Patents

Literature

84results about How to "The process is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery conductive additive and preparation method thereof

InactiveCN101997120AImprove performanceImprove conductivityCell electrodesAluminium-ion batteryLithium-ion battery

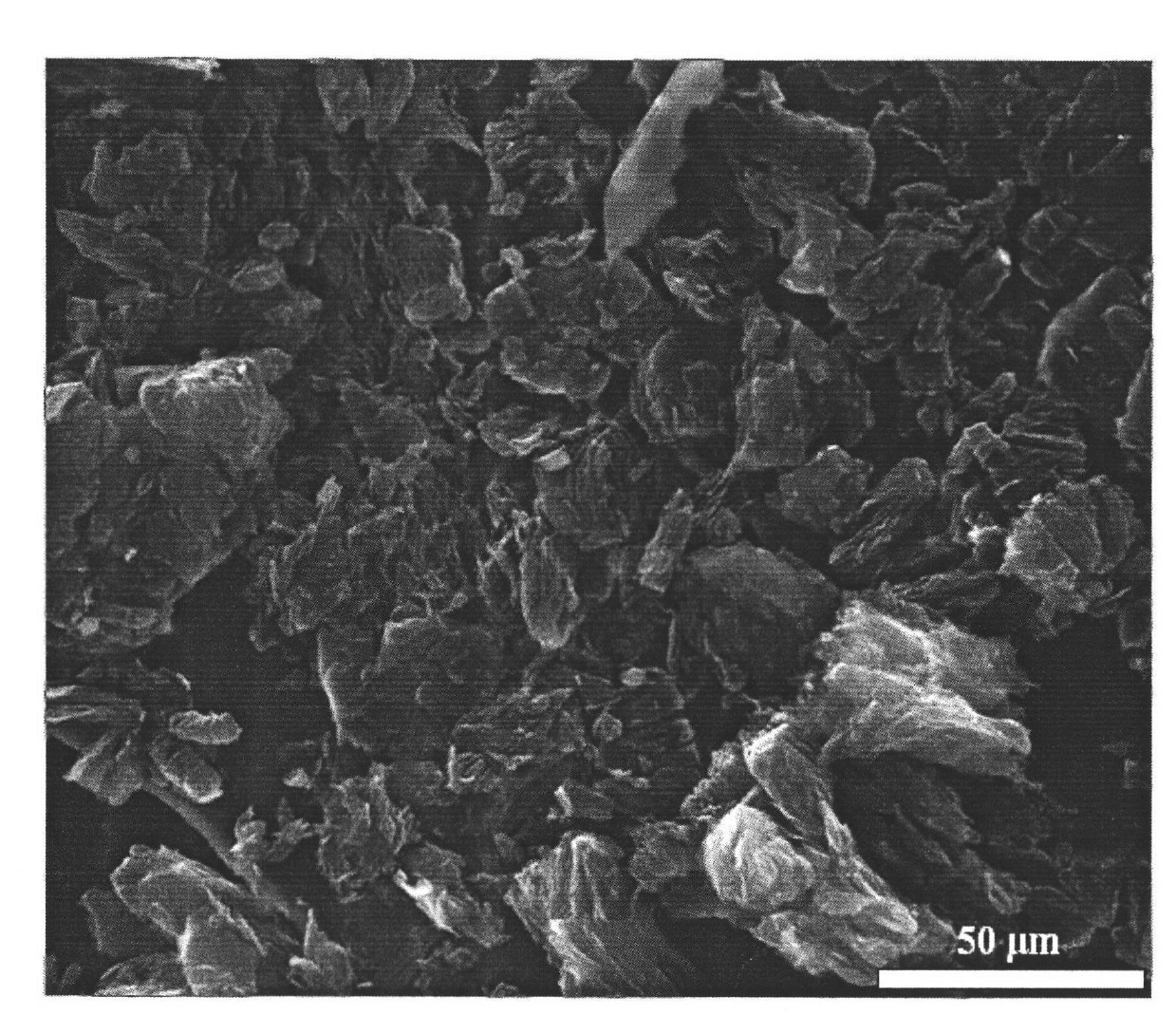

The invention discloses a lithium ion battery conductive additive and a preparation method thereof, and solves the technical problems of improving the conductive performance and cycle life of anode and cathode materials of a lithium ion battery. The lithium ion battery conductive additive is graphene, is black powder with grain size distribution of between 10 nanometers and 100 microns, and is a carbonaceous material consisting of single or 1,000 parallel or approximately parallel graphene lamellae. The preparation method comprises oxidization and stripping reduction. Compared with the prior art, the additive has higher electric conductivity; when the additive is applied to the electrode material, the performance of the conventional battery can be greatly improved only by a little amount; the material serving as the conductive additive has good conductive performance, is easy for dispersion, and can effectively enhance the conductive performance and the magnification charging and discharging performance of the electrode material of the lithium ion battery and prolong the cycle life; and the preparation method has low requirements for raw materials and equipment, is easy to control the process, and is suitable for industrialized production.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH +1

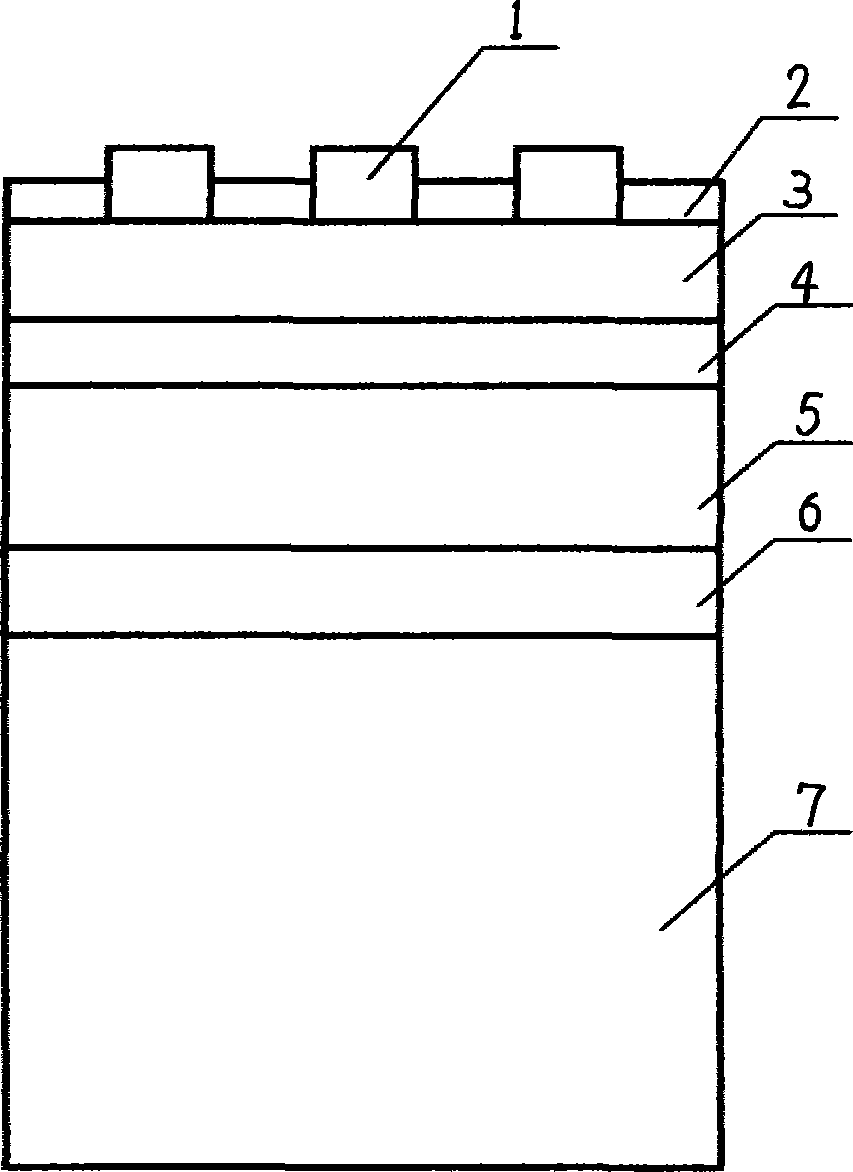

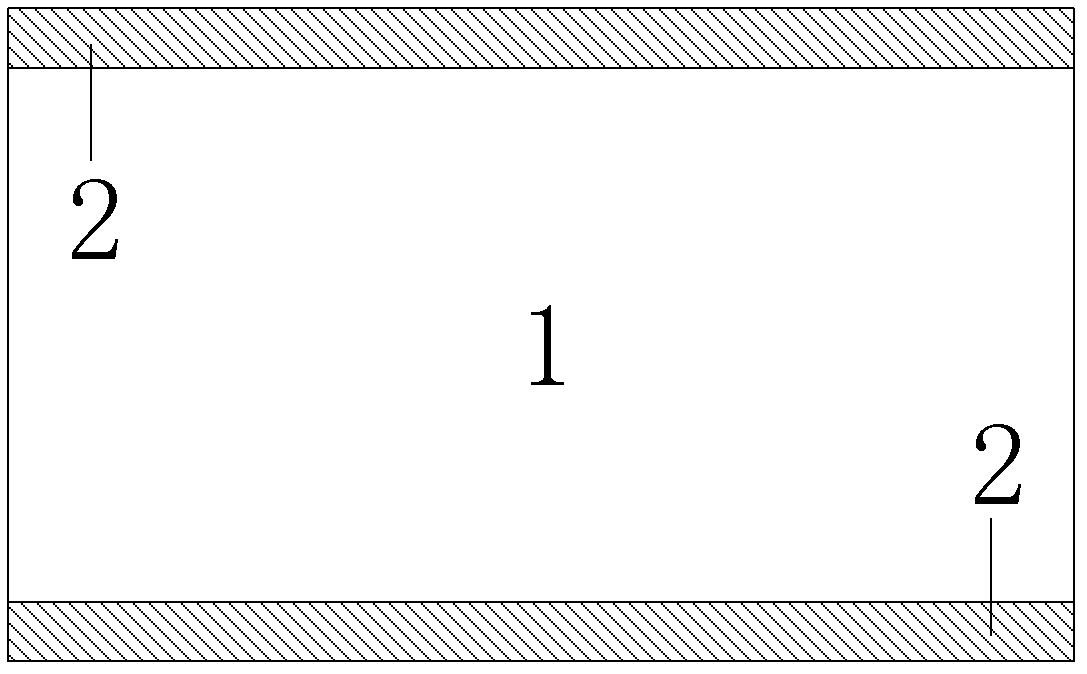

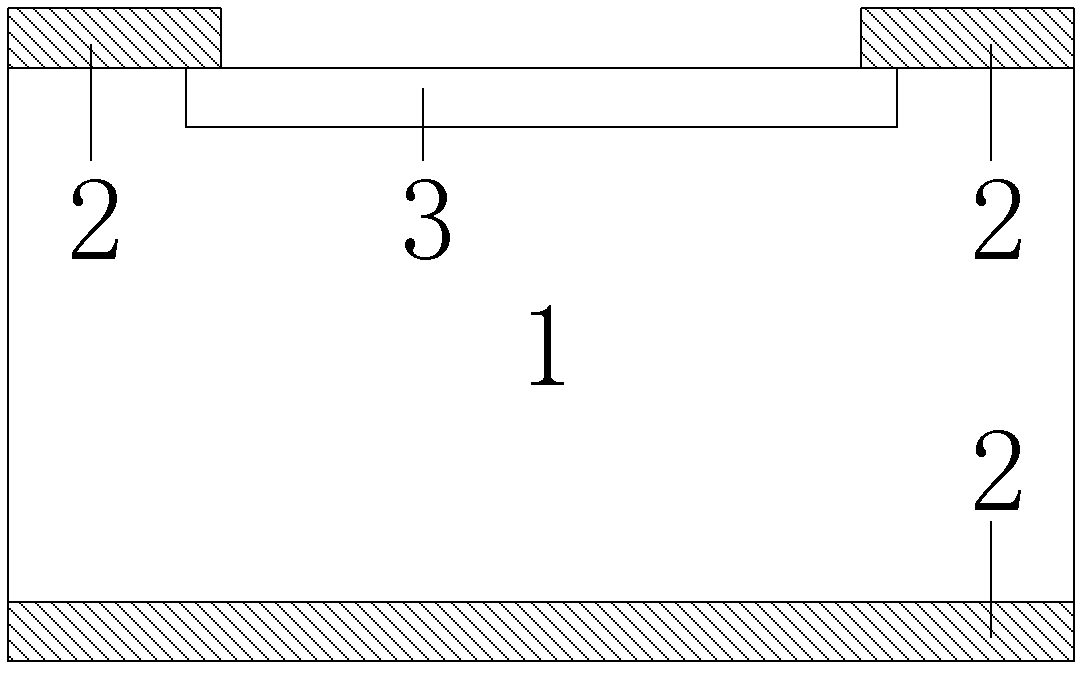

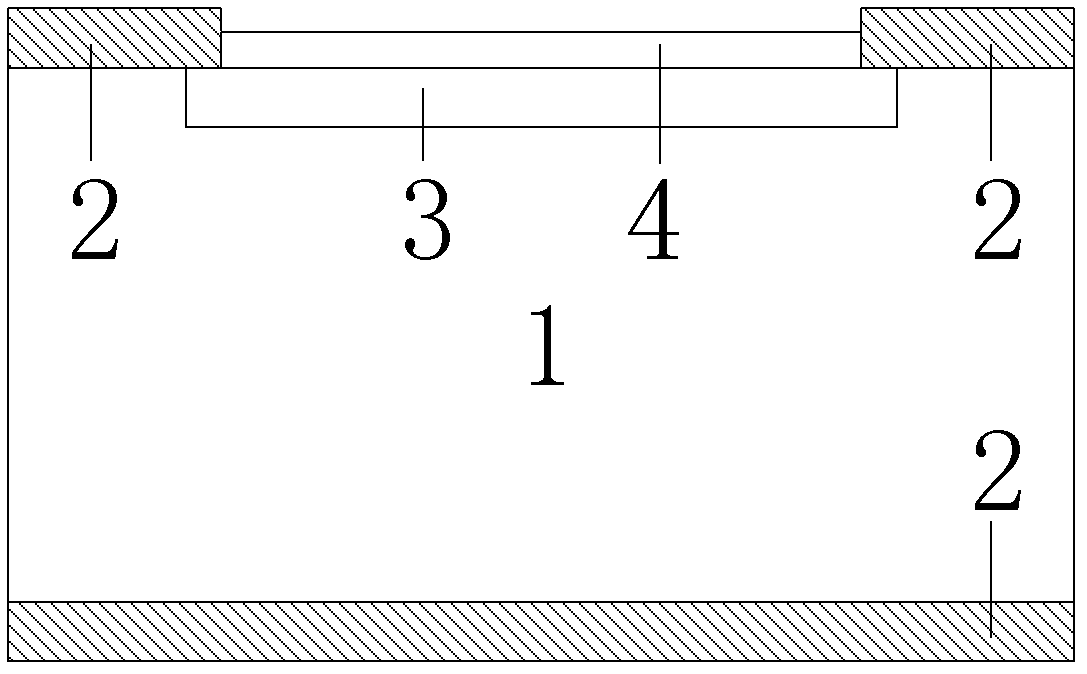

Flexible CIGS thin-film solar cell and absorption layer preparation thereof

ActiveCN101459200AReduce dosageThe process is easy to controlFinal product manufacturePhotovoltaicsIndiumMetallic materials

The invention belongs to a flexible CIGS thin-film solar cell and a process for preparing an absorption layer thereof, the flexible CIGS thin-film solar cell is a multi-layer film structure, which comprises an substrate, a bottom electrode, an absorption layer, a buffer layer, a window layer, an anti-reflecting film and an upper electrode, and the flexible CIGS thin-film solar cell is characterized in that the substrate is made of flexible metals or polyimide. The process for preparing the adsorption layer of the flexible CIGS thin-film solar cell is characterized in that the substrate is made of flexible metals or polyimide, the bottom electrode Mo of the thickness of 0.5-1.5 mu m is deposited by magnetron sputtering, a metal prefabricating layer is prepared on a Mo thin-film, and is in vacuum seal to be placed in a furnace to heat, the temperature of the area of a solid selenium source is controlled between 180-300 DEG C to perform selenizing treatment, thereby enabling the metal prefabricating layer to be transformed into a semiconductor thin-film. Through performing selenizing or vulcanizing under saturation vapor pressure of selenium or sulfur in a vacuum seal silica tube, controllable repeatability of the technique process is fine, use quantity of selenium or sulfur is reduced, besides, the process is controllable and the equipment is simple.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

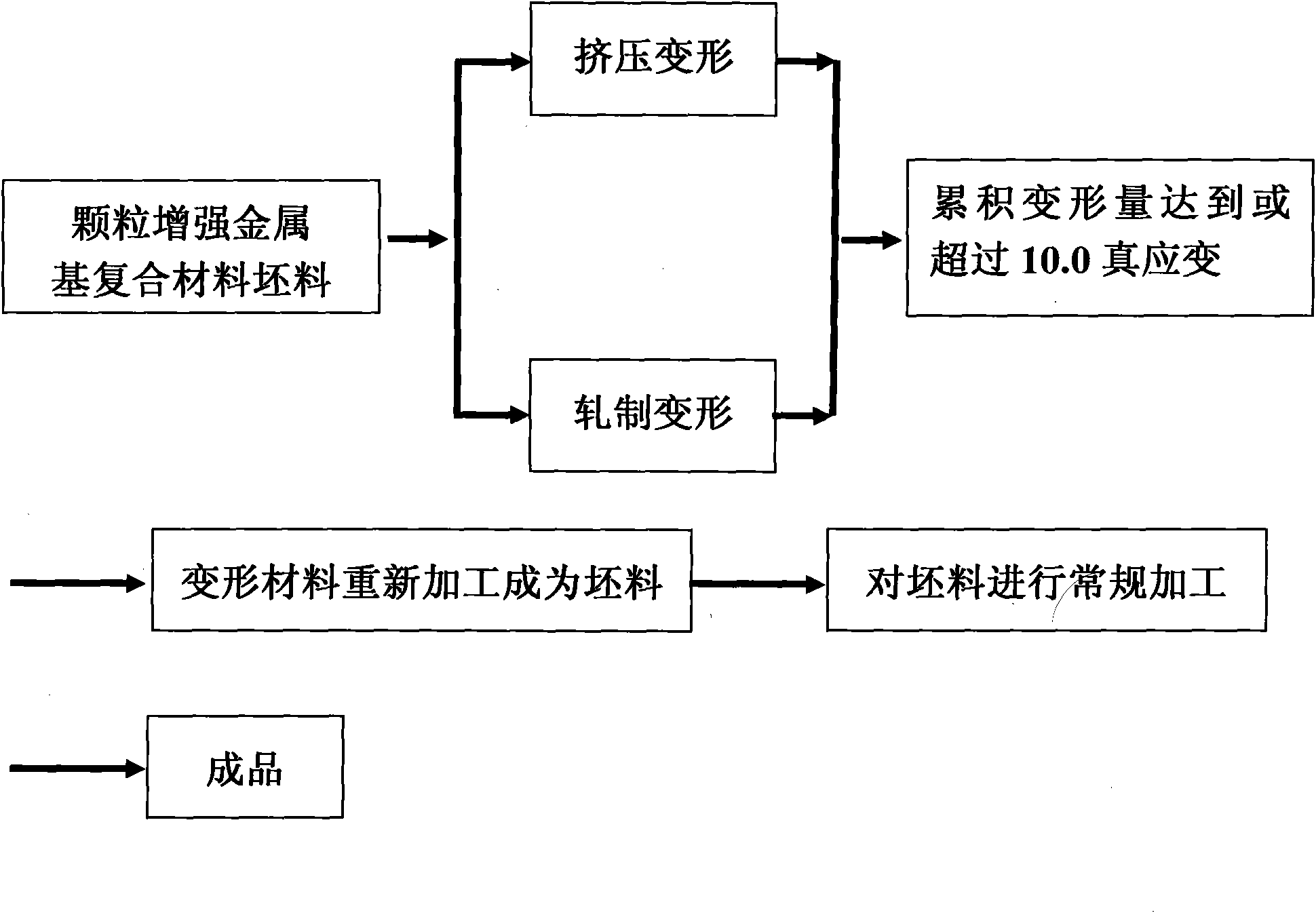

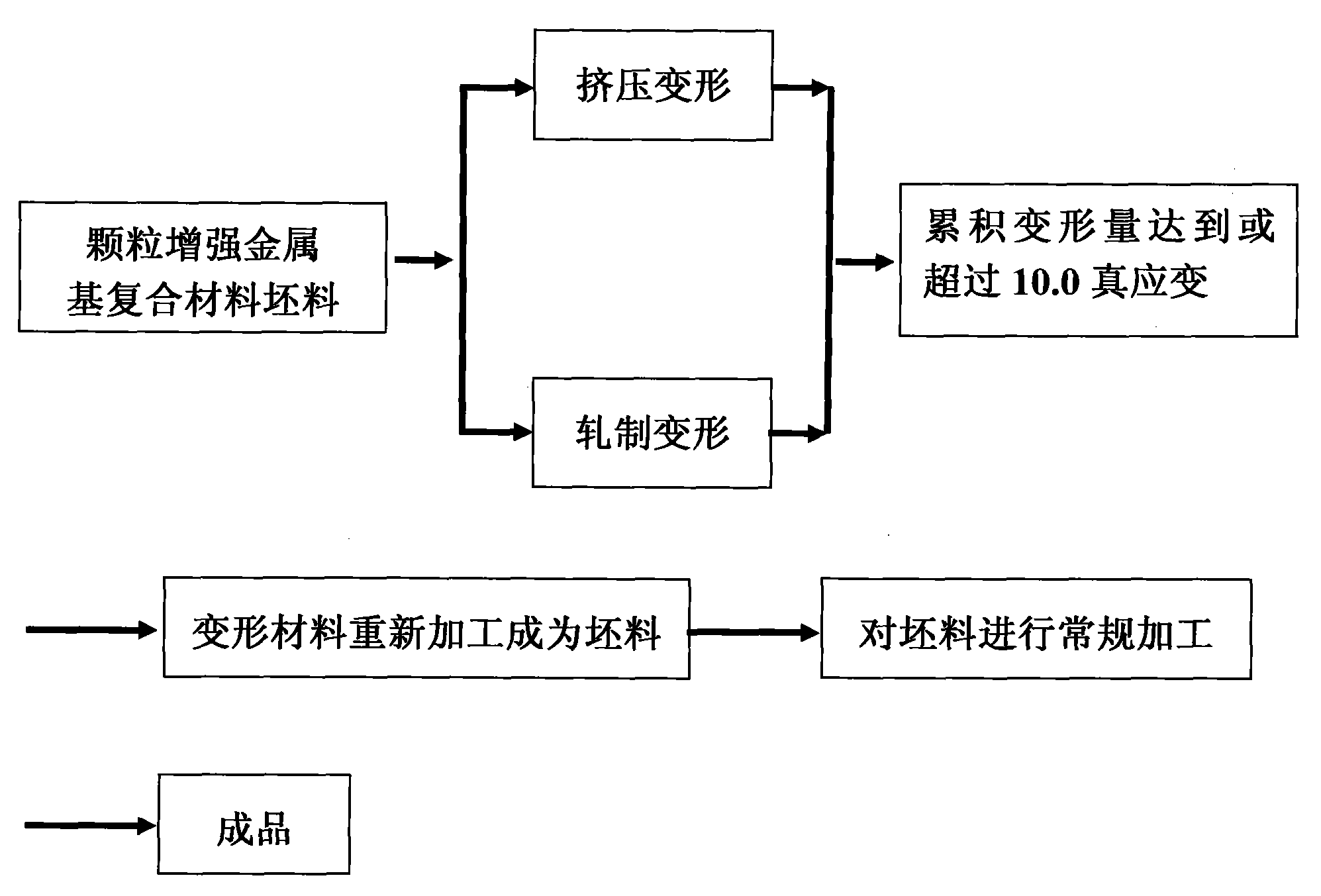

Uniformly-dispersed particle reinforced metal-based composite material and preparation method thereof

InactiveCN102134664AGood for comprehensive performanceEvenly distributedMetal rolling arrangementsMetal matrix compositeMaterials processing

The invention discloses a particle reinforced metal-based composite material product (rods, wires, sheets or belts, or parts) which is obtained, based on the severe plastic deformation theory of material, by the step of performing severe plastic / accumulated deformation processing on a particle reinforced metal-based composite material so that second phase particles agglomerated in a metallic matrix are uniformly distributed (dispersed) in the matrix, and then carrying out subsequent processing, thereby enhancing the quality and the yield of the particle reinforced composite material and lowering the processing cost of the material, and thus a particle reinforced metal-based composite material having the characteristic of the uniformly distributed second phase particles and excellent performance is obtained.

Owner:KUNMING UNIV OF SCI & TECH

Method for recycling zirconium oxide and yttrium oxide from yttrium oxide steady zirconium oxide solid fused mass waste matter

ActiveCN101244843ASignificant progressTo achieve the effect of resource utilizationRare earth metal compoundsZirconium oxidesZirconium hydrideYttria-stabilized zirconia

The invention relates to a method for recovering zirconia and yttria from the yttria-stabilized zirconia solid solution waste, which comprises the following steps: mixing the solid solution waste powder, sulfate and salt; acidizing and calcining at 200 to 320 DEG C; leaching the acidizing water and / or mother liquor under self-heating conditions; concentrating the leaching solution to leach zirconium sulfate; dissolving the zirconium sulfate in the water and purifying; neutralizing the zirconium hydroxide with alkali and precipitating; calcining the zirconium hydroxide to obtain zirconia; precipitating zirconium mother liquor to produce by-product of ammonium sulfate; neutralizing yttrium rich mother liquor and precipitating to obtain yttrium; dissolving yttrium rich residue with acid and purifying; precipitating oxalate to obtain yttrium oxalate; calcining to obtain the yttria. The method has the advantages of effectively separating the yttria from the zirconia in stable zirconia solid solution waste with optional yttrium ion under low temperature condition, changing the zirconia solid solution waste into valuables and utilizing the resources.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

Silicon detector structure with broad spectral response and method of making same

InactiveCN102290481AWide spectral response rangeImprove absorption rateFinal product manufactureSemiconductor devicesSpectral responseSilicon detector

The invention relates to a silicon detector structure with a wide spectral response range, which comprises an n-type silicon substrate, a silicon dioxide medium masking layer, a p-type doping layer, a front surface contact electrode, an antireflection film layer, a broad-spectrum absorbing black silicon layer, a medium passivating layer and a back surface contact electrode, wherein a circular groove is arranged on the surface of the n-type silicon substrate; the silicon dioxide medium masking layer is formed around the circular groove on the surface of the n-type silicon substrate, and the middle of the silicon dioxide medium masking layer is an annular structure; the p-type doping layer is arranged in the circular groove of the n-type silicon substrate; the front surface contact electrode is produced on the inner wall of the annular structure of the silicon dioxide medium masking layer and covers the partial edge of the surface of the annular structure to form an annular structure; the antireflection film layer is produced in the annular structure of the front surface contact electrode and covers the surface of the p-type doping layer; the broad-spectrum absorbing black silicon layer is produced on the back surface of the n-type silicon substrate; the medium passivating layer is point-type and is formed on the surface of the broad-spectrum absorbing black silicon layer; and the back surface contact electrode is produced on the surface of the broad-spectrum absorbing black silicon layer and covers the point-type medium passivating layer.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

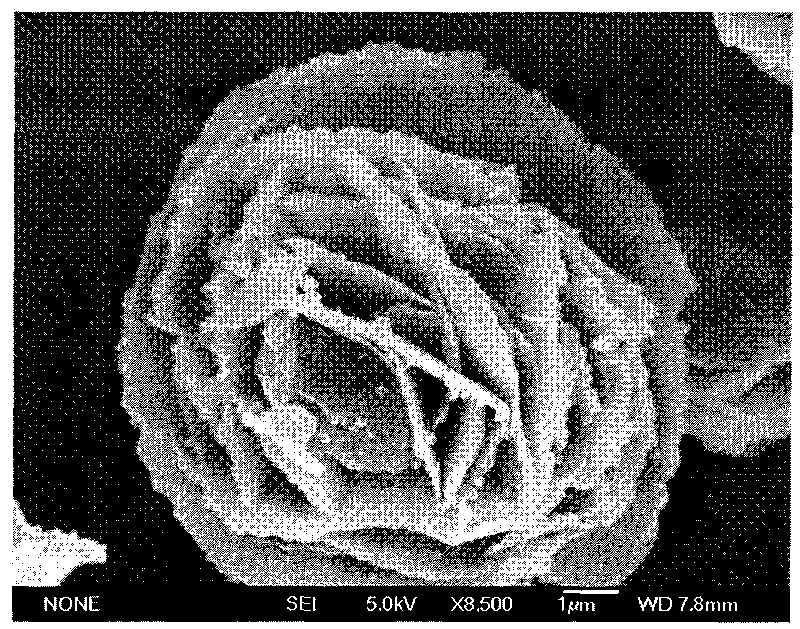

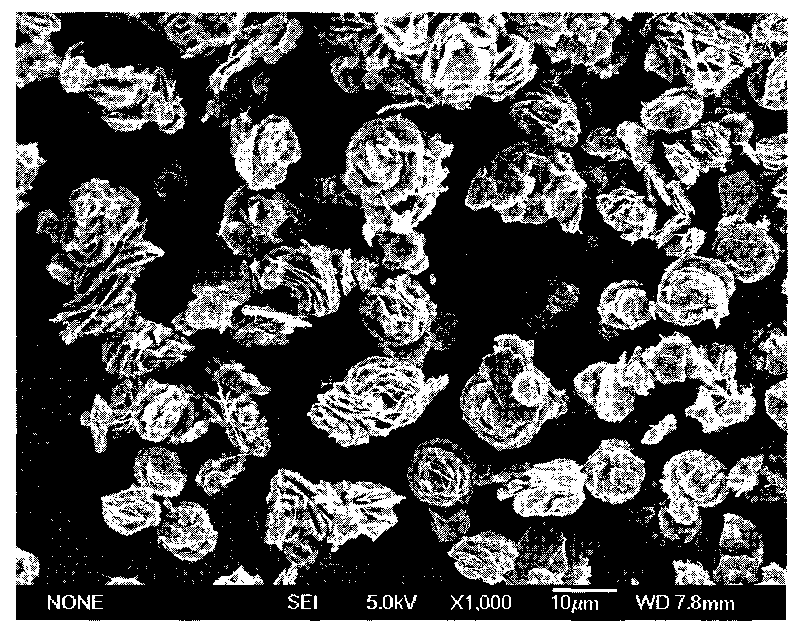

Method for preparing ferroferric oxide nano-piece through microwave method

InactiveCN101717122AMicrowave reaction time is shortThe process is easy to controlNanostructure manufactureFerroso-ferric oxidesSodium acetateMicrowave method

The invention relates to a method for preparing ferroferric oxide nano-piece through a microwave method, which belongs to the field of preparation of nano-material through a wet chemical method. The method comprises the following steps of: preparing a ferric salt solution by using ethylene glycol by using a soluble trivalent ferric salt as a raw material , adding the sodium acetate and a surfactant in the ferric salt solution, evenly stirring, and irradiating by using microwave to generate ferroferric oxide, filtering and washing the product, drying the product at a constant temperature in air to obtain the ferroferric oxide nano-piece material. The ferroferric oxide nano-piece material synthesized by the method has a thickness of 100nm below as well as the length and width of 1-10microns. The invention has the advantages of high purity of the prepared ferroferric oxide nano-piece, simple synthetic line, short period of microwave reaction of only tens of minute and easy control of the whole process, meets the demands of practical production, and has god application prospect in the fields of catalysis, biological medicine, energy and environment and the like.

Owner:HUAZHONG NORMAL UNIV

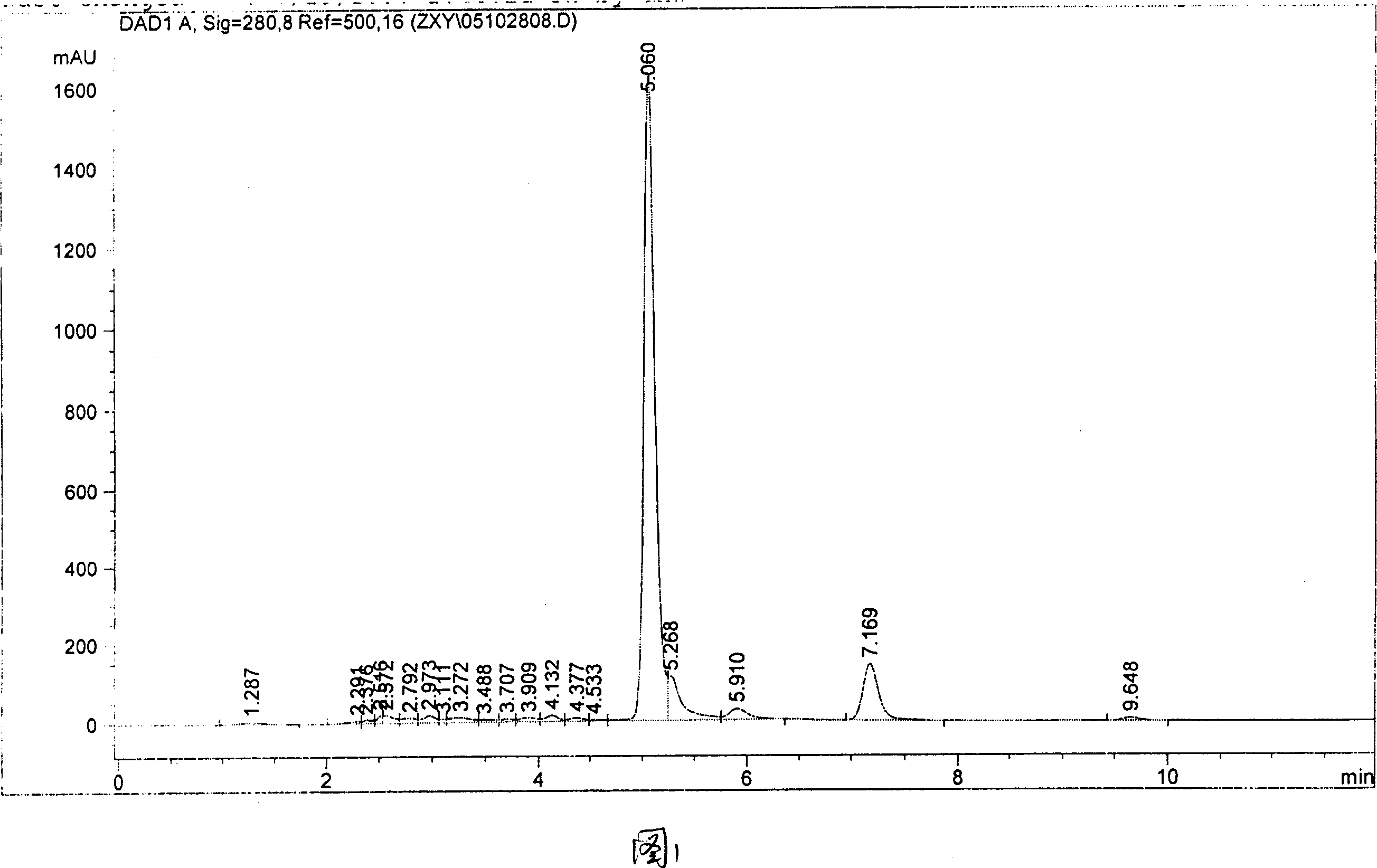

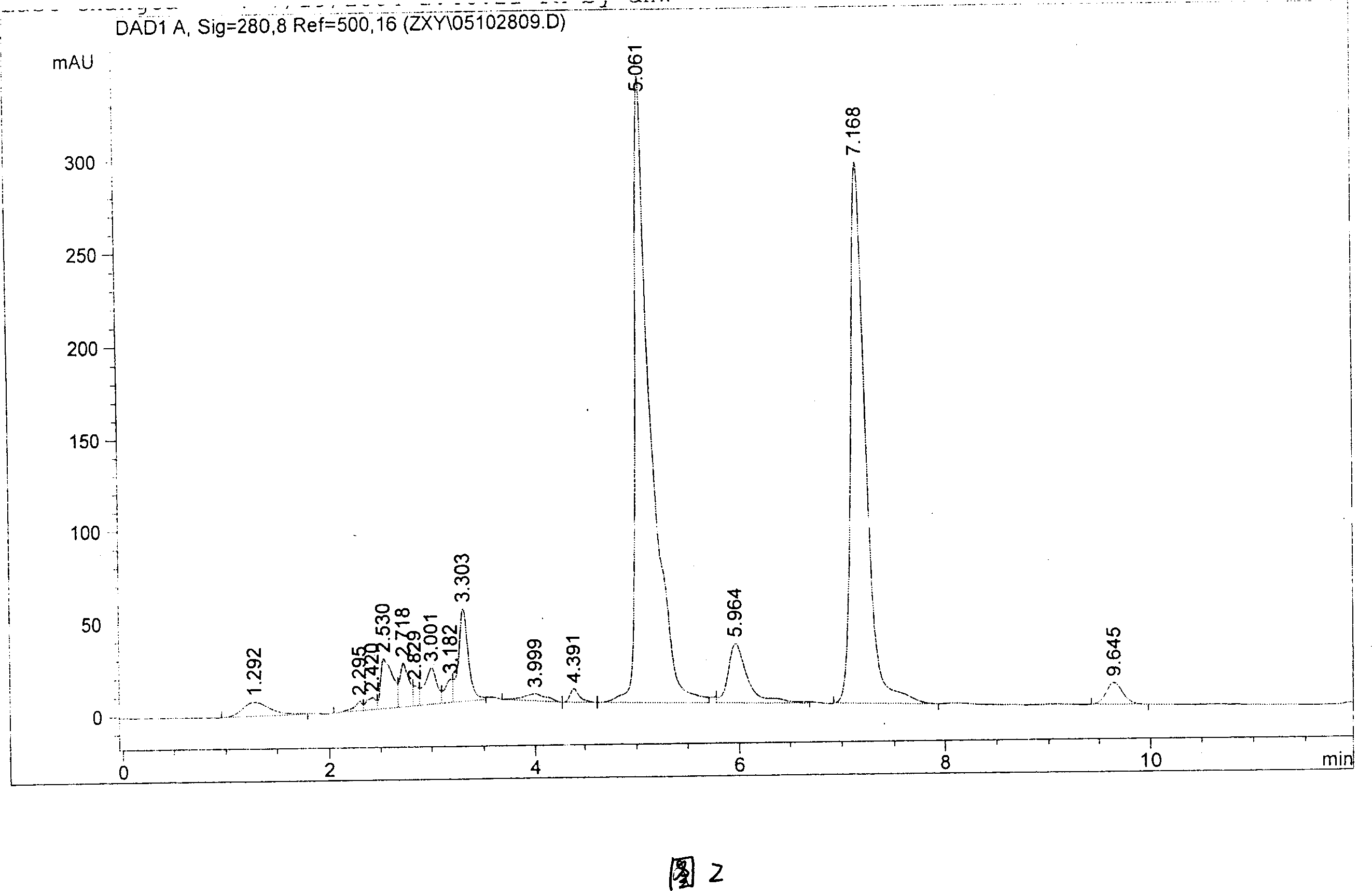

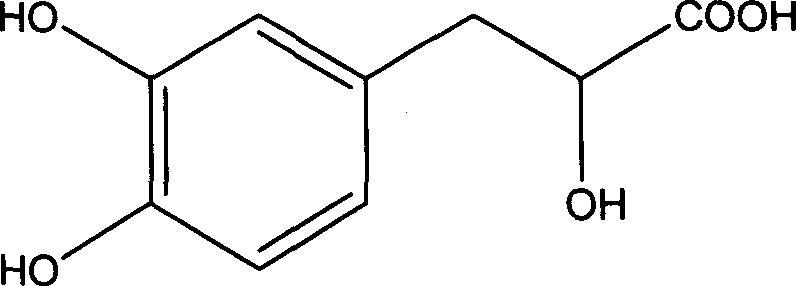

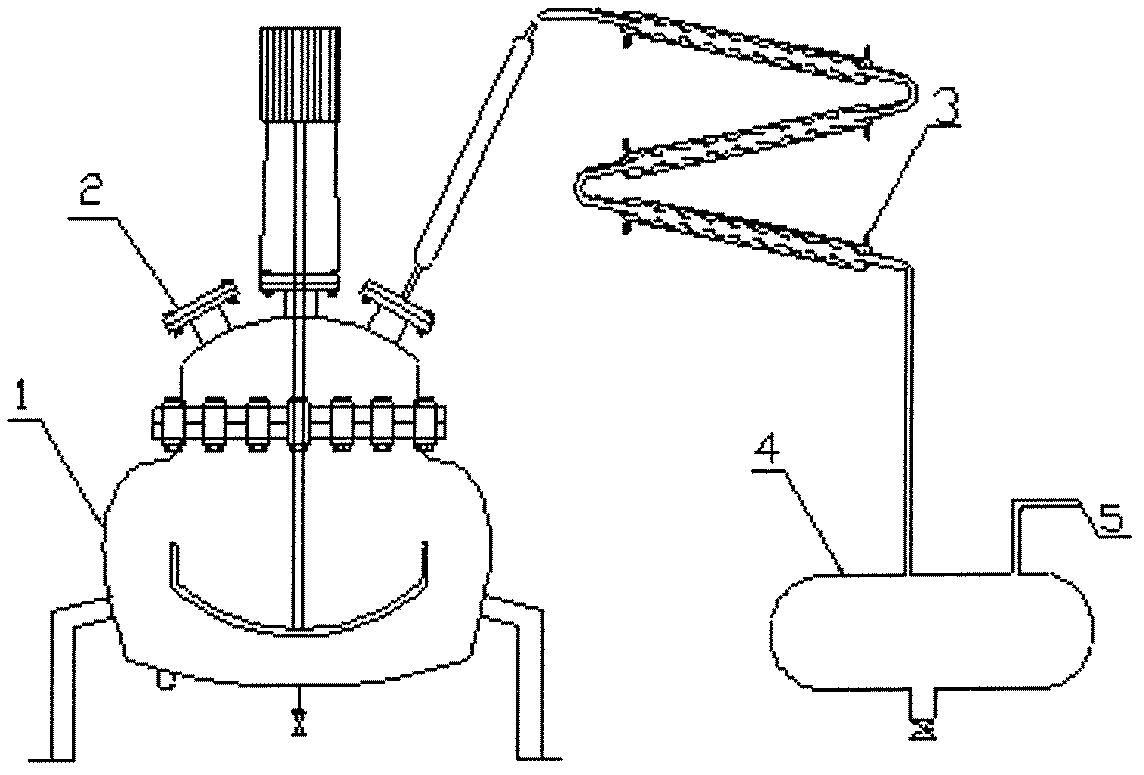

Method of preparing high purity Danshensu

InactiveCN101012163ASimple processThe process is easy to controlCarboxylic compound separation/purificationPlant ingredientsSephadexOrganic solvent

The invention discloses a making method of high-purity tanshinone, which comprises the following steps: (1) heating and refluxing to extract salvia miltiorrhizae root and stalk through 0.1-6.0mol / L acid water / alcohol solution; (2) adsorbing extract through adsorbing column with large-hole resin adsorbent; (3) eluting through water until pH value is 7 first and hydrophilic solvent then; collecting 3-5 column bulks to elute tanshinone completely; (4) evaporating; adding organic solvent; heating; dissolving; crystallizing; or adopting polyamide, gluglucosan gel Sephadex LH-20, MCI GEL CHP20P, C4, C8 or C18 bond phase; obtaining the product.

Owner:上海朗萨医药科技有限公司

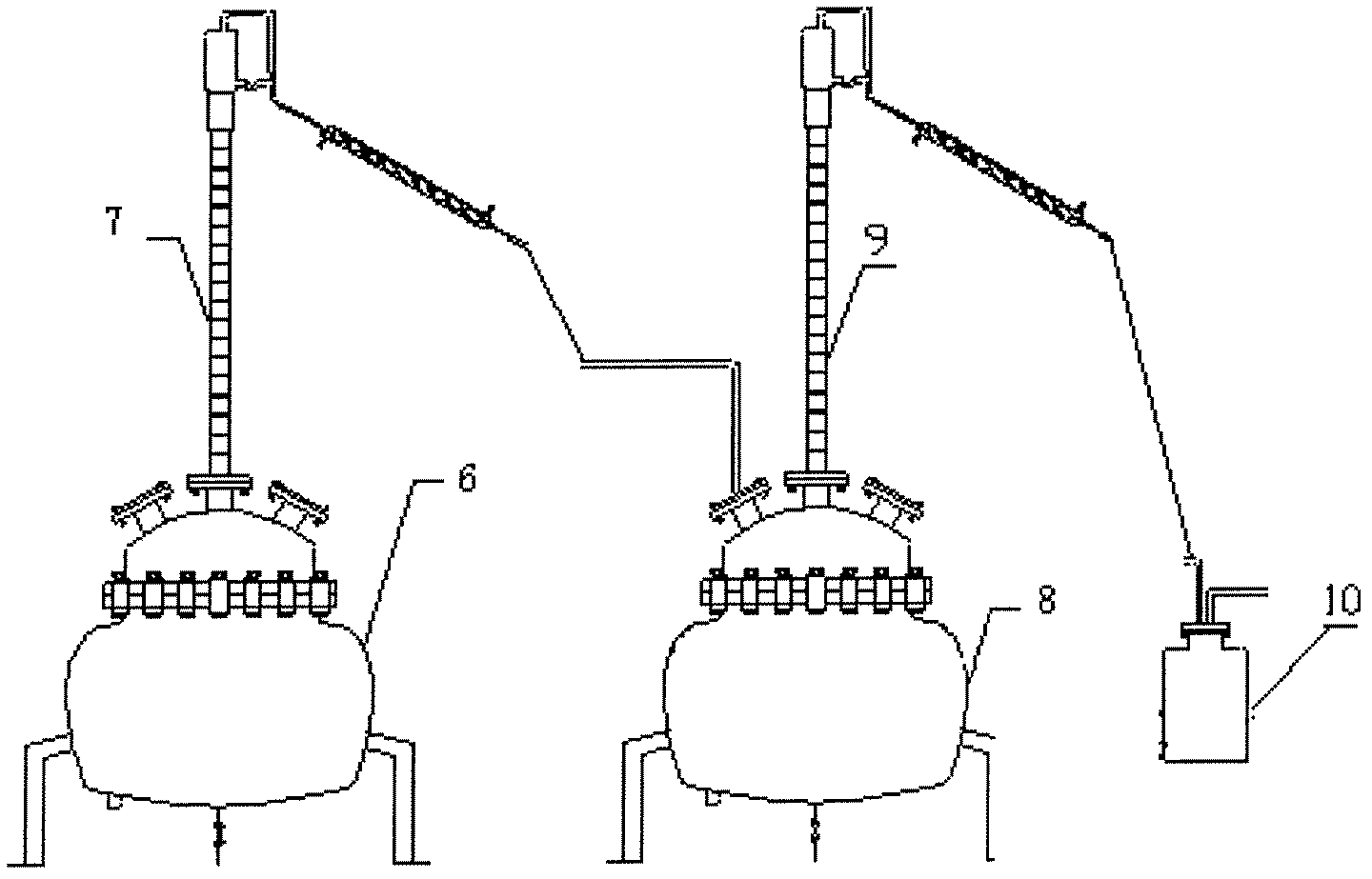

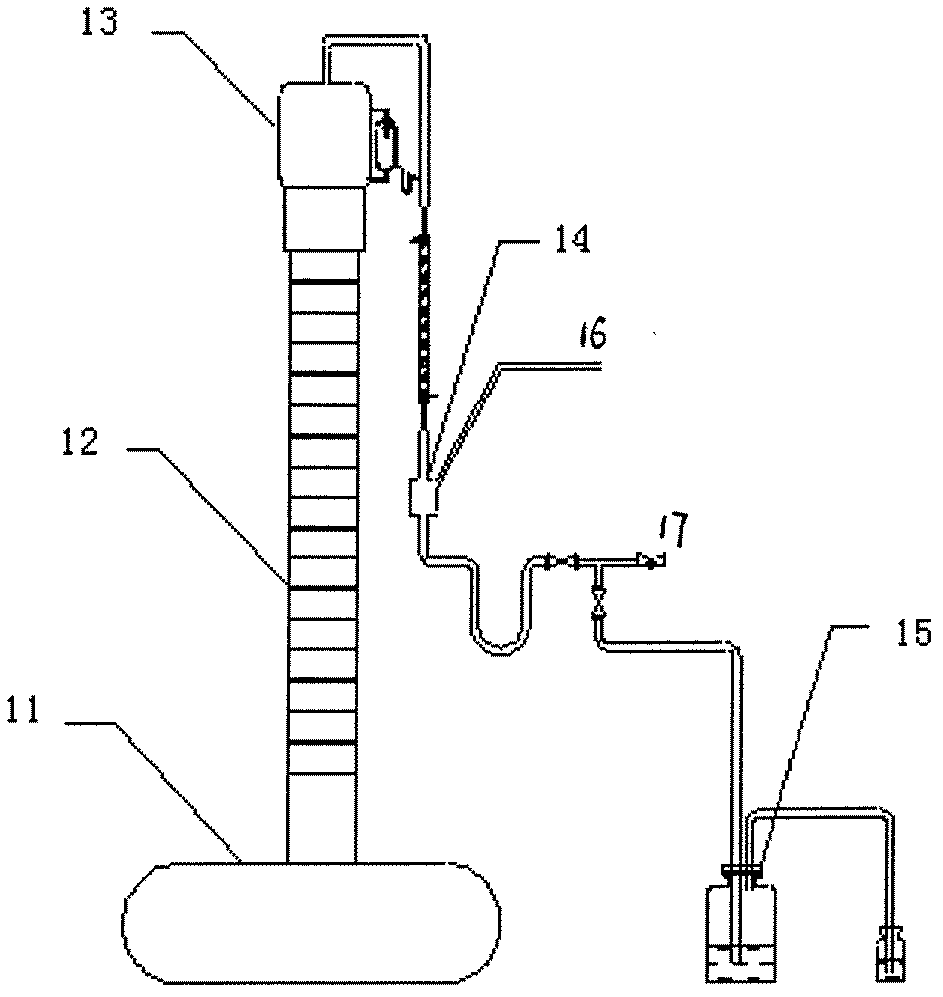

Preparation purification method of germanium tetrachloride for optical fiber

InactiveCN103183375AMeet the requirements of germanium tetrachlorideSuitable for mass production applicationsGermanium halidesPurification methodsDistillation

The invention provides a preparation purification method of germanium tetrachloride for optical fibers, which adopts germanium concentrate as a raw material; hydrochloric acid, sulfuric acid, and ferric trichloride are added into a chlorination reaction vessel according to a certain proportion for reaction to prepare crude germanium tetrachloride; the crude germanium tetrachloride is fully mixed with hydrochloric acid and manganese dioxide according to a certain proportion in a repeated distillation reaction vessel for distillation and purification to obtain preliminarily purified germanium tetrachloride; the germanium tetrachloride after repeated distillation purification is processed in a quartz rectifying tower in inert atmosphere by controlling a tower bottom temperature to be 75-95 DEG C, a tower column temperature to be 30-95 DEG C, and a reflux ratio of 4:1-14:1, so as to obtain high-purity germanium tetrachloride. The high-purity germanium tetrachloride prepared through three procedures of chlorination distillation, repeated distillation, and rectification purification, has a content of transition metal impurities of less than 3 ppb, a content of hydrogen-containing impurities of less than 1 ppm, and meets the requirements for perform rod germanium tetrachloride for optical fibers.

Owner:GRINM ELECTRO OPTIC MATERIALS

Inhomogeneous nucleation insulation coating processing method of metal soft magnetic composite material

ActiveCN104028747APrecise thickness controlPrecise control of its chemical compositionInorganic material magnetismInsulation layerSpray coating

The invention discloses an inhomogeneous nucleation insulation coating processing method of a metal soft magnetic composite material. The method includes the following steps that (1) particle size distribution is conducted on metal magnetic powder after sieving is conducted; (2) insulation coating is conducted on the distributed metal powder through an inhomogeneous nucleation method, and then the metal powder is dried; (3) the dried magnetic powder and a binding agent are evenly fixed, a release agent is added to conduct dry pressing and forming, and the mixture is pressed to form blank samples; (4) heat preservation is conducted on the blank samples for half an hour to two hours in a protective atmosphere, and air cooling and spray coating are conducted to obtain the target product. The composite powder prepared through the inhomogeneous nucleation method is even and compact in coating and controllable in coating layer thickness, and has high oxidation resistance, high resistivity, high saturation magnetization intensity, the good magnetic property and the good mechanical property; the surface of the metal magnetic powder is evenly coated with an A12O3 insulation layer through the inhomogeneous nucleation method, so that the coating effect is superior to that of an existing method, the operability is high and volume production is facilitated.

Owner:ZHEJIANG UNIV

Corrosion resistant brass alloy material for plate heat exchanger and processing technique thereof

A corrosion-proof brass band for plate heat exchanger and its production are both disclosed herewith. It contains (wt%): Cn 76-79, Al 1.0-3.5, Ni 0.3-1.5, B 0.002-0.015, As 0.01-0.1, Ce 0.05-0.2, and balanced with Zn, and with impurity not more than 0.3. It is produced by: weighing, smelting, casting, hot rolling, end-surface milling, primary rolling, inter-annealing, cold rolling, inter-annealing, edge cutting, pre-rolling, inter-rolling, fine rolling, final annealing, surface treating, cutting, and packing. It is of size (0.4-8.5mm)X(300-1000mm)X(500-3000mm), performance of Rm not less than 410MPa, A11.3 not less than 40%, Hv1 not less than 90, grain 0.010-0.030mm, and Ra larger than 0.2um without scratches.

Owner:中铝洛阳铜加工有限公司

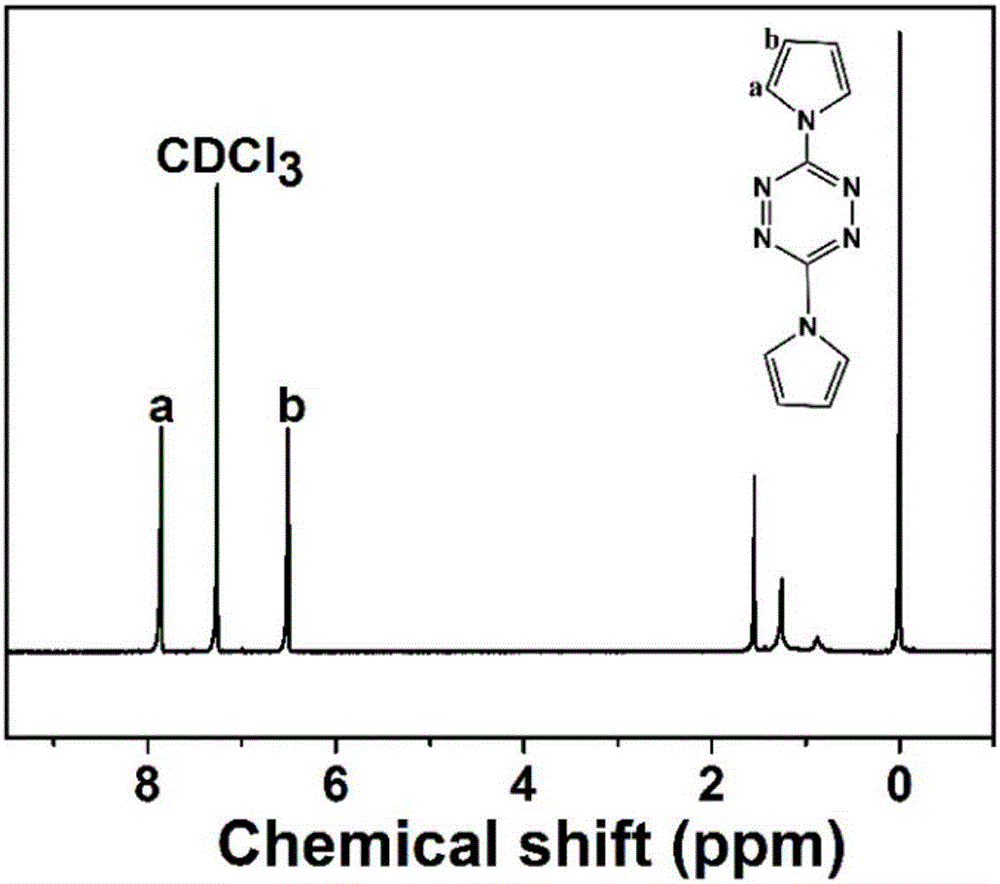

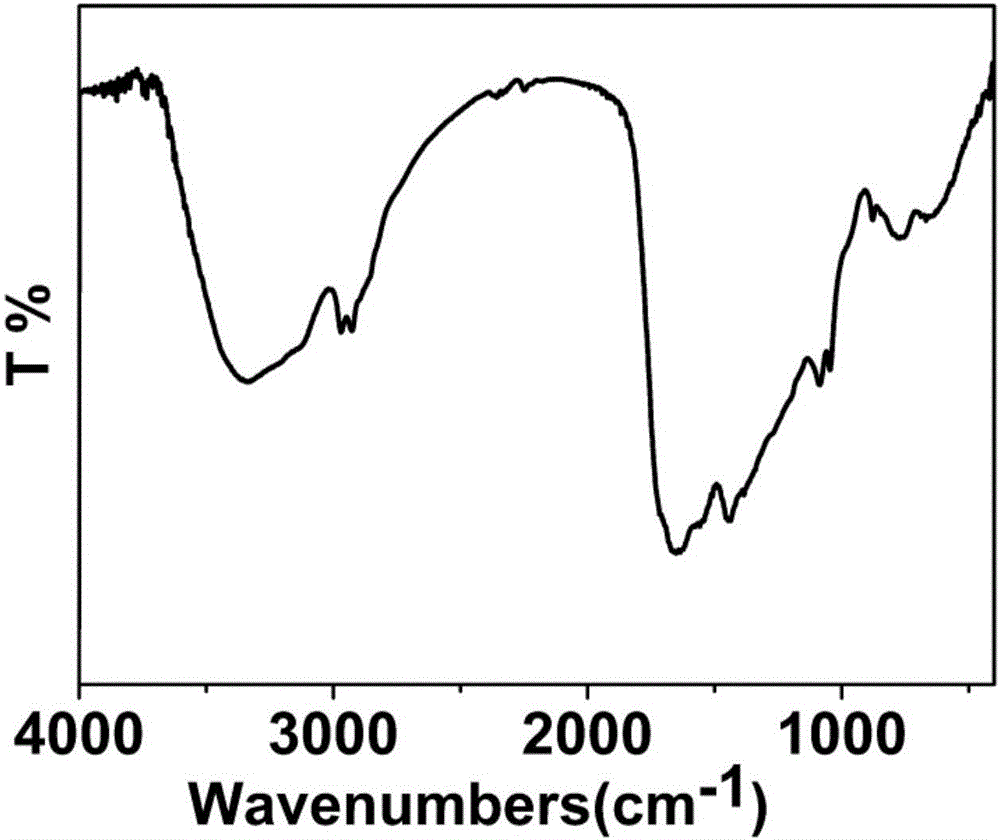

Oxygen reduction catalyst including pyrryl tetrazine ring and preparation method of oxygen reduction catalyst

InactiveCN106848334AImprove stabilityExcellent resistance to methanolCell electrodesThermal treatmentMedicinal chemistry

The invention discloses an oxygen reduction catalyst including a pyrryl tetrazine ring and a preparation method of the oxygen reduction catalyst. Monomer (pyrryl)n-1 and 2,4,5-tetrazine (n is 1 or 2) react with a catalyst and an alkylate reagent, a pyrryl tetrazine ring polymer is obtained, the pyrryl tetrazine ring polymer is subjected to thermal treatment in an inert atmosphere, and finally the oxygen reduction catalyst easy to operate, economical, efficient, high in stability and high in catalytic activity is obtained. Industrial production is promoted.

Owner:XIANGTAN UNIV

Preparing method of cocoa powder spice and application thereof

ActiveCN104804872ALower protein contentRich aromaTobacco preparationEssential-oils/perfumesFlavorCocoa Powders

The invention discloses a preparing method of cocoa powder spice. According to the method, biological compound enzymes are firstly used for carrying out biological fermentation processing on natural cocoa powder, then, fermentation liquid is used as a natural nitrogen source to take Maillard flavor enhancing reaction with a carbohydrate source, the cocoa powder spice with richer fragrance and higher flavor enhancing ingredient content is obtained, and the cocoa powder spice is applied to recombined tobacco leaves. Compared with the cocoa powder which is not subjected to enzymolysis fermentation and Maillard flavor enhancement, the cocoa powder has the advantages that the fragrance of the cigarettes is richer, the baking fragrance is enhanced, the smoke gas stimulation is reduced, and offensive odor is reduced, so that the smoking flavor defects of great stimulation and poor mouthfeel of the recombined tobacco leaves are overcome.

Owner:HUBEI CHINA TOBACCO IND

Method for preparing block of nano aluminum alloy in ultrahigh strength

InactiveCN1600466AEase of mass production scalePromote the development of industrializationNitrogenIngot

Owner:UNIV OF SCI & TECH BEIJING

Manufacture method of TPR (thermoplastic rubber) soft rubber insole

InactiveCN103192573ALow costImprove yieldInsolesSynthetic resin layered productsPolymer scienceInjection molding process

The invention discloses a manufacture method of a TPR (thermoplastic rubber) soft rubber insole. The manufacture method comprises the steps of: preparing raw materials of soft rubber, cutting a fabric, forming the soft rubber, gluing and trimming. The raw materials of the soft rubber comprise the following components in percent by mass: 20-29 percent of SEBS (styrene-ethylene-butadiene-styrene) resin, 70-79 percent of white oil, 0.1-1 percent of pigment and 0.2-2 percent of an assistant. The raw materials of the soft rubber are prepared by adopting the steps of: preparing pigment paste, preparing an assistant dispersing system and preparing the raw materials of the soft rubber. The technical scheme of the invention has the advantages of being high in yield of formed soft rubber, low in manufacture cost and simple in compound operation process of the soft rubber and the fabric, easily controlling the quality, and easily changing different styles of dies, is suitable for volume production, and is capable of reducing the production cost of the TPR soft rubber insole. Experiments prove that the manufacture method of the TPR soft rubber insole has the advantage that the processing cost is only 50-60 percent that of an existing injection molding process.

Owner:上虞舜美高分子材料有限公司

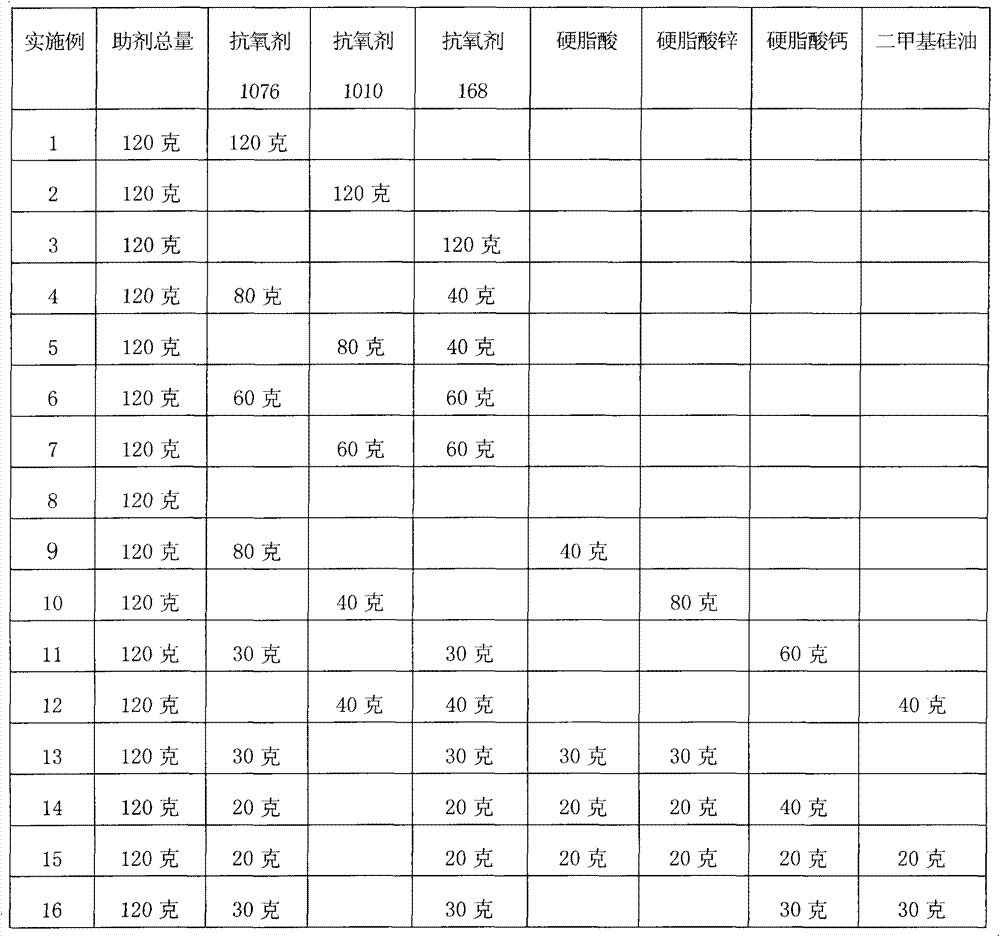

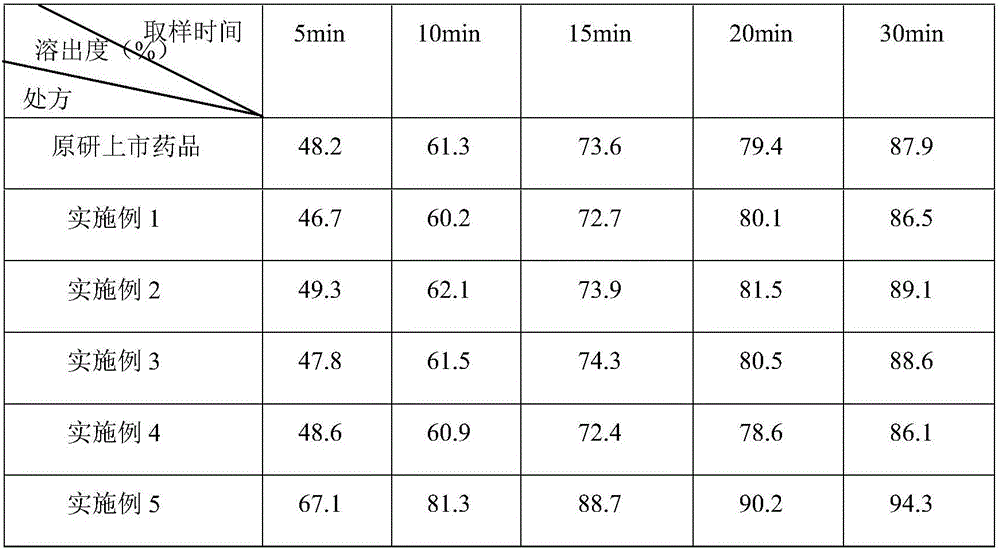

Sitagliptin phosphate tablet and preparation method thereof

InactiveCN106822017ASynthetic raw materials are readily availableFast disintegrationOrganic active ingredientsMetabolism disorderAdhesiveFiller Excipient

The invention belongs to the technical field of drug preparation and specifically relates to a sitagliptin phosphate tablet and a preparation method thereof. The sitagliptin phosphate tablet comprises the following raw materials in parts by weight: 30 parts of sitagliptin phosphate, 55-70 parts of filler, 0-5 parts of adhesive, 1.5-3.0 parts of disintegrating agent and 1.5-5.0 parts of lubricating agent; the filler is selected from one or more of microcrystalline cellulose, sugar and inorganic salt; the adhesive is selected from one or more of hydroxypropyl methylcellulose, hydroxypropylcellulose, povidone K30 and starch; the disintegrating agent is selected from one or more of crosslinking sodium carboxymethylcellulose, sodium carboxymethyl starch and polyvinylpolypyrrolidone. Compared with the prior art, the sitagliptin phosphate tablet provided by the invention has the technical effects of easily acquired compound raw materials, high disintegration speed, high dissolution rate, high stability, simple steps of preparation method, easily controlled technological process, short production period, low production cost and suitability for industrialized application.

Owner:CISEN PHARMA

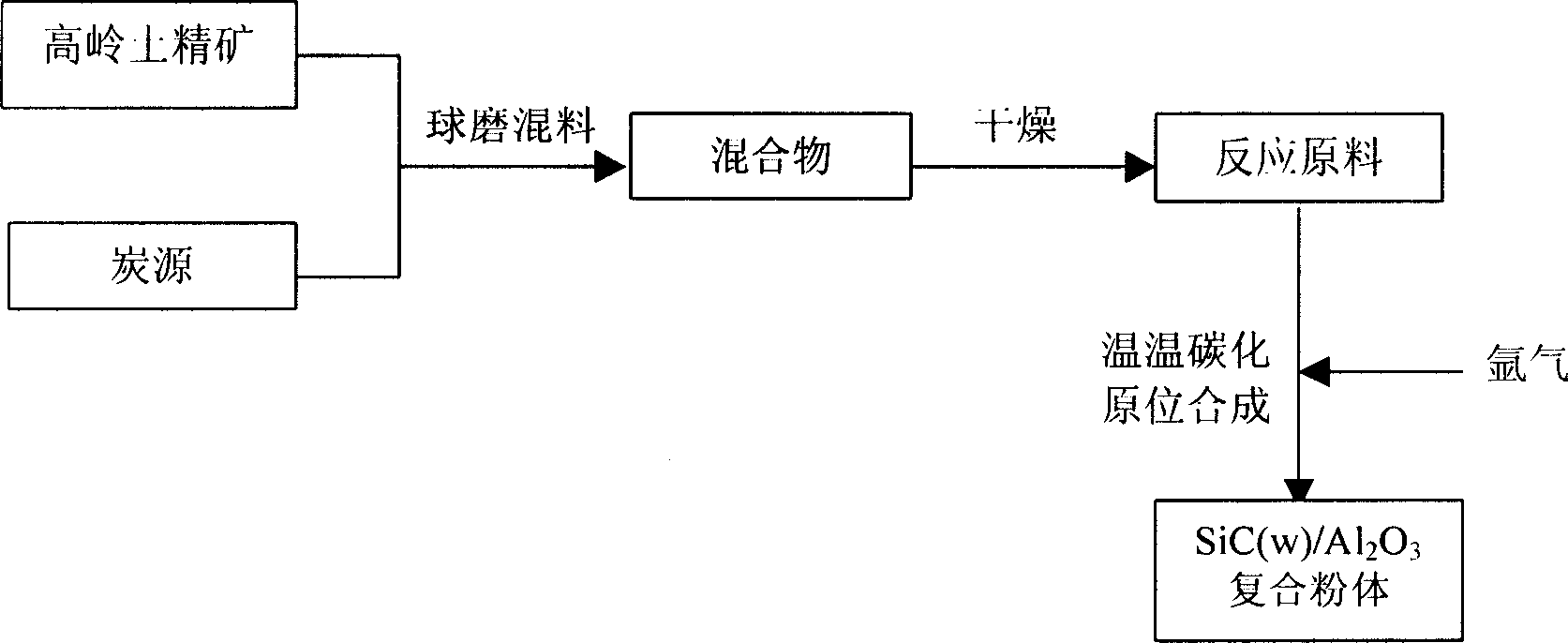

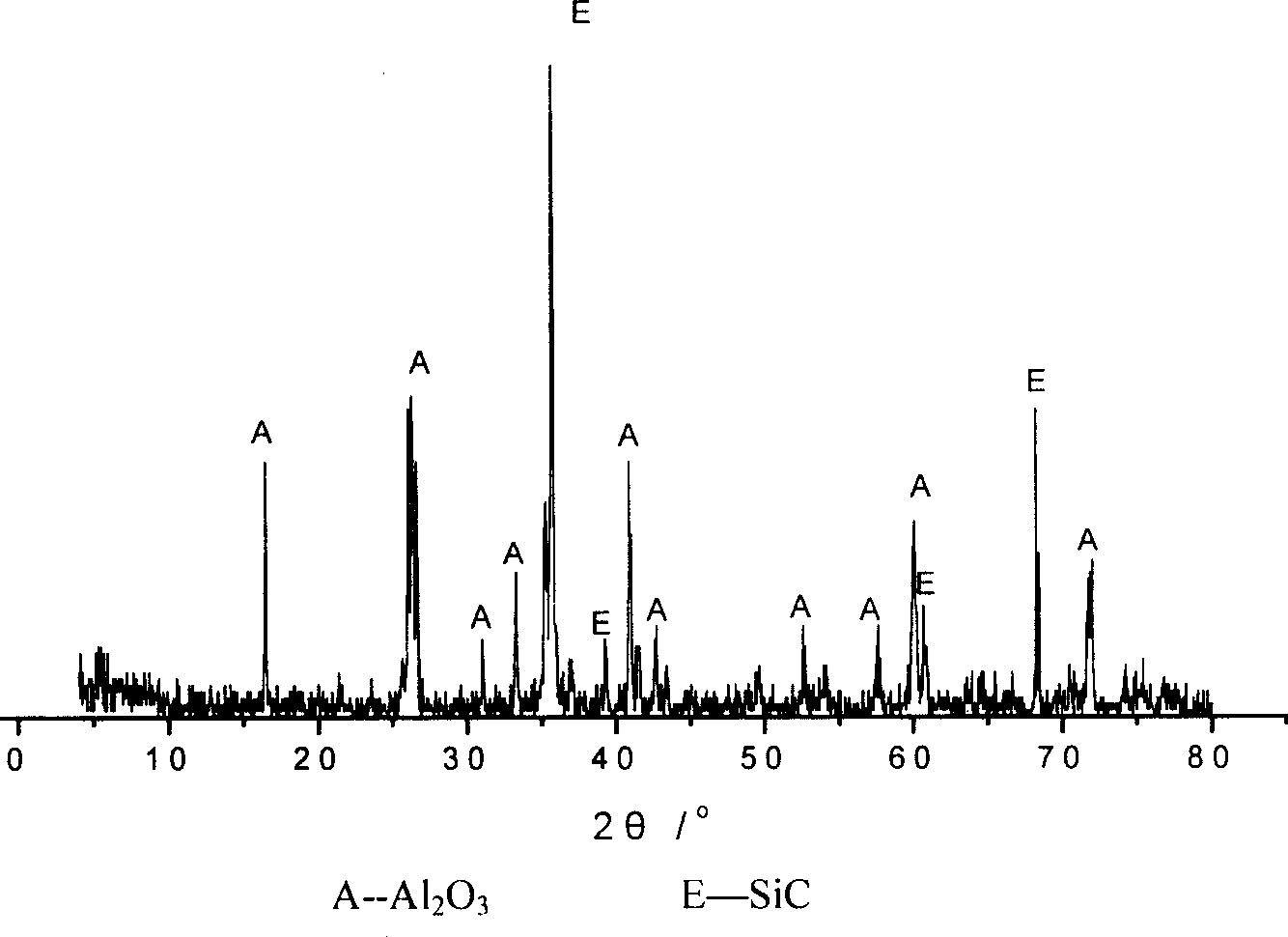

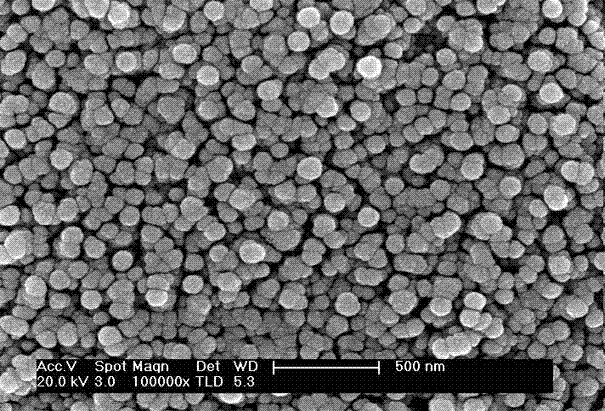

Method for preparing silicon carbide whisker/aluminium oxide composite ceramic powder using natural kaolin

The present invention discloses process of preparing composite ceramic powder of silico carbide whisker and alumina with natural kaolin. The preparation process includes ball milling and mixing the materials including natural kaolin and carbon source, which may be graphite, carbon black or organic high molecular matter, in the molar ratio of 1 to 3; drying and setting inside high alumina crucible and in furnace, which is first vacuum pumped and then filled with Ar in 1 atm as protecting atmosphere; raising the temperature at 10-15 deg.c / min speed to 1450-1550 deg.c, maintaining for 2-4 hr, and naturally cooling inside the furnace to obtain the composite ceramic powder of silico carbide whisker and alumina in nanometer level or sub-micron level. The present invention has cheap material, simple synthesis process and easy control the process, and the preparation composite ceramic powder has ideal shape and two-phase homogeneity.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of aluminium foil bionic nanostructured super-hydrophobic anti-condensation functional surface

The invention relates to a treatment method of an aluminium foil bionic nanostructured super-hydrophobic anti-condensation functional surface. The method comprises the following steps: firstly performing ultrasonic cleaning of an aluminium foil with acetone and deionized water, blowing to dry, soaking the aluminium foil into a 1 mol / L NaOH aqueous solution for treatment for 30-60 s, cleaning with ethanol and deionized water in order, blowing to dry so as to keep in reserve; soaking the pretreated aluminium foil in liquid which adopts a mixed aqueous solution of phosphoric acid and glycerol as an electrolyte, performing anodization under a room-temperature condition in a constant current density mode for 120-150 min; after the anodization is completed, taking the aluminium foil out, cleaning with ethanol and deionized water, blowing to dry; soaking the anodized aluminium foil in liquid stearic acid at 70 DEG C for 1 h, rinsing in hot ethanol with a temperature of 70 DEG C, curing in an oven with a temperature of 80 DEG C for 30 min so as to prepare the aluminium foil bionic nanostructured super-hydrophobic anti-condensation functional surface. The invention has a simple preparation process, no pollution, less substrate damage, excellent surface quality, and is applicable to popularization and application.

Owner:SOUTHEAST UNIV

Production of biological diesel oil with solid alkali

InactiveCN1896182ASimple and efficient removalMild reaction conditionsBiofuelsLiquid hydrocarbon mixture productionVegetable oilBiodiesel

Production of biological diesel oil by solid base is carried out by taking solid base as catalyst, and lipid exchange reacting for short-chain aliphatic alcohol and vegetable oil at suitable temperature and removing impurities of crude biological diesel oil to obtain the final product. The catalyst is re-useable and combined precipitant with flocculant It is simple and efficient, has gentle reactive condition and no environmental pollution.

Owner:TSINGHUA UNIV

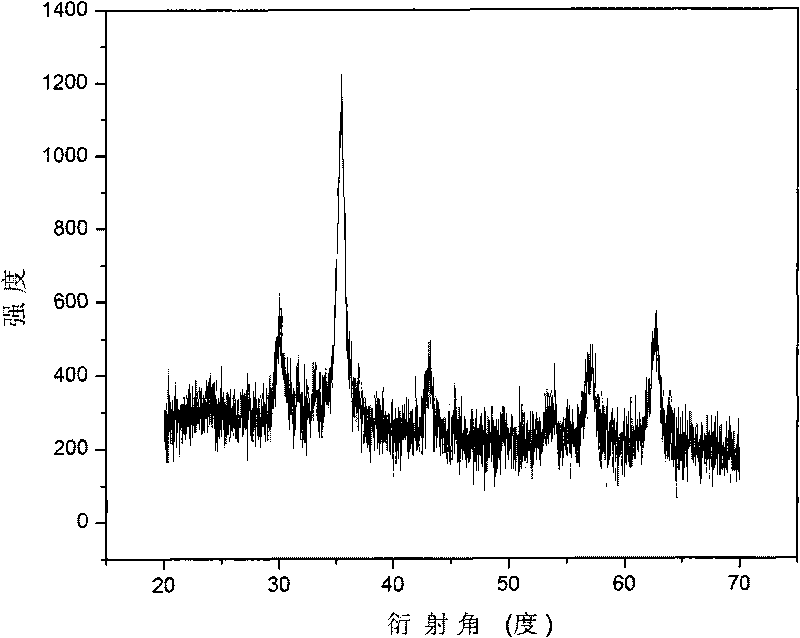

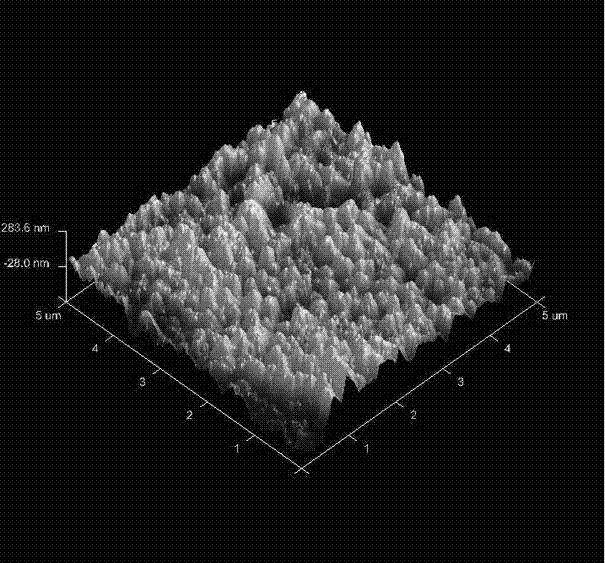

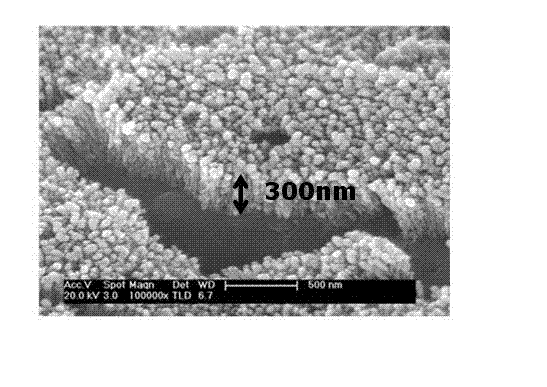

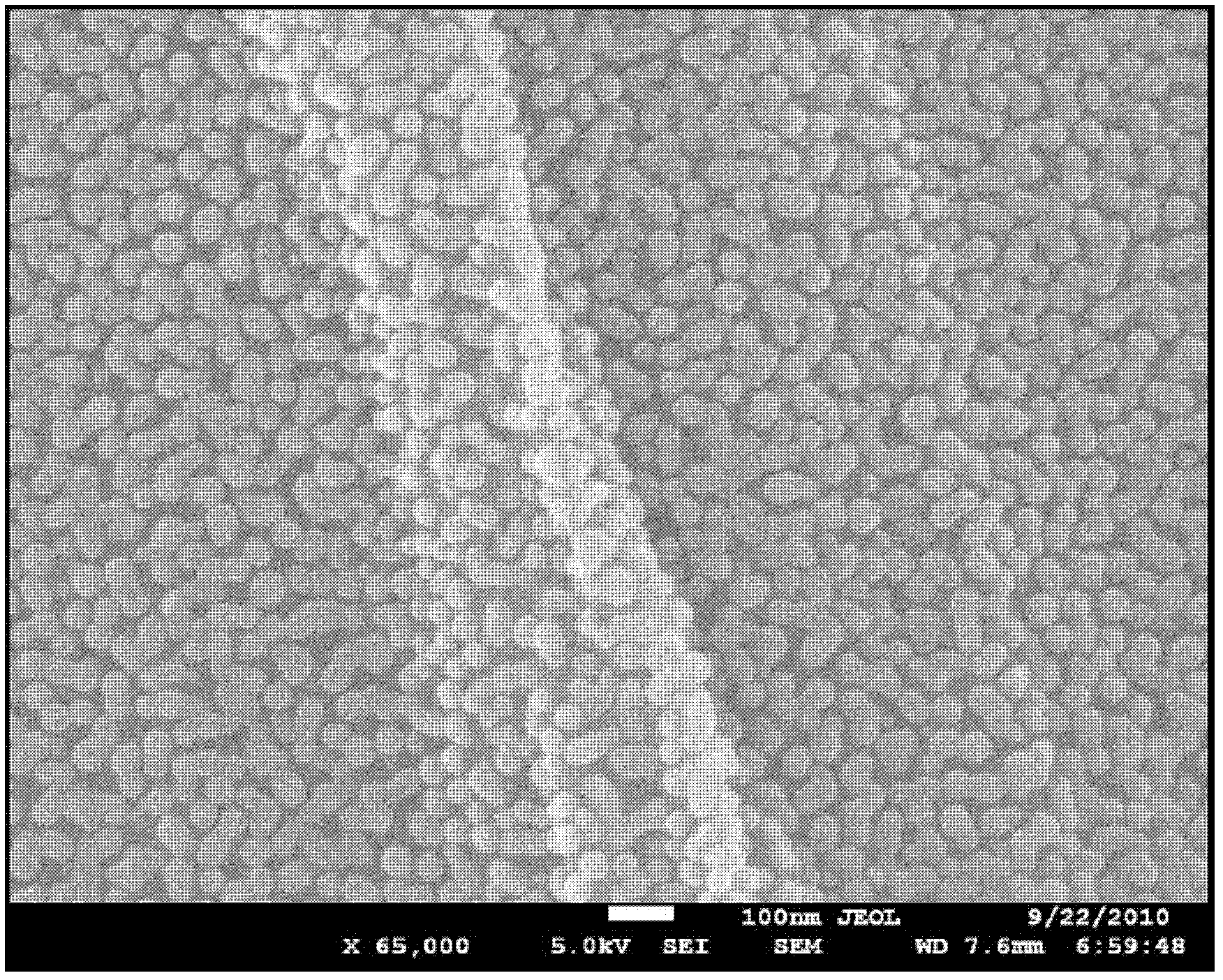

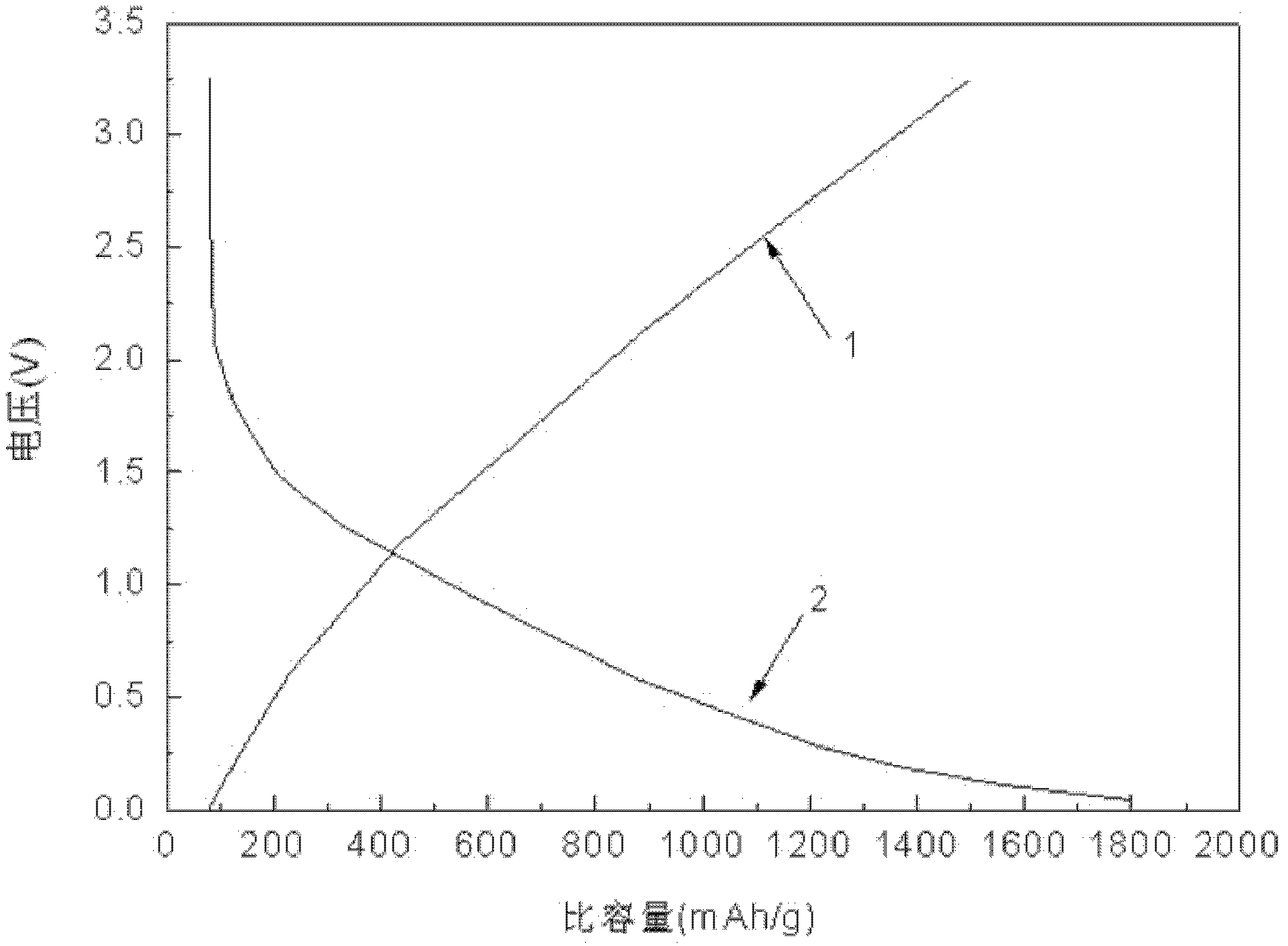

Graphene/chromium nitride nano-composite material and preparation method thereof

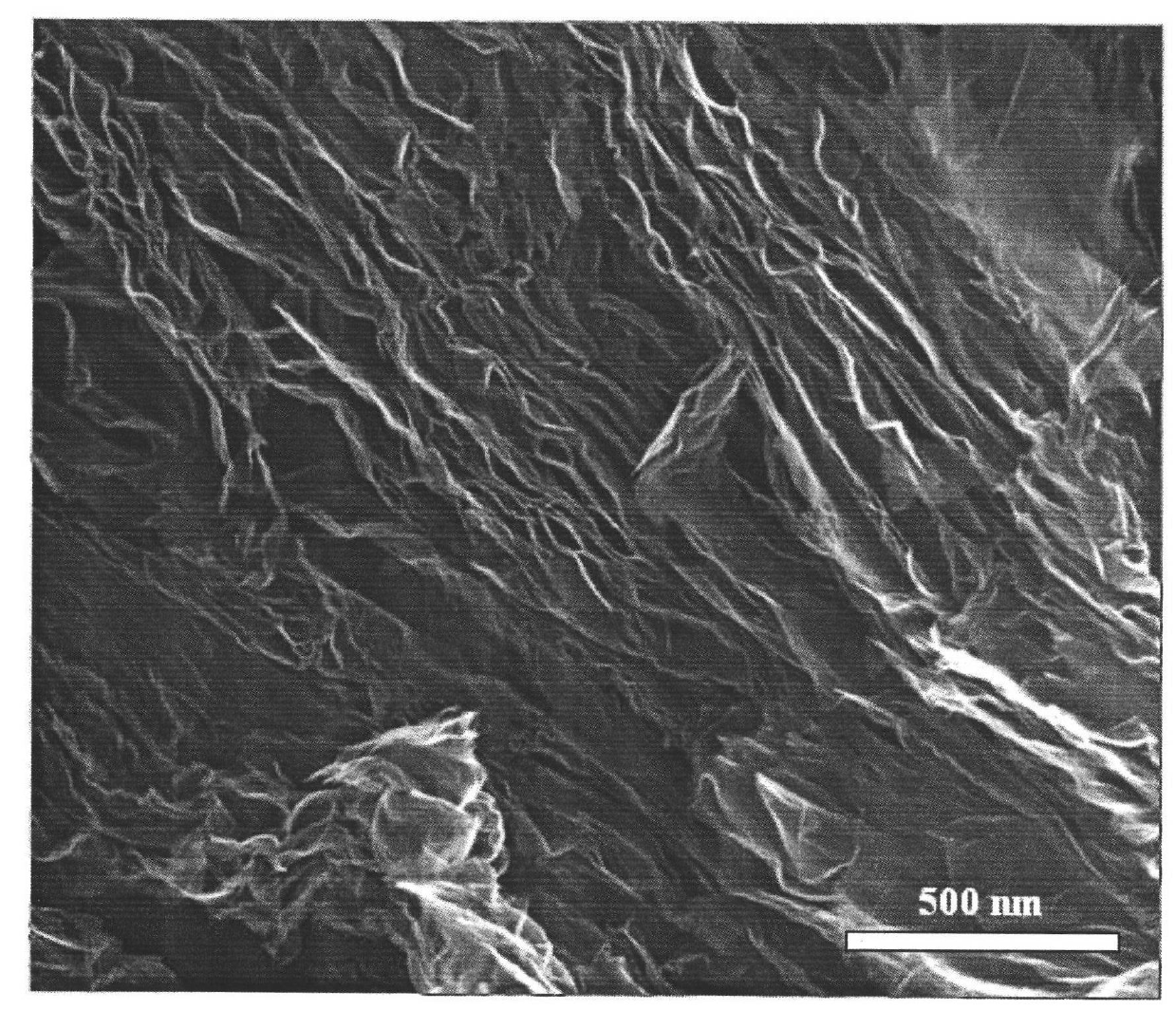

InactiveCN102332567ASimple preparation equipmentThe process is easy to controlMaterial nanotechnologyCell electrodesCvd grapheneUrea

The invention discloses a graphene / chromium nitride nano-composite material and a preparation method thereof, belongs to the electrochemical field, and aims to solve the technical problems of high difficulty in control over a technical process and high equipment cost existing in the magnetron sputtering method for preparing a CrN thin film. The composite material consists of graphene and chromium nitride. The preparation method comprises the following steps of: 1, weighing a natural graphite and chromium nitride urea complex; 2, preparing graphene suspension; 3, preparing aqueous solution of chromium nitride urea complex, adding into the graphene suspension obtained by the step 2, and continuously stirring to obtain uniform dispersion; 4, preparing the graphene / Cr2O3 composite material; and 5, filling the graphene / Cr2O3 composite material into an atmosphere furnace, introducing nitrogen, heating and preserving heat, then reducing to room temperature under the protection of nitrogen to obtain the graphene / chromium nitride nano-composite material. The material is used for a negative electrode of a lithium ion battery.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

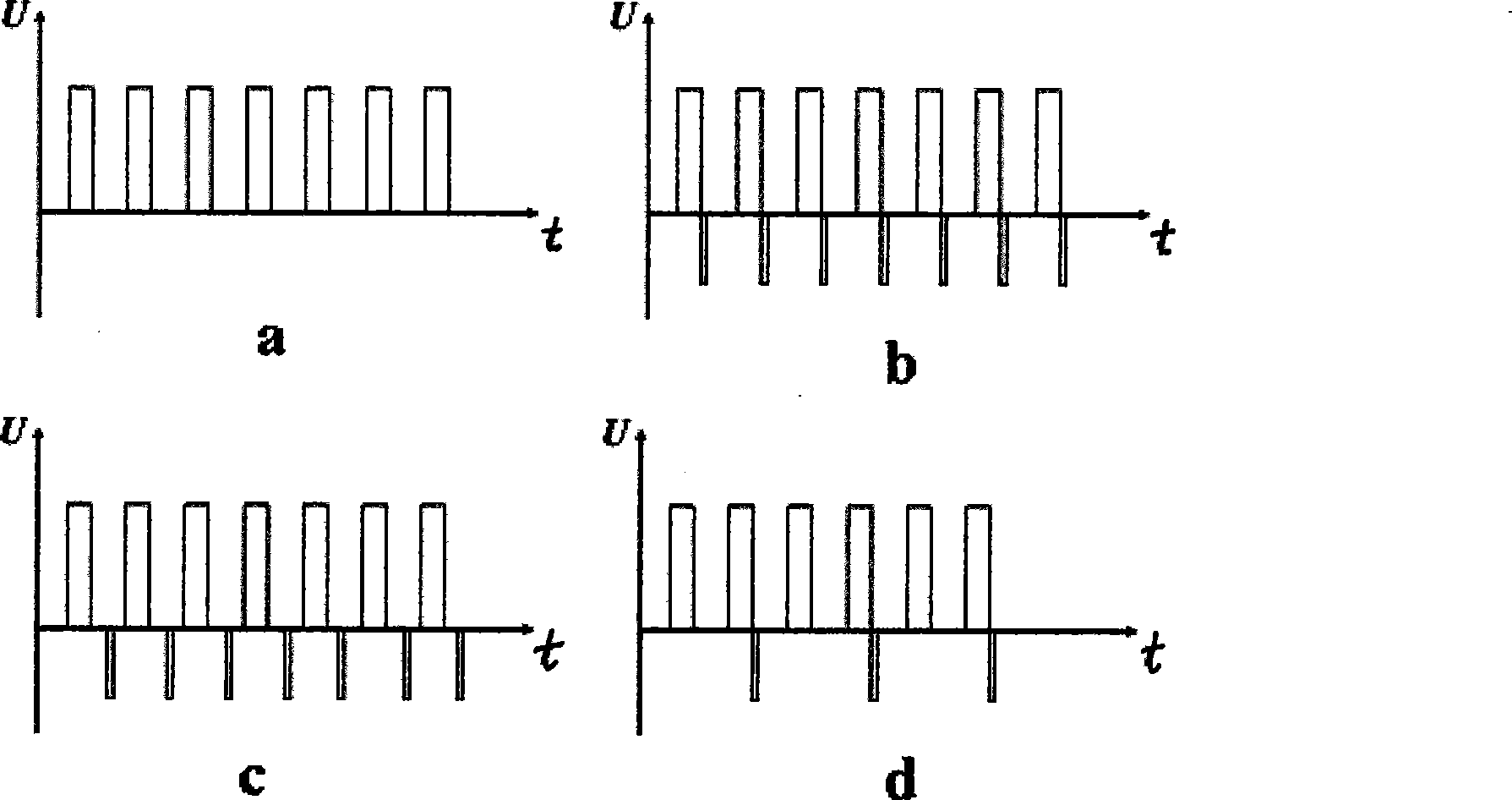

Non-equilibrium liquid condition composite pulse plasma polishing method

A polishing solution disclosed by the present invention is composed of the following components according to mass percentage: component A: (NH4)2SO4 aqueous solution with a concentration of 1% to 10%, component B: ethylene glycol with a concentration of 0.2% to 3% One or a combination of amine tetraacetic acid, ammonium citrate, sodium tartrate or sodium oxalate. The method of using the polishing liquid to carry out non-equilibrium liquid compound pulse plasma polishing, first prepare the polishing solution according to the above formula, then put the workpiece to be treated into the above prepared polishing liquid, add a compound electric pulse or an equivalent different Combination of positive and negative pulses, control positive pulse frequency 0.5-80kHz, duty cycle 5%-95%, voltage 200-480V, make the reaction in the most violent state, treatment for 1-5 minutes, that is to complete the polishing process. In the present invention, pulses are used instead of direct current, which is beneficial to the generation of plasma, so that the discharge plasma can obtain higher kinetic energy, better mirror effect and faster polishing speed.

Owner:XIAN UNIV OF TECH

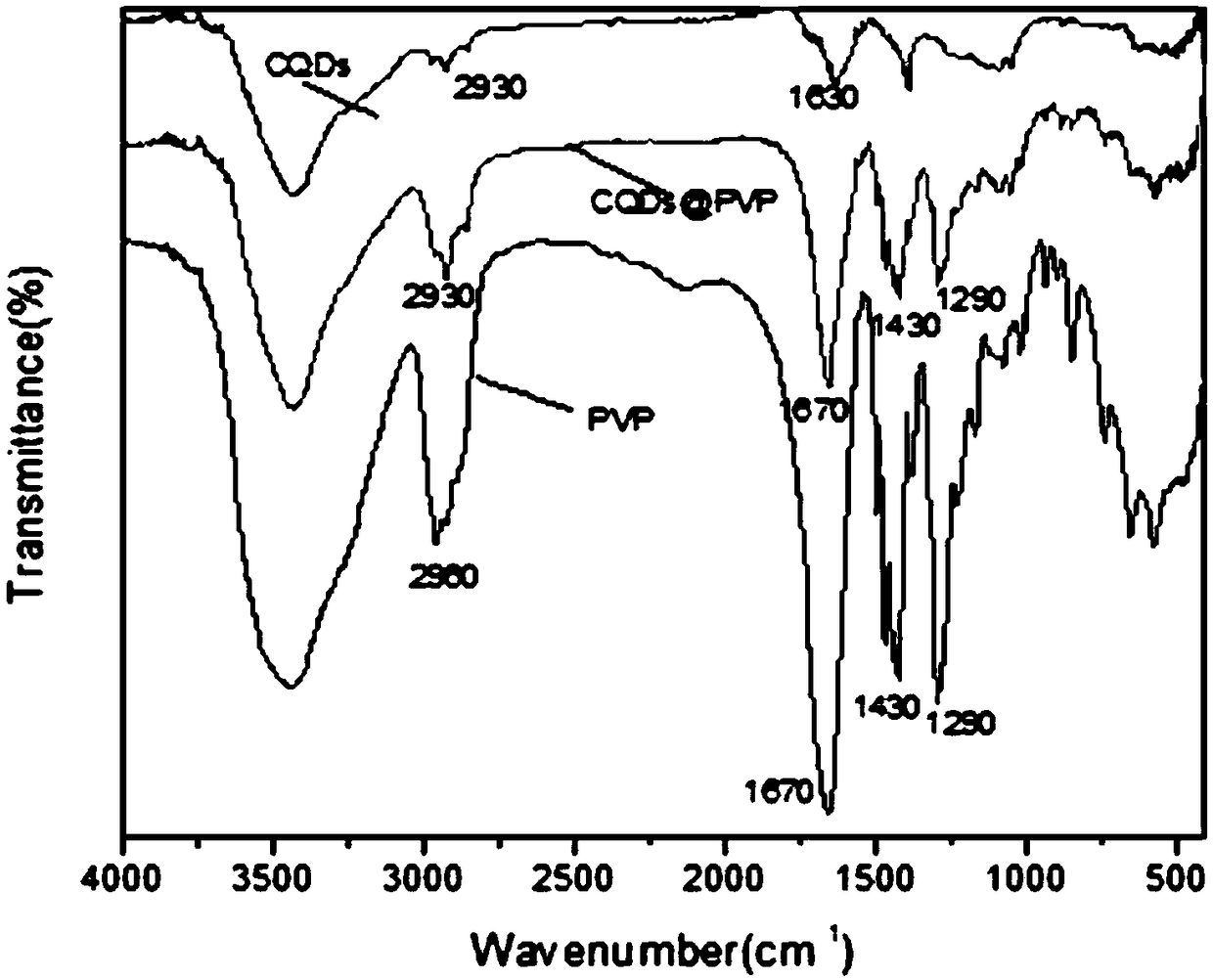

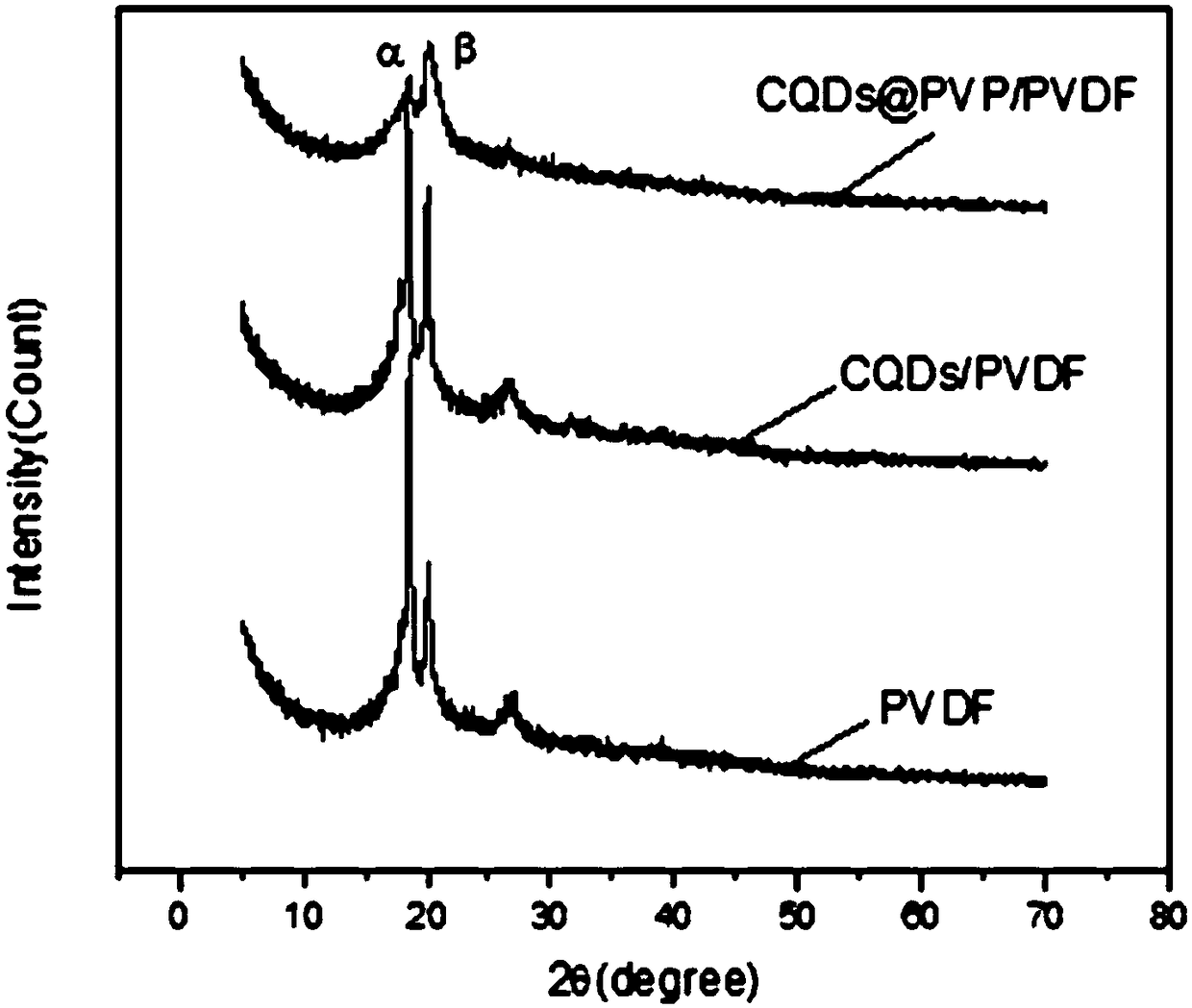

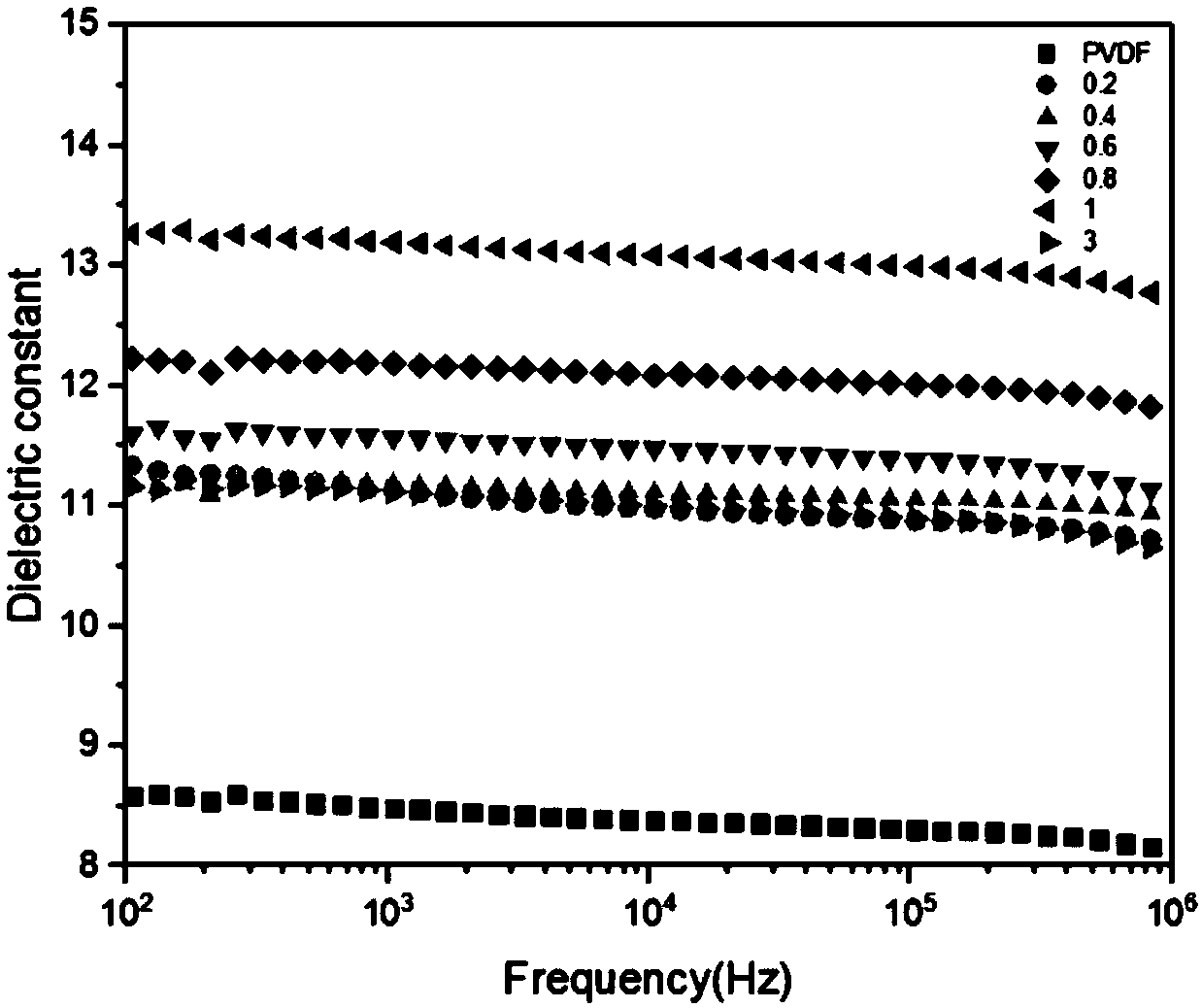

Preparation method for CQDs@PVP/PVDF composite dielectric film

The invention relates to a preparation method for a CQDs@PVP / PVDF composite dielectric film. The method comprises the following steps: firstly electrolyzing to obtain carbon quantum dots through a graphite rod electrode, secondly coating the carbon quantum dots in solution by using PVP so as to improve dispersity and interfacial compatibility of the carbon quantum dots, thirdly mixing the carbon quantum dots and the PVDF solution and performing film casting and hot-press shaping, and finally preparing the composite film which is good in toughness and excellent in dielectric property. The method is simple and easy to control, low in cost, and strong in repeatability. In addition, the prepared film is higher in purity, wide in application, and has better application prospect in the technicalfields of a non-volatile storage, an optical storage, a piezoelectric and photoelectric device and the like.

Owner:WUHAN UNIV OF TECH

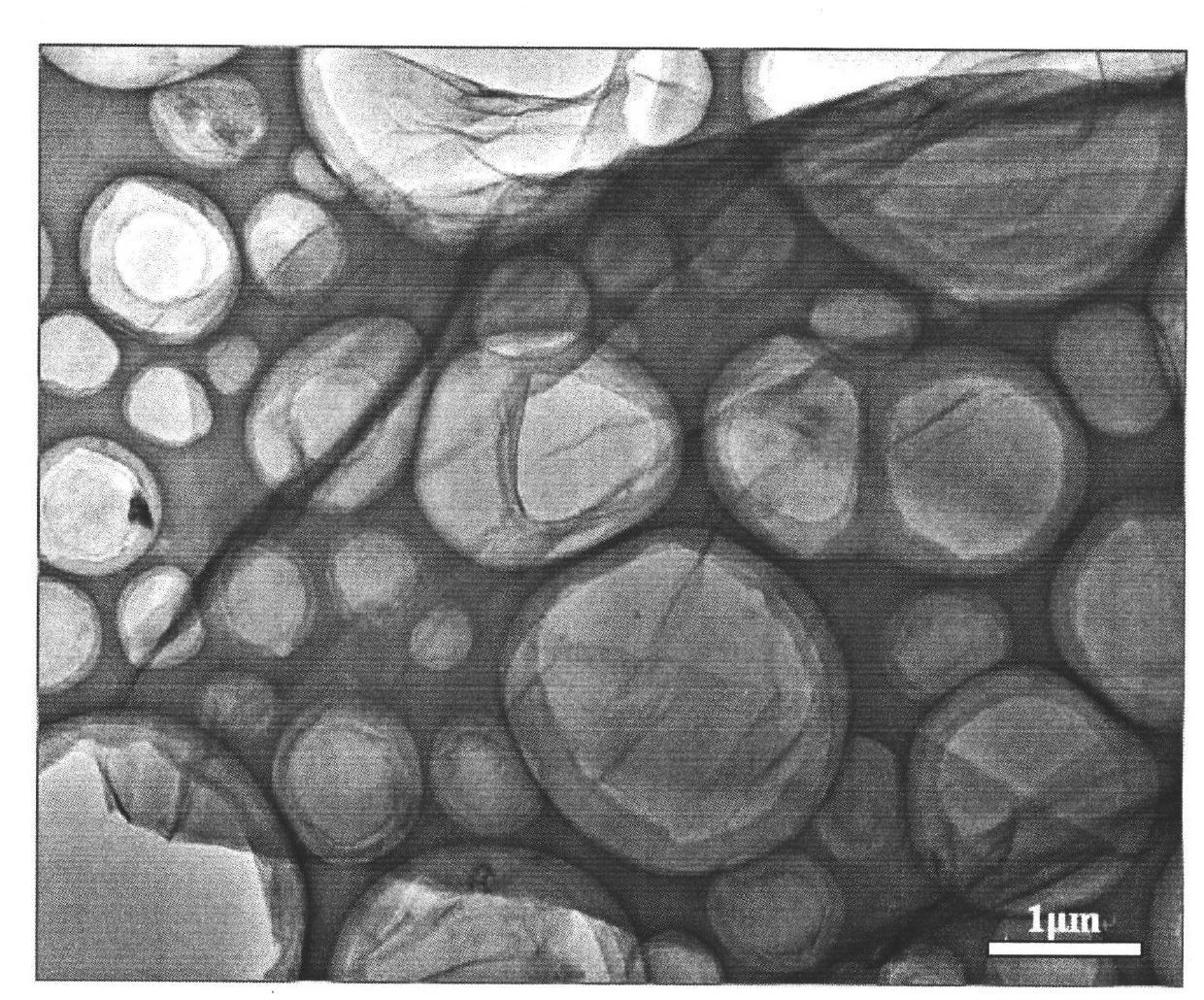

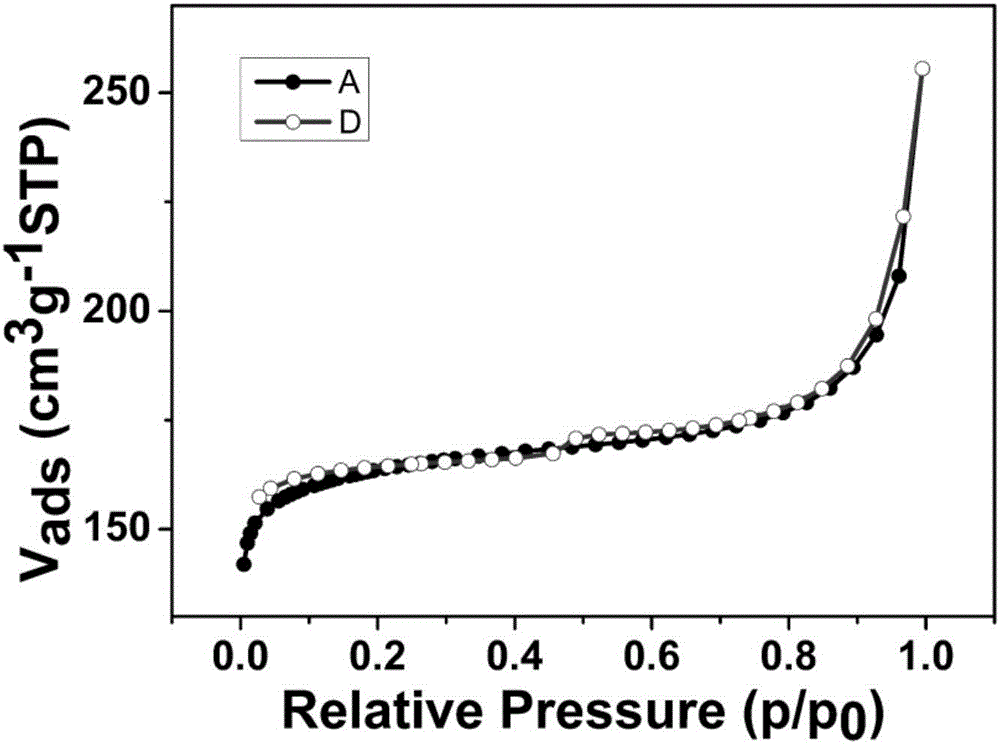

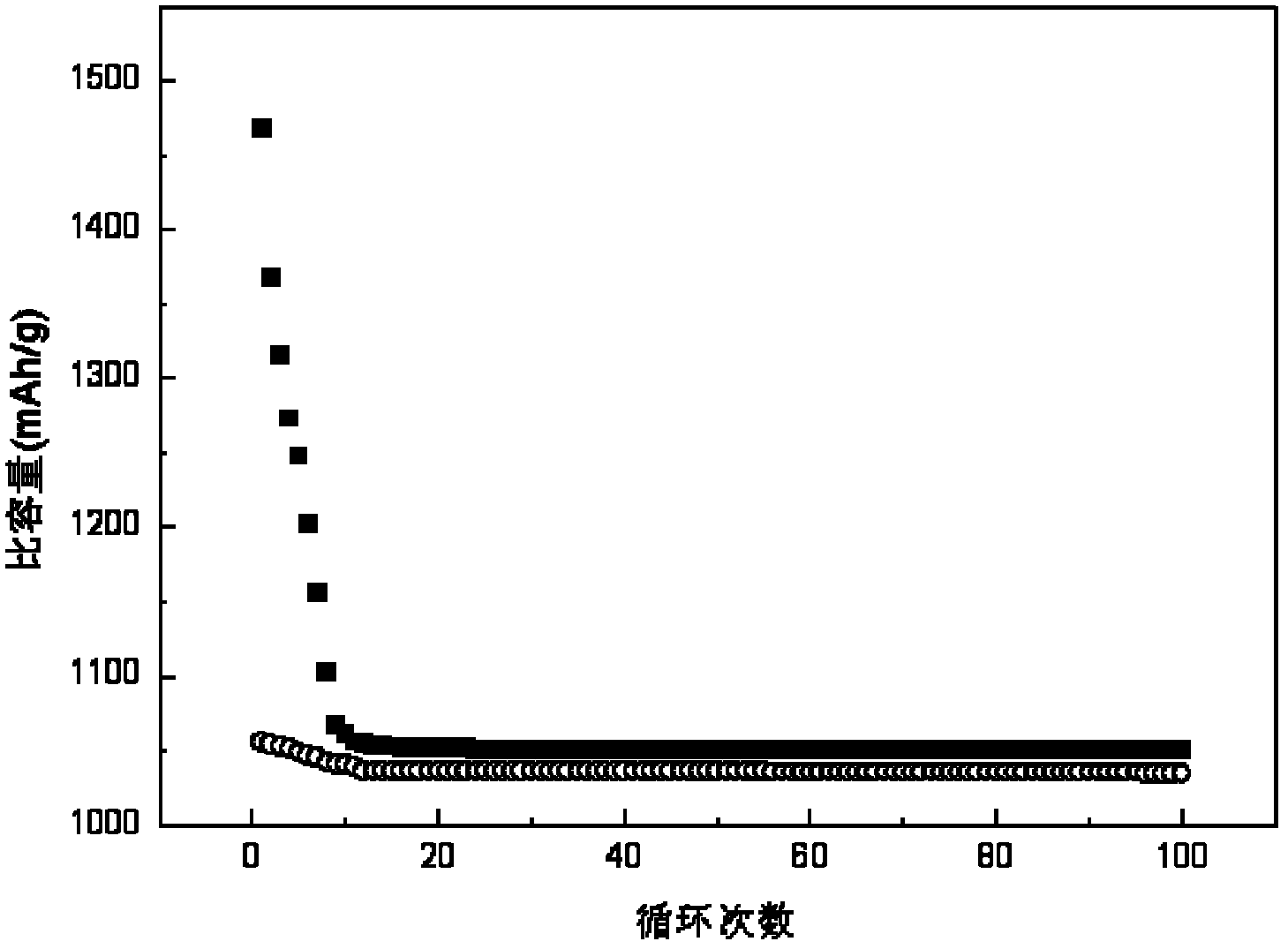

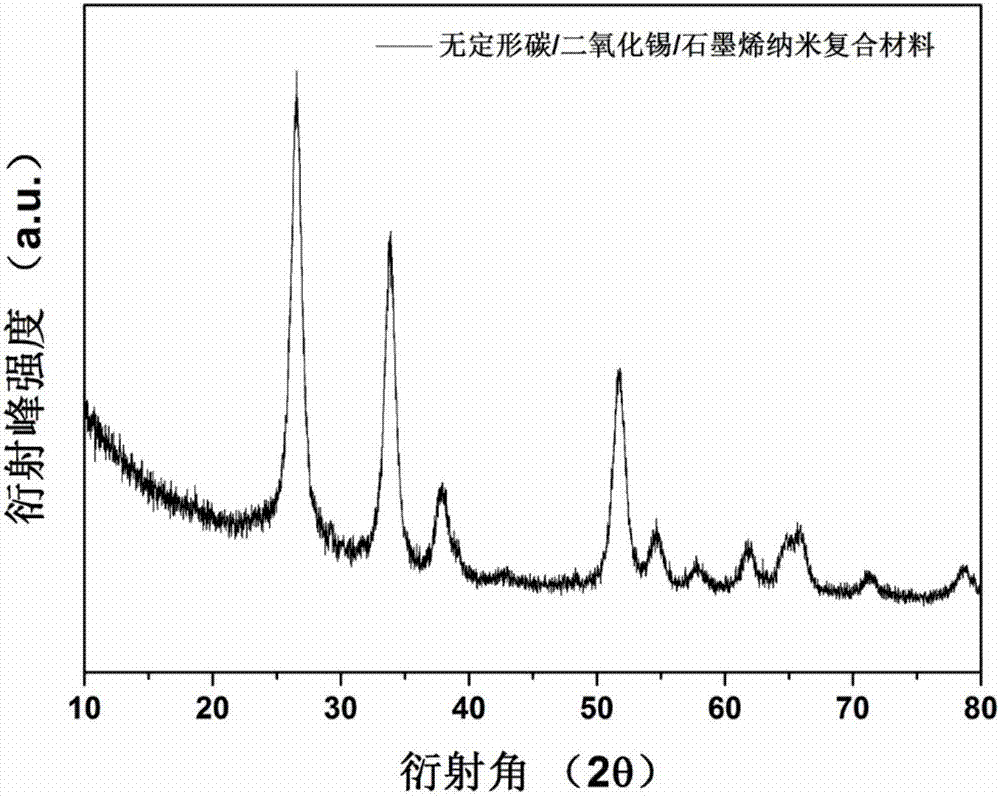

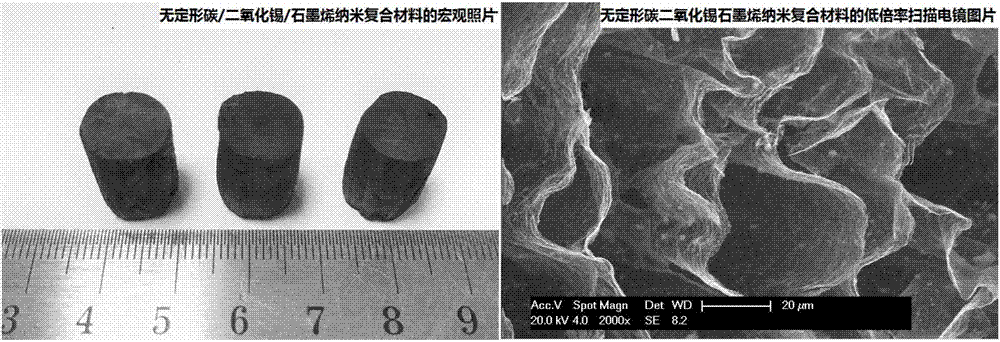

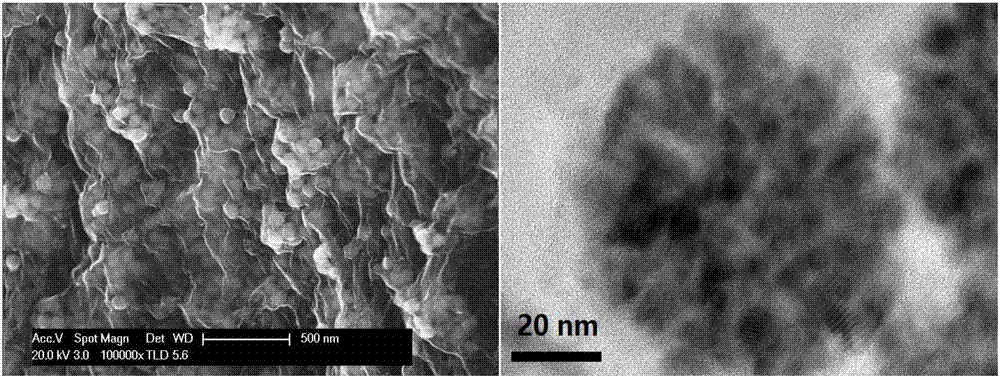

Method for preparing lithium-ion battery negative electrode material with three-dimensional porous structure

ActiveCN107069004AImprove performanceLow costMaterial nanotechnologySecondary cellsGraphene nanocompositesPolyvinyl alcohol

The invention discloses a method for preparing a lithium-ion battery negative electrode material with a three-dimensional porous structure. The method comprises the steps of firstly, preparing stannic oxide / glycan complex clusters by a hydrothermal method; then solving the clusters in mixed solution of water and ethanol and adding sodium carboxymethyl cellulose and polyvinyl alcohol successively into the solution, mixing the mixed solution uniformly, then adding low-concentration aqueous solution of graphene oxide into the solution, continuously stirring the solution at 50-70 DEG C for 12 hours, dripping the uniformly mixed solution into a silicone mould and freezing the solution from top to bottom by liquid nitrogen, demoulding the sample, and then placing the sample in a freezing drying box until the sample is thoroughly lyophilized; and finally calcining the obtained product at 350-550 DEG C for 2-4 hours. An amorphous carbon / stannic oxide / graphene nano-composite material prepared by the invention has a three-dimensional porous structure. Due to the excellent structural characteristics of the product, when used as a negative electrode material of a lithium-ion battery, the product shows very high capacity per gram, excellent rate capability and cycle stability.

Owner:SOUTHEAST UNIV

Method for firing volume-density controlled chromium oxide product

InactiveCN101224985AThe process is easy to controlLower firing temperatureProduct gasInternal pressure

The invention relates to a sintering method of chromium oxide product, of which the volume and density are controllable. Firstly, a mixed gas of N2O2 is filled into the nitriding kiln in which the chromium oxide products are prepared to be fired, meanwhile the flow of N2 and O2 is controlled to keep the oxygen partial pressure of the mixed gas between 10<-2>-10<-6>atm and ensure that the internal pressure is between 10pa to 50pa. Secondly, under the temperature between 1400 to 1500 degrees Centigrade, the chromium oxide product is treated with heat insulation for two to eight hours. The volume and density of chromium oxide product are between 3.8 to 4.8g / m<3>. The sintering method for chromium oxide product is characterized best in that the volume and density of the chromium oxide product can be controlled after sintering, and the production process is easy to control; the sintering temperature is fairly low with no pollution to chromium oxide products; in addition, the adoption of nitriding kiln contained with N2 in sintering technique is already mature at home, thus ensuring that the sintering method of chromium oxide product with controllable volume and density can be easily carried out in the industrial production.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

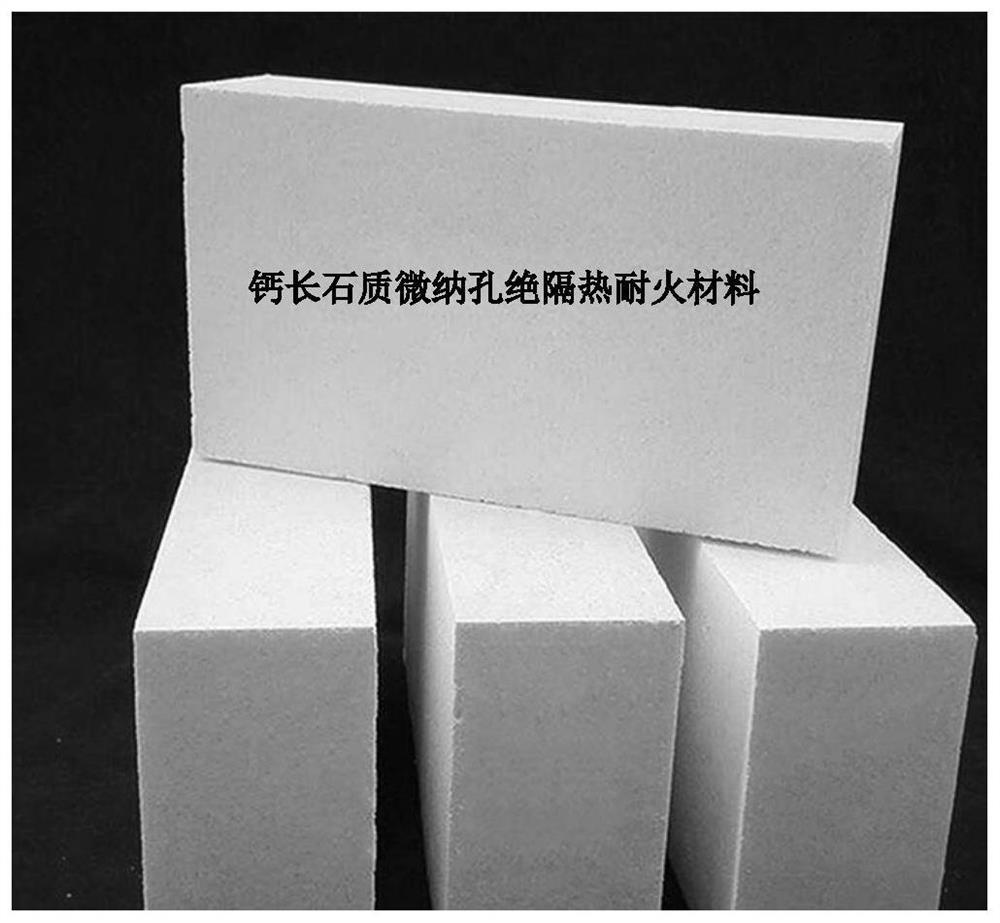

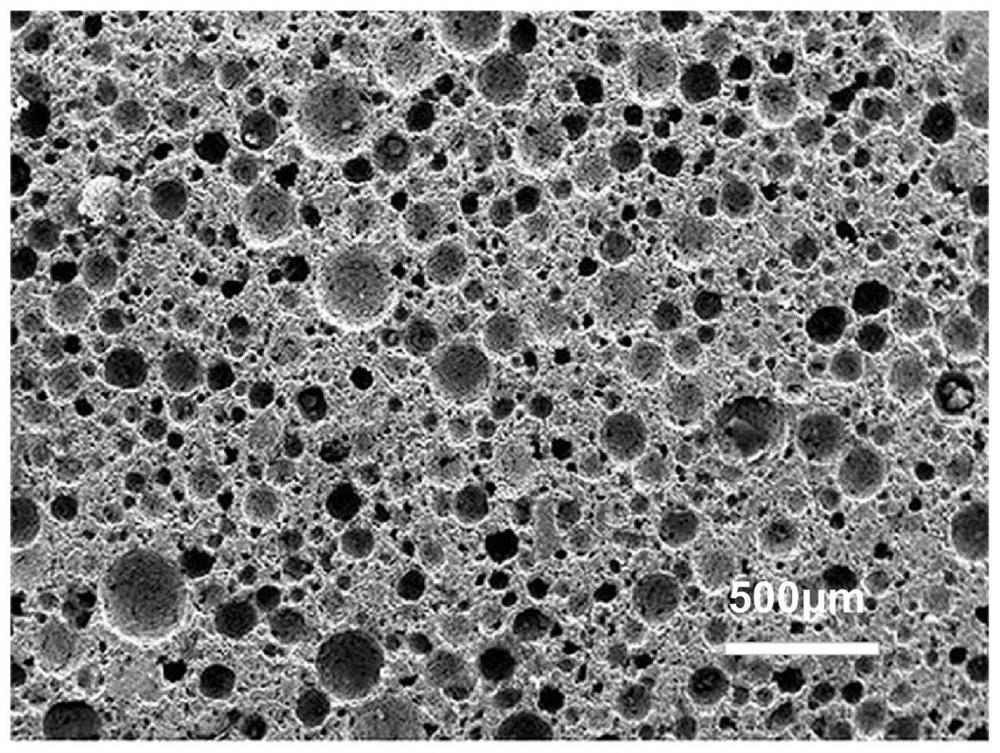

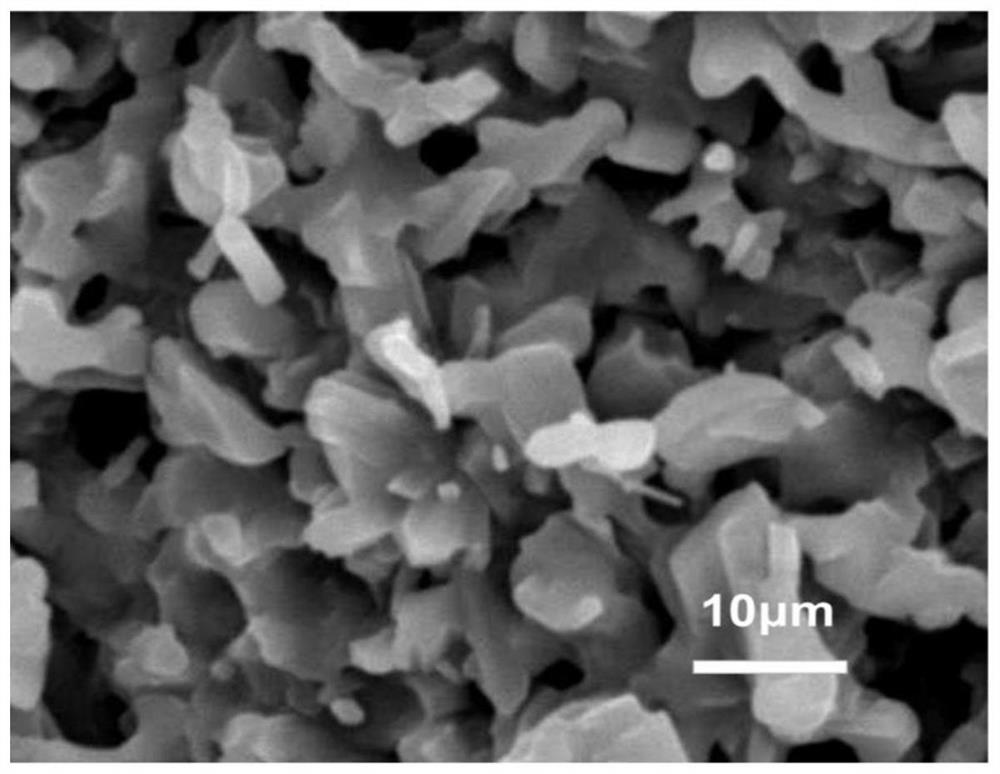

Aorthite micro-nano pore heat insulation refractory material and preparation method thereof

The invention belongs to the field of refractory materials, and particularly relates to an anorthite micro-nano pore heat insulation refractory material and a preparation method thereof. The anorthite micro-nano pore heat insulation refractory material is mainly prepared from a basic raw material, an additive and water. The anorthite micro-nano pore heat insulation refractory material is white, faint yellow or yellow in appearance, the principal crystalline phase of the product is anorthite, the mass content of CaO in the chemical composition is 4-22 wt%, the pore size distribution is 0.006-250 [mu] m, the average pore size is 0.1-19 [mu] m, and the pore structure of the micro-nano size ensures that the product has better heat insulation performance under the conditions of low volume density and high strength. The preparation method is green, environment-friendly and pollution-free, and the structure and performance of the product are easy to accurately regulate and control.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Method for extracting quinoline from coal tar wash oil

InactiveCN102746221AHarm reductionReduce manufacturing costOrganic chemistryBulk chemical productionQuinolineChemical separation

The invention relates to a method for extracting quinoline from coal tar wash oil, which belongs to the field of chemical separation. According to the method, alcohol is used as a supercritical solvent to extract the quinoline from the wash oil in an intermittent supercritical reaction kettle, predistillation is performed to the wash oil to obtain a fraction containing the quinoline, and the fraction reacts with acid to obtain quinoline salt to be neutralized with ammonia water, so that a coarse quinoline product is obtained. The coarse quinoline product is mixed with a certain quantity of alcohol solution then to be added to the supercritical reaction kettle for supercritical extraction. After the coarse quinoline is extracted through the supercritical alcohol, a gas extraction phase and a liquid raffinate phase are obtained, and after the gas extraction phase and the liquid raffinate phase are separated and cooled by a gas-liquid separator, an extraction liquid and a raffinate liquid are obtained. After the extraction liquid is refined, a quinoline product is obtained. According to the method, an acidic salt solution is used for replacing sulfuric acid to enrich the quinoline so as to prevent industrial waste acid from polluting the environment, the production cost is greatly reduced, and the whole process is simple and controllable.

Owner:韩钊武

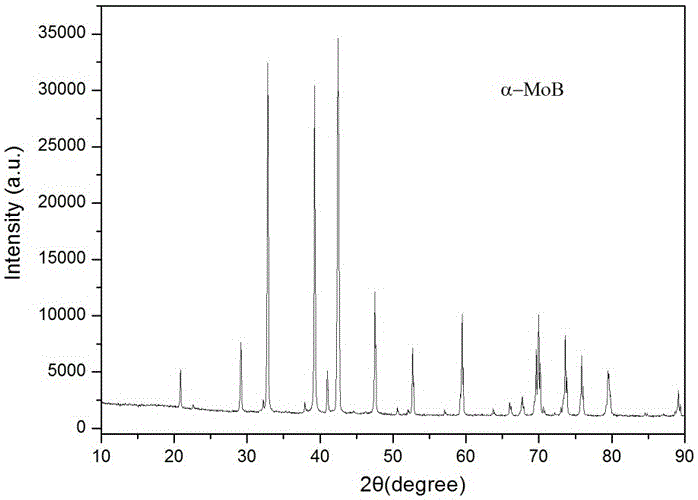

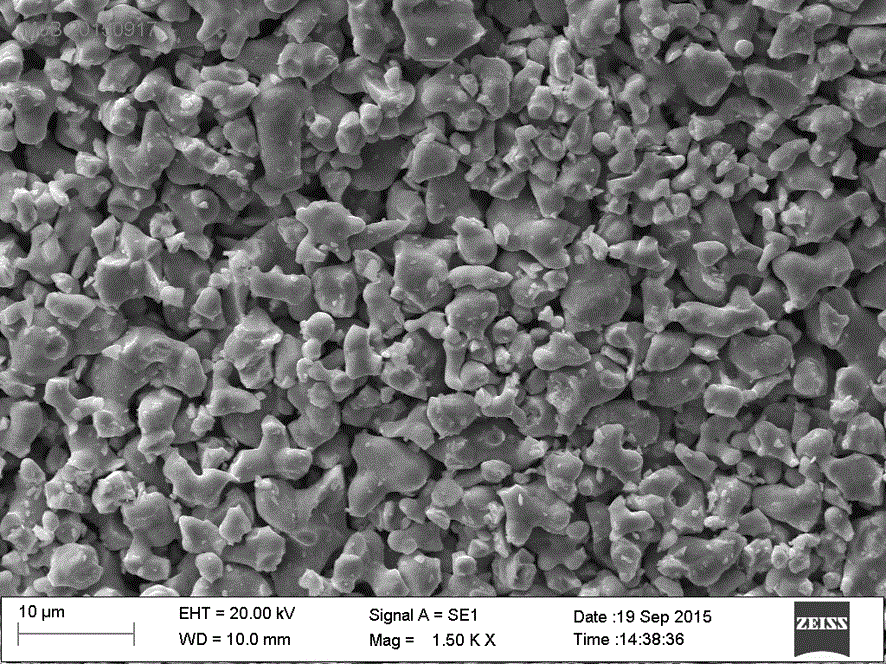

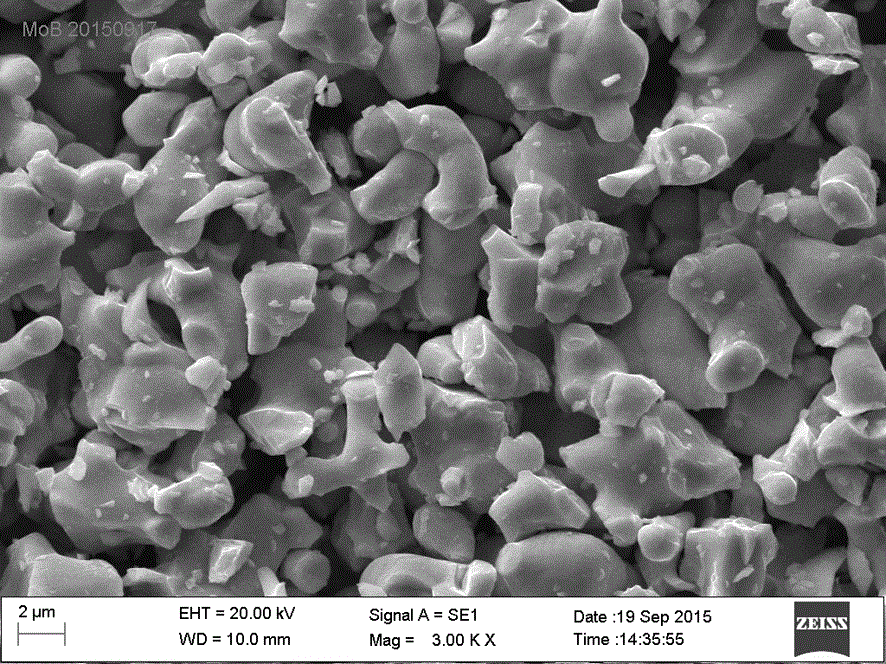

Preparation method of molybdenum boride powder

ActiveCN106276941AUniform particle sizeImprove performanceChemical industryMetal boridesMaterial DesignHigh pressure

The invention provides a preparation method of molybdenum boride powder. In the preparation steps, the molybdenum boride powder which completely accords with material design phase compositions can be controlled to be prepared by means of a high-temperature and high-pressure synthesis mode according to setting of the B / Mo mole ratio n (n=0.5, 1, 2, 2.5, 4) before synthesis, controllable synthesis of target molybdenum boride material phase compositions is achieved, and the synthesized molybdenum boride powder is uniform in particle size, complete in grain crystallization and excellent in property. The method is controllable in technological process, short in technological route, high in targeted property, convenient to operate, efficient, economical in energy, safe and good in reliability. The finished molybdenum boride powder is uniform in particle size distribution and complete in grain crystallization, the chemical purity is higher than or equal to 99.8%, and the product quality stability is good, the properties are obviously improved compared with a molybdenum boride material synthesized through a conventional method, and therefore the produced molybdenum boride material shows excellent physical and chemical properties in industrial application.

Owner:LUOYANG GOLDEN EGRET GEOTOOLS

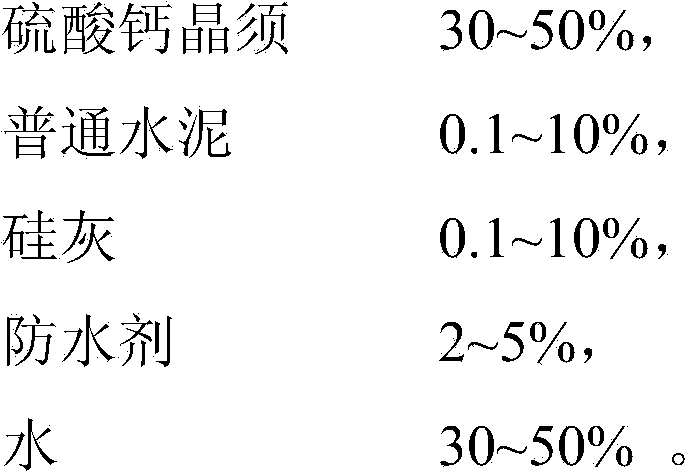

Inorganic calcium sulfate whisker heat retaining panel and preparation method thereof

The invention discloses an inorganic calcium sulfate whisker heat retaining panel. The inorganic calcium sulfate whisker heat retaining panel is characterized by being prepared from the following raw materials in percentage by weight: 30-50% of calcium sulfate whisker, 0.1-10% of Portland cement, 0.1-10% of silica fume, 2-5% of water-proofing agent and 30-50% of water. The invention also discloses a preparation method of the inorganic calcium sulfate whisker heat retaining panel. The inorganic calcium sulfate whisker heat retaining panel provided by the invention has the advantages of Al-grade fireproofing, light weight, high strength, excellent waterproof property, low heat conductivity coefficient and the like and is a high-quality heat retaining panel for building external walls, which has practical application value. According to the preparation method, a one-step molding method is adopted, and the technological processes comprise dry material premixing, liquid material premixing, pulping, standing still, molding, demolding, drying, high-temperature thermal treatment and the like.

Owner:SHANGHAI UNIV

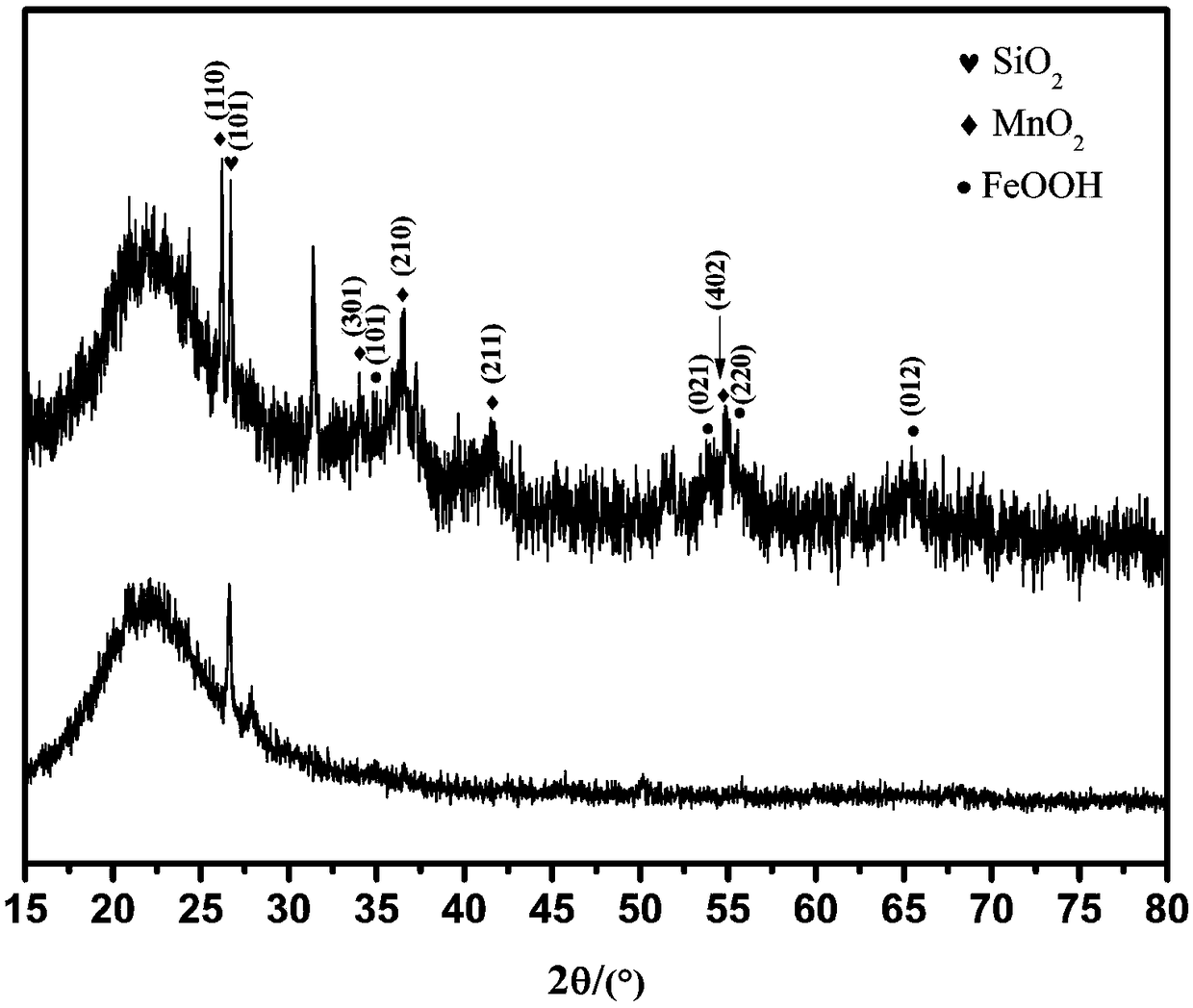

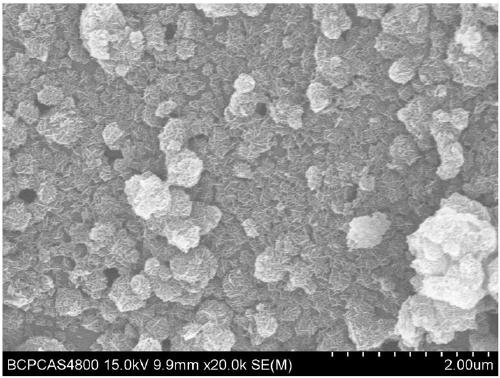

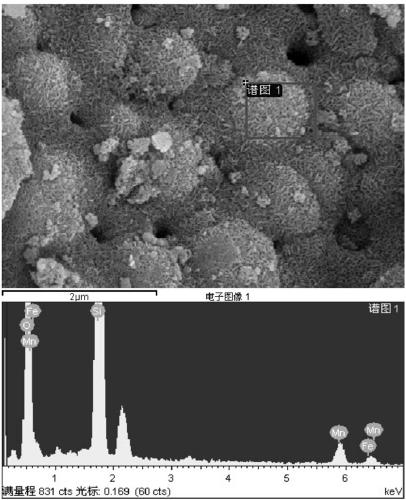

Preparation method of FeOOH/ MnO2@ diatomite composite material

ActiveCN109499523ALarge specific surface areaLarge adsorption capacityOther chemical processesWater contaminantsElectronPotassium permanganate

The invention discloses a preparation method of a FeOOH / MnO2@ diatomite composite material. The preparation method comprises the steps of adding FeCl3 into diatomite suspension liquid, adjusting thepH value, and then adding sodium dodecylbenzenesulfonate; then, slowly dropwise adding an ammonium manganese composite solution prepared by dissolving ammonium persulfate and potassium permanganate indeionized water, stirring and adding urea to prepare a diatomite composite solution; enabling the diatomite composite solution to be subjected to a hydrothermal reaction so as to obtain the diatomitecomposite material. The nano-flowered linear FeOOH / MnO2@ diatomite composite material is deposited on a diatomite algae plate, so that the absorption sensitivity of diatomite matrix to heavy metal arsenic ions is improved, and the absorption capacity of the arsenic ions is significantly increased while the specific surface area is enlarged; by adding activated carbon powder, iron and carbon electrodes are formed by iron oxides on the surface of diatomite, so that electron transport is facilitated, the oxidation of the trivalent arsenic ions is realized, and the toxicity of the trivalent arsenic ions is further reduced; the preparation method has great theoretical and practical significance.

Owner:BEIJING UNIV OF TECH +1

Green preparation technology for TiO2

InactiveCN105621479ARealize full resourceGood dispersionMaterial nanotechnologyCalcium/strontium/barium chloridesChlorine oxideGas release

The invention relates to a green preparation technology for TiO2. The green preparation technology for TiO2 takes titanium tetrachloride as the raw material and comprises the steps of titanium tetrachloride hydration, hydrogen chloride gas release / titanium-chlorine oxide hydrolysis and precipitation, titanic oxide solid-liquid separation, titanic oxide purification and calcination and hydrogen chloride gas comprehensive utilization. A mother liquor obtained from solid-liquid separation and a washing liquid in the purification process can be used for titanium tetrachloride hydration, the collected hydrogen chloride gas can be absorbed to be used for preparing hydrochloric acid or producing calcium chloride, and the titanic oxide can be processed to obtain high-purity titanium dioxide powder. The green preparation technology for TiO2 has the characteristics of simple flow, fully green process and good TiO2 product quality.

Owner:CHANGZHOU UNIV

Metallic surface modification process

InactiveCN101338429ALow costImprove antioxidant capacityMetallic material coating processesCarbon nanotubeChemical vapor deposition

A metal surface modification method belongs to the technical field of metal materials and is used for solving the problems of the high technical manufacturing cost, the complicated process and the difficult control of a composite carbon nano-tube with a metal surface. The technical proposal of the invention is that the raw material of the carbon nano tube is selected and the raw material is manufactured by the method of the deposition of catalyst chemical vapor containing iron catalyst, and the composite layer of the directional carbon nano tube with the thickness of 0.05 to 1.0mm is obtained on the metal surface by the processes of the grinding of the raw material, the preparation of the fused mass of the composite layer of the carbon nano tube, the magnetophoresis deposition of the superposed layer of the directional carbon nano tube, press-rolling cold-insertion, etc. The modification method can lead the carbon nano tube with the composite metal surface to be in ordered direction and can adjust the thickness of the composite layer; and the method combines the advantages of the common metal surface for the carbon nano-tube, thus improving the technical data of the carbon nano tube greatly, such as anti-oxidation, wear-resisting property, self-lubricity and strength, etc. Compared with the prior art, the modification method has low material cost and little investment in equipment, and the process of the modification method is easy to be controlled, so the modification method is suitable for continuous mass production.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com