Aluminum oxide carrier and preparation method thereof

A technology of alumina carrier and alumina, which is applied in the direction of catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of difficult preparation of alumina carrier with specific surface area and low strength of alumina carrier and other issues, to achieve the effect of increased strength, low price, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 4.2g of analytically pure ethyl silicate, slowly add it into 130ml of 16.5wt% nitric acid solution under strong stirring, and keep stirring for 30min before use.

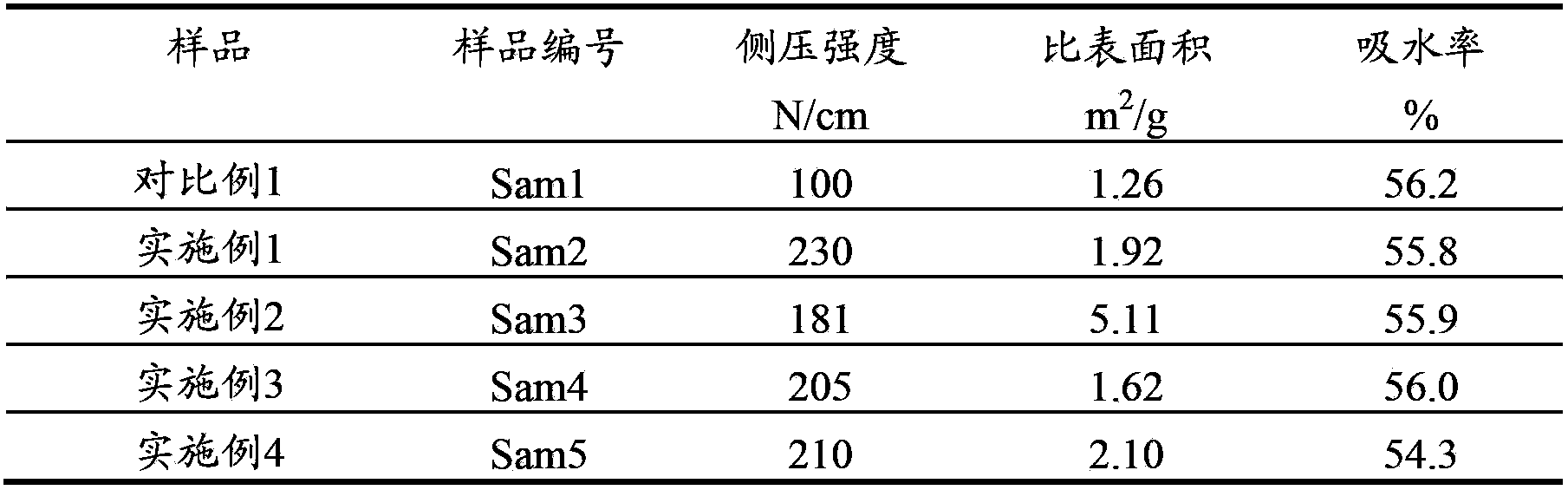

[0032]Put 440 g of 120-mesh pyrenite, 110.0 g of pseudoboehmite, and 8.0 g of ammonium fluoride into a mixer and mix evenly. Then transfer to a kneader, add the silicon-containing dilute nitric acid solution obtained above, and fully knead; then extrude into a five-hole column with an outer diameter of about 8.0mm, a length of 7.5mm, and an inner diameter of 1.0mm. Dry at 80°C for 10 hours to reduce the free water content to below 10wt%, and obtain an alumina carrier green body. Then it was placed in a high-temperature electric furnace, raised from room temperature to a roasting temperature of 1300°C over 30 hours, and kept at a constant temperature for 4 hours to obtain alumina carrier Sam2. The crushing strength, specific surface area and water absorption were measured. The results are shown in Table ...

Embodiment 2

[0034] The preparation method is roughly the same as that of Example 1, except that the calcination temperature is 1100° C., and the temperature is kept constant for 4 hours. The obtained alumina carrier Sam3 is measured for its crushing strength, specific surface area and water absorption. The results are shown in Table 1.

Embodiment 3

[0036] Weigh 4.3g of analytically pure ethyl silicate, slowly add it into 130ml of 16.5wt% nitric acid solution under strong stirring, and keep stirring for 30min before use.

[0037] Put 225.0g of 120 mesh pyrenite, 220.0g of 180~1000 mesh α-alumina trihydrate, 110.0g of pseudoboehmite, 8.0g of ammonium fluoride, and 1.0g of barium sulfate into the mixer and mix evenly . Then transfer to a kneader, add the silicon-containing dilute nitric acid solution obtained above, and fully knead; then extrude into a five-hole column with an outer diameter of about 8.0mm, a length of 7.5mm, and an inner diameter of 1.0mm. Dry at 80°C for 12 hours to reduce the free water content to below 10wt%, and obtain an alumina carrier green body. Then it was placed in a high-temperature electric furnace, raised from room temperature to 1300°C over 30 hours, and kept at a constant temperature for 4 hours to obtain alumina carrier Sam4. The crushing strength, water absorption and specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com