Method for preparing silicon carbide whisker/aluminium oxide composite ceramic powder using natural kaolin

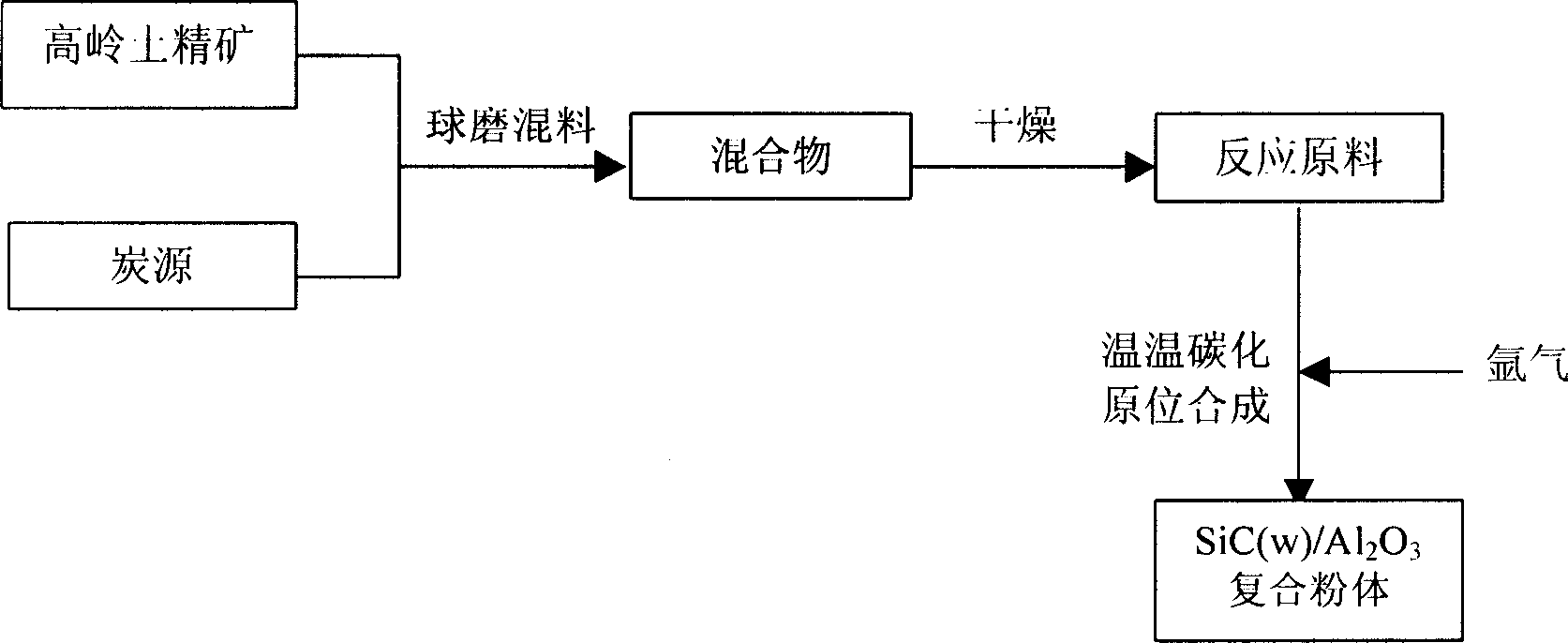

A technology for silicon carbide whiskers and composite ceramics is applied in the field of in-situ synthesis of natural kaolin to prepare silicon carbide whiskers/alumina composite ceramic powder, which can solve the problems that composite ceramics cannot give full play to their composite advantages, difficult to prepare, and expensive raw materials, etc. Achieve ideal morphology and two-phase uniformity, easy process control, and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

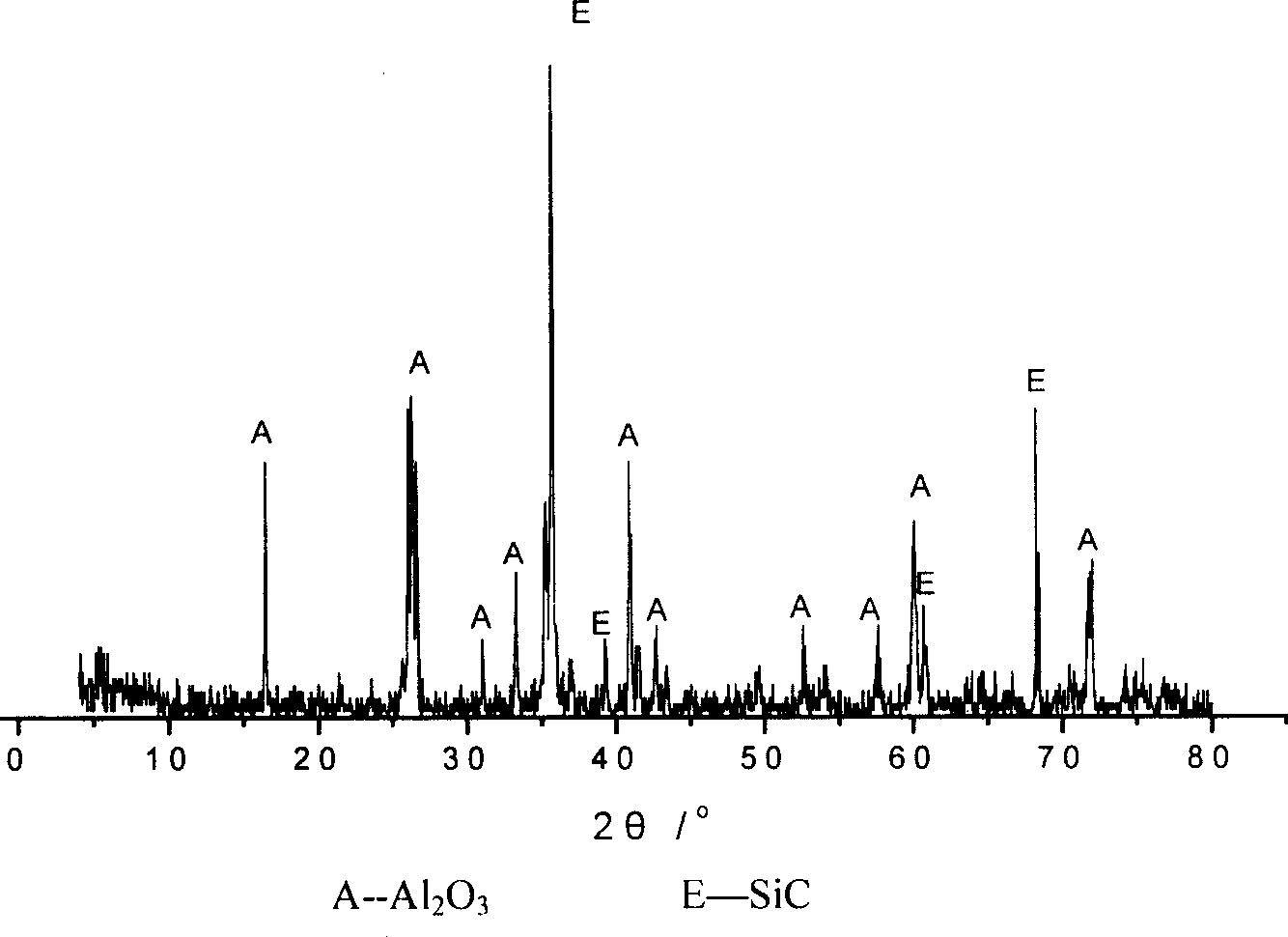

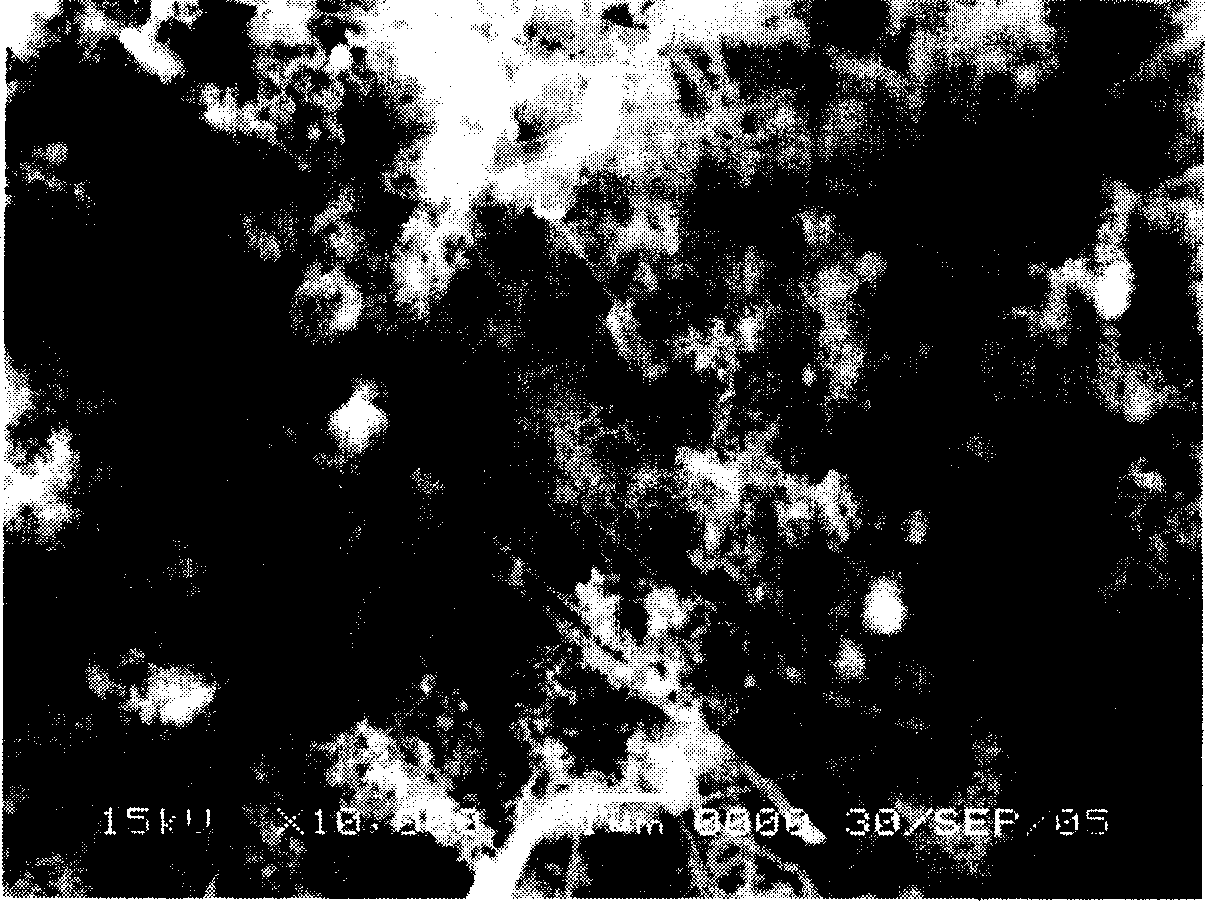

Embodiment 1

[0012] Weigh 272g of kaolin concentrate powder and 144g of carbon black, put them into a ball mill jar, and put in grinding balls (the ratio of material to ball is 1:5); after ball milling for 2 hours, take out the sample and place it in an oven to dry at 100°C for 2 hours; Put the high-alumina crucible into the atmosphere furnace, evacuate to <10Pa, close the vacuum system, fill with argon to an atmospheric pressure, open the exhaust valve and insert the exhaust pipe into the water seal; the temperature rise rate is 10°C per minute Raise the temperature to 1550°C and keep it warm for 2 hours. During this period, due to the rise in temperature, the gas in the furnace will expand, and some gas will be discharged through the water seal, but the air pressure in the furnace is basically constant at about one atmospheric pressure; after the heat preservation is over, cut off the power and turn off the The exhaust valve (to prevent the water seal from sucking back) will cool naturall...

Embodiment 2

[0014] Weigh 272g of kaolin concentrate powder and 144g of graphite, put them into a ball mill jar, and put in grinding balls (the ratio of material to ball is 1:5); after ball milling for 2 hours, take out the sample and place it in an oven to dry at 100°C for 2 hours; Put the high-alumina crucible into the atmosphere furnace, evacuate to <10Pa, close the vacuum system, fill it with argon to an atmospheric pressure, open the exhaust valve and insert the exhaust pipe into the water seal; heat up at a rate of 10°C per minute to 1500°C and keep warm for 2 hours. During this period, due to the increase in temperature, the gas in the furnace will expand, and some gas will be discharged through the water seal, but the air pressure in the furnace is basically constant at about one atmosphere; after the heat preservation is over, cut off the power supply and close the exhaust The gas valve (to prevent the water seal from sucking back) is naturally cooled slowly with the furnace; when ...

Embodiment 3

[0016] Weigh 272g of kaolin concentrate powder and 150g of activated carbon, put them into a ball mill jar, and put in grinding balls (the ratio of material to ball is 1:5); after ball milling for 2 hours, take out the sample and place it in an oven to dry at 100°C for 2 hours; Put the high-alumina crucible into the atmosphere furnace, evacuate to <10Pa, close the vacuum system, fill with argon to an atmospheric pressure, open the exhaust valve and insert the exhaust pipe into the water seal; the temperature rise rate is 10°C per minute Raise the temperature to 1450°C and keep it warm for 2 hours. During this period, due to the rise in temperature, the gas in the furnace will expand, and some gas will be discharged through the water seal, but the air pressure in the furnace is basically constant at about one atmospheric pressure; after the heat preservation is over, cut off the power and turn off the The exhaust valve (to prevent the water seal from sucking back) will cool natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com