Patents

Literature

215 results about "Pseudoboehmite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pseudoboehmite is an aluminium compound with the chemical composition AlO(OH). It consists of finely crystalline boehmite. However, the water content is higher than in boehmite.

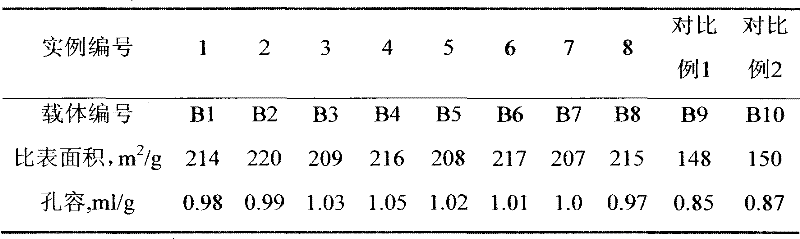

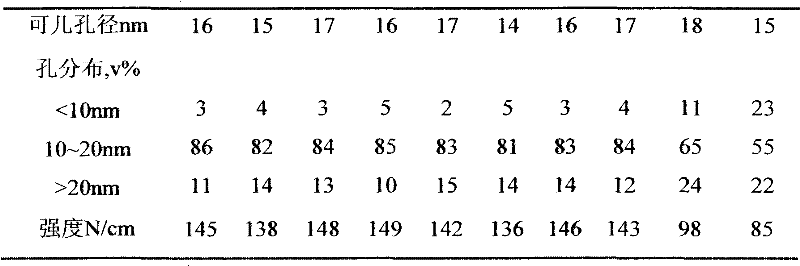

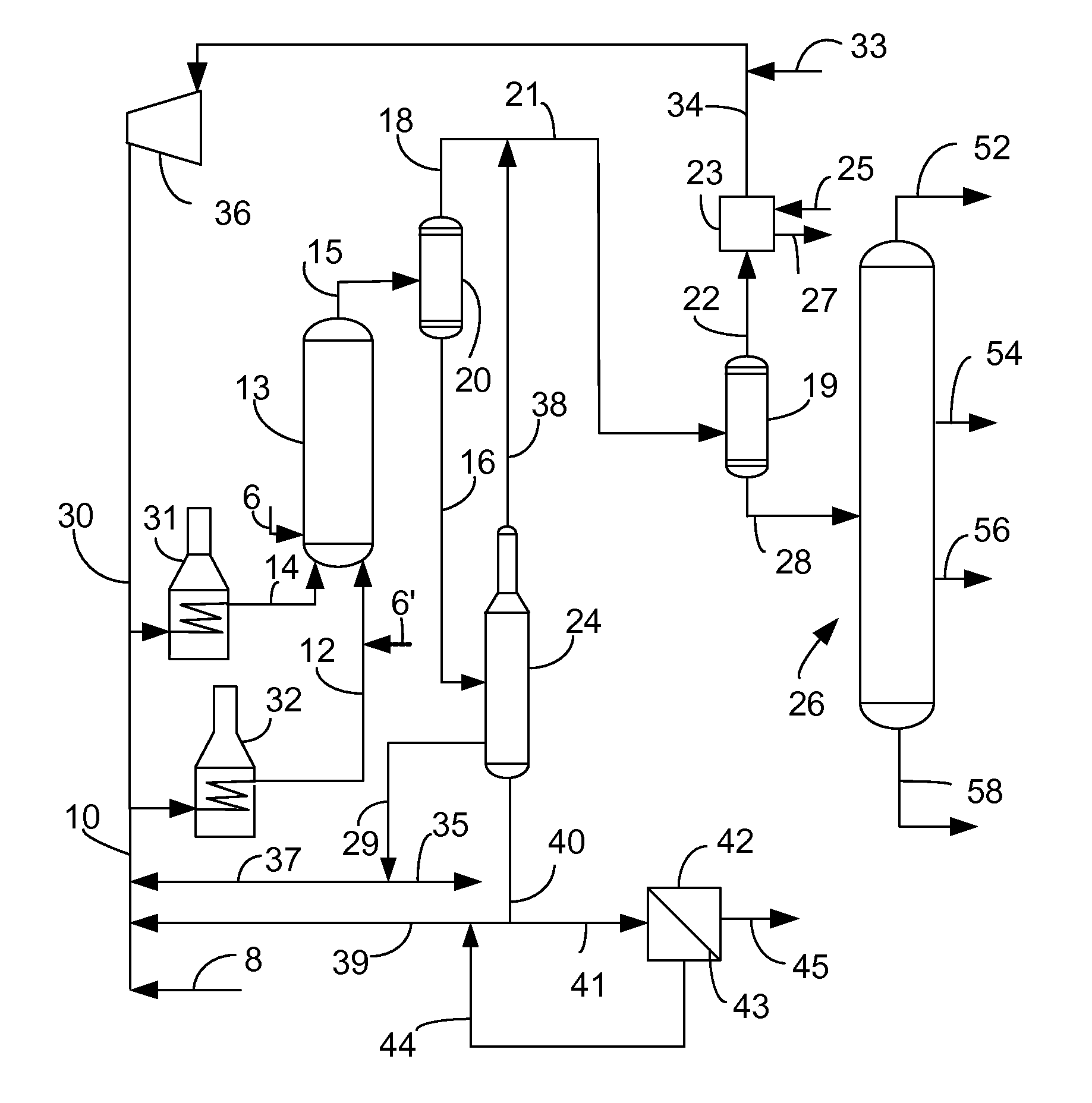

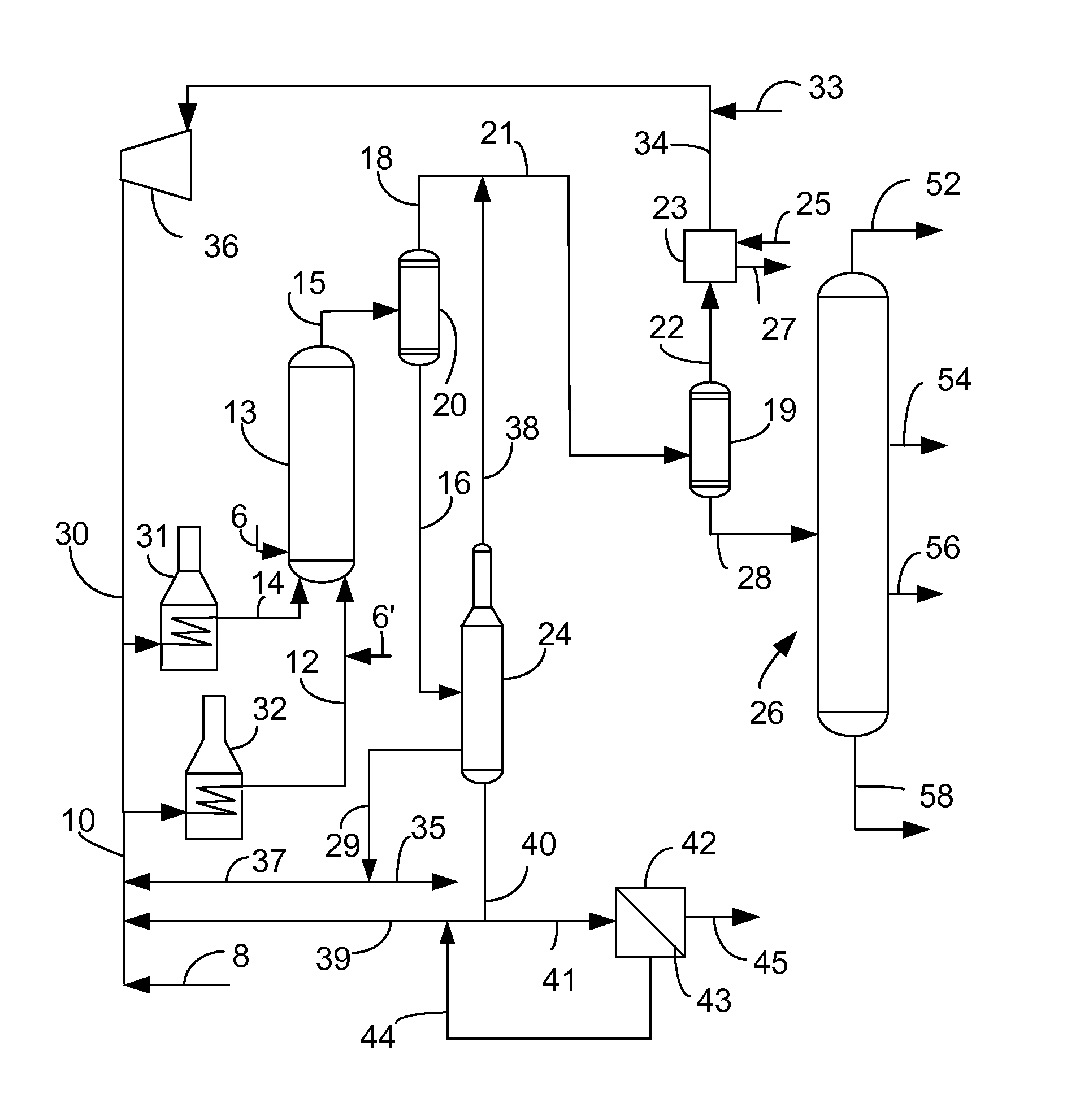

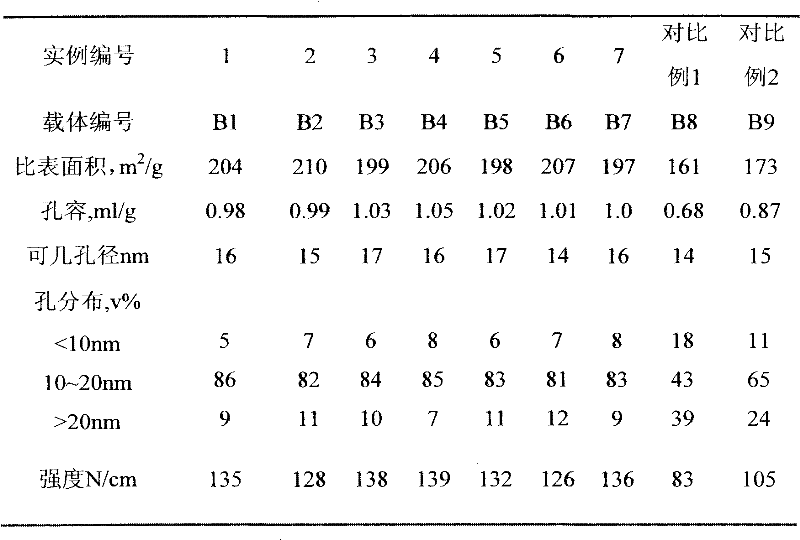

Preparation methods for macroporous alumina carrier and hydrodemetallization catalyst

ActiveCN102441437AModerate mechanical strengthModerate bulk densityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteMetal catalyst

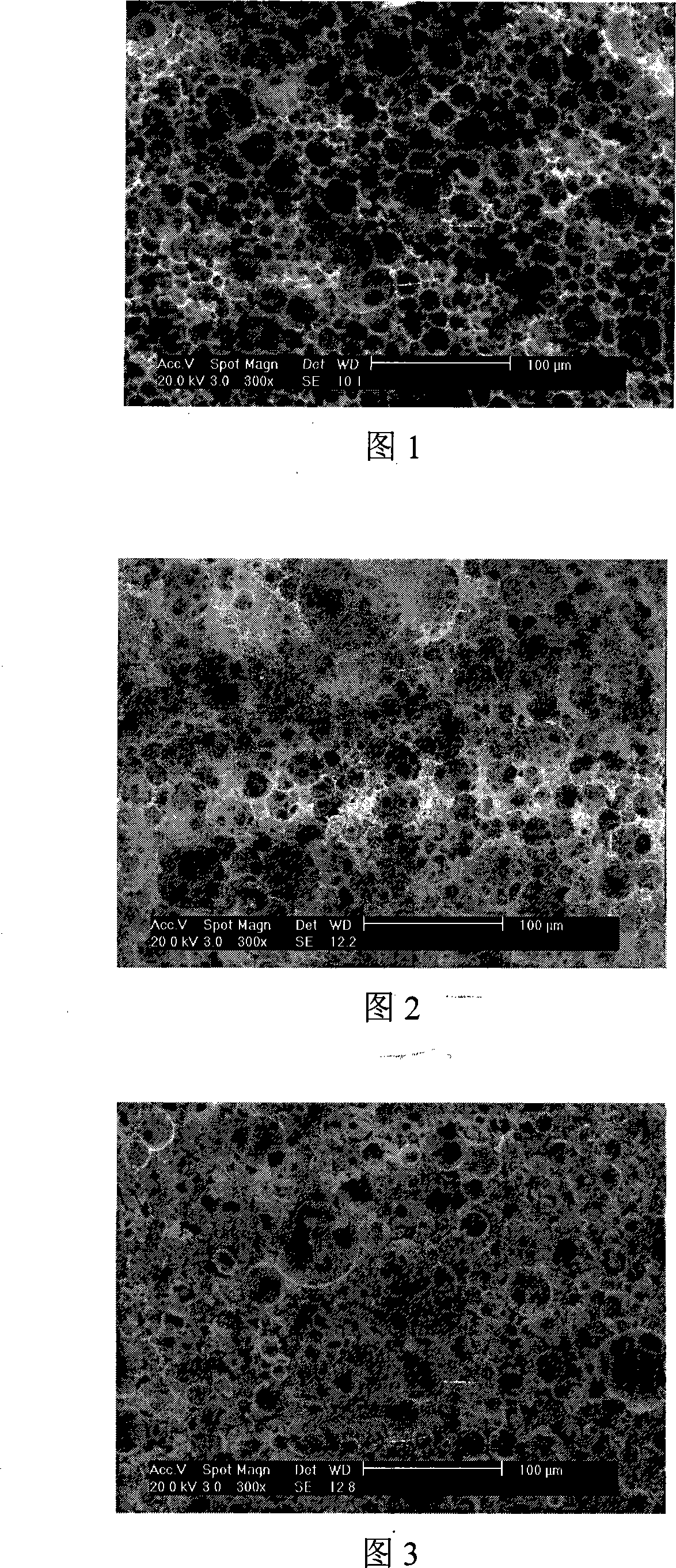

The invention discloses preparation methods for a macroporous alumina carrier and a hydrodemetallization catalyst. The preparation method for the macroporous alumina carrier includes the following steps: (1) dry pseudoboehmite gel powder is hydrothermally processed under high pressure; (2) the dry pseudoboehmite gel powder obtained in step 1 is kneaded into a plastic, and pore-expanding agent is added in step 1 or step 2; (3) the plastic obtained in step 2 is shaped, the shaped material is dried and baked, and thereby the macroporous alumina carrier is obtained. The impregnation method is adopted to prepare the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared by the method has large pore volume and pore diameter, centrally distributed pores, moderate mechanical strength and high activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pseudo thin allophane and its preparation method

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing integral macroporous alumina

InactiveCN101200297AEasy to operateEasy to manufactureCatalyst carriersOther chemical processesPseudoboehmiteEmulsion

The invention discloses a preparation method of integrated large-hole alumina, belonging to a preparation technique of integrated multi-hole inorganic oxide. The method comprises the following process: reverse concentrated emulsion method is adopted to prepare integrated large-hole organic template taking cinnamene and divinylbenzene as monomer; aluminum isopropoxide or pseudoboehmite is primarily used for preparing Al2O3 hydrosol; the Al2O3 hydrosol is filled into the integrated large-hole organic template; the filled integrated organic / inorganic composites are dried and then are roasted to remove the template, so as to obtain the integrated large-hole alumina. The invention has the advantages of simple and feasible preparation process, moreover the prepared integrated large-hole alumina has micrometer grade communicated large-hole channels (1-50um). The invention is applicable for catalyst carrier, absorption materials and separation materials.

Owner:TIANJIN UNIV

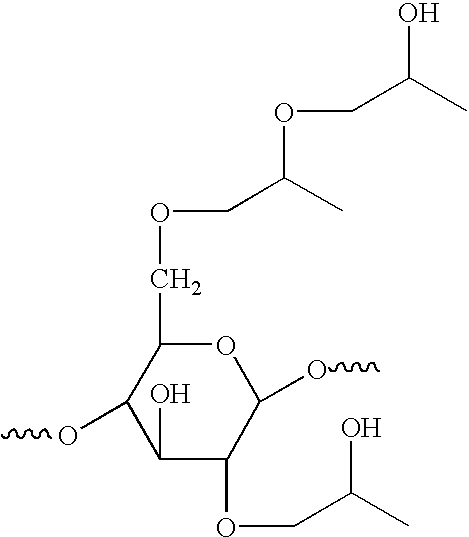

Methods of preparing separators for electrochemical cells

InactiveUS20070189959A1High porosityHigh strengthCell component detailsSpecial surfacesCarbonateOrganic polymer

Provided are methods of preparing a separator for an electrochemical cell comprising the steps of (a) coating onto a substrate a liquid mixture comprising an inorganic oxide, an organic polymer, a divinyl ether of an ethylene glycol, and / or an organic carbonate; (b) drying the coating; and (c) delaminating the coating from the substrate to form the separator comprising an inorganic oxide and the organic polymer, wherein the inorganic oxide of step (c) comprises a reaction product of the divinyl ether and / or the organic carbonate with the inorganic oxide of step (a). Preferably, the inorganic oxide of step (c) comprises a hydrated aluminum oxide of the formula Al2O3.H2O, wherein x is less than 1.0, and wherein the hydrated aluminum oxide comprises a reaction product of the divinyl ether and / or organic carbonate with the inorganic oxide of step (a), such as pseudo-boehmite.

Owner:CARLSON STEVEN ALLEN +1

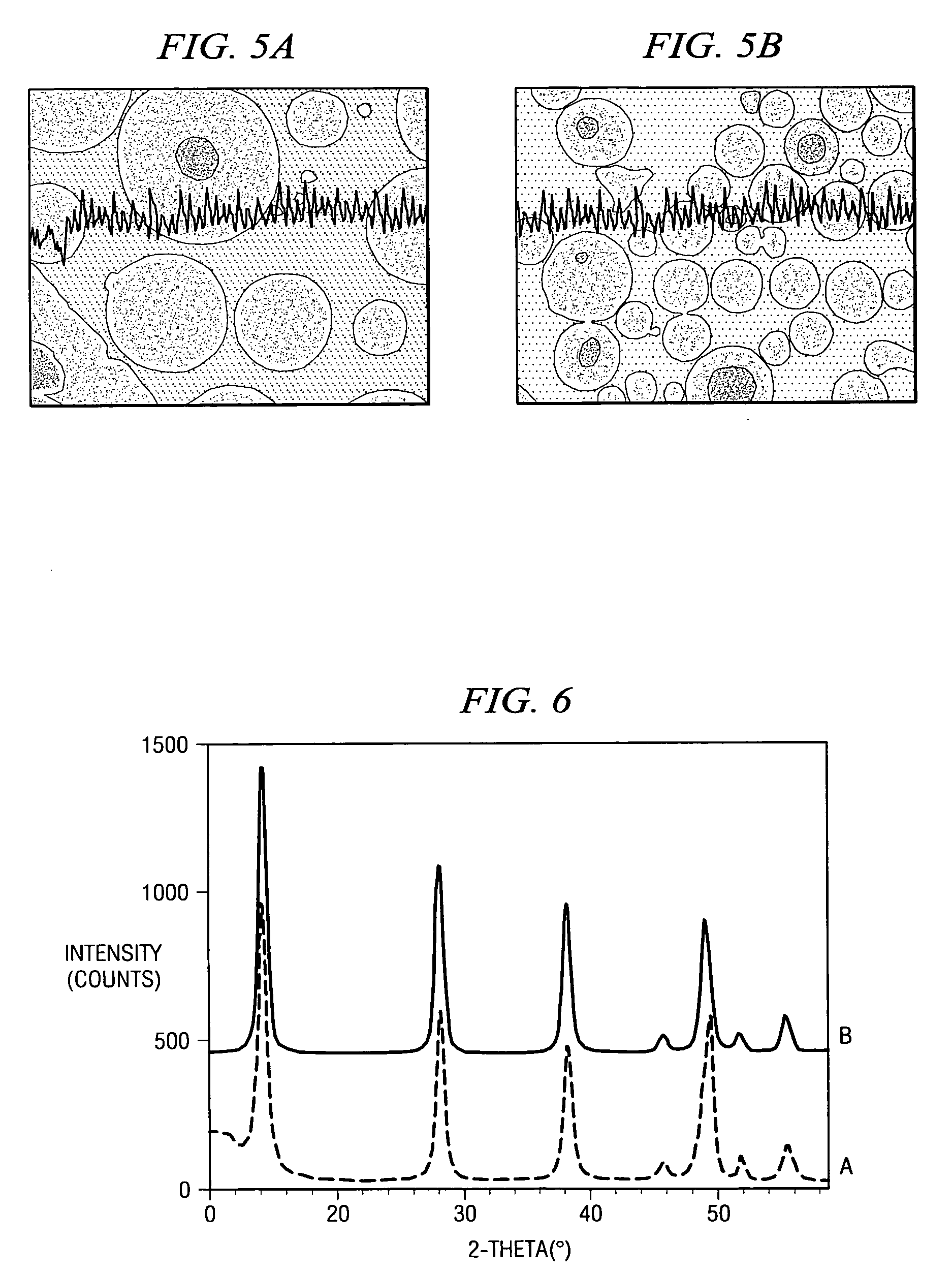

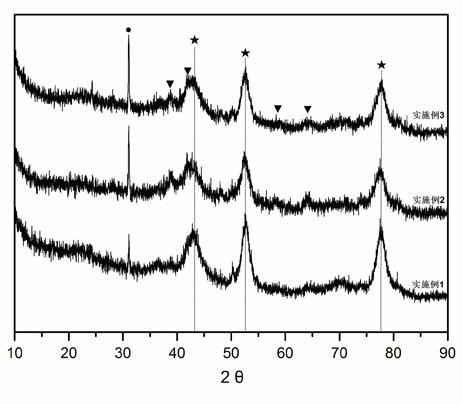

Fischer-Tropsch processes and catalysts made from a material comprising boehmite

ActiveUS7012104B2Improve performanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPseudoboehmiteCatalytic metal

A hydrothermally-stable catalyst, method for making the same, and process for producing hydrocarbon, wherein the catalyst is used in synthesis gas conversion to hydrocarbons. In one embodiment, the method comprises depositing a compound of a catalytic metal selected from Groups 8, 9, and 10 of the Periodic Table on a support material comprising boehmite to form a composite material; and calcining the composite material to form the catalyst. In other embodiments, the support material comprises synthetic boehmite, natural boehmite, pseudo-boehmite, or combinations thereof.

Owner:CLARIANT INT LTD

Composition of supported molybdenum catalyst for slurry hydrocracking

InactiveUS20110306490A1Catalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteSlurry

A composition is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a catalyst comprising molybdenum supported on a base, such as boehmite or pseudo-boehmite alumina. Iron oxide may also be in the base. The base is preferably bauxite. The heavy hydrocarbon slurry is hydrocracked in the presence of the catalyst to produce lighter hydrocarbons.

Owner:UOP LLC

Preparation method for alumina carrier

ActiveCN102441436AWell mixedLarge hole volumeCatalyst carriersAluminium oxide/hydroxide preparationPseudoboehmiteResidual oil

The invention discloses a preparation method for an alumina carrier, which includes the following steps: (1) dry pseudoboehmite gel powder and extrusion aid are uniformly mixed and then added into aqueous solution in which physical pore-expanding agent and chemical pore-expanding agent are dissolved; (2) the material obtained in step 1 is uniformly mixed and molded by extrusion on an extruder; (3) the material obtained in step 2 is dried and baked, and thereby the finished alumina carrier is prepared. The alumina carrier prepared by the method has large pore volume and pore diameter, centrally distributed pores and high mechanical strength, and is applicable to the preparation of heavy oil and residual oil hydrodemetallization catalysts and other fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

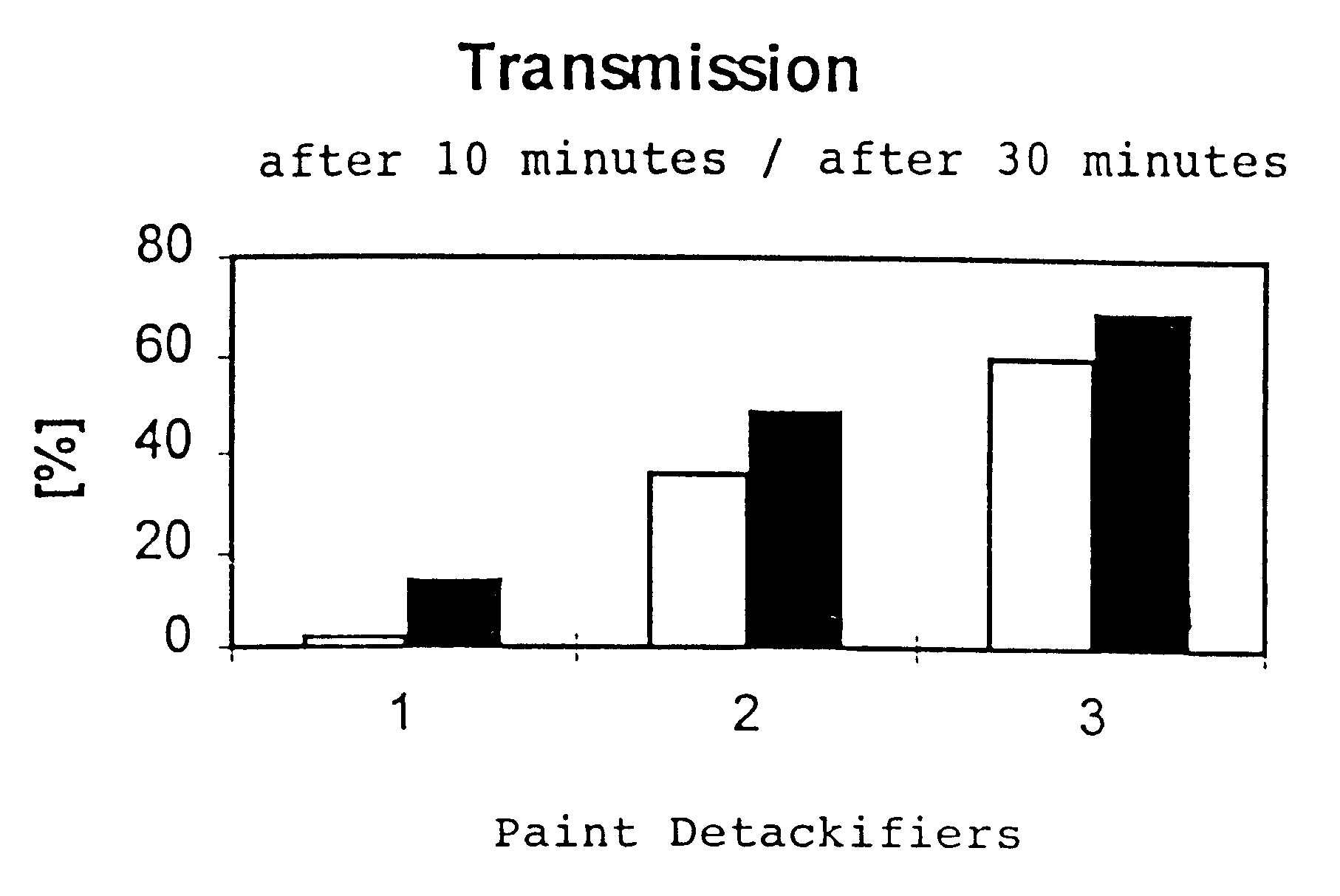

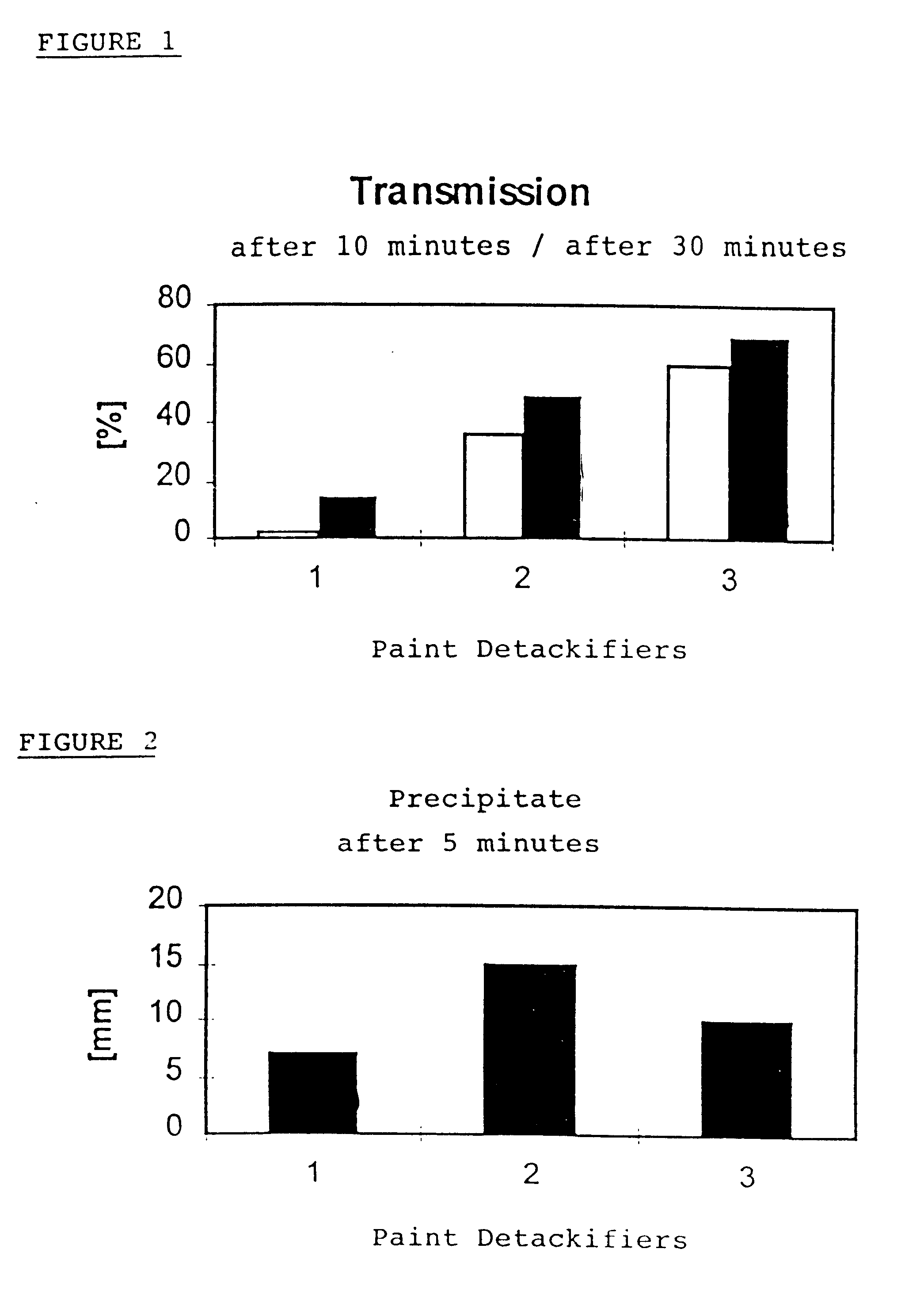

Agents for unsticking paint, and sedimentation agents

Paint detackifiers and / or sedimentation agents are provided which contain amorphous alumina and / or alumina in pseudoboehmite or boehmite form having an average crystallite size of from 0.1 to 15 nm and / or the hydrates and hydroxyalkylpolysaccharides thereof.

Owner:SASOL GERMANY GMBH

Method for preparing hydrogenation purification catalyst

InactiveUS6919294B2High mechanical strengthEasy to implementOther chemical processesManganese carbonylsPseudoboehmitePore diameter

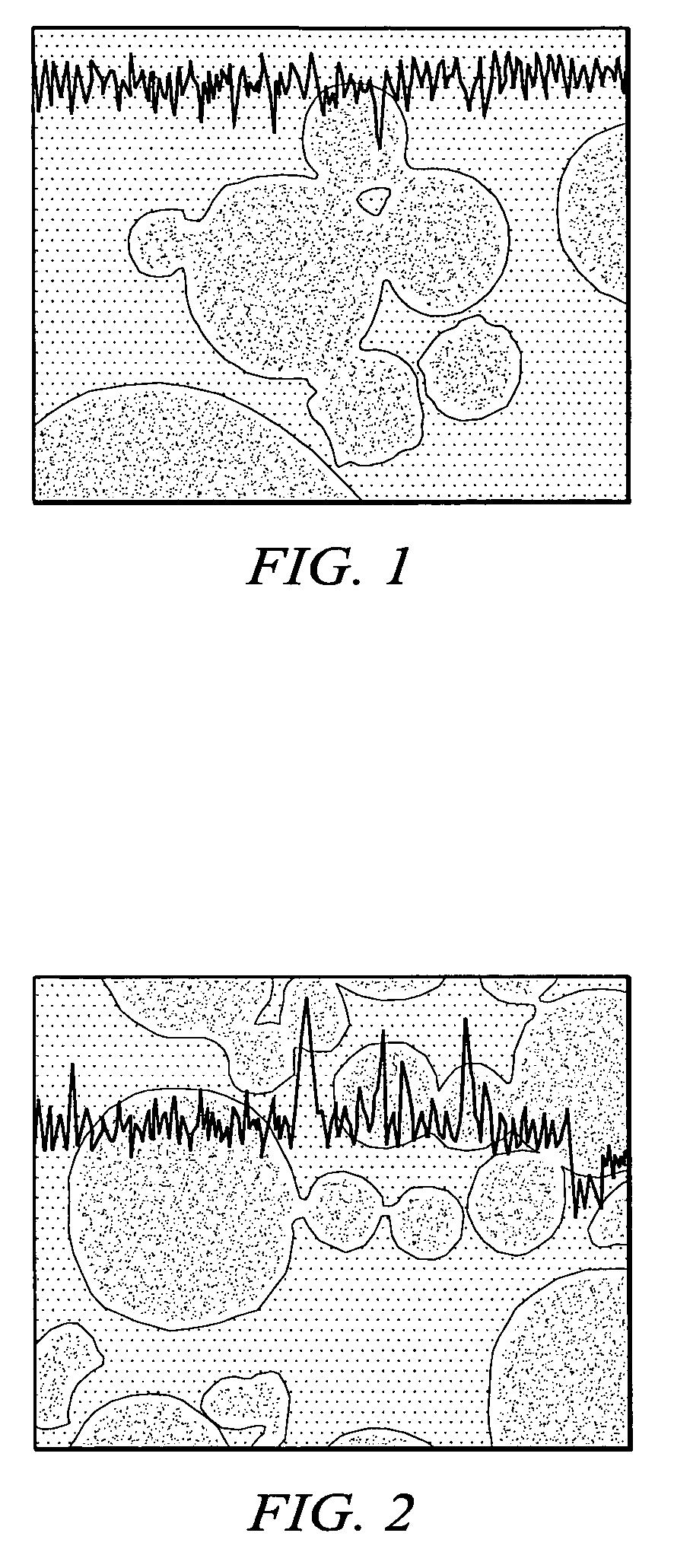

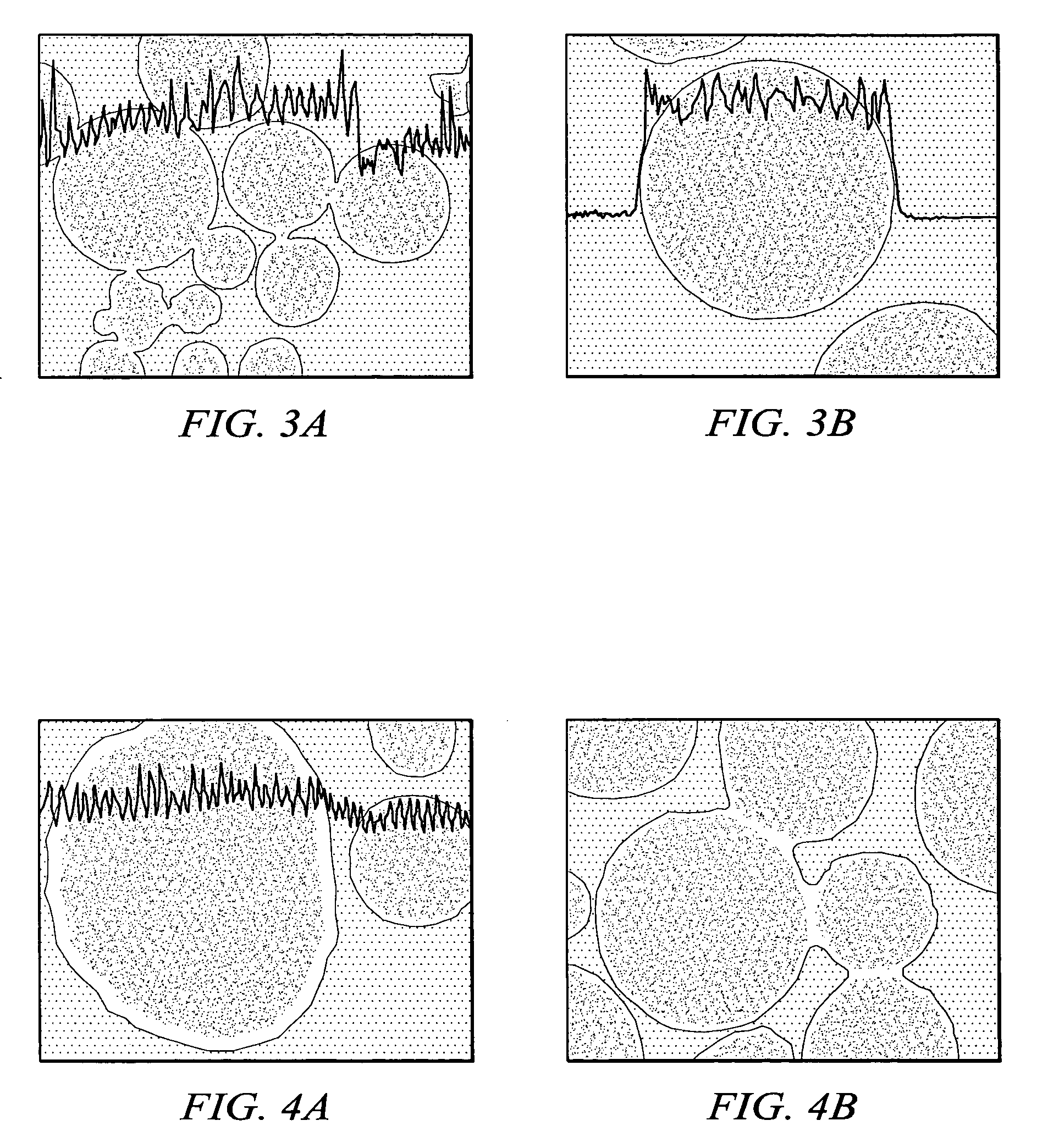

A method for producing a hydrorefining catalyst is used to produce the hydrorefining catalyst which contains an inorganic oxide carrier and a hydrogenation-active metal and which has such a bimodal pore characteristic that pores having pore diameters of not more than 50 nm have a pore volume of not less than 0.4 cm3 / g, pores having pore diameters of not less than 50 nm have a pore volume of not less than 0.2 cm3 / g, and pores having pore diameters of not less than 1000 nm have a pore volume of not more than 0.1 cm3 / g. The method comprises the steps of mixing and forming a pseudo-boehmite powder having a dispersibility index of 0.13 to 0.28, and calcinating the formed pseudo-boehmite under a condition in which the pseudo-boehmite is converted into γ-alumina. The hydrorefining catalyst, which has the bimodal pore characteristic, can be produced easily at low cost.

Owner:JAPAN ENERGY CORP

Separators for electrochemical cells

ActiveUS8883354B2High strengthIncrease flexibilityPrimary cellsElectrode carriers/collectorsPseudoboehmiteHydrated alumina

Provided are separators for use in an electrochemical cell comprising (a) an inorganic oxide and (b) an organic polymer, wherein the inorganic oxide comprises organic substituents. Preferably, the inorganic oxide comprises an hydrated aluminum oxide of the formula Al2O3.xH2O, wherein x is less than 1.0, and wherein the hydrated aluminum oxide comprises organic substituents, preferably comprising a reaction product of a multifunctional monomer and / or organic carbonate with an aluminum oxide, such as pseudo-boehmite and an aluminum oxide. Also provided are electrochemical cells comprising such separators.

Owner:LG ENERGY SOLUTION LTD

Microporous separators for electrochemical cells

InactiveUS20080182174A1High porosityHigh strengthLi-accumulatorsCell component detailsGlycol synthesisOragene

Provided are separators for use in an electrochemical cell comprising (a) an hydrated aluminum oxide of the formula Al2O3.xH2O, wherein x is less than 1.0 and (b) an organic polymer, wherein the hydrated aluminum oxide comprises organic substituents. Preferably, x of the hydrated aluminum oxide is less than 0.8, or more preferably, x is less than 0.6. Preferably, the organic substituents comprise a reaction product of a multifunctional monomer, such as a divinyl ether of an ethylene glycol, and / or an organic carbonate with an aluminum oxide, such as pseudo-boehmite or a hydrated aluminum oxide.

Owner:CARLSON STEVEN ALLEN +1

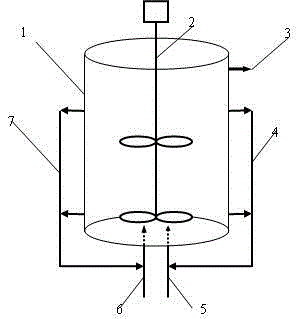

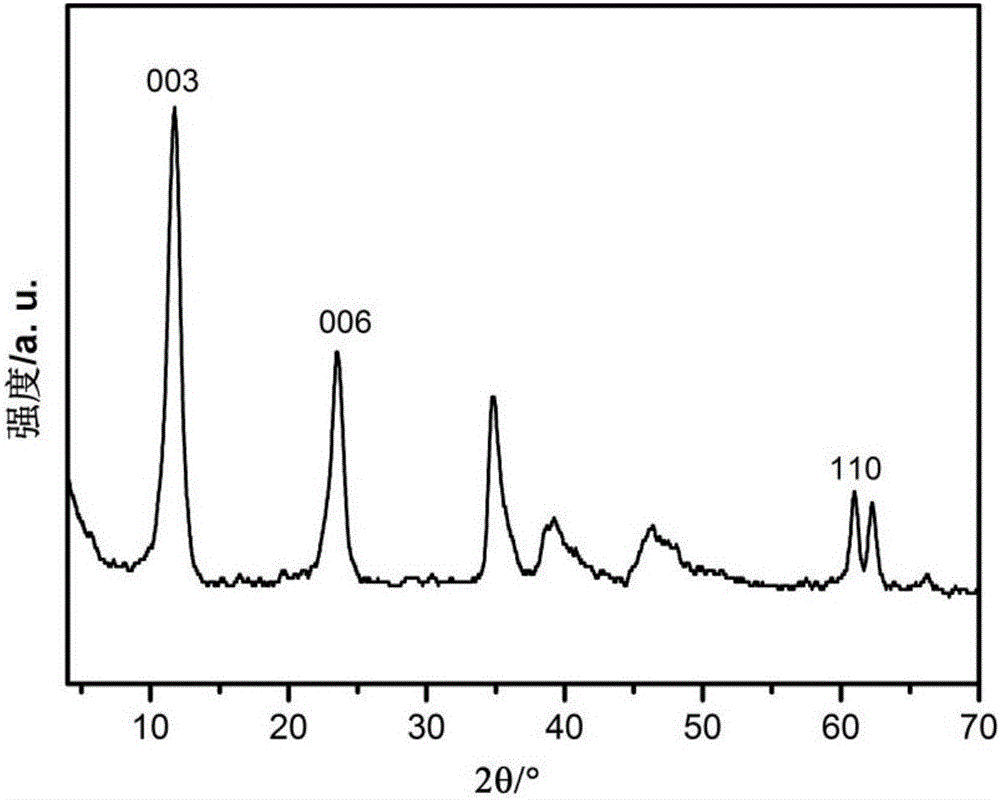

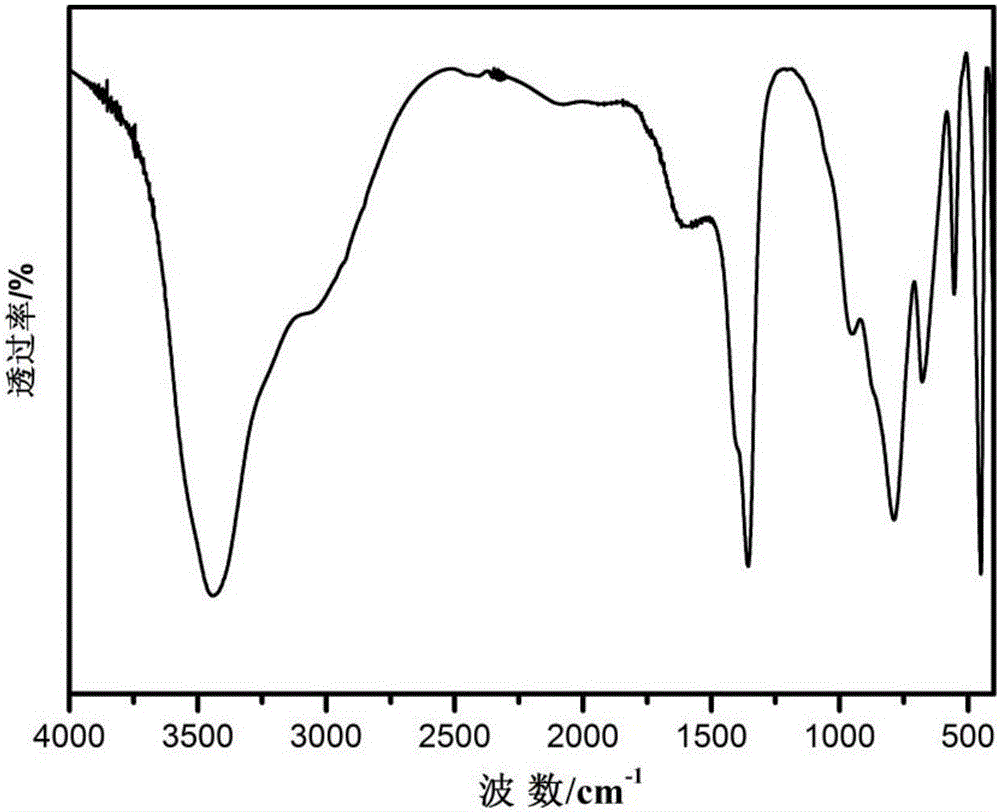

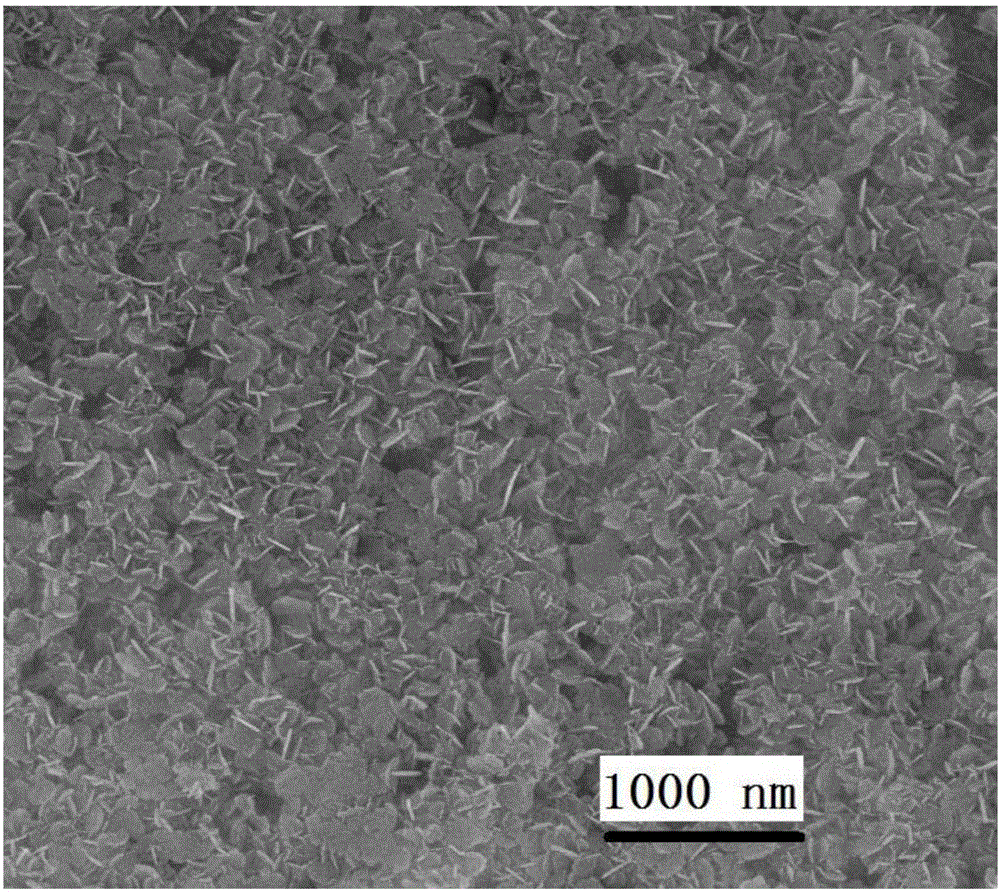

A method of preparing pseudoboehmite

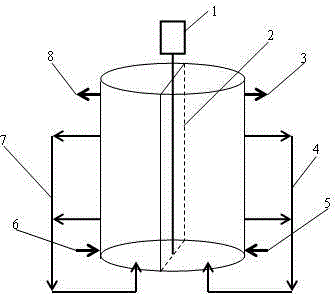

ActiveCN104671265AStable in natureUniform particle sizeAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPseudoboehmitePore distribution

A method of preparing pseudoboehmite is disclosed. The method includes preparing aluminium hydroxide precipitate, ageing, washing and drying. The preparation of the aluminium hydroxide precipitate adopts a reactor, wherein the reactor comprises a reactor cylinder and is provided with a stirrer inside, the bottom of the reactor cylinder is provided with two feeding ports, two material circulating pipelines are disposed outside the reactor cylinder, each of the material circulating pipelines is provided with at least one outlet, circulating material outlets are in the upper part of the reactor cylinder, inlets of the two material circulating pipelines are respectively connected to the two feeding ports through pipelines, and the upper part of the reactor cylinder is provided with an overflow port that is higher than the circulating material outlets. Pseudoboehmite particles prepared by the method are uniform in particle size, so that prepared aluminum oxide is large in pore volume, large in pore diameter and centralized in pore distribution, and the prepared aluminum oxide is uniform and constant in properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

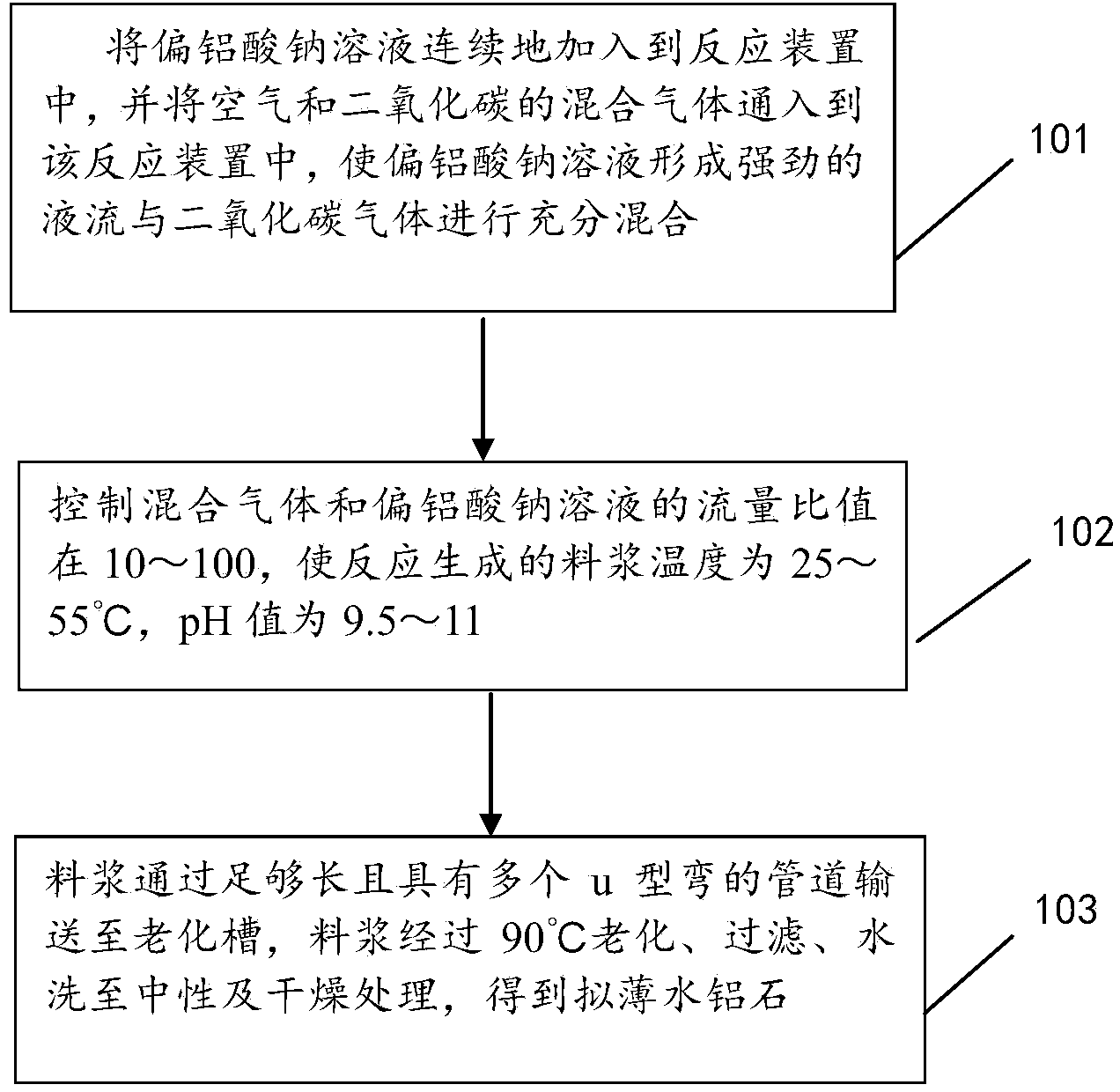

Method for continuously producing pseudoboehmite

ActiveCN103449484ASmall pore volumeLarge specific surface areaAluminium oxides/hydroxidesPseudoboehmiteSlurry

The invention discloses a method for continuously producing pseudoboehmite, belonging to the technical field of boehmite preparation. The method comprises the following steps: continuously adding a sodium metaaluminate solution into a reactor while introducing an air-carbon dioxide gas mixture, and forming a strong liquid flow of the sodium metaaluminate solution to be thoroughly mixed with the carbon dioxide gas; controlling the flow rates of the gas mixture and the sodium metaaluminate solution to control the temperature of the slurry generated by reaction at 25-55 DEG C and the pH value at 9.5-11; and after the slurry passes through a pipeline with a plurality of U-shaped bends, aging the slurry, filtering, washing with water, and drying to obtain the pseudoboehmite. The pseudoboehmite prepared by the method has the characteristics of large specific area and pore volume, reasonable peptization, continuous production, simple technique, high production efficiency, stable product quality, low equipment investment, reliable operation, low energy consumption, low labor intensity and the like, is convenient to operate and maintain, and is especially suitable for producing common pseudoboehmite, superfine aluminum hydroxide or aluminum oxide.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Pseudo thin allophane and its preparation method

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemical mechanical polishing composite of stainless steel surface polishing

InactiveCN101654599ASuppression of surface defectsFacilitates mechanical polishing capabilitiesPolishing compositions with abrasivesPseudoboehmiteHydrated alumina

The invention relates to a chemical mechanical polishing composite of stainless steel surface polishing; the polishing composite is composed of grinding material, oxidizer, polishing accelerant, metalchelator, penetrant, and surfactant; the invention is characterized in that: aluminum oxide sol, namely hydrated alumina dispersed in acidic aqueous solution in sol state, is added, the hydrated alumina can be boehmite, fake boehmite, diaspore or gibbsite.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Aluminum alloy member superior in corrosion resistance and plasma resistance

ActiveUS20040151926A1Improve corrosion resistanceAnodisationSemiconductor/solid-state device manufacturingPhosphoric acidCorrosion

An aluminum or aluminum alloy member superior in liquid and gaseous corrosion resistance and plasma resistance, which has an anodized film formed thereon which is composed of a porous layer and a non-porous barrier layer whose structure is at least partly boehmite or pseudo-boehmite. Said anodized film is characterized by that the film dissolving rate measured by the test for immersion in a mixture of phosphoric acid and chromic acid (conforming to JIS H8683-2) is less than 120 mg / dm<2> / 15 min, the ratio of area in which corrosion occurs after standing for 2 hours in an atmosphere of argon containing 5% chlorine (at 300° C.) is less than 15%, and the hardness (Hv) of the film is no lower than 420.

Owner:KOBE STEEL LTD

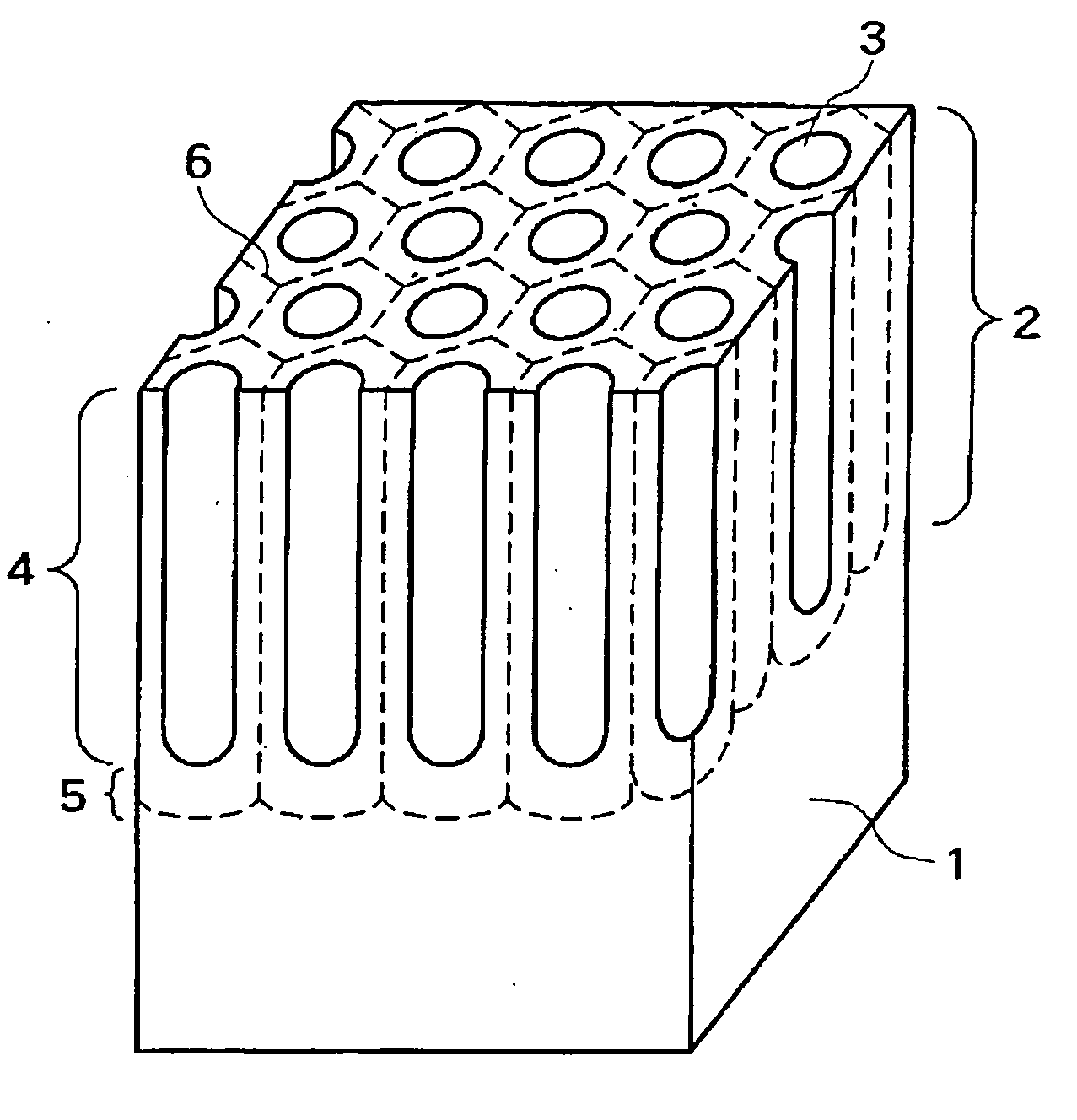

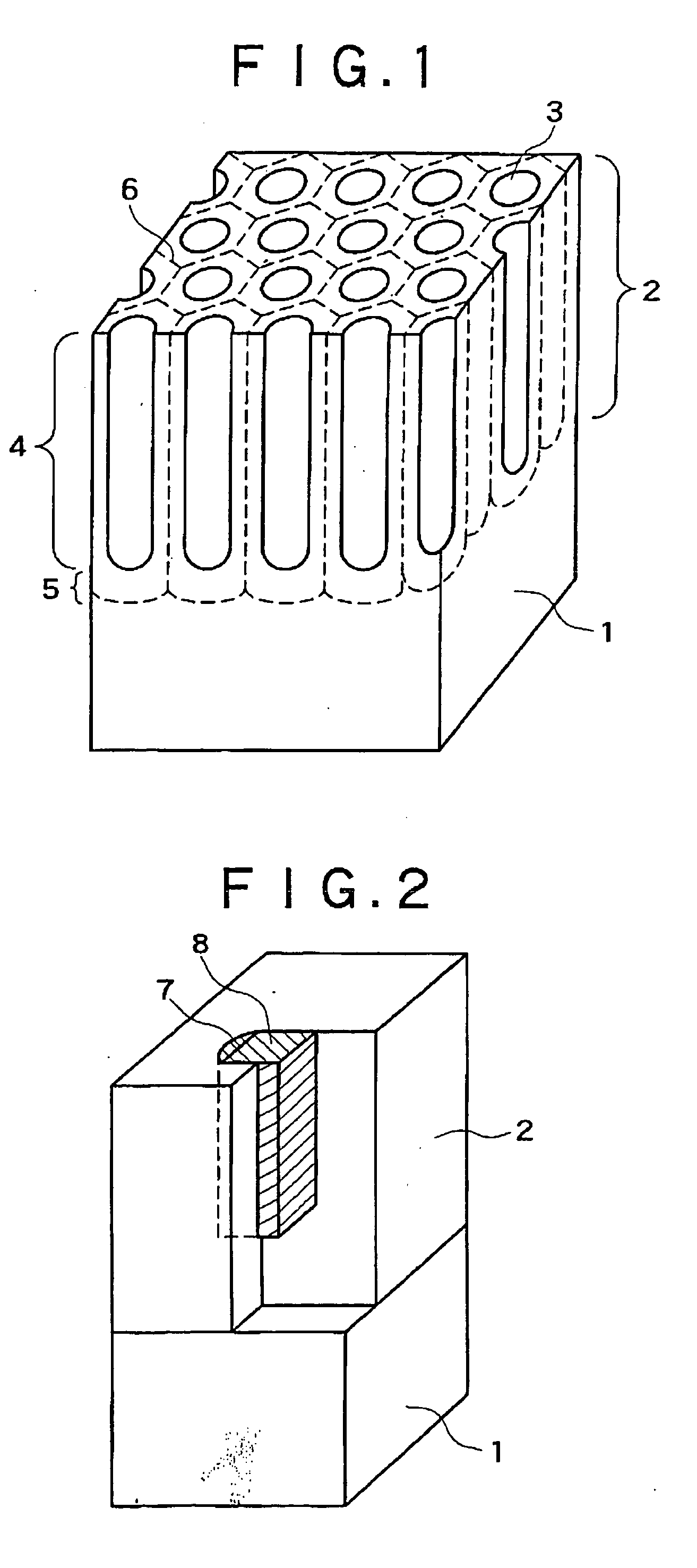

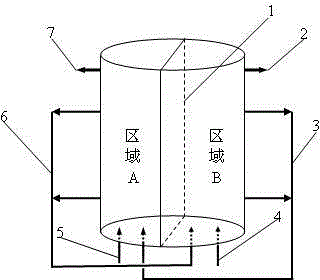

A reactor and a method of preparing pseudoboehmite by the reactor

ActiveCN104667841AIncrease profitUniform natureLiquid-liquid reaction processesAluminium oxides/hydroxidesPseudoboehmitePore distribution

A reactor and a method of preparing pseudoboehmite by the reactor are disclosed. The reactor comprises a reactor cylinder. A separating plate is disposed in the reactor cylinder to divide the inner cavity of the reactor into two zones along the axial direction. At least two material circulating pipelines are disposed outside the reactor cylinder. A circulated material outlet and a circulated material inlet in each material circulating pipeline are disposed in different zones. The circulated material outlets are at the upper part of the reactor cylinder and the circulated material inlets are at the bottom of the reactor cylinder. In each of the zones, the corresponding lower part of the reactor cylinder is provided with a material feeding port, and the corresponding upper part of the reactor cylinder is provided with an overflow port higher than the corresponding circulated material outlet. Continuous gel forming can be achieved by the reactor. Pseudoboehmite particles prepared by adopting the reactor are uniform in particle size, so that prepared aluminum oxide is large in pore volume, large in pore diameter and centralized in pore distribution, and the prepared aluminum oxide is uniform and constant in properties, and is not influenced by batch production scales.

Owner:CHINA PETROLEUM & CHEM CORP +1

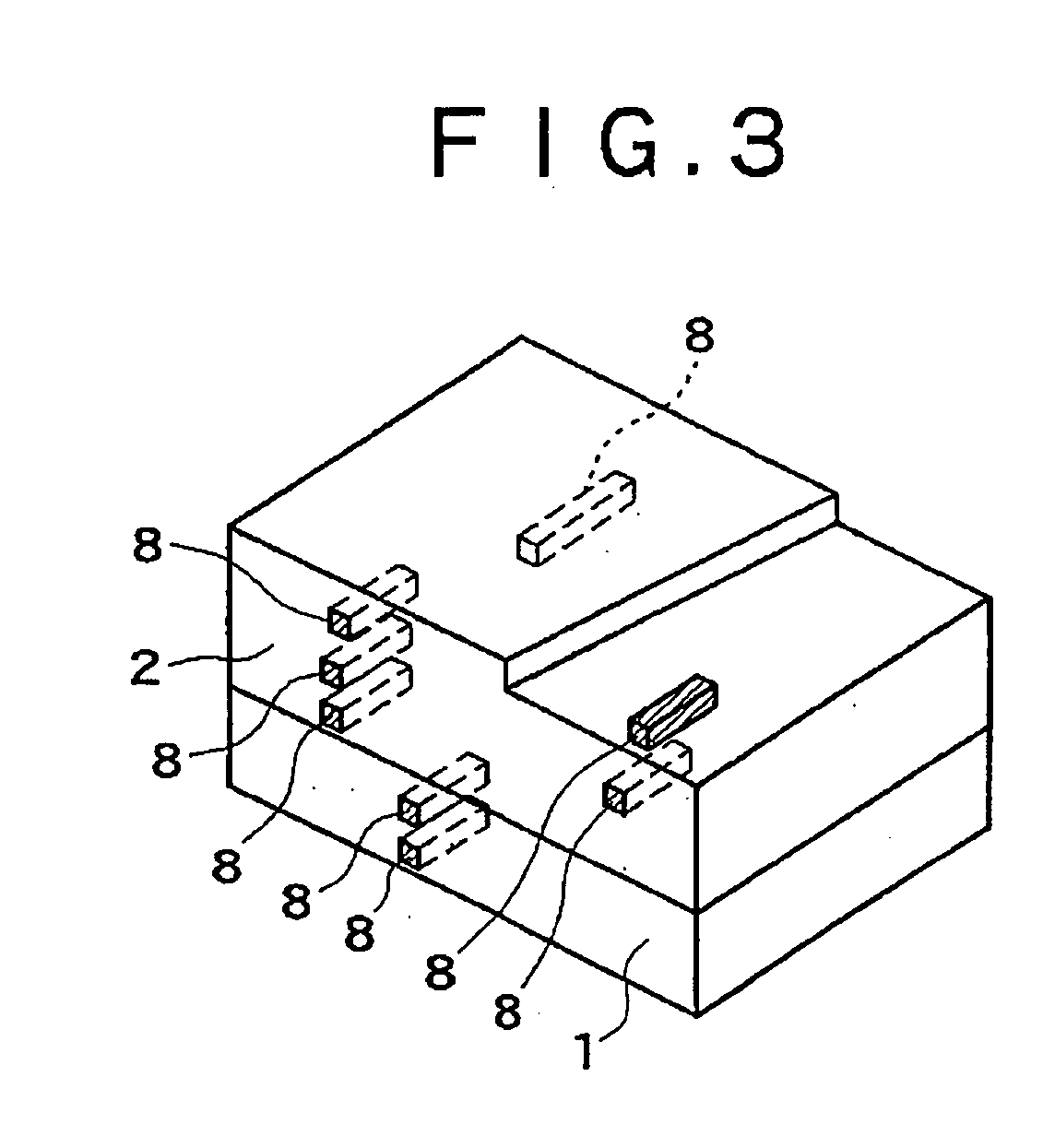

A reactor and a method of preparing pseudoboehmite by the reactor

ActiveCN104667850AIncrease profitOvercome a series of deficiencies caused by the continuous increase of solid contentChemical/physical/physico-chemical stationary reactorsAluminium oxides/hydroxidesPseudoboehmitePore distribution

A reactor and a method of preparing pseudoboehmite by the reactor are disclosed. The reactor comprises a reactor cylinder. A separating plate is disposed in the reactor cylinder to divide the inner cavity of the reactor into two zones along the axial direction, is disposed at a center shaft, and rotates along with rotation of the center shaft. In each of the zones, the corresponding lower part of the reactor cylinder is provided with a material feeding port, at least one material circulating pipeline is disposed outside the corresponding reactor cylinder, a circulated material outlet is at the upper part, a circulated material inlet is at the bottom, and the corresponding upper part of the reactor cylinder is provided with an overflow port higher than the corresponding circulated material outlet. Continuous gel forming can be achieved by the reactor. Pseudoboehmite particles prepared by adopting the reactor are uniform in particle size, so that prepared aluminum oxide is large in pore volume, large in pore diameter and centralized in pore distribution, and the prepared aluminum oxide is uniform and constant in properties, and is not influenced by batch production scales.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN1916116AHigh conversion capacity of heavy oilHigh yieldCatalytic crackingPseudoboehmiteMolecular sieve

This invention discloses a cracking catalyst, which comprises an appropriate amount of molecular sieve, and aluminum oxide containing 0.5-40 wt. % of additive. The cracking catalyst is prepared by: (1) mixing pseudoboehmite, water and acid by stirring to obtain mixed slurry; (2) aging the mixed slurry at room temperature to 90 deg.C for 0-24 h; (3) mixing the product of step 2 with the additive; (4) mixing the product of step 3 with the molecular sieve, drying and torrefying. The weight ratio of the acid to aluminum oxide in pseudoboehmite is 0.01-0.5. The cracking catalyst has better heavy oil reforming performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation tech. for producing pseudoboehmite

ActiveCN1861524AHeap ratio is lighterPure crystal phase and good molding performanceAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPseudoboehmiteSodium aluminate

Owner:PETROCHINA CO LTD

Clean preparation method of magnalium based laminated composite hydroxide

ActiveCN105836769ARich sourcesIncrease spawn rateAluminium compoundsZinc compoundsEnvironmental resistanceReaction temperature

The invention provides a clean preparation method of a magnalium based laminated composite hydroxide. The method uses magnesium hydroxide, magnesium oxide, pseudo boehmite, inorganic acid and a material containing functional anions as raw materials, uses magnesium chloride or magnesium nitrate as a circulation medium, and uses the property of peptization under acidic condition of boehmite to improve the reaction activity of pseudoboehmite; the concentration of magnesium ions in solution is increased by using magnesium chloride or magnesium nitrate. The method accelerates the formation rate of laminated composite hydroxide, promotes the dissolution of magnesium hydroxide and magnesium oxide, shortens the reaction time, overcomes the defects of high reaction temperature and long time consumption in hydrothermal method for synthesis of laminated composite hydroxide, and can rapidly prepare magnalium based laminated composite hydroxide under mild conditions. Magnesium chloride and magnesium nitrate can be recycled; and the preparation process has no waste discharge, and is green and environment-friendly. The method has the advantages of abundant raw materials, low cost, simple preparation process, mild reaction conditions, and easiness to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

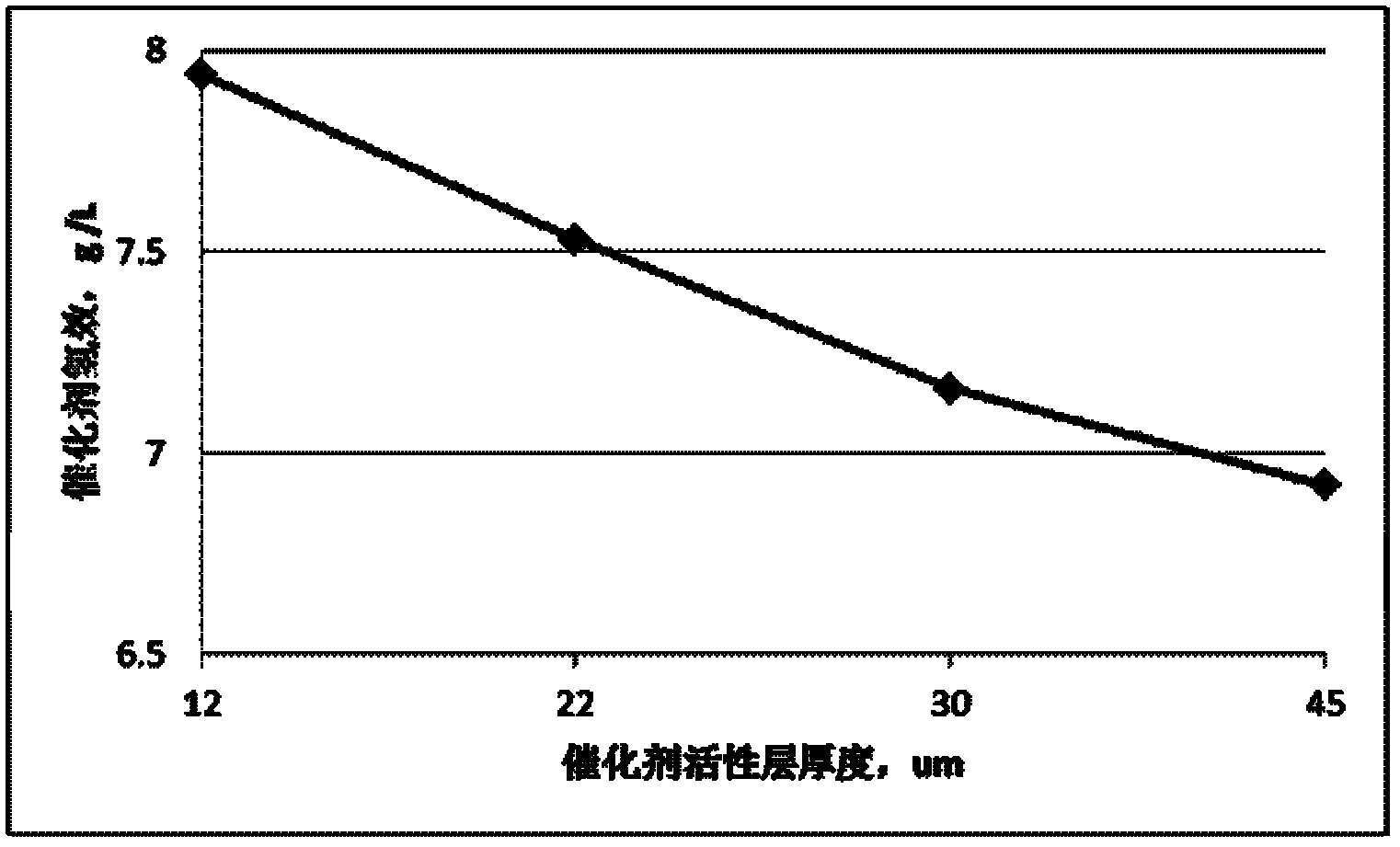

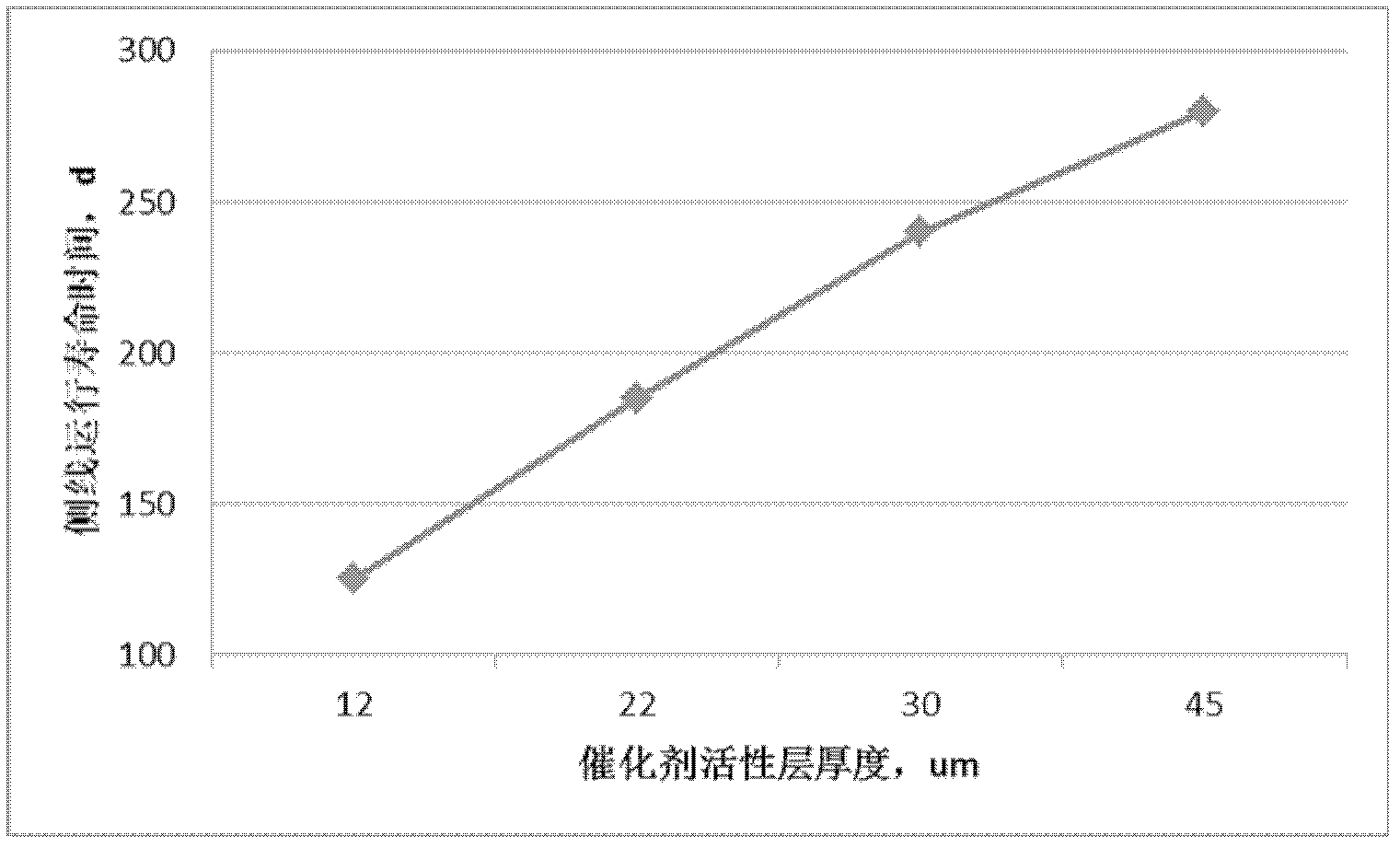

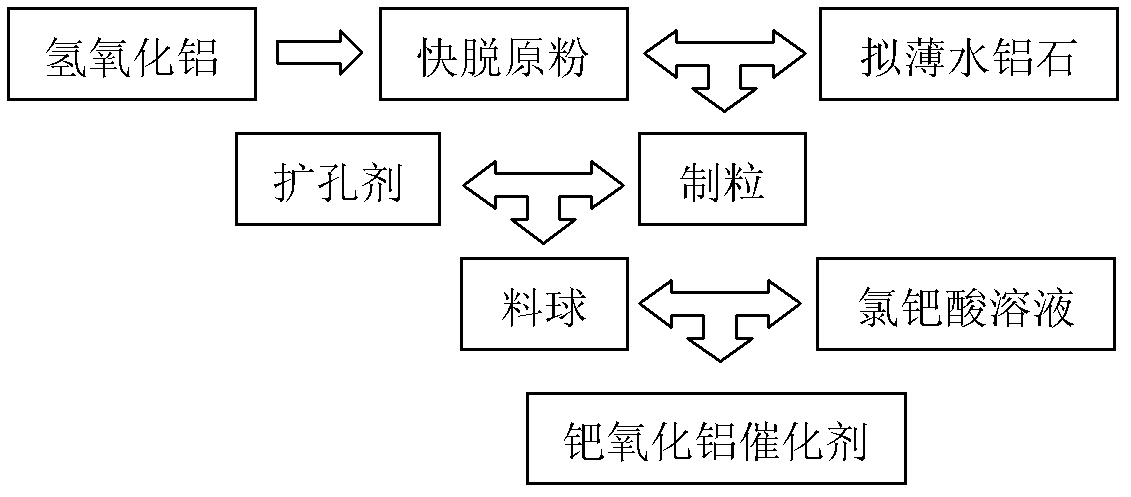

Palladium alumina catalyst for production of hydrogen peroxide by anthraquinone process and its preparation method

ActiveCN102626618AHigh activityHigh compressive strengthPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingPseudoboehmiteAluminium hydroxide

The invention discloses a palladium alumina for production of hydrogen peroxide by an anthraquinone process. The catalyst comprises gamma-Al2O3 as the carrier, the content of which is over 97wt%; and metal palladium as the main active component, the loading of which is 0.1wt%-0.5wt% and the dipping thickness of which is from 10 micrometers to 100 micrometers. The invention also discloses a preparation method of the catalyst, and the method consists of: roasting aluminum hydroxide, mixing the roasted aluminum hydroxide with pseudoboehmite, then adding a pore-expanding agent for molding, conducting surface treatment so as to obtain a catalyst carrier, then performing pre-spraying on the carrier with a locating agent, carrying out drying, and then putting the carrier into a chloropalladate solution for dipping. With appropriate specific surface area, pore volume and pore size distribution, the palladium catalyst provided in the invention is difficult to shed and fragment. In actual production of hydrogen peroxide by an anthraquinone process, the catalyst shows excellent balance between activity and selectivity, as well as good service life and regeneration cycle.

Owner:陕西开达化工有限责任公司

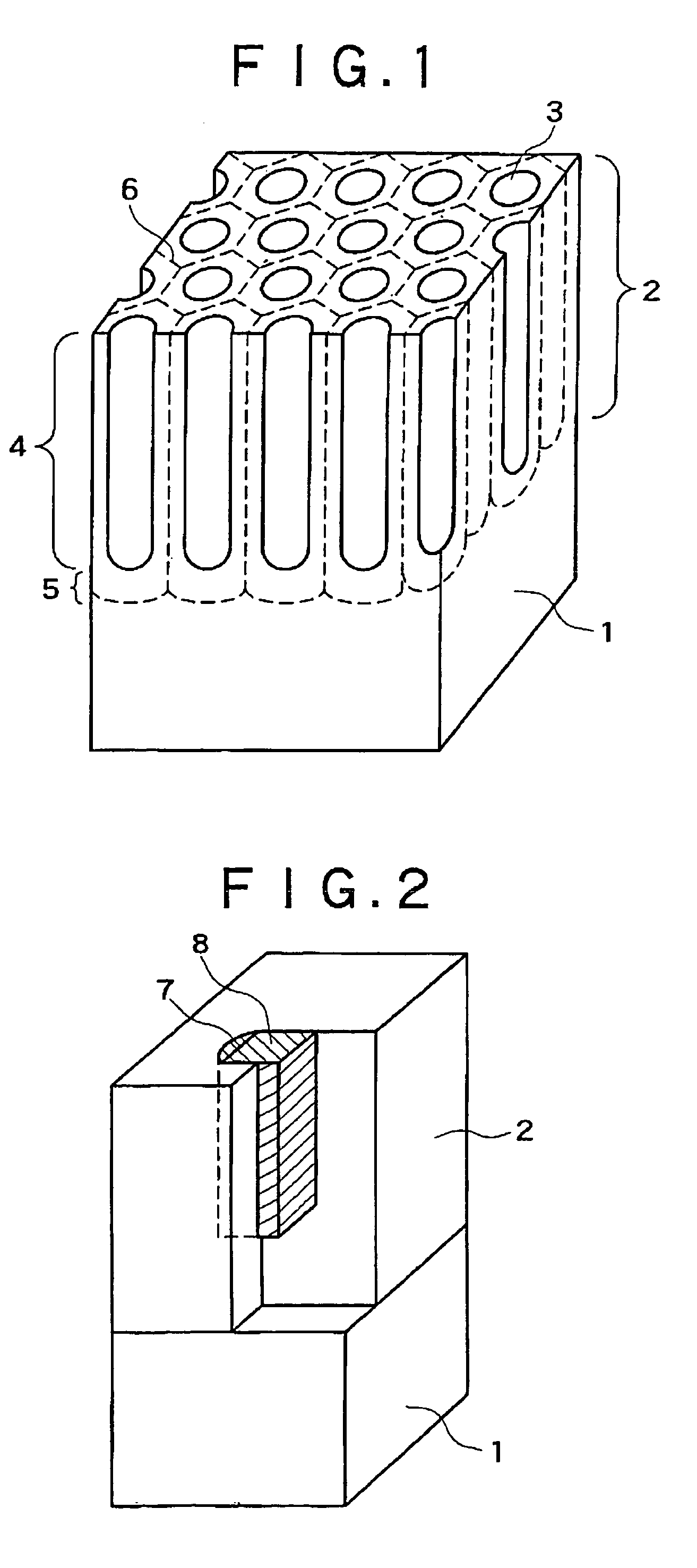

Ceramic honeycomb type denitrating catalyst and preparation method thereof

ActiveCN102302944AImprove performanceImprove yieldMolecular sieve catalystsDispersed particle separationGlycerolPOLYOXYETHYLENE ETHER

The invention discloses a ceramic honeycomb type denitrating catalyst. The ceramic honeycomb type denitrating catalyst is formed by mixing, forming and calcining a catalyst active ingredient, a catalyst carrier and a forming aid, wherein the catalyst active ingredient is ferrous sulphate. In an embodiment, the catalyst active ingredient comprises 20 to 40 weight parts of the ferrous sulphate; thecatalyst carrier comprises 60 to 90 weight parts of molecular sieve; the forming aid comprises 2 to 4 weight parts of citric acid, 2 to 6 weight parts of sodium carboxymethylcellulose, 2 to 6 weight parts of polyoxyethylene, 0.2 to 1.0 weight part of glycerol, 2 to 4 weight parts of nitric acid, 90 to 120 weight parts of pseudoboehmite, 30 to 40 weight parts of Suzhou clay, 2 to 6 weight parts ofsesbania cannabina pers powder and 10 to 30 weight parts of glass fiber. The raw materials of the catalyst have low cost and do not have toxicity. The denitrating catalyst module has high denitratingefficiency and certain anti-poisoning property and mechanical strength.

Owner:TSINGHUA UNIV +1

Novel organic sulfur hydrogenation catalyst carrier and preparation method thereof

ActiveCN102489336AReduce catalysisImprove adsorption capacityCatalyst carriersDispersed particle separationPseudoboehmitePtru catalyst

The invention relates to a novel organic sulfur hydrogenation catalyst carrier. A preparation method of the carrier comprises steps that: a neutralization material, pseudoboehmite (gamma-alumina), an adhesive, a hole expansion agent and a metal additive are mixed; the mixture is subject to knead-molding, drying, and roasting, such that a finished product is obtained. The method is characterized in that the neutralization material is prepared through steps that: pseudoboehmite is soaked by using an alkaline solution, and is neutralized by using an acid solution; and the pseudoboehmite is subject to washing and press-filtrating, such that the neutralization material is obtained. Therefore, impurity content in the pores is greatly reduced, such that the loading of active components is promoted. A catalyst prepared by using the carrier is suitable to be used in hydrogenation catalyzing of organic sulfur in natural gas, coke oven gas, exhaust gas, and the like. Organic sulfur is converted into inorganic sulfides; and the sulfides are removed with the cooperation of an inorganic sulfur desulfurizing agent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Aluminum alloy member superior in corrosion resistance and plasma resistance

ActiveUS7005194B2Improve corrosion resistanceIncrease resistanceAnodisationSemiconductor/solid-state device manufacturingPseudoboehmitePorous layer

Owner:KOBE STEEL LTD

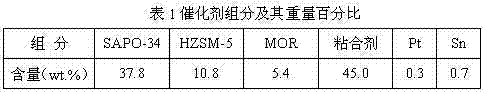

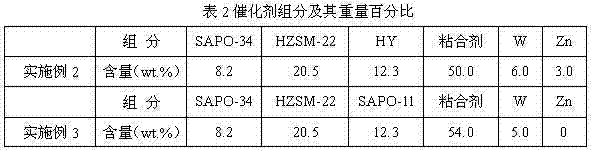

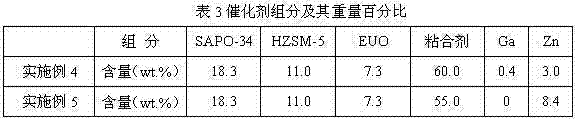

Catalyst for preparing methylbenzene by methanol conversion and preparation method and application thereof

InactiveCN102380415AHigh yieldHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsLiquid productSolvent

The invention discloses a catalyst for preparing methylbenzene by methanol conversion, which comprises, by weight, 30%-80% of composite molecular sieves, 0.1%-10% of modifier elements and the balance being binders. The composite molecular sieves are selected from SAPO-34, SAPO-11, HZSM-5, HZSM-22, HZSM-11, MCM-41, MCM-22, HBeta, HY, MOR or EUO; the modifier elements are selected from Cr, Mo, W, Cu, Zn, Fe, Co, Ni, Ga, Sn, Zr, Mn, Pd, Pt and Re; and the binders can be aluminum oxide, pseudoboehmite, silicone gel, silicon dioxide or diatomaceous earth. The catalyst for preparing methylbenzene by methanol conversion and a preparation method thereof have the following advantages that (1), the total recovery of methylbenzene is higher and the selectivity thereof is also higher; (2) raw material handling capacity is high; (3), non-aromatic and butylene products circularly enter a reactor to realize further reaction so that the total aromatic recovery and balanced reaction thermal effect areimproved; (4), non-aromatic liquid products can be used as solvent oil or gasoline components; and (5), the catalyst has long service life.

Owner:NORTHWEST UNIV

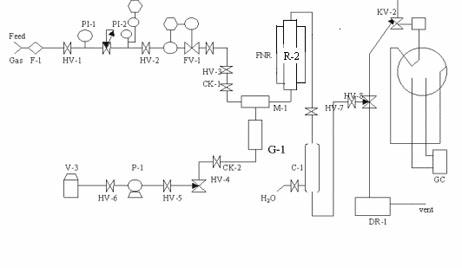

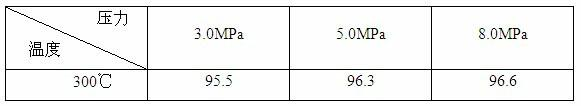

CO (carbon monoxide) sulfur tolerant shift catalyst applicable to high pressure process and preparation method thereof

ActiveCN102240556AImprove thermal stabilityEasy to makeCombustible gas catalytic treatmentMetal/metal-oxides/metal-hydroxide catalystsHydration reactionPseudoboehmite

The invention relates to a CO (carbon monoxide) sulfur tolerant shift catalyst applicable to a high pressure process and a preparation method thereof. The CO sulfur tolerant shift catalyst applicable to the high pressure process comprises a carrier and a catalyst active component, wherein the carrier is prepared from the following materials by mass percent: 5-40% of modified bauxite powder, 20-60% of pseudoboehmite or aluminum nitrate, and 10-40% of magnesium oxide or magnesium hydroxide; the catalyst active component comprises CoO, MoO3 and CeO2; and CoO is 0.5-5% of the weight of the catalyst, MoO3 is 1.0-15% of the weight of the catalyst and CeO2 is 0.3-2% of the weight of the catalyst. The preparation method comprises the following steps: raw materials mixing; kneading; strip extruding; roasting; isometric impregnation, and the like. The preparation process is simple and no waste water is discharged. The prepared catalyst carrier has excellent hydration resisting property and strength. The activating temperature of the catalyst is low. Under the conditions of high pressure, high gas to steam ratio and high temperature, the catalyst has excellent thermal stability.

Owner:福建三聚福大化肥催化剂国家工程研究中心有限公司

Method to raise the solid content of catalytic cracking catalyst slurry

ActiveUS20080058197A1Maintains anti-frictionMaintains reactivity performanceCatalytic crackingMolecular sieve catalystsPseudoboehmiteMolecular sieve

A method for preparing cracking catalyst. The method comprises making catalyst slurry having a homogeneous distribution of molecular sieve slurry, pseudoboehmite, clay, inorganic acid and aluminum-containing binder; and subsequent spray drying. Inorganic acid is added prior to the addition of pseudoboehmite; addition of molecular sieve is added after the addition of inorganic acid; and a phosphatic dispersant is added during preparation. Compared to conventional methods of preparing FCC catalyst slurry, the inventive catalyst slurry viscosity is decreased and the fluidity thereof is improved, while catalyst anti-friction is maintained. The solid content of the FCC catalyst slurry can be increased to about 40% or more. The gel forming time is significantly reduced with increased productivity and decreased catalyst production cost. Meanwhile, the catalyst has high pore volume and improved micro-reactivity. Overall reactivity performance of the catalyst is also improved.

Owner:PETROCHINA CO LTD

Catalyst for regenerating anthraquinone degradation products and preparation method thereof

ActiveCN101455959AFacilitate the reduction and regeneration reactionDoes not affect productionPhysical/chemical process catalystsPseudoboehmiteAluminium hydroxide

The invention discloses a catalyst for anthraquinone degradation product regeneration, wherein the content of alumina in the catalyst is 93 to 97 wt percent; the content of macropore above 75 nanometers in the catalyst is more than 5 percent; moreover, pore volume is more than 0.42ml / g, and micropore size distribution is mainly concentrated between 50 and 100. The invention also discloses a preparation method of the catalyst. The method comprises: a, crushing and roasting aluminium hydroxide to obtain raw powder; b, mixing the 85 to 95 wt percent raw powder obtained after roasting with 5 to 15 wt percent pseudoboehmite to prepare pellet on a pelleter; c, feeding the obtained pellet into rolling or rotating equipment to carry out surface treatment; d. storing the pellet at room temperature after surface treatment; e, carrying out water washing of the pellet obtained after storing in step d, by use of water below 80 DEG C; and f, roasting the pellet after water washing. The catalyst ensures that the reduction regeneration yield of anthraquinone degradation product reaches above 10 g / L, and effectively inhibits side reaction; moreover, product abrasion wear is less than 0.3 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

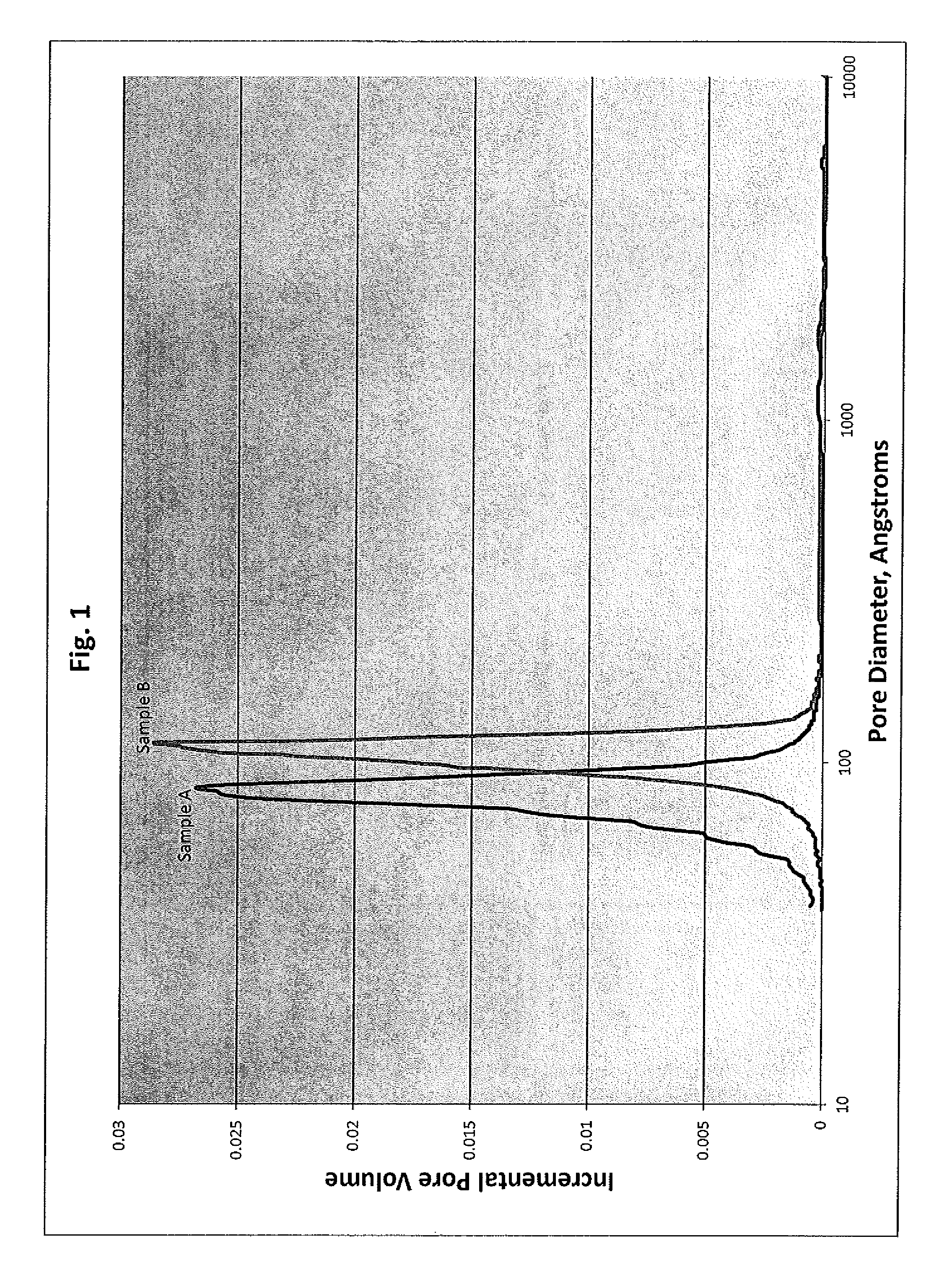

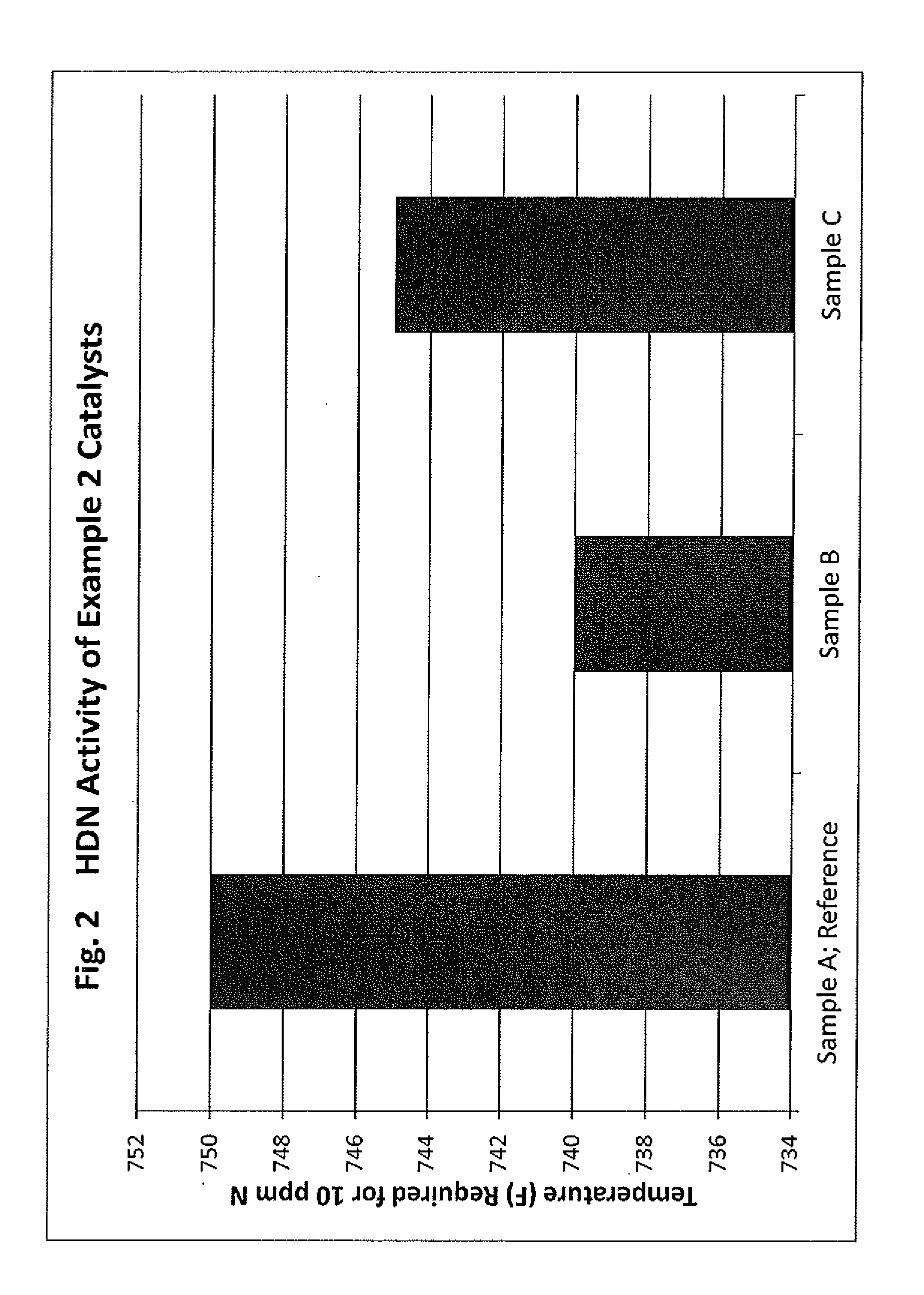

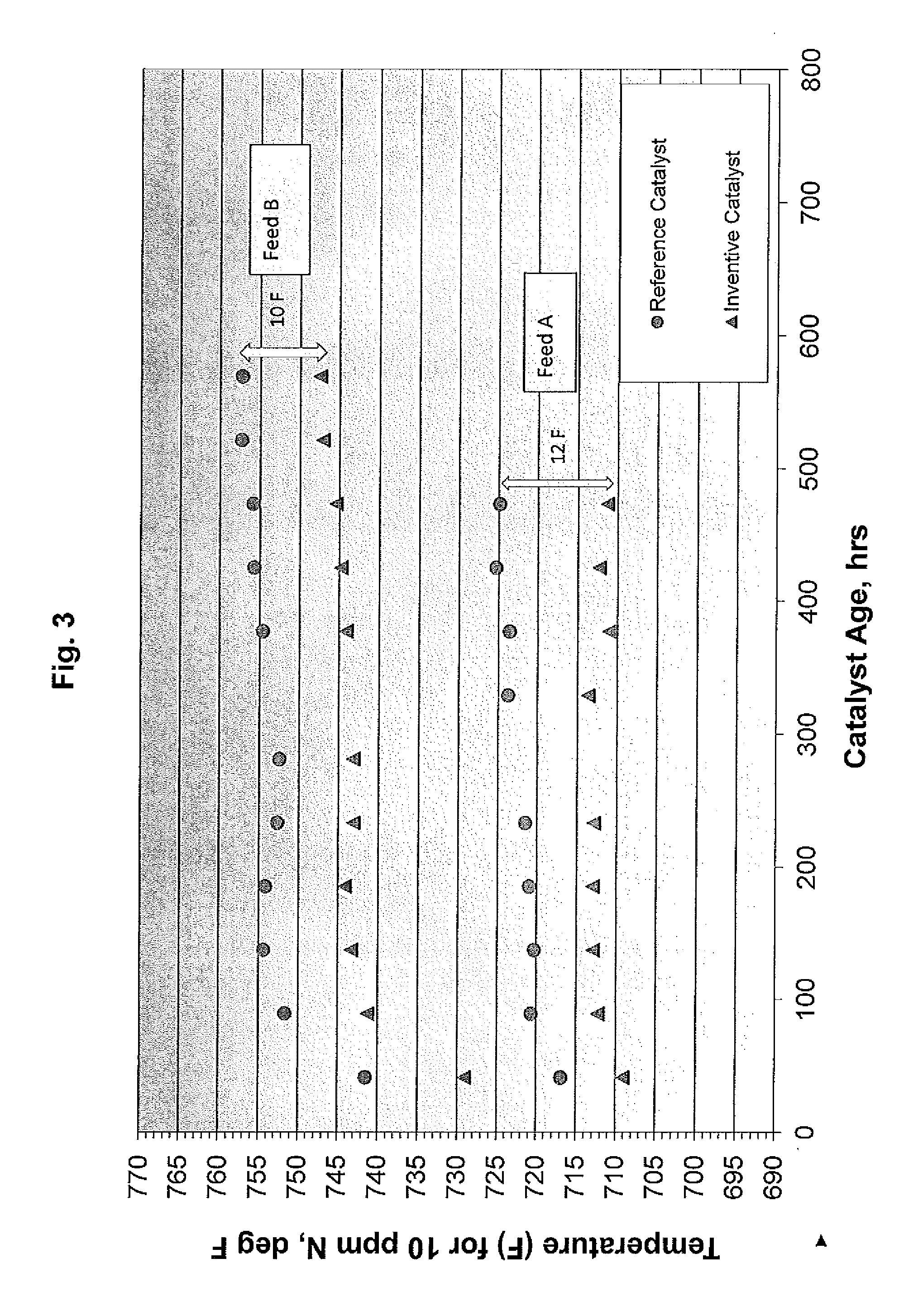

Process and catalyst for the hydrotreatment of a heavy hydrocarbon feedstock

ActiveUS20140315712A1Increase in relative volumetric activityReduce nitrogen contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmitePtru catalyst

A method of hydrotreating a heavy hydrocarbon feedstock using a hydrotreating catalyst having specific properties that make it effective in removing nitrogen and sulfur from the feedstock is disclosed. The catalyst is composed of an alumina support particle having a specific pore diameter distribution which is achieved in part, by the use of pseudo-boehmite as the alumina source and specific calcining temperatures. The hydrotreatment catalyst also comprises a Group 6 metal component (e.g., molybdenum) and a Group 10 metal component (e.g., nickel), and optionally, a phosphorus metal component, which are supported by the alumina support particle.

Owner:SHELL USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com