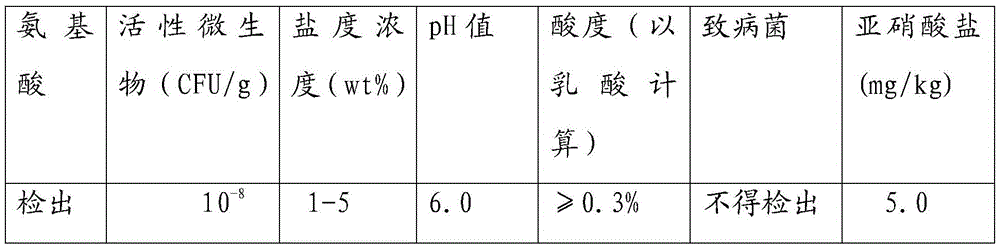

Preparing method for novel flavor Lao Tan pickled vegetables

InactiveCN105595272APromote reproductionInhibitory activityClimate change adaptationFood scienceLactic acid fermentationSaline solutions

The invention belongs to the technical field of food, and particularly relates to a preparing method for novel flavor Lao Tan pickled vegetables. The preparing method includes the steps that 1, a low-salt lactobacillus liquid pickled vegetable saline solution is prepared; 2, an aged pickled vegetable solution is prepared; 3, the aged pickled vegetable solution is concentrated at low temperature ina vacuum mode; 4, salted leaf mustard is prepared; 5, material stirring is conducted, wherein the salted leaf mustard is placed into the concentrated aged pickled vegetable solution, and chopped pickled peppers, chopped pickled ginger, gourmet powder, cane sugar, sesame oil, lactic acid, I+G and ethyl maltol are added and stirred uniformly; 6, the novel flavor Lao Tan pickled vegetable product isobtained through packaging, sterilizing and cooling. The method is simple in operation technology, unique flavor generated by the pickling technology of the pickled vegetables and specific taste generated by the salting technology of the salted pickled vegetables are combined, the prepared product has yellow brown color and luster, has lactic fermentation flavor of traditional Lao Tan pickled vegetables and sauce flavor of the salted pickled vegetables, has lasting and mellow taste and is fresh, tasty and refreshing, and the tart flavor is comfortable for people.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

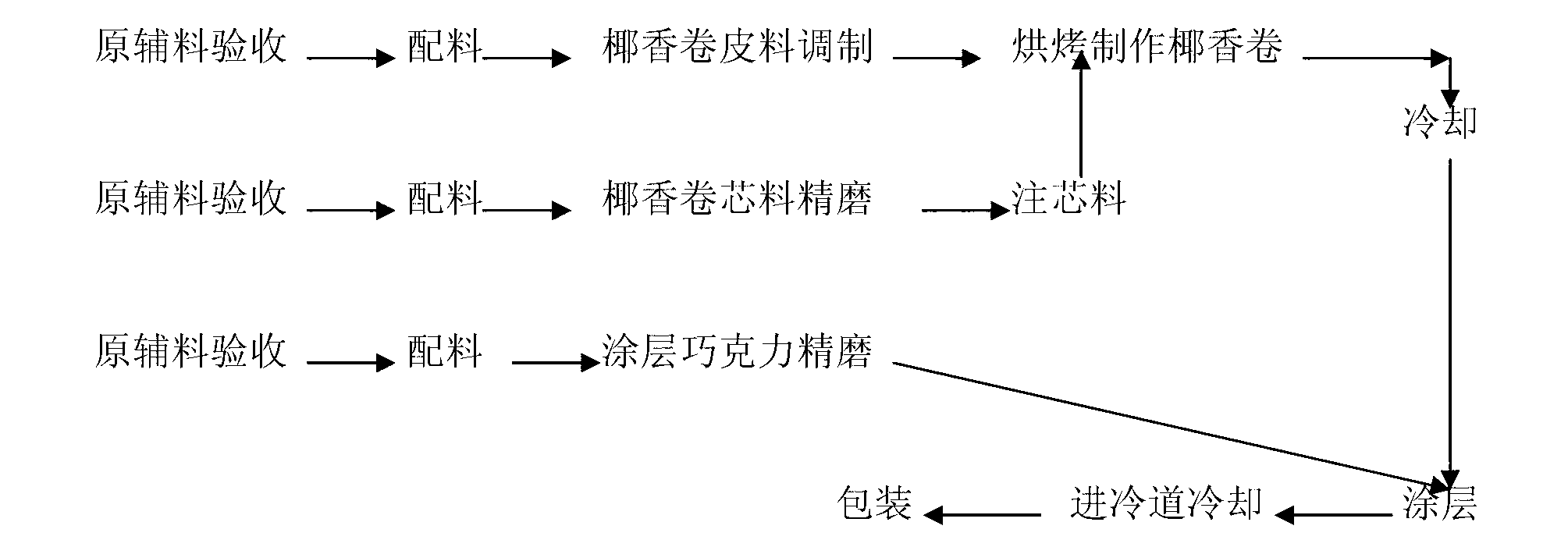

Chocolate coconut roll and preparation method thereof

The invention provides a chocolate coconut roll. The chocolate coconut roll comprises an egg roll, core stuffing which is filled in the egg roll, and a chocolate coating which is coated outside the egg roll; and the egg roll is prepared from the following ingredients: water, white granulated sugar powder, refined salt, phospholipid oil, salad oil, eggs, salt, beta-carotene and wheat flour, the core stuffing is prepared from the following ingredients: anhydrous margarine, lecithin, white granulated sugar powder, refined salt, grease milk powder, coconut powder, whey powder, toasted coconut essence, vanillin and ethyl maltol, and the chocolate coating is prepared from the following ingredients: cocoa butter substitute, lecithin, white granulated sugar powder, refined salt, grease milk powder, maltodextrin, whey powder, roasted coconut essence, vanillin and ethyl maltol. The invention also provides a preparation method of the chocolate coconut roll. The chocolate coconut roll is simple in preparation method, low in cost, rich in nutrients, reasonable in matching, good in taste and fragrant.

Owner:MASHI MANOR NANJING FOOD

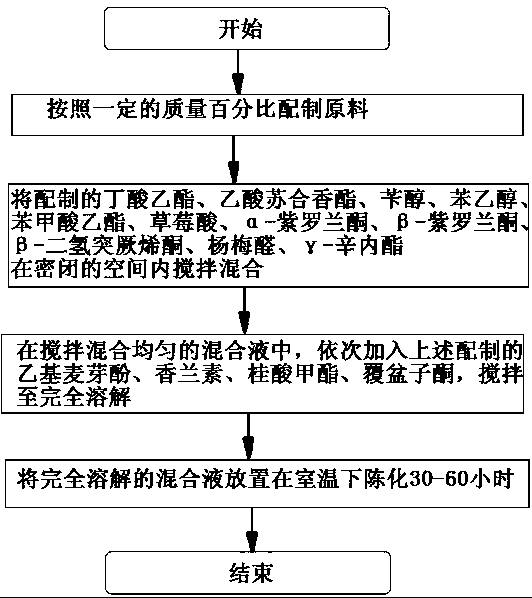

Preparation method of essence for electronic cigarette with strawberry flavor

ActiveCN103849465AIntense, mellow and long-lastingThe process is easy to controlTobacco devicesEssential-oils/perfumesPhenethyl alcoholEthyl butyrate

The invention relates to a preparation method of essence for an electronic cigarette with strawberry flavor. The preparation method comprises the following steps: a first step of preparing materials according to a certain mass percent; a second step of stirring and mixing prepared ethyl butyrate, styralyl acetate, benzyl alcohol, phenethyl alcohol, ethyl benzoate, strawberry acid, alpha-ionone, beta-ionone, beta-dihydrogen damascenone, waxberry aldehyde and gamma-octyl lactone in sealed space; a third step of adding the prepared ethyl maltol, vanillin, methyl cinnamate and raspberry ketone in the uniformly stirred and mixed liquor in sequence, and stirring until dissolving completely; and a fourth step of placing the completely dissolved liquor under the room temperature for ageing for 30 hours-60 hours. According to the preparation method disclosed by the invention, the whole process is simple and controllable, the prepared electronic cigarette has special thick fresh strawberry flavor which is strong and mellow, and lasting, so that breath of a user is fresh.

Owner:ENSHI JINHUA BIOLOGICAL ENG

Mixed stewed pork essence and making method thereof

InactiveCN104026546AHigh concentration of fragranceRealistic aromaFood preparation2-methyl-3-furanthiolFuran

The invention discloses mixed stewed pork essence which consists of furanone, ethyl maltol, 2-acetylpyrazine, methyl cyclopentenolone, difurfuryl sulfide, 3-sulfydryl-2-butanol, 2-methyl-3-furan mercaptan, di(2-methyl-3-furan mercaptan)-disulfide, methyl(2-methyl-3-furan mercaptan)-disulfide, acetic acid, 3-sulfydryl-2-butanone, 3-propionaldehyde, thiophane-3-acetone, 2,3,5-trimethyl pyrazine, counter,counter-2,4-decadiene aldehyde, furfuryl disulfide, furfurylmercaptan, anise camphor, anisic aldehyde, pepper essential oil, 2-acetyl thiazole, delta-dodecalactone, 4-methyl-5(beta)-hydroxyethyl thiazole acetate, onion oil alcohol, 4-methyl-4-bran sulfenyl-2-pentanone and glycerol triacetate. The mixed stewed pork essence is high in biofidelity and mellow and fine in fragrance, has a good application effect and is economical and practical.

Owner:SHANGHAI INST OF TECH

Iced tea melon seeds and production method thereof

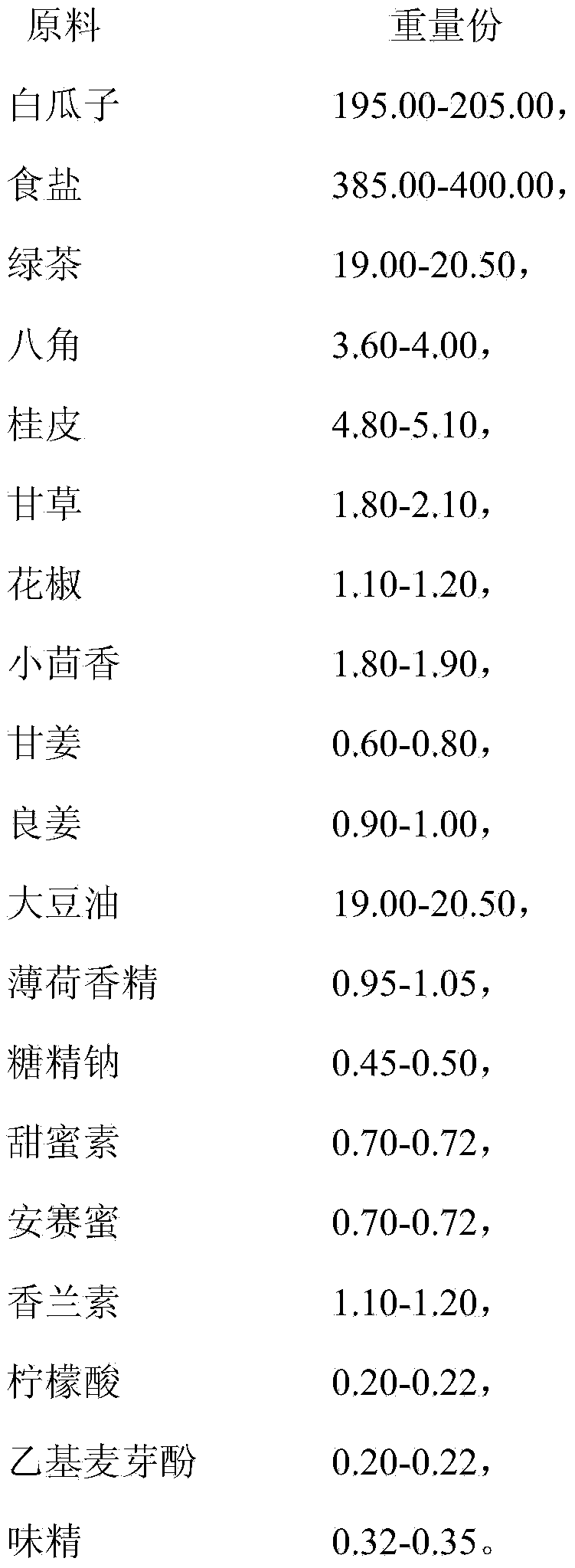

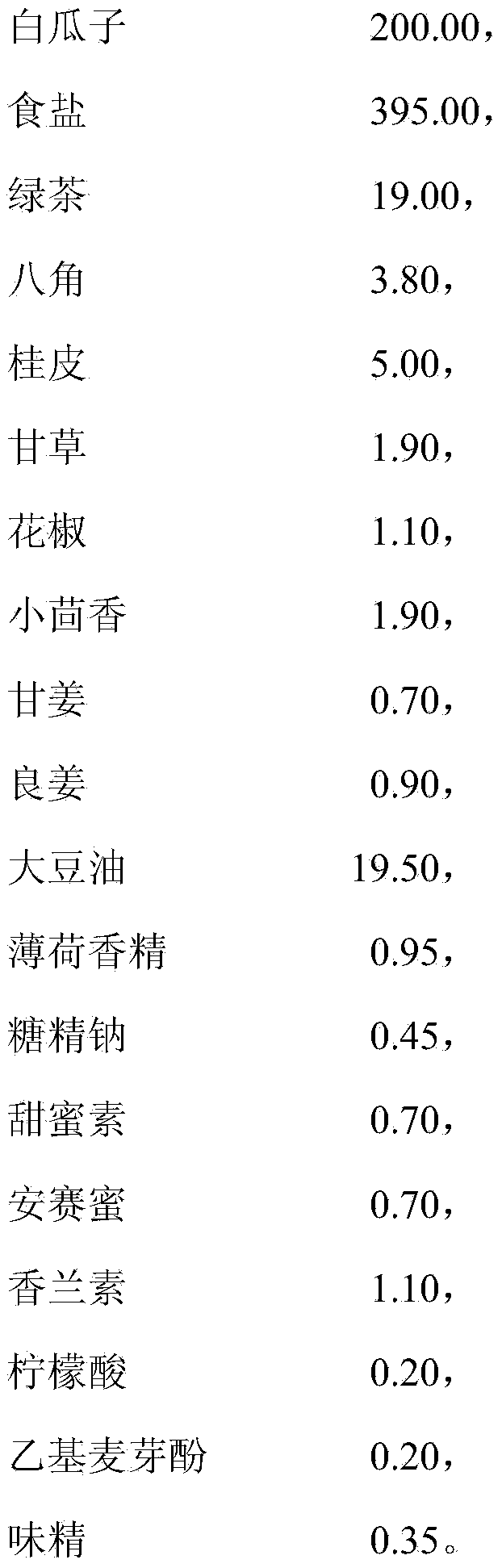

ActiveCN104172312AUneven appearanceParticles with uneven appearanceFood preparationMonosodium glutamateMint Flavor

The invention belongs to the technical field of food production of nuts and roasted seeds and nuts and particularly discloses iced tea melon seeds and a production method thereof. According to the iced tea melon seeds, raw materials adopt white melon seeds in the Northeast; natural spices adopt green tea, anise, cinnamomum tamala, glycyrrhiza uralensis fisch, zanthoxylum schinifolium, fennel, rhizoma zingiberis and alpinia officinarum hance; seasonings adopt table salt, soybean oil, mint essence, saccharin sodium, sodium cyclamate, acesulfame, vanillin, citric acid, ethyl maltol and monosodium glutamate. Before being fried, the white melon seeds are washed, are boiled and then are washed and peeled and a concentrated soup base is obtained by stewing; the auxiliary materials are added and the peeled white melon seeds are boiled in blended soup; the white melon seeds are stacked after being boiled and then are roasted and fried; and finally, the white melon seeds are finely selected and cooled and then are packaged and stored. The iced tea melon seeds have uniform appearance granules and bright color and luster; the white melon seeds are easy to crack and can be cracked into three parts once, so that shells and kernels are completely separated; people feel cool and refreshing when eating the white melon seeds; the white melon seeds have prominent mint flavor and rich tea flavor; the melon seed kernels are crispy and have a long aftertaste.

Owner:WUHAN XUDONG FOOD

Milk powder essence

The invention relates to a formulation for milk pulverous flavor and a preparation method thereof. The flavor mainly comprises powdered glucose, ethyl maltol, gamma-Nonanolactone, delta dodecalactone, vanillin, ethyl vanillin, ethyl caprylate, gamma-Heptalactone and other components, and has sterling full-bodied roast powdered milk aroma, delicious mouthfeel and pure flavor. In addition, the flavor has the advantages of high temperature resistance, long flavor lasting time and so on. The formulation and the preparation method are widely applied to food industry, and ensure that products keep sterling natural milk flavor.

Owner:广东雅和生物科技有限公司

Winter jujube vinegar beverage

InactiveCN101133886APlay a role in health careRich in nutrientsVinegar preparationFood scienceAdditive ingredientZiziphus jujuba

The present invention provides a winter jujube vinegar beverage, belonging to a fruit vinegar beverage. It is made up by using winter jujube juice, winter jujube vinegar, jujube flower honey, citric acid, sweetening agent, calcium lactate, ethyl maltol and water as raw material through a certain preparation process.

Owner:山东滨州冬枣研究院

Production method of potato flour and vermicelli

InactiveCN101797031AReduce material consumptionIncrease productivityFood preparationCarrageenanPhosphate

The invention provides a production method of potato flour and vermicelli. The production method comprises the following steps: taking the following components in parts by weight: 65-70 parts of potato flour, 25-35 parts of cassava modified starch, 5-8 parts of konjac fine flour or soybean flour, 5-10 parts of gluten flour, 0.25-0.5 part of sodium alginate, 0.3-0.6 part of guar gum, 0.1-0.3 part of carrageenan, 0.2-0.3 part of xanthan gum, 0.1-0.5 part of ethyl maltol, 0.1-0.5 part of composite phosphate, 1.0-4.0 parts of yeast extract, 0.3-0.8 part of hydrolyzed vegetable protein and 19-25 parts of water or vegetable juice; and mixing the components step by step, heating to 58-65 DEG C, mechanically stirring the mixture for 23-25 minutes into full flour floc, laying aside for 25-35 minutes, repeatedly rolling for 10-15 times by a noodle press, producing the vermicelli by a multifunctional double-drum self-cooked vermicelli machine, and treating by a dryer and a screening machine to obtain the vermicelli. The potato flour is prepared by firstly blending the cassava modified starch, the konjaku refined flour or soybean flour and the gluten flour into the flour floc and then processing the floor floc into the vermicelli. The adopted food nutrition additives are dissolved firstly and then used. The vermicelli can be produced into a vermicelli ball and dried, vacuumized, sealed with a film and added with a seasoning bag to produce a convenience food.

Owner:王忠玉

Essence for cigarettes and preparation method thereof

The invention discloses an essence for cigarettes and a preparation method thereof. As the essence for cigarettes is prepared by adding the components of jujube tincture, cocoa hull tincture, vanillin, ethyl maltol and the like to a blended essence base, the essence has a sweet and baked smell with grease smell and slight spicy smell. The content of the essence added to tobaccos is generally 0.10-0.20 wt% so that the essence can play the role of flavor increase and smoke lift, and endow the cigarettes with flavor style of Baisha cigarettes.

Owner:飞嘉创业化工(深圳)有限公司

Rose ice cream, ice cream bar and preparation method thereof

InactiveCN101703143AWith rose aromaUnique flavorFrozen sweetsMonosodium glutamateGlucose-Fructose Syrup

The invention provides rose ice cream, an ice cream bar and a preparation method thereof. Raw materials in weight proportion are: 40 to 70 kg of whole milk powder, 15 to 20 kg of corn starch, 35 to 50 kg of maltodextrin, 120 to 200 kg of white sugar, 50 to 150 kg of glucose syrup, 0.1 to 0.2 kg of protein sugar, 2 to 5 kg of edible roses, 15 to 20 kg of edible butter, 20 to 40 kg of shortening, 4 to 8 kg of ice cream stabilizer, 0.02 to 0.06 kg of ethyl maltol, 0.5 to 0.8 kg of sodium cyclamate, 0.3 to 0.4 kg of refined salt, 0.4 to 0.5 kg of monosodium glutamate, 0.4 to 1.5 kg of rose essence, and a proper amount of drinking water. The rose ice cream and the ice cream bar prepared by use of the formulation and the method of the invention have rose fragrance, special flavor, taste freshness and particularly good taste, have certain benefits for skin, health, facial and the like, change the flavor and taste of conventional ice cream, and are updated ice cream and ice cream bar.

Owner:李旭光

Waxberry fruit liqueur and production method thereof

The invention discloses waxberry fruit liqueur and a production method thereof and belongs to the technical field of liquor processing. The waxberry fruit liqueur is produced by adopting a method comprising the following steps of: soaking fresh waxberry in white wine to obtain waxberry normal juice liquor; placing roselle into white wine to extract a natural roselle extract; mixing the waxberry normal juice liquor, the natural roselle extract, waxberry concentrated juice and waxberry essence to obtain a mixed solution I; dissolving ethyl maltol, white granulated sugar, aspartame, citric acid and potassium sorbic with hot water to obtain a mixed solution II; adding the mixed solution I and the mixed solution II into spring water and white wine, and uniformly mixing to obtain a mixed solution III; adding a chitosan liqueur clarifying agent into the mixed solution III, oscillating and filtering on a shaking table, regulating the alcoholic strength to be 8-10 degrees, sterilizing in water bath, and filling, thereby obtaining the waxberry fruit liqueur. The prepared waxberry fruit liqueur is stable in quality and bright in colour, is ruby red, clear and transparent, is rich in taste and is sweet, scour and delicious, the production period is short, and the production method is simple and practicable.

Owner:INST OF QUALITY STANDARD & DETECTION TECH YUNNAN ACAD OF AGRI SCI

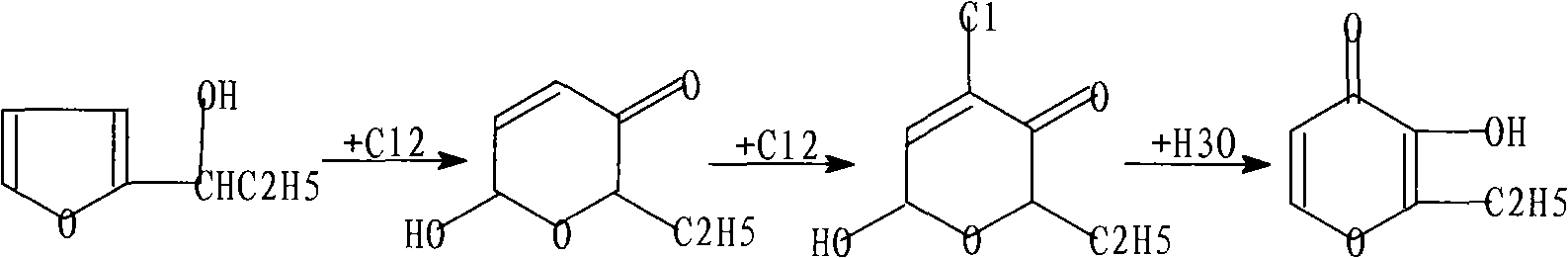

Synthetic process of ethyl maltol

The invention belongs to the technical fields of spices and in particular relates to a synthetic process of ethyl maltol. The process comprises a chlorination reaction step, a hydrolysis rearrangement step and a sublimating and purifying step, wherein the chlorination reaction is realized by reacting alpha-ethylfuran methanol with chlorine at the flow ratio of (1.8 to 2.3L):1kg to generate a hydroxy chlorovinylketone intermediate; the hydrolysis rearrangement means that the hydroxy chlorovinylketone intermediate is hydrolyzed at the temperature of 90 to 105DEG C for 3 to 4.5 hours to obtain an ethyl maltol coarse crystal; the coarse crystal is sublimated and purified under the conditions that the temperature is 200 to 225DEG C and the pressure is 0.080 to 0.090MPa to obtain an ethyl maltol product. The synthetic process disclosed by the invention is detailed and specific in operation and is stable; the chlorinating efficiency is improved and the generation of foamed yellow crystals is controlled; meanwhile, sublimating and purifying conditions are controlled, thereby effectively improving the yield and the purity of the ethyl maltol.

Owner:广东省肇庆香料厂有限公司

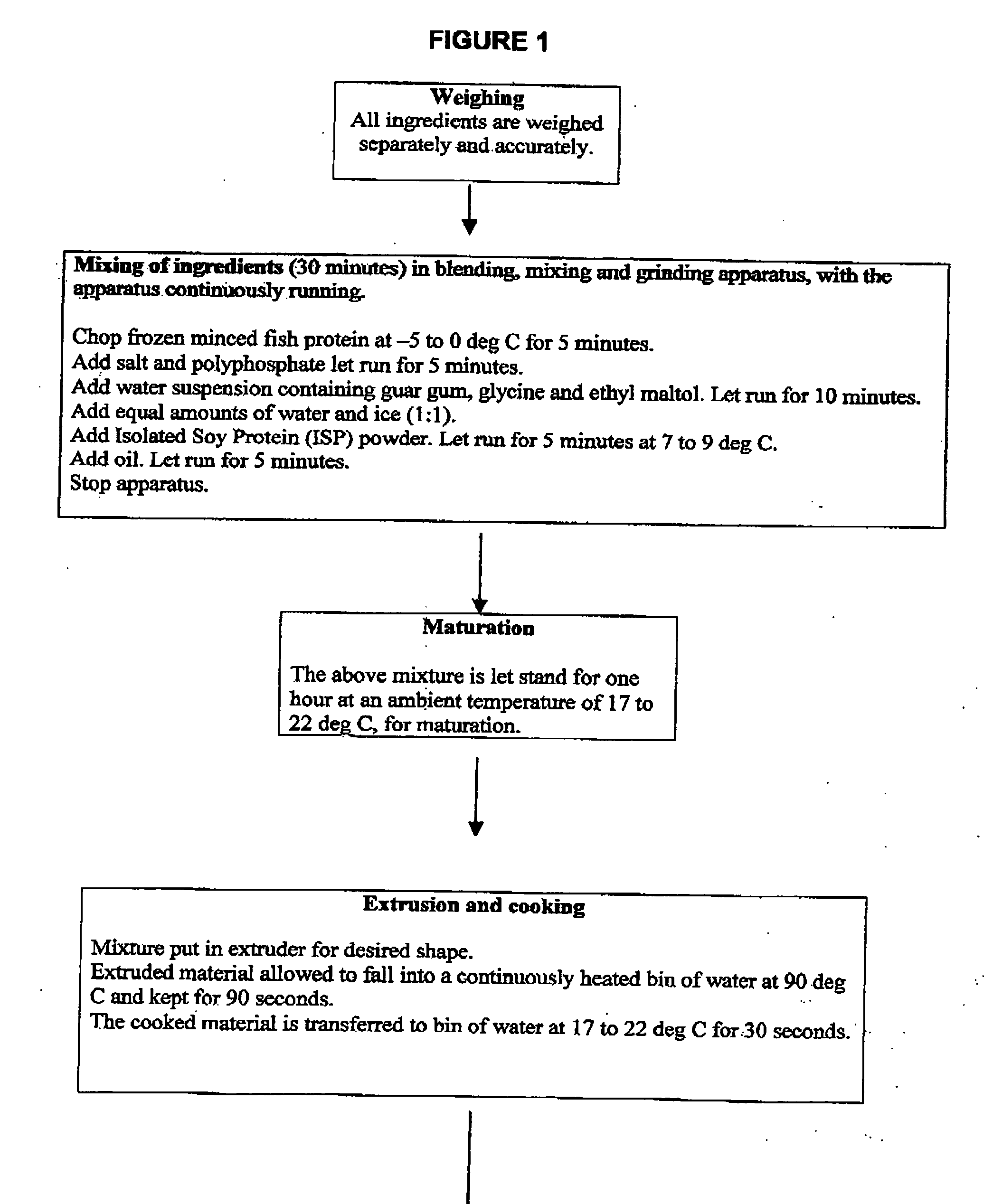

Nutritious edible compositions having zero digestible carbohydrates and high proteins and processes for making same

InactiveUS20070172575A1ZeroHigh in proteinDough treatmentMeat/fish preservationBiotechnologyAdditive ingredient

A nutritious, high protein, zero carbohydrate pasta or bread is formed by combining animal protein with a binder, wherein the binder comprises substantially no digestible carbohydrates. A preferred composition comprises fish protein combined with guar gum. In an embodiment, odor, taste, texture, and color modifying ingredients are added, including for example a plant protein, ethyl maltol, salt, egg white, calcium carbonate, glycine, and / or polyphosphate.

Owner:GUNE SHAMIKA ABHIJIT

Ethyl maltol synthetic method

InactiveCN101585822AReduce concentrationReduce contentOrganic chemistryHydrolysateReaction temperature

The invention relates to an ethyl maltol synthetic method, which includes an alpha-furans propanol chlorination rearrangement reaction and a hydrolysis reaction to the product of the alpha-furans chlorination rearrangement reaction. Wherein, the hydrolysis reaction comprises: hydrolyzing the mixture obtained in the chlorination rearrangement reaction under the temperature of 95-140 degrees centigrade and the pressure of 1.9-8.5Mpa for 1.5-5.5 hours; cooling to below 100 degrees centigrade; separating out the by-product: chloromethanes gas; and obtaining the hydrolysis mixed liquor containing the product: ethyl maltol. The invention can achieves the synthesized ethyl maltol yield of 60% which is improved by 4-6% compared with conventional methods; enables the hydrogen chloride generated in the reaction process to react with solvent methanol to generate a large amount of recyclable by-product: chloromethanes; reduces the hydrochloric acid concentration in the hydrolysate by 75-80%; reduces the sodium hydroxide used amount in the subsequent ethyl maltol separating and refining process; and reduces the sodium chloride content in the technique waste water; thereby, reduces environmental pollution and production cost.

Owner:CHUZHOU UNIV

Feed sweetener

ActiveCN102028098AIncrease feed intakeIncrease production capacityAnimal feeding stuffAccessory food factorsSucroseDecomposition

The invention discloses a feed sweetener which is prepared by mixing the following components in parts by weight: 25-70 parts of soluble saccharin, 5-70 parts of maltodextrin, 1-10 parts of sweet taste intensifier, 0.01-0.1 part of ethyl maltol and 0.01-0.1 part of ethyl vanillin, wherein the sweet taste intensifier is one of Acesulfame-K, sucralose, alitame and D-tryptophan or a mixture formed by mixing Acesulfame-K, sucralose, alitame and D-tryptophan according to any ratio. The sweetener enables animals to truly and effectively taste all the components, thereby increasing the feed intakes of the animals and improving the production performance of the animals. The sweetness of the sweetener is 150-500 times higher than that of sucrose, and the sweetener has sucrose-like fragrance and mouth feel, thereby reducing the additive amount of the sweetener in the feed and lowering the culture cost. The sweet taste intensifier in the invention has good stability, and the decomposition temperature is higher than the preparation temperature, so that the sweet taste intensifier can not be decomposed in the sweetener preparation process and the feed granulating process, thereby ensuring that the sweet taste is true and effective.

Owner:CHONGQING MINTAI NEW AGROTECH DEV GRP CO LTD

Brine sauce seasoning packet suitable for non-fried miscellaneous-grain instant noodles, and production method thereof

ActiveCN102845729AReduce lossesDistinctive flavor profileFood preparationBiotechnologyMonosodium glutamate

The invention discloses a brine sauce seasoning packet suitable for non-fried miscellaneous-grain instant noodles. The seasoning packet comprises a sauce packet, and a powder packet. The sauce packet comprises the raw materials of: beef, salad oil, butter, palm oil, white sugar, water, old ginger, green onion, garlic, star anise, cumin, fructus amomi, tsao-ko amomum fruit, dried tangerine peel, cinnamon, licorice, white buckle, rose pelargonium herb, angelica archang lica, kaempferiae, flatspine pricklyash, clove, whitefruit amomum fruit, edible salt, monosodium glutamate, I+G, ethyl maltol, maltodextrin, a yeast extract, HVP, a beef extract paste, and thermal reaction beef powder. The powder packet comprises the raw materials of: edible salt, monosodium glutamate, white granulated sugar, I+G, HVP, black pepper powder, creamer, yeast extract, beef powder, and turmeric powder. A dried vegetable packet comprises the raw materials of: Chinese cabbage, carrot, green onion, and caraway. The seasoning packet provided by the invention has the advantages of distinctive flavor, rich fragrance, and delicious taste. The production method is simple and is easy to command, the technology is mature, and the method provided by the invention is suitable for popularization.

Owner:SICHUAN JIUJIUAI FOOD

Flaxseed drink

ActiveCN104146313APromote absorptionFull of nutritionFood ingredient as thickening agentNatural extract food ingredientsHigh-fructose corn syrupAlpha-Linolenic acid

The invention discloses a flaxseed drink. The flaxseed drink comprises the following raw materials in parts by weight: drinking water 50-80, flaxseed water soluble powder 0.2-30, flaxseed gum 0.2-0.5, white granulated sugar 2-4, high fructose corn syrup 1-5, lecithin 0.04-0.1, a stabilizer 0.1-0.2, ethyl maltol 0.0006-0.001, aspartame 0.001-0.008, acesulfame potassium 0.01-0.03, lactic streptococcus 0.01-0.015, D-sodium erythorbate 0.01-0.015, vitamin E 0.008-0.01, tea polyphenols 0.012-0.015, an edible essence 0.01-0.03, and a proper amount of fruit and vegetable juice concentrate. The flaxseed drink is a health drink which is rich in alpha linolenic acid and a variety of balanced nutrients.

Owner:亚麻能量(北京)基因科技有限公司

Condensed milk essence

The invention relates to a condensed milk essence, which is composed of the following components in parts by weight: 0.1-100 parts of incense base, 0-99.9 parts of solvent, 0-20 parts of surfactant, 0-20 parts of cosurfactant, and 0-99.9 parts of carrier; wherein, the incense base is composed of the following components in parts by weight: 10-40 parts of ethyl maltol, 10-40 parts of capric acid, 5-20 parts of 5-decanolide, and 10-30 parts of delta-dodecalactone. The essence provided by the invention has natural condensed milk aroma and low cost, and beverages and other foods added with the condensed milk essence have aroma and taste of natural condensed milk.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

Walnut milk beverage and preparation method thereof

InactiveCN101999468ASolve the problem of weak flavor and poor stabilityEasy to controlMilk substitutesPectinaseCellulose

The invention discloses a walnut milk beverage and a preparation method thereof. The preparation method comprises the following steps of: adding 10% (g / ml) of walnut powder obtained by adding 90 U / g of alpha high-temperature resistant amylase to walnut pulp and baking the mixture at 90 DEG C to the walnut pulp, mixing the walnut powder and the walnut pulp, adding water which is 20 times the amount of the walnut pulp, and then adding 8% of cane sugar, 0.1% of citric acid, 0.1% of walnut essence, 0.05% of brighteners, 0.05% of ethyl maltol, 0.1% of mixtures of monoglyceride and sucrose ester inthe ration of 7:3 (g / g), 0.3% of mixtures of sodium carboxymethylcellulose and sodium alga acid in the ratio of 1:2 (g / g), 1.5% (g / ml) of composite enzyme comprising pectinase, cellulose and neutral protease and the balance of water. The invention solves the problems of boring flavor and poor stability of the traditional walnut milk and provides a novel walnut milk.

Owner:XINJIANG AGRI UNIV

Meat flavor composition

The invention discloses a meat flavor composition which comprises 4-methyl-5-(2-hydroxyethyl)-thiazole, 4-methyl-5-(2-hydroxyethyl)-thiazole-acetate, 2-methyl-3-furanthiol-acetate, 2-methyl-butyraldehyde, 2-methyl-furanthiol, 1,6-ethanthiol, 2-acetyl-4-methyl-thiazole, 2,4-decadienal, methyl mercatopropanol, 2,6-dimethoxyphenol, clove oil, butyl lactate, 3-methyl mercatopropanol, 2-methyl-2-mercapto-undecane, 3-tert-butyl-4-hydroxyanisole, 2,3,5-trimethylpyrazine, 2-methyl-3-mercaptofuran, ethyl maltol and the like, with the balance being an oil-soluble solvent. The invention also provides a preparation method for the composition.

Owner:WUTONG AROMA CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com