Patents

Literature

1012 results about "Rise rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and applications of lighter-than-air (LTA) platforms

InactiveUS7356390B2Large costLarge deploymentDigital data processing detailsPosition fixationGeolocationEngineering

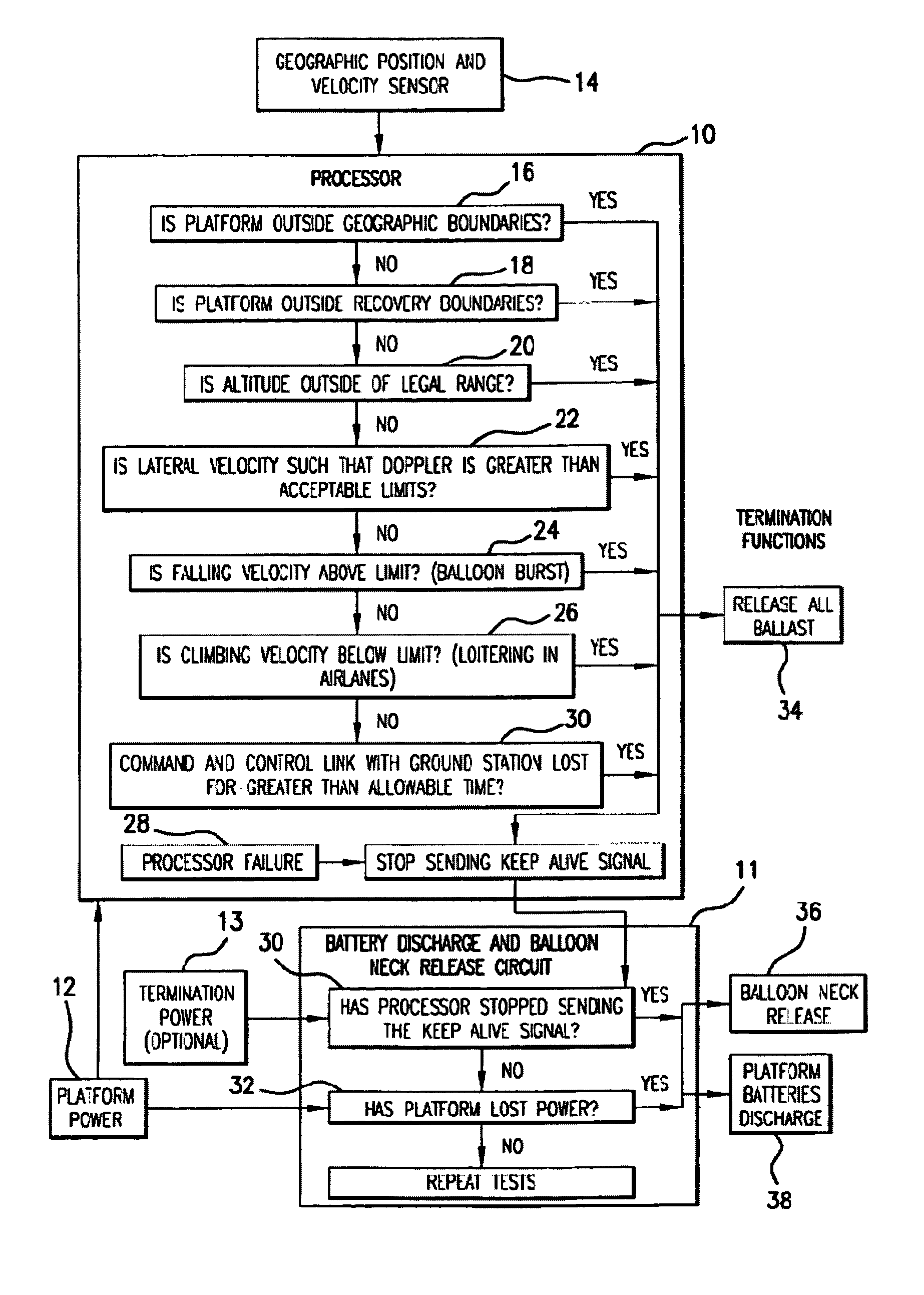

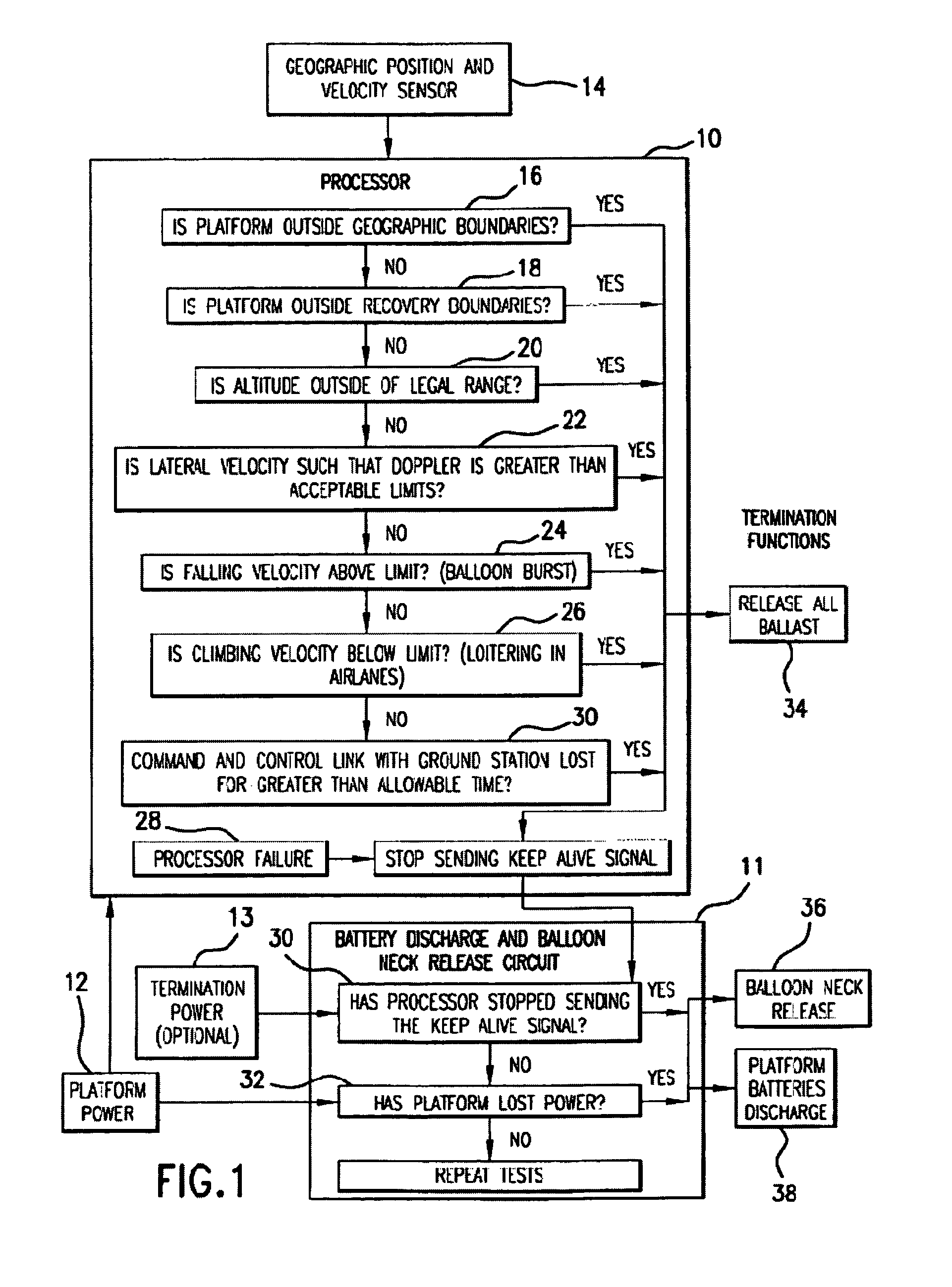

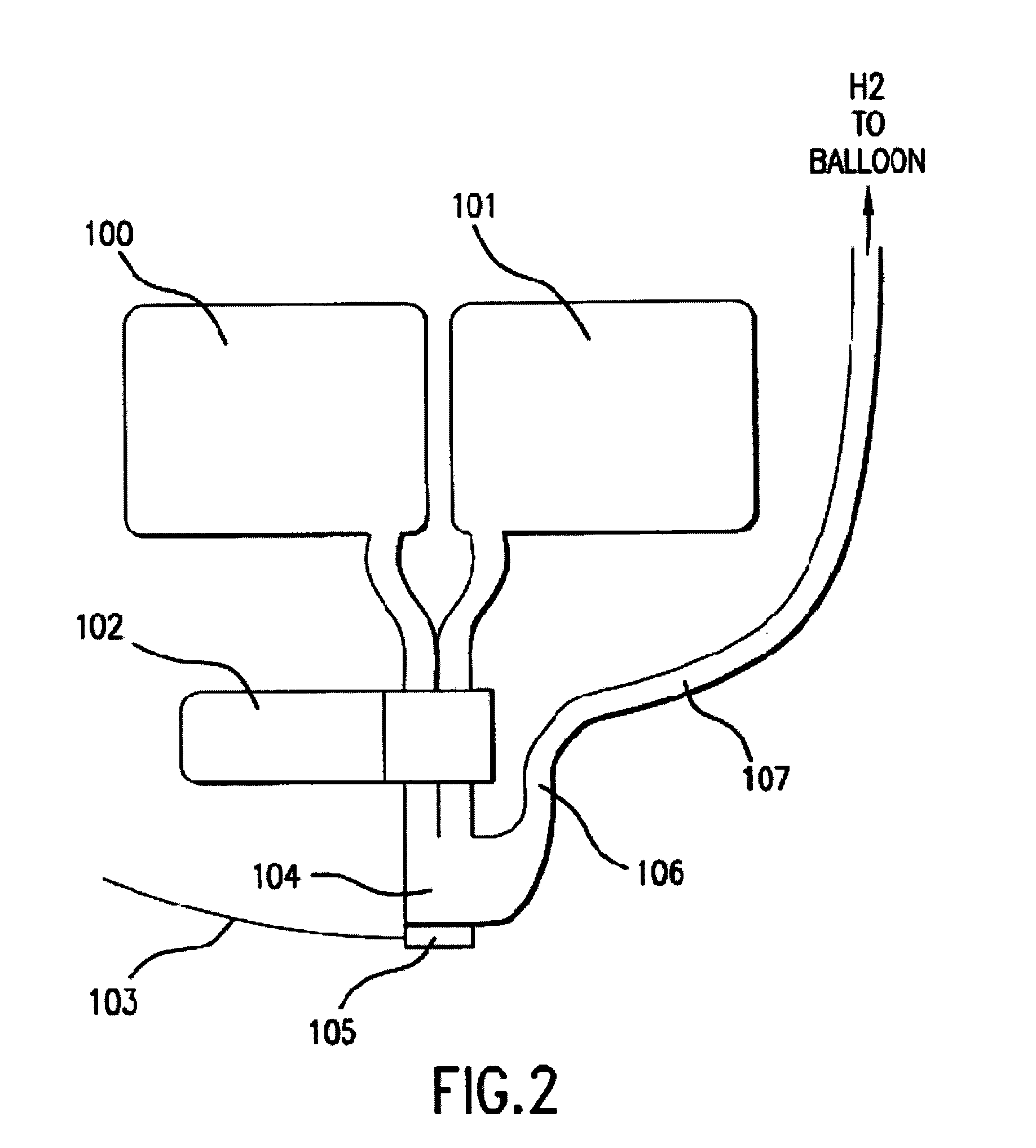

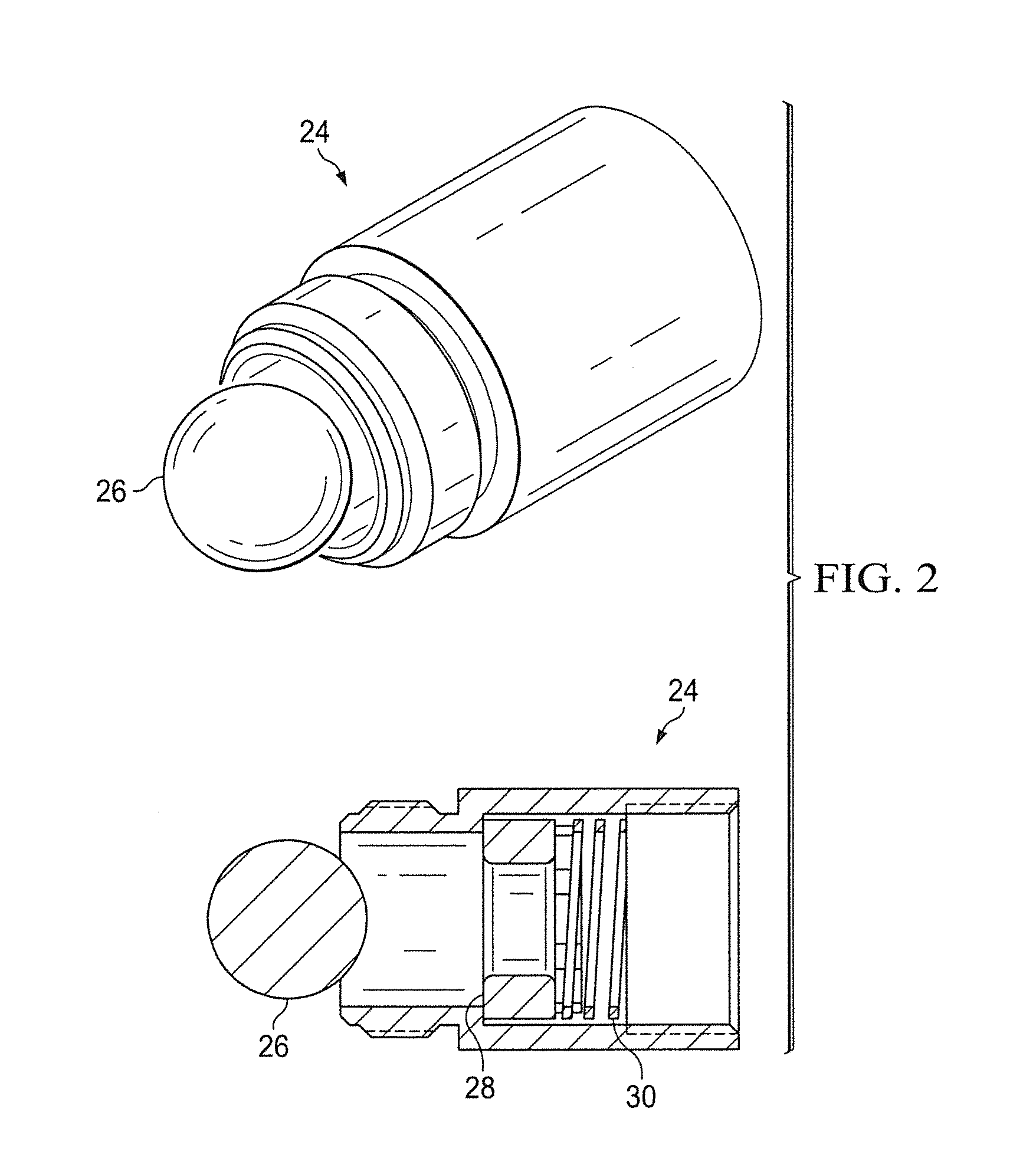

Innovative new methods in connection with lighter-than-air (LTA) free floating platforms, of facilitating legal transmitter operation, platform flight termination when appropriate, environmentally acceptable landing, and recovery of these devices are provided. The new systems and methods relate to rise rate control, geo-location from a LTA platform including landed payload and ground-based vehicle locations, and steerable recovery systems.

Owner:SPACE DATA CORP

Filter

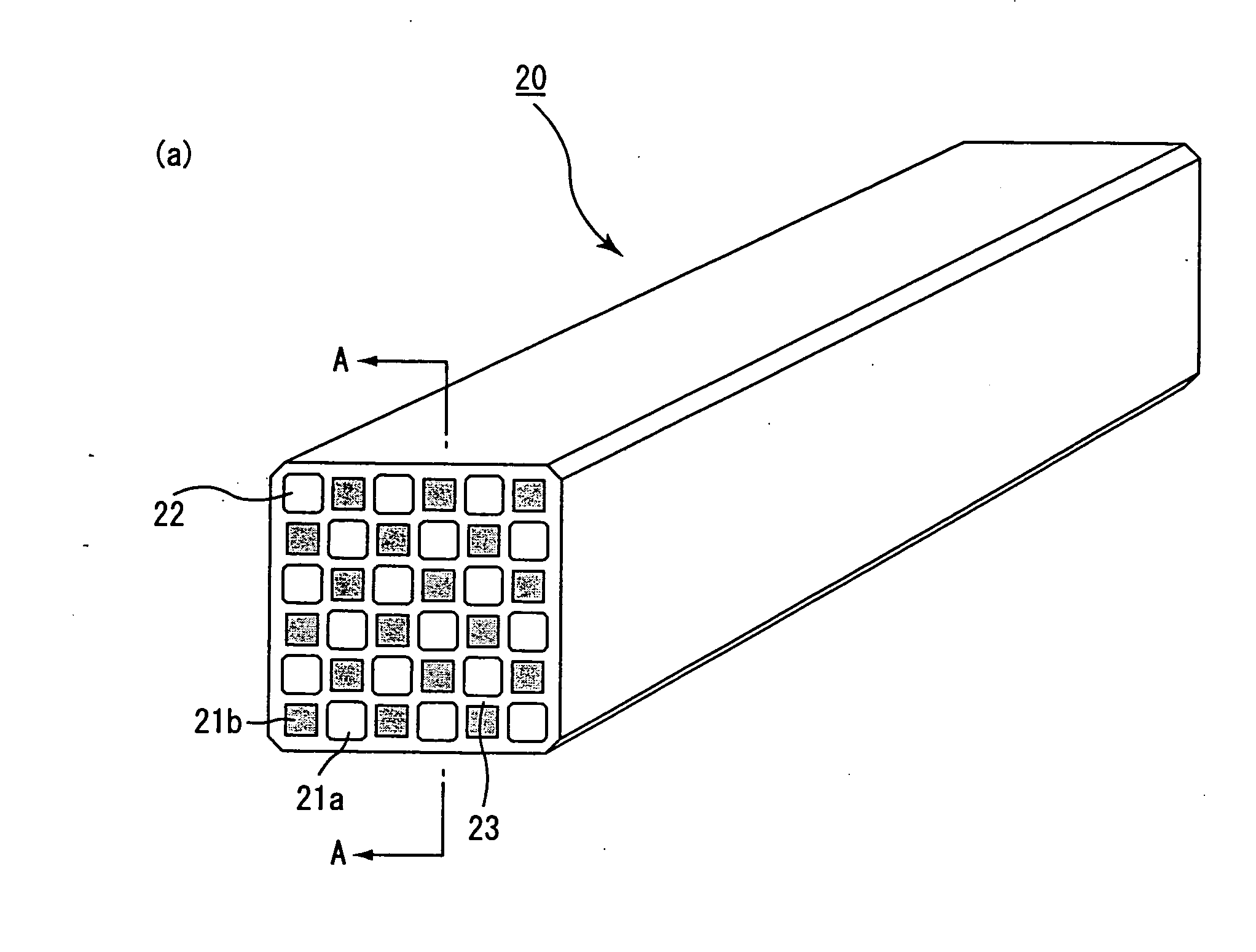

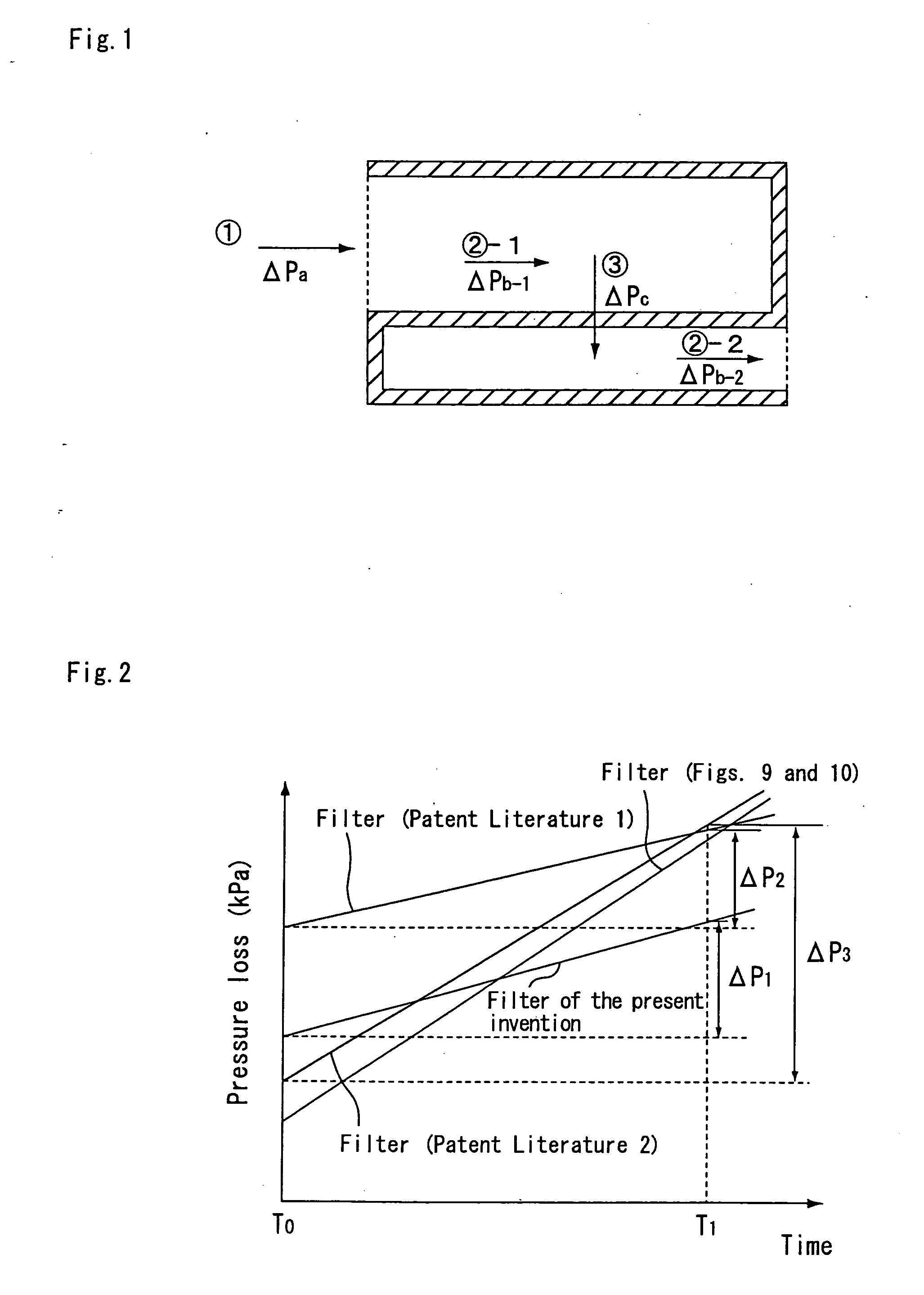

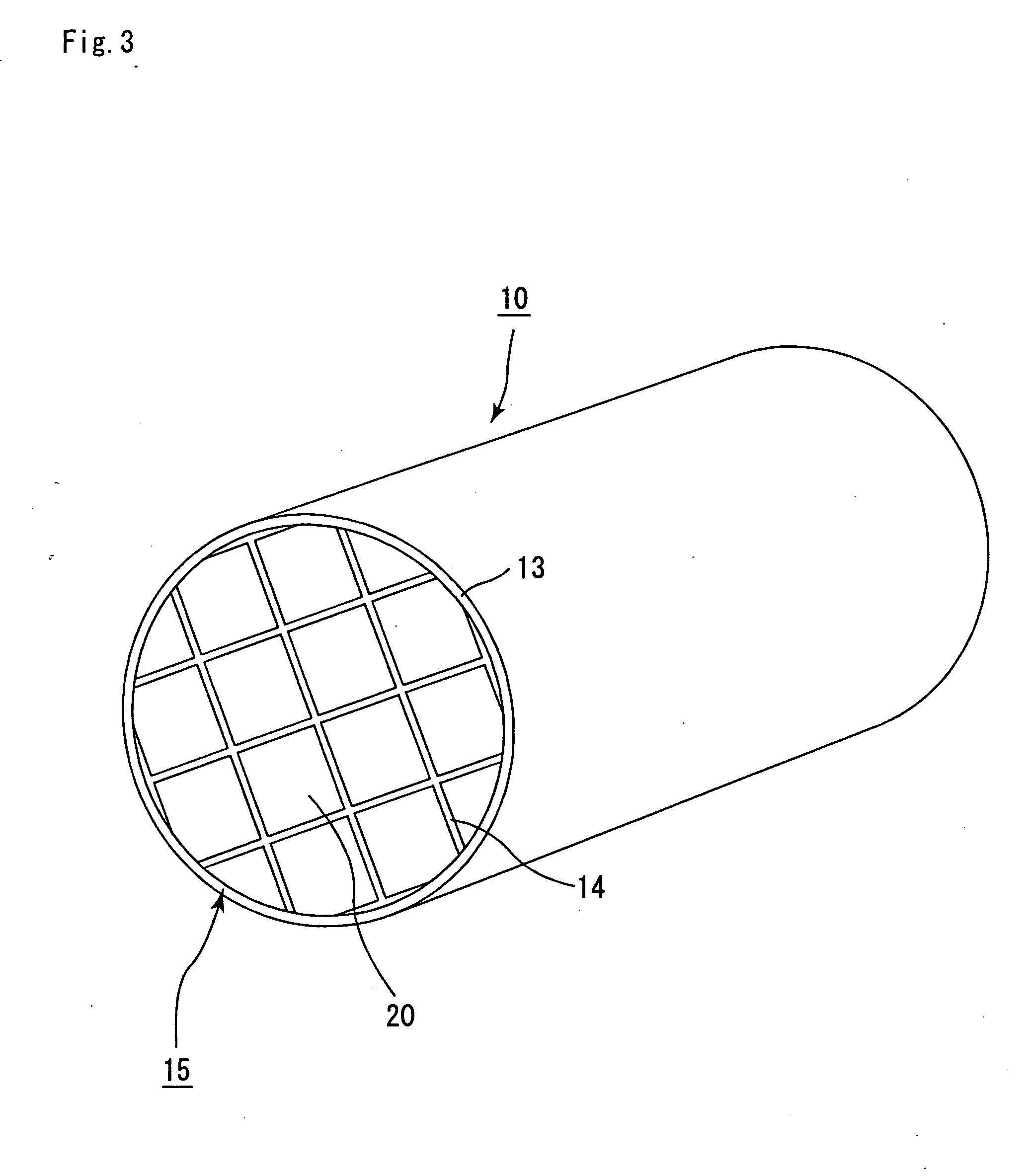

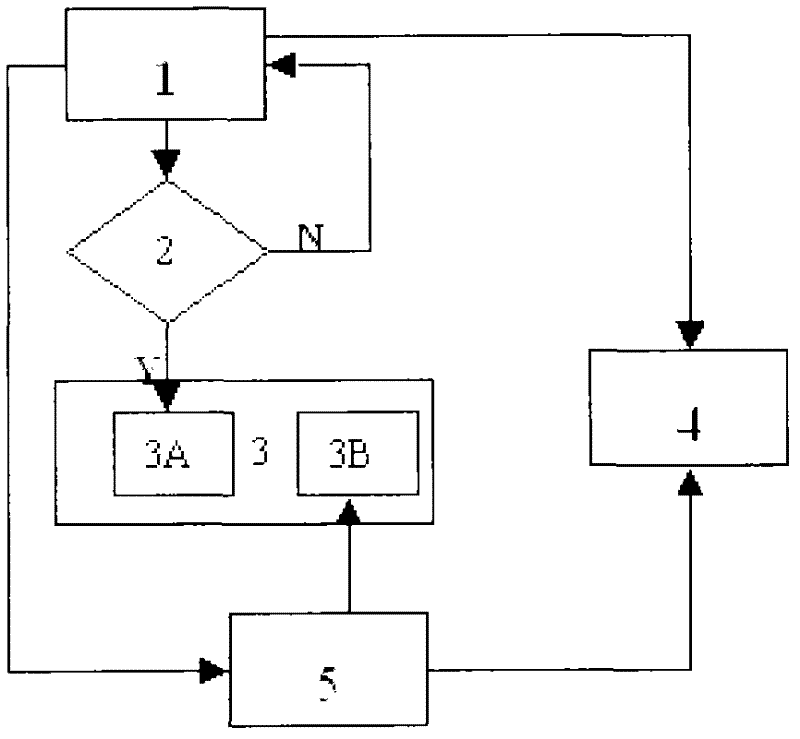

ActiveUS20050016141A1Low pressure lossImprove collection effectDispersed particle filtrationTransportation and packagingParticulatesEngineering

Owner:IBIDEN CO LTD

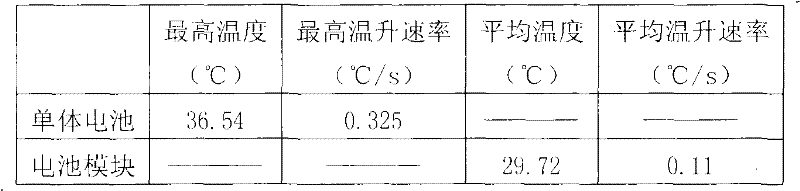

Thermal management device for power batteries and thermal management method for power batteries

InactiveCN102496747ACell temperature controlSecondary cells servicing/maintenancePower batteryElectrical battery

The invention discloses a thermal management device for power batteries and a thermal management method for the power batteries under abnormal working conditions. The thermal management device for the power batteries comprises an acquisition module, an evaluation module, a forecast module, a display module and a control module, wherein the forecast module is used for calculating the heat generation rate and the specific heat capacity according to temperature and temperature rise rate information obtained by the acquisition module and the evaluation module and information such as types, operating states, states of charge and the like of the power batteries so as to obtain forecasted temperature field distribution of a battery unit, and the display module is used for displaying the temperature field distribution of the battery unit forecasted by the forecast module and a current alarm status of the battery unit to a user. The thermal management method for the power batteries is capable of forecasting the temperature field distribution of the battery unit according to acquired temperature and temperature rise data, and at least one of control measures such as turn-off, heat dissipation, alarm and the like is effectively taken, so that the danger of an automobile due to the power batteries can be reduced under the abnormal working conditions.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

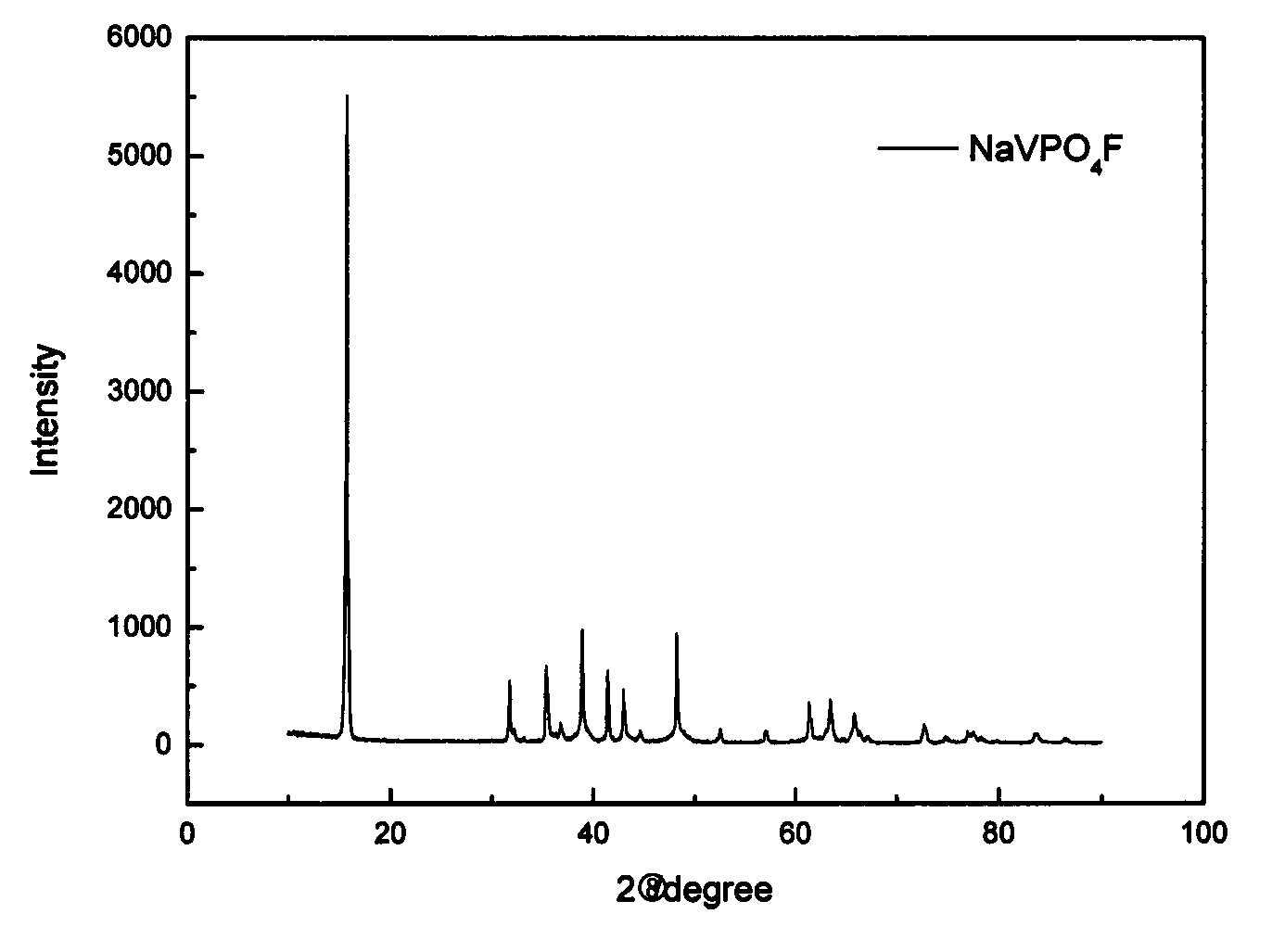

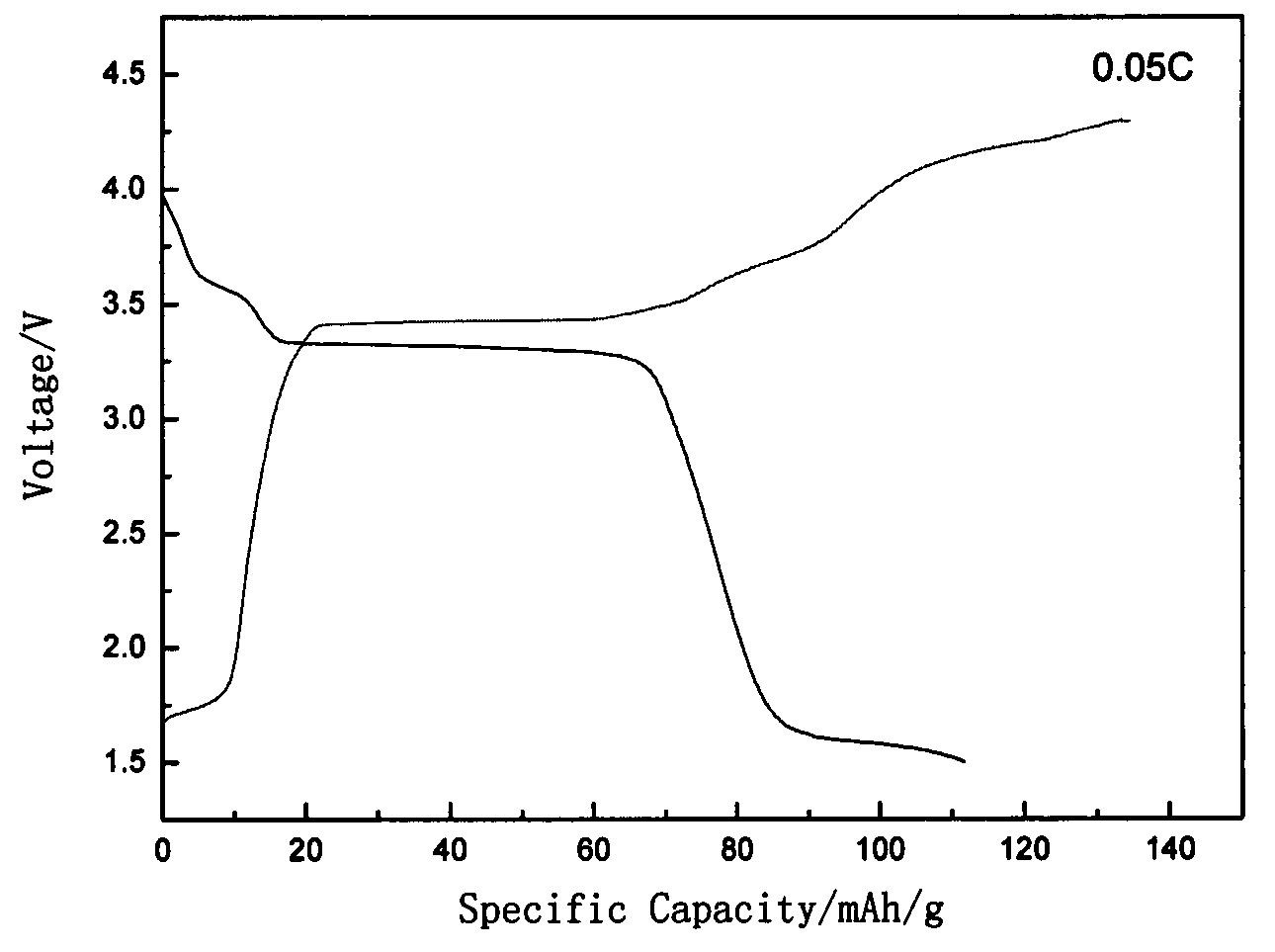

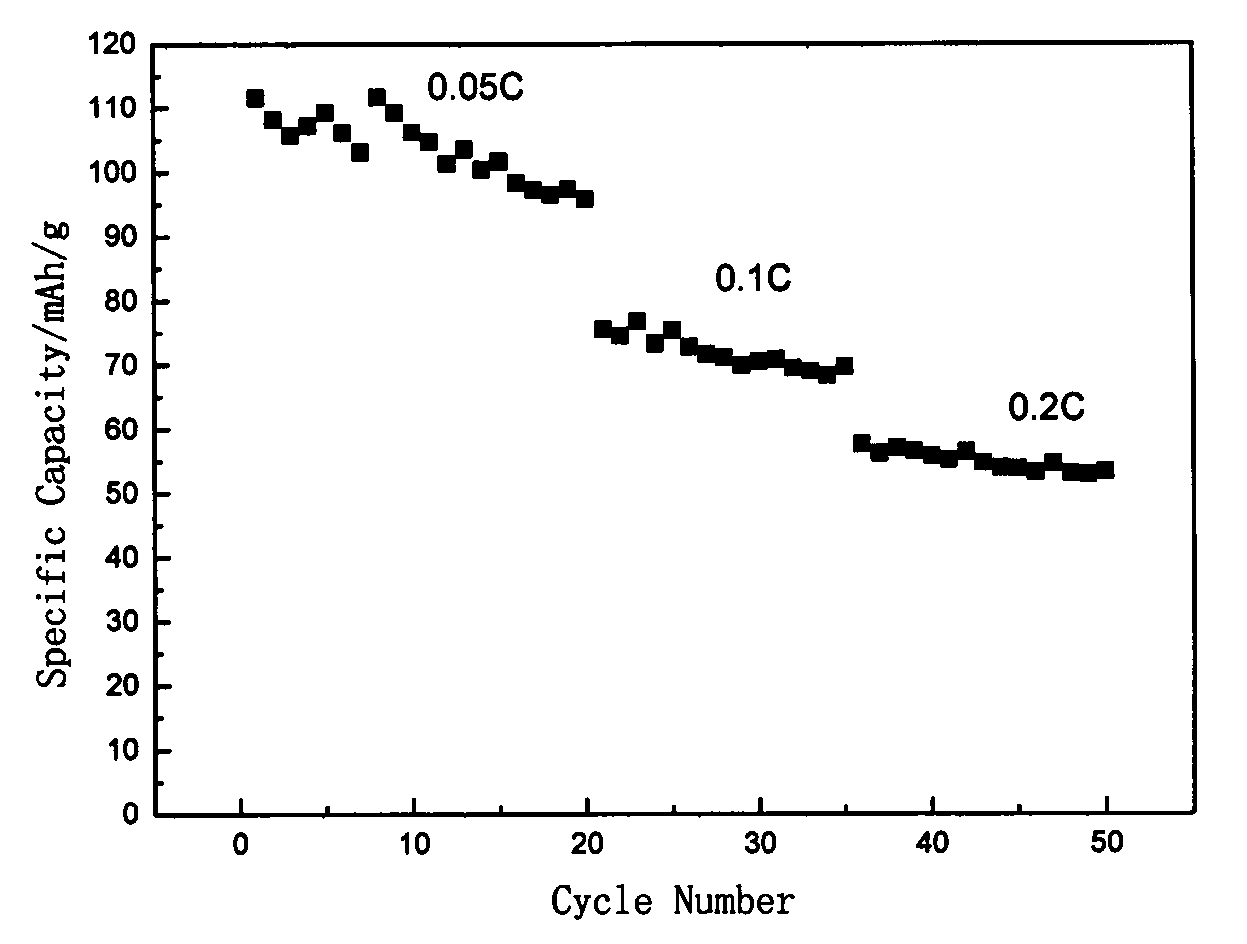

Method for preparing cathode material of sodium-ion battery, namely sodium vanadium fluorophosphates

InactiveCN103594716AImprove electrochemical performanceThe synthesis process is simpleCell electrodesWater bathsSodium-ion battery

The invention discloses a method for preparing a cathode material of a sodium-ion battery, namely sodium vanadium fluorophosphates. The method comprises the following steps: using a vanadium source, a phosphorus source and a carbon source as main synthetic raw materials; dissolving into deionized water according to the molar ratio 1:1:1.2 of vanadium: phosphorus: carbon, heating in water bath, and continuously stirring to obtain light green pulp; after vacuum drying, grinding, then transferring into a tube furnace, preburning in an inert atmosphere at a certain temperature rise rate, cooling and then taking out to obtain black VPO4 / C precursor powder; mixing the VPO4 / C with NaF according to a stoichiometric ratio, ball-milling for 3 hours, sending into the tube furnace, then roasting in the inert atmosphere at the certain temperature rise rate, and cooling along with the furnace to obtain a positive active material NaVPO4F / C. According to the invention, cheap and easily-obtained pentavalent vanadium oxide or trivalent vanadium oxide is used as the main raw materials to prepare the sodium vanadium fluorophosphates cathode material through a sol gel activated auxiliary two-step high-temperature solid phase method, and the sodium vanadium fluorophosphates cathode material has the advantages of good stability, uniform particle size and good electrochemical performance. Meanwhile, the method has the advantages of simple synthesis process, short period and low cost and is convenient for large-scale production.

Owner:TIANJIN POLYTECHNIC UNIV

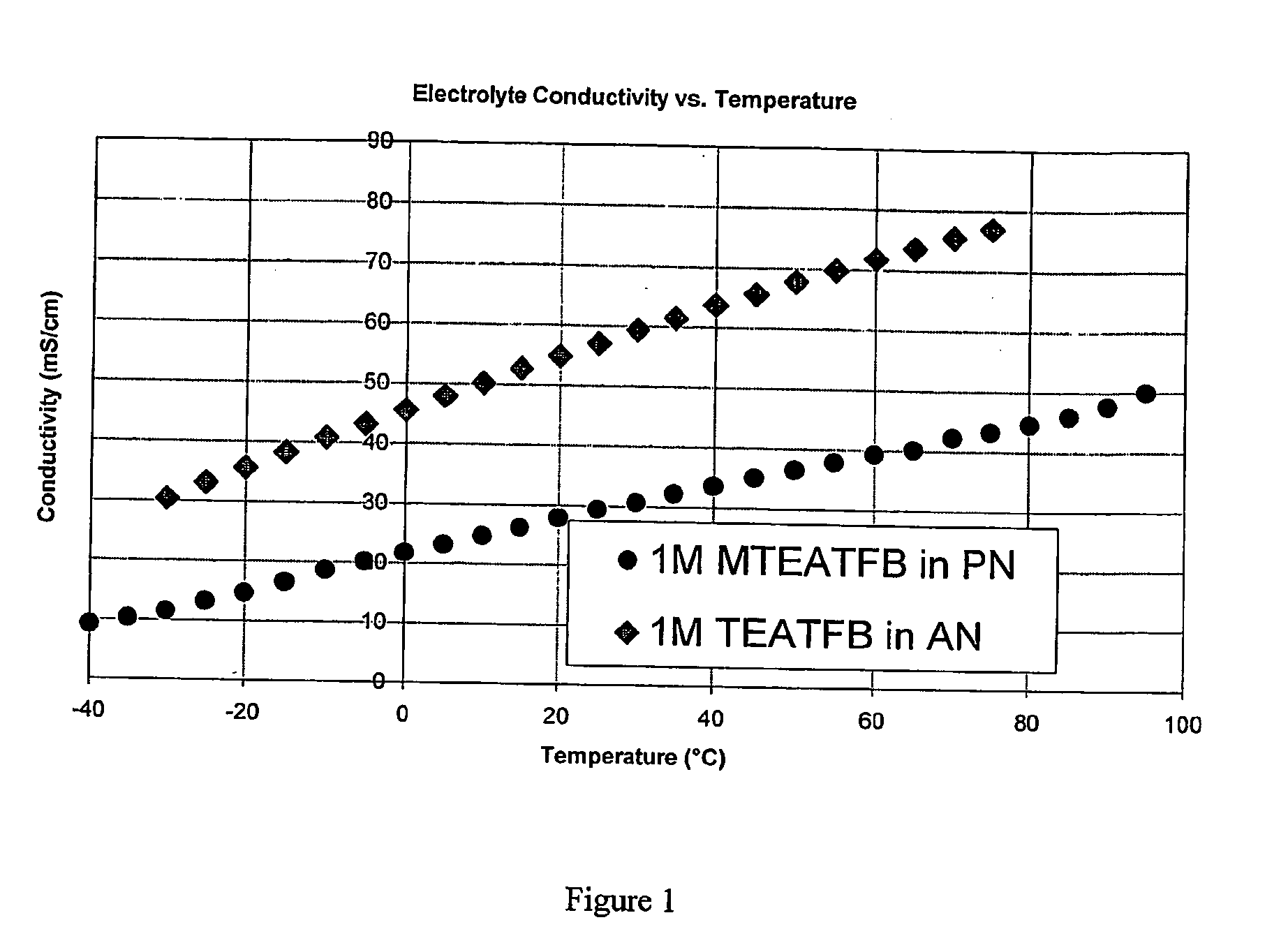

Electrolyte

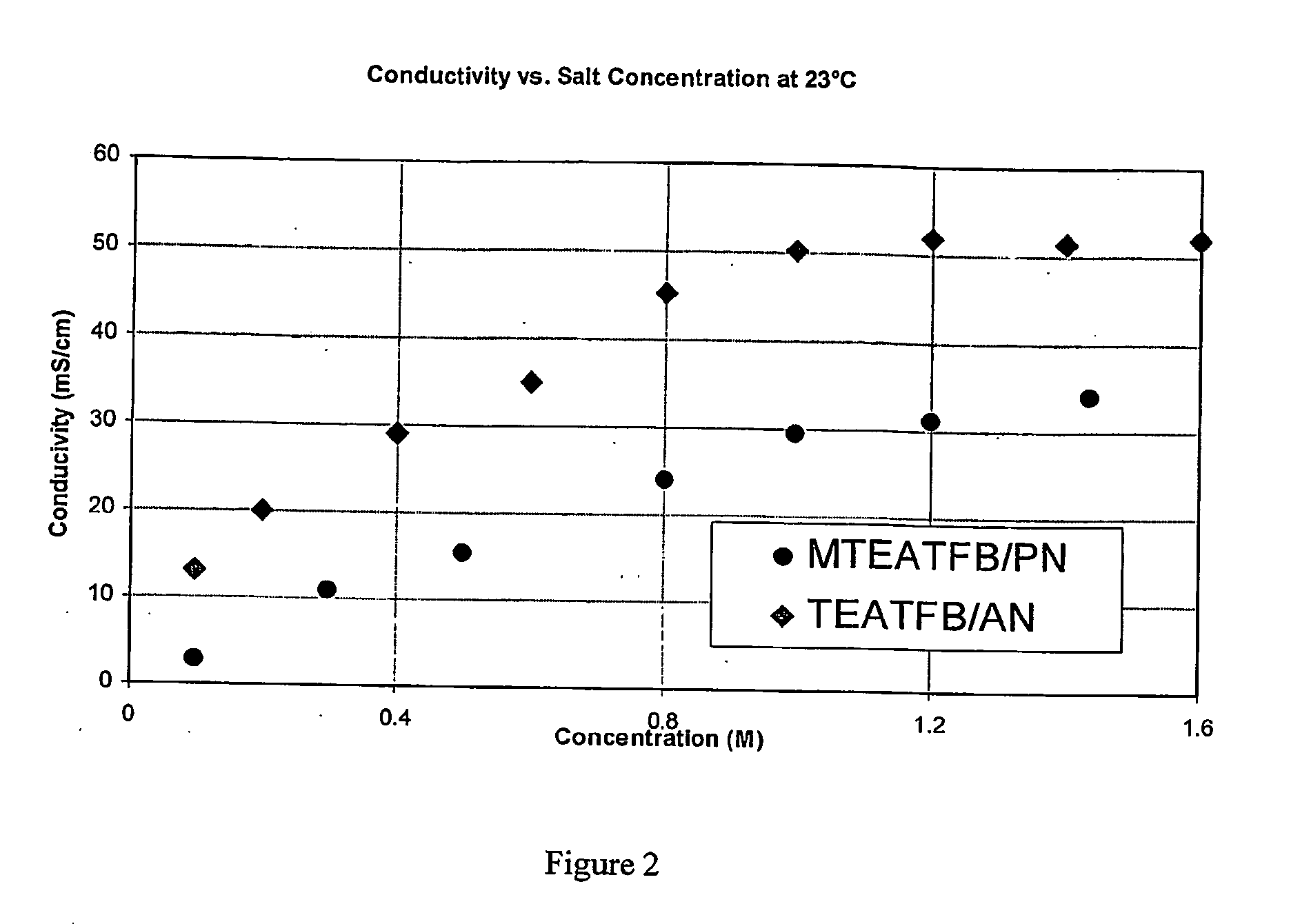

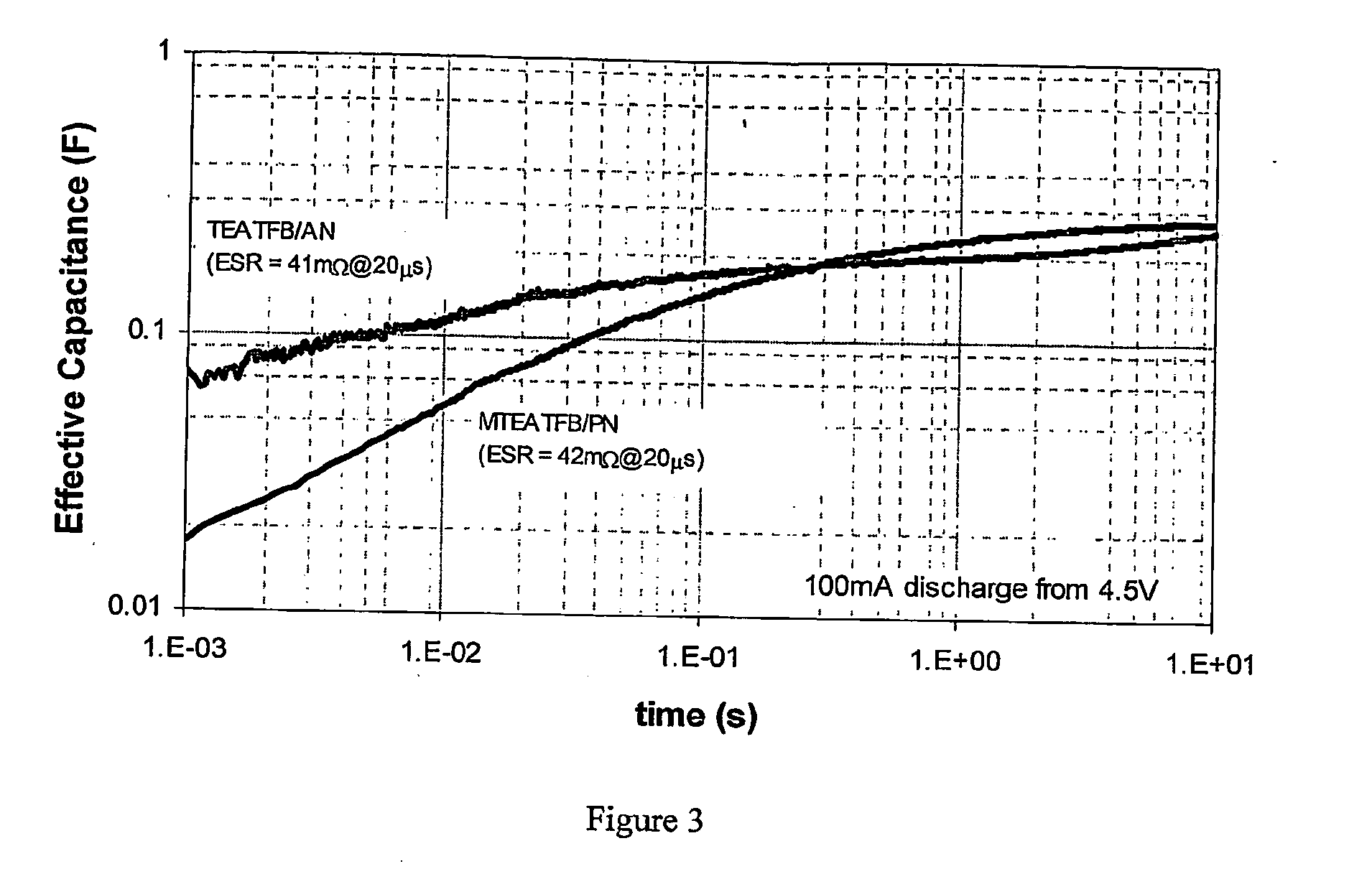

ActiveUS20100046142A1Good operational characteristicImprove stabilityHybrid capacitor electrolytesOrganic electrolyte cellsTetrafluoroborateSolvent

Electrolyte for use in an energy storage device such as a capacitor or supercapacitor which comprises a solvent (preferably propionitrile) and an ionic species (preferably methyltriethylammonium tetrafluoroborate). The electrolytes provide a low ESR rise rate, a high voltage and permit operation over a wide range of temperatures, which makes them beneficil for use in a range of energy storage devices such as digital wireless devices, wireless LAN devices, mobile telephones, computers, electrical or hybrid electrical vehicles.

Owner:CAP XX LTD +1

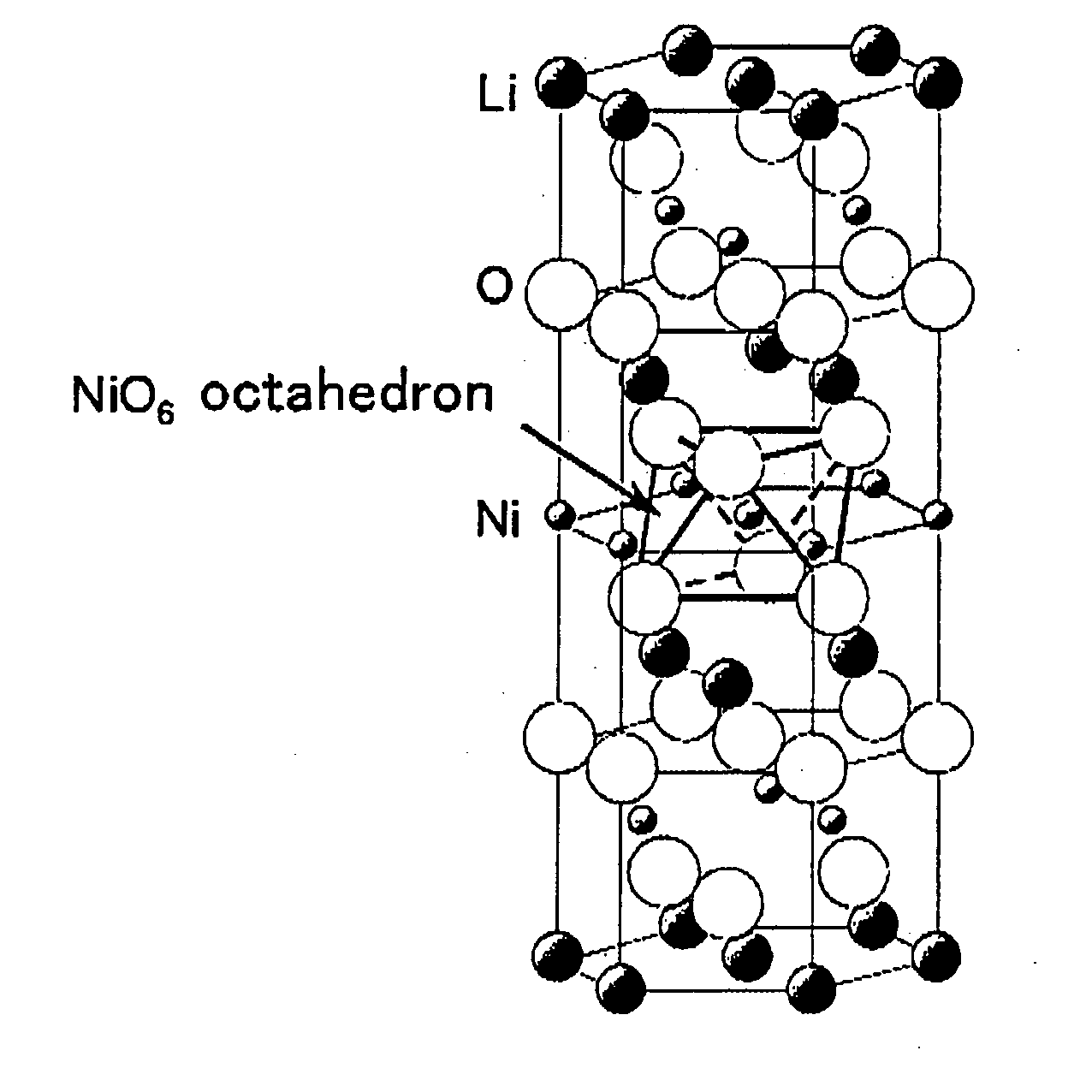

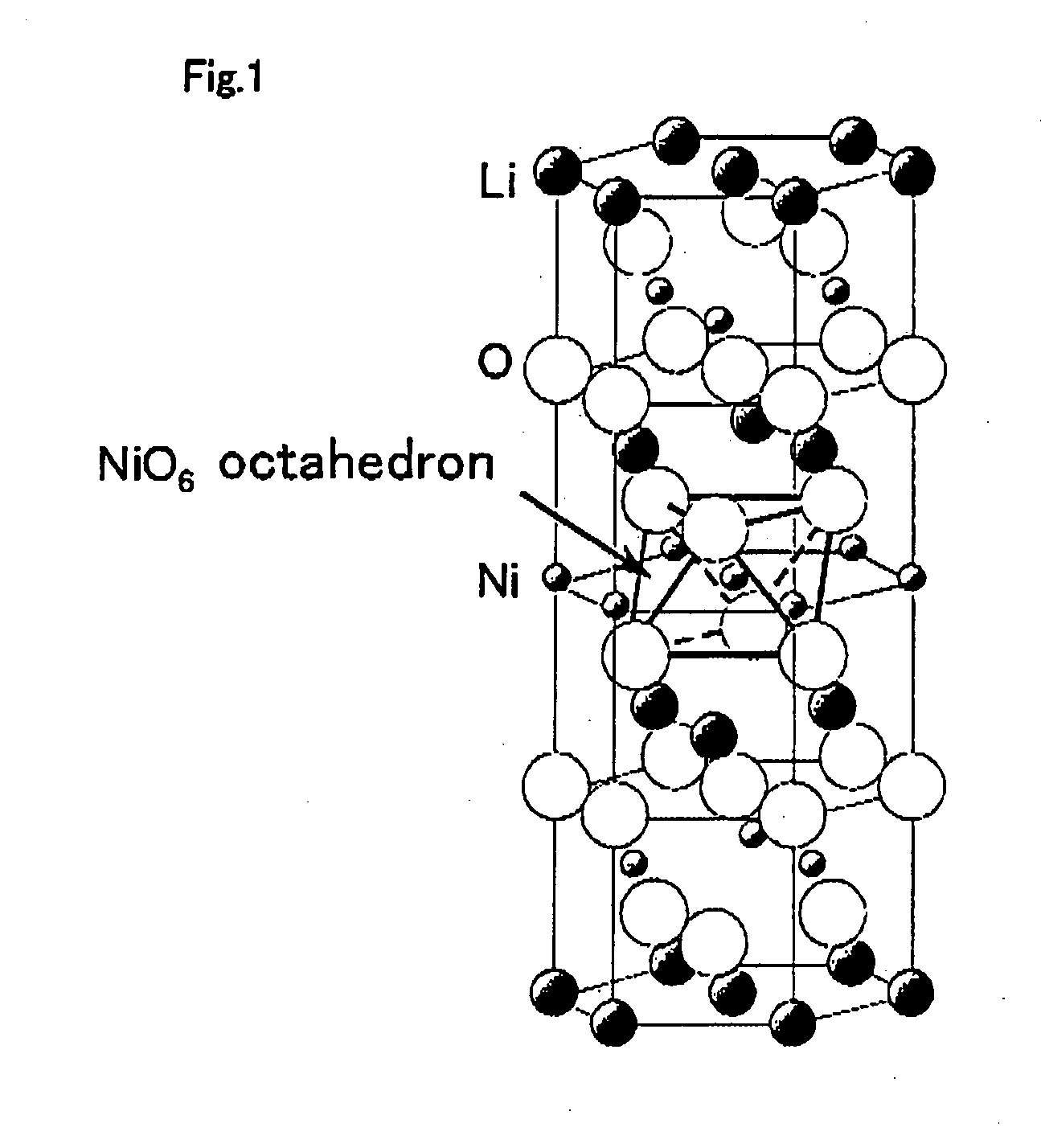

Positive electrode active material for non-aqueous electrolyte secondary battery and manufacturing method thereof, and non-aqueous electrolyte secondary battery using same

ActiveUS20070248883A1High power outputDecreasing resistance of batteryNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsCooking & bakingInternal resistance

To provide a positive electrode active material for a non-aqueous electrolyte secondary battery, which if used as a positive electrode for a lithium ion secondary battery, the battery internal resistance can be reduced, giving a secondary battery superior in output characteristics and life property. After mixing raw material powders in specified quantities of each so as to become a lithium-metal complex oxide represented by LizNi1-wMwO2 (wherein M is at least one kind or more of metal elements selected from the group consisting of Co, Al, Mg, Mn, Ti, Fe, Cu, Zn, and Ga; and w and z respectively satisfy 0<w≦0.25, and 1.0≦z≦1.1), baking is performed in two stages. At first the temperature is raised from room temperature to a first stage baking temperature (450 to 550° C.) at a temperature rise rate of 0.5 and 15° C. / min, and held for 1 to 10 hours. Then the temperature is raised to a second stage baking temperature (650 to 800° C.), and held for 0.6 to 30 hours.

Owner:SUMITOMO METAL MINING CO LTD +2

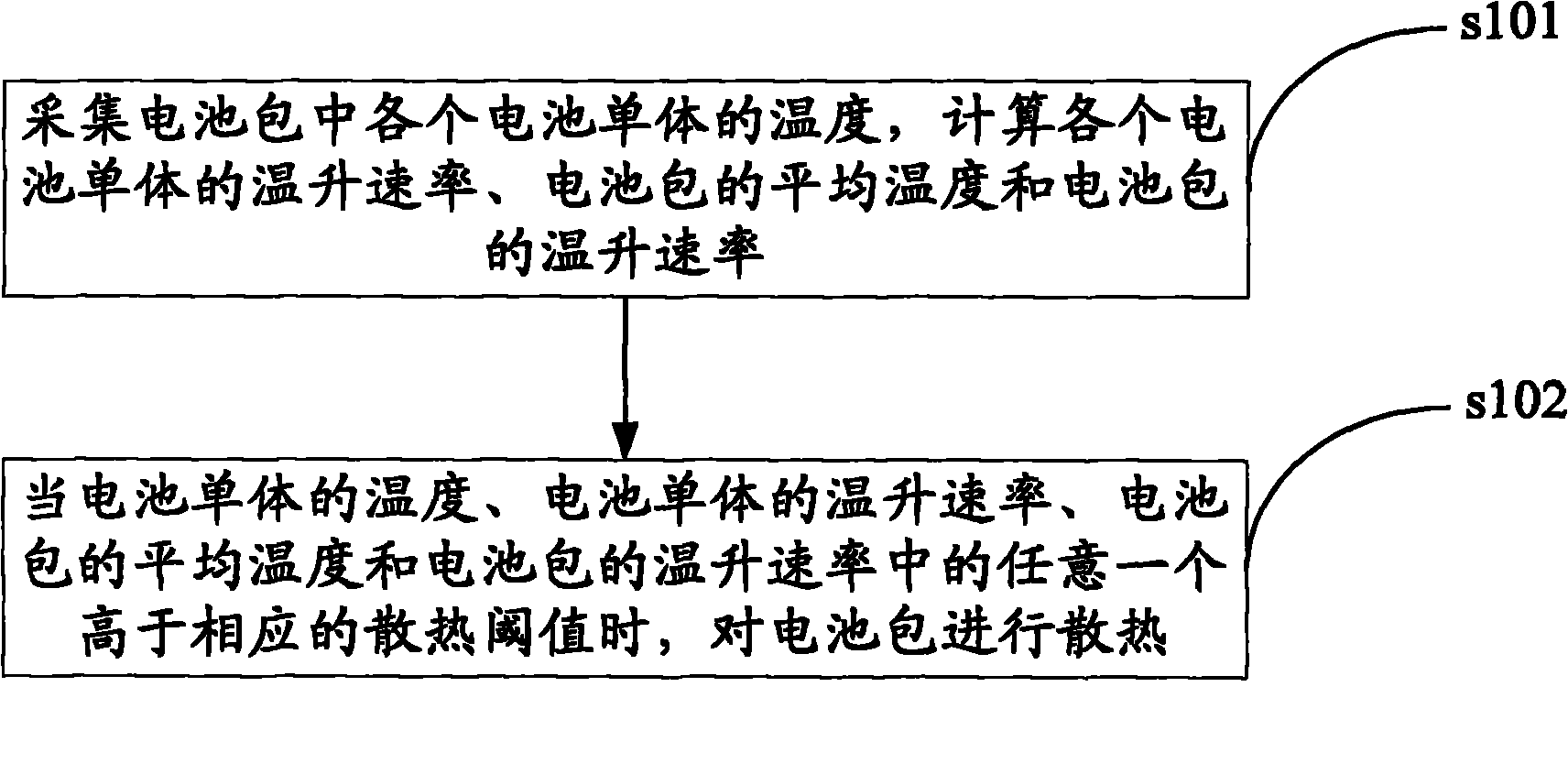

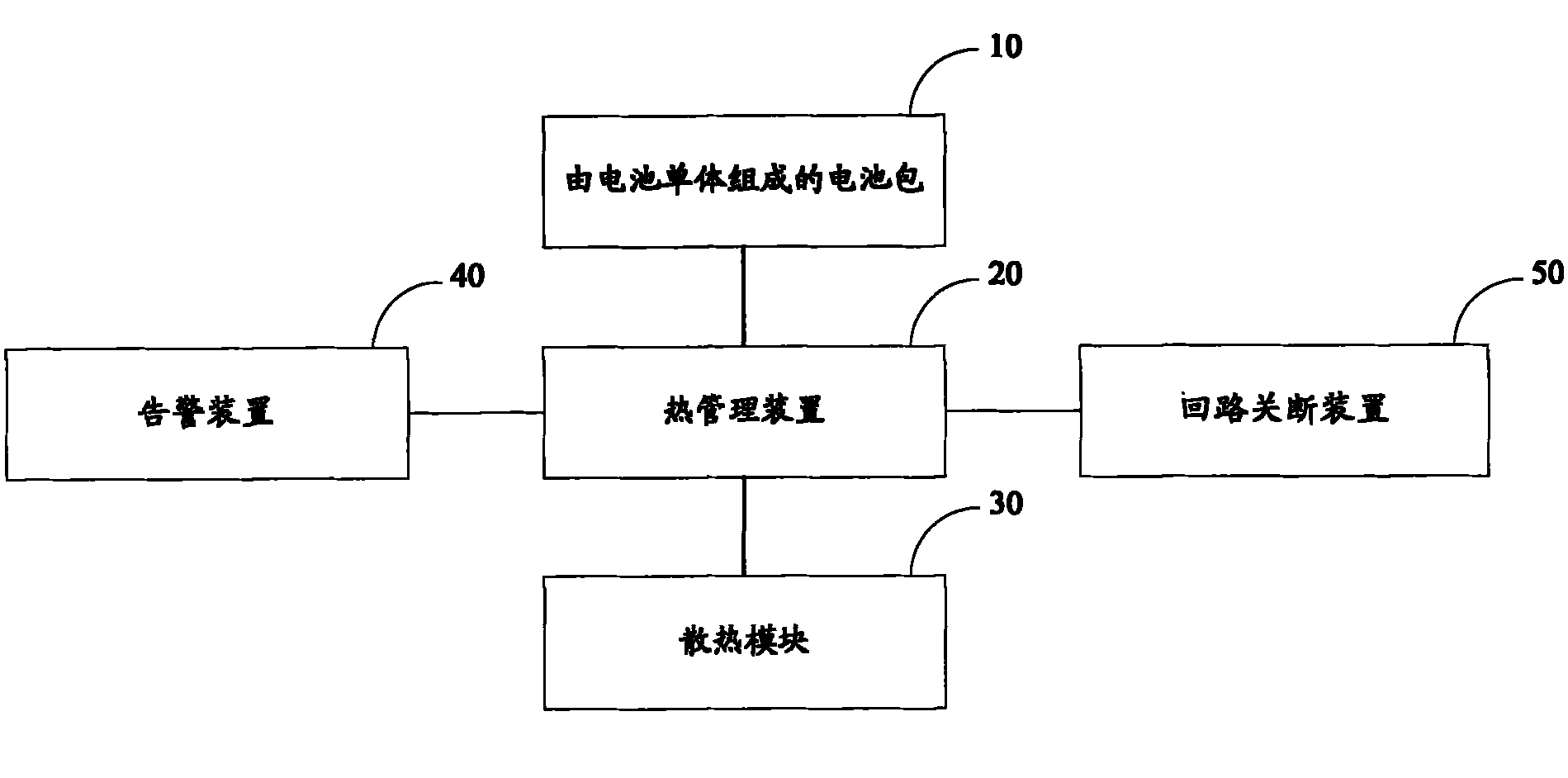

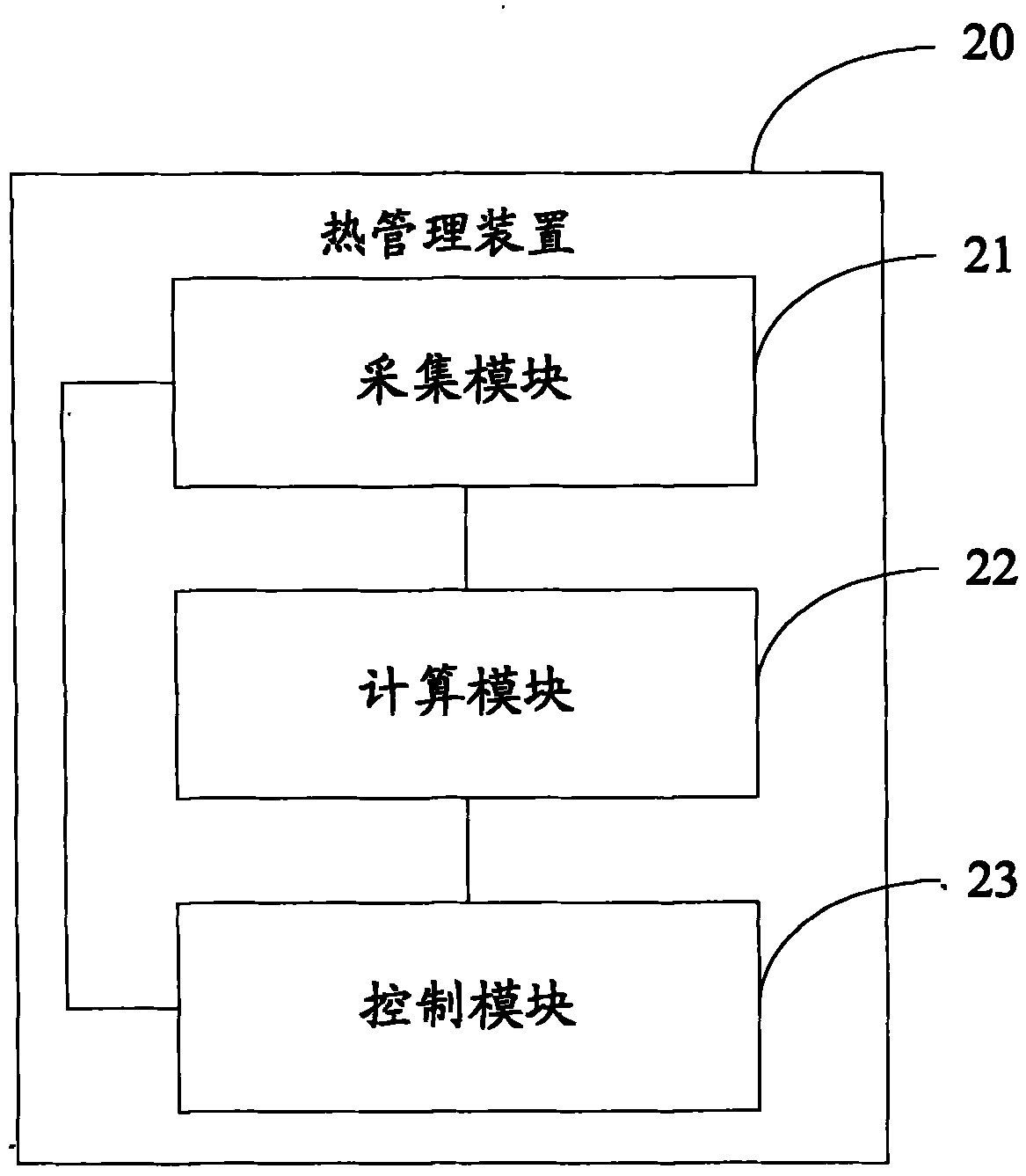

Thermal management method, system and device of battery

ActiveCN102122735ATrue reflection of heat dissipationEasy to controlCell temperature controlSecondary cells servicing/maintenanceEngineeringBattery thermal management

The invention provides a thermal management method, system and device of a battery. The method comprises the steps of: collecting the temperature of each single battery in a battery pack and calculating the temperature rising rate of the each single battery, the average temperature of the battery pack and the temperature rising rate of the battery pack; and when any one of the temperature of eachsingle battery, the temperature rising rate of the each single battery, the average temperature of the battery pack and the temperature rising rate of the battery pack is higher than the corresponding heat dissipation threshold value, carrying out heat dissipation on the battery pack. In the invention, the temperature value and the temperature rising rate of the single battery as well as the average temperature value and the temperature rising rate of the battery pack are used as references and the heat quantity of the battery pack under a working state is controlled to ensure that the thermal management can be controlled more accurately and the potential safety hazard can be eliminated.

Owner:CHERY AUTOMOBILE CO LTD

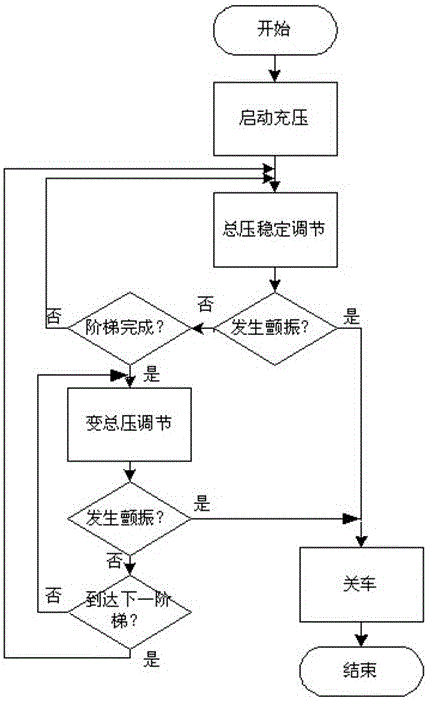

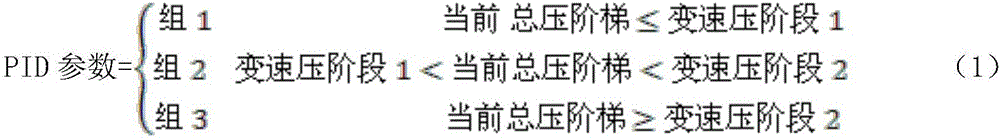

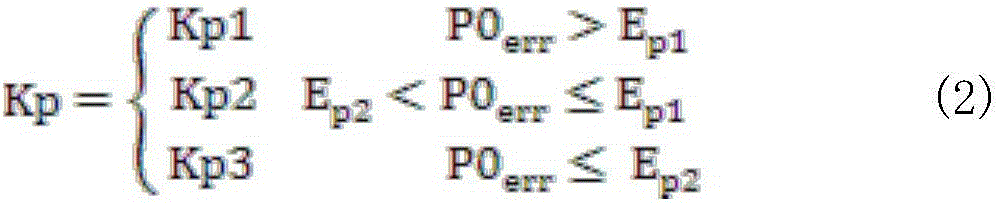

Method for controlling adjusting dynamic pressure flow field for large direct-current blow-down supersonic wind tunnel

ActiveCN106527519AHigh control precisionTotal pressure rise rate controllableFluid pressure control using electric meansEngineeringDynamic pressure

The invention, which relates to the field of supersonic wind tunnel test control, discloses a method for controlling an adjusting dynamic pressure flow field for a large direct-current blow-down supersonic wind tunnel. With the method provided by the invention, a problem that the supersonic flutter testing requirement can not be met because multi-step total pressure control can not be realized at single flight and the total pressure rising rate can not be controlled according to the conventional supersonic wind tunnel control method can be solved. The method comprises: wind tunnel starting and pressurizing are carried out and a flow field s established; a total pressure is adjusted stably; an adjusting dynamic pressure is adjusted; and flying machine closing is carried out by the wind tunnel. And different closing strategies are employed based on different situations, so that flying machine closing is realized securely by the wind tunnel. With the method, the requirement on adjusting dynamic pressure flow field control of the supersonic wind tunnel by a flutter test is met. The method has advantages of reliable operation, convenient parameter giving, low total pressure control overshooting, and high precision.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Ceramic heater

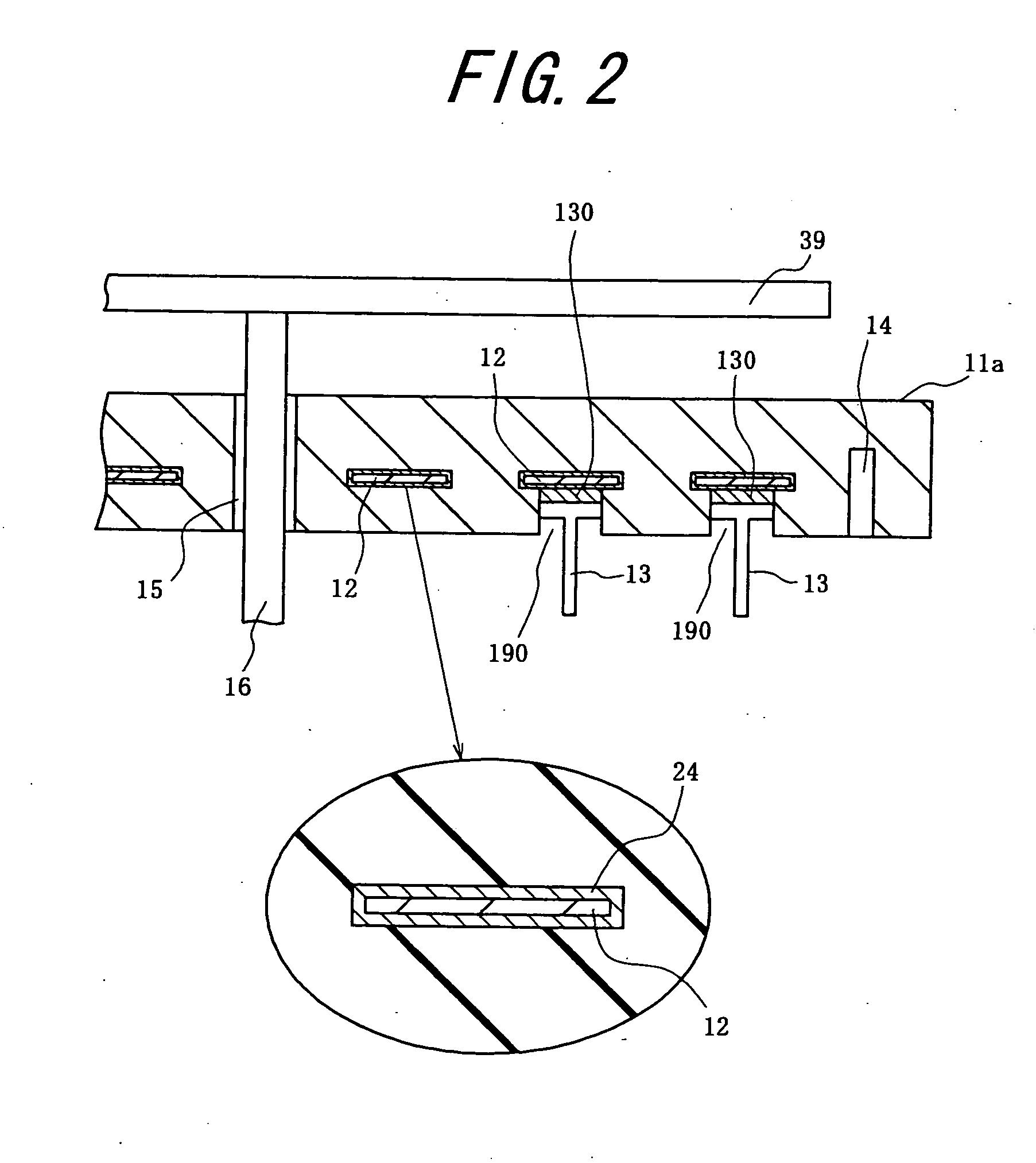

InactiveUS20050016986A1Efficient transferEliminate temperature differenceSemiconductor/solid-state device manufacturingHot plates heating arrangementsElectrical resistance and conductanceSemiconductor

The invention is a ceramic heater provided with a resistor heating body formed in an interior of a ceramic substrate, characterized in that the resistor heating body is made of an electrically conductive ceramic and a sintering aid containing layer is existent at least on the surface of the resistor heating body. This heater does not generate crack even in the rapid temperature rise, and has an effect of uniformizing the heating and rapidly increasing the temperature rising rate, and is used in an industrial field of semiconductor production-inspection apparatuses including an electrostatic chuck or plasma generating device, optical apparatuses and the like.

Owner:IBIDEN CO LTD

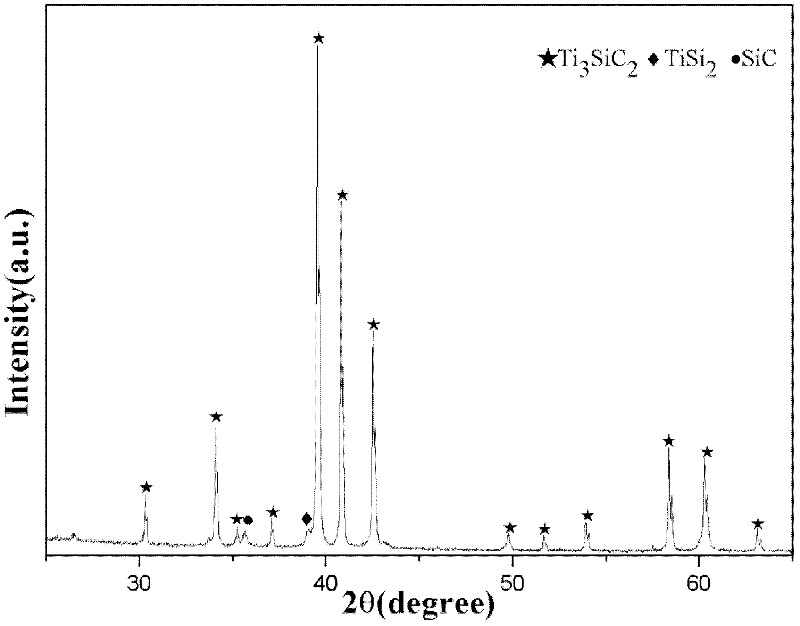

Method for preparing high-purity MAX-phase ceramic powder

InactiveCN102633505AHigh activityUniform distribution of temperature fieldChemical measurementBall mill

The invention discloses a method for preparing high-purity MAX-phase ceramic powder. The method includes approximately weighing raw materials according to stoichiometric ratios of various elements in a chemical formula of a MAX-phase ceramic material at first; then uniformly mixing the raw materials by the aid of a ball mill, placing mixture of the raw materials in a mold and prepressing the mixture to obtain a prepressed intermediate body; and finally placing the prepressed intermediate body into a special microwave oven, controlling the temperature rise rate by means of adjusting the microwave power in inertial atmosphere, increasing the temperature to a sintering temperature, keeping heat for a certain period, realizing furnace cooling to the room temperature, and grinding the mixture to obtain the MAX-phase ceramic powder with high purity, an excellent shape and a unique layered structure. The method for preparing the MAX-phase ceramic powder is speedy, efficient, energy-saving and environment-friendly and is low in cost and easy to realize large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

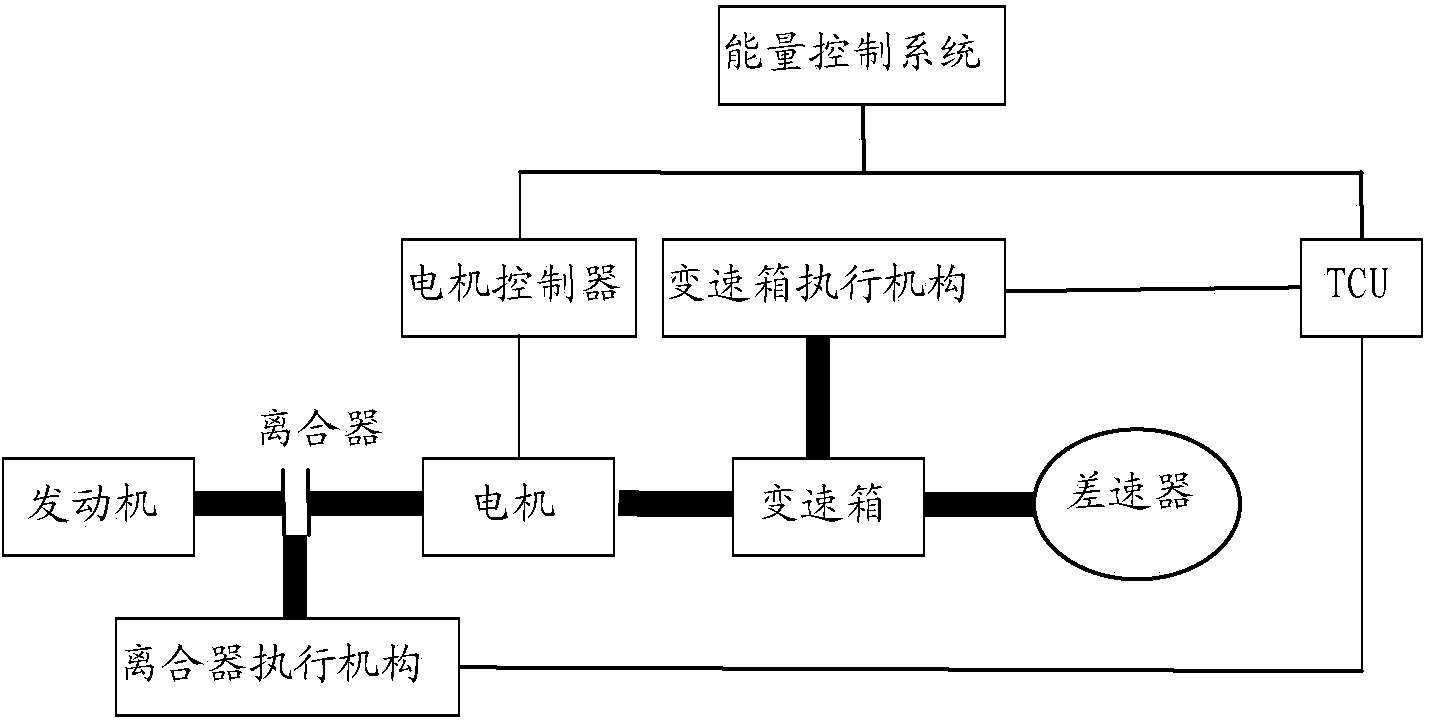

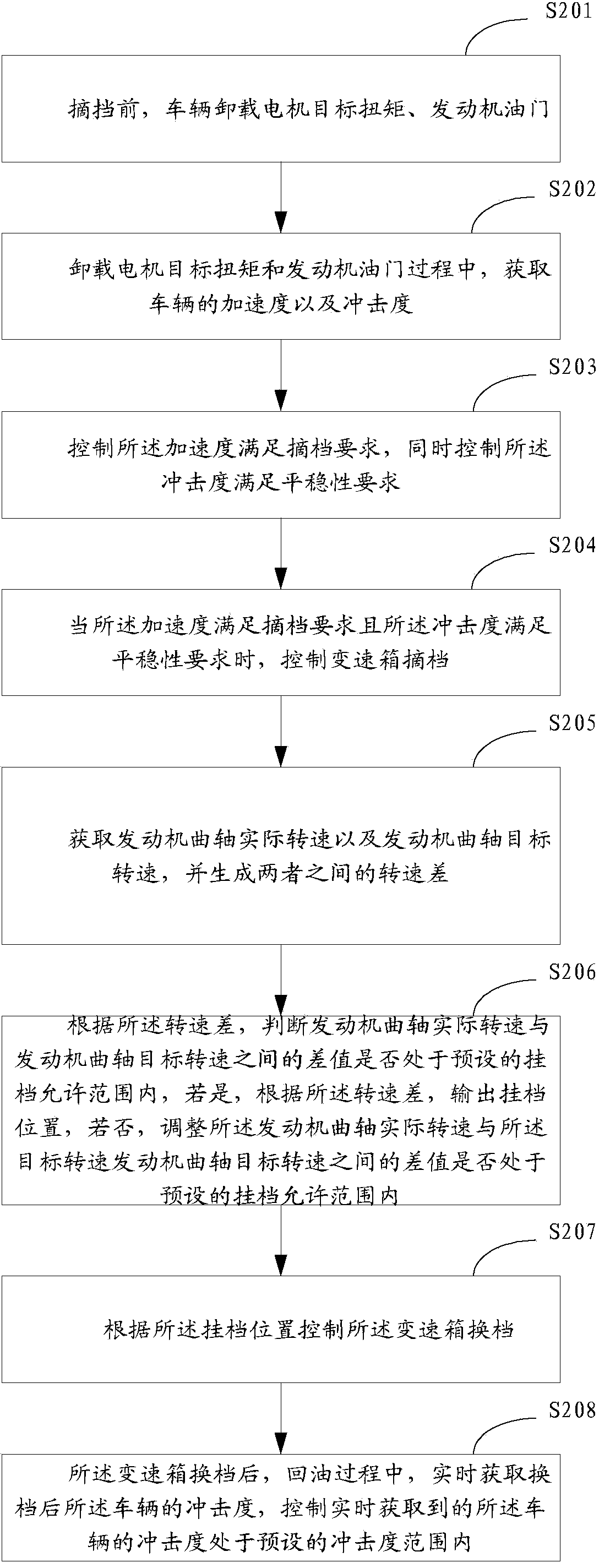

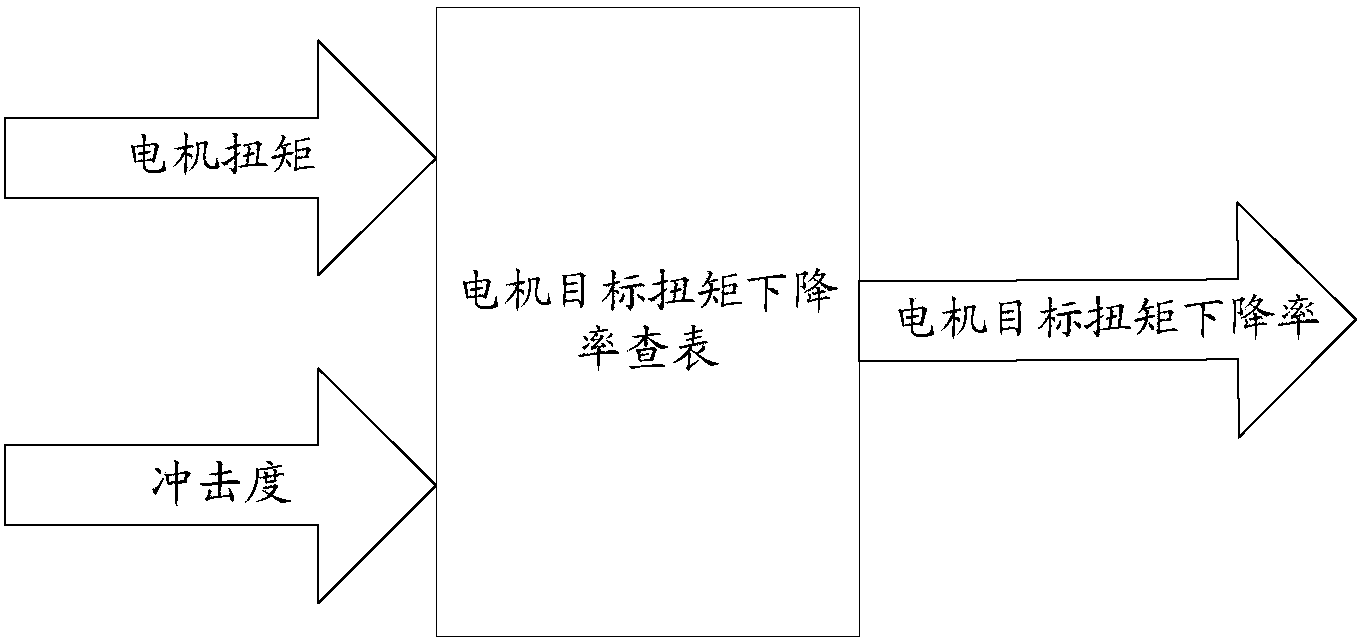

Gear shifting method and device based on AMT parallel hybrid vehicle system and vehicle with same

ActiveCN104002814AImprove stabilitySatisfy the extraction requirementsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric machineEngineering

The invention is applicable to the technical field of vehicles, and provides a gear shifting method and a gear shifting device based on an AMT parallel hybrid vehicle system and a vehicle with the same. The method comprises the steps that: before gear removal, controlling a motor torque and unloading of an engine throttle by the accelerated speed and the impact degree; controlling the accelerated speed to meet gear removal requirements, and controlling the impact degree to meet stability requirements; when the accelerated speed meets the gear removal requirements and the impact degree meets the stability requirements, controlling a gearbox to perform gear removal; obtaining actual rotating speed of the crank of an engine and target rotating speed of the crank of the engine, and generating the speed difference therebetween; judging whether the difference between the actual rotating speed and the target rotating speed of the crank of the engine is within a preset gear engaging permission range, if yes, outputting a gear engaging position according to the speed difference; controlling the gearbox to shift according to the gear engaging position, after gear engaging, controlling the motor torque and rising rate of the engine throttle by the accelerated speed and the impact degree. According to the gear shifting method and device, the stability of the vehicles is improved.

Owner:WUHAN HEKANG POWER TECH CO LTD

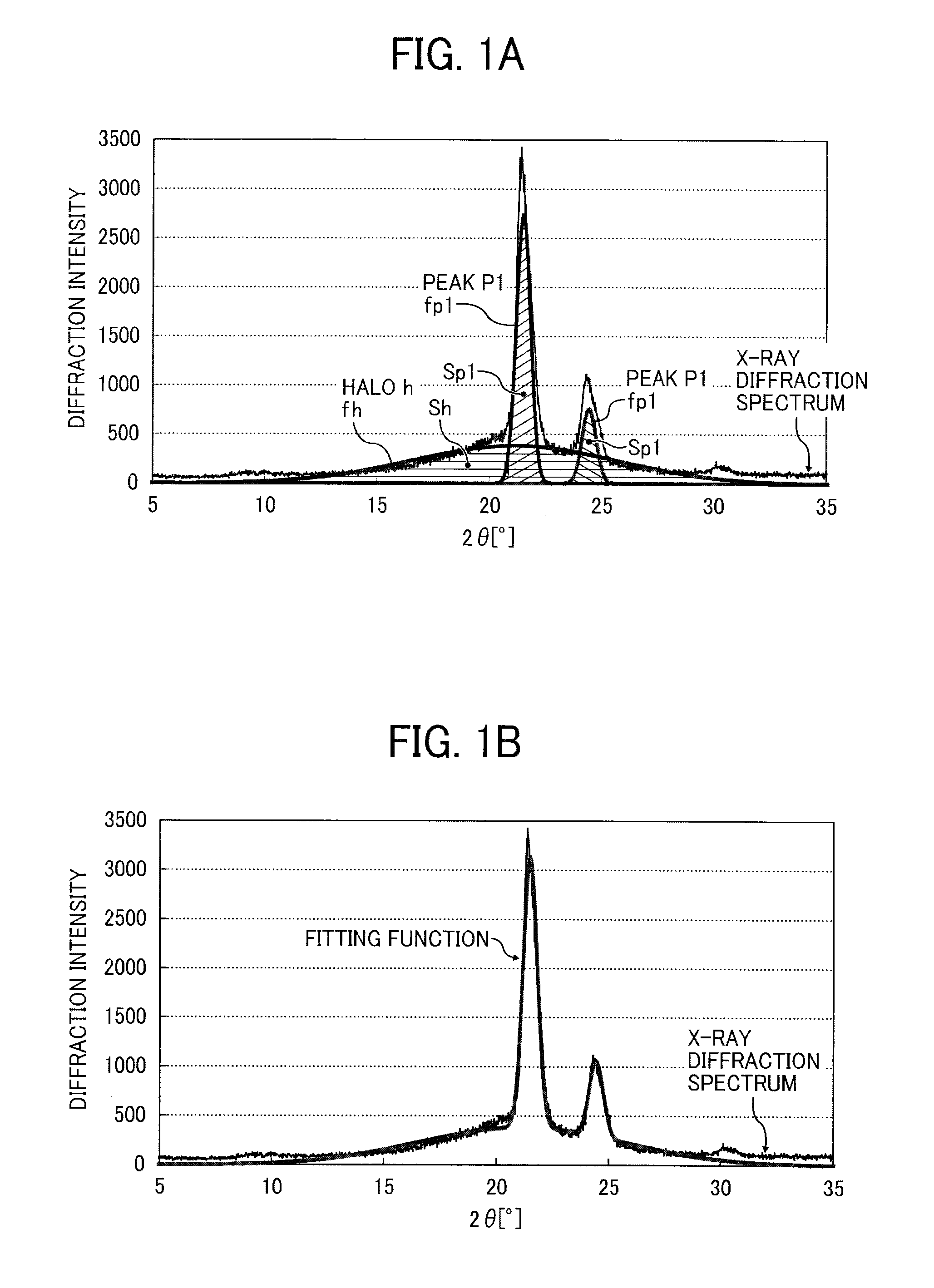

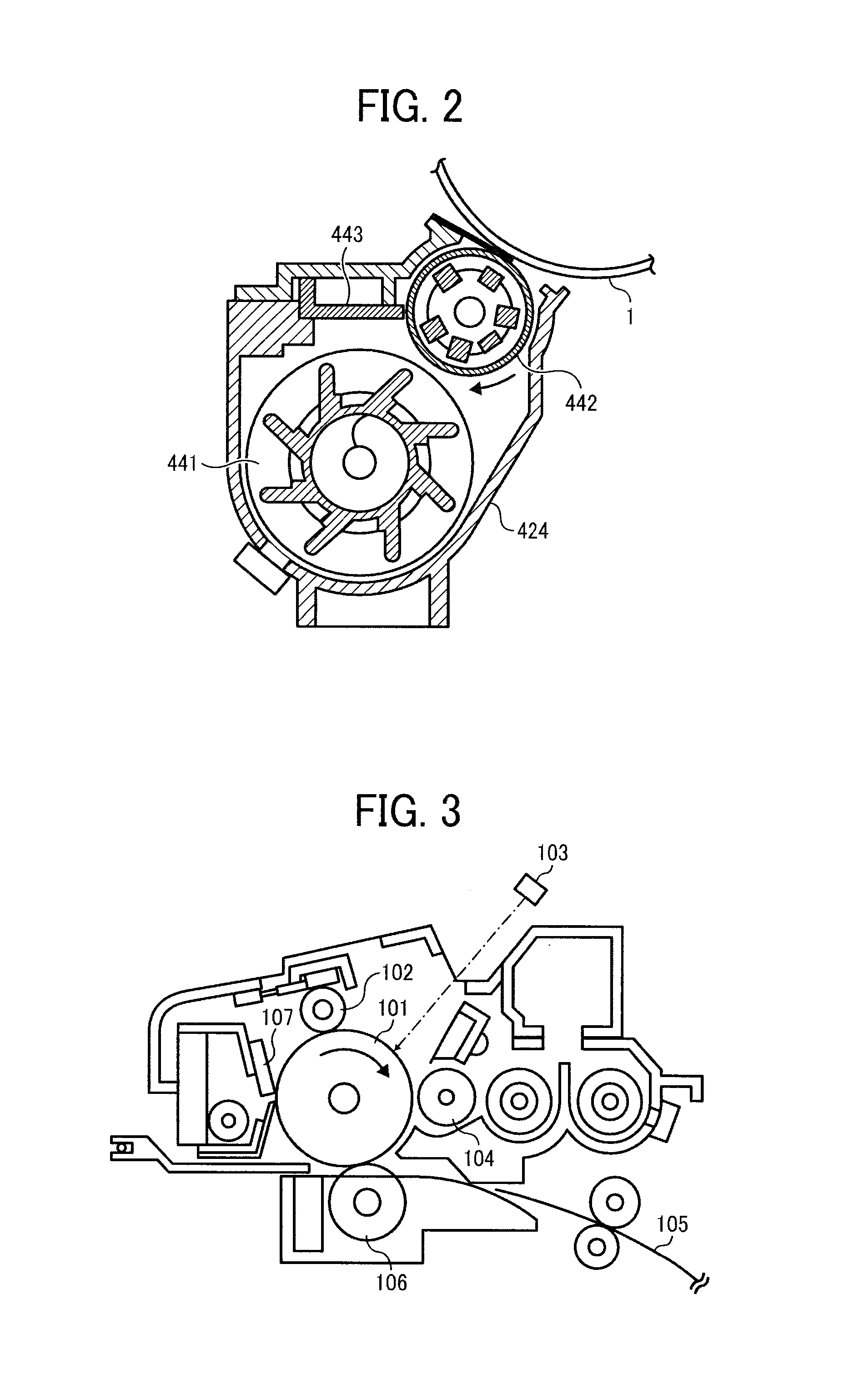

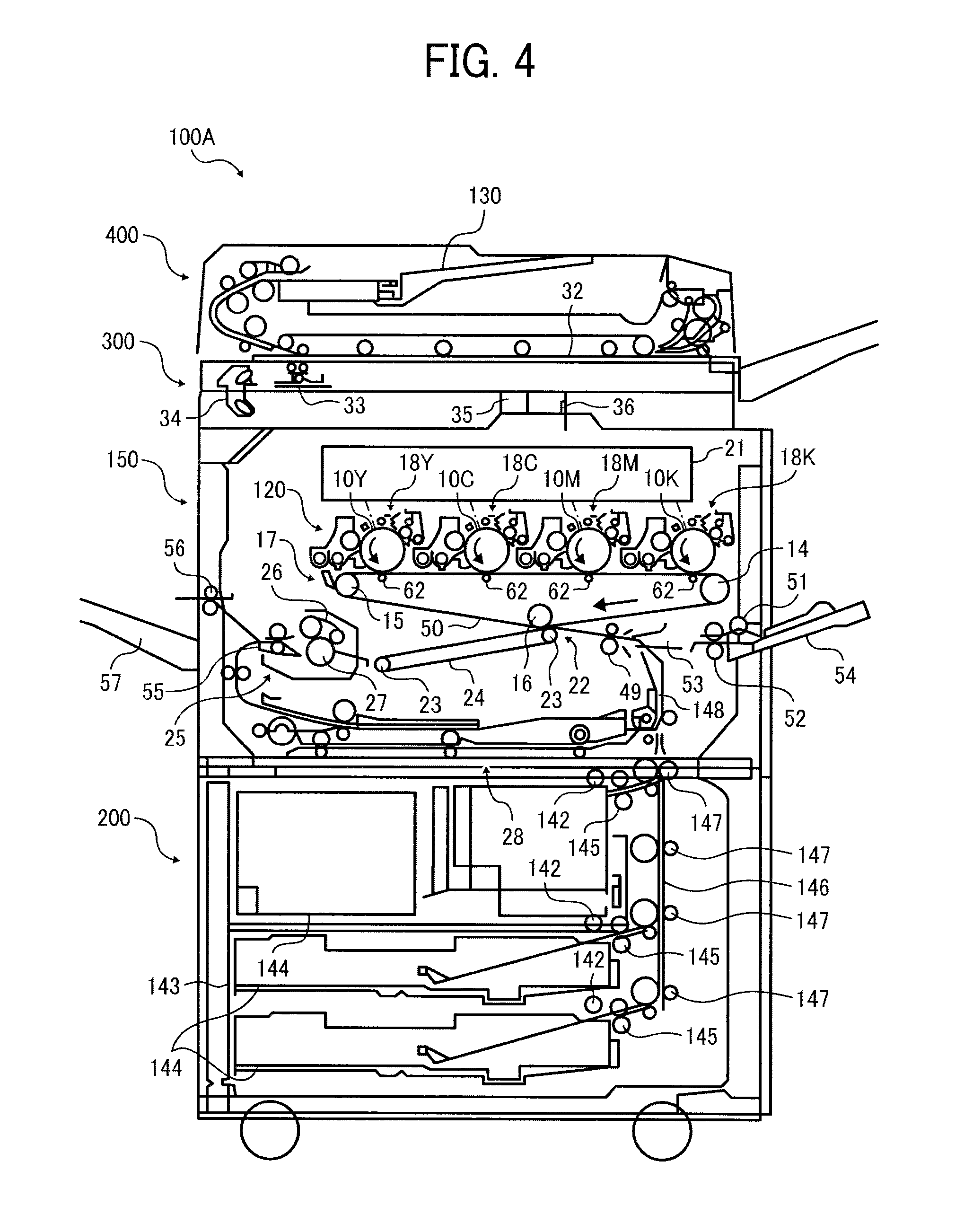

Toner, development agent, image forming apparatus, and process cartridge

Toner contains a binder resin containing a crystalline resin having a urethane and / or urea bonding; and a colorant, wherein in a diffraction spectrum of the toner as measured by an X-ray diffraction instrument, a ratio {C / (C+A)} of an integral intensity C of the spectrum derived from the crystalline structure to an integral intensity A of the spectrum derived from the non-crystalline structure is 0.12 or greater, wherein the toner satisfies the following relation 1: T1−T2≦30° C. (Relation 1), where T1 represents the maximum endothermic peak in the first temperature rising from 0° C. to 100° C. at the temperature rising rate of 10° C. / min and T2 represents the maximum exothermic peak in the first temperature falling from 100° C. to 0° C. at the temperature falling rate of 10° C. / min as T1 and T2 are measured by diffraction scanning calorimetry (DSC).

Owner:RICOH KK

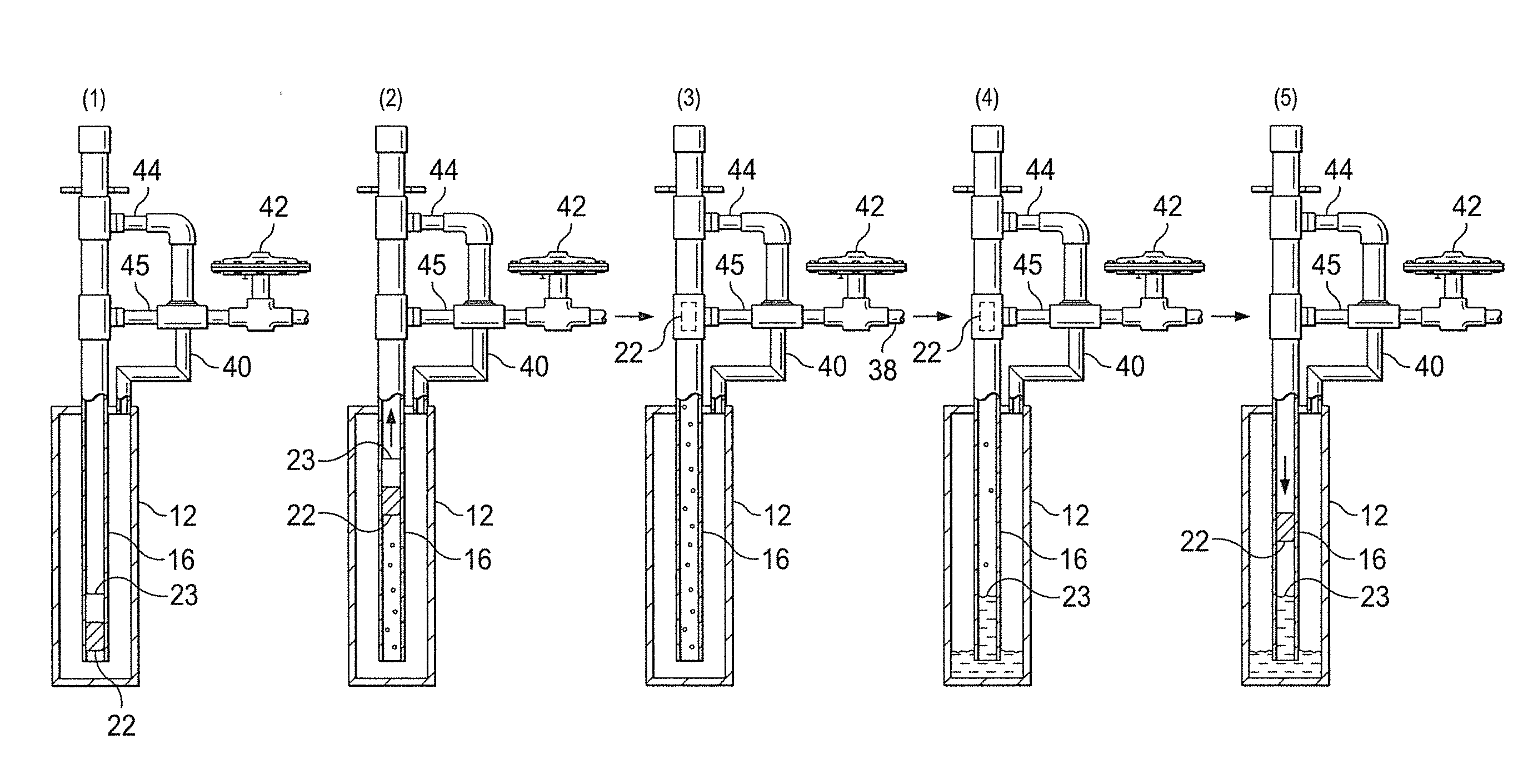

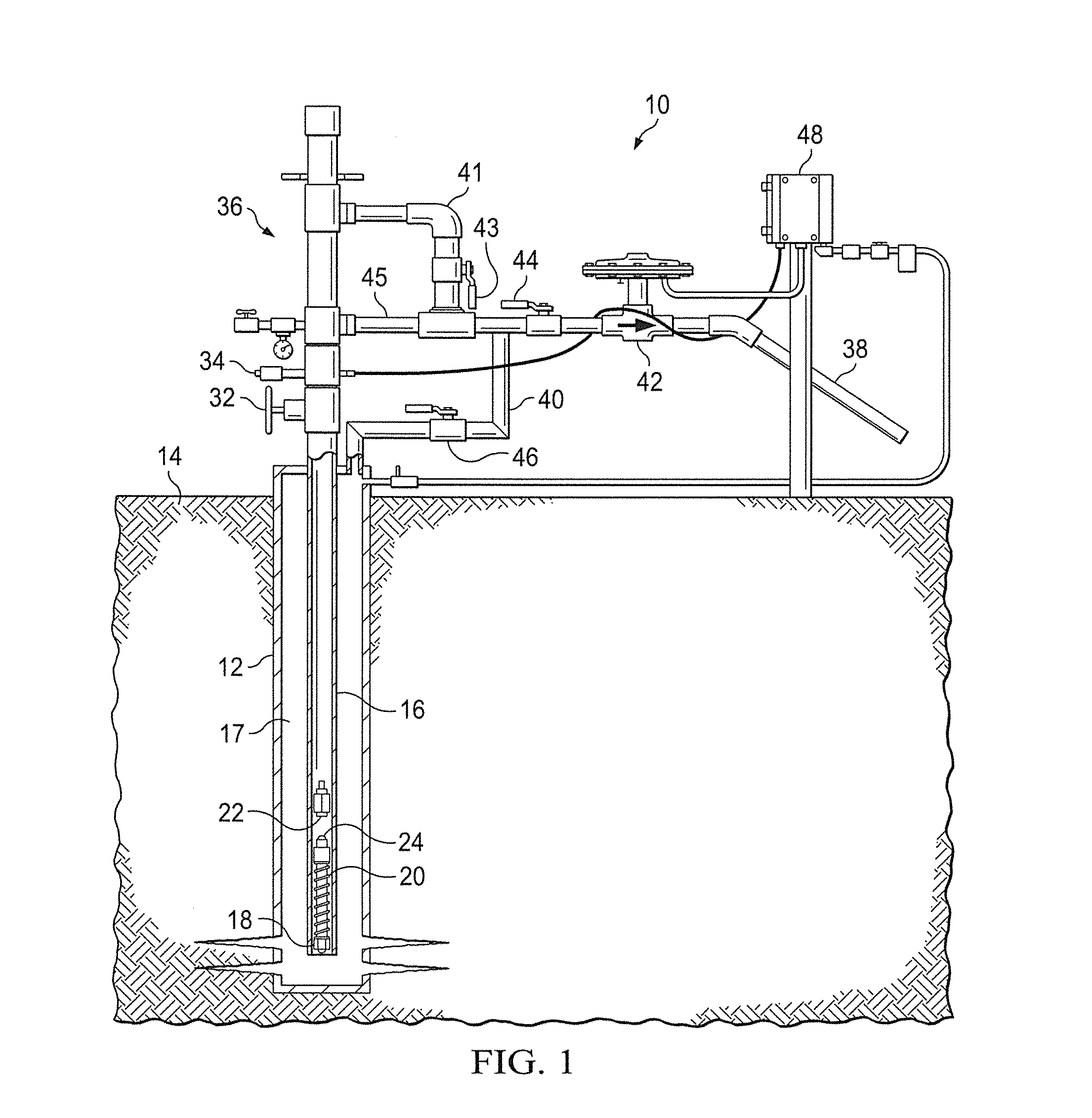

Plunger lift slug controller

ActiveUS20120318524A1Small sizeLiquid slug is reducedConstructionsFluid removalCycle controlFluid loading

A method for controlling the liquid load size of a plunger lift well during the shut in time of the well to facilitate a controlled plunger rise. Intra-cycle control allows dynamic adjustments within a cycle to keep the plunger running and not stalling out or rising too fast. The method includes the steps of shutting in the well to build up pressure within the well, adjusting a size of a liquid slug within the tubing while the well is shut in, opening a valve to relieve pressure within the well and raise the plunger within the tubing, pushing the liquid slug out of the well with the plunger, and closing the valve wherein the plunger falls within the tubing. The intra-cycle adjustments include reducing the size of the liquid slug for preventing fluid loading and increasing the size of the liquid slug for controlling a rise rate of the plunger.

Owner:LEA JR JAMES F

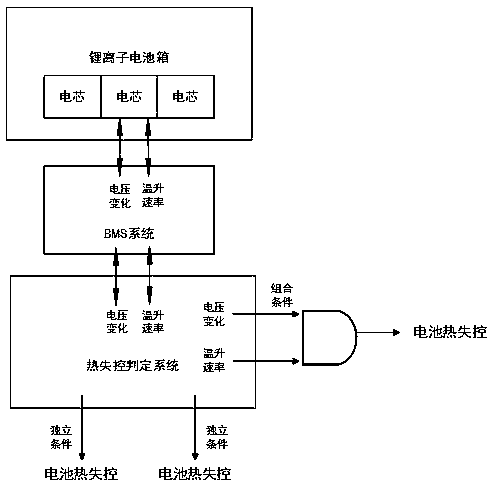

Method for monitoring thermal runaway of lithium ion battery of electric vehicle

The invention relates to a method for monitoring thermal runaway of a lithium ion battery of an electric vehicle. A voltage changing rate parameter when thermal runaway occurs in the lithium ion battery is monitored, and a battery voltage can be reduced abruptly, is maintained at a low voltage for 40-60 seconds and then is gradually raised to an initial voltage when the thermal runway occurs in the lithium ion battery; the fact that thermal runaway occurs in the battery can be judged by taking the battery voltage changing rate parameter as a monitoring object and is a first judgment method; abattery temperature rising rate changing parameter is monitored, the fact that thermal runaway occurs in the battery also can be judged when the battery temperature rising rate is larger than or equalto 10 DEG C per minute and is a second judgment method; and a battery management system (BMS) is used for monitoring, analyzing and judging the battery voltage changing parameter and the battery temperature rising rate parameter, the two methods are used as an independent condition or a logic combination condition and used as a technological basis for judgment on thermal runaway of the battery, and an early-warning signal can be given out in advance when thermal runaway occurs. By the method, the battery thermal runaway judgment time is greatly increased, and enough handling time is providedfor a person to escape and timely take a measure to prevent battery thermal runaway from being generated, propagating and being expanded.

Owner:应急管理部天津消防研究所

Polyesters, polyester compositions, pressure-sensitive adhesive compositions, pressure-sensitive adhesive layers and pressure-sensitive adhesive sheets

ActiveUS20110135924A1Excellent pressure-sensitive adhesive propertyMaintain good propertiesPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterDimer acid

The present invention provides a polyester, a polyester composition and a pressure-sensitive adhesive composition capable of obtaining a pressure-sensitive adhesive which is global-environmentally friendly and is excellent in pressure-sensitive adhesion properties, using a plant-derived raw material; and a pressure-sensitive adhesive layer and a pressure-sensitive adhesive sheet which can be obtained by using the same. A polyester of the present invention is a polyester comprising at least a lactic acid unit, a dibasic acid unit and a glycol unit, wherein the dibasic acid unit contains dimer acid, and the polyester has a glass transition temperature as measured at a temperature rising rate of 20° C. / minute using a differential scanning calorimeter, of −70 to −20° C., a weight average molecular weight of 20,000 to 300,000 and a hydroxyl value of 1 to 100 mgKOH / g.

Owner:NITTO DENKO CORP +1

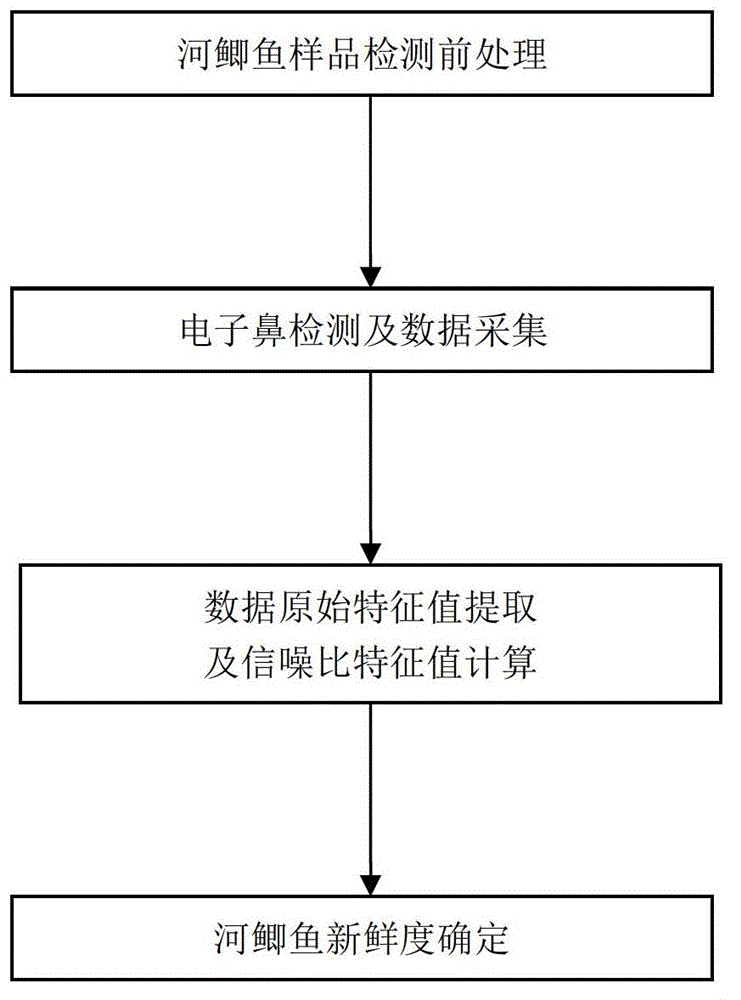

Method of using electronic nose for detecting freshness of river crucian carp

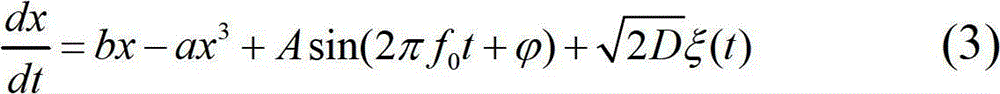

InactiveCN102879436ATo achieve the purpose of freshness detectionReduce dosageMaterial resistanceRise rateSignal-to-noise ratio (imaging)

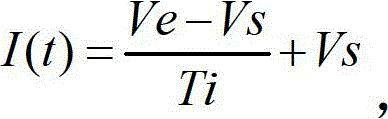

A method of using an electronic nose for detecting freshness of river crucian carp includes the steps: (1) placing river crucian carp samples to be detected into a sample container, sealing and standing for 20-40min at the room temperature; (2) inserting a filtered gas probe of the electronic nose into the sample container for 40-60s, and collecting top gas; (3) enabling the gas to enter a gas sensor array for detection and analysis; and (4) collecting and storing related data of gas according to the specific process: (4-1) extracting response characteristic values of the gas sensor array, wherein the response characteristic values include an initial value, a stable value, rise time and rise rate; (4-2) curing a non-linear stochastic resonance algorithm into a digital signal processor internally arranged in the electronic nose, and inputting the original response characteristic values of the electronic nose into a DSP (digital signal processor) and outputting a signal-to-noise-ratio spectral characteristic value by computing; and (4-3) computing a freshness value of the river crucian carp according to a freshness prediction model and the signal-to-noise-ratio spectral characteristic value. The method is simple, convenient, rapid and effective.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

High-strength Fe-Co-Ni-Cr-Mn high-entropy alloy and preparation method thereof

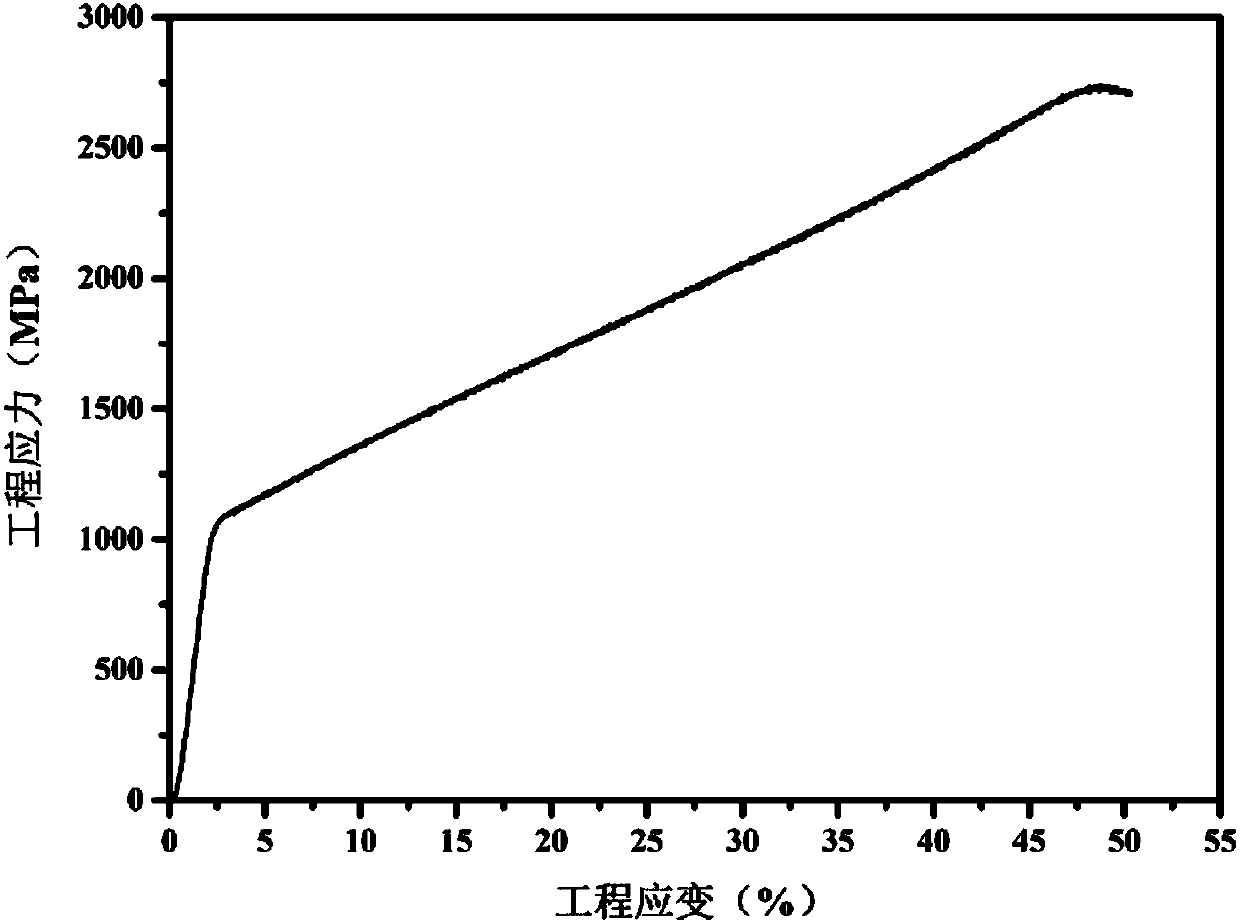

ActiveCN108103381AUniform composition and nearly full densitySimplified sintering processHigh entropy alloysHigh energy

The invention belongs to the technical field of high-entropy alloys, and particularly relates to a high-strength Fe-Co-Ni-Cr-Mn high-entropy alloy and a preparation method thereof. The preparation method comprises the following steps that (1) Fe, Co, Ni, Cr and Mn elemental powder is mixed for high-energy ball milling, the content of Fe is 30-60 at.%, the remaining elements are equal in atomic ratio, and alloy powder is obtained; and as for process conditions of ball milling, the ball-material ratio is 5:1-20:1, the rotational speed is 100-400 r / min, and the ball milling time is 10-60 h; and (2) discharging plasma sintering is conducted, as for process conditions, sintering equipment is a discharging plasma sintering system, the sintering current type is direct current pulse current, the sintering temperature is 800-950 DEG C, the temperature preservation time is 5-20 min, the sintering pressure is 30-50 MPa, and the temperature rising rate is 25-100 DEG C / min; and a high-entropy alloyblock material is obtained by sintering.

Owner:SOUTH CHINA UNIV OF TECH

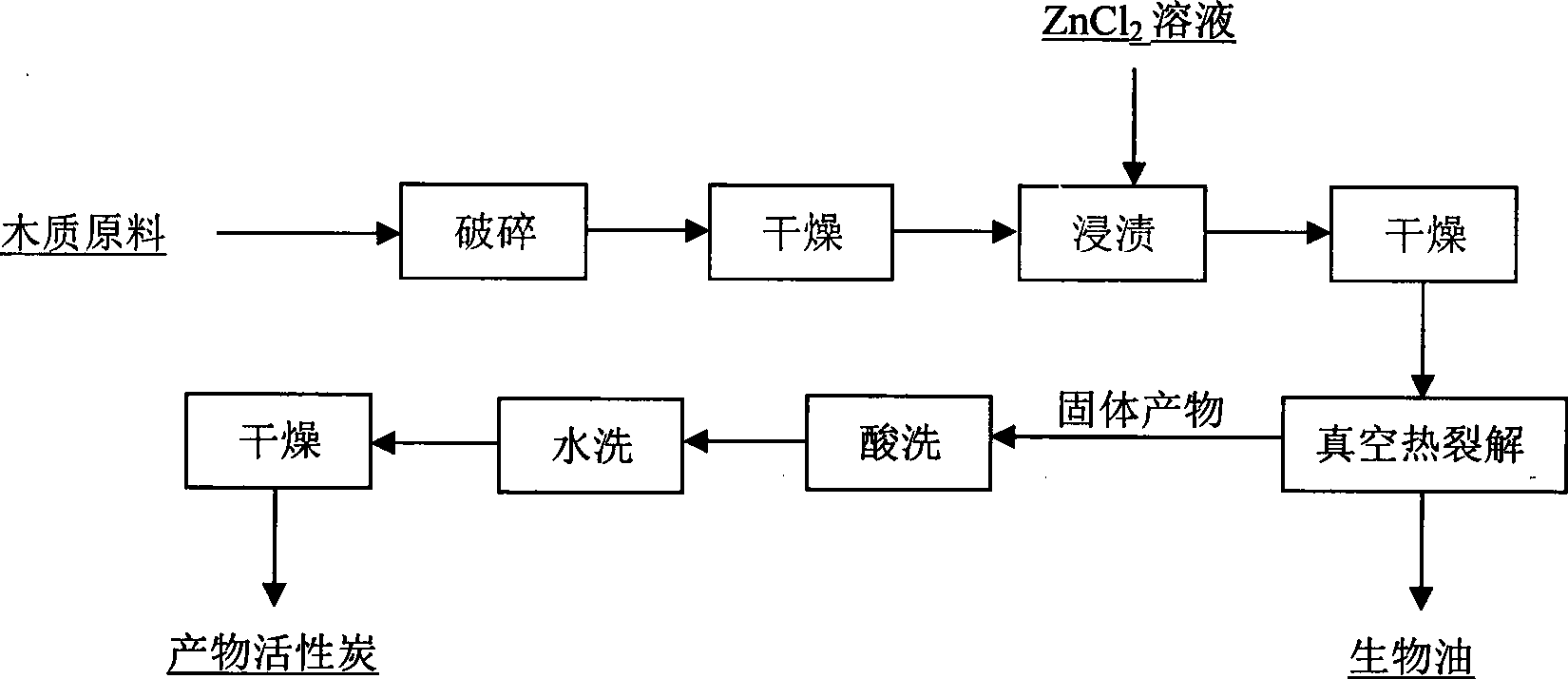

Method for preparing active carbon

InactiveCN101497439AAvoid secondary crackingReduce the overall heightActivated carbonResource utilization

The invention relates to a method for preparing active carbon, which comprises the following steps: crushing, sieving and drying woody raw materials, soaking the raw materials into a zinc chloride solution according to the mass ratio of the raw materials to zinc chloride of 1:1-4, and drying the solution; performing cracking activation under the vacuum condition, wherein the temperature rise rate is between 5 and 15 DEG C per minute, and the cracking final temperature is between 400 and 500 DEG C; maintaining at the cracking final temperature for approximately 1 hour; and performing acid washing, water washing and drying on the reaction product to obtain the product, namely the active carbon. Compared with active carbon prepared under the condition of normal pressure, the active carbon prepared by the method has the advantages that the micropore rate is improved by 5.34 to 13.18 percent, the specific surface area is increased by 6.21 to 20.31 percent, and the adsorption performance is superior. Moreover, a byproduct, namely biological oil, can be collected when the active carbon is obtained simultaneously, so that the resource utilization rate is high and the energy consumption is reduced.

Owner:CENT SOUTH UNIV

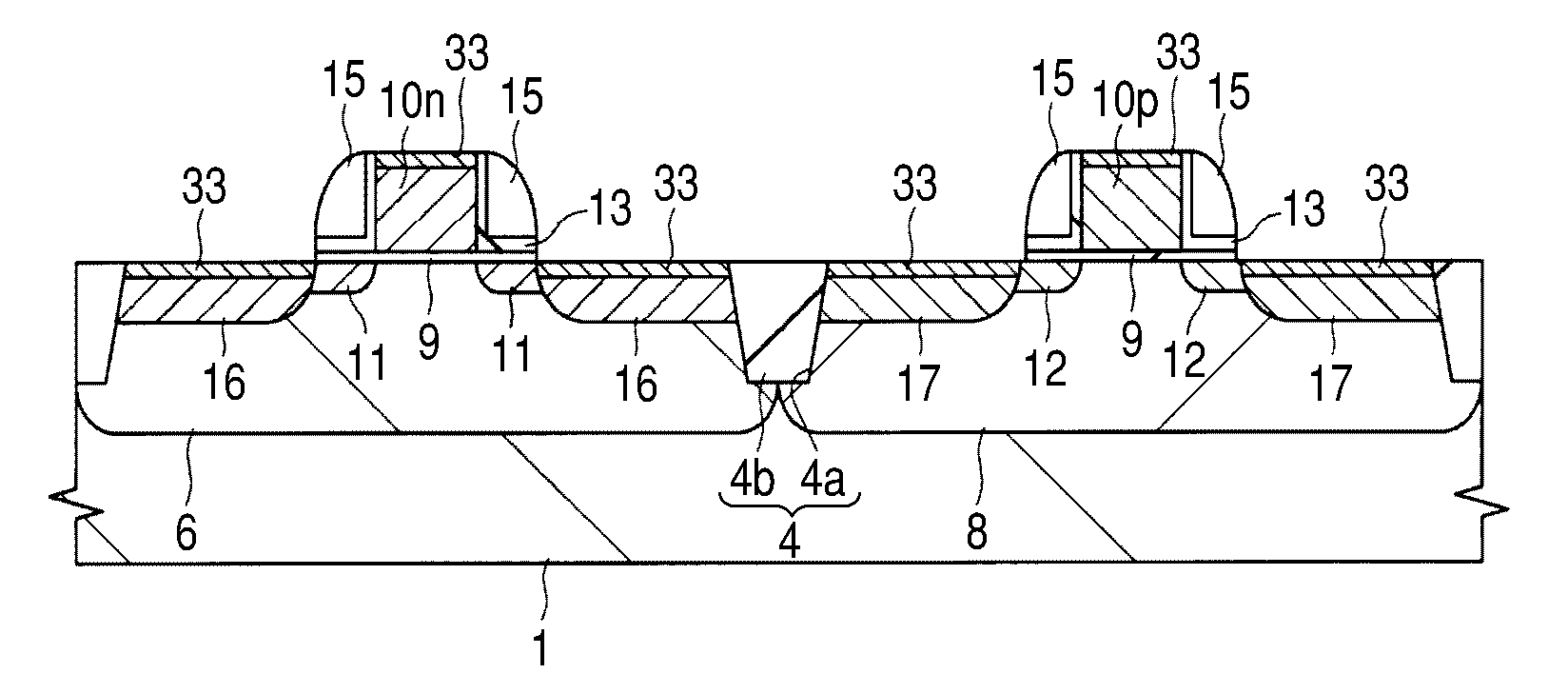

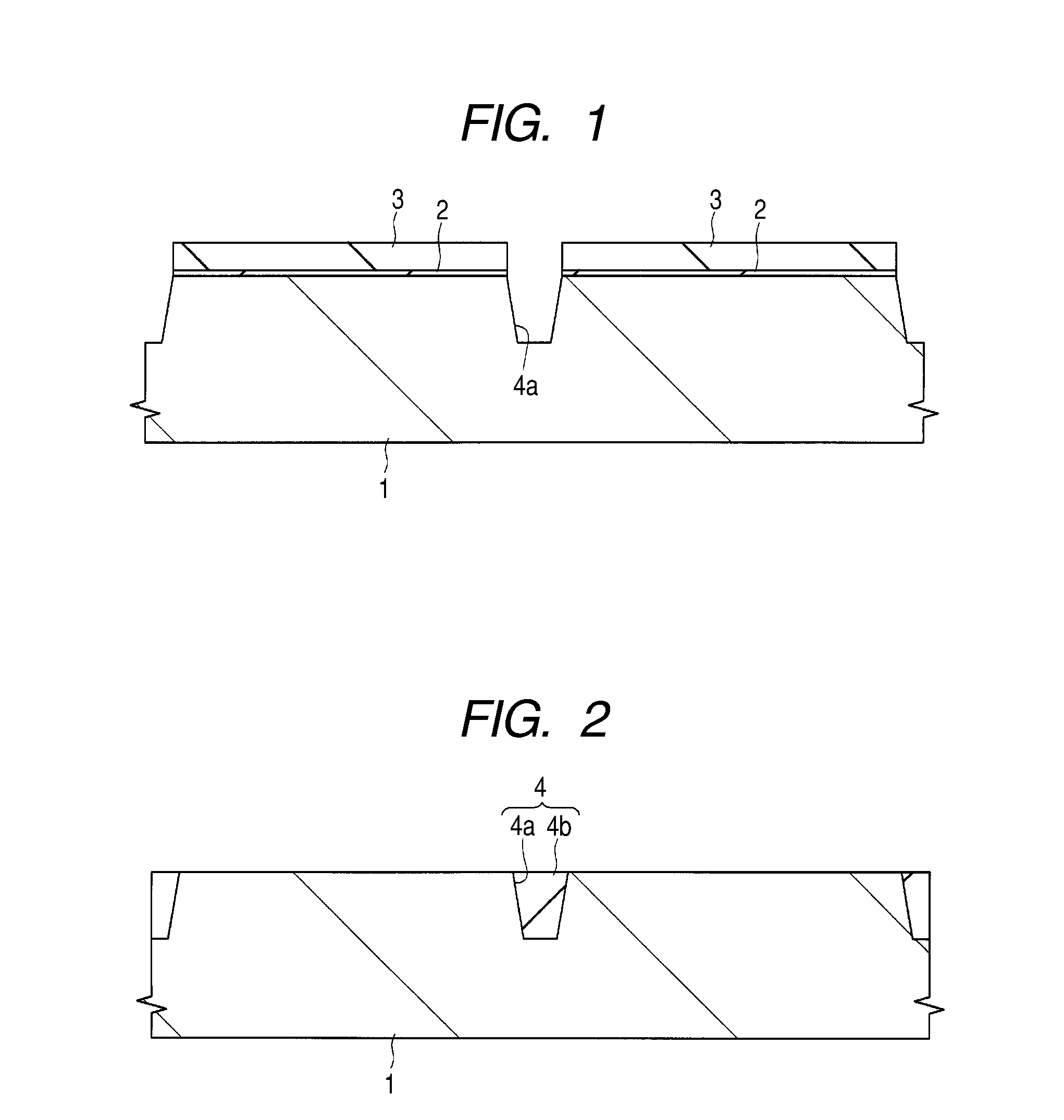

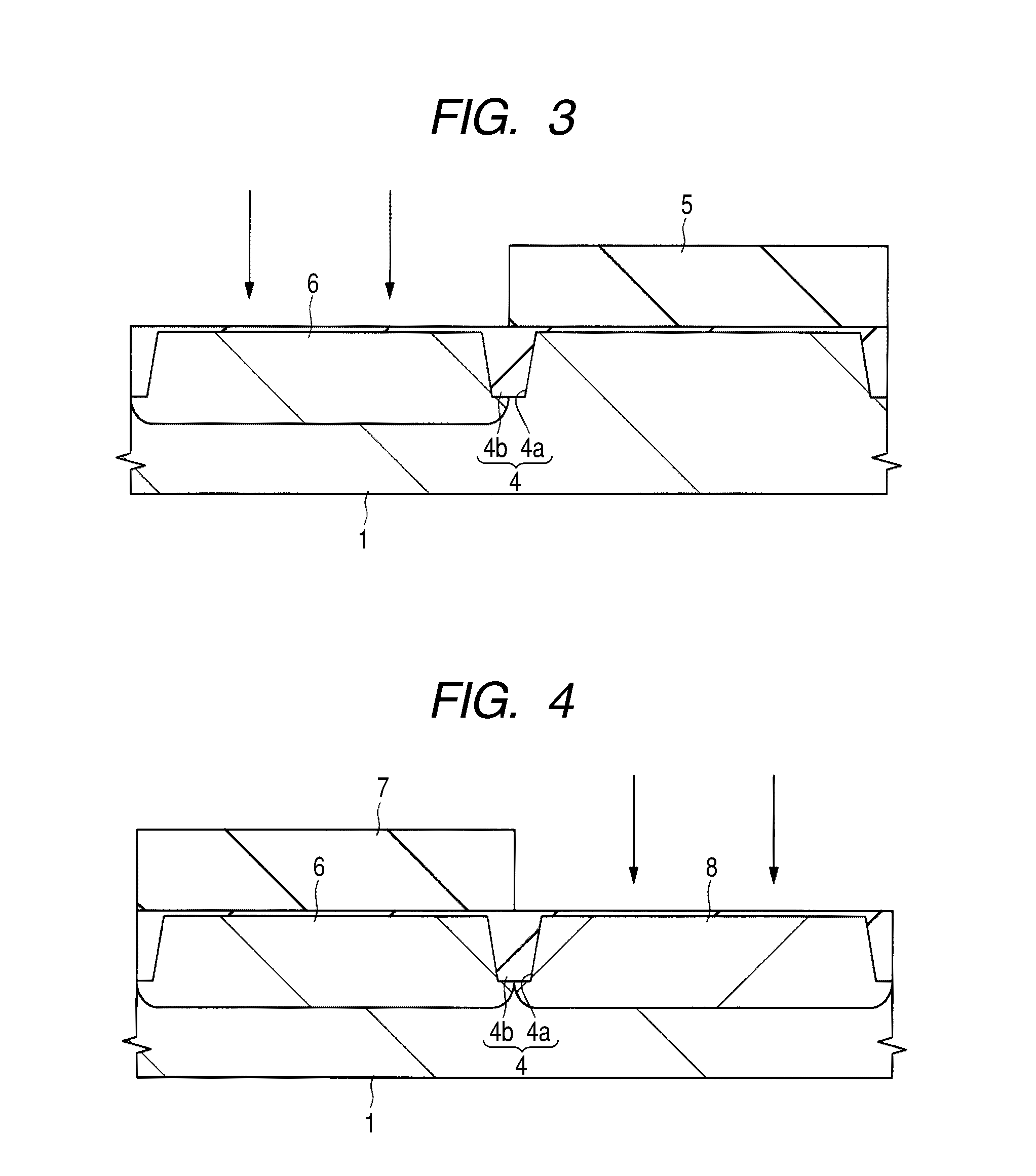

Method of manufacturing a semiconductor device

ActiveUS20090191707A1Lower resistanceImprove production yieldTransistorSemiconductor/solid-state device detailsPlatinumMetal silicide

To provide a technique capable of improving the reliability of a semiconductor element and its product yield by reducing the variations in the electrical characteristic of a metal silicide layer. After forming a nickel-platinum alloy film over a semiconductor substrate 1, by carrying out a first thermal treatment at a thermal treatment temperature of 210 to 310° C. using a heater heating device, the technique causes the nickel-platinum alloy film and silicon to react with each other to form a platinum-added nickel silicide layer in a (PtNi)2Si phase. Subsequently, after removing the unreacted nickel-platinum alloy film, the technique carries out a second thermal treatment having the thermal treatment temperature higher than that of the first thermal treatment to form the platinum-added nickel silicide layer in a PtNiSi phase. The temperature rise rate of the first thermal treatment is set to 10° C. / s or more (for example, 30 to 250° C. / s) and the temperature rise rate of the second thermal treatment is set to 10° C. / s or more (for example, 10 to 250° C. / s).

Owner:RENESAS ELECTRONICS CORP

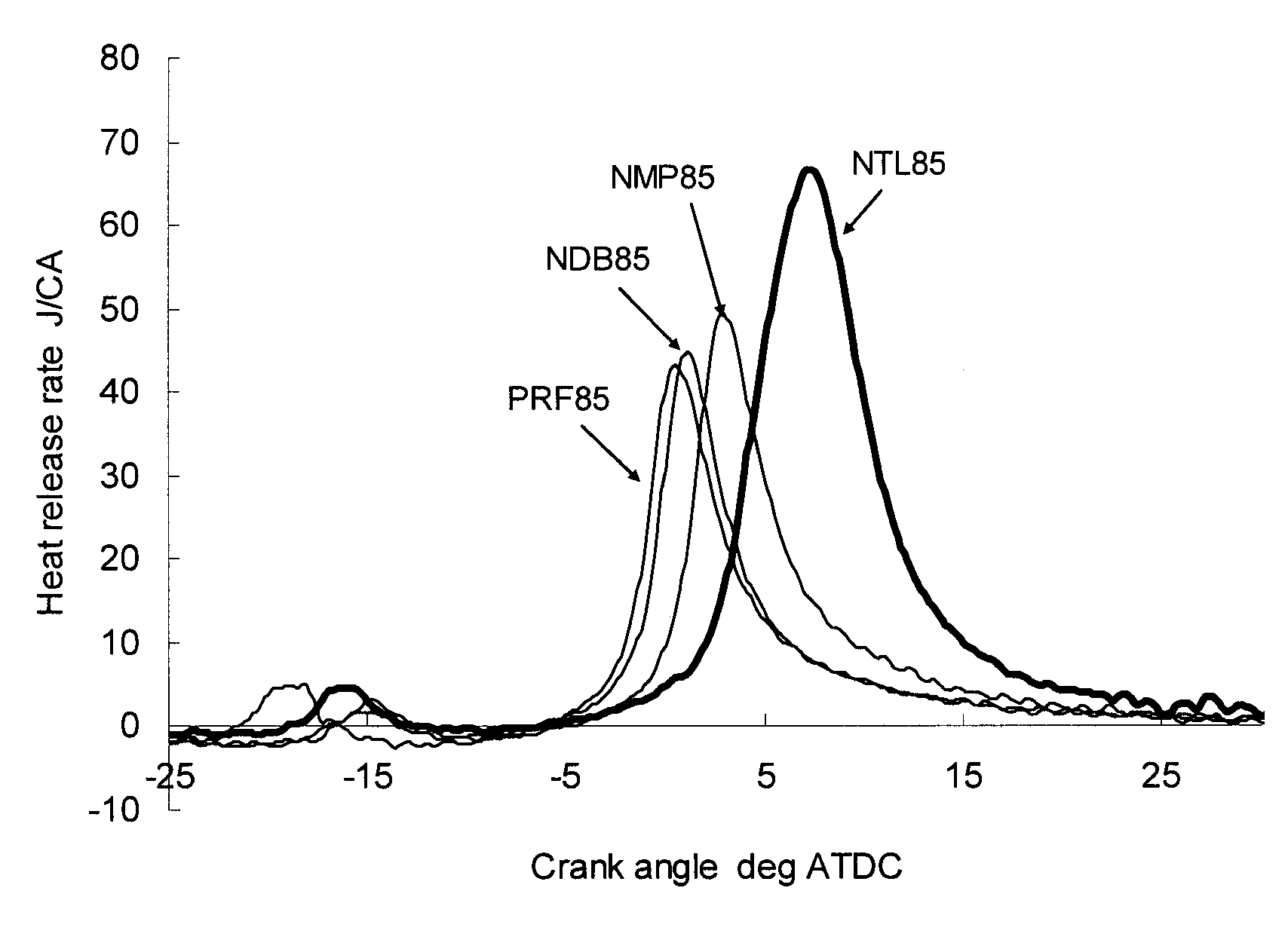

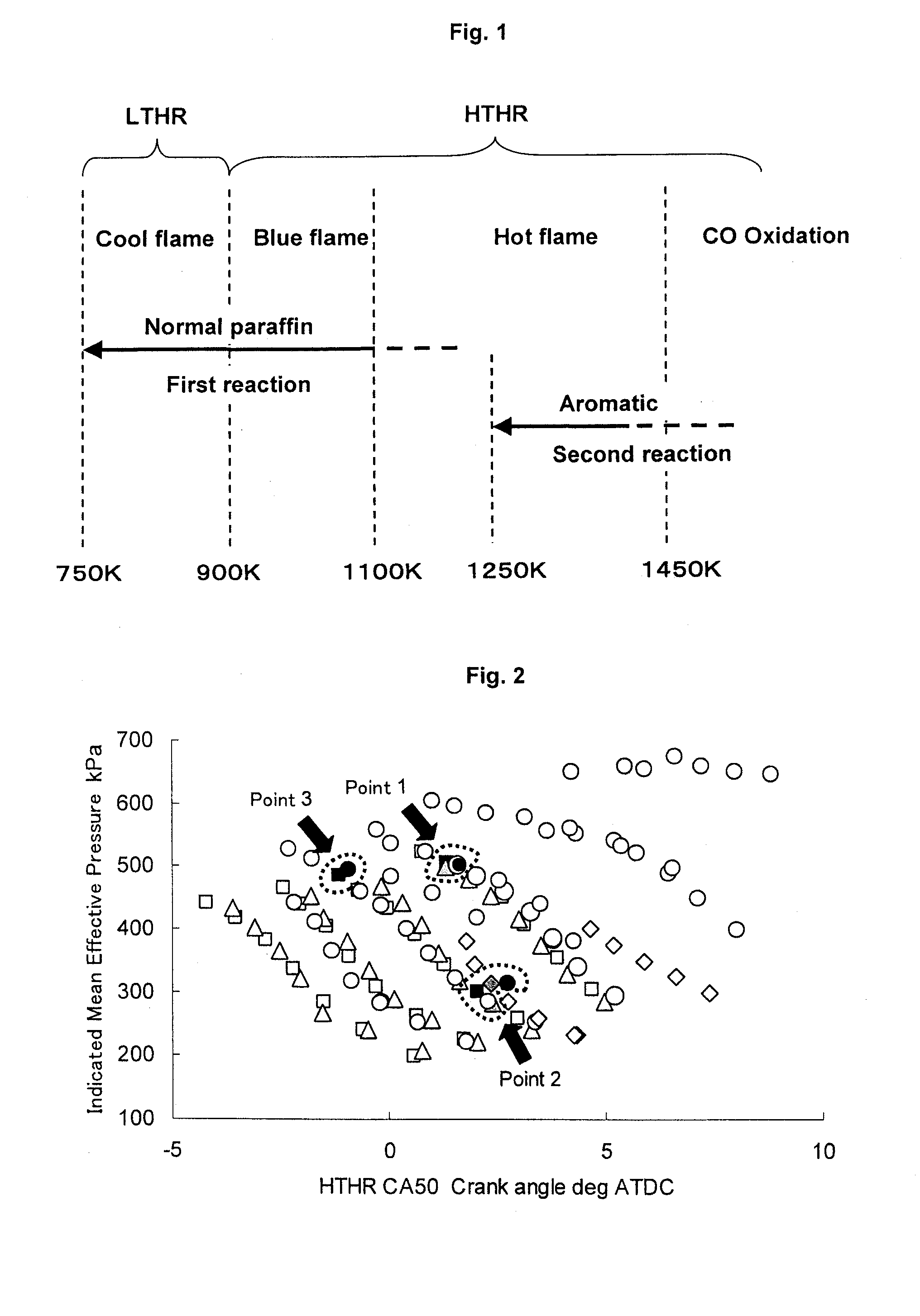

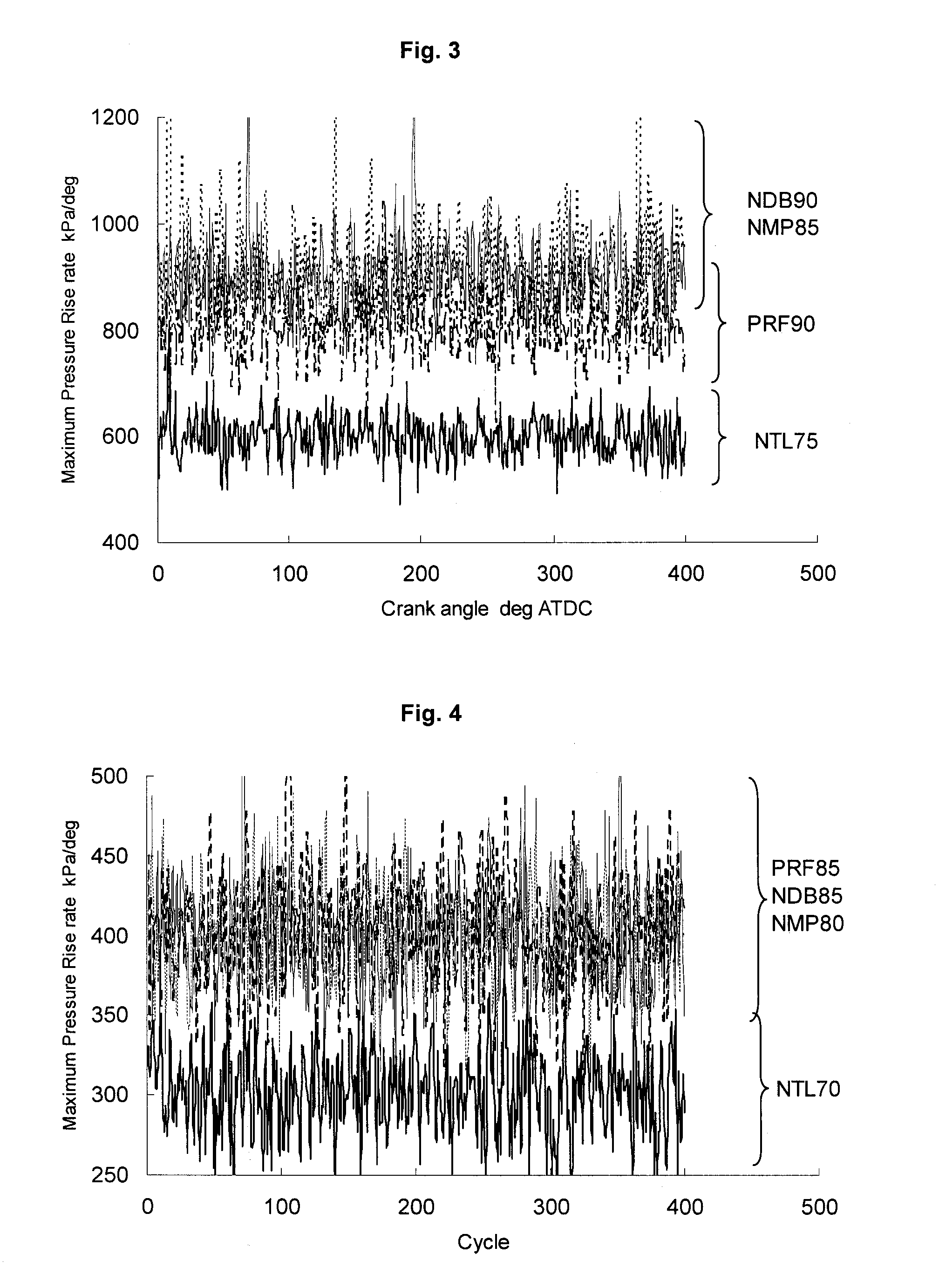

Fuels for Homogeneous Charge Compression Ignition Combustion Engine

InactiveUS20090151236A1Maximum pressure rise rateCombustion engineLiquid carbonaceous fuelsHomogeneous charge compression ignitionDistillation

The present invention provides a fuel capable of controlling the combustion reaction during homogeneous charge compression auto-ignition combustion to improve the engine thermal efficiency. The fuel satisfies specified characteristic requirements relating to: (1) the total content of C5 to C10 normal paraffins; (2) the total content of C6 to C11 aromatic hydrocarbons; (3) the content of olefinic hydrocarbons; (4) the content of oxygenates; (5) the research octane number; (6) the initial boiling point and end point in distillation characteristics; (7) the averaged maximum pressure rise rate of the fuel over continuous 400 cycles; and (8) the averaged IMEP of the fuel over continuous 400 cycles.

Owner:NIPPON OIL CORP

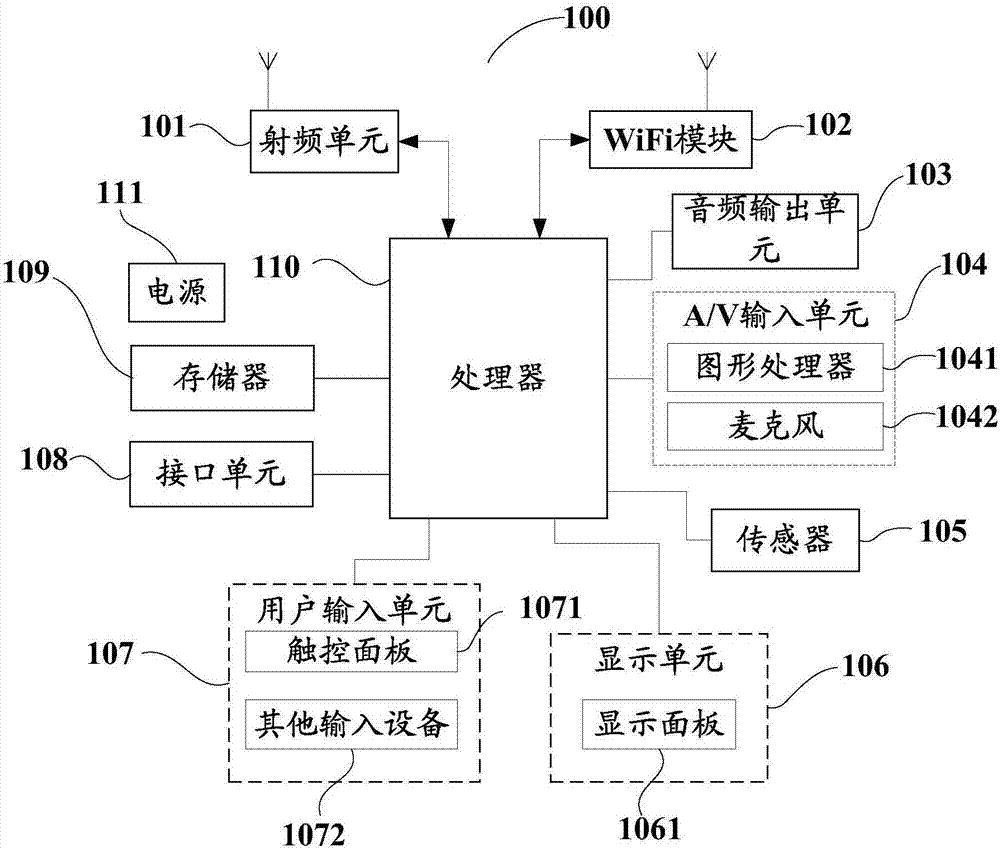

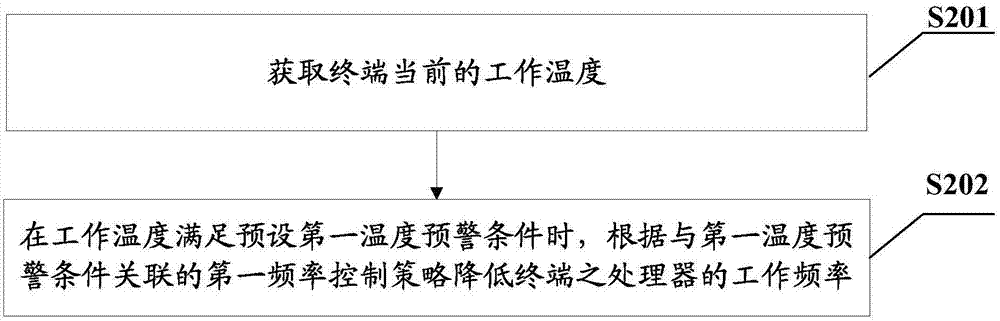

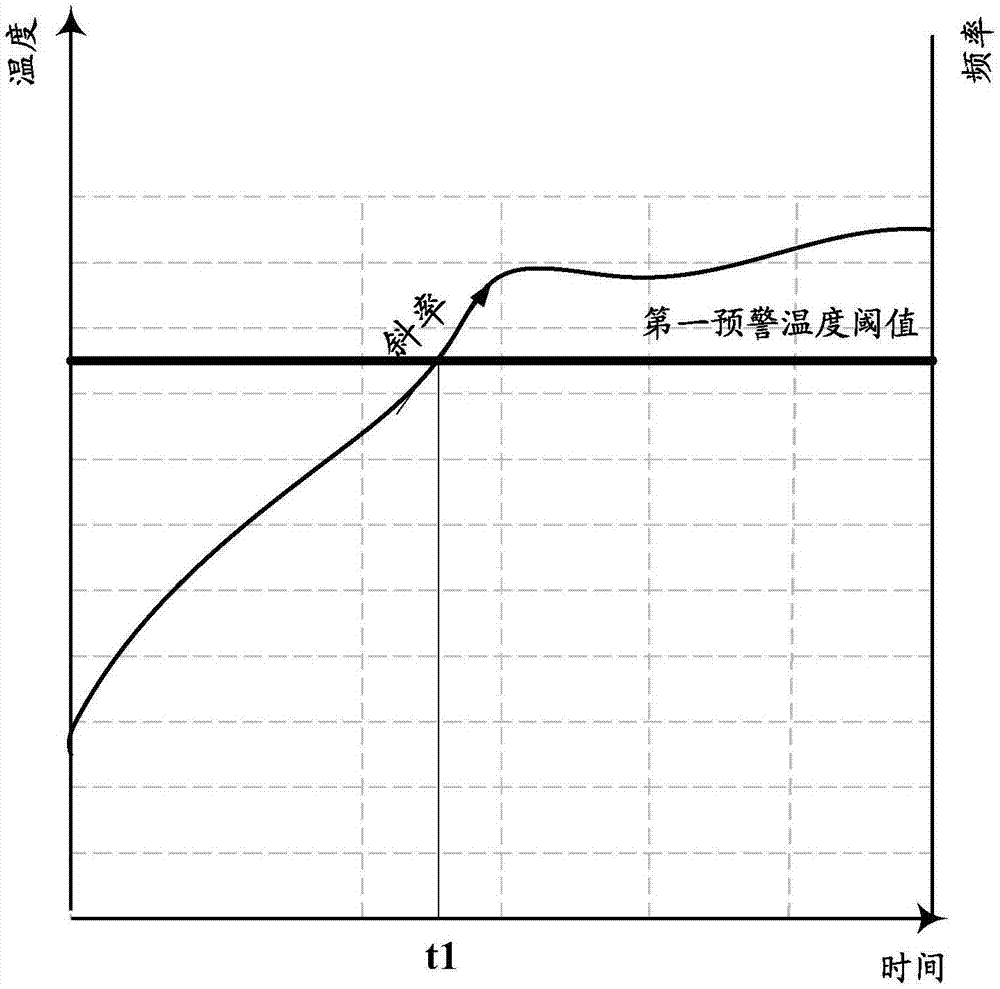

Frequency-based temperature control method, terminal, and computer-readable storage medium

ActiveCN107357385AReduce the temperatureImprove satisfactionDigital data processing detailsHardware monitoringTemperature controlComputer terminal

The invention discloses a frequency-based temperature control method, a terminal, and a computer-readable storage medium. The method comprises the following steps: acquiring a current operating temperature of the terminal; and when the current operating temperature satisfies a first temperature early warning condition, reducing the operating frequency of a processor of the terminal according to a first frequency control strategy associated with the first temperature early warning condition, wherein the first frequency control strategy comprises determining an operating frequency reducing amplitude of the processor according to a first temperature rise rate parameter corresponding to the current operating temperature of the terminal. The frequency-based temperature control method, the terminal and the computer-readable storage medium provided by the invention have the advantages that the operating frequency reducing amplitude of the processor is determined according to a temperature rise rate of the terminal, so that a process in which the frequency of the processor changes gradually is achieved; and the changing process is related to the temperature rise rate of the terminal, so that the frequency of the processor can be matched with a current operating scenario of the terminal during the changing process, and the frequency of the processor of the terminal can be further maintained within a reasonable range, which meets user requirements for the system performance of the terminal, and improves the user experience satisfaction.

Owner:NUBIA TECHNOLOGY CO LTD

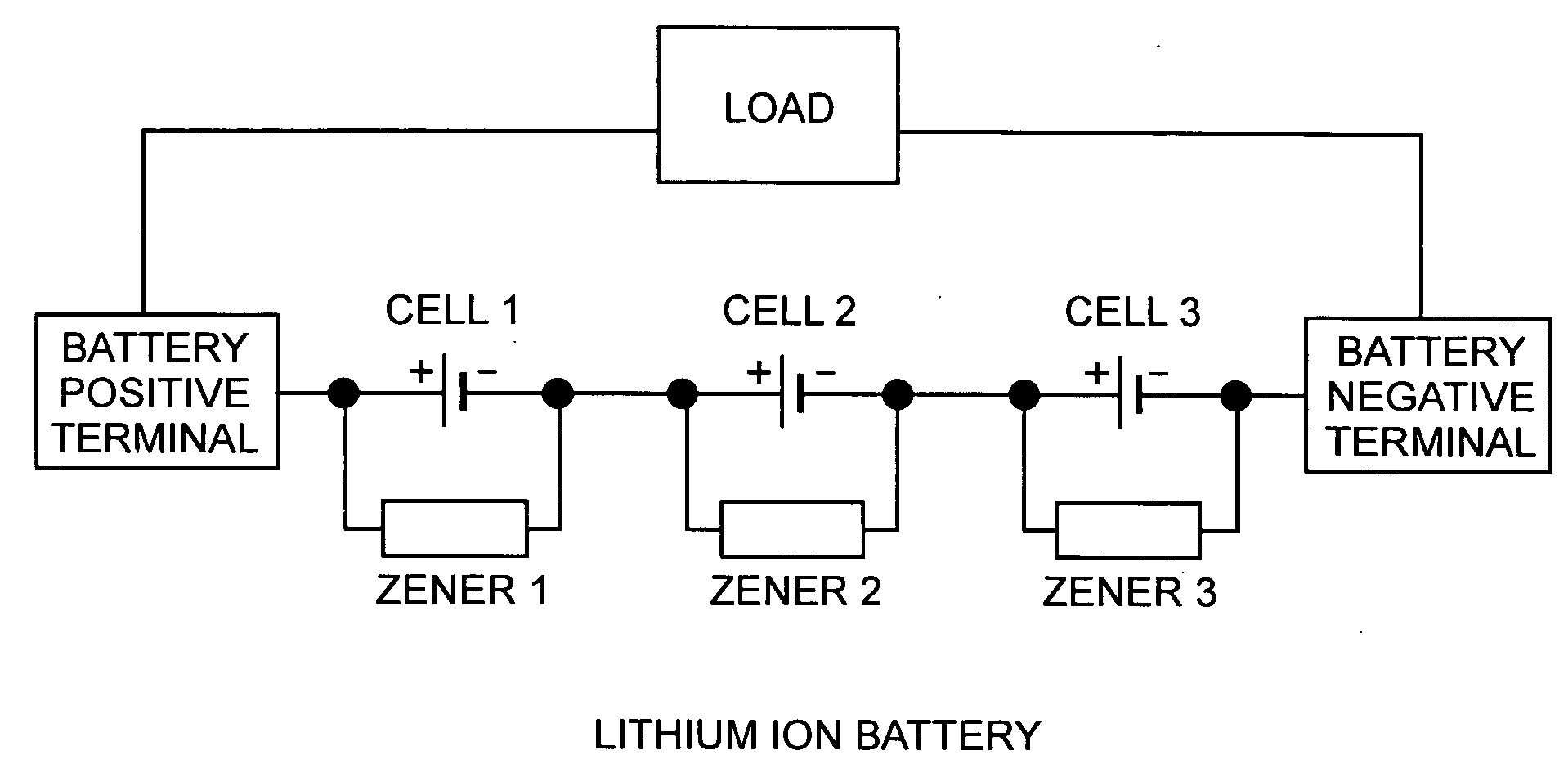

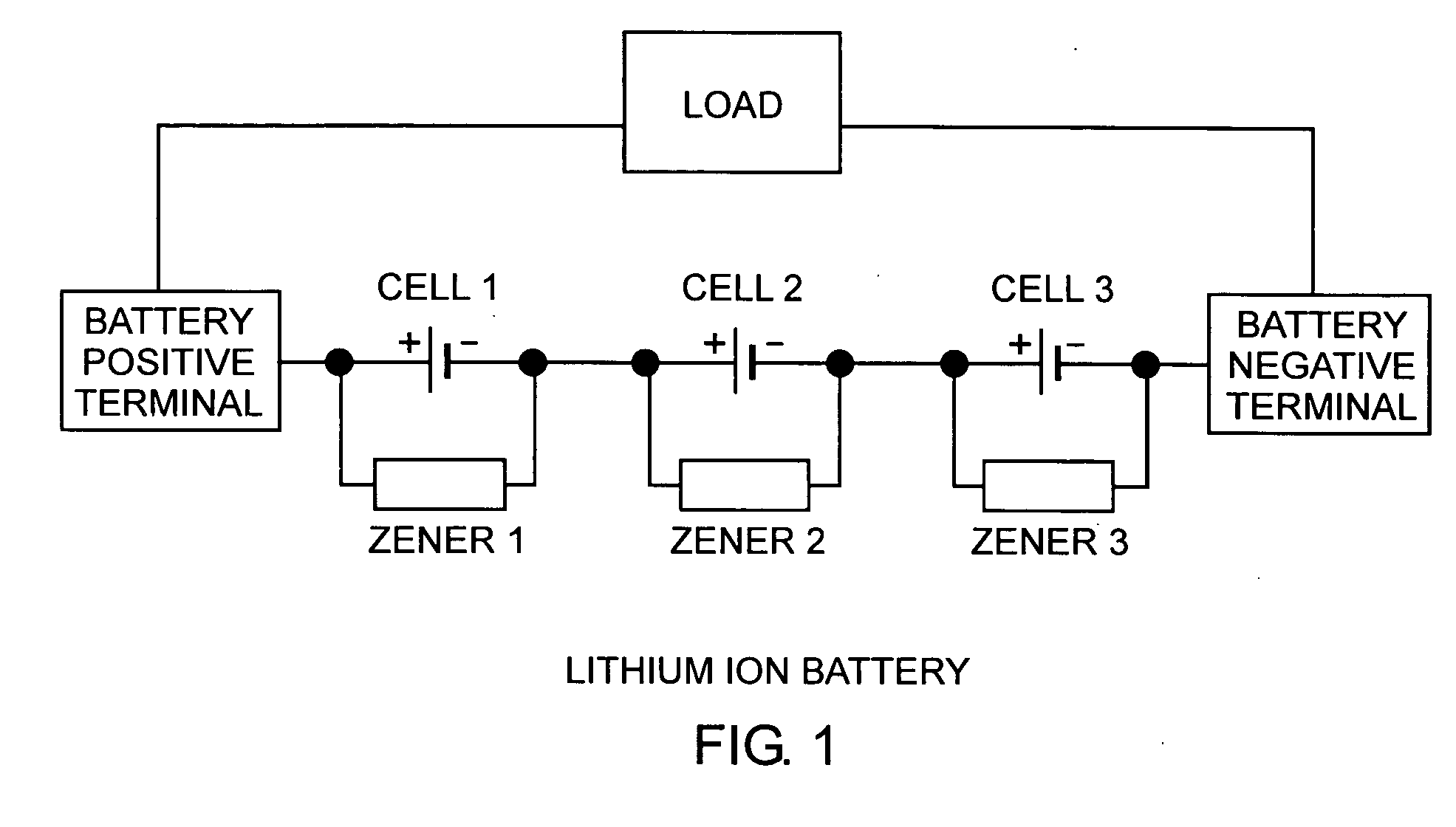

Balanced lithium ion battery

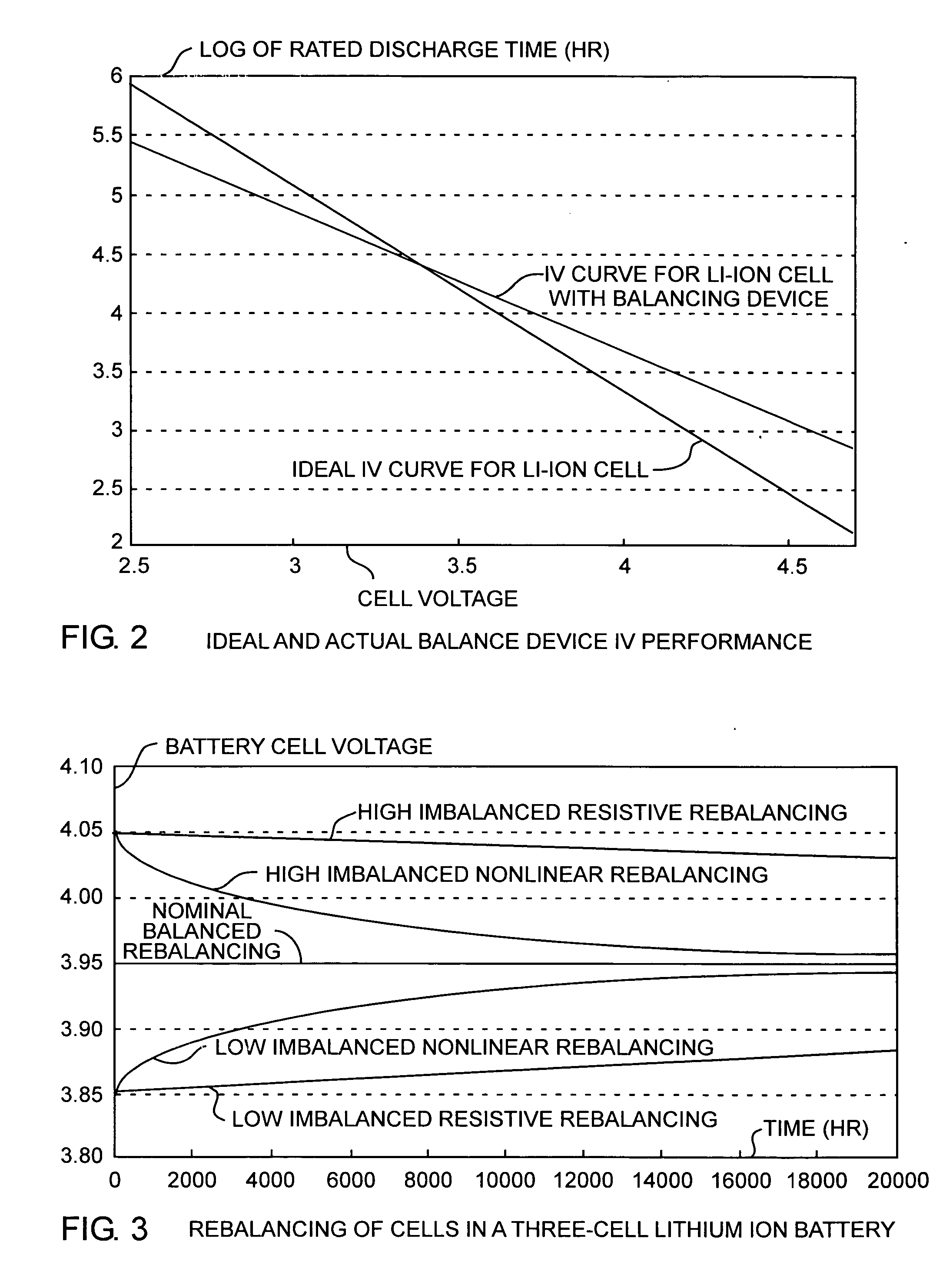

InactiveUS20060046104A1Primary cell to battery groupingCharge equalisation circuitZener diodeEngineering

A battery system uses passive nonlinear electronic devices, such as zener diodes, respectively connected in parallel to each of the serially connected battery cells, such as lithium ion battery cells, connected in a string, to maintain all of the cells at a balanced state of charge, and will automatically correct any initial imbalance in the states of charge of individual cells. The passive nonlinear devices are preferably matched to equally force each battery cell to have an exponentially rising rate of internal capacity loss as cell voltage increases, while keeping cell voltages and capacities matched. The devices will not accelerate open circuit losses of the cells as the cells become fully discharged as a consequence of conducting low currents compared to the cell charge and discharge currents without generating excessive heat for improved safety.

Owner:THE AEROSPACE CORPORATION

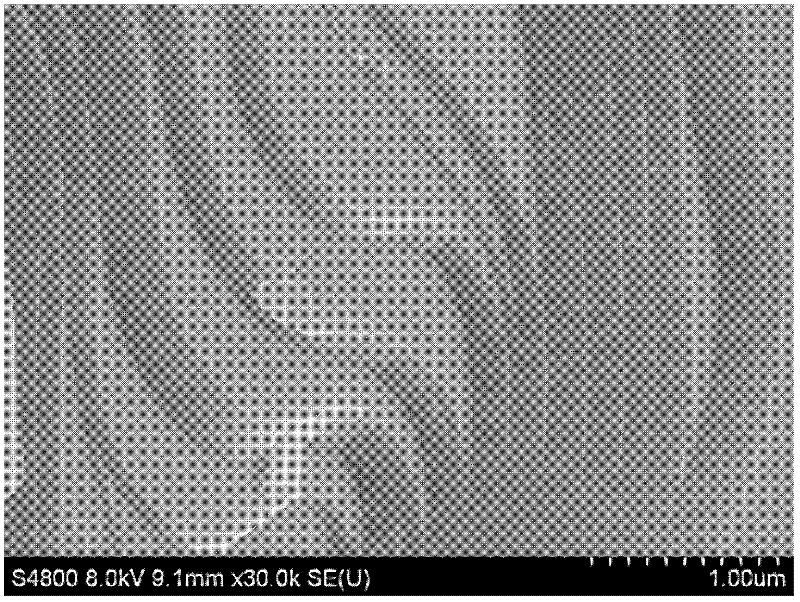

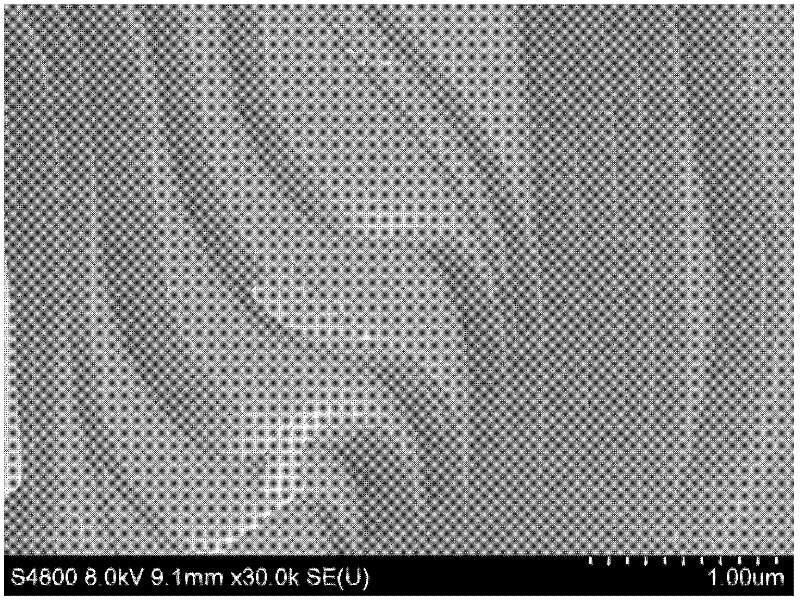

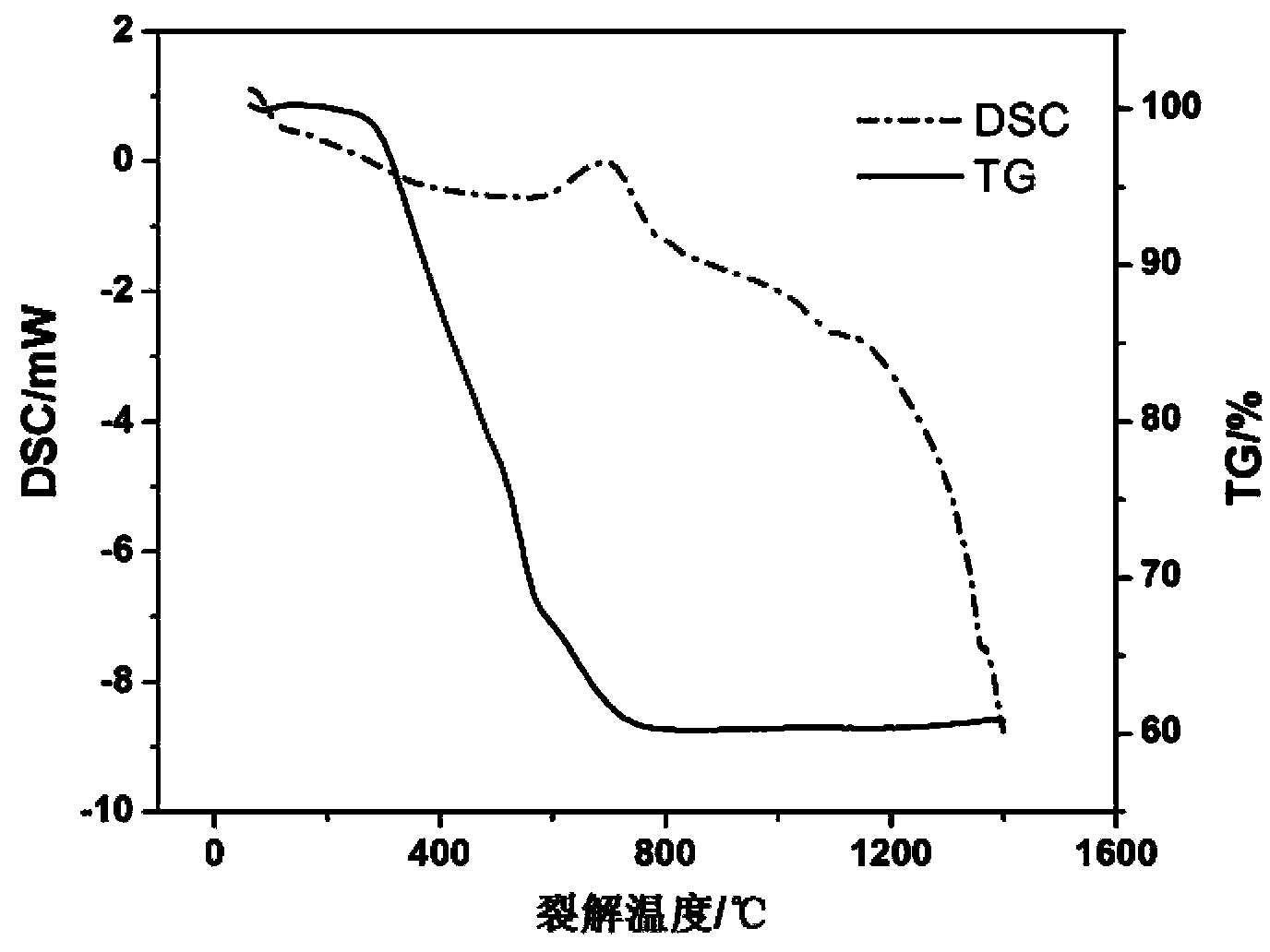

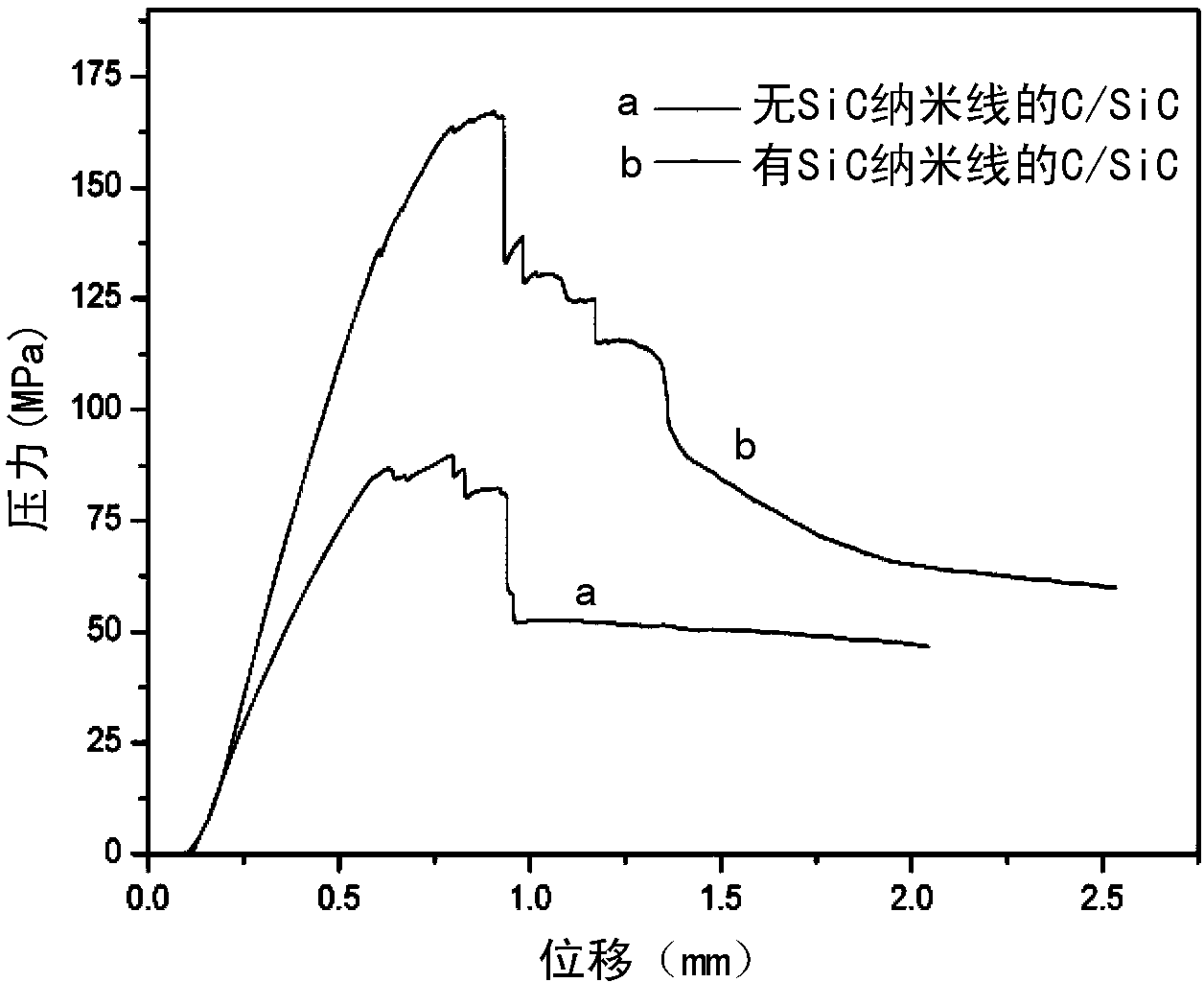

In-situ growth SiC nanowire enhanced C/SiC composite material and preparation method thereof

The invention relates to an in-situ growth SiC nanowire enhanced C / SiC composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing size, namely mixing and ball milling polycarbosilane, a catalyst and a solvent to prepare the size, wherein the catalyst is iron, nickel and / or ferrocene; (2) performing vacuum high pressure impregnation, namely immersing a C fiber preform in the size, keeping in a vacuum state for 0.1-1 hour, introducing high-pressure inert gases to 1-10MPa, and maintaining the pressure for 1-4 hours; (3) cross-linking and curing, namely performing cross-linking and curing on the impregnated C fiber preform in air for over 6 hours to prepare a preform; and (4) performing high-temperature pyrolysis, namely raising the temperature of the preform to be 1000-1300 DEG C at a temperature rise rate of 2-10 DEG C per minute in a protective atmosphere, keeping the temperature for 1-4 hours, and growing SiC nanowires in situ under the action of a metal catalyst in the polycarbosilane pyrolysis process, so that the in-situ growth SiC nanowire enhanced C / SiC composite material is prepared.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

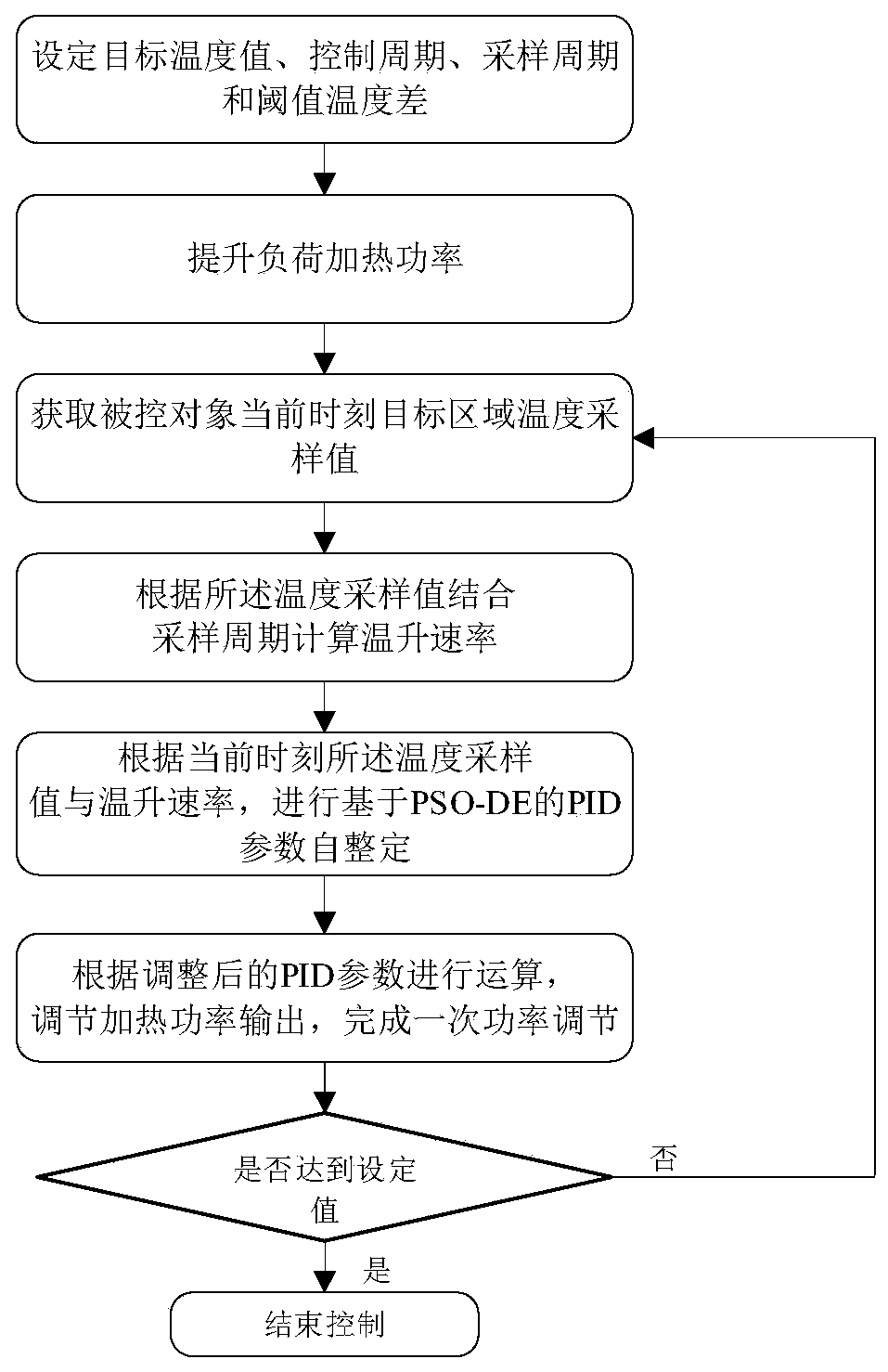

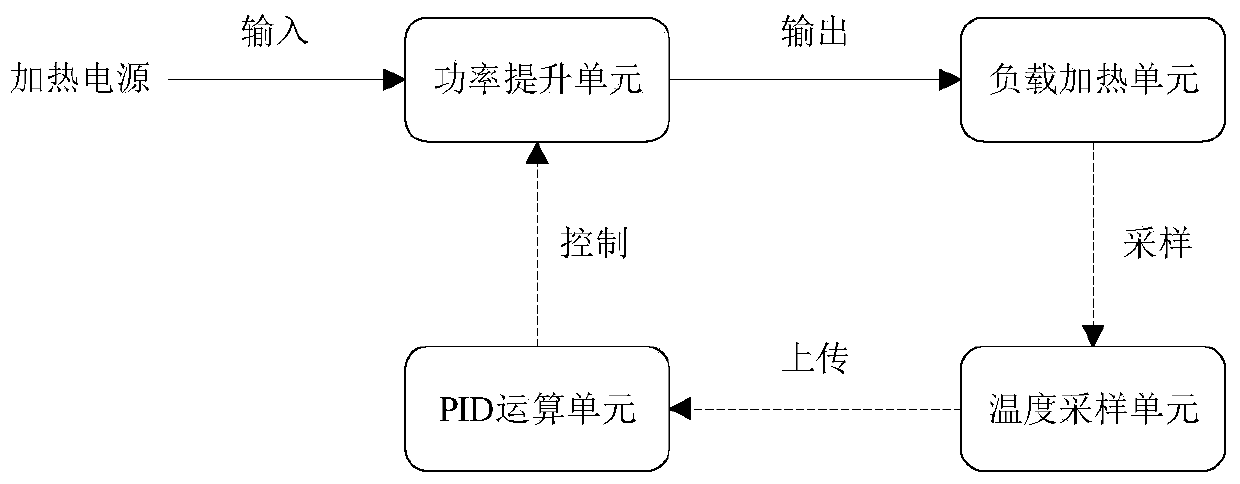

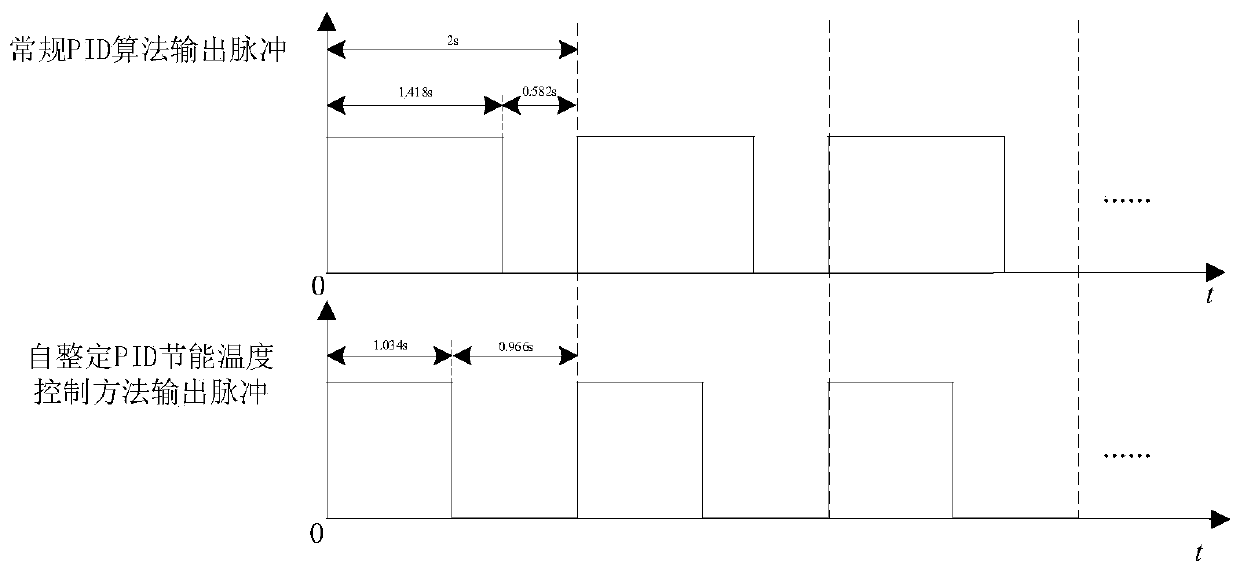

Self-tuning PID energy-saving temperature control method and module

ActiveCN109839967ASmall duty cycleIncrease load heating powerTemperature control using electric meansEngineeringParticle swarm algorithm

The invention relates to a self-tuning PID energy-saving temperature control method. The method comprises the steps that a target temperature value, a control period, a sampling period and a thresholdtemperature difference are set first; load heating power is increased; the current regional temperature sampling value of a controlled object is acquired, and the sampling period is combined to calculate the temperature rise rate; a PSO-DE algorithm combining particle swarm optimization (PSO) and differential evolution (DE) is used to adjust and calculate PID control parameters; the duty cycle ofthe output pulse of a control period is adjusted according to the operation result; heating power output is adjusted, so that the sampled temperature sampling value is approximately equal to the actual temperature value of the controlled object; a temperature error caused by the heating inertia is reduced; heating power is accurately controlled; and the energy saving effect is obvious. A self-tuning PID energy-saving temperature control module comprises the self-tuning PID energy-saving temperature control method, can accurately control the heating power, and has an obvious energy-saving effect.

Owner:广东国颂能源科技有限公司

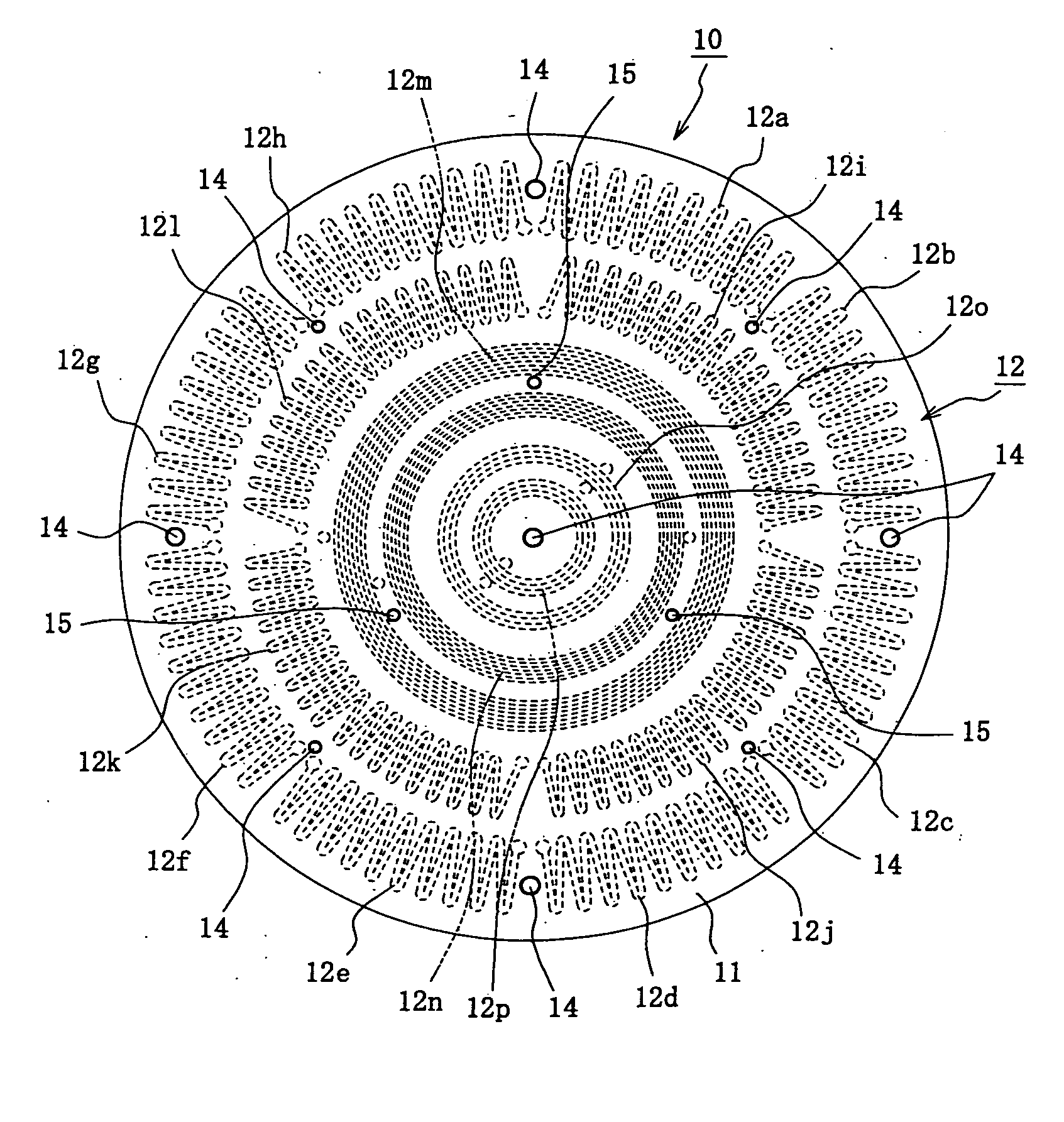

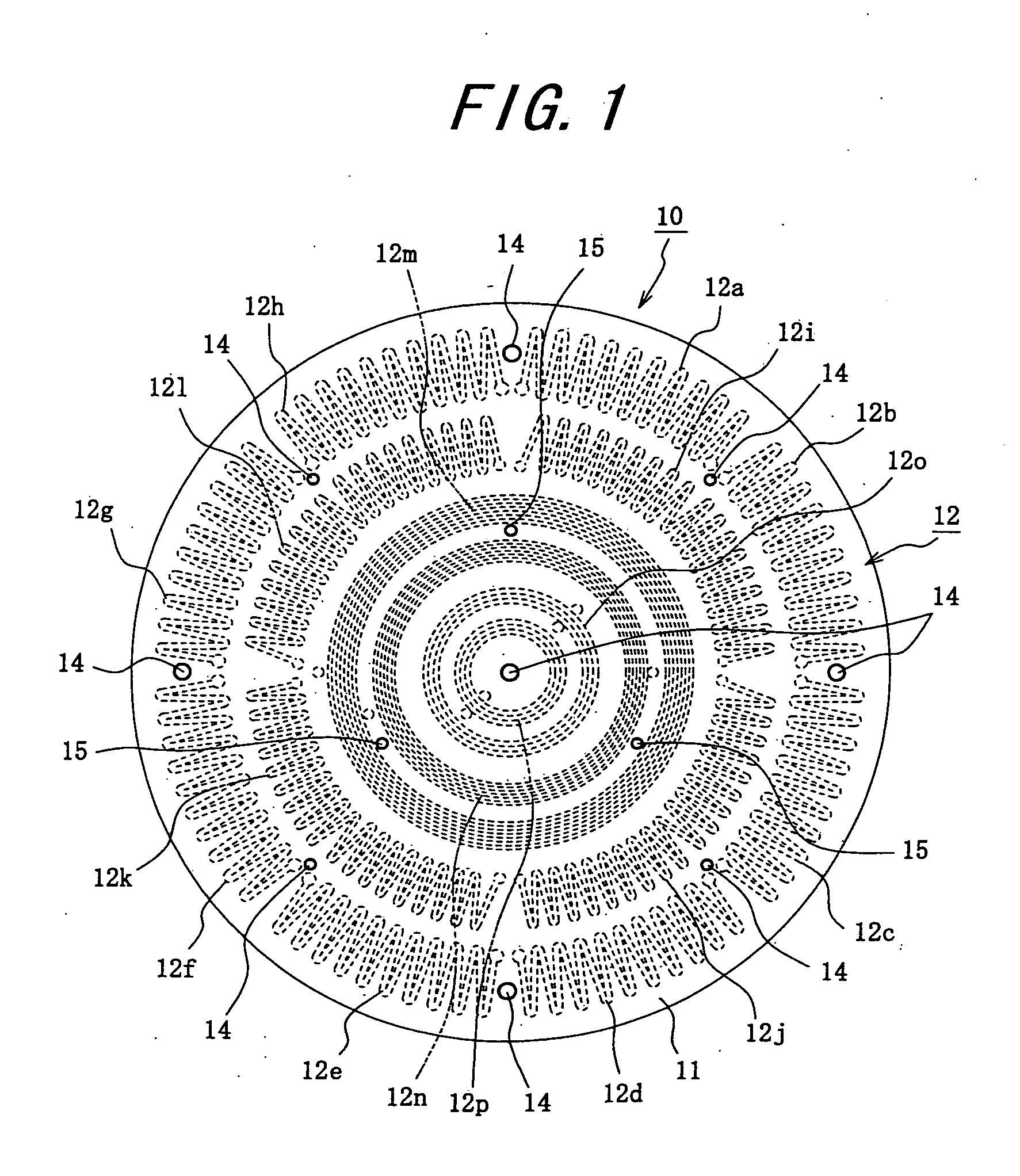

Carbon fiber, process for production thereof, prepregs, and golf club shafts

InactiveUS20070196648A1High compressive strengthTensile modulusSynthetic resin layered productsMonocomponent synthetic polymer artificial filamentCarbonizationGolf Ball

A carbon fiber tow composed of many carbon filaments and having a strand tensile strength of 3.8 to 5.5 GPa, a strand tensile modulus of 180 to 220 GPa and a carbon crystal size (Lc) of 13 to 18 Å. This carbon fiber tow can be produced by subjecting a precursor fiber tow composed of many polyacrylonitrile filaments which have a lightness difference (ΔL) of 50 or below and fineness of 1.1 to 1.7 dtex to oxidative stabilization and subjecting the stabilized fiber tow to carbonization with the maximum temperature within the range of 1,100 to 1,300° C. in an inert atmosphere while raising the temperature from 1,000° C. to the maximum temperature at a temperature rise rate of 100 to 2,000° C. / min.

Owner:TORAY IND INC

Method for low temp sintering, packaging and connecting high power LED by nano-silver soldering paste

InactiveCN1870310AImprove conductivityImprove thermal conductivitySemiconductor devicesScreen printingFree cooling

A method of using silver soldering nanopaste to package and connect large power LED in low temperature sintering includes utilizing screen printing to inject silver soldering nanopaste on base plate for connecting LED, sintering it in sintering furnace with temperature rising rate of 10deg.c / min, rising temperature to 50-70deg.c and holding it for 10-12 min. to remove off acetone, using temperature rising rate of 10deg.c / min. to rise temperature to 290deg.c then holding it for 35-40min. for ensuring bind intensity, cooling it by air to room temperature for finishing a sintering package of said LED.

Owner:TIANJIN UNIV

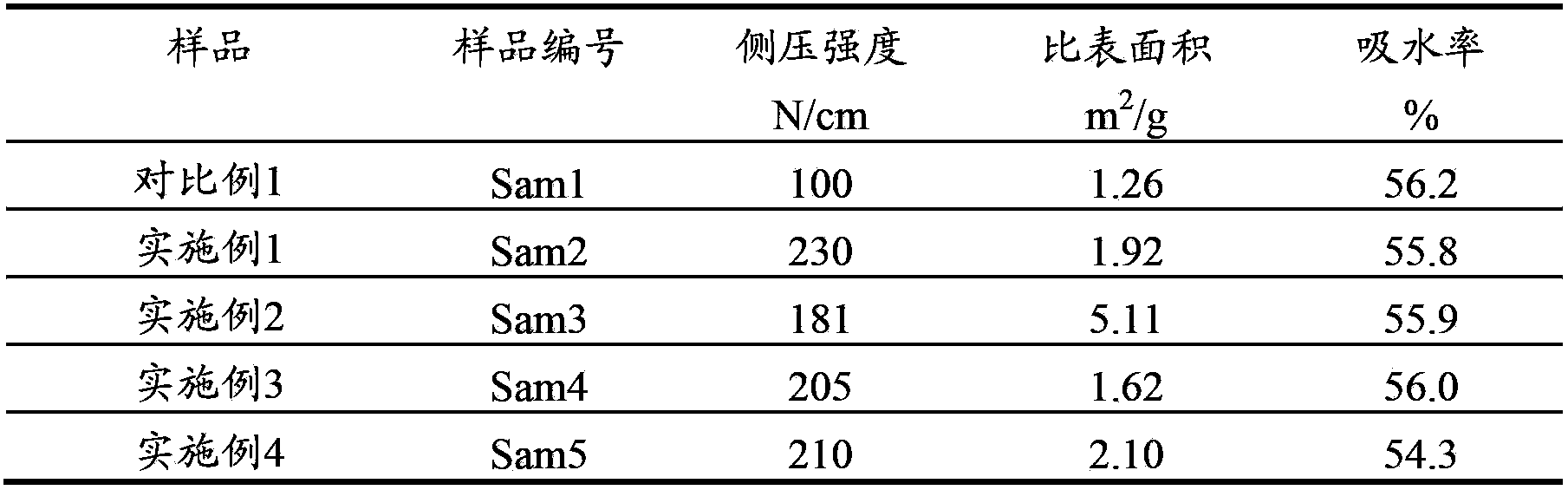

Aluminum oxide carrier and preparation method thereof

ActiveCN103816940AHigh strengthReduce manufacturing costCatalyst carriersOther chemical processesChemical industryWater vapor

The invention provides an aluminum oxide carrier which is higher in intensity and larger in specific surface area and is suitable for chemical industries such as olefin epoxidation reaction, alkyne and alkadiene selective hydrogenation or methane-steam conversion. The invention also provides an aluminum oxide carrier preparation method which is simple in technology and operation and has easily controlled conditions. Alpha-tri-hydro-aluminum oxide and / or surge aluminum stones and a proper amount of pseudo-boehmite and / or alumina sol which are low in cost and readily available are used as main raw materials, so that the production cost of the aluminum oxide carrier is lowered; meanwhile, due to the doping of a proper amount of a silicon source and other auxiliary ingredients, the strength of the carrier is obviously improved, and the specific surface area is properly enlarged; particularly, the strength of the carrier is further improved by controlling the temperature rise rate in a preparation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

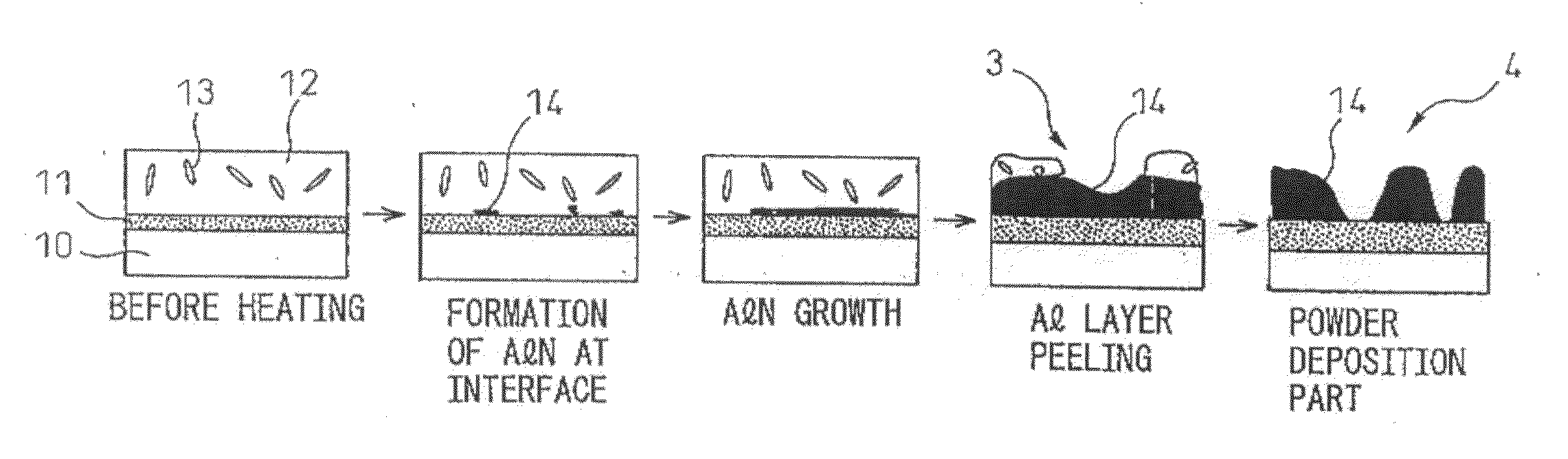

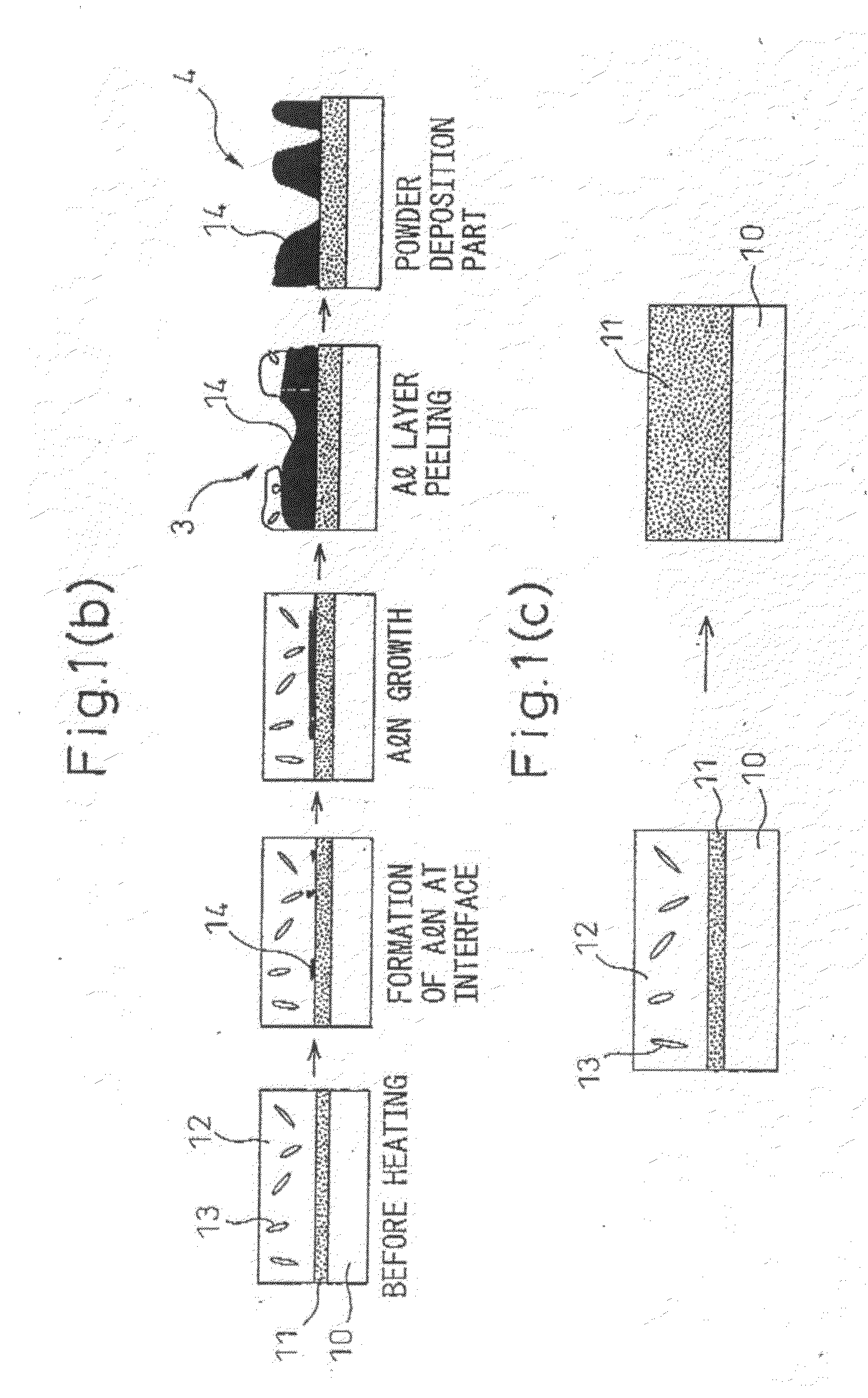

Aluminum plated steel sheet for rapid heating hot-stamping, production method of the same and rapid heating hot-stamping method by using this steel sheet

ActiveUS20110174418A1Eliminate generationReduce riskShaping toolsHot-dipping/immersion processesHot stampingHydrogen

The present invention solves the problem of melting of Al in heating before hot-stamping, which had been a problem in the past in applying hot-stamping to Al-plated steel sheet, and provides Al-plated steel sheet for hot-stamping and a method of hot-stamping using that Al-plated steel sheet to solve the problem of delayed fracture due to residual hydrogen, and, furthermore, a method of a rapid heating hot-stamping using that Al-plated steel sheet.The Al-plated steel sheet of the present invention is produced by annealing the Al-plated steel sheet as coiled in a box-anneal furnace for the time and at the temperature indicated in FIG. 5, and alloying of a plated Al and a steel sheet.Further, a method of rapid heating hot-stamping in the present invention is characterized by cutting out a stamping blank of an Al-plated steel sheet, and heating that blank in heating before hot-stamping by an average temperature with a rising rate of 40° C. / sec or more and a time of exposure to an environment of 700° C. or more of 20 seconds or less, and then hot-stamping it.

Owner:NIPPON STEEL CORP

High-heat-resistant and wear-resistant ball for ball mill

ActiveCN104087866AImprove heat resistanceImprove wear resistanceFurnace typesMetallic material coating processesWear resistantOptoelectronics

The invention discloses a high-heat-resistant and wear-resistant ball for a ball mill. The high-heat-resistant and wear-resistant ball comprises the following components: C, Mn, Si, Ni, Cr, Mo, V, W, Nb, Ca, Zr, Mg, Zn, Cu, S, P, Fe and impurities. Different temperature rise rates are adopted in the heat treatment process, and the surface of the wear-resistant ball is modified by using a laser cladding method. Laser cladding powder comprises the following components: Cr, C, Si, B, Re, Al2O3, Ni, nano CeO2 and nano SiC; the process parameters of laser cladding are that in single-channel scanning, a laser pool is protected by argon, the laser power is set to be 1.5-2.0KW, the light panel diameter is 1-2.5mm, and the cladding speed is 2-4mm / s. The high-heat-resistant and wear-resistant ball for the ball mill, which is disclosed by the invention, has excellent heat-resistant performance, and also has good wear-resistant performance, hardness and toughness.

Owner:宁国市宁武新材料科技有限公司

Resin composition, and method for producing the same

A resin composition having excellent impact resistance and heat resistance, comprising a poly-3-hydroxybutyrate, and a core-shell latex rubber comprising an acrylic rubber and / or silicone-acrylic rubber copolymer as a core component and polymethyl methacrylate as a shell component, or a specific thermoplastic polyurethane, is disclosed. The resin composition satisfies the following requirements (c) and (d): (c) a crystallization temperature when heated from room temperature to 180° C. at a temperature rising rate of 80° C. / min by a differential scanning calorimeter, maintained at 180° C. for 1 minute, and then cooled at a temperature lowering rate of 10° C. / min is 110-170° C.; and (d) a weight average molecular weight (Mw) in terms of polystyrene conversion when a chloroform soluble component is measured with a gel permeation chromatography is 100,000-3,000,000.

Owner:TOSOH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com