Patents

Literature

865 results about "Chromic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term chromic acid is usually used for a mixture made by adding concentrated sulfuric acid to a dichromate, which may contain a variety of compounds, including solid chromium trioxide. This kind of chromic acid may be used as a cleaning mixture for glass. Chromic acid may also refer to the molecular species, H₂CrO₄ of which the trioxide is the anhydride. Chromic acid features chromium in an oxidation state of +6 (or VI). It is a strong and corrosive oxidising agent.

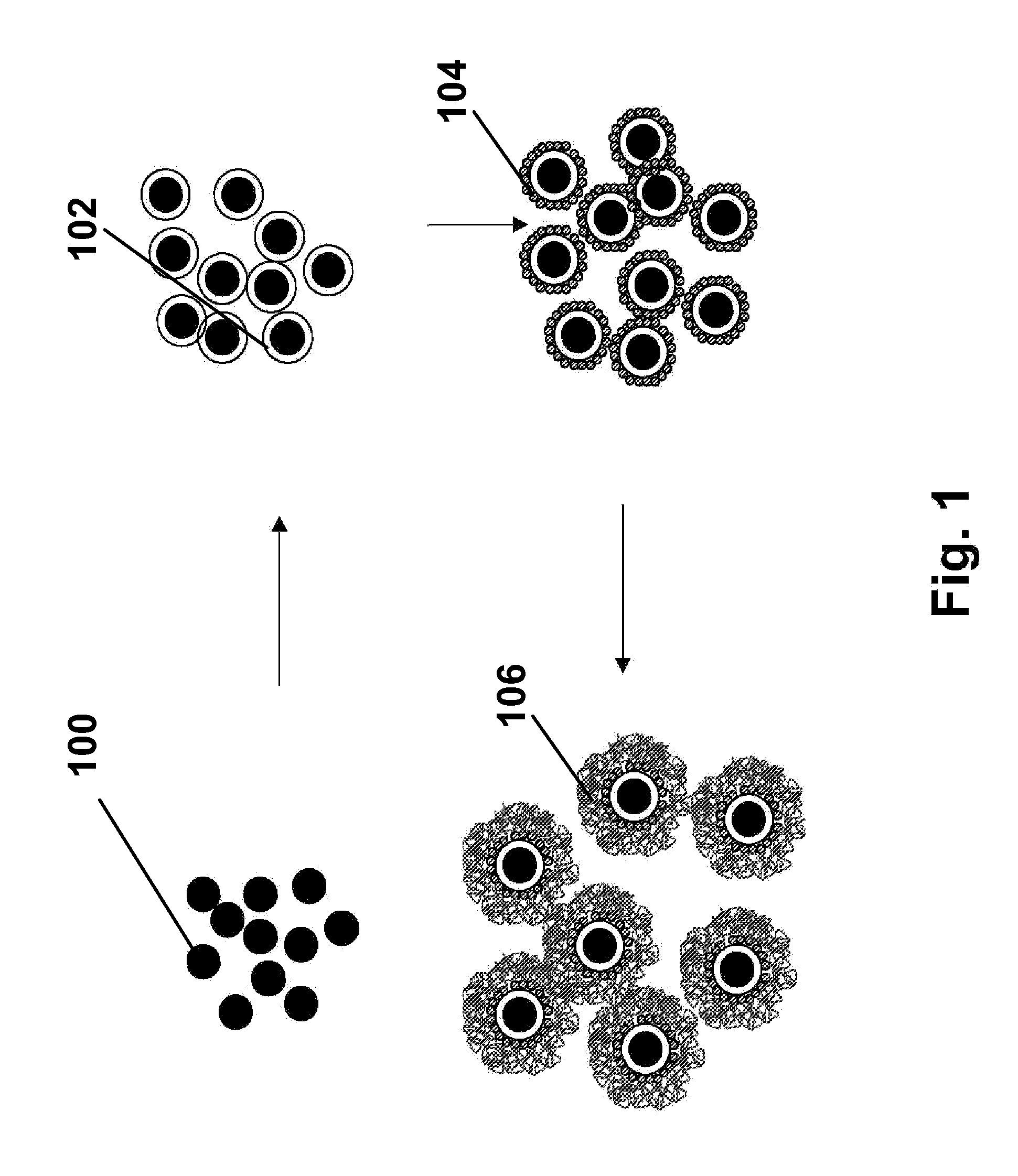

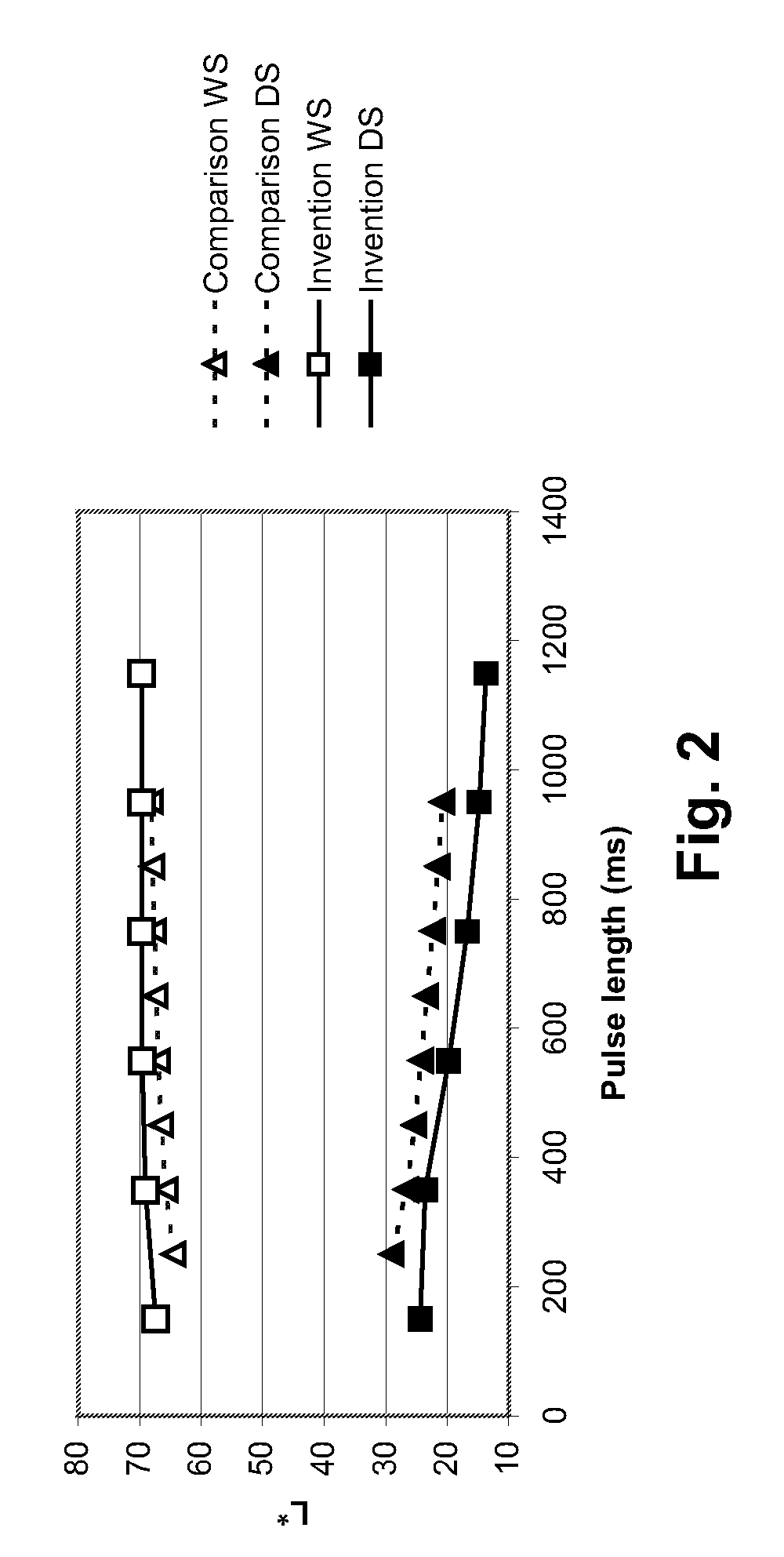

Electrophoretic particles, and processes for the production thereof

InactiveUS20050000813A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrophoresisCopper chromite

Owner:E INK CORPORATION

Non-chrome plating on plastic

InactiveUS20050199587A1Insulating substrate metal adhesion improvementDecorative surface effectsPERMANGANATE IONBiological activation

The invention comprises a process of preparing a non-conductive substrate for subsequent metalization. The process replaces the traditional chromic acid etching step with an etching solution comprising a permanganate and a mineral acid. The process also includes a novel activation solution comprising a palladium salt and an amine complexor. The new process of the invention is more environmentally friendly than the traditional chromic acid etching solutions but achieves a comparable result on most non-conductive substrates.

Owner:MACDERMID INC

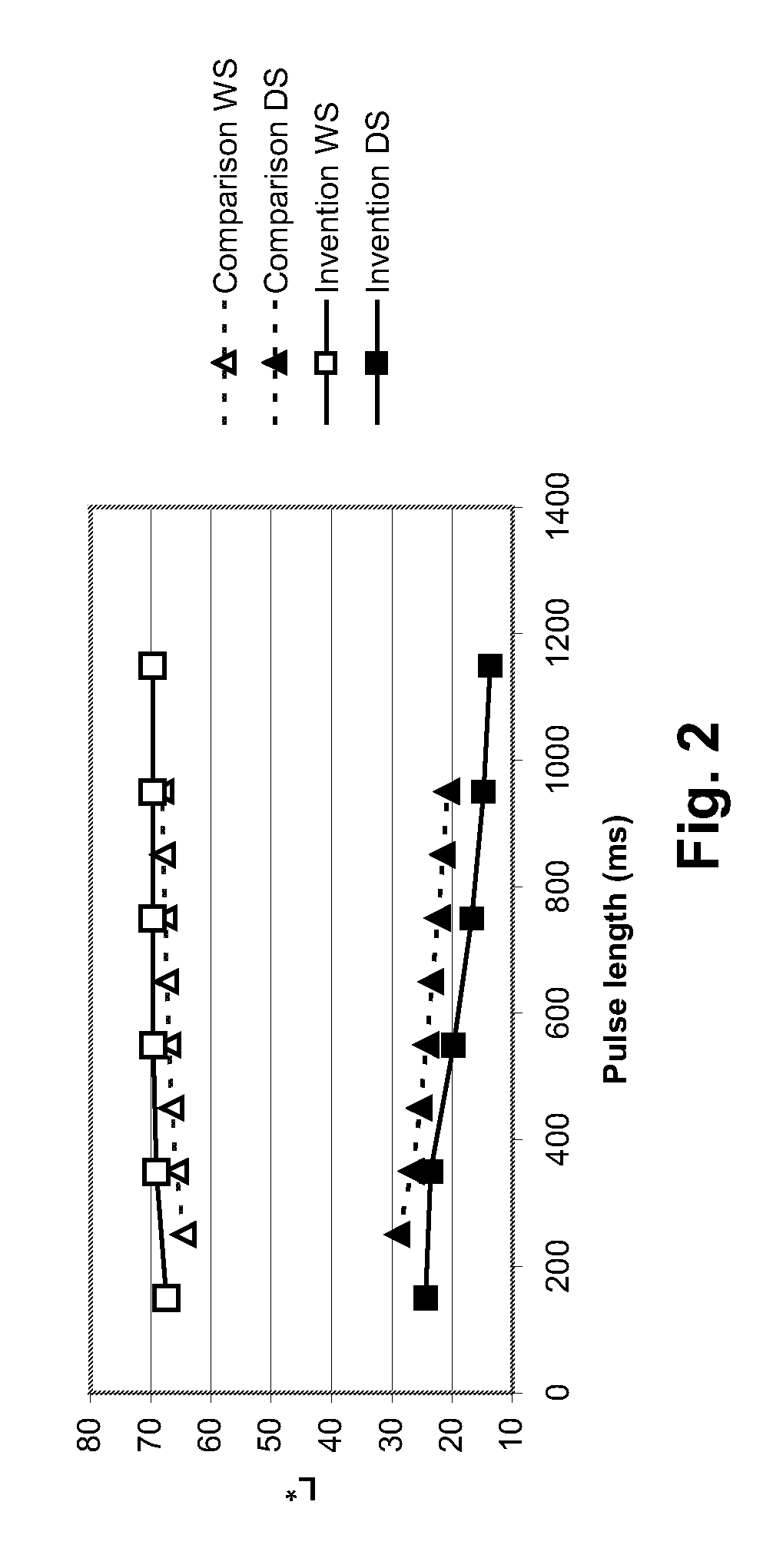

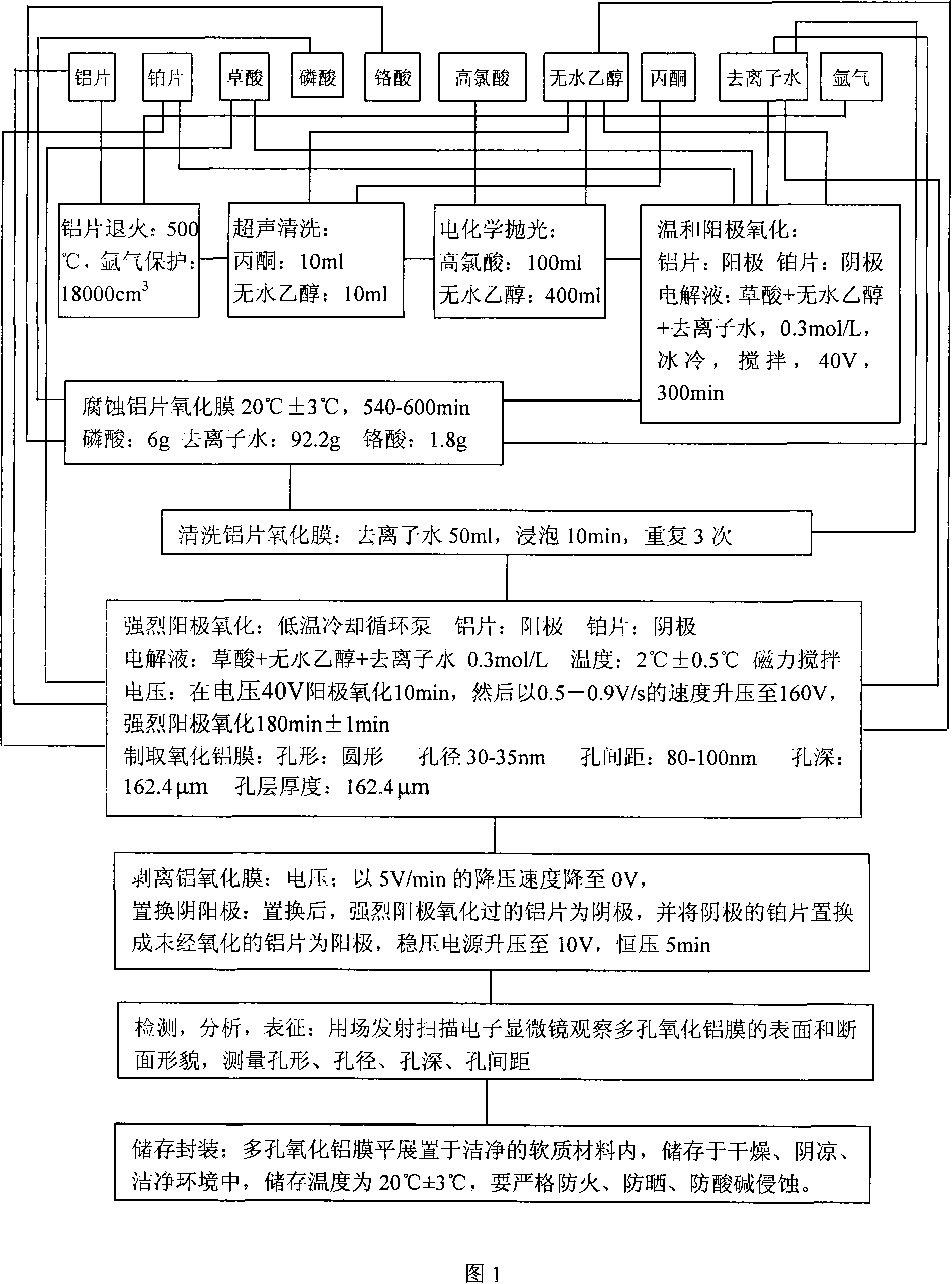

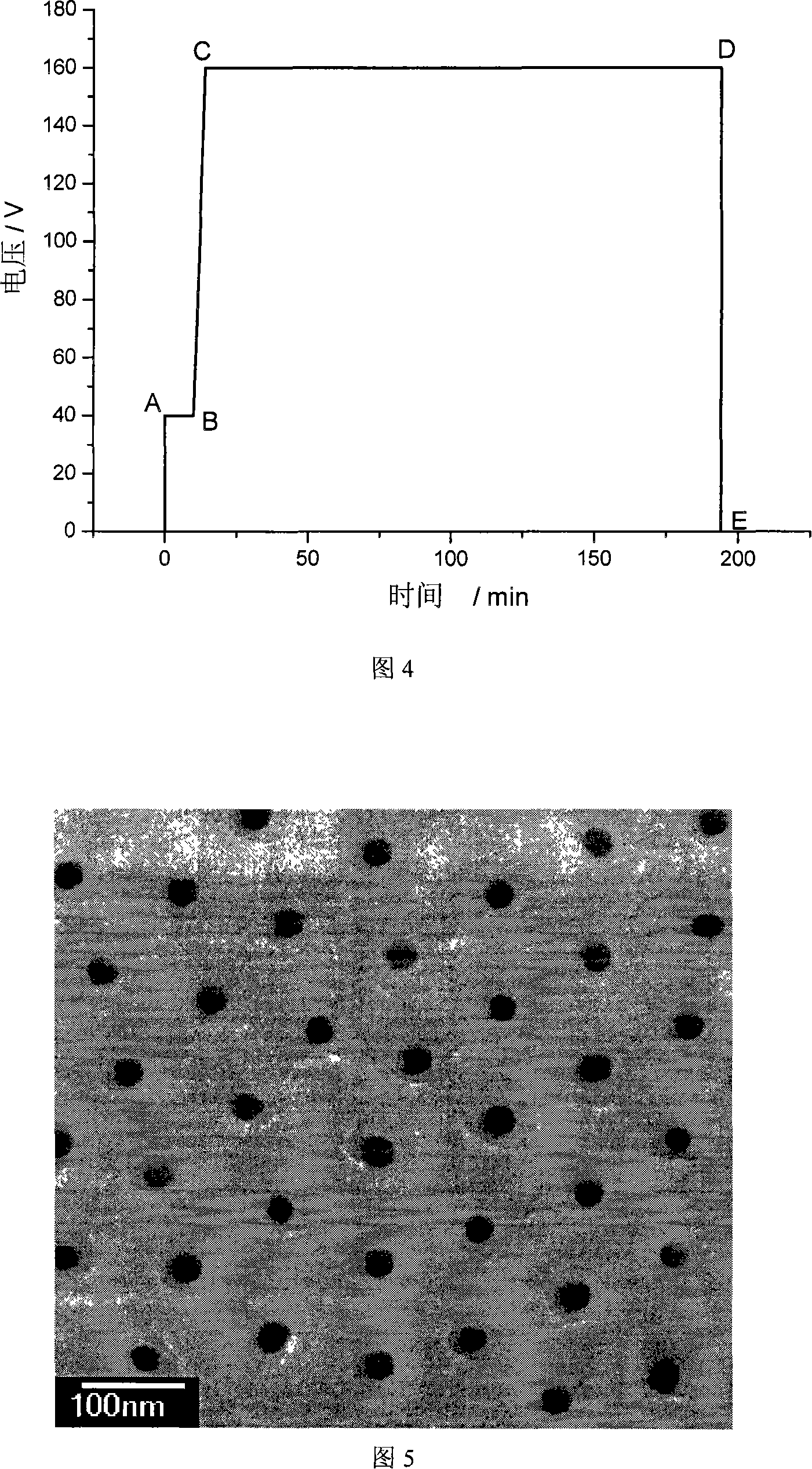

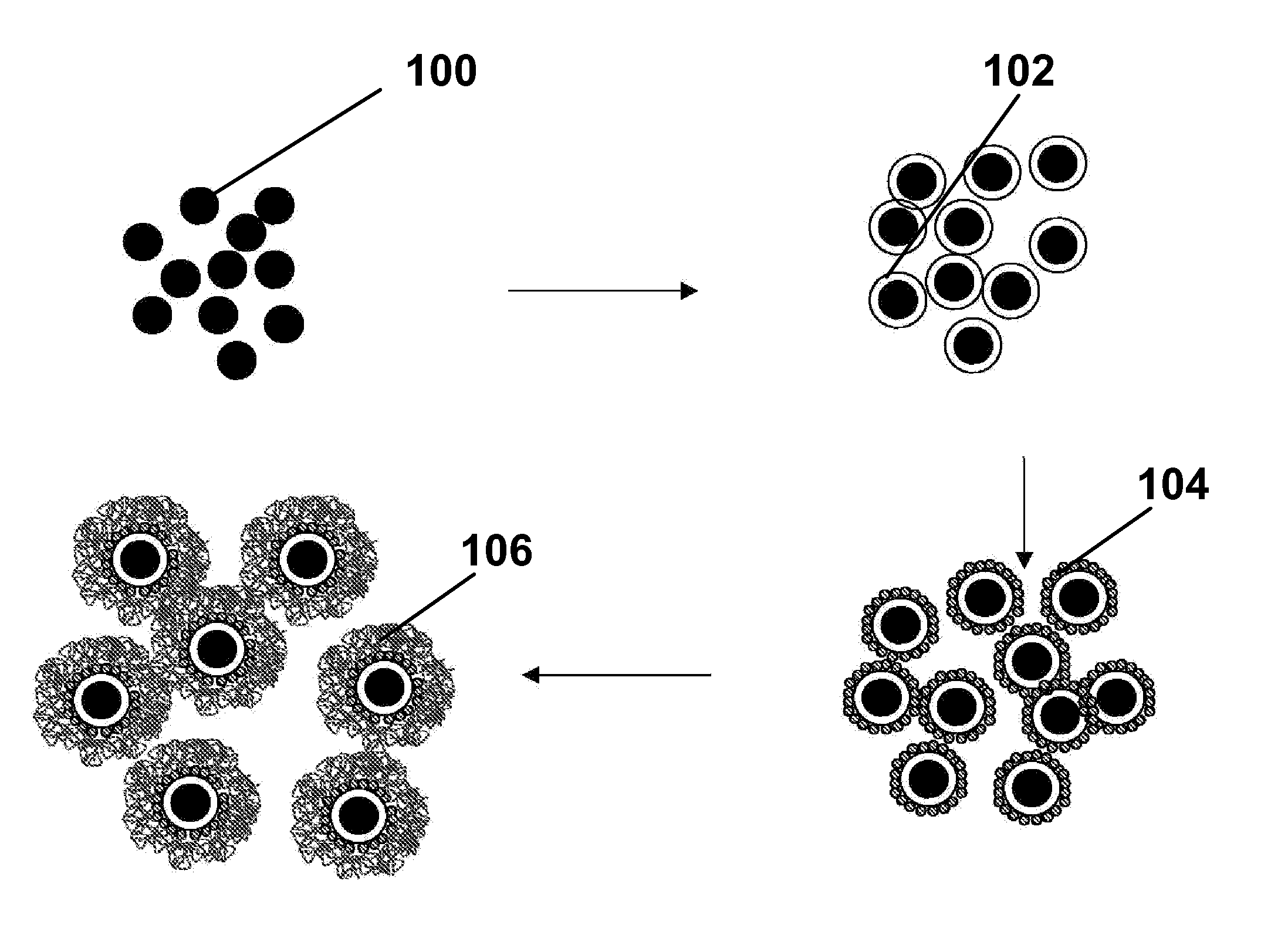

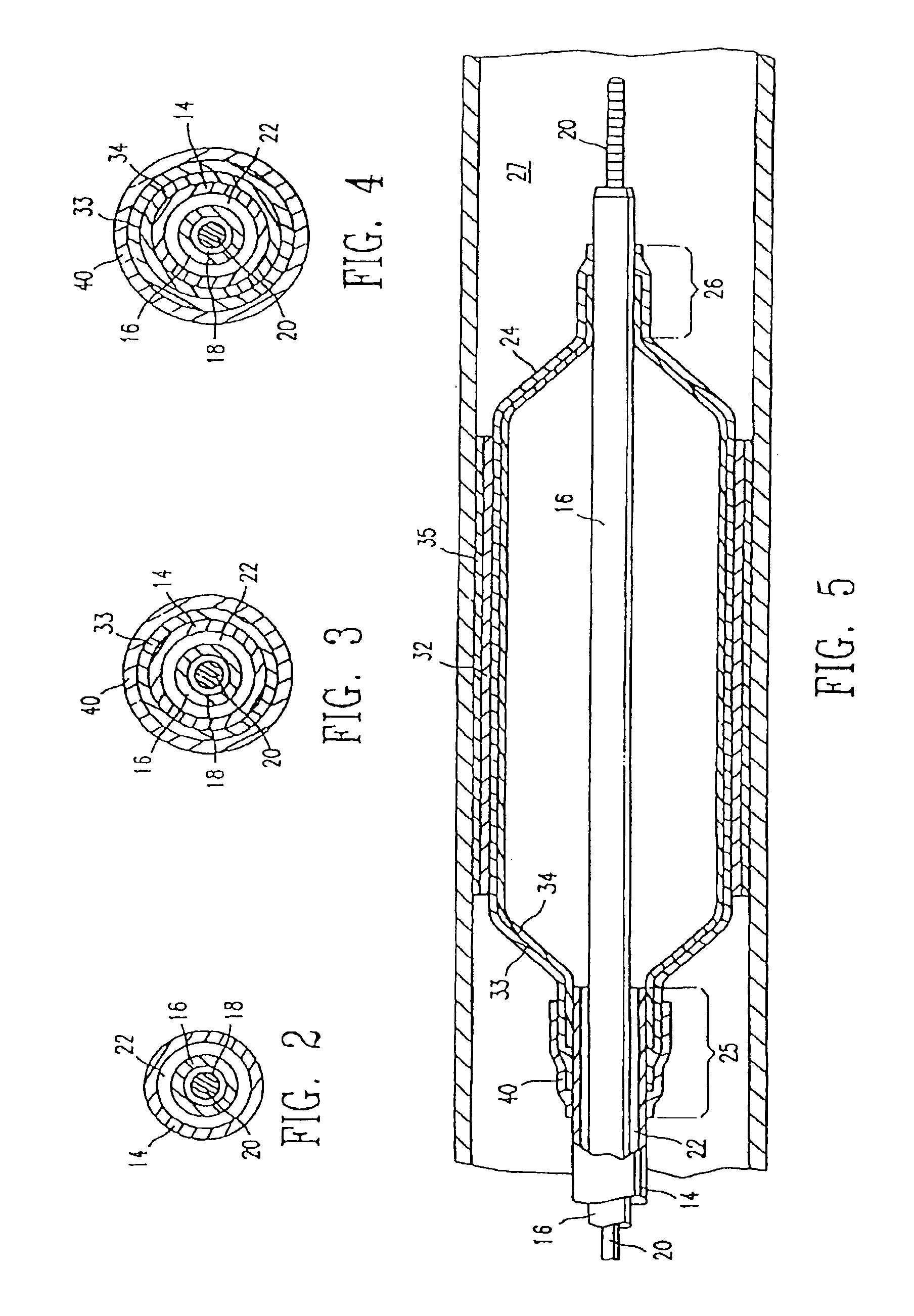

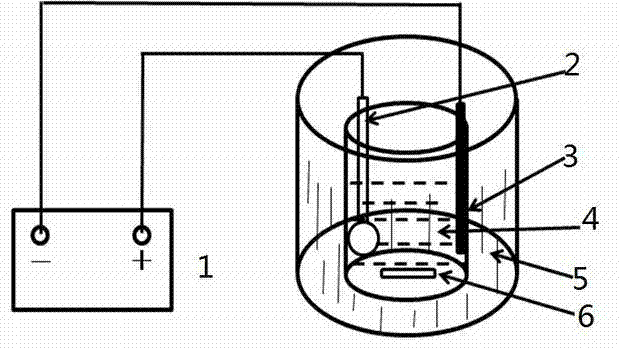

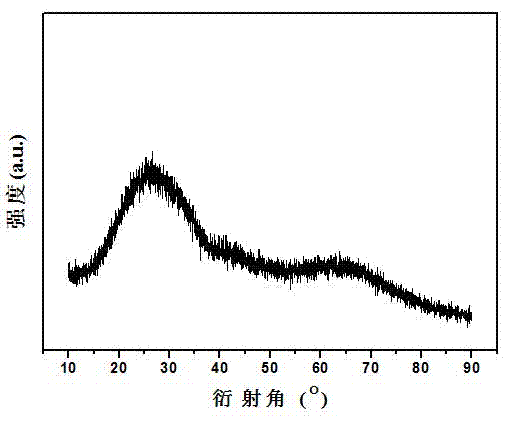

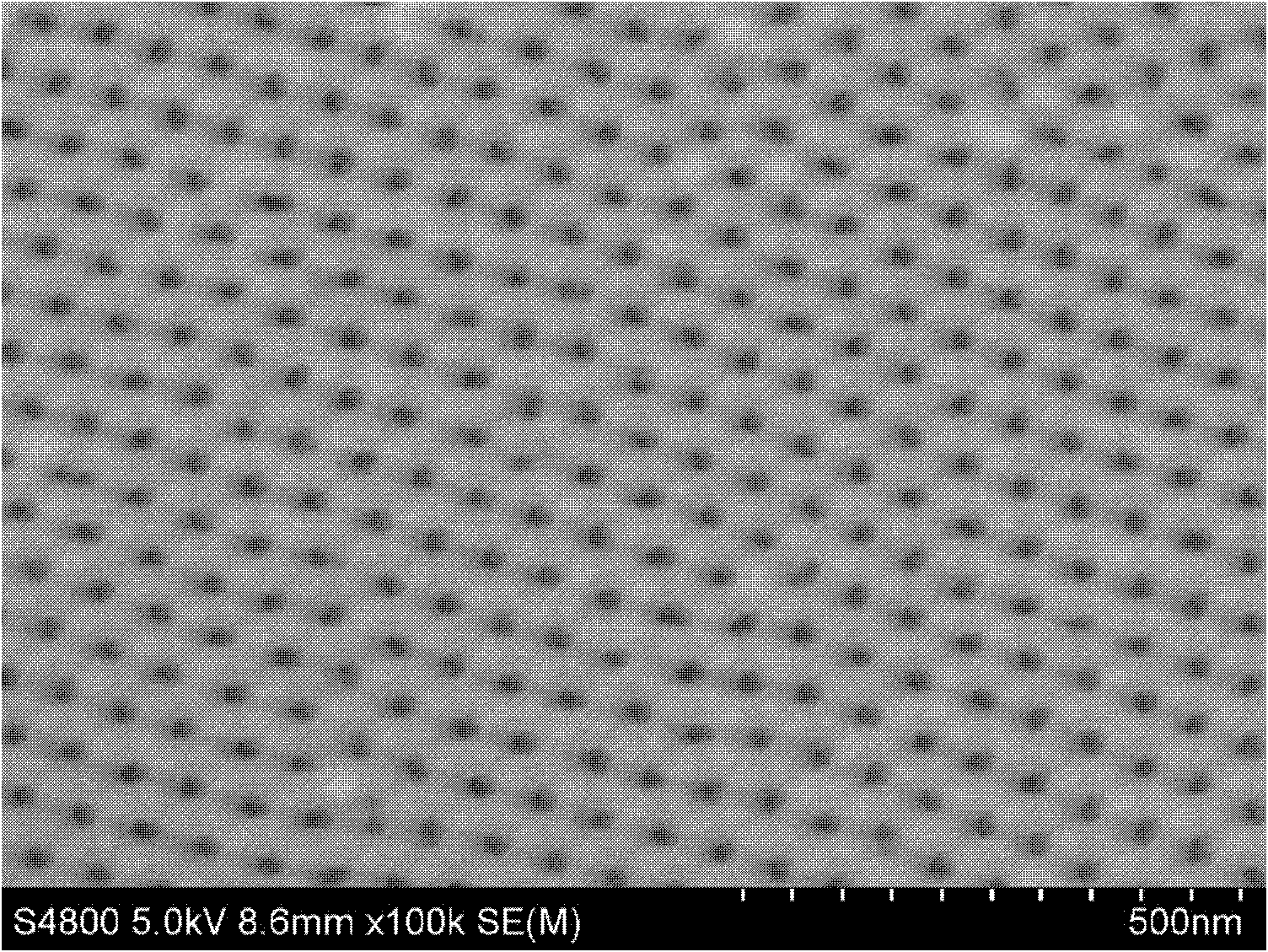

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

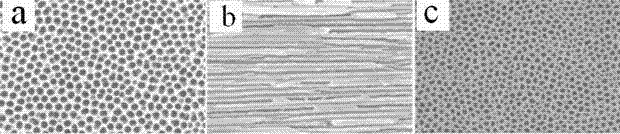

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

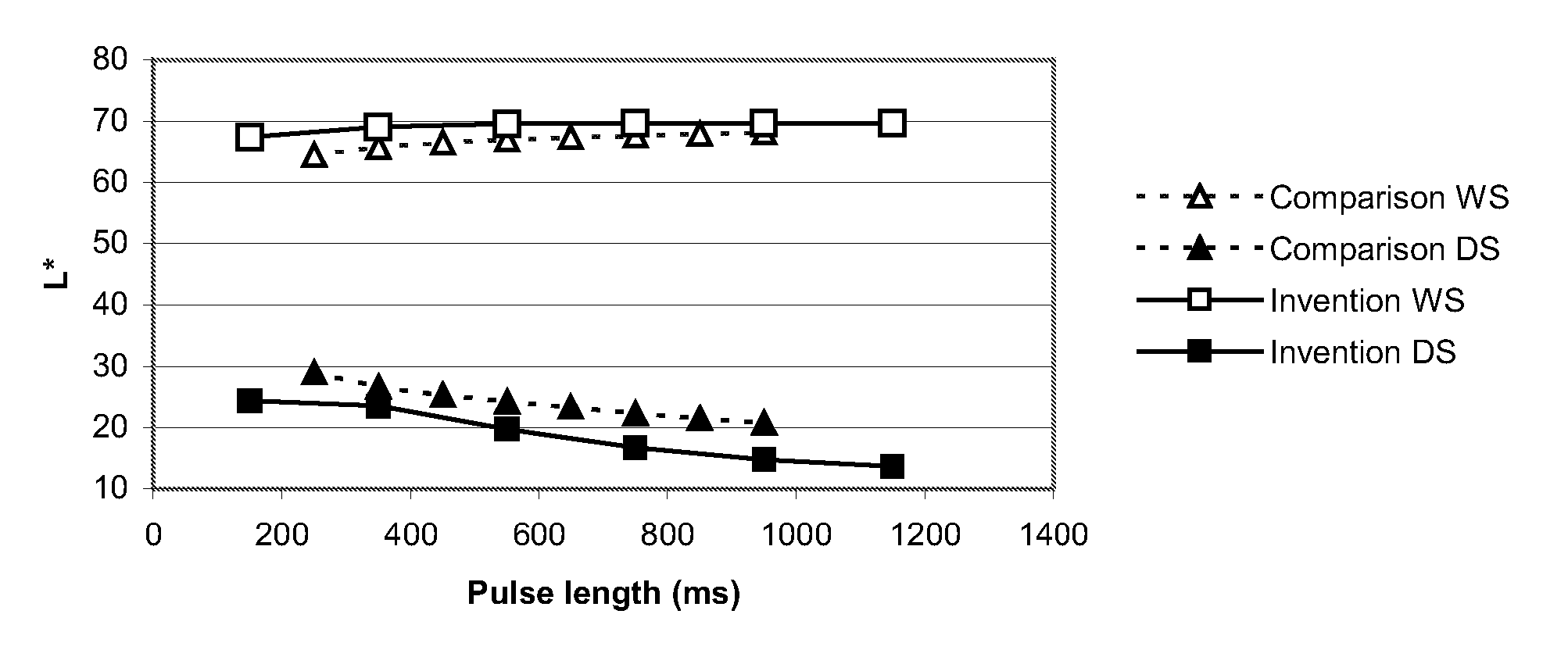

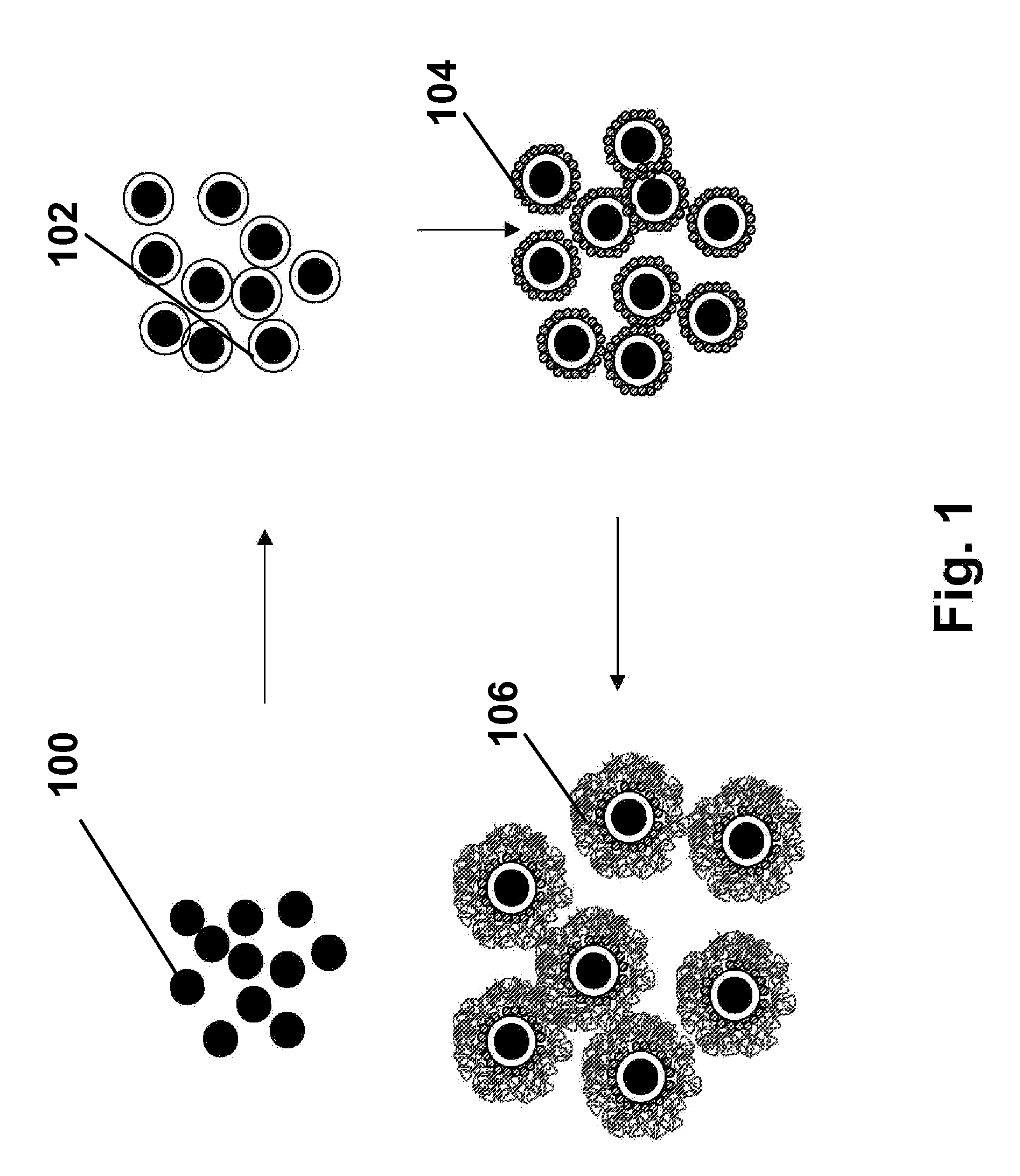

Electrophoretic particles, and processes for the production thereof

InactiveUS20060024437A1Material nanotechnologyLiquid surface applicatorsSilica coatingCopper chromite

Owner:E INK CORPORATION

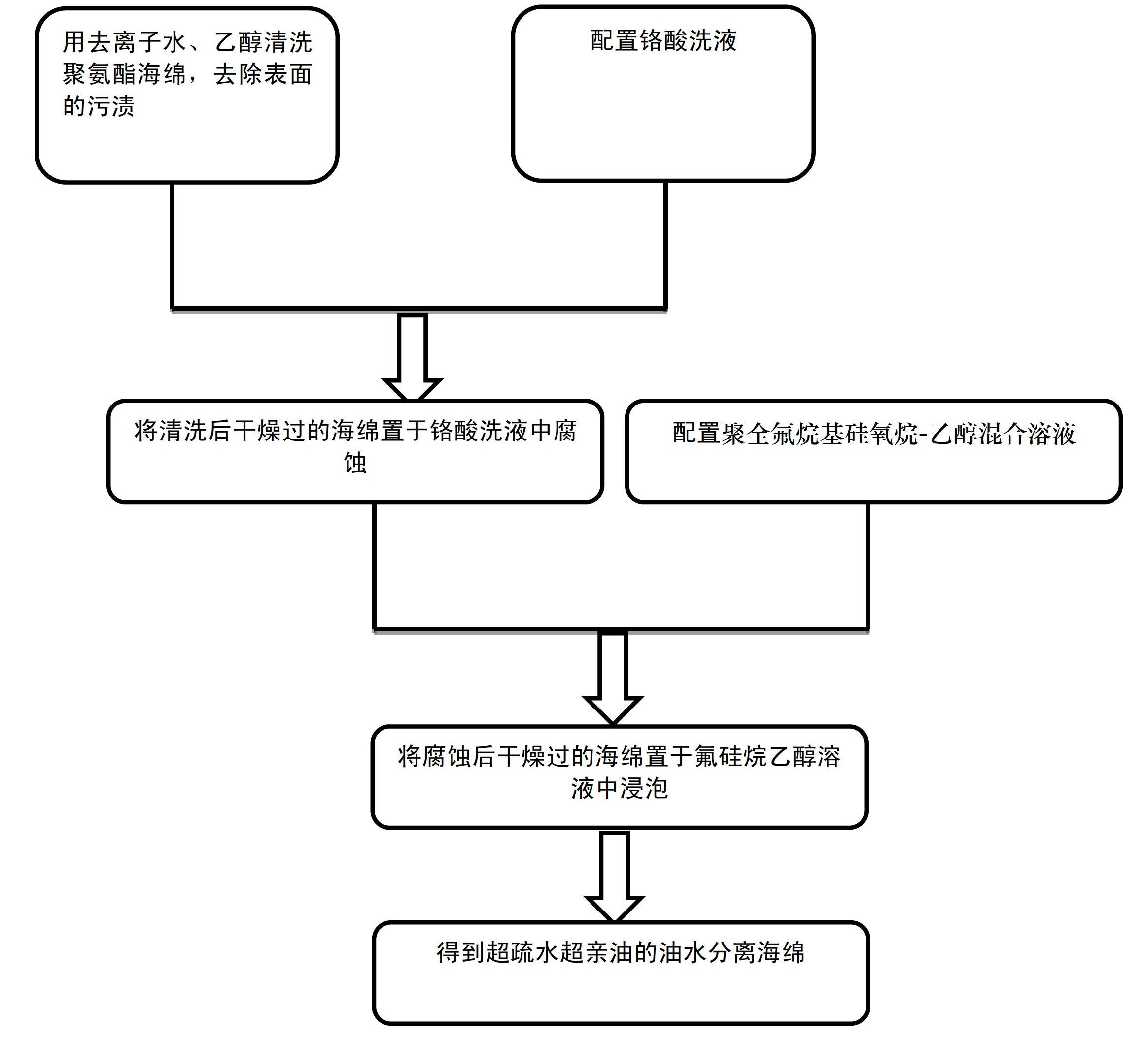

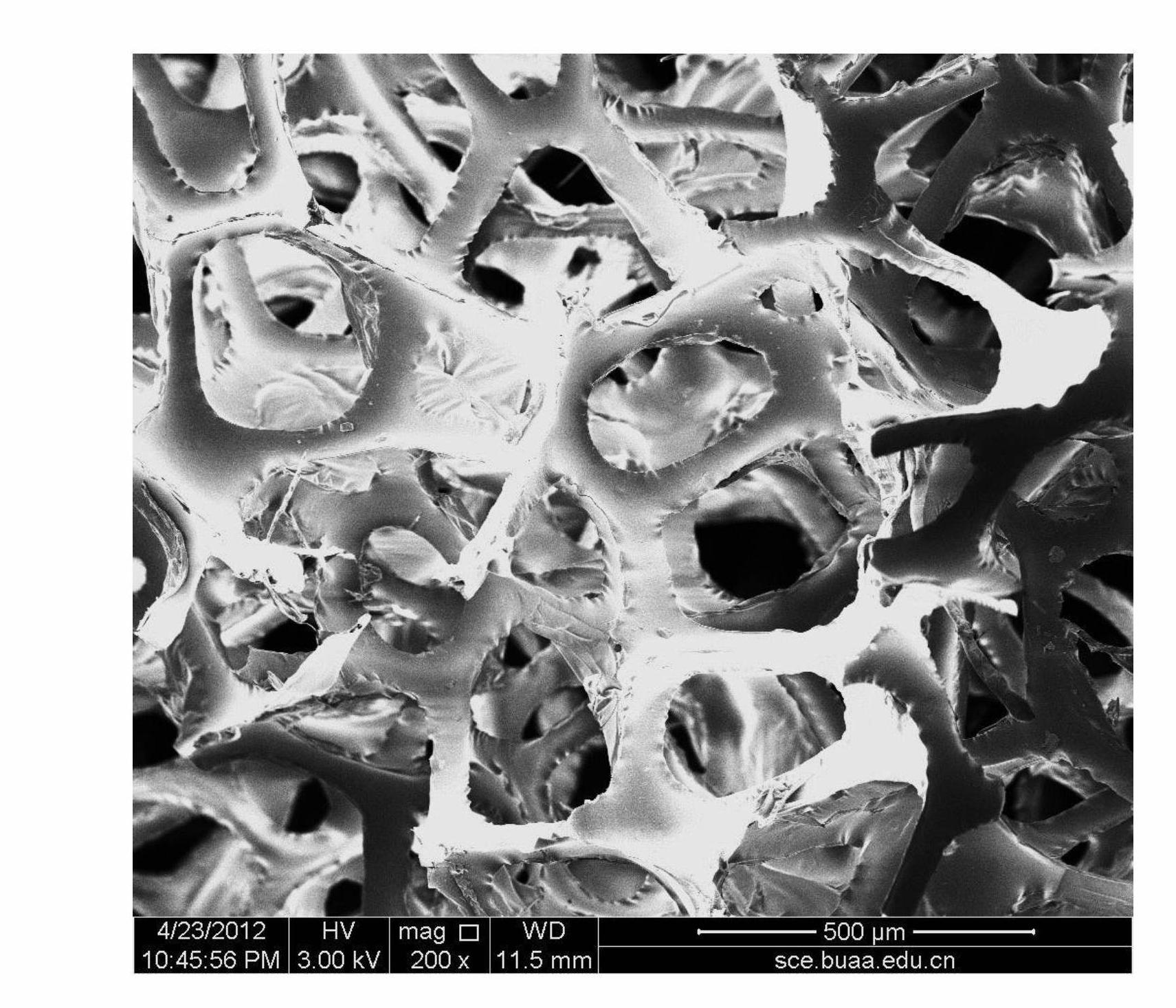

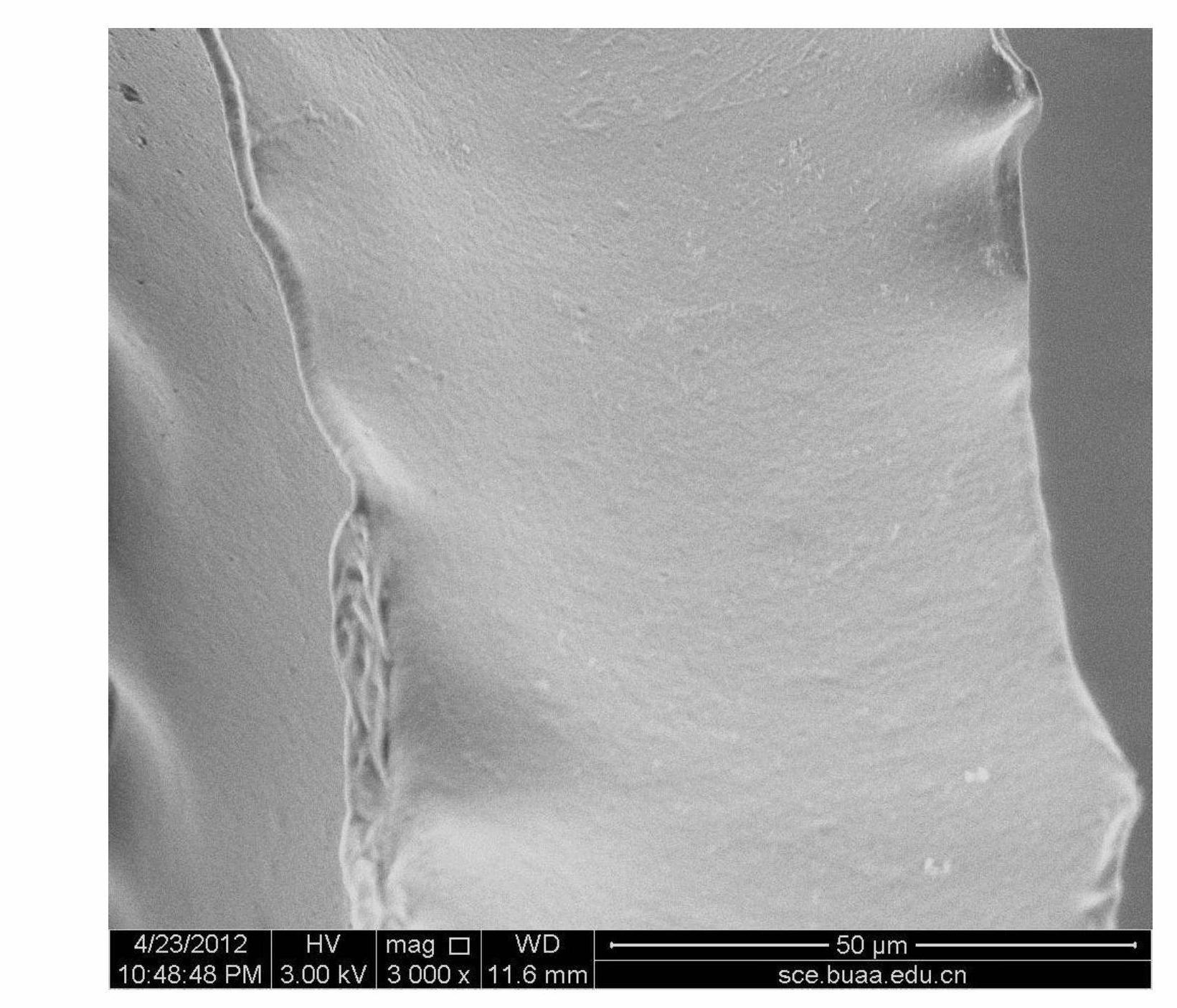

Preparation method of superhydrophobic/superoleophilic sponge

ActiveCN102660046AEasy to prepareRaw materials are easy to getLiquid separationPolymer scienceChemical reaction

The invention discloses a preparation method of a superhydrophobic / superoleophilic sponge, belonging to the technical field of functional materials. The method comprises the following steps: pretreating the sponge, preparing a chromic acid washing liquid, preparing a polyperfluoroalkylsiloxane-ethanol mixed solution, corroding by immersing the sponge in the chromic acid washing liquid, modifying by immersing the sponge in the polyperfluoroalkylsiloxane-ethanol mixed solution, taking out, drying and the like. The preparation method disclosed by the invention has the advantage of simple process; and by using the chromic acid corrosion and fluorosilane modification, a superhydrophobic / superoleophilic surface is formed on the surface of the polyurethane sponge. By the means of chemical reaction, the polyurethane sponge is firstly corroded by the chromic acid washing liquid and then modified by the polyperfluoroalkylsiloxane-ethanol solution to lower the surface energy, so that the sponge is superhydrophobic and superoleophilic, thereby enhancing the oil-water separation effect. The surface contact angle of gasoline is 0 degree, and the surface contact angle of water is greater than 150 degrees.

Owner:BEIHANG UNIV

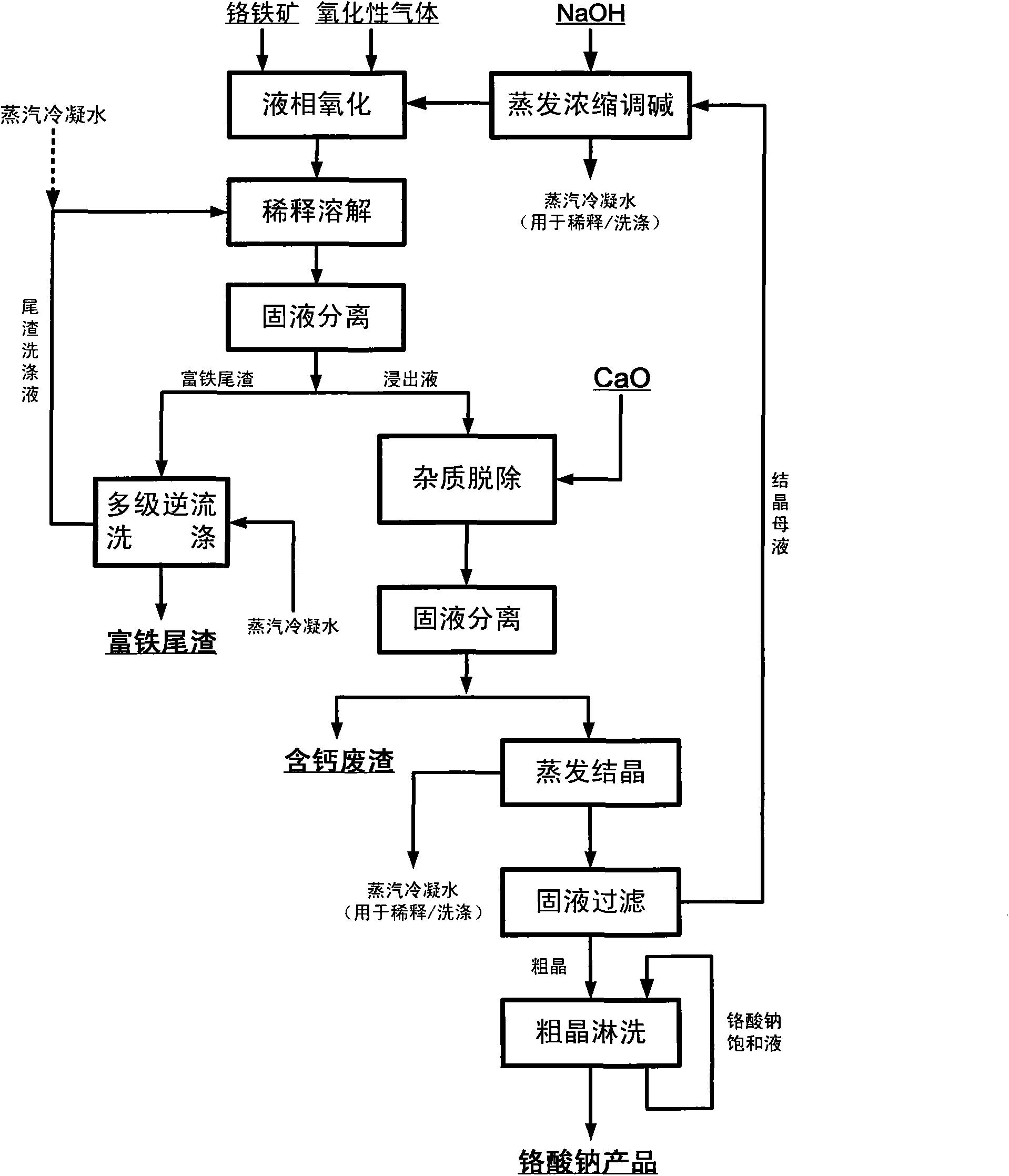

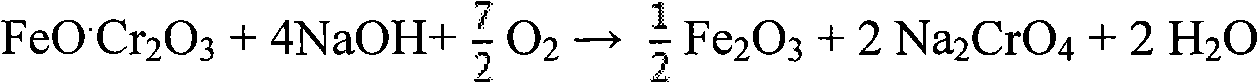

Method for pollution-free production of sodium chromate by pressure leaching of chromite

ActiveCN101817561AObvious superioritySimple ingredientsChromates/bichromatesReaction temperatureHydrometallurgy

The invention belongs to the field of chromite hydrometallurgy and chromium chemical industry, and in particular relates to a method for the pollution-free production of sodium chromate by pressure leaching of chromite. The method comprises the following steps of: 1) reacting the chromite with oxidizing gas in solution of NaOH; 2) diluting the product obtained by the step 1) and making subcrystalline sodium chromate to fully enter a liquid phase; 3) performing solid-liquid separation on the solid-liquid mixed slurry obtained by the step 2); 4) adding calcium oxide into the obtained diluent for removing impurities; and 5) evaporating and crystallizing the obtained solution without the impurities to obtain a sodium chromate crystal and crystallization mother solution; after the solid-liquid separation, rinsing the sodium chromate crystal by using saturated solution of sodium chromate; and drying to obtain a qualified sodium chromate product. The method has the advantages of simple reaction system component, no difficultly separated phase introduced in the system, contribution to high-efficiency separation of the sodium chromate, great reduction in reaction temperature, low energy consumption, effective reduction in production cost of the sodium chromate, and high chromium leaching yield.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

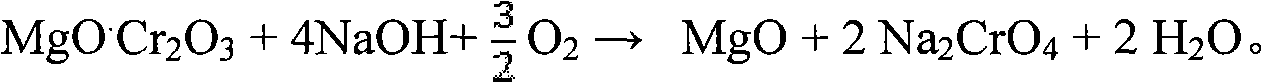

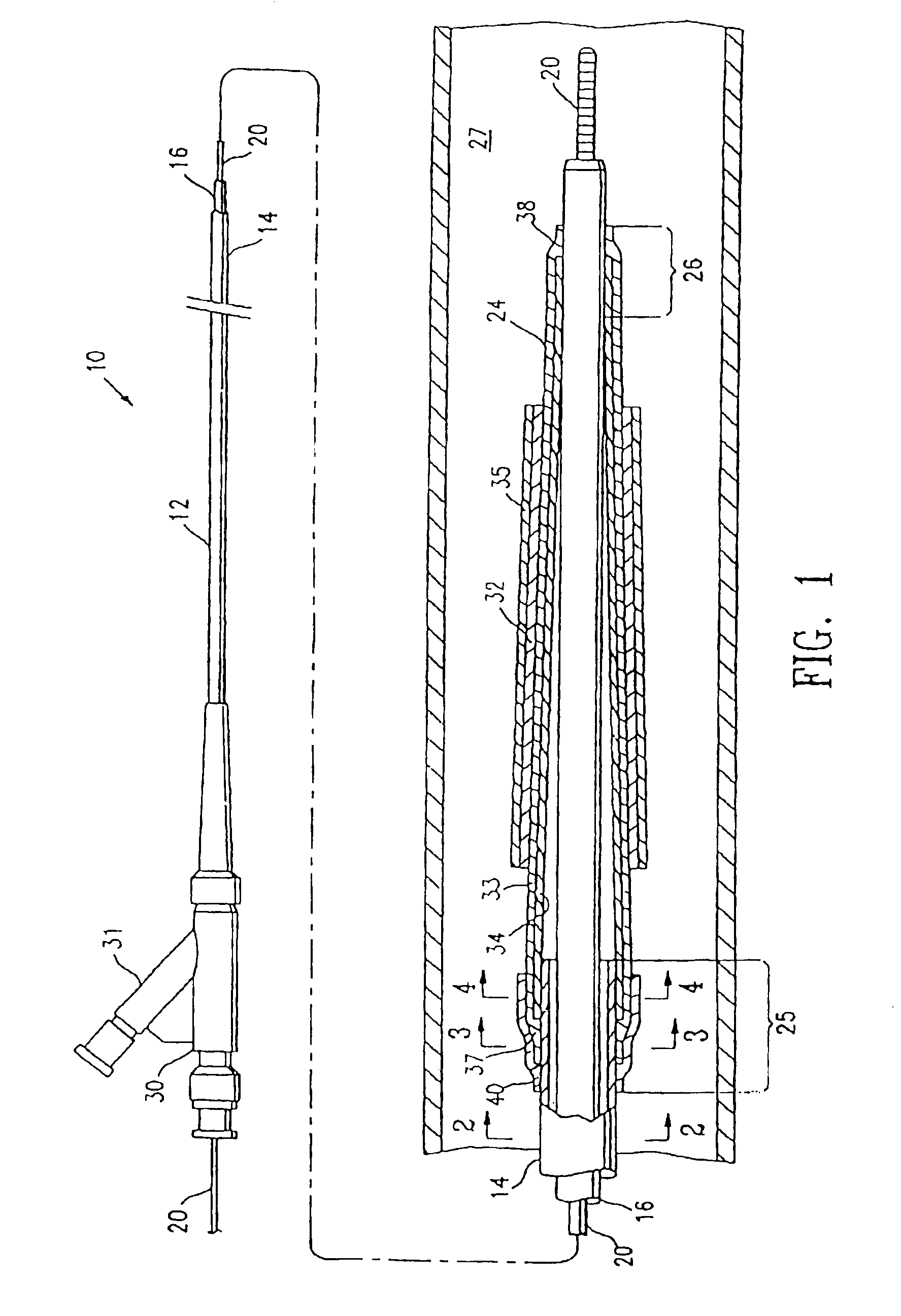

Surface modification of expanded ultra high molecular weight polyethylene (eUHMWPE) for improved bondability

InactiveUS6841029B2Improve bindingHigh bonding strengthBalloon catheterLamination ancillary operationsBalloon catheterUltra-high-molecular-weight polyethylene

A balloon catheter and a method of making the balloon catheter, having a balloon which is bonded to an elongated shaft, and which has a first layer and a second layer and an improved bond between the balloon and the shaft. One aspect of the invention is directed to a balloon in which the balloon first layer includes eUHMWPE and has at least a section that has been oxidized with a chromic acid solution to provide improved bondability.

Owner:ABBOTT CARDIOVASCULAR

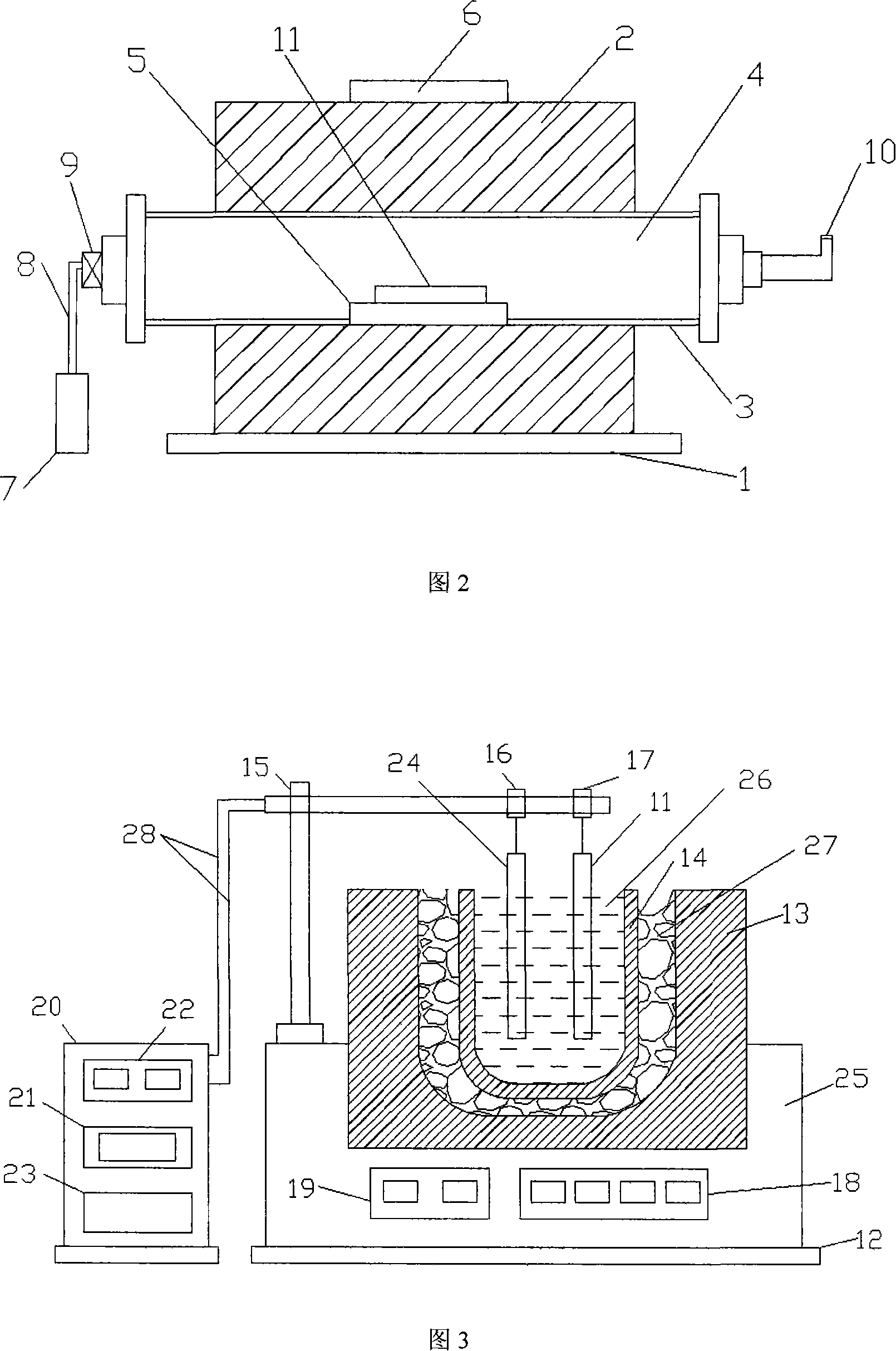

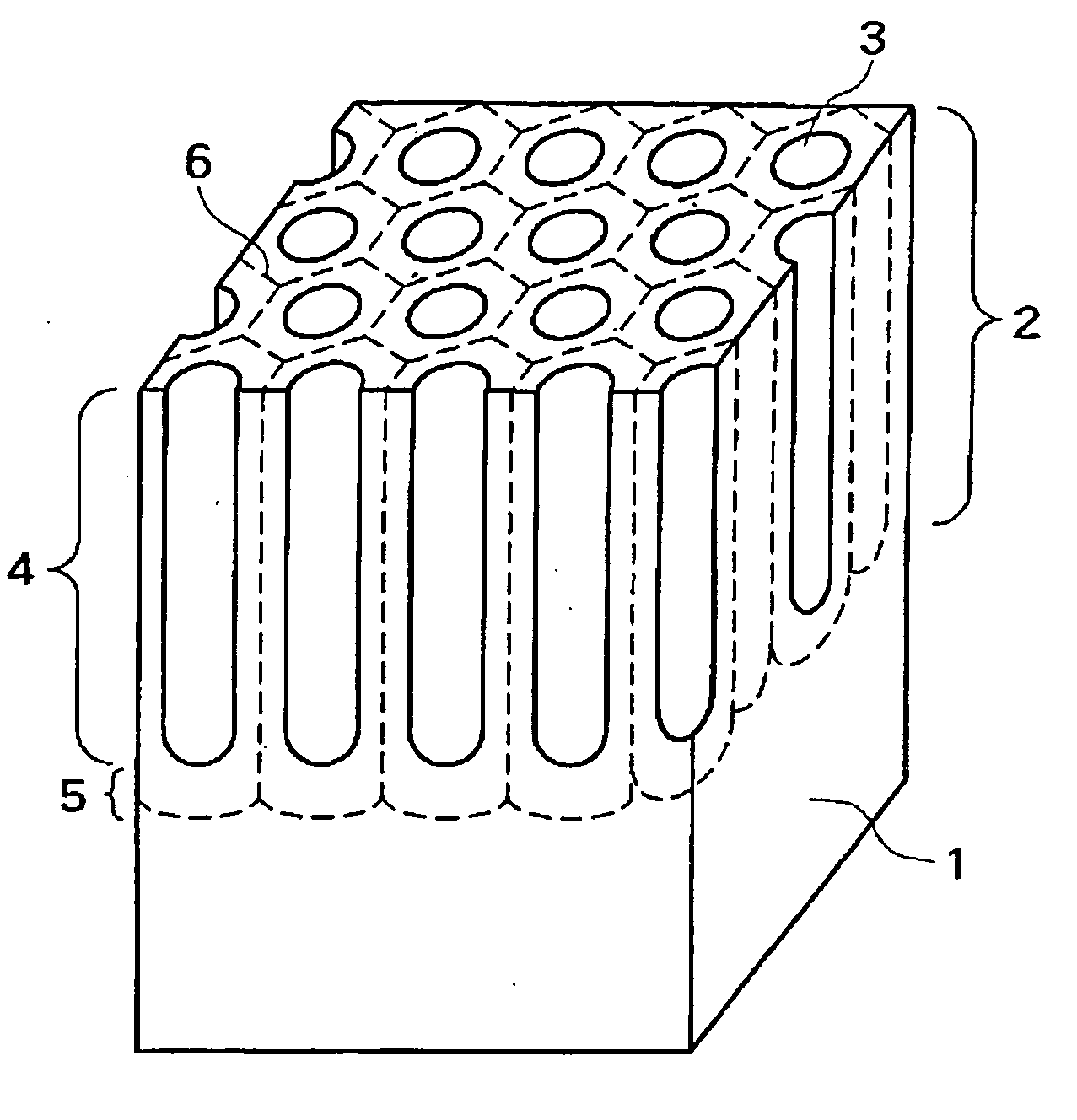

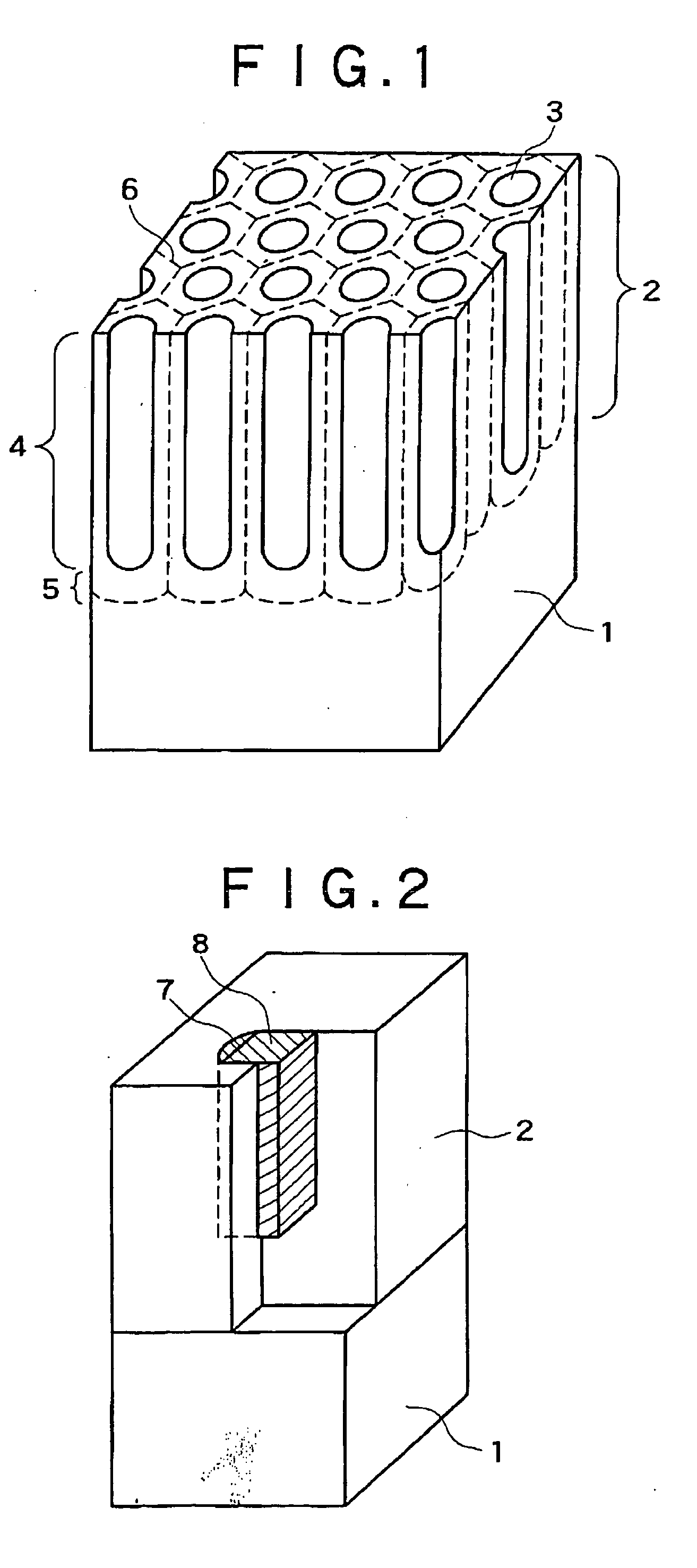

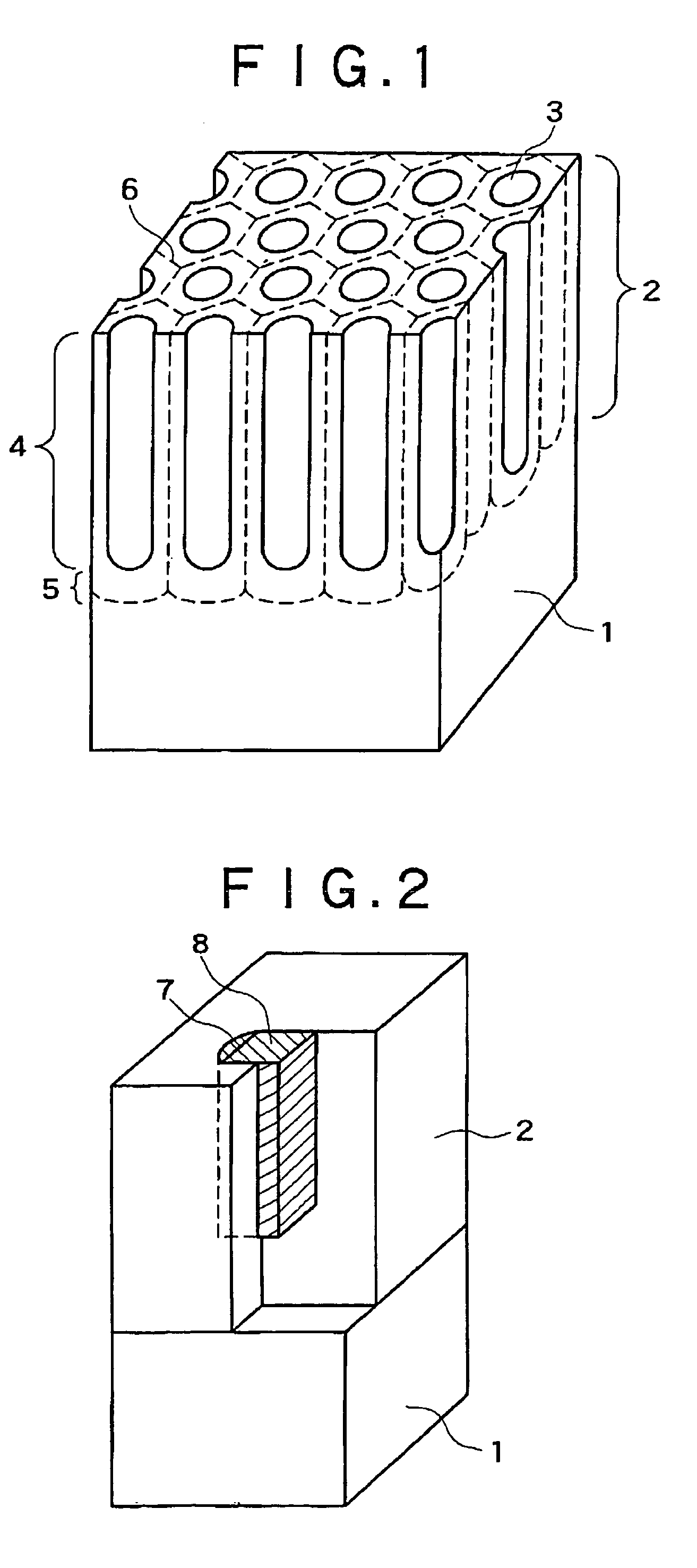

Thermoplastic resin coated aluminum alloy sheet, and method and apparatus for production thereof

InactiveUS6238783B1Cost advantageIncrease speedLiquid surface applicatorsChromatisationShell moldingAlloy

A thermoplastic resin coated aluminum alloy sheet has excellent processing adhesion and high adhesion after retort processing such that laminated thermoplastic resin layers do not peel off even when the alloy sheet is subjected to severe processing such as stretching after deep drawing and furthermore, ironing. A production method and a production apparatus for the alloy sheet are also described. A treatment by an alkaline solution and a treatment by an acidic solution are sequentially applied to bring the surface of an aluminum alloy sheet into a specific surface state and then electrolytic chromic acid treatment is carried out by a known method so as to laminate a thermoplastic resin to an aluminum alloy sheet having a two-layered film which comprises metallic chromium as the lower layer and a chromium hydrate as the upper layer and has a specific surface condition. As a result, a thermoplastic resin coated aluminum alloy sheet having excellent processing adhesion capable of withstanding molding and processing can be obtained.

Owner:TOYO KOHAN CO LTD

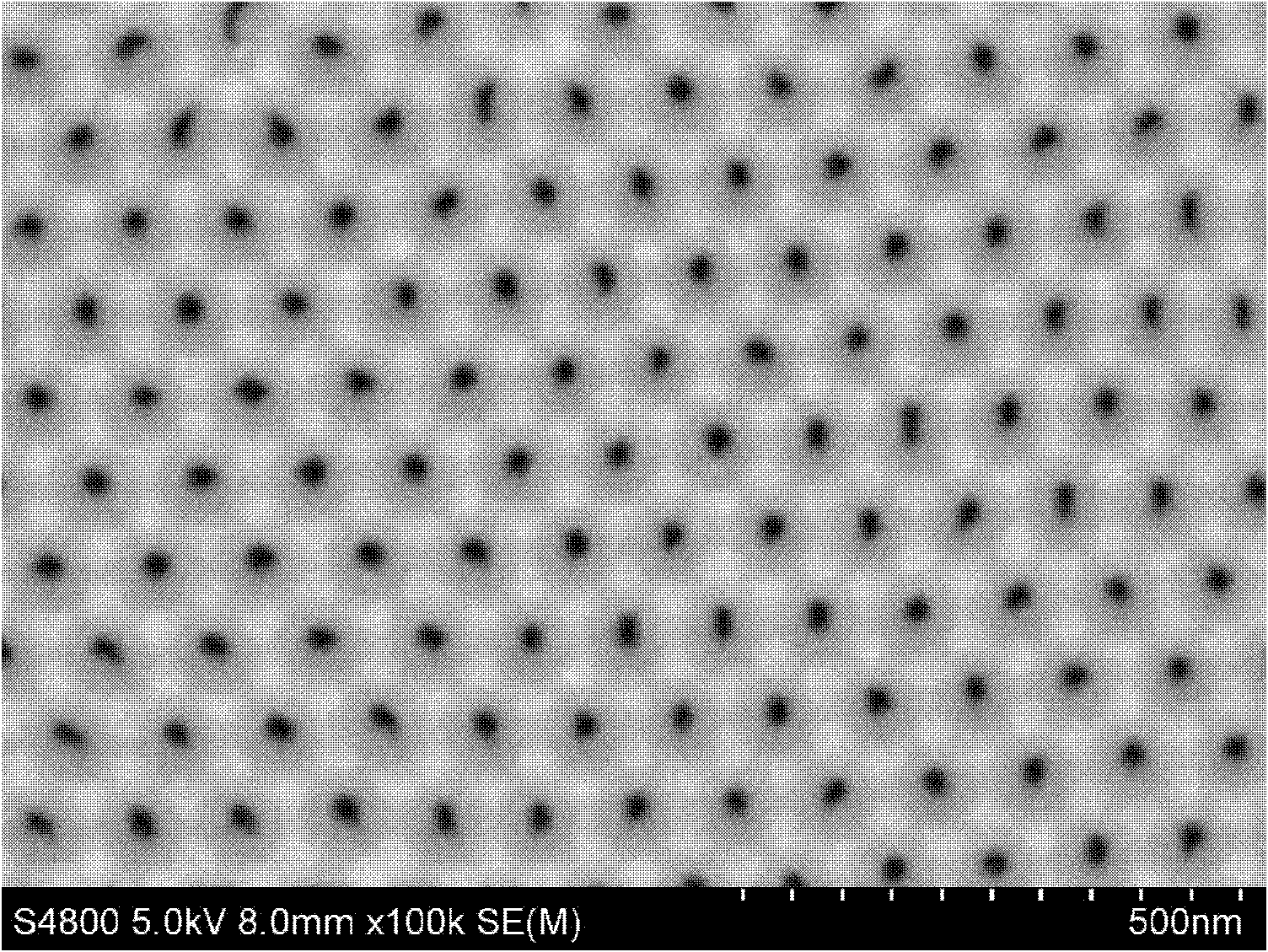

Preparation method of anodized aluminum film of through hole

InactiveCN102776542ALow process pollutionLow priceSurface reaction electrolytic coatingElectrolytic agentOXALIC ACID DIHYDRATE

The invention discloses a preparation method of an anodized aluminum film of a through hole. The preparation method mainly comprises the following steps: after a high-purity aluminum sheet is subjected to annealing, oxide layer removing, degreasing and electrochemical polishing treatment, placing into an anodizing electrolytic cell to carry out primary anode oxidation by taking oxalic acid, sulfuric acid or phosphoric acid solution as electrolyte, after an oxide layer is removed through treatment of mixed aqueous solution of chromic acid and phosphoric acid once, the secondary oxidation is carried out under the same conditions, the residual aluminum-based substrate is removed in acid solution, and reaming is carried in the phosphoric acid, so that the anodized aluminum film of the through hole with small aperture, and the controlled aperture and thickness is obtained. According to the invention, the relatively cheap device is used, through the simpler process, a large amount of anodized aluminum films of through holes can be simply and uniformly prepared in a lossless manner, and heavy metals are not introduced in a process of removing the residual aluminum substrate, so that environmental pollution is reduced. The prepared anodized aluminum film has the advantages of good uniformity and repeatability, highly ordered nanometer pore passage, uniform period, and controlled thickness and aperture.

Owner:SOUTH CHINA UNIV OF TECH

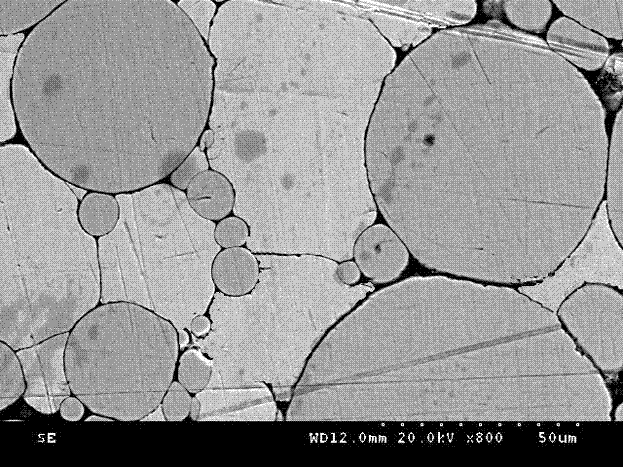

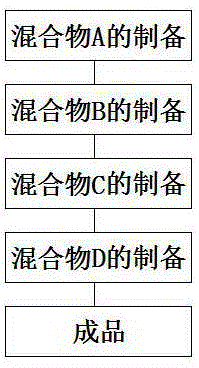

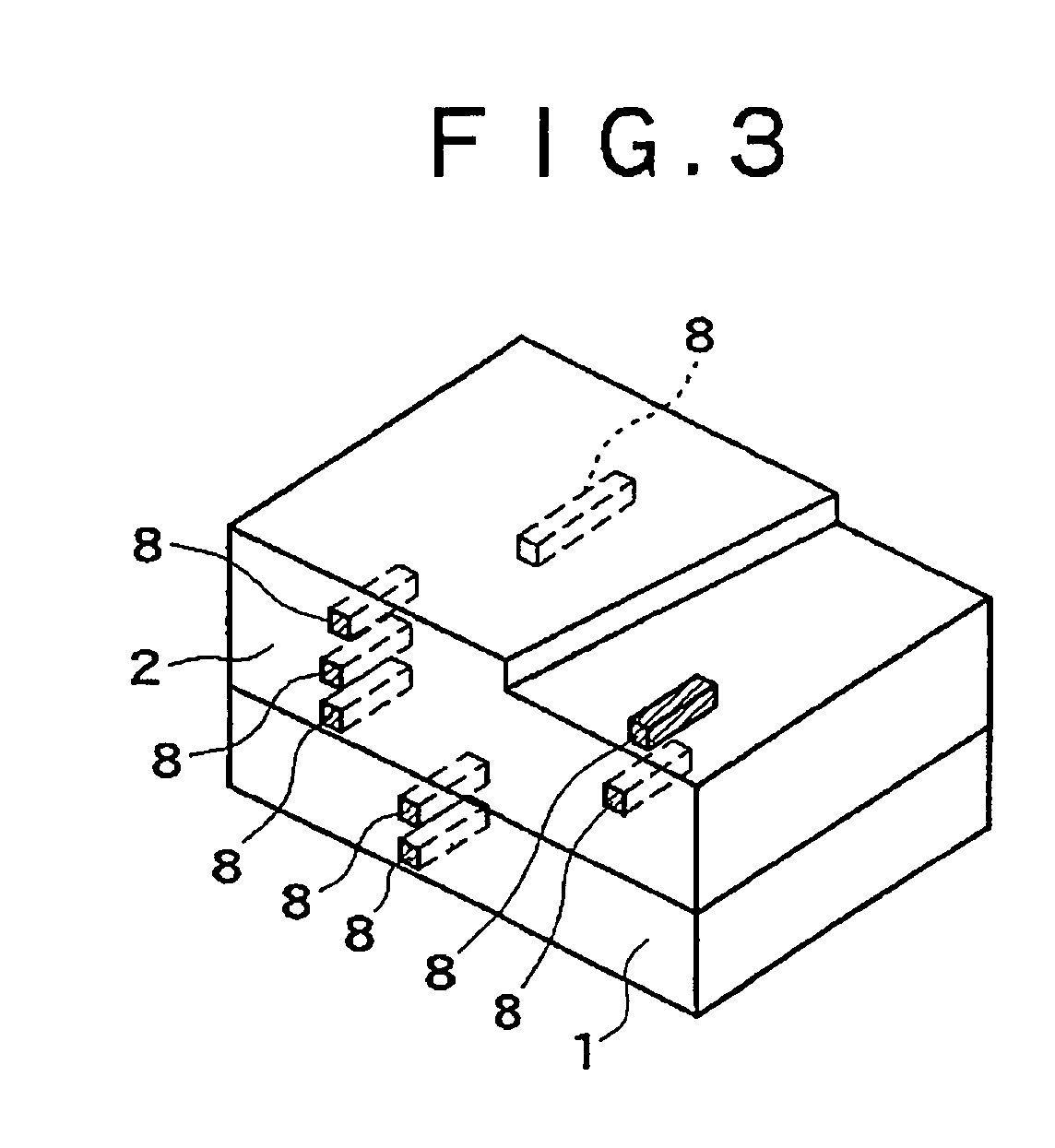

Manufacturing method of high-superposition low-loss metal magnetic powder core

ActiveCN103594218AGood electromagnetic propertiesImprove DC Superposition CharacteristicsInorganic material magnetismPhosphoric acidMechanical property

The invention discloses a manufacturing method of a high-superposition low-loss metal magnetic powder core, aiming to solve the problem of poor direct-current superposition performance of an inductor using metal magnetic powder cores in the prior art. The manufacturing method includes performing surface passivation on Fe (iron)-Si (silicon)-Al (aluminum) magnetic powder by a phosphoric acid acetone solution; adopting a secondary insulation process, in which a chromic acid solution is used for surface film formation and coating liquor is used for surface coating, on Fi-Ni (nickel) magnetic power; mixing the Fe-Si-Al magnetic powder and the Fi-Ni magnetic powder and adding a demolding lubricant; obtaining the finished metal magnetic powder core after dry pressing, secondary annealing and surface painting. The manufacturing method is simple in process procedure; as binding strength between a passivation film on the surface of the magnetic powder and the magnetic powder is high, the passivation film is not easy to separate from the magnetic powder; insulating materials are evenly coated on the surface of the magnetic powder and are not easy to crack or shed; the metal magnetic powder core obtained by the manufacturing method has good current superposition performance, low loss and excellent mechanical property.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Method for extracting vanadium and chromium from vanadium chromate mixed solution

InactiveCN106893877AReduce processing costsEasy to separateProcess efficiency improvementBarium saltSlag

The invention relates to a method for extracting vanadium and chromium from a vanadium chromate mixed solution. The method has the characteristics that the vanadium in the vanadium chromate mixed solution is separated and recycled through the crystallization precipitation method or the hydrolysis precipitation method or the calcium salt precipitation method at first, then the chromium in the enrichment solution is separated through the copper salt precipitation method or the barium salt precipitation method, an obtained chromium precipitation enrichment product is then transformed into chromium enrichment liquid, the chromium enrichment liquid is further processed into products of chromic acid and chromate, and production of vanadium-chromium reducing slag and ammonia-nitrogen wastewater in the separation and recycling process of the vanadium and the chromium in the solution is effectively avoided. The method for extracting the vanadium and the chromium from the vanadium chromate mixed solution has the advantages of being good in vanadium and chromium separation effect, short in technological process, high in metal recycling rate, easy and convenient to operate, low in production cost, environmentally friendly and the like and is suitable for industrial production and application.

Owner:CENT SOUTH UNIV

Aluminum alloy member superior in corrosion resistance and plasma resistance

ActiveUS20040151926A1Improve corrosion resistanceAnodisationSemiconductor/solid-state device manufacturingPhosphoric acidCorrosion

An aluminum or aluminum alloy member superior in liquid and gaseous corrosion resistance and plasma resistance, which has an anodized film formed thereon which is composed of a porous layer and a non-porous barrier layer whose structure is at least partly boehmite or pseudo-boehmite. Said anodized film is characterized by that the film dissolving rate measured by the test for immersion in a mixture of phosphoric acid and chromic acid (conforming to JIS H8683-2) is less than 120 mg / dm<2> / 15 min, the ratio of area in which corrosion occurs after standing for 2 hours in an atmosphere of argon containing 5% chlorine (at 300° C.) is less than 15%, and the hardness (Hv) of the film is no lower than 420.

Owner:KOBE STEEL LTD

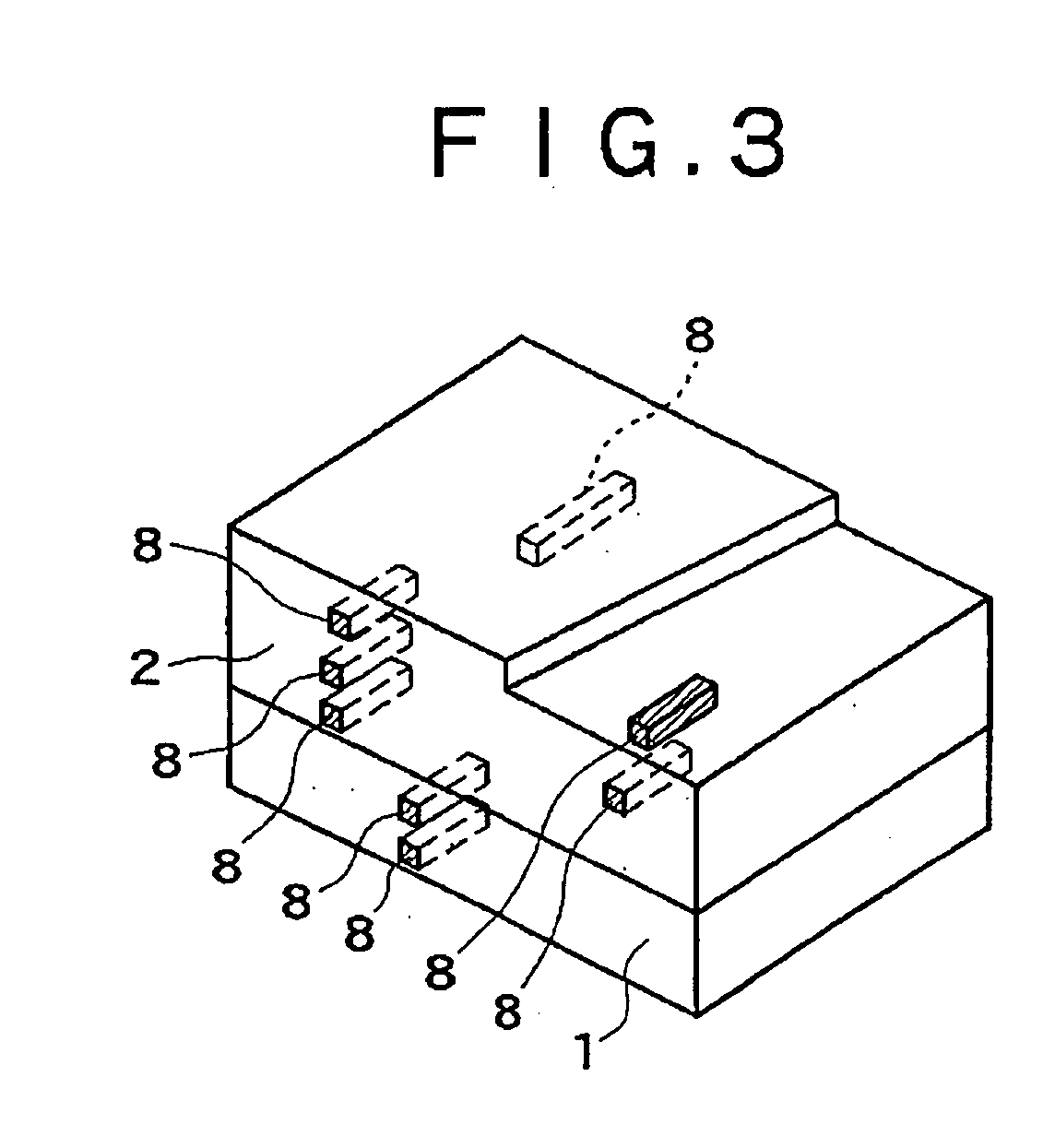

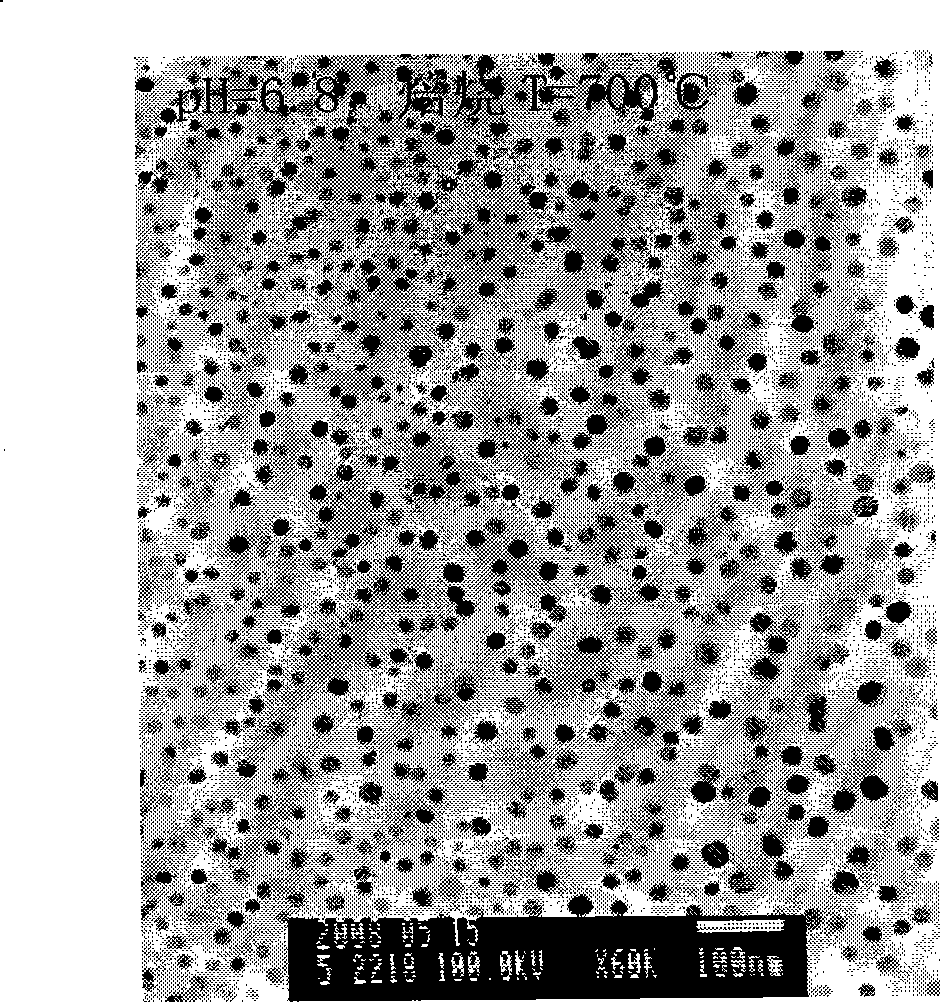

Ferrous metal electromagnetic screen fabric and method for making same

InactiveCN101113568ASpecial shielding propertiesImprove conductivityMagnetic/electric field screeningFibre treatmentFiberCopper plating

The invention relates to a black metallization electromagnet shield textile and a preparation method thereof. The preparation method comprises: (1) copper plated fiber textile is soaked in 3 mol / L chromic acid solution, then washed by clean water; (2) black nickel solution is prepared, pH value is regulated to 2 to 6, nickel anode is adopted under the temperature of 10 to 50 DEG C, the chemically plated copper textile is immersed and plated until the replacement reaction is completed, and a conductive fibre textile plated with black metallic nickel is obtained; (3) the plated fiber textile is washed by water and coated by protection resin, then dried. The textile has the advantages of excellent conduction, good wear resistant property, decay resistance and light absorption property and has functions of decoration, protection and light absorption, etc; meanwhile the textile has higher serviceability, which can be used in the areas such as conductive rubber bell, conductive machine weaving, conductive non woven fabric, shielding liner, etc.

Owner:DONGHUA UNIV +1

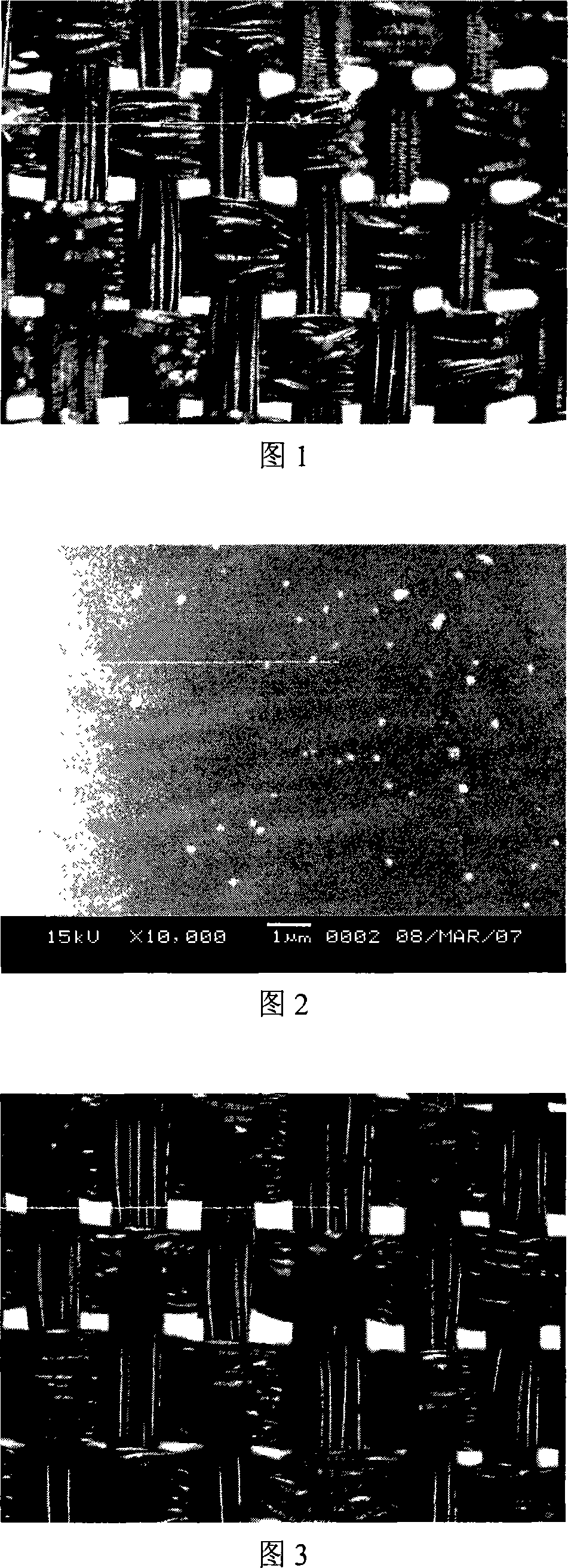

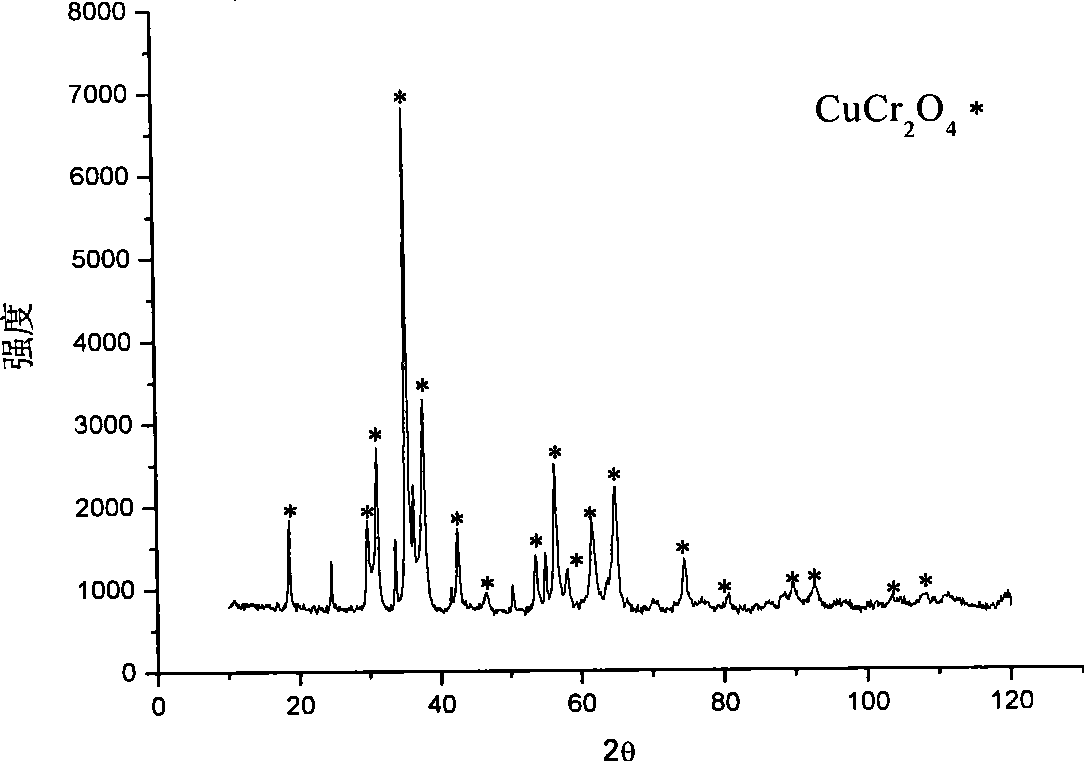

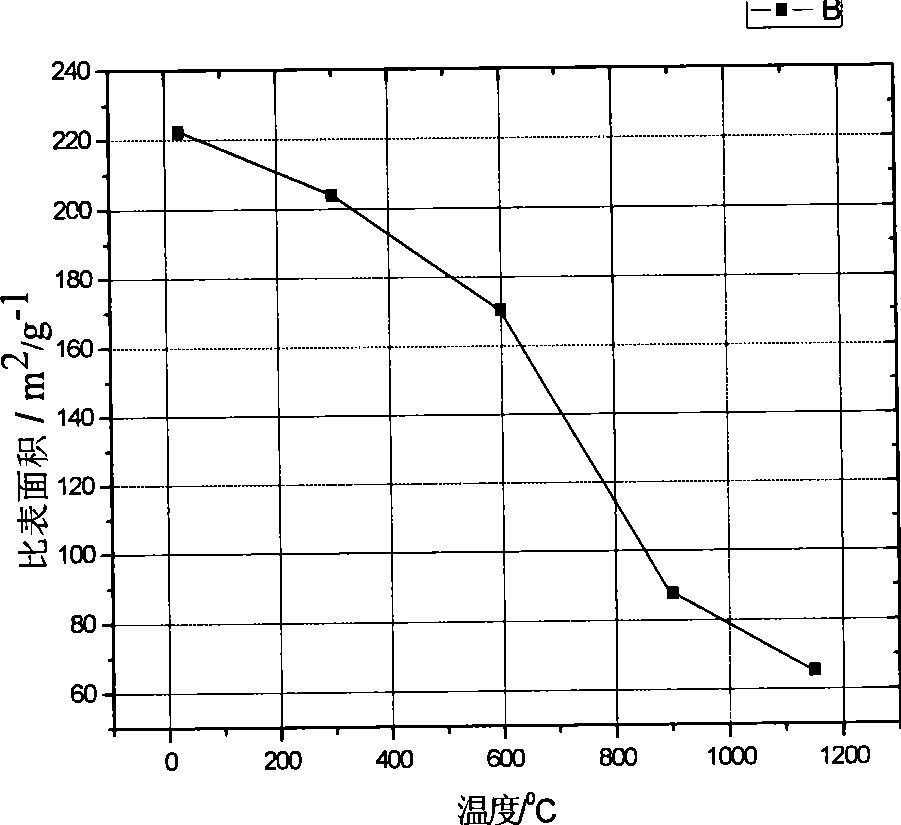

Method for preparing nano-catalyst copper chromite and copper ferrite

InactiveCN101367044AHigh puritySmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsWater bathsNano catalyst

The invention discloses a method for preparing a nano-size catalyst of copper chromite and copper ferrite, and belongs to the technical field of nano-size catalyst preparation. The method of the invention comprises a sol-gel process and a vacuum freezing drying (VFD) process. Firstly, a mixed solution is prepared from a soluble copper salt and a soluble chromium salt or iron salt, added with a surface active agent, and mixed uniformly, and then the system is added with a precipitating agent to carry out precipitation reaction under the condition that the pH value is between 6.8 and 9.5, then is kept stand, aged, washed and melted in a water bath for 2 to 8 hours at a temperature of between 70 and 95 DEG C, thus sol is obtained; then the sol is subjected to freezing drying in a vacuum freezing dryer to obtain dried gel which is a precursor of the catalyst; finally, the dried gel is roasted to obtain the nano-size catalyst of copper chromite (CuCr2O4) or copper ferrite (CuFe2O4). The catalyst prepared by the method has the advantages of high purity, small grain diameter, good dispersivity, high catalytic activity, and the like.

Owner:TSINGHUA UNIV

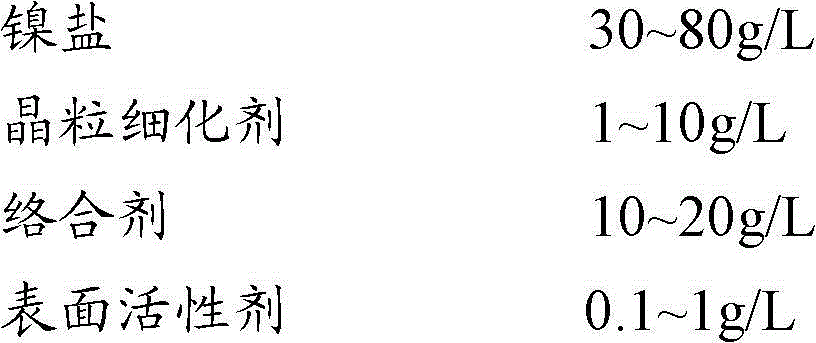

Electroplating solution for preparation of nanocrystalline nickel alloy plating and application thereof

The invention discloses an electroplating solution for preparation of a nanocrystalline nickel alloy plating. The electroplating solution comprises, in terms of mass concentration, 30 to 80 g / L of a nickel salt, 1 to 10 g / L of a grain-refining agent, 10 to 20 g / L of a complexing agent and 0.1 to 1 g / L of a surfactant. The invention also discloses an electroplating method for preparation of a nanocrystalline nickel alloy plating by using the electroplating solution and the prepared nanocrystalline nickel alloy plating which contains a certain amount of at least one inorganic element selected from the group consisting of nitrogen, carbon and boron besides the metallic element of nickel, wherein the inorganic element is introduced by the grain-refining agent. Compared with the prior art, the nanocrystalline nickel alloy plating prepared in the invention has a crystal grain size of less than 10 nm, a hardness of more than 800 Hv and good wear resistance; compared with conventional preparation methods for chromic acid plated hard chromium, the electroplating method provided by the invention has the advantages of simple equipment and process, easy operation, no pollution caused by hexavalent chromium and the like and has good market application prospects and research values.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

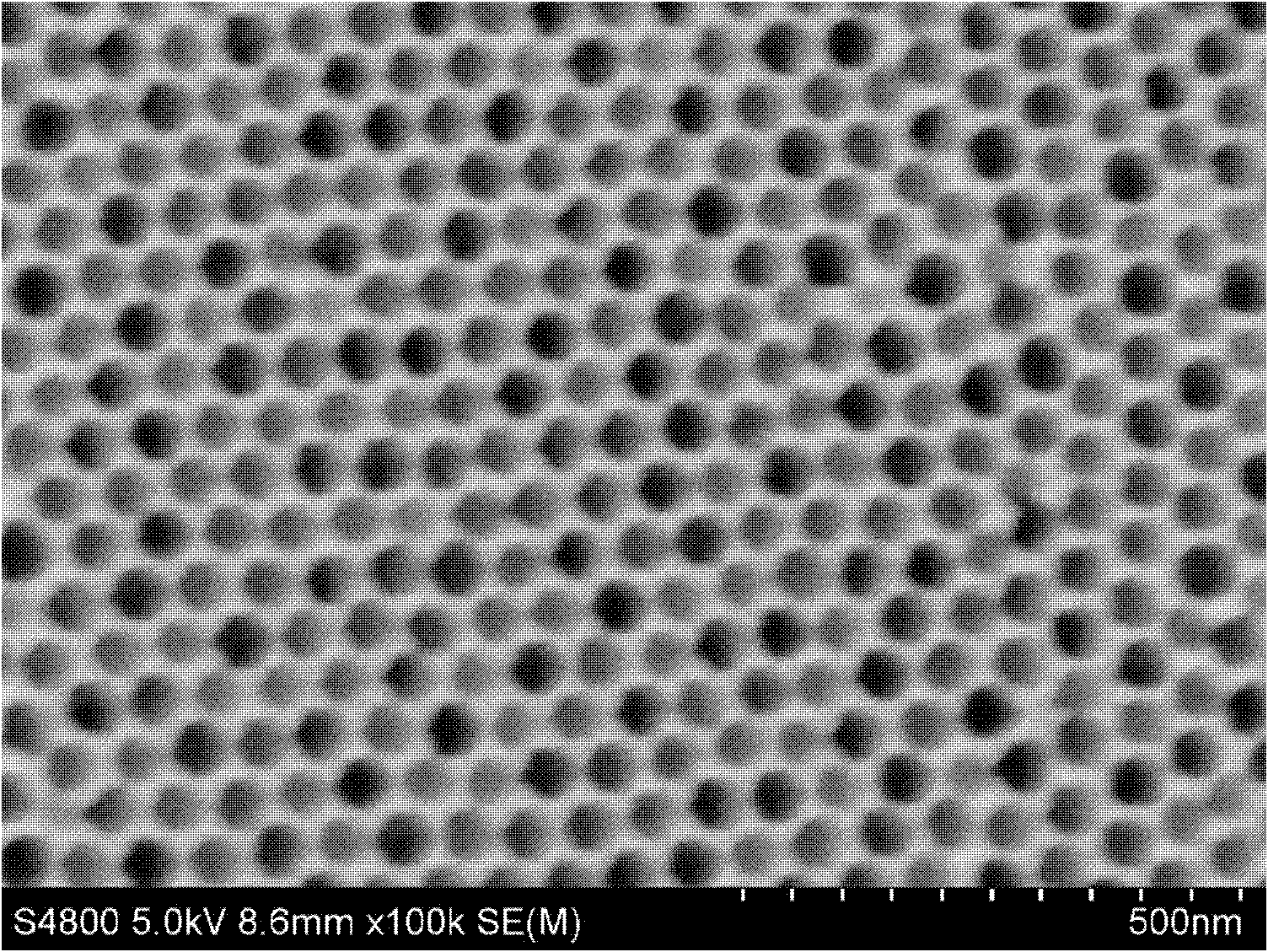

Method for preparing highly ordered aluminum oxide template by asymmetric two-step anodization

The invention discloses a method for preparing a highly ordered aluminum oxide template by asymmetric two-step anodization, which is characterized by comprising the following steps of: carrying out high-temperature annealing treatment on a highly pure aluminum sheet, and then carrying out electrochemistry polishing treatment, wherein the highly pure aluminum sheet has the purity being larger than or equal to 99.99wt%; anodizing for the first time in electrolyte by taking the highly pure aluminum sheet treated in the last step as the anode and a black lead as the cathode; dipping the highly pure aluminum sheet anodized for the first time into a mixed solution of phosphoric acid and chromic acid so as to remove an oxidation film on the surface of the highly pure aluminum sheet; anodizing for the second time in electrolyte different from the electrolyte for anodizing for the first time to obtain the aluminum oxide template, and then cleaning the aluminum oxide template to obtain the highly ordered aluminum oxide template. The invention widens the range of oxidation voltage for preparing aluminum oxide templates in electrolyte and realizes the modulation on the distance and the aperture between every two template holes to the larger extent.

Owner:CENT SOUTH UNIV

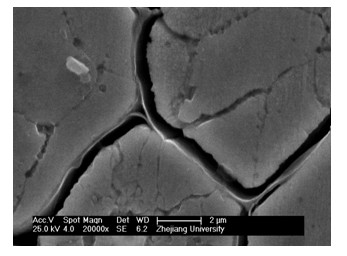

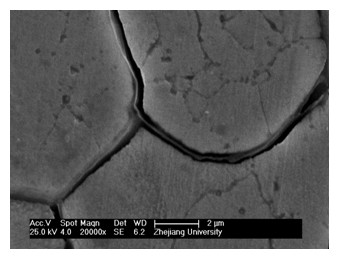

Electrochemical metallographic etching method universal for nickel-based alloys

InactiveCN101655426AFlat surfaceClear grain boundariesPreparing sample for investigationGlycerolPhosphoric acid

The invention discloses an electrochemical metallographic etching method universal for nickel-based alloys and relates to the electrochemical etching of the metallographic structure of a metal material. The method adopts the electrochemical metallographic etching method and takes an etching solution as a conducting medium, a metallographic specimen to be observed as an anode and a platinum electrode as cathode; the etching-control conditions comprise: the constant etching voltage: 2V / cm<2>-8Vcm<2>, the etching time: 1min-5min, the etching solution thereof contains in percentage by weight, 65%-85% of phosphoric acid, 5%-15% of sulfuric acid, 8%-15% of chromic acid and 3%-8% of glycerol, the prepared high-temperature corrosion-proof nickel-based alloys such as G-3, 825, X750 and the like have flat surface of metallograph, clear crystal boundary and clear crystal grain. Compared with chemical etching method, the electrochemical metallographic etching method has easily-controlled experimental conditions, good experimental repeatability and high experimental efficiency and is suitable for Ni-Fe-Cr alloys.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing porous alumina formwork with Y type structure

The invention discloses a method for preparing a porous aluminum oxide mould plate with Y-shaped structure. The method comprises the following steps: firstly, an aluminum sheet is annealed and chemically polished; secondly, the treated aluminum sheet is subjected to anode oxidation at a low voltage for some time; thirdly, the oxide layer generated during the first-time oxidation is washed off in an phosphoric acid / chromic acid mixing solution; fourthly, at a low voltage, the aluminum sheet is subjected to secondary anode oxidation for some time, and during the period of time, the oxidation voltage is raised, and the aluminum sheet is subjected to anode oxidation at a high voltage for some time; and finally, the prepared aluminum oxide mould plate is taken out, the barrier layer on the bottom part of the mould plate is further removed by phosphoric acid, so that the two-way porous aluminum oxide mould plate with Y-shaped structure. The method is not only widely applied to the preparation of various materials with one-dimensional nano structure, but also has potential purposes in the fields of the preparation of nano devices, photonic crystals and the like.

Owner:ANHUI UNIVERSITY

Method for chemical plating nickel-phosphorus alloy on surface of magnesium alloy

InactiveCN101275221AReduce pollutionHarm reductionLiquid/solution decomposition chemical coatingElectroless nickelChemical plating

The invention relates to a method of electroless Ni-P alloy on surface of magnesium alloy, comprising following steps: (1) degreasing: the magnesium alloy is degreased in non-phosphate alkaline degreasing solution with a temperature of 55 deg C to 65 deg C; (2) acid cleaning: a mixture of organic acid and anionic surfactant is used as magnesium alloy acid cleaning solution instead of traditional chromic acid solution to remove oxide film of the surface of the magnesium alloy; (3) surface conditioning: the acid cleaned magnesium alloy is processed surface conditioning in alkaline surface conditioning solution with a temperature of 80 deg C to 100 deg C; (4) activating: the surface conditioned magnesium alloy is processed activation in HF solution; (5) acid dipping zinc; (6) nickel plating: in a condition that the temperature is 80 deg C to 90 deg C and ph value is in the range of 5 to 6, a brightener is added into electroless nickel solution to process nickel plating reaction Ni-P alloy coating. The invention has following beneficial effects: (1) reducing pollution for environment and damage for bodies of operators, and at the same time, easily controlling the operation and uneasily losing control for process parameters; (2) improving appearance of the Ni-P alloy coating, and being provided with better decorative.

Owner:周学华

Preparation method of high-frequency high-magnetic-permeability low-loss iron nickel molybdenum metal magnetic powder core

ActiveCN102436894AReduce lossImproved high frequency magnetic performanceInorganic material magnetismInductances/transformers/magnets manufactureEpoxyStearic acid

The invention discloses a preparation method of a high-frequency high-magnetic-permeability low-loss iron nickel molybdenum metal magnetic powder core. According to the traditional method, during magnetic powder insulated costing, the quantity of on-magnetic substances is more, and the high density and high magnetic permeability of the iron nickel molybdenum magnetic powder core can not be realized. The preparation method provided by the invention comprises the following steps: firstly screening selected iron nickel molybdenum magnetic powder subjected to water atomization or iron nickel molybdenum magnetic powder subjected to gas atomization; secondly reacting the iron nickel molybdenum magnetic powder in a chromic acid aqueous solution, thus generating an insulation film on the surface of the magnetic powder; drying for two hours, and solidifying and stabilizing the insulation film on the surface of the magnetic powder; then adding zinc stearate serving as a lubricating agent into the iron nickel molybdenum magnetic powder, mixing and pressing the magnetic powder to obtain the iron nickel molybdenum magnetic powder core and carrying out annealing heat treatment under N2 atmosphere; and finally spraying epoxy paint on the iron nickel molybdenum magnetic powder core. The preparation method provided by the invention can be used for uniformly and firmly generating hundreds of nanometers of the insulation film on the surface of the iron nickel molybdenum magnetic powder, the insulated coating effect is good, the consumption of the non-magnetic insulants is reduced, and the purpose of improving the density and magnetic permeability of the magnetic core is achieved.

Owner:ZHEJIANG UNIV +1

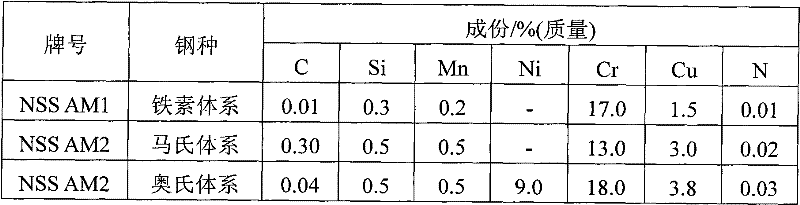

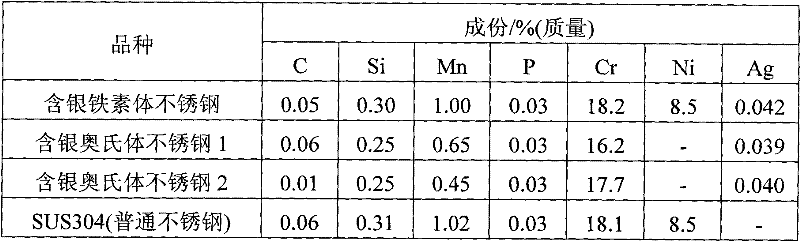

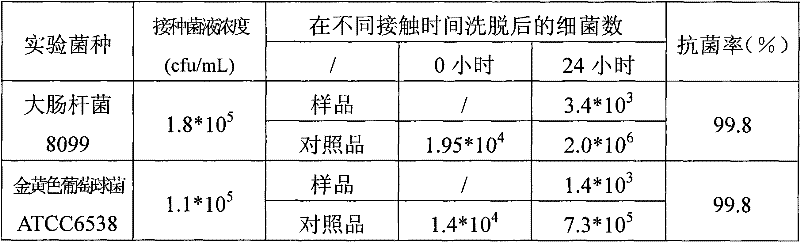

Antibacterial stainless steel with electrochemical oxidation film

The invention discloses antibacterial stainless steel with an electrochemical oxidation film. The stainless steel comprises a stainless steel matrix, wherein an antibacterial oxidation film is covered on the stainless steel matrix and the antibacterial oxidation film is a spinel type oxidation film. The invention also discloses a preparation method of the antibacterial stainless steel with the electrochemical oxidation film. The method comprises the following steps: placing a defatted stainless steel material in an electrochemical oxidation mixed solution, alternately changing positive electricity and negative electricity, wherein the current density is 10-100mA / dm<2>; processing for 5-20 minutes at 30-60 DEG C to form a thin spinel oxidation film, then cleaning the oxidation film with clean water and drying. The electrochemical oxidation mixed solution per litre is prepared by the following components: 200-500g of sulfuric acid, 50-250g of chromic acid, 5-20g of ammonium molybdate, 5-20g of manganese sulfate, 0.1-10g of silver salt and 0.2-20g of rare earth sulfate or rare earth nitrate. The invention has good antibacterial effect.

Owner:CHANGZHOU GARDENSUN ANTI BACTERIAL MATERIALS TECH

Detection method of plated layer corrosion rate in steel wire or steel wire rope

InactiveCN103353432AJudging the anti-corrosion abilityThe service life is easy to judgeWeighing by removing componentWeather/light/corrosion resistanceAlcoholSalt spray test

The invention relates to a detection method of plated layer corrosion rate in a steel wire or a steel wire rope. The method comprises the process steps that: 1, a sample is prepared, wherein a plated steel wire or steel wire rope is cut into N segments; the surfaces are cleaned by using alcohol cotton; and the ends are sequentially sealed by using a solid sealant (AB composite adhesive), such that N samples are prepared; 2, the samples are weighed; 3, a salt spray test is carried out, wherein the weighed samples are subjected to a neutral salt spray test in a salt spray box; 4, the surfaces of the samples are cleaned, wherein the samples after the salt spray test are washed in a container with a prepared chromic acid cleaning agent, such that residual salt and corrosives on the surface of the samples are completely removed; the samples are washed by using water, and are dried; and 5, weighing and calculation are carried out, wherein the dried samples are weighed, and the weights are adopted as after-test weights; and the corrosion rate is calculated according to the weight loss before and after the test. With the method provided by the invention, corrosion-resistant rates of various plated layers can be easily determined, and the service lives of the plated layer samples in the environment can be inferred.

Owner:JIANGSU FASTEN MATERIAL ANALYSIS & INSPECTION

Environment-friendly technology for copper and copper alloy surface treatment

The invention discloses an environment-friendly technology for copper and copper alloy surface treatment. The environment-friendly technology includes the following steps of (1) ultrasonic degreasing, (2) rinsing with clear water, (3) magnetic force polishing, (4) rinsing with clear water, (5) surface sealing, (6) centrifugal drying and (7) inspecting and packaging. A magnetic force polishing method is adopted to replace traditional three-acid pickling so as to conduct surface oxide skin removing operation on a copper alloy workpiece, and steel needles continuously collide and rub copper and the copper alloy workpiece so that surface oxide layers and tiny burrs can be removed and the purpose of surface smoothness can be achieved. The size of the copper alloy workpiece is not changed at all before and after treatment, and the poor size problem of the workpiece due to overpickling in the acid pickling process does not exist. A water-soluble environment-friendly sealing agent is adopted, the copper and the copper alloy workpiece with the smoothness surfaces after magnetic force polishing are subjected to sealing treatment, an organic closing membrane is used for replacing a chromic acid passivation membrane so that surface protection can be performed on the copper alloy workpiece, the adopted sealing agent is up to the ROSH standard and does not contain toxic and harmful substances, and the thickness of the surface closing membrane is controllable in the process; and moreover, the product has high fingerprint resistance, high salt spray resistance and high anti-tarnish performance.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Anticorrosive environment-friendly spray paint formula

InactiveCN105199580ABright colorGood light fastnessAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholChemical industry

The invention discloses an anticorrosive environment-friendly spray paint formula, and relates to the field of chemical industries. The anticorrosive environment-friendly spray paint formula comprises the following components in parts by weight: 28 to 35 parts of glacial acetic acid, 3 to 7 parts of organic fluorine epoxy resin, 7 to 12 parts of epoxy modified organic silicon resin, 2 to 6 parts of glycol monomethyl ether, 6 to 9 parts of dimethyl sulfoxide, 8 to 13 parts of zinc phosphate, 8 to 13 parts of barium chromate, 1 to 4 parts of ethanol, 2 to 7 parts of polyacrylate, 1 to 4 parts of alcohol soluble resin, 7 to 13 parts of diacetone alcohol, 6 to 9 parts of zinc oxide, 8 to 13 parts of toluene diisocynate, 3 to 7 parts of n-butyl acetate, 12 to 16 parts of benzophenone, 9 to 13 parts of triethanolamine and 3 to 7 parts of diphenyl polysiloxane. The paint is bright in color and good in air-curing resisting effect, can substitute medium chrome yellow in inorganic pigment, is applicable to the outer wall paint, and has no harm of heavy metals, no harmful substances, good environment protection effect, little odor, no peculiar smell after being smeared on the wall, good mechanical performance, excellent electric insulation performance, dampness and water resistance, rust and cold resistance and ozone aging resistance.

Owner:王海平

Aluminum alloy member superior in corrosion resistance and plasma resistance

ActiveUS7005194B2Improve corrosion resistanceIncrease resistanceAnodisationSemiconductor/solid-state device manufacturingPseudoboehmitePorous layer

Owner:KOBE STEEL LTD

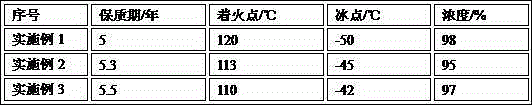

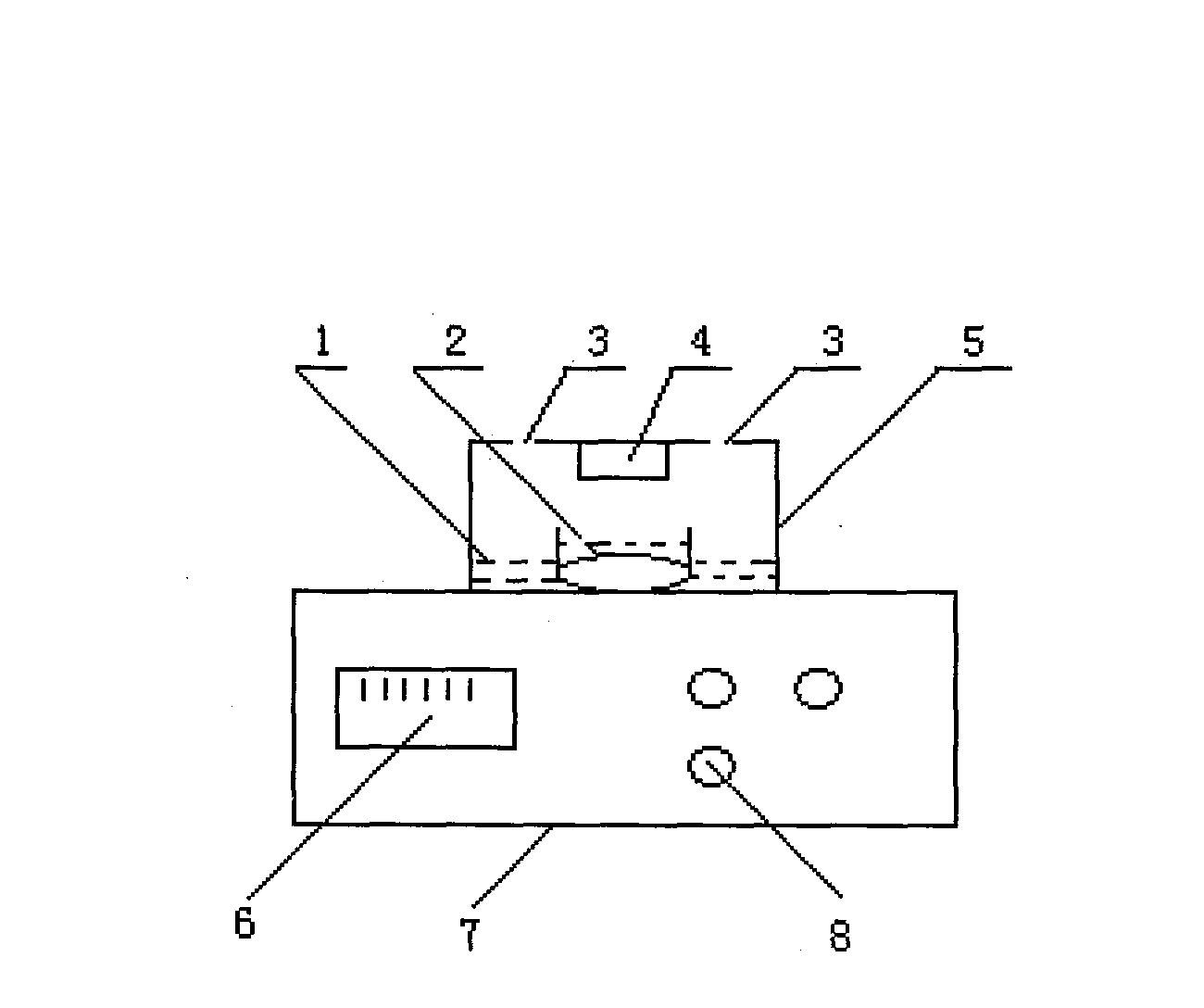

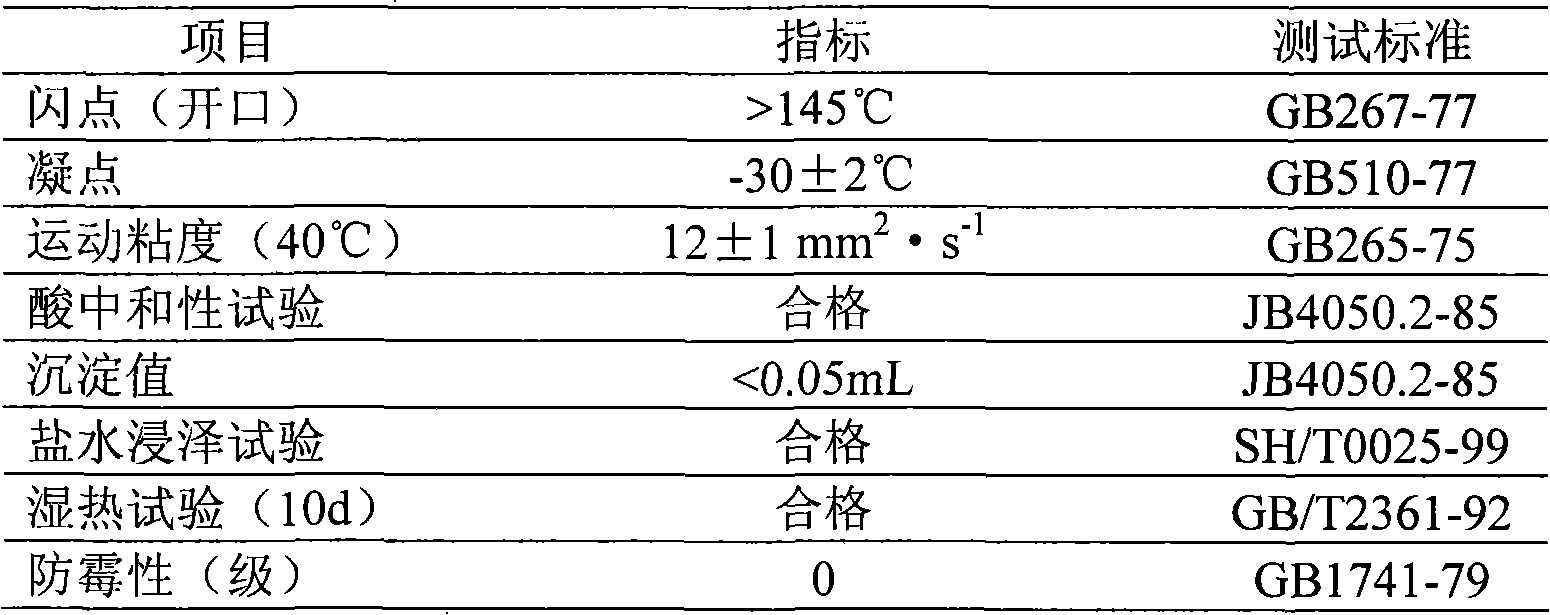

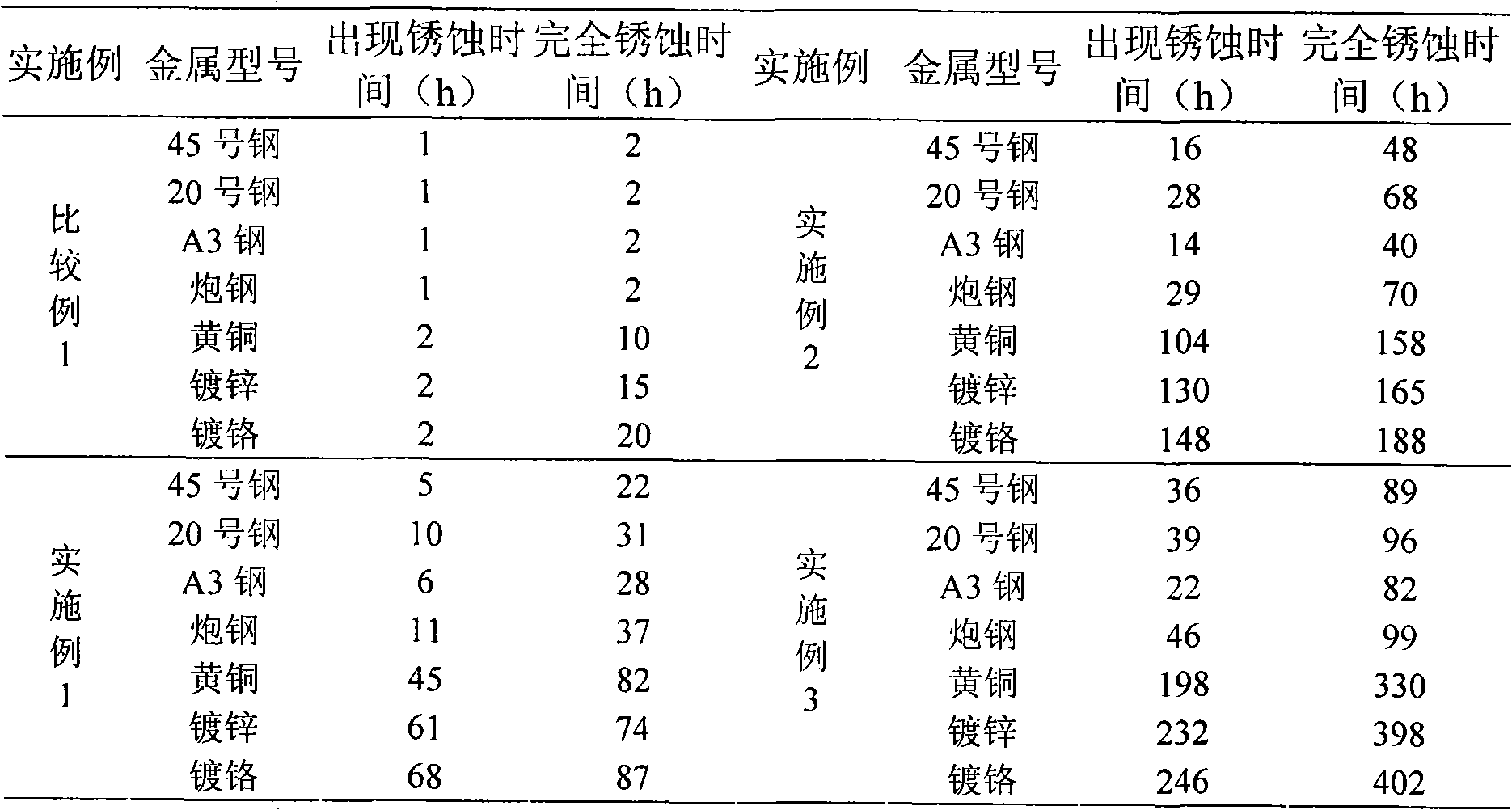

Multifunctional gaseous phase anti-rust oil

ActiveCN101638604AContact rust-proofWith gas phase corrosion inhibitor gas phase rust preventionAdditivesButanedioic acidGas phase

The invention discloses a multifunctional gaseous phase anti-rust oil which mainly comprises No. 25 transformer oil, oil-soluble vapor phase corrosion inhibitor, cosolvent dibutyl phthalate, defoamingagent polydimethylsiloxane, antioxidant zinc dialkyl dithiophosphate, mildewproof agent di-n-octyl-4-isothiazolin-3-ketone and the like; wherein the oil-soluble vapor phase corrosion inhibitor is prepared by mixing 10-40% of octadecyl butanedioic acid, 10-30% of 2-ethylamino heptadecenyl imidazoline, 2-20% of lanolin, 5-20% of zinc naphthenate and 15-30% of chromic acid tert-butyl ester. The gaseous phase anti-rust oil not only has the contact anti-rust property of the anti-rust oil, but also has the superior vapor phase anti-rust performance of the vapor phase corrosion inhibitor. The multifunctional gaseous phase anti-rust oil can be widely applied to long-term rust protection of military hardware and metal materials for civil use, more particularly, used for rust prevention of engines,large compressors, special gear boxes and the like, and mainly applicable to preventing a closed cavity system from rusting. The anti-rust oil not only can prevent black metal steel-made parts from rusting, but also has the function of rust prevention for multiple non-ferrous metal parts, thus effectively preventing metals such as steel, copper, zincification, chrome-plate and the like as well asalloy materials thereof from being corroded.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE +1

Anticorrosive Coating Compositions

InactiveUS20080000383A1Good storage stabilityAnticorrosive ability equalPigmenting treatmentOther chemical processesSingle substanceRust

It is an object of the present invention to provide an anticorrosive coating composition which uses a pollution-free (heavy metal-free) rust preventive pigment and exhibits anticorrosive performances equal or superior to those of lead compounds or chromic acid compounds even if the pigment is blended in various binder resins and also to provide an anticorrosive coating composition having excellent storage stability. The present invention relates to an anticorrosive coating composition comprising a binder resin and a pollution-free (heavy metal-free) rust preventive pigment containing a condensed calcium phosphate produced by baking a single substance or mixture of a calcium component and a phosphorous component in the following atomic ratio (Ca / P=m): 0.50<m<1.00, at 180 to 350° C.

Owner:DAI NIPPON TORYO CO LTD

Method for producing adipic acid and dibasic acid by using nitric acid to oxidizing cyclohexane bionic oxidation mixture

InactiveCN101186570ASolve the conversion rateSolve the large amount of cyclohexane circulationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexanoneDistillation

The invention relates to a method for directly preparing adipic acid and diacid from cyclohexane bionic oxidation mixture by nitric acid oxidation. The invention is characterized in that in the presence of 1-10mg / L metalloporphyrin catalyst, at 140-160DEG C and 0.8-1.2MPa, cyclohexane is oxidized by air, and the cyclohexane oxidation mixture is directly prepared into adipic acid and diacid by nitric acid oxidation. Compared with prior adipic acid preparation, the invention can simultaneously improve single-pass conversion of cyclohexane and total yield of diacid respectively more than 10% and 80%. At the same level of adipic acid yield, the circulation quantity of cyclohexane is reduced more than 50%, nitric acid consumption is reduced about 10%, to reduce the load on cyclohexane distillation system, reduce energy consumption, and reduce production cost. The invention can be directly used in prior industrial unit that prepares adipic acid from cyclohexane, to reduce production cost and improve yield. The invention can simplify prior production that prepares adipic acid by cyclohexane oxidation, to eliminate washing, cyclohexyl hydrogen dioxide decomposition, and cyclohexanone-and-cyclohexanol distillation systems, and avoid tert-butyl chromic acid catalyst.

Owner:SHENYANG POLYTECHNIC UNIV

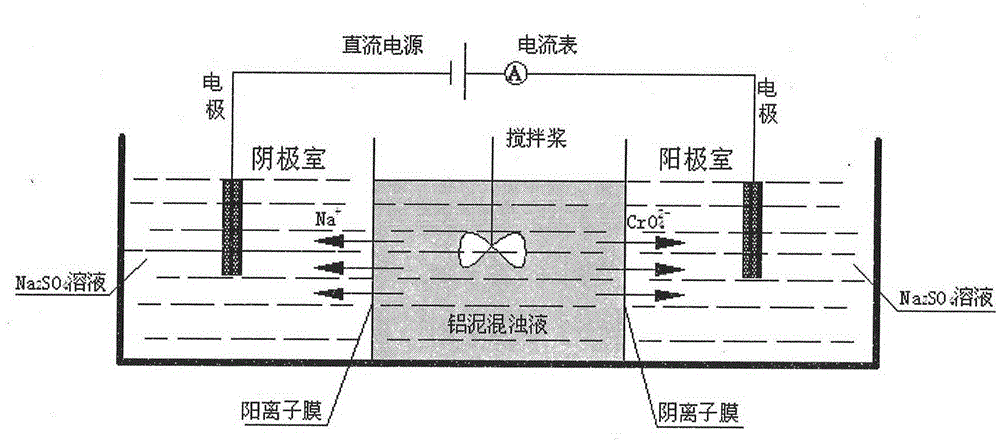

Process method for recovering chromium and aluminum by comprehensively utilizing waste aluminum residues

InactiveCN104805288AReduce pollutionShort reaction timeProcess efficiency improvementCarbonationScrap

The invention provides a process method for recovering chromium and aluminum by comprehensively utilizing waste aluminum residues, and relates to a novel method for recovering sodium chromate and aluminum oxide from industrial waste chromium-containing aluminum residues. The waste chromium-containing aluminum residues serve as a raw material and are separated with beating, water washing, electroosmosis and other processes, so that the sodium chromate solution is obtained and used for producing sodium dichromate products; the aluminum residues after dechroming processing are dissolved with a NaOH solution, and then a high-purity metallurgical grade aluminum oxide product is obtained with repeated continuous carbonation decomposition methods. With the adoption of the process method, hexavent chromium in the chromium-containing aluminum residues can be recovered, valuable metal aluminum in the aluminum residues is extracted, the qualified aluminum oxide product is produced, and meanwhile, the environment is effectively protected.

Owner:CHONGQING MINFENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com